Abrasion-resistant electricity and heat conducting material and preparation method thereof

A technology of electrical and thermal conduction and composite materials, which is applied in the field of α-Al2O3/Cu wear-resistant, electrical and thermal conduction metal matrix composite materials and its preparation, to achieve the effects of good reinforcement effect, high hardness and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: α-Al 2 o 3 / Cu composite material, its material ratio is: α-Al 2 o 3 / Cu mixed powder 94wt% (of which α-Al 2 o 3 Powder 15% (volume), Cu powder 85% (volume)), binder 6wt% (including HPMC15wt%, deionized water 85wt%). Seal the viscous powder and store it at room temperature for 24 hours; then press it in the mold at a speed of 2 MPa / s, and keep it for 1 minute after reaching a pressure of 300 MPa. After the pressed green body is naturally dried in the air at room temperature for 24 hours, the following comprehensive process of drying, degreasing and vacuum sintering is adopted:

[0024] Vacuum down to 10 -2 Pa; room temperature (20℃)~110℃, heating rate 10~15℃ / min; 110℃ for 2 hours; 110℃~400℃, heating rate 10~15℃ / min; 400℃ for 4 hours; 400℃~ 1030°C, heating rate 5-8°C / min; heat preservation at 1030°C for 2 hours; cooling with the furnace; open the furnace to pick up the parts when the furnace temperature drops to 120°C.

[0025] The cold plastic deforma...

Embodiment 2

[0028] Example 2: α-Al 2 o 3 / Cu composite material, its material ratio is: α-Al 2 o 3 / Cu mixed powder 94wt% (of which α-Al 2 o 3 powder 10% (volume), Cu powder 90% (volume)), binder 6wt% (including HPMC15wt%, deionized water 85wt%). Seal the viscous powder and store it at room temperature for 24 hours; then press it in the mold at a speed of 2 MPa / s, and keep it for 1 minute after reaching a pressure of 300 MPa. Subsequent process is the same as "embodiment 1".

Embodiment 3

[0029] Example 3: α-Al 2 o 3 / Cu composite material, its material ratio is: α-Al 2 o 3 / Cu mixed powder 96wt% (of which α-Al 2 o 3 powder 5% (volume), Cu powder 95% (volume)), binder 4wt% (including HPMC15wt%, deionized water 85wt%). Seal the viscous powder and store it at room temperature for 24 hours; then press it in the mold at a speed of 2 MPa / s, and keep it for 1 minute after reaching a pressure of 300 MPa. Subsequent process is the same as "embodiment 1".

[0030] In the above examples, α-Al 2 o 3 The average particle size of the powder is 7-10 μm, and the average particle size of the Cu powder is 5-20 μm.

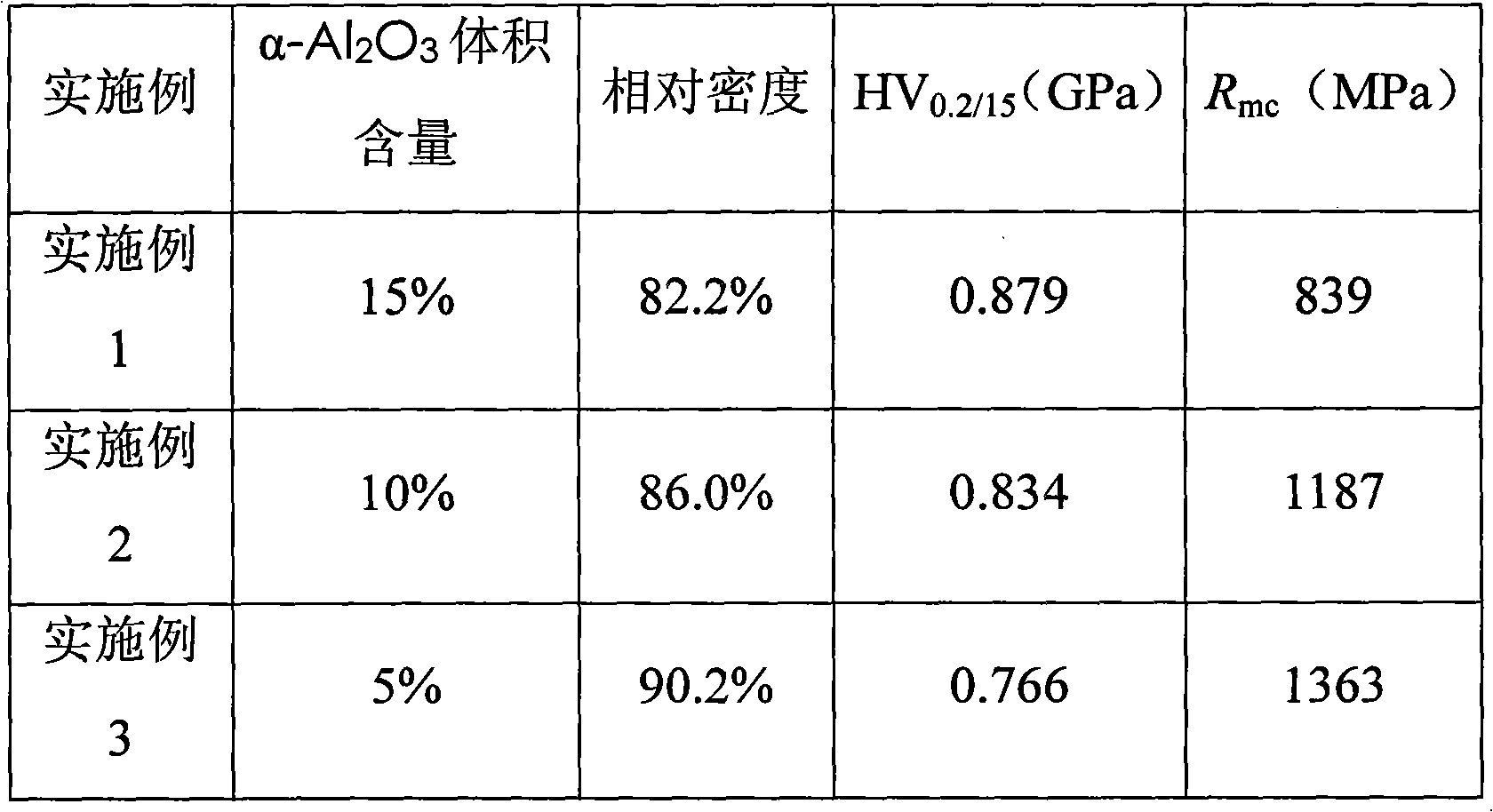

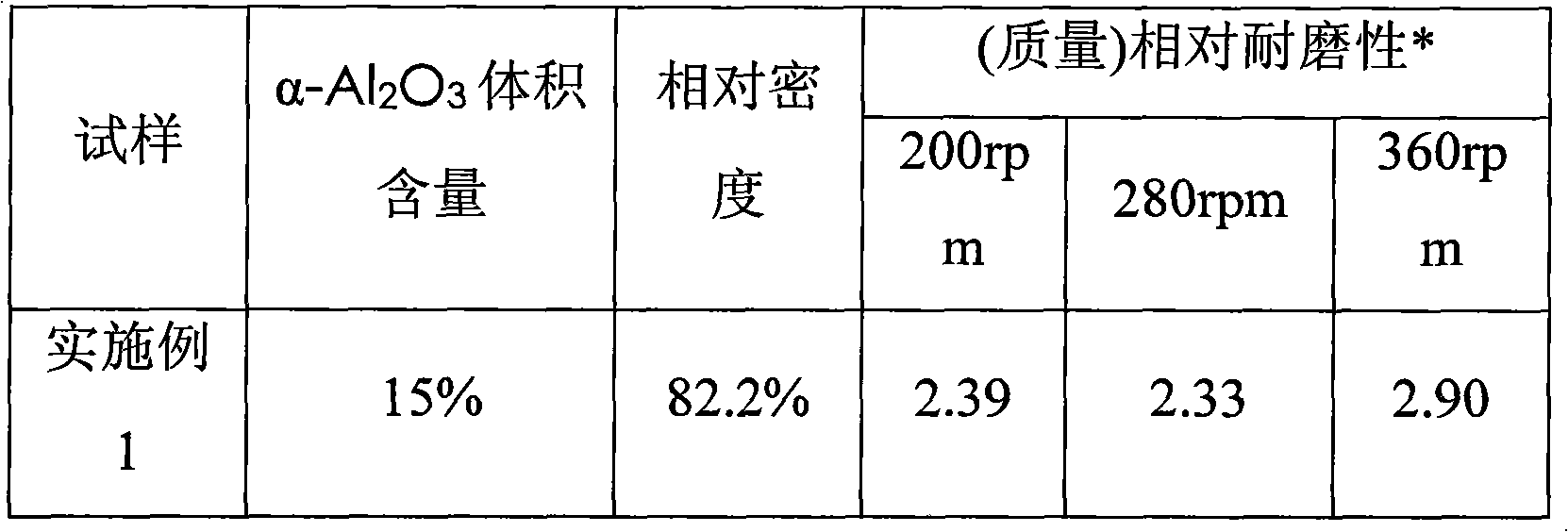

[0031] The sintered finished product of above embodiment is done performance test, and relative density test adopts the result calculation of Archimedes method to obtain; Test its microhardness on microhardness instrument, adopt 200 gram load, hold load 15 seconds; Compressive strength R mc carried out on a mechanical testing machine for materials. The tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com