Patents

Literature

65results about How to "Improve electronic conductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

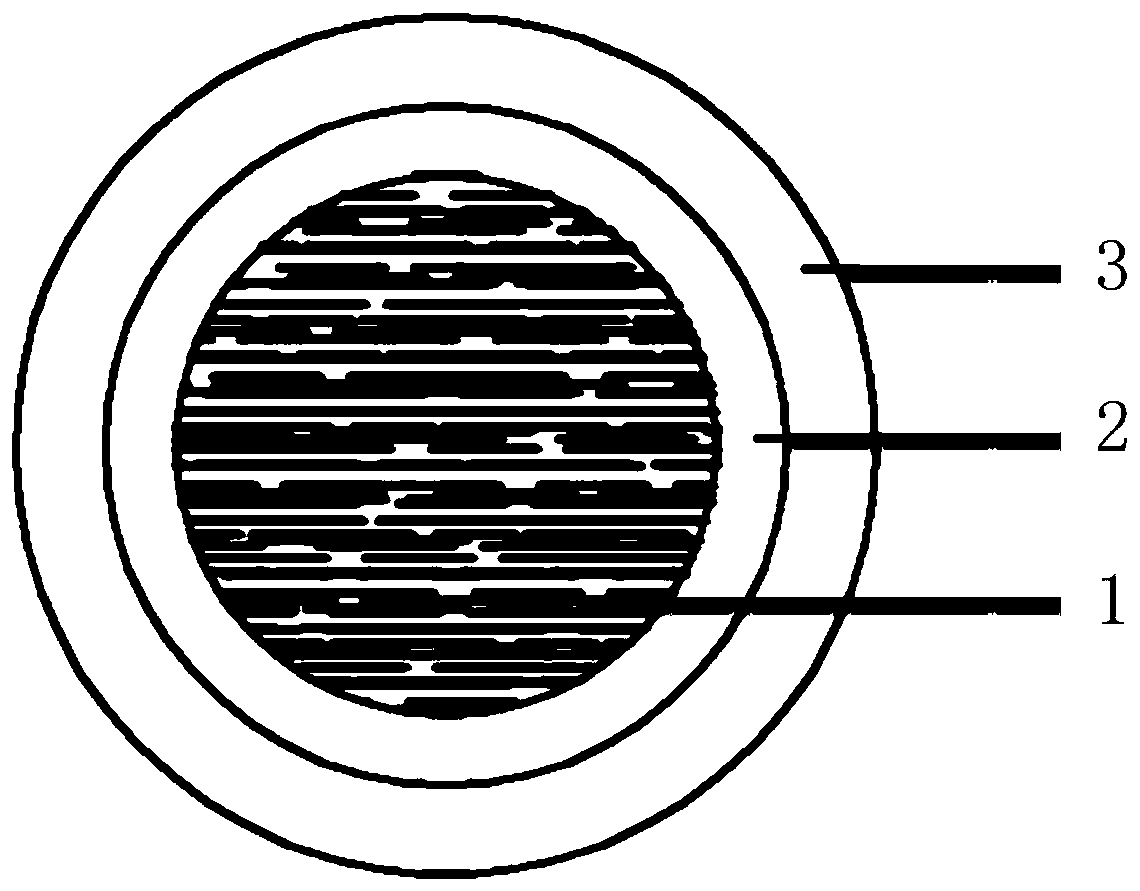

Silicon-oxygen composite negative electrode material and manufacturing method thereof

ActiveCN109755500AImprove electronic conductanceReduce lossCell electrodesLi-accumulatorsSilicon oxygenMetallurgy

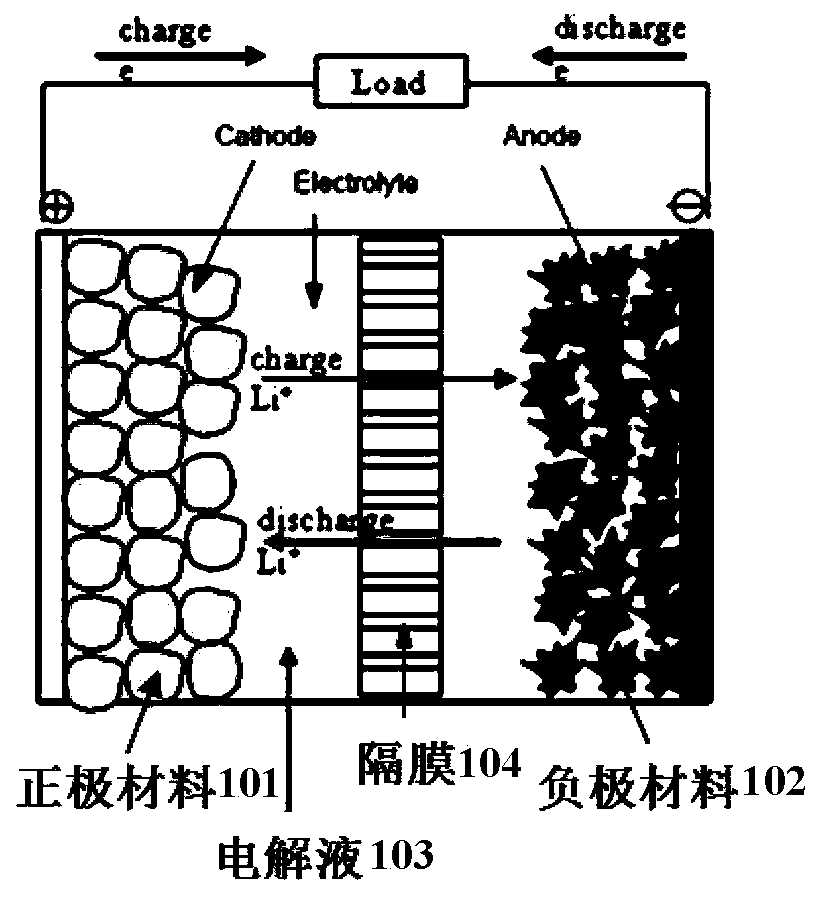

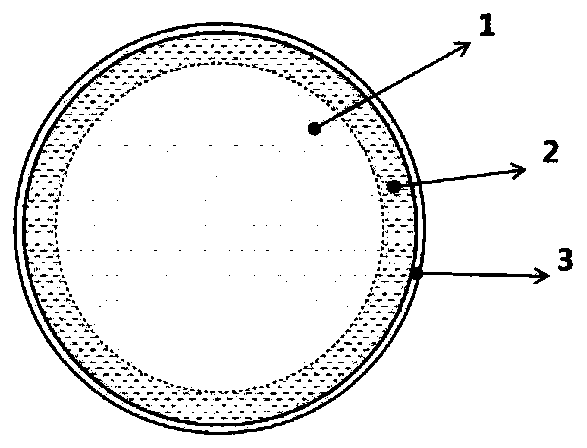

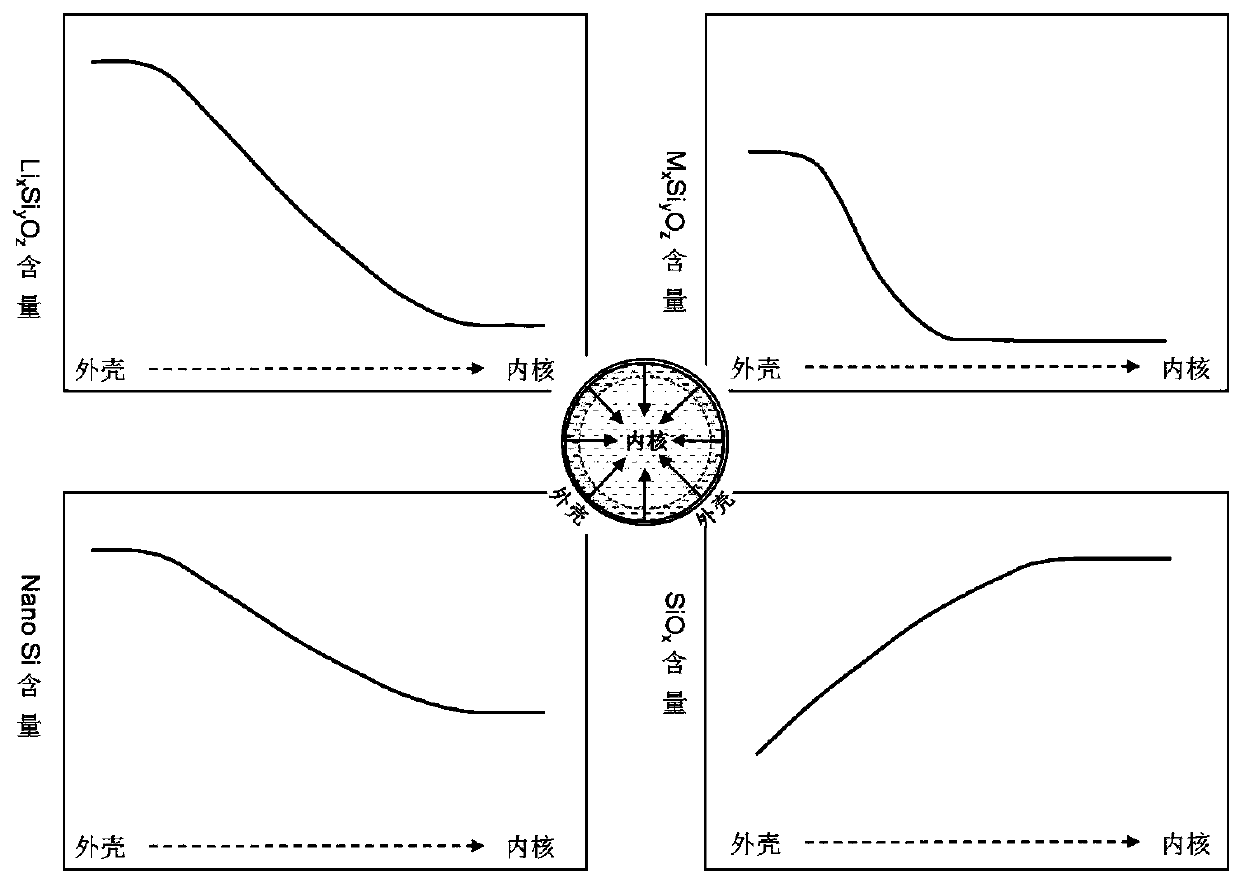

The invention discloses a silicon-oxygen composite negative electrode material which is used for manufacturing a negative electrode of a lithium battery; the negative electrode material comprises an inner core, a coating layer and a middle layer, wherein the coating layer wraps the inner core, and the middle layer is positioned between the inner core and the coating layer, wherein the middle layercomprises non-lithium silicate, and the non-lithium silicate refers to non-lithium silicate, wherein the mass content of the non-lithium silicate in the middle layer is gradually decreased from the middle layer to the inner core. The decrementing comprises a gradient reduction from the middle layer to the inner core, and the gradient reduction refers to the fact that the mass-duty ratios on the circumference parts which have the same central distance from the inner core are the same, and when the distance from the center of the inner core is reduced, the mass-duty ratio is reduced step by step. The non-lithium silicate is generated in situ on the outer layer of the inner core, and has a non-water-soluble or non-alkaline or weakly alkaline compact structure, so that the dissolution of theinternal water-soluble lithium silicate can be effectively relieved; and the pH value of the ghost-eye composite negative electrode material can be lowered.

Owner:HUAWEI TECH CO LTD

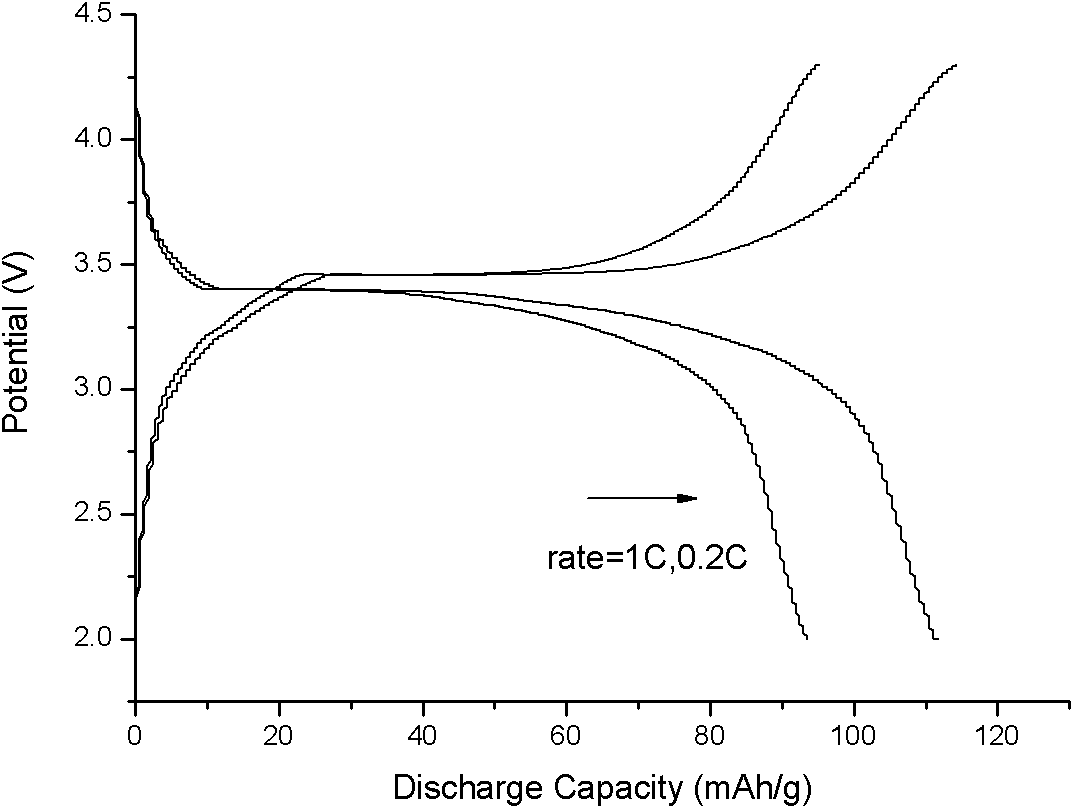

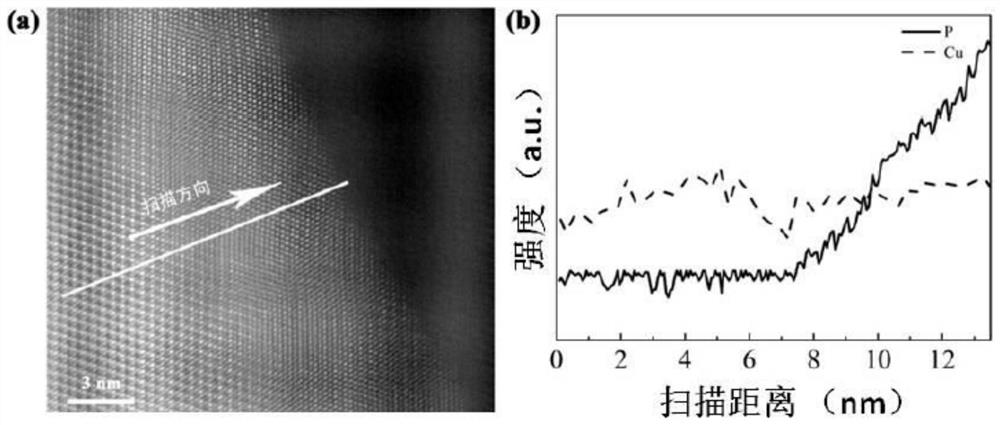

Lithium ion battery phosphatic composite cathode material and preparation method thereof

ActiveCN102244263AEasy to processImprove electrochemical performanceCell electrodesMicro structurePhosphoric acid

The invention discloses a lithium ion battery phosphatic composite cathode material and a preparation method thereof. The composite material is a multinuclear core shell structure composed of a plurality of cores and a housing layer, the cores are lithium iron phosphate particles wrapped by lithium vanadium phosphate and the housing layer is amorphous carbon. Preparation of the lithium iron phosphate particles wrapped by lithium vanadium phosphate comprises the following steps: preparing precursor sol with a sol gel method, adding lithium iron phosphate powder to disperse uniformly, carrying out spray drying on the above mixture, calcining the above resultant in inert gas, and followed by cooling and grinding to obtain the lithium iron phosphate particles wrapped by lithium vanadium phosphate. Preparation of the composite cathode material comprises the following steps: dissolving a carbon source compound into deionized water, adding core materials, dispersing the above resultant uniformly, carrying out second spray drying, calcining the above resultant in inert gas, and followed by cooling to obtain the composite cathode material. The composite material prepared in the invention has good electronic conduction performance, good ionic conduction performance and excellent electrochemistry performance. Because of existence of lithium vanadium phosphate, energetic density of a material is raised. Because of the multinuclear core shell structure like nano / micro structures, the composite material has good processing performance, and tap density of the material is greatly raised.

Owner:CENT SOUTH UNIV

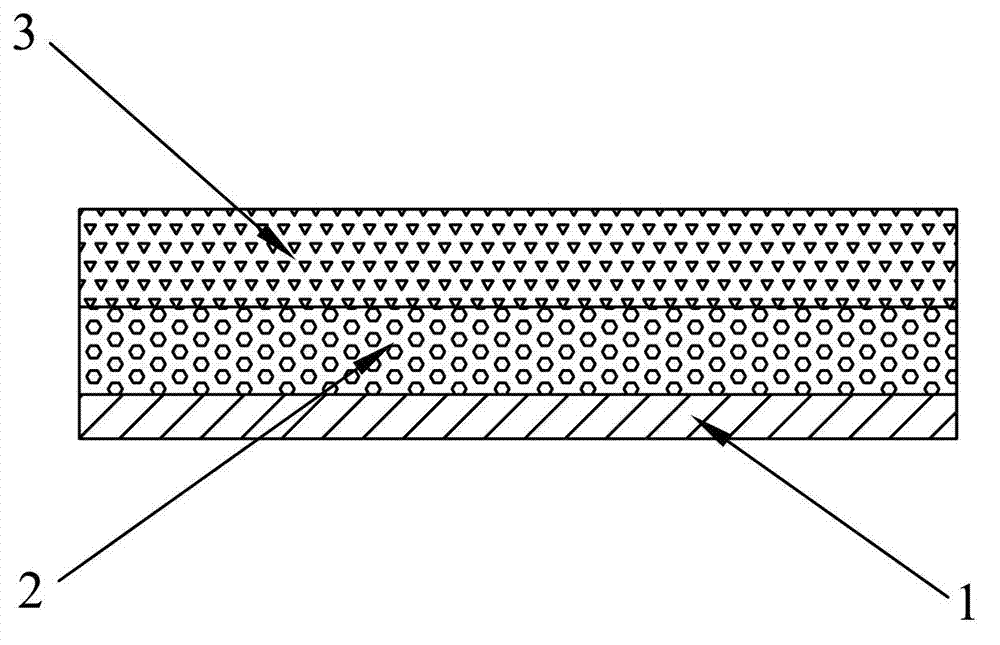

Positive pole piece and preparation method thereof and battery

InactiveCN103165863AIncrease internal resistanceImprove electronic conductanceCell electrodesEngineeringPole piece

The invention provides a positive pole piece which is characterized by comprising a positive pole current collector, a buffer conducting layer and a positive pole active layer in a sequential stacking mode. The buffer conducting layer comprises phosphate, a first conductive agent and a first binder. The phosphate has the following general formula: LiMPO4, wherein M is selected from one of Fe, Mn and Co or a composite of a plurality of Fe, Mn and Co. The thickness of the buffer layer is 2-50 millimeters, and the grain size of the first conductive agent is smaller than 75 millimeters. In the buffer conductive layer, the phosphate content is 40-90wt%, the first conductive agent content is 5-10wt%, and the first binder content is 5-50wt%. Meanwhile, the invention further discloses a preparation method of the positive pole piece and a battery adopting the positive pole piece. The battery prepared from the provided positive pole piece has good over-charging performance and the safety of the battery is greatly promoted.

Owner:SHENZHEN OCEANSUN BATTERY

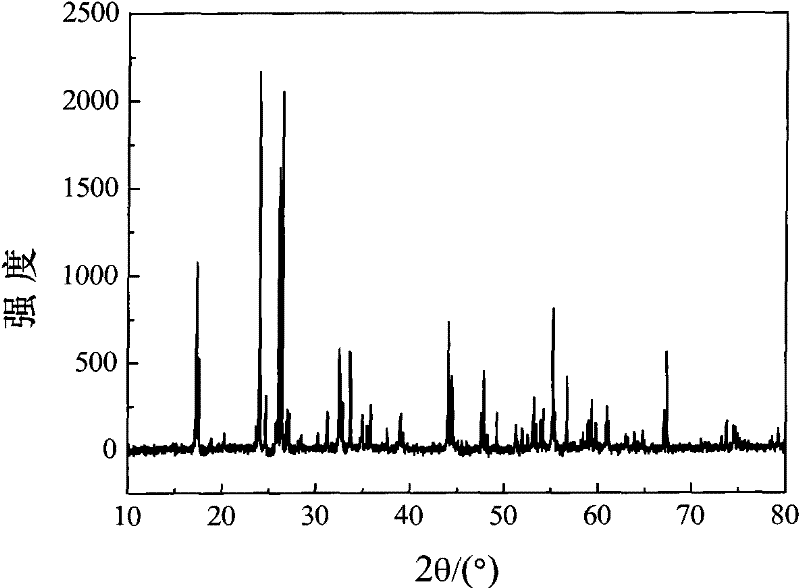

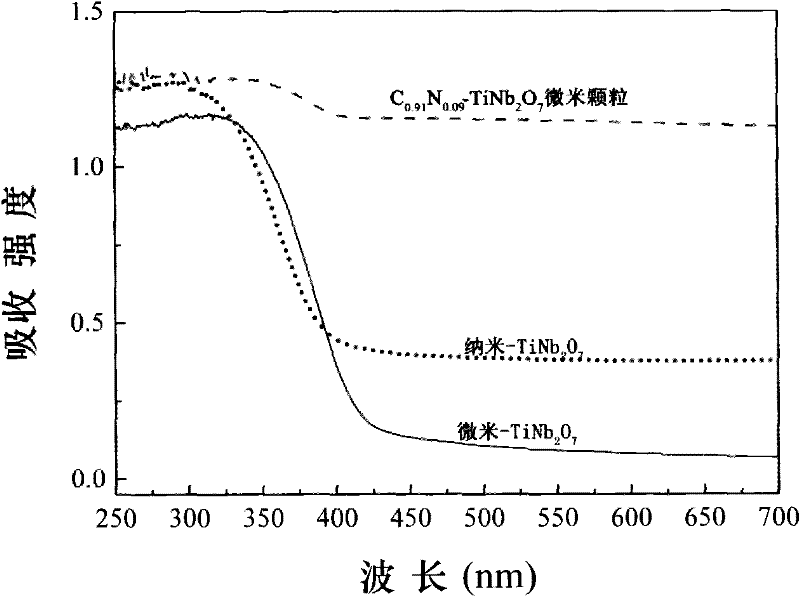

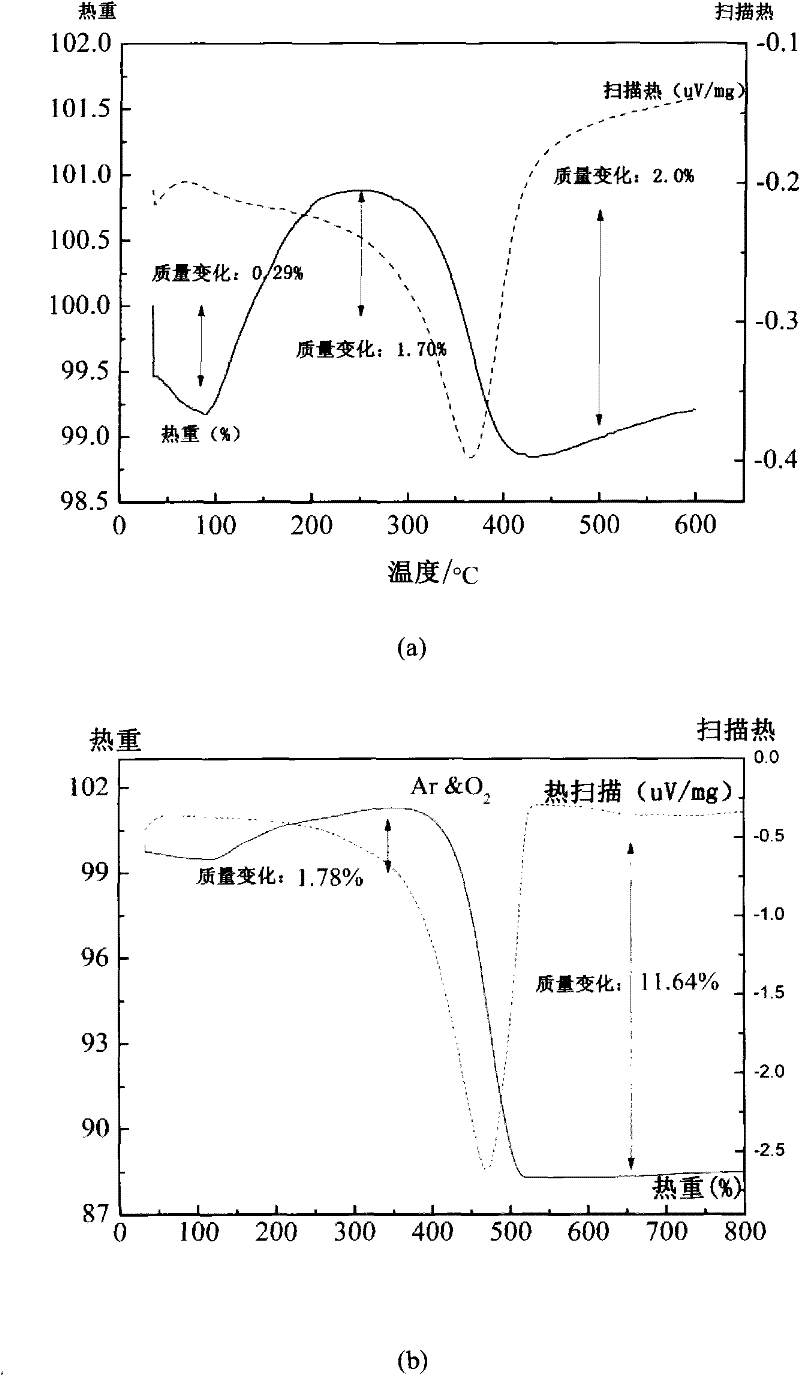

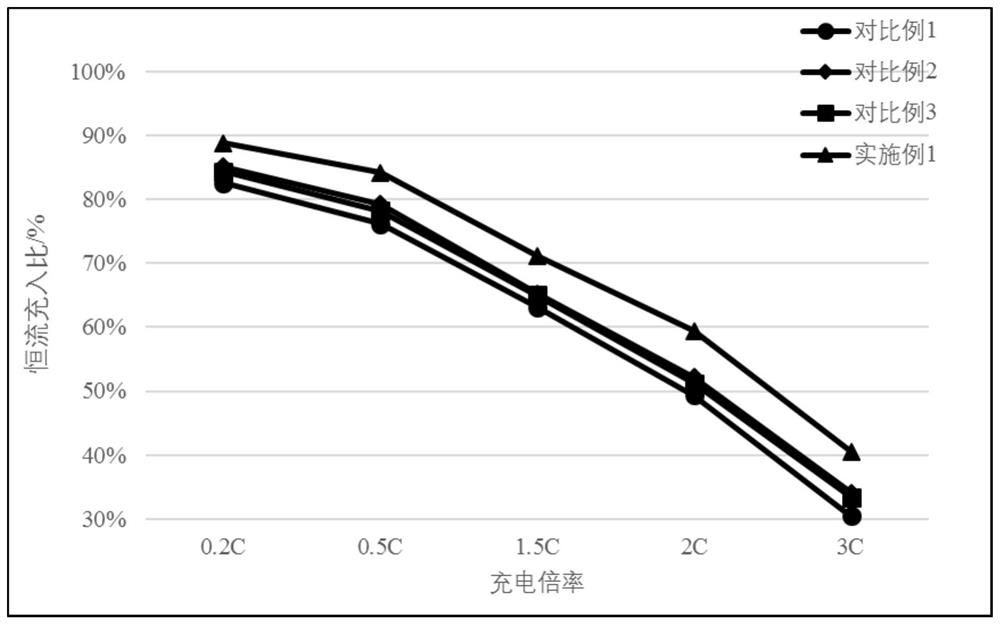

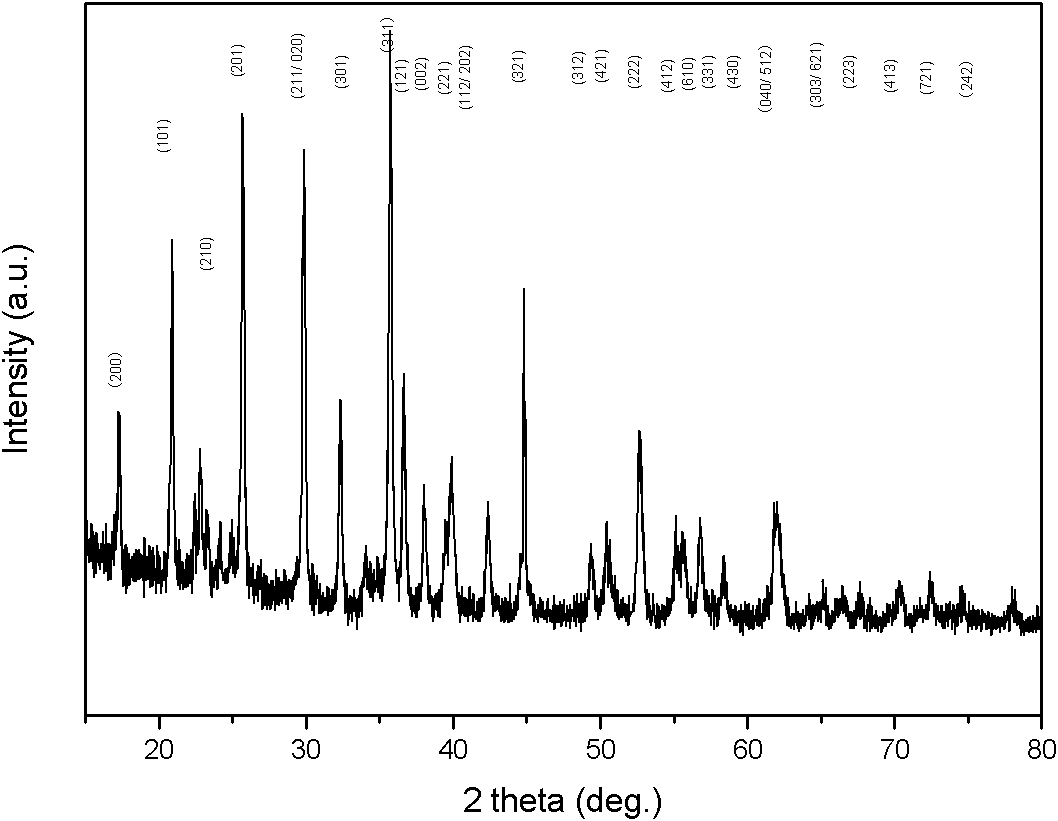

Titanium niobate composite material, preparation method thereof, and cathode and battery containing the same

ActiveCN102479950AImprove cycle performanceFacilitated DiffusionCell electrodesLi-accumulatorsHigh rateTitanium

The invention relates to a titanium niobate composite material, a preparation method thereof, and a cathode and a battery containing the composite material. The titanium niobate composite material is represented as BxCyNz-LaTibMcNbdOe, wherein BxCyNz represents a compound containing boron carbon or carbon nitrogen or boron carbon nitrogen; L represents Li or Na, preferably Li; M is one element selected from Al, B, V, Cr, Mn, Fe, Co, Ni, Ce, Y, Zr, Mo, La, Ta, N and P; x, y, z, a, b, c, d and e represent mole percentages, x is no less than 0 and less than 1, y is larger than 0 and less than 1, z is no less than 0 and less than 1, a is no less than 0 and no larger than 0.2, b is larger than 0.8 and no larger than 1.1, c is no less than 0 and less than 0.2, d is larger than 1.95 and no larger than 2.1, e is no less than 6.8 and no larger than 7, and x and y are not 0 at the same time. The composite material disclosed herein and used as a cathode material of a lithium ion battery has the advantages of high coulombic efficiency, high ionic and electric conductance, good cycling performance of high-rate charge and discharge, high safety, no pollution, and low price.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Positive plate and lithium ion battery comprising positive plate

InactiveCN111916665ALower internal resistanceImprove fast charge cycle performancePositive electrodesSecondary cells charging/dischargingInternal resistanceFast charging

The invention provides a positive plate and a lithium ion battery comprising the positive plate. The positive plate comprises a positive current collector, a first positive active material layer and asecond positive active material layer, wherein the first positive active material layer is arranged on the first surface of the positive current collector, and the second positive active material layer is arranged on the surface of the first positive active material layer; the first positive electrode active material layer comprises a first positive electrode active material, the second positiveelectrode active material layer comprises a second positive electrode active material, the first positive electrode active material is a positive electrode active material doped and / or coated with anMg element and an Al element, and the second positive electrode active material is a positive electrode active material doped and / or coated with an Al element. According to the positive plate, on theone hand, the high-temperature resistance and high-voltage resistance of positive active material particles on the surface of the positive plate can be ensured; on the other hand, the internal resistance of the positive plate is reduced, so the polarization in a quick charging process is reduced, and the quick charging cycle performance of the lithium ion battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

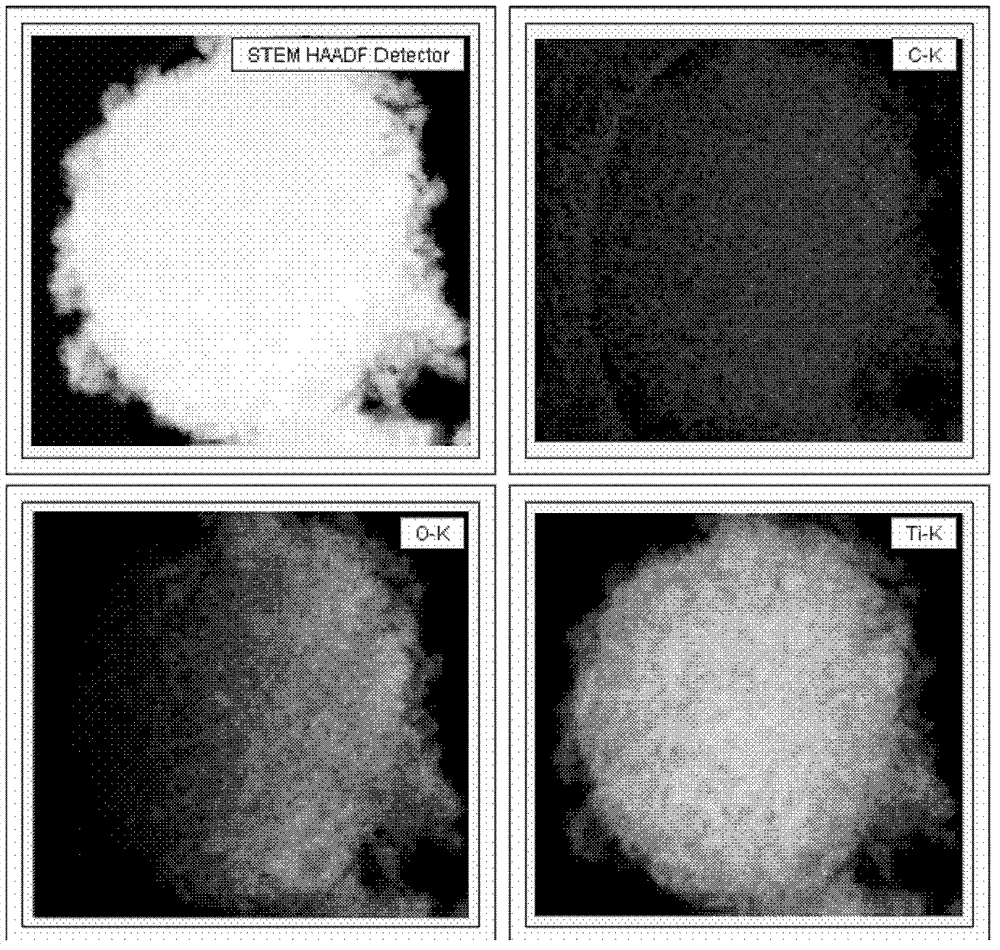

Preparation method of lithium ion battery cathode material SiOX-TiO2/C

ActiveCN105591080AImprove conduction abilityLow priceCell electrodesSecondary cellsElectrical batteryThermal insulation

The invention discloses a preparation method of a lithium ion battery cathode material SiOX-TiO2 / C. The preparation method comprises steps as follows: analytically pure organic silicon sources, organic titanium sources and organic carbon sources are weighed in a certain mole ratio; the organic silicon sources are dissolved in a mixed solution of deionized water and absolute ethyl alcohol and stirred, the pH of the solution is adjusted to be alkaline, and a mixed solution A is obtained; the organic titanium sources are dissolved in the absolute ethyl alcohol and stirred for a period of time, and a mixed solution B is obtained; the mixed solution B is added to the mixed solution A and left to stand at the room temperature after being stirred for a period of time, and a colloidal mixed solution is obtained; after the colloidal mixed solution is mixed with the organic carbon sources, mechanical ball-milling treatment is performed; the mixed solution after mechanical ball-milling treatment is dried, and a precursor is obtained; the precursor is put in a crucible and calcined under the protection of inert atmosphere, thermal insulation is performed for multiple hours, and a product is cooled to the room temperature with the furnace. Compared with the prior art, the cathode material prepared with the method has good rate performance, the raw materials are cheap, the preparation process is simple, and the yield is high.

Owner:UNIV OF SCI & TECH BEIJING

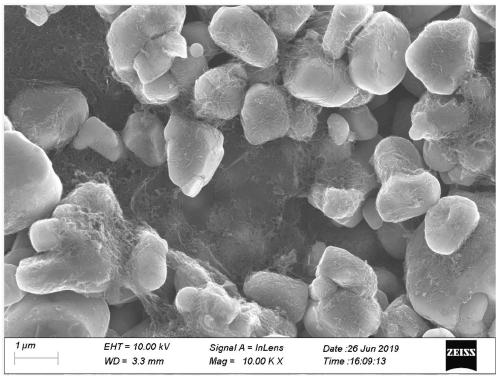

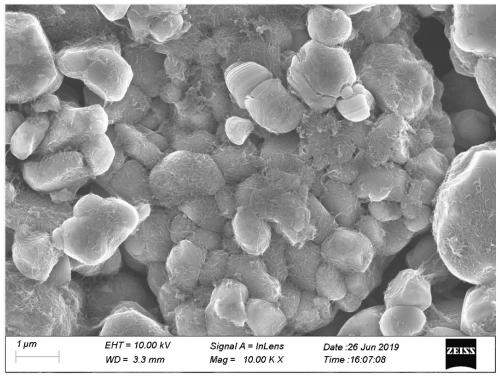

Preparation method of lithium ion battery negative electrode material silicon oxide-carbon/graphite

ActiveCN109560278AImprove electronic conductanceCoulombic efficiency is highCell electrodesSecondary cellsSucroseSilicon oxygen

The invention relates to a preparation method of a lithium ion battery negative electrode material silicon oxide-carbon / graphite. The preparation method comprises the steps of taking tetraethyl orthosilicate as a silicon source and sucrose as a carbon source, performing in-situ combination on a gel-state silicon oxide, the sucrose and the graphite by hydrolysis-condensation reaction of the tetraethyl orthosilicate, and performing ball-milling to disperse the graphite to obtain a uniform silicon-oxygen-sucrose-graphite precursor; and allowing the sucrose to split and reducing silicon oxide during the subsequent thermal treatment process so as to prepare the uniformly-combined silicon oxide-carbon / graphite material. The in-site process of the silicon oxide and the graphite is simple in process and low in cost, and the prepared silicon oxide-carbon / graphite material is uniform in combination; with the introduction of the graphite, the electron conductivity of the composite material can beimproved, the coulombic efficiency of the composite electrode material is effectively improved, so that the electrochemical performance of the electrode material is remarkably improved; and the silicon oxide-carbon / graphite material can be used as a potential high-performance lithium ion battery negative electrode material and is expected to be widely applied to the fields of various types portable electronic equipment, an electric automobile and aerospace.

Owner:UNIV OF SCI & TECH BEIJING

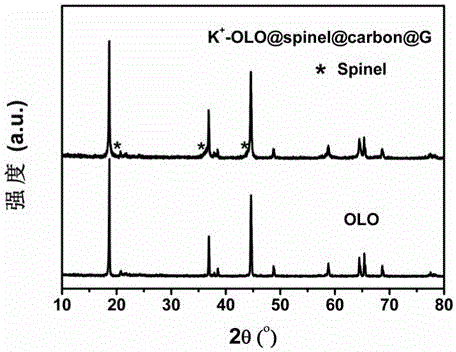

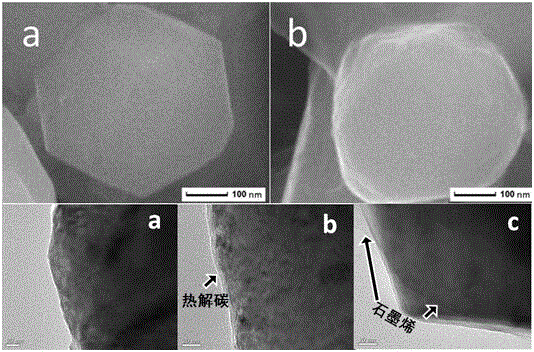

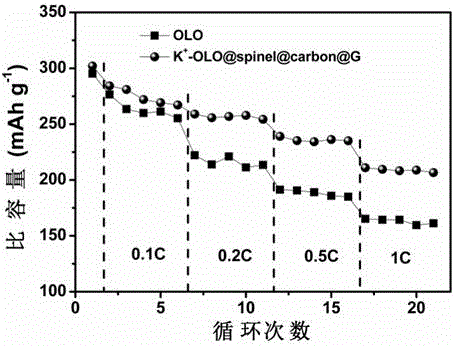

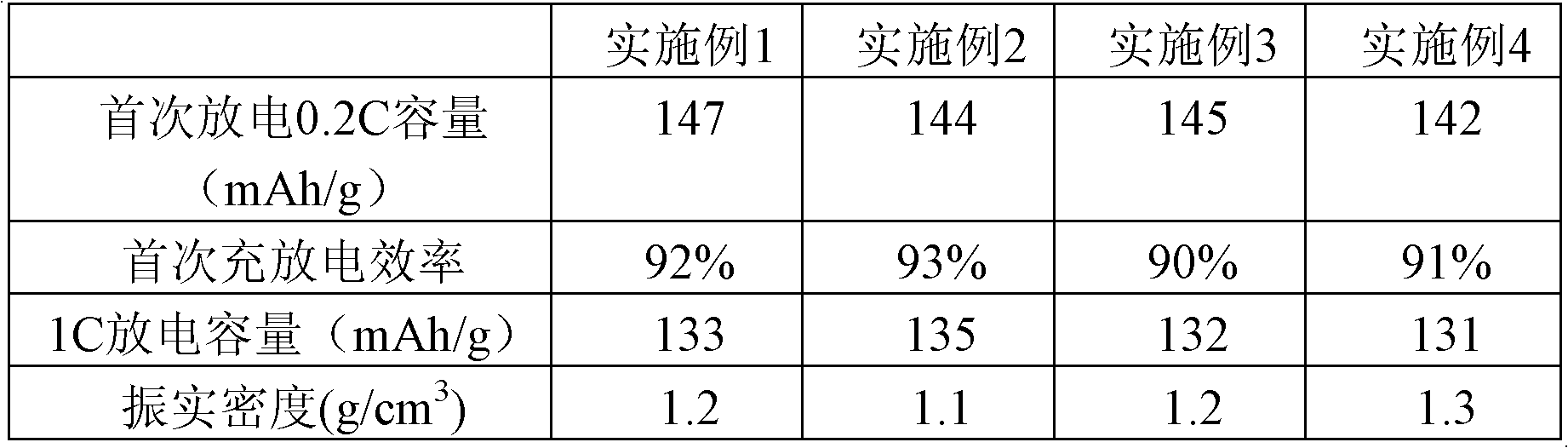

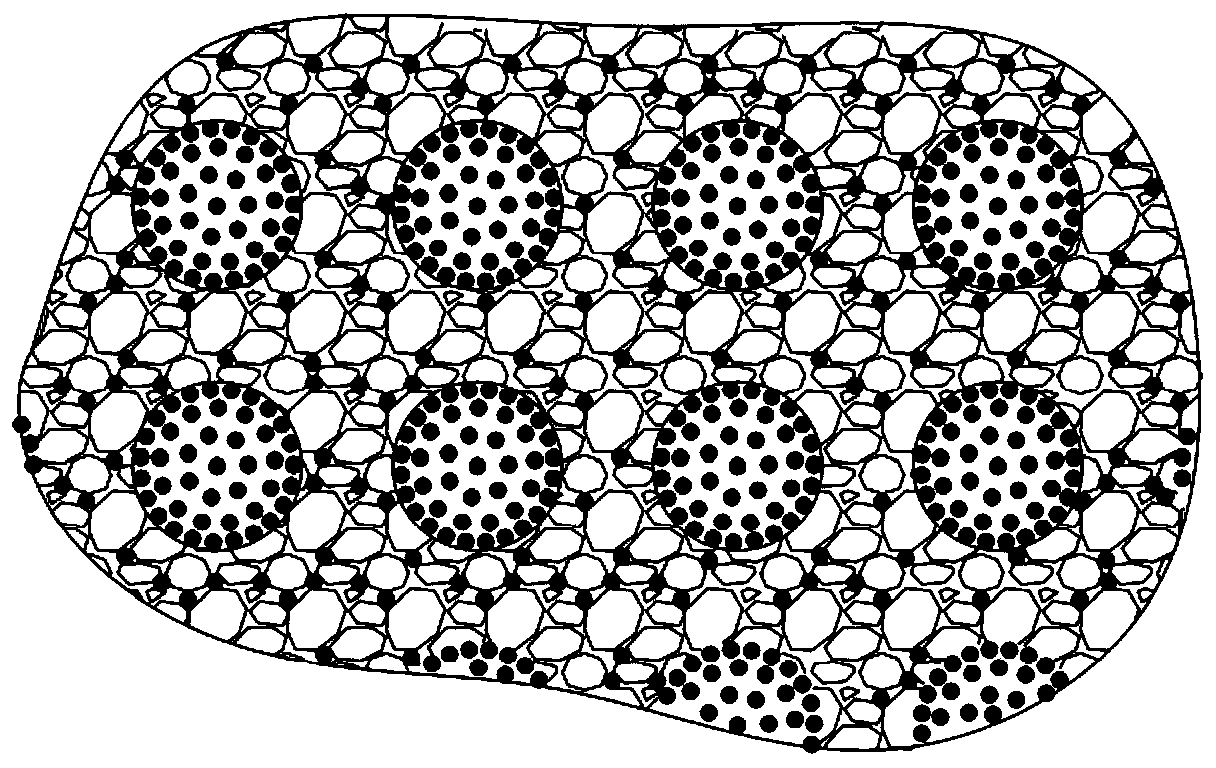

K ion-doped and high-voltage spinel/carbon double-layer coated lithium-rich anode material and preparation method thereof

ActiveCN106299342AImprove the problem of discharge median voltage decayInhibition transitionCell electrodesSecondary cellsCarbon coatingDouble coating

The invention discloses a K ion-doped and high-voltage spinel / carbon double-layer coated lithium-rich anode material and a preparation method thereof. The lithium-rich anode material comprises a K ion-doped modified core and a high-voltage spinel / carbon double coating layers, wherein the surface of the core is coated with the high-voltage spinel / carbon double coating layers, the core is Li1.2-xKxMn0.6-yNi0.2-yCo2YO2, x is equal to 0.00-0.1, and y is equal to 0.00-0.05; the component of the high-voltage spinel layer in the high-voltage spinel / carbon double coating layers is Li1-xKxMn1.5-yNi0.5-yCo2yO4, x is equal to 0.0-0.2, and y is equal to 0.0-0.1; the carbon coating layer is of a composite structure of dopamine polymer pyrolytic carbon and reduced graphene oxide. The preparation method includes the steps that through a spraying drying technology, the K ion-doped modified core is prepared, the surface of the core is coated with dopamine polymer, coating of graphene oxide is carried out on the basis, and through follow-up sintering, the K ion-doped and high-voltage spinel / carbon double-layer coated lithium-rich anode material is prepared. A modification step is easy to control, and the electrochemical performance of the lithium-rich anode material can be obviously improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing high-performance lithium iron phosphate cathode material by using compound type reducing agent

InactiveCN102097619AUniform temperatureStable structureCell electrodesNitrogen gasBiological activation

The invention relates to a method for preparing high-performance lithium iron phosphate cathode material by using compound type reducing agent, belonging to the technical field of preparation of a lithium ion battery cathode material. The invention has the technical point that the method comprises the following steps: carrying out uniform compound ball-milling on an iron source, a lithium source, a phosphorous source and a compound carbon source for 1-3 hours, wherein the stoichiometric ratio of the lithium source to the iron source to the phosphorous is (1-1.1): 1: 1, and the compound carbon source accounts for 6-10% of the total mass of the materials; drying size obtained by the compound ball-milling at the temperature of 100-120 DEG C and smashing the dried size; heating the smashed size to 650-800 DEG C in nitrogen atmosphere at the heating rate of 2-5 DEG C / min, insulating for 3-15 hours, and cooling to room temperature to obtain lithium iron phosphate powder. A method combining compound carbon thermal reduction and mechanical activation is adopted, cheap iron oxide is taken as the iron source, the doped compound carbon source is taken as reducing agent and conductive agent, and lithium iron phosphate cathode material with stable structure and high electrochemical activity is synthesized by one-step reaction.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Coating of lithium ion battery positive plate, coating preparation method and positive plate

ActiveCN101771148AImprove conductivityGood flexibilityCell electrodesPhysical chemistryLithium-ion battery

The invention is suitable for the field of battery manufacture and provides a coating of a lithium ion battery positive plate. The coating contains the solid matter in weight percent: 90 to 97 percent of anode active substance, 0.5 to 2 percent of acetylene black, 0.5 to 1.5 percent of crystalline flake graphite, 0.5 to 1.5 percent of Ketjen black and 1.5 to 5 percent of PVDF. After the technical scheme is adopted, due to the application of the acetylene black, the crystalline flake graphite and the electrocarbon black, the electrical conductivity and the flexibility of the positive plate are obviously improved, thereby being beneficial to the utilization of battery capacity and prolonging the service life of the battery.

Owner:SHENZHEN CHAM BATTERY TECHNOLOGY CO LTD

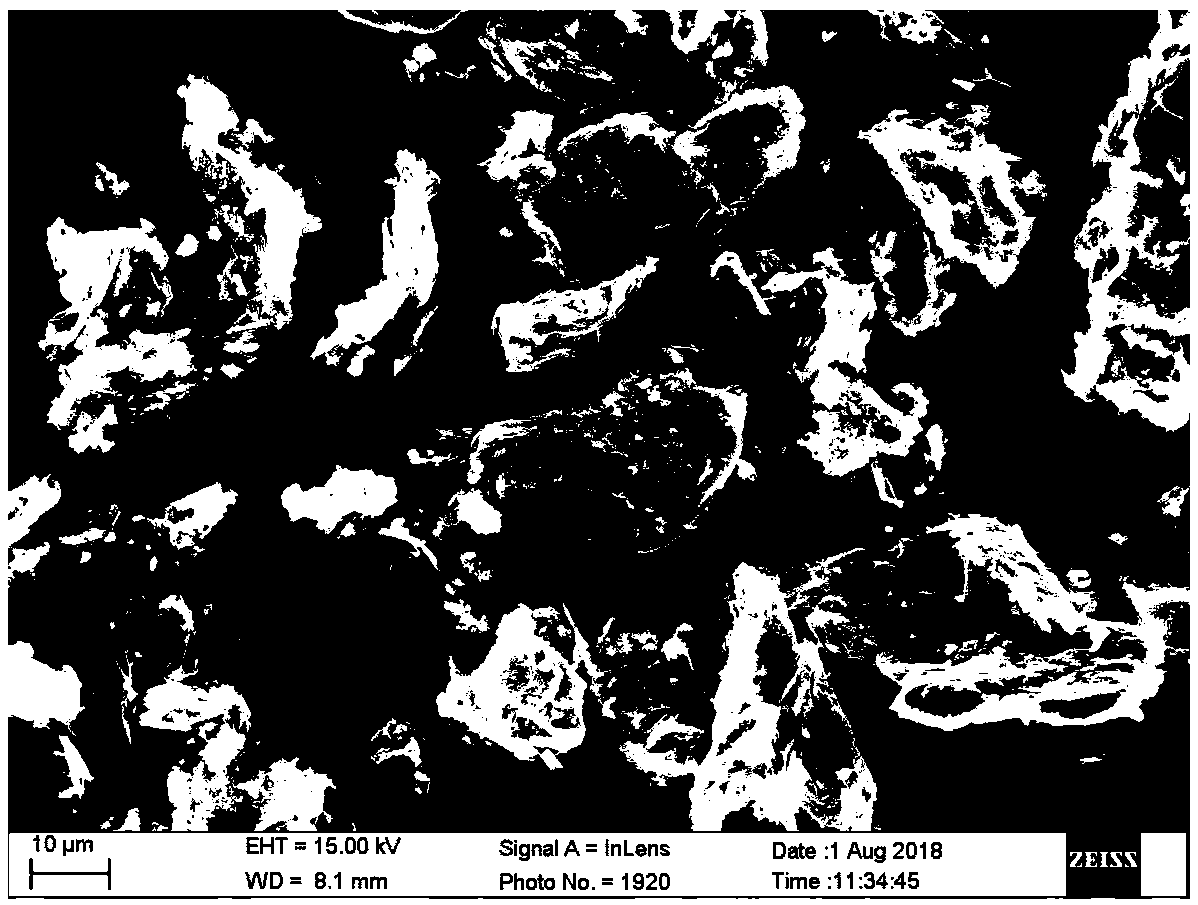

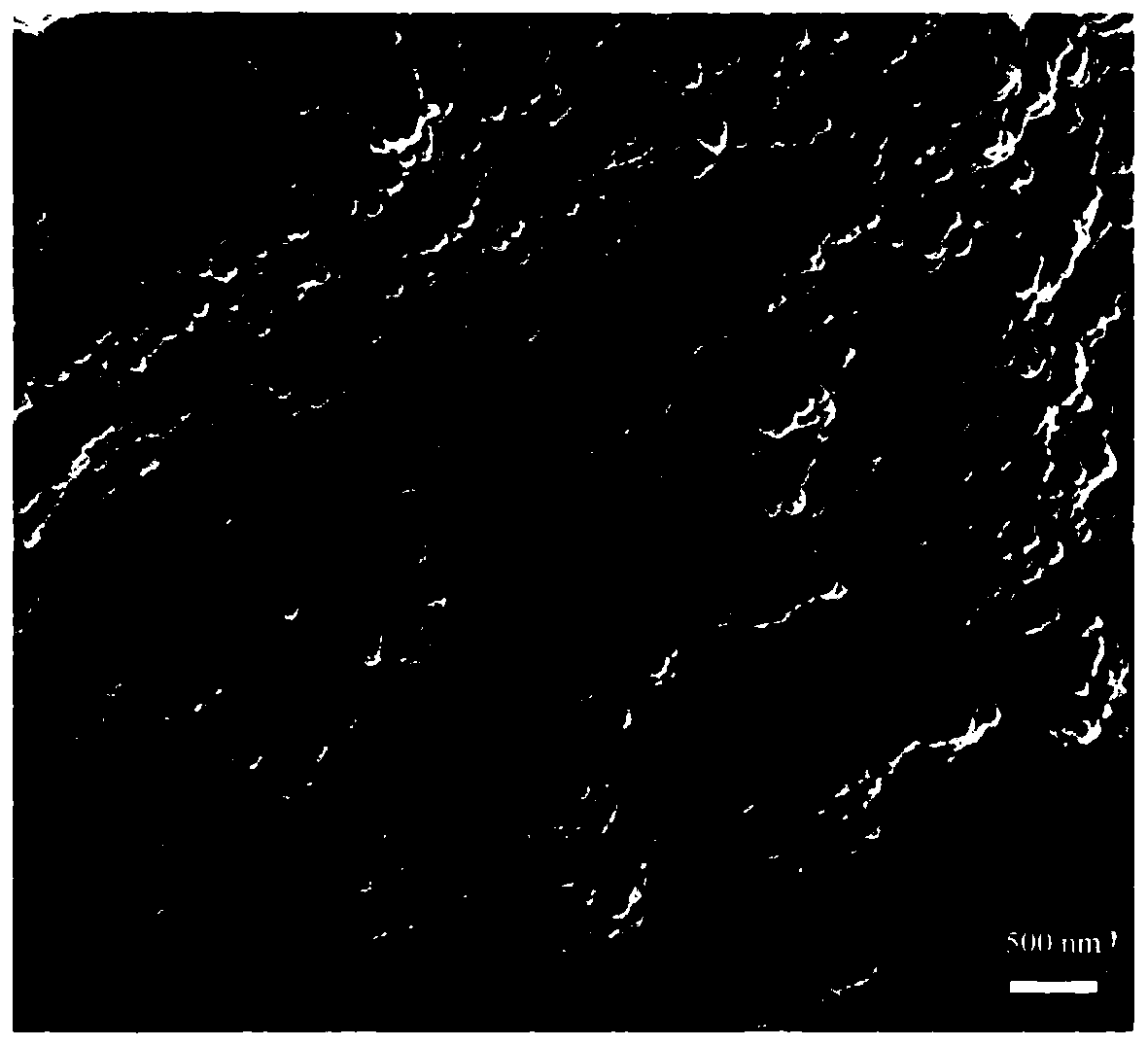

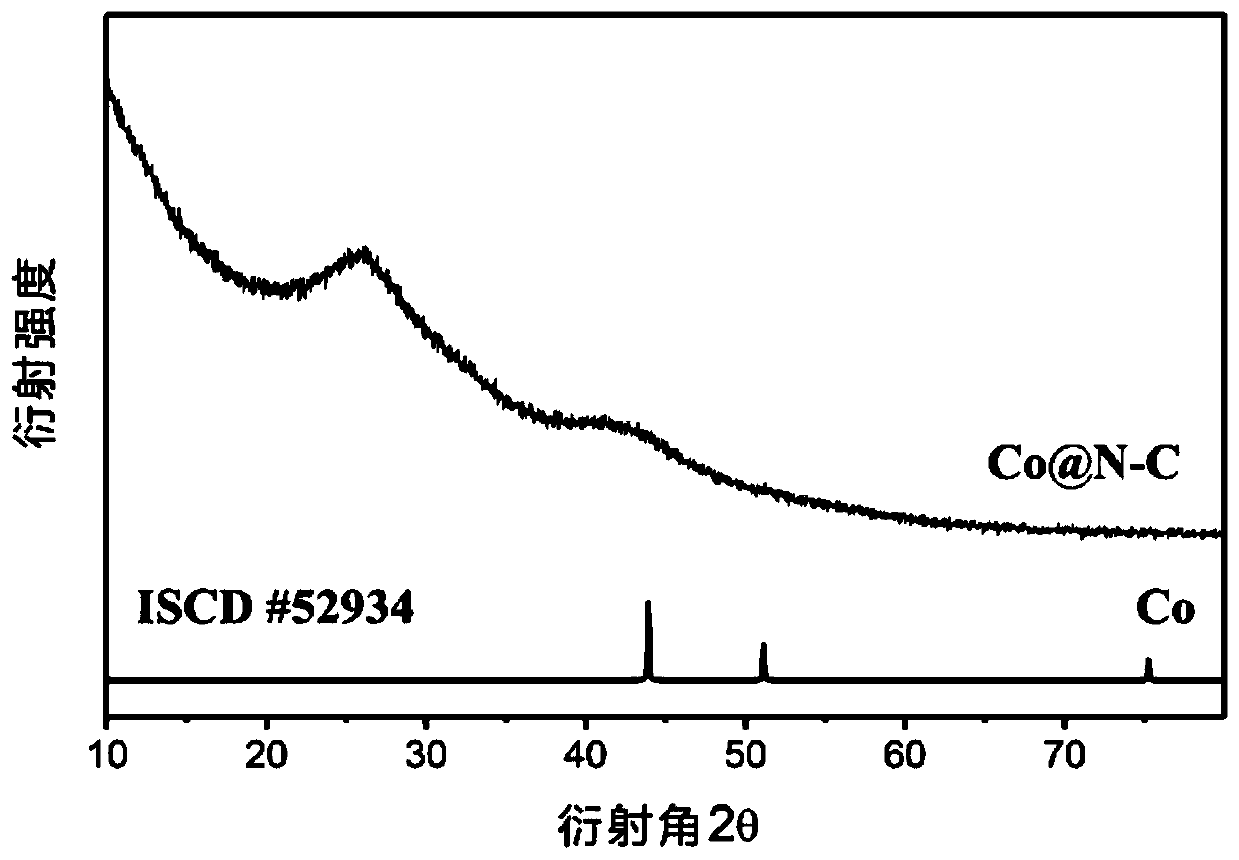

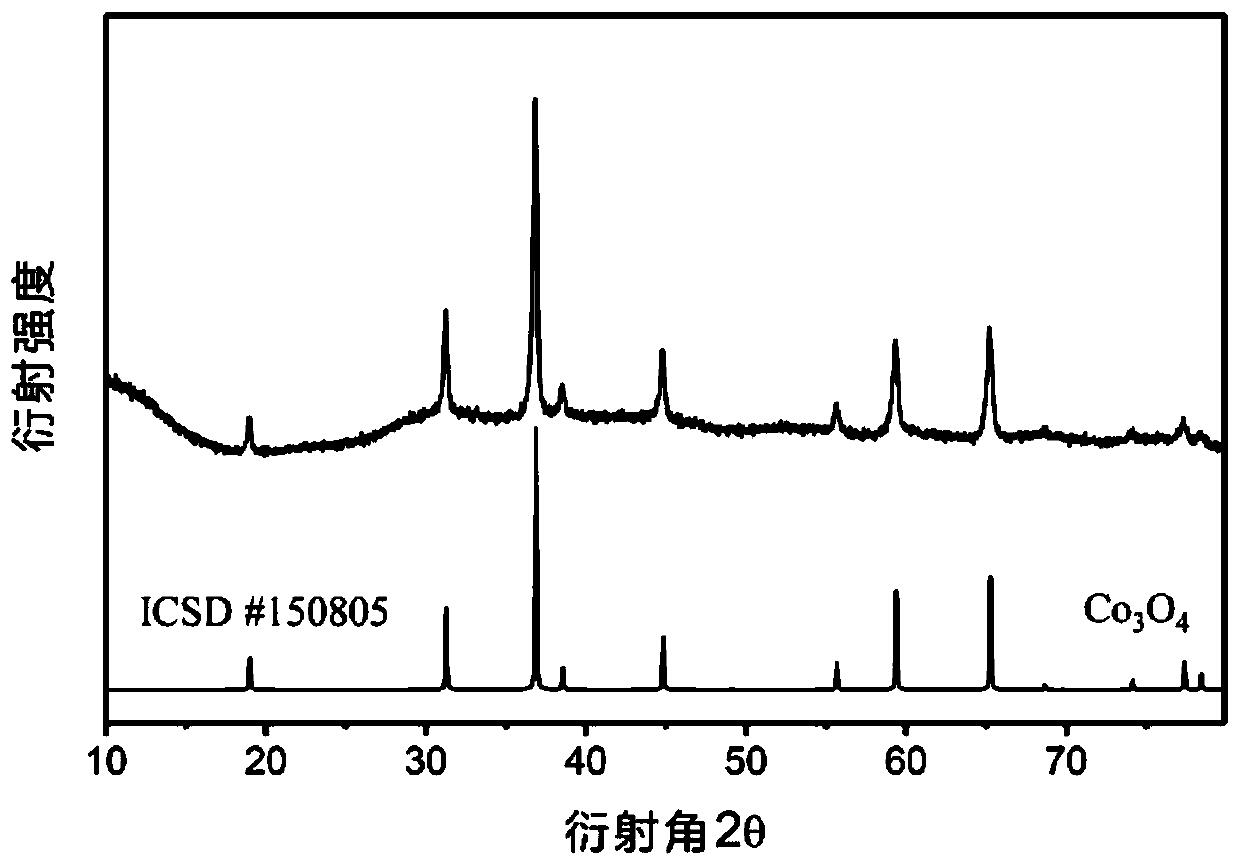

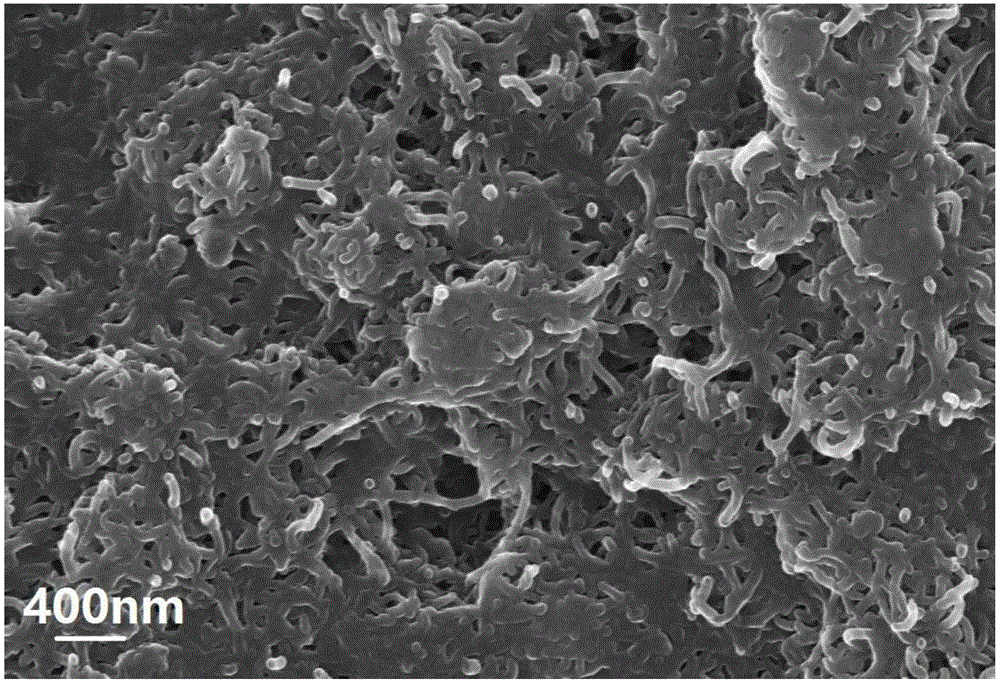

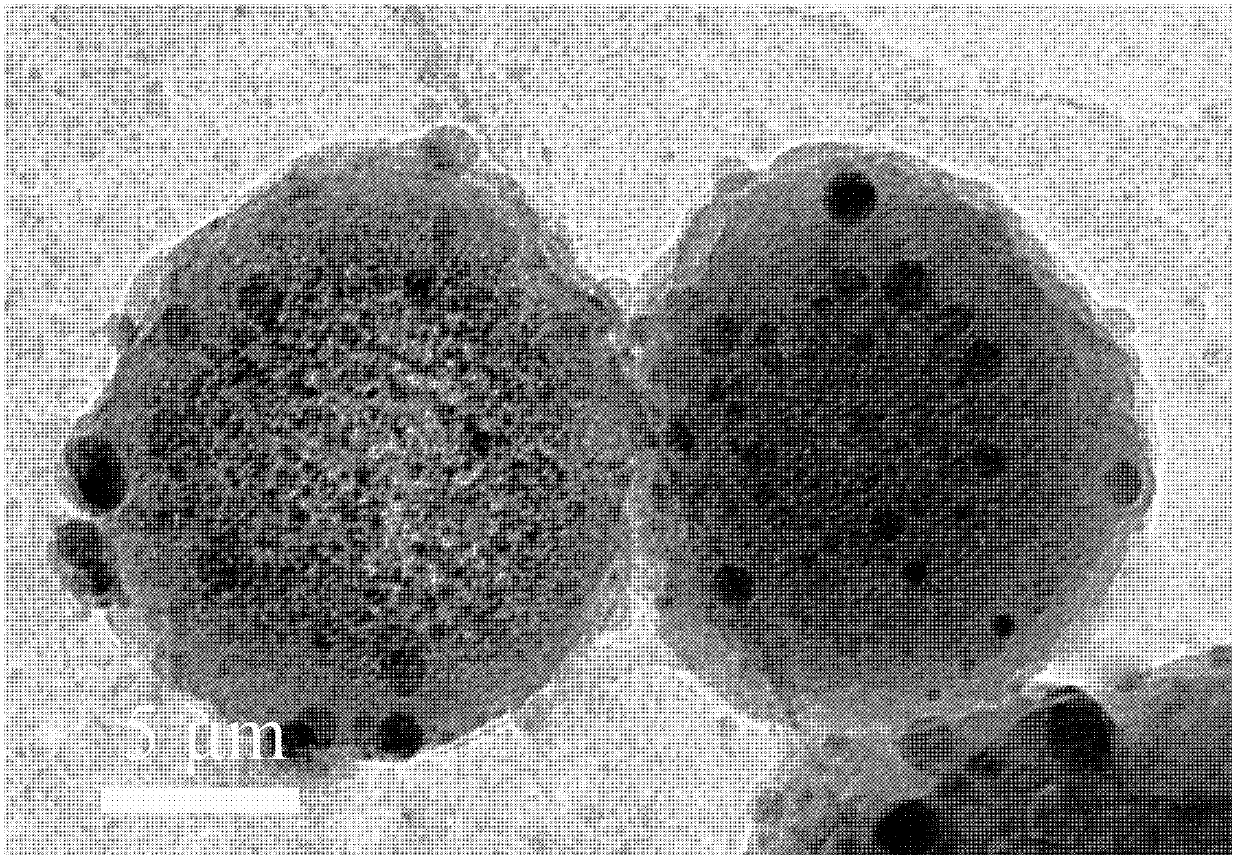

Transition metal cobalt single atom/cluster embedded nitrogen-doped carbon skeleton material, and preparation method and application thereof

InactiveCN110364705ACluster uniformEvenly dispersedCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a transition metal cobalt single atom / cluster embedded nitrogen-doped carbon skeleton material, and a preparation method and application thereof. The preparation method comprises the following steps: adding a cobalt source, a nitrogen-containing carbon source and silicon dioxide into a solvent, and carrying out ultrasonic stirring; carbonizing the obtained mixture in an inert atmosphere; carrying out pickling and etching on the obtained product in hydrochloric acid and hydrofluoric acid, and then washing and drying to obtain the transition metal cobalt single atom / cluster embedded nitrogen-doped carbon skeleton material. The method is simple in step and high in repeatability, and for the transition metal cobalt single atom / cluster embedded nitrogen-doped carbon skeleton, a mixed structure is endowed with enhanced electron conduction, and a large amount of uniformly dispersed N-C and Co-Nx active sites are introduced, thereby facilitating absorption of lithium ions and promotion of the interface reaction of the electrode material and the electrolyte. When being used as a lithium ion battery negative electrode material, the metal cobalt single atom / cluster embedded carbon hybrid material shows ultrahigh electrochemical activity and has very high potential application value.

Owner:SOUTH CHINA UNIV OF TECH +1

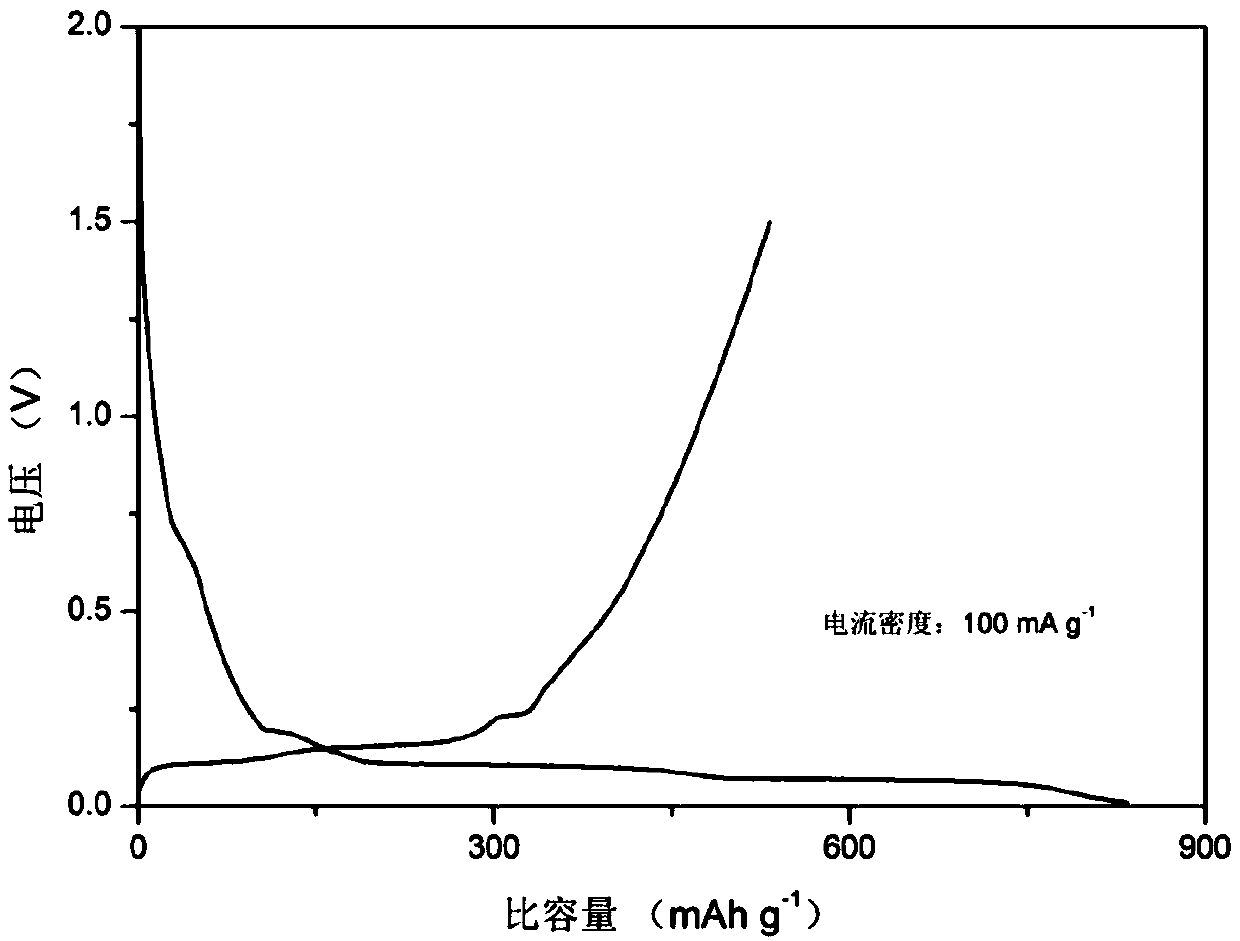

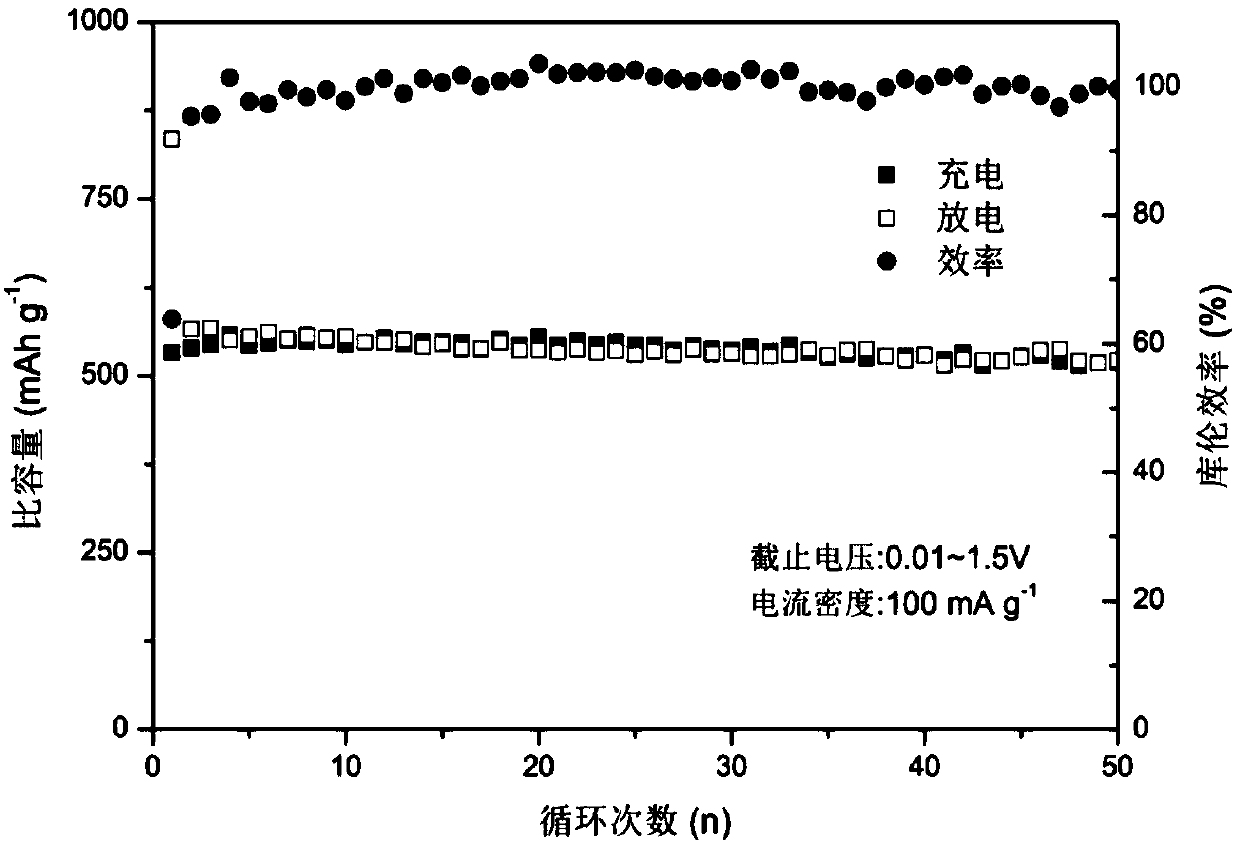

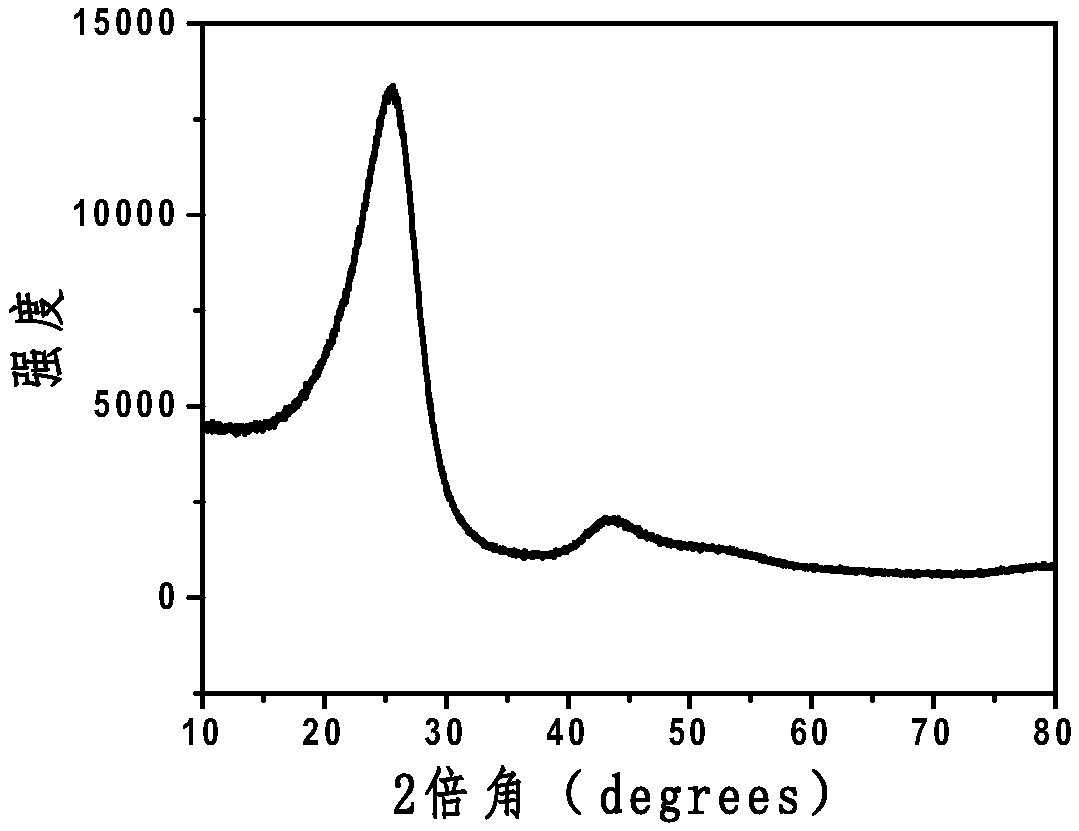

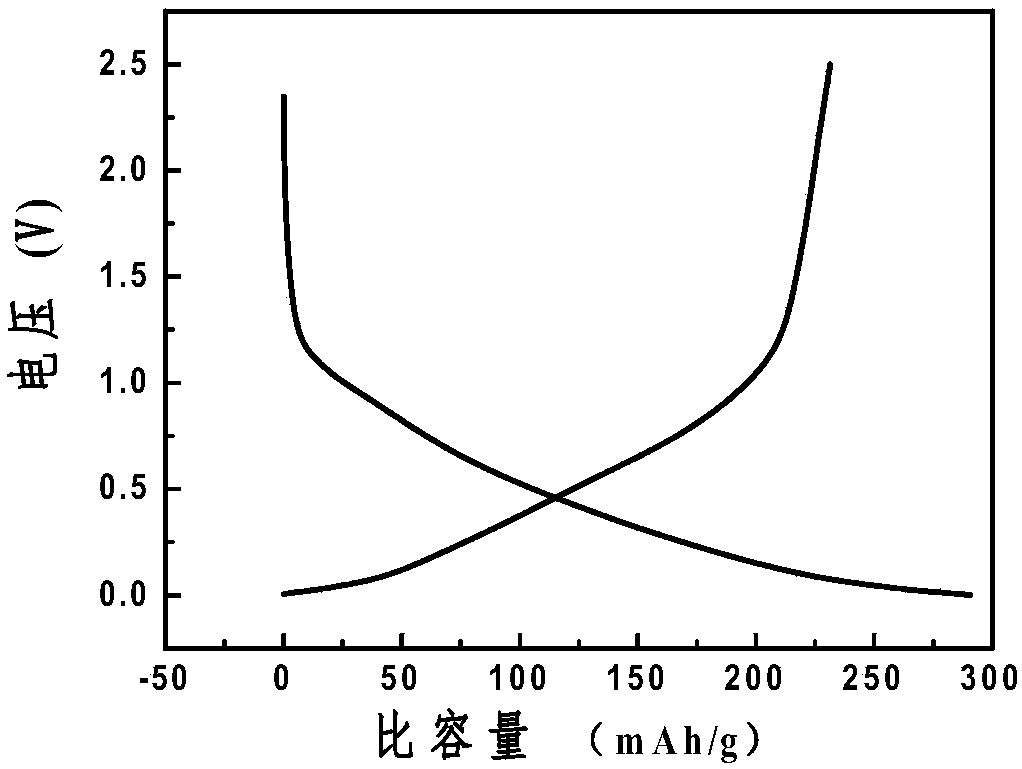

A carbon-based negative electrode material with high ramp capacity and a preparation method and use thereof

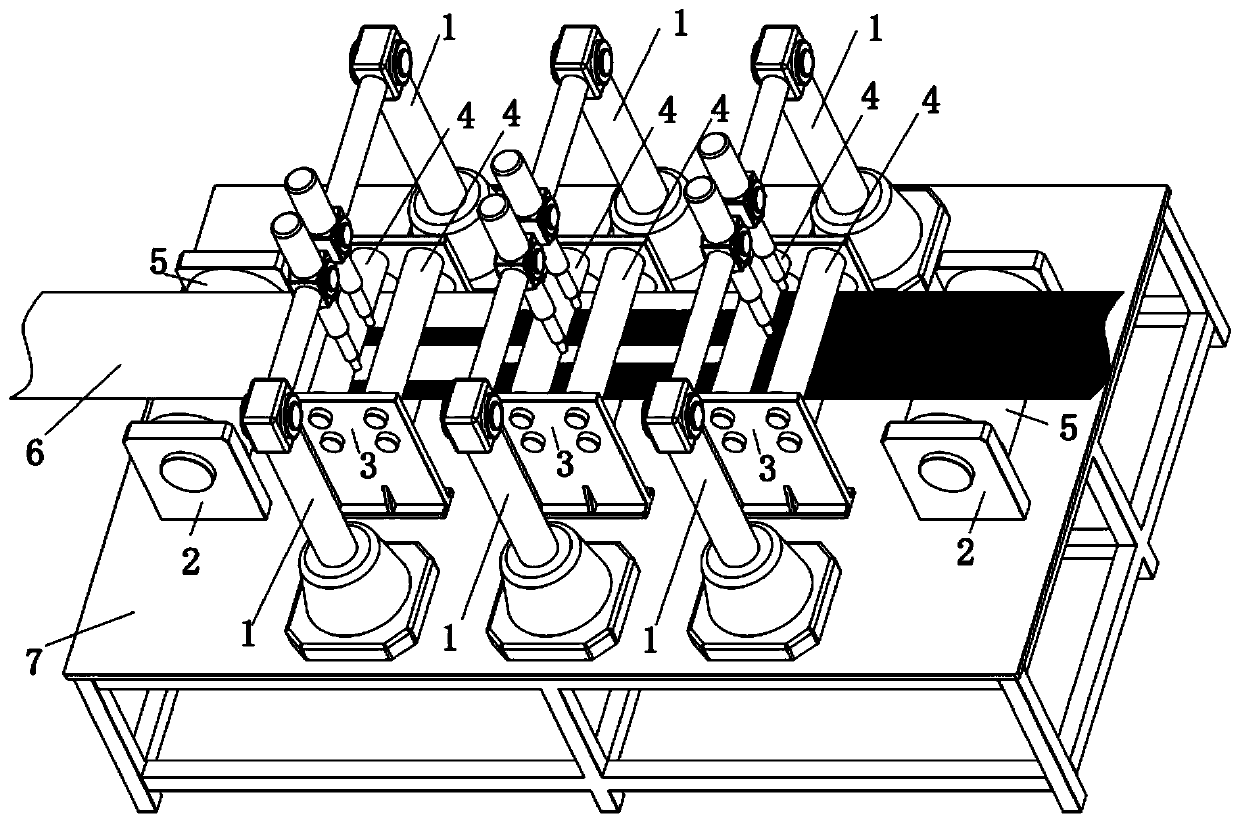

ActiveCN109148884ALow carbonization temperatureShort processing timeNon-aqueous electrolyte accumulatorsCell electrodesSodium-ion batteryCycle efficiency

An embodiment of the invention relates to a carbon-based negative electrode material with high ramp capacity and a preparation method and use thereof. The method comprises: placing a carbon source precursor in a crucible, placing the precursor in a heating device, and heating the precursor in an inert atmosphere at 0.2 DEG C / min to 30 DEG C / min to 400 DEG C to 1000 DEG C; wherein the carbon sourceprecursor comprises any one or a combination of at least two of fossil fuel, biomass, resin, and organic chemical; the carbon source precursor is subjected to heat treatment at low temperature at 400DEG C to 1000 DEG C for 0.5 to 48 hours, carbonizing that precursor of the carbon source to obtain a carbon-based negative electrode material; The specific surface area of carbon-based cathode material obtained by low temperature heat treatment is less than 10m2 / g. The carbon-based negative electrode material is assembled into the sodium ion battery, and then is charged and discharged between 0 to 2.5 V, and the voltage curve with high ramp capacity is obtained. The ramp capacity is above 180 mAh / g and the first-cycle Coulomb efficiency is above 75%. By coating the surface, the specific surface area can be further reduced, and the first-cycle efficiency and reversible specific capacity can be improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

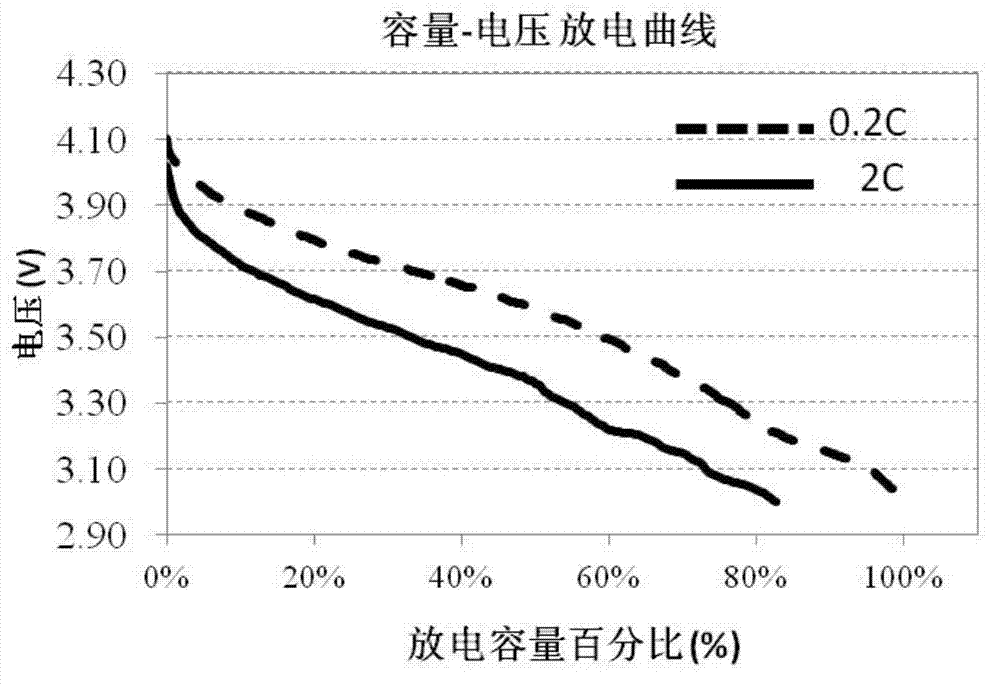

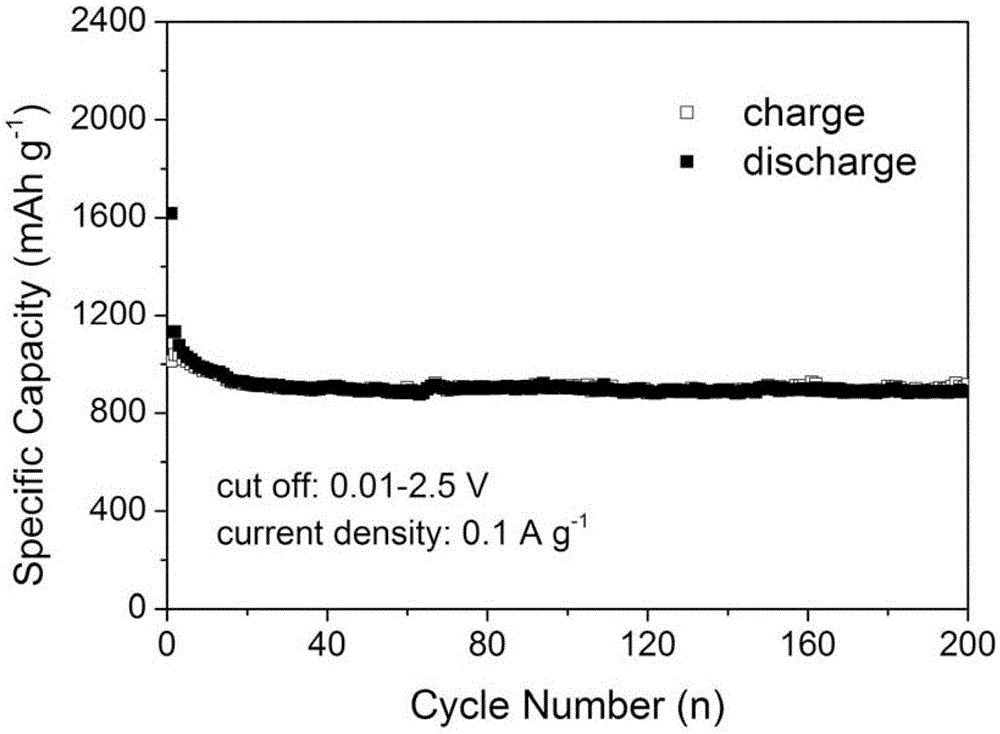

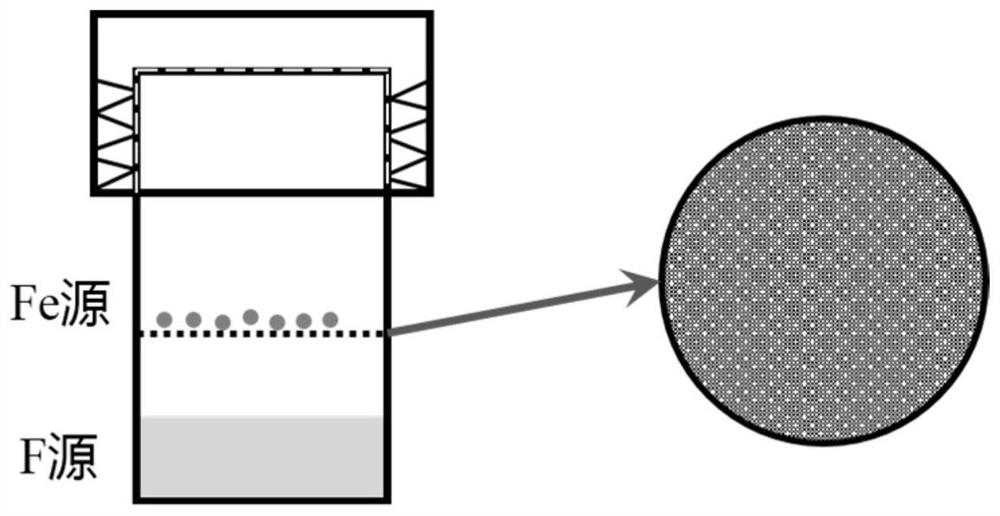

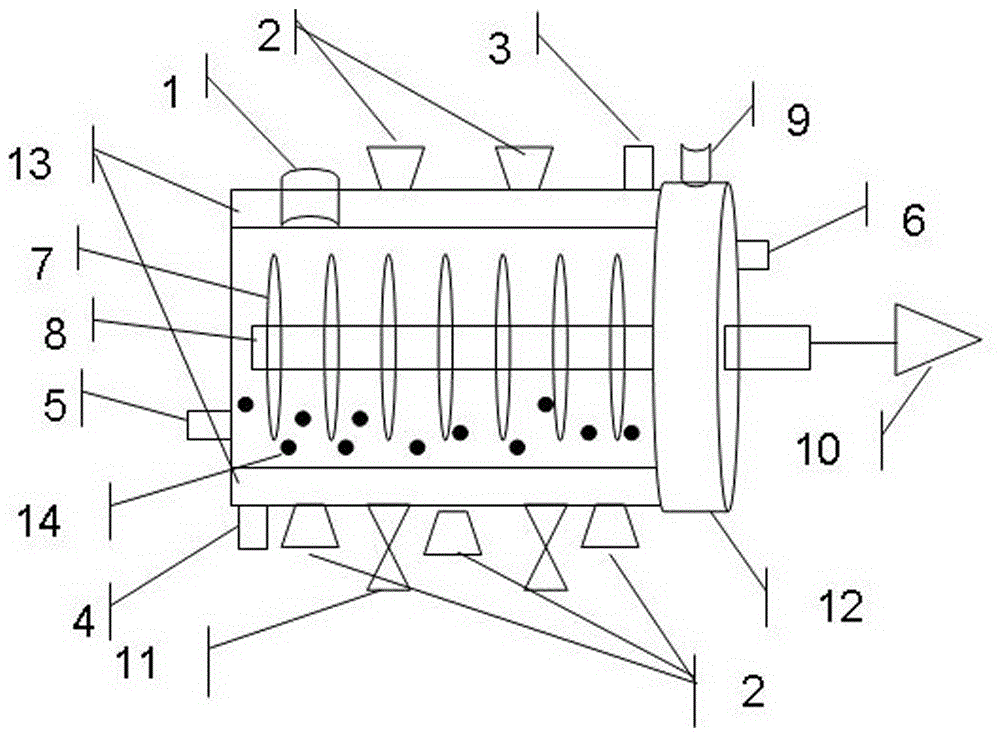

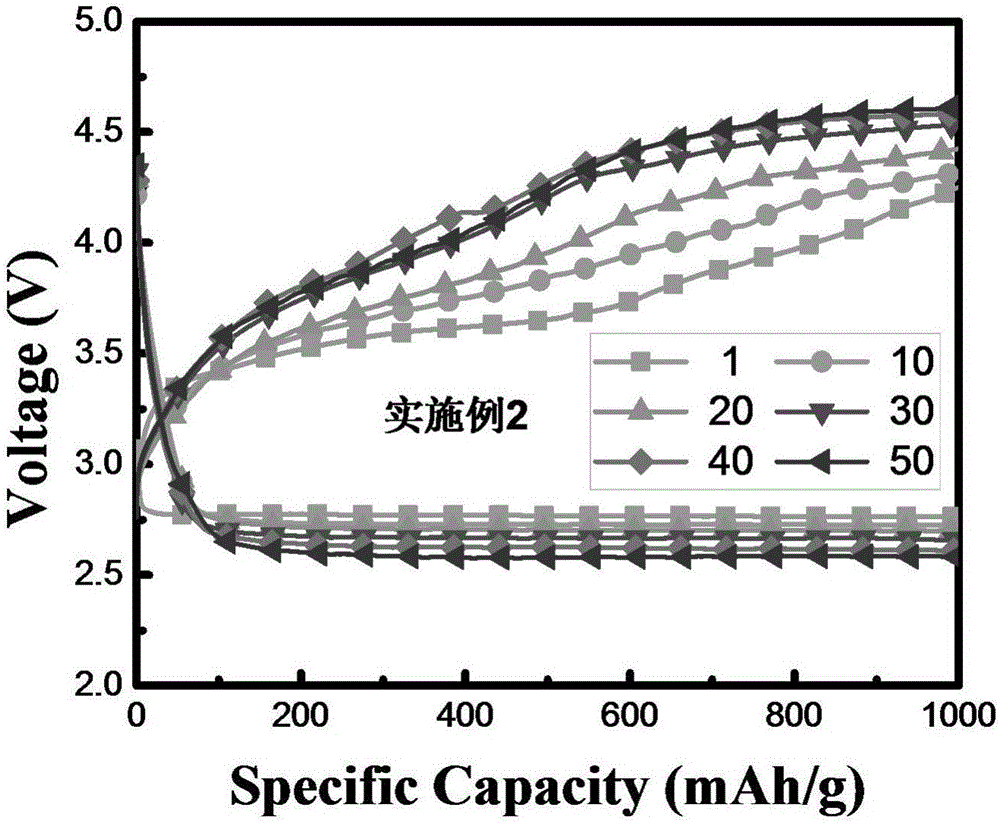

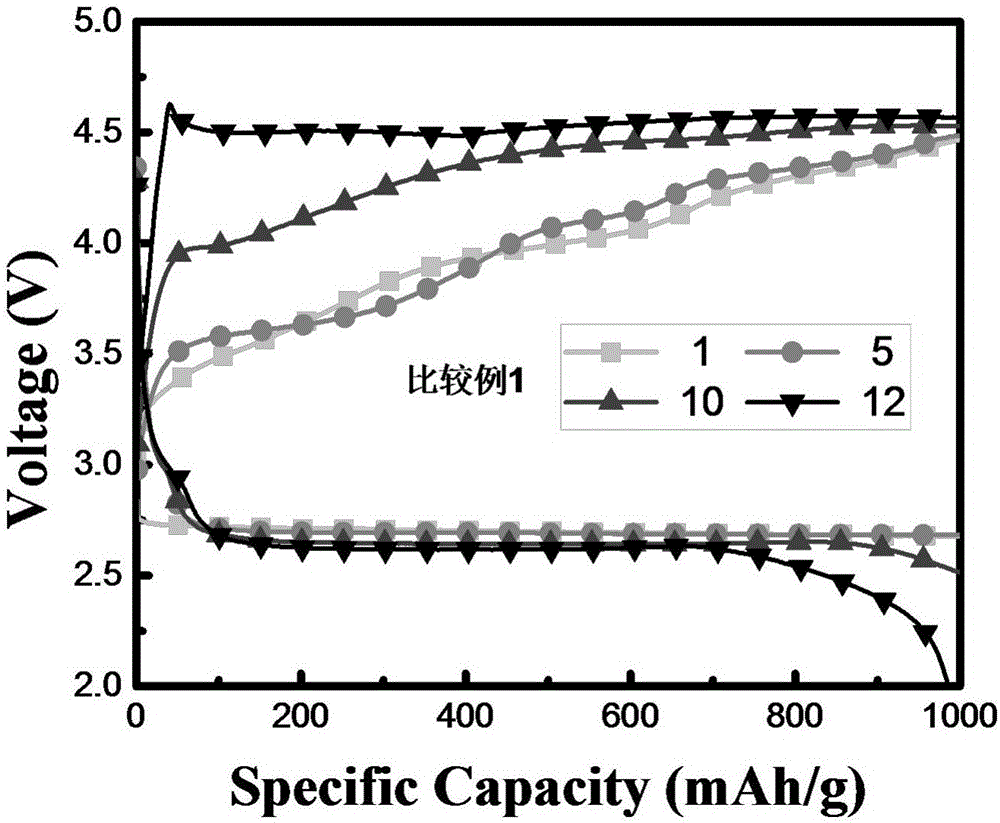

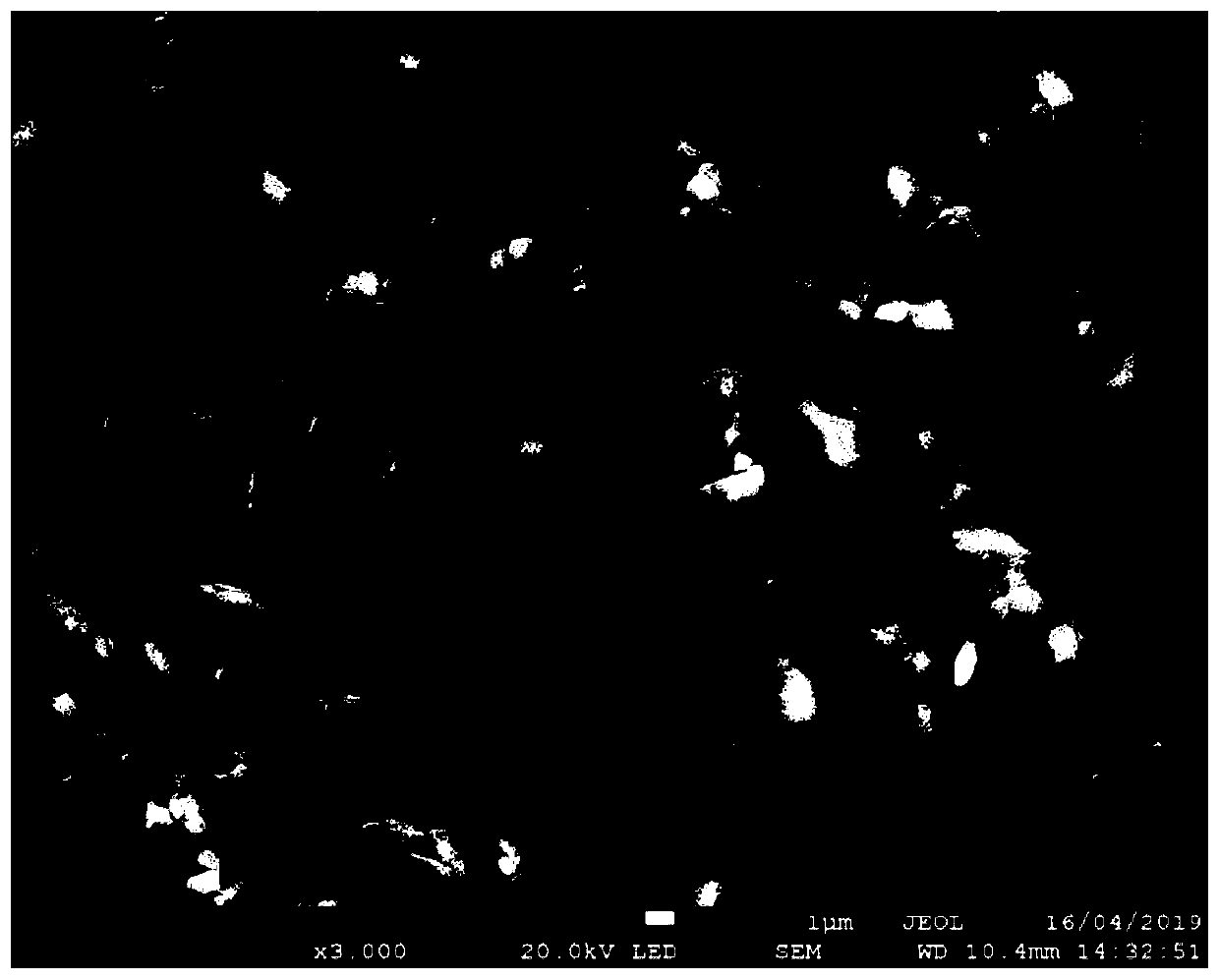

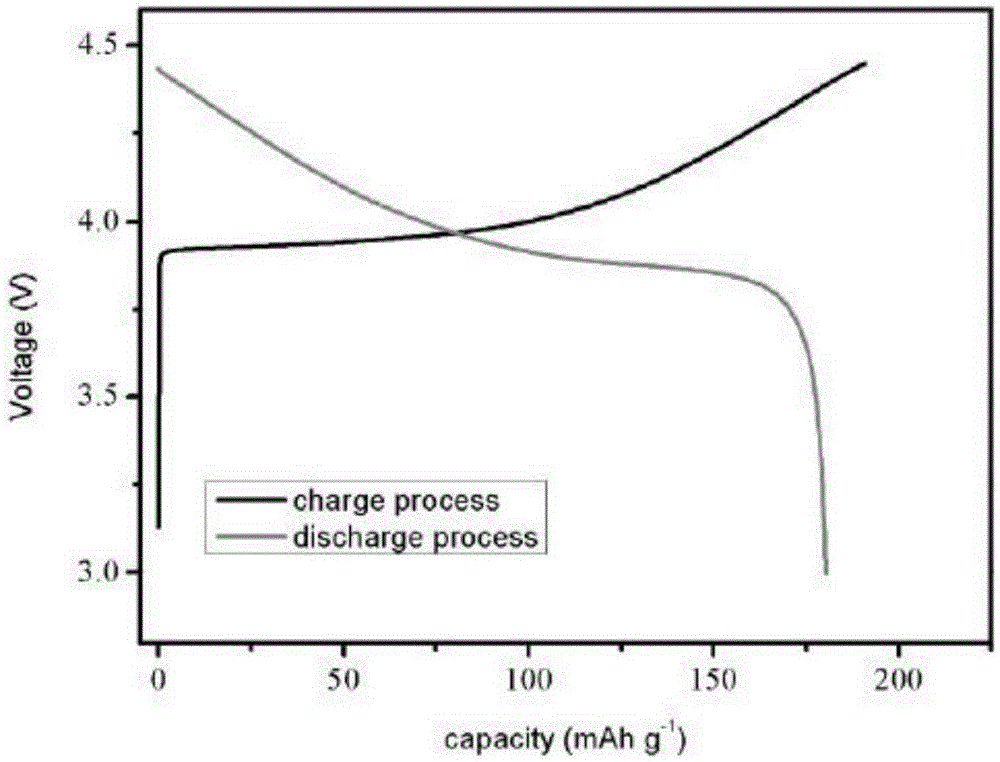

Iron fluoride/carbon composite positive electrode material, preparation method thereof and lithium ion battery

InactiveCN112701286AIn situ recombinationSmooth releaseSecondary cellsPositive electrodesCarbon compositesPhysical chemistry

The invention discloses an iron fluoride / carbon composite positive electrode material, a preparation method thereof and a lithium ion battery. The method comprises the following steps of: (1) reacting steam of a fluorine source and steam of a carbon-containing organic matter with an iron source to prepare a precursor; and (2) carrying out heat treatment on the precursor to obtain the iron fluoride / carbon composite positive electrode material. A fluorine source and a carbon source are introduced through gas-phase reaction, the powder morphology is controlled, and the high-performance iron fluoride positive electrode material is obtained. The lithium ion battery positive electrode material provided by the invention has the advantages of high reversible specific capacity and good cycling stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Preparation method of silicon-graphene compound conductive paste

InactiveCN106025202AImprove electronic conductanceAchieving face-to-face contactCell electrodesSecondary cellsConductive pasteGraphite

The invention discloses a preparation method of silicon-graphene compound conductive paste. The preparation method comprises the following steps: (1) pre-treating graphite: putting the graphite into a mixed solution composed of an oxidant and an intercalation agent; carrying out ultrasonic stirring treatment to obtain a product; washing, filtering and drying the product and then putting the product into a muffle furnace; carrying out high-temperature treatment in nitrogen atmosphere to obtain a graphene dispersed solution for later use; (2) preparing the silicon-graphene compound conductive paste: putting micron-grade high-purity silicon powder and a grinding ball into a grinding pot at the mass ratio of (1-50) to 1; after vacuumizing the system by a vacuum pump, introducing protective atmosphere; driving a stirring rod by a motor and driving the grinding ball by the stirring rod to grind and crush raw material power; adding a carbon binding agent and the graphene dispersed solution; and further stirring and crushing for 0.1h-3h to finally obtain the silicon-graphene compound conductive paste. The conductive paste can be directly prepared into an electrode through forming a film on a current collector without the utilization of the binding agent and the electronic conduction of the electrode is greatly improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

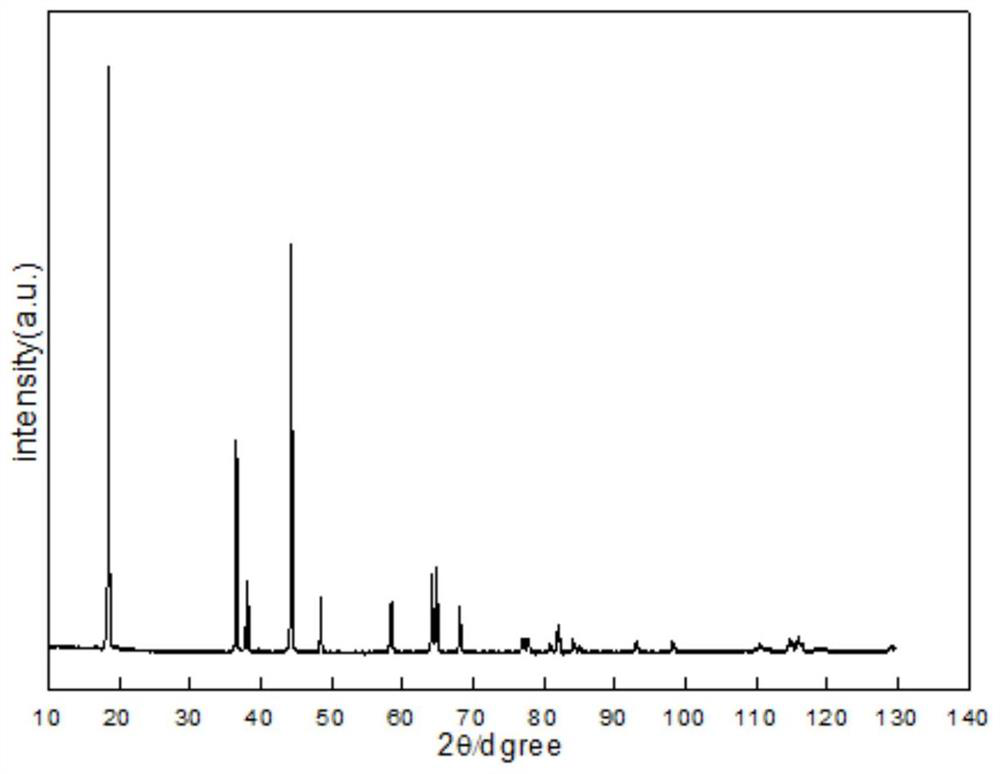

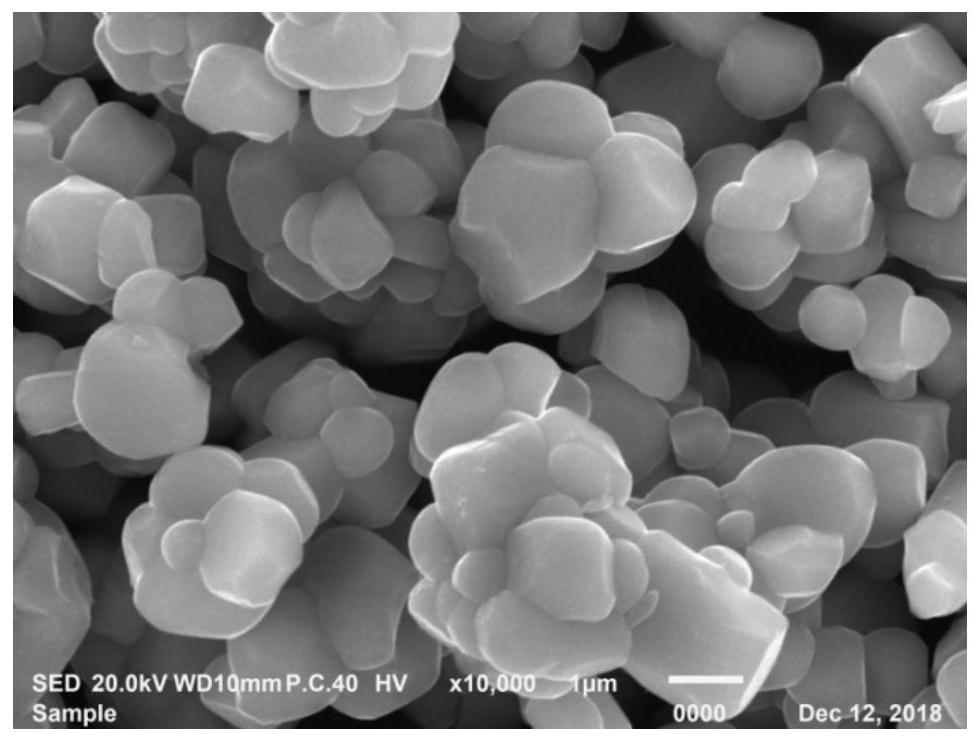

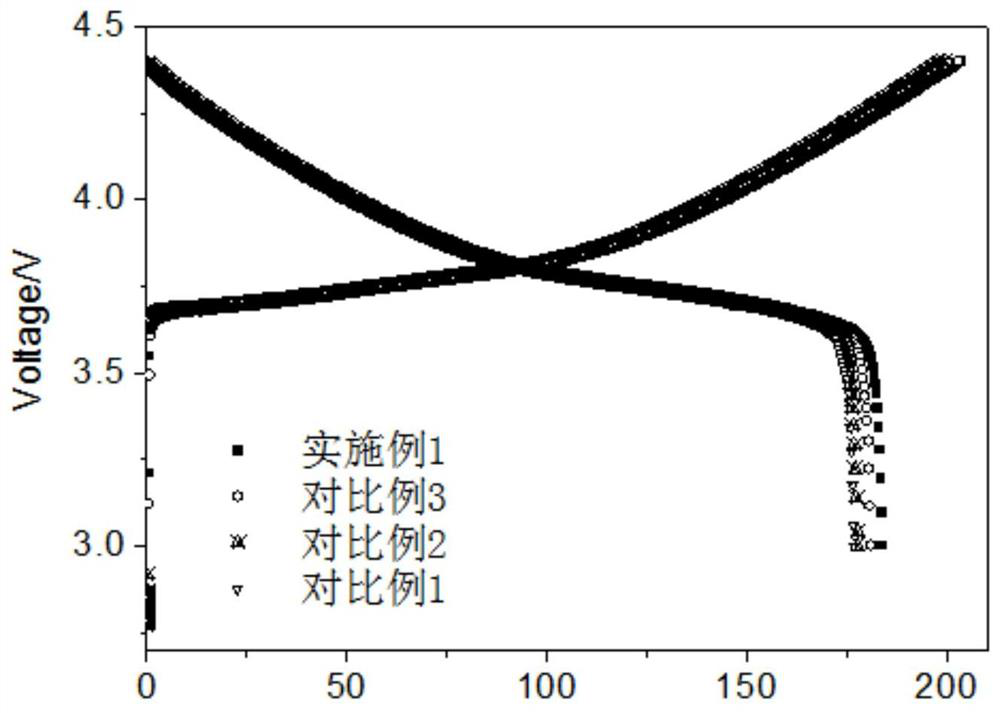

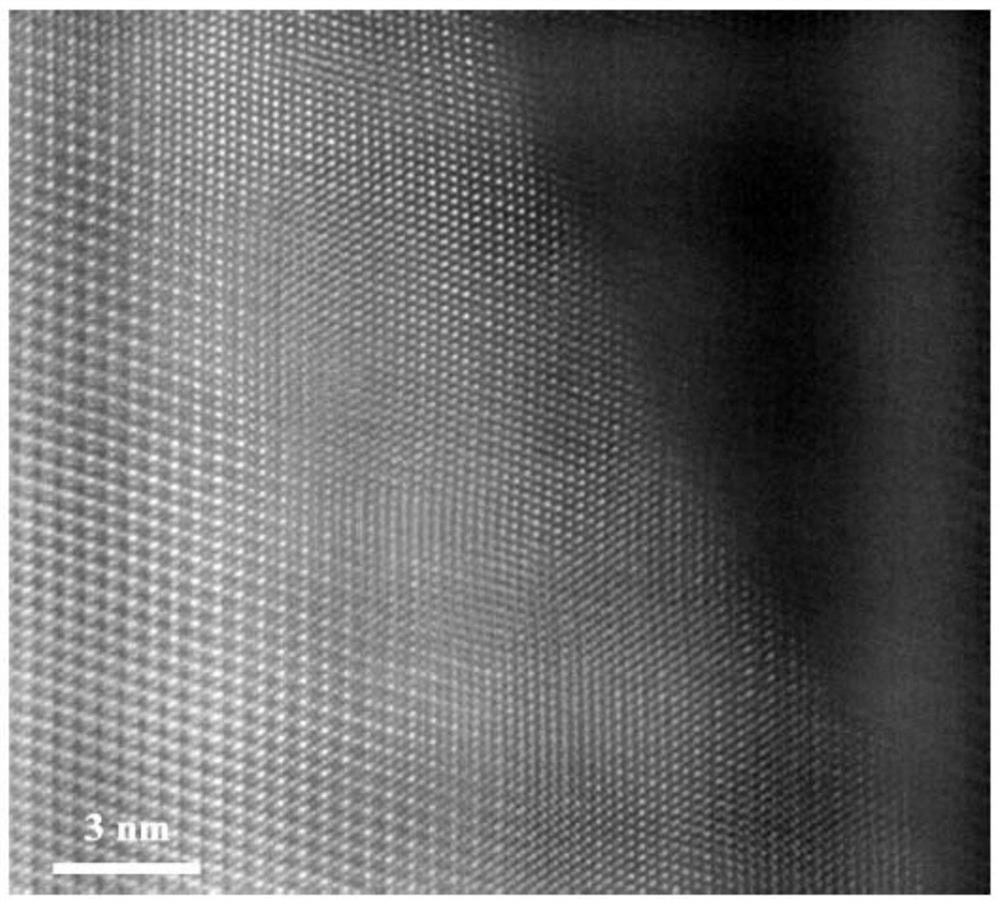

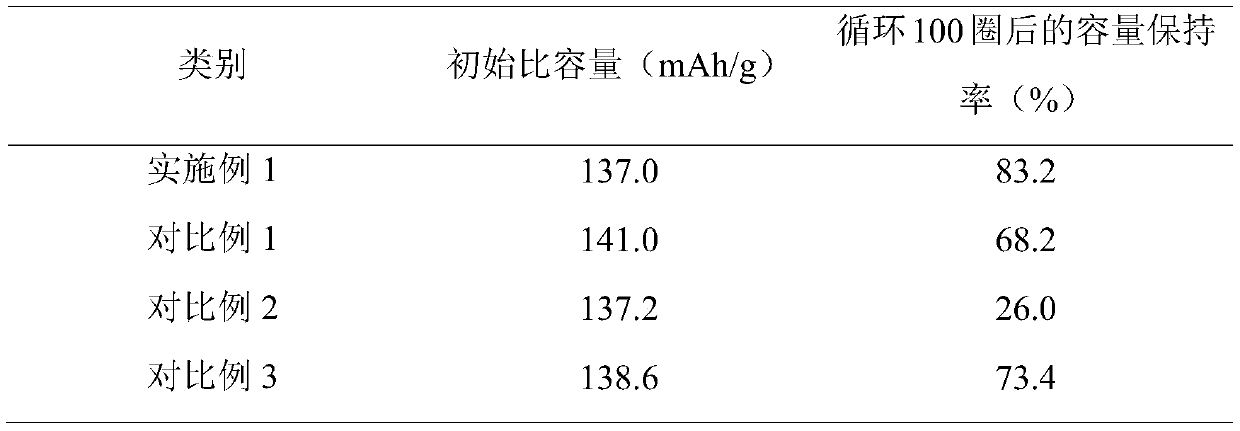

Selenium and silicate co-doped high-nickel cathode material, and preparation method and application thereof

ActiveCN109638275AImprove electrochemical performanceImproved lattice structureCell electrodesSecondary cellsStructural stabilitySe element

The invention relates to a selenium and silicate co-doped high-nickel cathode material, and a preparation method and application thereof. The cathode material is a selenium and silicate co-doped modified high-nickel cathode material, and has a chemical formula of LiNixM1-xSea (SiO4) bO2-a-b, wherein M is at least one of Mn, Co or Al, and 0.5 <= x < 1, 0 < a <= 0.05, 0 < b <=0.05. The high-nickel cathode material is doped with low-valence anions by the selenium and silicate so as to improve the lattice structure of the material. The selenium and the silicate have good synergistic effect, can improve the structural stability of the material under high voltage, and obviously improve the electrochemical performance of the high-nickel cathode material. The obtained cathode material has a firstcycle discharge specific capacity greater than or equal to 185mAh / g and a capacity retention rate greater than or equal to 85% after 200 cycles at a 2.5-4.2V voltage window and 0.1C current density, and has a good application prospect.

Owner:LANGFANG GREEN IND TECH CENT +1

Lithium ion battery positive electrode slurry as well as preparation method and application thereof

PendingCN111430708AAvoid excessive reunionImprove electronic conductanceSecondary cellsPositive electrodesElectrically conductiveCarbon nanotube

The invention discloses a lithium ion battery positive electrode slurry as well as a preparation method and application thereof. The preparation method comprises the following steps of (1) mixing a positive active material, a binder, a first conductive agent and a solvent to obtain the mixed slurry; and (2) mixing the mixed slurry with a second conductive agent so as to obtain the lithium ion battery positive electrode slurry, wherein the first conductive agent is composed of carbon nanotubes, graphene, conductive carbon black, a dispersing agent and the solvent, and the second conductive agent is conductive carbon black. By adopting the method, the distribution of the conductive agent in a positive plate can be remarkably improved, and the problem of poor electronic conductivity and ion transmission of the positive plate is solved, so that the positive plate can exert higher gram volume, and has better rate capability, low-temperature performance and cycle performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

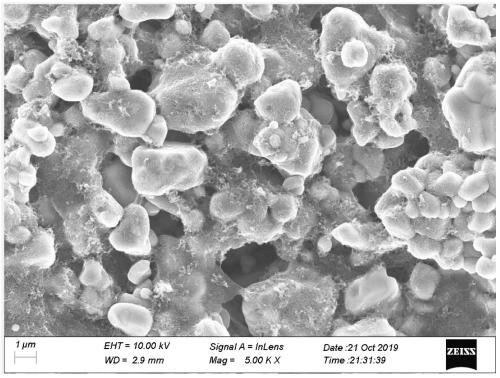

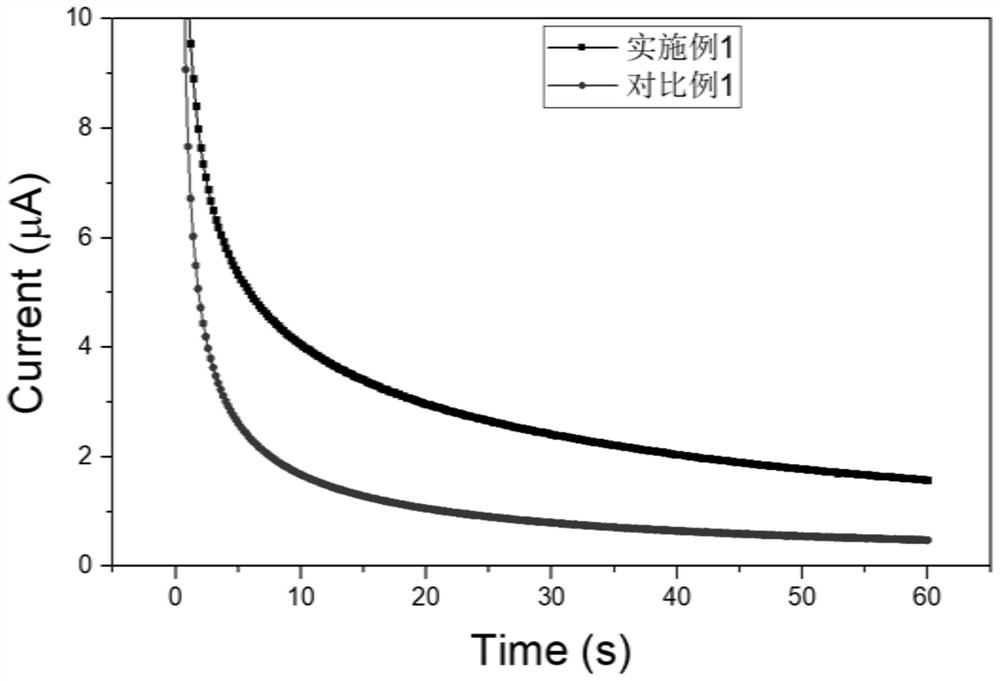

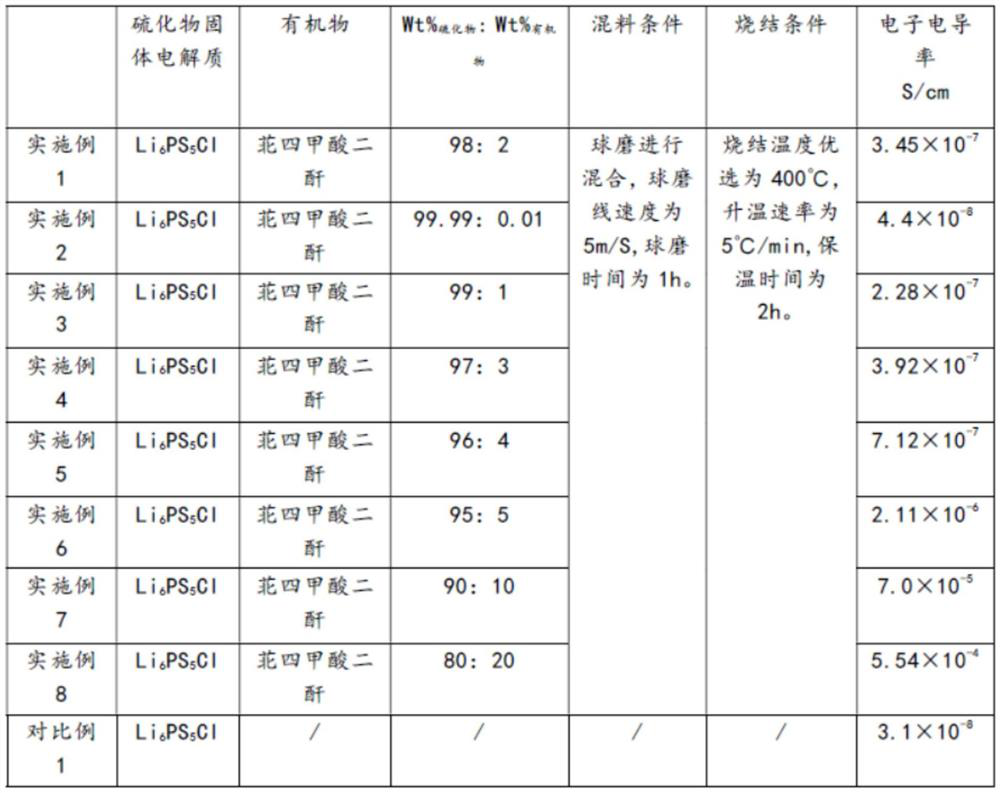

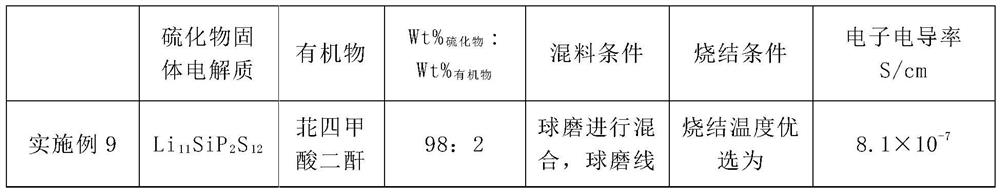

Carbon-containing sulfide solid electrolyte for solid-state lithium battery and preparation method of carbon-containing sulfide solid electrolyte

ActiveCN112768762AImprove electronic conductanceReduce interface resistanceSolid electrolytesSecondary cells servicing/maintenanceHigh electronSulfide compound

The invention discloses a carbon-containing sulfide solid electrolyte for a solid-state lithium battery and a preparation method of the carbon-containing sulfide solid electrolyte. The carbon-containing sulfide solid electrolyte is obtained by mixing a sulfide solid electrolyte with an organic matter and then sintering. The electronic conductivity of the carbon-containing sulfide solid electrolyte is obviously improved, the carbon-containing sulfide solid electrolyte is mixed with an oxide positive electrode to form an ion-electron hybrid network positive electrode with higher electronic conductivity, the interface resistance is reduced, and the stability of the positive electrode is improved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Auxiliary electrode film of lithium air battery as well as preparation and application method thereof

ActiveCN105977508AImprove cycle lifeOvercoming the disadvantages of failureFuel and primary cellsCell electrodesElectrical conductorElectrical battery

The invention discloses an auxiliary electrode film of a lithium air battery. A preparation method of the auxiliary electrode film comprises the steps of mixing a carbon material with a polyvinyl acetal based adhesive, then compounding the mixture on one side of a polyvinyl acetal based porous polymer film to obtain the auxiliary electrode film. An application method of the auxiliary electrode film comprises the steps of assembling the lithium air battery by using the auxiliary electrode film, enabling one side with a carbon material compound layer to face an air positive electrode, and enabling one side uncompounded with the carbon material to face a negative electrode or a diaphragm of the lithium air battery. The auxiliary electrode film of the lithium air battery has excellent structural stability and chemical stability; the inner resistance of a lithium air battery system can be reduced; reversible decomposition reaction of discharge products can be facilitated; more storage space is supplied to the discharge products; a stable three-phase reaction interface formed by an air channel, an ionic conductor and an electronic conductor is guaranteed in a lithium air battery open system and the long-term cycle process; the cycle life of the lithium air battery is significantly prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Silicon anode of lithium ion battery

InactiveCN106531970AGood flexibilityGood chemical stabilityCell electrodesSecondary cellsCyclic processSilicon dioxide

The invention discloses a silicon anode of a lithium ion battery. The silicon anode is formed by bonding a conductive agent and an anode material, the anode material comprises anode active matter and a binding material, the anode active matter comprises graphite and silicon dioxide, and the binding material is an organic solvent type binding agent. A conductive agent is of a silicon nanotube ball structure and comprises a plurality of evenly distributed silicon nanotubes, and the anode material is attached to the surfaces of the silicon nanotubes. A carbon material has high electronic conductivity and ionic conductivity, the rate capacity of the silicon material can be improved, and the volume effect of silicone in the circulating process can be inhibited. The silicon anode has high battery capacity and circulating stability.

Owner:SUZHOU GREEN POWER TECH CO LTD

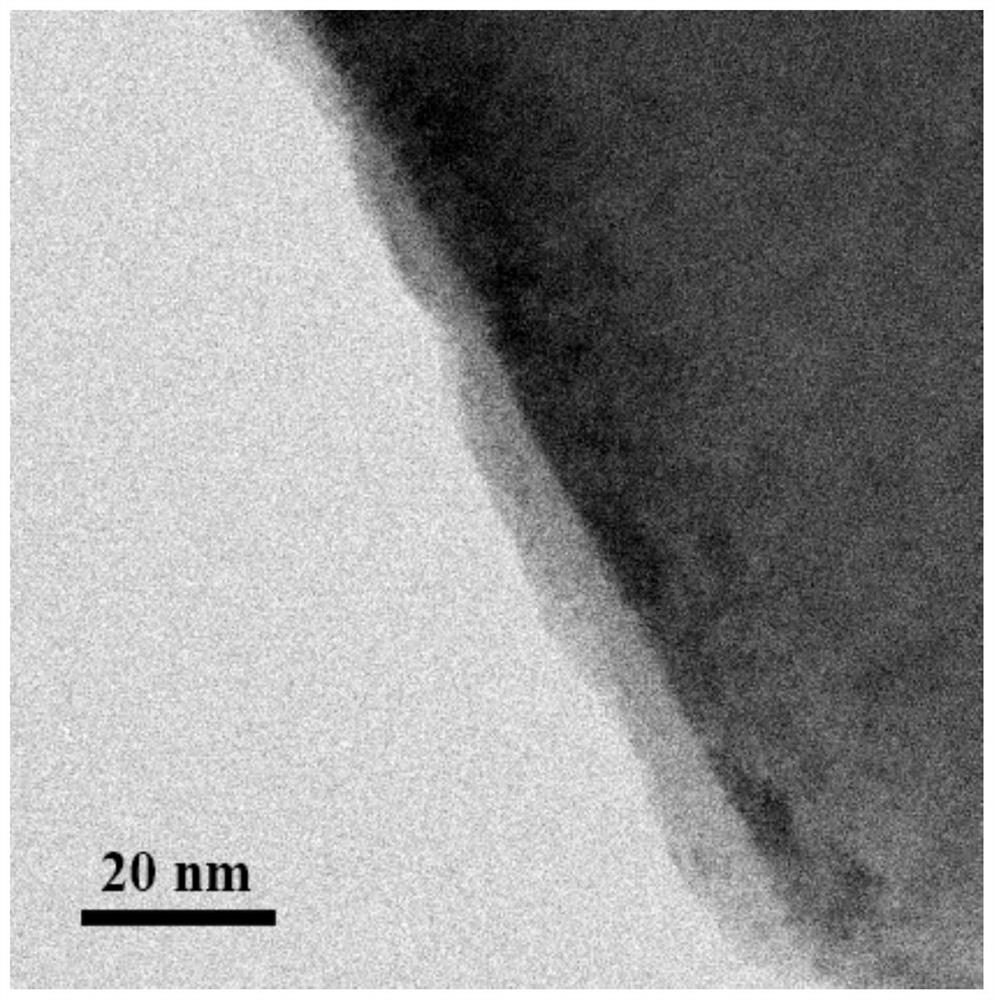

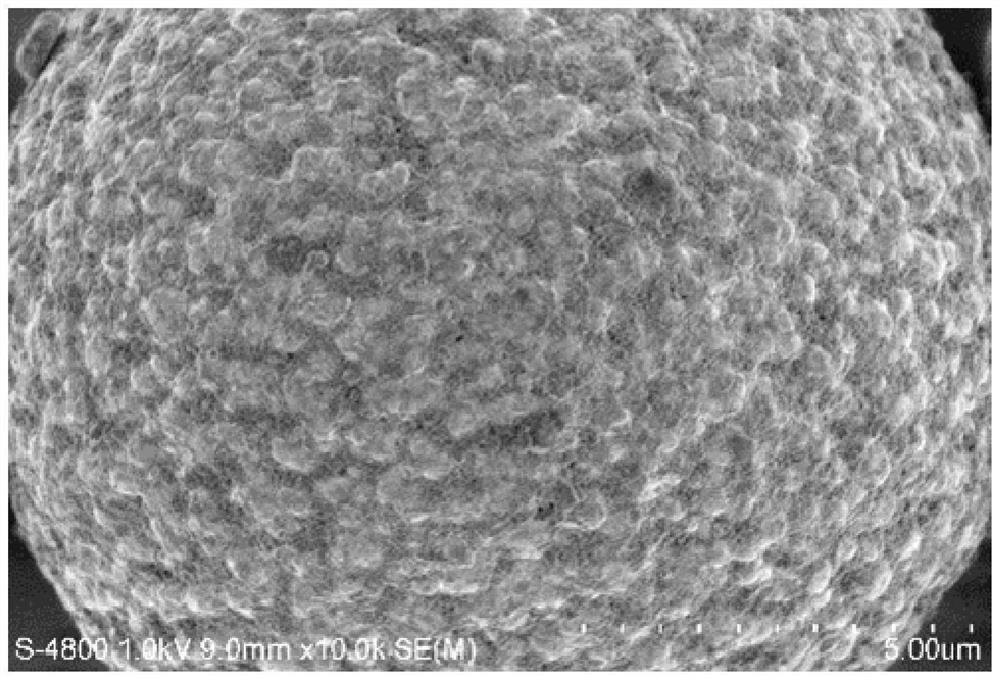

Lithium ion battery, lithium ion battery negative electrode material and preparation method thereof

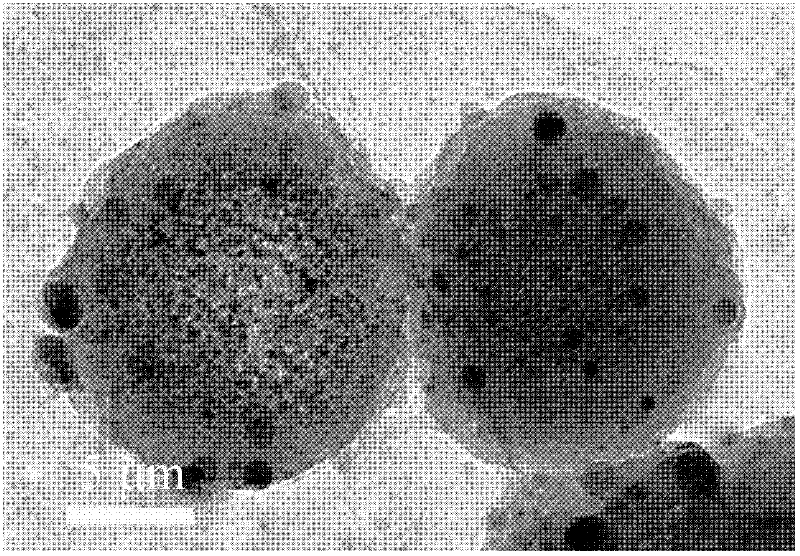

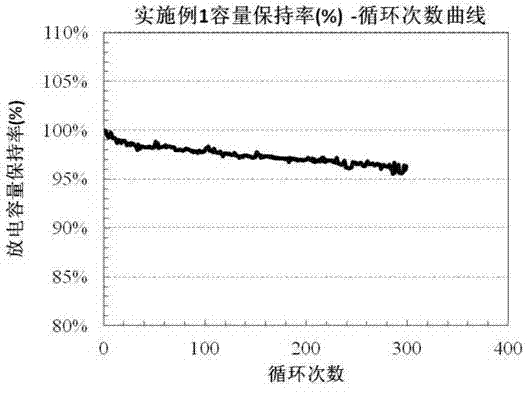

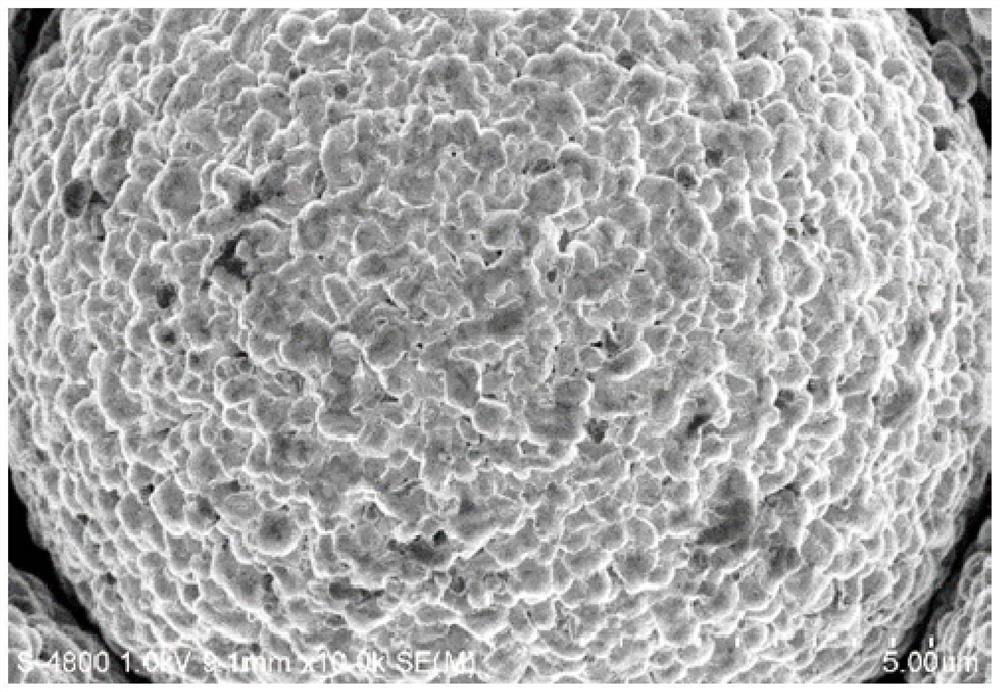

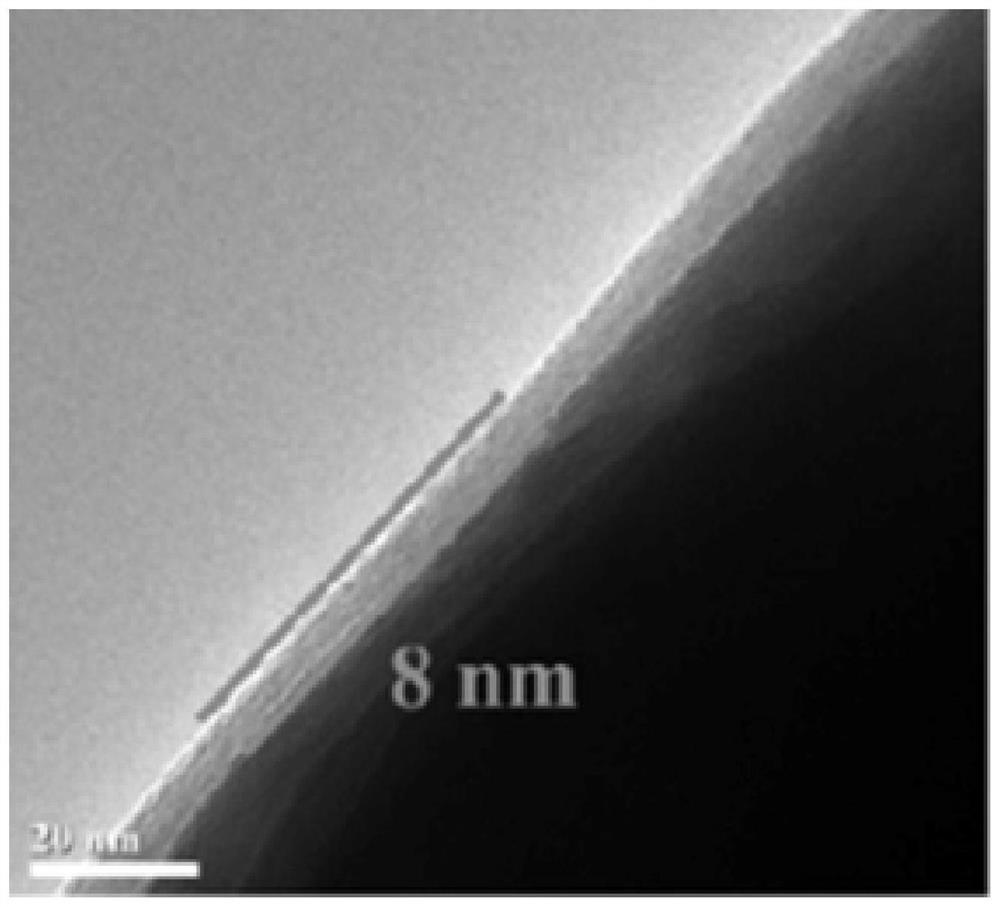

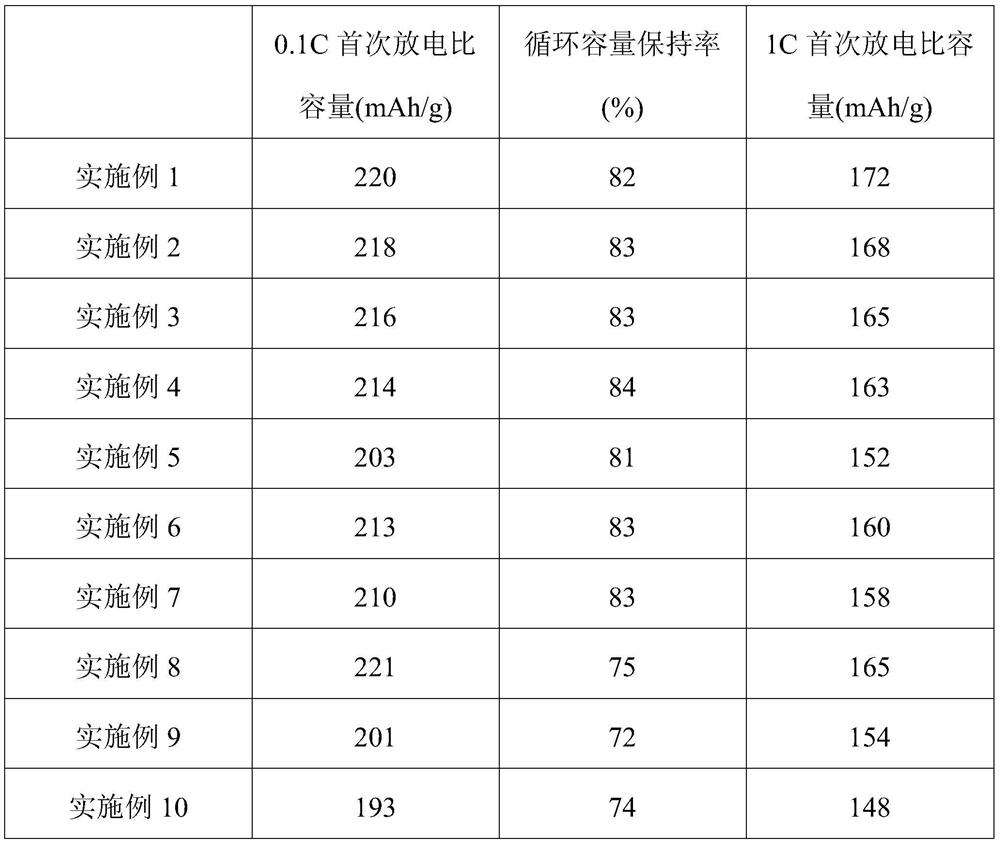

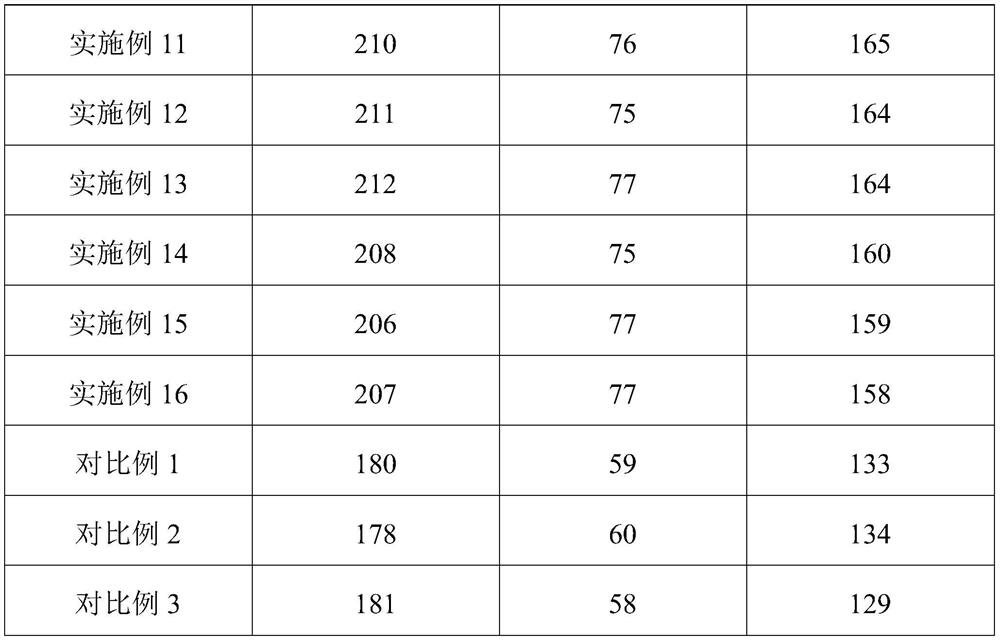

ActiveCN110416515AInhibition of volume expansionSmall specific surface areaMaterial nanotechnologyCell electrodesCopper platingMicrosphere

The invention discloses a lithium ion battery, a lithium ion battery negative electrode material and a preparation method thereof. The lithium ion battery negative electrode material comprises a composite microsphere of silicon / silicon oxide compound and graphite, an amorphous carbon layer coated on the surface of the composite microsphere and a copper layer coated outside a part of the amorphouscarbon layer. A copper-carbon double-layer coating structure is successfully constructed by coating the amorphous carbon layer on the composite microsphere of silicon / silicon oxide compound and graphite and then plating the copper layer outside the amorphous carbon layer. The copper can be used as a good conductor and can improve the electron conductance of the lithium ion battery, and the coppercan also be used as a ductile metal to provide a high-strength coating layer, effectively suppress the volume expansion of silicon, avoid the powdering of active materials such as silicon / silicon oxide compound, reduce the specific surface area of the composite microsphere by double-layer coating, reduce the contact area between the active materials such as silicon / silicon oxide compound and electrolyte and improve the first coulomb efficiency, rate performance and cycle performance of the lithium ion battery negative electrode material.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

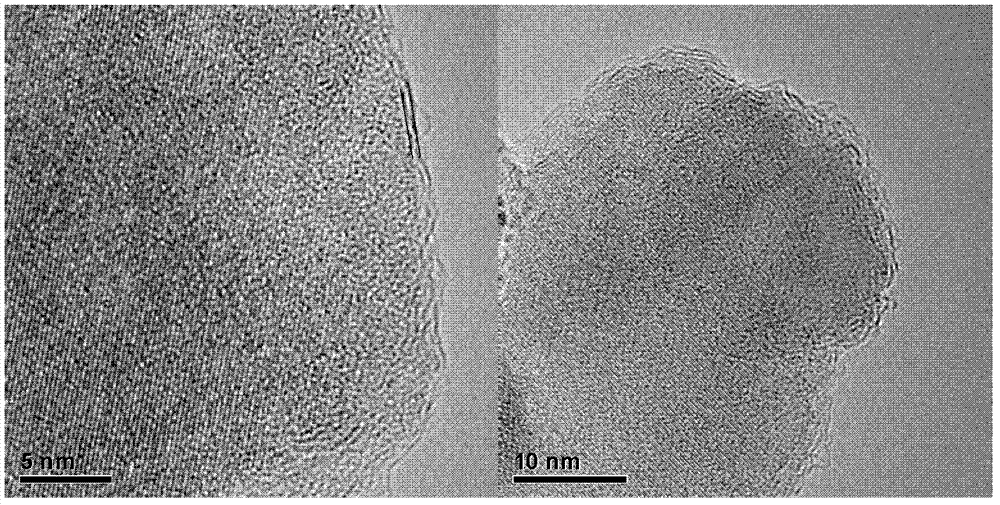

Low-temperature carbon-coated composite material, its preparation method and application

ActiveCN102956890AChange physical and chemical propertiesImprove electronic conductanceCell electrodesSecondary cellsCarbon coatedHigh conductivity

The invention provides a low-temperature carbon-coated composite material, its preparation method and application, and a secondary lithium battery containing the composite material. Specifically, the preparation method includes: leaving a carbon-containing precursor to react at a temperature of 200-600DEG C to generate a carbon material with high conductivity, and coating the surface of a used material evenly with the carbon material, thus obtaining the low-temperature carbon-coated composite material. The lithium secondary battery containing the composite material provided in the invention has the advantages of high reversible capacity, good circulation, outstanding rate performance, safety and reliability.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Lithium ion battery phosphatic composite cathode material and preparation method thereof

ActiveCN102244263BEasy to processImprove electrochemical performanceCell electrodesMicro structurePhosphoric acid

Owner:CENT SOUTH UNIV

Coating modification method for reducing metal dissolution of high-voltage ternary positive electrode material

The invention discloses a coating modification method for reducing metal dissolution of a high-voltage ternary positive electrode material. The method comprises the following steps of: (1) adding metal hydroxide into a phosphoric acid solution to prepare a metal phosphate solution, adding a ternary positive electrode material into the metal phosphate solution, stirring, and carrying out spray drying treatment to obtain a core layer solid mixture pre-coated with metal phosphate; and (2) mixing the core layer solid mixture obtained in the step (1) with a metal oxide and fluoride, carrying out ball milling for 1-20 hours, and sintering to obtain the coated modified ternary positive electrode material of which the inner layer is coated with metal phosphate and of which the outer layer is coated with metal oxide-fluoride. According to the core-shell structure coating method adopting the composite coating process, the coating form of a core-shell structure with the phosphate as the inner coating layer and the metal oxide-fluoride as the outer coating layer is adopted, uniform coating can be achieved, and the coating layers are high in strength and good in effect.

Owner:宜宾锂宝新材料有限公司

Positive electrode active material and preparation method thereof, positive electrode and lithium ion secondary battery

PendingCN114512642AImprove electrochemical performanceImprove efficiencyElectrode thermal treatmentPositive electrodesElectrical batteryManganate

The invention discloses a positive electrode active material which comprises a lithium nickel manganese oxide modified material and a coating layer on the surface of the lithium nickel manganese oxide modified material, and the coating layer is composed of an inorganic compound; the lithium nickel manganese oxide modified material comprises primary particles of a spinel phase and a rock-salt-like phase, the spinel phase is an inner core, and the rock-salt-like phase forms a shell; the spinel phase is of a nickel lithium manganate spinel structure; the rock-salt-like phase is formed by induction of a nickel lithium manganate spinel structure, the rock-salt-like phase contains at least one placeholder element of Mg, Zn, Ni, Mn, Fe, Co, Ti, Cr, Y, Sc, Ru, Cu, Mo, Ge, W, Zr, Ca, Ta, Sr, Al, Nb, B, Si, F and S, and the placeholder element is located at the 16c or 8a position of the spinel phase; the rock-salt-like phase is doped with phosphorus elements, and the phosphorus elements are distributed in a gradient mode from the outer surface of the rock-salt-like phase to the interior of the rock-salt-like phase. The invention also discloses a preparation method of the positive electrode active material, a positive electrode of a lithium ion secondary battery containing the positive electrode active material, and the lithium ion secondary battery.

Owner:SONGSHAN LAKE MATERIALS LAB +1

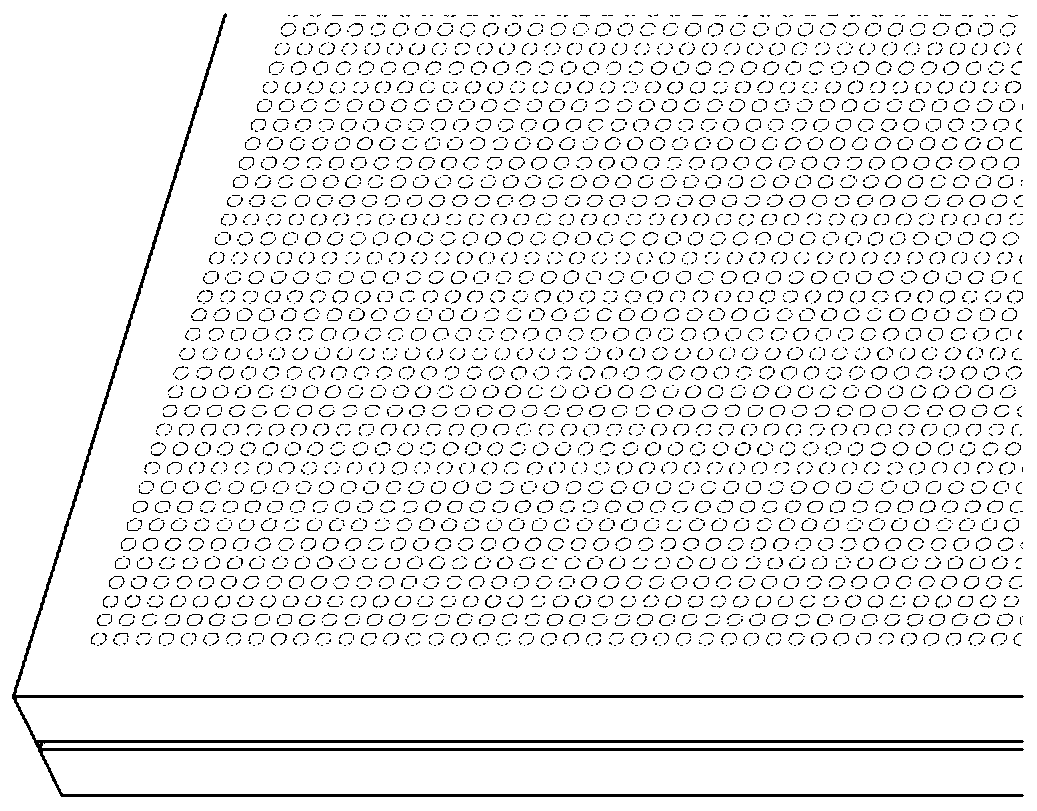

Electrode plate and preparation method thereof, and lithium ion battery

PendingCN111370648AImprove ionic conductanceIncrease liquid absorptionSecondary cellsNon-aqueous electrolyte accumulator electrodesInternal resistanceLithium-ion battery

The invention provides an electrode plate and a preparation method thereof, and a lithium ion battery. The electrode plate comprises a current collector and active substance layers positioned on two sides of the current collector, wherein the active substance layers are provided with holes, and the thickness of the electrode plate is more than 0.30 mm. The preparation method comprises the following steps: 1) coating two surfaces of the current collector with electrode slurry, and carrying out drying and rolling to obtain an unpunched electrode plate, wherein the thickness of the electrode plate which is not punched is 0.30 mm or above; and 2) punching the active substance layers of the unpunched electrode plate to obtain the electrode plate. According to the electrode plate provided by theinvention, by increasing the thickness of the electrode plate, the proportion of the current collector is reduced, and specific energy is improved; the electronic conductivity of the electrode plateis improved through the variety and proportion of a conductive agent; by punching holes in the active substance layers, the liquid absorption property of the electrode plate is improved, the polarization internal resistance of the electrode plate is reduced, the optimization of the ionic conductance of the electrode plate is improved, and the rate capability of the battery is maintained.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

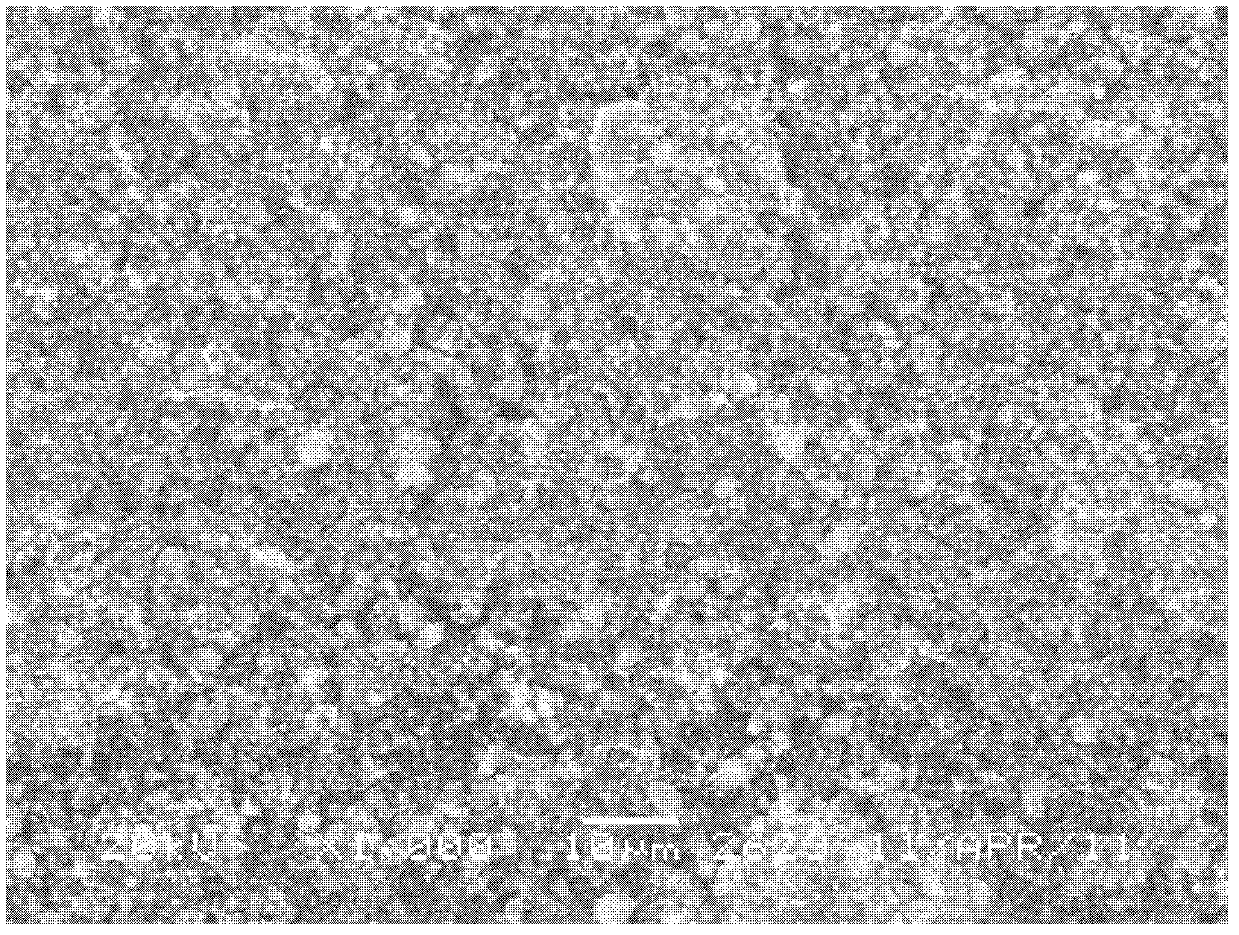

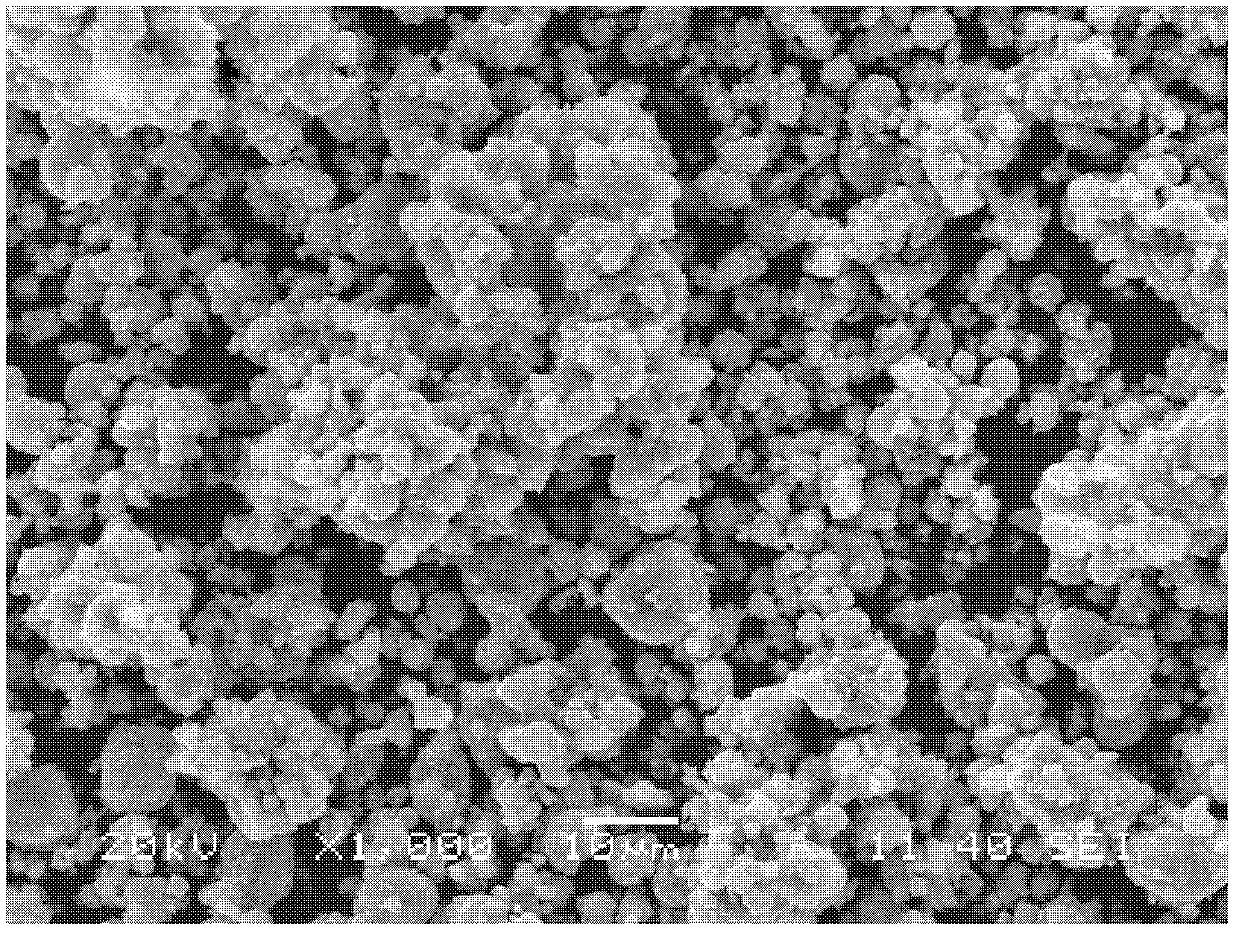

Graphene/TiO2 composite positive electrode preparation method

PendingCN110828780AReduce reunionImprove electronic conductanceSecondary cellsPositive electrodesOrganic solventGraphite

The invention discloses a graphene / TiO2 composite positive electrode preparation method, which comprises: (1) adding TiO2 to an organic solvent, carrying out ultrasonic treatment for 0.1-1 h, adding agraphene material, and carrying out ultrasonic treatment for 0.1-5 h to obtain a graphene / TiO2 dispersion liquid; and (2) adding a positive electrode active material into the graphene / TiO2 dispersionliquid, carrying out ball milling, and drying to obtain the graphene / TiO2 composite positive electrode. According to the preparation method, graphene / TiO2 is compounded with the positive electrode material, TiO2 can reduce the polarization degree and reduce agglomeration of graphene, so transmission of lithium ions among positive electrode particles is facilitated, and the electrochemical performance of the battery is improved; meanwhile, the graphene can also improve the defect of low electron conductivity of TiO2 and improve the overall electron conductivity of the positive electrode.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Positive electrode material, preparation method and application thereof, and lithium ion battery

PendingCN114447296AElectrochemically activeFacilitated DiffusionSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention relates to the field of lithium ion batteries, and discloses a positive electrode material, a preparation method and application thereof, and a lithium ion battery. The positive electrode material comprises a substrate and a coating layer coating the surface of the substrate, the matrix has a composition as shown in a formula I: Li < 1 + a > Ni < x > Co < y > Mn < z > M < k > O < 2 >, 0.5 < = a < = 0.3, 0 < = x < = 1, 0 < = y < = 1, 0 < = z < = 1, 0 < = k < = 0.06, 0lt; x + y + z + k is less than or equal to 1, and the coating layer has the composition as shown in a formula II: Ti < 1-alpha > M'alpha > Nb < gamma-beta > M '' beta O < 2 + 2.5 < gamma-delta > G < delta >, 0 < = alpha < = 0.5, 2 < = gamma < = 30, 0 < = beta < = 0.5, and 0 < = delta < = 0.4. The positive electrode material has high ion and electron conduction capability, side reaction between the positive electrode material and electrolyte can be avoided, the compatibility is improved, and the rate capability and the energy density of the lithium ion battery containing the positive electrode material can be further improved.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Coated lithium ion battery positive electrode material as well as preparation method and application thereof

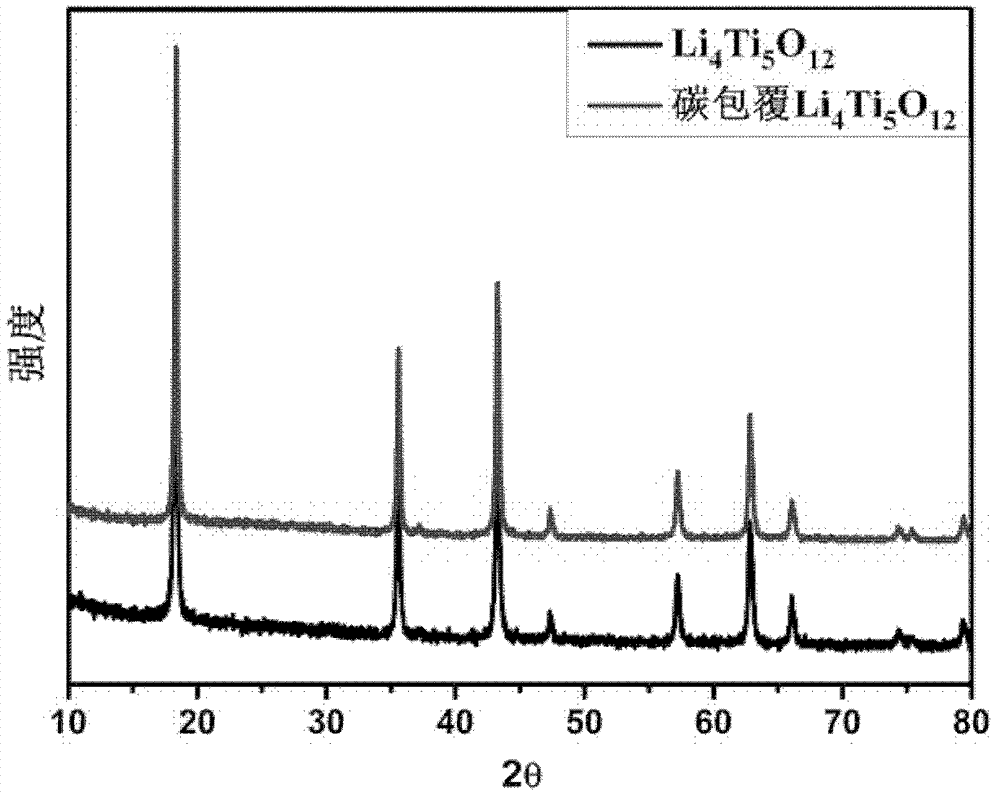

PendingCN114171733AImprove electronic conductanceImprove ionic conductanceCell electrodesSecondary cellsPhysical chemistryHigh electron

The invention provides a coated lithium ion battery positive electrode material as well as a preparation method and application thereof. The coated lithium ion battery positive electrode material comprises a lithium oxide core and a coating layer coating the lithium oxide core, the coating layer comprises a combination of Li4Ti5O12, TiO2 (titanium dioxide) and Ti4O7 (titanium dioxide). In the preparation process, a lithium oxide is used as a substrate, and a titanium source, an oxygen source and a lithium source are deposited on the substrate by using a deposition system to obtain the coated lithium ion battery positive electrode material. According to the positive electrode material provided by the invention, the Li4Ti5O12, the TiO2 and the Ti4O7 are coated on the inner core, so that the coating of a high-ionic-conductivity and high-electron-conductivity material is realized, the overall structural stability of the material can be improved, the reversible specific capacity and the cycling stability of the material are further improved, and the positive electrode material has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

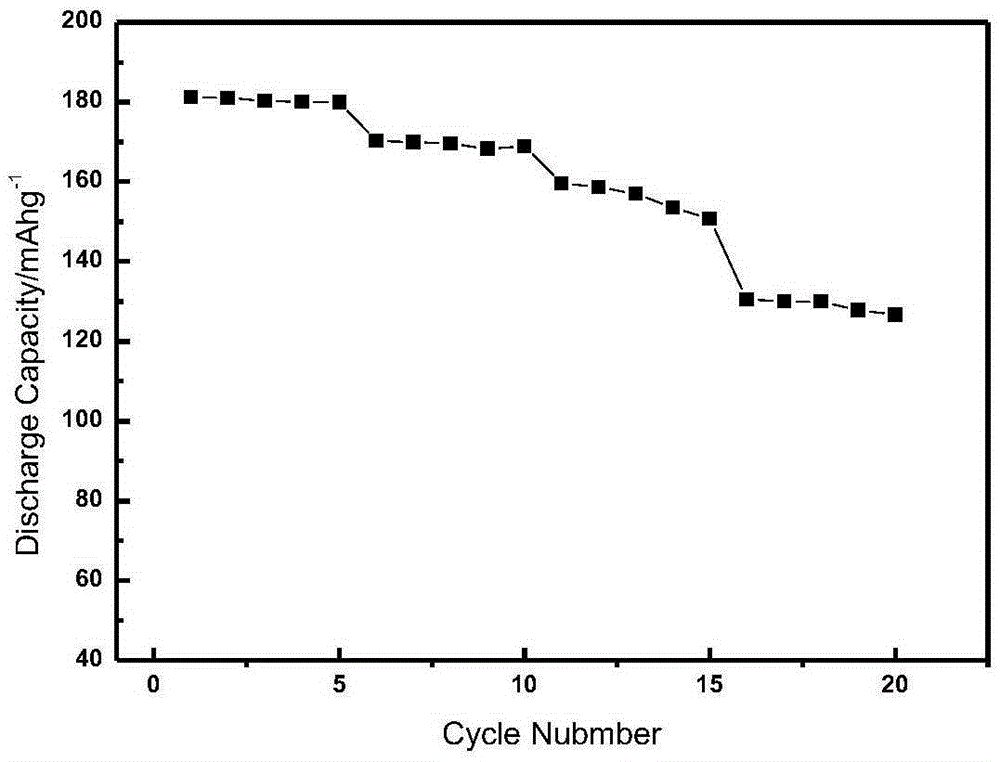

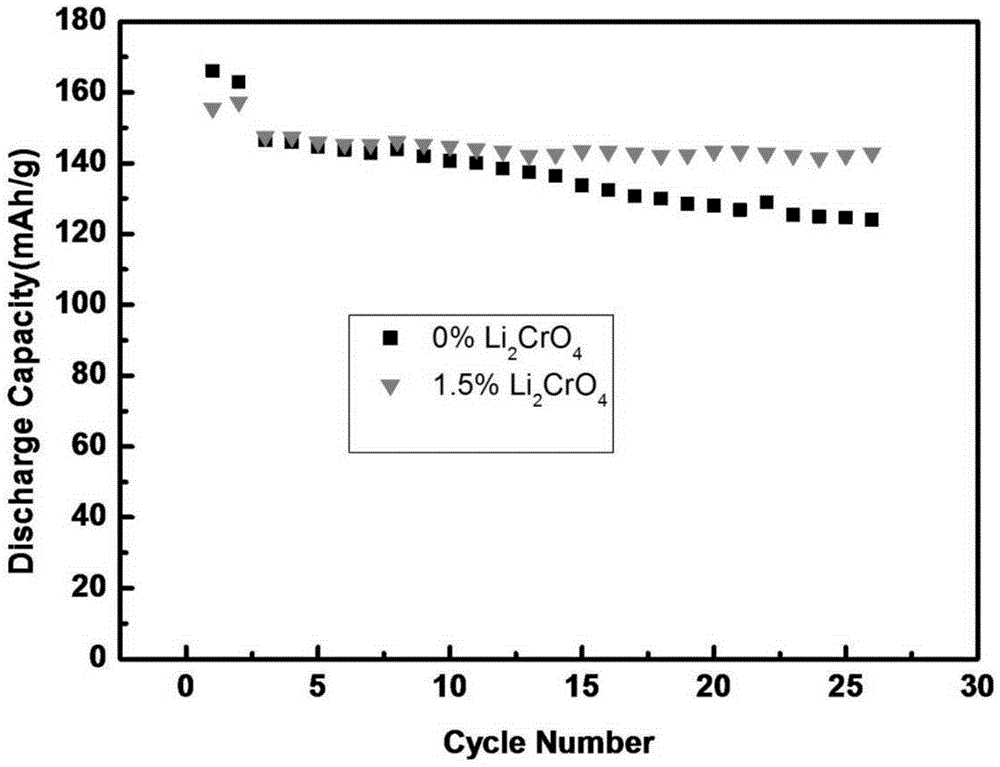

Modified lithium-ion battery and modifying method thereof

InactiveCN105406080AImprove electronic conductanceImproved magnification performanceCell electrodesSecondary cells servicing/maintenanceModified methodSpontaneous reaction

The invention discloses a modified lithium-ion battery and a modifying method thereof. The invention aims at providing the modified lithium-ion battery which has good conductivity and is capable of increasing electronic conductivity of a material and improving rate performance of the material and the modifying method thereof. According to the technical scheme, the modified lithium-ion battery is characterized in that Li2CrO4 is added in a conventional electrolyte, the Li2CrO4 is subjected to spontaneous reaction on the surface of a positive electrode material so as to form an Li2+xCrO4 coating layer, and an Li2+xCrO4 coating layer is formed after the Li2CrO4 is subjected to charging and lithium-embedding on the surface of a negative electrode material. The modified lithium-ion battery and the modifying method thereof belong to the technical field of batteries.

Owner:HEFEI RONGJIE ENERGY MATERIALS CO LTD

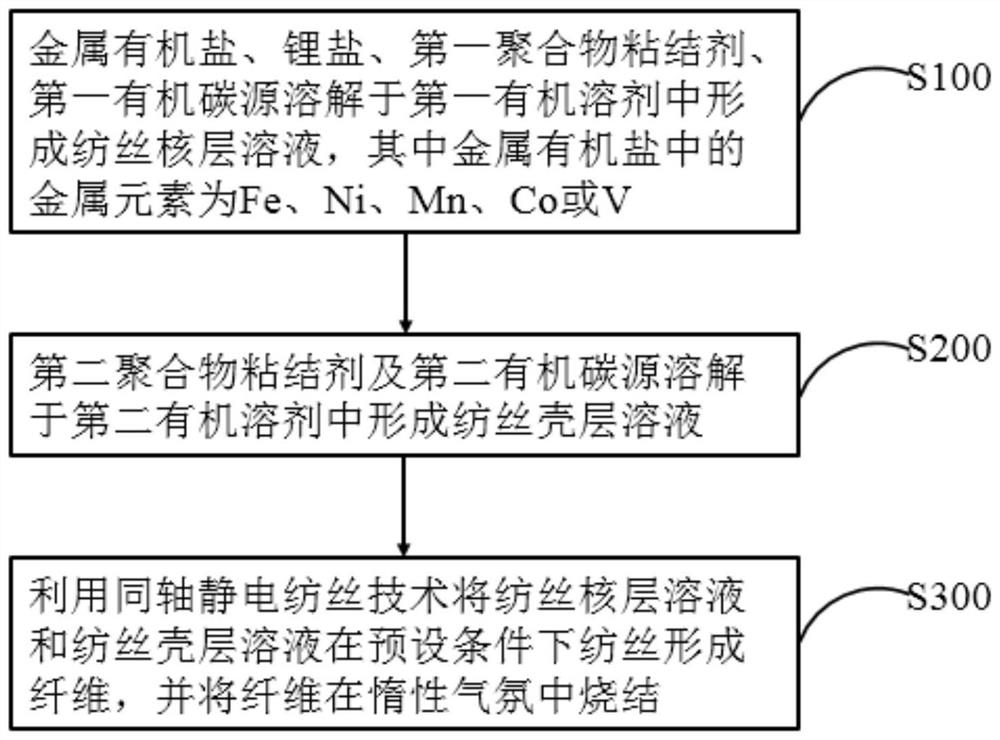

Carbon-coated nanofiber material, preparation method thereof and battery

InactiveCN113540444AImprove electronic conductanceImproved magnification performanceSecondary cellsPositive electrodesCarbon coatingFiber

The invention relates to the field of lithium ion battery electrode materials, in particular to a carbon-coated nanofiber material, a preparation method thereof and a battery. The preparation method of the carbon-coated nanofiber material comprises the following steps: dissolving metal organic salt, lithium salt, a first polymer binder and a first organic carbon source in a first organic solvent, and preparing a spinning core layer solution, wherein metal elements in the metal organic salt are Fe, Ni, Mn, Co or V; dissolving a second polymer binder and a second organic carbon source in a second organic solvent to prepare a spinning shell solution; and spinning the spinning core layer solution and the spinning shell layer solution under a preset condition by using a coaxial electrostatic spinning technology to form fibers, and sintering the fibers in an inert atmosphere. According to the method, the fiber can be subjected to in-situ carbon coating, and the electrical property of the battery is improved. The invention also provides the carbon-coated nanofiber material prepared by the preparation method and a battery comprising the material.

Owner:南方电网电动汽车服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com