Method and die for molding backseat side cover plate of automobile

A forming method and technology for rear seats, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high blank positioning difficulty, multiple stress concentration points and cracks, blank positioning failure, etc. Fatigue strength requirements, high product structural strength, and the effect of ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

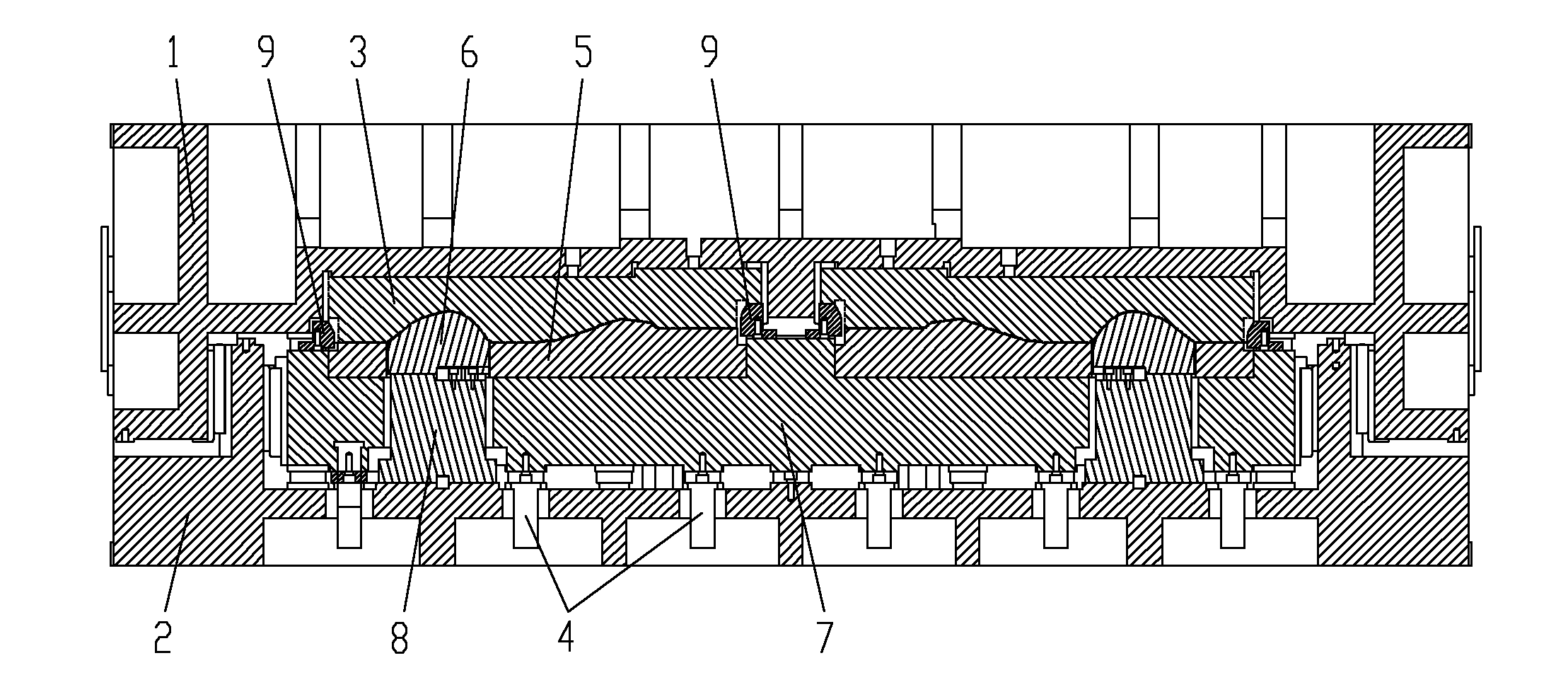

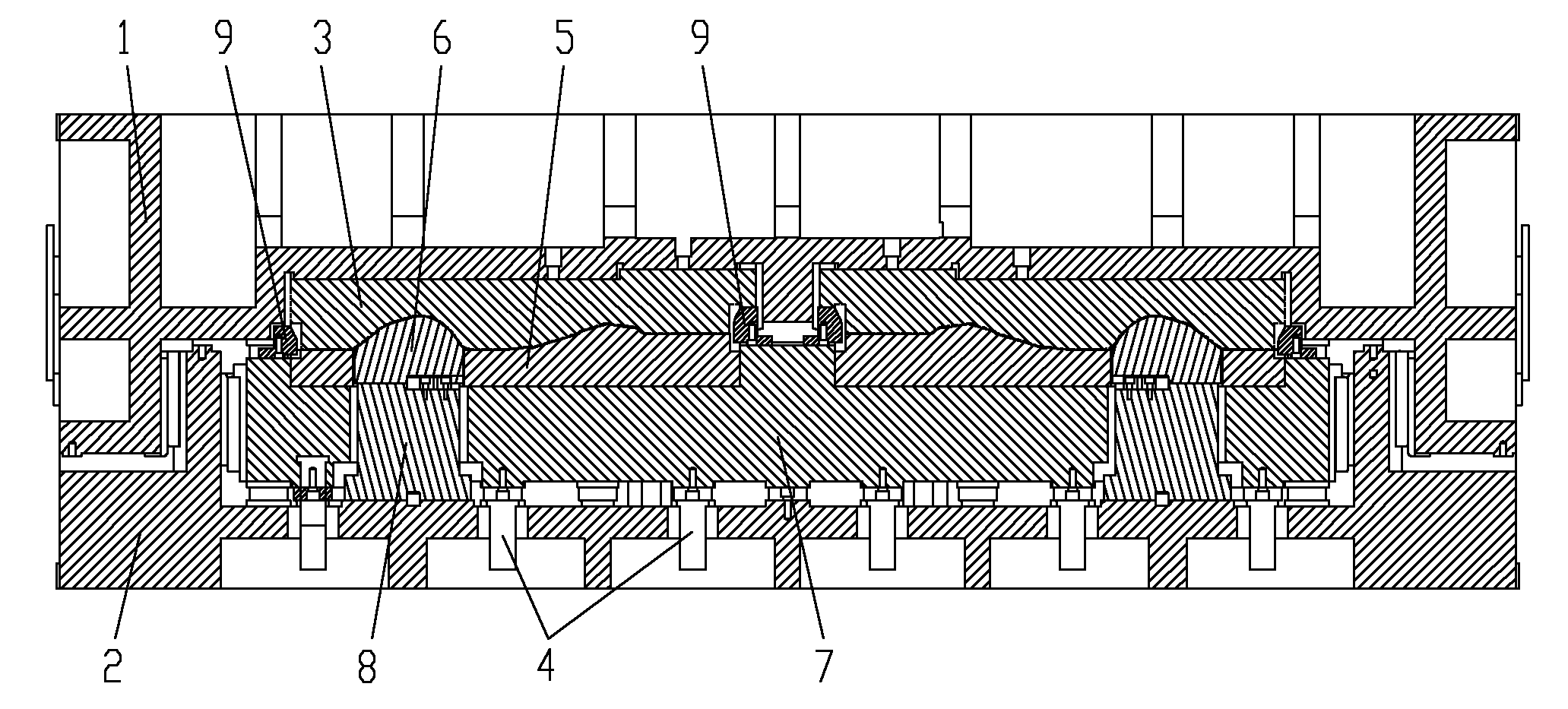

[0013] figure 1 It is a schematic diagram of the mold structure for forming the rear seat side cover of an automobile, as shown in the figure: the forming method of the rear seat side cover of the automobile in this embodiment includes blanking blanking, convex hull of the rear seat side cover and drawing forming of the curved surface of the panel , edge trimming, punching and flanging, the drawing forming of the convex hull of the rear seat side cover and the curved surface of the plate part includes primary drawing and secondary drawing, and the primary drawing is used for the blank of the rear seat side cover The initial forming of the convex hull and the forming of the plate part, the secondary drawing is used for the final forming of the convex hull, so that the convex hull of the rear seat side cover and the curved surface of the plate part are drawn and formed through the mold and the blank plate part of the rear seat side cover plate to form the curved surface The comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com