Preparation method of lithium titanium negative electrode composite material for lithium ion battery

A technology for lithium-ion batteries and composite materials, which is applied in the field of preparation of lithium titanate negative electrode composite materials for lithium-ion batteries, can solve the problems of dendrite short circuit, safety problems, electrolyte consumption and low initial Coulombic efficiency, etc., and achieve improved conductivity rate, improved conductivity, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

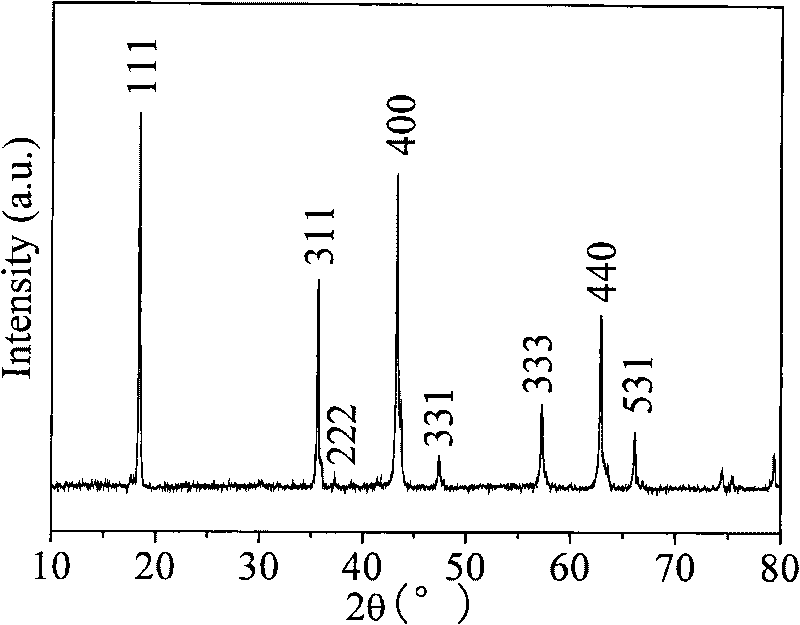

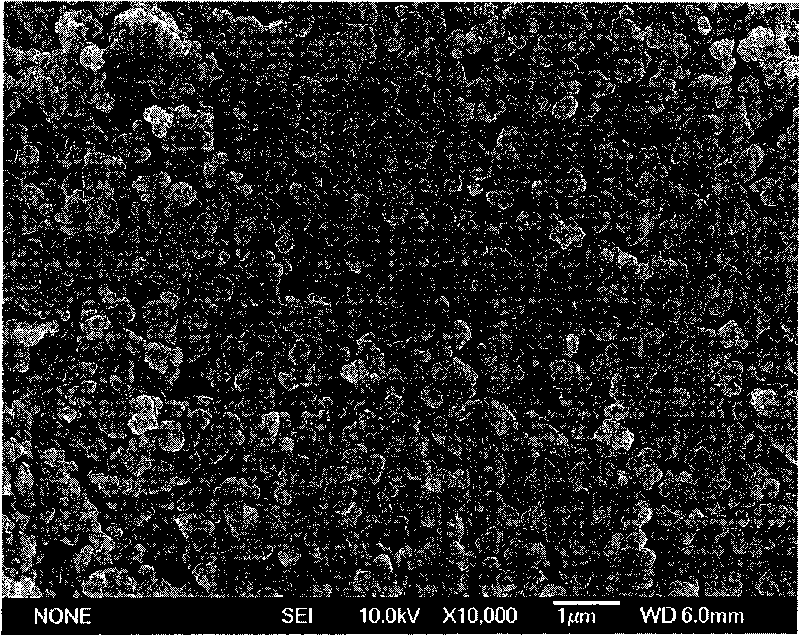

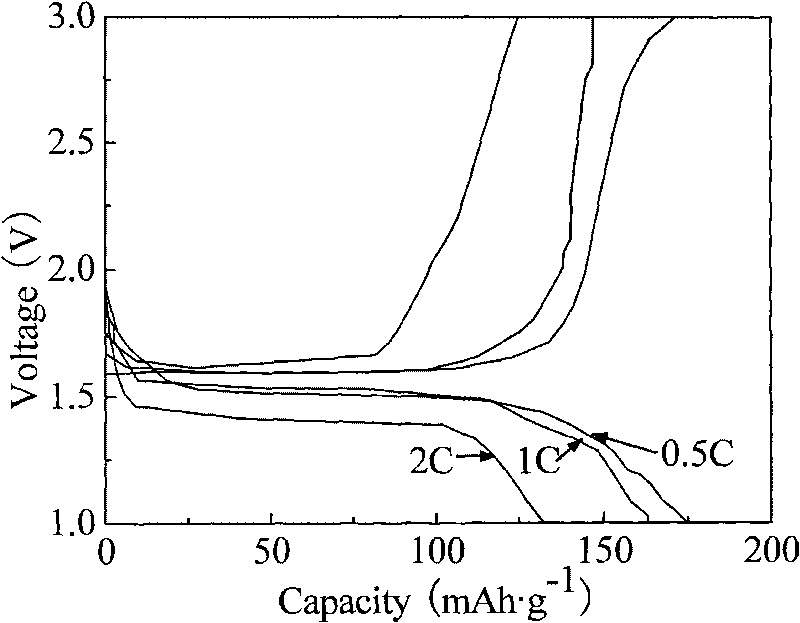

[0021] According to mol ratio Li: Ti=1, lauric acid: Ti=1: 5, take the tetrabutyl orthotitanate (analytical pure) of 8.51g, the lithium acetate (analytical pure) of 2.55g and 1g lauric acid (analytical pure) ), which were dissolved in 12ml of absolute ethanol respectively. Add the ethanol solution of lithium acetate dropwise to the ethanol solution of tetrabutyl orthotitanate, mix evenly under magnetic stirring, and react for about 10 minutes, then add the ethanol solution of lauric acid to the mixed solution, and react for 15 hours at room temperature Left and right, a uniform milky white gel was obtained. The gel was aged in the air for 24 hours, and then dried in an oven at 100° C. to obtain a pale yellow precursor. Put the precursor into a ball mill jar, add an appropriate amount of agate balls, and mill on a ball mill at a speed of 380r / min for 2 hours to obtain ultrafine precursor powder. Put the powder in the muffle furnace and raise the temperature to 500°C at a heat...

Embodiment 2

[0023] Synthesis of 0.005mol Li 4 Al 0.15 Ti 4.85 o 12 According to the molar ratio Li:Ti:Al=80:97:3, take by weighing 8.25g of tetrabutyl orthotitanate (analytical pure), 2.04g of lithium acetate (analytical pure) and 2.81g of aluminum nitrate (analytical pure) ), 0.125g lauric acid (analytically pure) and 0.44g citric acid (analytical pure), which were dissolved in 8ml of absolute ethanol respectively. Add the ethanol solution of lithium acetate dropwise to the ethanol solution of tetrabutyl orthotitanate, mix evenly under magnetic stirring, and react for about 10 minutes, then add the ethanol solution of aluminum nitrate to the mixed solution, and wait for about 10 minutes to react. The ethanol solution of citric acid and lauric acid was sequentially added into the solution, and reacted for about 20 hours at room temperature to obtain a uniform milky white gel. The gel was aged in the air for 24 hours, and then dried in an oven at 120° C. to obtain a pale yellow precurs...

Embodiment 3

[0025] Synthesis of 0.05mol LiFeTiO 3 , take by weighing 17g of tetrabutyl orthotitanate (analytically pure), 5.1g of lithium acetate (analytical pure), 20.2g of ferric nitrate (analytical pure), 2.9g ethylenediaminetetraacetic acid (analytical pure) and 2.5g oxalic acid (analytical pure), it is dissolved in the absolute ethanol of 12ml respectively. Slowly add the ethanol solution of lithium acetate to the ethanol solution of tetrabutyl orthotitanate, under magnetic stirring, mix evenly, react for about 10 minutes, then slowly add the ethanol solution of ferric nitrate into the mixed solution, and wait for 15 minutes to react For about 22 hours, add ethylenediaminetetraacetic acid and oxalic acid ethanol solution to the solution in turn, and react for about 22 hours at room temperature to obtain a uniform milky white gel. The gel was aged in the air for 10 hours, and then dried in an oven at 100° C. to obtain a pale yellow precursor. Put the precursor into a ball mill jar, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com