Patents

Literature

143results about How to "Reduce oxidative decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimicrobial cleaning agent for hard surfaces

InactiveUS20120213759A1Increase dilutionPrevent appearanceBiocideCationic surface-active compoundsAmmonium compoundsCompound (substance)

A surfactant-containing aqueous antimicrobially effective cleaning agent for hard surfaces includes at least one amphoteric polymer, a quaternary ammonium compound and formic acid. The agent may be used for the cleaning and / or antimicrobial treatment of hard surfaces, in particular in damp rooms such as bathrooms.

Owner:HENKEL KGAA

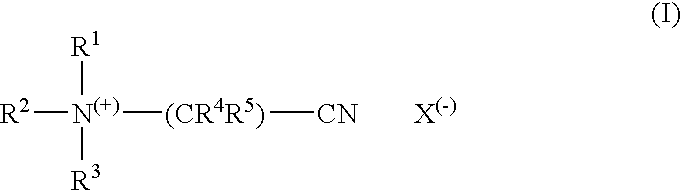

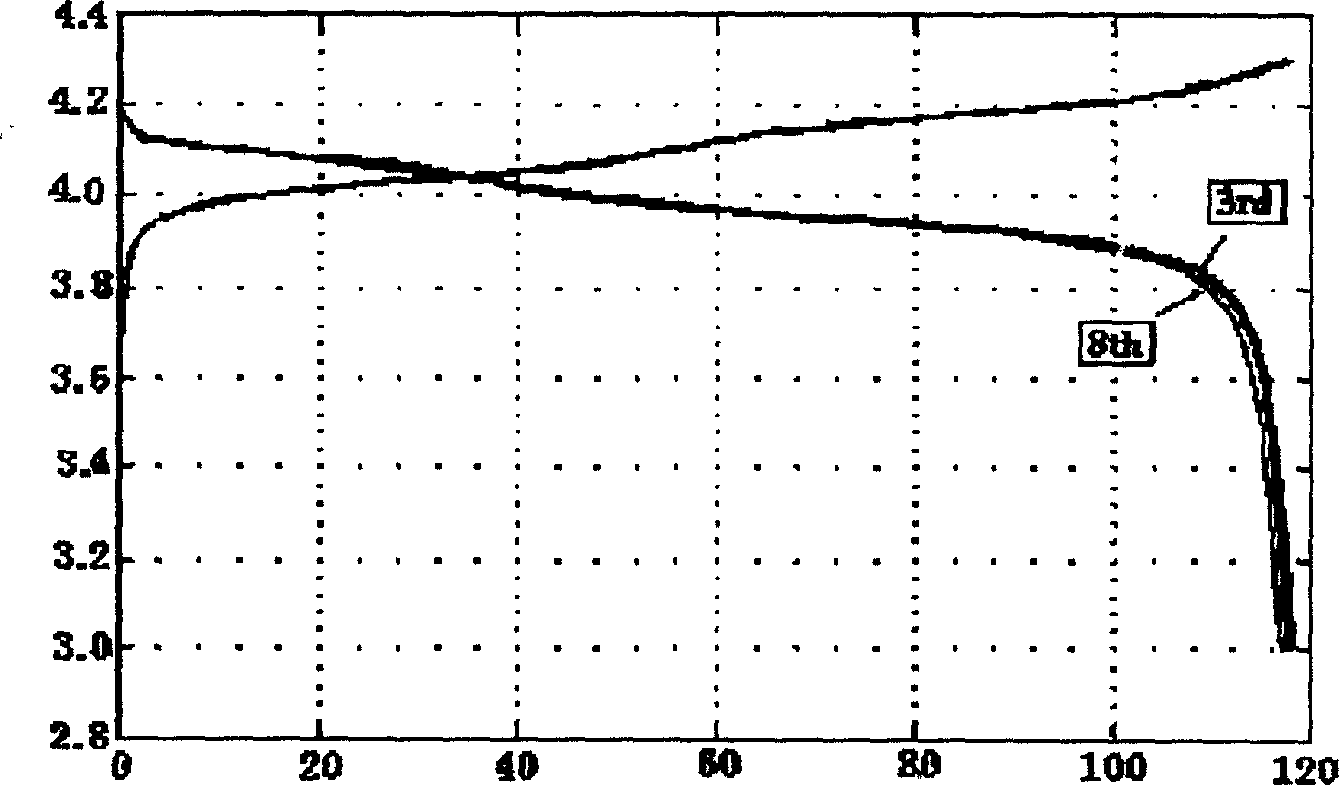

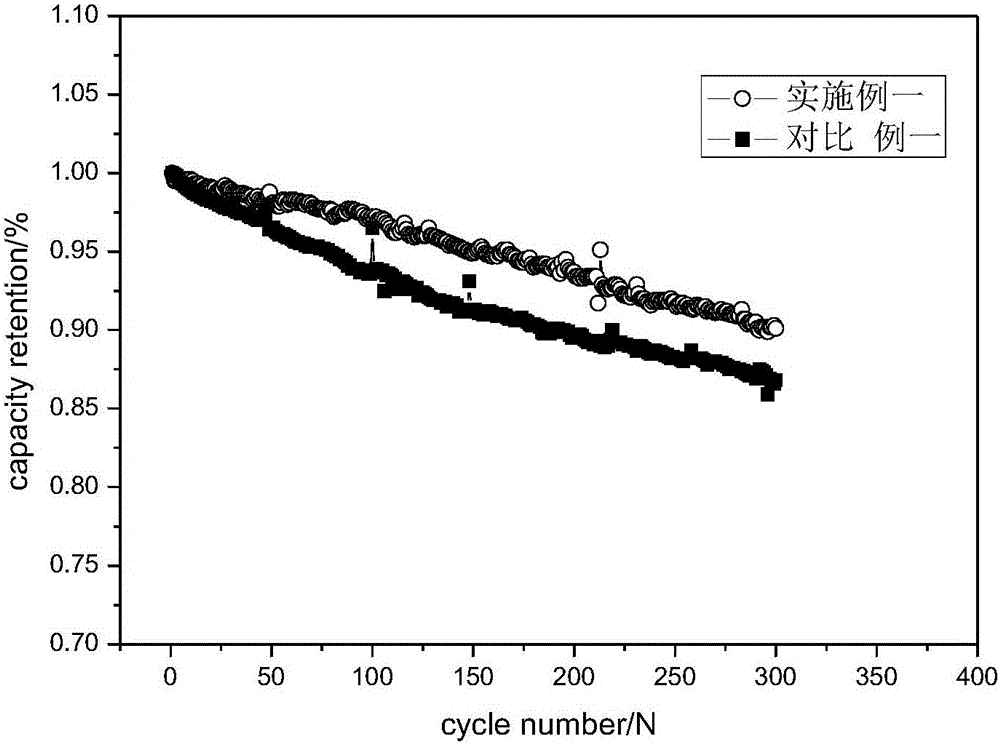

Electrolyte additive, high-voltage electrolyte and lithium ion battery containing electrolyte additive

InactiveCN103094616AInhibit surface activityAvoid contactSecondary cellsAluminium-ion batteryOrganic solvent

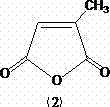

The invention discloses an electrolyte additive, a high-voltage electrolyte and a lithium ion battery containing the electrolyte additive. The high-voltage electrolyte is prepared by adding the electrolyte additive into the conventional electrolyte; the conventional electrolyte comprises a non-aqueous organic solvent and lithium salt, wherein the content of the non-aqueous organic solvent is 80-85 percent of the total mass; the mass of the electrolyte additive is 0.01-10 percent of the total mass; and the electrolyte additive is maleic anhydride C4H2O3 or one of derivatives thereof and has the structure formula as shown in the abstract. According to the high-voltage electrolyte, a stable interfacial film can be formed on the surfaces of a positive electrode and a negative electrode, the reaction activity on the electrode surface is inhibited, oxidative decomposition of the electrolyte is reduced, and gas swelling is effectively inhibited, so that the safety performance and the cycle performance of the lithium ion battery under normal pressure and high voltage are improved and the service life of the lithium ion battery under normal pressure and high voltage is prolonged. The electrolyte is simple in preparation process and is suitable for industrial production.

Owner:JIANGXI YOULI NEW MATERIALS

Secondary lithium battery and positive electrode material thereof, and positive electrode material preparation method

ActiveCN105098177AImprove lithium ion conductivityGood chemical stabilityElectrode thermal treatmentPositive electrodesPhosphateSodium-ion battery

The present invention provides a positive active material for use in a lithium ion battery, a method for preparing the positive active material and a lithium ion battery containing the positive active material. The positive active material includes a core of lithium containing transition metal oxide represented by Formula LixMyN1-yO2-αAβ and a coating layer of lithium containing transition metal phosphate represented by Formula LiaMbN′1-bPO4-λBζ in situ formed on the core, wherein 0.9≰x≰1.2, 0.6≰y≰1.0, 0.9≰a≰1.1, 0.6≰b≰1.0, 0≰α≰0.2, 0≰β≰0.4, 0≰λ≰0.5, 0≰ζ≰0.5. The positive active material for use in a lithium ion battery according to the present invention has high capacity, desirable cycling performance and safety performance, as well as desirable thermal stability.

Owner:CONTEMPORARY AMPEREX TECH CO

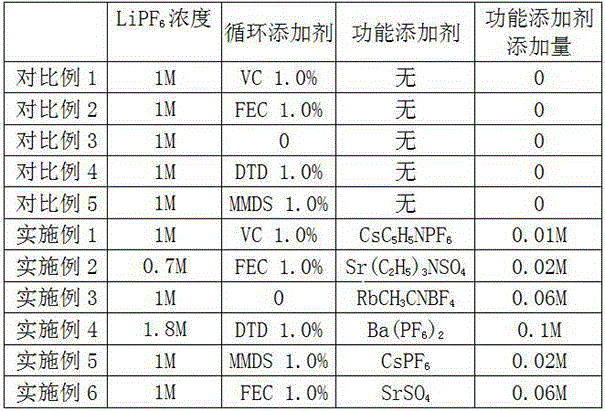

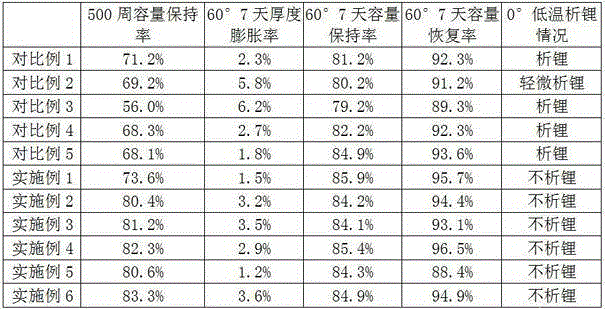

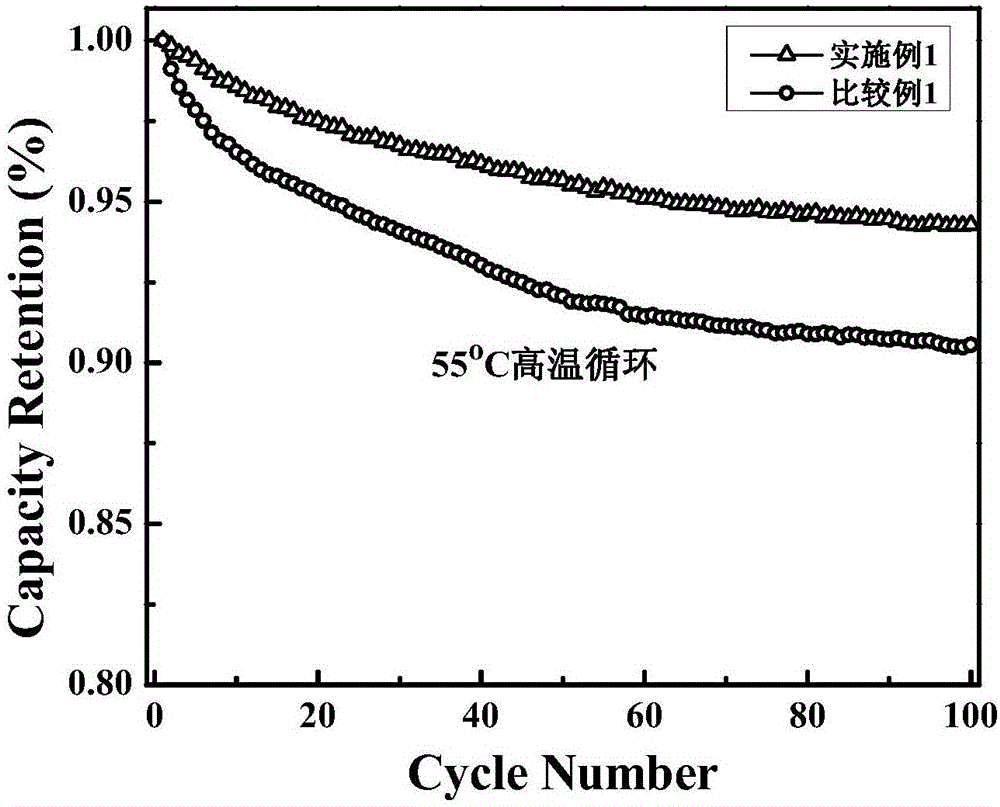

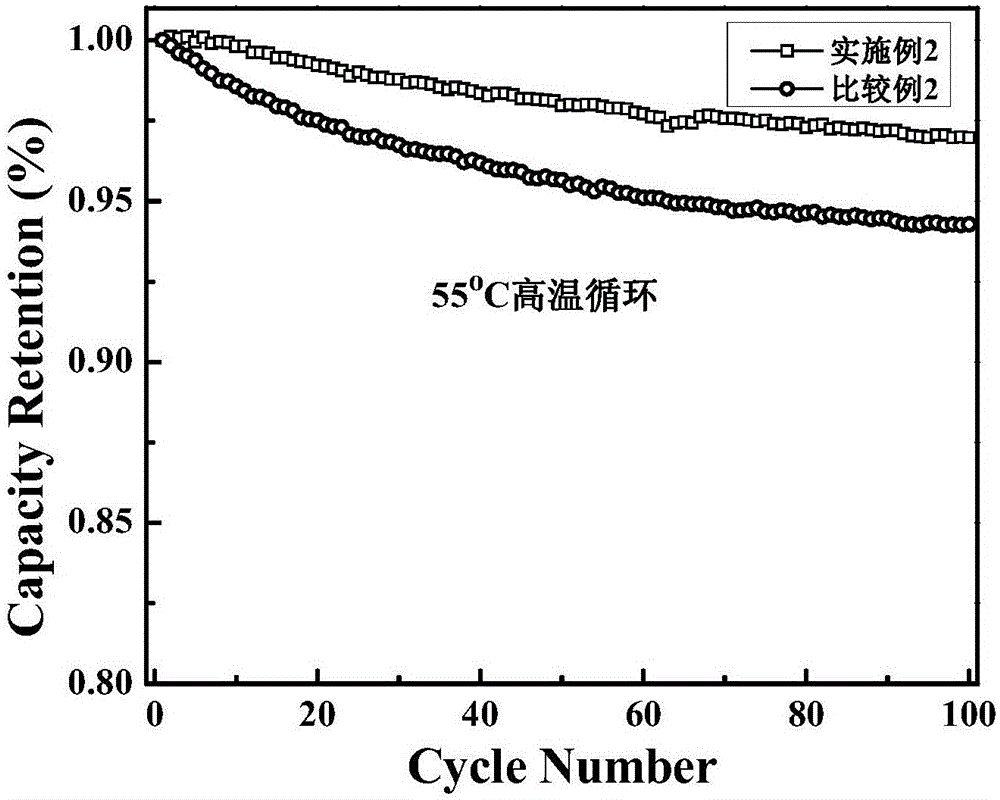

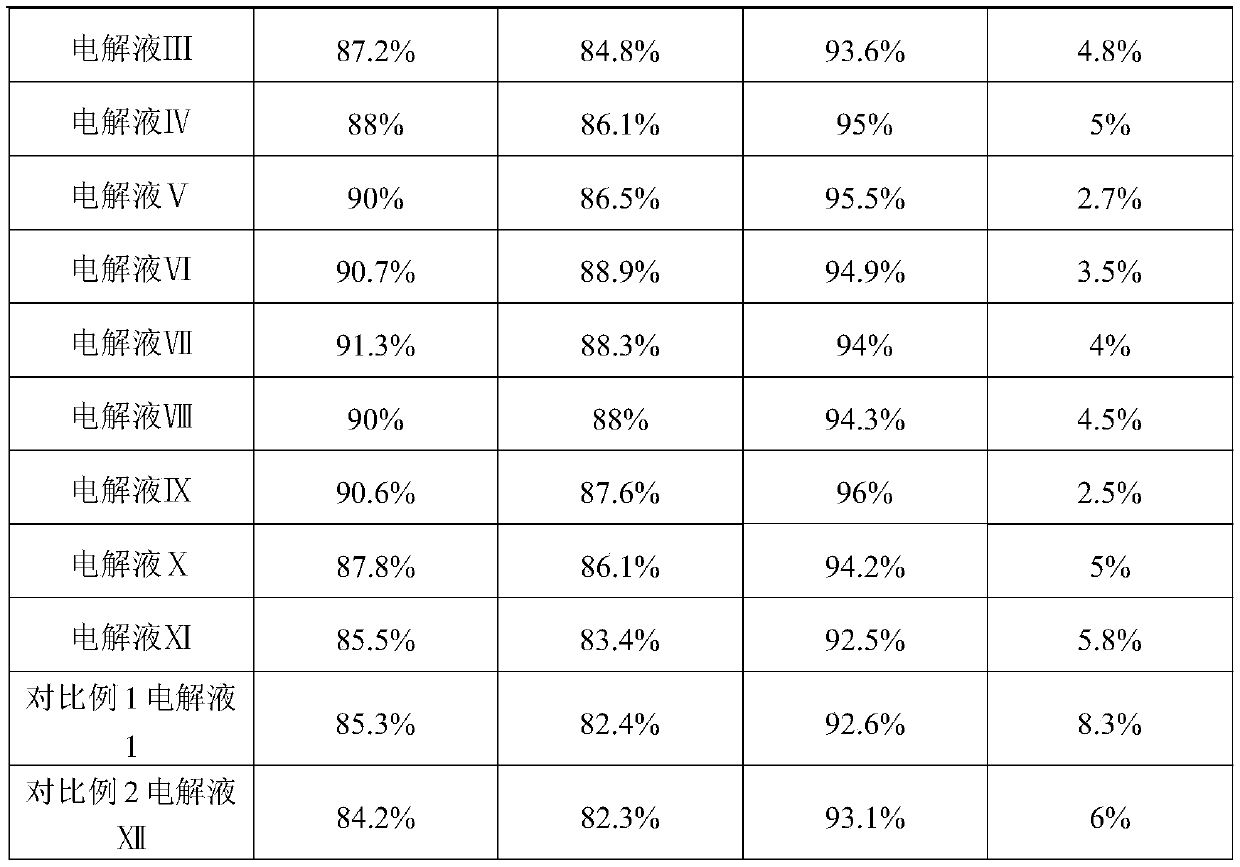

Lithium-ion battery electrolyte for high-voltage ternary positive electrode material system

ActiveCN105140564AImprove cycle performanceImprove high temperature performanceSecondary cellsOrganic electrolytesSolventStructural formula

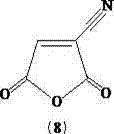

The invention provides a lithium-ion battery electrolyte for a high-voltage ternary positive electrode material system. The lithium-ion battery electrolyte comprises a non-aqueous solvent, lithium hexafluorophate and a functional additive; the functional additive comprises a cyclic anhydride compound, a lithium salt type additive and methylene methanedisulfonate; the general structural formula of the cyclic anhydride compound is as shown in the description, wherein R1, R2, R3 and R4 are independently selected from any one of hydrogen atom, fluorine atom, or straight chain or branched chain alkyl with the number of carbon atoms of 1-4. The cyclic anhydride compound used in the lithium-ion battery electrolyte is higher in reduction potential (the reduction potential of succinic anhydride is 1.50 V vs Li+ / Li) on the negative electrode surface, so that other components in the electrolyte can be preferably reduced into films in the first charging process of the battery, the formed SEI film is high in stability. The cyclic anhydride compound used in the lithium-ion battery electrolyte is capable of effectively improving the cycle performance and high-temperature performance of the battery; and compared with fluoroethylene carbonate, the cyclic anhydride compound has excellent high-temperature performance as well as capability of improving the cycle performance.

Owner:GUANGZHOU TINCI MATERIALS TECH

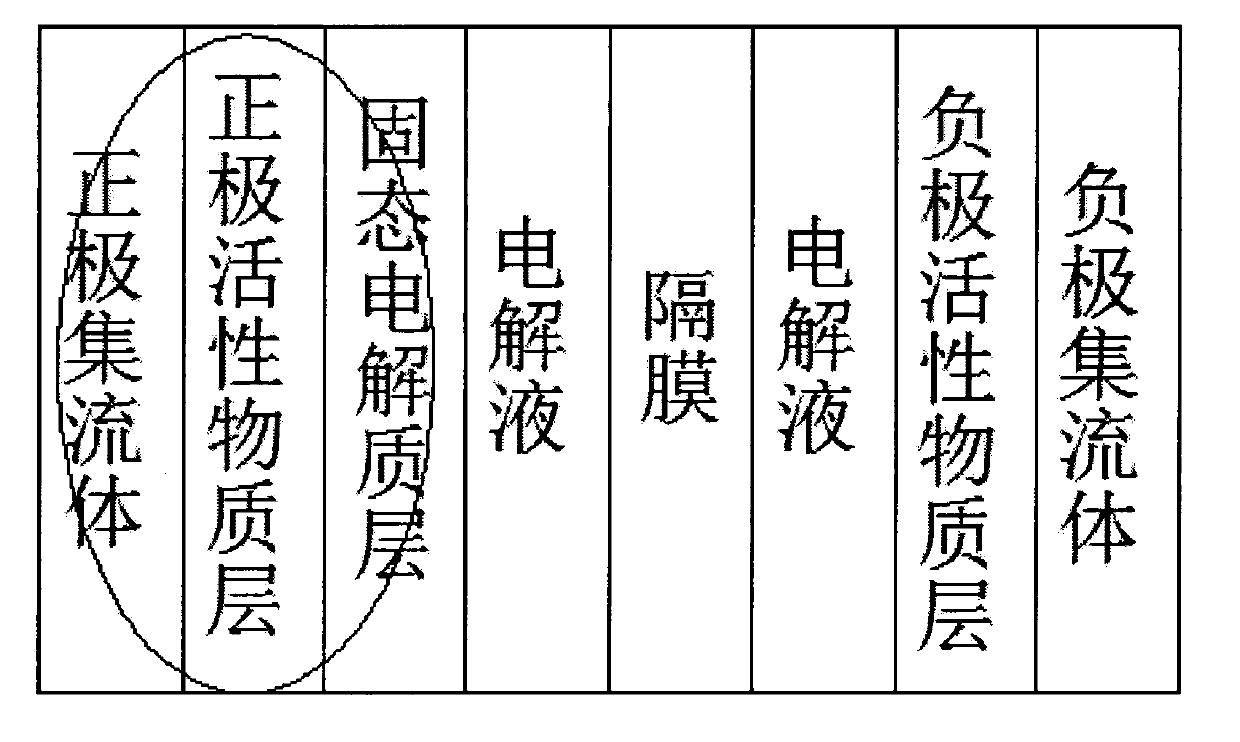

Preparation method of lithium ion battery coating pole piece

The invention discloses a preparation method of lithium ion battery coating pole piece. The preparation method comprises following steps: (1) weighing and dissolving a binder in a solvent, vacuum stirring for 1 to 10 hours to obtain a homogenous solution; (2) adding solid electrolyte powder to the solution prepared in the step (1), vacuum stirring for 1 to 12hours to obtain a solid electrolyte-binder-solvent mixture; (3) evenly coating the mixture prepared in the step (2) on the surface of the battery anode electrode, obtaining a solid electrolyte coating layer, which has a dry thickness between 2 and 5 [mu]m, after the mixture dries; (4) rolling the whole anode electrode prepared in the step (3) with a roller machine, and obtaining the lithium ion battery coating pole piece. The preparation method adds a solid electrolyte layer between the electrolyte liquid and the electrode active material, so that in the situation that active material lithium ion de-intercalation is not affected, contact between active material and electrolyte liquid can be effectively prohibited, oxygenolysis of electrolyte liquid under high voltage is reduced, and battery circulation lifetime is increased.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

High-voltage electrolyte and high-voltage lithium ion battery

InactiveCN105119014AReduce oxidative decompositionImprove high temperature performanceSecondary cellsElectrolytic agentOrganic solvent

The invention discloses a high-voltage electrolyte and a lithium ion battery. The high-voltage electrolyte comprises a non-aqueous organic solvent, an electrolyte salt, a conventional high-voltage electrolyte additive and a functional additive. The functional additive has a general chemical formula of AXB or AB. The electrolyte functional additive is added into the conventional high-voltage electrolyte additive so that the high-voltage electrolyte is prepared. The lithium ion battery containing the high-voltage electrolyte comprises a positive pole and a negative pole. In the lithium ion battery, the additives in the high-voltage electrolyte can produce synergism, can form interfacial films on surfaces of the positive and negative poles, can inhibit electrode surface reaction activity, can reduces electrolyte oxidation decomposition and can effectively inhibit Qi distention so that lithium ion battery high temperature performances, cycle performances at a normal temperature under normal pressure, and a service life are improved and lithium separation in the lithium ion battery working at a low temperature is reduced.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Ball-shaped toilet blocks based on anionic surfactants

InactiveUS20130239313A1Disadvantageous effect stabilityDisadvantageous effect appearanceAnionic surface-active compoundsLavatory sanitorySulfonatePolymer science

A toilet cleaning block which comprises perfume, at least one alkylbenzene sulfonate and at least one olefin sulfonate and not more than 2.5% by weight of nonionic surfactants can be shaped in a rolling machine or a press to give a rotationally symmetric body, especially to give a ball, and is employed in a system composed of at least one cleaning block and at least one release device.

Owner:HENKEL KGAA

Infant series yak milk formula milk powder and preparation method thereof

ActiveCN103621633APromote absorption and metabolismReduce stimulationMilk preparationBiotechnologyVegetable oil

The invention provides infant yak milk formula milk powder and a preparation method thereof. Raw materials for manufacturing products of one ton comprise 100-600 kg of yak milk, 2,000-4,500 kg of fresh milk, 200-500 kg of dried whey (D90), 20-120 kg of whey protein concentrate (WPC34), 0-110 kg of cream, 130-250 kg of refined vegetable oil and OPO structure grease, 15-65 g of lactose, and 0-50 kg of white granulated sugar. The infant yak milk formula milk powder facilitates infant absorption and metabolism, reduces stimulation to a gastrointestinal tract, can remove free radicals, enhances antioxidant ability and immunocompetence of bodies, promotes fat oxygenolysis, promotes human body protein synthesis, and has important function for promoting human body growth and development. The infant yak milk formula milk powder has the important functions for building normal gastrointestinal tract flora, adjusting the balance of various probiotics, stimulating immune cells, promoting intestinal tract movement, and preventing diarrhea and constipation.

Owner:甘南藏族自治州燎原乳业有限责任公司

Encapsulated active ingredient preparation for use in particulate detergents and cleaning agents

InactiveUS6979669B2Easy to usePrevent appearanceDetergent mixture composition preparationOrganic/inorganic per-compounds compounding agentsParticulatesFluidized bed

A granulate for particulate detergents or cleaning agents, the granulate containing a detergent or cleaning agent active ingredient and an outer encapsulation layer formed of polyvalent metal salts of an unbranched or branched, unsaturated or saturated, mono- or polyhydroxylated fatty acid having at least 12 carbon atoms or a mixture of the salts. Also, a process for making the granulate by applying to the granules an encapsulation material that comprises one or more polyvalent metal salt or salts, preferably in the form of an aqueous dispersion in a fluidized bed process.

Owner:HENKEL KGAA

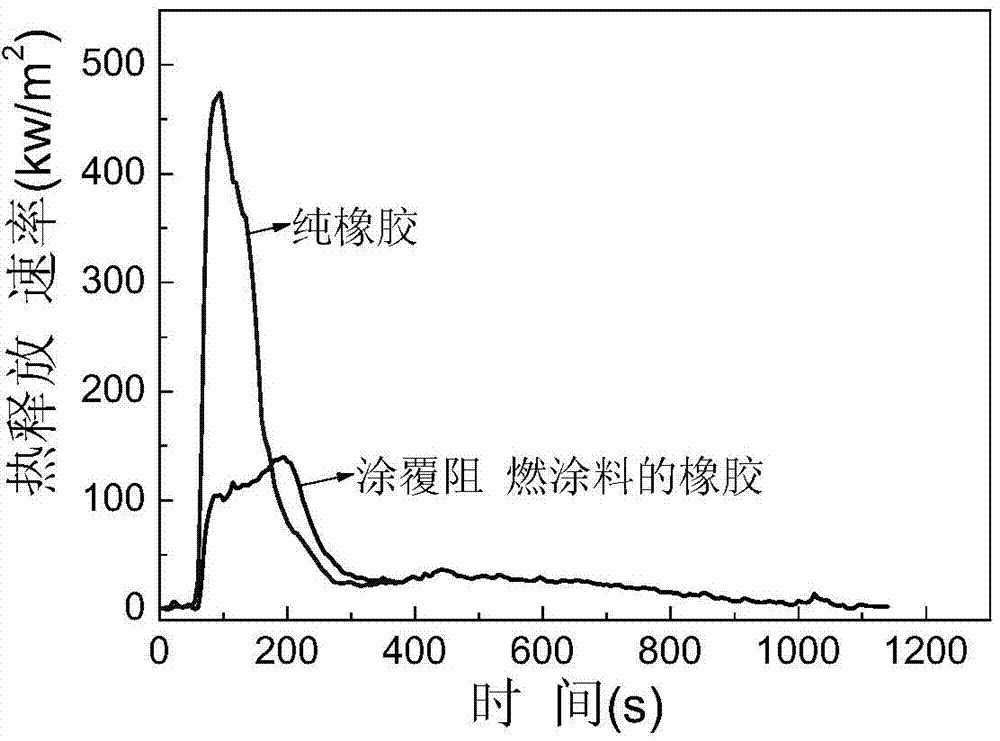

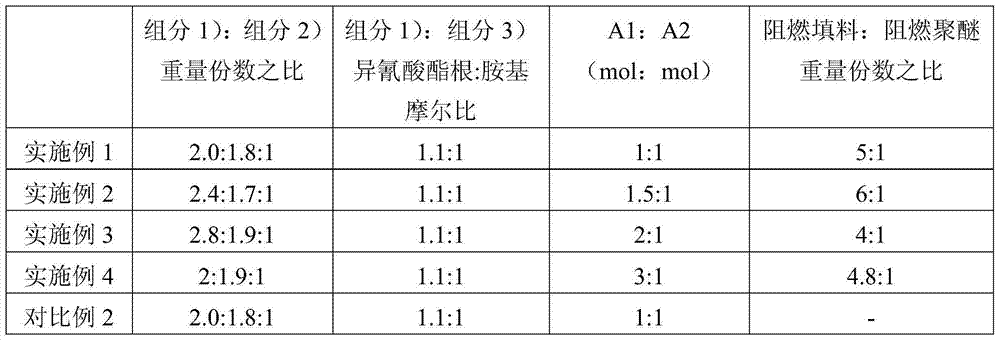

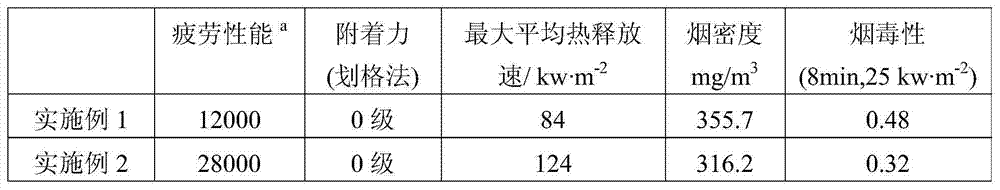

Inflaming retarding coating and application thereof

ActiveCN103756546AImprove flame retardant performanceImprove mechanical propertiesFireproof paintsPolyurea/polyurethane coatingsAcrylonitrileFire retardant

The invention discloses an inflaming retarding coating. The inflaming retarding coating comprises a component (1), namely an isocyanate pre-polymer, a component B (2), namely a fire retardant which comprises inflaming retarding polyether selected from acrylonitrile modified polyether and organic nitrogen compound modified polyether, and a component (3), namely a chain extender containing an amino. The inflaming retarding coating provided by the invention does not contain halogen elements, is high in solid content, low in moisture sensitivity and small in viscosity, needs a small quantity of diluting agent, causes small environmental pollution and has an environment-friendly effect; the inflaming retarding effect is prominent, and the adhesive force and the anti-fatigue performance are good; the migration and separation of the fire retardant are greatly relieved. More importantly, the coating provided by the invention does not lower the mechanical performance and the elasticity of a base material (such as a rubber element) and has low smoke and low toxin.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

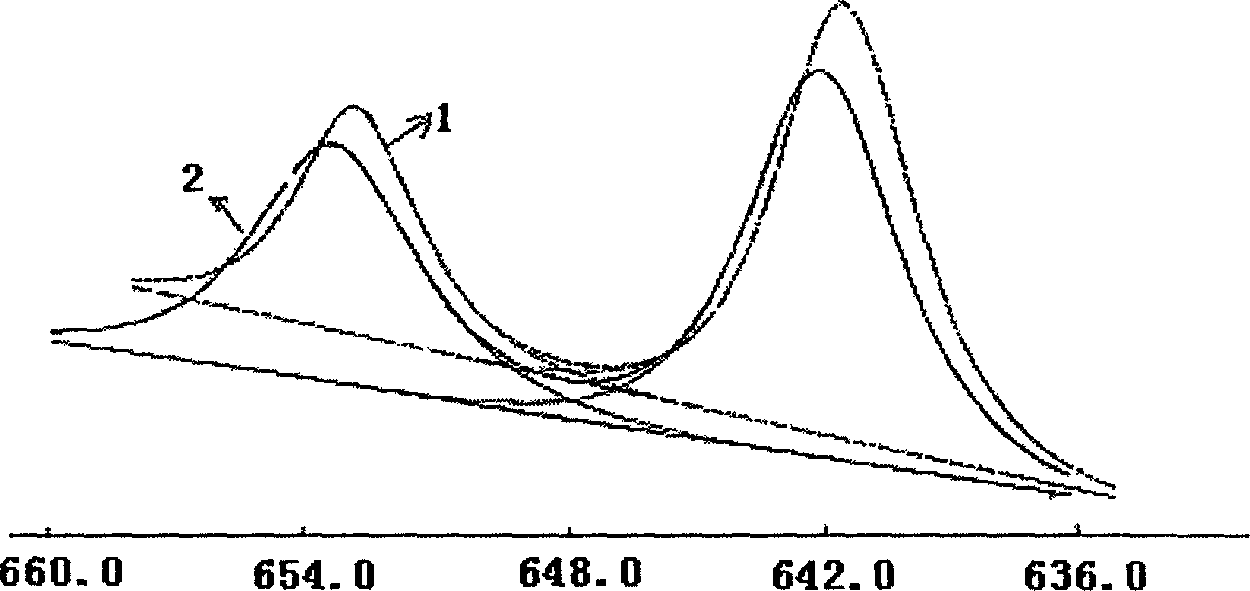

Positive electrode material for lithium ion cell, its preparing method and lithium ion cell

ActiveCN1652376AOvercoming the difficulty of fine particle coatingImprove high temperature cycle stabilityElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersLithiumConductive polymer

The disclosed electrode piece of LiMn2O4 is modified by polymer, which contains functional group of possessing complexation capability with Mn ion. The electrode piece solves issue of difficulties for cladding oxide and thin grains in LiMn2O4 material modified by conductive polymer as well as issue of easy dropping-out clad caused by regrinding. Since effects of complexation and valence bond between polar group of polymer and Mn ions at surfaces of LiMn2O4 grains, oxygenolysis ability of Mn4+ ions for electrolyte and disproportionation degree happened in Mn3+ ions are reduced so as to prevent digestion and migration of lithium ions and increase cyclical stability in high temperature of lithium cell by using LiMn2O4 as positive pole. Features of preparing technique are: simple, feasible and value of industrialization.

Owner:SICHUAN INDIGO TECH CO LTD

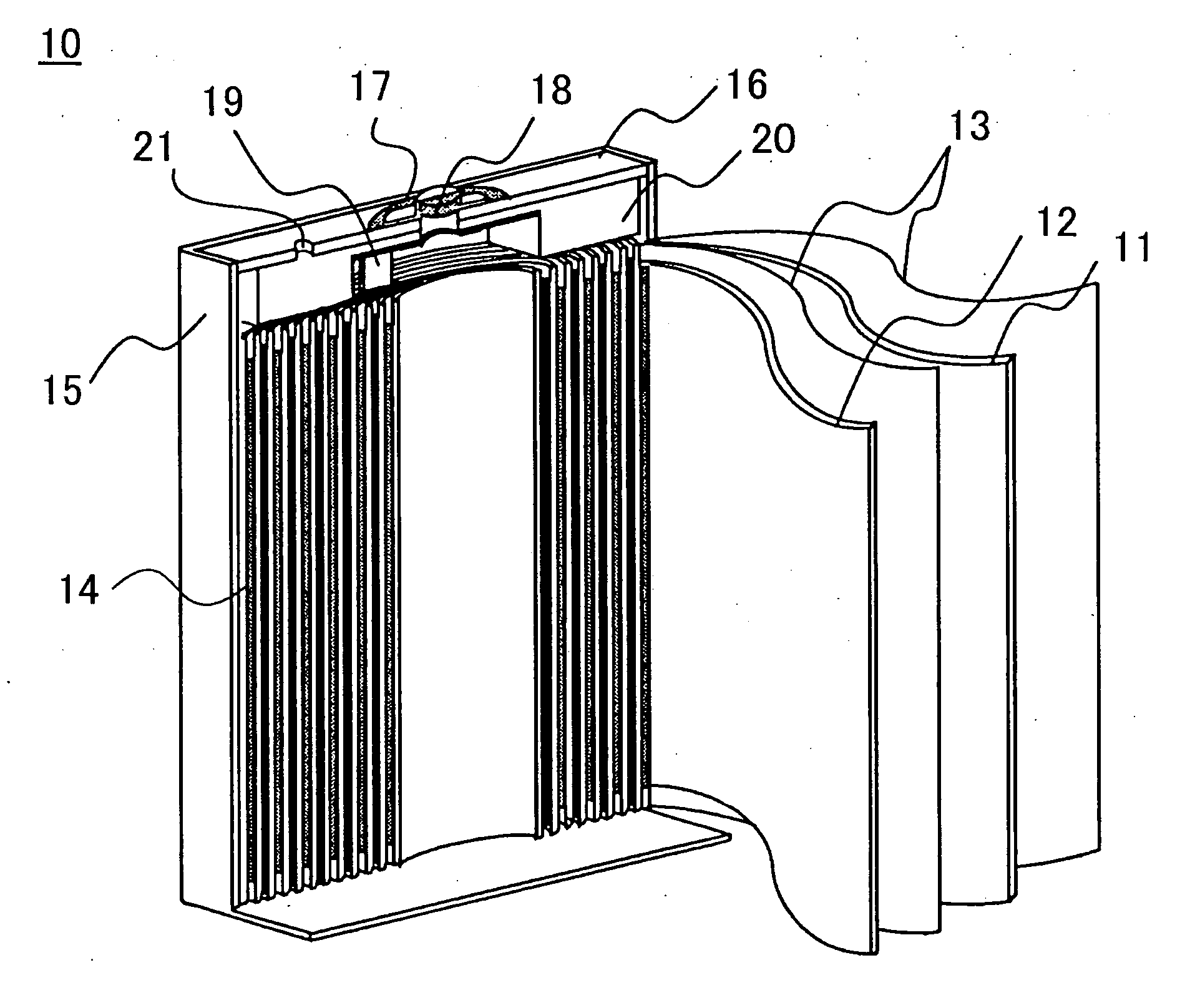

Non-aqueous electrolyte secondary battery

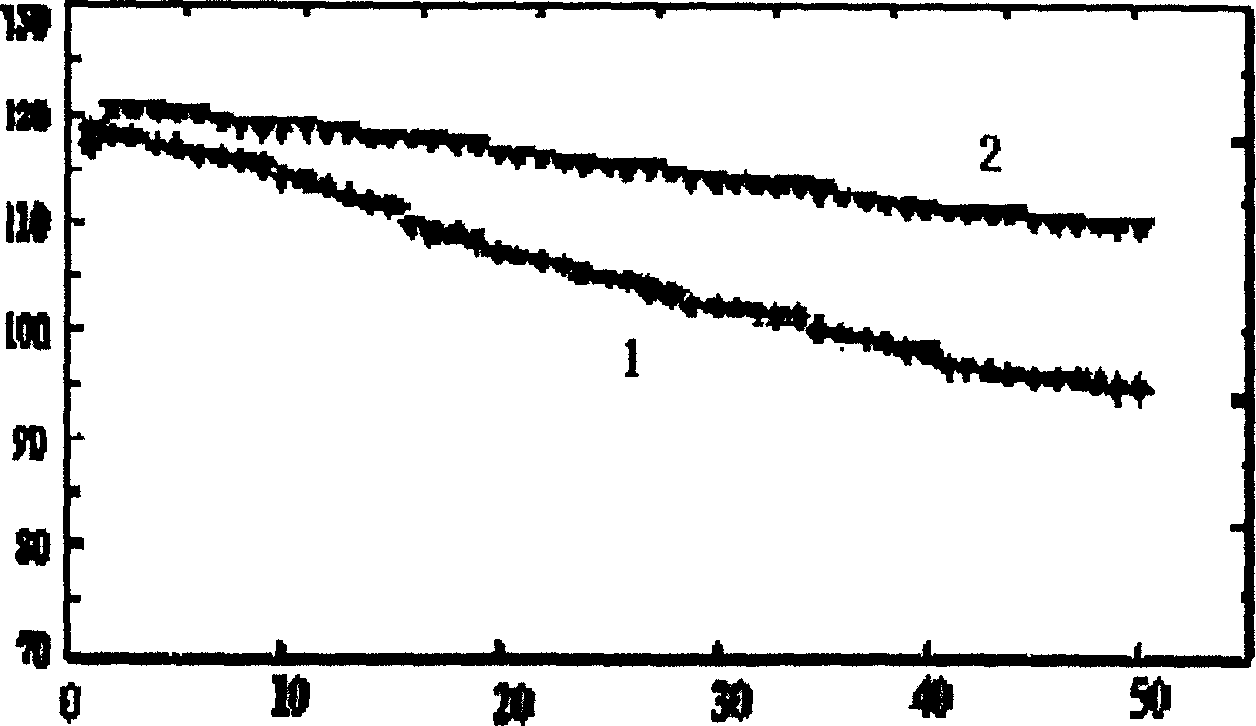

InactiveUS20060199077A1Reduce oxidative decompositionIncrease charging voltageDrying solid materials without heatOrganic electrolyte cellsManganeseSolvent

A non-aqueous electrolyte secondary battery with excellent discharge cycle characteristics and a charging termination potential ranging from 4.4 to 4.6 V based on lithium, consisting of a positive electrode comprising a positive electrode active material, a negative electrode, and a non-aqueous electrolyte containing a non-aqueous solvent and an electrolyte salt, in which the positive electrode active material comprises a mixture of a lithium-cobalt composite oxide containing at least both zirconium and magnesium in LiCoO2, and a lithium-manganese-nickel composite oxide having a layered structure and containing at least both manganese and nickel, and the potential of the positive electrode active material ranges from 4.4 to 4.6 V based on lithium, and the non-aqueous electrolyte contains at least one of aromatic compounds selected from the group consisting at least of toluene derivatives, anisole derivatives, biphenyl, cyclohexyl benzene, tert-butyl benzene, tert-amyl benzene, and diphenyl ether.

Owner:SANYO ELECTRIC CO LTD

Agent for treating hard surfaces

InactiveUS20120156377A1Low water contentStably storeOrganic detergent compounding agentsOther chemical processesAmmoniumAcrylic acid

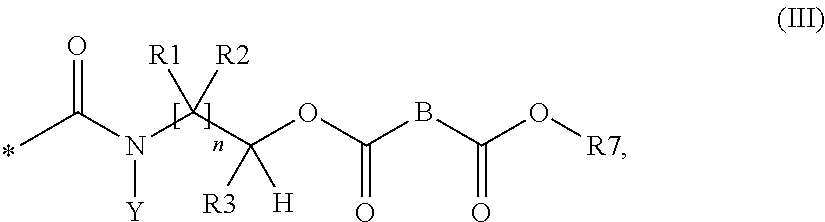

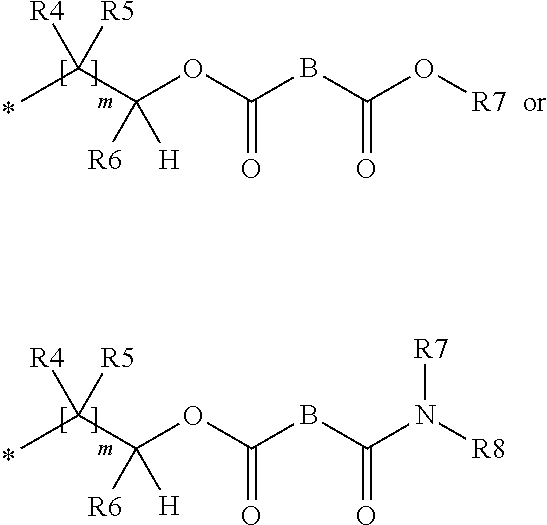

The present invention is an agent for treating a hard surface comprising at least two components selected from the group consisting of (a) multi-armed stellate polyalkoxylates; (b) polyesteramides; and (c) copolymers prepared from a quaternary ammonium acrylamide and acrylic acid. The agents of the present invention find use in cleaning hard surfaces and / or providing a soil-repellant finish to hard surfaces such as ceramic, glass, stainless steel and plastic.

Owner:HENKEL KGAA

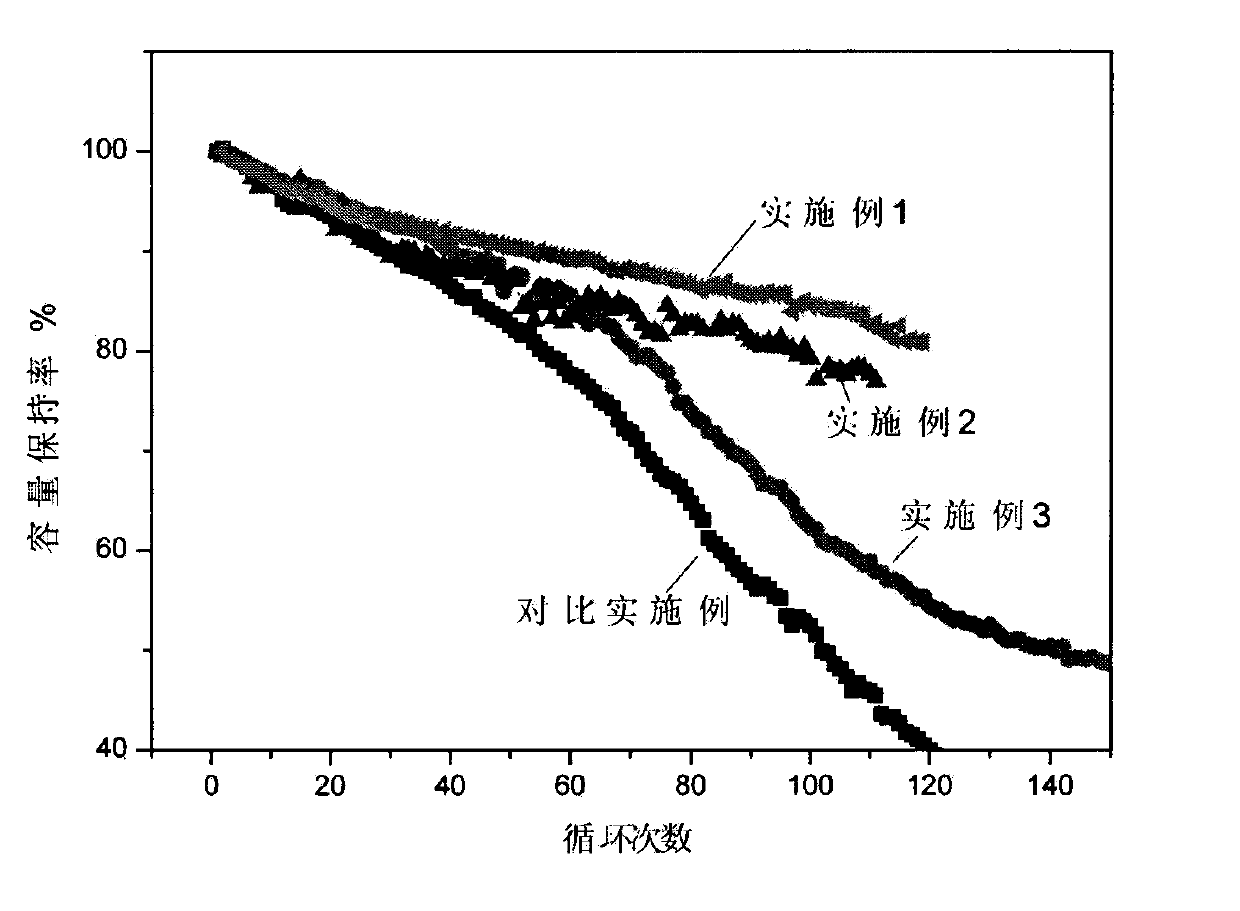

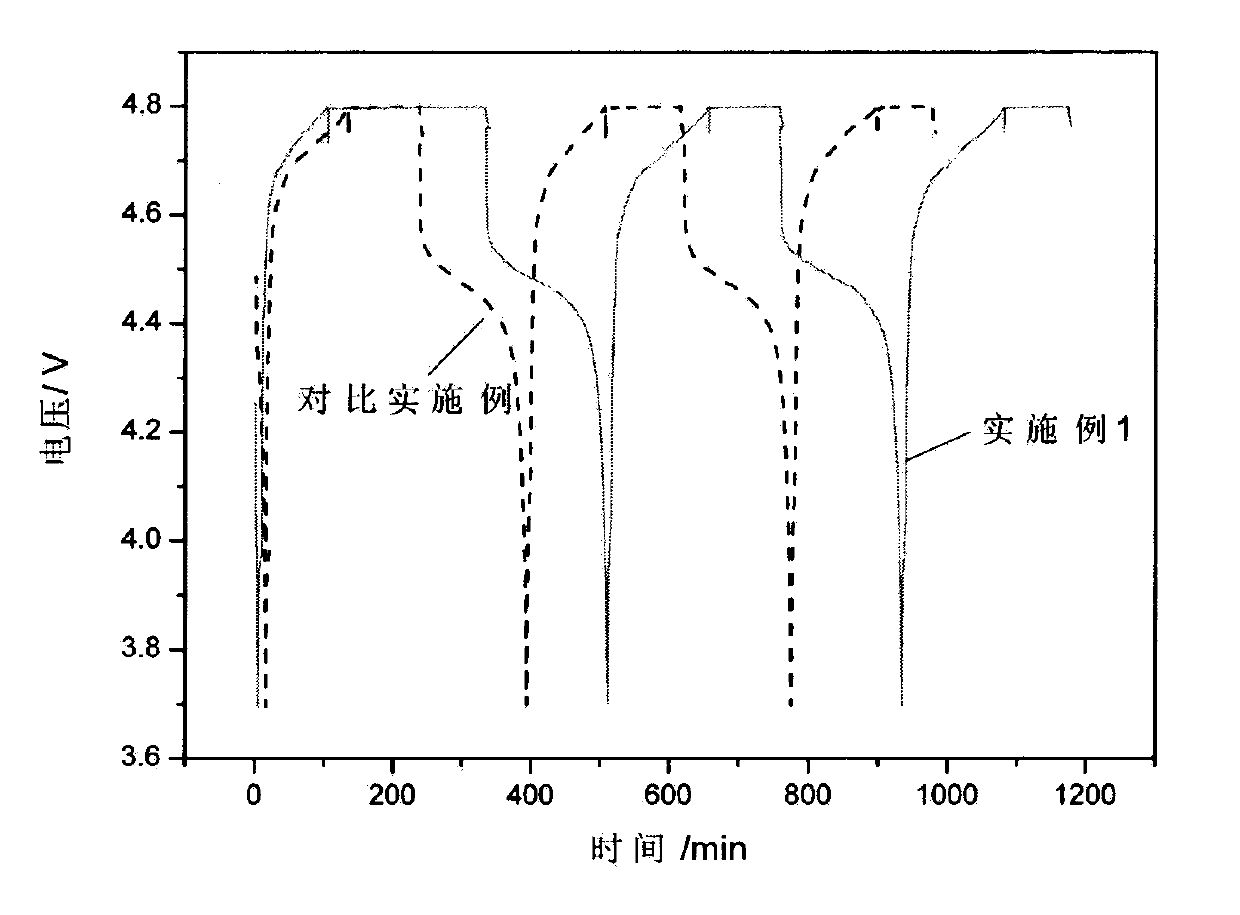

New use of rubidium cesium compound, high-voltage electrolyte additive, high-voltage electrolyte and lithium ion battery

InactiveCN106450452AImprove cycle stabilityExtend your lifeSecondary cellsOrganic electrolytesHigh current densityRubidium

The invention discloses a new use of a rubidium cesium compound in the field of lithium ion batteries as an additive in a high-voltage electrolyte, a high-voltage electrolyte additive, the high-voltage electrolyte and a lithium ion battery. The high-voltage electrolyte consists of an electrolyte lithium salt, an organic solvent and 0.05%-5% of rubidium cesium compound. The rubidium cesium compound as the high-voltage electrolyte additive for the lithium ion battery can protect an anode material, effectively reduces oxidative decomposition of the electrolyte on the anode surface, greatly upgrades the cycling stability of a battery, increases the battery life, and promotes truly commercial application of the high-voltage anode material. The high-voltage electrolyte using the rubidium cesium compound or the high-voltage electrolyte additive can effectively improve the discharge capacity of the high-voltage anode material under high current density, prolongs the cycling life of the high-voltage anode material battery, and simultaneously upgrades the power characteristic of the battery under high current density.

Owner:SHANGHAI RUGE TECH DEV CO LTD +1

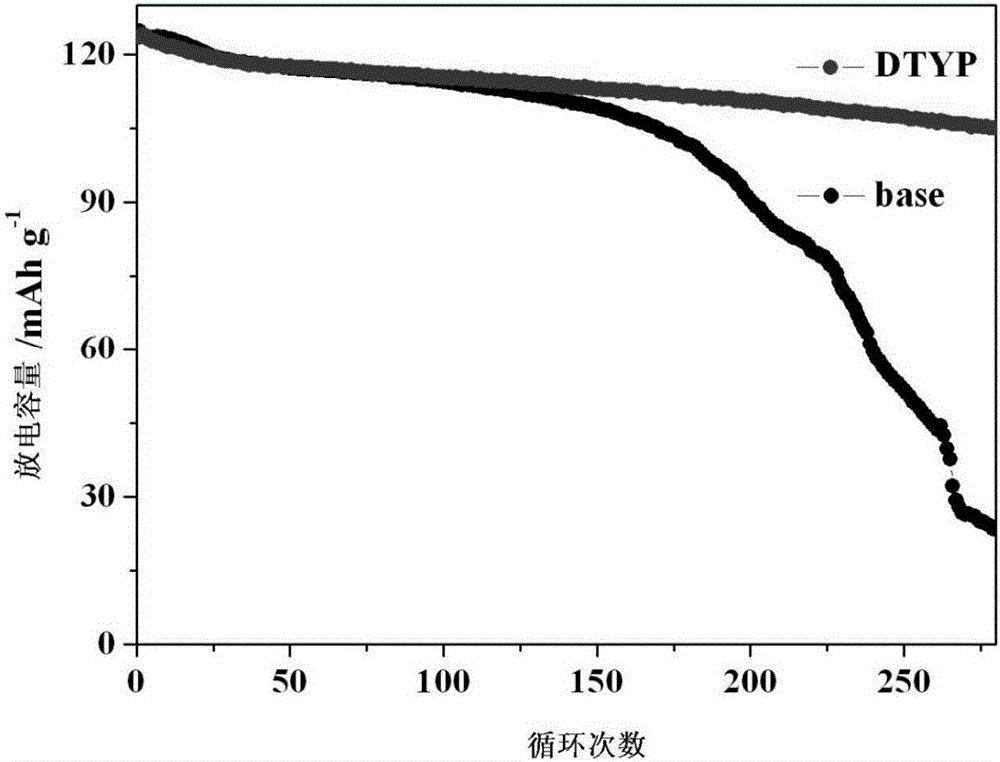

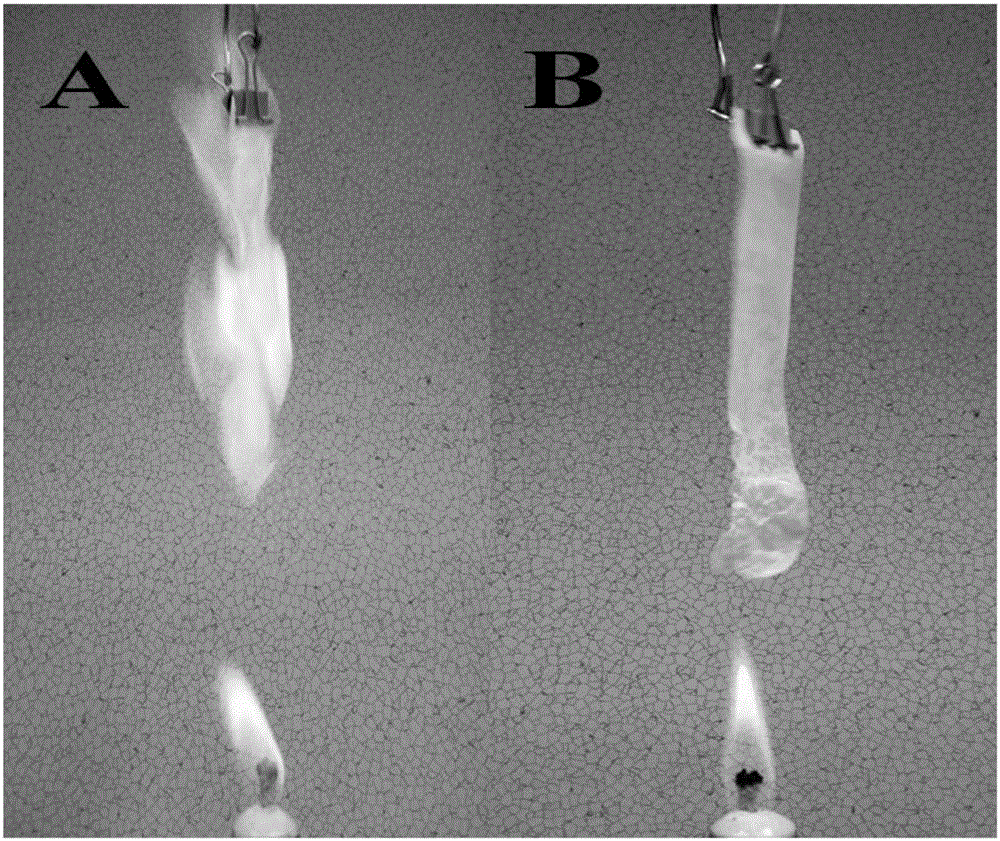

High-voltage functional electrolyte and preparation method and application therefor

ActiveCN105870501AGood charge and discharge performanceInhibit surface activityFinal product manufactureElectrolyte accumulators manufacturePhosphateRoom temperature

The invention belongs to the technical field of the lithium ion battery, and discloses a high-voltage functional electrolyte and a preparation method and an application therefor. The high-voltage functional electrolyte is prepared by adding a functional additive into the common electrolyte, wherein the functional additive accounts for 0.25-5% of the common electrolyte based on mass percentage; and the structural formula of the functional additive is as shown in the formula (1). The functional additive which is diethyl (thiophene-2-methyl) phosphate can be used as the high-voltage film-forming agent and the flame-retardant additive of the lithium ion electrolyte; the electrolyte containing the functional additive is non-combustible; and the room-temperature and high-temperature cycling performances of the lithium ion battery prepared from the electrolyte are both improved under 3-5.0V, so that the high-voltage functional electrolyte is wide in the application prospect.

Owner:SOUTH CHINA NORMAL UNIVERSITY

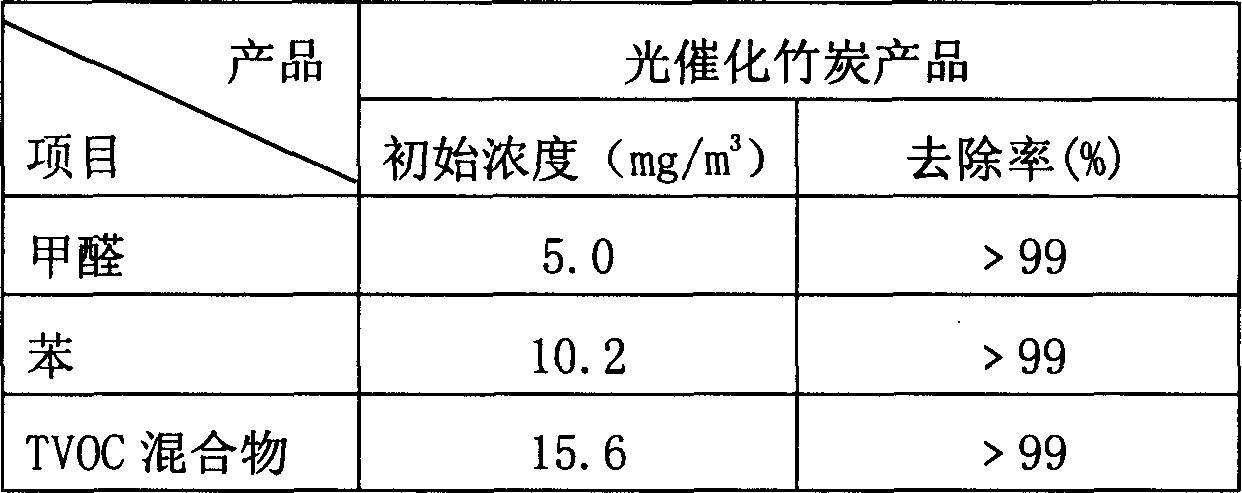

Nanometer modified photocatalytic bamboo charcoal

InactiveCN1846846AIncrease interface defectsLow light utilizationPhysical/chemical process catalystsOther chemical processesHazardous substanceHigh pressure

The present invention is nanometer modified photocatalytic bamboo charcoal and its preparation process. The preparation process includes the steps of: high pressure spraying nanometer hybridized and red shifted anatase type titania in fineness of 4-7 nm and in the mass fraction of 1-5 to 500 to the surface of bamboo, high temperature sealed heating at 100-800 deg.c for 20-25 days to carbonize, and crushing. It has bamboo charcoal grain size of 3-10 mm, fixed carbon content of 78-85 wt% and titania content of 0.2-1 wt%. Compared with common bamboo charcoal purificant, the present invention has powerful adsorption on vapor, harmful matter, impurity, etc, capacity of irreversibly decomposing adsorbed harmful matter and antibiotic effect. It has also longer photocatalytic response wavelength and higher air purifying effect.

Owner:马晓波 +1

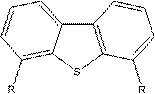

High-voltage electrolyte for lithium ion battery and lithium ion battery

InactiveCN108199076AReduce oxidative decompositionGood negative electrode film-forming performanceSecondary cellsDecompositionElectrical battery

The invention discloses a high-voltage electrolyte for a lithium ion battery and the lithium ion battery. The electrolyte comprises the following raw materials of a lithium salt, a non-aqueous solvent, an additive A and an additive B, wherein the non-aqueous solvent is a mixed solvent of linear carbonate ester and cyclic carbonate ester, the additive A is a benzothiophene or dibenzothiophene solvent, and the additive B is propenyl-1, 3-sultone. In the high-voltage electrolyte for the lithium ion battery and the lithium ion battery, a solvent containing a sulfur element is used as a high-voltage additive of the lithium ion electrolyte, oxidization and decomposition of the carbonate solvent on a surface of an electrode can be reduced, the propenyl-1, 3-sultone has good negative electrode film formation performance, a negative electrode material can be effectively coated, and the room-temperature cycle property under a high voltage can be greatly improved.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

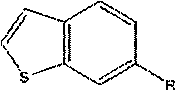

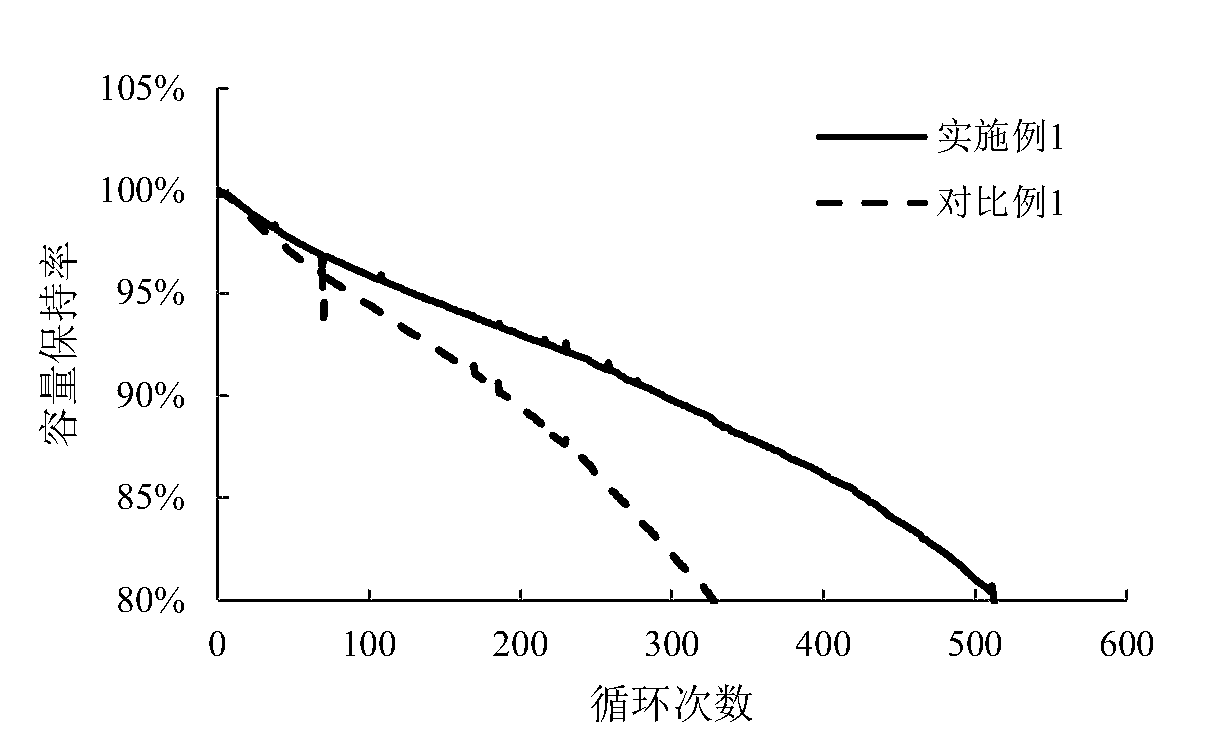

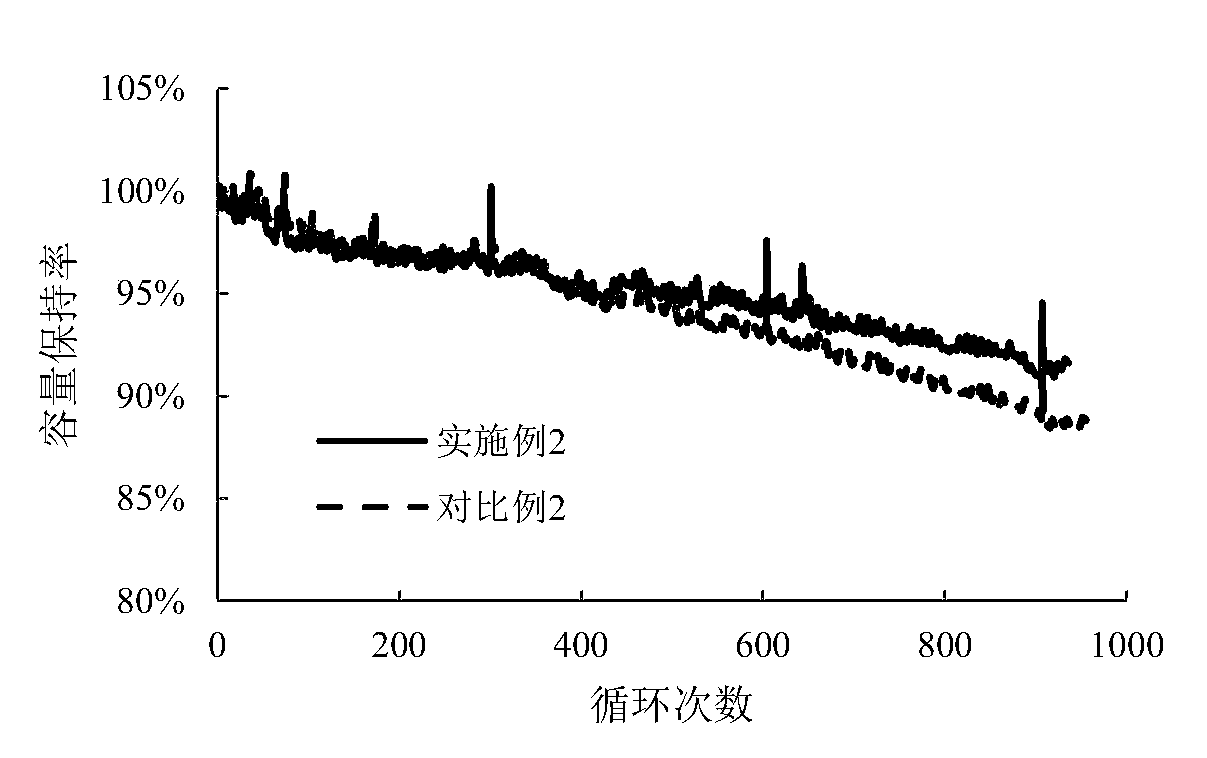

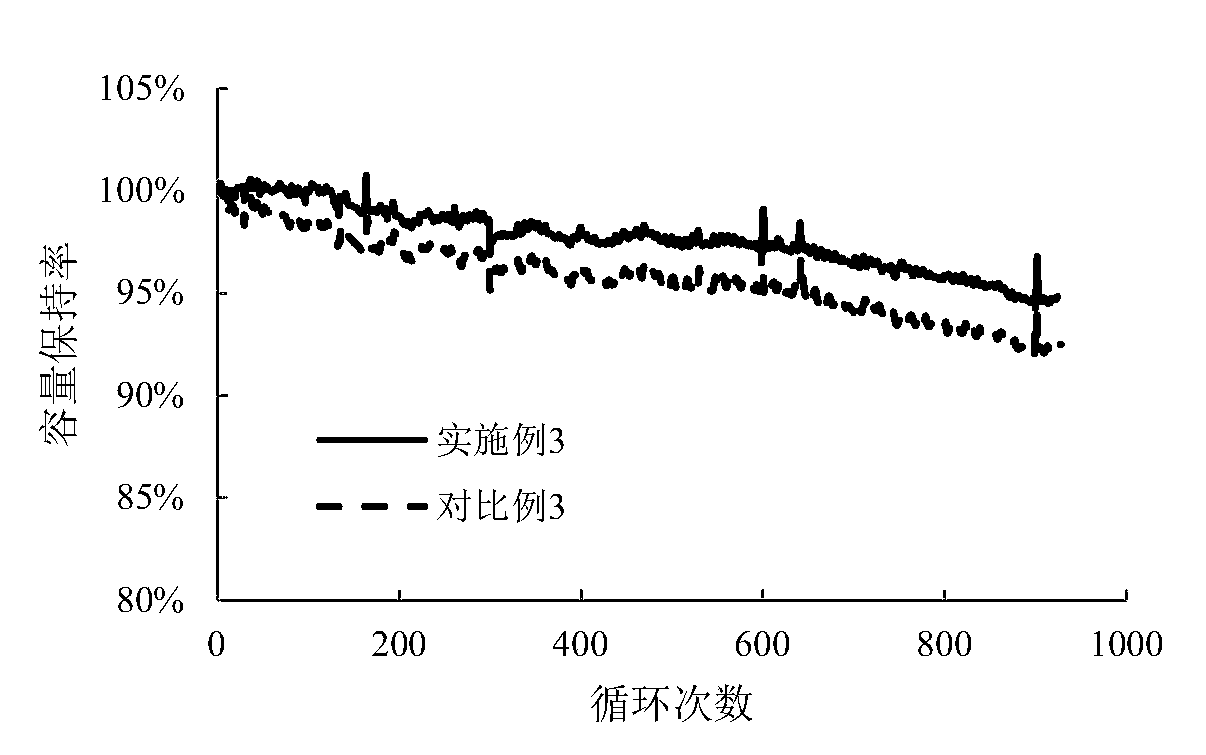

Lithium ion battery electrolyte suitable for NCM811 and SiO-C material system and preparation method

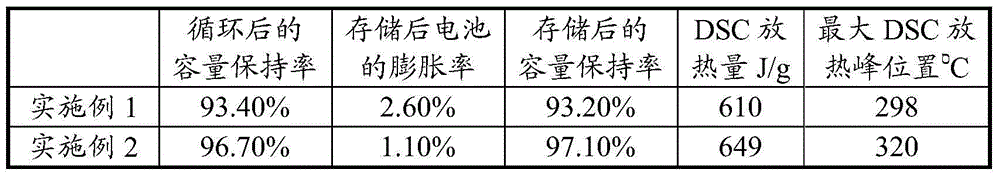

ActiveCN110600804AImprove cycle performancePromote circulationSecondary cellsDifluorophosphateSolid state electrolyte

The invention discloses a lithium ion battery electrolyte suitable for a NCM811 and SiO-C material system and a preparation method. In the electrolyte of the present invention, an organic solvent composed of ethyl methyl carbonate, diethyl carbonate, and ethylene carbonate, a lithium salt composed of lithium hexafluorophosphate and lithium difluorophosphate, and an additive composed of vinylene carbonate, fluoroethylene carbonate, ethylene sulfate, and 1,3-propane sultone are compounded in a certain proportion, and cooperate to react, during a lithium ion battery cycle, on the surface of NCM811 and SiO-C and form a stable solid electrolyte protective film to prevent direct contact between the electrolyte and NCM811 and SiO, thereby reducing the side reactions between the electrode and theelectrolyte, and reducing the phase transition and volume change of the material, and further improving the cycling performance of the lithium ion battery. Experimental results show that by using theelectrolyte of the present invention, the lithium ions of the NCM811 and SiO-C material system has a capacity retention rate of more than 90% after 500 cycles of 1C / 1C at room temperature, and has excellent cycle performance.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Positive electrode plate and preparing method thereof and lithium ion battery

InactiveCN105118958AReduce oxidative decompositionPromote migrationSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh temperature storageEngineering

The invention relates to a positive electrode plate and a preparing method thereof and a lithium ion battery. The positive electrode plate aims at solving the problems that for a positive electrode plate in the prior art, under the situation of high charging voltage, the battery circulation performance and the high-temperature storage performance are poor. The positive electrode plate comprises a positive electrode current collector and a positive electrode material layer attached to the surface of the positive electrode current collector. A poly-dopamine layer is further attached to the surface of the positive electrode material layer. Meanwhile, the invention discloses the preparing method of the positive electrode plate and the lithium ion battery with the positive electrode plate. The battery circulation performance and the high-temperature storage performance of the lithium ion battery prepared from the positive electrode plate are excellent under the situation of high changing voltage.

Owner:SHENZHEN 3SUN ELECTRONICS

Lithium ion battery cathode slurry and preparation method thereof

InactiveCN109768243AFast conductionHigh power discharge capabilityMaterial nanotechnologyElectrode manufacturing processesDecompositionALUMINUM PHOSPHATE

The invention discloses lithium ion battery cathode slurry and a preparation method thereof. A nanometer titanium aluminum phosphate powder additive is added to the cathode slurry to improve the lithium ion conductivity of a cathode; under the condition that the compaction density of a cathode material is increased and an electrolyte can not be fully infiltrated, the rapid conduction of a lithiumion can be improved, and the high power discharge performance of a battery can be improved; on the other hand, nanometer titanium aluminum lithium phosphate powder is uniformly wrapped on the surfaceof a cathode active material, the contact between the cathode material and the electrolyte can be reduced to a certain extent, the oxidation and decomposition of the electrolyte in a charged state isreduced, the consumption of the electrolyte is reduced, and the service life of the battery is prolonged; and the lithium battery prepared by the cathode slurry of the lithium battery, the energy density is high, the high temperature performance is excellent, the high power discharge performance is good, the cycle performance is good, and the service life is long. According to the preparation method, directly stirring and mixing is realized by using common stirring equipment, operating is convenient, and large-scale production can be realized.

Owner:上海力信能源科技有限责任公司

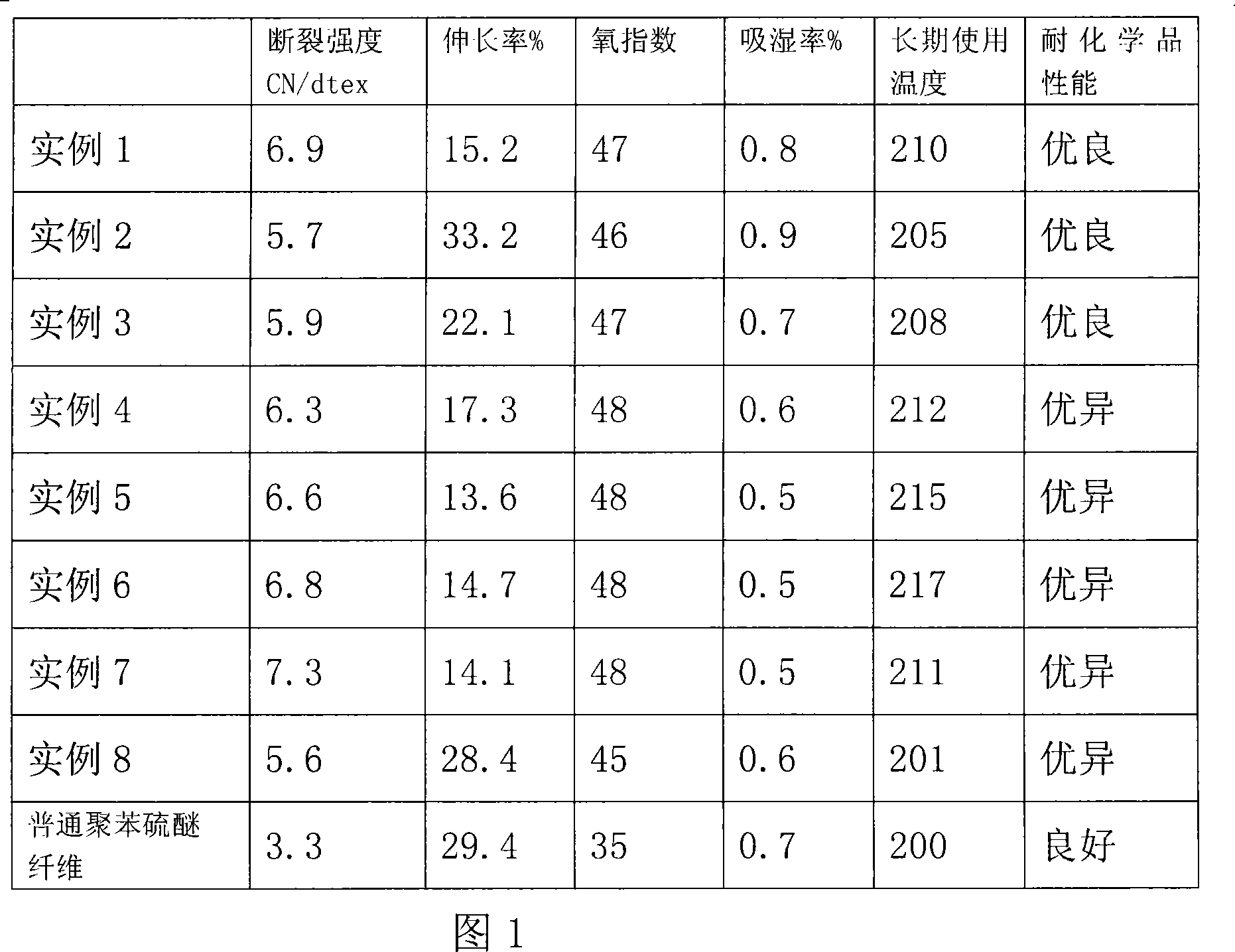

Copolymerized polyphenylene sulfide composite fiber manufacture method

ActiveCN101187091AHigh mechanical strengthReduce oxidative decompositionMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyester resin

The invention discloses a process for preparing copolyether polyphenylene sulfide composite fiber, raw materials use copolyether polyphenylene sulfide resins which are 80-100 percent by weight, polyester resins which are 5-0 percent by weight, and polyetheretherketone which is 15-0 percent by weight are used in a resin premixed compound treatment. After being stirred and mixed in a high speed, the raw materials are extruded by an extruder, and compound resin resins are obtained, and the weight average molecular weight of polyphenylene sulfide copolymer resin is 40-50 thousand. A spinning extruder has eight temperature ranges, a first range is 150 DEG C, a second range is 300 DGE C, a third range is 315 DGE C, a forth range is 330 DGE C, a fifth range is 330 DGE C, a sixth range is 315 DGE C, a seventh range is 300 DGE C, and an eighth range is 300 DEG C. The holding temperature of a spinning box is 325 DEG C, the crystal curing temperature is controlled at 256 DEG, the drafting rate of strand silk is 6-6.8 times, the roll-up speed of raw silk is 2300-2600 m / min, and the temperature range of crystal curing of the strand silk is 480-510m. The fracture strength of the manufactured copolyether polyphenylene sulfide composite fiber is 7.3 cm / dtex, and the average limited oxygen index is bigger than 47.

Owner:德阳科吉高新材料有限责任公司

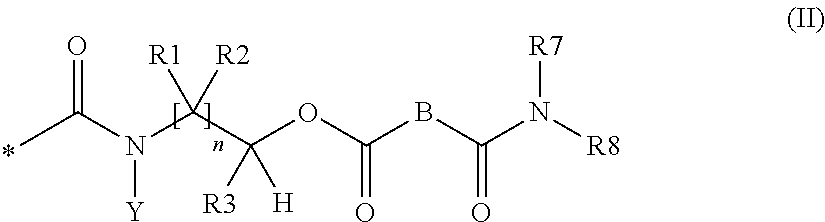

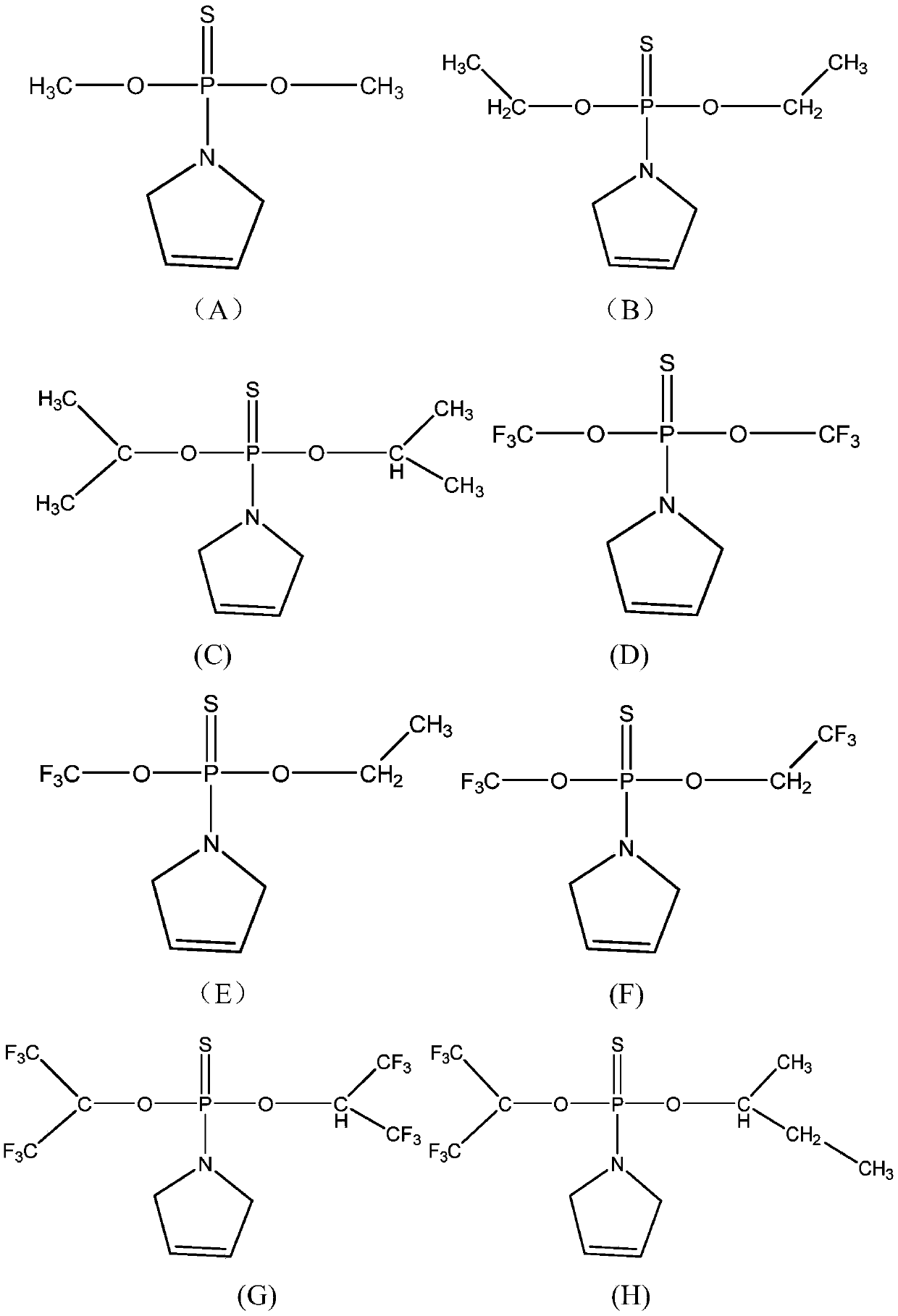

Electrolyte and lithium ion battery using same

ActiveCN105119019APromote circulationReduce flammabilitySecondary cells servicing/maintenanceCarbon numberAlkylphosphate

The invention relates to an electrolyte. The electrolyte comprises lithium salt, nonaqueous solvent and an additive; the additive is cycloalkene represented in the general formula (I) or the general formula (II), wherein R1 represents one of an alkyl phosphate group, a fluorinated phosphate group and a phosphazene group, R2 represents an alkyl group with the carbon number of 1-12, or an alkoxy carbanyl group with the carbon number of 1-12, or an alkyl sulfonyl group with the carbon number of 1-12 or an alkenyl group with the carbon number of 1-12, and all hydrogen atoms in the R2 substituent group are replaced by halogen atoms. When the electrolyte is used for manufacturing a lithium ion battery, stable interface films can be formed on the surfaces of the positive electrode and the negative electrode, so that reaction activity of the surfaces of the electrodes is restrained, oxygenolysis of the electrolyte is reduced, gas expansion is effectively restrained, then the safety performance and the cycling performance under high voltage particularly the high-temperature cycling performance of the lithium ion battery are improved, and the service life of the lithium ion battery is prolonged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

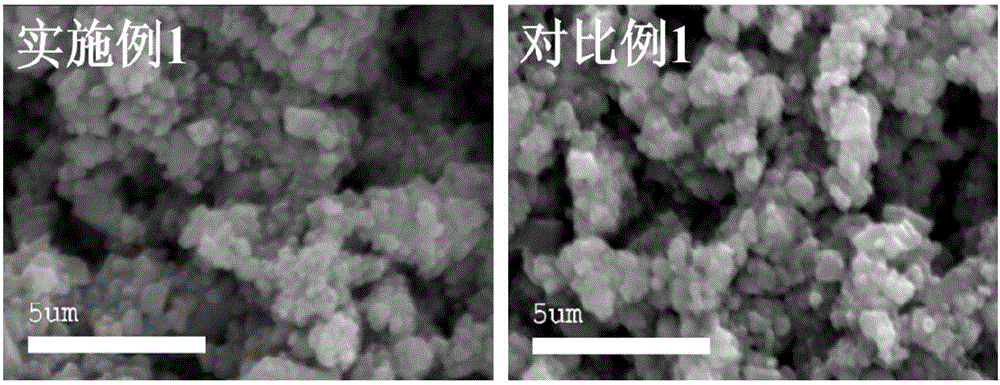

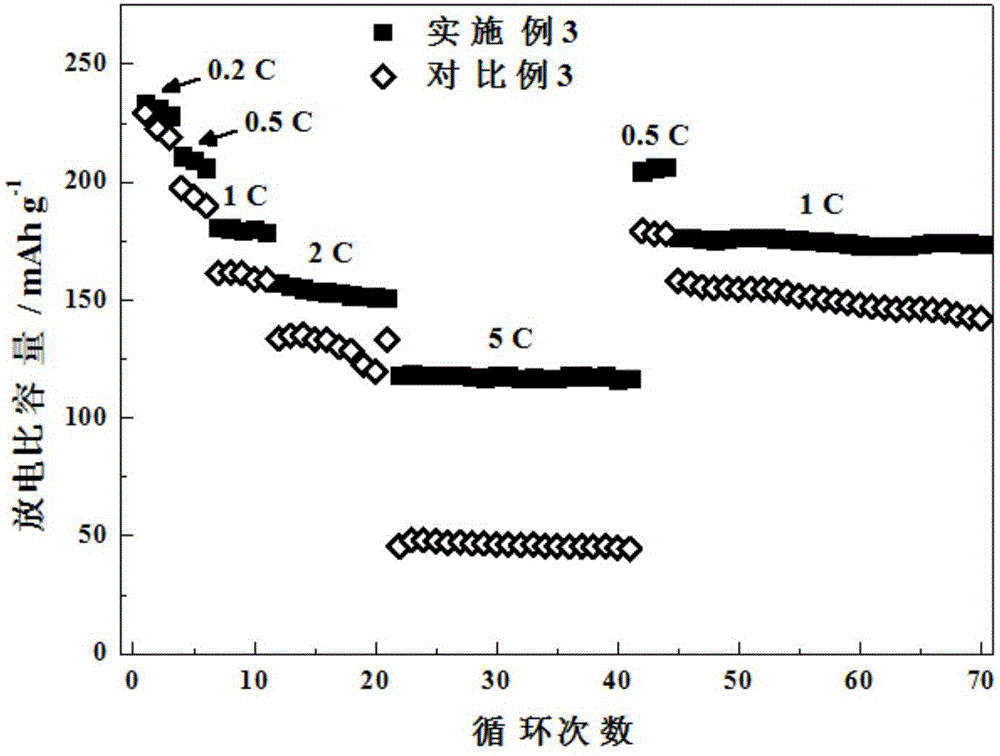

Manganese-based lamellar lithium-rich material provided with uniform lithium phosphate coating layer and preparation method thereof

ActiveCN106450194AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsManganeseLITHIUM PHOSPHATE

The invention belongs to the technical field of lithium ion batteries and discloses a manganese-based lamellar lithium-rich material provided with a uniform lithium phosphate coating layer and a preparation method thereof. The preparation method comprises the following steps that a hydrochloride buffering solution of trismetyl aminomethane with the pH range of 8-9 is prepared, then the manganese-based lamellar lithium-rich material is added under the stirring condition, stirring is performed for 1-2 hours, then dopamine hydrochloride is added, stirring is performed for 24-48 hours to obtain a precursor C; lithium phosphate is added to the precursor C under the stirring condition, stirring is performed while heating till only a solid is left, and a precursor D is obtained; the precursor D is put in a muffle furnace of 700-800 DEG C to be burned for 0-24 hours, namely the manganese-based lamellar lithium-rich material provided with the uniform lithium phosphate coating layer is obtained. The manganese-based lamellar lithium-rich material obtained by adopting the preparation method, provided with the uniform lithium phosphate coating layer and having high capacity and rate capability has high specific capacity, rate capability and good cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

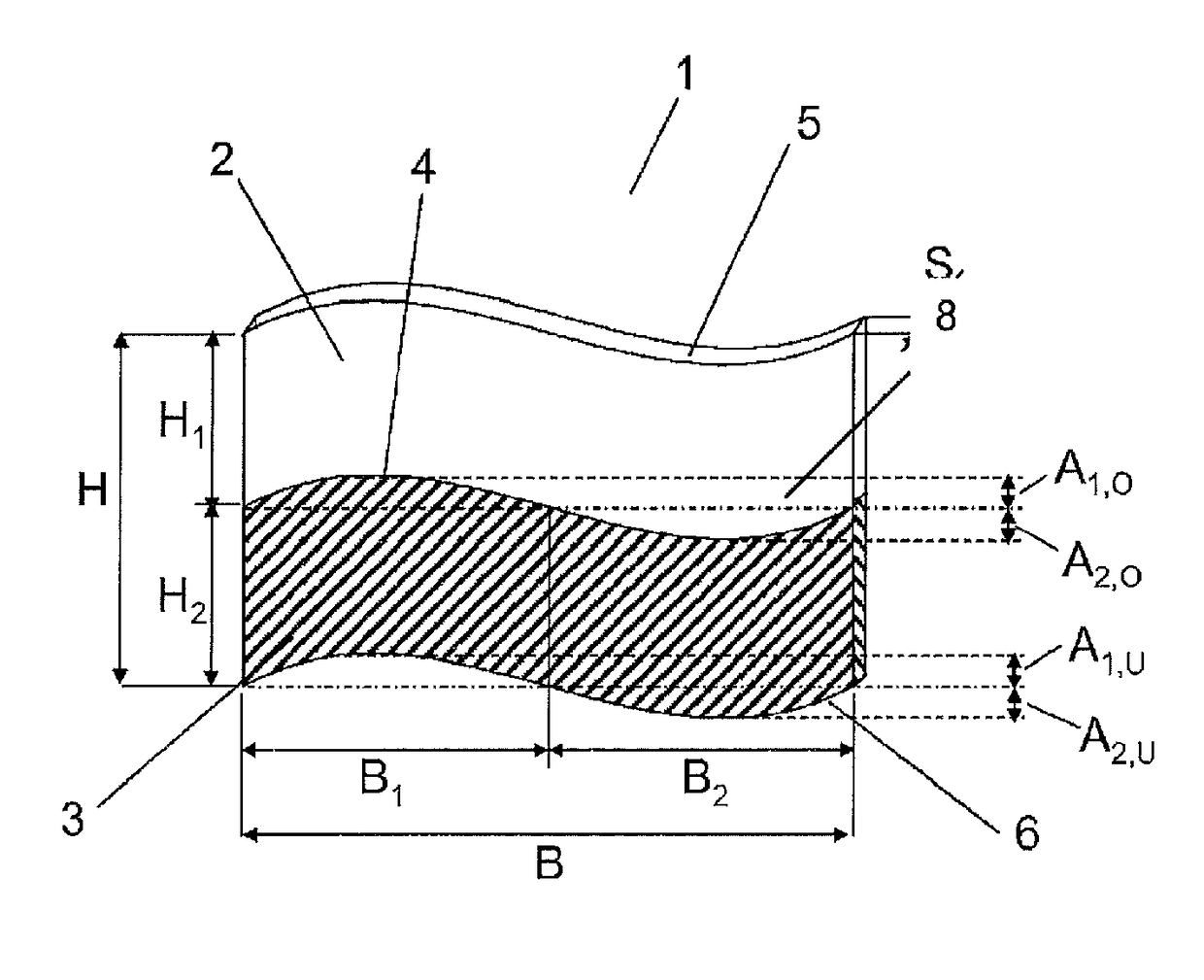

Strip-form WC cleaning product

ActiveUS9725686B2Disadvantageous appearanceDisadvantageous stabilityNon-ionic surface-active compoundsCarpet cleanersEngineeringCleaning product

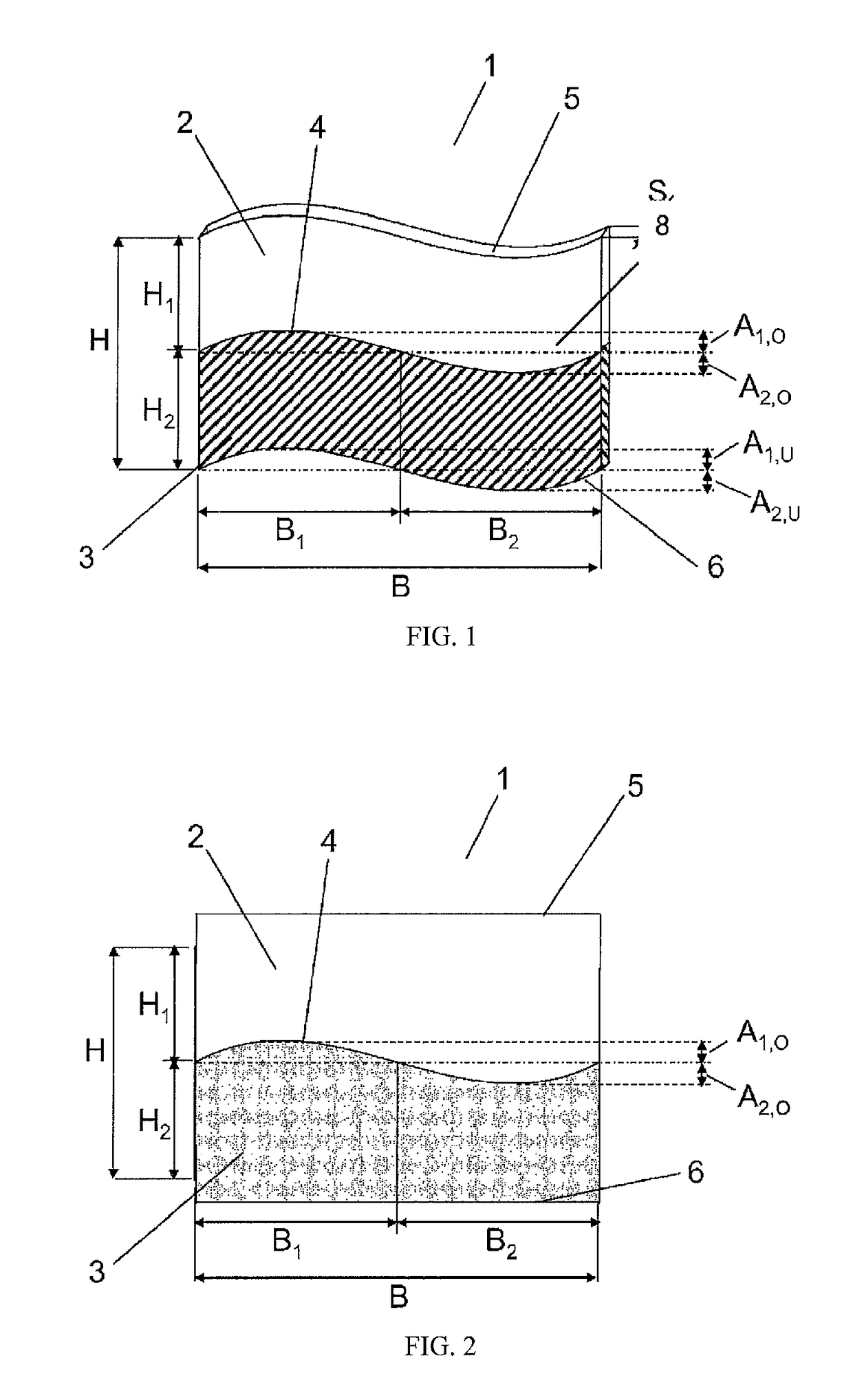

A strip-form toilet cleaning product comprising a width (B), a height (H) and a thickness (S), wherein the ratio between width (B), height (H) and thickness (S) is between 1:1:0.01 and 1:0.1:0.2, a first extruded phase and at least one second extruded phase, wherein at least the contour of a contact surface (4, 4a, 4b) along the center axis (8) takes the form of a sine wave which has an amplitude of A1,O, wherein the ratio of amplitude to width (B) A1,O:B amounts to between 1:10 and 1:25 and the periodic length of the sine wave corresponds to 0.1-1 times the width (B) of the toilet cleaning product.

Owner:HENKEL KGAA

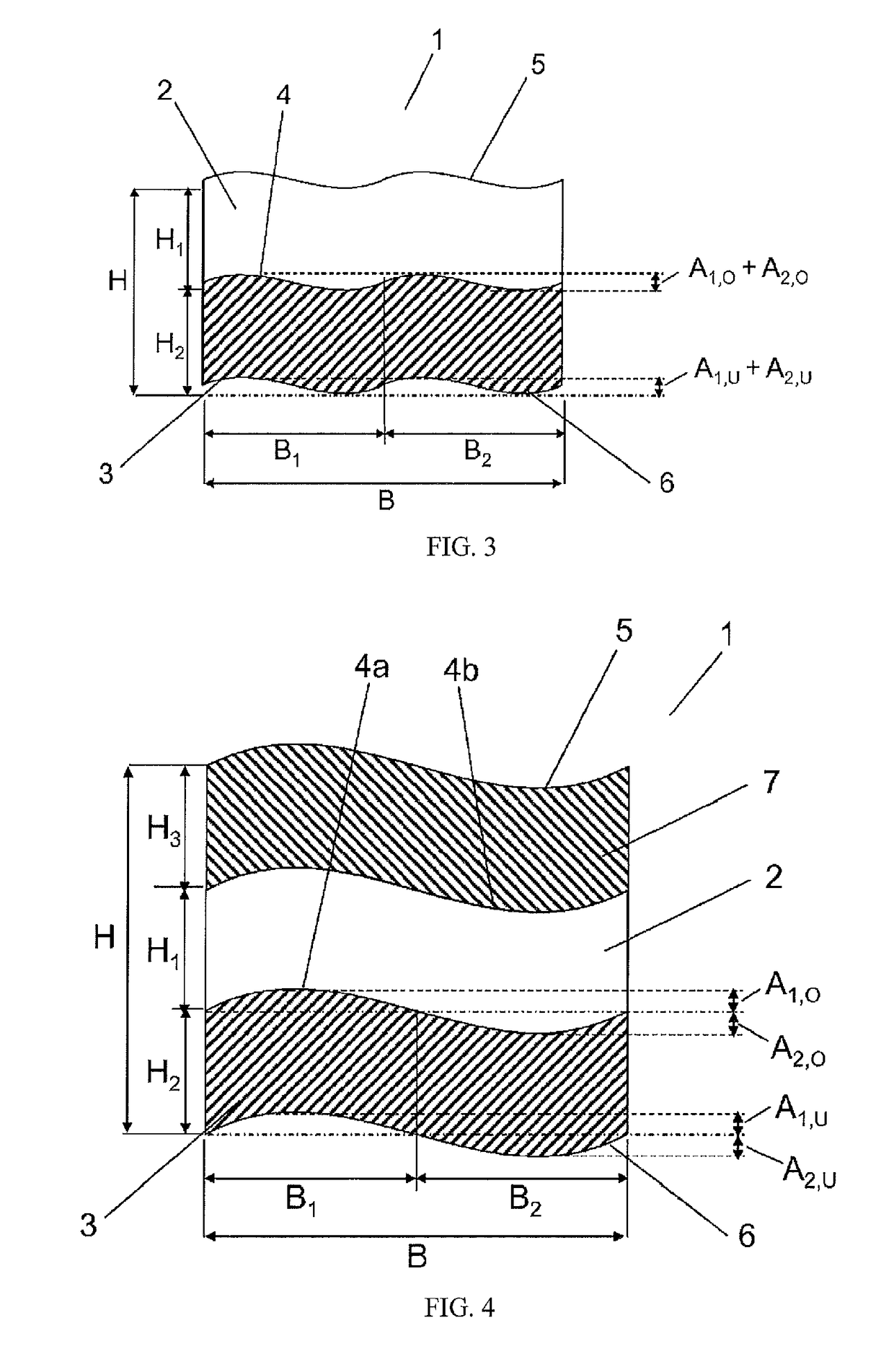

High-voltage additive and high-voltage electrolyte for lithium battery

The invention provides a high-voltage additive and a high-voltage electrolyte for a lithium battery. The high-voltage additive is a compound containing cyclic enamine and a thiophosphonate structure;the structural formula I is shown in the specification, wherein R1 and R2 are respectively one of an alkyl group with 1-8 carbon atoms, a halogenated alkyl group, an alkenyl group with 2-8 carbon atoms, a halogenated alkenyl group, an alkynyl group with 2-8 carbon atoms, a halogenated alkynyl group, an aryl group with 6-8 carbon atoms or a halogenated aryl group. According to the high-voltage additive, a stable and compact CEI film can be formed on a positive electrode, transition metal ions on the surface of a positive electrode material are stabilized, oxygen precipitation of the positive electrode material is inhibited, and oxygenolysis of an electrolyte is reduced; and a film can be formed on the negative electrode, so that the stability of a negative electrode SEI film is improved, and the performance of the lithium battery under a high-voltage condition is improved.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

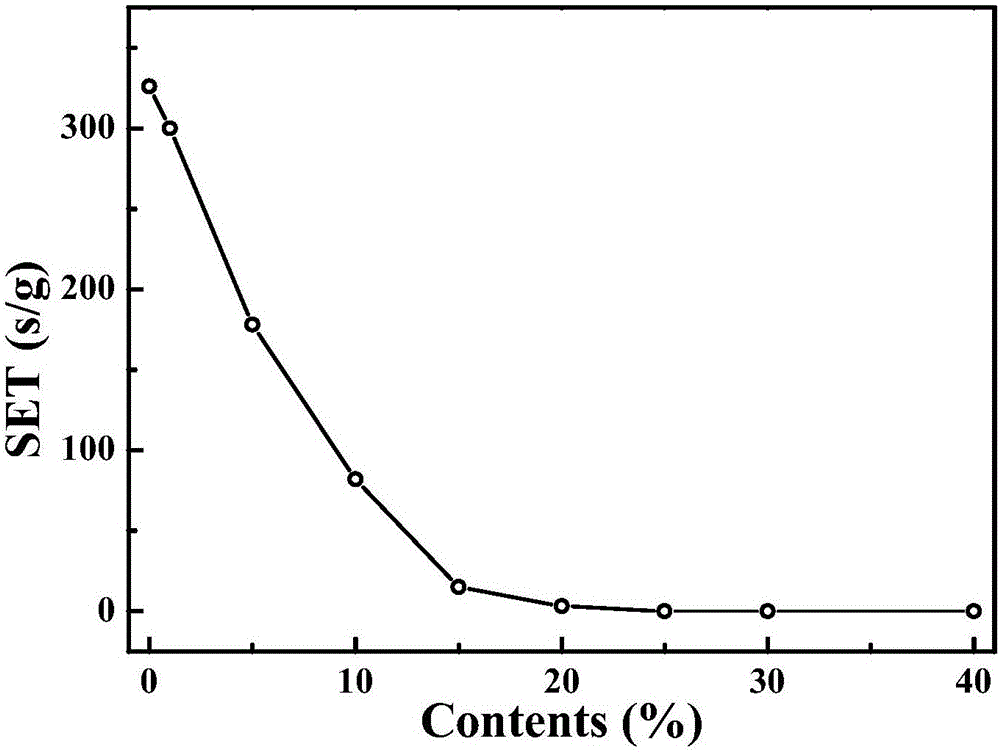

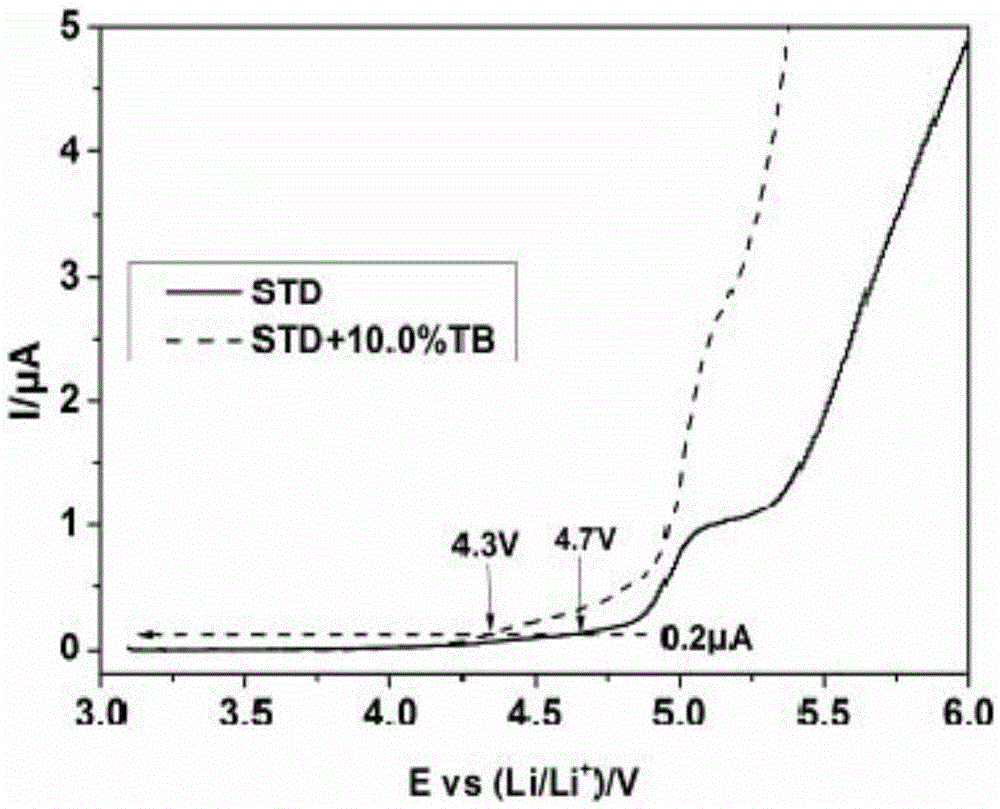

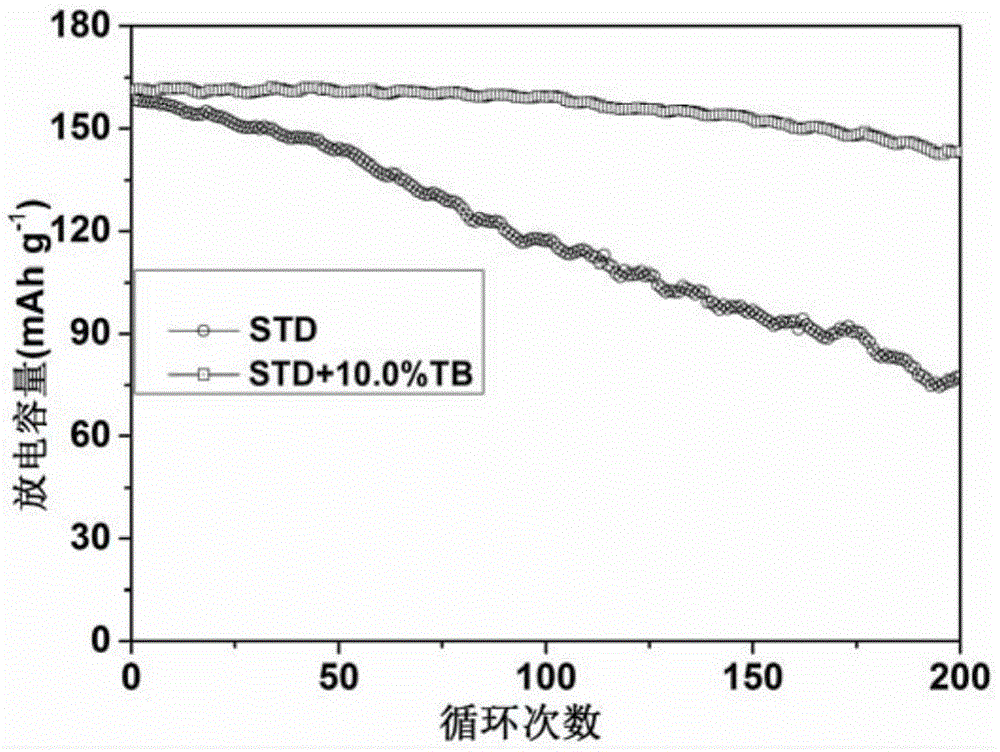

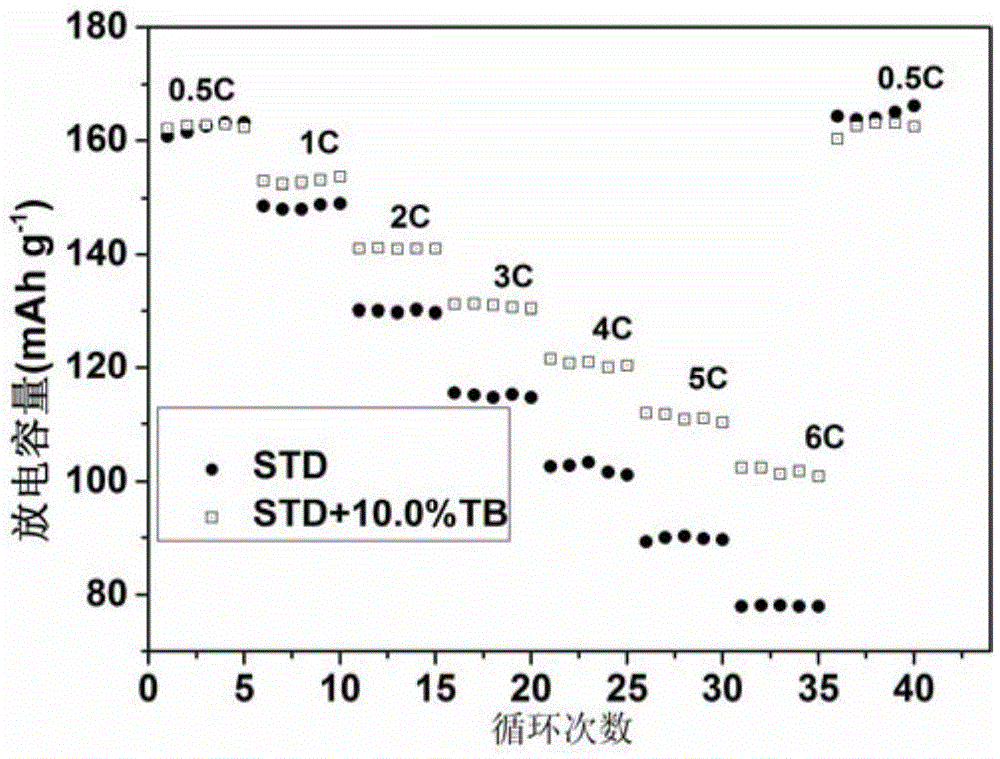

Trimethyl borate additive contained high-voltage functional electrolyte and preparation method and application therefor

InactiveCN105633464AInhibit surface activityLower resistanceSecondary cellsElectrolytesElectrolytic agentElectrical battery

The invention discloses a trimethyl borate additive contained high-voltage functional electrolyte and a preparation method and an application therefor. The electrolyte is obtained by adding a functional additive to a common electrolyte; the common electrolyte is formed by a cyclic carbonate solvent, a linear carbonate solvent and a conductive lithium salt; and the functional additive adopts trimethyl borate. According to the functional electrolyte, the trimethyl borate additive is taken as the high-voltage film-forming additive for the lithium ion electrolyte; the additive is relatively low in oxidization and reduction potential, so that a compact and stable SEI film layer can be formed on the surfaces of a positive electrode and a negative electrode in the first charge-discharge process; therefore, the films on the surfaces of the positive electrode and the negative electrode are optimized, the resistance between the positive electrode and the electrolyte is lowered, and the surface activity of the electrodes is restrained, so that the further contact between the electrolyte and the electrode active material is restrained consequently, and the oxidization and decomposition of the electrolyte main body solvent on the electrode surface is lowered; and the cycling performance and the rate capability of the electrolyte additive contained lithium ion battery under 3-4.5V can be improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

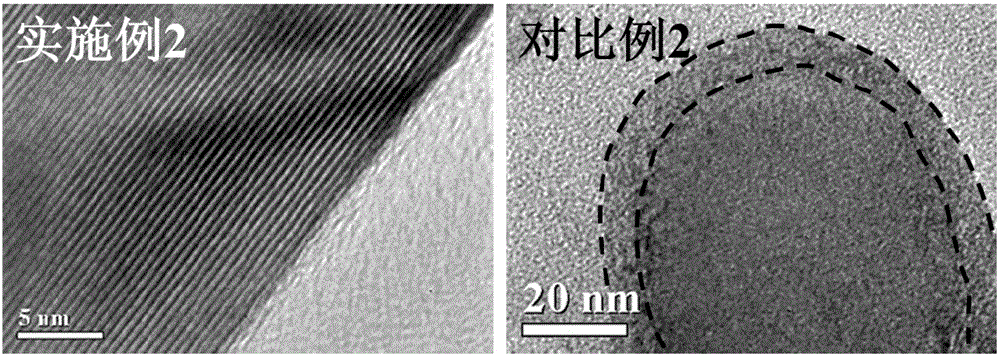

Preparation method of modified lithium nickel manganese oxide cathode material

ActiveCN106920952AReduce exposureReduce oxidative decompositionSecondary cellsPositive electrodesAir atmosphereNickel salt

The invention discloses a preparation method of a modified lithium nickel manganese oxide cathode material. The preparation method comprises the following steps: at first, mixing cerium-iron composite compounds with lithium salts, nickel salts, and manganese salts, carrying out ball milling to disperse the mixture, carrying out vacuum drying to obtain a cerium-iron composite compound coated precursor of a lithium nickel manganese oxide material; burning the precursor for 5 to 20 hours at a constant temperature of 700 to 1000 DEG C in air atmosphere, and naturally cooling the precursor to obtain the modified lithium nickel manganese oxide cathode material. The cerium-iron composite compound is coated on the surface of lithium nickel manganese oxide, a stable protective layer is formed, the contact between electrolyte and lithium nickel manganese oxide is reduced, the oxidation and degradation of electrolyte on the anode surface are reduced, thus the chemical stability of the anode material in a cell system is improved, and at the same time, the circulation performance is enhanced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

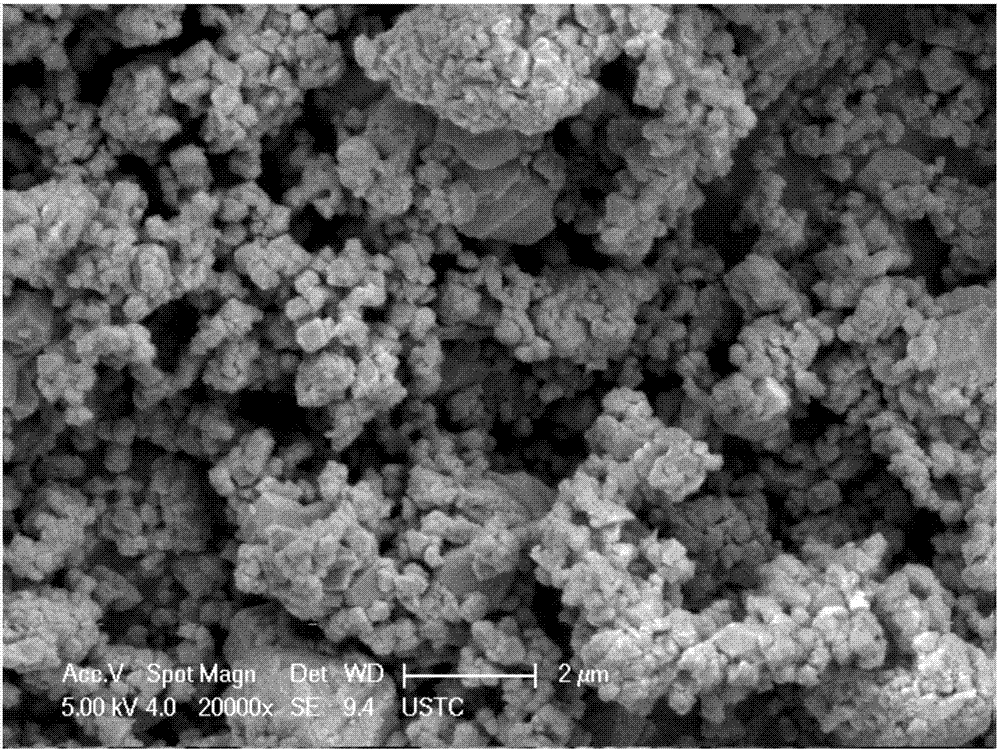

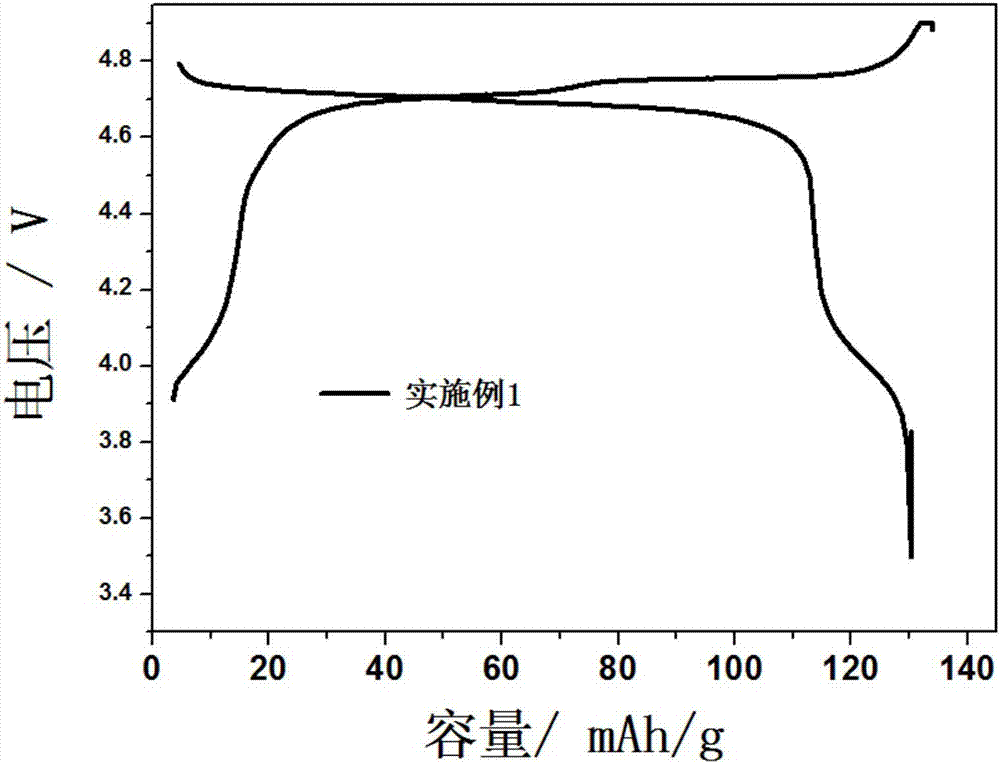

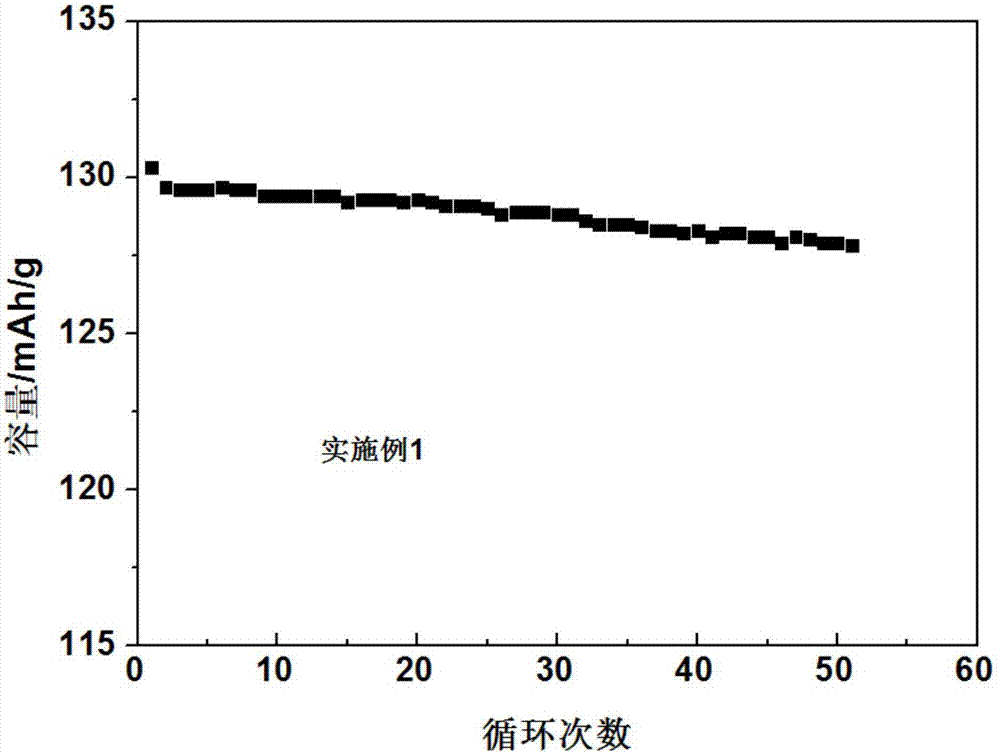

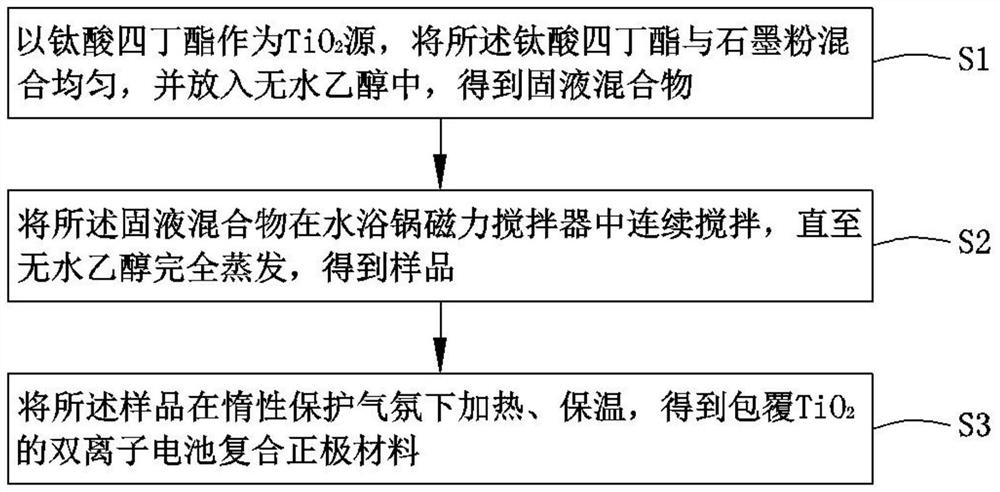

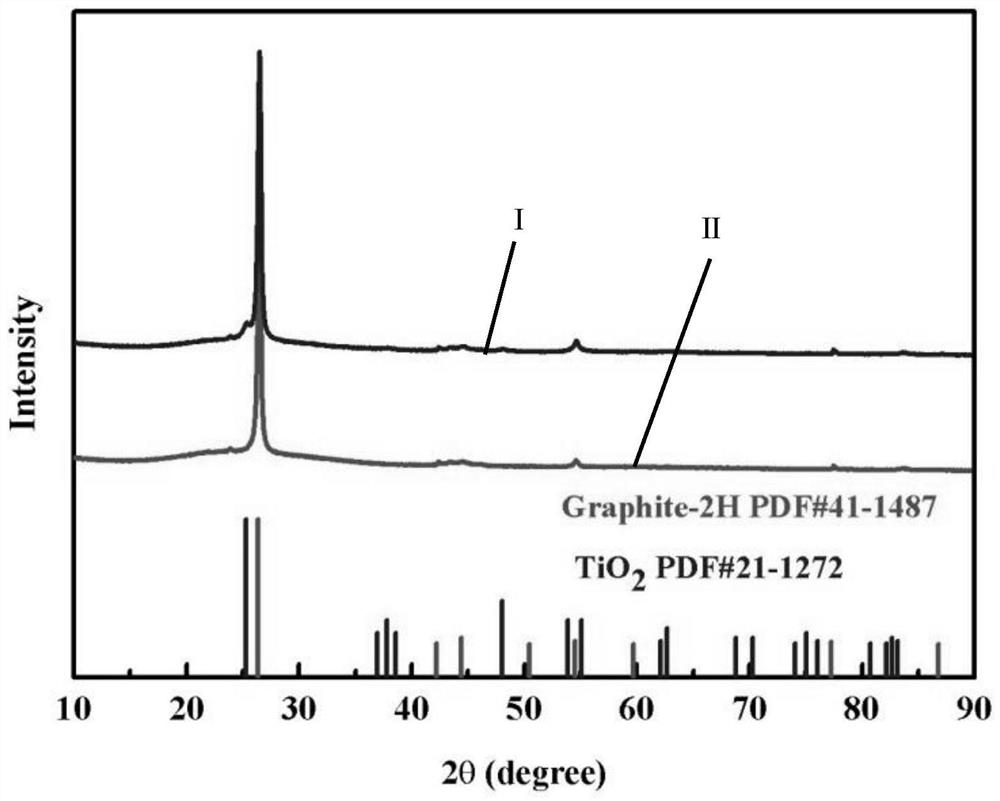

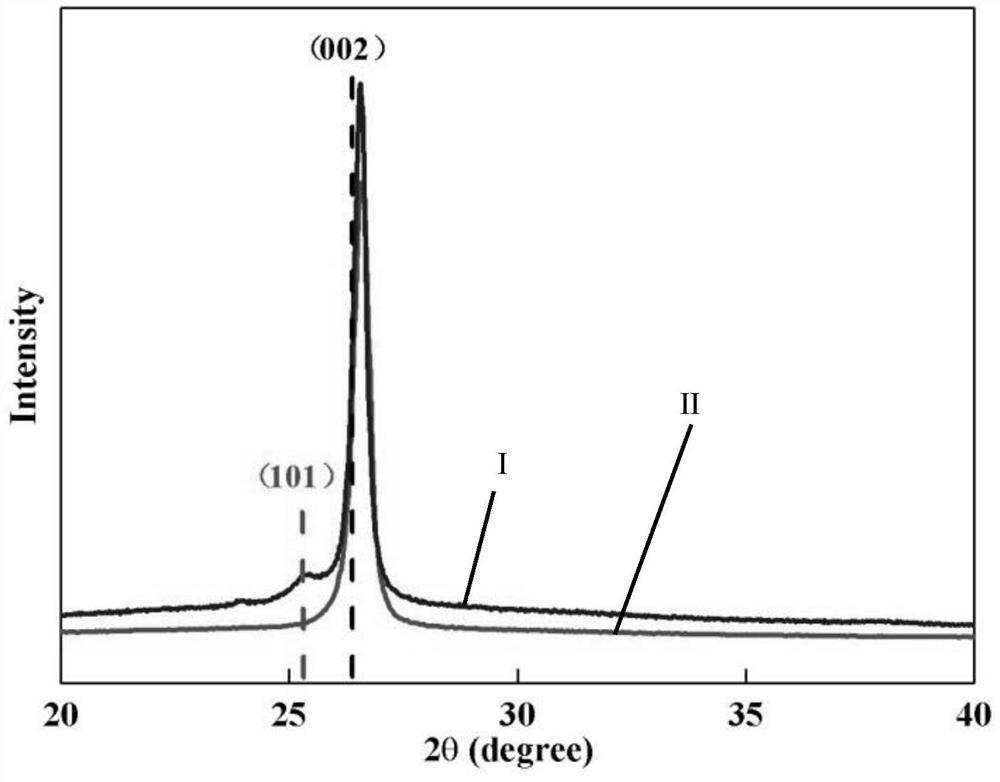

TiO2-coated graphite double-ion battery composite positive electrode material and preparation method thereof

ActiveCN111969185AImprove cycle stabilitySuppression of mechanical stressGraphiteCell electrodesGraphiteMagnetic stirrer

The invention provides a preparation method of a TiO2-coated graphite double-ion battery composite positive electrode material. The method comprises the following steps: S1, by taking tetrabutyl titanate as a TiO2 source, uniformly mixing the tetrabutyl titanate with graphite powder, and putting the mixture into absolute ethyl alcohol to obtain a solid-liquid mixture; S2, continuously stirring thesolid-liquid mixture in a magnetic stirrer of a water bath kettle until absolute ethyl alcohol is completely evaporated to obtain a sample; and S3, heating the sample in an inert protective atmosphere, and carrying out heat preservation to obtain the TiO2-coated graphite double-ion battery composite positive electrode material. The TiO2-coated graphite double-ion battery composite positive electrode material provided by the invention is relatively good in cycle performance.

Owner:HUNAN UNIV

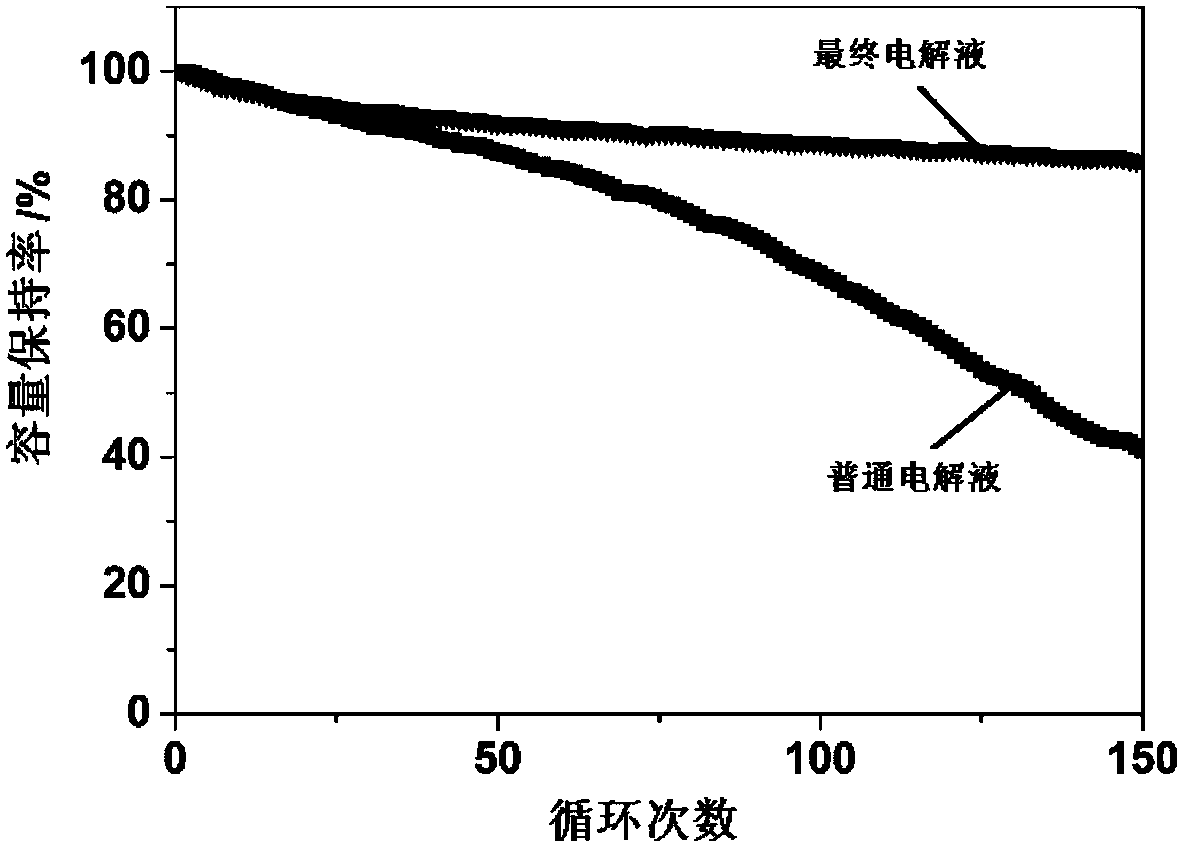

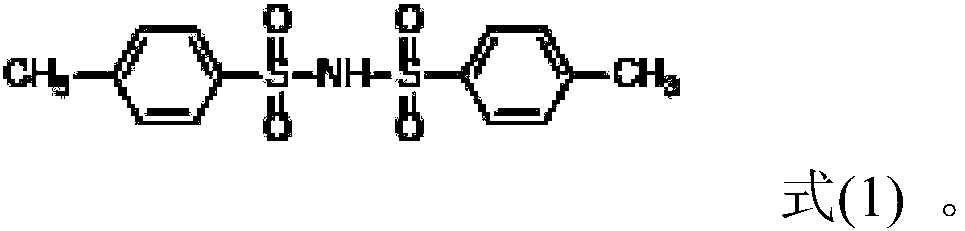

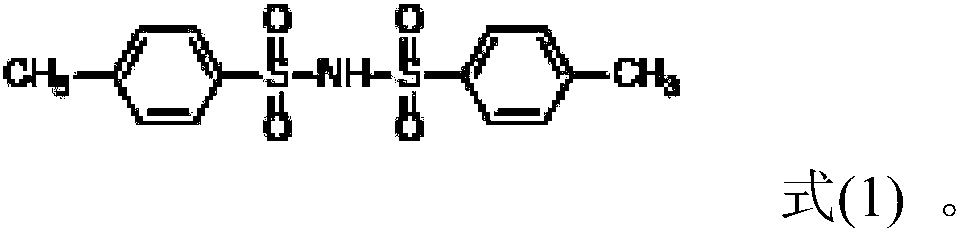

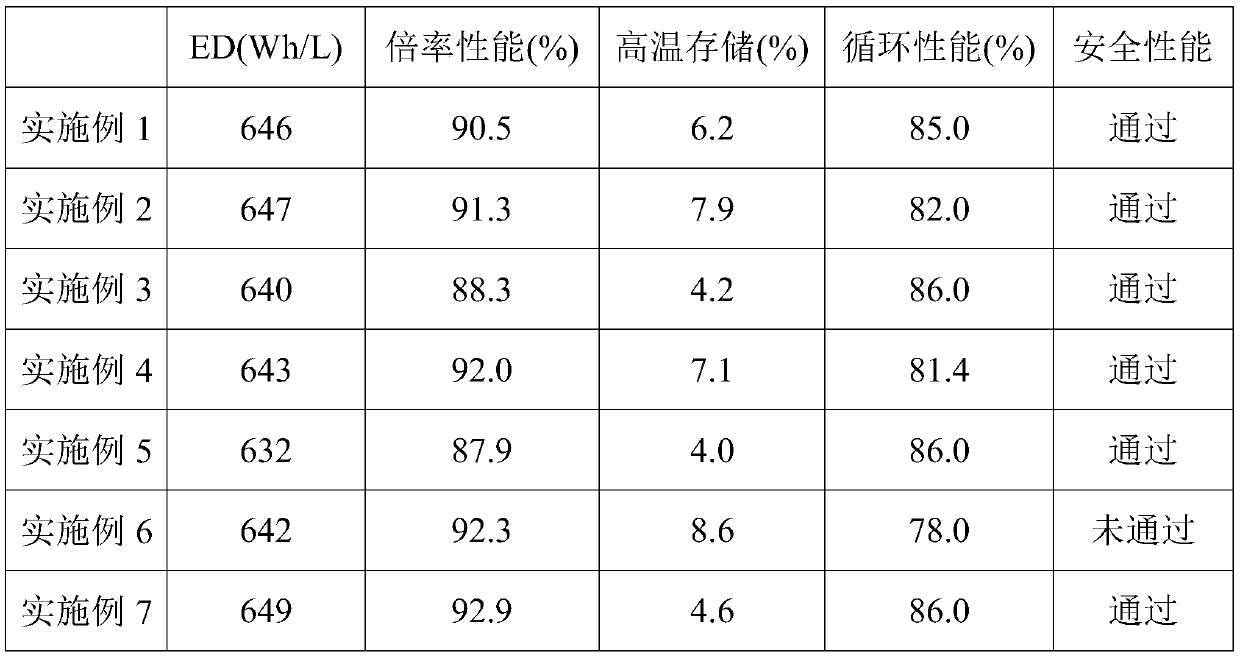

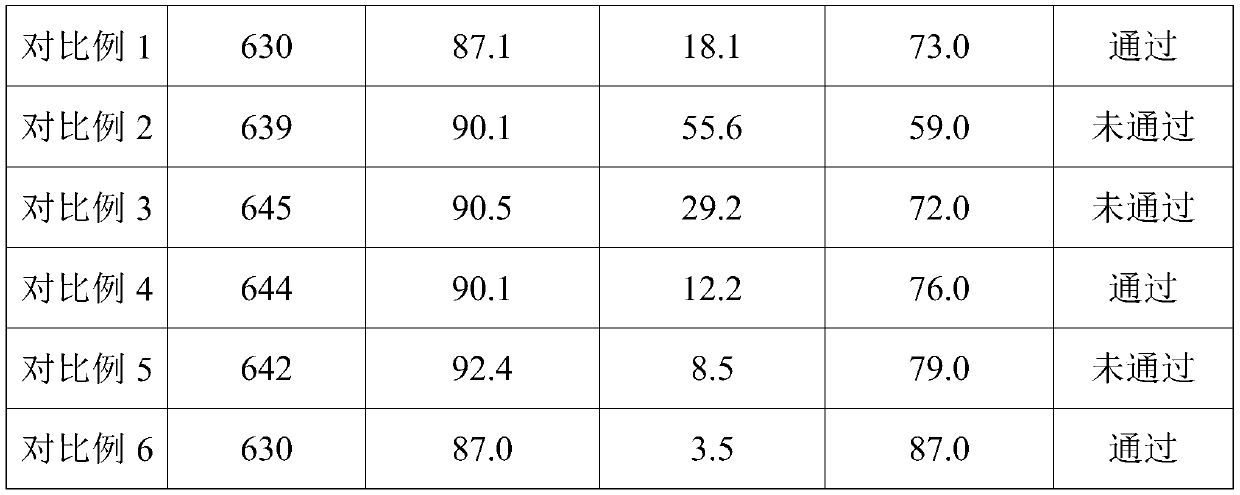

Electrolyte additive and electrolyte comprising additive, and lithium secondary battery

ActiveCN107799823ALower oxidation potentialRaise the reduction potentialSecondary cellsPhysical chemistryRoom temperature

The invention belongs to the field of a lithium ion battery material, and discloses an electrolyte additive and an electrolyte comprising the additive, and a lithium secondary battery. The electrolyteadditive is 4-methyl-N-tosyl benzene sulfonamide. A cyclic carbonate solvent and a linear carbonate solvent are mixed, and then are subjected to purification, impurity removal and dewatering, and a conductive lithium salt is added in the room temperature condition to obtain a common electrolyte; and next, an additive which accounts for 0.5-3.0% of the mass of the common electrolyte is added to the common electrolyte to obtain the final electrolyte. By taking 4-methyl-N-tosyl benzene sulfonamide as the additive of the lithium ion electrolyte, the cycle performance of the lithium secondary battery at a high pressure is improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Positive electrode material and preparation method and application thereof

InactiveCN110112393AIncrease energy densityImproved magnification performanceCell electrodesSecondary cellsState of artDecomposition

The invention relates to a positive electrode material and a preparation method and application thereof. The surfaces of a core layer material A composed of secondary spherical particles and a singlecrystal particle core layer material B composed of the secondary spherical particles are coated with a shell layer material to form a material A and a material B respectively, and then the material Aand the material B are mixed, so that the energy density, the rate capability, the high-temperature cycle and the safety performance of the positive electrode material are remarkably improved. The core layer material is coated with the shell layer material, so that the residual alkali of the positive electrode material can be remarkably reduced, the oxidative decomposition of the positive electrode material on the electrolyte is reduced, and the high-temperature cycle and safety performance of the positive electrode material are improved. Compared with the prior art, a lithium ion battery obtained by the invention can achieve very good energy density, cycle performance and safety performance under higher voltage (greater than or equal to 4.2V vs (Li + / Li)). Due to the fact that the charging cut-off voltage is increased, the battery has high energy density, and the requirement of people for thinness of the lithium ion battery can be met.

Owner:东莞维科电池有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com