Method for synthesizing composite molecular sieve by microwave method and catalytic performance application thereof

A technology of composite molecular sieves and synthesis methods, which is applied in the field of microwave synthesis of composite molecular sieves and their catalytic properties, can solve the problems of few reports and achieve the effects of no temperature gradient and thermal stress, time saving, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 21.3gNa 2 SiO 3 9H 2 O was dissolved in 29ml distilled water, stirred evenly, and 0.82g NaAlO was added under vigorous stirring 2 , continued to stir for 2h, and then aged at room temperature for 2d to obtain the directing agent. Add 2.82g NaOH to 89ml distilled water, slowly add 9ml guiding agent, 20.23g sodium silicate, 4g metakaolin powder under magnetic stirring, so that the molar ratio of raw materials is: SiO 2 :Na 2 O:Al 2 o 3 :H 2 O=1:1.33:0.167:47, continue to stir vigorously for 2 hours, put into a 100ml stainless steel reactor with polytetrafluoroethylene lining, and crystallize in an oven at 100°C for 12 hours to obtain a microporous precursor. Dissolve 6.17g of CTAB in 22ml of distilled water, stir to a colloidal solution, slowly drop this solution into the microporous precursor, stir evenly, so that the molar ratio of the final material is: SiO 2 :Na 2 O:Al 2 o 3 :CTAB:H 2 O=1: 1.33: 0.167: 0.16: 58, continue to stir rapidly 2h, adjust pH...

Embodiment 2

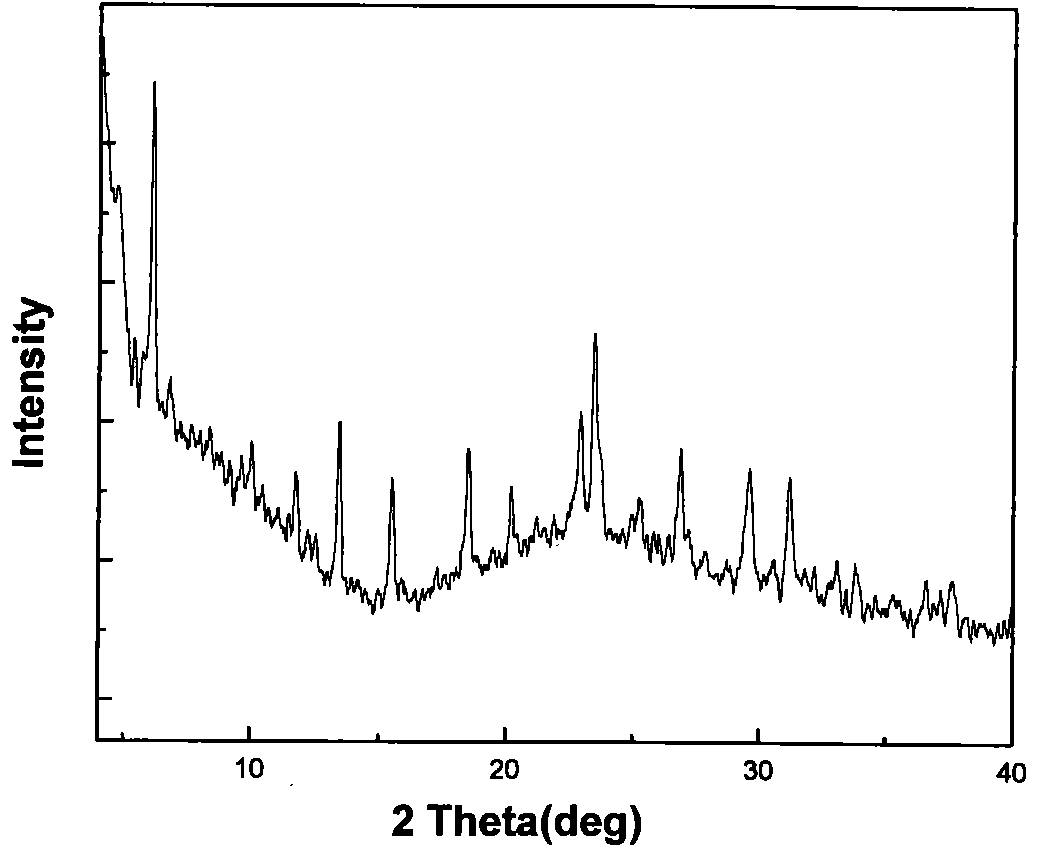

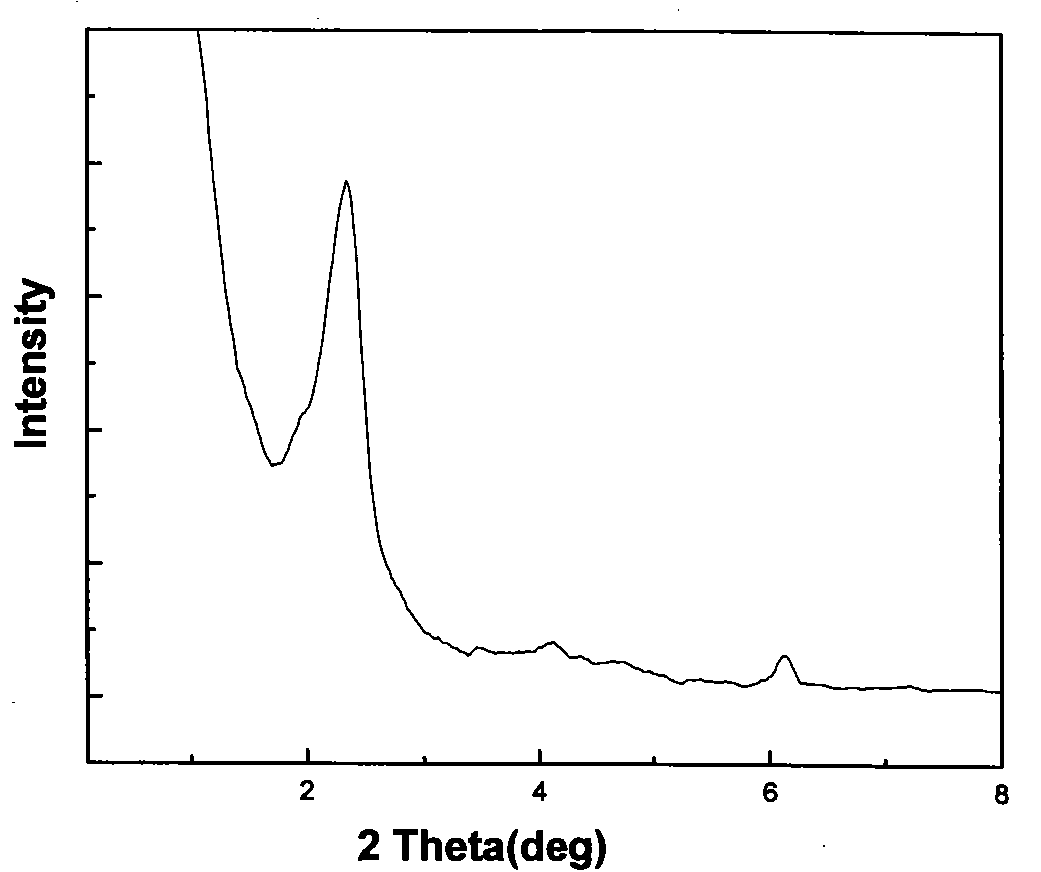

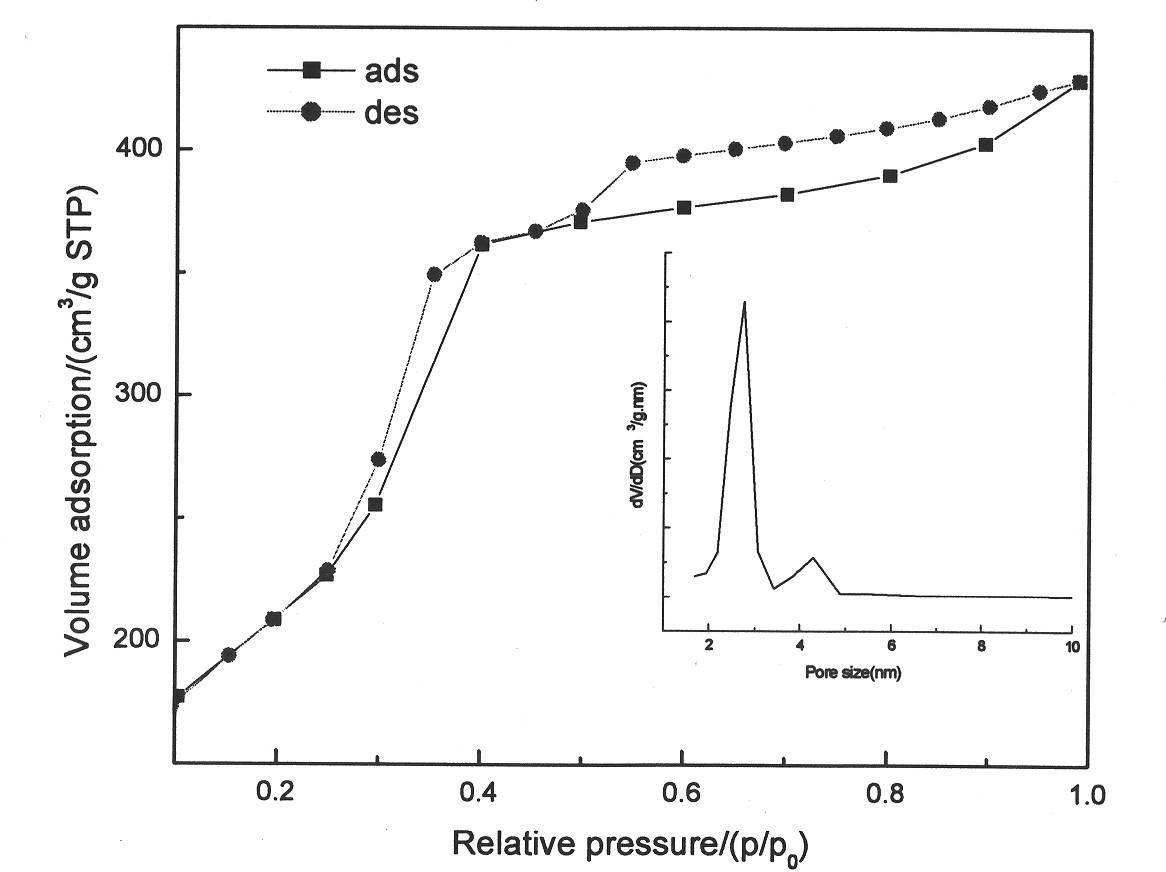

[0031] According to the method of Example 1, the conditions such as raw material ratio are unchanged, only the microwave power is changed, and the synthesis is carried out according to the microwave power of 160W and 220W respectively. Figure 7 is the N of samples obtained under different microwave powers 2 Adsorption-desorption isotherm and pore size distribution diagram. Depend on Figure 7 It can be seen that the adsorption isotherm of the sample is Langmuir IV type, which is a typical adsorption isotherm of mesoporous materials, which indicates that the synthesized composite molecular sieve has a mesoporous structure, and the specific surface area of the samples is greater than 500m 2 / g, in addition, the characteristic peak of mesoporous molecular sieve MCM-41 appeared on the small-angle XRD spectrum of the sample, and the diffraction peak of Y-type molecular sieve existed on the wide-angle XRD spectrum of the sample, indicating that the composite Molecular sieve.

Embodiment 3

[0033] According to the method of embodiment 1, keep the proportioning of other raw materials unchanged, only change the consumption of templating agent, respectively according to the molar proportion of raw material is SiO 2 :Na 2 O:Al 2 o 3 :CTAB:H 2 O=1:1.33:0.167:0.1:58 and the molar ratio of the final material is SiO 2 :Na 2 O:Al 2 o 3 :CTAB:H 2 O=1:1.33:0.167:0.3:58 was synthesized. Figure 8 It is the small-angle XRD spectrum of the synthesized sample. It can be seen that under the condition of changing the amount of template agent, the synthesized sample has the characteristic peak of mesoporous molecular sieve. In addition, wide-angle XRD diffraction also confirms that the sample has the characteristic peak of Y-type molecular sieve, indicating that Composite molecular sieves were synthesized with template dosage within a certain range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com