Inflaming retarding coating and application thereof

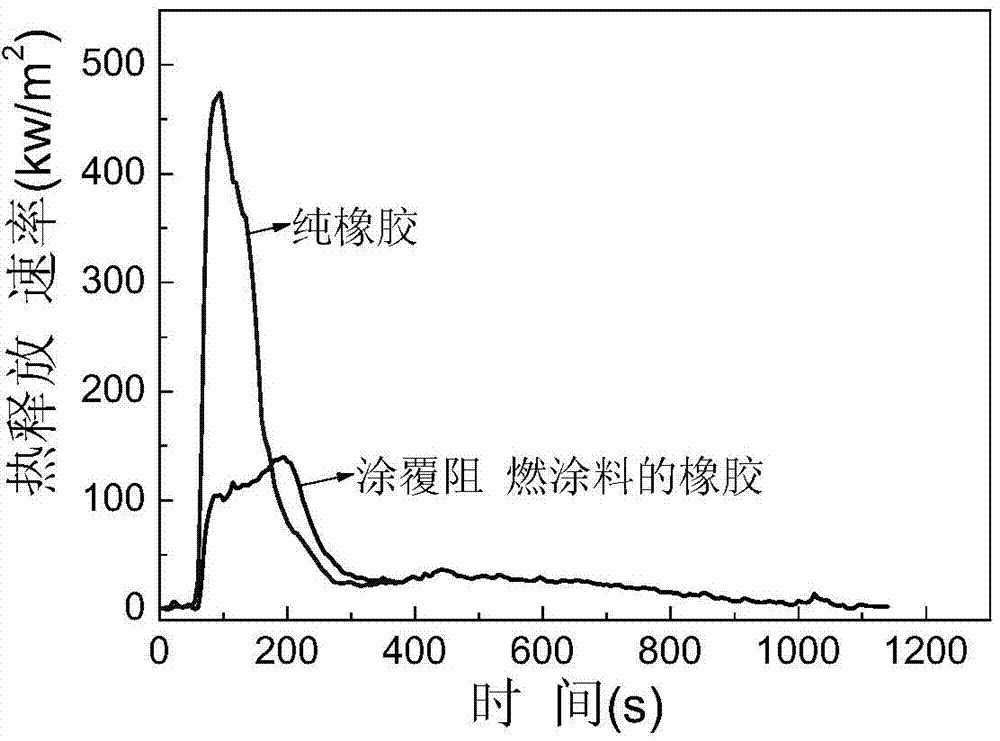

A technology of flame-retardant coatings and flame-retardant fillers, which is applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., and can solve the problem of unfavorable synergistic strain between flame-retardant coatings and rubber elastic element substrates, and high addition of flame-retardant substances , unfavorable process operation and other problems, to achieve the effect of good elasticity, good mechanical properties and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

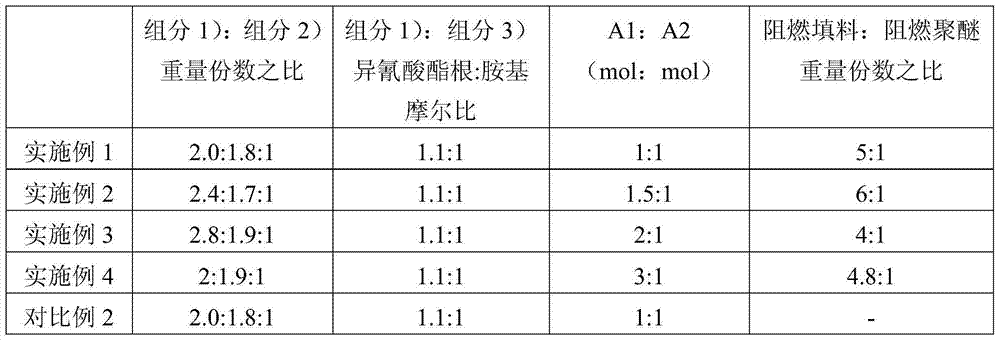

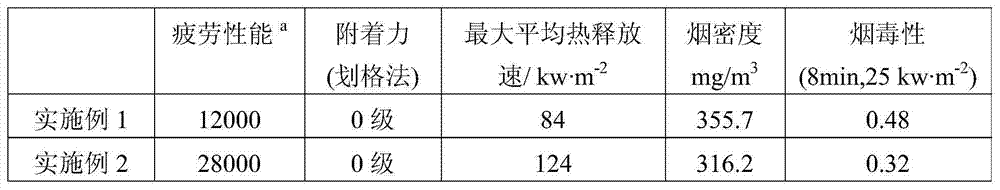

Embodiment 1

[0038] First, add 32.14 parts of A1 (HDI trimer) and 134.9 parts of A2 (prepolymer of TDI isocyanate and polytetrahydrofuran ether, grade C3090) according to the isocyanate molar ratio of 1:1, and 1.2 parts of defoamer BYK -141, 26.7 parts of diluent propylene glycol methyl ether acetate into the stirring tank, stirring at 800r / min for 5min, and discharging.

[0039] Next, weigh 86.4 parts of chain extender polyaspartate (NHQ640, amine value: 162) and 30.7 parts of melamine-modified polyether POP-290 into the stirring tank, and add 3.4 parts of dispersant BYK according to the experimental formula -163, 2.9 parts of defoamer BYK-392, 2.6 parts of leveling agent BYK-410 and 2.7 parts of organic bismuth catalyst (BiCAT8108) were dispersed at 1000r / min for 5min, and flame-retardant filler melamine-coated polyphosphoric acid was gradually added Ammonium (Exolit APP462) 46.2 parts, expandable graphite 20 parts, aluminum diethyl hypophosphite 48.7 parts, aluminum titanate 8 parts, un...

Embodiment 2

[0042] Add 33.9 parts of MDI trimer and 107.9 parts of TDI isocyanate elastic prepolymer C3090 according to the isocyanate molar ratio of 1.5:1, add 1.0 parts of defoamer BYK-141, 20.3 parts of diluent butyl acetate into the stirring tank, Stir at 800r / min for 5min and discharge.

[0043] Weigh 79.5 parts of chain extender polyaspartate (NHQ620, amine value: 193) and 14.6 parts of melamine-modified polyether POP-290 into the stirring tank, add 2.5 parts of dispersant BYK-163 according to the experimental formula , 2.9 parts of defoamer BYK-141, 1.7 parts of leveling agent BYK-358N, 2.4 parts of anti-sag agent BYK-333 and 1.7 parts of organic bismuth catalyst BiCAT8108 were dispersed at 1000r / min for 5min, and flame retardant fillers were added gradually 29.7 parts of amine-coated ammonium polyphosphate (APP462), 7.5 parts of expandable graphite, 31.7 parts of diethyl aluminum hypophosphite, 19.2 parts of melamine cyanurate, until all components are mixed evenly, add 4.4 parts ...

Embodiment 3

[0046] Add 42.8 parts of MDI trimer and 111.7 parts of IPDI isocyanate elastic prepolymer (prepolymer of IPDI and polyethylene oxide, Desmodur VPLS2371) at a molar ratio of 2:1 isocyanate, 0.8 parts of defoamer BYK- 141. Put 12.4 parts of diluent butyl acetate into the stirring tank, stir at 800r / min for 5min, and discharge.

[0047] Weigh 69.3 parts of chain extender polyaspartate (Desmophen NH1420, amine value: 202) and 23.5 parts of melamine modified polyether POP-290 into the stirring tank, add 1.8 parts of dispersant DISPERBYK-2025 according to the experimental formula , 1.3 parts of defoamer BYK-141, 1.3 parts of leveling agent BYK-358N, 2.0 parts of anti-sag agent BYK-333 and 1.8 parts of organic bismuth catalyst BiCAT8108 were dispersed at 1000r / min for 5min, and gradually added flame retardant filler Amine-coated ammonium polyphosphate (APP462) 47.1 parts, expandable graphite 29.8 parts, zinc borate 9.4 parts, until all components are mixed evenly, add 5.6 parts of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com