Fractal channel printed circuit heat exchanger

A kind of printed circuit board, heat exchanger technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

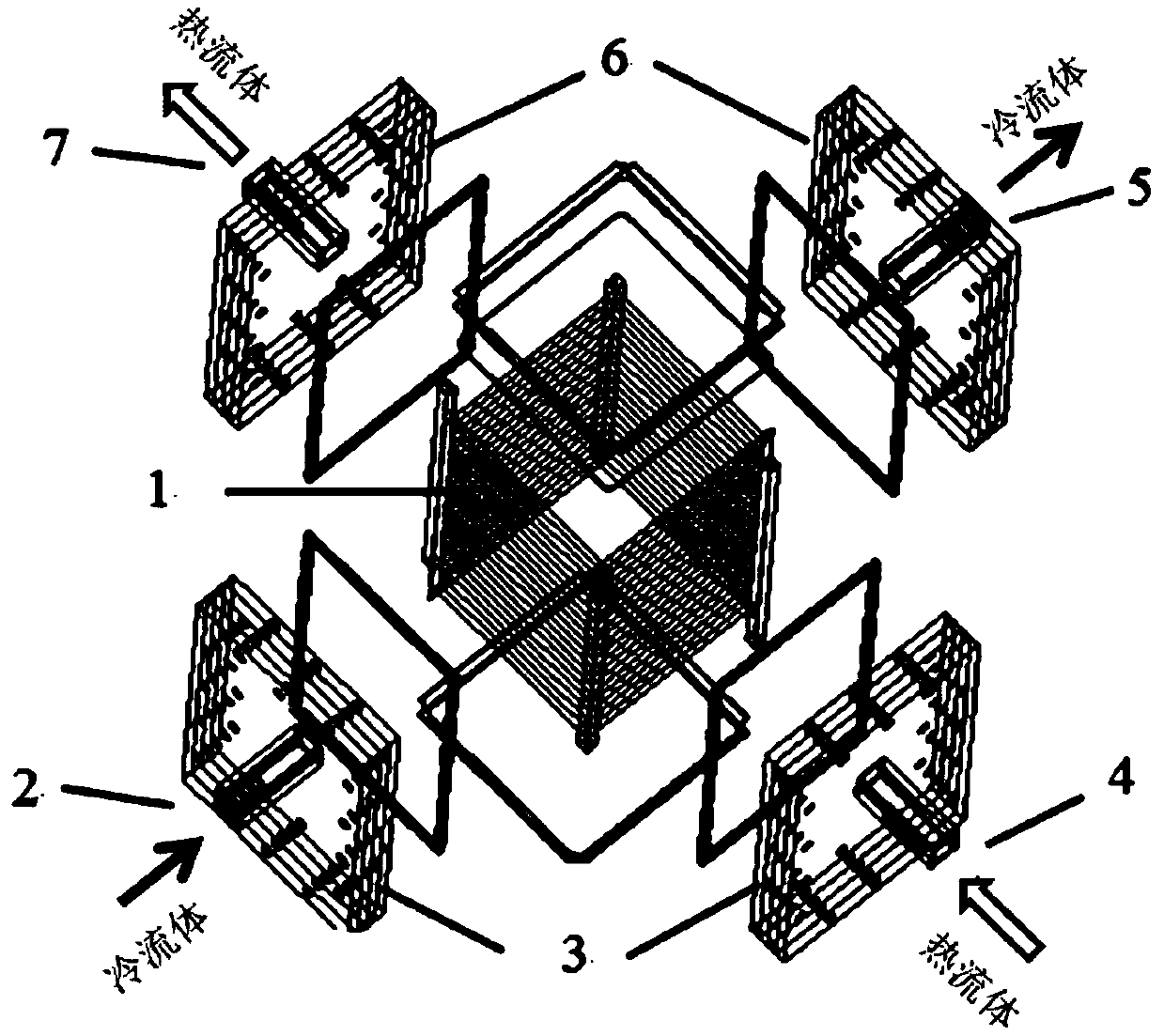

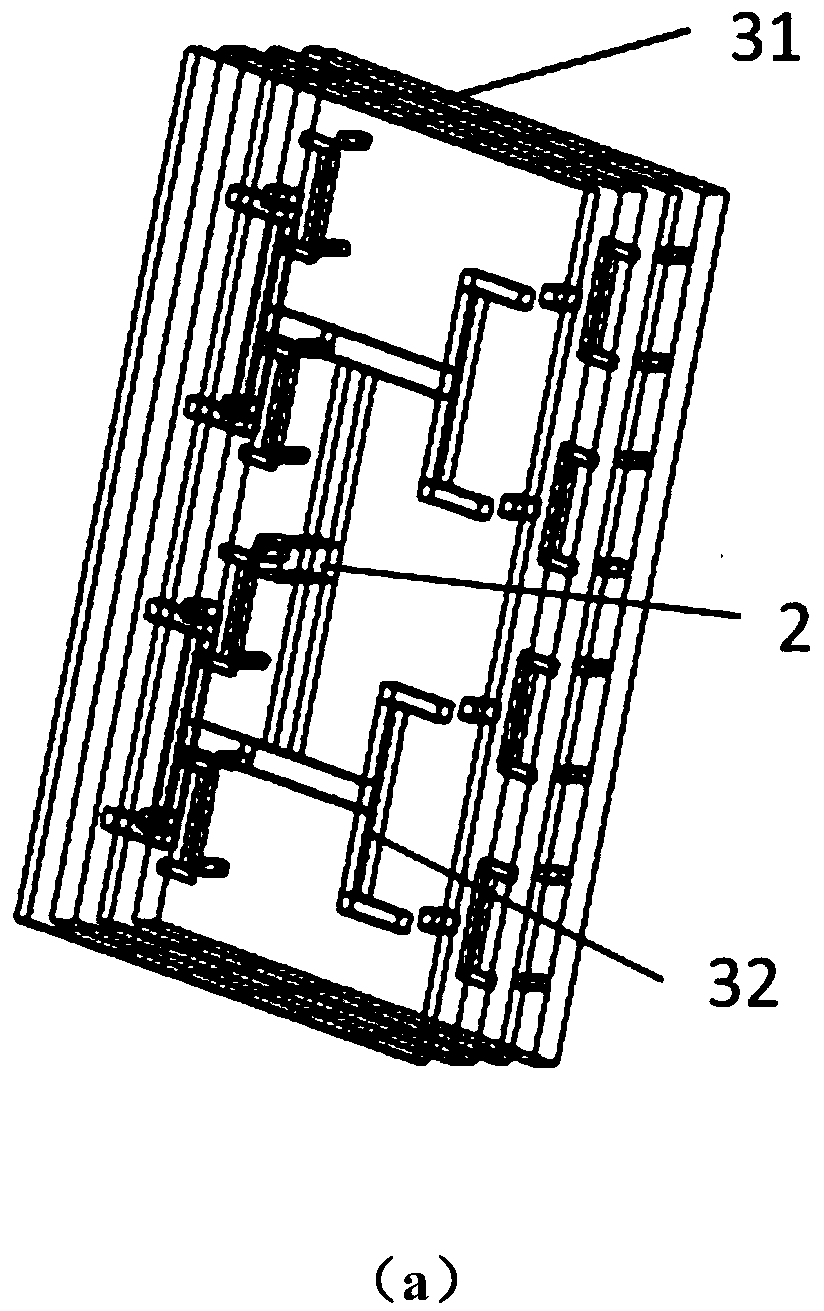

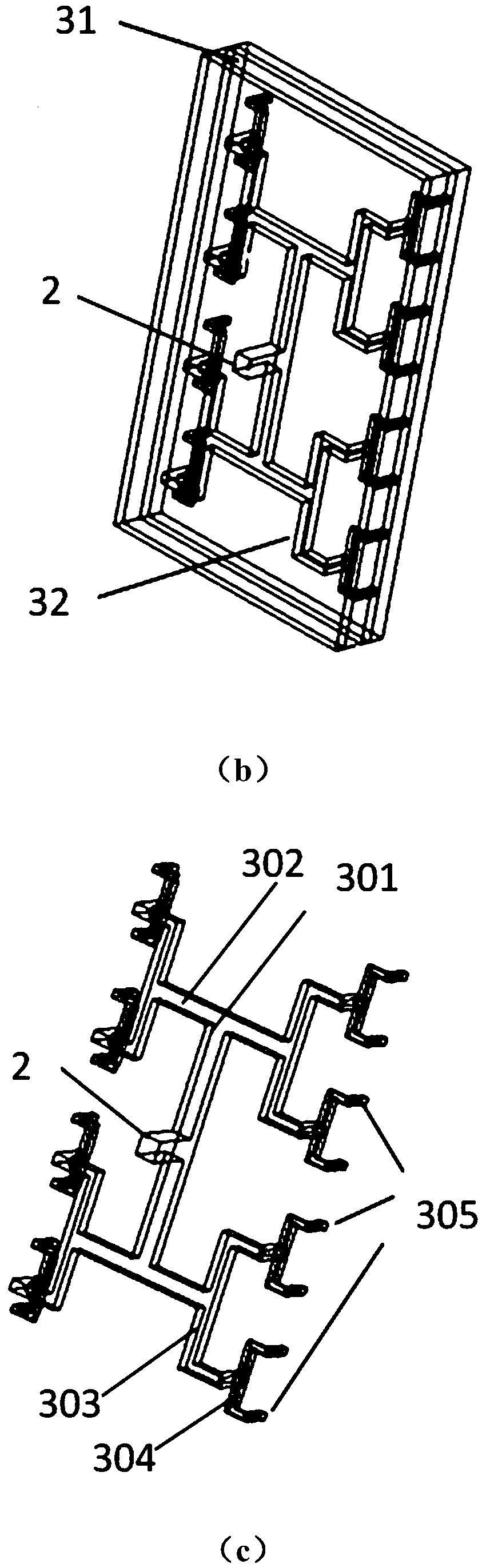

[0035] Such as figure 1 As shown, the fractal channel printed circuit board heat exchanger includes the inlet head, the heat exchanger core 1 and the outlet head. The inlet head and the outlet air head are respectively tightly connected with the heat exchanger core. The fluid distributor 3 is arranged, the fluid collector 6 is arranged in the outlet head, the inlet head is connected with the heat exchange fluid inlet channel of the heat exchange plate of the heat exchanger core 1 by the distributor 3, and the outlet head is connected by the collector 6 and the heat exchanger. The outlet of the heat exchange fluid channel of the heat exchange plate of the heater core 1 is connected, the distributor 3 is provided with a cold fluid inlet 2 and a hot fluid inlet 4 , and the collector 6 is provided with a cold fluid outlet 5 and a hot fluid outlet 7 . The heat exchange fluid channel in the distributor 3 and the collector 6 is a three-dimensional fractal tree-like channel network, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com