Supporting structure and supporting method for processing steel reinforcement cage by roll seam welding machine

A technology of support structure and support method, which is applied in the fields of roller electrode welding, metal processing equipment, manufacturing tools, etc., can solve the problems of deformation of main bars, unsatisfactory diameter of reinforcement cages, and non-straight lines of main bars, so as to achieve good support, Avoid deformation and ensure the effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0070] As a preferred embodiment of the present invention, the support method also includes:

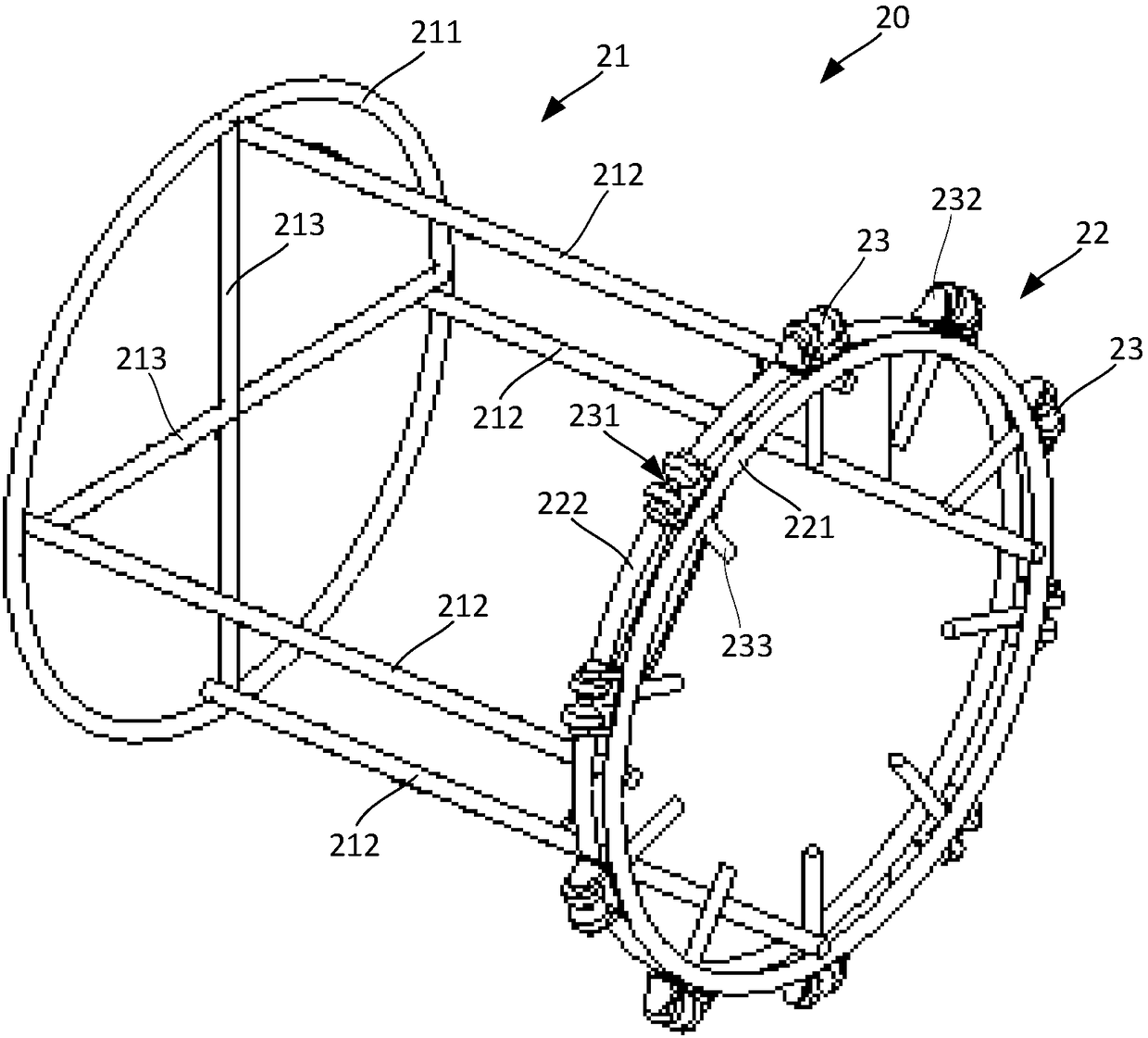

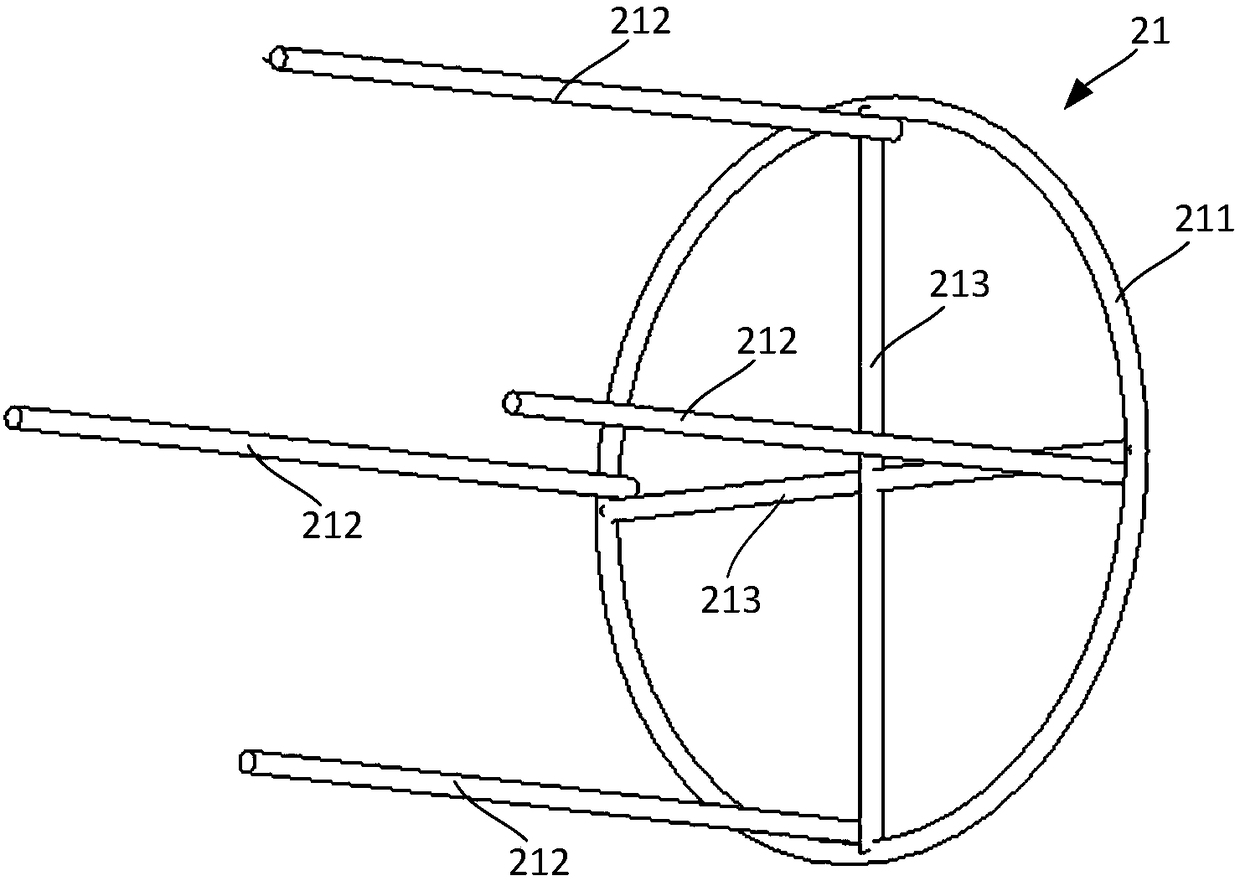

[0071] Such as figure 1 As shown, the middle part of the outer peripheral surface of the fixed pulley 23 is inwardly recessed to form an annular groove 231 suitable for the corresponding main rib, and the corresponding main rib is supported by the annular groove 231 . After the bracket 21 is fixed, the main rib is partially placed in the annular groove 231 of the corresponding fixed pulley 23. Through the provided annular groove 231, the contact between the fixed pulley 23 and the main rib is closer, and the supporting effect to the main rib is improved.

[0072] As another preferred embodiment of the present invention, providing the support ring 22 in the support method of the present invention includes:

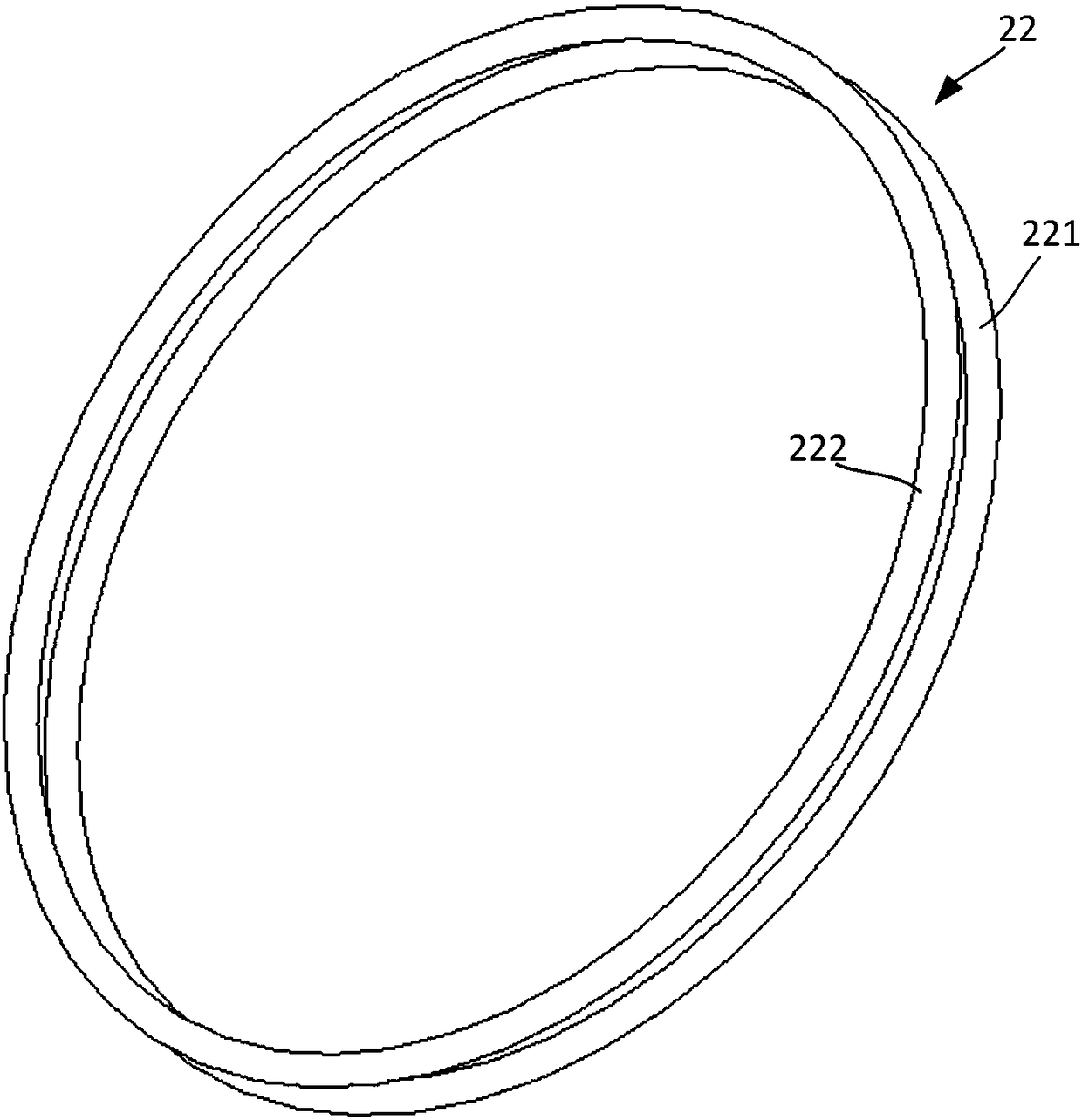

[0073] Such as figure 1 and image 3 As shown, the first circular rib 221 and the second circular rib 222 are provided, and the first circular rib 221 and the second circular r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com