Patents

Literature

302results about "Welding with roller electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

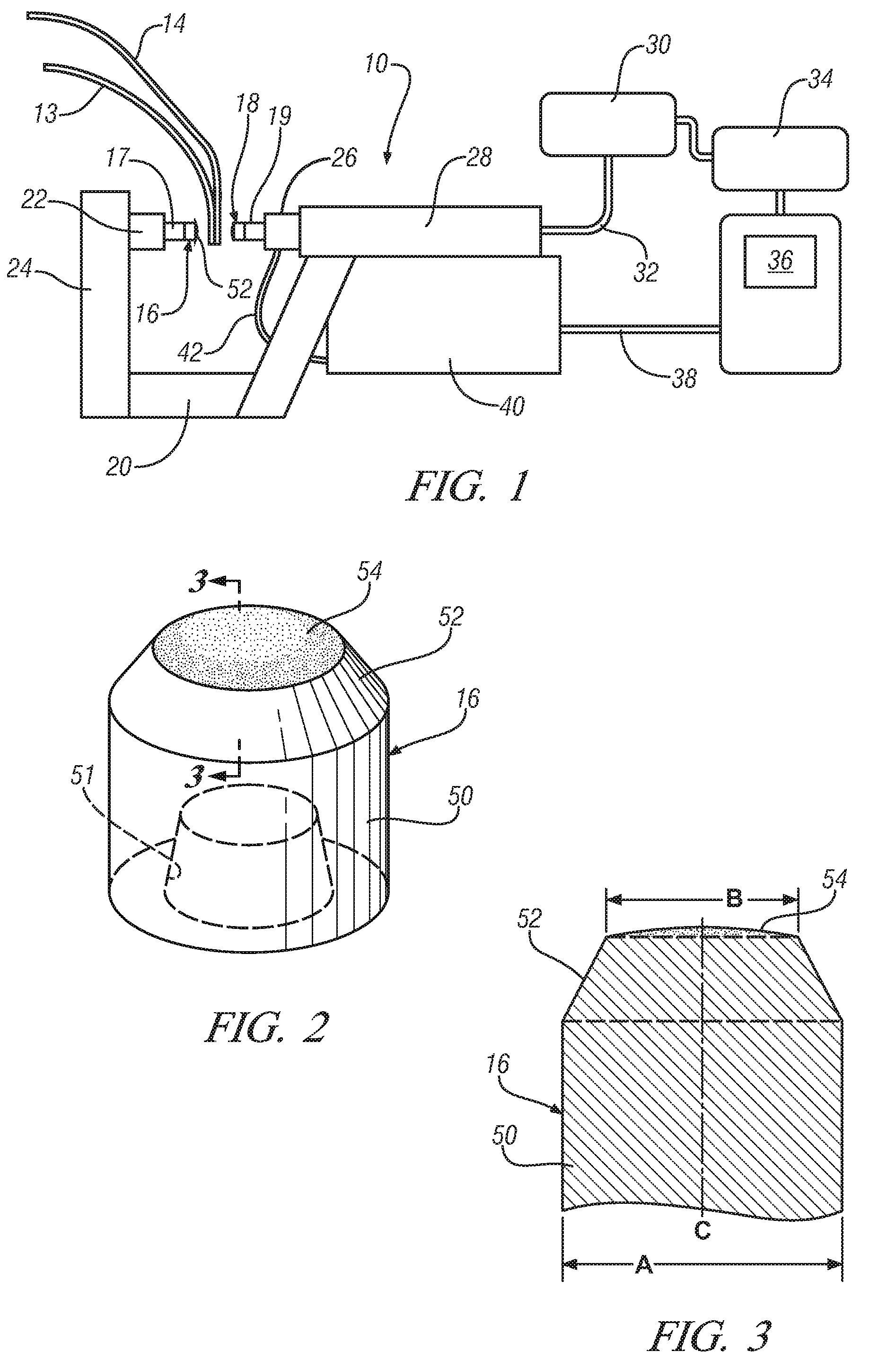

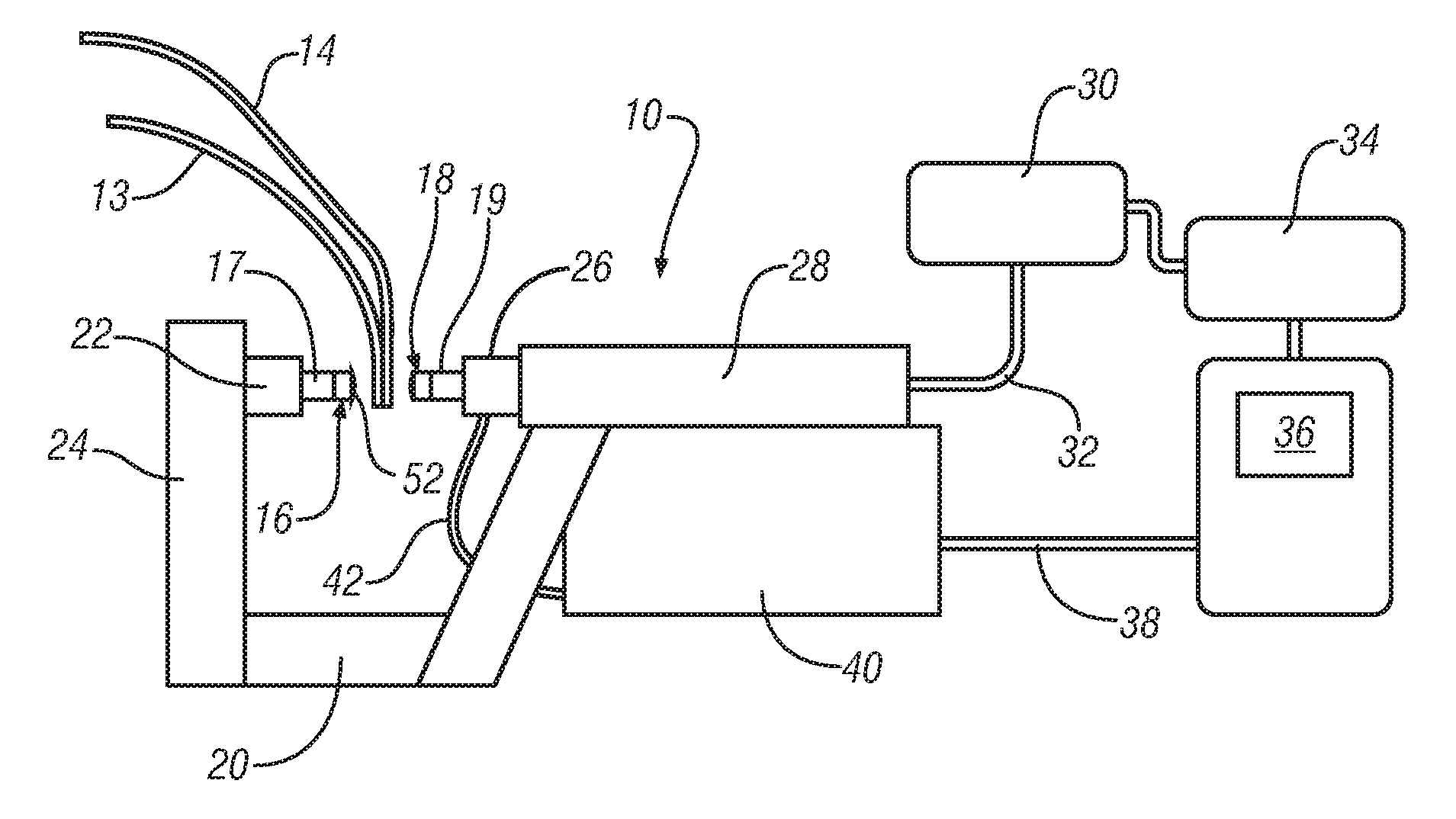

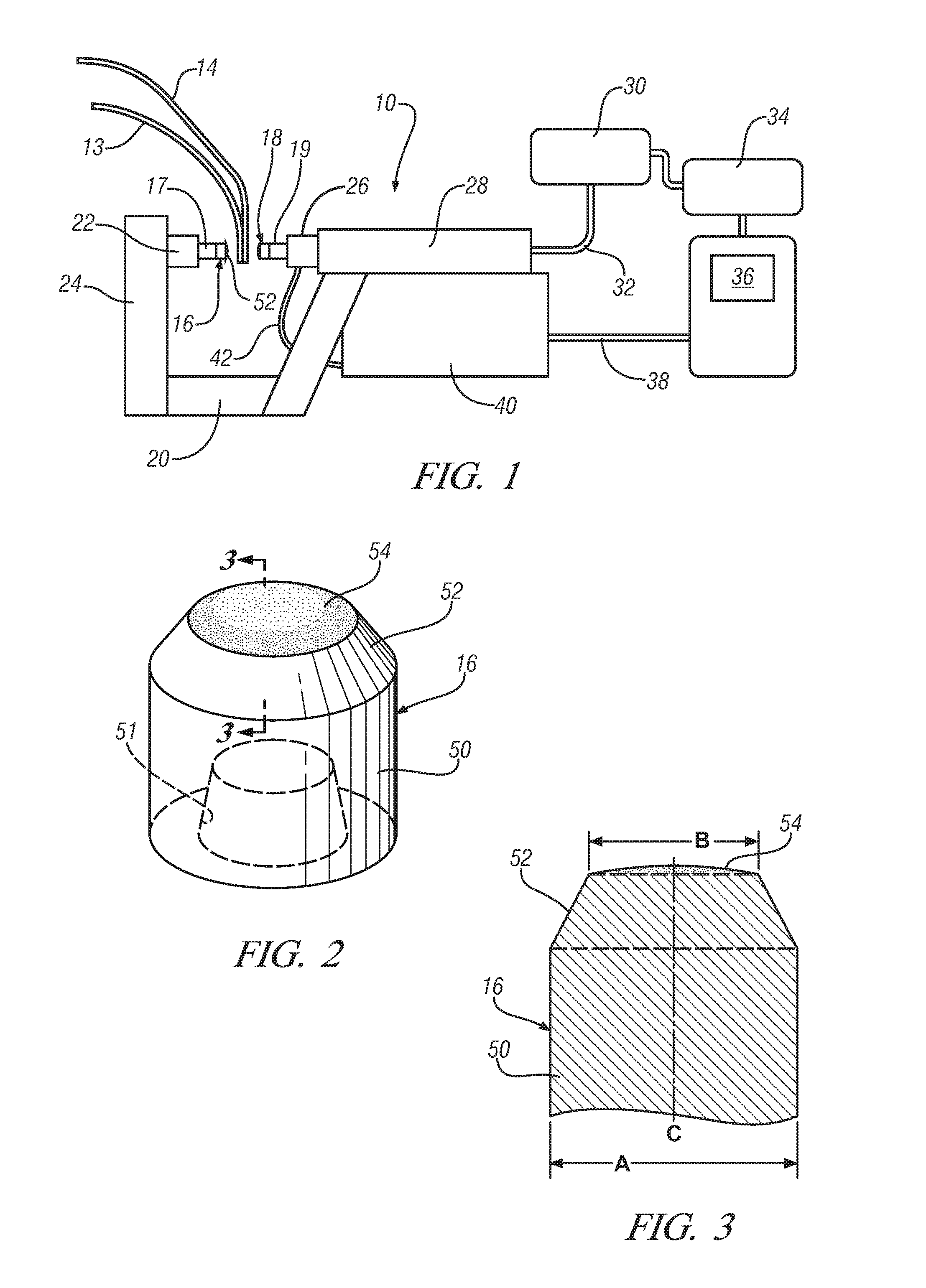

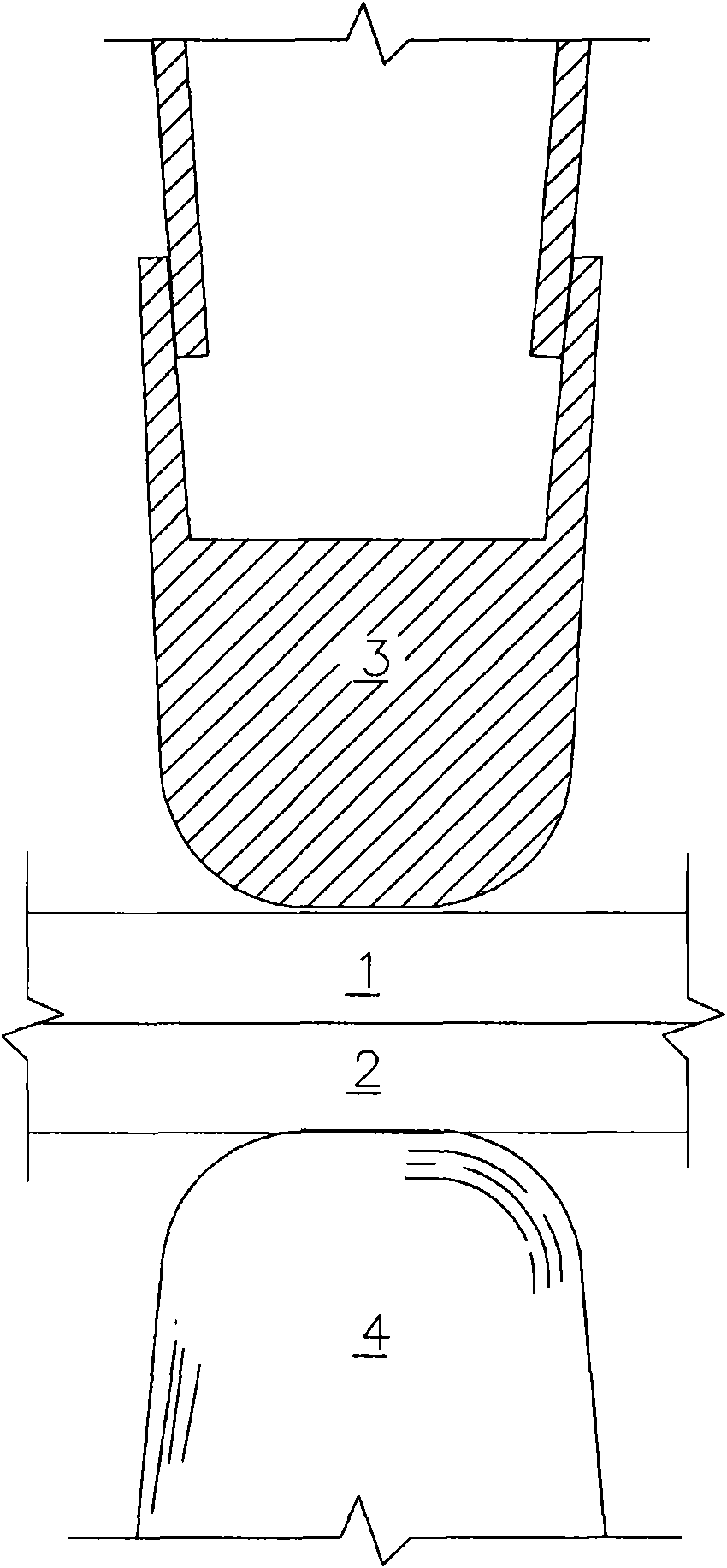

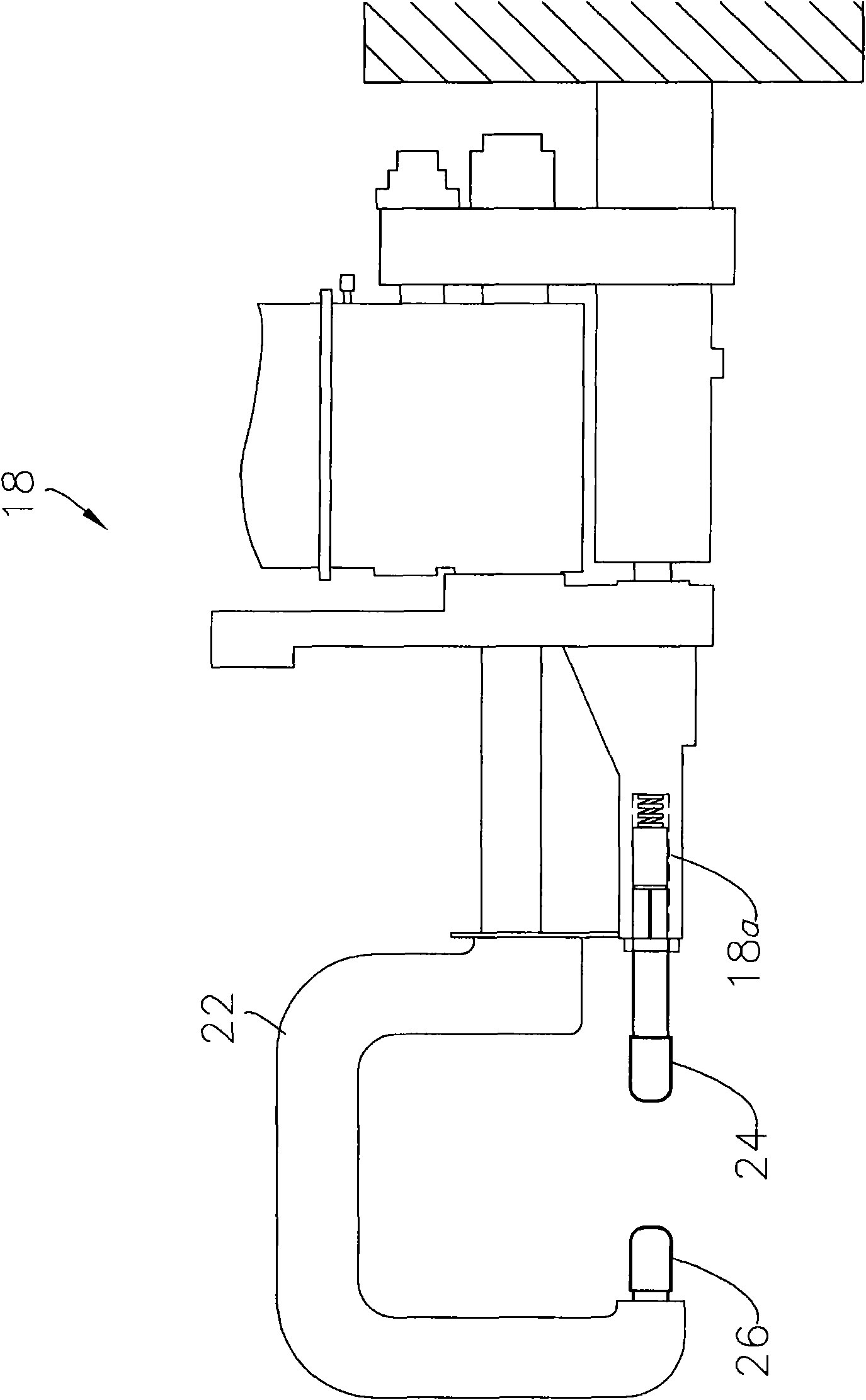

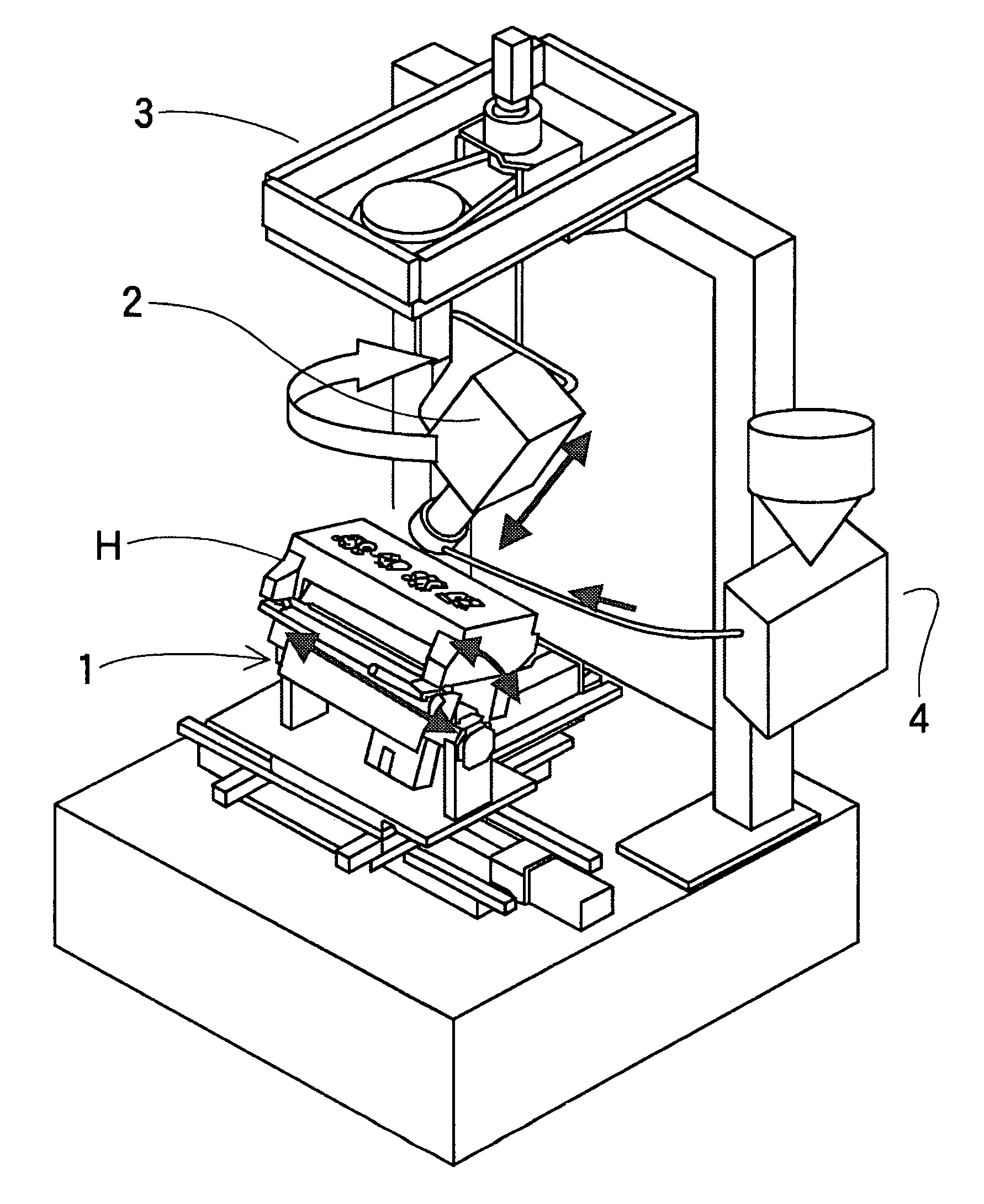

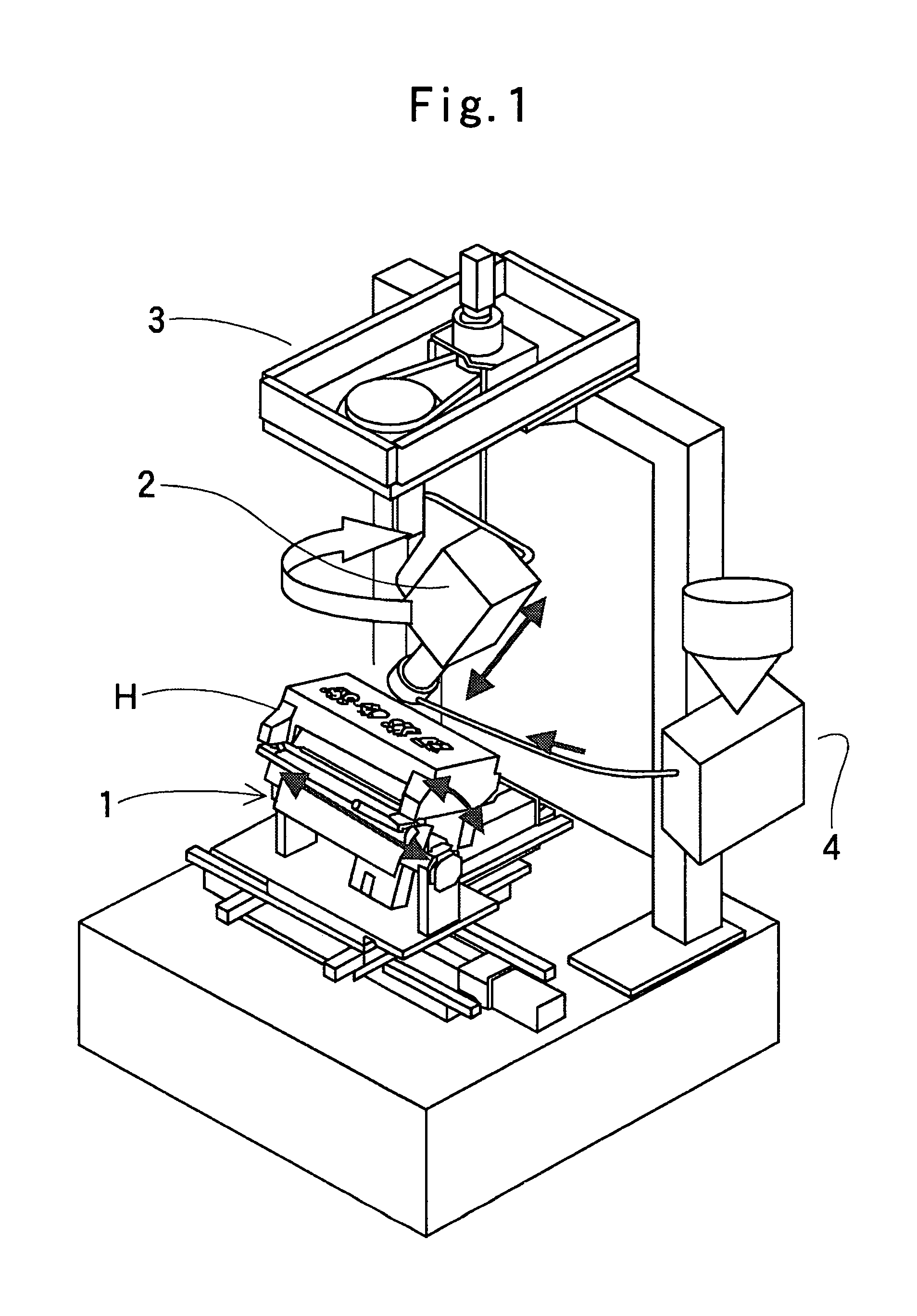

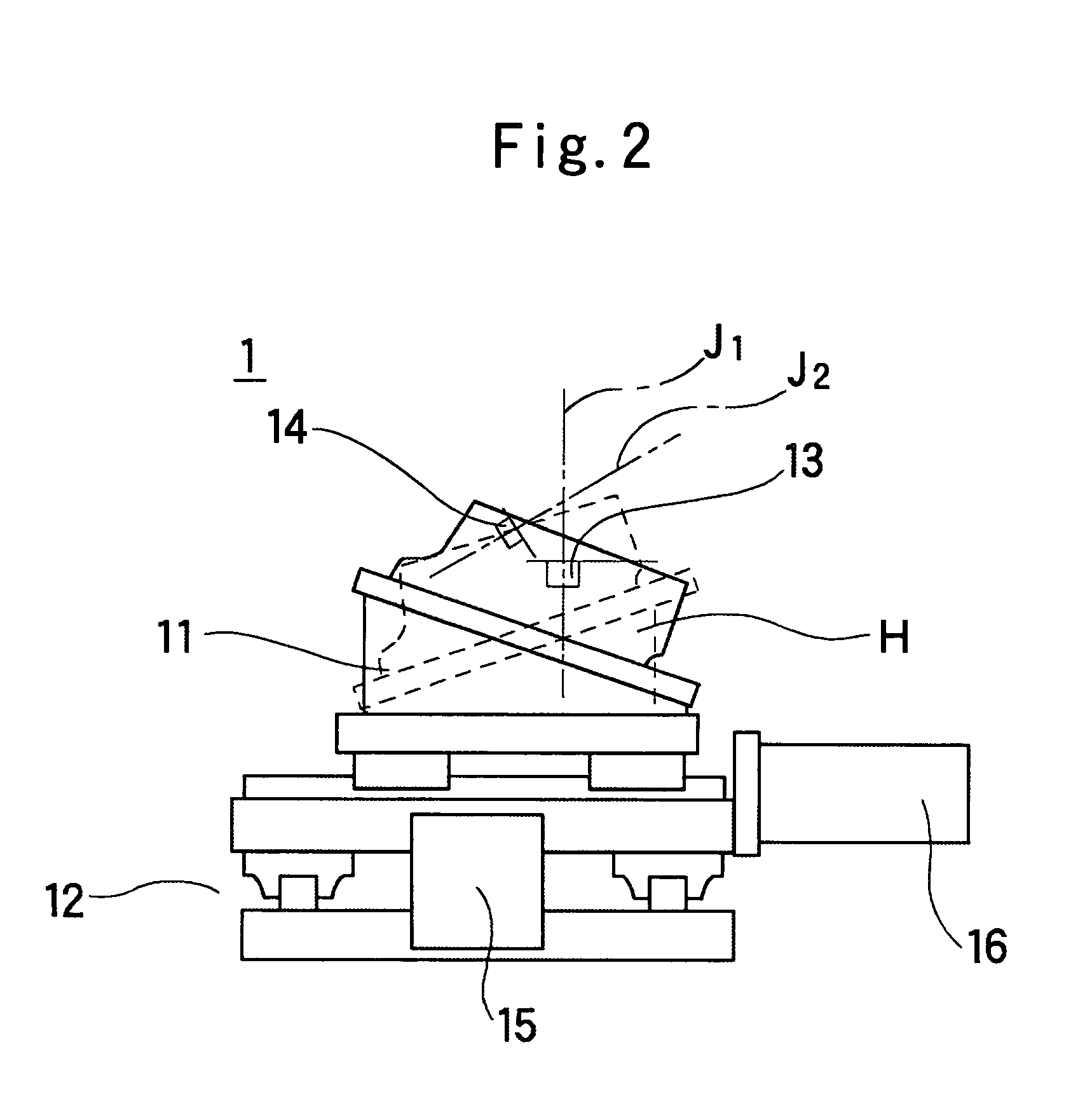

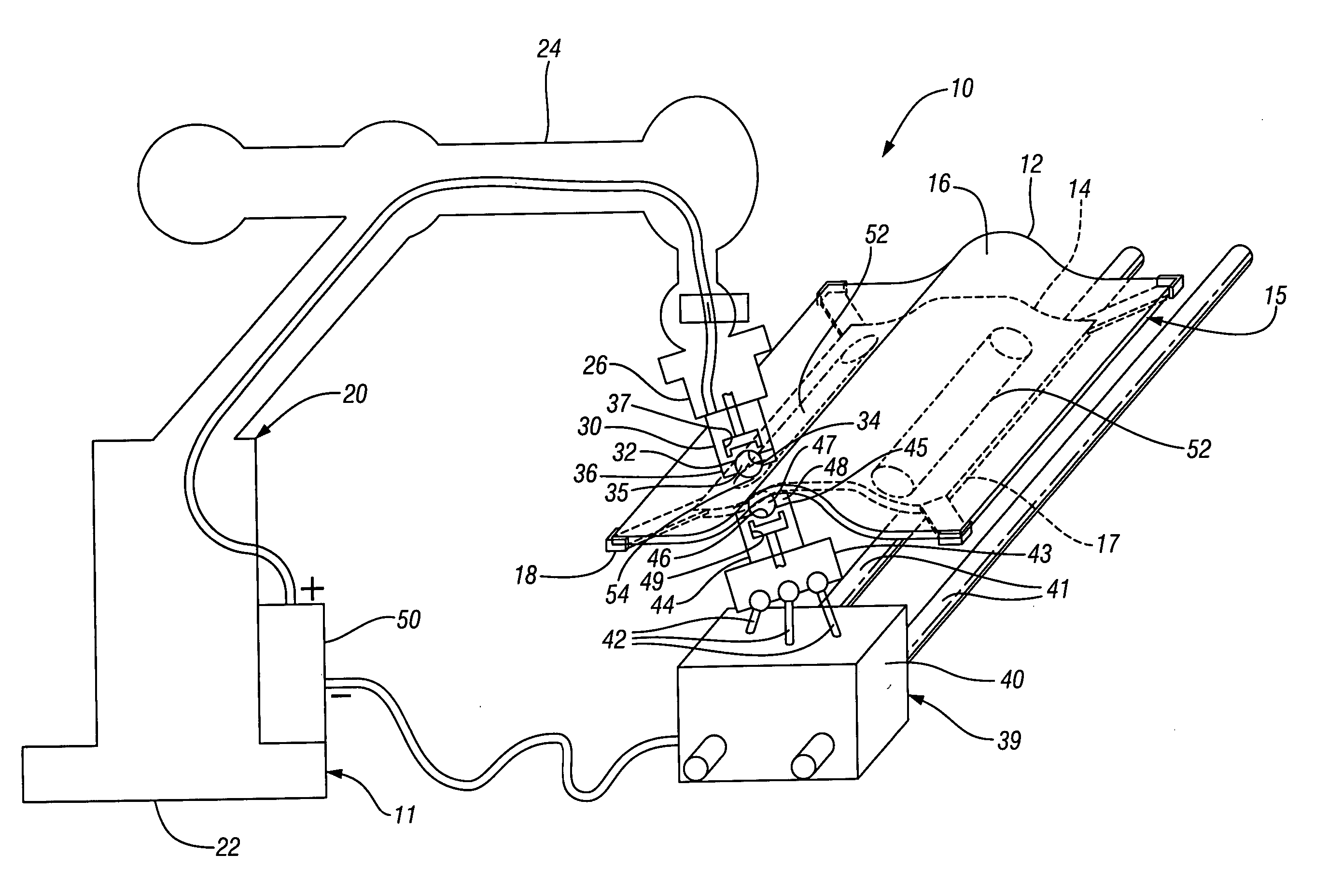

Laser cladding apparatus and method

ActiveUS20060169679A1Simplify constituent elementReduce facility costsCylinder headsElectrode featuresLaser processingCylinder head

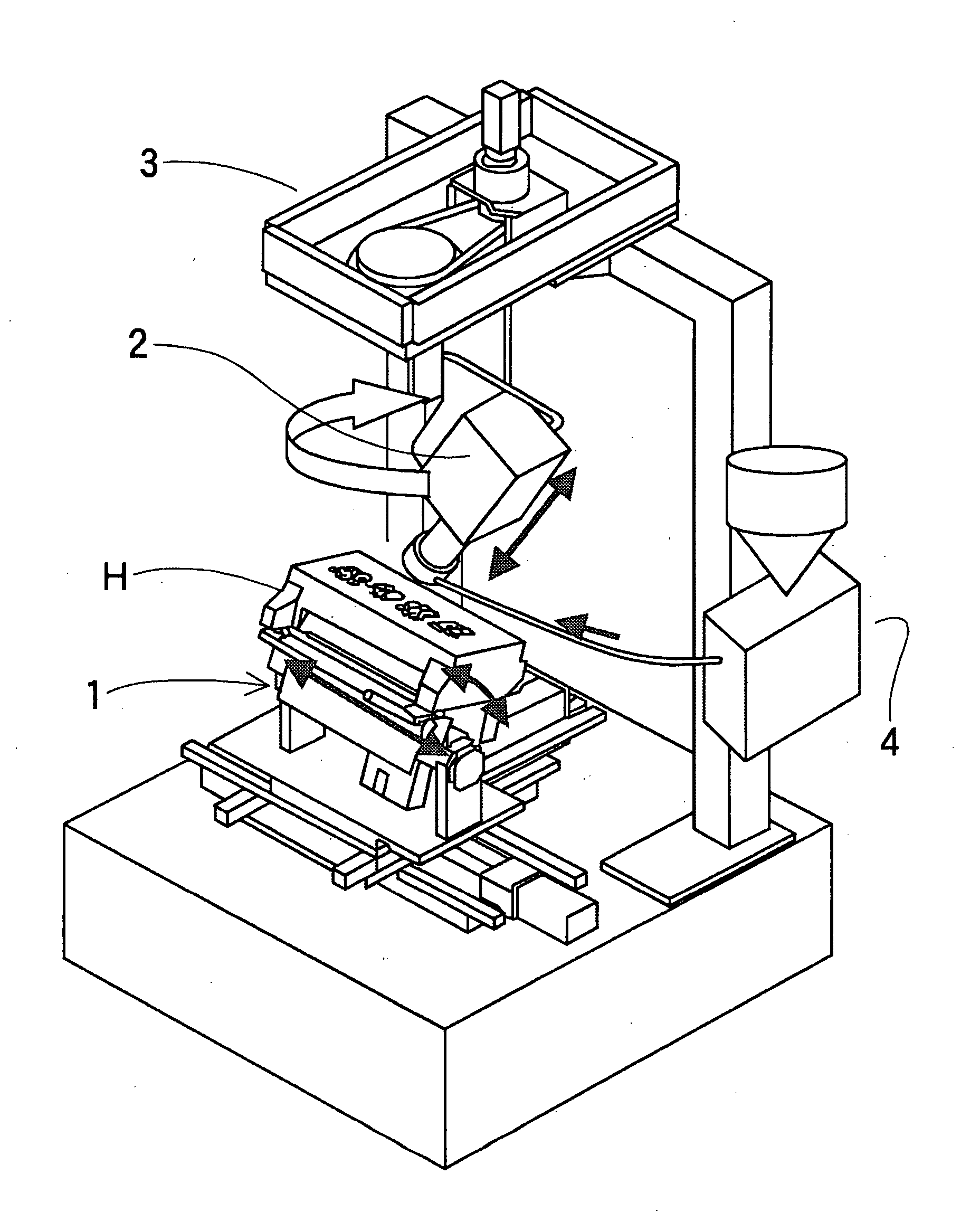

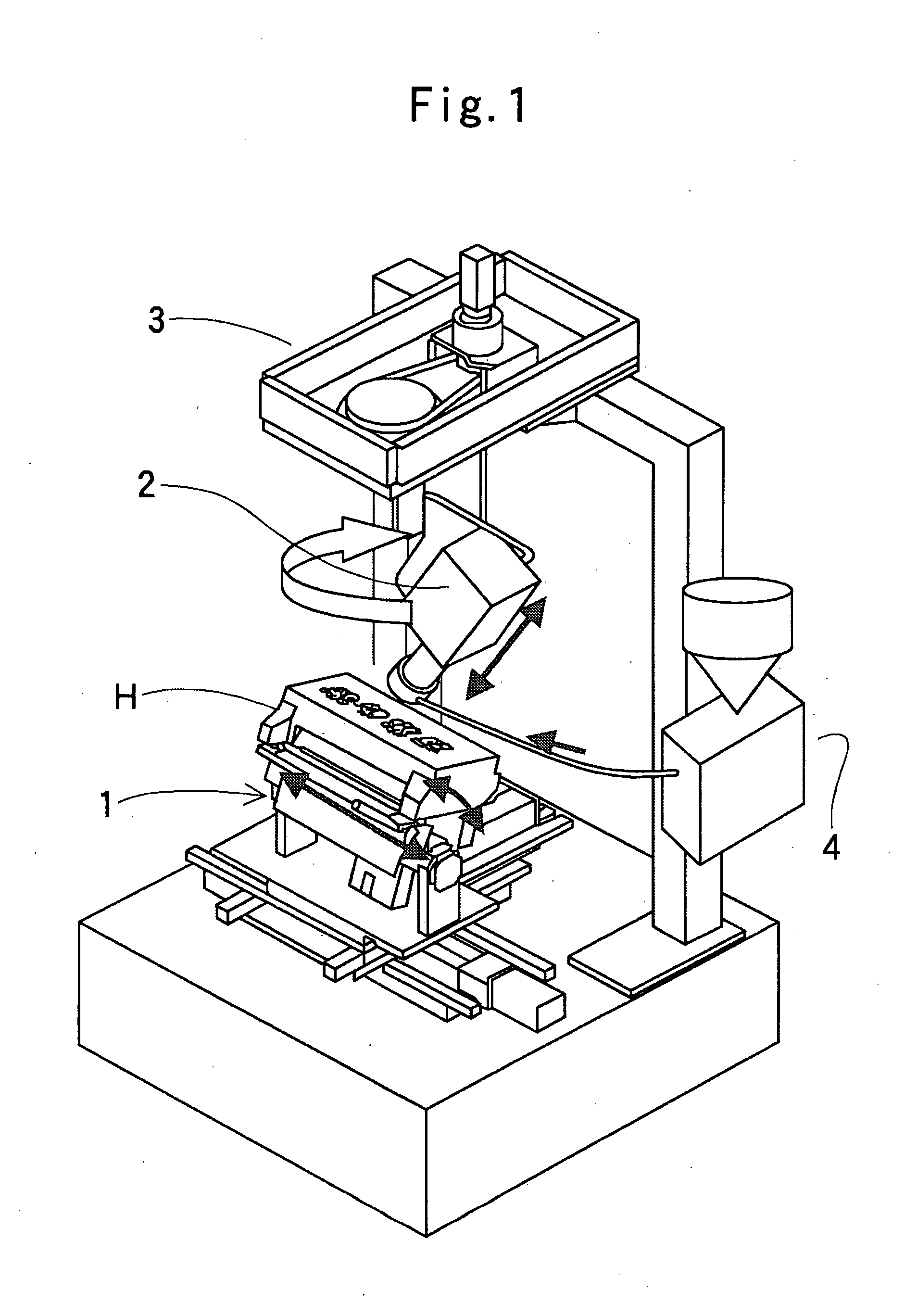

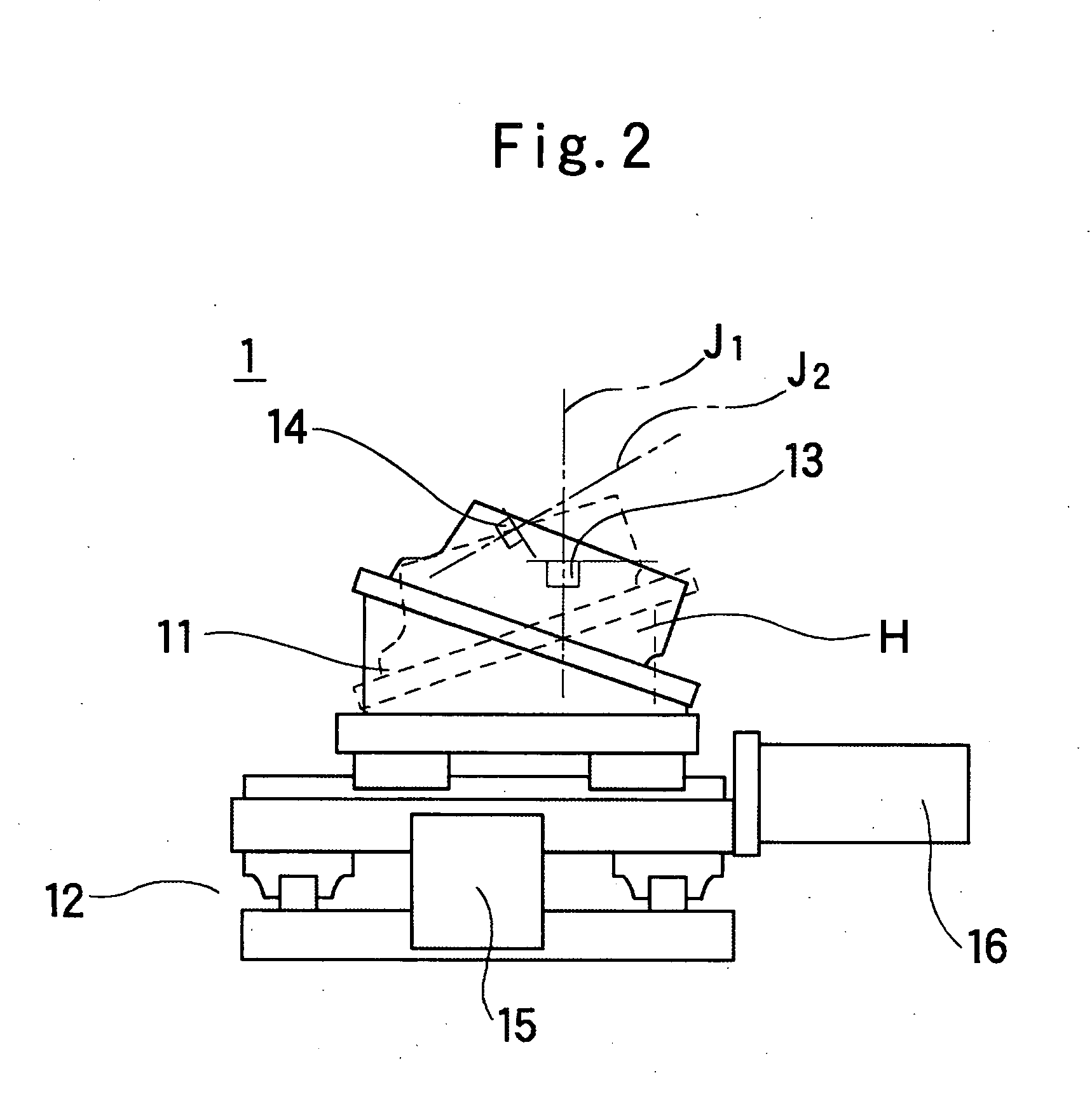

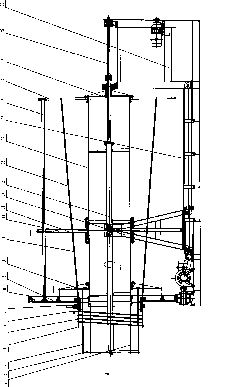

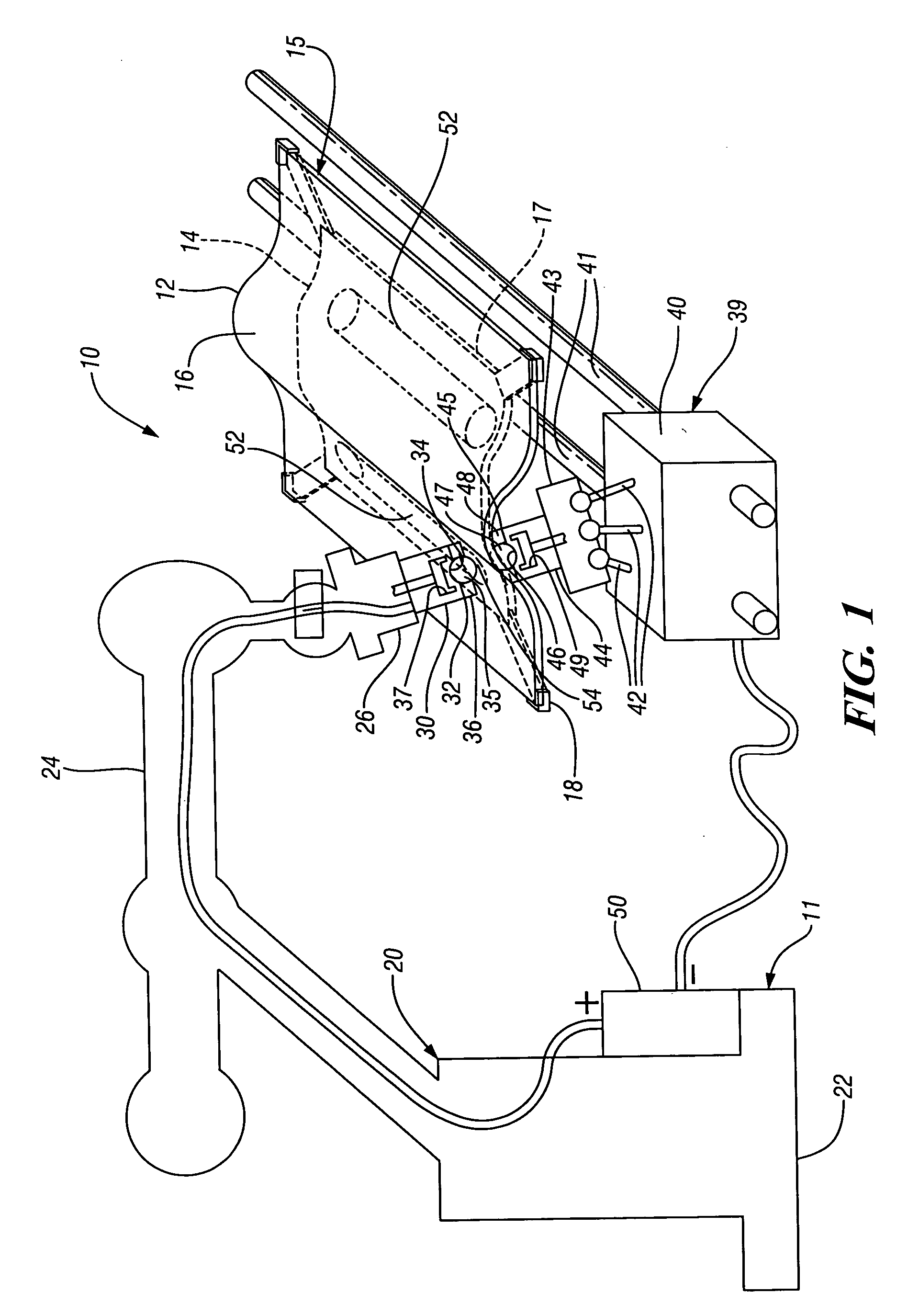

A laser-clad processing apparatus of the present invention is one which is for carrying out laser-clad processing onto a valve-seat portion of a cylinder head, and is characterized in that it comprises cylinder-head holding means (1) for holding a cylinder head (H) in an inclining manner so that the central axial line of a valve seat becomes the vertical direction, a laser-processing head (2) for irradiating a laser beam onto a process part of the valve seat and at the same time discharging a powdery material to this process part, rotary means (3) which rotates around the central axial line of the valve seat in such a state that the laser-processing head is inclined with respect to the vertical direction, and powdery-material supply means (4) for supplying the powdery material to the laser-processing head. Moreover, a laser-clad processing method of the present invention is characterized in that it fixes the cylinder head (H), and forms a clad layer while rotating the laser-processing head (2), which emits the laser beam with respect to the valve-seat portion of the cylinder head and discharges the powdery material, around the axial center line of the valve seat.

Owner:TOYOTA JIDOSHA KK

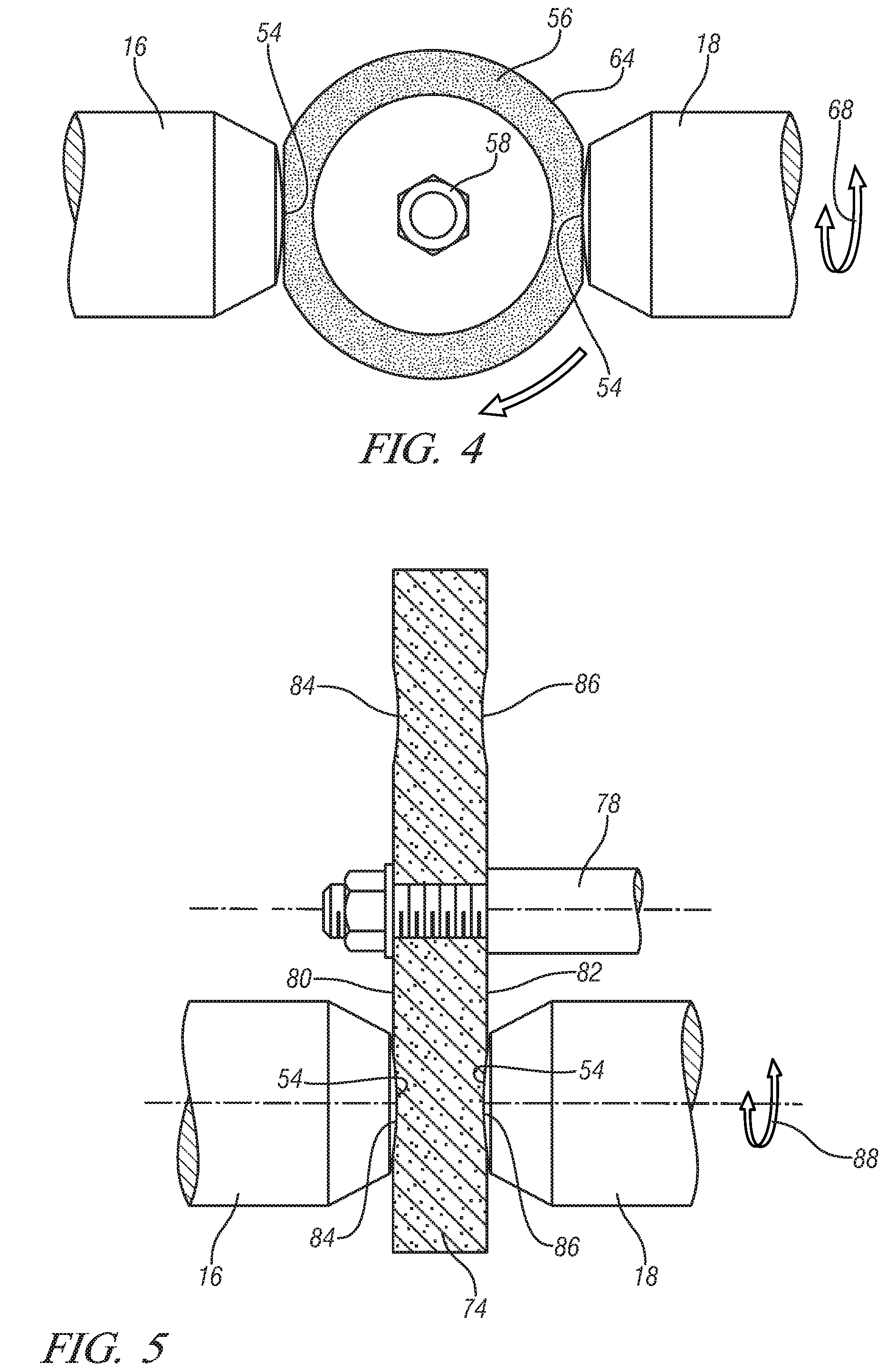

Welding electrode with contoured face

Owner:GM GLOBAL TECH OPERATIONS LLC

Automobile door reinforcing member

InactiveUS6591577B2High strengthSolve the lack of rigidityFlexible pipesSuperstructure subunitsEngineeringJoint surface

Owner:ASTEER

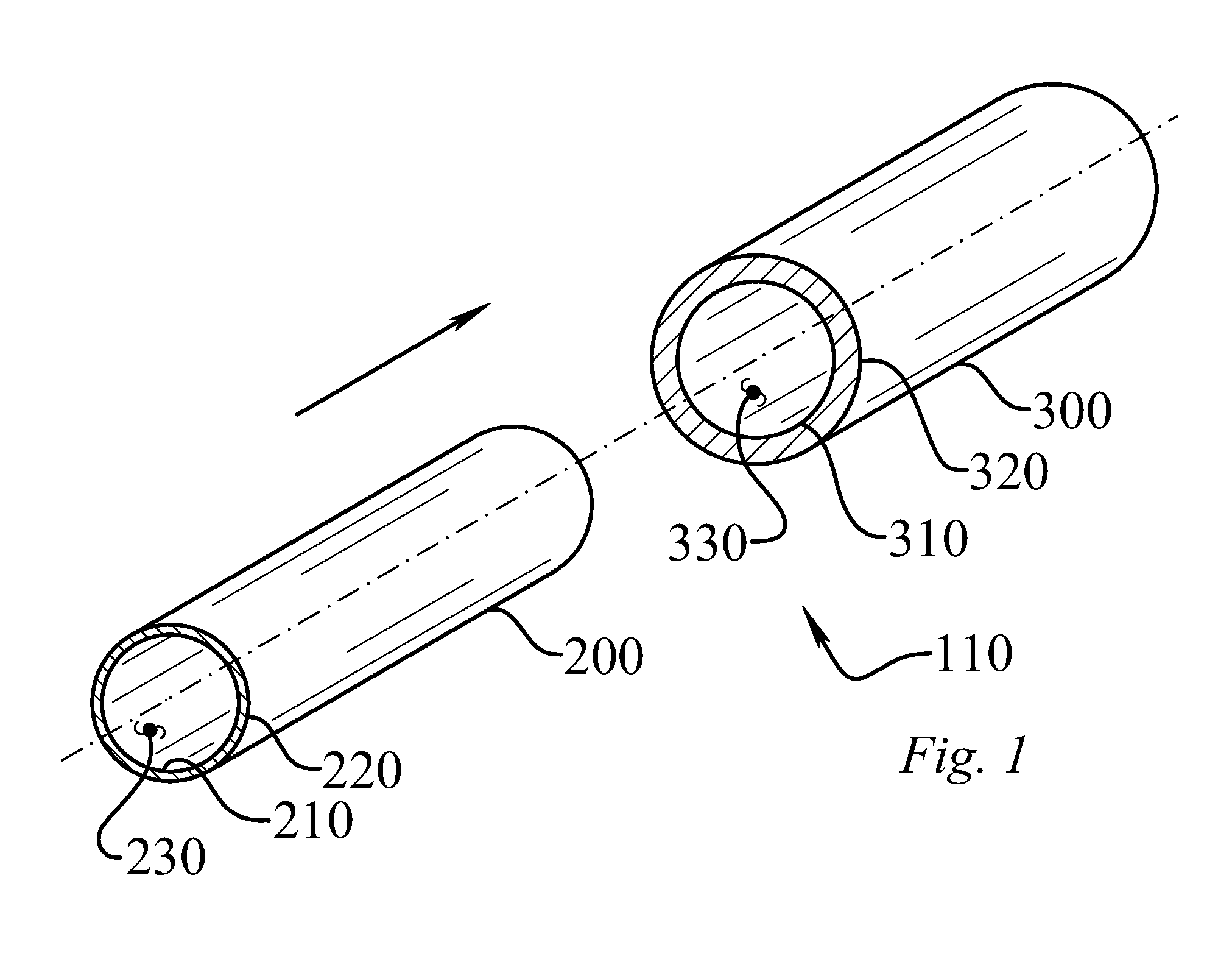

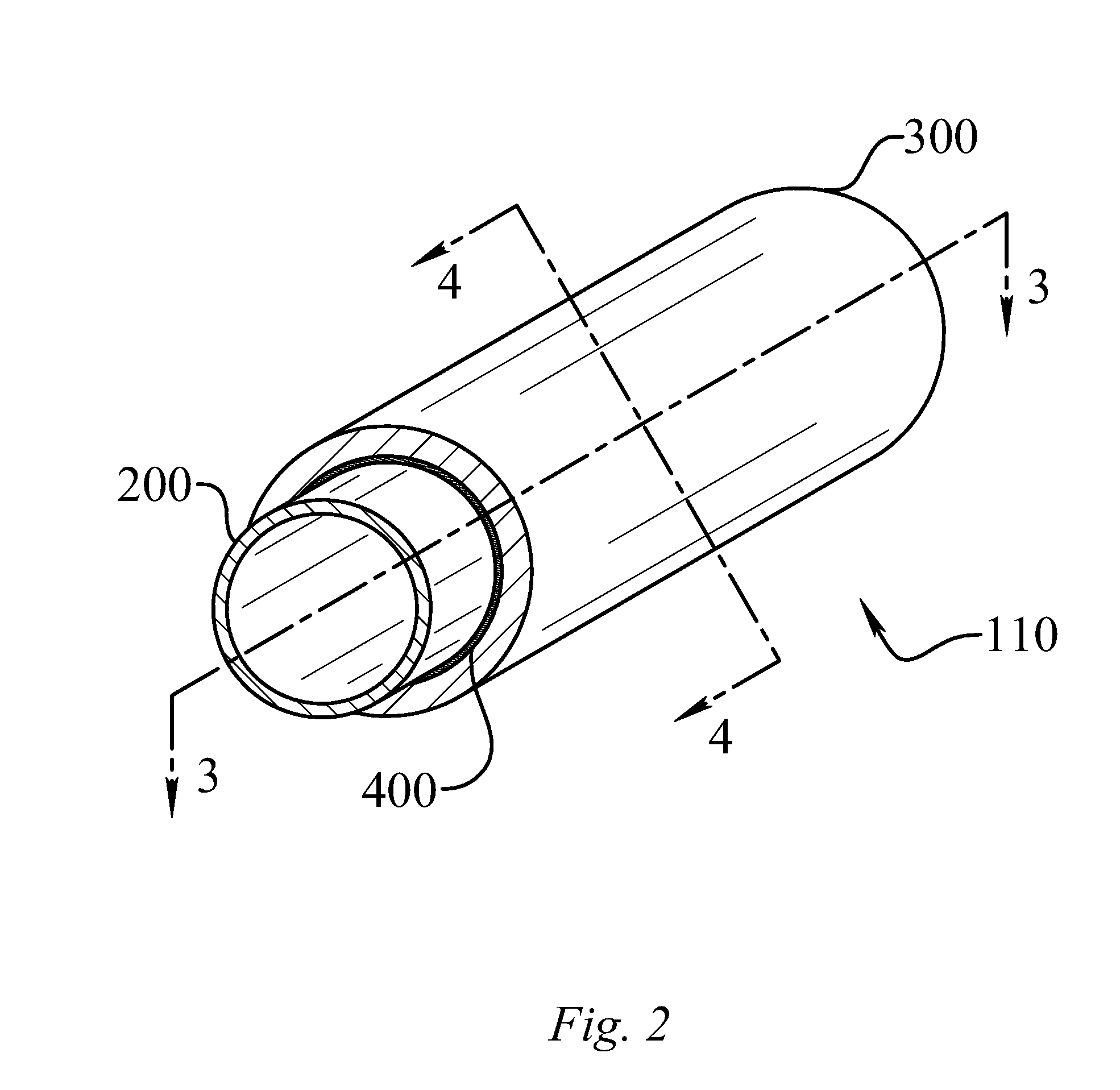

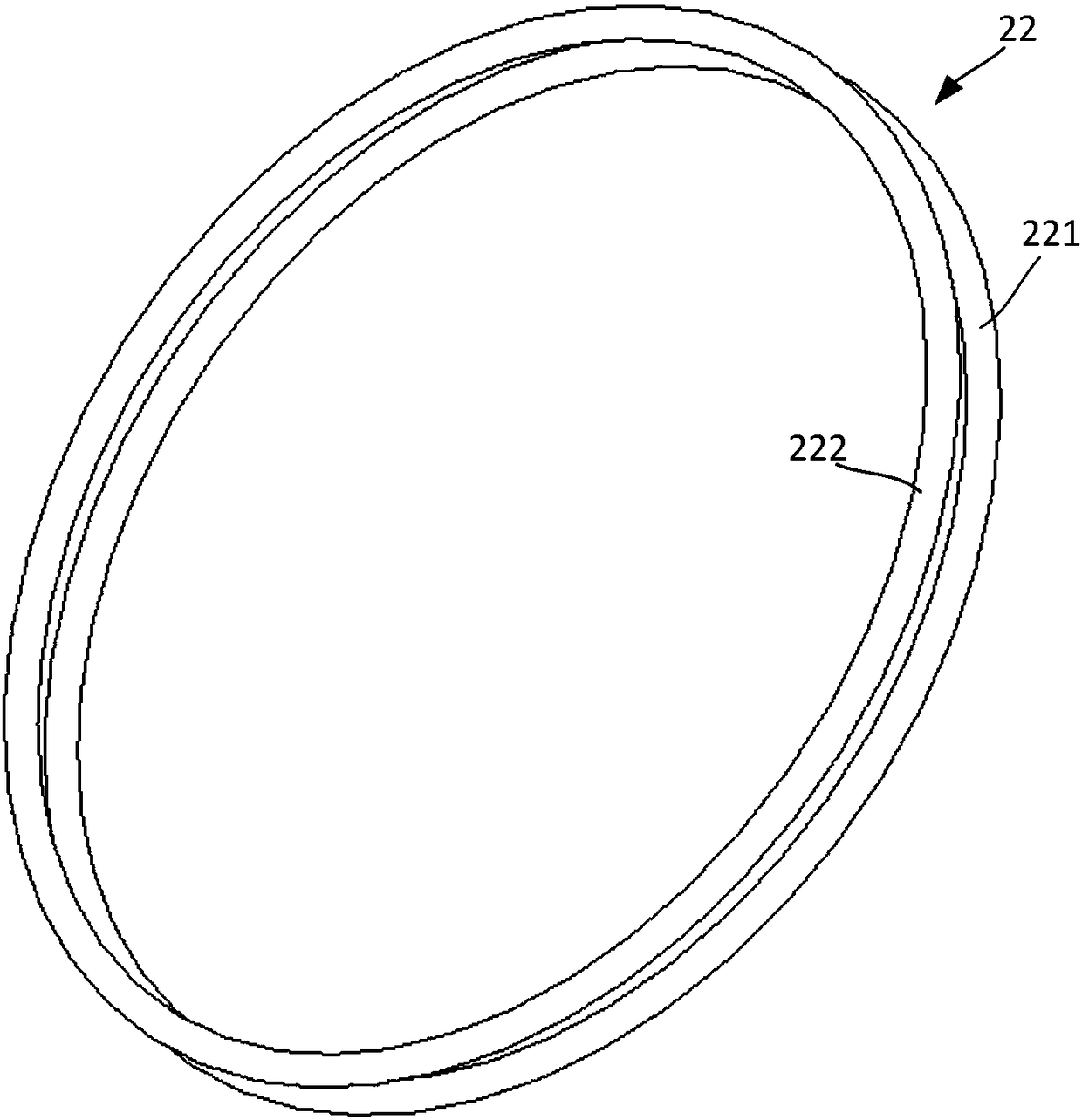

Metal foil tube and method and apparatus for production thereof

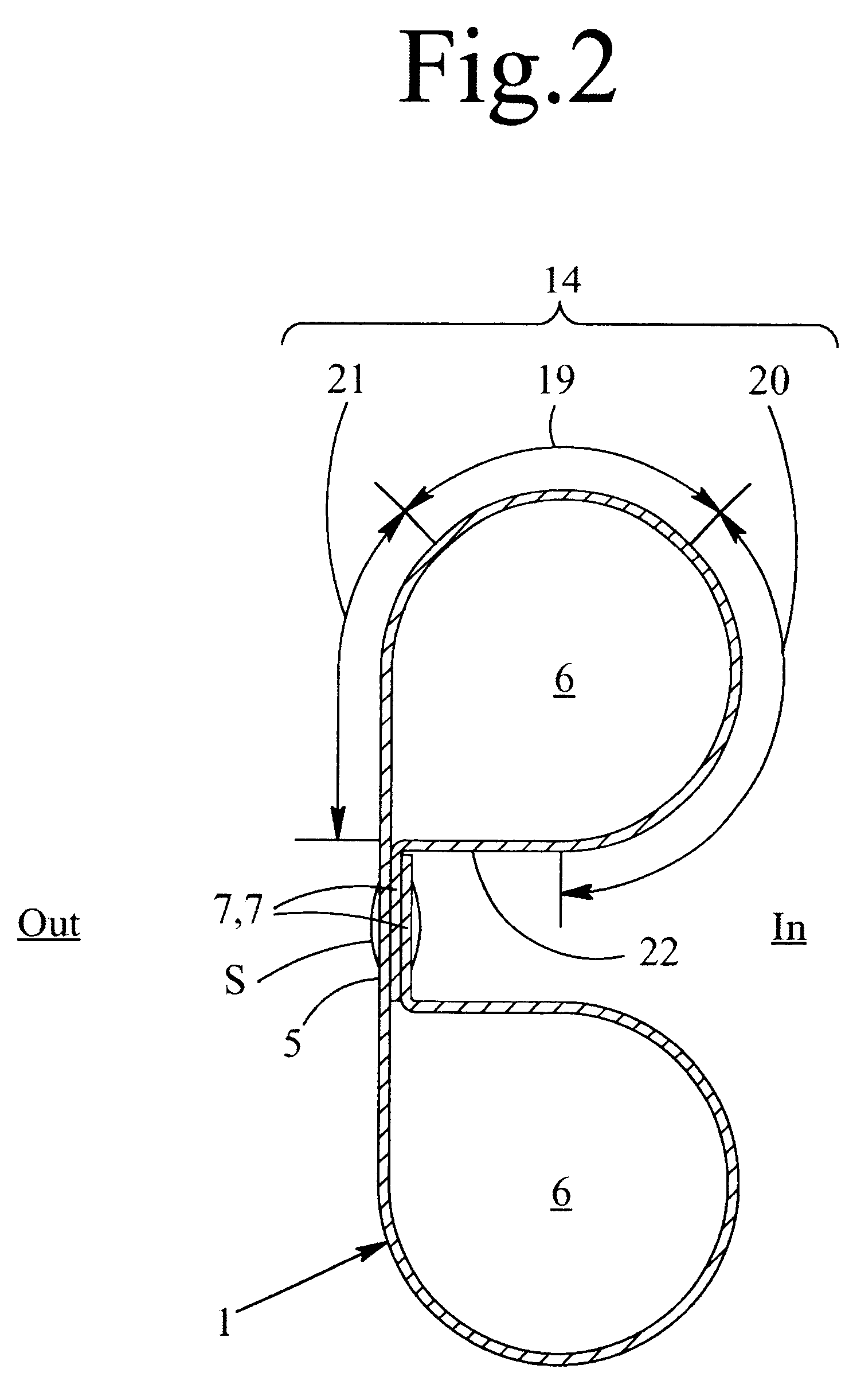

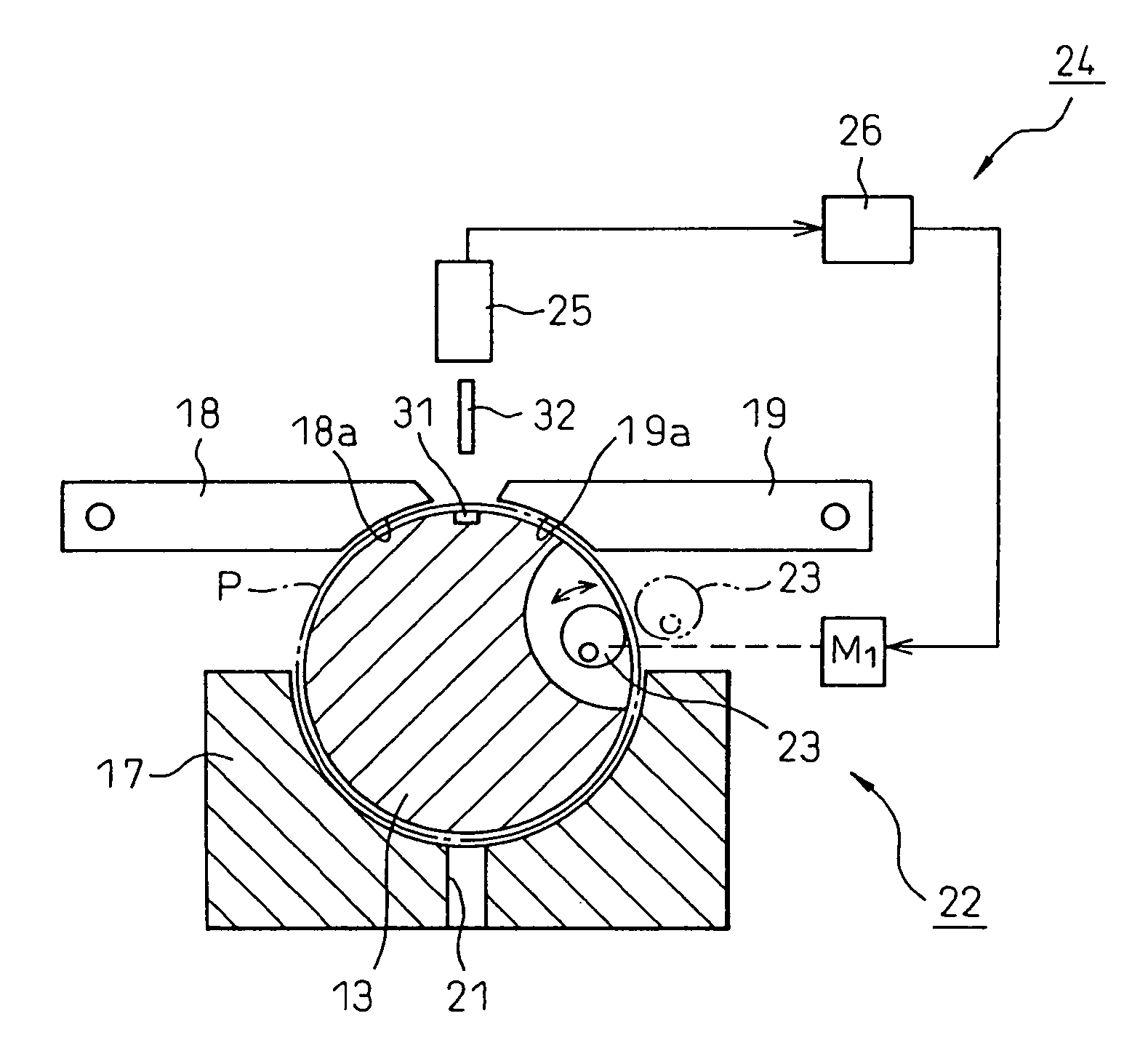

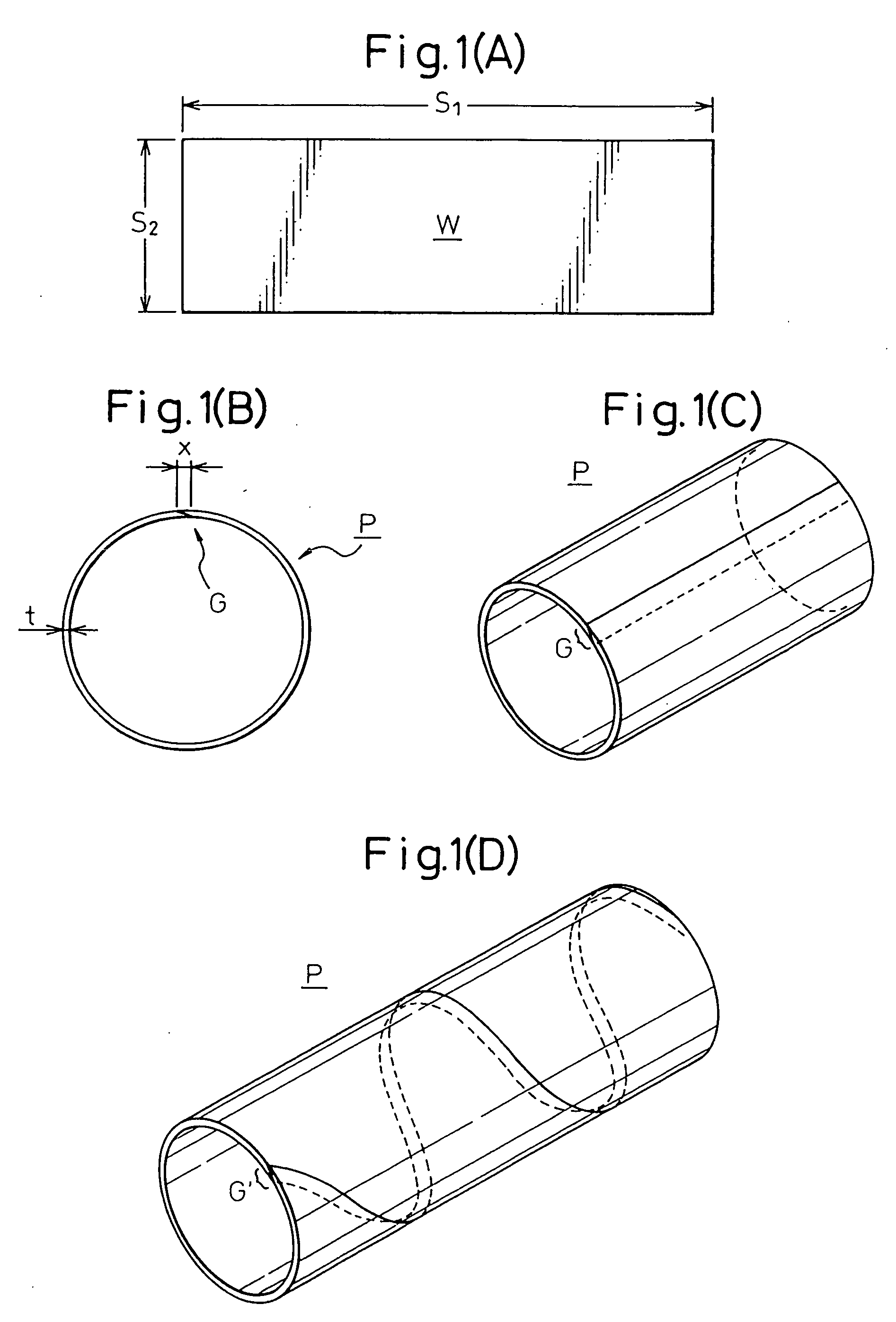

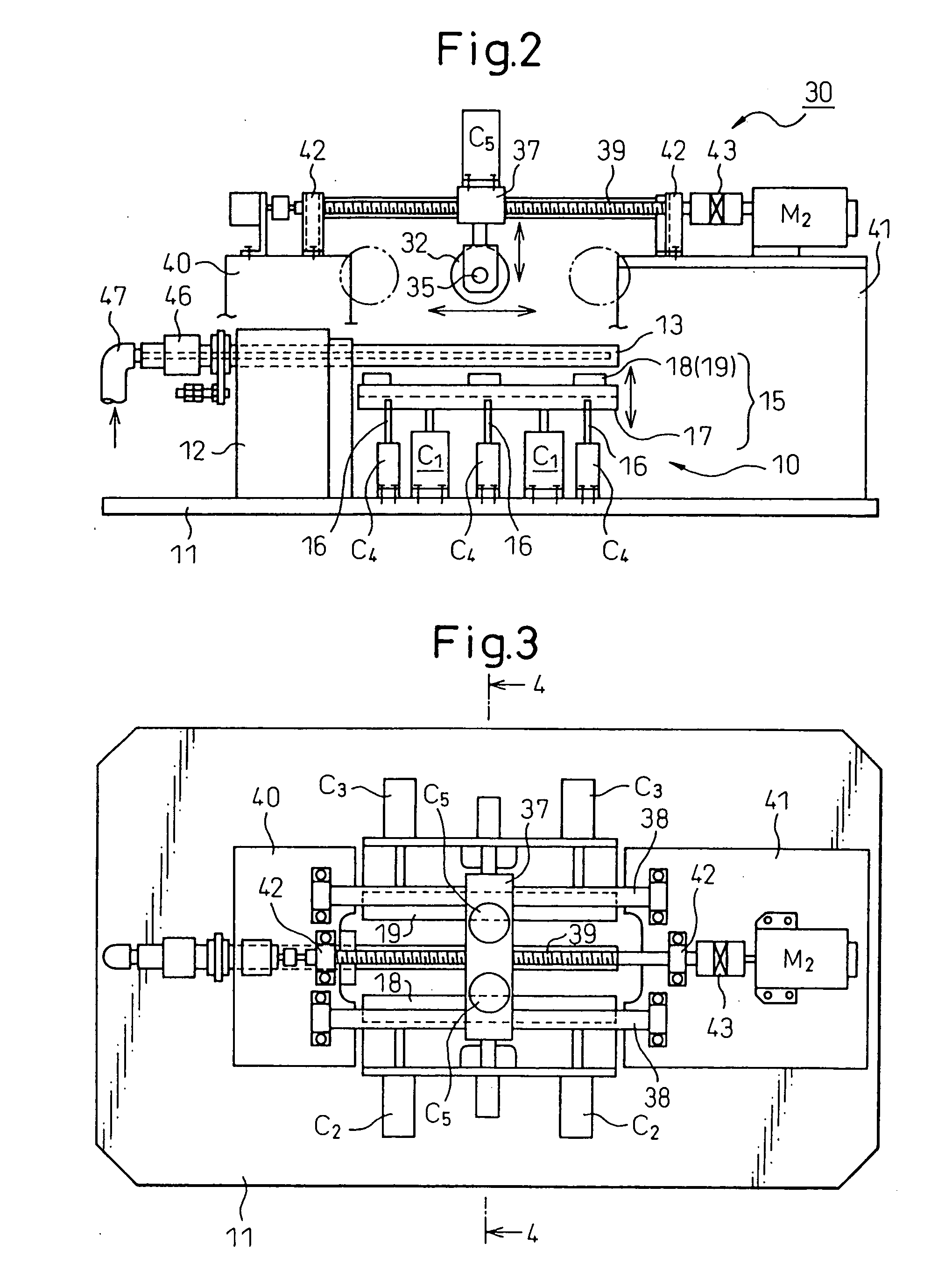

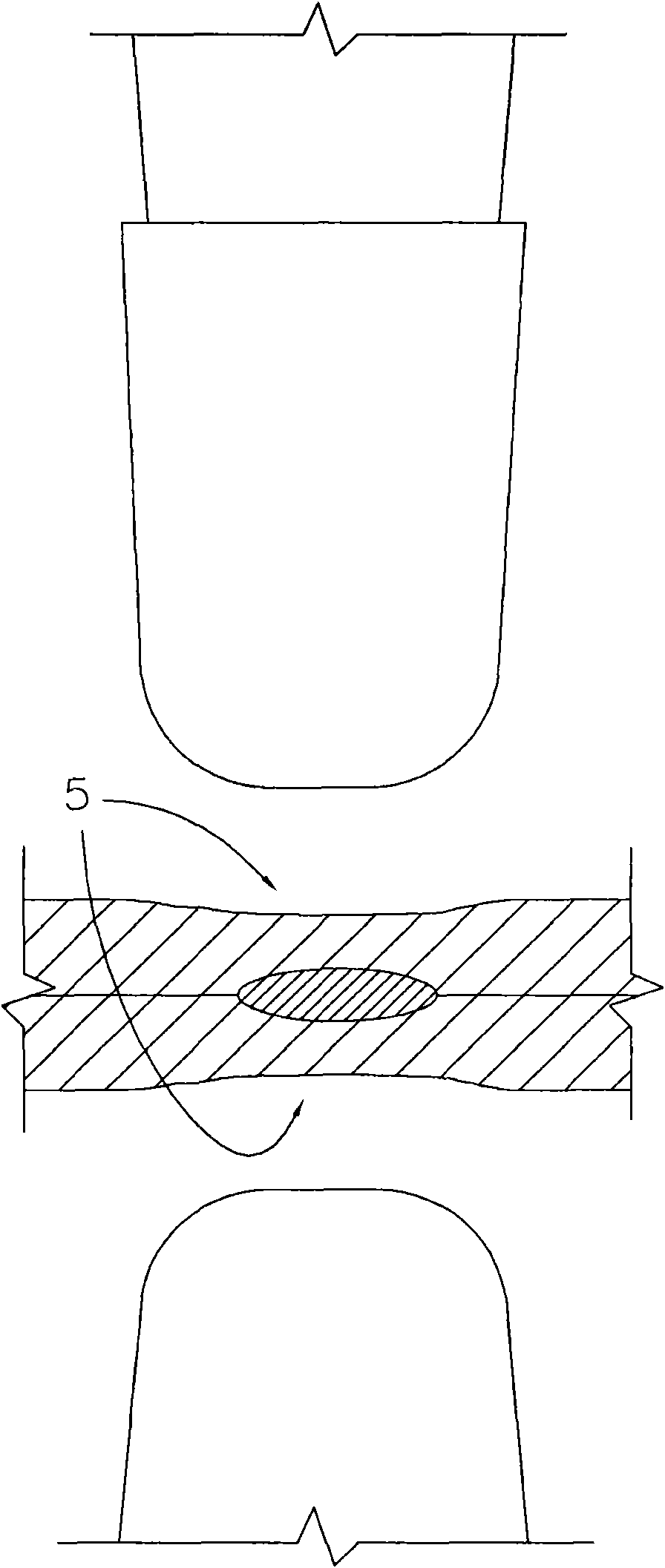

InactiveUS20060150388A1Even out shapeEven out surface roughnessWelding with roller electrodesElectrographic process apparatusThin metalMetallurgy

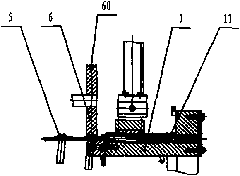

The present invention provides a metal foil tube with a thickness of 10 to 100 μm and a method and apparatus of production of the metal foil tube enabling even an extremely thin metal foil to be reliably finished into a tube, that is, a metal foil tube comprised of a metal foil sheet W with a thickness t of 10 to 100 μm joined by welding, the method of production of the metal foil tube shaping the metal foil sheet W to form an overlap part G, then welding the facing sides and finishing the weld zone part flat.

Owner:INADA KOKI +6

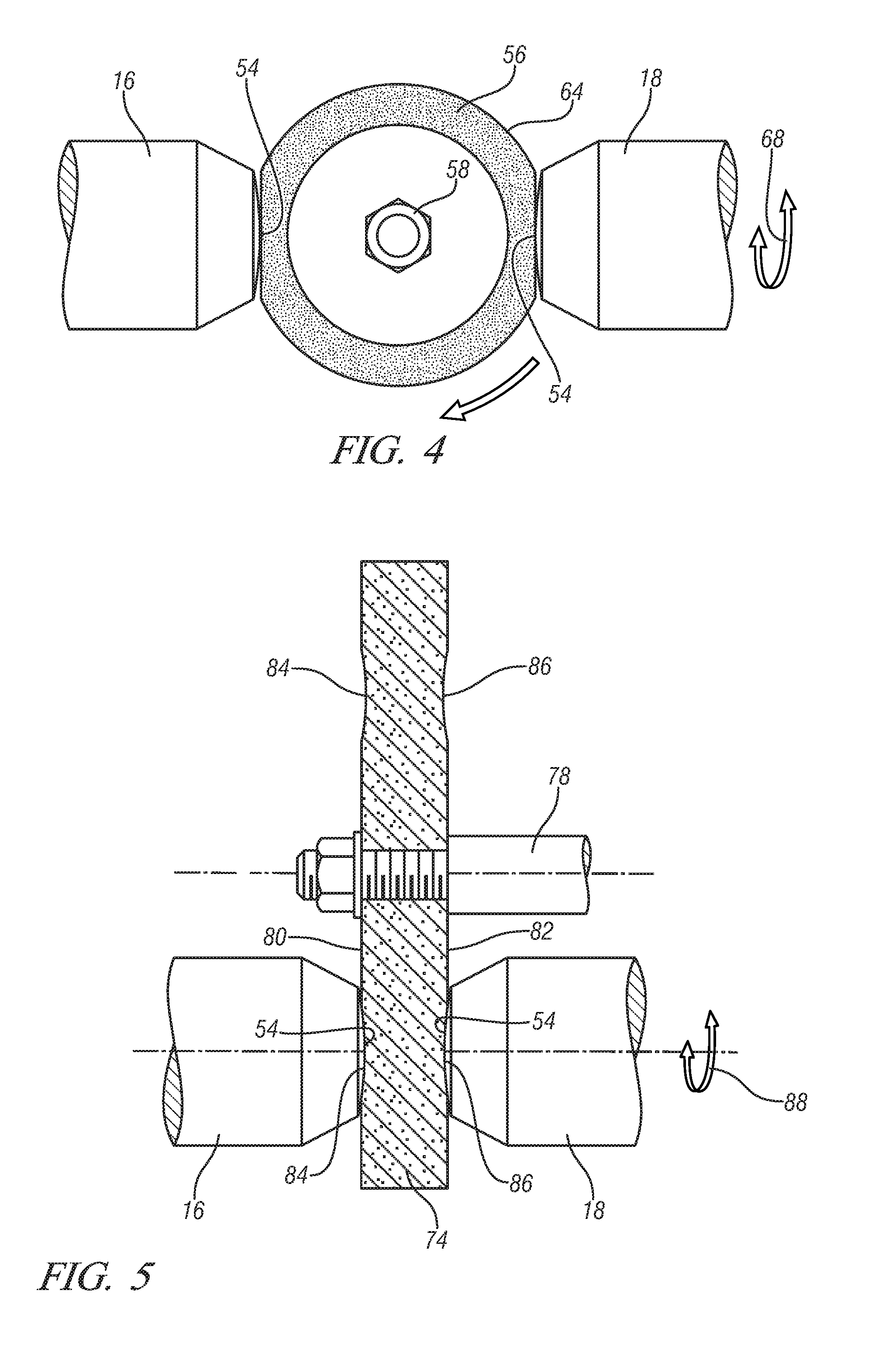

Welding Electrode With Contoured Face

ActiveUS20110266260A1Improve high temperature strengthLow efficiencyWelding with roller electrodesWelding/cutting media/materialsMaterials scienceElectrode

A method for welding a plurality of aluminum to aluminum welds and a plurality of steel to steel welds using the same welder includes providing a resistance spot welder with a pair of weld electrodes having an electrode face radius of curvature in the range between 20 mm and 40 mm. The series of aluminum to aluminum welds is first made, and then, after completing the aluminum to aluminum welds, the series of steel to steel welds are made. After completing the steel to steel welds the weld electrodes are cleaned by an abrasive to remove any buildup or contamination of aluminum on the electrodes. In the event the electrodes have mushroomed, then dressing of the electrodes is provided and then the abrasive cleaning is performed to restore the surface texture.

Owner:GM GLOBAL TECH OPERATIONS LLC

System for and method of projection weld-bonding workpieces

InactiveCN101579779AWelding with roller electrodesWelding/soldering/cutting articlesEngineeringWeld pool

Owner:GM GLOBAL TECH OPERATIONS LLC

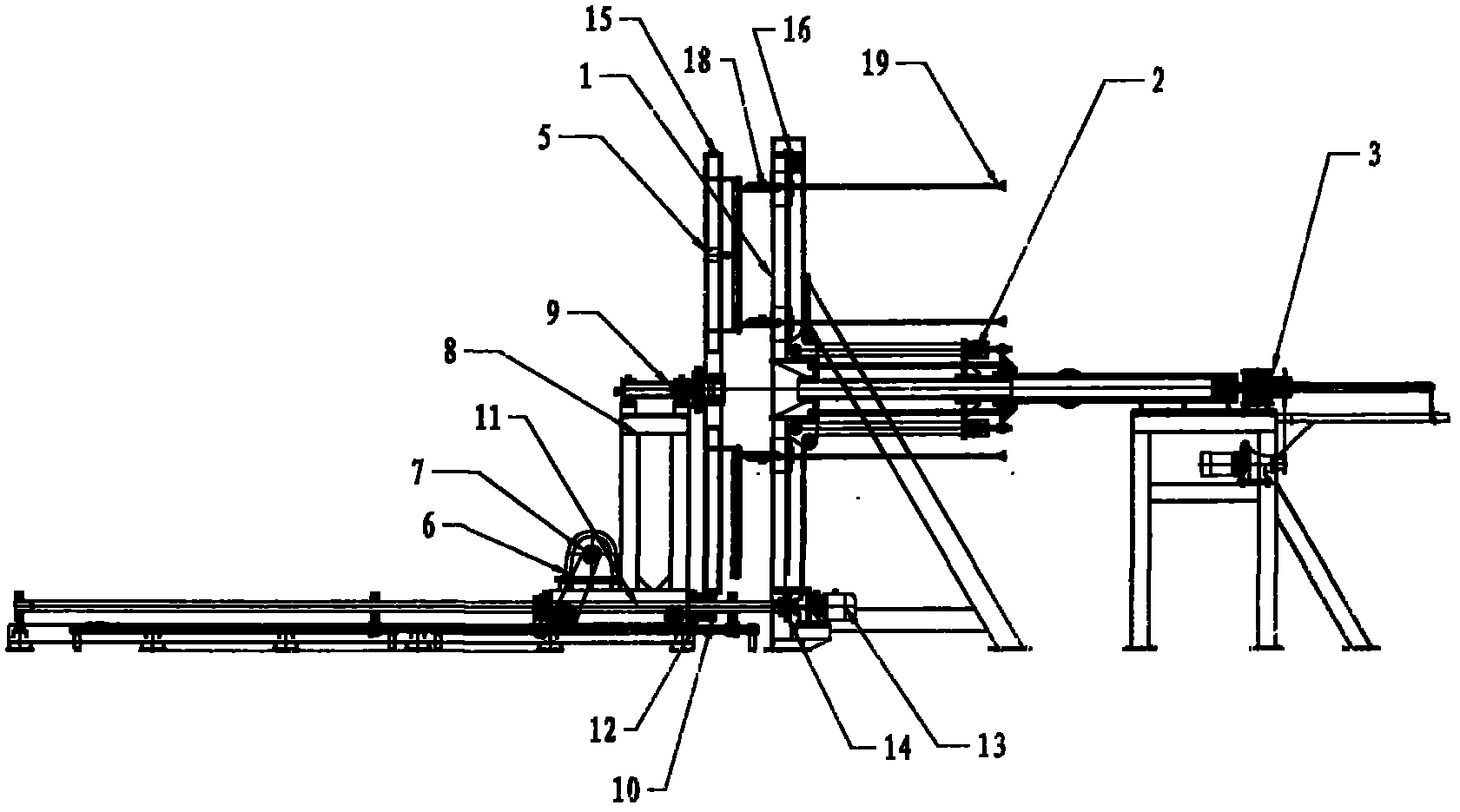

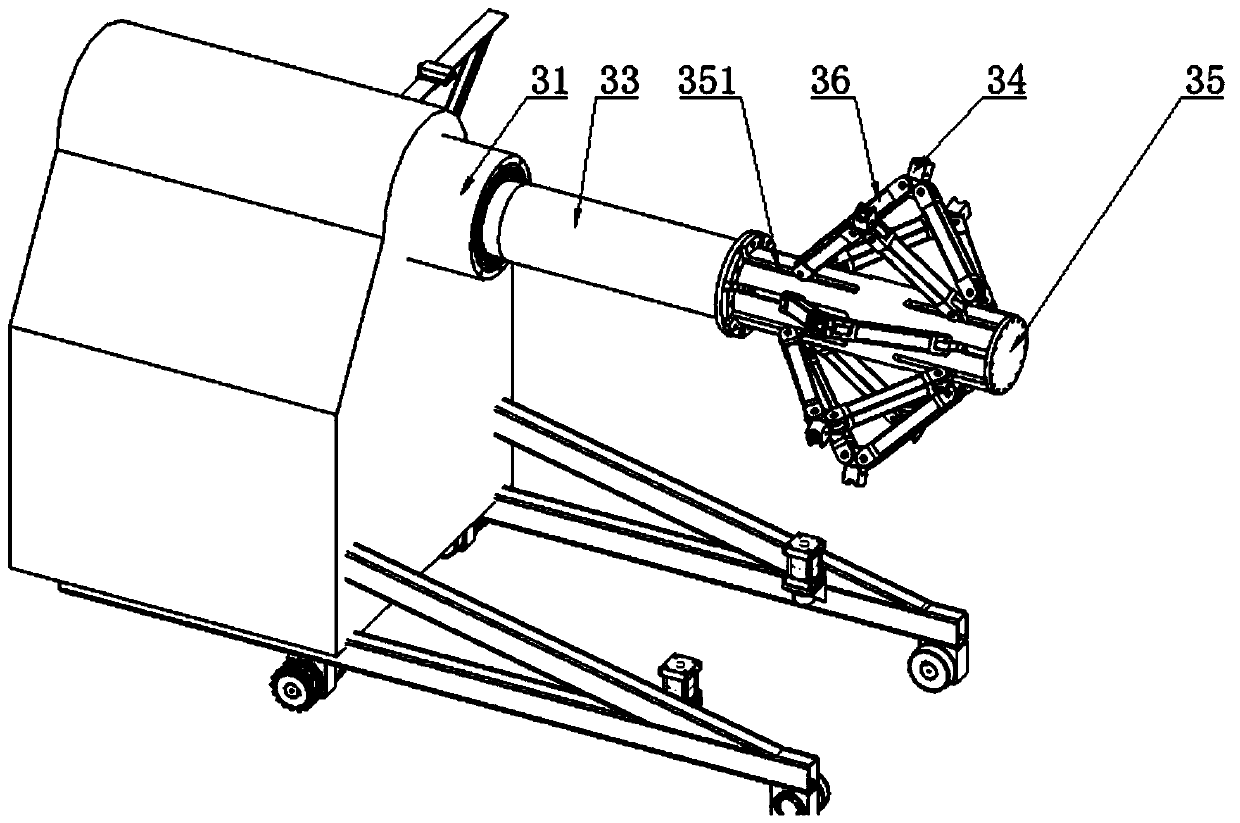

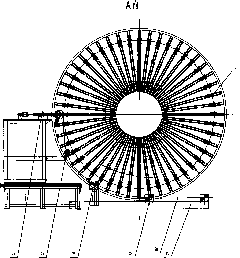

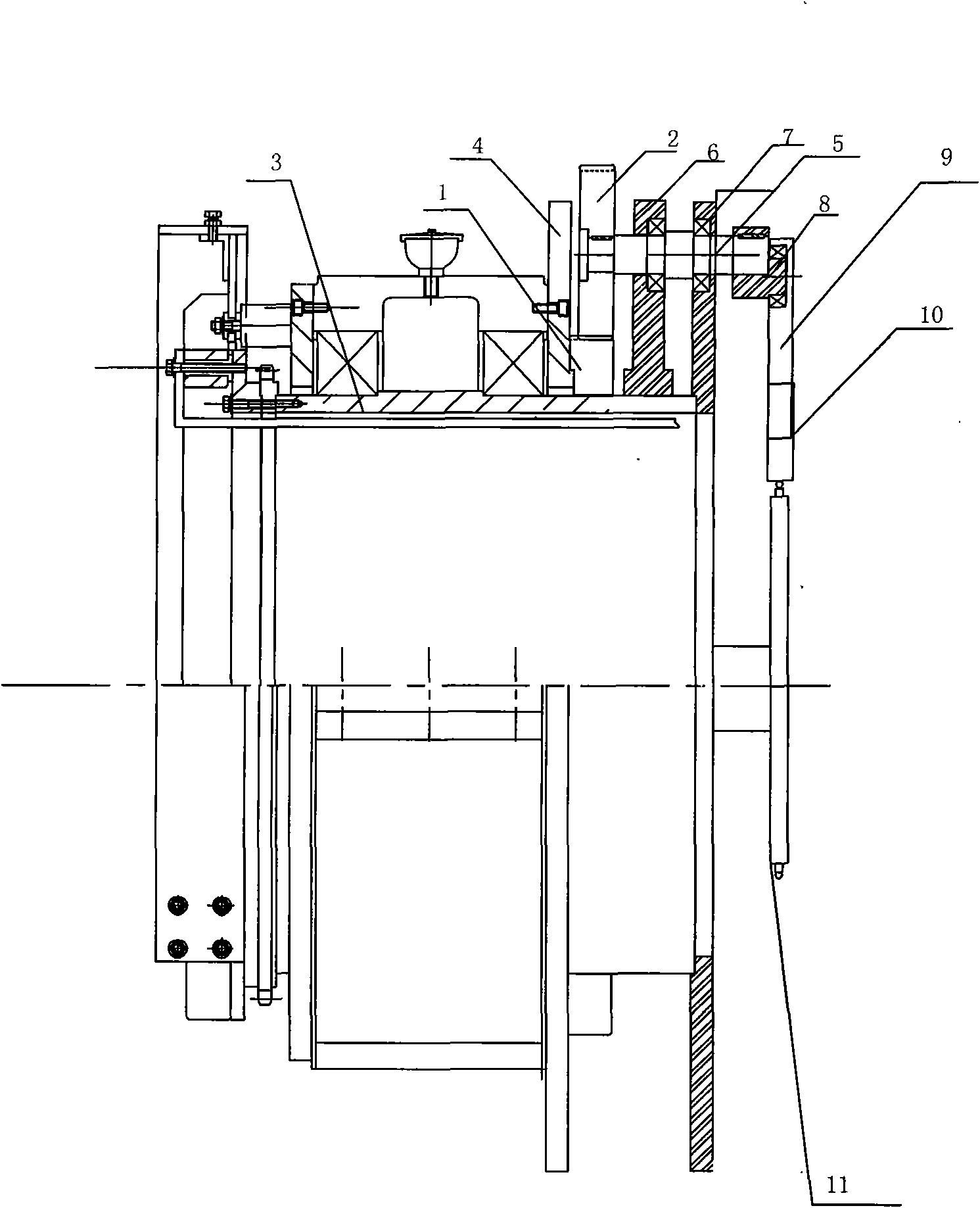

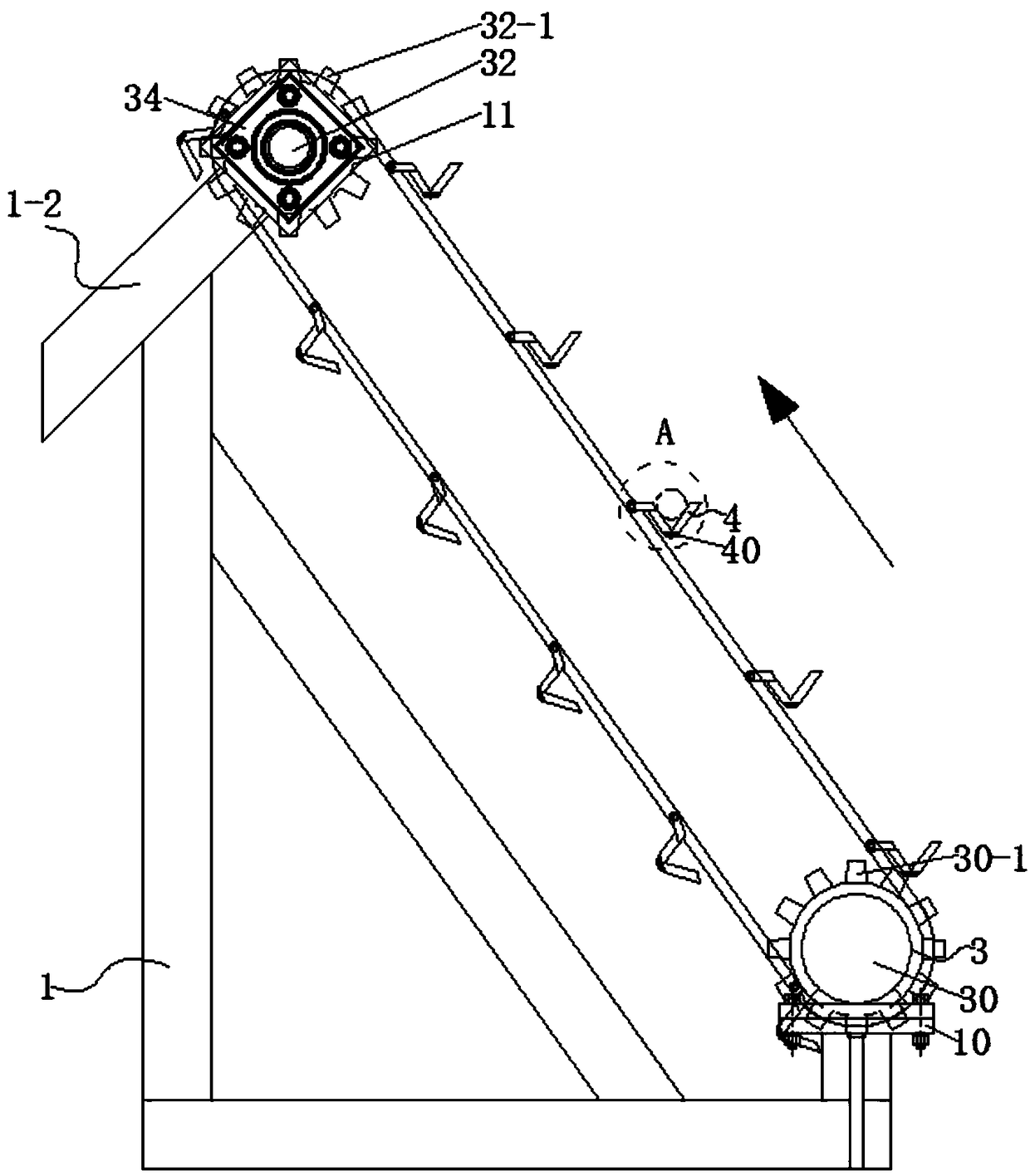

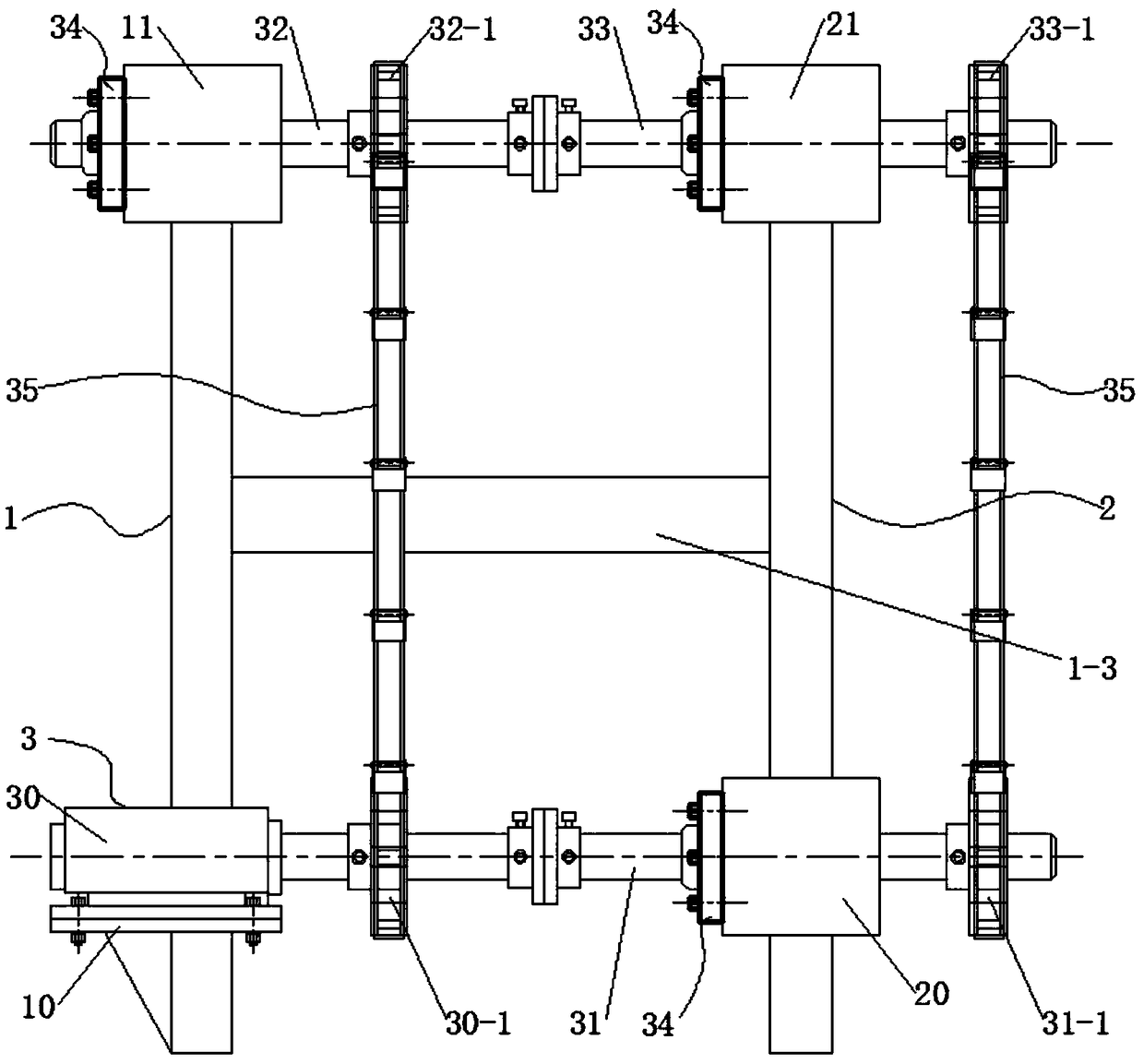

Traction type rolling welding machine

The invention relates to a traction type rolling welding machine, which comprises a master disc, a welding table reducing mechanism, an expanding mechanism, a welding mechanism, a traction disc chuck and a traction trolley, wherein the traction disc chuck keeps synchronous rotation with the master disc under the transmission of transmission square steel while clamping longitudinal bars of a steel reinforcement cage to make axial motion under the driving of the traction trolley. The traction disc chuck keeps synchronous rotation with the master disc under the transmission of the transmission square steel while dragging the longitudinal bars of the steel reinforcement cage to make axial motion under the driving of the traction trolley, so the bar twisting of the steel reinforcement cage can be avoided.

Owner:江苏邦威机械制造有限公司

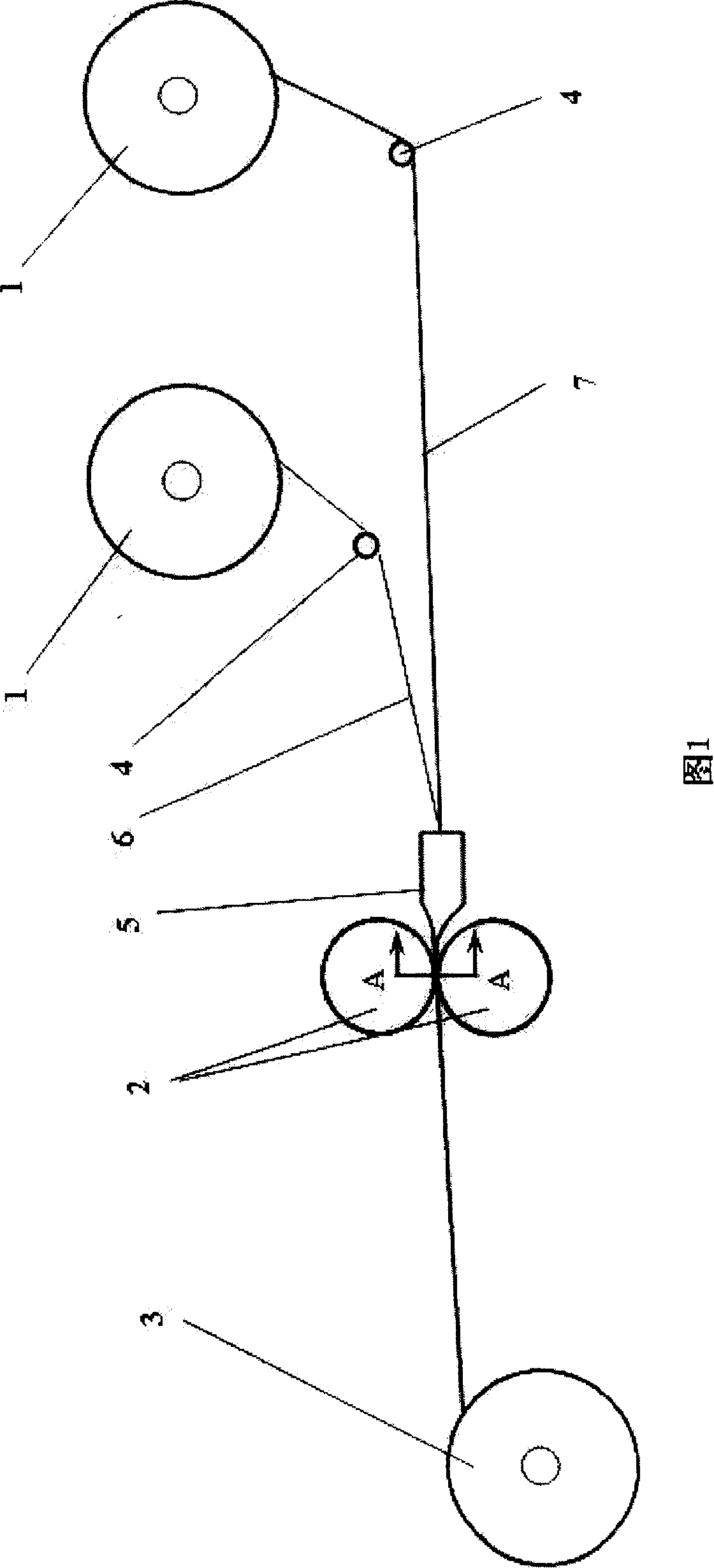

Laser cladding apparatus and method

A laser-clad processing apparatus of the present invention is one which is for carrying out laser-clad processing onto a valve-seat portion of a cylinder head, and is characterized in that it comprises cylinder-head holding means (1) for holding a cylinder head (H) in an inclining manner so that the central axial line of a valve seat becomes the vertical direction, a laser-processing head (2) for irradiating a laser beam onto a process part of the valve seat and at the same time discharging a powdery material to this process part, rotary means (3) which rotates around the central axial line of the valve seat in such a state that the laser-processing head is inclined with respect to the vertical direction, and powdery-material supply means (4) for supplying the powdery material to the laser-processing head.Moreover, a laser-clad processing method of the present invention is characterized in that it fixes the cylinder head (H), and forms a clad layer while rotating the laser-processing head (2), which emits the laser beam with respect to the valve-seat portion of the cylinder head and discharges the powdery material, around the axial center line of the valve seat.

Owner:TOYOTA JIDOSHA KK

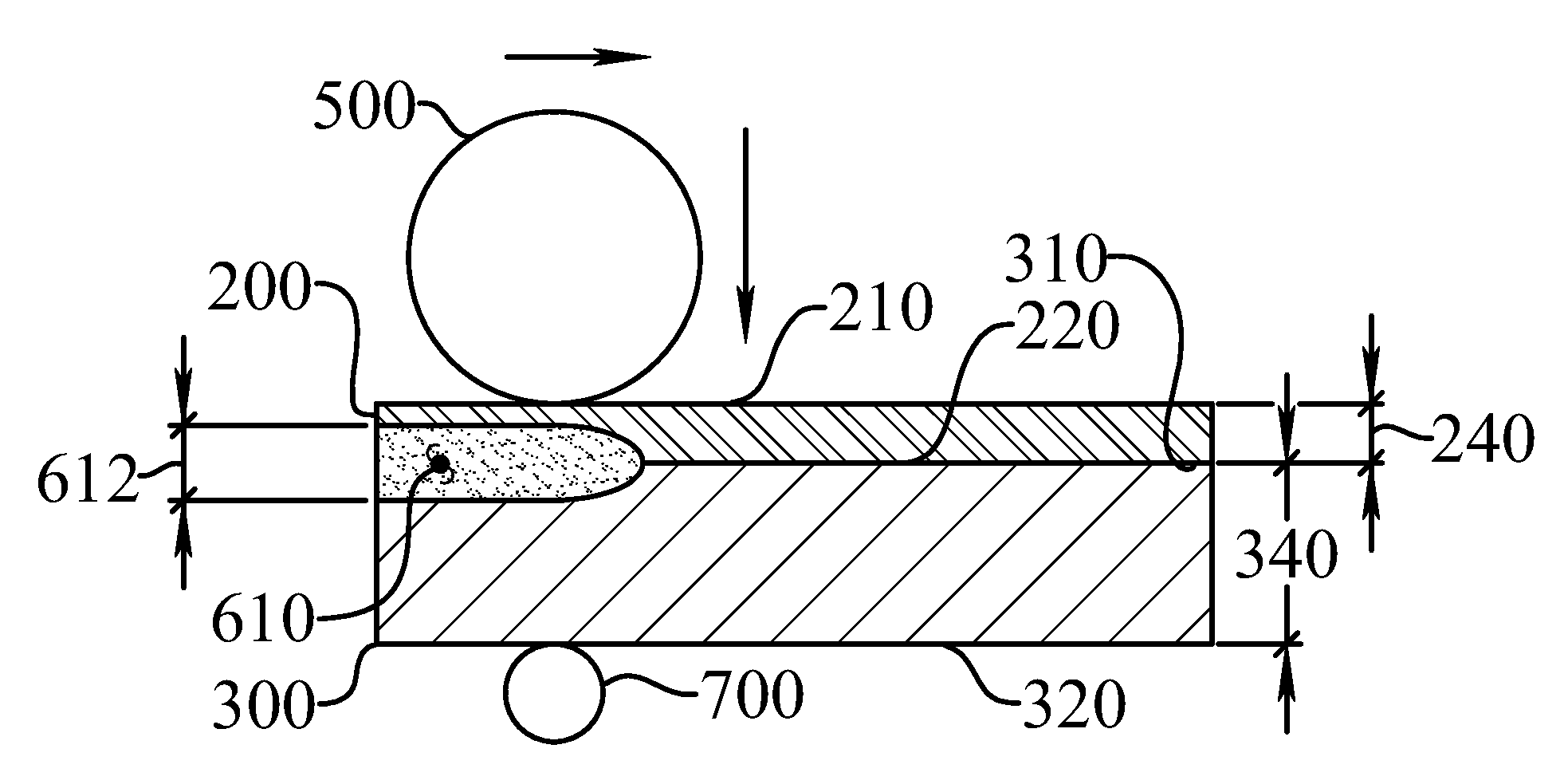

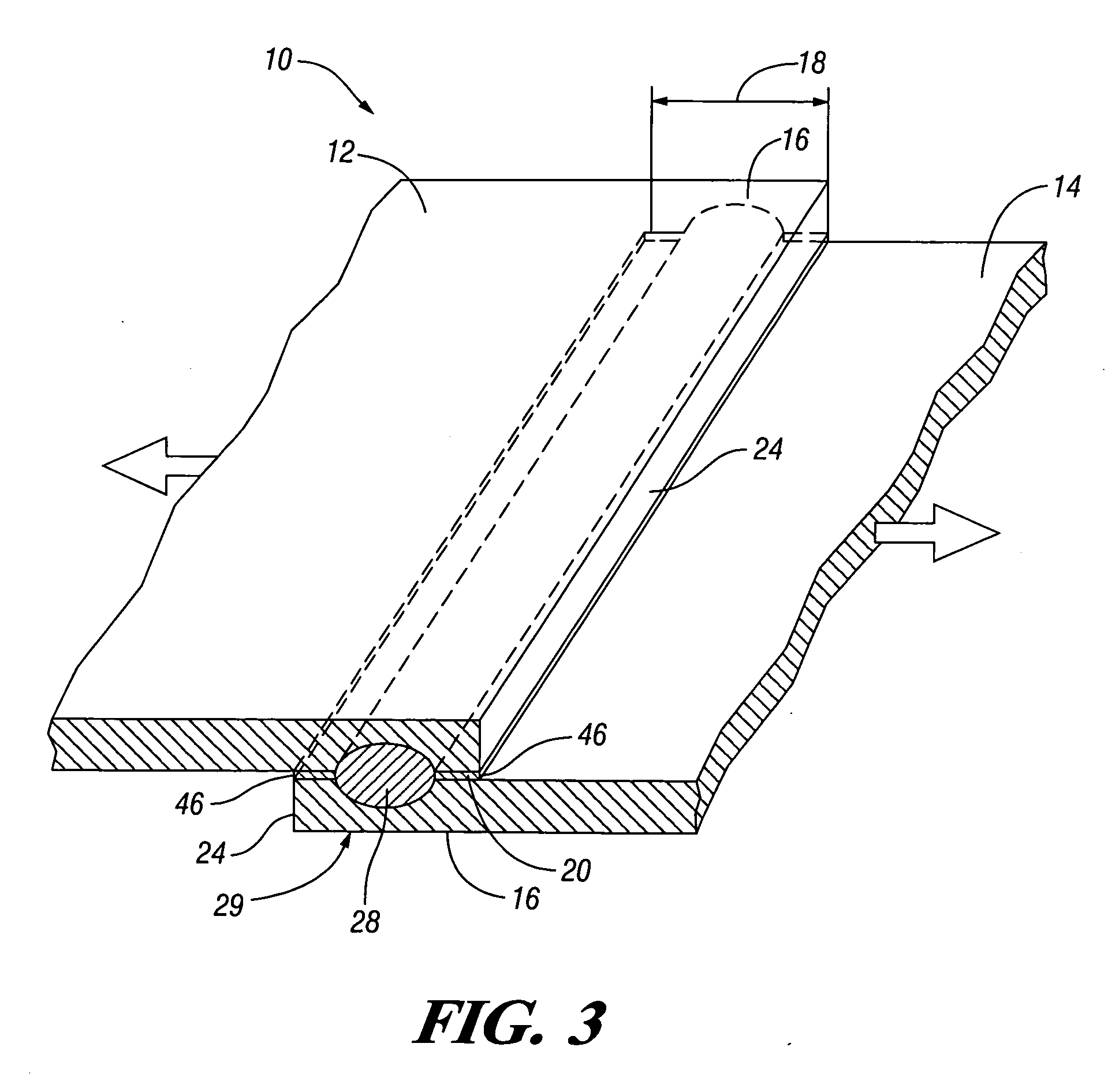

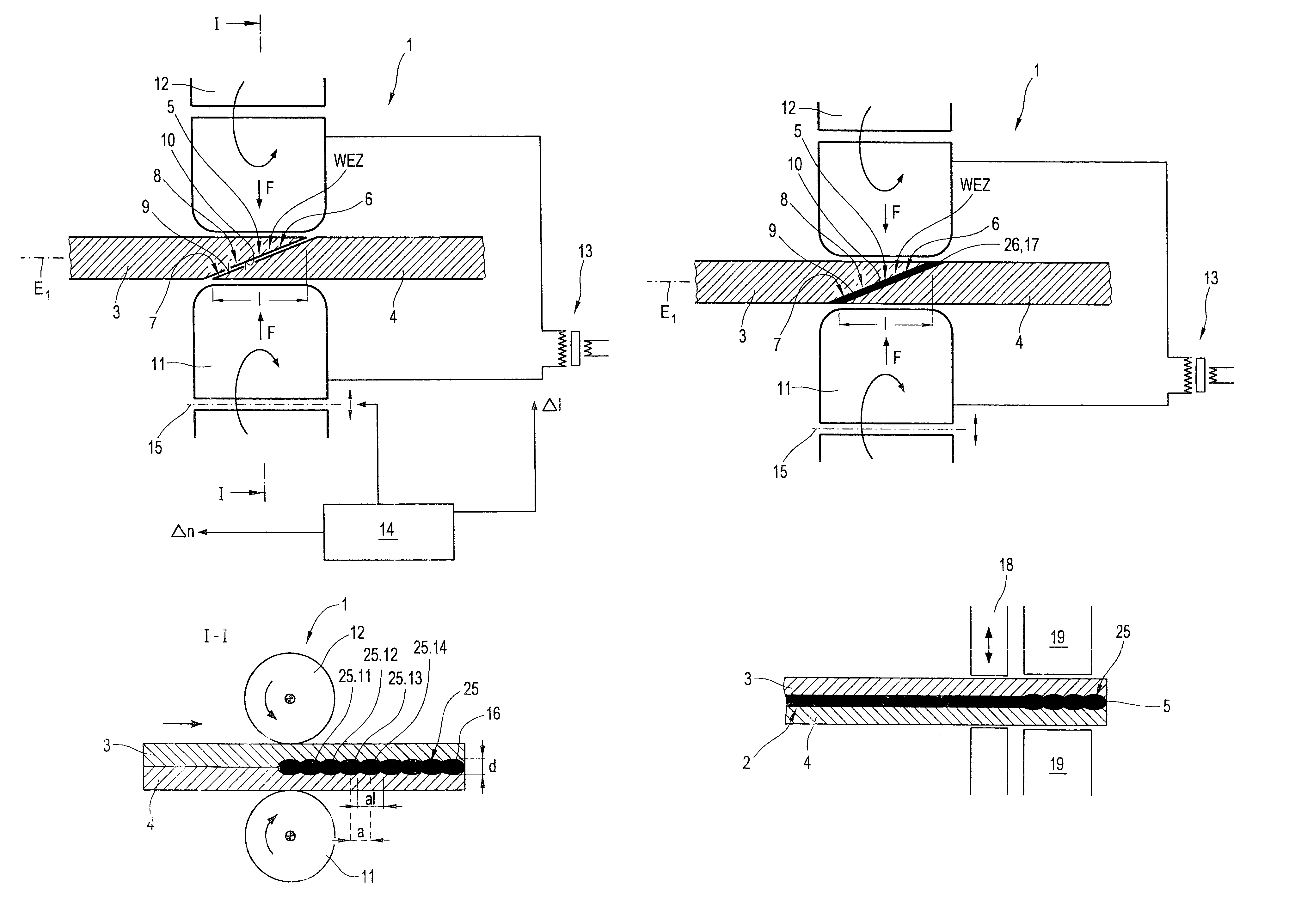

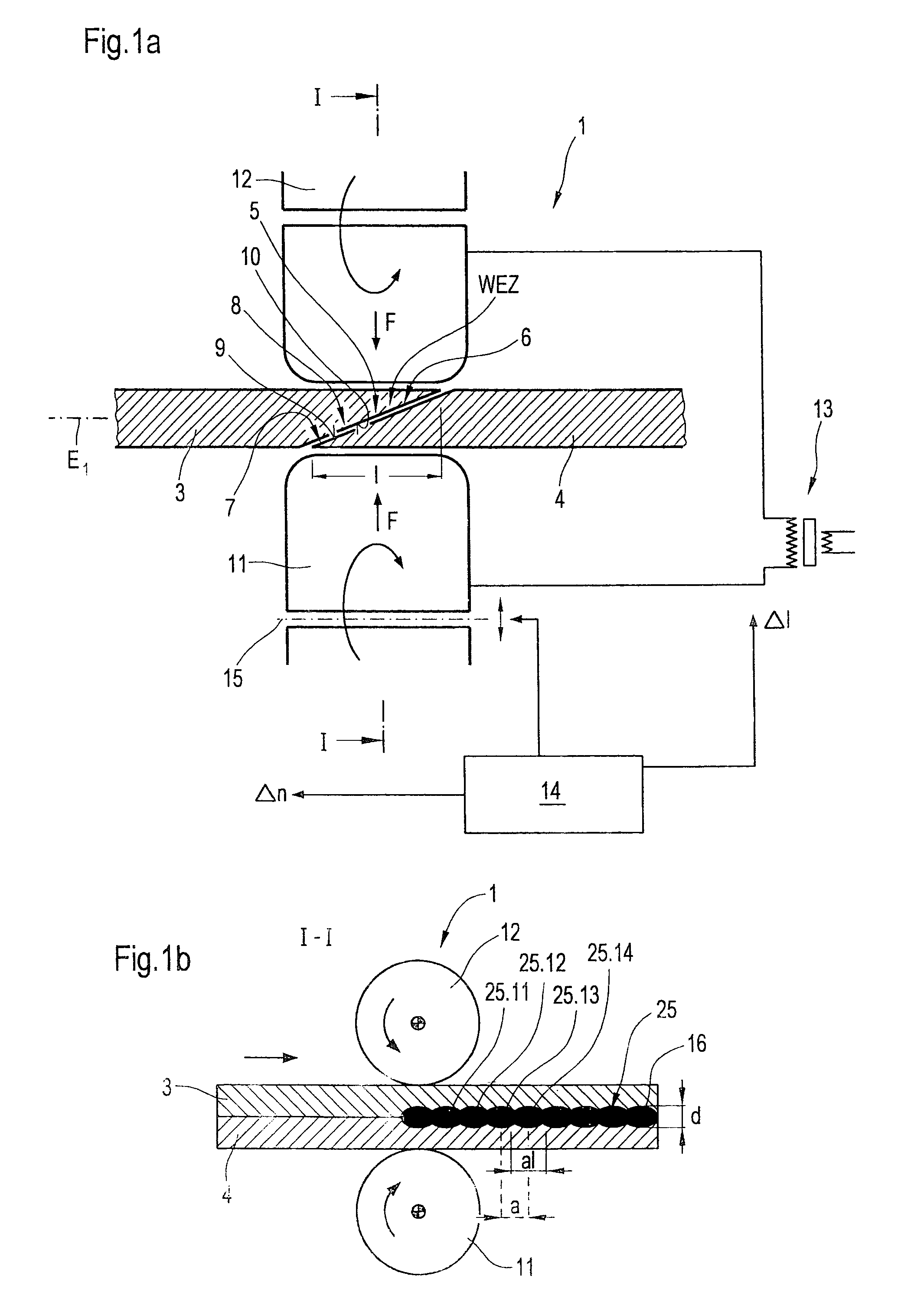

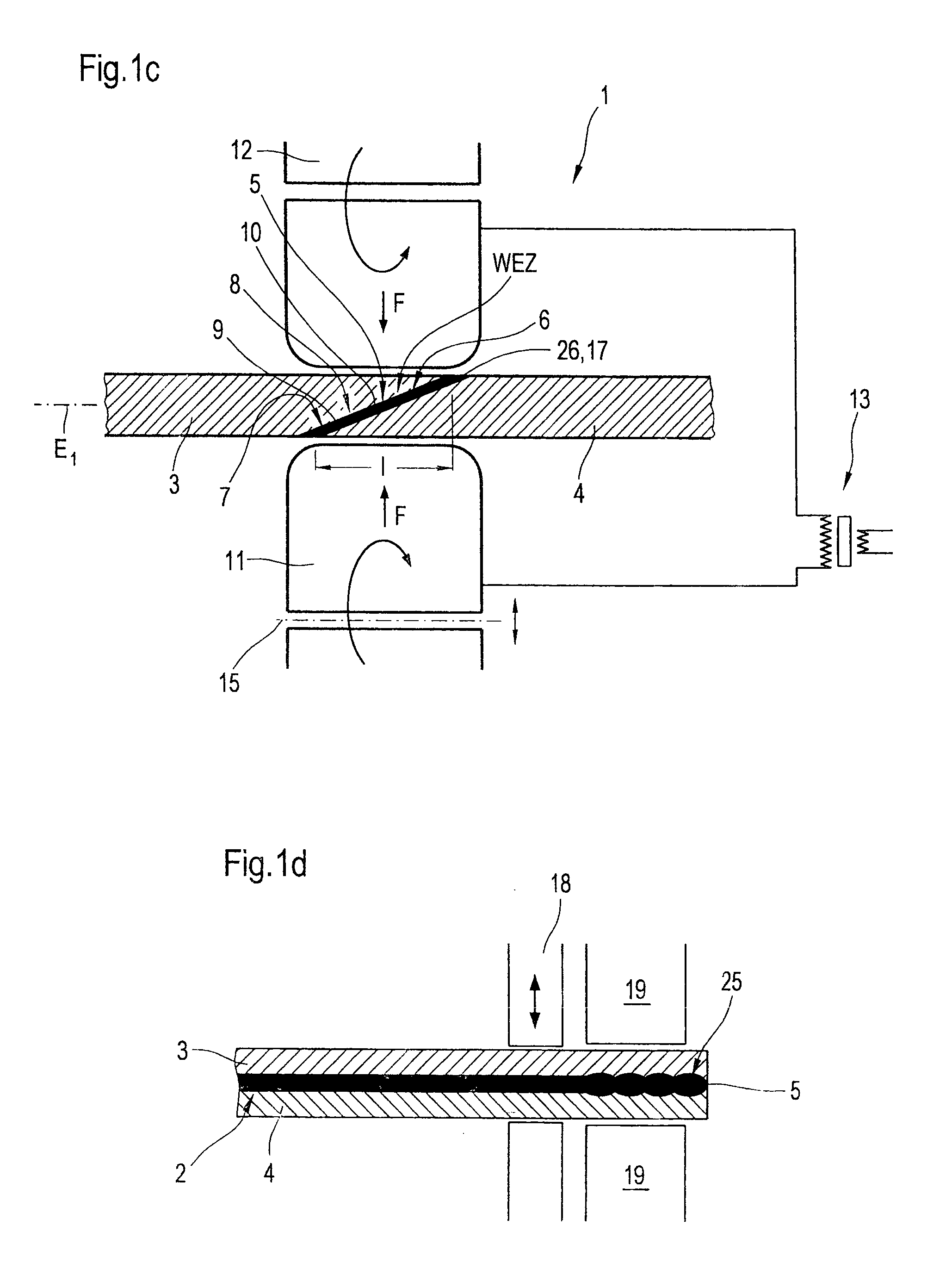

Method of creating a clad structure utilizing a moving resistance energy source

InactiveUS20090250439A1Reduce contact areaWelding with roller electrodesElectrical resistance and conductanceOptoelectronics

A method for forming a clad structure utilizing a moving resistance energy source. The method forms a metallurgical bond between a cladding layer and a primary layer such that at least 2% of a cladding layer surface is metallurgically fusion bonded to a primary layer surface. The fusion bond does not extend all the way through the primary layer or the cladding layer. Either, or both, of the layers may incorporate surface texturing to reduce the contact area between the layers, and melting point suppressants may be incorporated into the method.

Owner:EDISON WELDING INSTITUTE INC

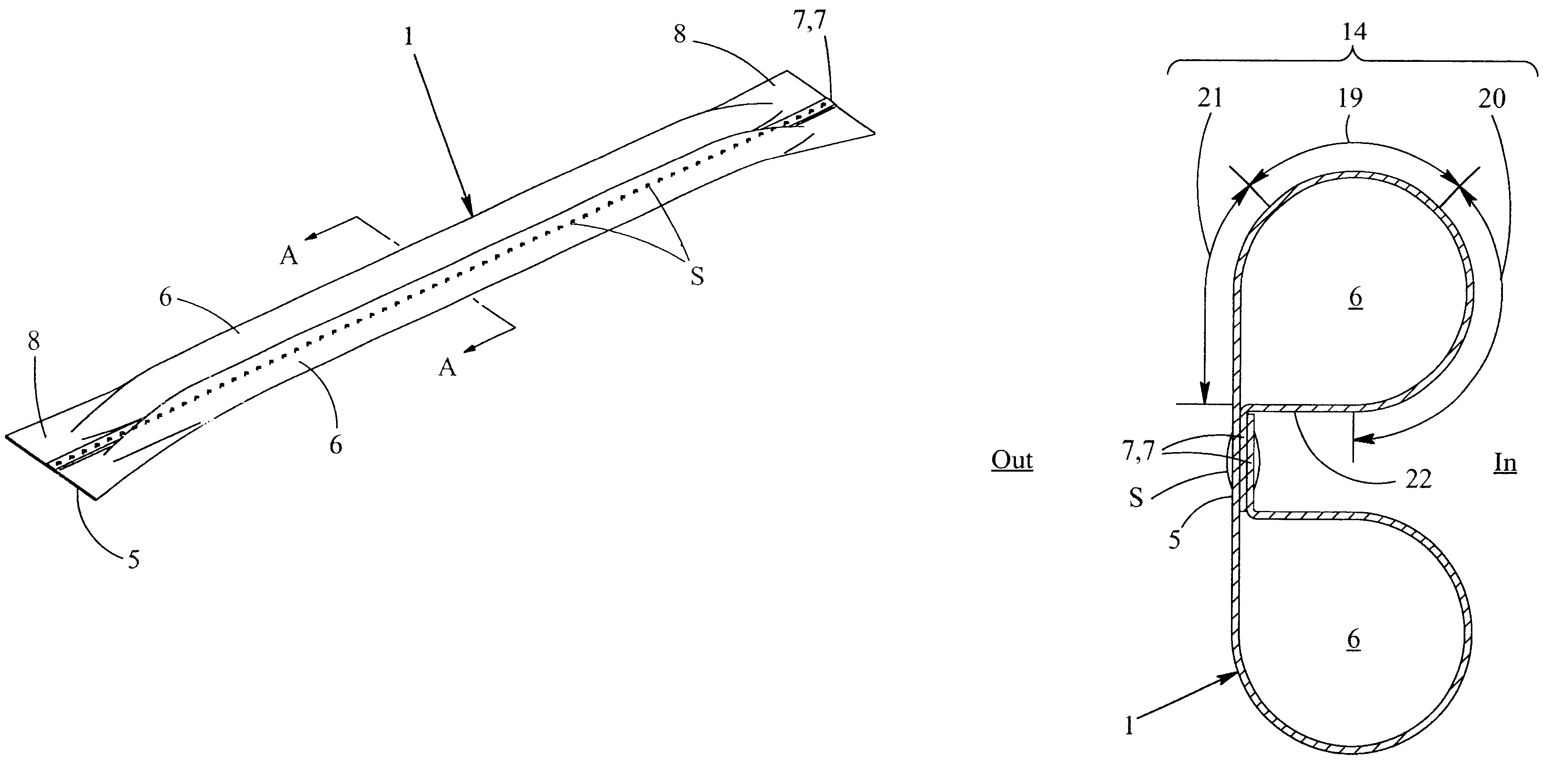

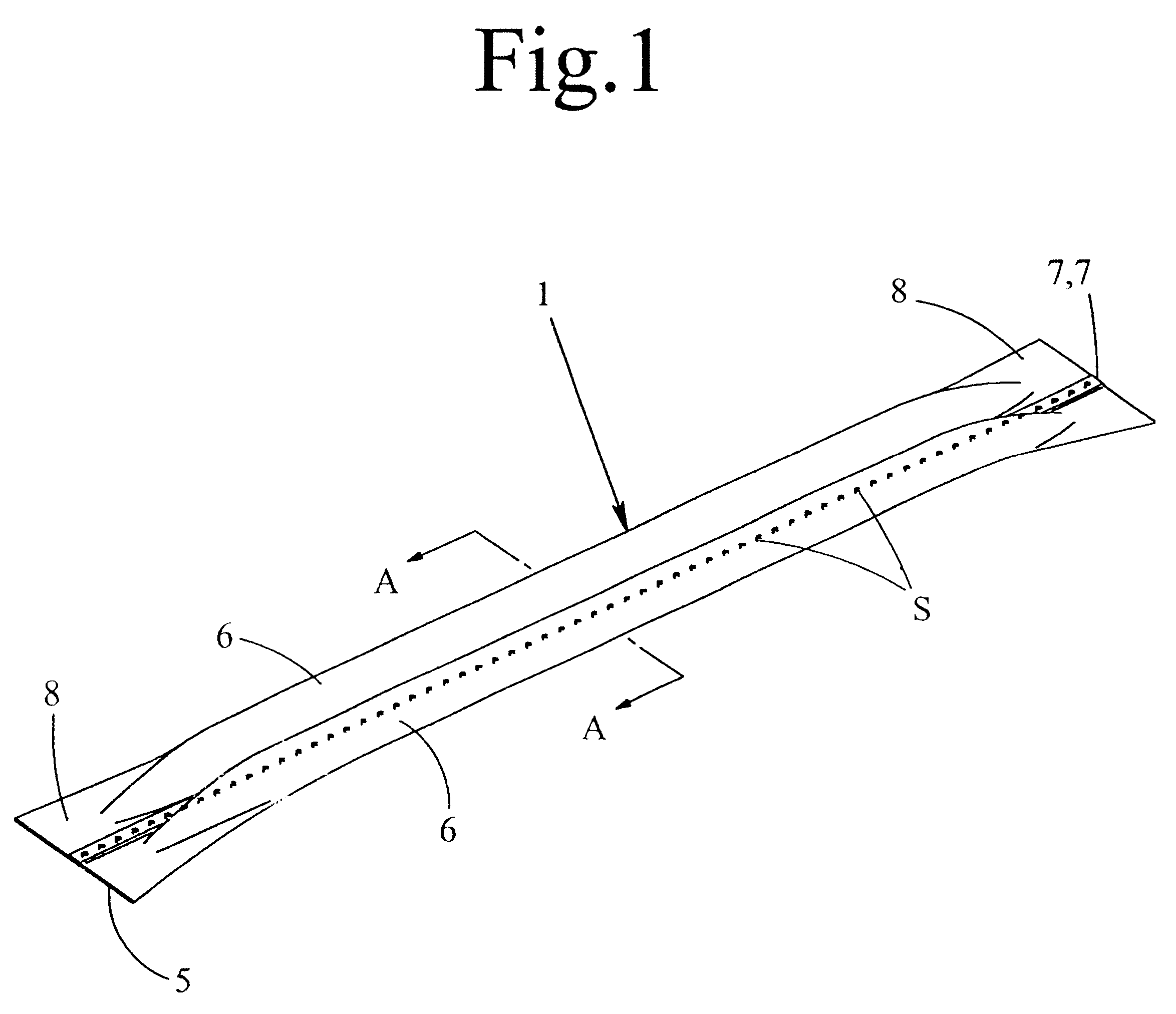

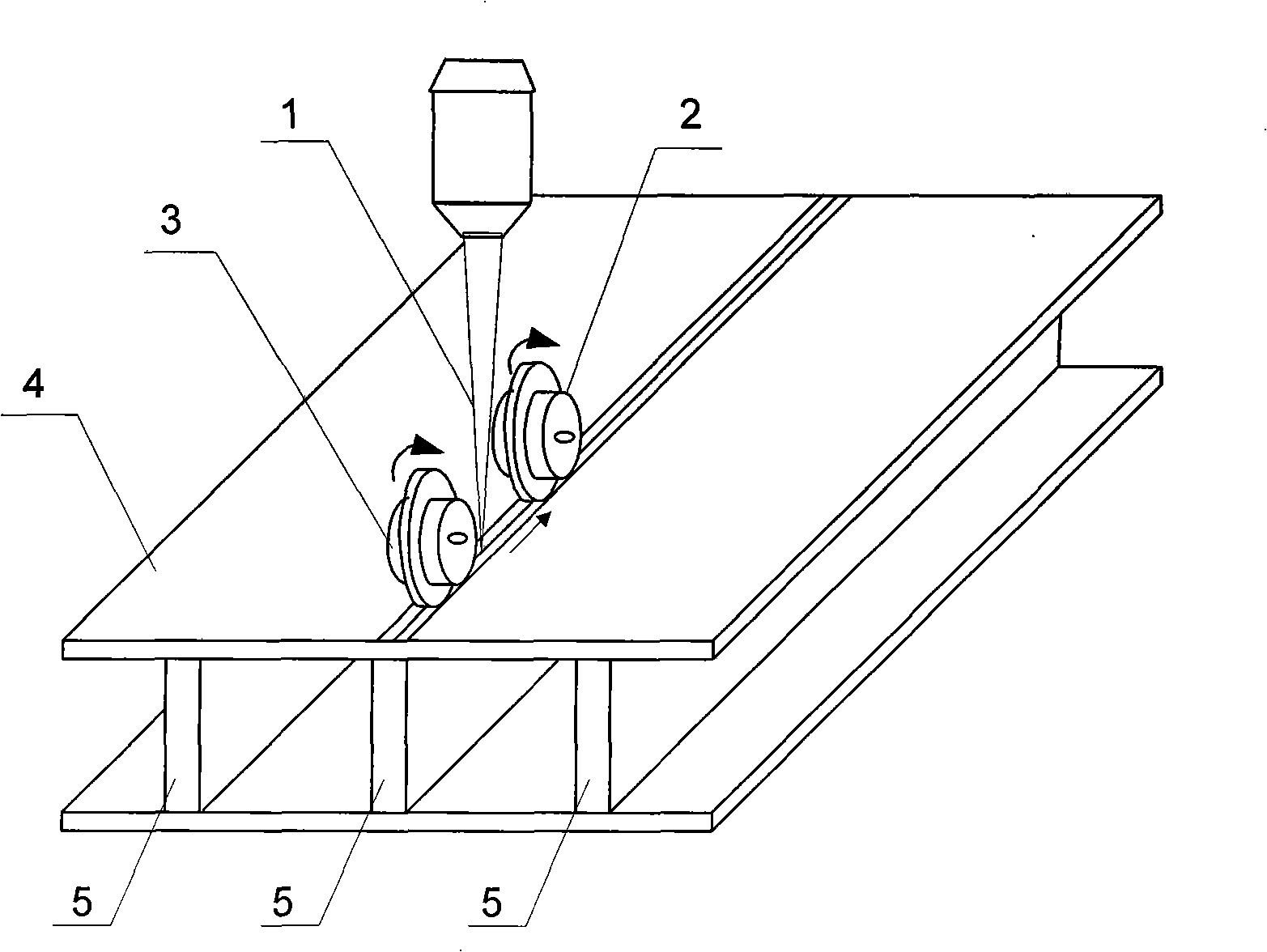

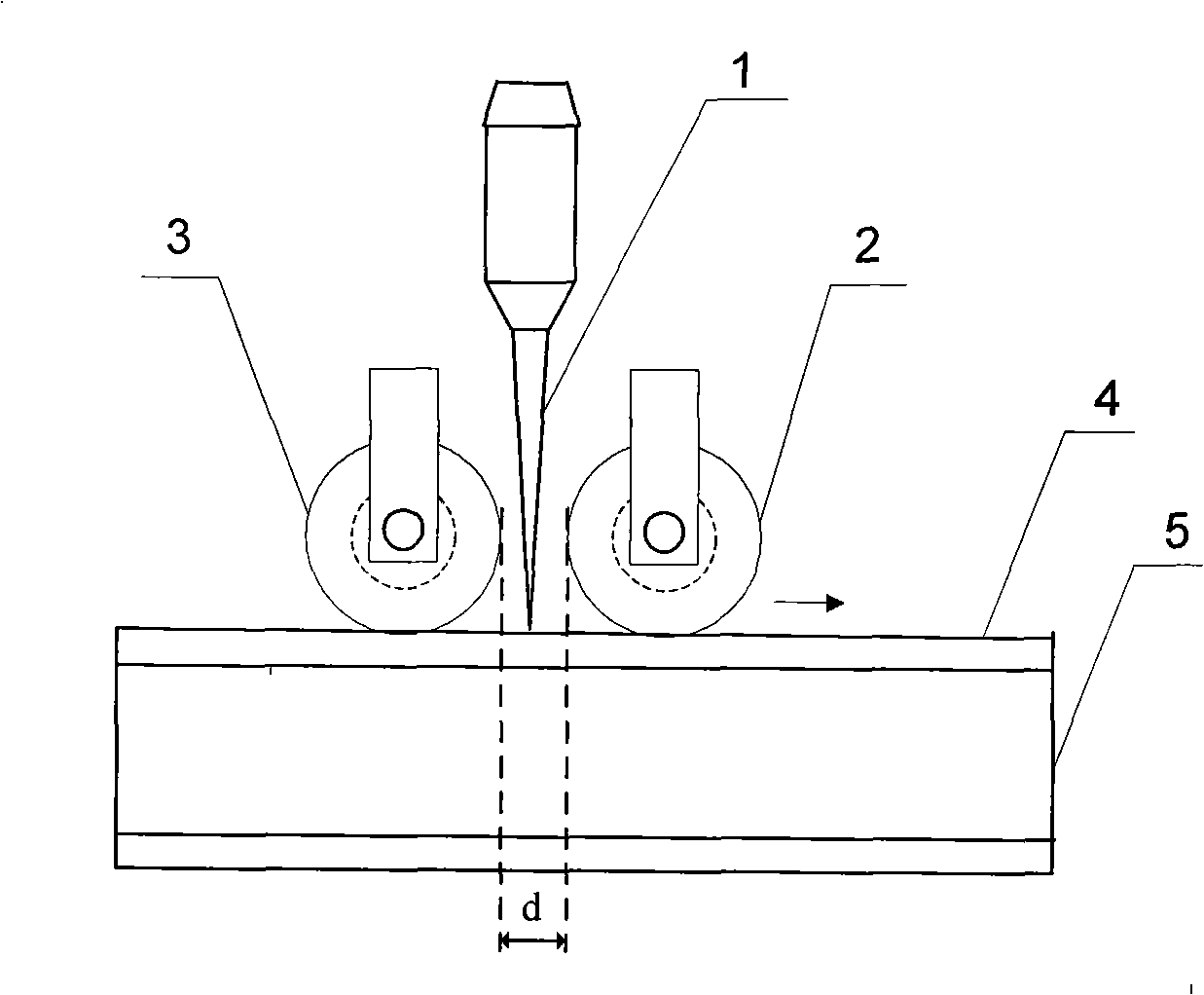

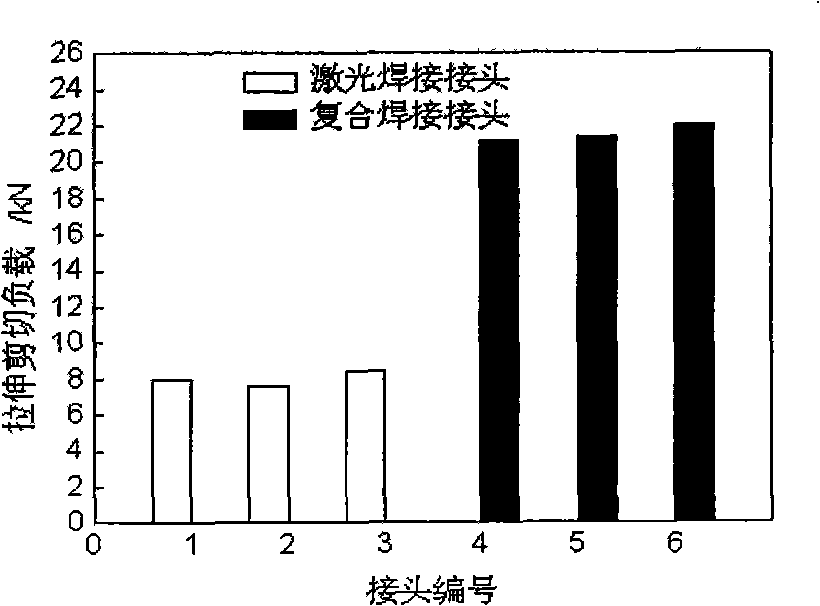

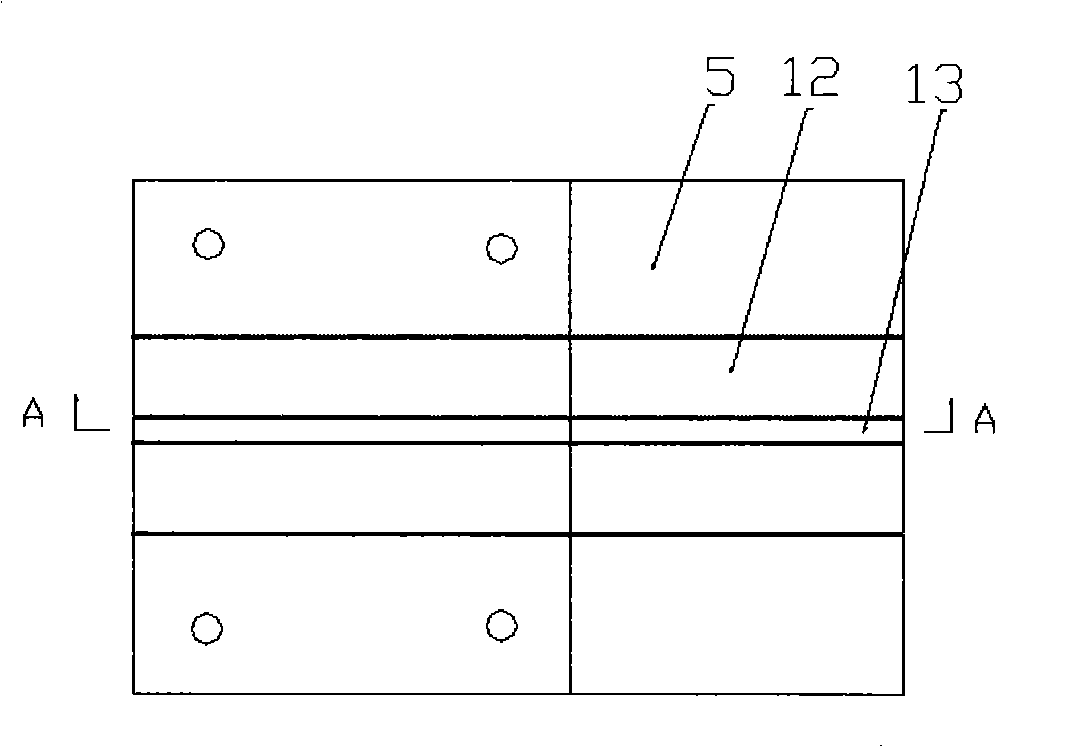

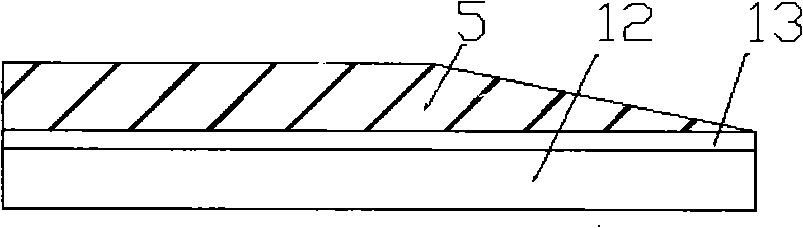

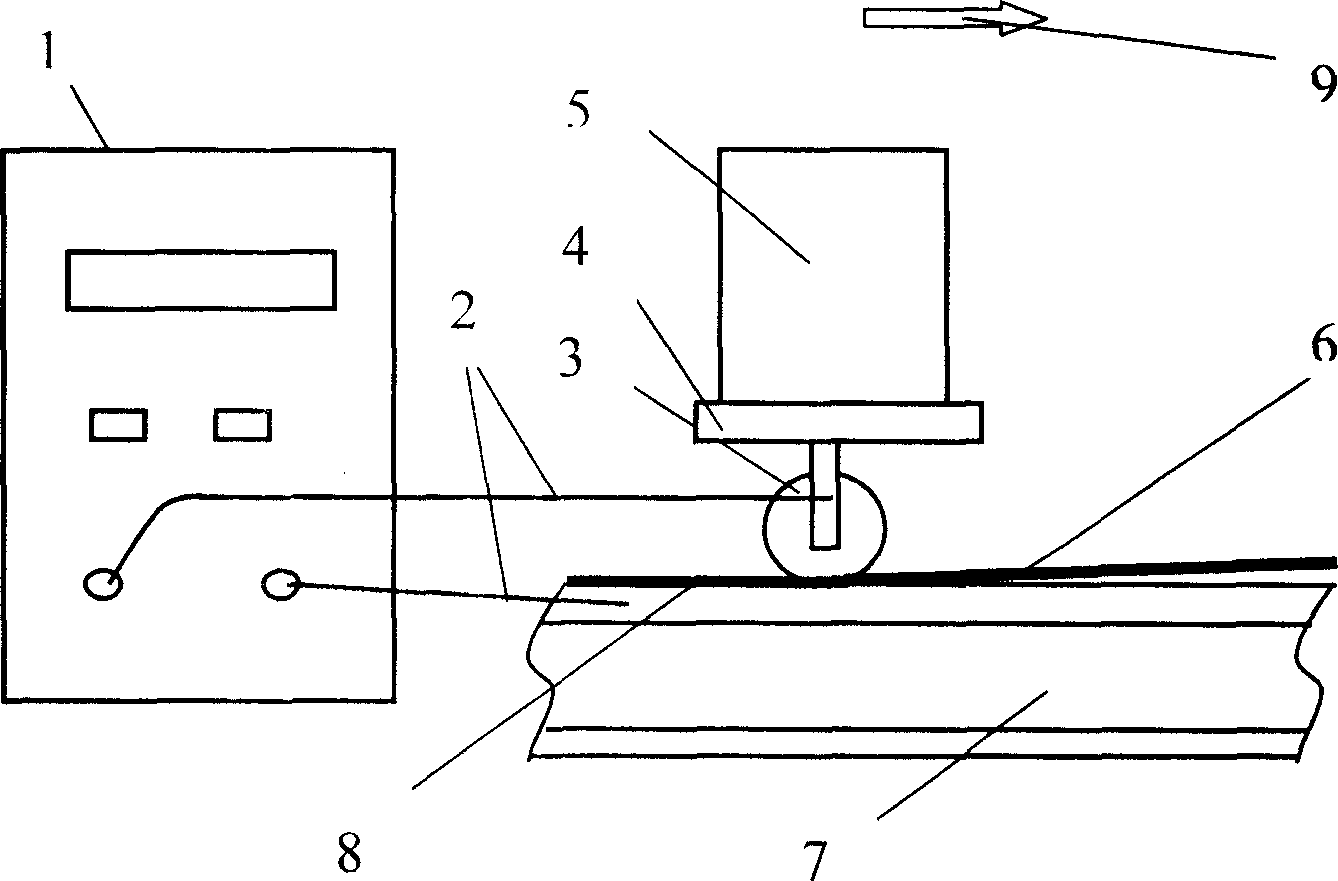

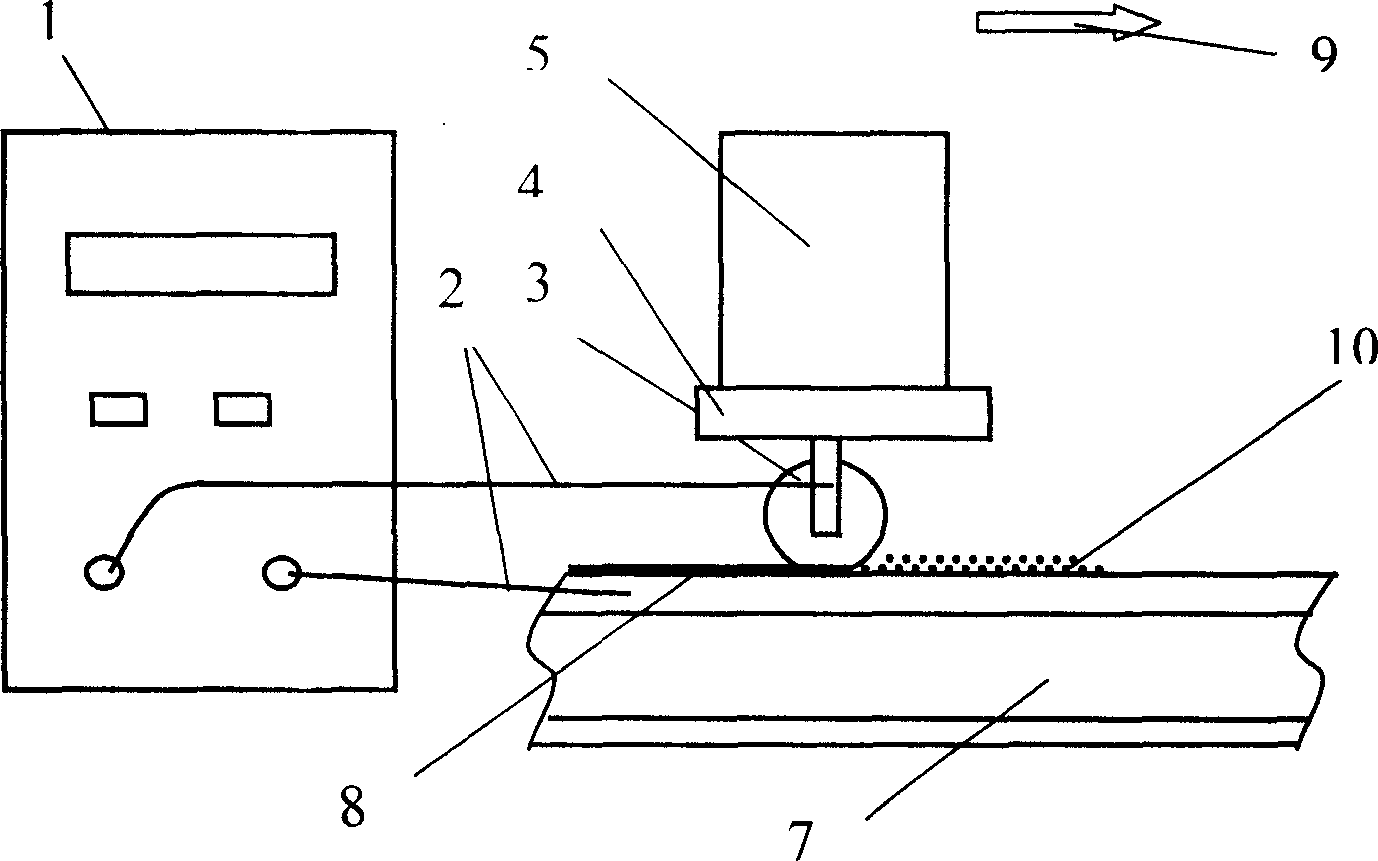

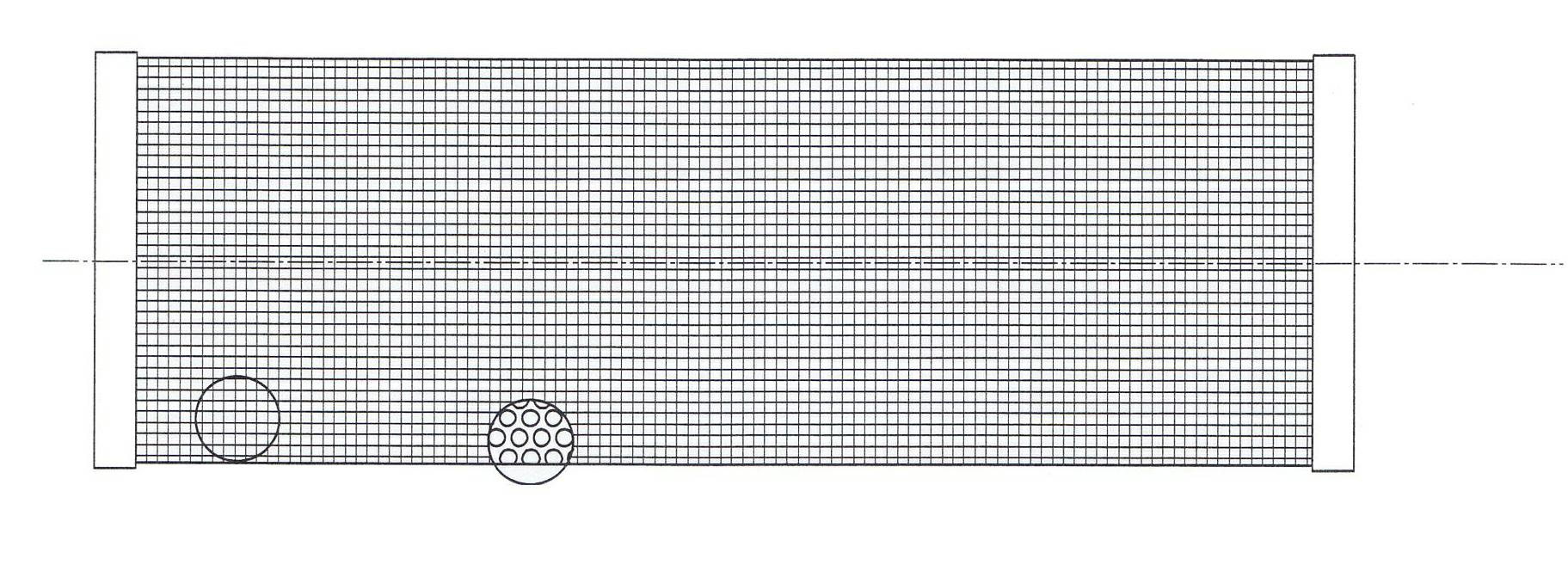

Laser-electric resistance seam welding in-phase compound welding method of frame-covering structure

InactiveCN101306491AFit tightlyImprove welding qualityWelding with roller electrodesLaser beam welding apparatusLight beamElectric resistance welding

A laser and electric-resistance seam-welding synchronous composite welding method for an envelope-framework structure relates to a novel laser and electric-resistance seam-welding synchronous composite welding method, belongs to the welding field, and aims to solve the problems in welding the envelope-framework structure by the single laser, such as narrow seam, low shear strength of the seam, a plurality of air vents on the faying surface of the envelope and the framework. The invention aims at the workpiece with the envelope-framework structure to be welded, and adopts the laser and the electric-resistance seam-welding synchronous composite welding; the electric-resistance seam-welding adopts double-roller single-side welding, two roller electrodes are disposed on the front and the back sides of the upper top surface of the envelope along the seam formed by the contact of the envelope and the framework, so that the envelope is pressed to the lower framework in the travel forward, and the laser beam is always positioned in the middle position of the two roller electrodes during the welding process. The seam formed by the welding method can improve the shear strength more than twice in comparison with the base material, and the air vent amount per area can be reduced from about 10% to about 2% of the laser welding.

Owner:HARBIN INST OF TECH

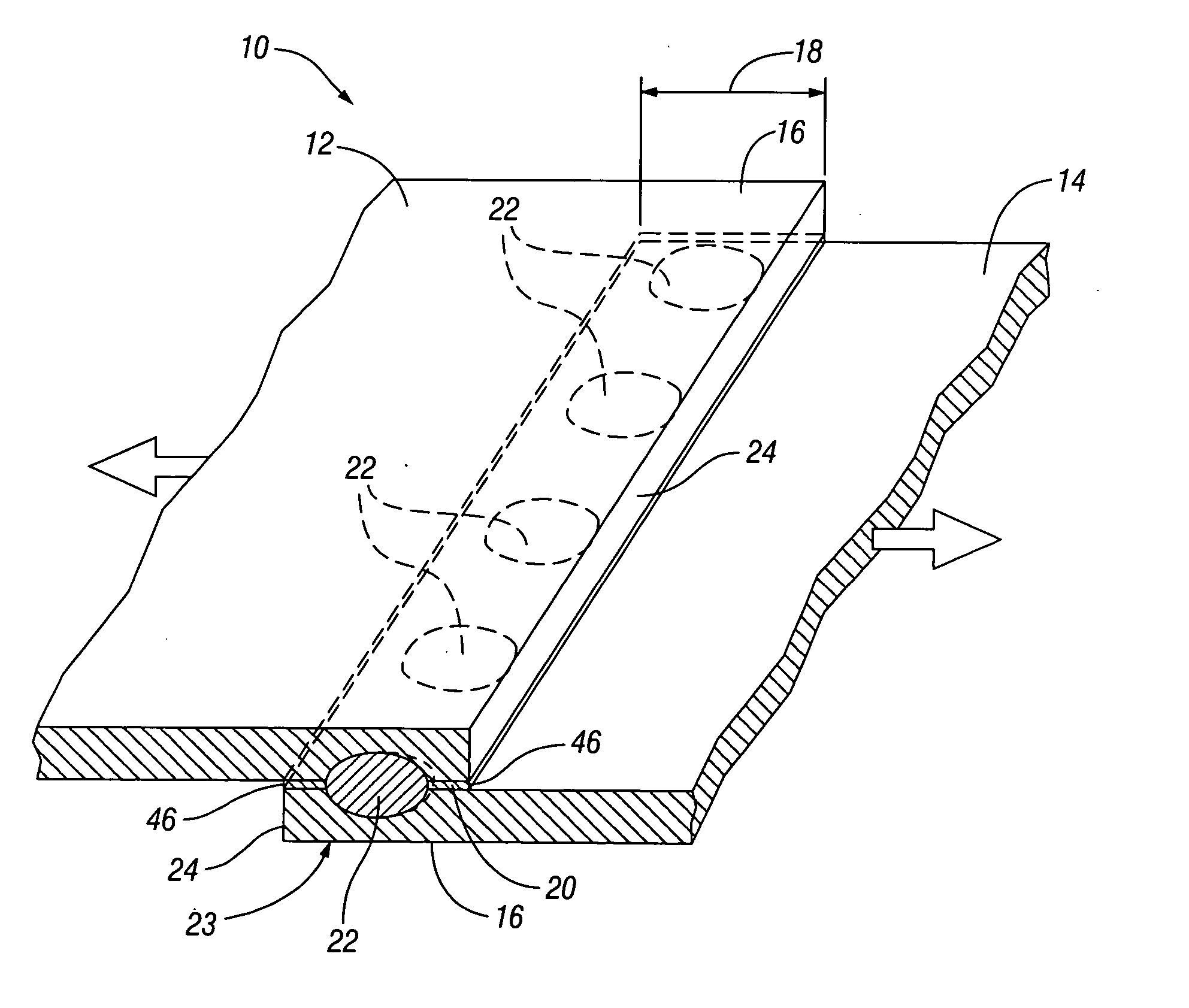

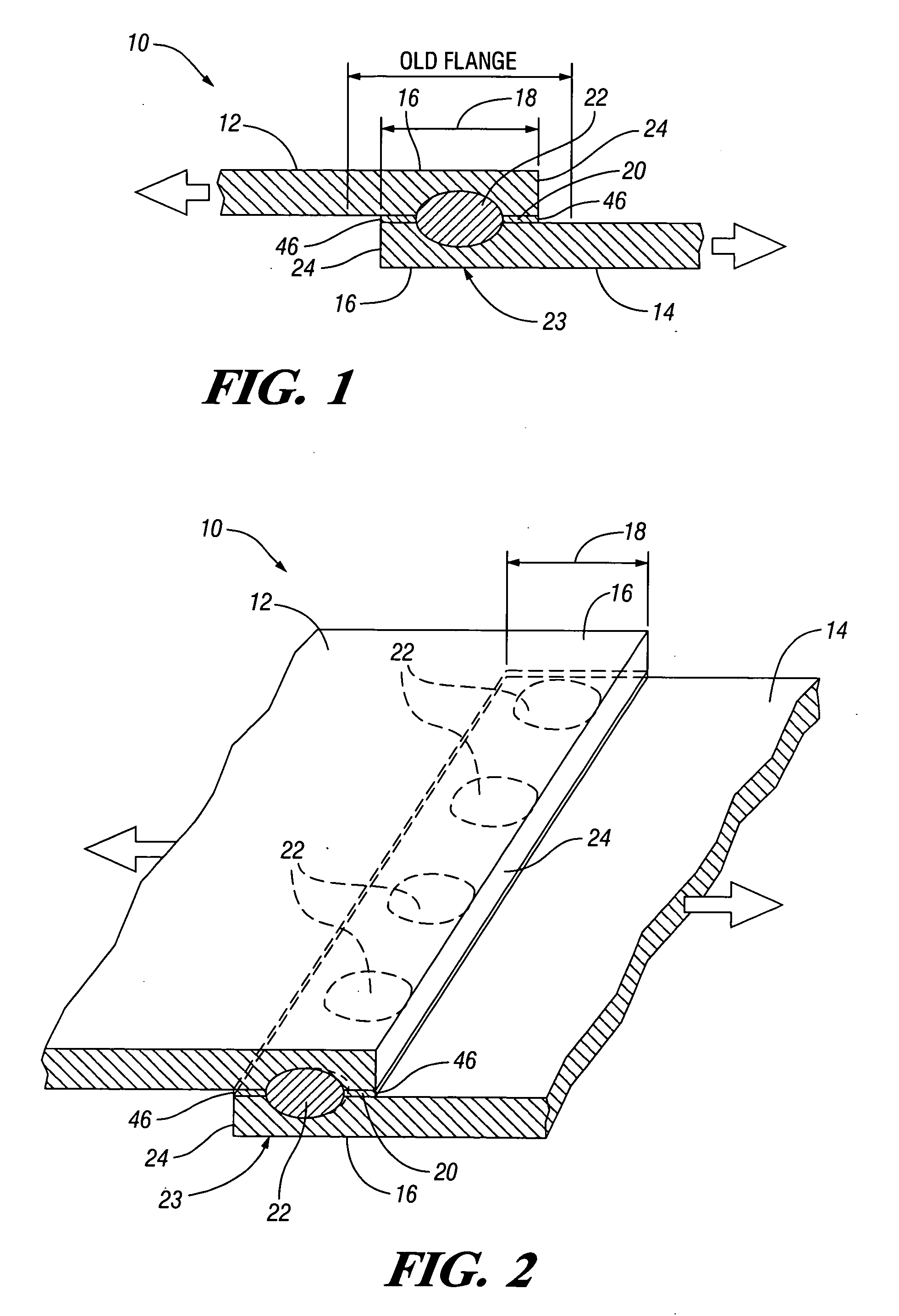

Sheet metal assembly and method to reduce weight

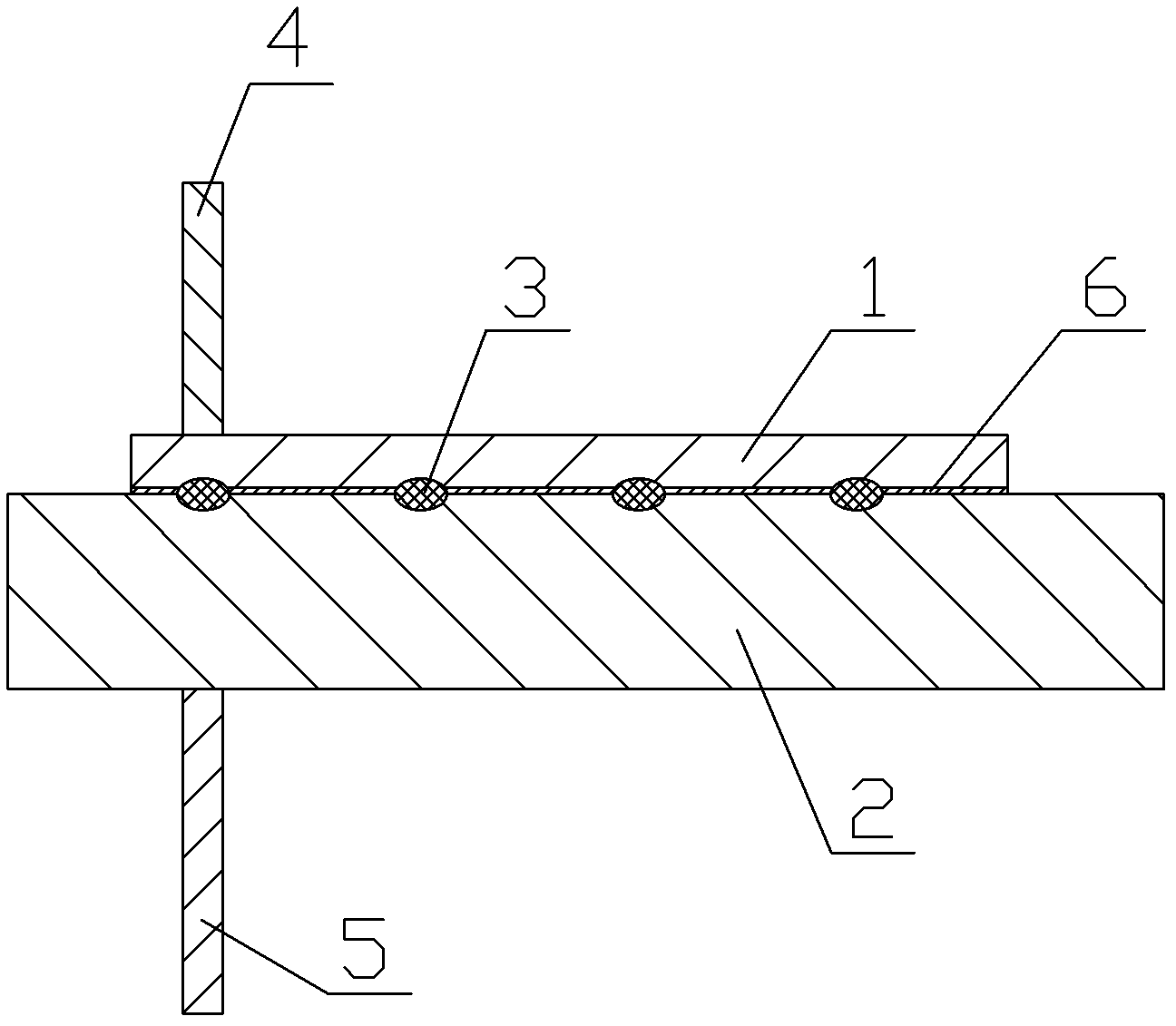

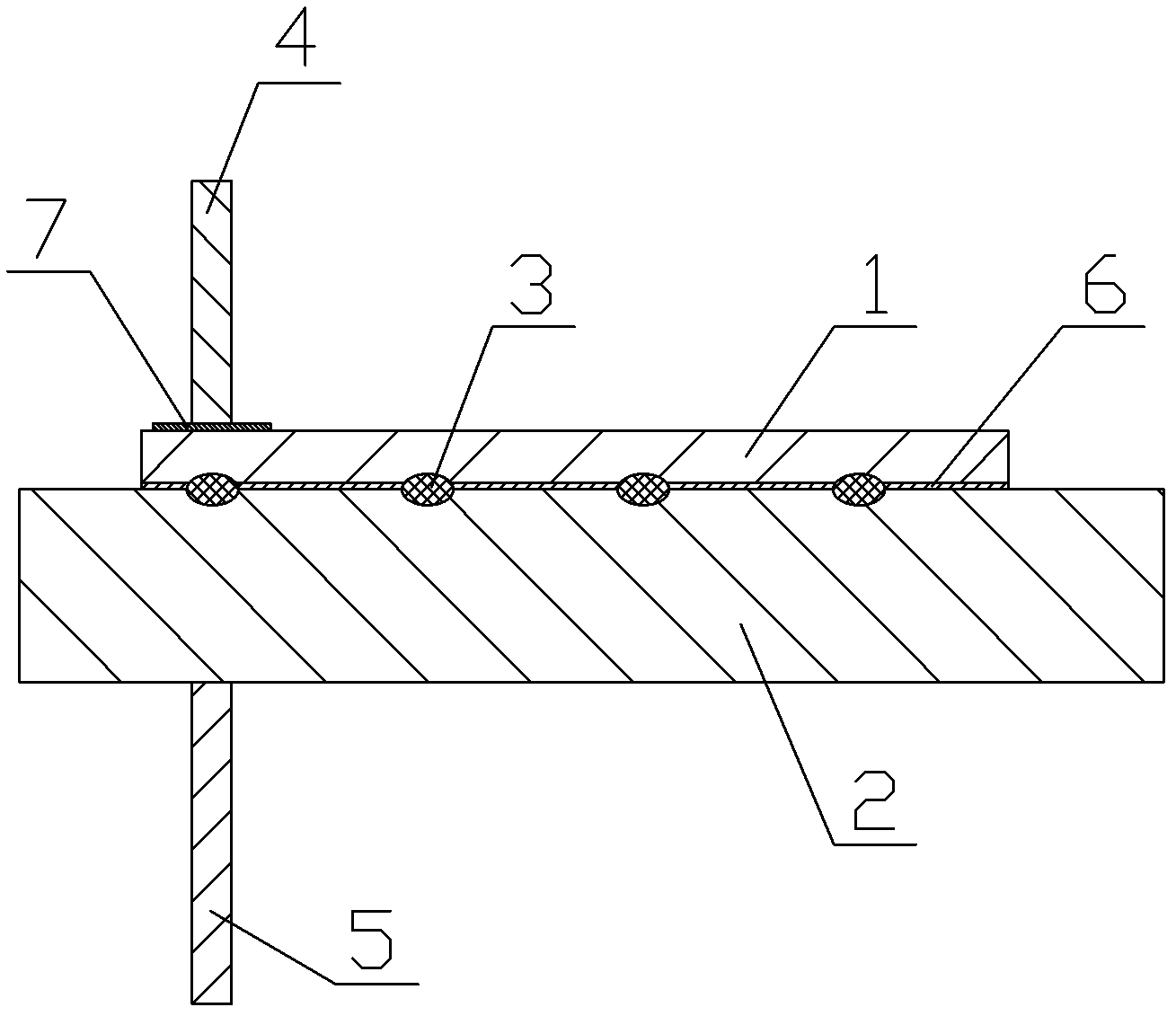

InactiveUS20050230361A1High mechanical strengthImprove mechanical propertiesArc welding apparatusWelding with roller electrodesElectrical resistance and conductanceEngineering

A sheet metal assembly includes first and second resistance weldable metal sheets having flanges extending from the sheets. The flanges overlap in parallel for a dimension. A resistance weldable metal shim is disposed between the flanges and extends to the outer edges thereof. A weld joins the metal sheets through the shim. The shim increases the mechanical strength of the assembly. The increase in mechanical strength from the shim allows for reductions to the flange width. As a result, a lighter assembly of equivalent strength is produced.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding method for 980MPa-level cold-rolled dual-phase steel

ActiveCN105618916ALower cost of capitalReduce manufacturing costWelding with roller electrodesWelding/soldering/cutting articlesCurrent rangeLap joint

The invention relates to a welding method for 980MPa-level cold-rolled dual-phase steel, and belongs to the technical field of steel strip welding. The welding method for the 980MPa-level cold-rolled dual-phase steel is provided for solving the technical problem. According to the method, a narrow lap welding machine is adopted for welding, and the strip tail of front rolled strip steel and the belt head of rear rolled strip steel are subjected to inlet shearing, and then are in lap joint for welding; and according to welding process parameters, the welding current ranges from 19 kA to 23 kA, the welding speed ranges from 6 m / min to 9 m / min, the welding wheel pressure ranges from 20 kN to 25 kN, the welding lap joint amount ranges from 1.5 mm to 1.7 mm, and the welding compensation amount ranges from 1.0 mm to 1.2 mm. The low-cost narrow lap welding machine is adopted for welding the 980MPa-level cold-rolled dual-phase steel, and a boldly innovative practice which breaks through the equipment limit and the product limit is achieved; and the existing narrow lap welding machine is adopted for welding the high-level dual-phase steel, equipment does not need to be modified, the cost of capital, production cost and equipment cost of the cold-rolled dual-phase steel are effectively reduced, and the aim of reducing the enterprise cost and increasing the enterprise benefits are achieved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

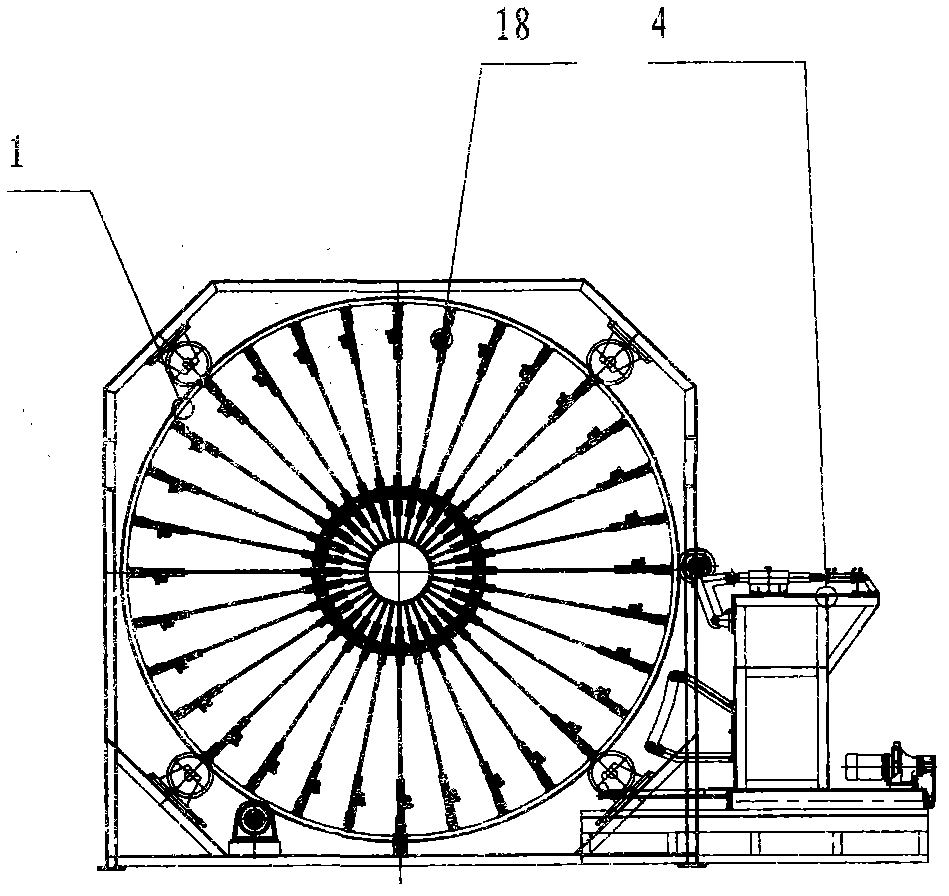

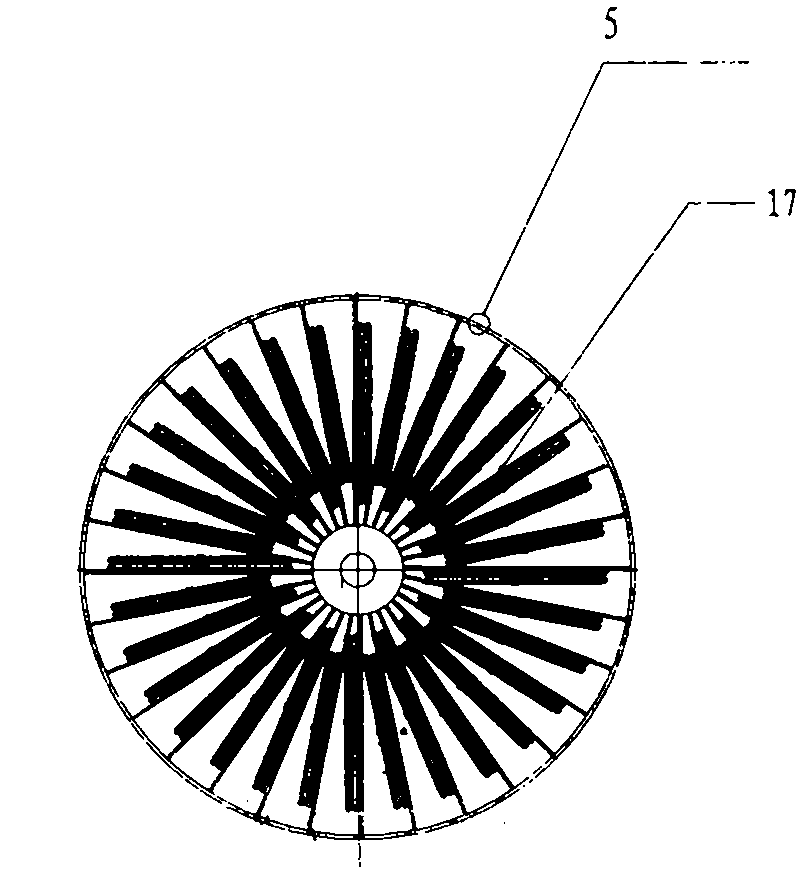

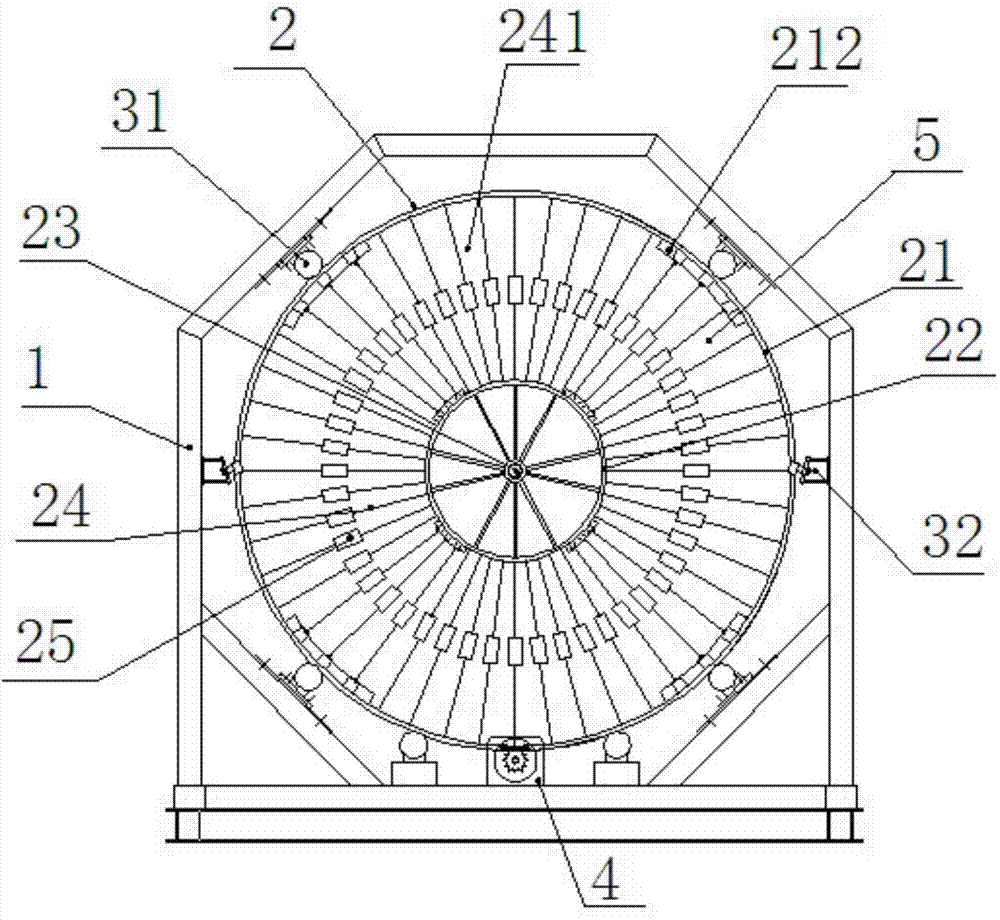

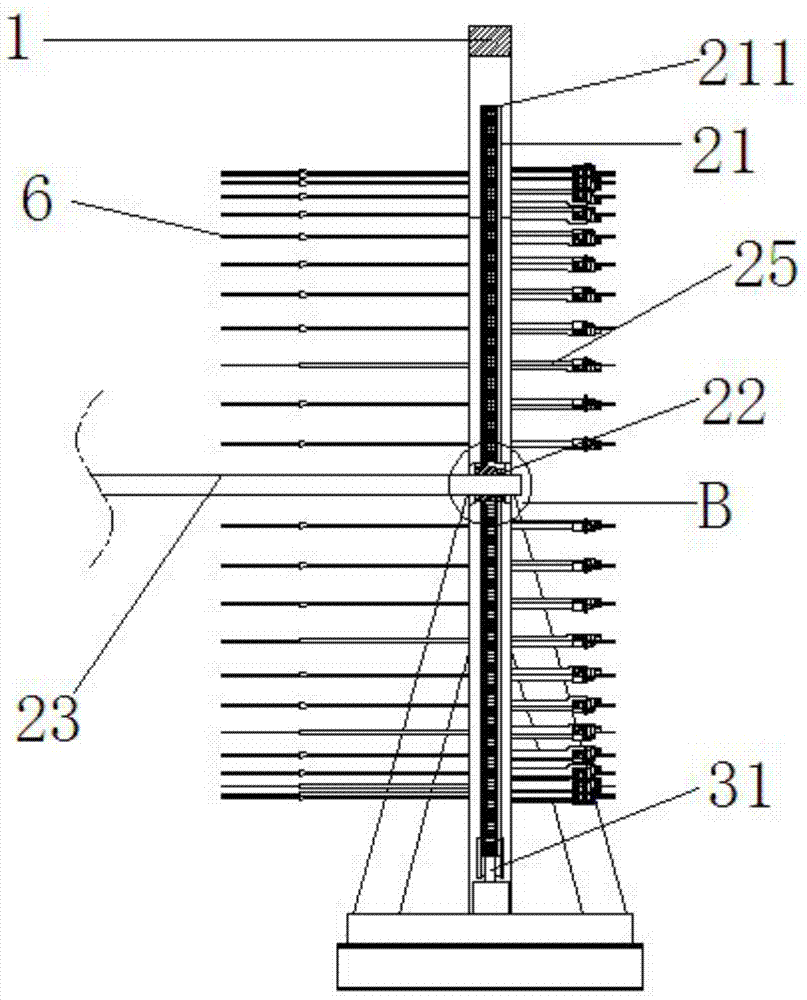

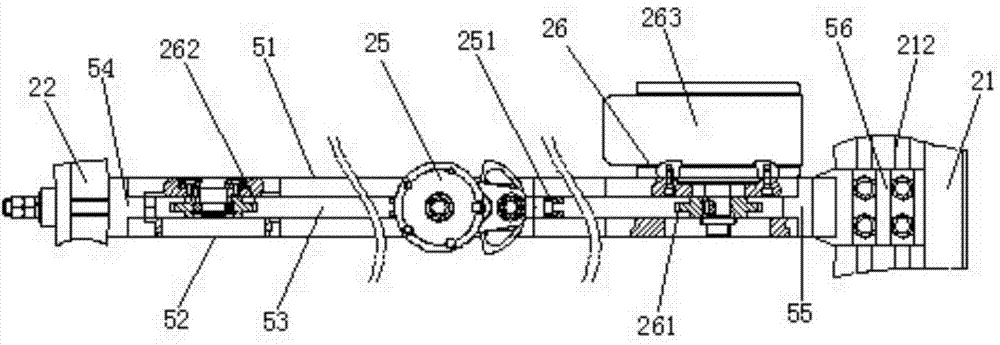

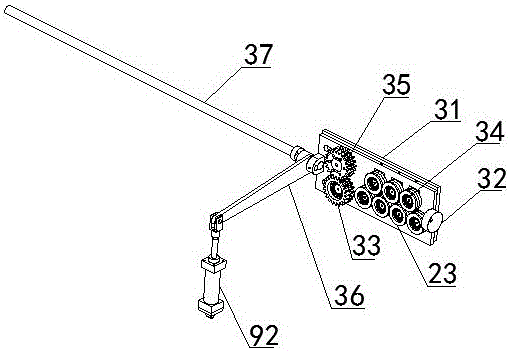

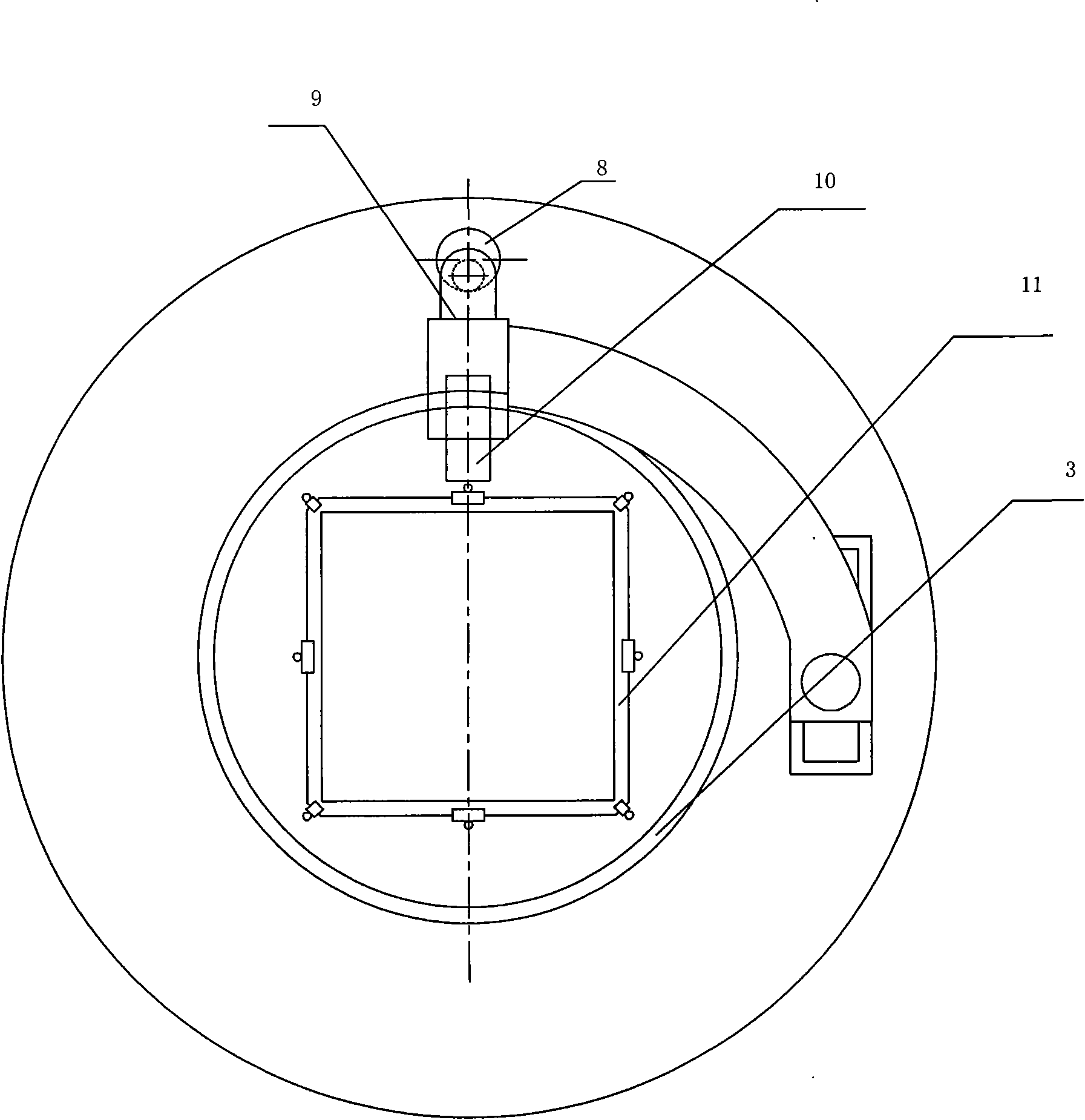

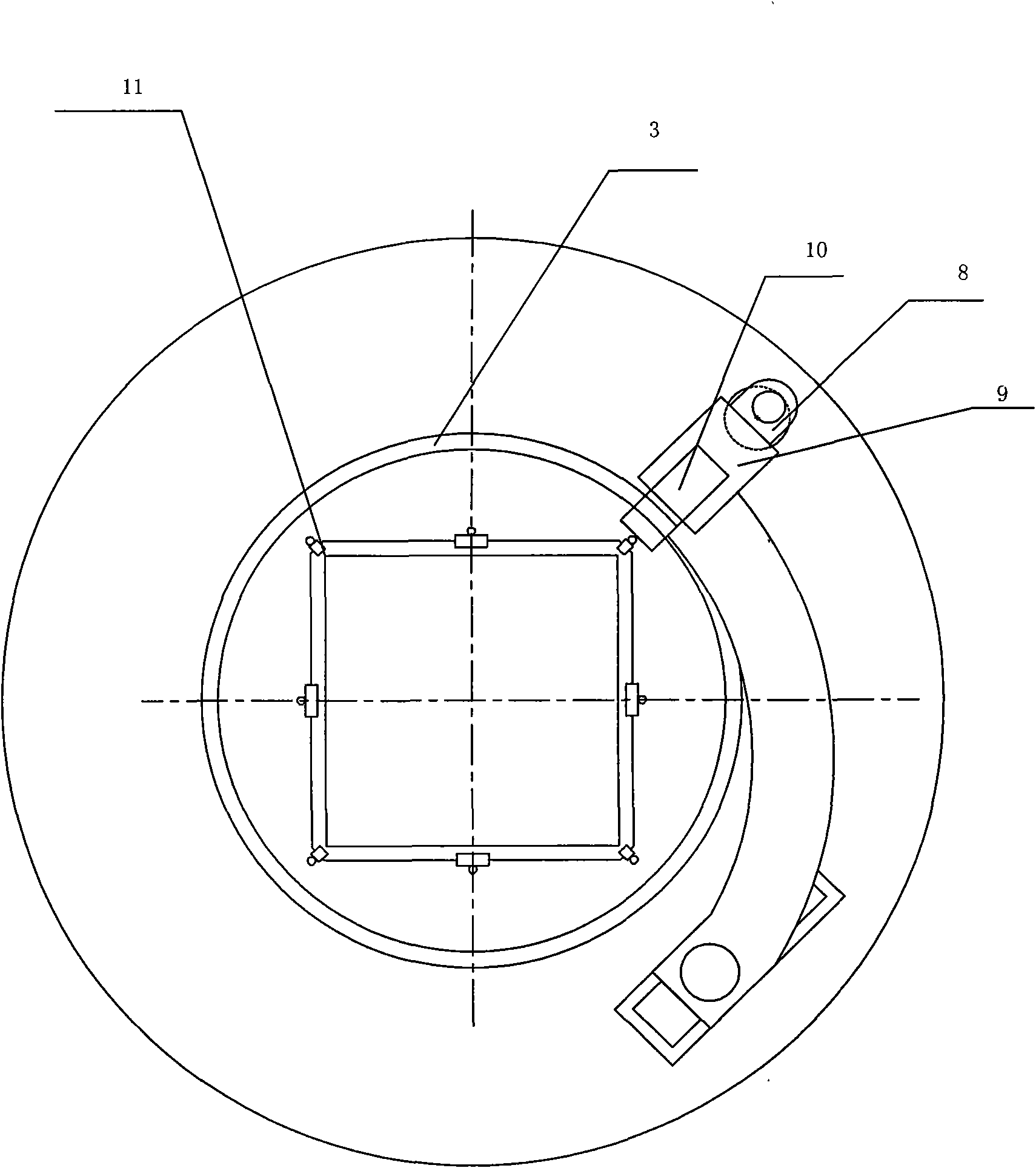

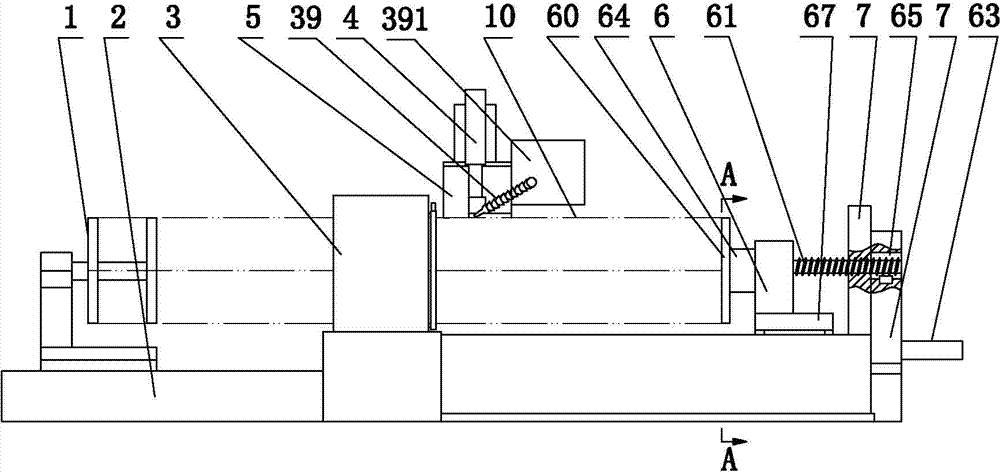

Automatic reducing system mechanism of rolling welder

InactiveCN104759821AImprove welding qualityIncrease flexibilityWelding/cutting auxillary devicesWelding with roller electrodesPersonal computerRebar

The invention discloses an automatic reducing system mechanism of a roller welder. The automatic reducing system mechanism of the roller welder comprises a face plate mechanism capable of rotating. The face plate mechanism comprises a face plate inner ring, a face plate outer ring, fixed wed plates and swinging web plates. Multiple annular sliding grooves are evenly and circumferentially distributed in the inner side of the face plate outer ring. The swinging wed plates can annularly slide along the annular sliding grooves and be fixed. Each fixed web plate and each swinging web plate are both provided with a welding seat and a web plate transmission mechanism controlled by an industrial personal computer. By the adoption of the structure, the welding seats can automatically move for a corresponding distance in the radial direction along the wed plates under the action of the web plate transmission mechanisms, and therefore various reinforcement cage cross-sectional shapes and reducing quantities can be accurately and rapidly formed; when reinforcement cages with cross sections provided with edges and corners are welded, the swinging web plates can be fine adjusted along the annular sliding grooves, and then it can be guaranteed that each corner of the cross sections, provided with the edges and corners, of the reinforcement cages is provided with a longitudinal rib; in this way, the automatic reducing system mechanism is high in flexibility.

Owner:JIANGSU UNIV OF SCI & TECH

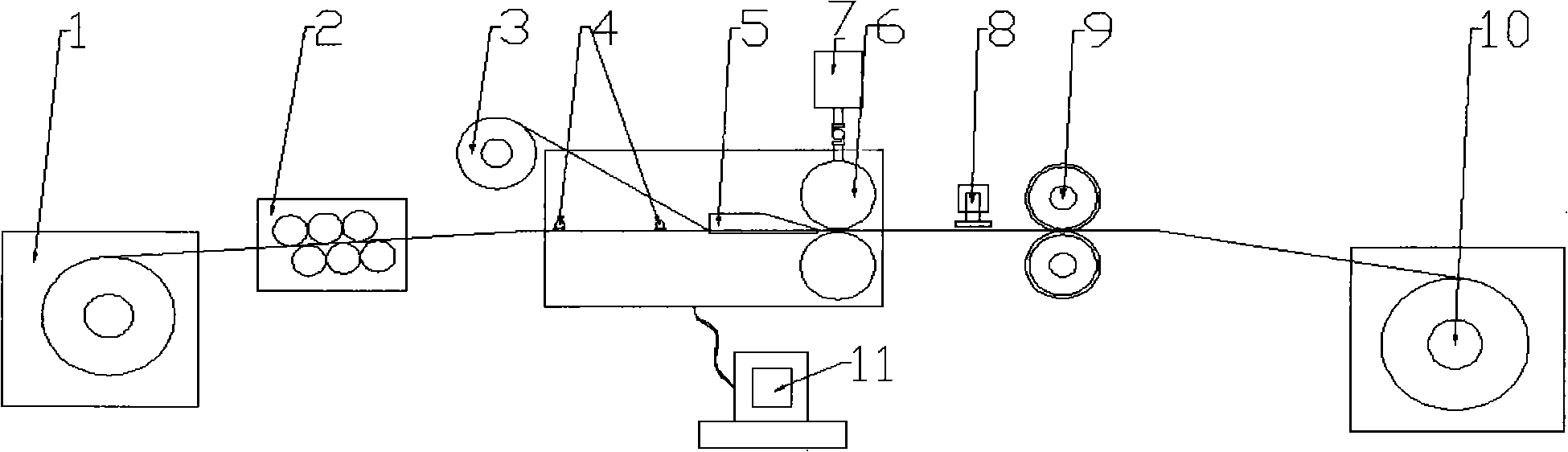

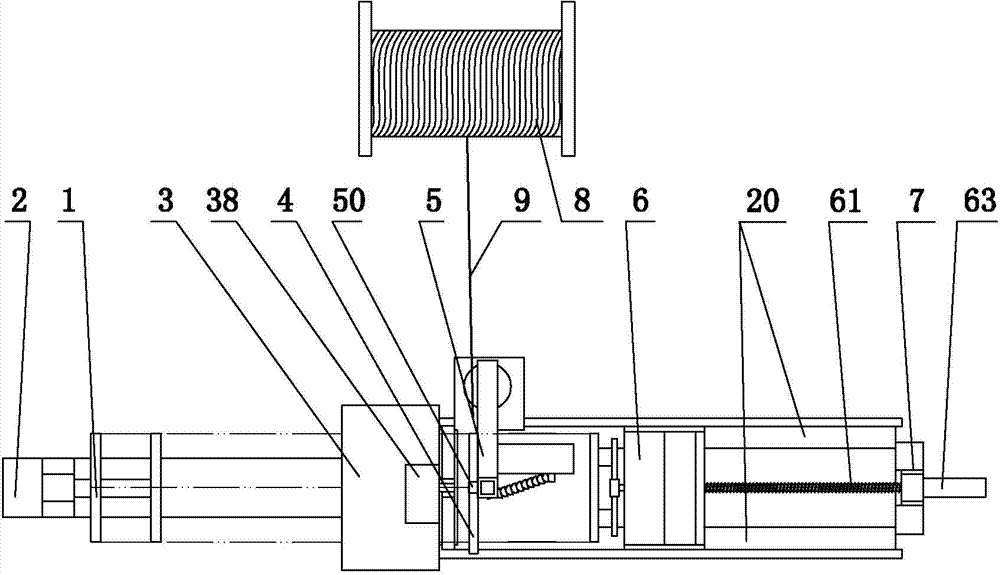

Roll welding device for producing noble metal composite band

InactiveCN101870034AImprove work efficiencyReduce labor intensityWelding with roller electrodesWelding power supplyEngineering

The invention discloses a roll welding device for producing a noble metal composite band. The roll welding device comprises a coiled material feeding mechanism, a leveling mechanism, a composite band feeding disk, a positioning mould, a roll welding wheel, a welding cylinder, a traction mechanism, a coiled material discharging mechanism, a welding power supply and an IPC controller, wherein the coiled material feeding mechanism, the leveling mechanism, the composite band feeding disk, the positioning mould, the roll welding wheel, the traction mechanism and the coiled material discharging mechanism are arranged in order; the welding power supply is connected with the IPC controller; and the IPC controller is connected with the welding cylinder. The roll welding device for producing the noble metal composite band has the advantages of high continuous welding speed, high welding quality and high production efficiency.

Owner:东莞市中一合金科技有限公司 +1

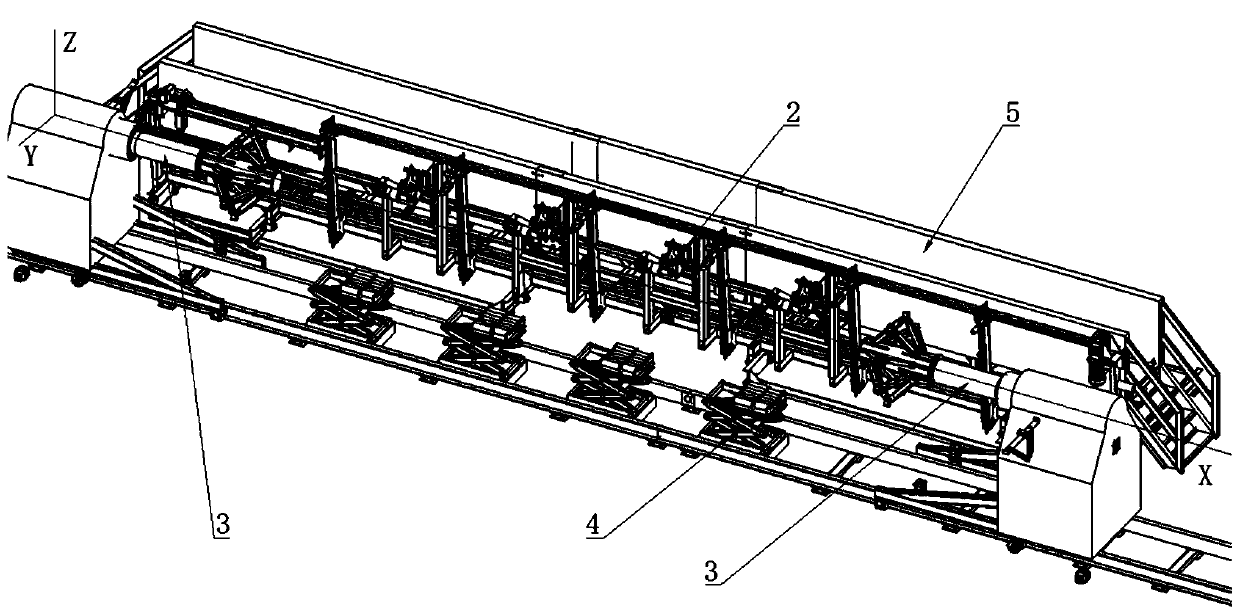

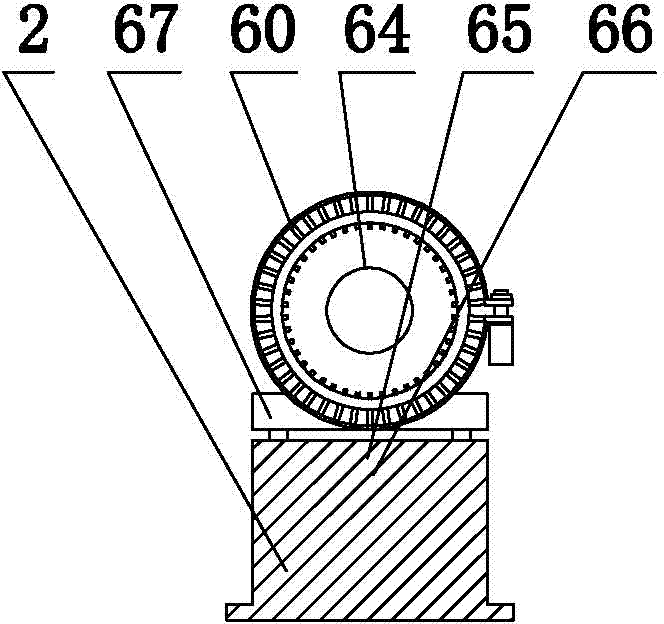

Reinforcement cage seam welder

ActiveCN106735812ASimple structureEasy maintenance and operationWelding with roller electrodesStirrupManipulator

The invention discloses a reinforcement cage seam welder. The reinforcement cage seam welder comprises a base; the base is provided with a bracket with a rail at the upper part and at least one U-shaped reinforcement cage welding frame body; a mobile frame is arranged on the rail of the bracket; a main stirrup fixed clamping device is arranged in the center position of the mobile frame; a fixed frame is arranged at the upper part of the right side of the bracket, and a lead screw traction device is arranged in the center position thereof; an outer stirrup conveying device is arranged at the middle part of one side of the reinforcement cage welding frame body, and a main rib push rotating device is arranged at the upper part of the same one side thereof; a support main rib device is arranged at the middle part of the reinforcement cage welding frame body; an outer stirrup welding manipulator and an inner stirrup welding manipulator are respectively arranged on the reinforcement cage welding frame body and at the upper part of the support main rib device; and main rib fixed adjusting devices are arranged at the upper parts of the outer stirrup welding manipulator and the inner stirrup welding manipulator on the reinforcement cage welding frame body. The reinforcement cage seam welder is adopted to realize the effects of simple structure, convenience to operate and maintain, good quality, high efficiency, low cost, unified specification and high automation degree.

Owner:山东五岭智能机械有限公司

Steel rail surface alloy layer welding method and its material

InactiveCN1803370AGood welding performanceImprove corrosion resistanceWelding with roller electrodesWelding/cutting media/materialsMetallic materialsAlloy

The invention discloses a self-melting alloy powder material in the metal welding and railway signal control method, which comprises the following steps: polishing the railway surface to obtain fresh metal surface; proceeding resistance seam welding through resistance seam welding equipment; producing the needed alloy; coating alloy powder on the metal surface at 1000-1130 deg C fusing point. The powder displays NiCrBSi system self-melting alloy powder or NiCrBSiCu alloy system with HRC20-HRC45 welding layer hardness. The weight percentage of NiCrBSiCu alloy system is 0.2-0.5 percent C, 0.5-5.0 percent B, 1.0-5.0 percent Si, 3.0-15 percent Cr, 2-12 percent Fe, 3-20 percent Cu and Ni. The invention improves the bonding surface of metal and steel, which solves the problem of big rail damage and low production efficiency.

Owner:阴生毅

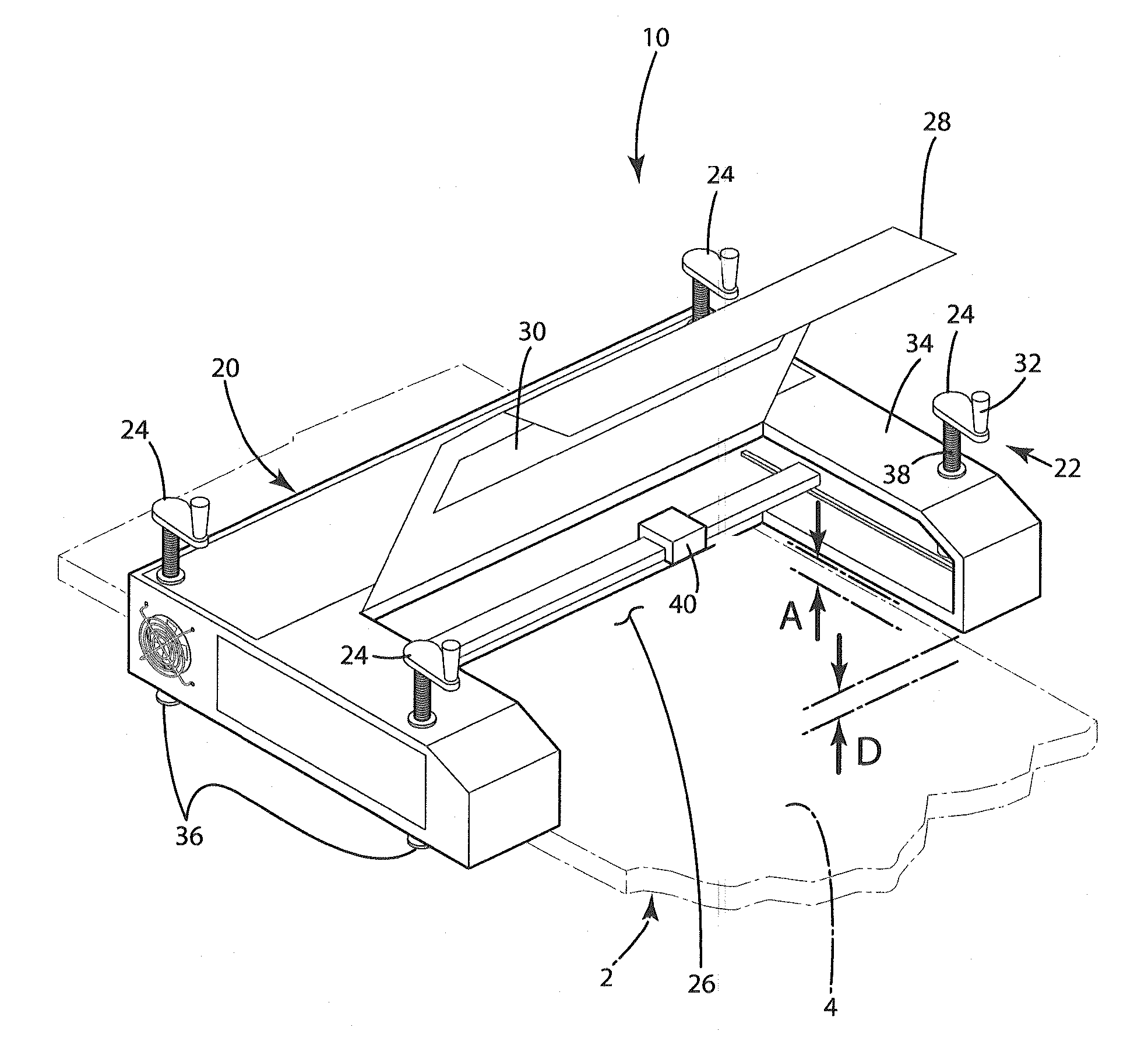

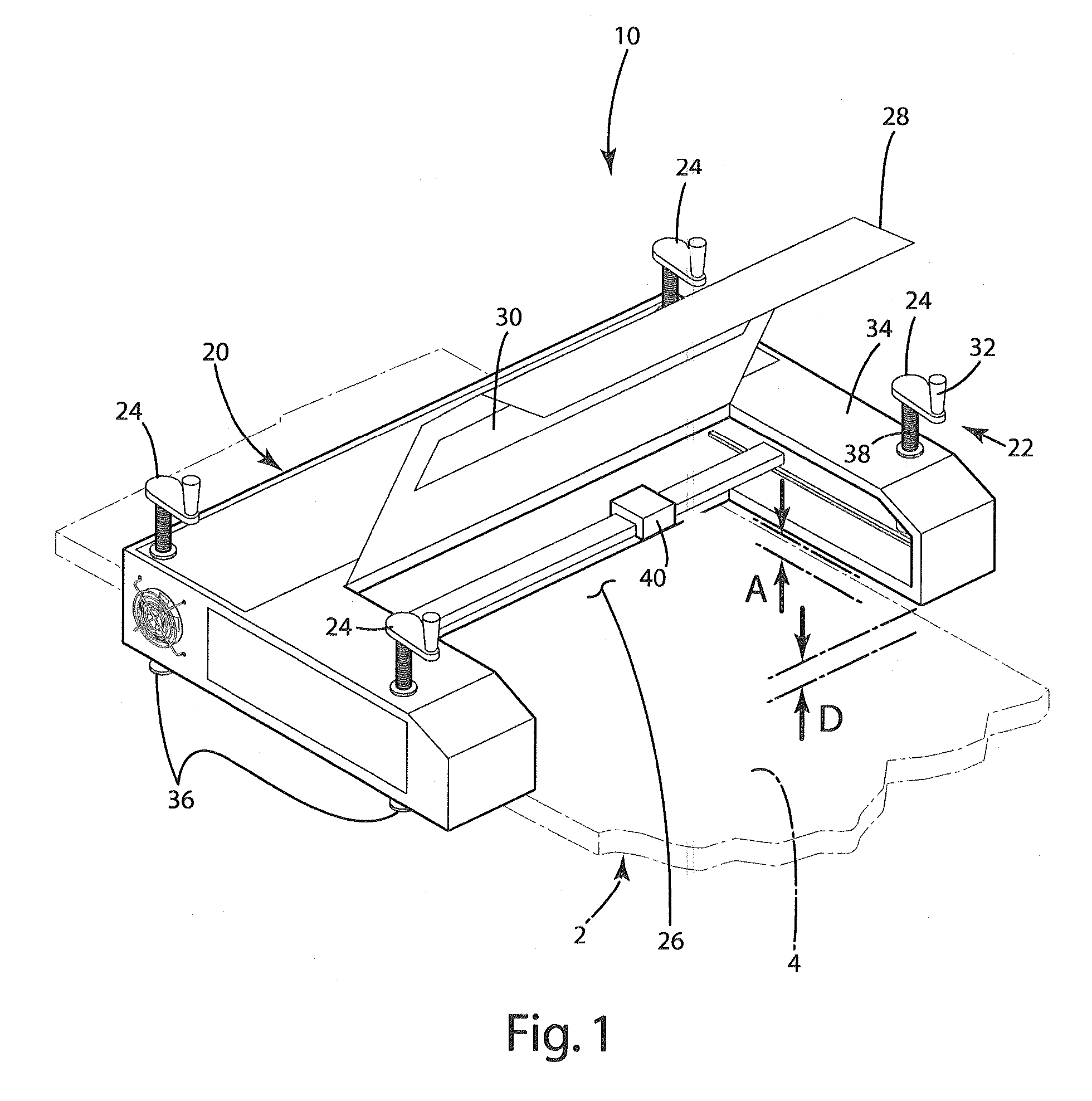

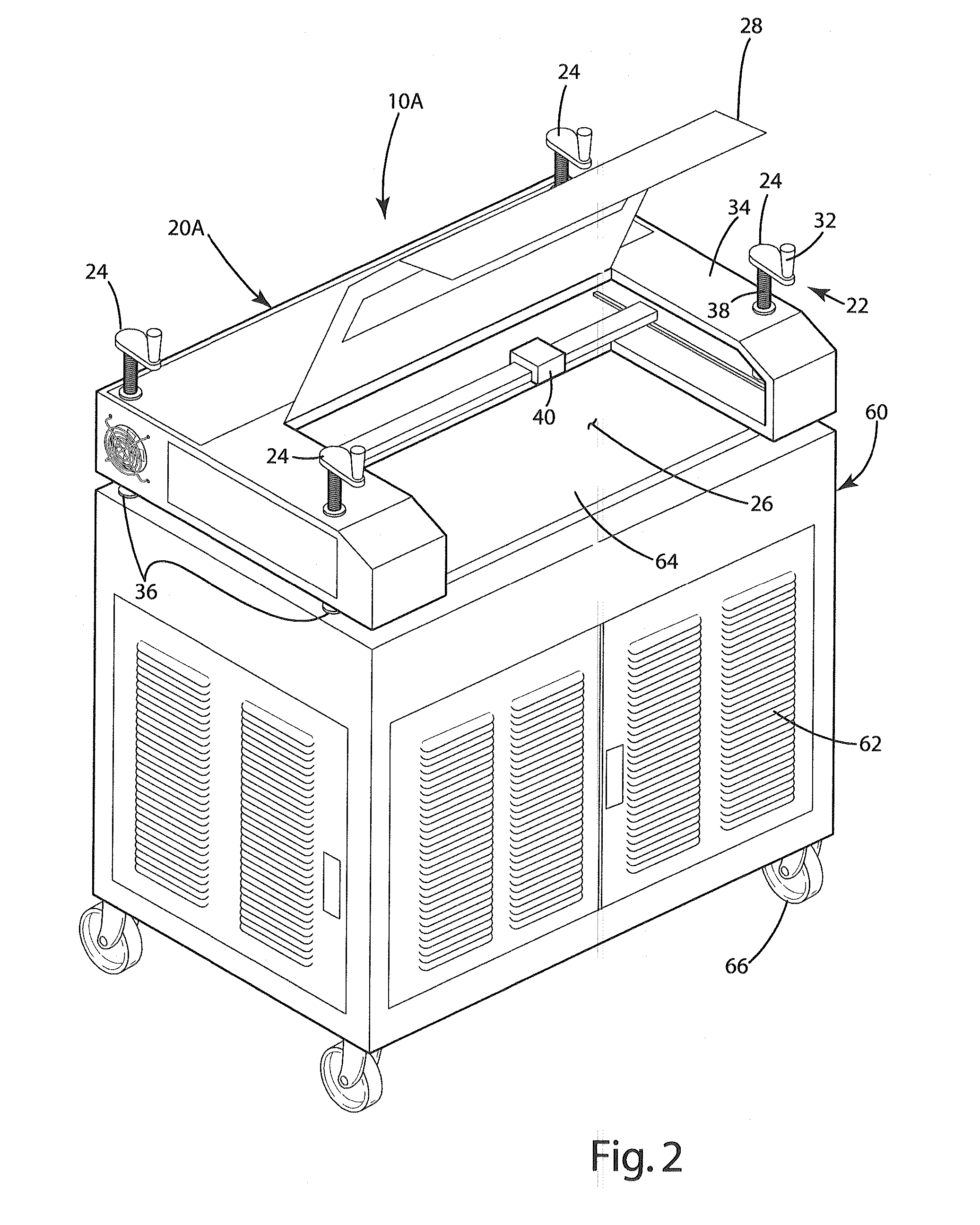

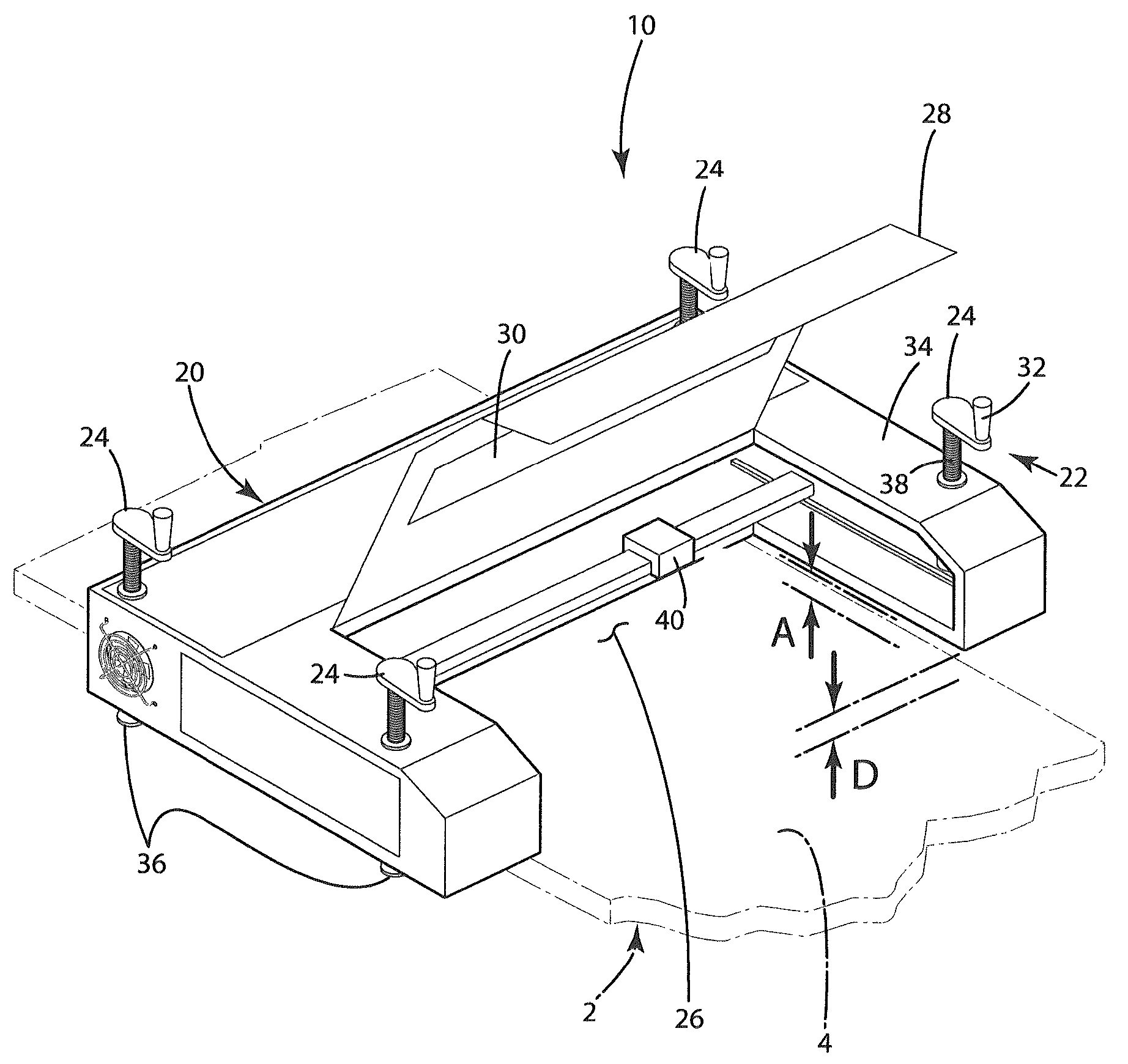

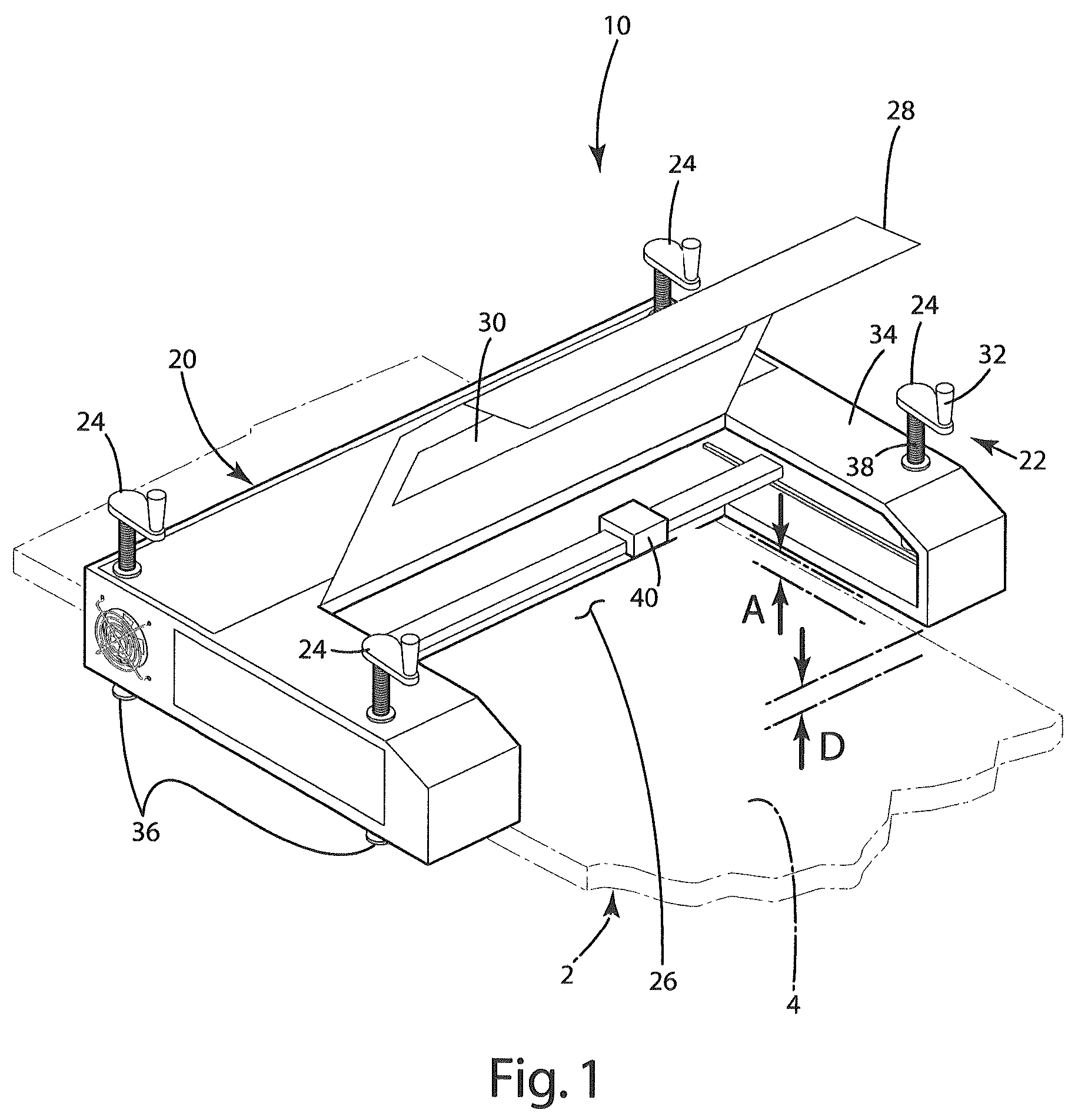

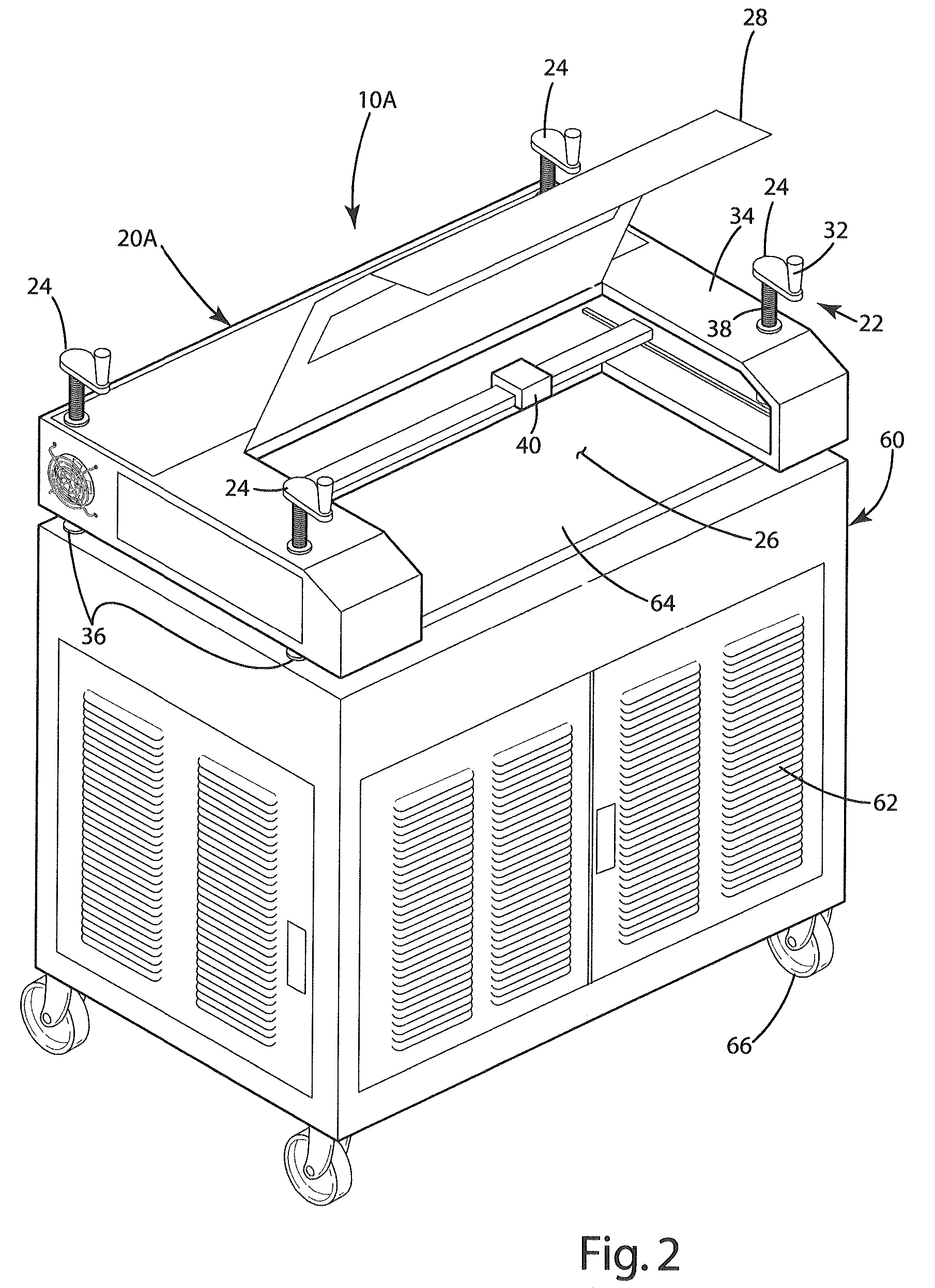

Portable engraving system

A portable engraving system comprises an enclosure adapted to operably accommodate an engraving device, wherein the enclosure comprises an adjustment system. The adjustment system comprises one or more adjustable devices, and the adjustable devices are adapted to adjust a distance between the enclosure and a work surface thereby allowing adjustment of the distance between the enclosure and the work surface, whereby the enclosure is adjustable with respect to the work surface. The enclosure further comprises an opening wherein the engraving device is operably positioned thereto, whereby the work surface is accessible to the engraving device therethrough. The enclosure is positionable adjacent the work surface and operably disposed thereto.

Owner:LI TONG

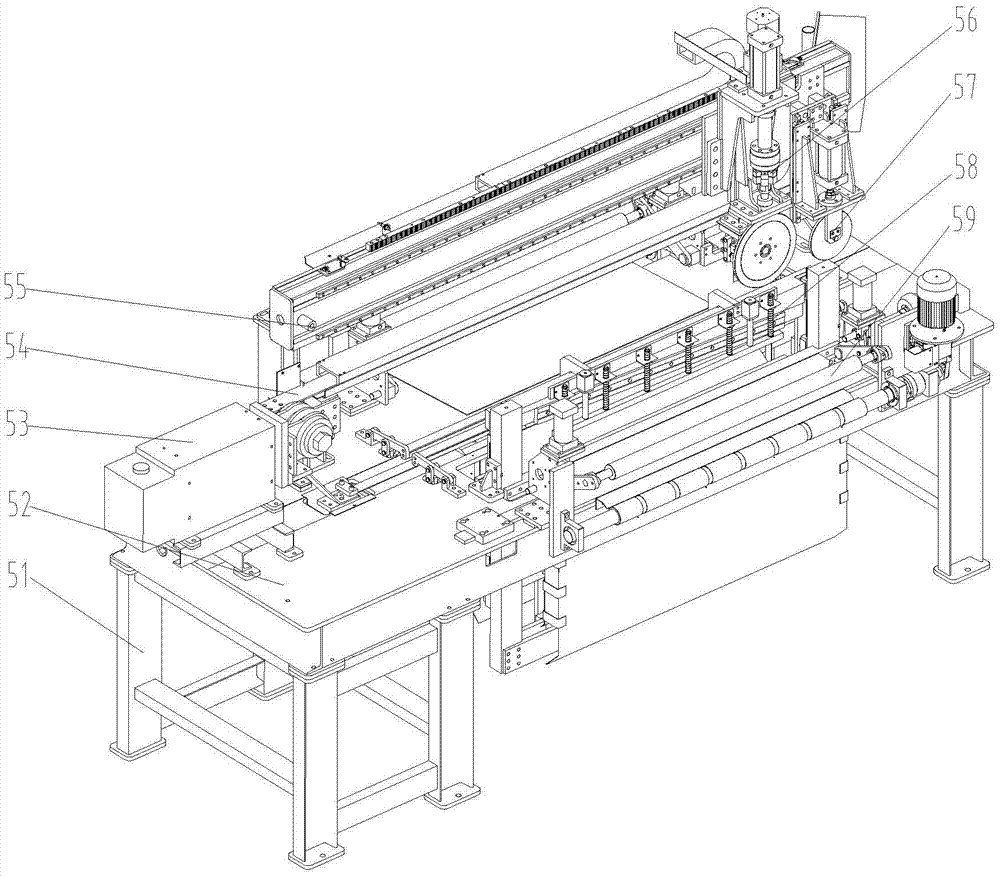

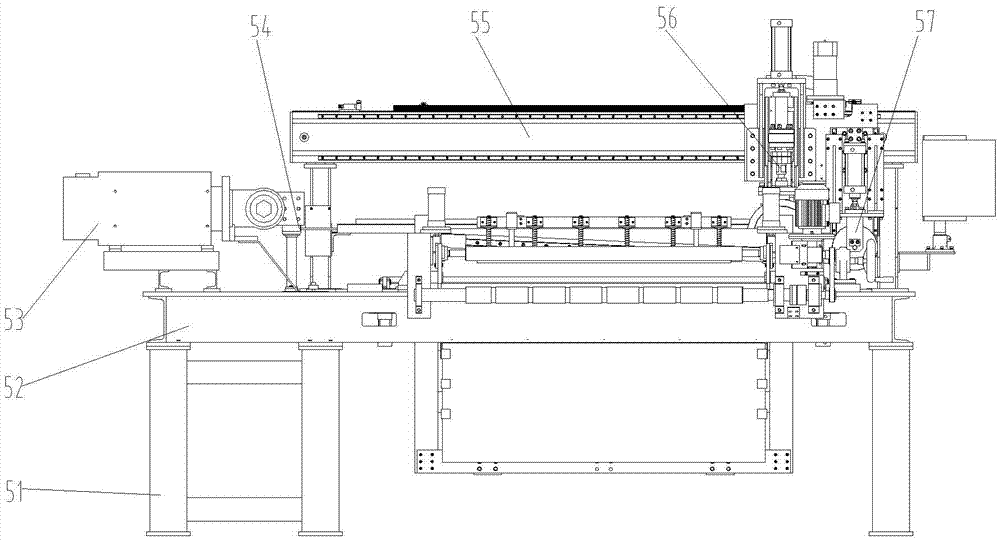

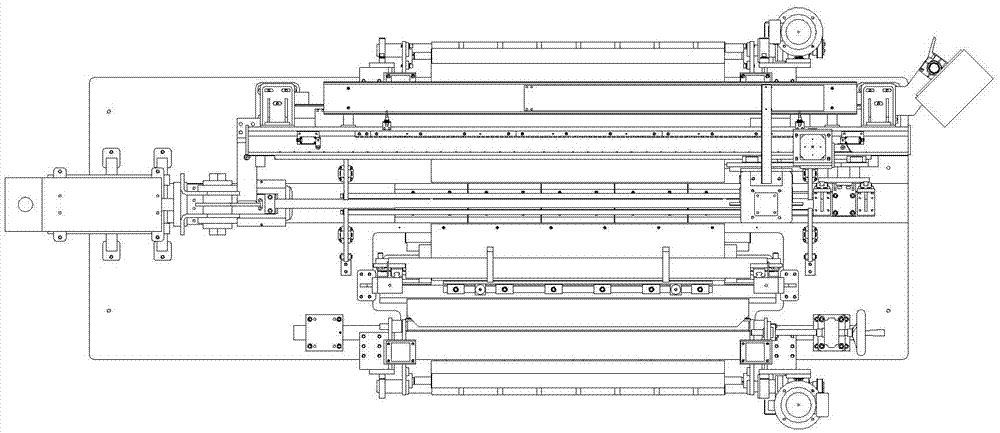

Fully-automatic narrow lap electric-resistance seam-welding machine for thin plates

ActiveCN105436681AReduce processing timeReduce processing efficiencyResistance electrode holdersShearing machinesEngineeringMetal sheet

The invention discloses a fully-automatic narrow lap electric-resistance seam-welding machine for thin plates, belongs to a thin plate seam-welding machine in the welding technical field, and aims to provide the fully-automatic narrow lap electric-resistance seam-welding machine, which is high in shearing efficiency and long in service life, for thin plates. According to the technical scheme, the fully-automatic narrow lap electric-resistance seam-welding machine comprises a rack and a workbench, wherein a clamping and delivering device and a single-blade shear are arranged on the rack or the workbench; a beam assembly is connected on the rack; a resistance welding device and a grinding device are connected on the beam assembly; the single-blade shear comprises a framework, wherein an upper shearing sheet, a lower shearing sheet and a shearing air cylinder are connected on the framework; a synchronous slide block is connected on the shearing air cylinder; link mechanisms are connected on the synchronous slide block; the two groups of link mechanisms are symmetrically arranged at left and right sides of the synchronous slide block, the upper shearing sheet and the lower shearing sheet; and the other ends of the link mechanisms are connected to the upper shearing sheet or the lower shearing sheet. The fully-automatic narrow lap electric-resistance seam-welding machine is suitable for shearing and welding metal thin plates in a finish machining continuous line of the metal thin plates.

Owner:CHENGDU HANYAN TECH

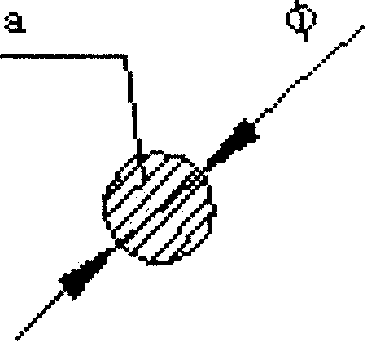

Method of producing tiny special-shaped composite connection point strip

ActiveCN101172314AHigh bonding strength between layersHigh bonding strengthWelding with roller electrodesContactsSeam weldingMetallurgy

The invention relates to a method for manufacturing a micro-shaped composite contact strip. In the method, the precious metal round wire and the matrix strip are directly composited by continuous rolling welding technology, and then the composited material is processed by precision rolling or rolling die drawing. Molding to prepare products of desired shape. The advantage of this method is that the precious metal is directly in the form of round wire, which not only increases the composite ratio of the precious metal and the base material, realizes the preparation of a micro-shaped composite contact strip with a large difference in width between the electrical contact layer and the base layer, but also improves the yield and Production efficiency, reducing production costs.

Owner:GRIKIN ADVANCED MATERIALS

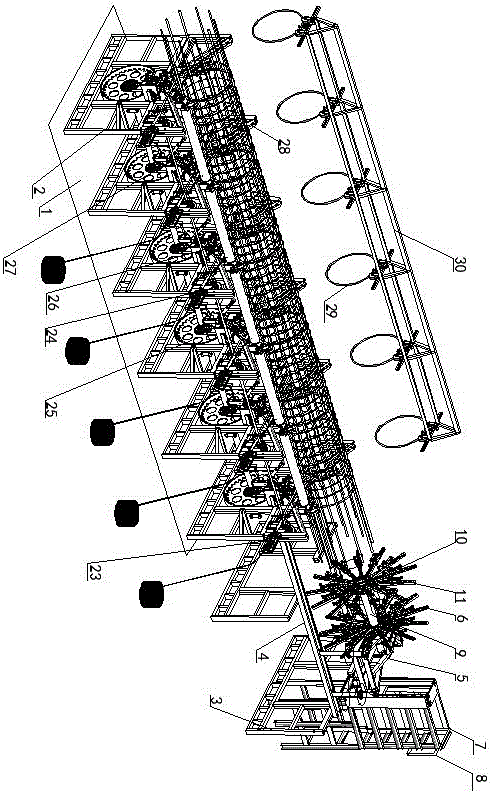

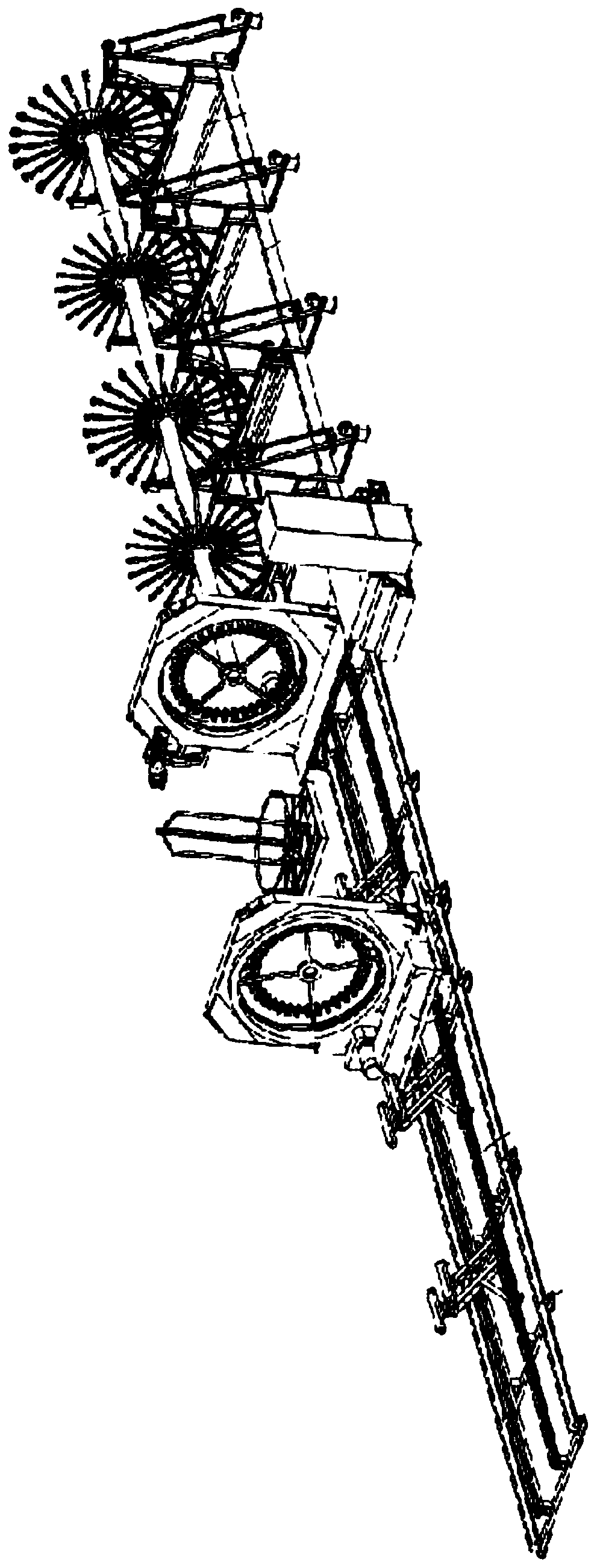

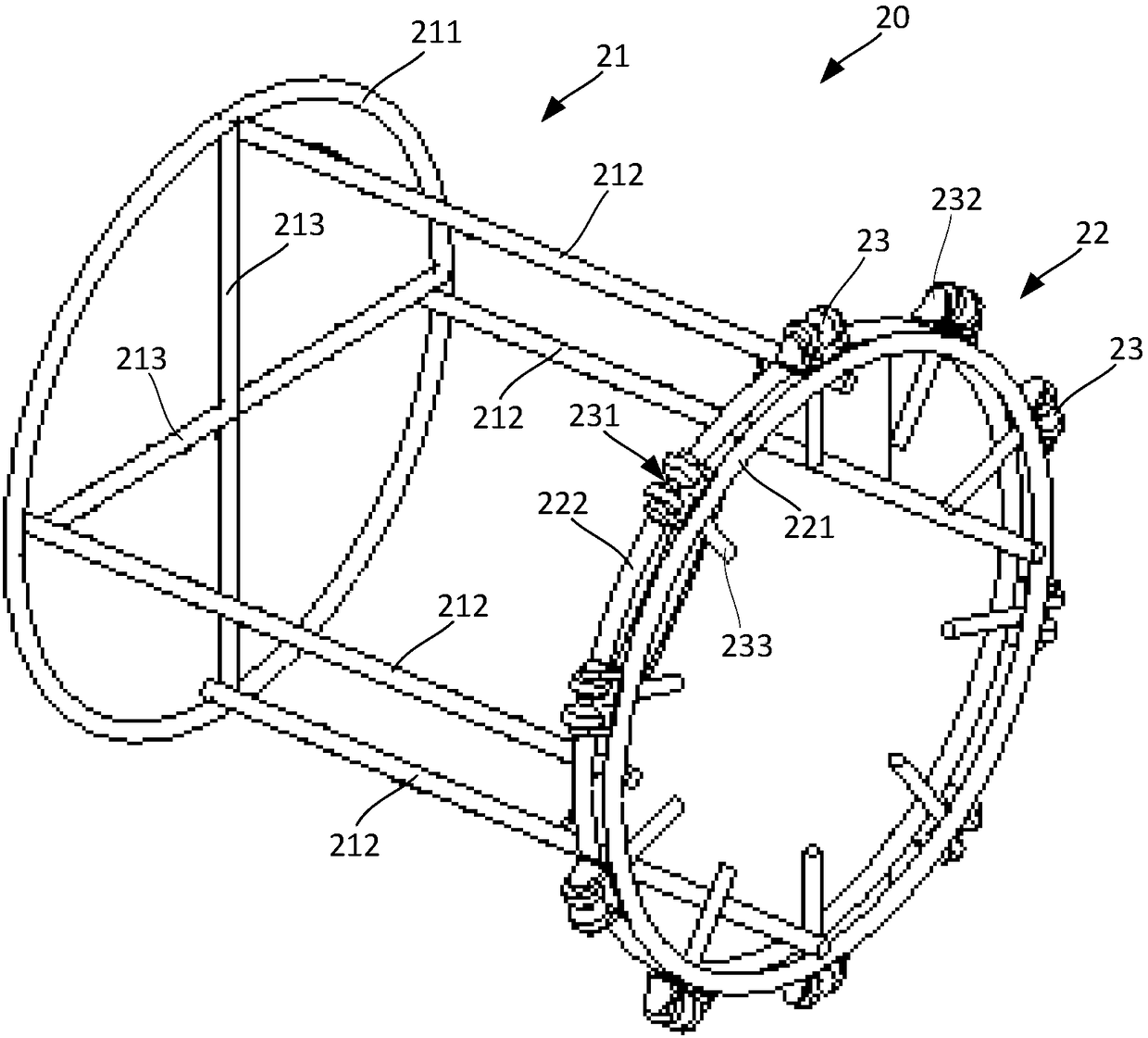

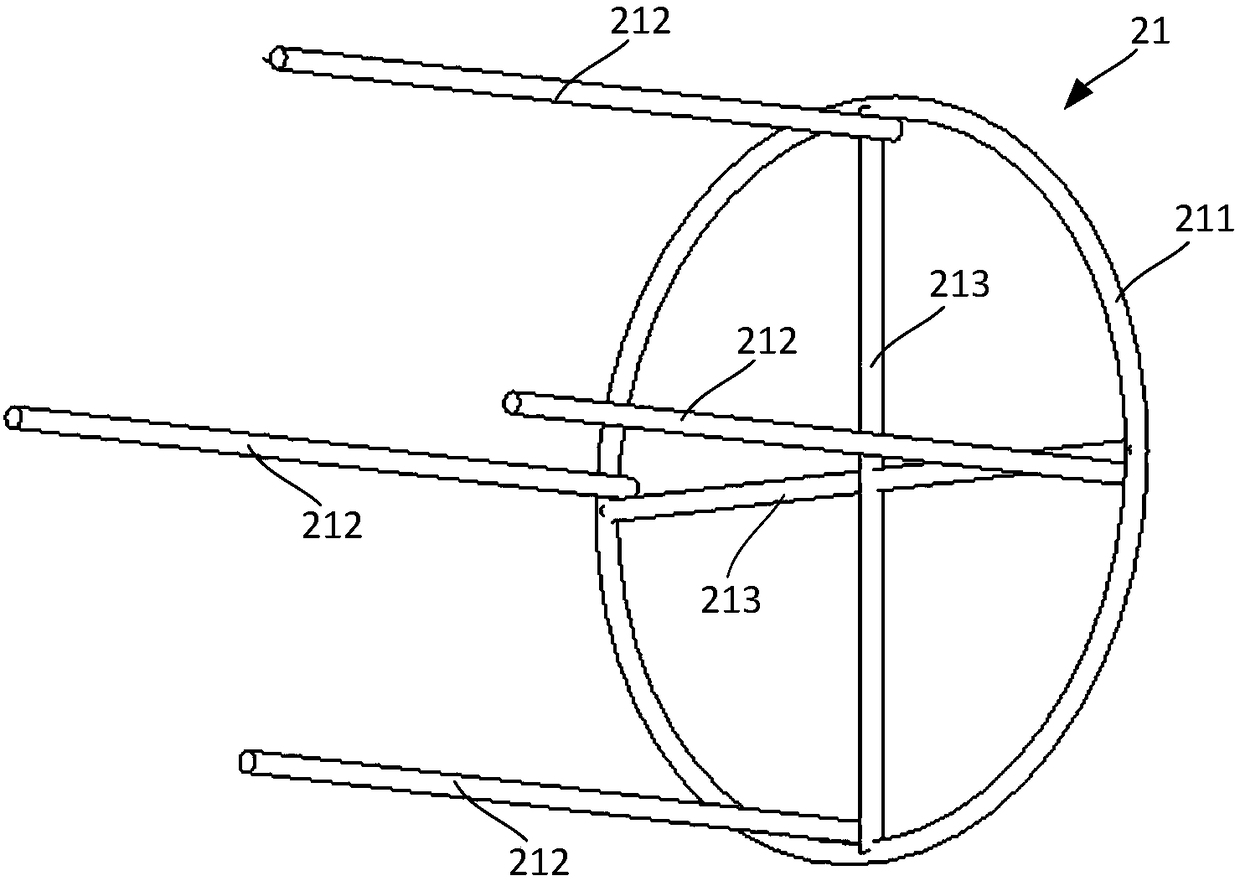

Reinforcement cage seam welder

PendingCN110000458AReduce labor intensityRealize automatic indexingWelding/cutting auxillary devicesWelding with roller electrodesWinding machineEngineering

The invention discloses a reinforcement cage seam welder, and belongs to the field of reinforcement cage manufacturing. The reinforcement cage seam welder comprises an inner supporting rib supportingdevice which is used for arranging and supporting a plurality of inner supporting ribs along a first straight line X, an inner supporting rib autorotation driving device which is used for driving theplurality of inner supporting ribs to synchronously rotate around the first straight line, a main rib feeding frame which is arranged on one side of the inner supporting rib supporting device and is used for conveying main ribs to the outer side walls of the plurality of inner supporting ribs, a movable wire winding machine which is arranged on either side of the inner supporting rib supporting device and can move in a reciprocating mode along a fifth straight line, wherein the first straight line X is parallel to the fifth straight line. According to the reinforcement cage seam welder, through the mode of arranging the inner supporting ribs, welding the main ribs and welding wound ribs in sequence and the mode of combining mechanical and manual work, the manufacturing efficiency of the reinforcement cage is greatly improved.

Owner:CHENGDU GUTE MACHIENRY WORKS

Double-reinforcement parallel-winding full-automatic reinforced concrete pipe reinforcement cage seam welder

The invention discloses a double-reinforcement parallel-winding full-automatic reinforced concrete pipe reinforcement cage seam welder, which relates to a seam welder. The seam welder can meet the requirement on double-reinforcement parallel winding, and can efficiently and accurately fabricate a stressless cage with a large caliber and a high reinforcement ratio. The double-reinforcement parallel-winding seam welder comprises a chassis, a main shaft, a reinforcement-pushing rod, a reinforcement-pushing shaft, a main faceplate, a flange plate, a rear faceplate, a reinforcement-pushing faceplate, a welding seat, a guide rod, a reinforcement-pushing trolley unit, a double-reinforcement guiding unit and a welding unit; the seam welder also comprises the double-reinforcement guiding unit, a reinforcement-threading unit and a reducing mechanism; the double-reinforcement guiding unit comprises a gradual guide roller group for a single reinforcement and a guide roller group for double-reinforcement combination; the reinforcement-threading unit comprises a reinforcement-threading tube with a longitudinal slot, a piece of reinforcement-pushing round steel, a reinforcement-pushing faceplate, the reinforcement-pushing trolley unit and a drive mechanism for driving the reinforcement-pushing faceplate to axially move; the reducing mechanism comprises the reinforcement-pushing rod-connecting flange plate, the reinforcement-pushing rod, the reinforcement-pushing shaft, a chain drive mechanism and a flange drive mechanism; and a welding electrode wheel is provided with a groove larger than the diameters of two circular reinforcements.

Owner:江苏中意建材机械有限公司

Portable engraving system

A portable engraving system comprises an enclosure adapted to operably accommodate an engraving device, wherein the enclosure comprises an adjustment system. The adjustment system comprises one or more adjustable devices, and the adjustable devices are adapted to adjust a distance between the enclosure and a work surface thereby allowing adjustment of the distance between the enclosure and the work surface, whereby the enclosure is adjustable with respect to the work surface. The enclosure further comprises an opening wherein the engraving device is operably positioned thereto, whereby the work surface is accessible to the engraving device therethrough. The enclosure is positionable adjacent the work surface and operably disposed thereto.

Owner:LI TONG

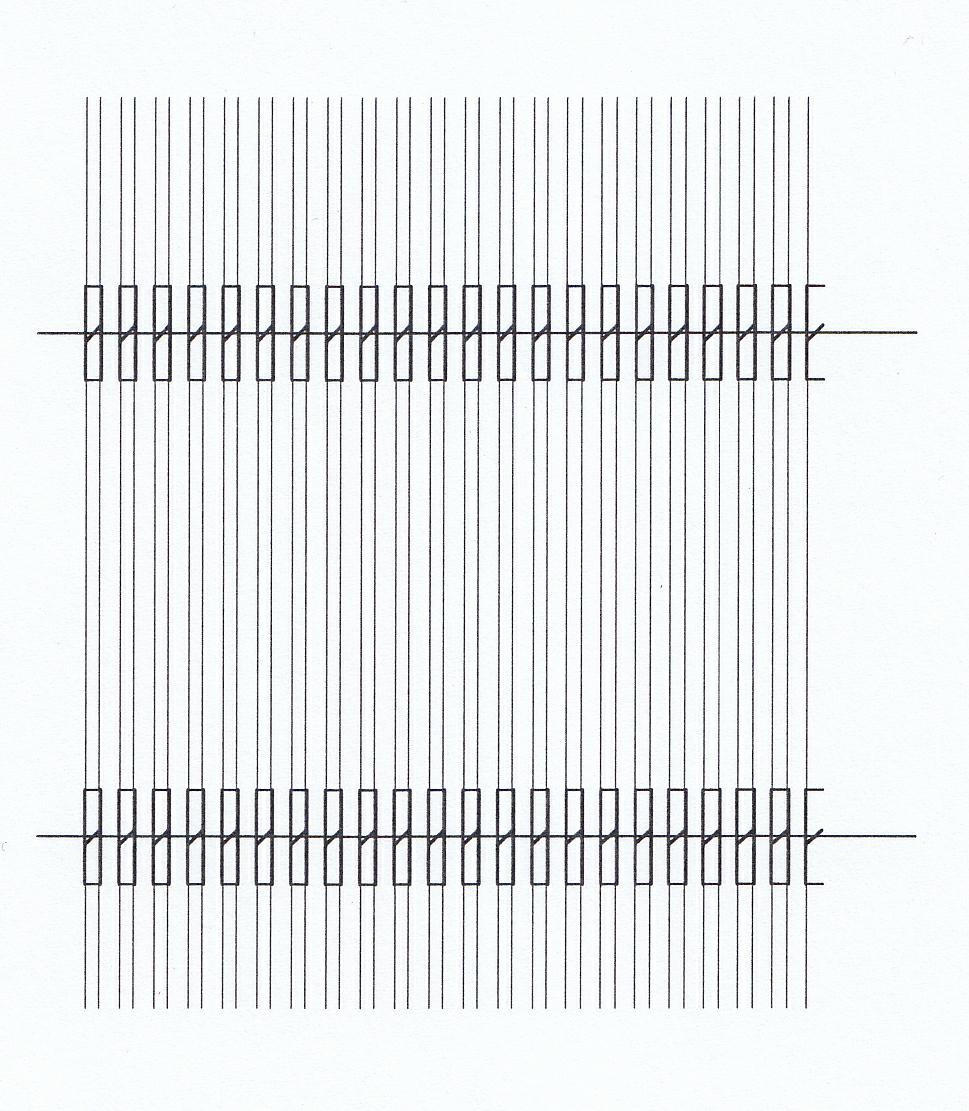

Method for producing permanent integral connections of oxide-dispersed (ODS) metallic materials or components of oxide-dispersed (ODS) metallic materials by welding

InactiveUS7038160B2Increase capacityHigh strengthWelding with roller electrodesWelding/cutting media/materialsMetallic materialsMelt temperature

A method for producing permanent integral connections of oxide-dispersed metallic materials by welding. The materials or components to be connected are overlapped to form an overlapping region in a joining region of the overlapping region. The materials or components are heated below the melting temperatures of the materials and are welded to at least partially form a diffusion bond by a welding method. A noble metal foil may be between the components to be connected. The diffusion bond is heated subsequently to a temperature below the melting temperature of the materials or components and the bond is mechanically recompacted by hammering.

Owner:GLAS SCHOTT +1

Method and device for manufacturing filter sieve

InactiveCN102211244AReduce manufacturing costSimple stepsWelding with roller electrodesEngineeringUltimate tensile strength

The invention relates to a method and a device for manufacturing a filter sieve. The filter sieve comprises a plurality of ribs, and metal wires fixedly arranged on the outer walls of the plurality of ribs. The method comprises the following steps of: fixedly distributing the plurality of ribs on the same cylindrical surface and fixing to form a rib whole; rotating the rib whole around the axis line of the rib whole, and moving the rib whole along the extending direction of the axis line of the rib whole; feeding the metal wires into the rib whole and welding; spirally winding the metal wires on the outer wall of the rib whole and reserving a fixed gap; welding the metal wires on the rib whole while winding to form a barrel-shaped filter sieve; and cutting the barrel-shaped filter sieve into the filter sieve with the required size. The filter sieve is formed by winding and welding the metal wires on the plurality of ribs, the strength of the sieve can be changed by increasing the number or size of the ribs, and a support framework is not needed; and the distance between two adjacent circles of metal wires can be effectively controlled to adjust the size and specification of the filter sieve, the steps are simple, manufacturing efficiency is high, and the manufacturing cost of the filter sieve is greatly reduced.

Owner:张家港市联通化机有限公司

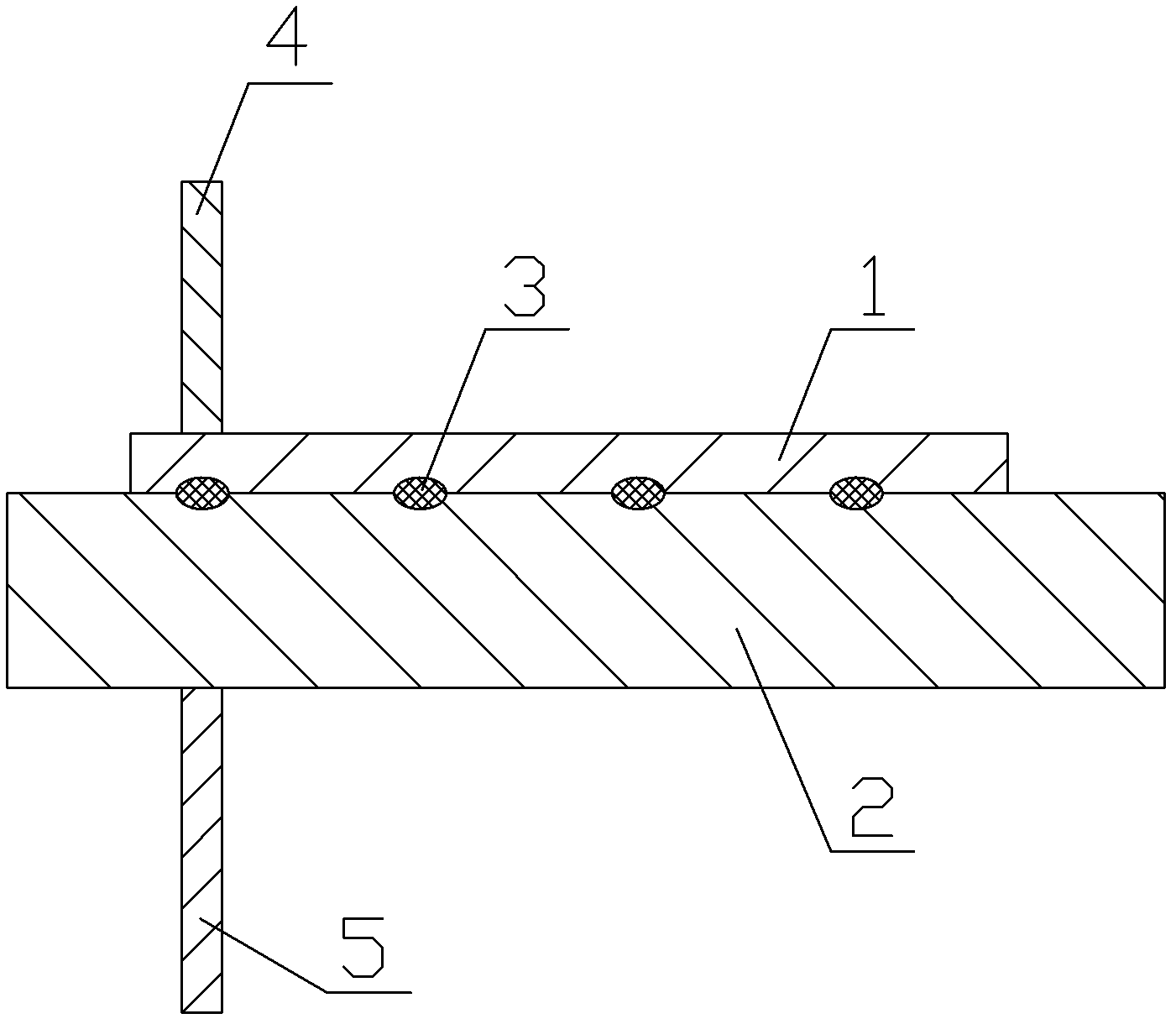

Preparation method for dissimilar metal plate loose lining

InactiveCN102500900AHigh strengthSimplify the process stepsWelding with roller electrodesWelding/soldering/cutting articlesNiobiumPetrochemical

The invention discloses a preparation method for a dissimilar metal plate loose lining, which comprises the following steps of: firstly, mechanically grinding and polishing a weld zone of steel plate base metal and removing an oxidation film; secondly, treating a weld zone of loose lining multiple-layer base metal by adopting a polishing or pickling method; thirdly, aligning the treated weld zone of the loose lining multiple-layer base metal with the mechanically-ground and polished weld zone of the steel plate base metal and fixing the loose lining multiple-layer base metal and the steel plate base metal together by adopting a positioning piece; and fourthly, placing the loose lining multiple-layer base metal and the steel plate base metal between an upper roller and a lower roller of an electric-resistance seam-welding machine and welding the loose lining multiple-layer base metal with the steel plate base metal by adopting electric-resistance seam welding. The preparation method has the advantages of simple process step, lower manufacturing cost, high degree of mechanization, convenience in operation and easiness for obtaining of high-strength welding seams; and the prepared dissimilar metal plate loose lining can be applied to the fields of petrochemical industry, pharmacy, metallurgy and electric power to manufacture nickel, copper, titanium, zirconium, tantalum, niobium and steel composite board equipment in stead of an explosive composite board under certain working conditions..

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

Supporting structure and supporting method for processing steel reinforcement cage by roll seam welding machine

PendingCN108581345AGuarantee molding qualityMake sure the line is straightWelding/cutting auxillary devicesWelding with roller electrodesSeam weldingPulley

The invention relates to a supporting structure and method for processing a steel reinforcement cage by a roll seam welding machine, which comprises a bracket fixedly connected with a roll seam welding machine; a top supporting ring fixedly connected with the bracket, the top supporting ring is arranged in the reinforcement cage surrounded by main ribs protruding from the roll seam welding machine, and the top supporting ring is arranged close to the welding construction position of the hoop rib which is adjacent to the main rib and is arranged on the outer periphery of the main ribs; a fixedpulley arranged on the top supporting ring and corresponding to the main ribs, wherein the surface of the fixed pulley is in contact with the corresponding main ribs; the corresponding main ribs are supported by the fixed pulley; and the fixed pulley rotates along with the movement of the main ribs. According to the invention, the top supporting ring and the fixed pulley are arranged in the innerpart of the main ribs, and support the main ribs from the inner part of the main ribs, the deformation of the main ribs is avoided, the forming quality of the reinforcement cage is guaranteed, and thelinear smoothness of the main ribs is ensured. The fixed pulley does not influence the movement of the main ribs and can provide good support for the main ribs.

Owner:中国建筑土木建设有限公司

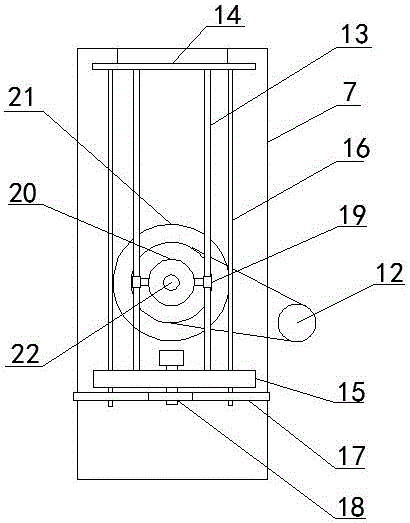

Welding automatic adjusting device for multifunctional seam welder

InactiveCN101590565AEnsure consistencyGood for stress reliefWelding with roller electrodesEngineeringSeam welding

The invention discloses a welding automatic adjusting device for a multifunctional seam welder. A master gear(1) is fixed on the outer surface of a seam welding cylinder(3); an auxiliary gear(2) is meshed with the master gear(1), and a rotary shaft(5) in the center of the auxiliary gear(2) is supported by a bearing(7) arranged in a bearing block(6); one end of the rotary shaft(5) is fixedly connected with the auxiliary gear(2), while the other end is connected with an eccentric wheel(8) connected with a connecting rod(9); one end of the connecting rod(9) is fixedly connected with the eccentric wheel(8), while the other end is connected with a movable electrode(10), which is opposite to a fixed electrode(11) of the seam welder; and the seam welding cylinder(3) drives the rotary shaft(5) to rotate through the master gear(1) and the auxiliary gear(2) orderly, the rotary shaft(5) drives the eccentric wheel(8) to rotate, and the eccentric wheel(8) drives the movable electrode(10) to move around the fixed electrode(11) through the connecting rod(9).

Owner:TAIZHOU HENGYUAN BUILDING MATERIALS MACHINERY

New process for manufacturing screen drum by utilizing strip-shaped screen

InactiveCN103831586AStable formationAvoid deformationWelding with roller electrodesEconomic benefitsEngineering

A new process for manufacturing a screen drum by utilizing a strip-shaped screen comprises the steps of mounting a fixing base and a traction base, fixing ribs and conducting roll welding forming. The process is simple, convenient to operate, and low in production cost, and an existing production method for manufacturing the screen drum by utilizing the strip-shaped screen is improved. Supporting rods are fixed on a base, a strip-shaped screen automatic welding machine directly welds grate bars on the surfaces of the supporting rods in the process of driving the supporting rods to move by the traction base, due to the fact that the relative positions of the supporting rods are not changed, the precision of the sizes, such as the diameter and the roundness, of the screen drum made by the screen is ensured well, treatment is carried out through blackening liquid while welding is carried out, a workpiece can be cooled, and meanwhile welding face corrosion-resistant treatment is carried out. Therefore, the welding point is solidly formed, not prone to deformation, and good in surface quality. The process improves shortcomings in the prior art, and has the good economic benefits and certain popularization value.

Owner:HUBEI QIAOGUANG PETROCHEM EQUIP CO LTD

Programmable resistance seam welding apparatus and method

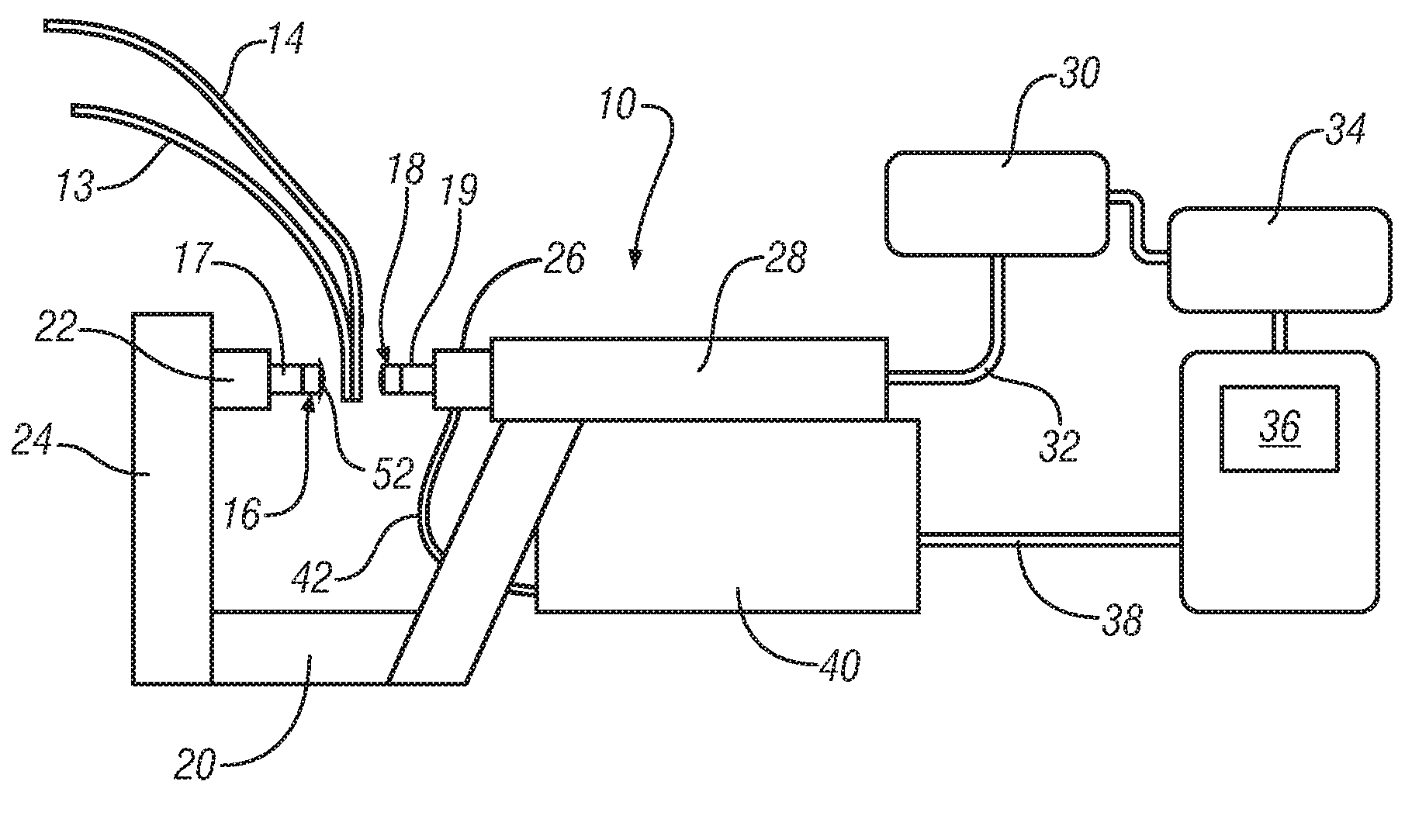

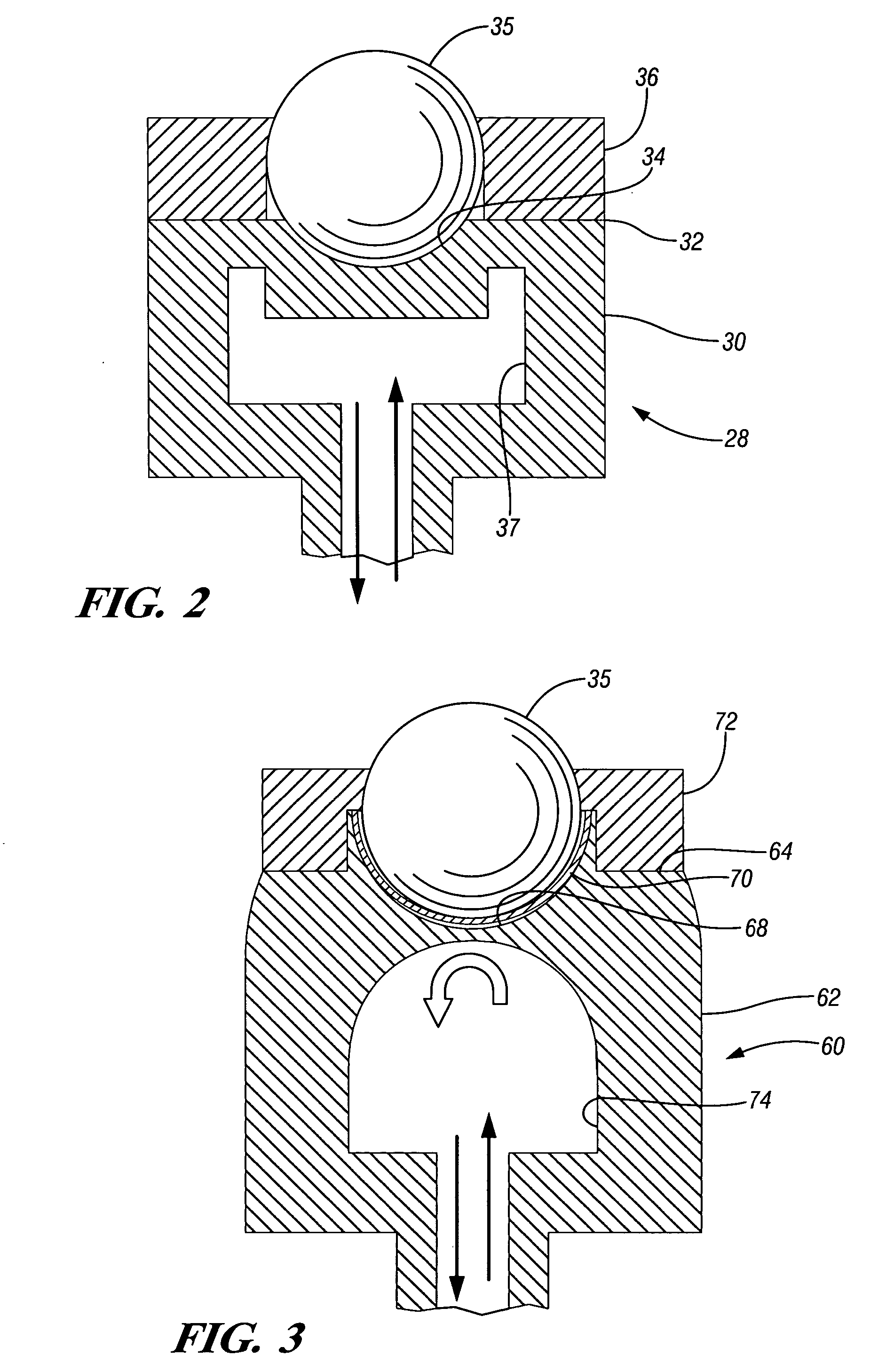

InactiveUS20060043074A1Small welding contact pointReduce amountOhmic-resistance electrodesWelding with roller electrodesElectrical resistance and conductanceEngineering

A resistance welding apparatus having a pair of programmable ball electrodes carried on universally movable positioners. The positioners are programmed to move the ball electrodes simultaneously along a seam line so that the ball electrodes clamp and support opposite sides of a pair of stacked workpieces and are electrically charged to form resistance seam welds along the seam lines to connect the workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

Main reinforcement loading device for roll seam welding machine for steel reinforcement framework

InactiveCN108723573ARealize automatic feedingAvoid bendingWelding with roller electrodesSprocketEngineering

The invention discloses a main reinforcement loading device for a roll seam welding machine for a steel reinforcement framework. The main reinforcement loading device comprises a main support, an auxiliary support, a loading mechanism and loading hooks, wherein the main support is connected with the auxiliary support through a cross brace; a motor plate is arranged at the lower end of the main support, and a support seat I is arranged at the upper end of the main support; a support seat II is arranged at the lower end of the auxiliary support, and a support seat III is arranged at the upper end of the auxiliary support; the loading mechanism is composed of a motor, a rotary shaft I, a rotary shaft II, a rotary shaft III, a mounted bearing and a chain; the rotary shaft I is rotationally connected with the support seat II; the rotary shaft II is rotationally connected with the support seat I; the rotary shaft III is rotationally connected with the support seat III; a chain wheel I is arranged on an output shaft of the motor; a chain wheel II is arranged on the rotary shaft I; a chain wheel III is arranged on the rotary shaft II; a chain wheel IV is arranged on the rotary shaft III; the chain wheel I is connected with the chain wheel III through the chain; the chain wheel II is connected with the chain wheel IV through the chain; and the loading hooks are hinged to a chain pin ofthe chain, and equidistantly arranged along the chain. Automatic main reinforcement loading is realized and bending during main reinforcement loading is prevented, so that the manual loading operationis more time-saving and labor-saving.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com