Patents

Literature

1025results about How to "Reduce burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

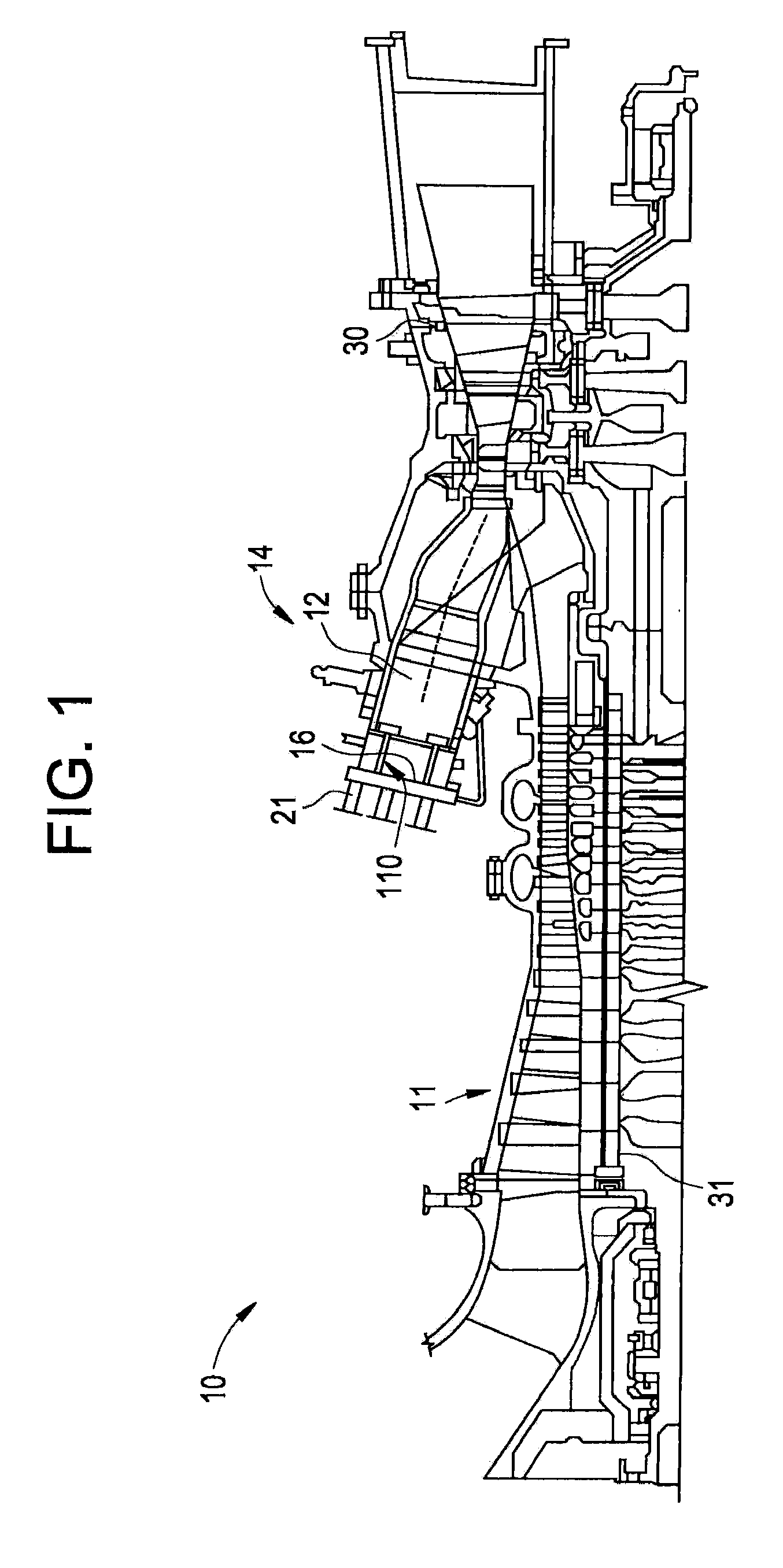

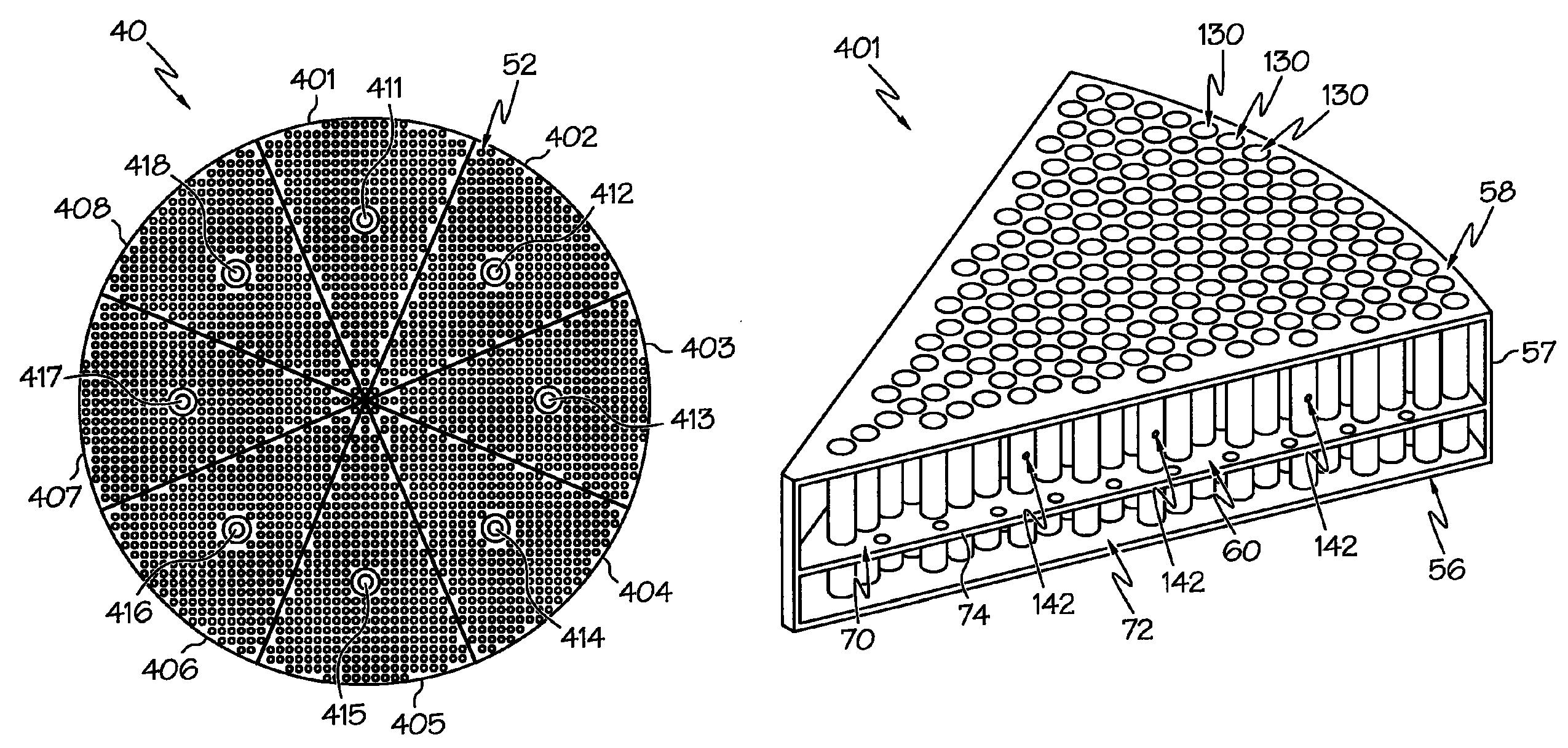

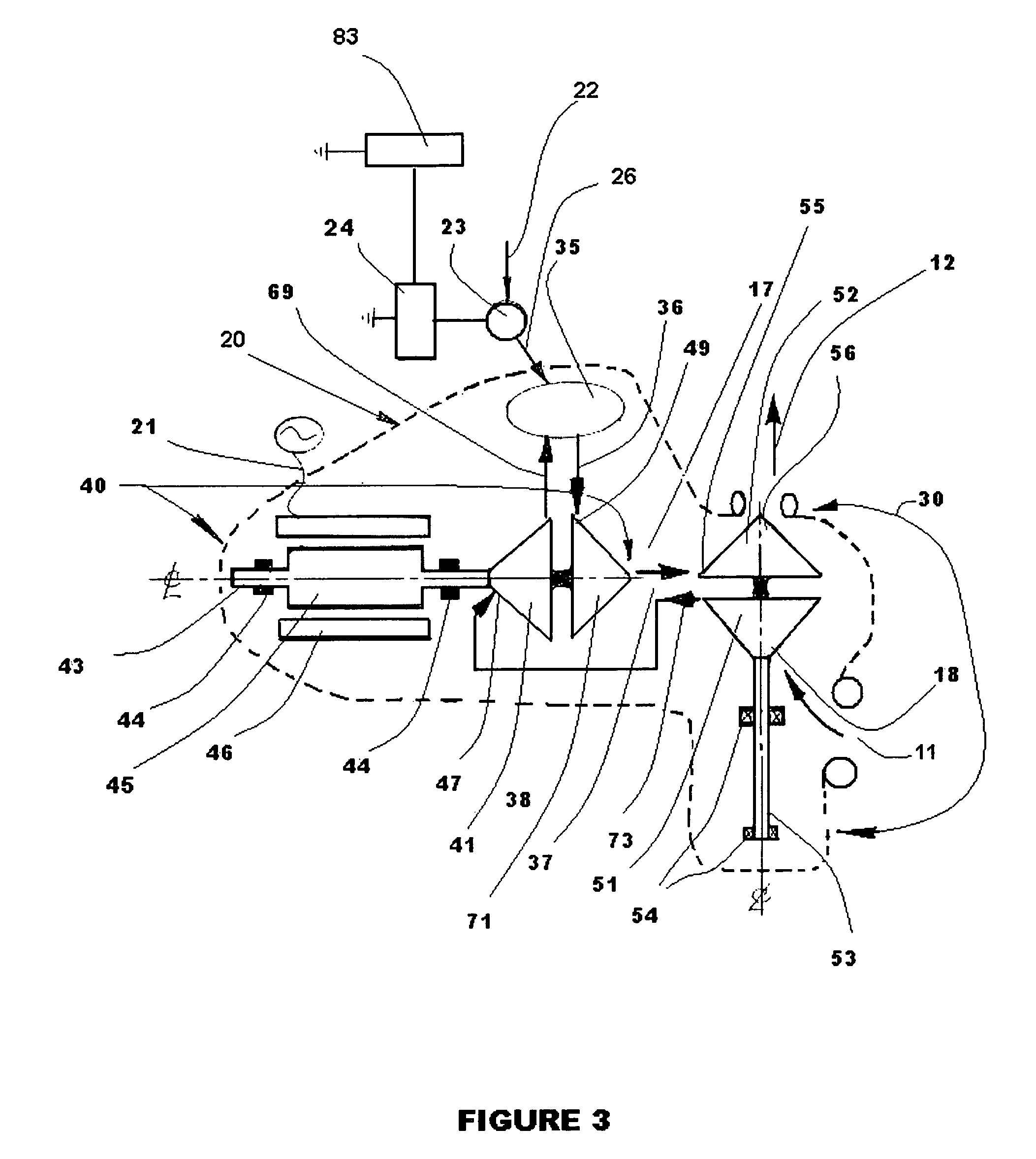

Premixed direct injection disk

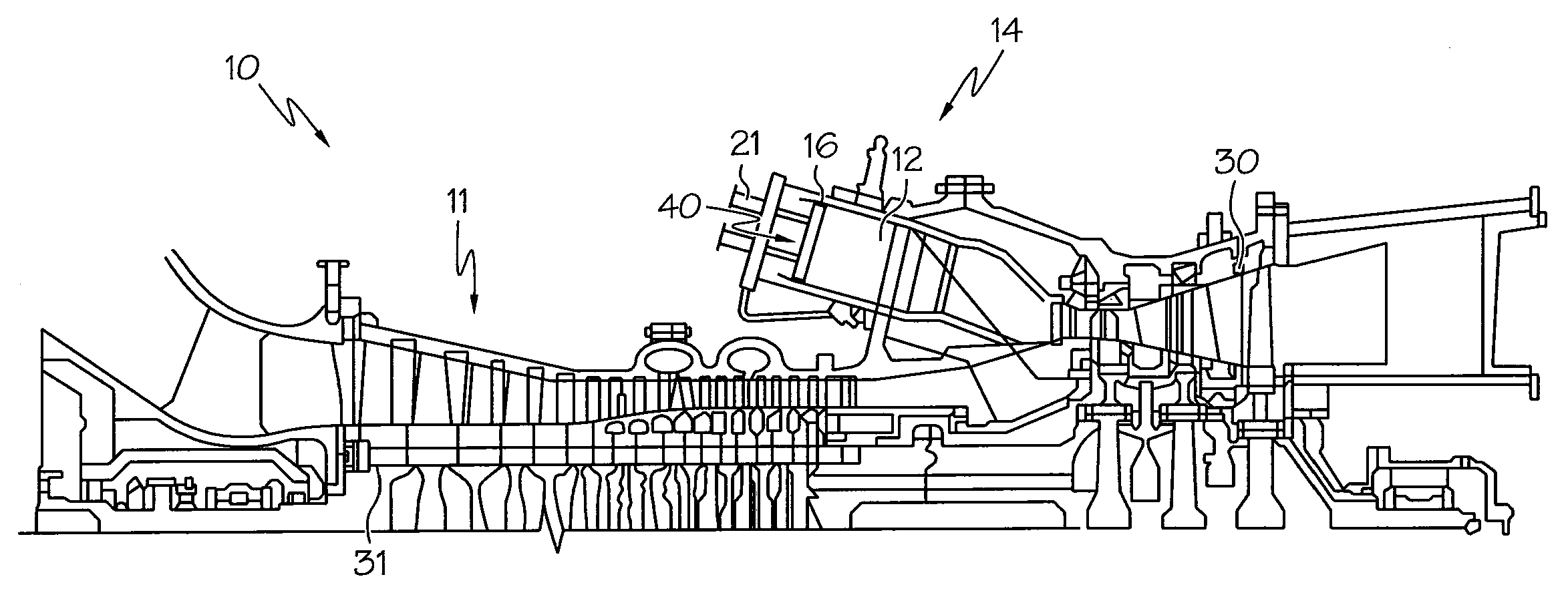

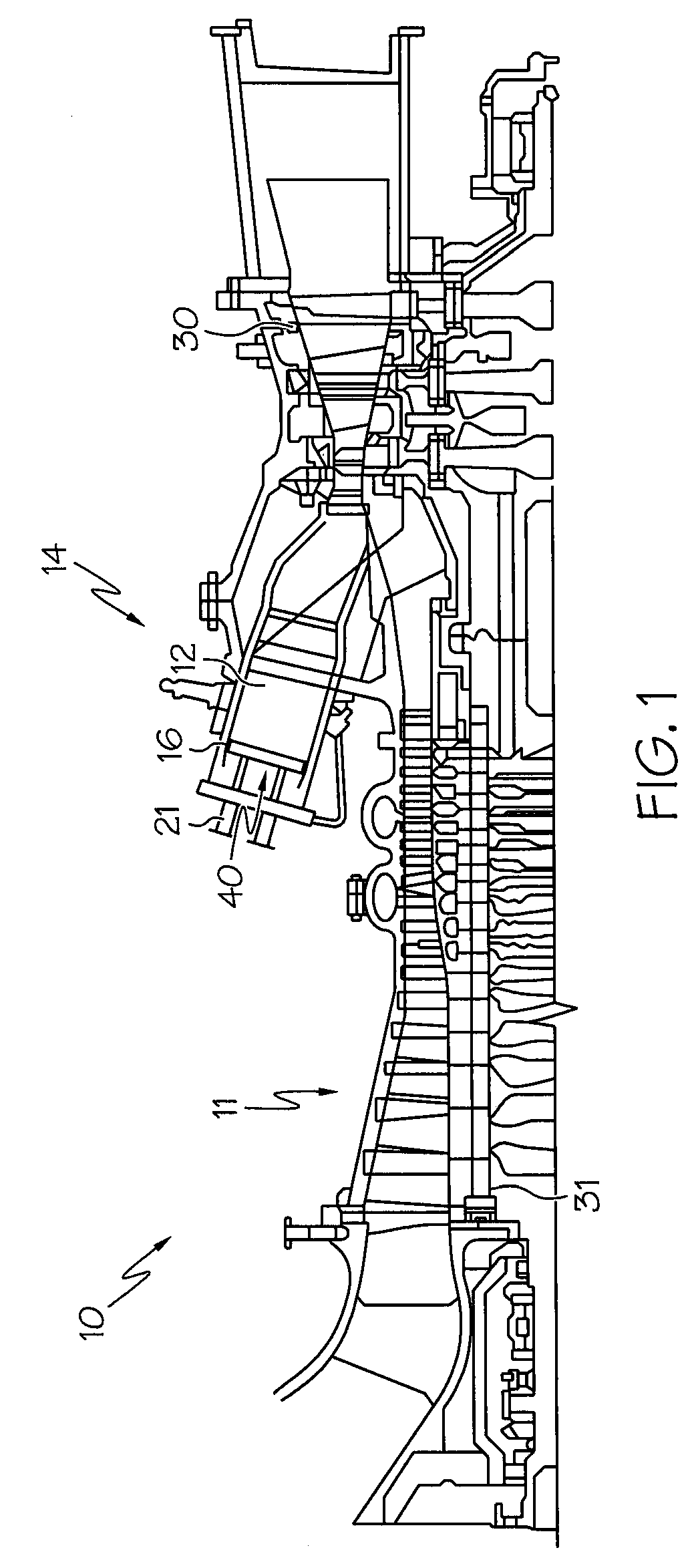

ActiveUS20100218501A1Reduce riskAir mix wellBurner safety arrangementsContinuous combustion chamberCombustorEngineering

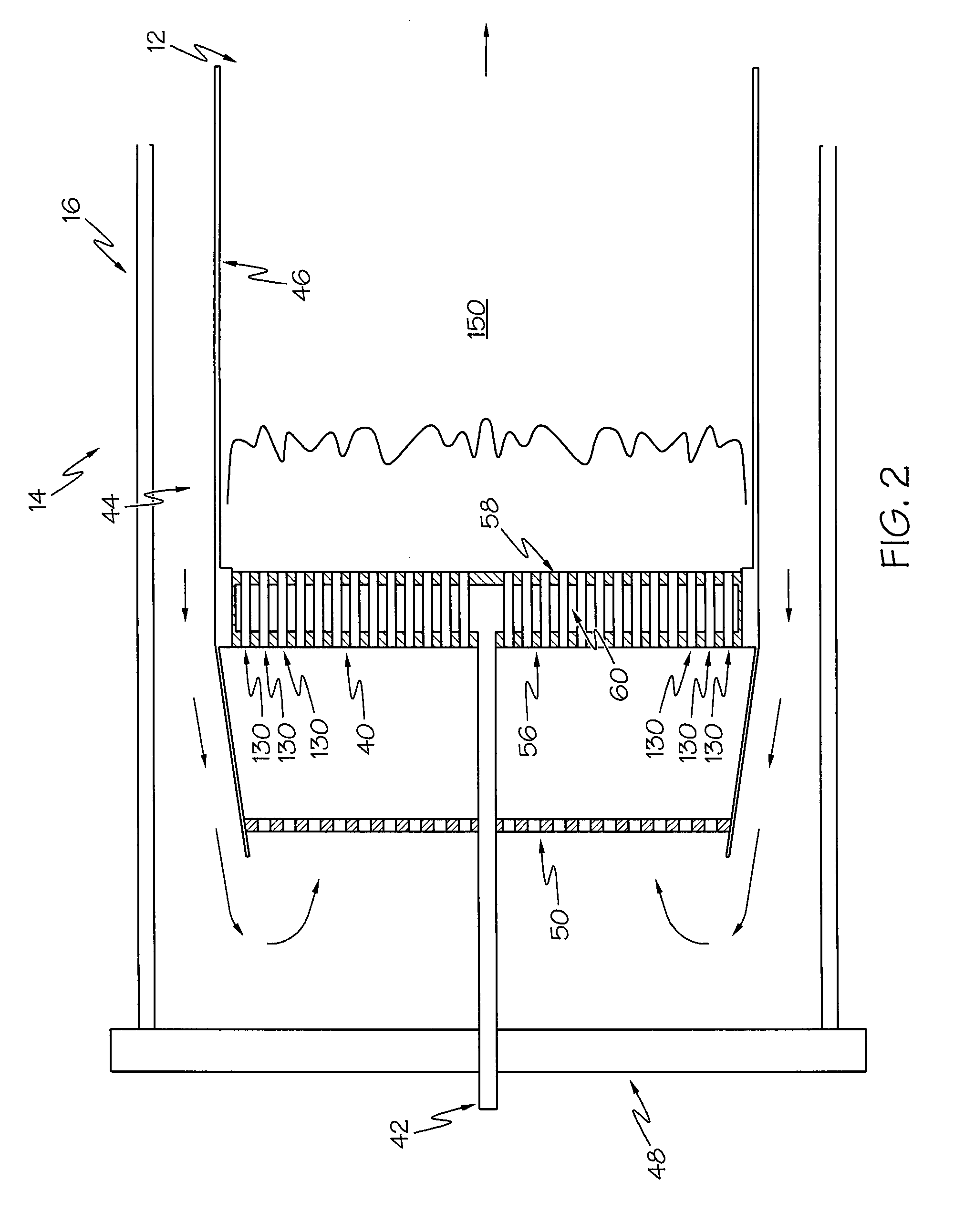

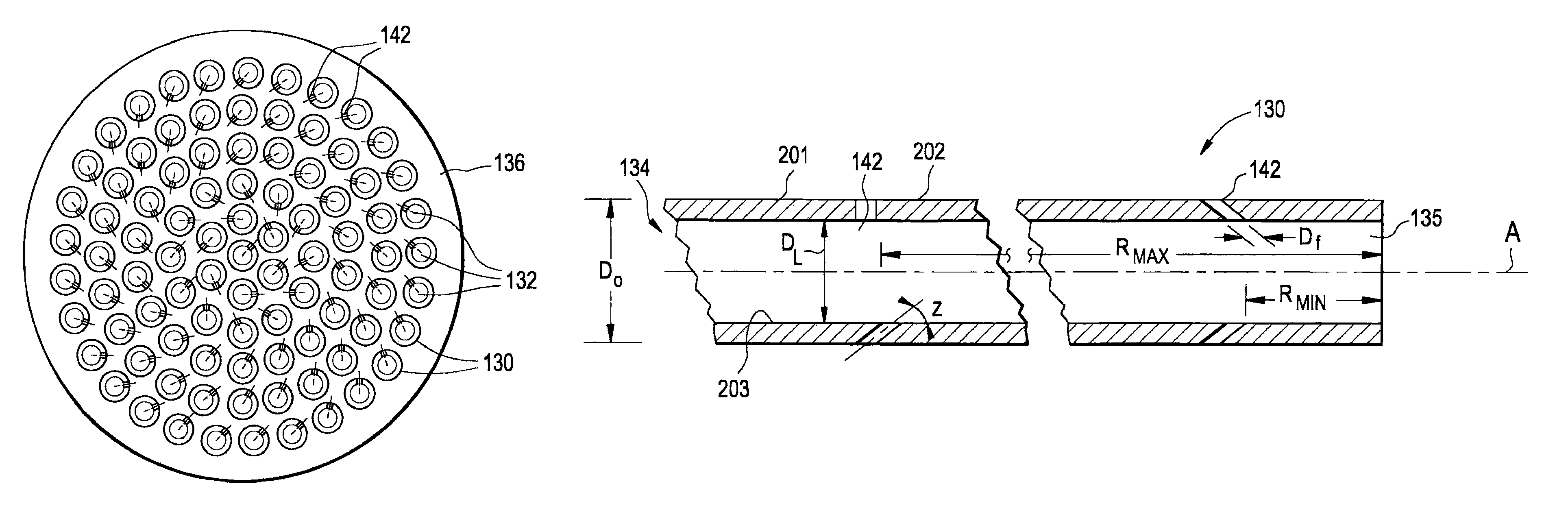

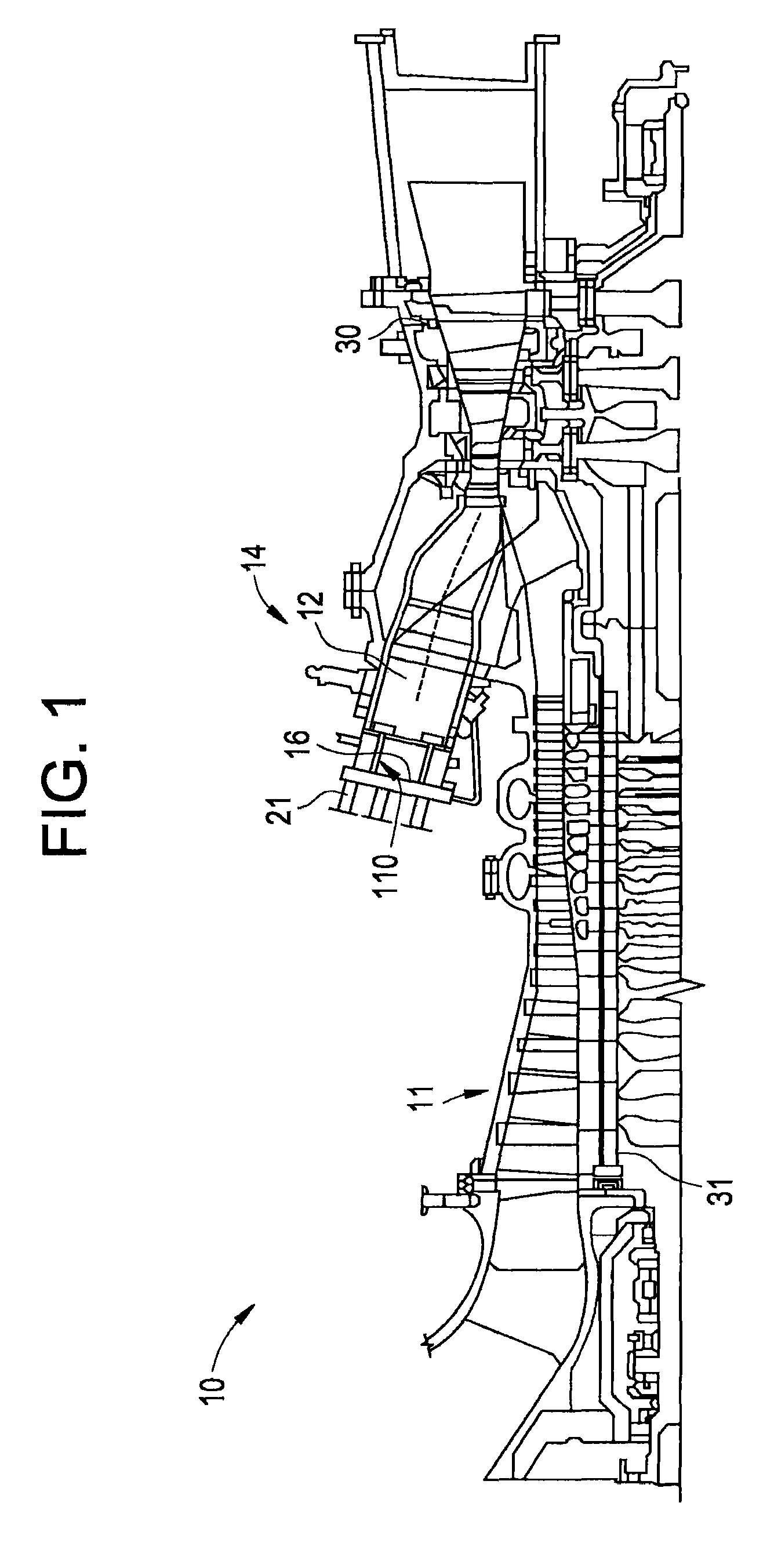

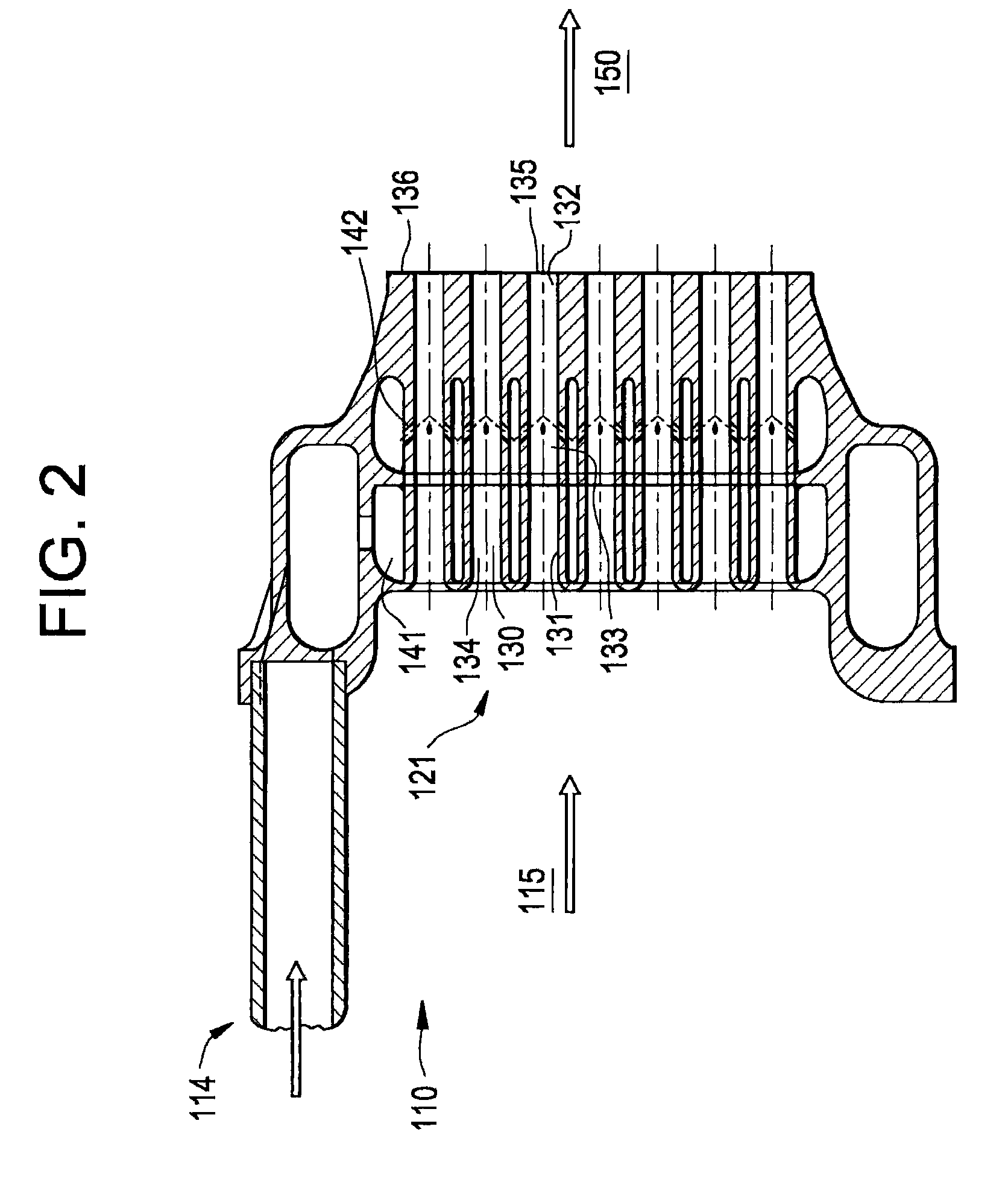

A fuel / air mixing disk for use in a fuel / air mixing combustor assembly is provided. The disk includes a first face, a second face, and at least one fuel plenum disposed therebetween. A plurality of fuel / air mixing tubes extend through the pre-mixing disk, each mixing tube including an outer tube wall extending axially along a tube axis and in fluid communication with the at least one fuel plenum. At least a portion of the plurality of fuel / air mixing tubes further includes at least one fuel injection hole have a fuel injection hole diameter extending through said outer tube wall, the fuel injection hole having an injection angle relative to the tube axis. The invention provides good fuel air mixing with low combustion generated NOx and low flow pressure loss translating to a high gas turbine efficiency, that is durable, and resistant to flame holding and flash back.

Owner:GENERAL ELECTRIC CO

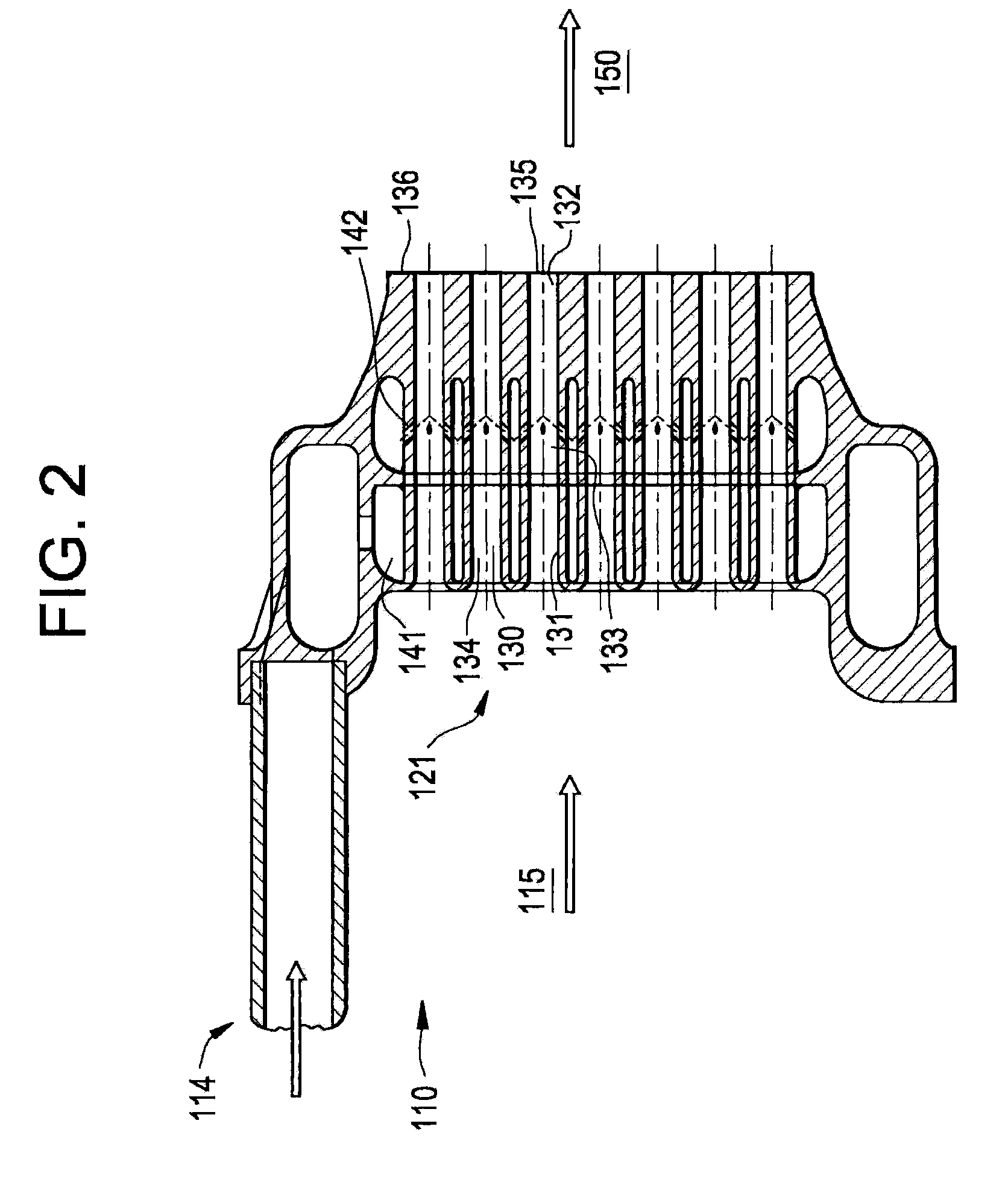

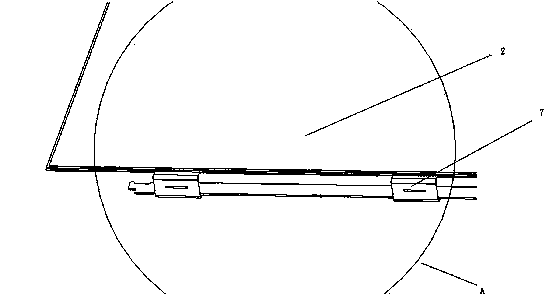

Premixed direct injection nozzle

ActiveUS20100192581A1Air mix wellReduce burnBurnersContinuous combustion chamberEngineeringGas turbines

A fuel / air mixing tube for use in a fuel / air mixing tube bundle is provided. The fuel / air mixing tube includes an outer tube wall extending axially along a tube axis between an inlet end and an exit end, the outer tube wall having a thickness extending between an inner tube surface having a inner diameter and an outer tube surface having an outer tube diameter. The tube further includes at least one fuel injection hole having a fuel injection hole diameter extending through the outer tube wall, the fuel injection hole having an injection angle relative to the tube axis. The invention provides good fuel air mixing with low combustion generated NOx and low flow pressure loss translating to a high gas turbine efficiency, that is durable, and resistant to flame holding and flash back.

Owner:GENERAL ELECTRIC CO

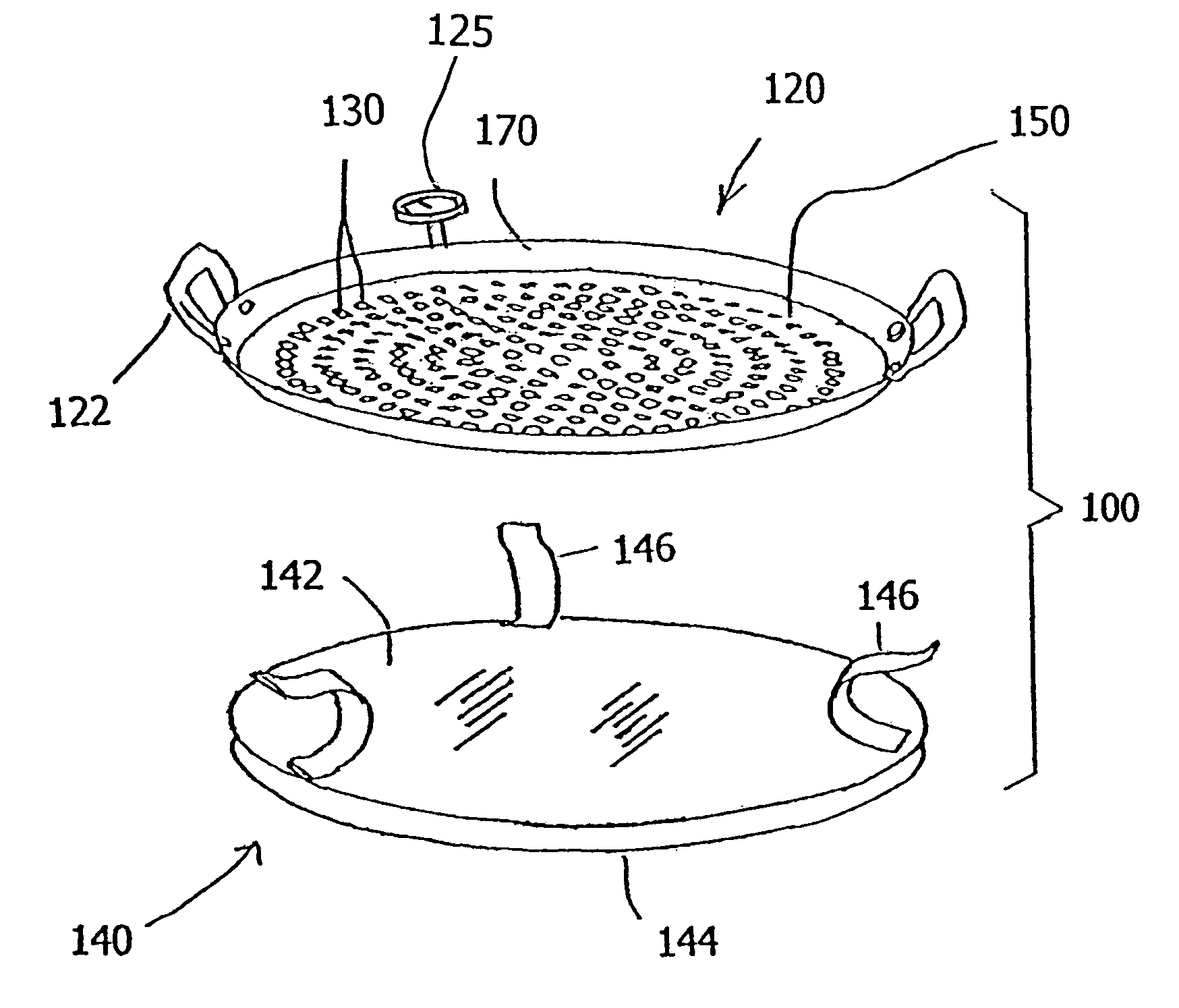

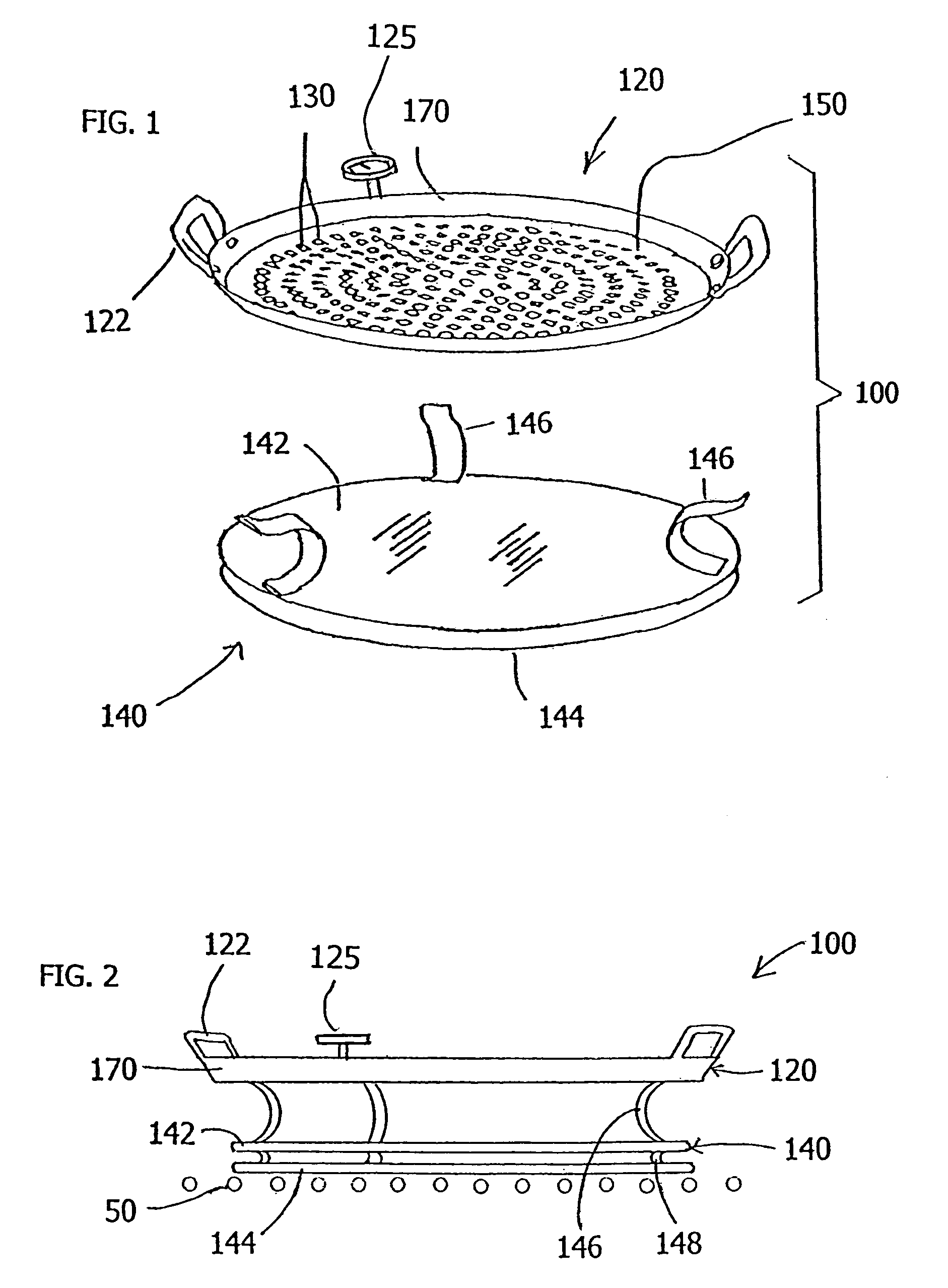

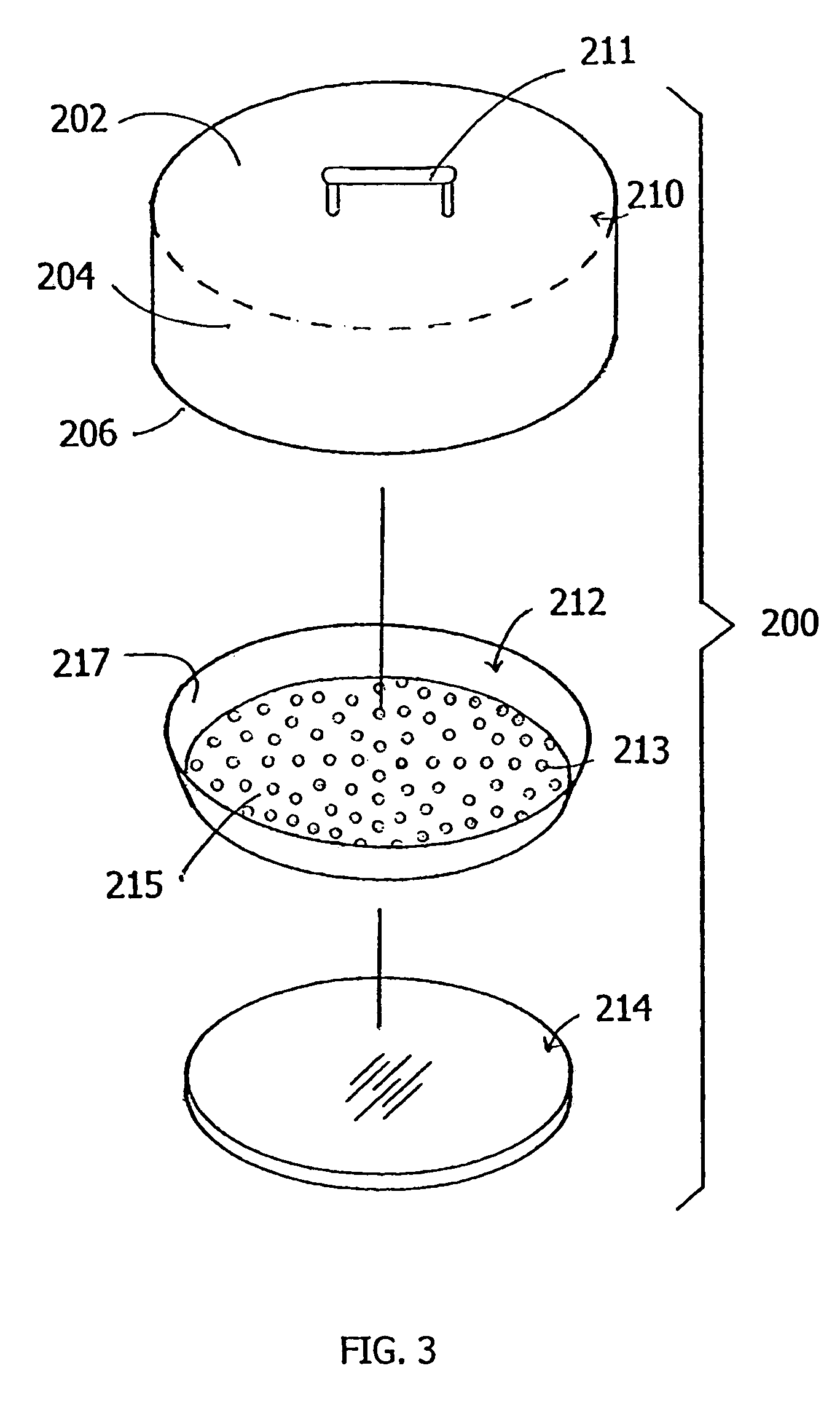

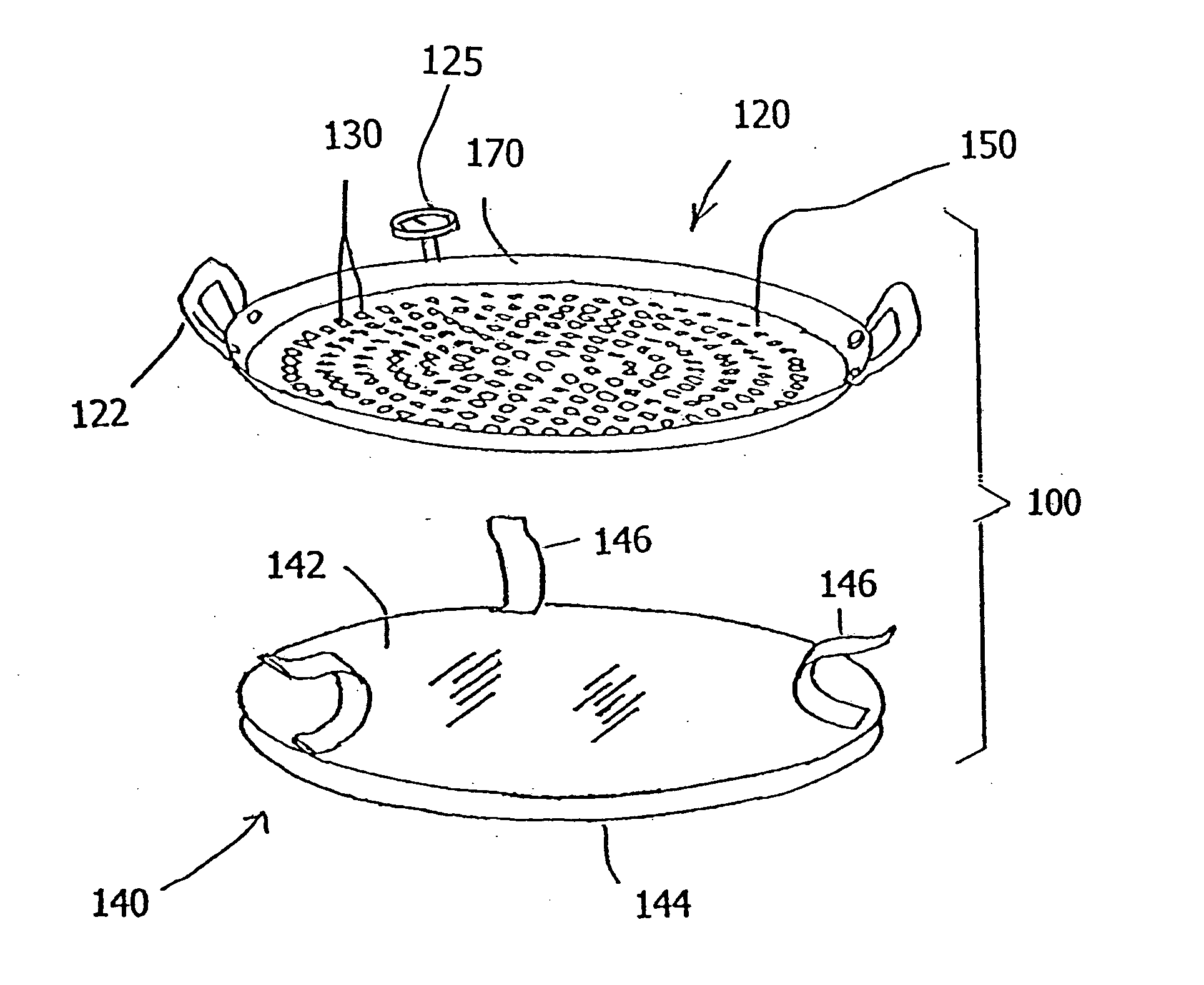

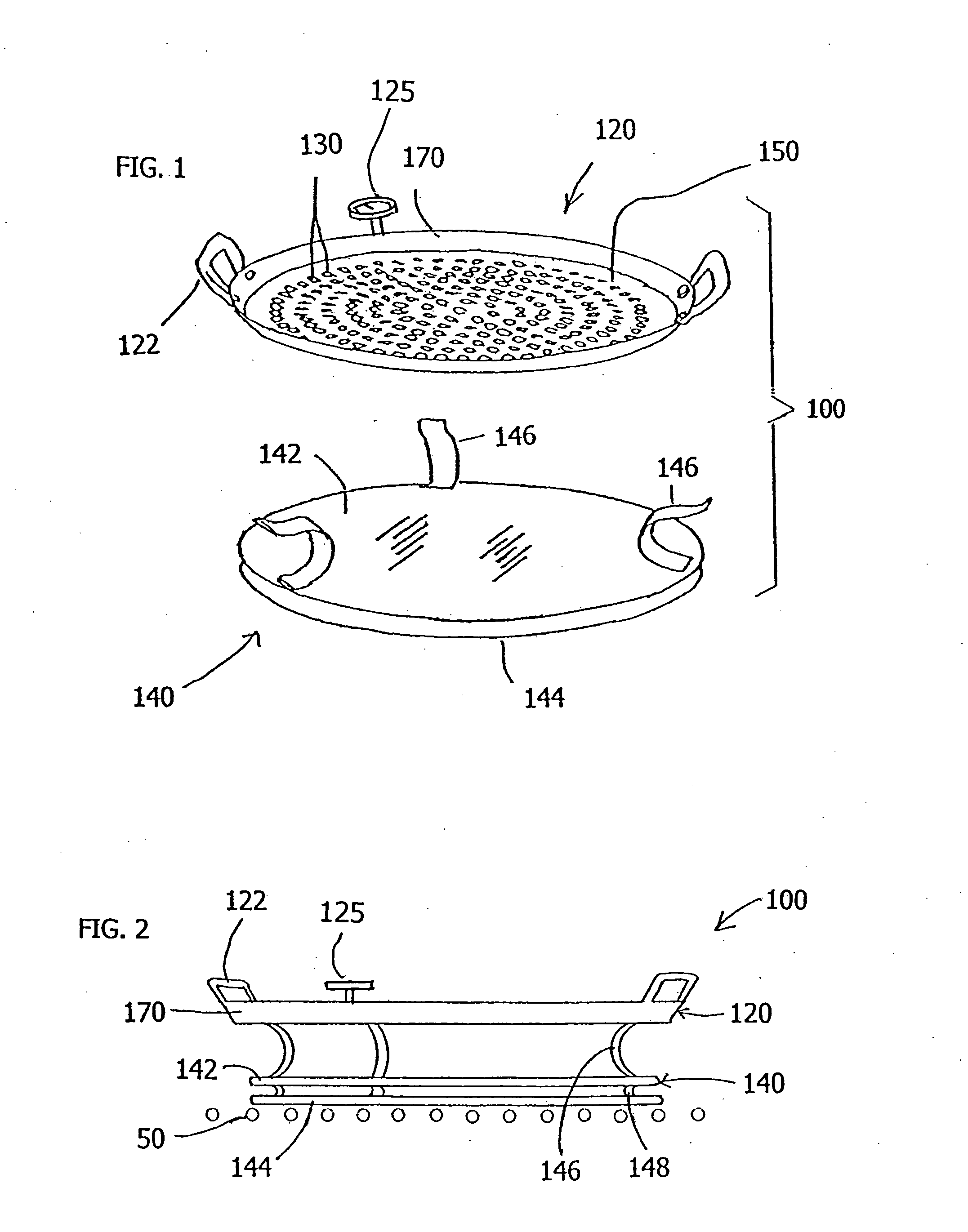

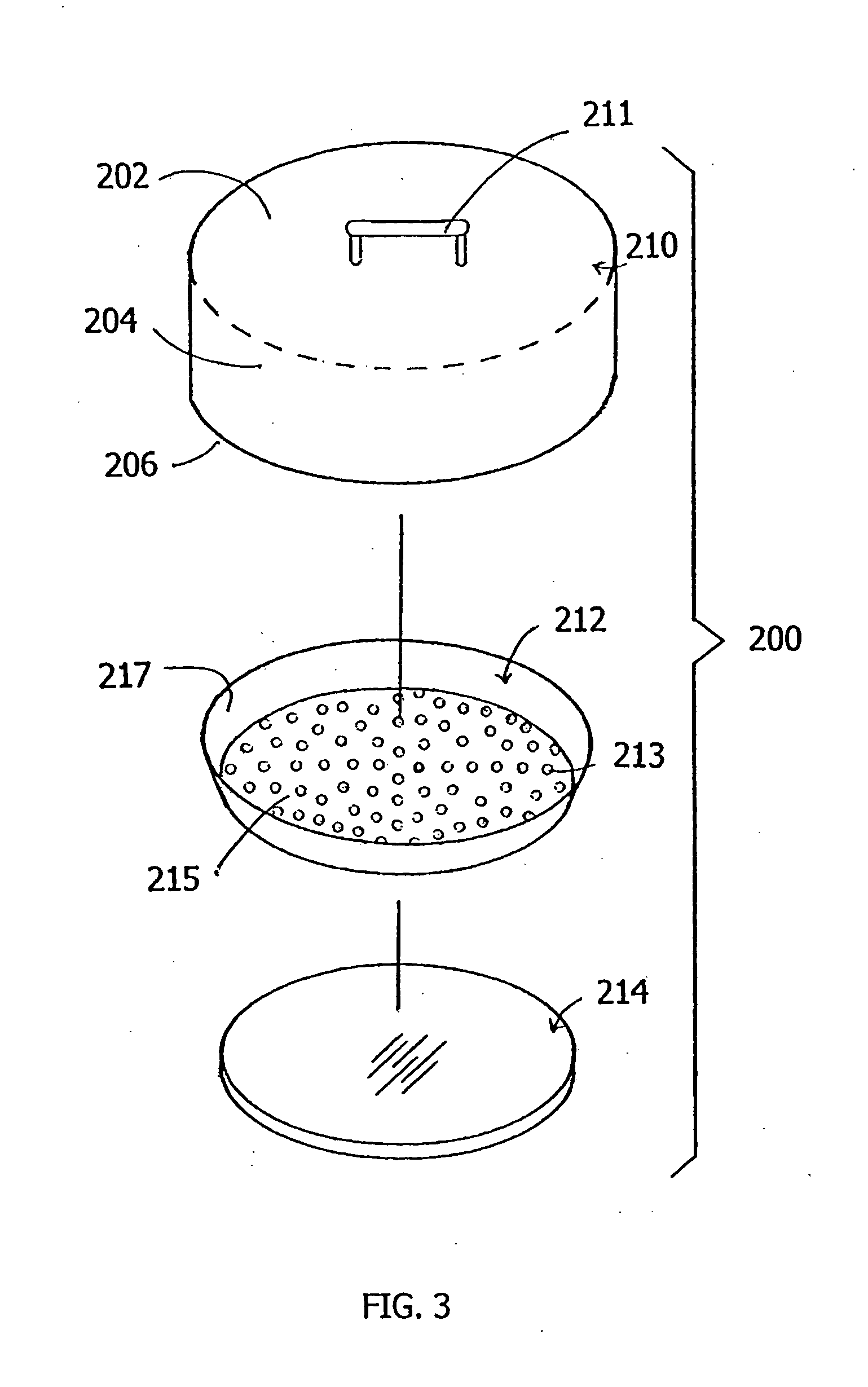

Kit, apparatus and method for use in cooking over an intense heat source

InactiveUS7219663B2Firm supportModerates being transferredDomestic stoves or rangesLiquid heating fuelEngineeringHeat shield

A portable cooking kit, apparatus and method is usable for moderating heat from an intense heat source, such as an outdoor grill or 1. The apparatus includes a food support member, including a perforated panel surrounded by a rim. The food support member rests on top of a heat shield made from a heat-tolerant material. During use, the heat shield is stably suspended over direct, intense heat from a heat source. The food to be cooked is placed on the food support member, and the food support member may then be placed on top of the heat shield. By buffering the direct heat from the heat source, the heat shield allows food placed on the food support member to cook, but protects the underside of the food from becoming scorched. Optionally, a dome-shaped cover may be used to cover both the food support member and the heat shield.

Owner:ISLANDER INNOVATIONS

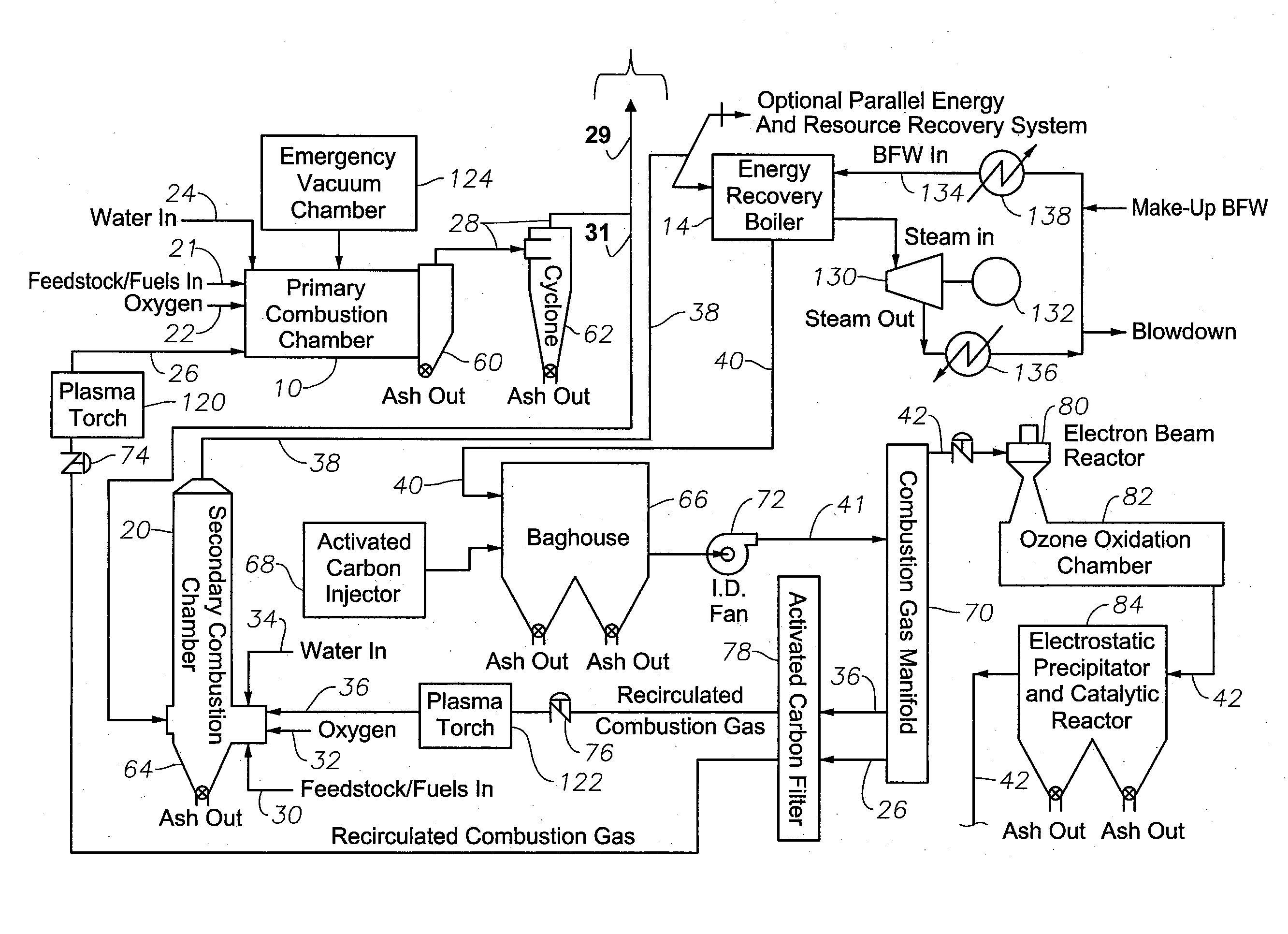

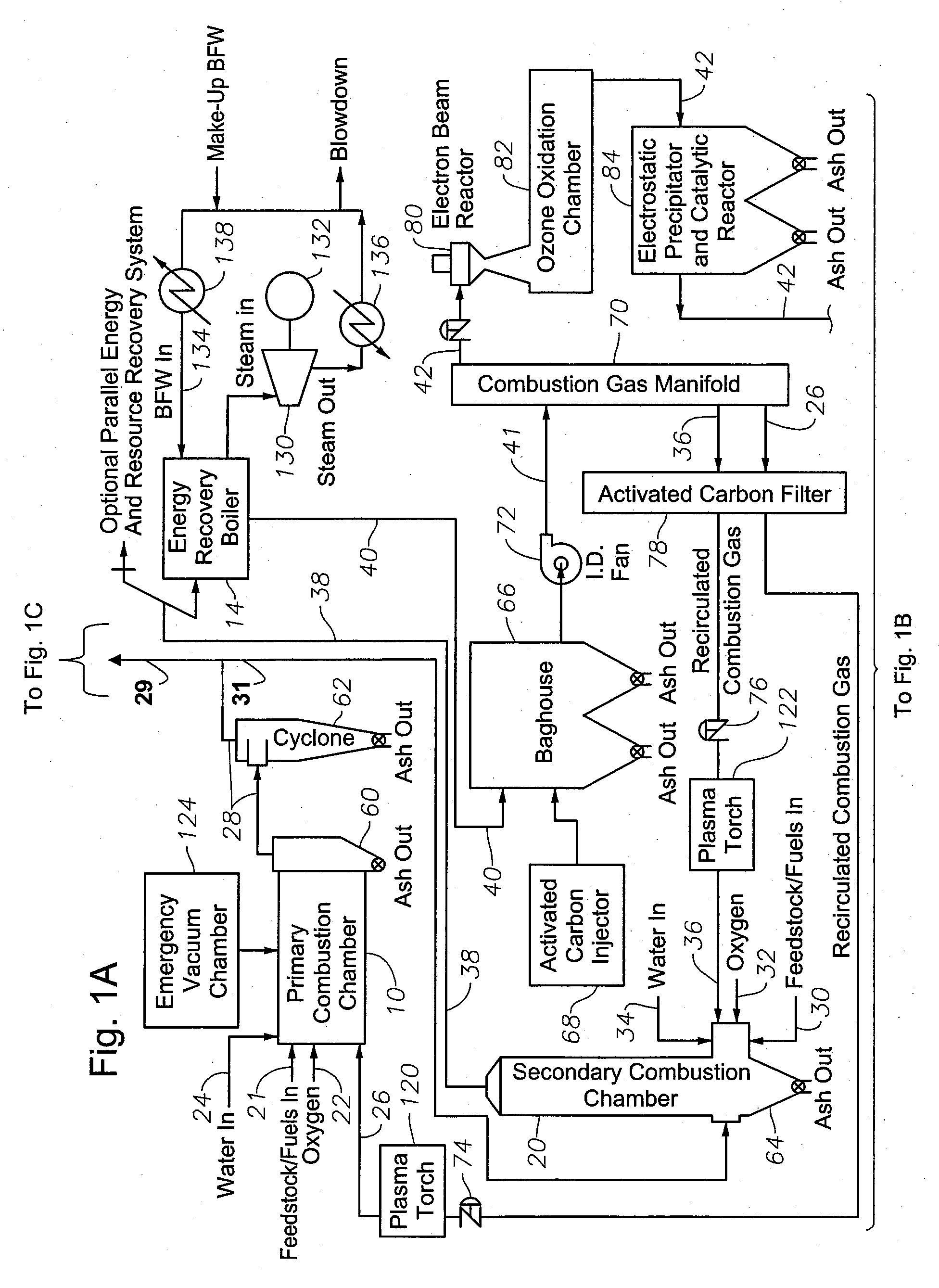

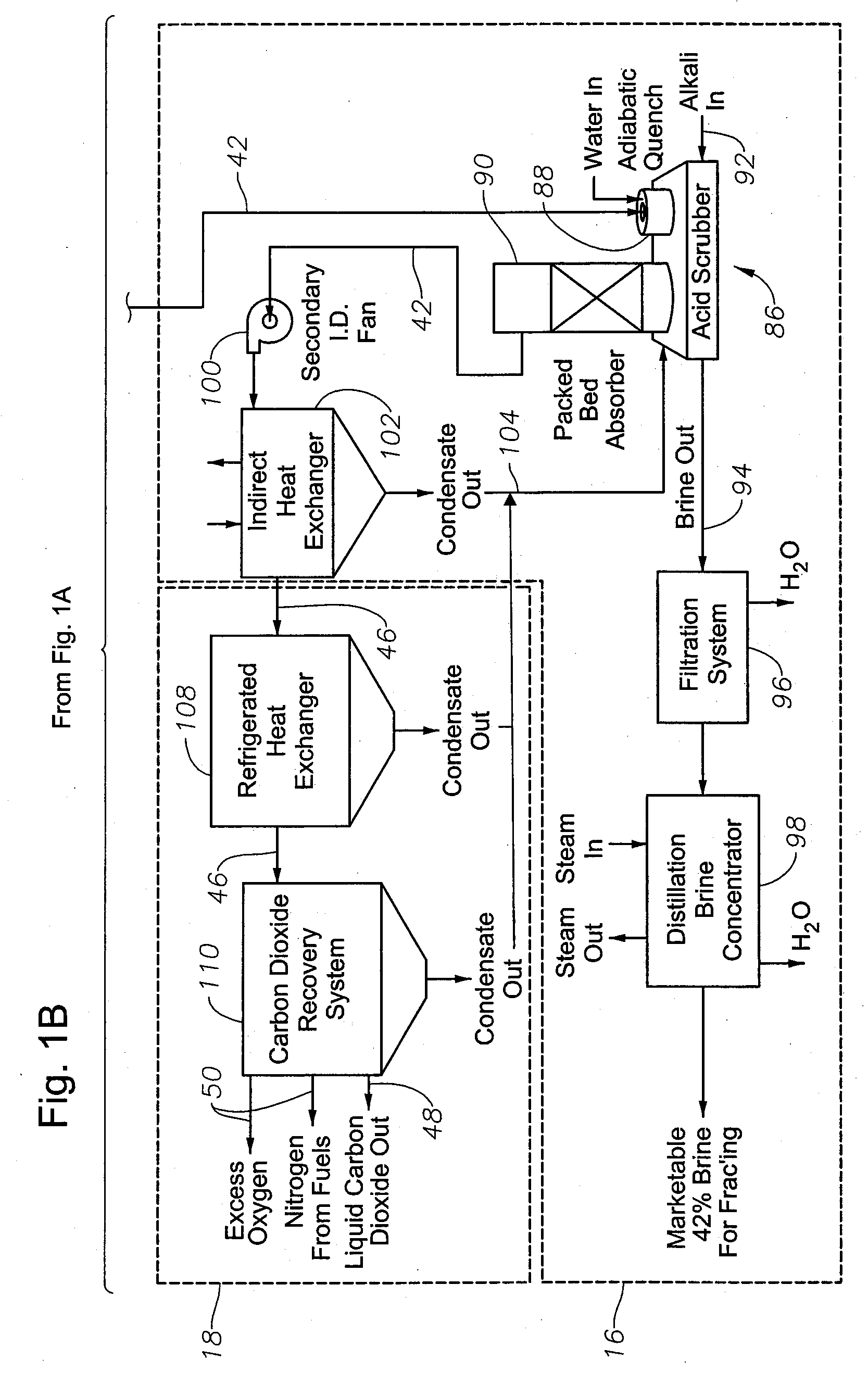

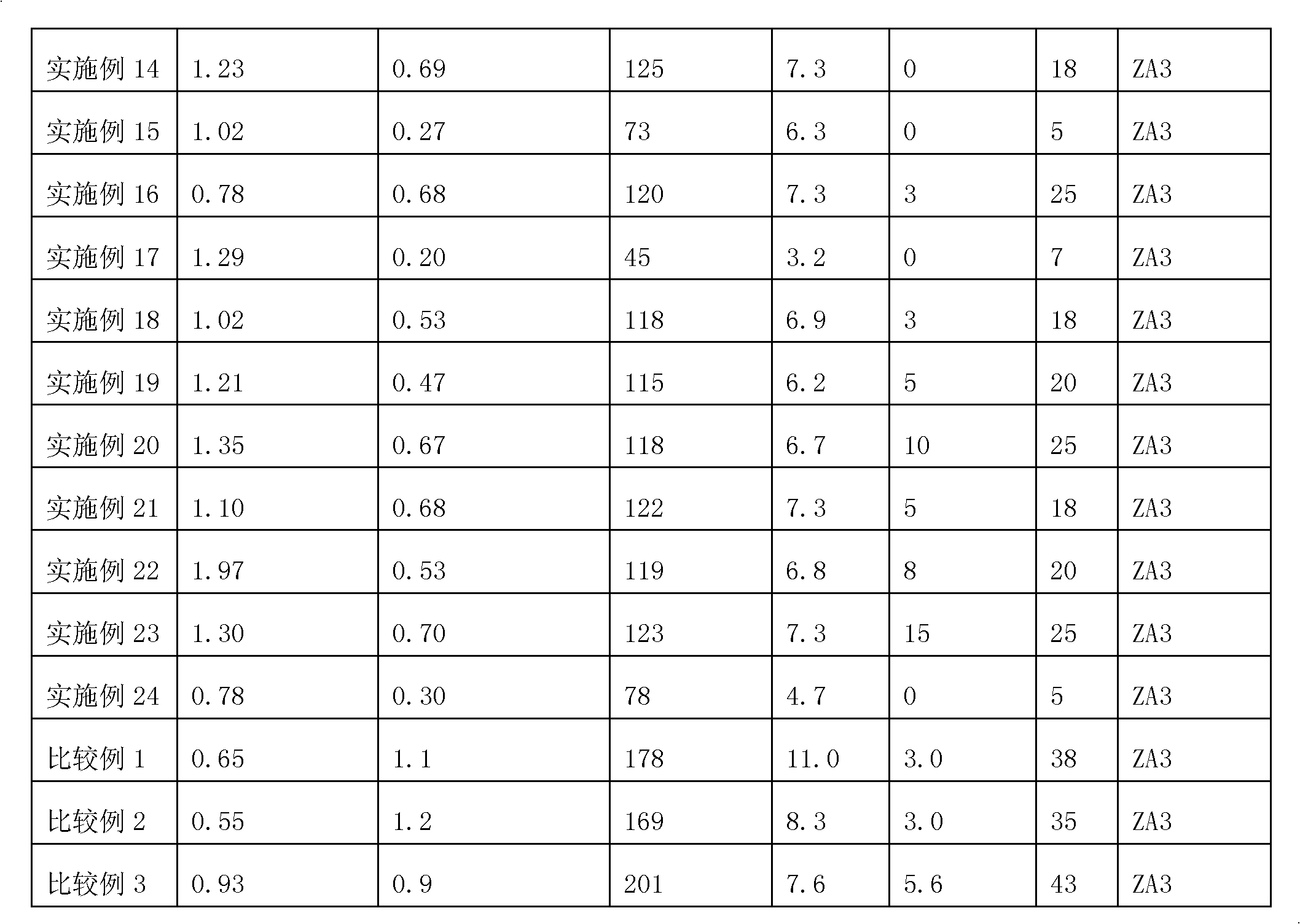

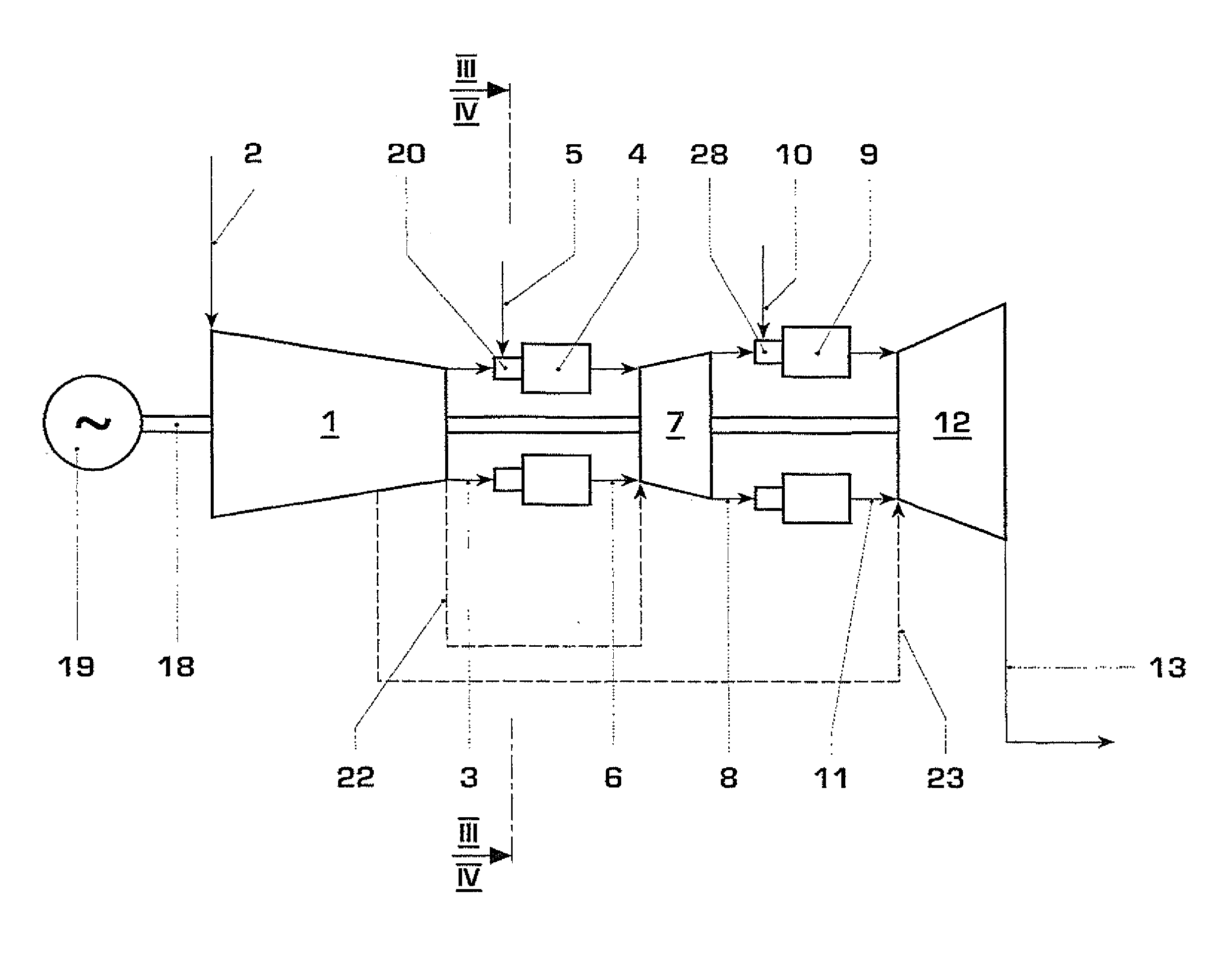

Reduced-Emission Gasification and Oxidation of Hydrocarbon Materials for Liquid Fuel Production

InactiveUS20080275278A1Reduce system sizeRaise the combustion temperatureGas modification by gas mixingLiquid hydrocarbon mixture productionThermal energyLiquid hydrocarbons

A system and process are disclosed for the controlled combustion of a wide variety of hydrocarbon feedstocks to produce thermal energy, liquid fuels, and other valuable products with little or no emissions. The hydrocarbon feeds, such as coal and biomass, are first gasified and then oxidized in a two-chamber system / process using pure oxygen rather than ambient air. A portion of the intermediate gases generated in the system / process are sent to a Fischer-Tropsch synthesis process for conversion into diesel fuel and other desired liquid hydrocarbons. The remaining intermediate gases are circulated and recycled through each of the gasification / oxidation chambers in order to maximize energy production. The energy produced through the system / process is used to generate steam and produce power through conventional steam turbine technology. In addition to the release of heat energy, the hydrocarbon fuels are oxidized to the pure product compounds of water and carbon dioxide, which are subsequently purified and marketed. The system / process minimizes environmental emissions.

Owner:CLARK STEVE L

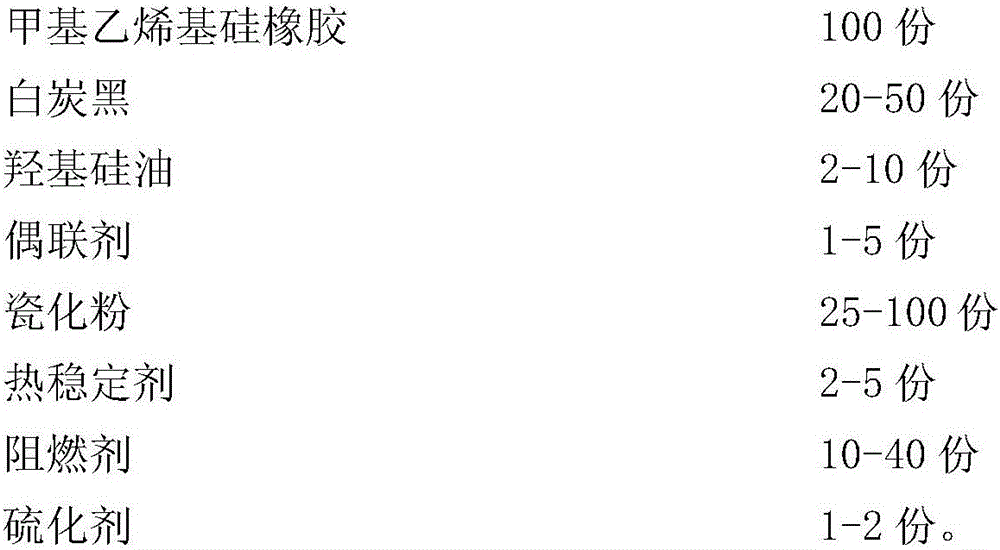

Preparation method of ceramizing fire-resistant silicon rubber

ActiveCN105694471AImprove flame retardant performanceWill not affect other performanceHalogenCombustion

The invention relates to a preparation method of ceramizing fire-resistant silicon rubber. The rubber comprises the following components in parts by weight: 100 parts of methyl vinyl silicon rubber, 20-50 parts of white carbon black, 2-10 parts of hydroxyl silicone oil, 1-5 parts of a coupling agent, 25-100 parts of ceramizing powder, 2-5 parts of a heat stabilizer, 10-40 parts of a fire retardant, and 1-2 parts of a vulcanizer. The preparation method includes the following steps: adding the methyl vinyl silicon rubber in a kneading machine; then adding the white carbon black and the hydroxyl silicone oil; mixing for 30 minutes at the temperature of 80 DEG C; then adding the coupling agent, the ceramizing powder, the heat stabilizer and the fire retardant; mixing for 1-1.5 hours; raising the temperature to be 100 DEG C and keeping high vacuum for 30 minutes; and after cooling to room temperature, adding the vulcanizer on an open mixing machine for mixing to obtain the ceramizing fire-resistant silicon rubber. The rubber has good mechanical property and electrical property at normal temperature, does not contain halogen, is smokeless and non-toxic during combustion, can be extinguished quickly and forms a ceramizing shell to guarantee integrity of the inside.

Owner:BEIJING UNIV OF CHEM TECH

Premixed direct injection disk

ActiveUS8424311B2Reduce riskAir mix wellBurner safety arrangementsContinuous combustion chamberCombustorGas turbines

Owner:GE INFRASTRUCTURE TECH INT LLC

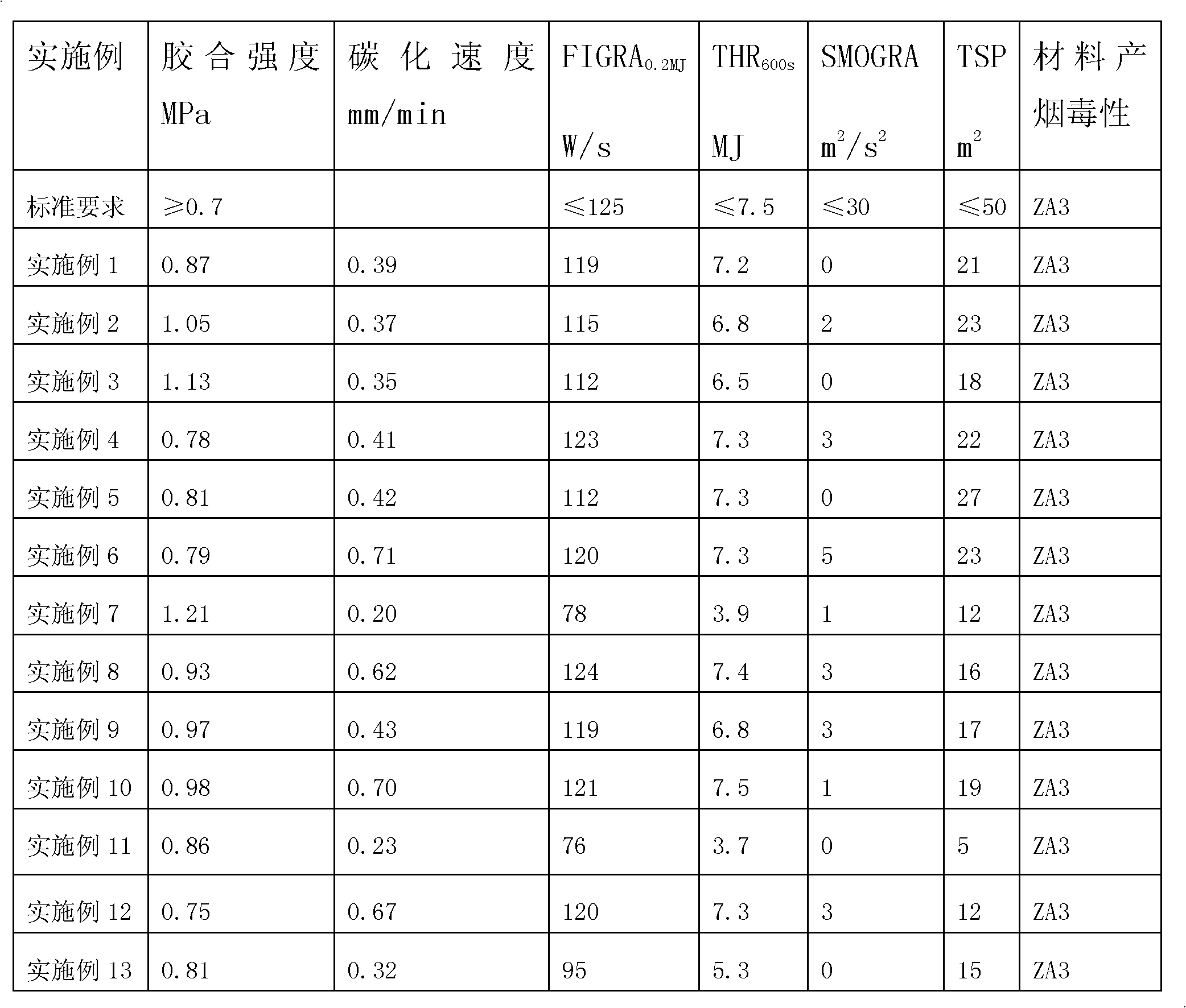

Antiflaming plywood or veneer lamination and manufacturing method thereof

ActiveCN102114650ASlow down the rate of carbonizationReduce burnWood veneer joiningWood impregnation detailsAdhesiveCarbonization

The invention discloses an antiflaming plywood or a veneer lamination, which comprises a wood veneer, a phosphorus-nitrogen fire retardant, a boron fire retardant, oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium, and an adhesive, which have over dry weight percentage ratio being 100:2-50:0.2-30:4-40. The antiflaming plywood or the veneer lamination has the characteristics of low carbonization speed, accordance with related standards on physical mechanics property, flame retardant property and smoke toxicity, low formaldehyde emission values, and the like; the invention further discloses a manufacturing method for the antiflaming plywood or the veneer lamination, which comprises the following steps: impregnating the phosphorus-nitrogen fire retardant, the boron fire retardant, the oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium on the wood veneer, coating the adhesive, and conducting processing of assembling, prepressing, hot pressing, sand polishing and the like.

Owner:固安盛辉阻燃材料有限公司

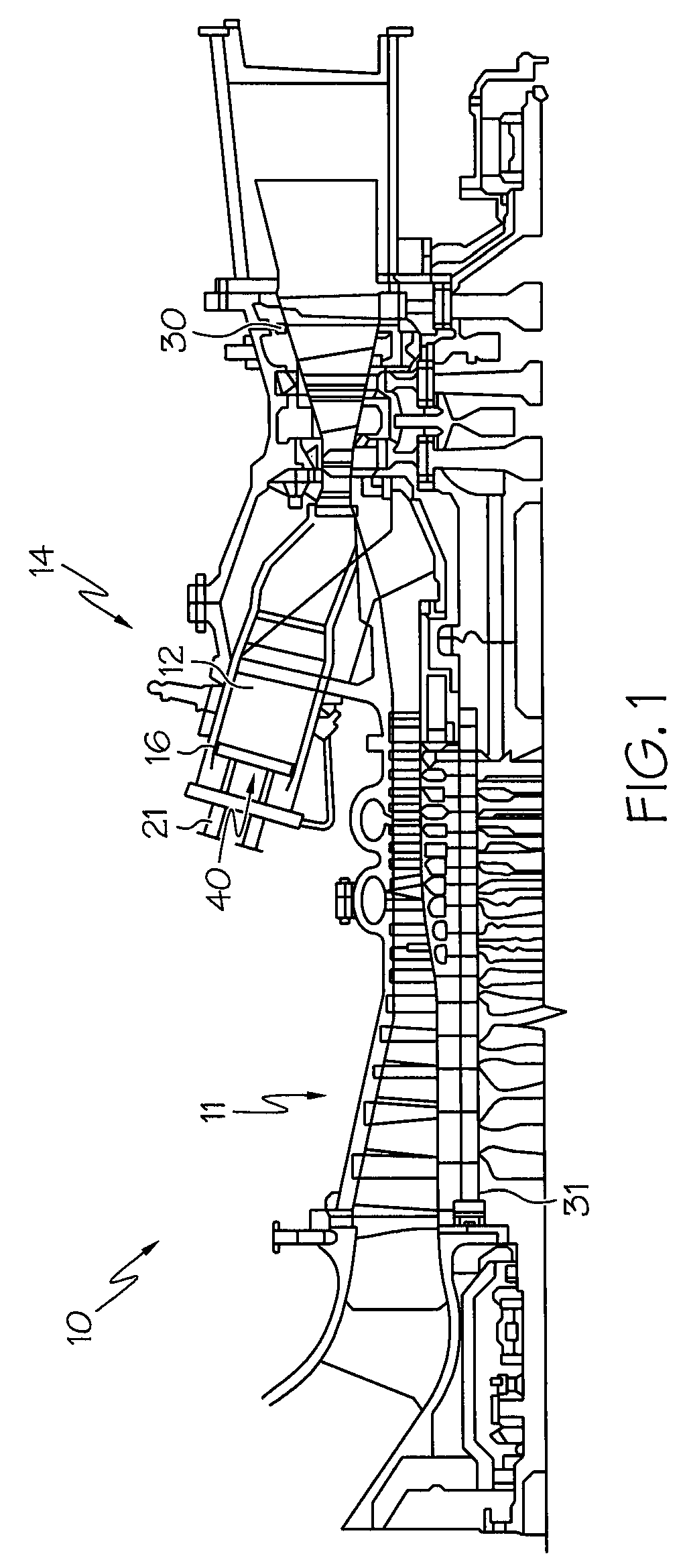

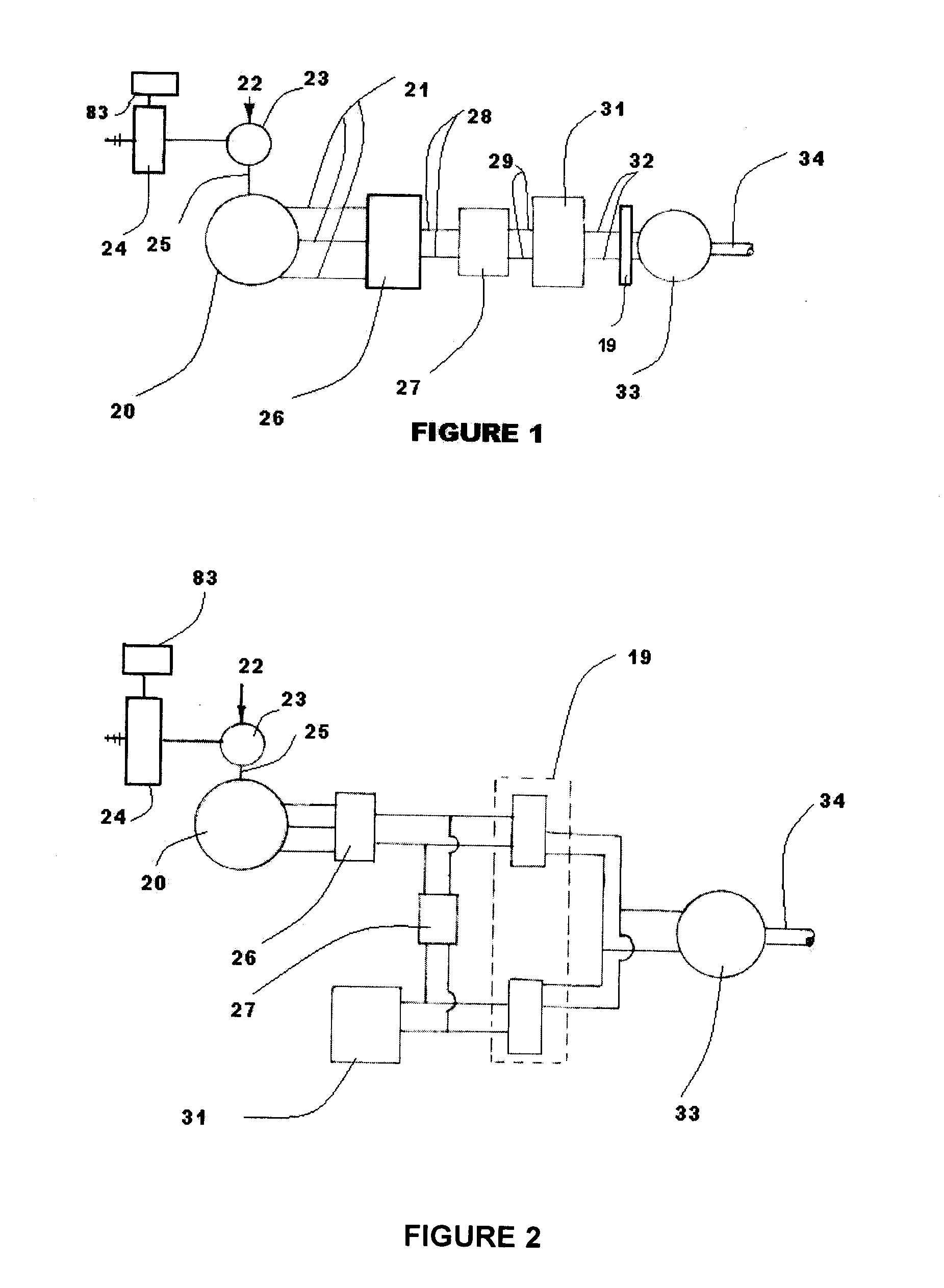

Hybrid electric power for vehicular propulsion

ActiveUS8552575B2Increase rangeIncrease usageNetwork traffic/resource managementRoad vehicles traffic controlElectric powerThrottle

Owner:TEETAB JOSEPH MICHAEL +1

Rigid polyurethane foam

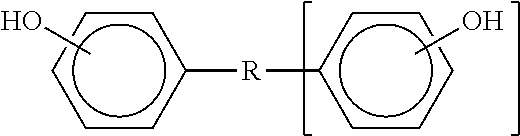

InactiveUS20120009407A1Reduce burnMinimized scorchSynthetic resin layered productsIsocyanateChemistry

A rigid polyurethane foam includes the reaction product of a resin composition and an isocyanate composition. The resin composition includes a novolac polyol that has a general chemical structure:In this structure, R is an alkyl or alkylene group and the novolac polyol has an average hydroxyl functionality of from 2 to 30 calculated by dividing the weight average molecular weight of the novolac polyol by the equivalent weight of the novolac polyol. The novolac polyol is present in an amount of from 3 to 65 parts by weight per 100 parts by weight of the resin composition.

Owner:BASF AG

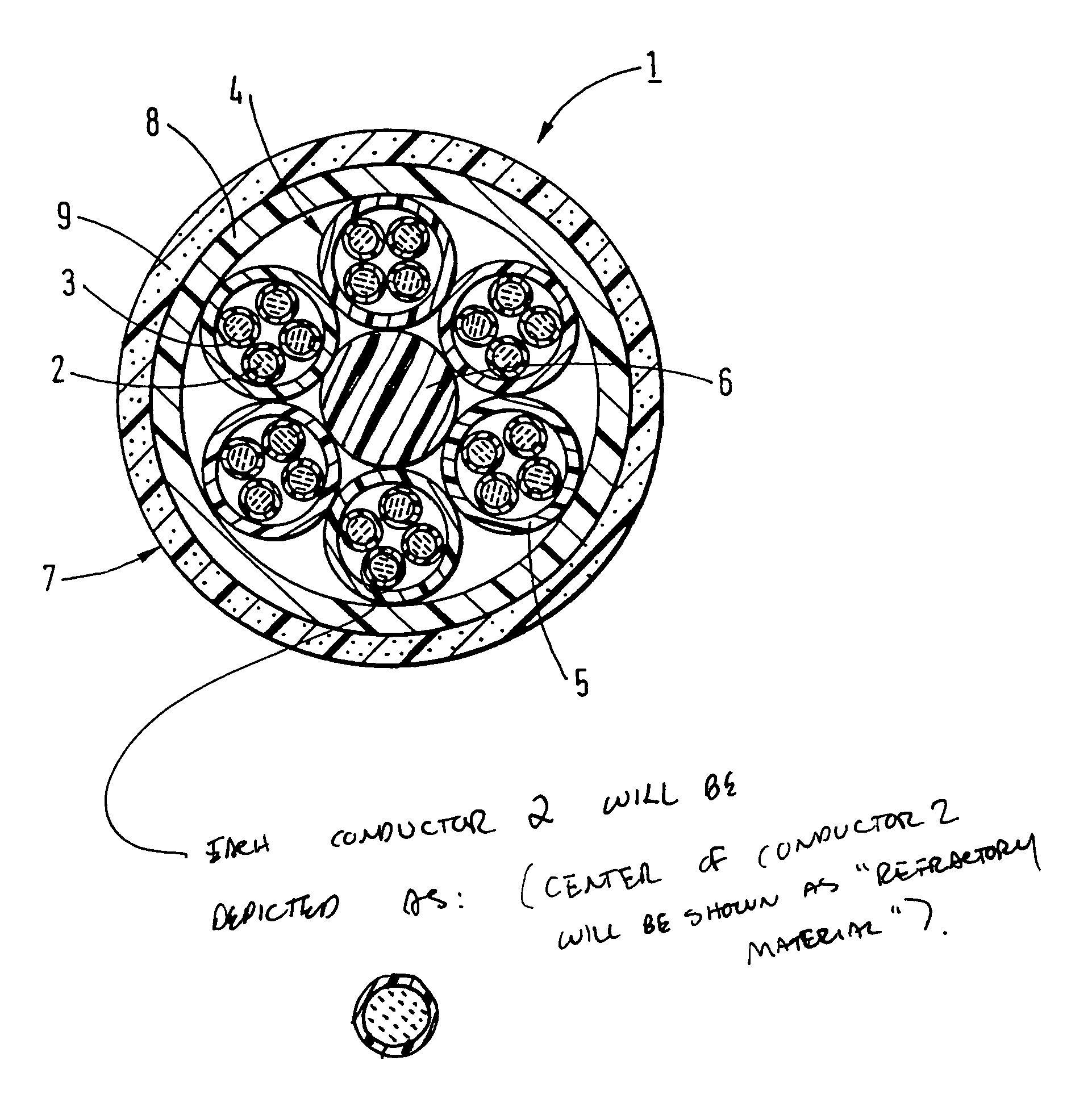

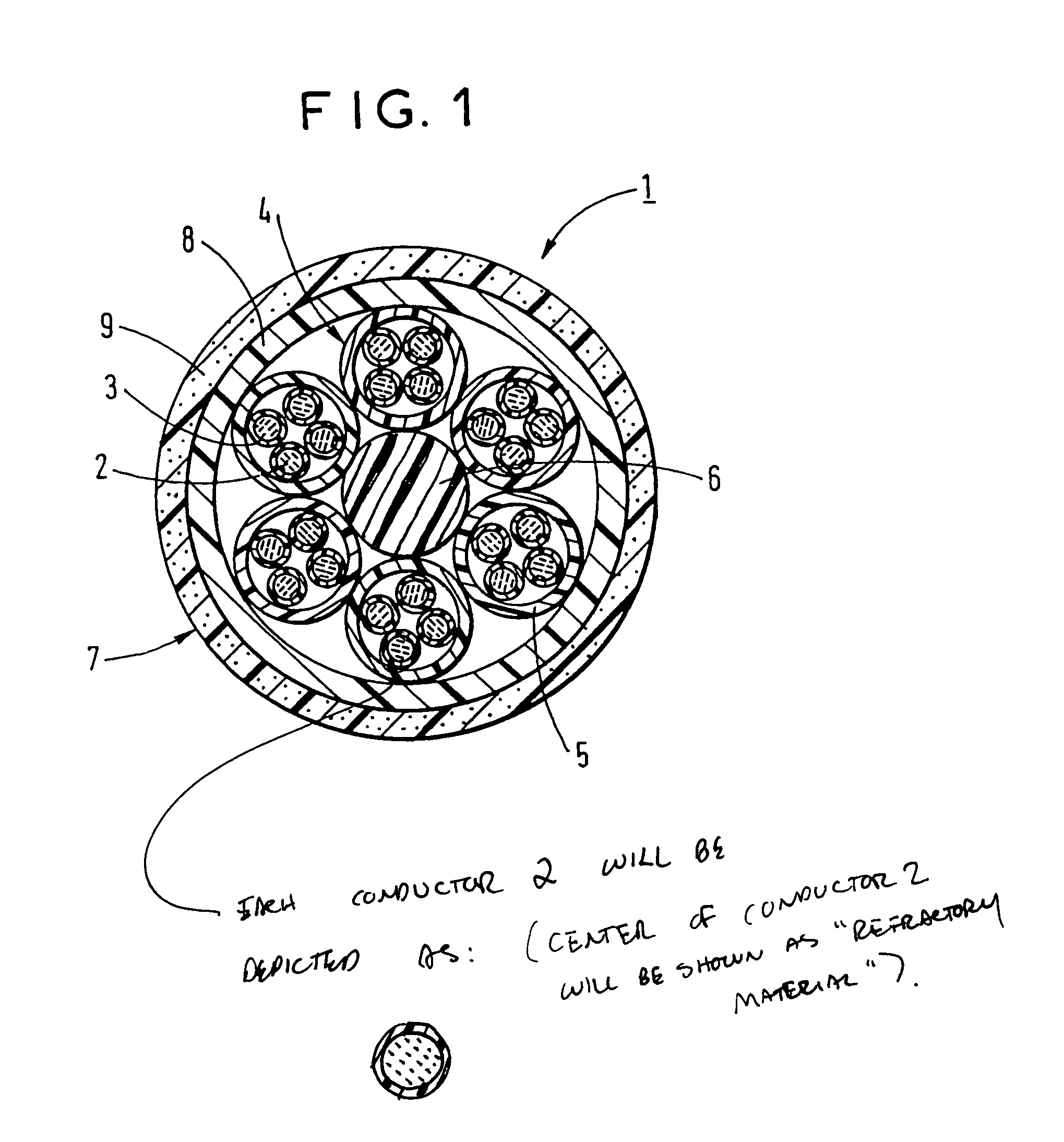

Cable sheath including a halogen-free intumescent composition

InactiveUS6998536B2Improve flame retardant performanceLow densityPlastic/resin/waxes insulatorsInsulated cablesLamellar crystalsPolyamide

The present invention relates to a sheath (7) for a cable (1), where the sheath contains, at least in part, a halogen-free intumescent composition. The composition of the sheath contains a mixture of a polymer matrix chosen from a polyethylene, a polypropylene, an ethylene copolymer, a propylene copolymer, a silicone, a polyamide, and a mixture thereof and at least one flame-retardant additive. The flame retardant additive has a first inorganic compound having a lamellar crystal structure, and a second inorganic compound inserted between the lamellae of the first compound, where the second compound causes the lamellae to move apart under the application of heat.

Owner:DRAKA COMTEQ BV

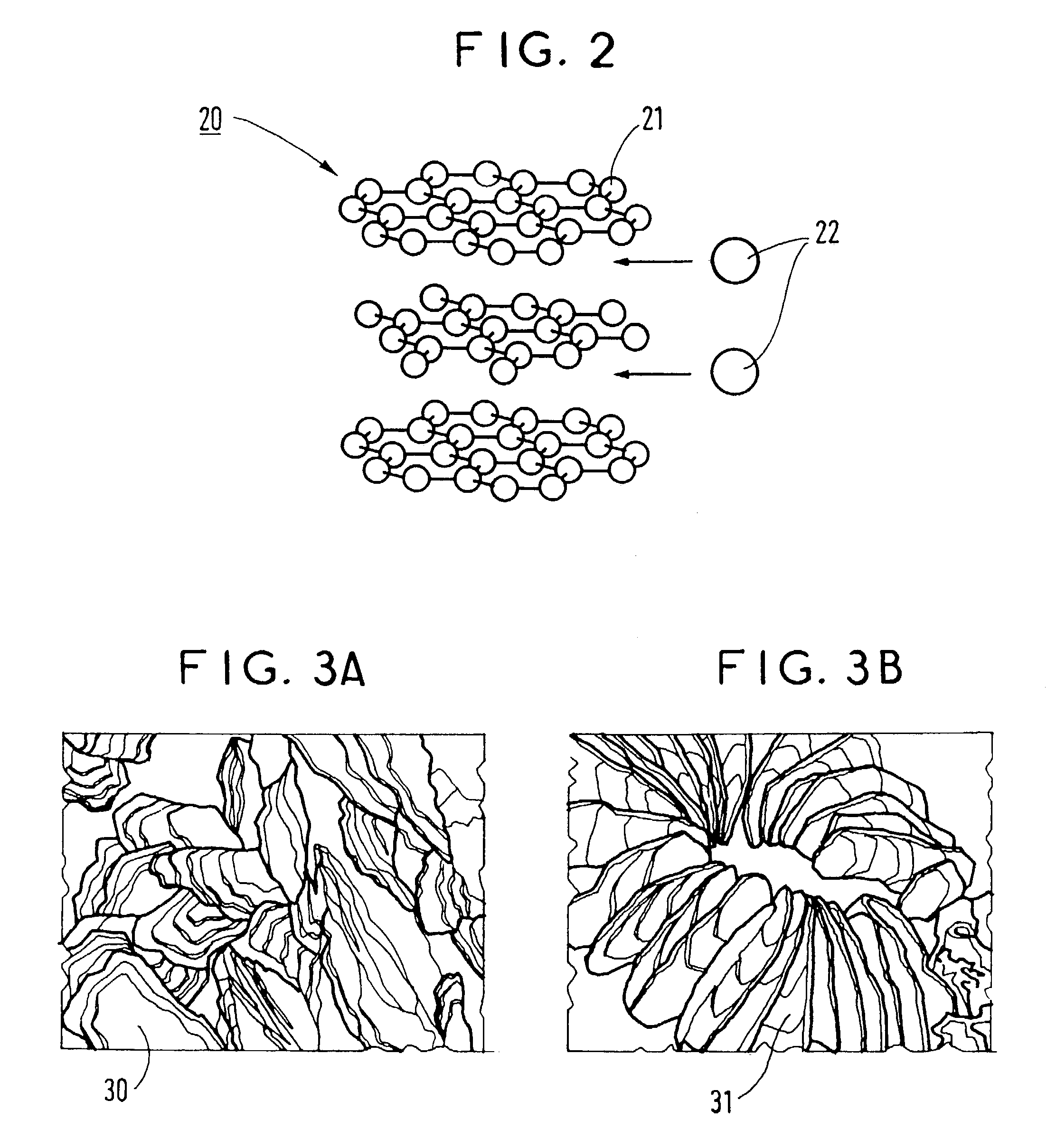

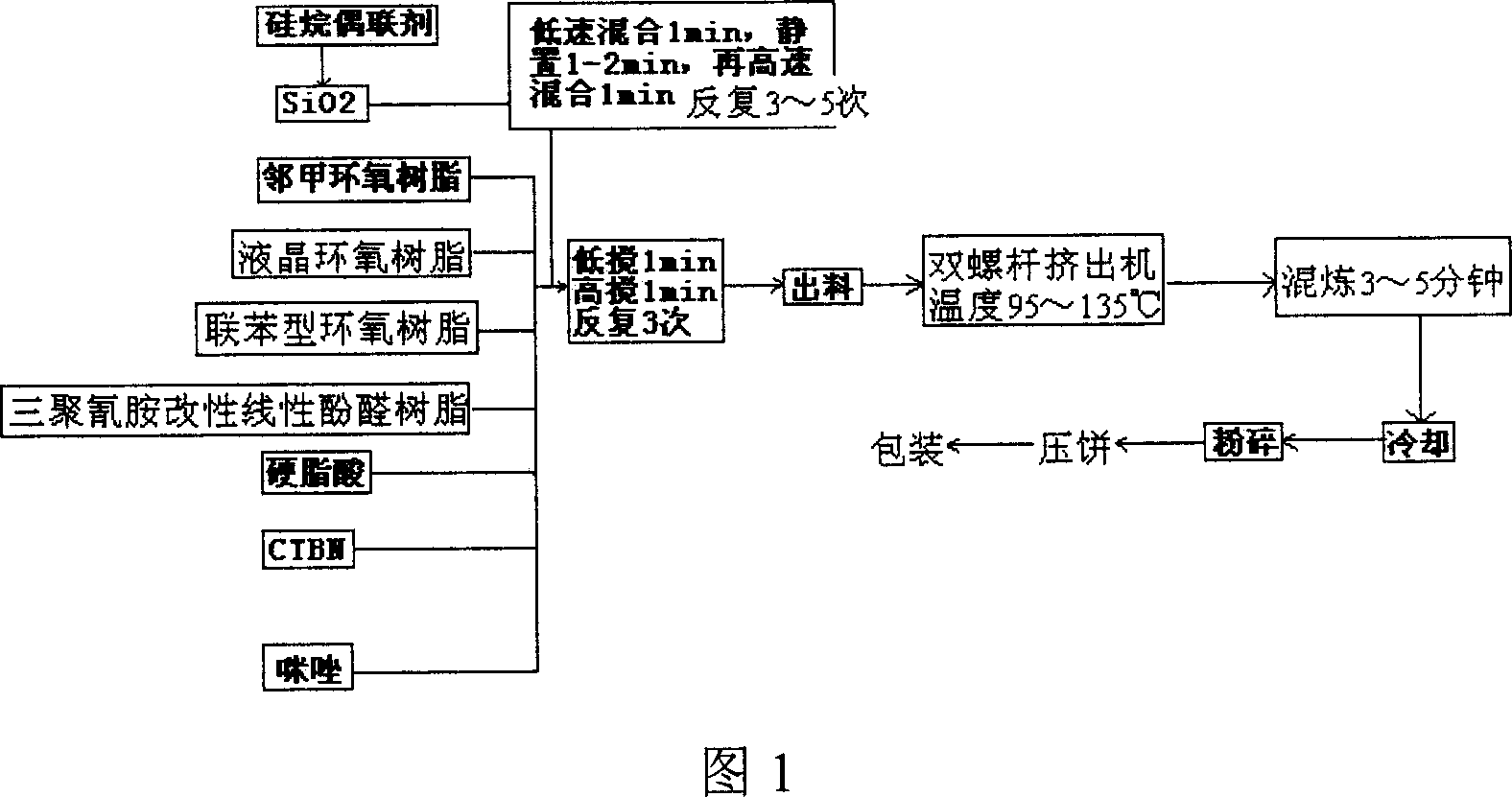

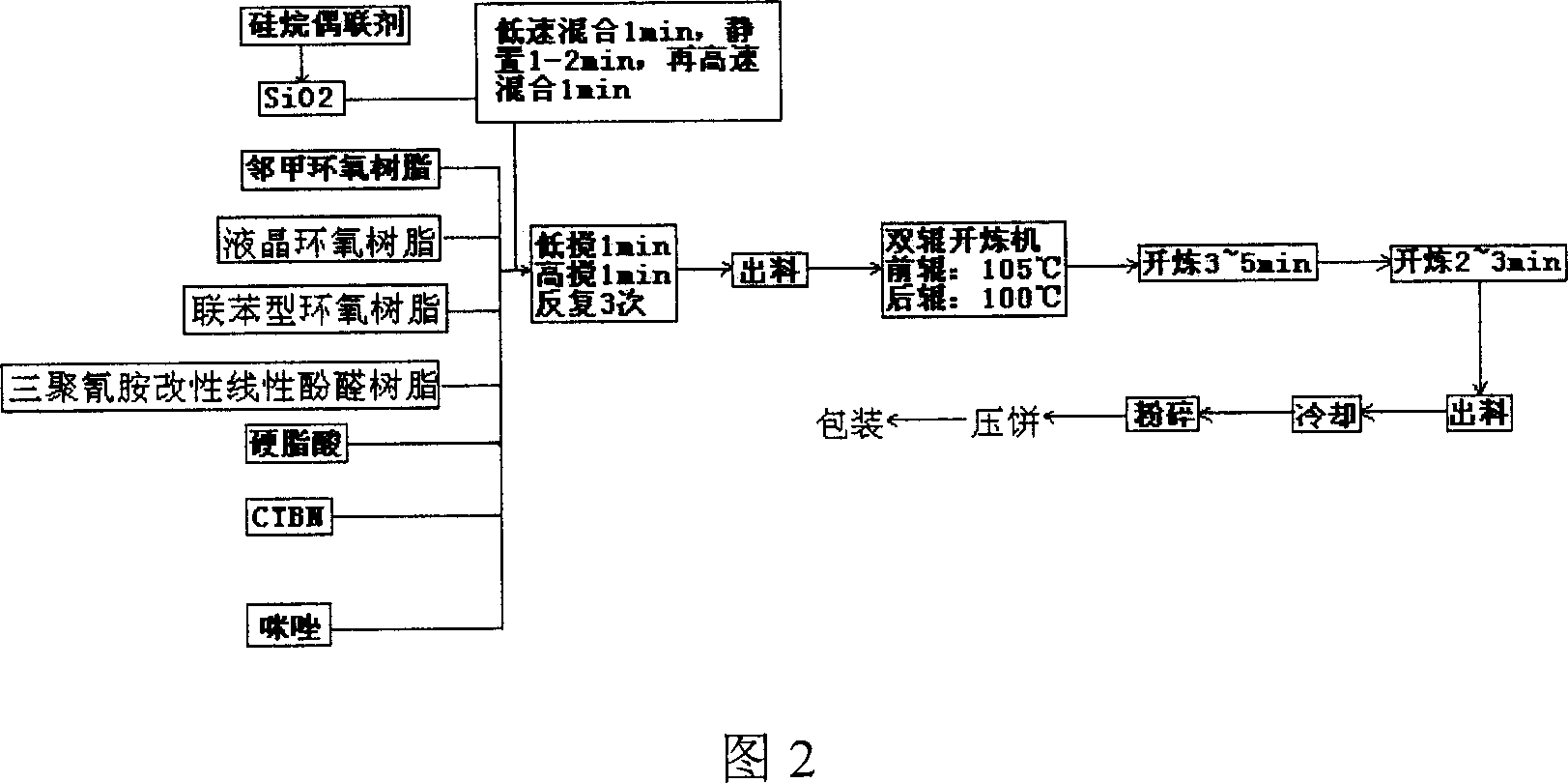

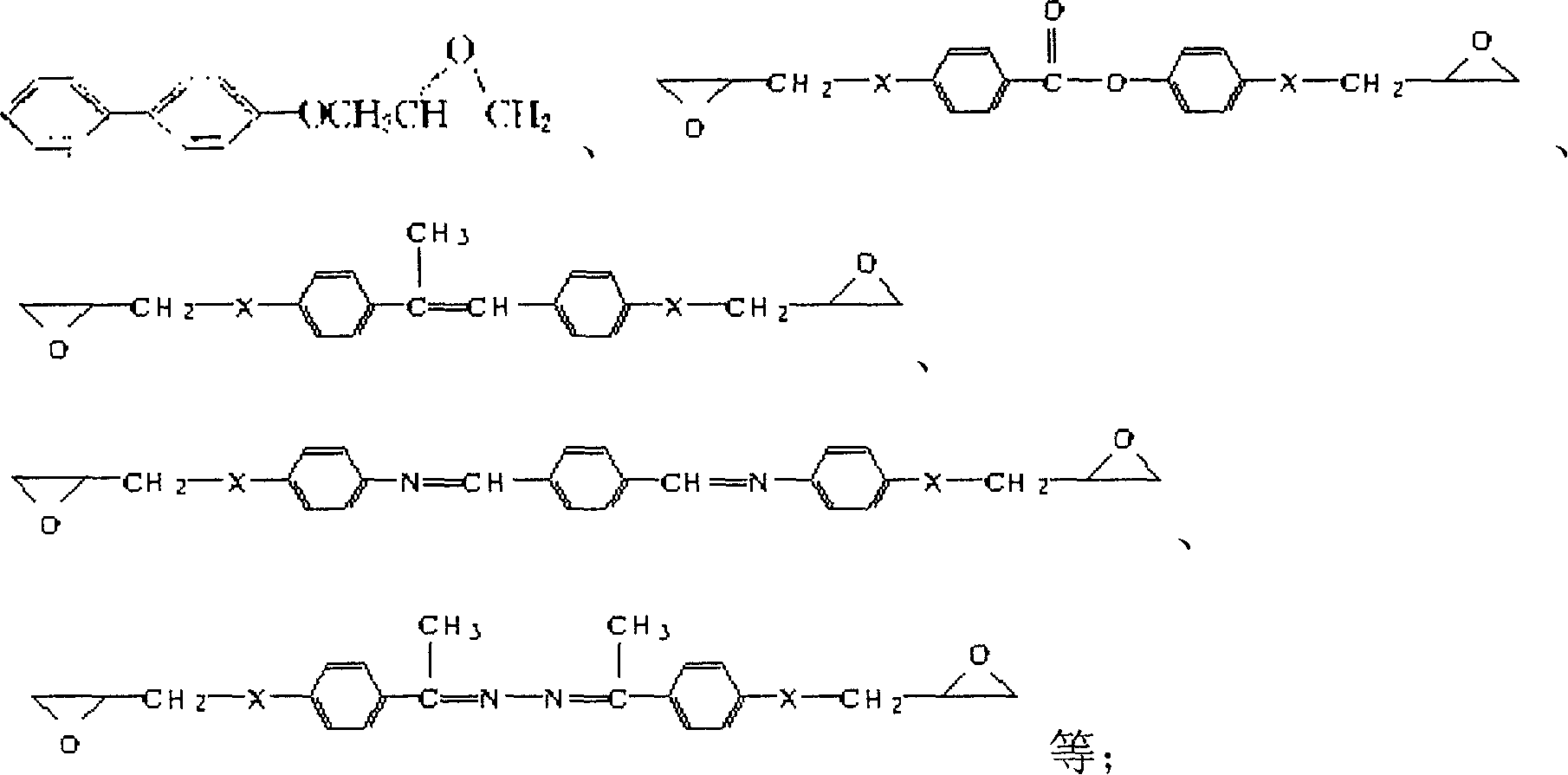

Epoxy-resin mould plastic for packing IC circuit and its production

InactiveCN101029165AHigh glass transition temperatureReduce melt viscositySemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

An epoxy resin mold plastic and its production are disclosed. The mold plastic consists of liquid-crystal epoxy resin, methyl-phenolic epoxy resin, epoxy resin containing biphenyl unit structure, melamine modified linear phenolic resin, silicone micro-powder, imidazo curing improver, toughening agent and silane coupling agent. The process is carried out by treating silicone micro-powder in mixer by coupling agent for 2-5mins, adding into other components, mixing for 3-5mins, melt milling at 95-135 degree for 3-5mins, cooling, crushing, mesh screening, pressing into material cake and storing below 6degree. Its advantages include low thermal expansion coefficient, excellent heat and fire resistances, better toughness and fluidity, no phosphor, no antimony and environmental pollution. It can be used to pack large-scale circuit and electronic devices.

Owner:GUANGDONG RONGTAI IND

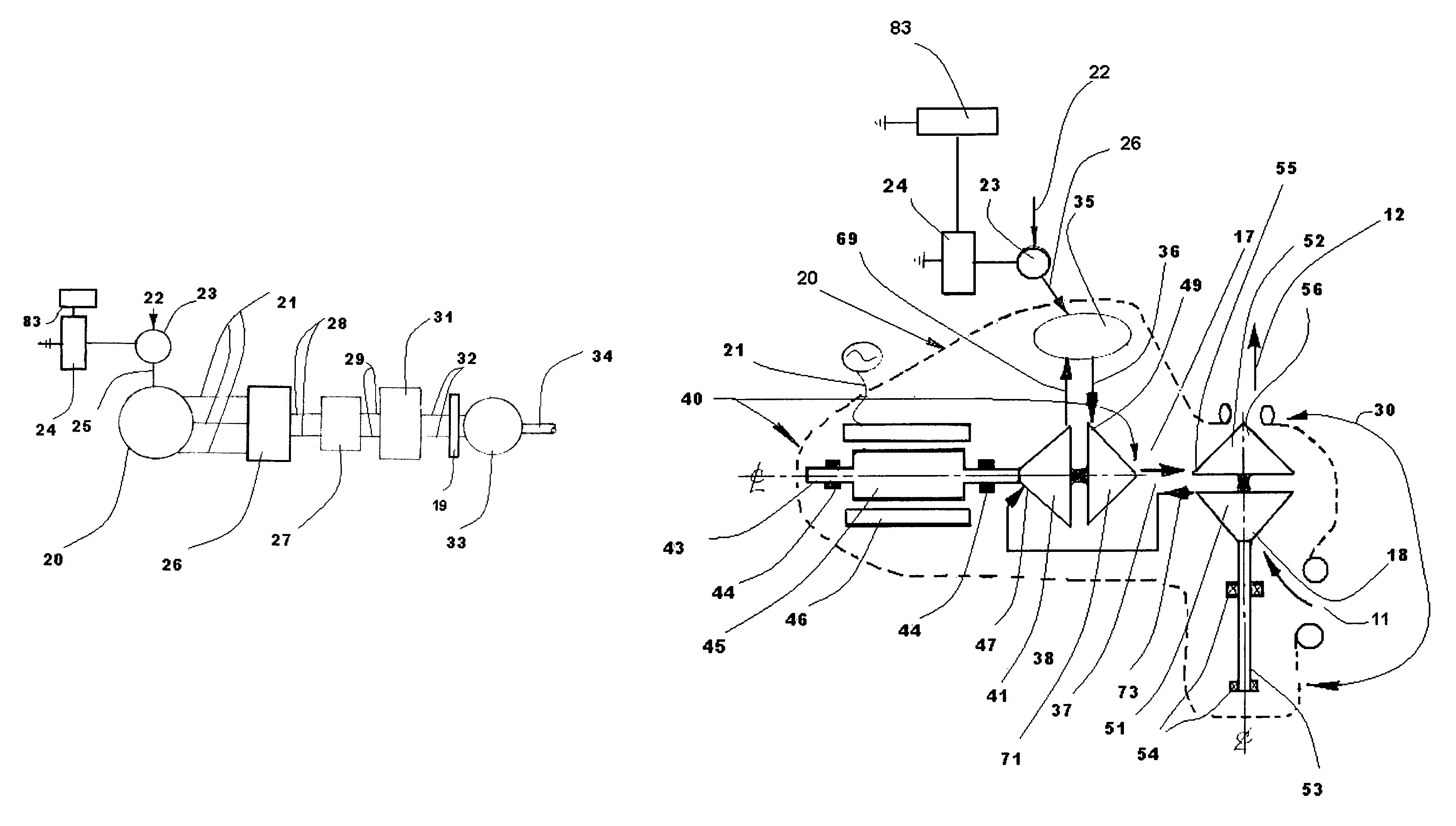

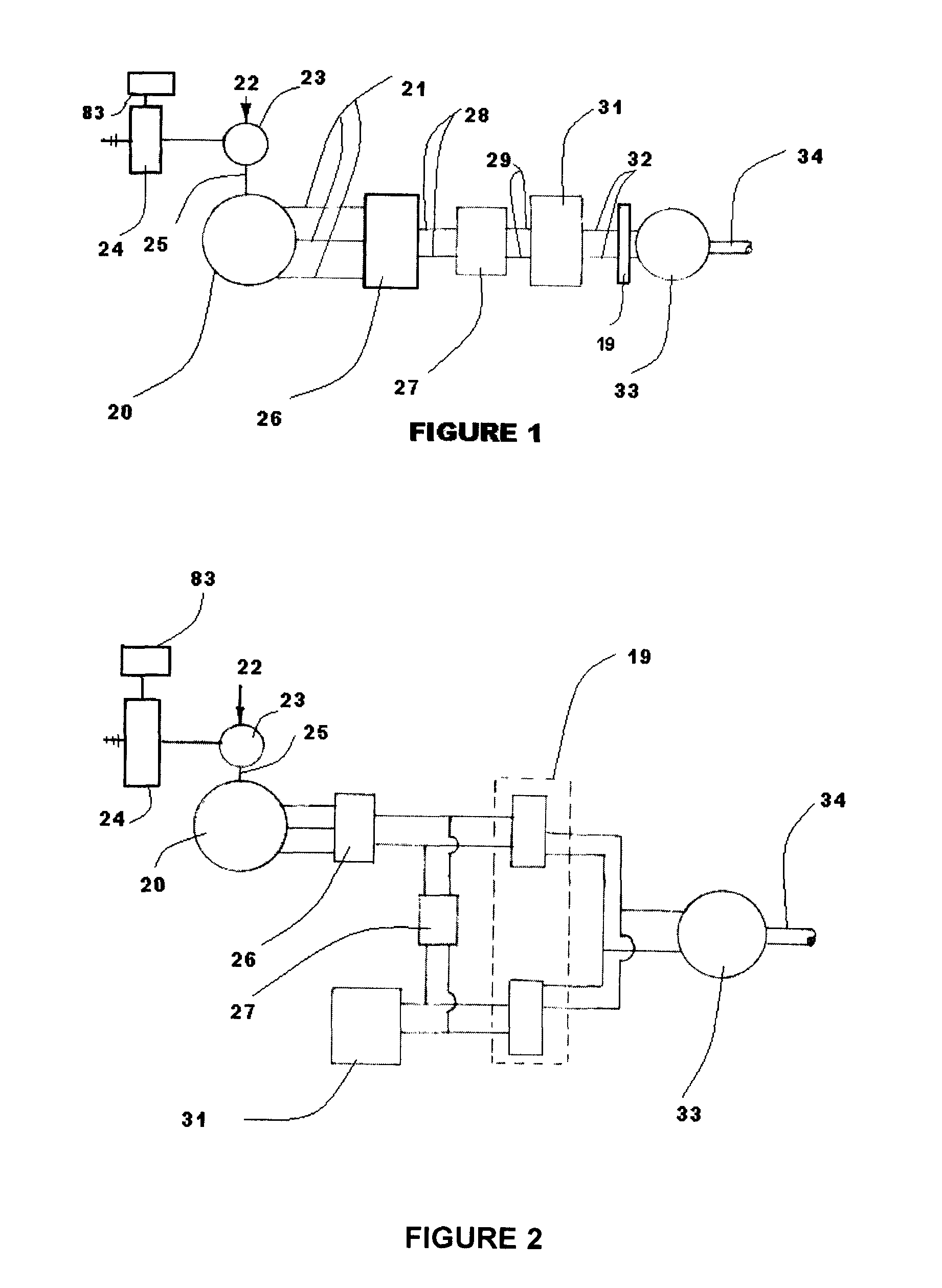

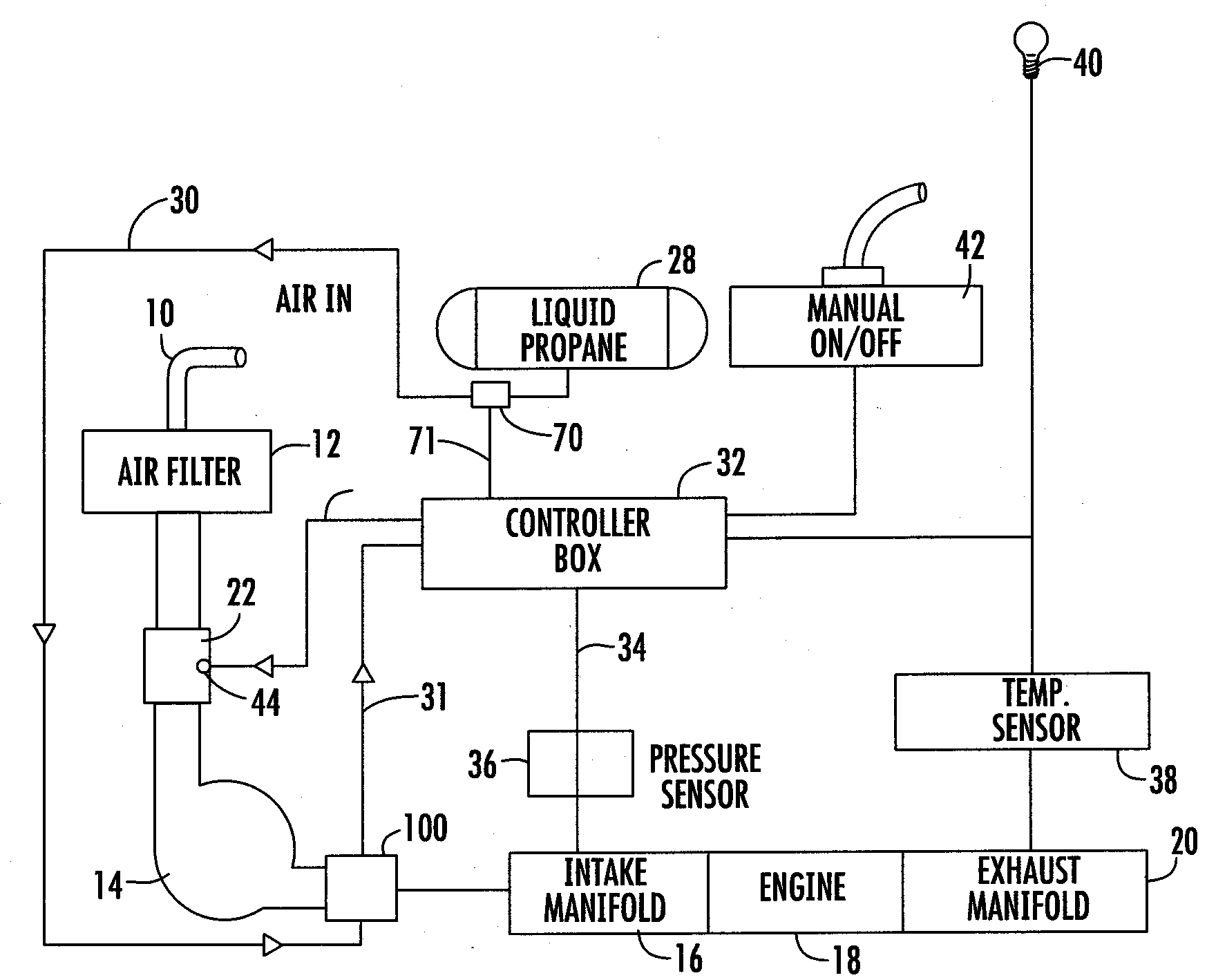

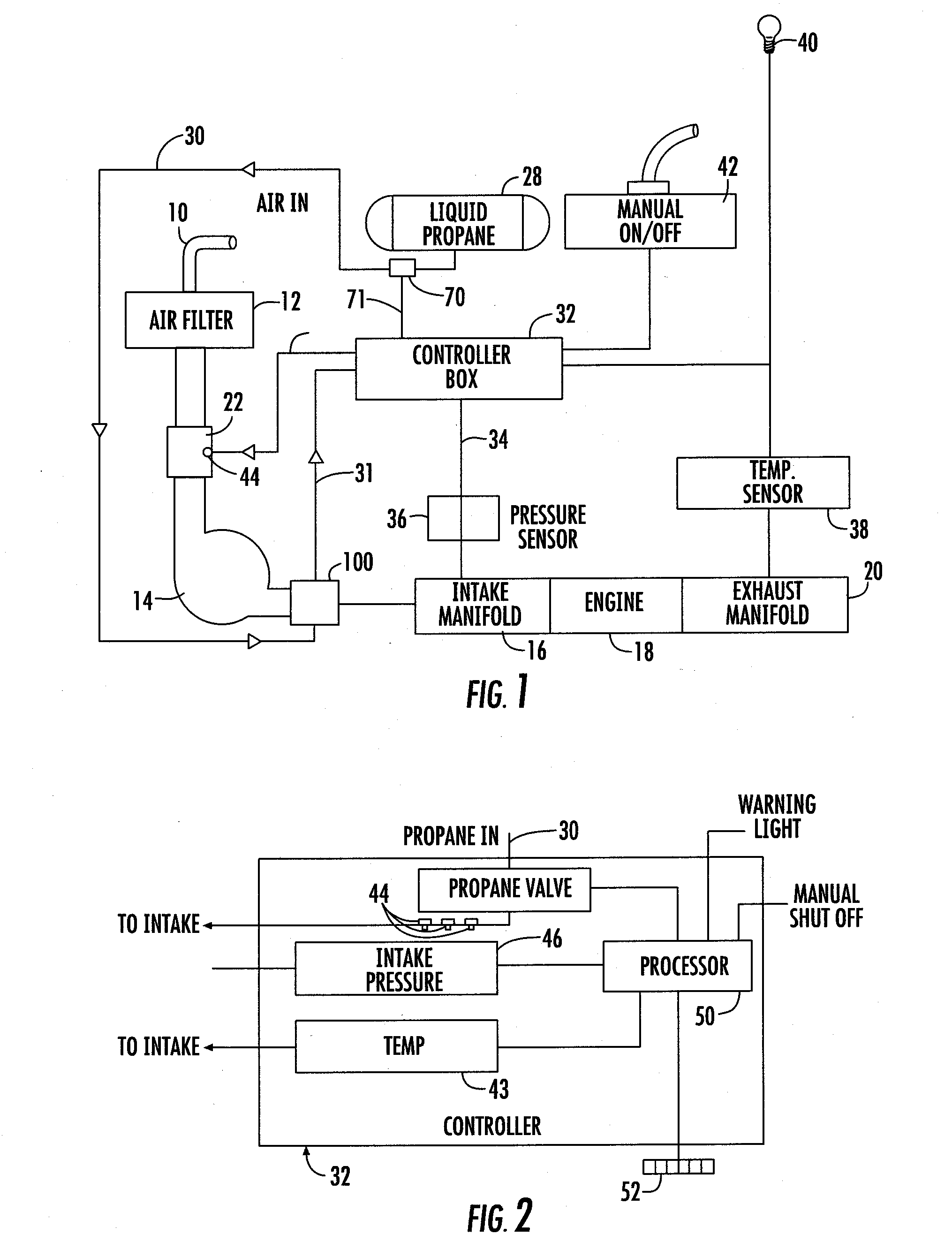

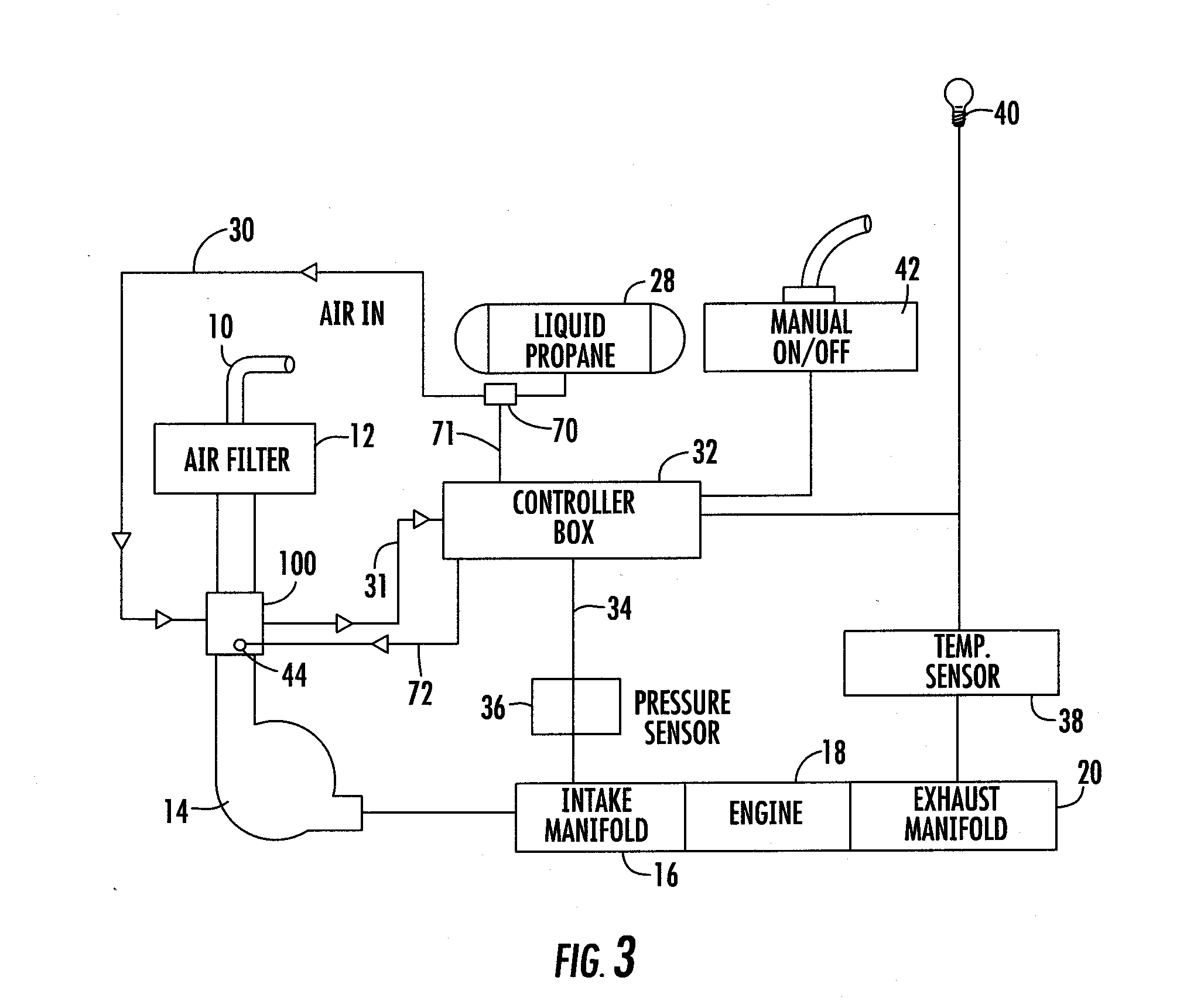

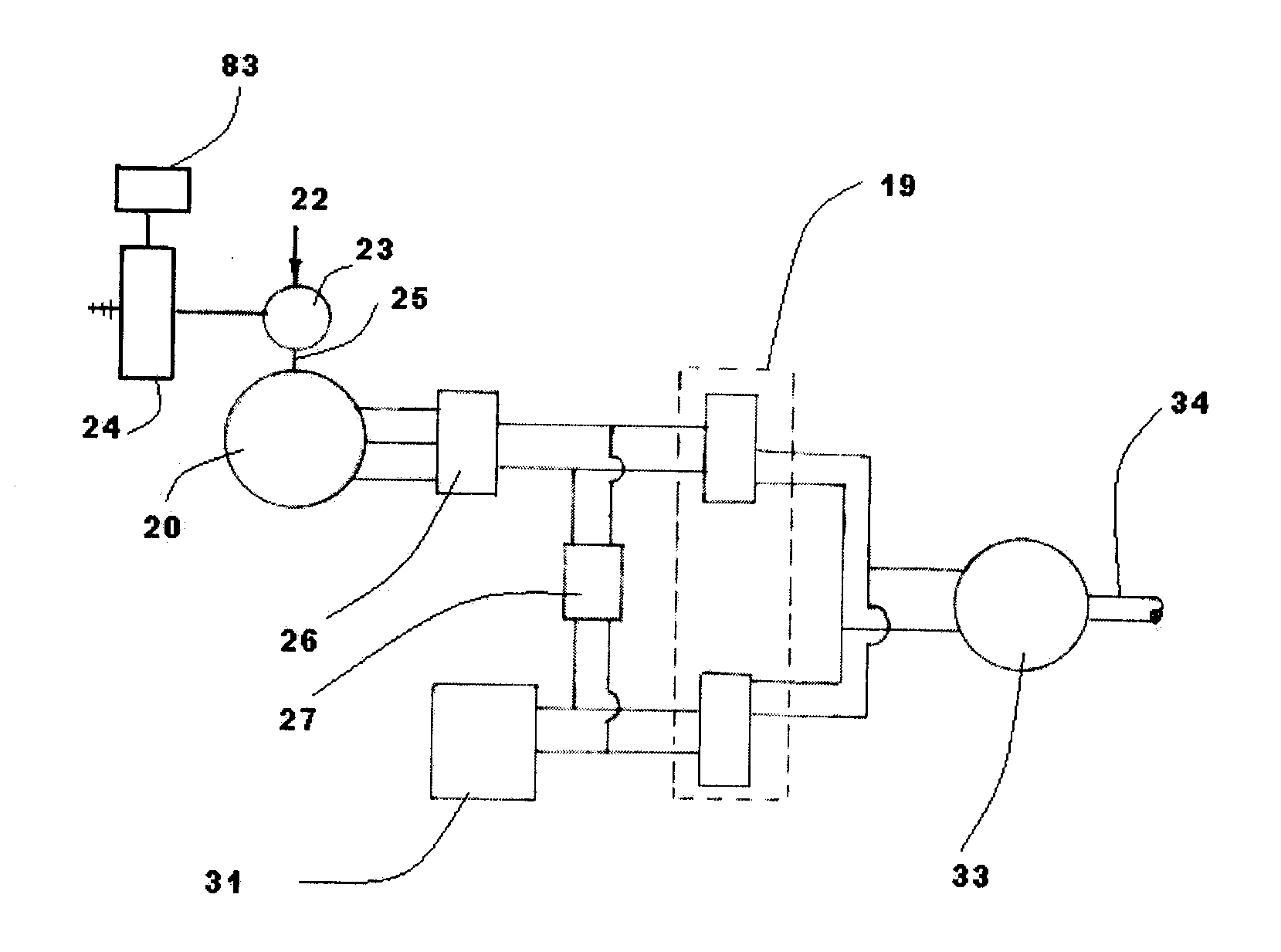

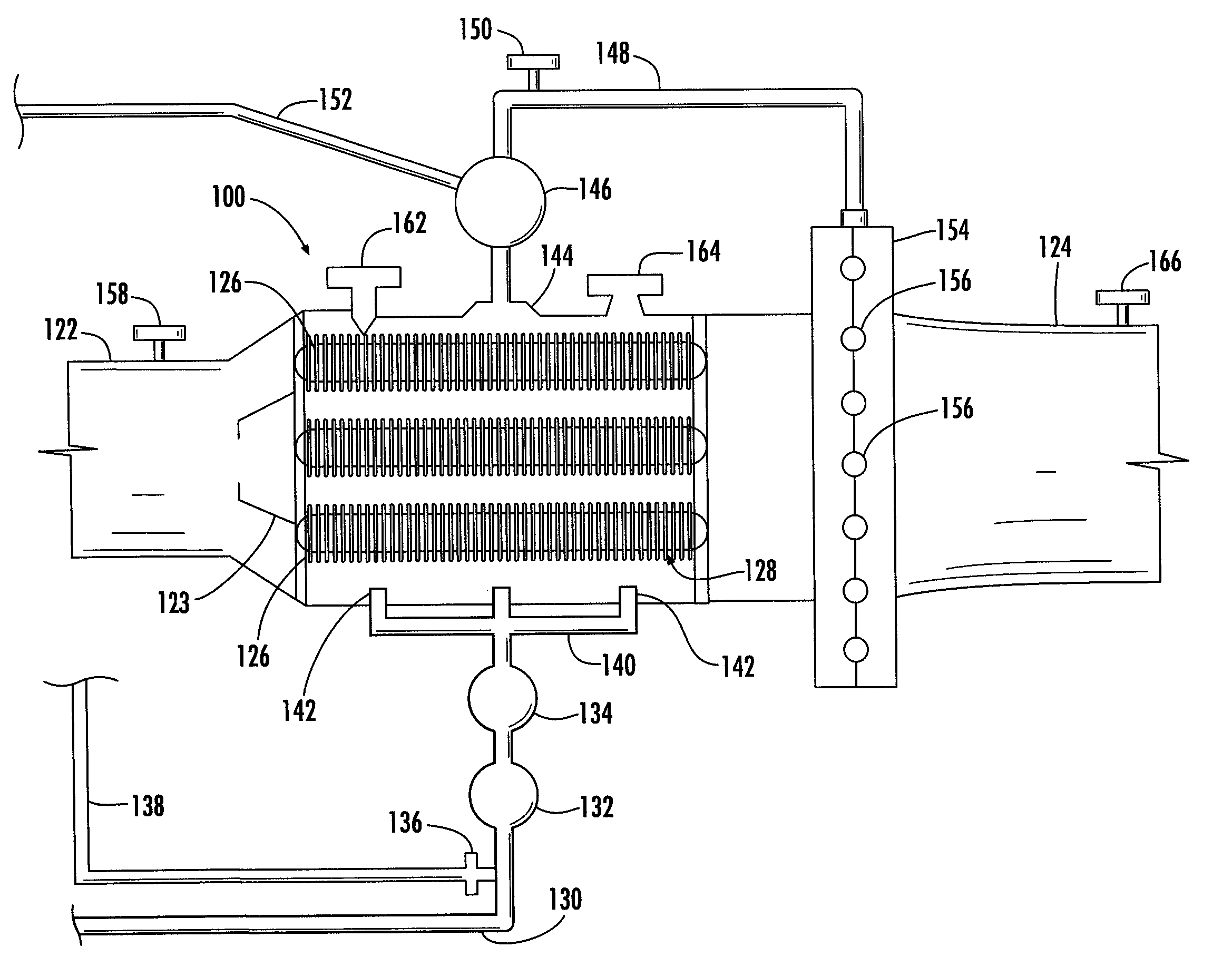

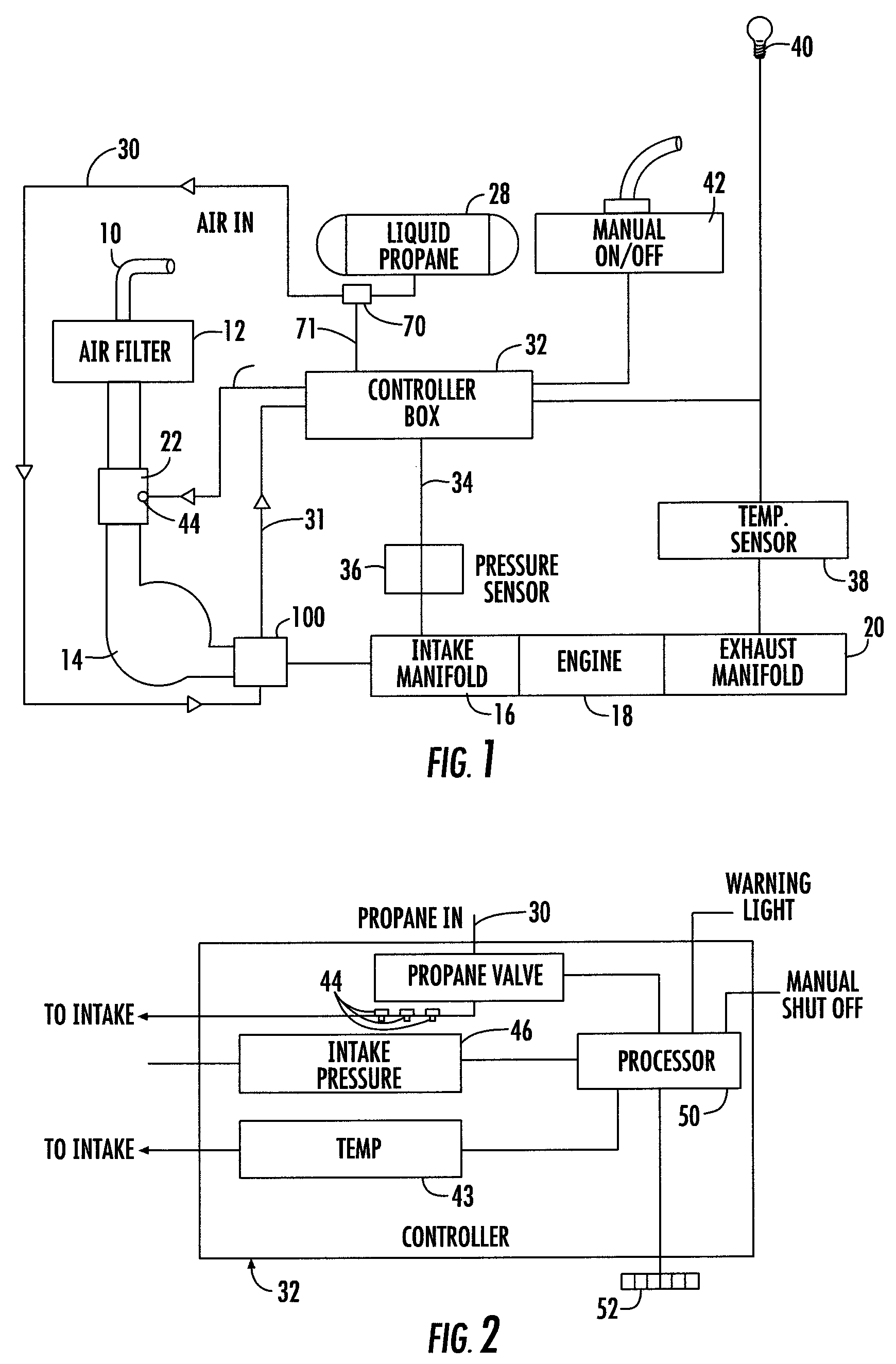

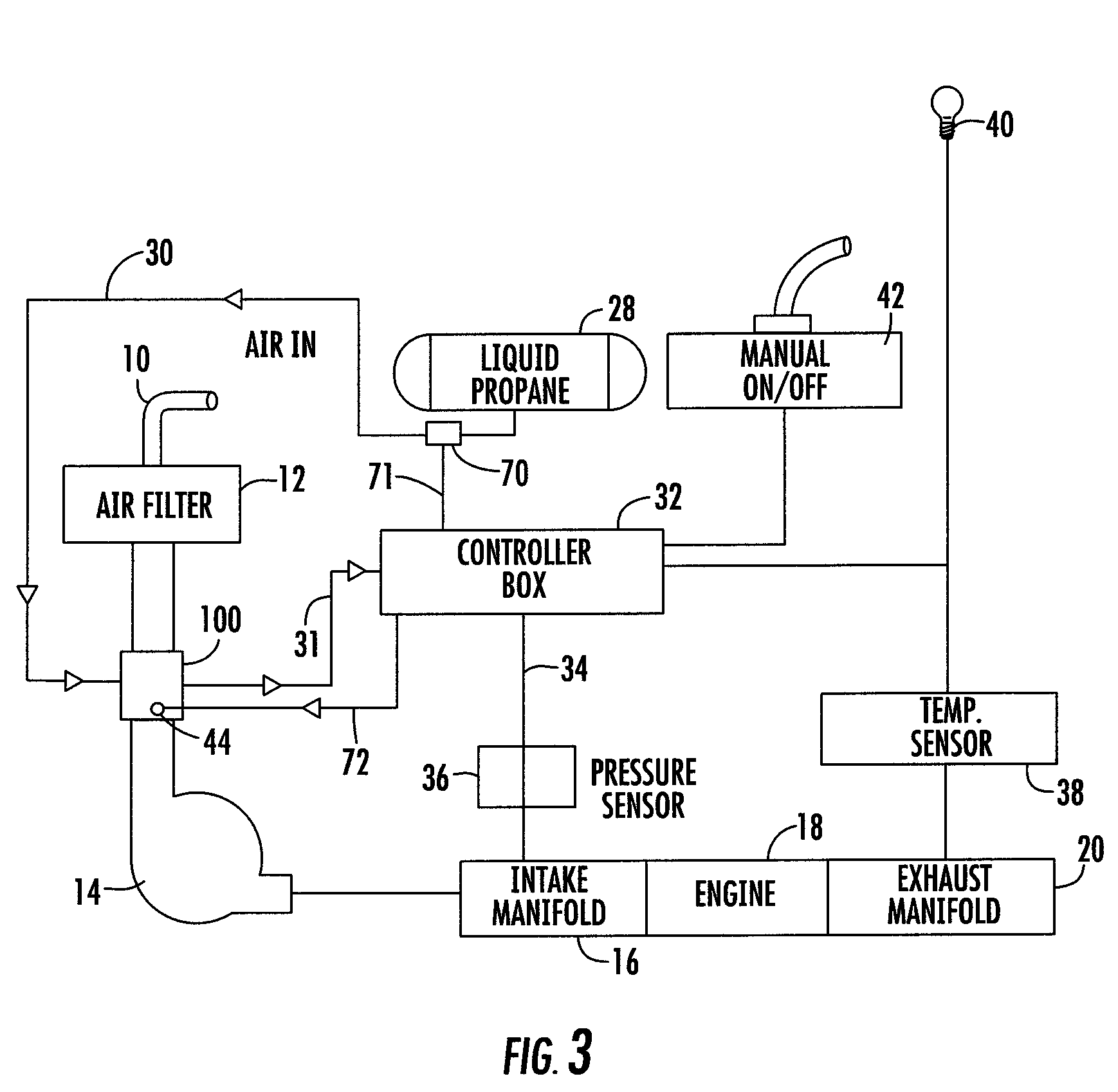

Super Cooled Air And Fuel Induction System For Internal Combustion Engines

ActiveUS20090126691A1Improved performance programmingMaximize fuel efficiencyElectrical controlInternal combustion piston enginesAlternative fuelsTurbocharger

The instant invention provides an apparatus and system for cooling the air charge of an internal combustion engine. More specifically, the instant invention provides an air-induction system suitable to provide cooled air charges to turbocharged, supercharged or naturally aspirated internal combustion engines to increase power output while reducing engine emissions. The system utilizes gaseous fuel stored as a liquid wherein the liquefied gaseous fuel is vaporized and warmed at least partially with heat removed from the intake air charge supplied to the engine from the turbocharger or supercharger. In a preferred embodiment, the compressed intake combustion air is first cooled in an aftercooler against an ambiently cooled coolant and is subsequently cooled further by the chiller of the instant invention which utilizes the change in phase, between liquid and gas, of the alternative fuel to cool the incoming air charge. The fuel, in the gaseous phase, is then supplied to the engine in a controlled manner for combustion by the engine. The operation of this system is measured and controlled by a control box mounted in the engine compartment.

Owner:DYNAMIC FUEL SYST

Non-scorch flame retarded polyurethane foam

InactiveUS20060122285A1Reduce burnQuality improvementPhosphorus organic compoundsFire retardantChemistry

The present invention relates to phosphorous based flame retardants useful in polyurethane foam and foams comprising the phosphorous based flame retardants.

Owner:FALLOON STEPHEN B +2

Kit, apparatus and method for use in cooking over an intense heat source

InactiveUS20050051157A1Firm supportModerates being transferredDomestic stoves or rangesLiquid heating fuelEngineeringIngested food

A portable cooking kit, apparatus and method is usable for moderating heat from an intense heat source, such as an outdoor grill or camprife. The apparatus includes a food support member, including a perforated panel surrounded by a rim. The food support member rests on top of a heat shield made from a heat-tolerant material. During use, the heat shield is stably suspended over direct, intense heat from a heat source. The food to be cooked is placed on the food support member, and the food support member may then be placed on top of the heat shield. By buffering the direct heat from the heat source, the heat shield allows food placed on the food support member to cook, but protects the underside of the food from becoming scorched. Optionally, a dome-shaped cover may be used to cover both the food support member and the heat shield.

Owner:ISLANDER INNOVATIONS

Melamine cyanuric acid red phosphorous-based microcapsule and its preparation method and use

Disclosed are melamine and its preparing method and application, with the characteristics that add 10-300 portions of red phosphorus powder, 100-1000portions of water into reactor with agitator and thermometer, make them to be dispersion in 50-130deg.C, the add into 0-300portions of antiflaming synergistic agent, 50-100 portions of melamine and 50-200 portions of cyanuric acid (emulsion or cream of ), which are stirred for 5 minutes to 2 hours in 50-150deg.C, in the course, can add into 100-1000 portions of water, generate the emulsion or cream of cyanuric acid which are filtered, are centrifugal separated, dried and scattered to be 0.01-500um powder product. The product can be used as flame retardant of polymer or method with other flame retardant.

Owner:SICHUAN UNIV

Hybrid electric power for vehicular propulsion

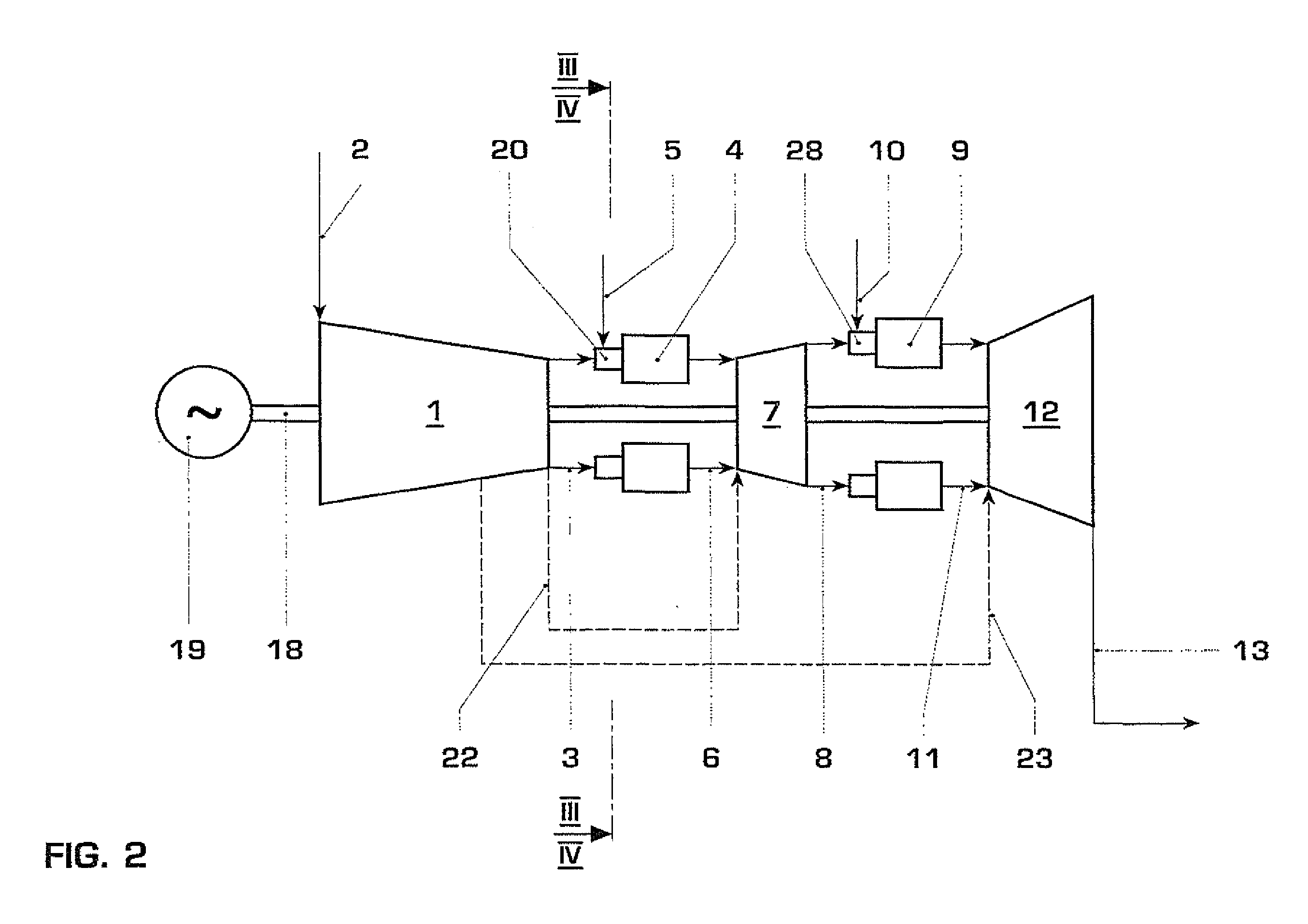

ActiveUS20130049364A1Increase rangeIncreased fuel usageNetwork traffic/resource managementRoad vehicles traffic controlElectric powerElectric generator

This invention relates to a hybrid gas turbine (HGT) engine powerplant having electrical output power and as a system independently or in combination with electrical energy storage means, supplies electrical power to at least one electric motor for vehicular propulsion.The HGT has a minimum of two spools at least one spool, the power spool, has integrated a compressor rotor, turbine rotor and alternator rotor; a minimum second spool for staged engine air compression has integrated a compressor and turbine rotors aero-coupled to the power spool.An electronic engine unit (EECU) supplies electrical power to the fuel control valve, has preprogrammed variable power spool speeds per output power requirements, exhaust gas turbine temperature limits for fuel economy considerations and is responsive thru vehicle throttle commands of accel, decel, constant vehicle operations, start-up, shut down, battery charger and auxiliary power applications (APU).

Owner:TEETAB JOSEPH MICHAEL +1

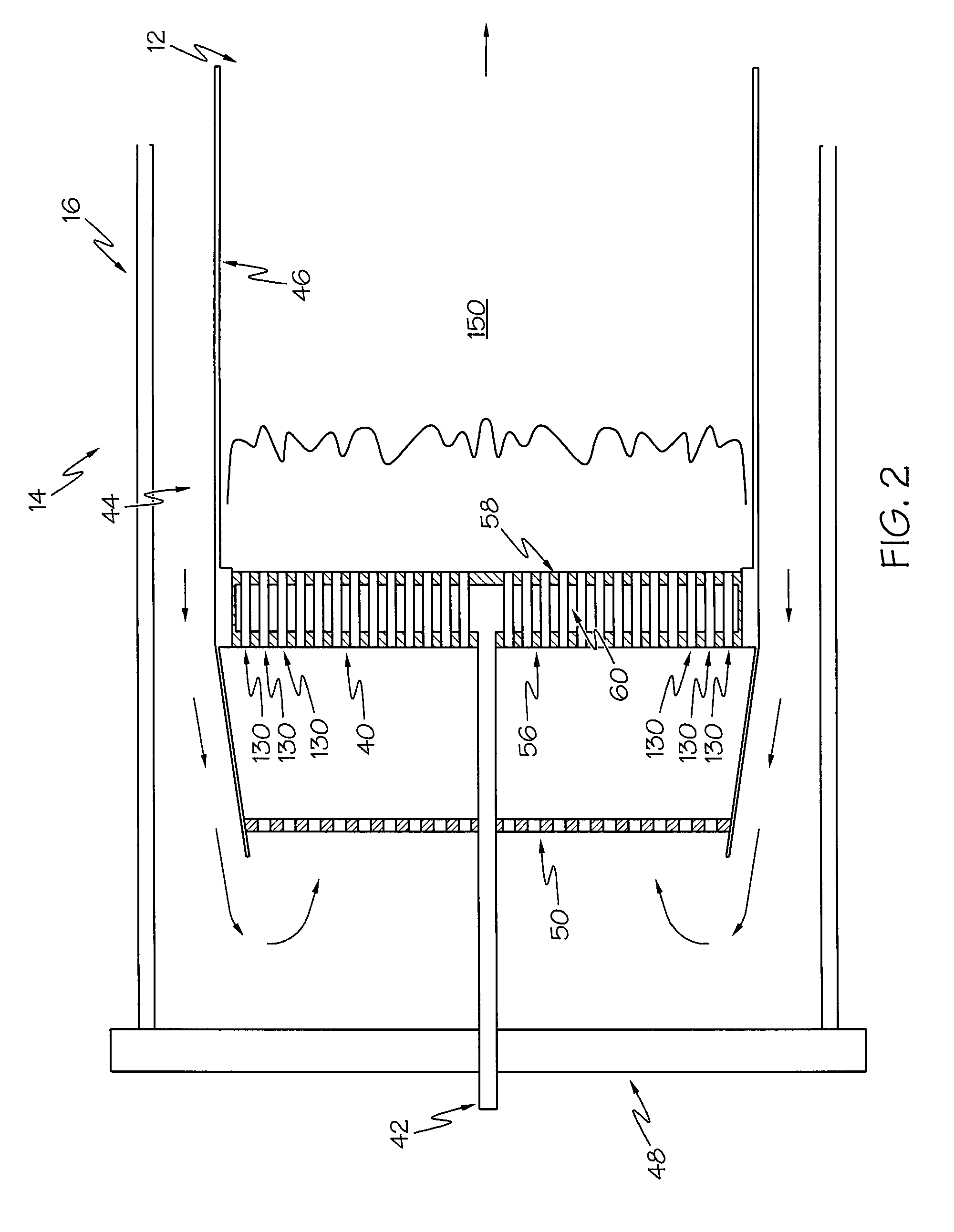

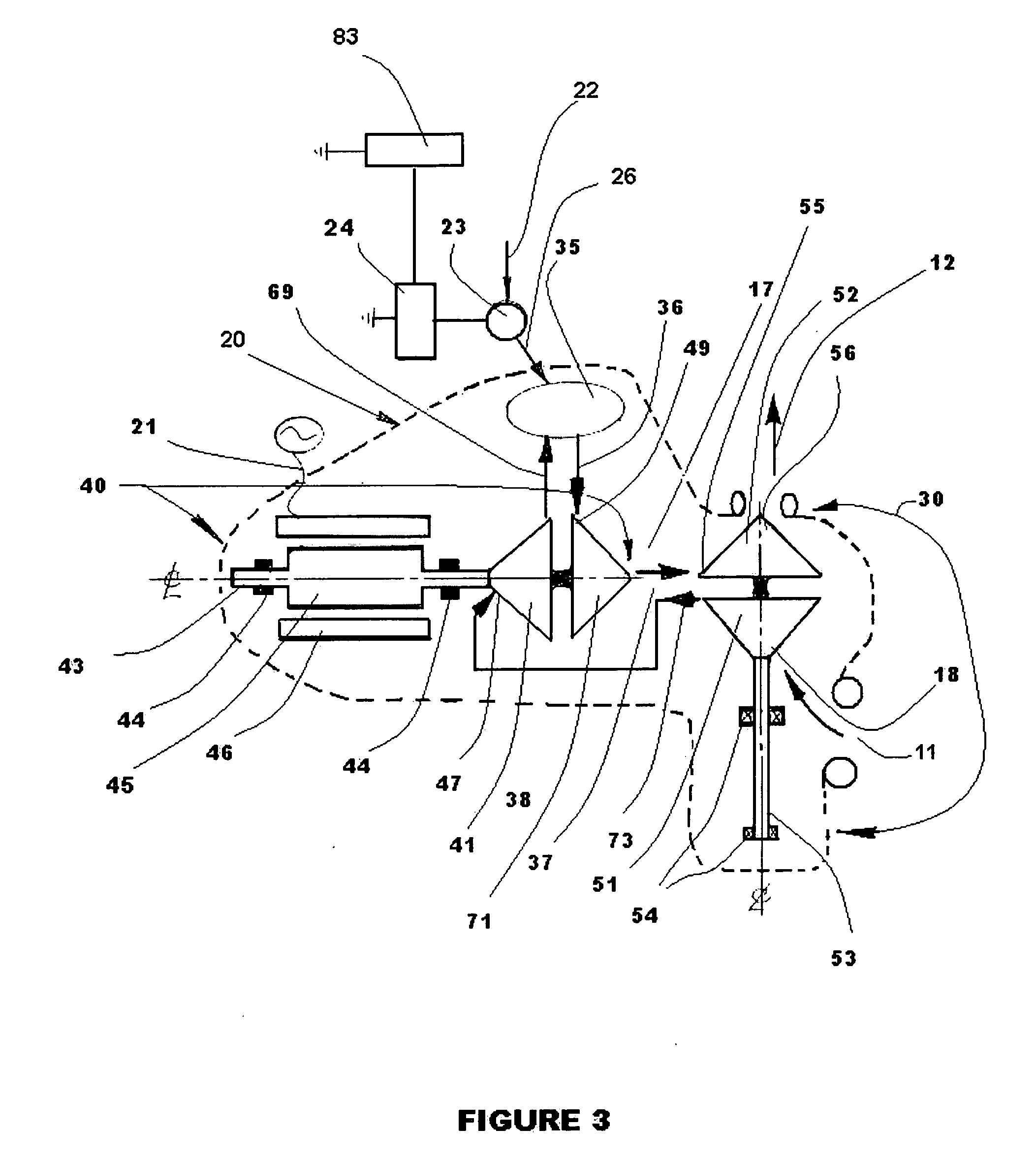

Gas turbine with water injection

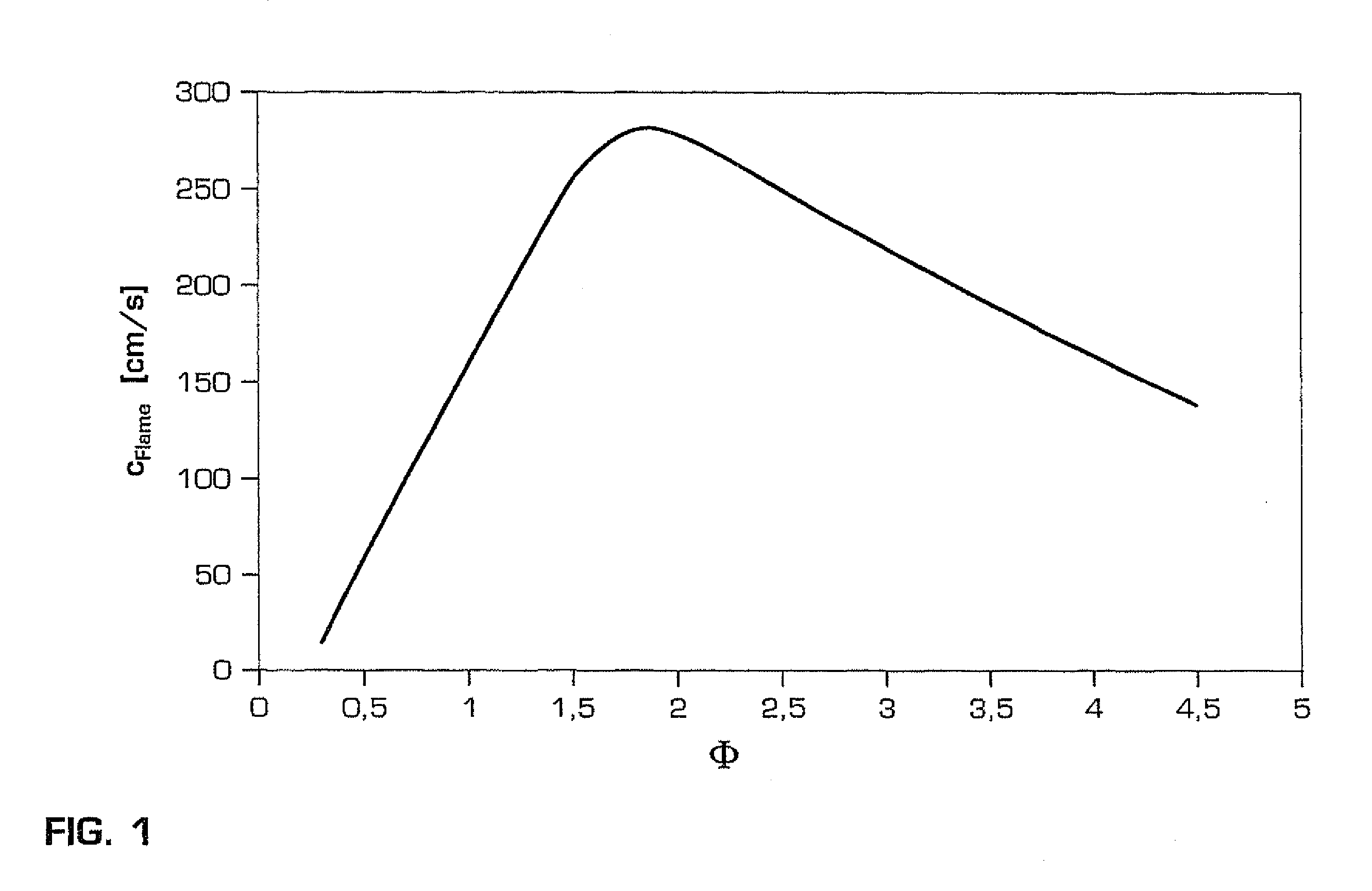

ActiveUS20100146984A1Reduce burnShorten speedContinuous combustion chamberGaseous fuel feeder/distributionHydrogenCombustor

Reliable, low-NOx-emission operation of a gas turbine plant with hydrogen-rich fuel gas, and a gas turbine plant with a device for water injection into hydrogen-rich fuels in a gas turbine, involves suitable water injection (21), a water-fuel gas mist, i.e., a fuel gas in which fine water droplets are suspended, is created in the fuel gas feed line (15). This mist is introduced into the burners (20) of the gas turbine. As a result of the water-fuel gas mist, four effects are combined for ignition delay and reduction of the flame velocity of hydrogen-rich fuel gas. When using a water-fuel gas mist, the water, in a directed manner, reaches the region in the burner (20) in which it directly has the greatest possible effect upon the flame or the flame velocity.

Owner:ANSALDO ENERGIA SWITZERLAND AG

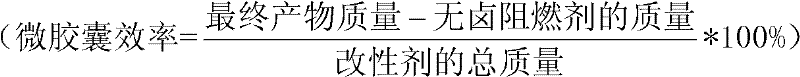

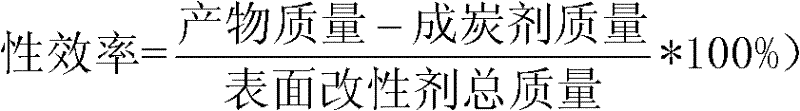

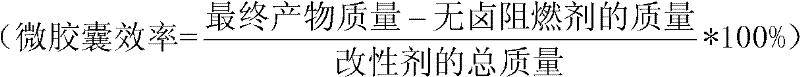

Preparation method of microencapsulated gradient halogen-free flame retardant system

InactiveCN102516603AEvenly dispersedLiquidMicroballoon preparationMicrocapsule preparationPolymer scienceMoisture

The invention relates to a preparation method of a microencapsulated gradient halogen-free flame retardant system. The preparation method comprises the steps of: mixing a phosphorus-series flame retardant with an inorganic flame retardant according to a certain ratio to obtain a microencapsulated halogen-free flame retardant, then carrying out surface modification on a charring agent, and then mixing the microencapsulated halogen-free flame retardant, a phosphorus-containing organic flame retardant and surface-modified charring agent according to a certain ratio to obtain the microencapsulated gradient halogen-free flame retardant system. By using the system, distributed gradient flame retarding is realized, the flame retardancy of a polymer material is greatly improved, the defect that compatibility between the flame retardant and the polymer is poor is solved, the migration of the halogen-free flame retardant from the polymer matrix under high-temperature and moisture conditions is significantly reduced, and the long-term storage of a flame-retardant polymer material is facilitated. The method has the characteristics of simple process, convenience for operation, environmental friendliness, and lower cost. The obtained flame retardant system has good flame retarding effect and wide application field.

Owner:JILIN UNIV

Super cooled air and fuel induction system for internal combustion engines

ActiveUS7841322B2Use minimizedImprove performanceElectrical controlInternal combustion piston enginesSuper coolingAlternative fuels

Owner:DYNAMIC FUEL SYST

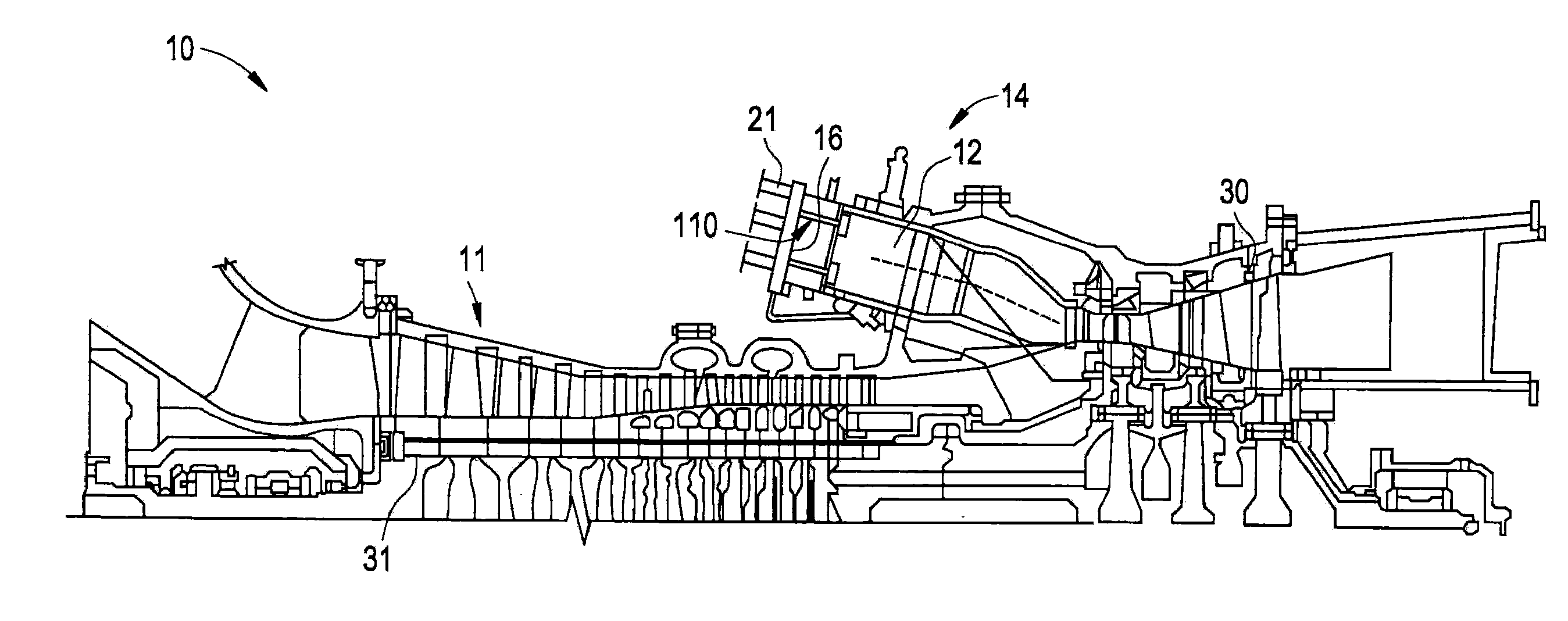

Premixed direct injection nozzle for highly reactive fuels

A fuel / air mixing tube for use in a fuel / air mixing tube bundle is provided. The fuel / air mixing tube includes an outer tube wall extending axially along a tube axis between an inlet end and an exit end, the outer tube wall having a thickness extending between an inner tube surface having a inner diameter and an outer tube surface having an outer tube diameter. The tube further includes at least one fuel injection hole having a fuel injection hole diameter extending through the outer tube wall, the fuel injection hole having an injection angle relative to the tube axis. The invention provides good fuel air mixing with low combustion generated NOx and low flow pressure loss translating to a high gas turbine efficiency, that is durable, and resistant to flame holding and flash back.

Owner:GE INFRASTRUCTURE TECH INT LLC

Low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and preparation method thereof

ActiveCN102093625AReliable Extrusion PerformanceReliable degree of cross-linkingInsulated cablesInsulated conductorsMasterbatchLow smoke zero halogen

The invention relates to a low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and the cable material contains the raw materials of flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent. The preparation method comprises the following steps: mixing flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent in a sealed mixer for absorption, discharging after 3-5 hours, and packaging to obtain the low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material finished product. Compared with the common low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material, the temperature resistant grade and mechanical properties of the product of the invention can be increased and the problem that the common low smoke non-halogen polyolefin cable material is easy to crack can be eliminated.

Owner:中广核三角洲(江苏)塑化有限公司

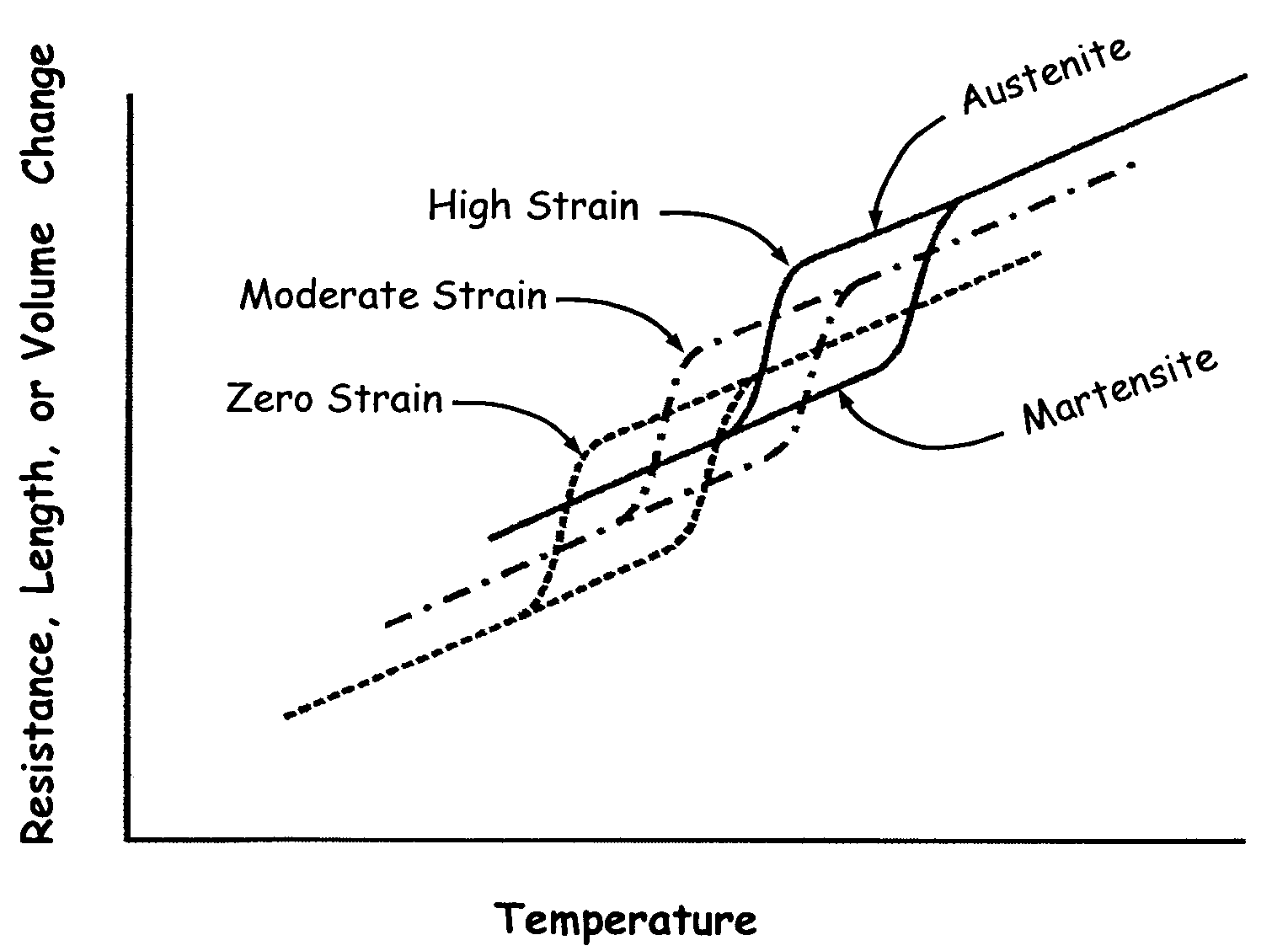

Pressure sensor with integrated bi-functional heater and methods of using

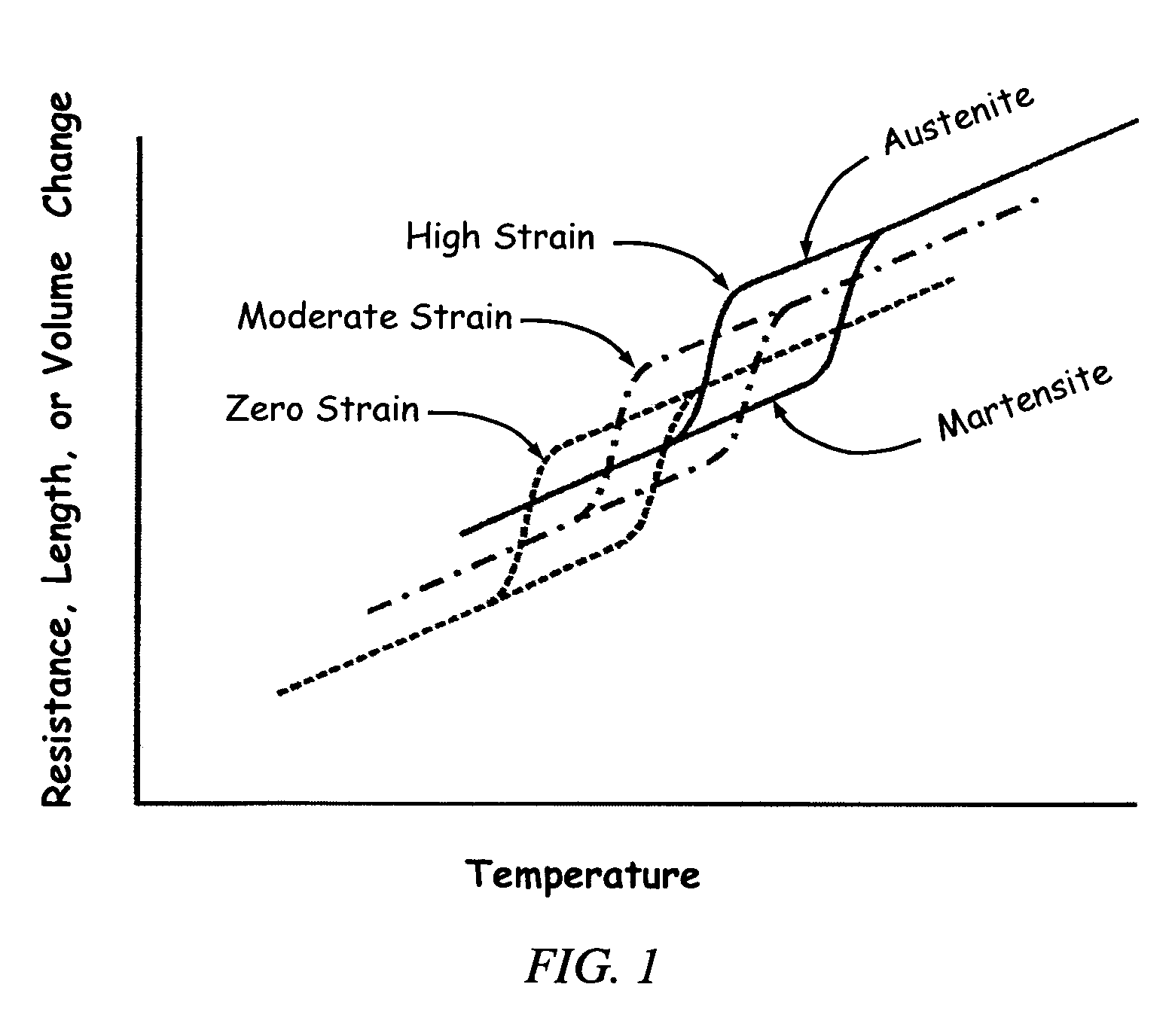

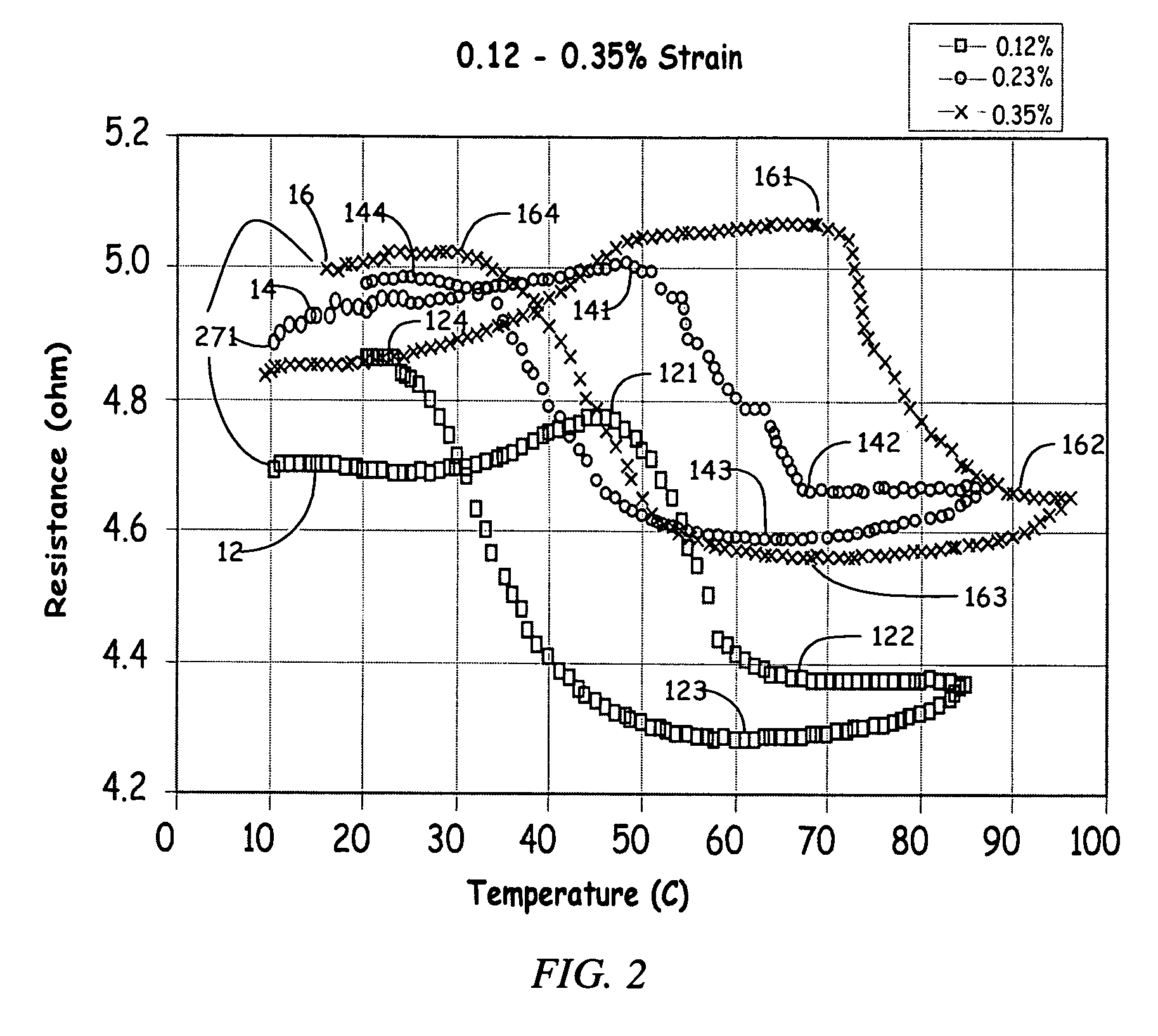

InactiveUS7258015B1Improve fuel efficiencyEmission reductionElectrical controlForce measurementPressure senseShape-memory alloy

The present invention relates to a method of determining both pressures and temperatures in a high temperature environment. The present invention also relates to a method of determining temperatures about a pressure-sensing element using a bi-functional heater. In addition, the present invention preferably relates to a pressure sensor with the pressure-sensing element and a heating element both integrated into the sensor's packaging, preferably onto the diaphragm of the pressure sensor, and particularly to such a pressure sensor capable of operating at high or elevated temperatures, and even more particularly to such a pressure sensor wherein the heating element is capable of both heating, at least in part, the pressure-sensing element and monitoring the temperature of the application area. Preferably, the pressure-sensing element is formed from shape memory alloy (SMA) materials that can be used at high or elevated temperatures as a pressure sensor with high sensitivity.

Owner:ORBITAL RES

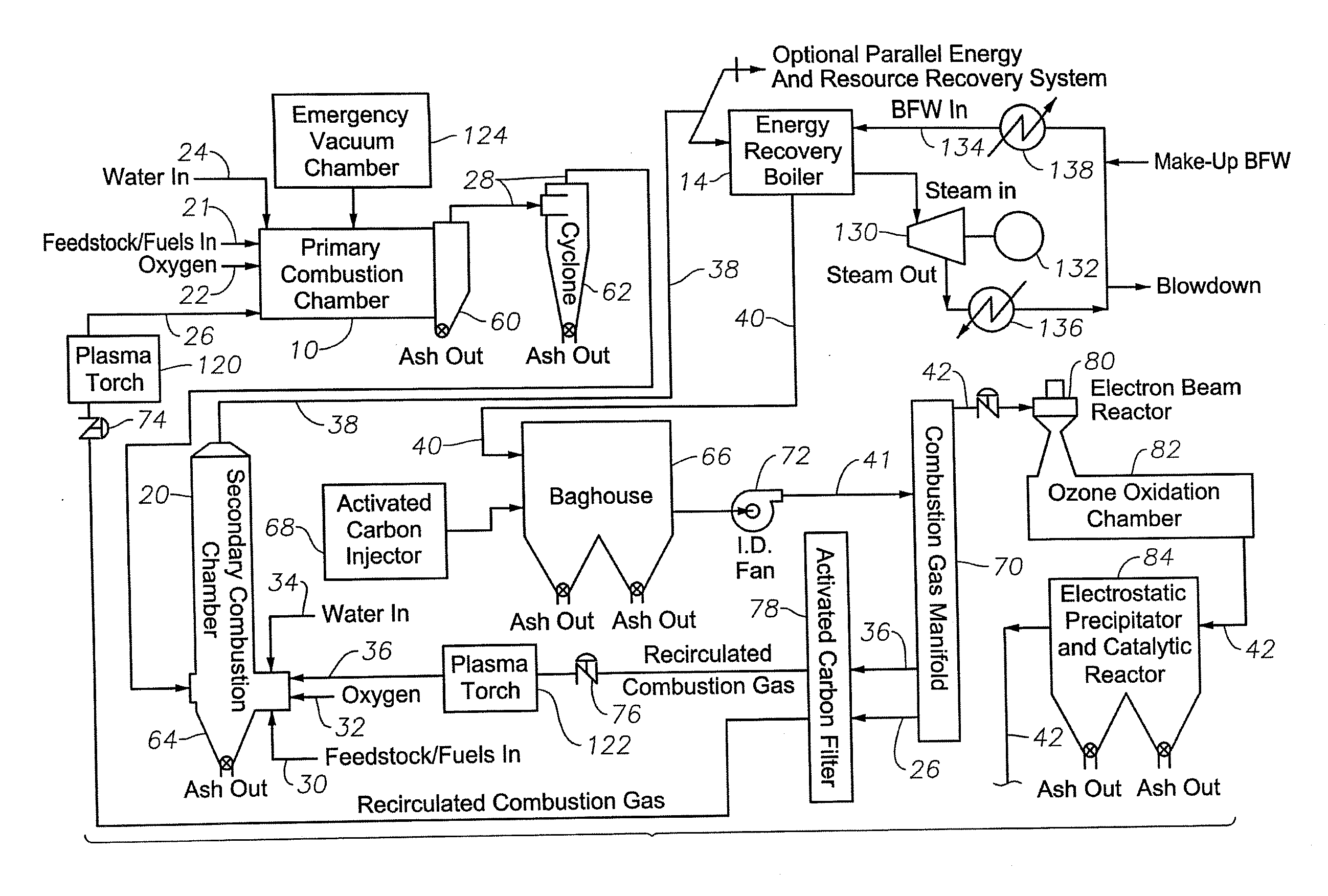

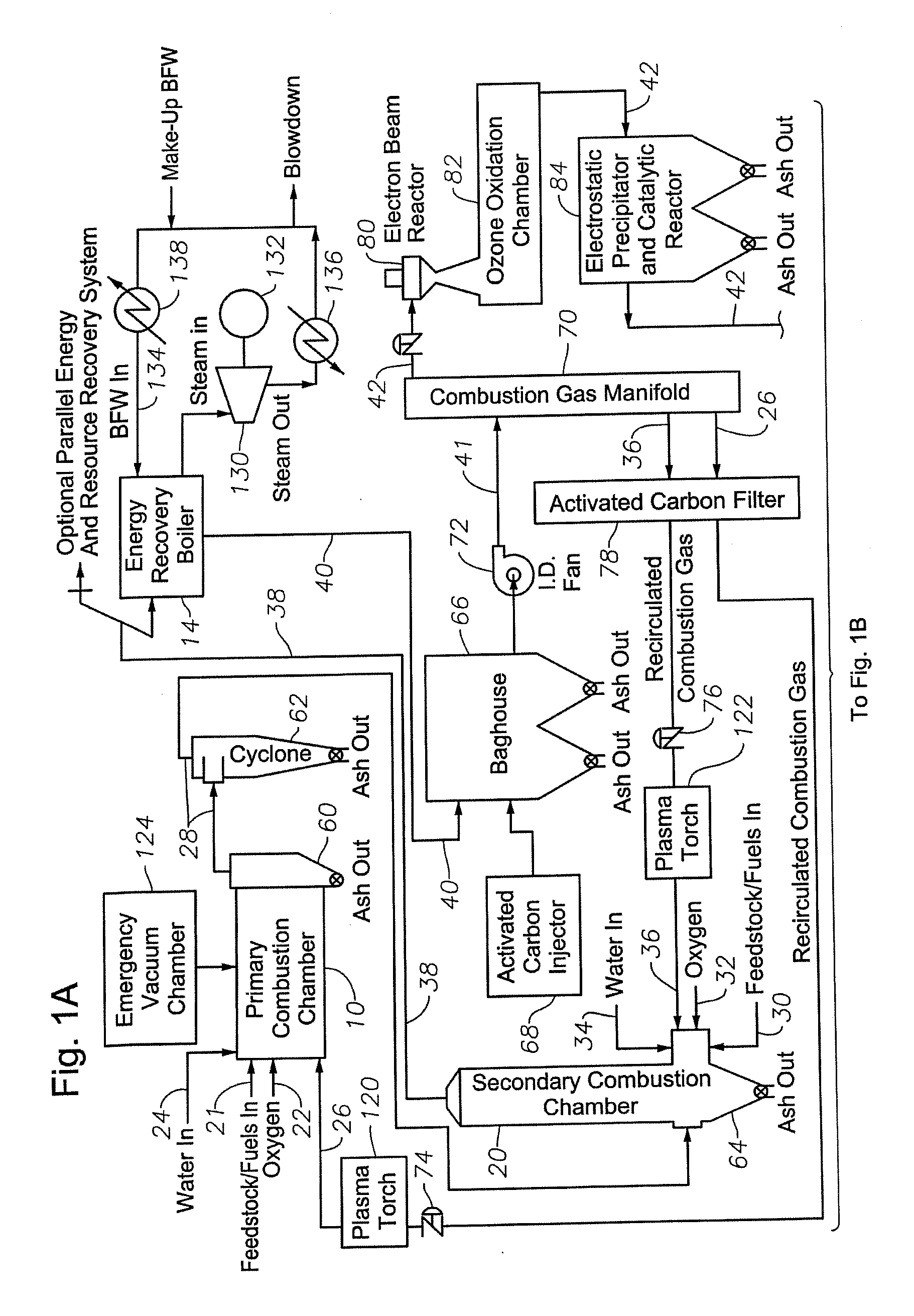

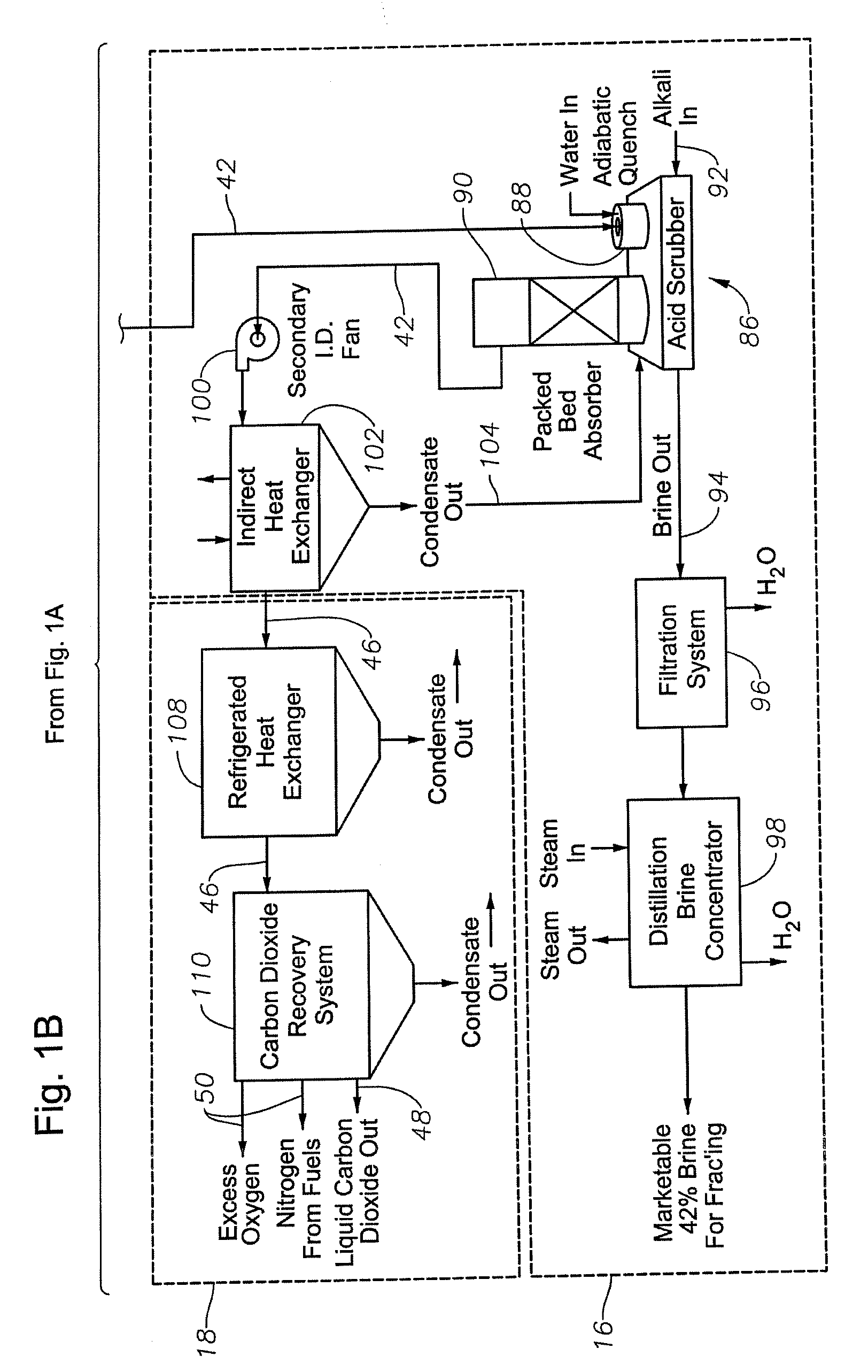

Reduced-emission gasification and oxidation of hydrocarbon materials for power generation

ActiveUS20080184621A1High heat transfer rateRaise the combustion temperatureGas modification by gas mixingSolid fuel combustionThermal energyEngineering

A system and process for maximizing the generation of electrical power from a variety of hydrocarbon feedstocks. The hydrocarbon feedstocks are first gasified and then oxidized in a two-chamber system and process using oxygen gas rather than ambient air. Intermediate gases generated in the system and process are recirculated and recycled to the gasification and oxidation chambers in order to maximize energy production. The energy produced through the system and process is used to generate steam and produce power through conventional steam turbine technology. In addition to the release of heat energy, the hydrocarbon feedstocks are oxidized to the pure product compounds of water and carbon dioxide, which are subsequently purified and marketed. The system and process minimizes environmental emissions.

Owner:CLARK STEVE L

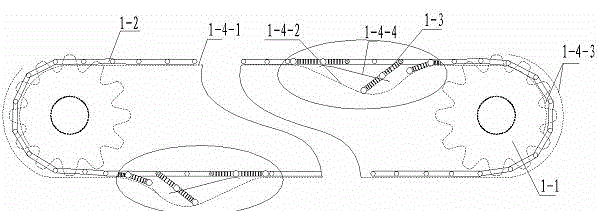

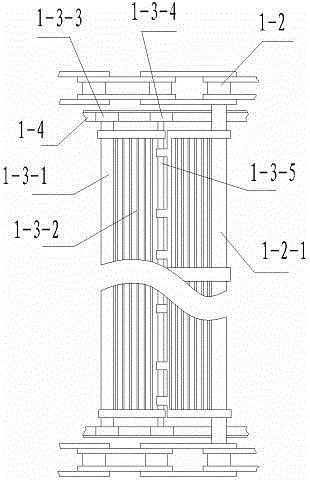

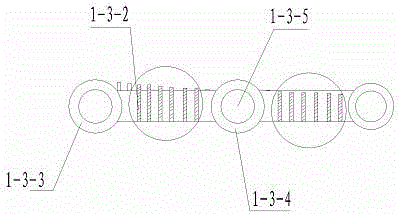

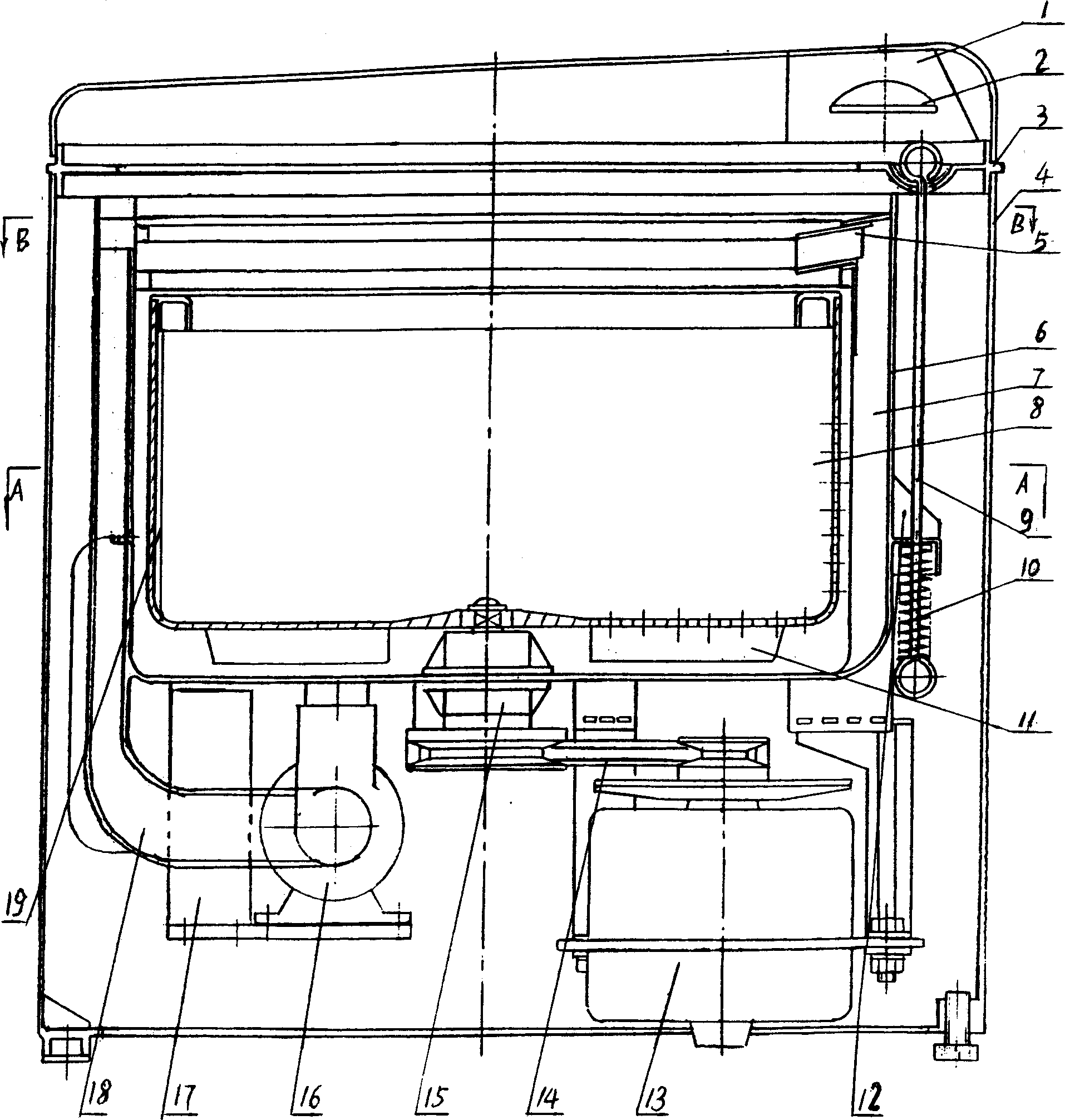

Chain plate conveying coal ball heat conduction oil dryer

ActiveCN104154728AUse diameter reductionImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsChain structureHeating effect

A chain plate conveying coal ball heat conduction oil dryer belongs to the field of drying equipment. The chain plate conveying coal ball heat conduction oil dryer comprises a heat insulation outer shell, a chain plate conveying mechanism, a feeding conveying belt, a discharging opening, a heating device and a waste heat using device. The chain plate conveying mechanism comprises a double-driving chain structure, a matched chain wheel, a bearing chain plate and a guiding sliding track. The bearing chain plate is a hollow-out structure formed by a frame and a grid bar and is located on a chain shaft in a hinge mode. The guiding sliding track is divided into an upper sliding track part and a lower sliding track part which have the same structure sequence. Each part is divided into a horizontal section, a V-shaped blanking section and an arc groove-shaped turning section which are connected in sequence. A falling zone corresponds to a lowering edge section of each V-shaped blanking section of the guiding sliding part. The heating device is connecting heat conduction oil furnace heat conduction calandrias which are distributed above and below a conveying interface formed by the bearing chain plate. An improved double-chain strip plate type conveyor is used, a high-efficiency heat conduction oil furnace is used as a heat source, a controllable heat conduction oil pipe composite layer distribution structure is used for improving the heating effect, and the effects of small space size, energy saving and environment protection are achieved.

Owner:HEBEI GOLD BANGZI BOILER

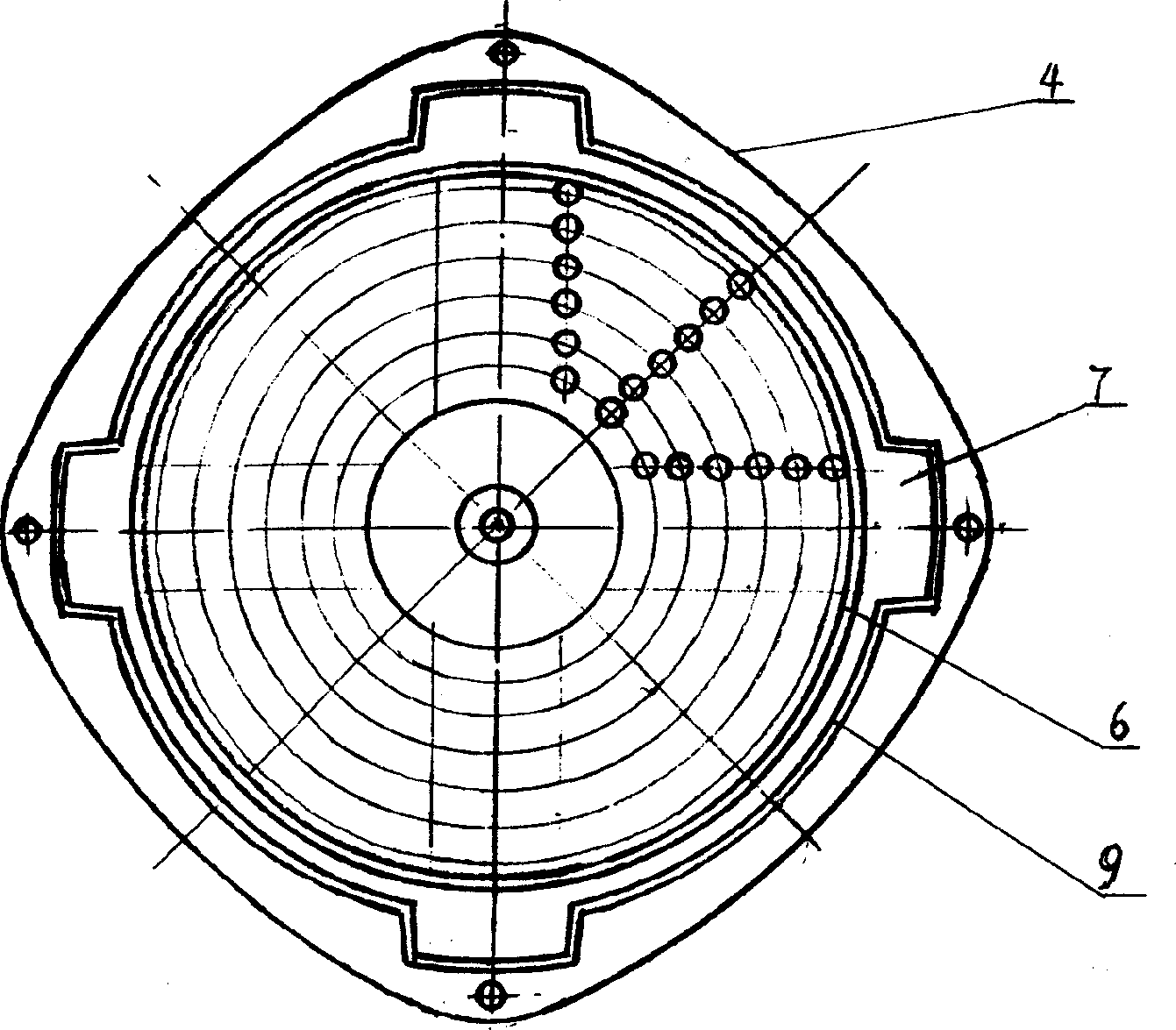

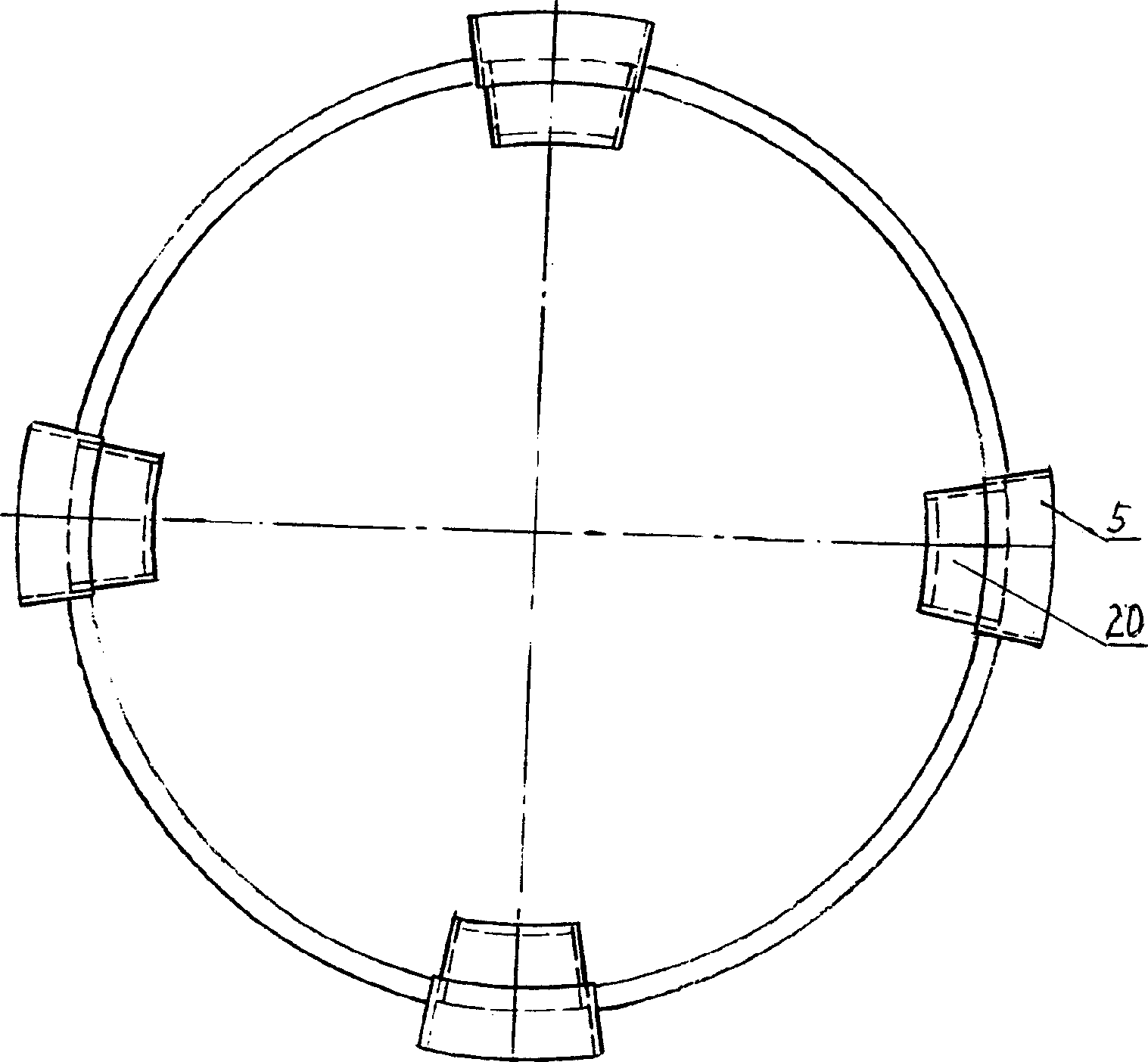

Vegetable and fruit cleaning machine

InactiveCN1543881AAvoid damageRelieve busy workKitchen equipmentFood treatmentWater savingEngineering

The main technical points of a vegetable and fruit cleaning machine comprising an outer housing body, an upper cover, an internal barrel, a vegetable-washing basket and a draining valve are as follows: the internal barrel is mounted at a bracket at inner side of the outer housing, the vegetable-washing basket equipped with a water-through hole is mounted inside the internal barrel, pump leaf blades are distributed at the bottom of the vegetable-washing basket, a rotary power take-off shaft is fixed at the central site at the bottom of the vegetable-washing basket; the internal barrel is further equipped with a vertical and protruding outwards open type channel with its top connected with a water spray nozzle for driving water to returning back to the vegetable-washing basket. The present invention has passed model machine experiments, exhibits very ideal vegetable-washing, disinfection and drying functions, avoids harms to vegetable and costermonger surfaces of manual work washing and can protect users' skins and hands. At the same time, the present invention is characterized by its reasonable structure, convenient manipulation, time and labor saving, economy of water consumption, environmental protection and sanitary, long service lifetime, wide application range and the like.

Owner:林德彬

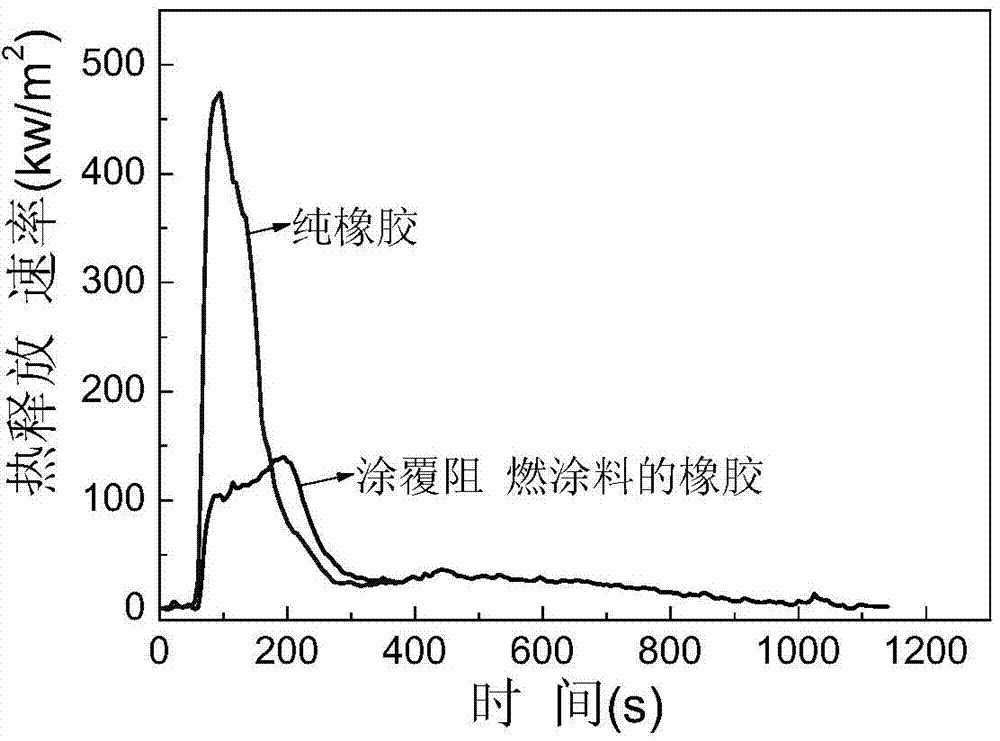

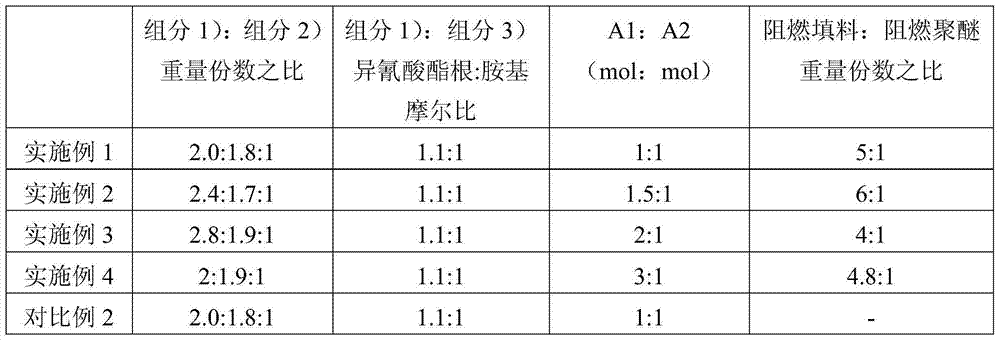

Inflaming retarding coating and application thereof

ActiveCN103756546AImprove flame retardant performanceImprove mechanical propertiesFireproof paintsPolyurea/polyurethane coatingsAcrylonitrileFire retardant

The invention discloses an inflaming retarding coating. The inflaming retarding coating comprises a component (1), namely an isocyanate pre-polymer, a component B (2), namely a fire retardant which comprises inflaming retarding polyether selected from acrylonitrile modified polyether and organic nitrogen compound modified polyether, and a component (3), namely a chain extender containing an amino. The inflaming retarding coating provided by the invention does not contain halogen elements, is high in solid content, low in moisture sensitivity and small in viscosity, needs a small quantity of diluting agent, causes small environmental pollution and has an environment-friendly effect; the inflaming retarding effect is prominent, and the adhesive force and the anti-fatigue performance are good; the migration and separation of the fire retardant are greatly relieved. More importantly, the coating provided by the invention does not lower the mechanical performance and the elasticity of a base material (such as a rubber element) and has low smoke and low toxin.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

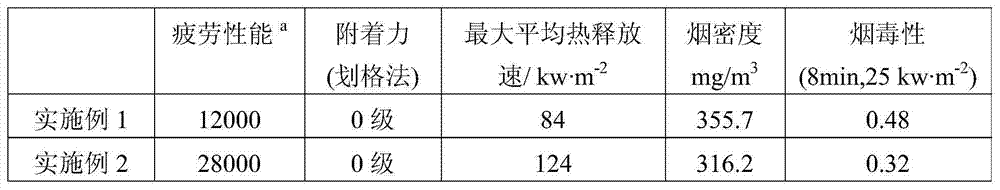

Flame-proof nitrocellulose lacquer prepared by halogen-free flame retardant and preparation method thereof

The invention discloses nitrocellulose lacquer which is prepared through utilizing free halogen flame retardant, and adding free halogen flame retardant on the basis of traditional nitrocellulose lacquer, whose proportion of components is that 13-18% nitrocellulose, 27-35% mixing solvent, 1-3% mixing auxiliary agent, 30-35% plasticizing agent, 7-10% transparent raw material liquid diluent and 10-15% color paste, which is characterized in that 7-10% free halogen flame retardant is added in the components. The invention further discloses a preparation process of nitrocellulose lacquer. The invention provides environment-friendly, no pollution nitrocellulose lacquer with excellent flame-retardant effect under the conditions of keeping basic property of original nitrocellulose lacquer and no changing functions.

Owner:刘春雨

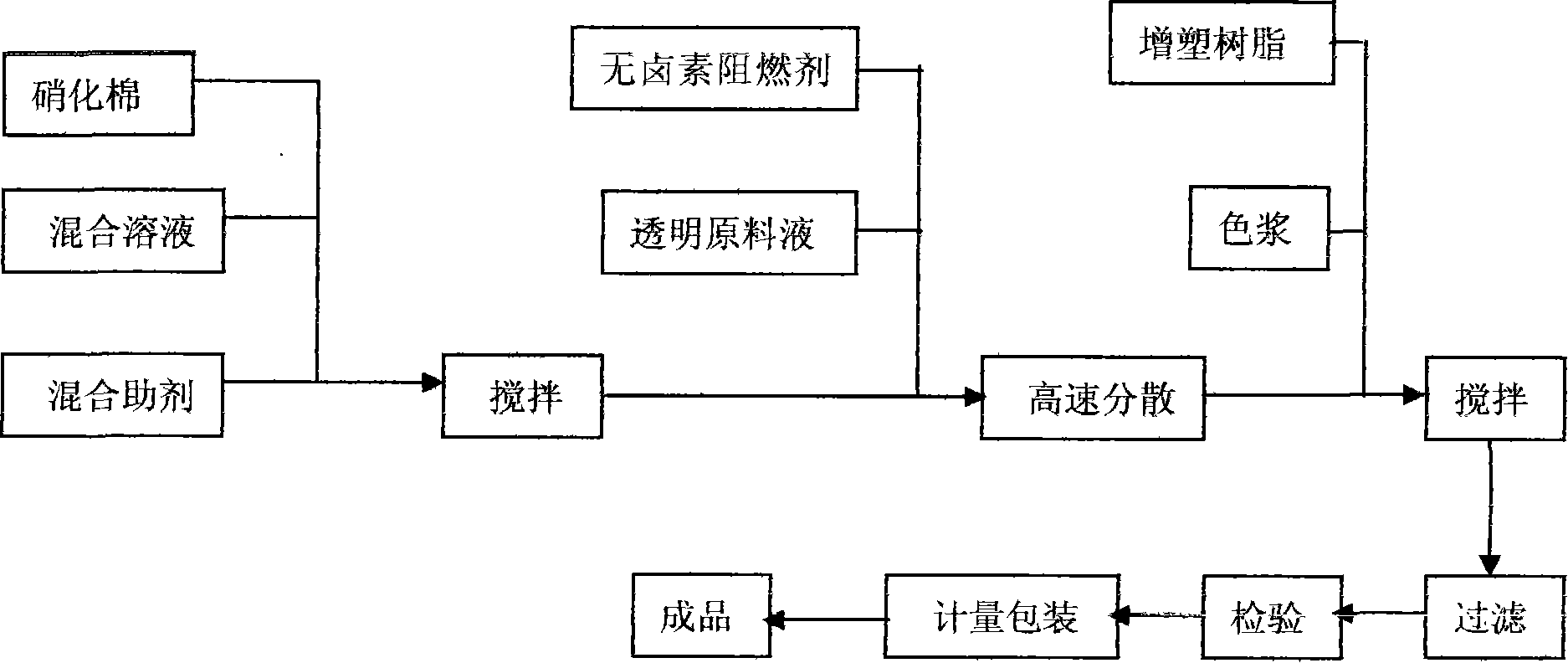

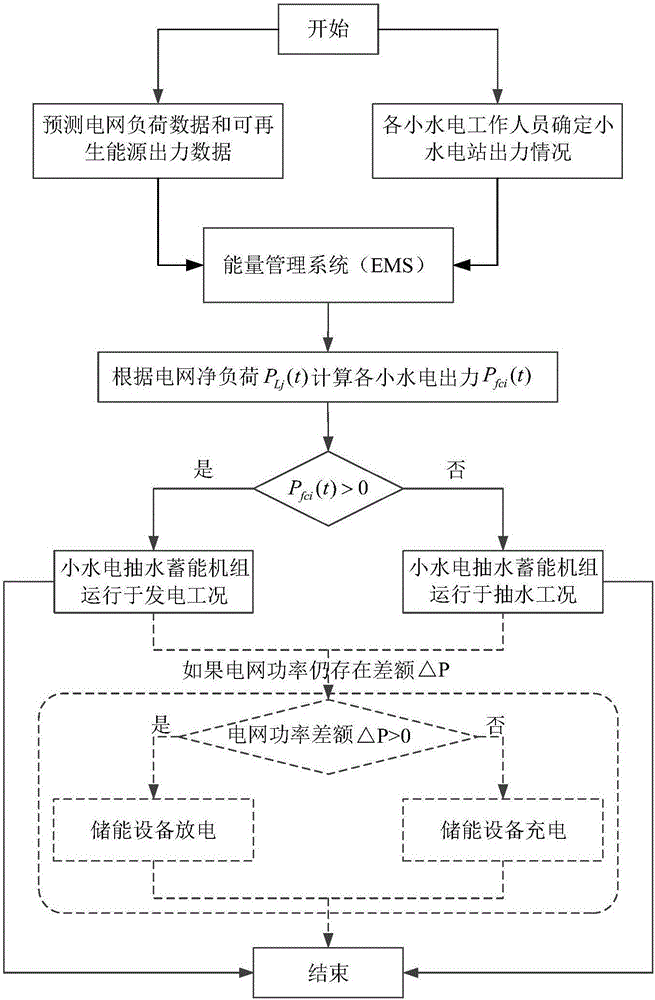

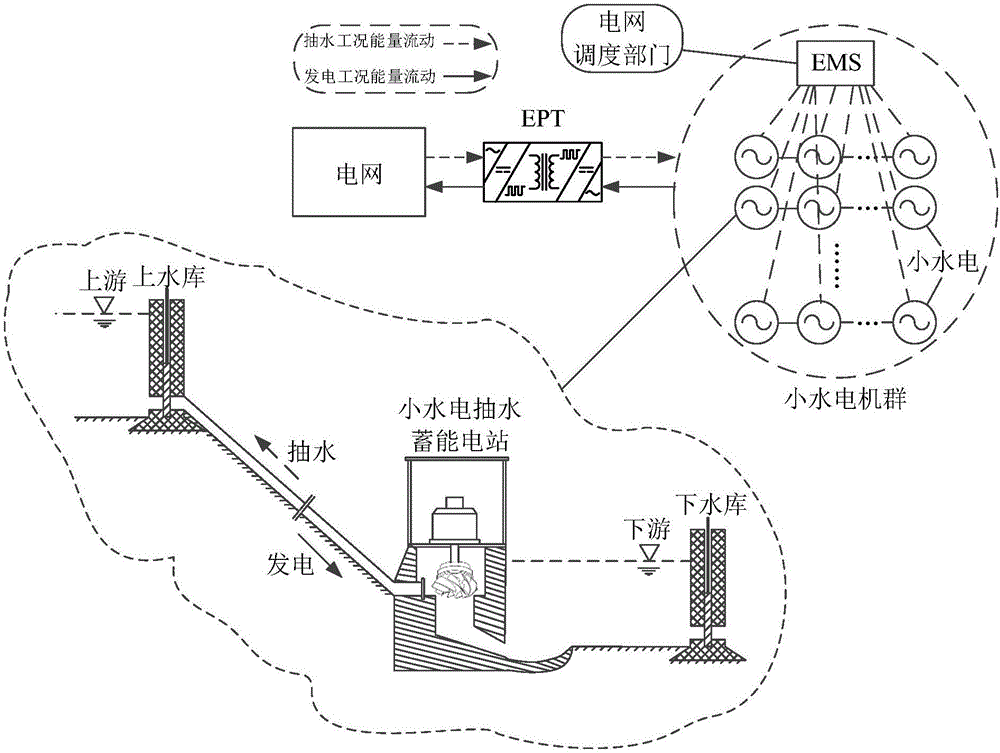

Method of forming distributed energy storage system by small hydropower cluster

ActiveCN106099960ALow costReduce construction difficultySingle network parallel feeding arrangementsHydro energy generationWater turbinePower grid

The invention discloses a method of forming a distributed energy storage system by a small hydropower cluster. The method comprises steps: a total net load value PLj(t) of all small hydropower stations at a tth time in an energy storage cycle T is acquired; according to an optimization objective, the total net load value PLj(t) and planned load pi(t) of an ith small hydropower station, the actual load pfci(t) of the ith small hydropower station is acquired; and according to the actual load pfci(t) of the ith small hydropower station, optimal efficiency control is carried out on a water pumping and water storing device of the ith small hydropower station, and the ith small hydropower station is made to operate under the optimal efficiency according to the actual load pfci(t), wherein the water pumping and water storing device is a hydraulic turbine, a water pump or a reversible hydraulic turbine. Through carrying out improvement on the small hydropower stations and using an energy management unit to manage the small hydropower stations in a unified mode, the multiple small hydropower stations can form a large energy storage system capable of power generation and energy storage, the problems of the operation efficiency and the utilization of the small hydropower stations can be solved, and the regulation capability of the power grid is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

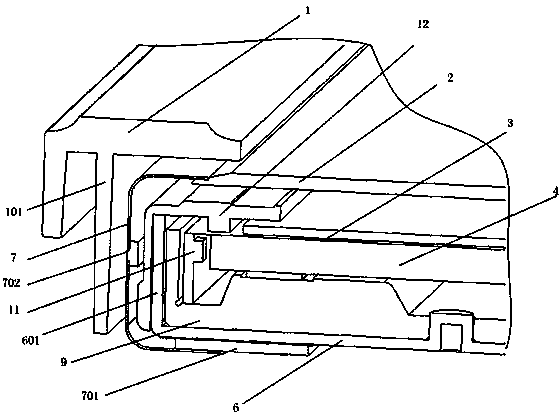

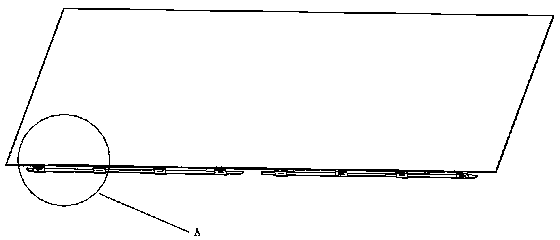

Backlight module and liquid crystal display device

ActiveCN103925531AImprove cooling effectLow thermal conductivityLighting heating/cooling arrangementsNon-linear opticsLiquid-crystal displayImage resolution

The invention discloses a backlight module and a liquid crystal display device, and relates to the technical field of liquid crystal display. The backlight module and the liquid crystal display device solve the problem of how to achieve a better radiating effect and lower the local temperature of a cover of a shell on the situation that resolution and refreshing frequency of a liquid crystal module are improved and the IC temperature of a COF chip is increased. The liquid crystal display device comprises a Source drive circuit board used for being connected with a liquid crystal panel and arranged on the outer wall of a bottom plate of a back plate, and a COF wound around the outside of a glue frame, wherein the COF is provided with a chip IC. An S plate shielding cover comprises a first folding edge connected with the out wall of the bottom plate of the back plate, and a second folding edge arranged on the periphery of the COF, wherein the first folding edge covers the Source drive circuit board, the second folding edge covers the portion, with the chip IC, of the COF, and a gap exists between the first folding edge and the Source drive circuit board.

Owner:HISENSE VISUAL TECH CO LTD

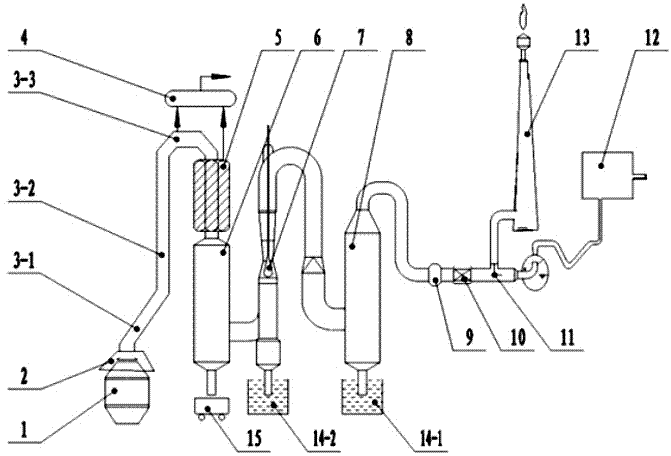

System and method for treating converter flue gas

InactiveCN102899444AEasy to controlEasy to operateIncreasing energy efficiencyManufacturing convertersEvaporative coolerDust control

The invention relates to an environmental-friendly device of an iron and steel enterprise and a dust removal method, that is to say, a system and a method for treating converter flue gas. The system comprises a furnace mouth nitrogen injection sealing petticoat pipe, a segmental evaporation cooling flue, a high-temperature heat pipe steam generator, a spray evaporation cooler, a long neck adjustable throat venturi tube, an impeller type composite dehydrator, a fan, an automatic continuous coal gas detector and a three-way switching valve, which are connected in sequence, wherein the three-way switching valve is connected with a gas chamber; or the three-way switching valve is communicated with a chimney. The method comprises the following steps of: forming a soft sealing screen between a furnace mouth and a petticoat pipe, after segmentally vaporizing and cooling the flue gas, and cooling in a high-temperature heat pipe; after carrying out spray evaporation, cooling and rough dust removal through a dry method, carrying out fine dust removal and cooling by a venturi tube through a wet method, dehydrating the flue gas, and entering into a coal gas recycling stage lastly. According to the invention, the wet method and the dry method are combined, waste heat recovery, coal gas recovery, sewage treatment and dust removal can be planned in a flue gas treatment and utilization system as a whole and the combination action of the device is fully exerted.

Owner:北京五一环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com