Coated lithium ion battery positive electrode material as well as preparation method and application thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of improving specific capacity and rate performance, improving electronic conductance and ion conductance, and prolonging cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

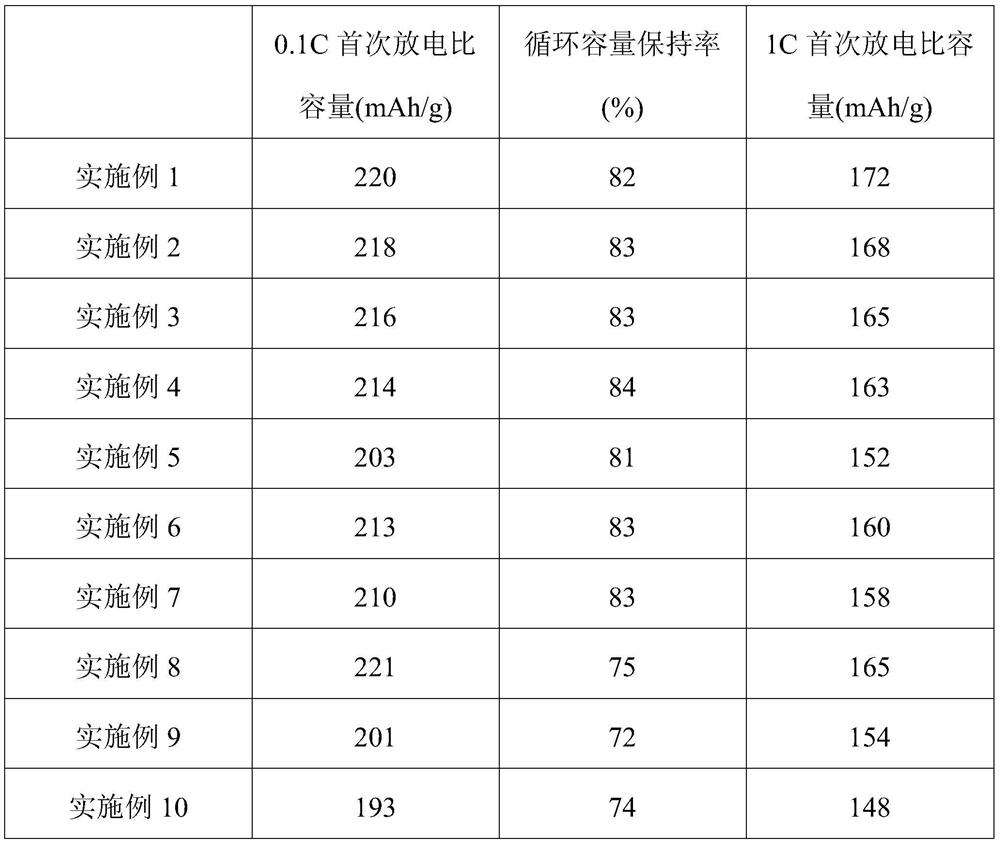

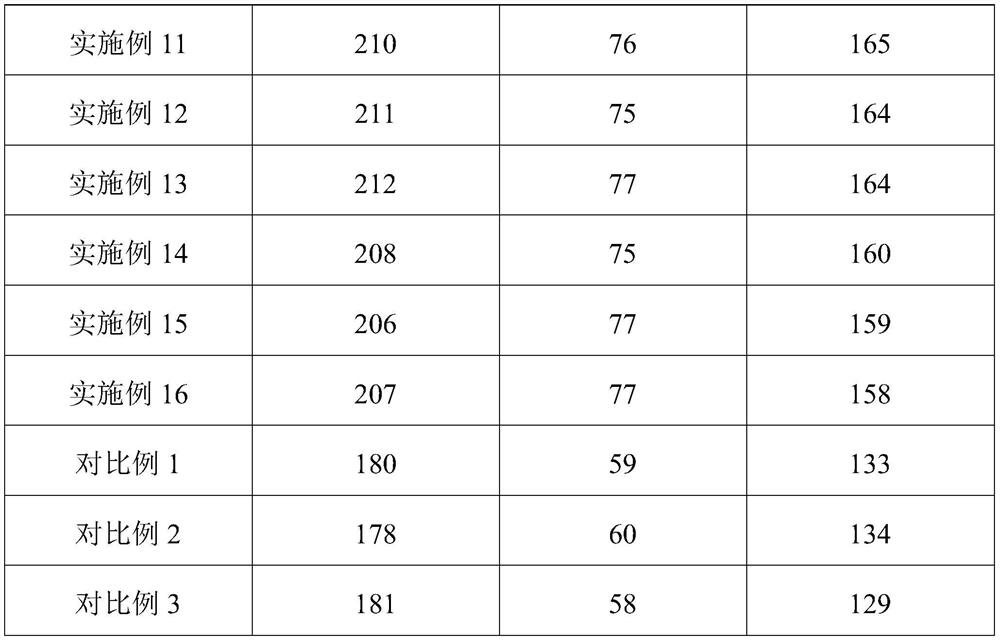

Examples

Embodiment 1

[0041] This example provides a coated lithium ion battery positive electrode material including a lithium oxide core and a coating layer covering the lithium oxide core; the lithium oxide The kernel is lithium nickel-watery (NCM811) with an average particle diameter of 5 μm; the cladding layer is a molar ratio of 1: 1: 1 4 Ti 5 O 12 , TIO 2 Ti 4 O 7 Combination; the mass ratio of the coating layer and the lithium oxide core is 0.05: 1.

[0042] The preparation method of the coated lithium ion battery positive electrode material includes the steps of:

[0043] Under the argon atmosphere, the nucleation is a substrate with a lithium oxide core, and the water and t-butanol are lithium tetrabutyl, and the ratio of atomic layer is performed during the surface of the substrate, and the ratio of LI, Ti and O is controlled. LI in the coating layer 4 Ti 5 O 12 , TIO 2 Ti 4 O 7 The molar ratio is 1: 1: 1 to obtain the coated lithium ion battery positive electrode material.

Embodiment 2

[0045] This example provides a coated lithium ion battery positive electrode material including a lithium oxide core and a coating layer covering the lithium oxide core; the lithium oxide The kernel is lithium nickel-watery (NCM811) with an average particle diameter of 3 μm; the cladding layer is a molar ratio of 0.8: 0.5: 1. 4 Ti 5 O 12 , TIO 2 Ti 4 O 7 Combination; the mass ratio of the coating layer and the lithium oxide core is 0.06: 1.

[0046] The preparation method of the coated lithium ion battery positive electrode material includes the steps of:

[0047] Under a nitrogen atmosphere, a lithium oxide core is a substrate, and the ratio of the atomic layer deposition in the surface of the base is performed by tetrachloride, water and lithium acetate, and the ratio of LI, Ti and O is controlled in the coating layer. 4 Ti 5 O 12 , TIO 2 Ti 4 O 7 The molar ratio was 0.8: 0.5: 1 to obtain the coated lithium ion battery positive material.

Embodiment 3

[0049] This example provides a coated lithium ion battery positive electrode material including a lithium oxide core and a coating layer covering the lithium oxide core; the lithium oxide The core is lithium nickel-watery (NCM811) with an average particle diameter of 5 μm; the cladding layer is a molar ratio 1: 0.8: 1.1 li 4 Ti 5 O 12 , TIO 2 Ti 4 O 7 Combination; the mass ratio of the coating layer and the lithium oxide core is 0.08: 1.

[0050] The preparation method of the coated lithium ion battery positive electrode material includes the steps of:

[0051] Under the conditions of argon atmosphere, the core is a substrate with a lithium oxide, and the water and lithium hydroxide are used, and the ratio of the atomic layer is performed during the surface of the substrate. The proportion of Li, Ti and O LI in the coating 4 Ti 5 O 12 , TIO 2 Ti 4 O 7 The molar ratio was 1: 0.8: 1.1 to obtain the coated lithium ion battery positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com