Patents

Literature

1689results about "Fuselage bulkheads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

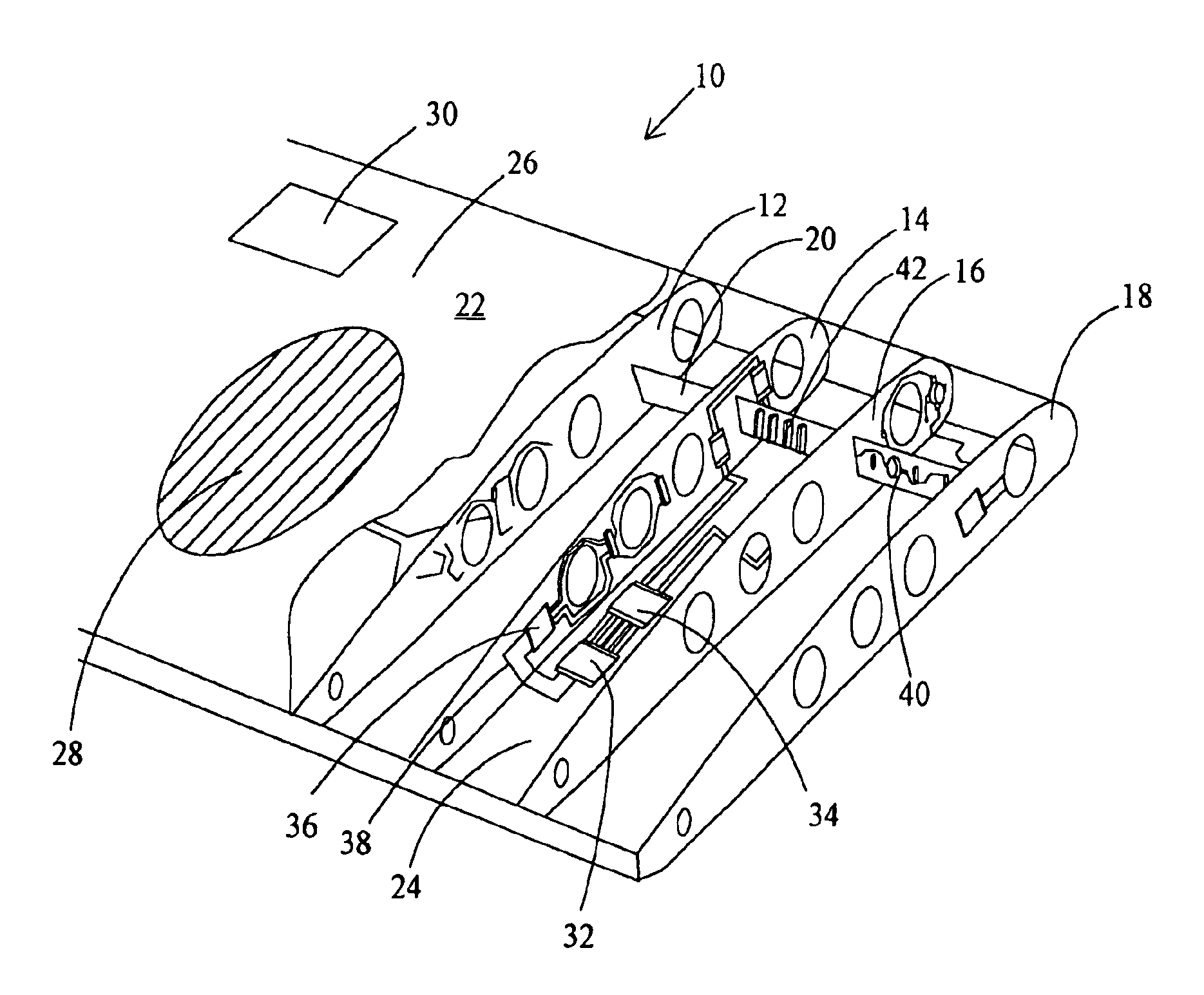

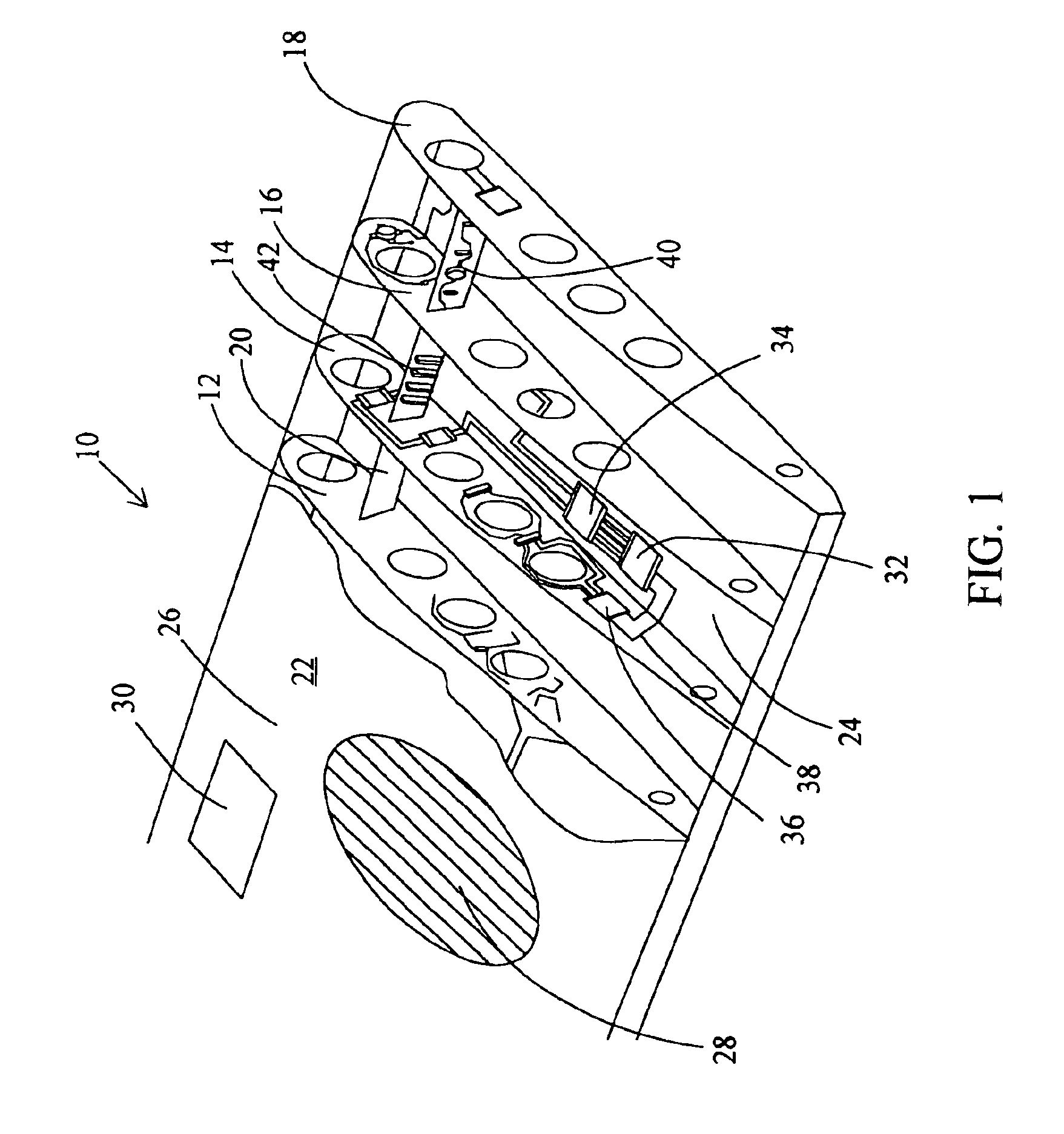

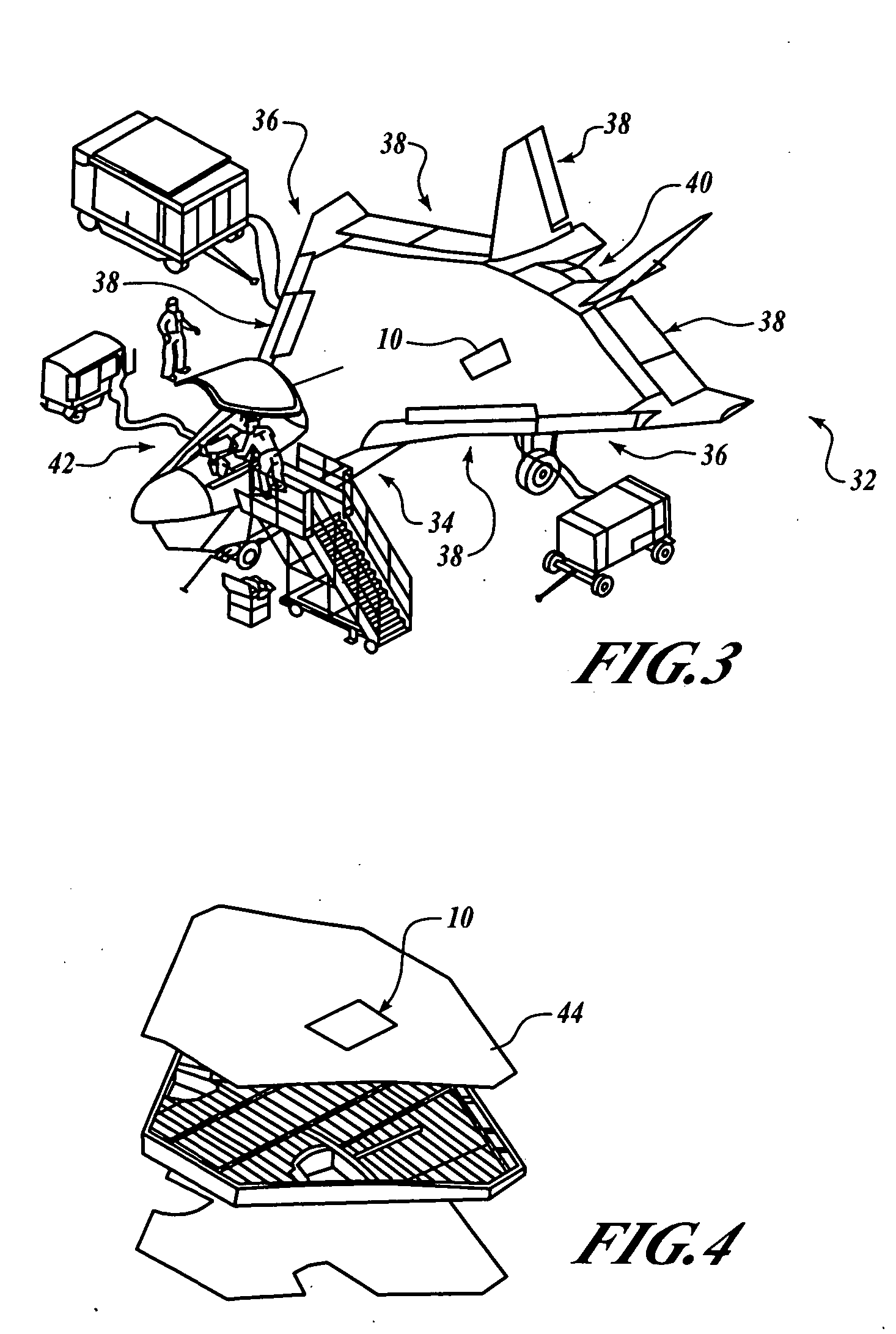

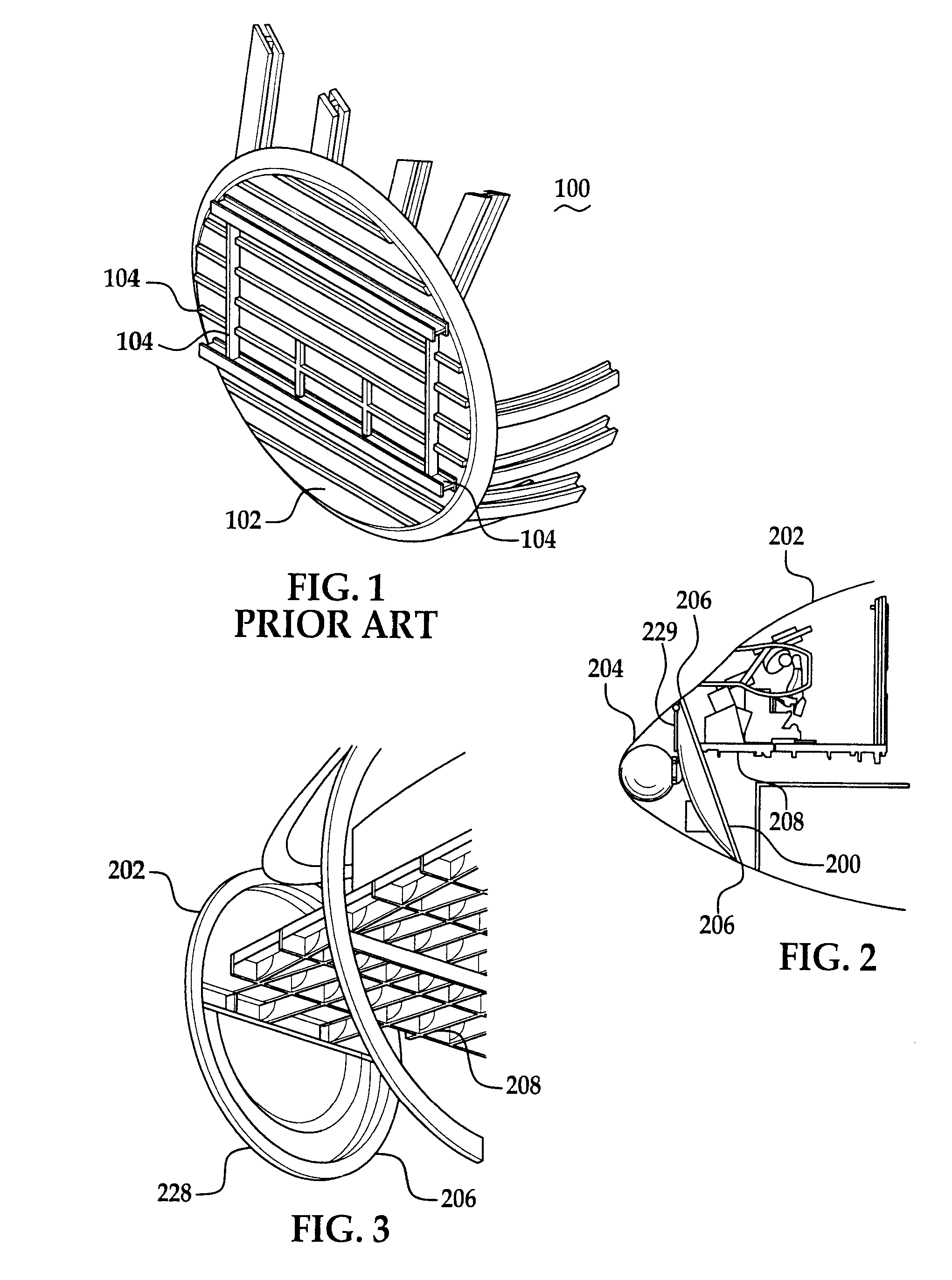

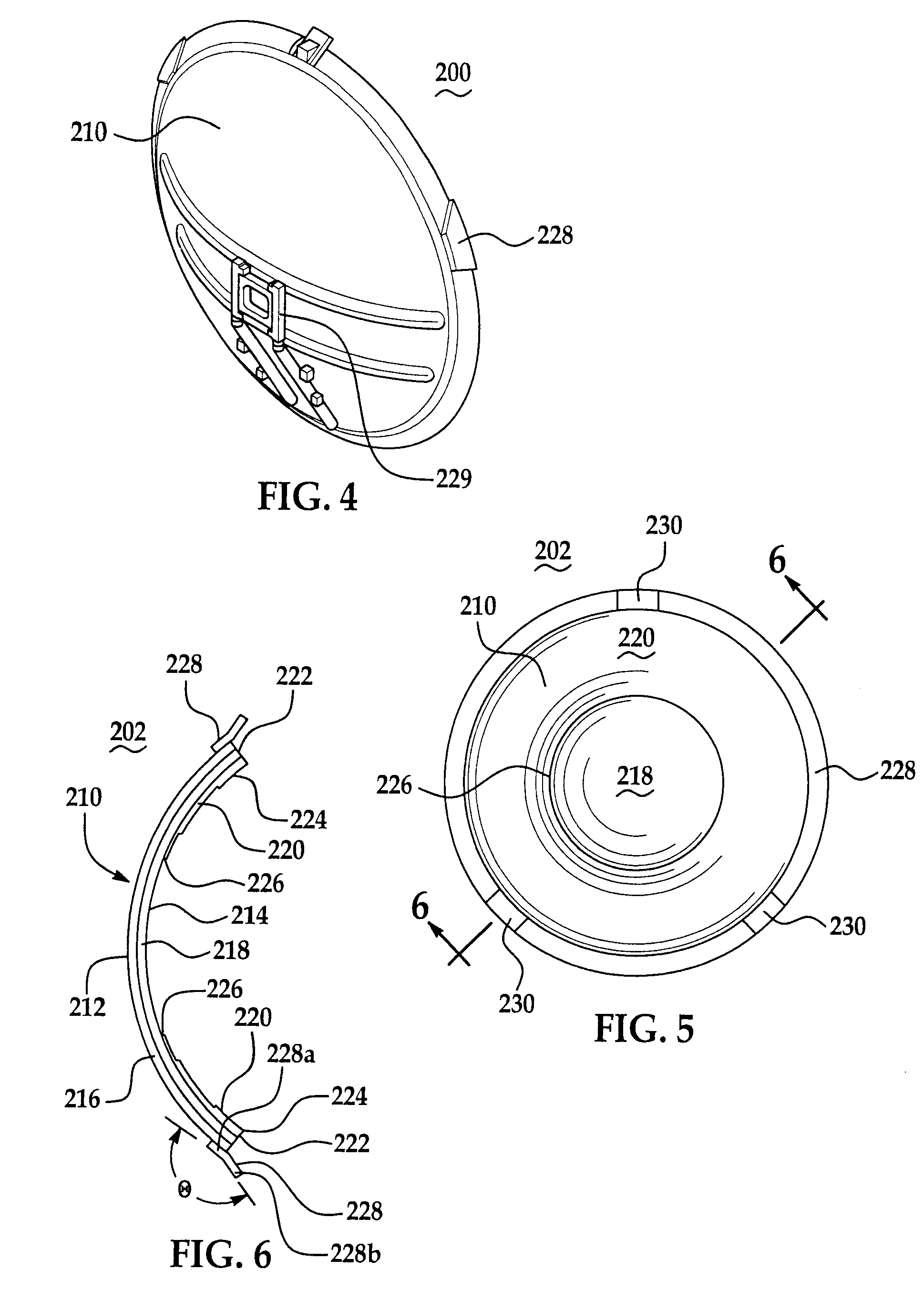

Unmanned aerial vehicle apparatus, system and method for retrieving data

InactiveUS6868314B1Unacceptable costHigh maintenance costFuselage framesDigital data processing detailsTerrainWireless transceiver

The present invention relates to a system for retrieving data from remote difficult to reach terrain, such as wilderness areas, etc. and in particular to a system comprised of one or more surface based data collectors in communication with one or more wireless transceivers adapted to transmit the collected data to an unmanned aerial vehicle adapted to fly within a predetermined distance from the data collector and receive data collected therefrom. The present invention further relates to an unmanned aerial vehicle adapted to fly a flight pattern relative to a moveable surface object or for controlling the position of a moveable surface object relative to the flight path of the unmanned aerial vehicle. Finally, the present invention relates to an improved unmanned aerial vehicle having airframe structural elements with electrical circuits adhered to the surfaces of the structural elements.

Owner:FRINK BENTLEY D

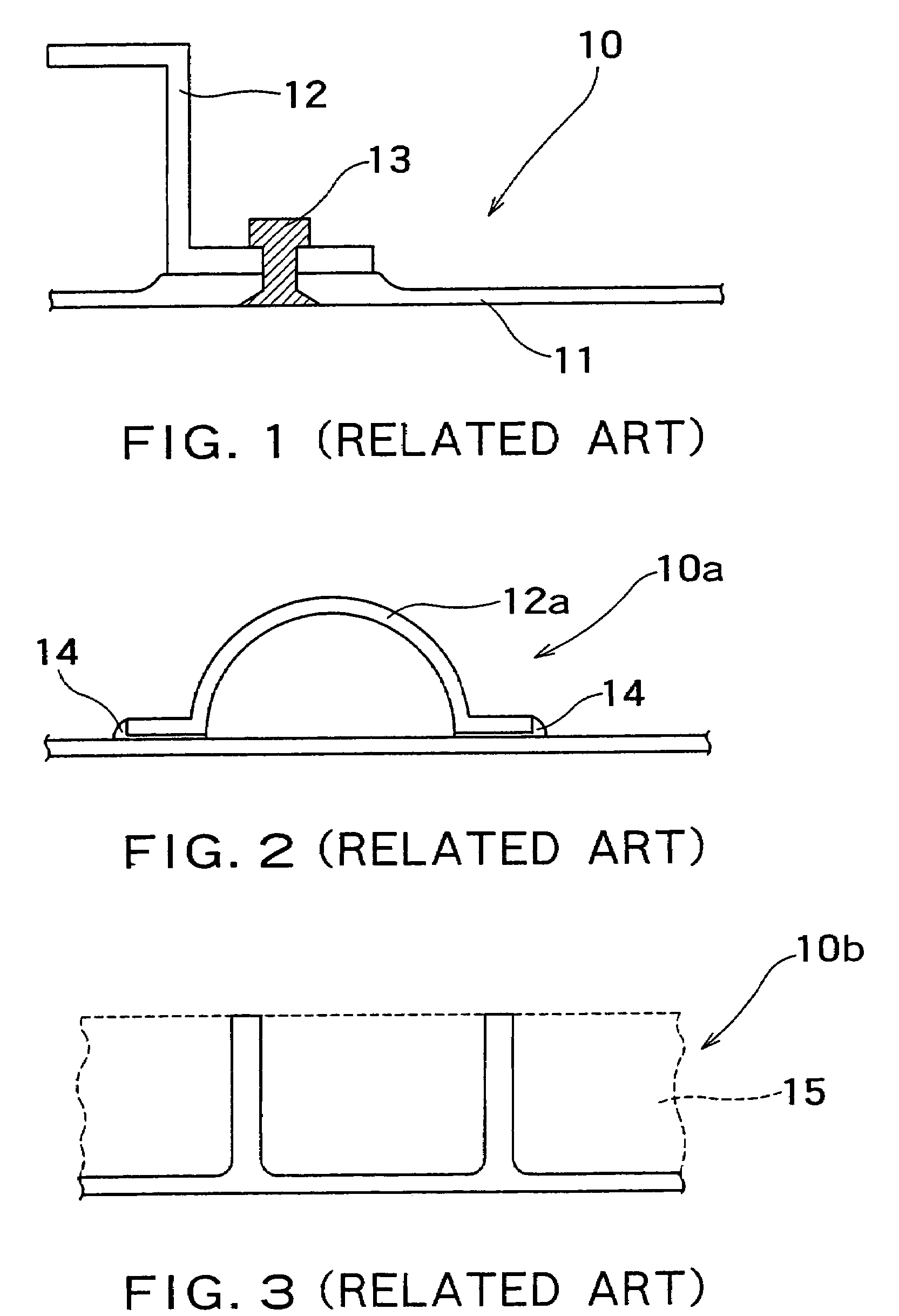

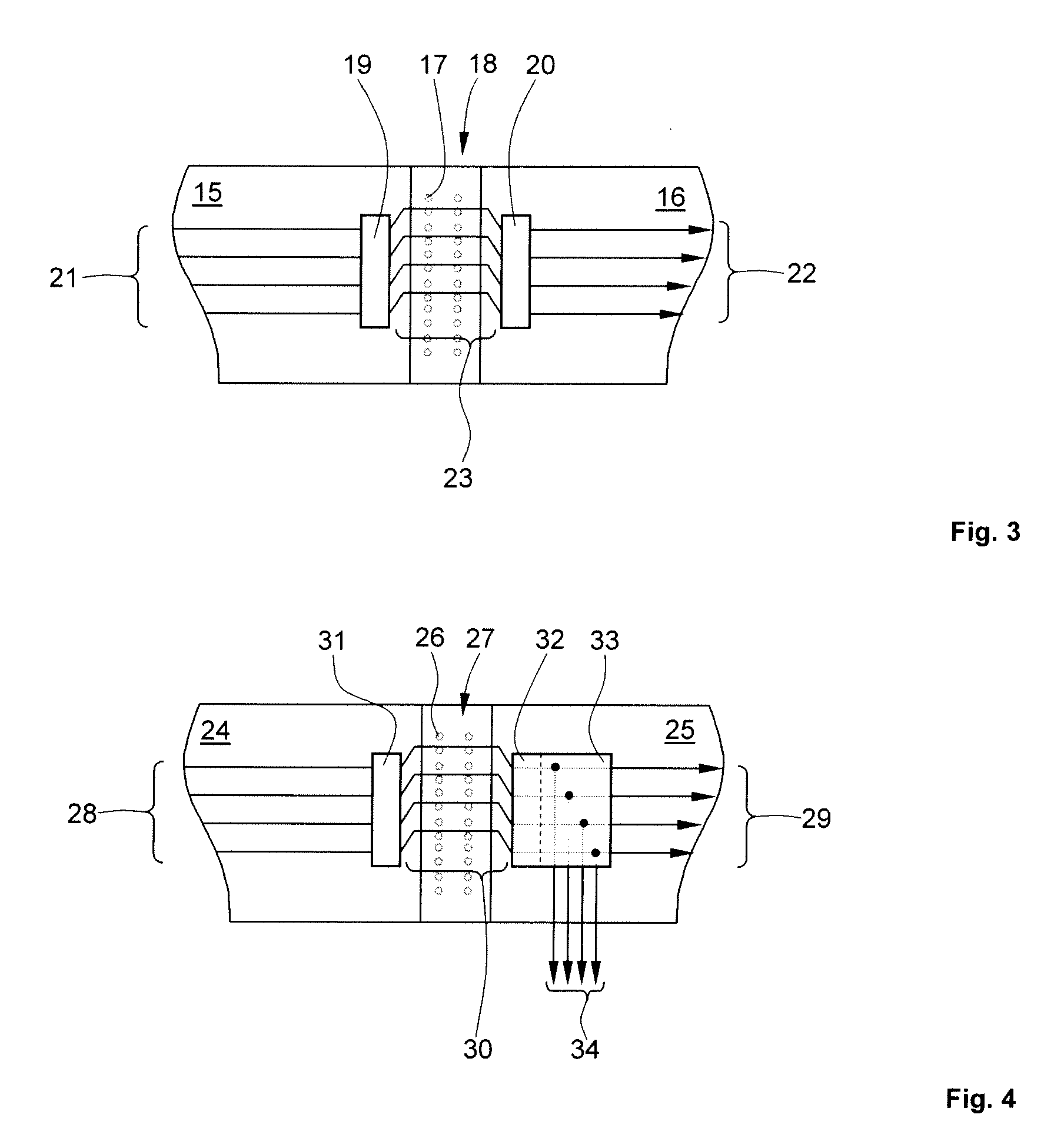

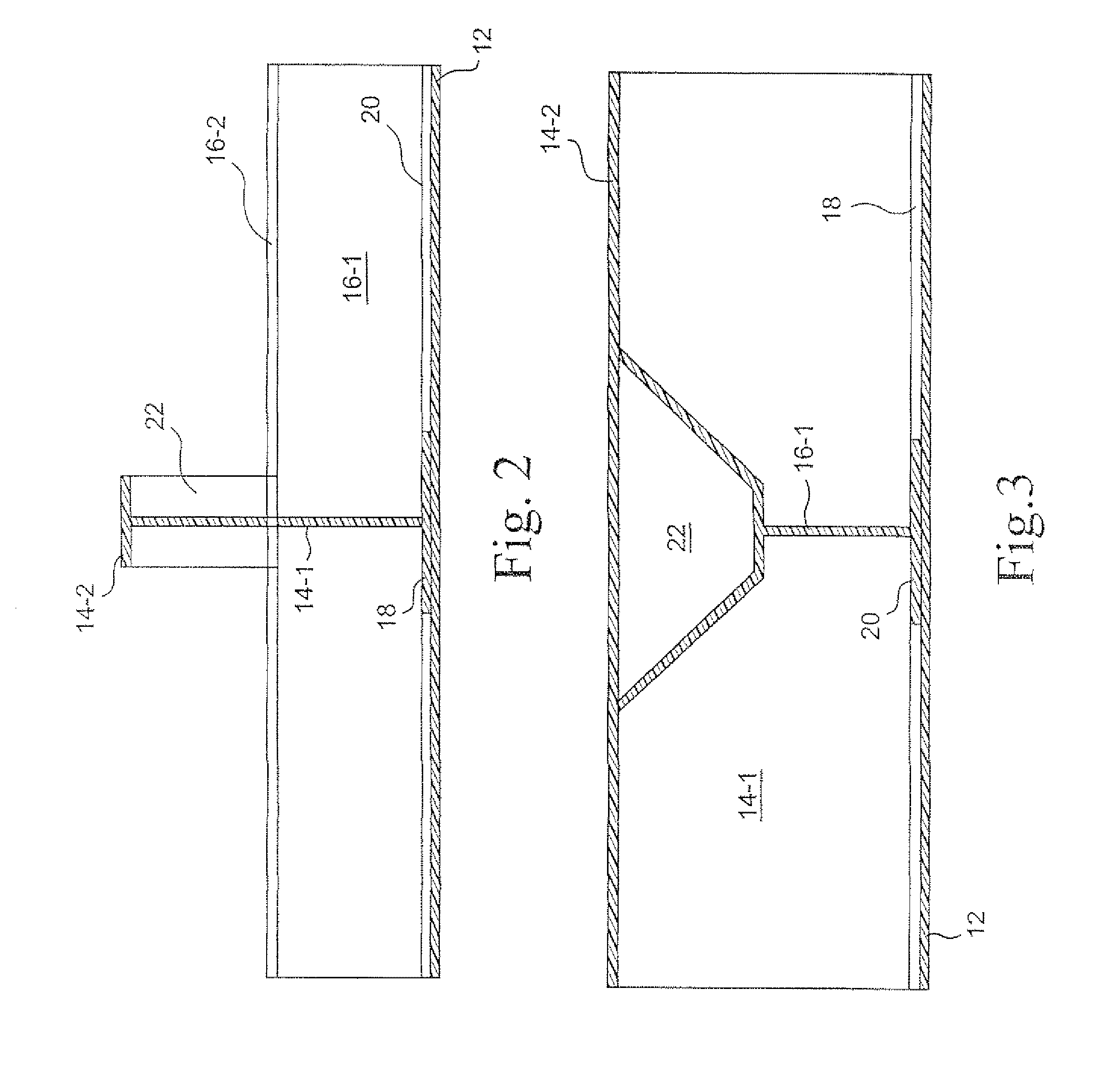

Shell component for an aircraft fuselage and method of manufacturing the same

A shell component for an aircraft fuselage includes a fuselage skin panel, a plurality of stringers extending in an aircraft lengthwise direction, and a plurality of frames extending crosswise relative to the stringers. The stringers and the frames are respectively welded onto the skin panel with the addition of a weld filler material. Each frame includes a frame root portion and a frame profile portion connected to each other. The frame root portion has cut-out notches receiving the stringers passing therethrough. The frame root portion is welded to the skin panel at the areas between the cut-out notches, and may be welded to the respective stringer in each cut-out notch. The stringers and frames are fabricated from webs and flanges, whereby a premanufactured grid of flanges may be used. The result is a very strong, yet simple shell component structure, that may be manufactured with a simple welding process, at a low cost and with low effort.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

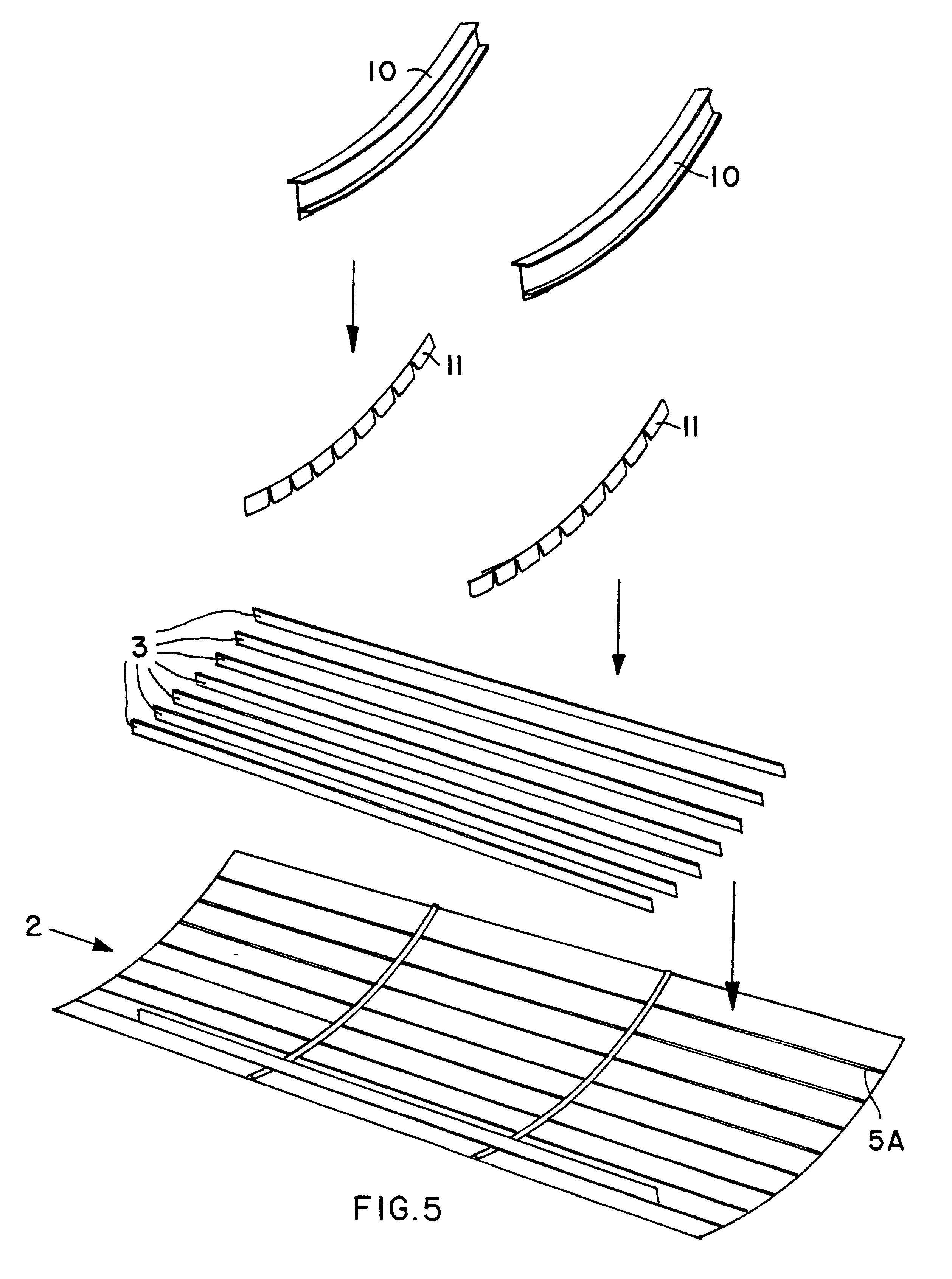

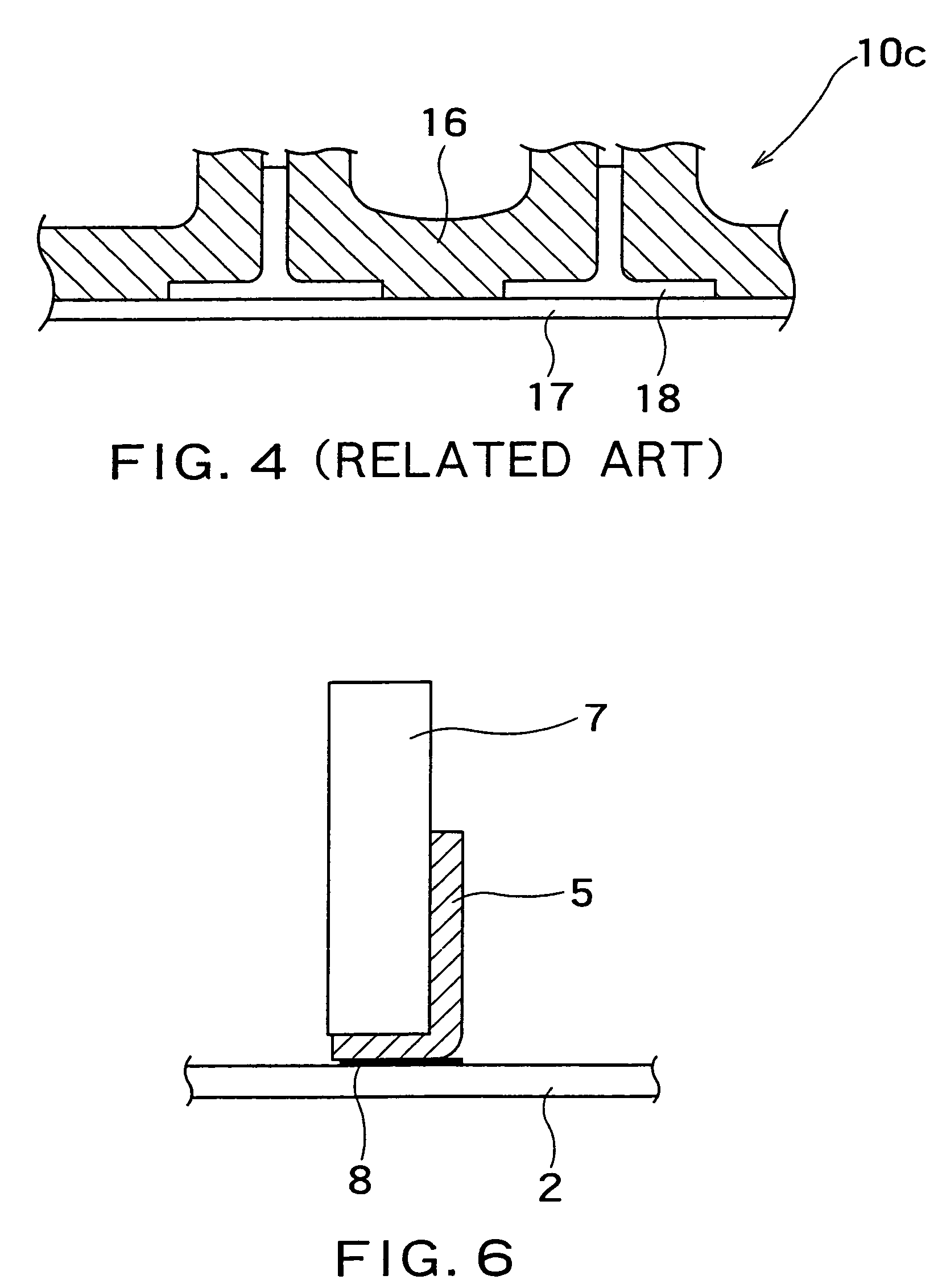

Composite material-stiffened panel and manufacturing method thereof

A composite material-stiffened panel has a skin obtained by molding a fiber-reinforced resin composite material into a flat skin, stiffeners arranged in rows on one surface of the skin, and a fiber-reinforced resin-composite material stitched on the skin covering the stiffeners. The composite material-stiffened panel can be manufactured as follows: A first fabric material is placed on a tool having a panel-shaped surface. Stiffeners are placed on the first fabric materials. A second fabric material is placed on the stiffeners to cover at least some of the stiffeners. The second fabric materials are reformed to match the shape of the stiffeners. The reformed second fabric material is stitched on the first fabric material along edges of the stiffeners. All the materials are covered with a bagging film for vacuum. Resin is infiltrated into the fabric materials by a RTM or a RFI method. The infiltrated resin is heated to be hardened.

Owner:SUBARU CORP

Component with carbon nanotubes

InactiveUS20090140098A1Lightning protection is goodAircraft lighting protectorsMilitary adjustmentAviationCarbon nanotube

The present invention relates to a component, in particular in the field of aviation and spaceflight, having a resin matrix in which carbon nanotubes are embedded for high conductivity of the component.

Owner:AIRBUS OPERATIONS GMBH

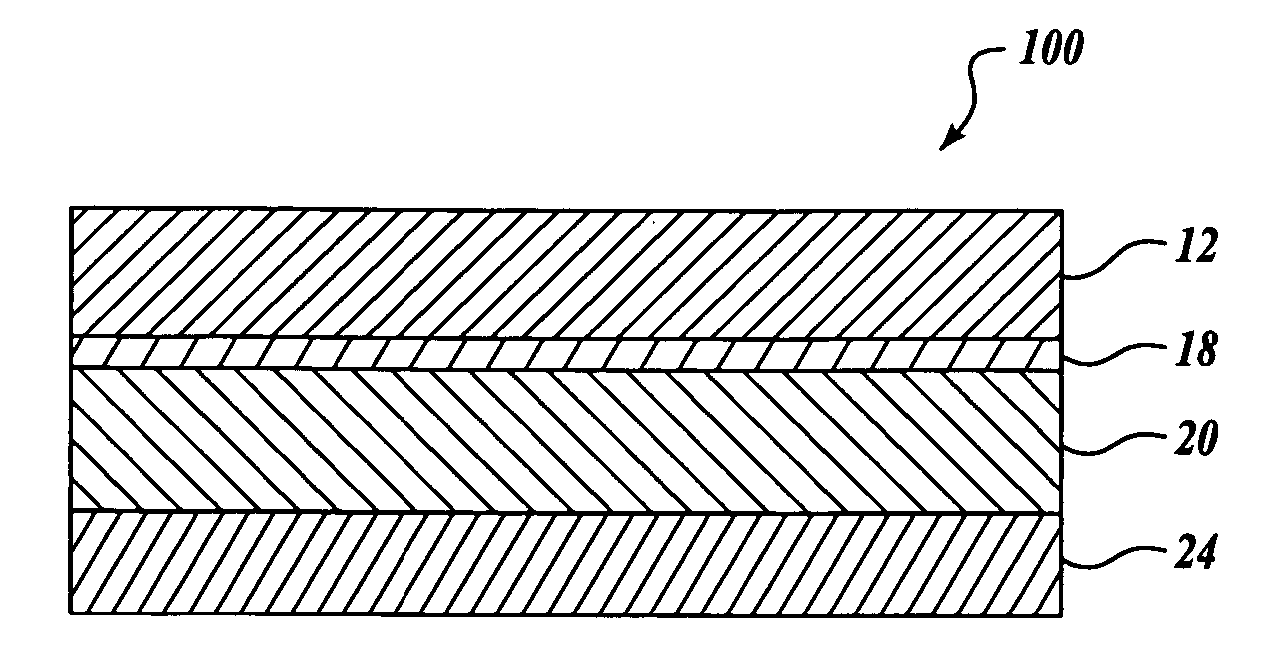

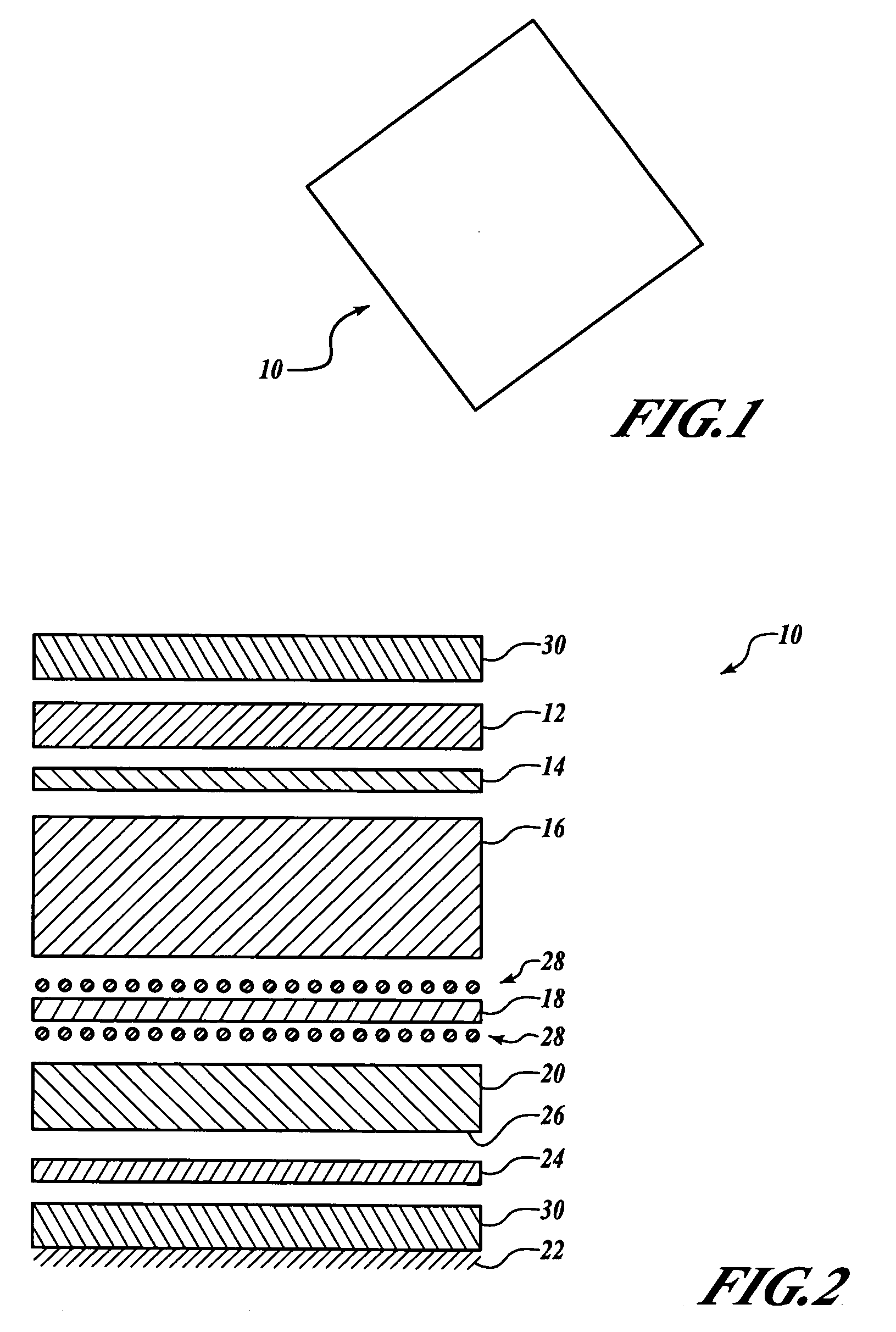

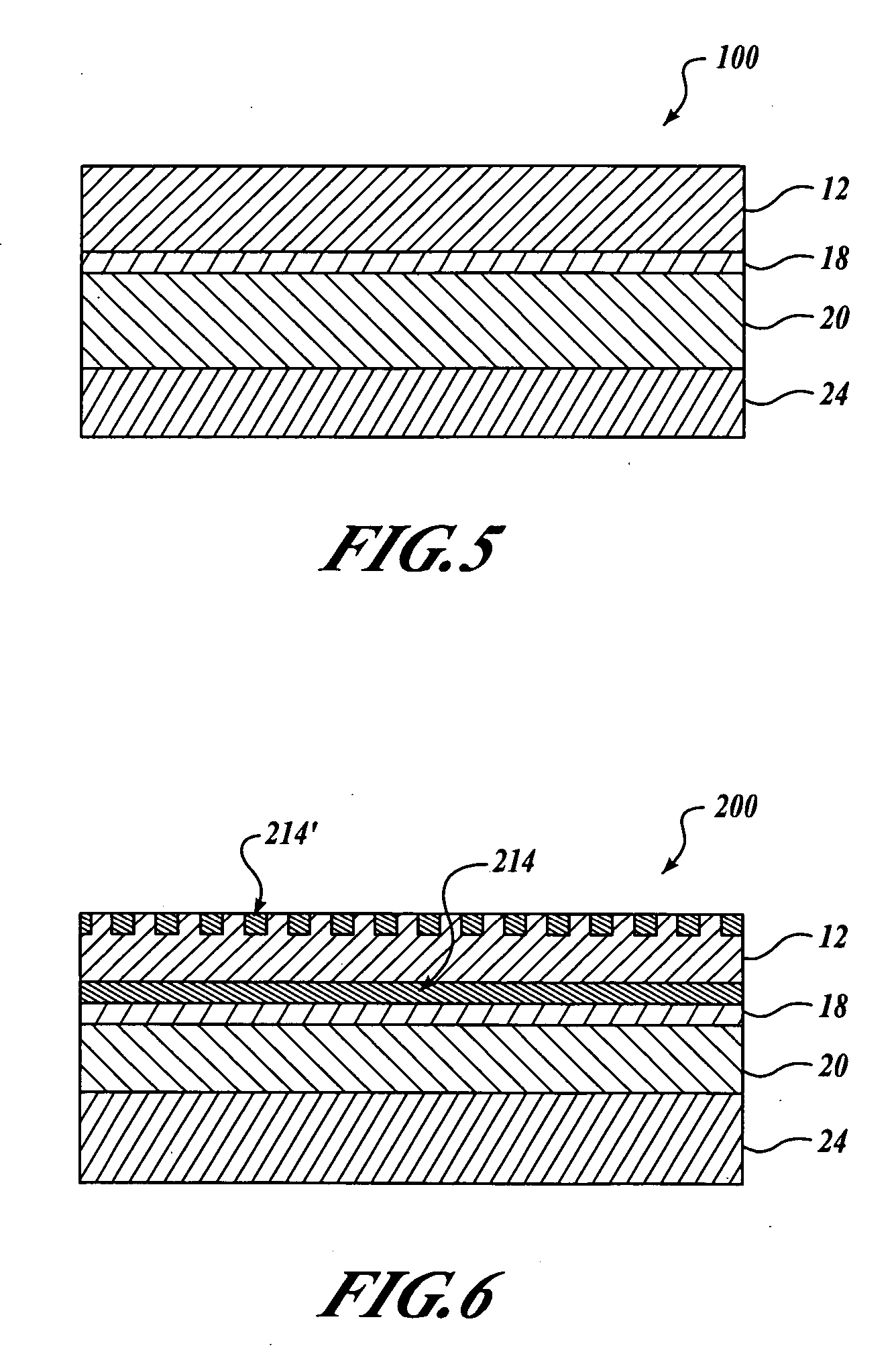

Applique

ActiveUS20050181203A1High porosityEnhancing static charge migrationDecorative surface effectsWingsFiberPolymer science

According to a non-limiting embodiment of the present invention, an appliqué coating is provided for a substrate. The appliqué coating includes a metal foil and a first polymer film underlying the metal foil. A topcoat overlying the metal foil may be provided as a layer of paint or as a second polymer film. An adhesive, such as a pressure sensitive adhesive, underlying the first polymer film may be provided to affix the appliqué coating to the substrate. If desired, fibers may be dispersed throughout the second polymer film to provide anti-static properties. Also, an ink layer may be provided between the metal foil and the second polymer film, if desired, for aesthetic and / or anti-static purposes.

Owner:THE BOEING CO

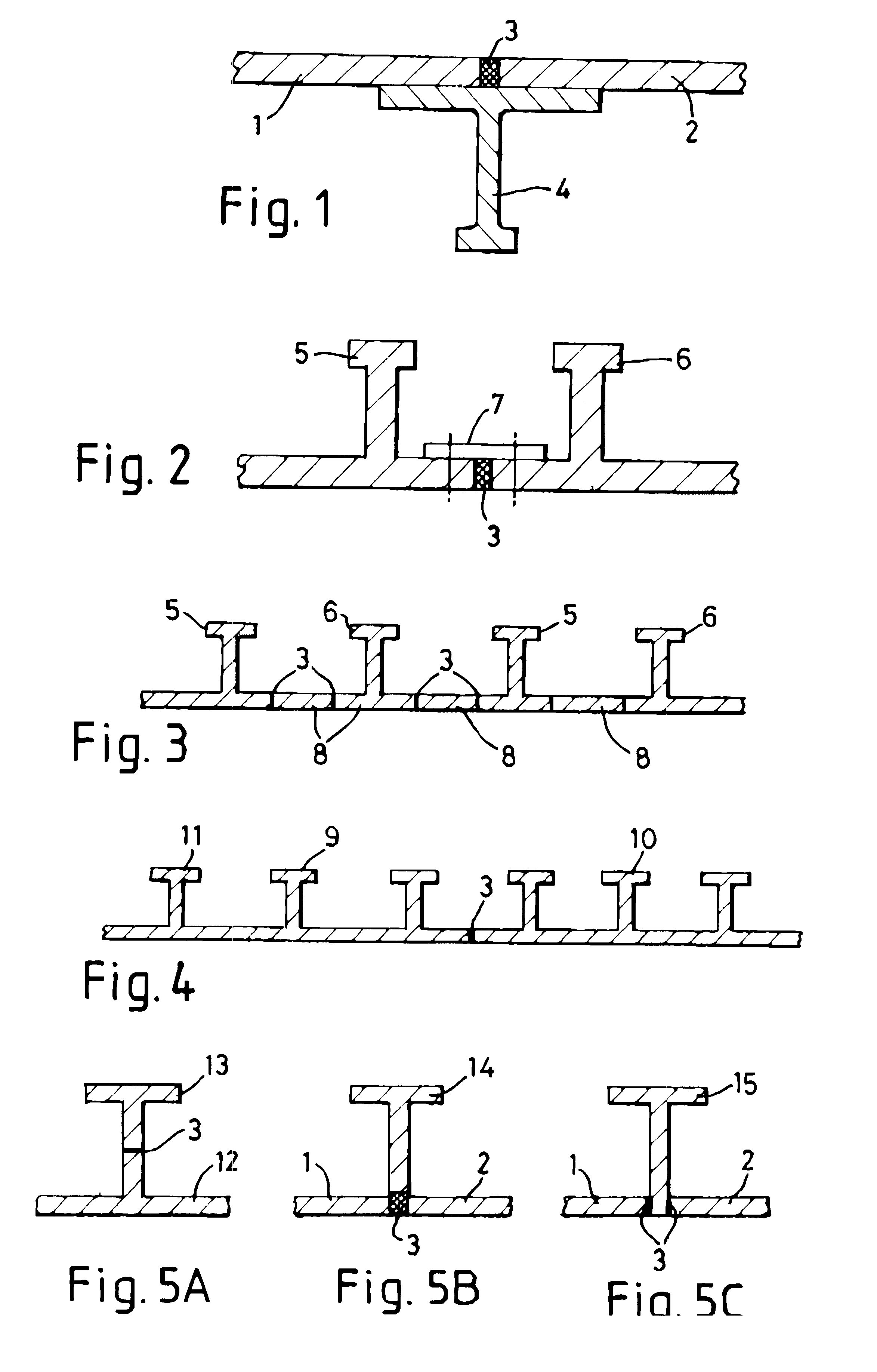

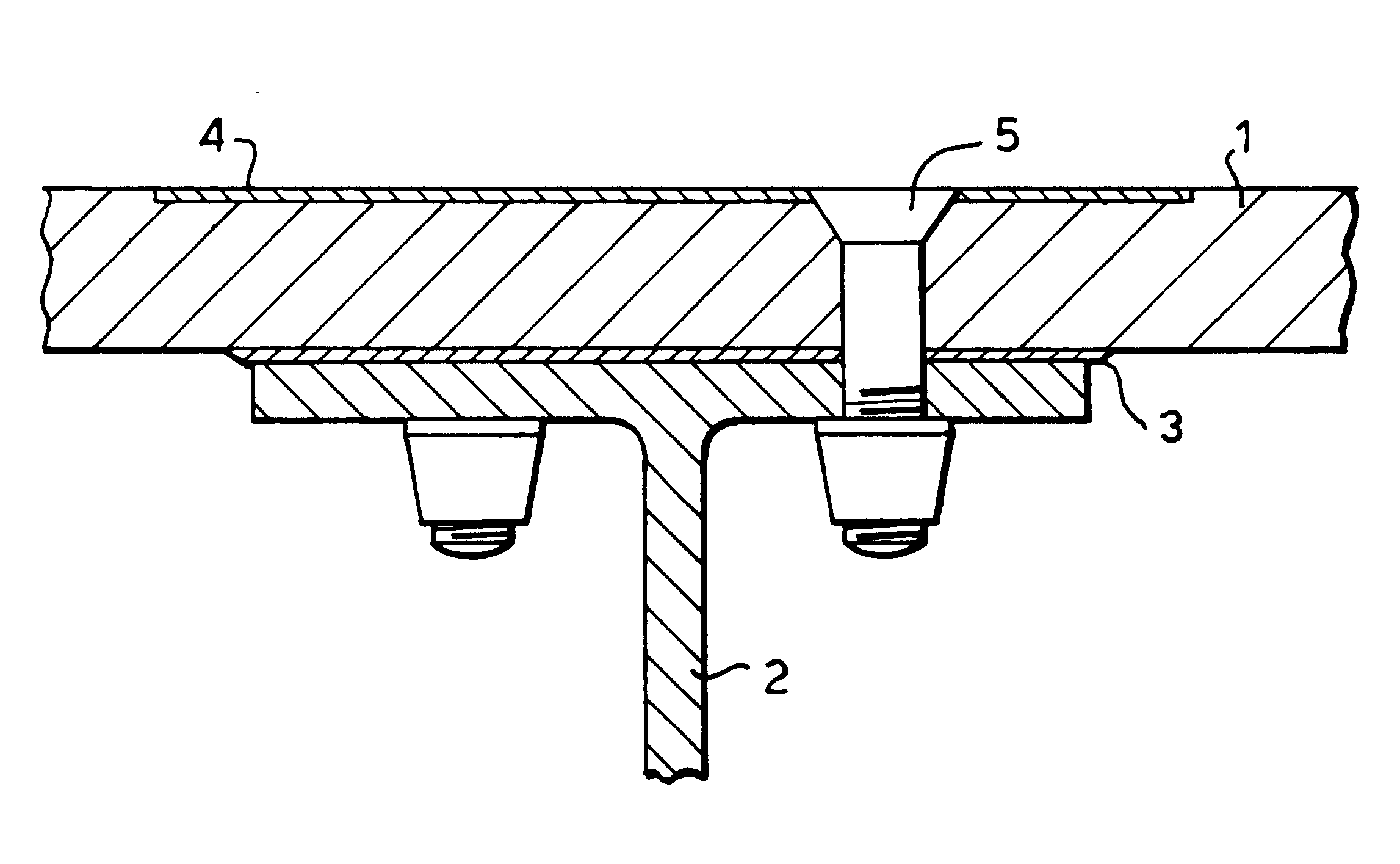

Friction welding metal components

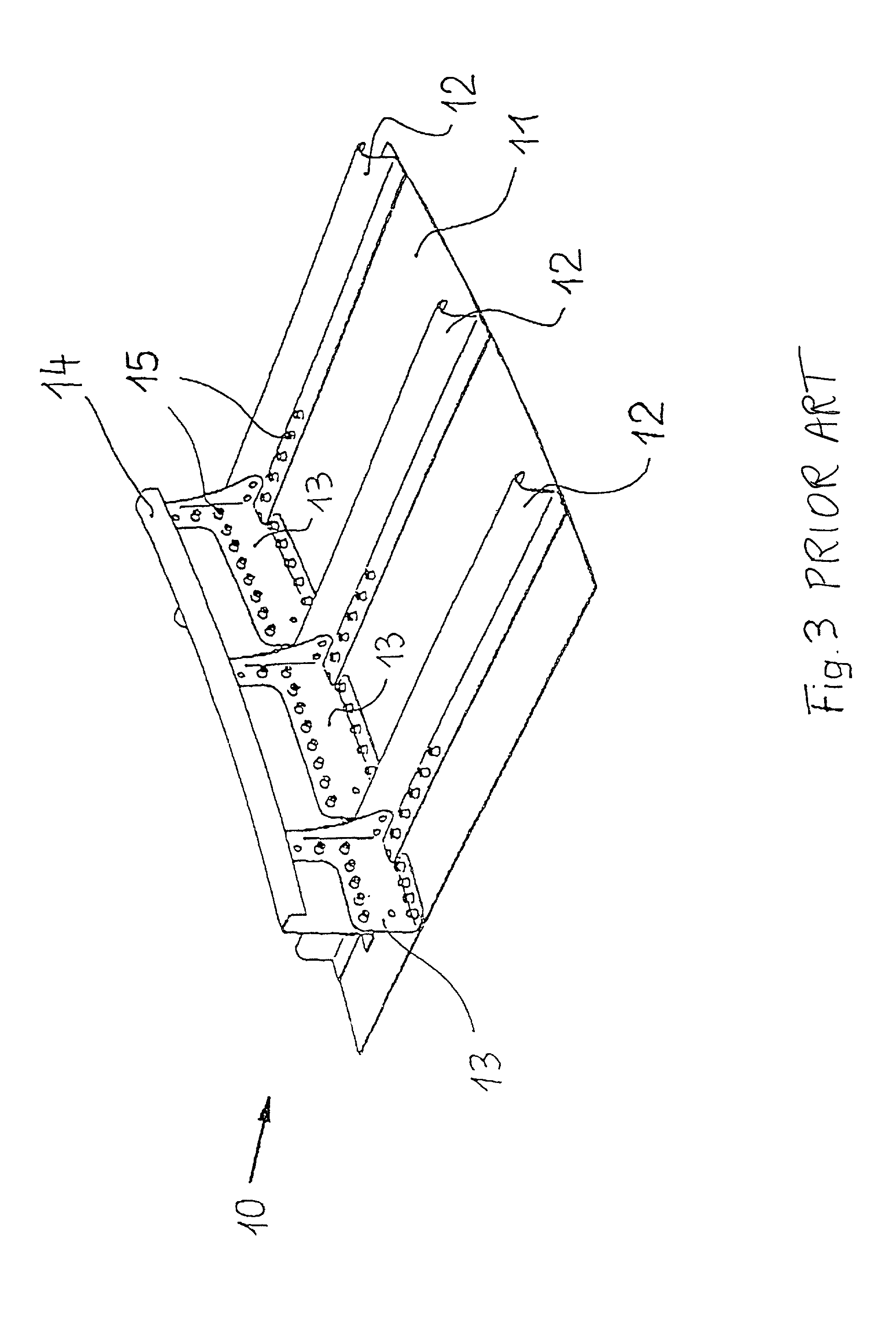

InactiveUS6328261B1Additions can be avoidedPrevent skinFuselage framesWingsFriction weldingButt welding

A method of forming a structural airframe component for an aircraft and an airframe structural component The method includes placing at least two components (1,2) in abutting relationship with each other and joining them together by friction stir butt welding (3), and the structural airframe component comprises a component manufactured according to the method of the invention.

Owner:AIRBUS OPERATIONS LTD

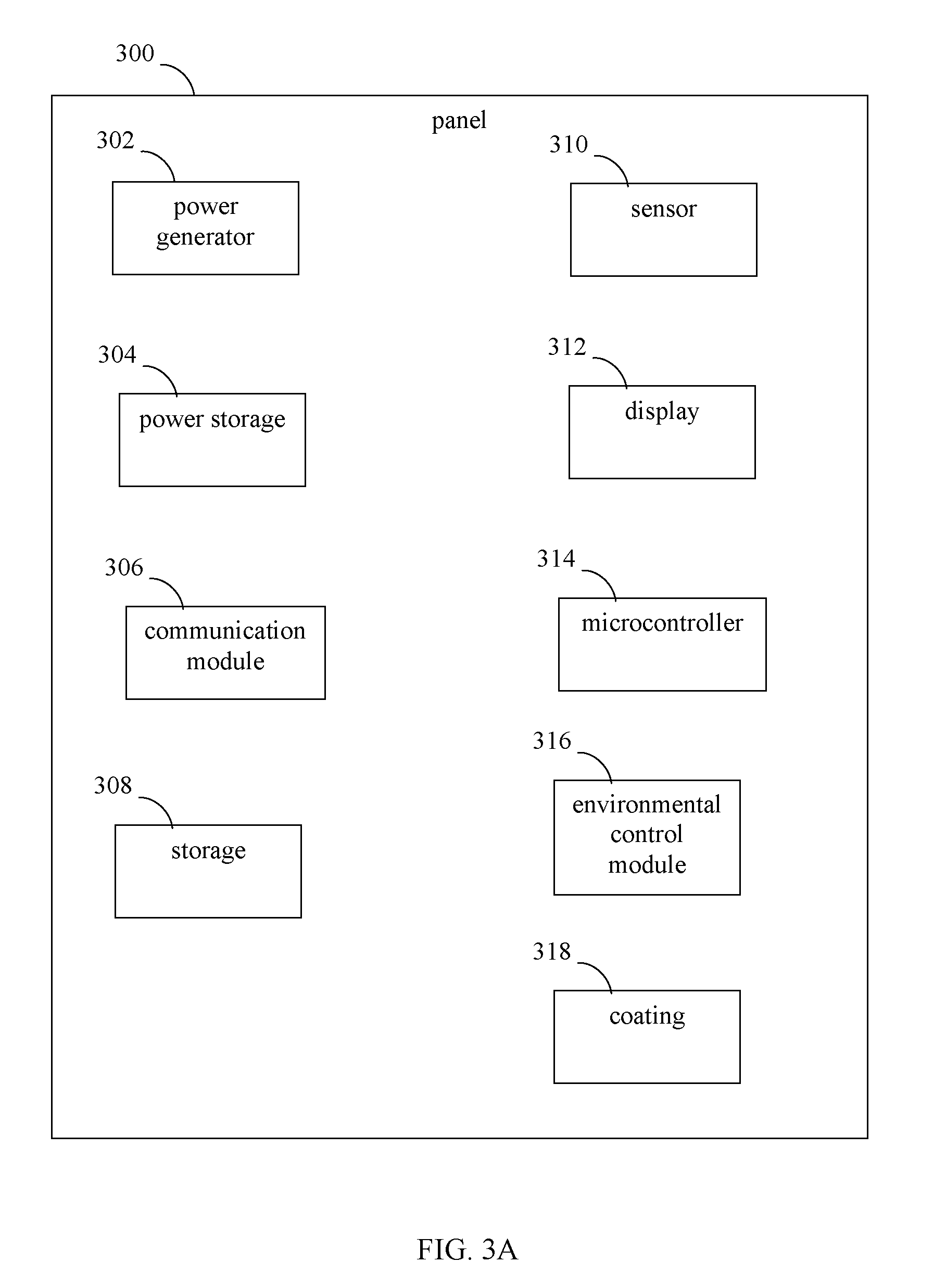

Nano-enhanced smart panel

InactiveUS20090047453A1Easy constructionMaterial nanotechnologyEnvelopes/bags making machineryMulti materialGraphics

Owner:SMART NANOMATERIALS

Wide area lightning diverter overlay

ActiveUS20060051592A1Reduce sparksReduction of Explosion HazardsDecorative surface effectsDuplicating/marking methodsWide areaParticulates

An overlay of patterned metal foil above a substrate to be protected supports development of localized coronas after a lightning strike. The localized coronas transport energy of a lightning strike above the substrate's surface with limited removal of metal foil from the lightning strike attachment point. A first polymer film underlies patterned metal foil. A topcoat overlies the patterned metal foil. An adhesive, underlying the first polymer film affixes the lightning diverter overlay to the substrate. If desired, semiconductor particulates may be dispersed throughout the second polymer film to contribute to instantaneous generation of localized coronas. Also, an ink layer may be provided between the patterned metal foil and the topcoat or on the exterior, if desired, for aesthetic and / or anti-static purposes.

Owner:THE BOEING CO

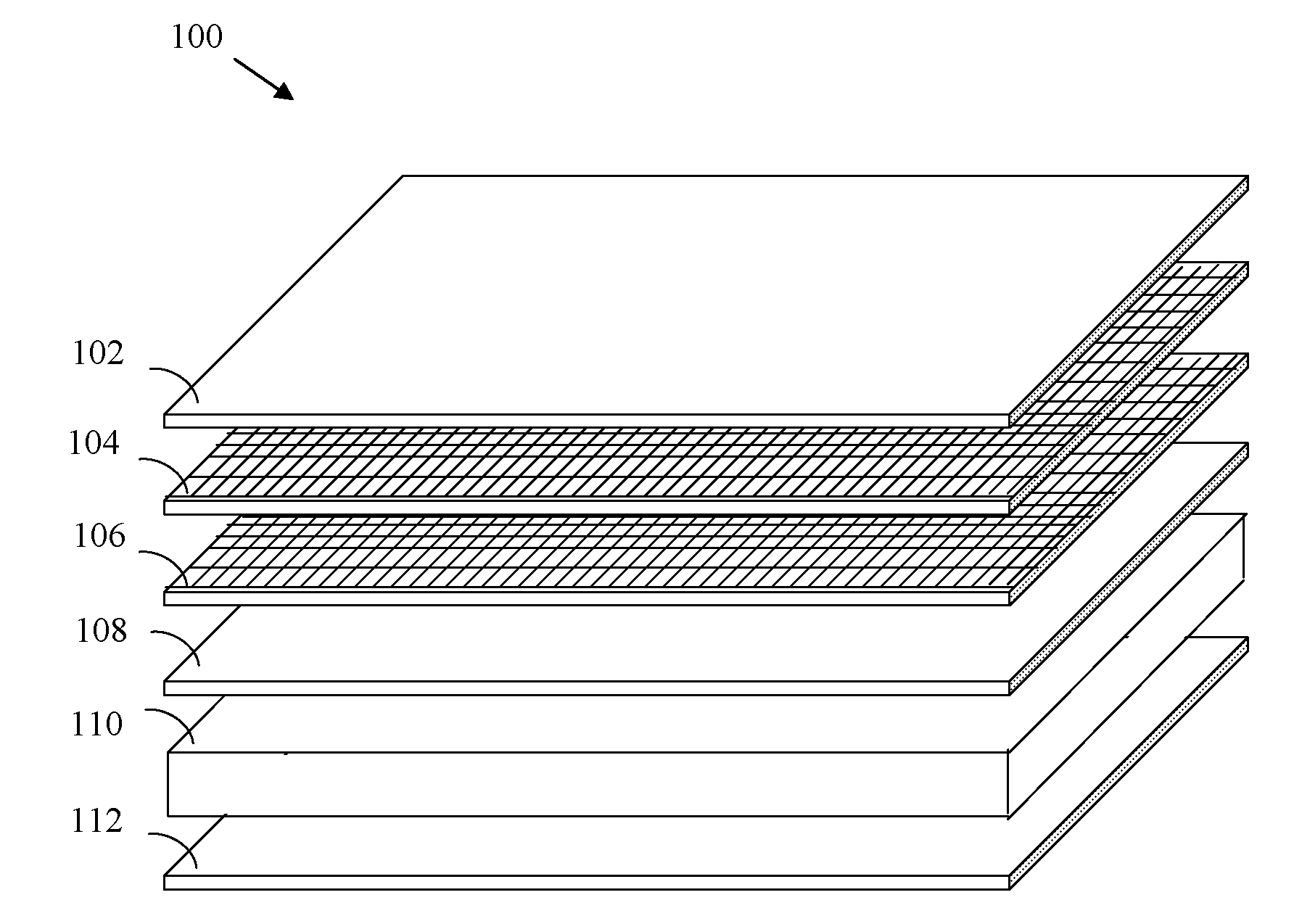

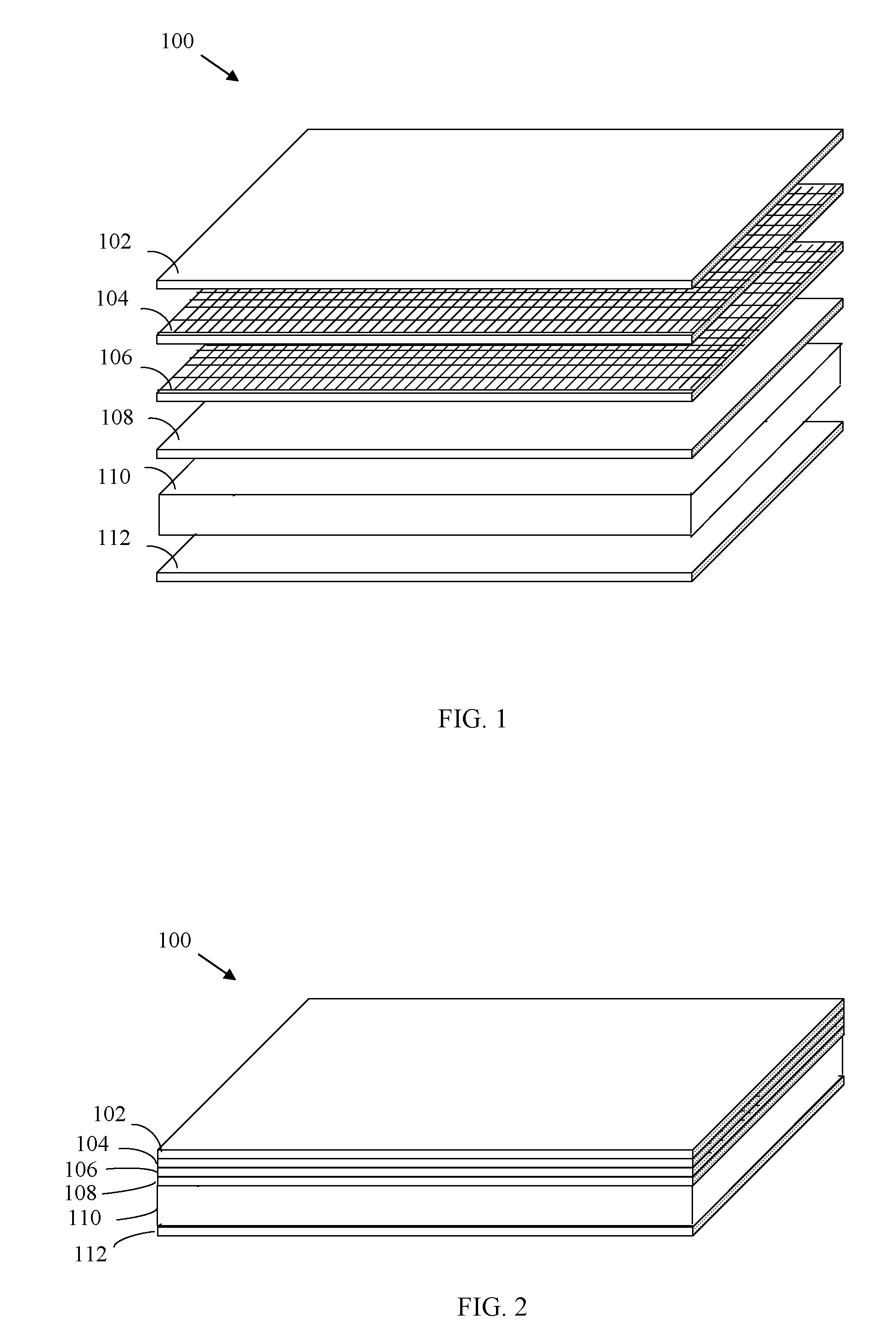

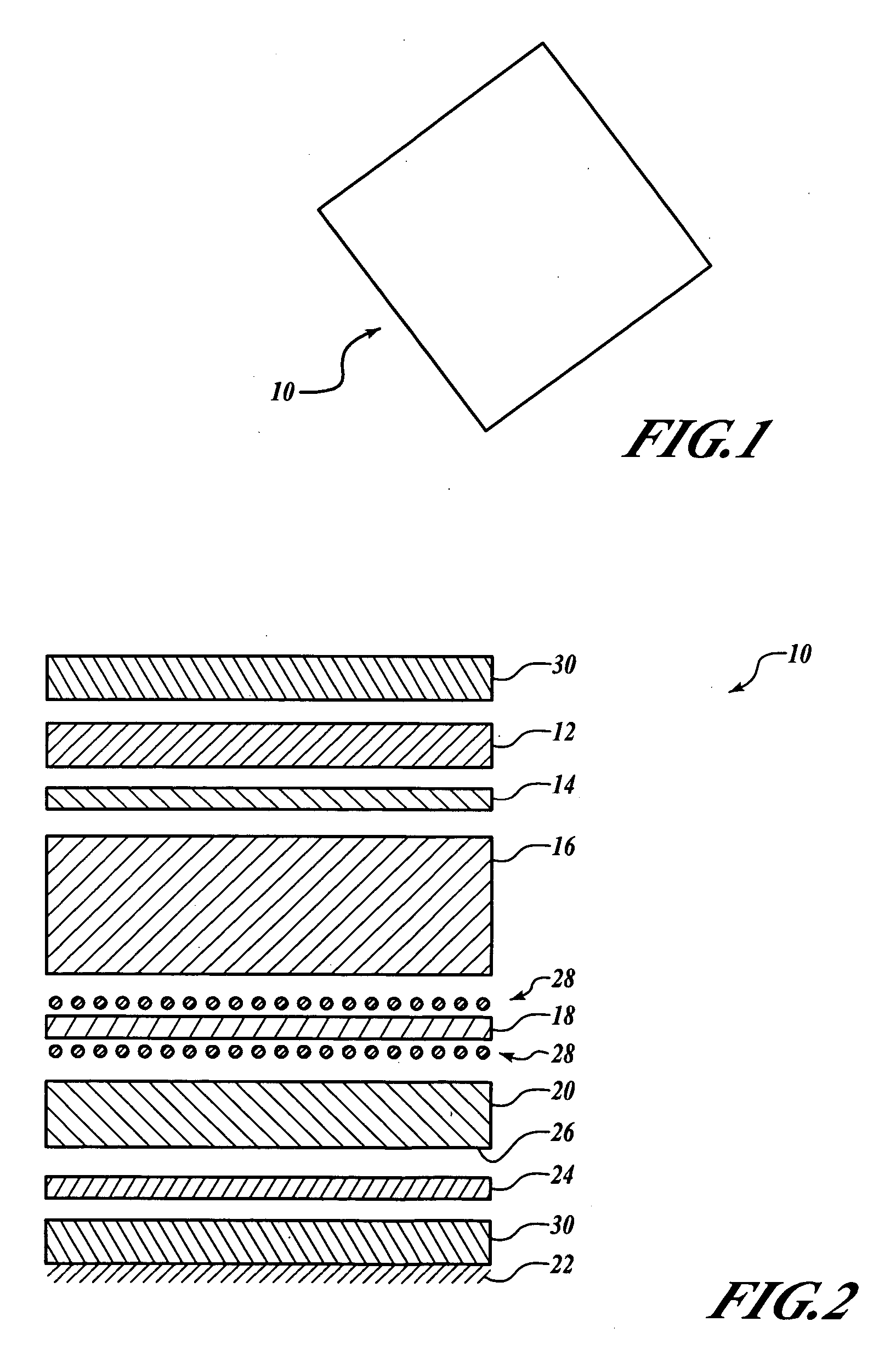

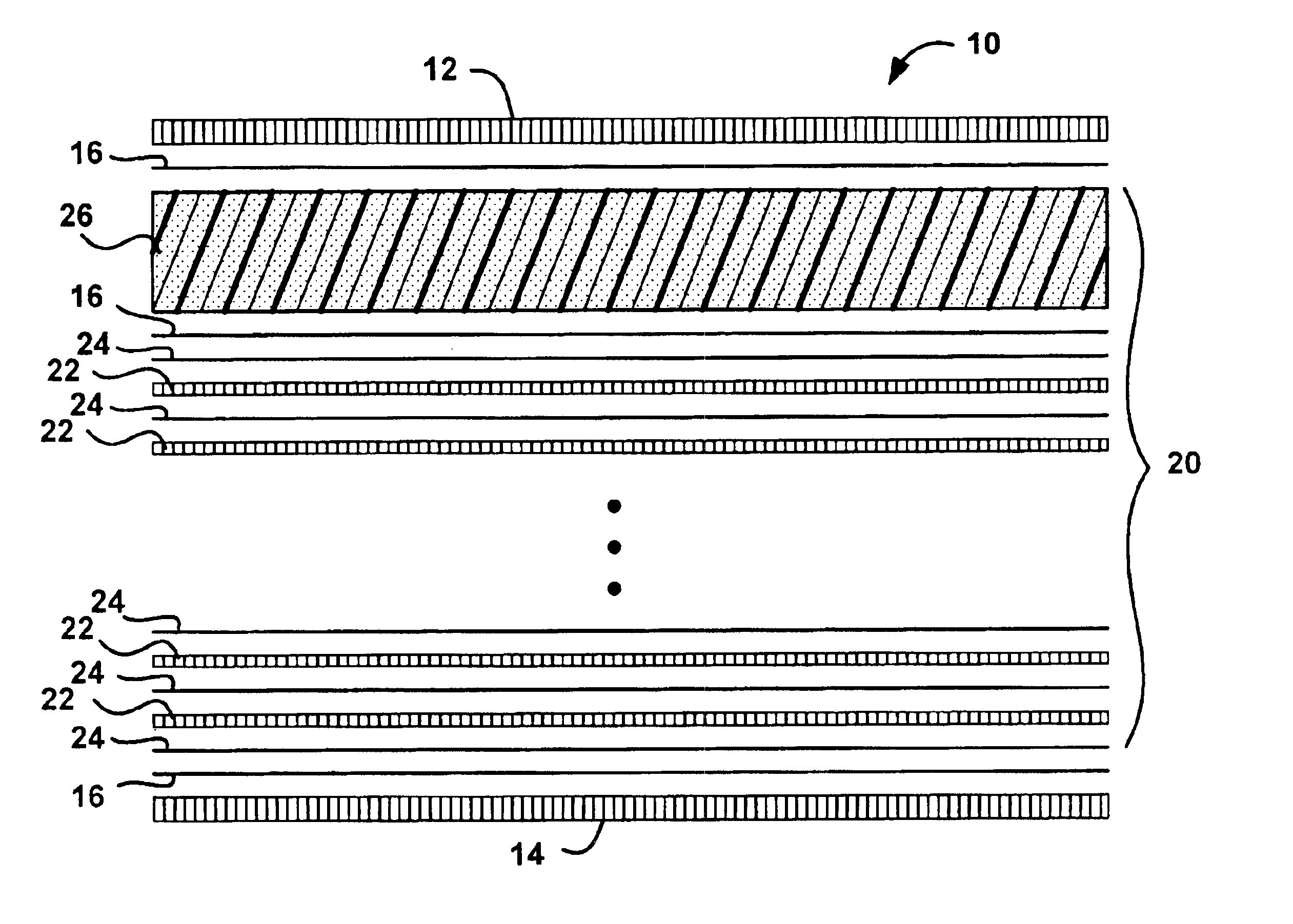

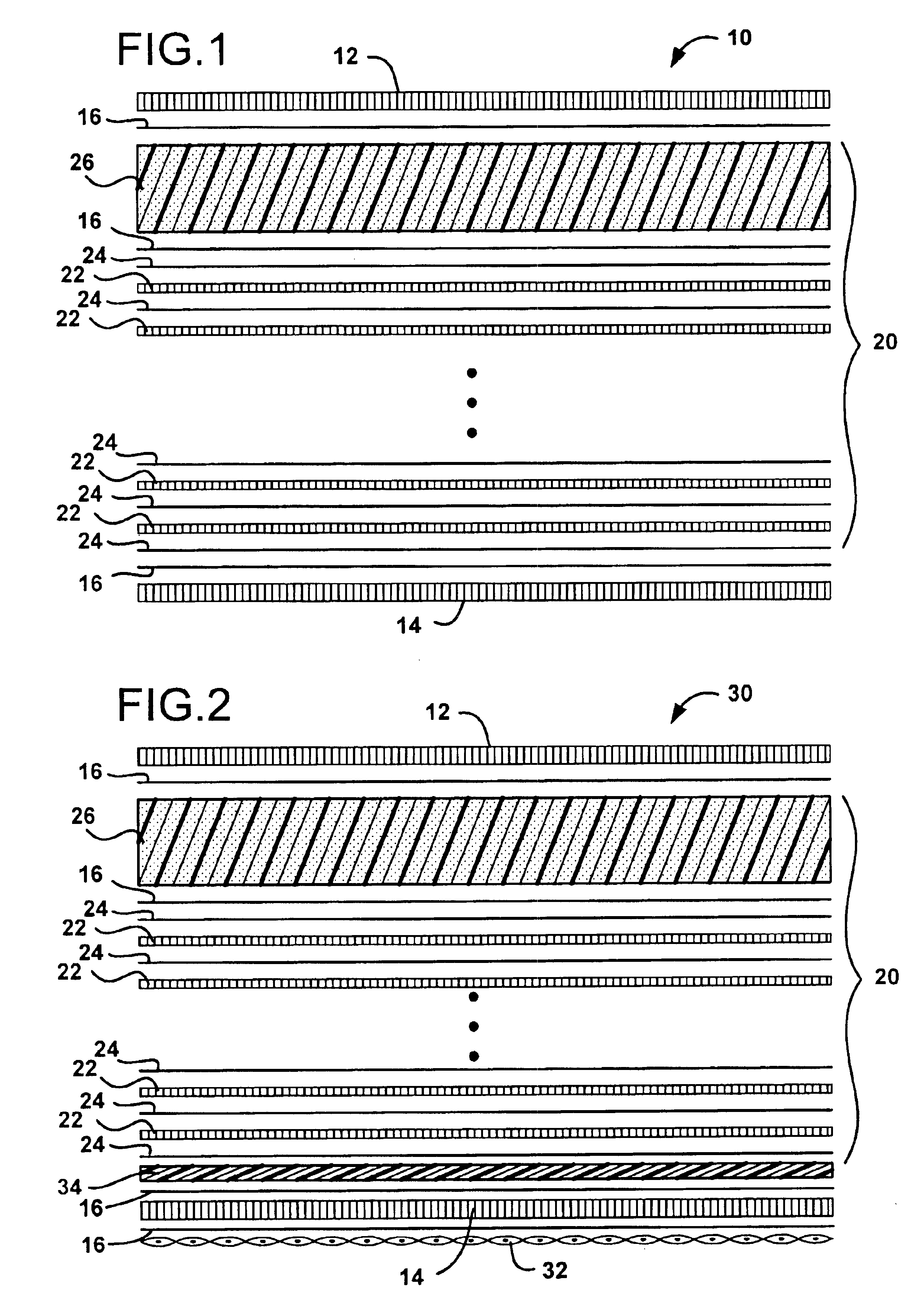

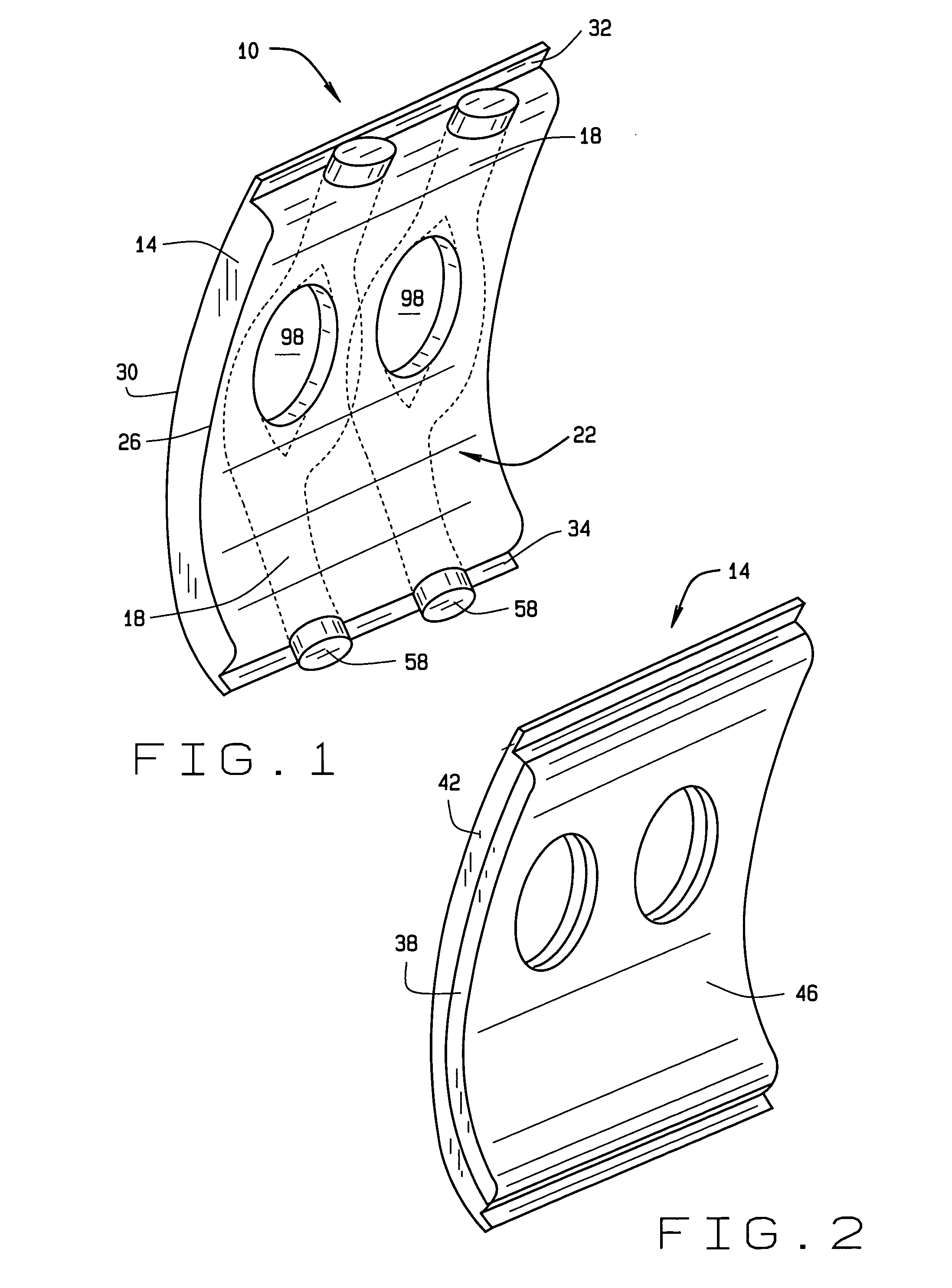

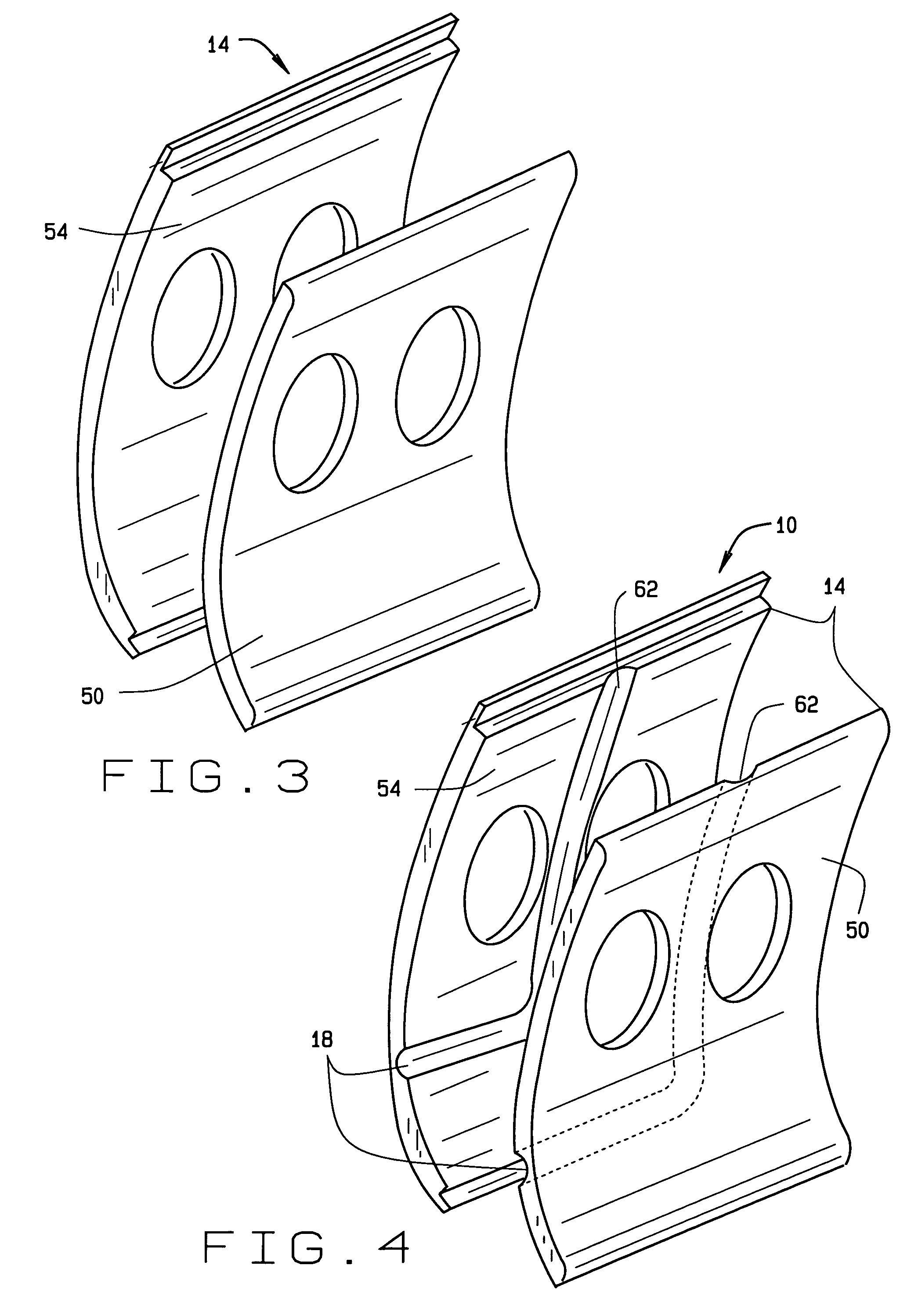

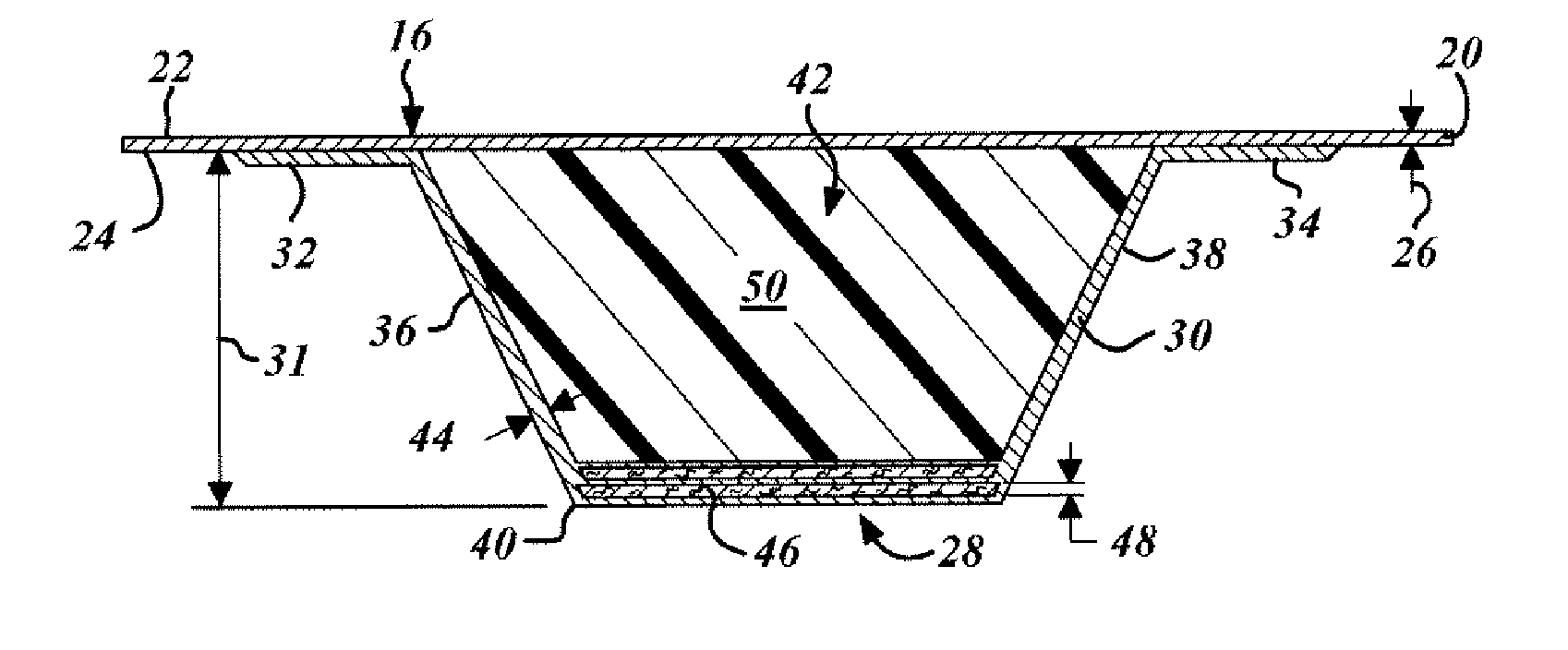

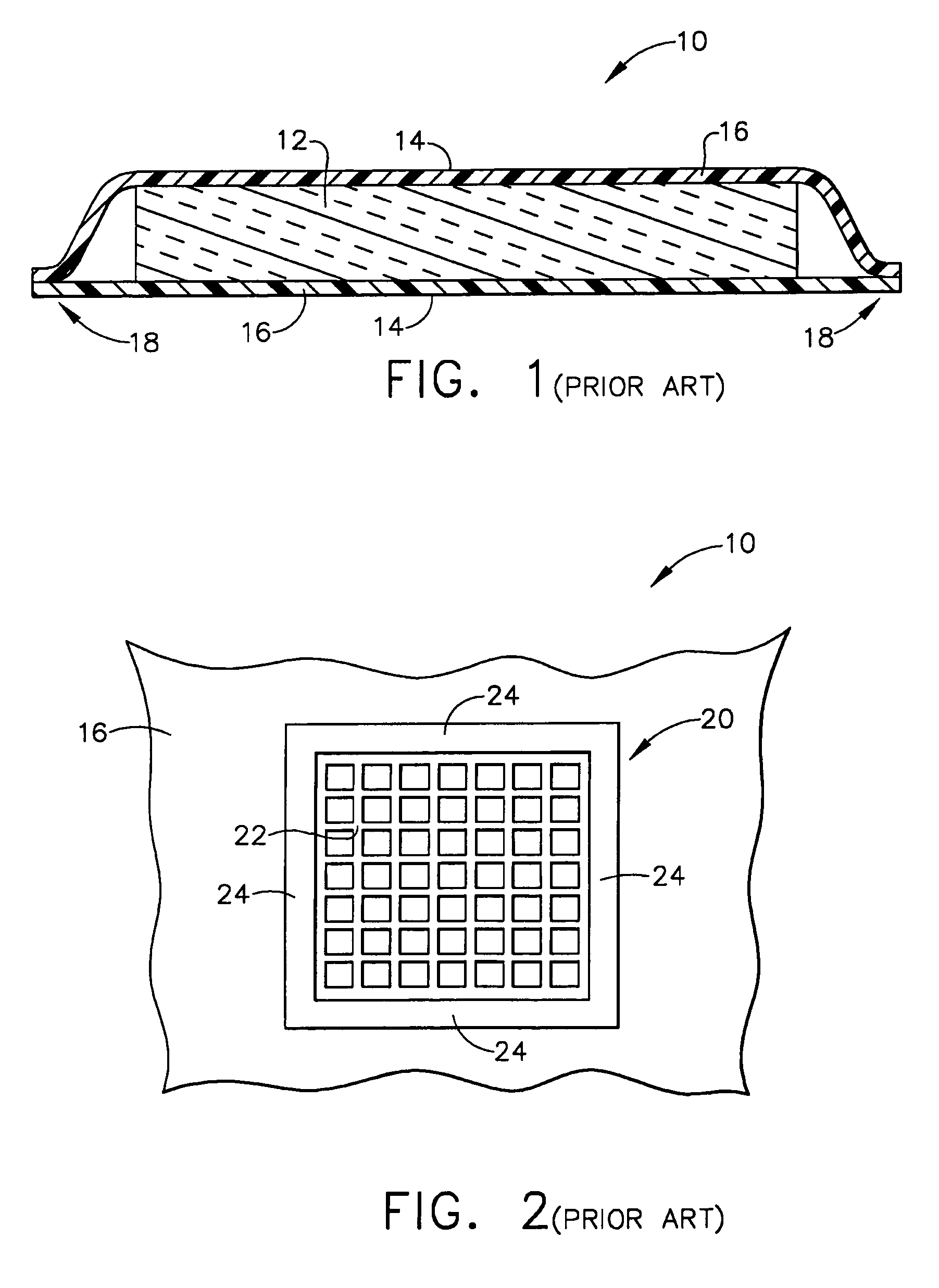

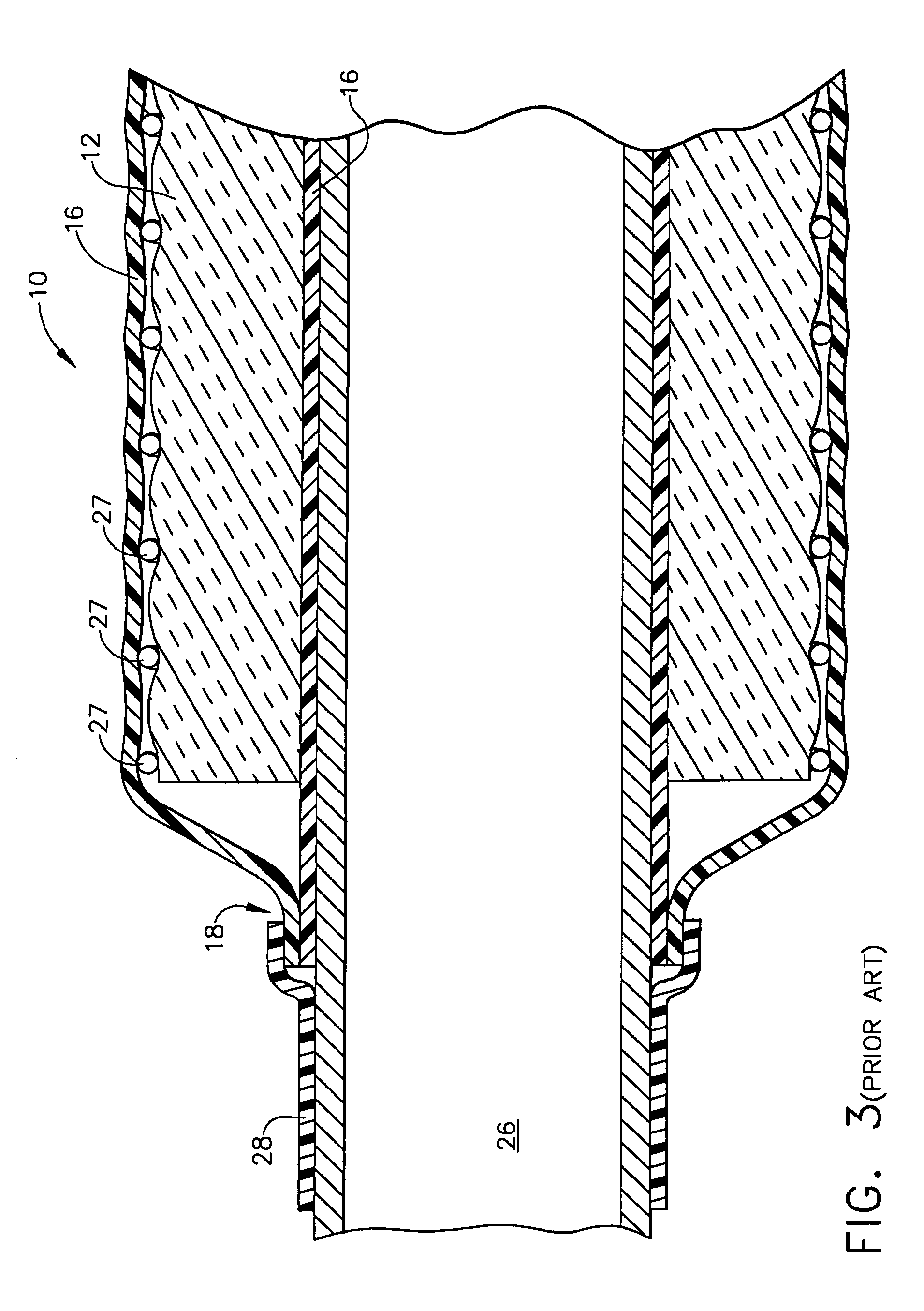

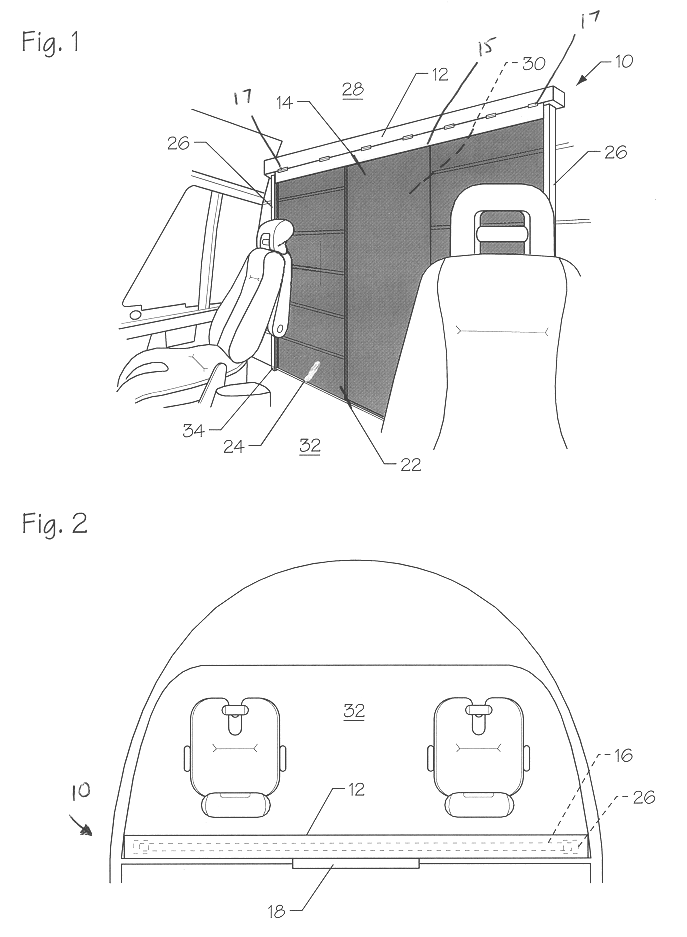

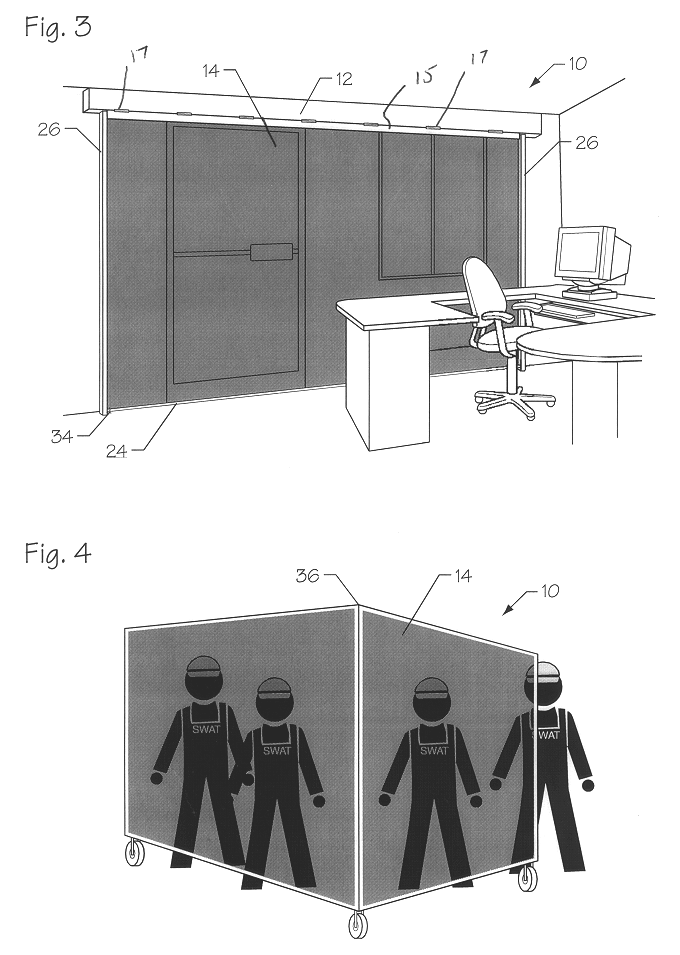

Lightweight ballistic resistant rigid structural panel

InactiveUS6825137B2Without sacrificing ballistic resistanceImprove fatigueFuselage framesFuselage bulkheadsAdhesiveEngineering

A lightweight ballistic resistant rigid structural panel especially for use in aircraft interiors is disclosed. The rigid structural panel is made up of a core layer including a plurality of sheets of flexible, high-tensile strength fabric interleaved with a plurality of sheets of a thermal-fusible film adhesive, and a sheet of cushioning material adhered to the plurality of sheets of flexible, high-tensile strength fabric. Fiber-reinforced face skins are adhered to exterior surfaces of the panel core for structural strength and rigidity. The rigid structural panel is capable of resisting ballistic attack from handguns and like weapons, while maintaining a high degree of strength and rigidity.

Owner:NORDISK AVIATION PRODS A S

Sidewall panel integrated with insulation and air ducts

A mobile platform interior panel is provided that includes a body formed by a low pressure injection process and at least one of a duct and a layer of insulation integrated with the body. The low pressure injection process allows the duct and insulation to be integrated with the body simultaneously with the forming of the panel. More specifically, the duct is integrated with the panel by forming at least one internal cavity within the panel as the panel is formed. Additionally, the insulation is integrated with the panel by forming the panel using a low pressure injection material having desired insulative properties.

Owner:THE BOEING CO

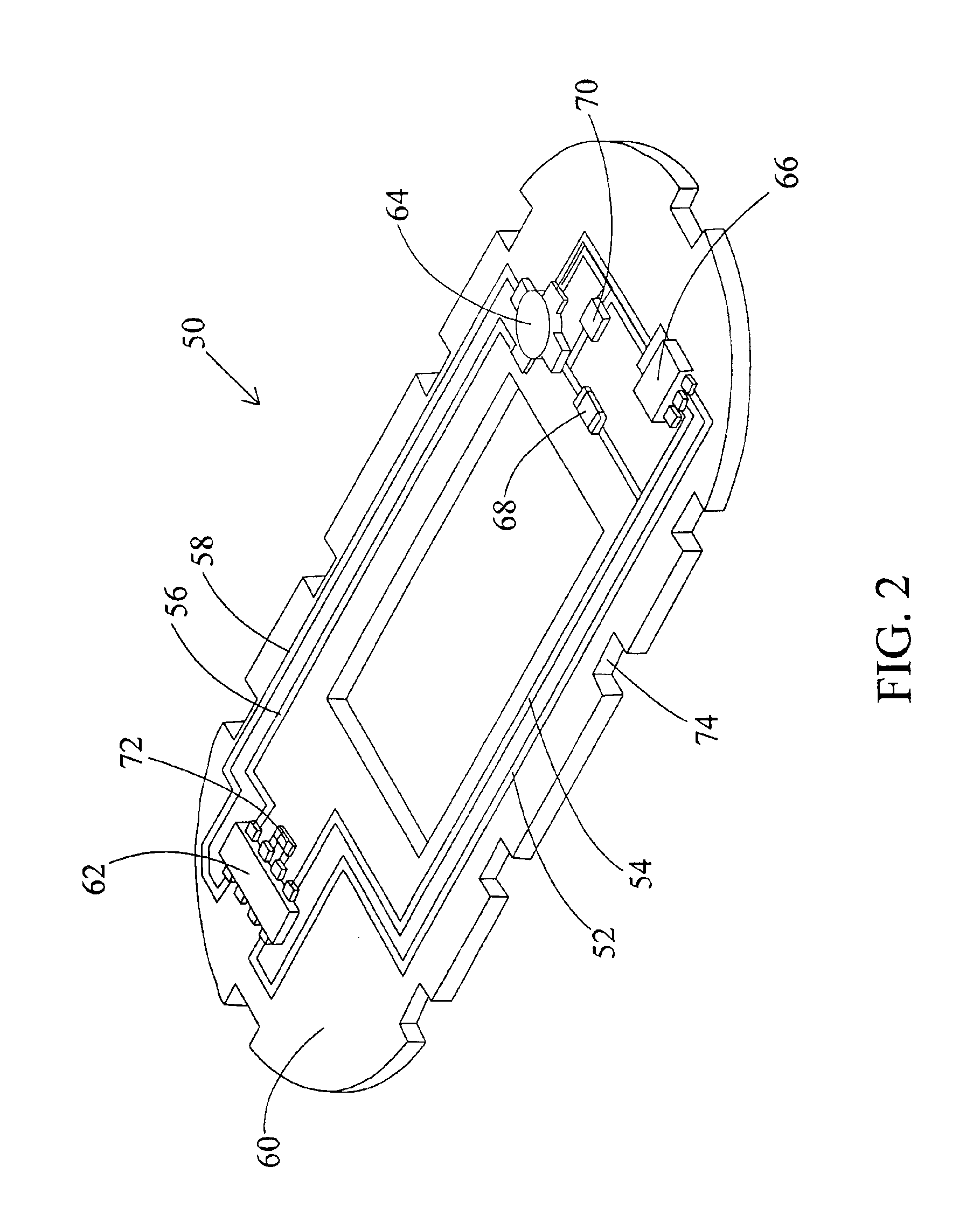

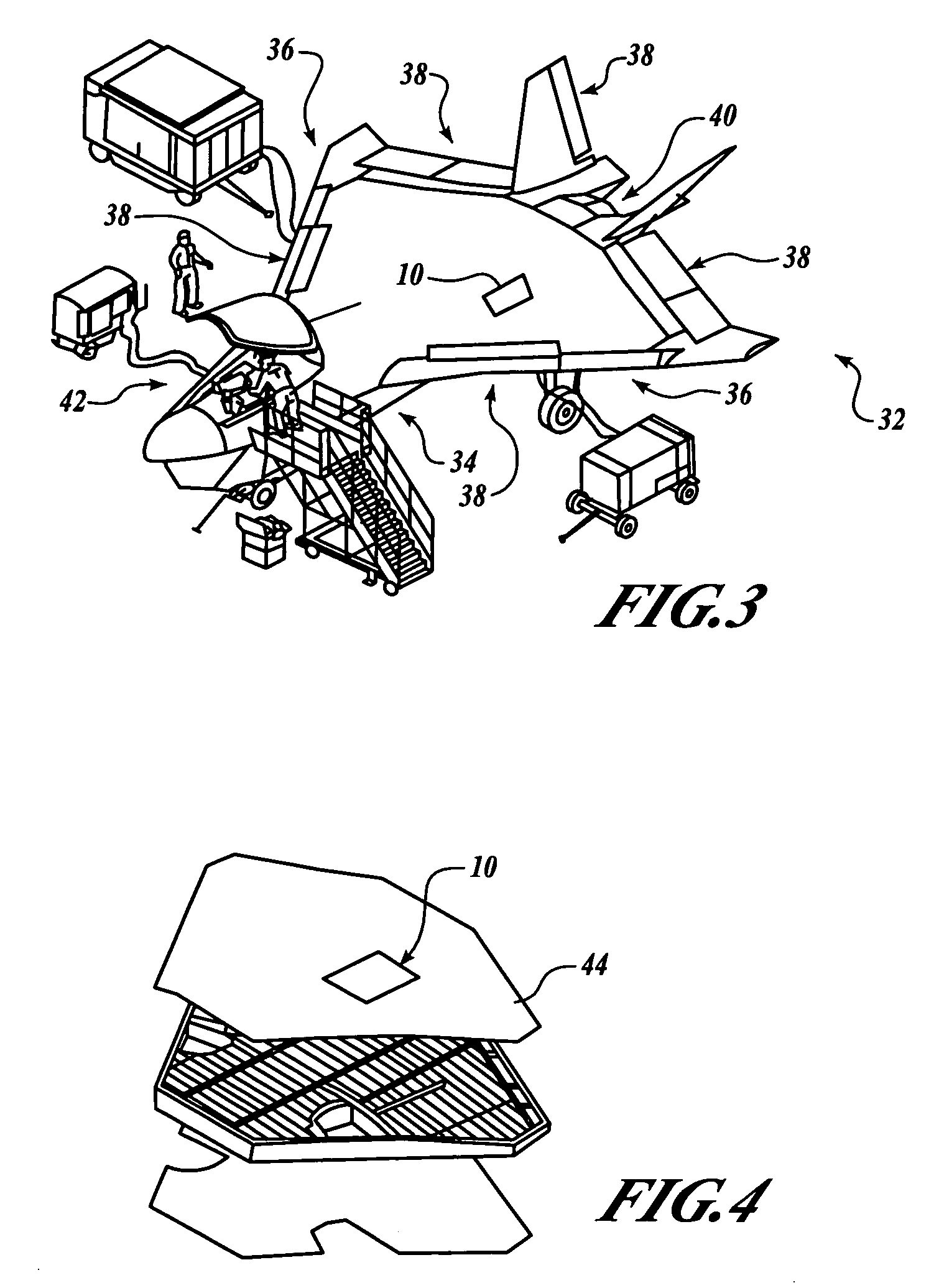

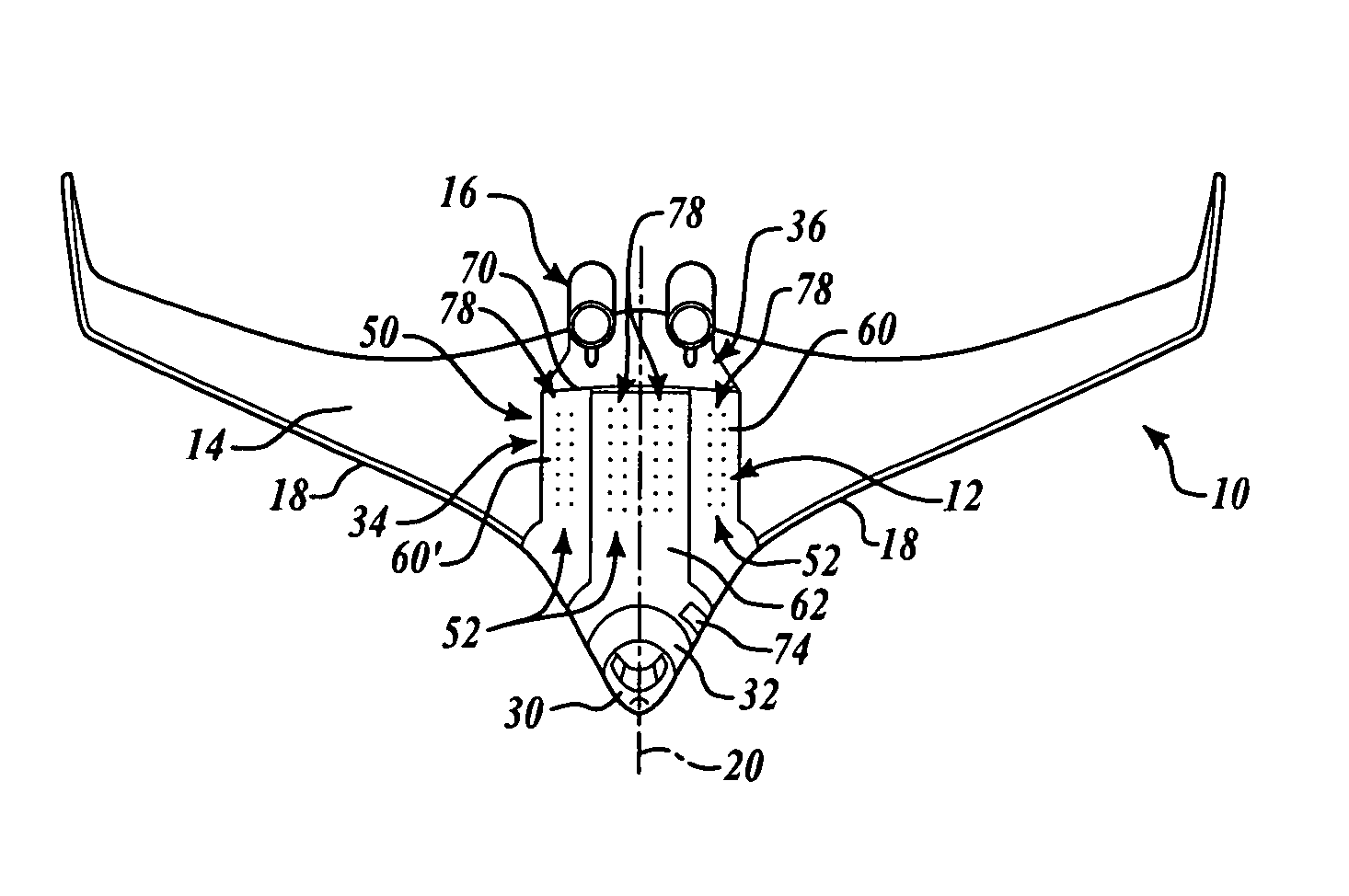

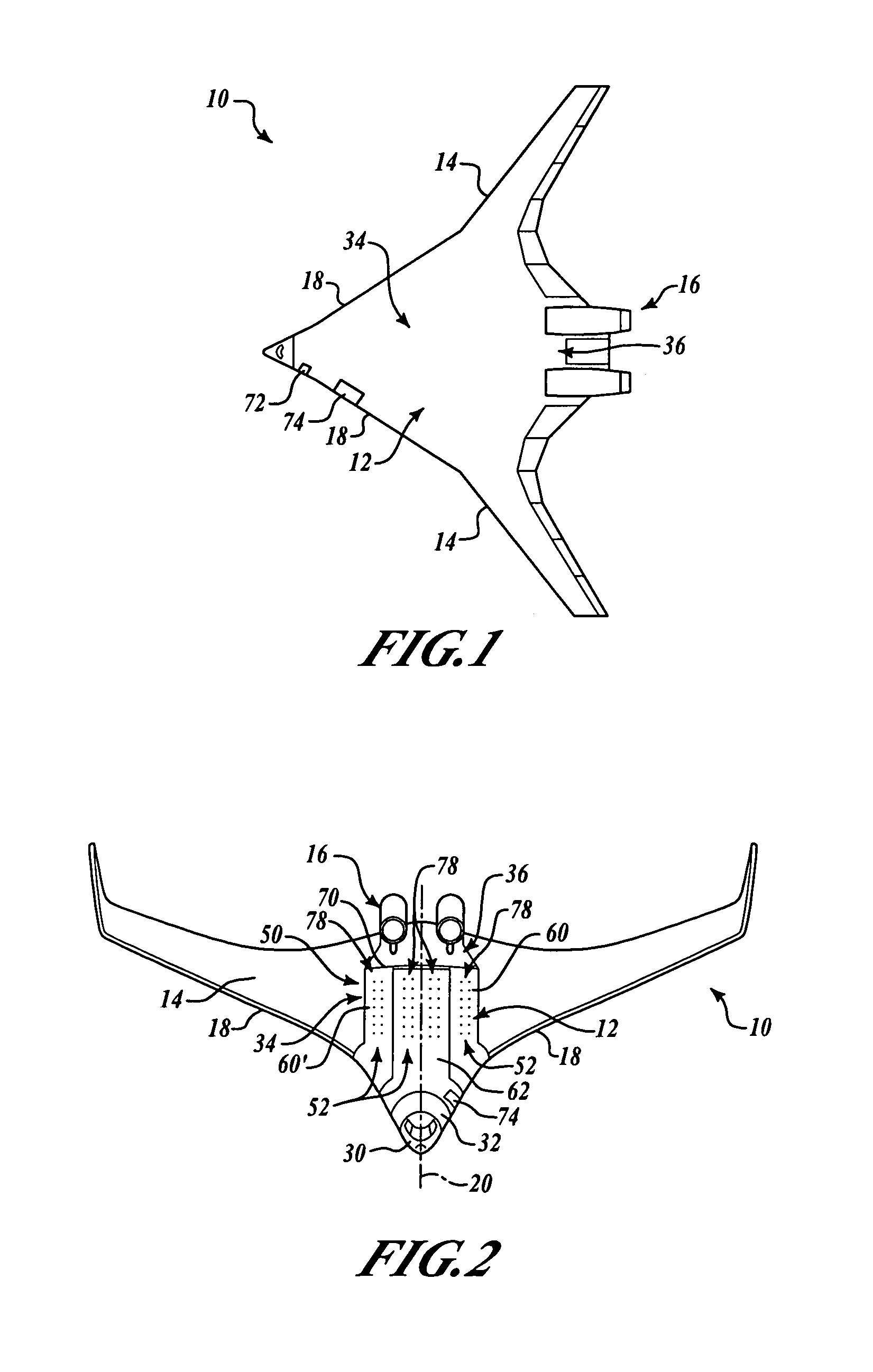

Transformable airplane

ActiveUS7093798B2Reconfigured easily and rapidlyLow costFuselage framesFuselage bulkheadsCommand and controlFlight vehicle

A transformable airplane may be reconfigured easily and rapidly to perform any one or a combination of tanking, transport, bombing, or command and control missions as desired for a tactical situation by installing or replacing mission-specific modules as desired. A reconfigurable aircraft includes a pair of wings and an aircraft body having at least one bay defined in an interior of the aircraft body. The at least one bay is configured to accept a plurality of removably replaceable modules that configure the aircraft to perform a plurality of missions. Transport mission modules may include space and tie-downs for cargo pallets and / or palletized seating. A roll-on / roll-off ramp may be provided. Tanking mission modules may include a remote aerial refueling operator station. Bombing mission modules may include a bomb rack and a bomb ejector. ISR mission modules may include command and control stations in signal communication with phased array antennas.

Owner:THE BOEING CO

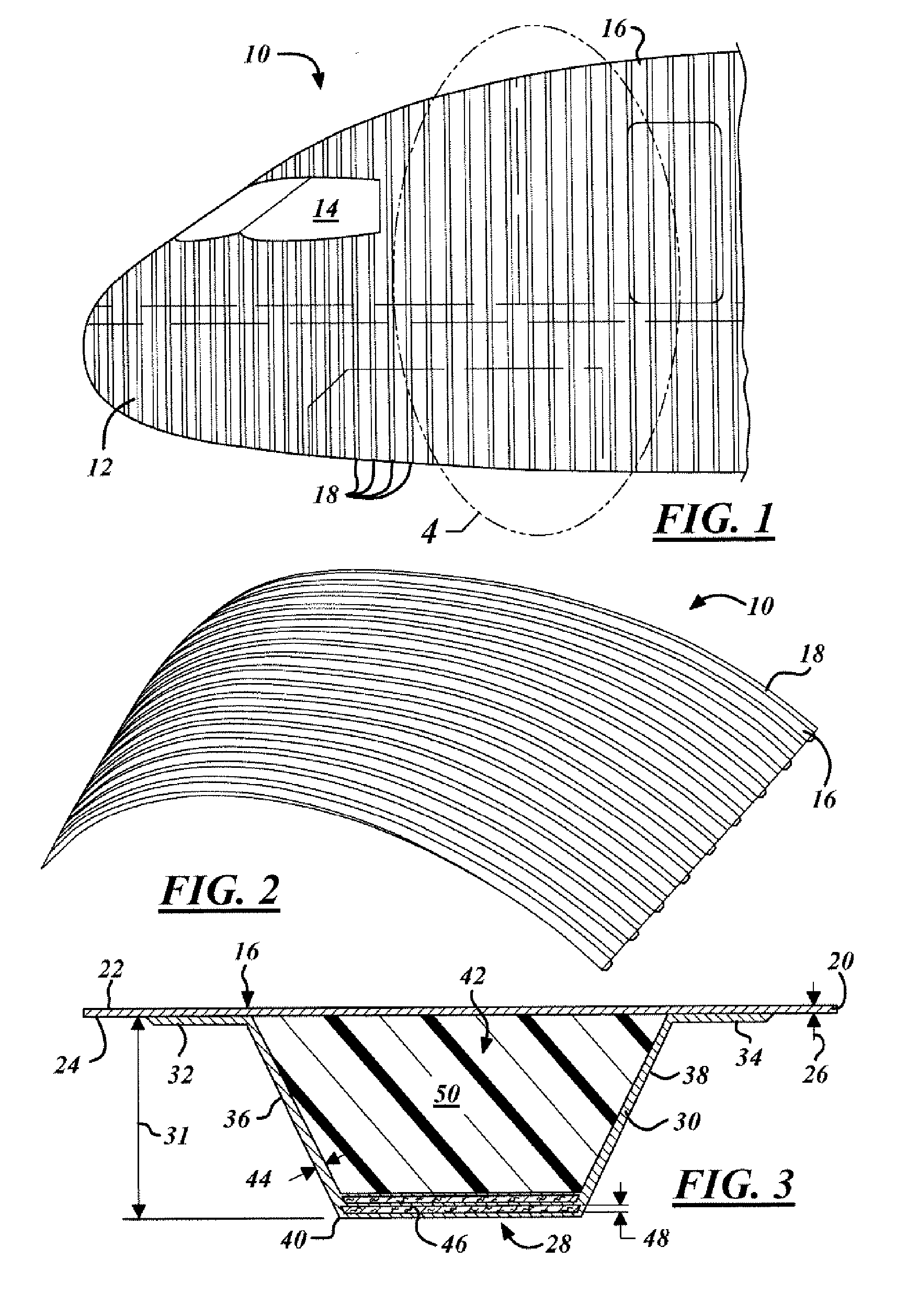

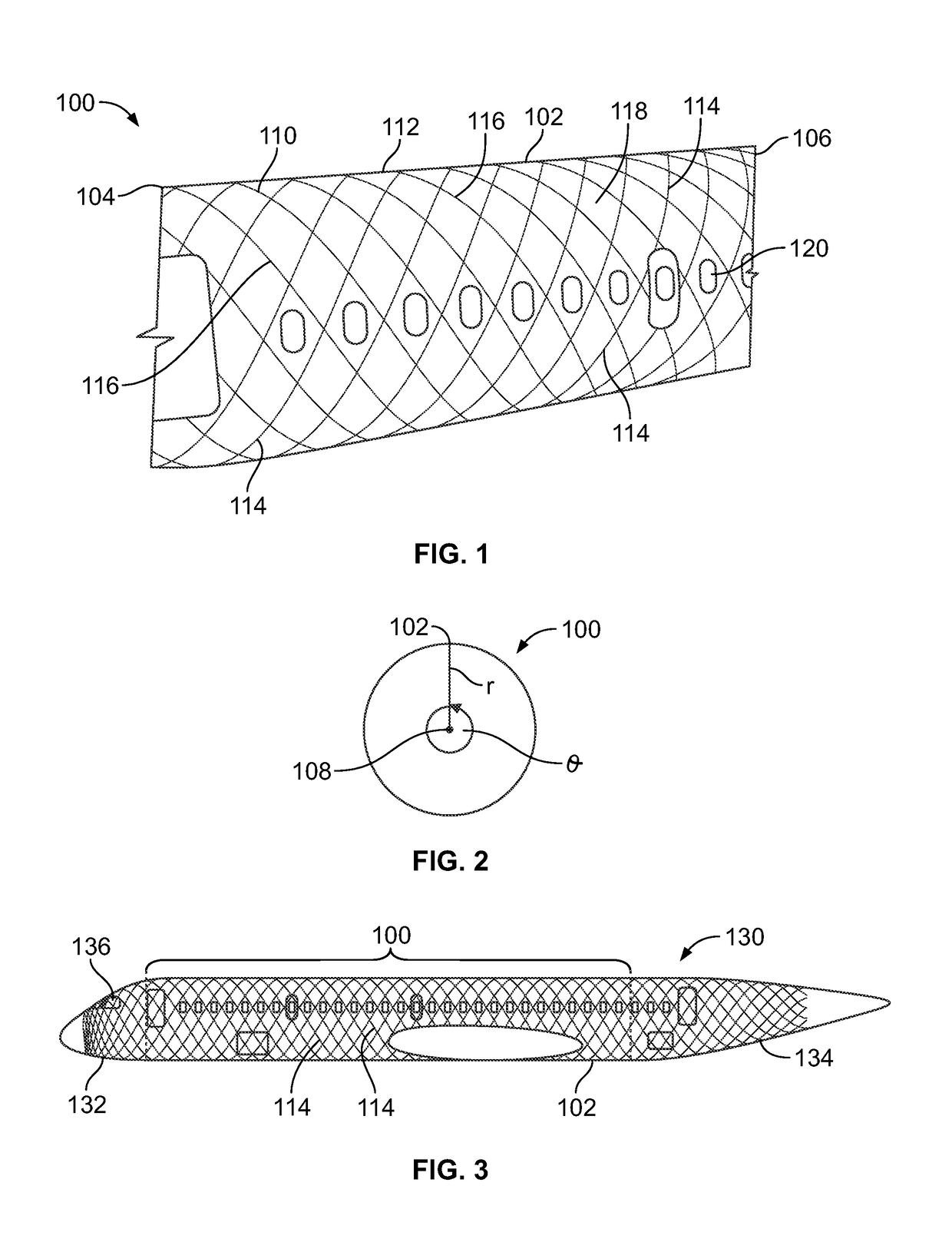

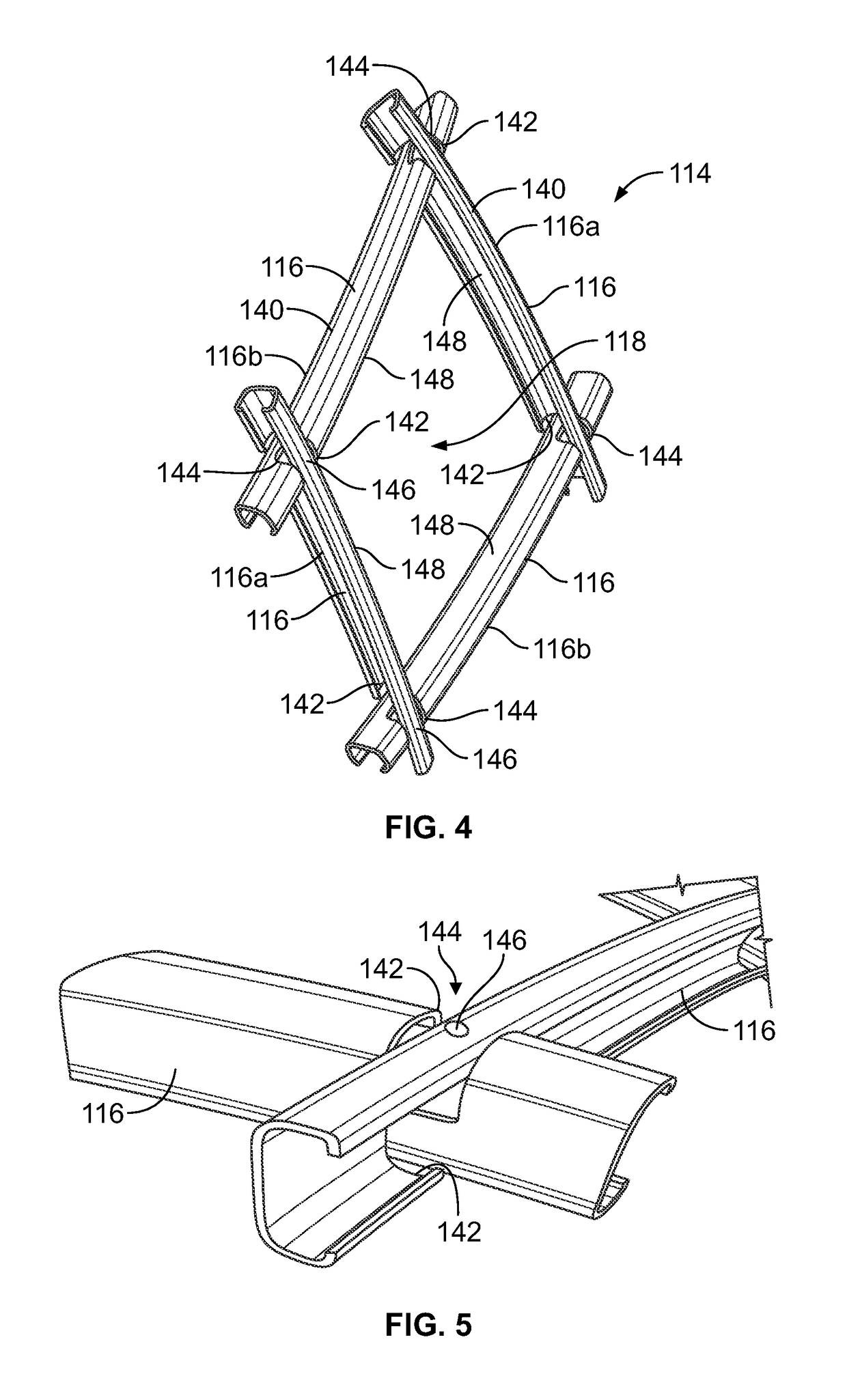

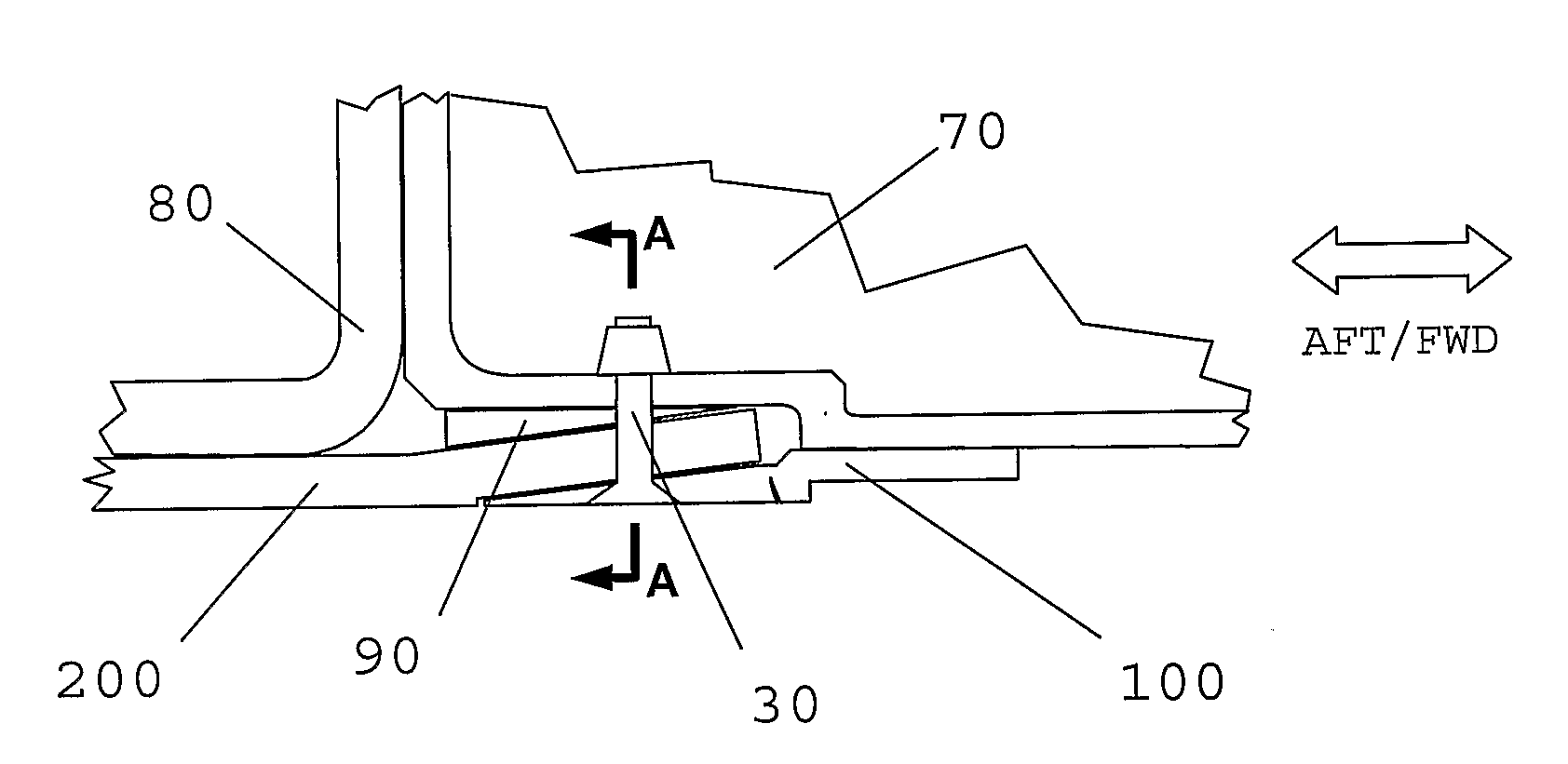

Single piece fuselage barrel

In accordance with the present invention an aircraft stringerless fuselage structure is provided comprising an impact compliant outer skin having a plurality of resin impregnated skin fibers forming an outer skin surface, an inner stringerless skin surface, and a skin thickness. A plurality of stiffeners is included, each comprising a plurality of resin impregnated stiffener fibers integrated into the inner stringerless skin structure. The plurality of resin impregnated skin fibers are not aligned with the plurality of resin impregnated stiffener fibers.

Owner:THE BOEING CO

Adhesively bonded joints in carbon fibre composite structures

InactiveUS6320118B1Improve performanceLightning protection is goodInstallation of lighting conductorsAircraft lighting protectorsFiberPower flow

A structural joint for the transmission and control of high current flows in a carbon fiber or carbon fiber hybrid composite structure, said joint includingat least two composite structures comprising a multiplicity of resin bonded carbon fiber plies,an adhesive applied there between and capable of conducting high currentssaid adhesive comprising a conductive carrier film comprising carbon fibers,wherein the electrical conductivity of the adhesive is comparable with that of the adjacent composite structures.

Owner:BAE SYSTEMS PLC

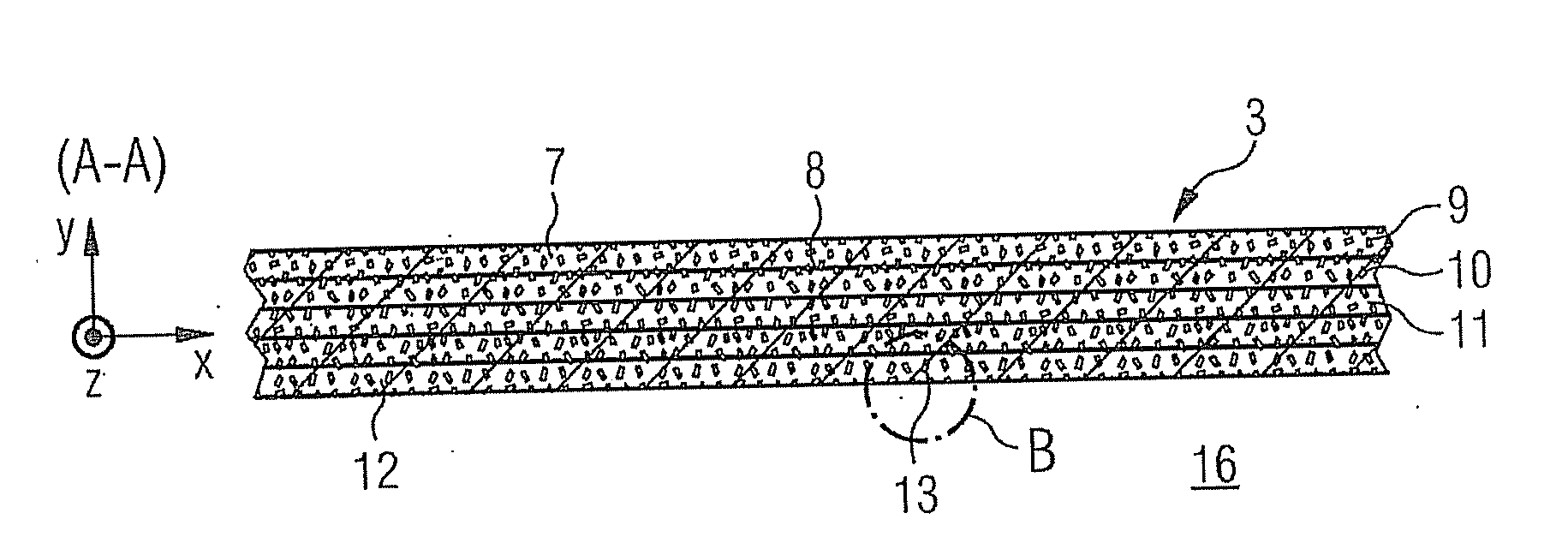

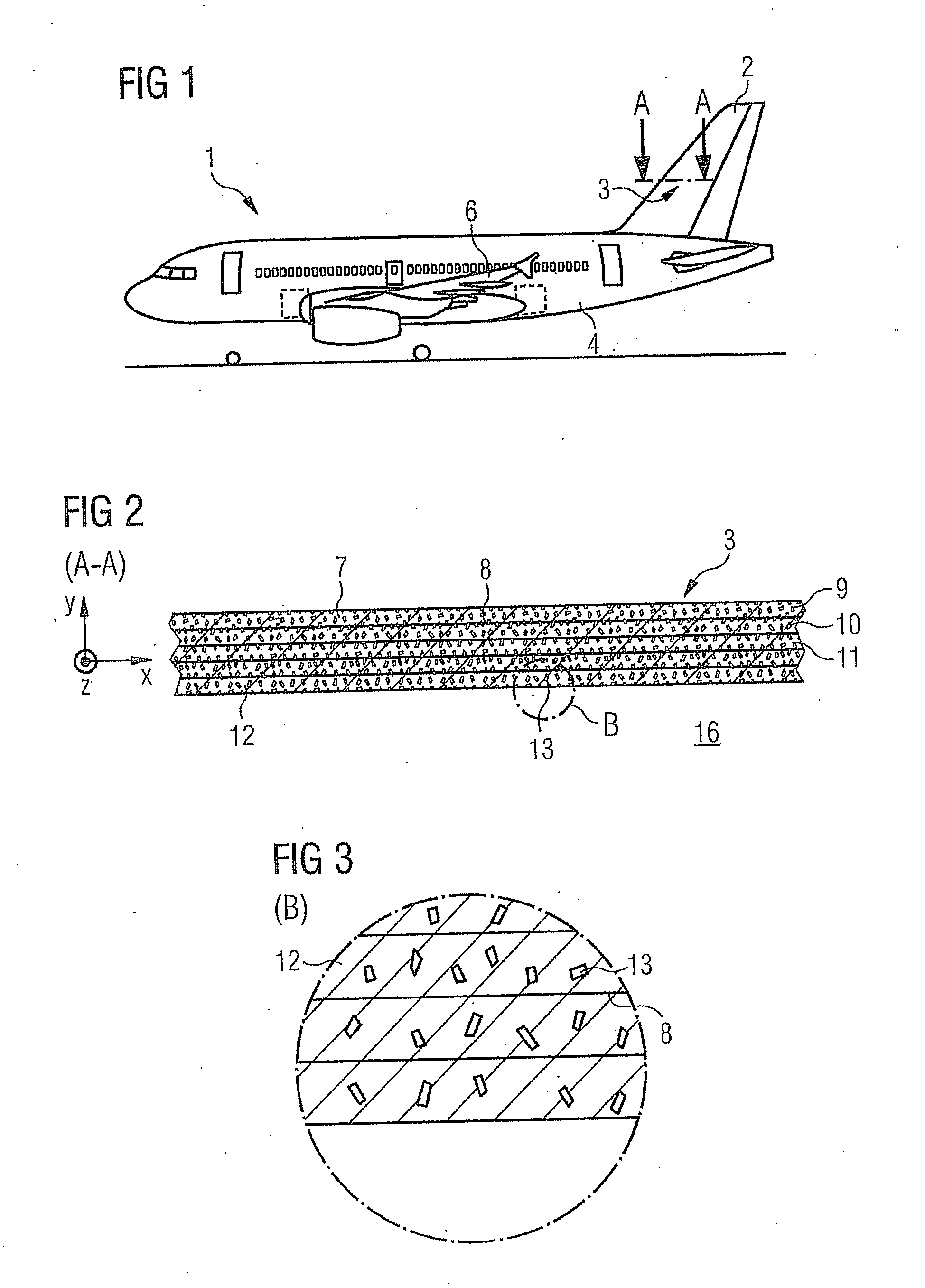

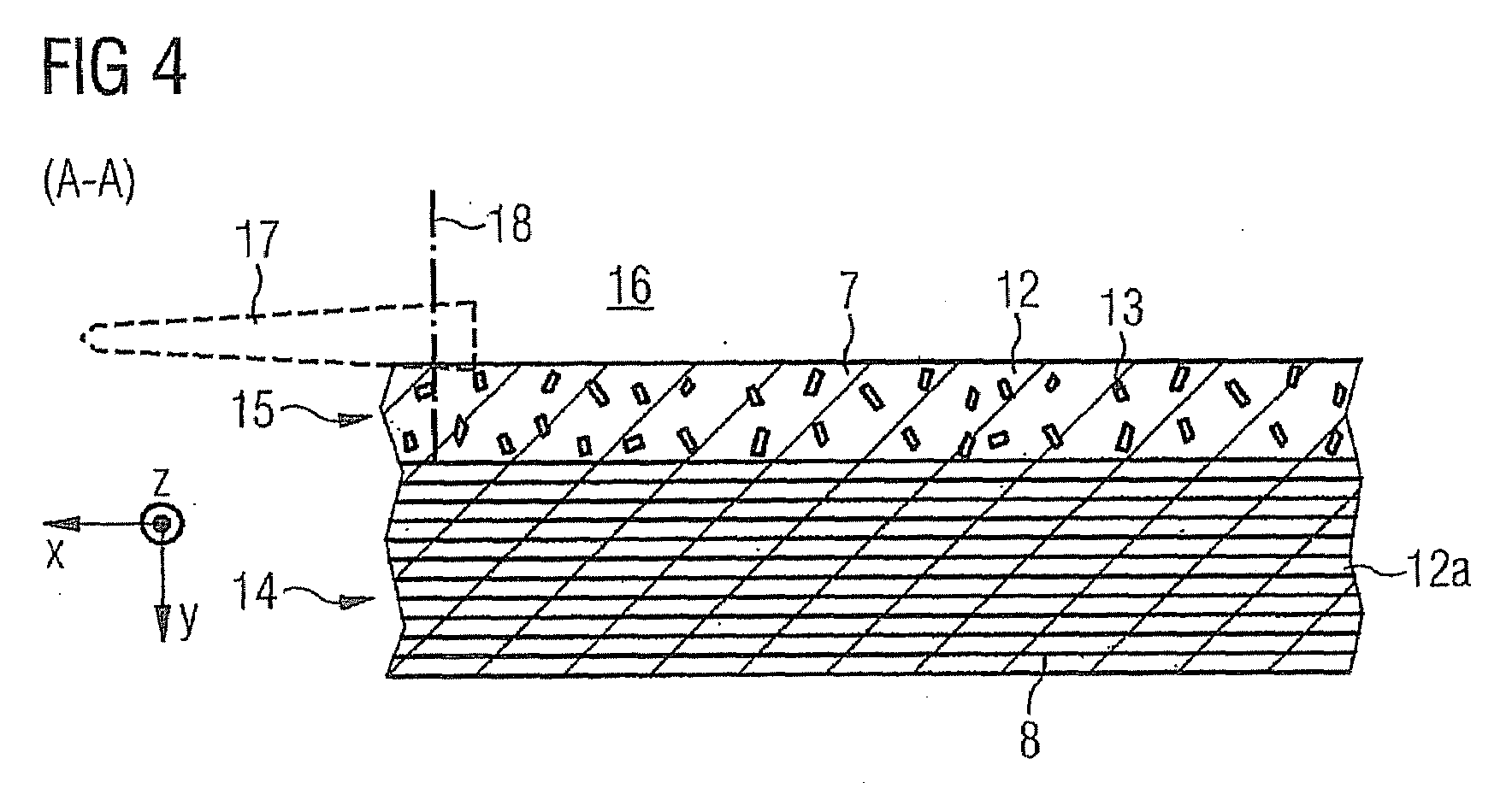

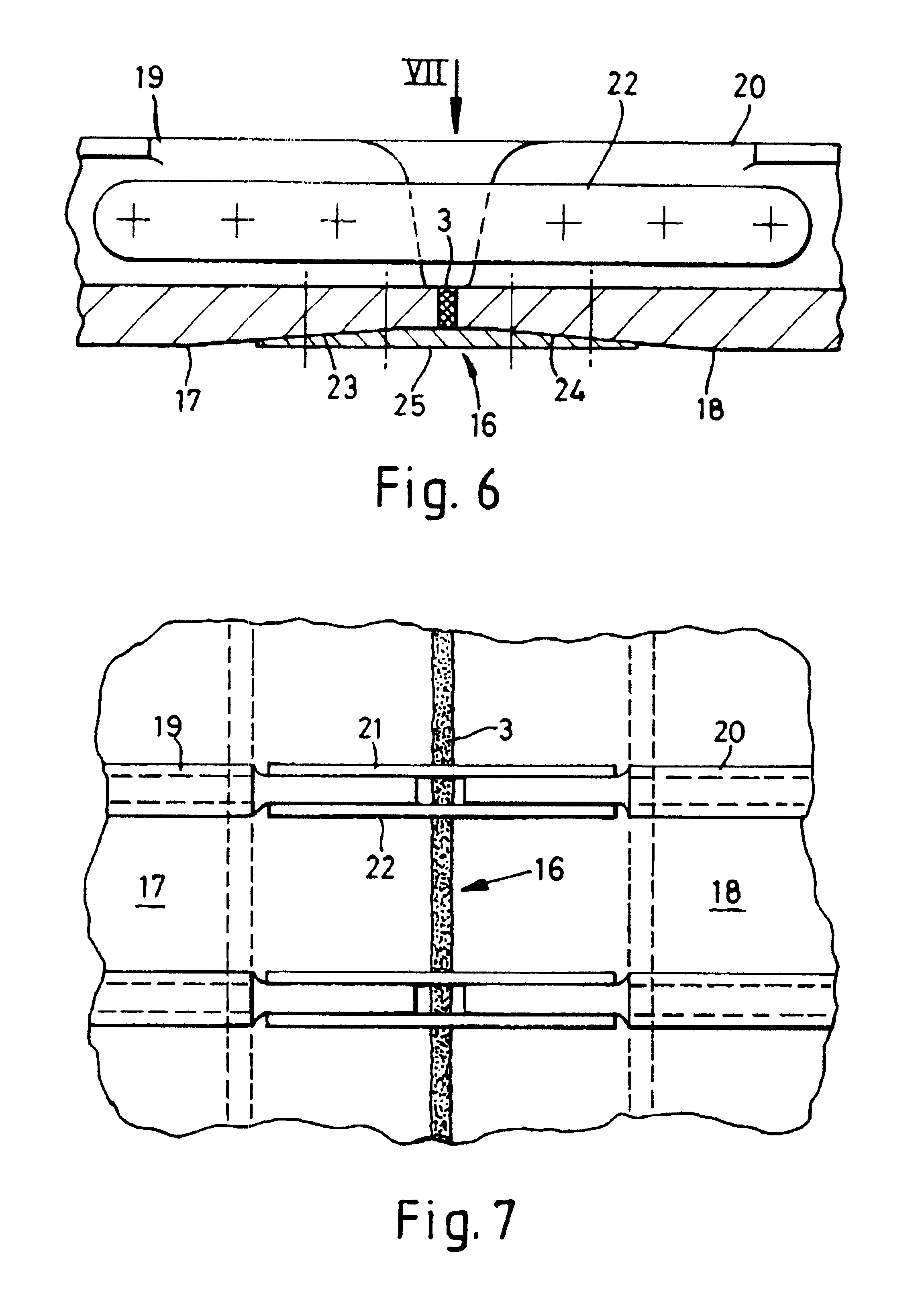

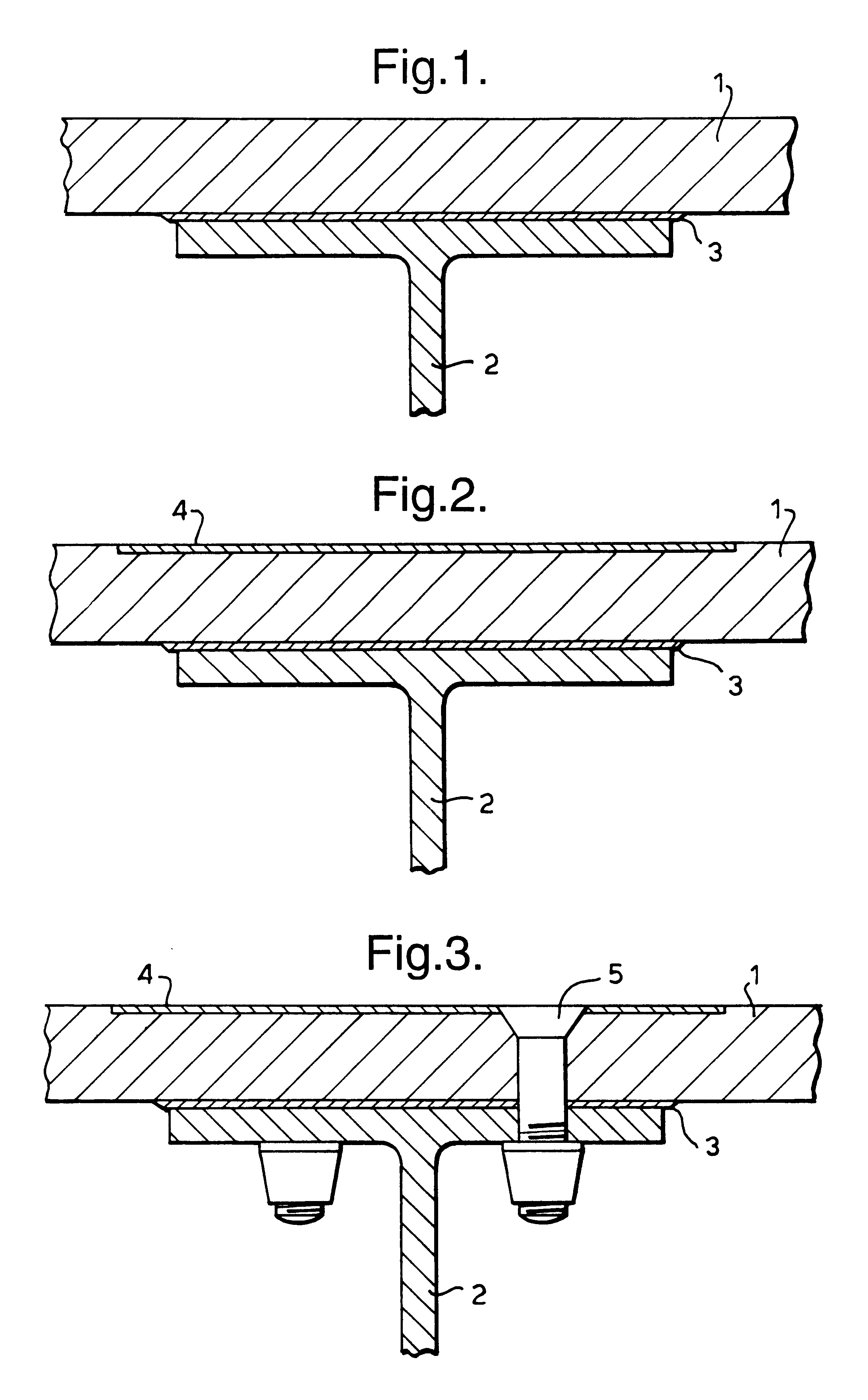

Line system for an aircraft

ActiveUS20080185478A1Reduce expensesReduce effortFuselage framesElectrical apparatusTransmitted powerEngineering

A line system for an aircraft, in particular an airplane, having multiple assemblies, in particular multiple fuselage sections of a fuselage cell and multiple wing shells, the line system including multiple lines for transmitting power and / or information, wherein the lines are integrated on and / or in a support layer, the support layer being situated on and / or in the shell-shaped assemblies.

Owner:AIRBUS OPERATIONS GMBH

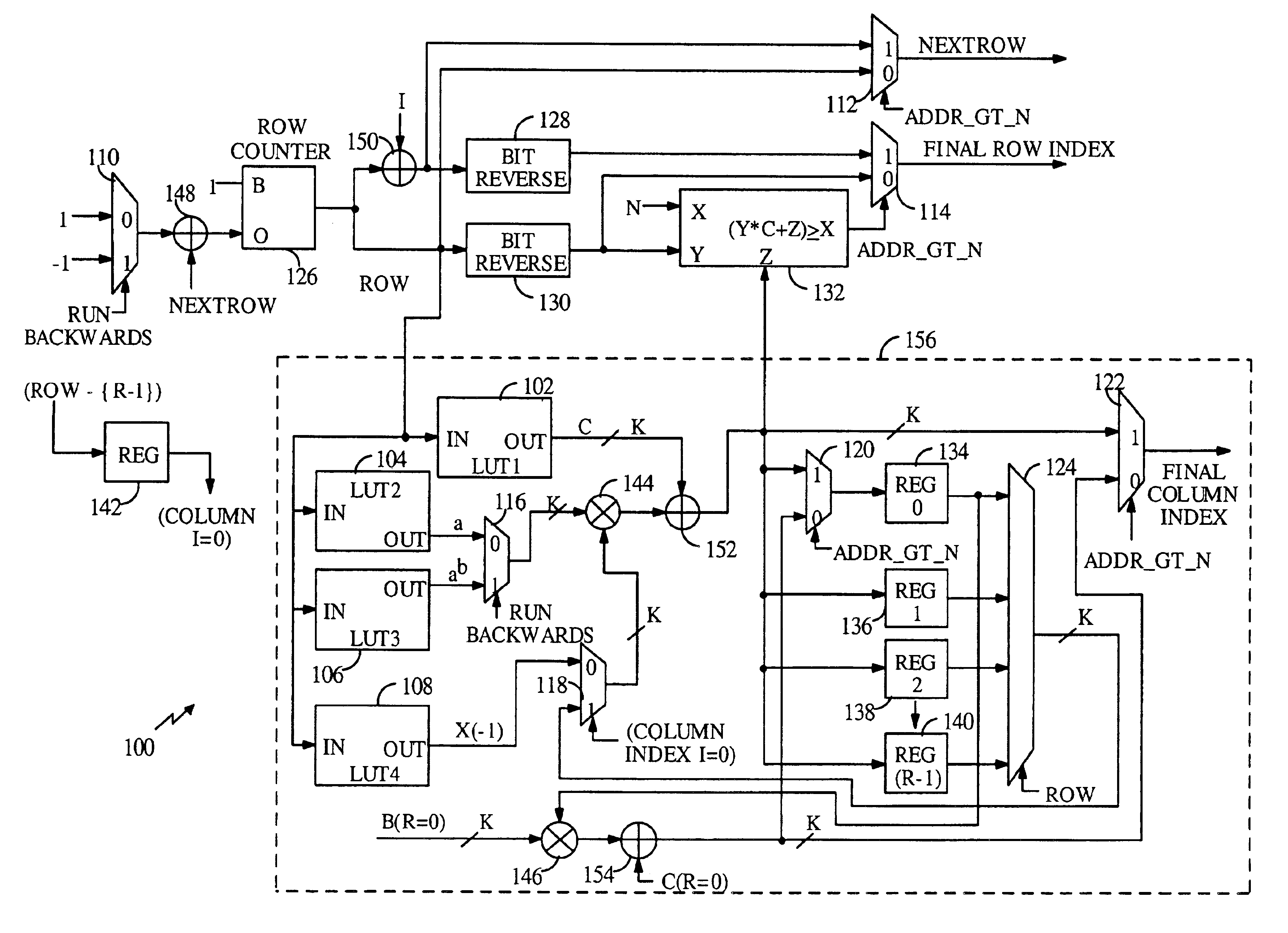

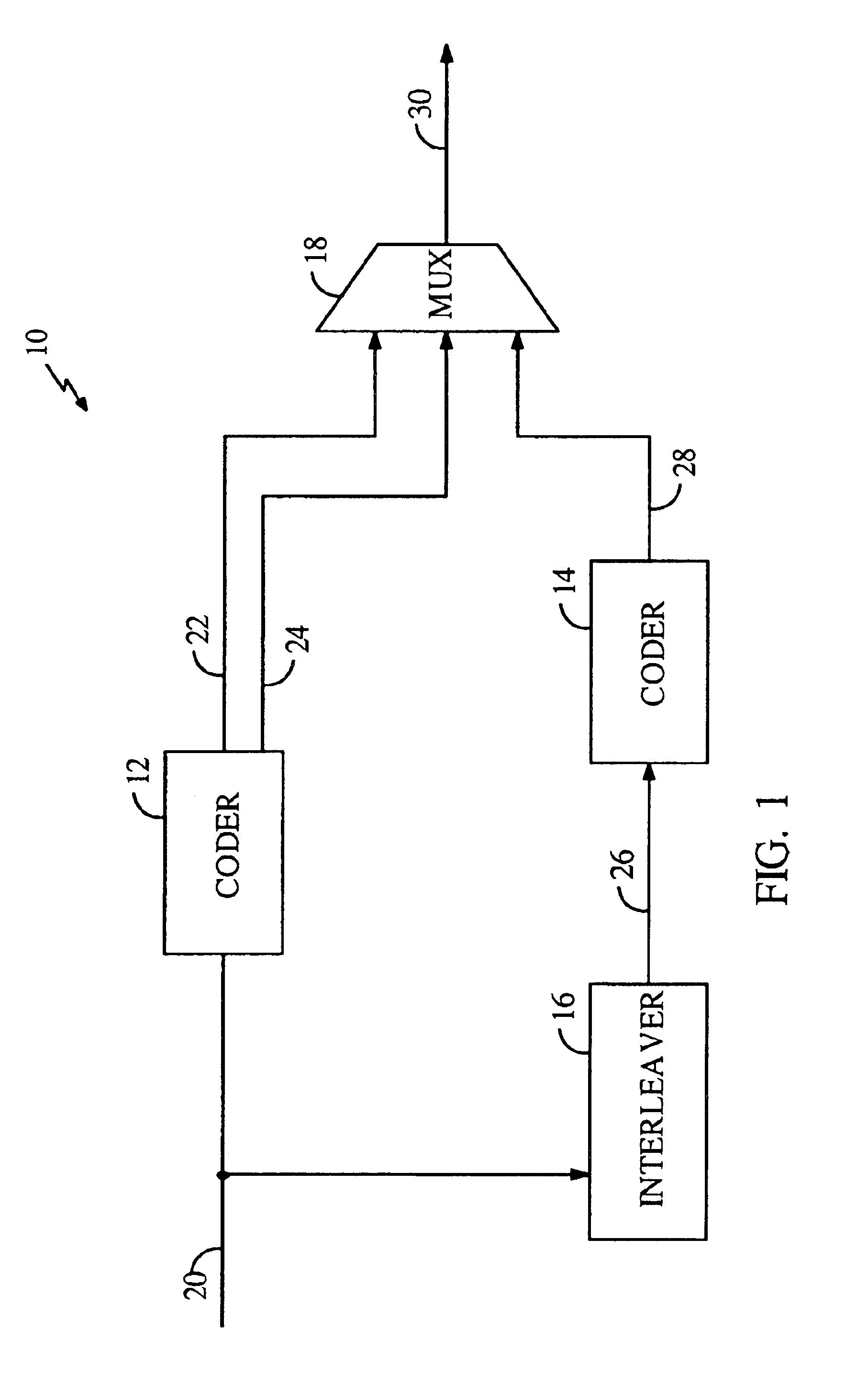

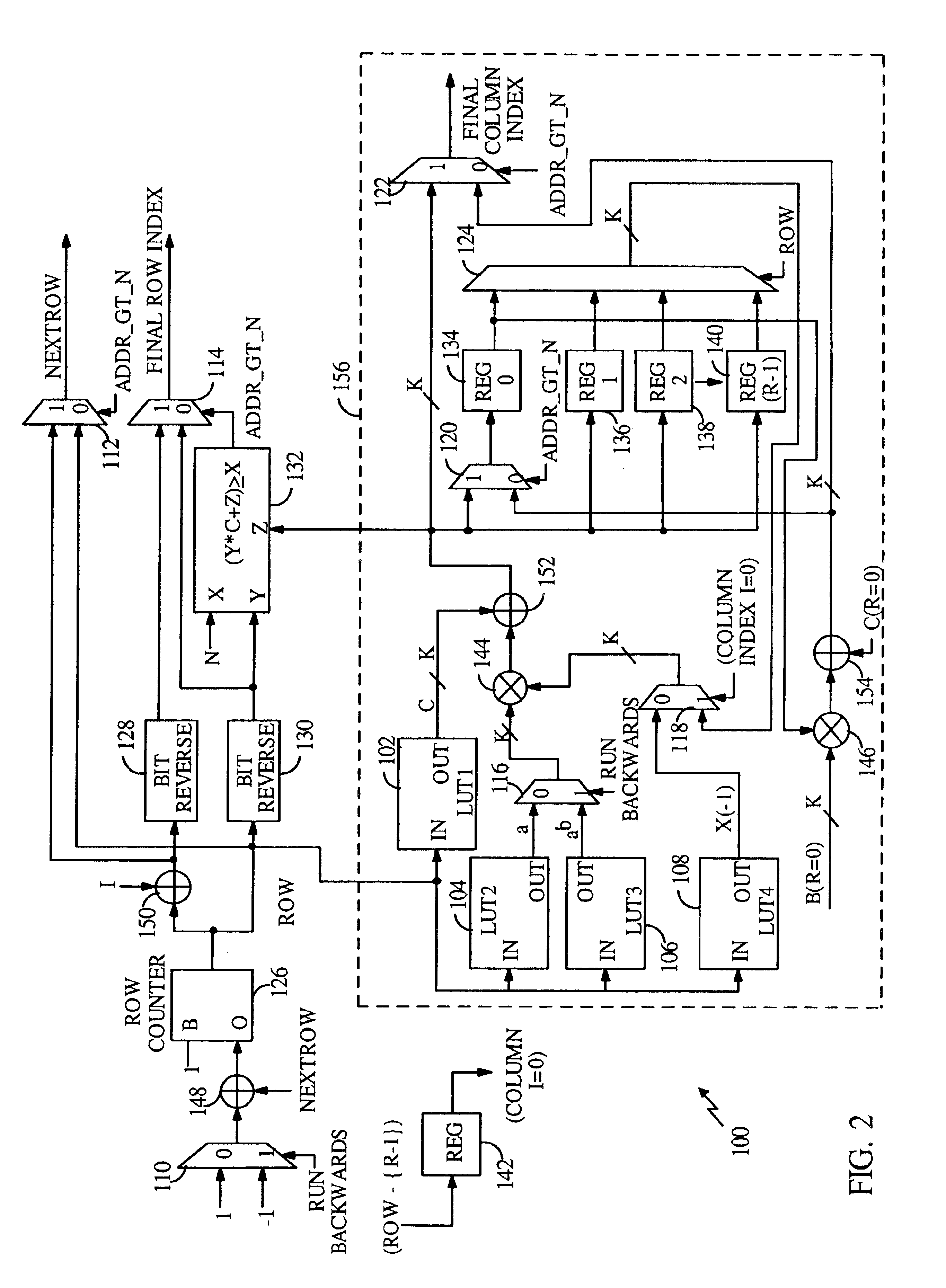

Random-access multi-directional CDMA2000 turbo code interleaver

InactiveUS6871303B2Fuselage framesData representation error detection/correctionControl signalParallel computing

An interleaver that implements the LCS turbo interleaver algorithm utilized by the CDMA2000 standard is described. The interleaver includes a first computation unit for receiving an input address and computing a first sequential interleaved address during a first clock cycle in response thereto. A second computation unit is included for receiving an input address and computing a second sequential interleaved address during the first clock cycle in response thereto. The interleaver further includes a comparator for determining whether the first or the second sequential interleaved address is invalid and generating a signal in response thereto. The output of the comparator provides a control signal to a switch which selects the first or the second sequential interleaved address as an output interleaved address for the first clock cycle. The interleaver is further designed to move in a forward direction or a reverse direction.

Owner:QUALCOMM INC

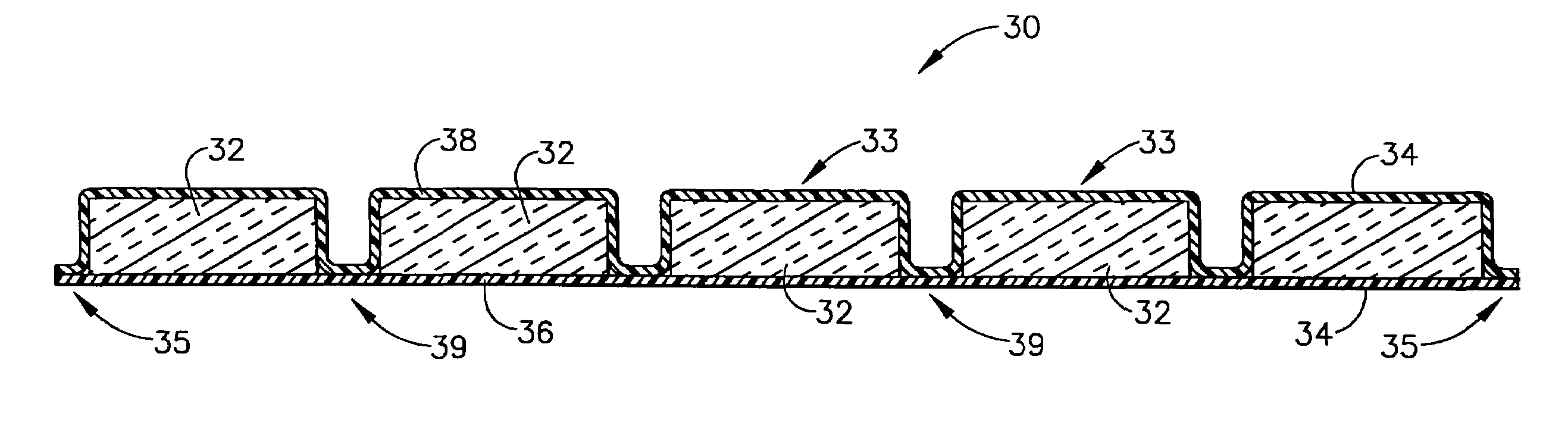

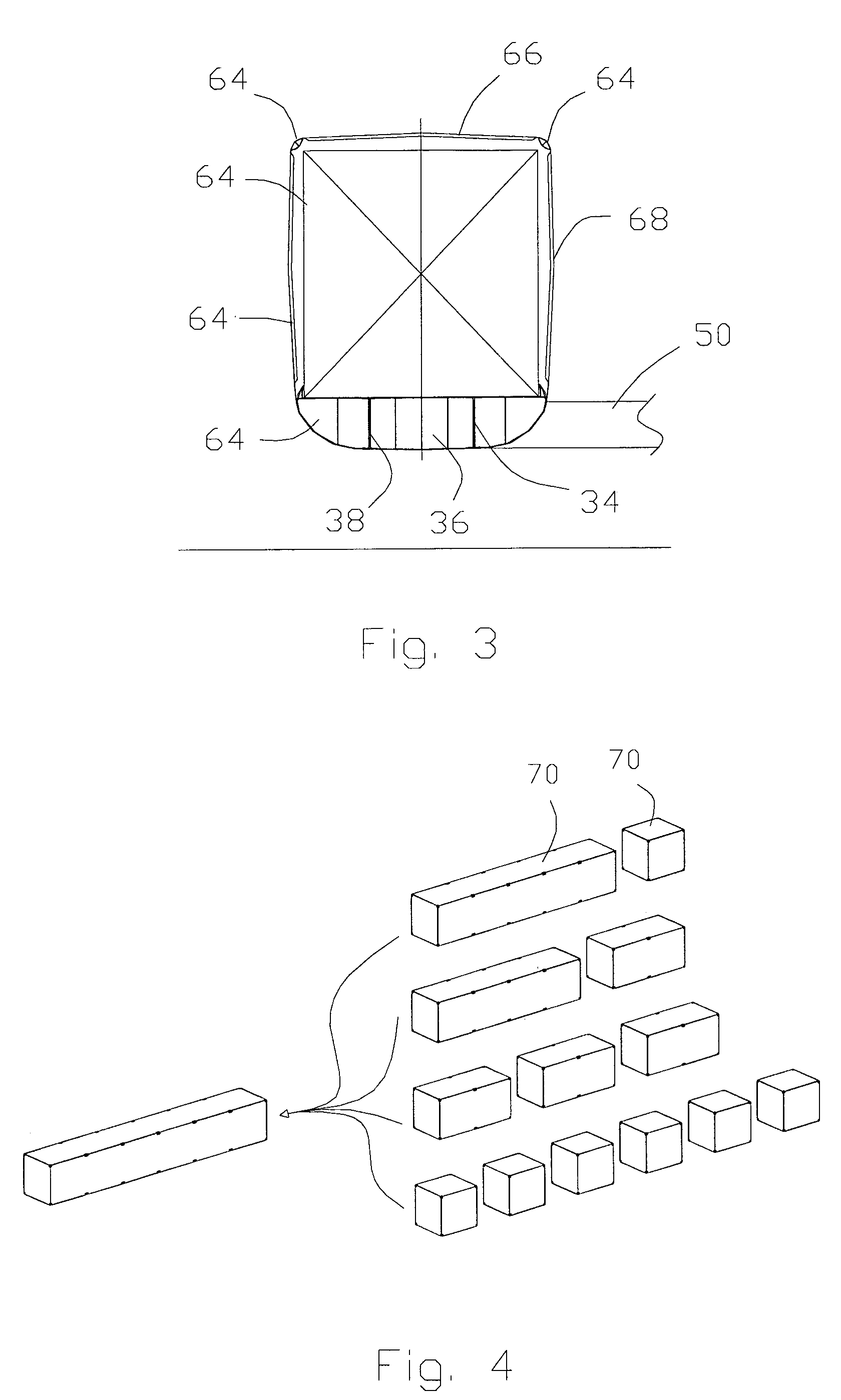

Modularized insulation, systems, apparatus, and methods

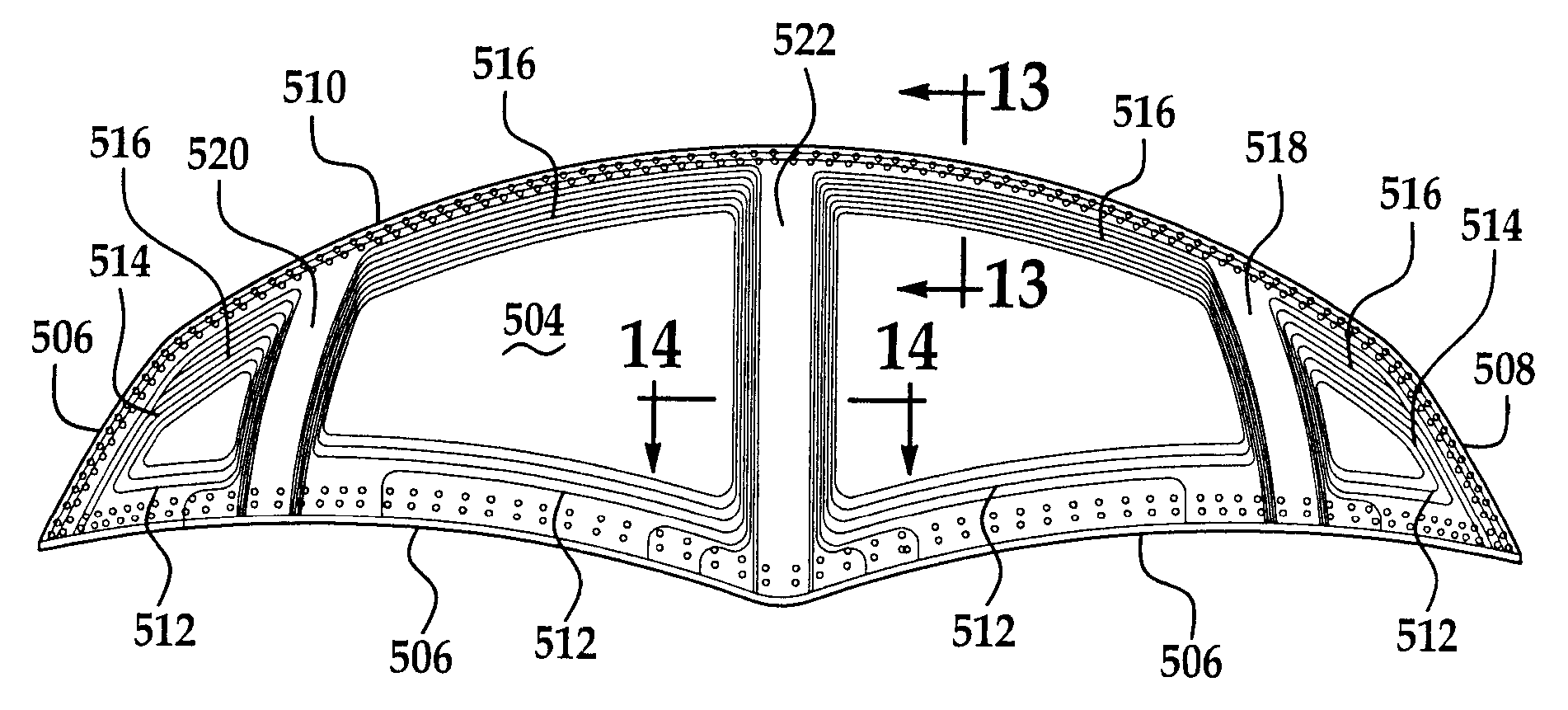

ActiveUS7083147B2Prevent and minimize shiftingLaborFuselage bulkheadsFuselage insulationSkin surfaceSurface structure

Modularized insulation blanket for thermal and / or acoustical insulation. The modularized insulation blanket has a cover formed of a distal layer and proximal layer in sealed mated relationship. The distal and proximal layers are sealed along longitudinal and latitudinal heat-sealed seams that define a plurality of modules. The heat-sealed seam may be creased so as to be foldable and / or perforated to provide a tear line. Within the modules are batting blocks. The blankets may be attached to surface structures such as the interior skin surface of an aircraft fuselage, pipes or other structures with retention systems. The blankets may be formed in an apparatus including a platen, heat seal rollers or heating sealing mechanisms, and edge sealers.

Owner:THE BOEING CO

Geodesic structure forming systems and methods

A system and method determine a size and a shape for identical geodesic modules that are used to form a structure. The system and method may include analyzing input data regarding a size and a shape of the structure to be formed, and determining the size and the shape for each of the identical geodesic modules based on the size and the shape of the structure to be formed. The structure may include a framework including the identical geodesic modules. Each of the geodesic modules has a size and a shape that are the same as all of the other of the geodesic modules. A forming system and method position a framework and a covering skin of the structure in relation to a mandrel, and drill and rivet the framework to the covering skin with a plurality of operating heads.

Owner:THE BOEING CO

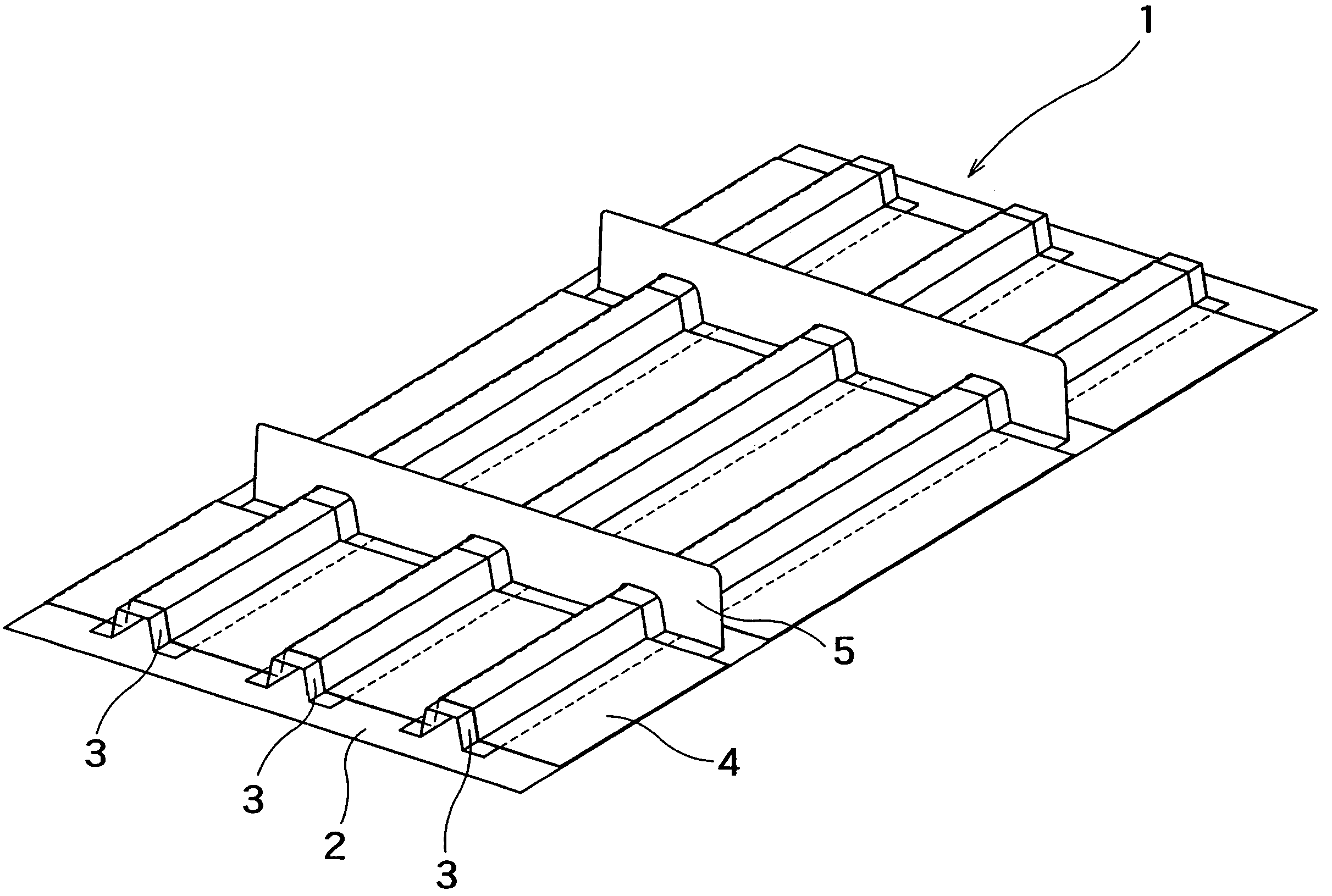

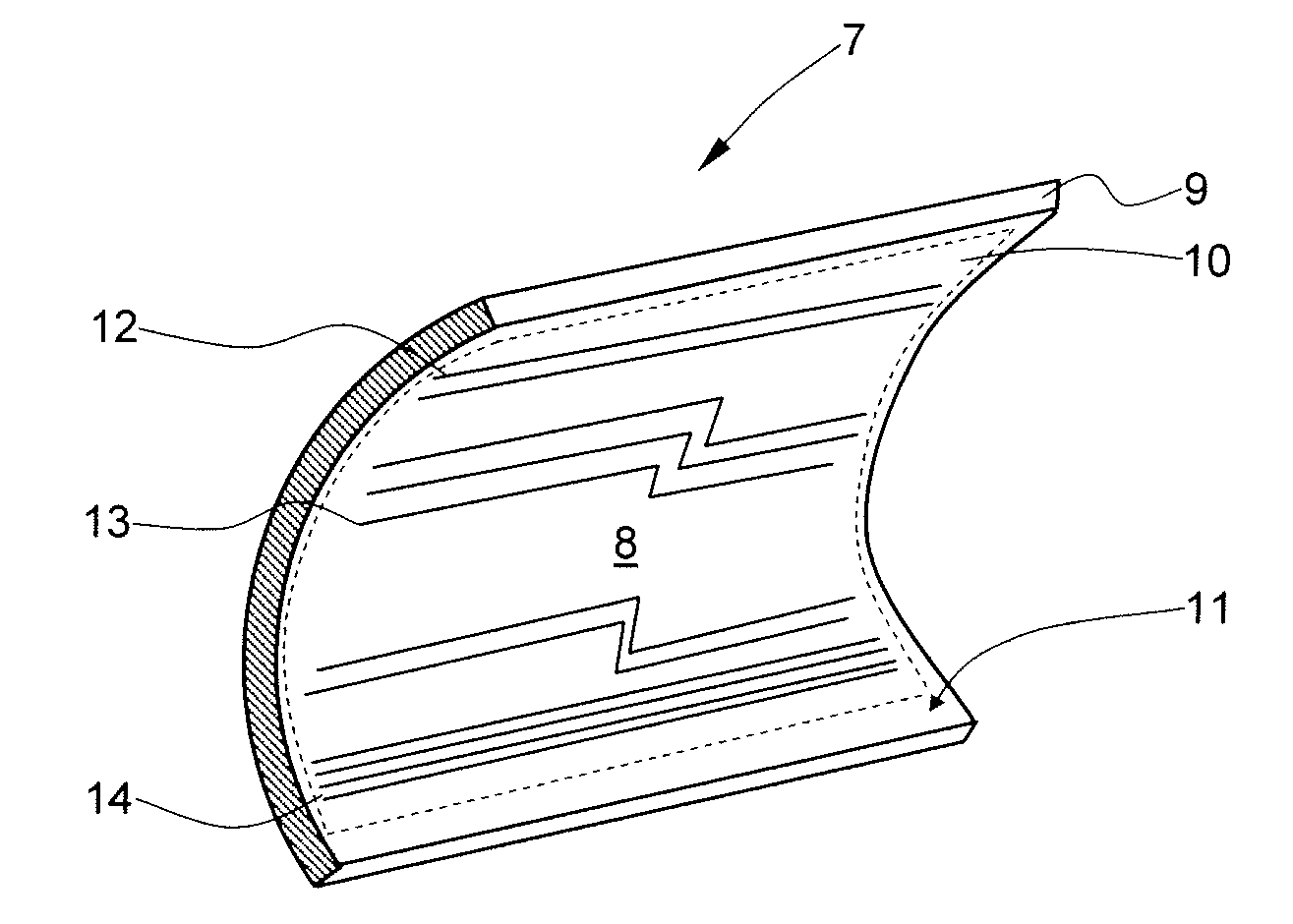

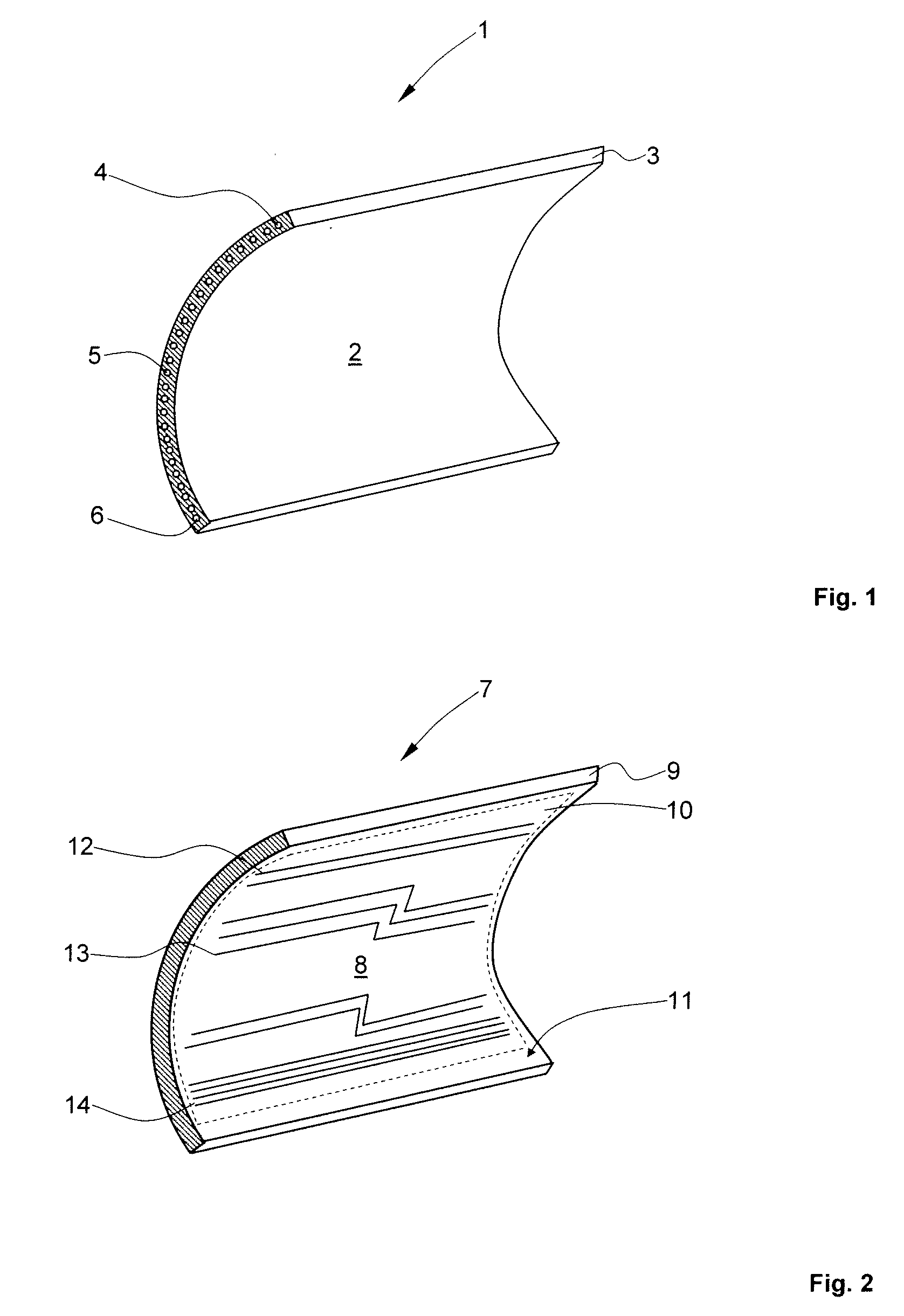

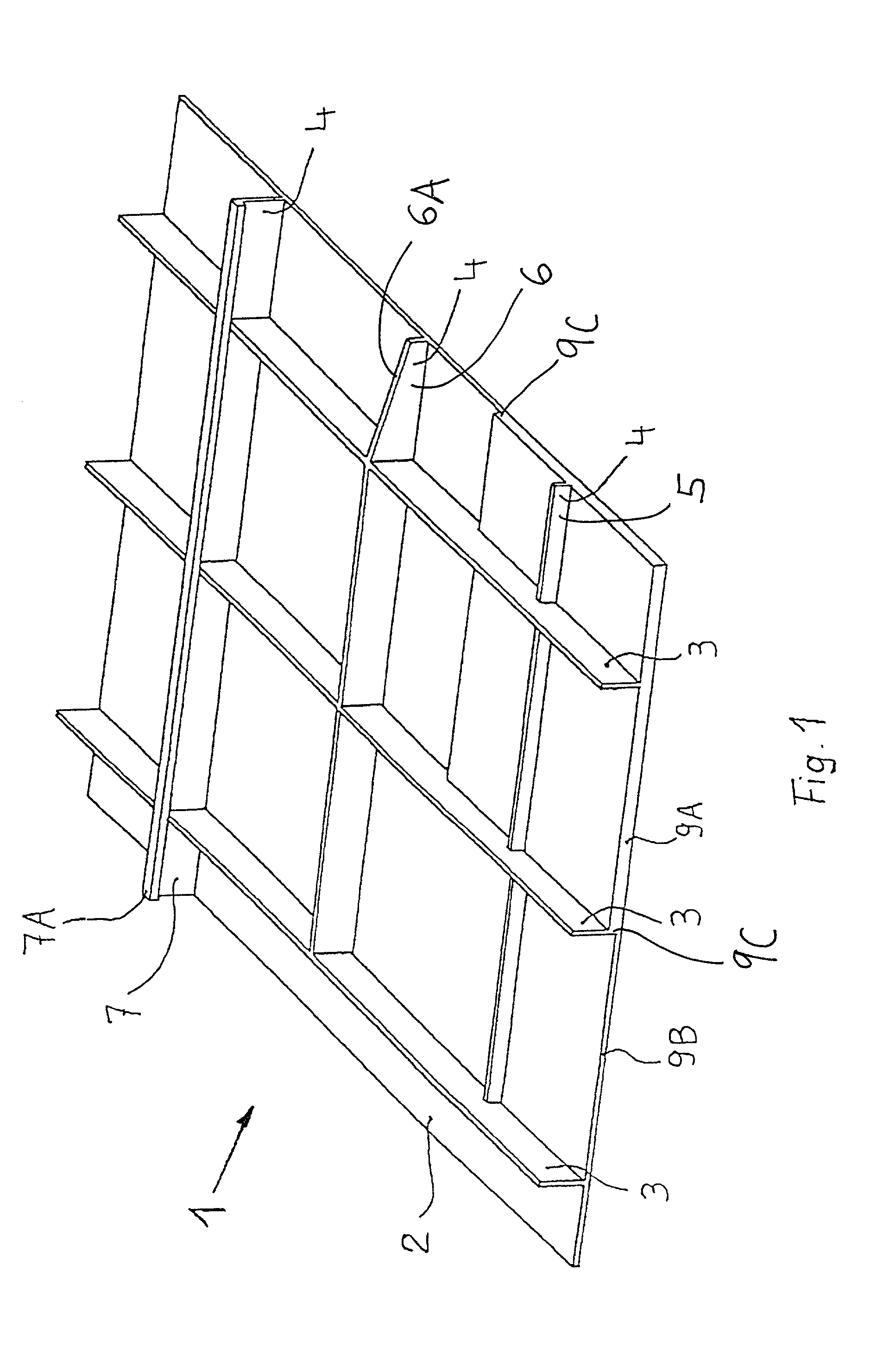

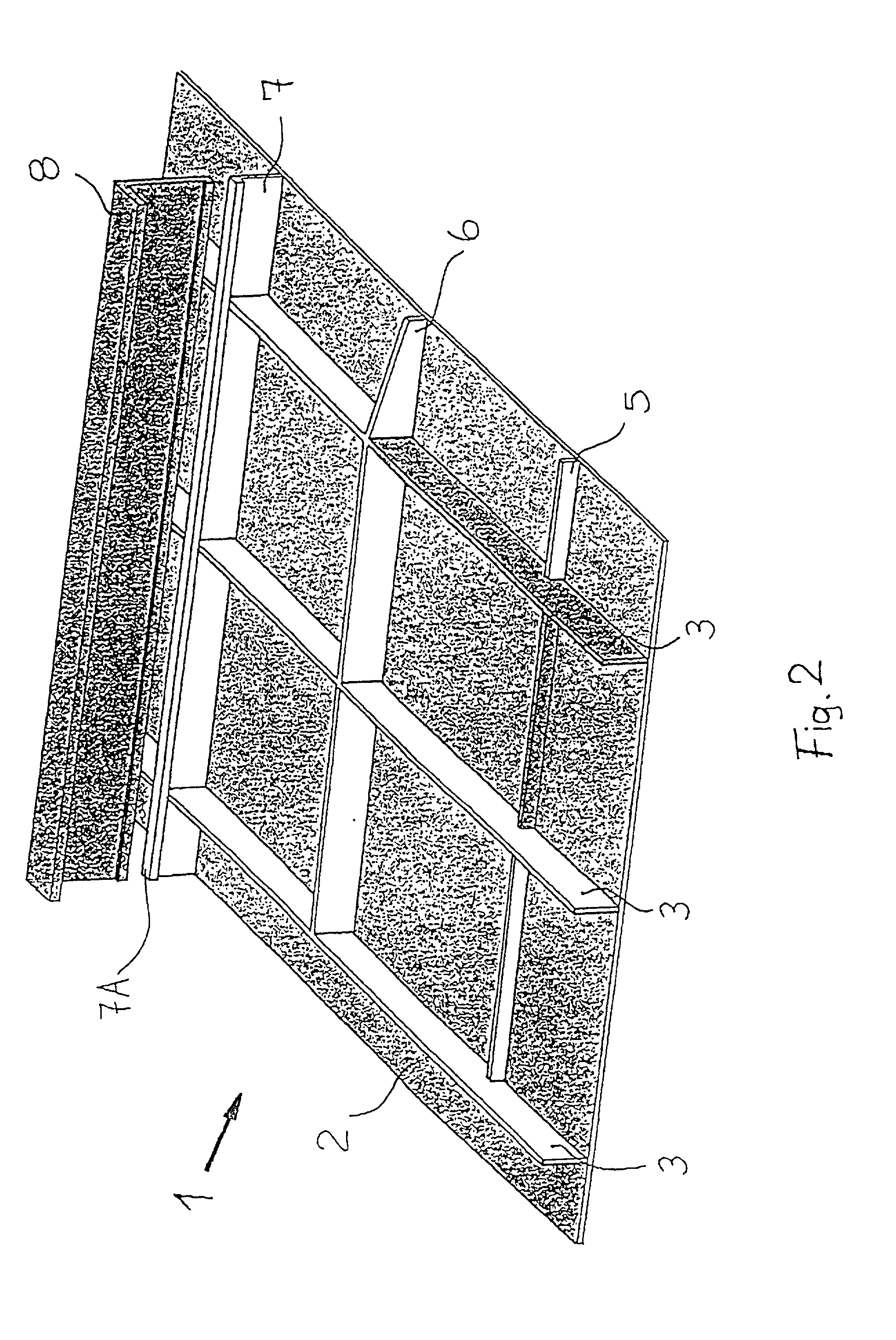

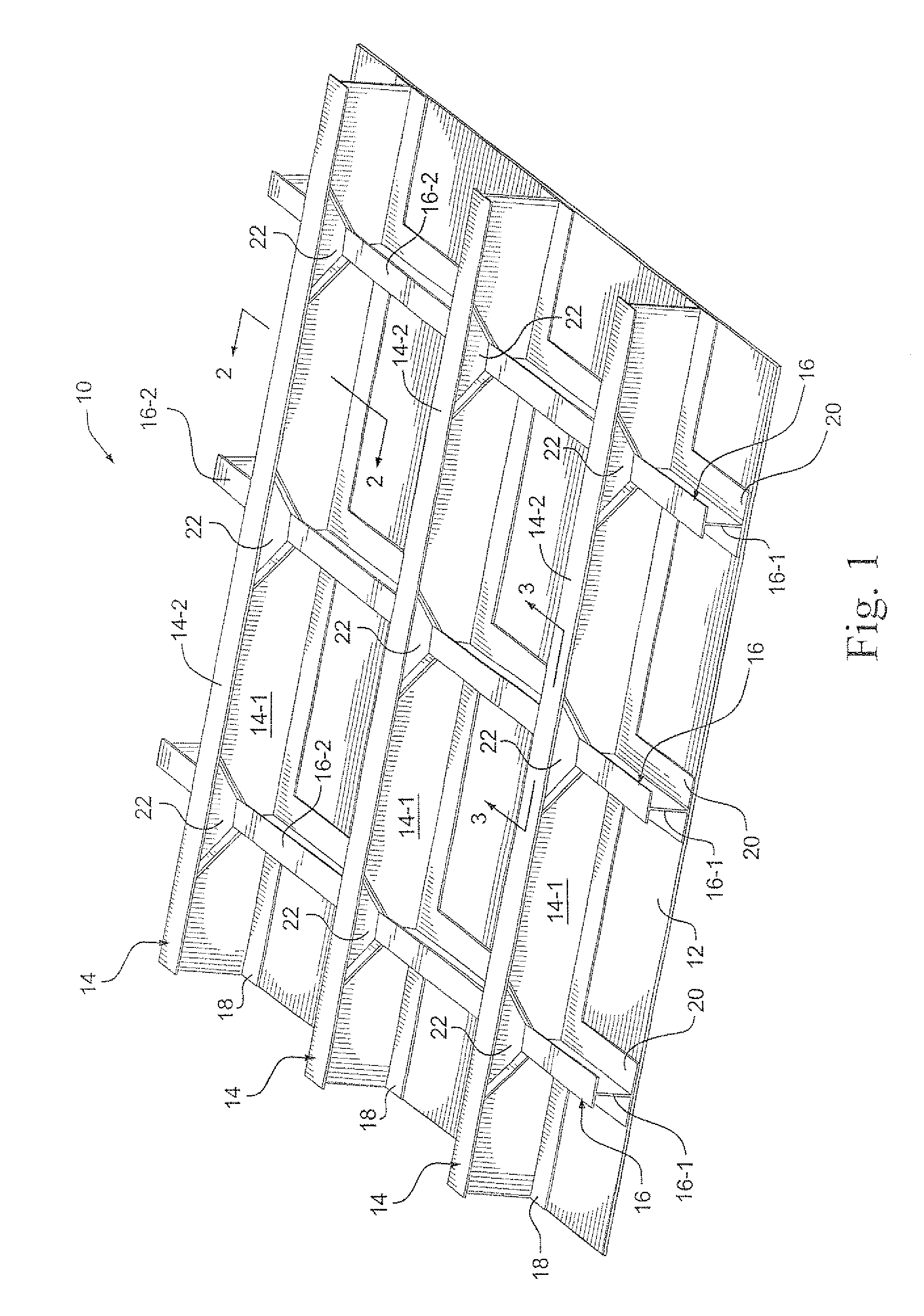

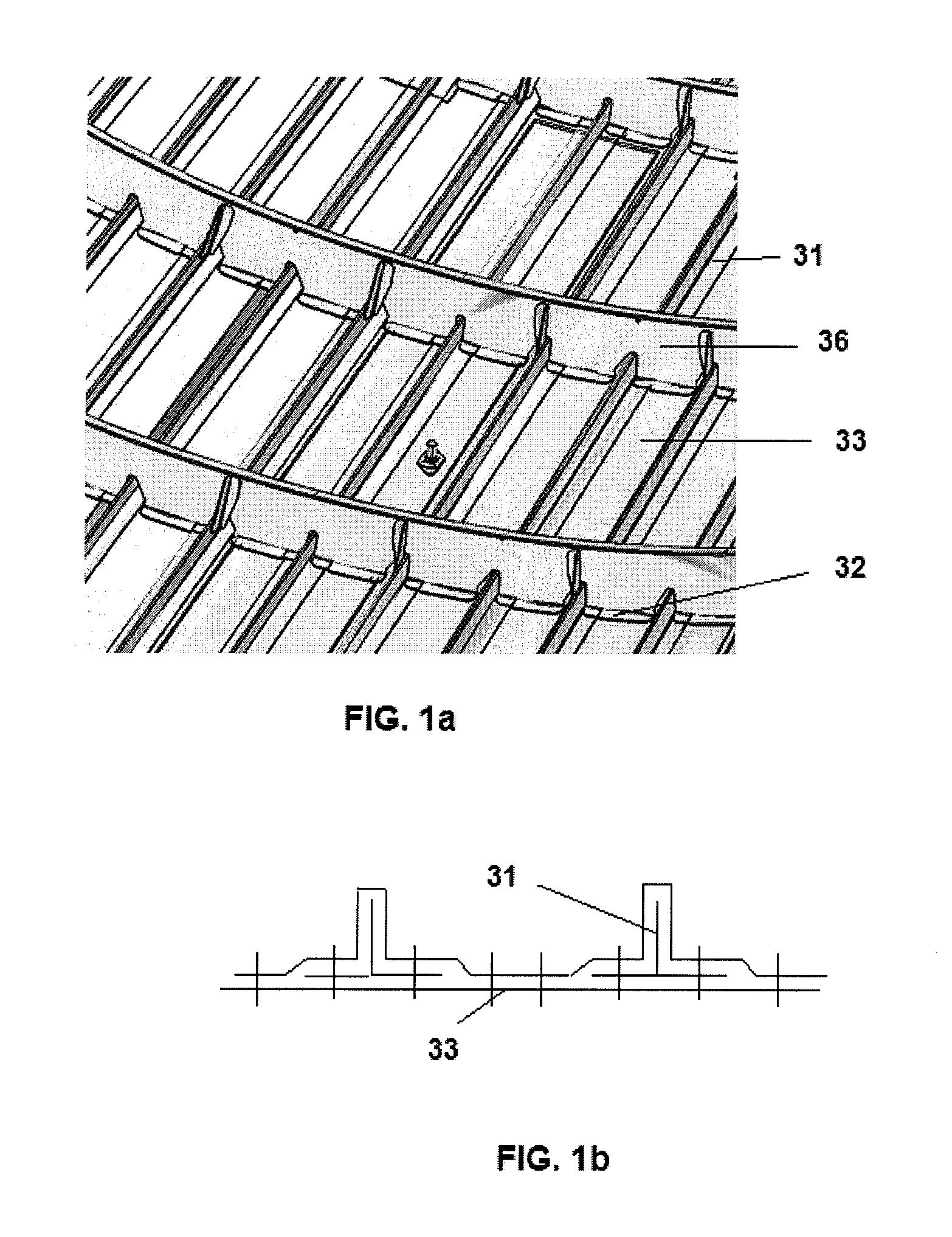

Integral structural shell component for an aircraft and method of manufacturing the same

A structural panel component, such as an aircraft fuselage shell component, includes a single integral part having longitudinal and crosswise stiffening elements integrally arranged on a skin sheet. This integral component has been formed by a high speed milling chip removal process applied to a solid plate-shaped semi-finished starting material. The skin sheet has areas of differing thicknesses, and the height, thickness, and spacing of the stiffening elements varies as needed, depending on the local loading conditions that will prevail on the finished structural component. The configuration of the component can be optimized to minimize the weight while satisfying all load strength requirements. The manufacturing method is very simple and economical.

Owner:AIRBUS OPERATIONS GMBH

Aircraft fuselage shell component with crack propagation resistance

InactiveUS6595467B2Increasing weight and costEasy to crackFuselage bulkheadsWelding apparatusResidual strengthFiber-reinforced composite

Owner:AIRBUS OPERATIONS GMBH

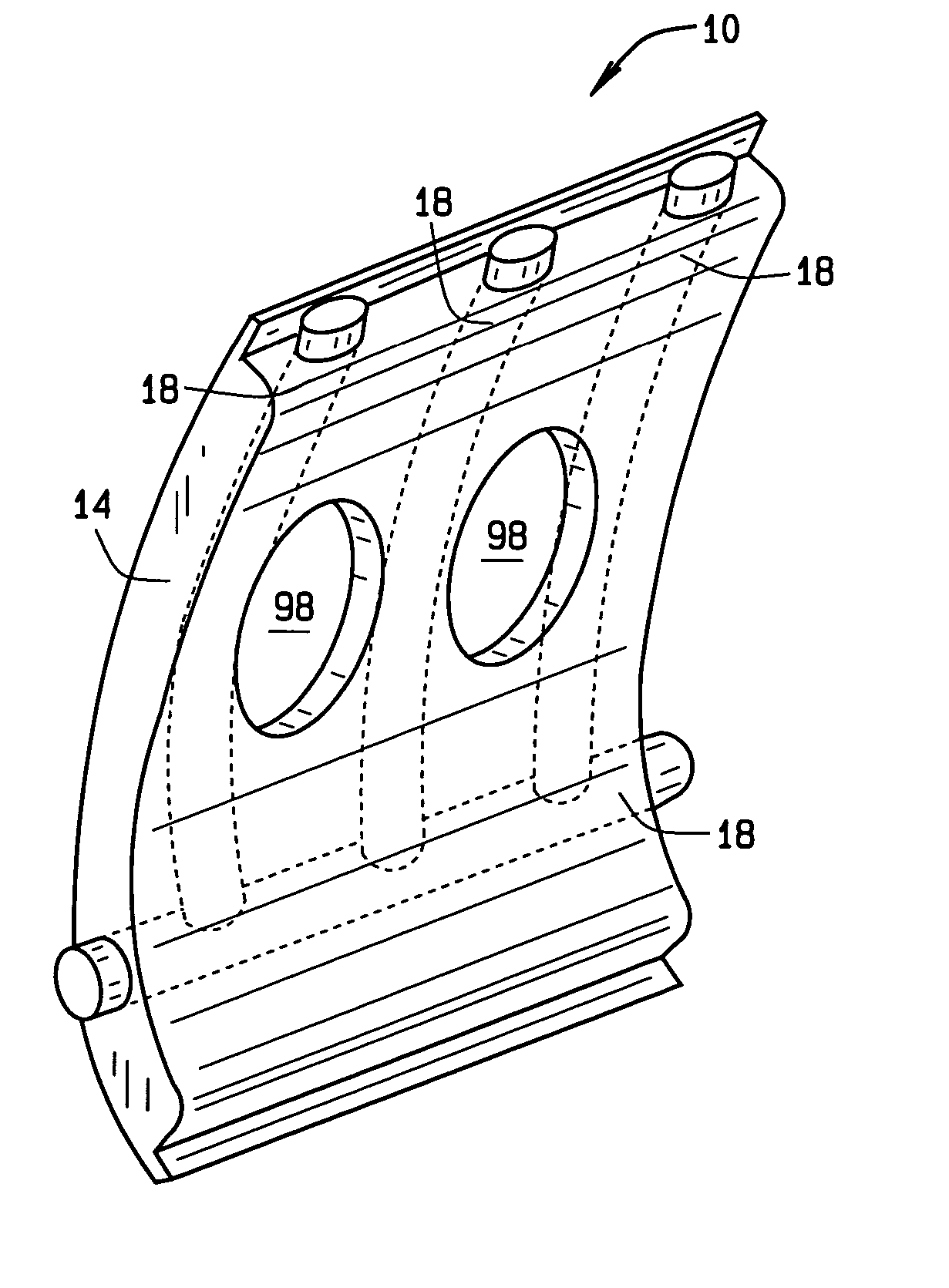

Compliant panel for aircraft

ActiveUS20080149769A1Increasing the thicknessEasy constructionMilitary adjustmentFuselage bulkheadsEnergy absorptionEngineering

A pressurized bulkhead or panel for an aircraft includes an energy absorbing skin that deforms in response to an object strike that imparts at least a threshold amount of impact energy to the skin. The skin may be configured as a dome or a lofted panel that is essentially free of rigid stiffeners and non-deformable reinforcement members that would otherwise hinder the flexible characteristics of the skin. The skin may be formed from a monolithic one-piece material, such as metal of composites, and may include various integrally formed reinforcing features.

Owner:THE BOEING CO

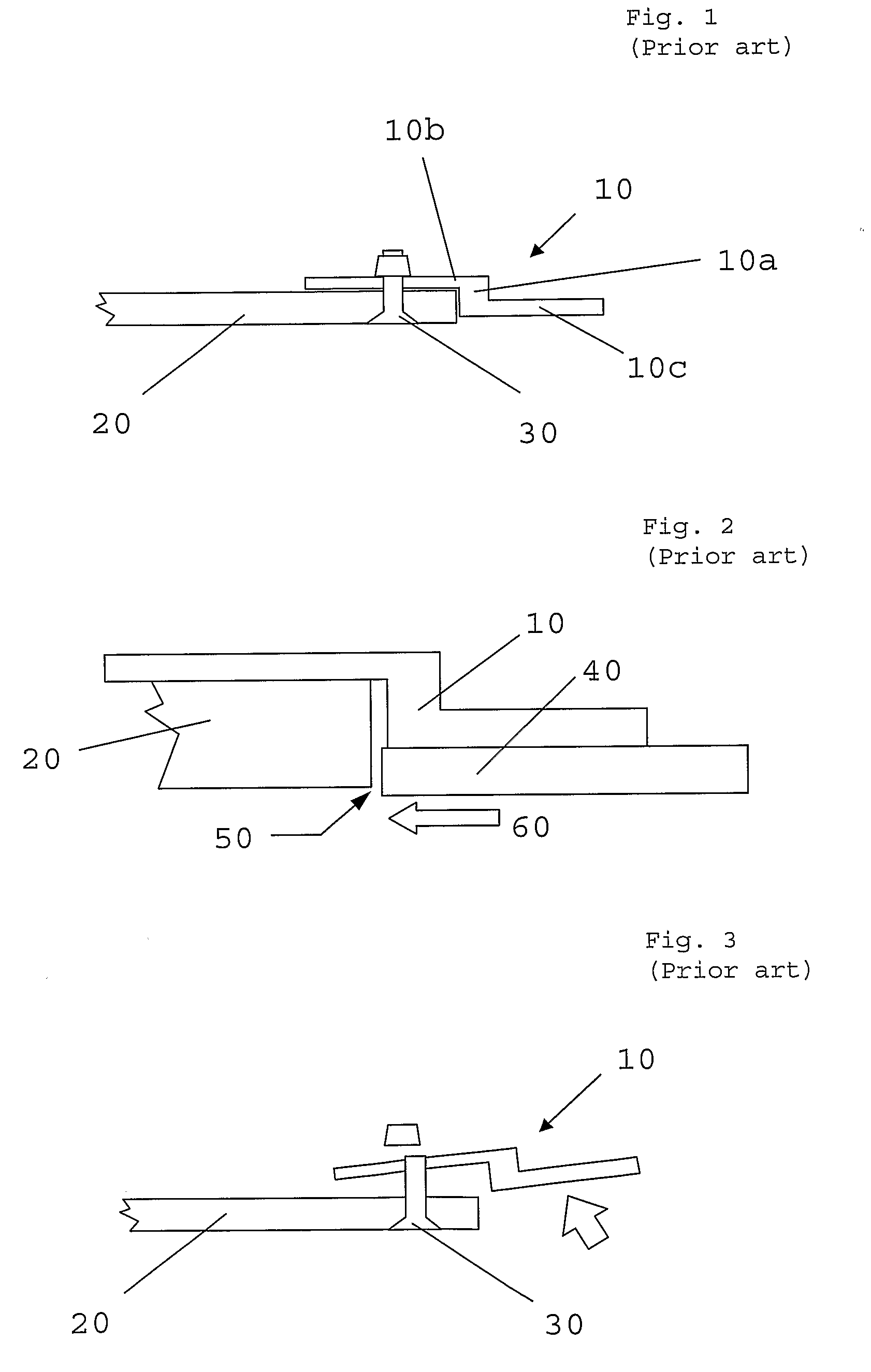

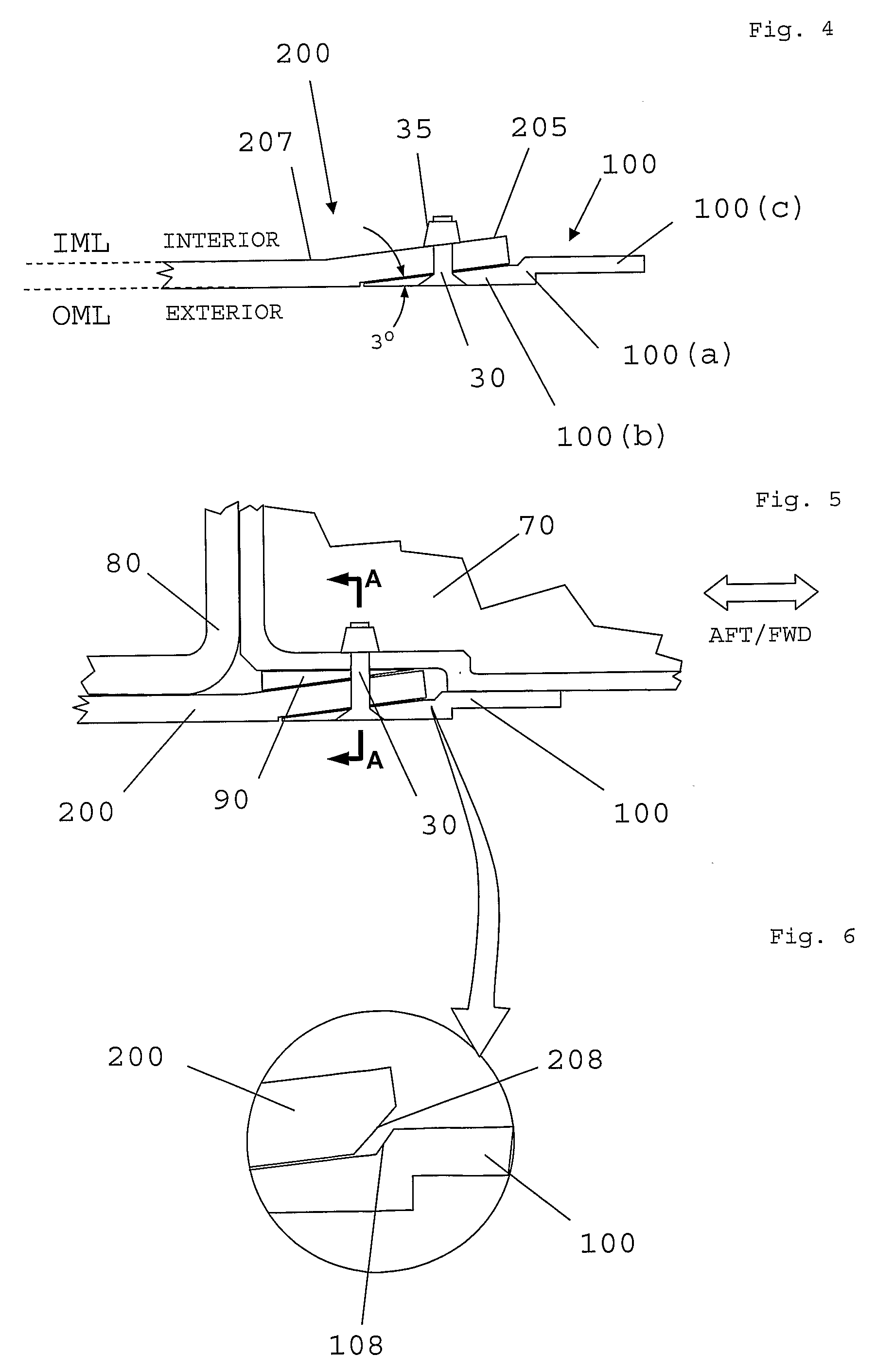

Joint for Use in Aircraft Construction

A joint for use in aircraft construction, for example a wing, comprises: a cover skin having an interior surface, an exterior surface and a distal portion, said distal portion having an exterior-facing surface; and a butt-strap having a first portion for connection to the skin, said first portion having an interior surface, an exterior surface and a distal end. The first portion of the butt-strap is connected to the distal portion of the skin such that a junction is formed between the exterior surface of the skin and the exterior surface of the first portion of the butt-strap. The exterior-facing surface of the distal portion of the skin is of a shape complementary to the shape of the interior surface of the first portion of the butt-strap. The first portion of the butt-strap tapers towards its distal end such that, at said junction, the exterior surface of the skin and the exterior surface of the first portion of the butt-strap form a substantially continuous exterior surface.

Owner:AIRBUS OPERATIONS LTD

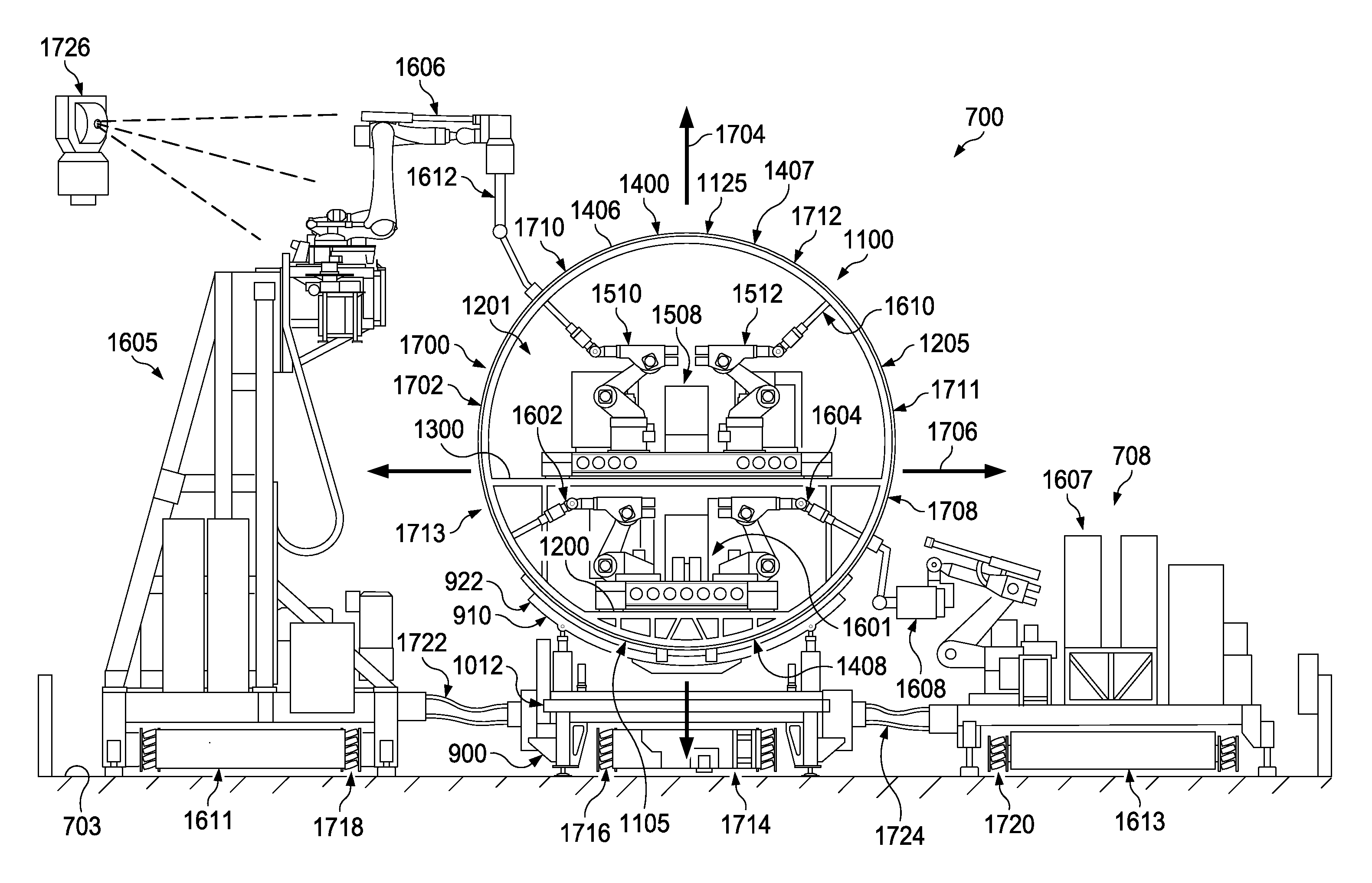

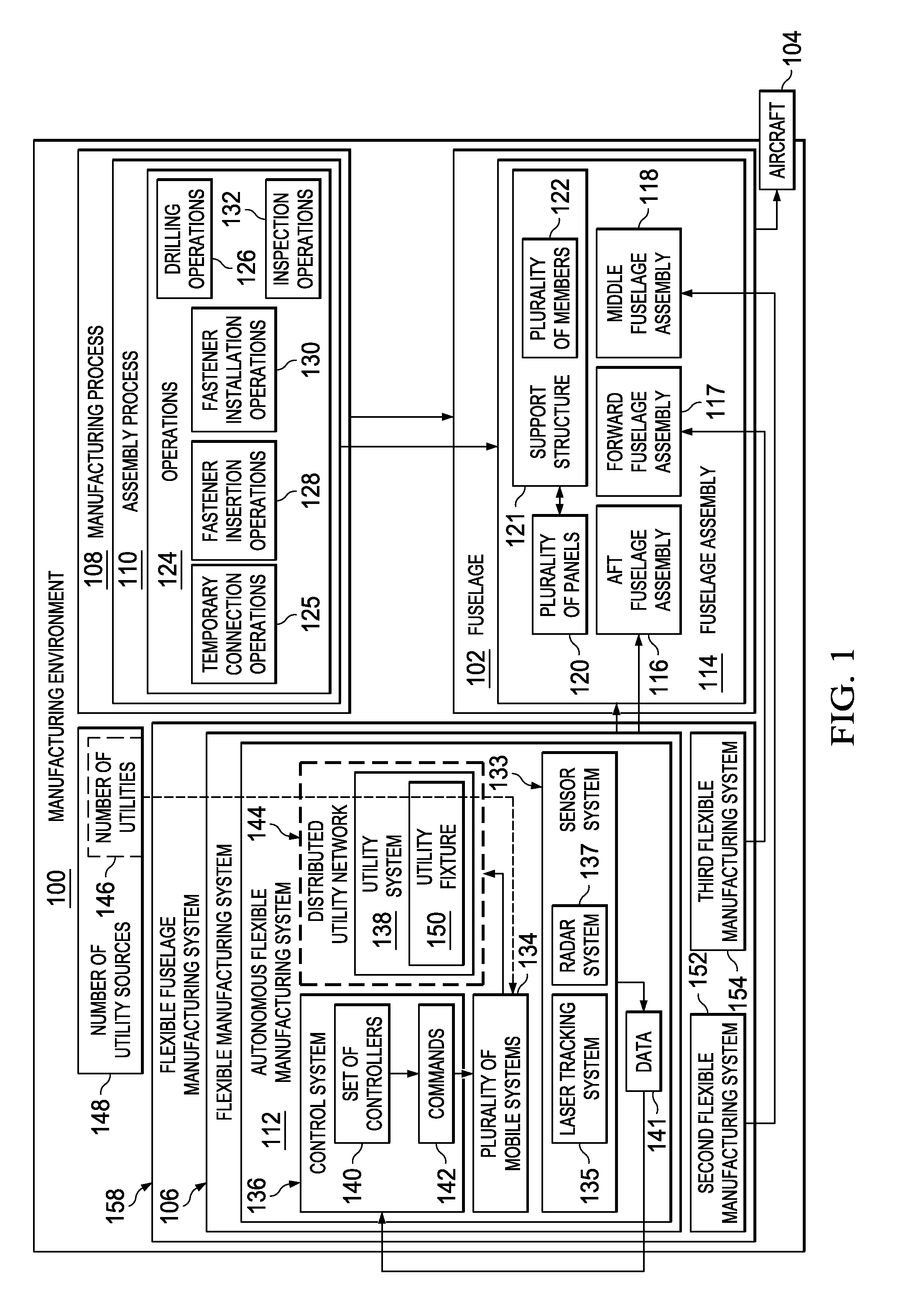

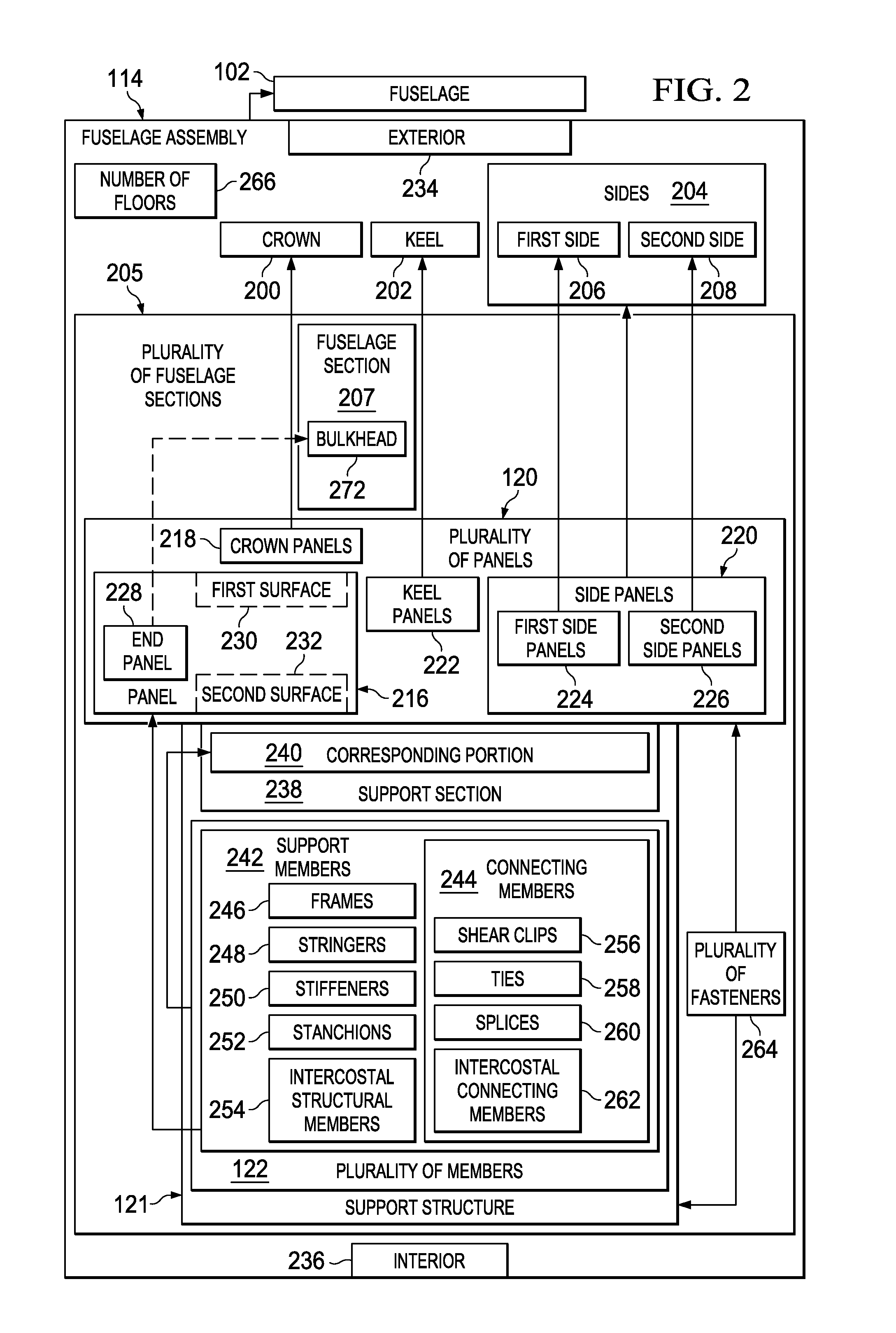

Mobile Platforms for Performing Operations Along an Exterior of a Fuselage Assembly

A method and apparatus for performing an assembly operation. A tool may be macro-positioned relative to an exterior of a fuselage assembly. The tool may be micro-positioned relative to a particular location on the exterior of the fuselage assembly. An assembly operation may be performed at the particular location on the panel using the tool.

Owner:THE BOEING CO

Hybrid aircraft fuselage structural components and methods of making same

InactiveUS20090277994A1Light weightEconomically manufacturedEfficient propulsion technologiesFuselage bulkheadsMetal frameworkFuselage

An aircraft fuselage assembly of basic construction in composite materials employs metallic frames with reduced quantity of metallic shear ties attached to the composite stiffened skin, formed by two or more longitudinal panels, spliced with longitudinal metallic splice members. Typically, the latitudinal metallic frame members are fastened to the inward outstanding flange portion of the composite stringers which are in turn integrated to the skin. As such, the frame members are spaced from (floating over) the fuselage skin. An electrical path may thus be established so as to protect the fuselage structure against the impact of electrical discharges commonly encountered in the atmosphere by providing metallic shear ties interconnecting the frame and splice members so as to span the space therebetween.

Owner:EMBRAER SA

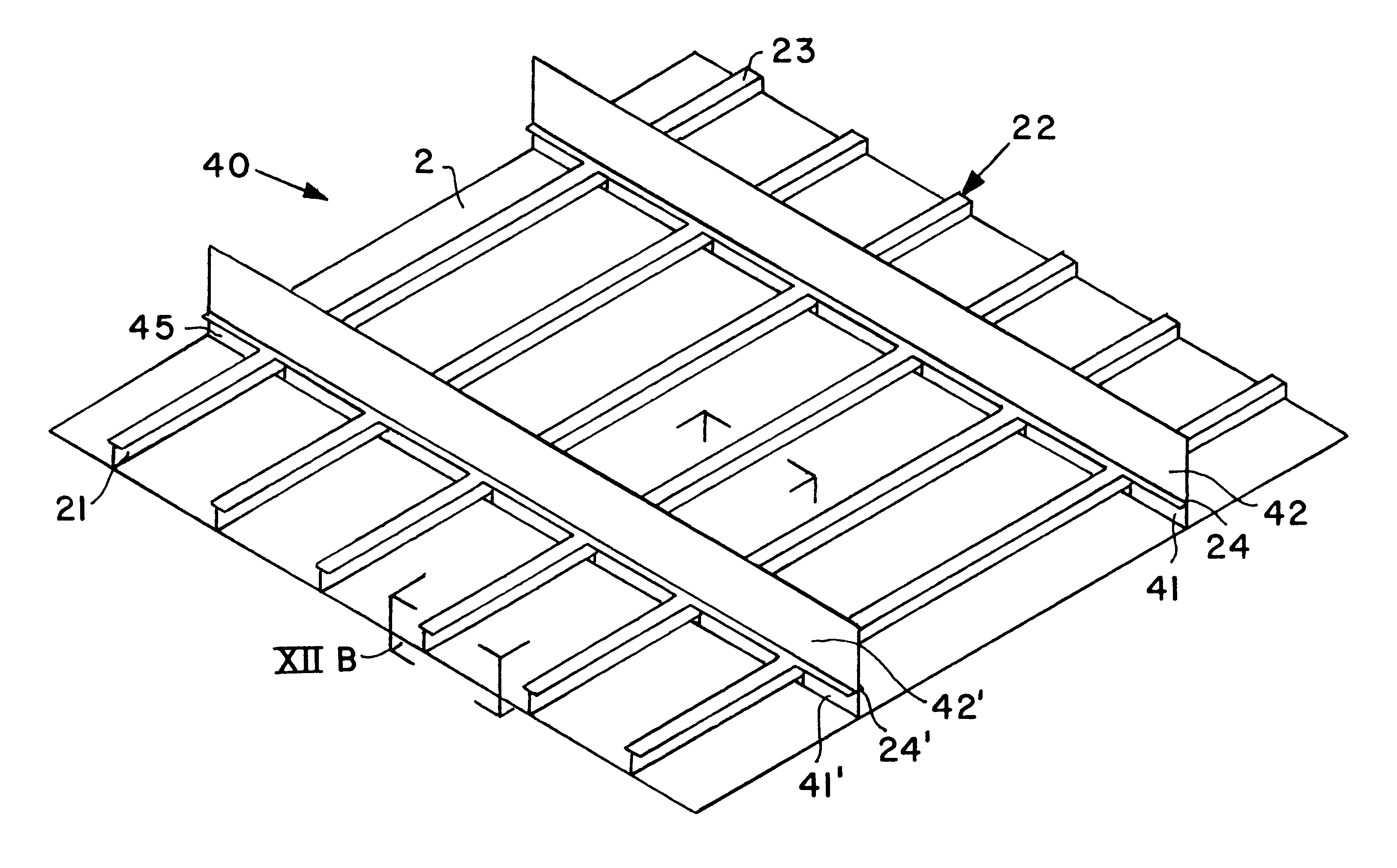

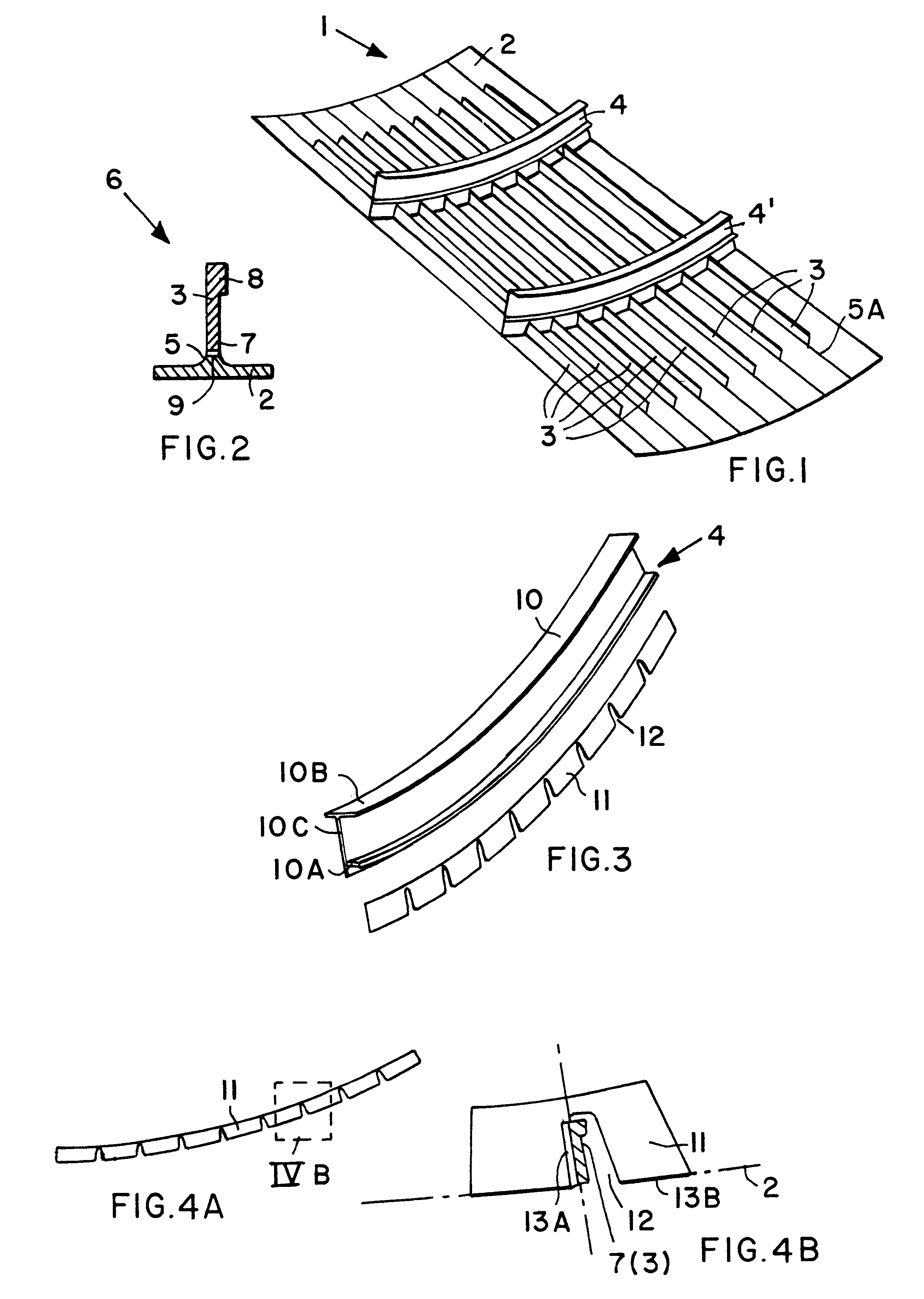

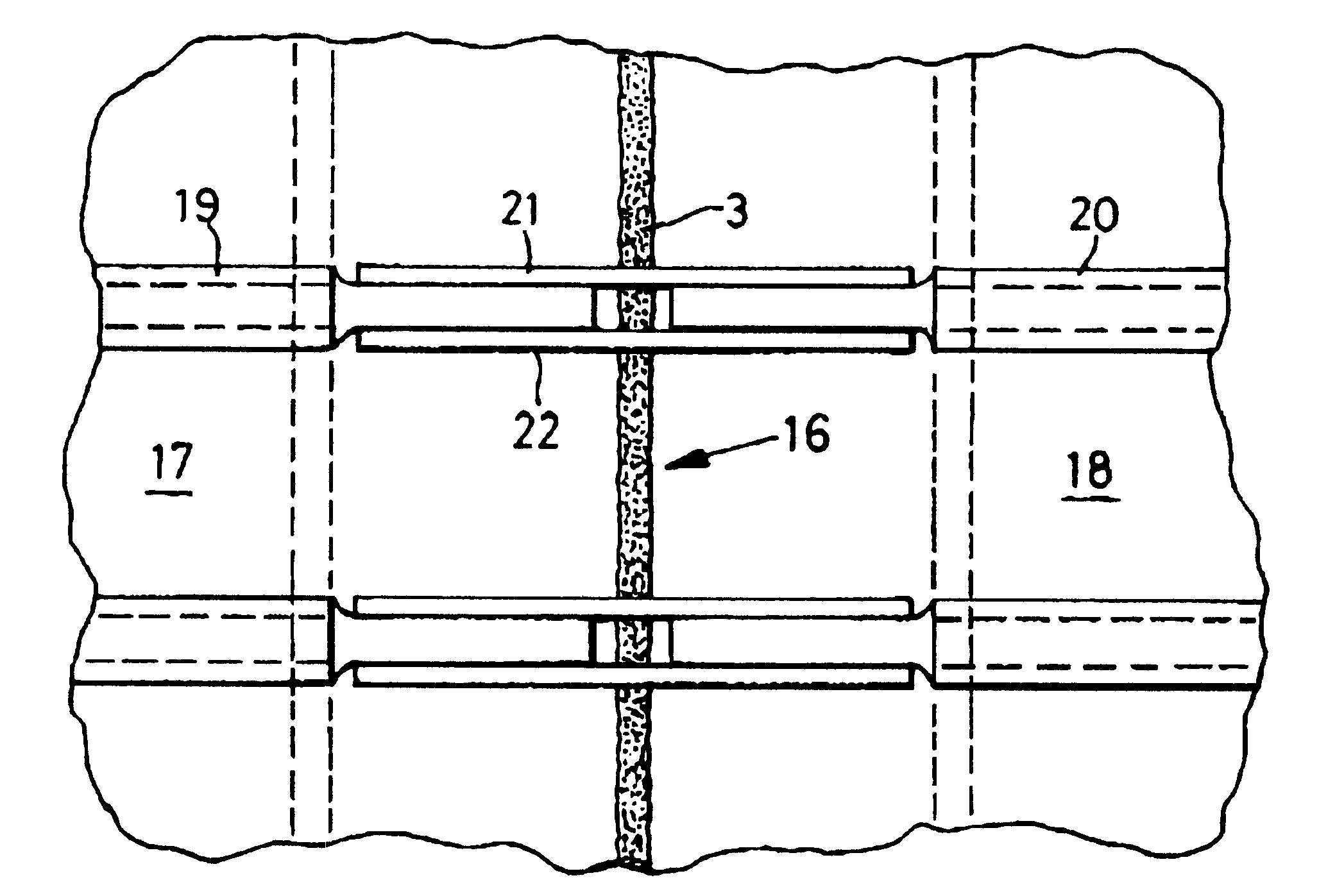

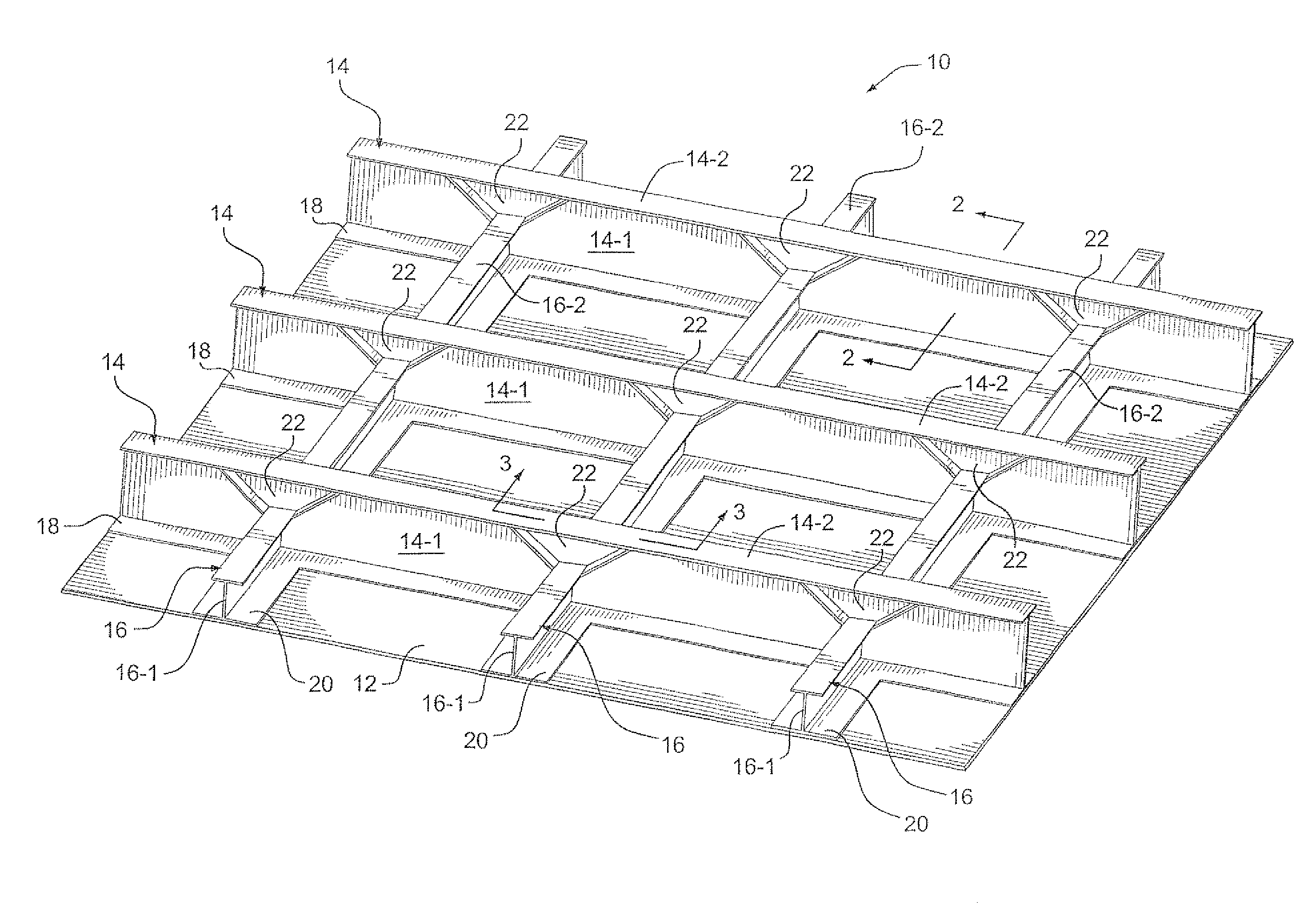

Monolithic integrated structural panels especially useful for aircraft structures and methods of making the same

Structural panels for use in manufacturing fuselage bodies and other aircraft structures are disclosed herein. In one embodiment, a monolithic integrated structural panel is configured to include a skin, an array of stiffeners and an array of frames which are preferably arranged in a mutually orthogonal layout, without the need of cut-outs in any of the crossing elements. One advantage of the disclosed embodiments is that the frame and stringer members have continuous flanges and spliced webs. The disclosed embodiments herein are compatible with composite materials technology, offering another advantage, namely the possibility of manufacturing integrated products in a single cure (“one-shot”) cycle. A structure of composite materials, e.g. carbon fiber reinforced plastics, typically comprises a skin panel, reinforced by frame and stringer members. A monolithic integrated structure constructed in accordance with the disclosed embodiments is well-suited for use as a portion of an aircraft structure, for example an aircraft fuselage, wing or empennage.

Owner:EMBRAER SA

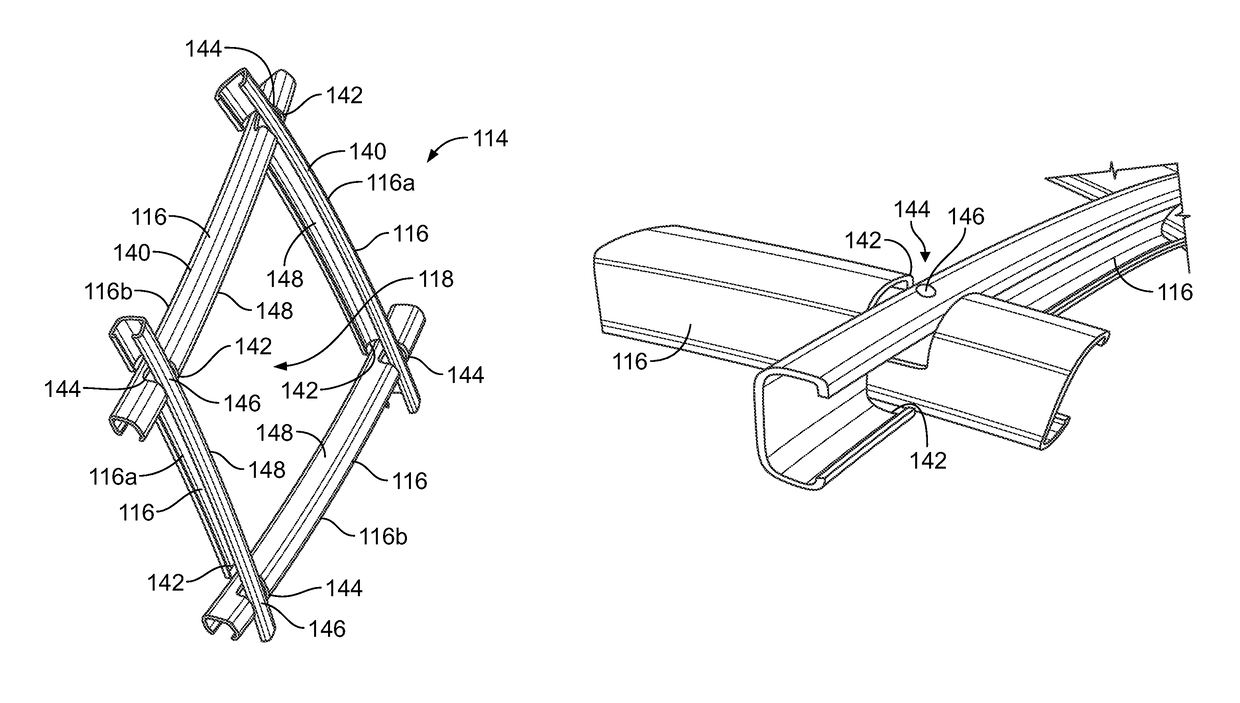

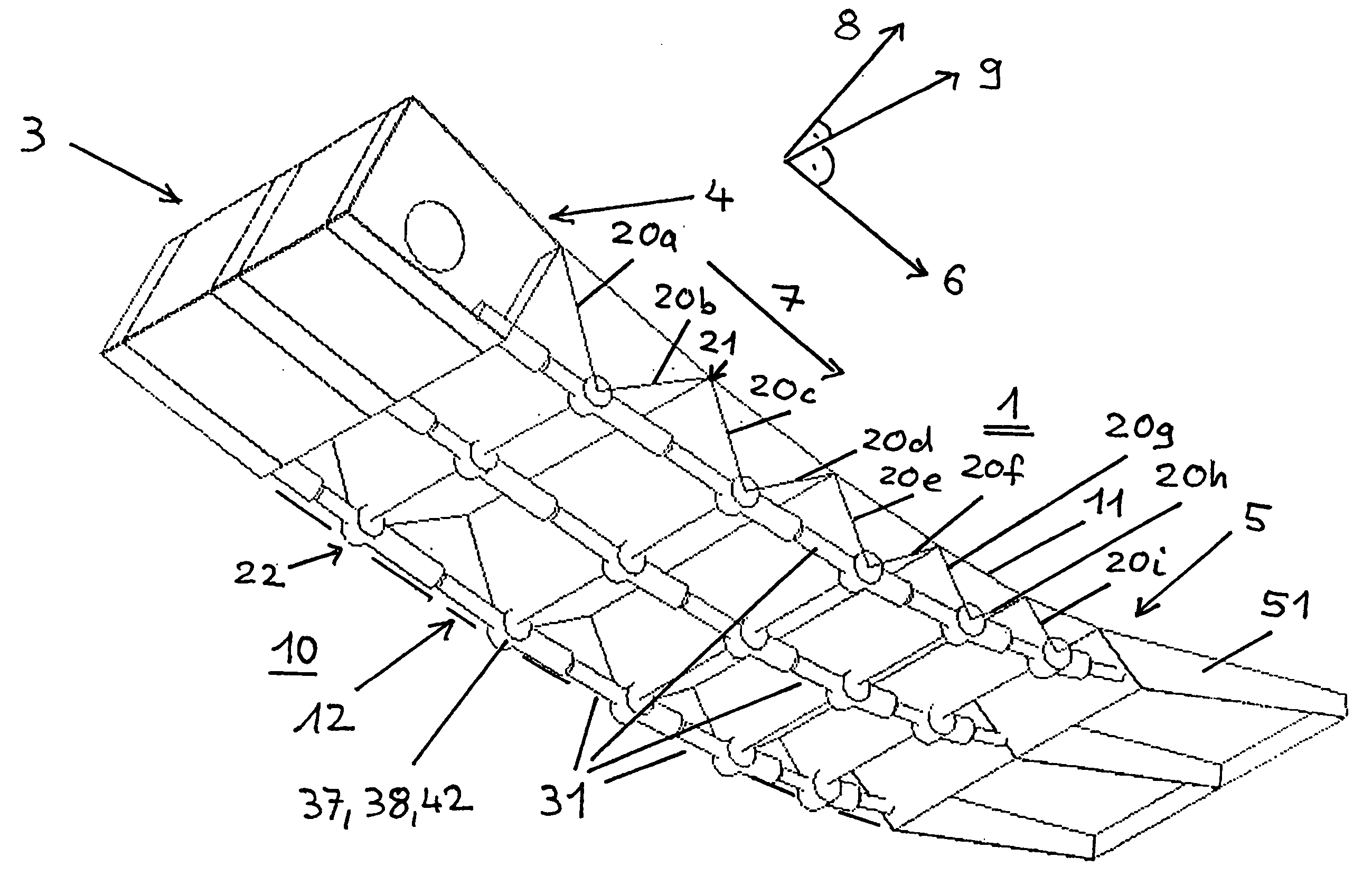

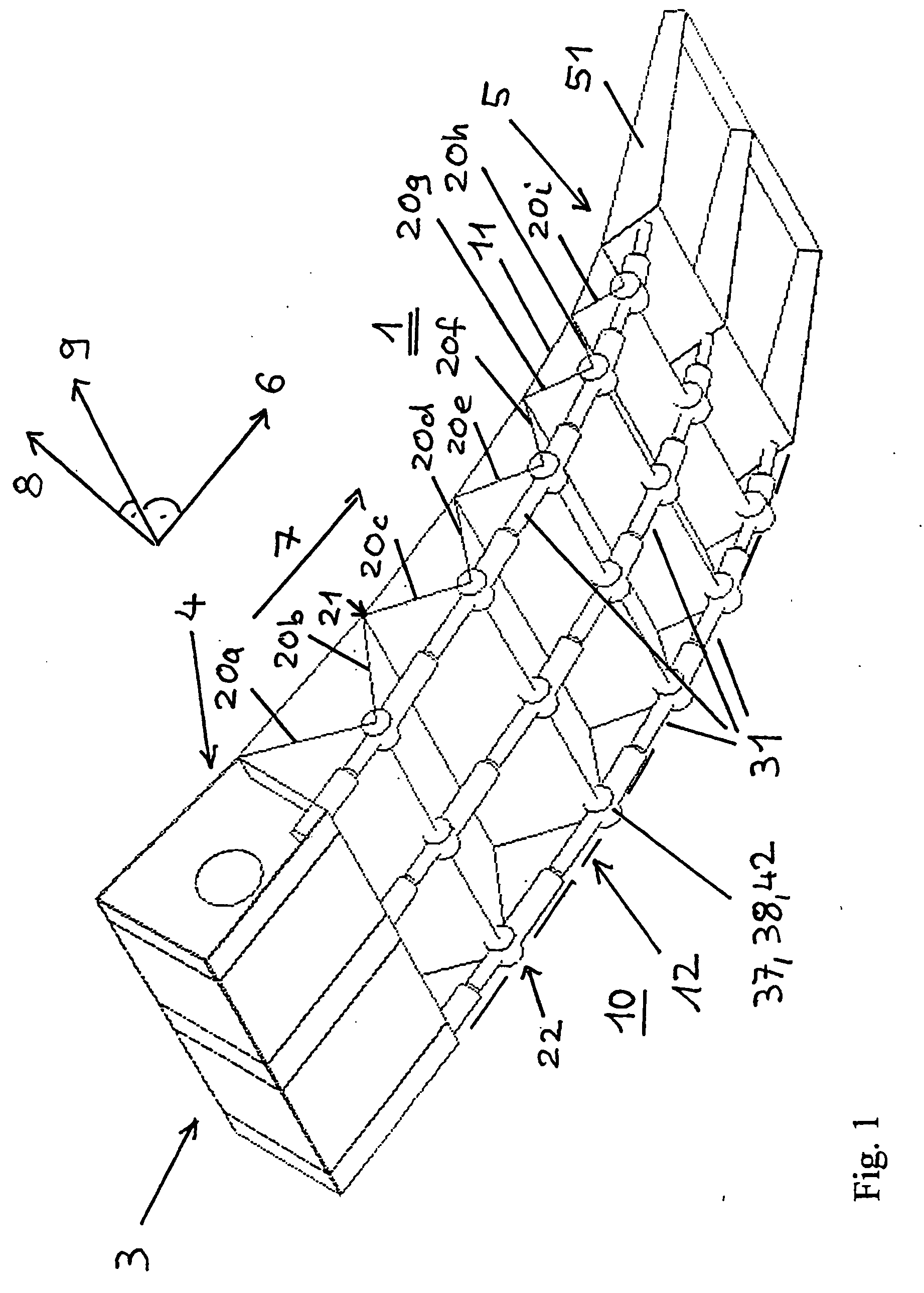

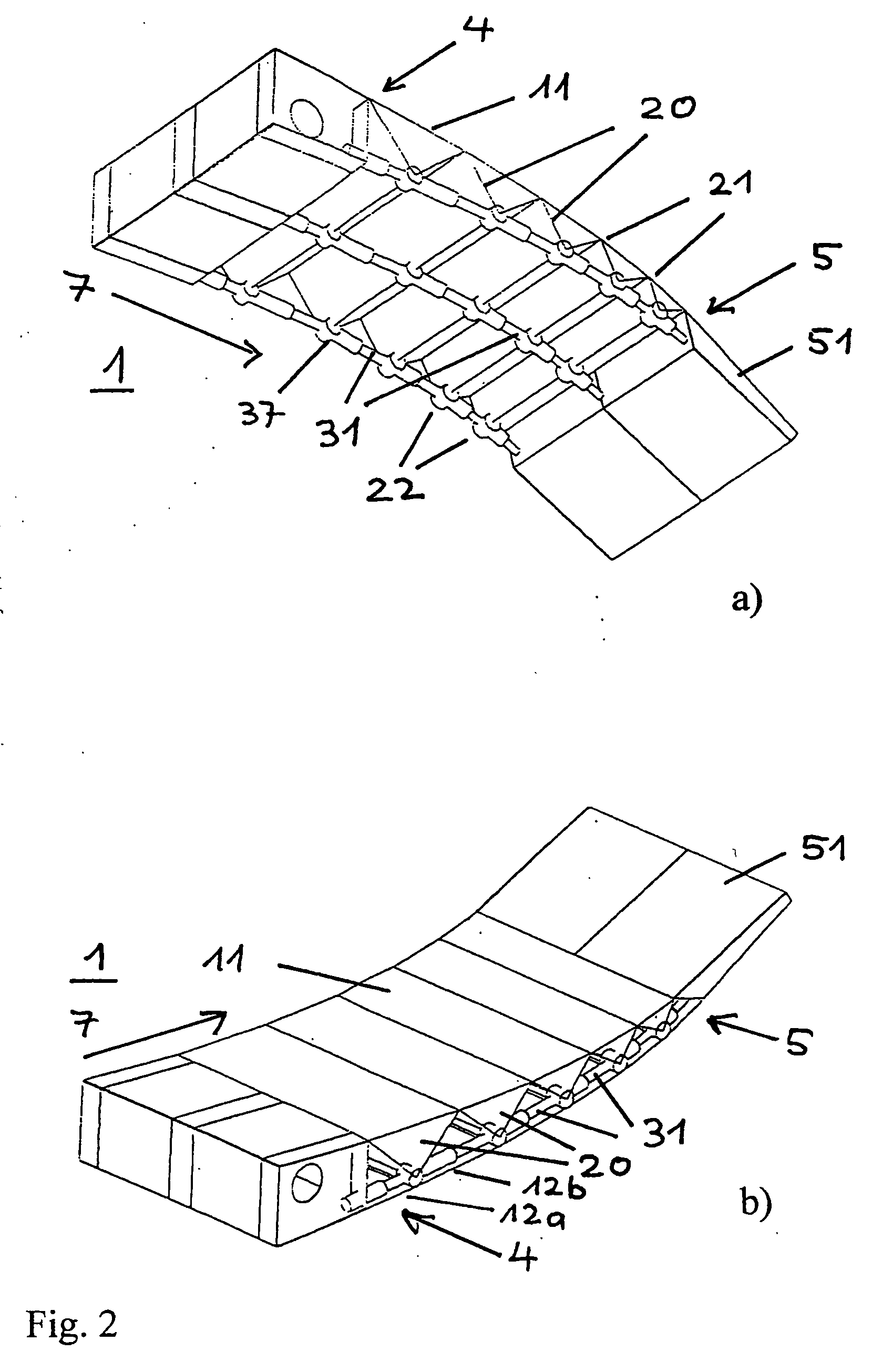

Wing, in particular airfoil of an aircraft, with a variable profile shape

ActiveUS20060157623A1Improved aerodynamicsImprove featuresAircraft stabilisationFuselage bulkheadsEngineeringDriven element

A wing, in particular a airfoil of an aircraft, with a variable profile shape, which wing comprises a first skin and a second skin and a supporting structure, arranged between the first and the second skin, which supporting structure in the direction of the wing depth extends between a first end and a second end, wherein the form of said supporting structure, for the purpose of varying the profile shape by means of a drive device comprising drive elements, is variable. The supporting structure comprises ribs, arranged one behind the other in the direction of the wing depth, which ribs at connection positions are interconnected so as to be articulated, wherein said ribs at first connection positions are connected to the first skin, and at second connection positions are connected to the second skin. For the purpose of setting the variable profile the mutual spacing of the second connection positions can be varied by means of the drive elements.

Owner:AIRBUS OPERATIONS GMBH

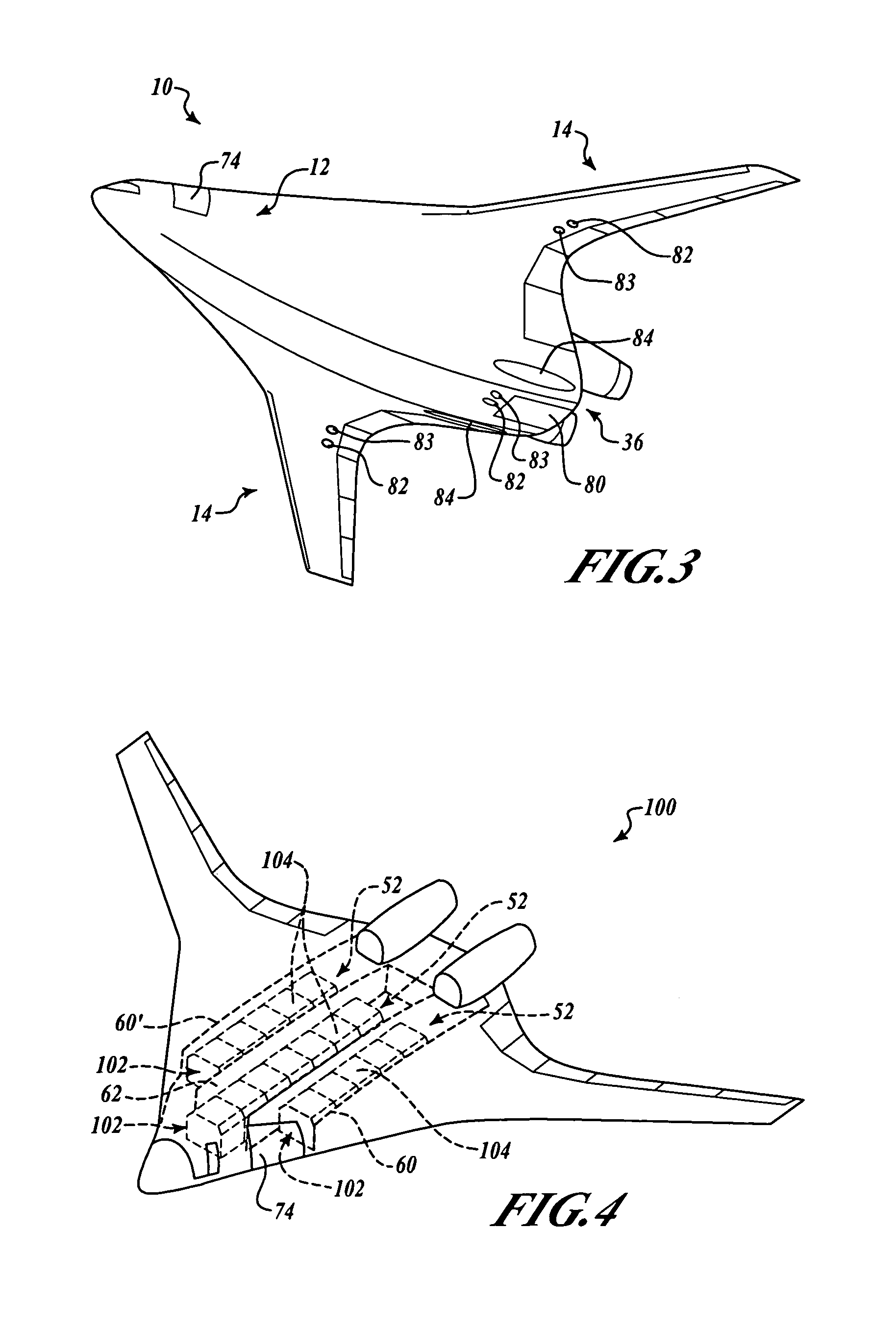

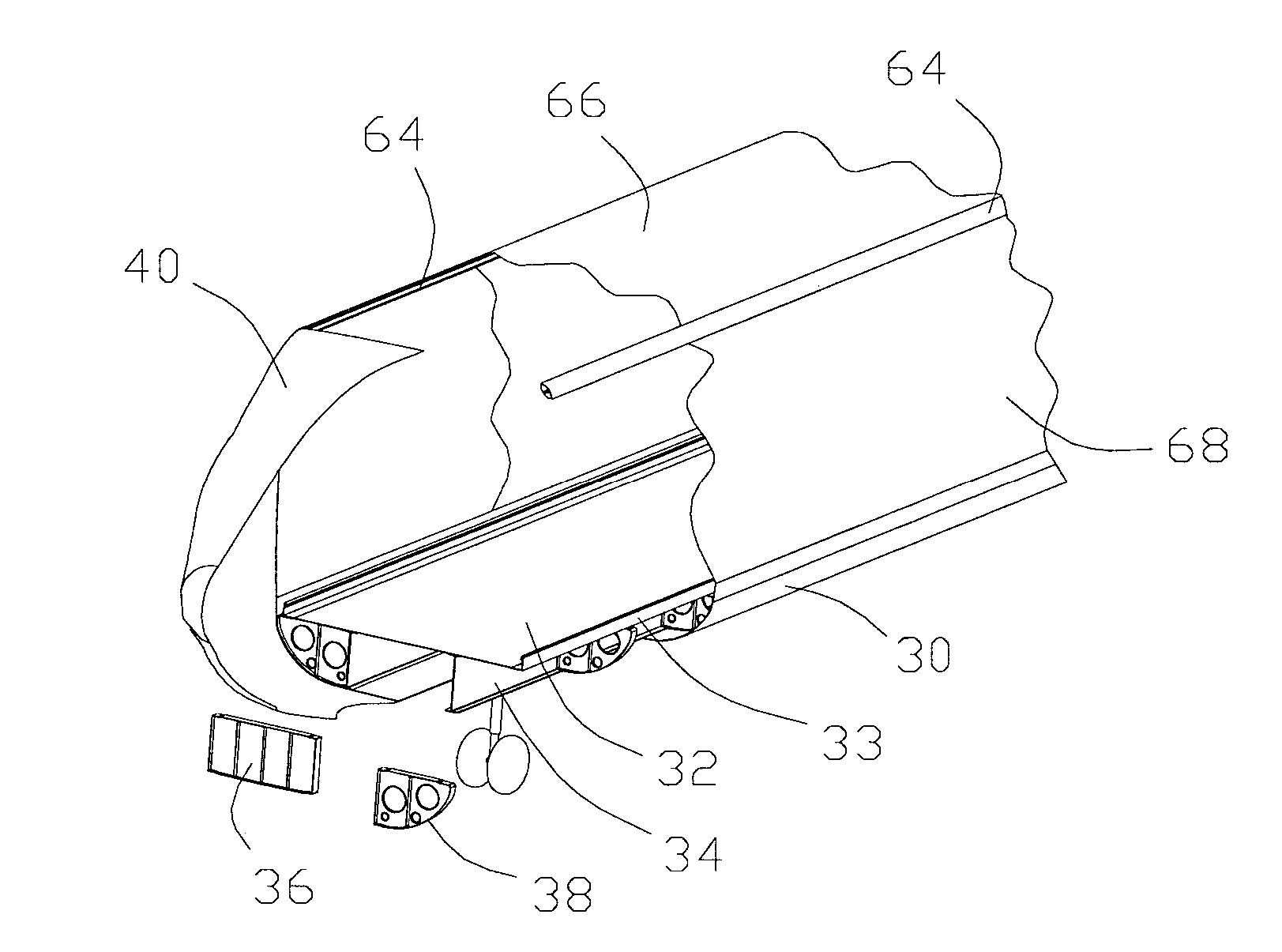

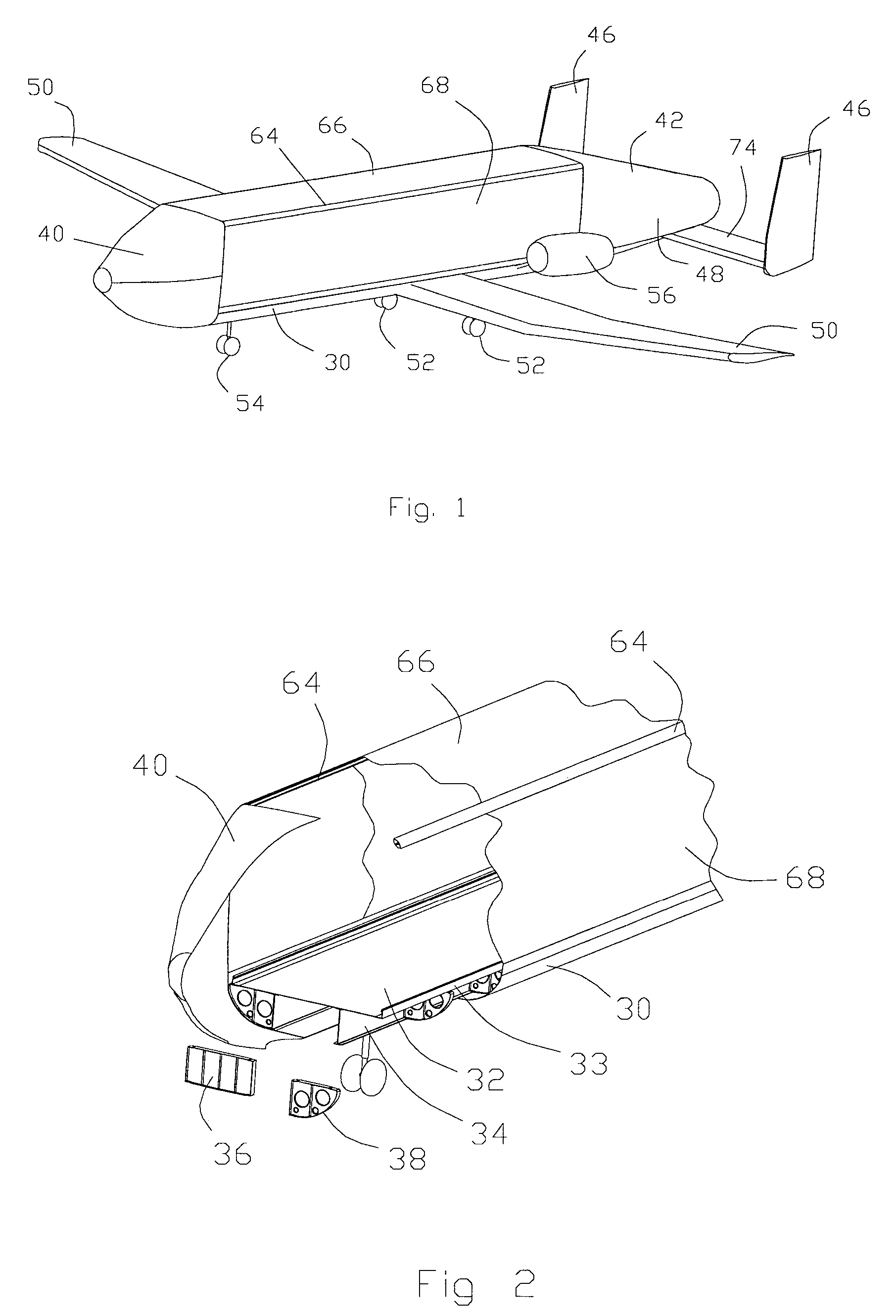

Cargo aircraft

ActiveUS7261257B2Provide structural rigiditySpeed efficientUnmanned aerial vehiclesEfficient propulsion technologiesEngineeringCargo container

An aircraft for carrying at least one rigid cargo container includes a beam structure with a forward fuselage attached to the forward end of the beam structure and an empennage attached to the rearward end of the beam structure. Wings and engines are mounted relative to the beam structure and a fairing creates a cargo bay able to receive standard sized intermodal cargo containers. Intermodal cargo containers of light construction and rigid structure are positioned within the cargo bay and securely mounted therein. The beam structure is designed to support flight, takeoffs and landings when the aircraft is empty but requires the added strength of the containers securely mounted to the beam structure when the aircraft is loaded. The aircraft is contemplated to be a drone.

Owner:BIOSPHERE AEROSPACE

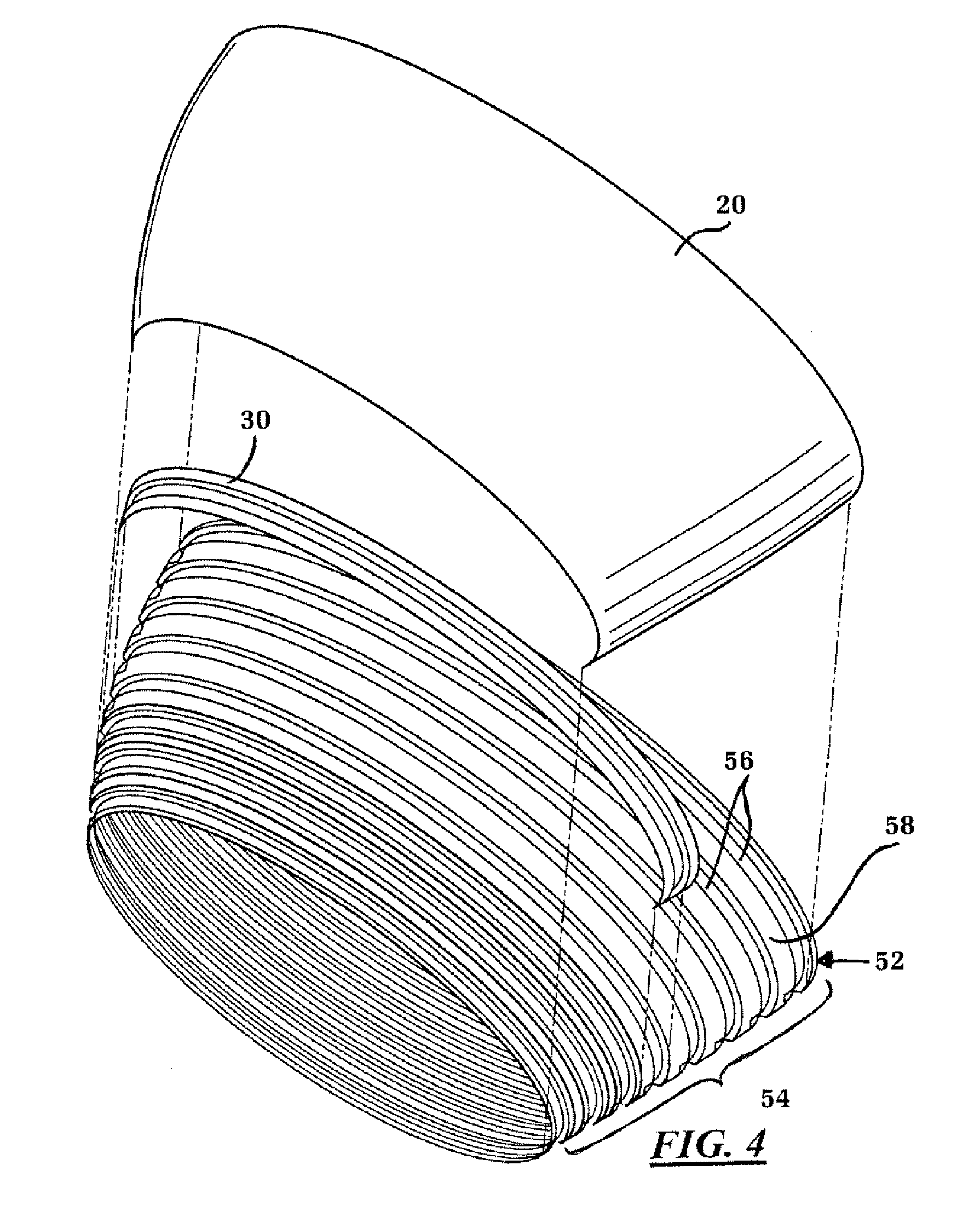

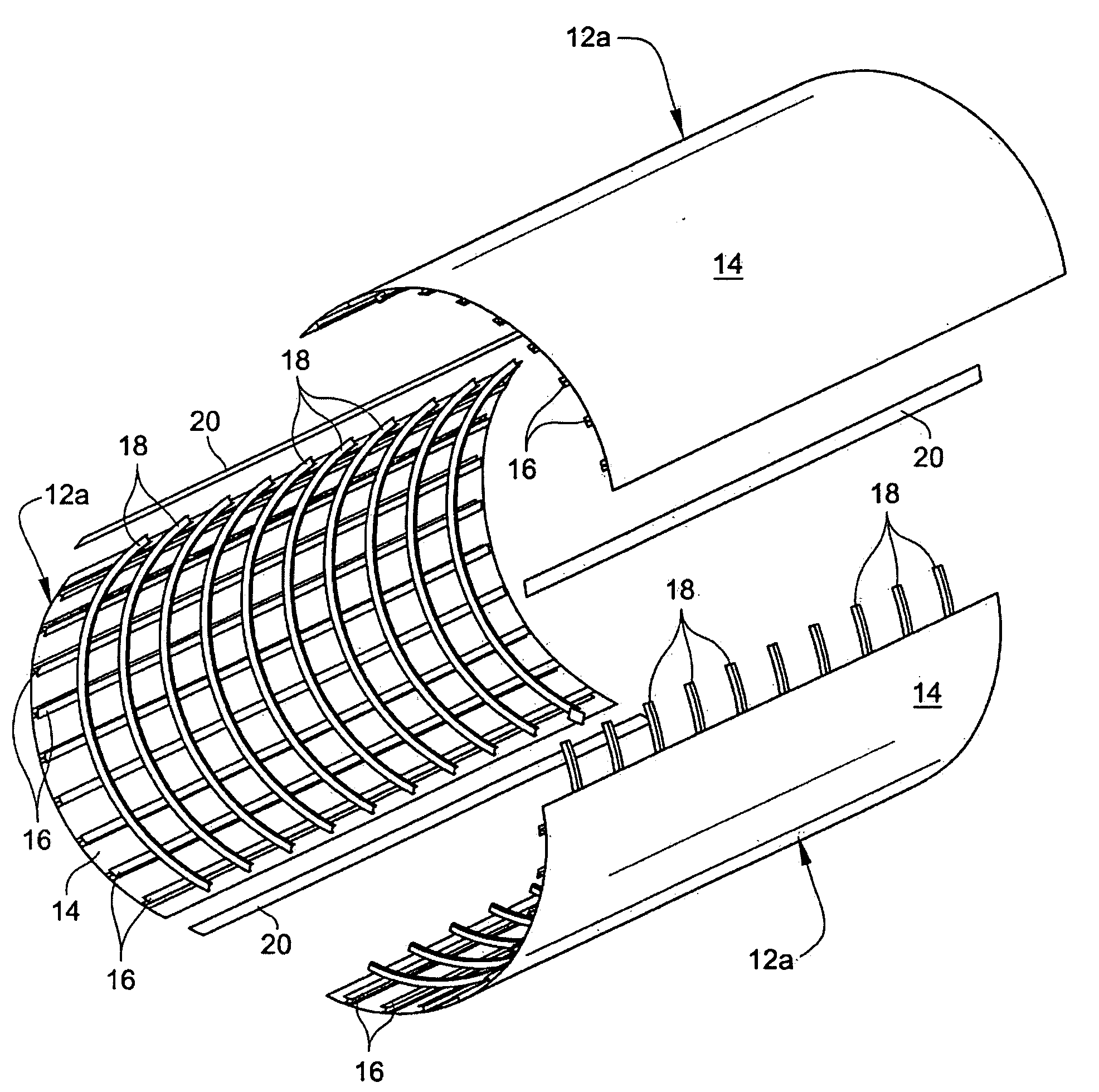

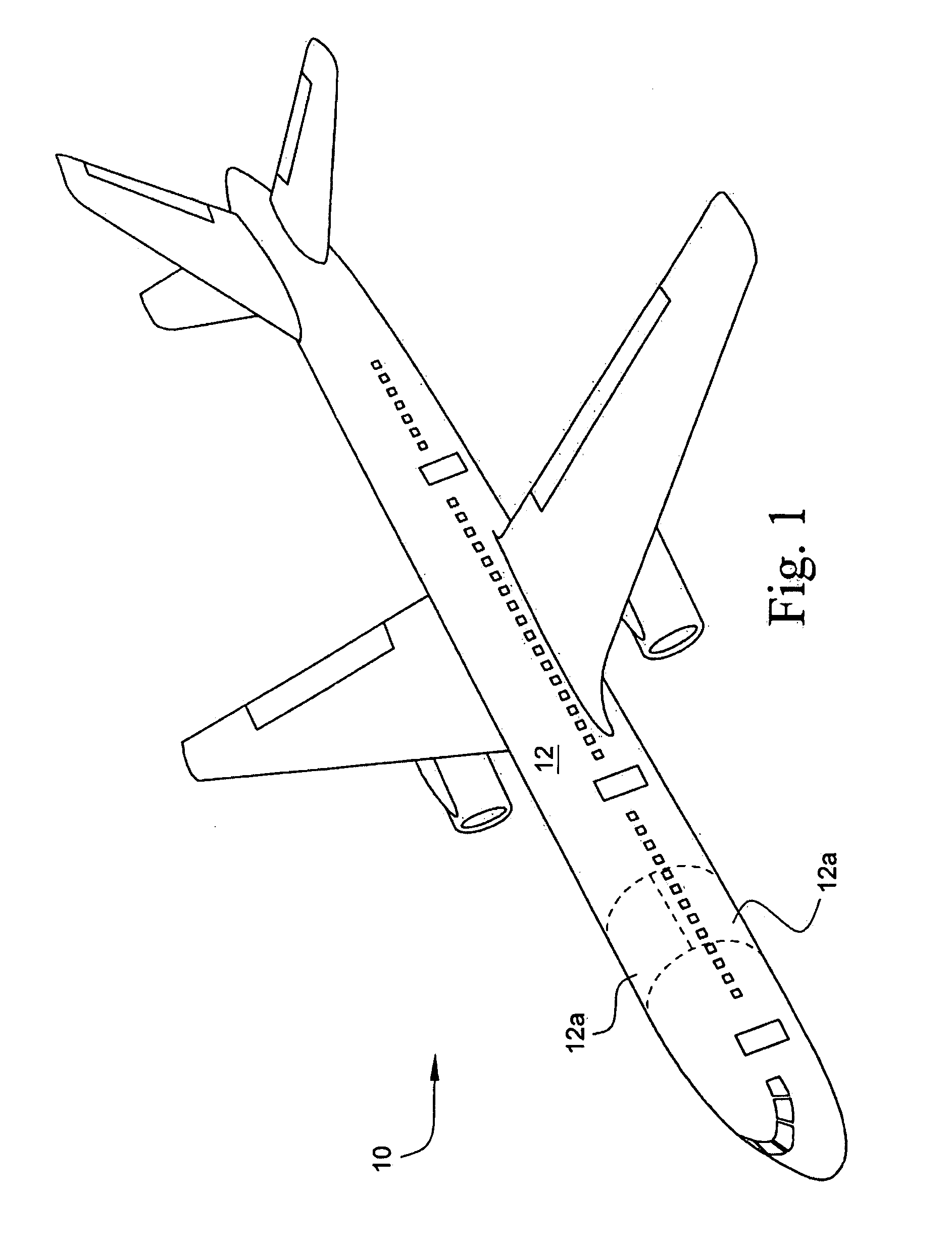

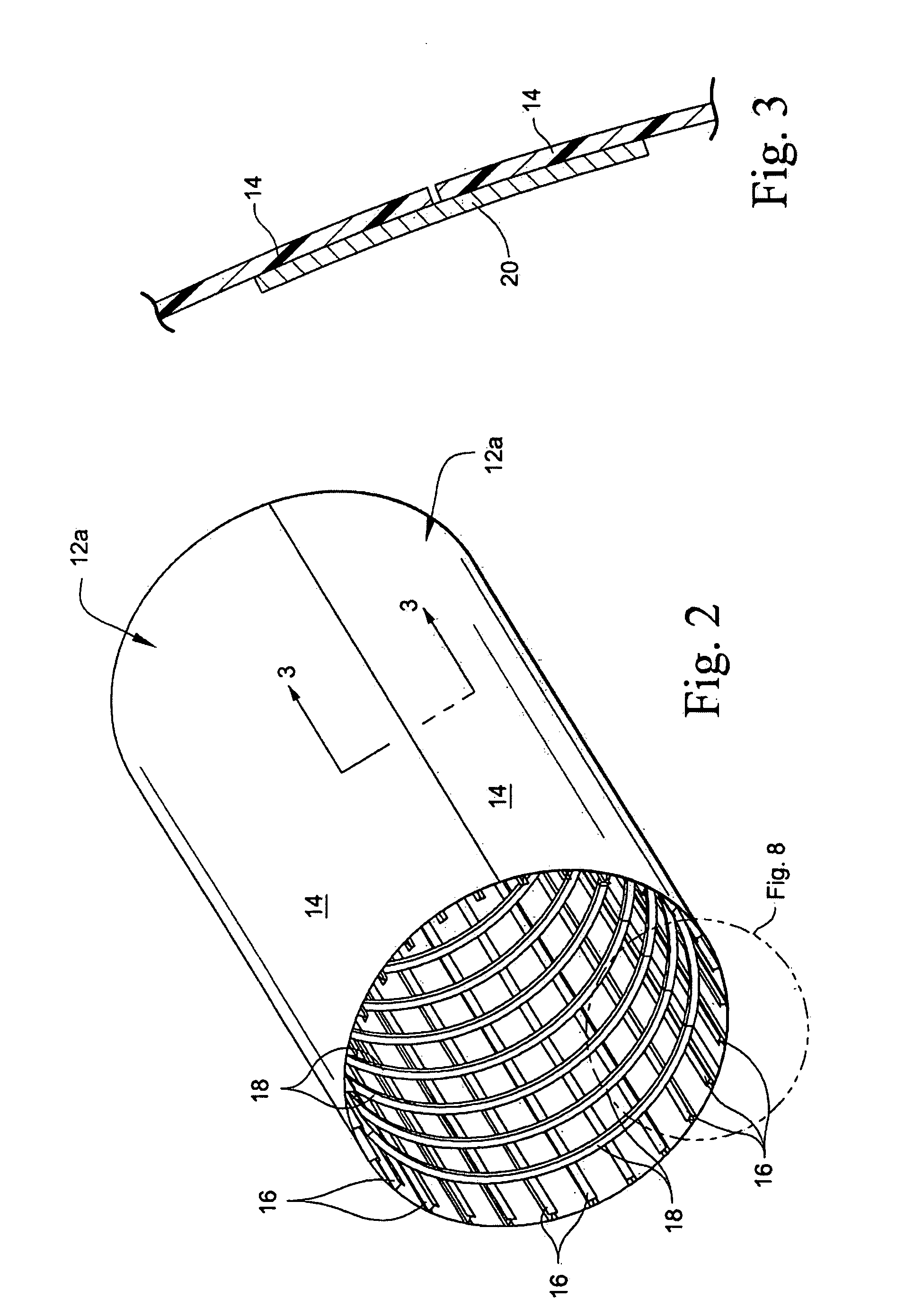

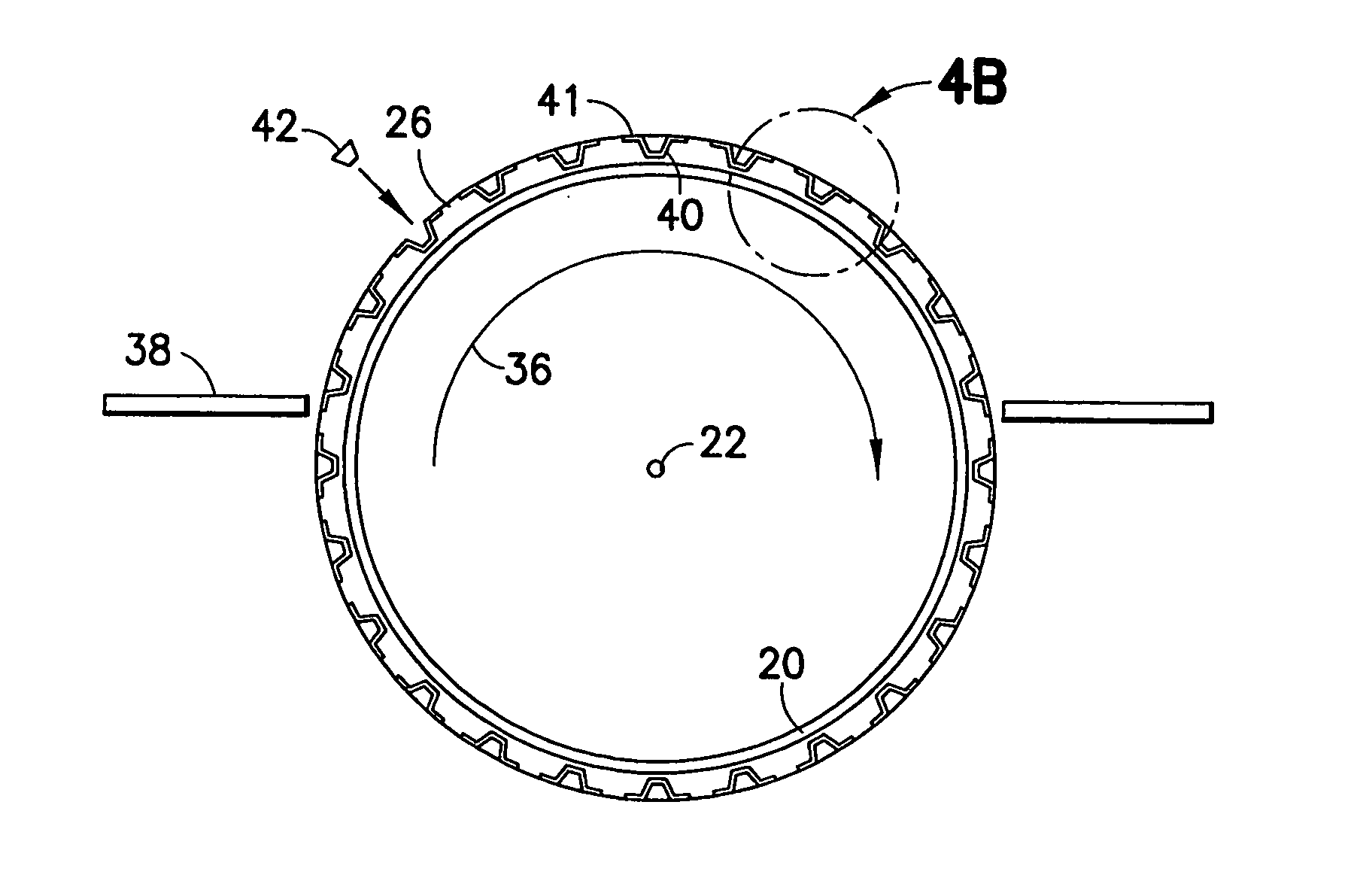

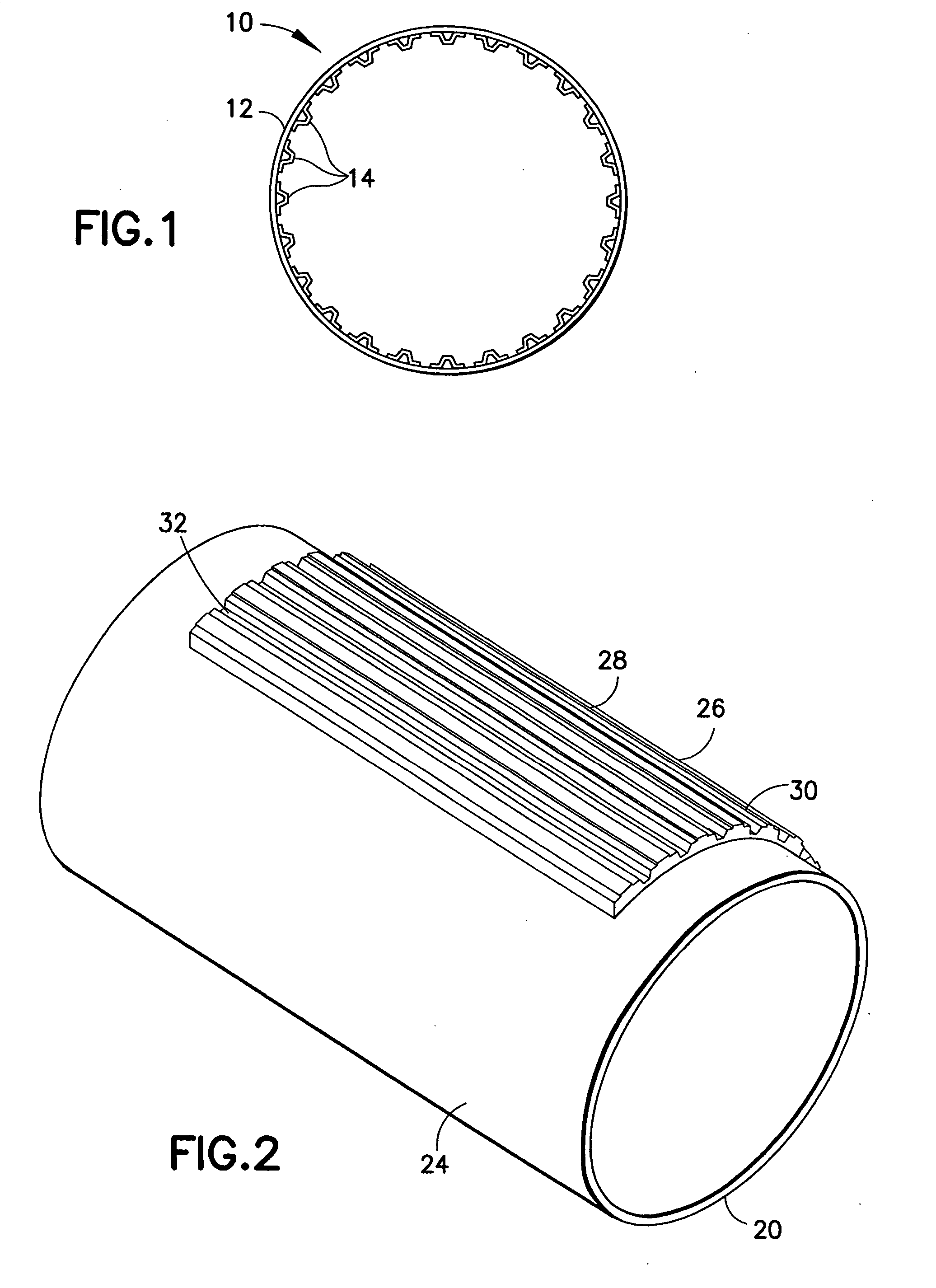

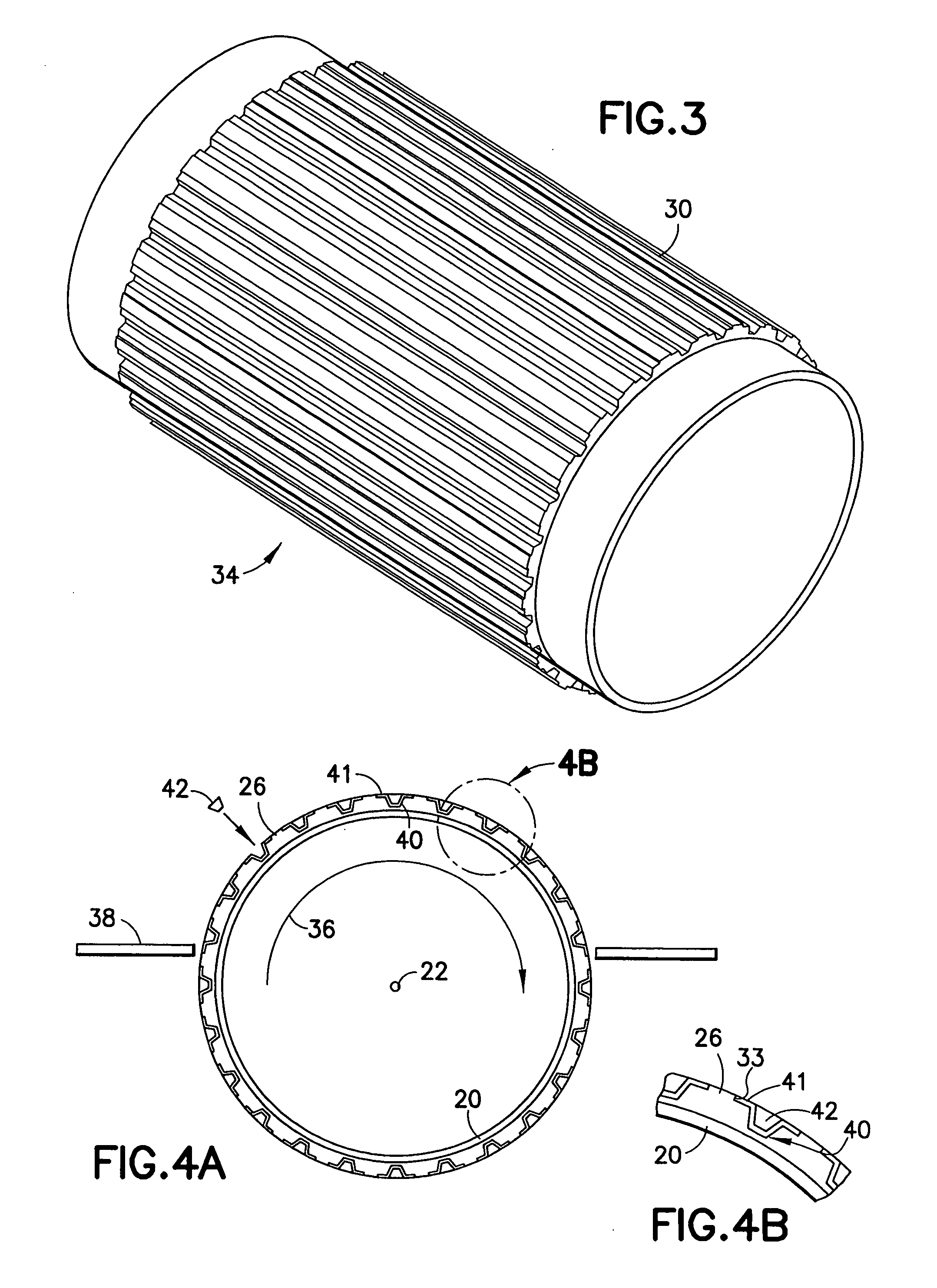

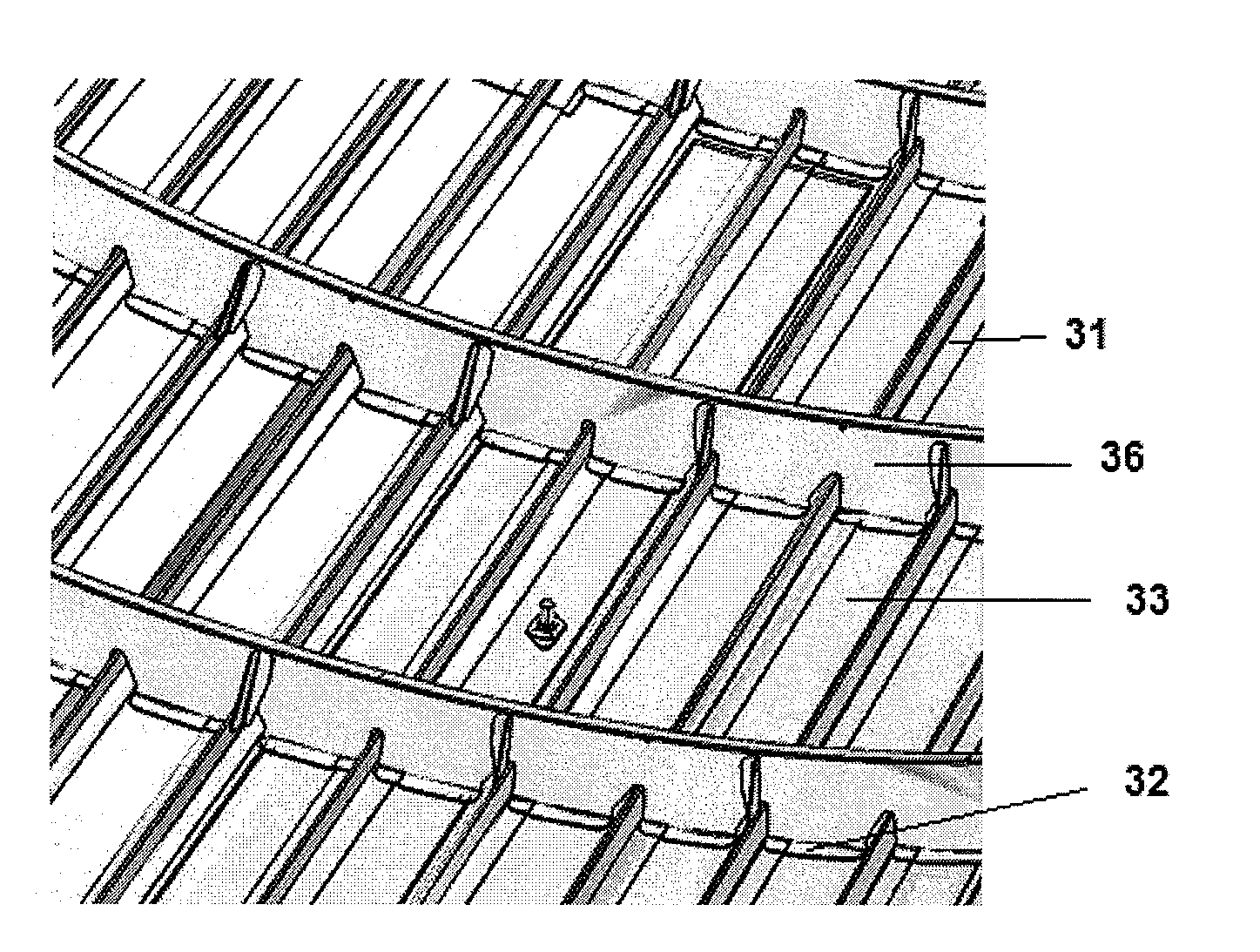

One-piece inner shell for full barrel composite fuselage

A method of manufacturing a unitary seamless section of an aircraft fuselage comprises disposing a thin lay-up mandrel element onto the outer shell surface of a cylindrical inner mandrel shell, thereby forming a mandrel with a lay-up surface. A plurality of resin impregnated stiffener fibers may be layed-up within a plurality of stiffener channels in the lay-up surface to form a plurality of stiffeners or stringers. The method further includes laying up a plurality of resin impregnated skin fibers onto the lay-up surface while the mandrel rotates to form a unitary pre-cured section of an aircraft fuselage.

Owner:THE BOEING CO

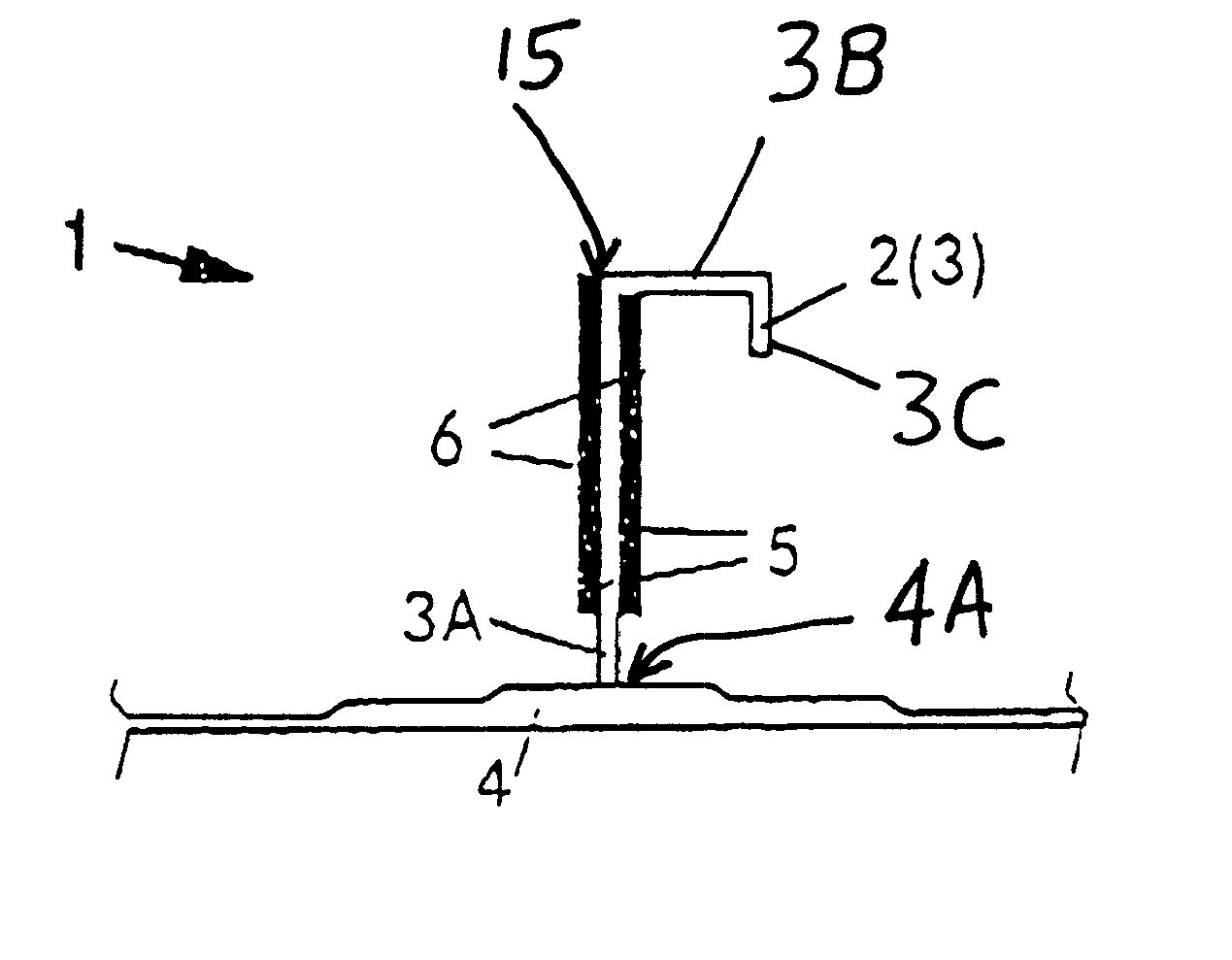

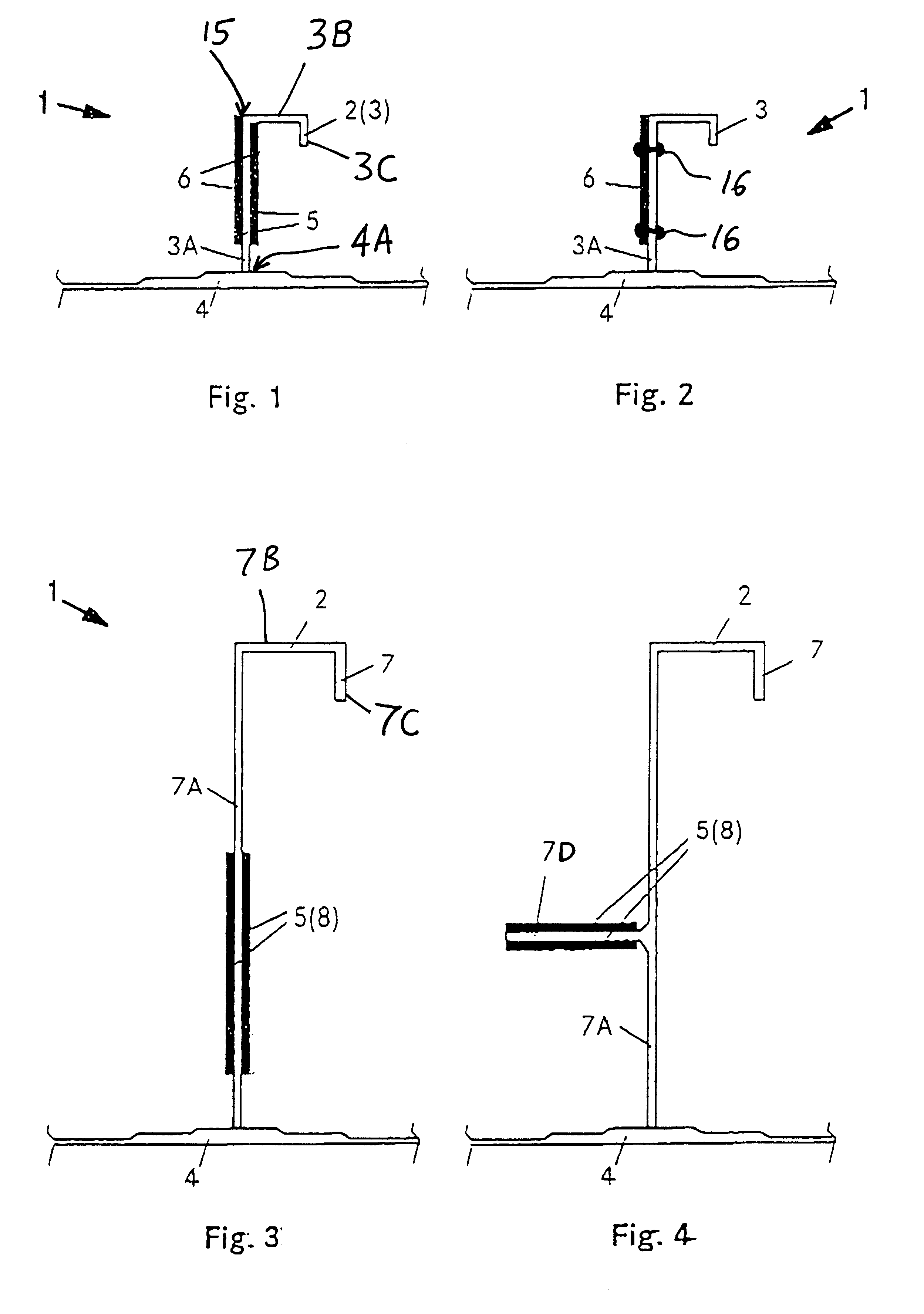

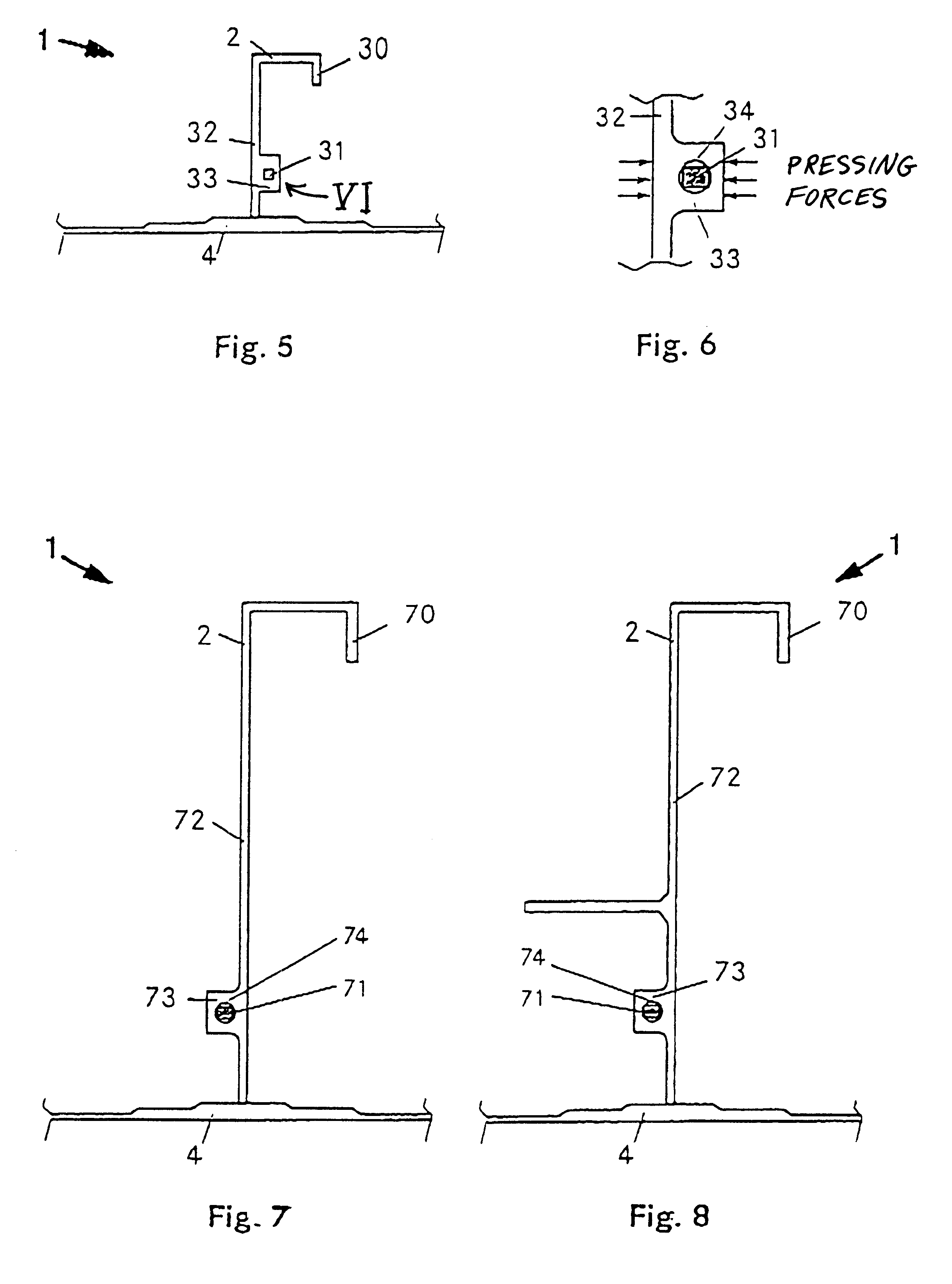

Integrated aircraft structure in composite material

ActiveUS20090283638A1Low costUniform transmissionFuselage framesSynthetic resin layered productsEngineeringFuselage

Integrated aircraft structure in composite material that comprises a skin and stringers (1), with the skin comprising a skin part (5) and a basic skin (3), and said structure further comprises U-shaped elements (15) each of which comprises in its turn two L-shaped sections (4a+5a and 4b+5b) together with the skin part (5), in such a way that these U-shaped elements (15) fulfil two structural functions in said structure at the same time, acting as frame feet and as skin, providing an integrated fuselage structure without rivets or joints. The invention also relates to a manufacturing process of an integrated aircraft structure in composite material.

Owner:AIRBUS OPERATIONS SL

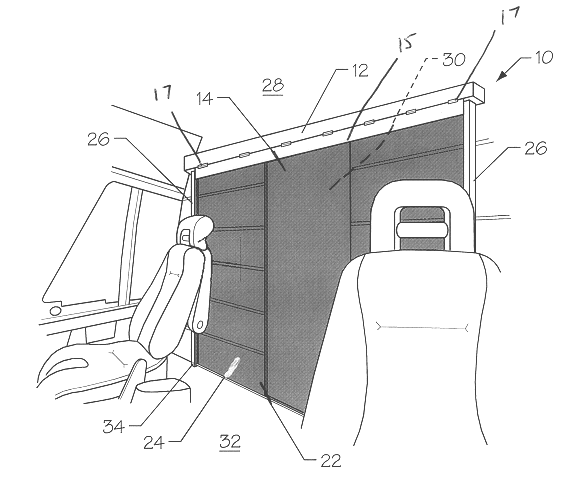

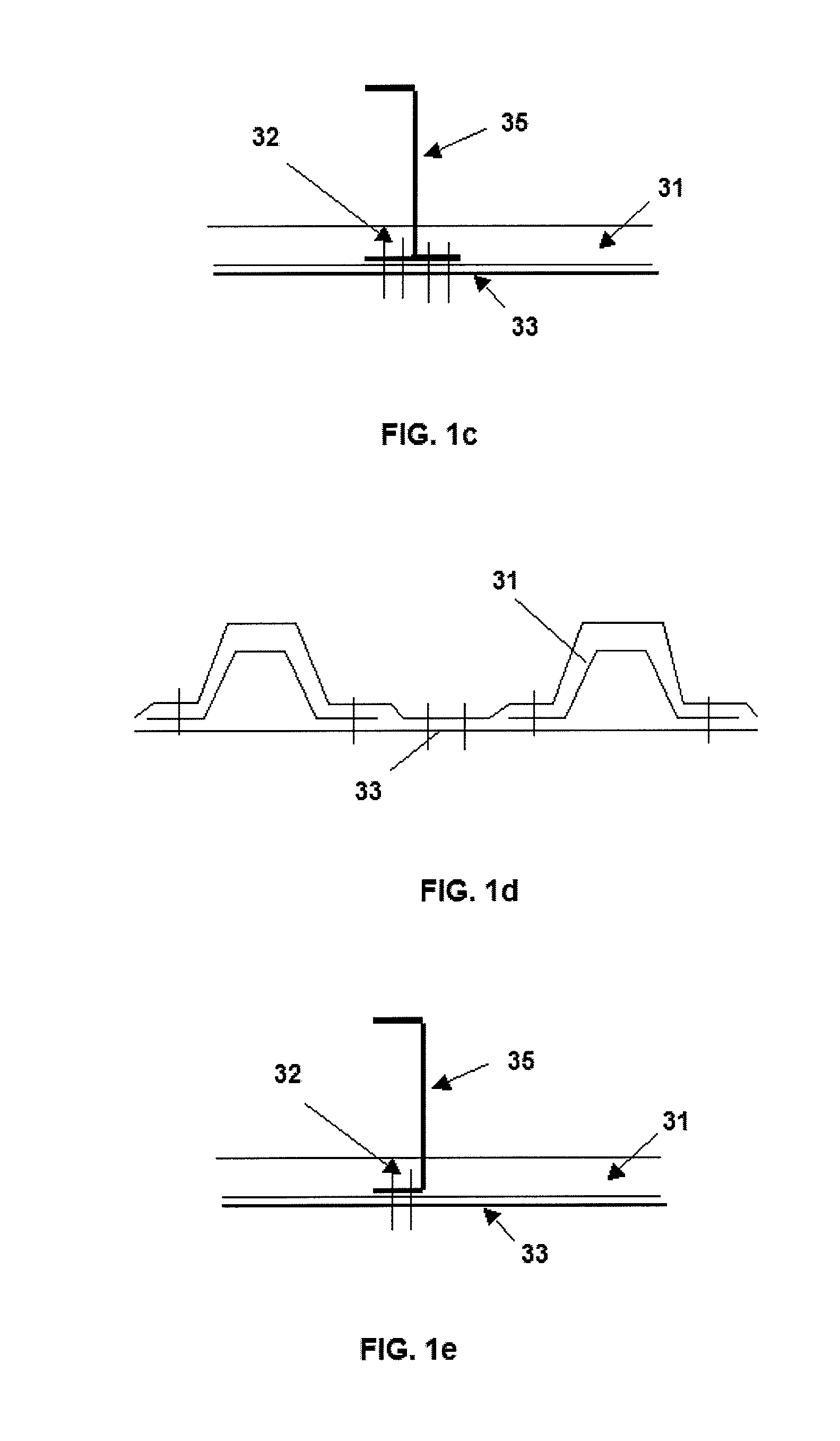

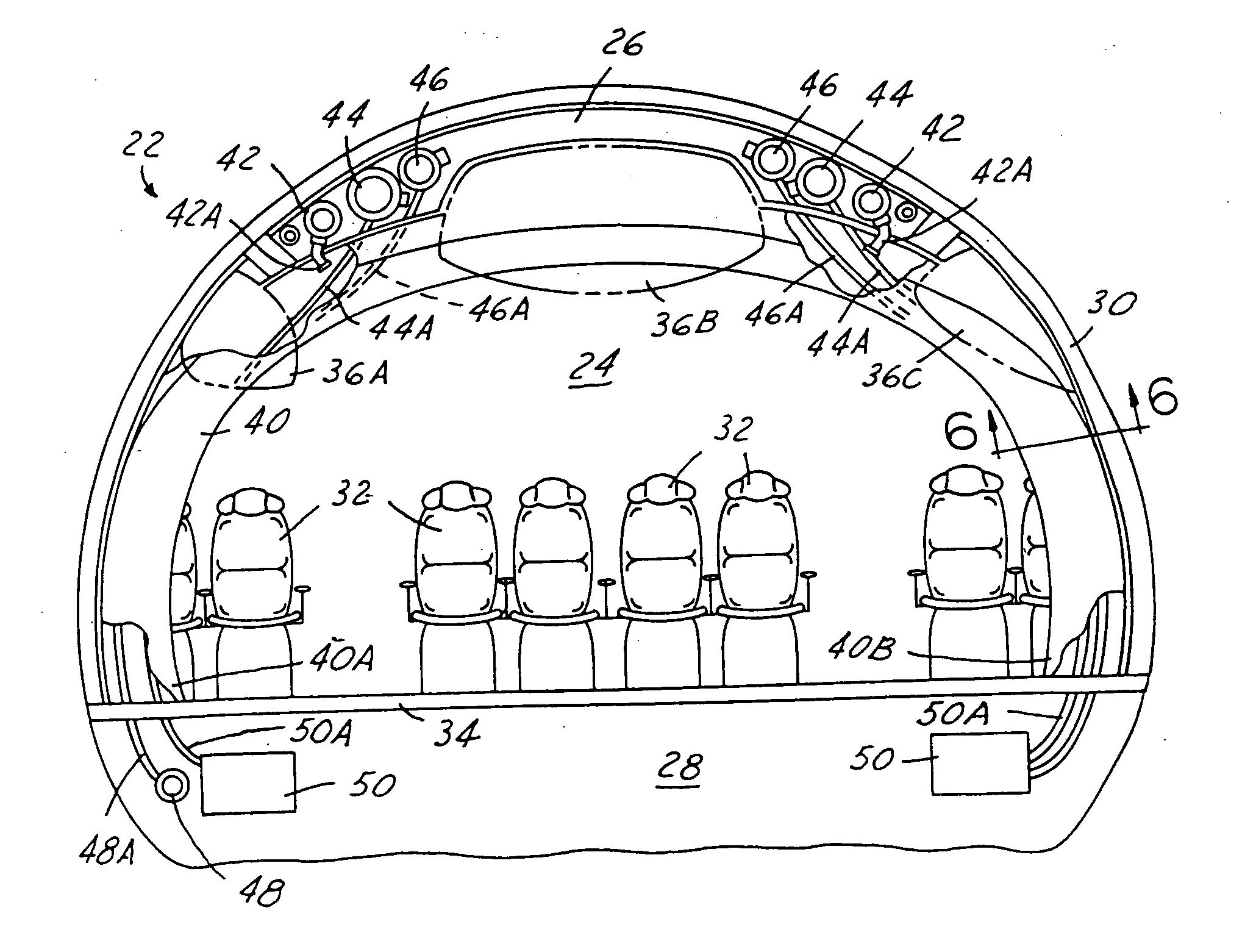

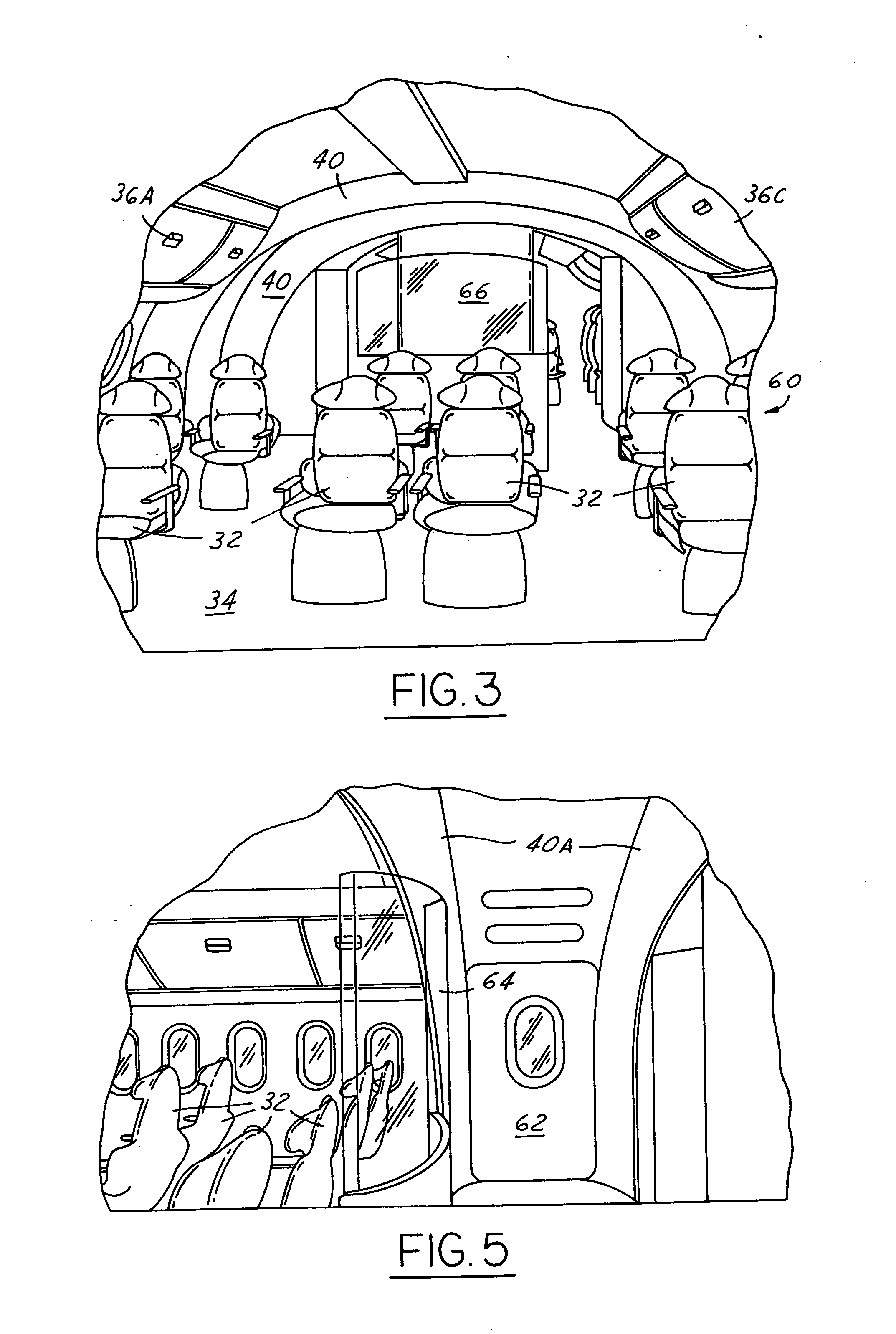

Aircraft archway architecture

ActiveUS20050082430A1Reduce impactReduce variationFuselage framesSeating arrangementsControl systemFlight vehicle

An architectural archway for an aircraft. The archways can be positioned individually, or in pairs or other sets along the length of an aircraft fuselage. The archways are used to run or connect various transport elements, such as electrical wiring, water lines, and environmental control system conduits, between the upper crown, lower bay and passenger cabin of the aircraft. The invention simplifies installation complexity and eliminates the installation and variability associated with running transport elements between the various sections of the aircraft.

Owner:THE BOEING CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com