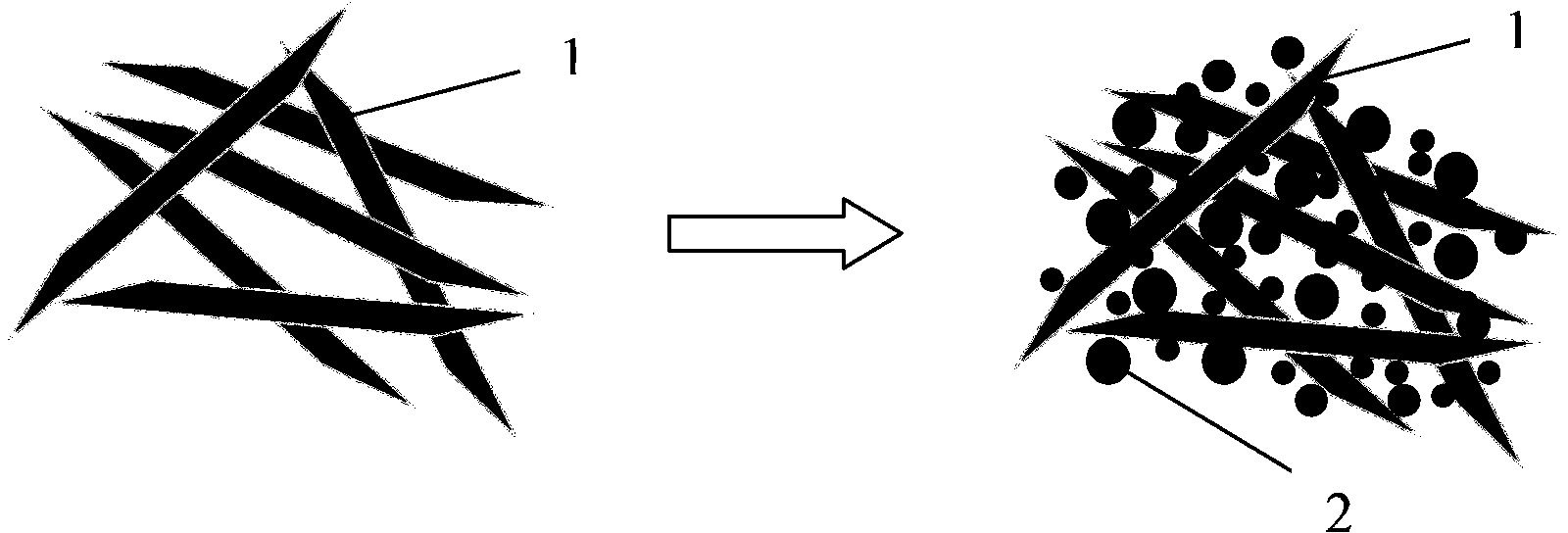

Graphene-based composite ternary material, preparation method thereof, and lithium ion battery

A ternary material and graphene-based technology, applied in the field of lithium-ion batteries, can solve the problems of poor electrode processing performance and low material conductivity, improve particle compaction resistance, improve reaction interface, improve high rate and cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

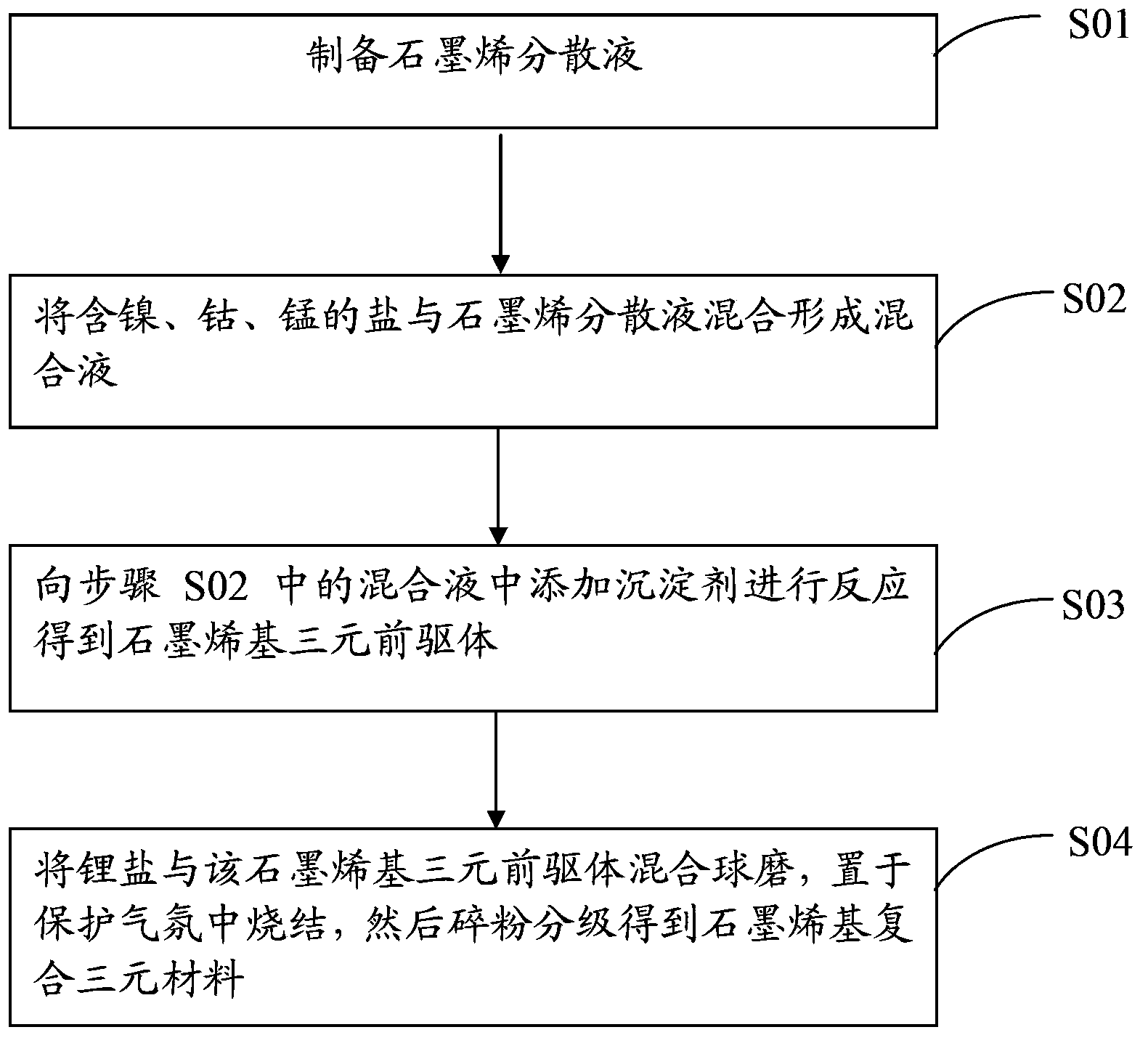

[0033] Such as figure 2 as shown, figure 2 It is the flowchart of the preparation method of a kind of graphene-based composite ternary material of the present invention, and the method comprises the steps:

[0034] Step S01, preparing a graphene dispersion;

[0035] Step S02, mixing salts containing nickel, cobalt, and manganese with the graphene dispersion to form a mixed solution;

[0036] Step S03, adding a precipitating agent to the mixed solution in step S02 for reaction to obtain a graphene-based ternary precursor;

[0037] Step S04, mixing the lithium salt and the graphene-based ternary precursor by ball milling, sintering in a protective atmosphere, and then grading the crushed powder to obtain a graphene-based composite ternary material.

[0038] Wherein, the preparation of the graphene dispersion includes the following steps: dissolving one or more of polyacrylic acid, polyvinyl alcohol, and polyvinylpyrrolidone in deionized water, and stirring to obtain a dispers...

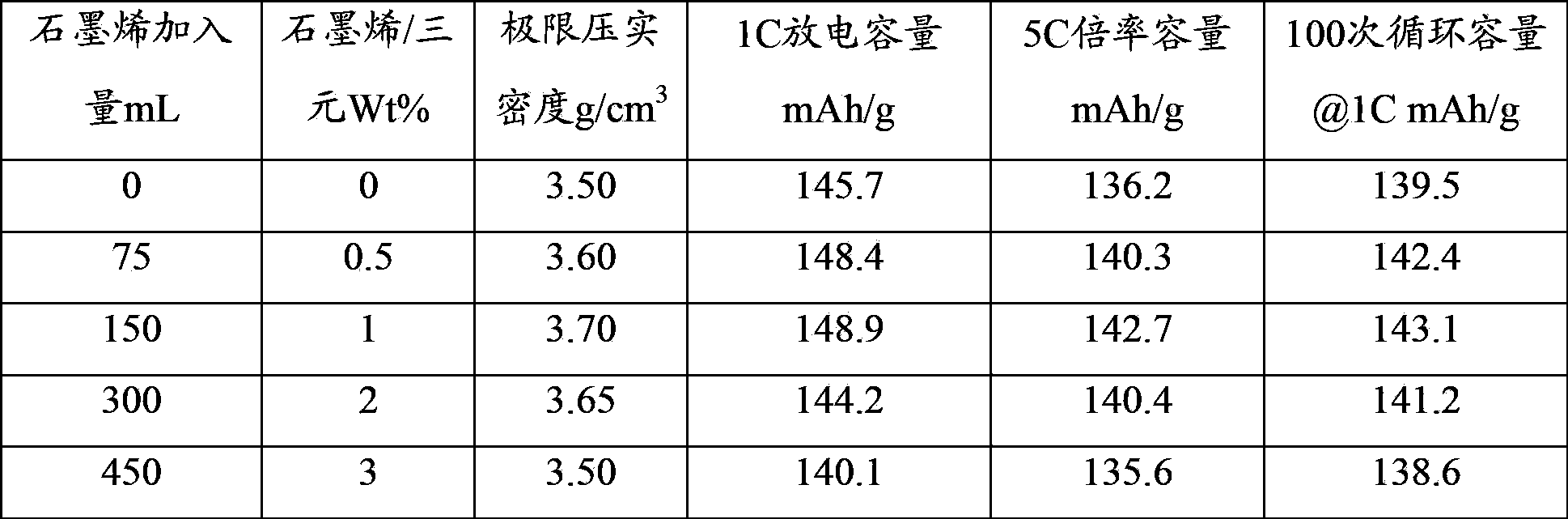

Embodiment 1

[0045] Step 1, preparation of graphene dispersion

[0046] Dissolve 1g of polyvinylpyrrolidone (PVP) in 100ml of deionized water, stir in a water bath until the PVP is completely dissolved, and obtain a dispersant solution with a solution concentration of 10mg / ml;

[0047] Take 0.1 g of graphene oxide powder and add it to 100 ml of dispersant solution, and disperse it ultrasonically for 120 minutes to obtain a 1 mg / ml tan monodisperse graphene dispersion. The number of graphene sheets selected is composed of a single layer or a multilayer graphene sheet with a layer number less than 10 layers.

[0048] Step 2. Preparation of graphene composite ternary precursor

[0049] Weigh NiSO according to the ratio of Ni:Co:Mn=1:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O each 0.05mol, add to a certain amount (for example: 0ml, 75ml, 150ml, 300ml, 450ml) of monodisperse graphene dispersion liquid and deionized water, and mix to obtain graphene / nickel with a sum of cations of 0.15m...

Embodiment 2

[0064] Step 1, preparation of graphene dispersion

[0065] The method is similar to Step 1 of Example 1, and a 1 mg / ml tan monodisperse graphene dispersion is prepared. Among them, only the selected dispersant solution is polyacrylic acid (PAA) with a solution concentration of 10 mg / ml.

[0066] Step 2. Preparation of graphene composite ternary precursor

[0067] Weigh Ni(NO) by adjusting the ratio of Ni:Co:Mn=5:2:3 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 4H 2 Each 0.05mol of O is added to a certain amount of 150ml monodisperse graphene dispersion and deionized water, and the proportioning to obtain the cation sum is the graphene / nickel-cobalt-manganese ion mixed solution of 0.15mol / L; configure 1mol / L of Na 2 CO 3 Solution 150ml; Graphene / nickel-cobalt-manganese ion mixture and Na 2 CO 3 The solution is dropped into the reactor simultaneously, the addition rate and the high-speed stirring rate of the two solutions are controlled, the pH value of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com