Patents

Literature

117results about How to "Reduce sparks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

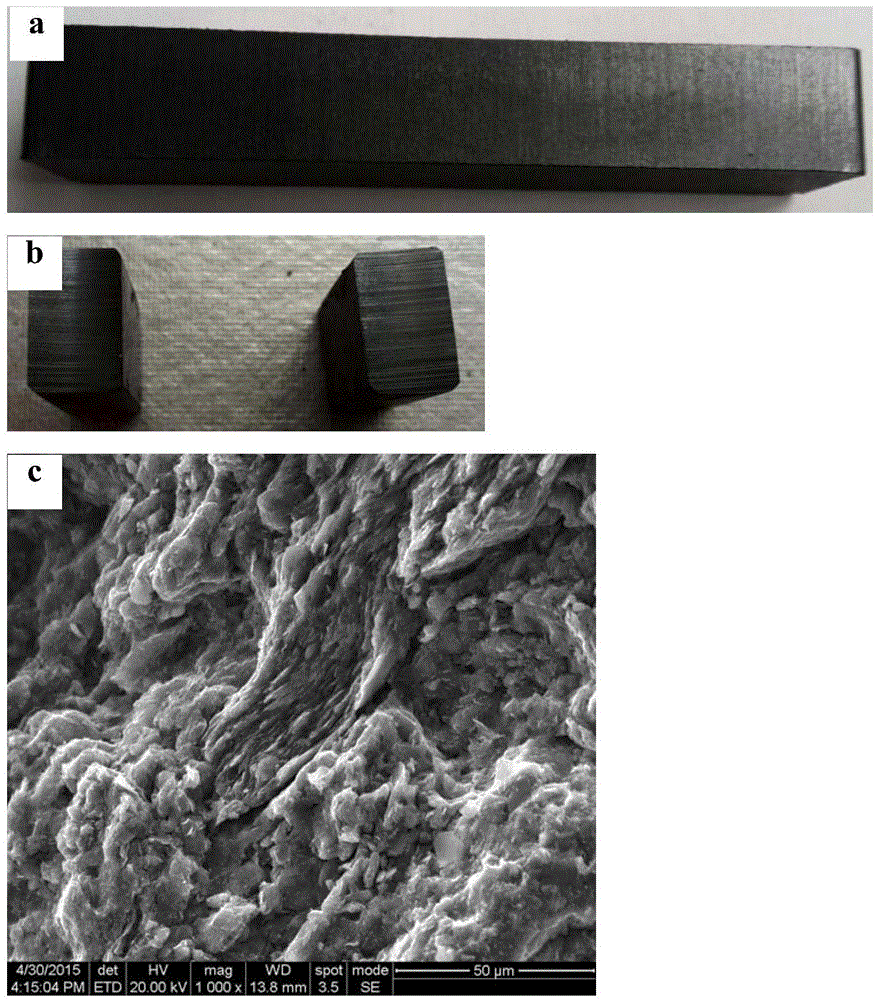

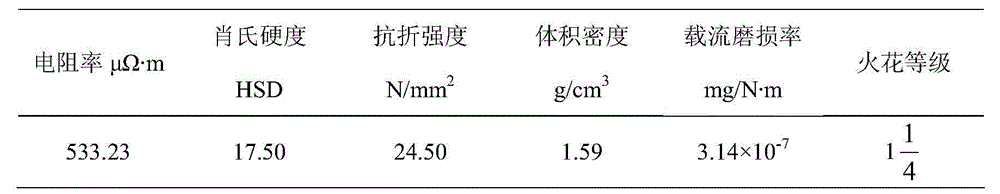

Self-homogeneity wearproof resin type carbon brush and preparation method thereof

ActiveCN104917020AImprove toughnessLimit thermal vibrationRotary current collectorBrushes manufactureGraphiteHigh wear resistance

The invention discloses a self-homogeneity wearproof resin type carbon brush and a preparation method thereof. The carbon brush comprises the following components: 5wt%-30wt% of sulphonated and oxidized graphene, 20wt%-65wt% of scale graphite powder and isopressing graphite powder (one or mixture of the two), 30wt%-50wt% of thermosetting resin and an additive. The self-homogeneity wearproof resin type carbon brush has the characteristics of self homogeneity and high wear resistance, is applicable to a motor for a high-power electric tool, in particular to a motor for a high-power cutter. Compared to an existing carbon brush with the same type, the carbon brush is excellent in homogeneity and wear resistance, and the commutation spark is stabilized at the level defined in the specification; The current-carrying wear rate of the carbon brush is 1 / 5-1 / 2 of that of the motor for the conventional high-power electric tool with the same type.

Owner:HUNAN UNIV

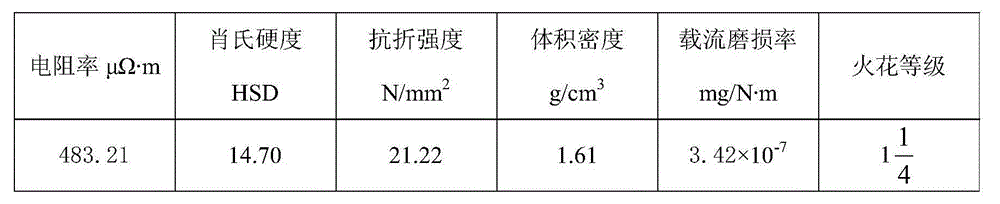

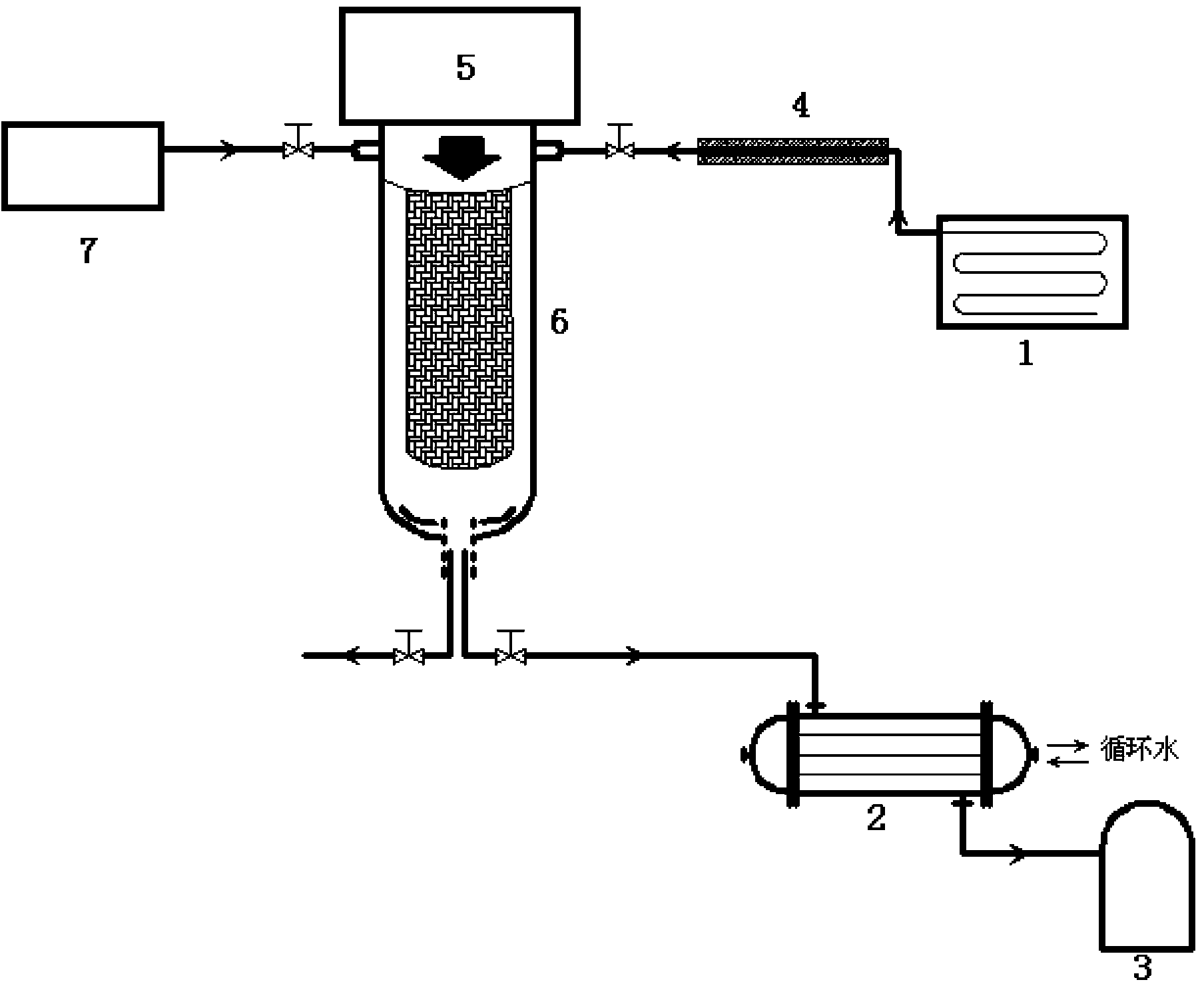

Desorption and regeneration method for organic matter adsorbent

InactiveCN103447015AReduce dosageReduce separation loadCombustible gas purificationEnergy based chemical/physical/physico-chemical processesDesorptionWater vapor

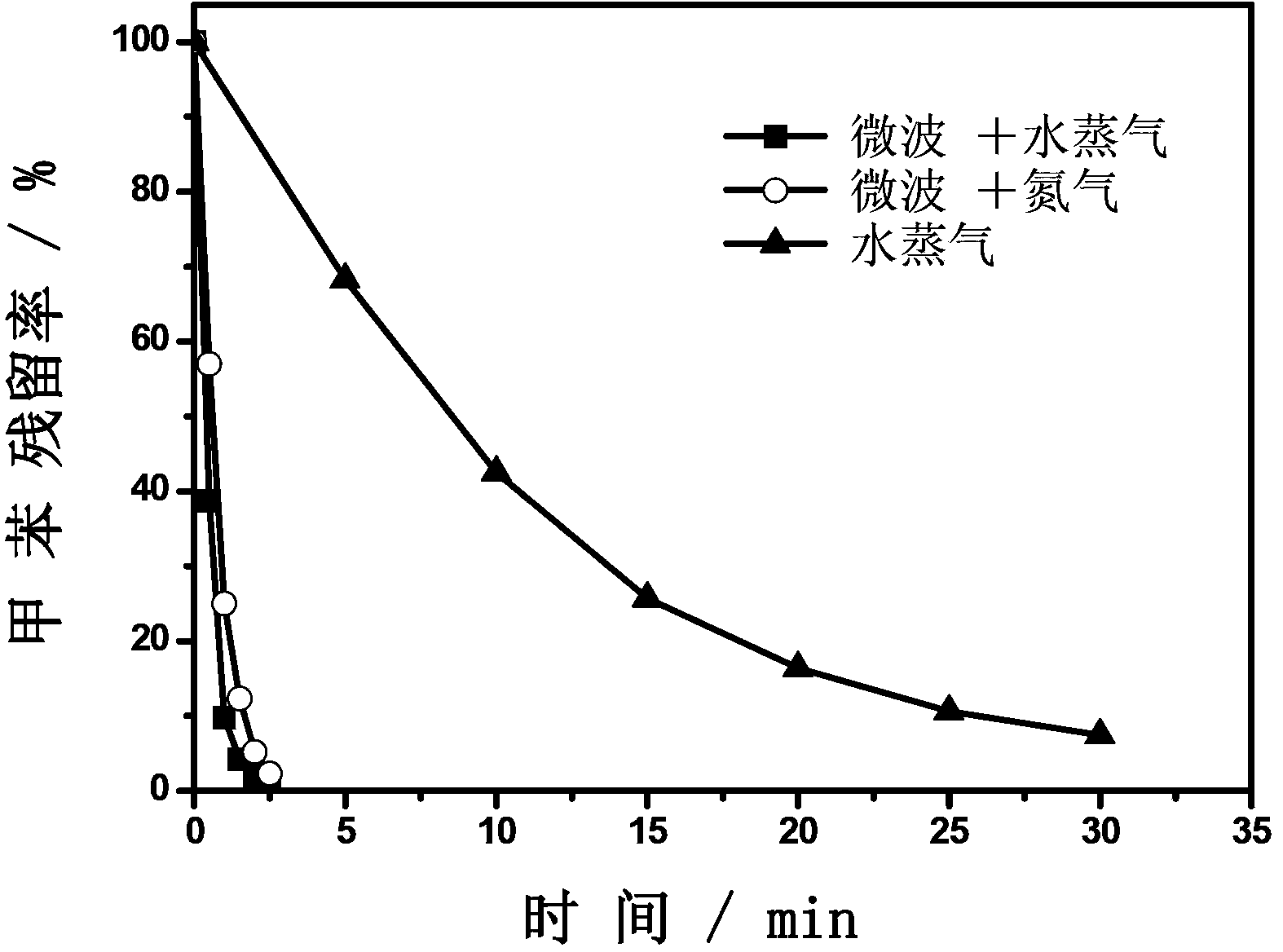

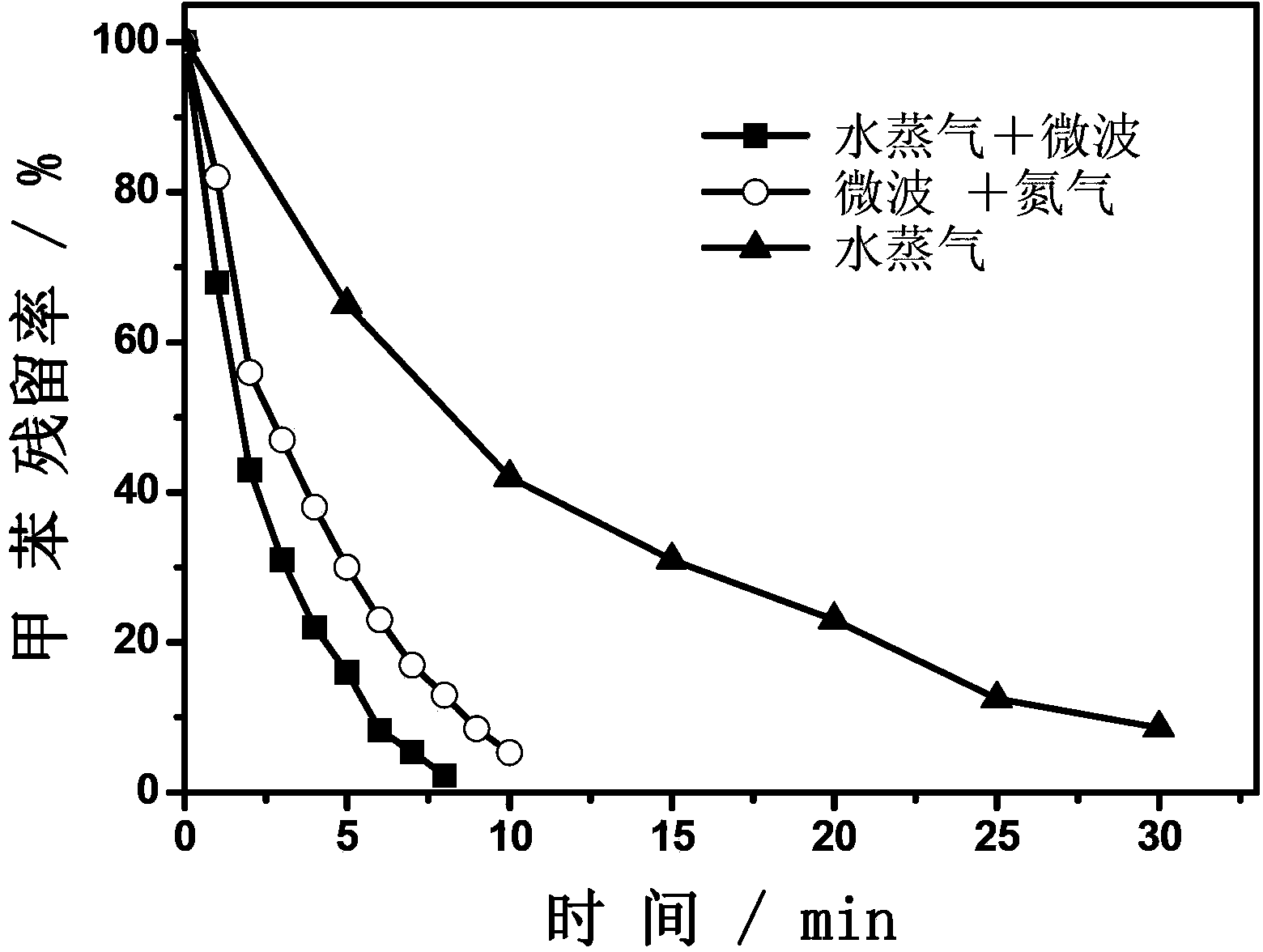

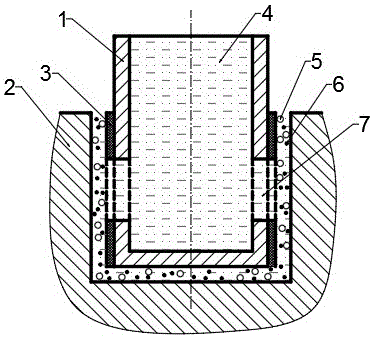

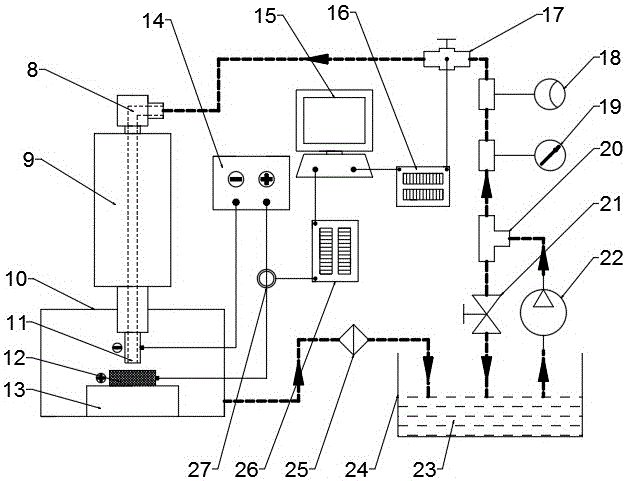

The invention discloses a desorption and regeneration method for an organic matter adsorbent. The method is characterized in that an organic matter adsorbent desorption and regeneration device of a microwave generator is arranged in a desorption tower; the to-be-desorbed adsorbent with organic matters is put in the desorption tower; steam is aerated from the top of the desorption tower; the microwave generator is started, wherein the microwave power is 500-10000W; desorption is carried out for 2-30 minutes; the desorbed organic matters and steam flow out from a steam outlet at the bottom of the desorption tower and enter a condenser for condensation; then the steam is cut off, nitrogen is aerated from the top of the desorption tower, and the nitrogen flows out from the bottom, wherein the microwave power is 200-2000W; drying treatment is carried out for 2-20 minutes; the microwave generator is turned off, and the nitrogen is cut off; the desorbed adsorbent is obtained. According to the method, the desorption rate is improved by a large margin by combining steam and the microwave technology, and less desorption residue is left.

Owner:ZHEJIANG UNIV OF TECH

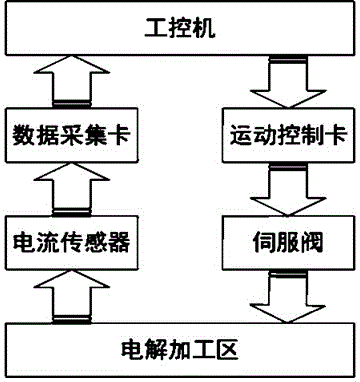

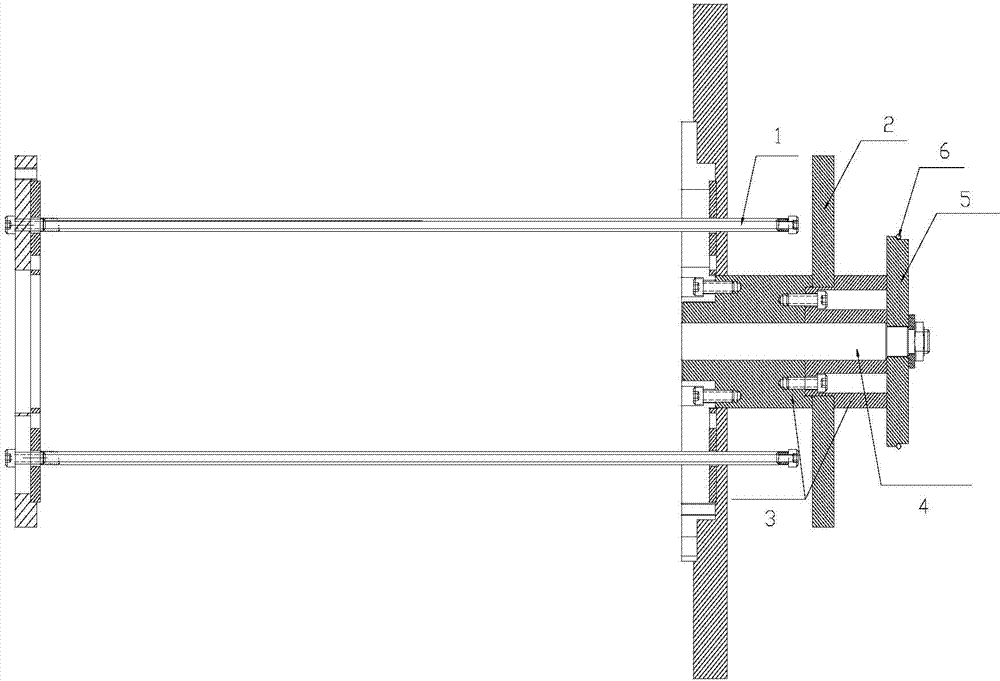

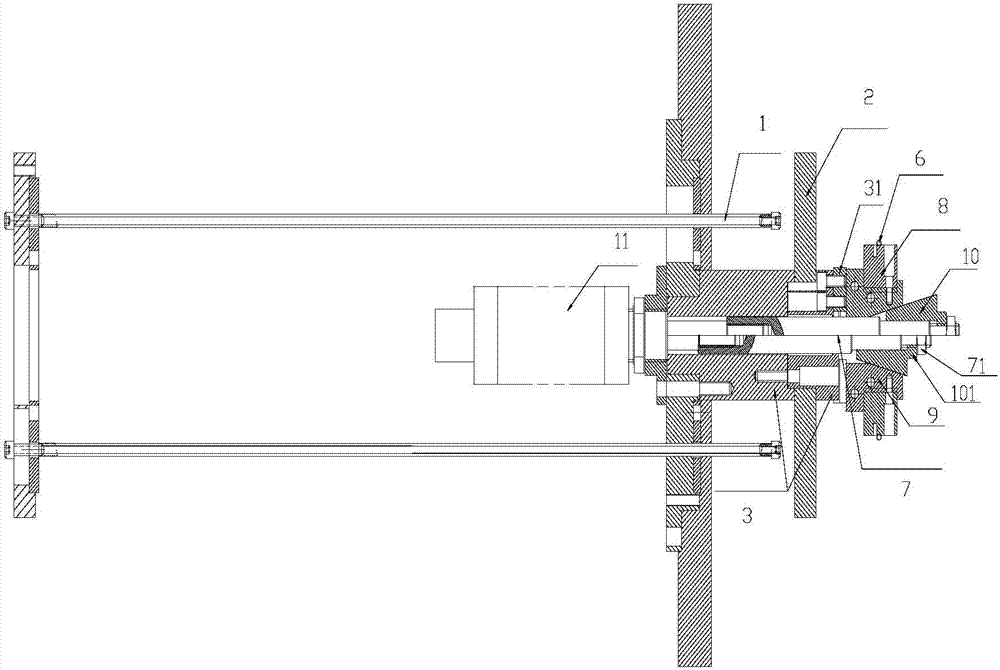

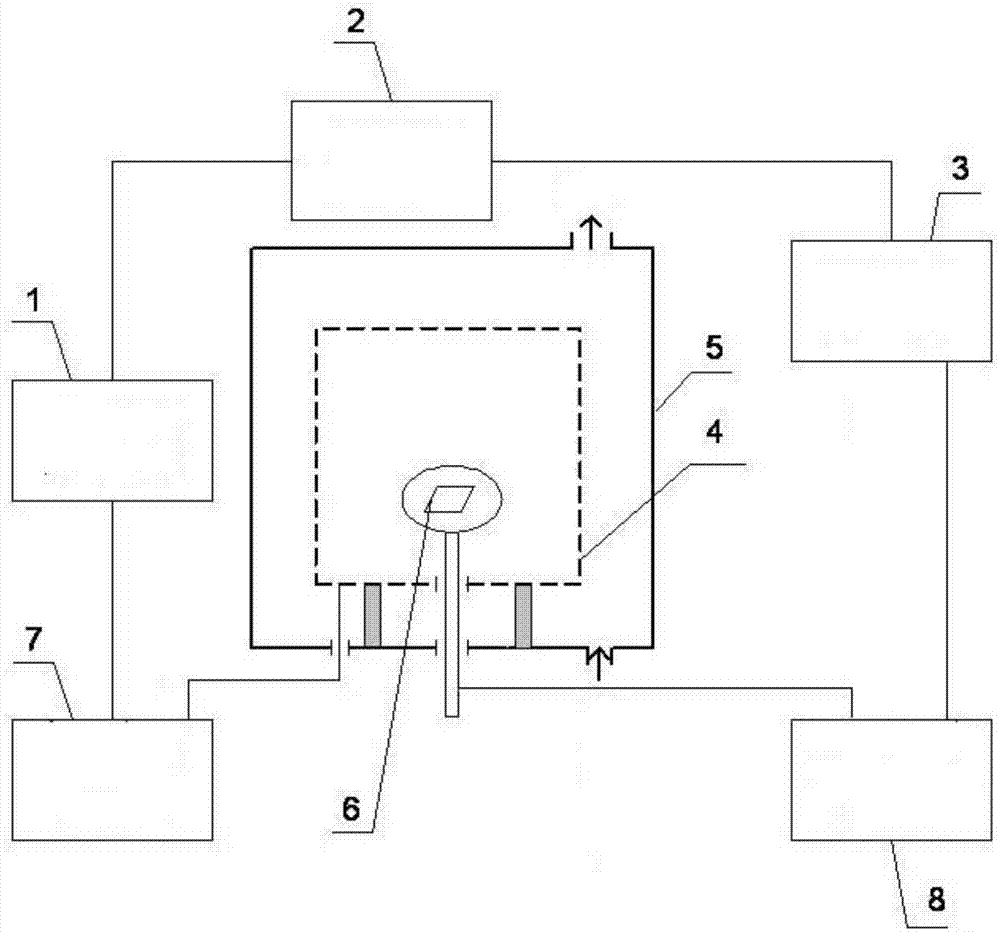

Internal liquid injecting electrolytic grinding and milling machining system and method

The invention relates to an internal liquid injecting electrolytic grinding and milling machining system and method, and belongs to the field of electrolytic grinding combined machining. The machining system comprises an electrolyte circulating system, a current detecting system and a servo valve control system. Internal injecting type liquid supply of electrolytic grinding and milling and filtering and recycling of electrolyte are achieved through the electrolyte circulating system. The current detecting system can detect current magnitude and the current sudden change condition in the machining process in real time. The servo valve control system can fast adjust electrolyte flow entering a machining area when an industrial personal computer detects the continuous sudden changes of currents, so that an electrolytic product and joule heat are fully discharged. The system and method have important significance on improvement of the stability of the electrolytic grinding and milling machining process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

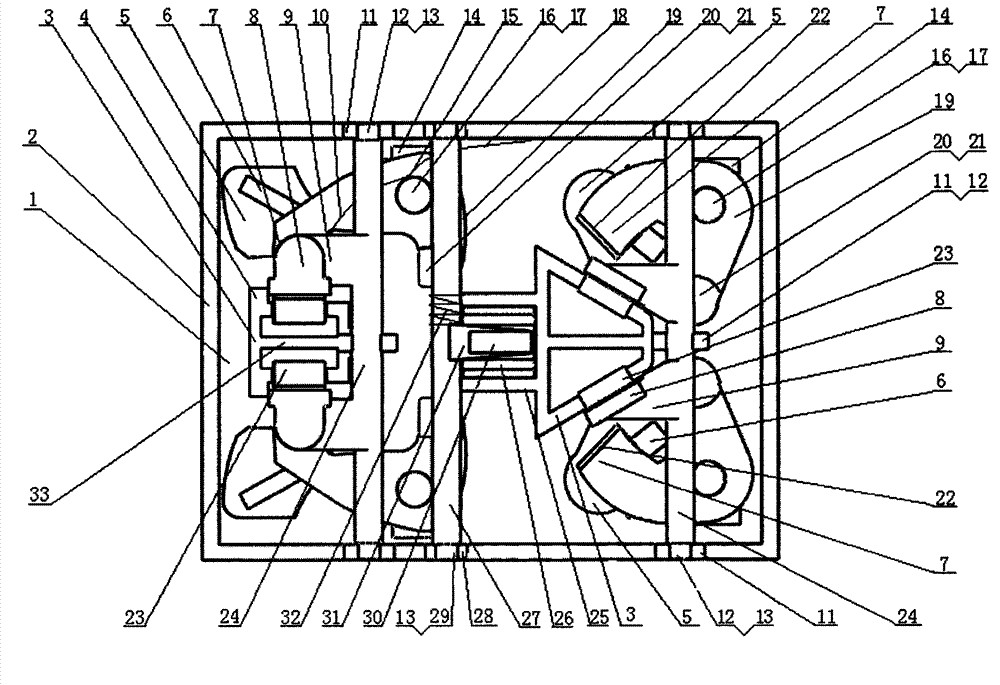

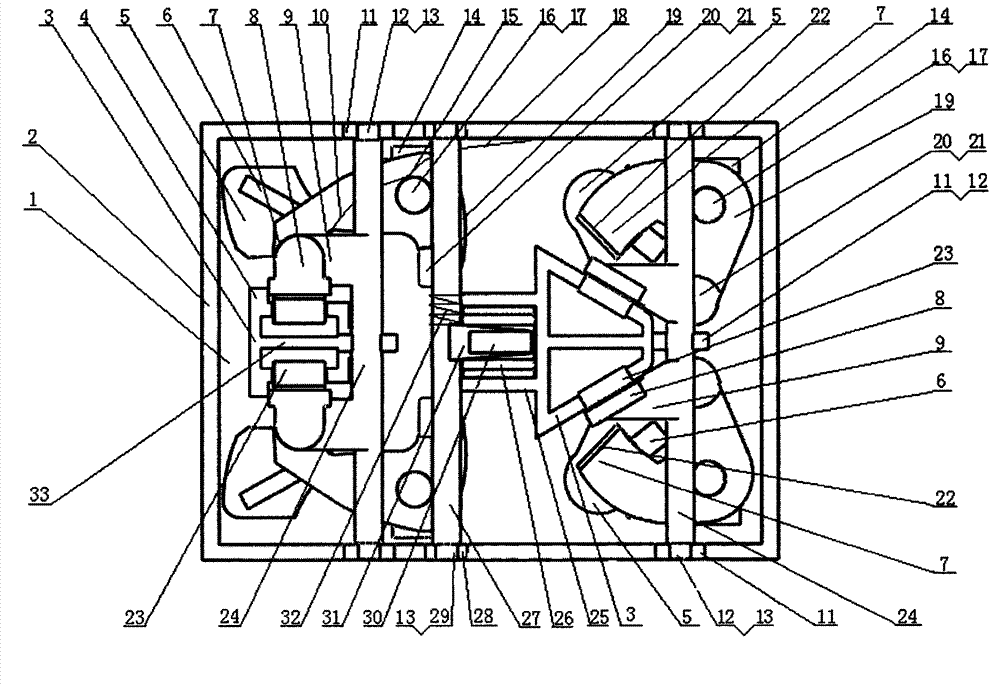

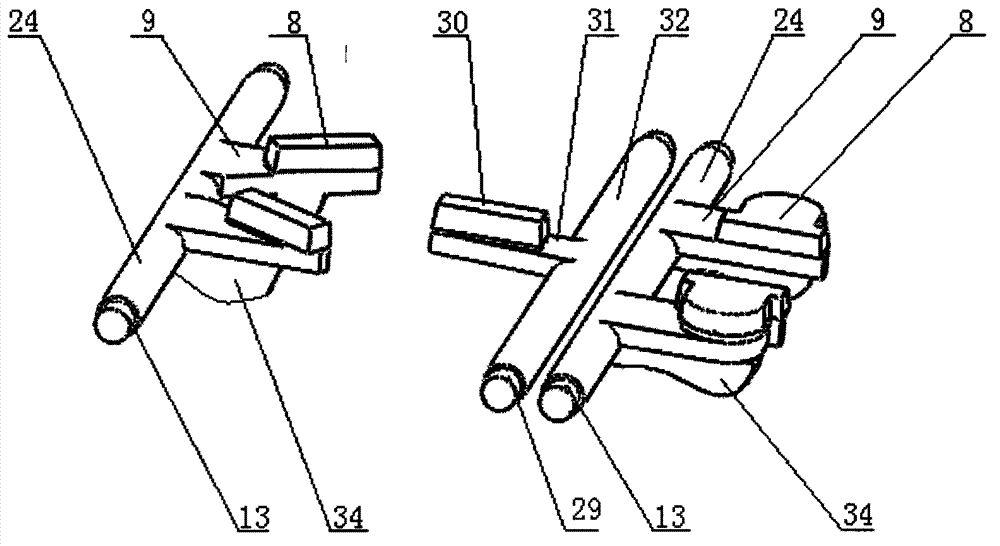

Independently-targeted hole-free socket

InactiveCN103199374AIncreased security measuresThere will be no floating connection phenomenonCoupling device detailsEngineeringCam

An independently-targeted hole-free socket comprises a protection door rotary device and a rotary conducting strip installing device, and is characterized in that a cam is installed below a protection door, a rotary frame is installed on a socket base and is used for carrying out open-closed rotation of the protection door through a rotary frame shaft, the rotary frame shaft is connected with the socket base, a spring is installed on the rotary frame shaft, and the protection door is installed on a protection door shaft which is installed on a protection door shaft frame. When a plug is pressed on the protection door, the protection door rotates downwards, so that plug holes are exposed out, after the plug is plugged into the plug holes, the cam behind the protection door pushes the tail of the rotary frame and enables the tail of the rotary frame to rotate outwards, a rotary frame head with a conducting strip rotates inwards through a lever principle and is tightly clamped on a plug pin of the plug, and phenomena of virtual connection and suspension connection are avoided, the appearance of the socket is like a sealed cube, no plug holes can be seen, security coefficients are greatly improved, phenomena of the virtual connection, the suspension connection, ceaseless spark and enlarged resistance do not occur, and the service life is greatly prolonged.

Owner:山西腾行智能科技有限公司

Lead-free, corrosion-resistant projectiles and methods of manufacture

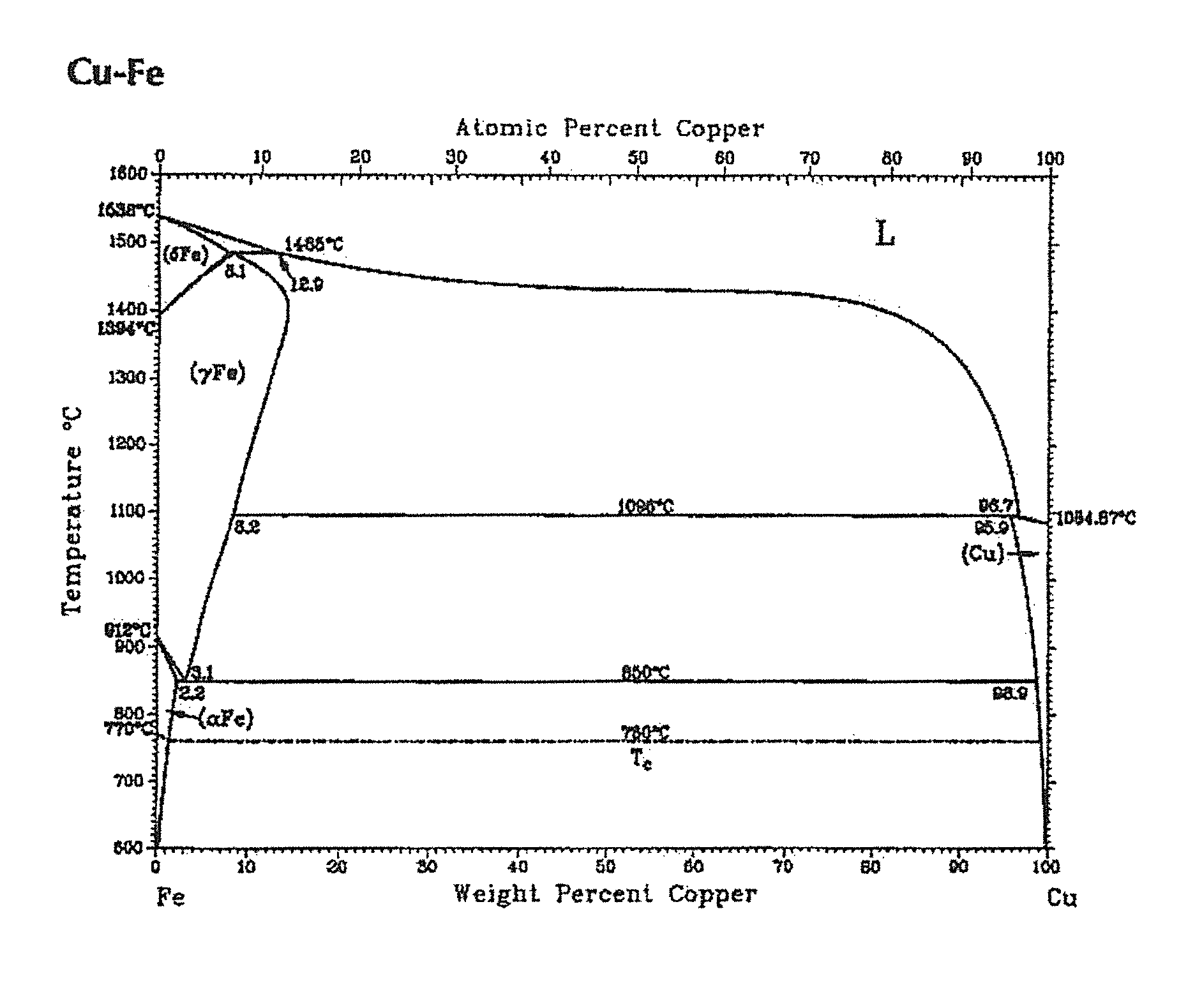

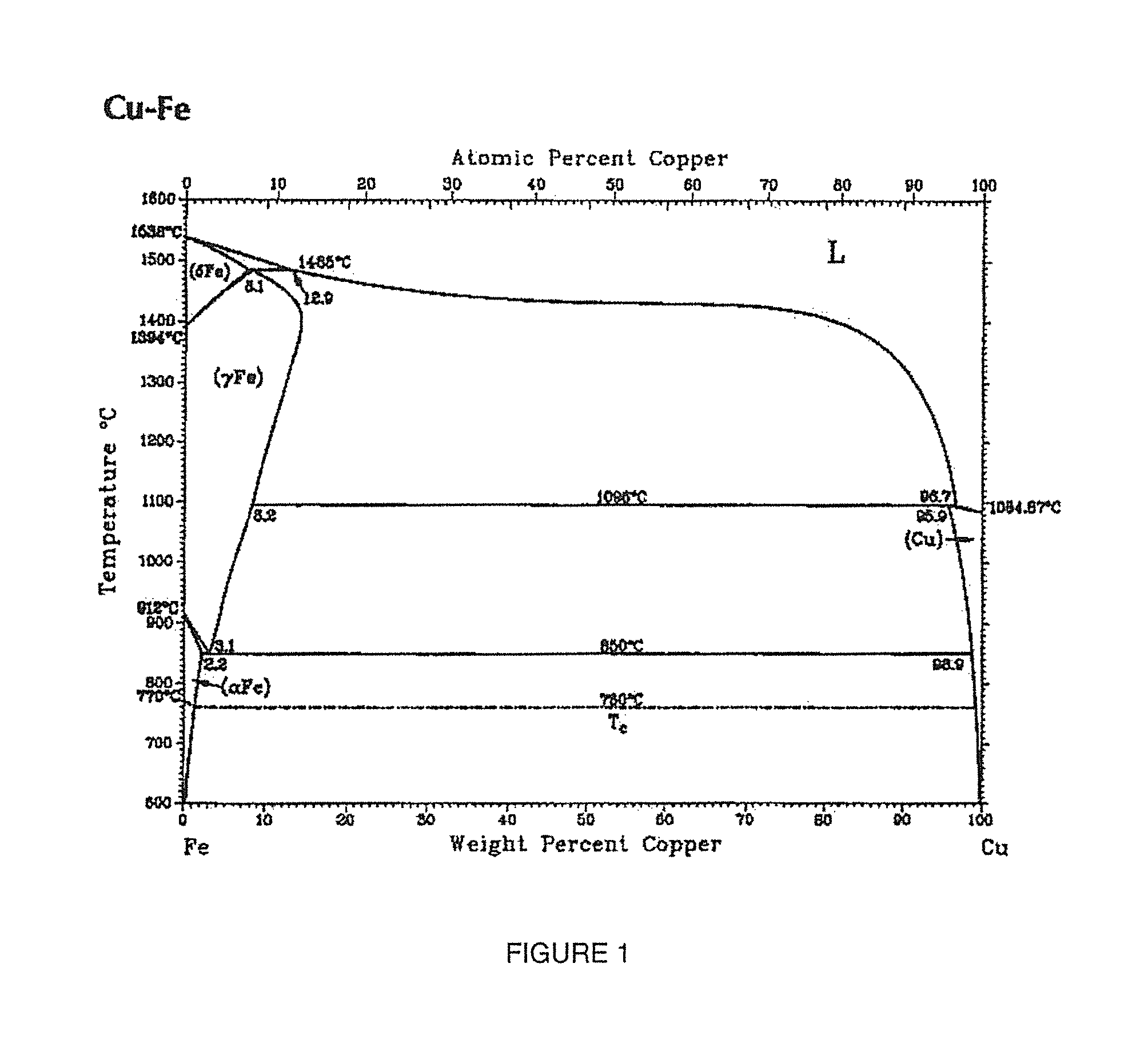

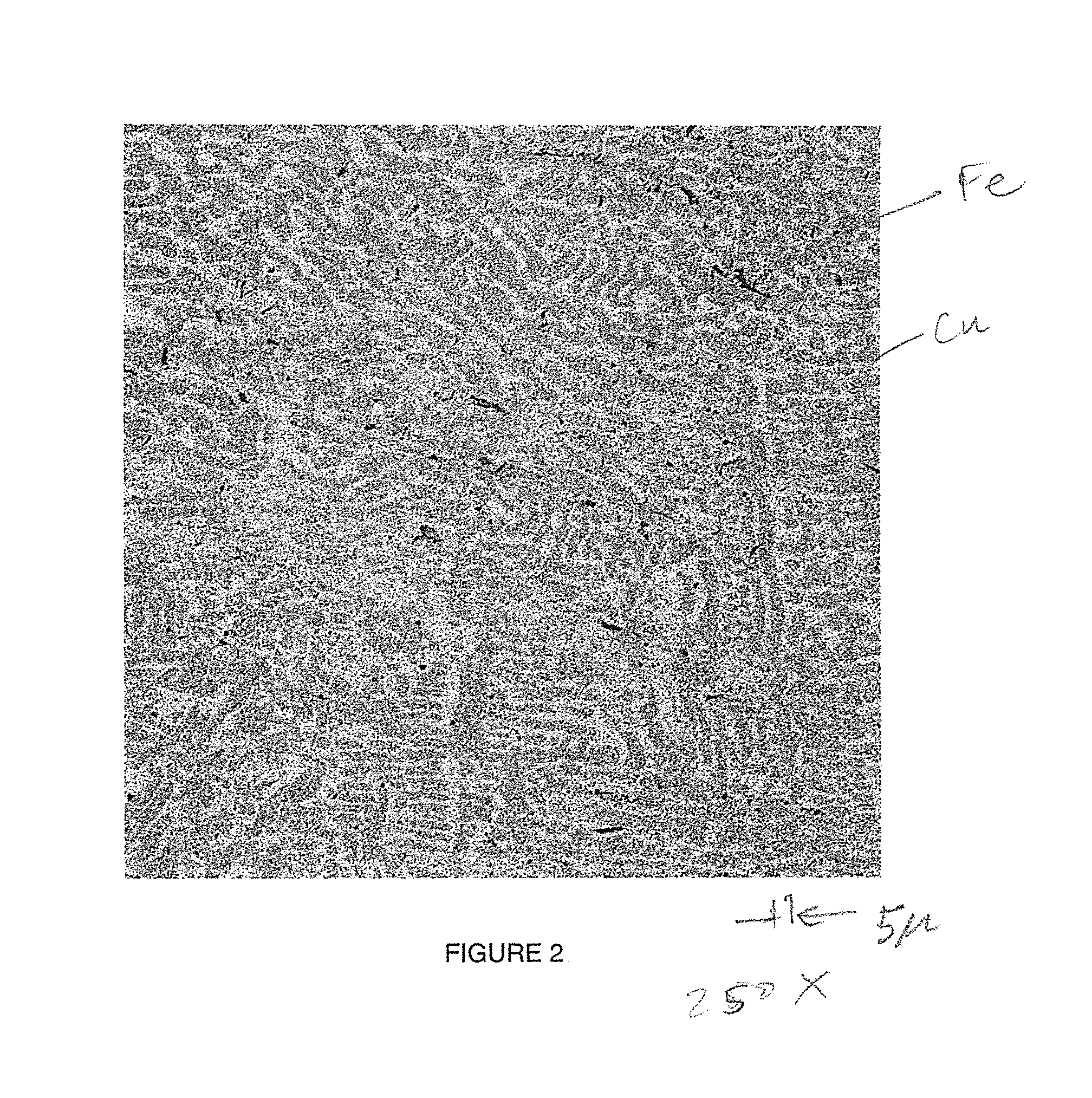

ActiveUS9188416B1Enhanced strengthEnhance corrosion resistanceAmmunition projectilesTraining ammunitionCorrosion resistantMicrostructure

To produce lead-free projectiles, iron and copper are melted at a predetermined ratio and rapidly quenched to yield a fine-grained microstructure with uniformly distributed copper and iron phases. The iron-copper alloy may be made into a powder through atomization, with the iron-copper molten metal being dispersed using a rapidly moving gas, liquid stream, or via mechanical dispersion. The step of forming the bullet may include solid-state sintering of the atomized powder, including heating at a temperature below 1083° C., the melting point of copper. Alternatively, the step of shaping the mixture into a bullet-shaped form may include casting and / or uniaxially pressing the mixture into a mold. A ceramic powder may be added to the copper-iron mixture prior to forming to produce a frangible projectile. Chromium, including chromium from recycled stainless steel, may be added to increase corrosion resistance and / or reduce manufacturing cost.

Owner:ERVIN IND

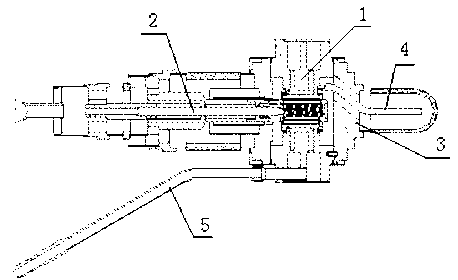

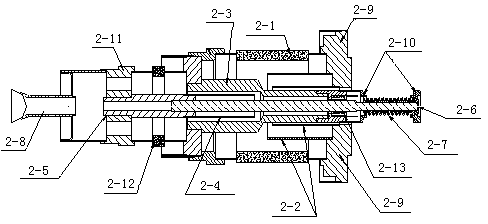

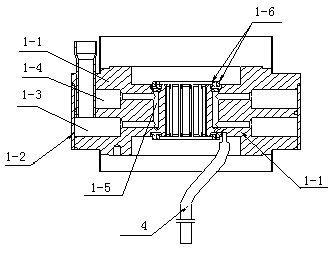

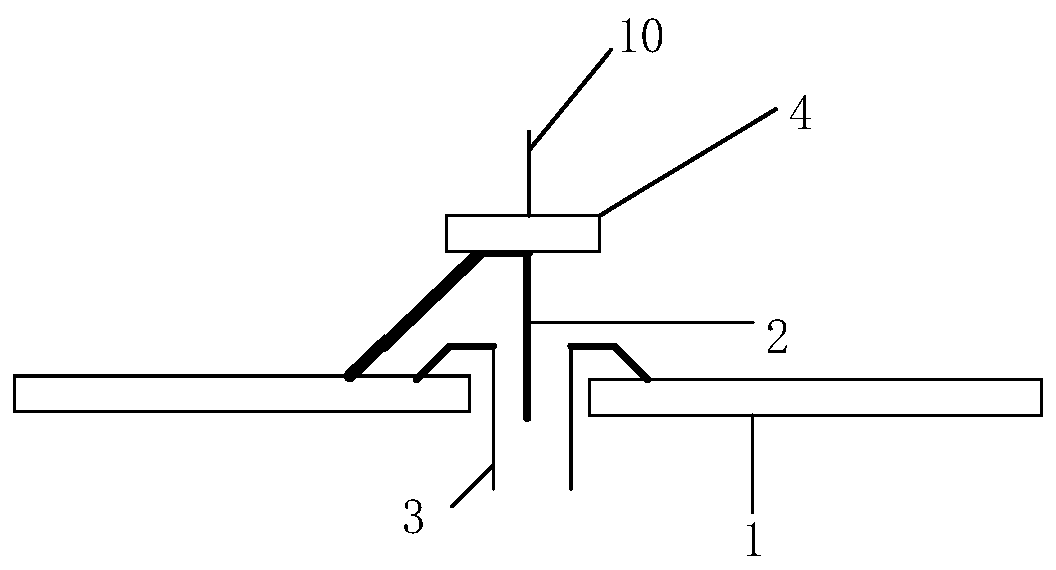

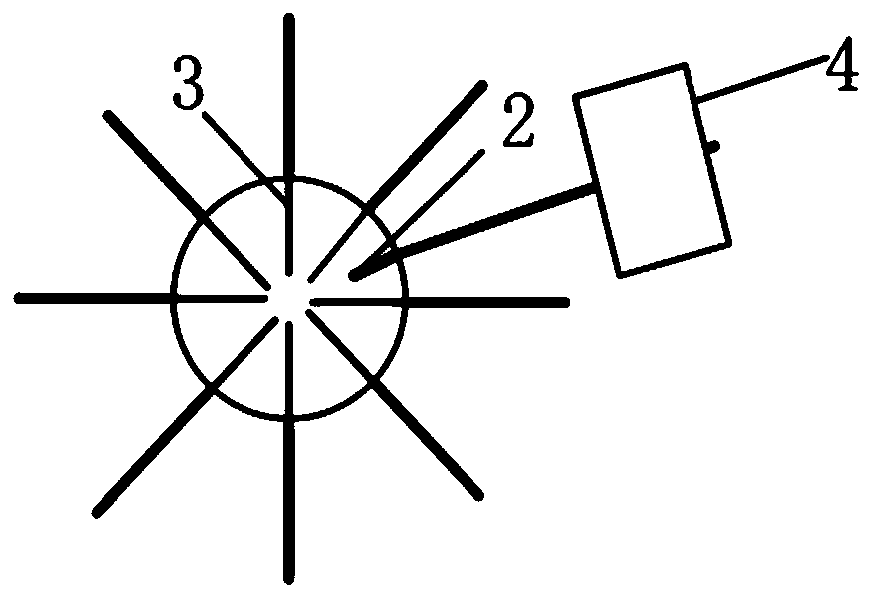

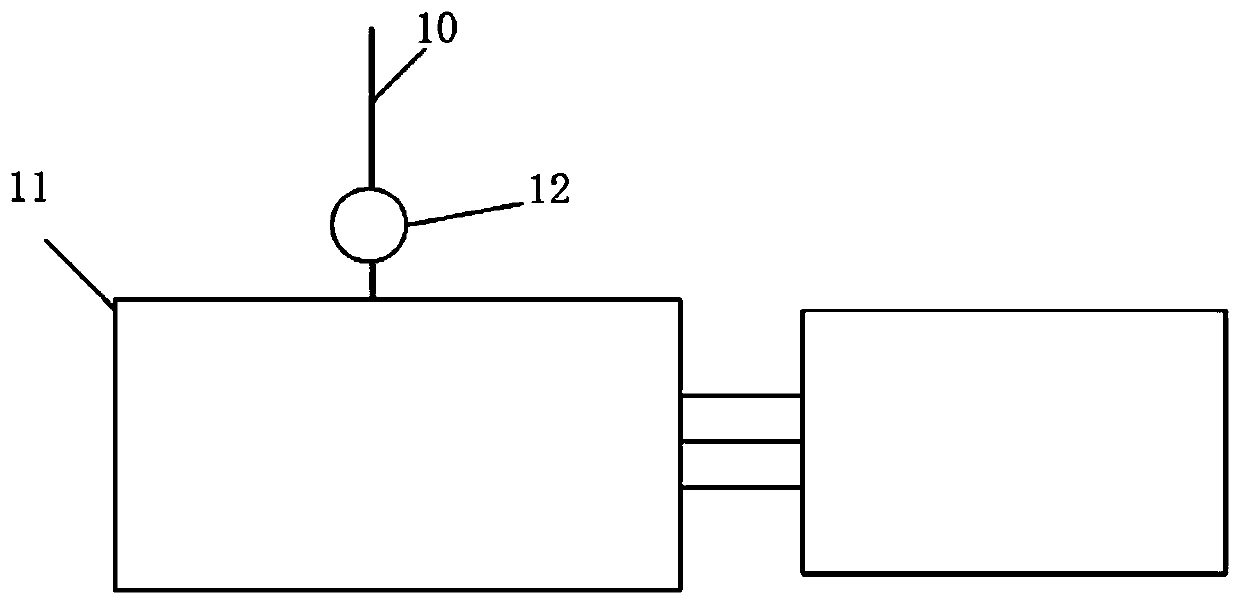

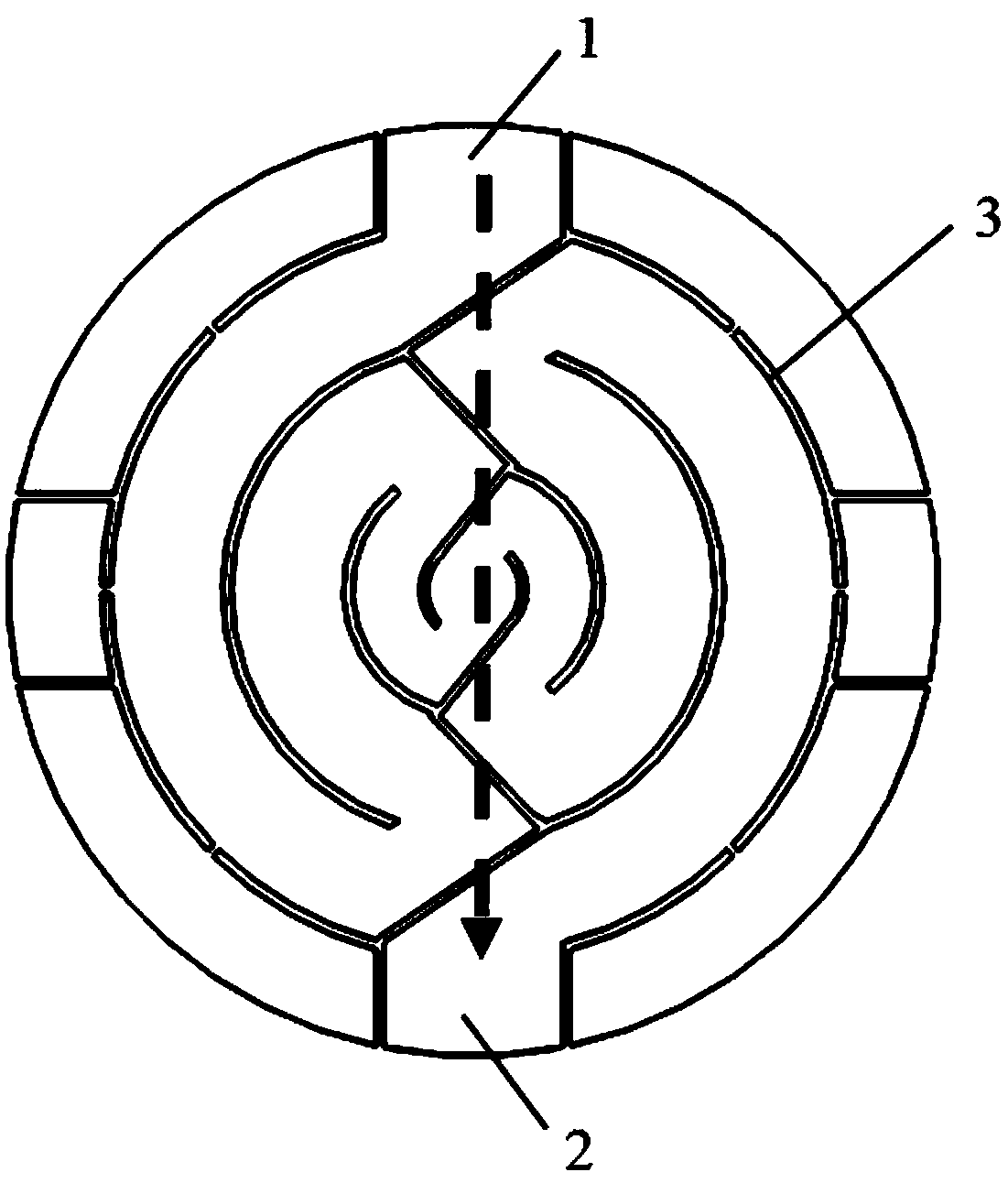

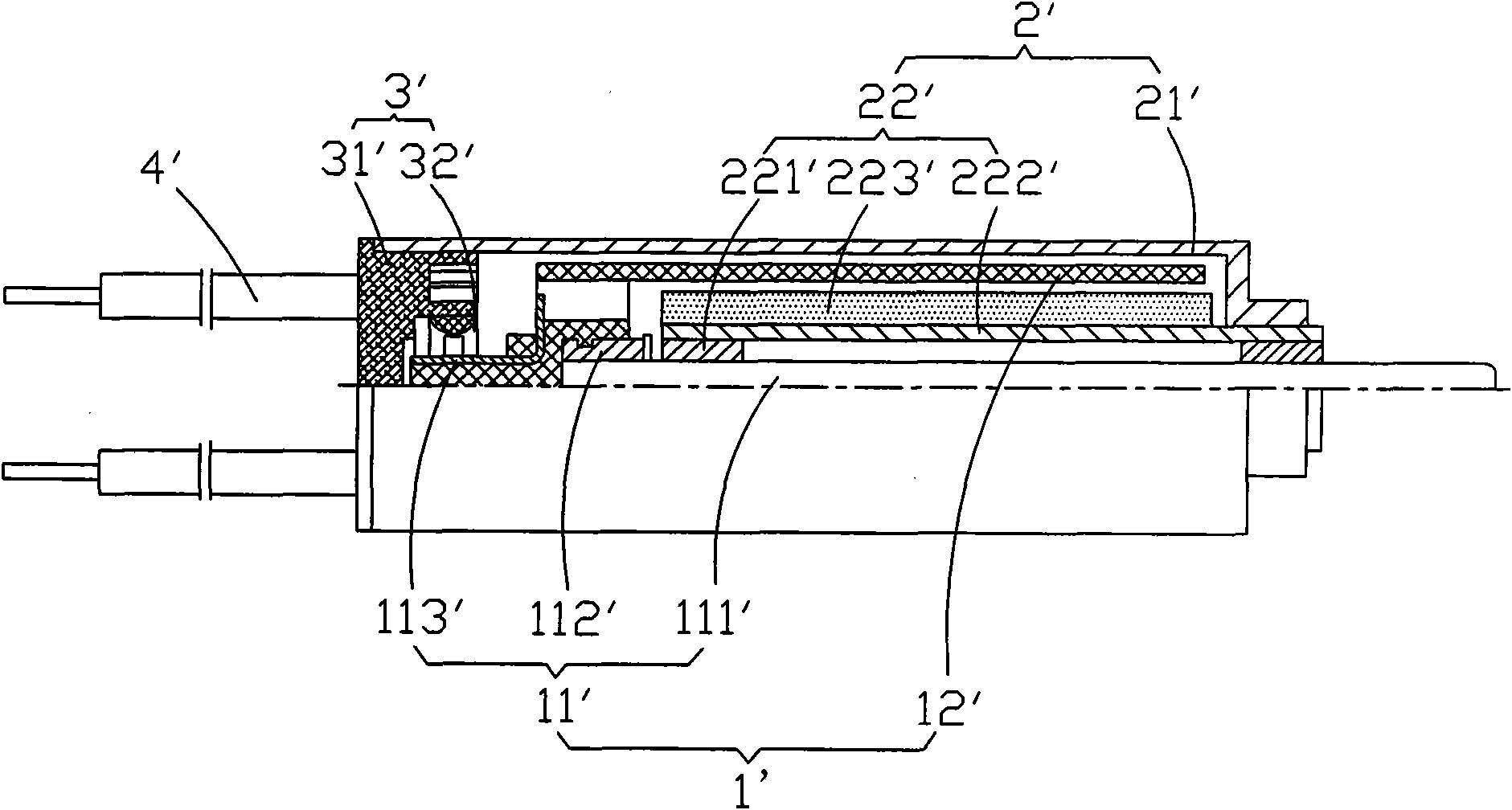

2450-MHz high-power continuous-wave magnetron and preparation method thereof

ActiveCN103346053AImprove pressure resistanceExtended service lifeMagnetronsTransit-tube collectorsCavity magnetronMicrowave

The invention discloses a 2450-MHz high-power continuous-wave magnetron and a preparation method thereof. The 2450-MHz high-power continuous-wave magnetron comprises an anode cavity combination unit (1), a cathode outgoing line combination unit (2), an output window combination unit (3) connected with the anode cavity combination unit (1), and an output antenna (4) fixed at the anode cavity combination unit (1); the other end of the output antenna (4) is arranged inside the output window combination unit (3); and the anode cavity combination unit (1) is connected with a cavity cooling water inlet-outlet pipe (5). The structure of the provided continuous-wave magnetron is designed reasonably; the power of the magnetron is high and the output power can reach over 30 KW; the service life can reach more than 5000 hours; the microwave leakage is less; and the security performance is high. Besides, according to the preparation method of the continuous-wave magnetron, lots of experiment screening is carried out; and the method has the advantages of reasonable process design and high operability. Moreover, the prepared magnetron with characteristics of high gas tightness, a high vacuum degree, low sparking probability and stable performance enables various defects existing in the prior art to be overcome.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP +1

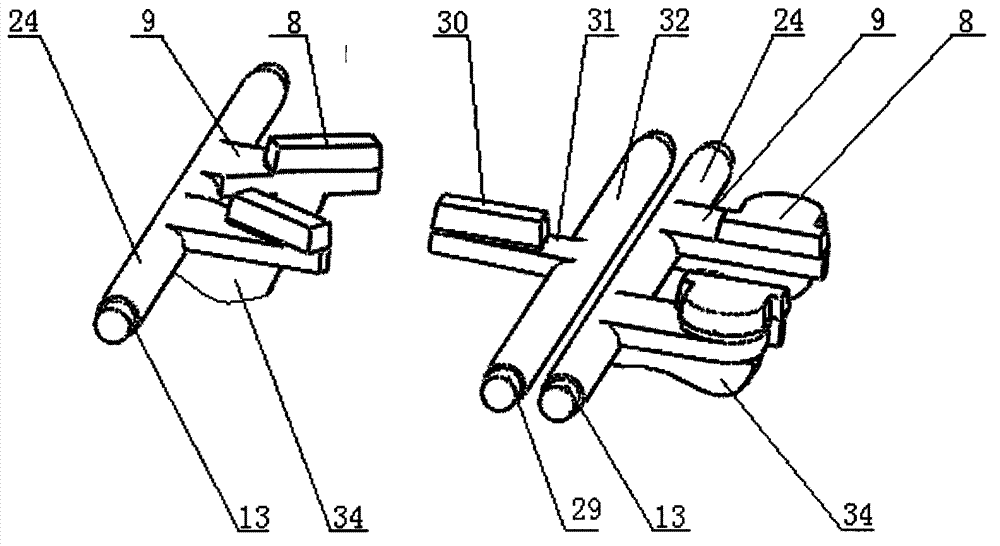

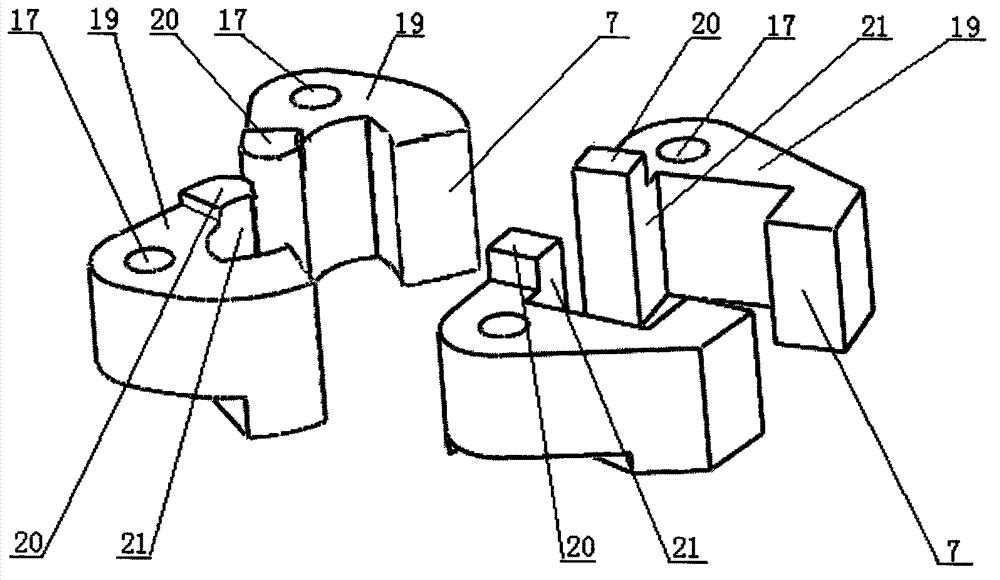

Independently-targeted hole-free socket

InactiveCN103199374BIncreased security measuresThere will be no floating connection phenomenonCoupling device detailsEngineeringCam

An independent holeless socket comprises: a shutter rotation device and a rotary conducting sheet mounting device. A cam (34) is mounted below a shutter (9), a rotary bracket (19) is mounted on a socket base (1), the rotary bracket (19) enables, by a rotary bracket shaft(16), the shutter (9) to open or close in a rotation manner, the rotary bracket shaft(16) is connected to the socket base (1), a spring (15) is mounted on the rotary bracket shaft(16), the shutter (9) is mounted on a shutter shaft (24), and the shutter shaft (24) is mounted on a shutter shaft bracket (11). When a plug is pressed against the shutter (9), the shutter (9) rotates downwards to expose holes (41), and after the plug is inserted, the cam (34) behind the shutter (9) pushes a rotary bracket tail to enable the rotary bracket tail to rotate outwards, and enables, according to the lever principle, rotary bracket heads of the electrified conducting sheets to rotate inwards to be fastened on the pins of the plug, thereby avoiding disconnected phenomenon. The appearance of the socket is a sealed cube and holes cannot be seen, so the socket is safer, disconnection is avoided, no spark flashes, the resistance is not increased, and the service life is prolonged.

Owner:山西腾行智能科技有限公司

Probe card, test equipment comprising probe card, and test method

PendingCN110231501AReduce sparksEnsure safetyElectrical measurement instrument detailsElectrical testingProbe cardSemiconductor chip

The invention provides a probe card, test equipment comprising the probe card, and a test method. The probe card comprises a PCB board, a hollow needle and a probe; the hollow needle and the probe arerespectively connected with the PCB board, and the hollow needle and the probe are adjacently arranged; the hollow needle is used for releasing flame-retardant gas. During testing, the needle tip ofthe hollow needle can be used to spray the flame-retardant gas to form a flame-retardant gas protective atmosphere, so that an ignition phenomenon of a semiconductor chip during the testing can be effectively reduced. The test equipment comprises the probe card, a pipeline and a high-voltage test device, wherein the pressure cavity of the probe card is connected with the pipeline, and the probe card is inserted into the high-voltage test device through an interface. The test equipment is used to prevent the ignition phenomenon during the testing of the semiconductor chip, and the safety of thesemiconductor chip is guaranteed, and the test precision is greatly improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

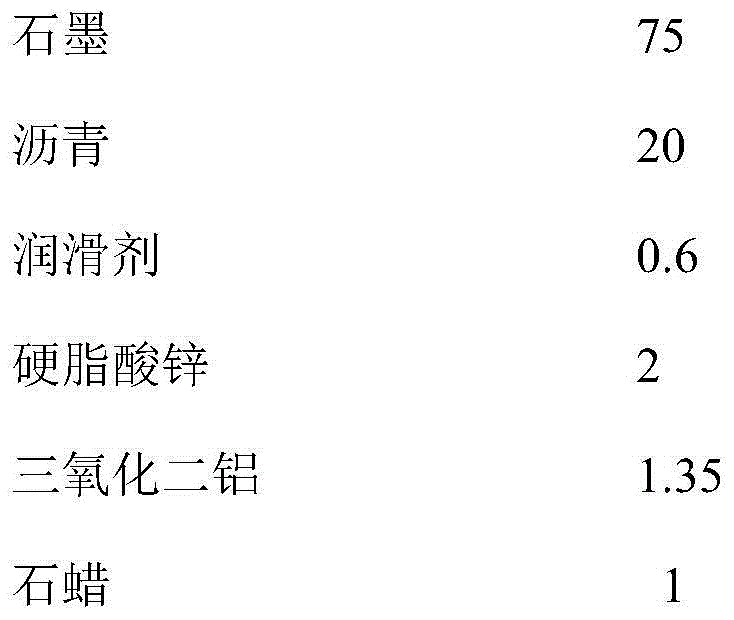

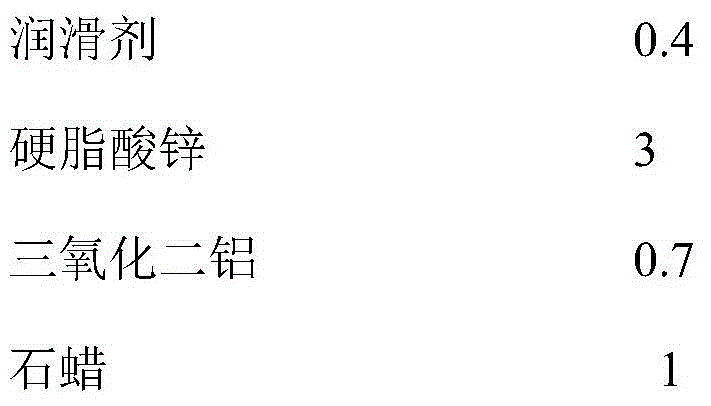

Electric brush for motor of electric tool and preparation method for electric brush

ActiveCN104659626ALight in massGood lubricityRotary current collectorBrushes manufactureElectric machineryAluminium

The invention discloses an electric brush for a motor of an electric tool and a preparation method for the electric brush. Constituent materials of the electric brush for the motor belong to the field of material science and the electric brush is prepared from the following raw materials in parts by weight: 30-90 parts of graphite, 10-35 parts of asphalt, 0.2-1.0 part of a lubricating agent, 0.5-5 parts of zinc stearate, 0.5-3 parts of aluminum oxide and 0.5-5 parts of paraffin. The electric brush disclosed by the invention is low in resistivity, excellent in abrasion resistance, high in commutation performance, high in interference resistance and long in service life and is importantly high in abrasion resistance and high-voltage resistance and low in spark grade.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Functional graphene lubricating grease material and preparation method thereof

InactiveCN107267269AImprove the lubrication effectLong application lifeLubricant compositionMechanical wearGraphene

The invention discloses a functional graphene lubricating grease material. The functional graphene lubricating grease material comprises 10-20 wt% of a thickener, 0-5 wt% of an additive, and the balance of graphene base oil. The functional graphene lubricating grease material has good lubricity and long application life, has good mechanical wearing preventing, friction head dispelling and mechanical life prolonging effects, also has fine metal damage filling and metal surface smoothing effects, has metal corrosion preventing and sealing dedusting effects, can be widely applied to devices, mechanical parts and vehicles, also can be applied to the contact point protection of industrial motors and electronic devices to effectively lubricate the electrically made contact points, reduce sparks and improve the safety of fire alarm, has a very good effect on electronic harmonic waves on the electronic contact points to well protect the working stability of a line. A preparation method of the functional graphene lubricating grease material has the advantages of simplicity, low preparation cost, wide application range, and worthiness promoting.

Owner:柯良节 +2

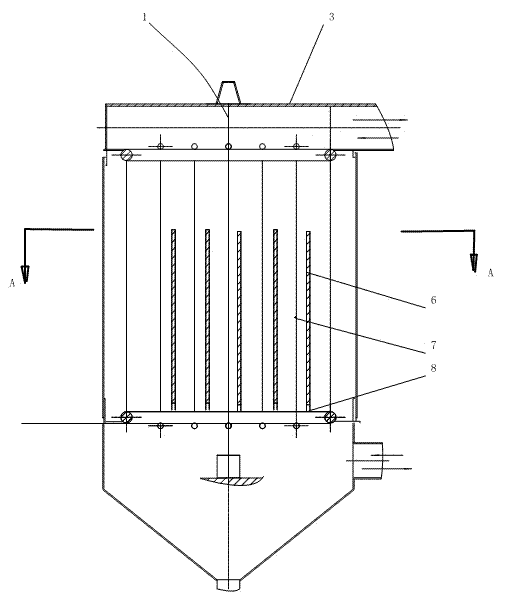

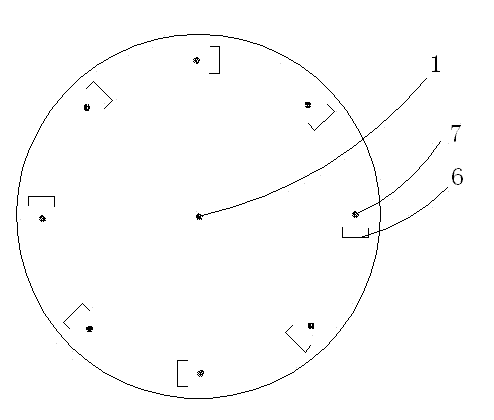

Electrostatic dust collector

ActiveCN102896044AEasy to neutralize condensationFast solutionExternal electric electrostatic seperatorElectrode constructionsOptoelectronicsDumbbell shaped

The invention relates to an electrostatic dust collector, belonging to the technical field of electrostatic dust collection. The dust collector comprises a housing, a cathode and an anode made of electric conductive wires are arranged in the housing, and a dust collection board which is parallel with the anode and whose length is basically equal to that of the anode is arranged close to the anode; the dust collection board semi-surrounds the anode from one side of the anode, the scope of the distance between the dust collection board and the anode is 5-150mm, and the upper end and the lower end of the dust collection board are respectively and fixedly arranged on the upper end and the lower end of the housing through an insulator; and the overall insulator is of an umbrella shape or a dumbbell shape. According to the electrostatic dust collector, the dust collection efficiency is high, various specific resistance dusts can be collected, and any modulation is not needed.

Owner:易敏红

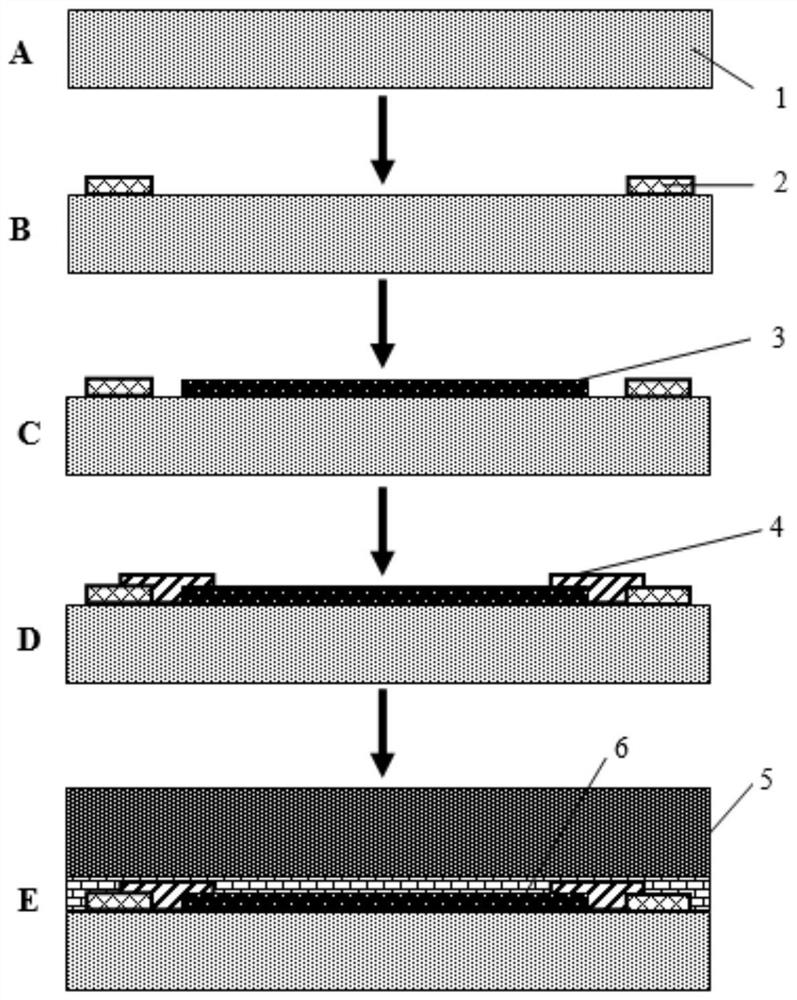

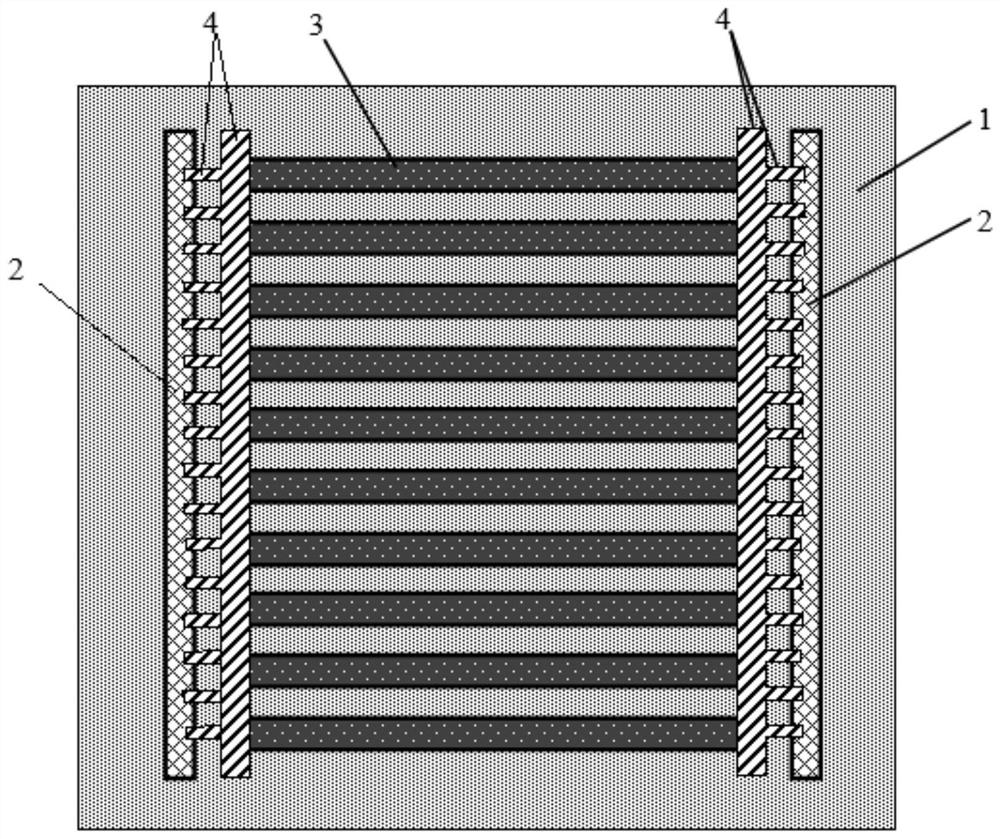

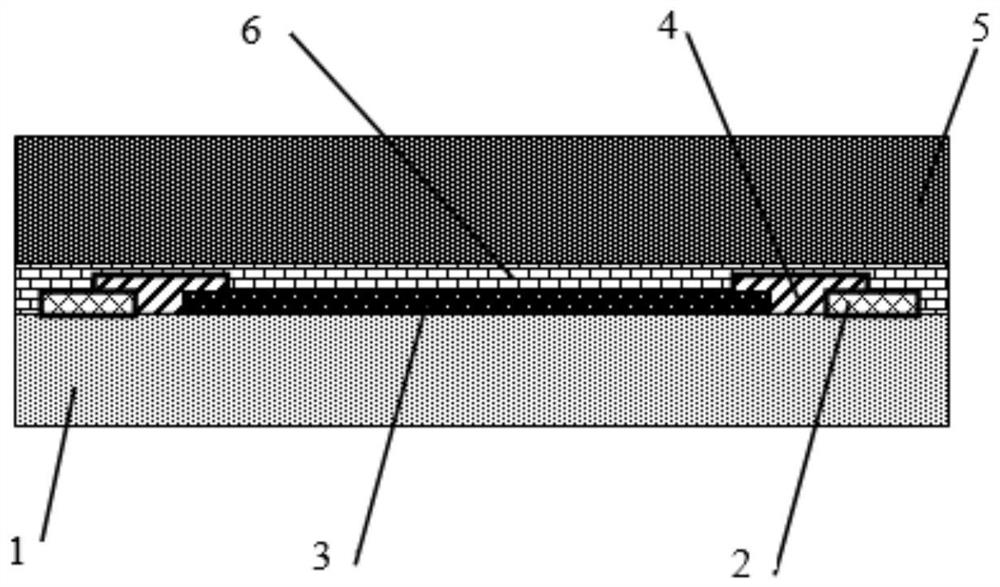

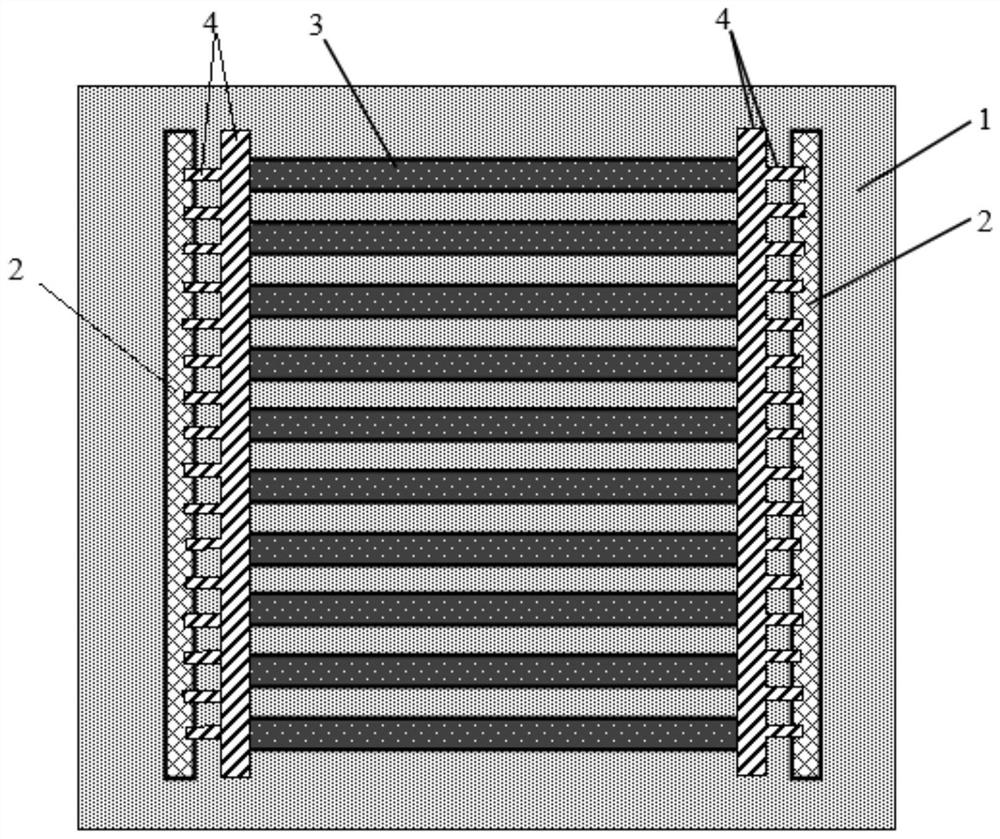

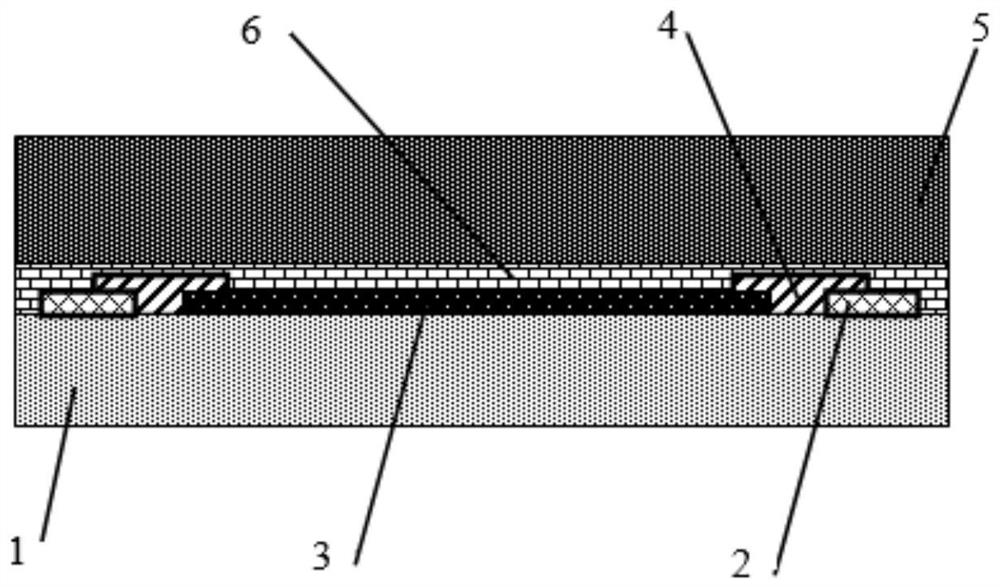

Graphene electrothermal film for floor heating

PendingCN111712001AStrong adhesionReliable electrical connectionLamination ancillary operationsSynthetic resin layered productsFlexible circuitsCopper electrode

The invention discloses a graphene electrothermal film for floor heating, which is prepared according to the following steps: coating a graphene heating film on the surface of an insulating substrateof the electrothermal film, and implanting copper electrodes into two opposite sides of the graphene heating film; printing bridging electrodes on the surfaces of the graphene heating film and the copper electrode; and then covering and packaging the second insulating substrate to form the flexible circuit board. The heating body of the graphene electrothermal film for floor heating is in good contact with the bridging electrode and the copper electrode. The bridging electrode completely coats the copper electrode. The contact resistance between the bridging electrode and the surface of the copper current-carrying electrode is obviously reduced. The graphene electrothermal film has the advantages that the the peeling resistance is improved, the risk of fire caused by edge sparking of the heating body is effectively solved, the energy utilization rate is increased, the whole-process automatic production is more favorably realized, and the problem that the copper electrode compounding process is easy to be abnormal and cannot be automatically connected with the front-end process in the traditional production process is completely eradicated.

Owner:安徽宇航派蒙健康科技股份有限公司

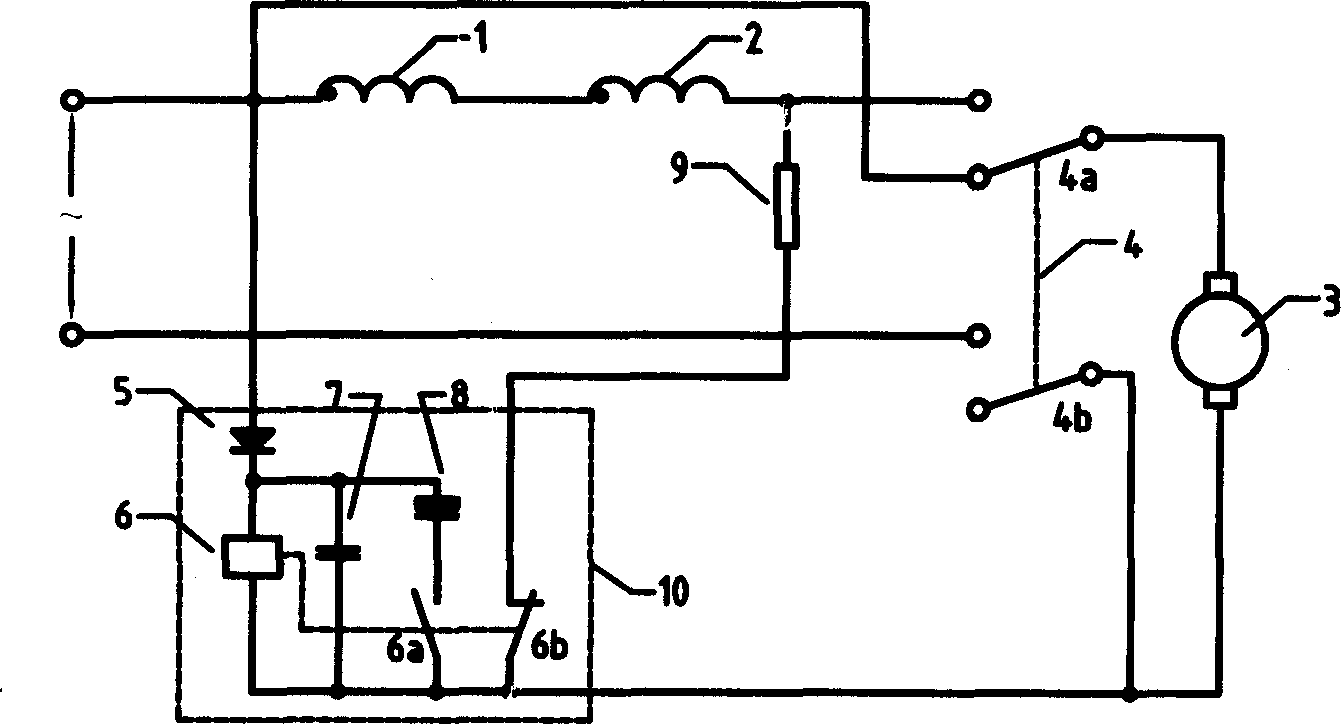

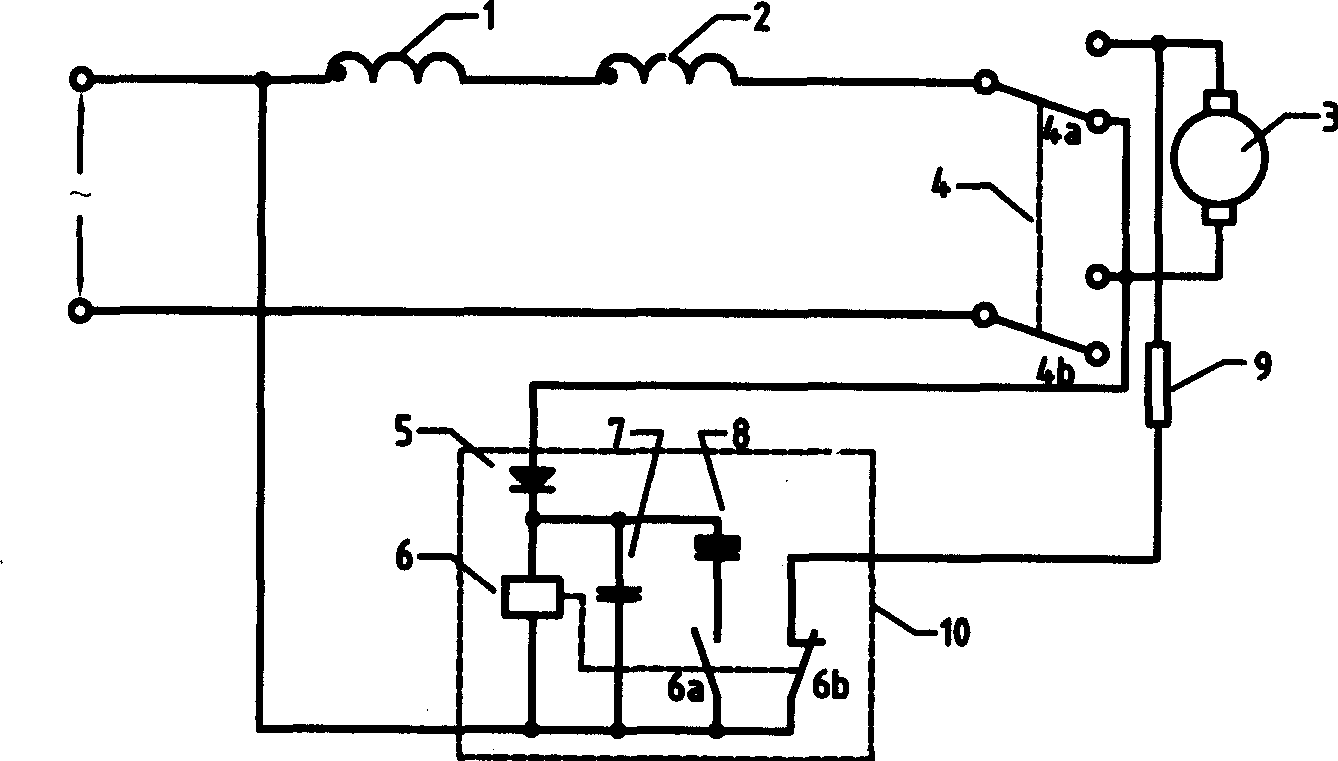

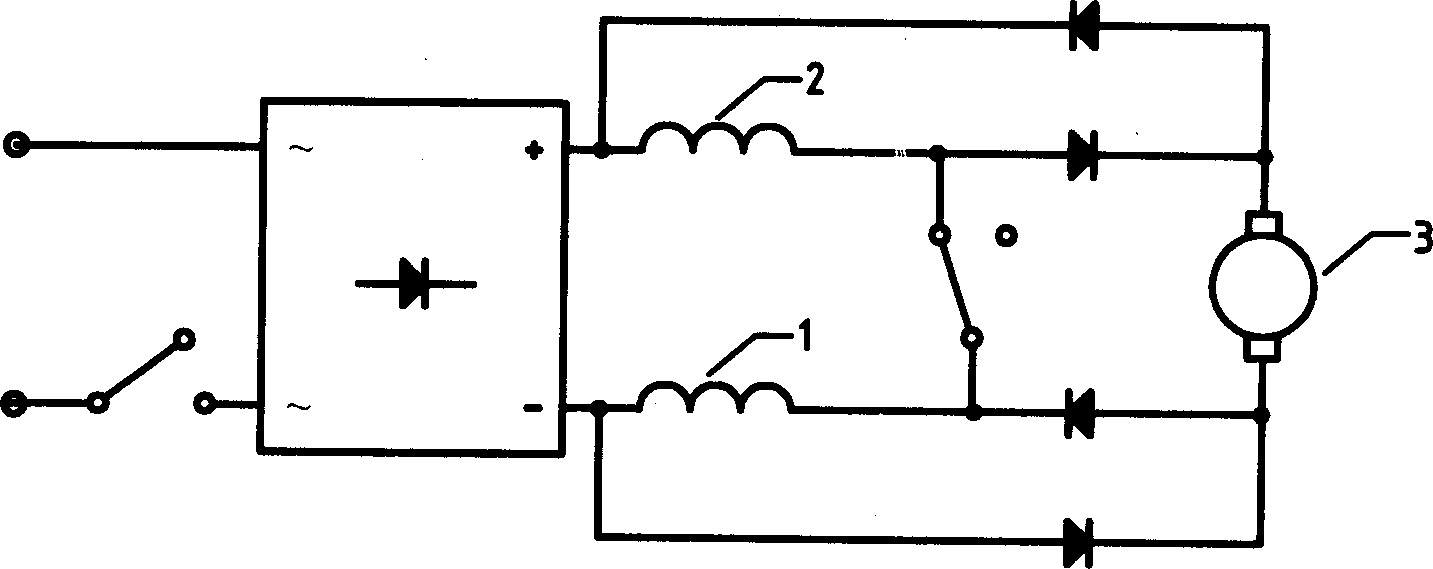

Series electric machine with electric braking function

This invention relates to a series excited machine with an electric braking function including an excitation winding and an armature serial to the excitation winding, a power cut-off backing switch, a brake resistor and a delay control device, in which, the power cut-off backing switch cuts off the power to back the two ends of the excitation winding or the armature to be delayed by the delay control device then serial to the braking resistor to form a braking loop with the excitation winding and the armature, which rotates to generate braking current generating brake moment to brake the motor.

Owner:孙鹤鸣

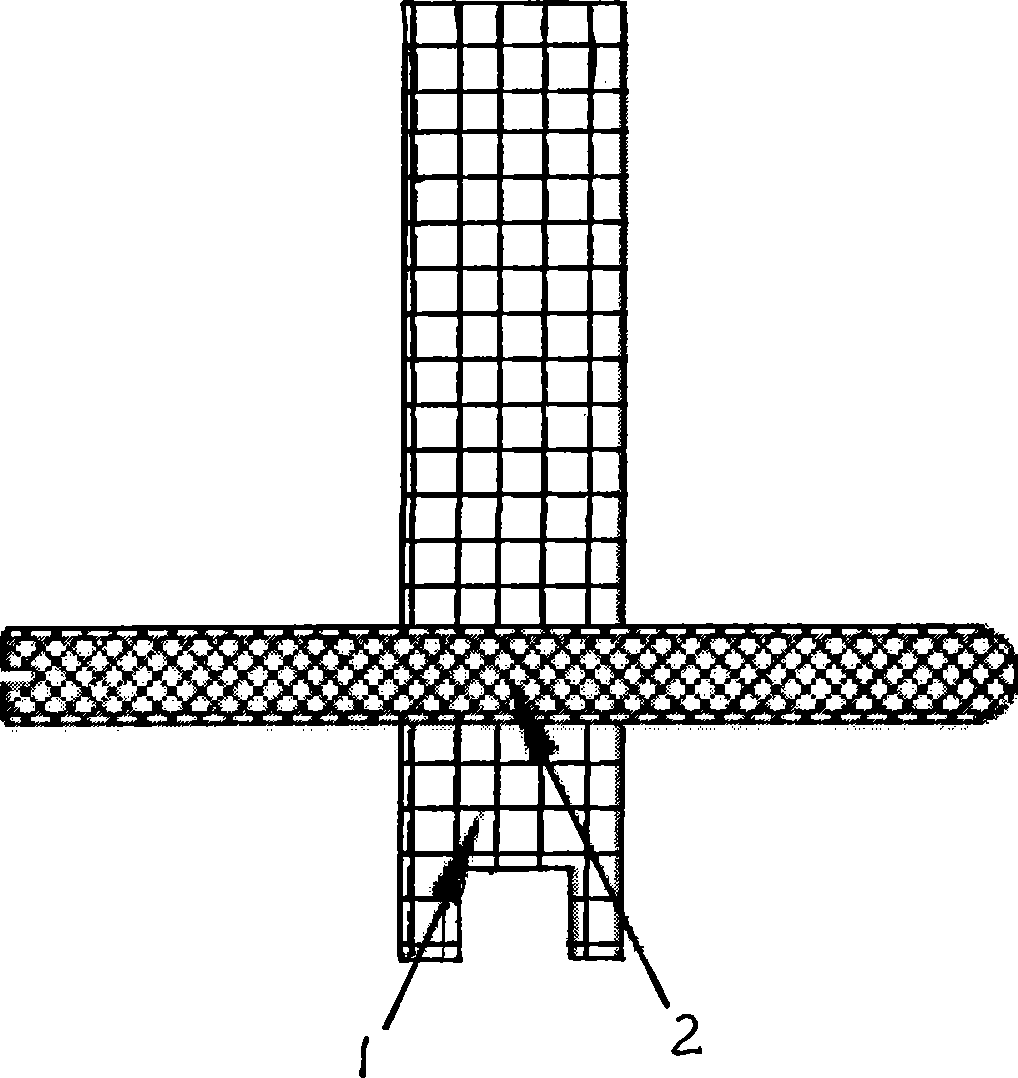

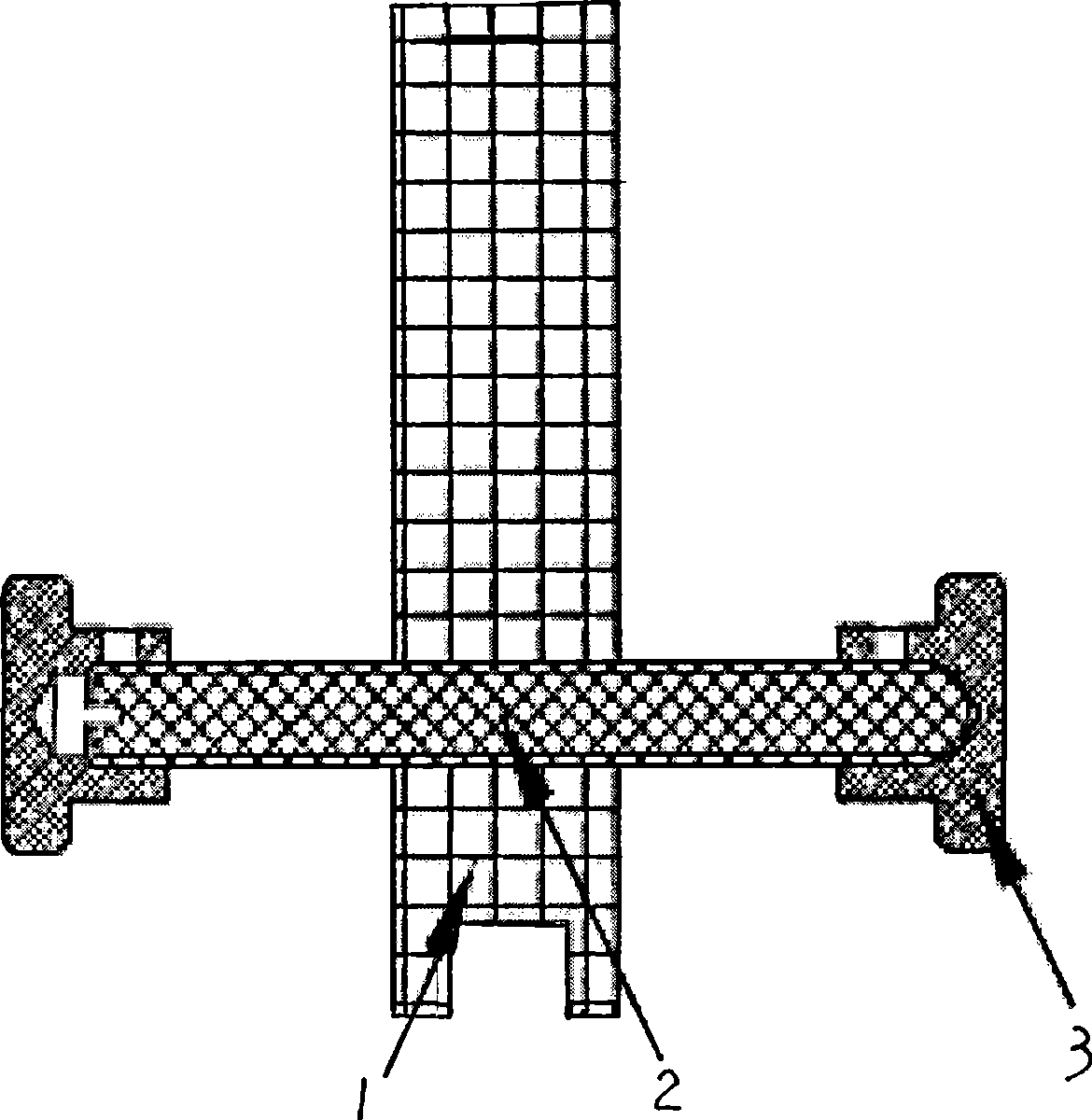

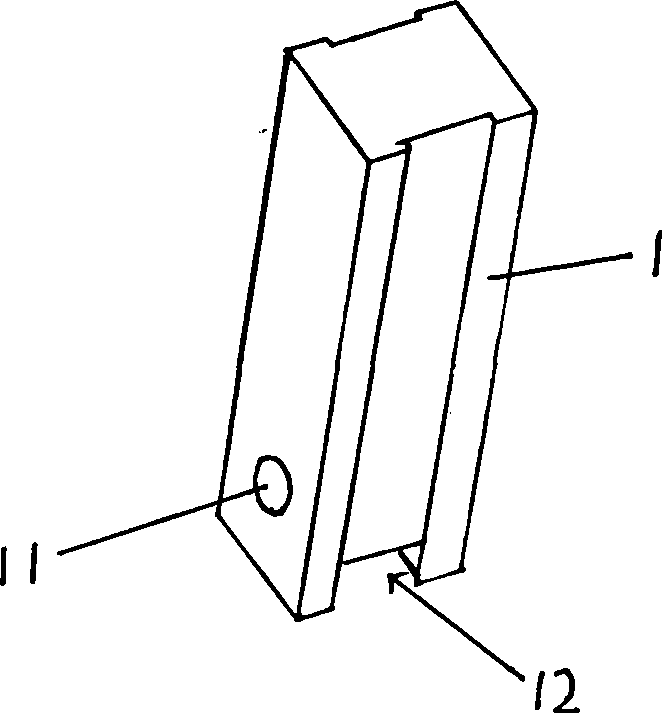

Welding method and device of frame support rings of bag type dust collector

The invention relates to a welding method and a device of frame support rings of a bag type dust collector. After longitudinal steel wires are straightened, the steel wires are inserted into welding equipment according to the number of frame longitudinal steel wires; support rings are put in to perform the spot welding connection with the longitudinal steel wires; and the radial expansion force is applied to the support rings before the welding, so that all the welding points of the support rings and the multiple longitudinal ribs are fully contacted. Compared with the prior art, the welding method and device can prevent the pseudo soldering phenomenon of synchronous welding of multiple points caused by the size errors of the support rings and devices for supporting the support rings.

Owner:上海袋式除尘配件有限公司

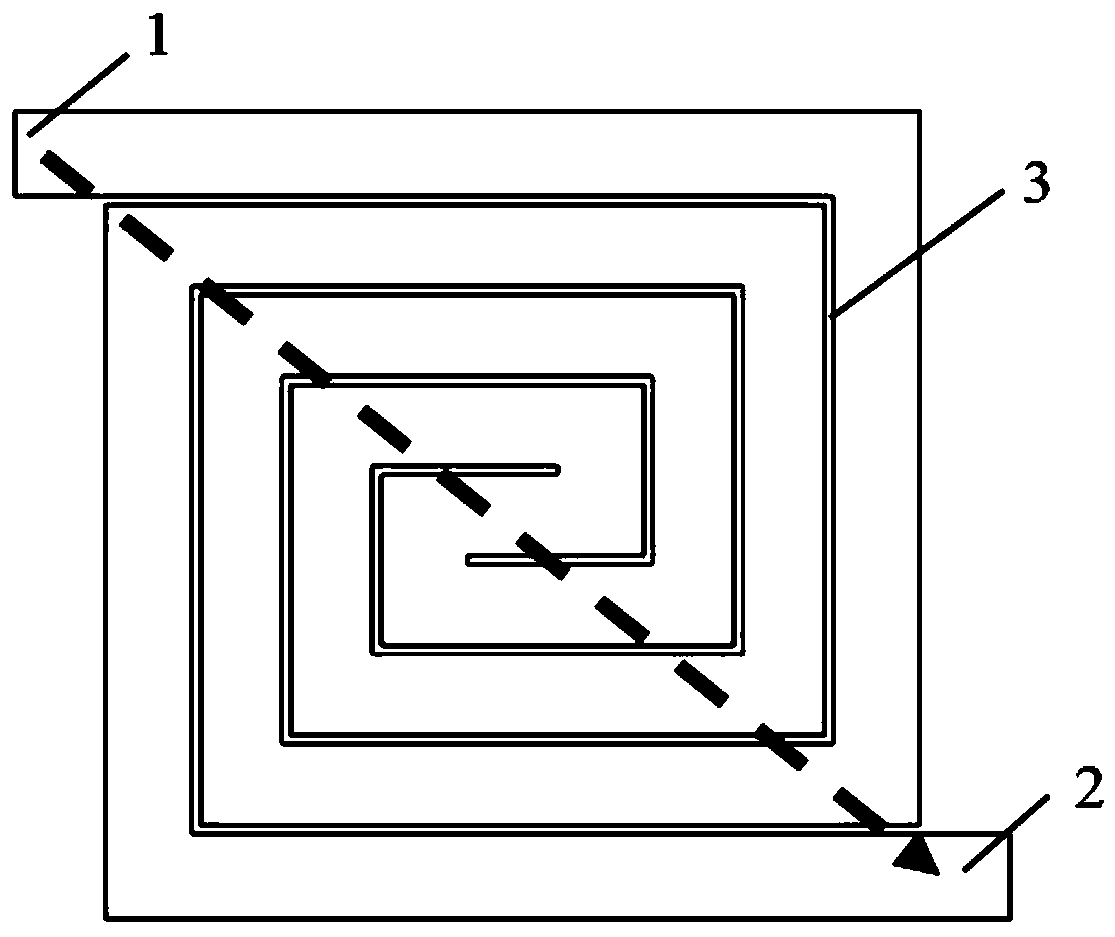

A flat filament for an X-ray CT tube

PendingCN109065430AAvoid stress deformationExtended service lifeX-ray tube electrodesX-ray tube cathode assemblyX-rayCentrifugal force

The invention discloses a flat-plate filament for an X-ray CT tube, belonging to the technical field of medical instruments. The flat filament for an X-ray CT tube includes a flat plate and an emitting structure formed on the flat plate. The emission structure is a four-pin square or circular structure formed by a plurality of through grooves, and the stability of the structure is improved throughthe four-pin structure, and the filament stress deformation caused by the strong centrifugal force generated by the high-speed rotation of the CT machine is avoided. The plate filament prolongs the service life of the filament by optimizing the groove structure and reducing the ignition caused by the pressure difference between the grooves. By reasonably directing the electric current, the influence of the self-generated magnetic field of the flat filament on the electron beam focusing is weakened, and the focal spot quality is ensured.

Owner:麦默真空技术无锡有限公司

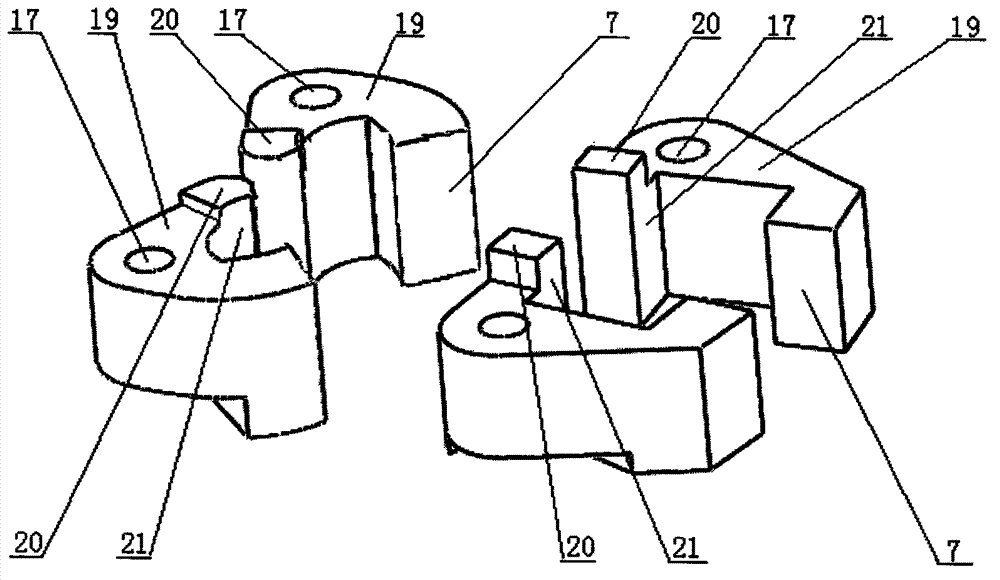

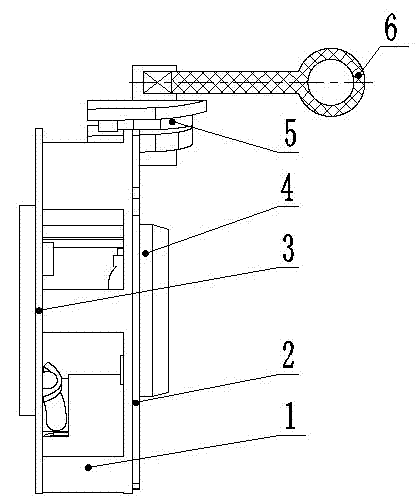

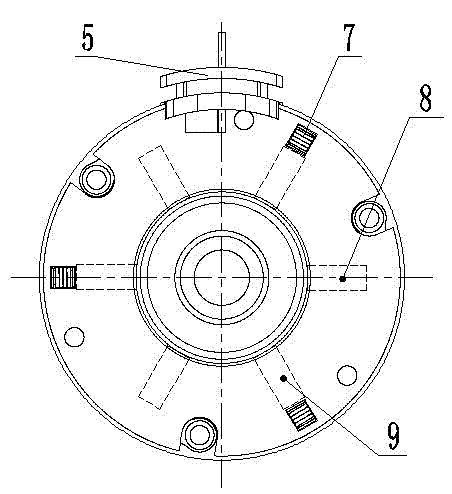

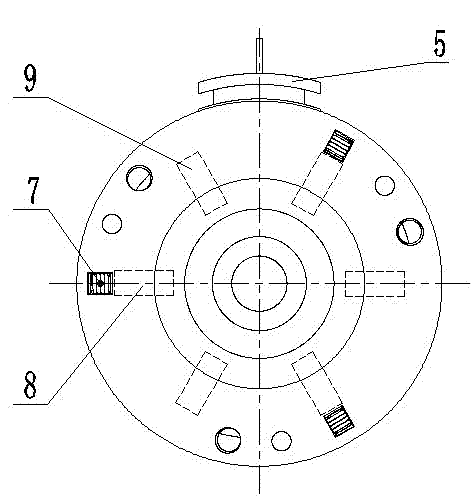

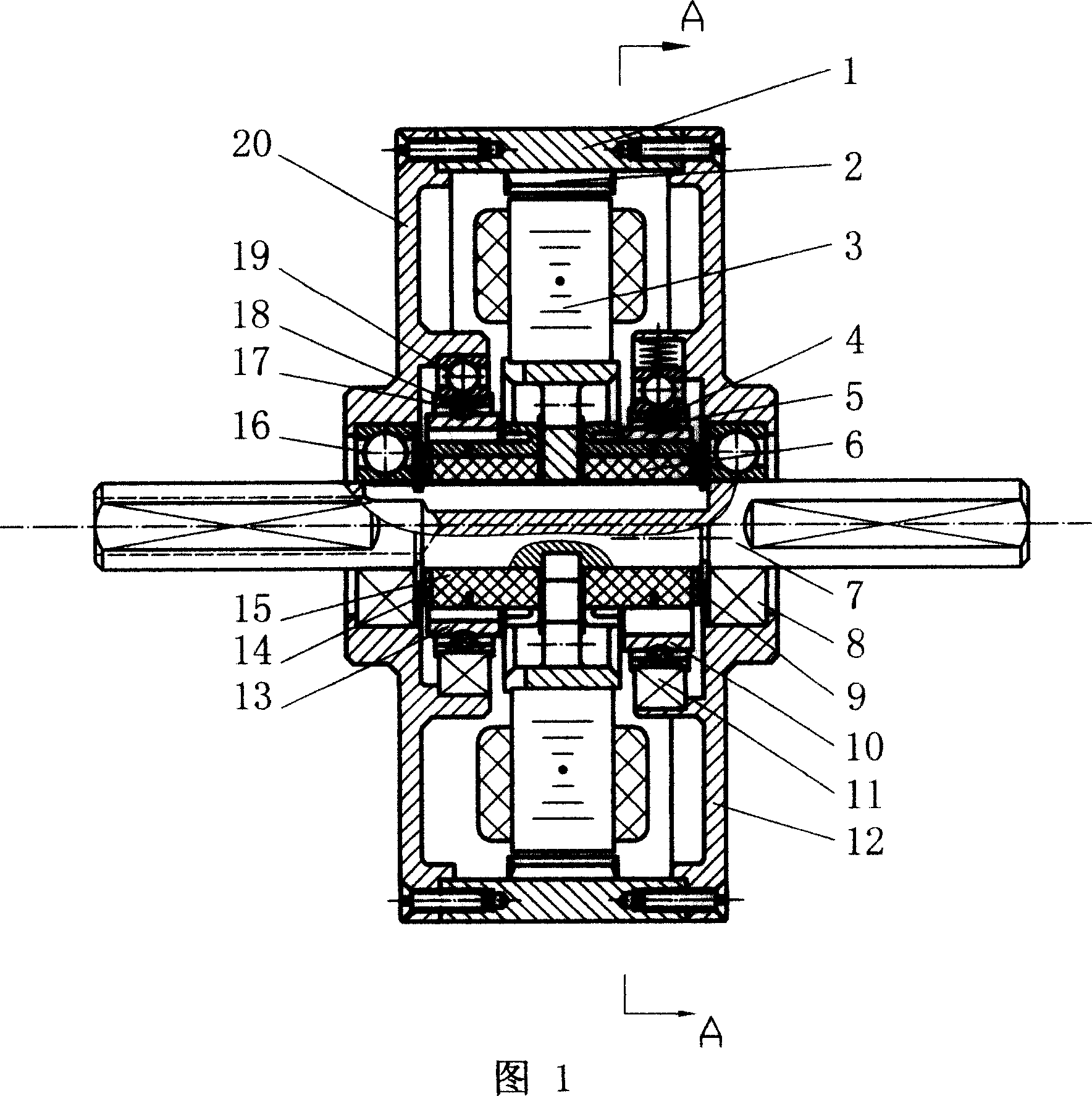

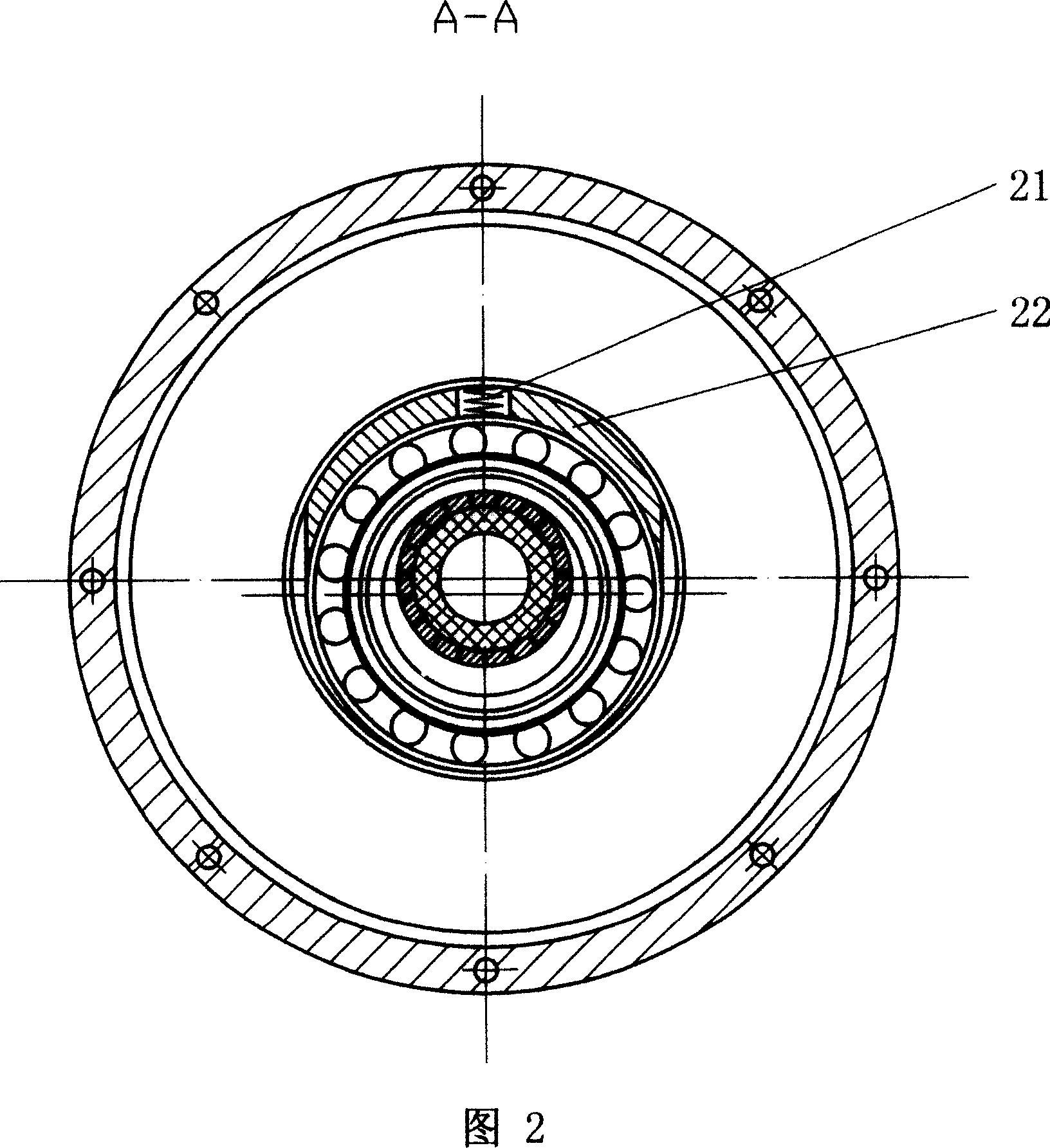

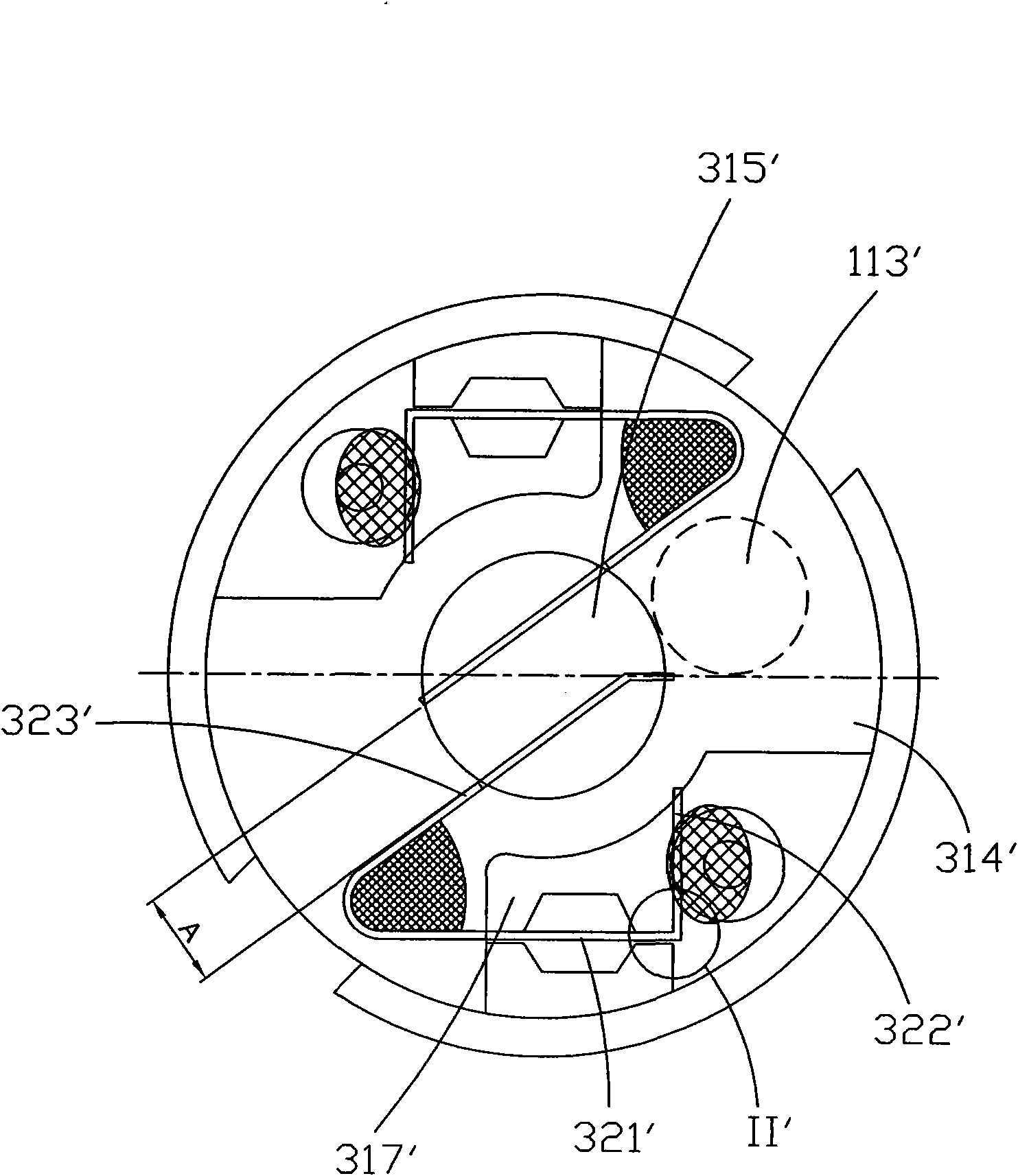

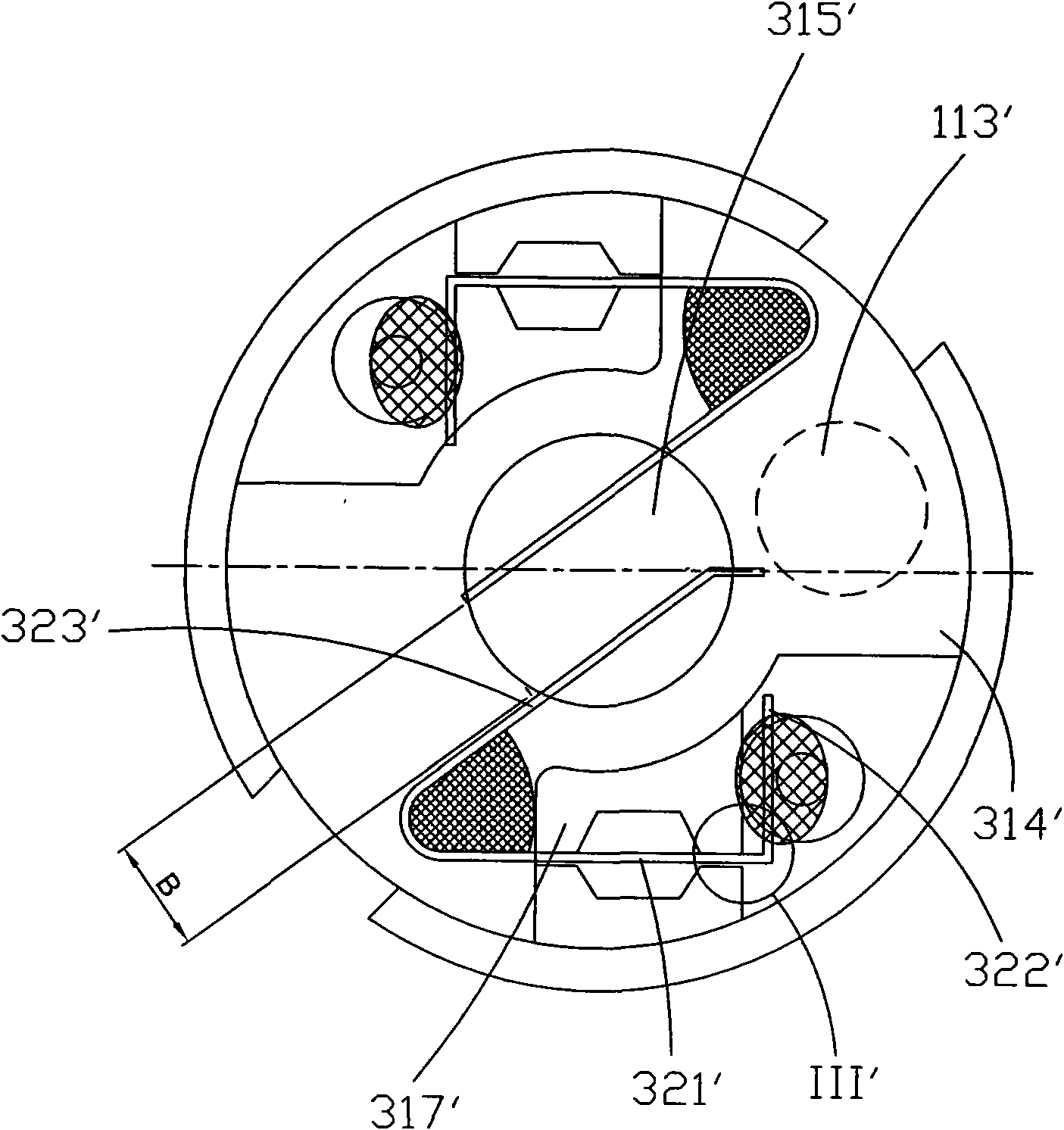

Carbon brush holder assembly for starter and assembling method thereof

ActiveCN102709772ASmall current fluctuationImprove performanceLine/current collector detailsRotary current collectorWork performanceInjection moulding

The invention provides a carbon brush holder assembly for a starter, which comprises a brush holder box, a positive pole baseplate and a negative pole baseplate which are arranged on the brush holder box, positive pole carbon brushes, negative pole carbon brushes, springs for driving the positive pole carbon brushes and the negative pole carbon brushes to move, an insulating sheath, a positive pole connecting wire and a carbon brush temporary fixing ring, wherein the brush holder box, the positive pole baseplate and the negative pole baseplate are correspondingly provided with a coaxial hollow hole for a starter rotary shaft to pass through. The assembly is characterized in that three positive pole carbon brushes and three negative pole carbon brushes are respectively welded on the positive pole baseplate and the negative pole baseplate, the brush holder box is formed by one-time injection molding and is provided with three positive pole brush holder grooves and three negative pole brush holder grooves respectively corresponding to the negative pole carbon brushes and the negative pole carbon brushes, the positive pole baseplate and the negative pole baseplate are provided with square grooves which respectively corresponds to the positive pole brush holder grooves and the negative pole brush holder grooves and are used for assembling the springs. A six-brush assembling structure can increase the working performance and prolong the service life. The assembly has a simple assembling process and convenience in assembling, thus improving the assembling efficiency obviously.

Owner:JINZHOU HALLA ELECTRICAL EQUIP

Brushless synchronous communicating DC hub motor

InactiveCN101001041AIncrease contactImprove efficiencyRotary current collectorCoupling device detailsMotor driveEngineering

This invention relates to a brushless synchronous commutating DC hub motor driven by power used in electromotive cars, in which, a stator is placed at the middle of the shell and fixed on the main shaft with commutators at both sides composed of a supply ring and commutating plates tangent to synchronous rings inside or outside jacketed on bearings in right and left covers of the shell by a flexible universal ring, the rotor is fixed in the shell composing an output structure with it, a lead enters via a main shaft hole and is connected with a supply touch plate to constitute a supply input structure, and the leads at both ends, the supply touch plates, a supply ring, a synchronous ring, commutating plates and the stator winding coil make up of a closed circuit, when it is turned on, it generates electromagnetic induction to push the rotor to drive the synchronous rings to move periodically along the commutator to turn current to commutate and drive the rotor rotating in the same direction.

Owner:杨光笋 +2

Structural steel welding rod and method for preparing same

ActiveCN106825991ALess smokeReduce sparksWelding/cutting media/materialsSoldering mediaSmokeWelding joint

The invention provides a structural steel welding rod and a method for preparing the same. The structural steel welding rod comprises welding cores and coating. The coating wraps the welding cores. The coating comprises, by weight, 5-35 parts of titanium dioxide powder, 20-27 parts of reduction titanium, 7-8.5 parts of medium manganese, 7-10 parts of lime mud, 5 parts of mica, 3 parts of argil, 2-4 parts of feldspar, 7-8.5 parts of marble, 0-2 parts of wood meal, 1-3 parts of celluloses, 0-30 parts of rutile and 0-5 parts of illite. The method includes steps of adhesive adding and wet mixing, press coating and drying. The diameters of the welding cores are 2-4 mm. The structural steel welding rod and the method have the advantages that processes for manufacturing the structural steel welding rod are simple, the coating and the welding cores are good in connection performance, the structural steel welding rod generates little smoke and is low in spark splashing during use, and welded joints are attractive and are high in smooth finish; the structural steel welding rod is good in secondary arc strike property and is environmentally friendly and safe during use, slag is easy to remove, and the work efficiency can be greatly improved.

Owner:石家庄旭家焊接材料有限公司

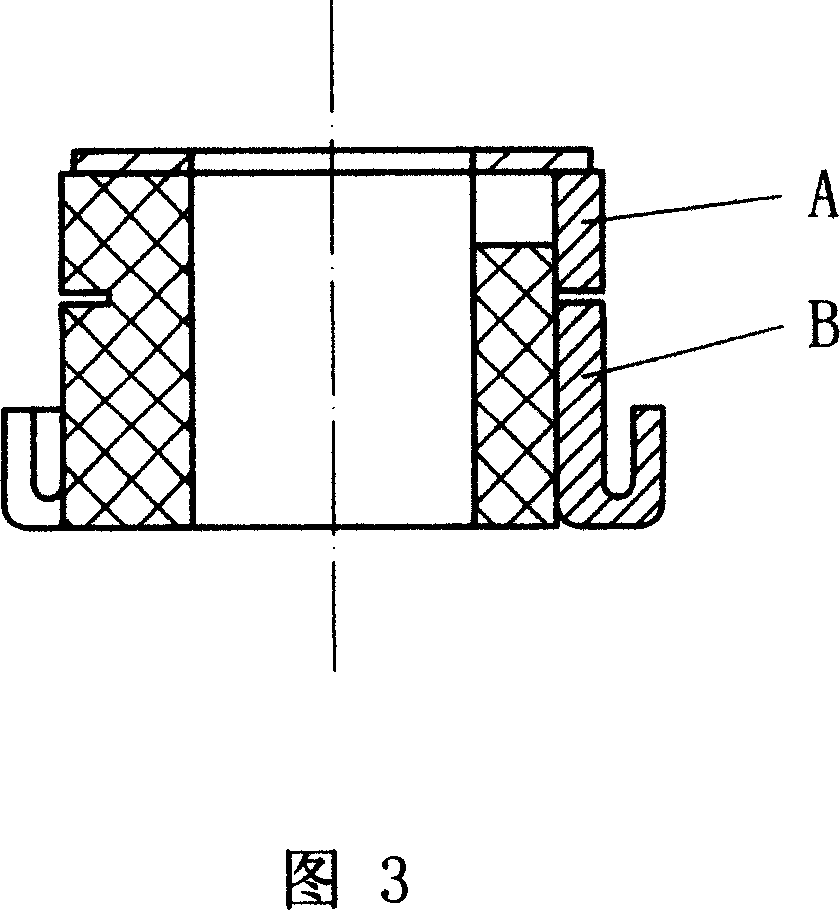

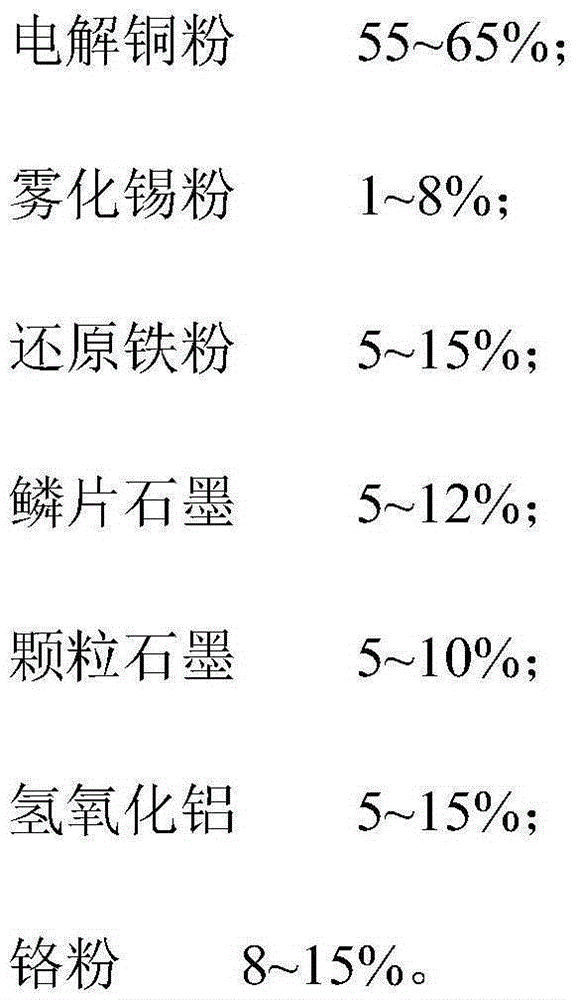

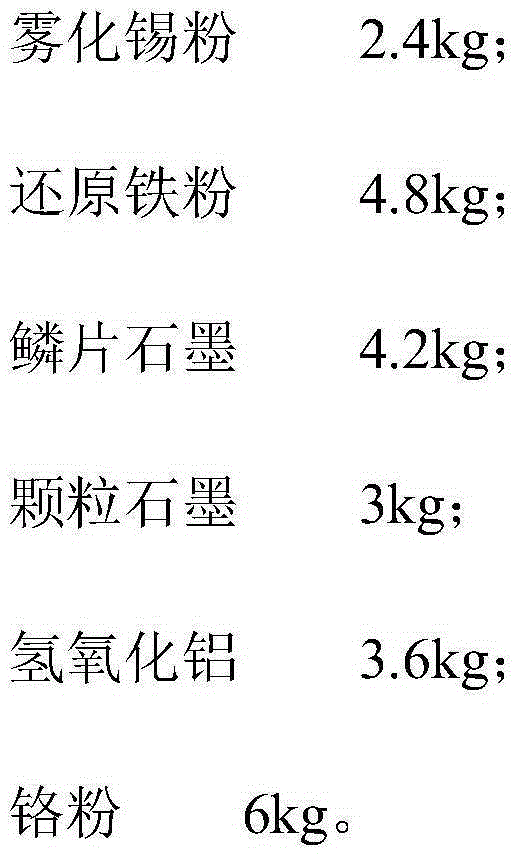

Main shaft brake lining of wind-driven generator and preparation method thereof

ActiveCN105422702AStable coefficient of frictionStrong wear resistanceFriction liningActuatorsWind drivenBrake lining

The invention discloses a main shaft brake lining of a wind-driven generator. The brake lining is composed of, by weight, electrolytic copper powder of 55-65%, atomization tin powder of 1-8%, reduced iron powder of 5-15%, flake graphite of 5-12%, granular graphite of 5-10%, aluminum hydroxide of 5-15% and chromium powder of 8-15%. The invention further discloses a preparation method of the main shaft brake lining of the wind-driven generator. The brake lining is obtained through the steps of material proportioning, material mixing, cold blank compression forming, high temperature sintering in an elevator furnace, furnace cooling and final machining. The brake lining manufactured through the method is stable in friction coefficient, high in wear resistance, free of sparks in braking, long in service life and small in wear to mating plates, and can fully meet the braking requirement of a main shaft of the wind-driven generator.

Owner:JIANGXI HUAWU BRAKE

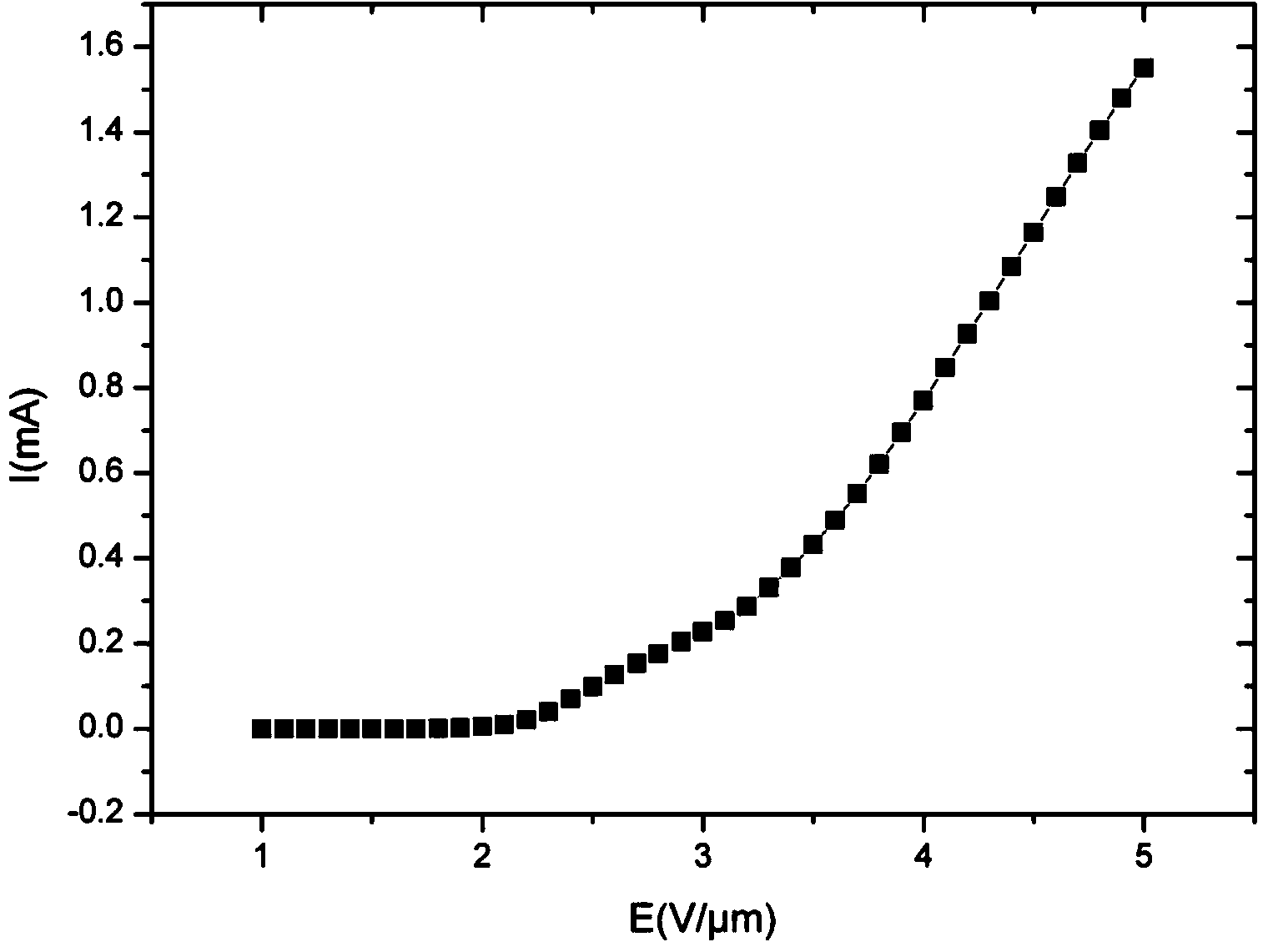

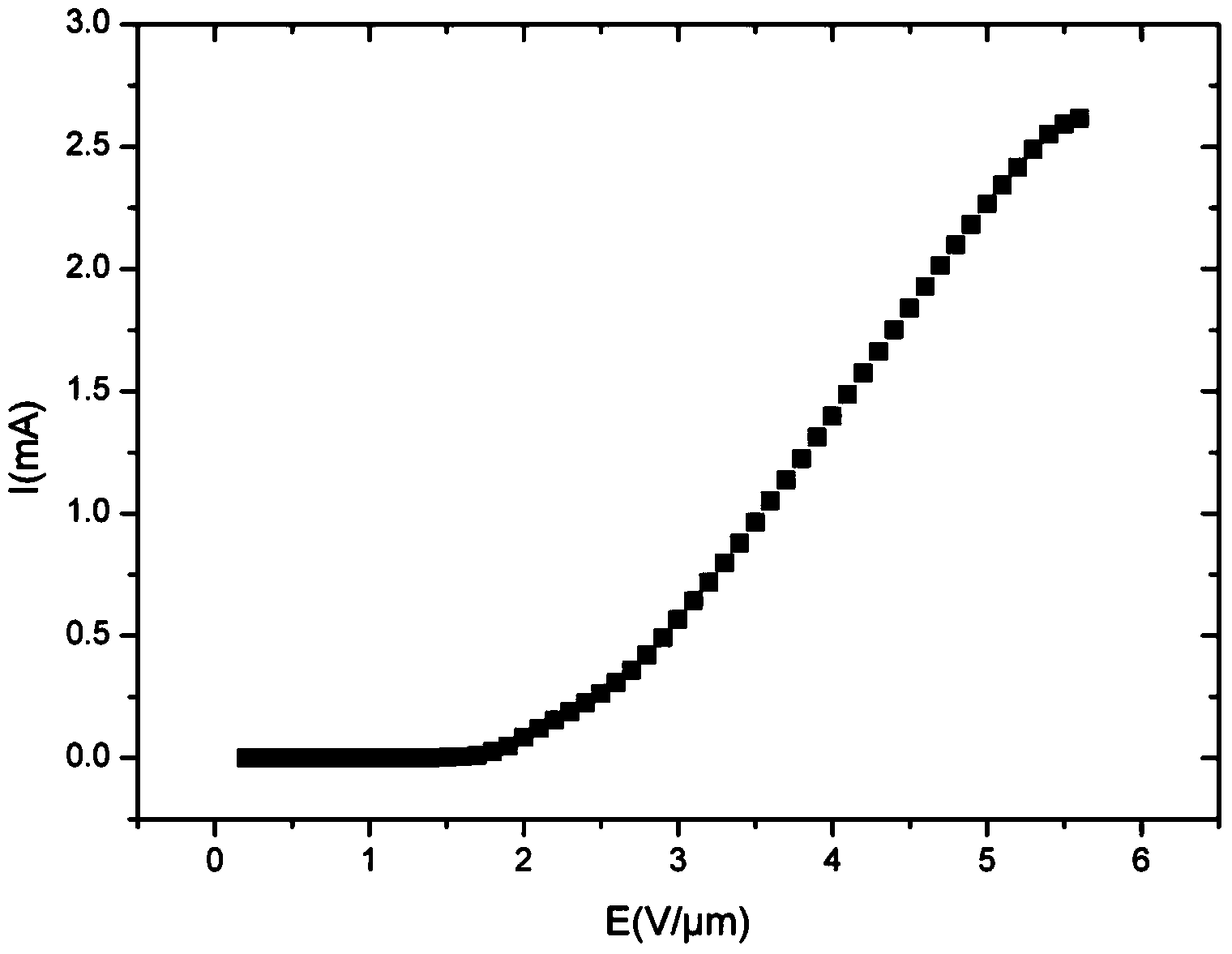

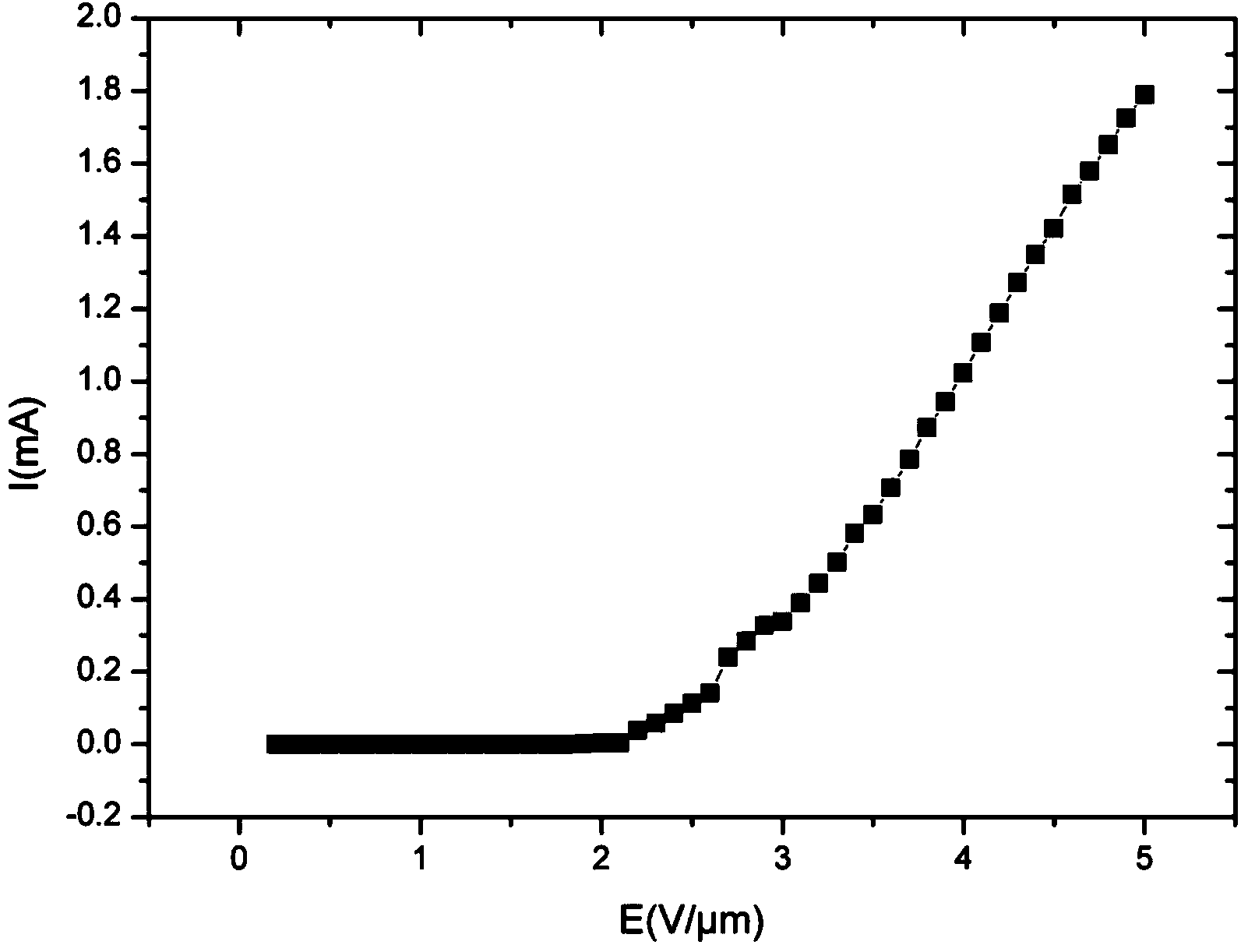

Carbon nano tube cathode and preparation method thereof

ActiveCN103545158ASimple preparation processIncrease emission currentDischarge tube/lamp detailsCold cathode manufacturePower flowElectrophoresis

The invention provides a preparation method of a carbon nano tube cathode and the carbon nano tube cathode obtained through the method. The preparation method includes the steps that a bonding agent layer is arranged on an electric conduction substrate in an electrophoretic deposition mode; a carbon nano tube thin film is arranged on the electric conduction substrate in an electrophoretic deposition mode, wherein the bonding agent layer is also deposited on the electric conduction substrate; in a vacuum or protective atmosphere environment, hot pressed sintering is conducted on the carbon nano tube thin film and the bonding agent layer, so that the carbon nano tube cathode is obtained. According to the carbon nano tube cathode and the preparation method thereof, the hot pressed sintering technology is adopted, the root portion of a carbon nano tube is embedded into a base body of a bonding agent under the action of pressure, so that firm combination is formed, meanwhile, the contact resistance of the carbon nano tube and the base body is lowered, hence, emission currents of the carbon nano tube are increased, and the current stability of the carbon nano tube is improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for preparing wires from difficult-to-deform cobalt-based high-temperature alloy

The invention discloses a method for preparing wires from difficult-to-deform cobalt-based high-temperature alloy. The method comprises the following steps that 1, mother alloy of the cobalt-based high-temperature alloy is melted, then is refined, and then undergoes vacuum suction casting to obtain a cobalt-based high-temperature alloy round bar; 2, the cobalt-based high-temperature alloy round bar is placed into a quartz glass pipe, then is put into a quartz glass wire-drawing machine, and then is heated to obtain the cobalt-based high-temperature alloy liquid, when the quartz glass which isin contact with the cobalt-based high-temperature alloy liquid is softened, wire drawing is carried out, and cooling is carried out to obtain the cobalt-based high-temperature alloy wire crude productcoated with the quartz glass; and 3, the cobalt-based high-temperature alloy wire crude product coated with the quartz glass sequentially undergoes coating removing, rotary forging and drawing finishing to obtain the cobalt-based high-temperature alloy wires. According to the method, the quartz glass pipe is adopted to coat the cobalt-based high-temperature alloy round bar, then heating the wiredrawing are carried out, the diameter of the cobalt-based high-temperature alloy wires is controlled by controlling the wire-drawing shape of the quartz glass pipe, then the cobalt-based high-temperature alloy wires with the diameter ranging from 1 mm to 3 mm are obtained, and the problem that the cobalt-based high-temperature alloy is poor in molding and difficult to deform is solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Coupling structure of filter

InactiveCN101471472AGuaranteed stabilityStability is easy to seeCoupling devicesCouplingDumbbell like

The invention provides a filter coupling structure, which comprises a support, an M3 adjusting screw, or two flanges. A screw hole through two opposite sides is formed on the lower part of the support; the M3 adjusting screw penetrates the screw hole of the support and is connected with lower part of the support; and the two flanges are respectively connected with both ends of the M3 adjusting screw to form a dumbbell-like structure. Compared with the prior, the filter coupling structure has good product consistency, stability and reliability.

Owner:ALLRIZON TONGGUANG COMM EQUIP SHANGHAI

Novel electric brush production technology

The invention discloses a novel electric brush production technology. The production technology sequentially comprises the following steps of: I, selecting raw materials including silver powder, copper powder, ceramic powder, graphite powder, resin and binder; II, mixing the silver powder, copper powder, ceramic powder, graphite powder, resin and binder at a weight ratio of 2:4:1:2:1:1, and heating and stirring, wherein the temperature is 40-60 DEG C; III, grinding the mixture in a grinder, screening the granular mixture, and soaking the granular mixture in a container for 5-6 hours; IV, pressing the soaked granular mixture in a mould to obtain a semi-finished product; and V, performing finishing molding of the semi-finished product. The technology disclosed by the invention is simple, generates relatively little spark and realizes relatively long service life.

Owner:海门市通达碳业有限公司

Grid plasma immersion ion deposition dlc method with bias regulation

ActiveCN105112883BRealize the structureEnhanced sputter cleaning actionChemical vapor deposition coatingIon depositionHigh voltage pulse

Bias regulation grid plasma immersion ion deposition DLC method. It involves plasma immersion ion deposition DLC method. The invention aims to solve the problems of poor binding force, difficult adjustment and control of film performance and non-uniformity of DLC film deposited on large or complex parts existing in the existing MPIID method for depositing DLC films. Method: 1. Put the grid and the workpiece in the vacuum chamber, put the workpiece on the sample rack in the grid, insulate the grid from the workpiece, connect the grid to the high-voltage pulse power supply of the grid, and connect the workpiece to the high-voltage pulse power supply of the workpiece; 2. Splash the workpiece 3. Plasma nitriding treatment; 4. Sputtering etching treatment; 5. Preparation of SiC transition layer; 6. Preparation of bias control thin film. The invention is used for preparing DLC film deposited by plasma immersion ion deposition of bias voltage control grid.

Owner:HARBIN INST OF TECH

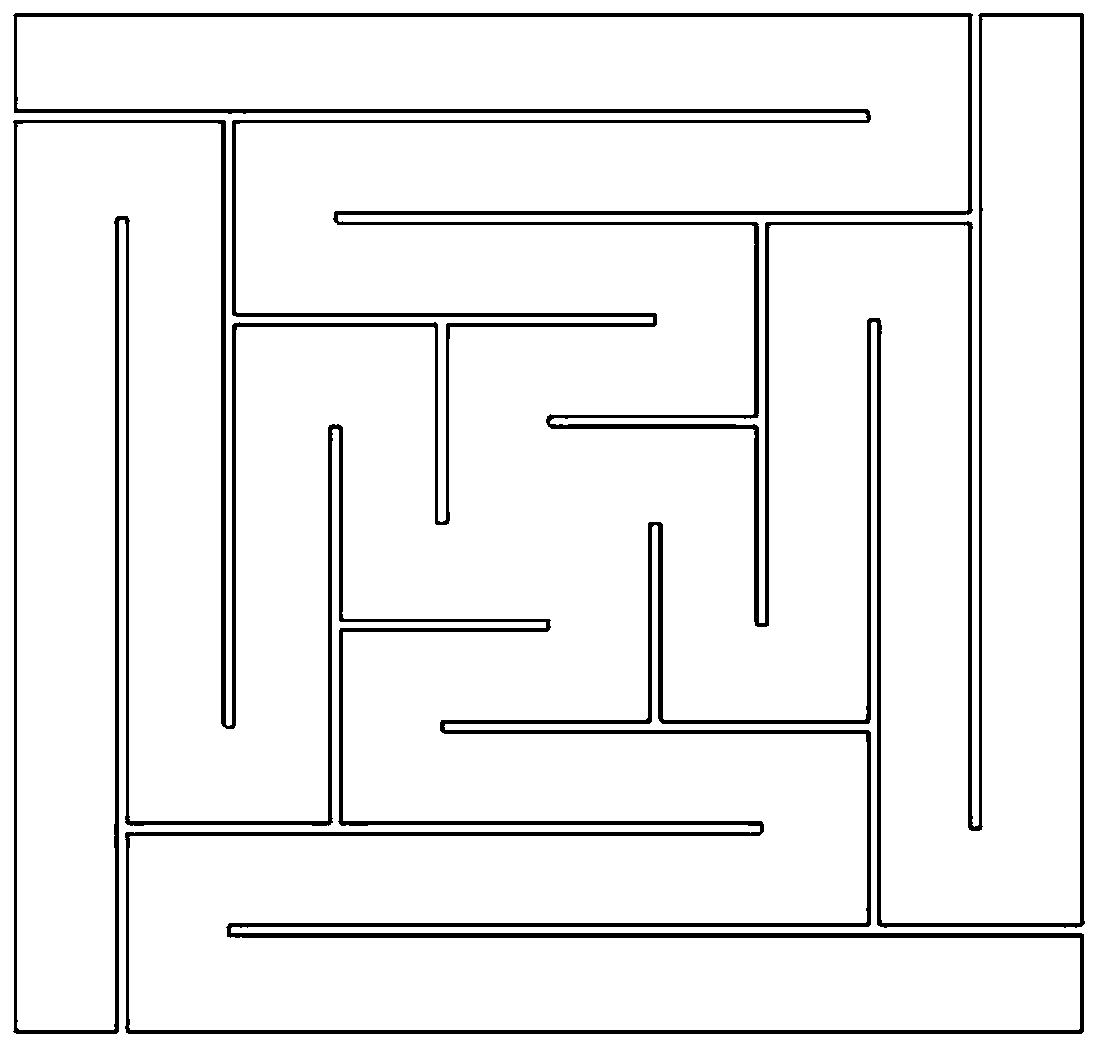

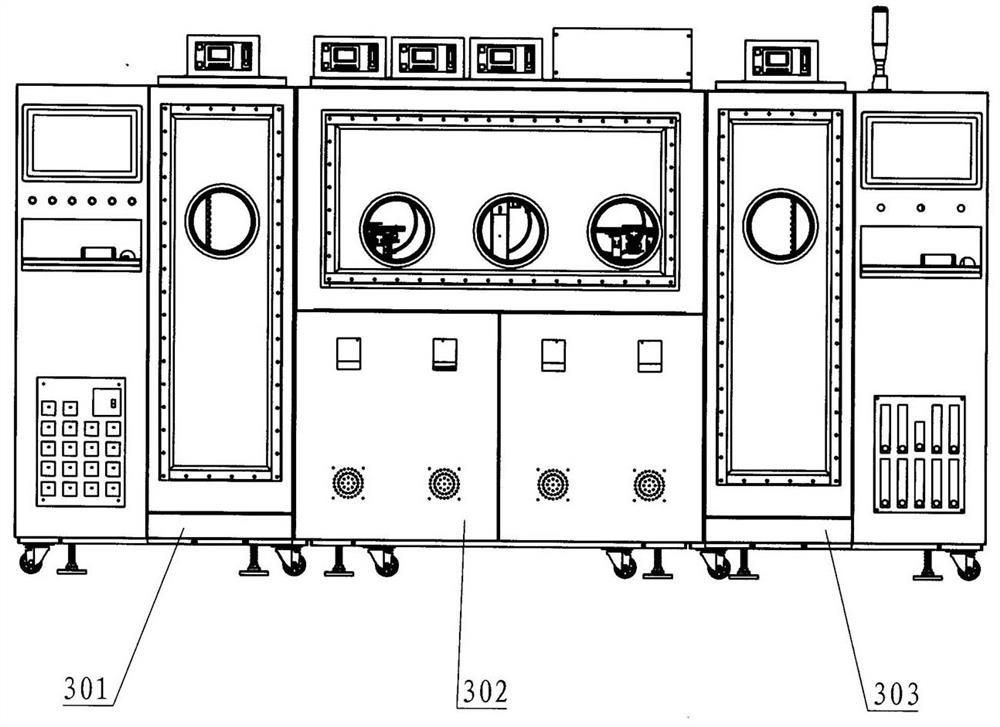

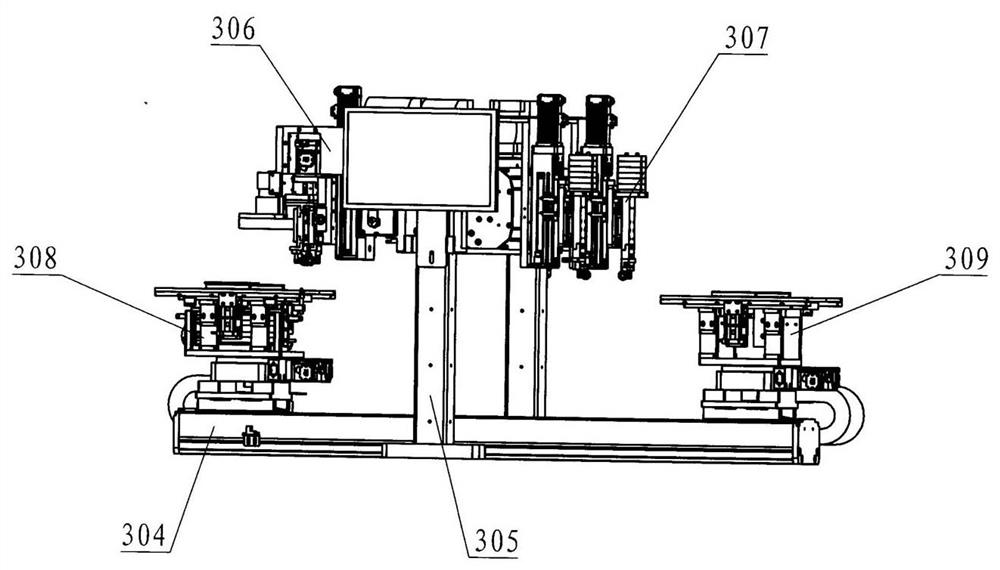

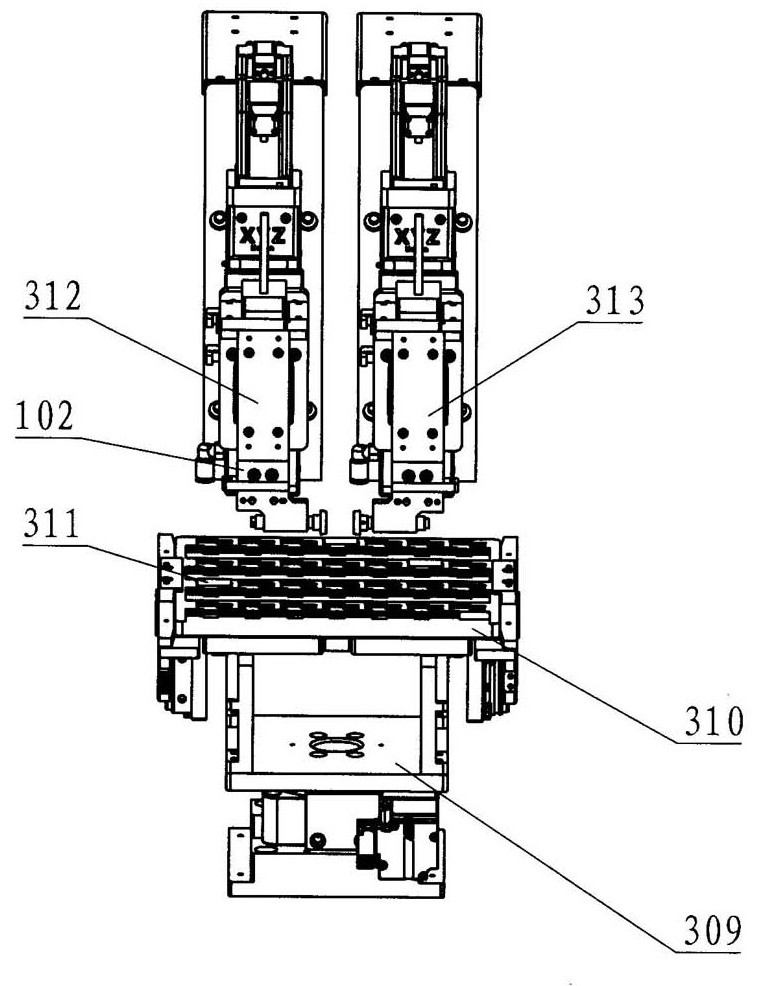

Split type full-automatic parallel sealing welding machine

ActiveCN114850640AEffective protectionImprove sealing and welding qualityFinal product manufactureWelding with roller electrodesEngineeringSpot welding

The invention discloses a split type full-automatic parallel seal welding machine which solves the technical problems of how to integrally improve the quality of the environment atmosphere of a parallel welding cavity and how to reduce the occurrence probability of sparking in seal welding. An X-direction welding material tray conveying module (304) and a welding mechanism installation portal frame (305) are arranged in the welding chamber (302), the X-direction welding material tray conveying module penetrates through the welding mechanism installation portal frame, a spot welding mechanism (306) and a seal welding mechanism (307) are arranged on a cross beam of the welding mechanism installation portal frame, a spot welding platform (308) is arranged under the spot welding mechanism, and the seal welding mechanism (307) is arranged under the spot welding platform (308). A seal welding platform (309) is arranged under the seal welding mechanism. A left sealing welding head mechanism (312) and a right sealing welding head mechanism (313) are arranged on the sealing welding mechanism, a material disc is arranged on a sealing welding platform (309) under the left sealing welding head mechanism and the right sealing welding head mechanism, and the sealing welding quality of elements is improved.

Owner:西北电子装备技术研究所

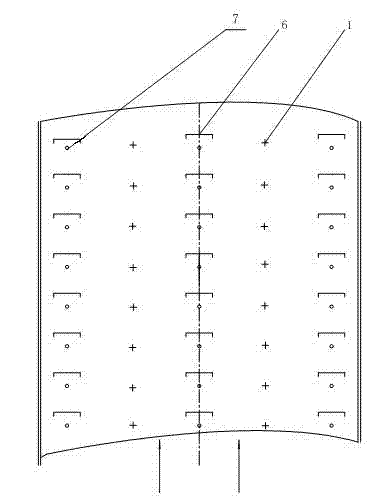

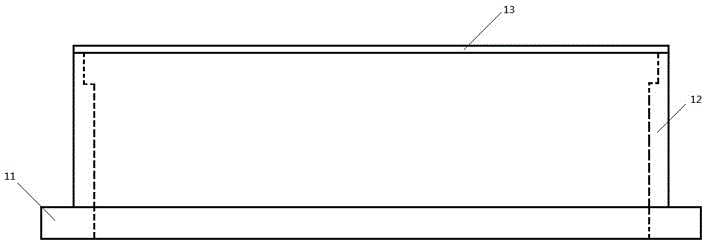

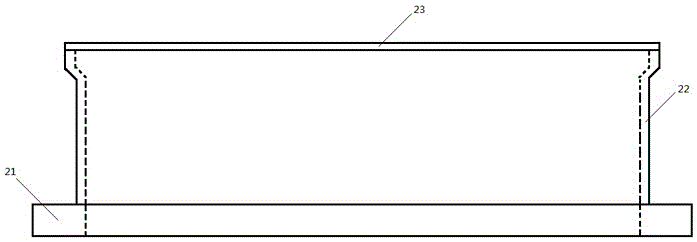

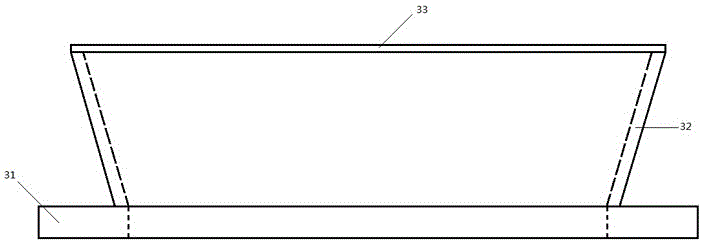

Magnetron sputtering planar target material shield cover

InactiveCN106011770AReduce deformationKeep the distance betweenVacuum evaporation coatingSputtering coatingEngineeringFilm coating

The invention relates to a magnetron sputtering planar target shielding cover, comprising a target back plate, surrounding side baffles and a cover plate, the cover plate is fixed on the surrounding side baffles, and the surrounding side baffles are fixed on the target back plate , the distance between the upper positions of at least two opposite side guards among the surrounding side guards is greater than the distance between the bottom positions. It can reduce the deformation during the installation and the actual coating heating process, keep the distance between it and the target base stable, and reduce the frequency of sparking caused by the close distance between the cathode and anode.

Owner:江苏宇天港玻新材料有限公司

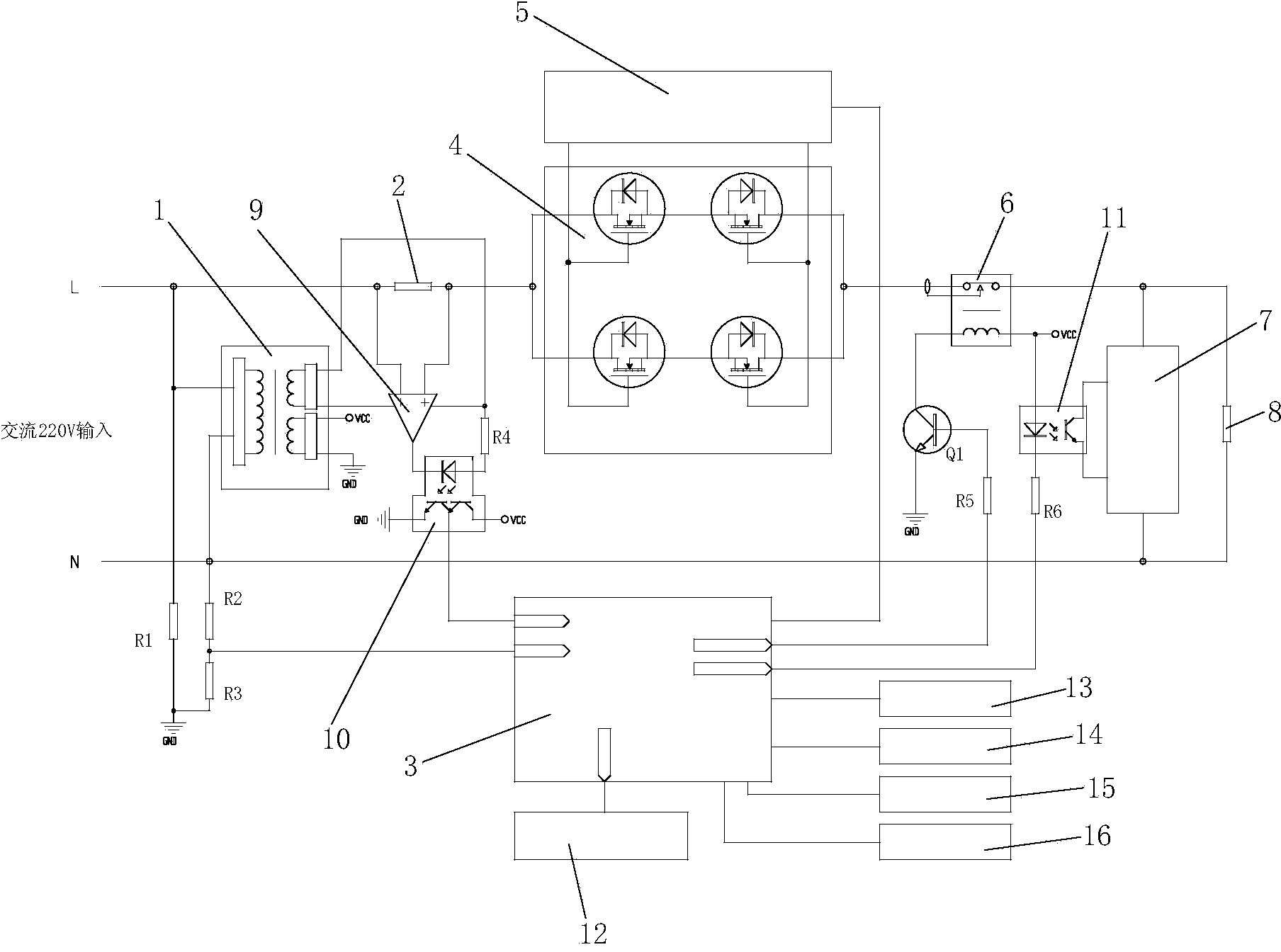

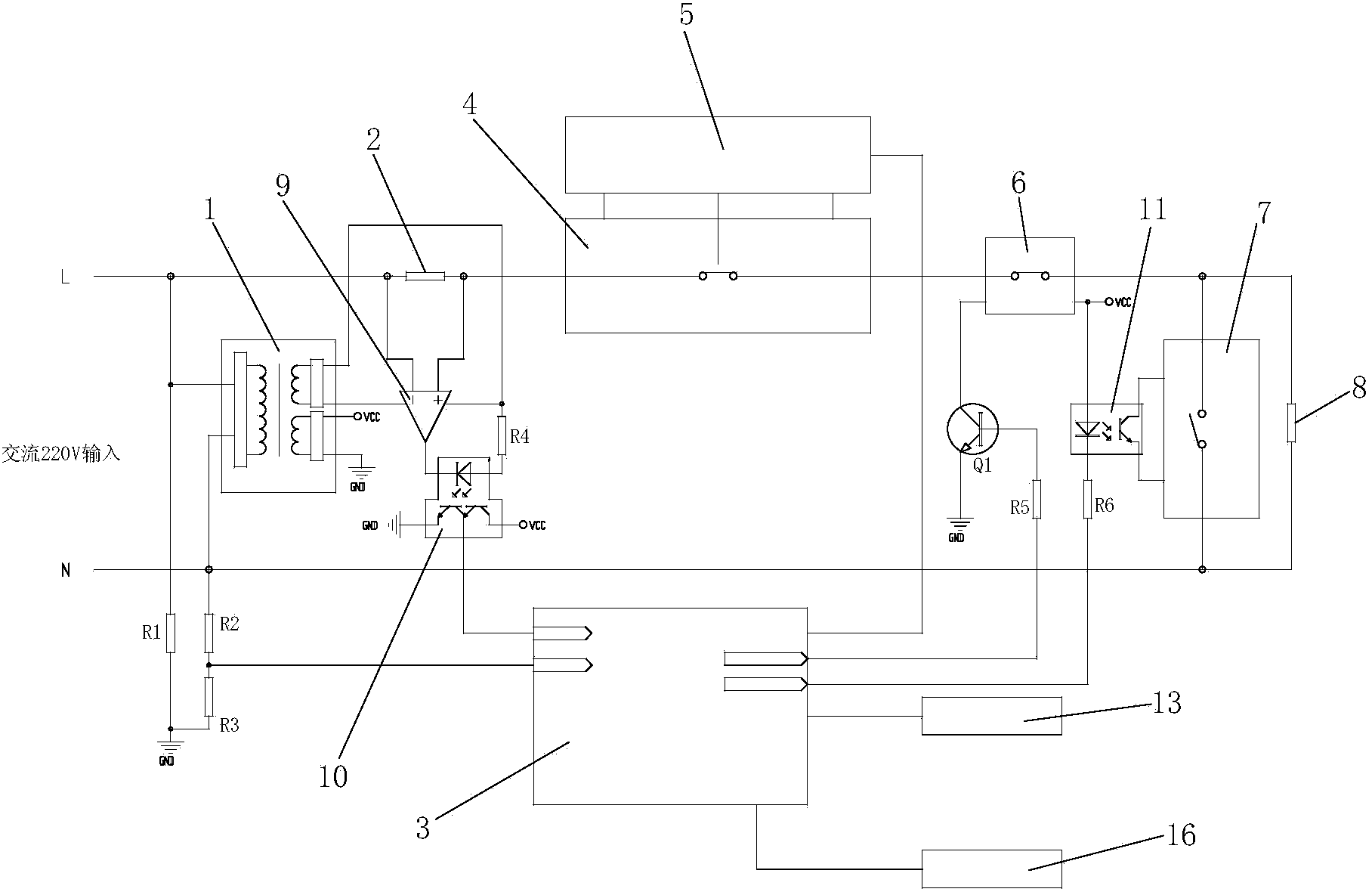

Multifunctional fireproof short-circuit protector with redundant device

ActiveCN103746331AImproved breaking timeExtension of timeArrangements responsive to excess currentShort circuit protectionAlternating current

The invention relates to the technical field of an electric short-circuit protection device, in particular to a multifunctional fireproof short-circuit protector with a redundant device. The multifunctional fireproof short-circuit protector comprises a switch power supply, a current sampling device, a digital signal processor, a large-current power module, an isolation driving module, a redundant device, a charge absorption circuit and a load; the redundant device is a controlled mechanical switch, and an end L of an alternating-current power 220V is respectively connected with a resistor R1, the input end of the switch power supply, the input end of a differential amplifier and one end of the current sampling device. The multifunctional fireproof short-circuit protector is used in different alternating-current strong current fields such as household power, industrial power and the like, when the load is short-circuited, the abnormal power supply circuit is disconnected instantaneously at a microsecond speed, and no dangerous spark is produced on the short-circuit position; when the abnormal situation such as electric leakage happens in an electrical loop, the electric-leakage circuit is also disconnected at a high speed by the device; through the redundant device, even when the extreme situation that the large-power current module or the digital signal processor is abnormal occurs, the reliability of the device also can be guaranteed.

Owner:SHANGHAI HUASU ELECTRIC

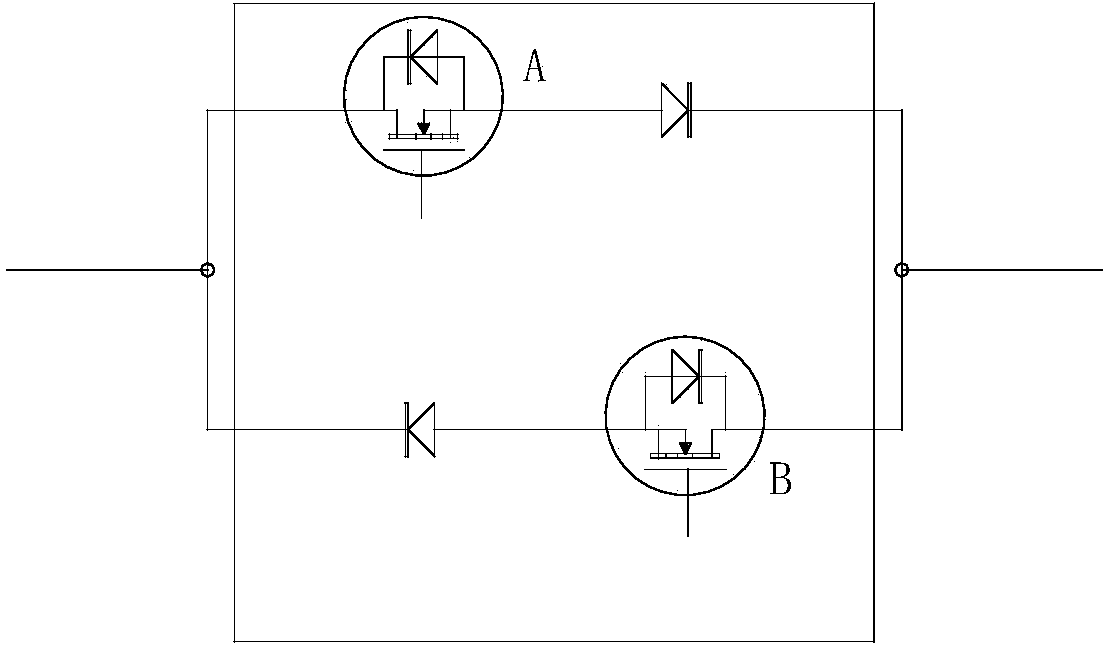

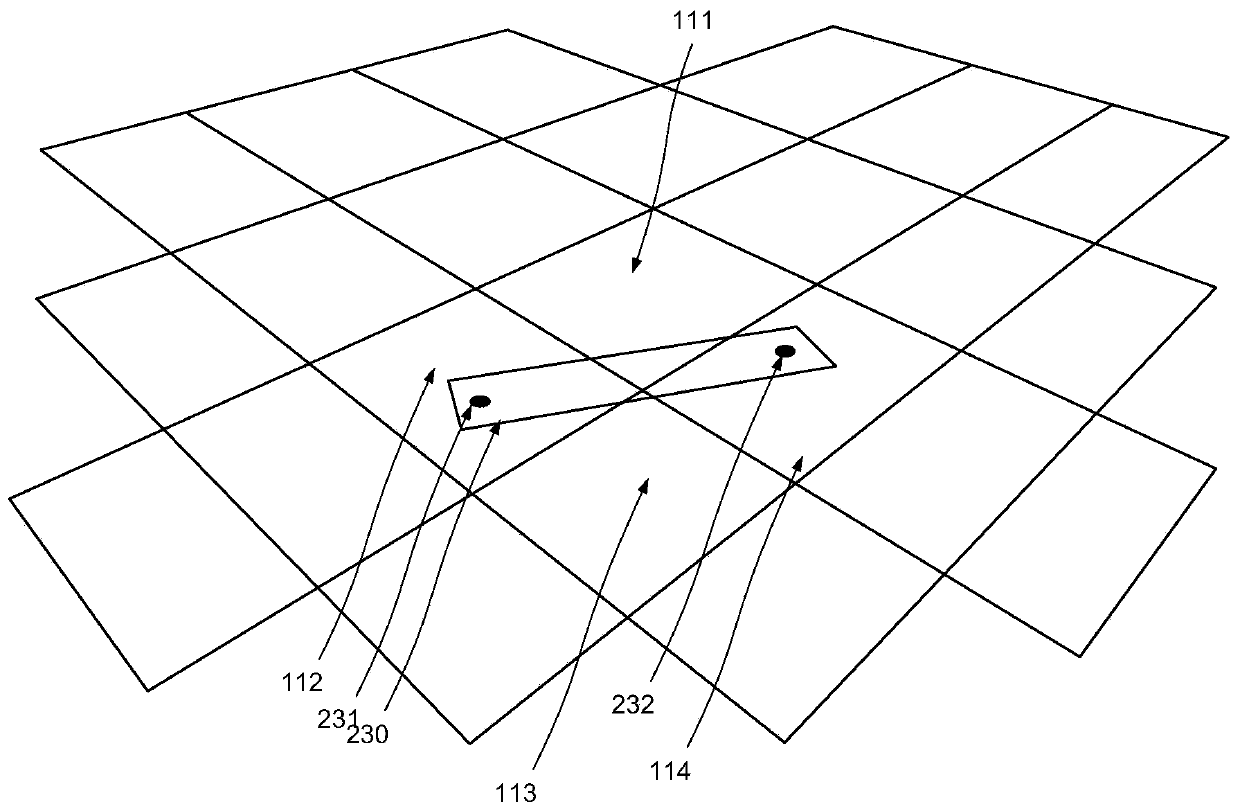

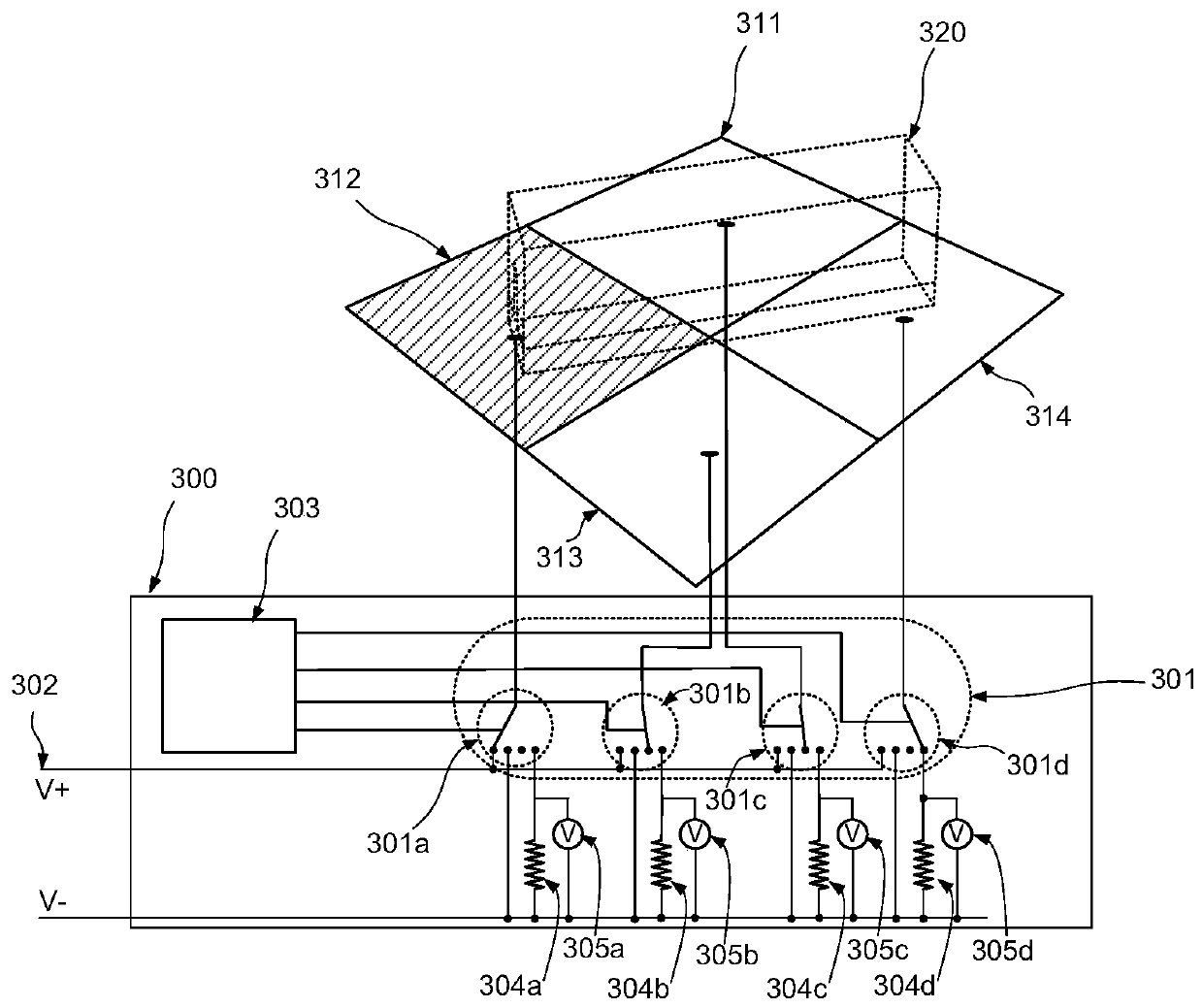

Coupling interface and method of operation

PendingCN110800187AReduce energy consumptionReduce riskCurrent/voltage measurementCoupling device detailsMOSFETVoltage drop

A charging surface comprising multiple conductive regions can be used to charge an electronic device placed on it the surface so that electrodes on the device engage respective conductive regions of the surface. In order to distinguish such chargeable devices from short circuits and other spurious connections, the coupling interface associated with the charging surface is controlled so as to establish a text voltage across each pair of conductive regions in sequence, and look for pairs of conductive region demonstrating a voltage drop characteristic of a particular class of device. Relationships between every pair of conductive regions can be determined and recording, and the voltage level supplied to each conductive region set accordingly. The coupling interface may furthermore operate toidentify device classes, and to set supply voltages or establish additional connections on the basis of stored device class information. Discrimination on the basis of voltage drop can be enhanced bythe provision of a coupling adapted associated with a device to be detected, where the coupling adapter demonstrates an anti-inversion characteristic, for example implemented with a MOSFET, across atleast a pair of these electrodes.

Owner:ENERGYSQUARE

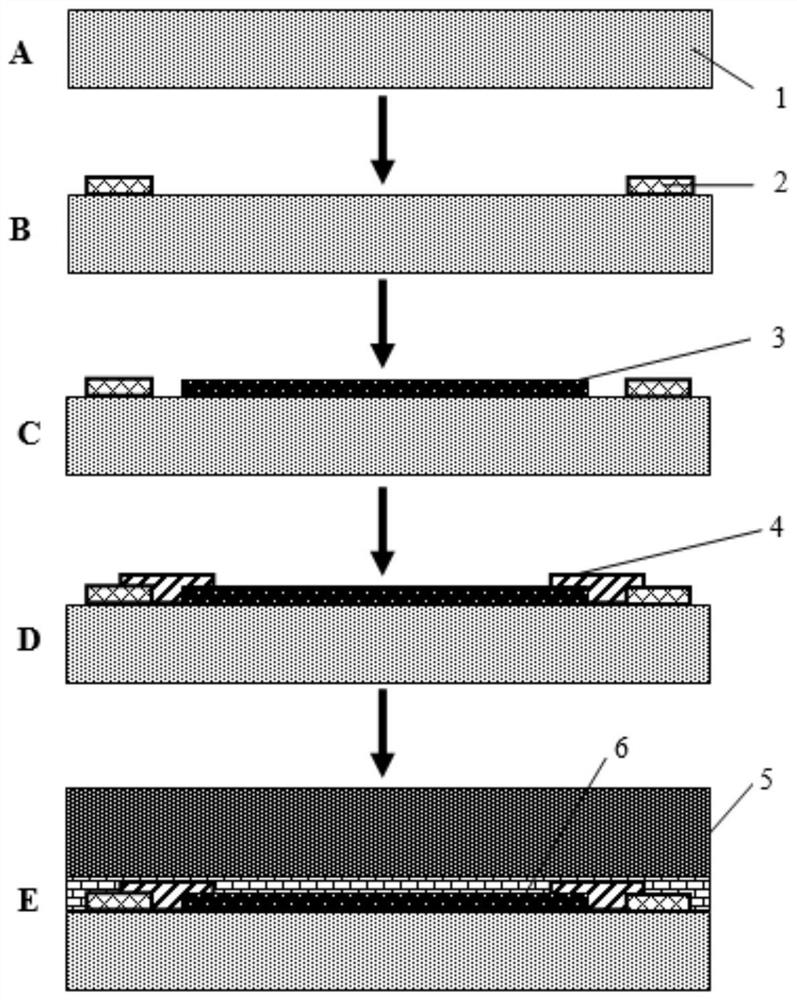

Preparation method of graphene electrothermal film for floor heating

PendingCN111669846AReliable electrical connectionEnhanced resistance to peelingLighting and heating apparatusElectric heating systemHeating filmCopper electrode

The invention discloses a preparation method of a graphene electrothermal film for floor heating, which comprises the steps of coating the surface of an insulating base material of the electrothermalfilm with a graphene heating film, implanting copper electrodes into two opposite sides of the graphene heating film, and arranging the graphene heating film and the copper electrodes at intervals; and printing a bridging electrode on the surfaces of the graphene heating film and the copper electrodes. A heating body of the graphene electrothermal film for floor heating prepared by the method is in good contact with the bridging electrode and the copper electrodes; the bridging electrode completely coats the copper electrodes; the contact resistance between the bridging electrode and the surface of the copper current-carrying electrode is obviously reduced; and the peeling resistance is improved, the risk of fire caused by edge sparking of the heating body is effectively solved, and the energy utilization rate is increased. In addition, the whole-process automatic production is more favorably realized, and the problem that the copper electrode compounding process is easy to be abnormaland cannot be automatically connected with the front-end process in the traditional production process is completely eradicated.

Owner:安徽宇航派蒙健康科技股份有限公司

Ultraminiature continuous current dynamo for facilitating commutator installation

ActiveCN101789668AControl installation locationConsistent brush distanceDC commutatorSupports/enclosures/casingsConductor CoilDynamo

The invention relates to an ultraminiature continuous current dynamo for facilitating commutator installation, comprising a rotor, a stator and a brush group. The rotor comprises a rotor support and a winding; while the rotor support comprises a revolving shaft, a fixed ring sheathed at one end of the revolving shaft and a commutator located at one end of the revolving shaft. The brush group comprises a base plate at one end of a machine shell and an upper electric brush and a lower electric brush which are arranged on the base plate; the central part of the base plate, which is close to the machine shell is provided with center holes; each electric brush is provided with a straight panel part, a vertical part which vertical extends out from one end of the straight panel part and a slant part which slantly extends out from the other end of the straight panel part in a bent manner. Wherein, an end surface of the base plate, which is close to the machine shell is provided with a commutator installation slide rail, one end of the slide rail is communicated with the center holes, the lower edge of the slide rail is contacted with the edges of the center holes and the spacing between the lower edge of the slide rail and the slant part of the electric brush is equal to allowed deformation of the electric brush. With the structure adopted, when being installed, the commutator can slide along the lower edge of the slide rail to the center of the base plate, thus effectively avoiding deformation of the electric brush.

Owner:SHENZHEN SHUANGHUAN QX MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com