Automatic reducing system mechanism of rolling welder

A technology of seam welding machine and rotary drive mechanism, which is applied in the direction of roller electrode welding, welding equipment, auxiliary welding equipment, etc., can solve the problems of low work efficiency, high production cost, difficulty in adapting to automatic production, etc., and achieves strong flexibility, The effect of high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

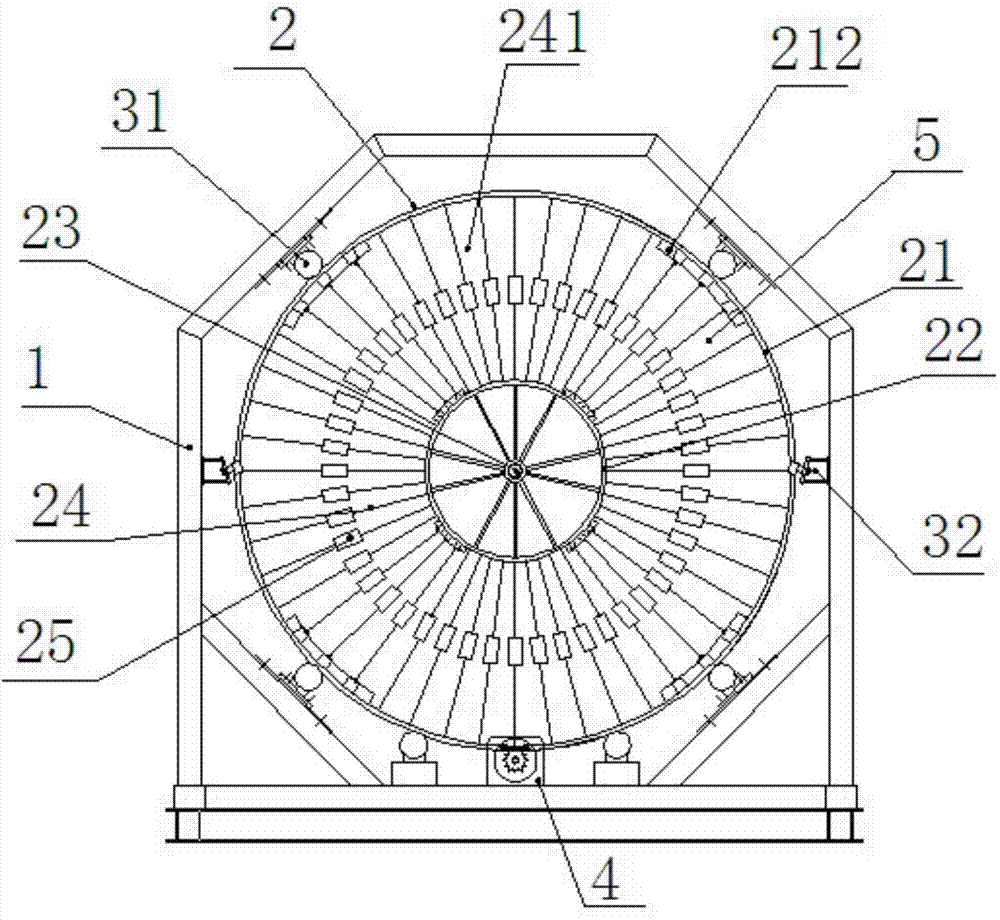

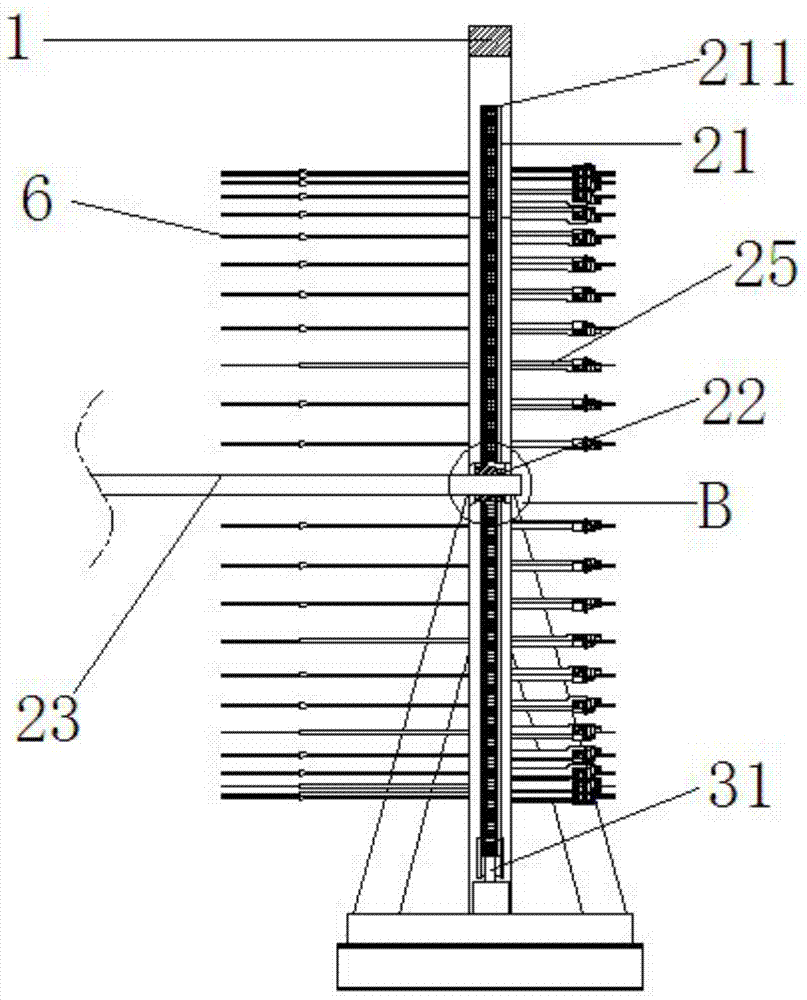

[0034] Such as figure 1 with figure 2 As shown, an automatic diameter reduction system mechanism of a seam welding machine includes a support frame 1 , a faceplate mechanism 2 , a guide limit mechanism and a faceplate rotation drive mechanism 4 .

[0035] support frame 1, such as figure 1 As shown, it preferably includes a base frame and a regular octagonal bracket fixedly connected with the base frame.

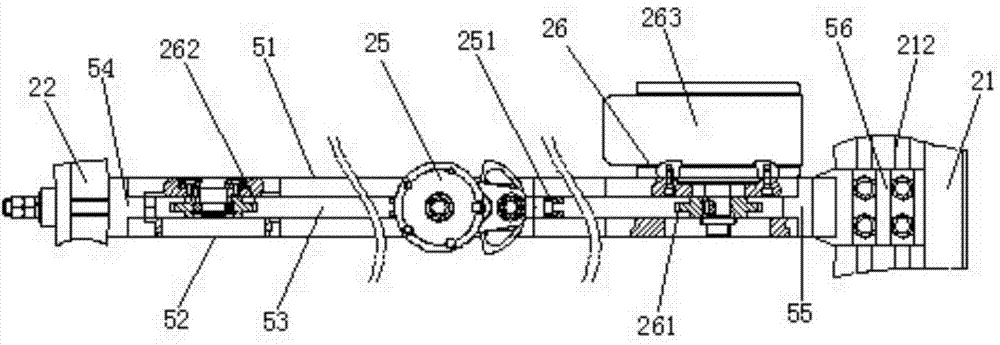

[0036] The above-mentioned faceplate mechanism 2 is arranged in the inner frame of the regular octagonal support, and the above-mentioned faceplate mechanism 2 includes a faceplate outer ring 21 , a faceplate inner ring 22 , a central axis 23 , a web 24 , a welding seat 25 and a web transmission mechanism 26 .

[0037] Wherein, the central axis 23, the inner ring 22 of the faceplate and the outer ring 21 of the faceplat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com