Patents

Literature

315results about How to "Composition controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

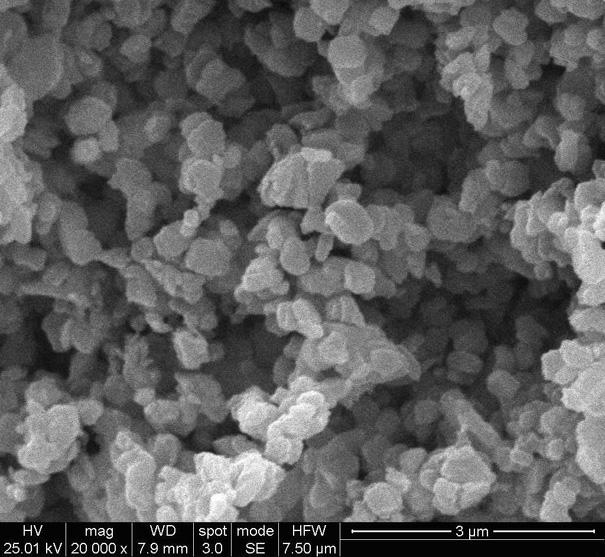

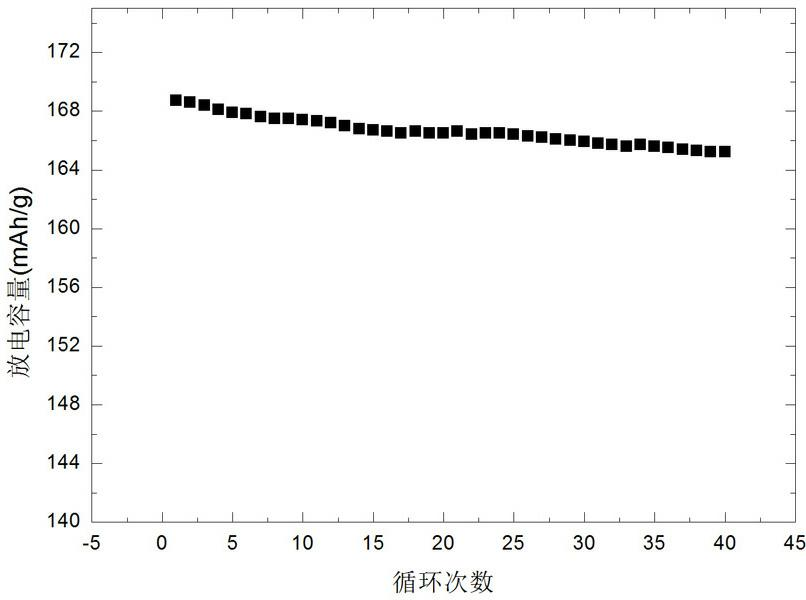

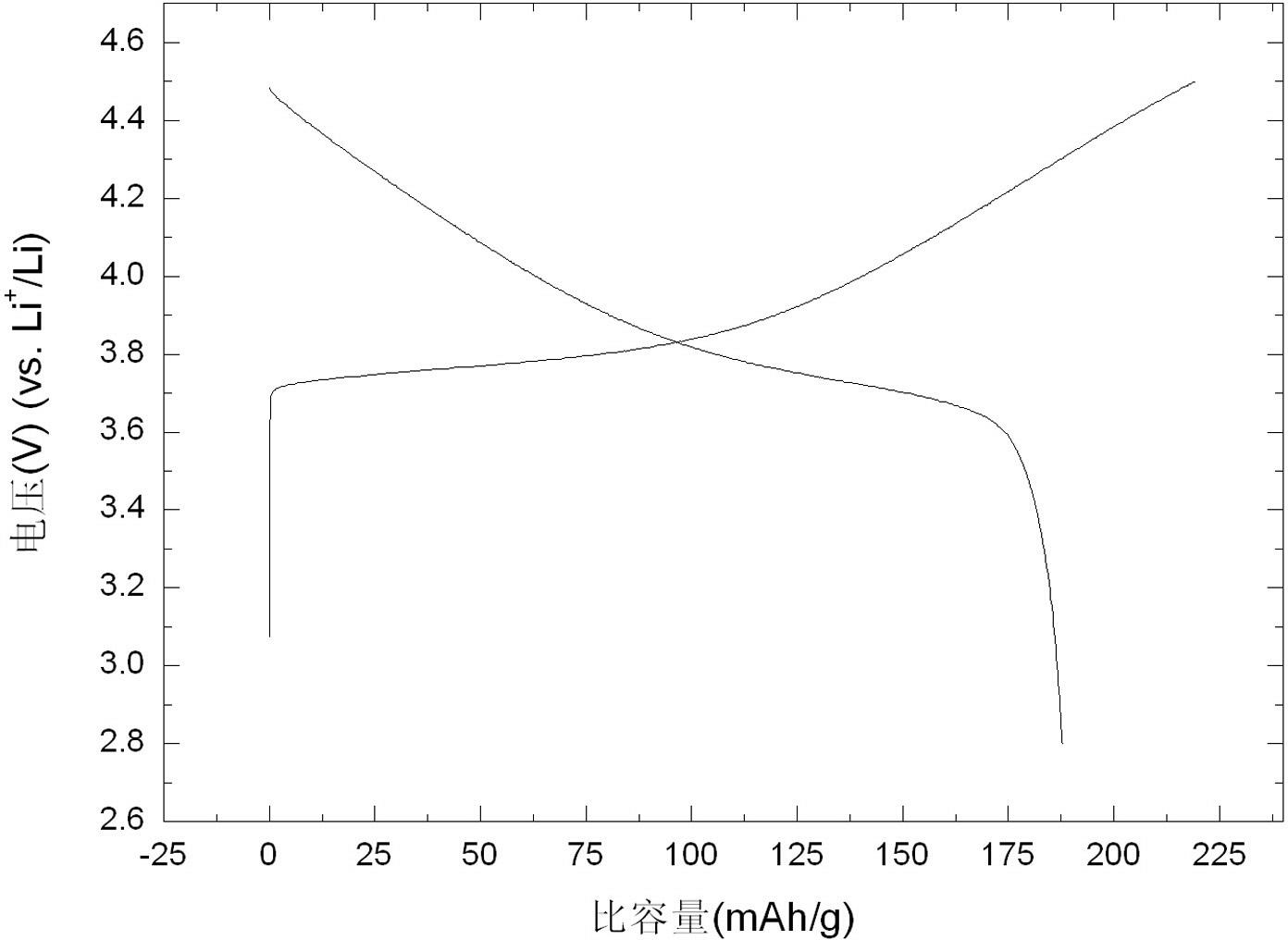

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

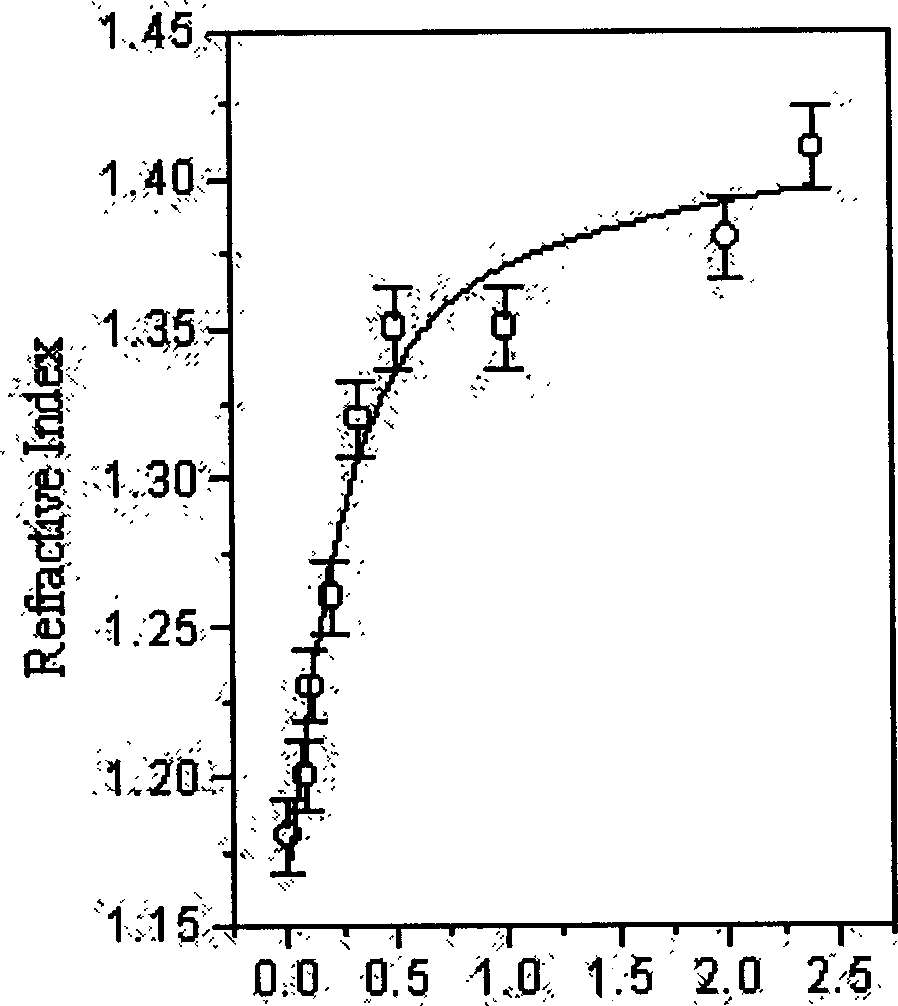

Preparing method for nanometer porous silica thin-membrane

InactiveCN1553219AHigh refractive indexLow refractive indexOptical elementsPtru catalystSilicic acid

The preparing method is as the follows, positive silester is used as presoma alcohol as solvent and ammonia water as well as hydrochloric acid as catalysts, they are become basic and acidic soliquid after hydrolyzation and polycondensation are carried out silica soliquid can be obtained by further polycondensation and hydrolyzation after basic silica soliquid is agitated in some acidic soliquid, a complete nanomultihole network structure which is not simply piled up can be formed by closely combining particles to be film when using acidic soliquid as coupling agent to link basic soliquid particles together.

Owner:TONGJI UNIV

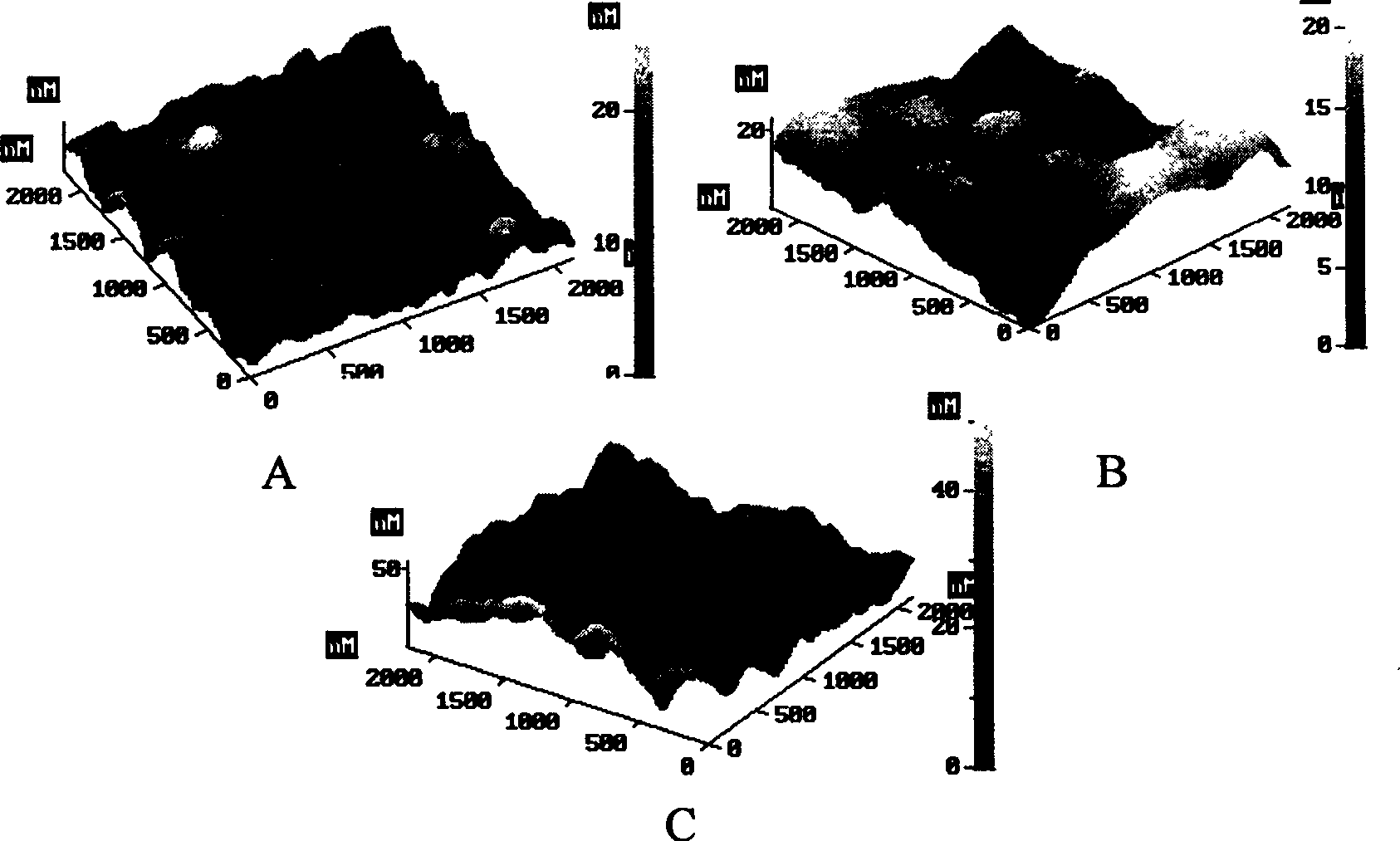

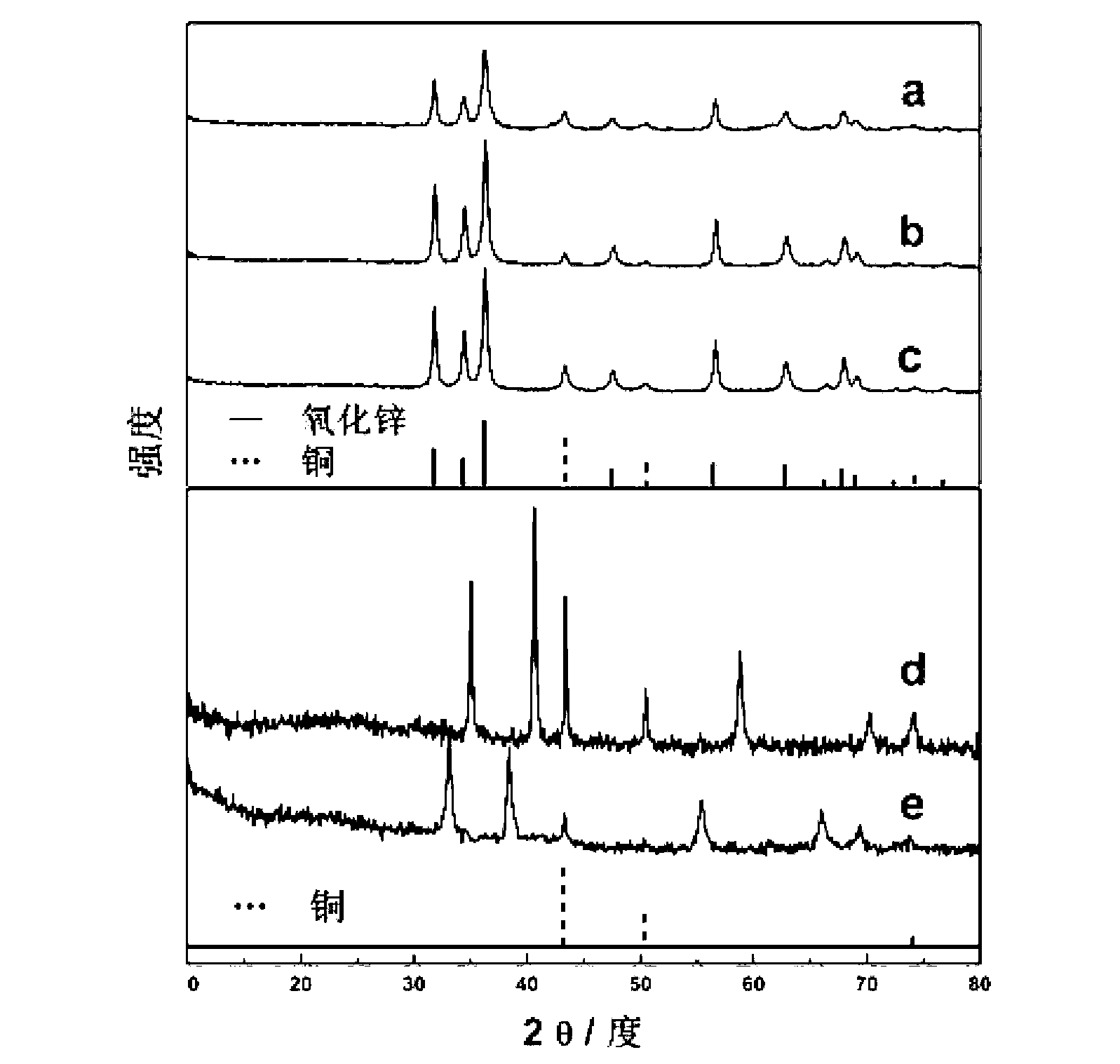

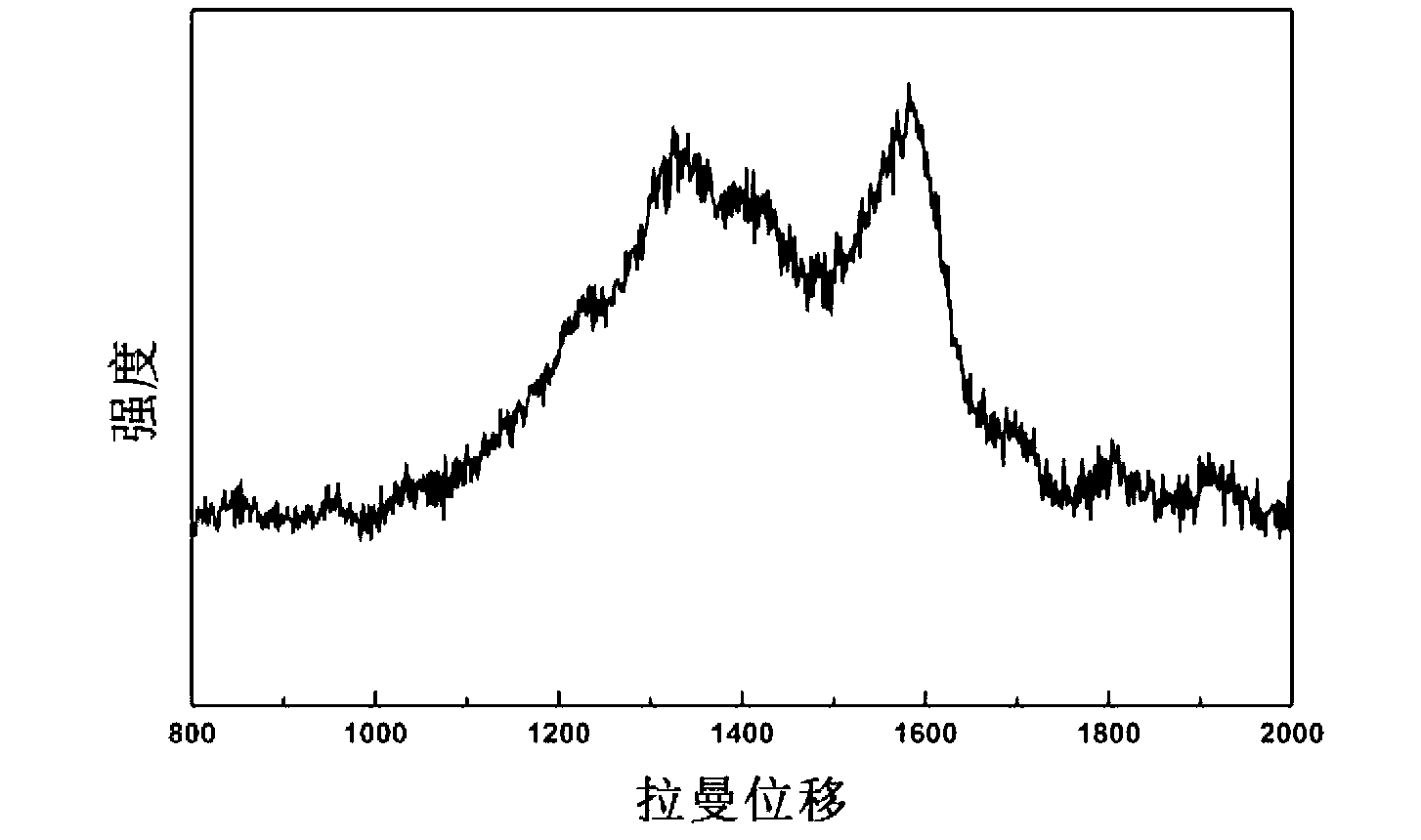

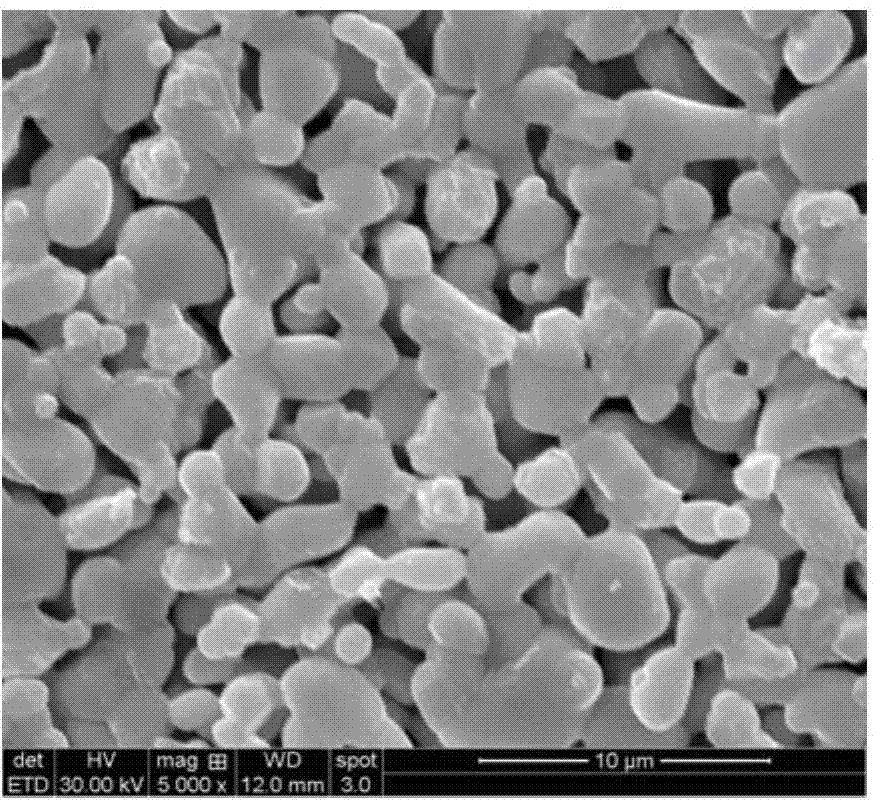

Carbon/copper/metal oxide composite porous material and preparation method and application thereof

InactiveCN103268929ALow costComposition controllableMaterial nanotechnologyCell electrodesNanoparticleOxide composite

The invention relates to a carbon / copper / metal oxide composite porous material and a preparation method and application thereof. The composite porous material is of a composite structure consisting of carbon, metal copper nano particles and metal oxide nano particles; in the composite structure, the metal oxide nano particles are stacked to form a three-dimensional porous skeleton; the metal copper nano particles are attached to the metal oxide nano particles; and the carbon wraps the surfaces of the metal copper nano particles and the metal oxide nano particles. The invention also provides a preparation method and application of the composite porous material. According to the carbon / copper / metal oxide composite porous material and a preparation method and application thereof provided by the invention, the reaction conditions are mild, the preparation process is simple and easy to implement and environment-friendly, the components are controllable, the output is high, and large-scale production is easy to realize; and due to the addition of the carbon and copper nano component, the prepared carbon / copper / metal oxide composite porous material obviously improves the electrical conductivity and is favorable for the functionalization application of the metal oxide nano material.

Owner:SHANDONG UNIV

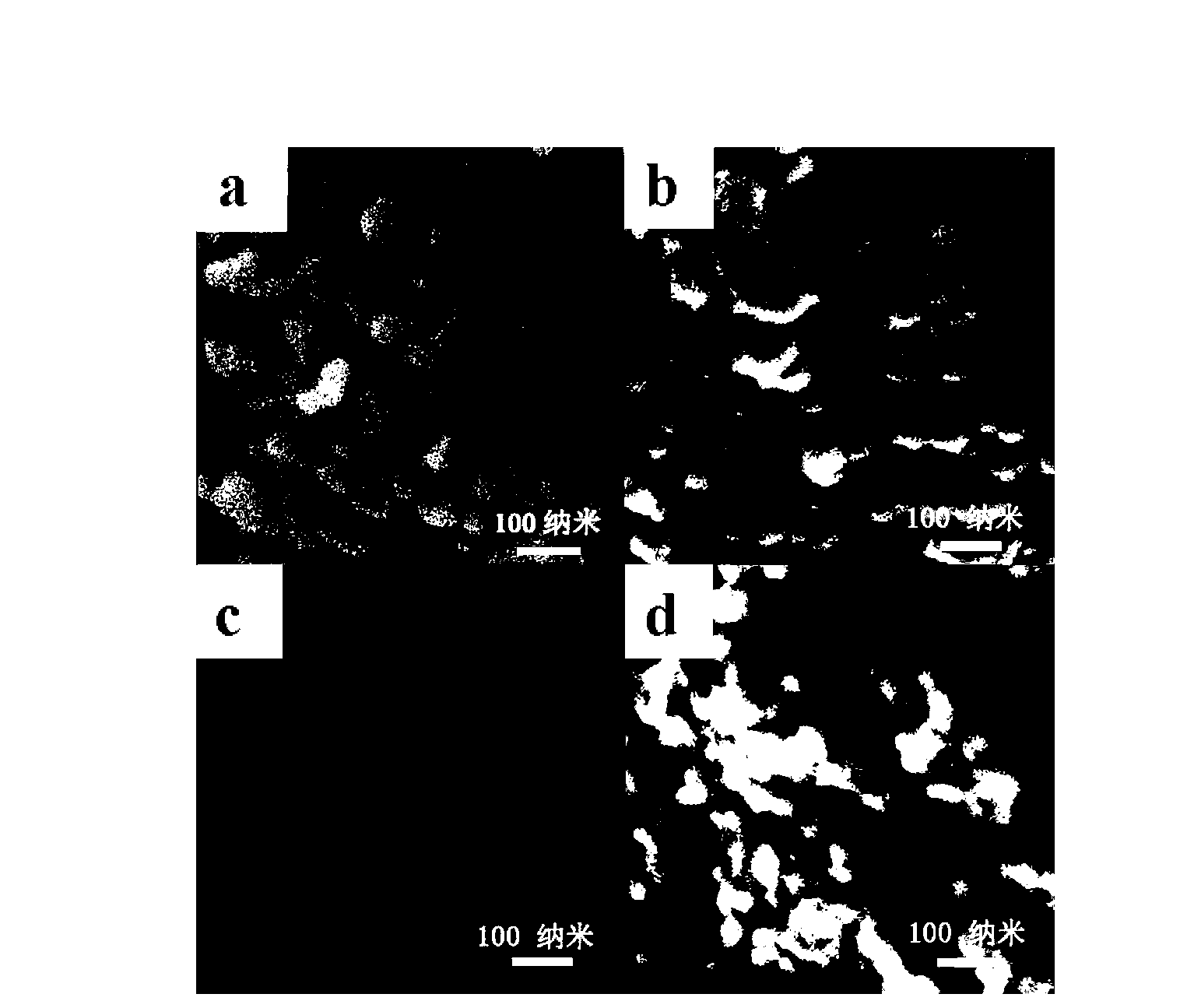

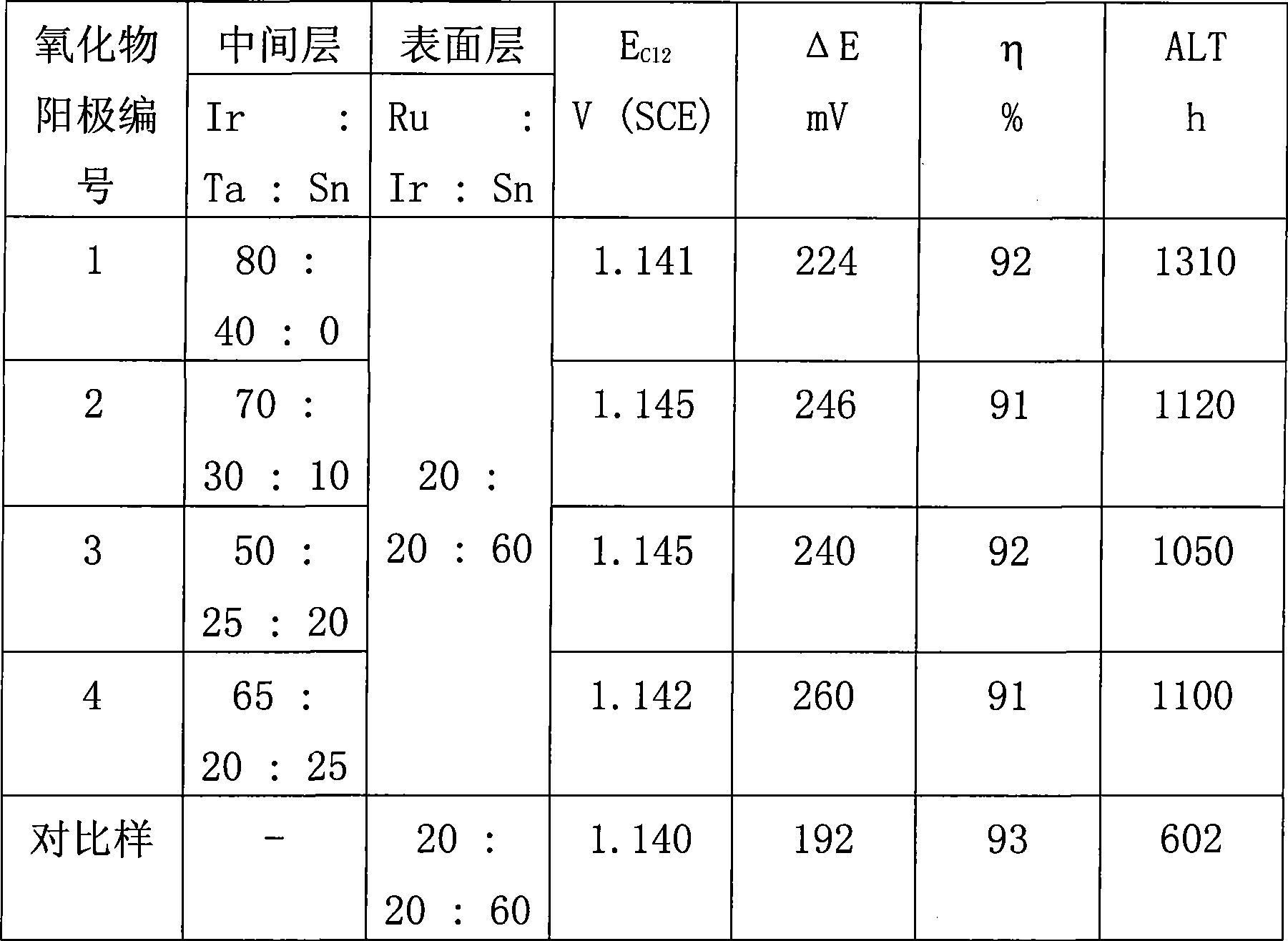

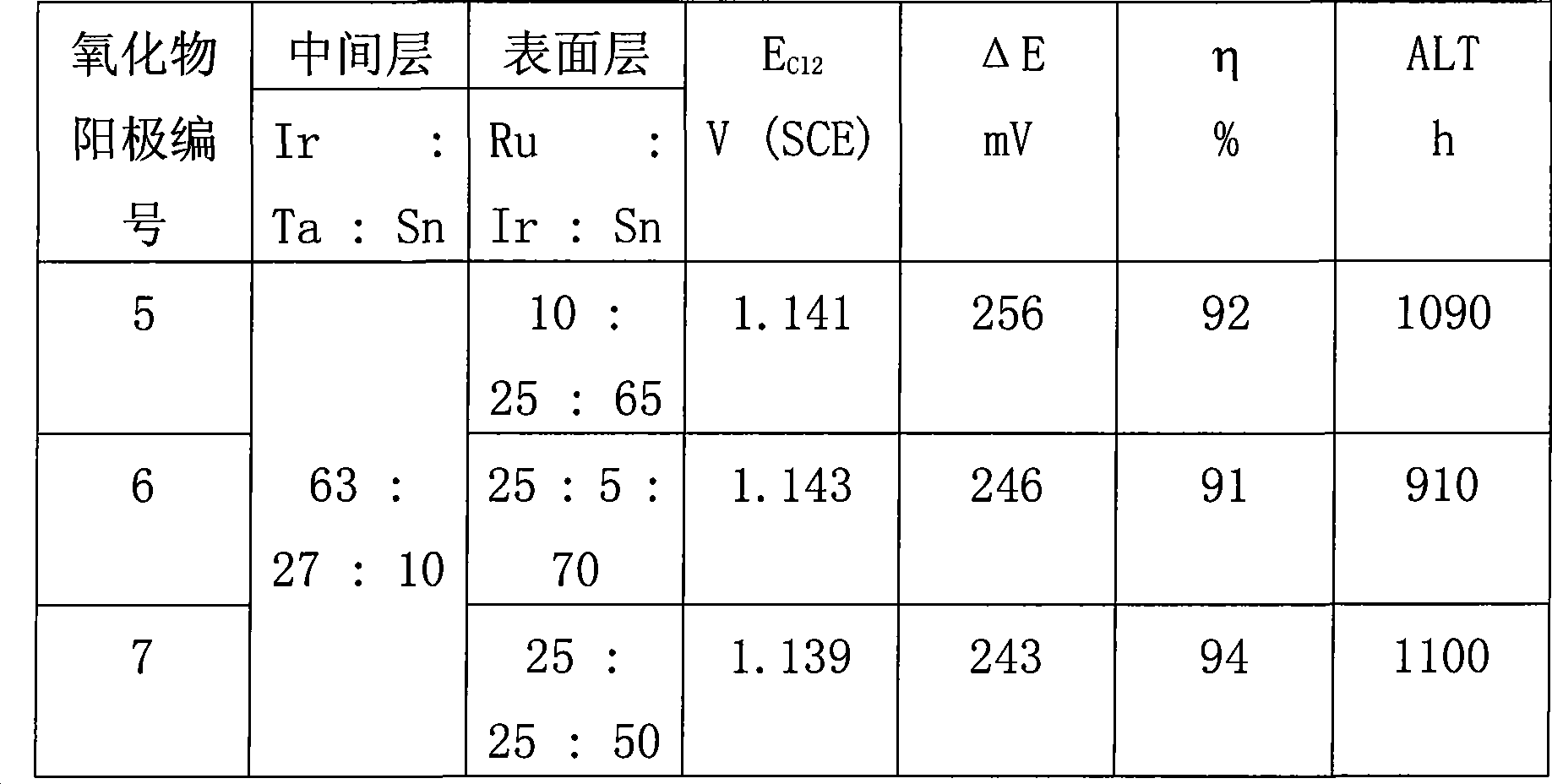

Nanocrystal metal oxide composite electrode and method for preparing same

The invention relates to a nanocrystal metal oxide composite electrode and a method for preparing the same. The electrode is suitable for a seawater electrolysis device for preventing the contamination of sea creature and used for electrolytic production of sodium hypochlorite, cathode protection and other electrochemical engineering; a main structure of the electrode comprises a substrate, an anticorrosive antipassivated middle layer and a surface activity layer, wherein the substrate is metal titanium; the purity of the metal titanium is over 99 percent; the middle layer is iridium-tantalum or iridium-tantalum-tin oxide; the surface activity layer is ruthenium-iridium-tin metal oxide; a process for preparing the electrode adopts a sol-gel method and comprises three process steps of the pretreatment of the substrate, the preparation of the anticorrosive antipassivated middle layer and the preparation of the surface activity layer; and the electrode has the characteristics of even compositions, difficulty for burning loss, fine crystal grains, simple preparation process, controllable process and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

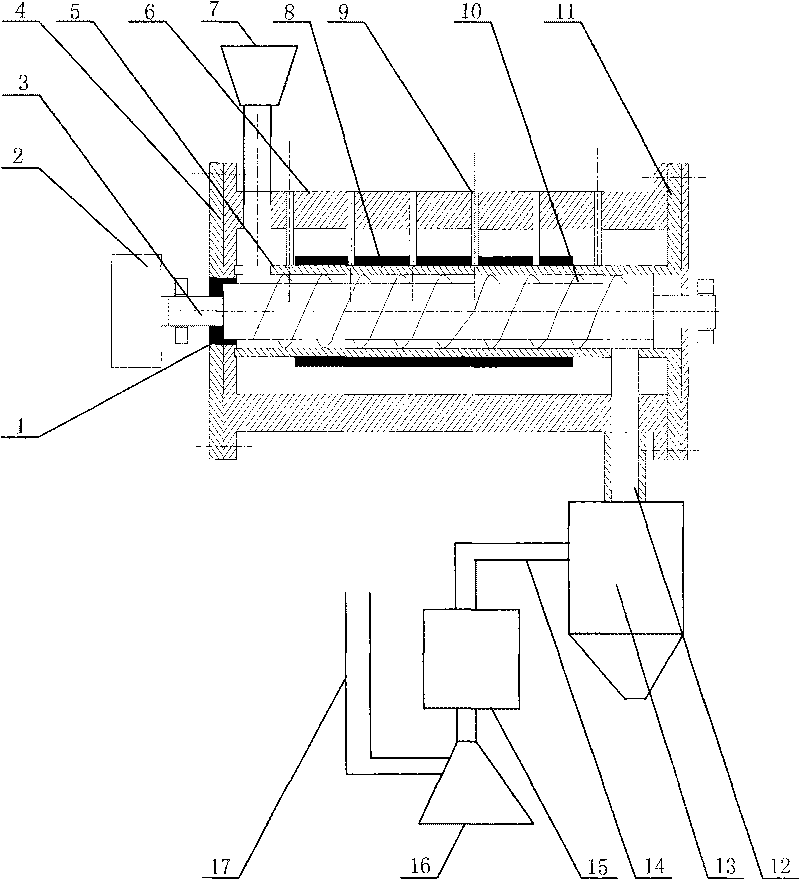

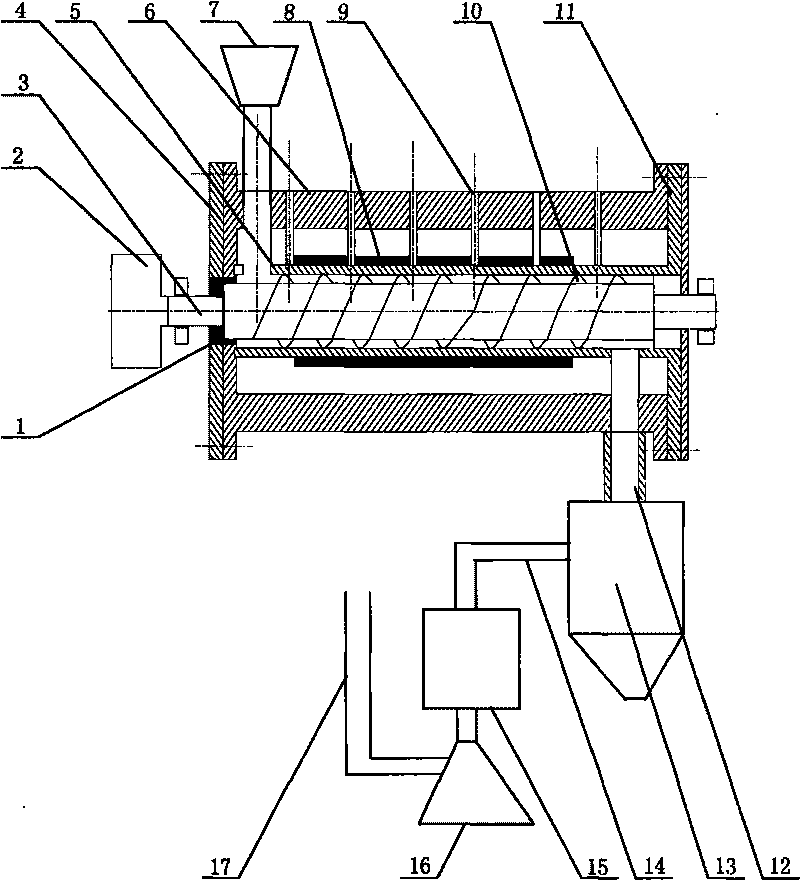

Biomass spiral pyrolysis device and pyrolysis process

InactiveCN101709224AControl dwell timePrevent slippingLiquid hydrocarbon mixture productionCollection systemPropeller

The invention relates to a biomass pyrolysis device and a process thereof. The device comprises a charging system, a spiral pyrolysis reactor and a product collection system, wherein a rotating shaft which is communicated with a variable-frequency motor and provided with a spiral propeller is arranged in center holes on two end covers of a cylinder body of the reactor; the side wall of the cylinder body is provided with a biomass feed pipe and a pyrolysis product outlet pipe; the outlet pipe is vertically extended into a coke collection tank; and the coke collection tank are communicated with a condenser, a bio-oil collection tank and a tail gas discharge pipe in turn through an air outlet pipe on the side wall. The process comprises the following technological processes: firstly, starting an external heating system to ensure that the temperature in a reactor is between 500 and 550 DEG C; secondly, putting biomass granular raw materials into the reactor through an inlet pipe, simultaneously starting the variable-frequency motor, and determining the rotating speed n of the variable-frequency motor according to the set residence time t, and the axial length L and the screw pitch l of the spiral propeller; and finally, starting the pyrolysis product collection system. The biomass pyrolysis device can accurately control the pyrolysis time and control the pyrolysis temperature in a partitioning mode so that the obtained bio-oil components are controllable and are easy to extract chemical products.

Owner:UNIV OF SCI & TECH OF CHINA

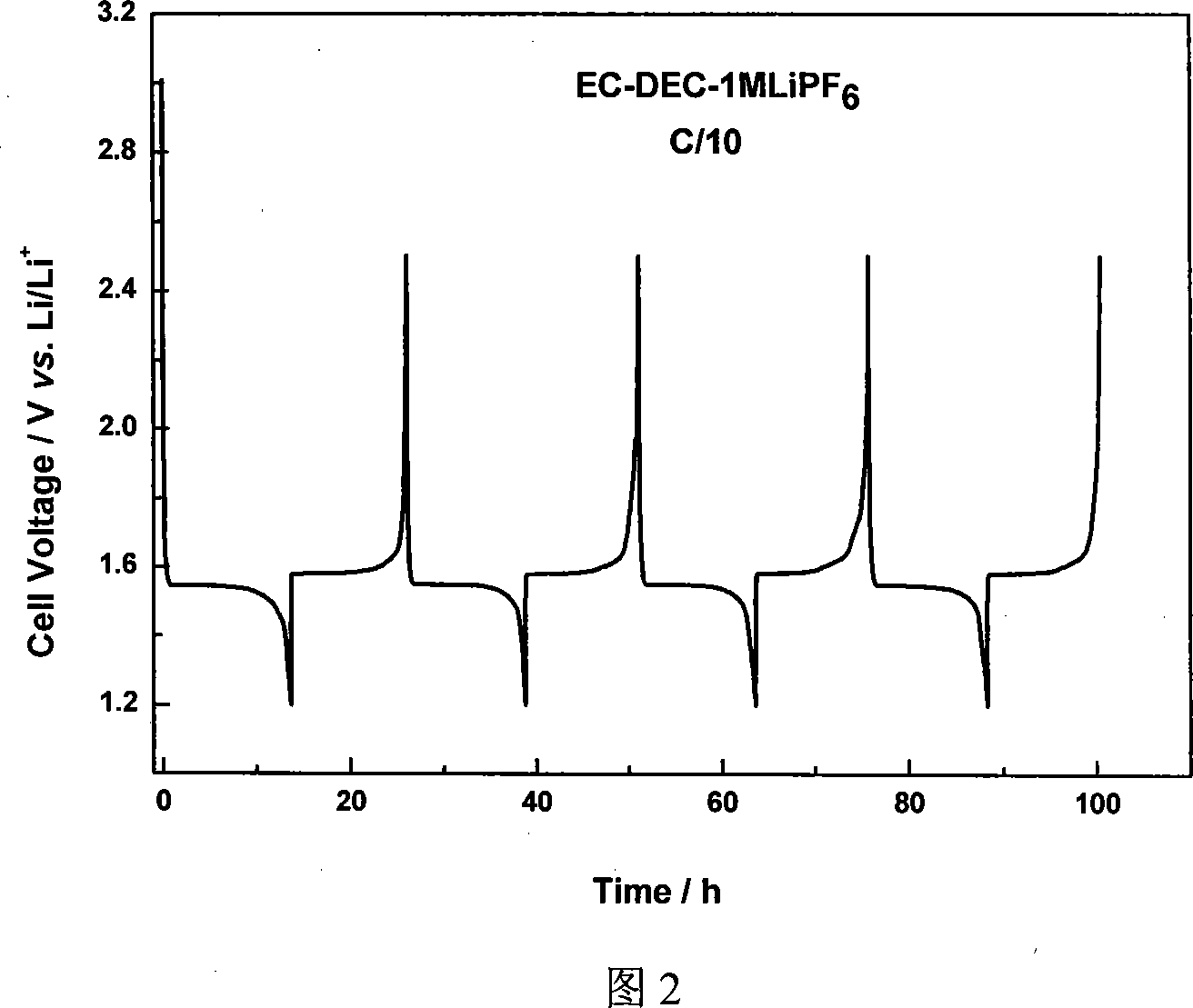

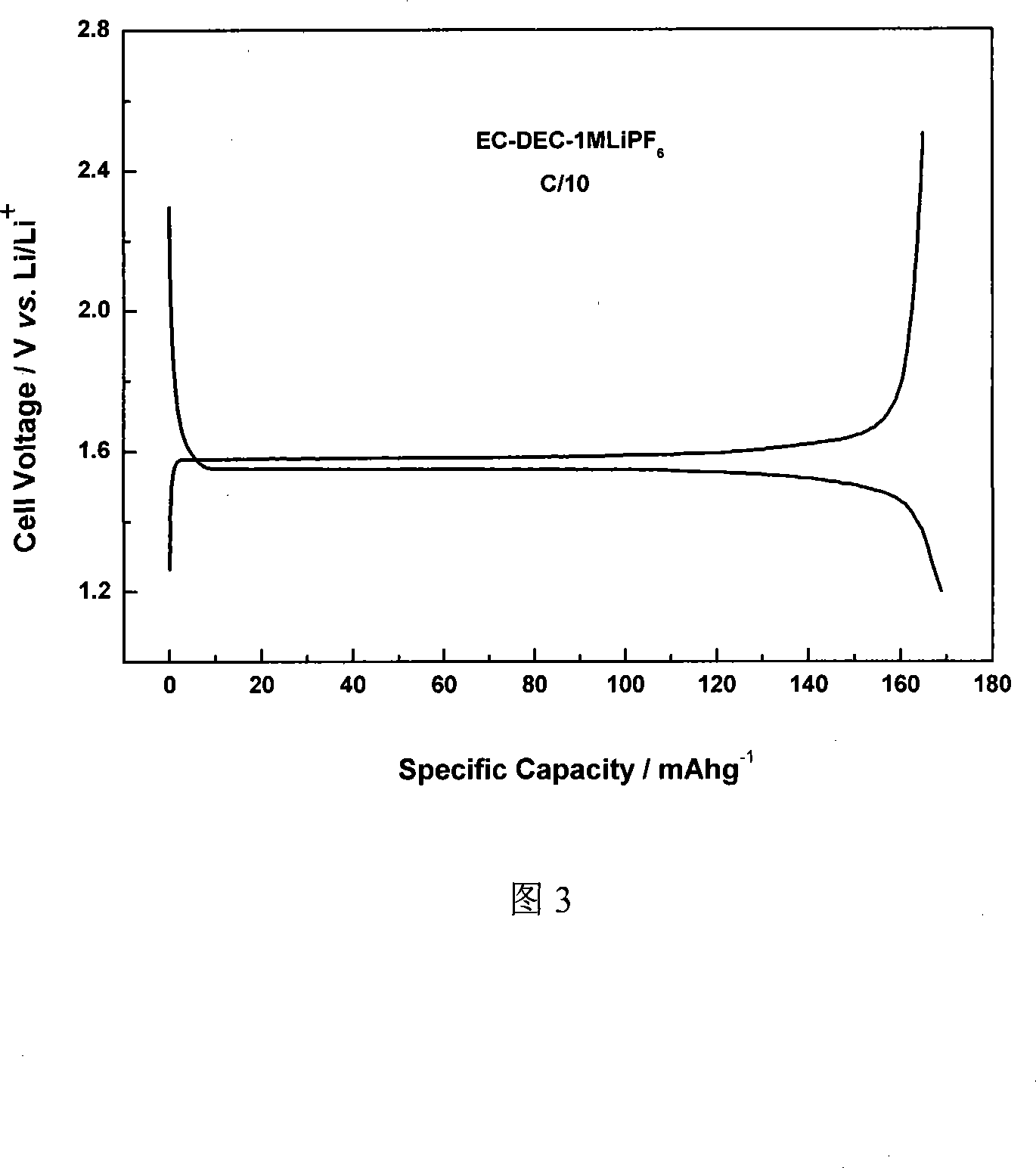

Method for preparing nano-crystal lithium-titanium composite oxide

InactiveCN101058438ARich reservesReserves are cheapNanostructure manufactureCell electrodesCapacitanceWater baths

The invention discloses a making method of nanometer crystal Li-Ti composite oxide, which comprises the following steps: adopting titanium powder or titanium compound as raw material; blending the materials with 30% hydrogen peroxidate under low temperature; adding certain quantity of lithium salt solution and moulder; stirring evenly; reacting under water bath condition at 50-100 deg. c completely; drying the composite system directly to produce predecessor; proceeding heat disposal for the predecessor at 200-400 deg. c for 2-6h; heating to 600-1000 deg. c; sintering 8-36h; cooling; grinding; obtaining the nanometer crystal Li-Ti composite oxide with spinel structure and the content of Li4Ti5O12 over 90%; controlling the even grain size of the product between 15nm and 100nm and specific surface area between 10 and 100m2 / g due to different aperture shape of moulds, sintering time and temperatures; making the reversible specific capacity of the product over 160mAh / g under 0. 1C charging and discharging condition; keeping the capacity maintaining rate between 50% and 70% under discharging condition at 100deg. c as ideal negative electrode material of lithium ion dynamic battery and lithium ion super-capacitance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Epigallo-catechin gallate (EGCG) with high purity and preparation method thereof

ActiveCN101643466AThe process route is simple and easySuitable for mass industrial productionAntibacterial agentsIon-exchange process apparatusCrystallizationChemistry

The invention provides an epigallo-catechin gallate (EGCG) with high purity and a preparation method thereof. The EGCG content is 98.0 percent to 99.9 percent. The preparation method mainly comprisesthe working procedures of extracting, separating by a chromatography and crystallizing. The invention has favorable reproducibility of preparation process, high acquired EGCG content, low cost and stable and controllable quality and is suitable for industrialized production.

Owner:JIANGSU TIANSHENG PHARMA

Zirconium oxide thermal barrier coating for turbine buckets of gas turbine and preparation method thereof

ActiveCN102094170AProcess parameters are easy to controlComposition controllableBlade accessoriesVacuum evaporation coatingZirconium hydrideThermal barrier coating

The invention relates to a zirconium oxide thermal barrier coating for turbine buckets of a gas turbine and a preparation method thereof. The zirconium oxide thermal barrier coating for the turbine buckets of the gas turbine is characterized in that adhesive layer materials and ceramic layer materials are plated on a metal surface; the adhesive layer materials include the following materials in percentage by weight: 15-30% of Co, 20-30% of Cr, 6-16% of Al, 0.2-1.0% of Y, and the balance of Ni; and the ceramic layer materials are zirconium oxide (ZrO2 / (5-8%)Y2O3) with stable yttrium oxide. The prepared zirconium oxide thermal barrier coating has compactness, good combining capacity with a base body and good thermal cycle resisting capacity and high temperature corrosion resisting capacity.

Owner:沈阳天贺新材料开发有限公司

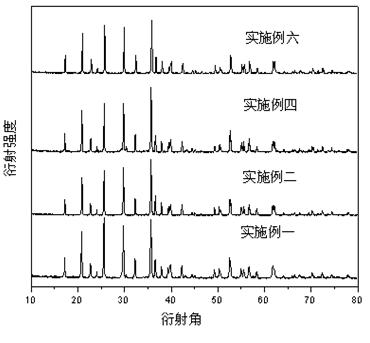

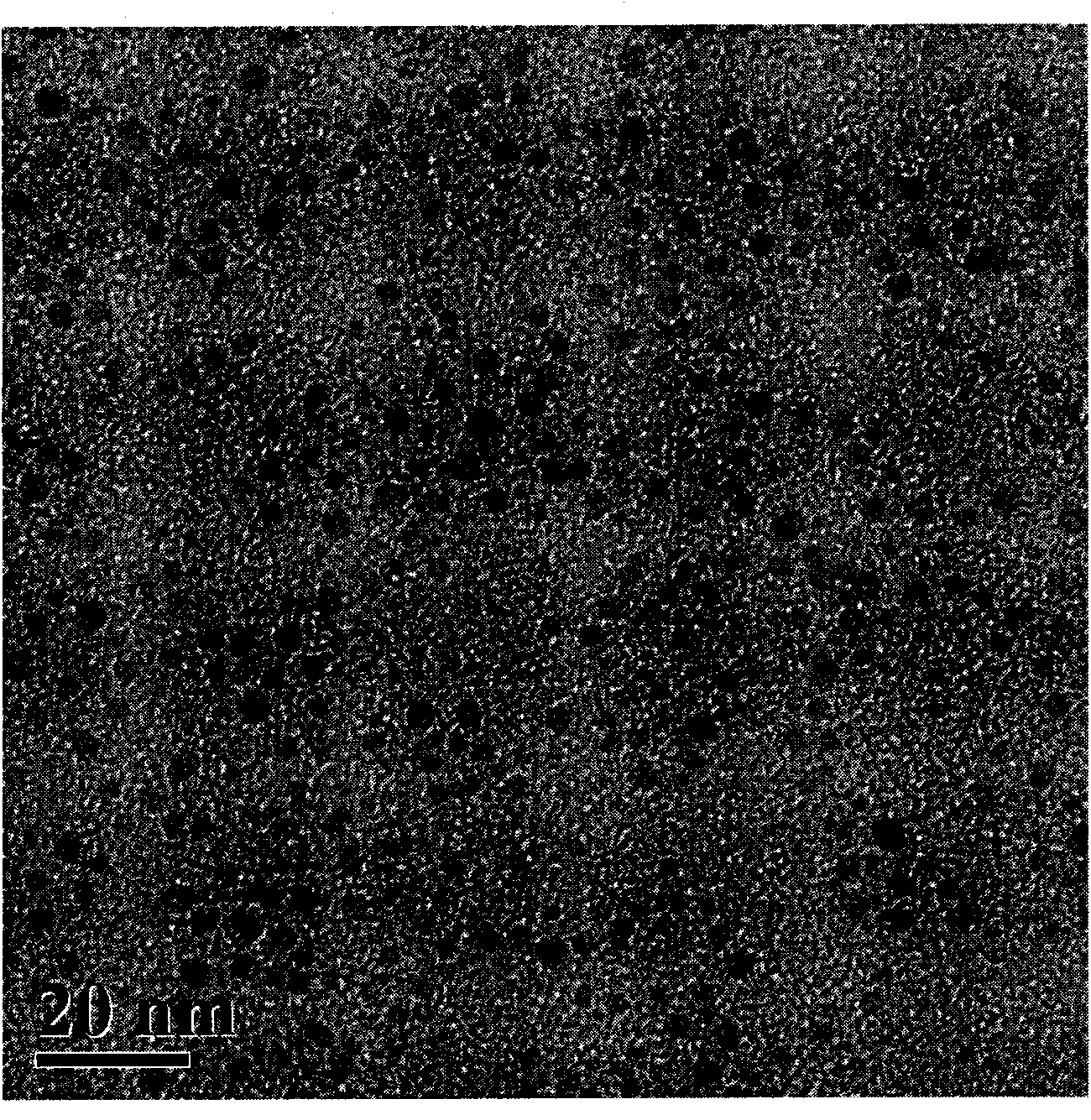

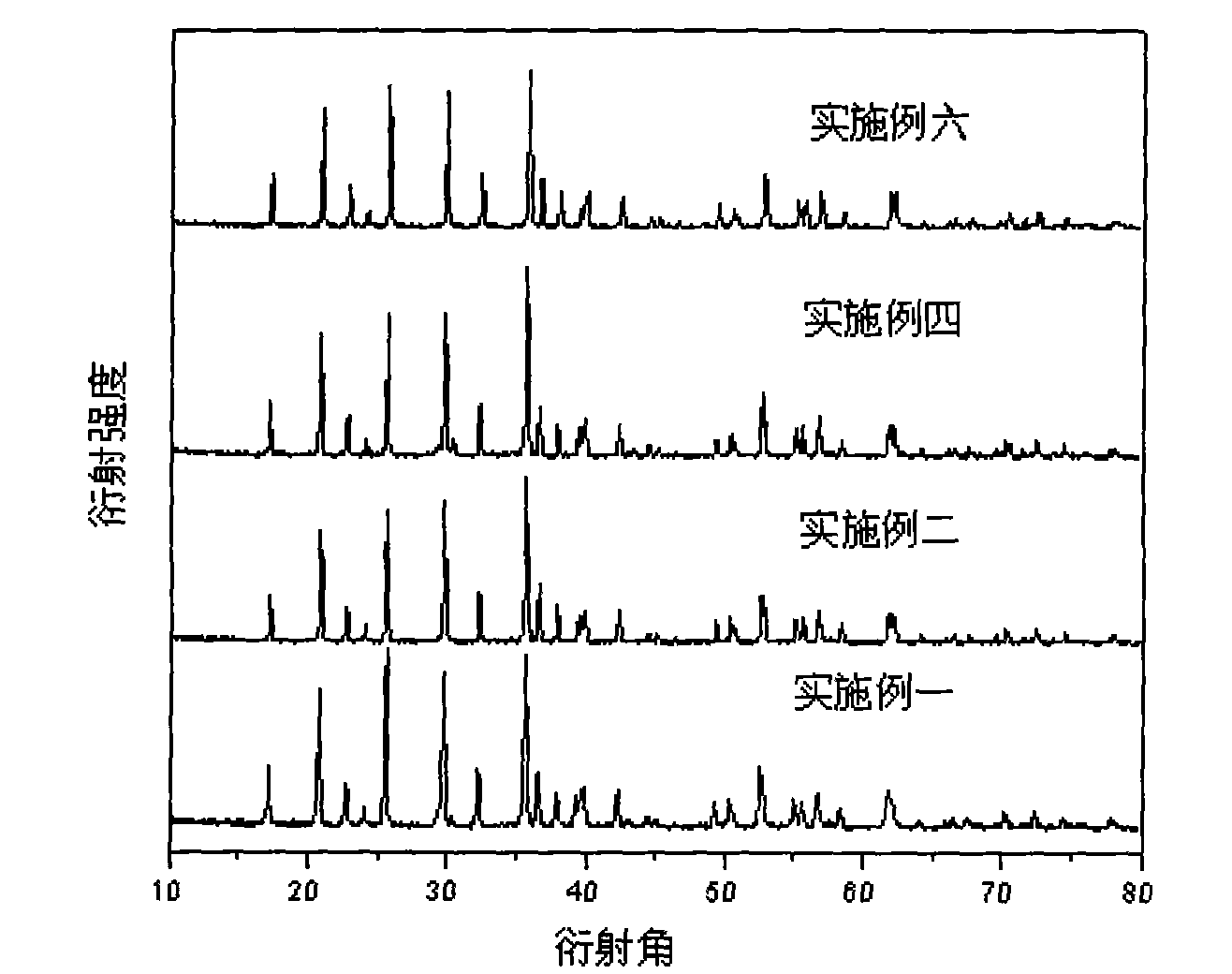

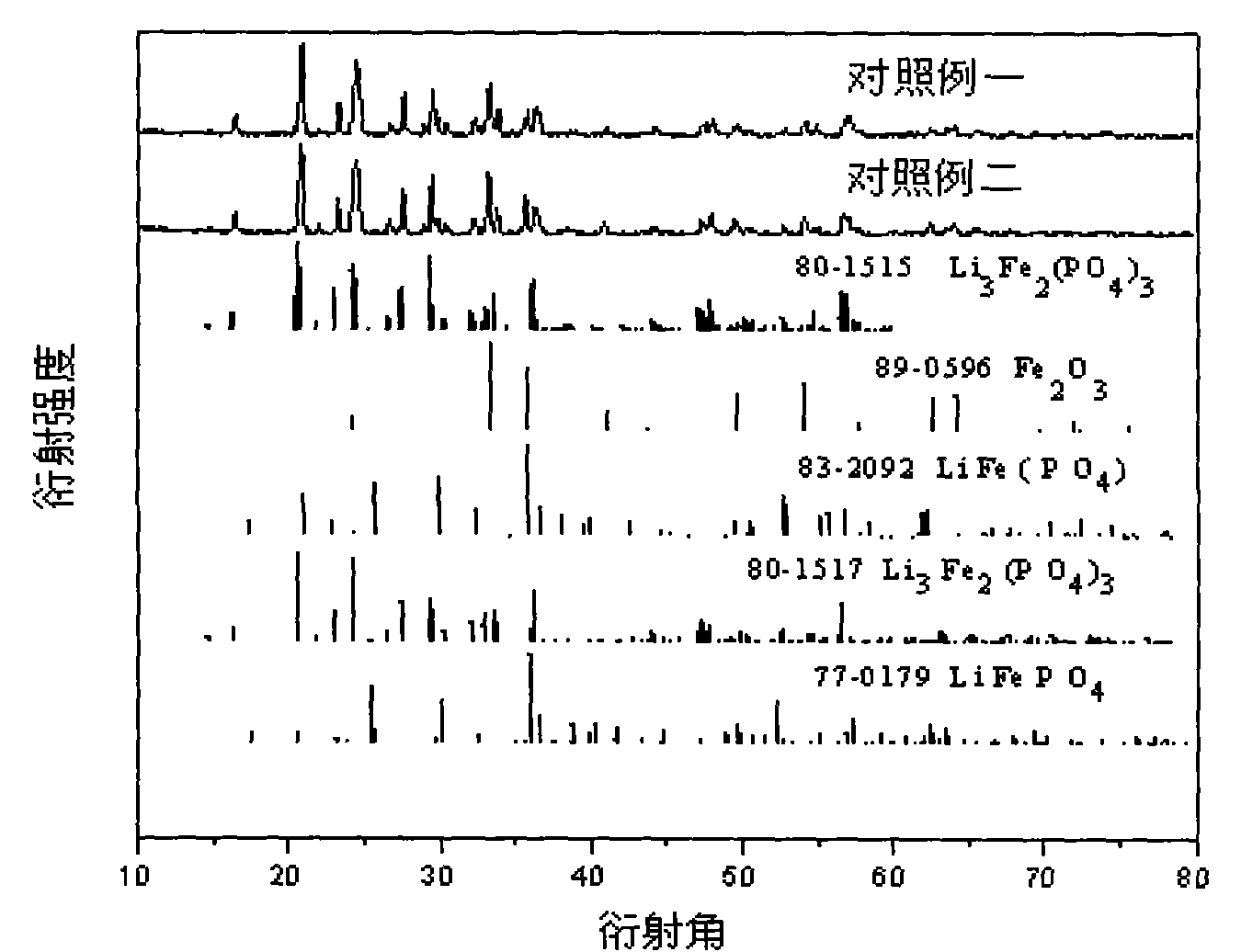

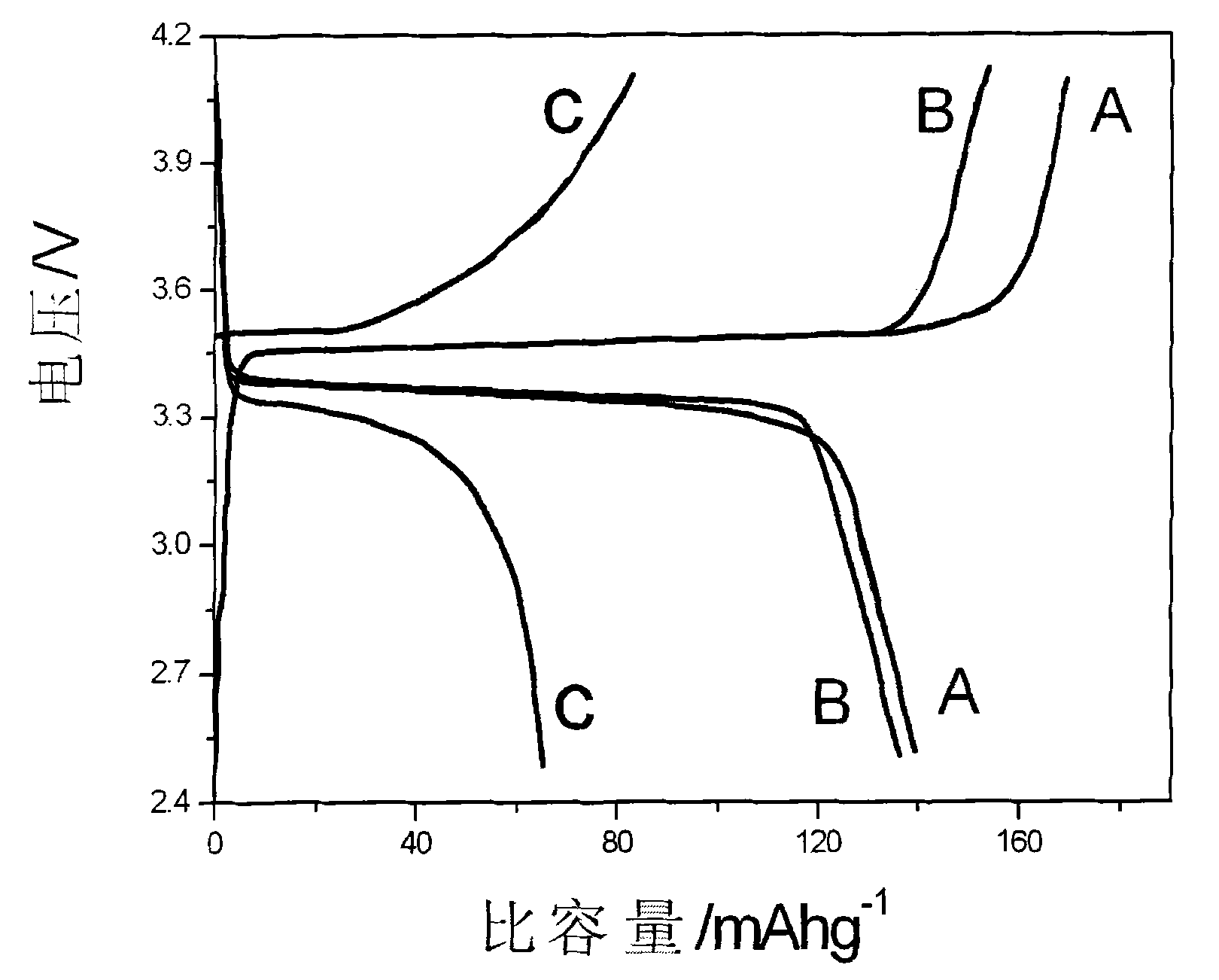

Preparation method of anode active material lithium iron phosphate of lithium battery

InactiveCN102651474AComposition controllableUniform compositionCell electrodesLithium iron phosphatePhysical chemistry

The invention discloses a preparation method of an anode active material lithium iron phosphate of a lithium battery and relates to a method for preparing an anode active material lithium iron phosphate of a secondary lithium battery by a solution-spray drying-roasting method. The preparation method is characterized in that an iron salt, a lithium salt and a phosphoric acid which are soluble, and a metal source and a carbon source precursor which are selectively added are taken as raw materials in the preparation process and the preparation process comprises the following steps of: preparing the raw materials into a mixed solution; carrying out spray drying on the mixed solution to obtain powder; and then carrying out roasting under protective atmosphere, thus preparing the anode active material lithium iron phosphate of the lithium battery. By virtue of the preparation method, high-property lithium iron phosphate powder with controllable and uniform components and fine crystal grains can be obtained, and the lithium iron phosphate powder can serve as the high-quality anode active material of the secondary lithium battery. The preparation method is available for production in batches.

Owner:SICHUAN KENENG LITHIUM BATTERY

Method for preparing load type high-dispersion multi-component precious metal nanoparticle catalyst

InactiveCN102974365AGood dispersionUniform particle size distributionMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureSurface-active agents

The invention relates to a method for preparing a load type high-dispersion multi-component precious metal nanoparticle catalyst. The method comprises the steps of 1) under inert atmosphere, uniformly stirring a solvent and a surface active agent, then adding a precious metal precursor solution, rising the temperature, reacting for a certain period of time, cooling to the room temperature, adding normal hexane, and performing extraction layering; 2) uniformly mixing the obtained upper layer nanoparticle solution with a carrier, and stirring or performing ultrasonic treatment; and 3) centrifugating, washing and drying or baking the mixed solution to obtain the catalyst. For the precious metal catalyst, even under a relatively high carrying amount, relatively good precious metal nanoparticle dispersion degree can be still guaranteed; the particle sizes of the particles are uniformly distributed; the precious metal carrying amount is controlled easily and accurately; the particle sizes and the components of multi-component particles can be controlled; and the catalysis application range is wide. The process is simple; the preparation cost is low; the applicability is high; and load-type high-dispersion precious metal and the multi-component precious metal nanoparticle catalyst can be prepared in a large scale.

Owner:TIANJIN POLYTECHNIC UNIV

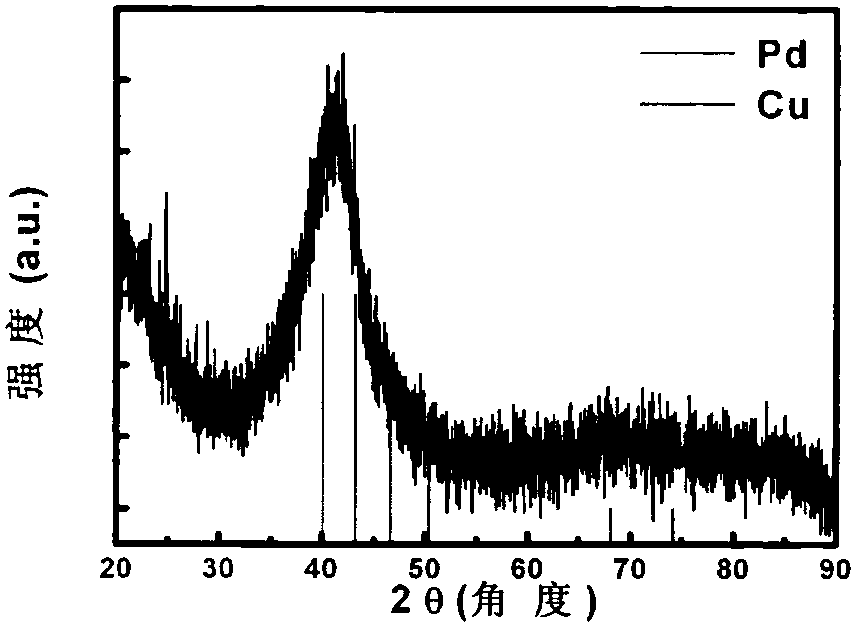

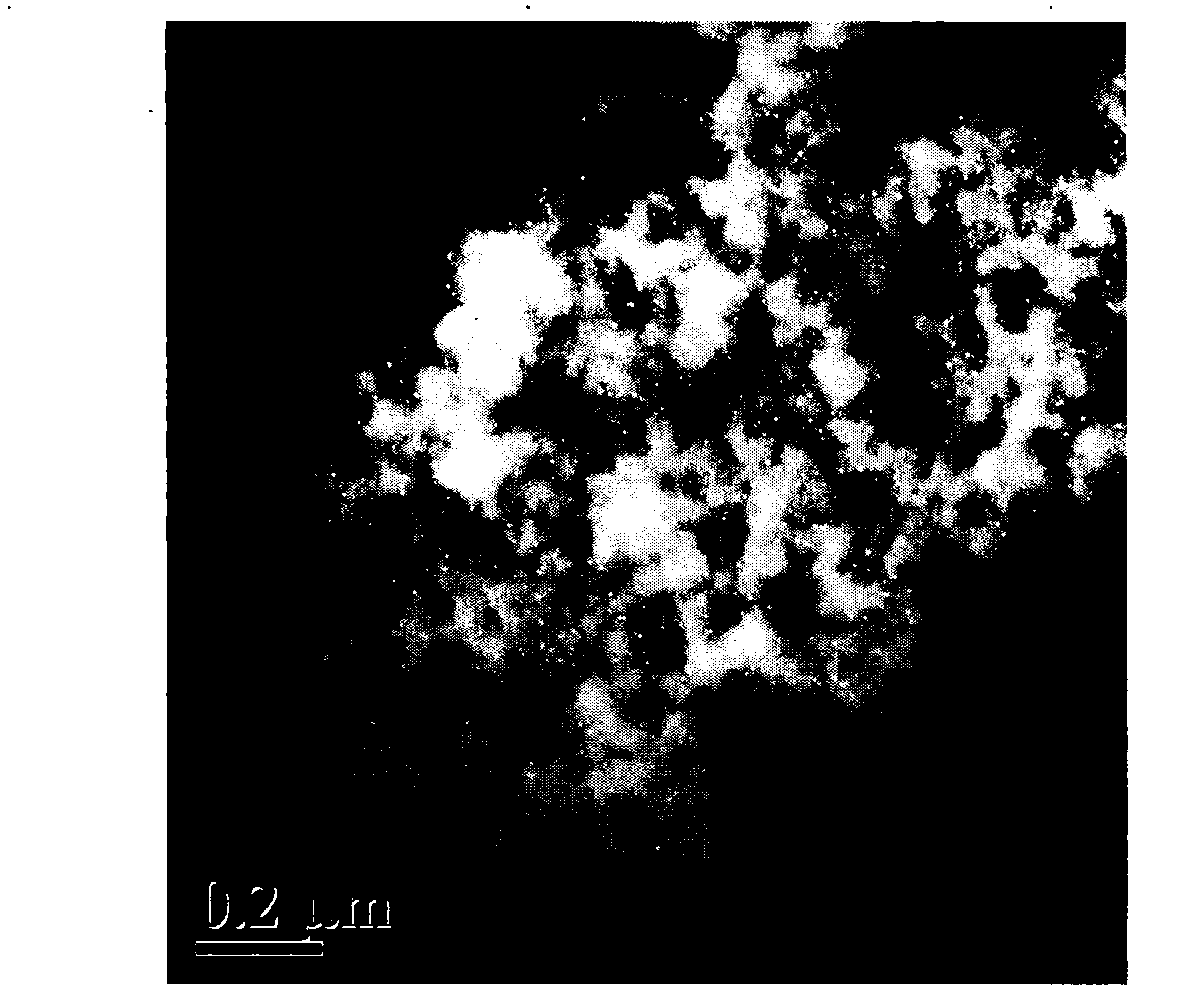

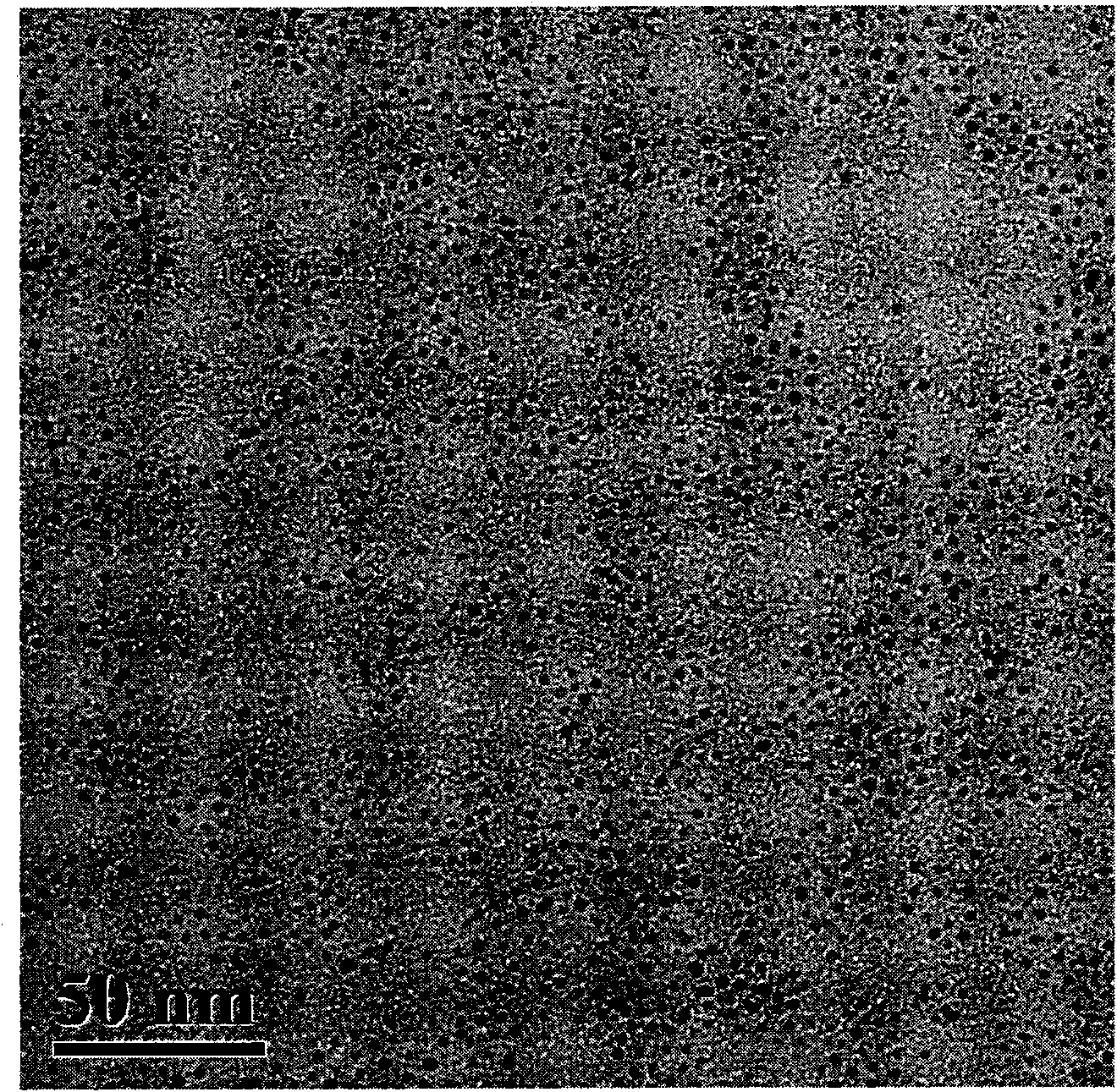

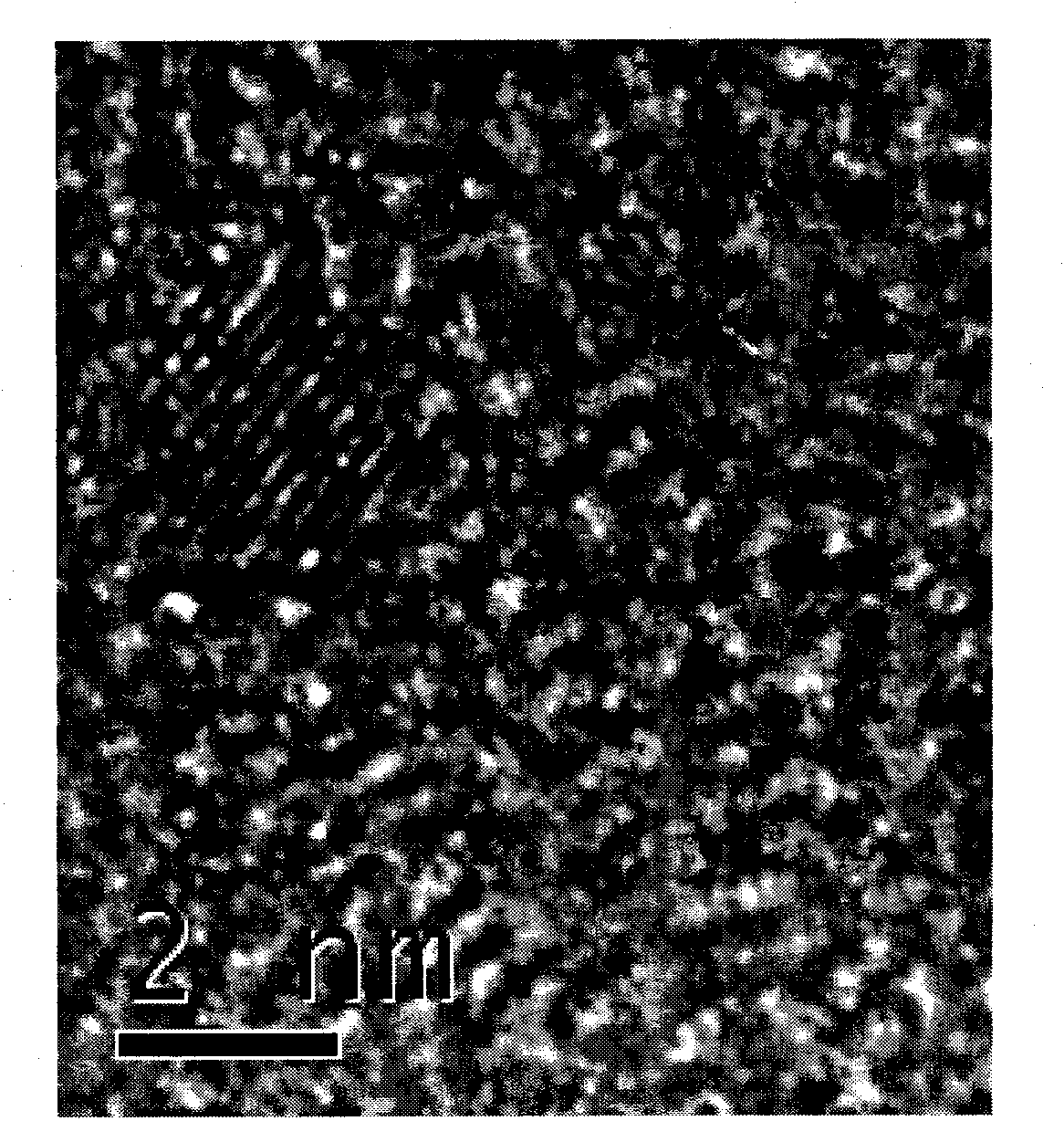

Method for preparing high-dispersion precious metal and alloy nanoparticles thereof

The invention relates to a method for preparing a high-dispersion precious metal and alloy nanoparticles thereof, which comprises: 1) uniformly stirring glycol and specific surfactant in a certain proportion in an inert atmosphere to prepare milky emulsion; 2) adding solution of precursor of the precious metal into the mixed solution, heating the resulting solution to a given temperature, keeping the temperature for a certain time period with stirring, cooling to room temperature, adding nonpolar solution and extracting; and 3) performing the rotary evaporation of upper solution to remove solvent, washing with ethanol or mixed solution of ethanol and normal hexane, centrifuging and obtaining the high-dispersion precious metal and the alloy nanoparticles thereof. The nanoparticles prepared by the method have uniform particle size and high monodispersity, and can be separated easily; the alloy is controllable in particle size and composition; the process is simple; the preparation cost is low; the solvent system is cheap; and the method is widely applicable and can realize large-scale preparation easily.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

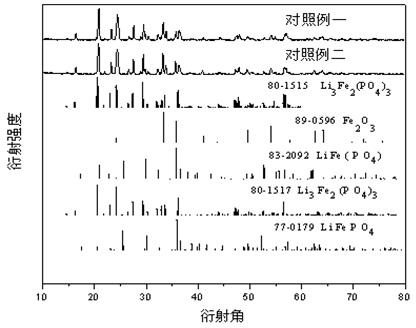

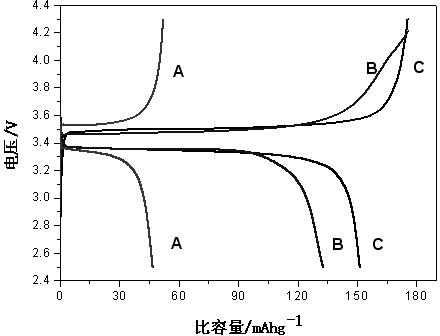

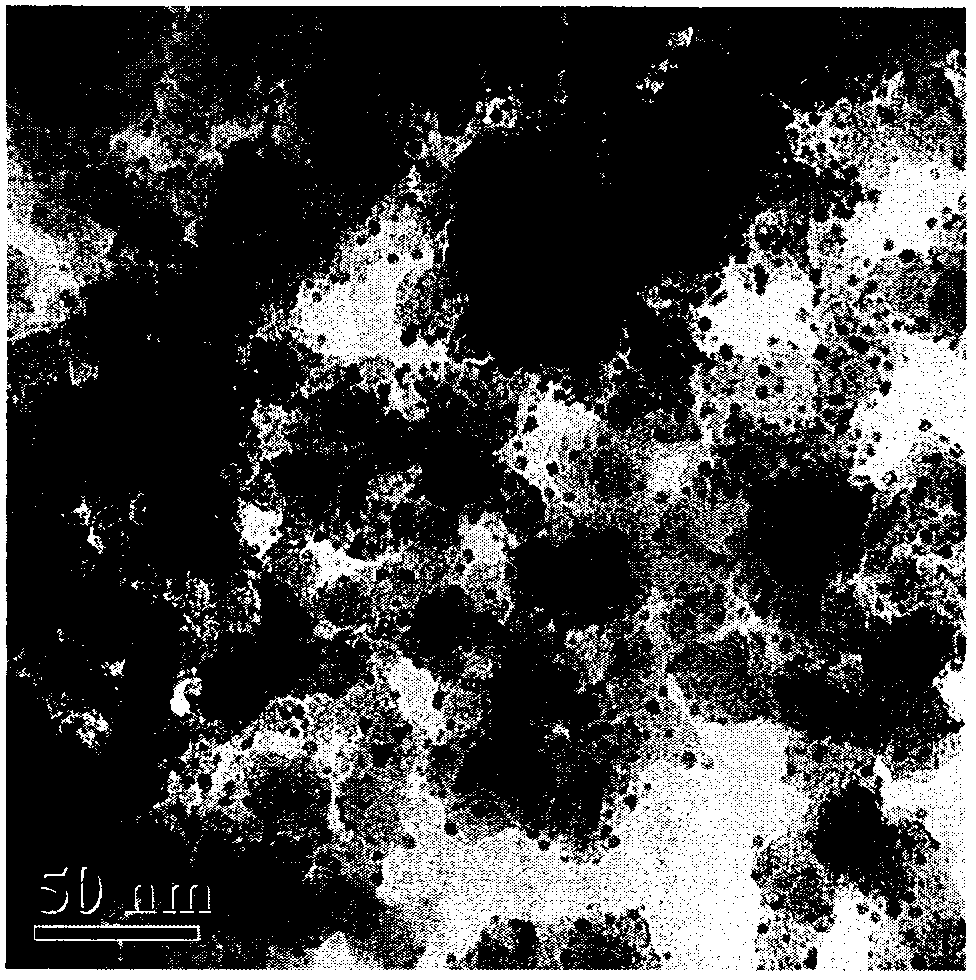

Method for preparing lithium iron phosphate serving as positive active material of lithium battery

InactiveCN101814600AImprove conductivityComposition controllableCell electrodesPhosphoric acidHYDROSOL

The invention discloses a method for preparing lithium iron phosphate serving as a positive active material of a lithium battery, and relates to a method for preparing lithium iron phosphate serving as a positive active material of a high-power lithium ion secondary battery by adopting a sol self-propagation method. The method is characterized by comprising the following preparation processes: manufacturing sol by using soluble iron salt, lithium salt, phosphoric acid, complexing agent and doped metal source and carbon source precursors as raw materials, concentrating the sol, and then initiating self-propagation combustion at the temperature of between 650 and 750 DEG C to synthesize olivine-type pure lithium iron phosphate, doped lithium iron phosphate or composite powder of carbon and one of the olivine-type pure lithium iron phosphate and the doped lithium iron phosphate. By using the method of the invention, the self-propagation combustion is directly initiated at the background temperature of between 650 and 750 DEG C in the non-oxidizing atmosphere without a gel process, so high-performance lithium iron phosphate powder with controllable components, uniformity and fine grains in 3 to 60 minutes can be obtained, wherein the lithium iron phosphate powder can be used as the high-quality positive material of the secondary lithium battery. The method can be used for batch production.

Owner:SICHUAN NON FERROUS METALLURGY RES

Silicon nitride porous ceramics and its preparing method

The porous silicon nitride ceramic is prepared with C and CO2 in 75-95 wt%, silicon nitride 1-10 wt%, and sintering assistant 2-20 wt%. The C / CO2 weight ratio is 0.4-0.6; and the sintering assistant is at least one the metal oxides Y2O3, Al2O3 and MgO. The preparation process includes the following steps: ball milling the materials, drying and sieving to obtain mixture powder; pressure forming in mold; and sintering in a nitrogen atmosphere furnace through raising temperature at the rate of 600deg.c / hr to 1500deg.c, further raising temperature at the rate of 180deg.c / hr to 1700-1800deg.c, and maintaining at nitrogen pressure of 6-10 atm for 2-8 hr to obtain the sintered body. The porous silicon nitride ceramic may be used as base filter material for separating gas in high temperature and corrosive atmosphere, heat resisting material and reinforcing material in gas turbine, engine, space shuttle, etc.

Owner:XI AN JIAOTONG UNIV

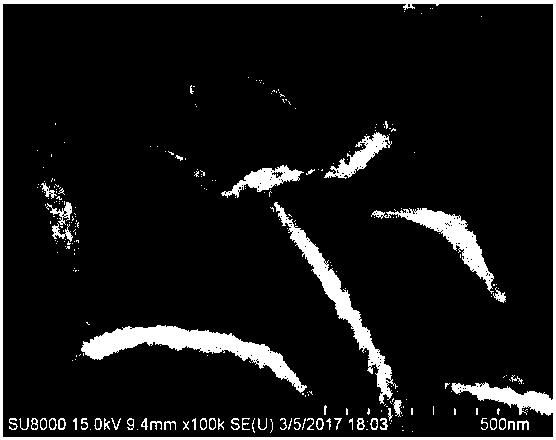

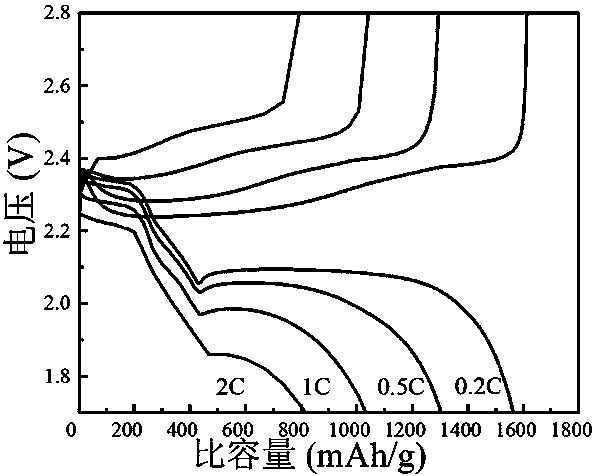

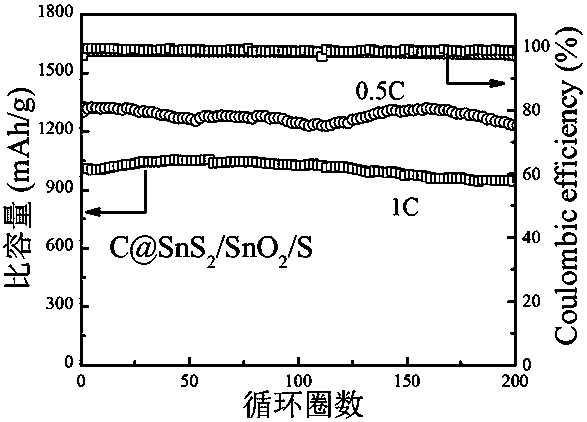

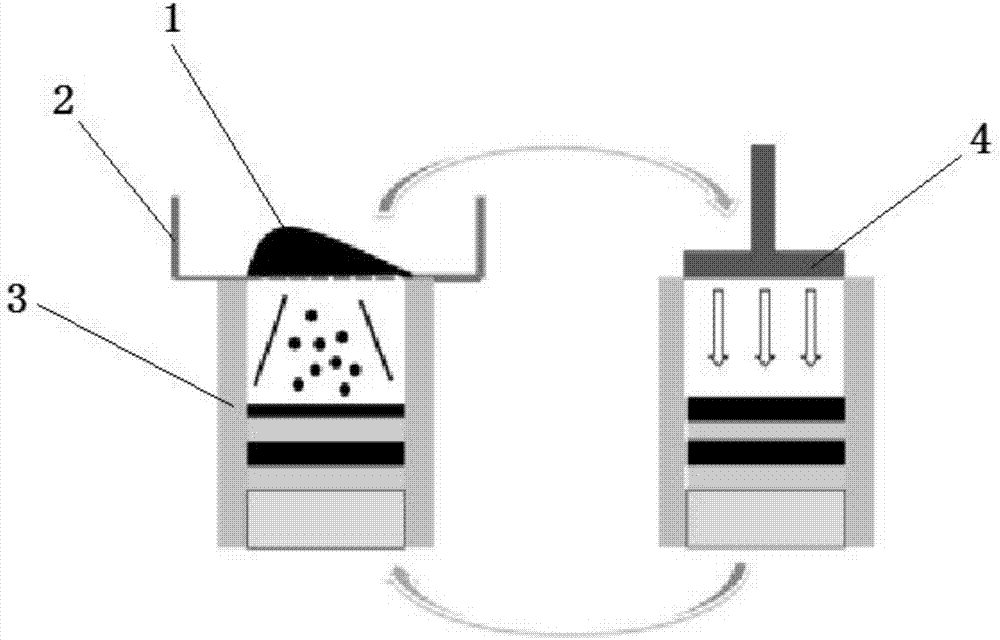

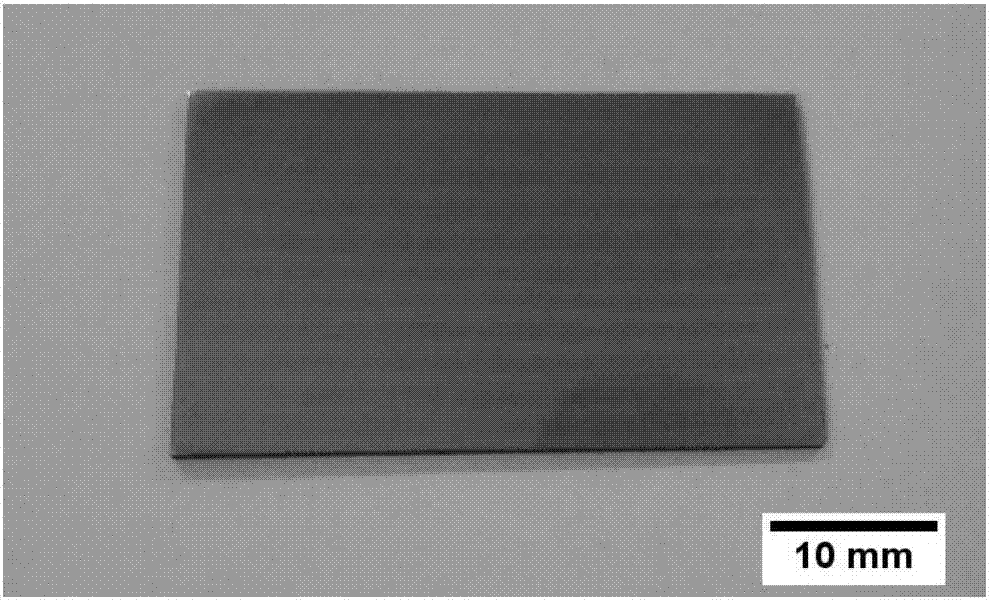

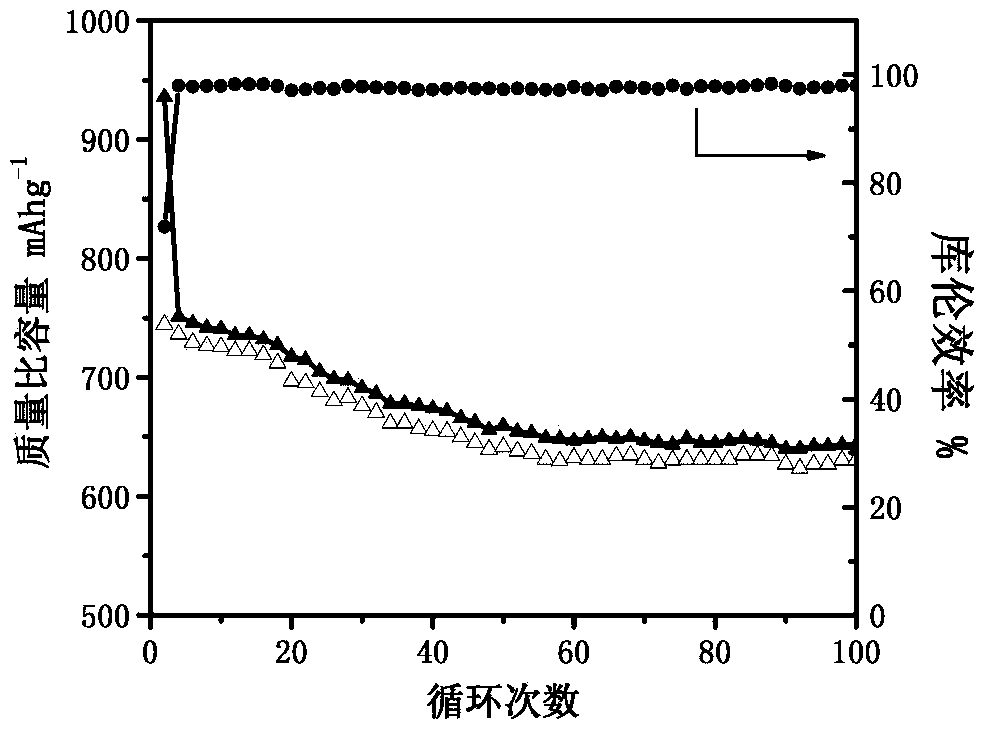

Preparation method and application of carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with heterojunction structure

ActiveCN107768620AGood adsorption capacity of lithium polysulfideImprove stabilityMaterial nanotechnologyLi-accumulatorsHeterojunctionTin dioxide

The invention relates to a preparation method and application of a carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with a heterojunction structure, and belongs to the technical field of an energy material. The method comprises the following steps: 1, dissolving tin tetrachloride, thioacetamide and carbon nanofiber into polypropyl alcohol and performing hydrothermal reaction to obtain a carbon nanofiber, tin disulfide and tin dioxide composite material with the heterojunction structure; 2, dipping the composite material obtained in the step 1 into a sulfur solution, taking out after 5 minutes, vacuum-drying and calcining at high temperature to obtain the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure. The preparation method and the application of the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure have the following advantages: the composite material has special interface effect, can effectively increase electrode surface electron and ion transmission speed and is favorable for realize efficient utilization of the sulfur and obtainingthe cyclic stable lithium sulfur battery. The composite material can be prepared by directly utilizing a one-step hydrothermal method, the preparation method is simple and practical, and the components are controllable.

Owner:HARBIN INST OF TECH

Method for preparing layered titanium-based composite material based on powder laying - hot pressing sintering

ActiveCN106853530AGuaranteed interface bonding strengthComposition controllableTitanium matrix compositesMaterials preparation

The invention relates to a method for preparing a layered titanium-based composite material based on powder laying - hot pressing sintering. The method aims to solve problems that the interface bonding strength of the layered titanium-based composite material is low, the layer thickness and ingredients of each layer cannot be controlled easily and the material preparation process is complex. According to the method, in a powder mixing - powder layering - hot pressing sintering mode, after titanium alloy powder and an enhanced body are evenly mixed, manual powder laying is performed, the process of preparing a blocky material is omitted, each layer of material does not need to be prepared in advance and the titanium-based composite material is prepared through direct hot pressing sintering. By adjusting the content of the enhanced body and powder laying parameters, preparation of the layered material with the controllable ingredients and the adjustable layer thickness is implemented. The method is used for preparing the layered titanium-based composite material.

Owner:HARBIN INST OF TECH

Method for electro-deposition of magnesium nickel alloy in ionic liquid

InactiveCN103422123AImprove the kinetic performance of hydrogen storageComposition controllableNickel saltMagnesium salt

The invention relates to a method for electro-deposition of magnesium nickel alloy in ionic liquid, and belongs to the technical field of metal materials. The method for electro-deposition of the magnesium nickel alloy in the ionic liquid comprises the steps that (1) magnesium salt, nickel salt and additives are added to the ionic liquid in sequence through protection of inert gas, even mixing is carried out to obtain an ionic liquid electrolyte, (2) a preprocessed matrix serves as a cathode, metallic nickel, magnesium and graphite or other inert materials serve as an anode, constant-current deposition is carried out in the obtained ionic liquid electrolyte for 2-6 hours under the conditions that the current density is 10-100A / m<2>, and the temperature is 20-100DEG C, the cathode is taken out, washing and drying are carried out, and the magnesium nickel alloy can be obtained on the surface of the cathode matrix. The method for electro-deposition of the magnesium nickel alloy in the ionic liquid solves the problems that when a high-temperature melting method is used for preparing the magnesium nickel alloy, components cannot be easily controlled, and energy consumption is high, and the problems that mechanical alloying is high in equipment requirement, impurities can be easily introduced, and cost is high.

Owner:KUNMING UNIV OF SCI & TECH

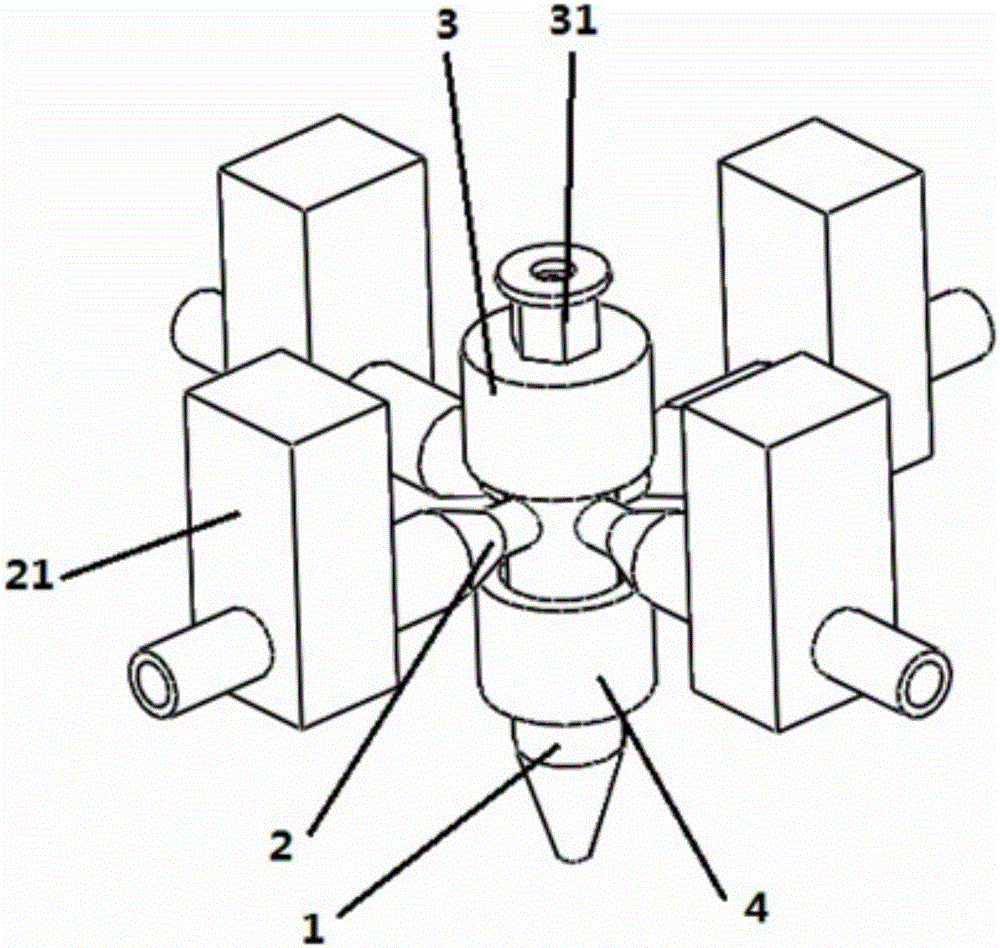

Multi-material 3D printing sprayer and operating method thereof

InactiveCN106393679ASolve printing problemsSimple structure3D object support structuresApplying layer meansState of artMulti material

The invention discloses a multi-material 3D printing sprayer and an operating method thereof. The multi-material 3D printing sprayer comprises a sprayer body, a plurality of feeding channels, a sprayer cover and an ultrasonic oscillating ring, wherein the sprayer cover is mounted on the sprayer body; the feeding channels are arranged on a cylindrical surface above the sprayer body in a surrounding mode in the circumferential direction, communicate with an inner cavity of the sprayer body, and are located below the sprayer cover and above the ultrasonic oscillating ring; and the upper portion of a discharging port of the sprayer body is sleeved with the ultrasonic oscillating ring. According to the multi-material 3D printing sprayer and the operating method thereof, the single sprayer body connected with the multiple feeding channels is arranged, and the ultrasonic oscillating ring is mounted on the upper portion of the discharging port for uniform mixing so that mixed printing or separated printing of various materials can be achieved, printing of gradient material products can be completed, and the purpose for printing the gradient material products in the prior art is effectively achieved; the multi-material 3D printing sprayer and the operating method thereof have the advantages that the structure is simple, and the cost is low; and proportional valves are used for controlling the feeding quantities of the feeding channels so that components can be controlled for multi-material printing.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

Preparation of single-component alkali-activated cement and application method thereof

ActiveCN102730996AExpand the range of raw materialsEasy to GrindClinker productionAlkali activatedMixed materials

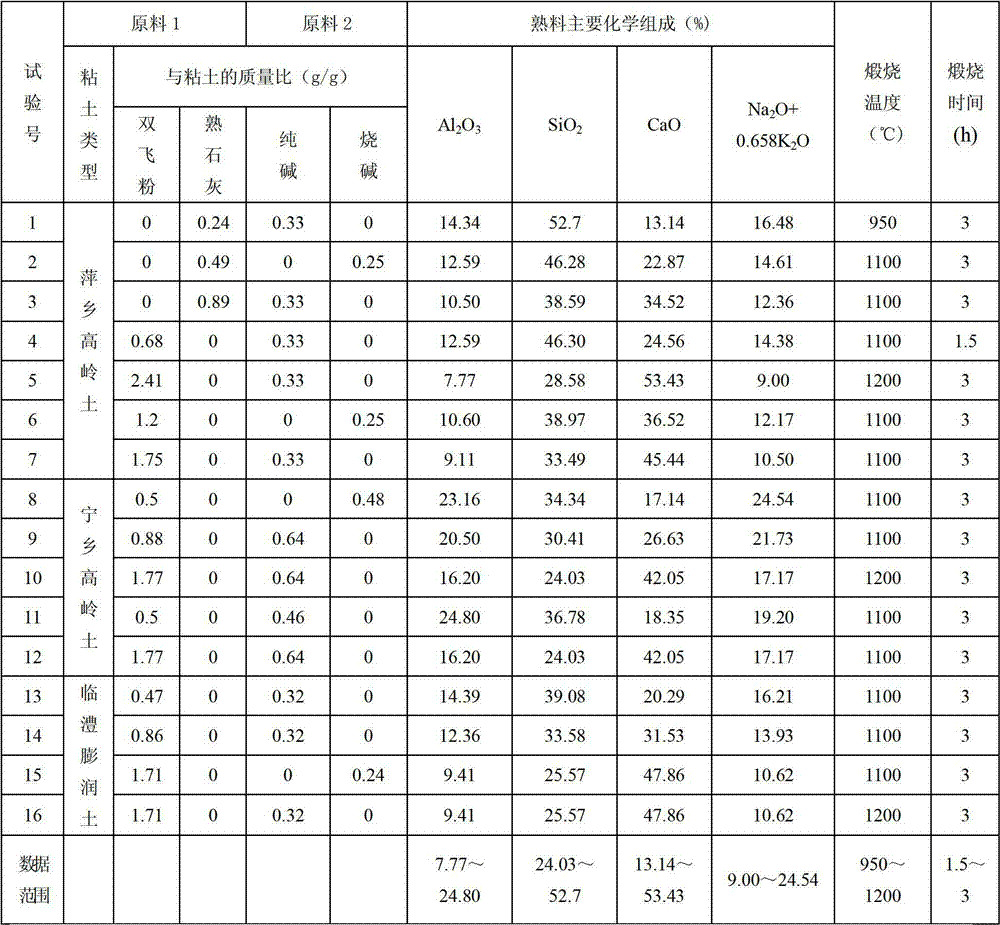

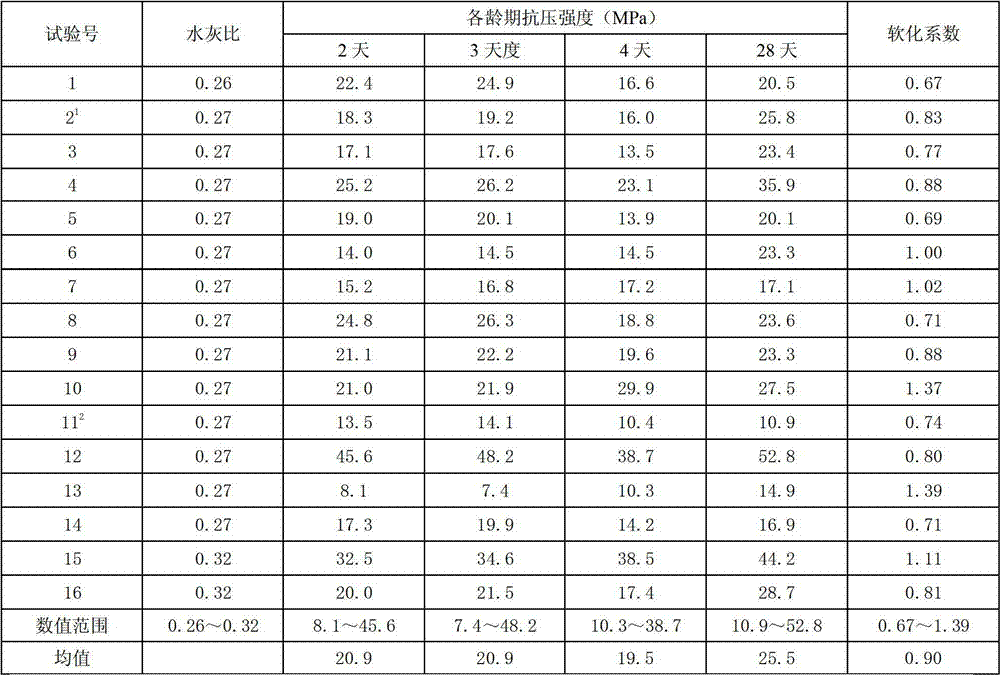

The invention belongs to the novel cement material field and specifically relates to the preparation of a single-component alkali-activated cement and an application method thereof, wherein a raw material 1 including SiO2, Al2O3, and CaO are mixed with the raw material 2 including Na2O in a certain ratio; the ratio should be decided so that the percentage of the weight of each component of the calcined product, which is obtained by calcining the mixed materials at a temperature greater than or equal to 1100 DEG C, in the total weight is as follows: Al2O3: 8-25%; SiO2: 24-55%; CaO: 10-55%; and Na2O +0.658K2O: 6-25%; after being calcined at a temperature ranging from 950-1200 DEG C for 1.5-3 h, the mixed materials are then ground to obtain cement powder; the cement powder is mixed with water into paste; next, the paste is cured at 50-80 DEG C for 2-3 days so that neat cement paste briquettes excellent in strength can be obtained; and the strength can be continuously increased if curing is continuously performed under normal temperature. The preparation of the single-component alkali-activated cement has the following advantages that: the raw material range of the alkali-activated cement is greatly expanded; the storage, transportation and utilization of the cement are more convenient; and the improvement of the cementitious activity of the cement and the reduction of the cost are expected to be realized.

Owner:HUNAN UNIV OF SCI & TECH

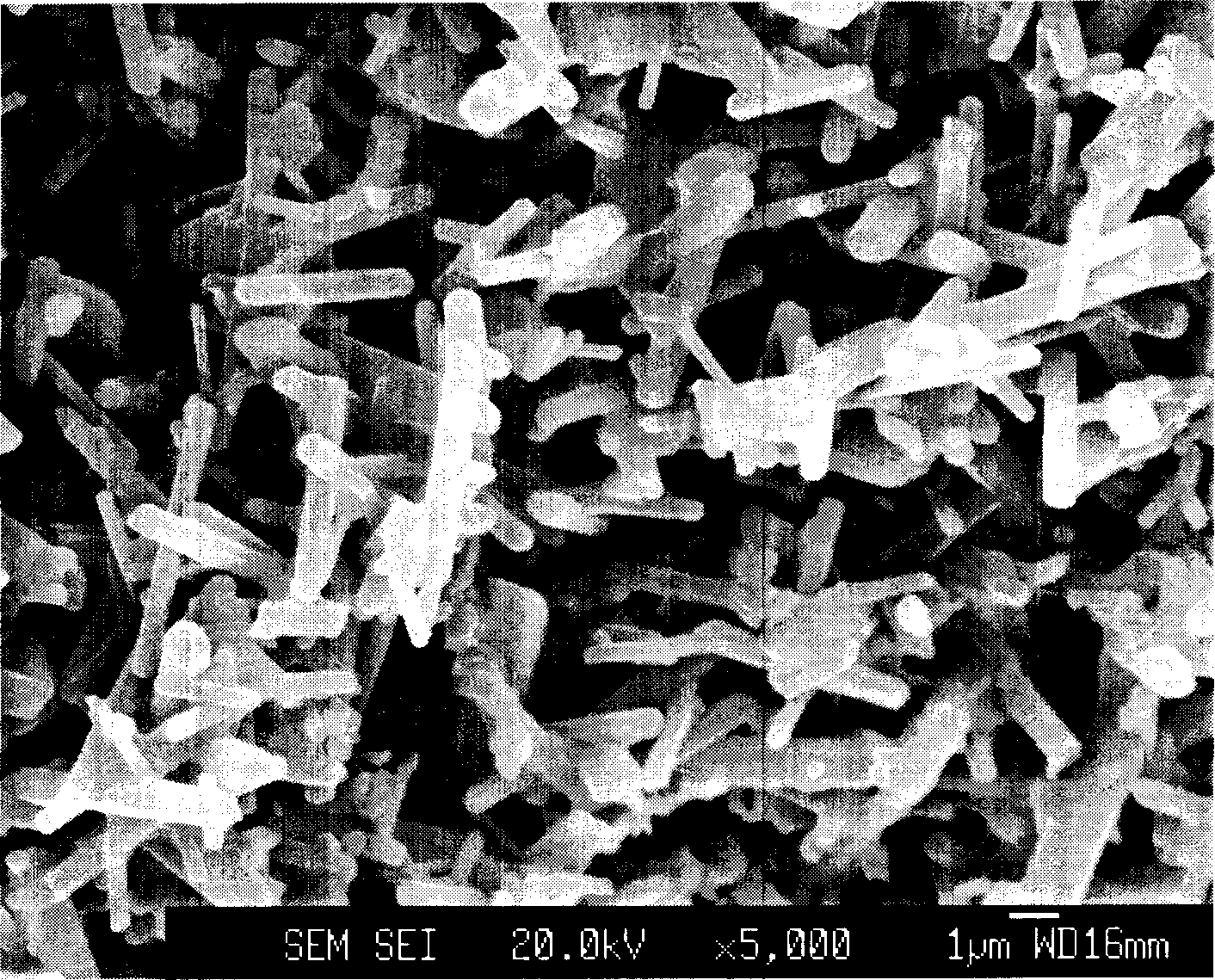

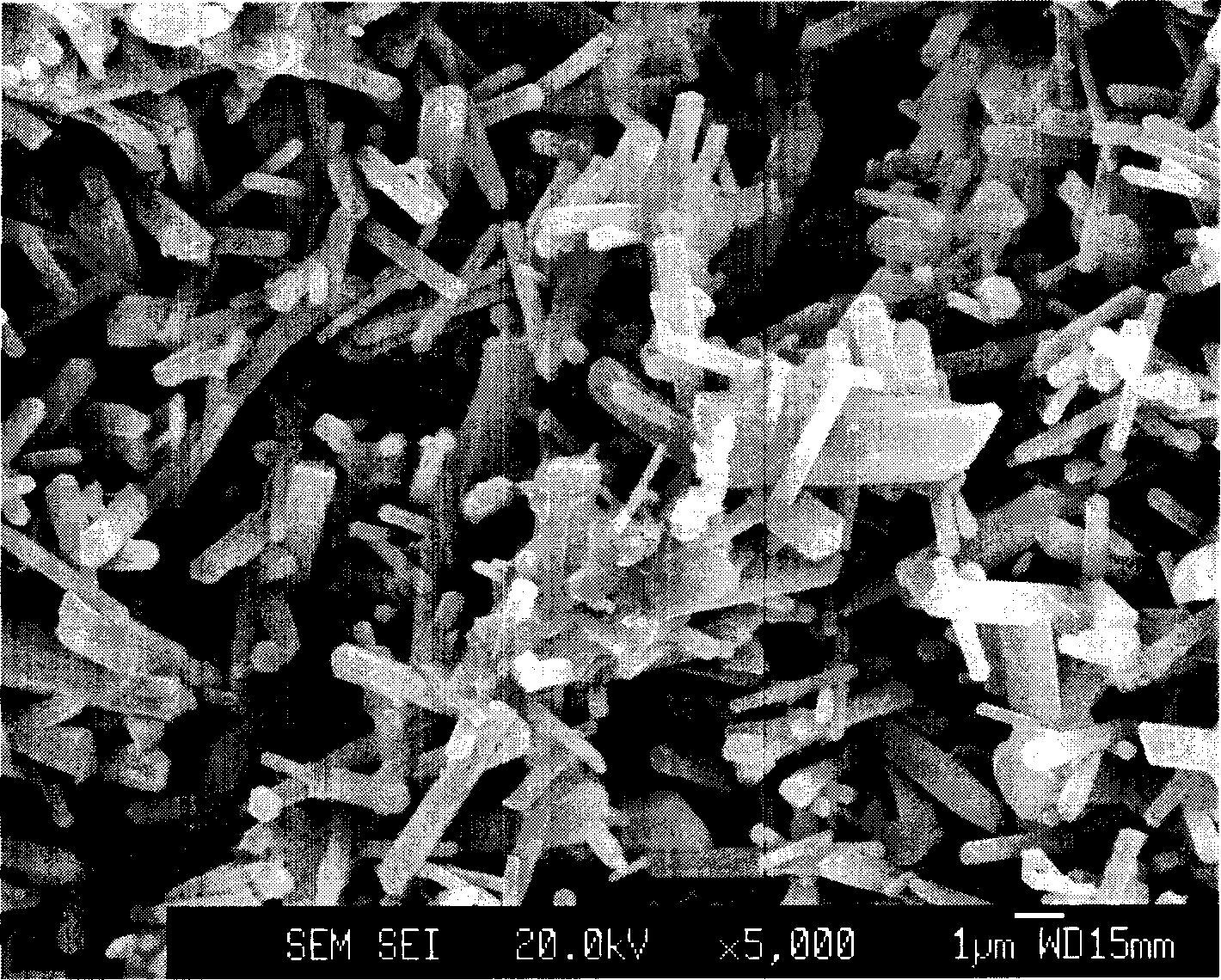

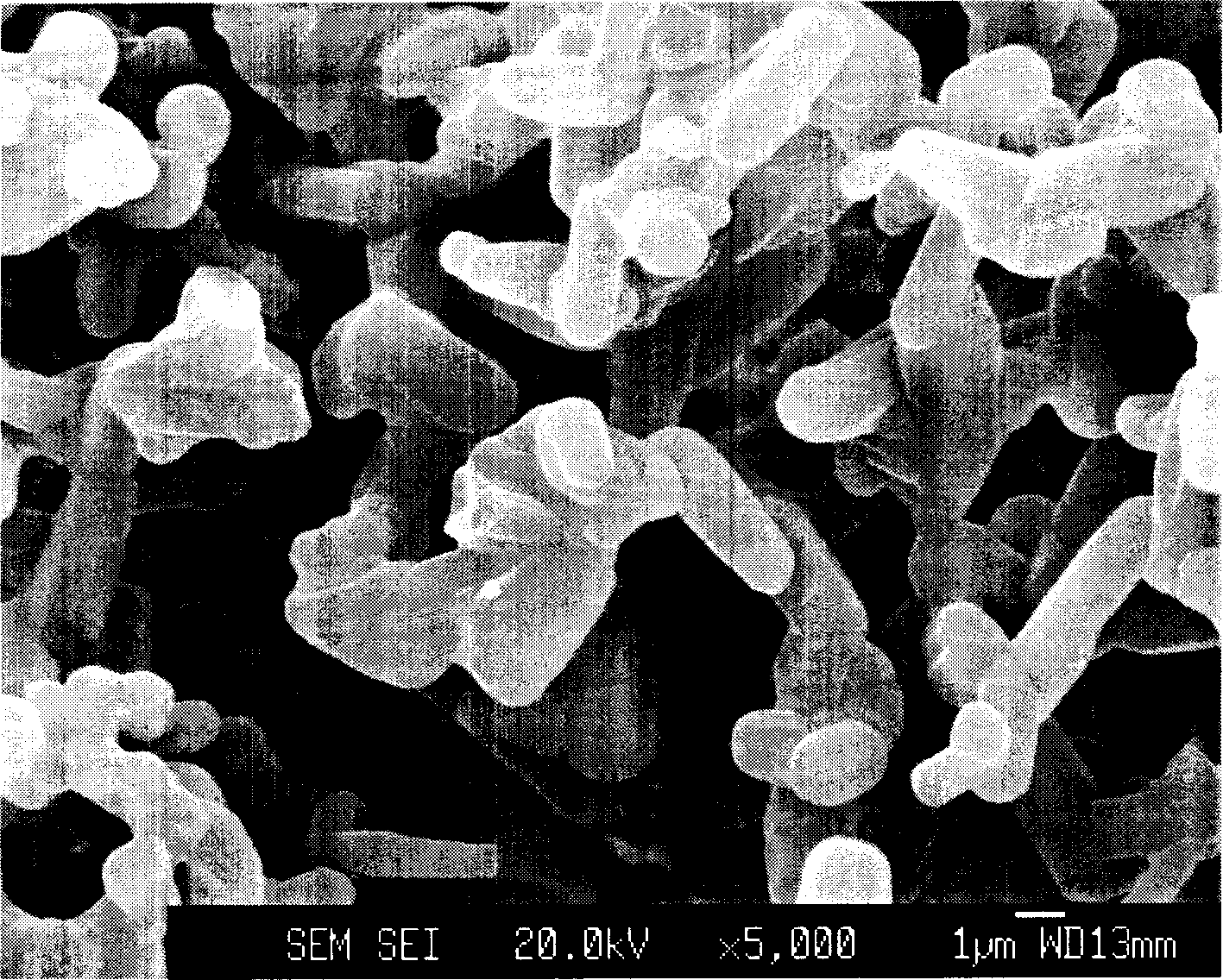

Nb-doped nano indium tin oxide powder and method for preparing high density sputtering coating target thereof

InactiveCN101580379AHigh puritySmall granularityVacuum evaporation coatingSputtering coatingIndiumNiobium

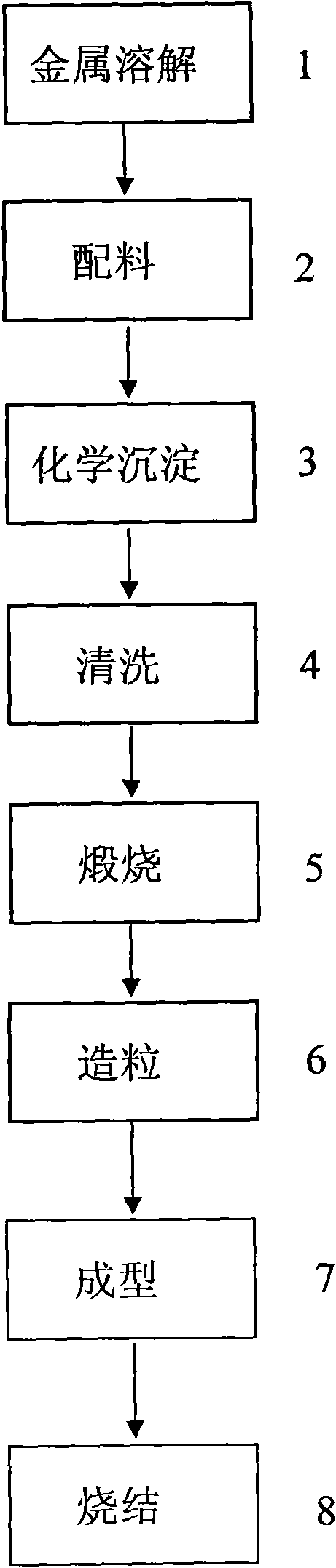

The invention relates to an Nb-doped nano indium tin oxide powder and a method for preparing high density sputtering coating target thereof. The method comprising the following steps: (1) dissolving high pure metals: high pure metal niobium, high pure metal indium and high pure metal tin are respectively dissolved into transparent solutions by inorganic acid; (2) mixing: the obtained transparent solutions are respectively filled into containers according to the proportion; (3) chemical precipitation: the three transparent solutions are made into Nb-doped and heavily tin-doped indium hydroxide nano-powder; (4) washing: the Nb-doped and heavily tin-doped tin indium hydroxide nano-powder is washed by de-ionized water and then precipitated; (5) calcinating: the nano-powder is calcined, and the Nb-doped nano indium tin oxide powder is prepared; (6) granulation: the Nb-doped nano indium tin oxide powder is added with a bonding agent and then dried, so that Nb-doped nano indium tin oxide powder before molding can be prepared; (7) molding: the Nb-doped nano indium tin oxide powder before molding is pressed into early embryo; (8) sintering: the early embryo is sintered under the normal pressure, and the high density sputtering coating target of the Nb-doped indium tin oxide can be prepared; in addition, pressure sintering can be adopted to further improve the density of the target.

Owner:BEIHANG UNIV +1

Silicon heterojunction solar cell with electroplating electrode and manufacturing method thereof

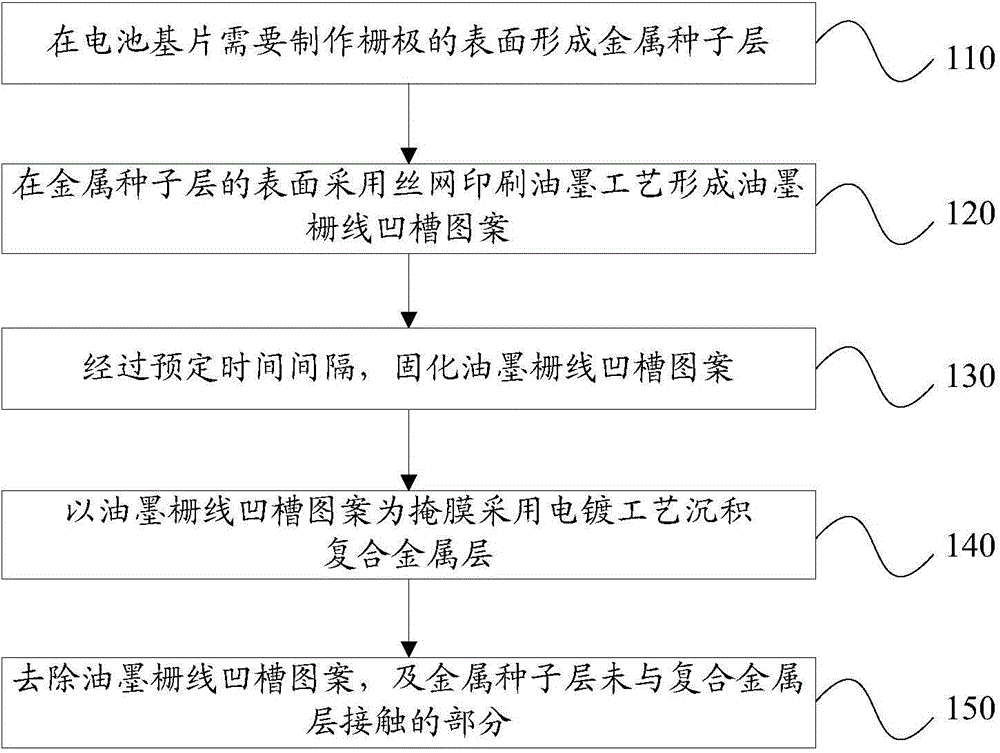

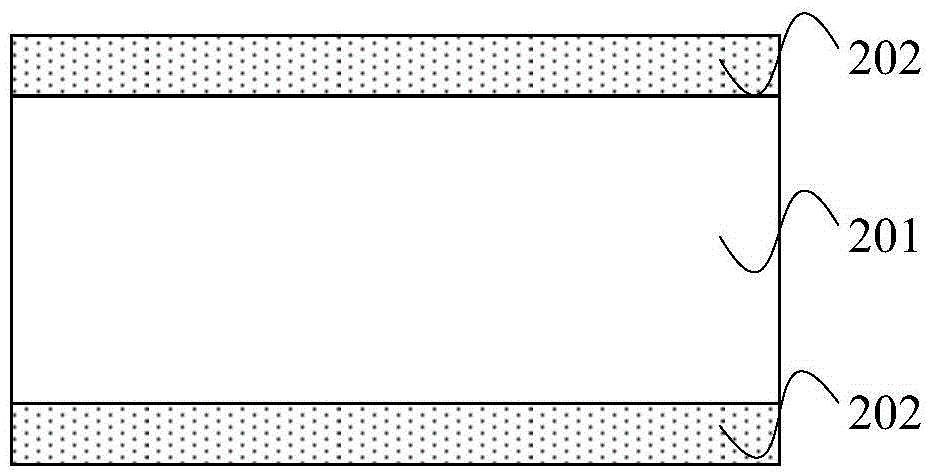

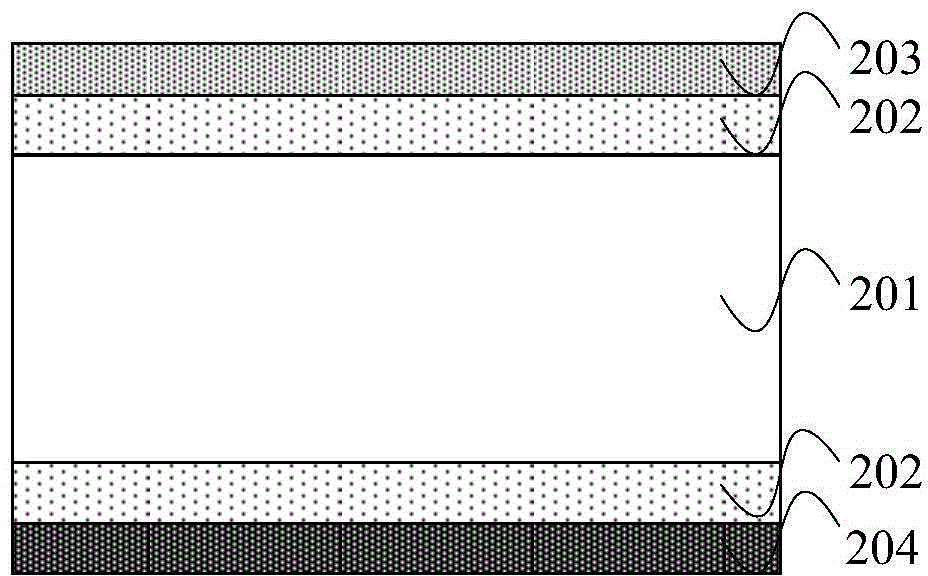

InactiveCN104538495AGood removal effectUniform expansion deformationPhotovoltaic energy generationSemiconductor devicesScreen printingManufacturing technology

The embodiment of the invention discloses a silicon heterojunction solar cell with an electroplating electrode and a manufacturing method thereof. The method comprises the steps that a metal seed layer is formed on the surface, where a grid needs to be manufactured, of a cell substrate; a silk-screen printing ink process is used for forming an ink grid line groove pattern on the surface of the metal seed layer; after a preset time interval, the ink grid line groove pattern is cured; the ink grid line groove pattern is used as a mask film, an electroplating process is used for depositing a composite metal layer; the ink grid line groove pattern and the part, which is not in contact with the composite metal layer, of the metal seed layer is removed. The implementation mode for forming the ink grid line groove pattern by the silk-screen printing ink process is simple and controllable, moreover, ink can be removed easily, and the manufacturing technology is simple. In the curing process, the ink can be evenly expanded and deformed, the width of an opening of the obtained ink grid line groove pattern is small, the depth-width ratio of a formed metal grid line is large, the light shading area is small, and the efficiency of the silicon heterojunction solar cell with the electroplating electrode is improved.

Owner:ENN SOLAR ENERGY

Method for preparing Fe-6.5 wt% Si thin plate using continuous magnetic control sputtering physical gas phase depositing

InactiveCN1944706ADeposited Si with high purityComposition controllableVacuum evaporation coatingSputtering coatingGas phaseSingle crystal

The continuous magnetically controlled sputtering and physically vapor depositing process of preparing Fe-6.5 wt%Si sheet includes the first sputtering with monocrystalline or polycrystalline silicon as the cathode target and low silicon steel strap as the anode to deposit silicon substance on single or double sides of the steel strap, and the subsequent high temperature inward diffusing of silicon atoms until reaching the total silicon content of 6.5 wt % and obtaining high silicon steel strap with excellent soft magnetic performance. The present invention has high work efficiency, easy control of the technological parameters and high product quality, and is suitable for industrial application.

Owner:BEIHANG UNIV

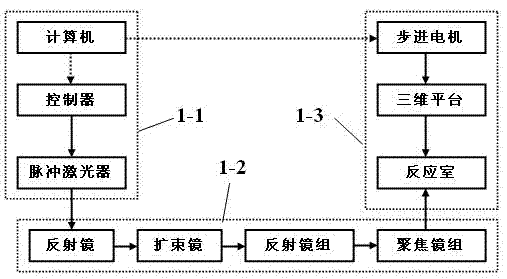

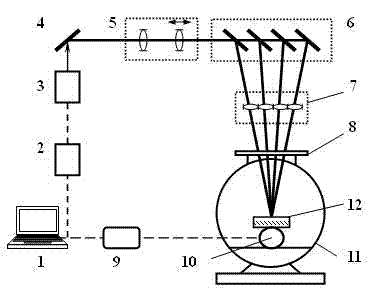

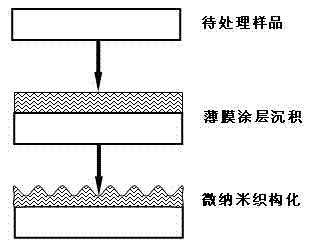

Method and device for preparing film coating micronano texture

InactiveCN102418082AImprove anti-friction and anti-wear propertiesControllable texture sizeDecorative surface effectsNanotechnologySurface engineeringChemical reaction

The invention relates to a method and a device for preparing a film coating micronano texture and belongs to a film coating of surface engineering. The preparation method comprises the steps of preparing at early stage, depositing the film coating, preparing the micronano texture and performing aftertreatment. The special device is a multi-beam pulse laser micronano texture processing system device. The multi-beam pulse laser micronano texture processing system device comprises a pulse laser module, an optical path transmission module and a precise scanning module which are connected with one another sequentially. The invention has the advantages that: the method and the device are convenient in processing and high in efficiency; preparation for the film coating deposition micronano texture on the surface of a material is realized by one laser source; the process is simple, and easy to control; the prepared samples are not subjected to a complex posttreatment process; the application range is wide; ultraviolet pulse laser has the characteristics of large photon energy and short wavelength and can perform precise micronano texture treatment on any materials; chemical reaction of various gases can be induced; and film coating deposition can be performed efficiently.

Owner:CHINA UNIV OF MINING & TECH

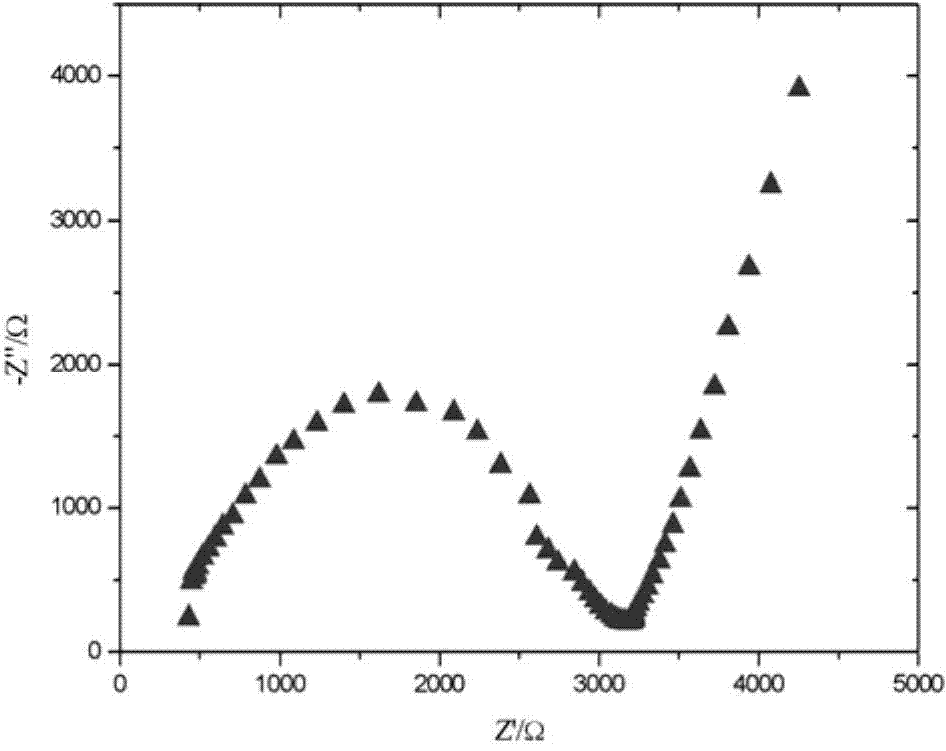

Garnet-structure lithium lanthanum tantalate-based solid electrolyte material and preparation method thereof

InactiveCN103594726AWill not cause churnImprove electrochemical performanceFinal product manufactureElectrolyte accumulators manufactureLanthanumElectrochemistry

The invention discloses a garnet-structure lithium lanthanum tantalate-based solid electrolyte material and a preparation method thereof. The lithium lanthanum tantalate-based solid electrolyte material is a compound of Li5La3Ta2O12 doped at the lanthanum site and / or tantalum site; and the preparation method comprises the following steps: dissolving tantalum pentoxide in a H2C2O4 solution; adding lithium salt and lanthanum slat and the salt of a lanthanum site-doped compound and / or the salt of a tantalum site-doped compound, and mixing to obtain a solution; adding EDTA into the obtained mixed solution for reaction until transparent and clear sol appears; adding a water-soluble high-molecular polymer and continuously reacting until gel appears; drying the obtained gel and calcining; performing mould pressing of the calcined particles to obtain a blank; and further calcining the blank to obtain the solid electrolyte material. The preparation method is mild in conditions, simple in process and simple to operate, and can realize industrial production; the prepared solid electrolyte material has good electrochemical stability and relatively high electrical conductivity, and can be used for preparing an all-solid-state lithium ion battery.

Owner:CENT SOUTH UNIV

Refined-smelting ladle furnace calcium carbide deoxidation method

The invention relates to a calcium carbide oxidizing method of ladle fining furnace. The calcium carbide is completely substituted for aluminum for plain carbon steel, for low silicon aluminum killed steel and pipeline steel, according to the station of slag series, the aluminum of the weigh from 0.4 kg to 0.8 kg is added to the molten steel of per ton, milled on the flux of 500 L per minute of argon gas, then the calcium carbide of the weigh from 0.6 kg to 1.2 kg is also added to the molten steel of per ton, the calcium carbide is used for oxidizing, submerged-arcing and slagging. The method not only lessens the pollution of the lard of aluminum oxide for molten steel, forms foaming slag and benefits for ladle furnace submerged-arc slagging, but also reduces noise, shields the heat radiation of molten steel, saves the power use. At the same time, the method reduces the acid smelting aluminum, the use of calcium wire, enriching-lard, effectually prevents the phenomena of circumfluence from taking place and improves the inherent quality of the billet.

Owner:ANGANG STEEL CO LTD

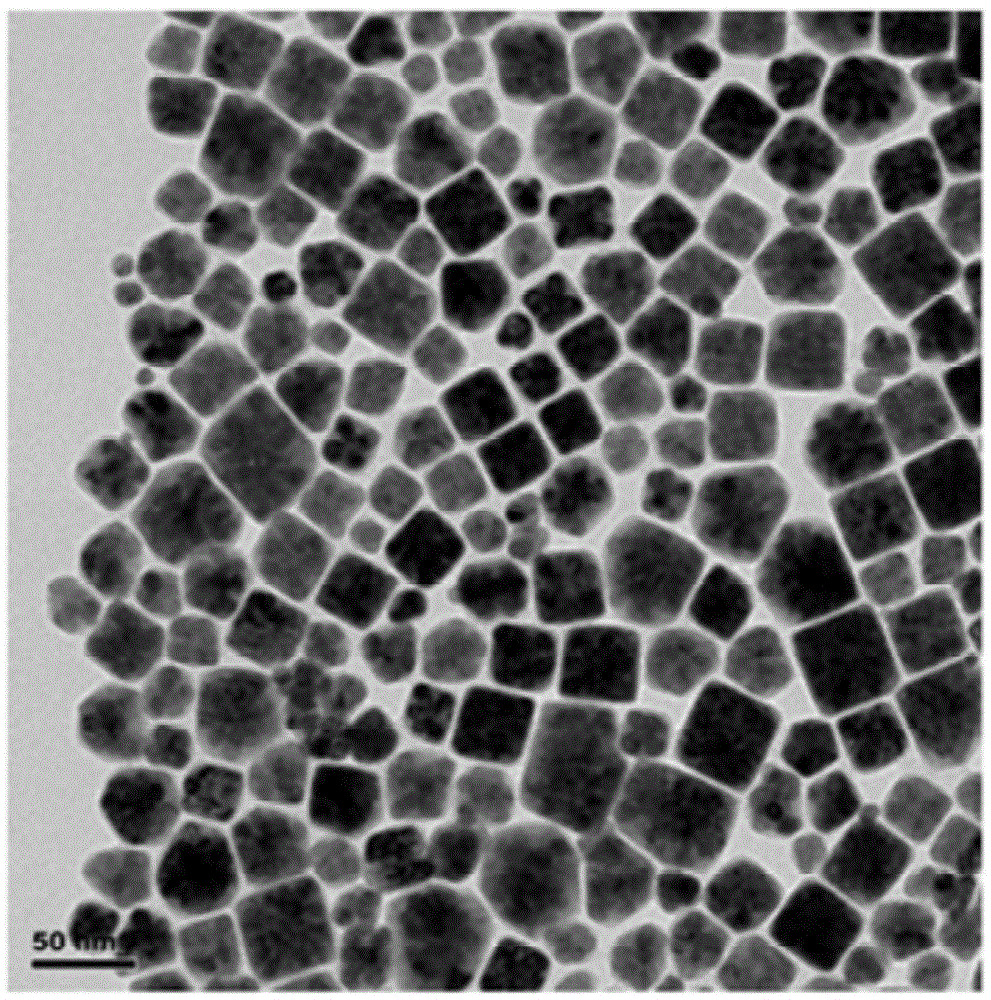

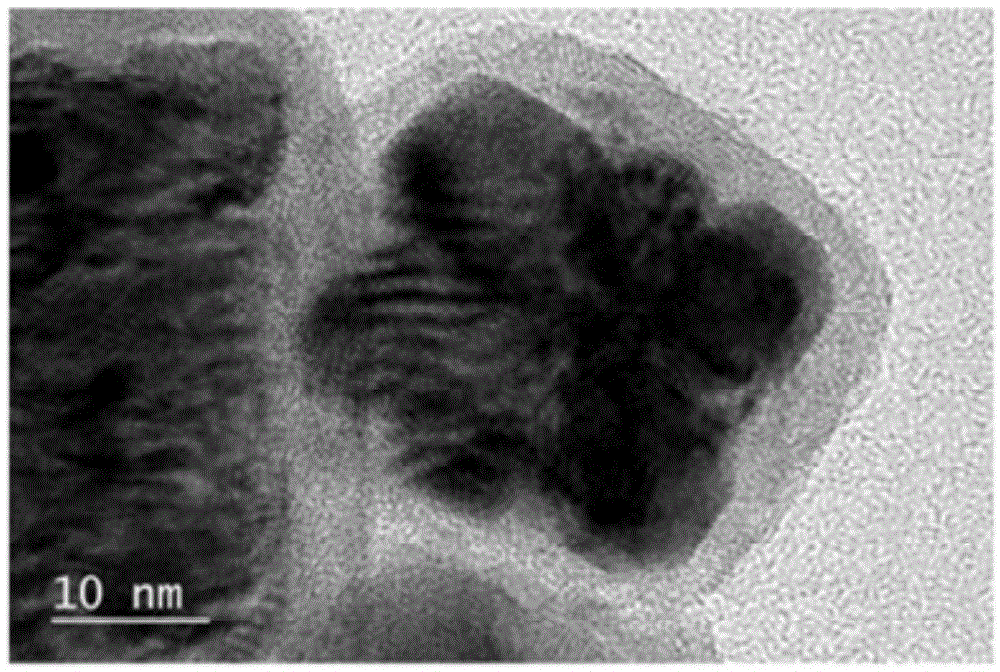

Platinum alloy nano core-shell cube and preparation method thereof

The invention provides a platinum alloy nano core-shell cube and a preparation method thereof. The preparation method comprises the following steps: 1) under the protection of an inert gas, adding platinum acetylacetone, an acetylacetone metallic compound, alkylamine and an alkyl acid in a reaction vessel simultaneously to be homogenized to obtain a uniformly mixed first mixed solution; 2) quickly transferring the first mixed solution obtained in the step 1) to a high-temperature oil bath, preserving heat for a preset time, then introducing a reducing gas for reaction to obtain a black suspension; and 3) sequentially conducting organic solvent cleaning, magnetic separation and vacuum drying on the obtained black suspension to obtain the platinum alloy nano core-shell cube. The platinum alloy nano core-shell cube is good in dispersity, controllable in components and easy to collect and is magnetic; and in the preparation method, a one-pot oleylamine system is adopted and the used reagents are nontoxic, and the preparation method is simple, and is easy to operate.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

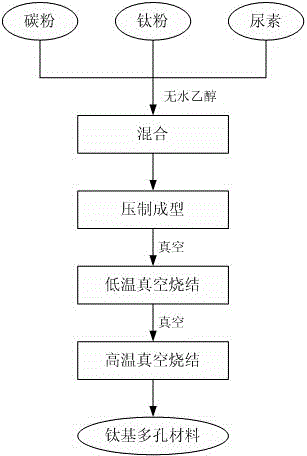

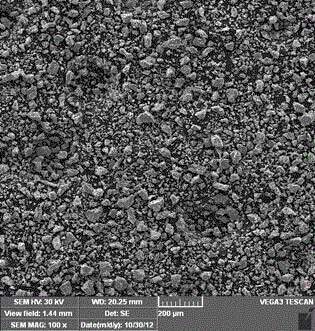

Preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials

The invention discloses a preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials. A powder metallurgy pore forming substance technology is used, and urea, carbon powder and titanium powder are used for being subjected to mixing, pressing forming and sintering to prepare the titanium-based multi-hole composite materials. The urea is used as a pore forming substance. Absolute ethyl alcohol is used as binding agents. Components of the titanium-based multi-hole materials are easy to control. Meanwhile, the advantage that raw material cost is low is achieved. A two-stage type sintering process is used for reducing energy consumption, equipment cost is lowered, and benefit is improved. In addition, the titanium-based multi-hole composite materials prepared with the preparing method of the in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials are high in intensity, good in comprehensive mechanical property and high in anti-corrosion performance, the durability of the titanium-based multi-hole composite materials is improved, a new technology path is provided for sewage purification, biology implant materials and the like, and great application prospect is achieved.

Owner:CHONGQING UNIV

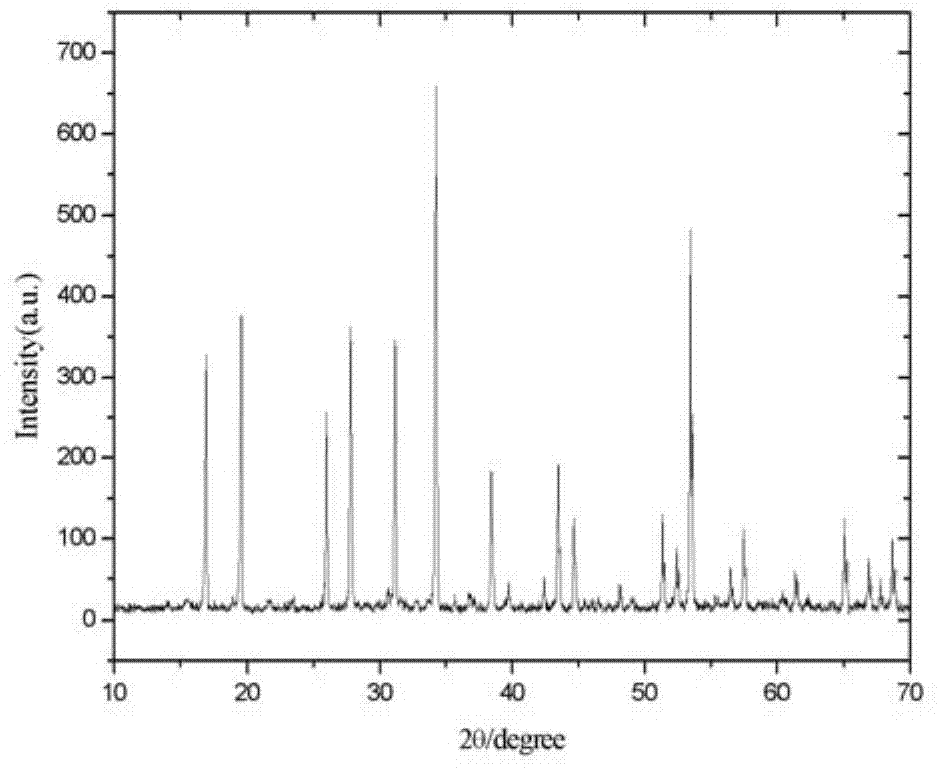

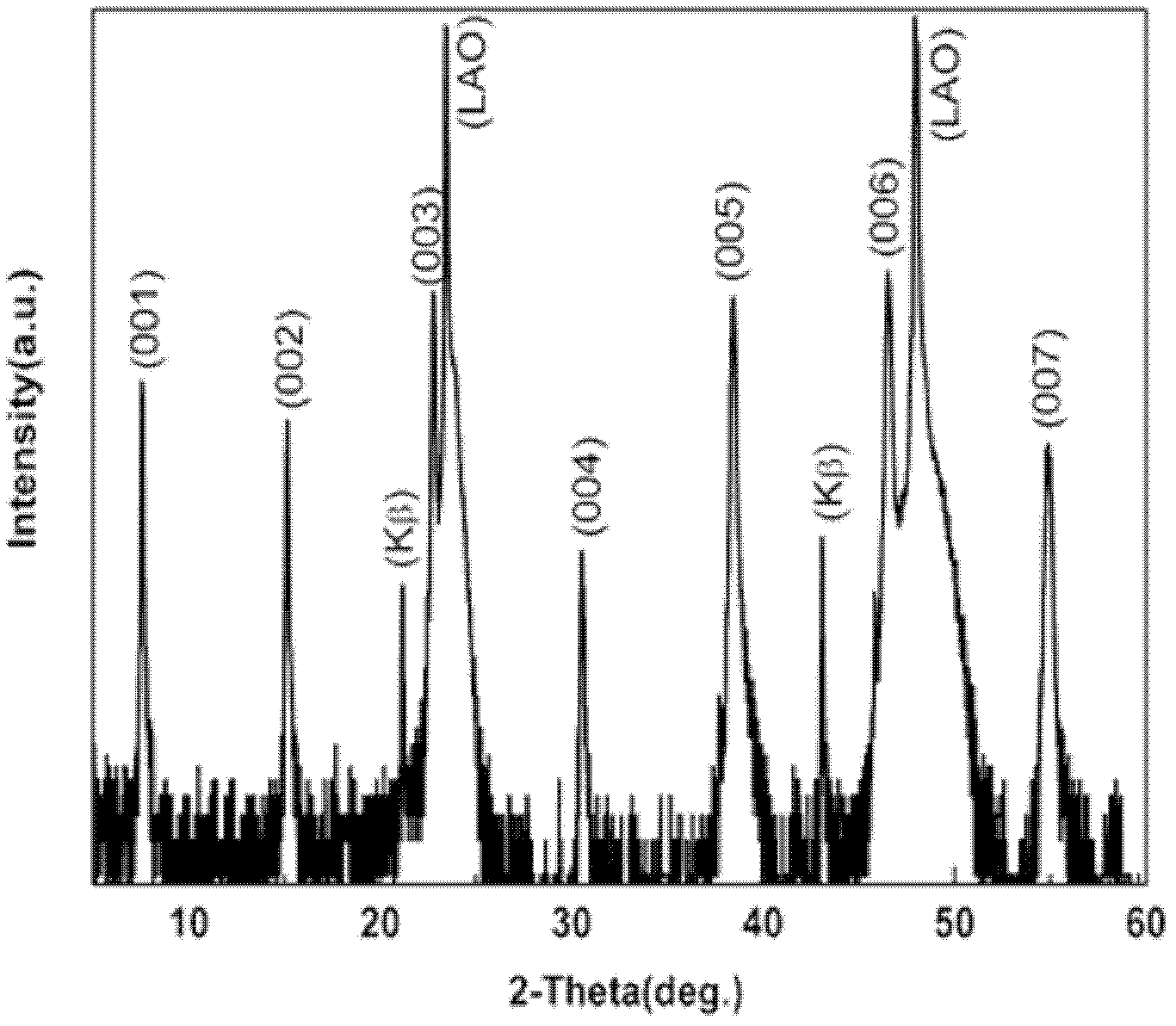

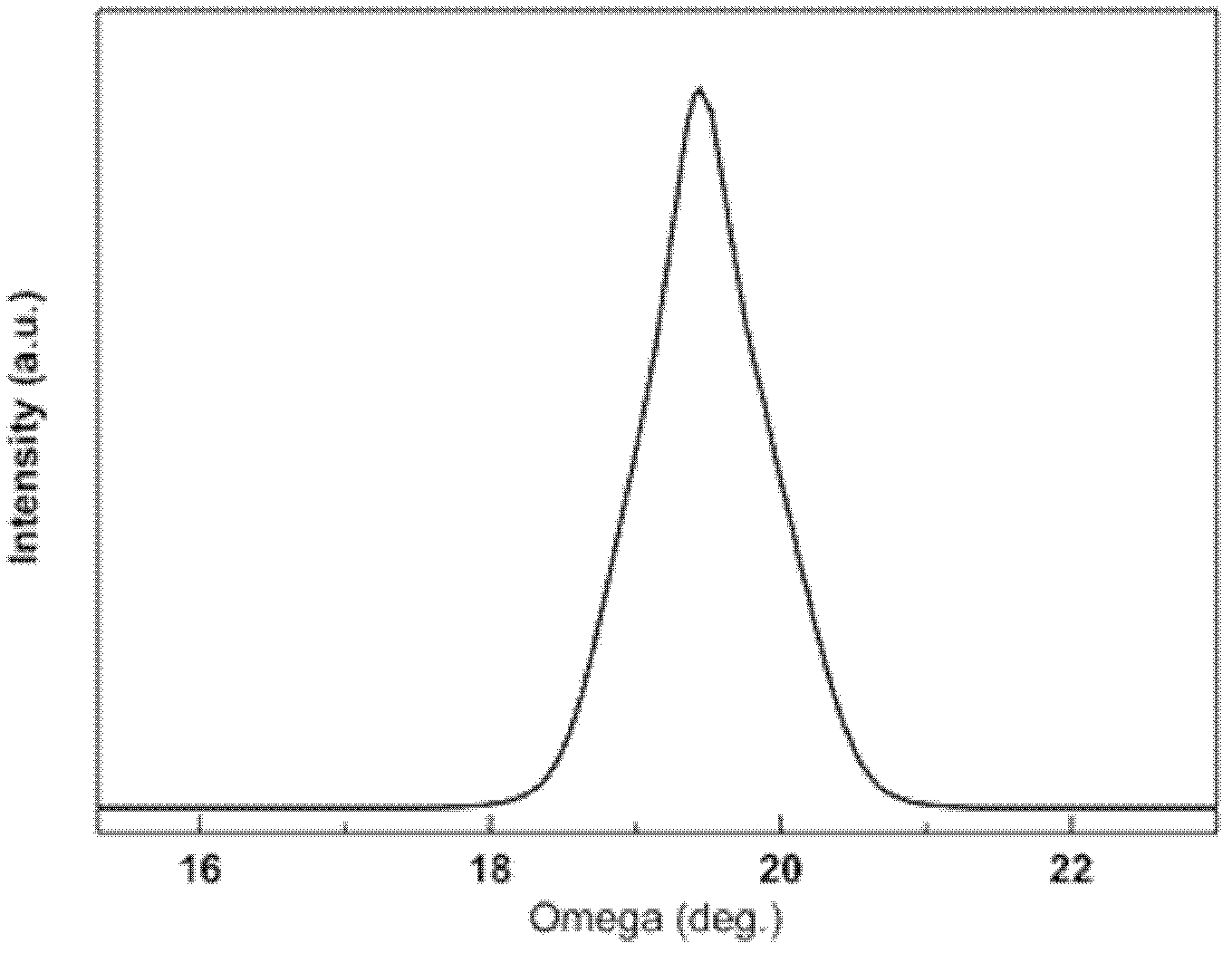

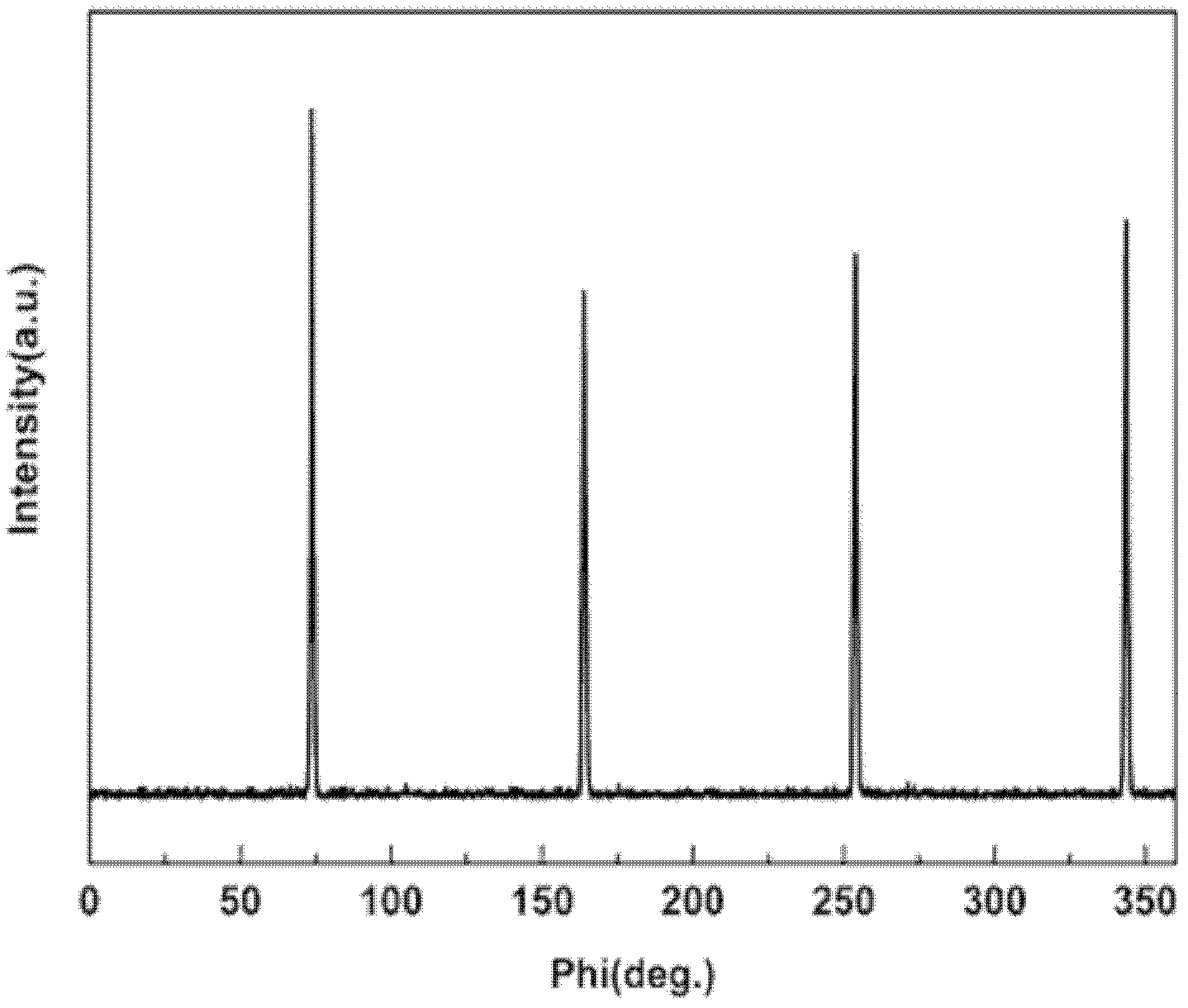

Yttrium barium copper oxide superconducting thin film mixed with samarium and manufacture method thereof

InactiveCN102491740AGood c-axis textureGood in-plane and out-of-plane textureYttrium barium copper oxideChemical composition

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of tin oxide-graphene composite carbon film

The invention discloses a preparation method of a tin oxide-graphene composite carbon film. The method comprises the steps of feeding ethylene glycol into graphene oxide water dispersion solution, evenly dispersing in an ultrasonic way, feeding a tin source and PVP, dissolving by stirring, and carrying out microwave heating; after reaction, cooling to the room temperature, carrying out suction filtration, washing by distilled water, and carrying out vacuum drying; and carrying out heat treatment to obtain the composite carbon film. In the reaction system, ethylene glycol is taken as not only a solvent but also a reducing agent, and the reduction products, namely oxalic acid and PVP, have the function of stabilizing the sizes of nano particles; a microwave way is used for heating, so that the temperature of the system is increased rapidly, and tin oxide particles with small sizes can be easily prepared; before the reaction, tin source ions are evenly absorbed on the surface of graphene oxide, so that the tin oxide particles in the product can be evenly distributed, oxidation hydrolysis of the tin source and the reduction of graphene oxide can be realized synchronously, and the components can be controlled. The prepared material is stable in structure, and can be directly used as an electrode for assembling a lithium ion battery after being simply cut.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

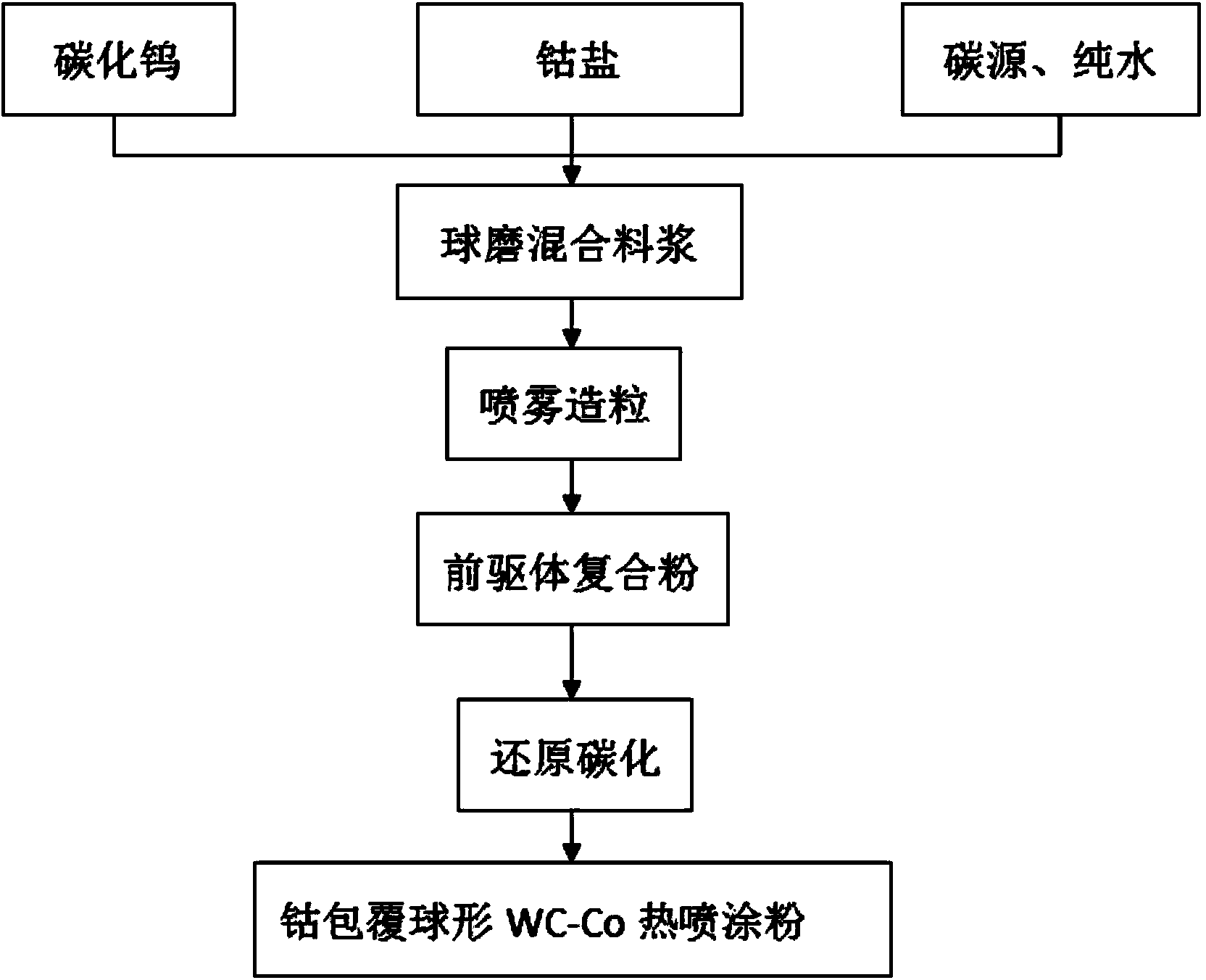

Method for preparing WC-Co powder used for thermal spraying

ActiveCN103920887AHigh free carbon contentAvoid compositional segregationMolten spray coatingSolubilityThermal spraying

The invention provides a method for preparing WC-Co powder used for thermal spraying. The method includes the following steps that tungsten carbide, water solubility cobalt salt, carbon sources and water are mixed to acquire mixed slurry; after ball-milling and even blending are conducted on the mixed slurry, spray granulation is conducted, and WC precursor powder coated by the cobalt salt is acquired; reduction and carbonization are conducted on the WC precursor powder coated by the cobalt salt, and the WC-Co powder is acquired. According to the method, the water solubility cobalt salt serves as the cobalt sources, the WC precursor powder coated by the cobalt salt is prepared by the adoption of the liquid phase method, so that the cobalt can evenly coat the surface of the WC in a solution molecular mode, reduction and carbonization are conducted on the WC precursor powder coated by the cobalt salt, and the WC-Co powder is acquired. The acquired WC-Co powder by the adoption of the method is even in granularity, controllable in ingredients, even in powder ingredients, free of W2C, eta-Co3W3C, eta-Co6W6C, metal tungsten and the like in the ingredients, the degree of sphericity is high, mobility is good, the decarburization phase and phase decomposition does not occur on the surface of the spraying matrix.

Owner:ADVANCED FOR MATERIALS & EQUIP

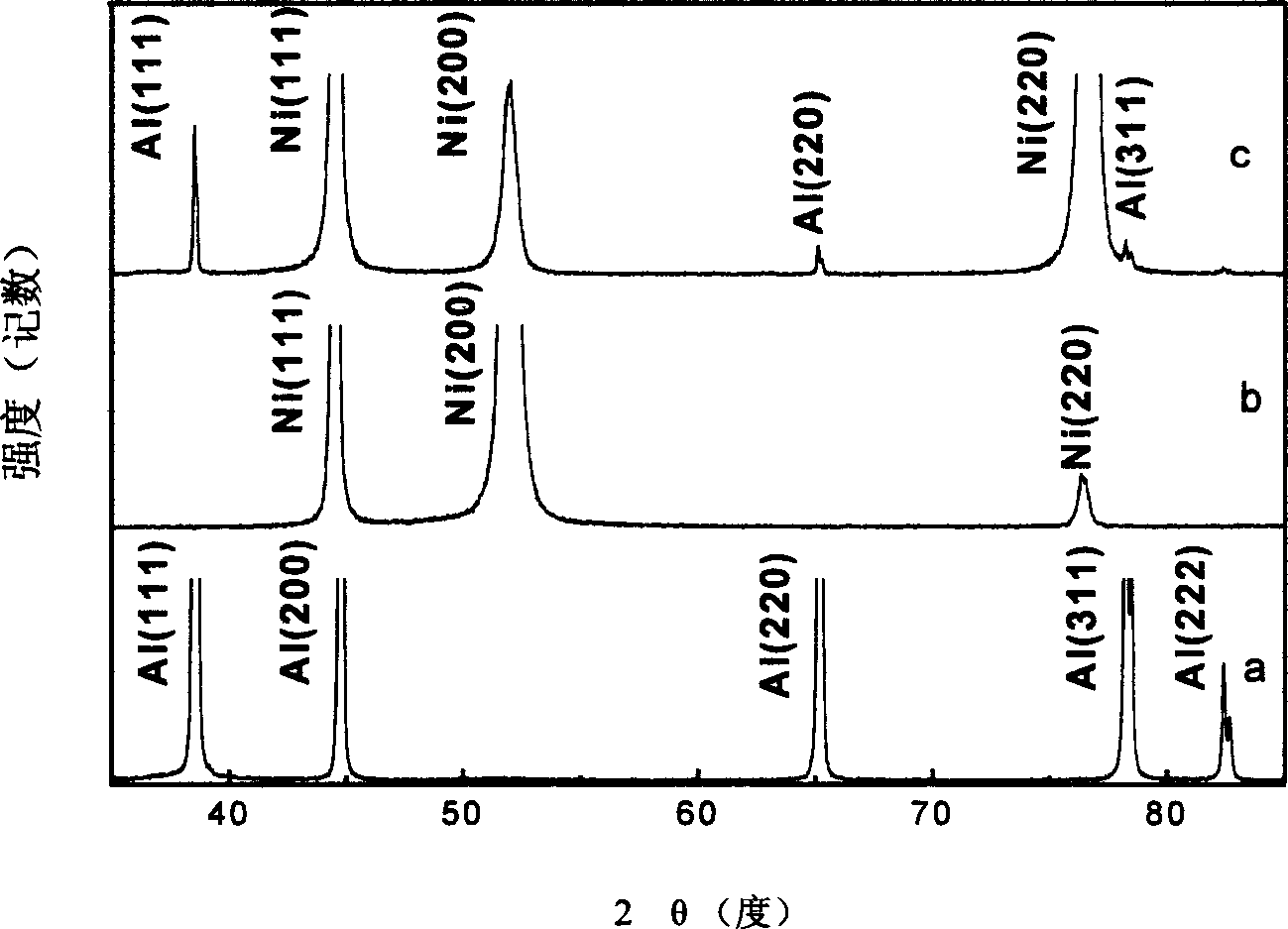

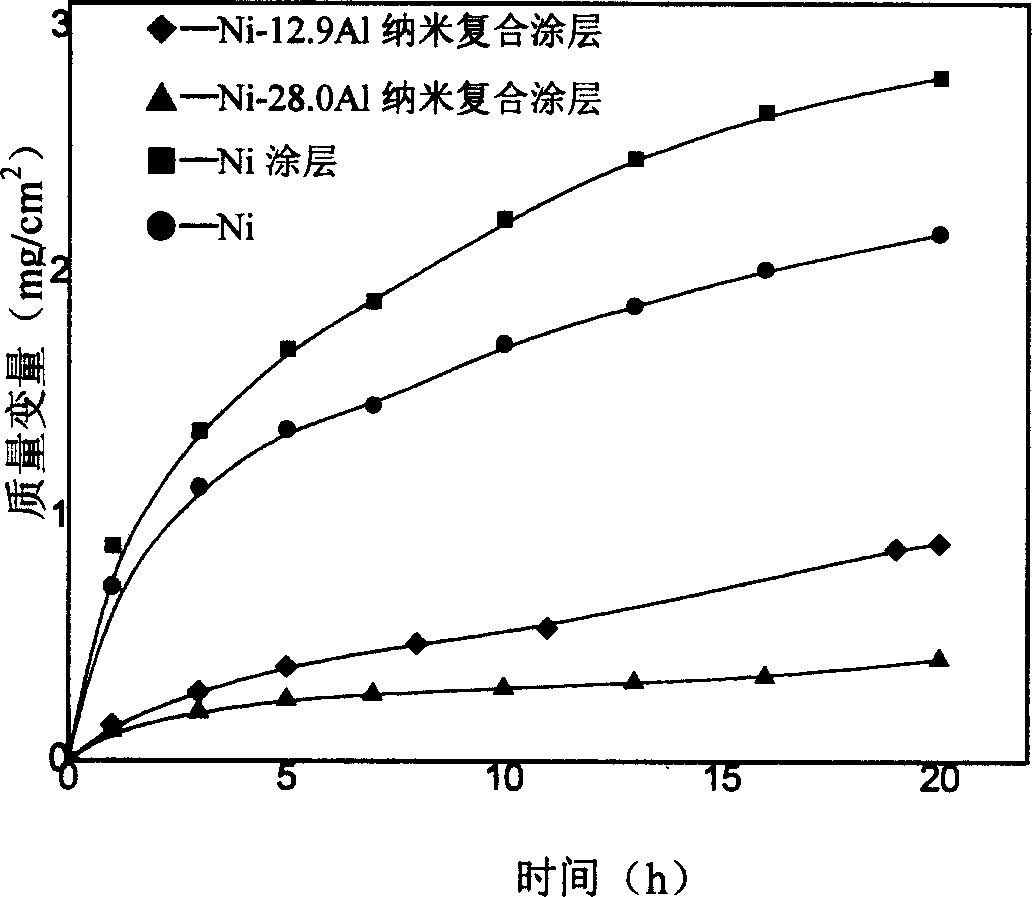

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1576398AIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

The thermally grown Al2O3 film type M-Al nano composite coating consists of nano crystal M coating and nano metal Al grains dispersed in the coating, where M is Ni, Fe or Co. The Al content is 9.8-35 wt%, and M is the rest. The nano composite Ni-Al, Fe-Al or Co-Al coating is prepared through composite electroplating process to deposit metal M and Al coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Al2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com