Method for preparing load type high-dispersion multi-component precious metal nanoparticle catalyst

A nanoparticle and precious metal technology is applied in the field of preparation of supported high-dispersion multi-component precious metal nanoparticle catalysts, which can solve the problems of uneven component distribution, large metal loading, and low metal dispersion, and achieve high catalytic activity. and stability, uniform particle size and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

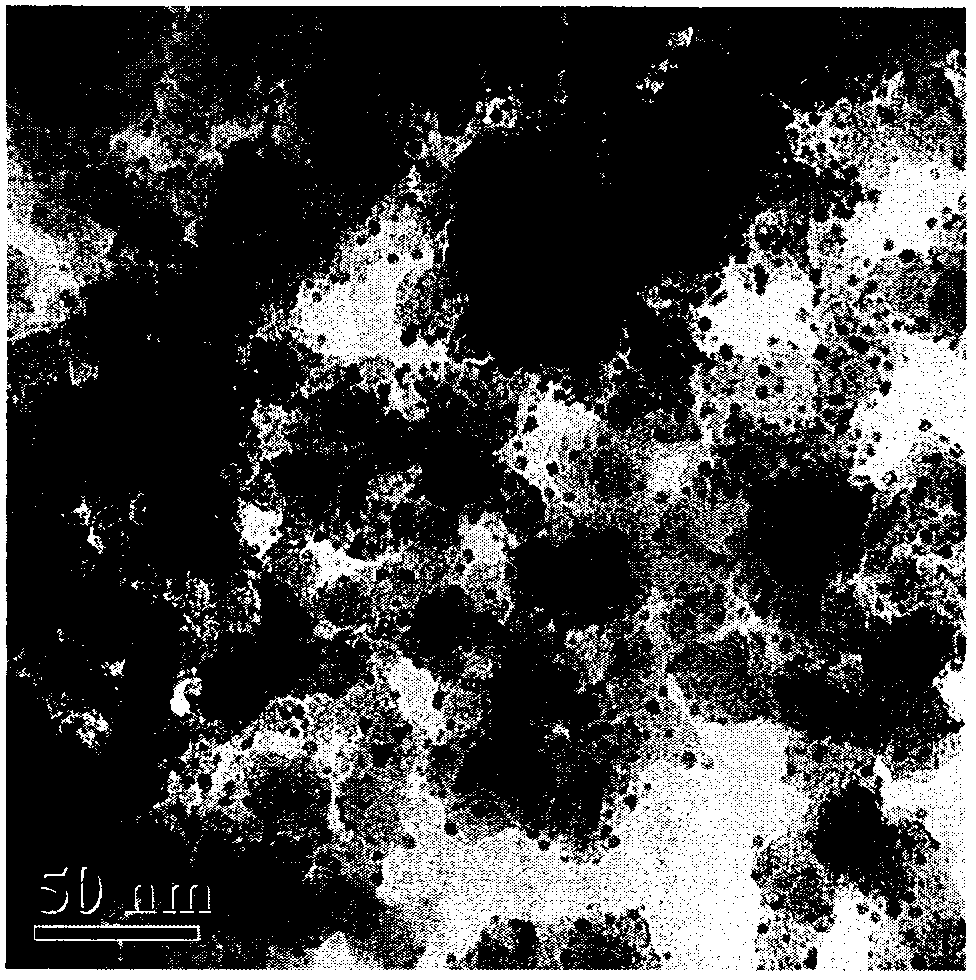

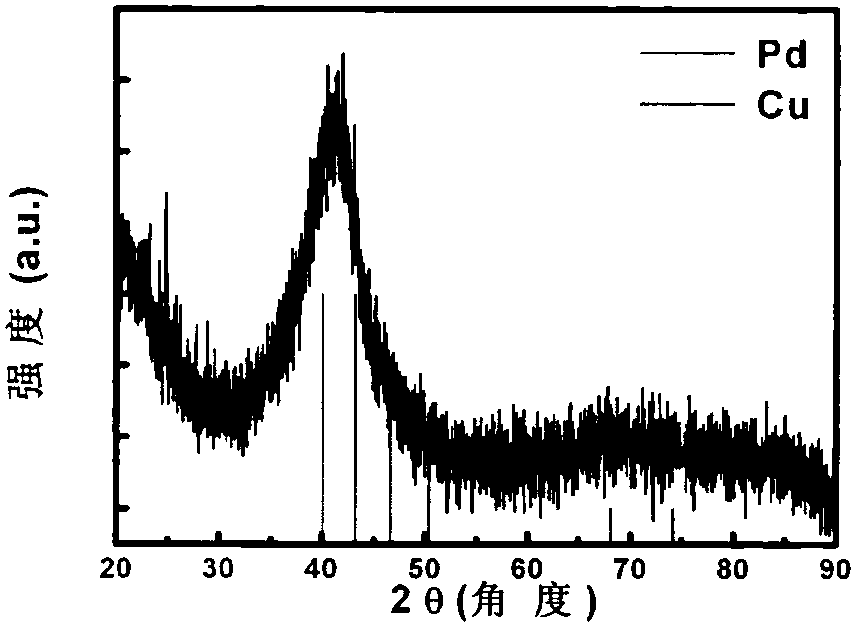

[0027] Take 100 mL of ethylene glycol and add it into a three-necked flask, then add 1 mL of oleic acid and 1 mL of oleylamine, and stir and mix evenly at room temperature under an argon atmosphere. Dissolve 1mmol of copper acetate in 10mL of water, 1mmol of palladium acetate in 10mL of acetone solution, add the two solutions into the mixed solution of ethylene glycol, then heat up to 120°C, keep the temperature for 30 minutes, Continue to heat up to 200°C and keep the temperature constant for 90 minutes. After the reaction was completed, it was naturally cooled to room temperature, then 50 mL of n-hexane was added, and the mixture was allowed to stand for stratification, and the upper layer was the obtained nanoparticle solution. Take the solution of the nanoparticles in the upper layer and mix it with the carrier white carbon black of the catalyst, then stir for 24 hours, centrifuge, wash, dry in vacuum at 40 degrees, and obtain the loaded type after 4 hours, then add ethano...

Embodiment 2

[0029] Take 100 mL of ethylene glycol and add it into a three-necked flask, then add 1 mL of oleic acid and 1 mL of oleylamine, and stir and mix evenly at room temperature under an argon atmosphere. Dissolve 1mmol of copper acetate in 10mL of water, 1mmol of palladium acetate in 10mL of acetone solution, add the two solutions into the mixed solution of ethylene glycol, then heat up to 120°C, keep the temperature for 30 minutes, Continue to heat up to 200°C and keep the temperature constant for 60-90 minutes. After the reaction was completed, it was naturally cooled to room temperature, then 50 mL of n-hexane was added, and the mixture was allowed to stand for stratification, and the upper layer was the obtained nanoparticle solution. Get the solution of the upper nanoparticle and mix it with the carrier white carbon black of the catalyst, then stir for 24 hours, centrifuge, wash, dry, in 400 degrees 5% H 2 +Ar atmosphere and calcined for 3.5 hours to obtain the supported PdCu...

Embodiment 3

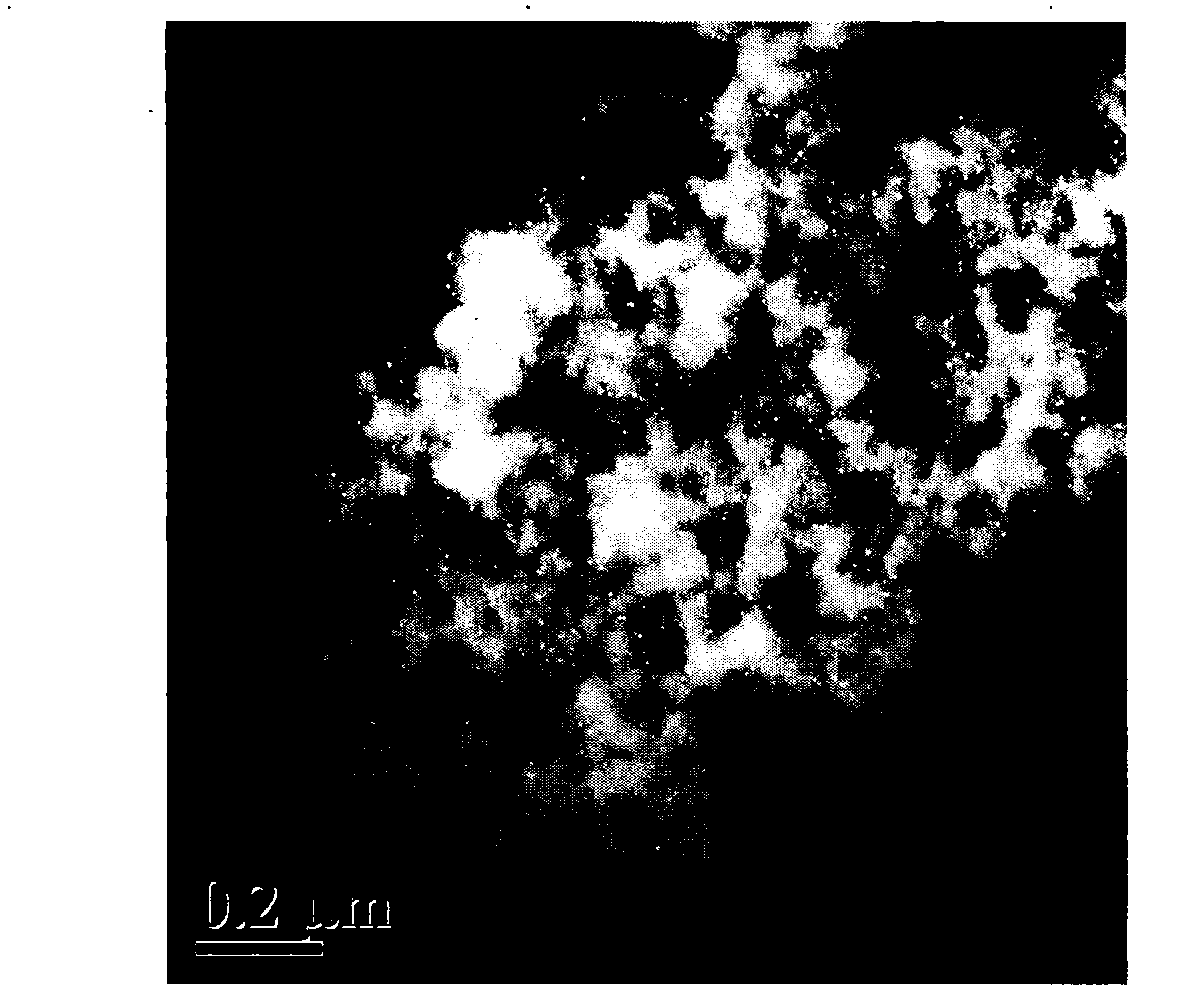

[0031]Take 100mL of ethylene glycol and add it into a three-necked flask, then add 1mL of oleic acid and oleylamine, and stir and mix evenly at room temperature under an argon atmosphere. Dissolve 1mmol of copper acetate in 5mL of water, 1mmol of palladium acetate in 5mL of acetone solution, add the two solutions into the mixed solution of ethylene glycol, then heat up to 120°C, keep the temperature for 30 minutes, Continue to heat up to 200°C and keep the temperature constant for 60-90 minutes. After the reaction was completed, it was naturally cooled to room temperature, and then 45 mL of n-hexane was added, and the mixture was allowed to stand for stratification, and the upper layer was the obtained nanoparticle solution. Get the solution of upper layer nanoparticle and the carrier aluminum oxide of catalyst and mix, then stir 24 hours, centrifuge, wash, dry, obtain loaded type PdCu two-component nanoparticle catalyst ( Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com