Patents

Literature

95results about How to "No thermal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

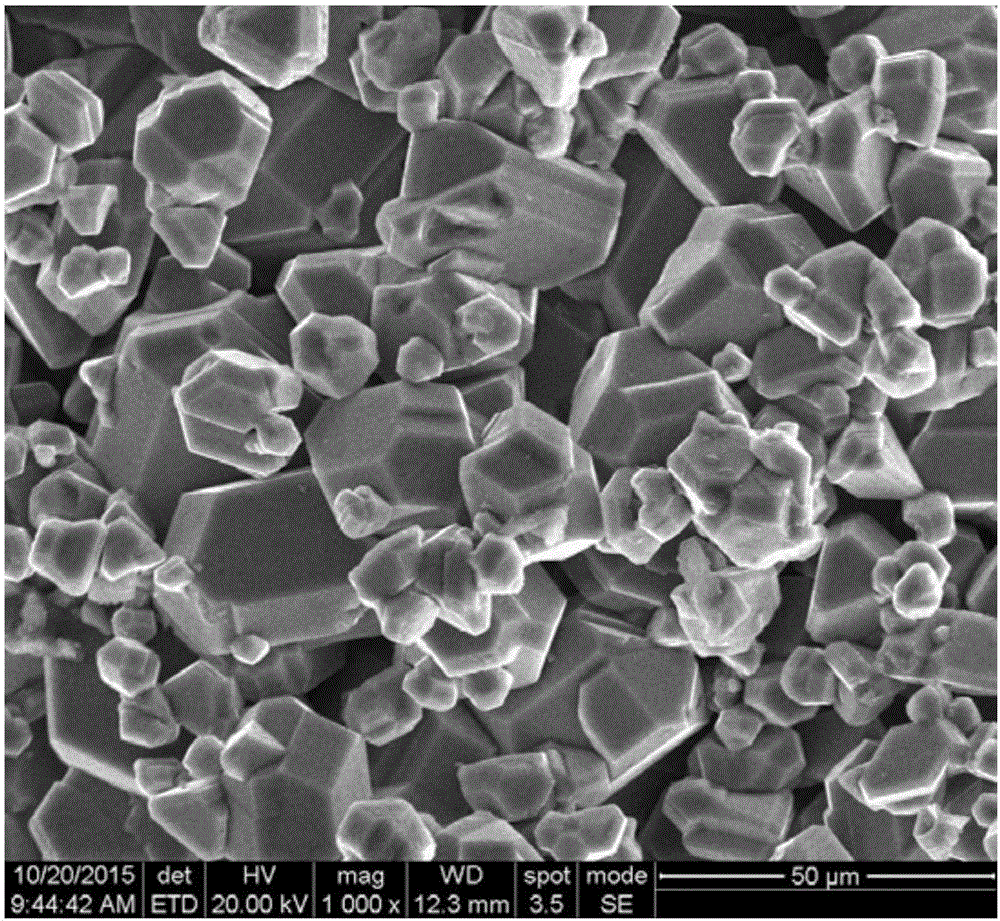

Method for synthesizing composite molecular sieve by microwave method and catalytic performance application thereof

InactiveCN102000604AHigh selectivityLarge particlesOrganic chemistryMolecular sieve catalystsMicrowave methodCatalytic effect

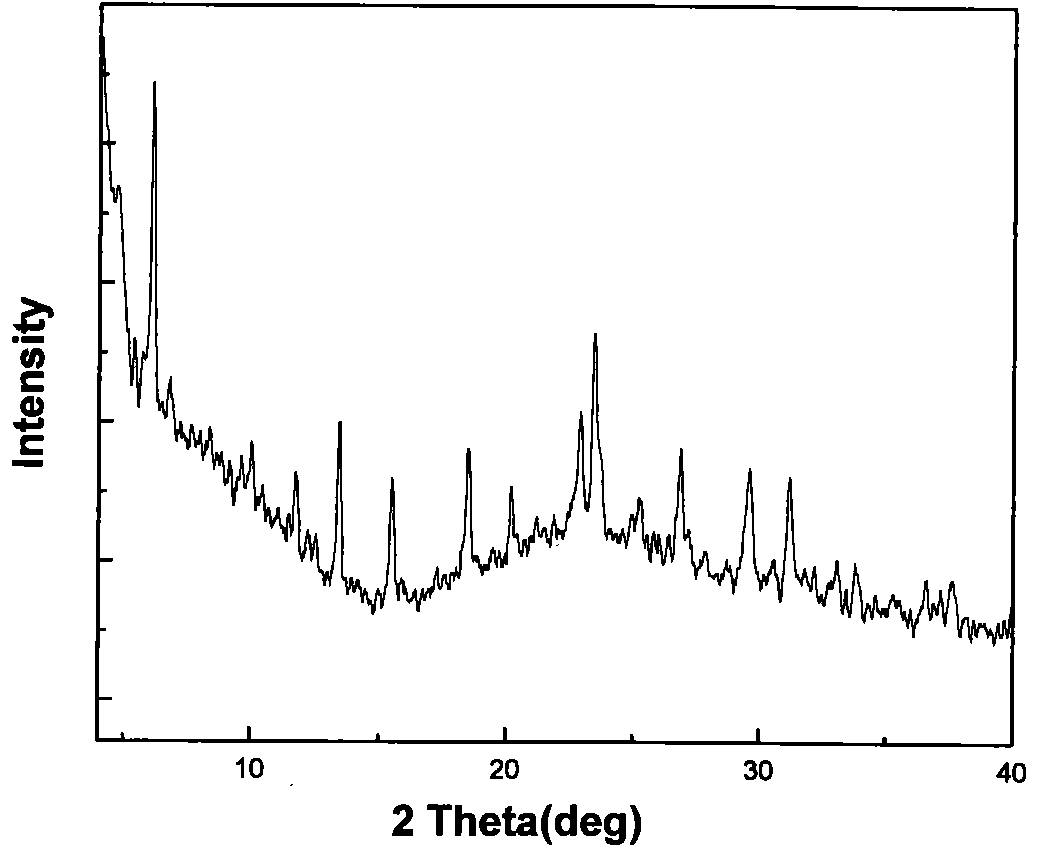

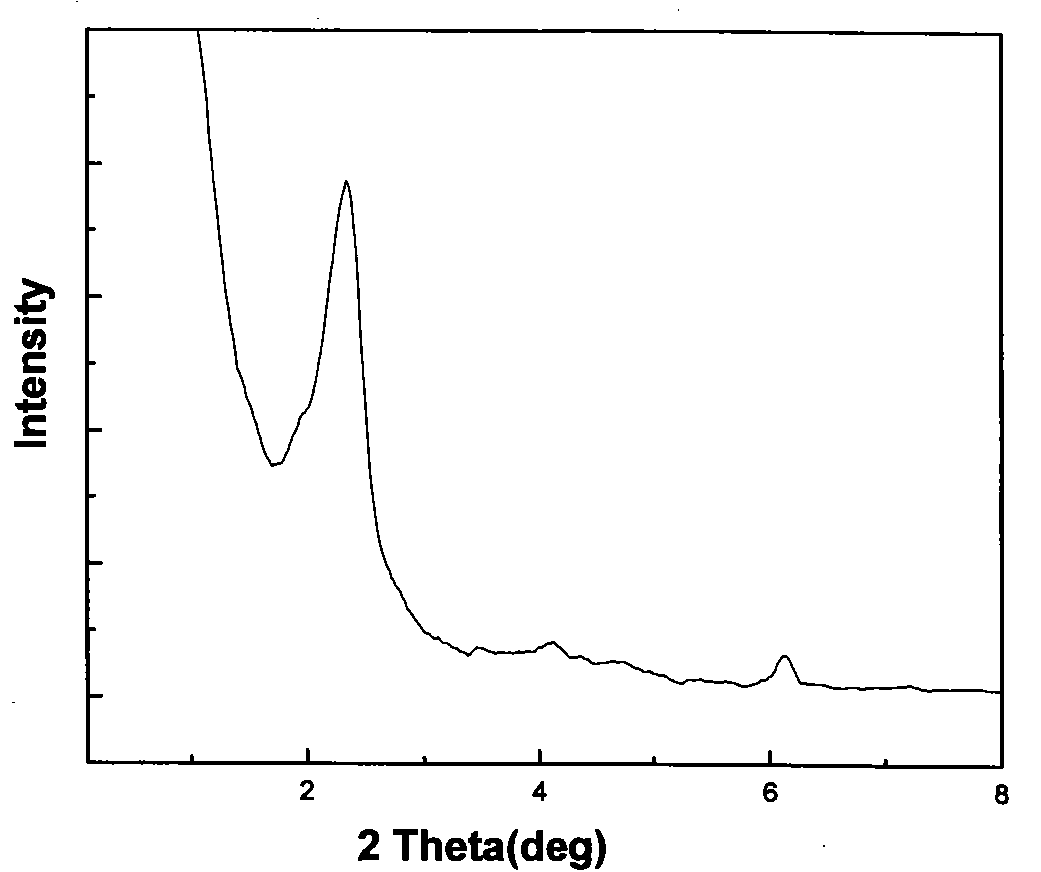

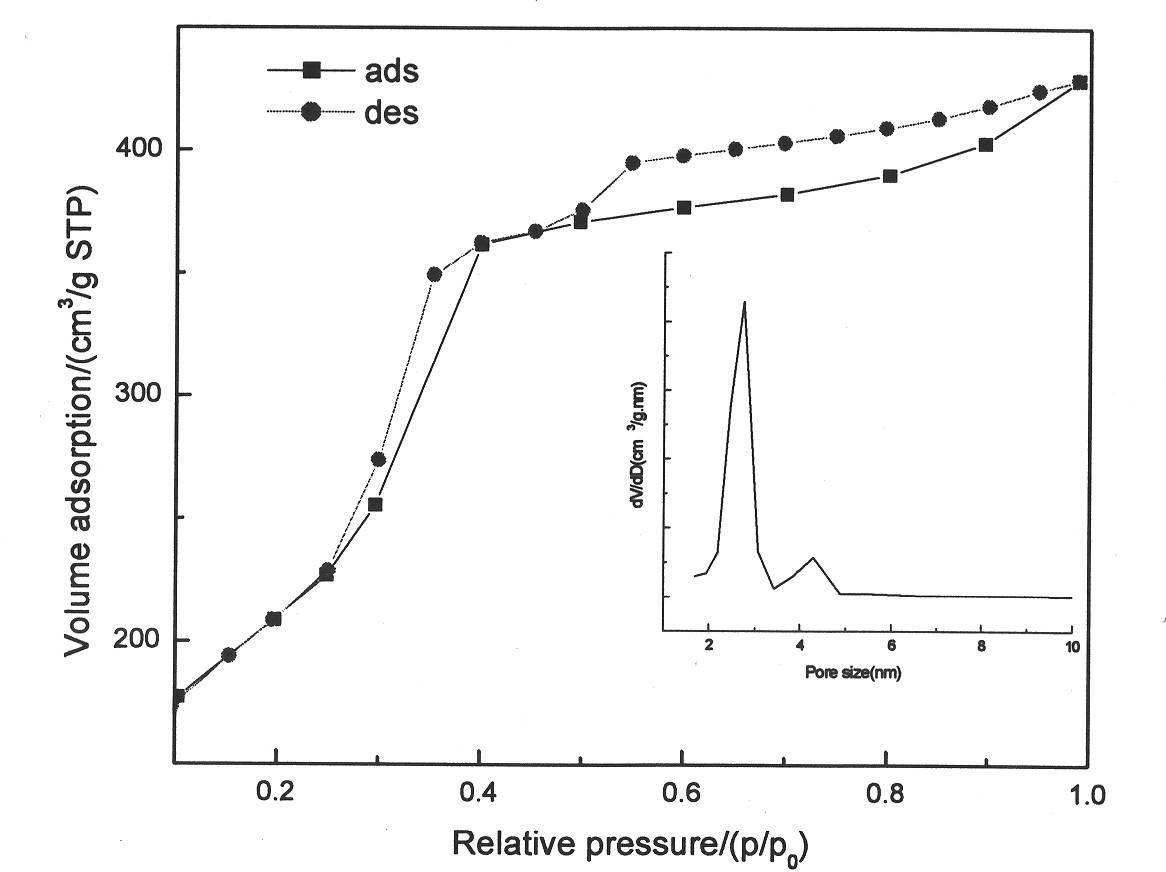

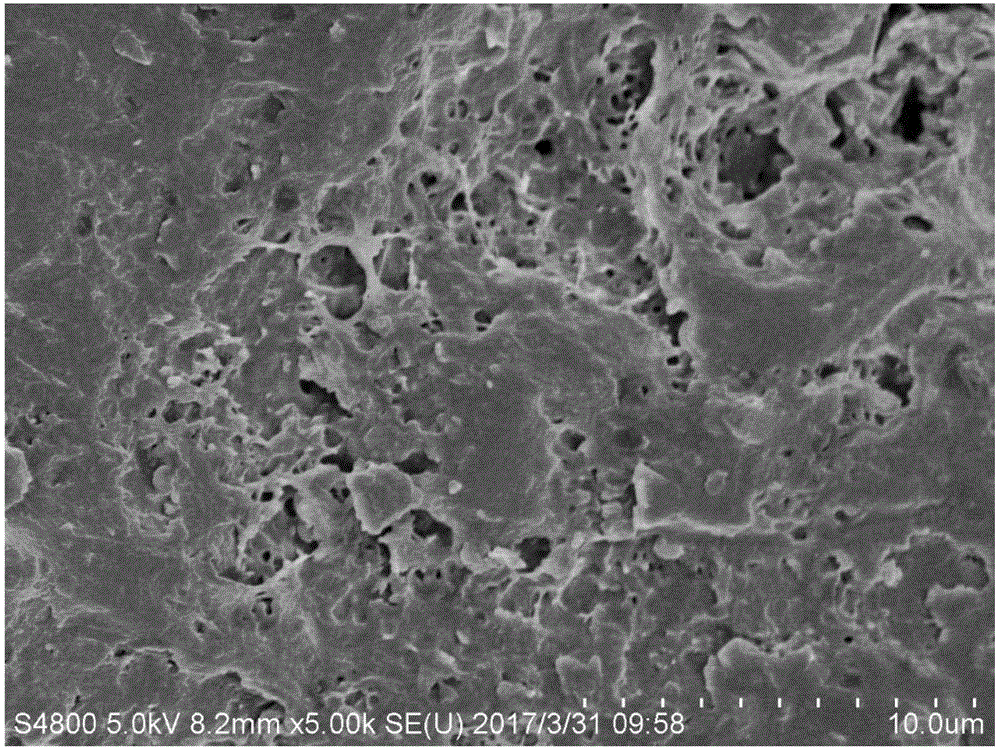

The invention discloses a method for synthesizing a composite molecular sieve by a microwave method and catalytic performance application thereof. In the method for preparing the composite molecular sieve by the microwave method, kaolin is taken as a raw material, inorganic silicate is taken as an additional silicon source, and the prepared composite molecular sieve is applied to the alkylation reaction of phenol and tertiary butanol. The method comprises the following steps of: adding a certain amount of sodium silicate into the kaolin serving as the raw material to synthesize a Y type molecular sieve precursor; and preparing a composite molecular sieve Y / MCM-41 by the microwave method by using hexadecyl trimethyl ammonium bromide serving as a template. The synthesized molecular sieve has two pore structures, namely micropores and mesopores; the specific surface area of a sample is more than 550 m<2> / g; the average pore size is roughly 2.7 nm; and the sample has a regular and ordered hexagonal pore structure. The synthesized molecular sieve has good catalytic effect on the alkylation reaction of the phenol and the tertiary butanol, and particularly the selectivity of 4-tertiary butyl phenol is up to 86.3 percent.

Owner:JIANGSU UNIV

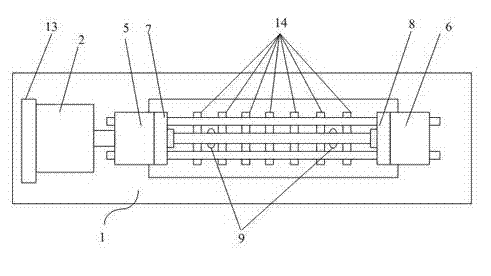

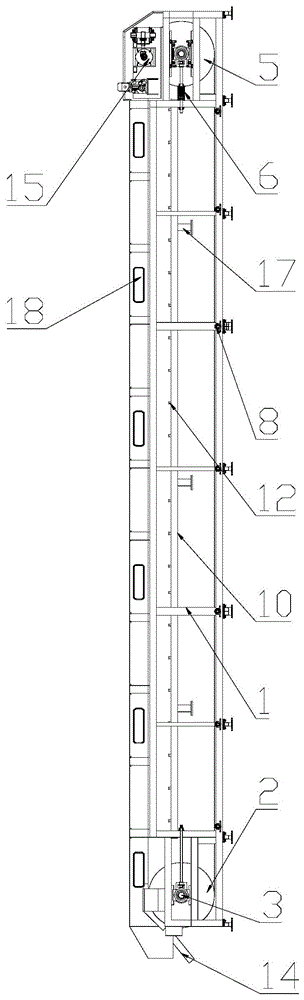

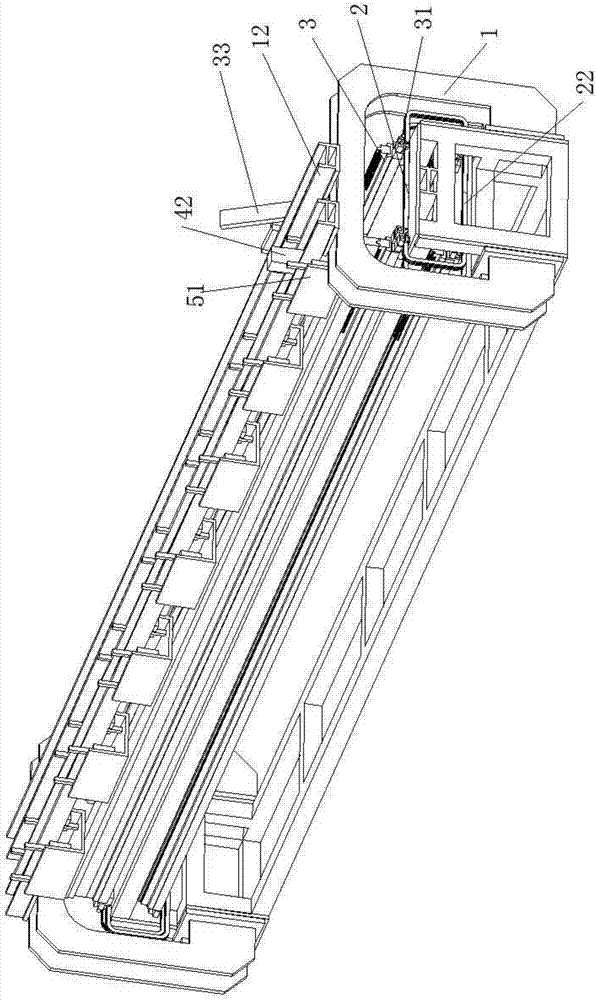

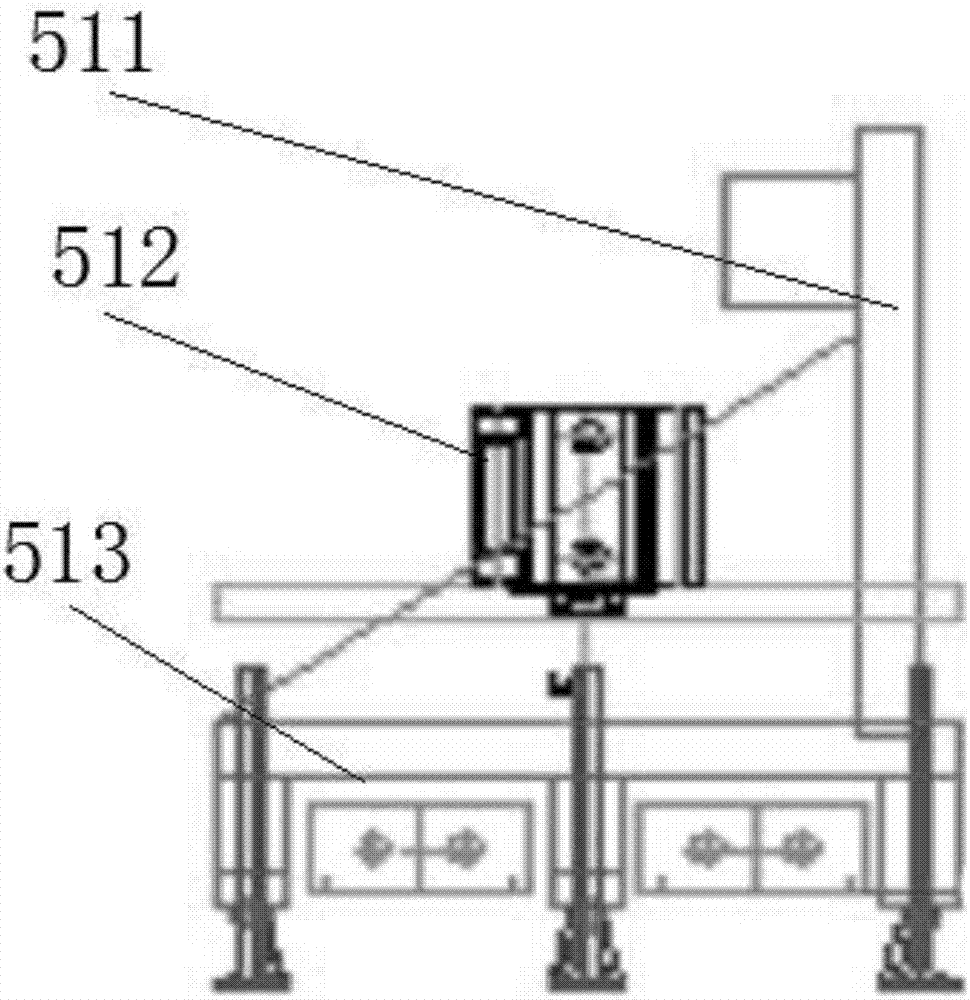

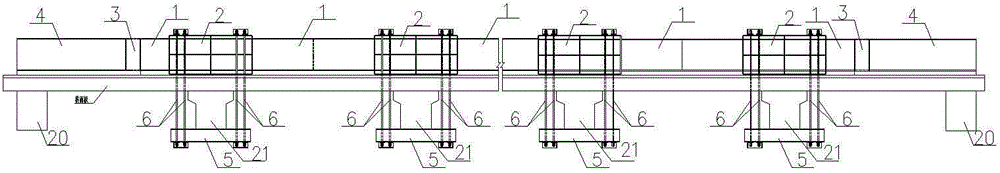

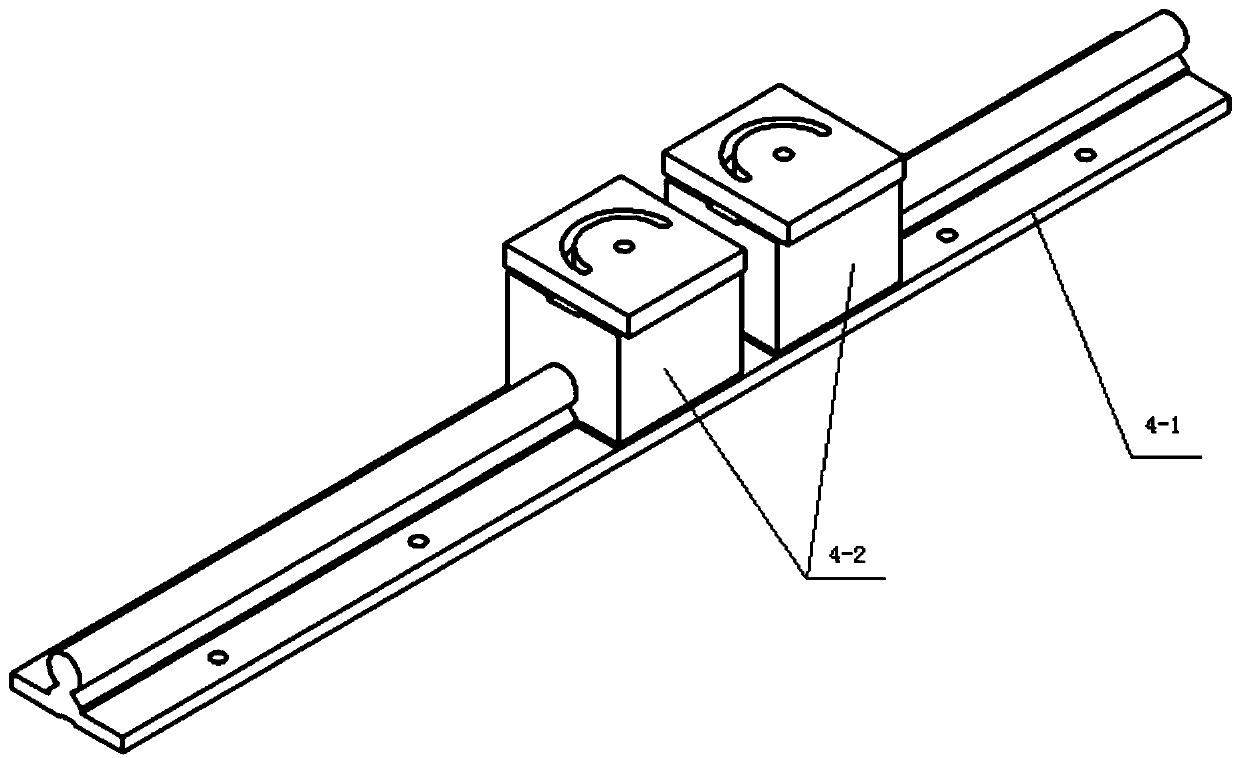

Tensile straightening device for on-line heating and straightening process of magnesium alloy extrusion

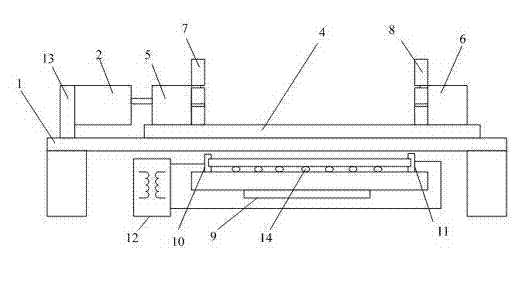

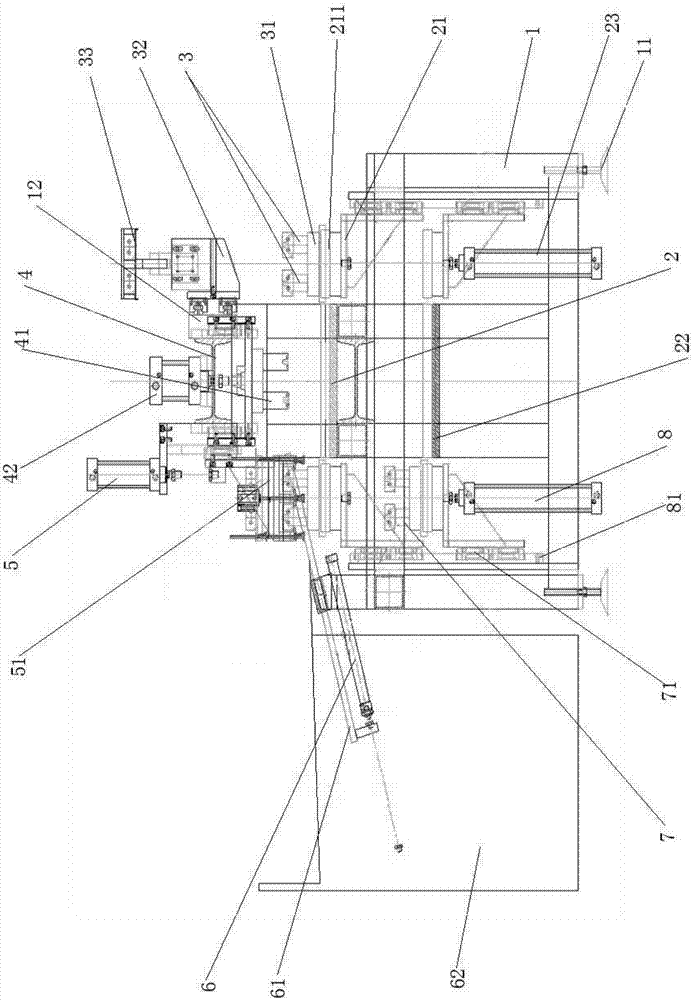

The invention discloses a stretching-straightening device for an online heating-straightening process of a magnesium alloy extrusion material, comprising a stretching-straightening device and a heating device. The stretching-straightening mechanism comprises a bracket, a stretching drive mechanism and a clamping drive mechanism. Double rails are arranged on the bracket. The rail is provided with a chuck I and a chuck II which are matched with the surfaces of the rails in a sliding manner. At least one chuck is capable of sliding forward and backward along the rail direction with the action ofthe stretching drive device. The chuck I and the chuck II are used for generating clamping forces via the clamping drive mechanism respectively. The heating device comprises a lifting mechanism and aheating mechanism. The heating mechanism comprises a positive clamping electrode, a negative clamping electrode and a transformer. The lifting mechanism is arranged under the double rails. The heating device of the stretching-straightening device is capable of guaranteeing that the extrusion material is expanded freely during heating without generating heat stress. The bending phenomenon caused by the heat stress and the instability phenomenon caused by the combined action of the heat stress and the self gravity are avoided via effective support during heating.

Owner:重庆昱华新材料科技有限公司

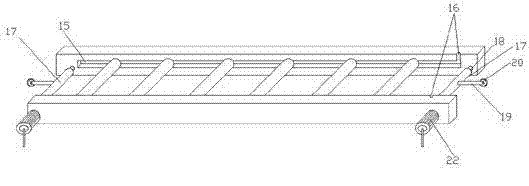

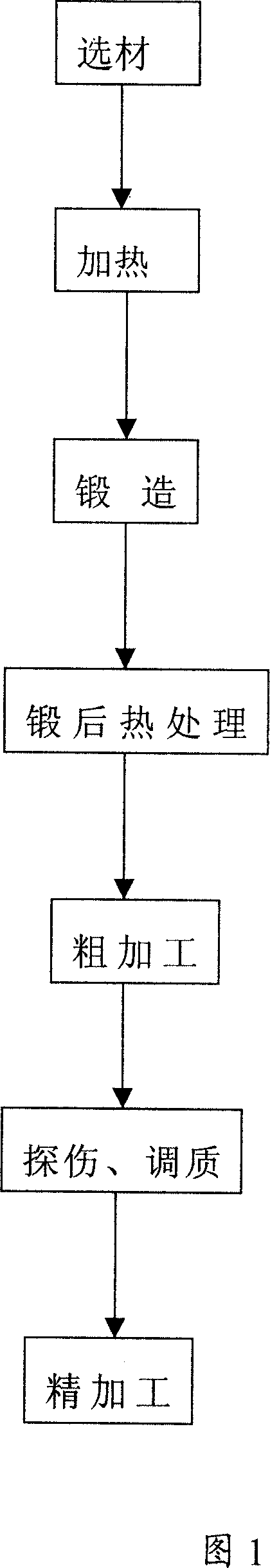

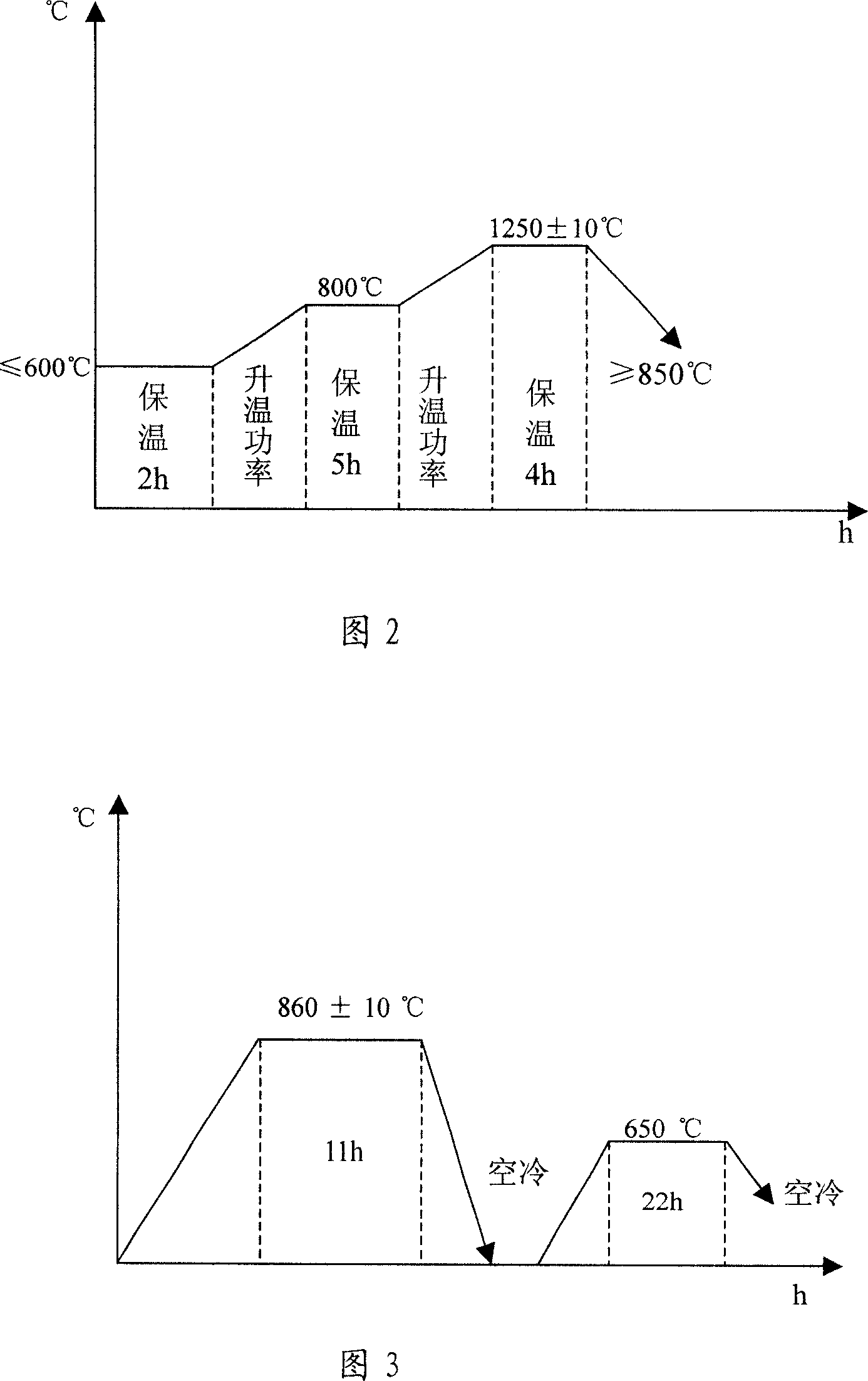

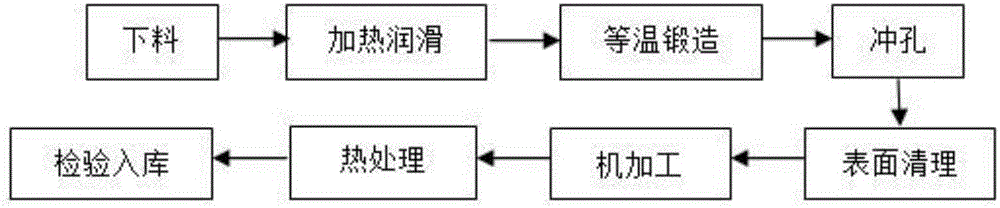

Method for making hammer stem for forging equipment

ActiveCN1962177ALarge amount of deformationImprove mechanical propertiesForging hammersFurnace typesElectricityThermal insulation

The invention relates to a method for producing hammer rod in forge device, wherein it comprises selecting material, forging, thermal treatment, rough treatment, defect detection, adjusting material, and fine treatment. The invention uses steel block, rolling material or forge material refined from steel pack or slag fusion technique. The invention uses gradient heating, multistage thermal insulation to heat, and uses hydraulic machine to forge, and it has defect detection after rough treatment to select different adjustments, therefore, the final metal phase and mechanical property can reach best. The invention can improve the service life of hammer rod, while the average hammer times can reach 300 thousand.

Owner:CHONGQING CHANGZHENG HEAVY IND

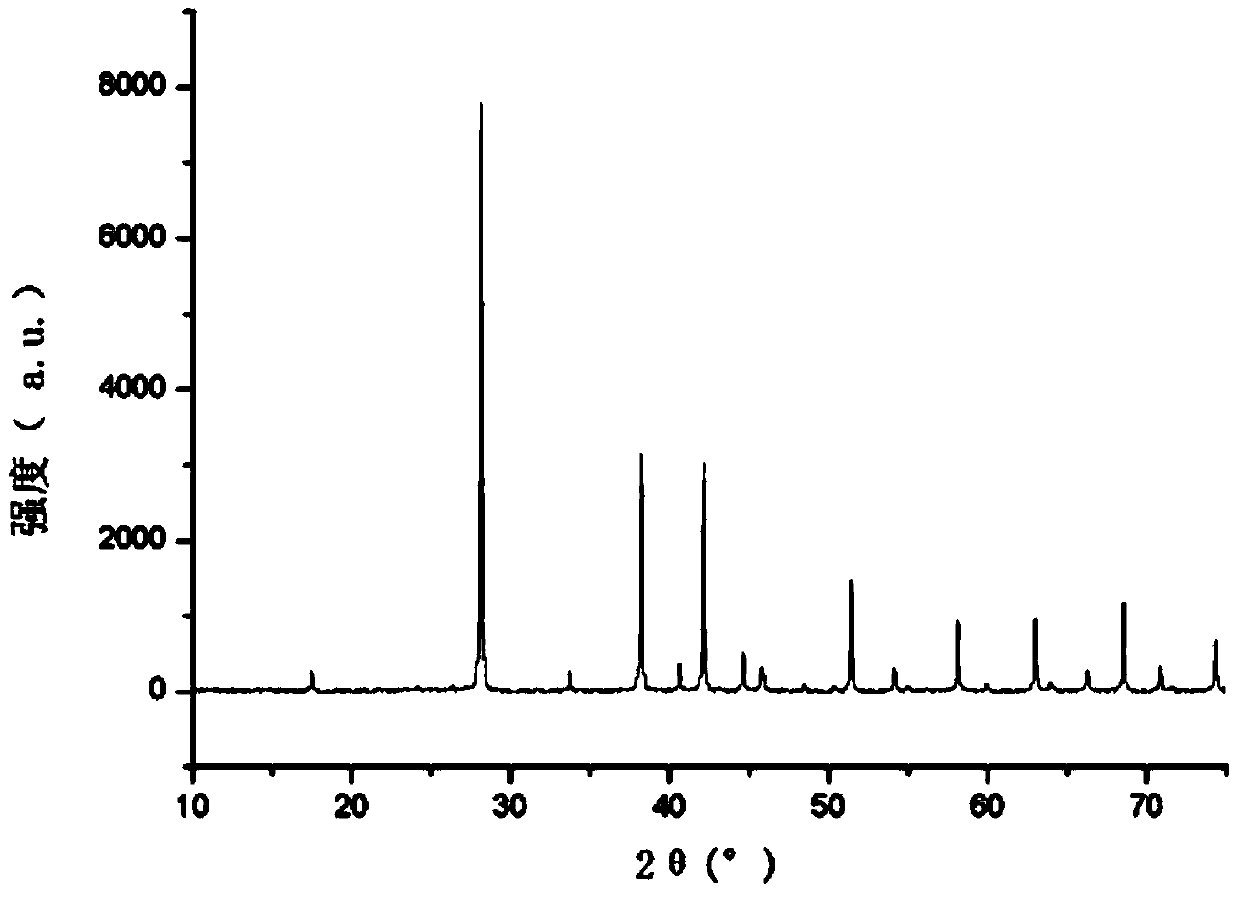

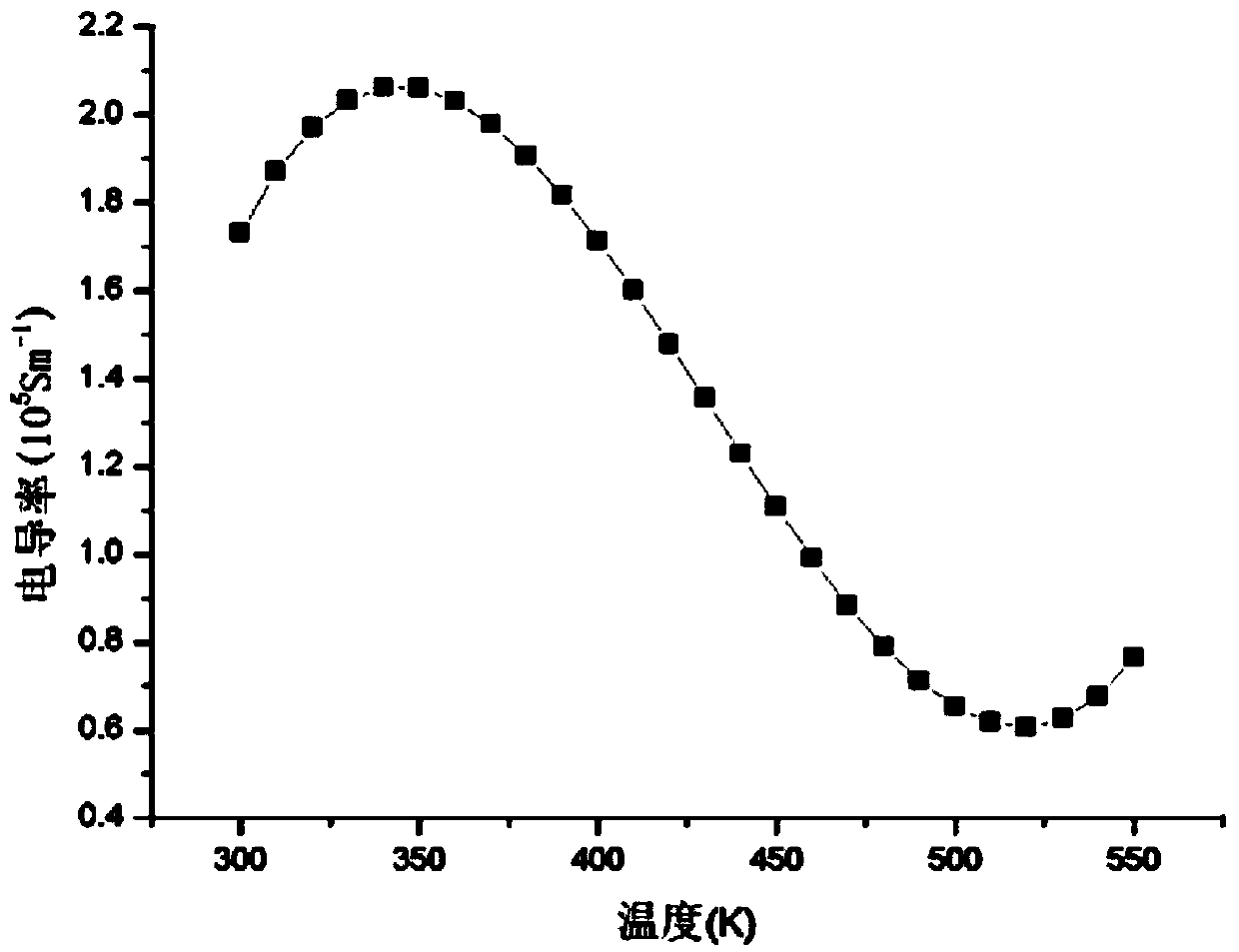

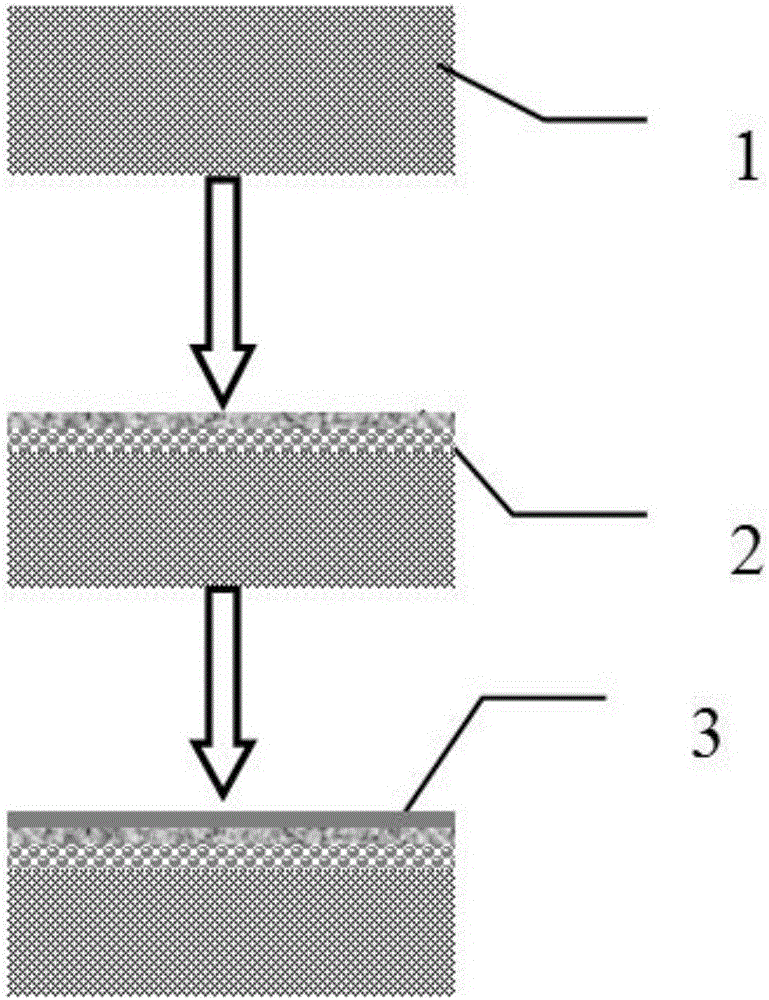

Preparation method of flexible pyroelectric film

The invention discloses a preparation method of a flexible pyroelectric film. The preparation method comprises the following steps of compounding a pyroelectric material casting ingot; grinding and screening the compounded pyroelectric material casting ingot, and obtaining a pyroelectric material powder; mixing an adhesive, a dispersive agent and an organic solvent, uniformly stirring, and preparing a slurry; uniformly mixing and stirring the pyroelectric material powder and the slurry, so as to obtain a mixture material; depositing the mixture material on a flexible substrate by a screen printing method or a tape casting method, and obtaining a precursor of the flexible pyroelectric film; drying the precursor, sintering by microwave, and cooling, so as to obtain the flexible pyroelectric film. The method has the advantages that the bottleneck of the process of using pyroelectric material with high melting point to prepare the film on the flexible substrate with low melting point is overcome, and the flexible pyroelectric film with high quality and excellent pyroelectric property can be obtained under the conditions of shorter time and lower sintering temperature.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Graphite material with SiC coating and preparation method thereof

The invention discloses a graphite material with a SiC coating and a preparation method thereof. The graphite material comprises a graphite base and a SiC coating. The SiC coating comprises a primary SiC layer and a secondary SiC layer. The primary SiC layer permeates into the graphite base from the surface of the graphite base and is formed by an in-situ reaction of gaseous silicon and the graphite base. The secondary SiC layer is located on the primary SiC layer. The preparation method comprises 1, carrying out vapor silicon infiltration sintering on a graphite material to obtain a graphite material with the primary SiC layer and 2, carrying out vapor deposition of the secondary SiC layer. The graphite material with the SiC coating has the advantages that the SiC coating has good cohesiveness to the graphite material, has no thermal expansion coefficient mismatch, is compact and has high oxidation resistance. The preparation method effectively solves the problem of thermal expansion coefficient mismatch in preparation of the SiC coating on the surface of the graphite material directly through a CVD technology, and guarantees high bonding strength between the coating and graphite.

Owner:NAT UNIV OF DEFENSE TECH

Joining method of SiC ceramic through combining nano-impregnated transient co-crystal phase with chemical vapor infiltration as well as prepared ceramic connector

The invention belongs to the technical field of ceramic joining and discloses a joining method of SiC ceramic through combining a nano-impregnated transient co-crystal phase with chemical vapor infiltration as well as a prepared ceramic joining part. The method comprises the following steps: firstly, mixing SiC powder with Al2O3-Re2O3, adding a solvent and a ball milling medium for mixing and drying to obtain mixed powder; granulating the mixed powder and spreading the granulated powder between two pieces of polished SiC to form a sandwich structure; putting a sample with the sandwich structure into a heat treatment furnace, raising the temperature to 1000 to 1400 DEG C for heat treatment in a vacuum or protective atmosphere, adding organic carbon silane doped with filler and carrying outchemical vapor infiltration at 1300 to 1600 DEG C to obtain a joining part of the SiC ceramic. According to the joining method disclosed by the invention, low-temperature pressure-free joining of theSiC ceramic is realized by combining the nano-impregnated transient co-crystal phase with the chemical vapor infiltration and the leakage rate at the joint reaches 0 to 1*10<-10> Pa.L / s.

Owner:GUANGDONG UNIV OF TECH

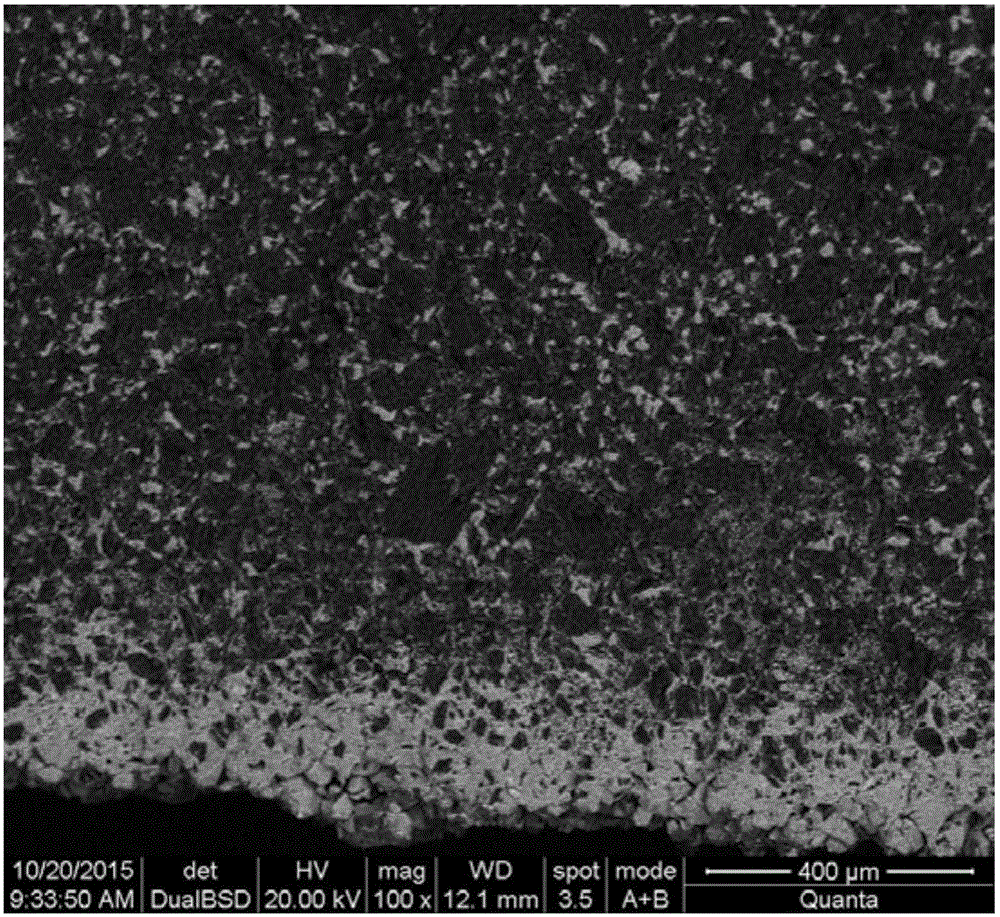

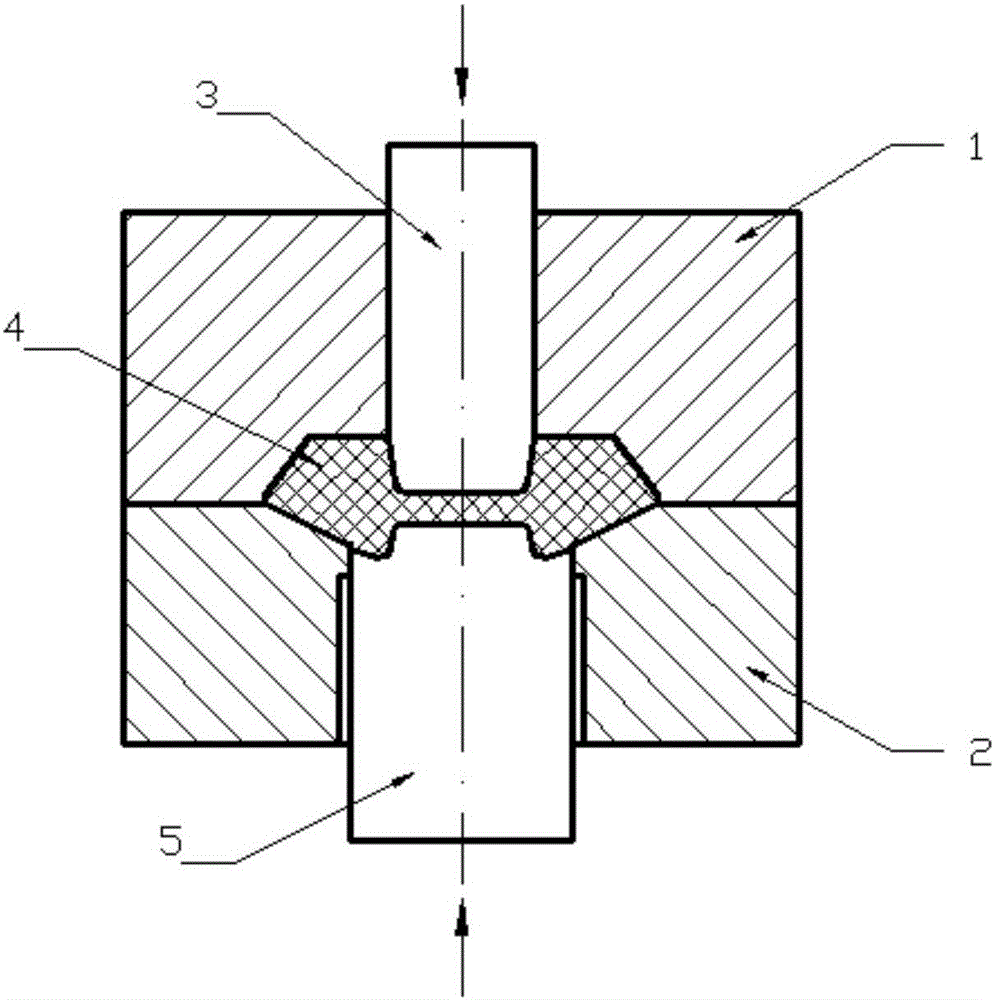

Isothermal forging method of straight bevel gear

InactiveCN105921672AAvoid chillingPromote plastic flowMetal-working apparatusWheelsGear wheelBevel gear

The invention discloses an isothermal forging method of a straight bevel gear. A blank and a mold are heated to roughly consistent temperatures respectively, then the blank is placed into the mold and is subjected to forging molding in the mold at the relatively low strain rate, and the straight bevel gear is obtained through aftertreatment, wherein the relatively low strain rate is lower than 0.1 mm / s, and the mold adopts a closed mold forging structure. According to the method, firstly, the blank and the mold are heated to the equal temperature or basically equal temperatures, so that the chilling effect produced when the temperature of the mold is lower than that of the blank is avoided, and the plastic flow of the blank is improved; secondly, the mold adopts the closed mold forging structure, the blank bears three-dimensional compressive stress in the forging process, and thus molding of the blank is facilitated; thirdly, the strain rate is lower than 0.1 mm / s, accordingly, the deformation amount of the blank in unit time is small, deformation is sufficient, and molding of the blank is more facilitated.

Owner:SHANDONG UNIV +1

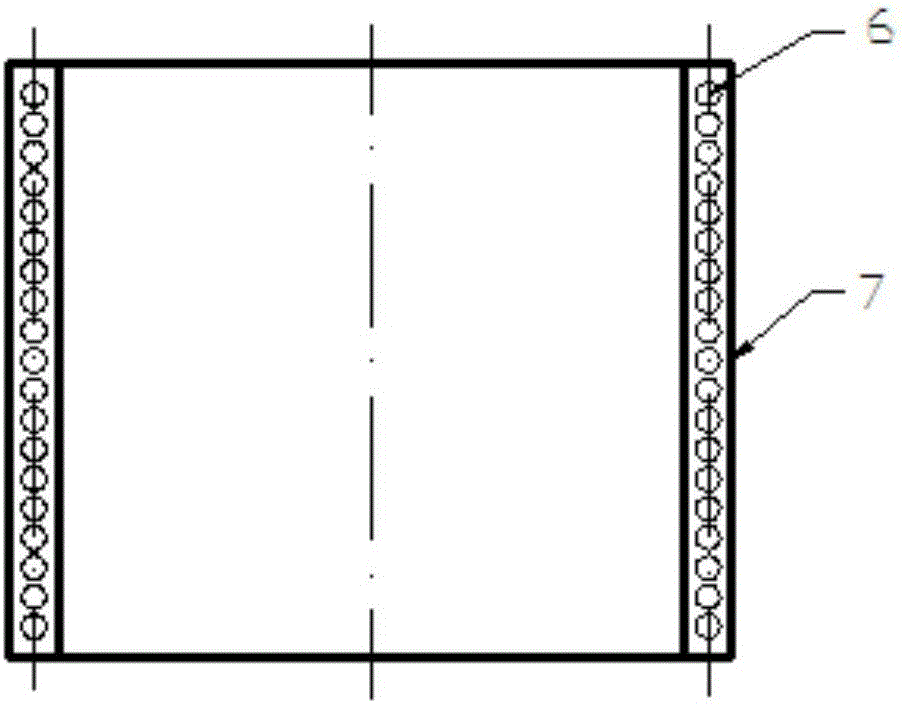

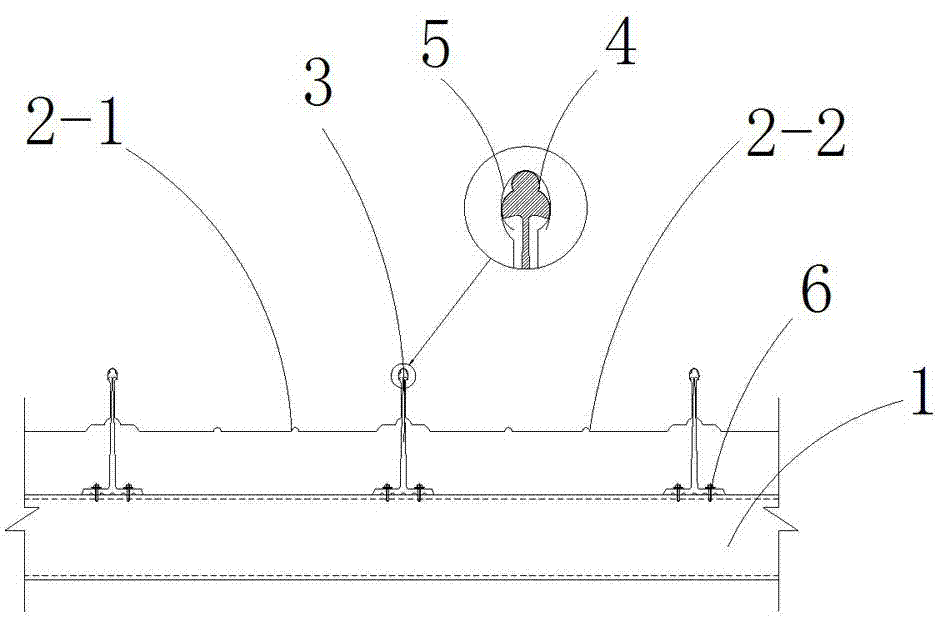

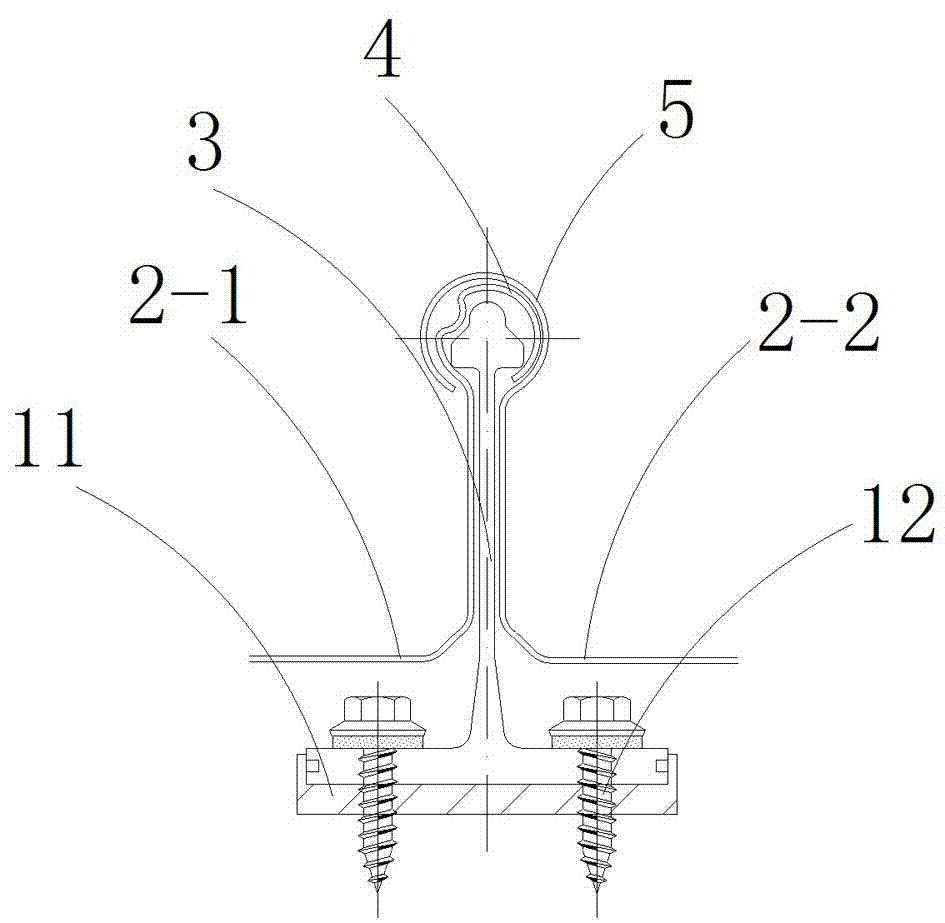

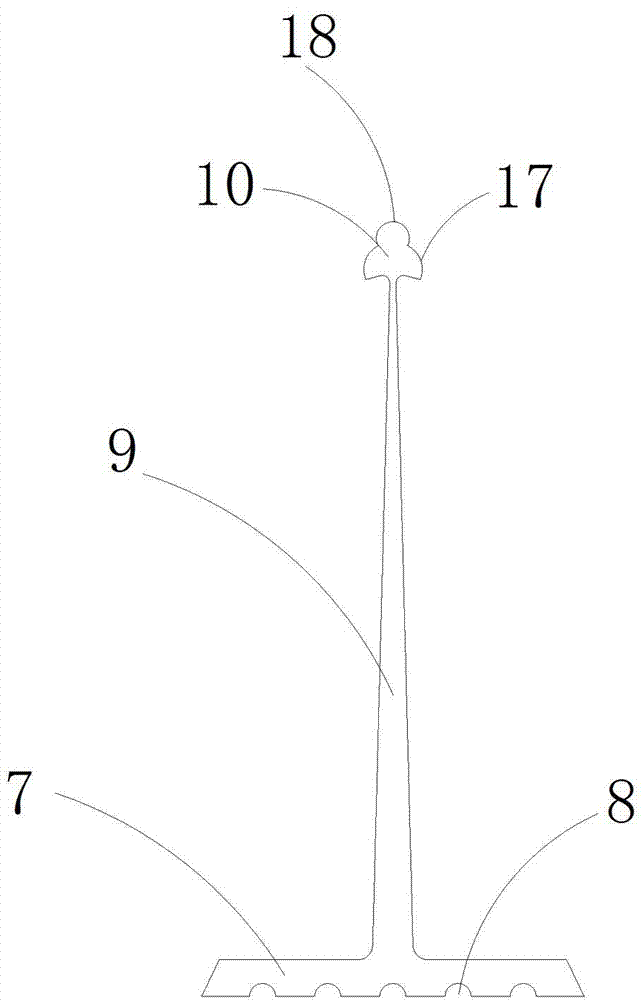

Metal roof board system

InactiveCN102733550AGuaranteed reliabilitySolve the insurmountable temperature deformation problemRoof covering using slabs/sheetsEngineeringMetal roof

The invention relates to a roof board, and particularly relates to a metal roof board system belonging to the field of steel structures. The metal roof board system comprises a purline and at least two metal roof boards, wherein the upper part of the purline is uniformly provided with fixing seats; both ends of each metal roof board are distributed upwards; the end part at the left end of each metal roof board is provided with a small flanged edge; the end part at the right end of each metal roof board is provided with a big flanged edge; and the head of each fixing seat is wrapped by the small flanged edge of one metal roof board, and the small flanged edge is wrapped by the big flanged edge of the other metal roof board. The metal roof board system has the advantages of simple structure, reliable performance, high support performance and good water resistance.

Owner:浙江东南网架股份有限公司

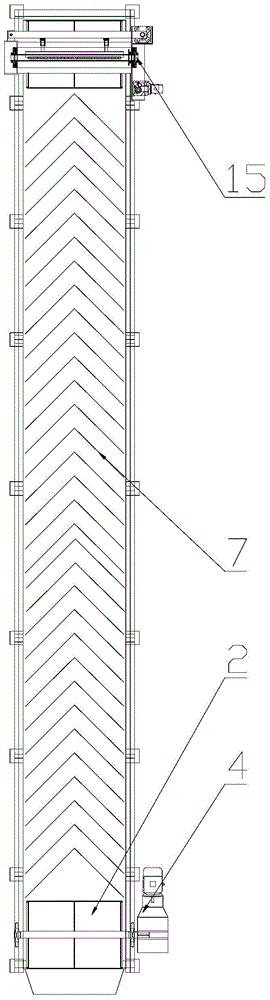

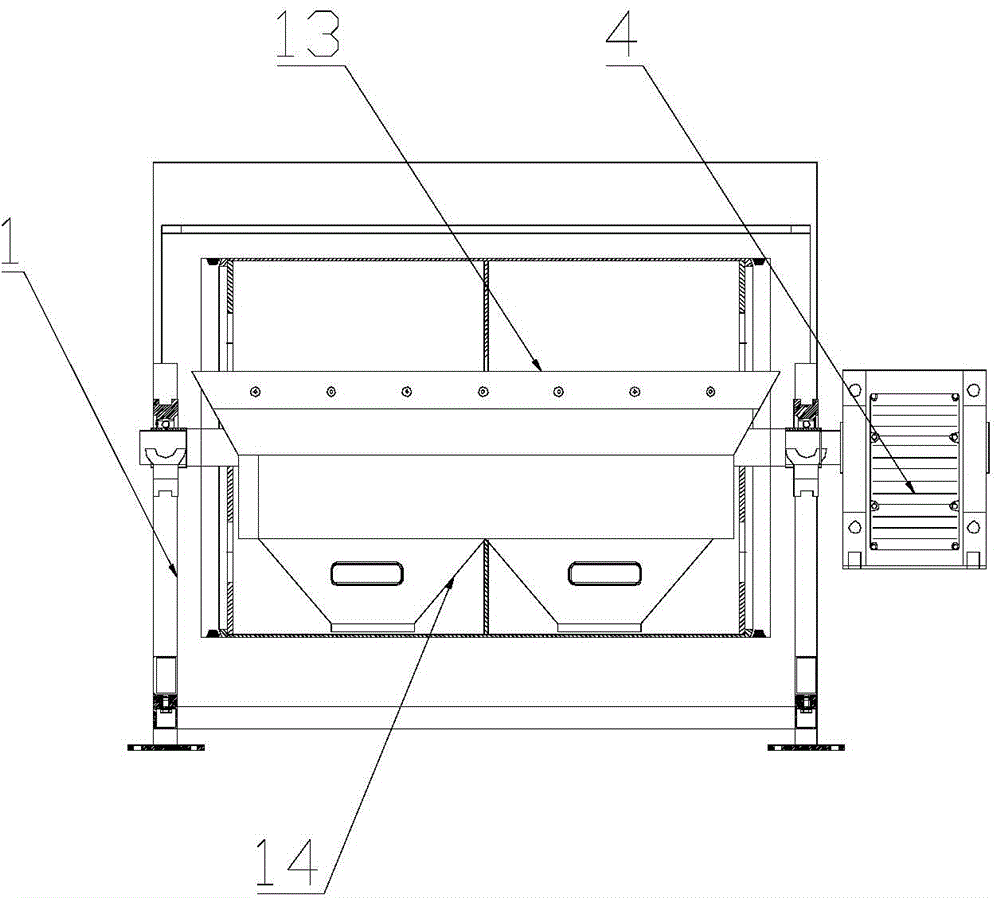

Steel band condensation and granulation unit

The invention relates to cooling and curing equipment, in particular to a steel band condensation and granulation unit. The steel band condensation and granulation unit comprises a combined rack, a steel band transmission drum, a steel band transmission reduction gearbox, a steel band passive drum, a steel band tension automatic adjustment mechanism, a steel band bracket, a steel band idling wheel, a transmission steel band, a water collection tank, a cooling spray pipe, an atomizing spray head, an unloading scraper, a feed opening, a distributor, a water inlet pipe, a drainage hole and a dust-proof housing, wherein a molten material with smelting point of 50-300 DEG C is uniformly distributed on the transmission steel band through the distributor; under forcible cooling of the water collection tank, the cooling spray pipe and the atomizing spray head arranged on the lower side of the transmission steel band, the material is quickly cooled and cured in the movement and conveying processes under the condition that the steel band is not in contact with water; the pelletized product prepared by the equipment has attractive appearance, is uniform, and is close to a half ball shape; particles have no thermal stress and are easier to package, transport and store.

Owner:ZHANGJIAGANG RAIDSANT MACHINERY

Carbon substrate surface TaC coating layer and preparation method thereof

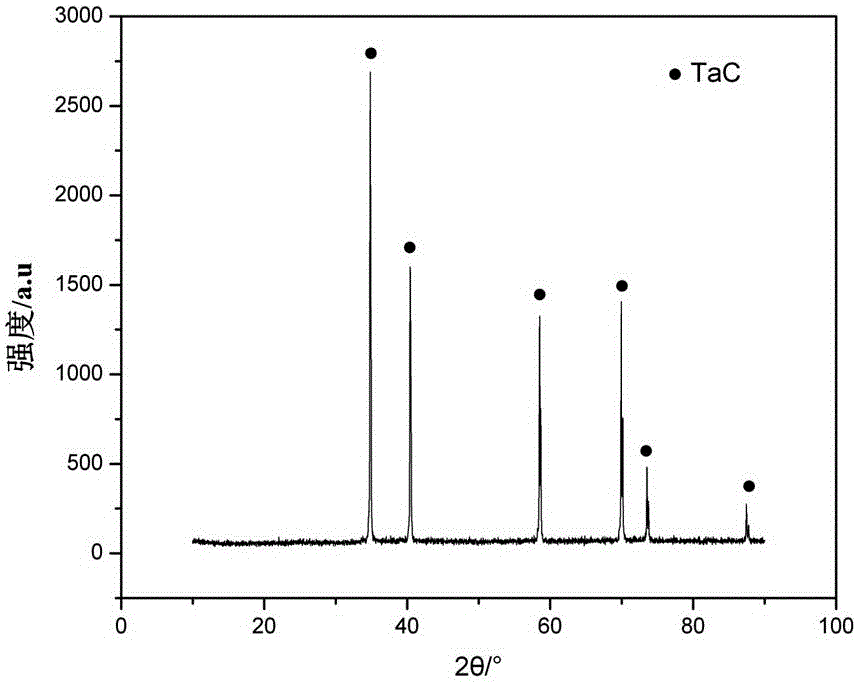

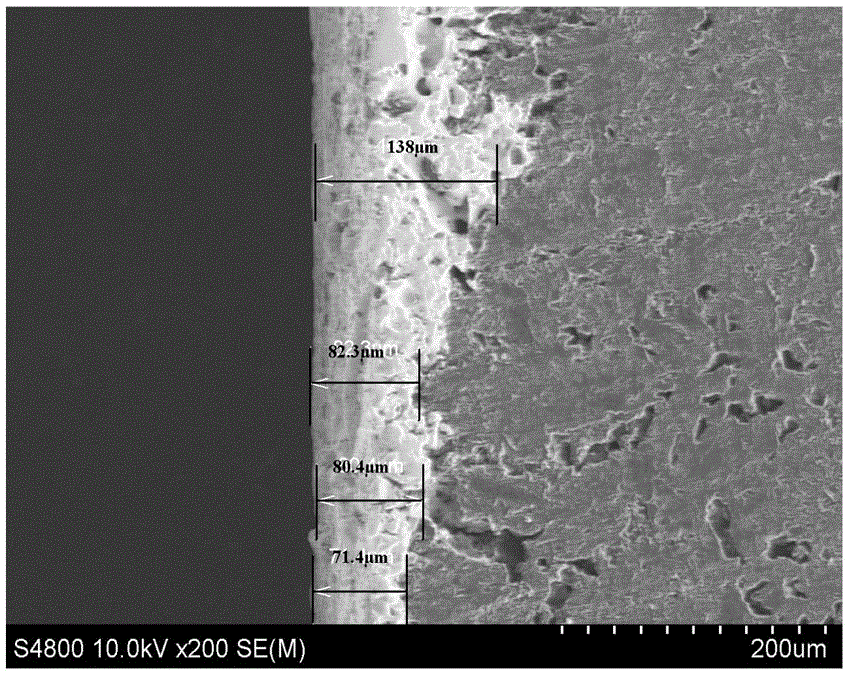

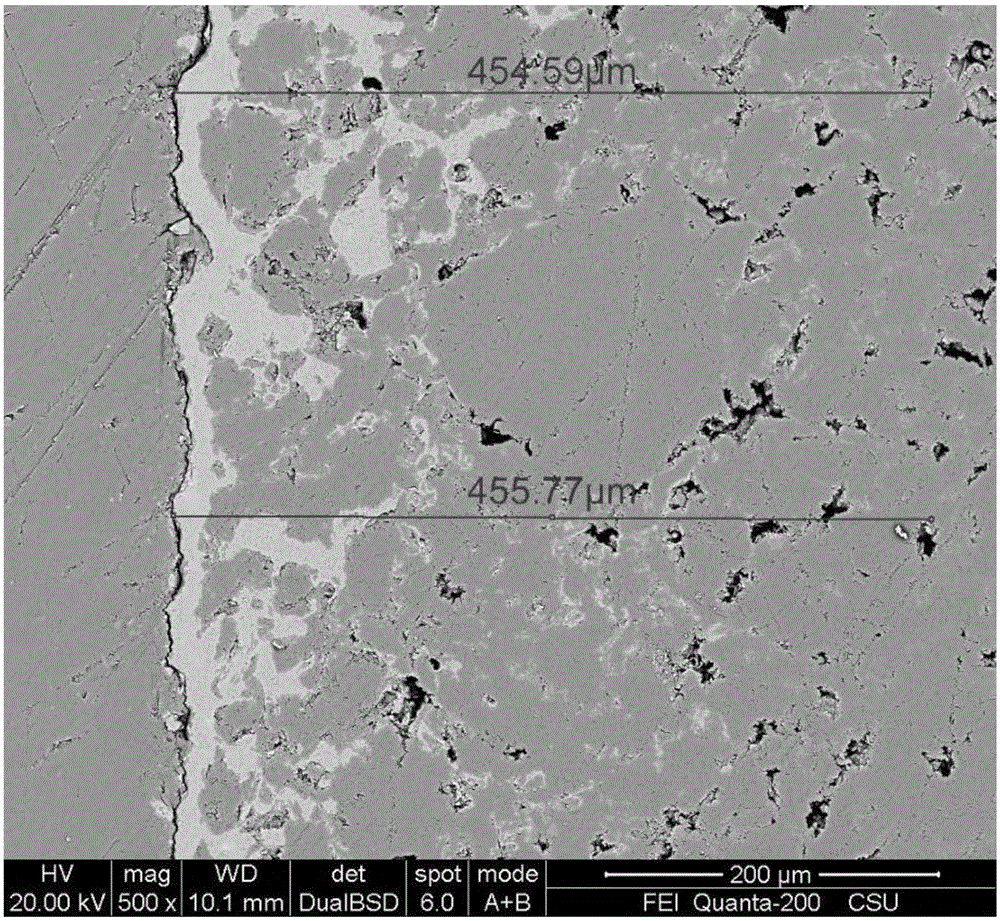

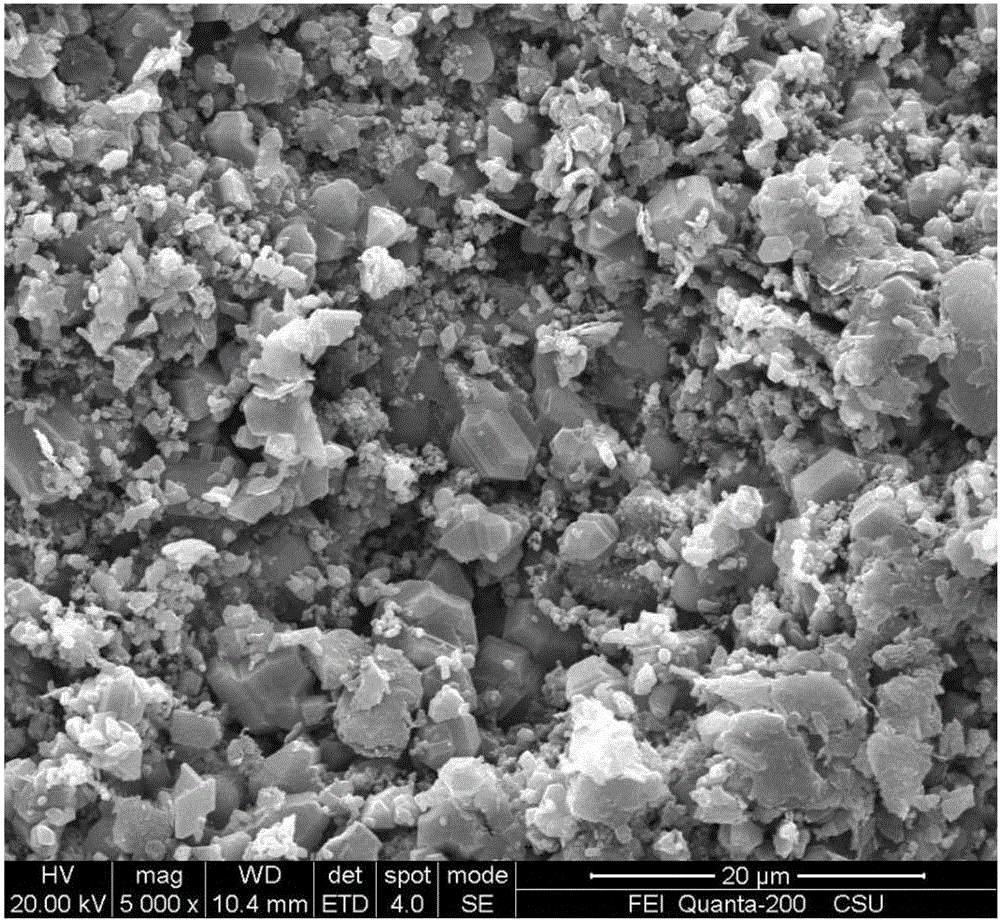

InactiveCN106298448AHigh bonding strengthNo thermal stressSemiconductor/solid-state device manufacturingIn situ reactionDecomposition

The invention discloses a carbon substrate surface TaC coating layer and a preparation method thereof. The carbon substrate surface TaC coating layer comprises TaC generated by in-situ reaction of a hybrid complex of Ta and C and carbon of a carbon substrate, and TaC generated by decomposition of the hybrid complex of Ta and C. The preparation method comprises the following steps of (1) synthesizing a TaC precursor; (2) preparing TaC precursor paste; and (3) performing high-temperature segmented thermal processing. The carbon substrate surface TaC coating layer has the advantages of high bonding strength with the substrate, high crystallinity, uniformity, compactness, corrosion resistance, remarkable thermal stability and the like. The preparation method is simple in requirement on a process device, short in period and low in cost and has wide adaptability.

Owner:NAT UNIV OF DEFENSE TECH

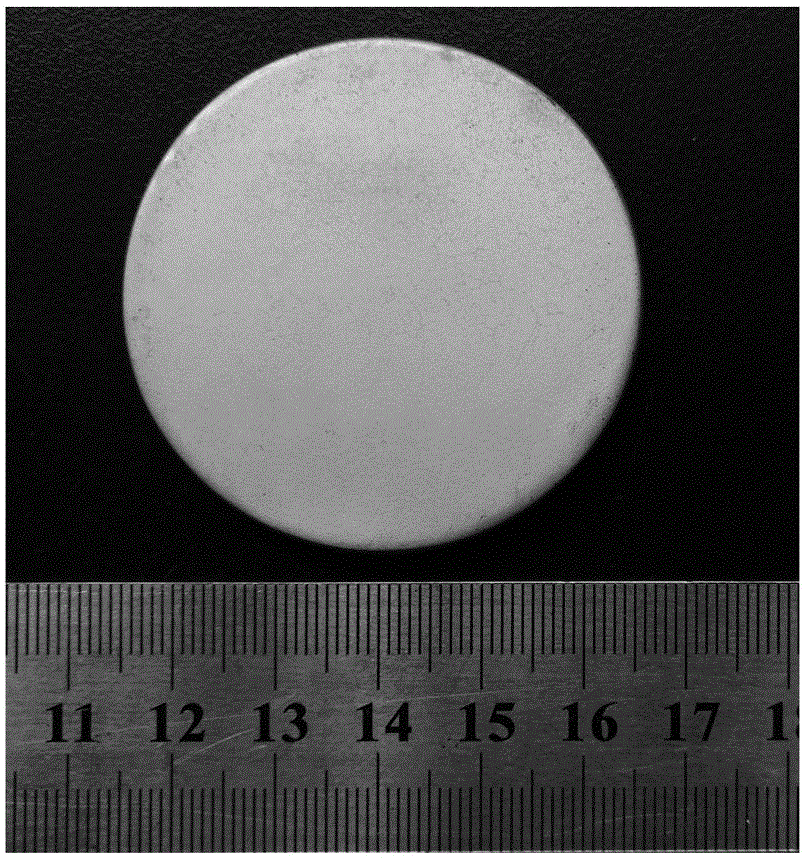

Polycrystalline diamond compact and preparation method thereof

ActiveCN104863513AImprove wear resistanceImprove thermal stabilityDrill bitsMetal catalystHeat stability

The invention provides a polycrystalline diamond compact and a preparation method thereof. The polycrystalline diamond compact comprises a cemented carbide substrate layer and a polycrystalline diamond layer synthesized on the cemented carbide substrate layer, wherein the upper surface of the polycrystalline diamond layer is a pure polycrystalline diamond layer formed by diamond. The invention further provides the preparation method of the polycrystalline diamond compact. The preparation method is characterized by adopting an acid pickling method for removing a metal catalyst on the upper surface of a precursor of the polycrystalline diamond in the conventional polycrystalline diamond compact. The polycrystalline diamond compact provided by the invention is better in abrasive resistance and higher in heat stability, and the preparation method provided by the invention is simple and easy to operate.

Owner:FUNIK ULTRAHARD MATERIAL

Graphite material with SiC doped layer and preparation method of graphite material

The invention discloses a graphite material with a SiC doped layer and a preparation method of the graphite material. The preparation method of the graphite material with the SiC doped layer comprises the following step: by taking mixed powder of silicon-containing powder and boron nitride as a silicon source, performing liquid-phase siliconing sintering on a graphite material, thereby obtaining the graphite material with the SiC doped layer. The graphite material with the SiC doped layer prepared by using the method comprises a graphite substrate and the SiC doped layer on the surface of the graphite substrate, the SiC doped layer is well combined with the graphite substrate without thermal mismatch, the graphite material is good in oxidation and corrosion resistance and relatively low in cost, and a small amount of silicon is adhered to the surface of the graphite material.

Owner:NAT UNIV OF DEFENSE TECH

Structure and method for conductive connection between copper materials or between copper material and other components

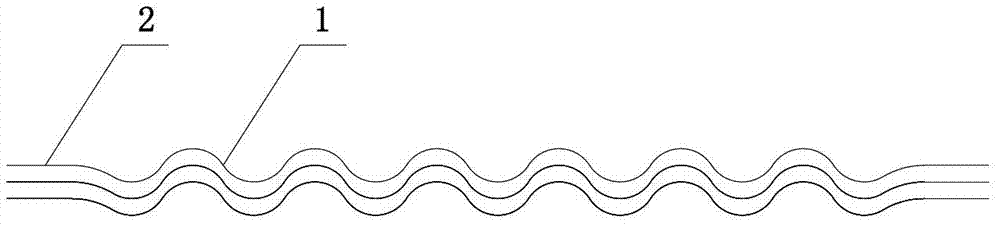

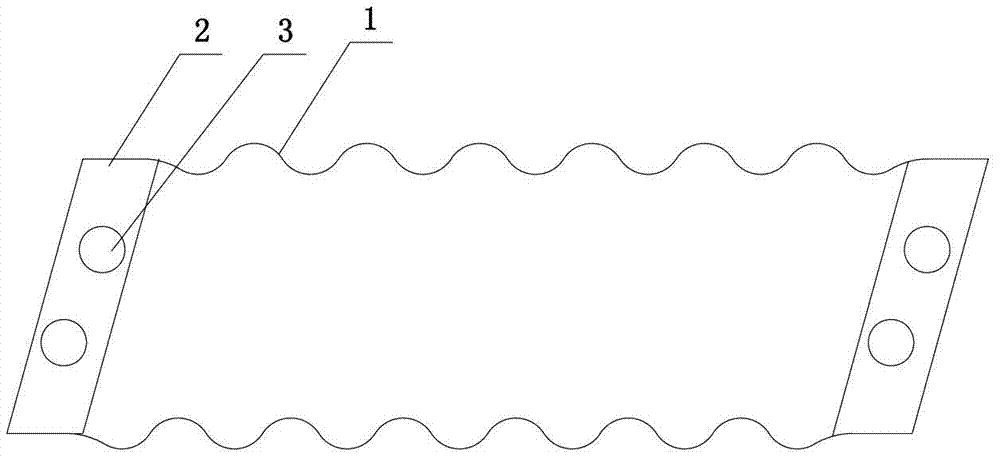

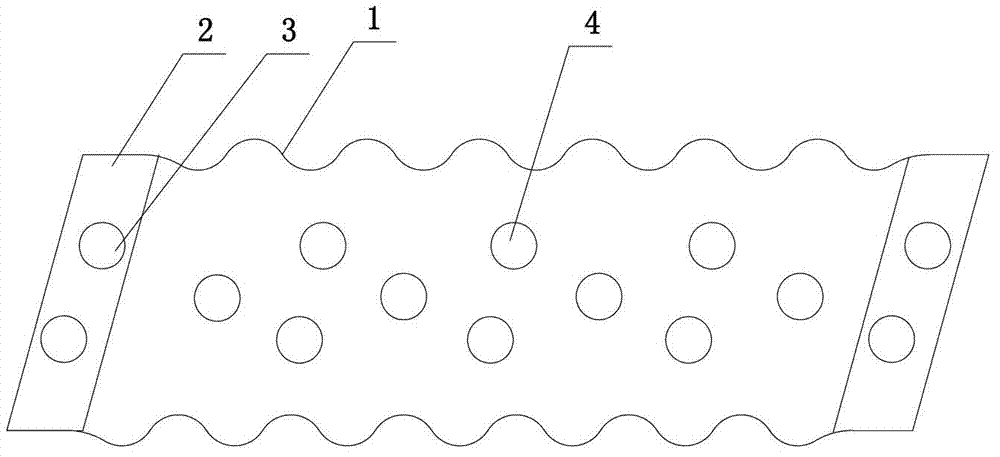

InactiveCN102738600AFully contactedClosely connectedLine/current collector detailsClamped/spring connectionsState of artWave shape

The invention relates to a connection technology between copper materials or between a copper material and other components, in particular to a structure and method for conductive connection between copper materials or between a copper material and other components. A multi-layer copper foil flexible connection structure is connected between the copper materials or between the copper material and other components, the copper foil flexible connection structure is a multi-layer structure formed by superposing wave-shaped or snake-shaped or unfolded spiral copper foil strips, the middle wave-shaped or snake-shaped or unfolded spiral copper foil strips are in a free layering state, and two ends of the wave-shaped or snake-shaped or unfolded spiral copper foil strips of the multi-layer structure are directly connected to the copper materials or other components. The structure and method for conductive connection disclosed by the invention solve the problems of unsatisfactory conductive performance, low reliability and the like of the prior art, the copper foil flexible connection which has a simple structure and high reliability and is convenient to maintain is adopted, and the conductive connection structure not only has a good conductive performance, but also has good heat compensation ability and a vibration isolation effect.

Owner:江西九星铜业有限公司

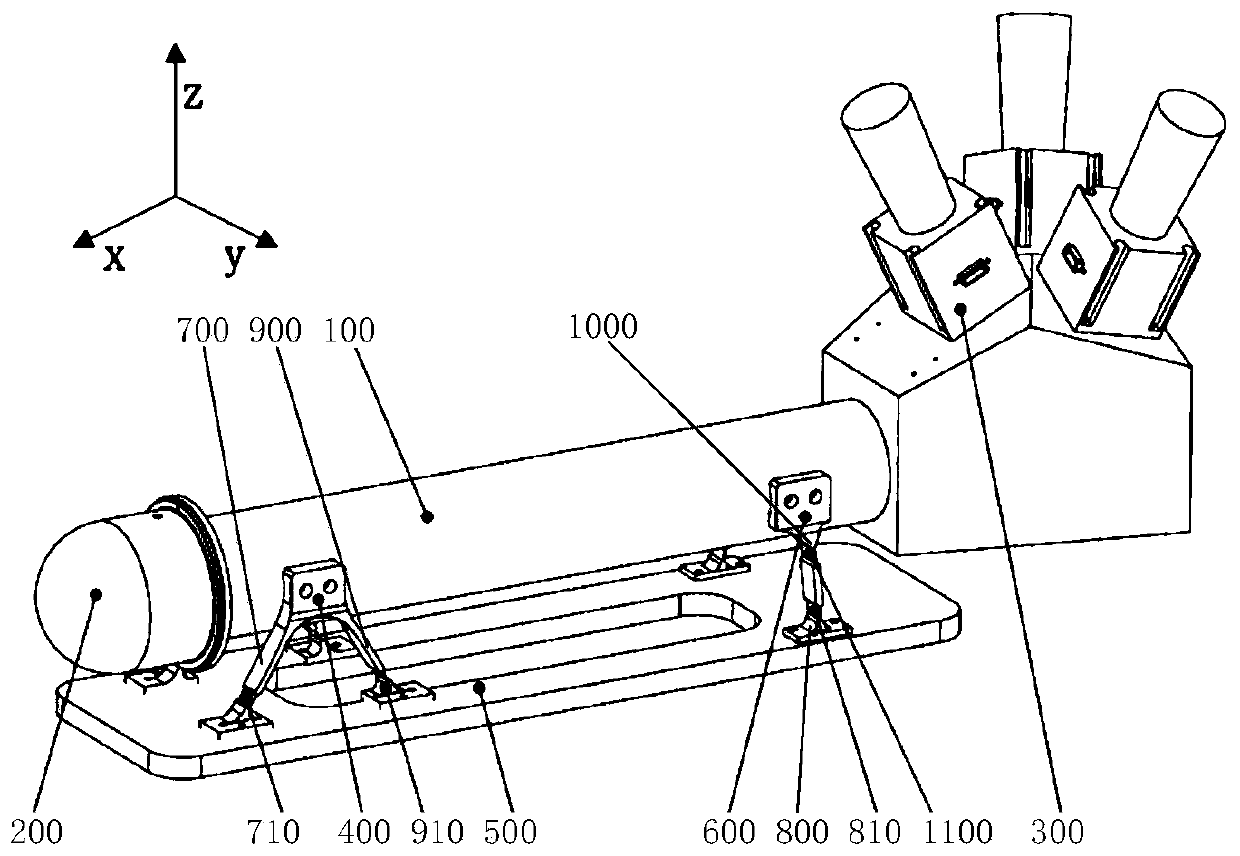

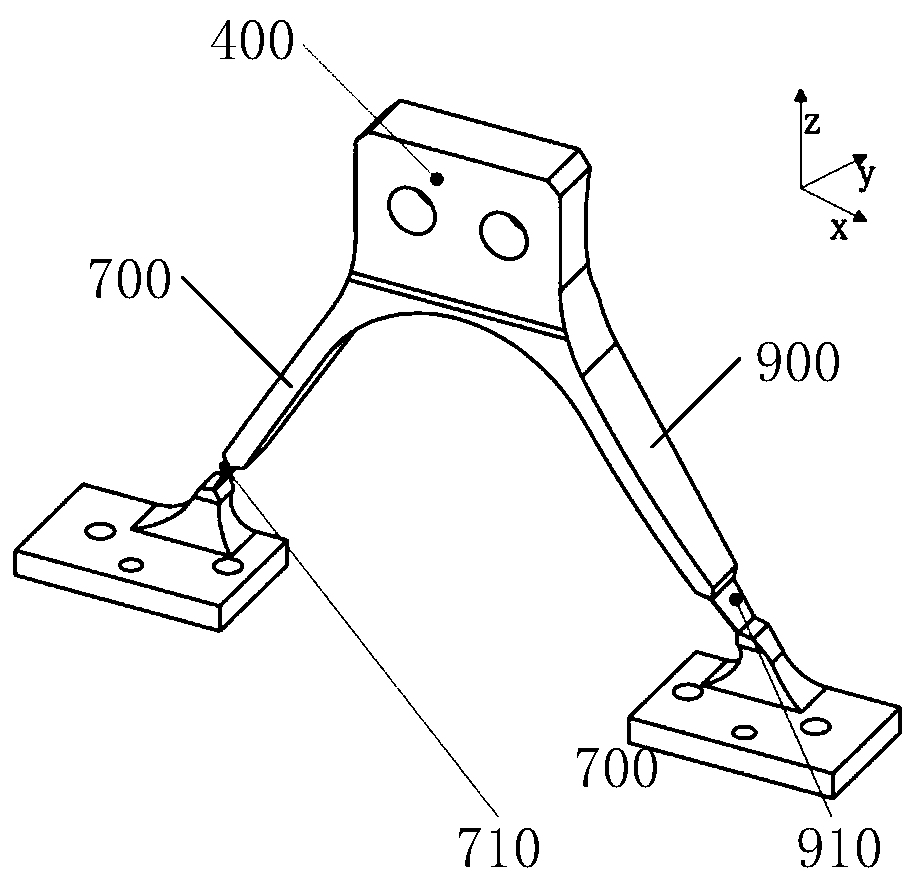

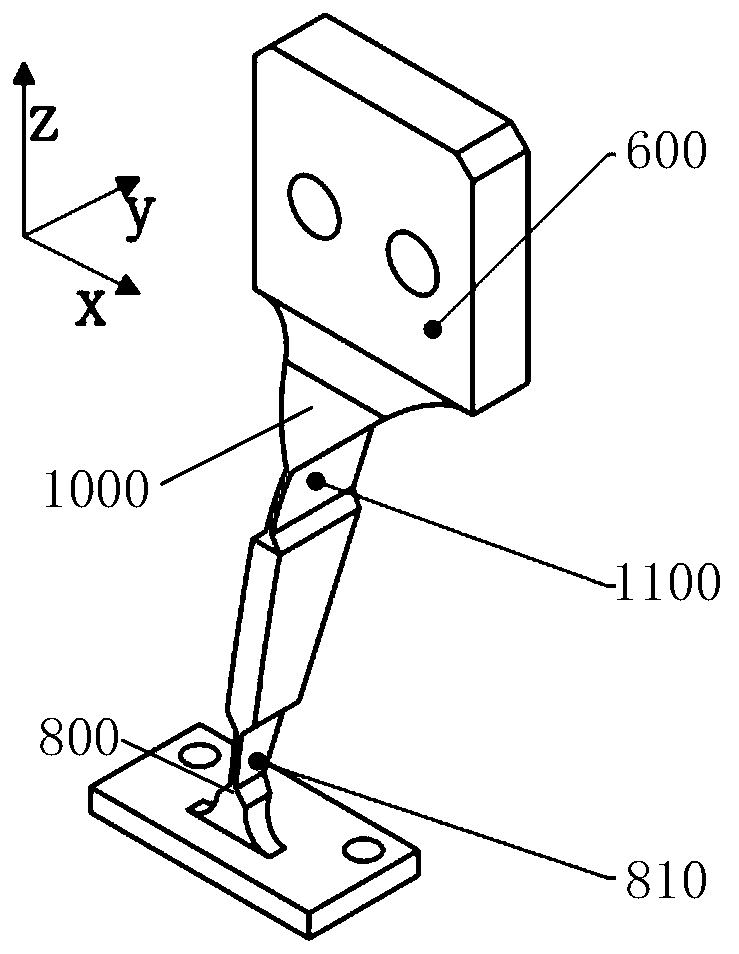

Integrated platform supporting hinge

ActiveCN110906116AStable platform configurationImprove support stiffnessStands/trestlesPhysicsSatellite

The invention provides an integrated platform supporting hinge, which comprises an integrated connecting rod, a magnetometer, an attitude measuring instrument, a Y-shaped supporting flexible hinge, asupporting platform and an I-shaped supporting flexible hinge. The magnetometer and the attitude measuring instrument are arranged at two ends of the integrated connecting rod respectively; and the integrated connecting rod is connected to the supporting platform in a supporting mode through the Y-shaped supporting flexible hinge and the I-shaped supporting flexible hinge. Through thermodynamic decoupling of the Y-shaped supporting flexible hinge and the I-shaped supporting flexible hinge in two dimensions and high rigidity in the vertical direction, no-thermal stress support of the Y-shaped supporting flexible hinge and the I-shaped supporting flexible hinge and constancy of the positions of key components of the magnetometer are realized, thereby facilitating scientific tests and applications in satellite fields such as space magnetic field and gravitational field detection. The integrated platform supporting hinge has the advantages of no thermal stress support, constant key component pose, stable platform configuration, high support rigidity, reliable performance and simple structure and the like.

Owner:SHANGHAI SATELLITE ENG INST

Hydraulic pressure tube expanding device

PendingCN107570614AImprove stabilityAvoid restrictionsHeat exchange apparatusEngineeringScrew thread

The invention relates to cooling part machining equipment, in particular to a hydraulic pressure tube expanding device. According to the hydraulic pressure tube expanding device, a water swelling gunhead is driven by an air cylinder to be inserted into a drain tube end port, the high impermeability can be ensured, meanwhile, the stability of tube expanding is increased, and the phenomenon of falling off is avoided. Through direct compressing connection of the water swelling gun head and the drain tube end, repeated connection and disassembly can be carried out. Meanwhile, according to the hydraulic pressure tube expanding device, restriction on a drain tube is reduced, tube expanding can be conducted on the multiple models of drain tubes, and the range of application of the device is enlarged. Through hydraulic pressure tube expanding, heat produced from tube expanding can be taken away while tube expanding is conducted. The tube wall temperature does not rise basically after tube expanding, and thermal stress can not be generated. Tube expanding is conducted by means of a water expanding mode, and the attaching rate of a fin and the drain tube is greatly improved. Inner screw threads on the inside wall of the drain tube are not destroyed, the tube expanding precision is improved, and the product quality and performance are ensured.

Owner:常州恒创热管理有限公司

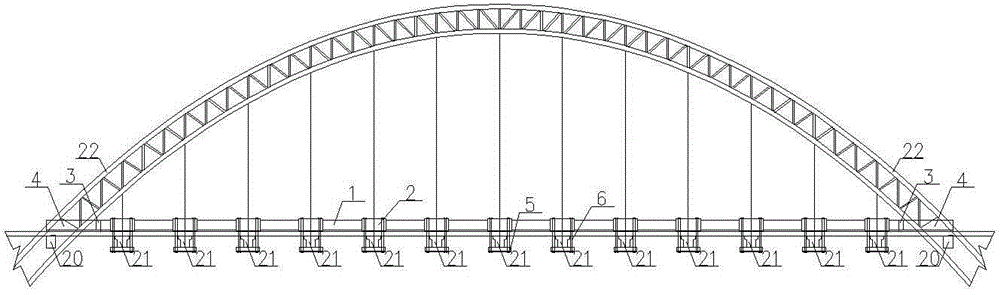

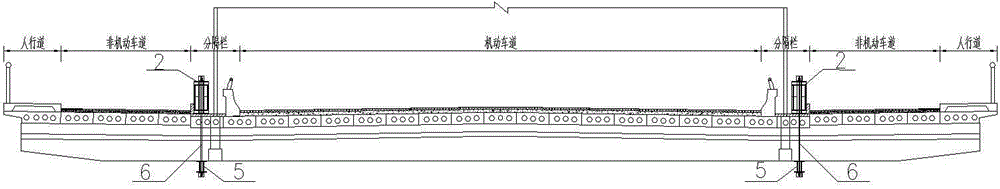

Safe early warning beam structure for longitudinal-beam-free middle bearing type arch bridge and early warning method of structure

ActiveCN104358208AReduce section sizeLow costBridge structural detailsArch-type bridgeStructural engineeringMechanical engineering

The invention relates to a safe early warning beam structure for a longitudinal-beam-free middle bearing type arch bridge and an early warning method of the structure. A structure of the longitudinal-beam-free middle bearing type arch bridge does not adopt a longitudinal main beam, and when a hanging rod of the arch bridge fractures, beam falling accidents can be caused. The safe early warning beam structure comprises a continuous longitudinal beam consisting of a middle spanning connecting beam, a middle spanning support beam, a side spanning connecting beam and a side spanning support beam, wherein the continuous longitudinal beam extends to a cross beam between ribs, the middle spanning support beam forms a bag hanger on the hanging rod cross beam through the cross beam support beam and the connecting hanging rod, the top surface of the middle spanning connecting beam is provided with a longitudinal semitransparent communicating pipe, the inside of the middle spanning connecting beam is filled with low-volatility lubricating oil, the liquid level height differences of lubricating oil at the two ends of the communicating pipe are observed by the semitransparent communicating pipe, and the monitoring on the deformation of the middle spanning connecting beam is realized. The structure and the method have the advantages that the longitudinal beam basically bears no load in the operation stage, when small probability events such as hanging rod fracture occur, the longitudinal beam starts to take effects, the occurrence of the beam falling accidents is prevented, through the adopted communicating pipe, the deformation condition of the longitudinal beam can be observed, and the feasibility of monitoring the hanging rod safety on the basis of longitudinal beam deformation is improved.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

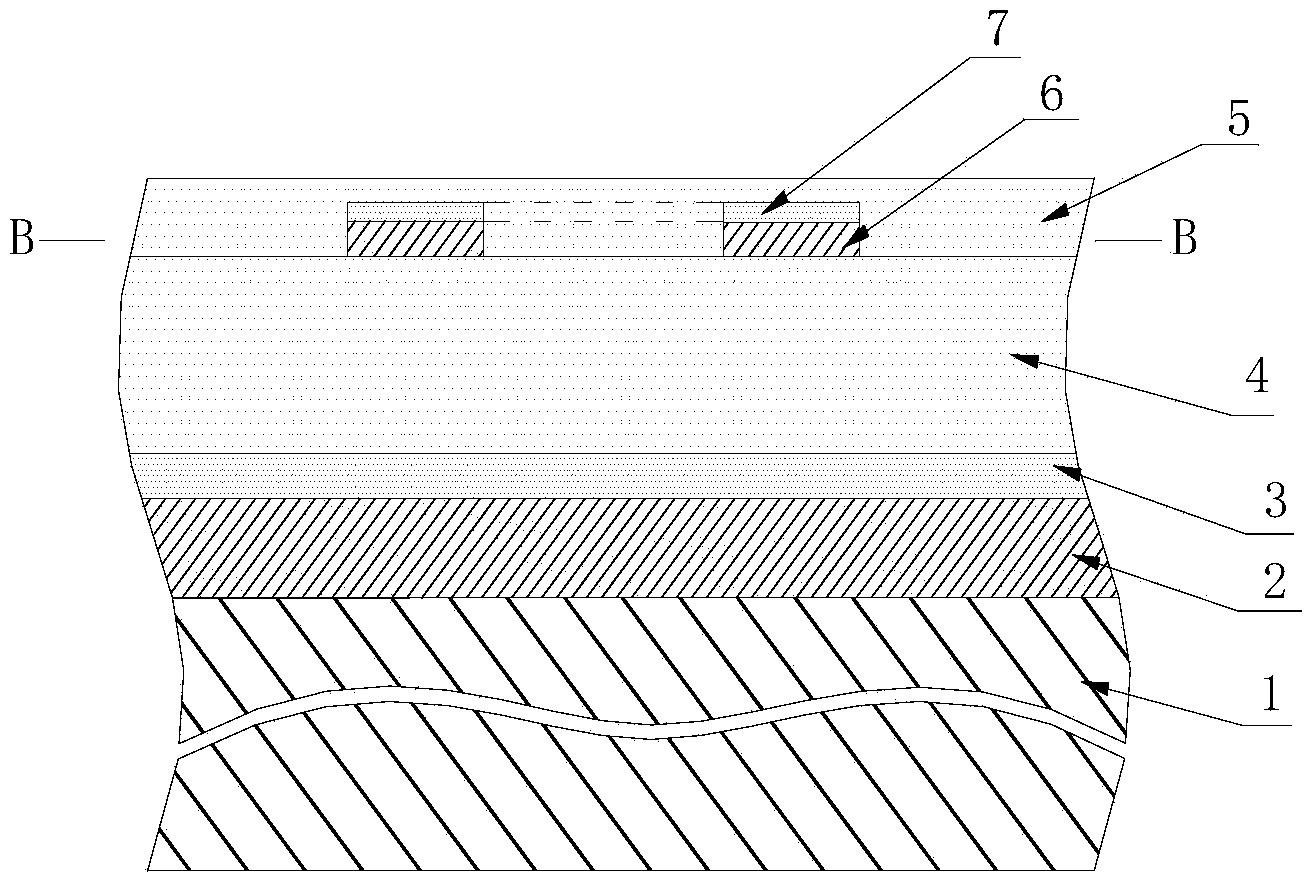

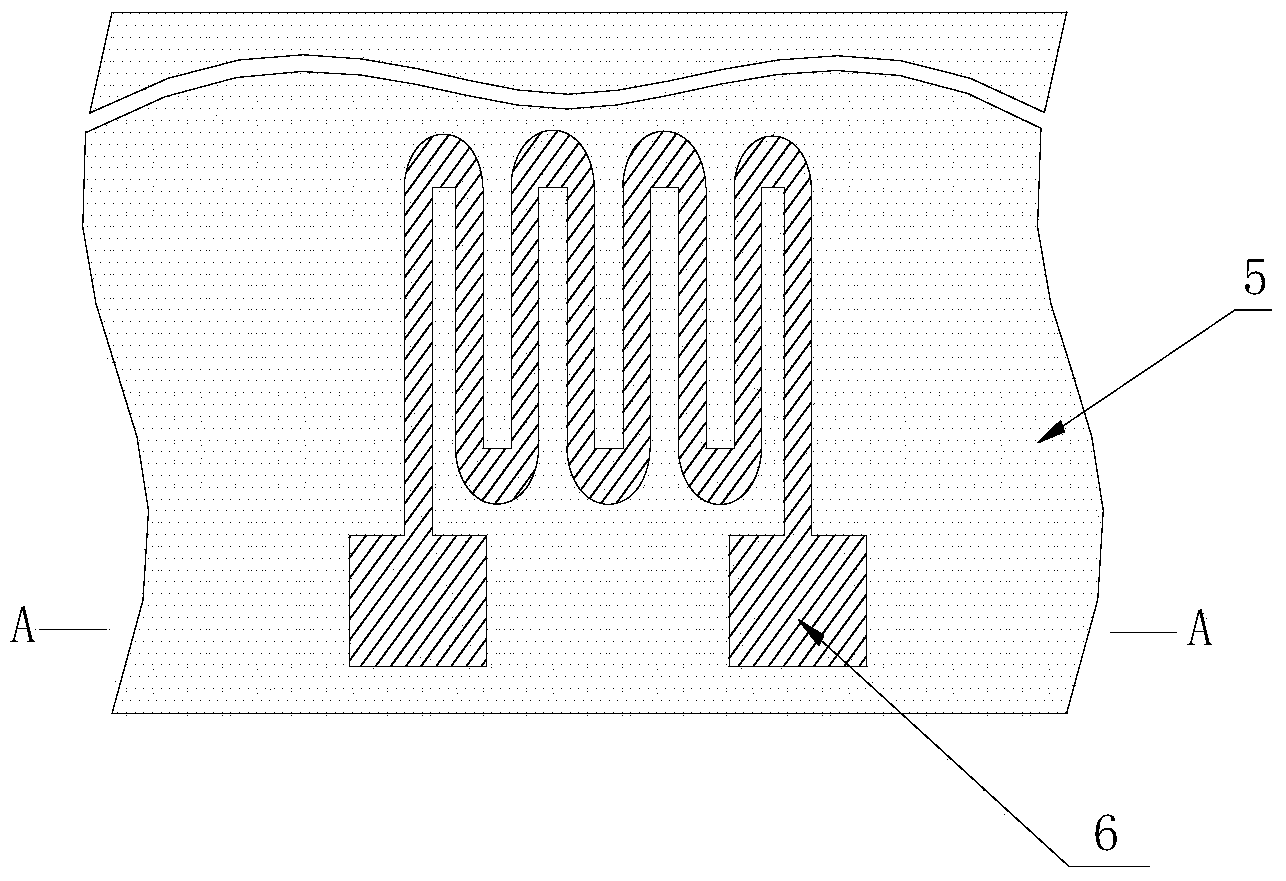

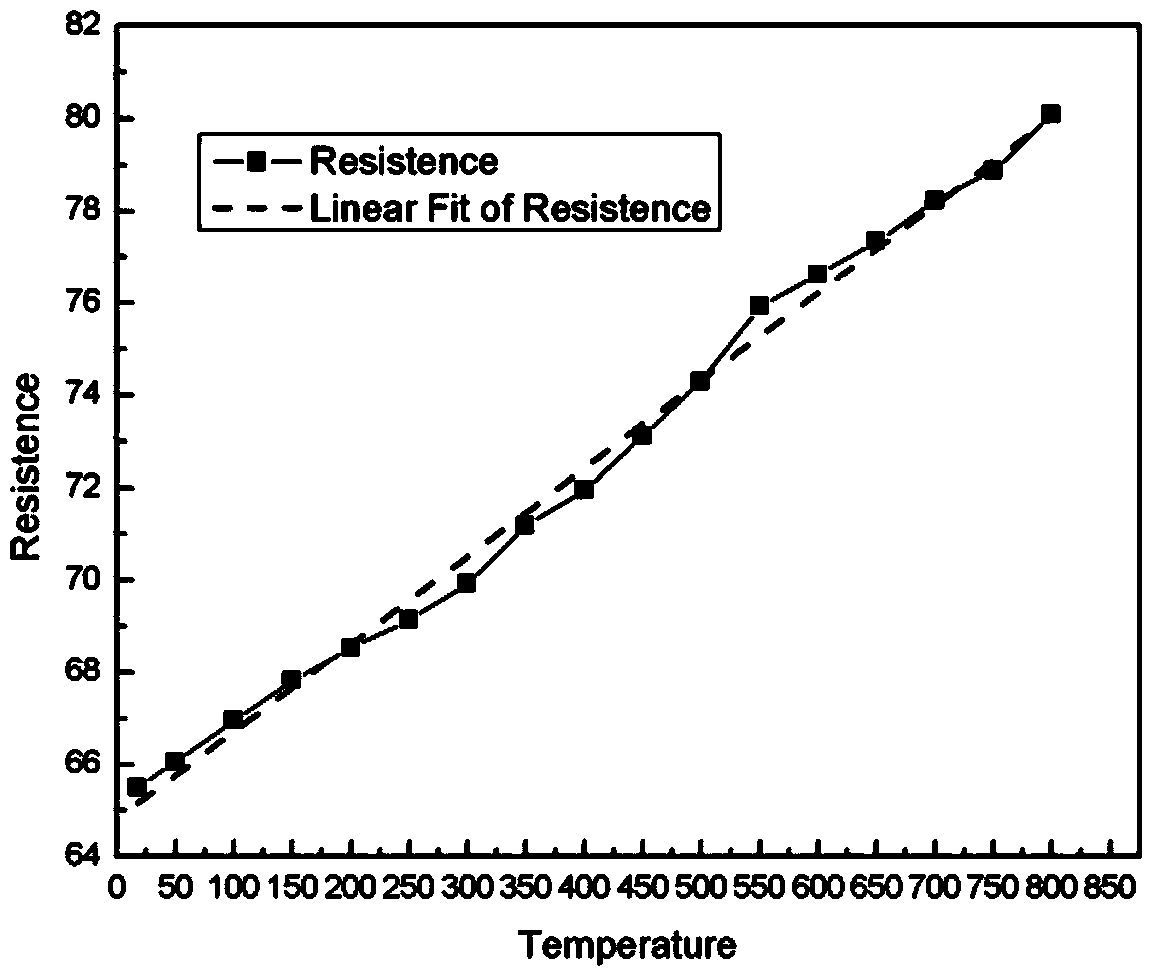

Thin film strainometer and preparation method thereof

InactiveCN103921500AImprove antioxidant capacityImprove stabilityElectrical/magnetic solid deformation measurementCeramic layered productsWorking environmentAlloy substrate

The invention provides a thin film strainometer and a preparation method thereof. The preparation method comprises the following steps: carrying out surface treatment on an alloy substrate; depositing a NiCrAlY transit layer on the alloy substrate; preparing an Al2O3 coupling layer; arranging an Al2O3 ceramic insulating layer; arranging a thin film strainometer function layer, arranging a thermal oxidation Al2O3 protective layer and finally arrange an Al2O3 ceramic protective layer. According to the thin film strainometer and the preparation method thereof, NiCrAlY alloy is adopted as a function layer, and the Al2O3 protective layer formed on the surface of the NiCrAlY alloy through aluminum separation and oxidation is more dense and stable, so that good protection of the thin film strainometer function layer is achieved; the function layer and the transit layer both adopts the same NiCrAlY alloy material and treatment technique, have the same thermal expansion coefficient and are not likely to fall off under high temperature work environment; the temperature strain does not occur, and the service life of the thin film strainometer is prolonged.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

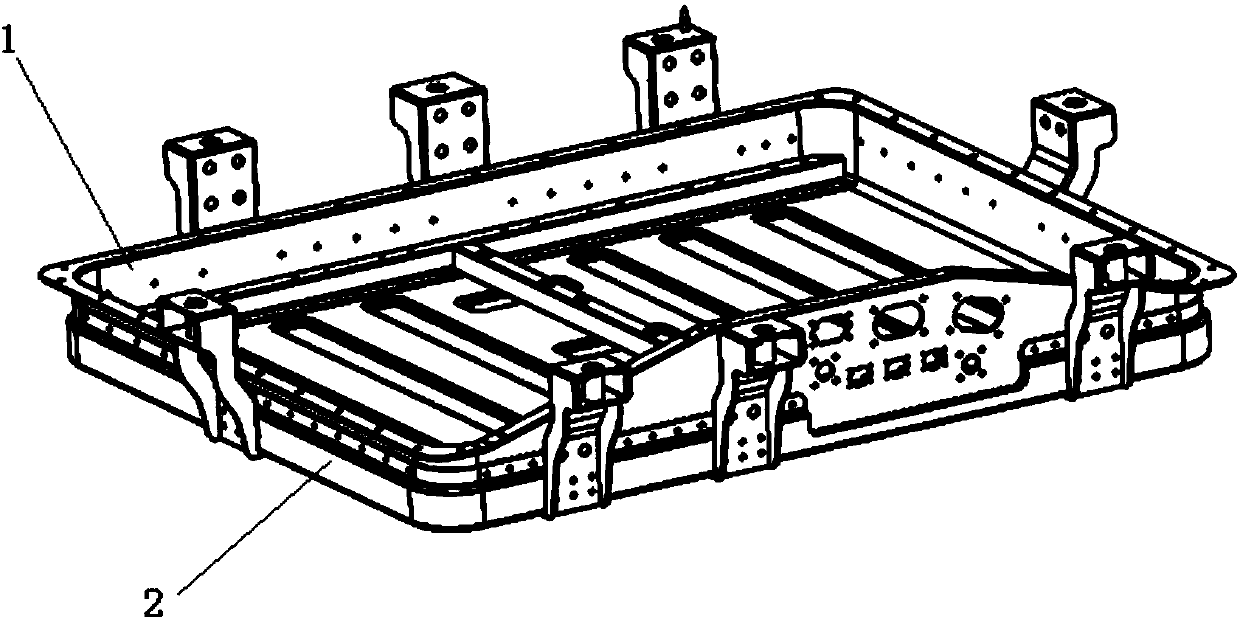

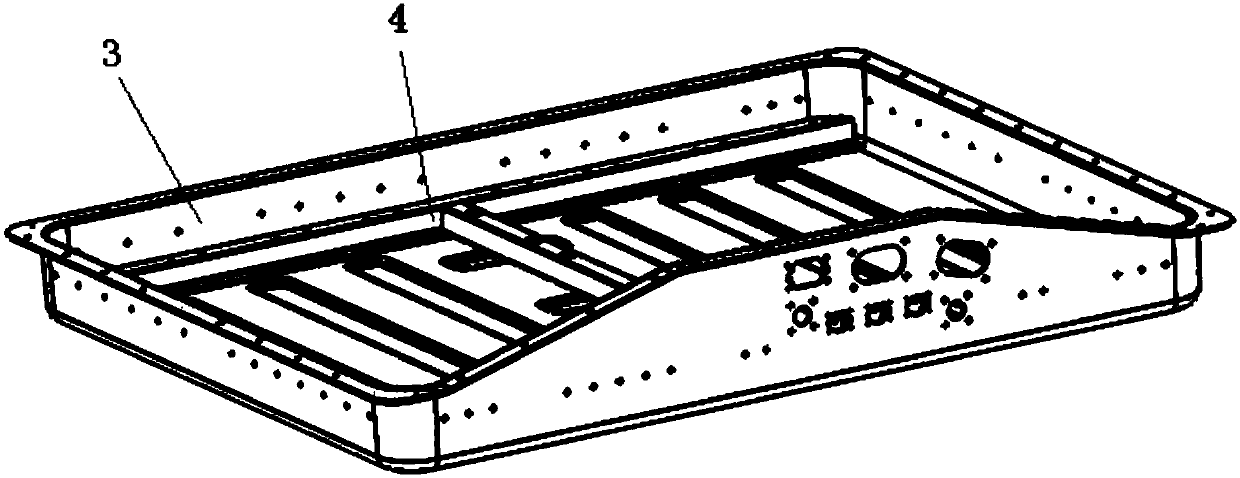

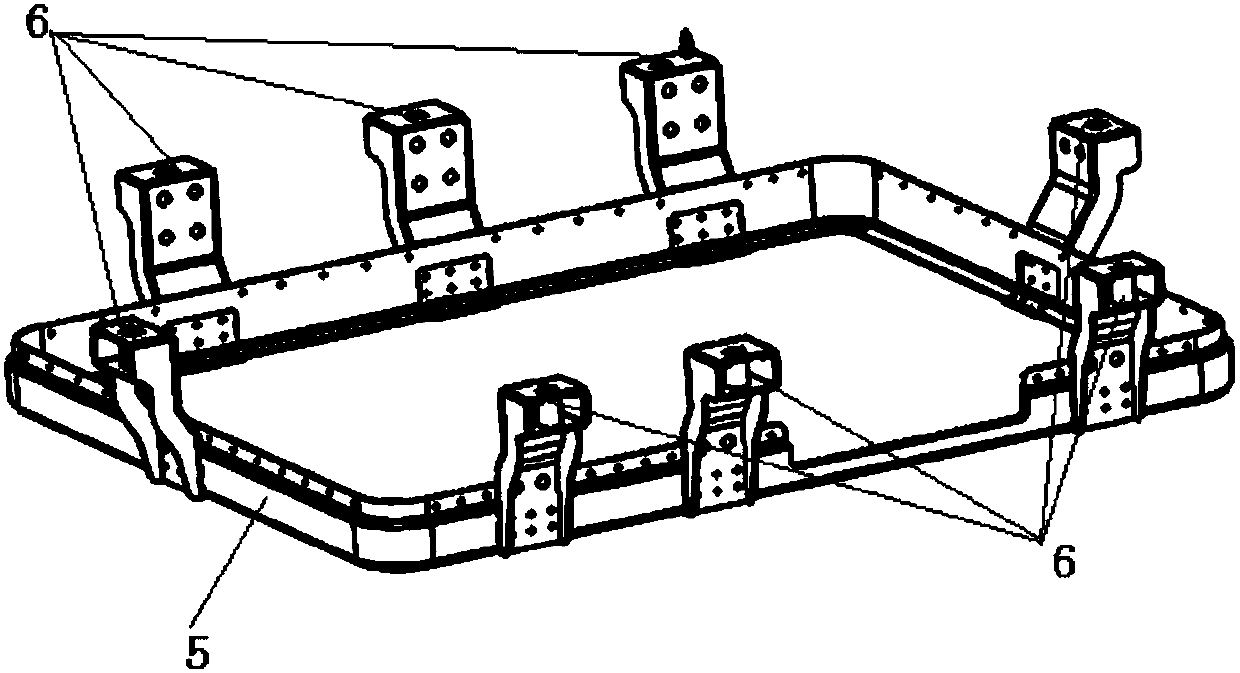

Lightweight power battery box capable of steel and aluminum riveting

ActiveCN107946509ARealize mass productionShort production processBattery isolationPower batteryElectrical battery

The invention discloses a lightweight power battery box capable of steel and aluminum riveting. The lightweight power battery box comprises an inner container assembly and a bracket assembly, whereinthe inner container assembly is fixedly connected with the bracket assembly in lock riveting and adhesive bonding manners; the inner container assembly comprises a protective shell and an H-shaped installation cross beam, and the installation cross beam is connected to the interior of the protective shell by additionally installing a thread lock through a riveting technology; the bracket assemblycomprises a bottom shell hemming, and a plurality of lifting lugs bent by a metal plate or formed by stamping are arranged on the outer side face of the bottom shell hemming at intervals. The productcan realize batch production, the riveting assembling materials can be produced in parallel, the production process is short, and the efficiency is high. Most components of the product are made of aluminum alloy, and the final product can realize light weight. The lock riveting process is controllable in quality, the protective shell is free of damage, and the water prevention and dust preventionperformances are excellent. The assembling process is free of heat input, and the product is basically free of deformation. The aluminum alloy has excellent corrosion resistance, and does not need extra surface treatment, so that the environment is protected, and the aluminum alloy is also saved.

Owner:赵明星

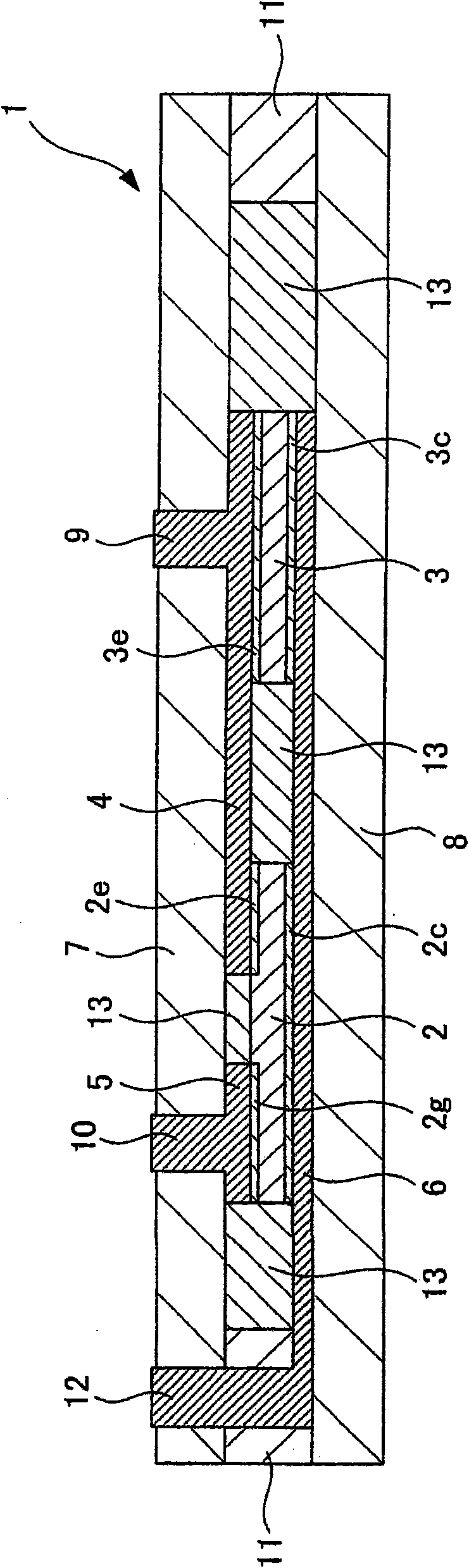

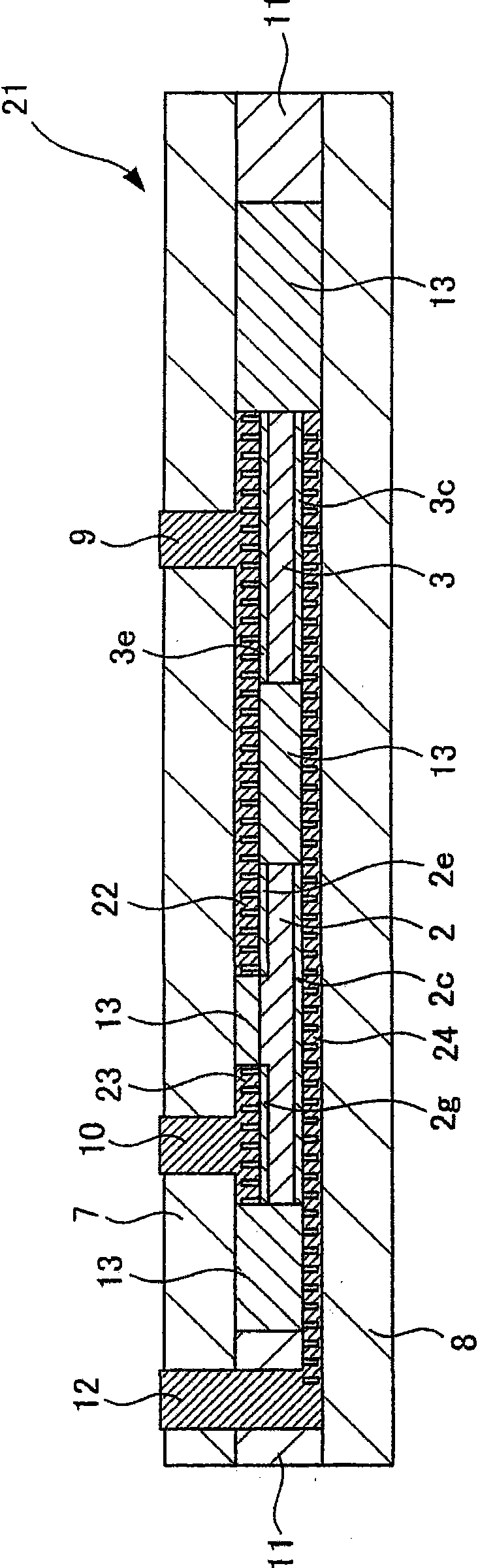

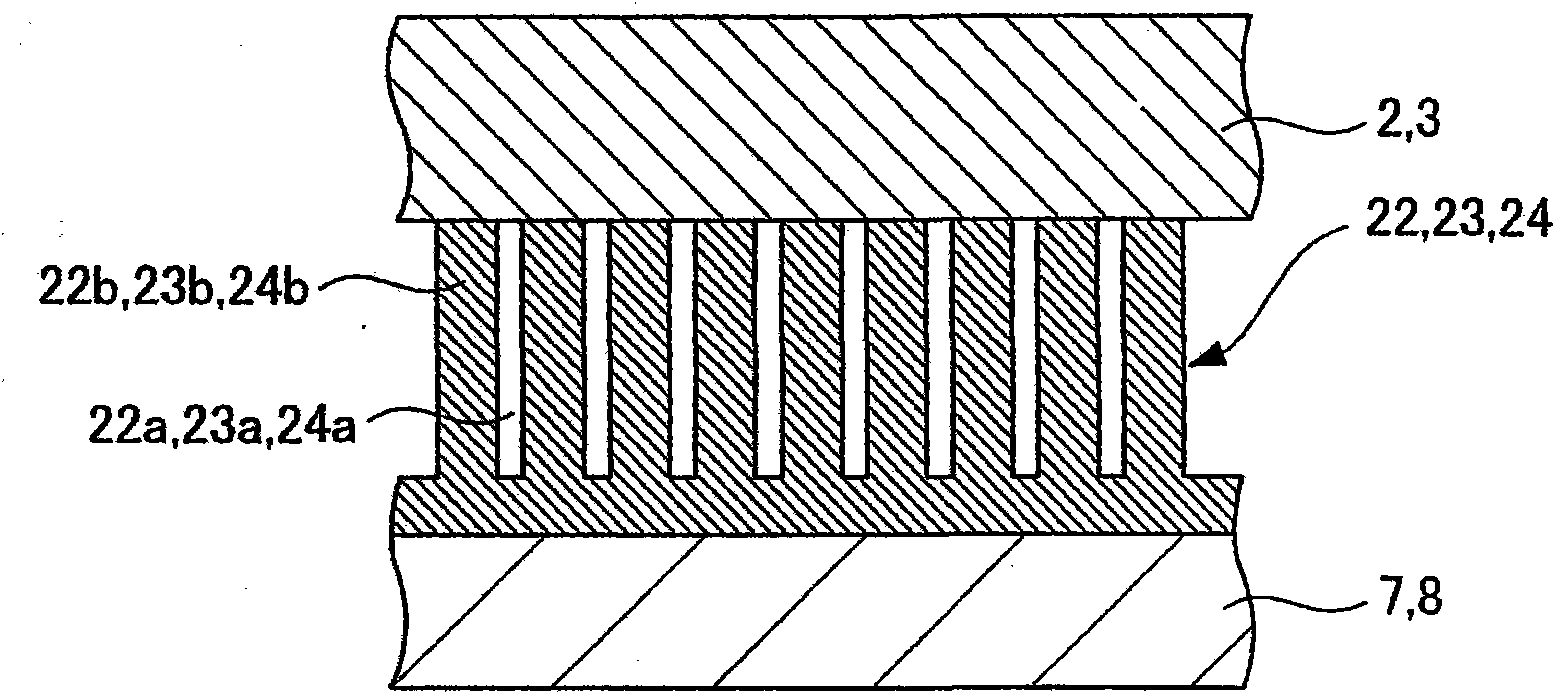

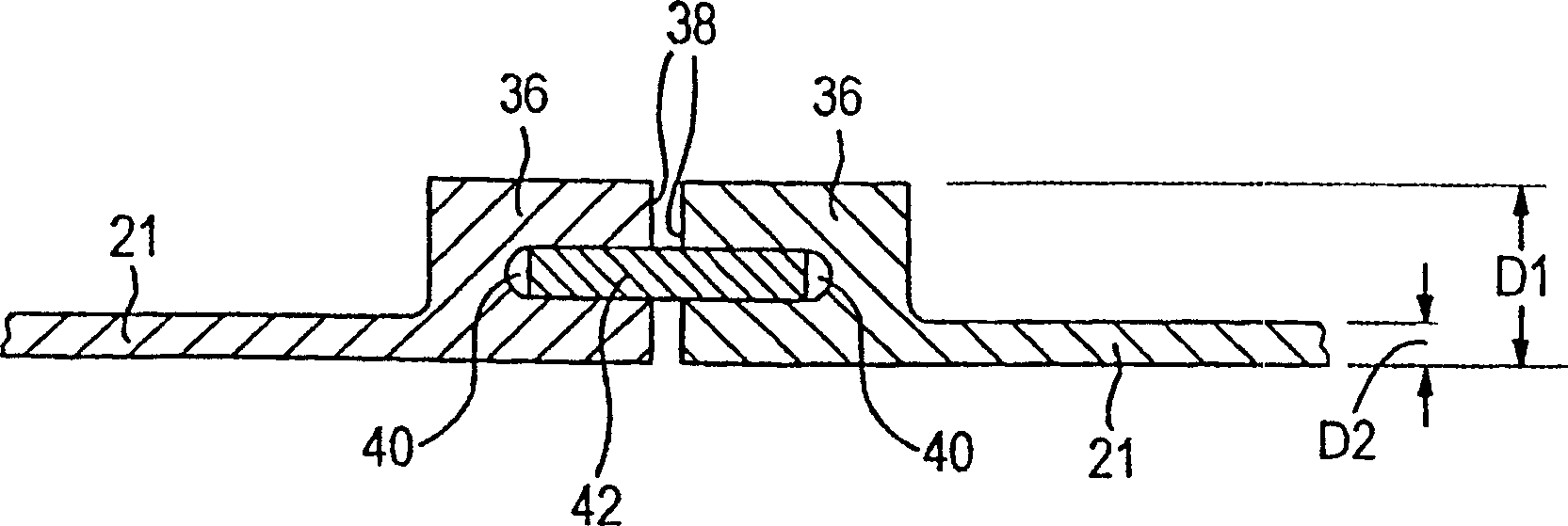

Semiconductor element module and method for manufacturing the same

InactiveCN101946318AImprove cooling effectIncreased durabilitySemiconductor/solid-state device detailsSolid-state devicesMetallurgySurface binding

Provided are a semiconductor element module which is excellent in terms of thermal connection and electric connection, the cooling performance of which can be fully secured, and which is highly reliable, and a method for manufacturing the same. The semiconductor element module comprises an IGBT (2) and a diode (3) on both surfaces of which an electrode is formed, a ceramic substrate (7) on the surface of which wiring circuit layers (4, 5) which are bonded to one surface of the IGBT (2) and the diode (3) are formed and the thermal conductivity of which is high, a ceramic substrate (8) on the surface of which a wiring circuit layer (6) which is bonded to the other surfaces of the IGBT (2) and the diode (3) is formed and the thermal conductivity of which is high, and a sealing member (11) which is sandwiched between the outer edges of the ceramic substrates (7, 8) and with which the inside is sealed. These members are bonded by an ordinary temperature bonding method.

Owner:MITSUBISHI HEAVY IND LTD

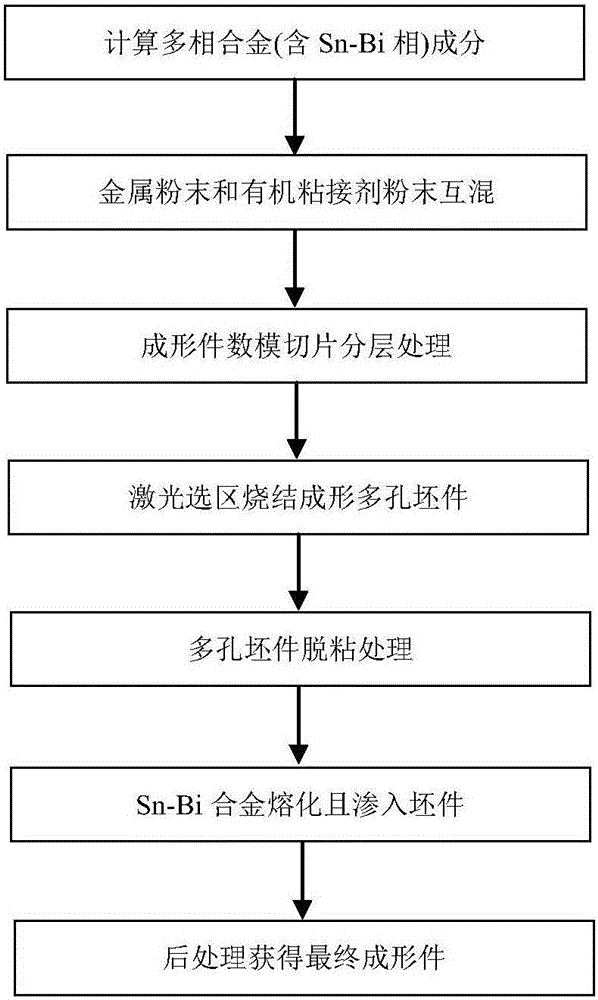

Selective laser sintering method for preparing zero-expansion/shrinkage-rate metal parts

ActiveCN106001572ANo internal stressNo thermal stressAdditive manufacturing apparatusTransportation and packagingSmooth surfaceAfter treatment

The invention relates to a selective laser sintering method for preparing zero-expansion / shrinkage-rate metal parts. The method comprises calculation of multi-phase alloy components, mixing of metal powder and organic adhesive powder, digital-analog slice layering treatment of formed parts, molding of porous blanks through selective laser sintering, debonding treatment of the porous blanks, melting of Sn-Bi alloys and infiltration in the blanks, and obtaining of final formed parts through after-treatment. After two structures with zero expansion rate and zero shrinkage rate are mixed, the metal parts with zero expansion rate and zero shrinkage rate can be obtained by an added material manufacturing forming technology and a diffusion metalizing method. The preparation method has advantages such as convenient operation, reliable performance, low comprehensive cost, light weight of the metal formed parts, smooth surface and capability of satisfying the use requirements and prolonging the service life, and can be widely popularized and applied.

Owner:四川三阳激光增材制造技术有限公司

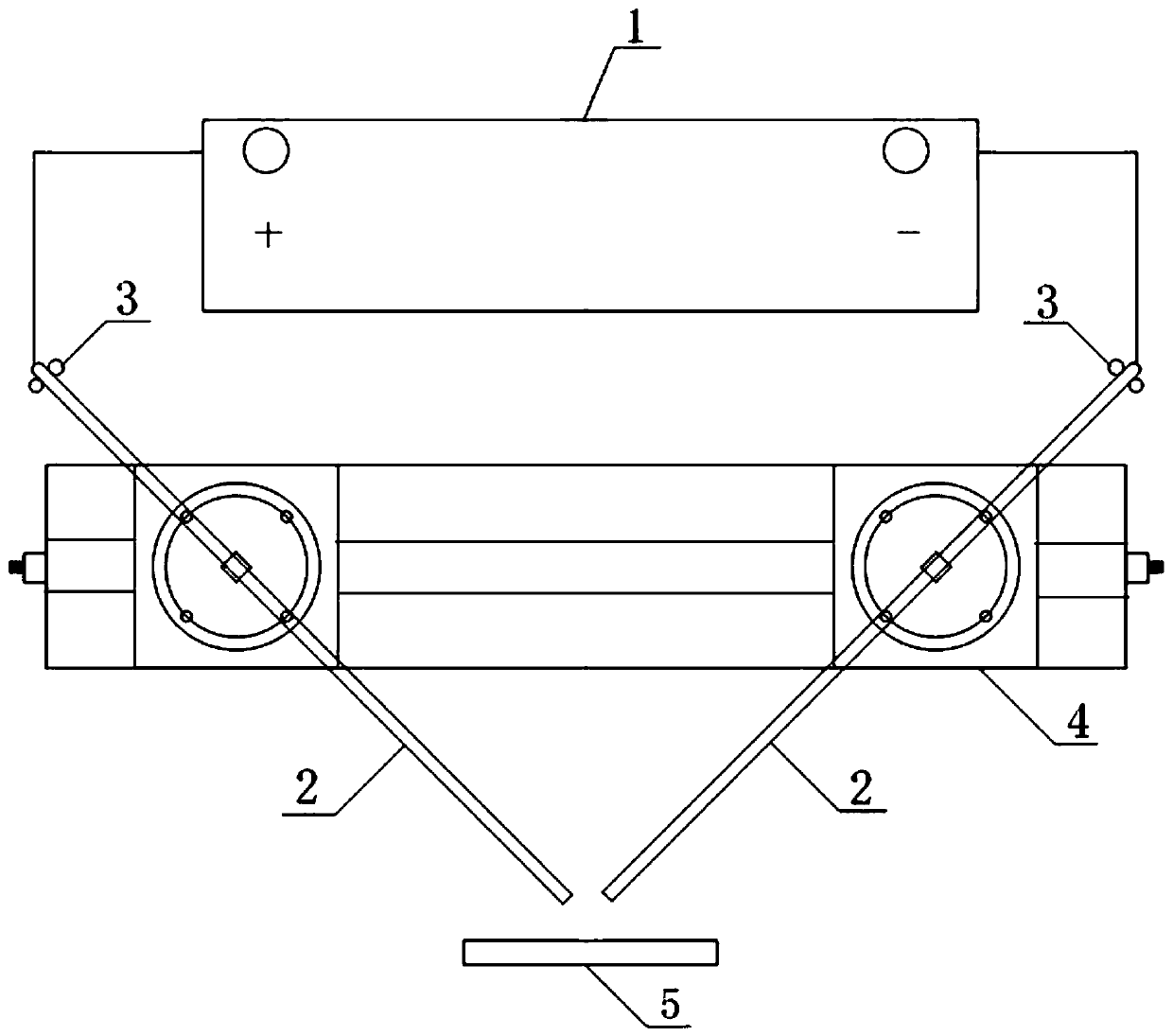

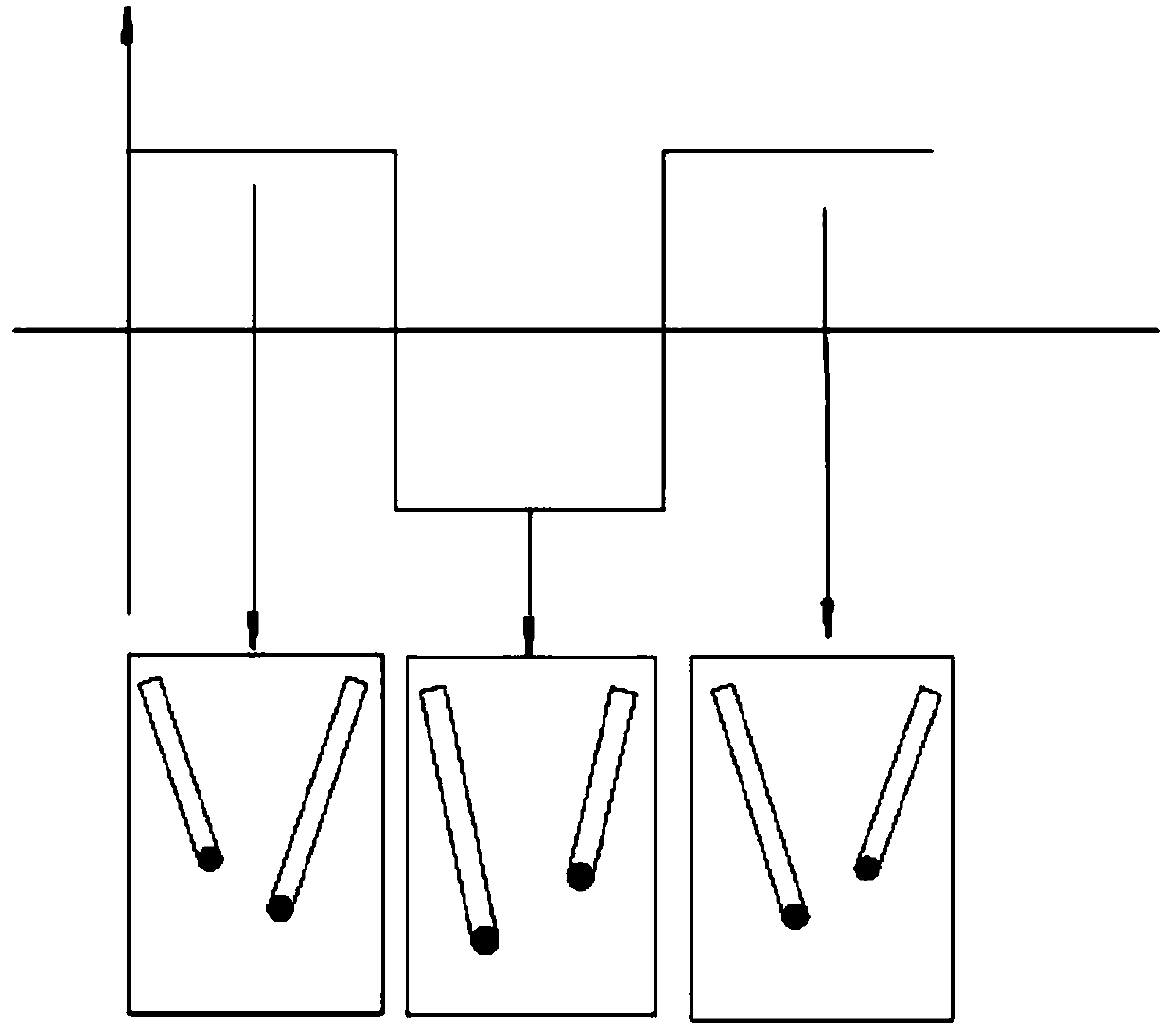

High-entropy alloy additive manufacturing device and additive manufacturing method

PendingCN110091035ASimple structureEasy to useElectrode supporting devicesWelding/cutting media/materialsHigh entropy alloysAlternating current

The invention relates to the technical field of high-entropy alloy additive manufacturing, and particularly discloses a high-entropy alloy additive manufacturing device and additive manufacturing method. The high-entropy alloy additive manufacturing device comprises a welding wire clamp used for fixing two welding wires, an alternating-current power source and two wire feeders. The two welding wires are located on the same plane, axes of the two welding wires are crossed, the alternating-current power source is provided with two output ends, the two output ends are connected with a conductivenozzle of one welding wire, the two wire feeders are connected with one welding wire, are located on the ends, close to the conductive nozzle, of the welding wires, and are used for enabling the welding wires to be axially fed, the traditional high-entropy alloy additive manufacturing mode is changed, the high-entropy alloy of the complex structure can be manufactured, in the preparing process, the alternating-current double-wire indirect electric arc welding is used, heat transfer and medium transfer decoupling control is achieved, heat input is controlled within a certain range while the deposition rate is improved, and the device is more efficient and energy-saving.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

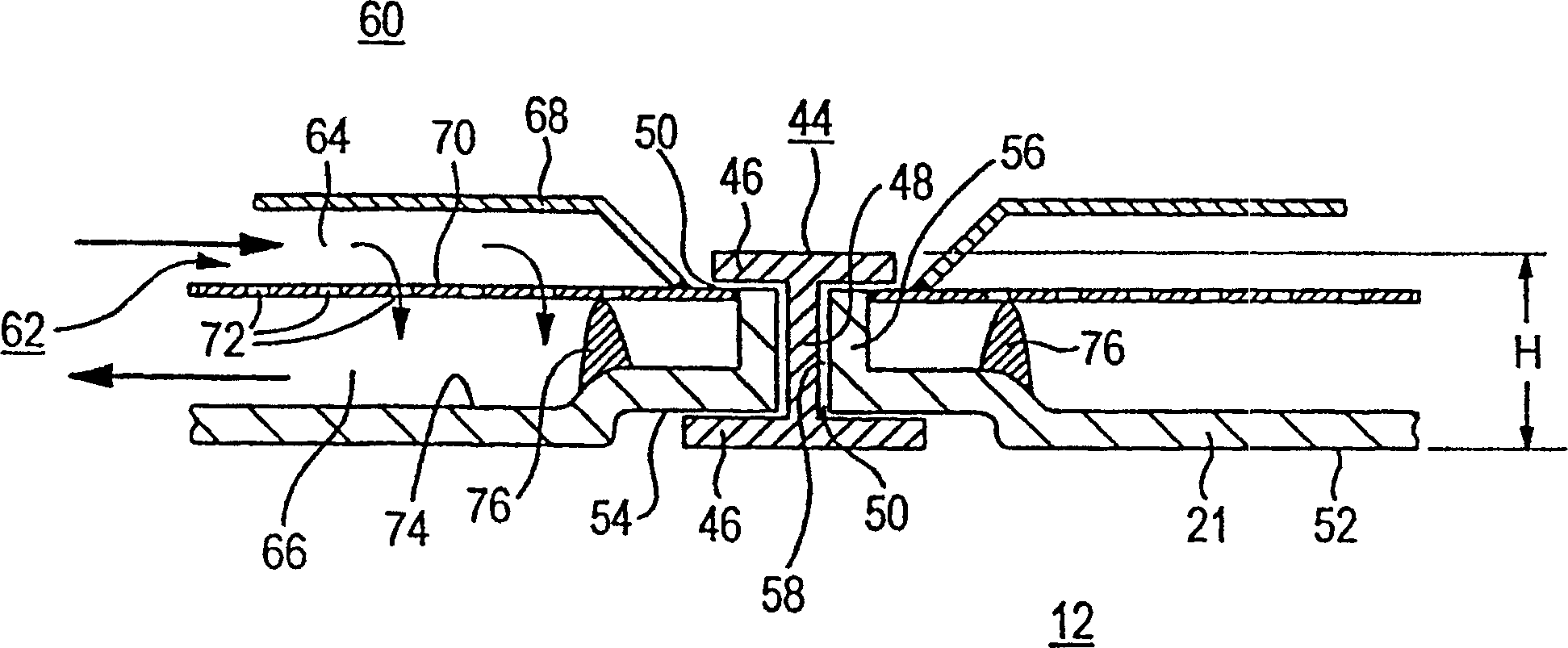

Turbine

InactiveCN1408049AHas a high cooling effectCool evenlyBlade accessoriesLeakage preventionEntire footEngineering

The invention relates to a turbine (6), especially a gas turbine. According to the invention, a sealing element (44) with a receiving area (50) is provided for sealing the guide blades (18) which are adjacent to each other in the peripheral direction (36) of the turbine (6). The foot plates (21) of the guide blades (18) extend into said receiving area. The edge area of the foot plates (21) does not have to be reinforced compared to a conventional seal, which enables the entire foot plate to be cooled homogeneously. A closed cooling system (62) can therefore be used for cooling, especially with steam.

Owner:SIEMENS AG

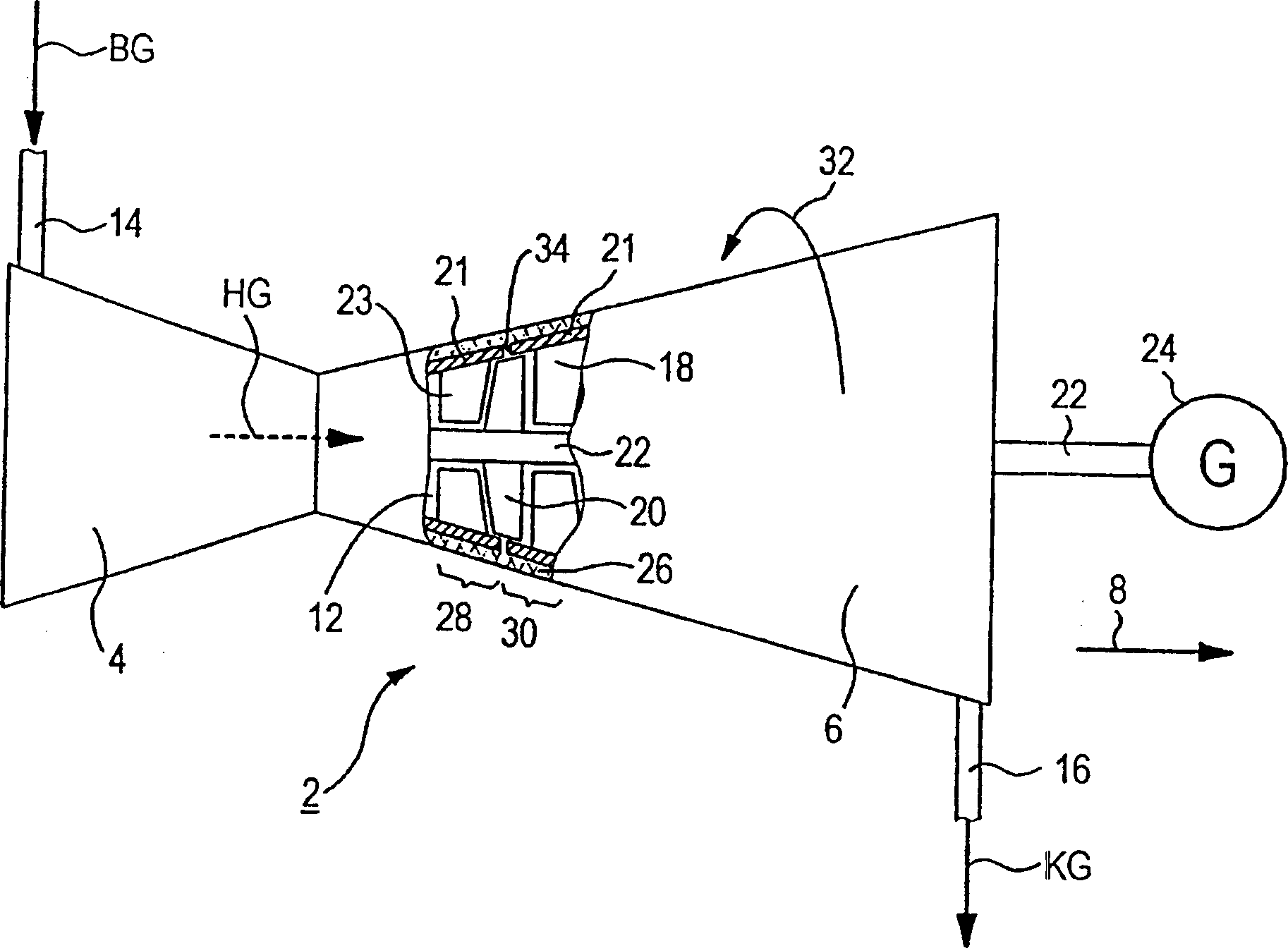

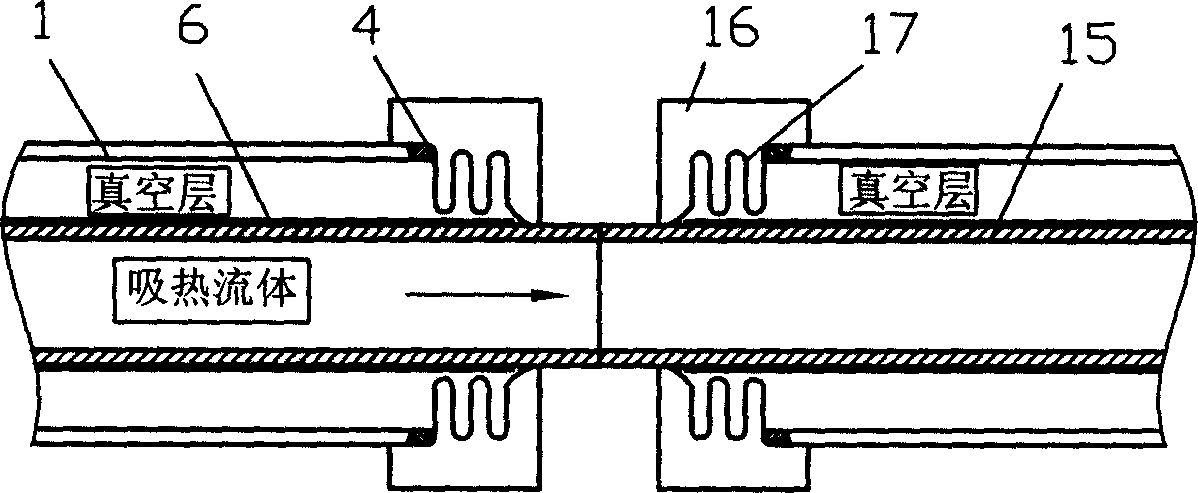

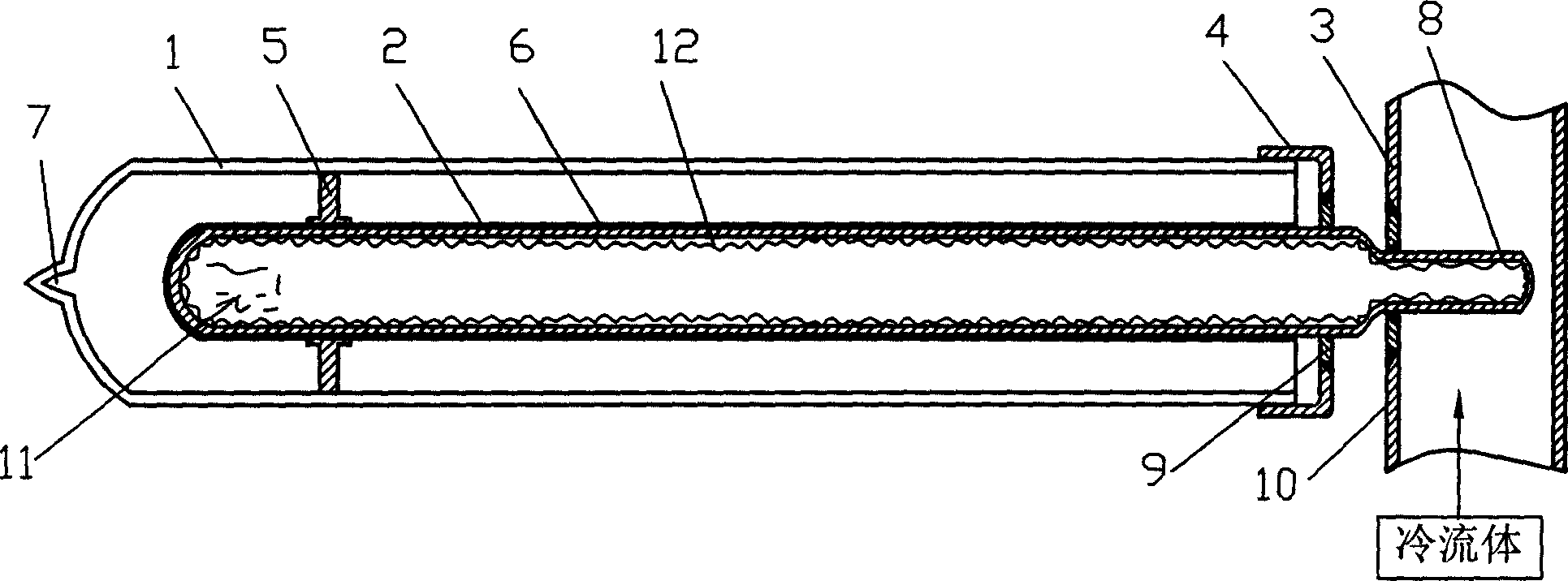

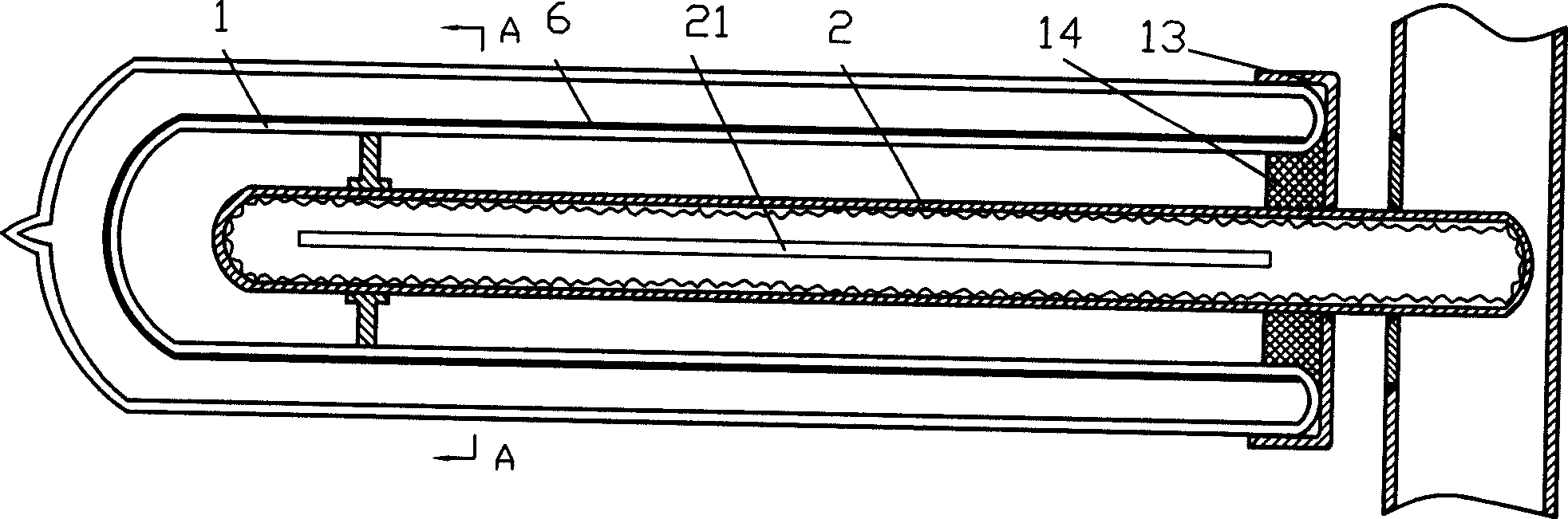

Heat pipe receiver in intermediate temperature in use for generating electricity from solar heat

InactiveCN1916525AGood attractionImprove heat transfer performanceSolar heating energySolar heat devicesElectricityEngineering

A medium temperature heat tube receiver used on heat power generation unit of solar energy is featured as inserting medium temperature heat tube in glass jacket tube, setting condensation section on portion exposed from glass jacket tube by said heat tube, setting condensation section in channel of cooling fluid and connecting it with cooling fluid channel in seal connection mode, using seal element to make seal connection between opening end of glass jacket tube and said heat tube.

Owner:NANJING TECH UNIV

Method for joining nano-impregnated transient eutectic phase with SiC ceramic as well as ceramic prepared by method and application

ActiveCN109437910AAchieve connectionNo void defectOptical rangefindersNuclear energy generationMetallurgySolvent

The invention belongs to the technical field of ceramic joining and discloses a method for joining a nano-impregnated transient eutectic phase with SiC ceramic. The method comprises the following steps: taking mixed powder A of SiC powder and Al2O3-MxOy as a joining material, wherein MxOy is Ho2O3 or CeO2; adding a solvent and a ball milling medium into the mixed powder A for mixing and drying, then spreading powder obtained by granulating obtained mixed powder B between two pieces of polished SiC to form a sandwich structure; then carrying out isostatic cool pressing treatment, and pressurizing to 0.01 to 0.1MPa in a vacuum or atmosphere protection; raising the temperature to 600 to 1000 DEG C and insulating I; raising the temperature again to 1450 to 1600 DEG C and insulating II at the pressure of 200 to 500 MPa, and joining to obtain the nano-impregnated transient eutectic phase joined SiC ceramic. The method disclosed by the invention realizes low-temperature and low-pressure joining of the SiC ceramic, and the leak rate of the joining part reaches 0 to 1*10<-8> Pa.L / s.

Owner:GUANGDONG UNIV OF TECH

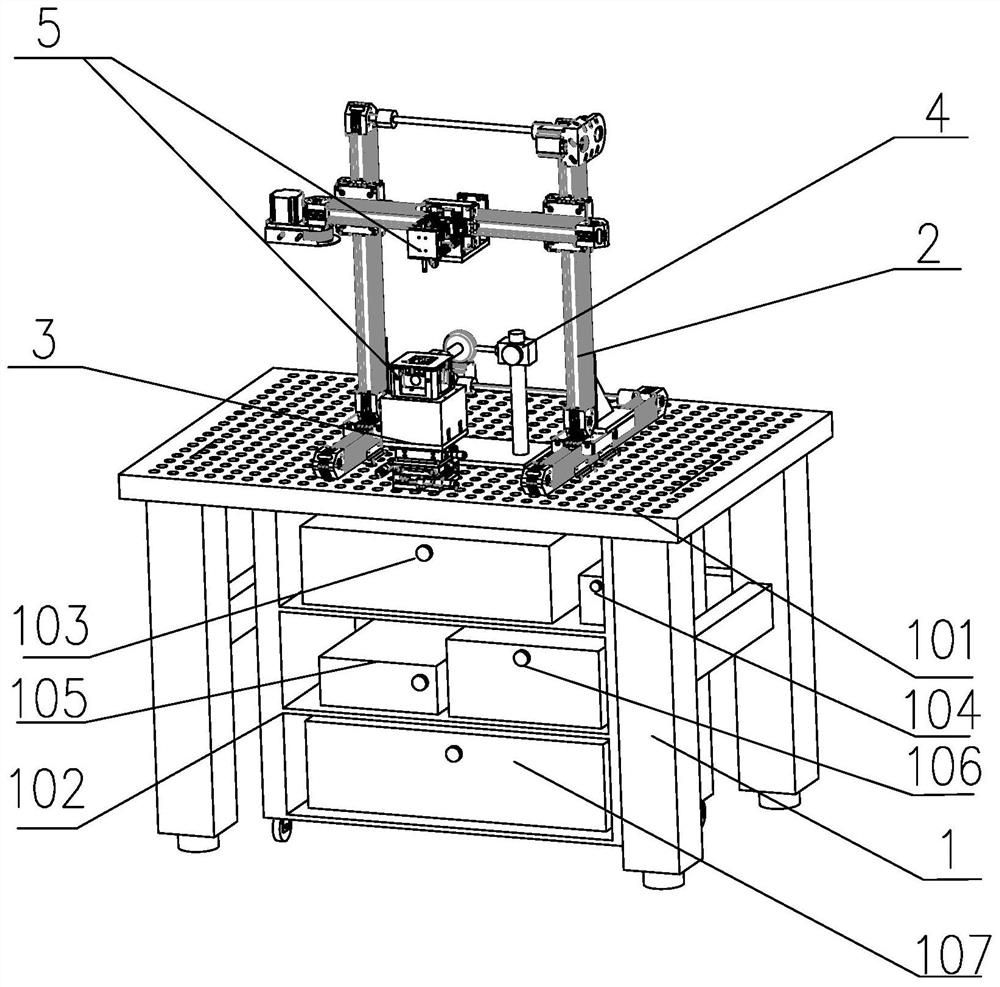

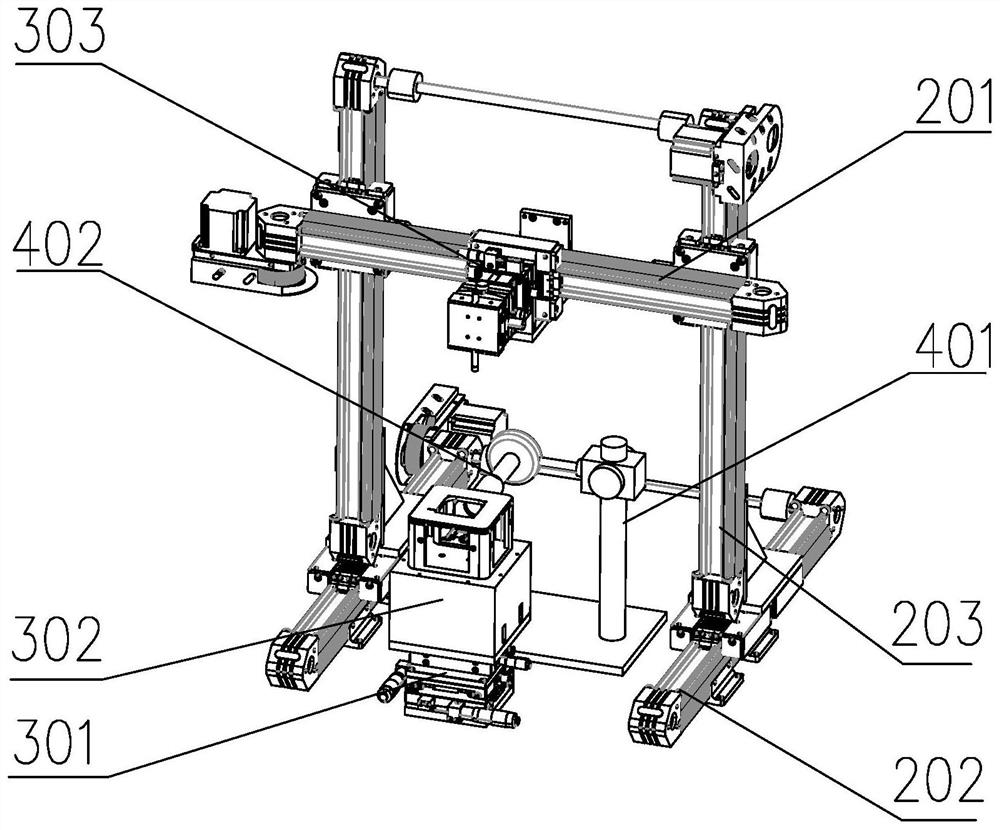

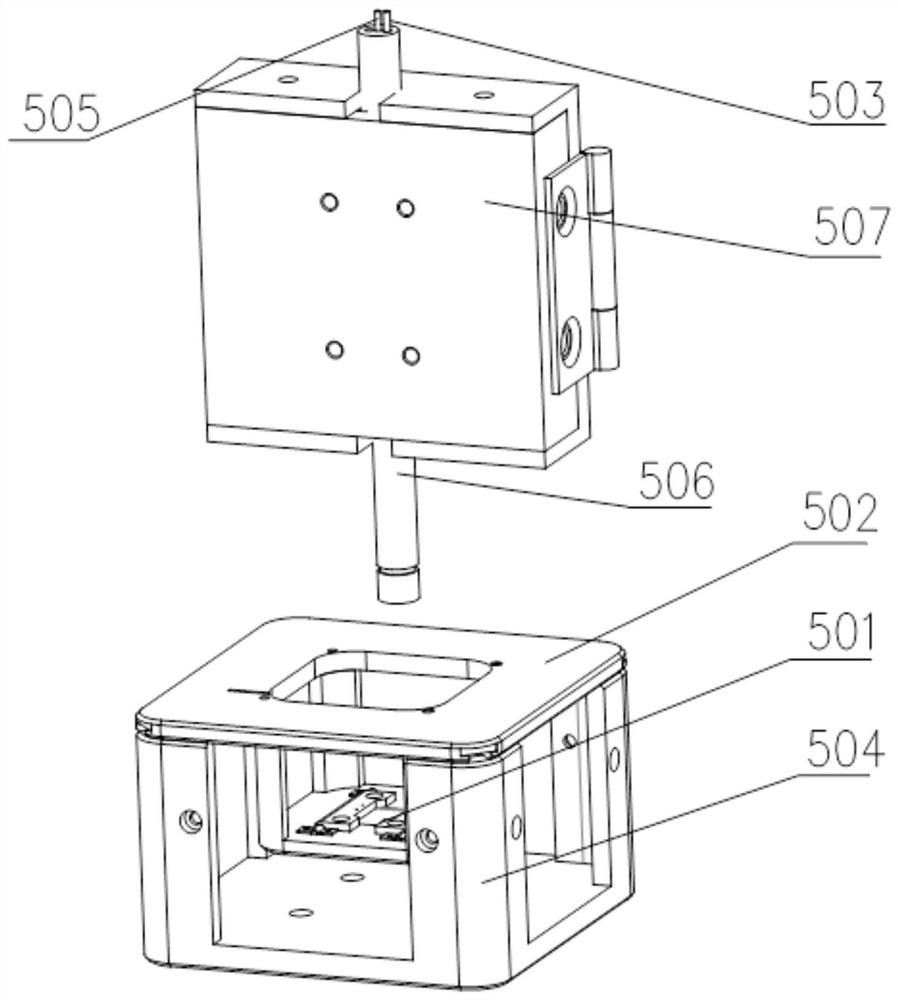

Additive manufacturing device and method based on meniscus constrained electrodeposition

PendingCN113355702AAchieve Z-direction extensionDeposition stabilityAdditive manufacturing apparatus3D structure electroformingPipetteEngineering

The invention discloses an additive manufacturing device and method based on meniscus constrained electrodeposition, and belongs to the technical field of additive manufacturing. The additive manufacturing device comprises a vibration isolation module, an additive manufacturing motion platform, a precision positioning module, a monitoring module and an electrode module. By utilizing a meniscus constrained electrodeposition technology, electrodeposition is carried out in a liquid meniscus between the tip of a transfer pipette and a conductive substrate, a liquid bridge extends in multiple directions under movement of a movable sliding table, the relative positions of the substrate and the transfer pipette are compensated through precise cooperation movement of a six-axis PI motion console and the movable sliding table, the stable liquid bridge is continuously kept between the substrate and the transfer pipette, and therefore a complex uniform deposition structure with high quality, high compactness and high surface smoothness is formed. Forward micro-additive manufacturing of the submicron glass transfer pipette is achieved in a real sense, mechanical micro-motion and a microfluid technology are integrated through a localized electrochemical technology, and the whole deposition process is more stable and has higher ductility.

Owner:CHANGCHUN UNIV OF SCI & TECH

Machining method for fastening sealing hoops made of FRP composite building material for prefabrication assembly system

The invention provides a machining method for fastening sealing hoops made of an FRP composite building material for a prefabrication assembly system. According to the following technical scheme, the machining method for the fastening sealing hoops made of the FRP composite building material for the prefabrication assembly system is characterized by including the steps that the FRP material is compounded through a compounding wire twisting board and a compounding wire twisting groove, the FRP material and iron wires of iron wire coils are formed into inner cores through an FRP rib forming pipe and an FRP rib wire outgoing board, the inner cores are dried through a drying box and cooled through ventilation of an air blower, fastening sealing spiral hoop wires made of the FRP composite building material are formed and twisted around a die core column so as to be formed, and the hoops are used for tying operation according to the reinforcing steel bar sample size on a vertical reinforcing steel bar framework of a wall of the prefabrication assembly system to meet the requirement of a design drawing. The method has the beneficial effects that the process is simple and site machining can be achieved; and FRP composite ribs are low in weight and high in specific strength, the tensile strength is higher than that of reinforcing steel bars, the corrosion resistance and the fatigue resistance are good, the service life of the structure is prolonged, flexibility is good, the hoops can be directly twisted on a site, time and labor are saved compared with the situation that a single hoop is manufactured and transported to the site, and cost is low.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

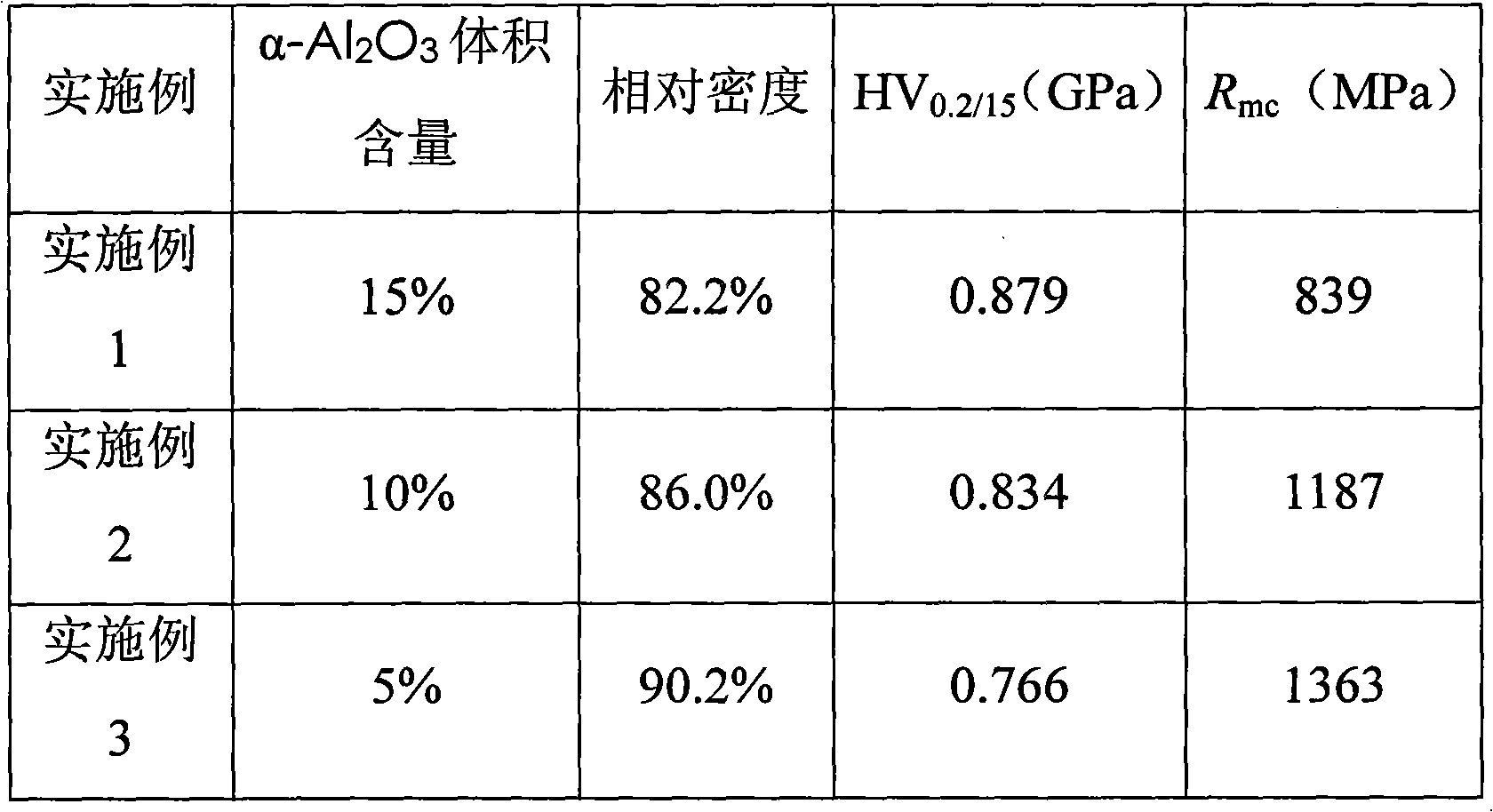

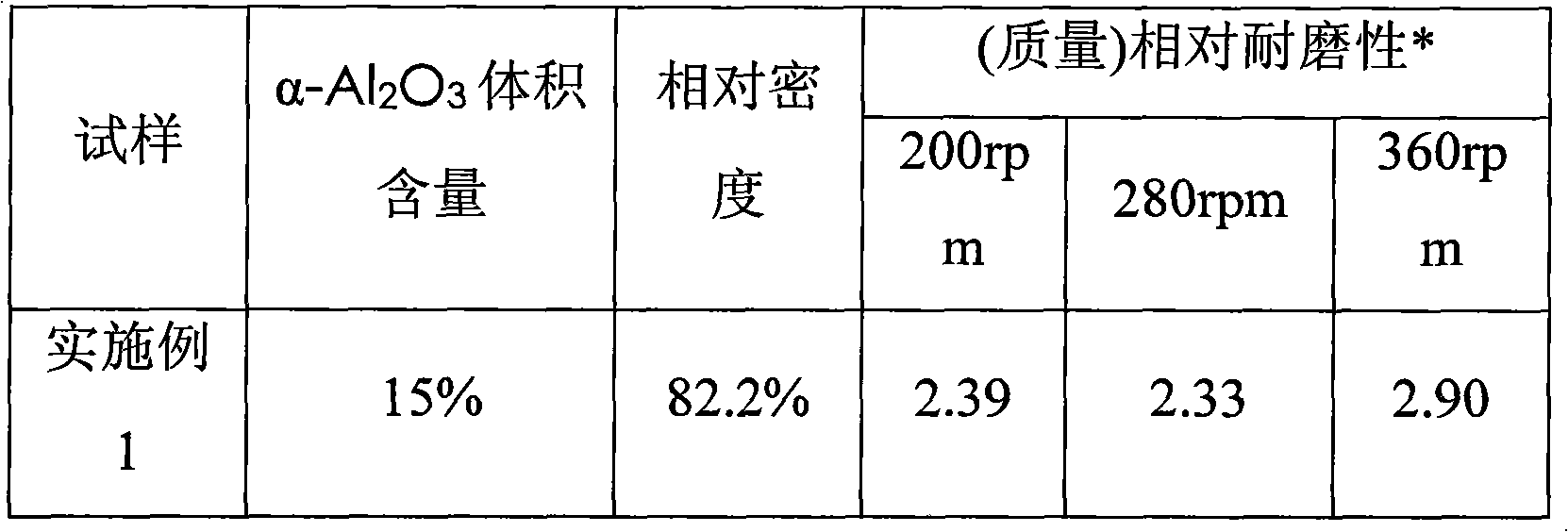

Abrasion-resistant electricity and heat conducting material and preparation method thereof

The invention discloses an abrasion-resistant electricity and heat conducting metal-based composite material and a preparation method thereof, and belongs to the field of abrasion-resistant electricity and heat conducting materials. The abrasion-resistant electricity and heat conducting material comprises the following components in percentage by volume: 5 to 25 percent of alpha-Al2O3 powder and 95 to 75 percent of Cu powder. The preparation method comprises the following steps of: mixing the two powder raw materials and adhesive according to a proportion; cold-pressing and shaping the fully mixed powder; naturally drying the obtained blank in room-temperature air, then thermally drying and thermally degreasing the blank under a vacuum environment, and sintering and shaping the blank under a vacuum environment or an inert gas environment with increased pressure; and treating the prepared alpha-Al2O3 / Cu composite material by adopting cold plastic deformation and secondary sintering processes. The composite material has the advantages of easily controlled material components, low cost, excellent abrasion resistance and electricity and heat conduction and the like, and can be widely applied to manufacture of abrasion-resistant electricity and heat conducting components in multiple fields.

Owner:BEIJING UNIV OF TECH

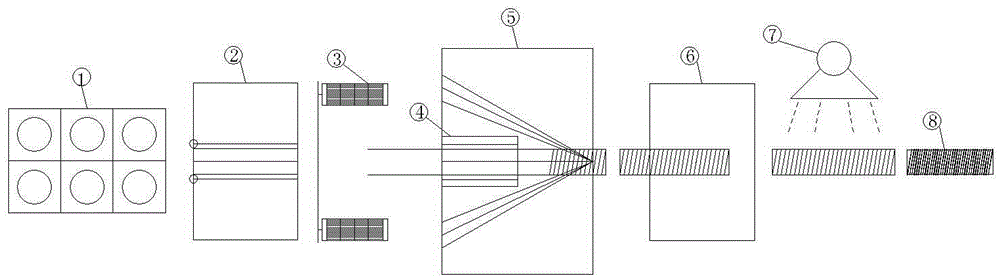

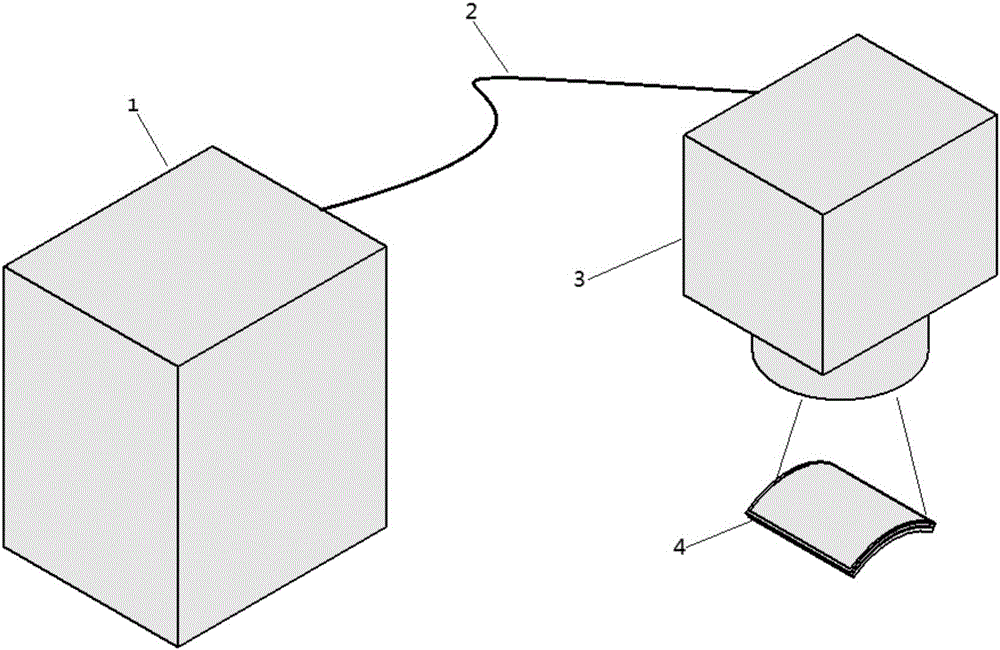

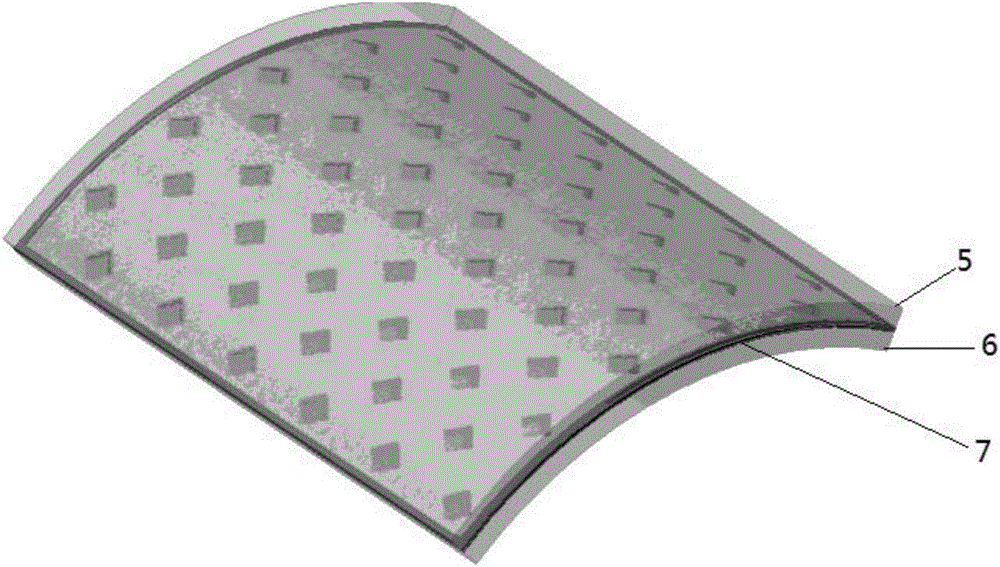

Method and device for packaging flexible OLED screens through laser welding

The invention provides a method and device for packaging flexible OLED screens through laser welding. The method comprises the steps that laser beams emitted by a laser device are transmitted to a 3D dynamic focusing vibration lens, and through high-speed scanning of the 3D dynamic focusing vibration lens, the laser beams penetrate through upper layer light-transmitting materials of the flexible OLED screens and reach lower layer light absorbing materials of the flexible OLED screens; and through a set packaging track, contact faces of upper layer packaging materials and lower layer packaging materials of the flexible OLED screens are fused. The process is simple, the consistency is good, and automatic production can be achieved easily.

Owner:HANS LASER TECH IND GRP CO LTD

Fractal channel printed circuit heat exchanger

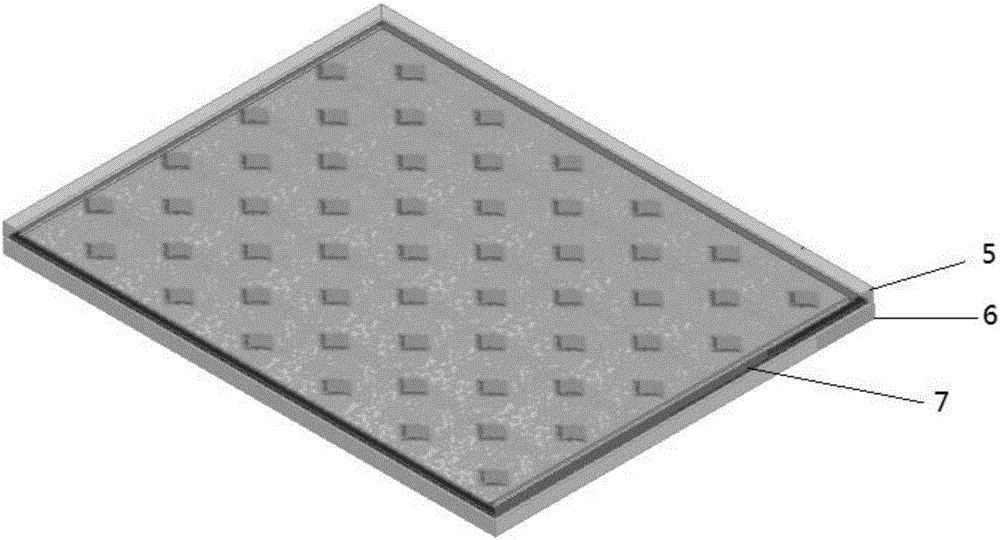

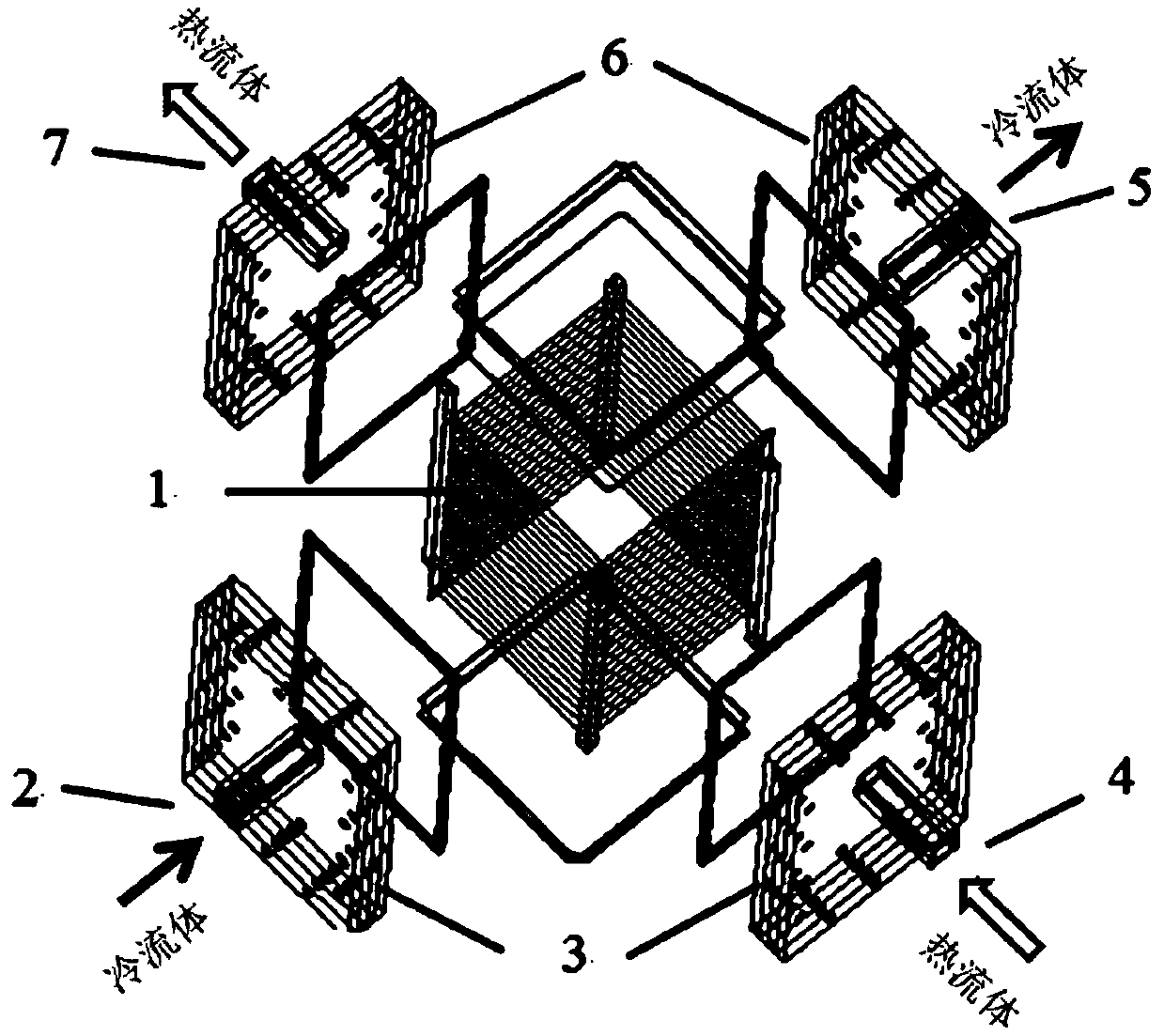

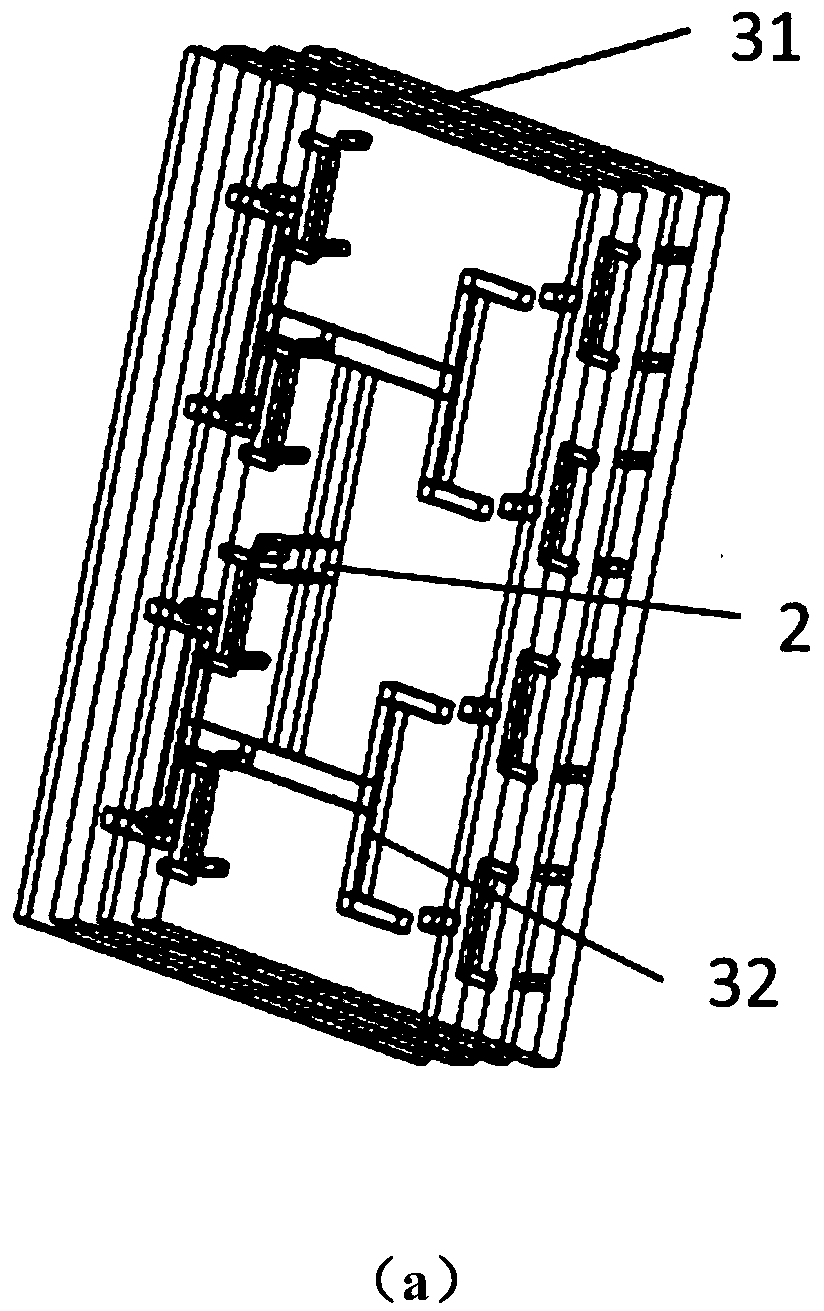

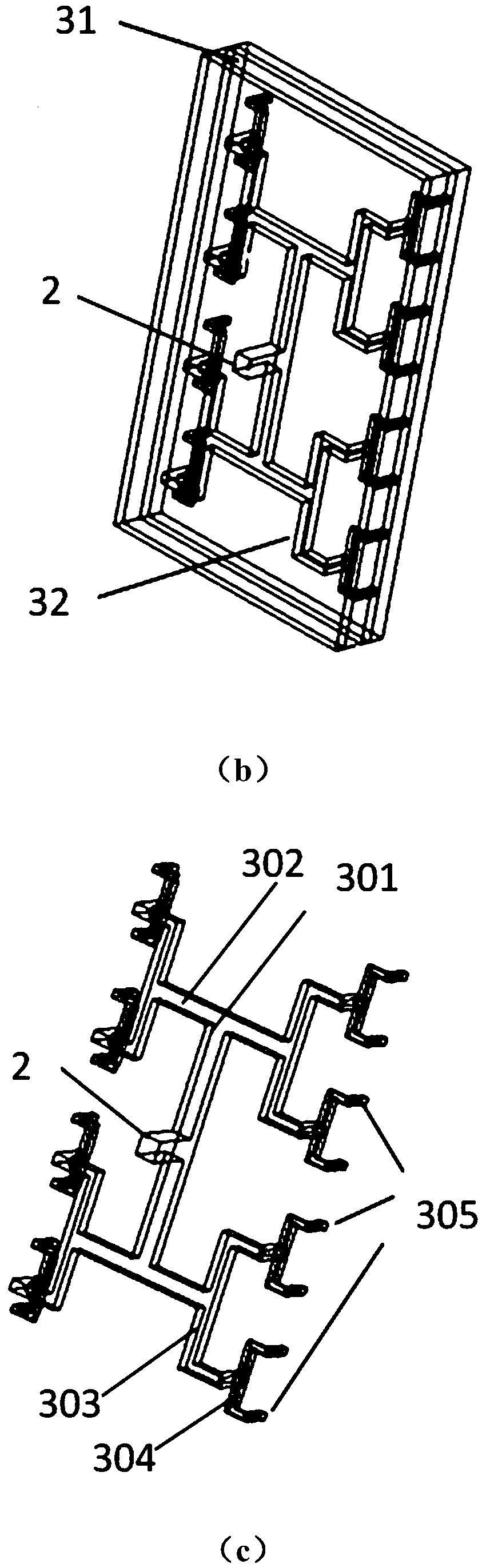

ActiveCN109579575ANo thermal stressSmall circulation resistanceLaminated elementsStationary plate conduit assembliesCavitationChannel network

The invention relates to a fractal channel printed circuit heat exchanger. The printed circuit heat exchanger (PCHE) is provided with heat exchange fluid channels of three-dimensional layer-by-layer diffusion type fractal tree-shaped channel networks through distributors and collectors which are arranged in inlet and outlet sealing heads, the heat exchange fluid channels are connected with inletsand outlets of the fractal tree-shaped heat exchange fluid channels on each heat exchanging plate constituting a heat exchanger core body in a matched mode, and cold and hot fluid experiences bionic complex flow and heat exchange processes such as multi-scale flow from large size main channel to micro-scale branch tail end channel in the heat exchanger core body, convective heat exchange with theheat exchanging plates and heat exchange in the heat exchanging plates; the characteristics of a heat exchange medium of low flow resistance, high heat exchange efficiency and no thermal stress in theheat exchanging plates are realized by producing coordinated equilibrium and stable velocity distribution, temperature distribution and uniform temperature distribution in the heat exchanging plates;and moreover, a bifurcation structure can effectively eliminate fluctuating vibration of flow pressure caused by driving force and inhibit a circulating cavitation phenomenon of liquid.

Owner:DALIAN MARITIME UNIVERSITY

Intelligent ice melting and water draining module for air cylinder of commercial vehicle

PendingCN112833233AHeating up fastFast conductionVessel mounting detailsValve members for heating/coolingEngineeringCommercial vehicle

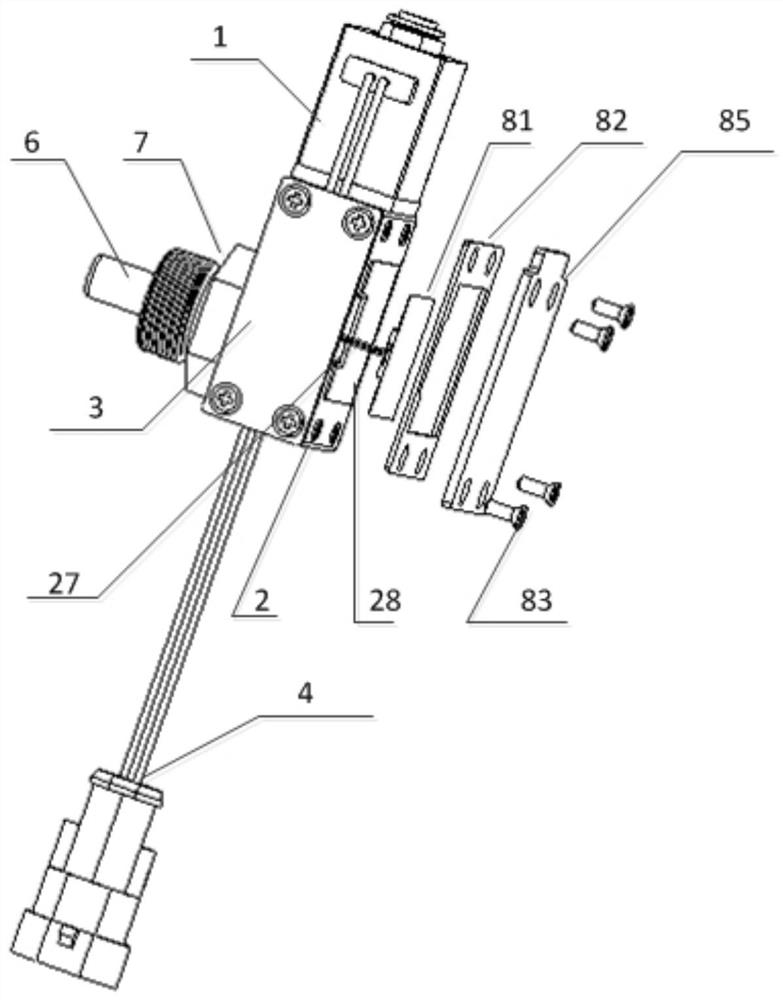

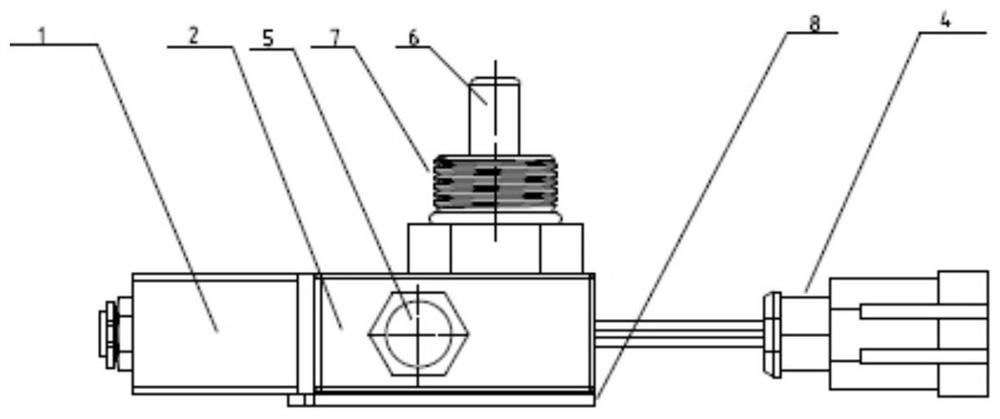

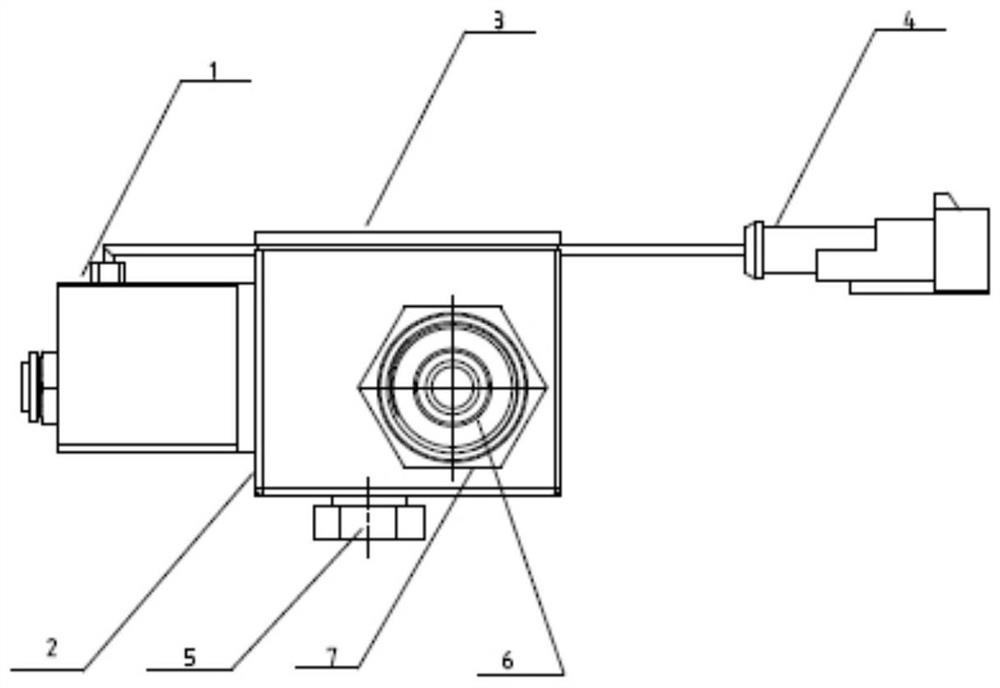

The invention discloses an intelligent ice-melting and water-draining module for an air cylinder of a commercial vehicle. The ice-melting and water-draining module is rapid and timely in ice-melting and water-draining The intelligent ice melting and water draining module comprises a valve body (2), an electromagnet assembly (1) and a controller assembly (3), a water cavity (25) communicating with a water draining pipe (24) is formed in the valve body (2), and the electromagnet assembly (1) controls connection and disconnection of the water draining pipe (24) and the water cavity (25); the intelligent ice melting and water draining module further comprises a thermal resistance type heating film assembly (8) which is tightly attached to the outer wall of the valve body (2) and electrically connected with the controller assembly (3), and the thermal resistance type heating film assembly (8) comprises a heating film (81), a heating film gasket (82), a fixing screw (83), gum (84) and a heating film pressing plate (85); and the heating film (81) is pasted on the outer wall of the valve body (2) through gum (84), and the heating film pressing plate (85) fixes the heating film (81) on the outer wall of the valve body (2) in an attached mode through the fixing screw (83) and the heating film gasket (82).

Owner:南京易孚科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com