Graphene/TiO2 composite positive electrode preparation method

A composite positive electrode and graphene technology, which is applied in positive electrodes, battery electrodes, active material electrodes, etc., can solve problems such as difficult industrial production, and achieve the effects of simple preparation process, reduced spontaneous agglomeration, and increased contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

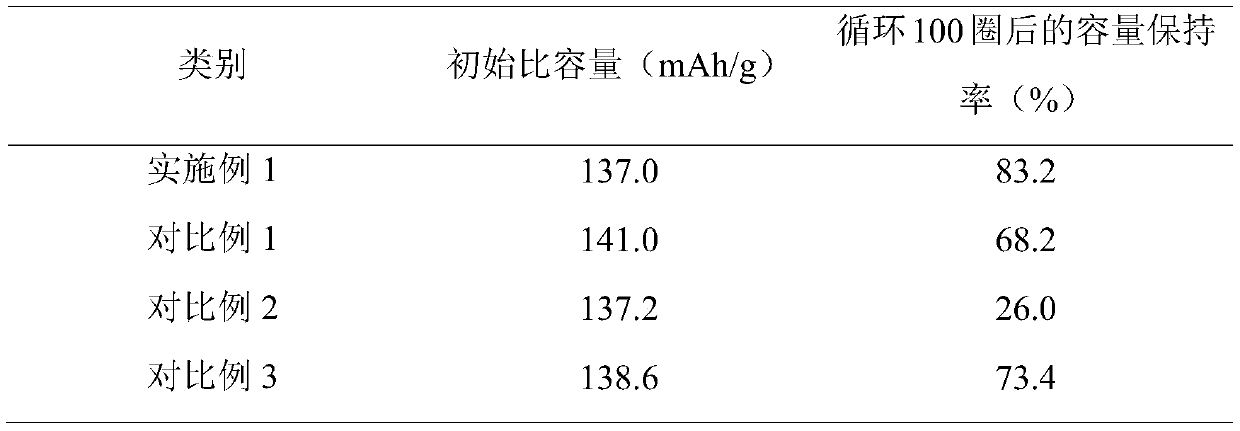

Examples

Embodiment 1

[0028] A kind of graphene / TiO of the present invention 2 Composite cathode (G / TiO 2 @NCM523) preparation method, comprises the following steps:

[0029] (1) Weigh 0.003g TiO 2 (particle size 60nm) and 10g N-methylpyrrolidone (NMP), ultrasonic 10min (ultrasonic power is 300W); then add 0.1g graphene, continue to adopt cell pulverizer ultrasonic dispersion 1h (ultrasonic power is 300W), obtain graphene / TiO 2 Dispersions;

[0030] (2) to graphene / TiO 2 Add 2g NCM523 (nickel cobalt lithium manganese oxide) positive electrode active material in the dispersion liquid, seal ball milling 40min under 300r / min (ball material ratio 20:1, adopt zirconia beads), resulting in graphene / TiO 2 Mixture with NCM523;

[0031] (3) Air-dry the mixed solution at 100°C for 72 hours, grind it, and pass through a 325-mesh sieve to obtain graphene / TiO 2 Composite cathode powder with NCM523, No. G / TiO 2 @NCM523.

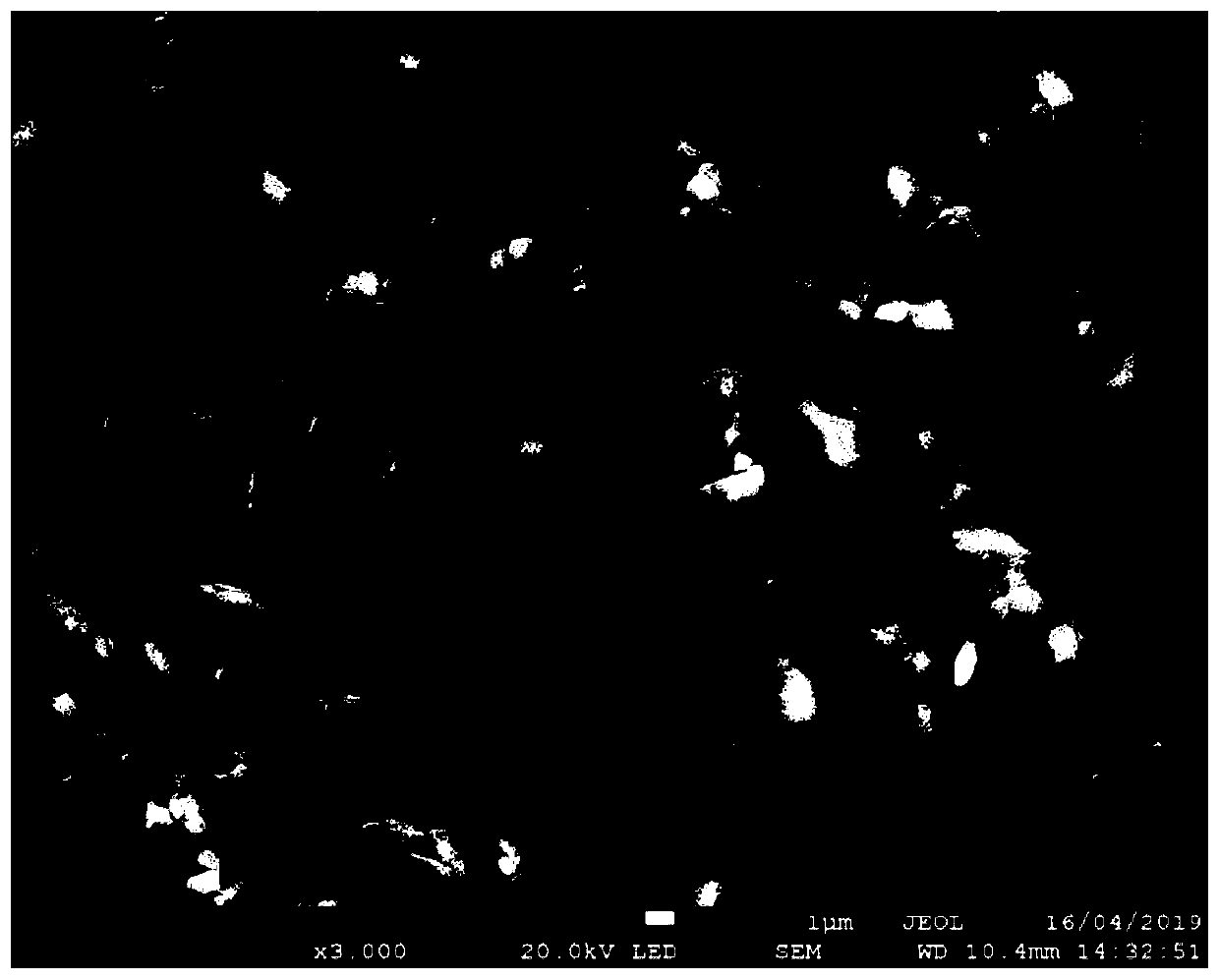

[0032] The scanning electron microscope of the composite positive electrode is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com