High-voltage additive and high-voltage electrolyte for lithium battery

A high-voltage, electrolyte technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of battery performance degradation and affecting the performance of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

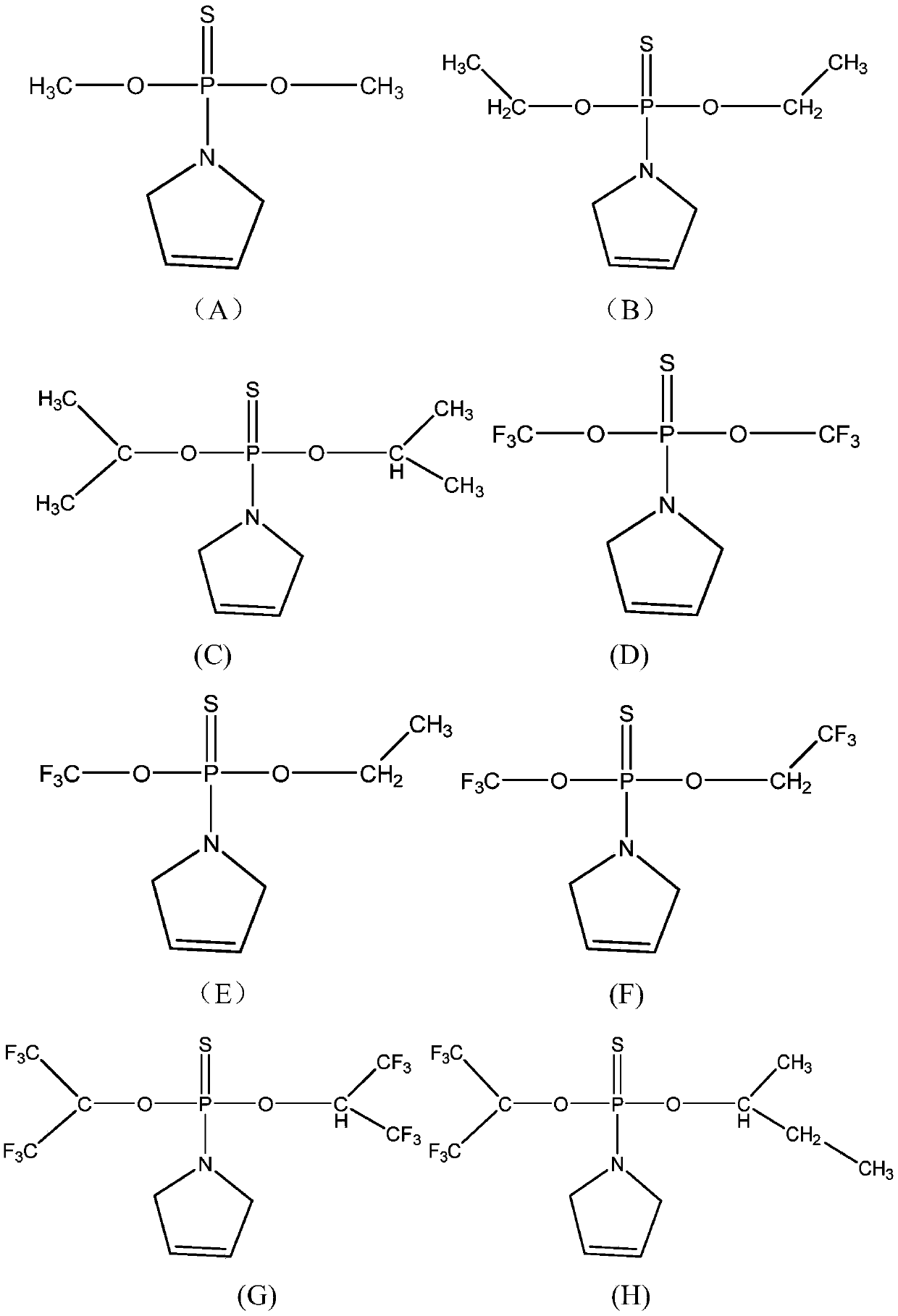

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of lithium battery

[0024] (1) Select lithium cobalt oxide suitable for high voltage as the positive electrode material, and the positive electrode material LiCoO 2 , CNTs, and PVDF are mixed evenly according to the ratio of 98:1:1, coated on the aluminum foil current collector, dried in an oven, rolled on a roller press, and the compacted density is 4.1g / cm 3 , to obtain the desired positive electrode sheet.

[0025] (2) Choose artificial graphite as the negative electrode material, mix graphite, CMC, conductive agent, and binder according to the ratio of 95:1.2:1.8:2, and prepare the negative electrode sheet. The compacted density of the electrode sheet is 1.7g / cm 3 .

[0026] (3) The ceramic-coated PE film is selected as the separator (9+3) um, and the pole piece is made into a 1Ah small soft-pack battery by lamination method, which is used for the test of high-voltage electrolyte.

Embodiment 2

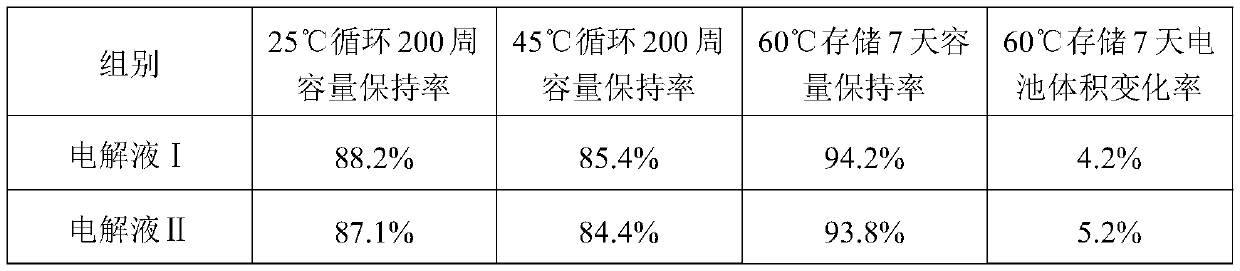

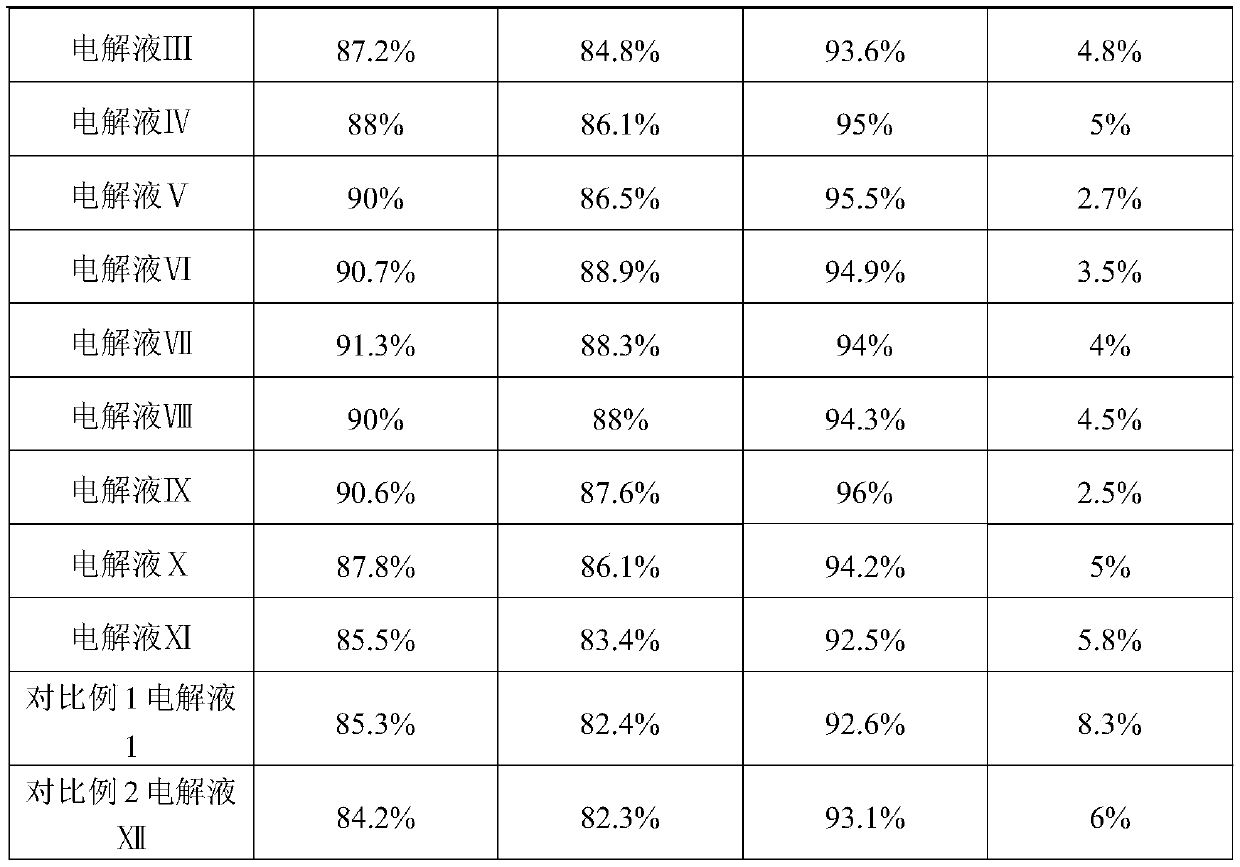

[0027] Embodiment 2: Lithium battery performance test

[0028] The charging and discharging voltage window of the lithium battery is 2.8-4.5V; the cycle test of the battery is room temperature 25°C and high temperature 45°C, and the cycle charge and discharge current is 0.5C; the high temperature storage performance test is 60°C, 100% SOC storage for 7 days , The charge and discharge current is 0.5C.

Embodiment 3

[0030] In an argon atmosphere, the environmental index is H 2 O≤0.5ppm, O 2 In a glove box of ≤2.0ppm, mix the organic solvents EC, FEC, and DEC according to the mass ratio EC / FEC / DEC=25 / 5 / 70, then add lithium hexafluorophosphate to dissolve, and prepare an electrolyte with a lithium hexafluorophosphate concentration of 1M, and then press The mass fractions are 1%, 0.7%, and 1%, adding auxiliary additives VC, LiPO 2 f 2 and PS, and then add 1% of high-voltage additive A to prepare electrolyte I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com