Patents

Literature

691results about How to "Large particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

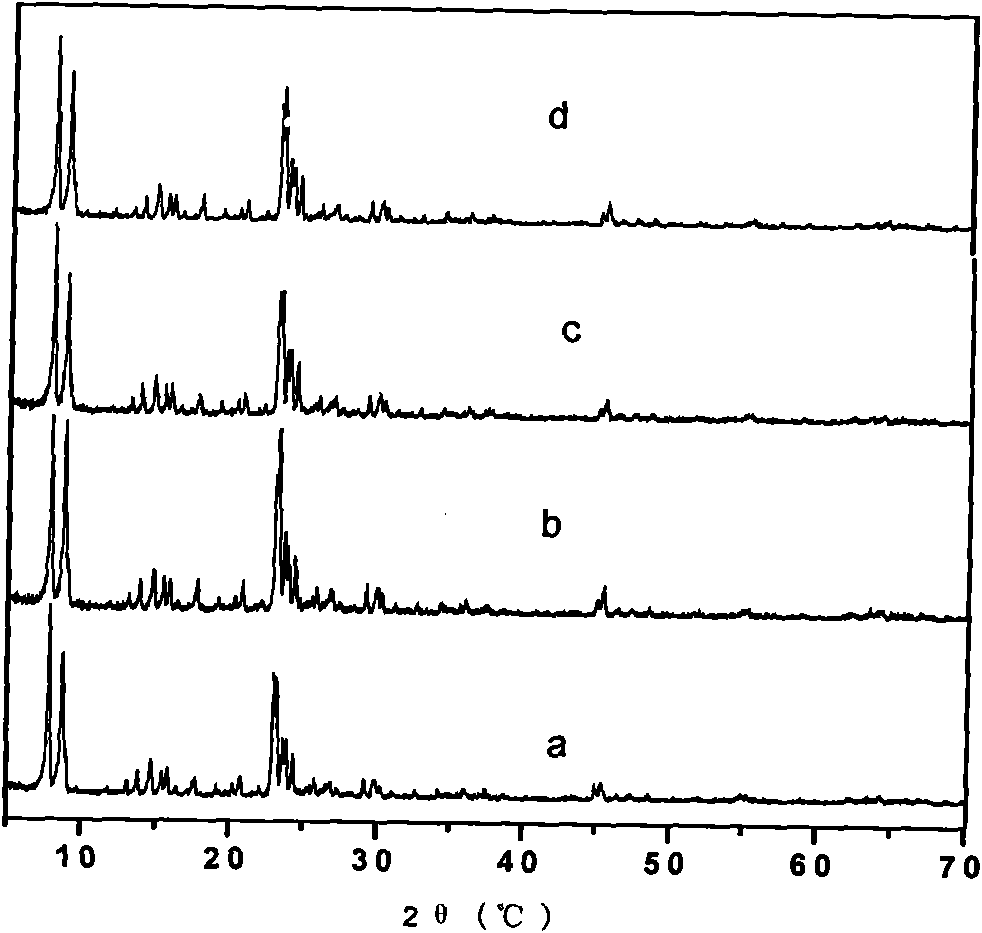

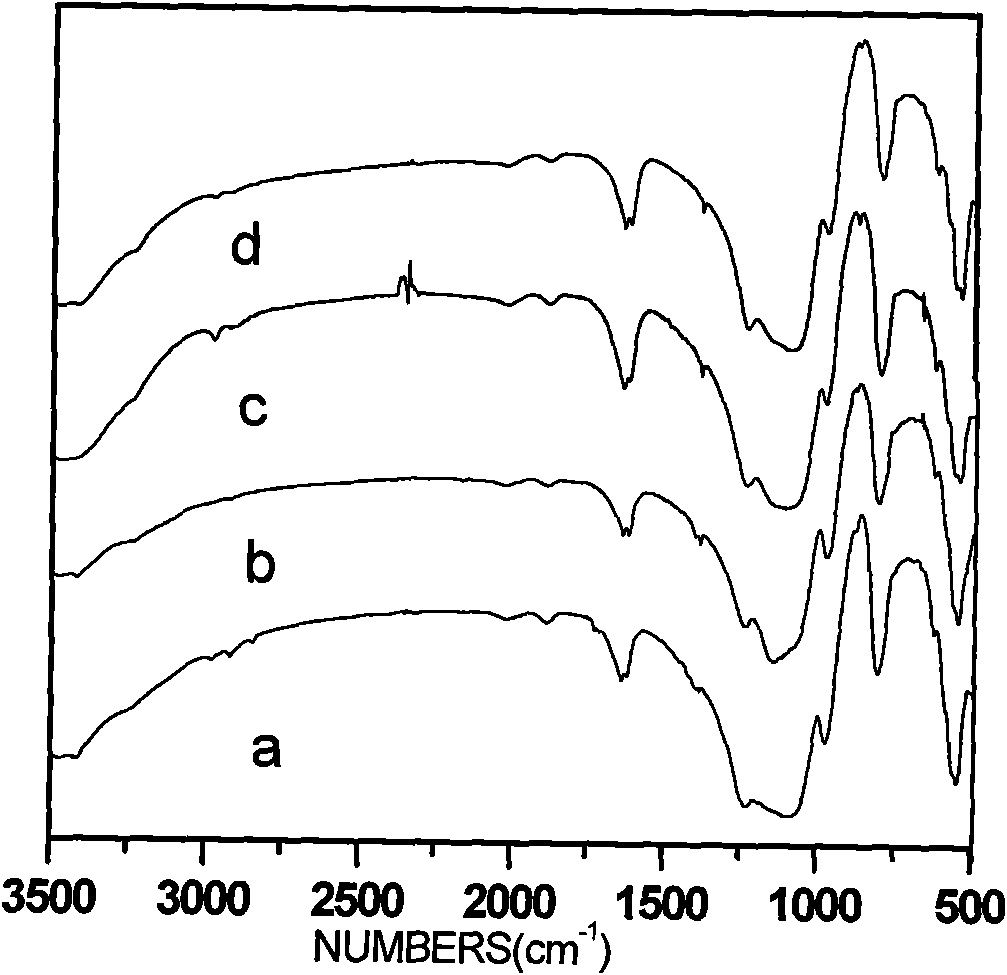

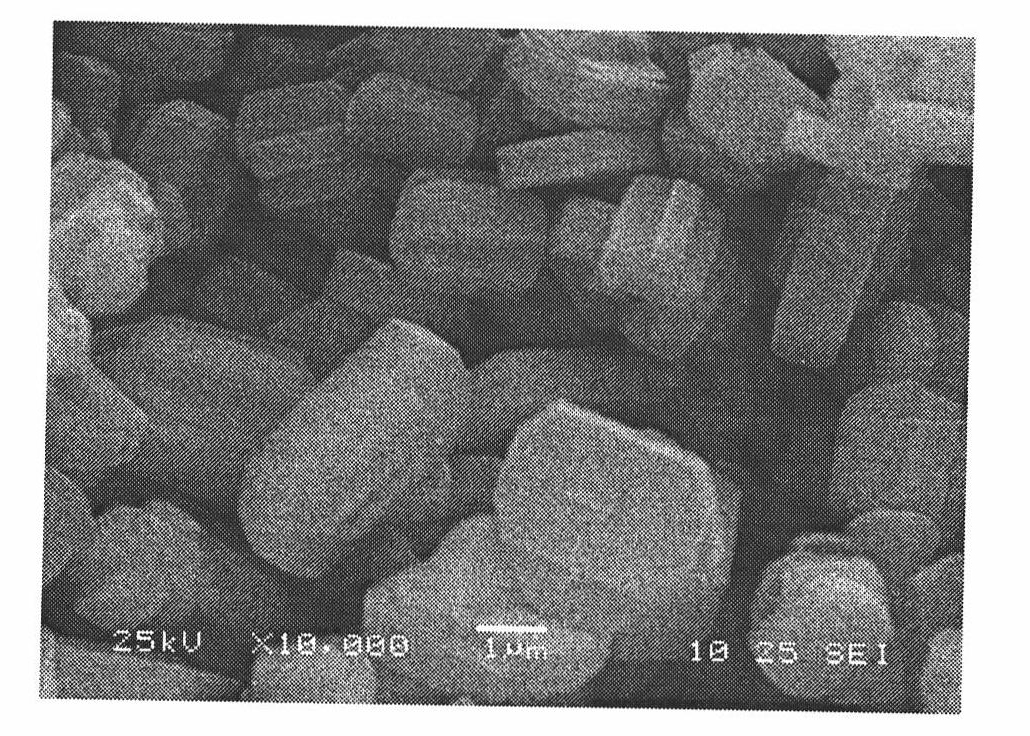

Titanium silicalite TS-1 catalyst preparation method

InactiveCN101767036AHigh activityLow costMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMicrometer

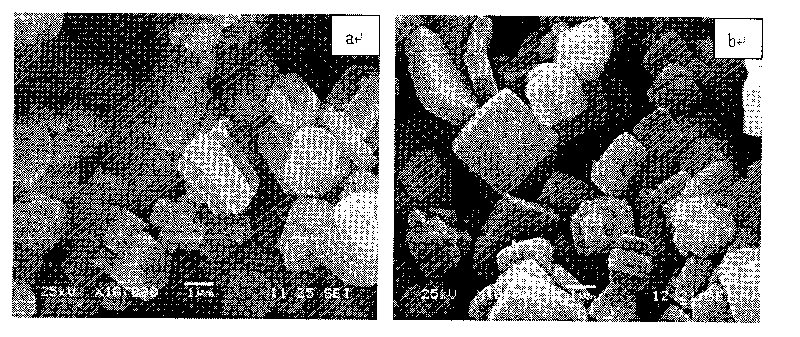

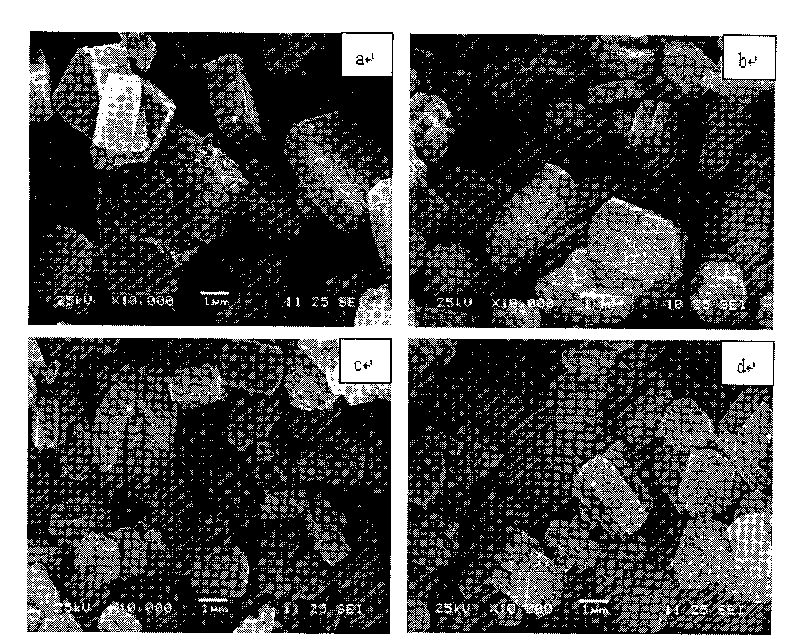

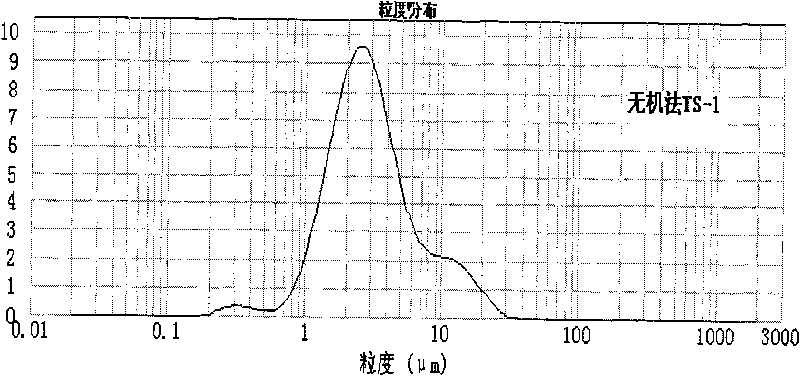

The invention discloses a titanium silicalite TS-1 catalyst preparation method. Cheap inorganic Titanium silicalite is used as raw material, low quantity of tetrapropylammonium hydroxide or tetrapropylammonium bromide is adopted as template agent, and inorganic alkali such as ammonia water is used as alkali source so that the raw materials for preparation have low price and the production cost isgreatly reduced. The precursor preparation process is simple and easy to control, seed crystal is added to reduce the crystallization time and the repeatability is good. As secondary crystallization is adopted, the non-framework titanium is further reduced, and the acid site of the molecular sieve is reduced, the grain size is controllable within certain range, the molecular sieve channel becomessmoother to facilitate direct membrane separation of micrometer crystalline grains, and the obtained Titanium silicalite TS-1 catalyst has large grains, high activity, stable catalytic performance and broad industrial application prospect.

Owner:XIANGTAN UNIV

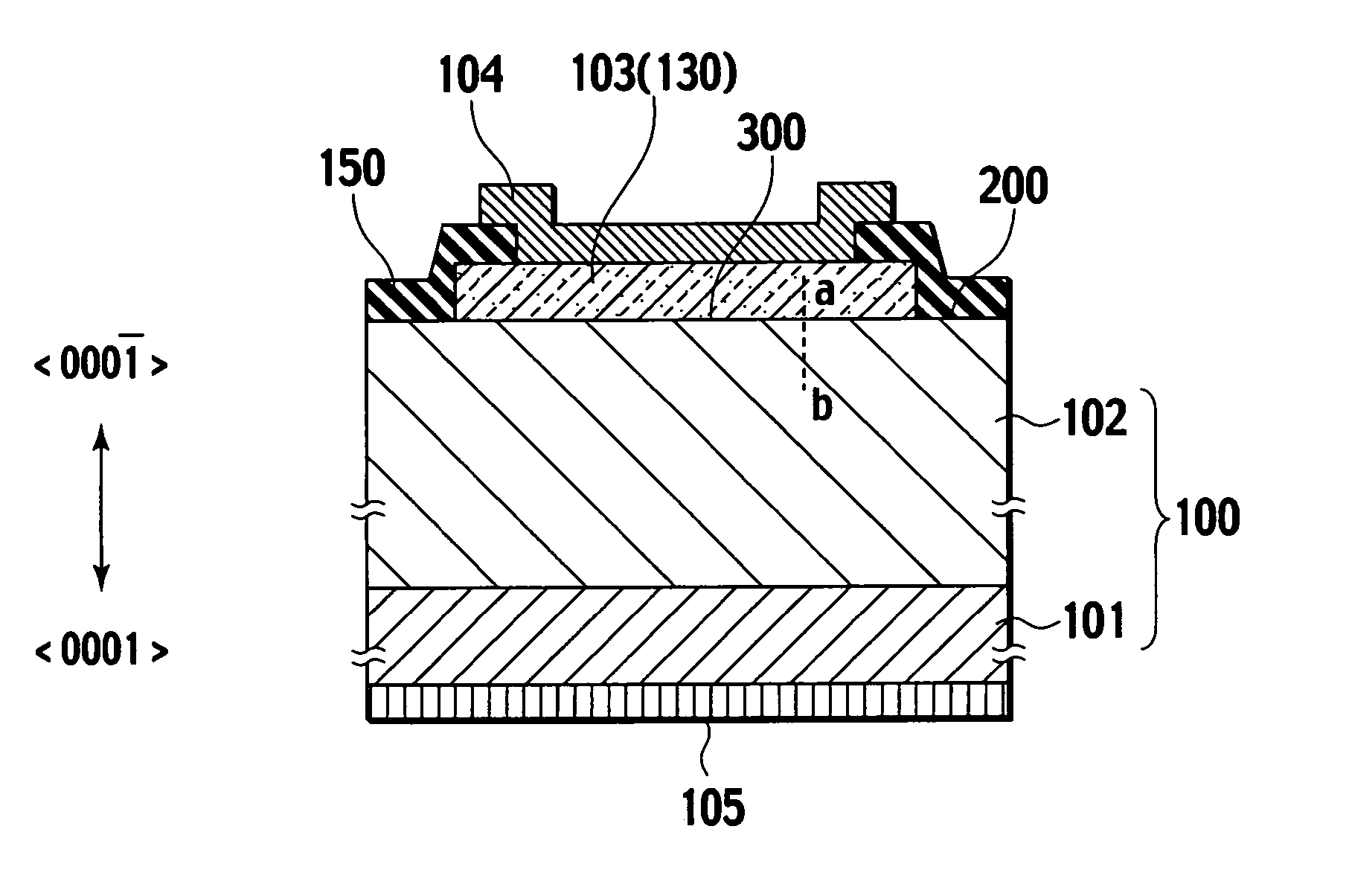

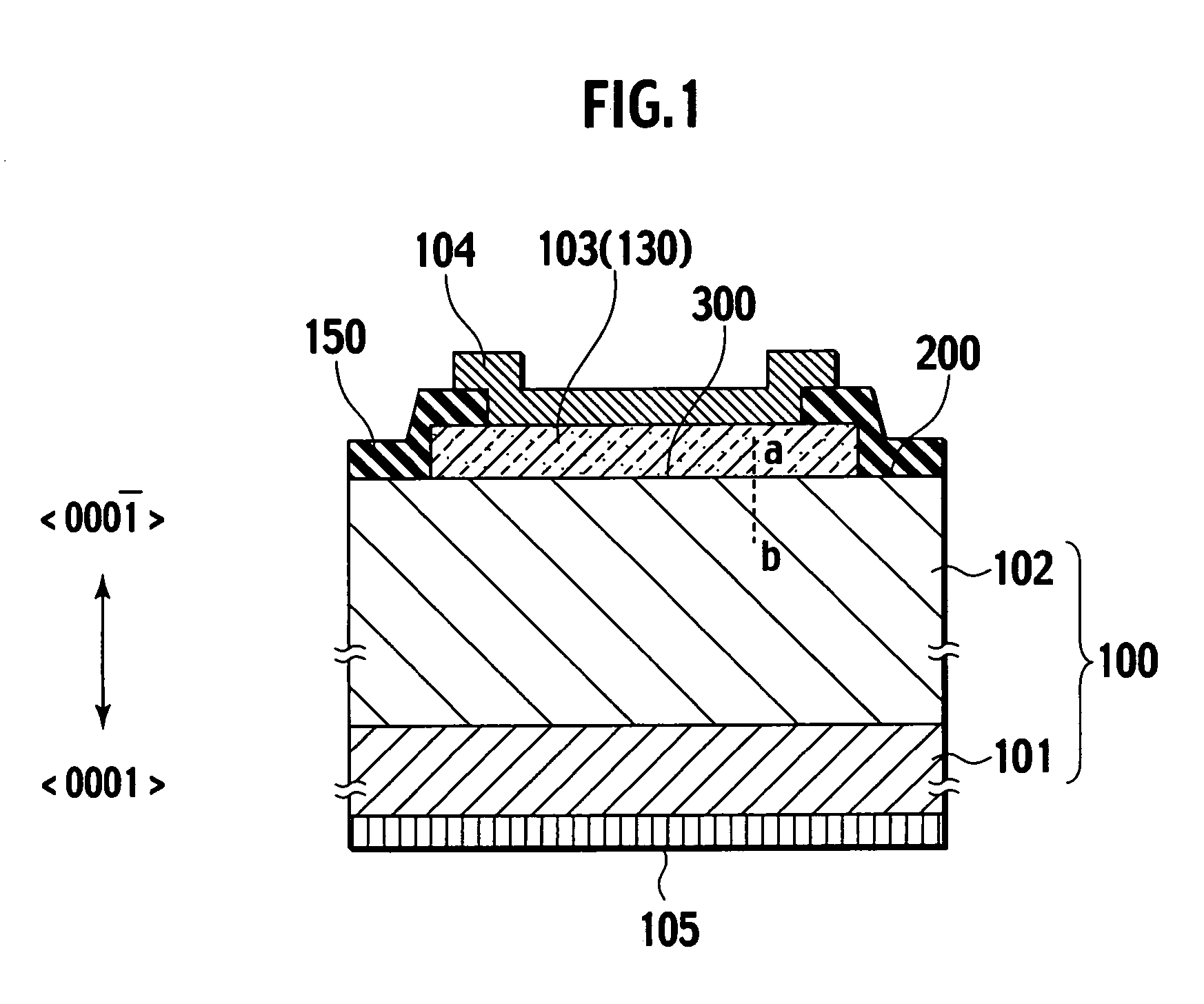

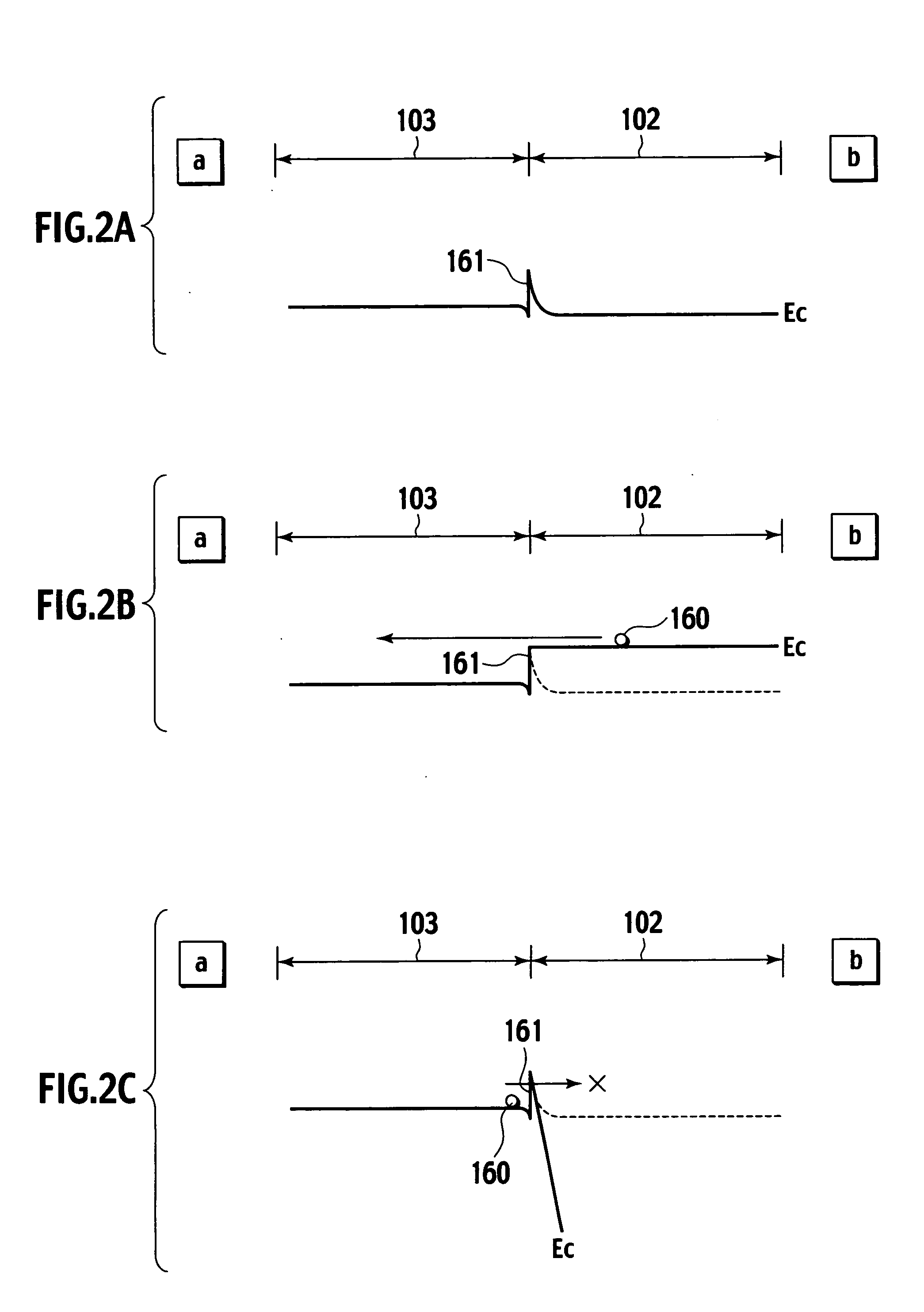

Semiconductor device with heterojunction

InactiveUS20050224838A1Increase manufacturing costLimit on characteristicSolid-state devicesSemiconductor devicesHeterojunctionContact formation

An aspect of the present invention provides a semiconductor device that includes a semiconductor base essentially made of a first semiconductor material of a first conductivity type, a hetero-semiconductor region essentially made of a second semiconductor material whose band gap is different from that of the first semiconductor material, formed on the semiconductor base, and forming a heterojunction with the semiconductor base, a cathode electrode formed in contact with the semiconductor base, and an anode electrode formed in contact with the hetero-semiconductor region, wherein the first semiconductor material is a silicon-carbide (SiC) single crystal and the heterojunction is formed on a {0001-} crystal face of the silicon-carbide single crystal.

Owner:NISSAN MOTOR CO LTD

Method used for in vitro proliferation of NK cells

ActiveCN103756963AIncrease lethalityEasy to synthesizeBlood/immune system cellsSerum free mediaPeripheral blood mononuclear cell

Owner:SHANGHAI CLAISON BIOTECH

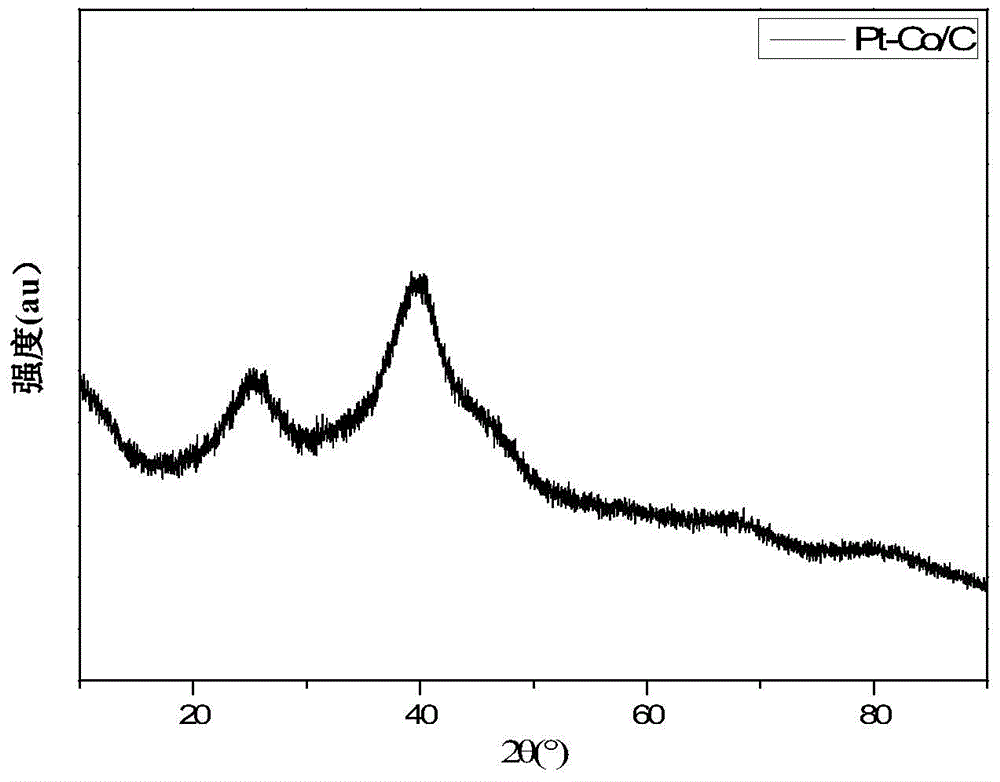

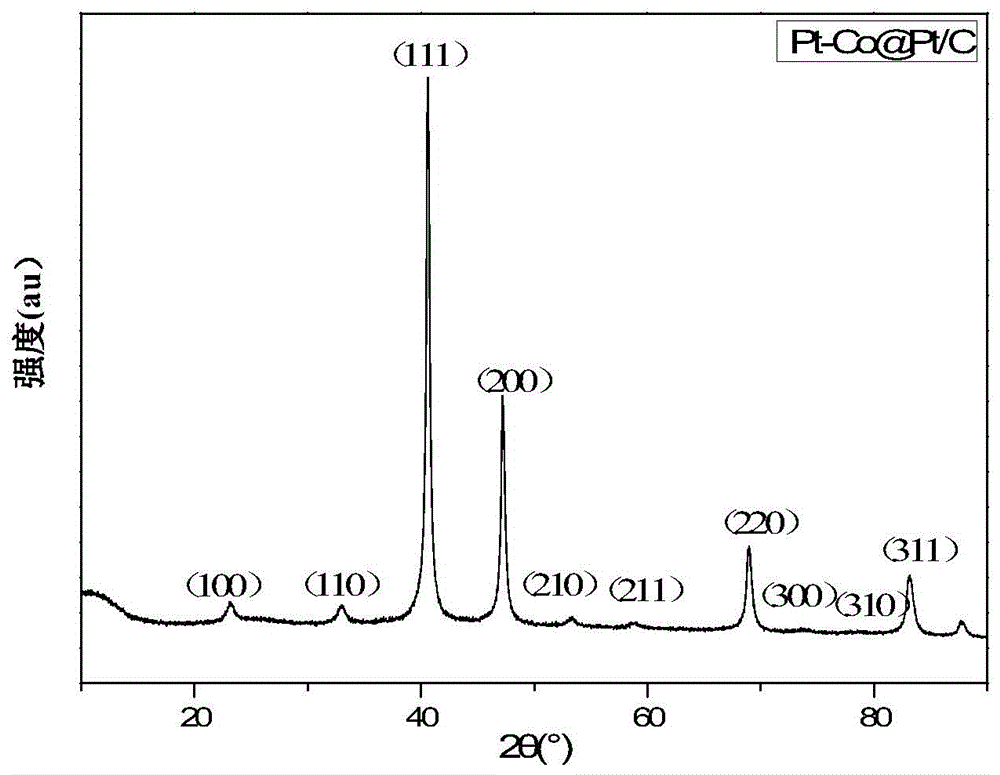

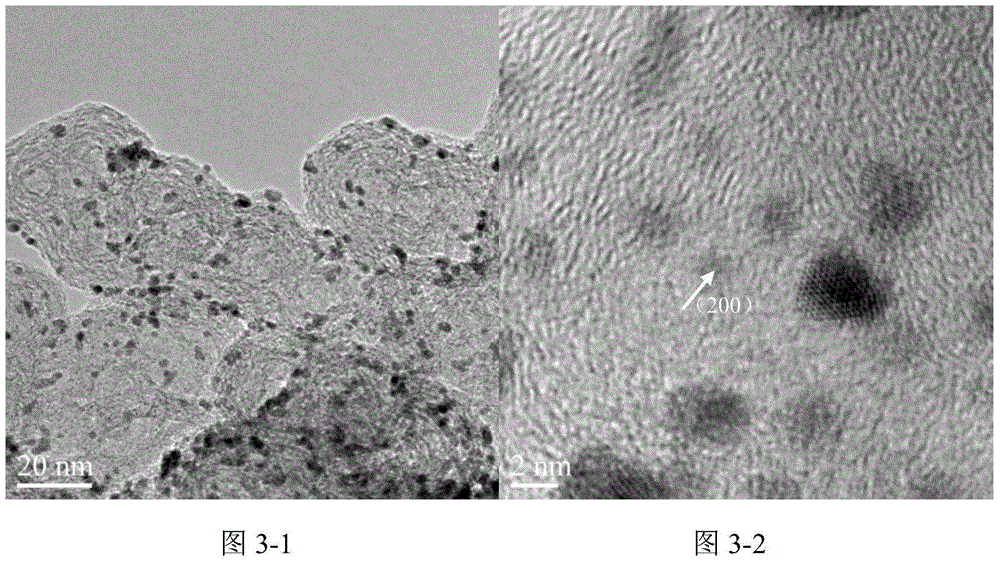

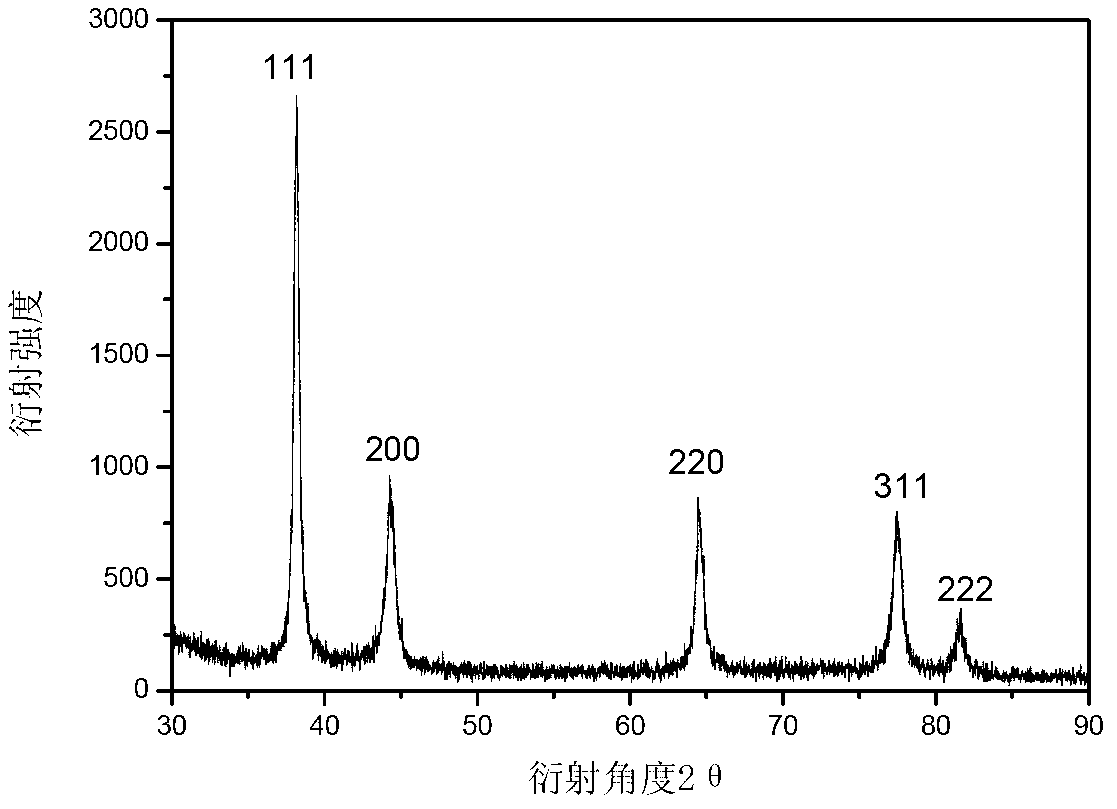

Carbon-supported core-shell type platinum cobalt-platinum catalyst for fuel cells and preparation method for carbon-supported core-shell type platinum cobalt-platinum catalyst

ActiveCN104475126AImprove utilization and stabilityLow cost of preparationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryCarrying capacity

The invention relates to a carbon-supported core-shell type platinum cobalt-platinum catalyst for fuel cells and a preparation method for the carbon-supported core-shell type platinum cobalt-platinum catalyst, belonging to the field of electrochemistry. The catalyst comprises the following components in percentage by weight: 60%-90% of a carrier, 1%-20% of cobalt, and 9%-20% of platinum. According to the invention, a mixed solution of ethylene glycol and sodium borohydride acts as a reducing agent, the core-shell type platinum cobalt-platinum catalyst Pt-Co@Pt / C with an ordered structure is prepared by high-temperature annealing treatment. The catalyst with the ordered structure, which is prepared by the invention, has the advantages of low Pt carrying capacity, high catalysis activity, high stability and the like, and the development of fuel cells can be promoted further.

Owner:BEIJING UNIV OF CHEM TECH

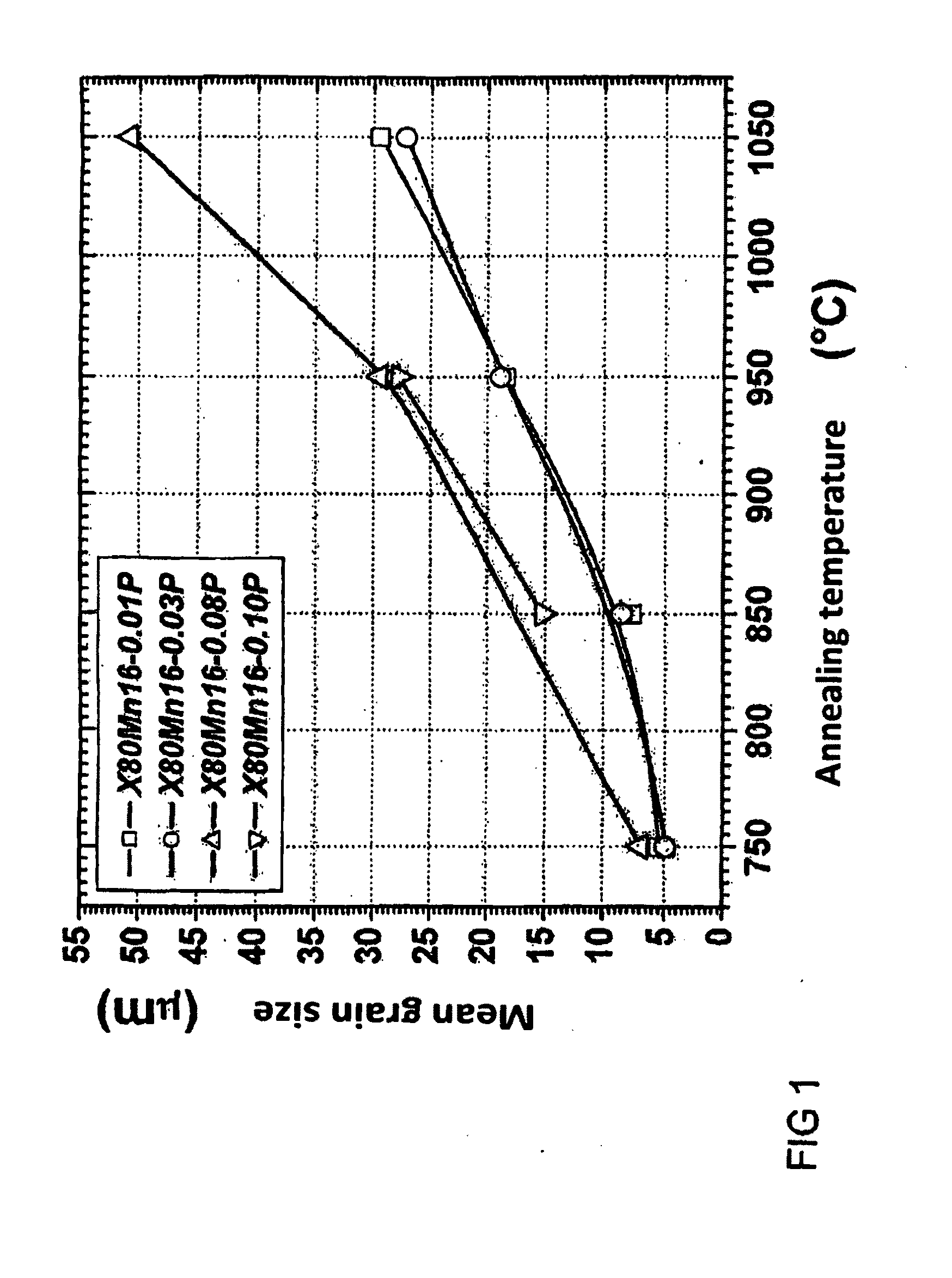

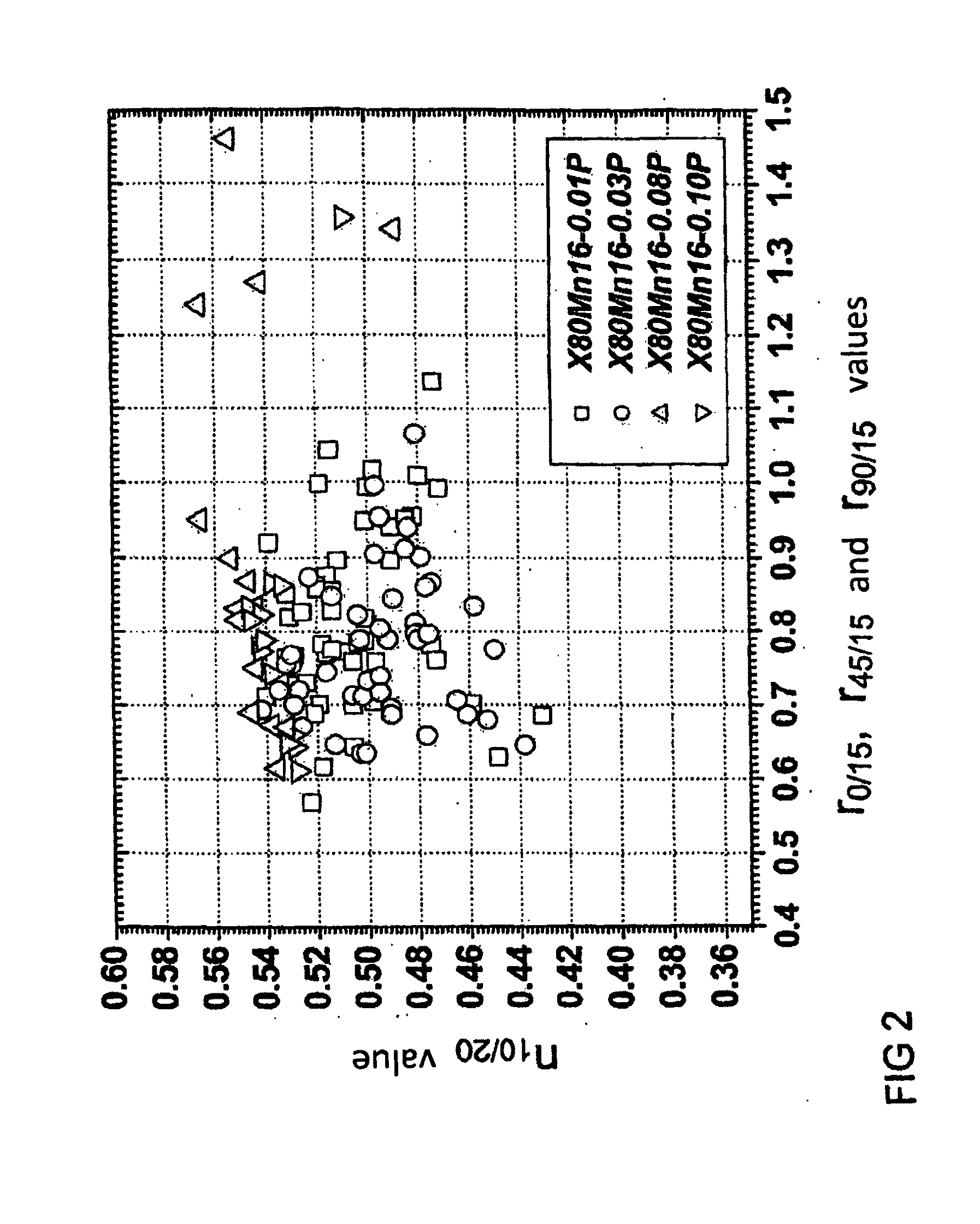

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

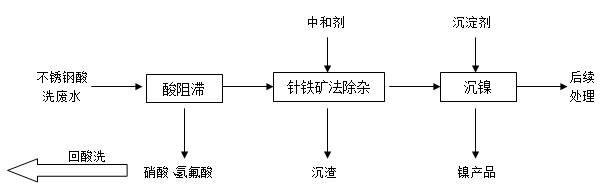

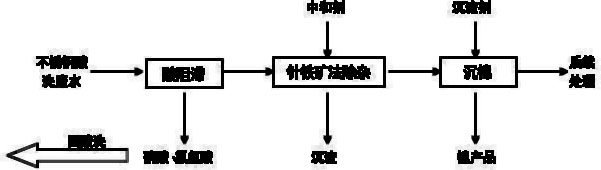

Recycling harmless treatment method of stainless steel pickling waste water

ActiveCN102659274AHigh recovery rateSmall footprintSludge treatmentSolid waste disposalIndustrial waste waterSS - Stainless steel

The invention discloses a recycling harmless treatment method of stainless steel pickling waste water, belonging to the toxic and harmful industrial waste water treatment field. The method comprises the following steps of: 1) recycling inorganic acids by an acid separation method: pumping stainless steel pickling waste water in which suspended matters are removed through filtering into a resin column so that the inorganic acids are absorbed on the resin; 2) removing impurities by a goethite method: pumping heavy metal ion solution into a reaction kettle, adjusting pH to a range from 3.5 to 5.0, and continuing reacting for 30-90 min, thereby removing iron, chromium and fluorine in the heavy metal ion solution in the form of dregs; 3) recycling nickel by a neutralized sedimentation method: feeding an alkaline liquor to nickel solution to adjust pH to a range from 9.5 to 12.5, and filtering and washing the filter residues, thereby obtaining nickelous hydroxide; and 4) performing harmlesstreatment on the dregs: after washing the dregs, adding lime powder to the dregs to realize stabilization treatment of harmful elements. The method is simple in operation and convenient for management; the high-concentration inorganic acids and nickel and the like contained in the waste water are all recycled, and simultaneously the generated dregs are harmlessly treated; and therefore the integration of economic benefit,environmental benefit and social benefit is realized.

Owner:NANJING UNIV

Karst grouting reinforcement water-stop constructing method

The invention discloses a karst grouting reinforcement water-stop constructing method, which is to construct according to sizes of karst caves by adopting a principle of from big to small regarding a certain area, construct by adopting a principle of from outside to inside for the karst caves with the same size, and construct by adopting a principle of from the bottom to the top in a vertical direction. On the basis of the construction principles, the method comprises the following steps of: (1) forming grouting holes by adopting a core drill; (2) forming construction exhaust and drainage pressure relief holes; (3) inserting grouting pipes into the grouting holes, wherein the grouting pipes comprise steel pipes, grouting shock pipes and sleeve valve pipes; (4) cleaning the holes, wherein when the step (3) is completed, the grouting pipes are cleaned with clean water; (5) grouting; and (6) drawing out the grouting pipes after the grouting is completed, and blocking the grouting holes with cement mortar or concrete. By adopting the constructing method, the pertinence to karst caves is strong, the grouting quantity is small, the engineering work amount is small, the cost is low, and the effect of filling and reinforcing is good.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

Method for harmless and recycling treatment of stainless steel acid washing waste water neutralization sludge

ActiveCN101982433ASolve the problem of sediment lossImprove water qualitySludge treatmentMultistage water/sewage treatmentSludgeAcid washing

The invention discloses a method for harmless and recycling treatment of stainless steel acid washing waste water neutralization sludge, belonging to the field of harmful and valuable heavy metal resource recovery. The stainless steel acid washing waste water neutralization sludge is leached out by sulphuric acid, harmful and poisonous metals manganese, nickel and chromium enter into the leachate, and harmless treatment is carried out on the sludge. Separation, enrichment and recovery of metal resources of iron, manganese, chromium and nickel in the leachate are realized by adopting goethite method, potassium permanganate oxidation method, anion resin exchange method and chelate resin absorption method respectively, and effluent up to the standard is discharged after treatment or is returned to water consuming link in technologic process. The method of the invention has short technological flow, simple operation, management convenience, high recovery rate of valuable metal resources of manganese, nickel and chromium, recycling of multiple valuable metals is realized while the sludge is subject to harmless treatment, and unification of economic benefit, environmental benefit and social benefit is realized.

Owner:NANJING UNIV

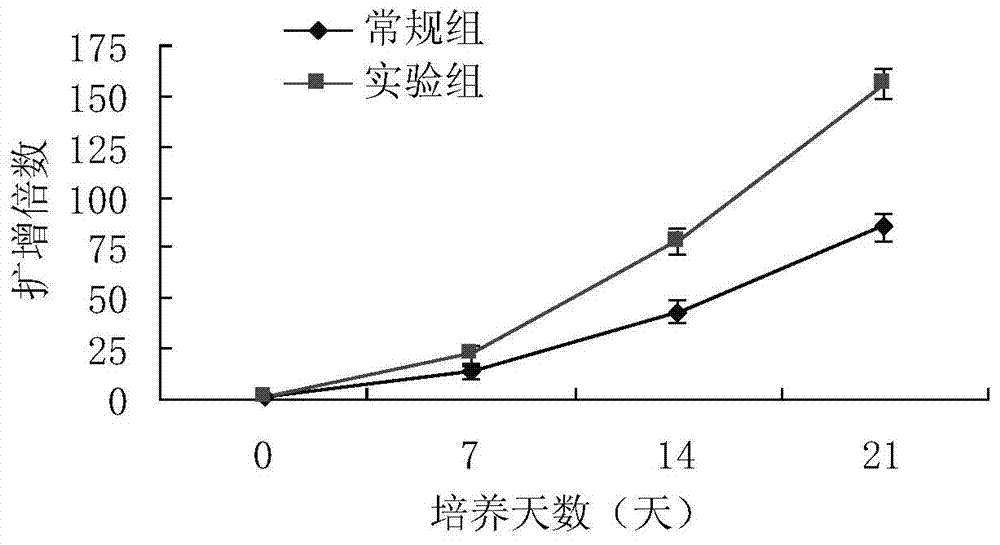

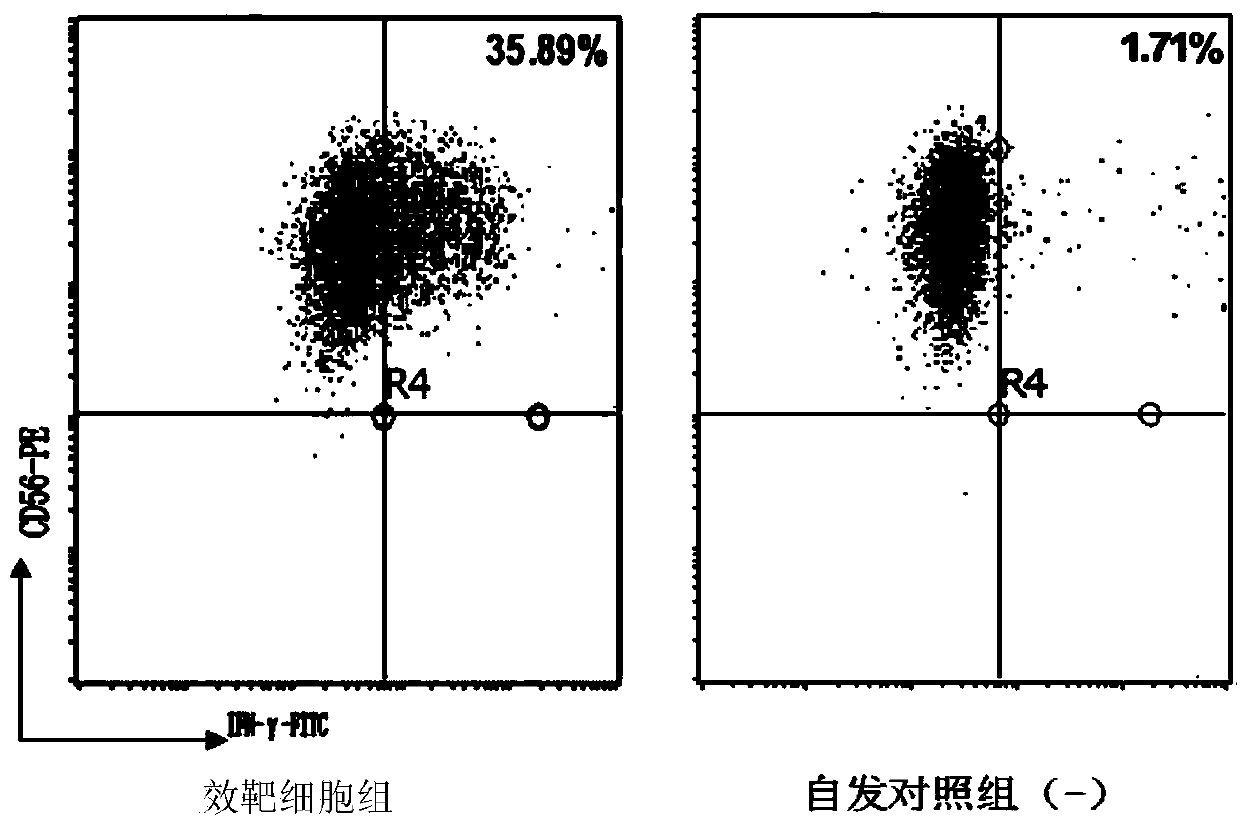

Method for in-vitro amplification of NK cells

InactiveCN102994449AEasy to synthesizeIncrease lethalityBlood/immune system cellsSerum free mediaPeripheral blood mononuclear cell

The invention relates to a method for in-vitro amplification of NK cells, and in particular relates to a method for massive in-vitro amplification of NK cells, wherein the method comprises the following steps of: a, inoculating a peripheral blood mononuclear cell in a CD3McAb and CD226McAb pre-coated culture bottle for coculture; b, adding 1L-2 and 1L-18, coculturing for 72hours to stimulate amplification of NK cells; c, transferring the NK cells, K562 cells after lethal treatment and a serum-free medium containing 1L-2 and 1L-18 in a cell culture bag for coculture; and d, collecting the NK cells. According to the method for in-vitro amplification of the NK cells, two antibodies CD3McAb and CD226McAb are simultaneously coated, so the cell factor synthesis and ADCC effect are promoted, and killing toxicity of the NK cells is remarkably improved; the activation and amplification on the NK cells are achieved just by the 1L-2 and 1L-18 cell factors, so the amplification multiple and cell toxicity of the NK cells are guaranteed, and the cost of cell culture is reduced.

Owner:SHANGHAI CLAISON BIOTECH

Titanium-silicon molecular sieve TS-1 catalyst for catalyzing ketone oximation reaction

InactiveCN101757945AHigh activityHigh reuse rateMolecular sieve catalystsCatalyst activation/preparationKetoneLarge particle

The invention relates to a titanium-silicon molecular sieve TS-1 catalyst for catalyzing ketone oximation reaction. In order to solve the problems of small particles, difficult separation and reutilization, high synthesis cost, strict and complex requirements in the process of gluing, poor repeatability and stability and the like in the prior art, the invention provides a new titanium-silicon molecular sieve TS-1 catalyst for the catalyzing ketone oximation reaction, which is prepared from the following steps: mixing the titanium-silicon molecular sieve TS-1 with one or more solutions of organic amine, ammonium salt, ammonia water and urea, carrying out crystallization again under the self-generating hydro-thermal pressure, and filtering, washing, drying and roasting to obtain the product. The prepared titanium-silicon molecular sieve TS-1 catalyst has large particles and easy separation and recovery after reaction, can improve the reutilization ratio, is especially suitable for ketone oximation reaction using hydrogen peroxide as an oxidizing agent, and can not produce byproducts, thereby protecting the environment and being beneficial to industrial application.

Owner:XIANGTAN UNIV

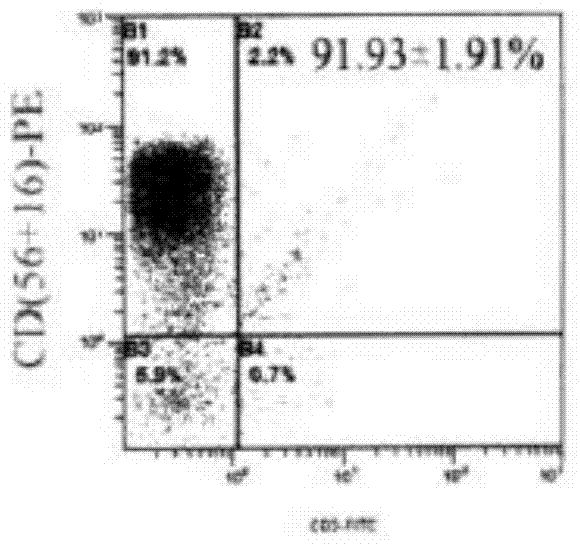

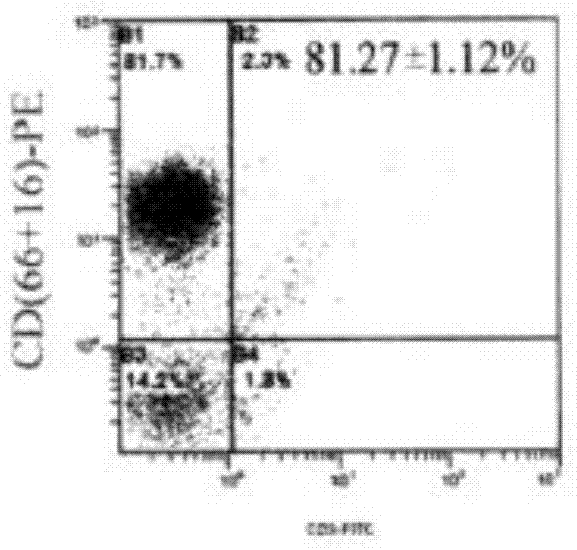

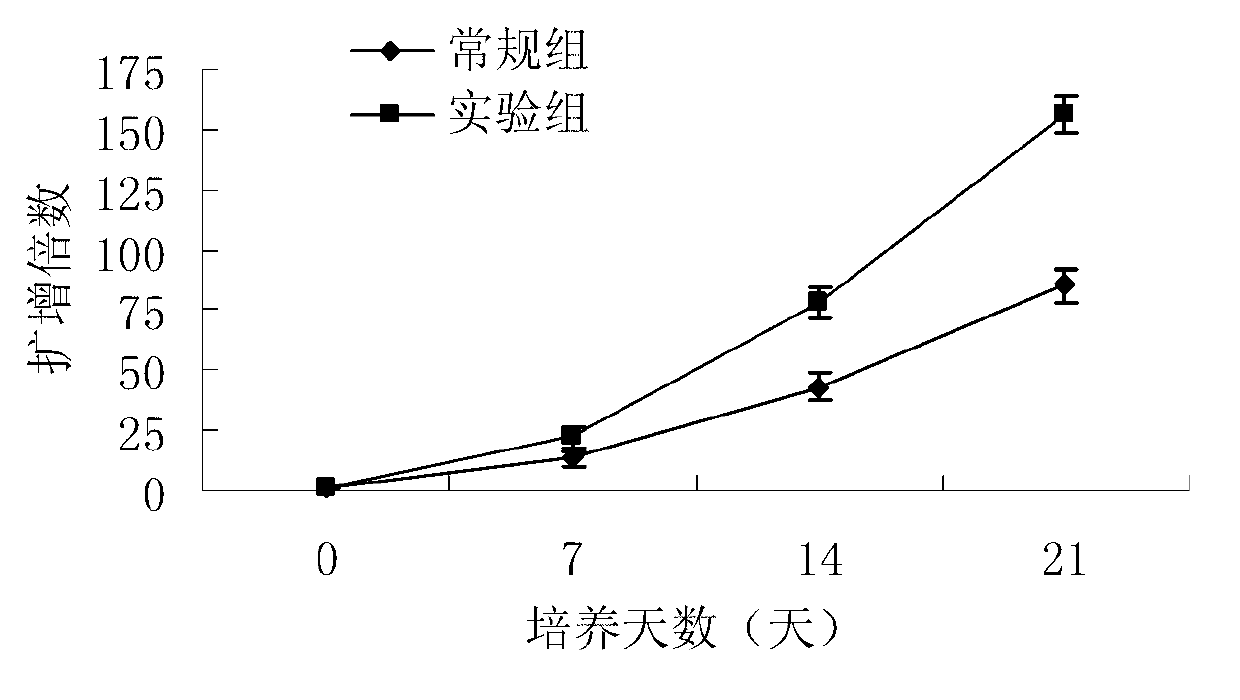

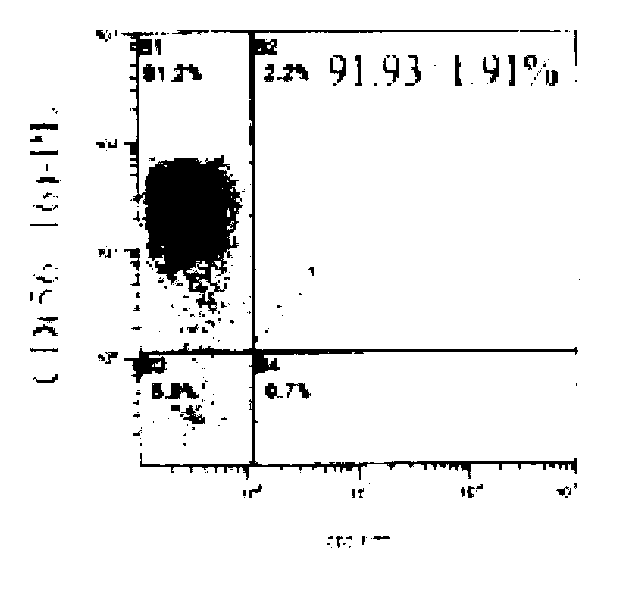

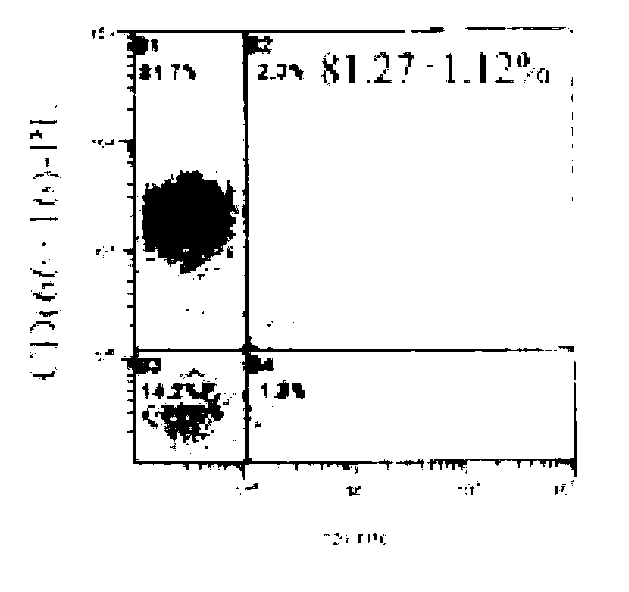

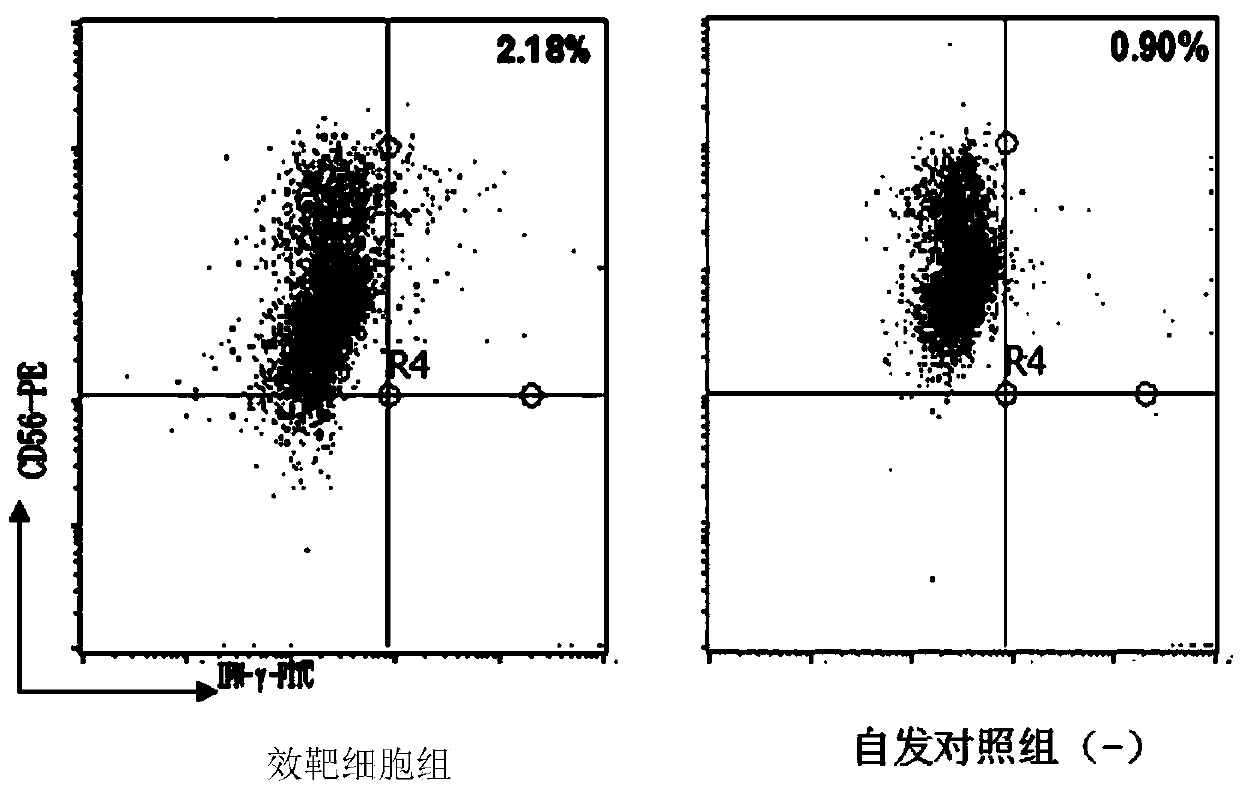

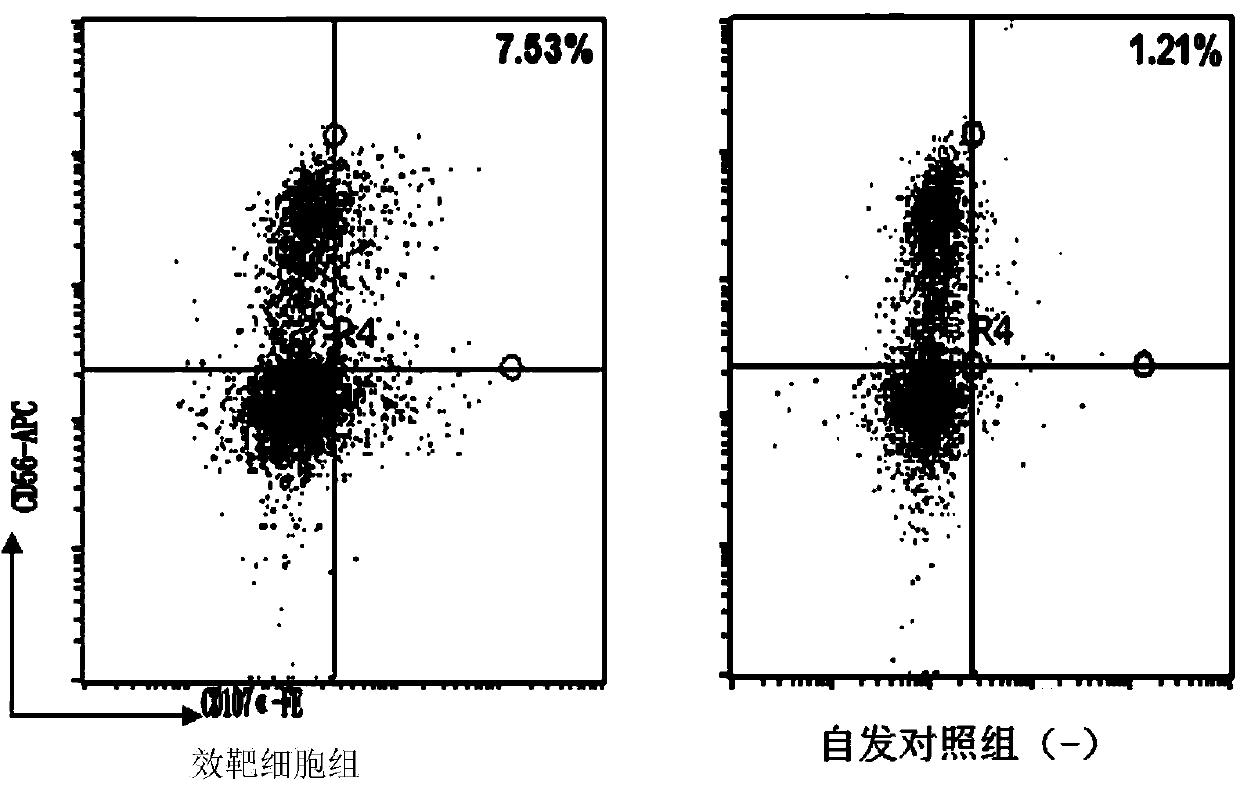

Method for simultaneous and efficient amplification of CD<3+>CD<56+>CIK cells and CD<3->CD<56+>NK cells

ActiveCN104357390AHigh purityHigh activityBlood/immune system cellsAdoptive cellular immunotherapySerum free media

The invention discloses a method for simultaneous and efficient amplification of CD<3+>CD<56+>CIK cells and CD<3->CD<56+>NK cells. The method comprises the steps as follows: the concentration of separated PBMC (peripheral blood mononuclear cells) is adjusted by a serum-free medium containing autologous plasma, an Anti-CD16 antibody, IL-2 and IL-15 are added, and then the mixture is transferred into a T175 culture flask for culture; an Anti-CD3 antibody and an Anti-CD137 antibody are added; a serum-free medium containing the autologous plasma, IL-2 and IL-15 is supplemented every two days according to the cell growth condition; the cell concentration is controlled to be about 1.5*10<6> / ml; and after culture is performed for 14-21 days, large quantities of high-purity CD<3+>CD<56+>CIK cells and CD<3->CD<56+>NK cells can be obtained simultaneously, and the total cell quantity can reach an effective value of the cell quantity required for adoptive cellular immunotherapy clinically for tumor. The method for simultaneous and efficient amplification of the CD<3+>CD<56+>CIK cells and the CD<3->CD<56+>NK cells is simple, convenient, effective and high in cell killing activity.

Owner:HRYZ (SHENZHEN) BIOTECH CO +1

Preparation method for hollow nano metal

InactiveCN103231069AReduce sizeControl shapeMicroballoon preparationMicrocapsule preparationSurface-active agentsAzeotropic distillation

The invention relates to a preparation method for hollow nano metal, which comprises the following steps: a), reducing agent is dissolved into deionized water firstly, then is mixed with organic solvent and surface active agent, and stirring is performed for preparing microemulsion; b), water inside a system is evaporated through azeotropic distillation till the solution is clear and colorless, and at the moment, and the reducing agent is coated with the surface active agent and exist in the system in a state of monodispersed nano particles; c), metallic compound is added into the system after getting complexing through complexant, and metal is obtained through the reduction of the metallic compound on the surface of the reducing agent; and d), centrifugal separation is performed on the system after reduction reaction, precipitation is taken, and the hollow nano metal can be obtained through centrifugation after water washing. A micro-emulsion method is utilized for preparing the hollow nano metal in an assisting manner, and since the reducing agent is used as a hard template, the size and the appearance of the hollow nano metal can be effectively controlled. The prepared hollow nano metal has excellent monodispersity and is uniform in size.

Owner:CHANGZHOU UNIV

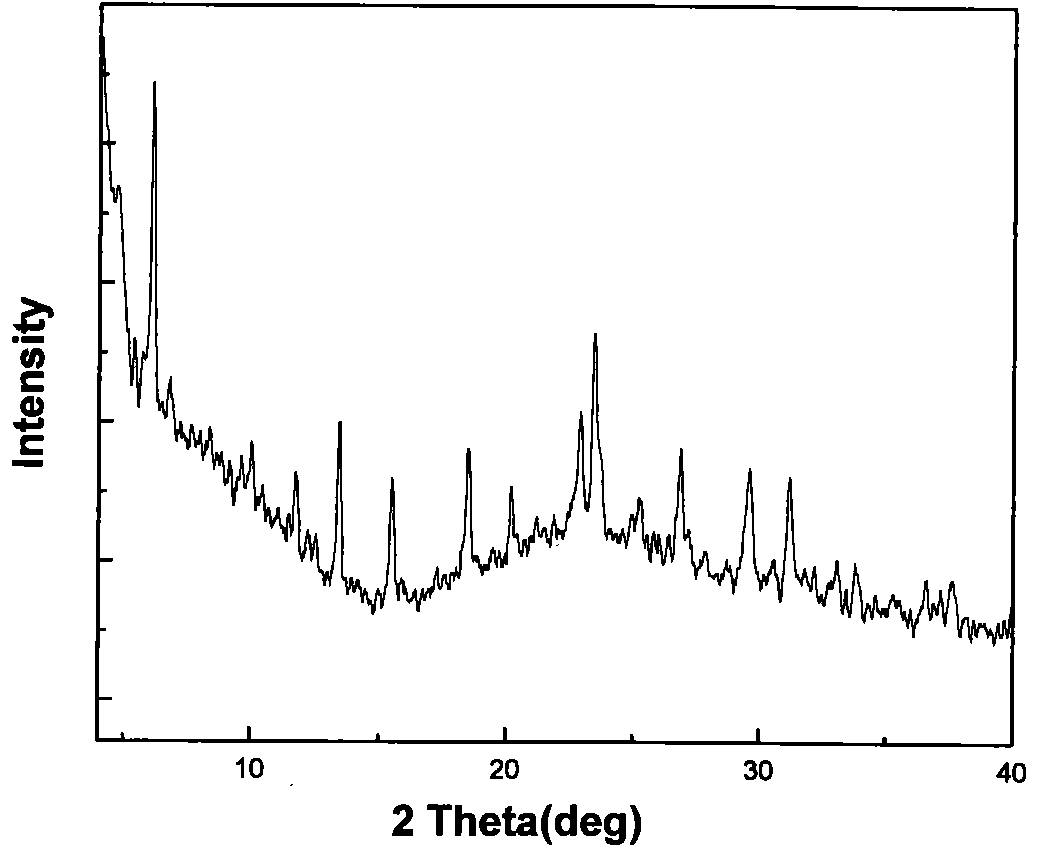

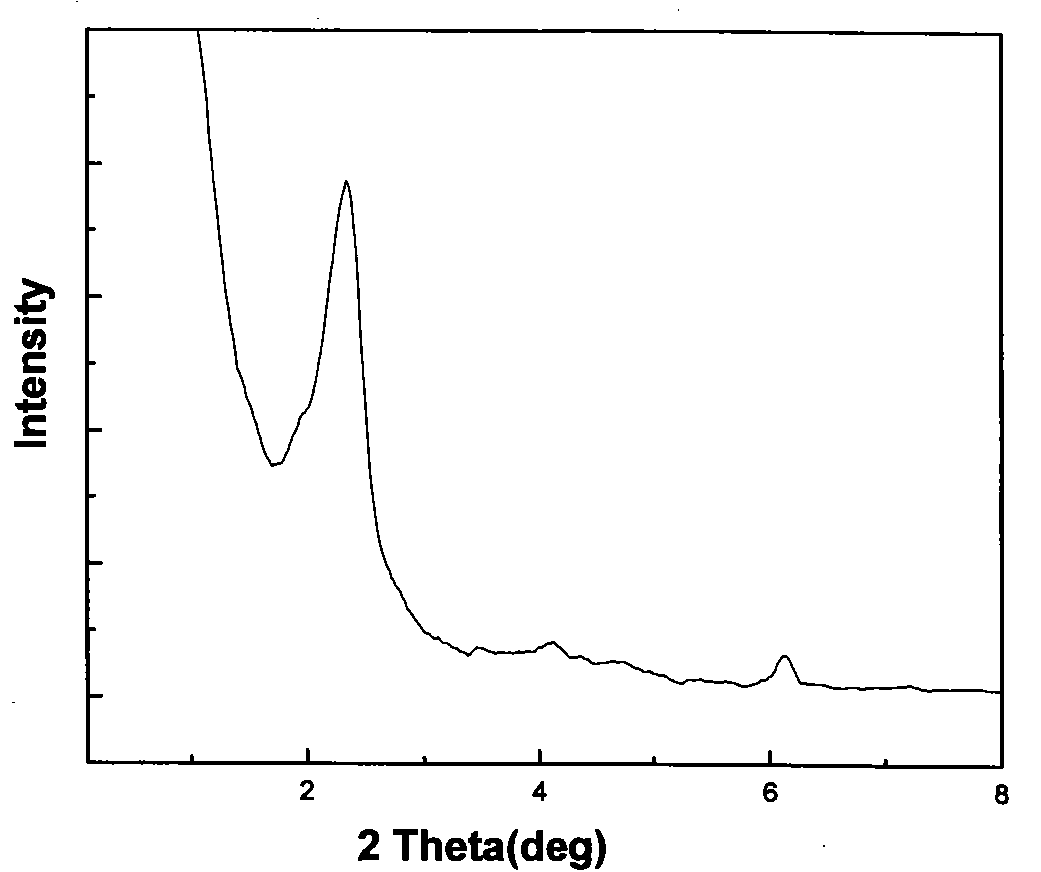

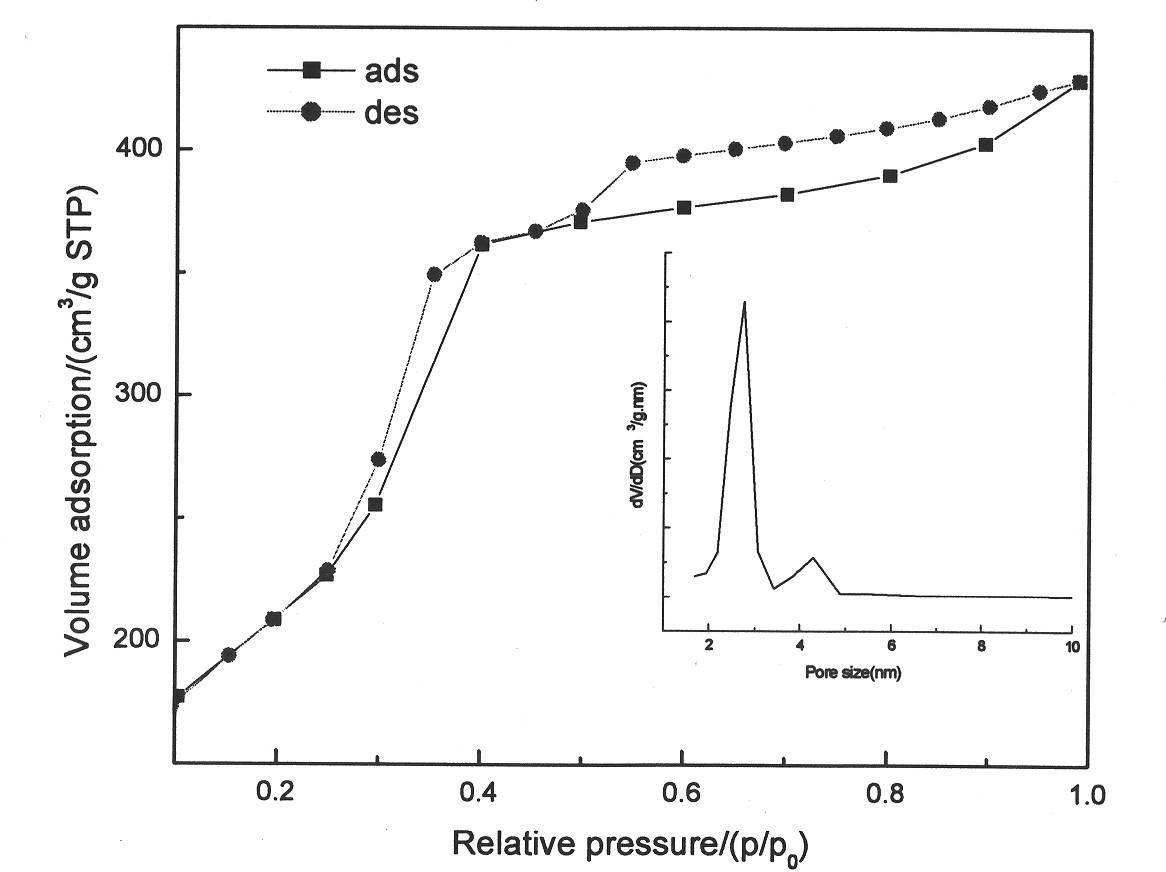

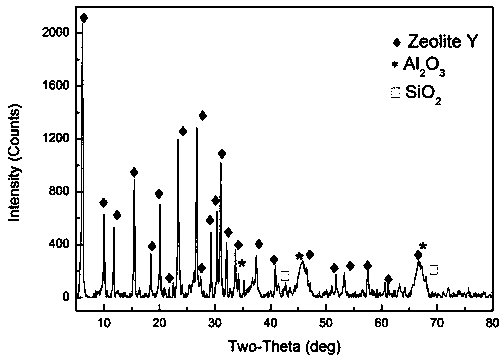

Method for synthesizing composite molecular sieve by microwave method and catalytic performance application thereof

InactiveCN102000604AHigh selectivityLarge particlesOrganic chemistryMolecular sieve catalystsMicrowave methodCatalytic effect

The invention discloses a method for synthesizing a composite molecular sieve by a microwave method and catalytic performance application thereof. In the method for preparing the composite molecular sieve by the microwave method, kaolin is taken as a raw material, inorganic silicate is taken as an additional silicon source, and the prepared composite molecular sieve is applied to the alkylation reaction of phenol and tertiary butanol. The method comprises the following steps of: adding a certain amount of sodium silicate into the kaolin serving as the raw material to synthesize a Y type molecular sieve precursor; and preparing a composite molecular sieve Y / MCM-41 by the microwave method by using hexadecyl trimethyl ammonium bromide serving as a template. The synthesized molecular sieve has two pore structures, namely micropores and mesopores; the specific surface area of a sample is more than 550 m<2> / g; the average pore size is roughly 2.7 nm; and the sample has a regular and ordered hexagonal pore structure. The synthesized molecular sieve has good catalytic effect on the alkylation reaction of the phenol and the tertiary butanol, and particularly the selectivity of 4-tertiary butyl phenol is up to 86.3 percent.

Owner:JIANGSU UNIV

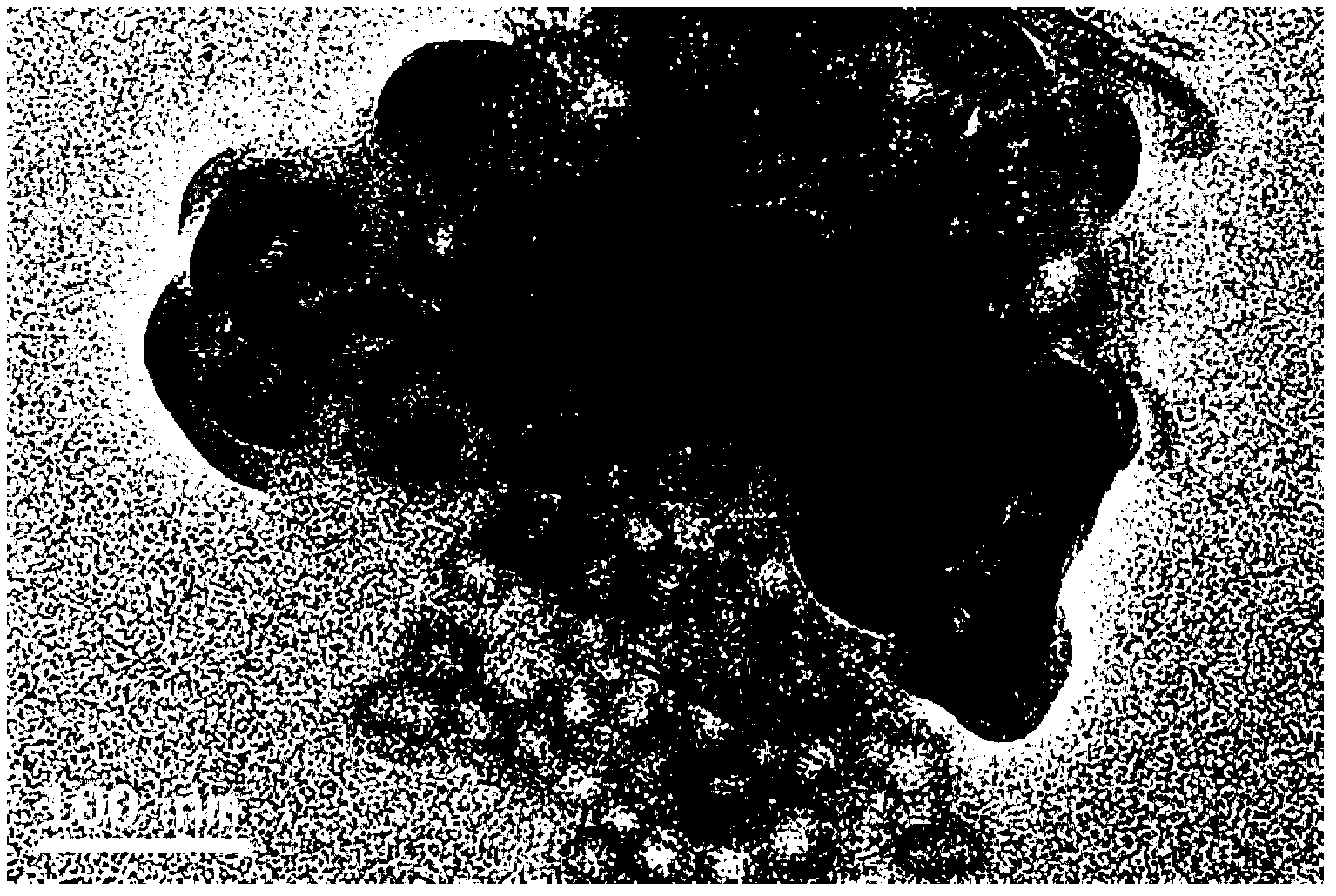

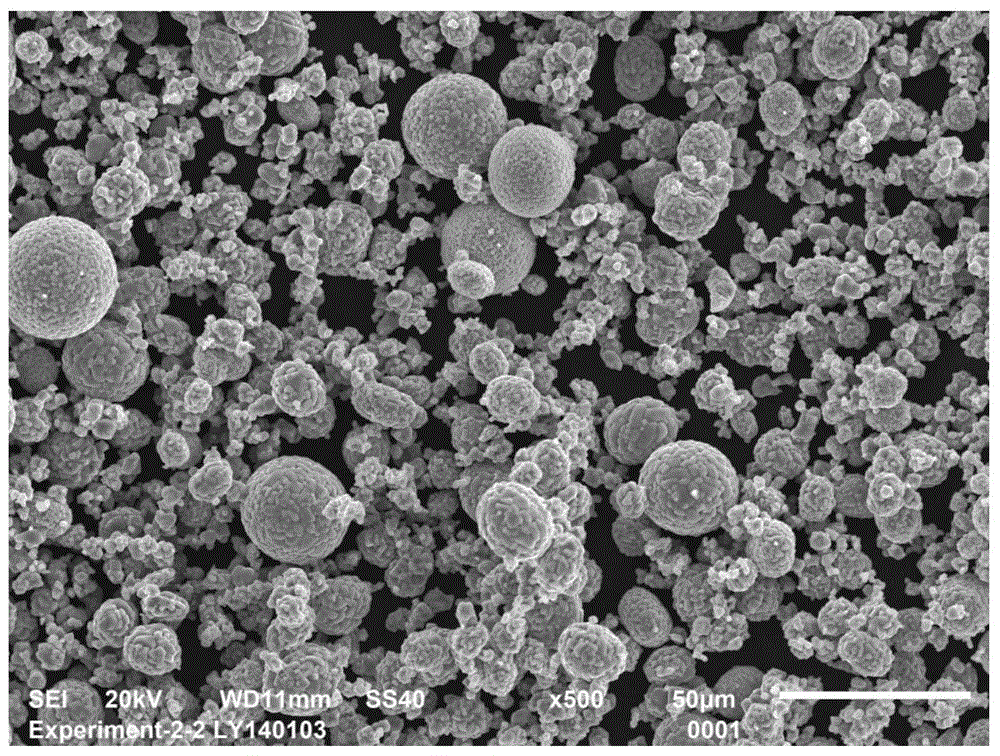

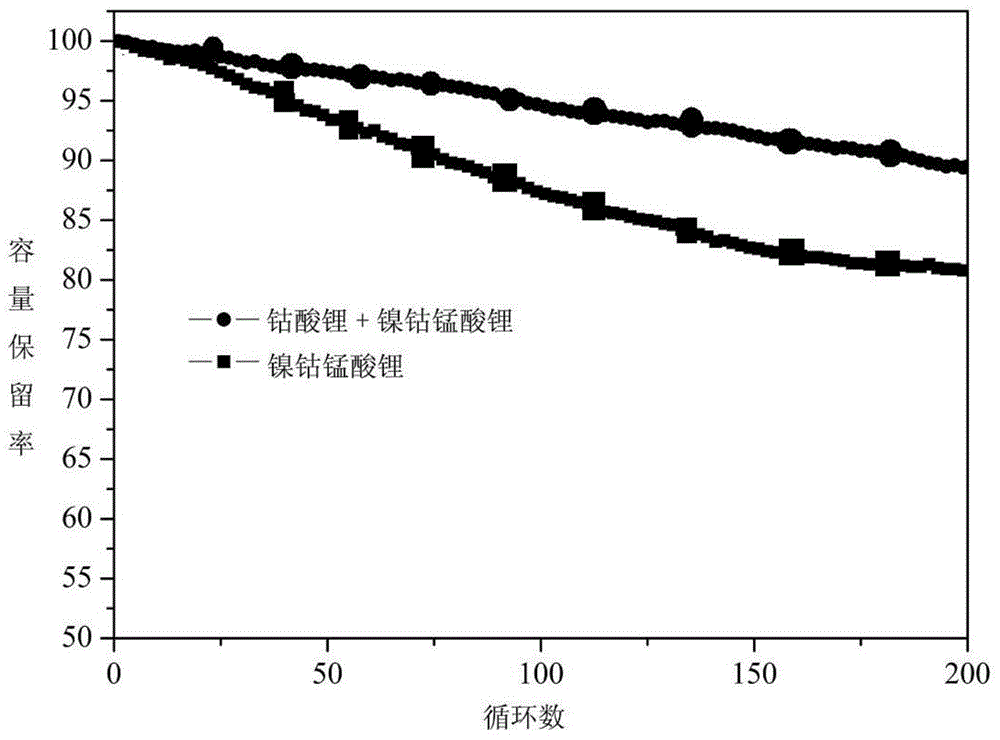

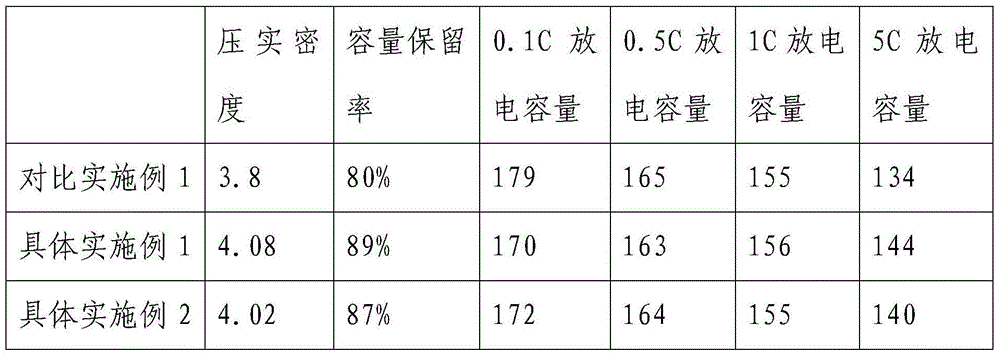

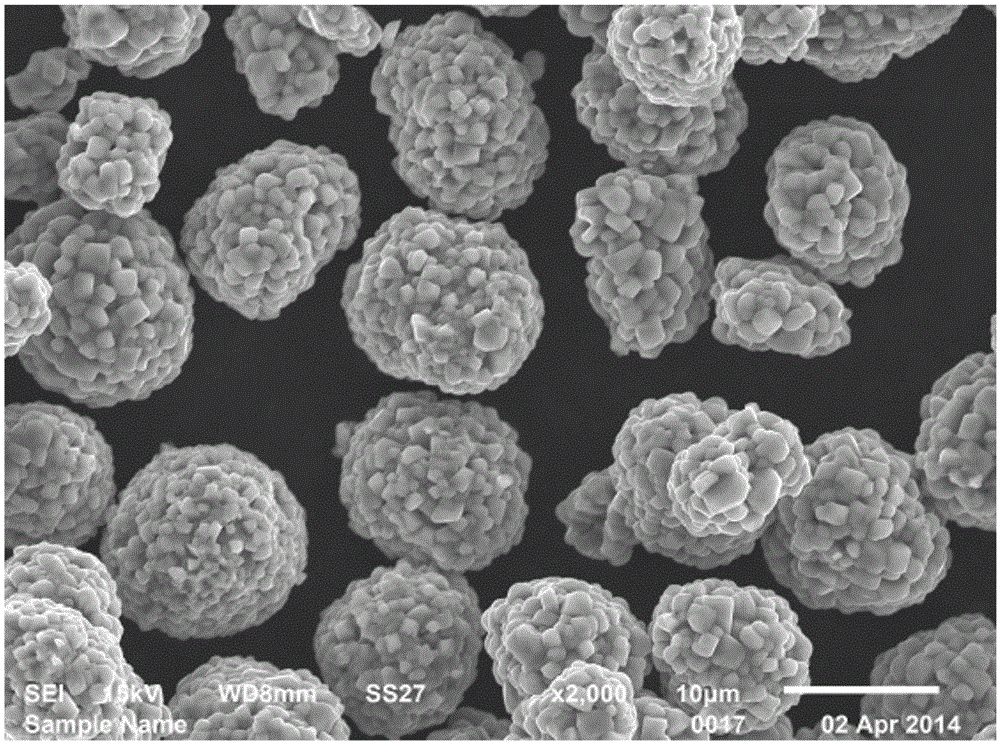

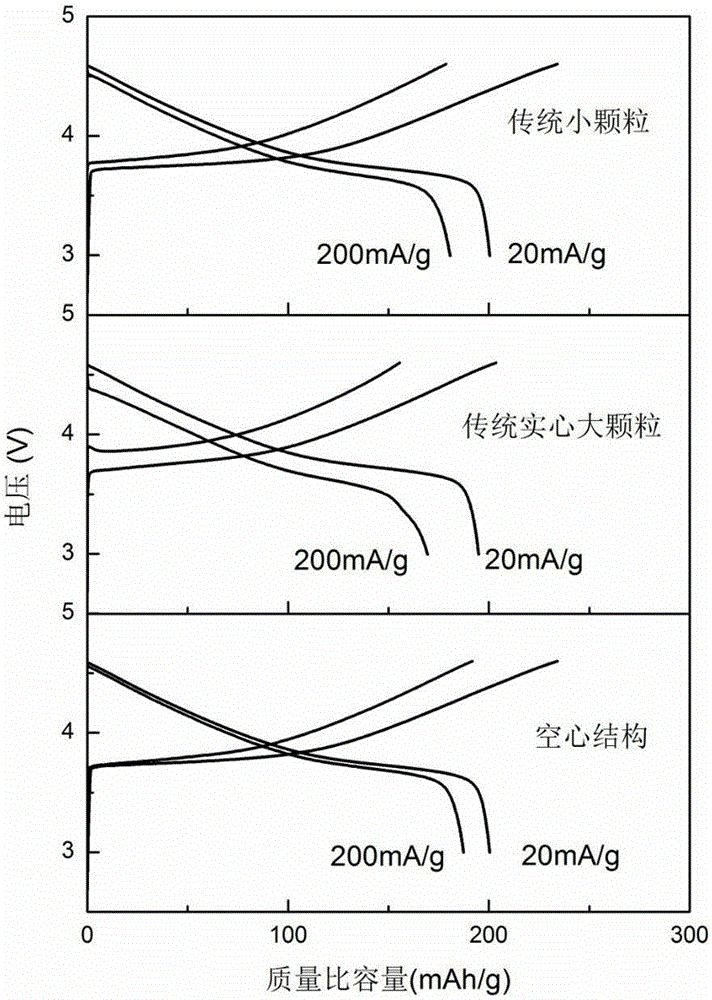

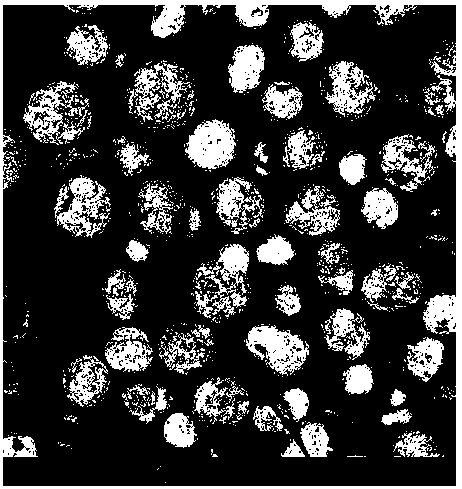

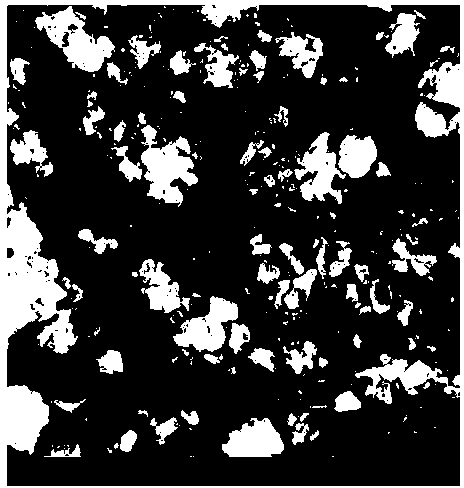

Mixed lithium battery positive material and preparation method thereof

InactiveCN103985857ALarge particlesSmall particlesCell electrodesSecondary cellsDecompositionManganese

The invention belongs to the field of inorganic non-metallic materials and relates to a mixed lithium battery positive material and a preparation method thereof. The preparation method comprises the following steps: mixing cobalt oxide and a nickel-cobalt-manganese ternary material precursor, and performing two-step sintering, thereby directly obtaining a mixed positive material of lithium cobalt oxide and nickel cobalt lithium manganate, wherein a microscopic structure formed by coating nickel cobalt lithium manganate particles with lithium cobalt oxide particles is shown in the figure in the specification, and the diameter of the lithium cobalt oxide particles is less than that of the nickel cobalt lithium manganate particles. According to the structure that large and small spheres of lithium cobalt oxide and nickel cobalt lithium manganate are arranged in a mixed manner, gaps the material can be effectively filled, and the compaction density of the material is improved; the conductivity of the material can be improved after the material is coated with lithium cobalt oxide, dislocation of Li and Ni in a nickel cobalt lithium manganate crystal structure can be effectively alleviated, and decomposition of high-valence nickel ion catalytic electrolyte is inhibited; moreover, the compaction density of nickel cobalt lithium manganate can be improved after being coated with lithium cobalt oxide, so that the capacity, stability, high-current discharge capacity and rate performance of the battery in unit volume can be effectively improved.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

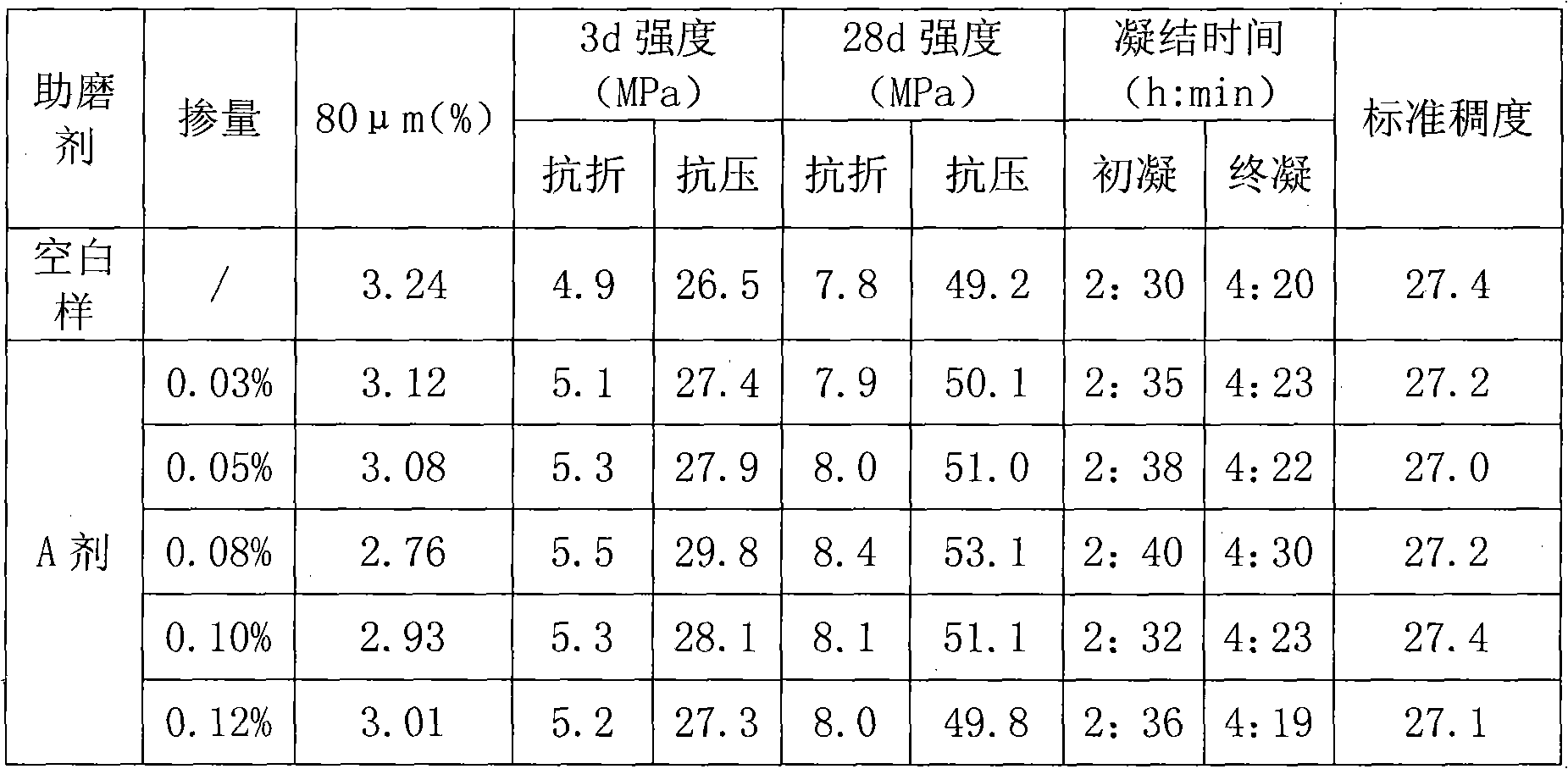

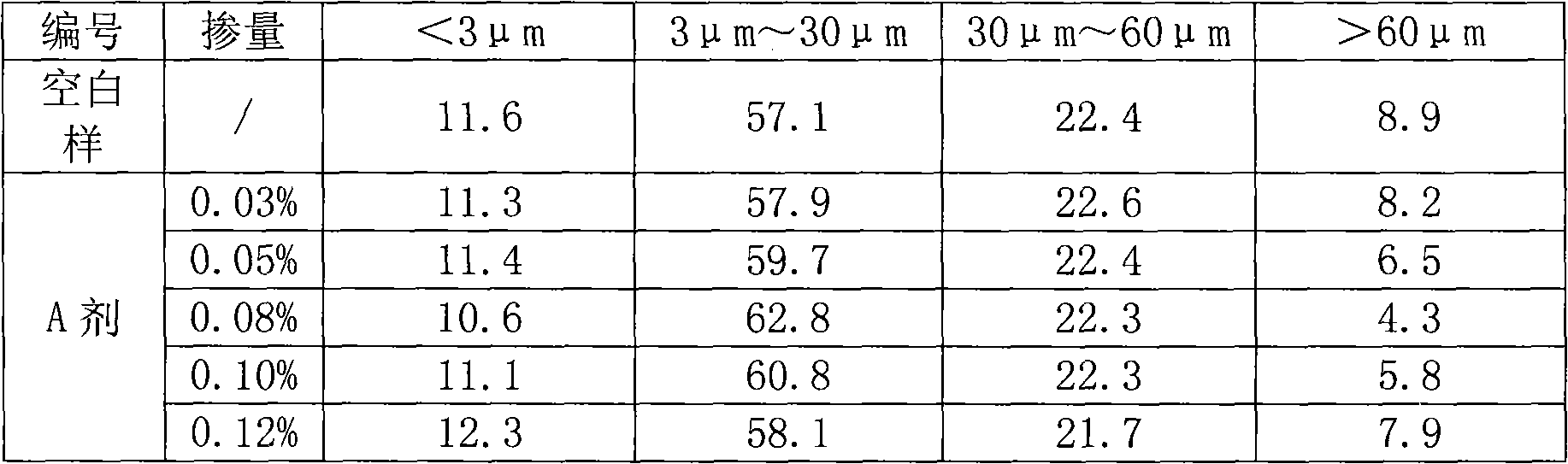

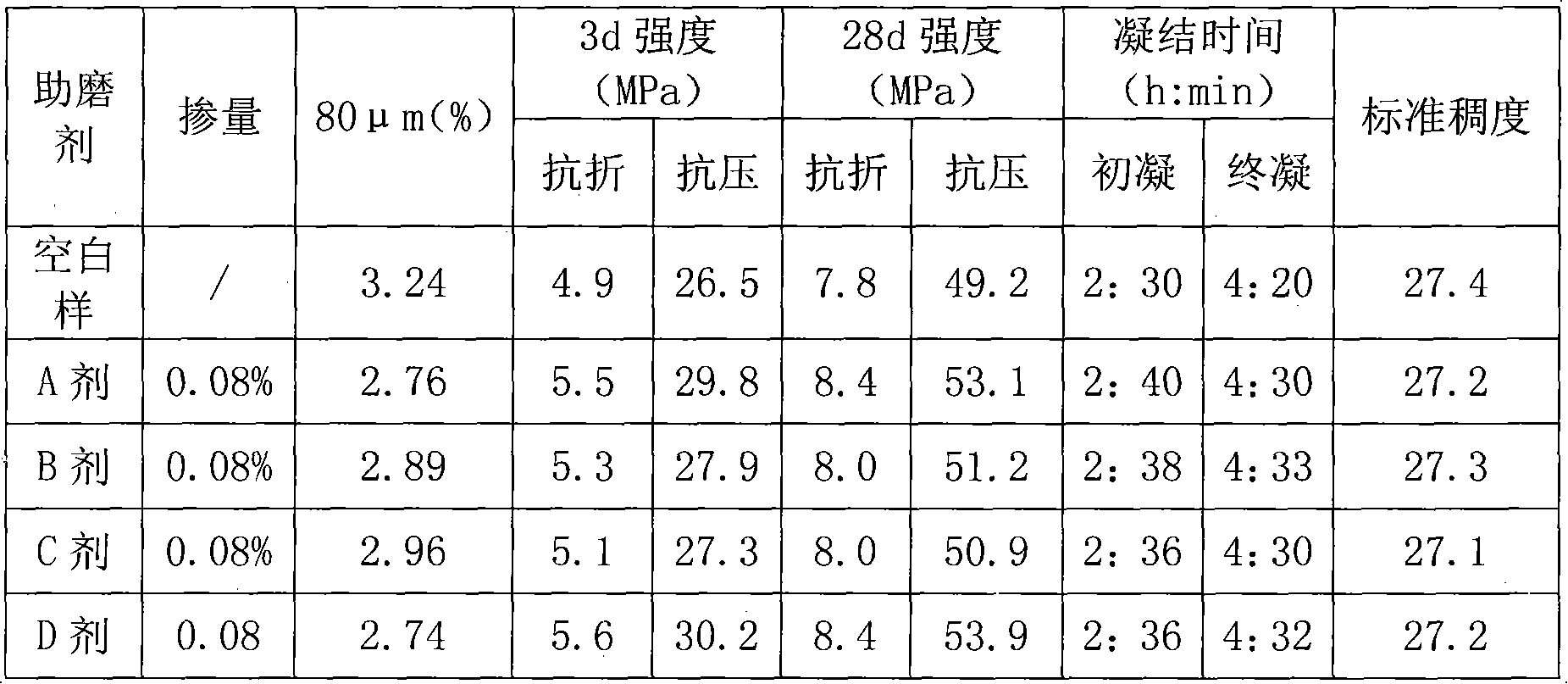

Cement grinding aid

InactiveCN101898878AIncrease productionReduce power consumptionCement productionCalcium formateGlycerol

The invention discloses a cement grinding aid, comprising calcium formate solution, compound glycerol distilled residue solution, triethanolamine, diols and molasses. While the product reutilizes the industrial wastes, the components of the product synergistically act to optimize the efficacy of the grinding process and the product modifies the cement particles, thus improving the quality and performance of the cement while improving the cement yield and saving electricity, and the product does not only have grinding function.

Owner:宜兴市宏伟科技有限公司

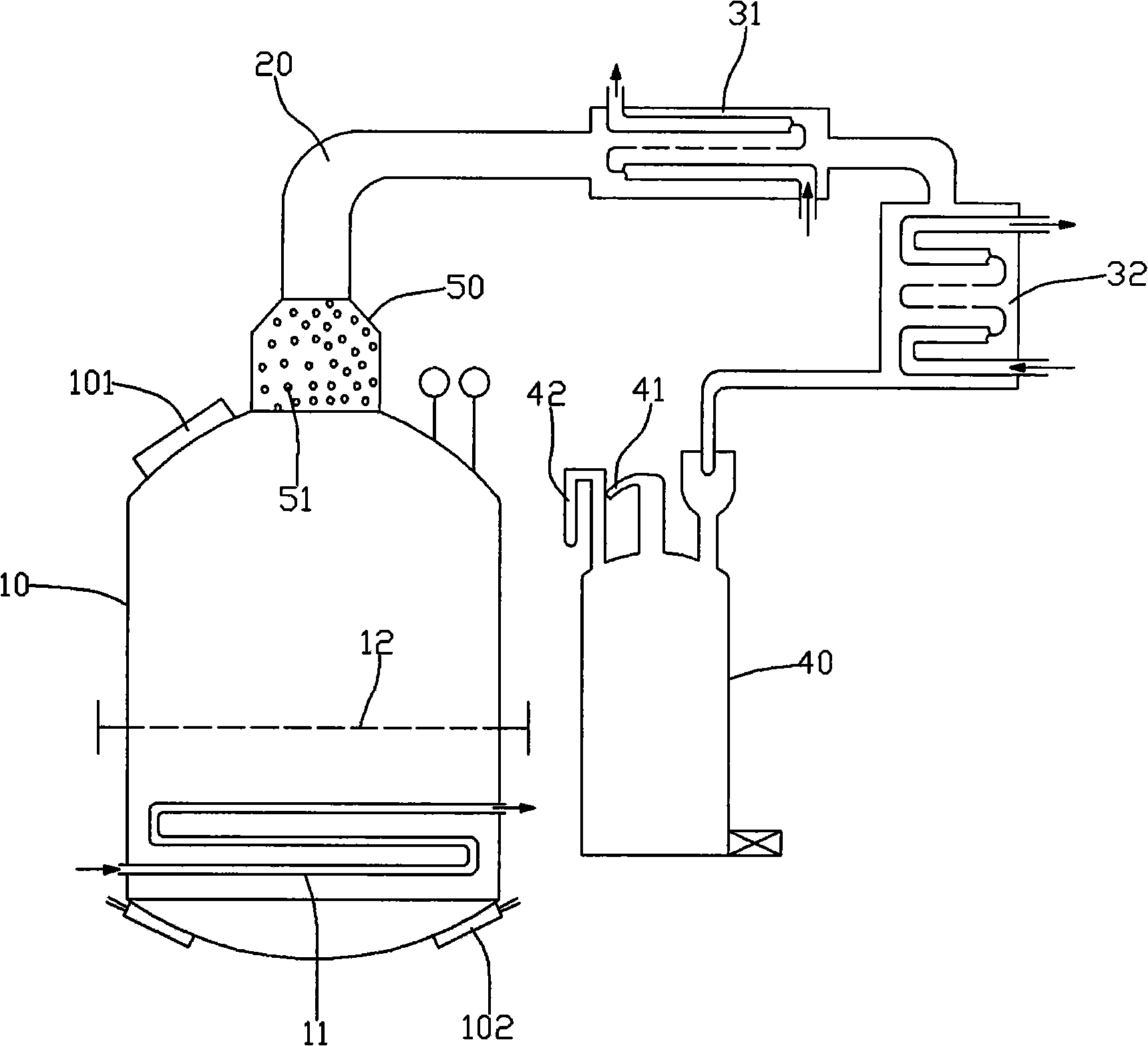

Rose essential oil and rose pure dew extraction equipment

InactiveCN101353611AAvoid direct accessInhibition of dissolutionEssential-oils/perfumesDistillationEngineering

The invention discloses extraction equipment for rose essential oil and rose hydrosol which mainly includes a distillation still, a steam conduit, a condenser and an oil-water separator, wherein, the distillation still is connected with the oil-water separator by the steam conduit and the condenser; the lower end of the interior of the distillation still is provided with a steam heating coil; and the upper part of the steam heating coil is provided with a transverse plate sieve which can be opened freely. An adsorption plant is arranged between the top of the distillation still and the steam conduit and internally filled with active ceramic rings serving as an absorbent. The extraction equipment of the invention has the advantages of simple operation, convenient use and high production efficiency, and can greatly enhance the quality of the rose essential oil and the rose hydrosol.

Owner:许向梅

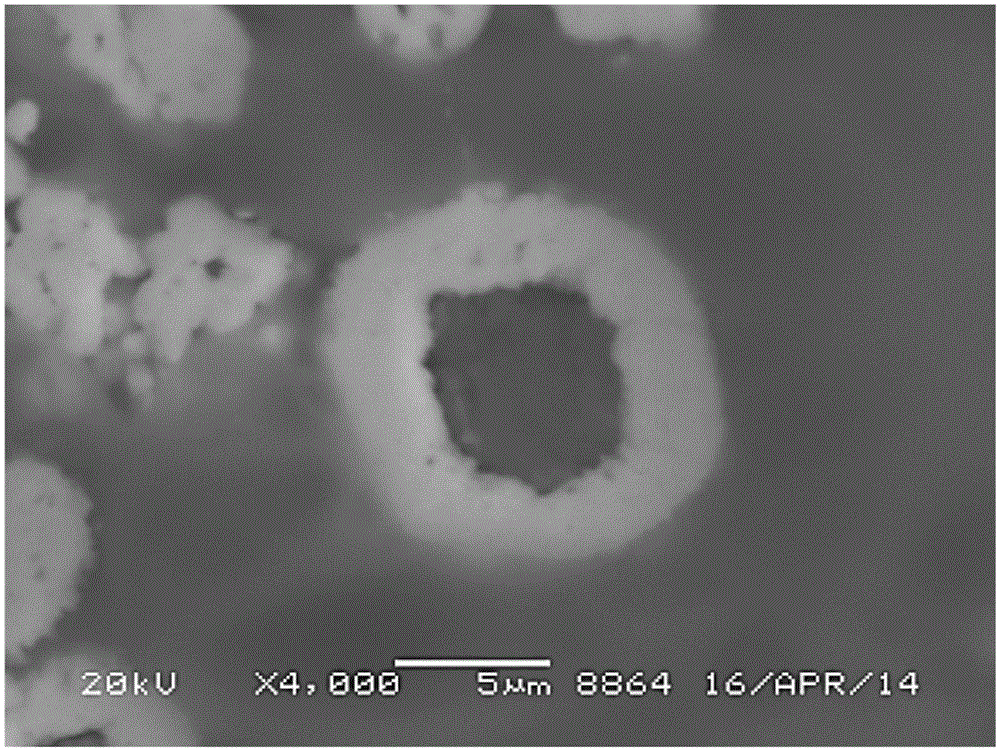

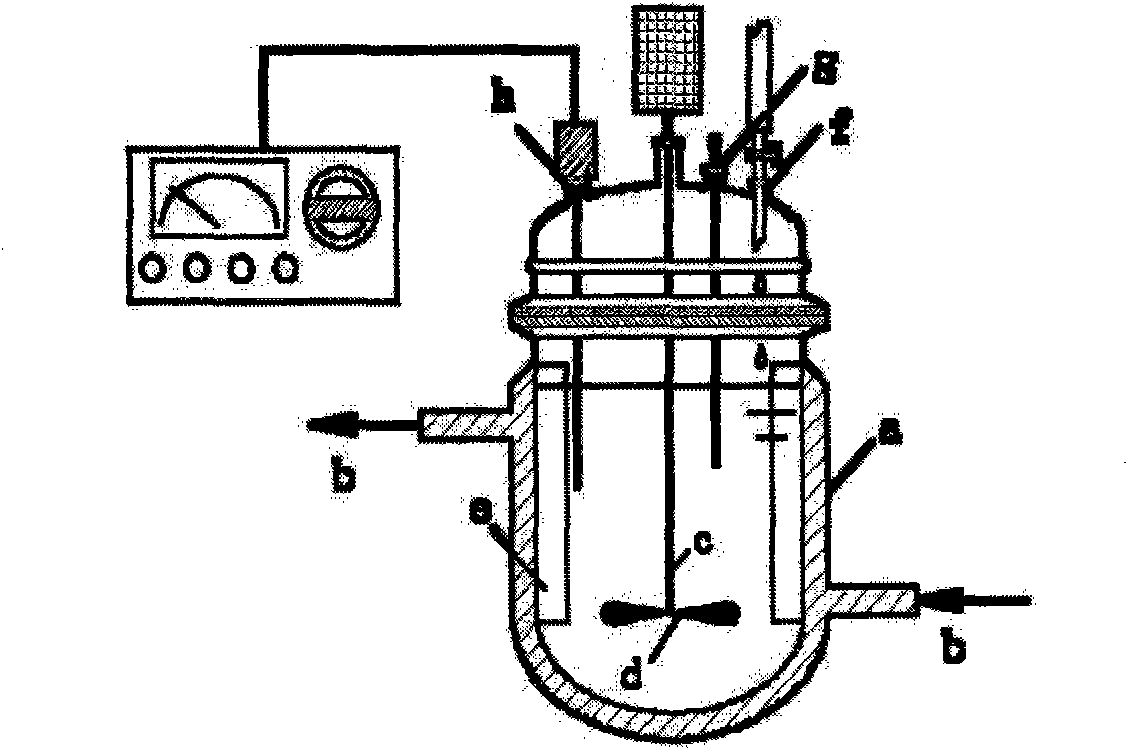

Hollow structure lithium-ion battery positive electrode material and preparation method thereof

ActiveCN105185979ALarge particlesImprove Interface StabilityCell electrodesSecondary cellsChemistryLithium electrode

The present invention discloses a hollow structure lithium-ion battery positive electrode material and a preparation method thereof. The preparation method comprises: preparing a metal salt solution, adding the metal salt solution, a precipitation agent and a complexing agent into a reaction kettle, carrying out co-precipitation to prepare a precursor, uniformly mixing the precursor and a lithium source, and carrying out sectional temperature control calcination to obtain the positive electrode material. According to the present invention, the preparation process is simple, the cost is low, the application prospects are broad, and the prepared positive electrode material has characteristics of substantially-improved electrochemical performance, good rate performance, and good cycle performance.

Owner:CENT SOUTH UNIV

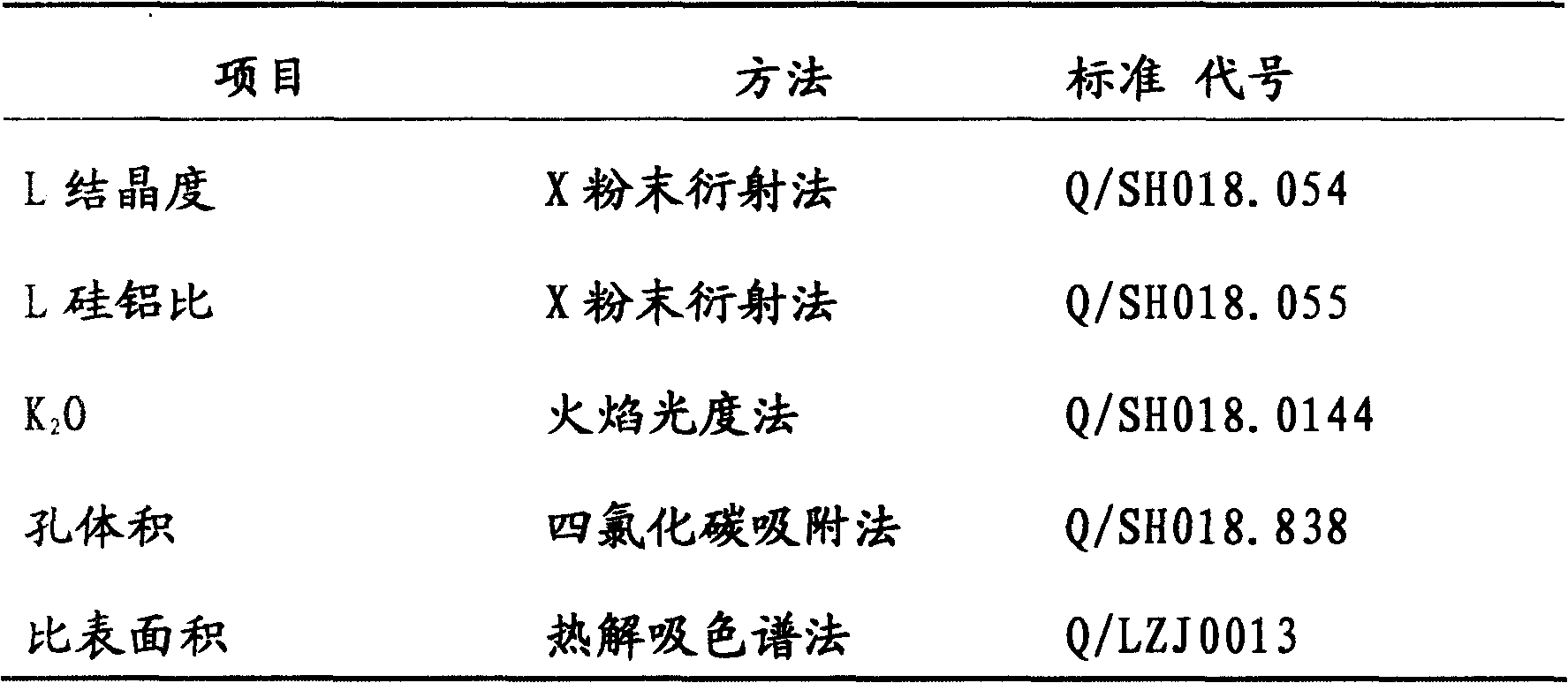

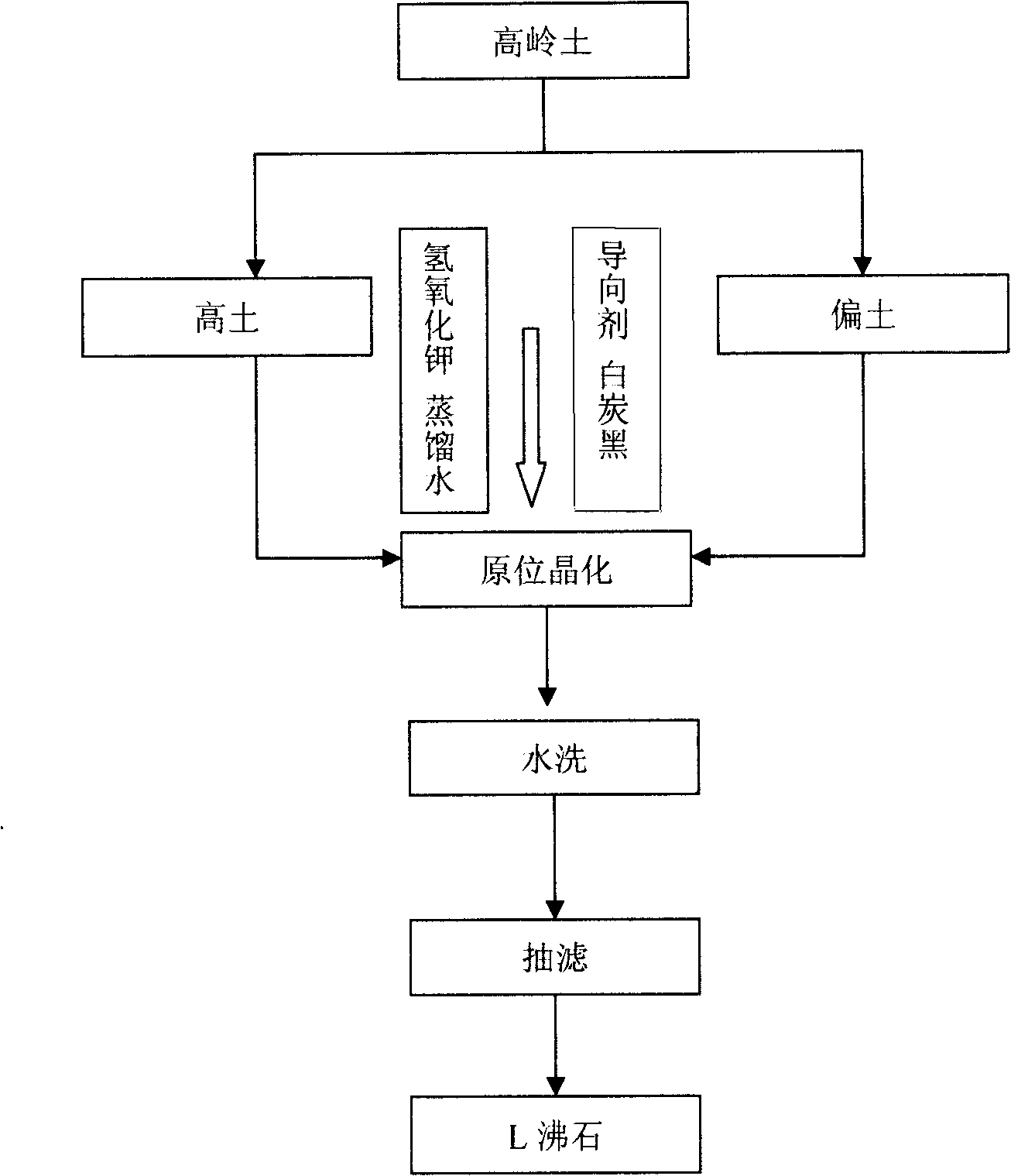

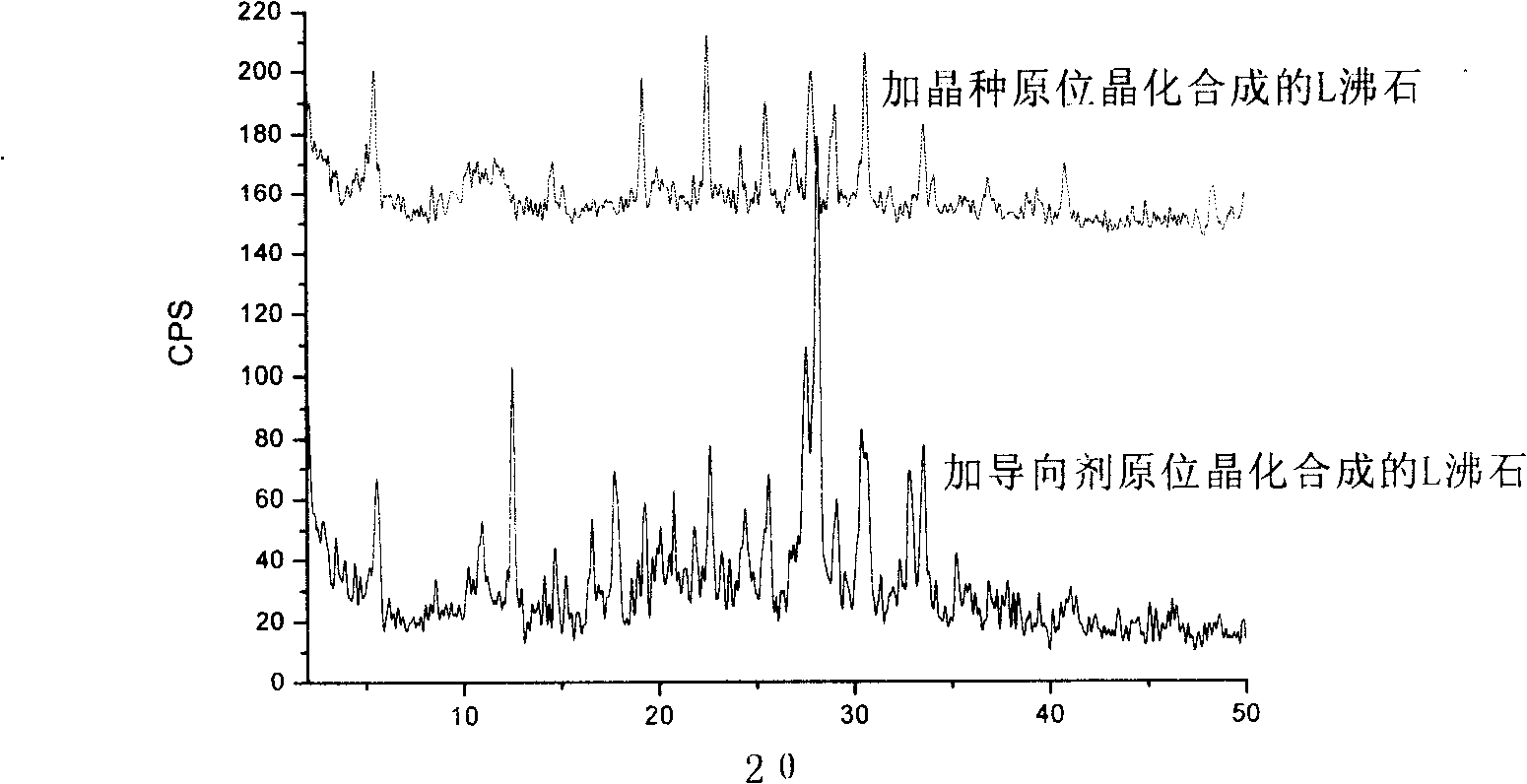

Method for crystallization synthesis of L zeolite molecular sieve with kleit in situ

ActiveCN101293659AHigh crystallinityLow raw material costAluminosilicate zeolite type-LIn situ crystallizationMolecular sieve

The invention relates to a method which takes kaolin as raw material and synthesizes in-situ crystal into an L zeolite molecular sieve. The method is characterized in that a part of the kaolin is calcined at high temperature to get roasting soil with high temperature, high soil is for short; the other part of the kaolin is roasted at lower temperature to get metakaolin, partial soil is for short; the two kinds of soil are mixed in a certain proportion and then is added into crystal seeds or a directing agent for the process of in-situ crystallization in an alkaline system, finally an L molecular sieve is obtained. The L molecular sieve produced by the method has the characteristic picture diffracted by X ray powder of the L molecular sieve.

Owner:LESHAN SHENGHE RARE EARTH CO LTD

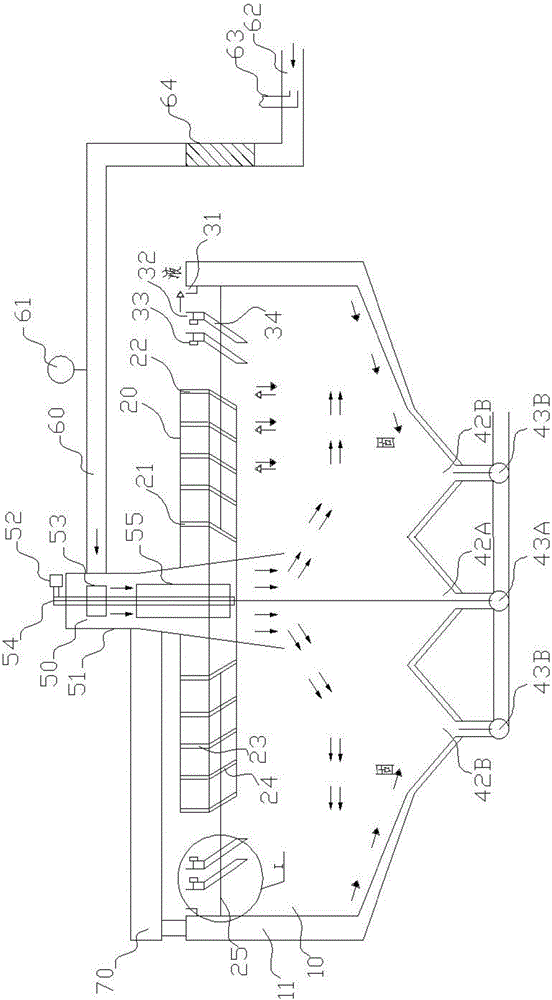

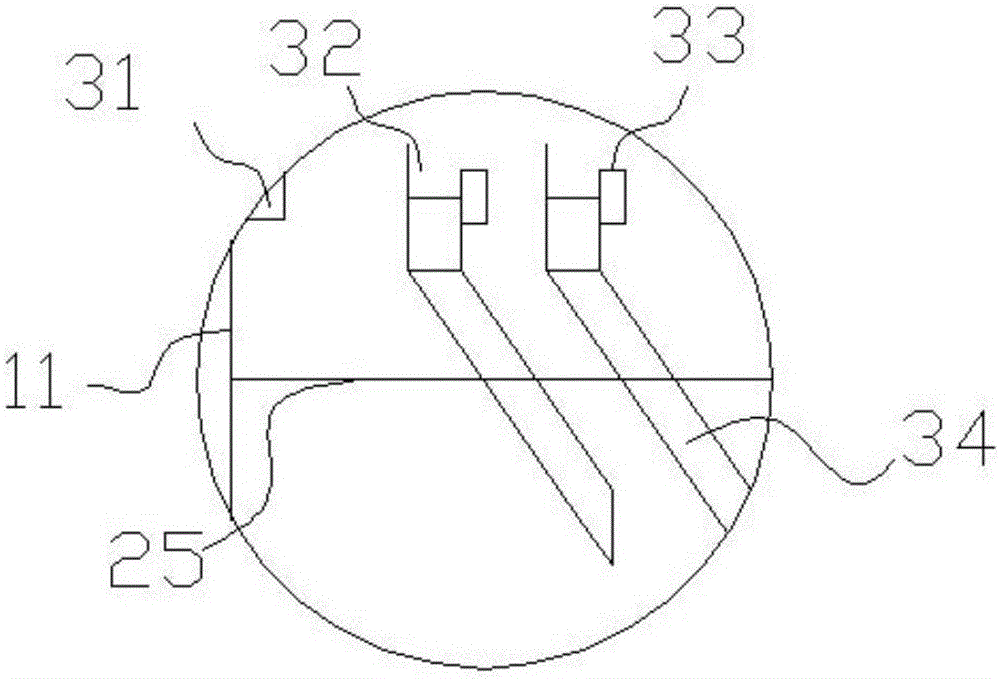

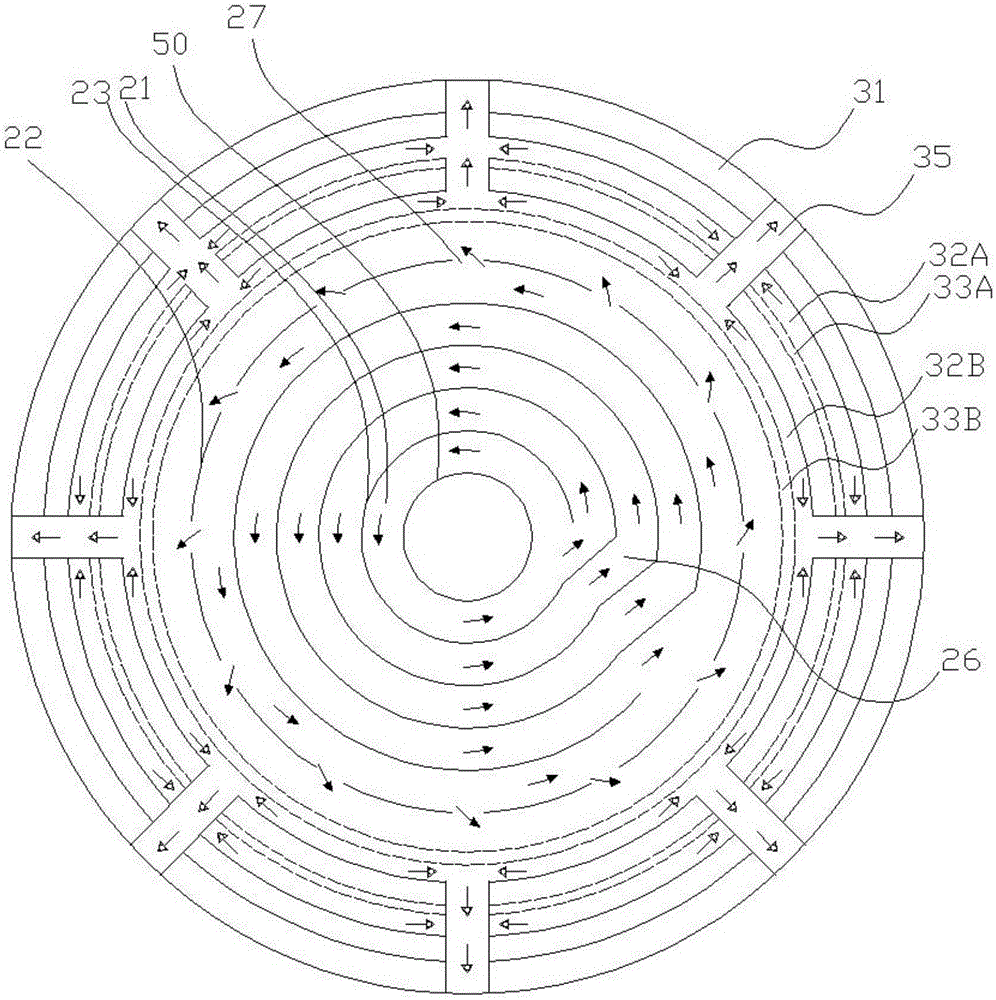

Rake-free thickener with rotary annular channels

ActiveCN105944407AEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

Container culture medium prepared from edible fungi residue and production method thereof

InactiveCN102210256ALarge particlesPromote growthCultivating equipmentsSoilless cultivationBiotechnologyPlant roots

The invention relates to a container culture medium prepared from edible fungi residue and a production method thereof, and the container culture medium comprises the edible fungi residue. The container culture medium comprises the following raw materials and auxiliary raw materials in naturally stacked parts by volume: 50-60 parts of the edible fungi residue, 30-70 parts of grass carbon, 0.8-1.2 parts of vermiculite, 0.3-0.7 part of pearlite, 5-20 parts of cake fertilizer, and 2-4 parts of mineral fertilizer. Wood chips, wheat bran, residual mycelia and other larger particles are contained in the edible fungi residue, thereby having higher air porosity and good water retention property and permeability, being more conductive to growth of a plant root system, creating a good rooting zone environment for growth of crops and providing a large number of nutrients for the crops; and the supply of the edible fungi residue is sufficient, and the material can be got from local resources, thereby reducing the production cost of the container culture medium to the maximal extent.

Owner:TIANJIN HONGFENGLIN MIAOMU CULTIVATION PROFESSIONAL COOP

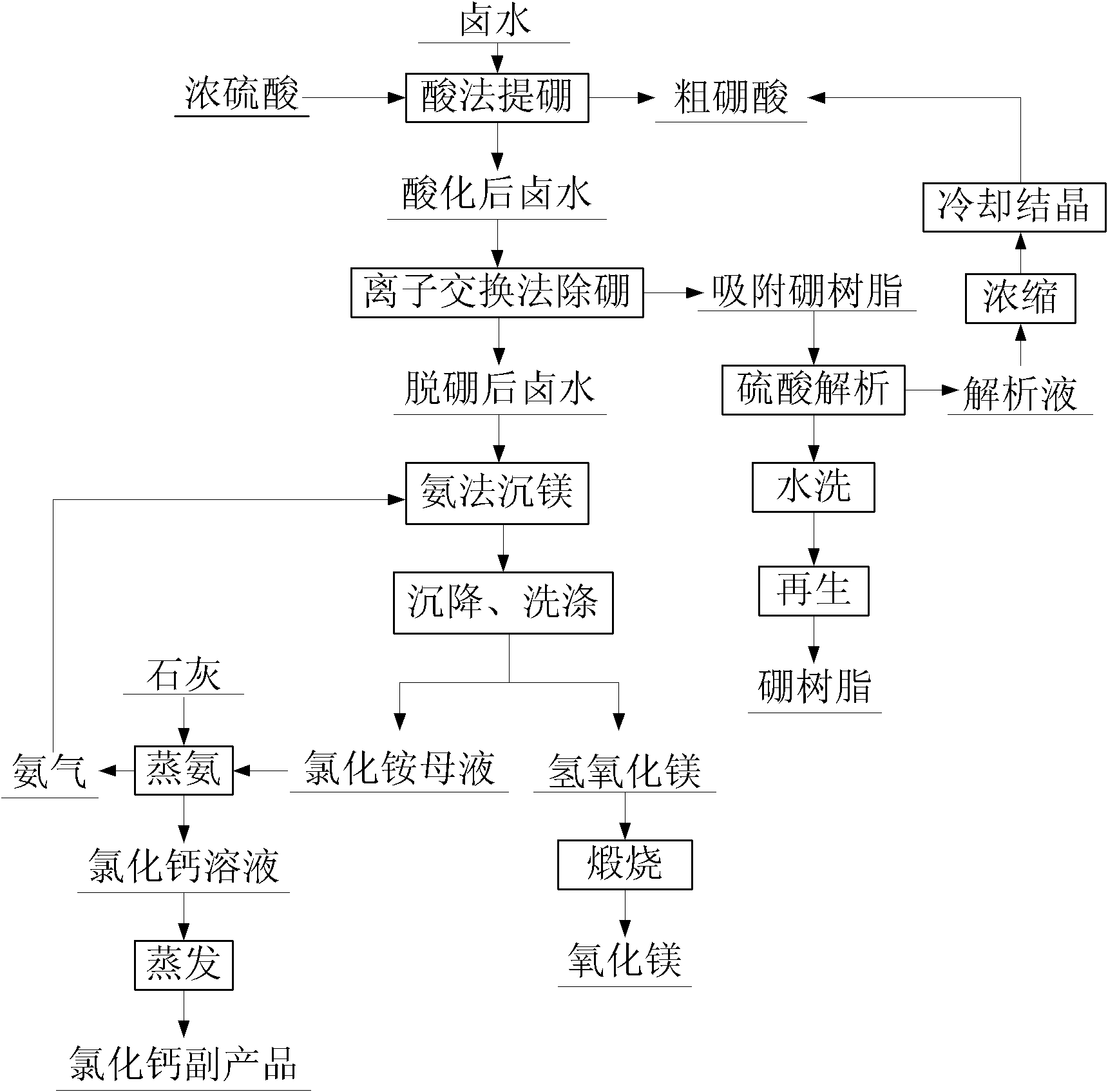

Method for preparing high-purity magnesium oxide with high boron salt lake brine

InactiveCN102491379ALarge particlesReduce extraction costsBoron-oxygen compoundsMagnesiaReaction temperatureIon-exchange resin

Provided is a method for preparing high-purity magnesium oxide with high boron salt lake brine. Salt lake brine is evaporated through a salt pan, concentrated to crystallize potassium sulfate, sodium chloride and potassium chloride and is drawn with lithium in adsorption mode so as to obtain master sauce brine containing magnesium and boron. Concentrated sulfuric acid is added into master sauce brine for reacting, and coarse boracic acid and acidized brine are obtained after cooling and filtering. Potential of hydrogen (pH) value of acidized brine is adjusted to be 5.5-6.5, and acidized brine passes through ion exchange resin adsorbing boron. When boron concentration in effluent liquid is higher than 5 mg / L, brine is not injected, boron-removed brine is obtained, then boron-removed brine and ammonium chloride solution are filled with ammonia for stirring and to produce magnesium sedimentation reaction, reaction temperature ranges from 60 DEG C to 80 DEG C, pH ranges from 7.5 to 8.0, the reaction is stopped when concentration of free ammonia reaches 1.8-2.2 mol / L, and magnesium hydroxide and magnesium sedimentation mother solution are obtained. Magnesium oxide is obtained by calcining magnesium hydroxide, content of magnesium oxide is larger than 99.8%, and magnesium extraction ratio is larger than 90%. Sedimentation mother solution adopts lime to steam ammonia, and generated ammonia circulates to magnesium sedimentation reaction. Mother solution after ammonia steaming is evaporated, concentrated and crystallized to obtain calcium chloride. Ion exchange resin adsorbing boron is washed, analyzed and regeneratively cycled for use. Boron-containing analysis solution is concentrated and cooled to pick up coarse boracic acid, and coarse boracic acid is recrystallized to obtain refined boracic acid with purity larger than 99%. High-purity magnesium oxide prepared by the method is high in purity, good in economic benefit, free of environment pollution, strong in operability and favorable for industrial production.

Owner:CENT SOUTH UNIV

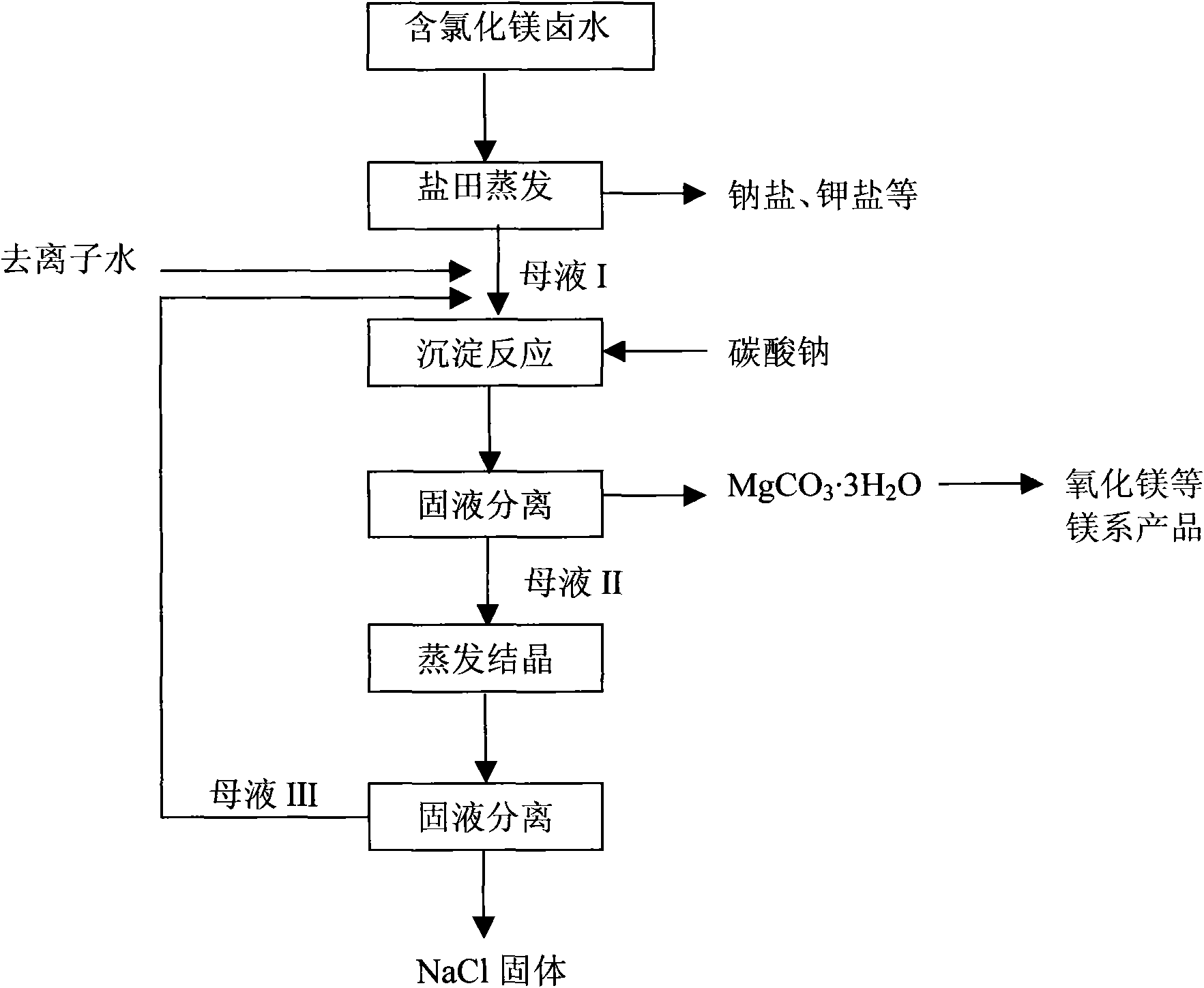

Method for preparing magnesia by taking magnesium chloride containing brine as raw material

The invention belongs to the field of salt chemical engineering, in particular relates to a method for preparing magnesia by taking magnesium chloride containing brine as a raw material. The method comprises the following steps of: obtaining an intermediate (the purity is 99.0 percent) of magnesium carbonate trihydrate with good needle-shaped crystalline form by taking the magnesium chloride containing brine as the raw material and sodium carbonate as a precipitator and controlling the reaction conditions of reaction temperature, stirring rotary speed and charging speed of the sodium carbonate and the like; calcining the obtained intermediate of the needle-shaped magnesium carbonate trihydrate crystal at a high temperature to prepare high-purity magnesium oxide (the purity is 99.4 percent); after reaction, filtering a coarse product of the magnesium carbonate trihydrate to obtainsodium chloride containing crystalline mother liquor; by vaporizing, condensing and crystallizing the crystalline mother liquor, extracting a sodium chloride crystal; and filtering the sodium chloride crystal to obtain a sodium chloride crystal. The method aims to produce the intermediate of the needle-shaped magnesium carbonate trihydrate by rich brine from sea and salt lakes, and further prepares the high-purity magnesia. The method has the advantages of good economic benefits, no environmental pollution, strong operability and easy realization of industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

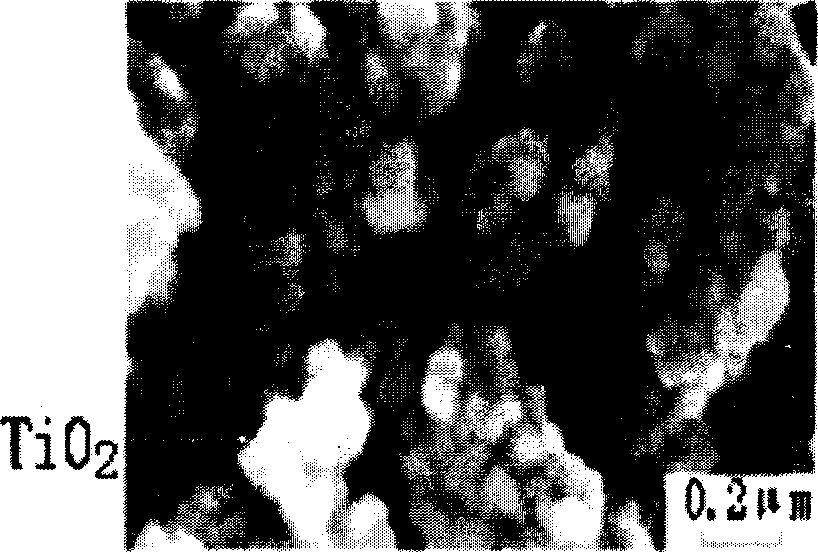

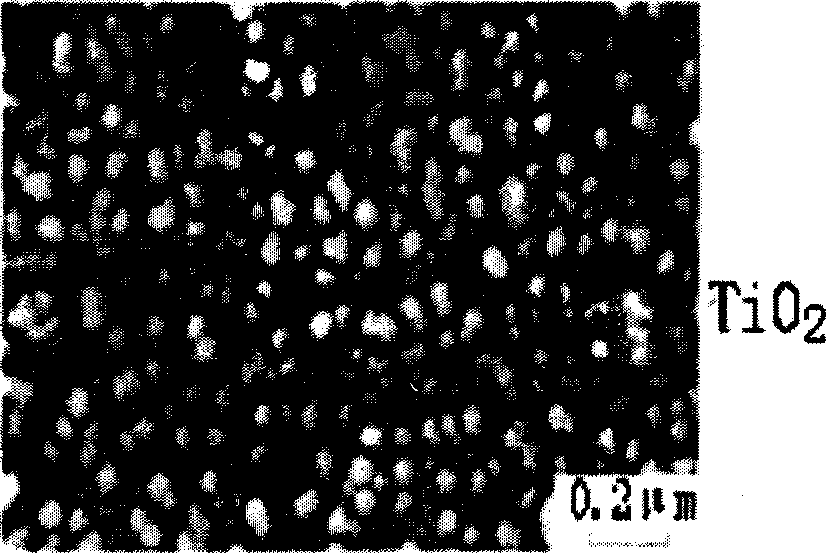

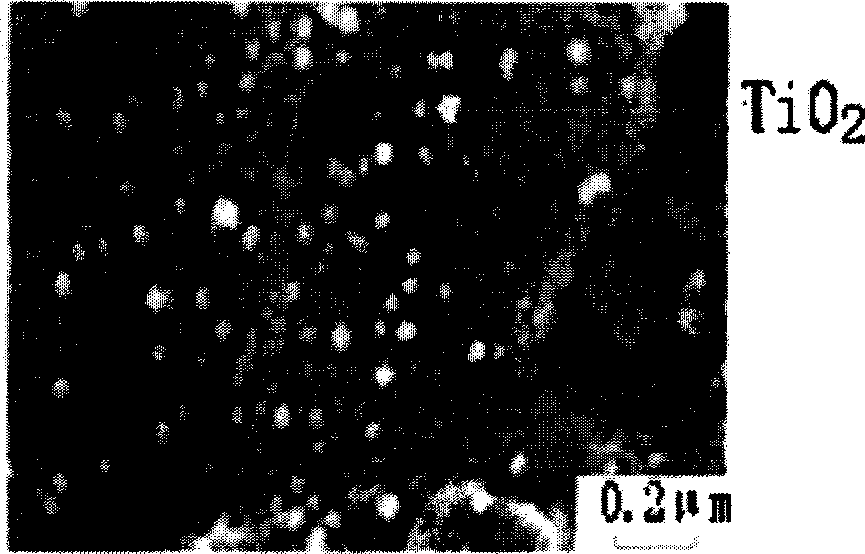

Nano titanic oxide photocatalyst responding to visible light and preparation method thereof

InactiveCN101497038AWide wavelength rangeTake advantage ofMetal/metal-oxides/metal-hydroxide catalystsVisible light photocatalyticPt element

The invention discloses a nanometer titanium dioxide photocatalyst responding visible light with high absorbance and a wide wavelength range on the visible light. The photocatalyst is characterized in that a mass ratio of nanometer TiO2 to active carbon is 1:5-15; a mass ratio of metal silver to the nanometer TiO2 is 0.5-2:100; and a mass ratio of metal copper or iron or rhodium or platinum or gold or tin to the nanometer TiO2 is 0-2:100. The method for preparing the photocatalyst comprises the following steps: preparing a titanium ester solution and a soluble metal salt solution to be mixed and evenly stirred; evenly loading TiO2 particles and metal ions onto the surface of the active carbon by a sol-gel method; and carrying out thermal treatment under the protection of inert gases at a temperature of between 300 and 600 DEG C for 2 to 6 hours so as to prepare the metal doped and active carbon loaded anatase type TiO2 photocatalyst. The photocatalyst and the method have a simple process; compared with the prior loading type visible light photocatalyst, the prepared product can sufficiently utilize sunlight, has the absorbance to the visible light reaching about 85 percent and wide wavelength range, can be industrially applied, has the characteristics of energy conservation, environmental protection and the like; meanwhile, due to larger particles of the active carbon, recycle of the photocatalyst is convenient, and treatment cost is reduced.

Owner:HUNAN CITY UNIV

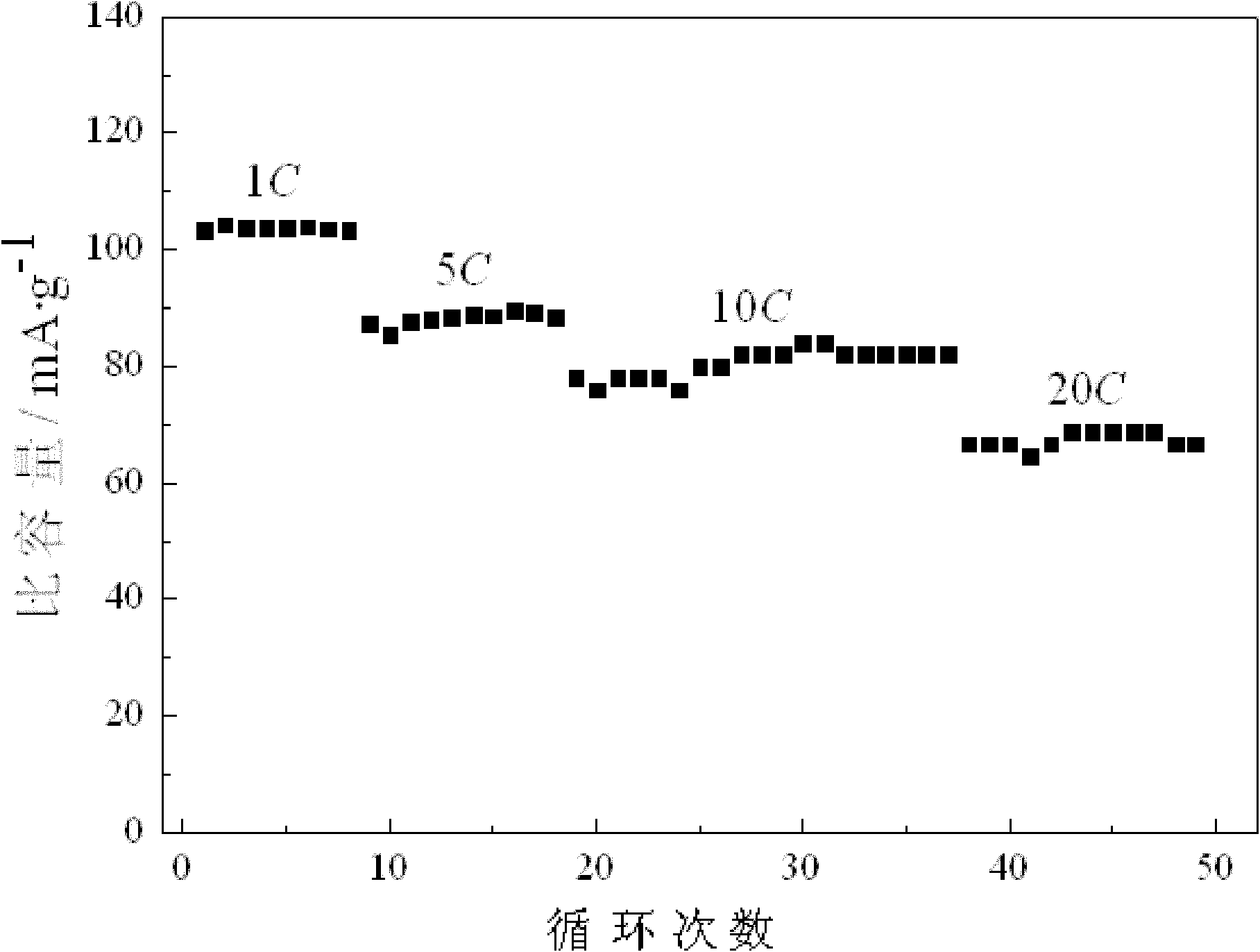

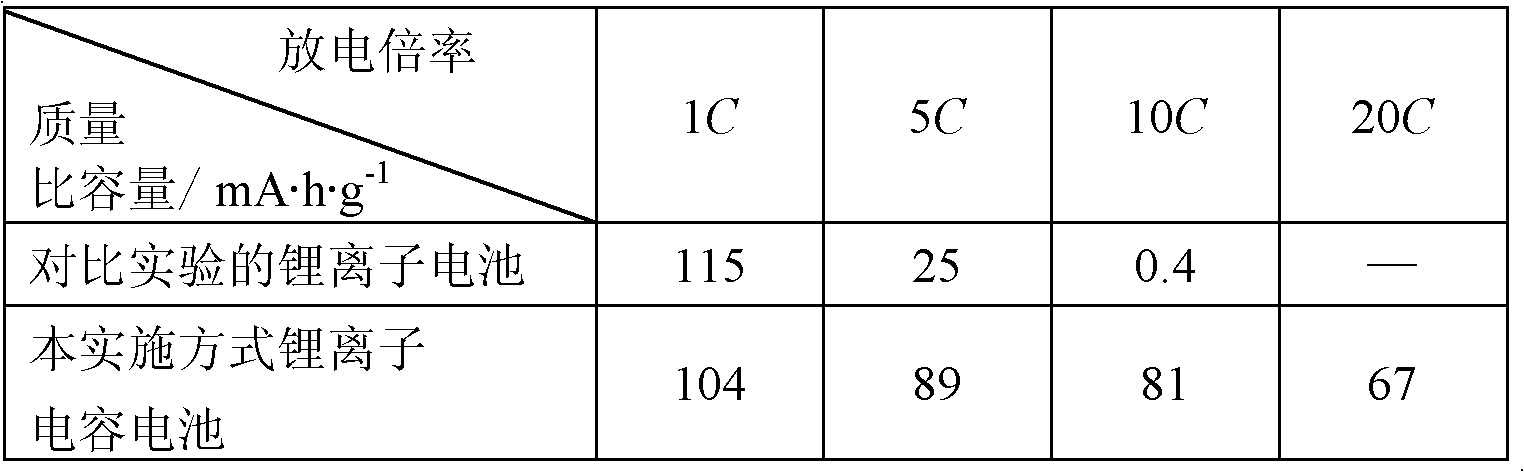

Capacitor carbon/lithium iron phosphate composite material, preparation method thereof and lithium-ion capacitor battery using same as cathode material

InactiveCN101944588AImprove high rate charge and discharge performanceIncrease surface areaElectrolytic capacitorsNon-aqueous electrolyte accumulator electrodesCapacitanceElectrical battery

The invention discloses a capacitor carbon / lithium iron phosphate composite material, a preparation method thereof and a lithium-ion capacitor battery using the same as a cathode material and relates to a lithium iron phosphate material, a preparation method and a lithium-ion capacitor battery using the lithium iron phosphate material as a cathode material, solving the problems of higher preparation cost of the traditional lithium iron phosphate and poor high-magnification charge / discharge properties of the lithium-ion batteries prepared from the traditional lithium iron phosphate. The composite material is formed by loading the lithium iron phosphate on activated carbon. The preparation method comprises the following steps of: preparing a lithium iron phosphate precursor by using a trivalent ferric salt, a phosphorus compound, a lithium source compound and an organic micromolecule carbon source as raw materials; and then mixing the precursor with the activated carbon and sintering. In the invention, the cathode sizing agent of the lithium-ion capacitor battery comprises the capacitor carbon / lithium iron phosphate composite material, a conductive agent and a bonding agent; the particle size distribution of the composite material is uniform; the trivalent ferric salt is used as a raw material, and the cost on the preparation is low; and the capacitor battery has good charge / discharge cycle performances and the mass specific capacity larger than 60mA.h.g<-1> under 20C magnification.

Owner:HARBIN INST OF TECH

Basic copper chloride production method

ActiveCN103351020AImprove recycling effectSimplified processing stepsCopper chloridesAmmoniacal nitrogenTribasic copper chloride

The invention discloses a method for producing tribasic copper chloride. The method for producing the tribasic copper chloride includes the following steps of: (1) removing impurities from an acidic etching waste solution; (2) adding clean water or a tirbasic copper chloride production mother solution to a synthesis reactor, performing preheating, and then, preheating the acidic etching waste solution whose impurities have been removed and an alkaline solution of sodium hydroxide and mixing the two solutions for a reaction with the pH value and temperature of the reaction being controlled so as to gradually form the tribasic copper chloride, and discharging partial materials after a certain amount of reaction time; (3) filtering the materials discharged from the reaction system, and performing washing, suction filtration, centrifugation and drying on the filtrated residues to obtain the tribasic copper chloride; and (4) performing ammonia nitrogen removal treatment on filtrated liquid. By adopting the method for producing the tribasic copper chloride in the invention, continuous production can be achieved and the tribasic copper chloride with large particle size and high purity can be produced; further, production cost can be reduced and overall process can be integrated; and the method for producing the tribasic copper chloride is advantaged in simple ultimate steps of ammonia nitrogen removal, easiness in operation as well as reduced difficulty and cost of ammonia nitrogen treatment.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

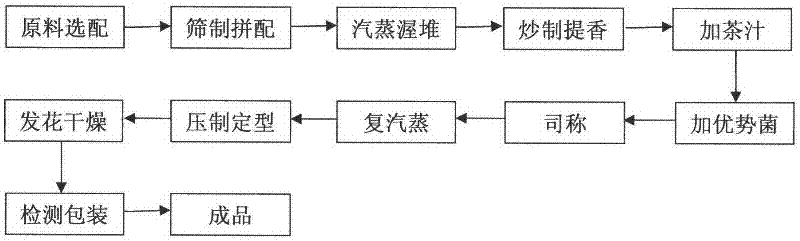

Method for processing fu brick tea by using southern Shaanxi sun-dried crude tea

ActiveCN102524435ALarge golden flowerBright golden colorPre-extraction tea treatmentClimate change adaptationFlavorChemistry

The invention relates to a method for processing fu brick tea by using southern Shaanxi sun-dried crude tea, relating to a method for processing fu brick tea, belonging to the field of tea processing. The method comprises the main processes of: selecting raw materials, screening, blending, steaming, piling, stir-frying to improve fragrance, adding tea juice, adding dominant bacteria, steaming once again, pressing, forming, rehydrating, drying, detecting and packaging. The defect of poor quality of the traditional fu brick tea raw materials is overcome, and the problems of different qualities and low and deep fragrance of the fu brick tea easy to produce in the traditional process are solved. The fu brick tea has large golden flower particles, golden yellow and bright color, common and flourish rehydration, bright red core and soup color, rich fragrance, obvious arohid flavor and heavy and mellow taste, the production period is effectively shortened, and the quality of the fu brick teais improved.

Owner:XIANYANG JINGWEI EIGHT TEA CO LTD

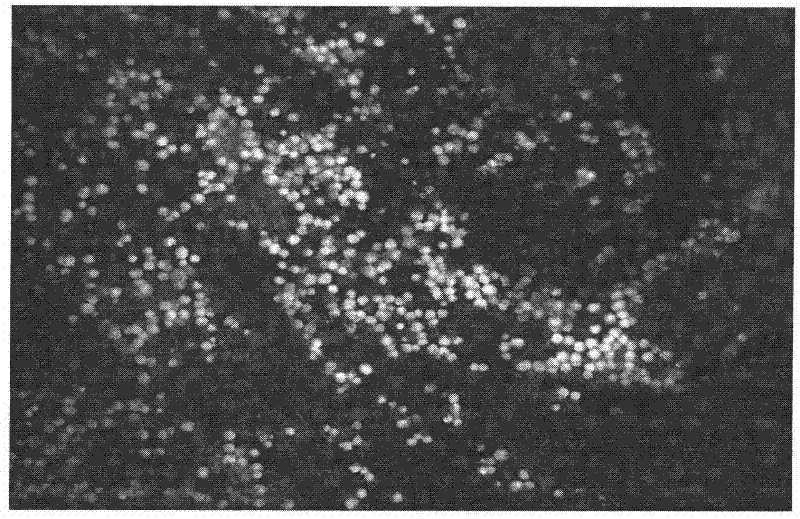

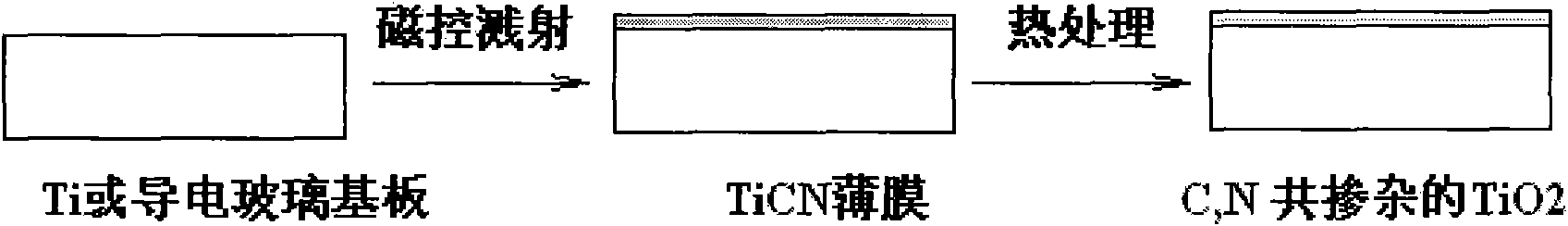

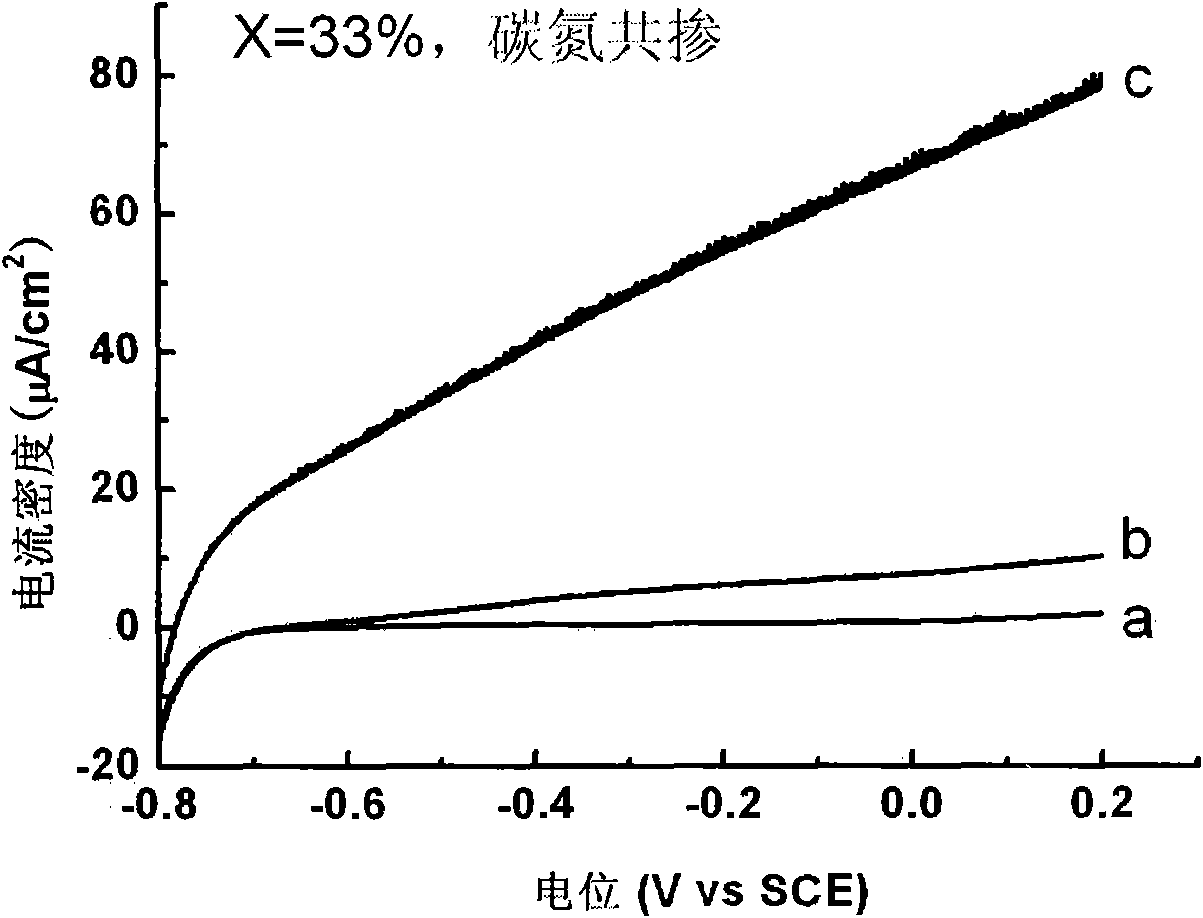

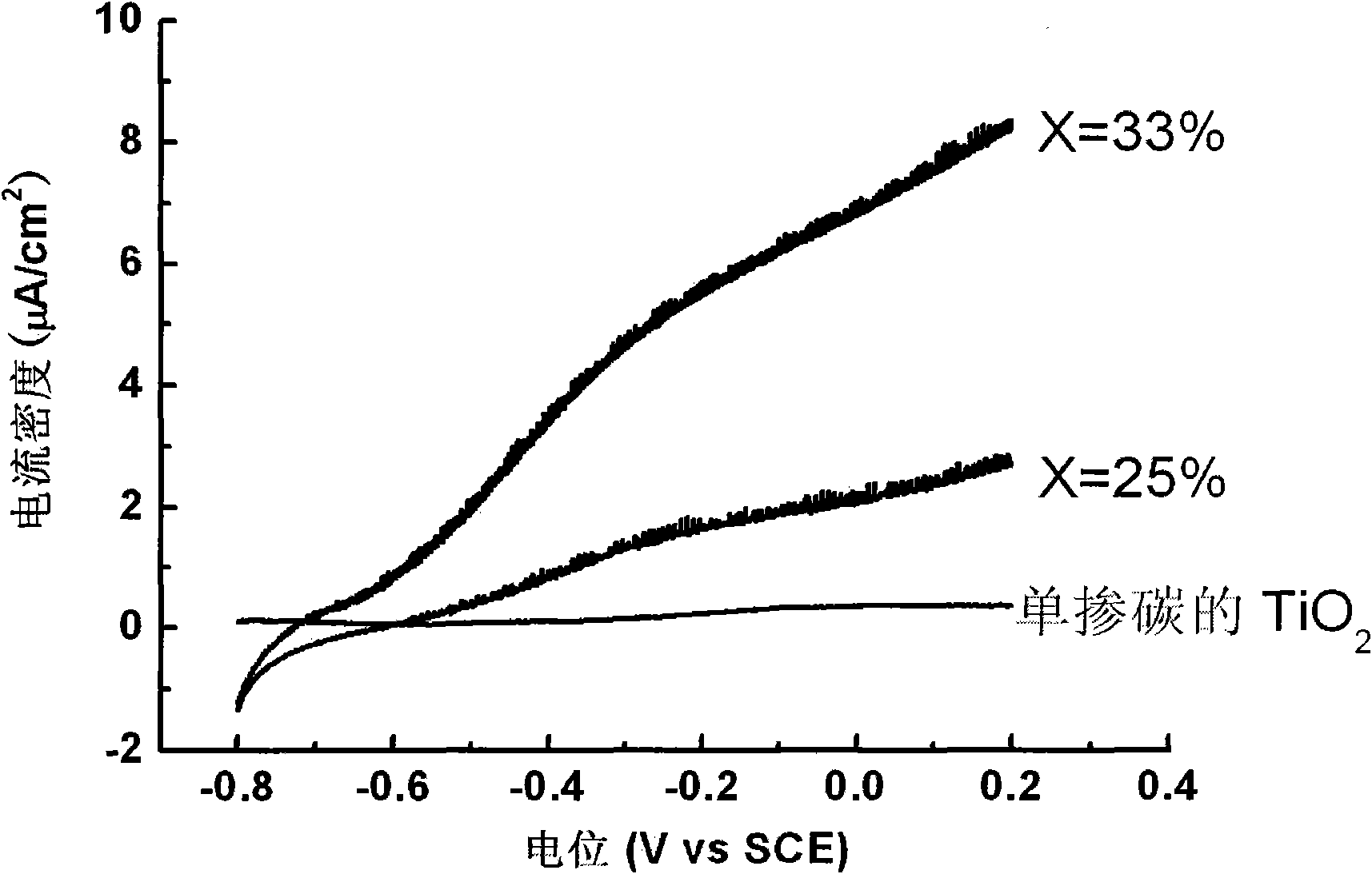

Method for preparing co-doping nanometer TiO2 film with adjustable C and N contents

InactiveCN101591769AHigh activityLarge particlesVacuum evaporation coatingSputtering coatingCoating systemPhotocatalytic degradation

The invention belongs to the technical field of TiO2 photo-catalysis, and in particular relates to a method for preparing a co-doping nanometer TiO2 film with an adjustable content ratio of C to N. The method comprises the following steps: firstly preparing a TiCN film with adjustable C and N components by a reaction magnetron sputtering coating method, and then processing the TiCN film by a common thermal oxidization method to prepare the C and N co-doping nanometer TiO2 film; and main equipment are a magnetron sputtering coating system and a muffle. In the prepared film, the relative contents of the C and the N can be controlled by adjusting the area ratio of C to Ti and the volume ratio of N to Ar in a target. The film has good activity of water splitting; and photo-catalysis test results show that the film has obvious activity of photocatalysis and degradation of methylene blue, and can be applied to photocatalysis and degradation of organic pollutants.

Owner:FUDAN UNIV

Preparation technology of p-tert-butyl benzoic acid

ActiveCN101648866ASimple preparation processReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidOrganic synthesis

The invention discloses a preparation technology of p-tert-butyl benzoic acid, comprising the following steps: firstly, adding toluene, isobutene and concentrated sulfuric acid into a reaction kettle, carrying out alkylation reaction to obtain coarse p-tert-butyl toluene, and rectifying to obtain fine p-tert-butyl toluene; secondly, adding a composite catalyst containing the p-tert-butyl toluene,cobalt acetate and bromide into the reaction kettle, heating and introducing oxygen to obtain coarse p-tert-butyl benzoic acid, decoloring by activated carbon and diatomite , crystallizing and dryingto obtain fine p-tert-butyl benzoic acid. The prepared p-tert-butyl benzoic acid is an organic synthesis intermediate, can be used for the fields of additives, antioxidants, alkyd resin modifying agents, soldering fluid, dye, and the like of polypropylene nucleating agents, polyvinyl chloride heat stabilizers, metal machining and lubricating oil and has excellent performance. The p-tert-butyl benzoic acid has low energy consumption, high yield, simple separation, and the like and can satisfy ever-increasing market demands of the p-tert-butyl benzoic acid.

Owner:JIANGXI YONGTONG TECH

Method for preparing Y-type molecular sieve from FCC waste catalyst by microwave heating

InactiveCN108190910AEfficient use ofSolve the problem of massive emissions polluting the environmentFaujasite aluminosilicate zeoliteChemical recyclingMolecular sieveMicrowave power

The invention relates to a method for preparing a Y-type molecular sieve from an FCC waste catalyst by microwave heating, and belongs to the technical field of secondary resource comprehensive recovery and utilization. The method comprises the following steps: first, removing toxic metals, namely, vanadium, nickel and iron, from the FCC waste catalyst by soaking for 10 to 60 minutes at 50 to 120 DEG C by a chemical method, wherein a molecular sieve framework structure must be remained simultaneously; taking metal-removed reactivated FCC waste catalyst as an aluminium source, performing seed crystal growth for 10 to 60 minutes at the microwave power of 400 to 1,600 W at 80 to 140 DEG C in the situation of externally adding a silicon source, a sodium source, water and a guiding agent, cooling to 60 to 120 DEG C, crystallizing for 0.5 to 3 hours at the microwave power of 400 to 1,600 W, and drying to obtain the Y-type molecular sieve. According to the method, the problem of massive discharging of the FCC waste catalyst can be solved, high-efficiency and quick utilization of the FCC waste catalyst can also be realized, and the problem about the aluminium source required in a preparation process is also solved.

Owner:KUNMING UNIV OF SCI & TECH +1

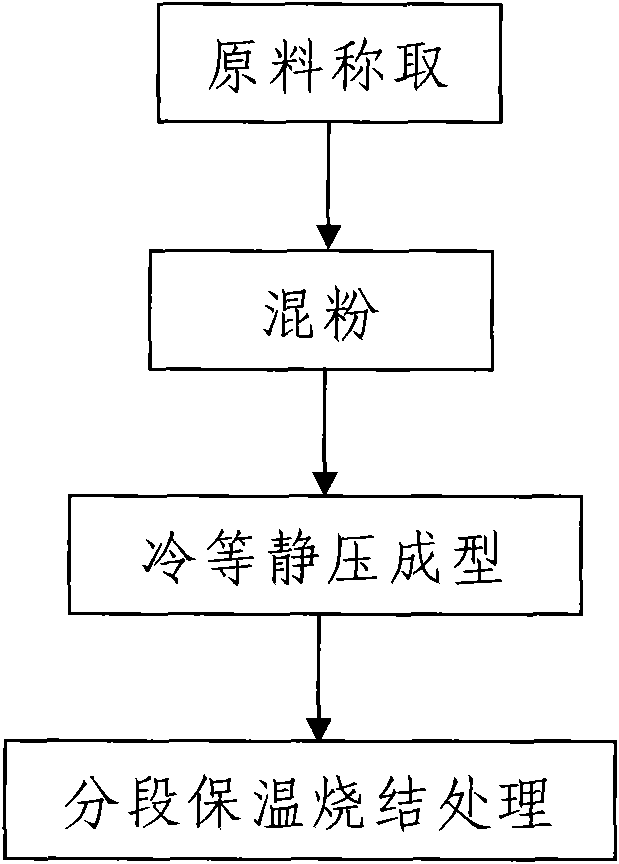

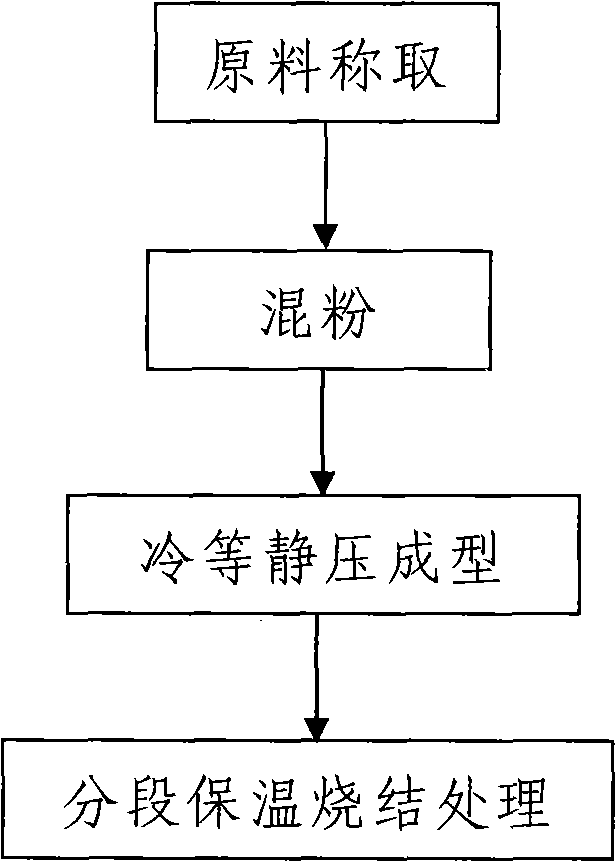

Method for preparing large powder metallurgy TZM blank with uniform carbon and oxygen distribution

The invention discloses a method for preparing a large powder metallurgy TZM blank with uniform carbon and oxygen distribution, which comprises the following steps of: 1, weighing raw materials; 2, mixing powder, namely mixing the weighed four raw materials twice under vacuum or the protection of inert gas, mixing titanium hydride powder, zirconium hydride powder and carbon black powder to prepare mixed powder, adding a volatile organic solvent into the mixed powder, uniformly stirring to prepare suspension, adding the weighed molybdenum powder into the suspension for uniform mixing, and adding residual molybdenum powder for uniform mixing; 3, performing cold isostatic pressing; and 4, sintering by keeping the temperature at stages, namely adopting a vacuum sintering furnace and sintering at three stages, wherein the process comprises the following steps of: raising the temperature at the first stage, raising the temperature at the second stage, and sintering at high temperature. The preparation method has the advantages of reasonable design, simple and convenient operation, and good using effect. The carbon content in the center and on the surface of the prepared larger-size TZM blank can be controlled to be approximately consistent, and the oxygen content in the center and on the surface of the TZM blank also can be reduced to a lower level.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com