Patents

Literature

169results about "Branding equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marking diamond

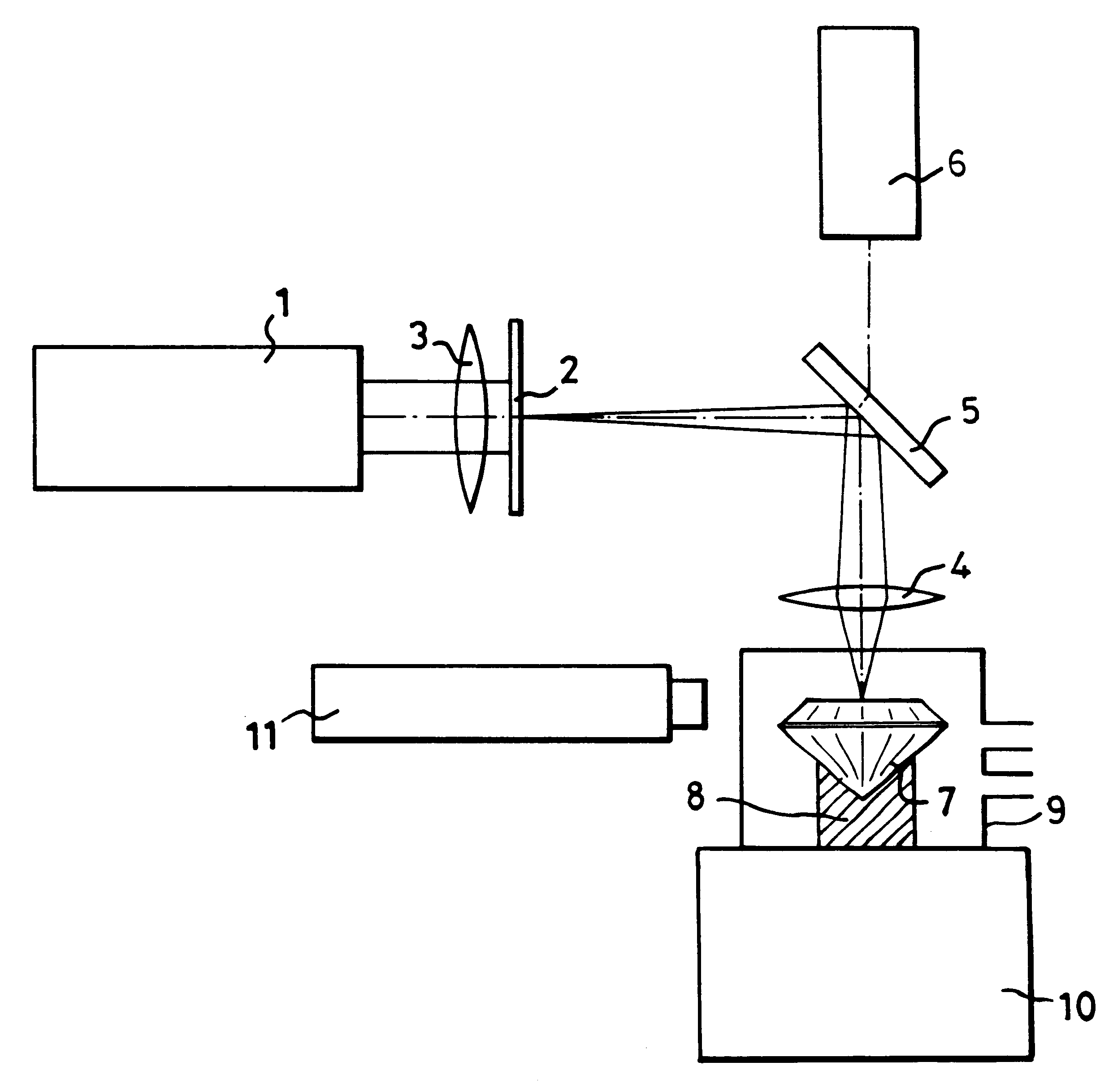

InactiveUS6187213B1Avoid overall overheatingAvoid necessityBranding equipmentPolycrystalline material growthMicroscopic observationGemstone

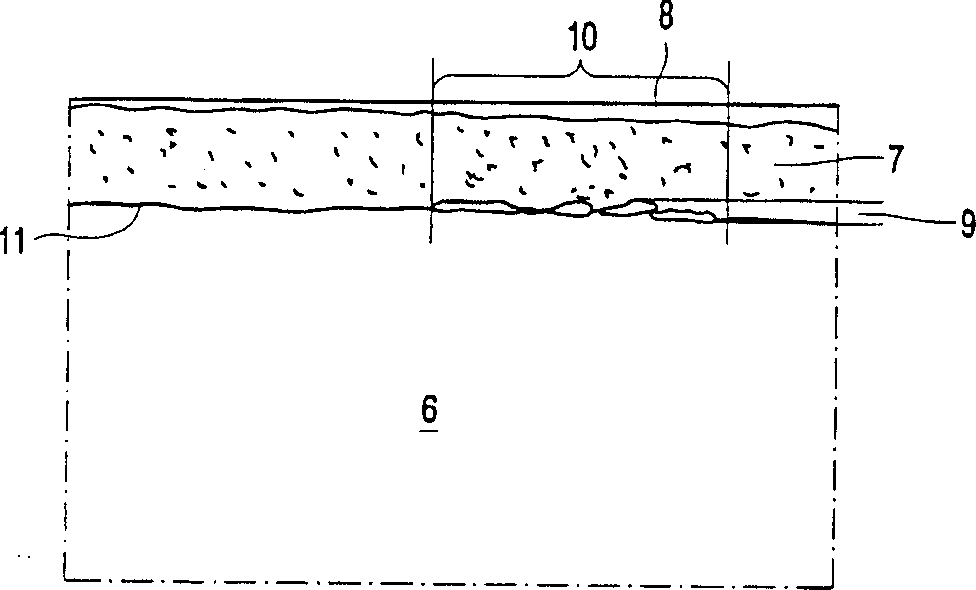

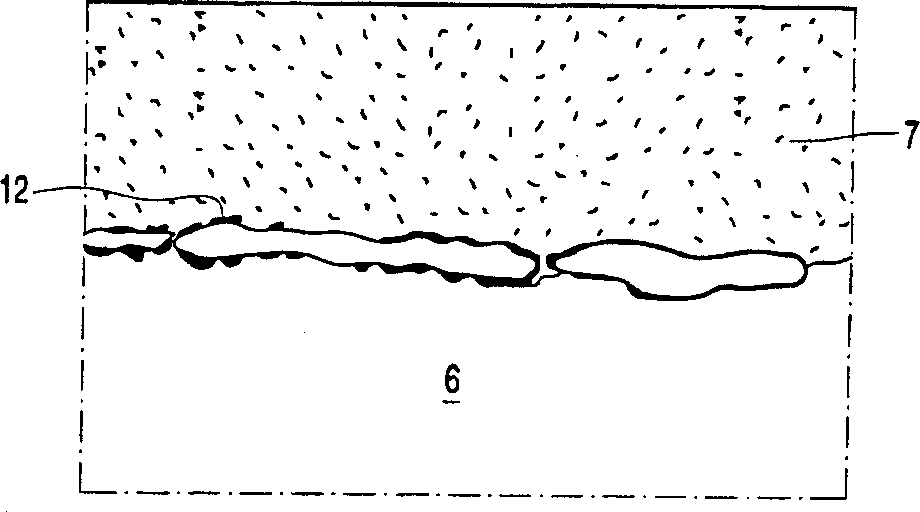

In order to produce on the table of a diamond gemstone (7), an information mark which is invisible to the naked eye using a x10 loupe, an ultraviolet laser (1) having a wavelength of 193 nm is used in association with a mask (2) to irradiate the surface of the stone (7) at a fluence of less than 2 J / cm2 per pulse and with not fewer than 100 pulses, in the presence of air which reacts with the diamond (7) and causes the mark to be formed without any darkening which is visible when viewing using a microscope.

Owner:GERSAN ESTAB

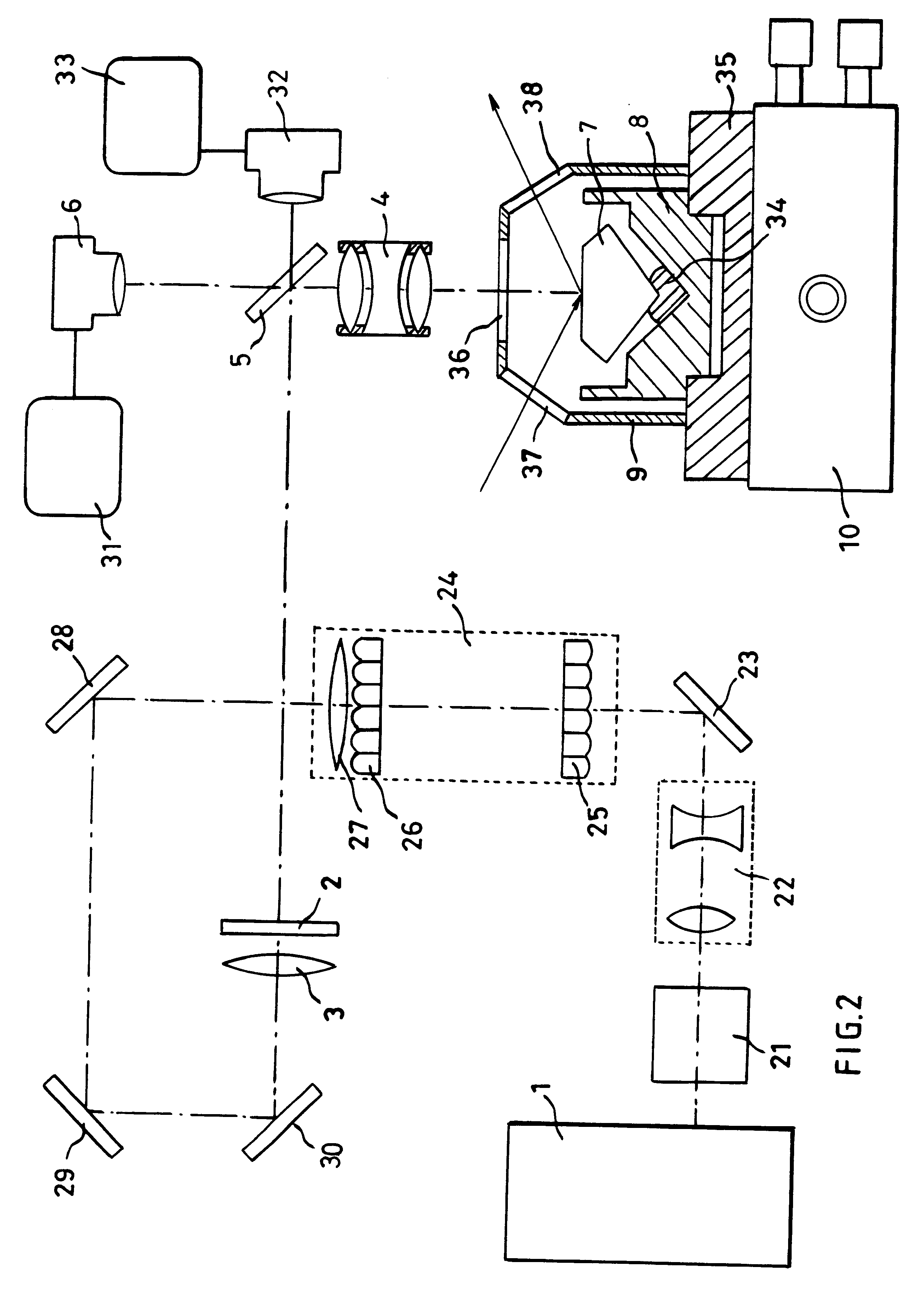

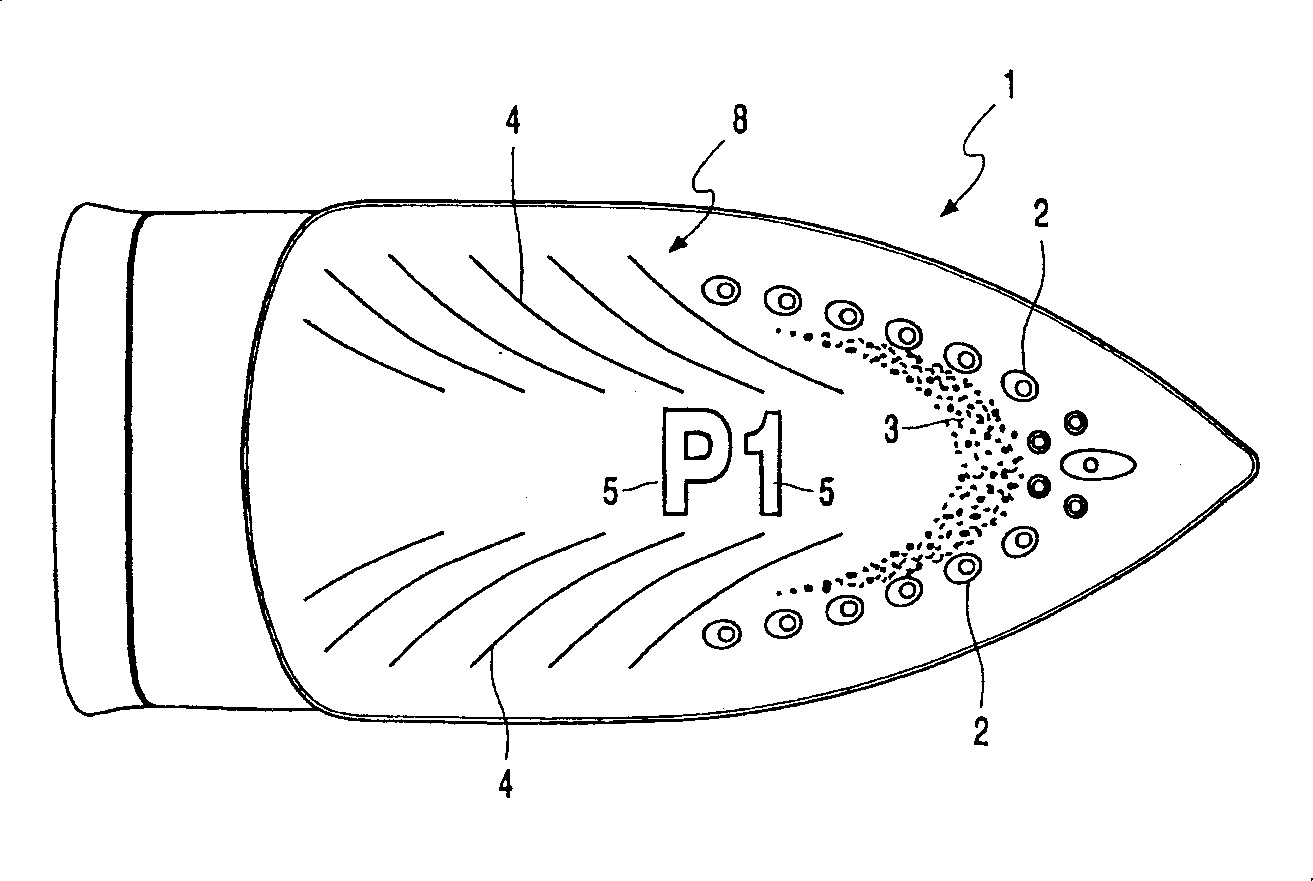

Marking of an anodized layer of an aluminium object

InactiveCN1336878ANo reduction in protective effectNo or almost no reduction in protective effectBranding equipmentDecorative surface effectsVisual markingAlloy

A marking (3 to 5) is provided in a surface (8) of an element (1) which comprises a substrate (6) of aluminum or an alloy thereof and an anodized outer layer (7) in that a region (10) of the surface (8) is irradiated with a laser beam such that at least one visual property of the surface (8) in said region (10) is changed and a visual marking (3 to 5) is obtained which is observable to the human eye. The laser beam penetrates the anodized outer layer (7) at least to a major degree and induces the change in the at least one visual property substantially locally only in a zone (9) where the anodized outer layer (7) adjoins the substrate (6).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

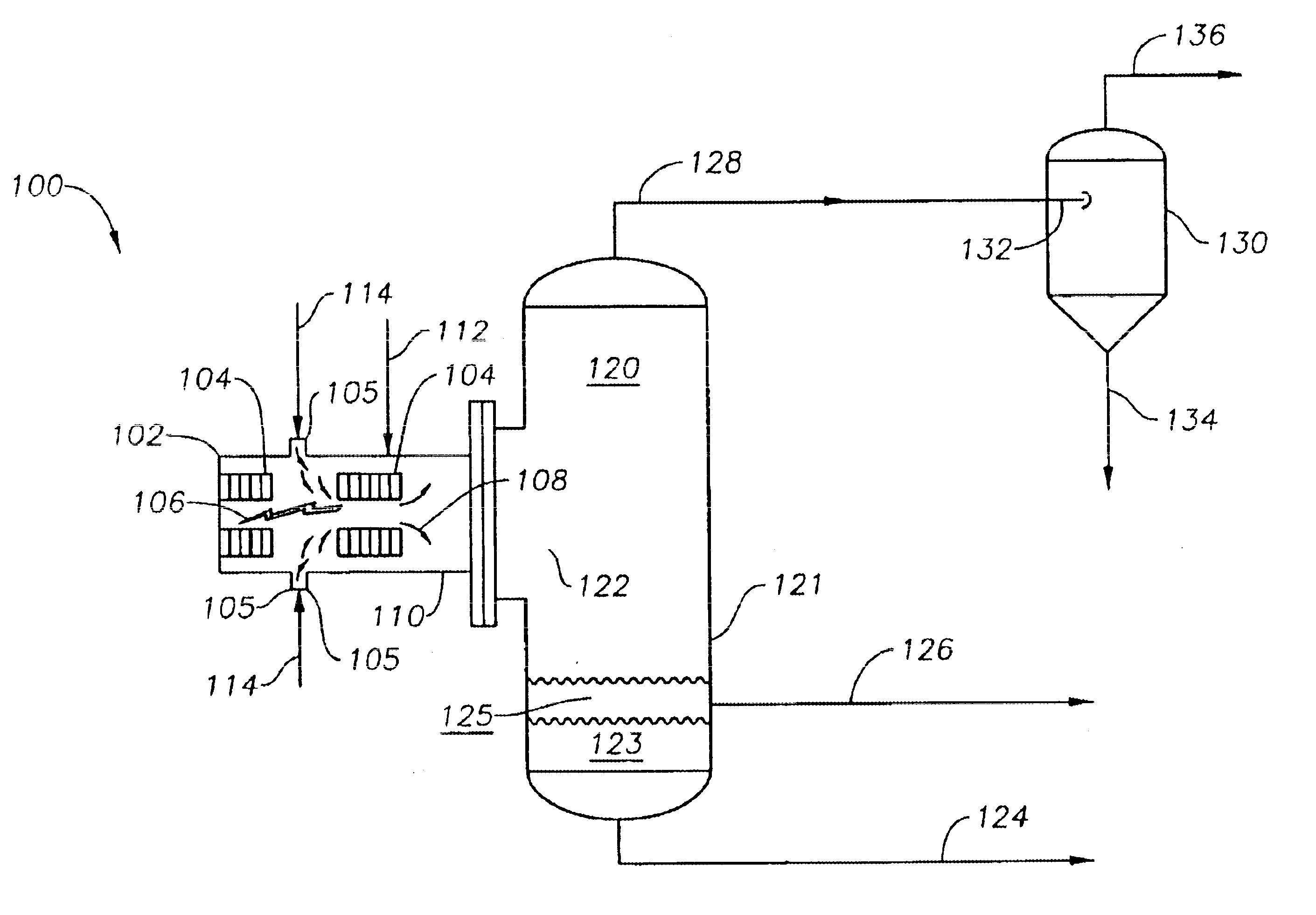

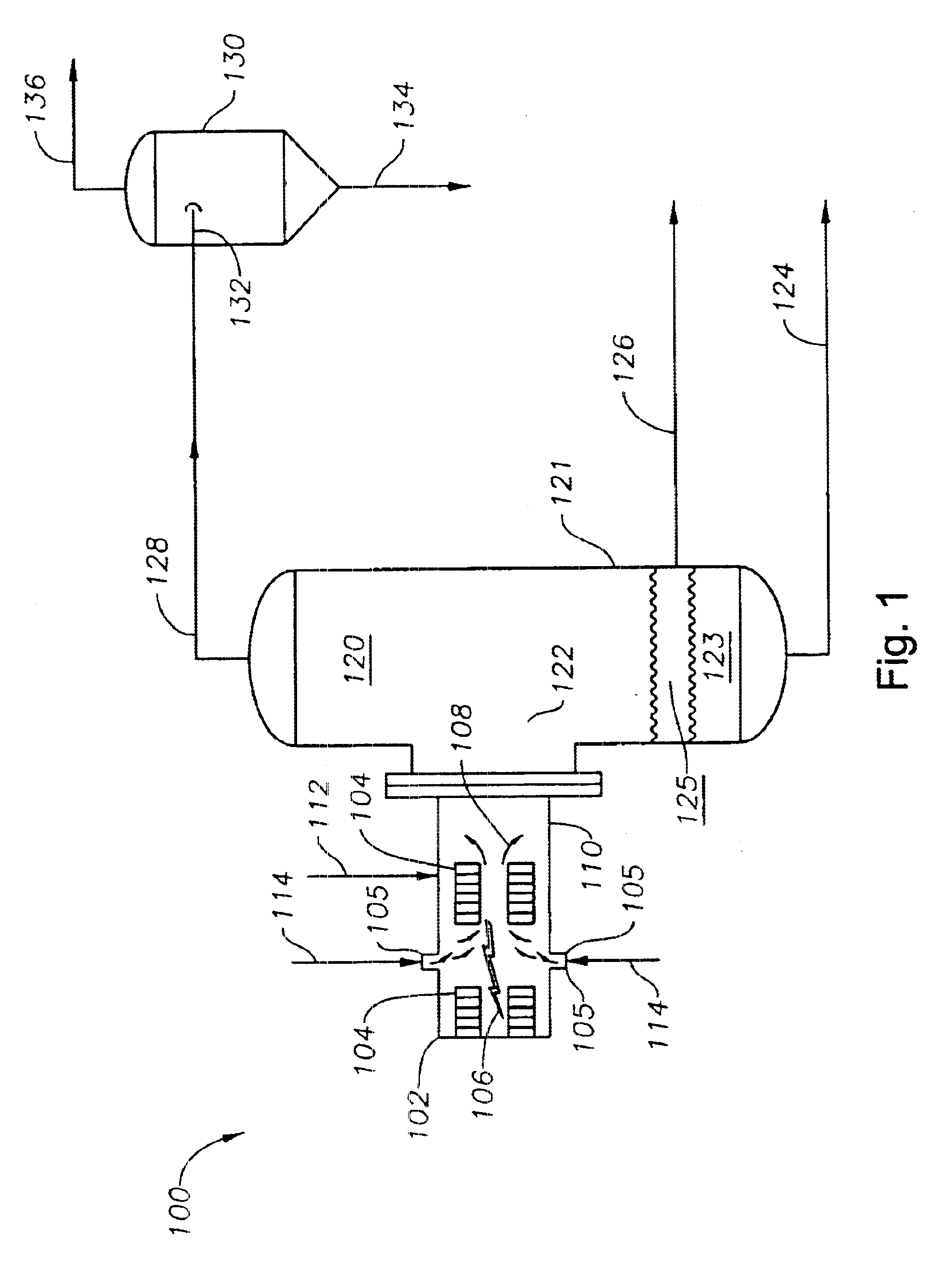

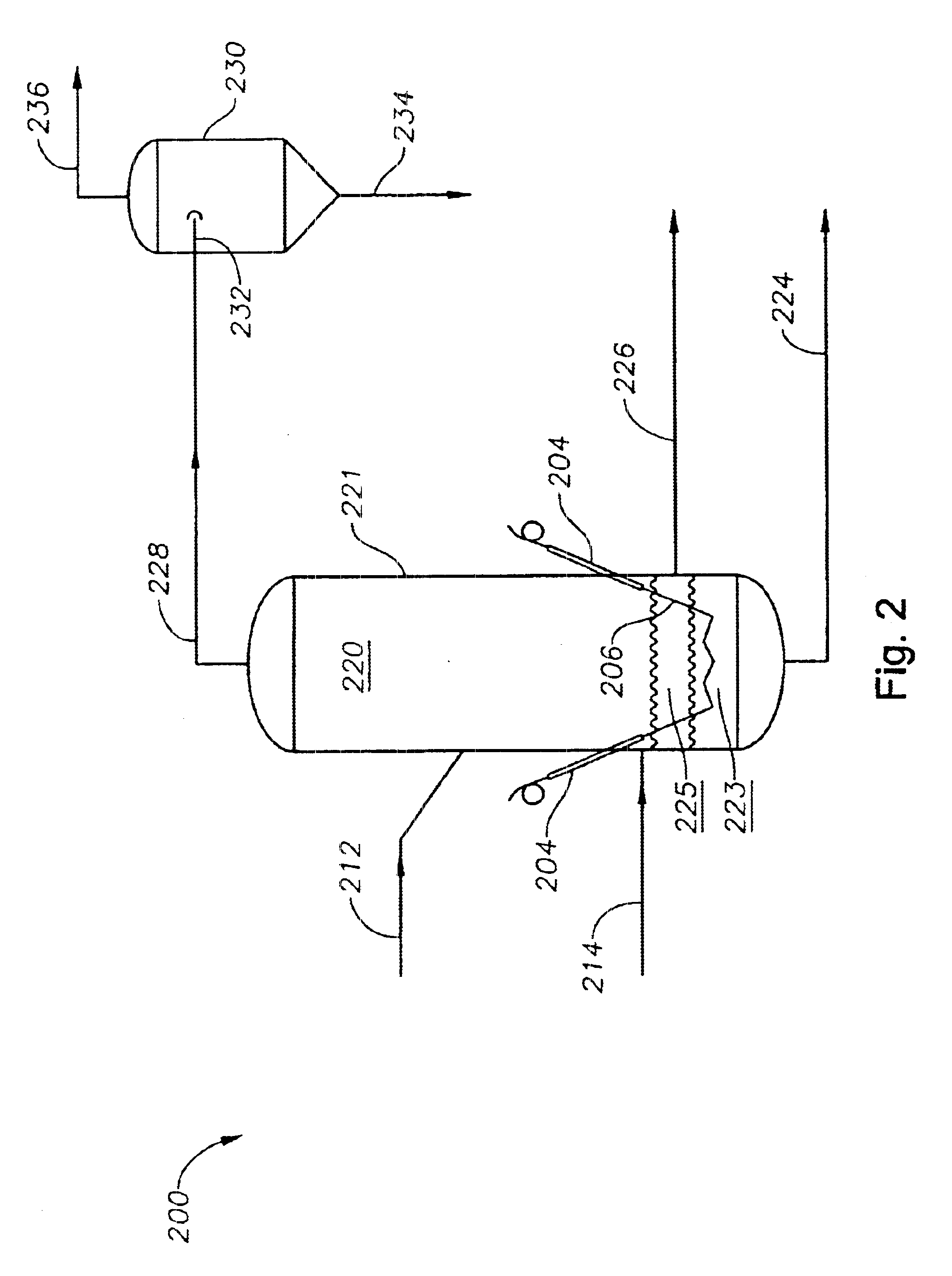

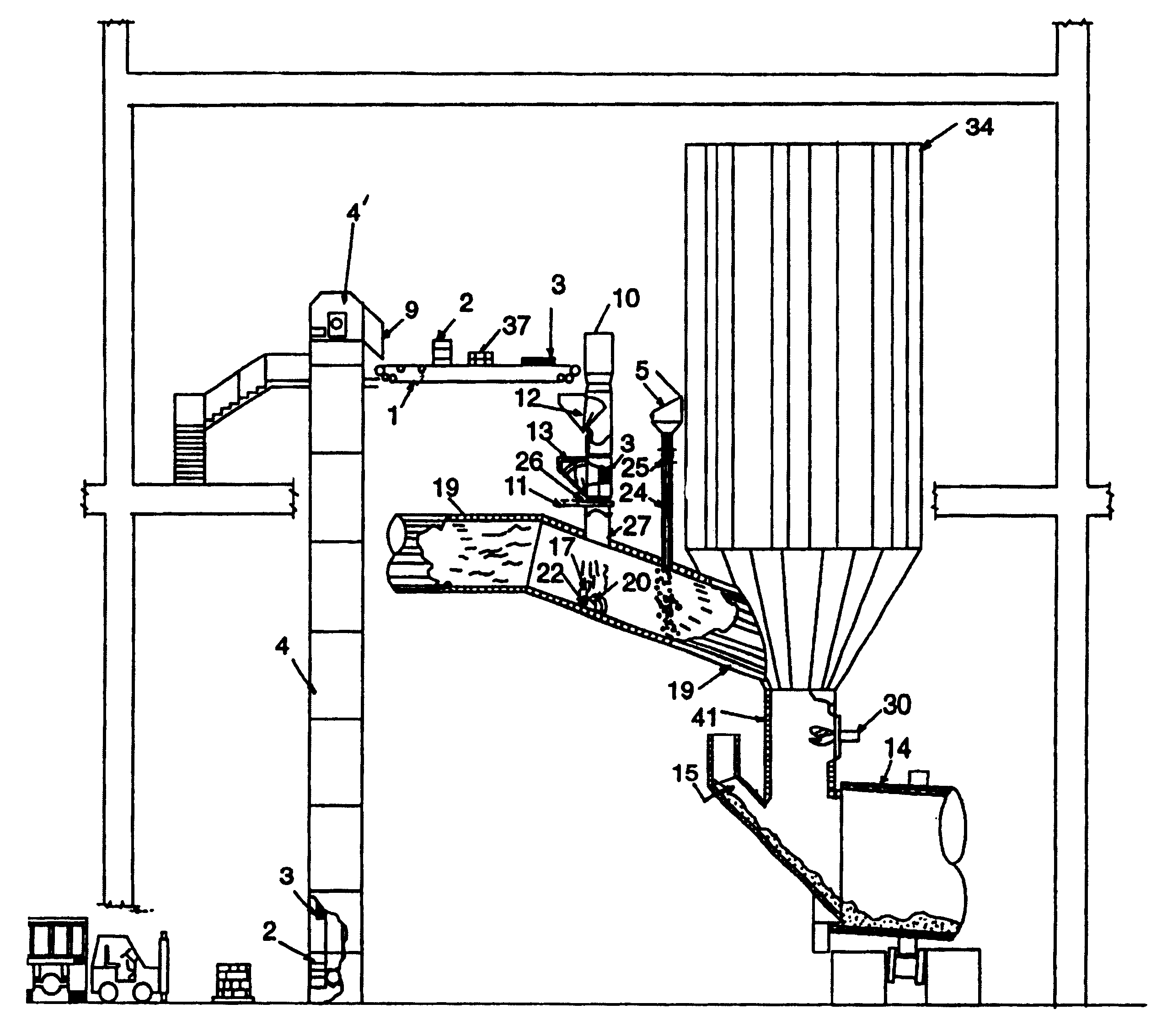

Method and apparatus for processing a waste product

A method and apparatus for processing a waste product and producing a synthesis gas is provided. The system includes a sealed, heated rotatable drum for preheating and preparing the waste material suitable for a plasma reactor, and processing the material in the reactor. The synthesis gas created by the reactor is used to preheat the waste material by circulating the hot synthesis gas around the drum. In an alternative embodiment, the hot synthesis gas flows through the drum to preheat the waste material and to clean the synthesis gas. Different methods of cooling and cleaning the synthesis gas are used. The system may comprise two plasma reactors in combination with a rotating desorber drum.

Owner:CLEAN HARBORS SAN LEON INC

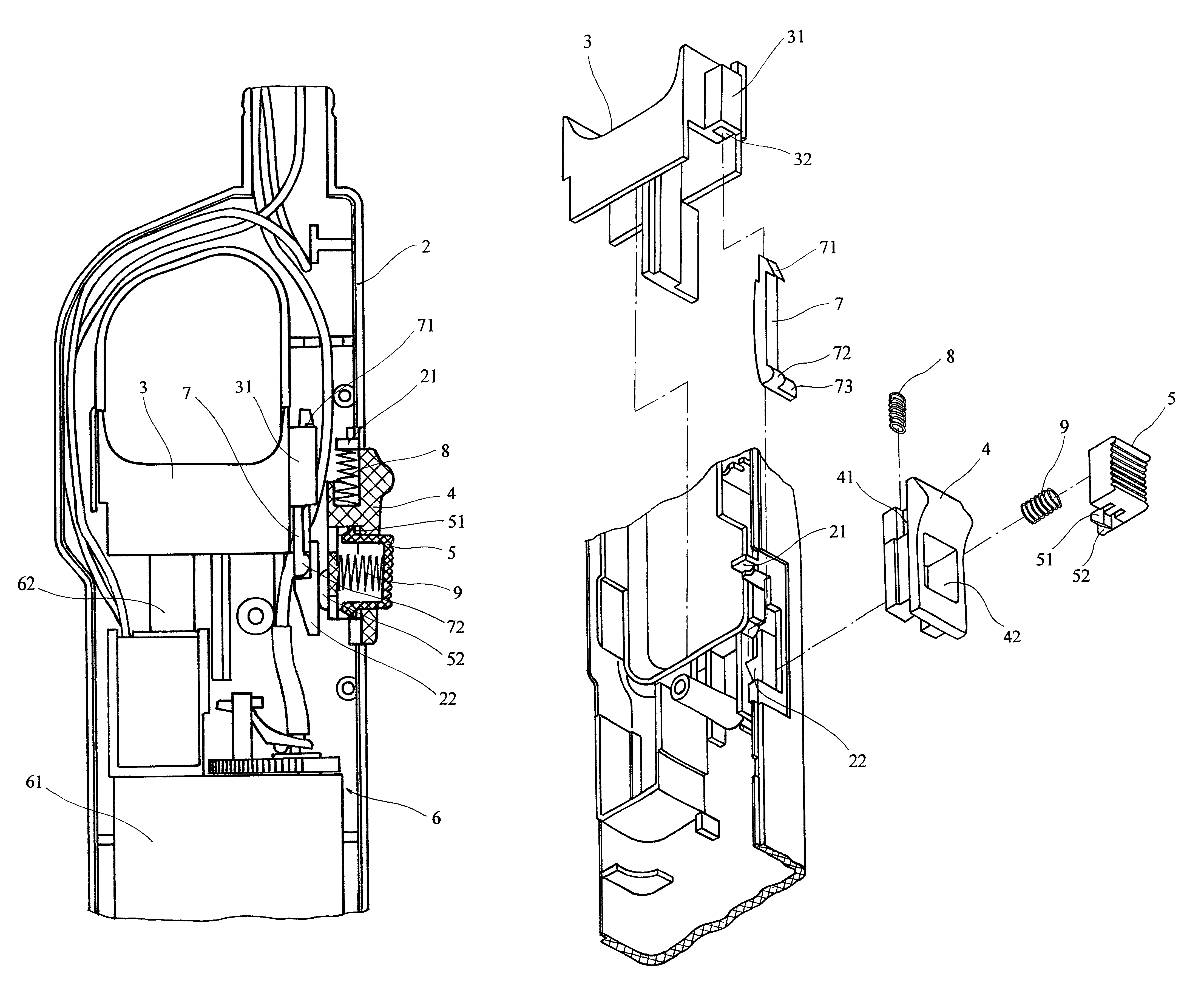

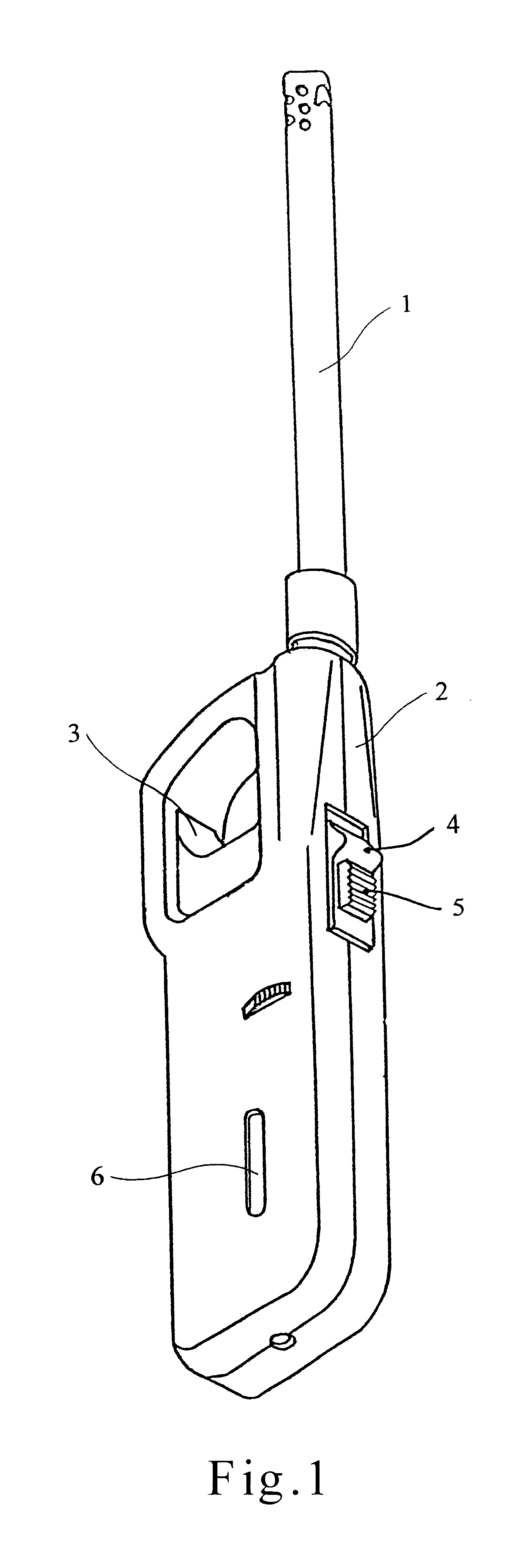

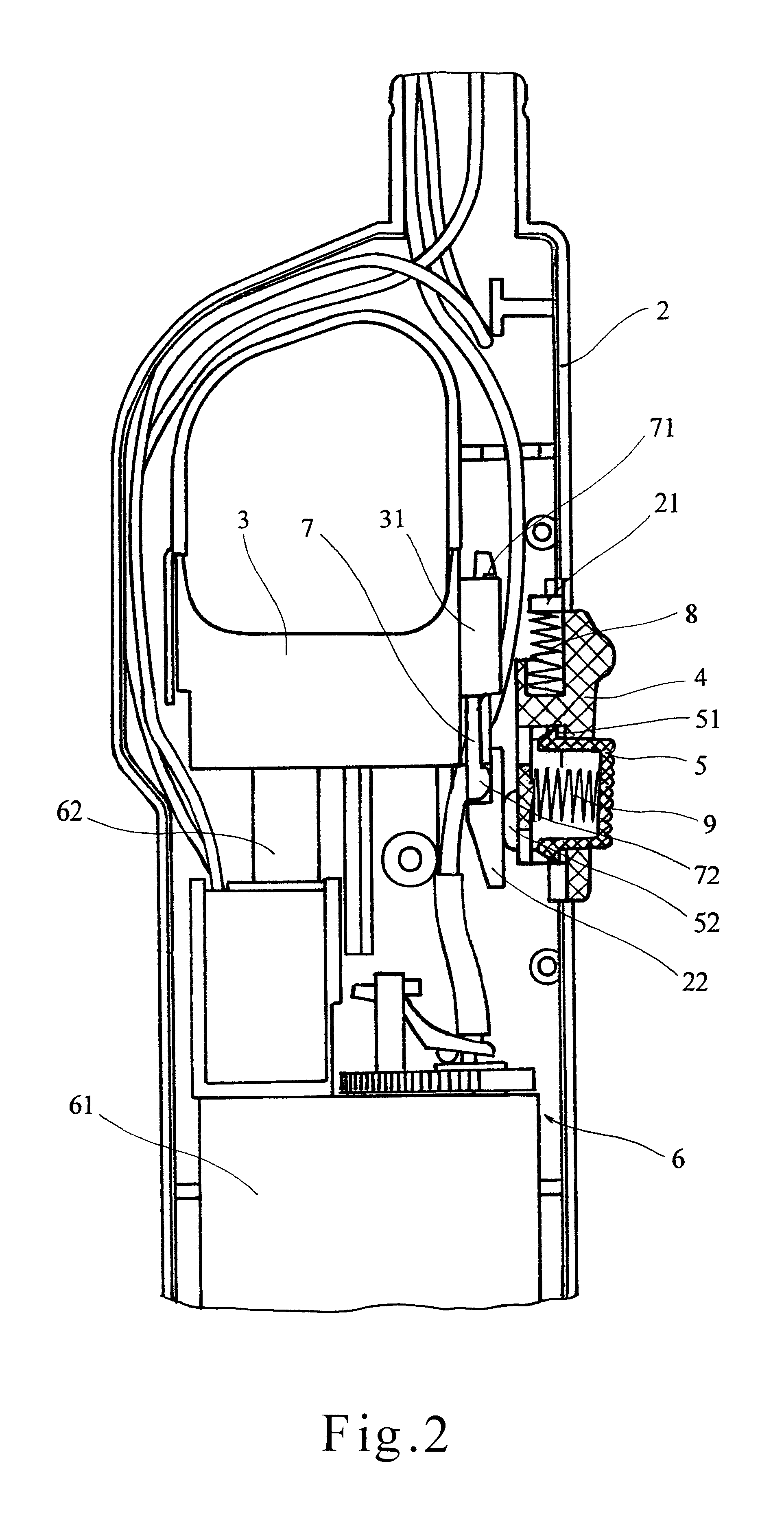

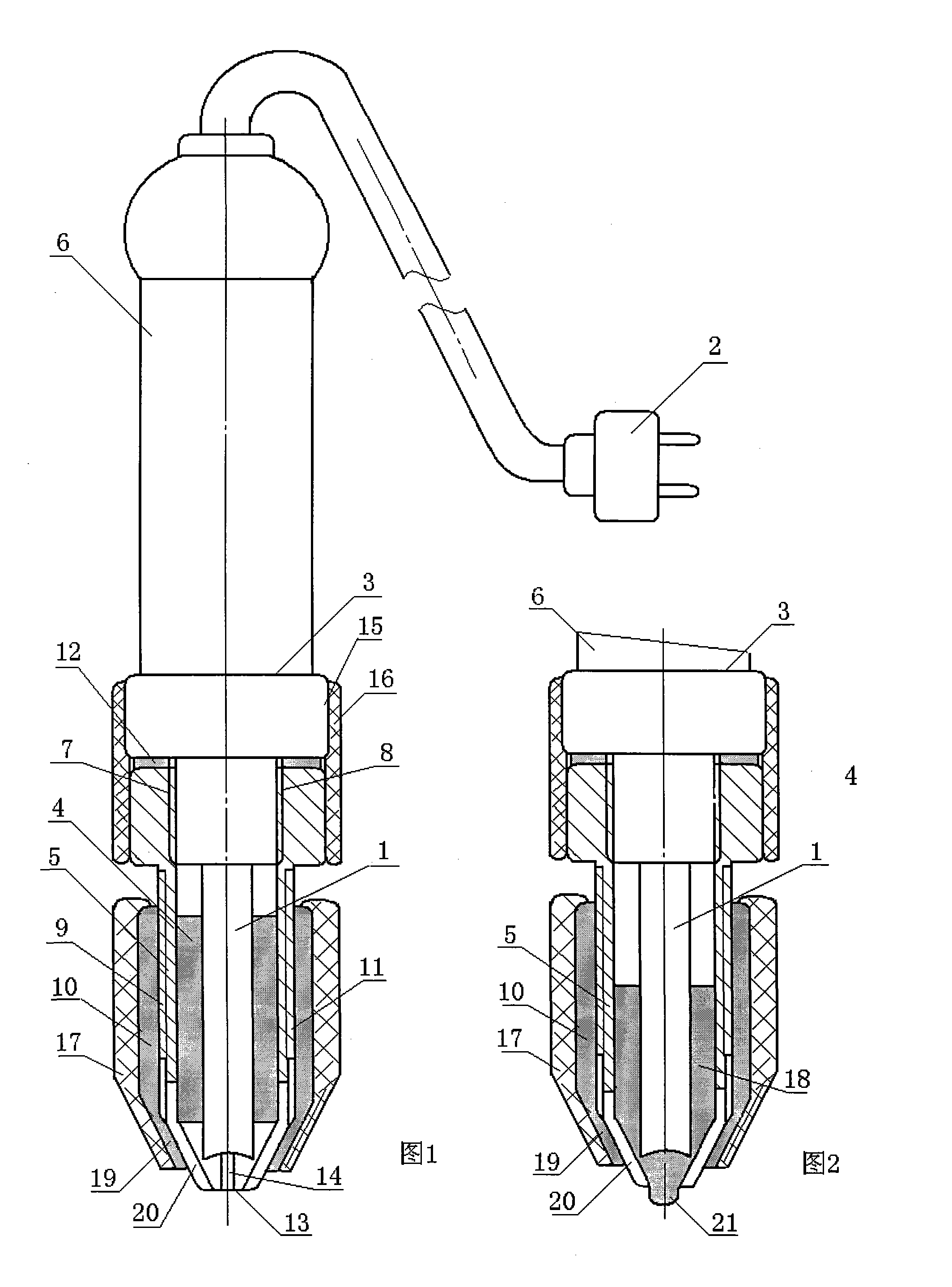

Igniter with a push-button and an elastic bar

InactiveUS6887072B2Promote fireSolve the real problemBranding equipmentIncandescent ignitionNatural statePush ups

Igniter with safety unit, the safety unit comprises a push-button that is arranged at the backside of the gun body and partially protrudes out of the gun body, it can be pushed forward and return relative to the gun body; a elastic limit bar that is arranged at the side of the part of the ignition trigger that is towards the backside of the gun body, in natural condition, its end keeps against a barrier block which is integrated with the inner wall of the gun body; a button that is arranged in the push-button and protrudes out of the push-button, it can be pressed into the gun body and return. A protruding part arranged on the button's inner side protrudes towards a mid-portion of the gun body. In natural condition, the protruding part is towards the blank part, but when the push-button is in pushed up condition, the protruding part is near the end of the elastic limit bar and opposite to it. Thereby, if the button is pressed down, the protruding part of the button pushes the end of the elastic limit bar to make it distort and deflect from the barrier block on the inner wall of the gun body. The locking situation of the ignition trigger can be released. The apparatus can fire the flammable gas only by doing the two compound actions i.e. pressing down the button and pushing up the push-button simultaneously, thus further improving the safety of the ignitor.

Owner:JUDENG ZHANG

Method and apparatus for recovering energy from wastes by combustion in industrial furnaces

InactiveUS6470812B1Efficient energy recoveryEffective recoveryBranding equipmentMechanical apparatusWastewaterAtmospheric pollution

Method and apparatus to recover energy from waste by means of combustion of such waste in industrial furnaces, particularly of the rotary type, that has an external calciner, feeding such waste into the tertiary air duct of the calciner and burning the waste inside the duct itself, to efficiently make use of the energy produced by such combustion, as a contribution of the total cost of fuel necessary to operate the industrial furnace. The method and apparatus permit the elimination of hazardous wastes that are efficiently disassociated when burned sufficiently to produce effluents that are typically non-toxic, producing greatly reduced or even no atmospheric pollution nor environmental damage.

Owner:CEMEX DE C V

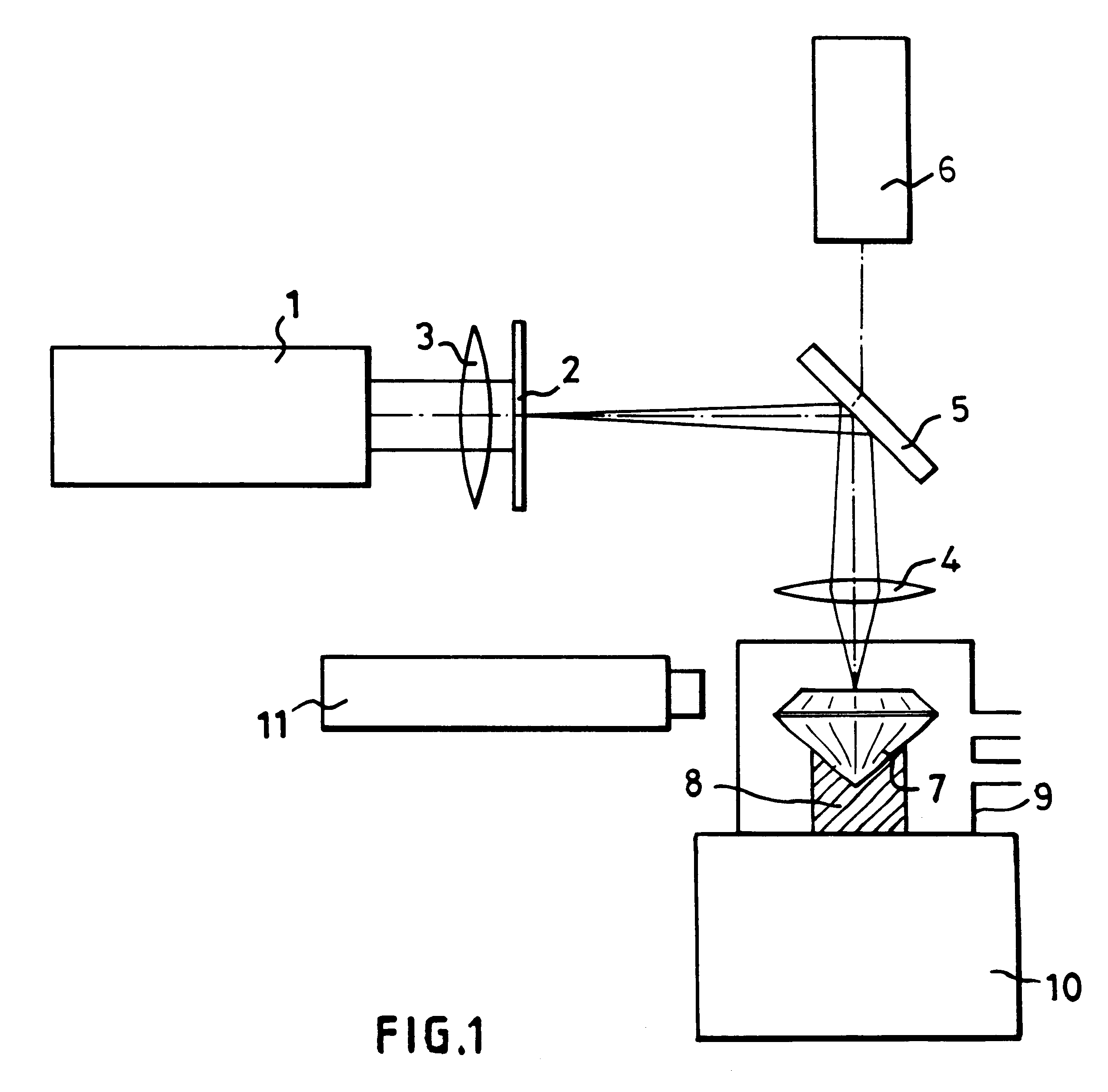

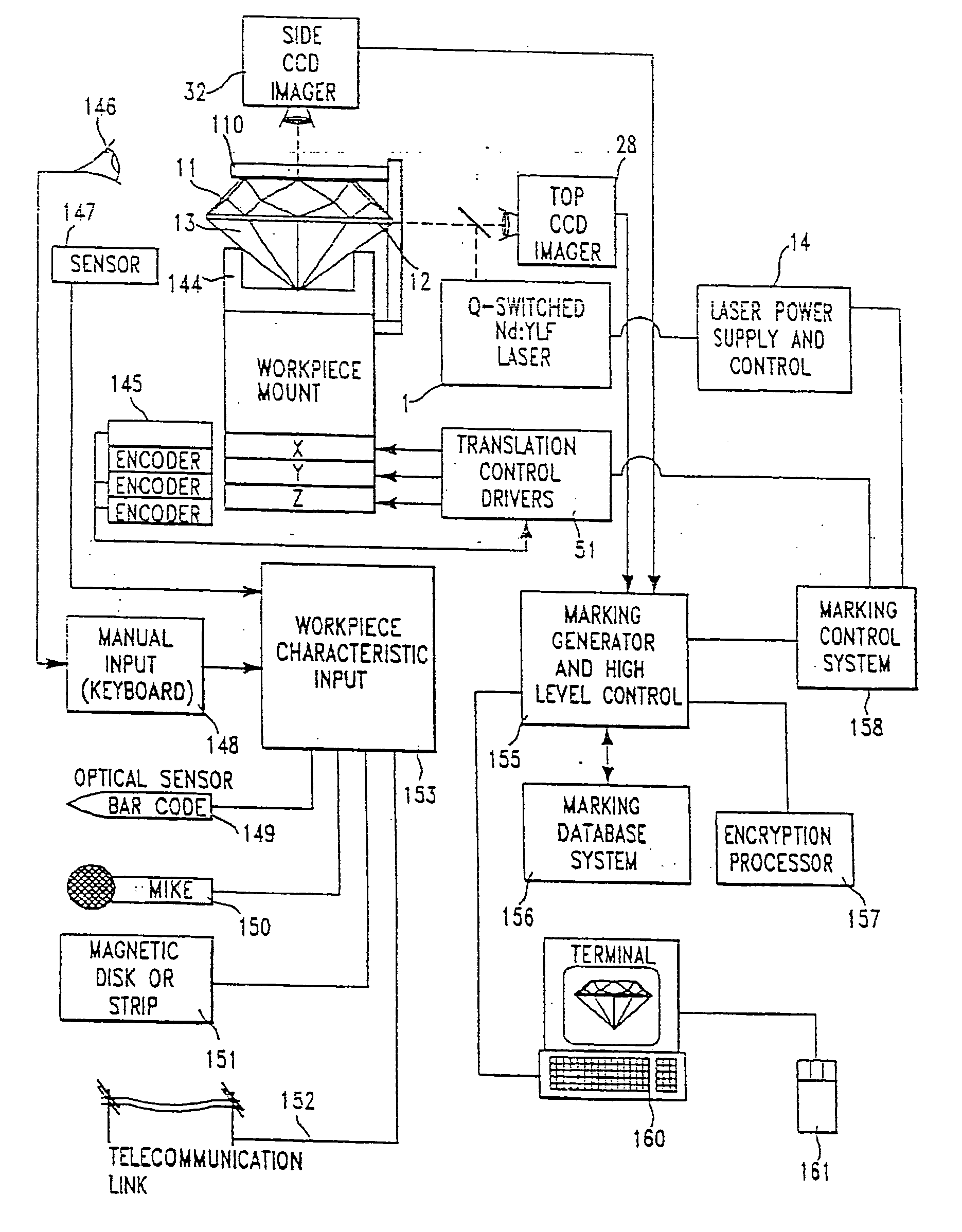

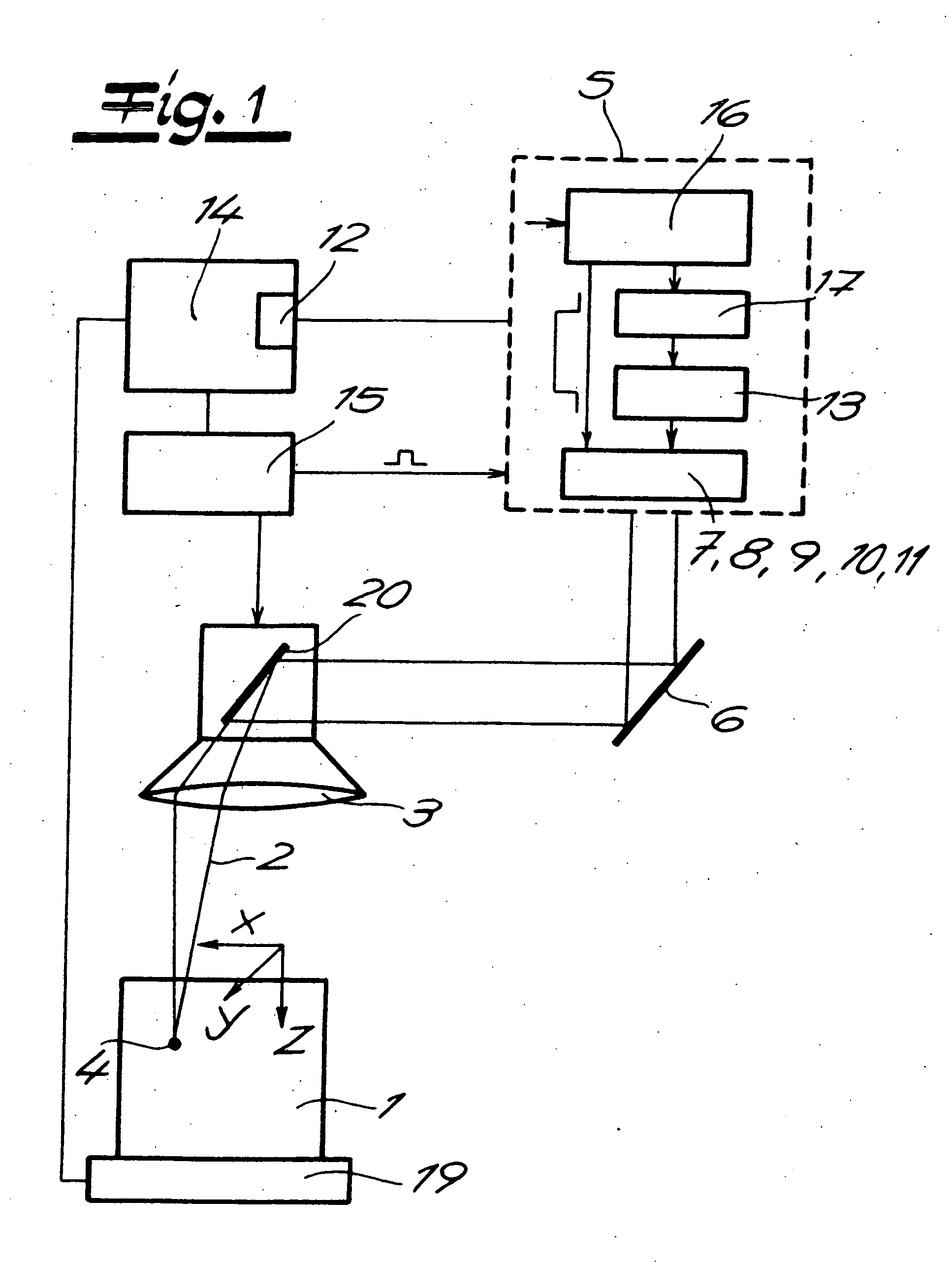

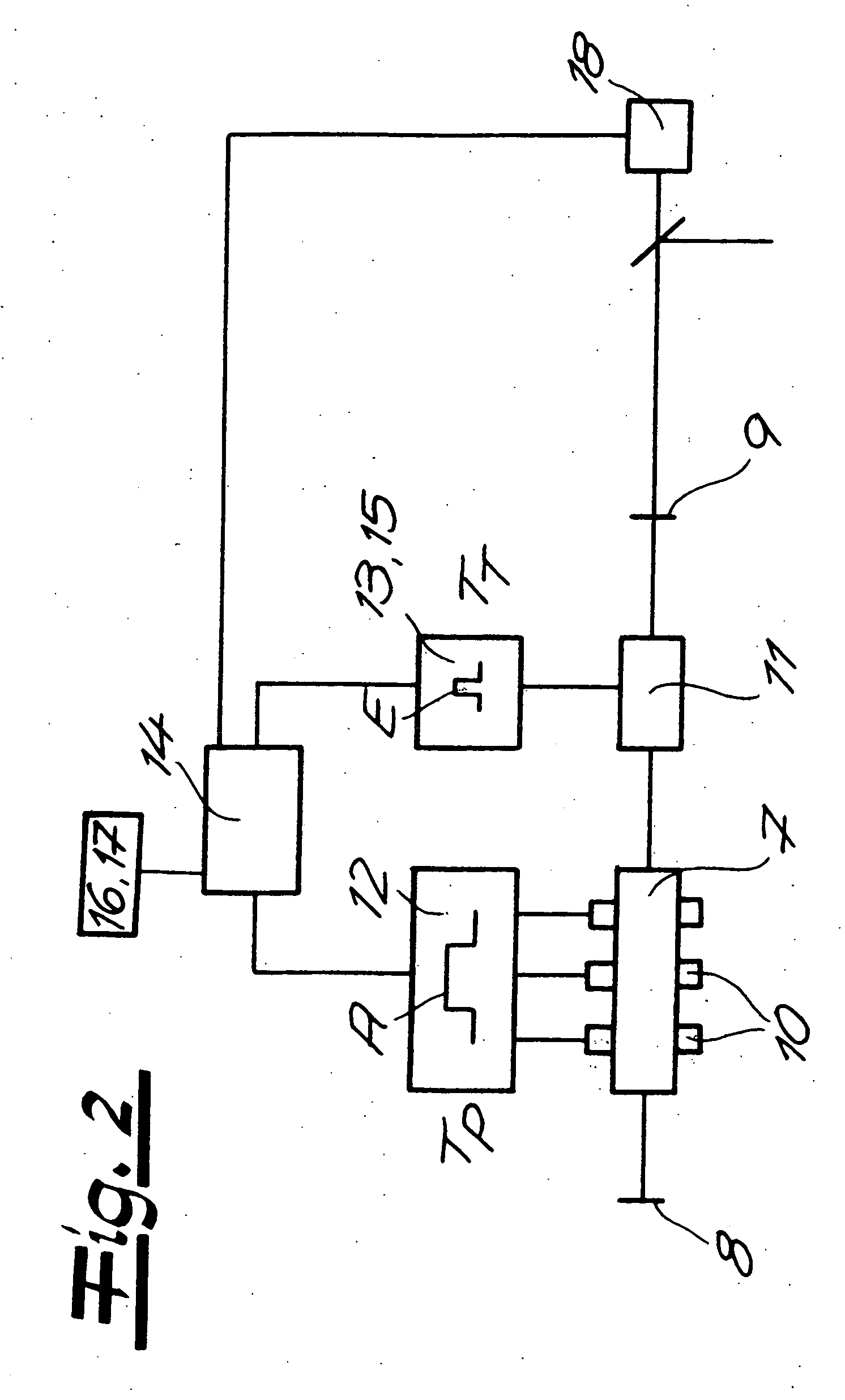

Laser marking system

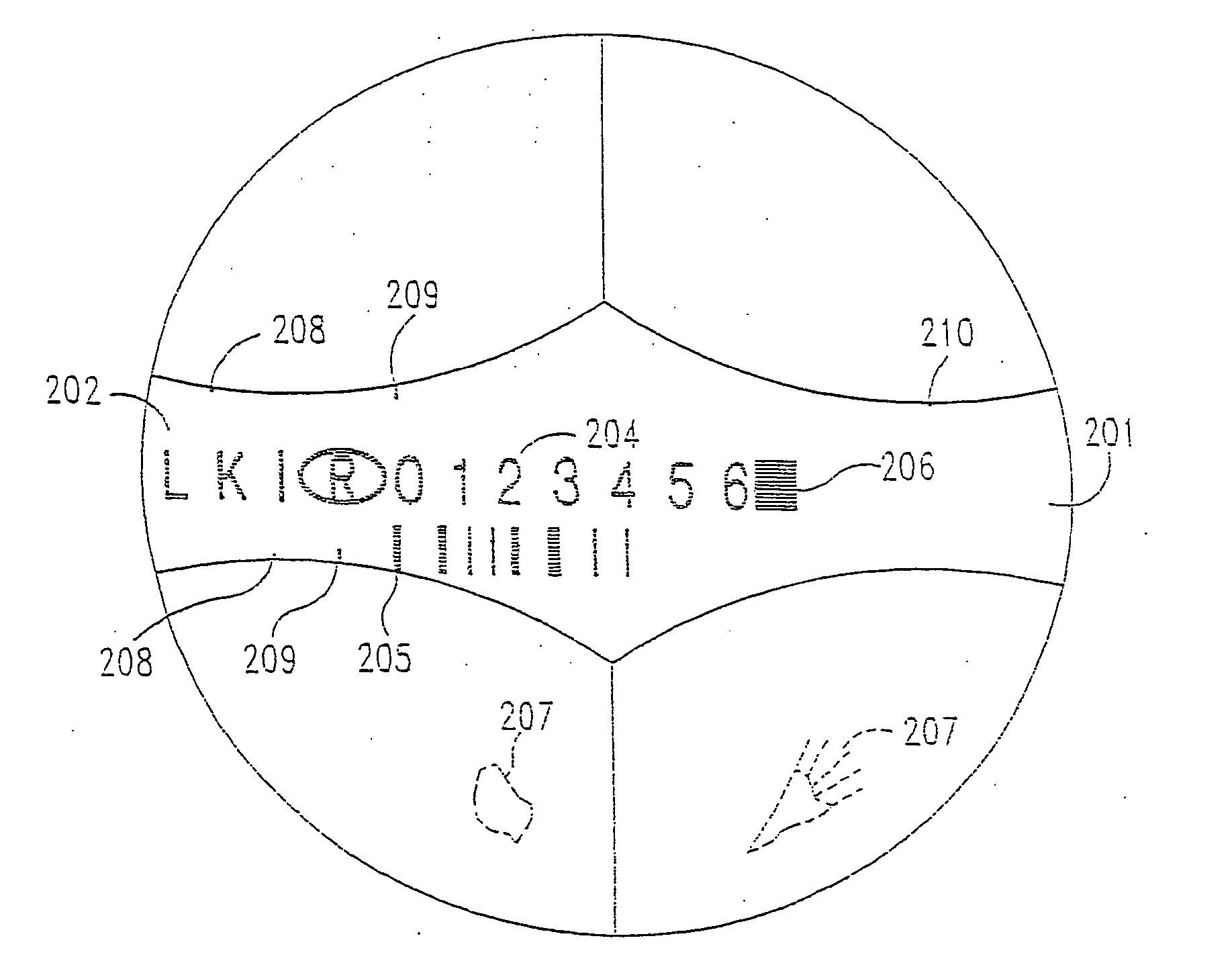

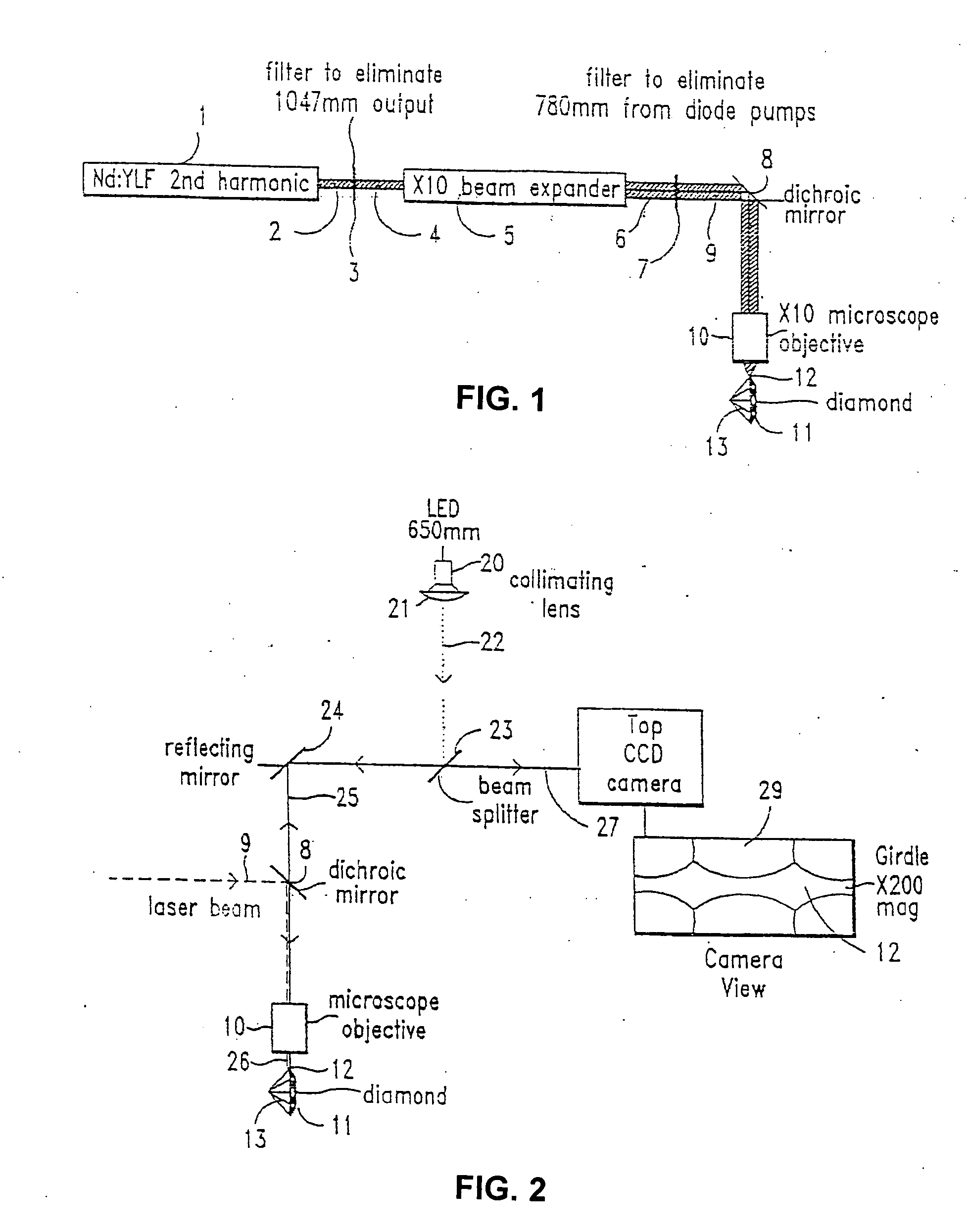

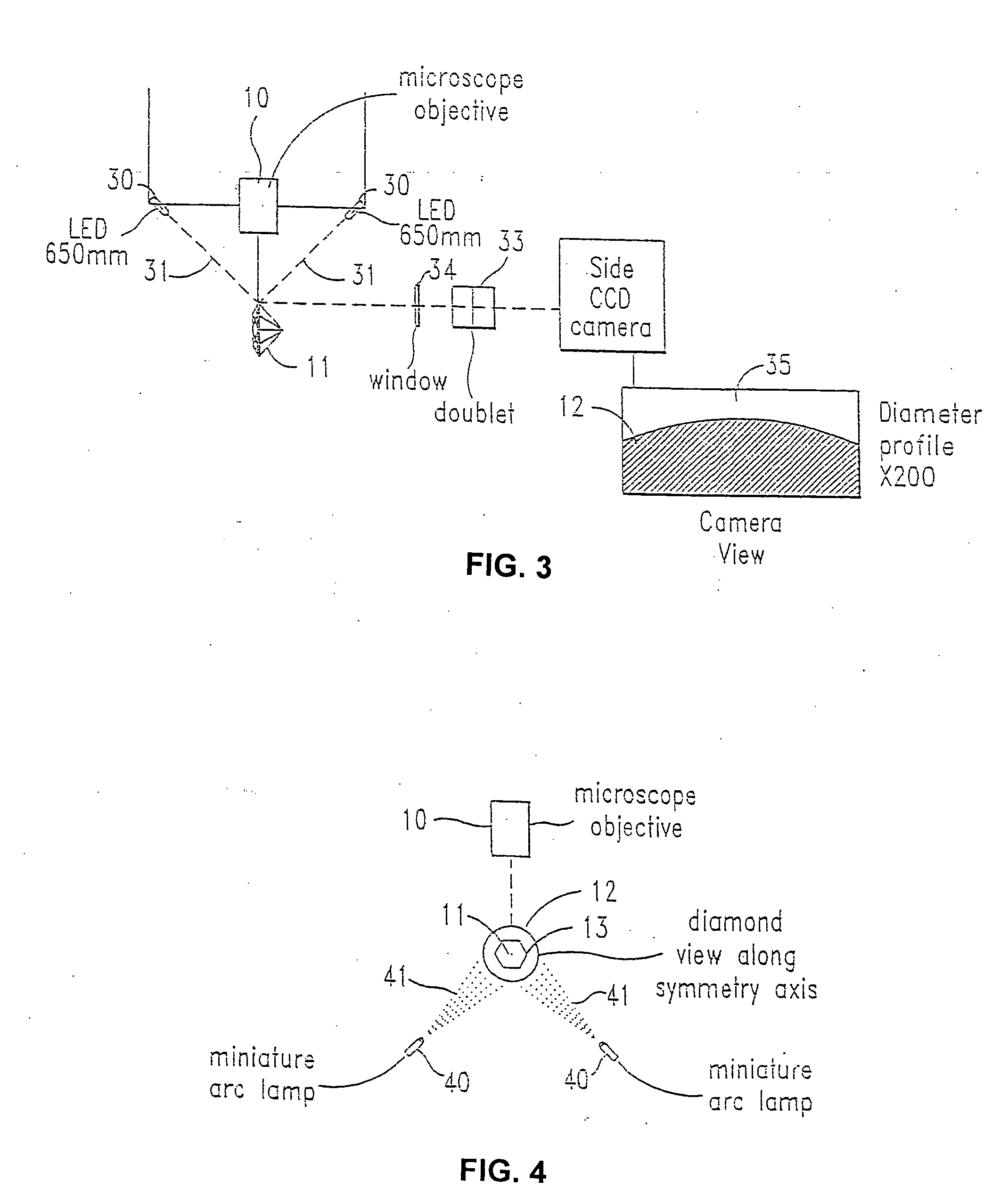

InactiveUS20050103760A1Improve immunityBranding equipmentDecorative surface effectsGemstoneElectron storage

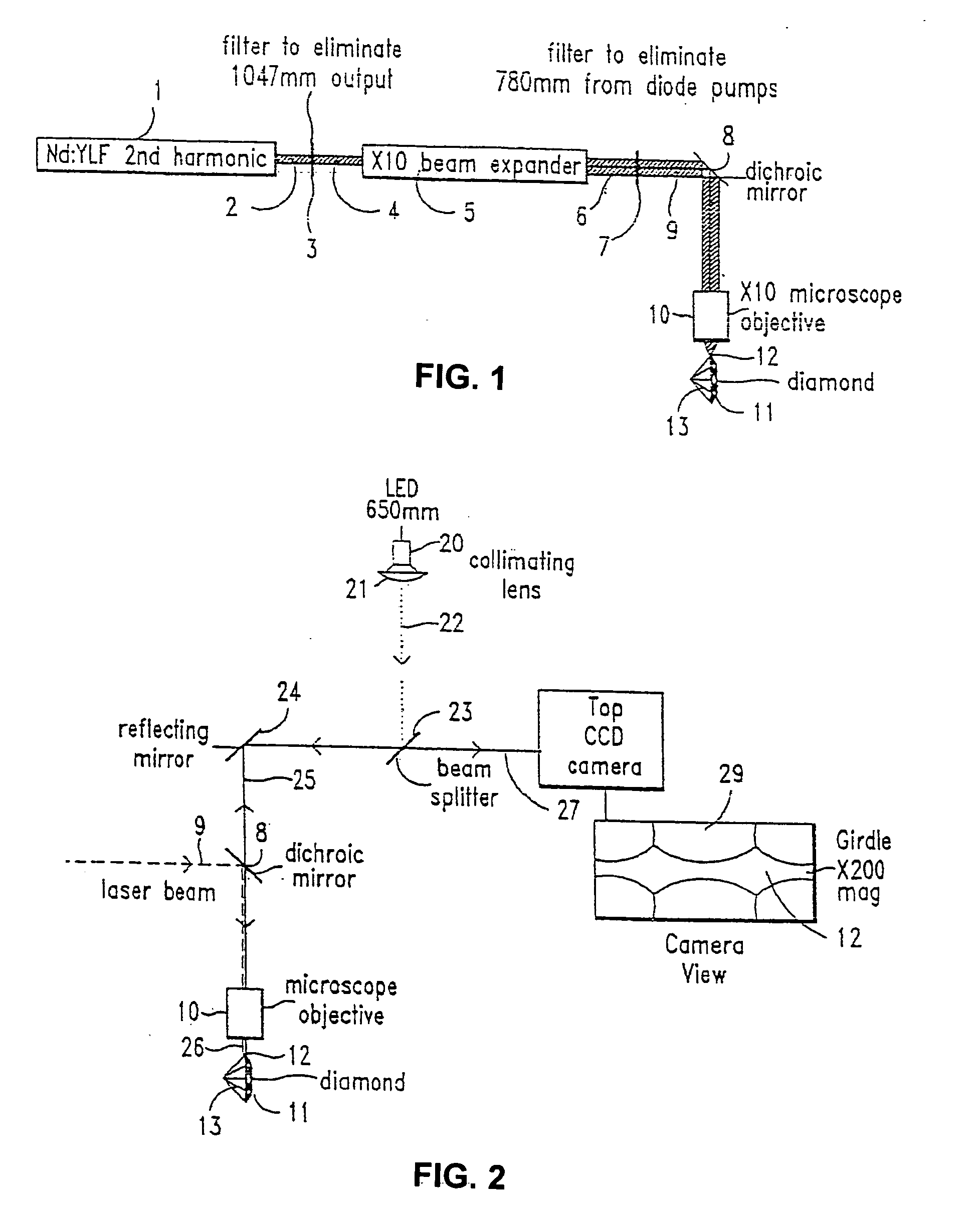

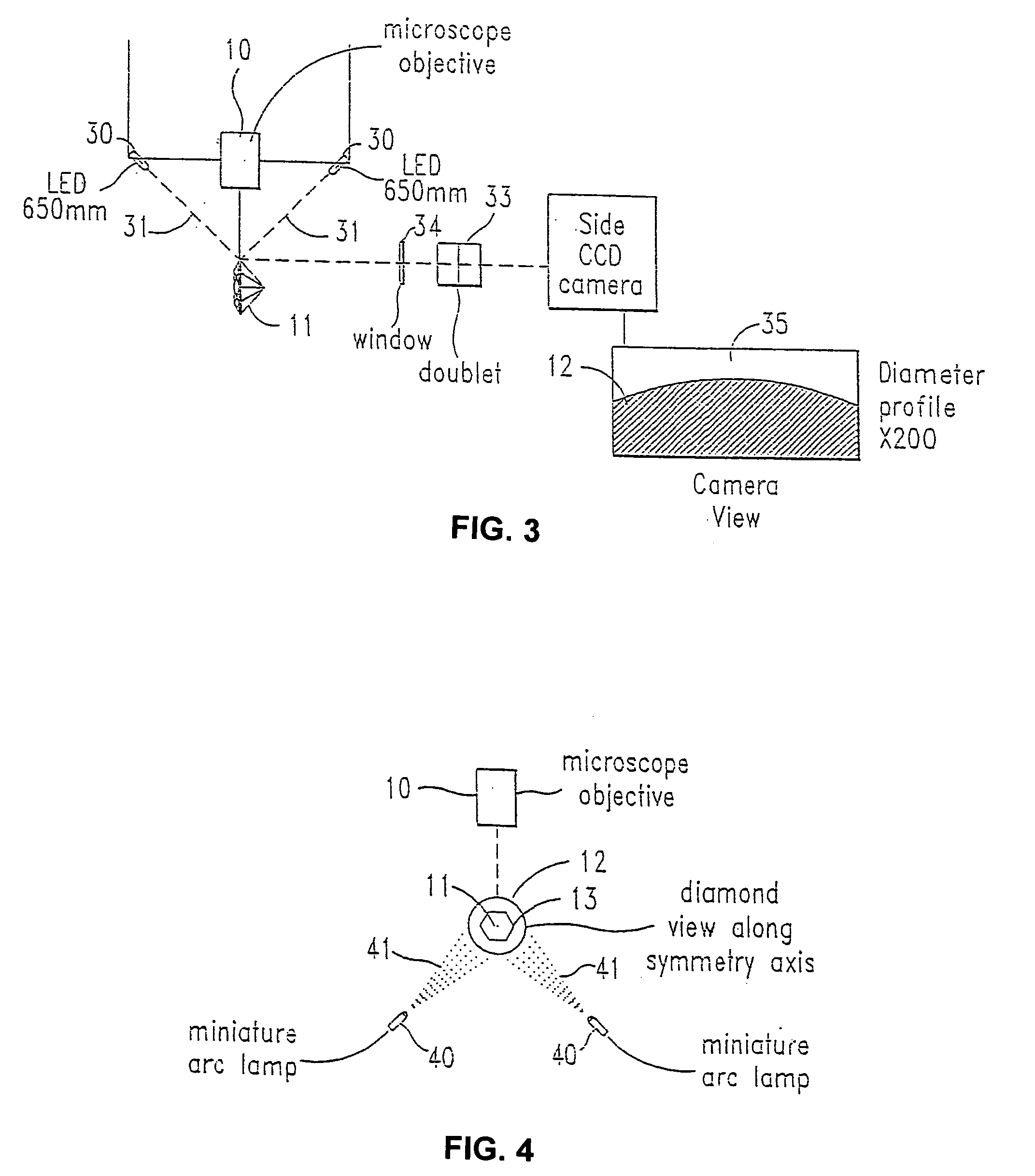

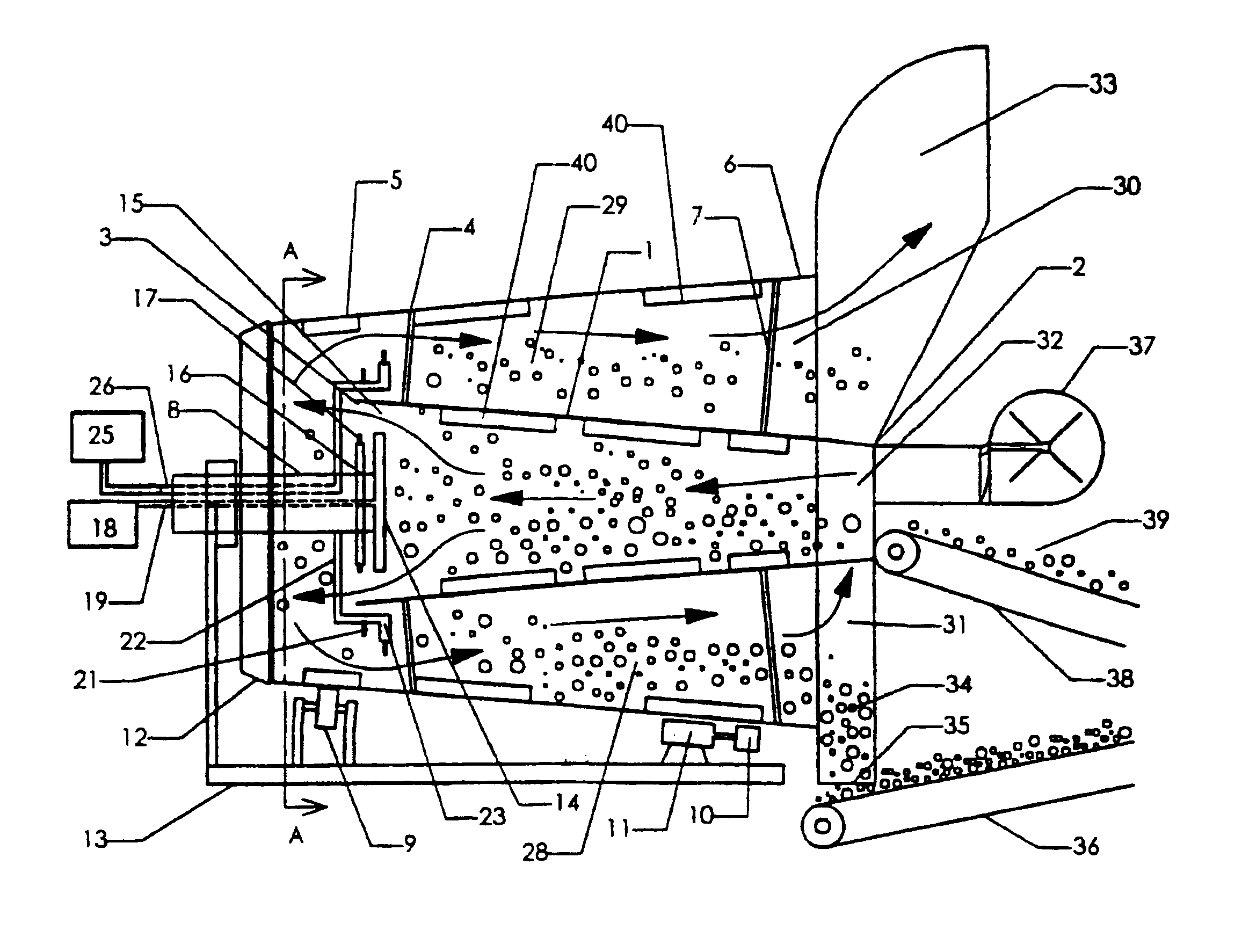

A laser energy microinscribing system, comprising a semiconductor excited Q-switched solid state laser energy source; a cut gemstone mounting system, allowing optical access to a mounted workpiece; an optical system for focusing laser energy from the laser energy source onto a cut gemstone; a displaceable stage for moving said gemstone mounting system with respect to said optical system so that said focused laser energy is presented to desired positions on said gemstone, having a control input; an imaging system for viewing the gemstone from a plurality of vantage points; and a rigid frame supporting said laser, said optical system and said stage in fixed relation, to resist differential movements of said laser, said optical system and said stage and increase immunity to vibrational misalignments. The laser energy source is preferably a semiconductor diode excited Q-switched Nd:YLF laser with a harmonic converter having an output of about 530 nm. The system may further comprise an input for receiving marking instructions; a processor for controlling said displaceable stage based on said marking instructions and said imaging system, to selectively generate a marking based on said instructions and a predetermined program; and a storage system for electronically storing information relating to images of a plurality of workpieces. A secure certificate of authenticity of a marked workpiece is also provided.

Owner:KAPLAN GEORGE R +3

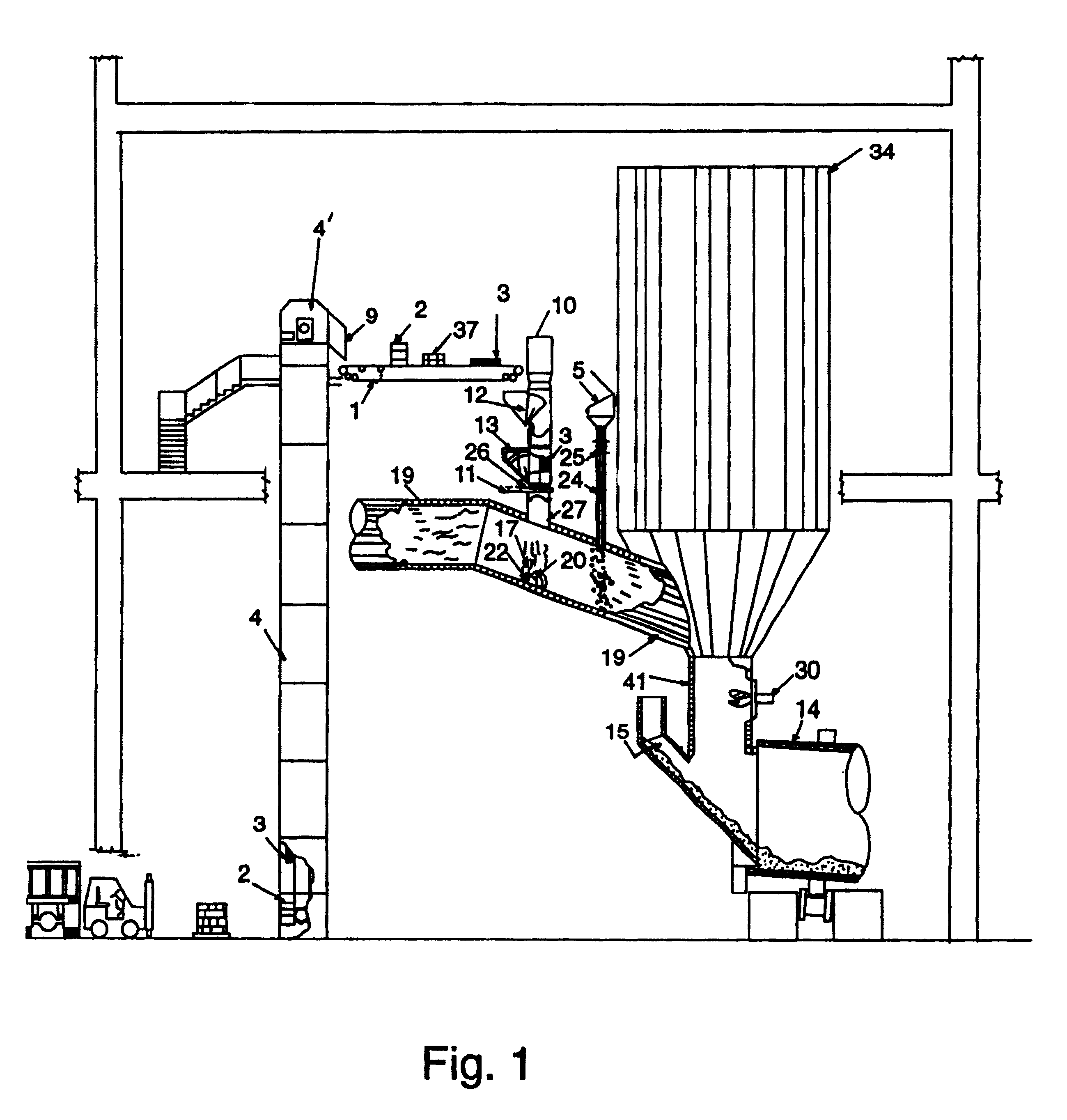

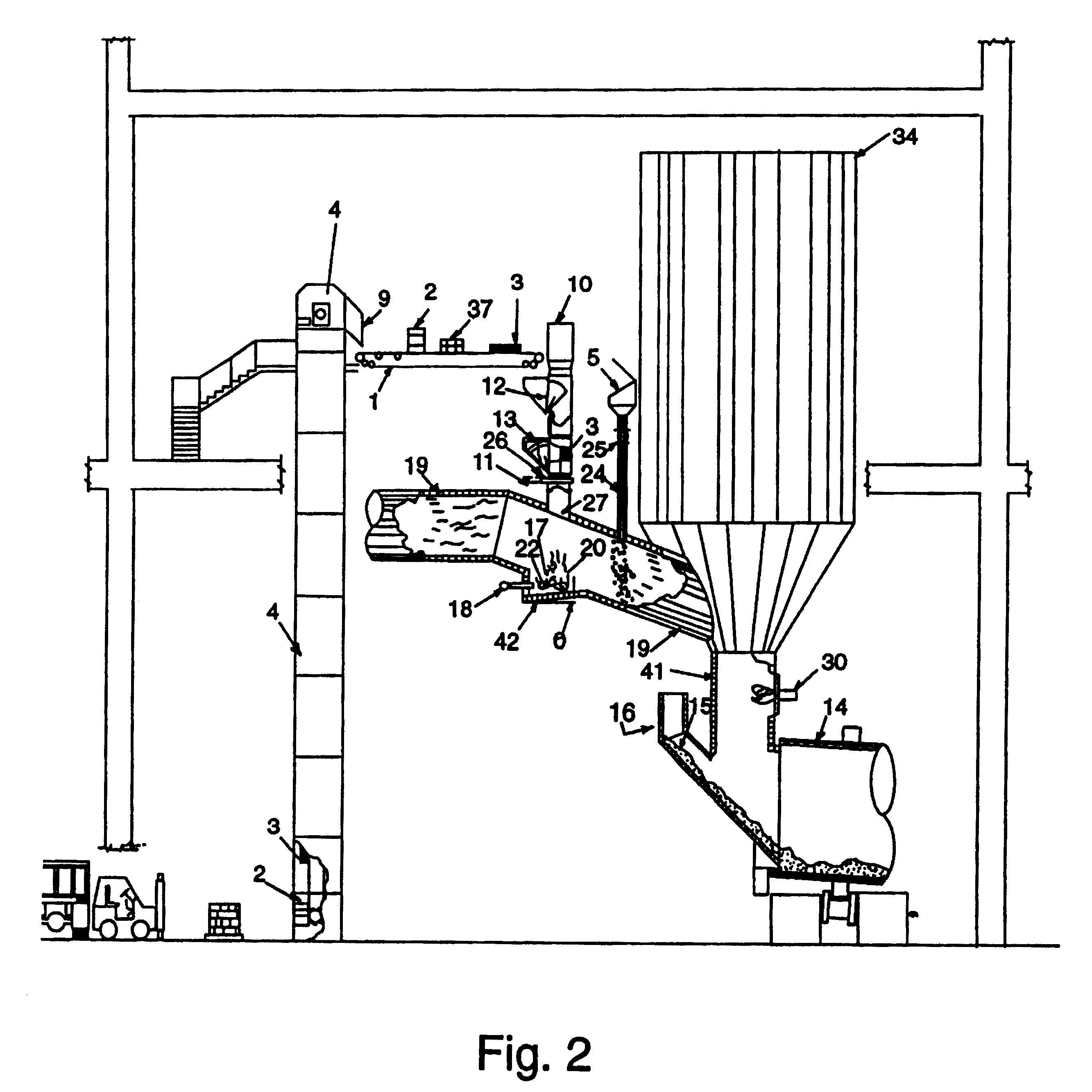

Multiple drum mixing system

InactiveUS6363625B1Reduce burnWell mixedBranding equipmentRotary drum furnacesImpellerInvestment material

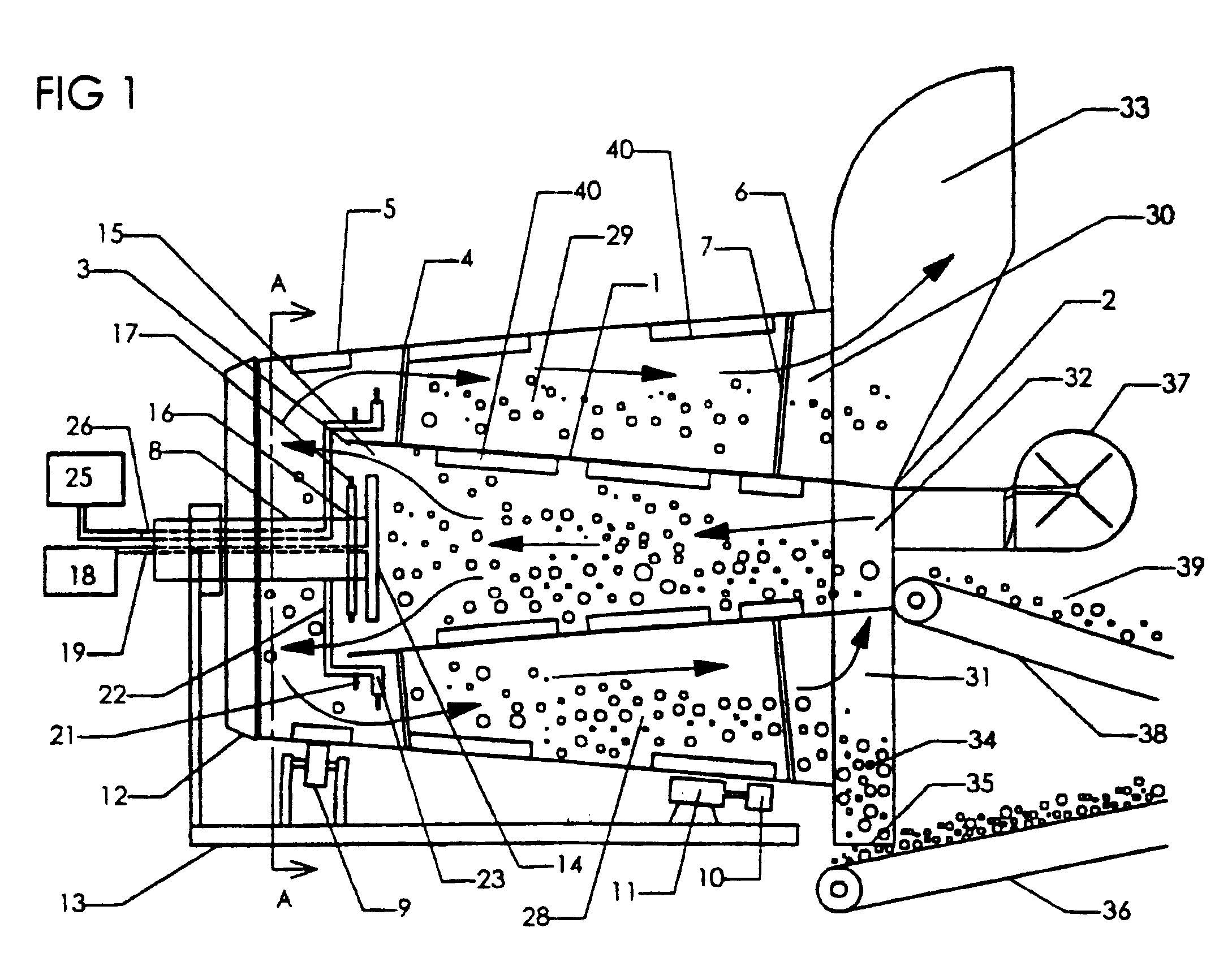

A drying and mixing plant is provided comprising a tapered inner drum (1) and an oppositely tapered outer drum (4) attached together concentrically and rotated as a unit. A burner (37) directs a hot air stream into the small end (2) of the inner drum (1). Material is fed into the small end of the inner drum, where impellers (40) lift it and drop it into the hot air stream and move the material through the inner drum (1) aided by the downward taper of the inner drum. The material exits the inner drum and enters the outer drum (4) where an additive material is introduced and mixed with the material (42) as both move through the chamber (28) between the inner and outer drums to a material outlet. The receiving end (5) of the outer drum (4) is enclosed in a shroud (12), therefore the air stream is directed through the chamber (28) between the drums, the chamber having an expanding cross section which slows the air down allowing fines to precipitate out. The device may include nozzles (17) for spraying water across the path of the air stream and material flow, and further may include, for fluid additive materials, additive nozzles (21, 23) spraying the additive material across the path of the air and material. A third drum (43) may be provided inside the inner drum (1), allowing separate addition of a third material (47), and further reducing fines in the air. The device is particularly suitable for mixing asphalt paving mix.

Owner:NIEW INDS

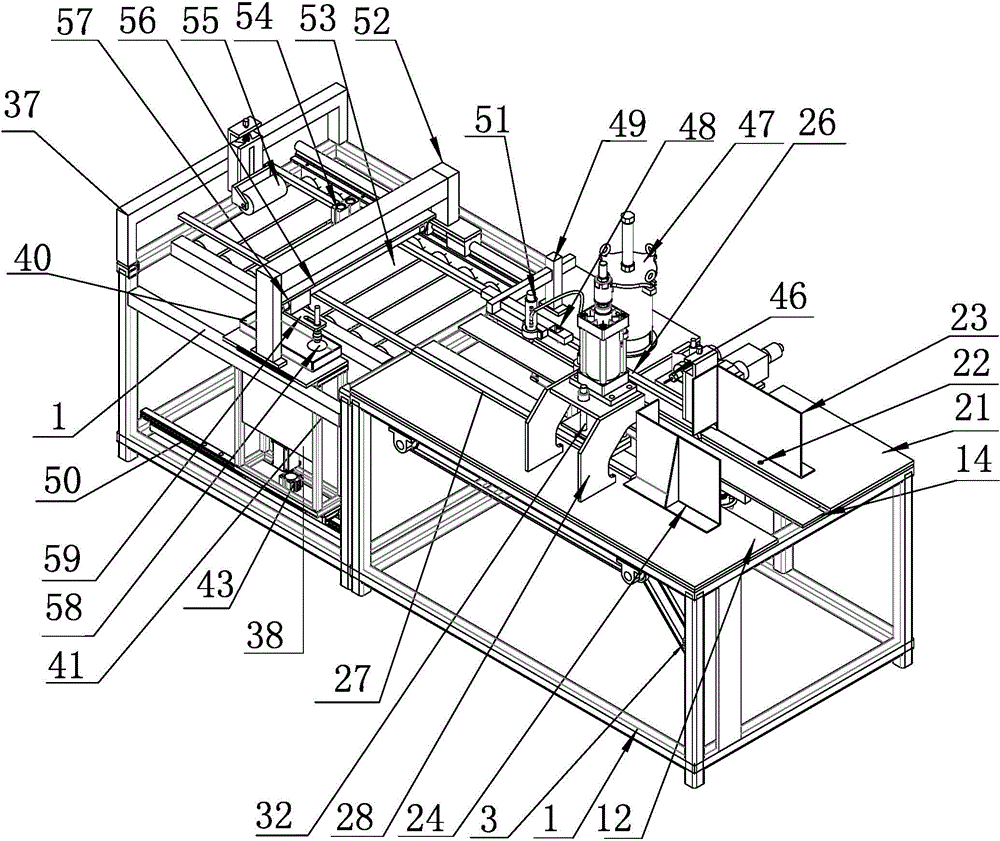

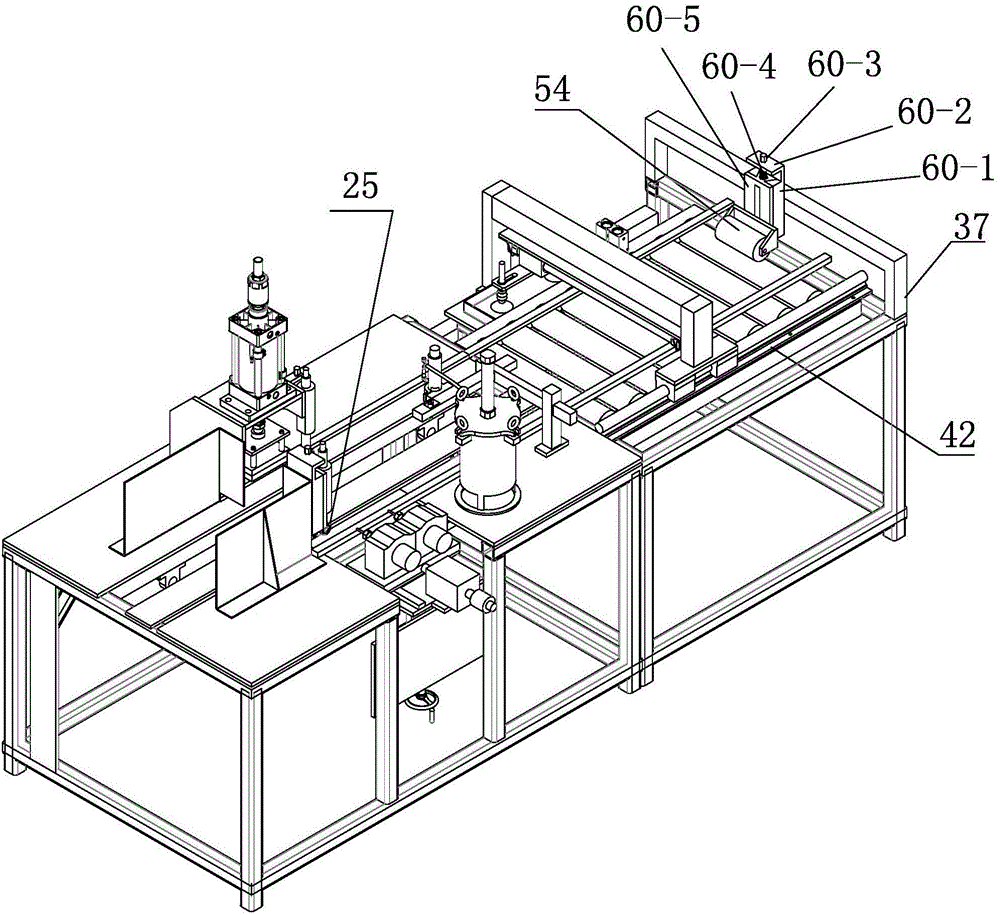

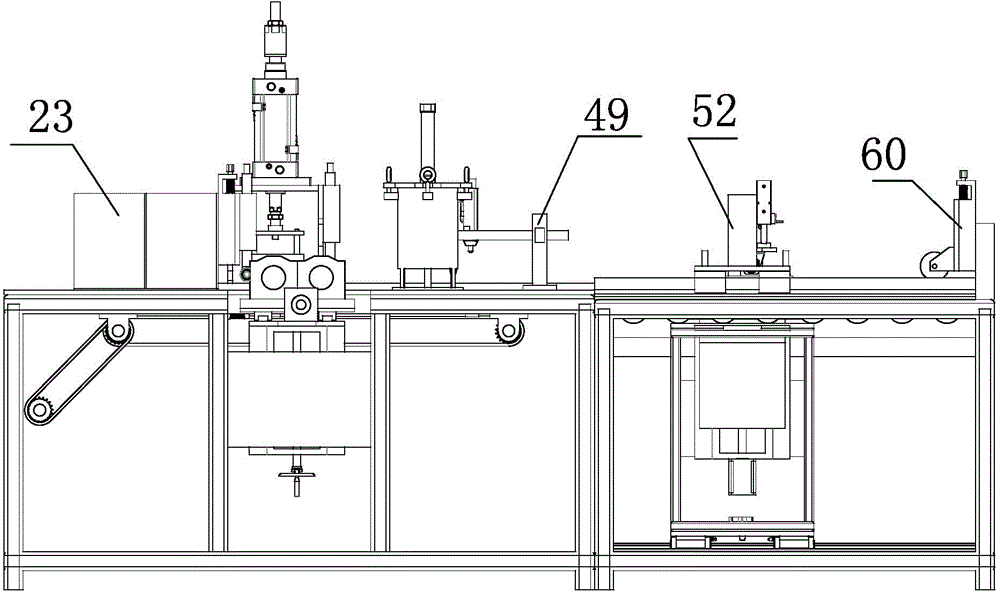

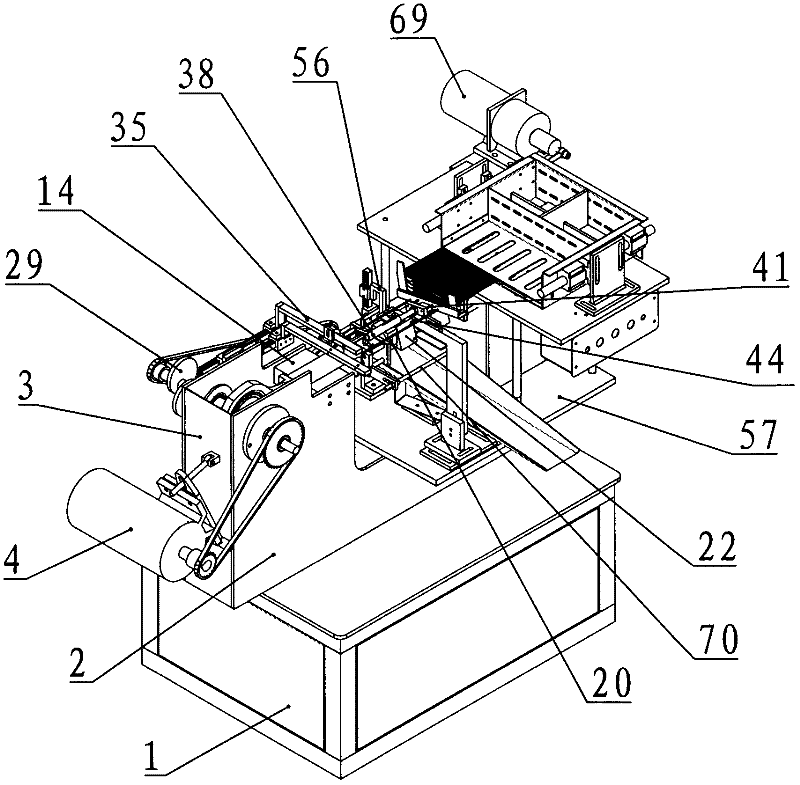

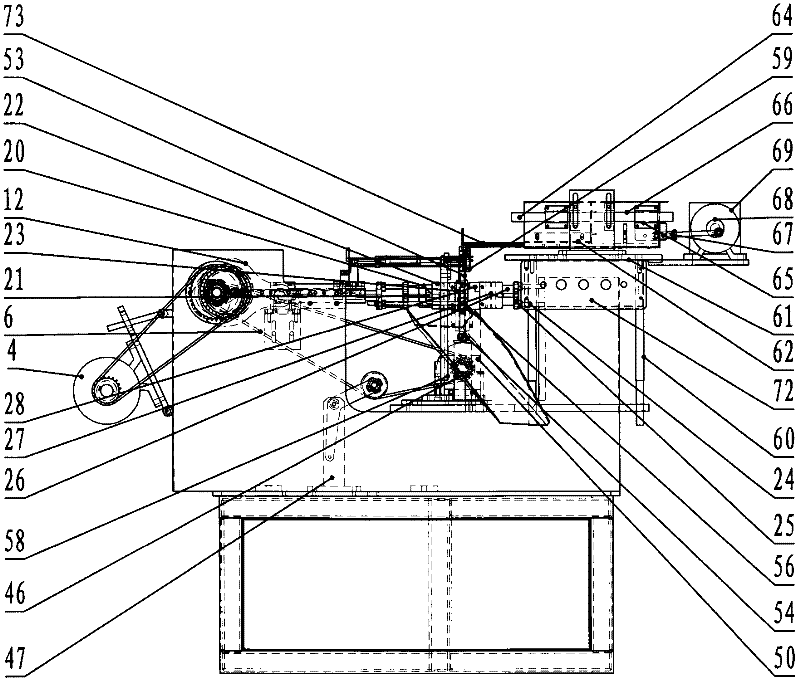

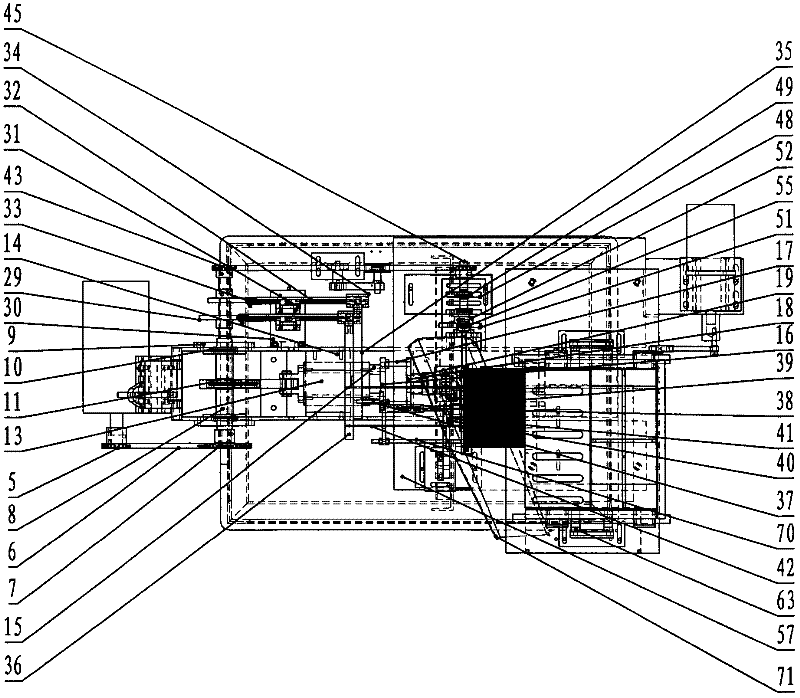

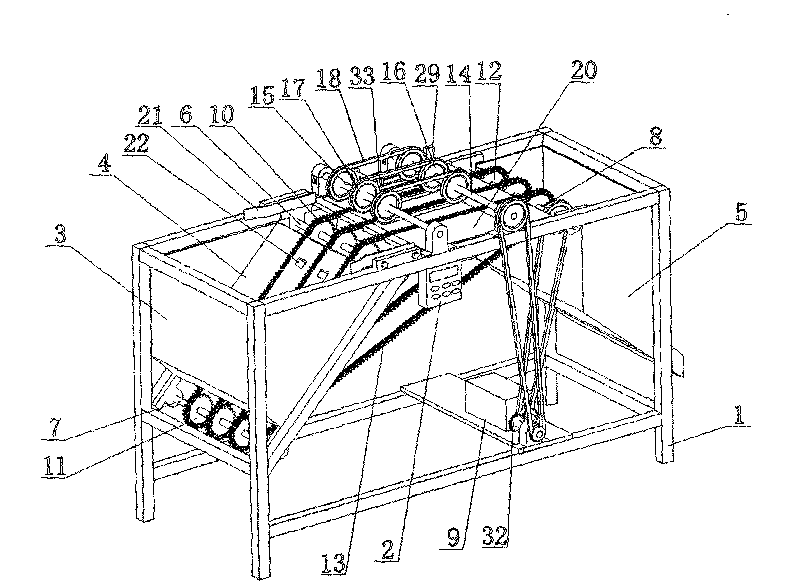

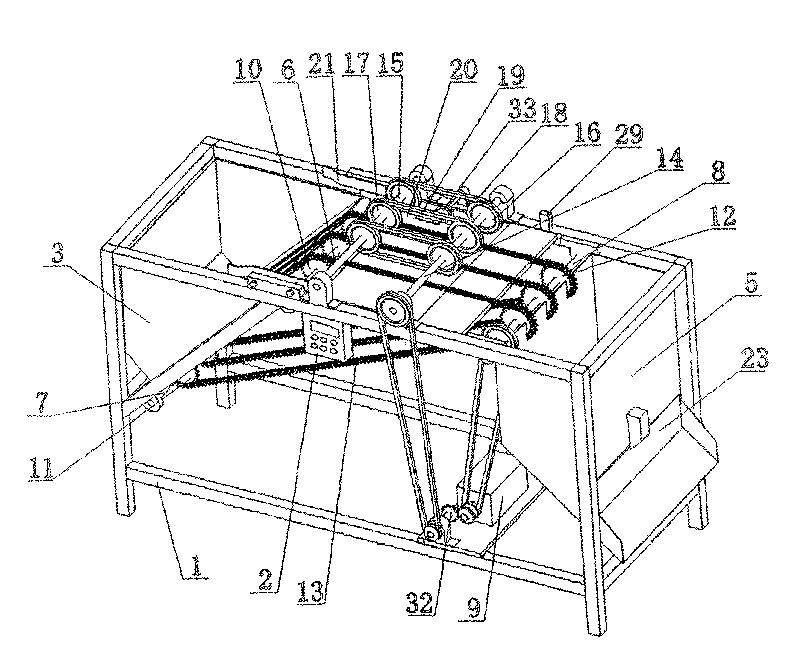

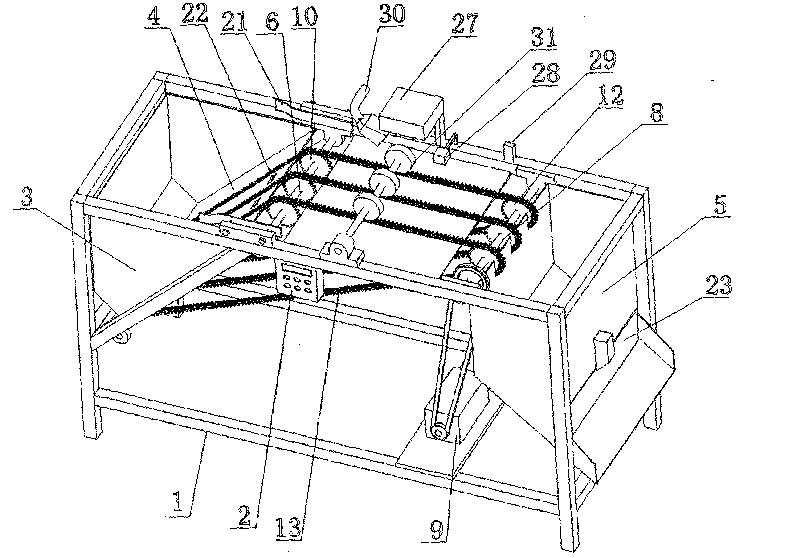

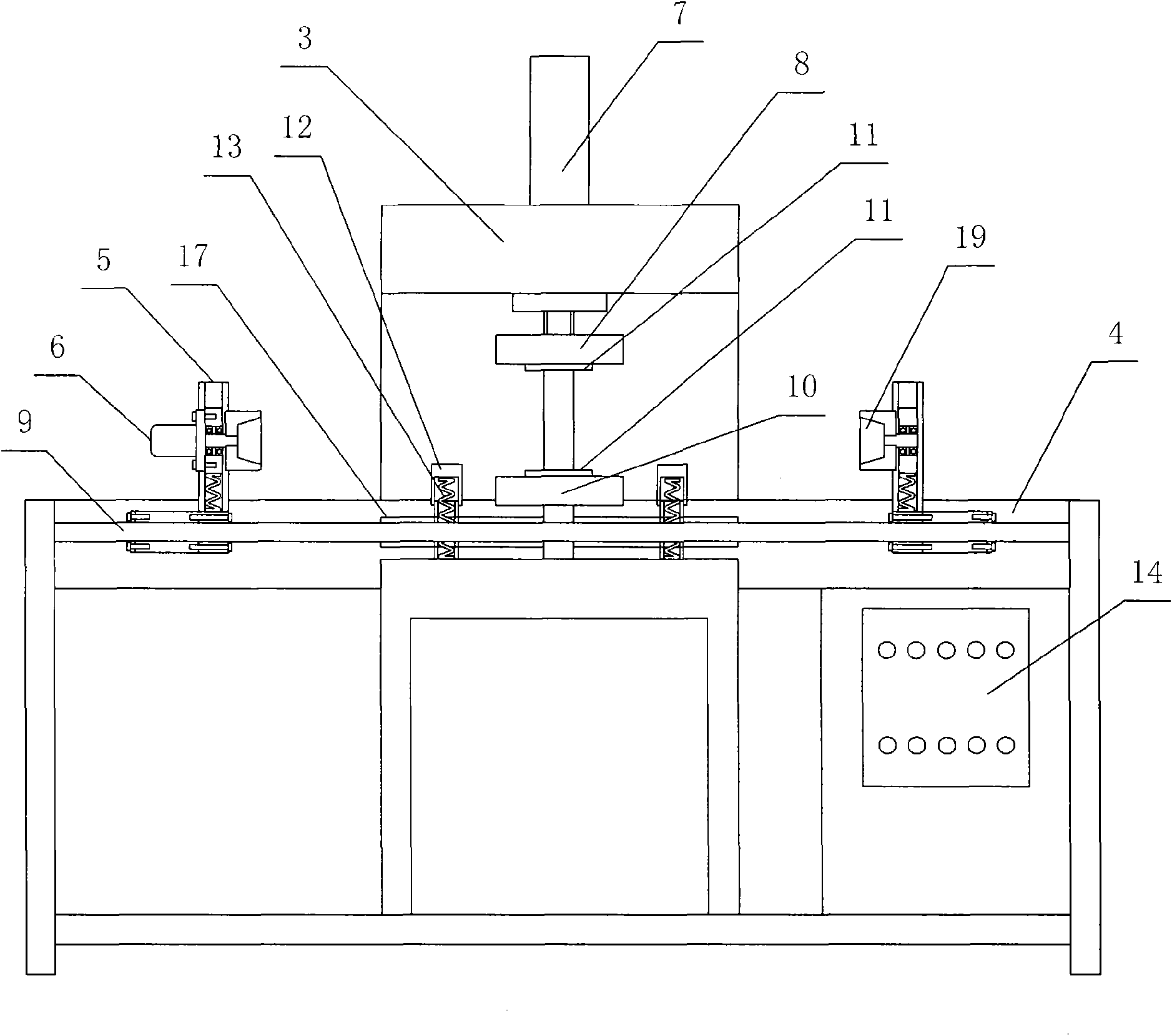

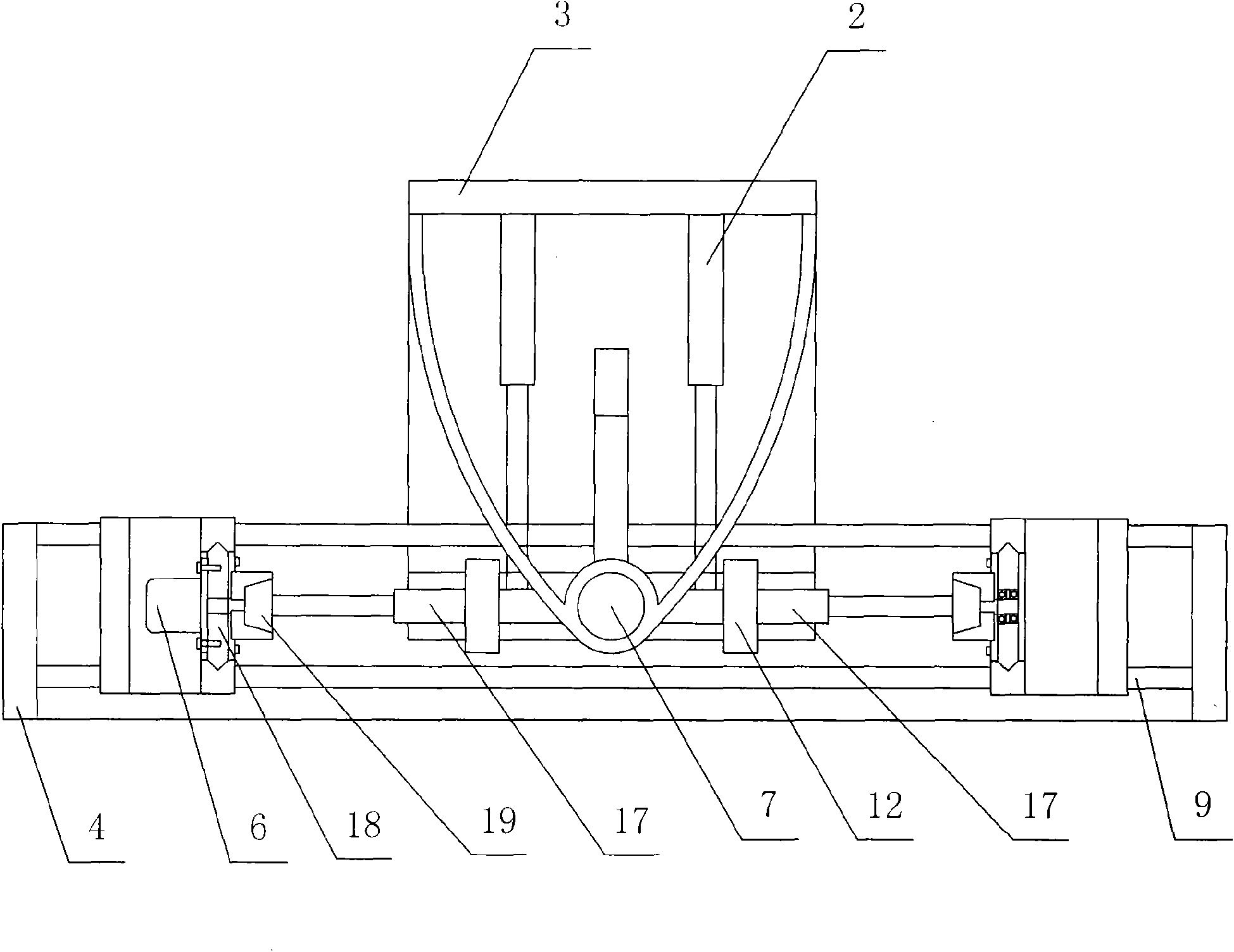

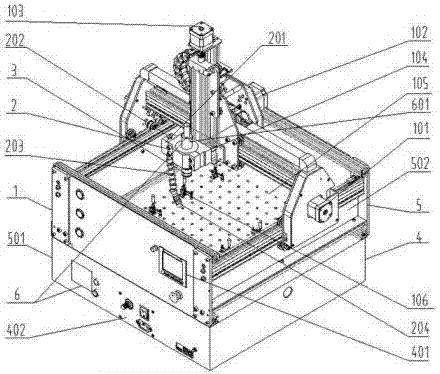

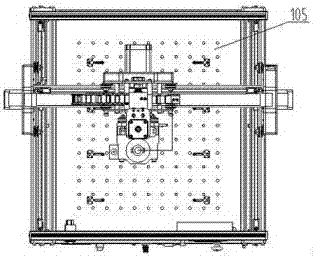

Automatic branding, drilling and labelling machine

InactiveCN104385420AContinuous brandingContinuous drillingBranding equipmentStationary drilling machinesButt jointWorkbench

The invention relates to an automatic branding, drilling and labelling machine, which can be used for sequentially finishing the procedures of conveying, branding, drilling, glue dripping, labelling and the like, can be used for machining products of various specifications and has the characteristics of high working efficiency, convenience in adjustment, and the like. According to the technical scheme, the automatic branding, drilling and labelling machine comprises a front half part and a back half part, wherein the front half part comprises a feeding mechanism arranged on the front segment of a frame, a fixed workbench arranged on the left side of the feeding mechanism, and a movable workbench arranged on the right side of the feeding mechanism; a hand drill hole lifting mechanism and a glue dripping mechanism are arranged on the fixed workbench; a branding mechanism is arranged on the movable workbench; the back half part comprises a drum group arranged on the back segment of the frame, a labelling device arranged above the drum group, a label lifting mechanism arranged on the right side of the drum group, and a label pressing mechanism arranged at the back end of the drum group; the front end of the drum group is in butt joint with the back end of the feeding mechanism.

Owner:ZHEJIANG TIANZHU IND & TRADE

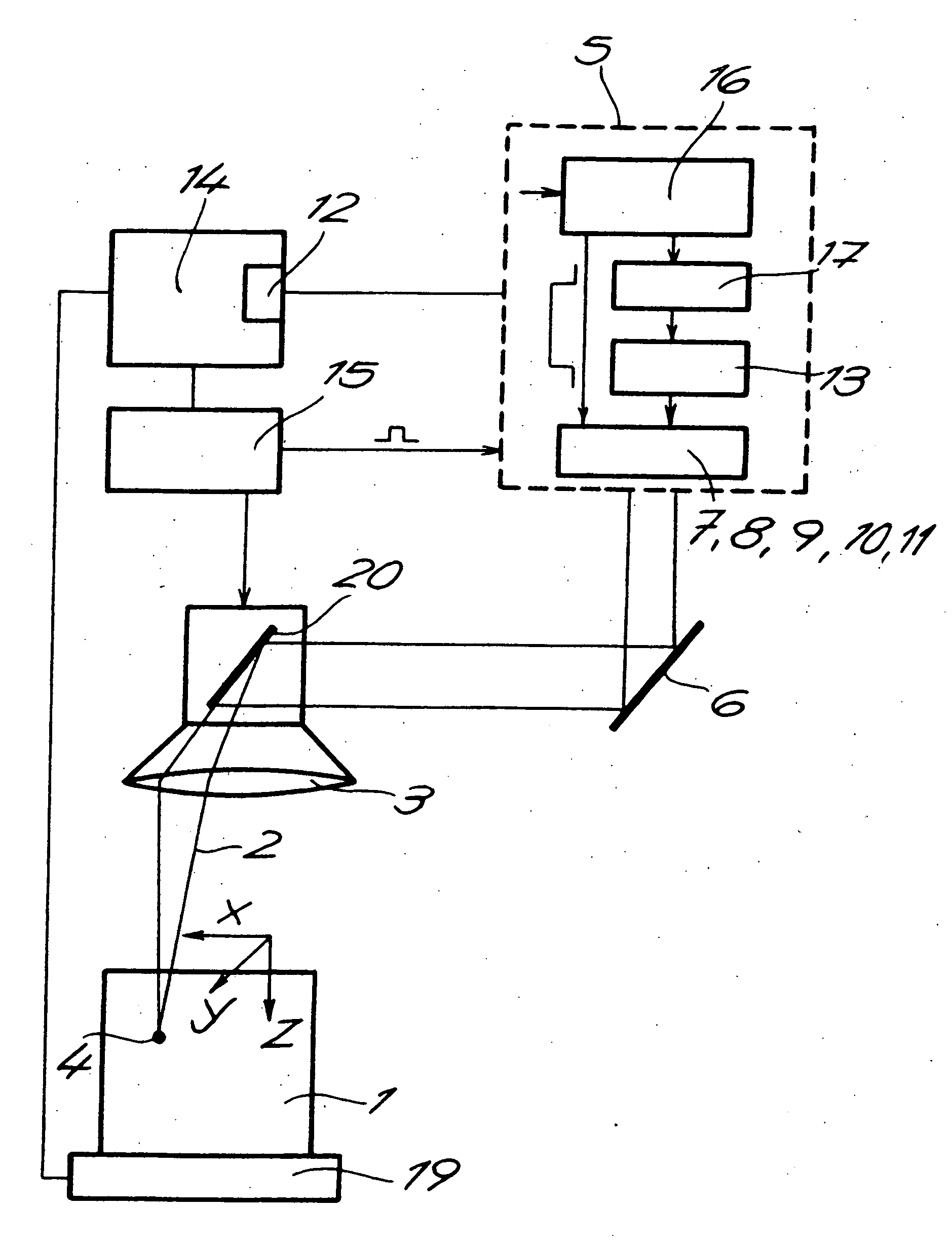

Laser marking system

InactiveUS20050005642A1Improve immunityLarge isolationBranding equipmentDecorative surface effectsGemstoneElectron storage

A laser energy microinscribing system, comprising a semiconductor excited Q-switched solid state laser energy source; a cut gemstone mounting system, allowing optical access to a mounted workpiece; an optical system for focusing laser energy from the laser energy source onto a cut gemstone; a displaceable stage for moving said gemstone mounting system with respect to said optical system so that said focused laser energy is presented to desired positions on said gemstone, having a control input; an imaging system for viewing the gemstone from a plurality of vantage points; and a rigid frame supporting said laser, said optical system and said stage in fixed relation, to resist differential movements of said laser, said optical system and said stage and increase immunity to vibrational misalignments. The laser energy source is preferably a semiconductor diode excited Q-switched Nd:YLF laser with a harmonic converter having an output of about 530 nm. The system may further comprise an input for receiving marking instructions; a processor for controlling said displaceable stage based on said marking instructions and said imaging system, to selectively generate a marking based on said instructions and a predetermined program; and a storage system for electronically storing information relating to images of a plurality of workpieces. A secure certificate of authenticity of a marked workpiece is also provided.

Combustion heated hair dryer

A portable hair dryer that utilizes portable stove and portable grill sized propane tanks to supply fuel to a heat exchanger including a gas burner. The discharge vent of the heat exchanger includes a flame arrester screen at least three inches form the outer edge thereof.

Owner:PORTER KATHERINE

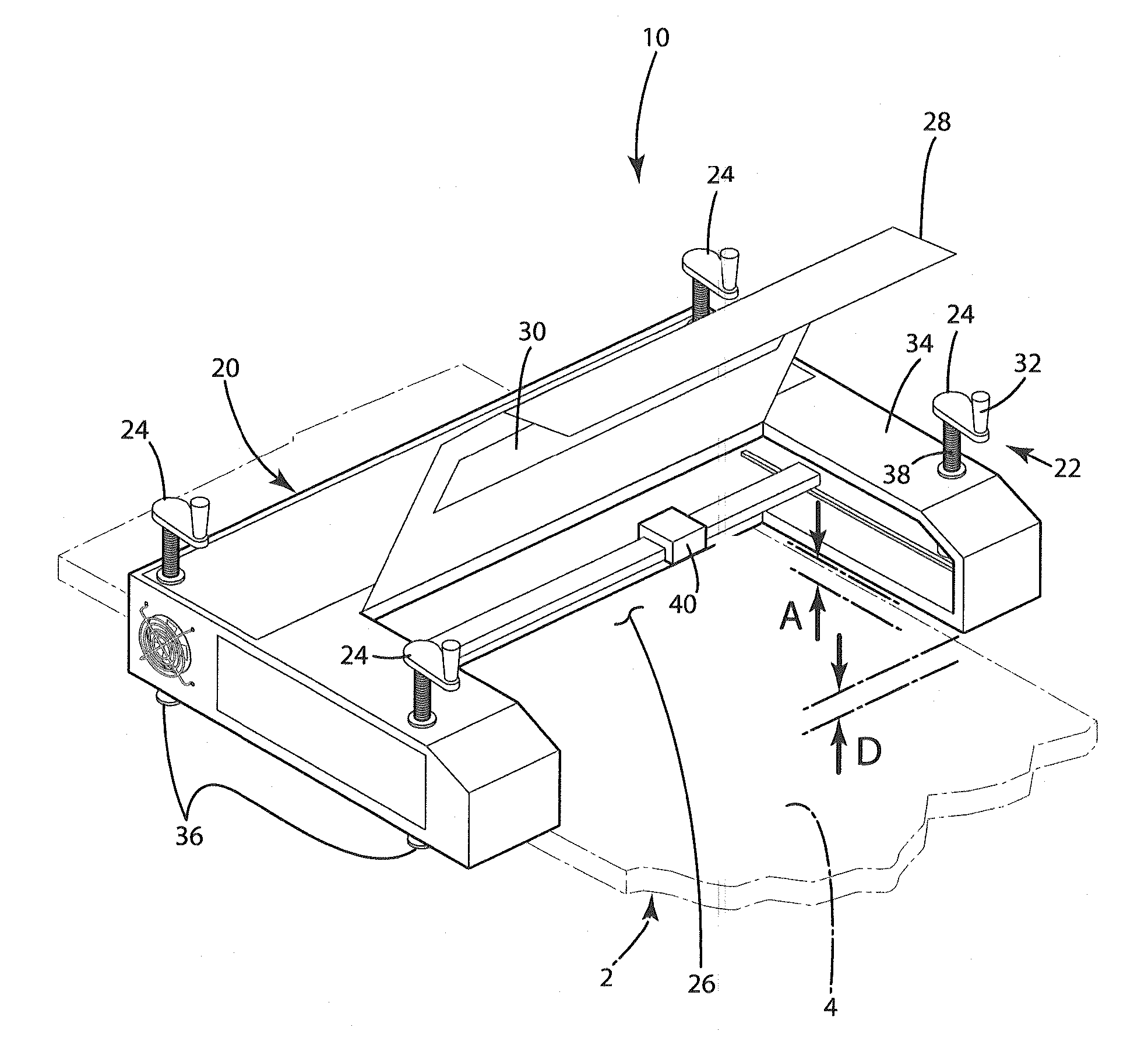

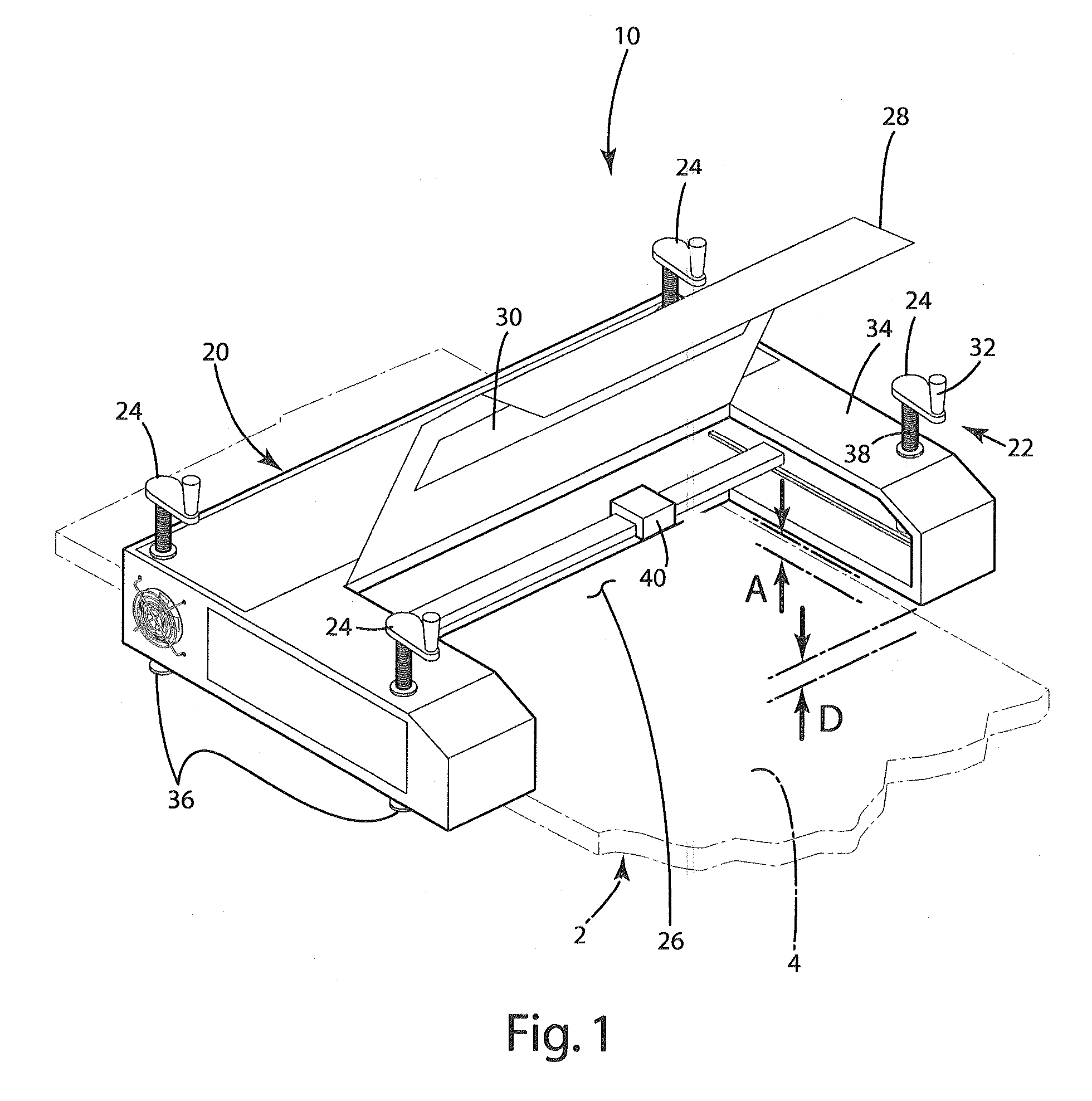

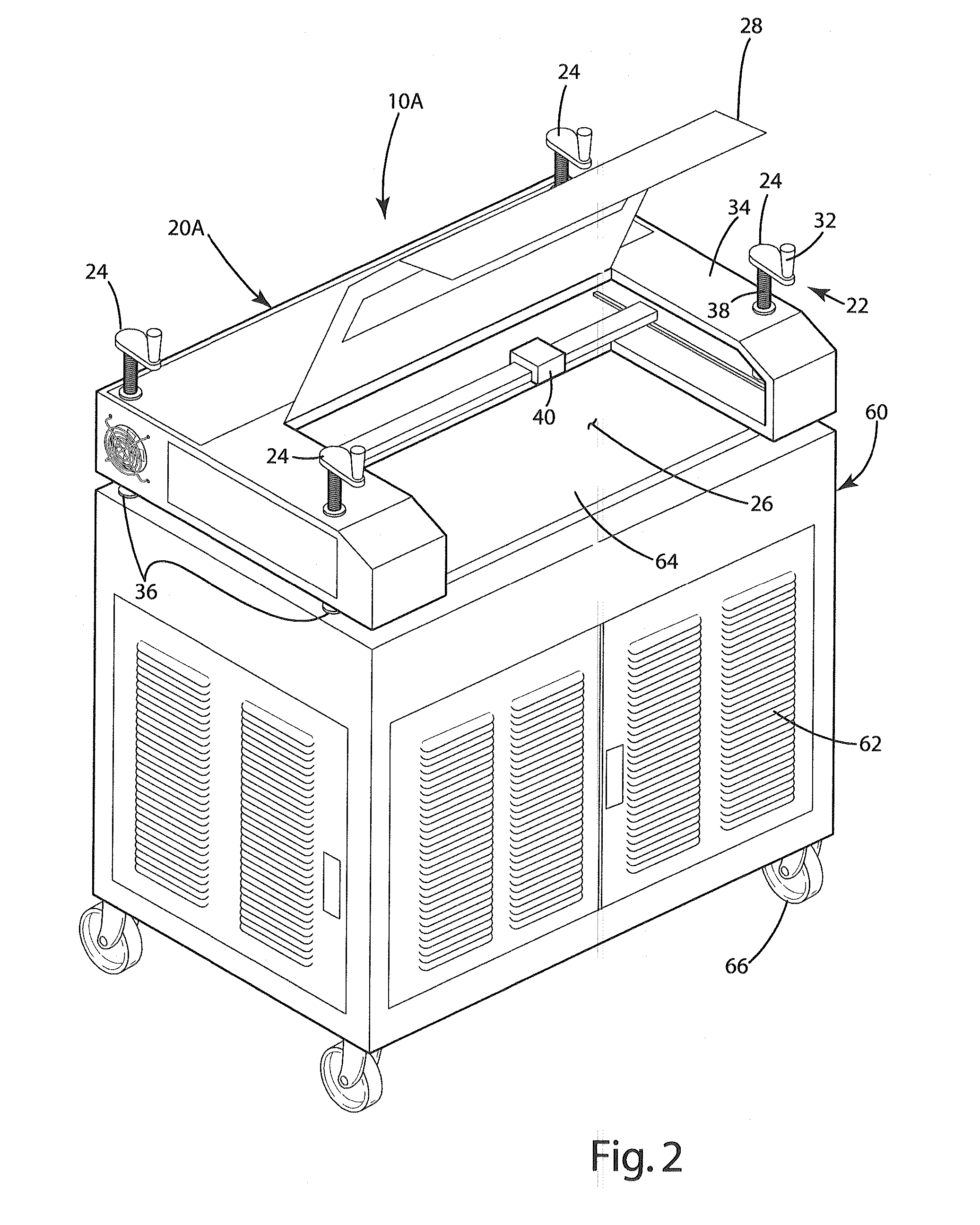

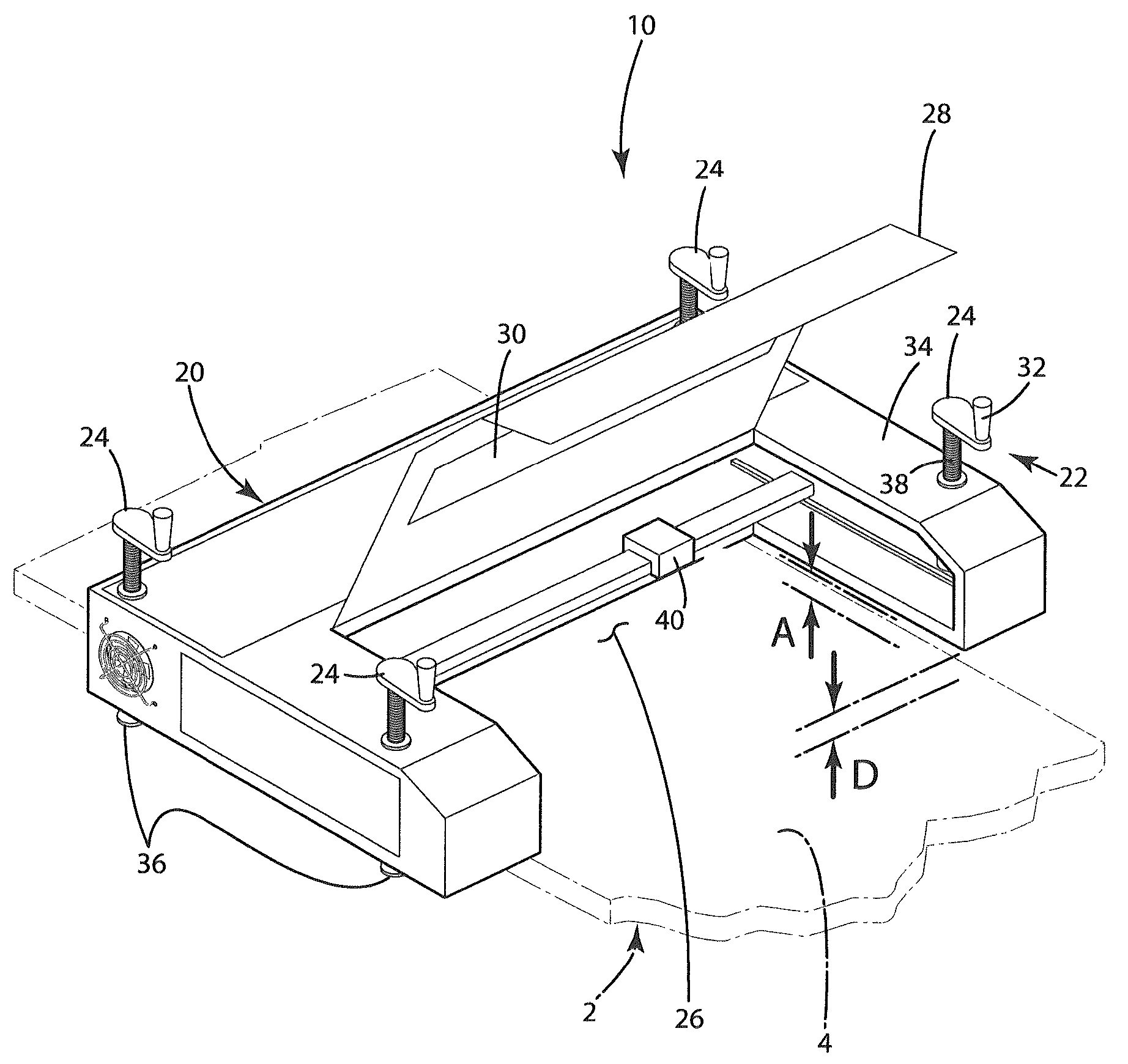

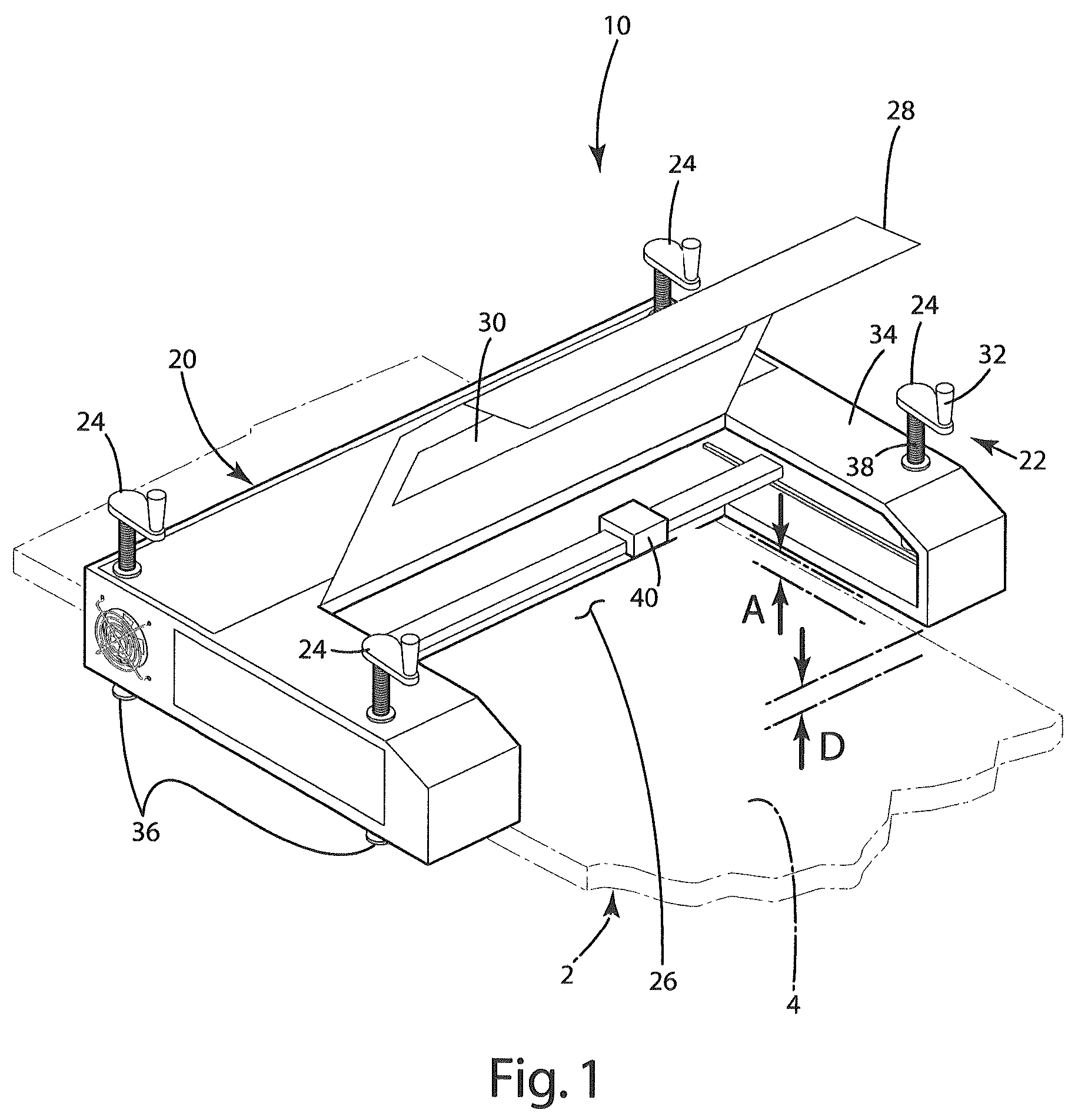

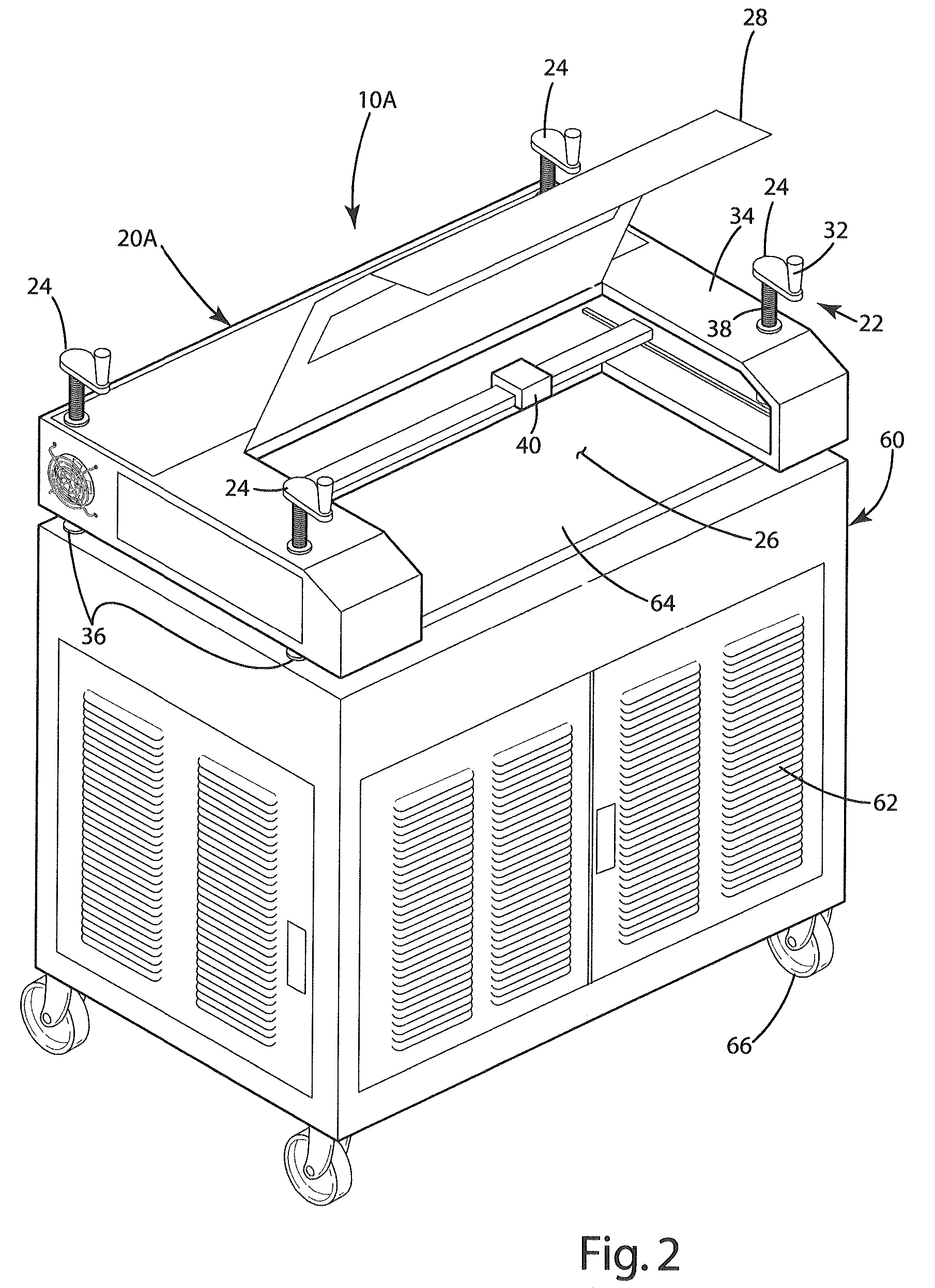

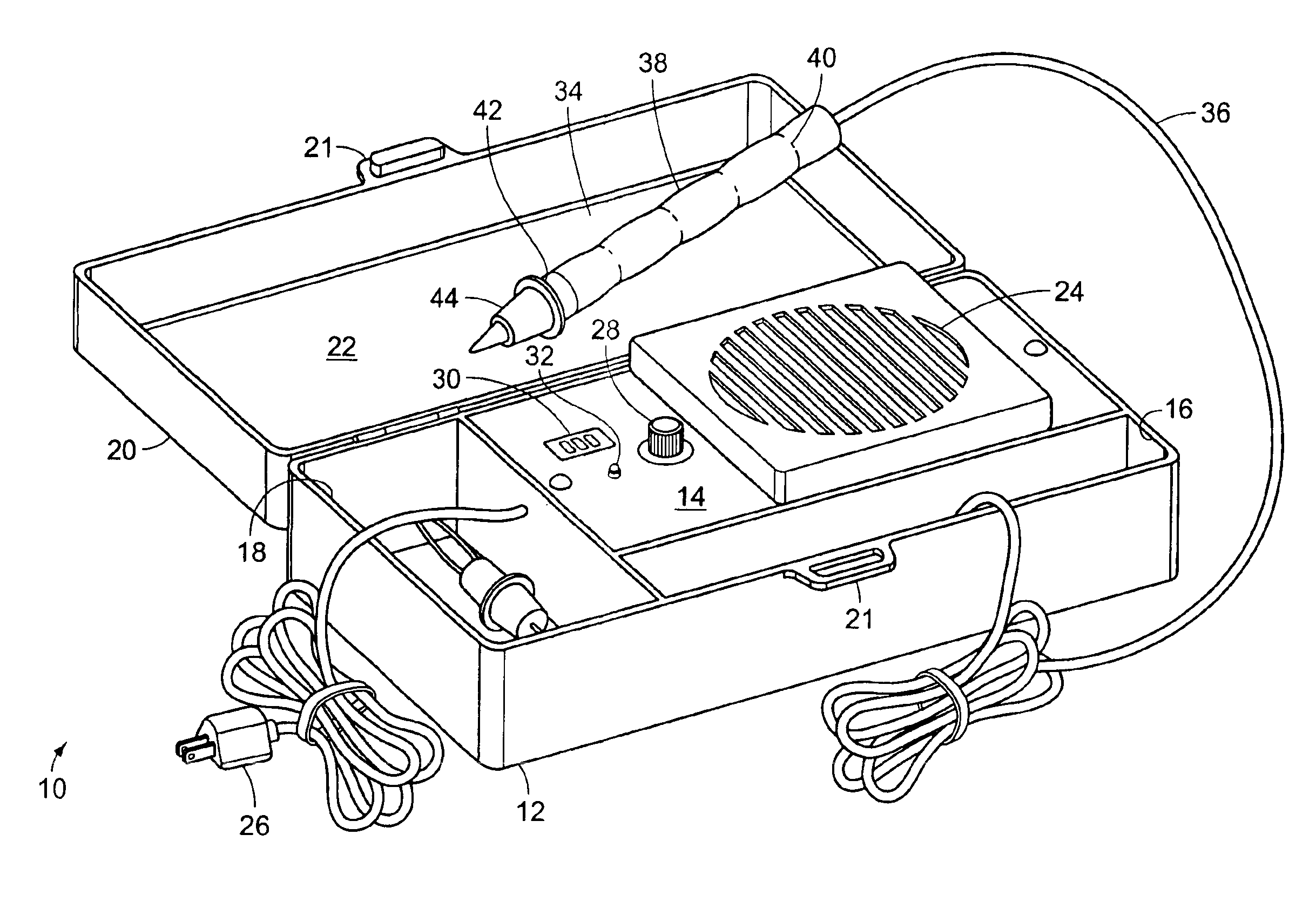

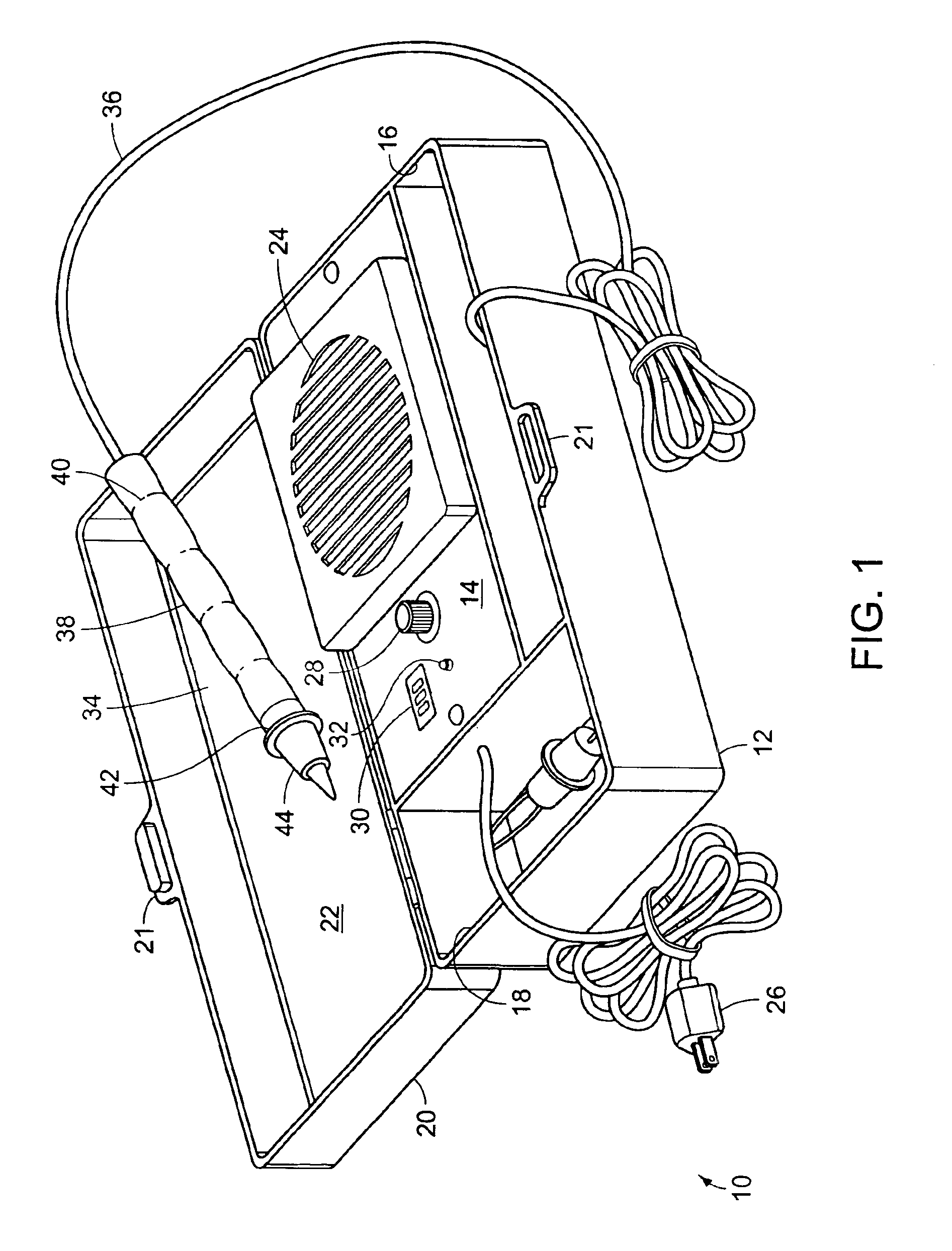

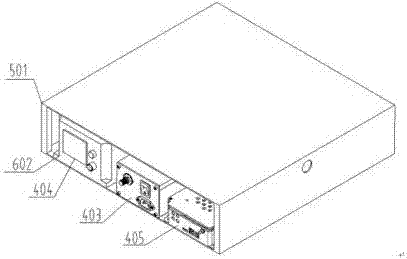

Portable engraving system

A portable engraving system comprises an enclosure adapted to operably accommodate an engraving device, wherein the enclosure comprises an adjustment system. The adjustment system comprises one or more adjustable devices, and the adjustable devices are adapted to adjust a distance between the enclosure and a work surface thereby allowing adjustment of the distance between the enclosure and the work surface, whereby the enclosure is adjustable with respect to the work surface. The enclosure further comprises an opening wherein the engraving device is operably positioned thereto, whereby the work surface is accessible to the engraving device therethrough. The enclosure is positionable adjacent the work surface and operably disposed thereto.

Owner:LI TONG

Portable engraving system

A portable engraving system comprises an enclosure adapted to operably accommodate an engraving device, wherein the enclosure comprises an adjustment system. The adjustment system comprises one or more adjustable devices, and the adjustable devices are adapted to adjust a distance between the enclosure and a work surface thereby allowing adjustment of the distance between the enclosure and the work surface, whereby the enclosure is adjustable with respect to the work surface. The enclosure further comprises an opening wherein the engraving device is operably positioned thereto, whereby the work surface is accessible to the engraving device therethrough. The enclosure is positionable adjacent the work surface and operably disposed thereto.

Owner:LI TONG

Marking diamond

InactiveUS6358427B1High enough resolutionPoorly defined edgeBranding equipmentStampsResistUltraviolet

An invisible information mark is provided on a facet of a diamond gemstone by applying a plasma resist to the exposed surface of the gemstone, applying an electrically conducting layer of metal to the region where the information mark is to be formed, ablating a selected zone of the metal and resist layers by ultraviolet laser thus forming a mask on the surface of the facet, electrically connecting the metal layer and plasma etching the facet through the mask, thus forming a mark of appropriate depth on the surface of the gemstone.

Owner:GERSAN ESTAB

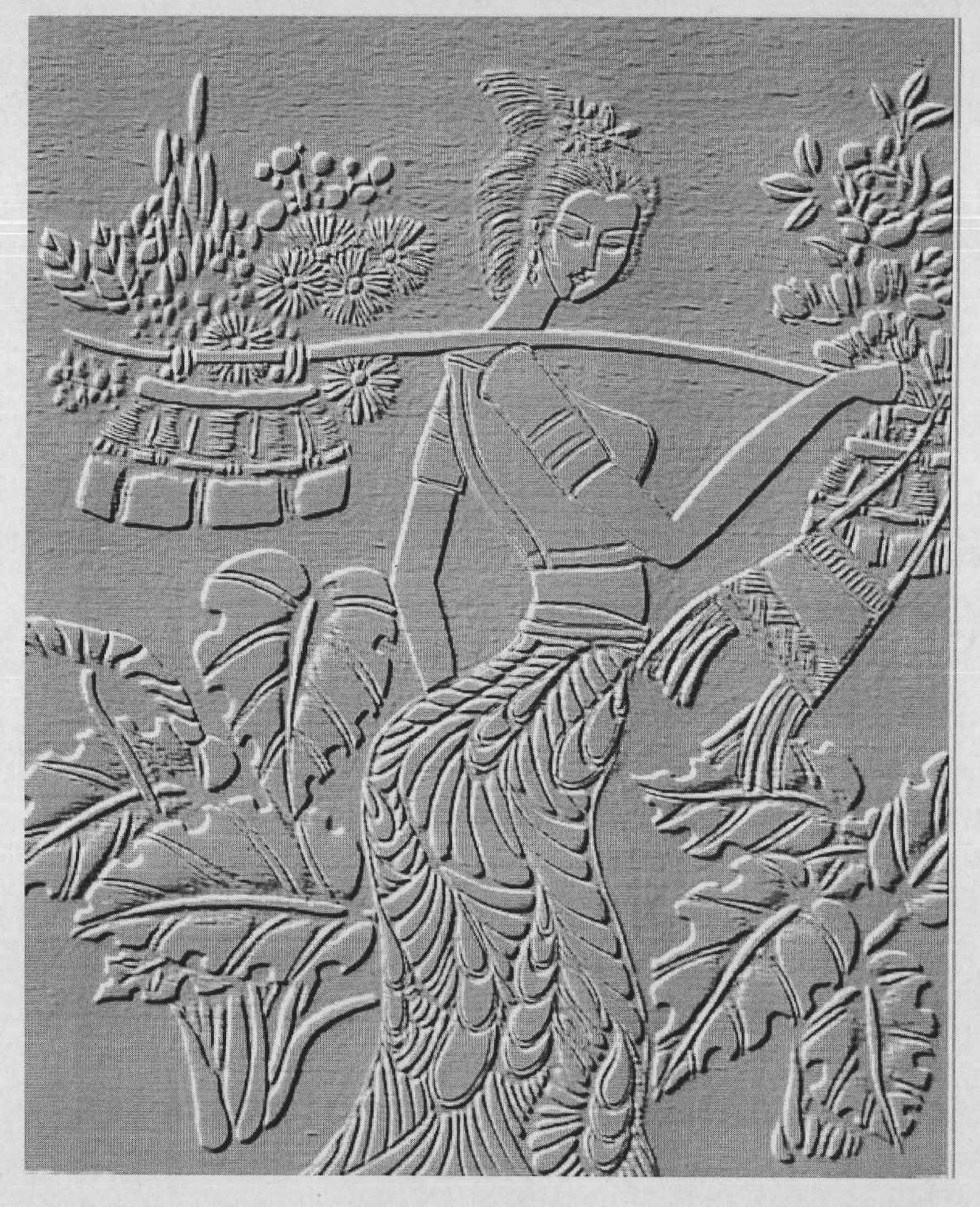

Wood floor board with laser carved pattern and manufacturing method thereof

The present invention discloses one wood floor board with laser engraved patterns and its making process. The wood floor board with laser engraved graphics, texts or antiskid patterns is made through the first computer typesetting to design patterns, and the subsequent CO2 laser engraving to form vivid stereo images by means of local high temperature to gasify wood material.

Owner:捷伟实业有限公司

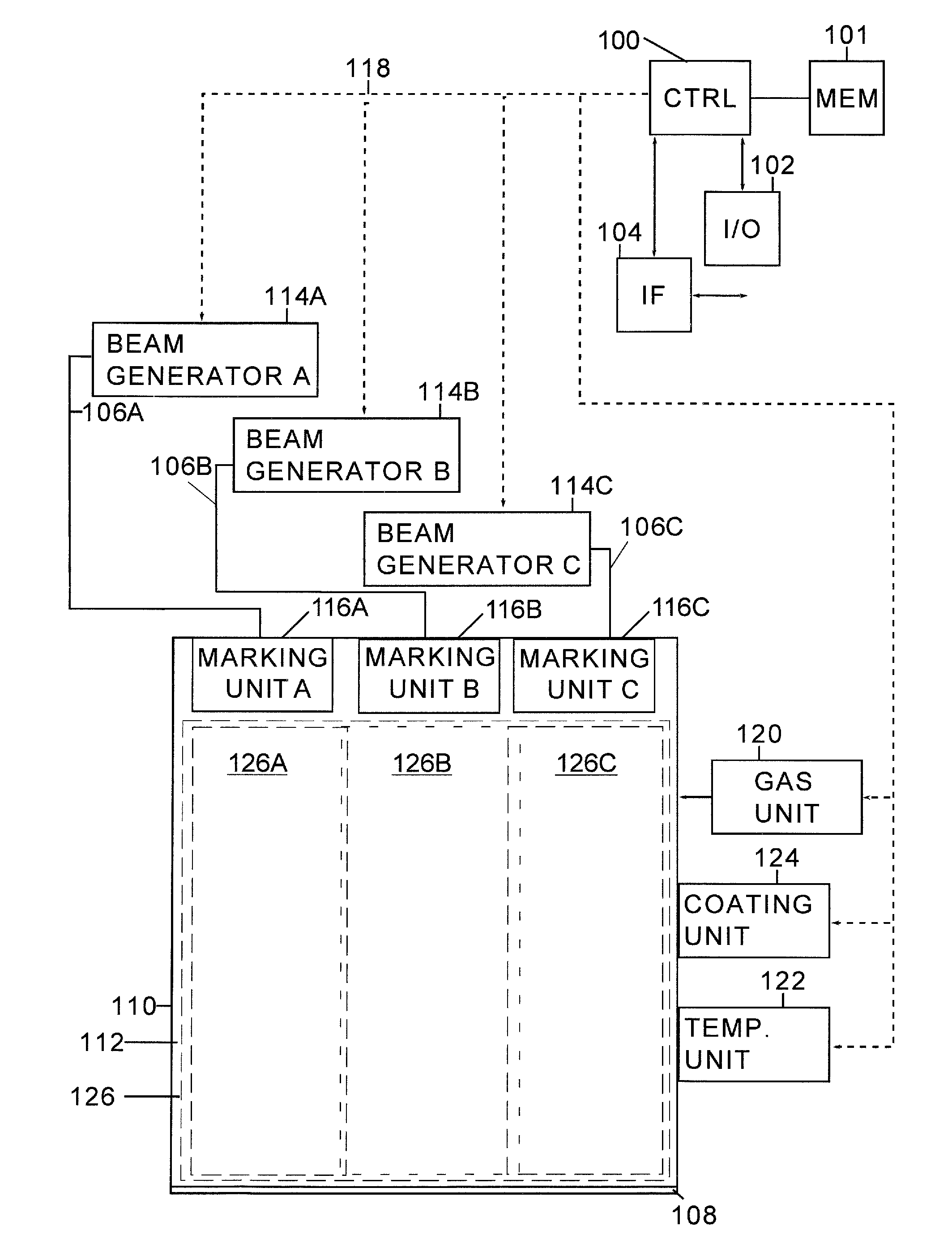

Colour marking metal surfaces

ActiveUS20160144457A1Durable against wearDurable corrosionBranding equipmentLiquid surface applicatorsControl dataEngineering

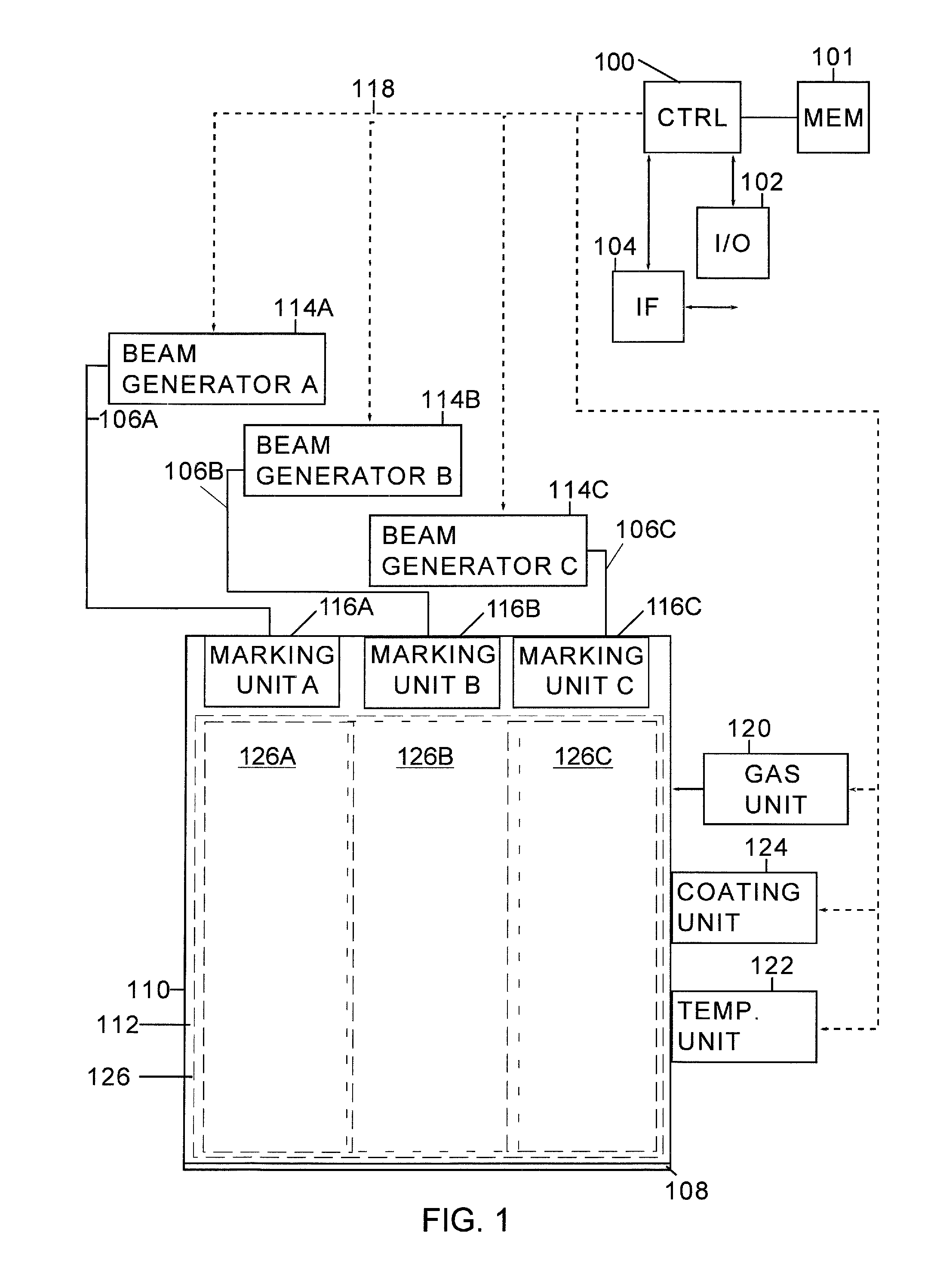

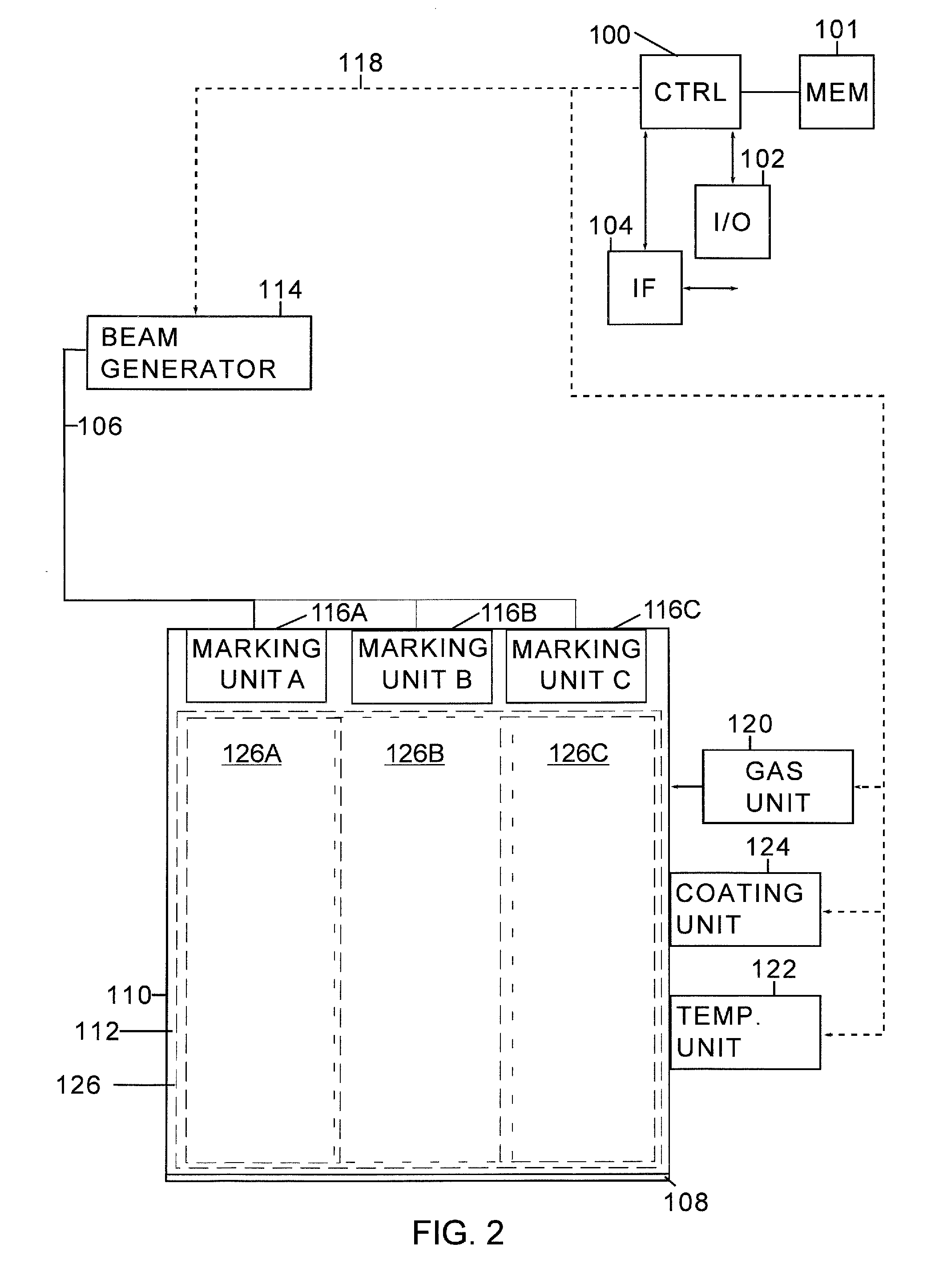

Apparatus related to marking a metal surface are provided. The solution includes a bed for an object including a metal surface, the bed including a total marking area; a cover forming an airtight space over the bed; one or more laser marking units capable of directing a laser beam onto the metal surface located within a unit marking area, wherein the unit marking area is smaller than the total marking area. In the proposed solution control data including information on the marking of a pattern on the metal surface is received; the focus, bandwidth and movement of the one or more laser marking units is controlled on the basis of the control data to produce the pattern defined in the control data on the metal surface.

Owner:CAJO TECH

Method for fabricating nonmetallic slices by using laser

InactiveCN101049772ARemove blur effectSame sizeBranding equipmentDecorative surface effectsLaser processingMetal sheet

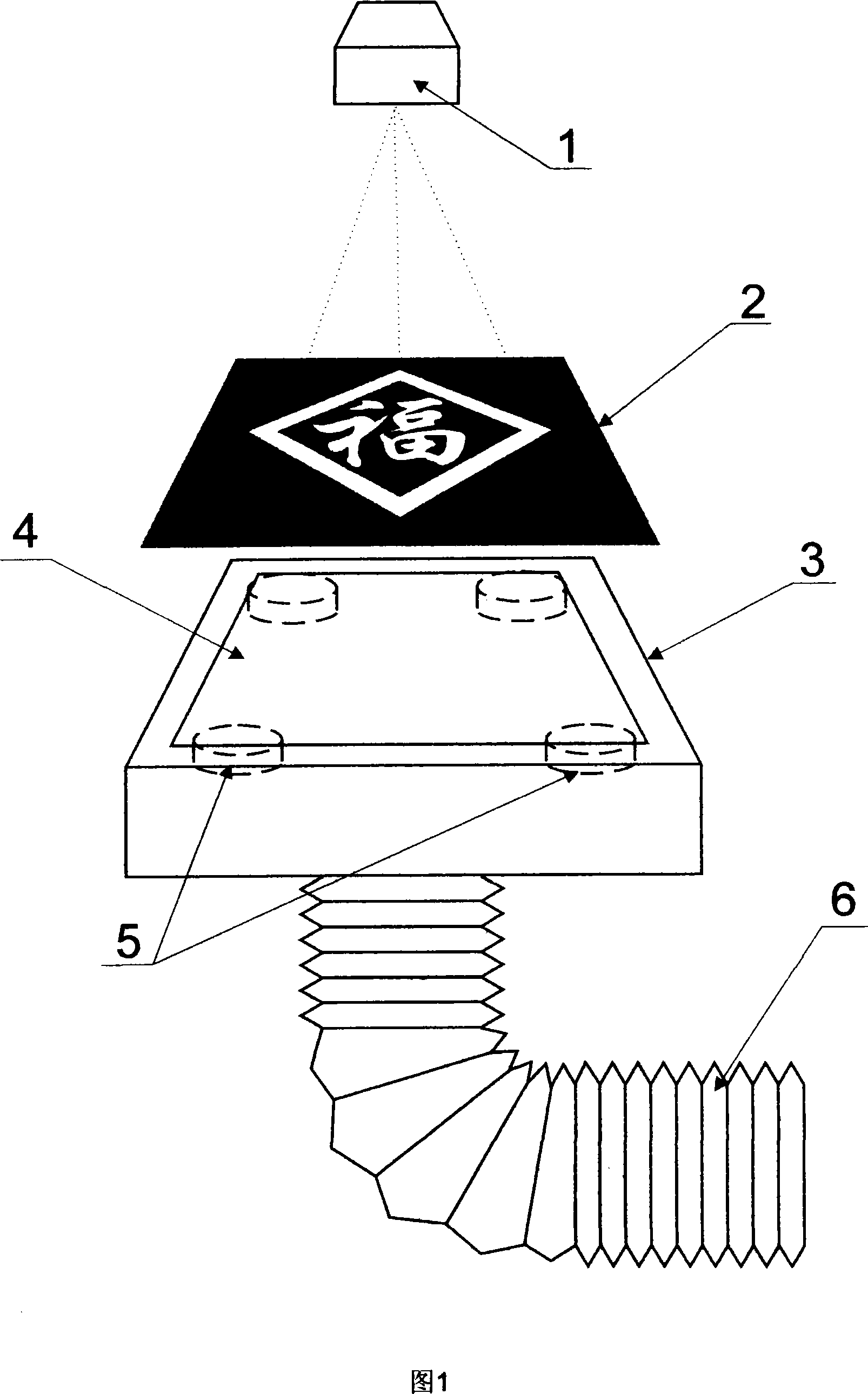

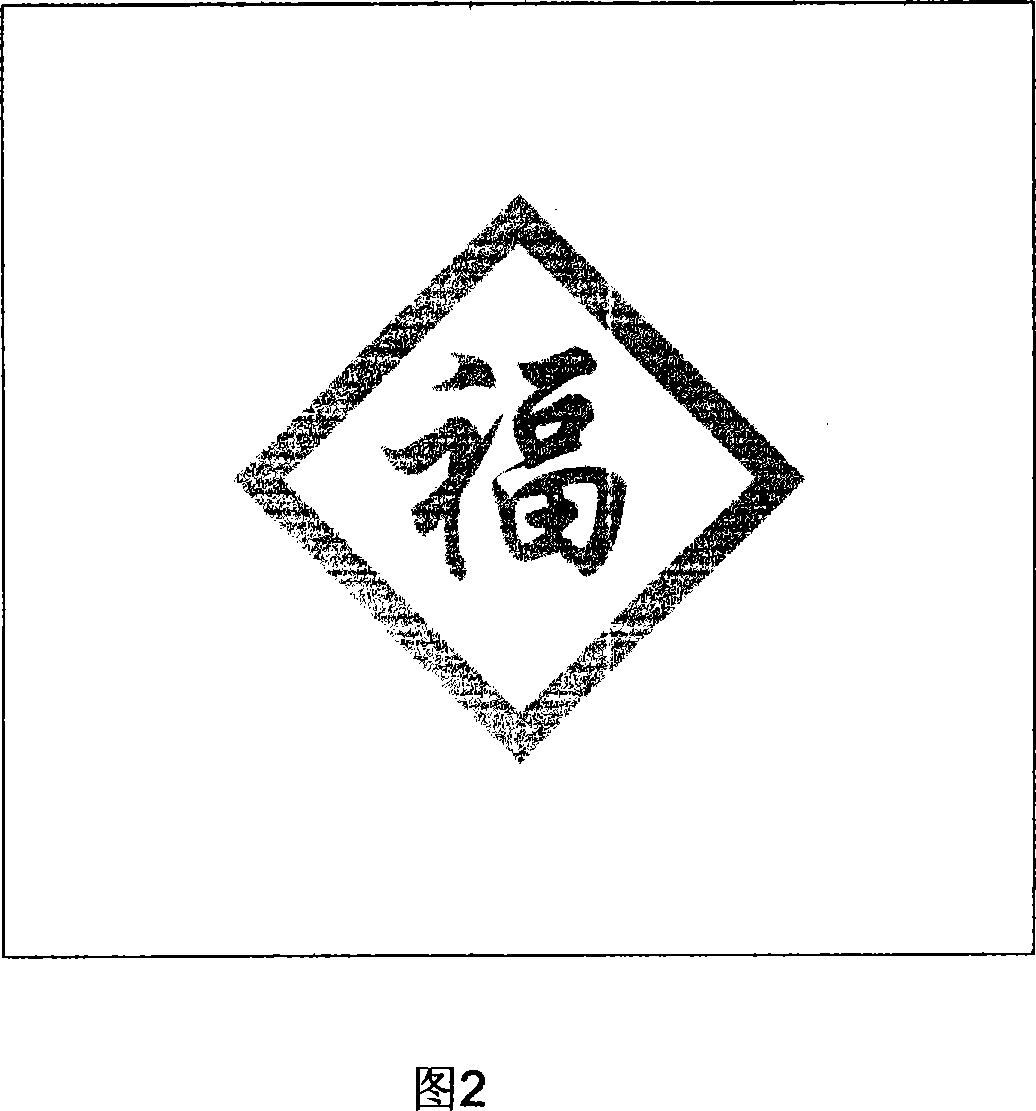

A method for machining on non-metal sheet by laser includes such steps as preparing a metallic mask with carved pattern, putting the metallic mask on the non-metal sheet to be machined, and using laser beam to scan on the mask for etching on the non-metal sheet to generate the needed pattern. Its apparatus is also disclosed.

Owner:陈伟良

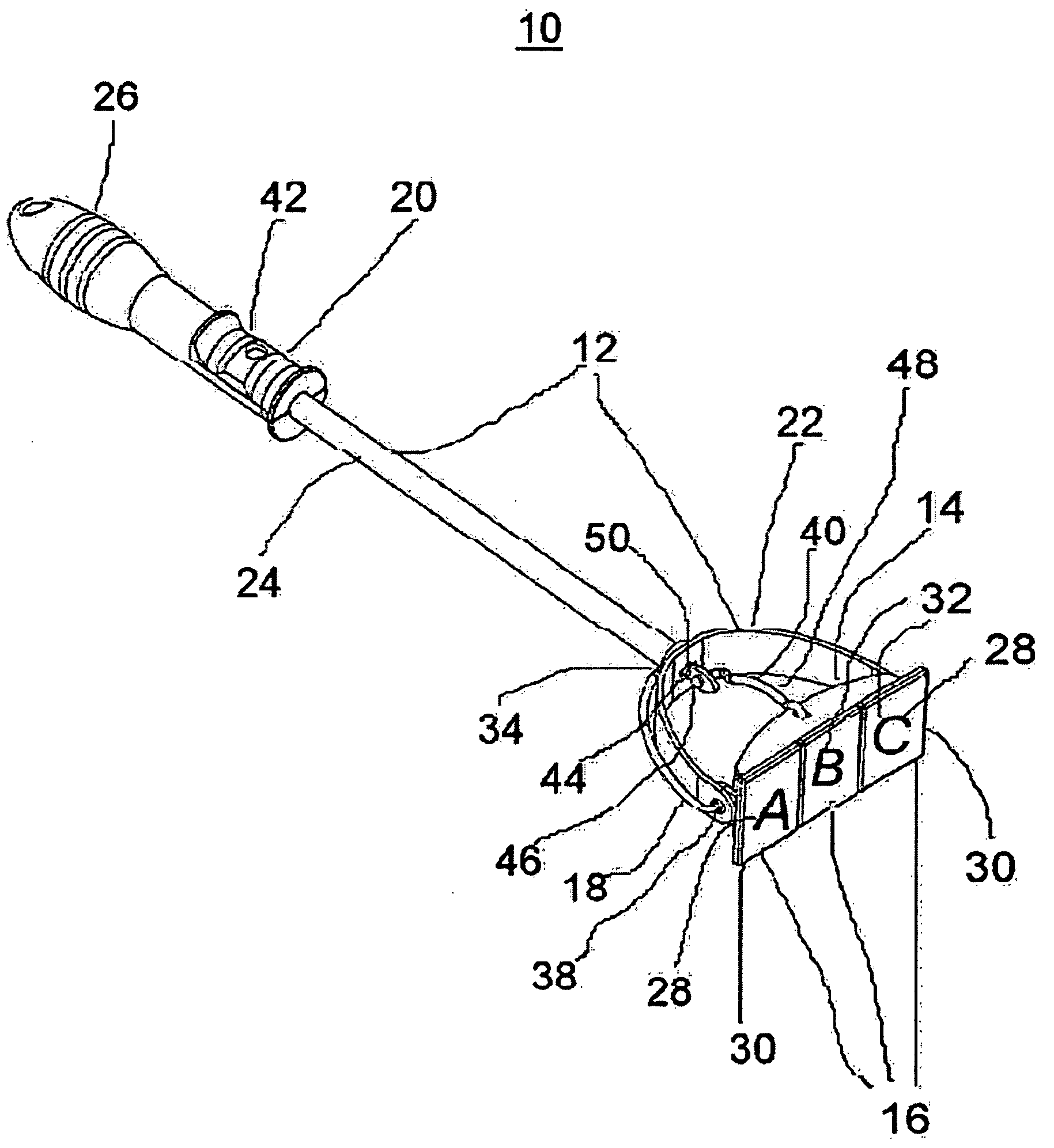

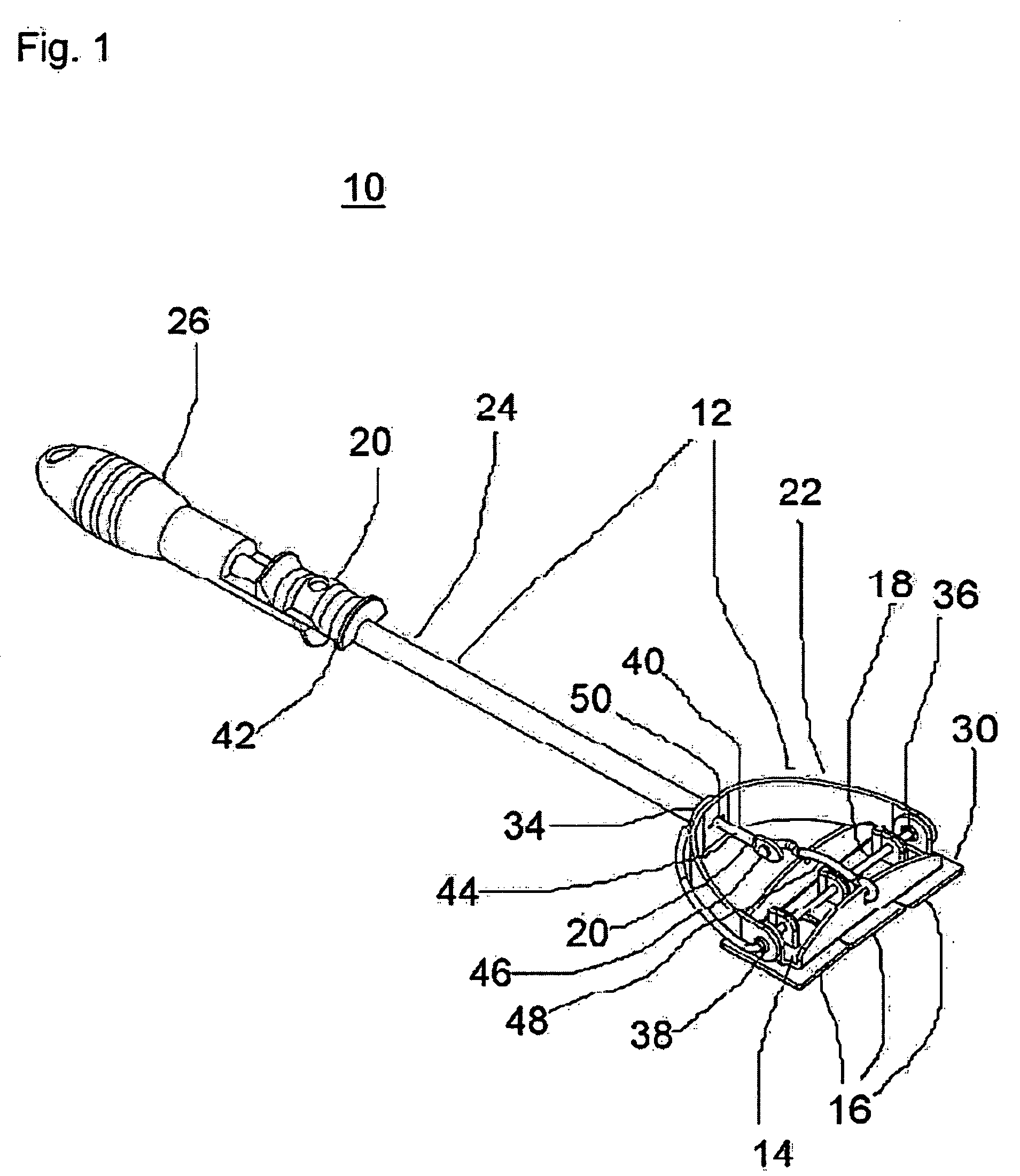

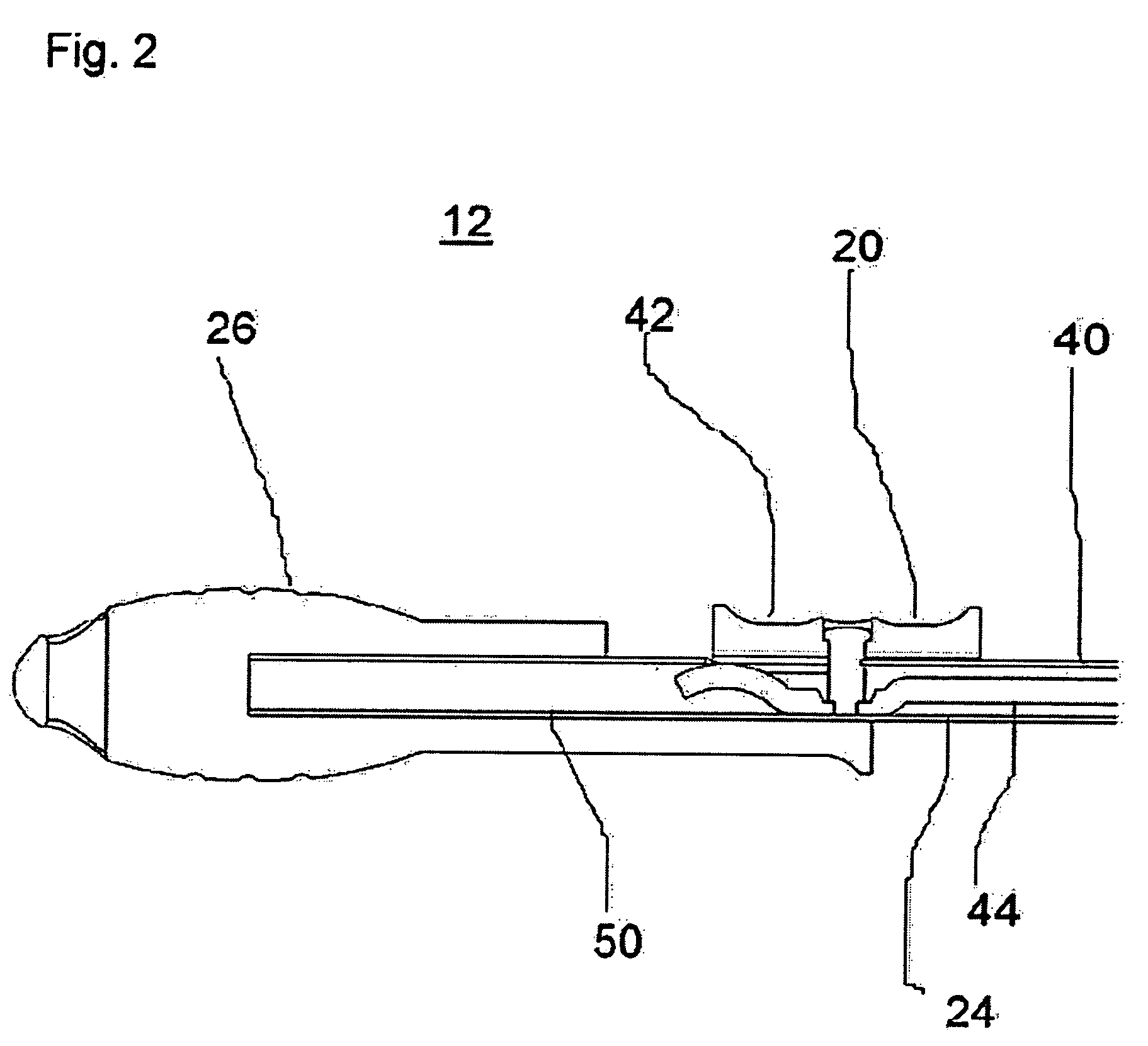

Branding iron

A personalized branding iron with interchangeable symbols, including: a handle arrangement having a first end and a second end; a mounting arrangement mechanically connected to the first end; and at least one unitary substantial symbol configured for branding. The mounting arrangement and the symbol are configured for convenient mechanical connection of the symbol to the mounting arrangement.

Owner:AD ON MARKETING

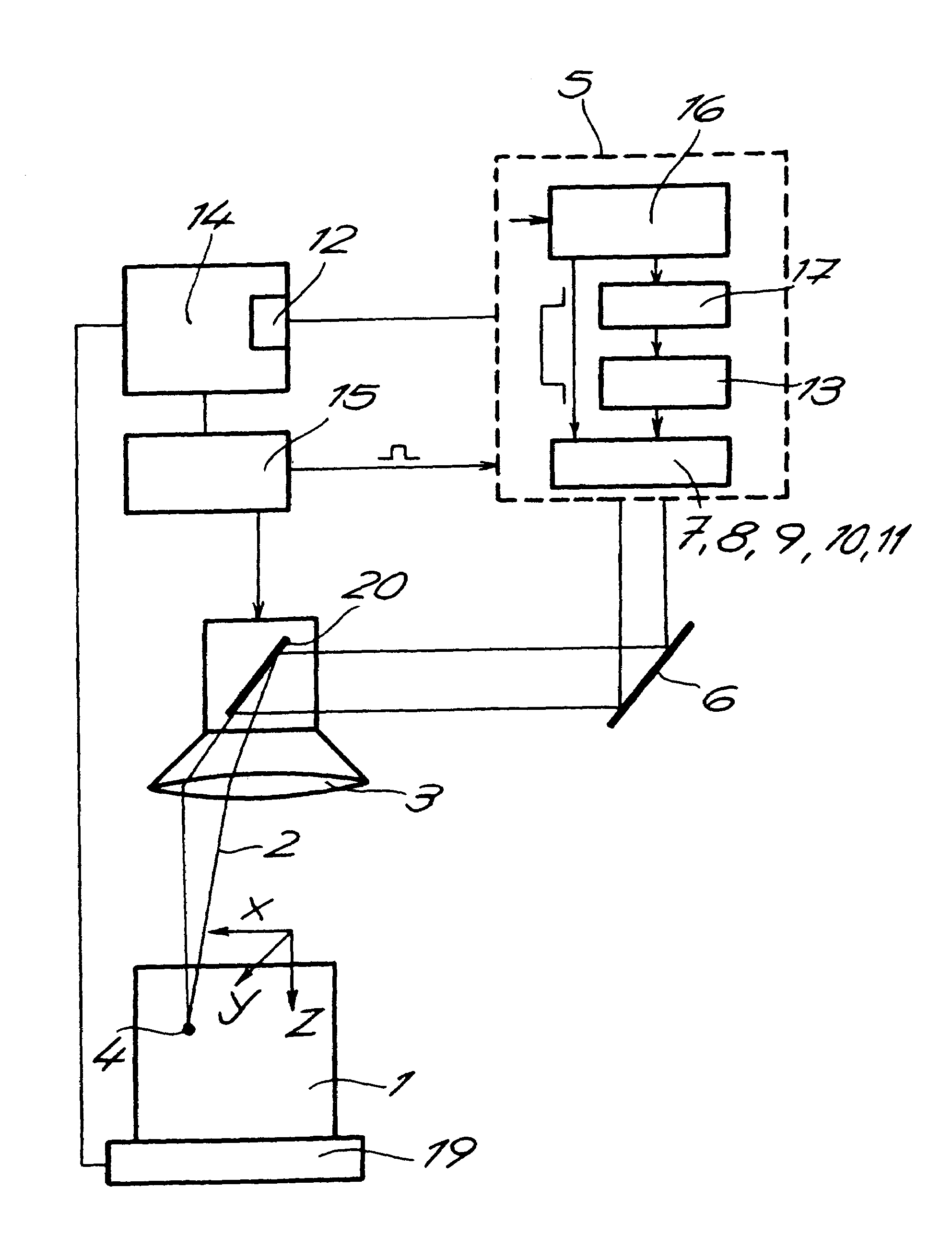

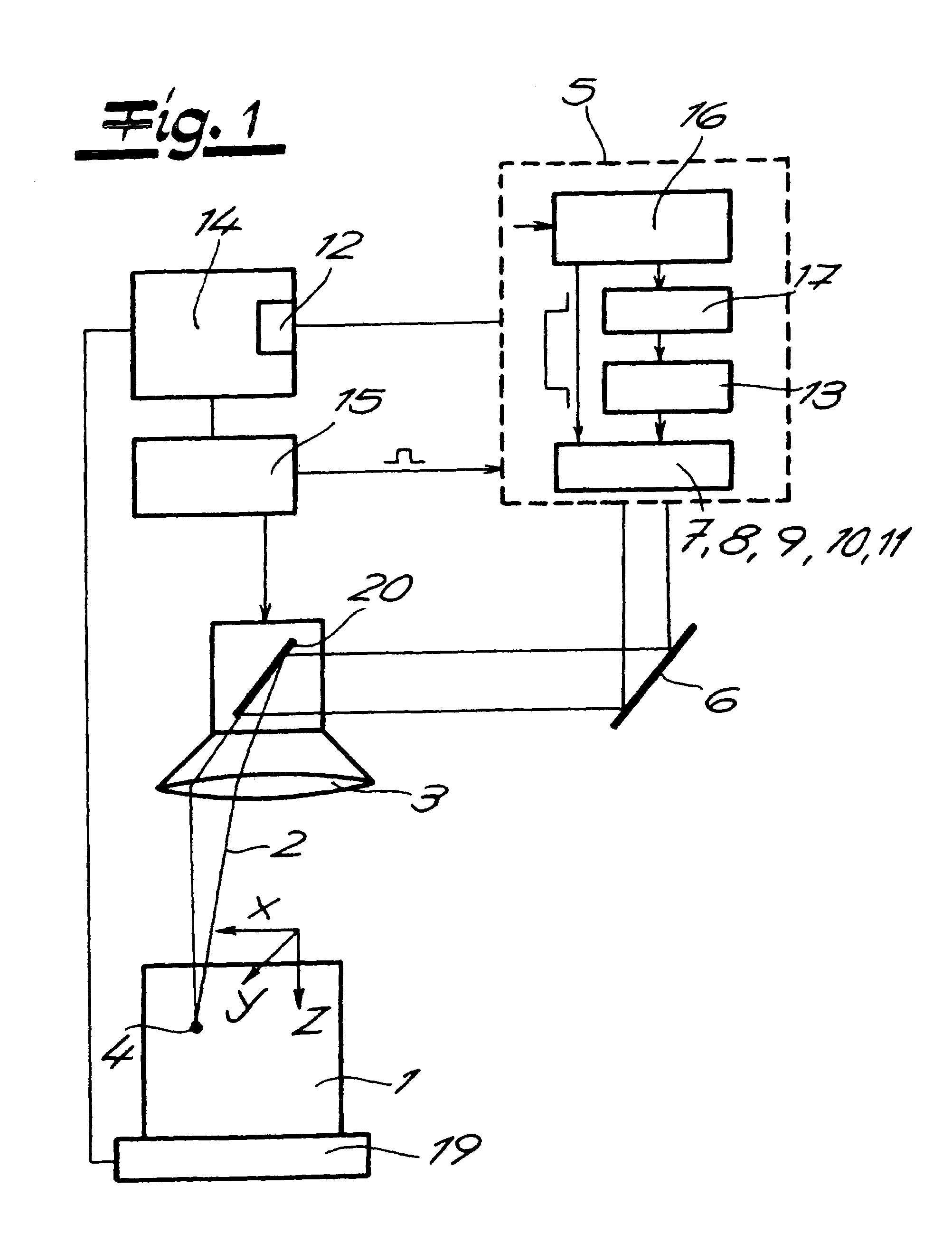

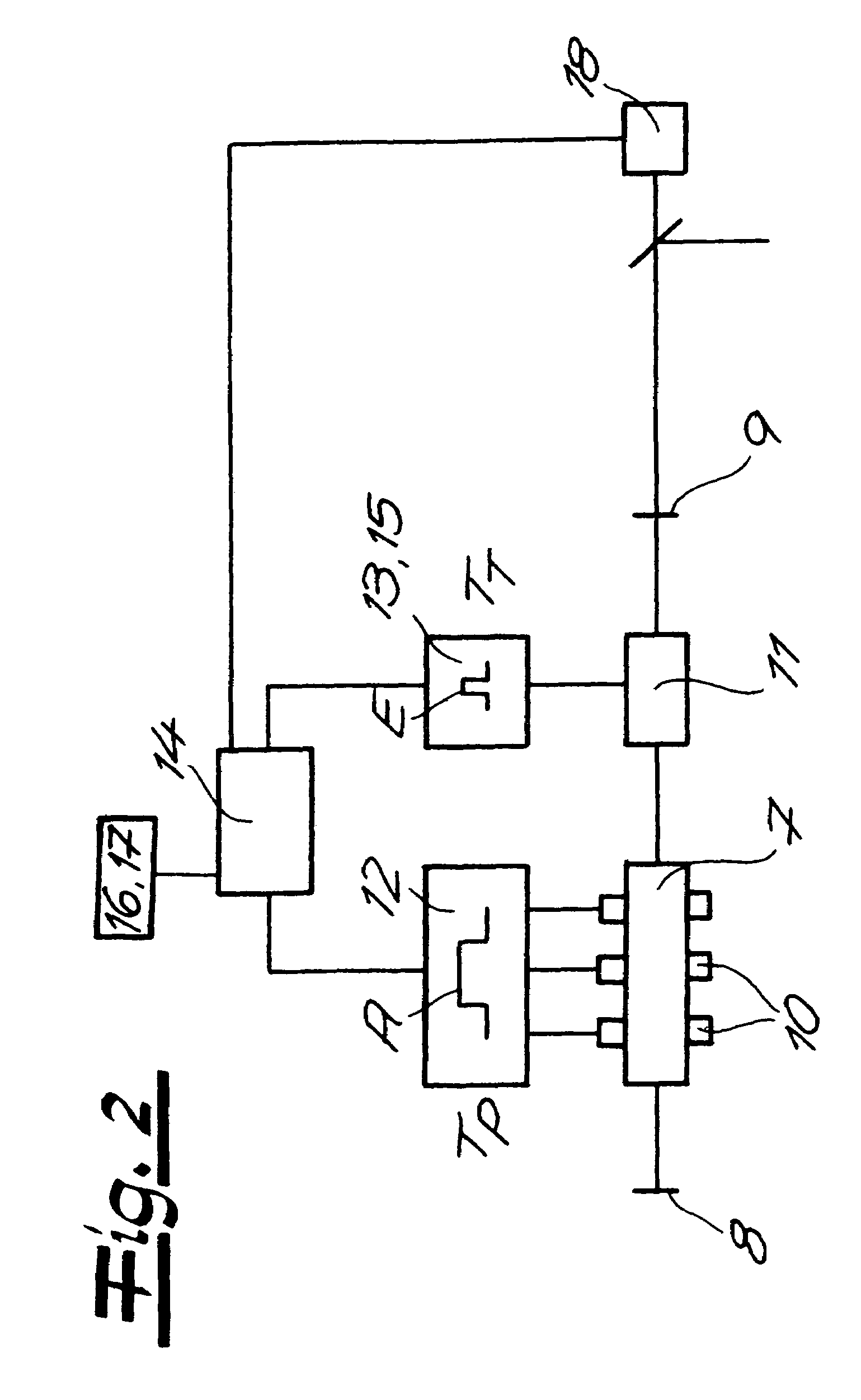

Method and device for producing subsurface markings in a transparent material body

InactiveUS20060249490A1Simple designEasy to operateBranding equipmentLaser detailsEngravingOptical property

A method and device for producing subsurface markings in a transparent material body by focusing a pulsed laser beam in the interior of the material body so that the laser beam exceeds the destruction threshold of the material body to produce a permanent marking. Individual markings form a freely selectable internal engraving as a result of a relative movement between the laser beam and the material body. The laser pulse is varied with respect to its pulse energy (P) by means of a discharge pulse (E) that has an adjustable time delay from an excitation pulse (A). Markings that have varying optical properties depending on the pulse energy (P) are produced in this fashion.

Owner:VITRO LASER TECH AG

Automatic bamboo stick-branding machine

InactiveCN102501697ASimple and fast operationImprove work efficiencyBranding equipmentAgricultural engineeringEngineering

An automatic bamboo stick-branding machine comprises a base, and is characterized in that: supporting plates are mounted on the base, a main motor is mounted on the left ends of the supporting plates, a first shaft is mounted on the top right corners of the top left parts of the supporting plates, a big first shaft eccentric wheel is mounted at the middle of the first shaft, and is wrapped by an eccentric sleeve, the right side of the eccentric sleeve is connected with a dovetailed slider, an insulation board is mounted on the right side of the dovetailed slider, a hooked discharging driving lever is mounted on the front end of the insulation board, a left turning plate is mounted on the right side of the insulation board, a left heating plate is mounted on the right side of the left turning plate, a front-branding die is mounted on the left heating plate, a trough-fixing plate is mounted on the top right ends of the supporting plates, two vertical trough holders are symmetrically mounted at the front and the rear ends of the trough-fixing plate, trough guide ways are mounted on the trough holders, and a trough is mounted between the front and the rear trough guide ways. The automatic bamboo stick-branding machine solves the problem that the conventional bamboo stick-branding equipment cannot carry out continuous branding, and is suitable for branding characters or signs.

Owner:QINGDAO HAIGANG GILDING PRESS EQUIP

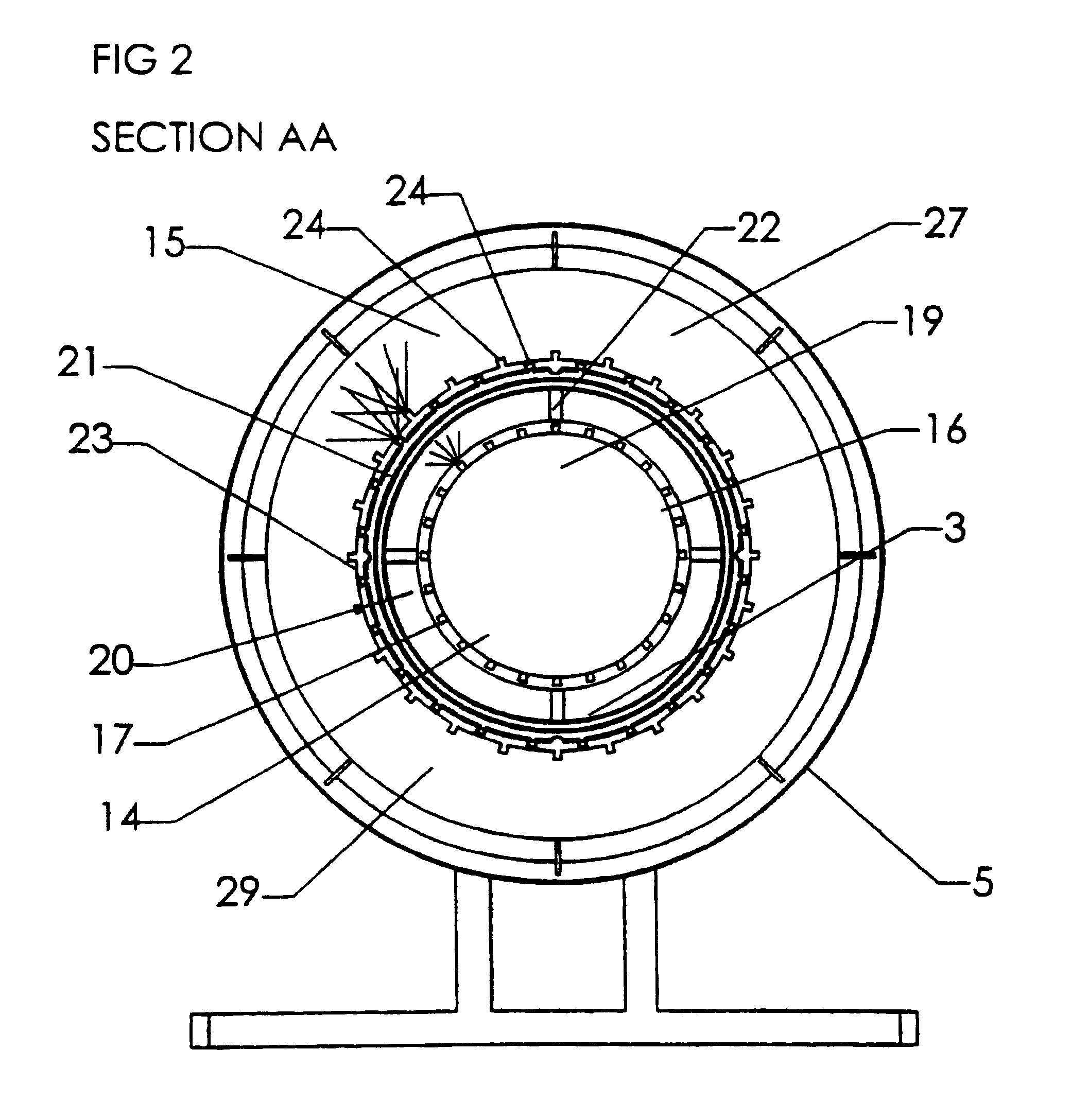

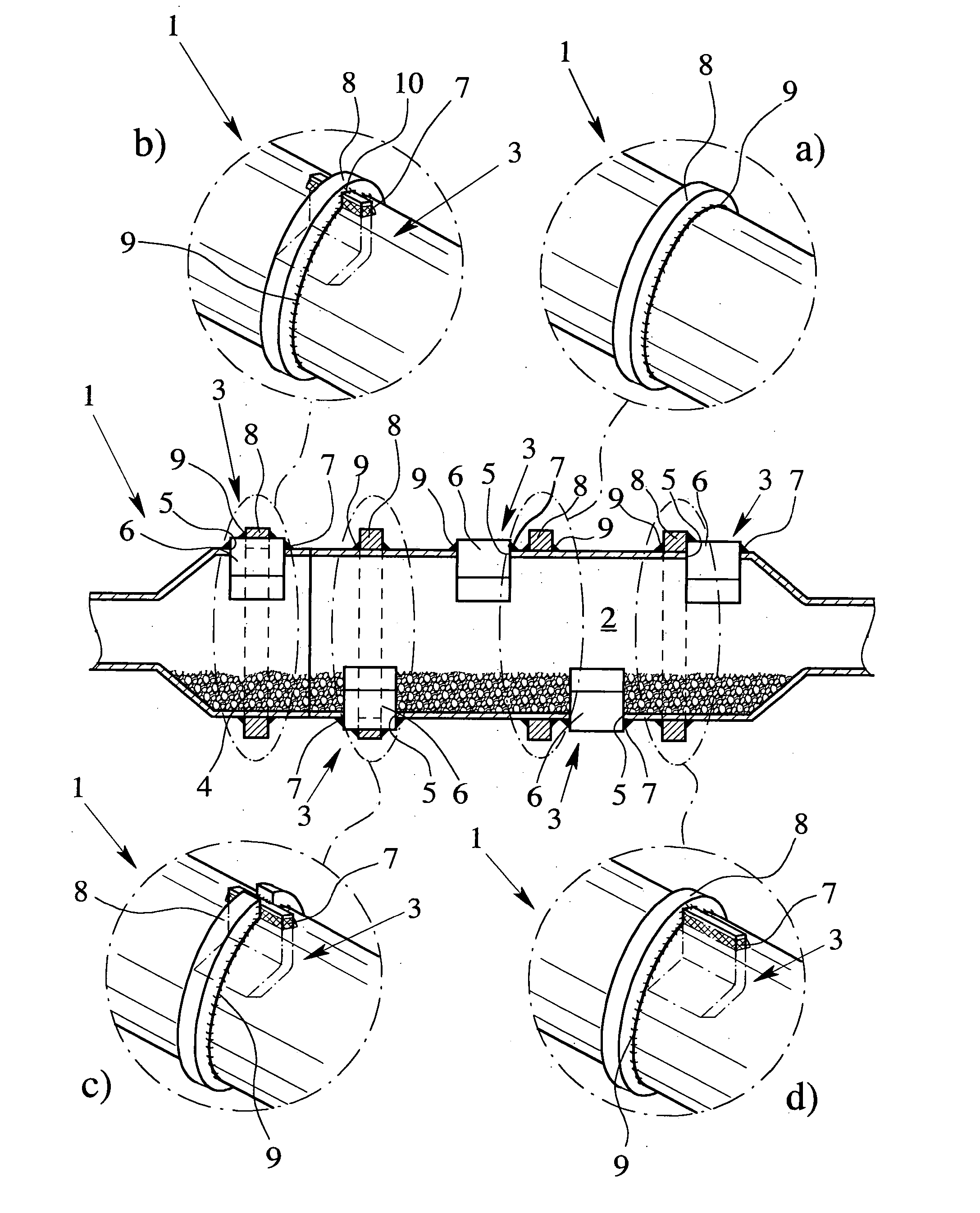

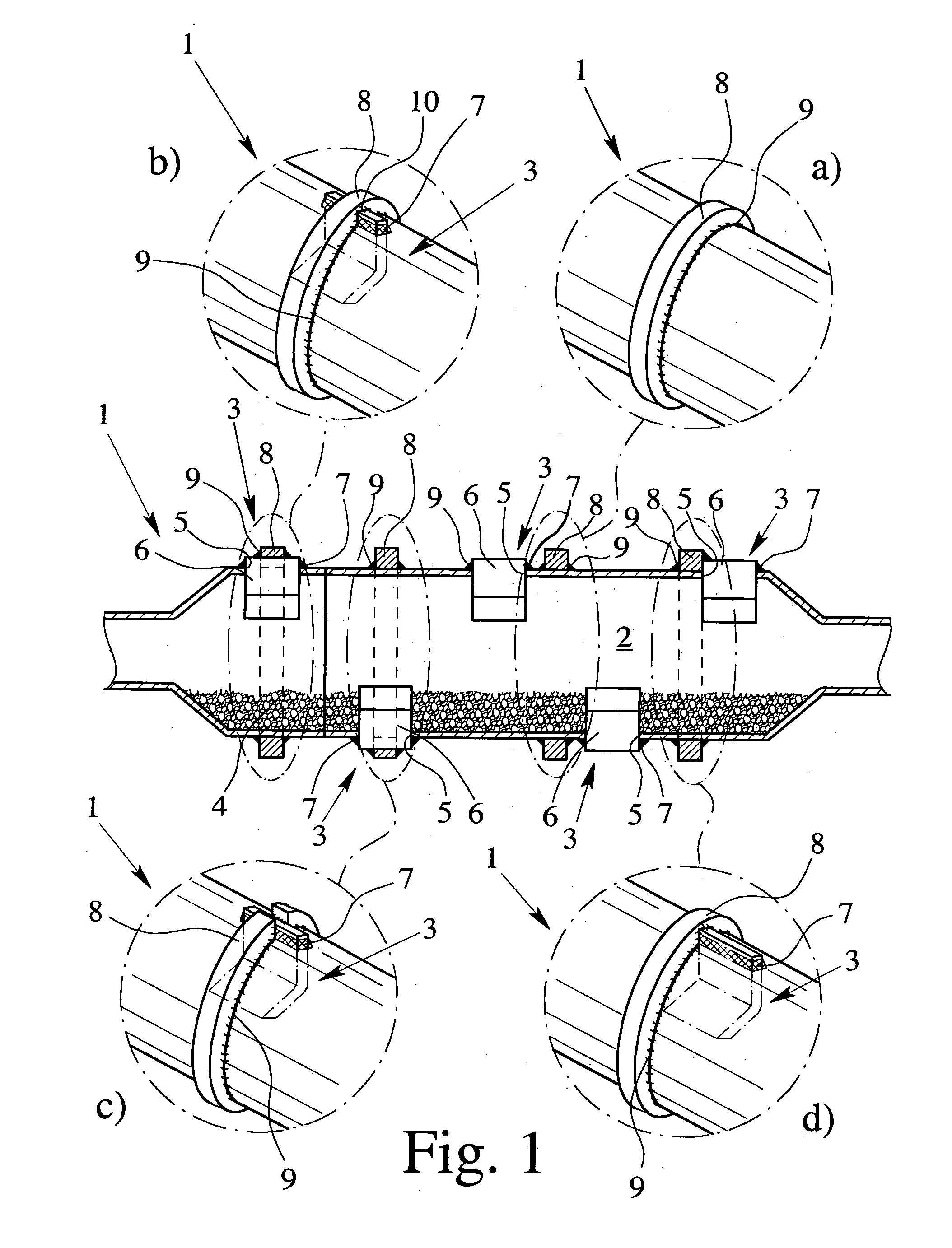

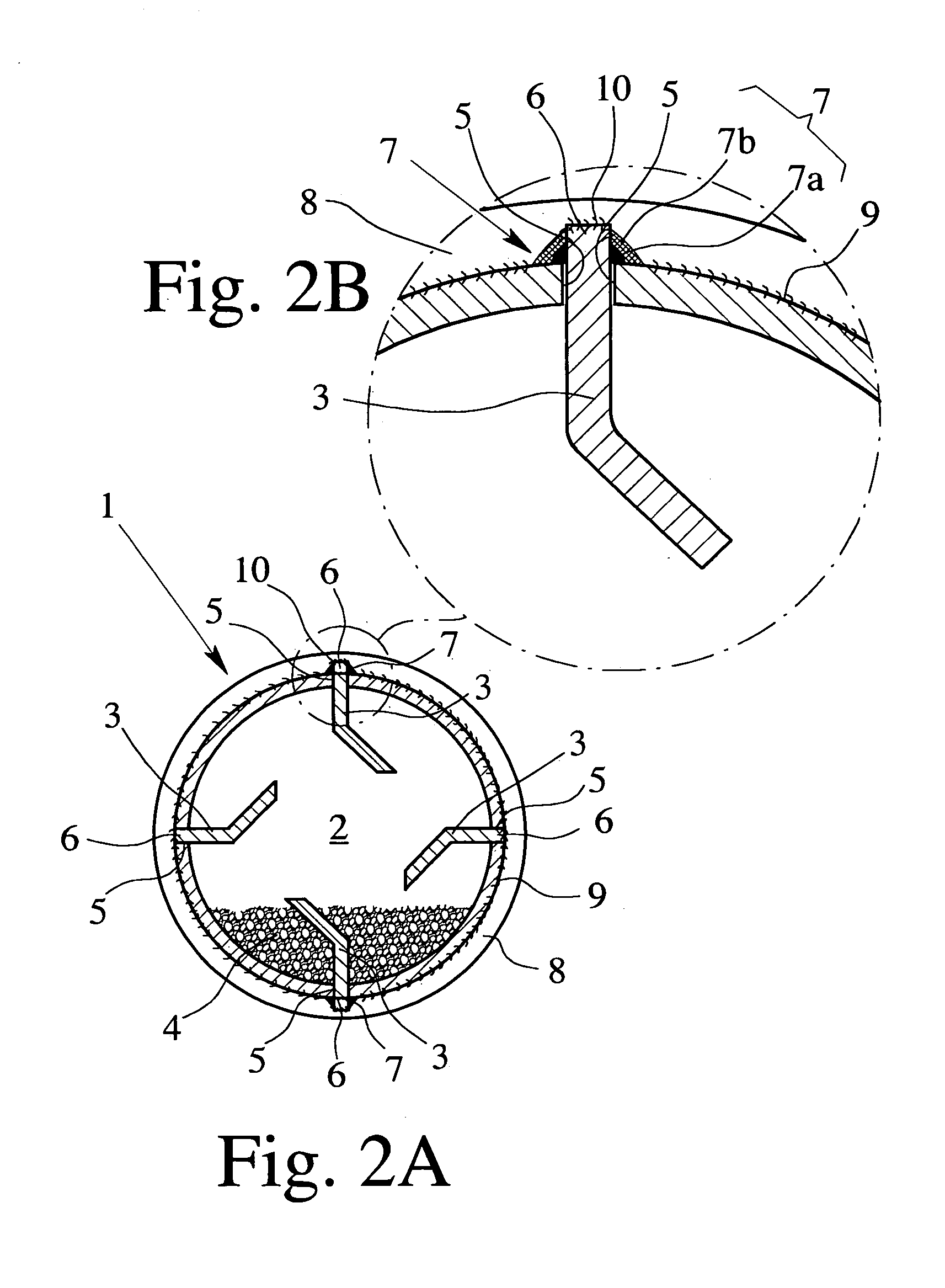

Rotary tubular kiln for the production of activated charcoal

The subject of the invention is a rotary tube (1), in particular for a rotary tubular kiln for the production of activated charcoal, according to the invention the rotary tube (1) being provided on its outside with at least one reinforcing element (8) for stabilizing the rotary tube (1) in the operating state. As a result, the rotary tube (1) exposed under operating conditions to high temperatures and consequently easily deformable is stabilized in its cross section and / or in its longitudinal direction, depending on the arrangement of the reinforcing element. In particular, the rotary tube (1), for example when it is used for the production of activated charcoal, with the accompanying high operating temperatures, is equipped with efficient resistance to pronounced pressure fluctuations occurring due to the method employed and is therefore also suitable, in particular, for carrying out processes under reduced or increased pressure.

Owner:BLUCHER GMBH

Method and device for producing subsurface markings in a transparent material body

InactiveUS7388889B2Realistic optical propertyLow costBranding equipmentLaser detailsPermanent markerEngraving

Owner:VITRO LASER TECH AG

Variable wood burning tool

A variable wood burning tool for burning woods at varying temperatures and providing alternate uses essentially comprised of a container and a lid hingedly secured thereto. An interior surface of the lid has a heat resistant tray disposed therein. A heating element is disposed within the container. A burning wand is operatively coupled with the heating element. A plurality of tips are provided that are each adapted for removably coupling with the burning wand.

Owner:VERET VICTORIA

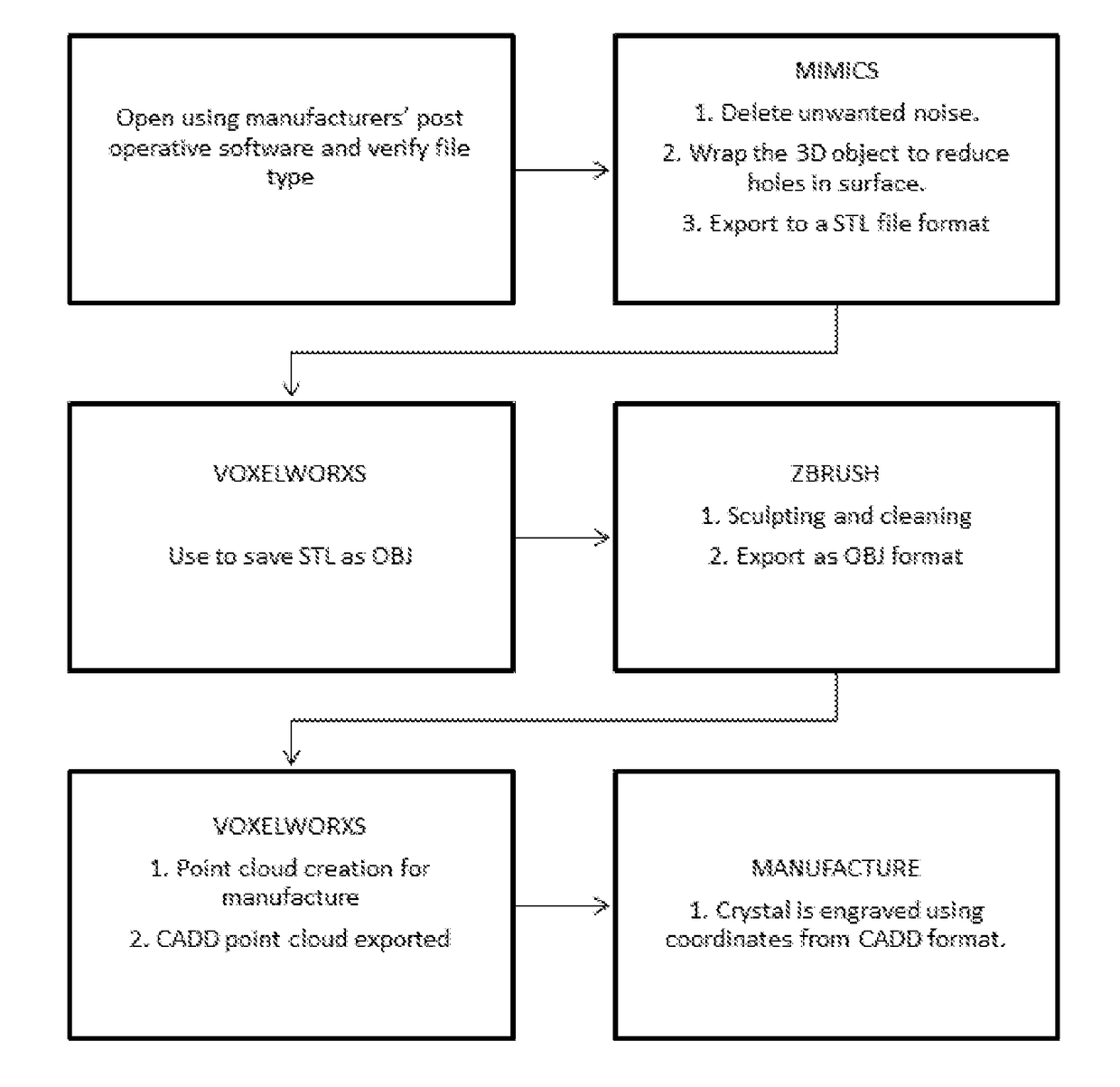

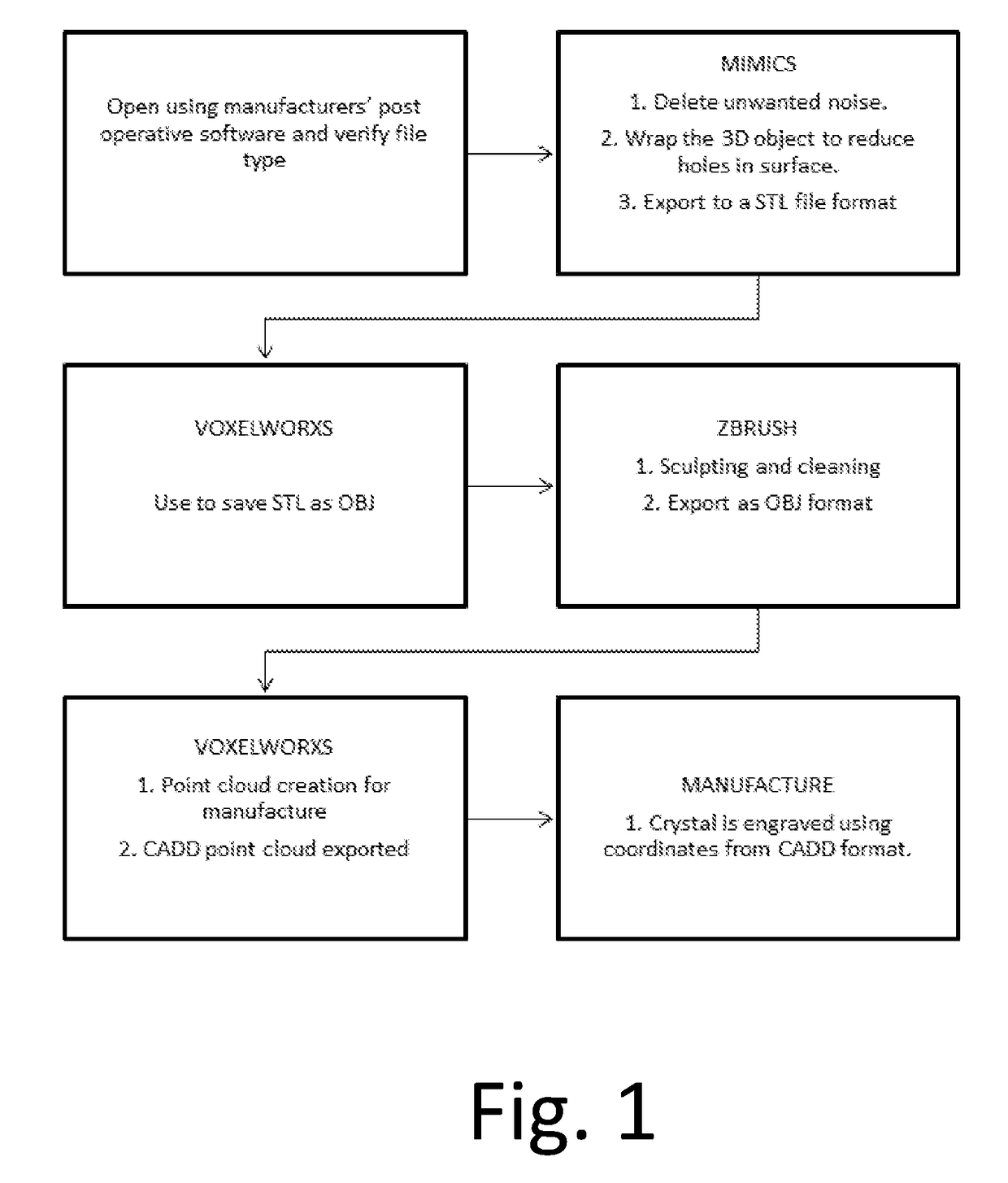

Method of creating a subsurface 3D engraving in a crystal

A method of creating a subsurface engraved crystal comprising the steps of: performing a 3D / 4D scan of a subject; saving the volumetric data; generating a point cloud based on the volumetric data; outputting the point cloud to a laser engraver; and engraving a crystal with the laser engraver.

Owner:ULTRASOUND BABY FACE

Subsurface engraving of three-dimensional sculpture

InactiveUS20030068468A1Range of controlOptimization of detailsBranding equipmentPicture framesLaser engravingHost material

A matrix is formed into a desired shape by pouring transparent liquid material into a mold. The material progresses from the liquid to the gelatinous state. Laser sculpting steps are performed when the material is still in a gelatinous condition to form small spots in the matrix. Because the material is non-solid gel when the laser beam applies its focused energy, there is no cracking or destruction. Intensity and duration of the laser pulse determine the size of the spots as does the timing in relation to the matrix material finally changing from gel to solid. Particular visual effects are produced at different degrees of solidity when sculpting. The liquid in the mold may be pressurized for removal of air bubbles after initial pouring of the matrix material and application of pressure after the laser sculpting controls the size of the spots in the finished product.

Owner:TREX ENTERPRISES CORP

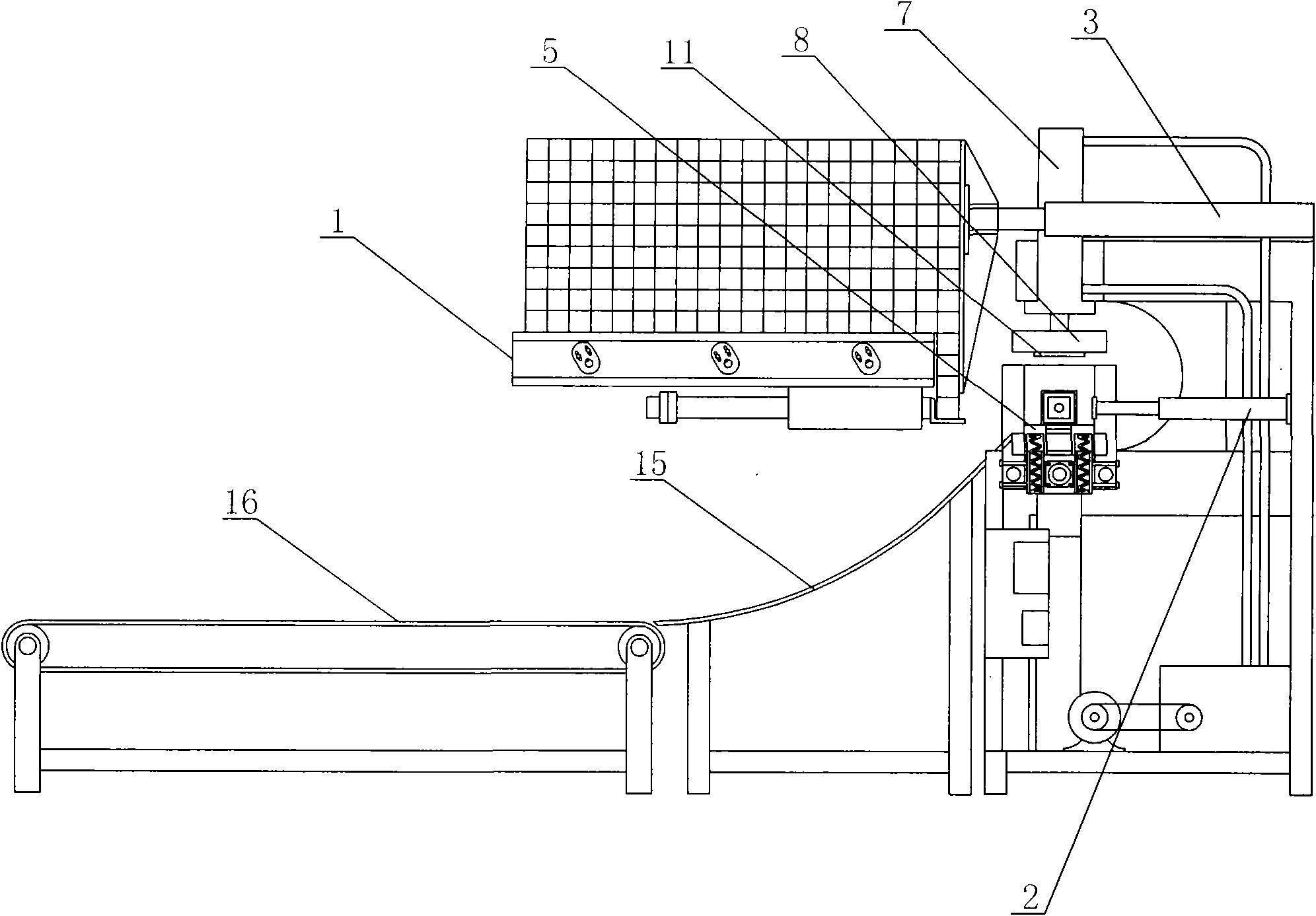

Bamboo stick pyrograph machine

InactiveCN101746201AEasy to processSimple structureBranding equipmentAblative recordingComputer controlAutomation

The invention discloses a bamboo stick pyrograph machine, comprising a frame, an electric appliance control mechanism, a feeding hopper and a discharging hopper, wherein a conveying chain is arranged between the feeding hopper and the discharging hopper, a laser pyrograph mechanism or an electro-heating pyrograph mold is arranged above or below the conveying chain between the feeding hopper and the discharging hopper, the adoption of the laser pyrograph mechanism requires a programmable controller or a computer to control and design pyrograpic patternsm and the adoption of the electro-heating pyrograph mold is in need of setting a bamboo stick compression rolling mechanism. The outer side of each of inner chain sheets and outer chain sheets of the conveying chain is provided with two protrusions, between which a U-shaped groove capable of accommodating the conveyed bamboo sticks is formed. The bamboo stick pyrograph machine with simple structure, high automation degree and high working efficiency can achieve accurate and eye-pleasing pyrograph.

Owner:YANTAI JINGJIANG BAMBOO HANDICRAFT

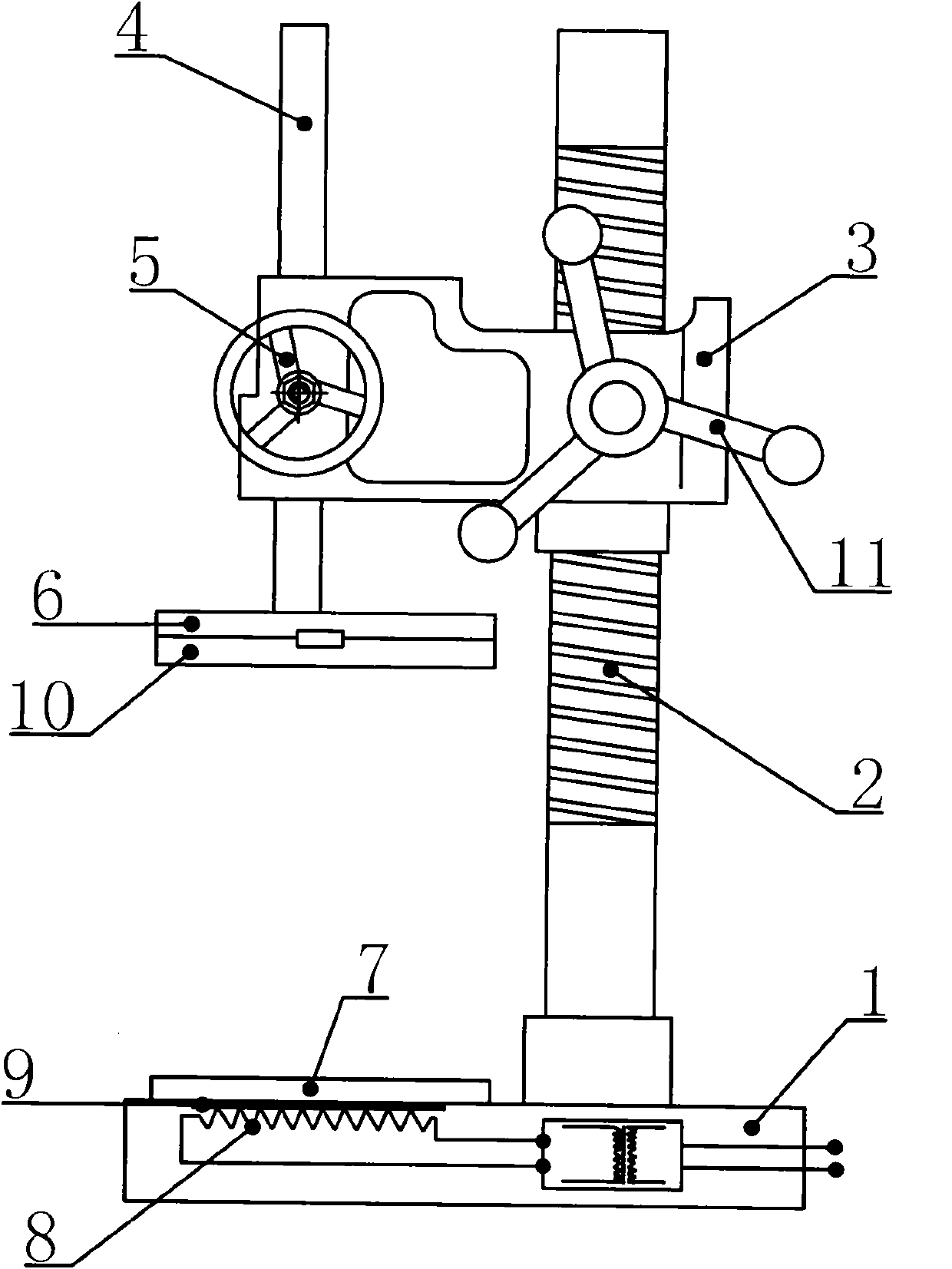

Bamboo wood product pressing machine

InactiveCN101564962AIncrease productivityGuaranteed qualityBranding equipmentEmbossing decorationsPulp and paper industryAutomatic controller

The invention discloses bamboo wood product pressing machine comprising a feed apparatus, a main frame, a affiliated frame and an up-down pressure device and characterized in that a discharging device is connected on the main frame; a mobile locking apparatus is arranged on the affiliated frame and provided with a rotation device. The up-down pressure device is provided with an electric heating device moving up and down followed by the up-down pressure device. The bamboo wood product pressing machine is controlled by an automatic controller. The bamboo wood product pressing machine is provided with two electric heating devices equipped with dies. Two sides are pressed once. A rotating device is arranged on the mobile locking apparatus, rotates the bamboo or wood after two sides pressing and presses the other sides continuously, thus improving the production efficiency. A series of working procedures from charge-in to discharge are automatically finished. The product quality is ensured and the manpower expense is decreased.

Owner:南通长城装饰木制品制造有限公司

Quick picture-poking device

InactiveCN101767506AMeet needsChange copyBranding equipmentArchitectural engineeringUltimate tensile strength

The invention discloses a quick picture-poking device, which is mainly characterized in comprising a work table, wherein the work table is provided with a mould steel plate and a screw rod; the screw rod is provided with a lifting arm, and the lifting arm is movably in screw thread connection with the screw rod through a lifting handle; the other end of the lifting arm is penetrated with a compression bar, and the compression bar is movably connected with the lifting arm by trimming a fixed handle; the lower end of the compression bar is provided with a pressure steel plate, and the bottom face of the pressure steel plate is embedded with a wood plate; and a mica plate and an electric stove wire are sequentially arranged on the work table and under the mould steel plate. By adopting the scheme, the device can carve different steel plate grinding apparatuses according to market demand, wherein each grinding apparatus can print ten of thousands of products, is convenient in use and convenient in operation, reduces the labor intensity, shortens the production period, reduces the production cost, and greatly improves the production efficiency.

Owner:NANYANG INST OF TECH

Electrical purography pen

The invention relates to an electrical purography pen which comprises an electrical heating element and an attaching plug. The electrical purography pen is provided with a metal liquid penpoint which consists of the electrical heating element, a metal stannum core and a pen tip. The electrical heating element of the metal liquid penpoint is fixedly connected in the pen tip,the metal satnnum core is arranged in the pen tip and is sheathed outside the electrical heating element. The working theory of the electrical purography pen is as follows: the electrical purography pen is connected with a power supply; the electrical heating element in the electrical purography pen is used for melting the metal stannum core into metal liquid; and the metal liquid is used for pyrographing. The electrical purography pen has the beneficial effects that the metal liquid is used for pyrographing, due to the compact contact of metal liquid pyrography with a drawing board, the speed of the metal liquid pyrographing is faster than the pyrographing speed of an ordinary electrical cautery pen; the electrical purography pen saves electrical energy; the penpoint is liquid, so the electrical purography pen does not damage the drawing board easily.

Owner:NANTONG YAOLONG METAL MFG

Board pyrograph manufacturing method and device

InactiveCN106985586ARealize high-precision and high-quality heat transfer processingQuality improvementBranding equipmentDecorative surface effectsNumerical controlEngineering

The invention mainly relates to the technical field of pyrograph machining, in particular to a full-automatic board pyrograph manufacturing method and a device based on image identification, laser processing and numerical control technology. The device comprises a numerical control motion platform, an exhaust device, an optical zooming mirror, an electric control system, a box body and a laser; a pyrograph machining device adopts a three-axle portal mechanical structure; a worktable is mounted in the numerical control motion platform; the continuous and automatic manufacturing of board pyrograph is finished through controlling three process parameters of the laser output strength of the laser, the time of irradiating a board by the laser and the gap between a laser output head and the board by combining with space motions of each servo shaft; and the device comprises main operating steps of: pyrograph pattern selection, digital pyrograph image processing, image parameter and processing parameter conversion, selection and installation of machining raw materials, machine tool pyrograph manufacturing, and pyrograph aftertreatment. The device is high in automation degree, high in manufacturing efficiency and stable in manufacturing quality, and realizes continuous batch production.

Owner:邢康林

Method for marking valuable articles

The invention relates to methods for marking valuable articles, mainly precious stones, in particular cut diamonds and can be used for article identification. The inventive method for marking valuable articles consists in forming a mark image visible in reflected light on a polished surface by modifying the ions of a surface area to be marked by means of the ion beam having the given ion energy and, while modifying, in converting the structure of the surface layer of a base in such a way as to change the optical characteristics of the modified areas in comparison to the optical characteristics of the untreated areas of the surface to be marked. The area to be marked is modified by a pulsed ion beam through a stencil mask by ion implantation of a modifier into a crystal lattice in the marked area of the base surface layer without destructing covalent bonds between the lattice atoms, i. e. without breaking the original shape of said layer. The optical characteristics of the modified area are changed by using, in the form of a modifier, the material, the ions of which change the integral refraction index of the base material when they are implanted into the crystal lattice in the form of impurity additives.

Owner:VALINMARK

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com