Welding seam tracking system and method of laser welding machine

A laser welding machine and tracking system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as insufficient technical maturity, achieve the effect of improving technology level, reducing production cost, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

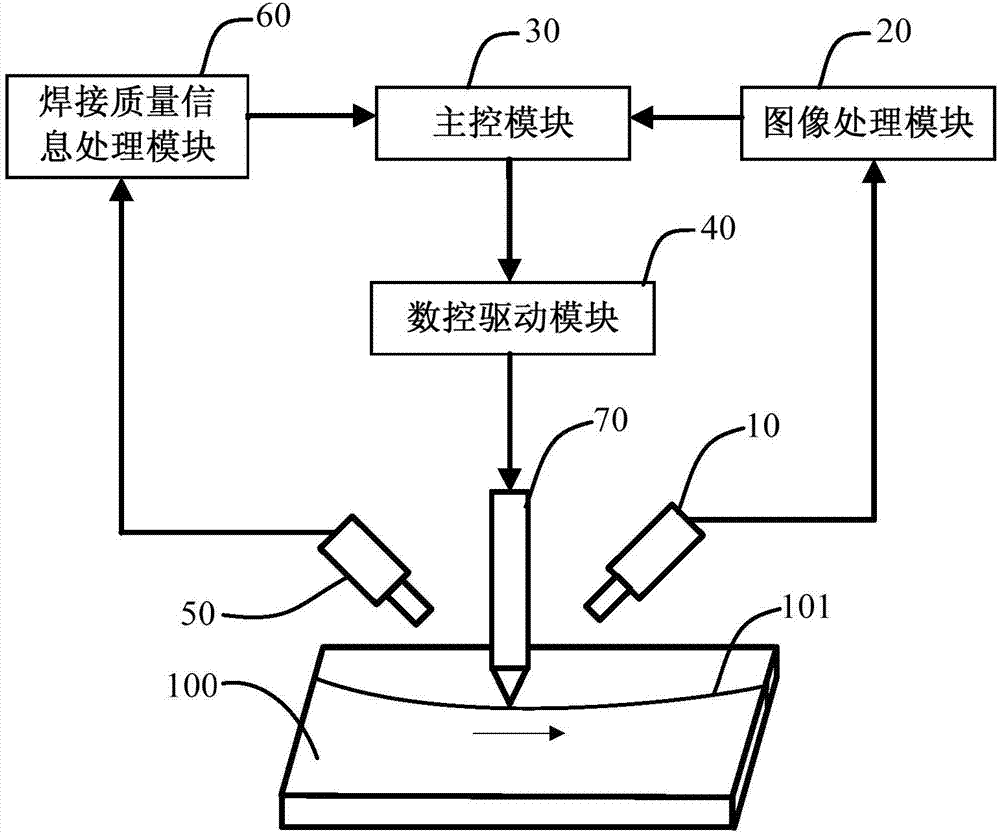

[0018] The invention discloses a laser welding machine seam tracking system, such as figure 1 As shown, it includes:

[0019] A CCD vision sensor 10, which is used to convert the light signal collected by it into image data which is serially output in time series, so as to obtain the image of the welding seam path, through which the CCD vision sensor 10 can realize high-speed and high-precision detection of the position of the welding seam Take pictures continuously to obtain the characteristic parameters such as the center position of the weld seam and the shape and size of the weld seam section.

[0020] An image processing module 20, which is connected to the CCD vision sensor 10, the image processing module 20 is used to preprocess the weld path image, calculate the actual weld path width and tracking direction, combine the detected workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com