Three-dimensional weaving composite integrally-formed rotor wing blade and manufacturing method thereof

A composite material and three-dimensional weaving technology, which is applied to propellers, aircraft parts, transportation and packaging, etc., can solve problems such as low interlayer strength, poor integrity, and inability to ensure the uniformity of blades, so as to avoid structural load-bearing stiffness and strength The effect of reducing, improving fatigue performance and damage tolerance, avoiding delamination and bond failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

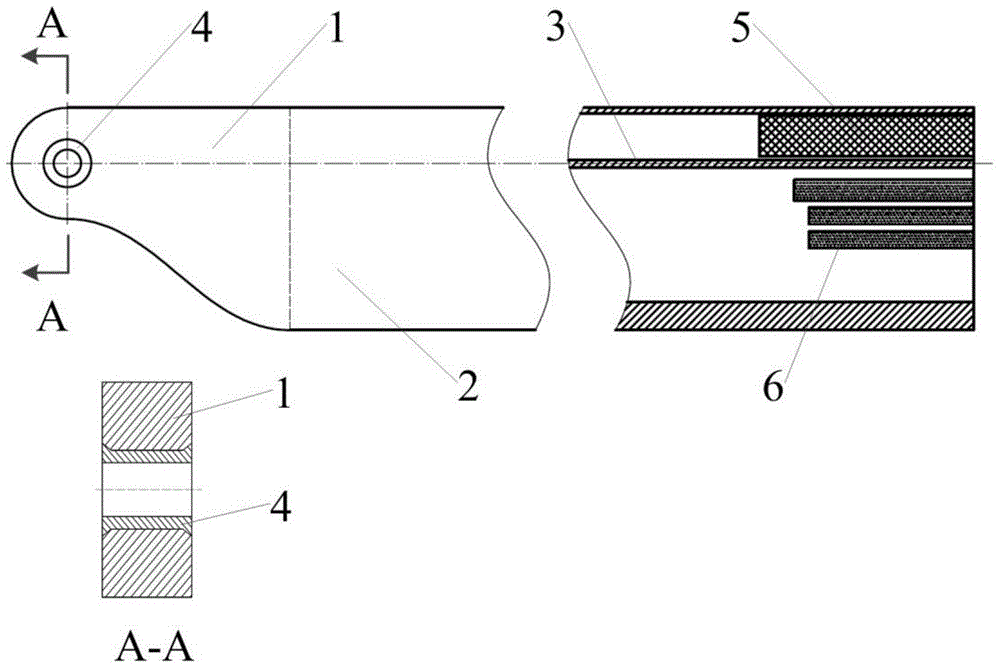

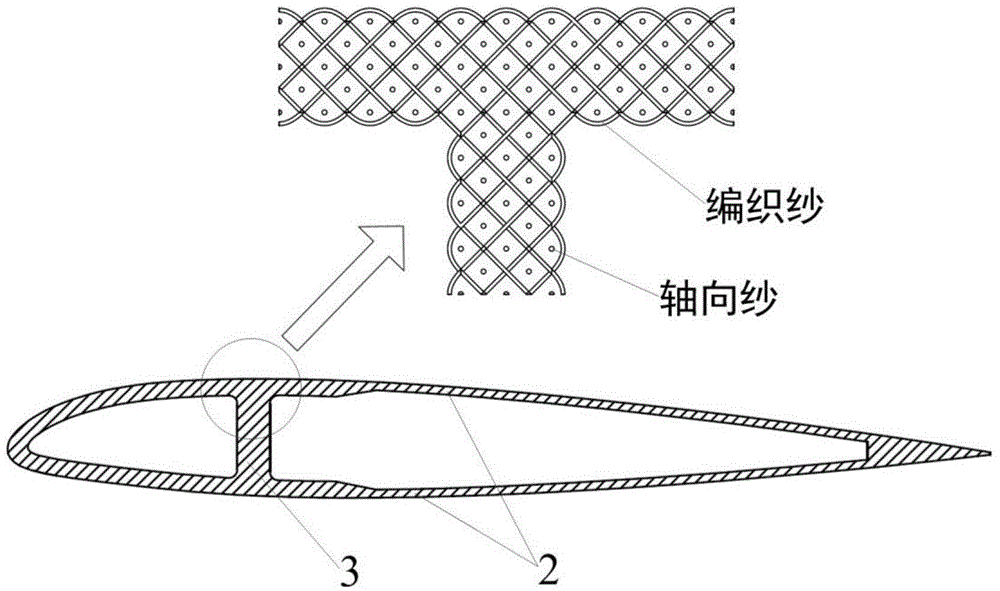

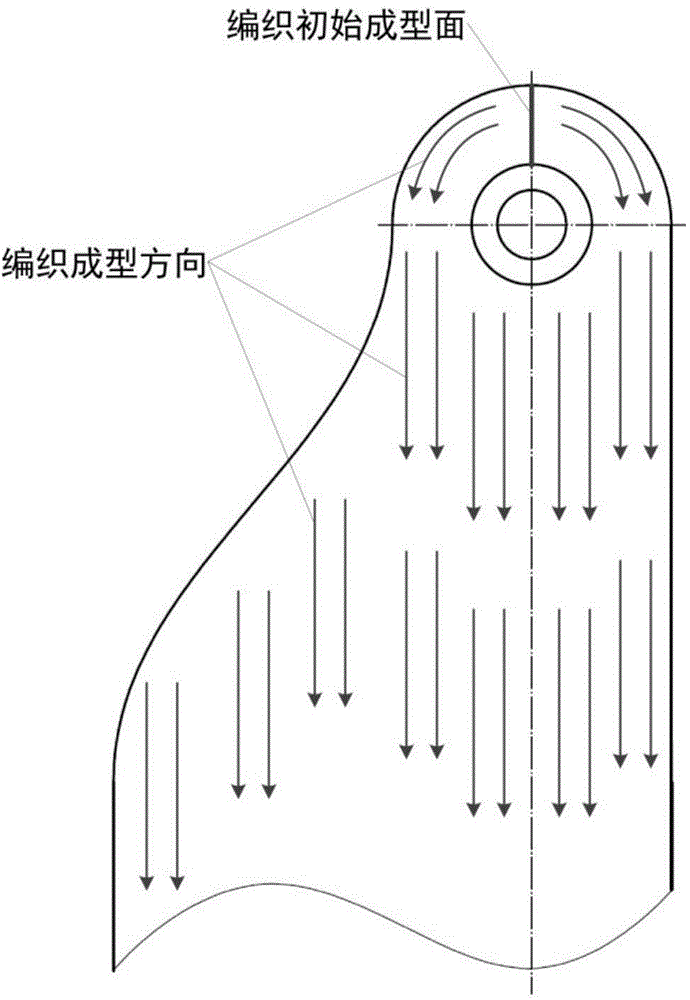

[0031] refer to figure 1 and figure 2 , the present invention provides a three-dimensional braided composite material integrally formed rotor blade, the root connection joint 1, the upper and lower airfoil skins 2, the load-bearing girder 3 and the metal bushing 4 of the root connection hole of the rotor blade are formed during the weaving process. One-piece construction. Such as figure 2 As shown, the braided yarn bundle runs continuously through the load-carrying girder 3 and the upper and lower airfoil skins 2, ensuring that these two components are integrally formed during the braiding process.

[0032] The present invention also provides a method for manufacturing the integrally formed rotor blade of the three-dimensional braided composite material, the specific steps are as follows:

[0033] Step 1: Paddle weaving process design:

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com