Flat-plate-type thermoelectric generator and thermoelectric power generating component partition arrangement method

A technology of thermoelectric generator and thermoelectric power generation, which is applied in the direction of generator/motor, electrical components, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited thereto.

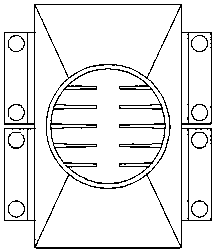

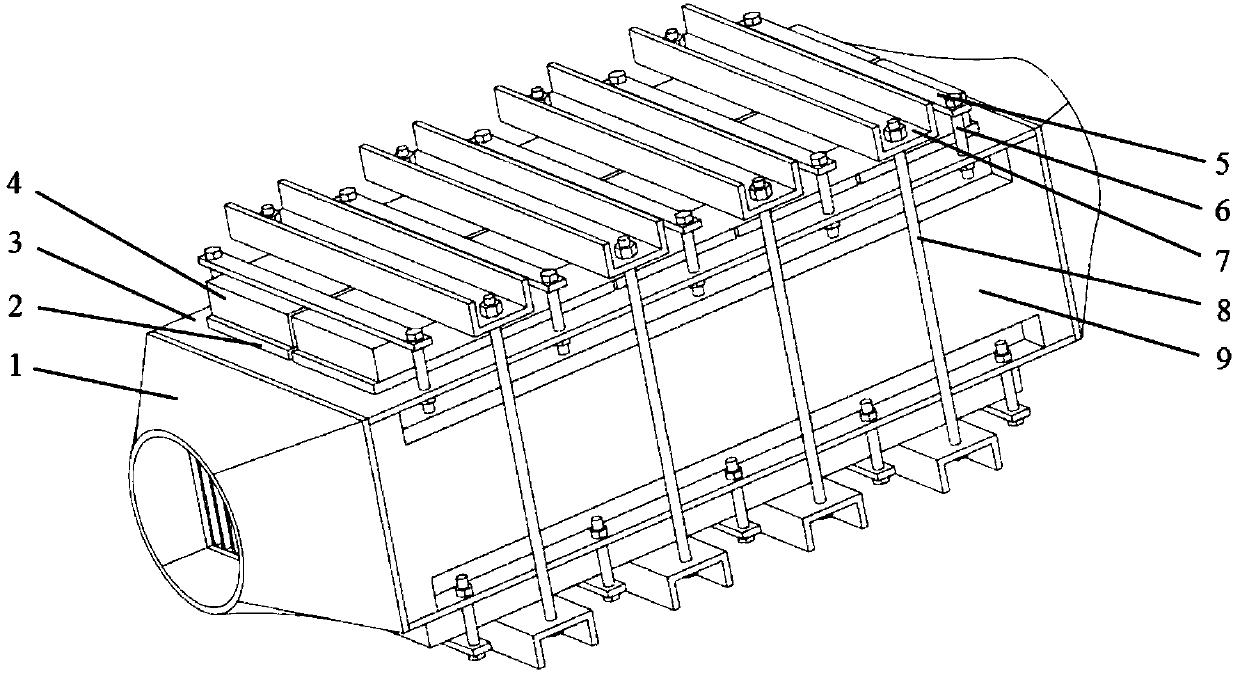

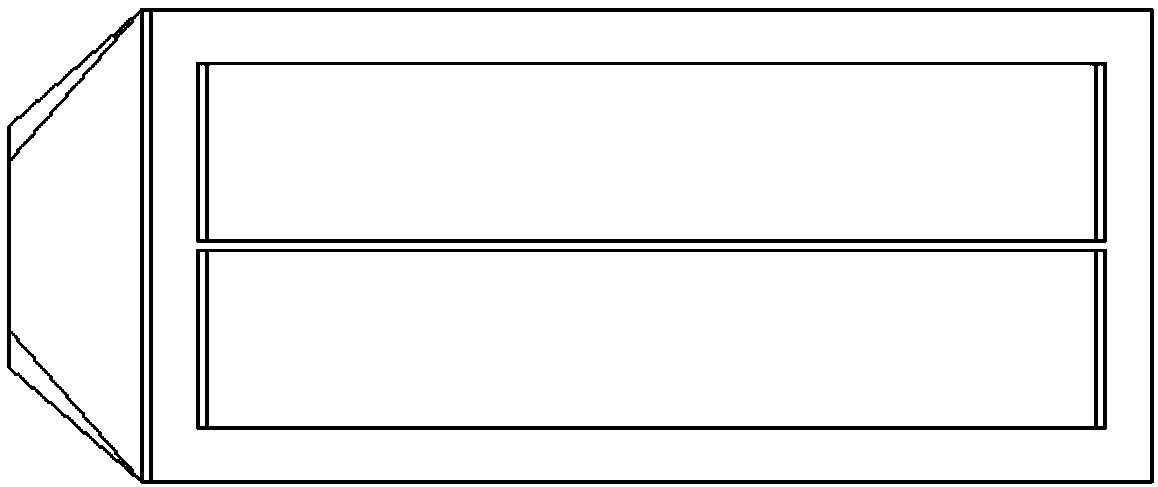

[0080] like figure 1 As shown, the flat-plate thermoelectric generator provided in this embodiment includes a heat collecting end panel 3, a heat insulating plate 9 and an end cover 1, and the heat collecting end panel 3, the heat insulating plate 9 and the end cover 1 Constitute a closed heat collection box, the number of the heat collection end panel 3, the heat insulation plate 9 and the end cover 1 is two, and the two heat collection end panels constitute the upper and lower two of the heat collection box. On the end face, two heat shields form the left and right sides of the heat collection box, and the two end covers 1 form the inlet and outlet of the heat collection box respectively. Heat collecting fins are distributed on one end surface of the heat collecting end panel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com