Split type full-automatic parallel sealing welding machine

A parallel sealing welding, fully automatic technology, used in welding equipment, resistance welding equipment, roller electrode welding, etc., to achieve reliable positioning and clamping, improve sealing welding quality, and easy maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with the accompanying drawings:

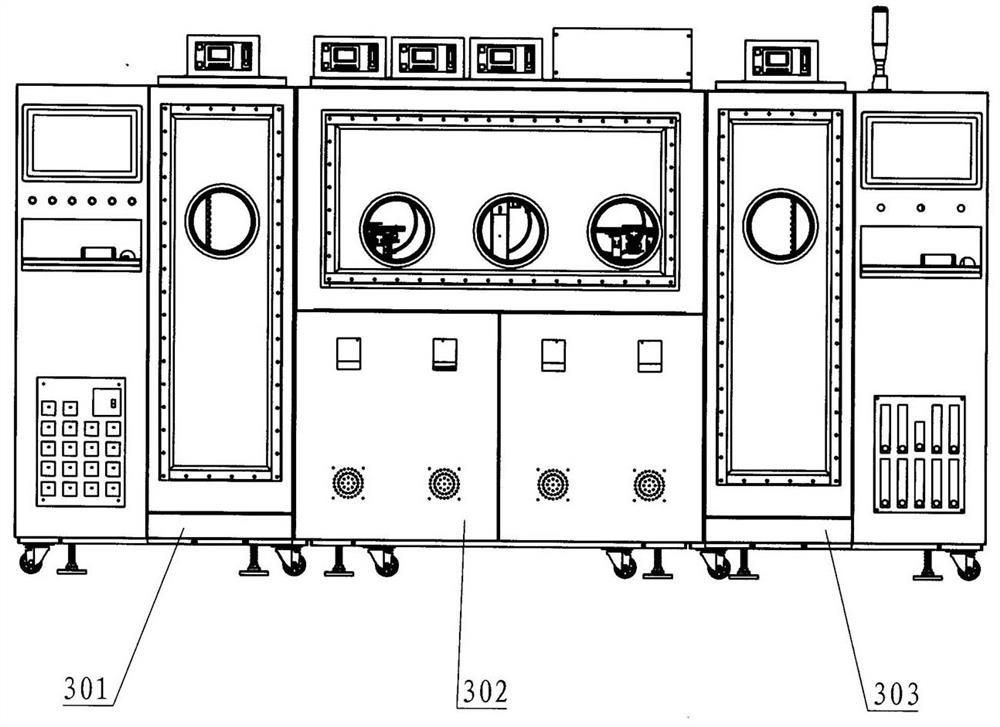

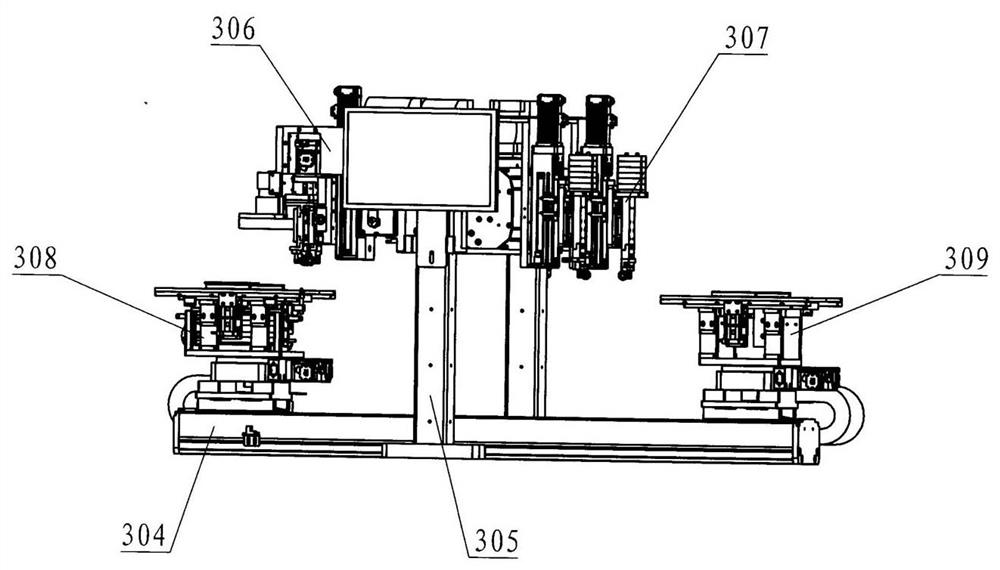

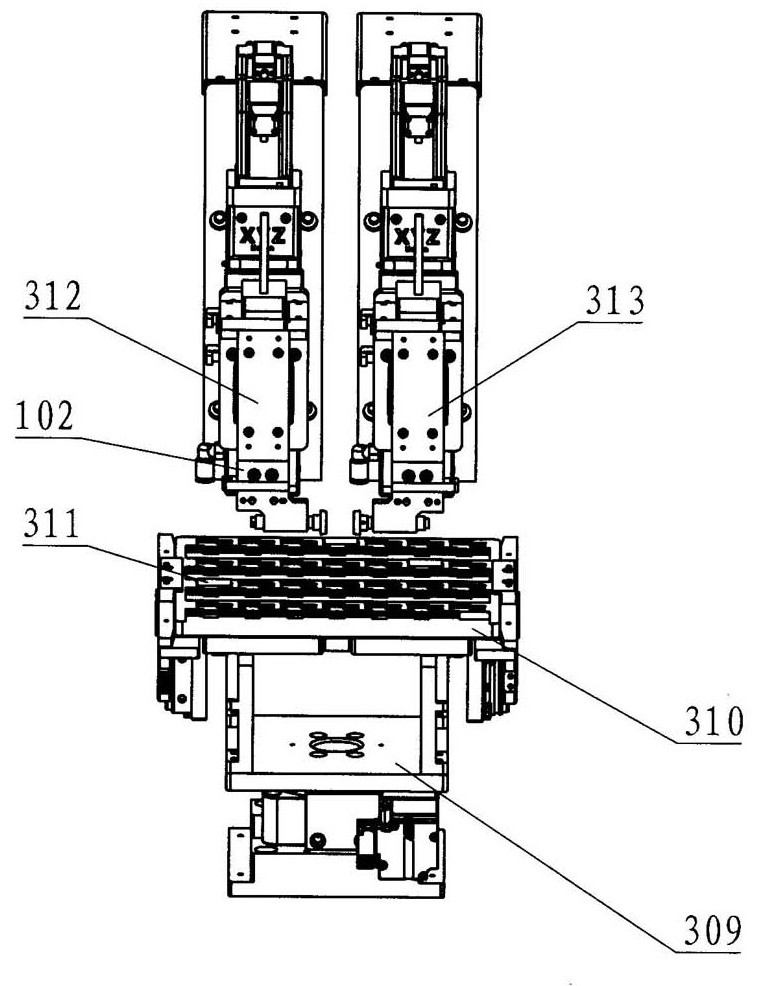

[0024] A split-type fully automatic parallel sealing and welding machine, including a feeding chamber 301, a welding chamber 302 and a feeding chamber 302, which are independently set up respectively, a feeding door is set between the feeding chamber 301 and the welding chamber 302, and a feeding door is arranged between the feeding chamber 301 and the welding chamber 302. A discharge door is arranged between 302 and the unloading chamber 302, and the welding chamber 302 is filled with nitrogen; The transfer module 304 to the welding material tray passes through the installation gantry 305 of the welding mechanism. On the beam of the installation gantry 305 of the welding mechanism, a spot welding mechanism 306 and a sealing welding mechanism 307 are respectively arranged. A spot welding platform 308 is set directly below, and a sealing welding platform 309 is set directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com