Double-acting thermo-acoustic power generation system simultaneously recycling cold energy and heat energy

A power generation system, double-acting technology, applied in the direction of machines/engines, mechanical power generating mechanisms, mechanical equipment, etc., can solve the problem of not being able to use cold sources and heat sources at the same time, to improve thermoelectric conversion efficiency, increase temperature ratio, The effect of improving the ability of vocal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

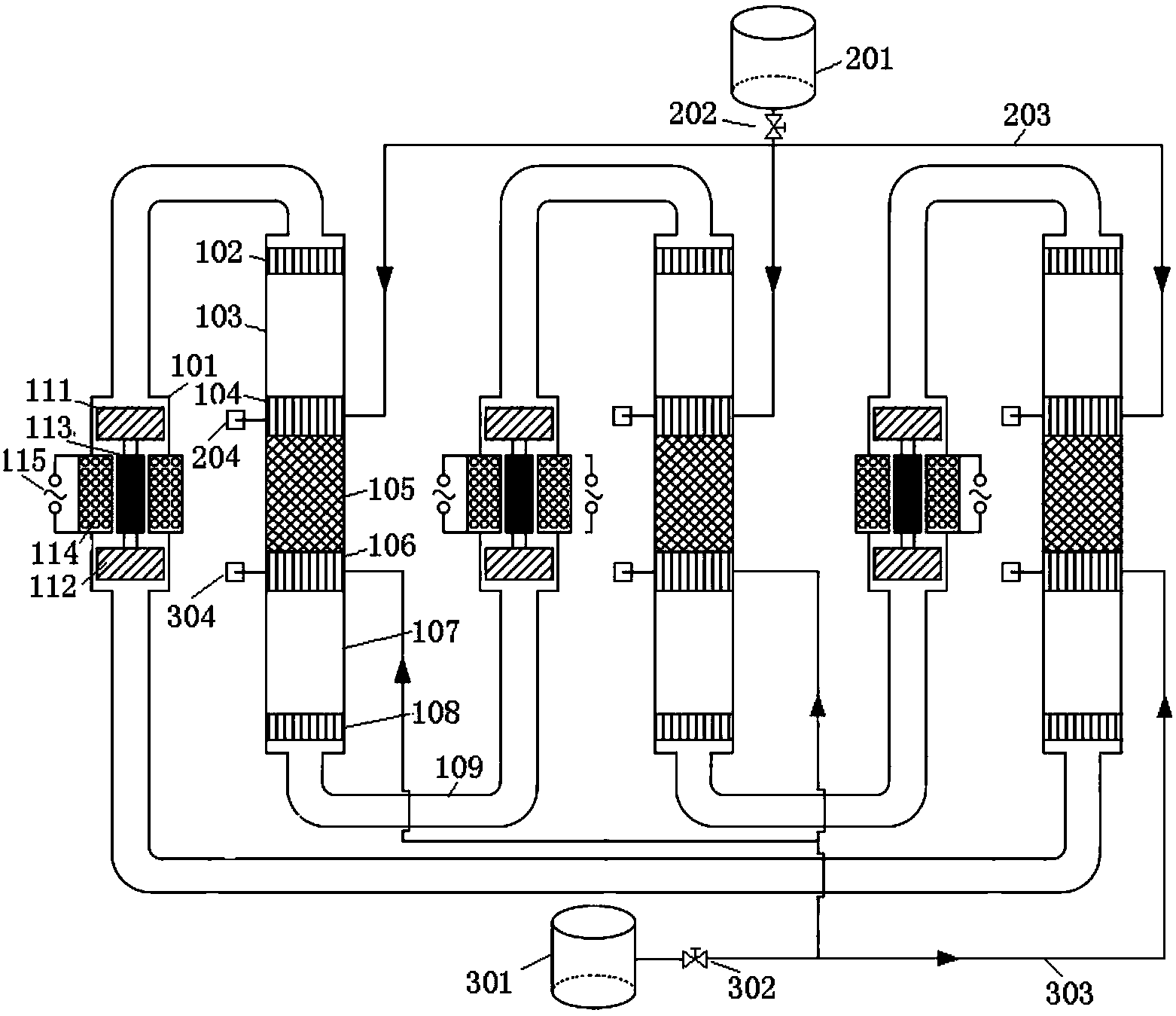

[0027] figure 2 It is a structural schematic diagram of a dual-action thermoacoustic power generation system (Example 1) that simultaneously recovers and utilizes cold energy of low-temperature fluid and low-grade heat energy in the present invention; its structure includes three sets of thermoacoustic power generation units; each of the three sets of thermoacoustic power generation units A set of thermoacoustic power generation units is composed of a linear generator 101 and a thermoacoustic engine; the three groups of thermoacoustic power generation units form a loop;

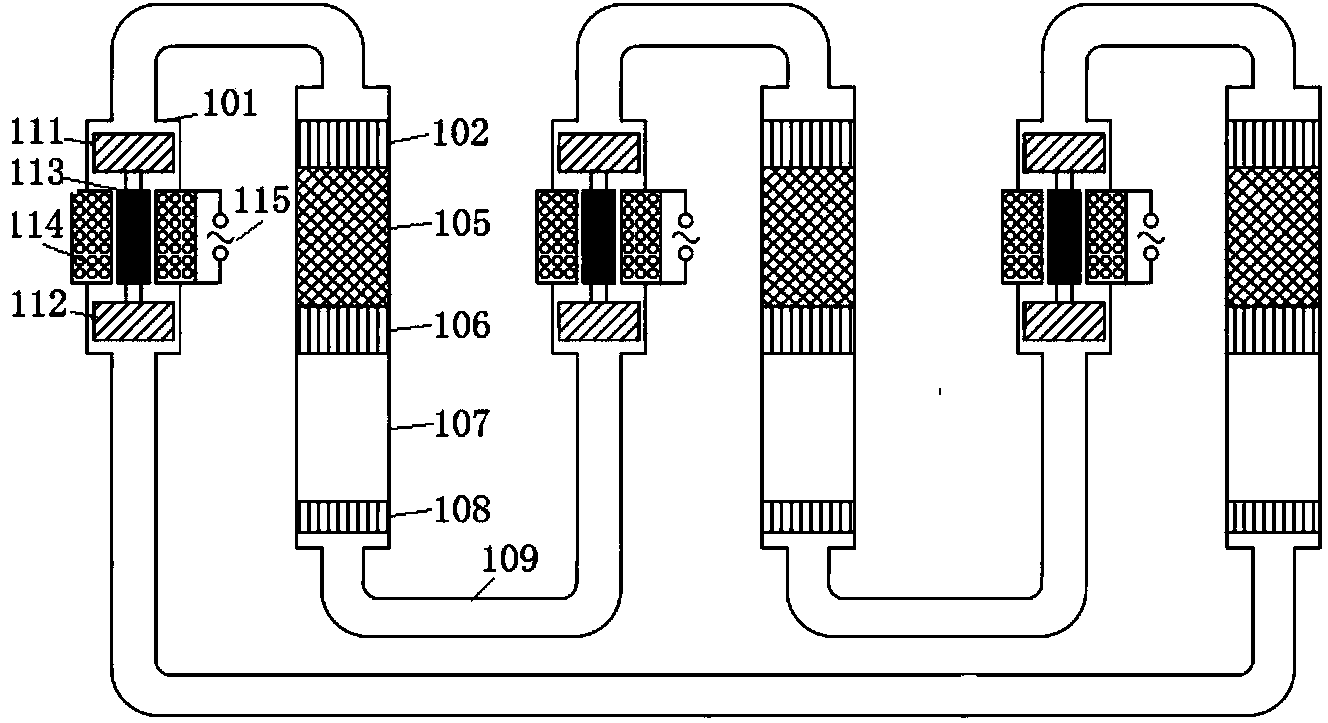

[0028]Each linear generator 101 is composed of a cylinder, a compression piston 111 and an expansion piston 112 placed at both ends of the cylinder, a generator mover 113 connected to the compression piston 111 and expansion piston 112, and a power generator wound around the periphery of the generator mover 113. Composed of a generator stator coil 114 and a generator load 115 electrically connected to the ge...

Embodiment 2

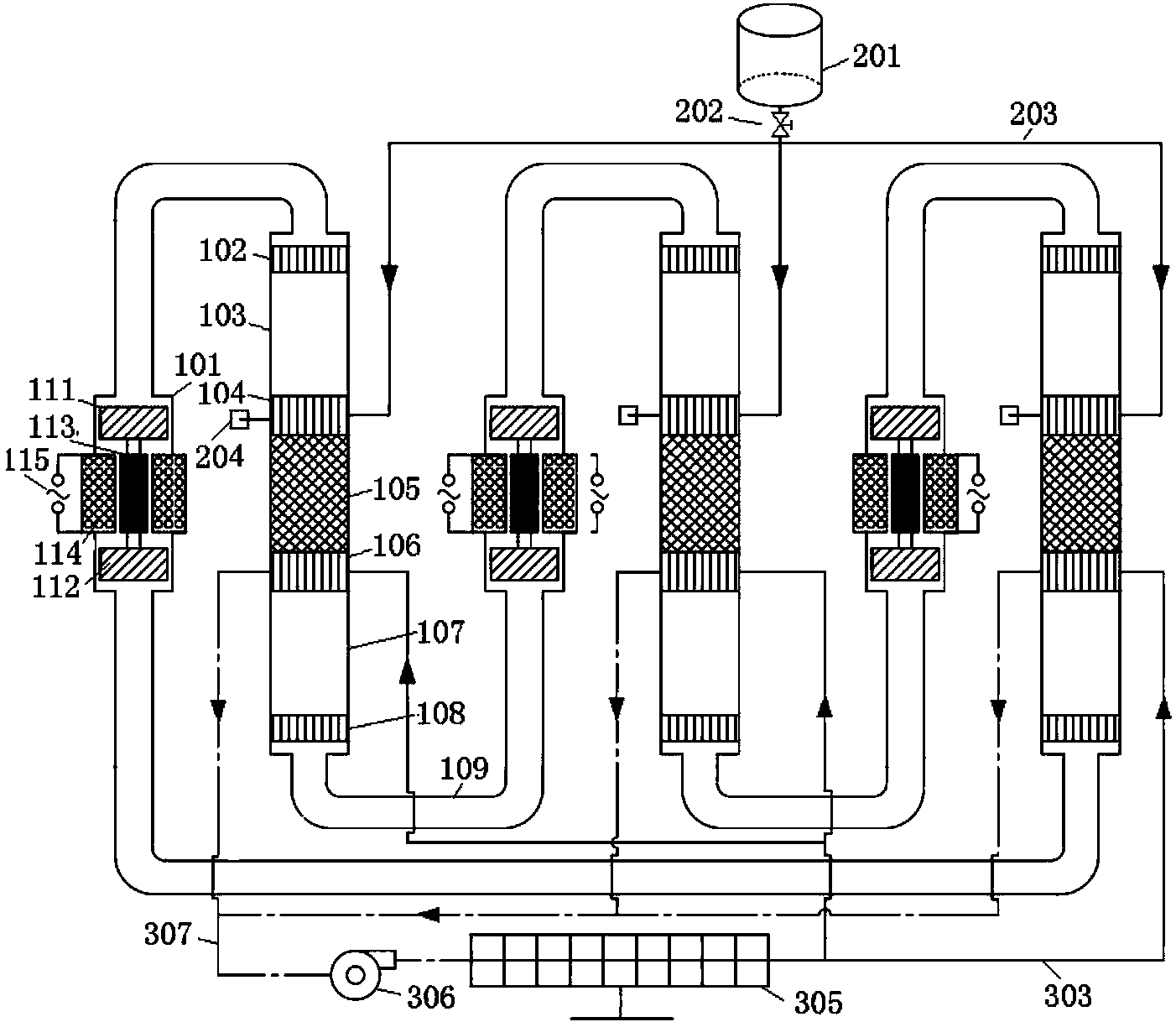

[0034] image 3 It is a structural schematic diagram of a dual-action thermoacoustic power generation system (Example 2) that simultaneously recycles cold energy of low-temperature fluid and low-grade heat energy of the present invention; this example is based on Example 1, and the heat source supply system adopts trough solar energy Heat source supply system, cold source supply system adopts liquid nitrogen or liquefied natural gas cold source supply system.

[0035] Each of the three groups of thermoacoustic power generation units is composed of a linear generator 101 and a thermoacoustic engine; the three groups of thermoacoustic power generation units form a loop, and its structure is the same as in Embodiment 1;

[0036] The trough solar heat source supply system includes: a trough heat collector 305, an oil pump 306, a thermal energy output pipeline 303, and a thermal energy input pipeline 307; both ends of the thermal energy input pipeline 307 of each group of thermoaco...

Embodiment 3

[0042] Figure 4 It is a schematic structural diagram of a dual-action thermoacoustic power generation system (Example 3) that simultaneously recycles cold energy of low-temperature fluid and low-grade heat energy of the present invention. In this embodiment, on the basis of Embodiment 2, the three sets of linear generators and engines in the thermoacoustic power generation system are extended to four sets of linear generators and engines, and the trough solar heat source and liquid nitrogen or liquefied natural gas cold source supply system It is just a simple addition of a pipeline, which improves the power density and overall power generation of the system after a simple structural change. At the same time, according to the specific power demand and size requirements, four or more system combinations can be selected, and the arrangement can be in the form of a loop or side by side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com