Manganese-based lamellar lithium-rich material provided with uniform lithium phosphate coating layer and preparation method thereof

A lithium-rich material, lithium phosphate technology, applied in the field of lithium-ion batteries, can solve the problems of reduced rate performance, low electronic and ionic conductivity, etc., and achieve the effect of improving rate performance, high specific capacity, and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

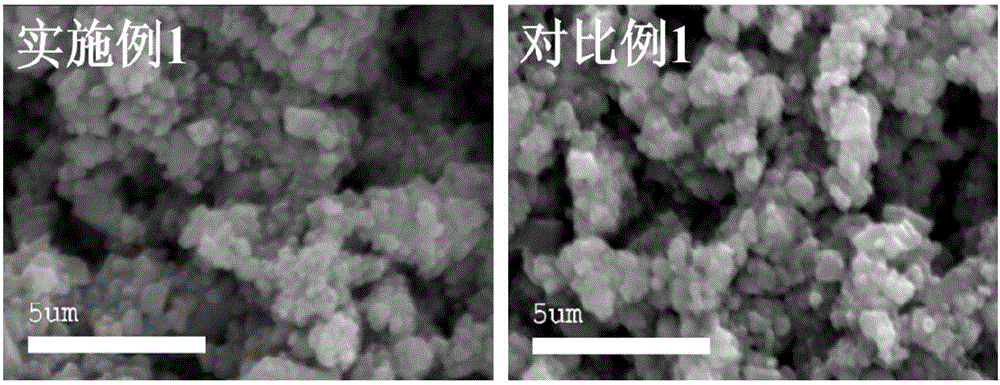

Embodiment 1

[0034] A method for preparing a manganese-based layered lithium-rich material with a uniform lithium phosphate coating layer with high capacity and high rate performance, comprising the following steps:

[0035] (1) Add 100mL deionized water into a 250mL high-necked beaker, then stir at a stirring speed of 300r·min -1Add 1.5g tris hydroxymethyl amino methane under the condition of , and make it dissolve fully, obtain solution A;

[0036] (2) At 600r·min -1 Under mechanical stirring, slowly add 1 mol·L solution A at the rate of 3 drops per second -1 hydrochloric acid solution and detect the pH value of solution A in real time with a pH meter, so that its pH value reaches 8.0 and stop adding hydrochloric acid to obtain solution B;

[0037] (3) Add 20mL deionized water into a 100mL high-necked beaker, then stir at a stirring speed of 300r·min -1 Add 5g manganese acetate and 1.7g nickel acetate under the condition of , and make it fully dispersed, obtain mixed solution;

[003...

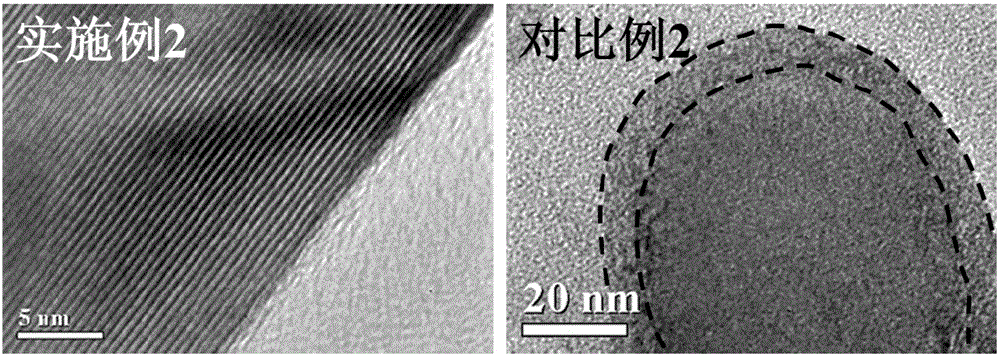

Embodiment 2

[0044] A method for preparing a manganese-based layered lithium-rich material with a uniform lithium phosphate coating layer with high capacity and high rate performance, comprising the following steps:

[0045] (1) Add 200mL deionized water into a 500mL high-necked beaker, and then stir at a stirring speed of 600r·min -1 Add 2g tris hydroxymethyl amino methane under the condition of , and make it dissolve fully, obtain solution A;

[0046] (2) At 700r·min -1 Under mechanical stirring, slowly add 2 mol·L solution A at the rate of 1 drop per second -1 hydrochloric acid solution and detect the pH value of solution A in real time with a pH meter, so that its pH value reaches 8.5 and stop adding hydrochloric acid to obtain solution B;

[0047] (3) Add 30mL deionized water into a 100mL high-necked beaker, and then stir at a stirring speed of 800r min -1 Add 10g of manganese acetate, 5.1g of nickel acetate and 5.1g of cobalt acetate under the conditions of , and make it fully dis...

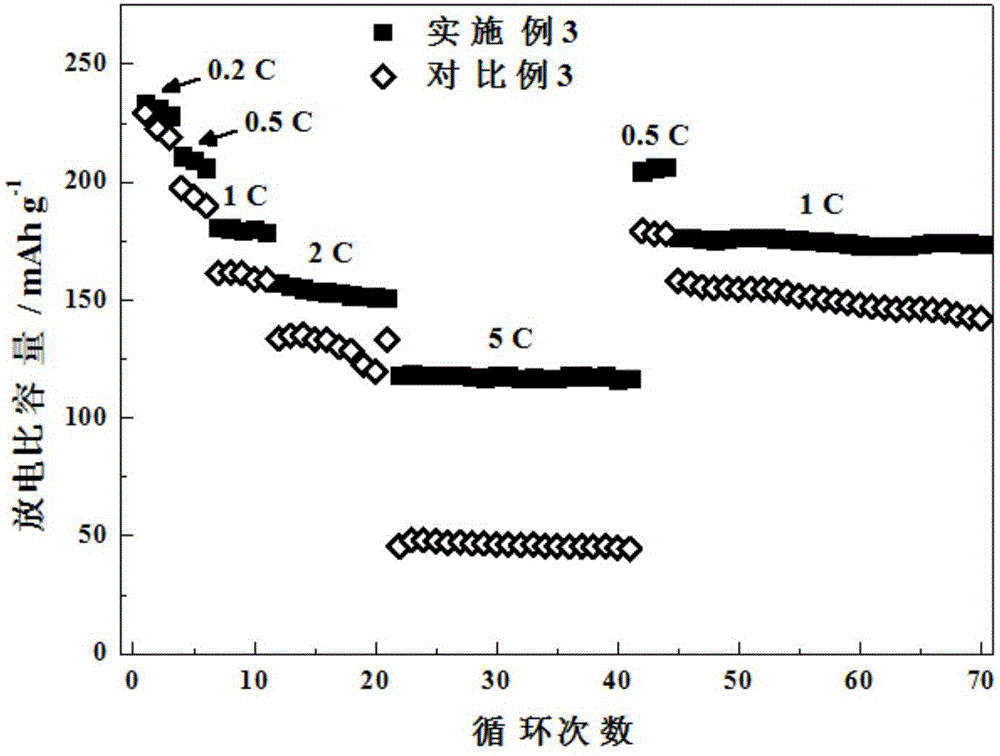

Embodiment 3

[0054] A method for preparing a manganese-based layered lithium-rich material with a uniform lithium phosphate coating layer with high capacity and high rate performance, comprising the following steps:

[0055] (1) Add 80mL deionized water into a 400mL high neck beaker, and then stir at a stirring speed of 500r·min -1 Add 1.2g tris hydroxymethyl aminomethane under the condition of , and make it dissolve fully, obtain solution A;

[0056] (2) At 800r·min -1 Under mechanical stirring, slowly add 5mol·L -1 hydrochloric acid solution and detect the pH value of solution A in real time with a pH meter, so that its pH value reaches 8.2 and stop adding hydrochloric acid to obtain solution B;

[0057] (3) Add 50mL deionized water into a 100mL high-necked beaker, and then stir at a stirring speed of 500r·min -1 Add 8g of manganese acetate, 1.9g of nickel acetate, 2.4g of cobalt acetate and 0.8g of iron nitrate under the condition of , and make it fully dispersed to obtain a mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com