Preparation method of nano tio2 modified pvdf ultrafiltration membrane

An ultrafiltration membrane and nanotechnology, applied in the field of membrane separation, can solve the problems of shortened membrane life, reduced membrane flux, and high driving force, and achieve the effects of extending membrane life, reducing agglomeration, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

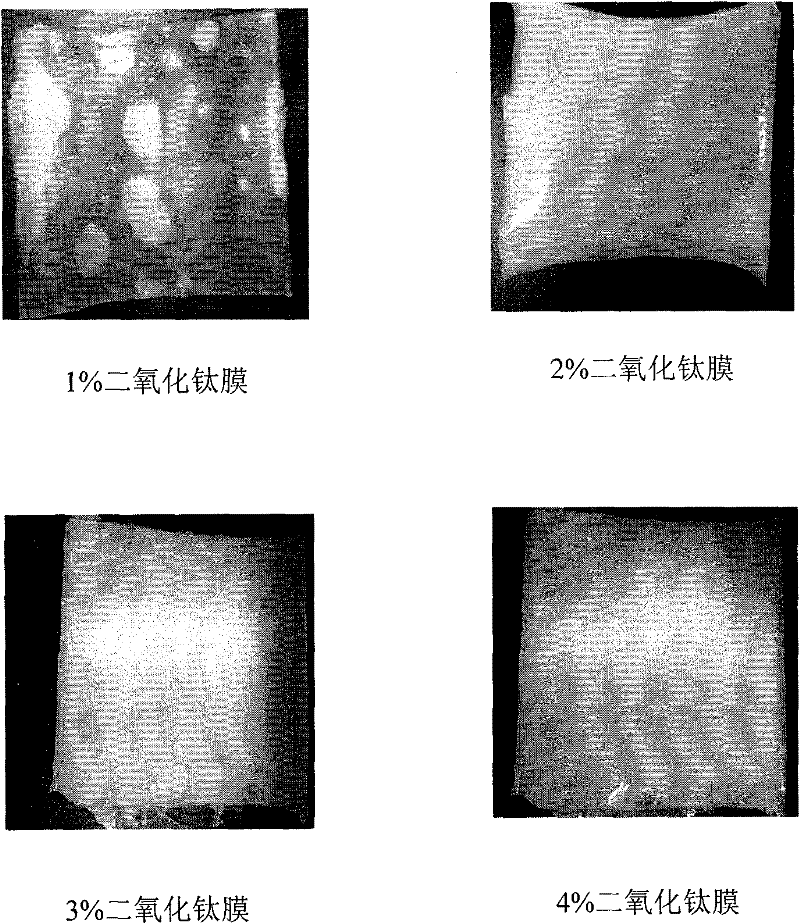

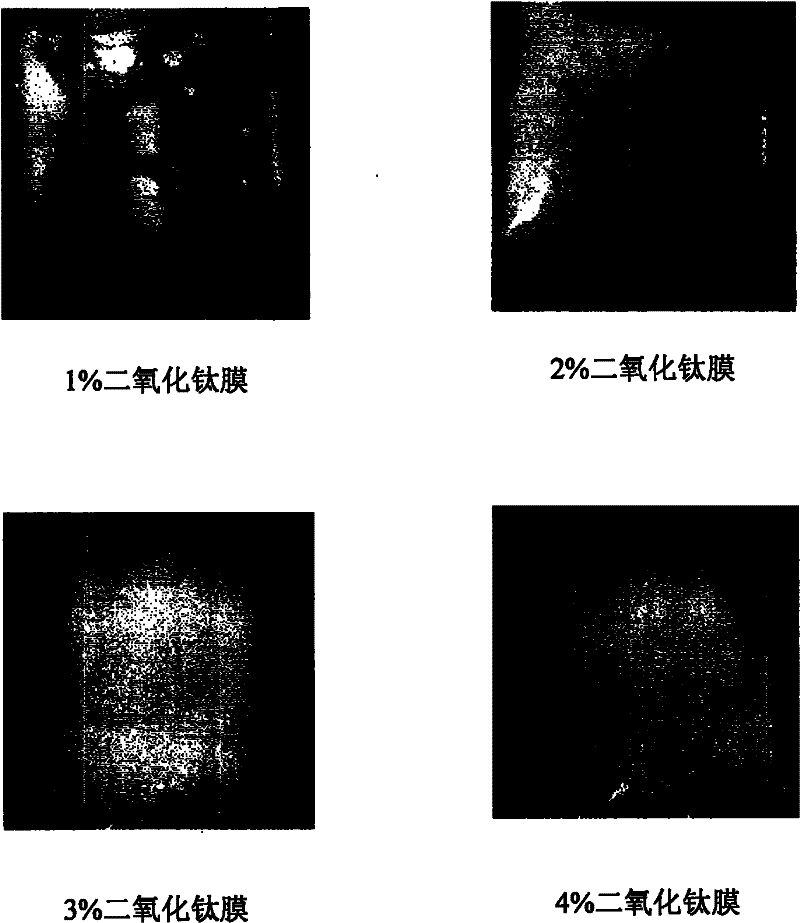

[0026] Weigh 17g of PVDF and 75g of N,N-dimethylformamide in a beaker, stir well at room temperature until PVDF is completely dissolved; then add 2g of polyvinylpyrrolidone, nano-TiO 2 2g, 4g of sodium lauryl sulfate, stir well until the solid powder is completely dissolved; place the solution in the beaker in an ultrasonic extractor for ultrasonic oscillation at 20KHZ frequency and 2000W power for 5 minutes, and then use a 500-mesh copper mesh to Suction filter the film-making solution to remove solid particles; place the film-making solution in the beaker in a constant temperature box at 0-3°C for 24 hours for defoaming, and scrape the degassed film-making solution with a flat-plate scraper with a scraper. A liquid film of a certain thickness (requirement: the scraper must be absolutely dry, clean, and free of impurities); after standing in the air for 30 seconds, the scraper and the liquid film are immersed in a 25-degree coagulation bath (60-75% ethanol aqueous solution), ...

Embodiment 2

[0028] Weigh 16g of PVDF and 75g of N,N-dimethylformamide in a beaker, stir well at room temperature until PVDF is completely dissolved; then add 2g of porogen polyvinylpyrrolidone, nano-TiO 2 3g, sodium lauryl sulfate 4g, stir well until the solid powder is completely dissolved; place the solution in the beaker in an ultrasonic extractor for ultrasonic oscillation and act on it for 4 minutes at a frequency of 20KHZ and a power of 2000W, and then use a 500-mesh copper mesh to Suction filter the film-making solution to remove solid particles; place the film-making solution in the beaker in a constant temperature box at 0-3°C for 24 hours for defoaming, and scrape the degassed film-making solution with a flat-plate scraper with a scraper. A liquid film of a certain thickness (requirement: the scraper must be absolutely dry, clean, and free of impurities); after standing in the air for 30 seconds, the scraper and the liquid film are immersed in a 20-degree coagulation bath (60-75%...

Embodiment 3

[0030] Weigh 16g of PVDF and 74g of N, N-dimethylformamide in a beaker, stir well at room temperature until PVDF is completely dissolved; then add porogen 2g of polyvinylpyrrolidone, nano-TiO 2 4g, sodium lauryl sulfate 4g, stir well until the solid powder is completely dissolved; place the solution in the beaker in an ultrasonic extractor for ultrasonic oscillation and act on it for 6 minutes at 20KHZ frequency and 2000W power, and then use a 500-mesh copper mesh to Suction filter the film-making solution to remove solid particles; place the film-making solution in the beaker in a thermostat at 0-3°C for 24 hours for defoaming, and scrape the degassed film-making solution with a flat-plate scraper with a scraper. A liquid film of a certain thickness (requirement: the scraper must be absolutely dry, clean, and free of impurities); after standing in the air for 30 seconds, the scraper and the liquid film are immersed in a 30-degree coagulation bath (60-75% ethanol water solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com