Patents

Literature

169results about How to "High damage tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

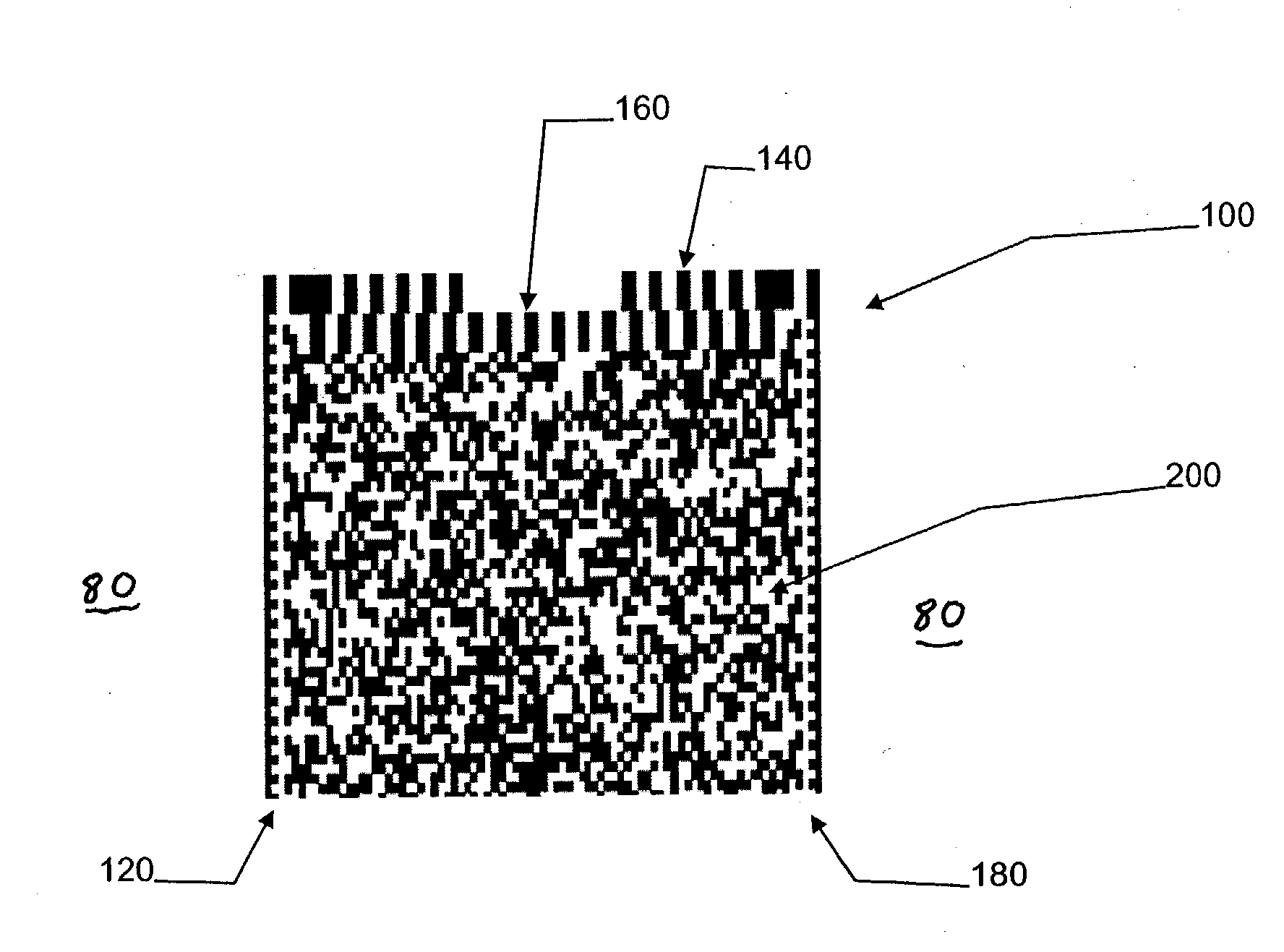

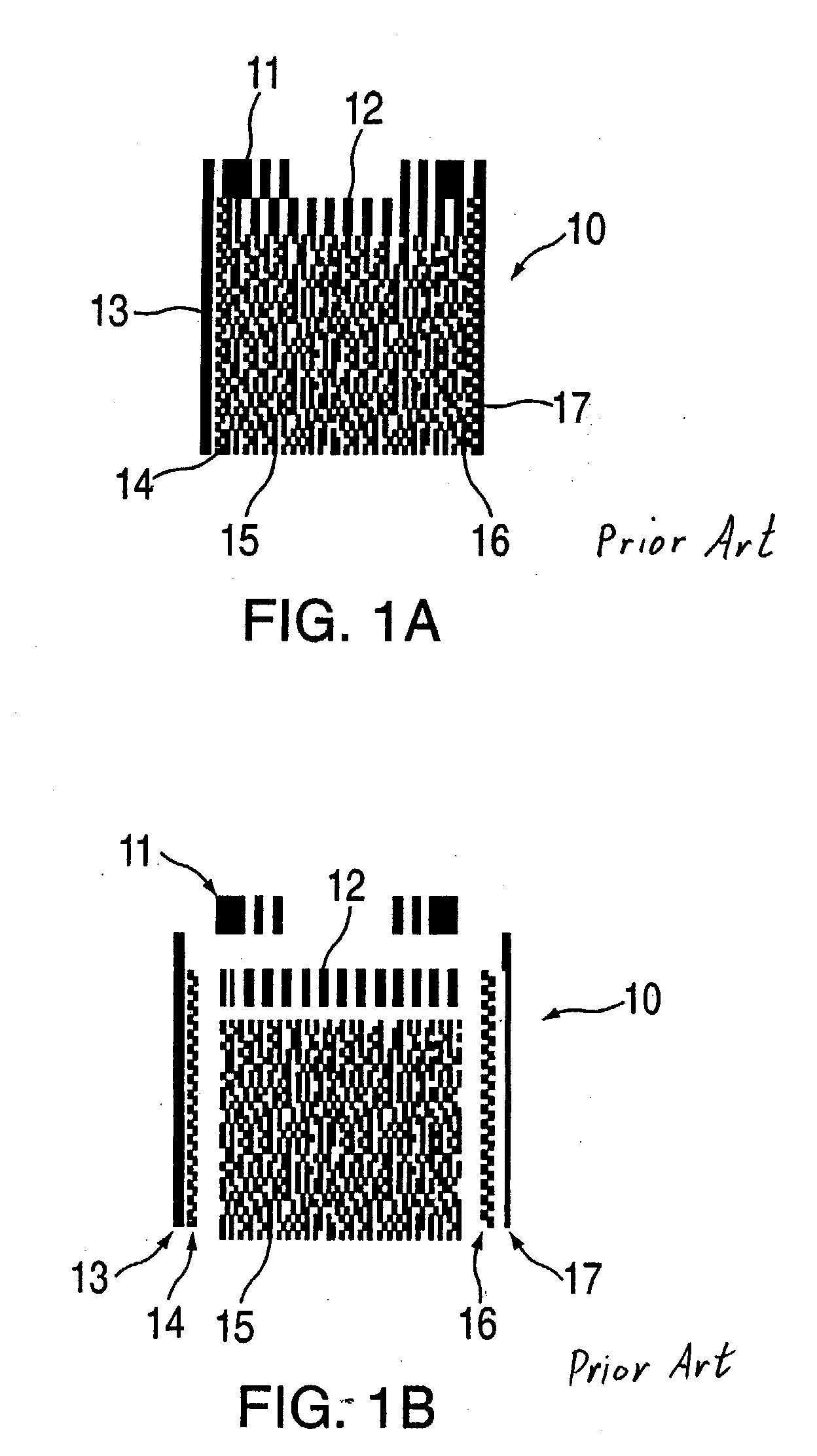

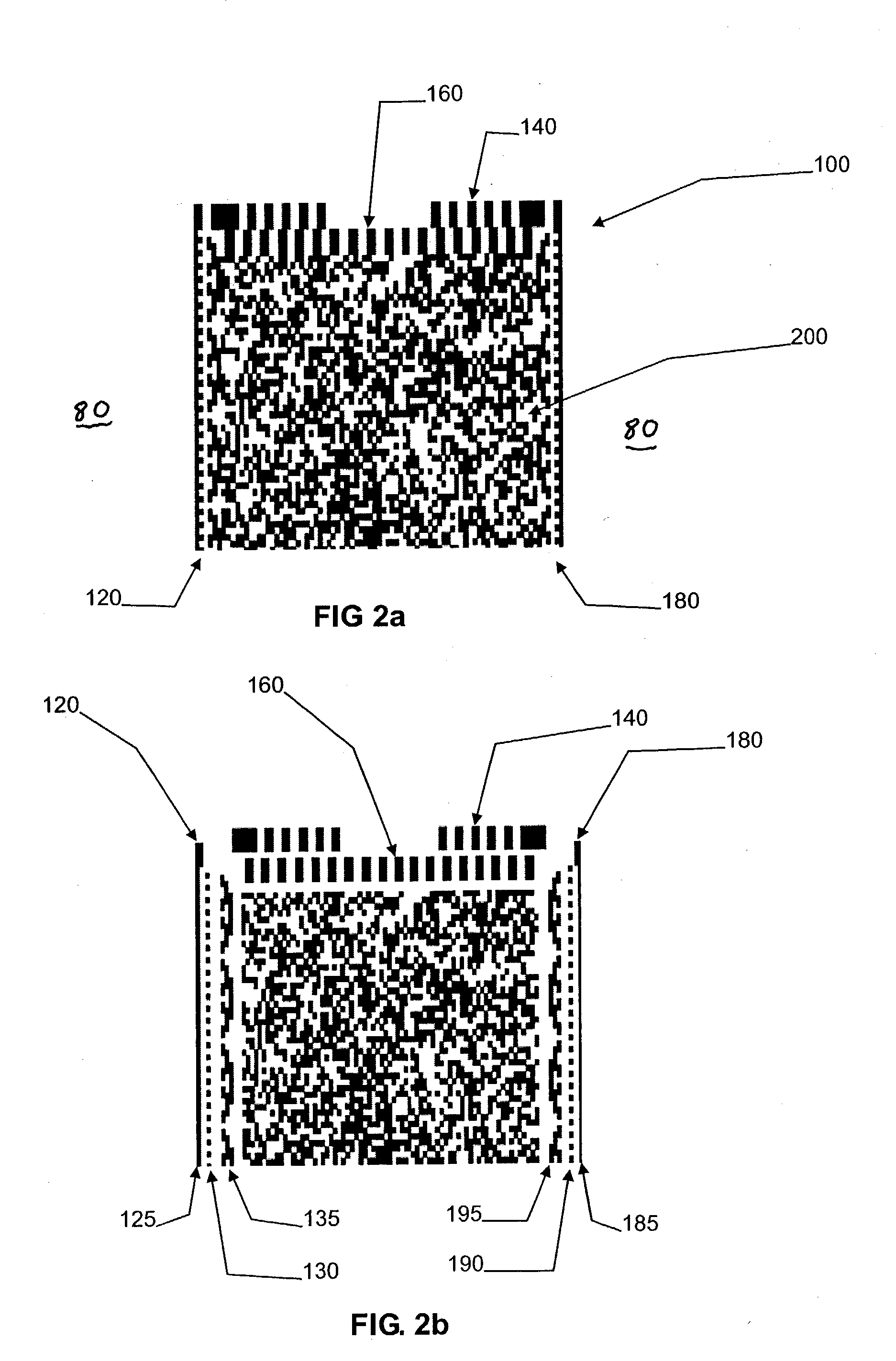

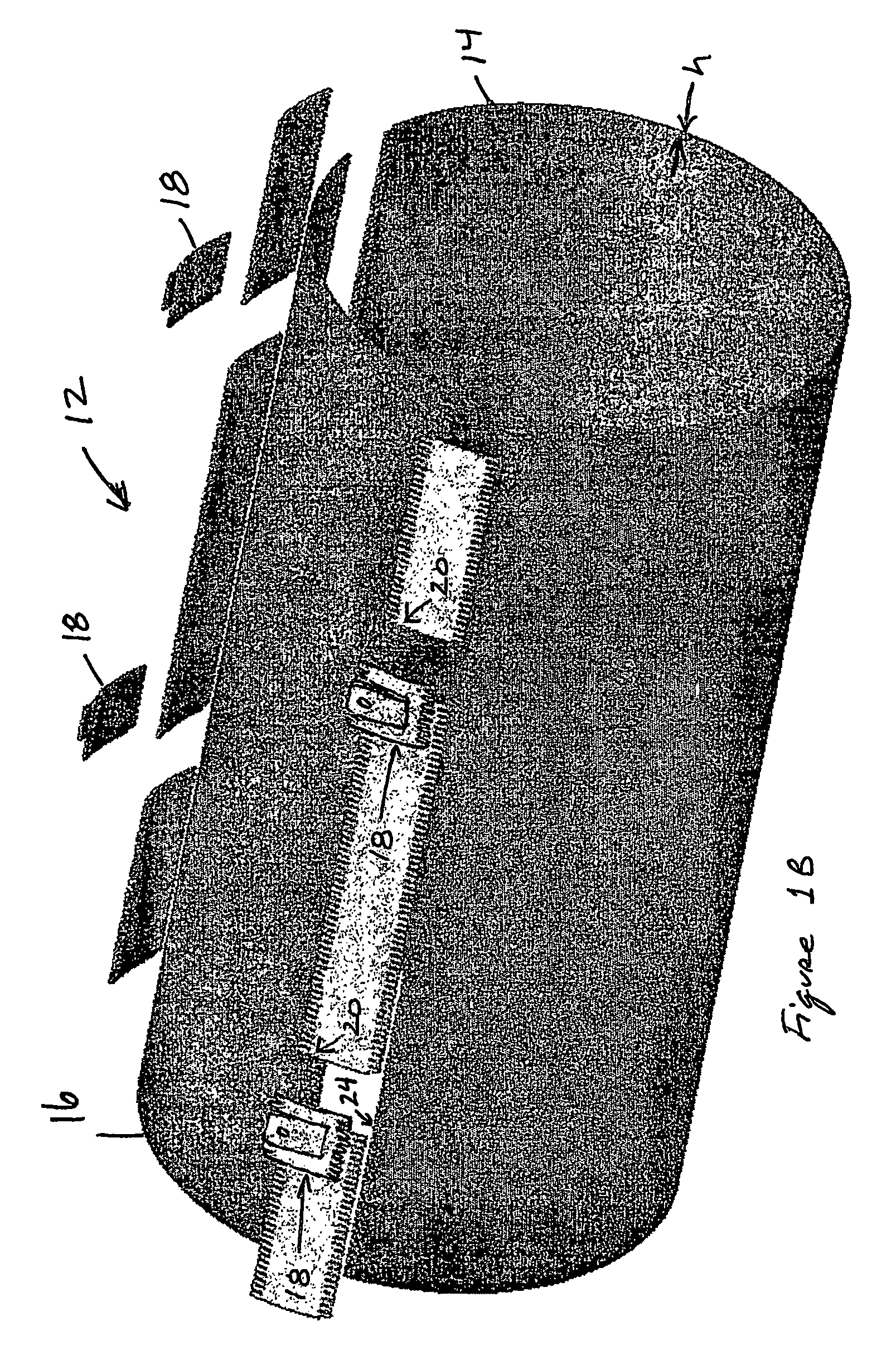

Two-dimensional printed code for storing biometric information and integrated offline apparatus for reading same

InactiveUS20050138527A1Increase capacityImprove performanceCode conversionSensing record carriersComputer hardwareHigh density

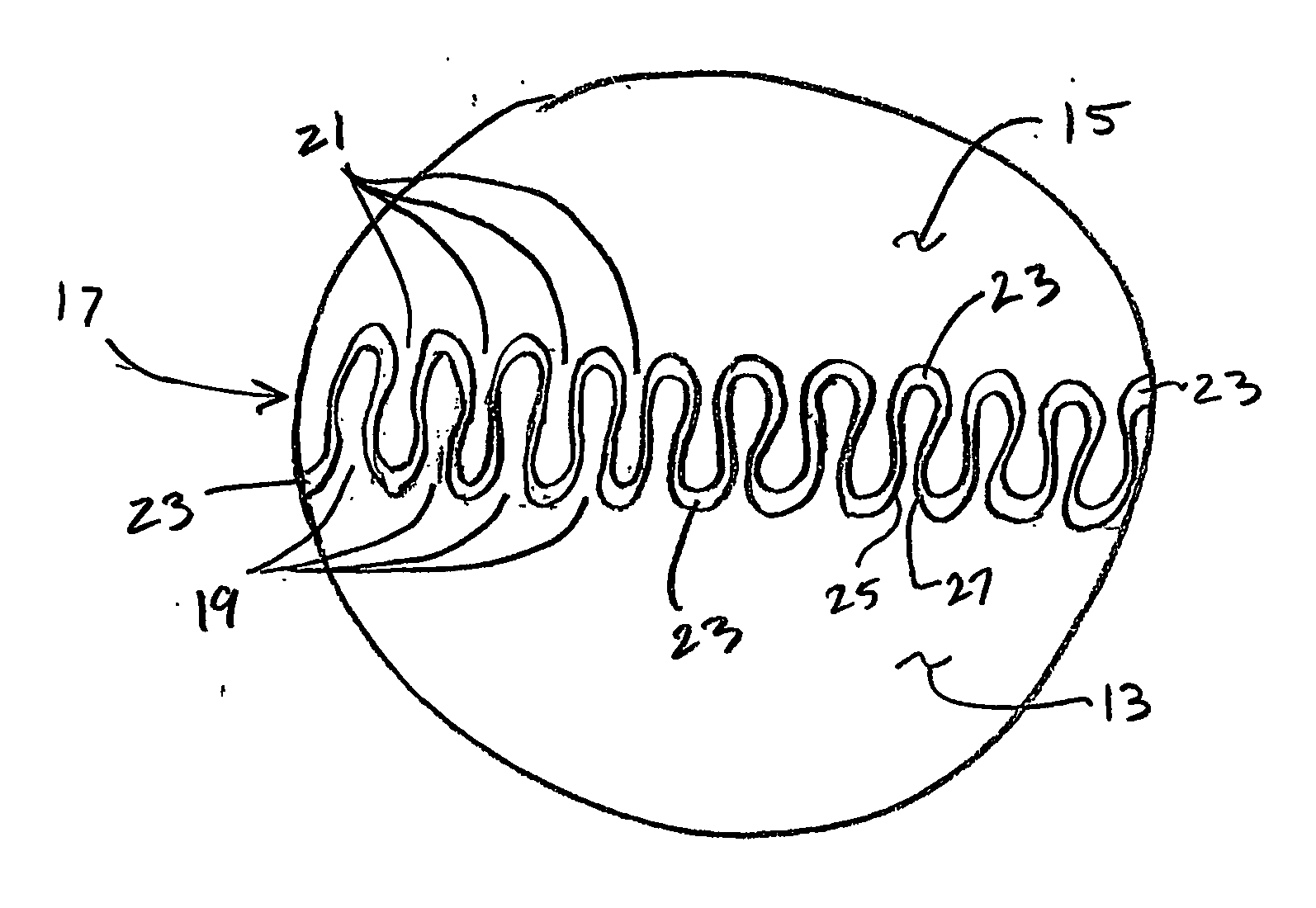

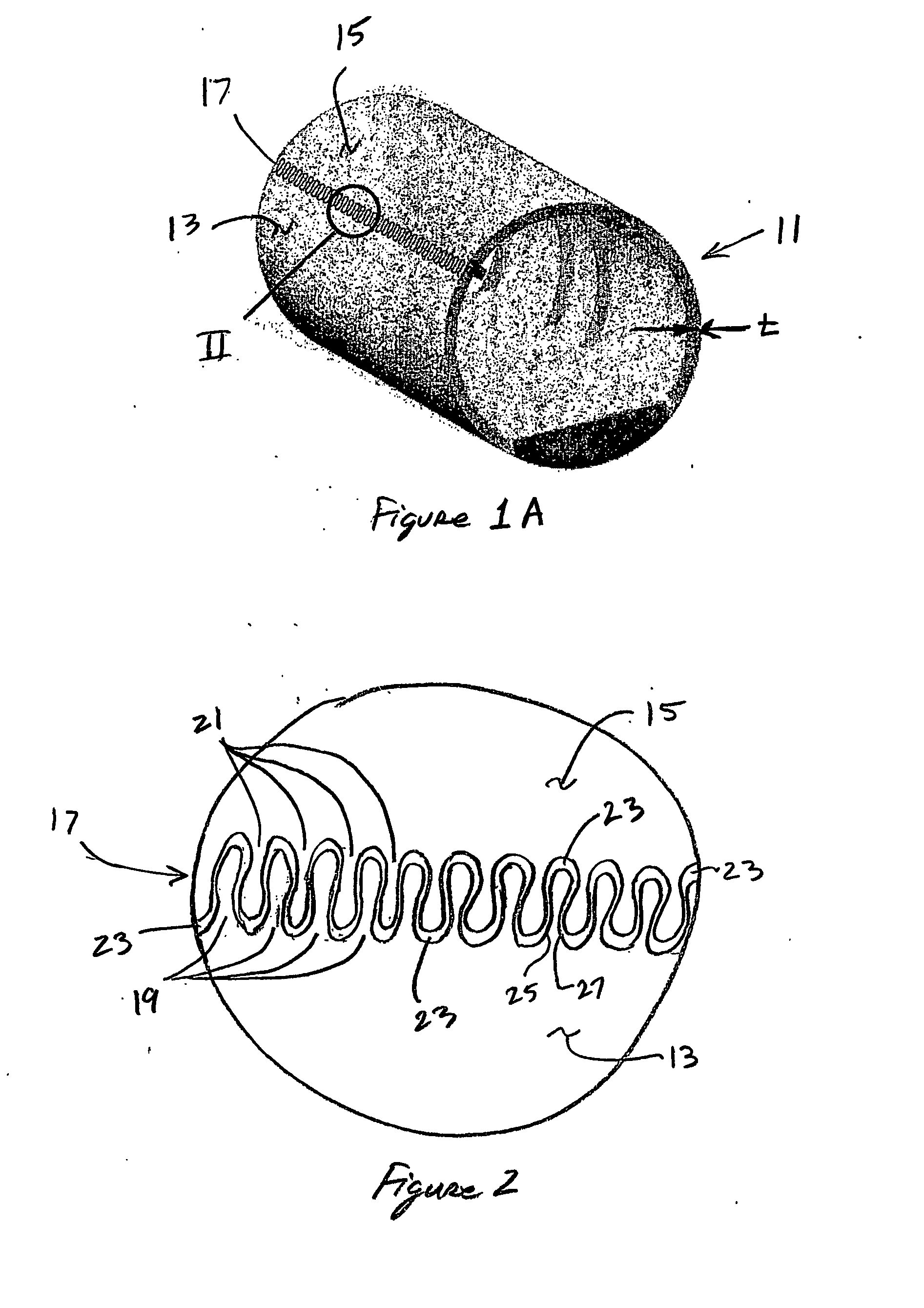

A two-dimensional, high-density, damage-tolerant printed code suitable for encoding multiple biometrics and text for positive off-line identity verification comprises a horizontal header section; a vertical header section; a start pattern; a left row address pattern; an encoded data portion; a right two address pattern; and stop pattern. The horizontal header section encodes the number of bit areas in a transverse row of the encoded data portion; and the vertical header section encodes the vertical height of each bit area. The start and stop patterns of the code demarcate the lateral extent of the code (i.e., the beginning and end) from the adjacent quiet zone. Information is encoded into the ended information portion in bit areas that may be printed or blank. The information is encoded sequentially in the information portion from the top of the encoded information portion along each transverse row of bit areas to the next row of bit areas until the end of the encoded information portion. Error correction is applied to subunits of information from the encoded information portion by dividing the user messages and applying error correction to subunits of the user message. The two-dimensional, high-density, damage-tolerant printed code is suitable for printed on a conventionally sized ISO cord or other papers used in verifying identity. An ISO-sized cord or other identity paper bearing a two-dimensional, high-density, damage-tolerant printed code encoding multiple biometrics, e.g., encoded image likeness and multiple finger print templates, maybe used with an off-line integrated positive identity verification apparatus that is capable of decoding the image and fingerprint samples taken from an individual whose identity is sought to be verified.

Owner:DATASTRIP IOM

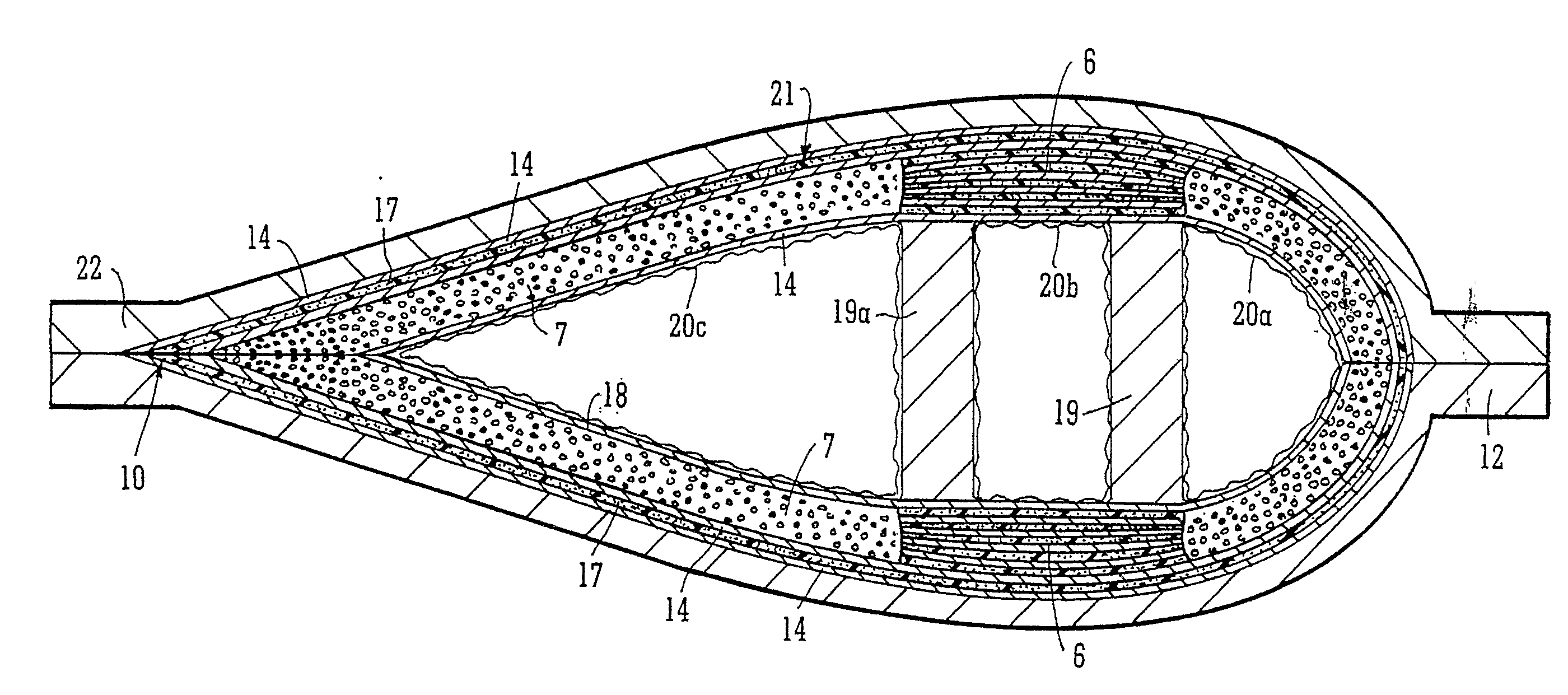

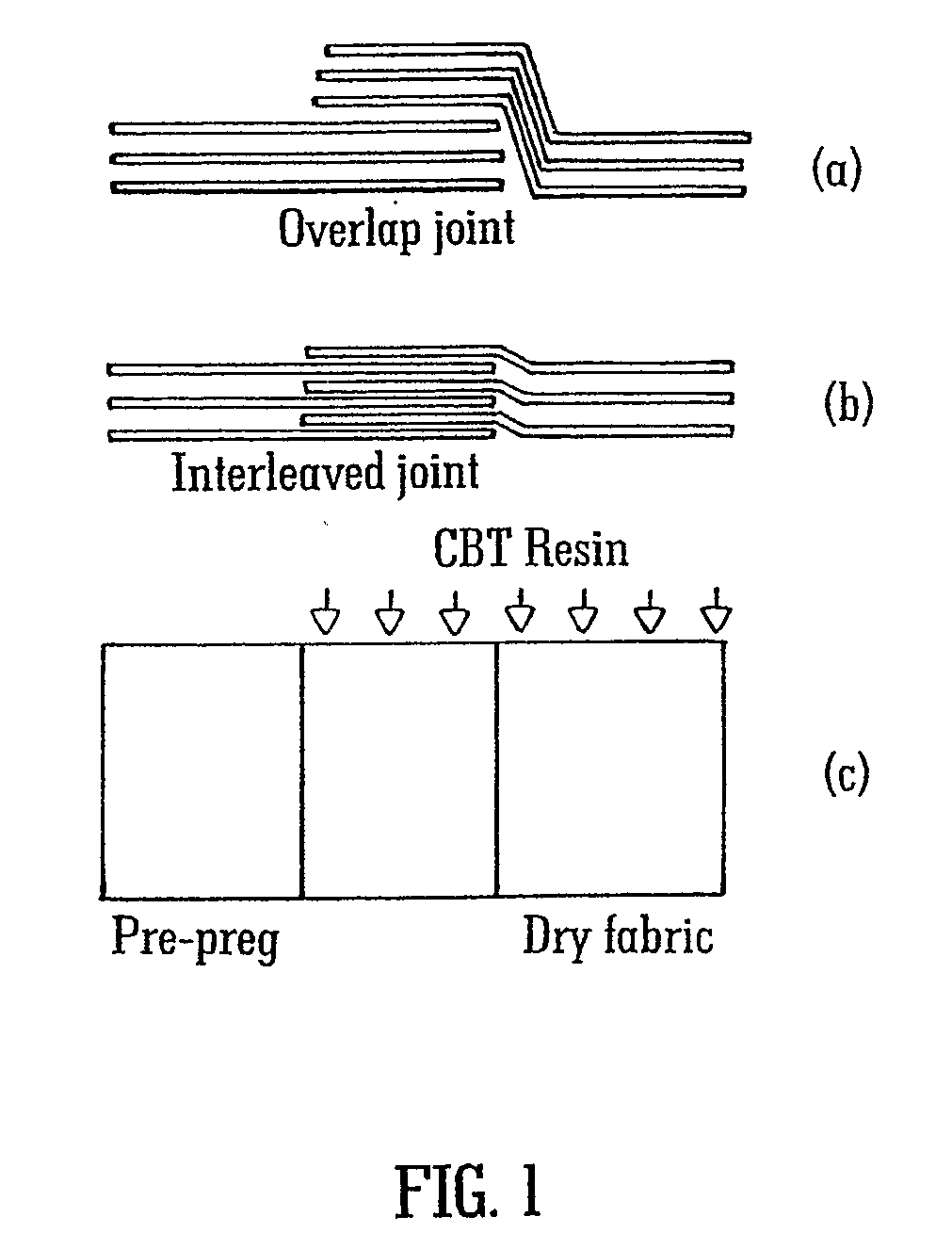

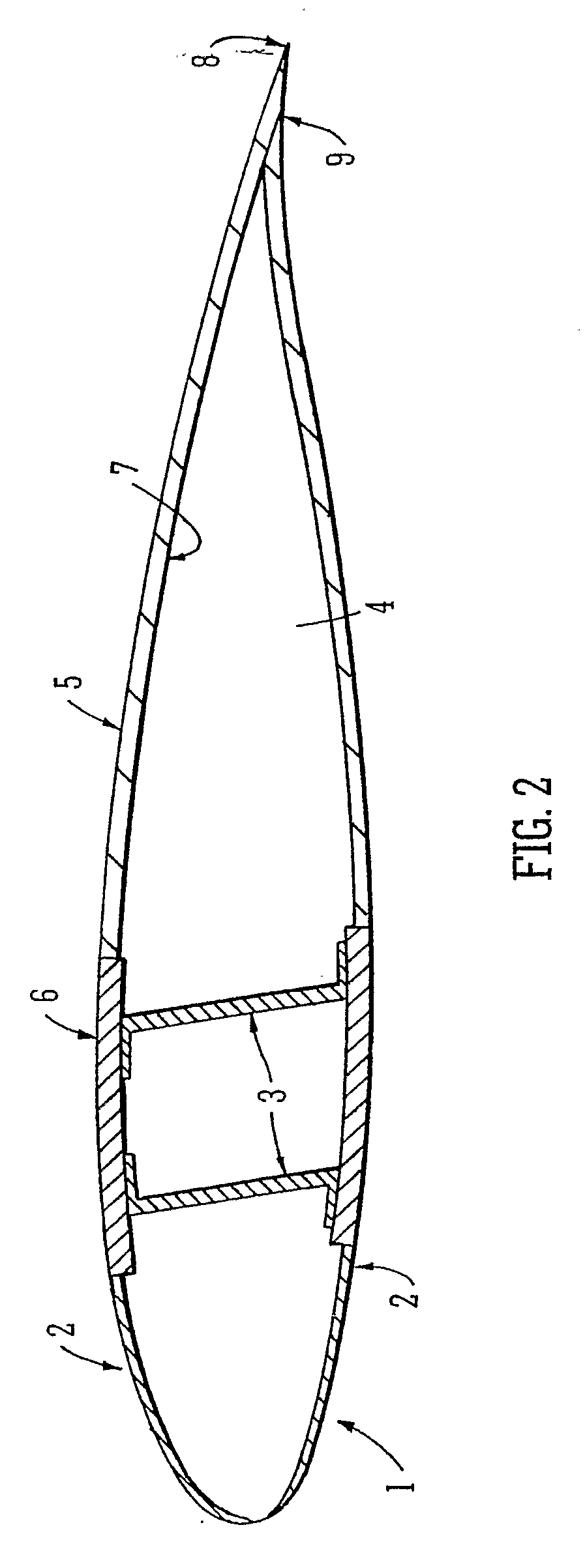

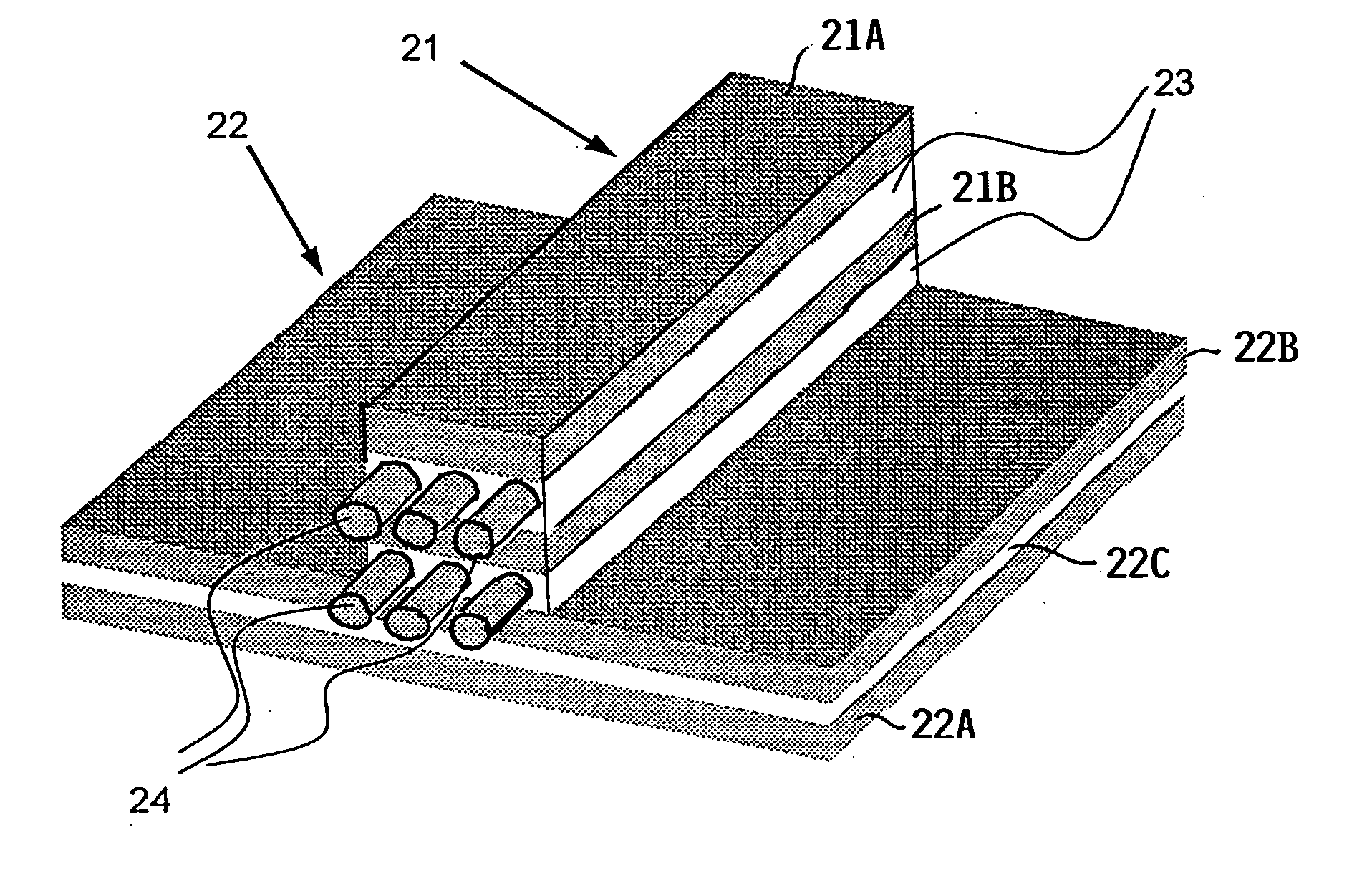

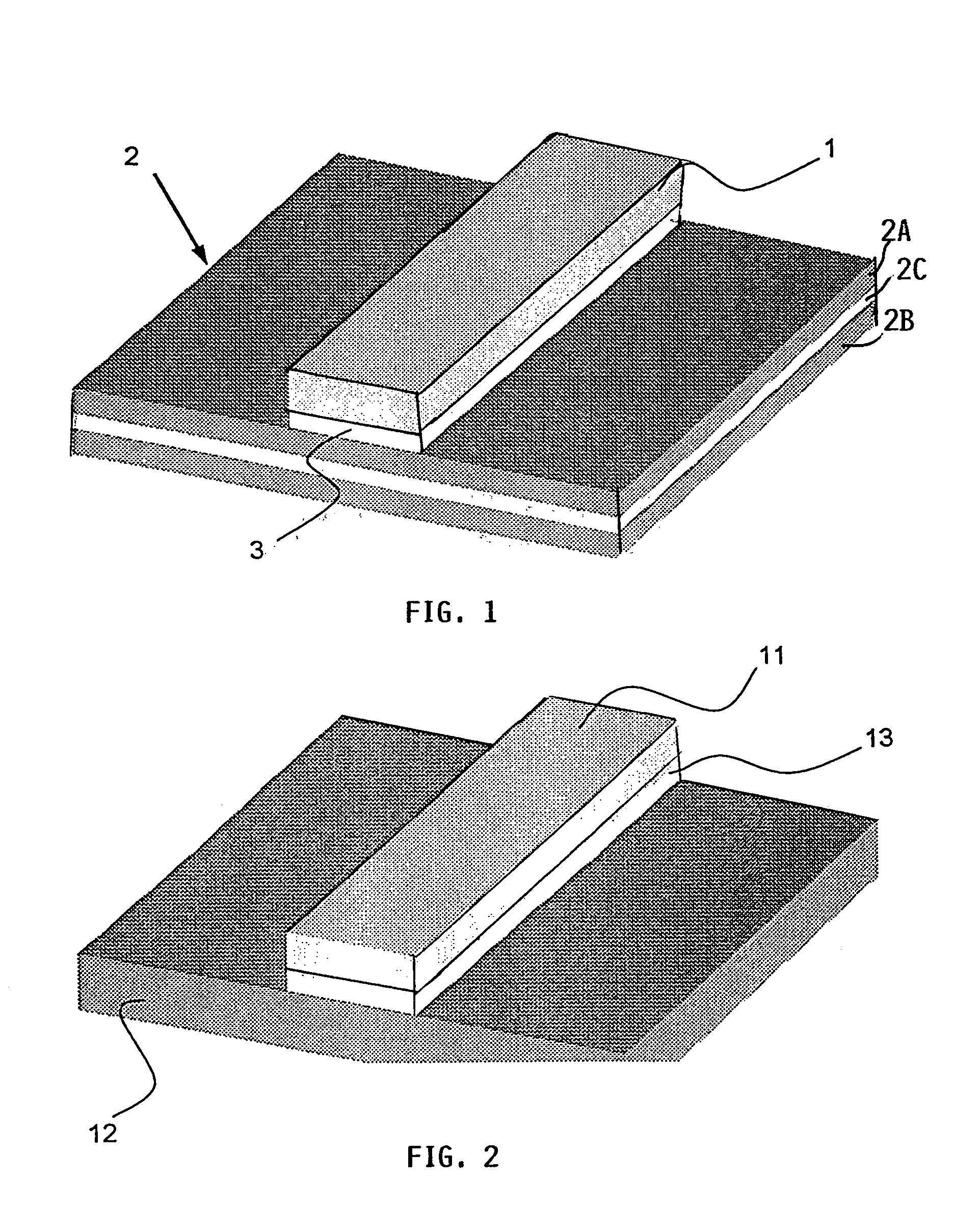

Composite Articles Comprising In-Situ-Polymerisable Thermoplastic Material and Processes for their Construction

InactiveUS20100062238A1Reliable constructionLow costFinal product manufacturePretreated surfacesTurbine bladeIn situ polymerization

A process for the manufacture of a composite article is described wherein the process comprises the steps of (i) providing on a tool (22) a fibrous material (14) having associated therewith in at least one region thereof an in-situ polymerisable non-fibrous form of a thermoplastic material; (ii) applying heat and a vacuum to said material; and additionally (iii) drawing into the fibrous material, from a source external to the tool, additional thermoplastic pre-polymer material. The process described is particularly useful for the manufacture of a large composite structure such as thermoplastic composite wind turbine blade, for example.

Owner:UNIVERSITY OF LIMERICK +2

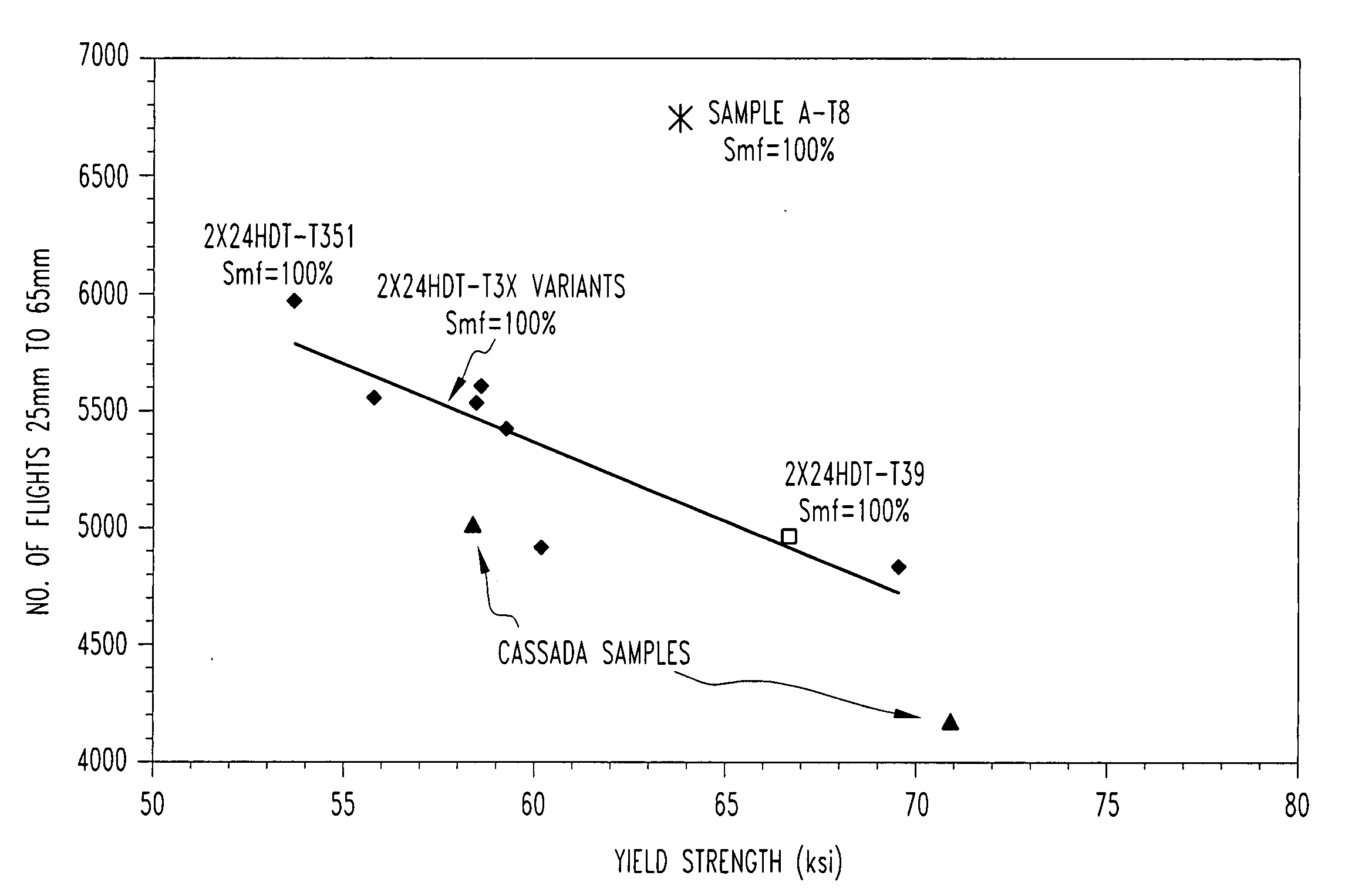

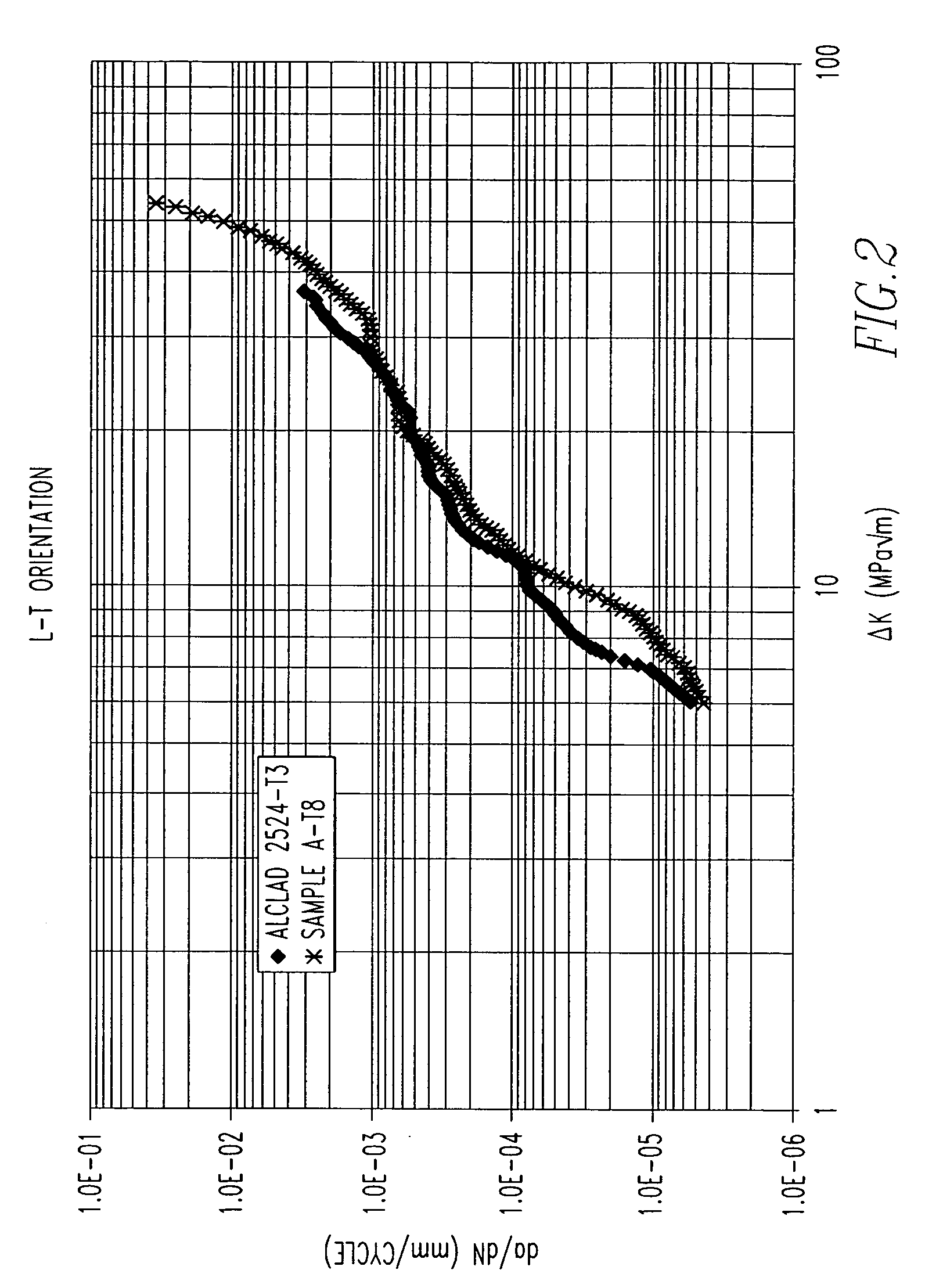

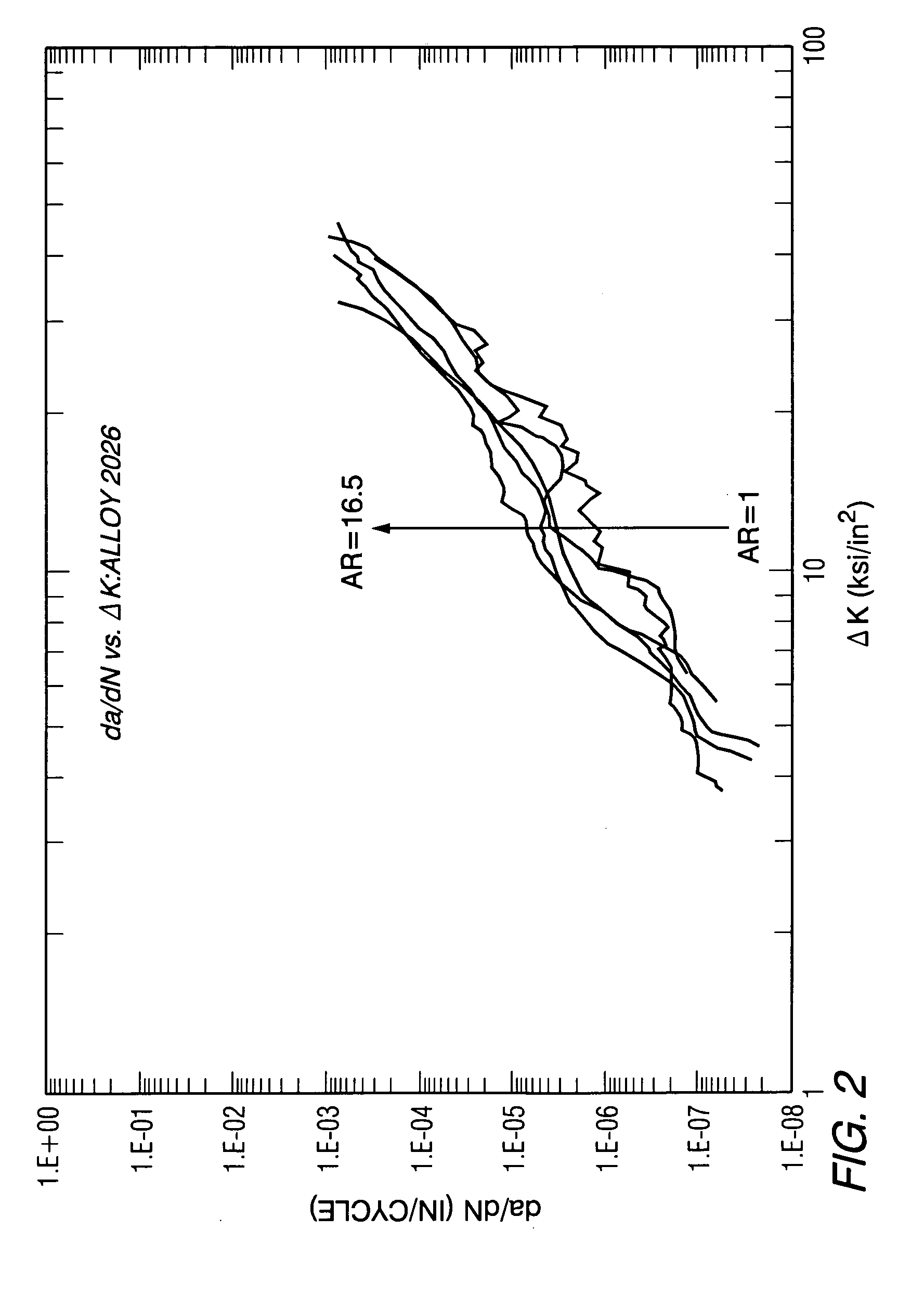

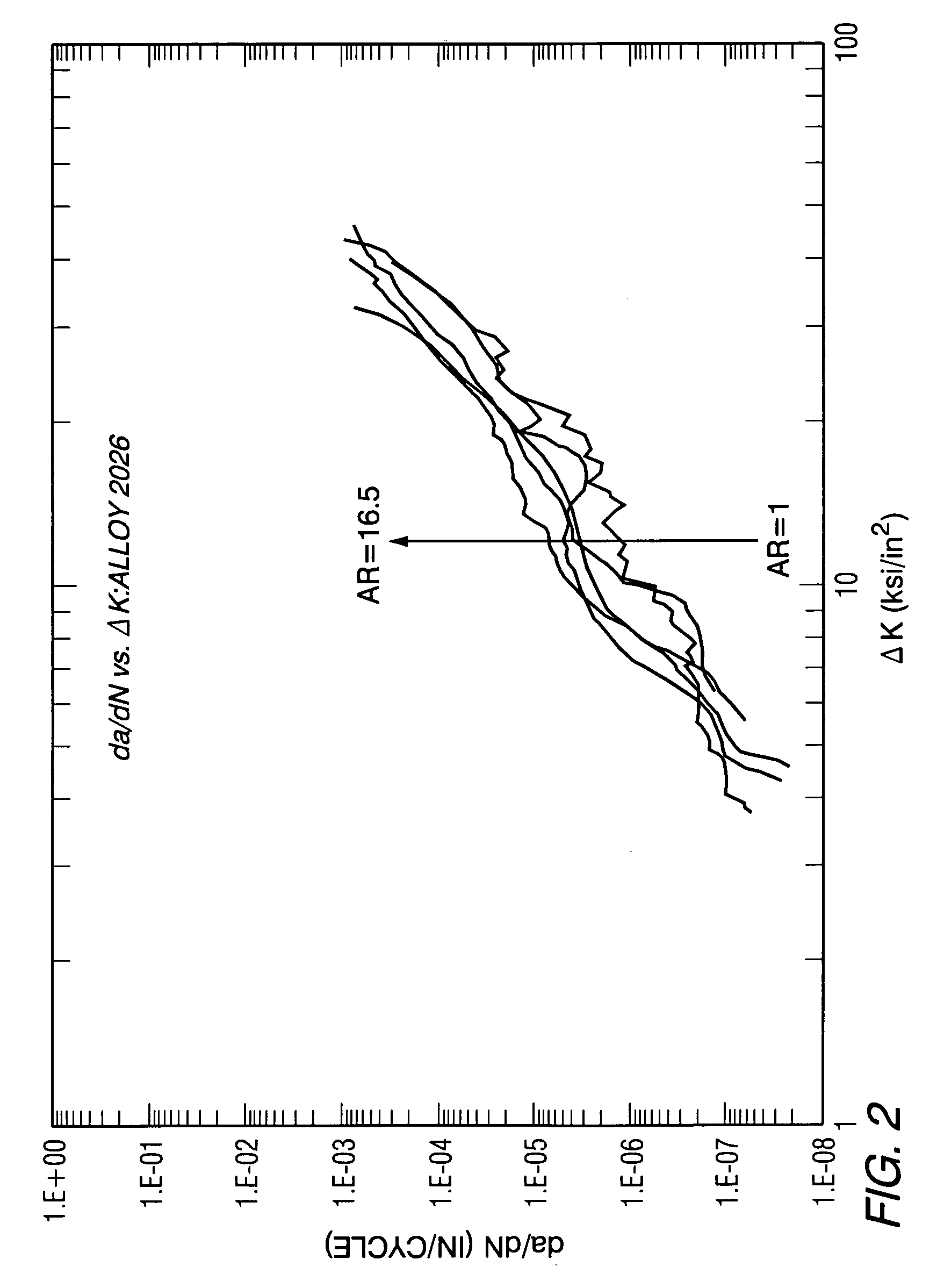

2000 Series alloys with enhanced damage tolerance performance for aerospace applications

The invention provides a 2000 series aluminum alloy having enhanced damage tolerance, the alloy consisting essentially of about 3.0-4.0 wt % copper; about 0.4-1.1 wt % magnesium; up to about 0.8 wt % silver; up to about 1.0 wt % Zn; up to about 0.25 wt % Zr; up to about 0.9 wt % Mn; up to about 0.5 wt % Fe; and up to about 0.5 wt % Si, the balance substantially aluminum, incidental impurities and elements, said copper and magnesium present in a ratio of about 3.6-5 parts copper to about 1 part magnesium. The alloy is suitable for use in wrought or cast products including those used in aerospace applications, particularly sheet or plate structural members, extrusions and forgings, and provides an improved combination of strength and damage tolerance.

Owner:ARCONIC TECH LLC

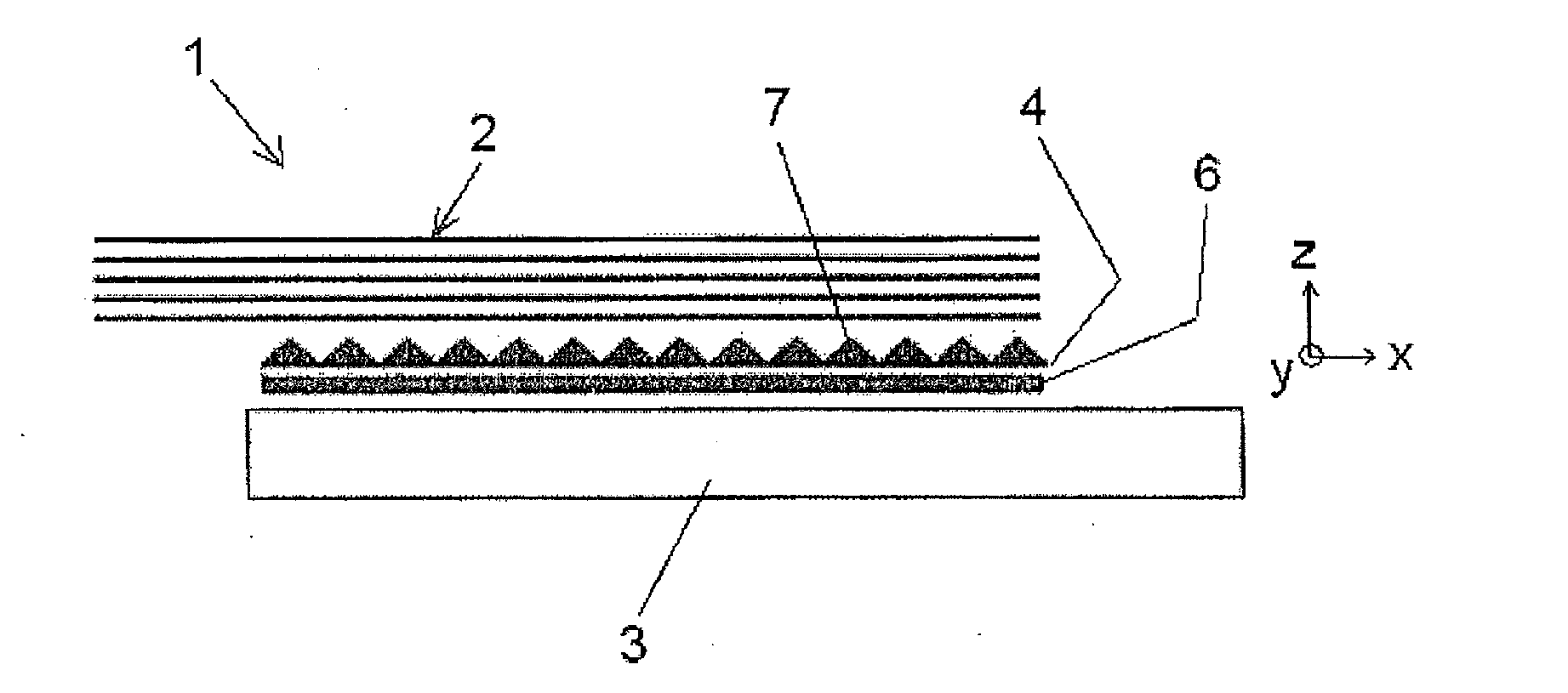

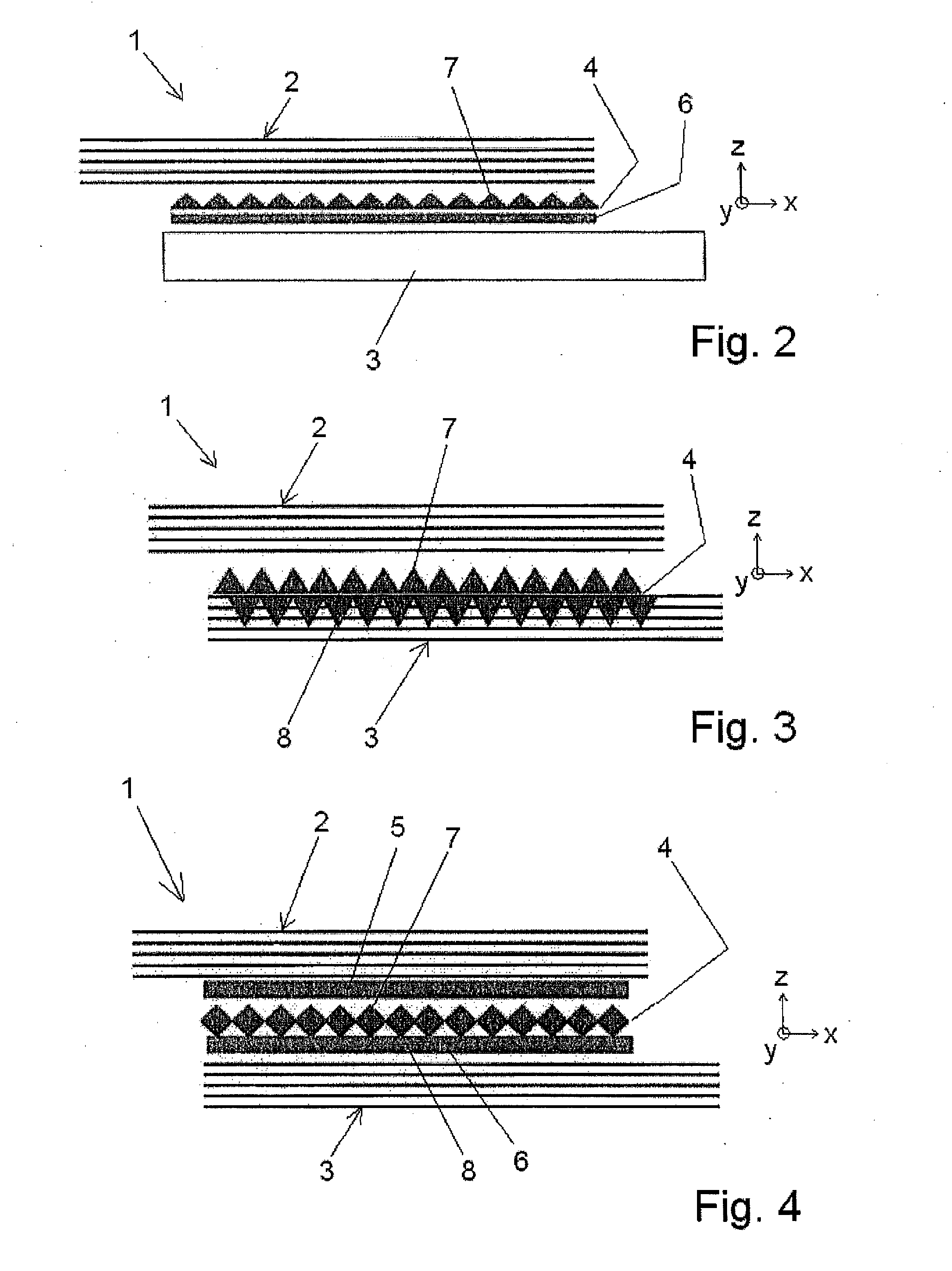

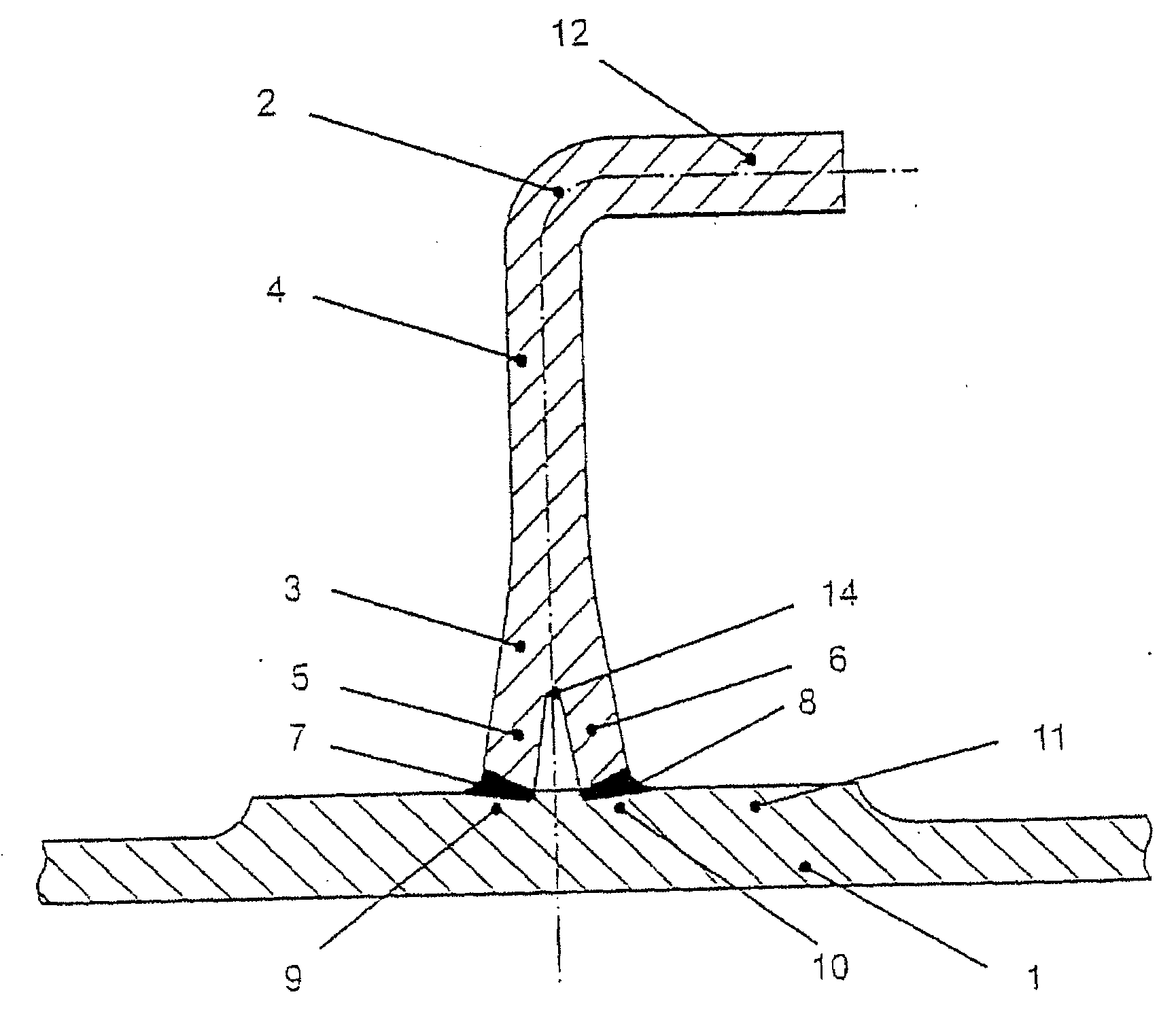

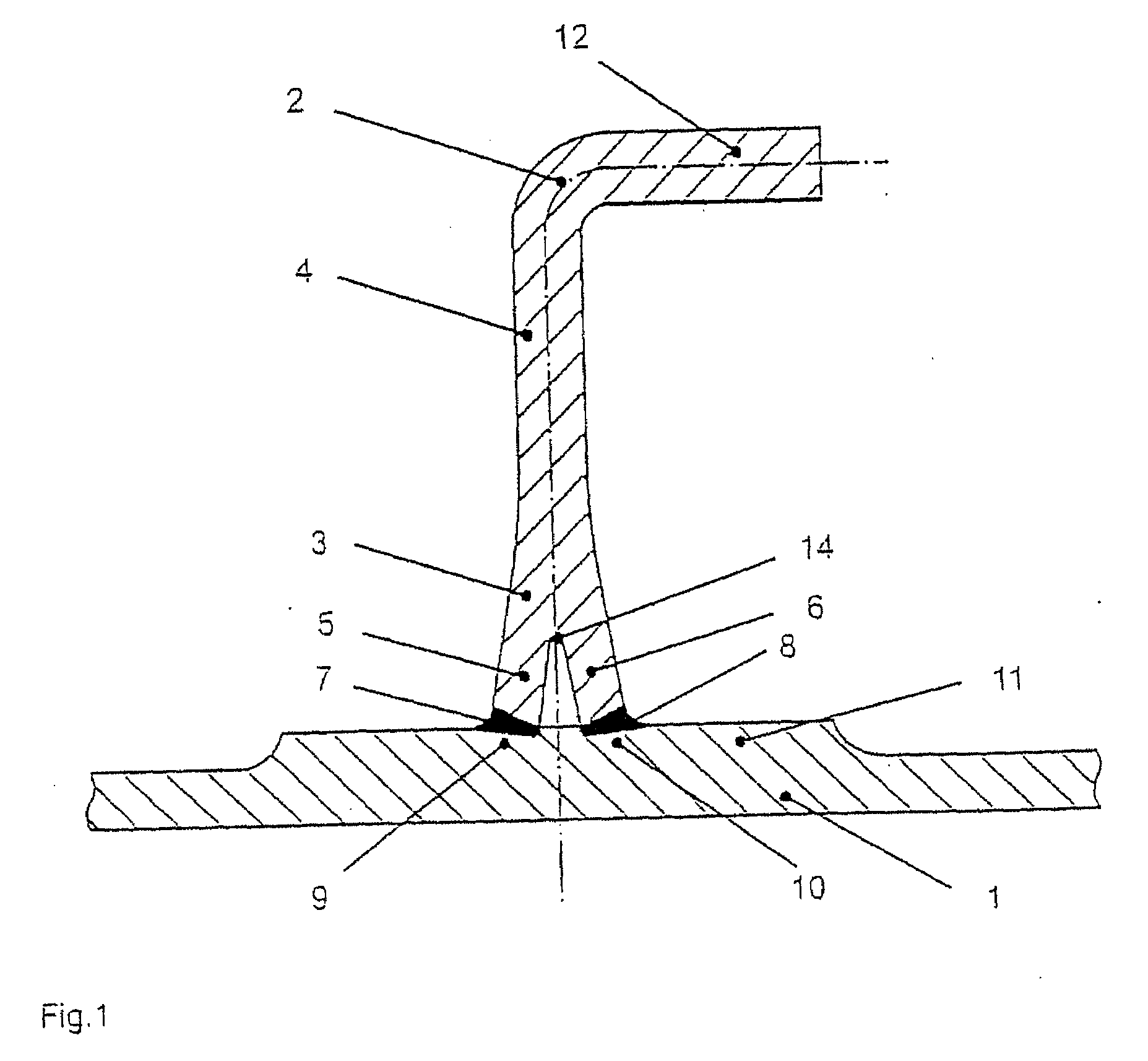

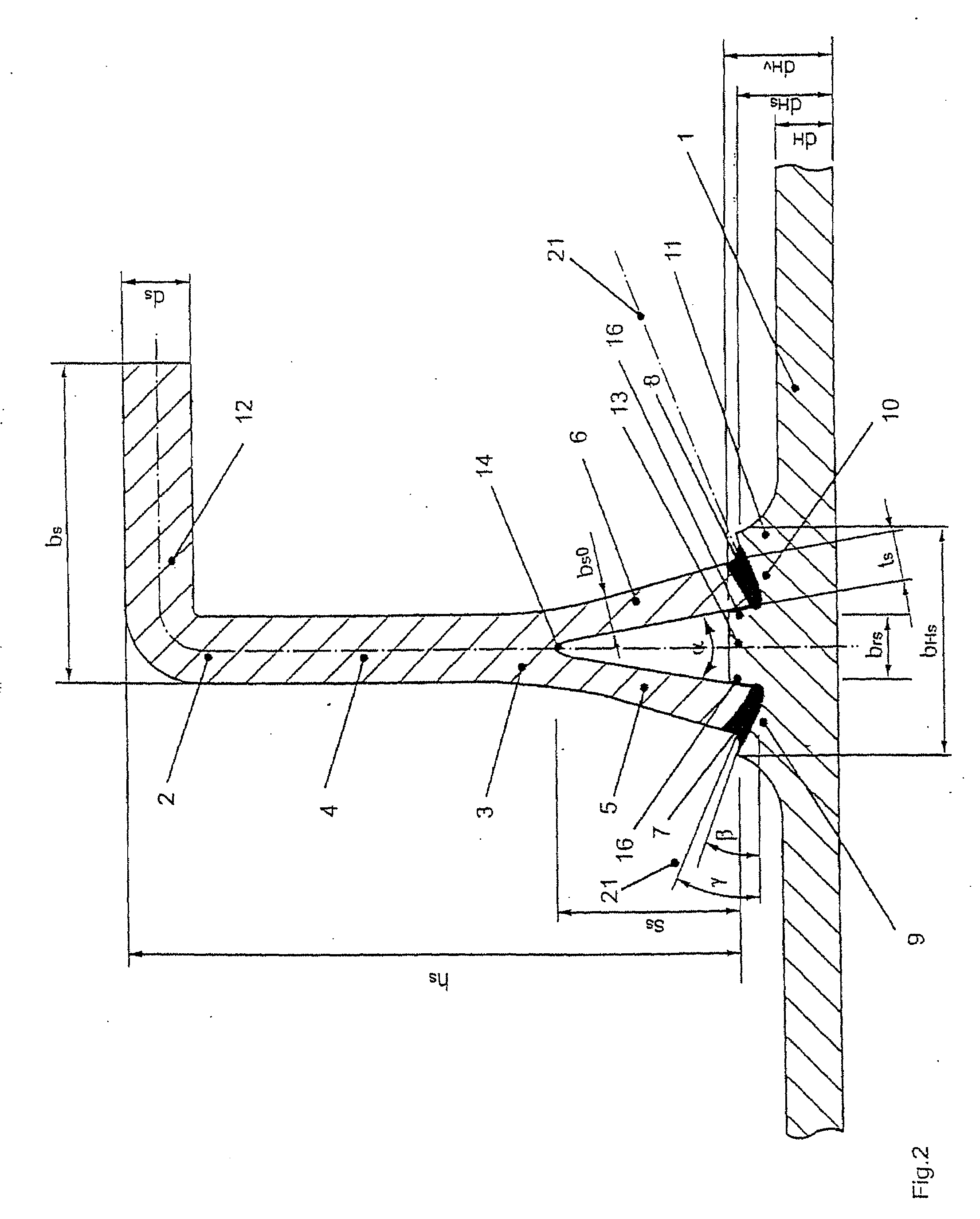

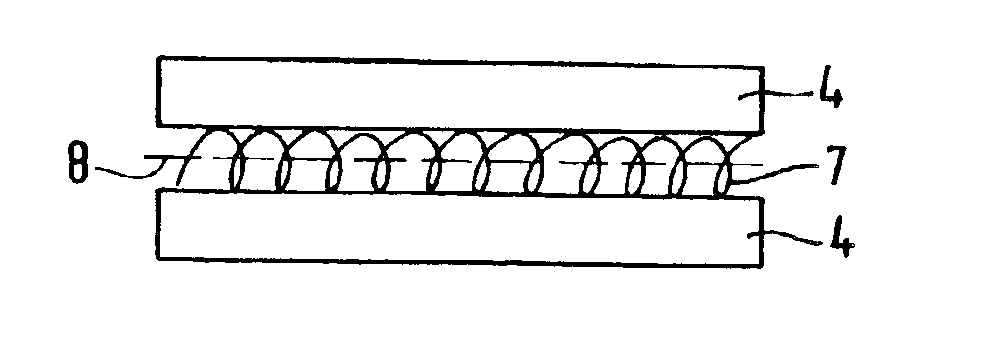

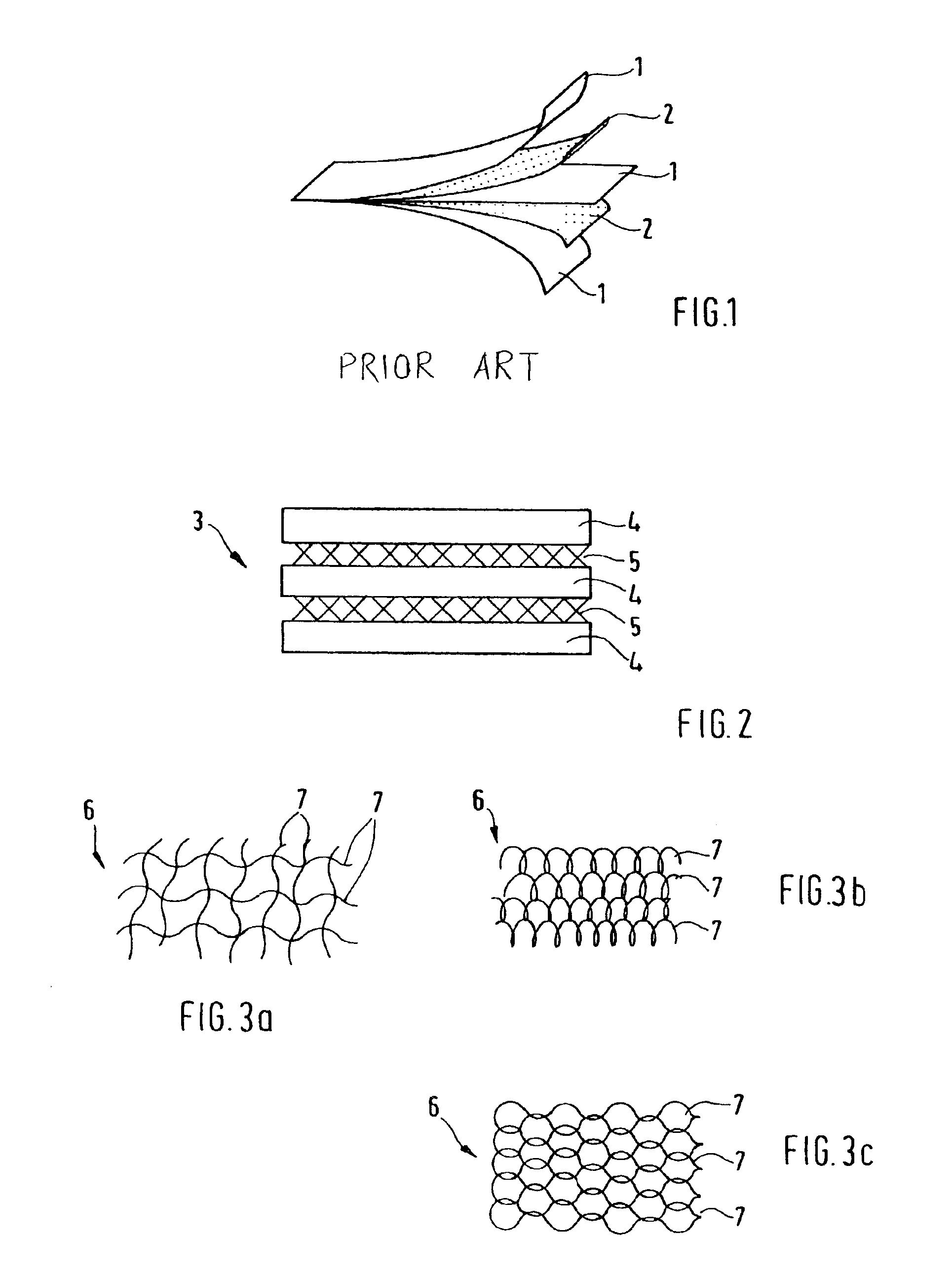

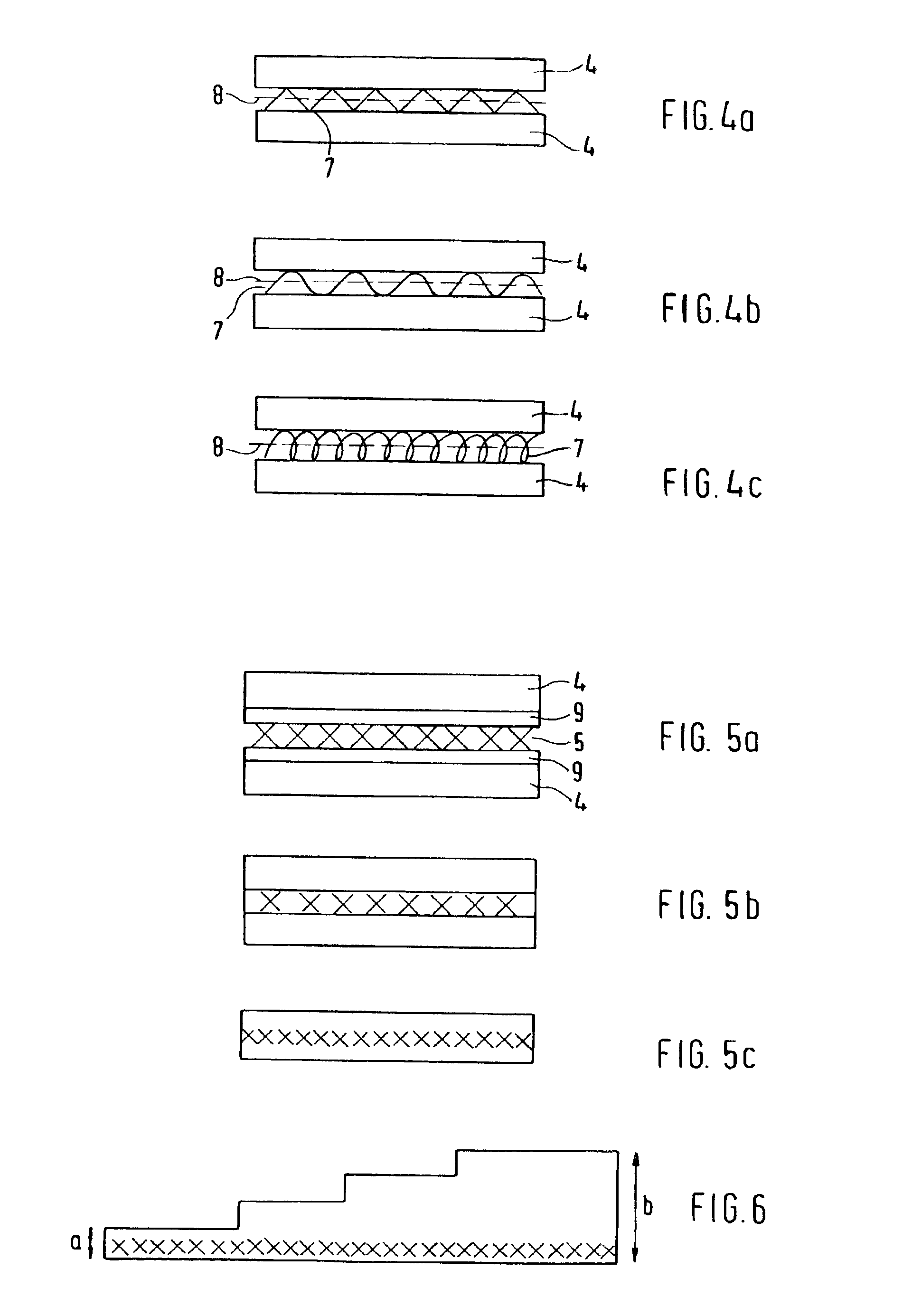

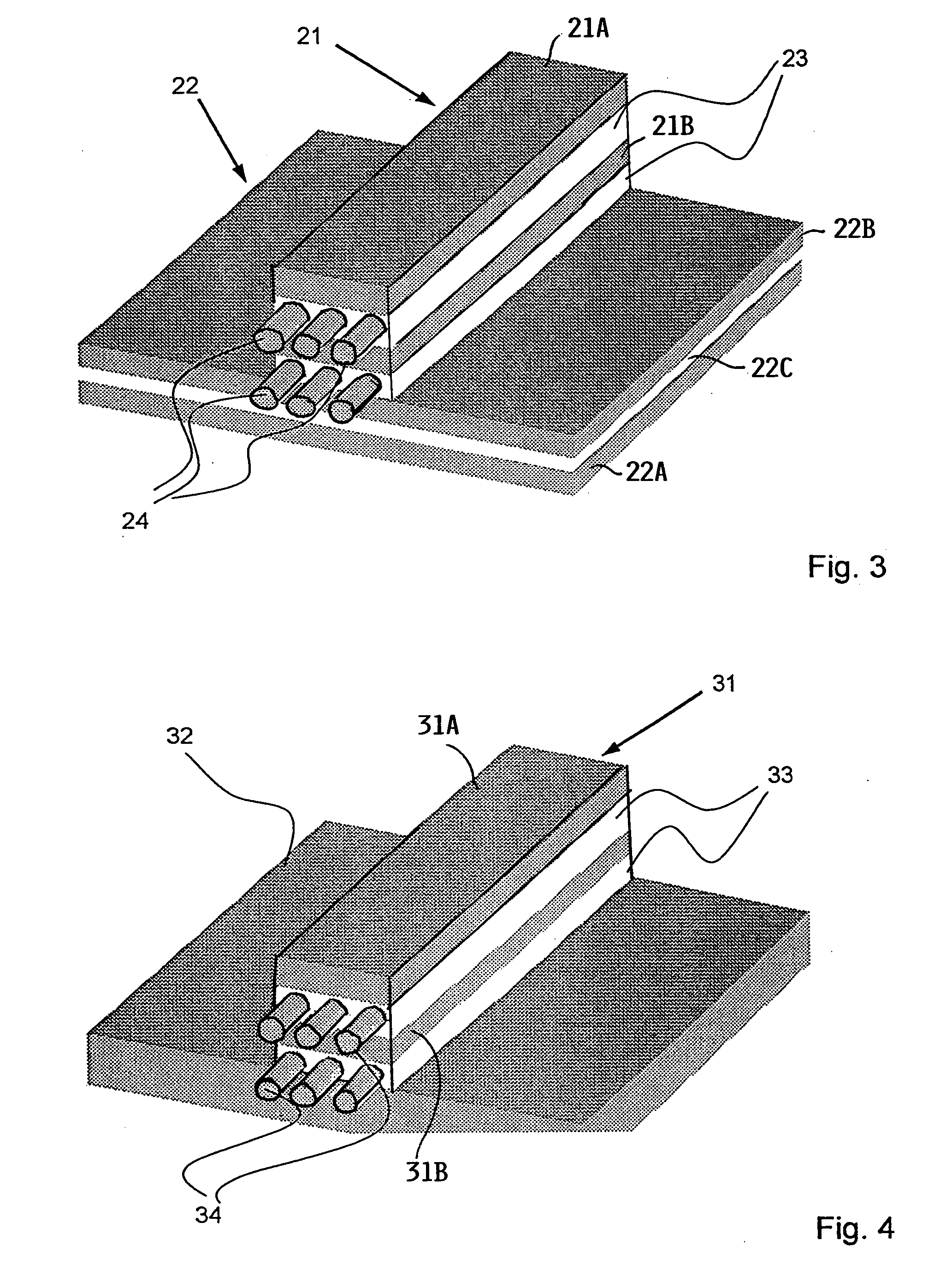

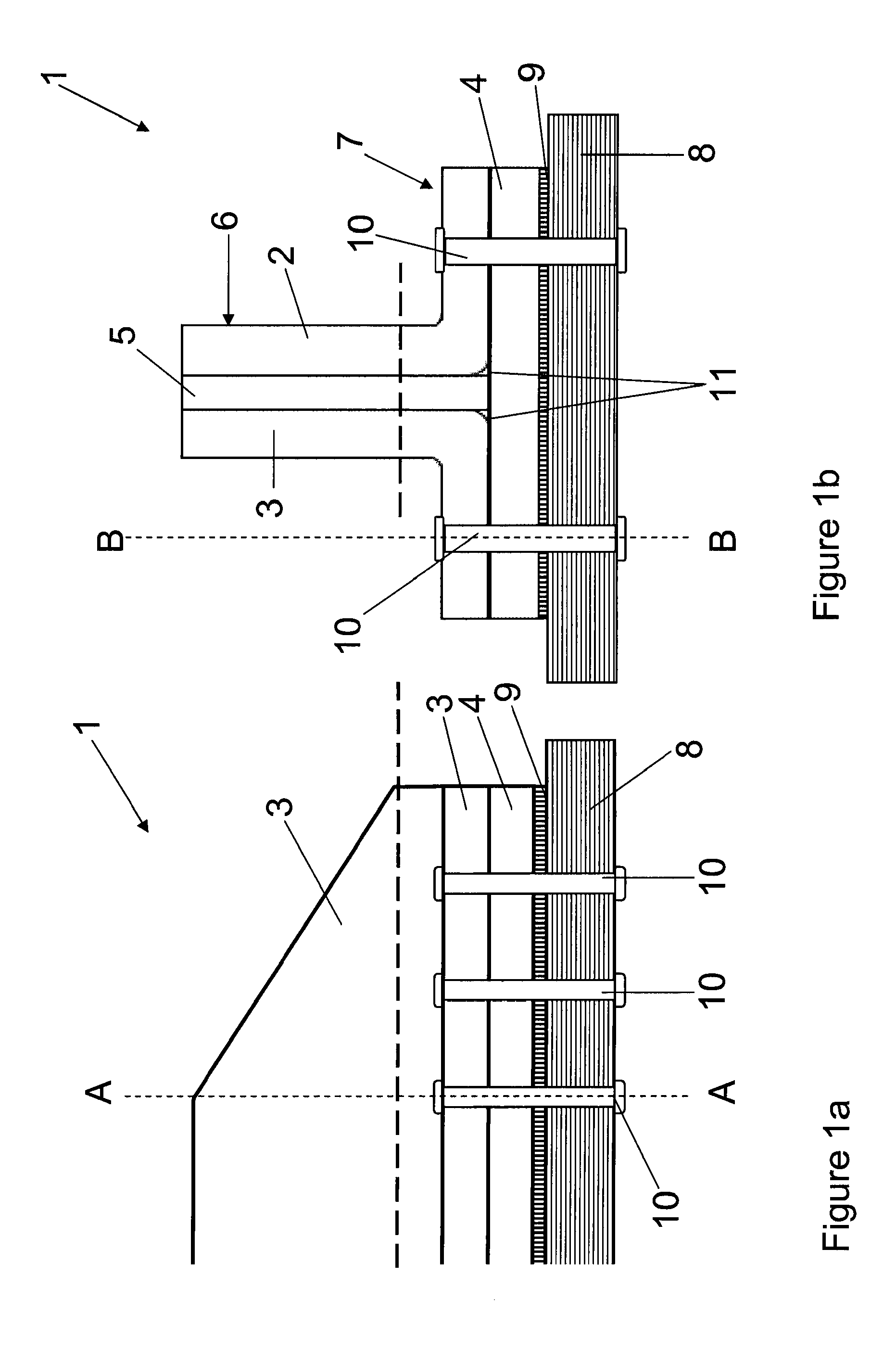

Method for connecting a fibre composite component to a structural component of an aircraft and spacecraft and a corresponding arrangement

InactiveUS20130149501A1High damage toleranceAvoid componentsLayered productsMetal-working apparatusMetal foilFibrous composites

In the case of a method for connecting a fibre composite component to a structural component of an aircraft and spacecraft, a metal foil is provided as a transverse reinforcement element between the fibre composite component and the structural component. It is formed with at least one anchoring portion which protrudes from the surface facing the fibre composite component and is inserted between the fibre composite component and the structural component. A corresponding arrangement is produced in accordance with this method.

Owner:AIRBUS OPERATIONS GMBH

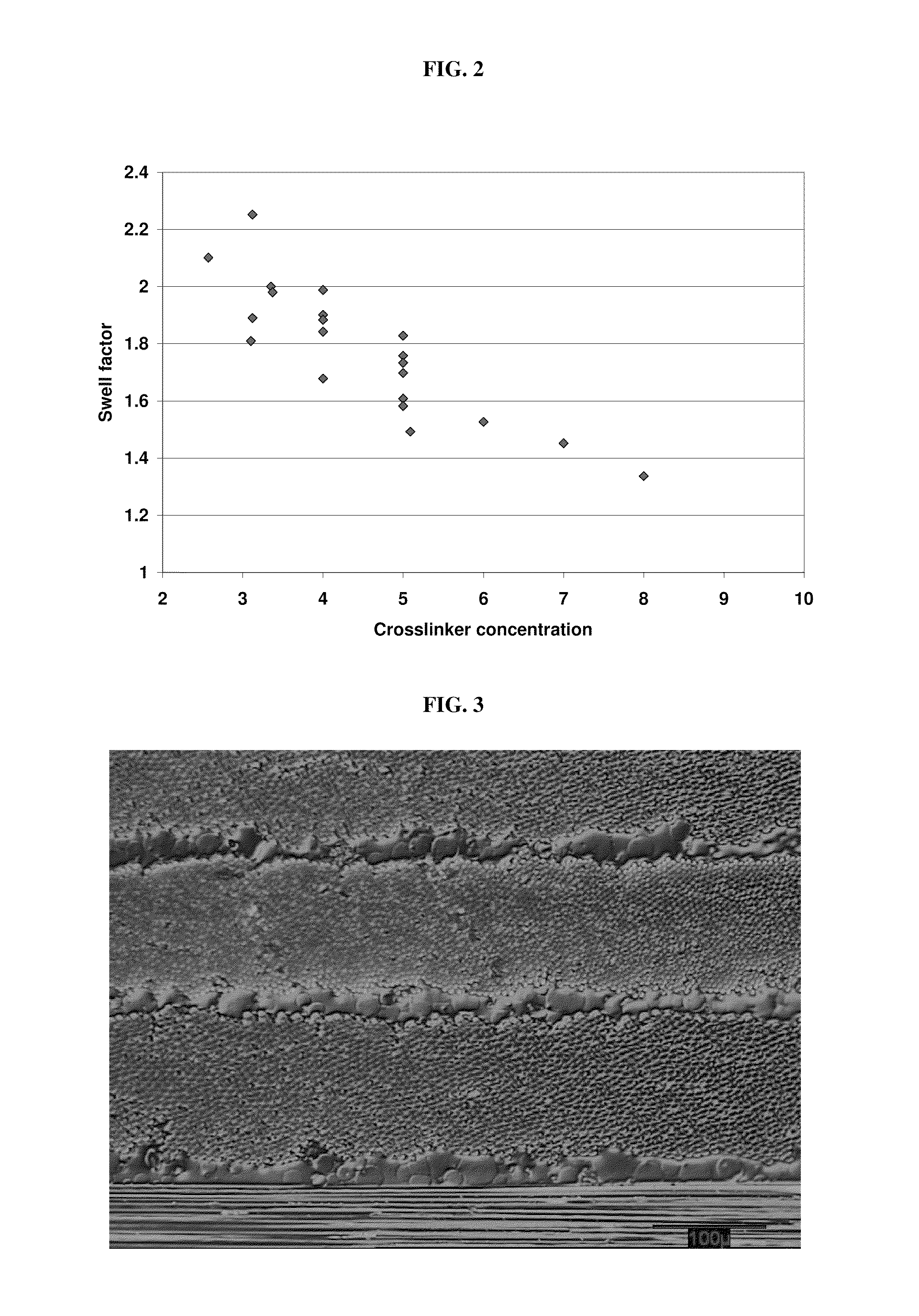

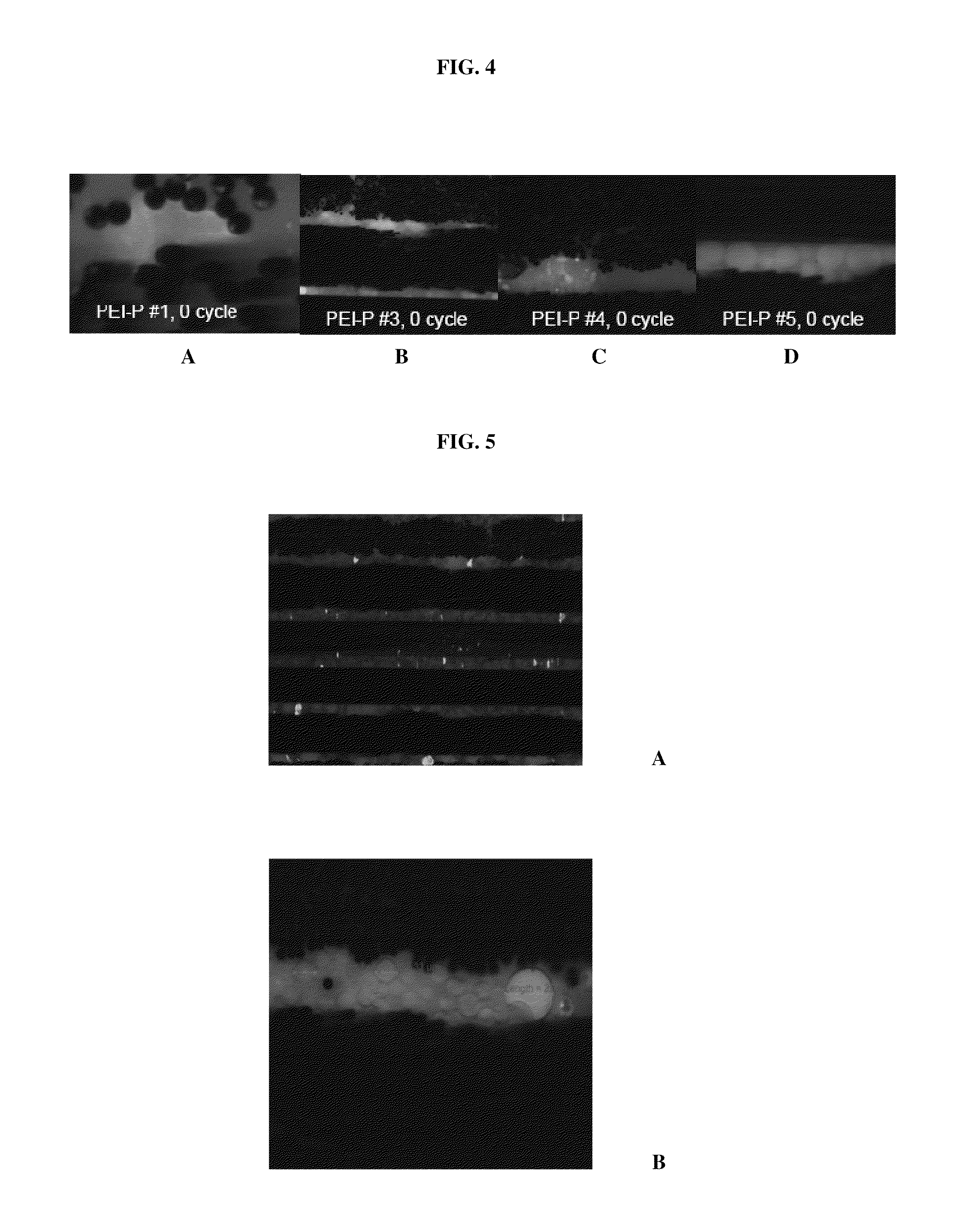

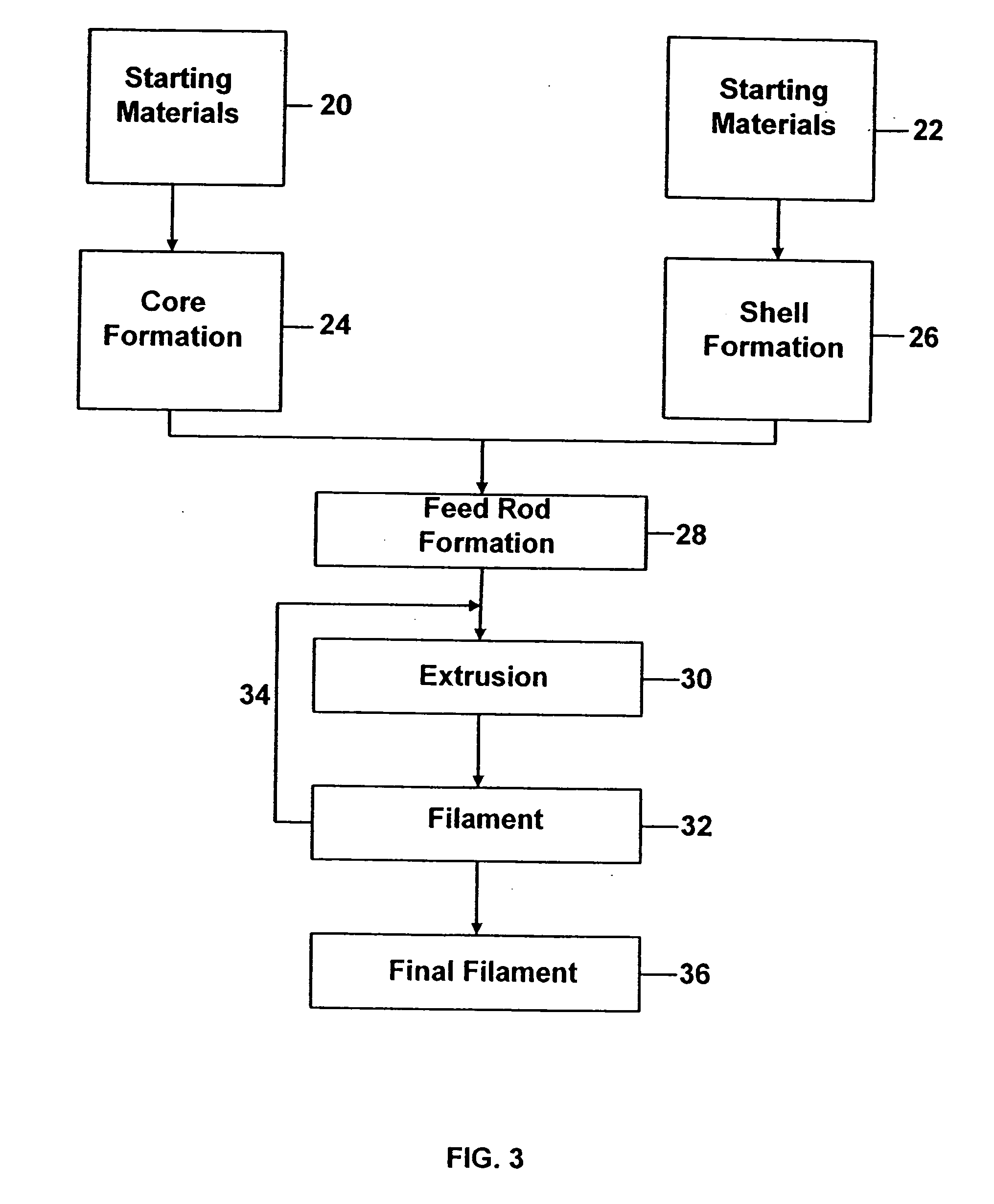

Engineered cross-linked thermoplastic particles for interlaminar toughening

ActiveUS8846818B2Improve toleranceImprove toughnessSynthetic resin layered productsCellulosic plastic layered productsCross-linkPolymer network

Owner:CYTEC TECH CORP

Lightweight structural component in particular for aircraft and method for its production

InactiveUS20080296433A1Efficient productionHigh damage toleranceLoad-supporting pillarsFuselage bulkheadsEngineeringAirplane

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

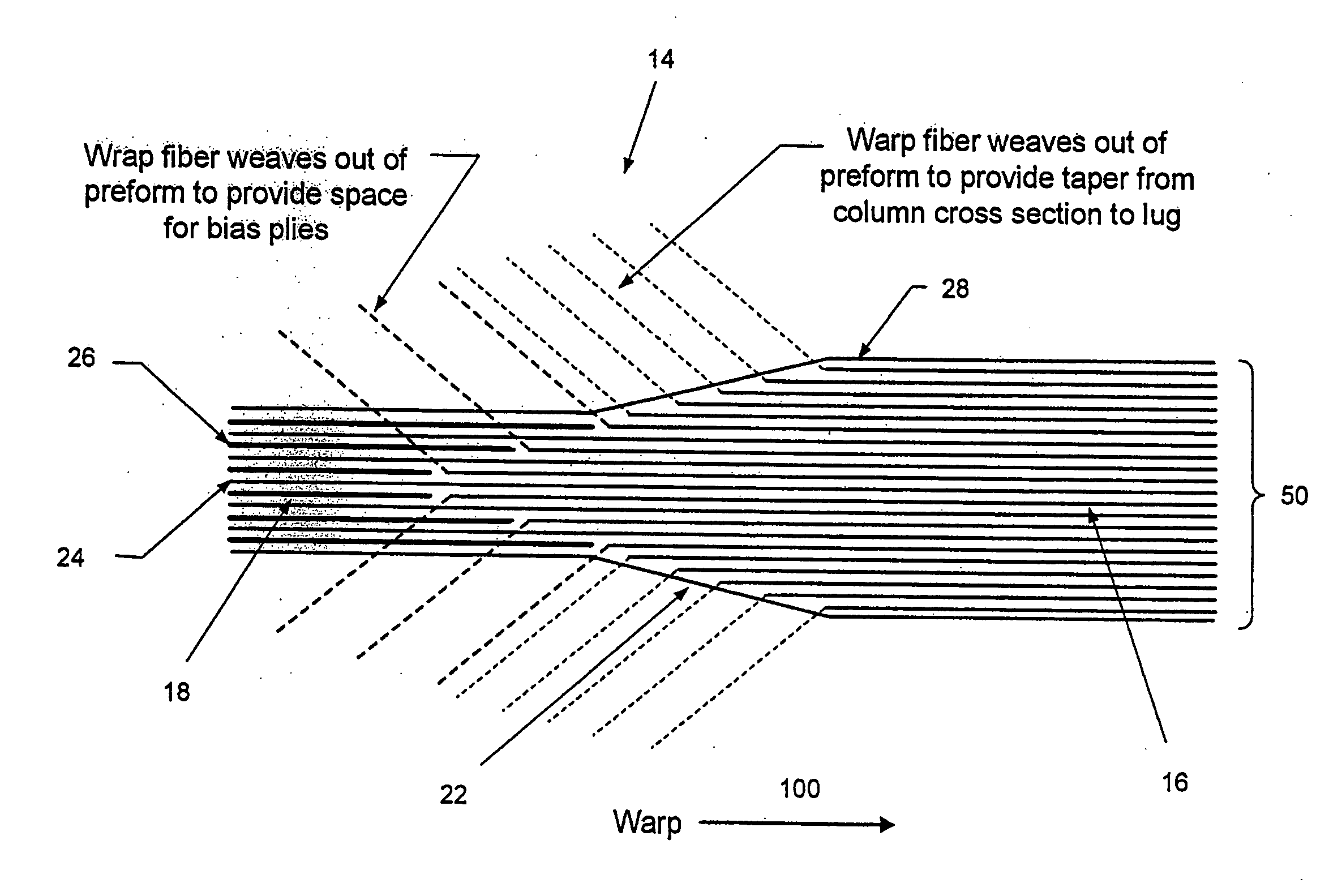

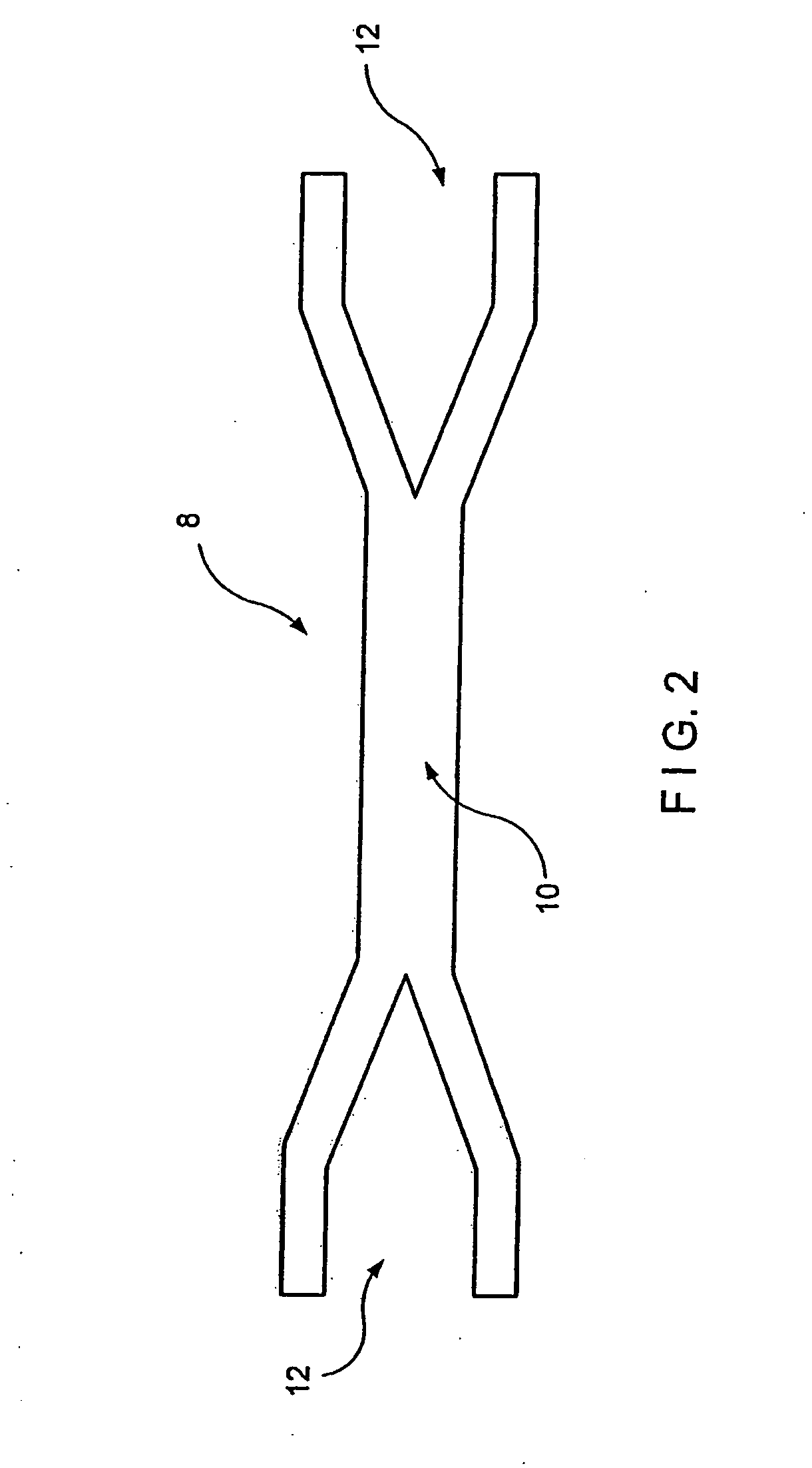

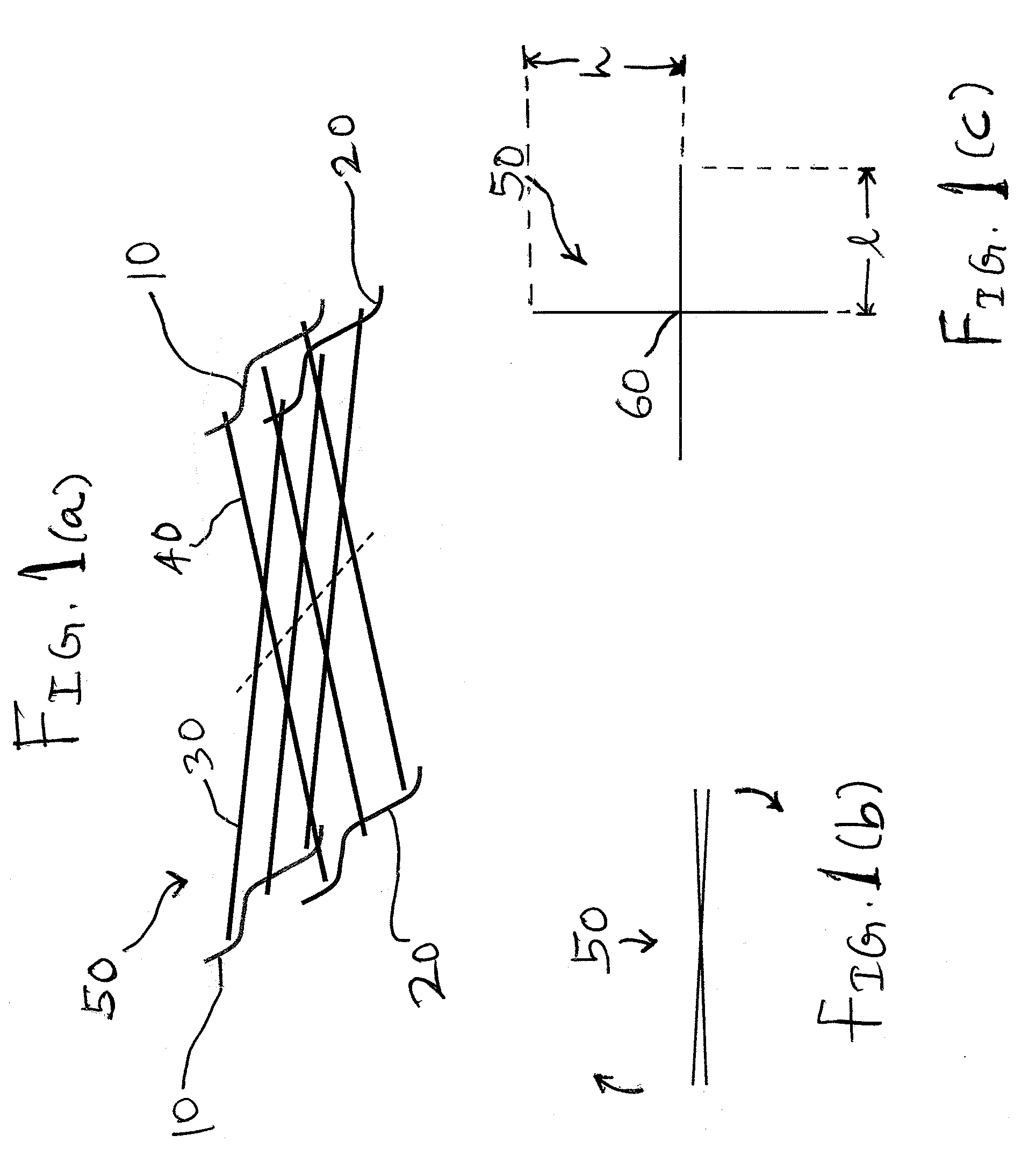

Hybrid Three-Dimensional Woven/Laminated Struts for Composite Structural Applications

ActiveUS20080261474A1High damage toleranceImprove through thickness propertySewing-machine elementsLoomsFiberEngineering

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies. The first and second end portions can have through thickness reinforcements comprising reinforcement fibers that traverse through the independent woven layers and the bias plies, locking them together.

Owner:ALBANY ENGINEERED COMPOSITES

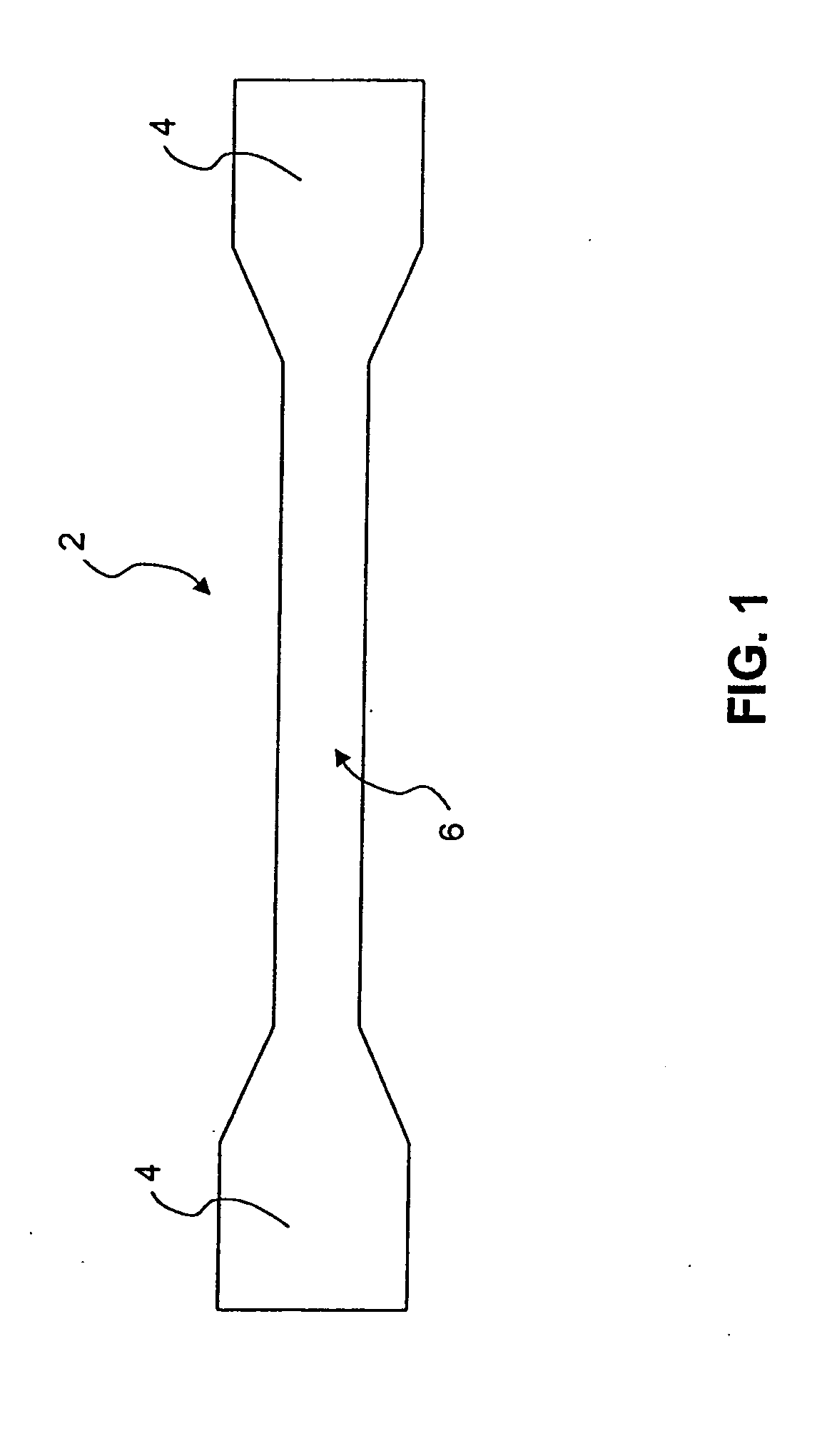

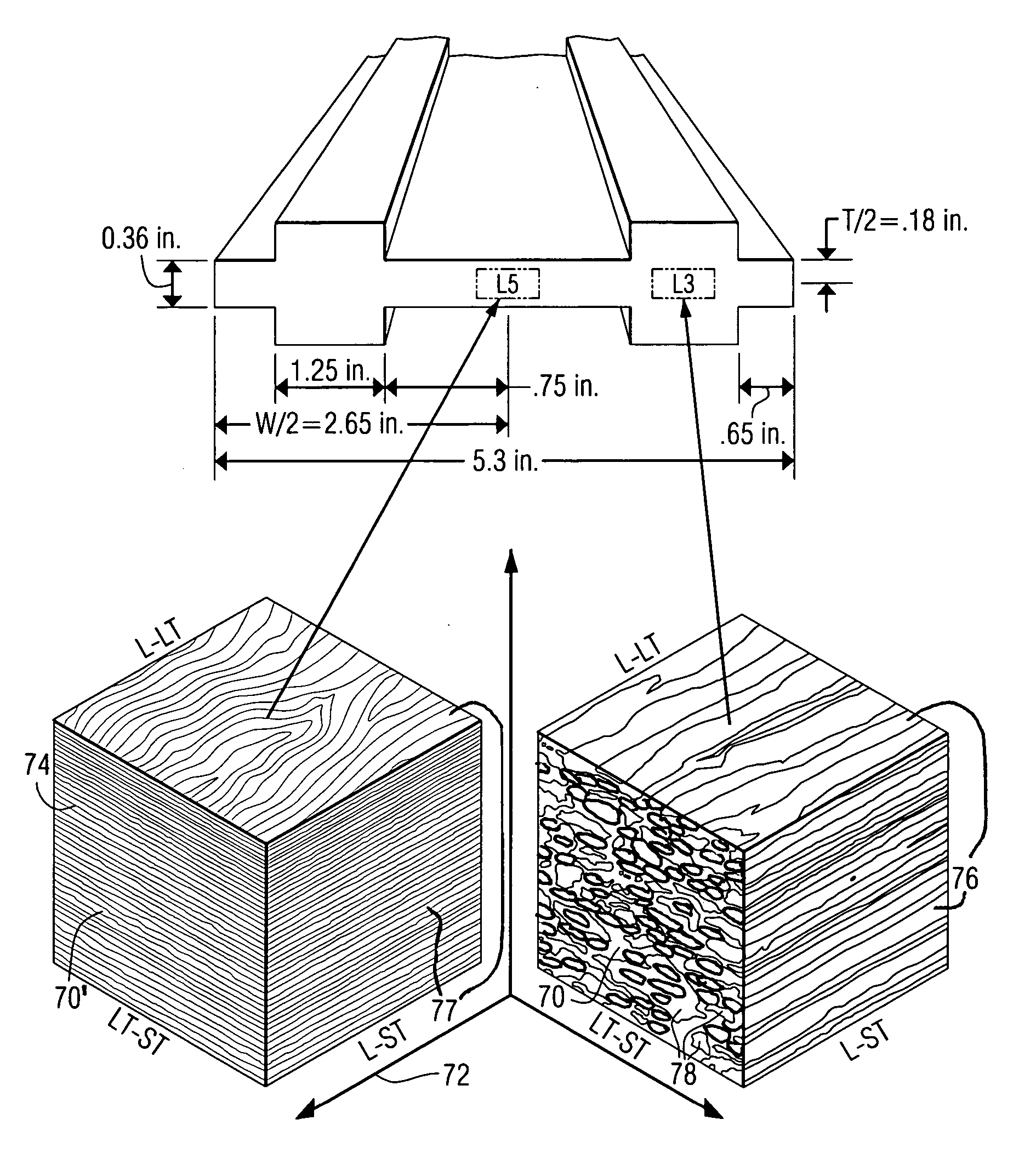

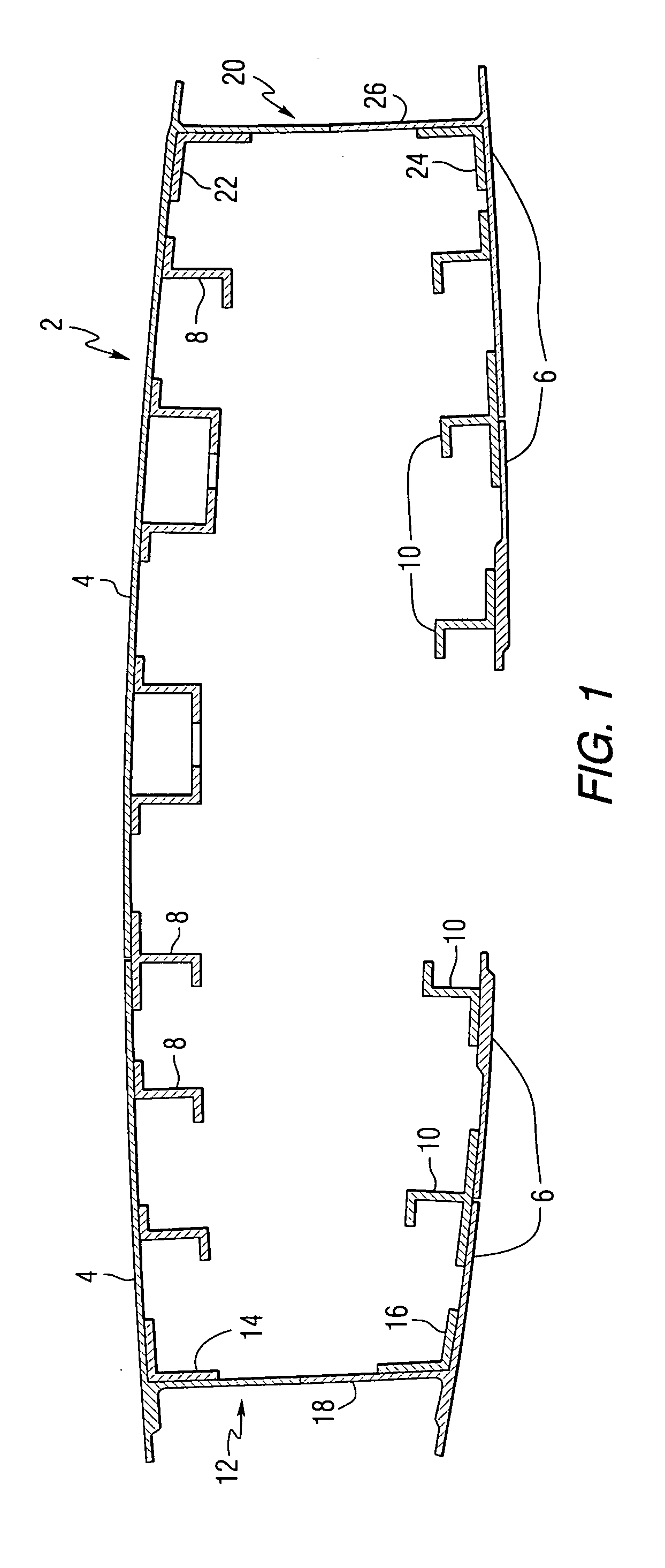

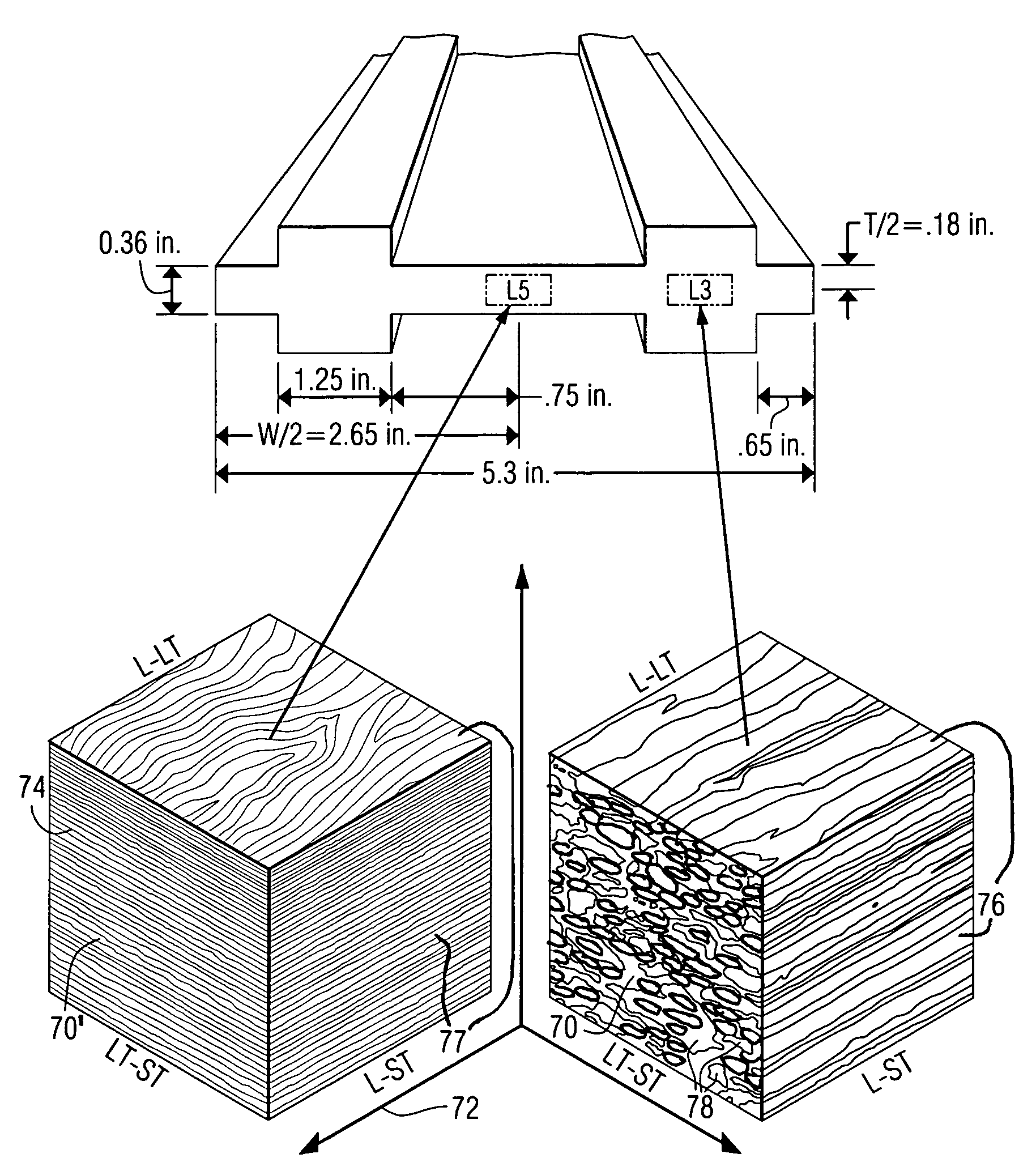

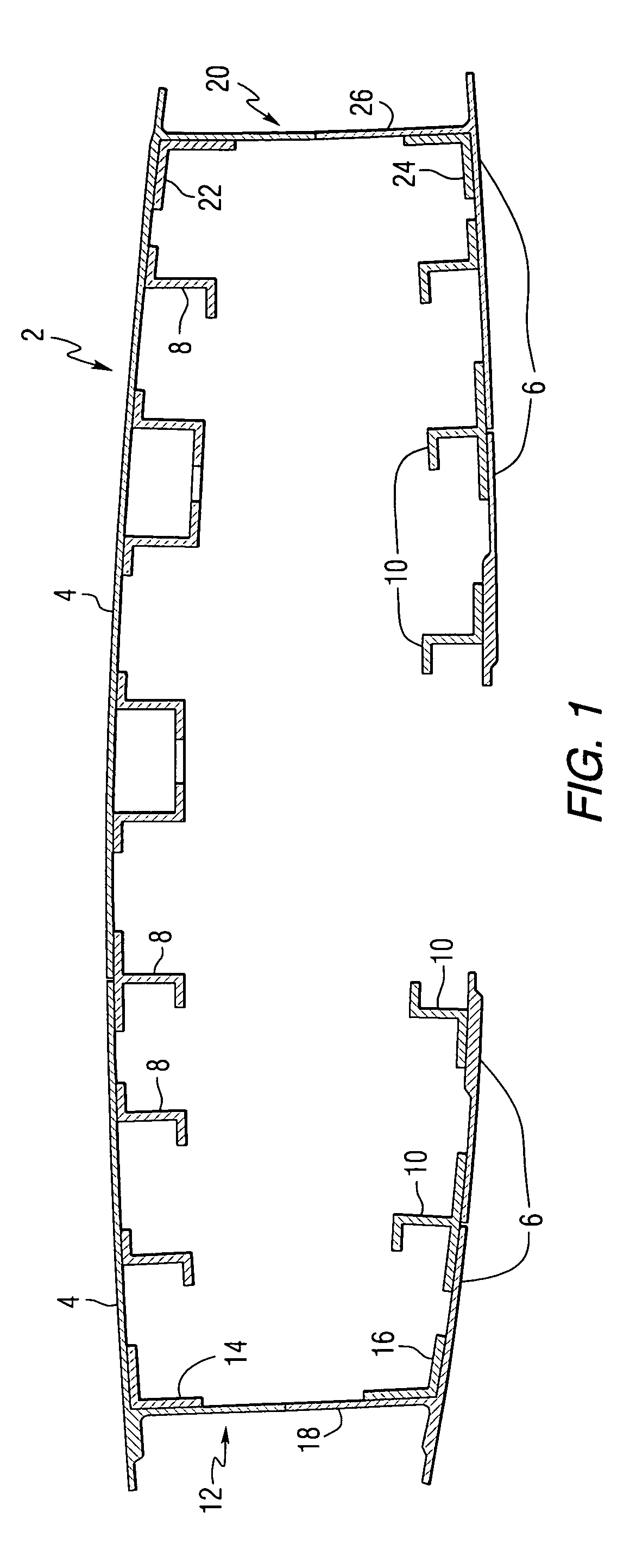

Structural members having improved resistance to fatigue crack growth

InactiveUS20050241735A1High damage toleranceReduce rate of fatigue crack growthLayered productsExtrusion containersFiberDamage tolerance

An extruded structural member having improved damage tolerance containing a base section (6); a stiffening section having at least one pair of structural stiffeners (10), the structural stiffeners integral with the base section (6) and projecting outwardly thereof; and at least one intra-stiffener (90) area positioned between the pair of structural stiffeners (10), the intra-stiffener area (90) having a microstructure with intentionally increased amounts of fiber texture to reduce the rate of fatigue crack growth in the extruded structural member.

Owner:ARCONIC INC

Method of producing a high strength balanced Al-Mg-Si alloy and a weldable product of that alloy

ActiveUS6994760B2High damage toleranceBalanced propertyThin material handlingMetal layered productsSpecific energyIntermetallic

The present invention relates to a method for producing high strength balanced Al—Mg—Si alloy with an improved fatigue crack growth resistance and a low amount of intermetallics, comprising the steps ofa) casting an ingot with the following composition (in weight percent) Si: 0.75–1.3, Cu: 0.6–1.1, Mn: 0.2–0.8, Mg: 0.45–0.95, Fe: 0.01–0.3, Zr: <0.25, Cr: <0.25, Zn: <0.35, Ti: <0.25, impurities each less than 0.05 and less than 0.20 in total, balance aluminum,b) optional homogenization of the cast ingot,c) pre-heating the ingot after casting for 4 to 30 hours with temperatures above 520° C.,d) hot working the ingot and optionally cold working,e) solution heat treating, andf) quenching the worked product.The pre-heating is preferably performed for 6 to 18 hours with temperatures between 530° C. and 560° C. The alloy has a fatigue crack growth rate at ΔK=20 MPa√m of below 9.0E−04 and at ΔK=40 MPa√m of below 9.0E−03, wherein the amount of intermetallics within the finally worked alloy product, according to the measured specific energy Delta H associated with the DSC signal, is below 1.5 J / g.

Owner:NOVELIS KOBLENZ GMBH

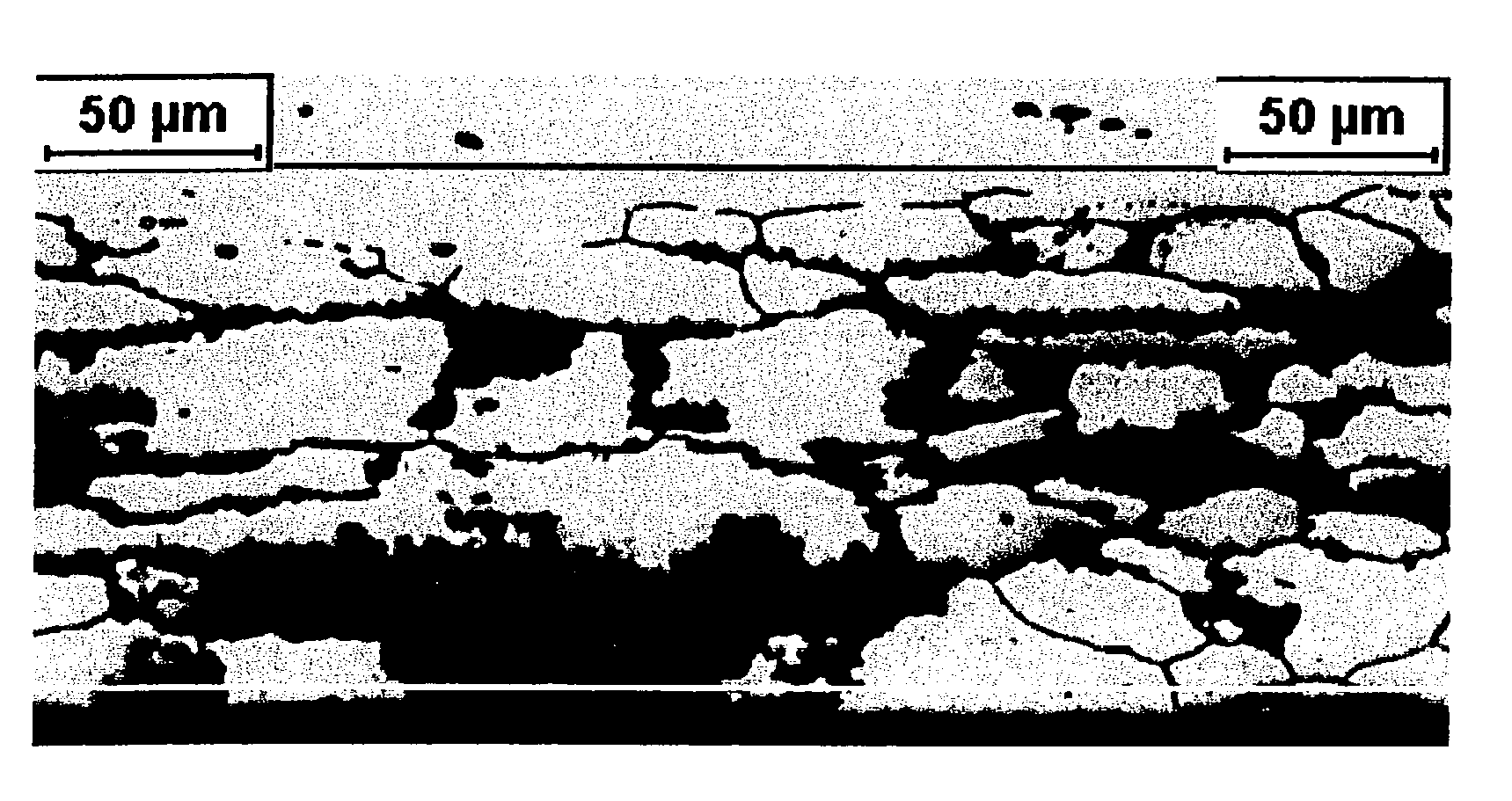

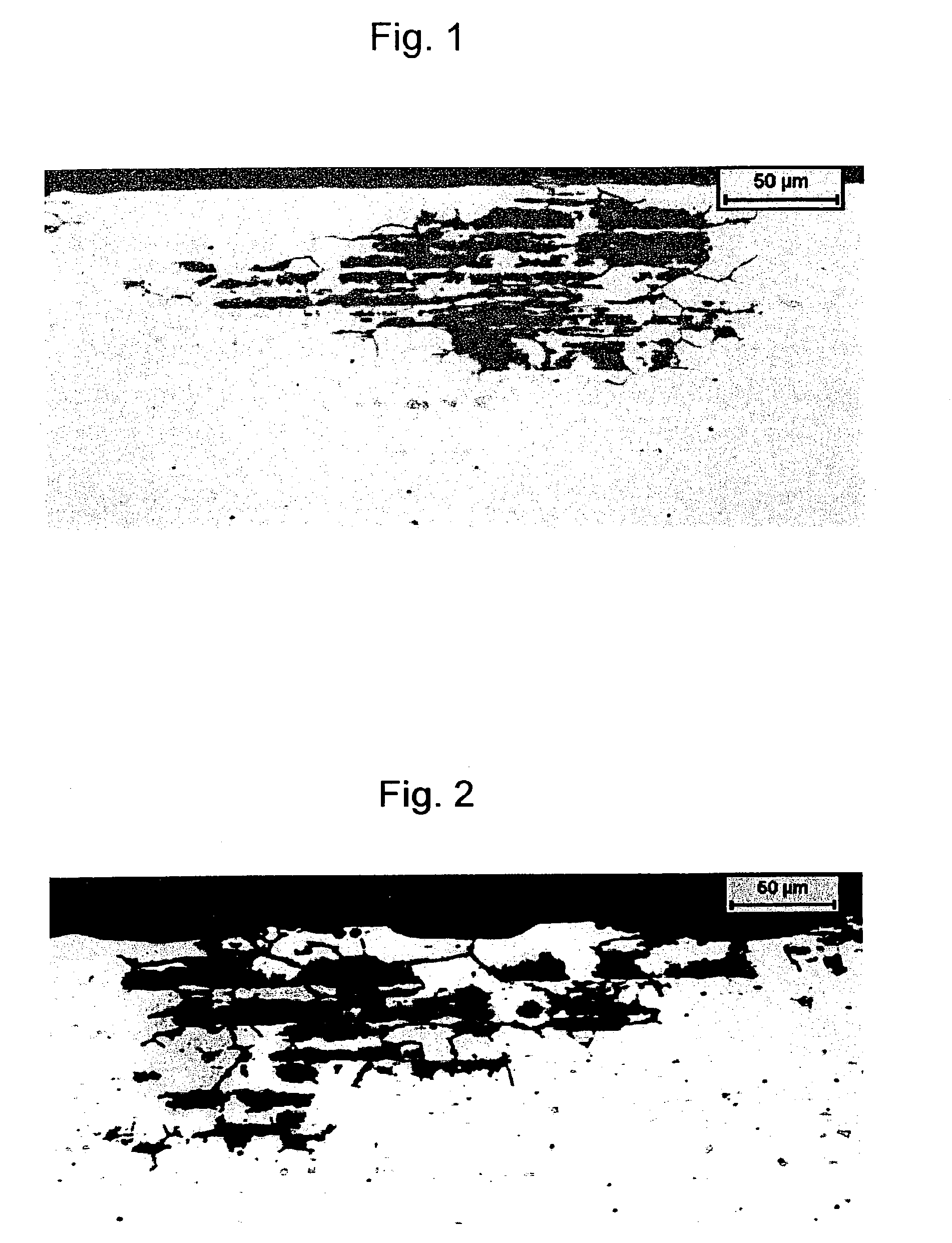

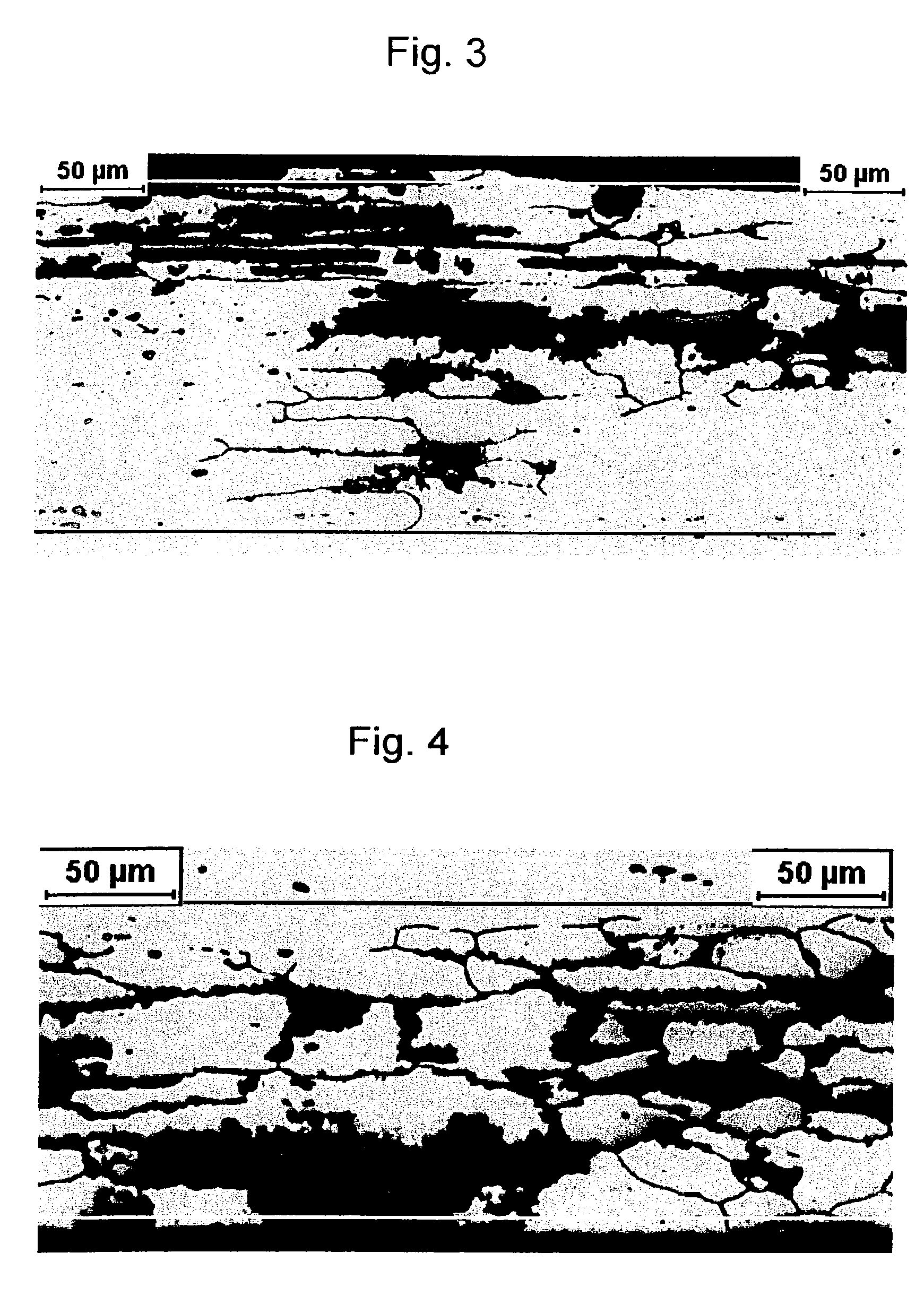

Metal fiber-reinforced composite material as well as a method for its production

InactiveUS6861156B2Simple procedureEasy to useArmour platesThin material handlingMetal fiberMetallic materials

A metal fiber-reinforced composite material can be produced by providing metal layers and reinforcing layers disposed alternately into a sandwich structure, the reinforcing layers containing fibers of a high-strength metallic material, which are disposed in the form of a loose structure between the metal layers, in order to create a material excess of fibers in the reinforcing layers, the sandwich structure being bonded by a thermomechanical process in such a manner, that the fibers are lengthened because of the excess of material, the sandwich structure being bonded.

Owner:AIRBUS OPERATIONS GMBH

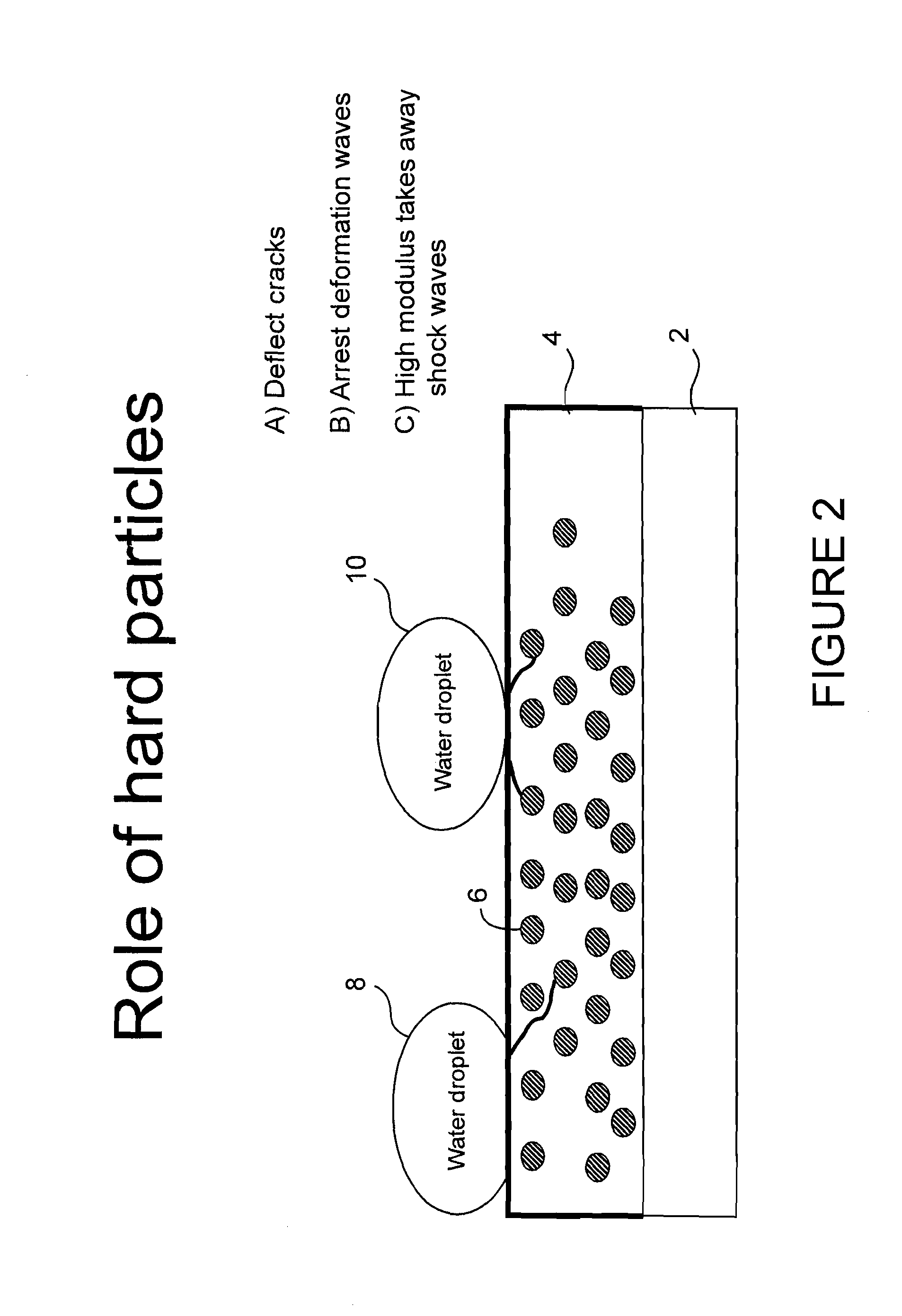

Erosion and corrosion resistant coating system for compressor

InactiveUS20110165433A1Improve corrosion resistanceImprove erosion resistanceLiquid surface applicatorsBlade accessoriesCoating systemVanadium nitride

Process for providing a protective coating to a metal surface by applying a nickel or tantalum plate layer to the surface and dispersing particles of a hard material such as diamond, alumina, vanadium nitride, tantalum carbide and / or tungsten carbide within the nickel or tantalum plate layer as the plating is occurring.

Owner:GENERAL ELECTRIC CO

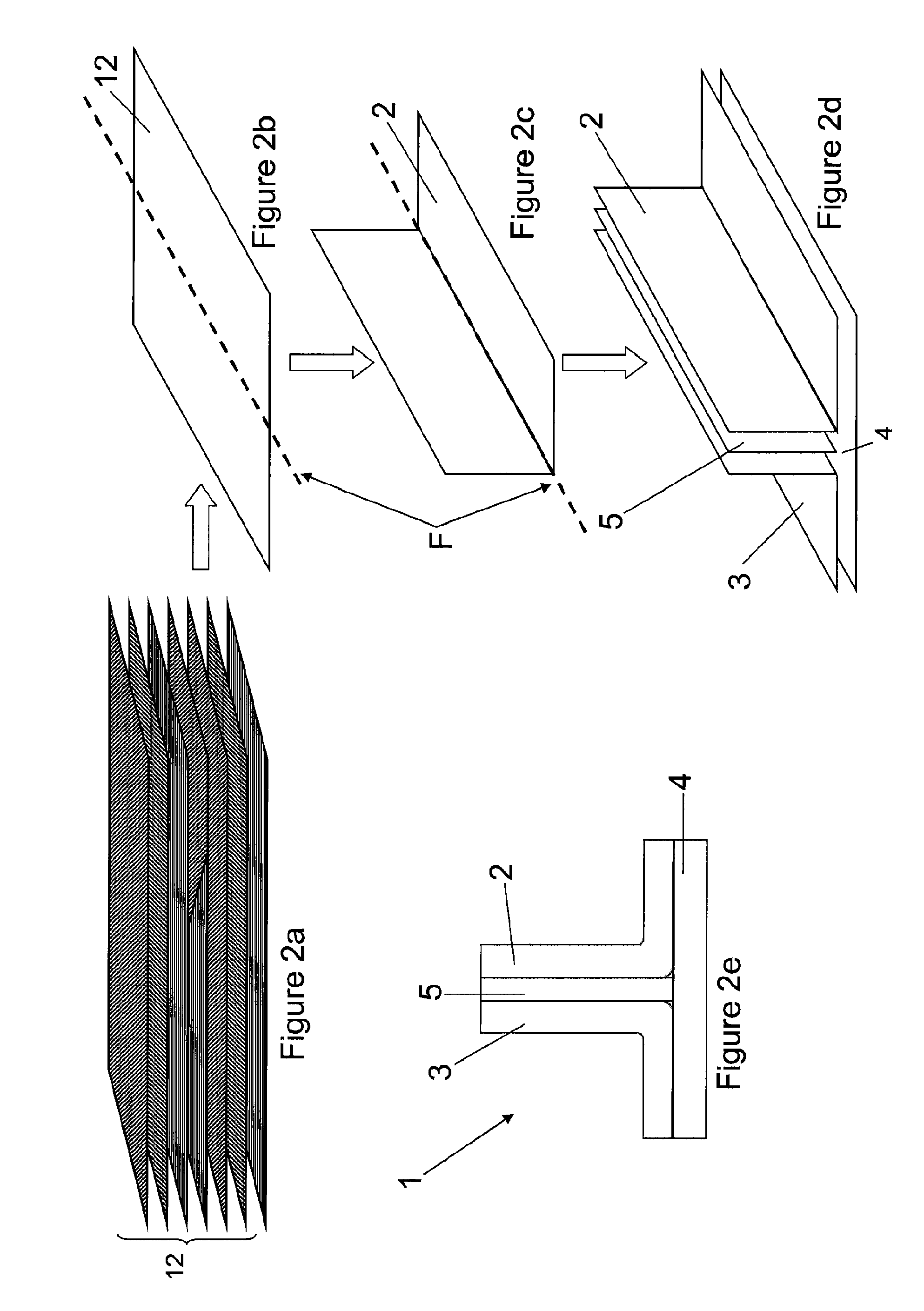

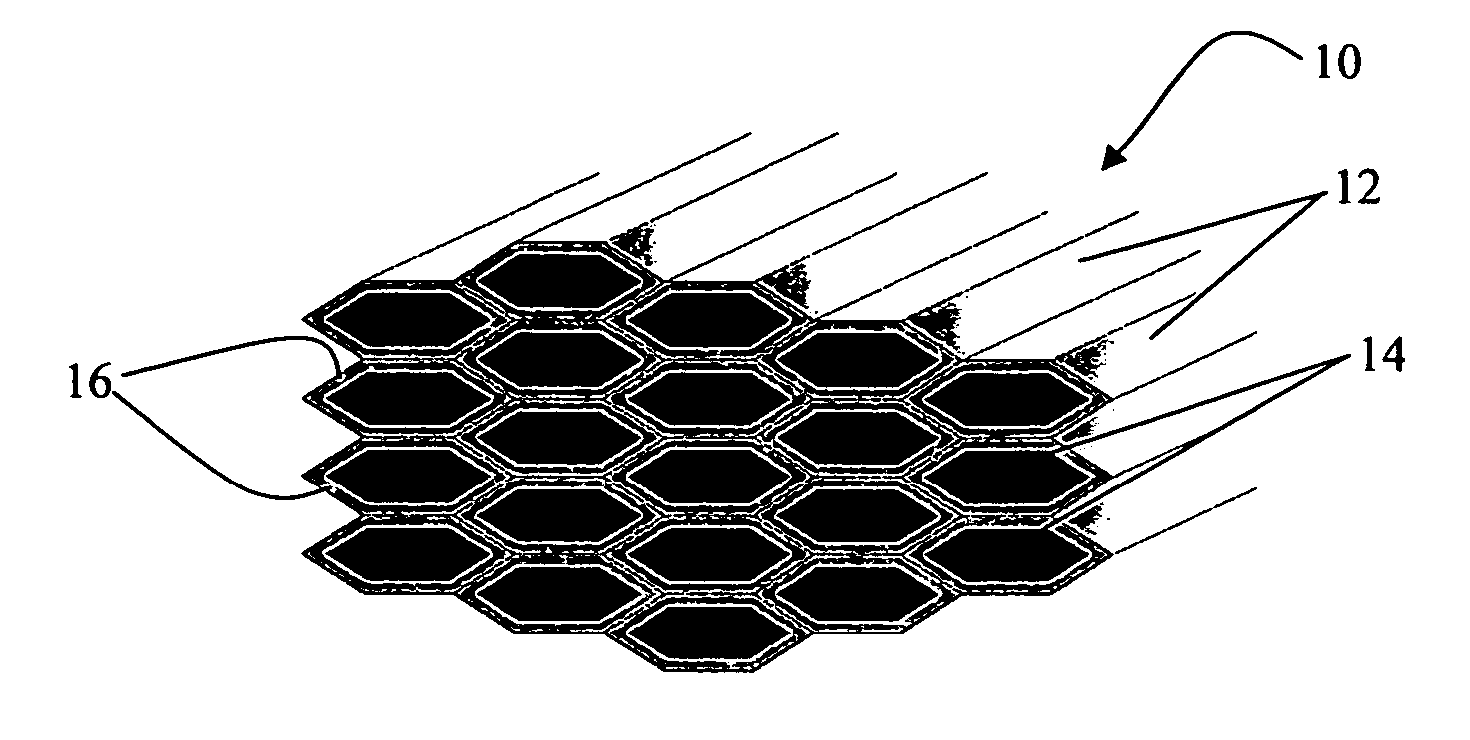

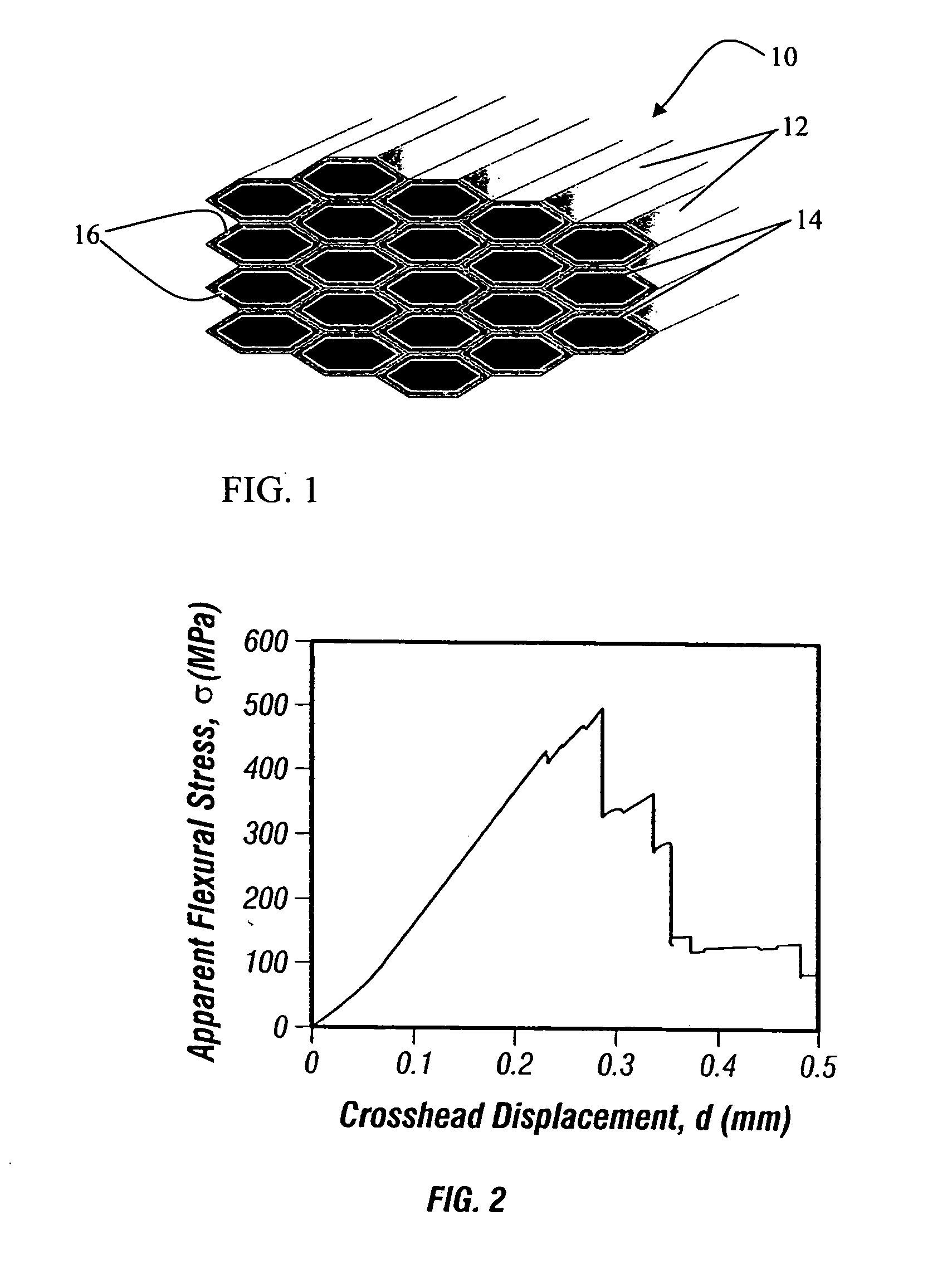

Method for Weaving Closed Structures with Intersecting Walls

ActiveUS20090149100A1Shorten manufacturing timeLow costSmallware loomsOrnamental textile articlesShell moldingTransfer molding

The present invention generally relates to a woven preform for reinforced composite materials and a method of making thereof. Specifically, the present invention is a method of machine weaving fiber preforms for polymer matrix composites that consist of closed perimeters with multiple intersecting members in their interiors. More specifically, the invention is a woven preform and a method of forming thereof with closed cells at the outer edges with continuous hoop reinforcement in each cell of the preform. The woven preform is woven flat in both the warp and weft directions, and then unfolded to achieve the final shape of the structure, and can be processed into composite structural components using known methods such as resin transfer molding or chemical vapor infiltration. Thus, complicated shapes of all sizes can be woven on a conventional loom using the instant method.

Owner:ALBANY ENGINEERED COMPOSITES

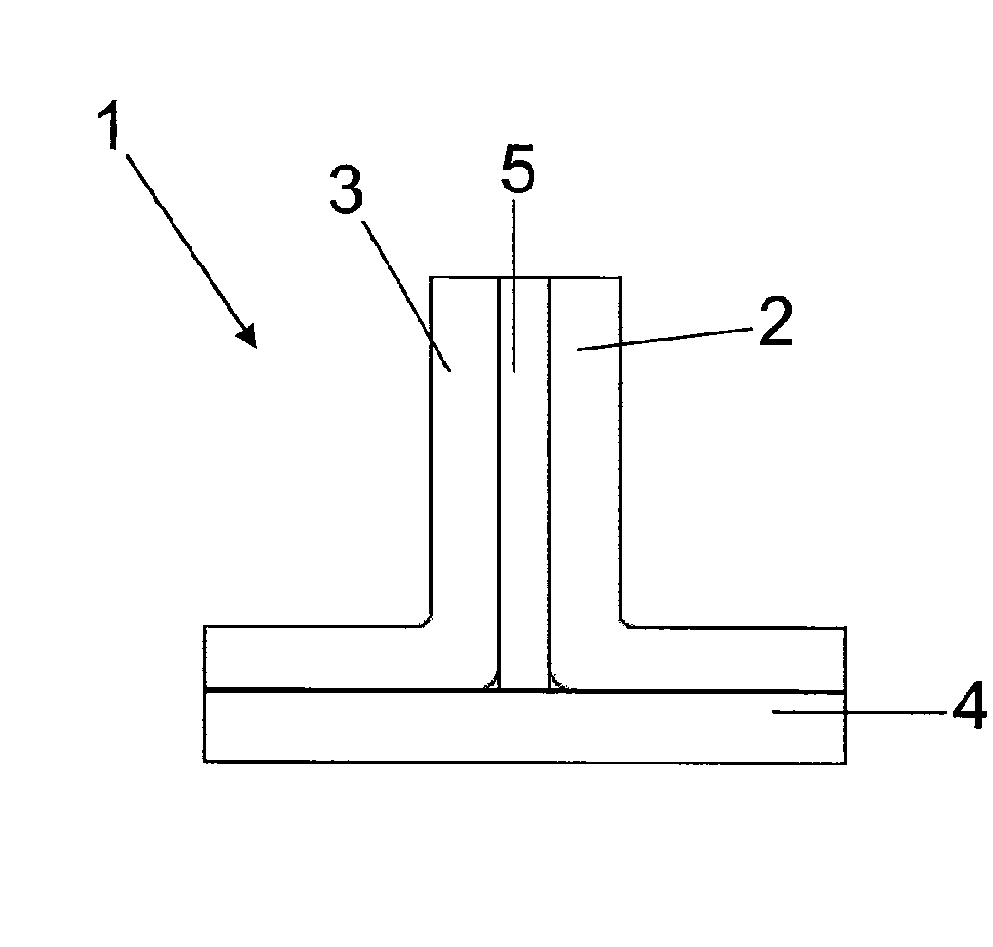

Interlocking tooth bond for assembly of fiber composite laminates

ActiveUS20060251847A1Cost efficientEffective weightAdhesive processesLamination ancillary operationsComposite laminatesImproved method

An improved method of joining fiber composite laminates is disclosed. Two fiber composite laminates may be joined together end-to-end. The bonding is done through the thickness of the fiber composite laminates. There are two ways to form the bond: (1) non-interlocking; and (2)

Owner:BELL HELICOPTER TEXTRON INC

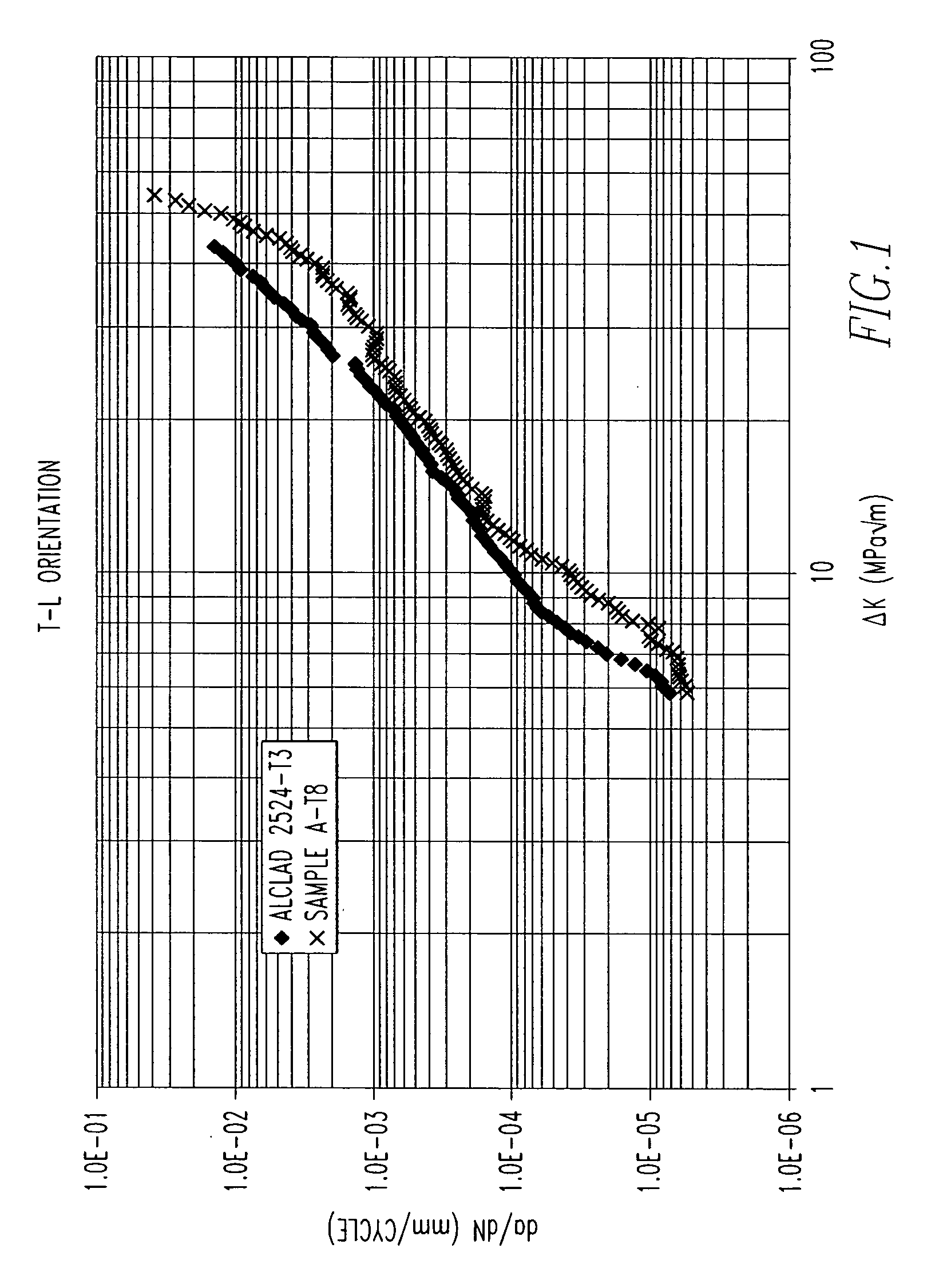

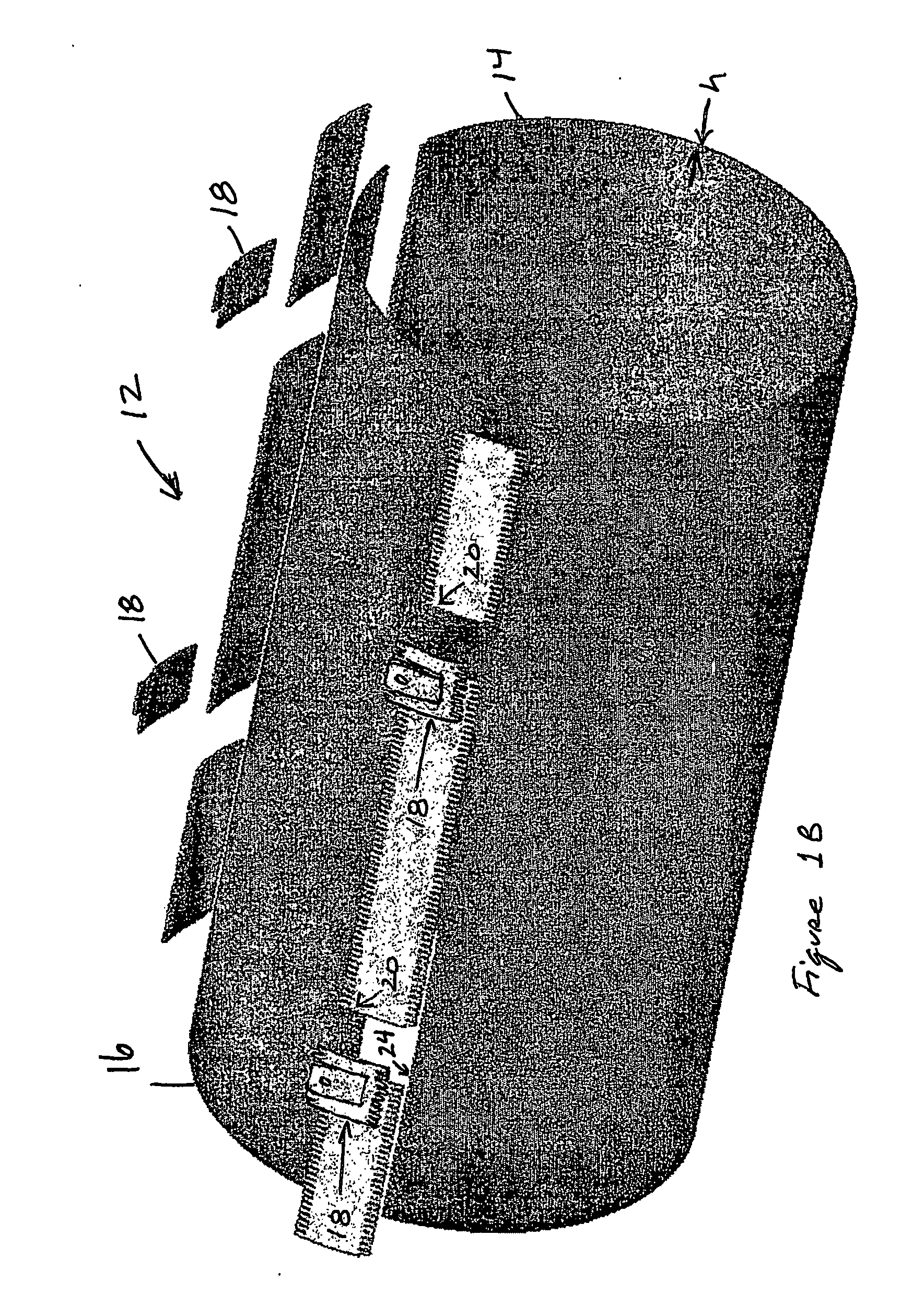

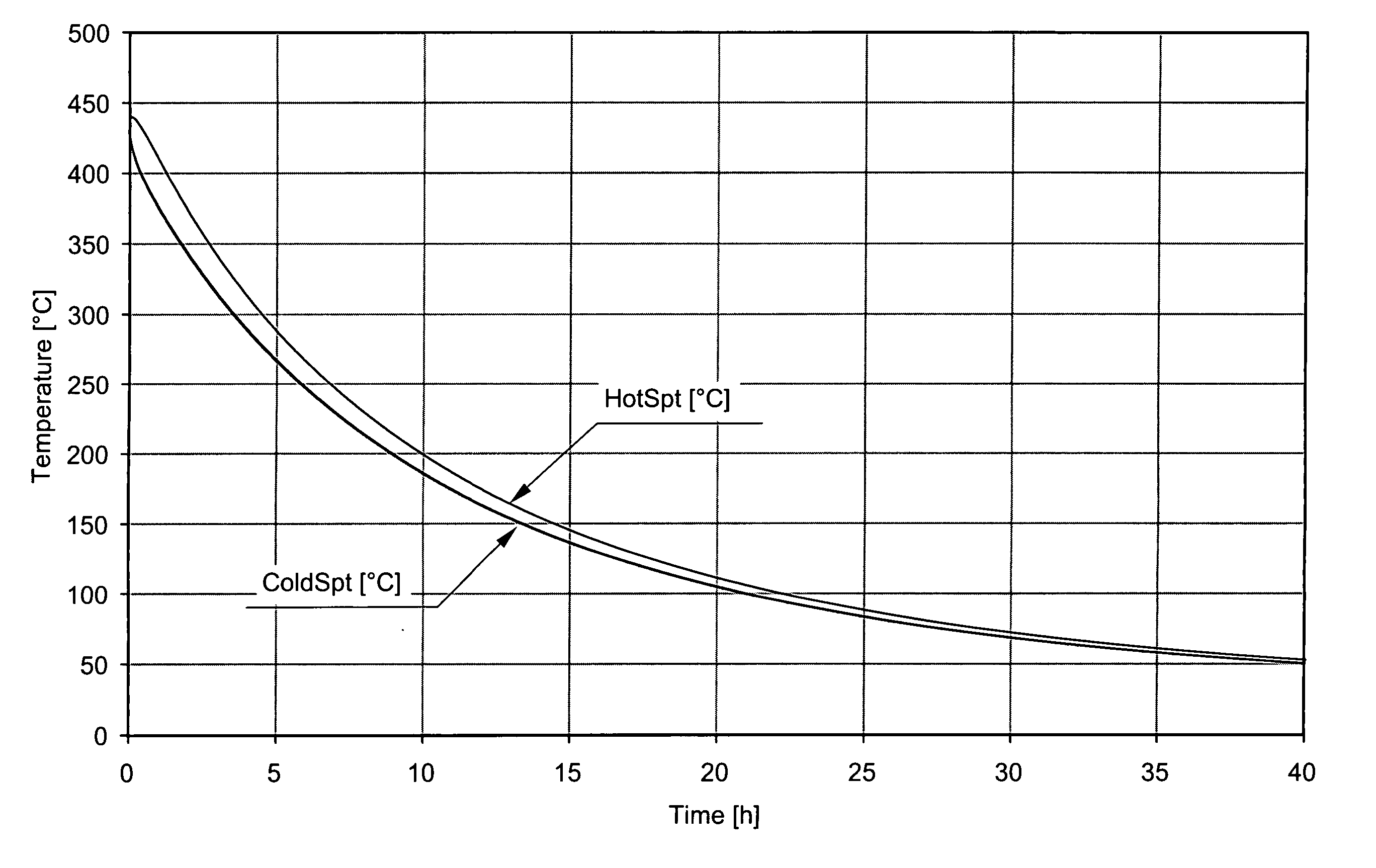

Method for producing a high damage tolerant aluminium alloy

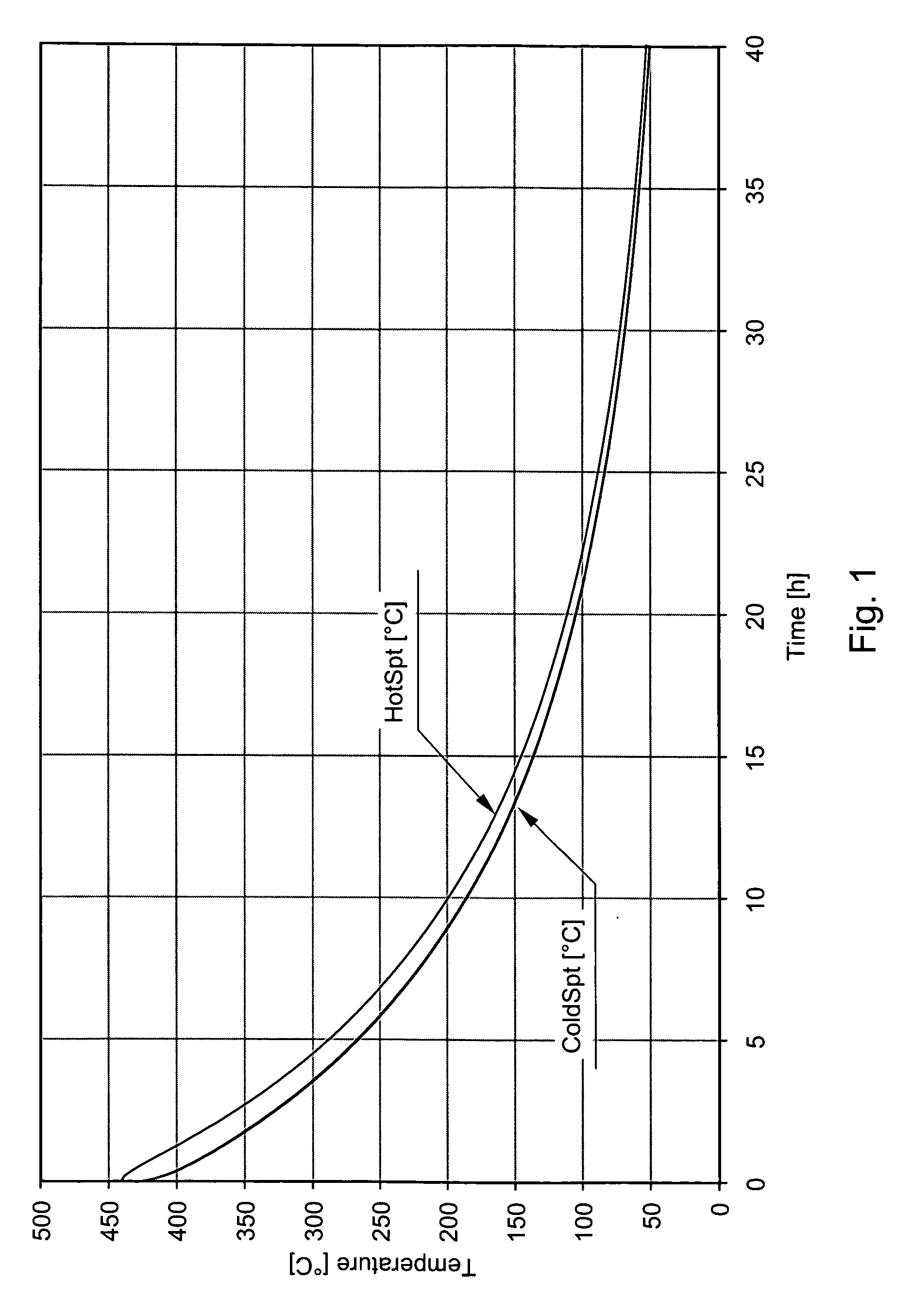

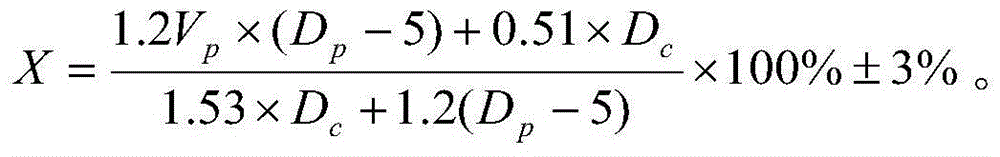

The present invention relates to a method of producing a high damage tolerant aluminium alloy rolled product a high toughness and an improved fatigue crack growth resistance, including the steps of: a.) casting an ingot having a composition selected from the group comprising AA2000, AA5000, AA6000, and AA7000-series alloys; b.) homogenising and / or pre-heating the ingot after casting; c.) hot rolling the ingot into a hot rolled product and optionally cold rolling the hot rolled product into a cold rolled product, wherein the hot rolled product leaves the hot rolling mill at an hot-mill exit temperature (TExit) and cooling the hot rolled product from the TExit to 150° C. or lower with a controlled cooling cycle with a cooling rate falling within the range defined by: T(t)=50−(50−TExit)eαt and wherein T(t) is the temperature (° C.) as function in time (hrs), t is the time (hours) and α is in the range of −0.09±0.05 (hrs−1).

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Aircraft structural member made of an Al-Cu-Mg alloy

ActiveUS7294213B2Improve propertiesIncrease costThin material handlingMetal layered productsAlloyDissolution

The invention relates to a work-hardened product, particularly a rolled, extruded or forged product, made of an alloy with the following composition (% by weight):Cu 3.8-4.3; Mg 1.25-1.45; Mn 0.2-0.5; Zn 0.4-1.3; Fe<0.15; Si<0.15; Zr≦0.05; Ag<0.01,other elements <0.05 each and <0.15 total, remainder Al treated by dissolution, quenching and cold strain-hardening, with a permanent deformation of between 0.5% and 15%, and preferably between 1.5% and 3.5%. Cold strain-hardening can be achieved by controlled tension and / or cold transformation, for example rolling, die forging or drawing. This cladded metal plate type product is a suitable element to be used as aircraft fuselage skin.

Owner:CONSTELLIUM ISSOIRE

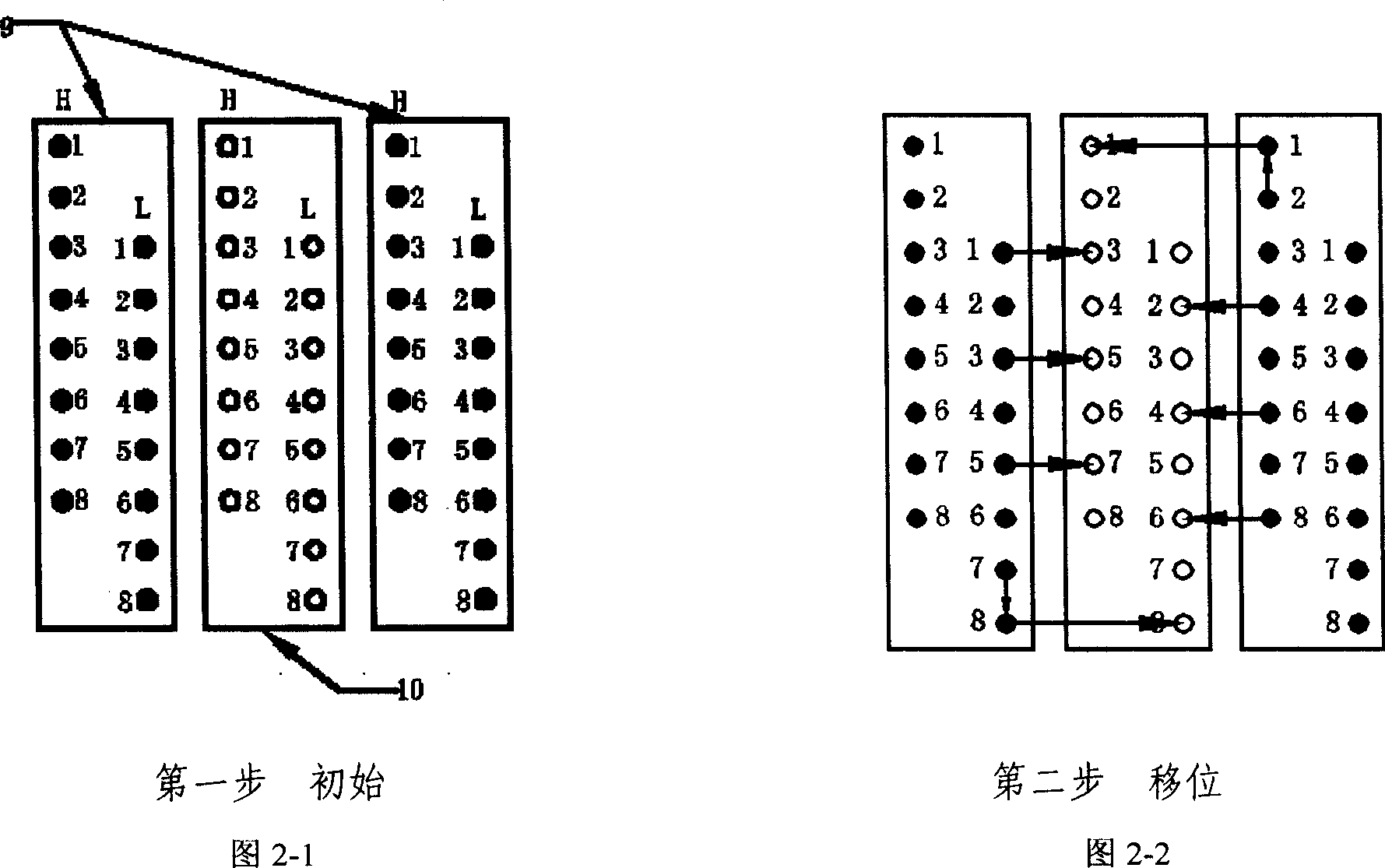

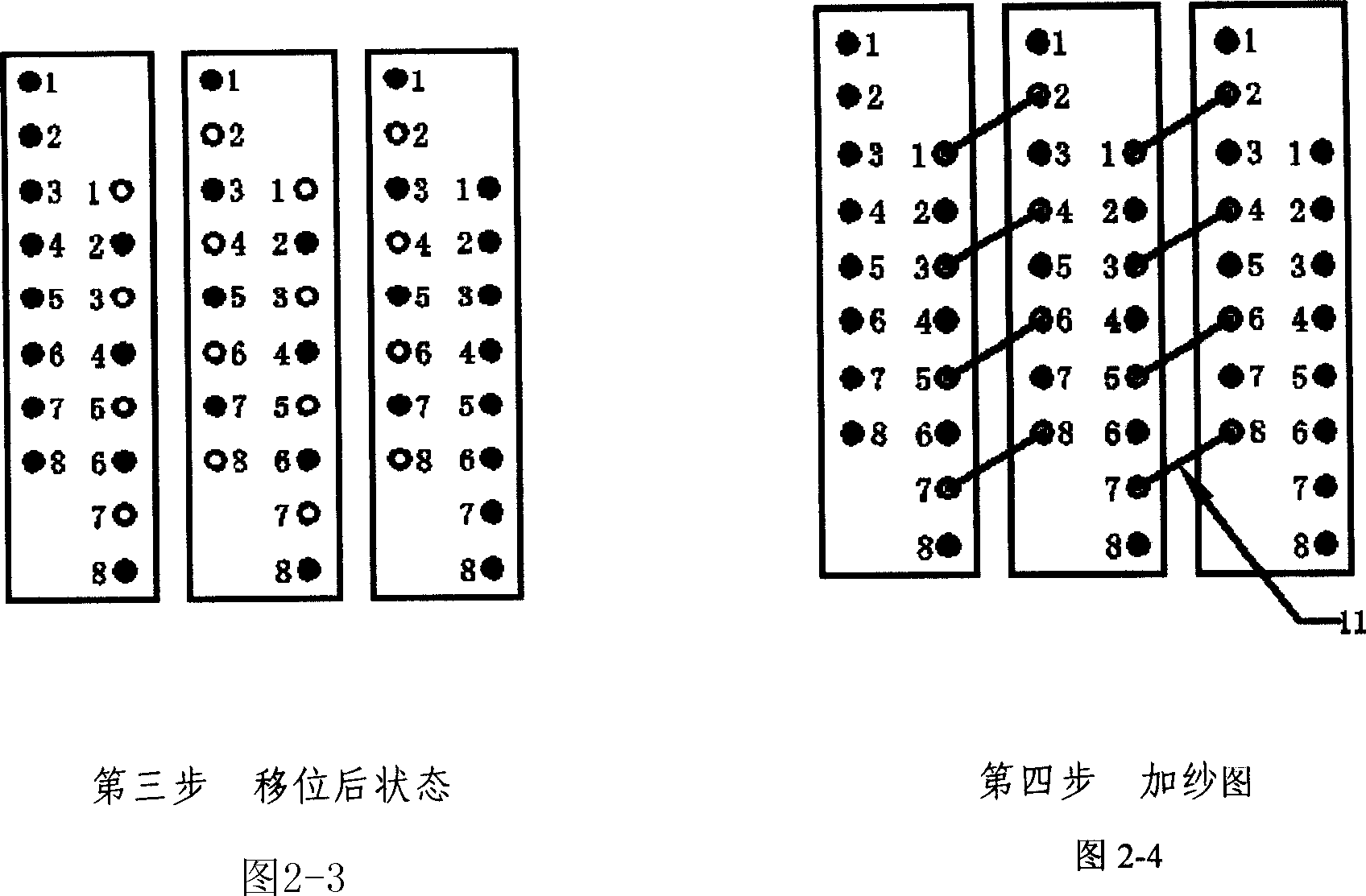

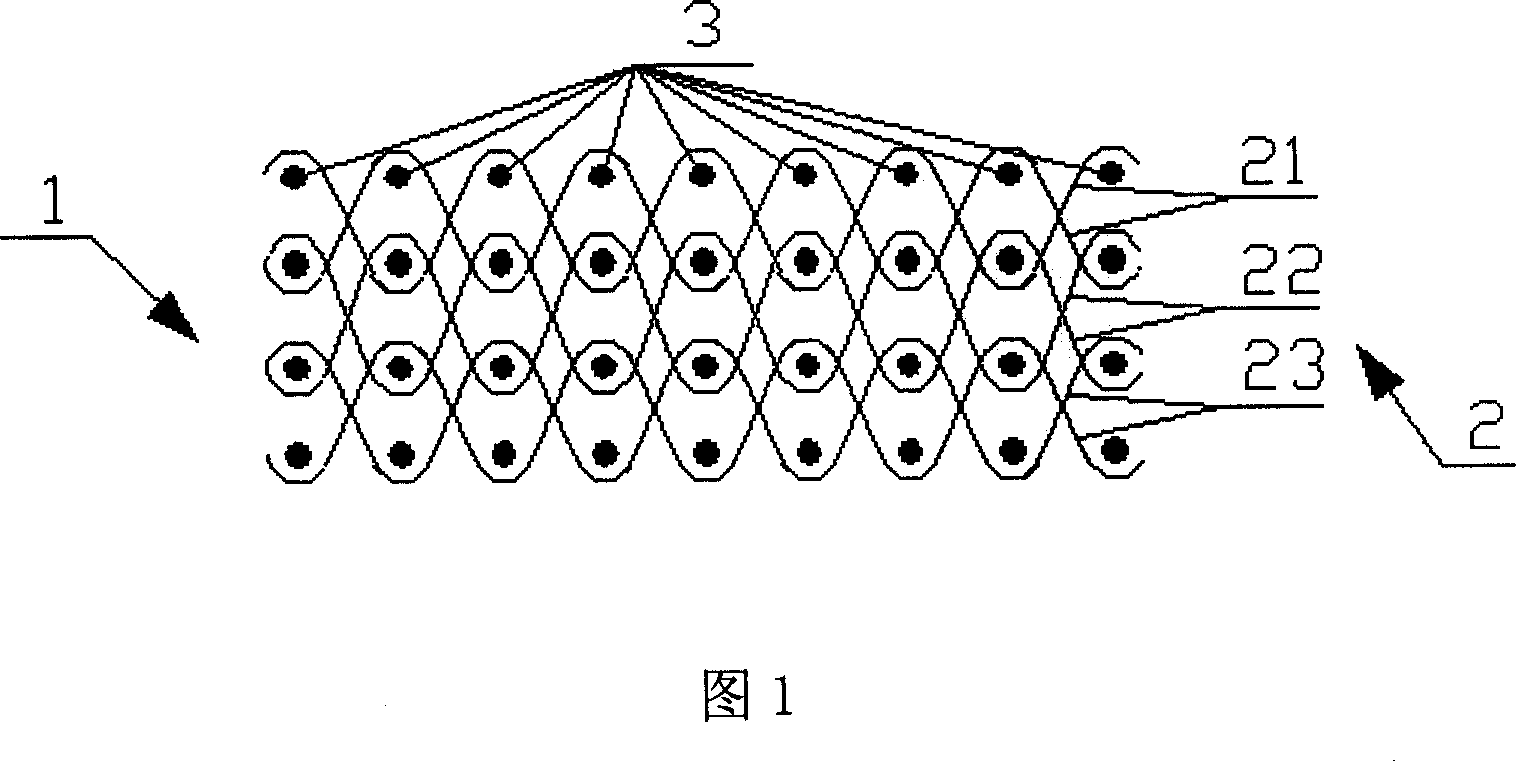

Method for knitting 2.5-dimension integral knit multiple-pass fabric

The invention relates to a weave method of 2.5-dimensional overall braided multi-through pipe fabric. The weave method is characterized in that (1) the structure of the fabric adopts a 2.5-dimensional shallow-cross bended-connection structure; (2) the overall weaving of the fabric adopts core imitation-shaped weaving to ensure the internal molded surface dimension of the fabric; (3) the fabric is divided into two parts, namely a connecting body part and a through pipe part, wherein the connecting body is a part connected with the through pipes, while the through pipes are connected through the same connecting body; (4) the lower section of each through pipe is provided with warp yarns of the part in advance; (5) weft yarns between through pipes in the same plane are lined between the warp yarns layer by layer through adopting a weft insertion process; (6) when the horizontal section of the connecting body increases, warp yarns are increased through adopting a shift yarn adding method, and the method can effectively improve the hole phenomenon in yarn-adding points; and (7) when the horizontal section of the connecting body decreases, warp yarns are reduced through adopting a shift yarn reduction method. The 2.5-dimensional multi-through pipe fabric woven by the weave method has the advantages of better overall property, controllable shaping, high damage tolerance, excellent performances of impact resistance, delamination resistance, fatigue resistance, and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

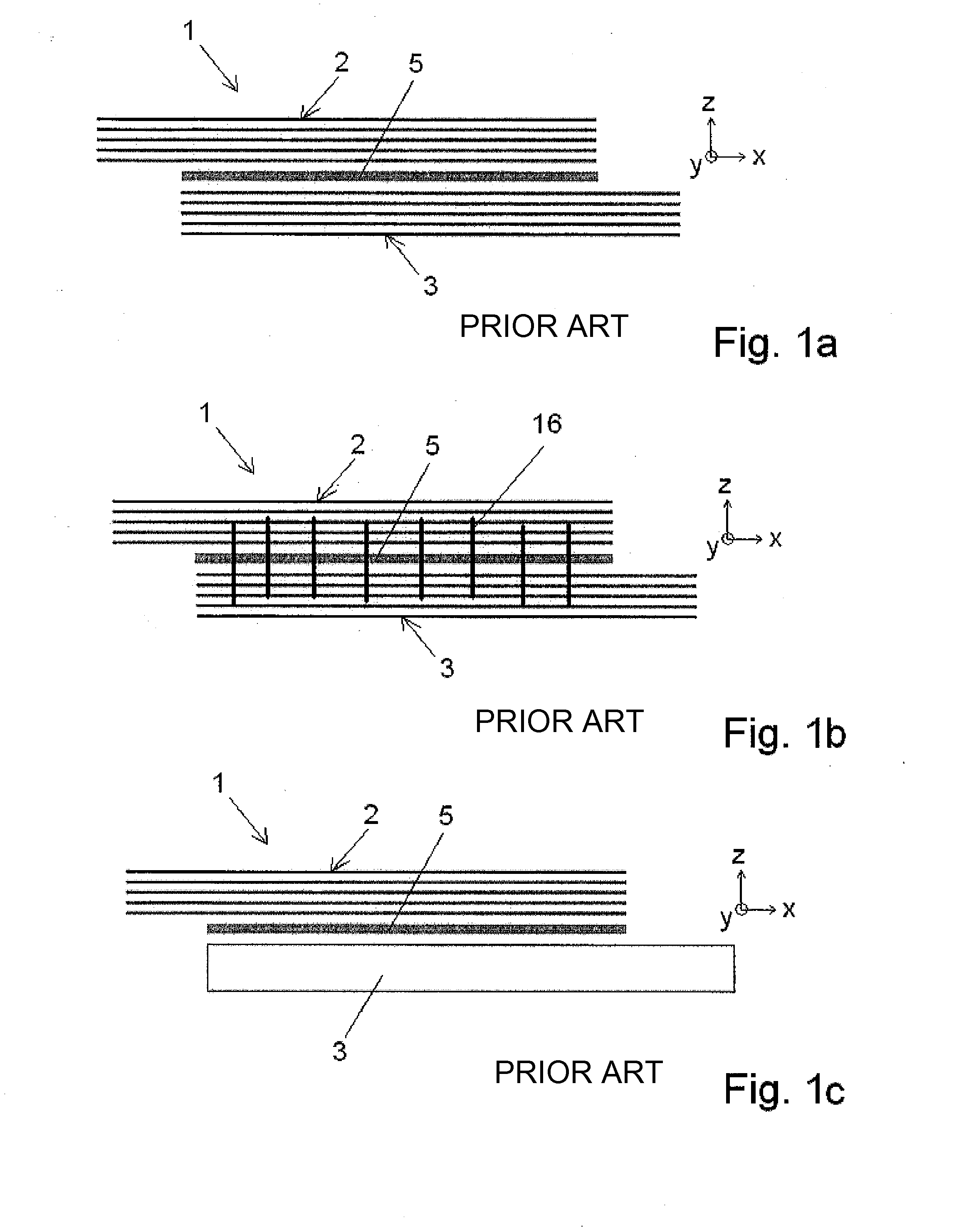

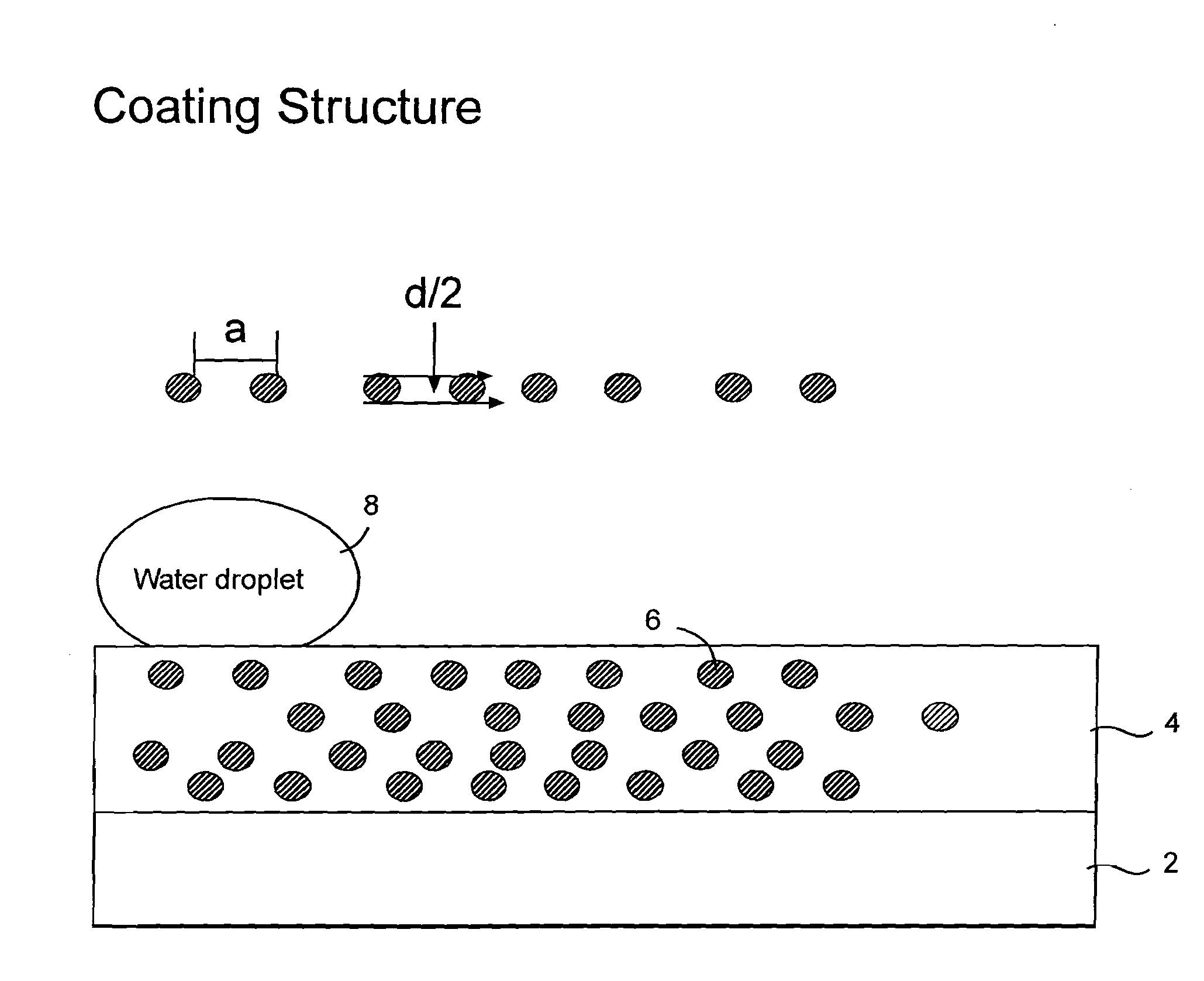

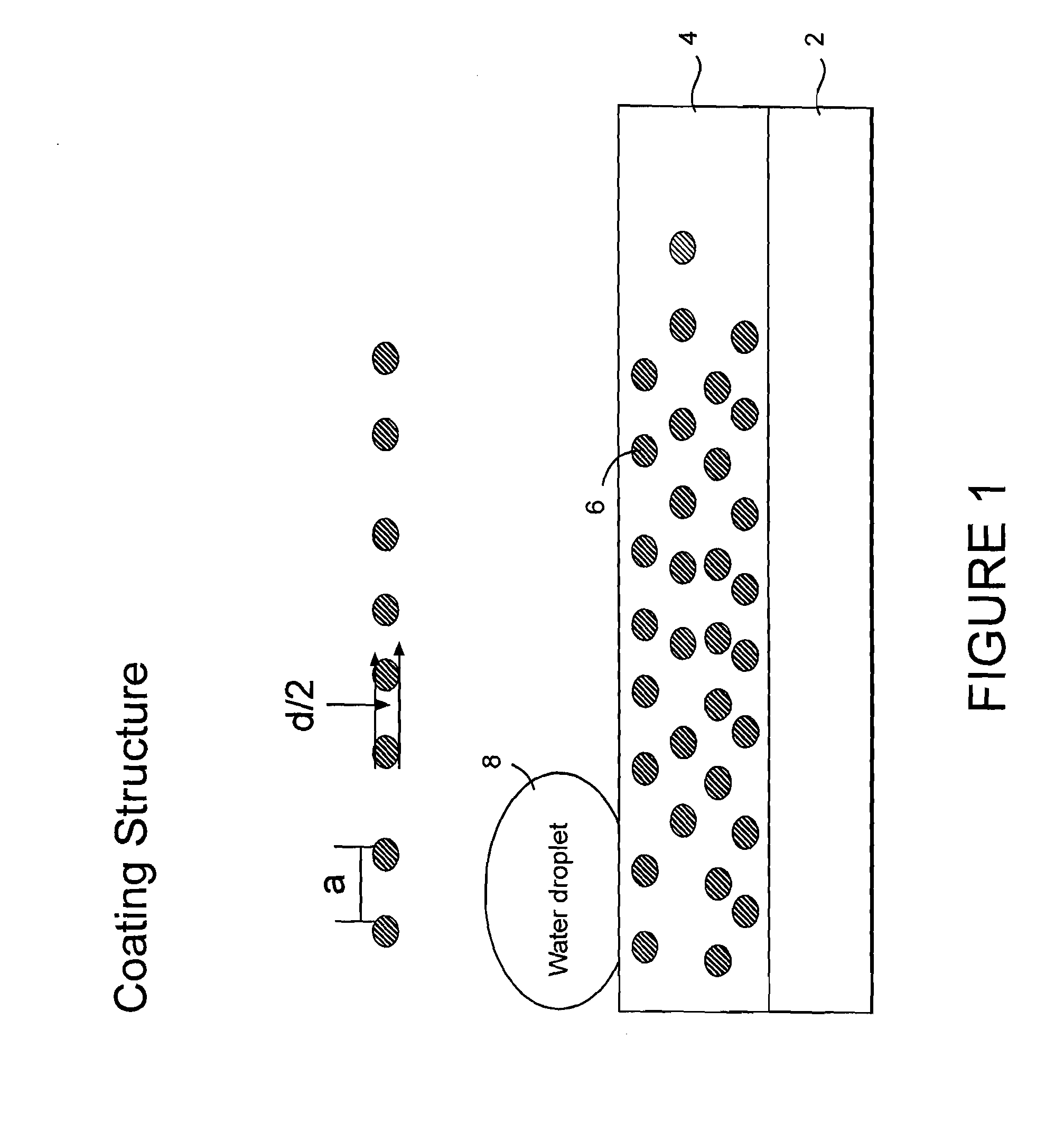

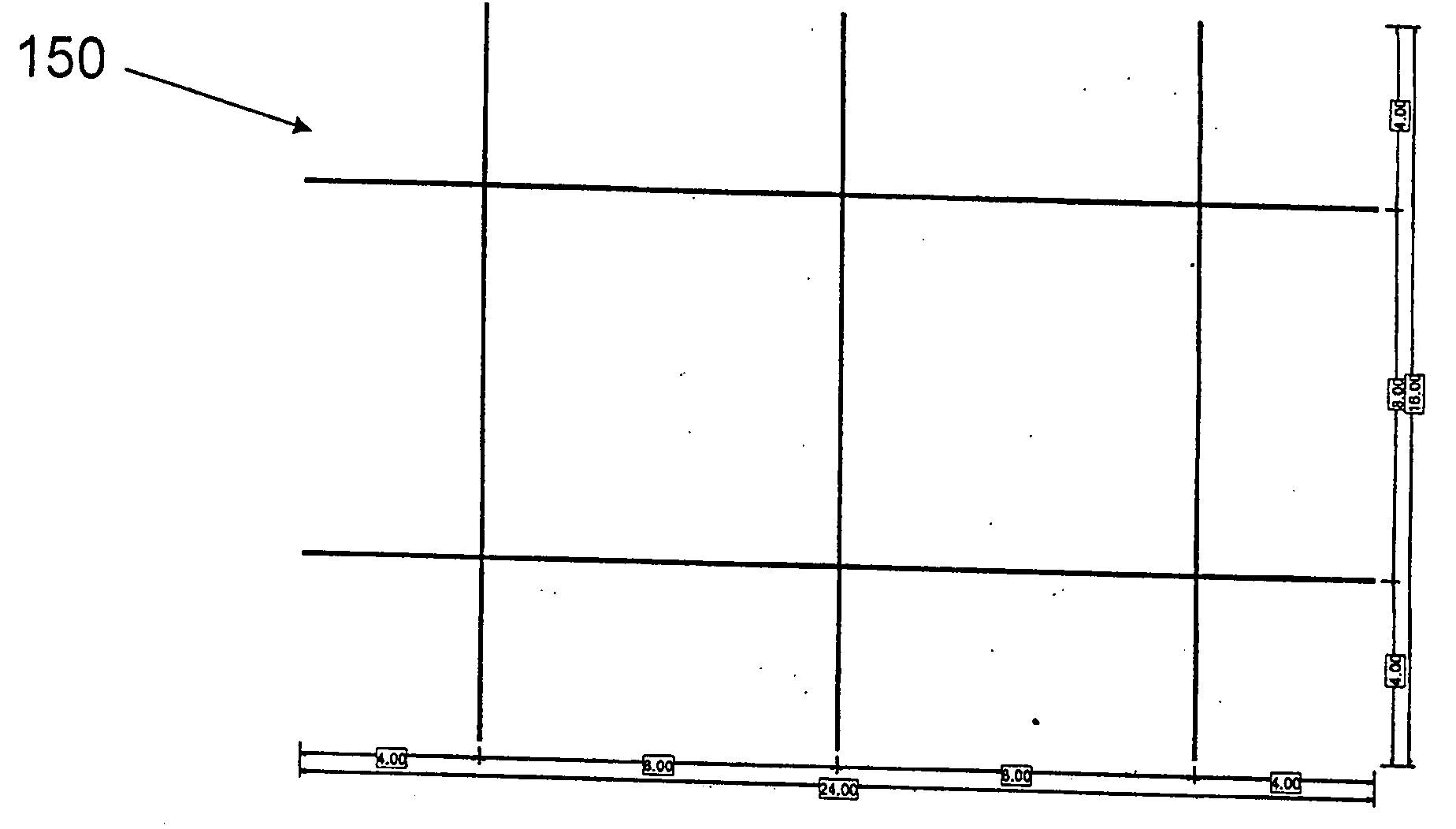

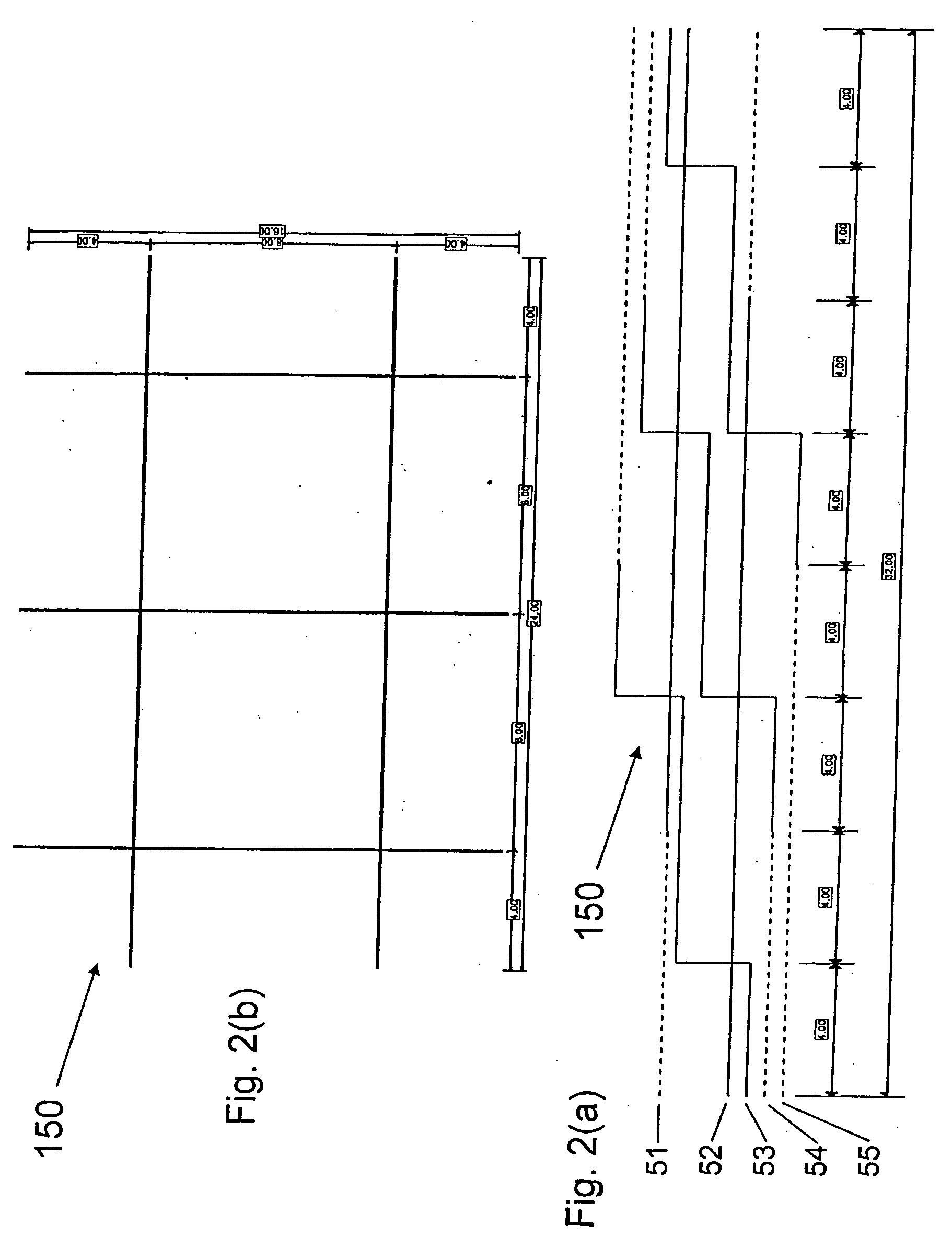

Lightweight structure particularly for an aircraft

ActiveUS20050112348A1Simple structureEasily damagedSynthetic resin layered productsNon-woven fabricsHigh intensityFibrous composites

An outer skin, for example of an aircraft body, is supported by a frame of longitudinal girders and circumferential ribs interconnecting the girders. Additionally, the outer skin is strengthened by reinforcing strips adhesively bonded to the outer skin between the ribs and girders. The reinforcing strips are made of material that is damage tolerant, for example high strength aluminum alloys and fiber composite materials are suitable for making the reinforcing strips. These reinforcing strips may extend in parallel to the stringers and / or the ribs and preferably form a lattice work. The reinforcing strips need not cross each other at right angles but should cross a crack propagation direction in the outer skin.

Owner:AIRBUS OPERATIONS GMBH

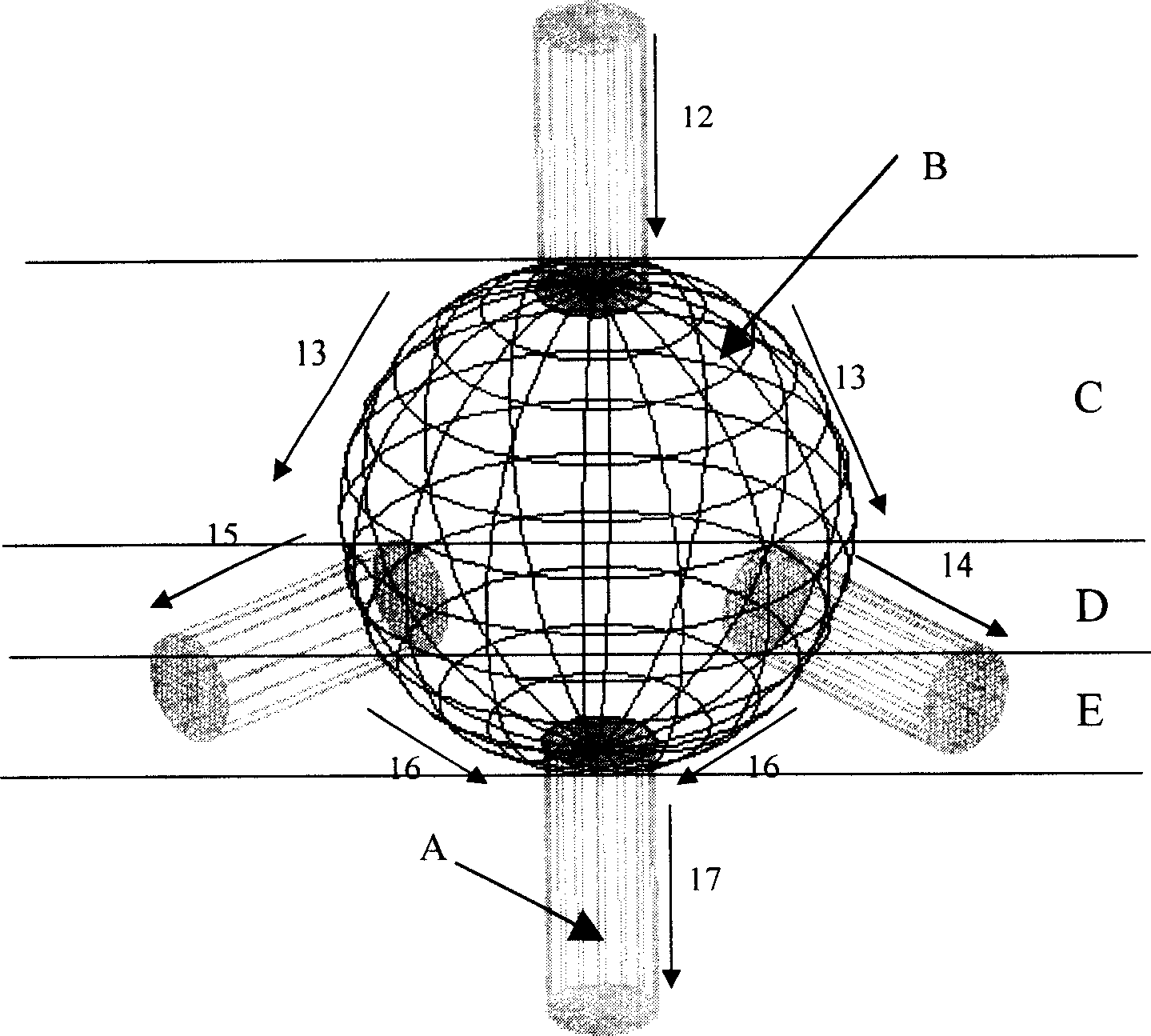

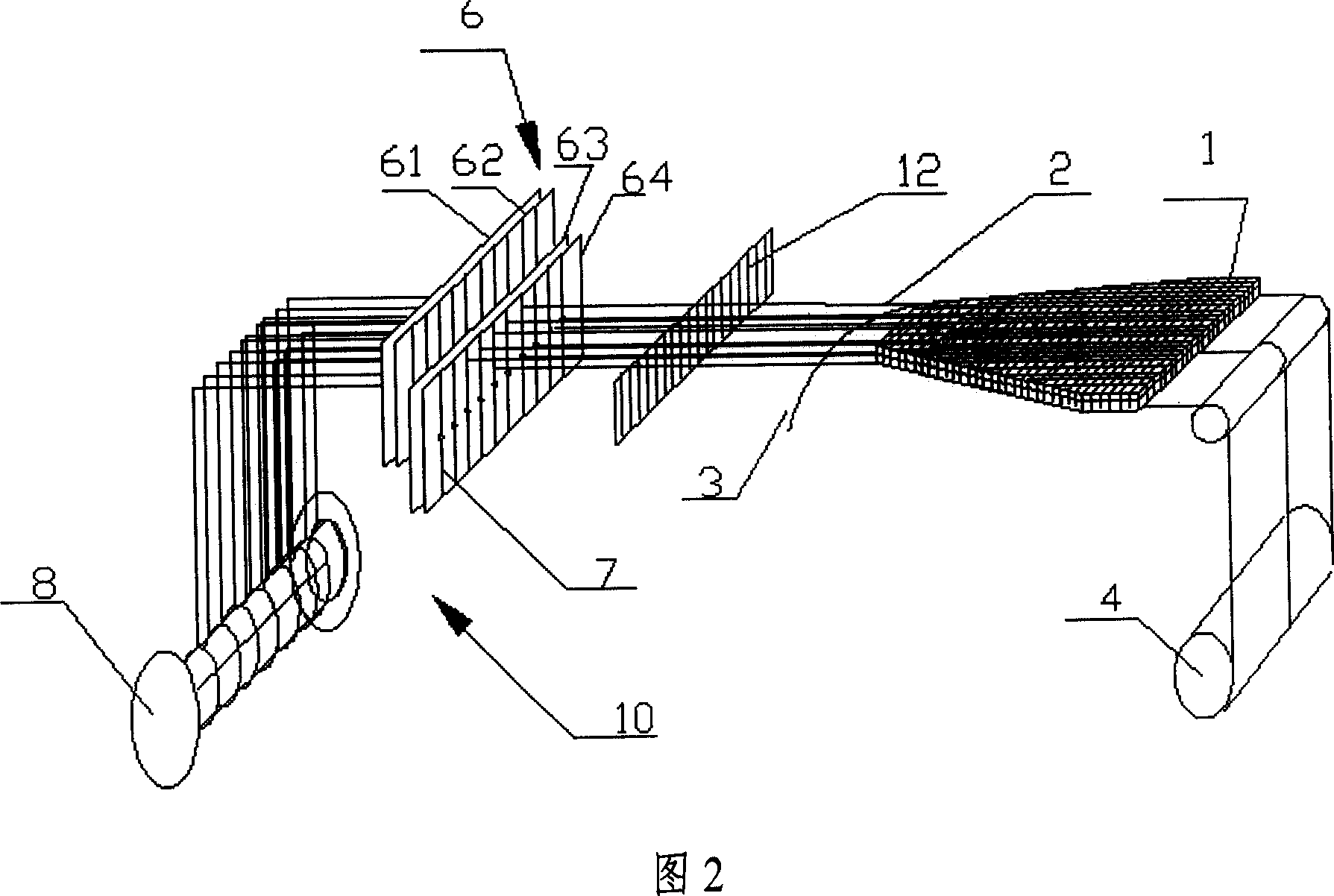

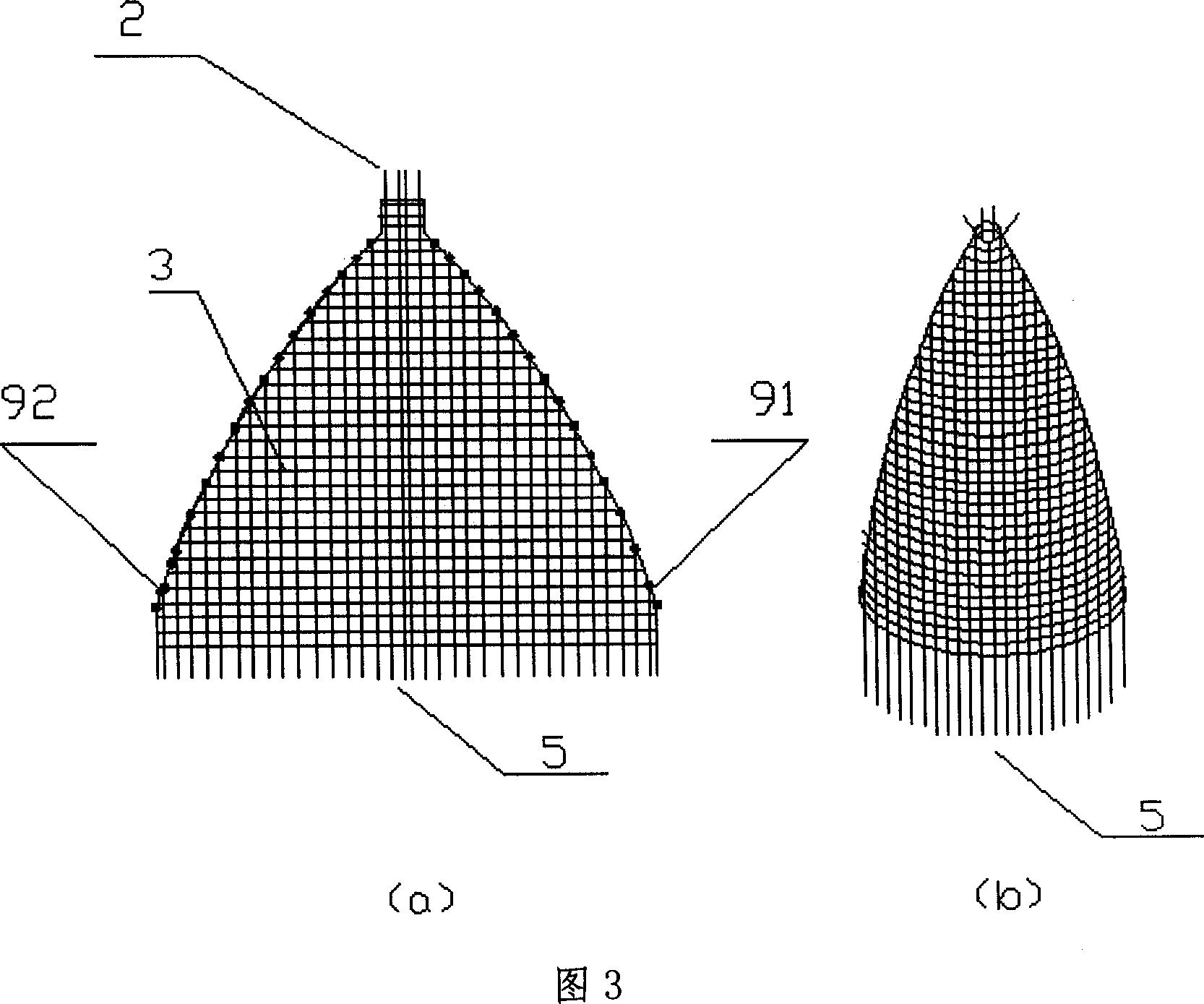

Weaving process in three-dimensional conic-casing loom and its product

InactiveCN1932102ARealize planar overall weavingImprove integrityWoven fabricsDamage toleranceEngineering

The present invention is weaving process of three-dimensional conic-casing fabric and its product. The weaving process includes the following steps: 1. pre-setting warp yarns based on the fabric structure and in tubular fabric weaving process; 2. introducing weft yarns in planar helical wefting method and interweaving with preset warp yarns; 3. setting warp cutting points on two sides based on the planar shape of the fabric and performing copying warp cutting operation; and 4. repeating the steps 2 and 3 until finishing the weaving of the three-dimensional conic-casing fabric. The present invention has short weaving period, low cost, simple operation, high efficiency, high adaptability and other features, and the fabric has high integrality, high damage tolerance, high impact resistance and other advantages.

Owner:TIANJIN POLYTECHNIC UNIV

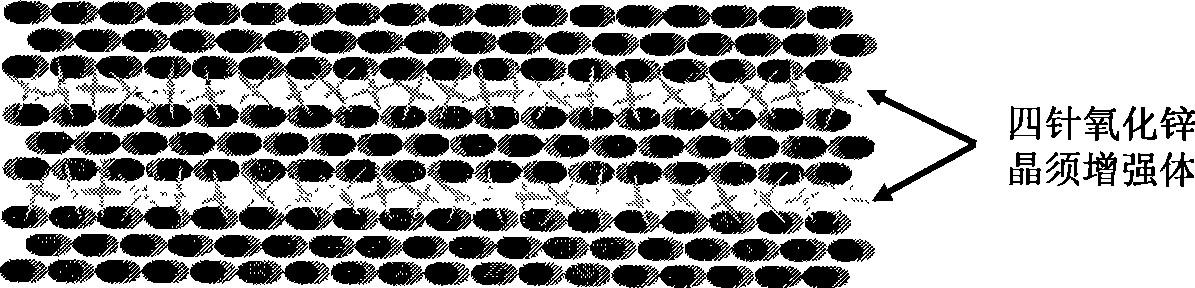

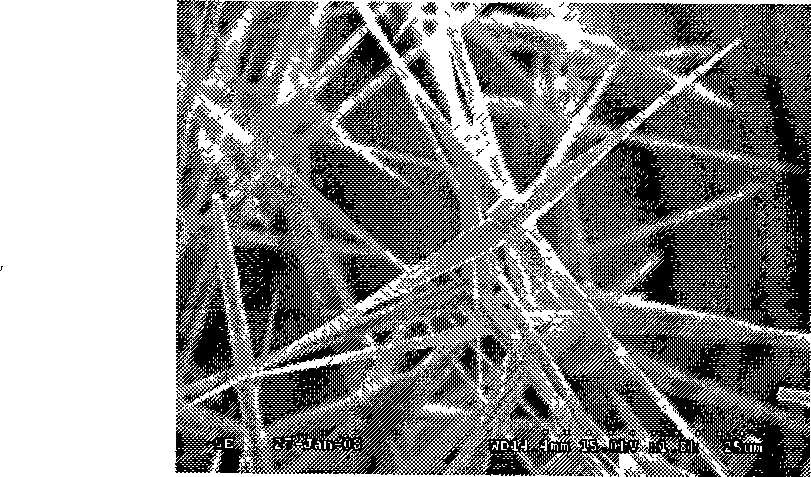

Method for preparing rigid three-dimensional crystal whisker interlayer modified continuous fiber composite material

ActiveCN101423618AImprove the strength-toughness performanceAvoid difficultiesMicron scaleTransfer molding

The invention belongs to a technology for preparing composite materials and relates to a method for preparing rigid three-dimensional crystal whisker interlaminar modified continuous fiber composite materials. The interlaminar modified thermosetting resin composite materials are prepared by the following method by adoption of a micron-scale heteropical rigid micro 3-3 structure and adoption of a four-pin zinc oxide crystal whisker as an interlaminar reinforcement: firstly, the four-pin zinc oxide crystal whisker which is subjected to vacuum drying for 2 hours at a temperature of 100 DEG C is deposited on the surface of fabrics by means of a mechanical vibrating screen or electrostatic adherence or deposition through a fluidized bed or powdering through a drum-type silk screen, and modified fabrics are obtained; and secondly, after the modified fabrics are laid as required, the resin transfer molding technology or the resin membrane permeation technology is utilized for preparing the composite materials by the prior matrix resin solidifying technology. The method can improve the strong interlaminar toughening performance of the composite materials, obtain high surge impedance and high damaged tolerance, and cover the temperature range of structural application of typical aerospace composite materials and particularly cover the high temperature range of more than 300 DEG C.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

2.5-dimension (2.5d) multidirectional extensible weaving method

The invention relates to a 2.5-dimension (2.5D) multidirectional extensible weaving method, which is characterized in that (1) a fabric adopts a 2.5D structure; (2) weaving of the fabric adopts core die simulation weaving; (3) top pavement weaving on the top of the center is finished by the conventional yarn paving and weft lining technology; and (4) after the top pavement weaving on the top of the center is finished, expansion is executed by selecting an expansion shape consistent with the top shape of the fabric according to the top shape. The 2.5D multidirectional extensible weaving method has the advantages that (1) bidirectional or multidirectional expansion of the top of the fabric can be realized, and overall forming of the fabric with a relatively complicated top shape is facilitated; (2) the fibers on the top are high in continuity; and (3) the uniformity during fabric forming is easy to control. The fabric woven by the weaving method has comprehensive performances such as high strength, high modulus, high damage tolerance, impact resistance, layering resistance and fatigue resistance; and the method can be widely applied to weaving fabrics which have sealed tops and are in various shapes in the field of stereo fabrics.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Nonwoven fabric containing metal coating as well as product thereof

ActiveCN103552318ATougheningConductiveSynthetic resin layered productsMetal layered productsMetal coatingThin layer

The invention relates to a nonwoven fabric containing a metal coating as well as a product thereof. The nonwoven fabric containing the metal coating is mainly characterized in that the structural characteristic of the nonwoven fabric is that the nonwoven fabric is a thin layer which has a network structure and is formed by low-surface-density fibers; a metal layer of copper, silver, nickel, nickel coated copper or nickel-copper-nickel is coated on the surface of the nonwoven fabric and has the thickness of 100nm-5 micron m, so that the nonwoven fabric layer has electrical conductivity and keeps soft, also can obviously intensify the interlayer fracture toughness and electrical conductivity of laminated plates when being applied to intercalation compounding material lamination plates, and meanwhile a compound material is endowed with higher shock damage impedance and damage tolerance as well as higher electrical conductivity. Corresponding prepregs can be directly used for laying and covering so as to obtain a high-electrical-conductivity compound material, and the corresponding compound material product can be used for high-electrical-conductivity shock-resistant occasions and aircraft lightning protection structural bodies.

Owner:AVIC COMPOSITES

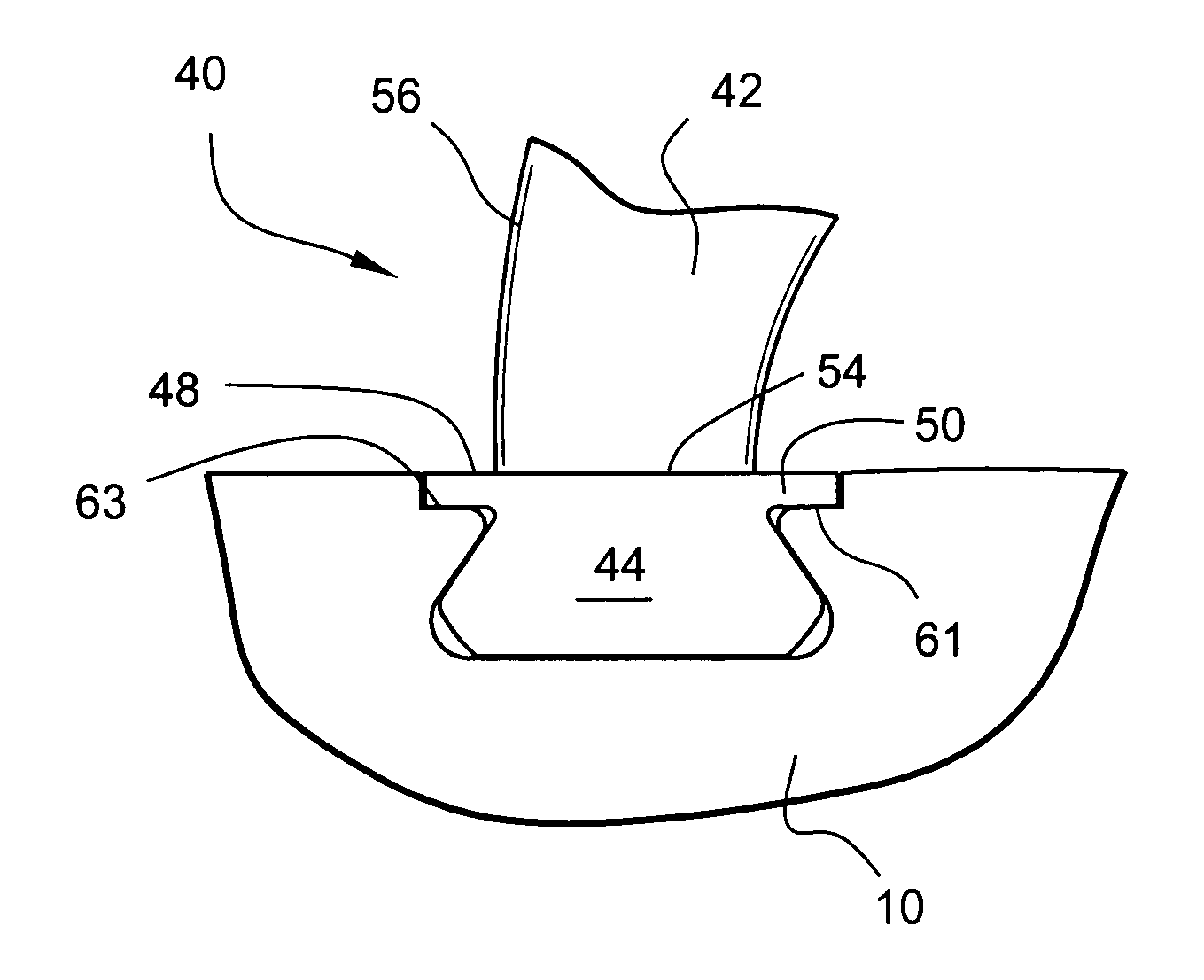

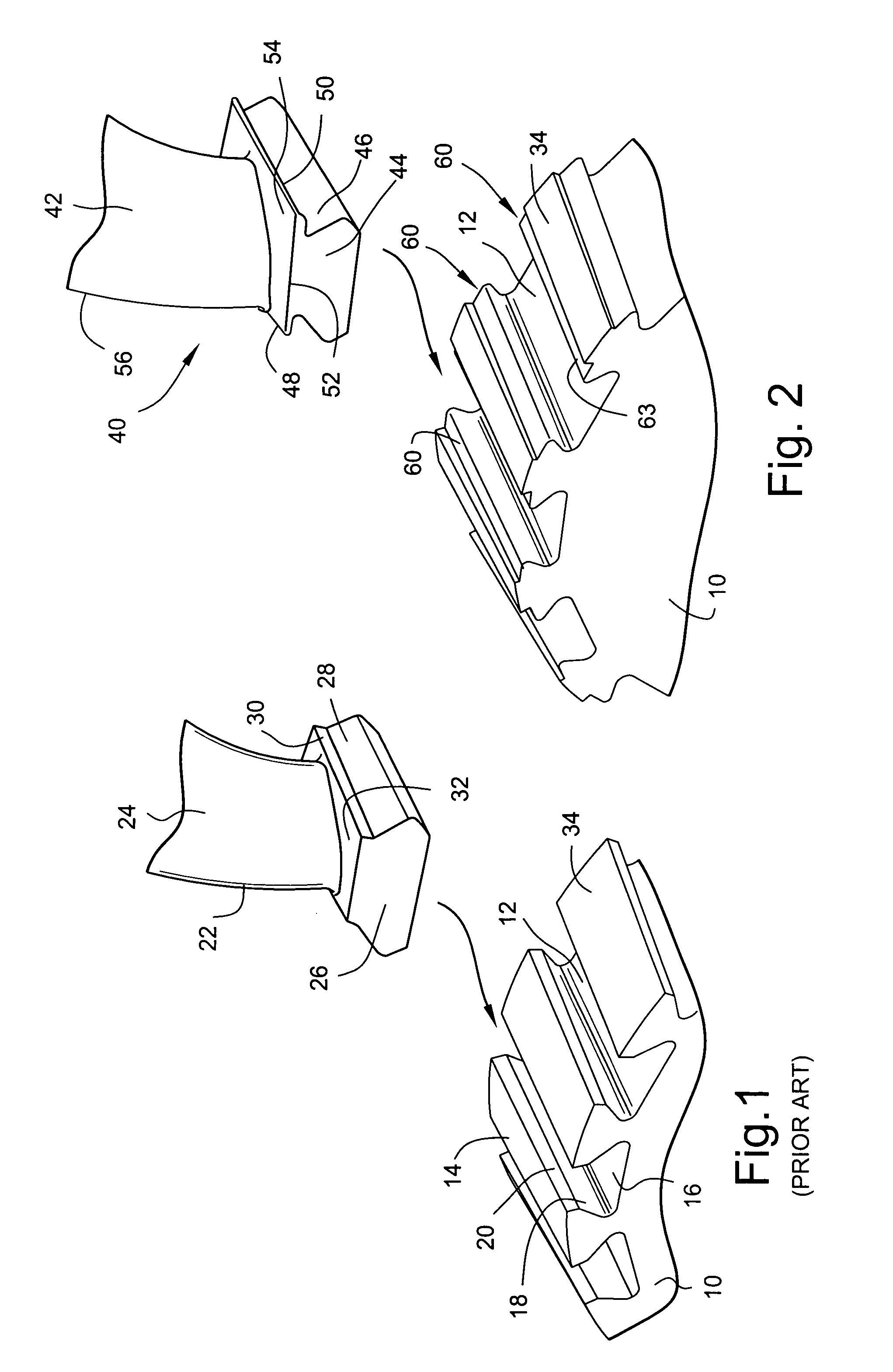

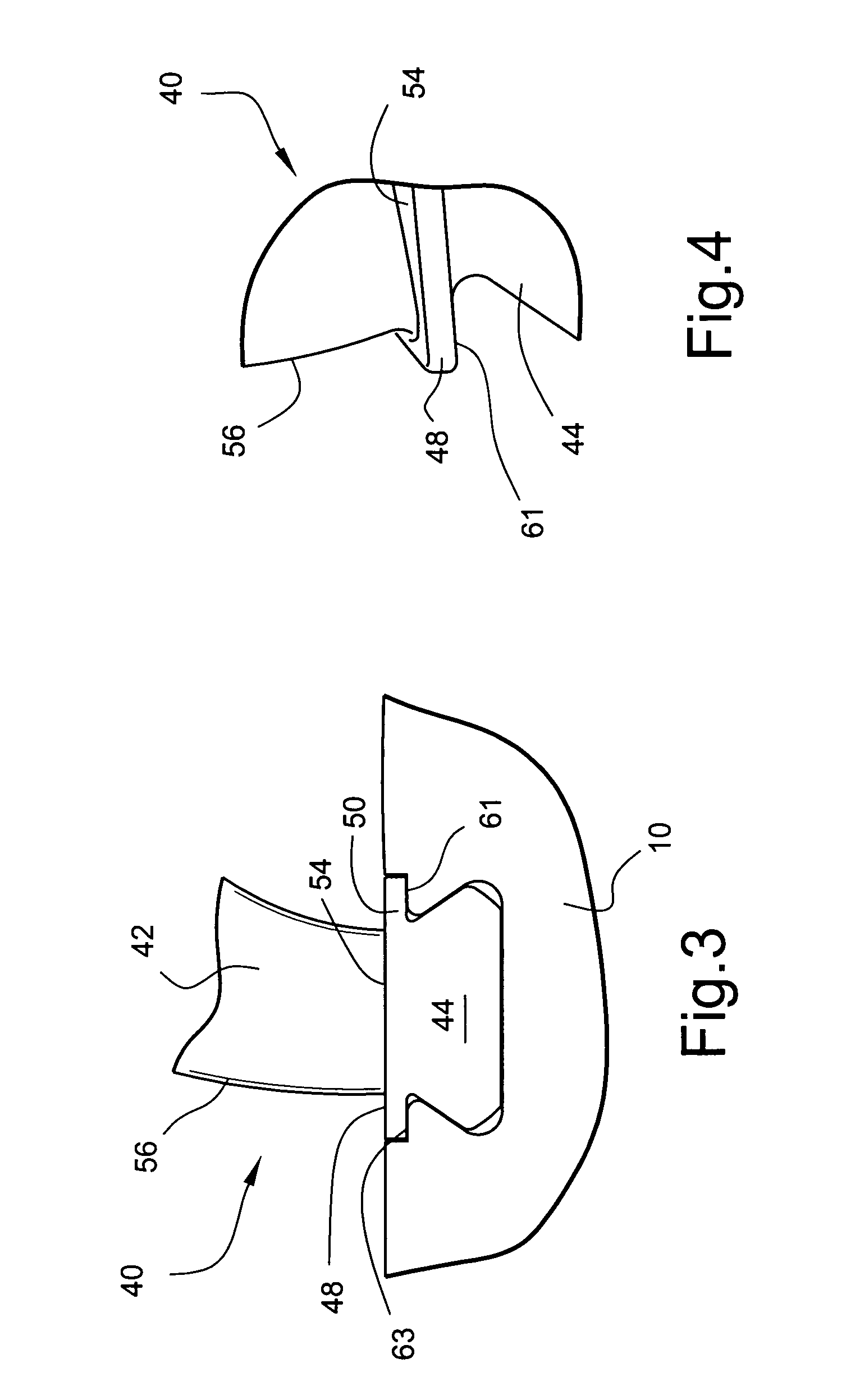

Compressor blade platform extension and methods of retrofitting blades of different blade angles

ActiveUS7104759B2Increased blade angleStress minimizationPropellersPump componentsLeading edgeImpeller

Blades of increased blade angle may be retrofitted onto existing compressor rotor wheels as replacement blades whereby higher performance and efficiency without replacing the rotor wheel may be achieved. The base attachments of replacement blades are provided with lateral extensions or flanges and the rim of the compressor wheel is provided with recesses straddling the grooves to accommodate the flanges. The leading edge of the replacement blade is positioned circumferentially for support only by the platform extension thereby limiting the mean and vibratory stresses in the leading edge of the airfoil and maximizing damage tolerance.

Owner:GENERAL ELECTRIC CO

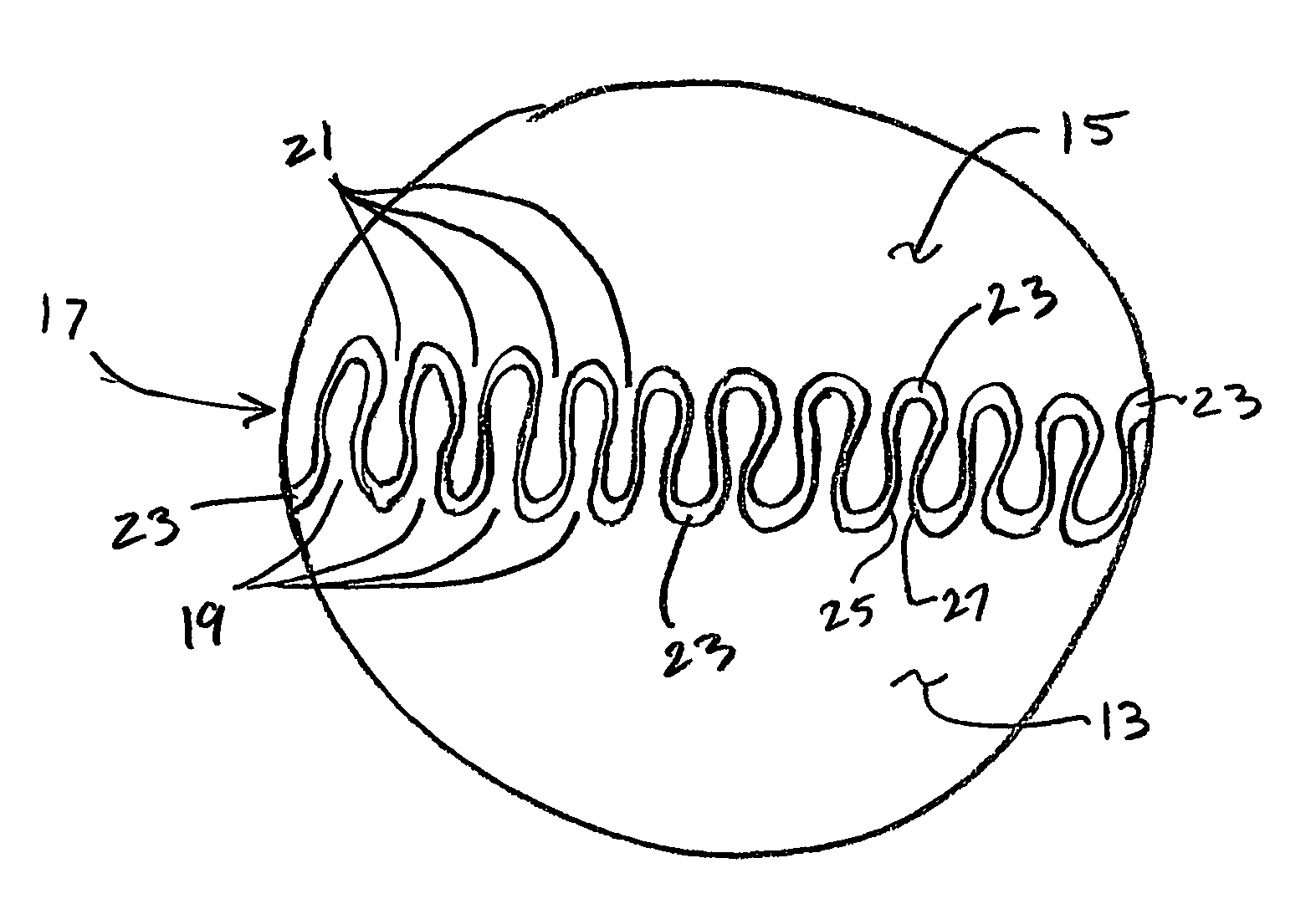

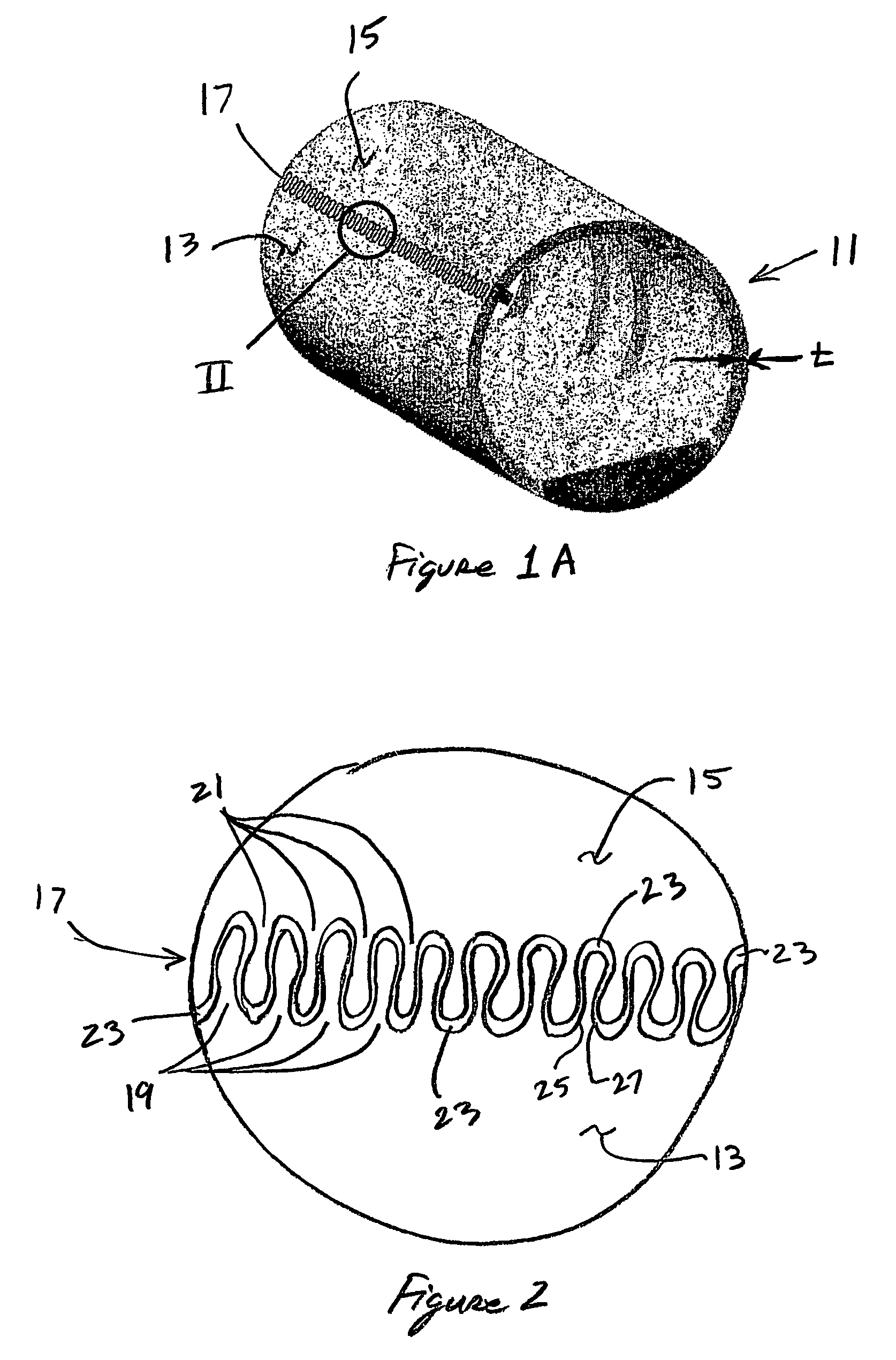

Composite structural member

InactiveUS20120308770A1Axial stiffness is lowIncrease stiffnessAdhesive processesLayered productsComposite constructionFiber

Owner:AIRBUS OPERATIONS LTD

Preparation method for in-situ generated Ti3SiC2-phase toughening silicon carbide ceramic matrix composite material

The invention belongs to the technical field of the ceramic matrix composite material preparation, and particularly relates to a preparation method for an in-situ generated Ti3SiC2-phase toughening silicon carbide ceramic matrix composite material. The method comprises the following steps: enabling TiC powder, connection resin and an organic solvent to be prepared as slurry, and preparing prepregwith fibers, to obtain a fiber / C-TiC porous body through hot-pressing and carbonizing, covering the surface of the porous body by using Si powder, and generating Ti3SiC2 in situ in a process of generating a silicon carbide matrix by using a high-temperature melting silicon permeation technology. The method is capable of not only eliminating the residual silicon content in the matrix, but also weakening the adverse effect of silicon to mechanical properties of the composite material; in addition, because of an own stratified structure of a MAX-phase material, while the ceramic matrix compositematerial bears load, a crack is expanded to the layer interface and is hindered so that deflection or passivation is produced, the stress concentration of the point of the crack is weakened, and the toughening to the ceramic matrix composite material is finally realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

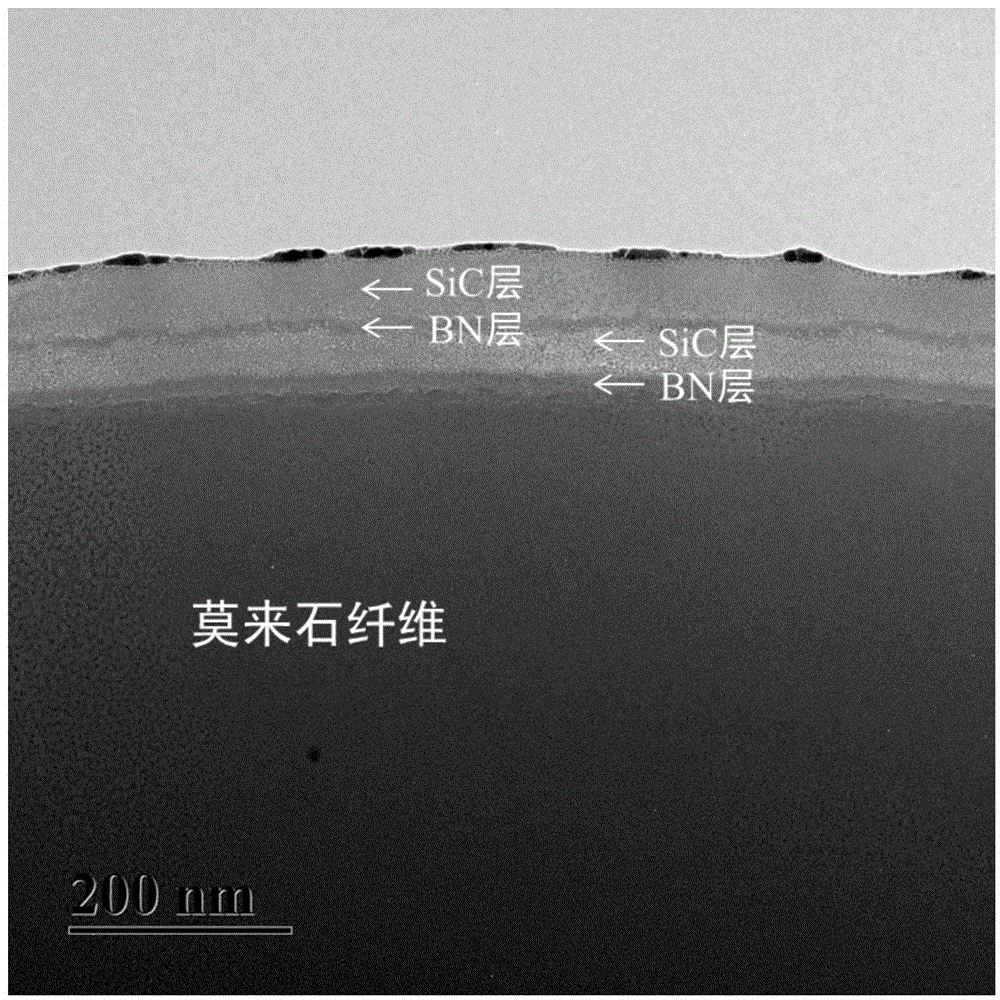

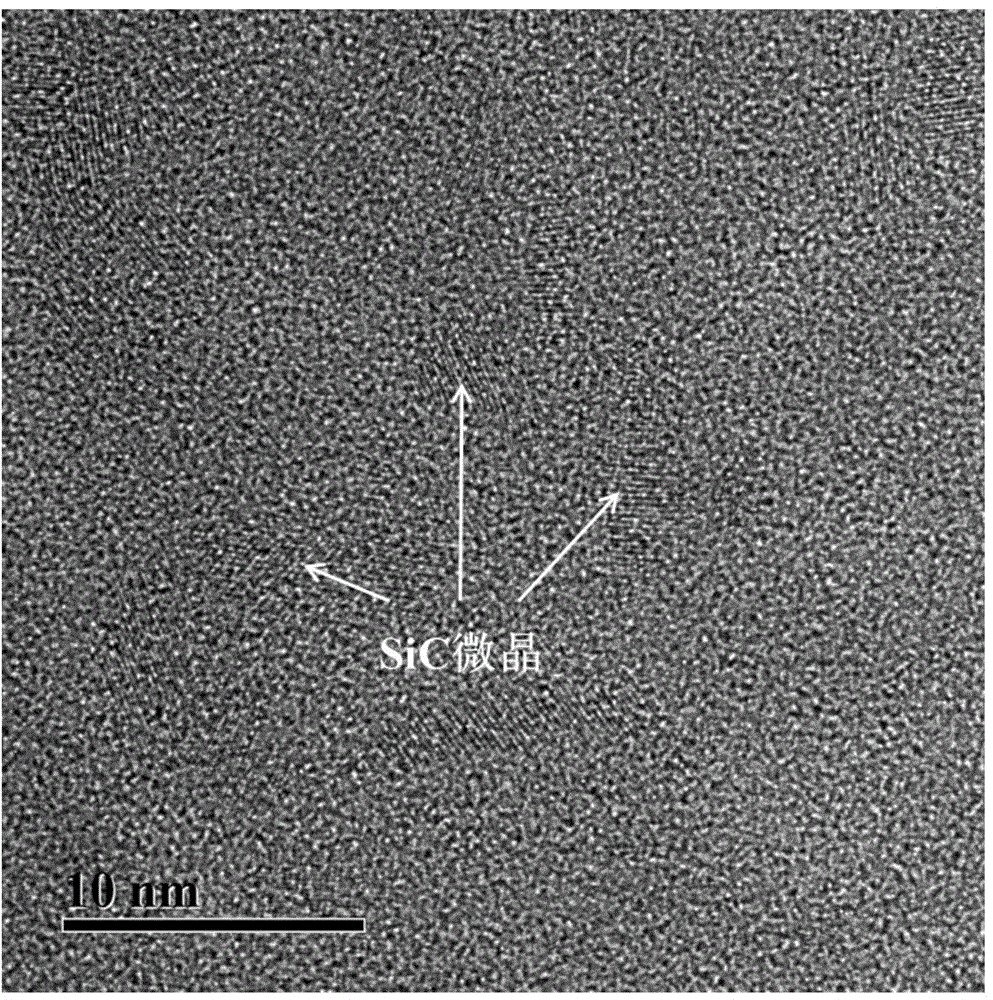

(BN/SiC)n composite interface-phase coating, coating fiber and preparation method

The invention discloses a (BN / SiC)n composite interface-phase coating. The (BN / SiC)n composite interface-phase coating has a periodic laminated structure, wherein BN layers and SiC layers are alternatively and periodically overlapped; the thickness of the BN layers is not greater than that of the SiC layer. A coating fiber comprises a fiber substrate and the (BN / SiC)n composite interface-phase coating; the innermost layer closest to the fiber substrate is the NB layer and the outermost layer further away from the fiber substrate is the SiC layer. A preparation method for the coating fiber comprises the steps: cleaning the fiber substrate; putting into a deposition hearth, vacuumizing and filling with inert gases to exchange with air; realizing a preset vacuum degree and a preset temperature; bringing precursors into the reaction by carrier gas in a bubbling manner, maintaining a specified pressure of a reaction system, and alternatively depositing the BN layers and the SiC layers on the fiber substrate through changing a precursor gas source. The product has the advantages of good compatibility, high-temperature resistance, anti-oxidation and good toughening effect.

Owner:NAT UNIV OF DEFENSE TECH

Aligned composite structures for mitigation of impact damage and resistance to wear in dynamic environments

InactiveUS20060091580A1Improve mechanical propertiesIncrease insensitivityNatural cellulose pulp/paperFilament/thread formingFiberDamage tolerance

Fibrous monolith composites having architectures that provide increased flaw insensitivity, improved hardness, wear resistance and damage tolerance and methods of manufacture thereof are provided for use in dynamic environments to mitigate impact damage and increase wear resistance.

Owner:ADVANCED CERAMICS

Al-Mg-Sc-Zr aluminum alloy plate and manufacturing method thereof

ActiveCN104694801ARaise room temperatureImprove mechanical propertiesHigh concentrationCarrying capacity

The invention provides an Al-Mg-Sc-Zr aluminum alloy plate and a manufacturing method thereof, and relates to the Al-Mg-Sc-Zr aluminum alloy plate and the manufacturing method thereof. Traditional aluminium magnesium alloy is replaced by the novel aluminum alloy plate, so that the purposes of further reducing the dead-weight of aerospace crafts such as spacecrafts, missiles and satellites, improving the carrying capacity, increasing the useful load, and lowering the cost for launching are achieved. The Al-Mg-Sc-Zr aluminum alloy plate contains the following elements: Mg, Mn, Sc, Zr, Ti and Be. The manufacturing method comprises the steps of firstly, burdening; secondly, smelting; thirdly, casting; fourthly, homogenizing annealing; fifthly, hot rolling; sixthly, prestretching; seventhly, finished product saw cutting; and then the Al-Mg-Sc-Zr aluminum alloy plate is obtained. The Al-Mg-Sc-Zr aluminum alloy plate has the advantages that the normal-temperature and low-temperature mechanical property and the damage-resisting tolerance are higher, the welding performance and the corrosion resistance are excellent, and the high concentration hydrogen peroxide compatibility is better. The Al-Mg-Sc-Zr aluminum alloy plate is applicable to the manufacturing field of astronautic and aeronautic aluminum alloy plates.

Owner:NORTHEAST LIGHT ALLOY CO LTD

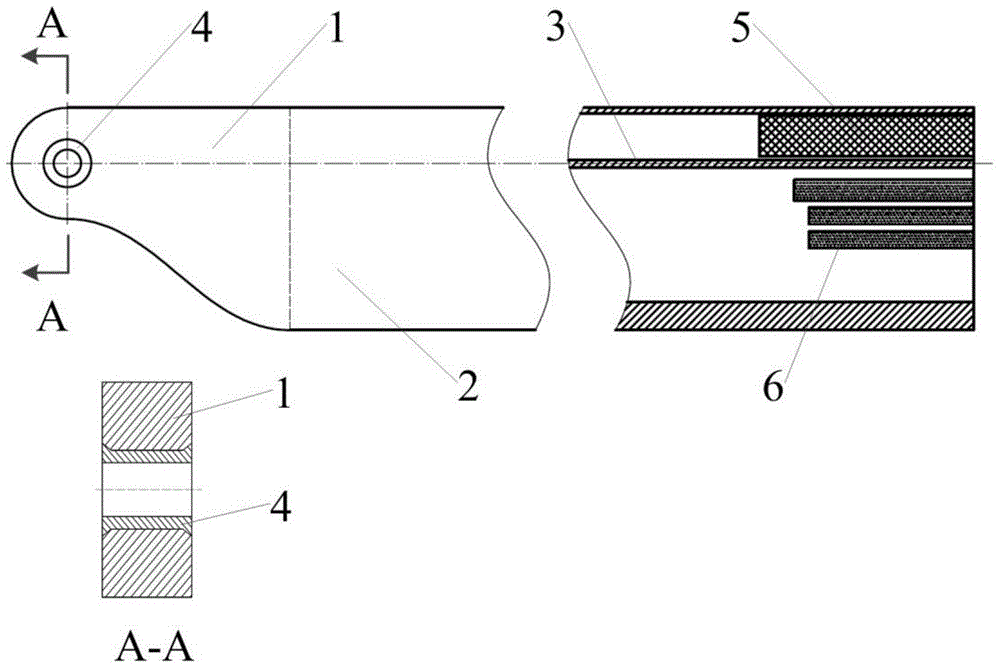

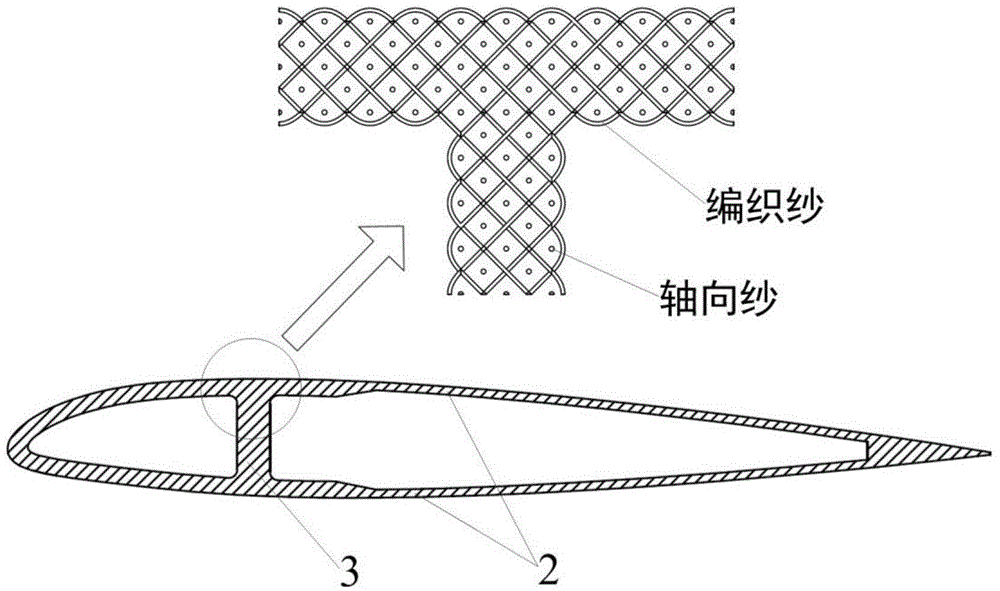

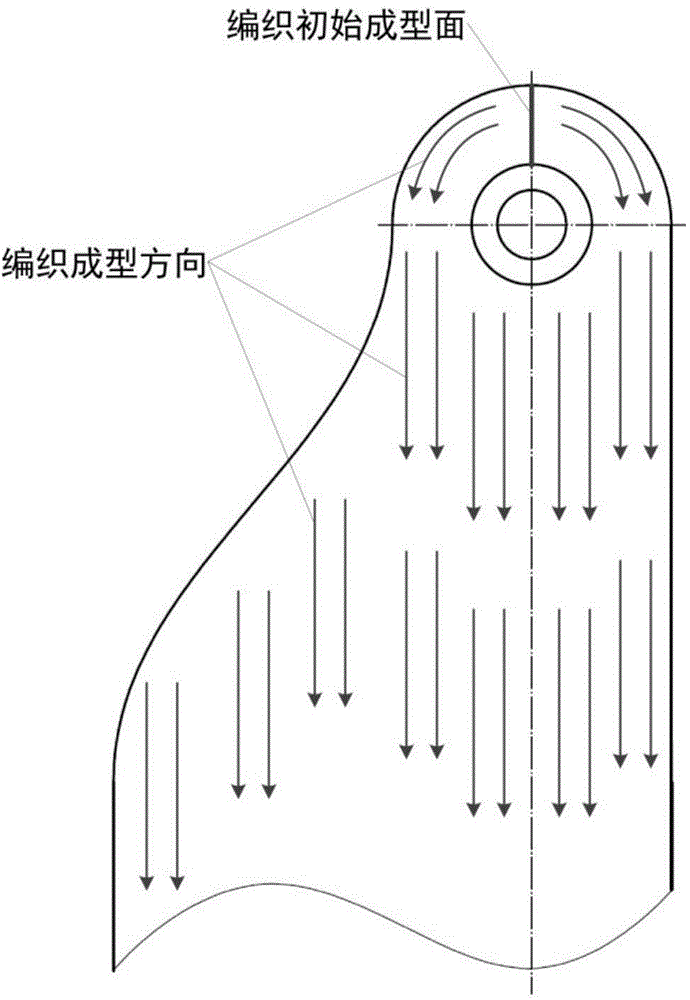

Three-dimensional weaving composite integrally-formed rotor wing blade and manufacturing method thereof

The invention discloses an integrally-formed three-dimensional weaving composite rotor wing blade and a manufacturing method thereof. The blade mainly consists of main parts of a root connecting joint, a blade up and down wing surface skin and a bearing main beam. The overall structure of the blade adopts is integrally formed by carbon fibers through a three-dimensional weaving process, and is integrally cured through an RTM process so as to finish blade processing. Compared with the conventional laminated composite blade, the blade in the scheme does not need secondary cementing and machining, the continuity of the bearing fiber inside the blade structure is ensured, the bearing efficiency of the structure is improved, meanwhile, the advantages of the three-dimensional weaving composite are fully played, the problems of lamination and cementing failures of the laminated composite are avoided, and the fatigue property and damage tolerance of the blade are improved.

Owner:BEIHANG UNIV

Structural members having improved resistance to fatigue crack growth

InactiveUS6974633B2High damage toleranceReduce rate of fatigue crack growthLayered productsExtrusion containersFiberDamage tolerance

An extruded structural member having improved damage tolerance containing a base section (6); a stiffening section having at least one pair of structural stiffeners (10), the structural stiffeners integral with the base section (6) and projecting outwardly thereof; and at least one intra-stiffener (90) area positioned between the pair of structural stiffeners (10), the intra-stiffener area (90) having a microstructure with intentionally increased amounts of fiber texture to reduce the rate of fatigue crack growth in the extruded structural member.

Owner:ARCONIC INC

Interlocking tooth bond for assembly of fiber composite laminates

ActiveUS7731817B2Cost efficientEffective weightAdhesive processesLamination ancillary operationsComposite laminatesImproved method

An improved method of joining fiber composite laminates is disclosed. Two fiber composite laminates may be joined together end-to-end. The bonding is done through the thickness of the fiber composite laminates. There are two ways to form the bond: (1) non-interlocking; and (2) interlocking.

Owner:BELL HELICOPTER TEXTRON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com