Preparation method of lithium ion battery cathode material SiOX-TiO2/C

A technology for lithium-ion batteries and negative electrode materials, applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of high raw material prices, low yields, and complicated preparation methods, and achieve simple preparation methods, high yields, and improved The effect of ground conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

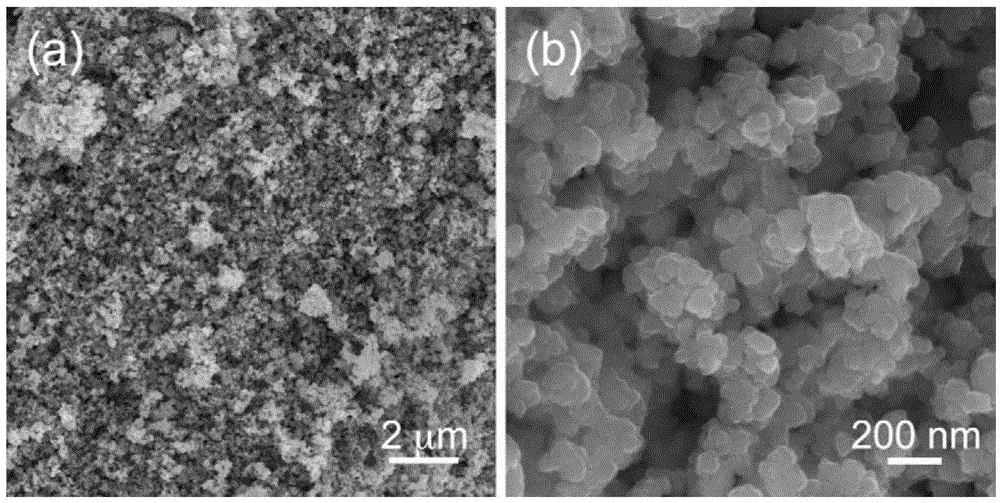

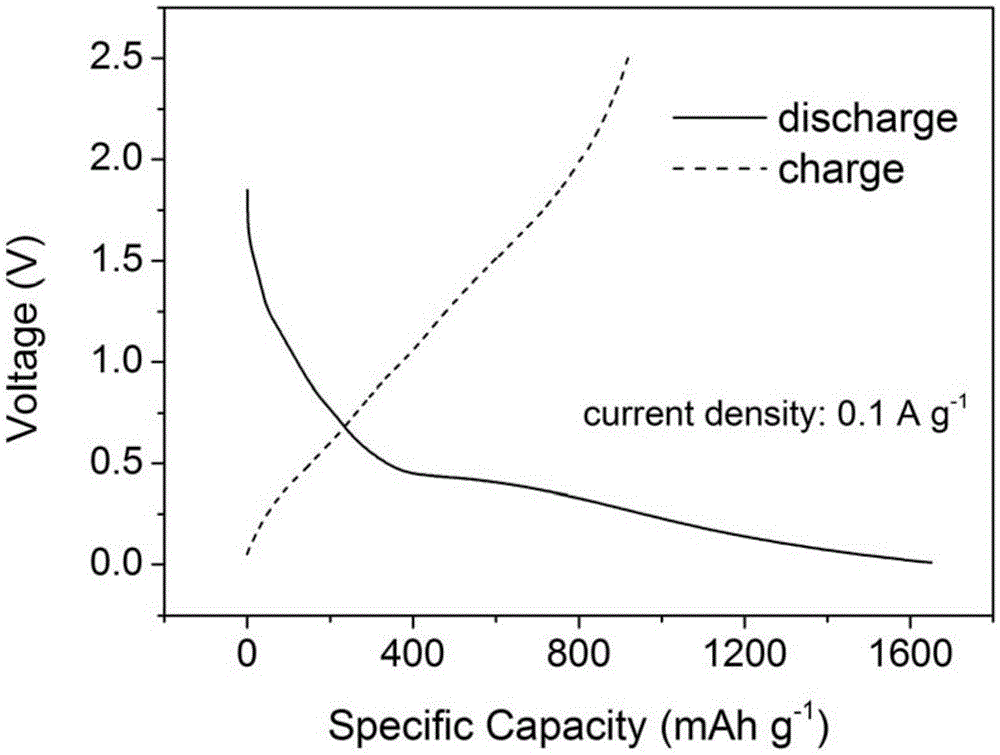

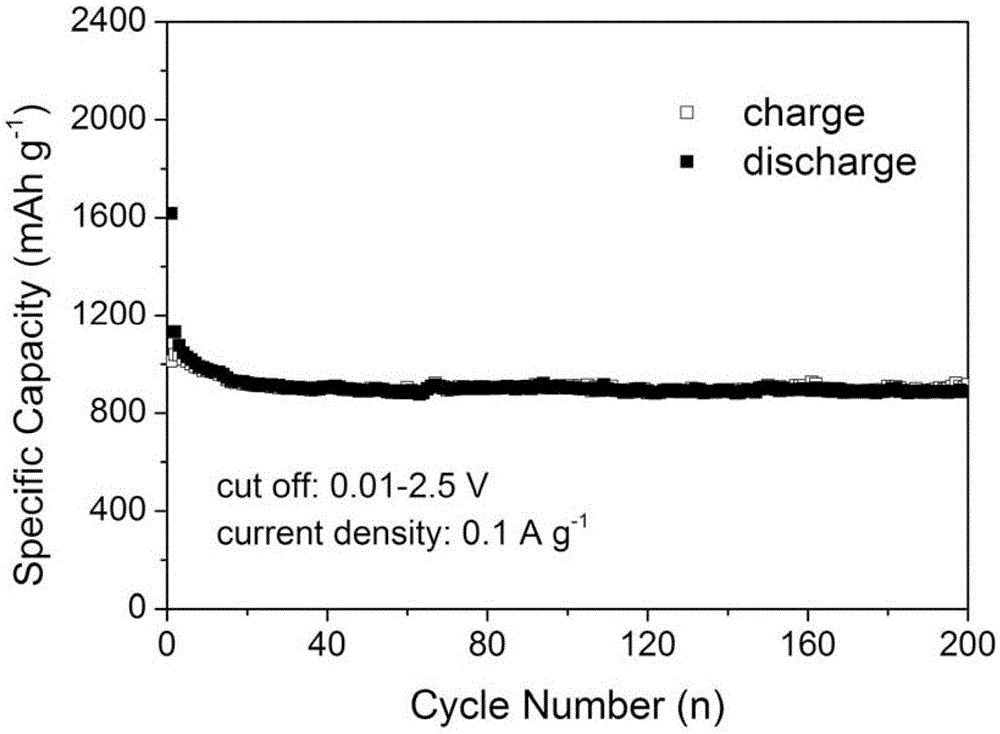

[0026] A new type of anode material SiO for lithium ion battery provided by an embodiment of the present invention x -TiO 2 The preparation method of / C can include:

[0027] (1) Weigh the analytically pure organic silicon source, organic titanium source and organic carbon source according to a certain molar ratio; dissolve the organic silicon source in a mixture of deionized water and absolute ethanol and add a small amount of glacial acetic acid as a catalyst, and stir After a period of time, adjust the pH of the solution to the alkaline range with ammonia to obtain mixed solution A; dissolve the organic titanium source in absolute ethanol and stir for a period of time to obtain mixed solution B;

[0028] (2) Add the mixed solution B to the mixed solution A, and after stirring for a period of time, let it stand for a period of time at room temperature to obtain a colloidal mixed solution;

[0029] (3) After mixing the colloidal mixture with the organic carbon source, perform mechan...

Embodiment 1

[0042] Weigh 12g of trimethylsilanol and dissolve it in a mixed solution of 9ml of absolute ethanol and 3ml of deionized water, and then add 1ml of glacial acetic acid as a catalyst. After stirring for a while, add aqueous ammonia solution to adjust the pH of the solution to 7 to obtain a mixture Liquid A. Weigh 3 g of tetraisopropyl titanium, dissolve it in 6 ml of absolute ethanol, and stir for a while to obtain mixed solution B. Add the mixed solution B to the mixed solution A, stir for a while, and then stand at room temperature for 10 hours. After mixing the sucrose aqueous solution containing 18.3 g of sucrose with the static sol, it is placed in a ball milling tank for mechanical ball milling, and then the ball milling stock solution is dried to obtain a precursor. The precursor was placed in a quartz crucible, under an inert protective atmosphere of Ar, the temperature was set to 700℃, and the holding time was 1h for treatment. After the reaction, it was cooled with th...

Embodiment 2

[0044] Weigh 12g of trimethylsilanol and dissolve it in a mixed solution of 36ml of absolute ethanol and 12ml of deionized water, and then add 1ml of glacial acetic acid as a catalyst. After stirring for a while, add aqueous ammonia solution to adjust the pH of the solution to 10 to obtain a mixture Liquid A. Weigh 15.2 g of tetraisopropyl titanium and dissolve it in 30.4 ml of absolute ethanol, and stir for a while to obtain mixed solution B. Add the mixed solution B to the mixed solution A, and after stirring for a while, let it stand at room temperature for 40h. After mixing the sucrose aqueous solution containing 18.3 g of sucrose with the static sol, it is placed in a ball milling tank for mechanical ball milling, and then the ball milling stock solution is dried to obtain a precursor. The precursor is placed in an alumina crucible, under an inert protective atmosphere of Ar, the temperature is set to 1000 ℃, and the holding time is 5 hours for treatment. After the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com