Method for preparing rigid three-dimensional crystal whisker interlayer modified continuous fiber composite material

A continuous fiber and composite material technology, applied in the field of composite material preparation, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

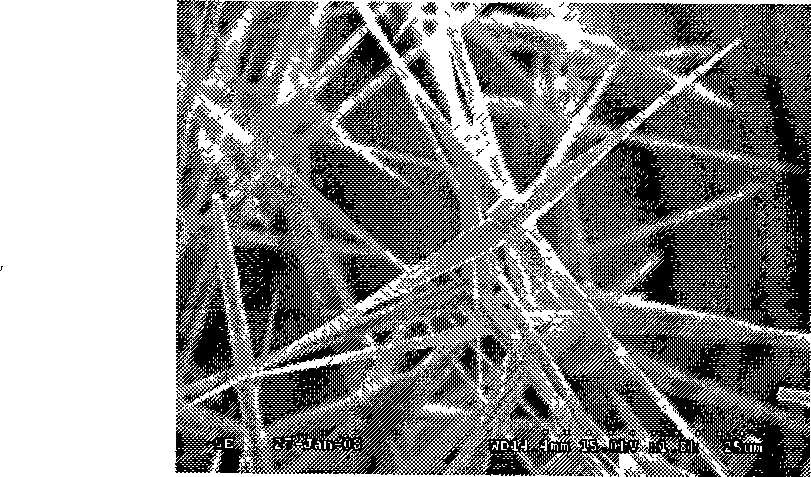

[0026] The four needle-shaped zinc oxide whiskers that were vacuum-dried at 100°C for 2 hours were deposited on the surface of high-strength alkali-free glass fiber fabric SW280 through a 60-mesh mechanical vibrating sieve, according to [(0 / 90)] 8 The method is anisotropic layering, and the zinc oxide whisker content between the two layers of fibers is guaranteed to be 5g / m 2 , Clamping. Press the typical aviation epoxy resin system E into the closed mold with a pressure of 0.1MPa to complete the mold filling.

[0027] After the mold filling process is completed, the mold is kept closed, and heating initiates the curing reaction of the epoxy resin of the closed mold. Curing conditions: at a heating rate of 2°C / min, the temperature was raised from room temperature to 180°C under normal pressure, kept at a temperature of 2h, and at the same time kept at a pressure of 0.20Mpa for 2h. Then, raise the temperature from 180°C to 200°C at the same rate, and increase the pressure fro...

Embodiment 2

[0033] The tetraacicular zinc oxide whiskers, which were vacuum-dried at 100°C for 2 hours, were deposited on the surface of continuous glass fiber fabric SW280 through a 60-mesh mechanical vibrating sieve, according to [(0 / 90)] 8 The method is anisotropic layering, and the zinc oxide whisker content between the two layers of fibers is guaranteed to be 5g / m 2 , Clamping. Press the typical aerospace epoxy resin system 3xxx into the closed mold with a pressure of 0.1MPa to complete the mold filling.

[0034] After the mold filling process is completed, the mold is kept closed, and heating initiates the curing reaction of the epoxy resin of the closed mold. Curing conditions: at a heating rate of 2°C / min, the temperature is raised from room temperature to 80°C under normal pressure, kept for 4 hours, and at the same time, the pressure is kept at 0.20Mpa for 2 hours. Then, raise the temperature from 80°C to 120°C at the same rate, and increase the pressure from 0.20MPa to 0.40MP...

Embodiment 3

[0040] The tetraacicular zinc oxide whiskers, which were vacuum-dried at 100°C for 2 hours, were deposited on the surface of the continuous carbon fiber fabric U-3160 through a 60-mesh mechanical vibrating sieve, according to [0] 12 The method is anisotropic layering, and the zinc oxide whisker content between the two layers of fibers is guaranteed to be 5g / m 2 , Clamping. The typical aviation RTM molding process bismaleimide (BMI) resin is pressed into the closed mold with a pressure of 0.1MPa to complete the mold filling.

[0041] After the mold filling process is completed, the mold is kept closed, and the curing reaction of the resin in the closed mold is initiated by heating. Curing conditions: at a heating rate of 2°C / min, the temperature is raised from room temperature to 130°C under normal pressure, kept at a temperature of 1h, and at the same time, the pressure is kept at 0.20MPa for one hour. Then, raise the temperature from 130°C to 190°C at the same rate, and inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com