Heat engine of alkali metals

An alkali metal and heat engine technology, which is applied to motors, thermoelectric devices, generators/motors, etc. applying thermal effects, can solve the problems of low power density, limited thermoelectric conversion efficiency, large size and weight of the device, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

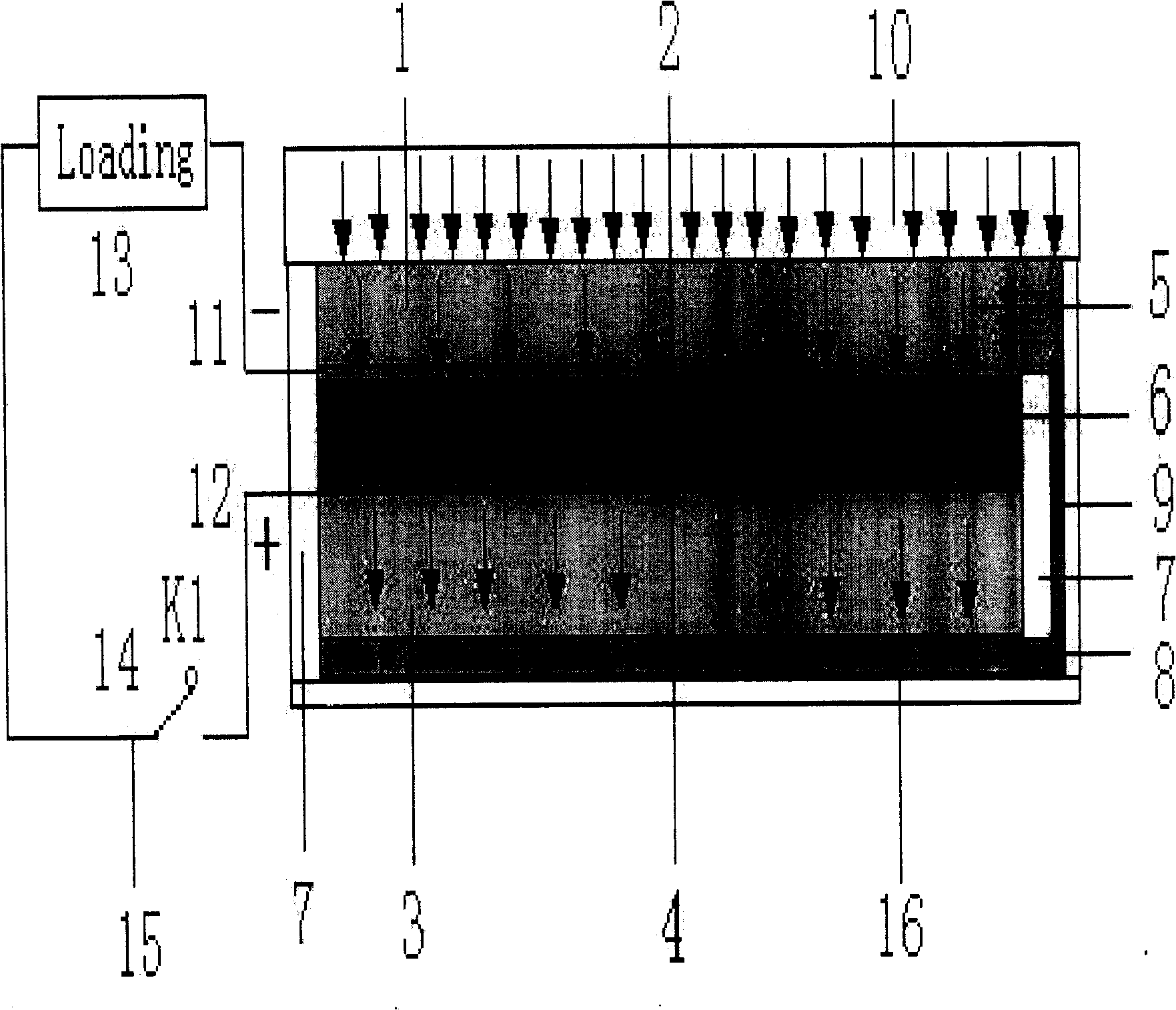

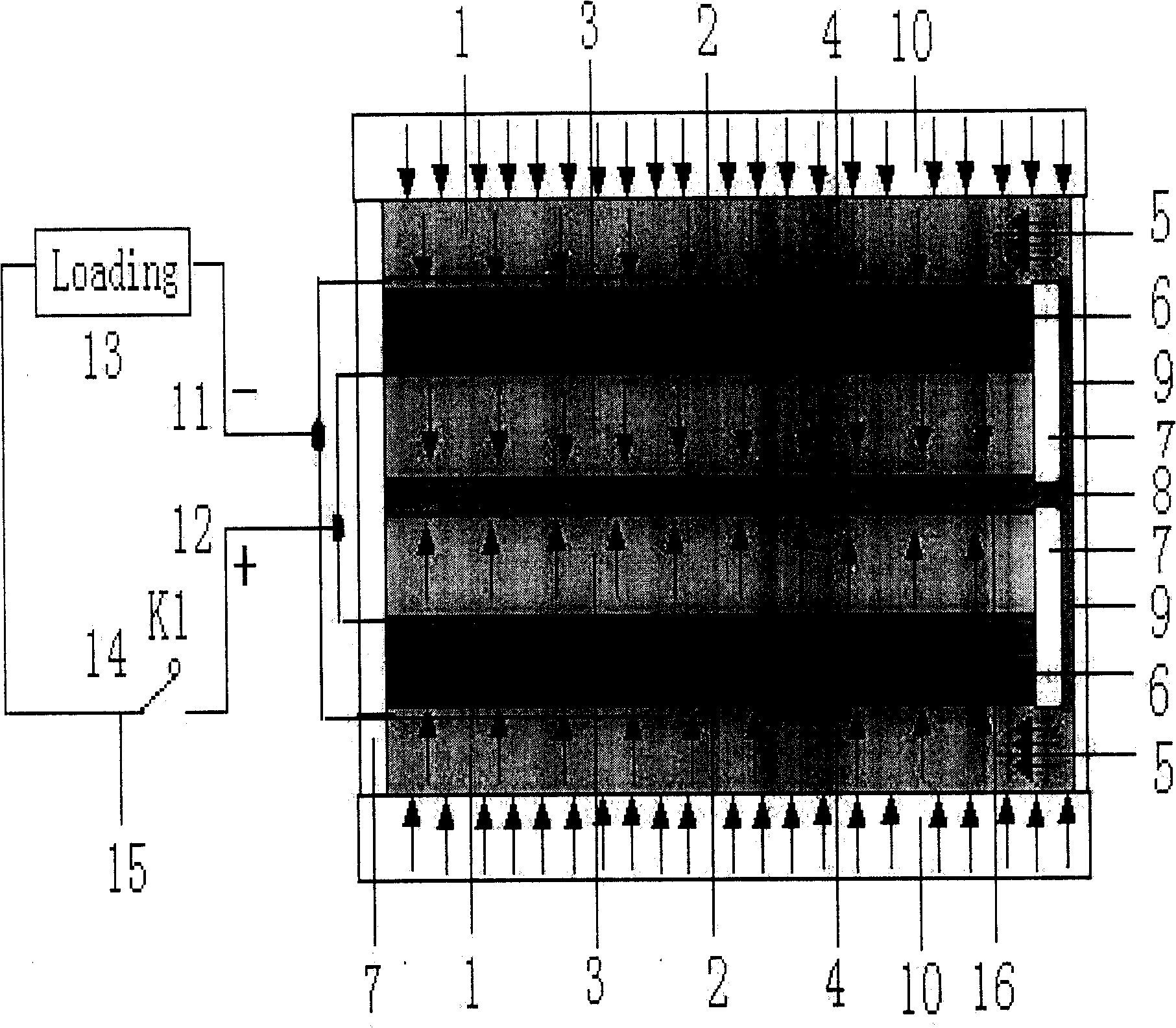

[0054] Such as figure 1 As shown, in a working container, the solid electrolyte β”-Al 2 o 3 The membrane 5 / porous electrode membrane 4 assembly and the working fluid circulation mechanism 9 (electromagnetic pump or capillary core) divide its interior into two parts, the high pressure end 1 and the low pressure end 3, and the alkali metal passes through the electromagnetic pump or the capillary core 9. End 3 reaches high pressure end 1 to form a circulating working fluid system. The top is the heat source 10, and the bottom is the flat-plate condenser 16. Between the heat source 10 and the condenser 16 is the circulating working fluid. The solid electrolyte film supported by the porous electrode film separates the working fluid into a high-pressure end 1 and a low-pressure end 3. Two parts, the upper working fluid close to the heat source 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com