Patents

Literature

49results about How to "Improve ionic conductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of lithium ion battery cathode material SiOX-TiO2/C

ActiveCN105591080AImprove conduction abilityLow priceCell electrodesSecondary cellsElectrical batteryThermal insulation

The invention discloses a preparation method of a lithium ion battery cathode material SiOX-TiO2 / C. The preparation method comprises steps as follows: analytically pure organic silicon sources, organic titanium sources and organic carbon sources are weighed in a certain mole ratio; the organic silicon sources are dissolved in a mixed solution of deionized water and absolute ethyl alcohol and stirred, the pH of the solution is adjusted to be alkaline, and a mixed solution A is obtained; the organic titanium sources are dissolved in the absolute ethyl alcohol and stirred for a period of time, and a mixed solution B is obtained; the mixed solution B is added to the mixed solution A and left to stand at the room temperature after being stirred for a period of time, and a colloidal mixed solution is obtained; after the colloidal mixed solution is mixed with the organic carbon sources, mechanical ball-milling treatment is performed; the mixed solution after mechanical ball-milling treatment is dried, and a precursor is obtained; the precursor is put in a crucible and calcined under the protection of inert atmosphere, thermal insulation is performed for multiple hours, and a product is cooled to the room temperature with the furnace. Compared with the prior art, the cathode material prepared with the method has good rate performance, the raw materials are cheap, the preparation process is simple, and the yield is high.

Owner:UNIV OF SCI & TECH BEIJING

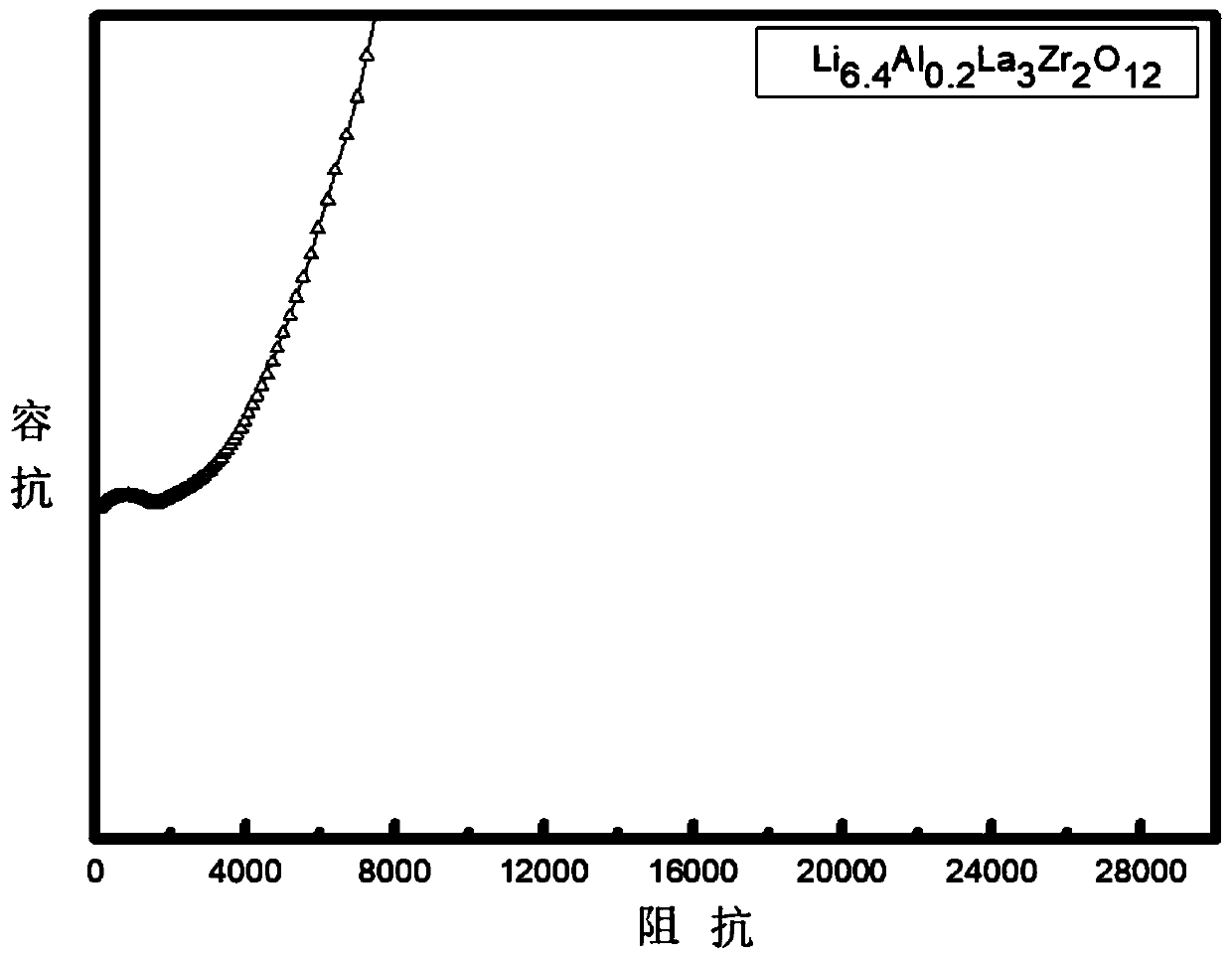

Preparation of garnet type solid electrolyte and secondary battery using garnet type solid electrolyte

InactiveCN109742442AWide electrochemical windowImprove stabilityFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteAll solid state

The invention relates to preparation of a garnet type solid electrolyte material, and a buffer layer design and the solid electrolyte of the type are applied to a solid-state lithium ion secondary battery. The preparation in the invention can be applied to all-solid-state lithium ion batteries, lithium-sulfur batteries and the like and has the functions of electrolyte and diaphragms. The solid electrolyte of the type has the characteristics of high ionic conductivity, stability, chemical stability, wide electrochemical window and the like, the preparation process of the lithium ion battery canbe simplified, the cost can be reduced, and the safety of the battery can be remarkably improved.

Owner:BEIJING UNIV OF CHEM TECH

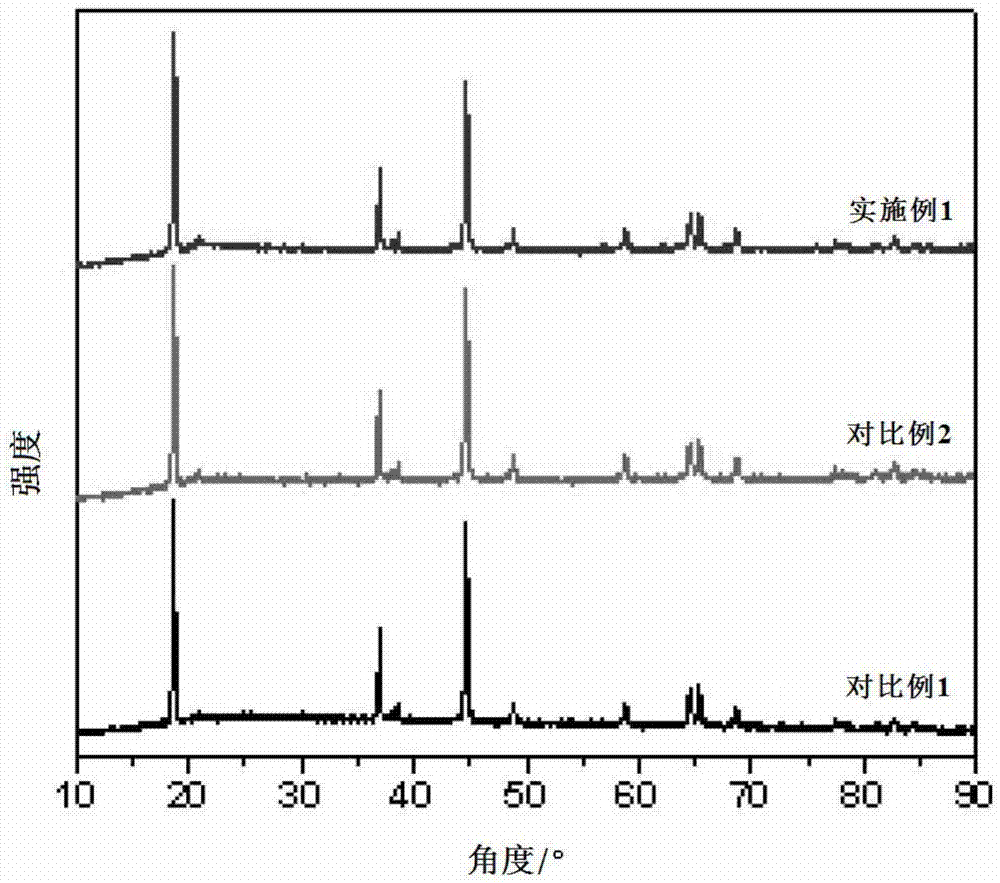

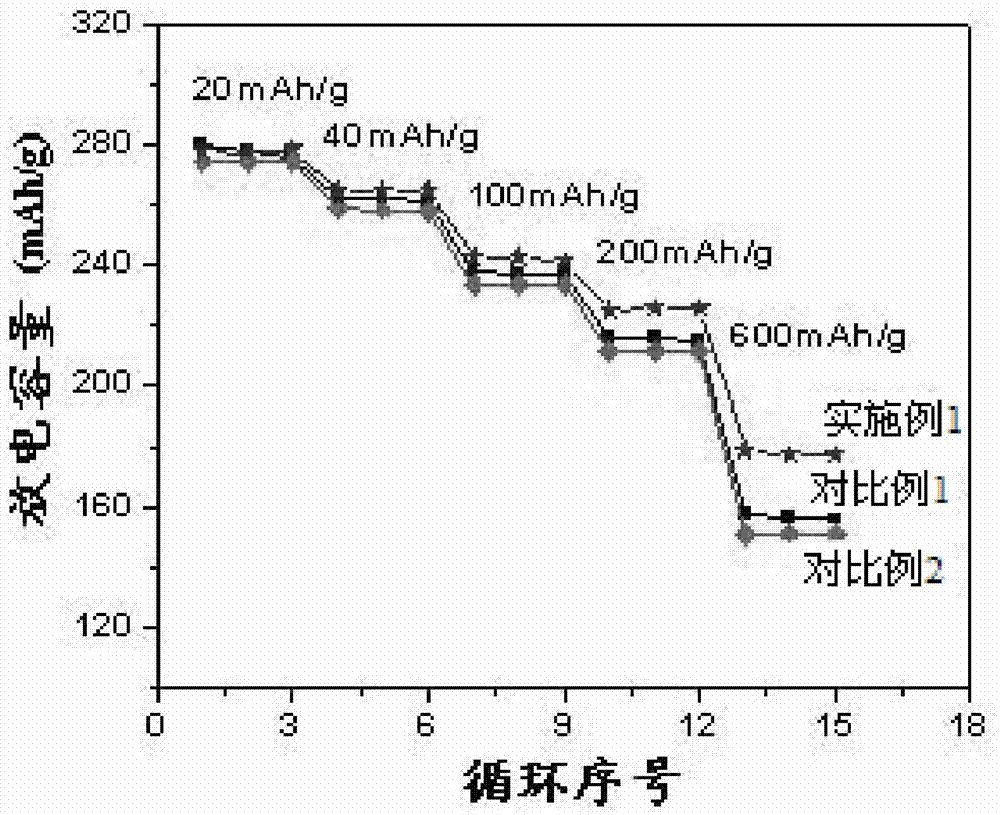

Surface double-coated lithium-enriched material and preparation method thereof

The invention discloses a surface double-coated lithium-enriched material and a preparation method thereof. The surface double-coated material is a composite material formed by sequentially coating the outer surface of a lithium-enriched material with a metal compound layer and a carbon layer, wherein the lithium-enriched material has a chemical formula of Li<1+>xMnyMzAwOr, M is at least one of Ni, Co, Al, Mg, Ti, Fe, Cu, Cr, Mo, Zr, Ru and Sn, and A is at least one of S, P, B and F; and x is more than 0 and less than or equal to 1, y is more than 0 and less than or equal to 1, z is more than or equal to 0 and less than 1, w is more than or equal to 0 and less than or equal to 0.2, and r is more than or equal to 1.8 and less than or equal to 3. The preparation method comprises the following steps: preparing a soluble metal salt solution; soaking the lithium-enriched material in the solution, adding a precipitator, stirring, filtering, drying and heating; soaking the heated sample in a carbon source-contained solution for stirring, and drying; heating and carbonizing the dried sample at a protective atmosphere to obtain the surface double-coated lithium-enriched material. According to the surface double-coated lithium-enriched material, the stability and conductivity of the material structure can be improved, and the circulating performance and rate performance of the lithium-enriched material can be improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

Preparation method for porous graphene micro-sheet

InactiveCN105449210ALarge specific surface areaIncreased diffusion rateNegative electrodesSecondary cellsPorous grapheneNitrogen gas

The invention discloses a preparation method for a porous graphene micro-sheet. The preparation method is characterized by comprising the following steps: 1) pretreatment of graphite: putting graphite into a mixed solution consisting of an oxidizing agent and intercalator, performing ultrasonic stirring for 3-5h; washing, filtering and drying the obtained product, and putting the product into a muffle furnace, and processing the product in nitrogen atmosphere at a high temperature of 600-1,200 DEG C for 2-6h to obtain an expanded graphite product for use; and 2) preparation of the porous graphene micro-sheet: dissolving the expanded graphite obtained in the above step into a certain amount of deionized water, adding 0.1-2wt% of surfactant, performing ultrasonic stirring for 0.5-2h, and then adding a certain amount of pore forming agent, and putting into the muffle furnace under the N2 protective atmosphere for processing for 1-3h; washing the obtained product by dilute acid or dilute alkali and the deionized water solution for multiple times; drying the product in a vacuum drying oven for 2-6h to obtain the porous graphene micro-sheet. The porous graphene micro-sheet prepared by the preparation method provided by the invention is relatively high in specific surface area (850-1,000 m2 / g); and due to the porous structure, the diffusion rate of the lithium ions can be improved, and a relatively better electrochemical performance can be obtained.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

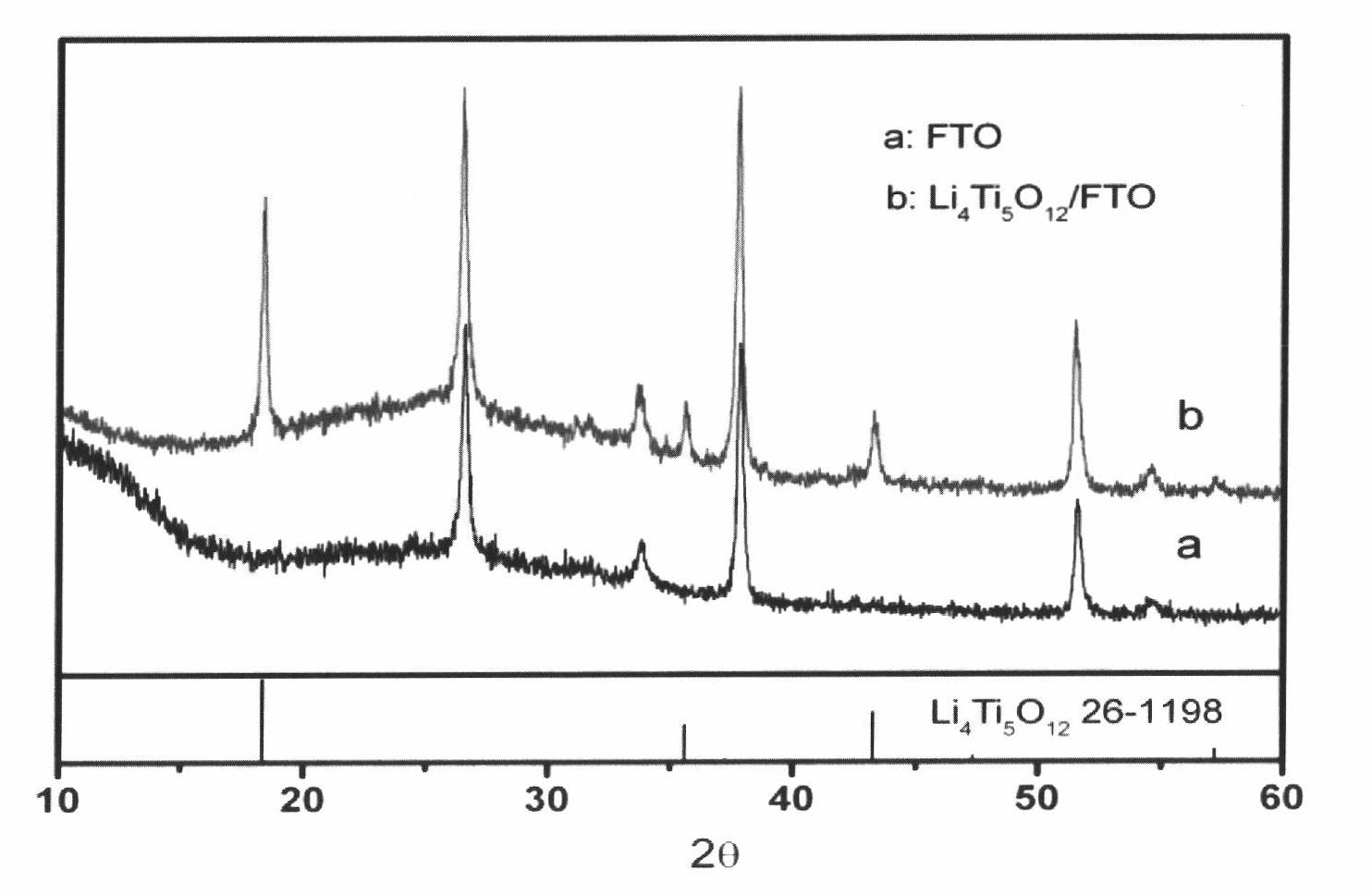

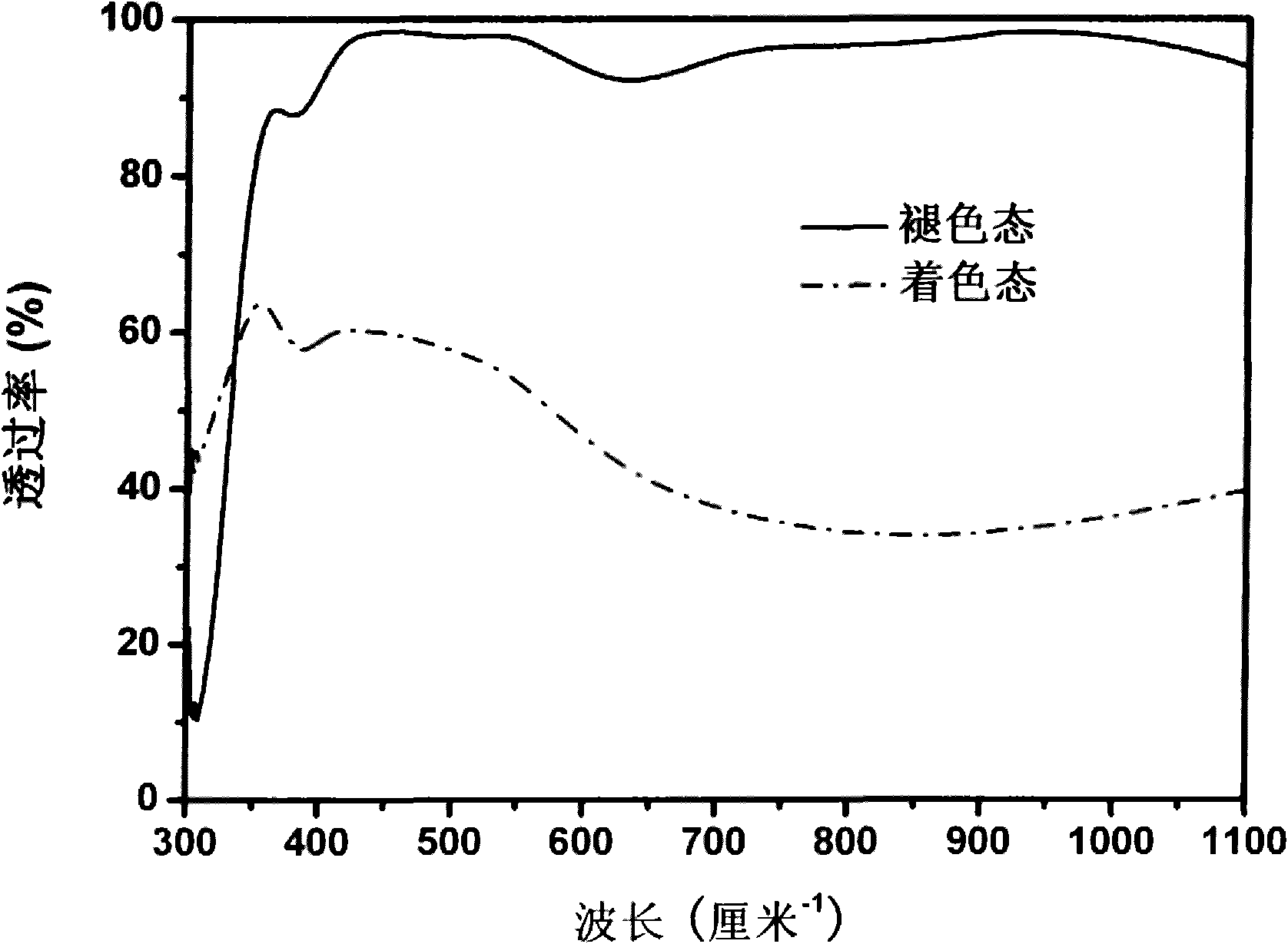

Photoelectric device including lithium titanate membrane electrode and application thereof

The invention provides a photoelectric device including a lithium titanate membrane electrode, which at least comprises a lithium titanate membrane electrode, electrolyte and a counter electrode, wherein a lithium titanate membrane grows on a transparent conductive substrate, and the thickness of the membrane is 1nm-100mum. The lithium titanate membrane comprises a substance with a chemical composition of Li4+xAaTi5-yO12-zBb, wherein A is selected from at least one of H, Na, K, Mg, Ca, Sr, Ba, B, Al, Ga, In, Si, Ge, Sn, Pb, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd,La, Ce, Pr, Nd, Sm, Eu, Gd, Er, Tm, Yb, Lu, W, Pt, Au or Bi; B is selected from at least one of N, P, S, Se, F, Cl, Br or I; x, a, y, z and b represent molar percent; and x is larger than or equal to-4 and smaller than or equal to 4, a is larger than or equal to 0 and smaller than or equal to 4, y is larger than or equal to 0 and smaller than or equal to 4, z is larger than or equal to 0 and smaller than or equal to 3 and b is larger than or equal to 0 and smaller than or equal to 4.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

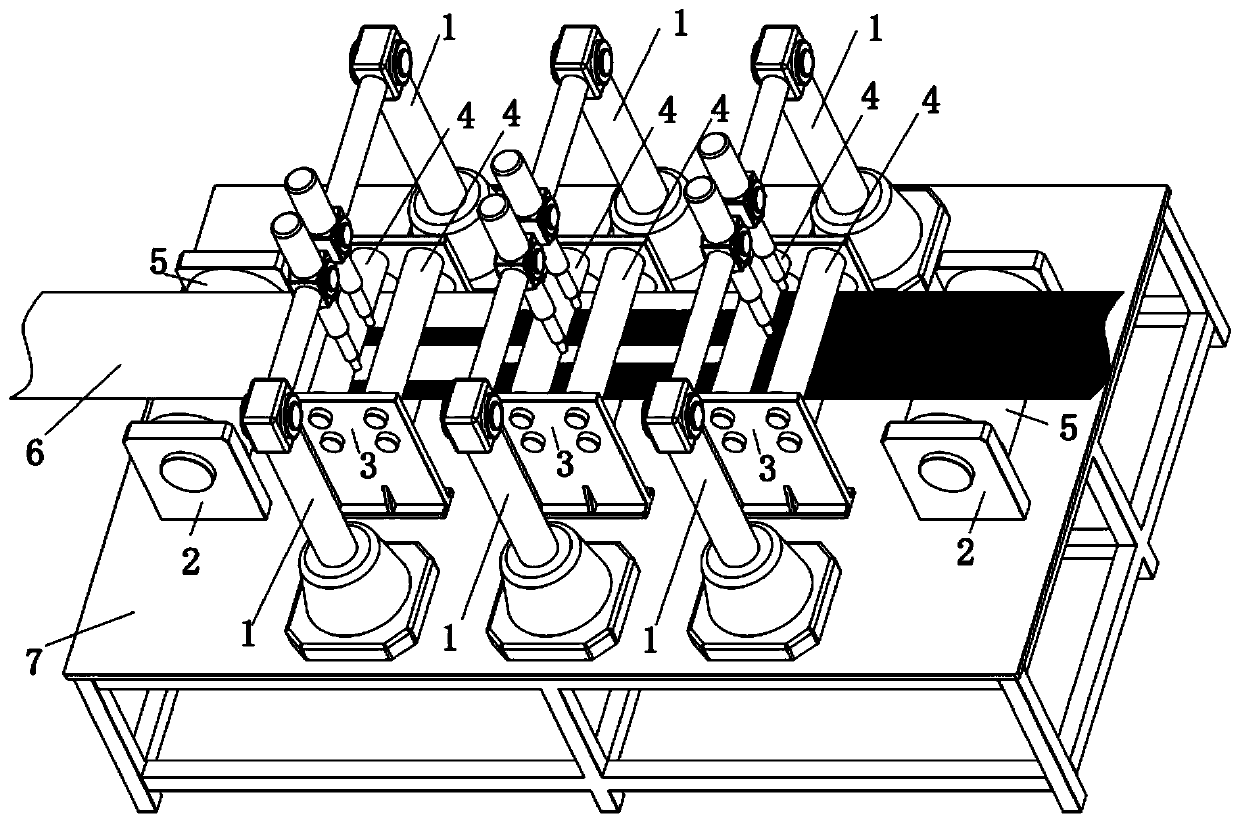

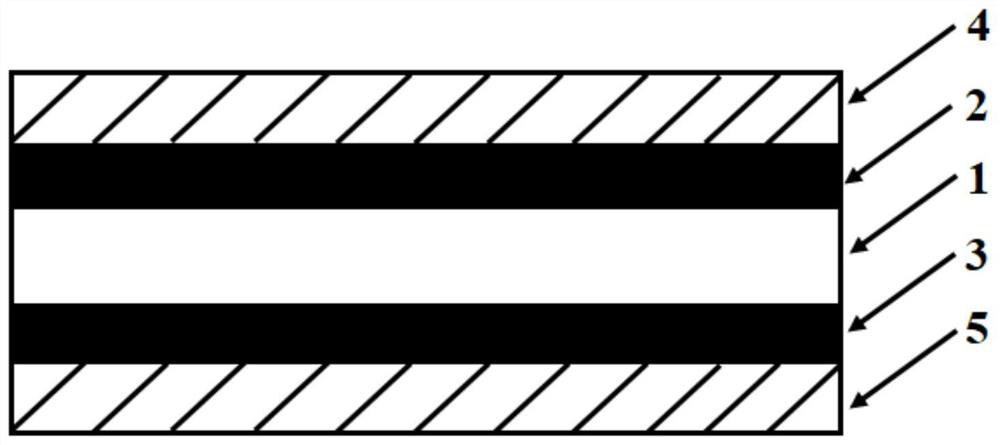

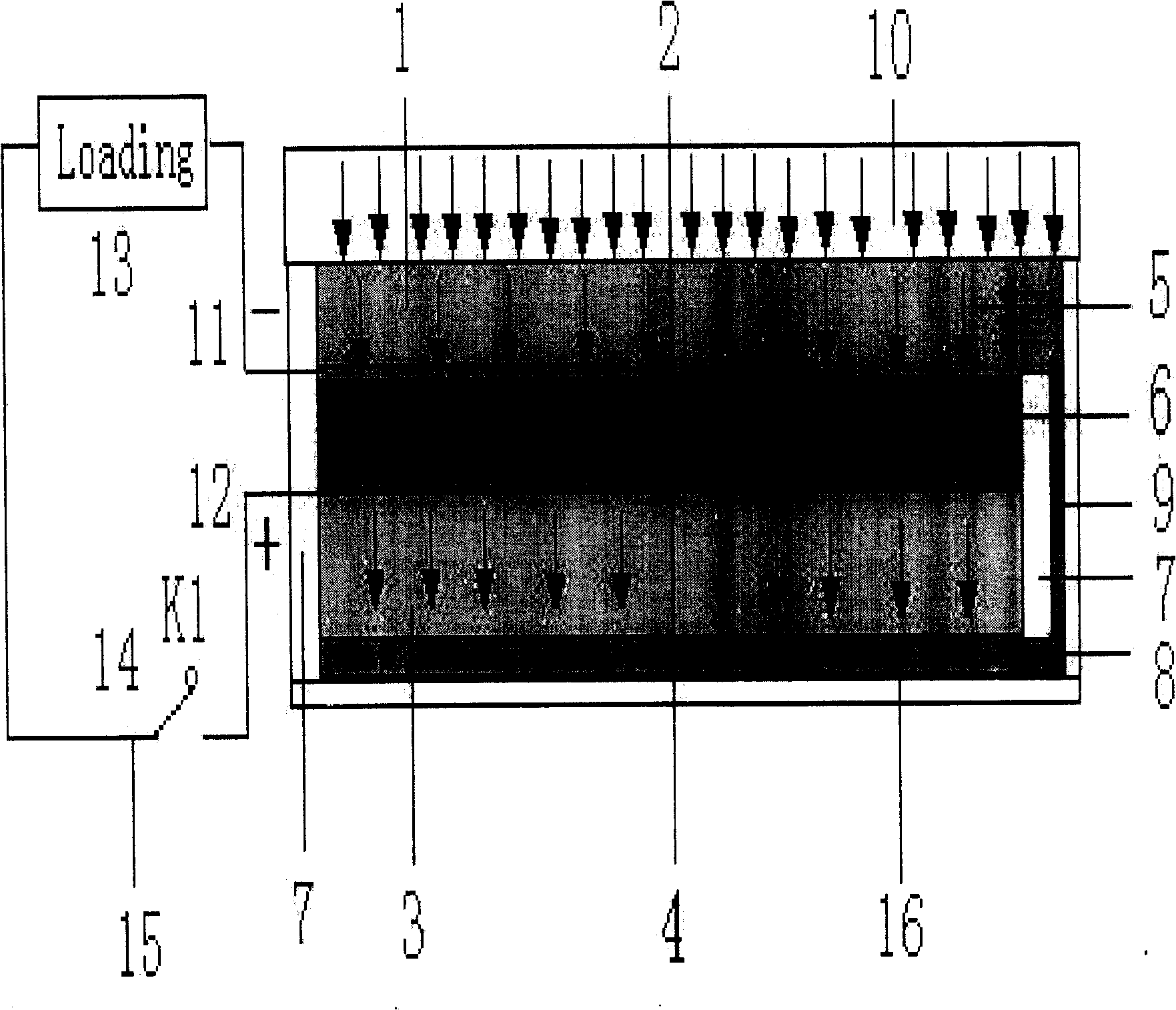

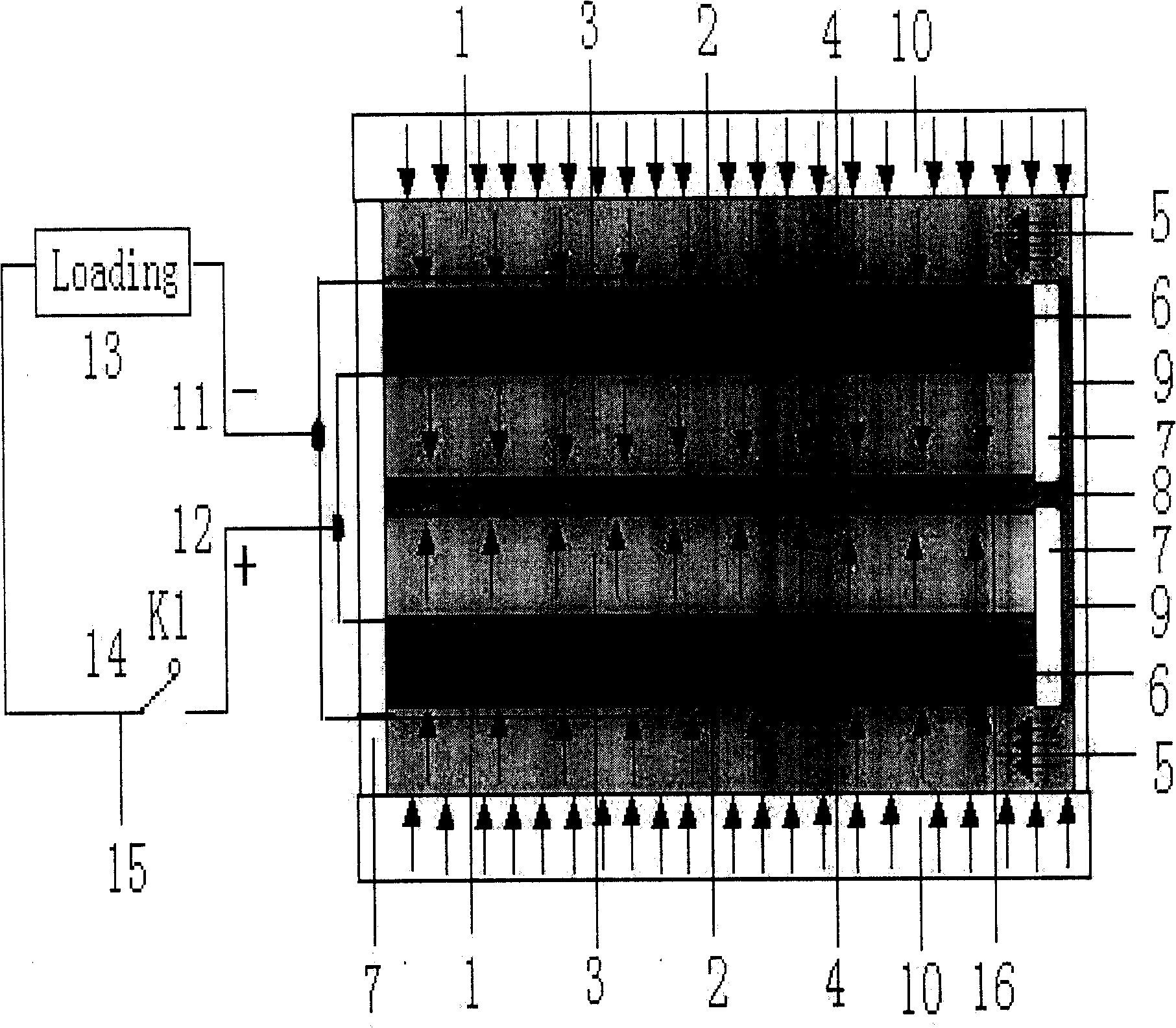

Spray pyrolysis battery manufacturing method of double-layer film all-solid-state film lithium battery

InactiveCN102456928AImprove ionic conductanceImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureLithium-ion batteryCell resistance

Owner:NINGBO UNIV

Solid-state lithium ion battery applying composite positive electrode as well as assembly method and application thereof

PendingCN111224064AImprove securityImprove stabilityAssembling battery machinesFinal product manufactureSolid-state batteryElectrical battery

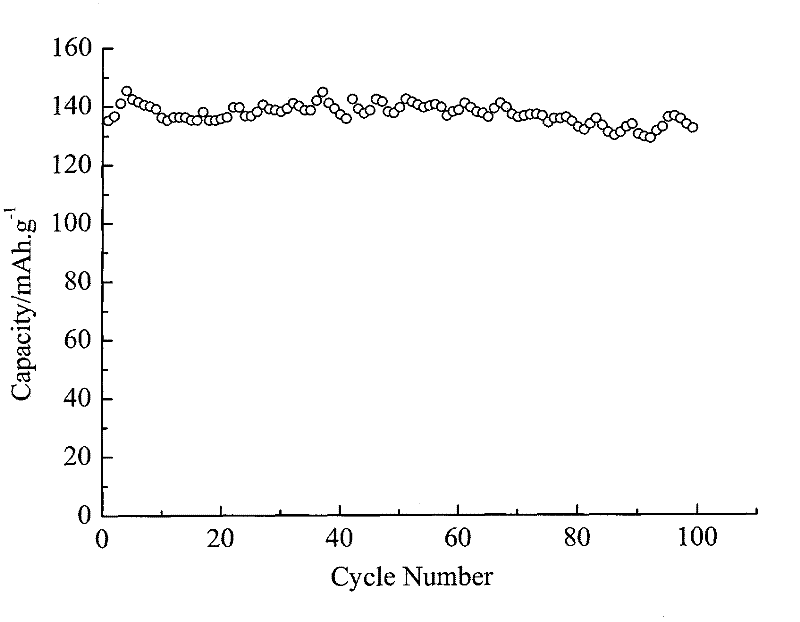

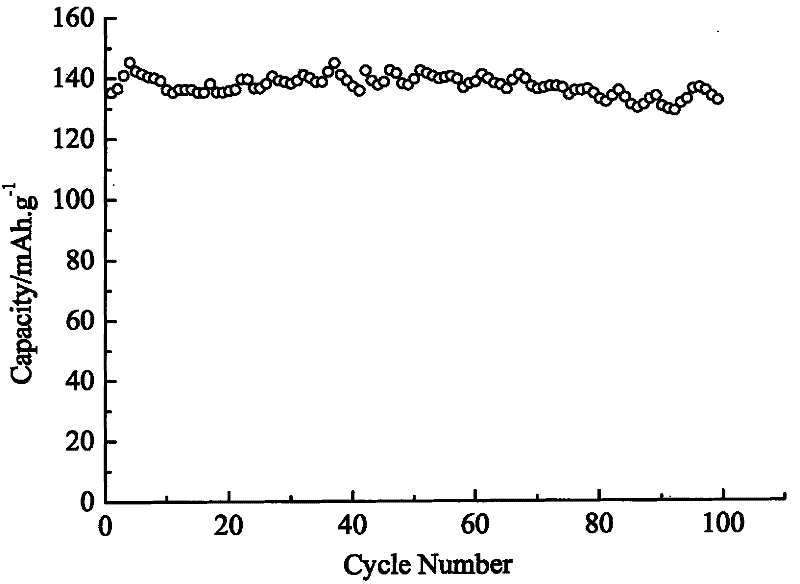

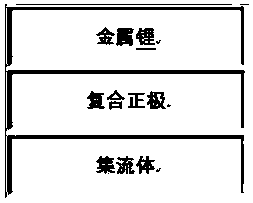

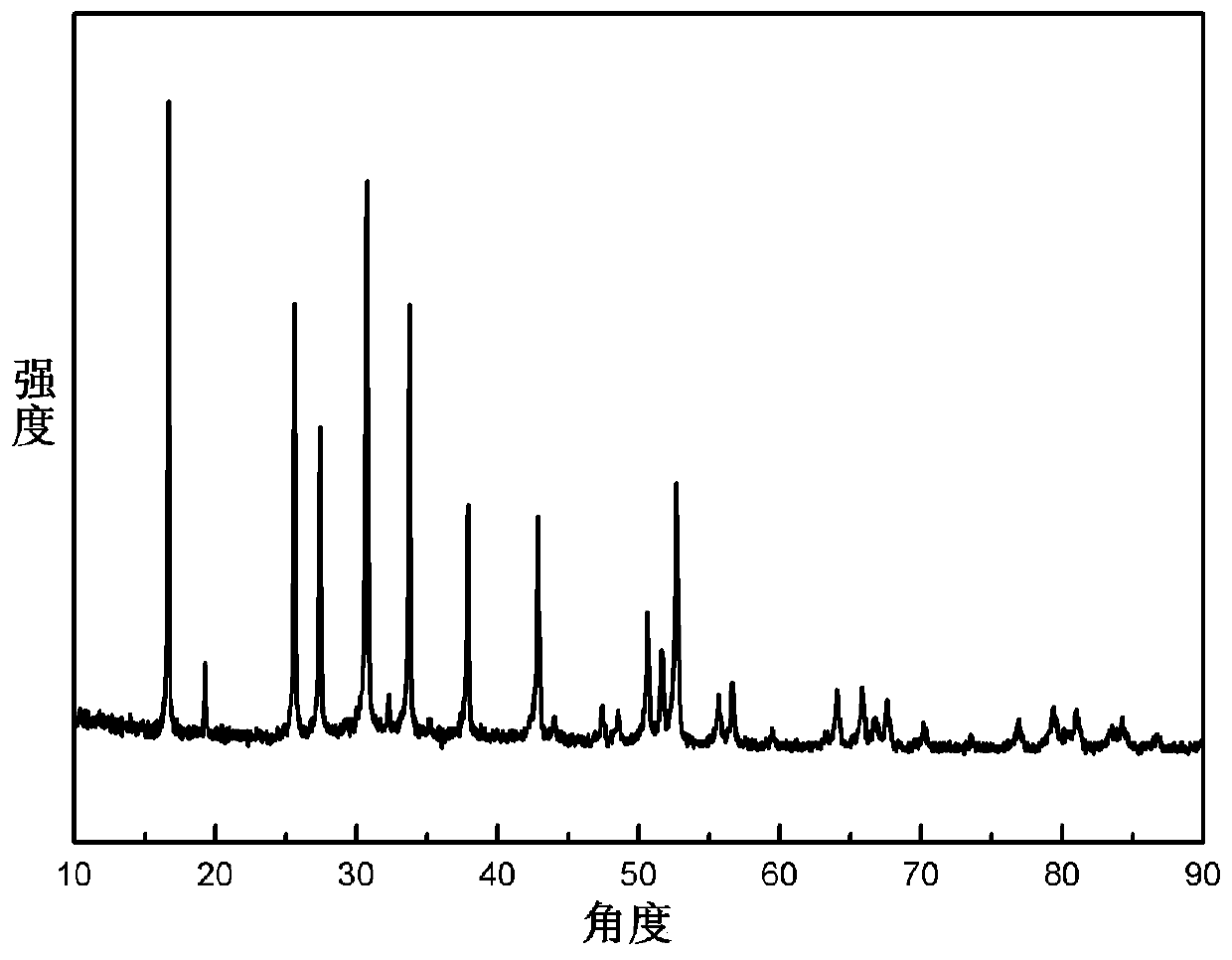

The invention discloses a solid-state lithium ion battery applying a composite positive electrode as well as an assembly method and application of the solid-state lithium ion battery. The assembly method comprises the steps of (1) mixing an electrode material, a binder and a conductive additive, and uniformly grinding, then adding the mixture into an N-methyl pyrrolidone solvent, fully grinding and uniformly mixing, coating a current collector aluminum foil with the mixture, and drying to obtain a positive pole piece; (2) mixing and grinding the solid electrolyte powder and a binder, adding the mixture into an NMP solvent, performing wet grinding, and performing ultrasonic dispersion to obtain a uniformly dispersed solid electrolyte dispersion liquid; coating the dispersion liquid of the solid electrolyte on the surface of the positive pole piece, forming a solid electrolyte coating on the surface of the positive pole piece by using a scraper film forming method, and completely dryingto obtain a composite positive pole piece; and (3) taking the composite positive pole piece as a positive electrode in the solid-state battery, taking a metal negative electrode material as a negativeelectrode, activating the interface, packaging in a button battery shell, and pressurizing and sealing to obtain the solid-state battery.

Owner:SUN YAT SEN UNIV +1

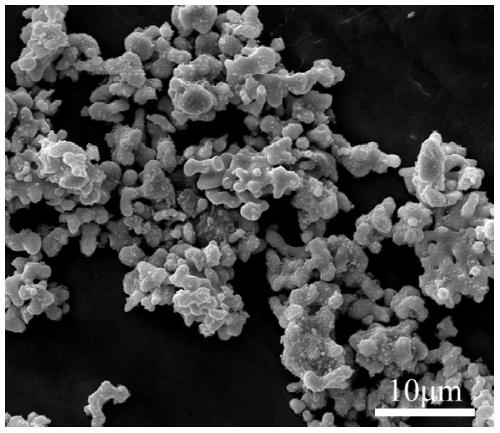

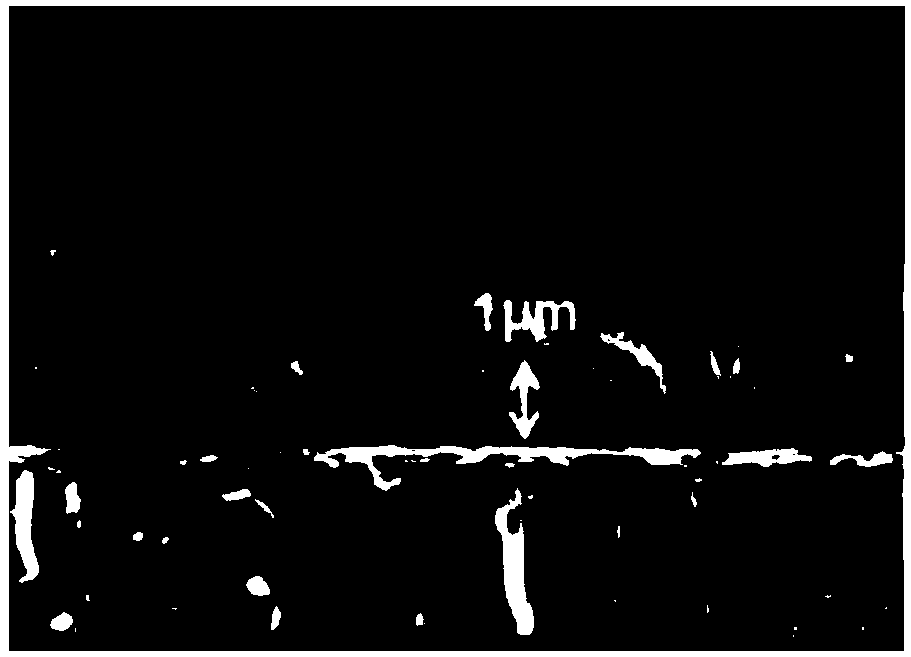

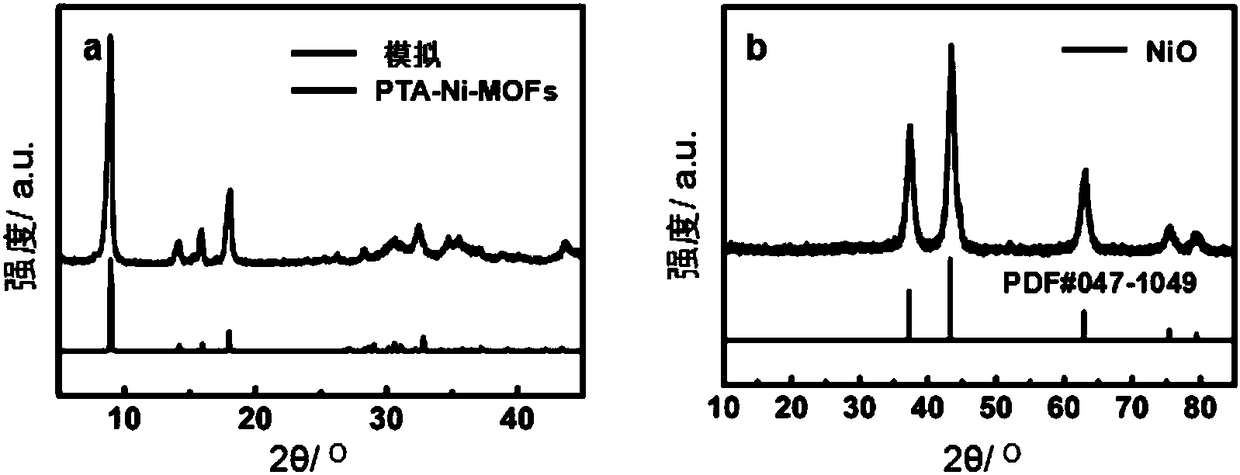

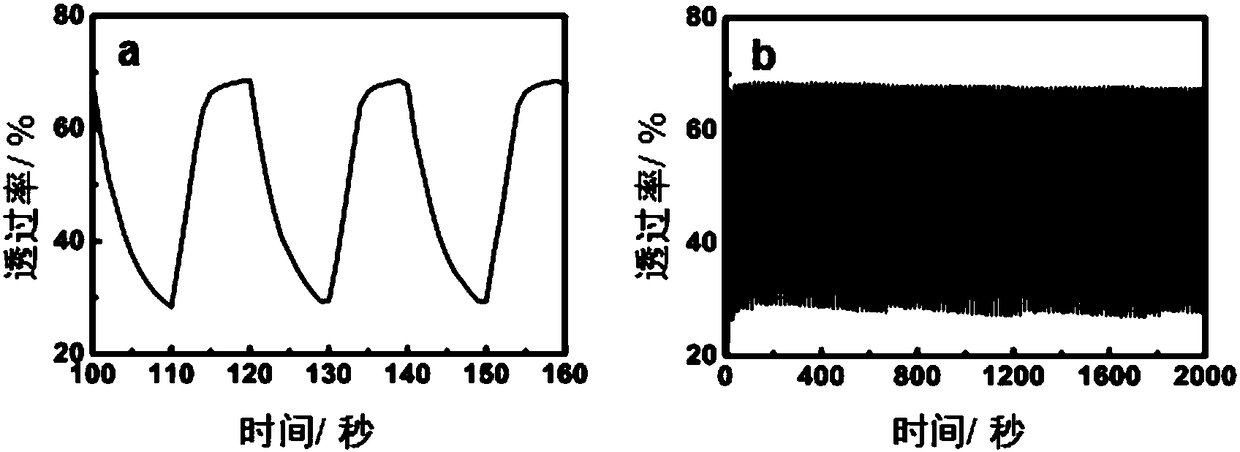

Preparation method of MOFs derivative NiO electrochromic film

The invention relates to a preparation method of an MOFs derivative NiO electrochromic film. The method comprises the steps of dissolving terephthalic acid PTA and nickel salt into N,N-dimethyl formamide DMF, dropwise adding deionized water, and obtaining a PTA-Ni-MOFs precursor solution; putting pretreated FTO glass into the precursor solution, carrying out hydrothermal reaction, cooling, washing, vacuum drying, and obtaining FTO glass coated with a PTA-Ni-MOFs thin film; carrying out heat treatment, and obtaining the MOFs derivative NiO electrochromic film. The preparation method provided bythe invention is simple and convenient, and can be produced in a large scale; the obtained MOFs derivative NiO electrochromic film has a perfect porous structure and a high-efficient and stable electrochromic property, and has an important application value in the fields such as electronic display, building curtain walls and smart home.

Owner:DONGHUA UNIV

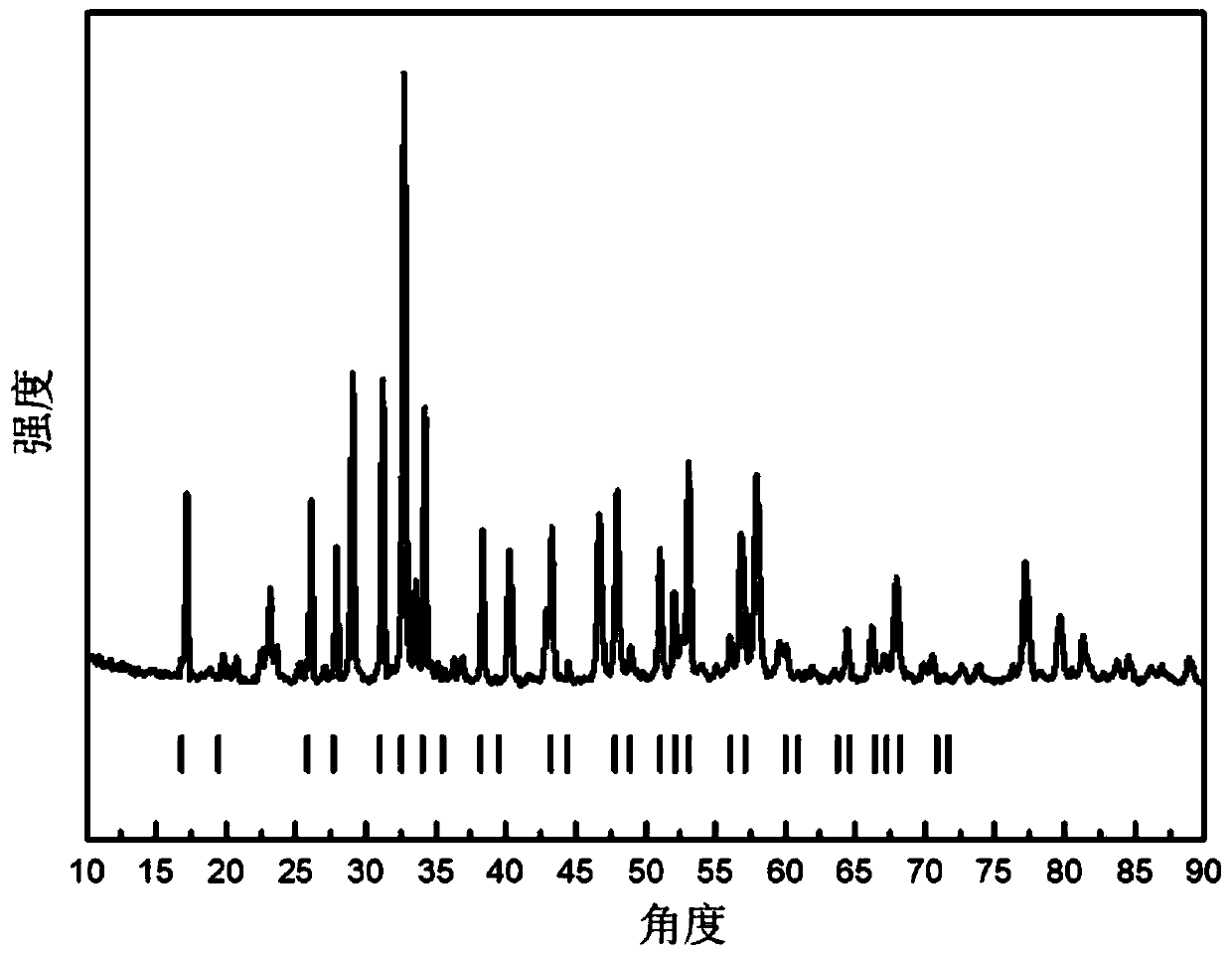

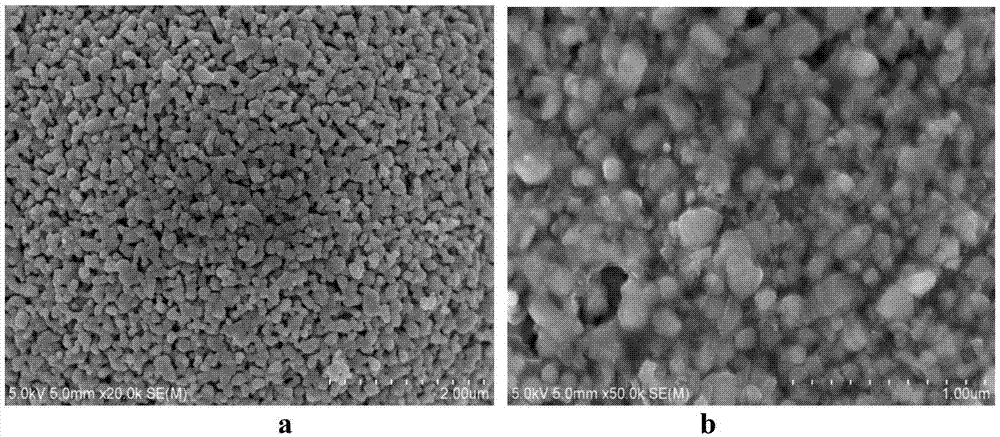

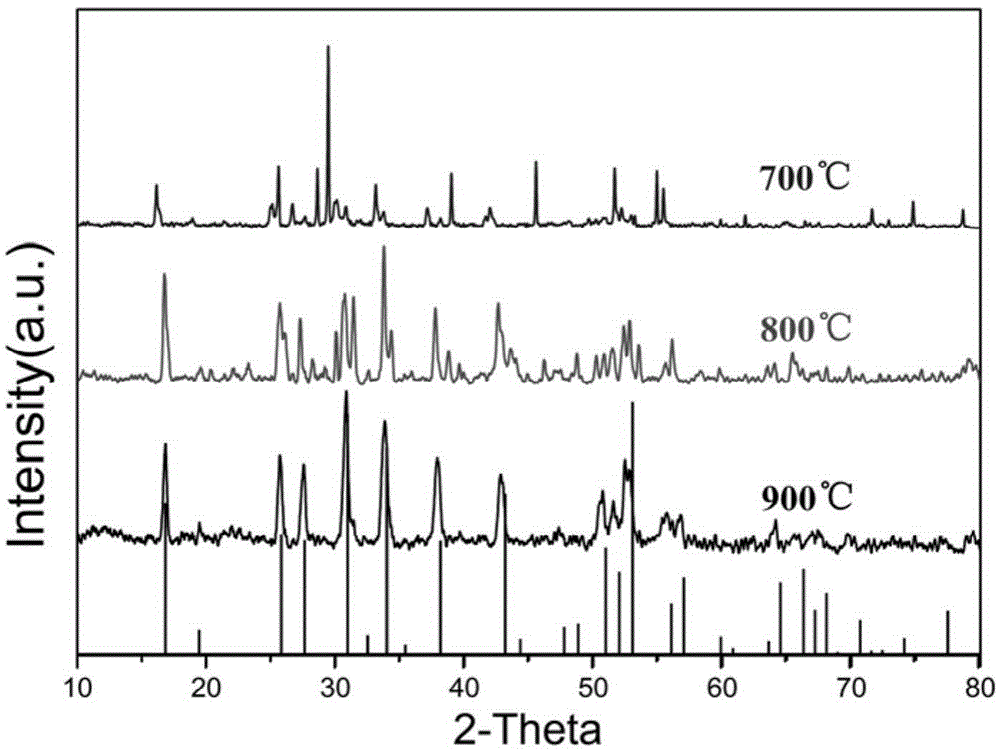

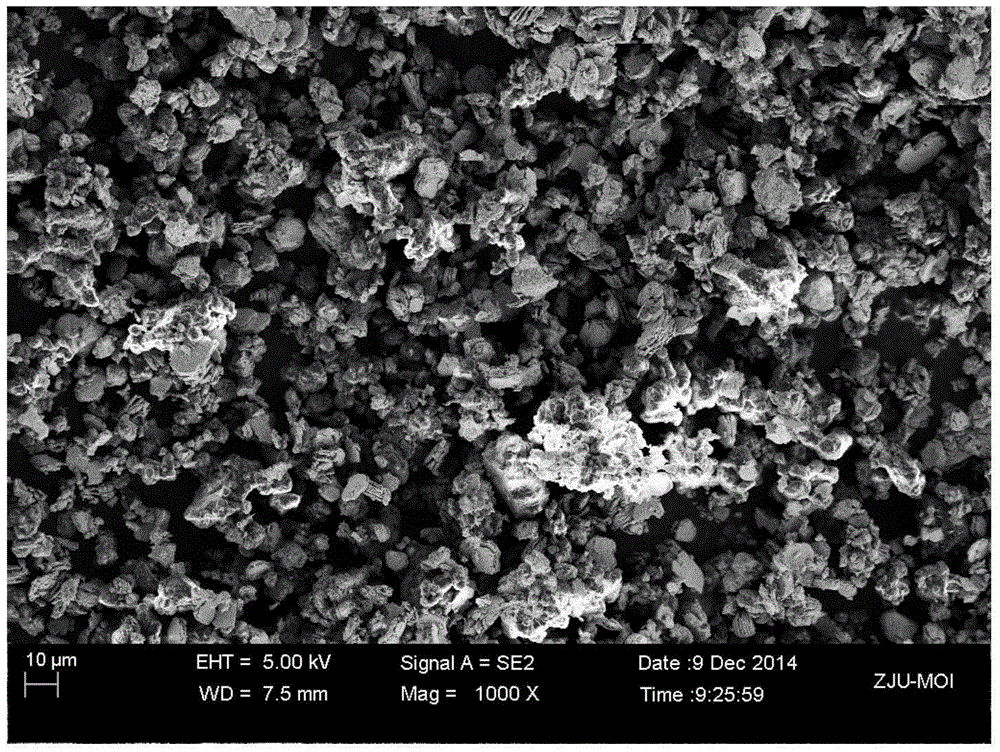

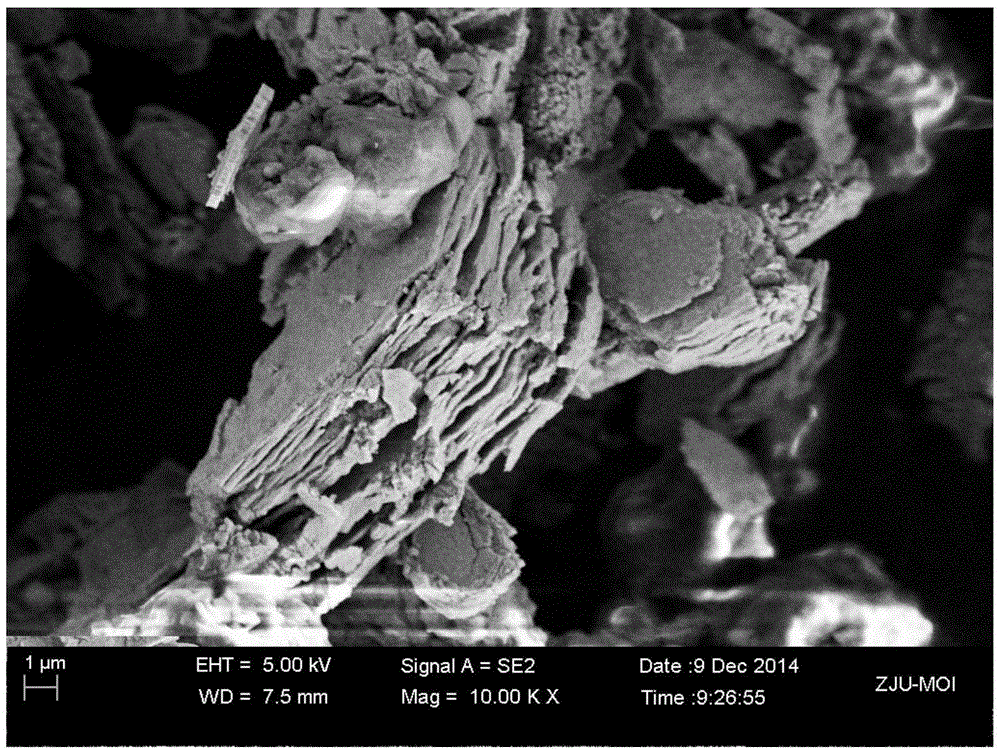

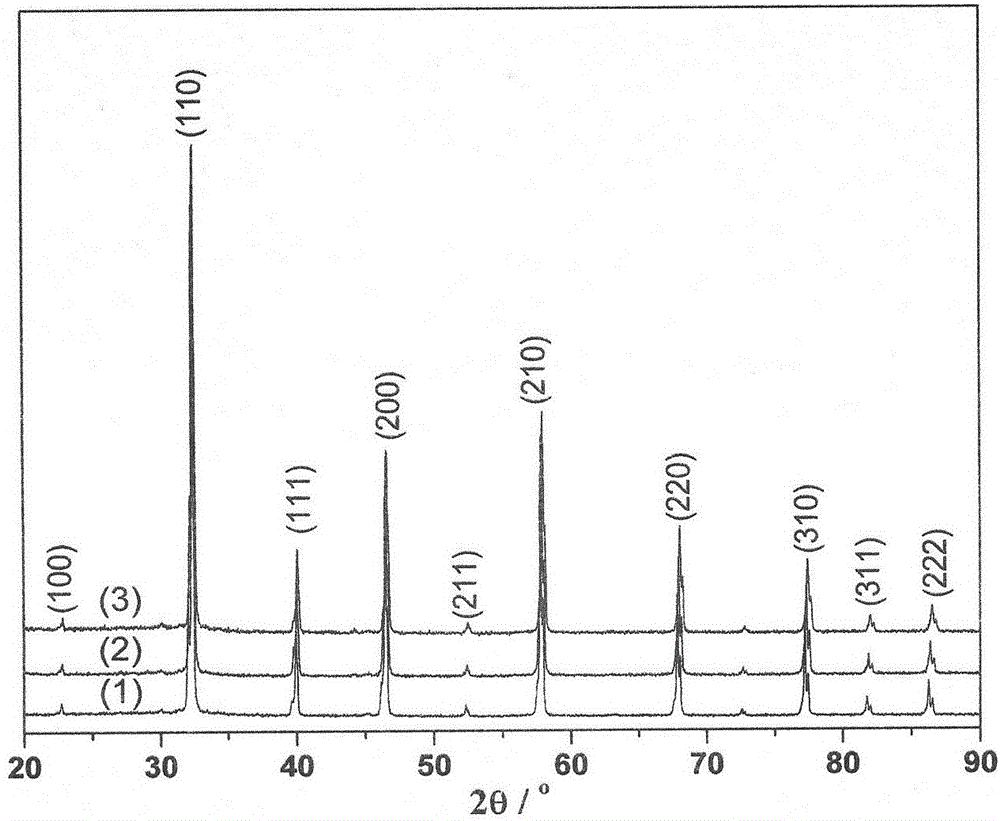

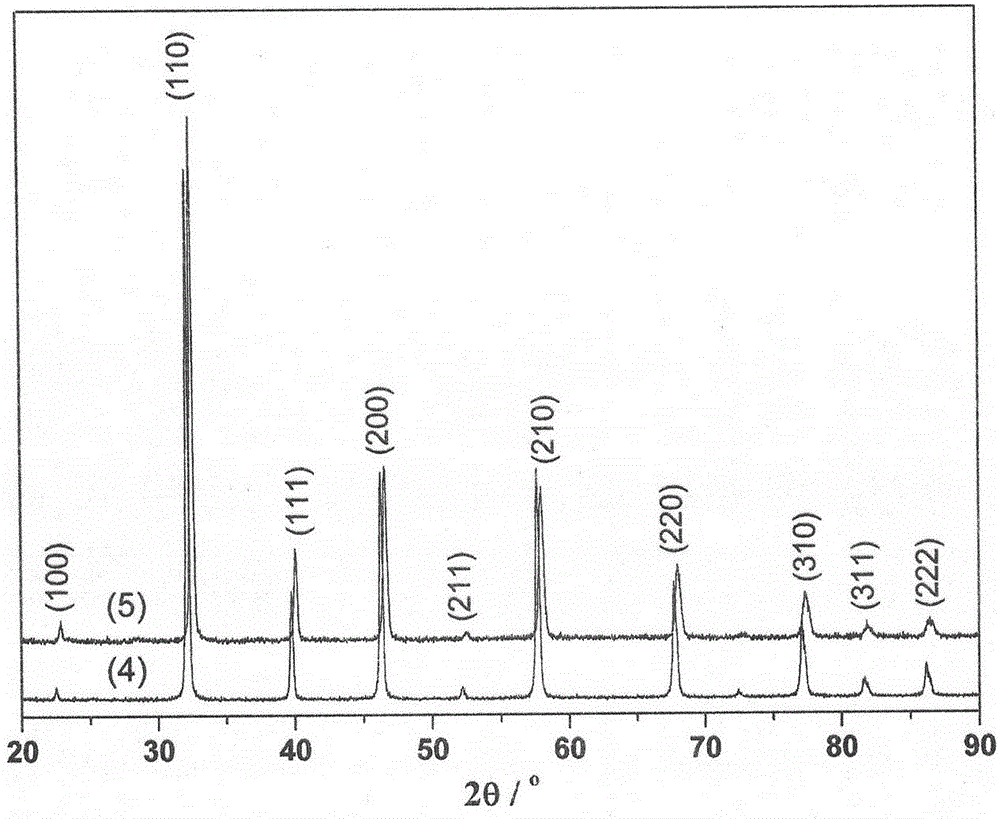

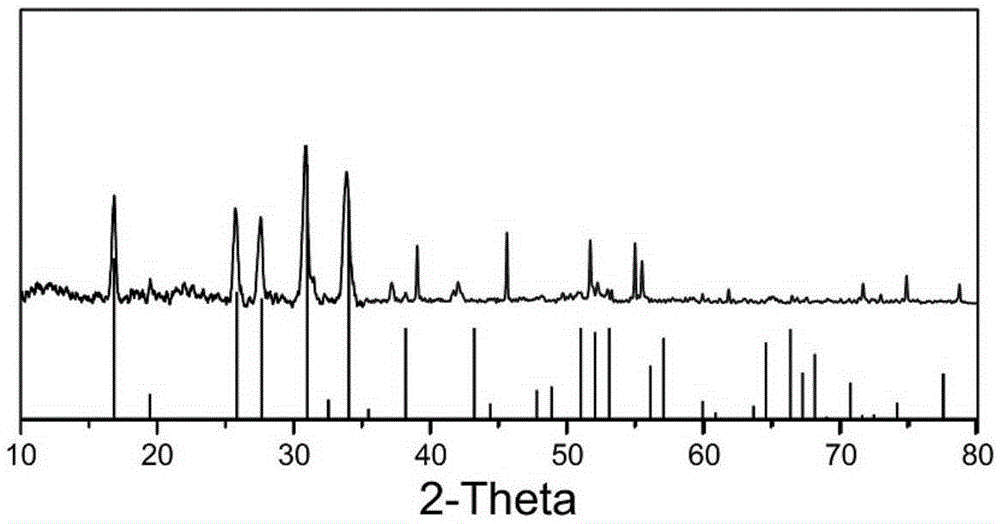

Preparation method for all-solid-state lithium ion electrolyte material Li7La3Zr2O12

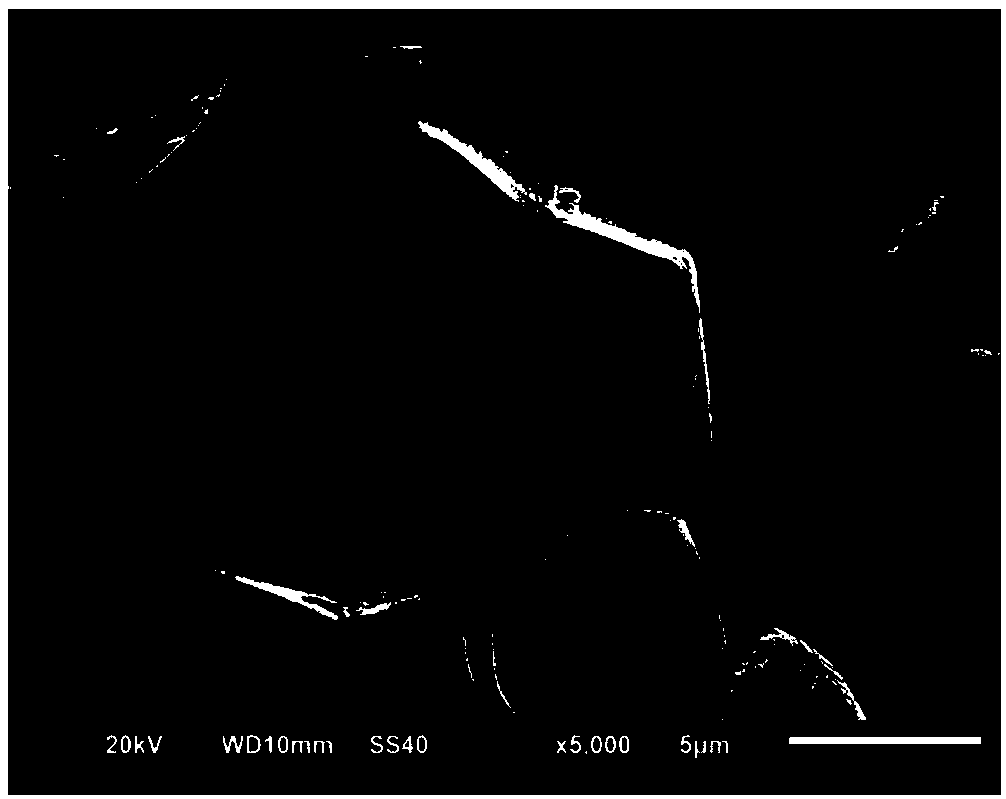

InactiveCN105406117ASpeed up ion transportImprove ionic conductanceSecondary cellsElectrolytesAll solid stateForeign matter

The invention discloses a preparation method for an all-solid-state lithium ion electrolyte material Li7La3Zr2O12. The preparation method comprises the following steps: (1) taking LiNO3 and LiOH as fused salt and a lithium source, and mixing and grinding LiNO3, LiOH, La2O3 and ZrO2; and (2) performing calcining on the grinded mixture in an inert atmosphere at the temperature of 700-900 DEG C for 3-5 hours, and then naturally cooling to the room temperature to obtain the all-solid-state lithium battery ion material Li7La3Zr2O12. The preparation method provided by the invention is short in calcining time, low in temperature, and simple in operation without introducing non-reactant foreign matters; and the product has a nanosheet laminated structure and a high specific surface, so that the ionic conductance at the normal temperature is greatly improved.

Owner:QINGDAO NENGXUN NEW ENERGY TECH CO LTD +1

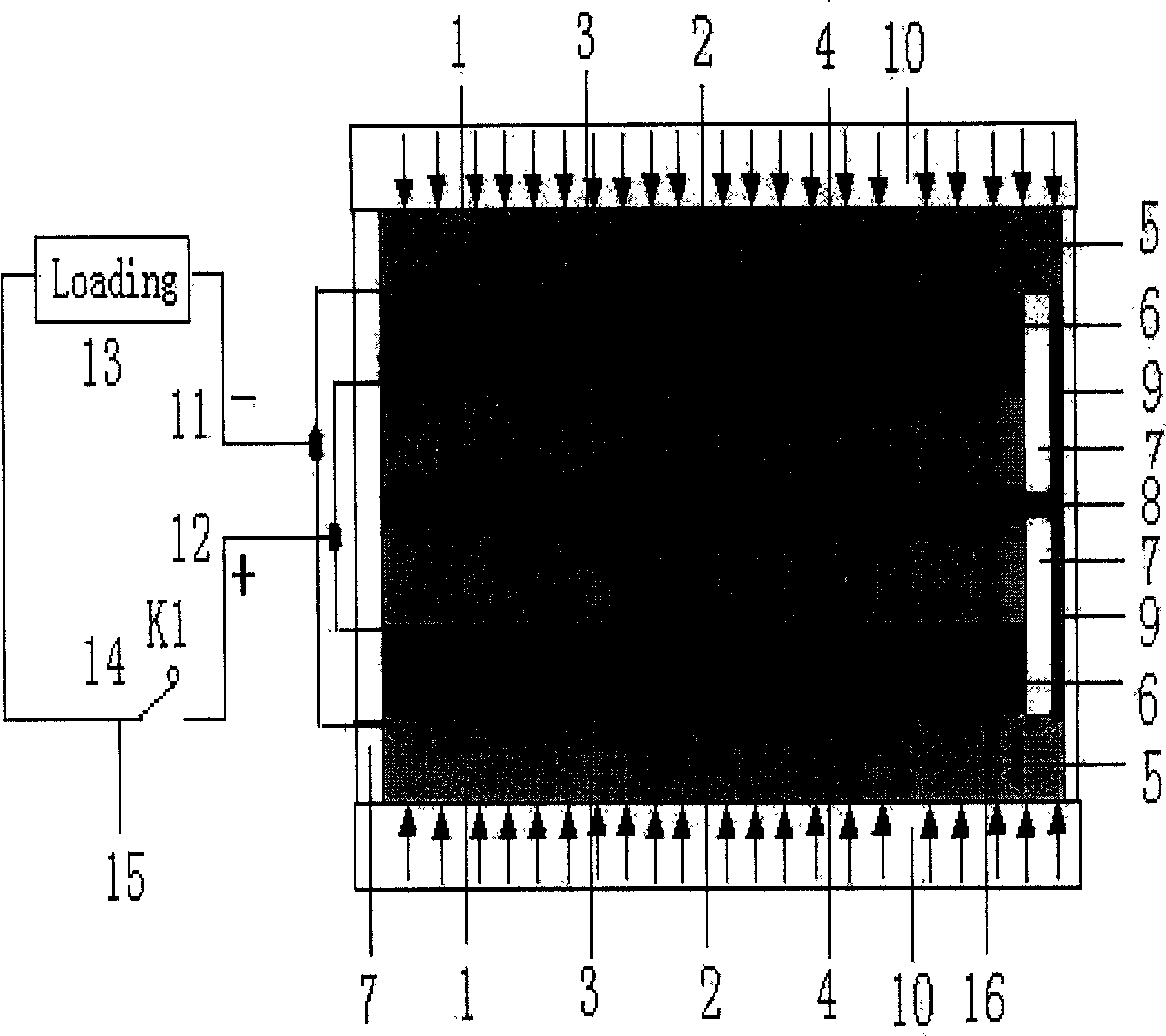

Heat engine of alkali metals

InactiveCN1761081AImprove thermoelectric conversion efficiencyLimit power densityElectric discharge tubesThermal electric motorEngineeringEnergy conversion efficiency

The heat engine is related to Beta-Al2O3 as solid electrolyte, and alkali metals as working medium. Film of the said solid electrolyte partitions metal closed container, which is filled by alkali metals, into two parts: pressure and temperature parts. Working medium of alkali metals is heated by heat source. Being driven by chemical potential gradient, working medium of alkali metals is ionized so as to generate potential difference. Circulation of alkali metals as working medium realizes uninterrupted thermoelectric conversion to provide stable output of electric power. The heat engine possesses features of no moving part, long service life, no noise, small pollution, and free from maintenance. Advantages are: reduced thickness caused by tabulate bipolar structure, and electrolyte prepared through thin film technique, raised energy conversion efficiency and power density, small volume and light weight.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

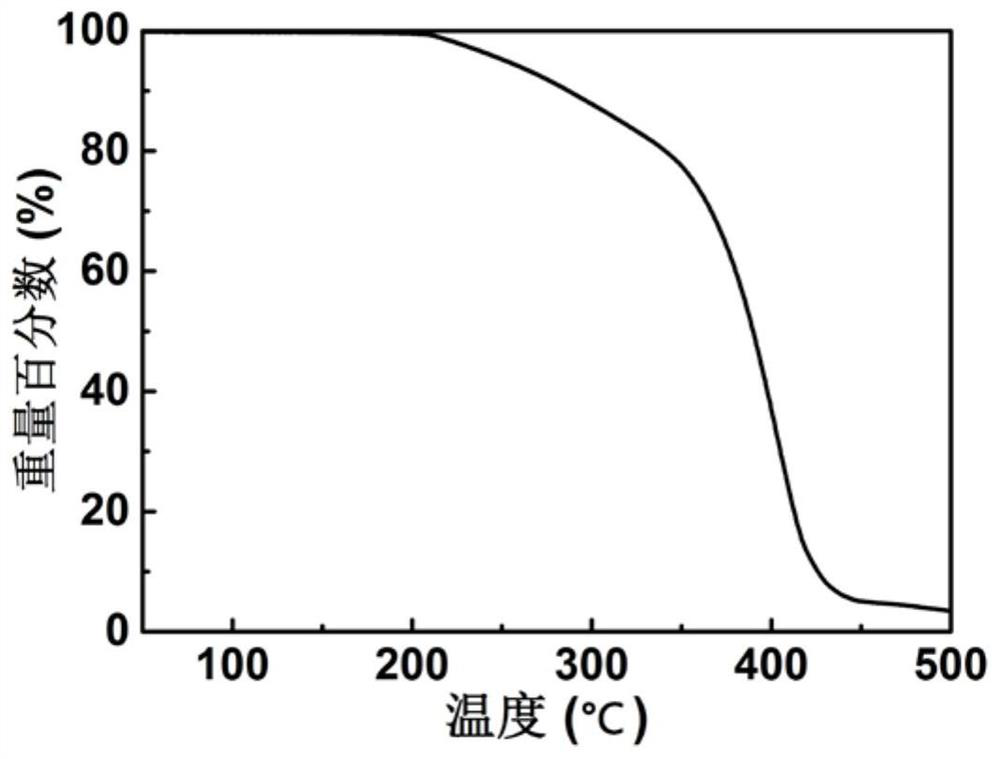

Polymer electrolyte capable of working in wide temperature range and preparation method thereof

ActiveCN112358624AImprove stabilityLess side effectsFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesIn situ polymerization

The invention discloses a polymer electrolyte capable of working in a wide temperature range, a preparation method of the polymer electrolyte and application of the polymer electrolyte in a solid-state lithium (sodium) secondary battery. The polymer electrolyte is prepared from a precursor solution containing a polymeric monomer, an initiator and an electrolyte salt on the surface of a base material in an in-situ polymerization manner, and is of a hyperbranched structure without a main chain and with multiple branched chains. The polymer electrolyte has the advantages of high ionic conductivity and transference number, wide electrochemical window, good mechanical strength and the like, and can stably work in a temperature range of -40-110 DEG C. Meanwhile, the preparation method of the polymer electrolyte is simple, mild in condition, low in preparation cost, easily available in raw materials and suitable for large-scale production. The polymer electrolyte disclosed by the invention isused for constructing a solid-state lithium (sodium) secondary battery, so that the working temperature of the battery can be effectively expanded, and the safety of the battery under extreme workingconditions is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Mica based electrolyte membrane for solid oxide fuel cell and preparation method thereof

The invention relates to the field of electrolyte membrane materials, and specifically relates to a mica based electrolyte membrane for a solid oxide fuel cell and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing cetyltrimethylammonium bromide and sericite powder; and thermally processing for 3-5h under the temperature of 40-80 DEG C; (2) processing the product obtained in step (1) through 20-30MHz ultrasonic wave for 1-4h; and roasting the product obtained in ultrasonic processing for 30-180min under the temperature of 400-800 DEG C to obtain two-dimensional nano mica; (3) mixing the precursor liquid of electrolyte and the two-dimensional nano mica; and spraying to deposit on the anode surface of an electrode under the temperature of0.5-0.8MPa; and (4) processing the deposited membrane obtained in step (3) with laser to obtain the mica based ultra-thin electrolyte membrane. The electrolyte membrane has the thickness at nanometerlevel, and is outstanding in oxygen ion transfer performance.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

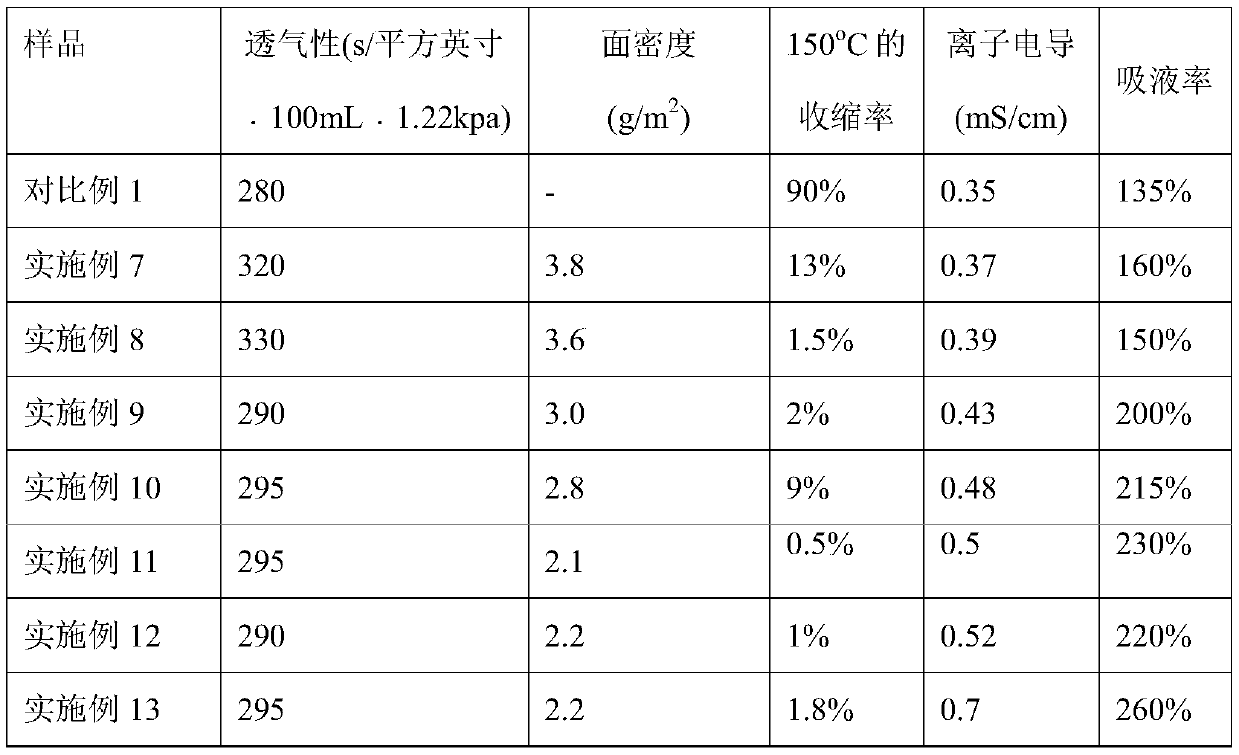

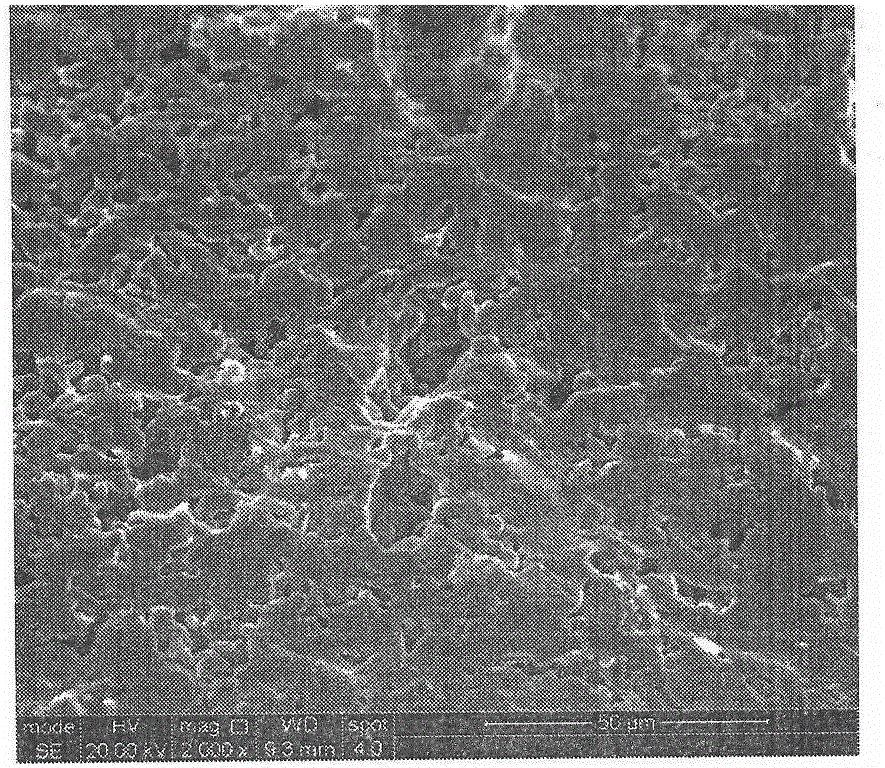

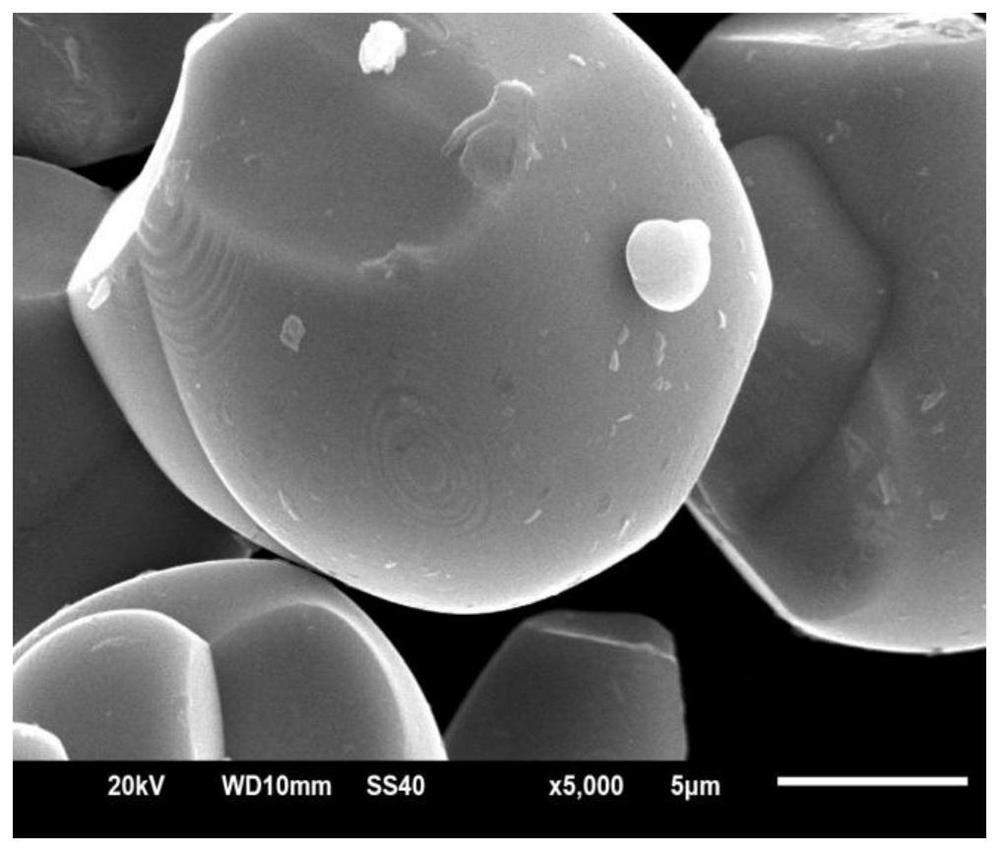

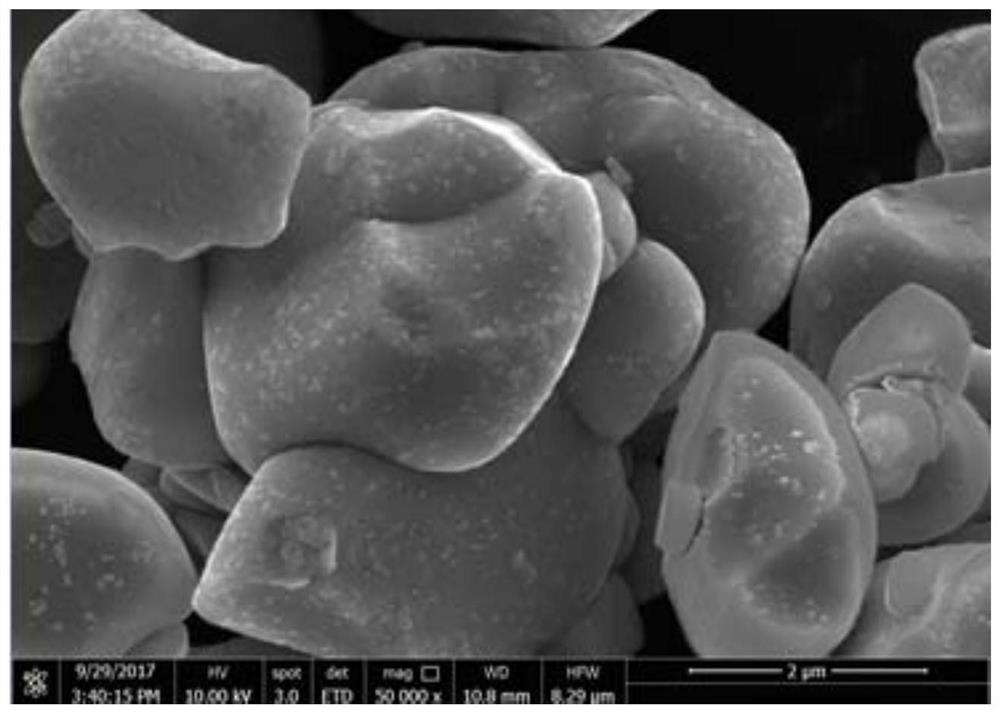

Preparation method and application of porous SiO2 microspheres for lithium ion battery diaphragm

InactiveCN110767863AEasy to operateImprove thermal stabilityCell seperators/membranes/diaphragms/spacersPhysical chemistryLithium-ion battery

The invention provides a preparation method and application of porous SiO2 microspheres for a lithium ion battery diaphragm, which belong to the technical field of battery diaphragm coating. The preparation method for the porous SiO2 microspheres for the lithium ion battery diaphragm comprises the following steps of: preparing spherical SiO2 particles, adding the prepared spherical SiO2 particlesinto water, adding a protective agent, adding an alkaline solution, conducting stirring, conducting centrifuging and cleaning after etching for a certain time and acquiring a porous SiO2 microspheres.In addition, the invention also provides application of the porous SiO2 microspheres for the lithium ion battery diaphragm, and the application comprises the following steps of: taking a certain amount of porous SiO2 microspheres, dispersing the porous SiO2 microspheres by using a dispersing agent, adding a certain amount of a binder, preparing a coating solution, and coating a base membrane by using the coating solution. The porous SiO2 microspheres prepared by the preparation method disclosed by the invention are simple to prepare, and the coated diaphragm is good in air permeability and good in thermal stability, and has a good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Lanthanum indium co-doped strontium titanate conductor material and preparation method thereof

InactiveCN105976892AImprove electronic conductivityImprove ionic conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrical conductorLanthanum

The invention provides a lanthanum indium co-doped strontium titanate conductor material and a preparation method thereof. According to the invention, a material chemical general formula is Sr1-xLaxTi1-yInyO3, and 0.1< / =x< / =0.4 and 0.03< / =y< / = 0.1; tetrabutyl titanate is used as a titanium source; anhydrous ethanol and isopropyl alcohol are used as solvents; the oxide of lanthanum and indium is used as a dopant raw material; a sol-gel method is used to prepare the lanthanum indium co-doped strontium titanate conductor material; the lanthanum indium co-doped strontium titanate conductor material has a single cubic phase perovskite structure, has the advantages of good stability, excellent electronic conduction and ion conductance, and can satisfy the application needs of many fields such as a fuel cell anode material, an oxygen permeation membrane, an automobile exhaust gas sensor and the like; and compared with a traditional solid-phase sintering method, the preparation method provided by the invention has the advantages of short reaction time, low energy consumption, high product density, uniform composition, wide application prospect and the like.

Owner:HONGHE COLLEGE

Sintering method for reducing lithium ion loss of solid-state lithium ion electrolyte material Li7La3Zr2O12

InactiveCN105428707AFast deliveryAvoid introducingFinal product manufactureSecondary cells manufactureLithiumImpurity

The present invention discloses a sintering method for reducing lithium ion loss of a solid-state lithium ion electrolyte material Li7La3Zr2O12. The method comprises a step of carrying out mixed sintering on lithium sources, La2O3 and ZrO2. The method is characterized in that the lithium sources are Li2CO3, LiNO3 and LiOH, and a sintering temperature of the method is 750-900 DEG C, wherein a mass ratio of Li2CO3 to LiNO3 to LiOH is 1:(2-3):(1-2). The sintering method disclosed by the present invention is low in burning temperature, is simple to operate, avoids introduction of non-reaction-product impurities, which is caused by high-temperature burnout, and can reach ion conductivity of 2.23*10-4S / cm under the normal temperature.

Owner:QINGDAO NENGXUN NEW ENERGY TECH CO LTD +1

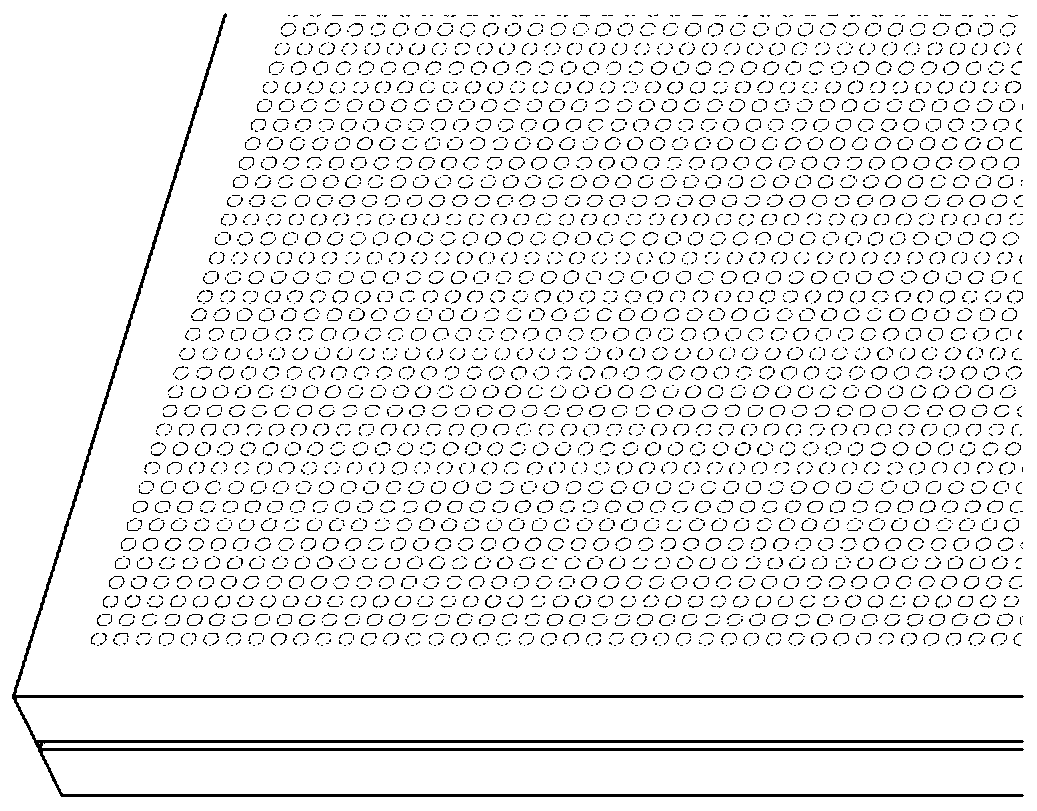

Electrode plate and preparation method thereof, and lithium ion battery

PendingCN111370648AImprove ionic conductanceIncrease liquid absorptionSecondary cellsNon-aqueous electrolyte accumulator electrodesInternal resistanceLithium-ion battery

The invention provides an electrode plate and a preparation method thereof, and a lithium ion battery. The electrode plate comprises a current collector and active substance layers positioned on two sides of the current collector, wherein the active substance layers are provided with holes, and the thickness of the electrode plate is more than 0.30 mm. The preparation method comprises the following steps: 1) coating two surfaces of the current collector with electrode slurry, and carrying out drying and rolling to obtain an unpunched electrode plate, wherein the thickness of the electrode plate which is not punched is 0.30 mm or above; and 2) punching the active substance layers of the unpunched electrode plate to obtain the electrode plate. According to the electrode plate provided by theinvention, by increasing the thickness of the electrode plate, the proportion of the current collector is reduced, and specific energy is improved; the electronic conductivity of the electrode plateis improved through the variety and proportion of a conductive agent; by punching holes in the active substance layers, the liquid absorption property of the electrode plate is improved, the polarization internal resistance of the electrode plate is reduced, the optimization of the ionic conductance of the electrode plate is improved, and the rate capability of the battery is maintained.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

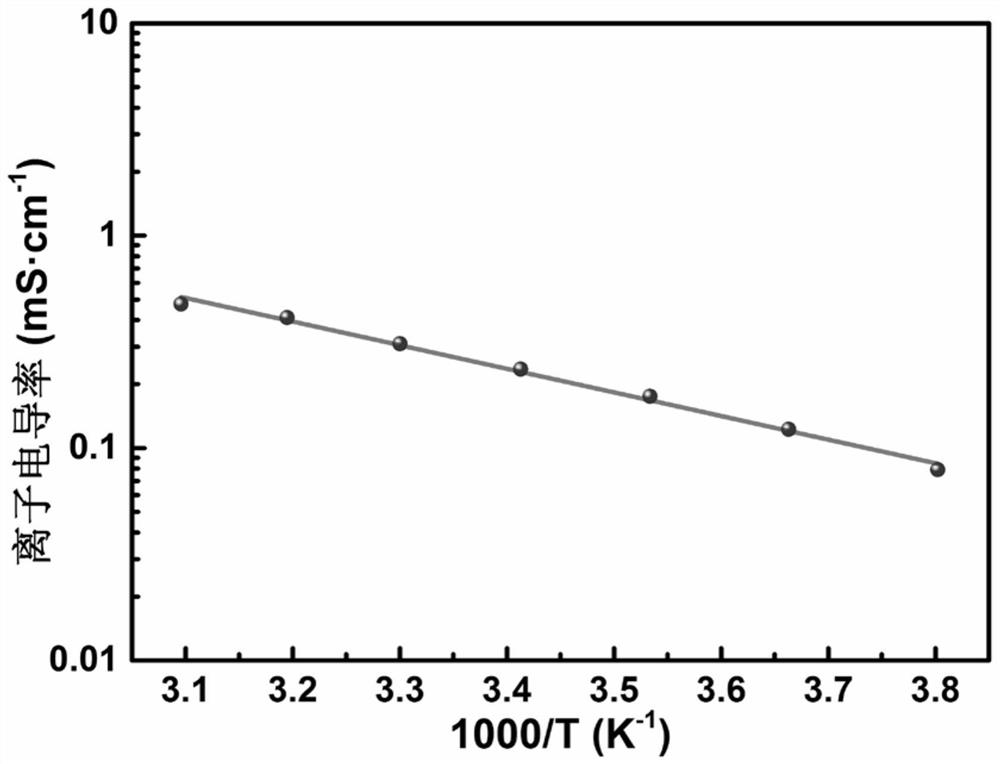

Flame-retardant solid-liquid mixed solid electrolyte, preparation method and lithium battery containing flame-retardant solid-liquid mixed solid electrolyte

ActiveCN113178617AGood ionic conductanceImprove ionic conductanceLi-accumulatorsSecondary cells servicing/maintenancePhosphoric Acid EstersPolymer network

The invention discloses a flame-retardant solid-liquid mixed solid electrolyte, a preparation method and a lithium battery containing the flame-retardant solid-liquid mixed solid electrolyte. The flame-retardant solid-liquid mixed solid electrolyte comprises a flame-retardant liquid phase component, a lithium salt and a polymer network structure, wherein the flame-retardant liquid phase component and the lithium salt are dispersed in the polymer network structure; the flame-retardant liquid phase component comprises a phosphorus-containing organic compound; the phosphorus-containing organic compound comprises phosphate ester, phosphite ester, phosphonate and halides thereof, and is efficient flame-retardant liquid; the high-molecular network structure is obtained by polymerizing high-molecular network structure monomers; and the polymer network structure monomer is selected from at least one of ester compounds containing C = C, and has high mechanical strength. According to the electrolyte obtained by the invention, the cycle performance and the safety performance of the battery can be well improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

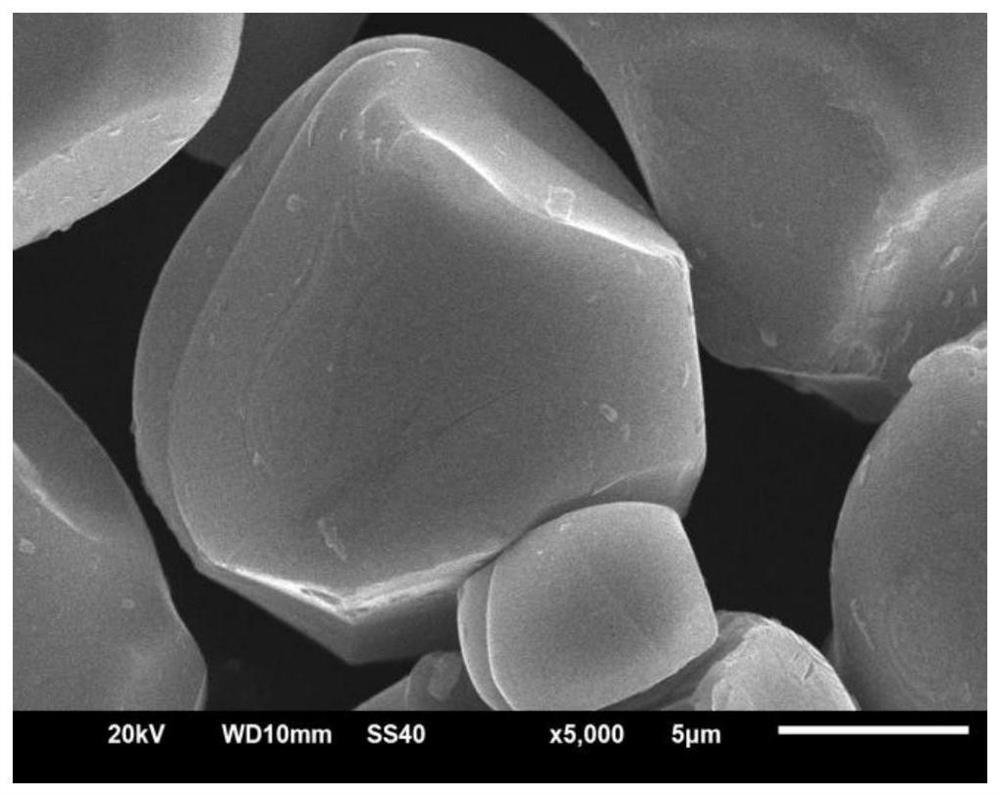

Preparation method of low-cobalt single-crystal positive electrode material

PendingCN113707872AEasy to synthesizeImprove high temperature stabilitySecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention belongs to the field of batteries and relates to a preparation method of a low-cobalt single-crystal positive electrode material. The preparation method comprises the following steps of: mixing a nickel-cobalt-manganese precursor, an oxidizing lithium salt and an additive I; and performing primary roasting to obtain the low-cobalt single-crystal positive electrode material. The low-cobalt and cobalt-free positive electrode material is used as a matrix, oxygen is obtained by oxidative decomposition of the lithium salt, on one hand, a lithium source is provided, and on the other hand, positive ion mixing and high-temperature oxygen loss reaction of the positive electrode material are effectively inhibited; through bulk phase doping and surface coating, the inhibition of change of a crystal structure and reduction of side reaction of an electrolyte and the material are benefited, so that the prepared low-cobalt and cobalt-free low-cobalt single-crystal positive electrode material is good in crystal structure and free of chemical valence defects, has the characteristics of low preparation cost, simple process and short preparation period, can be applied to a lithium ion battery, and improves physical and chemical properties and electrical properties.

Owner:宁夏汉尧石墨烯储能材料科技有限公司 +1

Coated lithium ion battery positive electrode material as well as preparation method and application thereof

PendingCN114171733AImprove electronic conductanceImprove ionic conductanceCell electrodesSecondary cellsPhysical chemistryHigh electron

The invention provides a coated lithium ion battery positive electrode material as well as a preparation method and application thereof. The coated lithium ion battery positive electrode material comprises a lithium oxide core and a coating layer coating the lithium oxide core, the coating layer comprises a combination of Li4Ti5O12, TiO2 (titanium dioxide) and Ti4O7 (titanium dioxide). In the preparation process, a lithium oxide is used as a substrate, and a titanium source, an oxygen source and a lithium source are deposited on the substrate by using a deposition system to obtain the coated lithium ion battery positive electrode material. According to the positive electrode material provided by the invention, the Li4Ti5O12, the TiO2 and the Ti4O7 are coated on the inner core, so that the coating of a high-ionic-conductivity and high-electron-conductivity material is realized, the overall structural stability of the material can be improved, the reversible specific capacity and the cycling stability of the material are further improved, and the positive electrode material has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

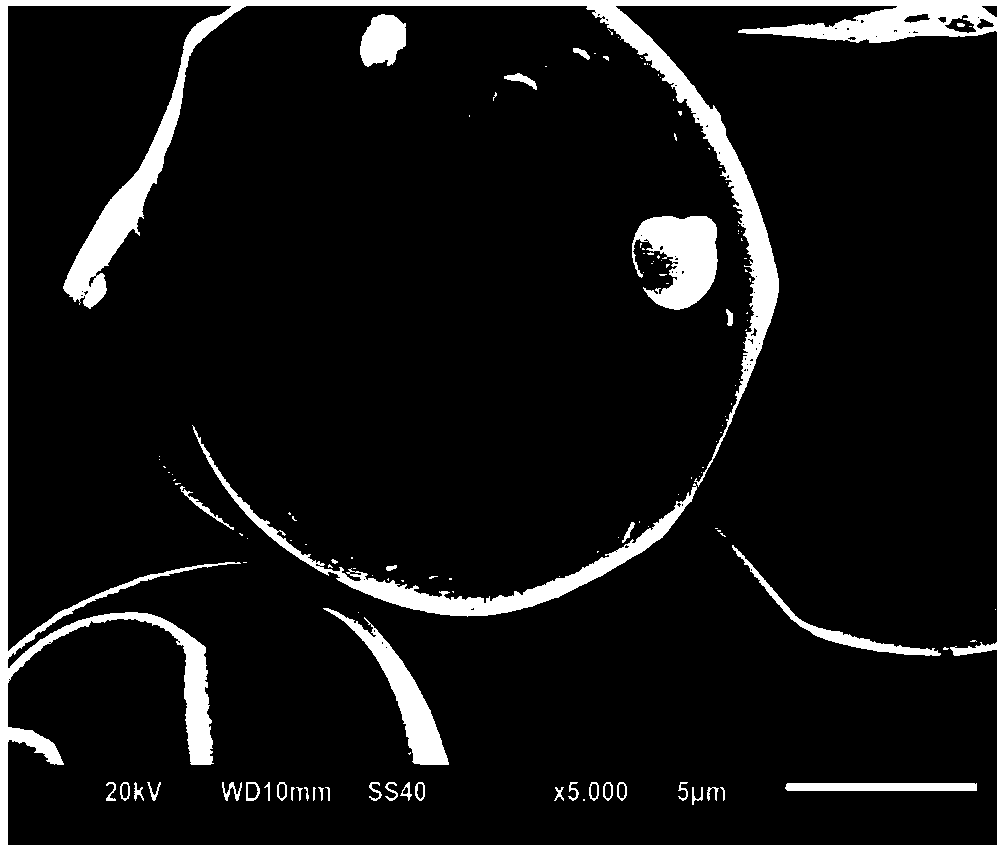

Lithium-ion battery lithium cobalt oxide cathode material and coating method thereof

ActiveCN110137437BImprove cycle stabilityImprove Coulombic efficiencySecondary cellsPositive electrodesElectrolytic agentPhysical chemistry

The invention provides a lithium cobalt oxide positive electrode material coated with a tin compound on the surface, and the positive electrode material can be prepared by a dry method or a wet method. The coating layer effectively reduces the direct contact between lithium cobaltate particles and the electrolyte, reduces the occurrence of side reactions and the dissolution of cobalt in the electrolyte, and improves the utilization rate of the positive electrode material during the cycle, thereby effectively improving Cycling stability and Coulombic efficiency of lithium cobalt oxide cathode.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Lithium ion battery lithium cobalt oxide cathode material and coating method thereof

ActiveCN110137437AImprove cycle stabilityImprove Coulombic efficiencySecondary cellsPositive electrodesCyclic processDissolution

The invention provides a lithium cobalt oxide cathode material with a surface coated with a tin-containing compound. The cathode material can be prepared by a dry method or a wet method. The coating layer effectively reduces the direct contact between lithium cobalt oxide particles and an electrolyte, reduces the generation of a side reaction and dissolution of cobalt in the electrolyte and improves the utilization rate of the cathode material in the cycle process so as to effectively improve the cycle stability and the coulombic efficiency of the lithium cobalt oxide cathode.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

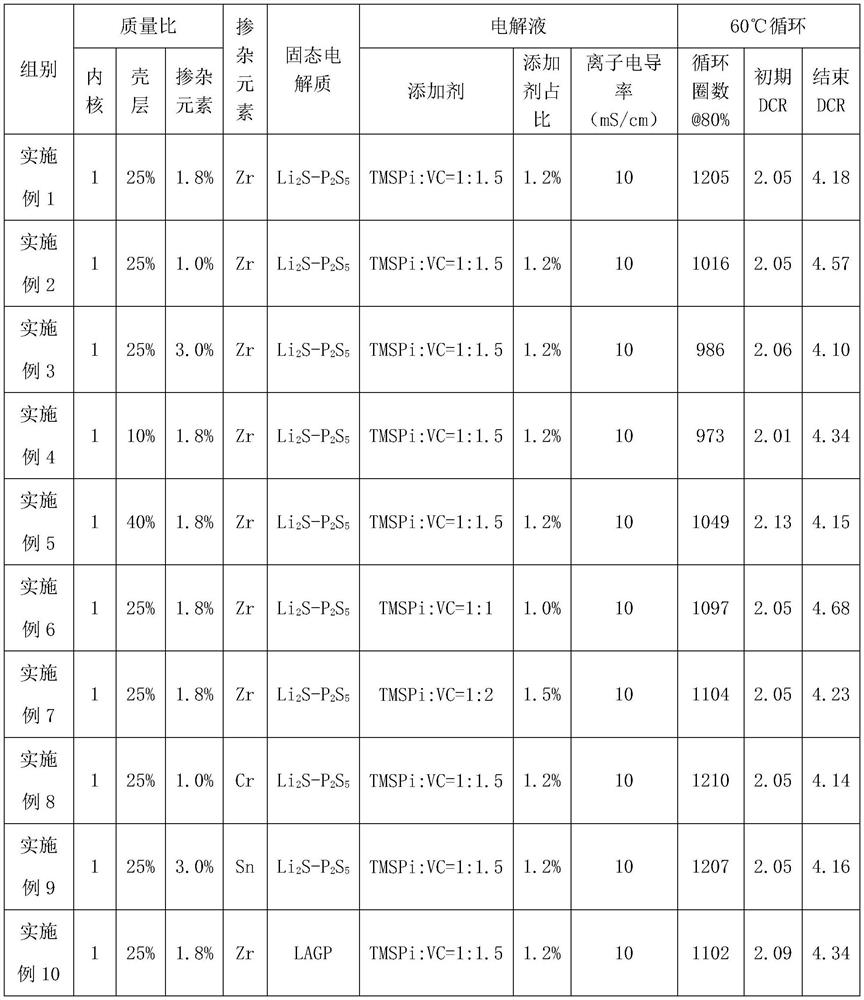

High-temperature-resistant positive electrode material and electrolyte composition, lithium battery and preparation method

PendingCN114709412AStructural Collapse MitigationImprove structural strengthFinal product manufactureCell electrodesSolid state electrolyteElectrolytic agent

The invention discloses a high-temperature-resistant positive electrode material and electrolyte composition, a lithium battery and a preparation method, the high-temperature-resistant positive electrode material comprises an inner core and a shell layer, the inner core comprises a nickel-cobalt-manganese ternary positive electrode material and doping elements, and the shell layer is a solid electrolyte; the ionic conductivity of the electrolyte is larger than or equal to 9.8 mS / cm, and the functional additive in the electrolyte is at least one of TMSPi + VC, HFiP, LiTFSI and VC + LiPF6. The functional additive in the electrolyte and the solid electrolyte jointly form a thicker and stable protective film, so that the cycle performance of the battery cell is greatly improved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Molybdenum disulfide/sulfur-doped graphene composite material as well as preparation method and application thereof

ActiveCN113241440AImprove electronic conductanceImprove ionic conductanceNegative electrodesSecondary cellsCarbon layerDoped graphene

The invention discloses a molybdenum disulfide / sulfur-doped graphene composite material and a preparation method and application thereof. The molybdenum disulfide / sulfur-doped graphene composite material comprises a carbon layer, molybdenum disulfide and sulfur-doped graphene. The preparation method comprises the following steps: mixing raw materials of molybdenum salt, graphene oxide dispersion liquid, dimethyl trisulfide and an oxygen-containing organic carbon source, then carrying out hydrothermal reaction, and carrying out heat treatment to obtain the molybdenum disulfide / sulfur-doped graphene composite material. The preparation method disclosed by the invention is simple to operate, mild in reaction condition and suitable for industrial production; and according to the molybdenum disulfide / sulfur-doped graphene composite material prepared by the preparation method, the electronic conductivity, the ionic conductivity and the specific capacity are greatly improved, and the cycling stability is good.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

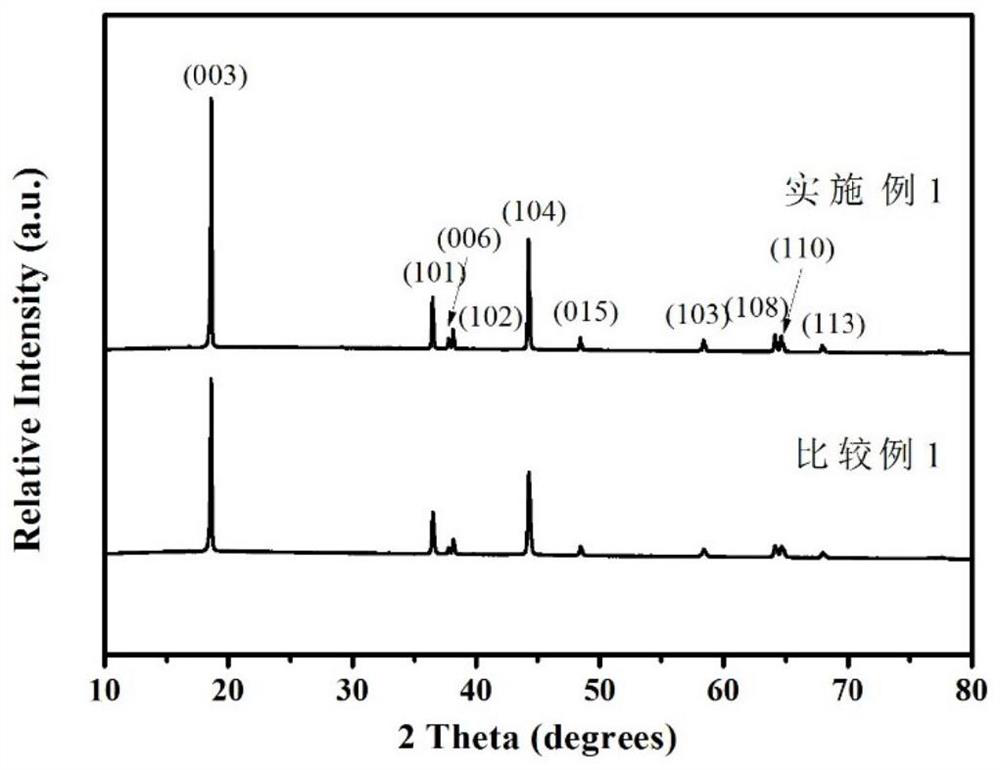

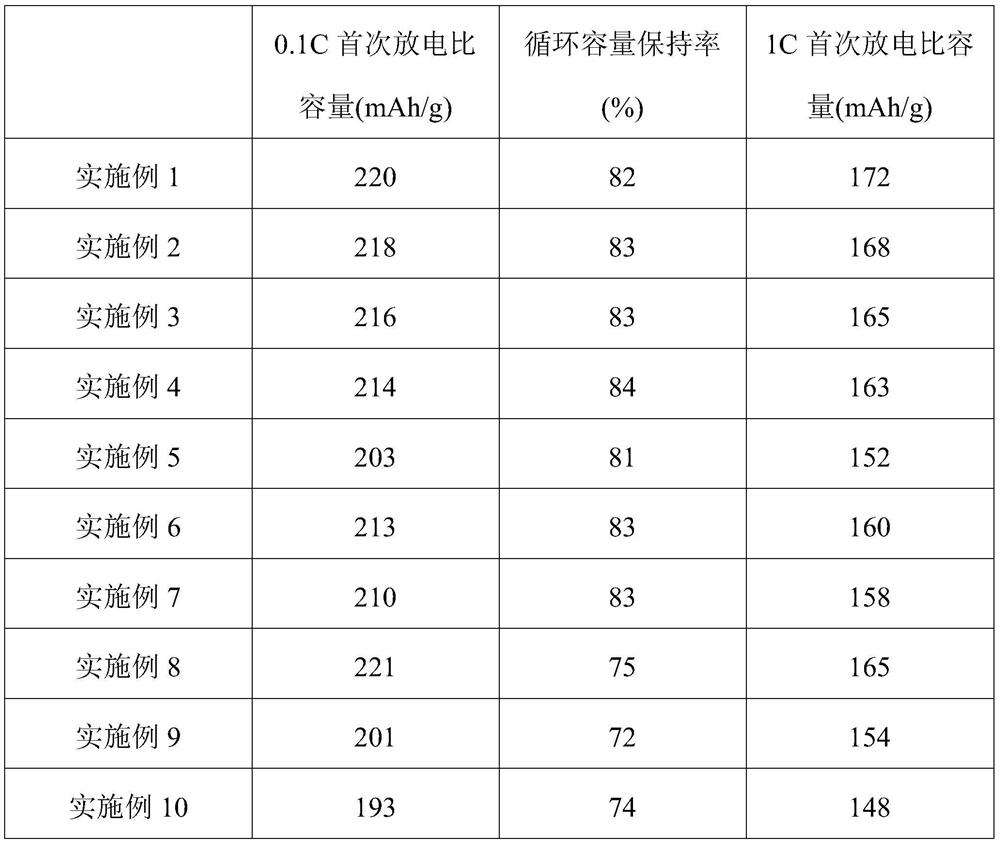

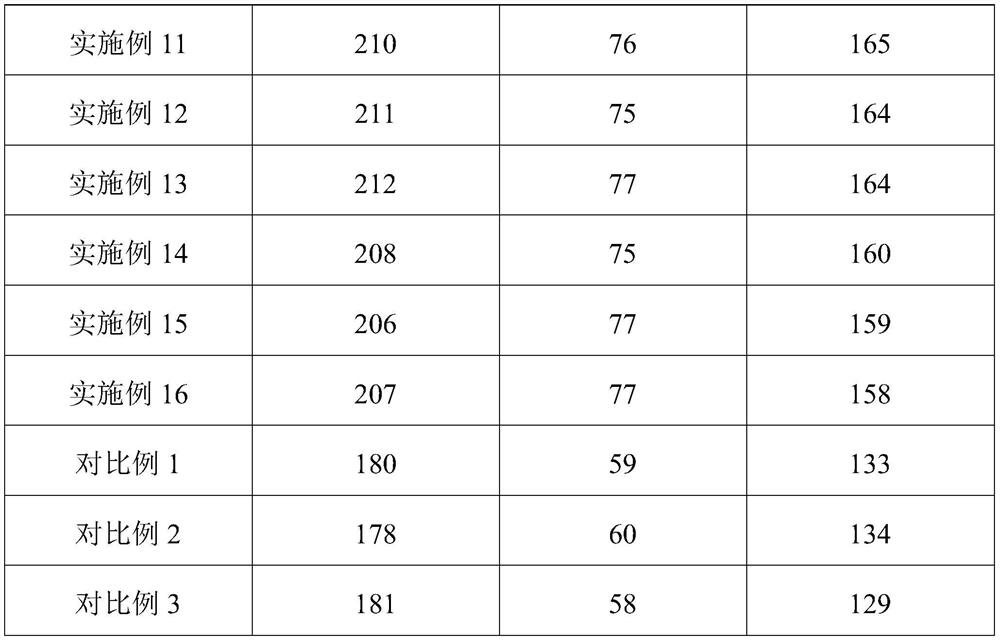

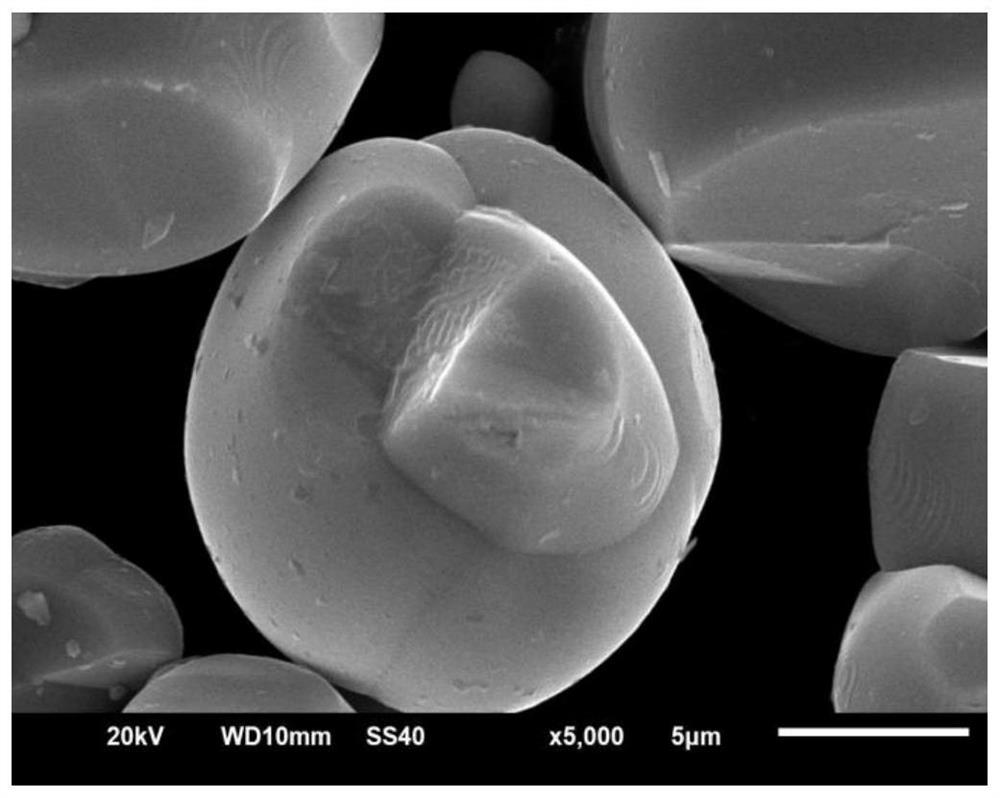

A kind of preparation method of quasi-single crystal high nickel multicomponent material

ActiveCN109301189BImproved magnification performanceImprove ionic conductivityCell electrodesSecondary cellsManganesePhysical chemistry

The invention provides a method for preparing a kind of single-crystal high-nickel multi-component material, which is characterized in that it comprises the following steps: preparing a quasi-single-crystal high-nickel positive electrode precursor: adding additive A to the reaction kettle bottom liquid in a nitrogen protective atmosphere; A mixed solution of nickel-cobalt-manganese ternary salt solution and additive B is added into the reactor, wherein the molar ratio of Ni, Co, and Mn in the nickel-cobalt-manganese ternary salt solution is 1-a-b:a:b, 1>1 ‑a‑b≥0.6, 0.4≥a≥0, 1≥b>0, the mass ratio of nickel-cobalt-manganese ternary salt solution to additive B is 1:(0.01%‑0.1%), controlled by alkaline solution containing ammonia pH value for co-precipitation reaction. The preparation method of the quasi-single-crystal type high-nickel multi-element material of the present invention prepares a kind of quasi-single-crystal high-nickel multi-element material that can be formed by roasting at low temperature. surface nickel content.

Owner:TIANJIN ENERGIES

Electrophoretic deposition-microwave sintering combined processing method for nickel-chromium baked porcelain denture

ActiveCN106283156AUniform coatingImprove bindingElectrophoretic coatingsMetallic material coating processesNichromeMicrowave sintering

The invention discloses an electrophoretic deposition-microwave sintering combined processing method for a nickel-chromium baked porcelain denture. The method includes depositing a porcelain layer with a specific thickness on the surface of a nickel-chromium alloy by an electrophoretic deposition method and cladding the porcelain layer on the nickel-chromium alloy by means of microwave heating so as to obtain the nickel-chromium baked porcelain denture. The nickel-chromium baked porcelain denture prepared by the method is uniform in coating and good in bonding force, and accordingly the method can be widely applied to a nickel-chromium baked porcelain denture processing process.

Owner:CHINA UNIV OF MINING & TECH

Safety coating, positive pole piece and application

ActiveCN114300649APromote infiltrationTurn fasterSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrolytic agentPhysical chemistry

The invention provides a safety coating, a positive pole piece and application. The safety coating comprises 5-25 parts of a lithium salt, 1-20 parts of a pore forming agent, 25-75 parts of a binder and 5-25 parts of a conductive agent. The lithium salt is added into the safety coating, so that the number of movable lithium ions in the safety coating is increased, the ionic conductivity of the safety coating is improved, the impedance of the safety coating in a normal-temperature state is reduced, and the rate capability of the battery can be improved; meanwhile, a pore-forming agent is added into the safety coating to construct a porous structure, the wettability of an electrolyte is improved, and when the temperature rises, the volume of a binder expands, the distance between conductive agent particles is increased, and the porous structure is filled, so that the resistance of the safety coating is increased, and the effect of protecting the lithium ion battery is achieved.

Owner:APOWER ELECTRONICS CO LTD

Heat engine of alkali metals

InactiveCN100414730CImprove thermoelectric conversion efficiencyLimit power densityElectric discharge tubesThermal electric motorEngineeringEnergy conversion efficiency

The heat engine is related to Beta-Al2O3 as solid electrolyte, and alkali metals as working medium. Film of the said solid electrolyte partitions metal closed container, which is filled by alkali metals, into two parts: pressure and temperature parts. Working medium of alkali metals is heated by heat source. Being driven by chemical potential gradient, working medium of alkali metals is ionized so as to generate potential difference. Circulation of alkali metals as working medium realizes uninterrupted thermoelectric conversion to provide stable output of electric power. The heat engine possesses features of no moving part, long service life, no noise, small pollution, and free from maintenance. Advantages are: reduced thickness caused by tabulate bipolar structure, and electrolyte prepared through thin film technique, raised energy conversion efficiency and power density, small volume and light weight.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

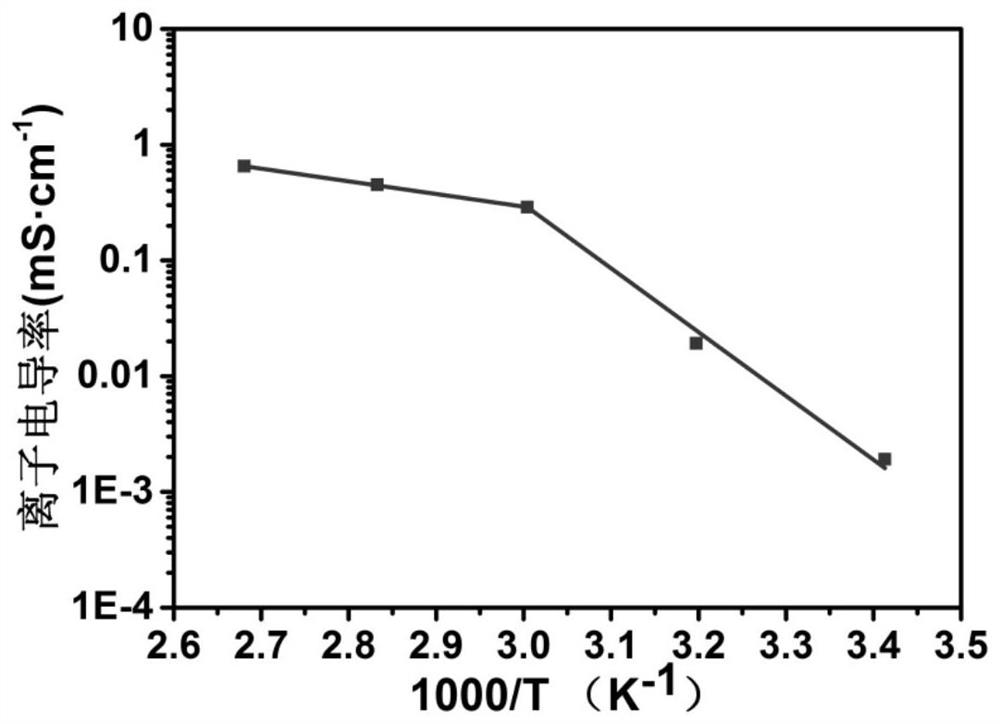

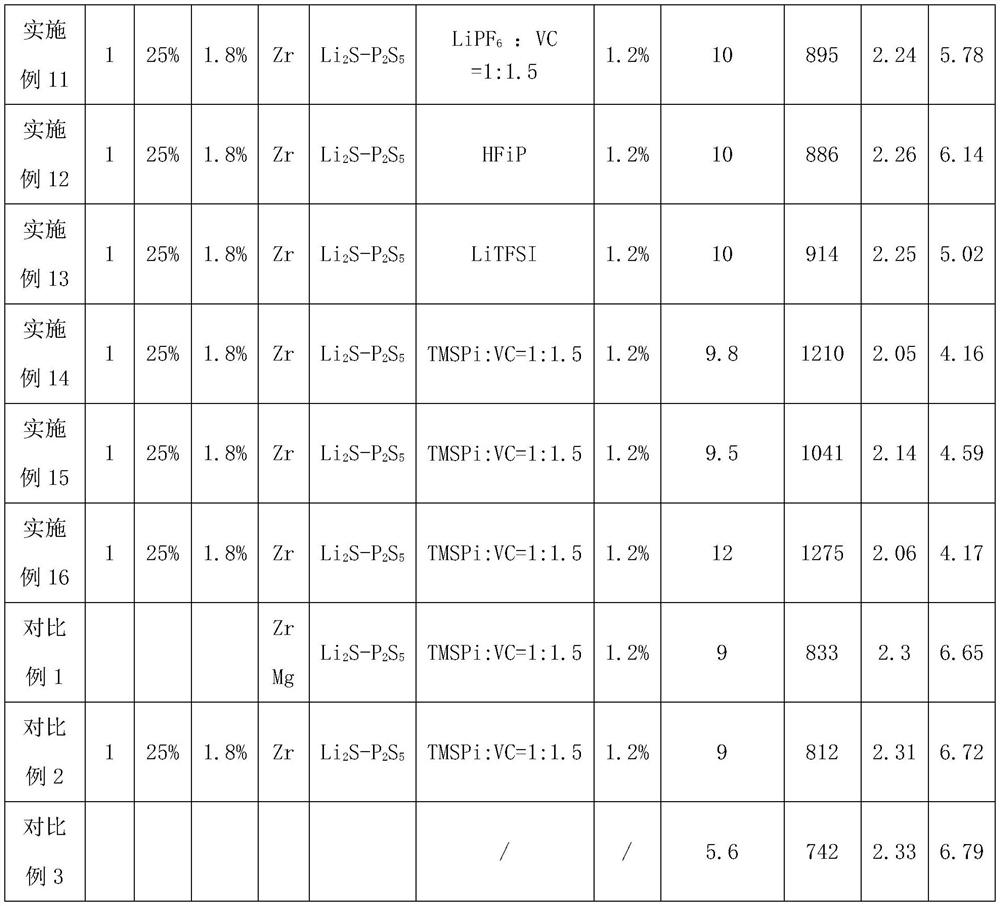

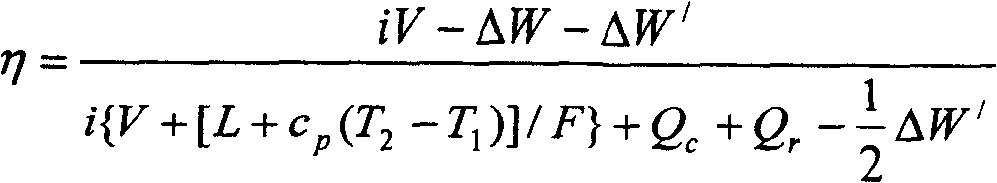

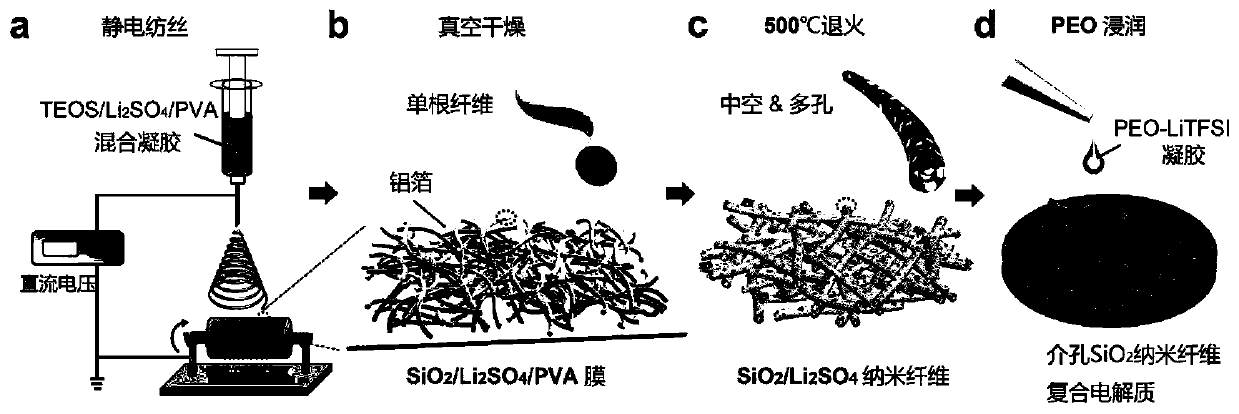

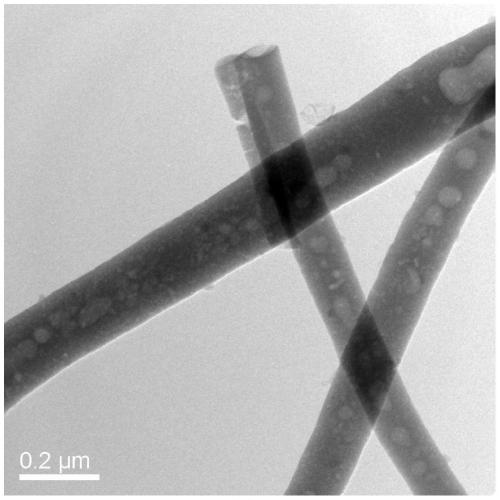

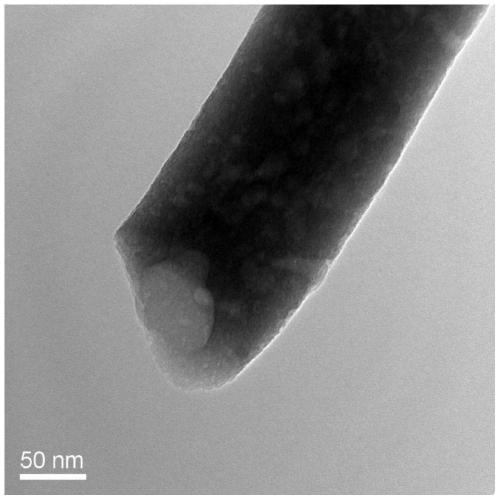

A kind of preparation method of solid electrolyte membrane

ActiveCN109390625BImprove ionic conductanceImprove conductivityMaterial nanotechnologySolid electrolytesSolid state electrolyteElectrospinning

The invention discloses a preparation method of a solid electrolyte membrane. The method adopts an electrospinning method and adds different concentrations of Li 2 SO 4 Preparation of SiO with mesoporous structure 2 Nanofiber, its main preparation method comprises the following steps: (1) prepare SiO 2 and Li 2 SO 4 (2) Preparation of nanofibers by electrospinning; (3) Cutting into discs according to the rules; (4) High temperature sintering; (5) Dropping PEO to prepare solid electrolyte. Experience of the invention 2 SO 4 doped mesoporous SiO 2 Compared with the solid electrolyte prepared by nanofibers without doping Li 2 SO 4 SiO 2 Nanofibers greatly enhance the conductivity of lithium ions and have good cycle stability.

Owner:南京宁智高新材料研究院有限公司

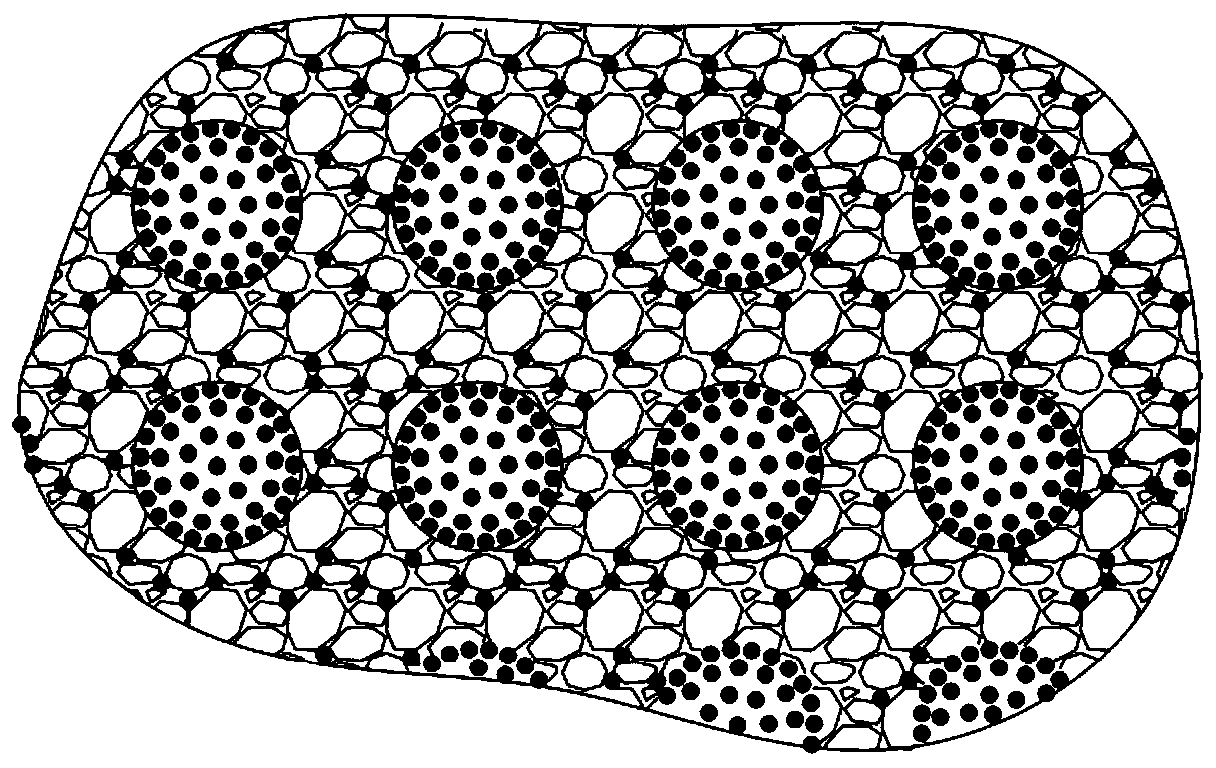

A kind of negative electrode of lithium ion battery and preparation method thereof

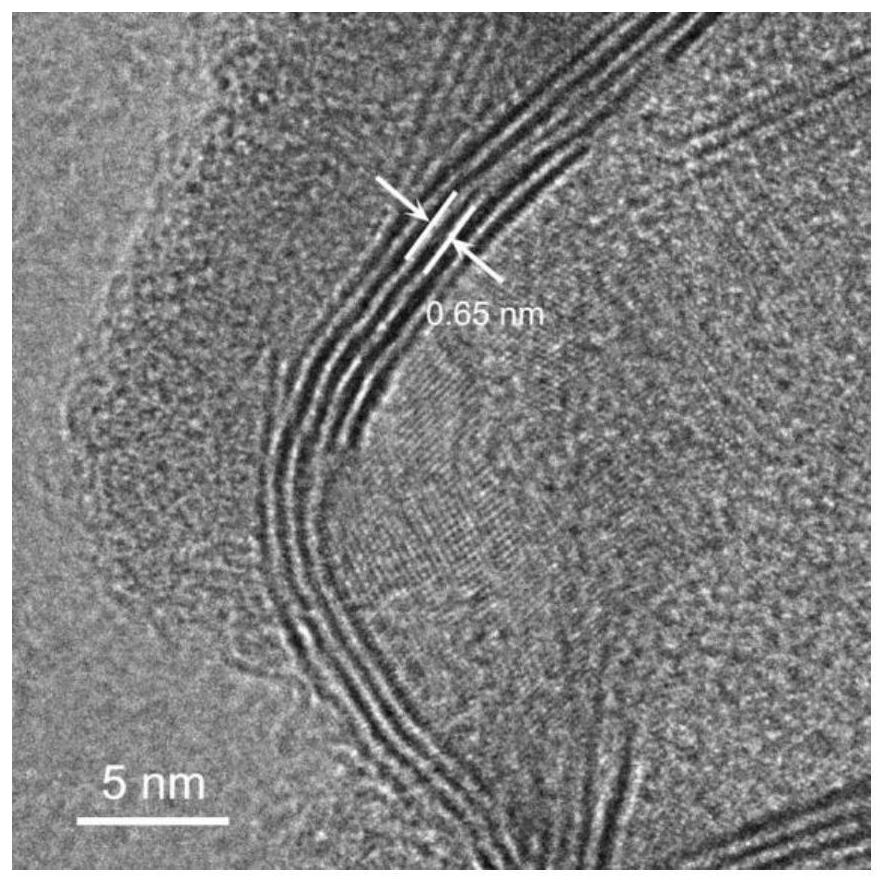

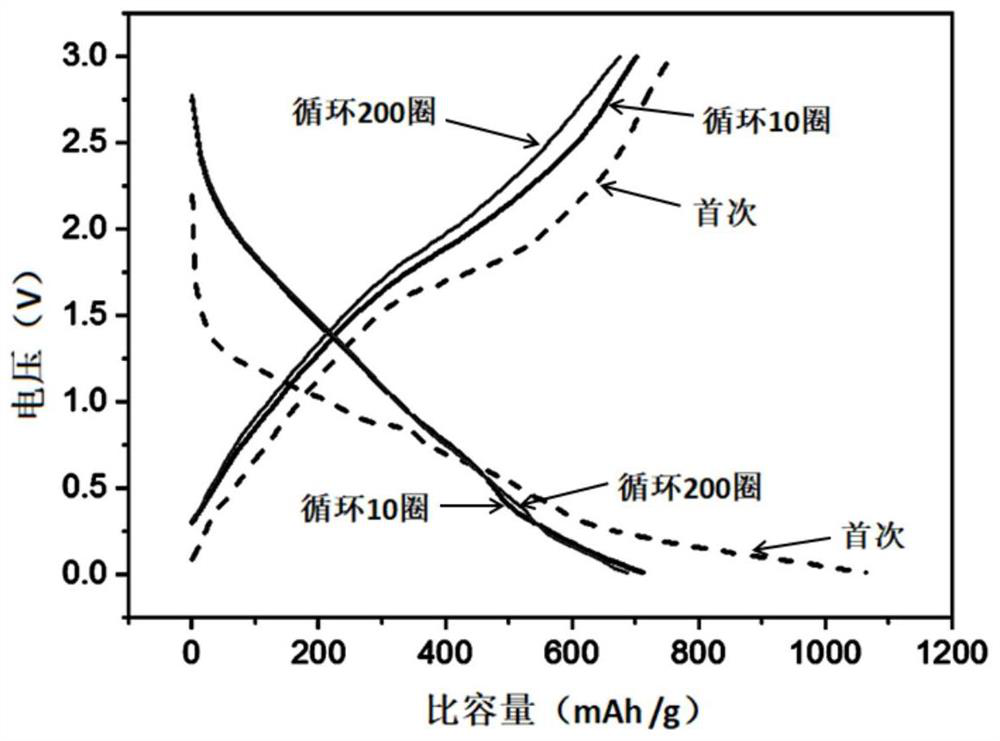

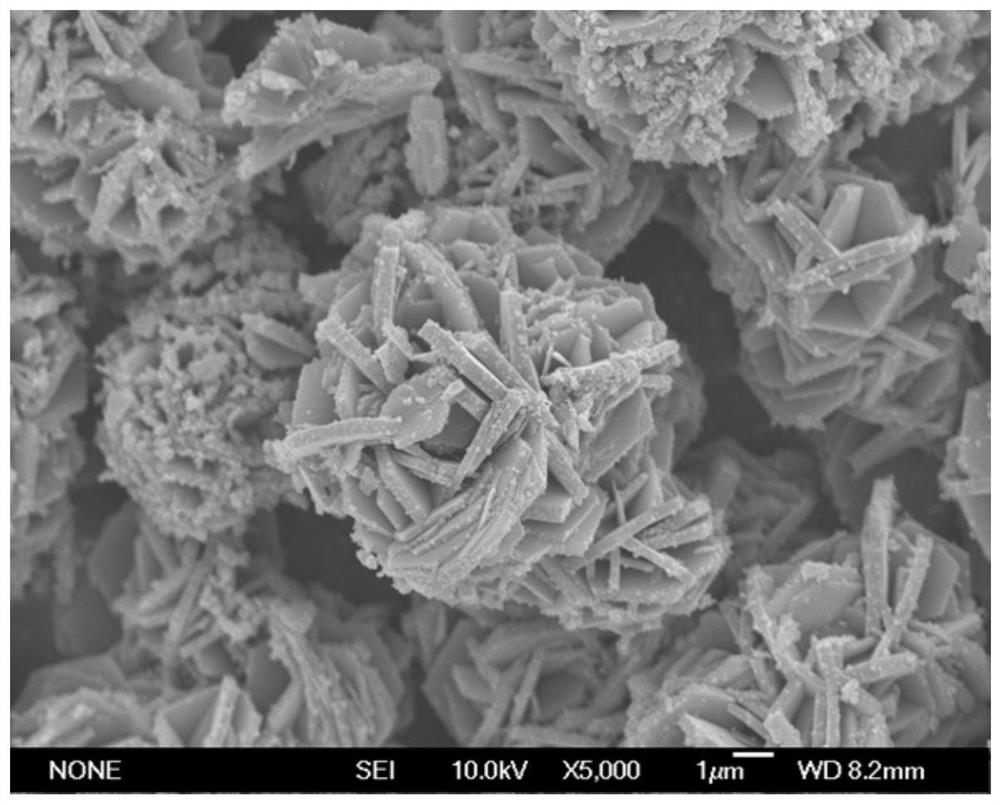

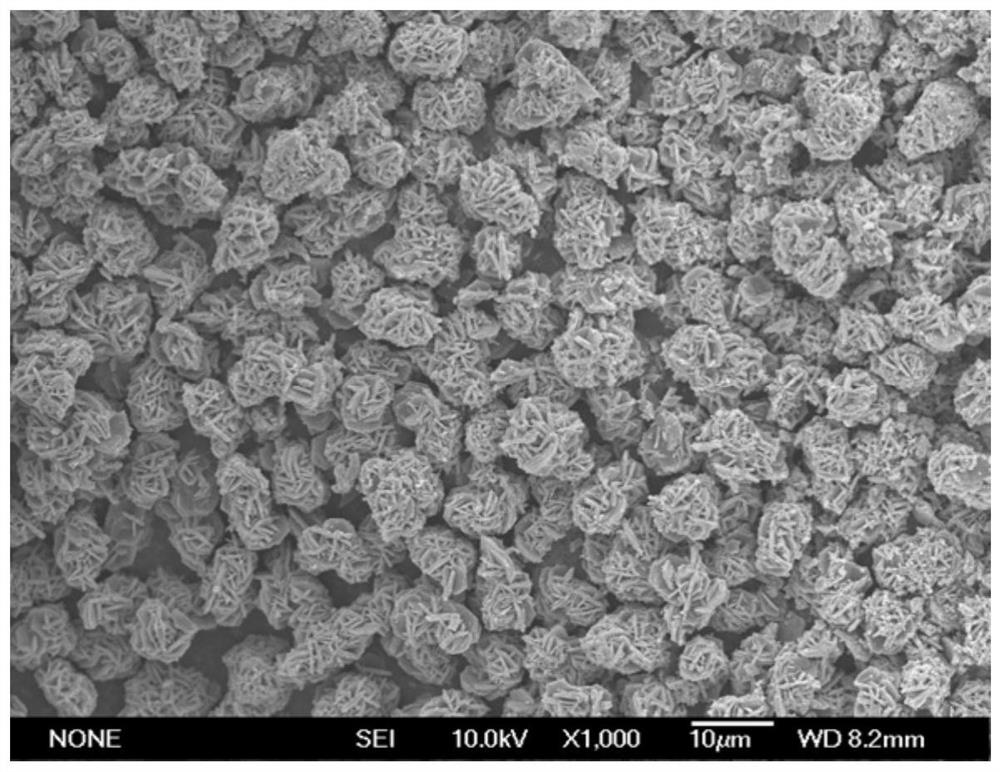

ActiveCN109817952BHigh reactivityMake up for the lack of poor electronic conductivityMaterial nanotechnologyCell electrodesElectrical batteryCarbon nanotube

The invention discloses a lithium ion battery negative electrode and a preparation method thereof, comprising silicon and a frame material, the silicon is distributed in the frame material in nanometer size, and the frame material is made of carbon nanotubes or carbon black or carbon aerogel or a combination of them. Aiming at the problems of large volume expansion and low conductivity of the existing silicon negative electrode, the present invention designs a carbon nanotube or carbon black or carbon aerogel or a combination of them as the frame, and silicon particles are evenly distributed in the frame in nanometer size. Silicon-containing composite negative electrode, this design improves the reactivity of the material and shortens the diffusion path of lithium ions. The introduced frame material reserves a space for the expansion of the silicon material, and at the same time improves the electronic and ion conductance between the material particles, and through the method of the present invention The synthesized silicon-containing composite negative electrode material has a reversible capacity higher than 800mAh / g and good cycle stability. The method is simple and efficient, and is suitable for large-scale production.

Owner:赣州市康达新能源材料有限公司

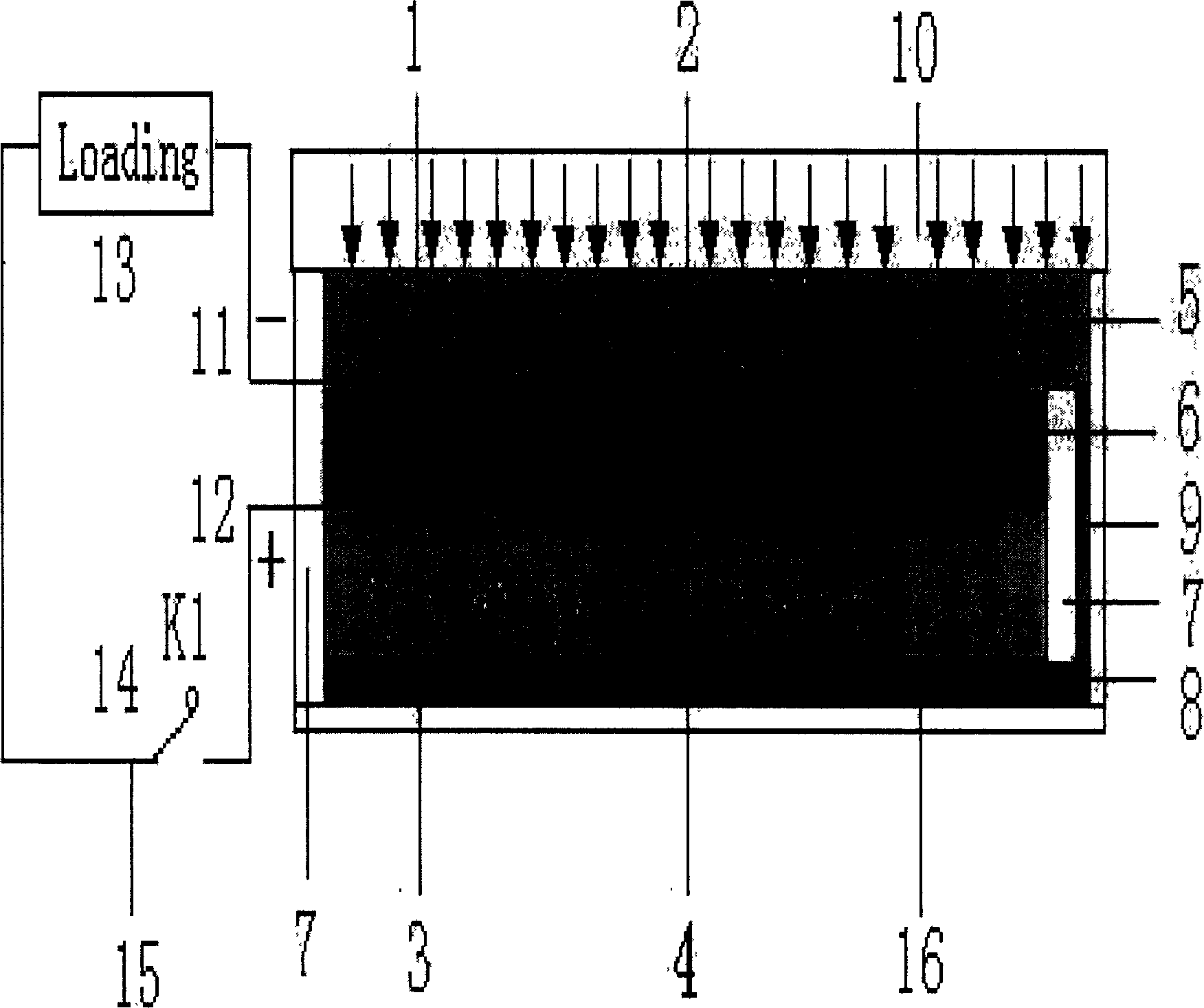

A kind of double-layer film all-solid-state film lithium battery spray pyrolysis battery manufacturing method

InactiveCN102456928BImprove ionic conductanceImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureFilm resistanceSpray pyrolysis

An all-solid-state lithium thin film that deposits the positive electrode material and the solid electrolyte together to form a double-layer film structure and uses a double spray gun to simultaneously spray the precursor solution of the two layers at the junction of the positive electrode solid electrolyte layer and the negative electrode layer to form a buffer layer. Ion battery spray pyrolysis manufacturing method. It is characterized in that the interface between one layer of film is reduced, the battery resistance is reduced and the ionic conductivity of the positive electrode material is improved at the same time; at the same time, the content of the two layers of components in the buffer layer between the two deposition layers is gradually changing, and the composition of the lower layer The content of the component gradually decreases, while the content of the upper component gradually increases. Thus forming a tight combination of the upper and lower layers, increasing the matching of the upper and lower layers, reducing stress and grain boundaries, and improving the conductance of the interface; thus greatly improving the conductance of the entire all-solid-state thin film battery, improving the stability and cycle performance of the battery.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com