Patents

Literature

79results about How to "Easy to control accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

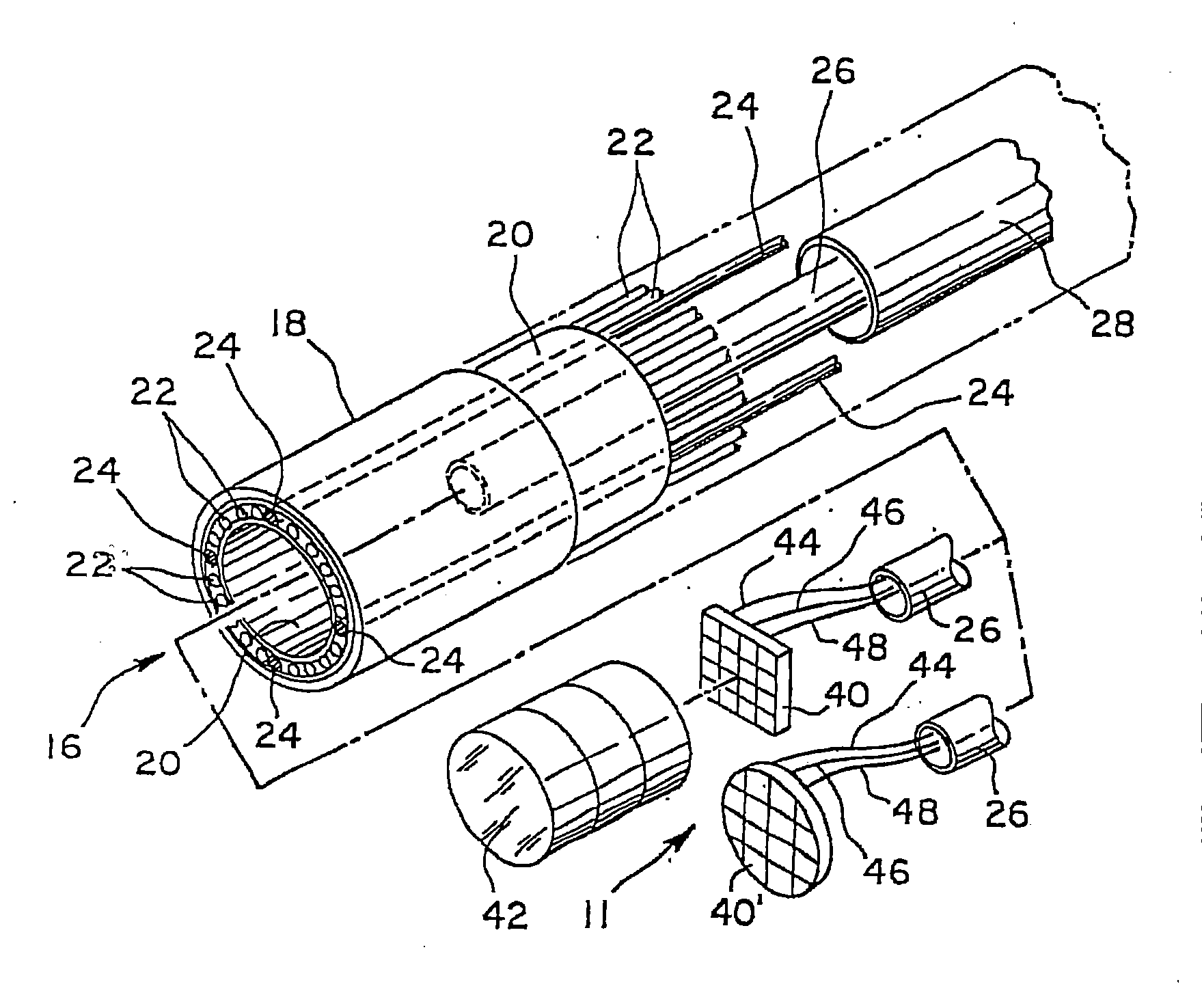

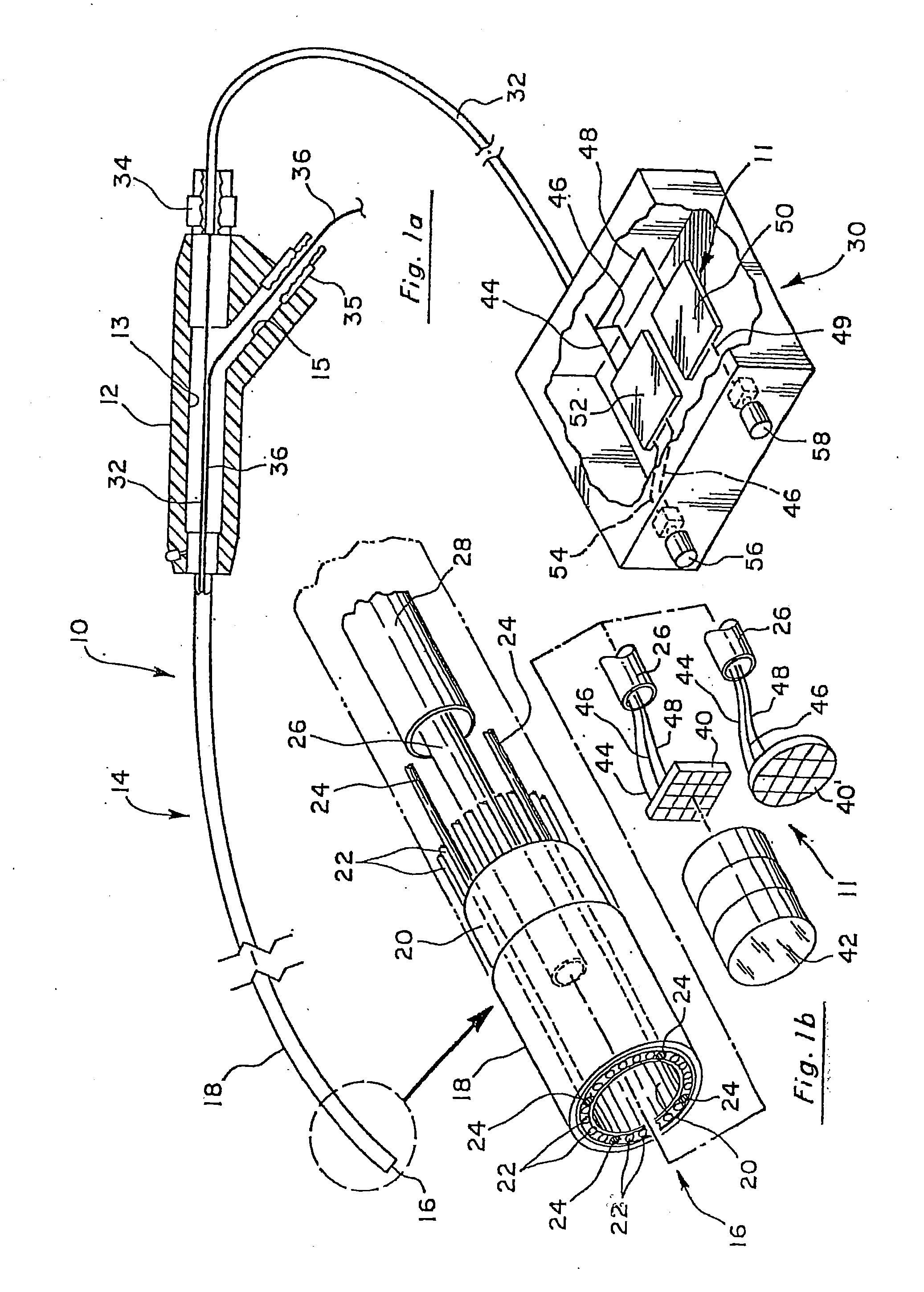

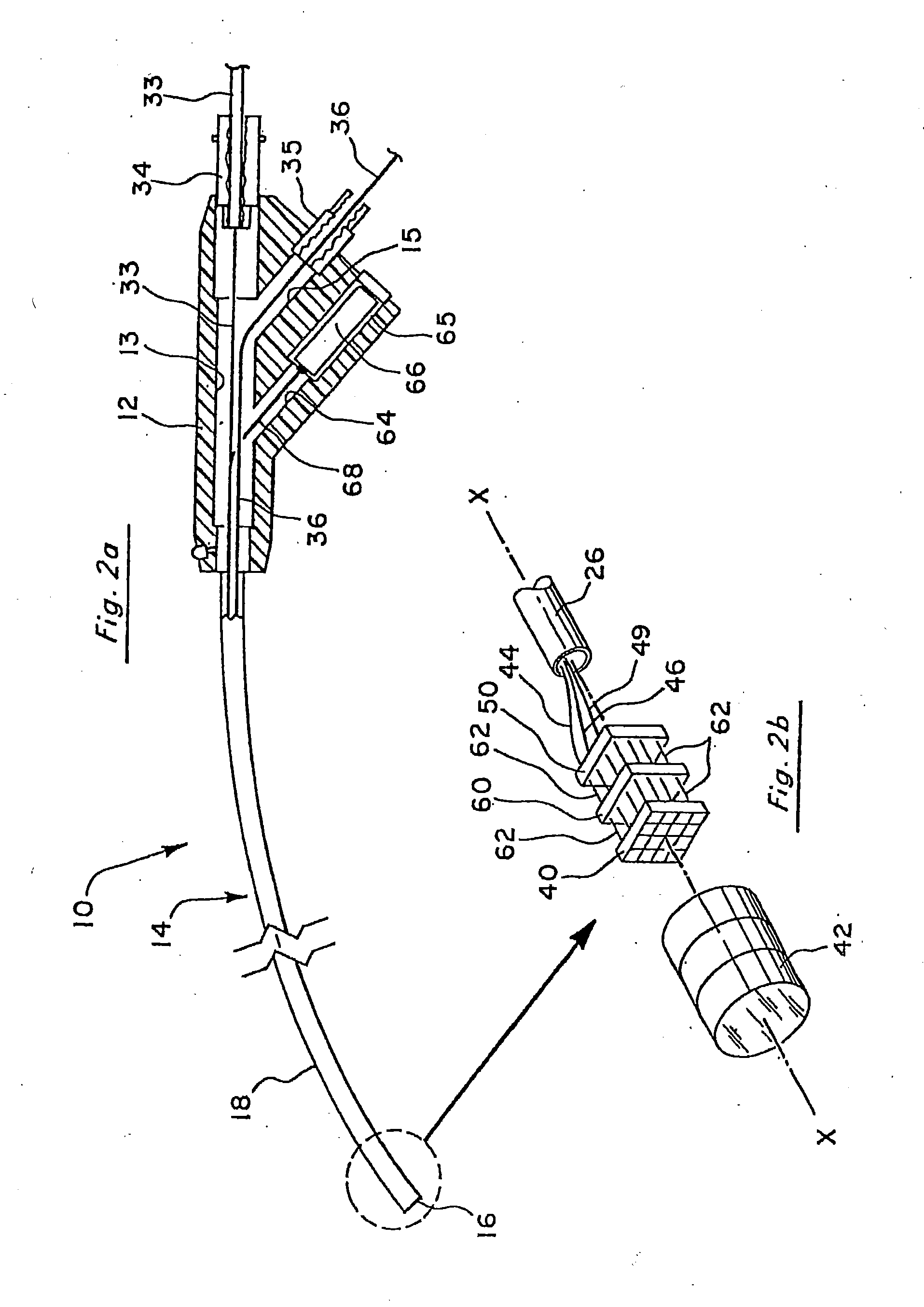

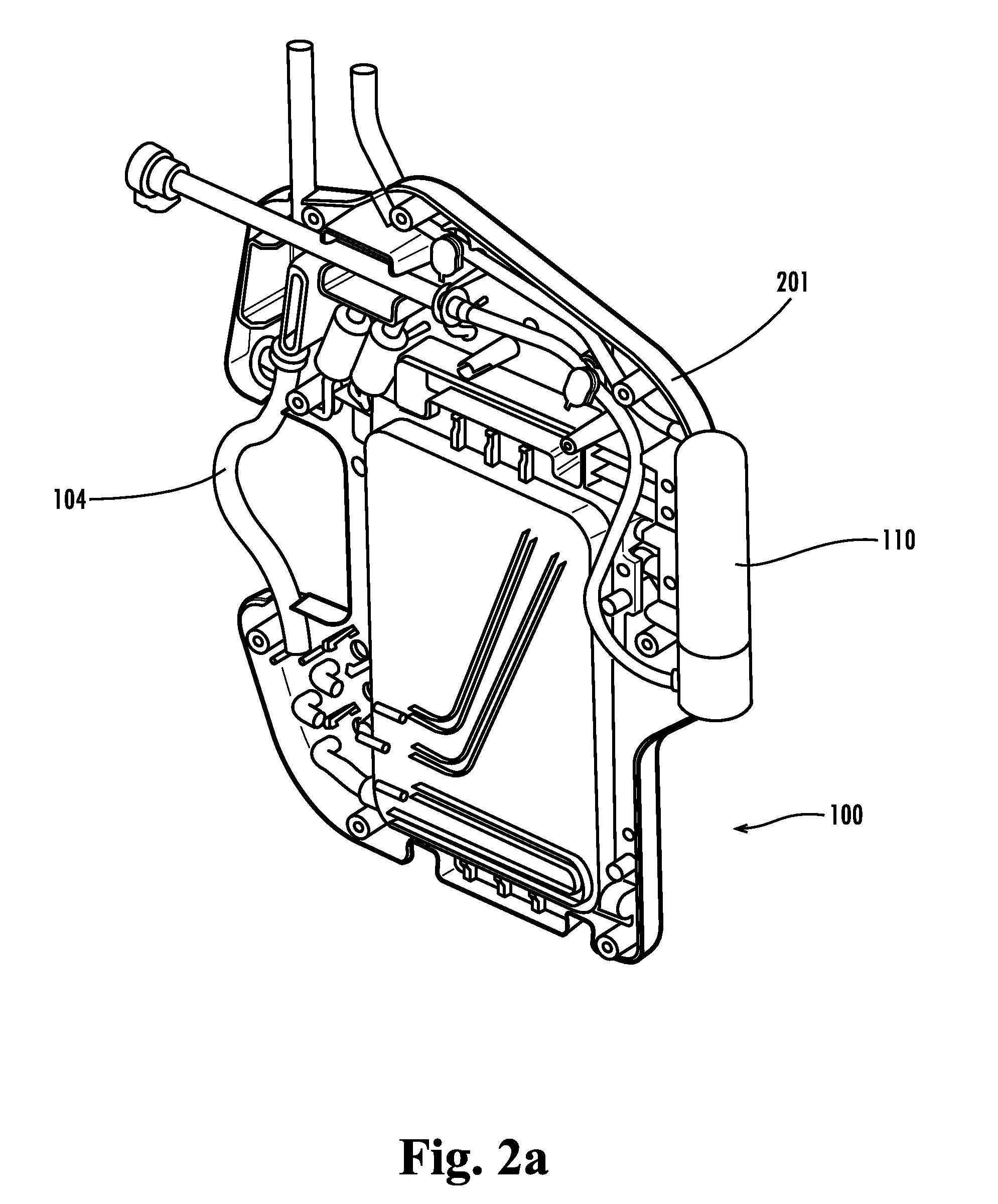

Reduced area imaging device incorporated within wireless endoscopic devices

InactiveUS20110034769A1Good precisionEasy to control accuratelyTelevision system detailsSurgeryElectricityDental instruments

A reduced area imaging device is provided for use in medical or dental instruments such as an endoscope. The imaging device is provided in various configurations, and connections between the imaging device elements and a video display may be achieved by wired or wireless connections. A connector assembly located near the imaging device interconnects the imaging device to an image / power cable extending through the endoscope. The connector provides strain relief and stabilization for electrically interconnecting the imager to the cable. The connector also serves as the structure for anchoring the distal ends of steering wires extending through the body of the endoscopic device. The connector includes a strain relief member mounted over a body of the connector. The connector allows a steering wire capability without enlarging the profile of the distal tip of the endoscopic device.

Owner:MICRO IMAGING SOLUTIONS

Dynamic Range Motor For A Pump Device

ActiveUS20080145249A1High flow accuracyReducing undesired variationFlexible member pumpsMedical devicesElectricityDigital signal processing

A pump system selectably and dynamically controls the flow rate of a fluid being delivered to a patient's body over a wide range of flow rates. The pump system includes an infusion tubing, a pumping mechanism, a motor drive assembly in mechanical communication with the pumping mechanism, a user input control, and an electronic controller in electrical communication with and at least partially controlling the motor drive assembly. The electronic controller include a digital signal processing controller in electrical communication with the motor drive assembly that is configured to receive a signal from the user input control and to cause power to be supplied to the motor drive assembly in response at least partially to the signal from the user input control. The pump system may selectably deliver fluid at rates from about 1 milliliter per hour to at least about 3000 milliliters per minute.

Owner:SMISSON CARTLEDGE BIOMEDICAL

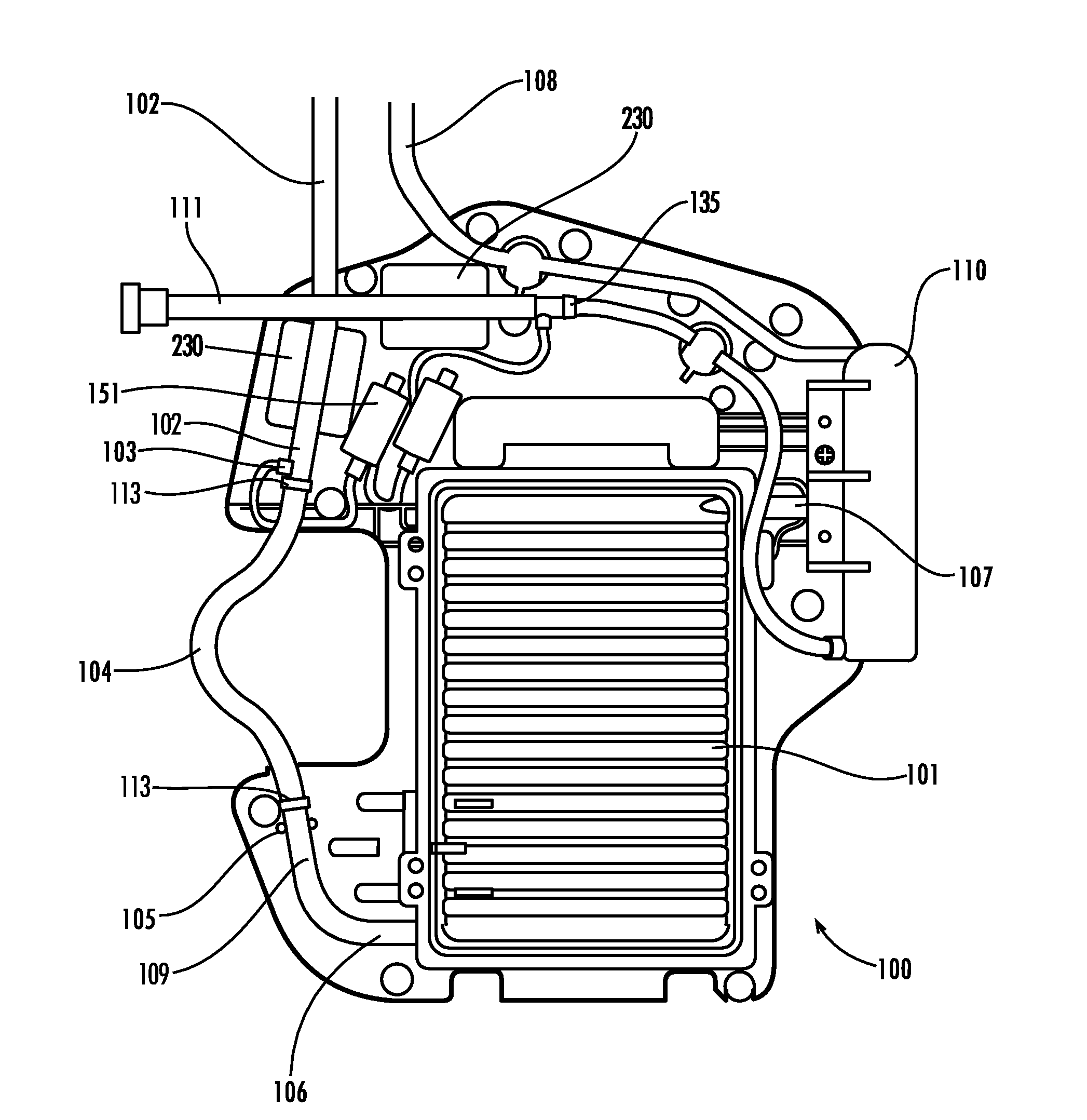

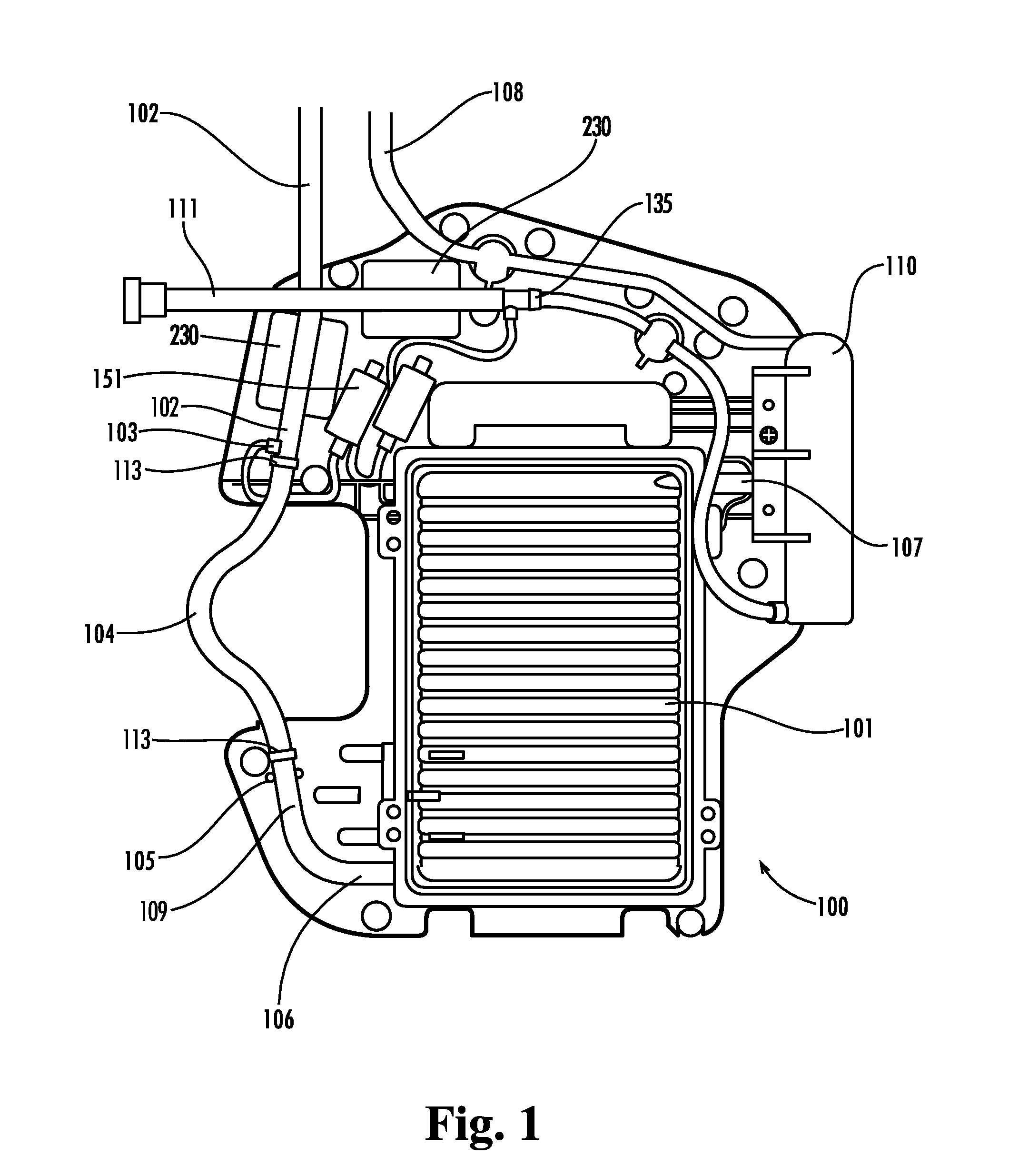

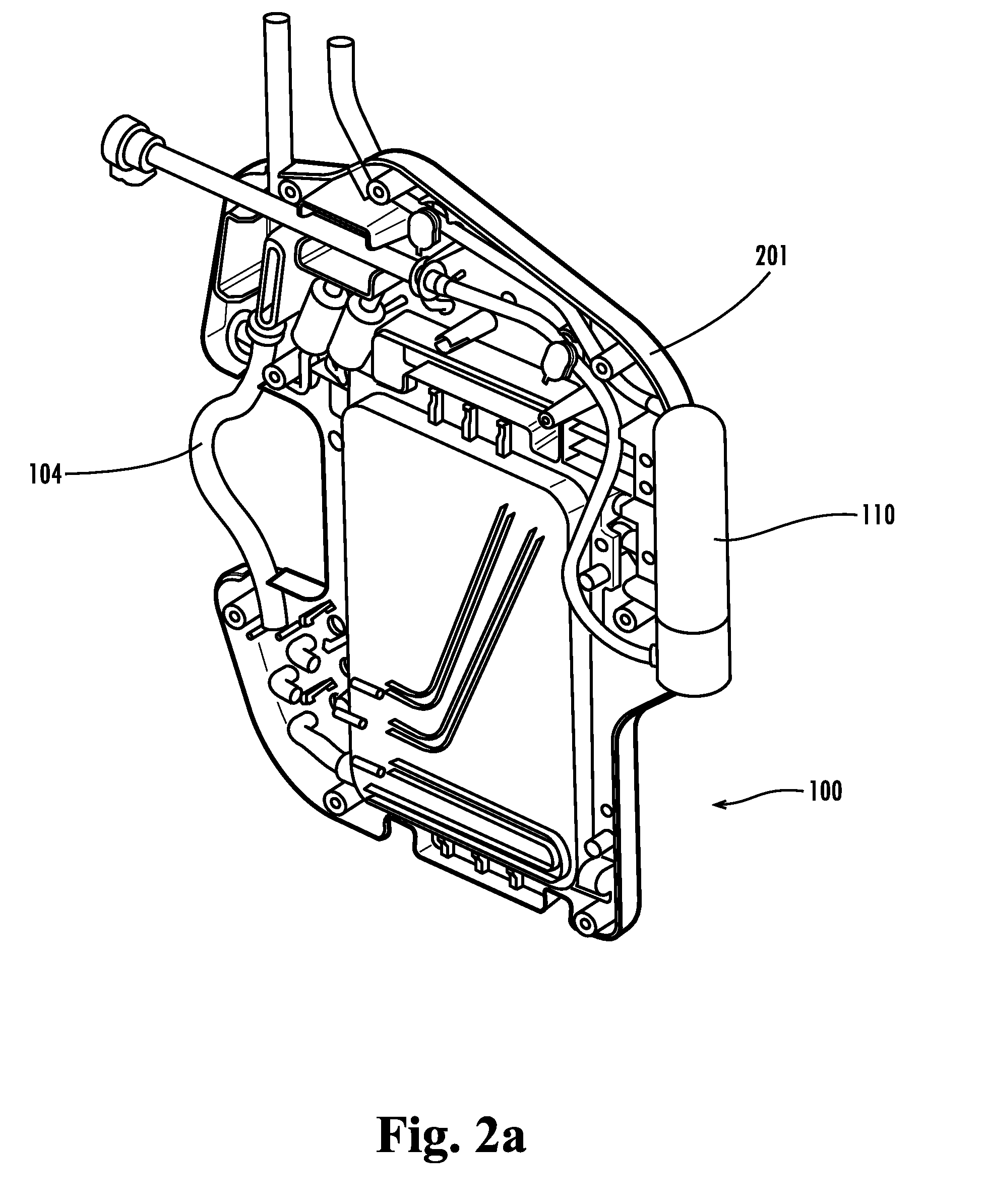

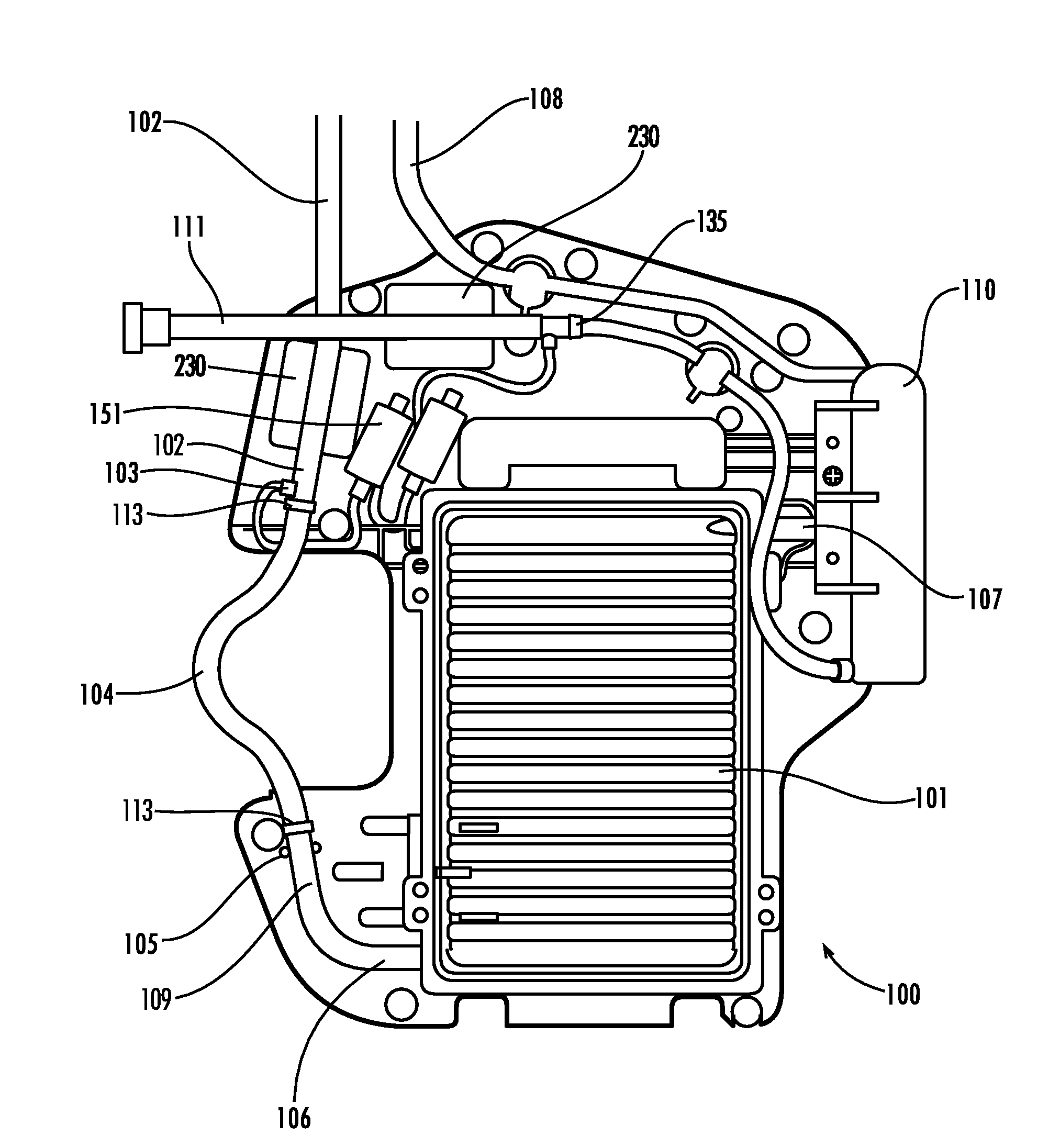

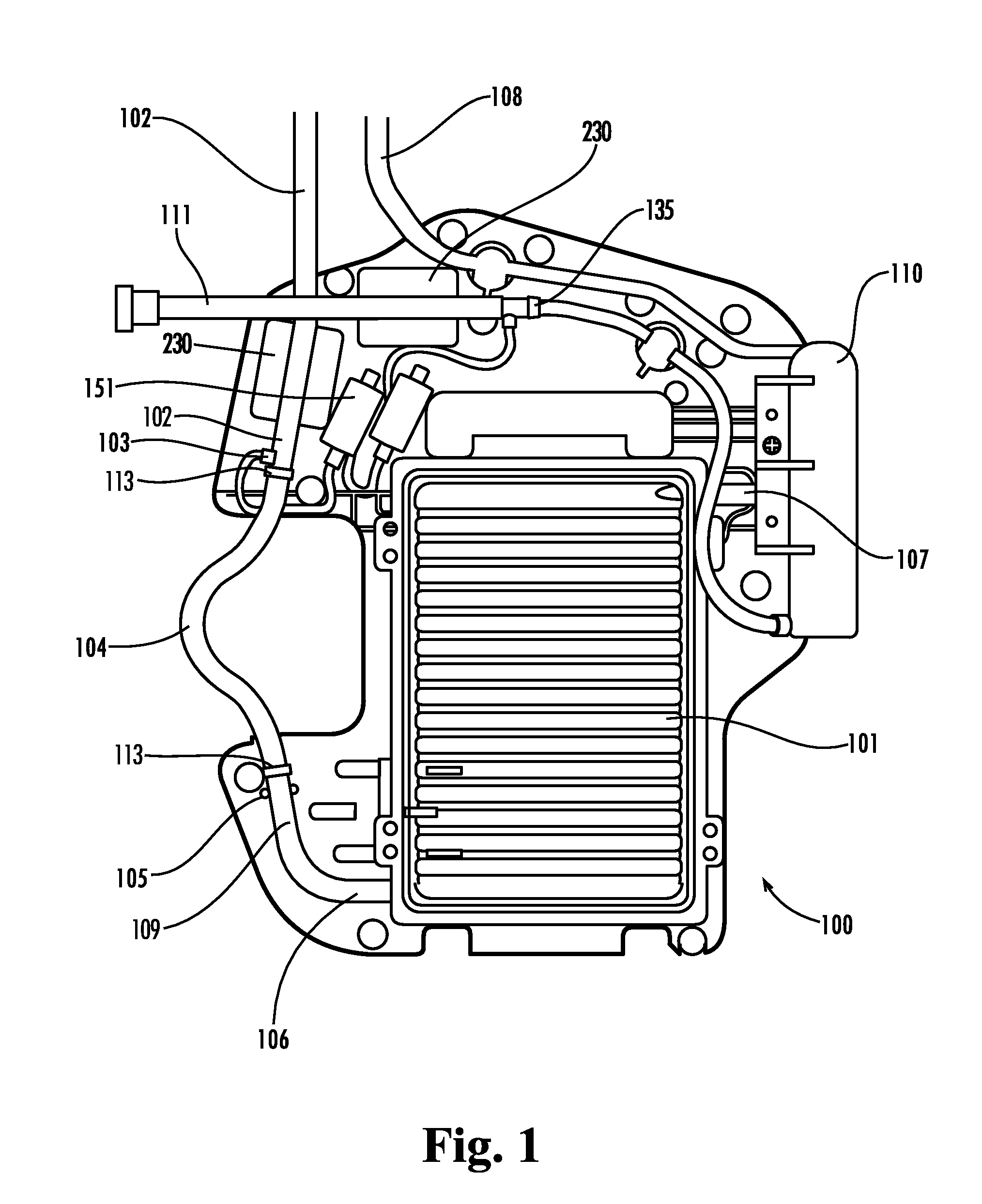

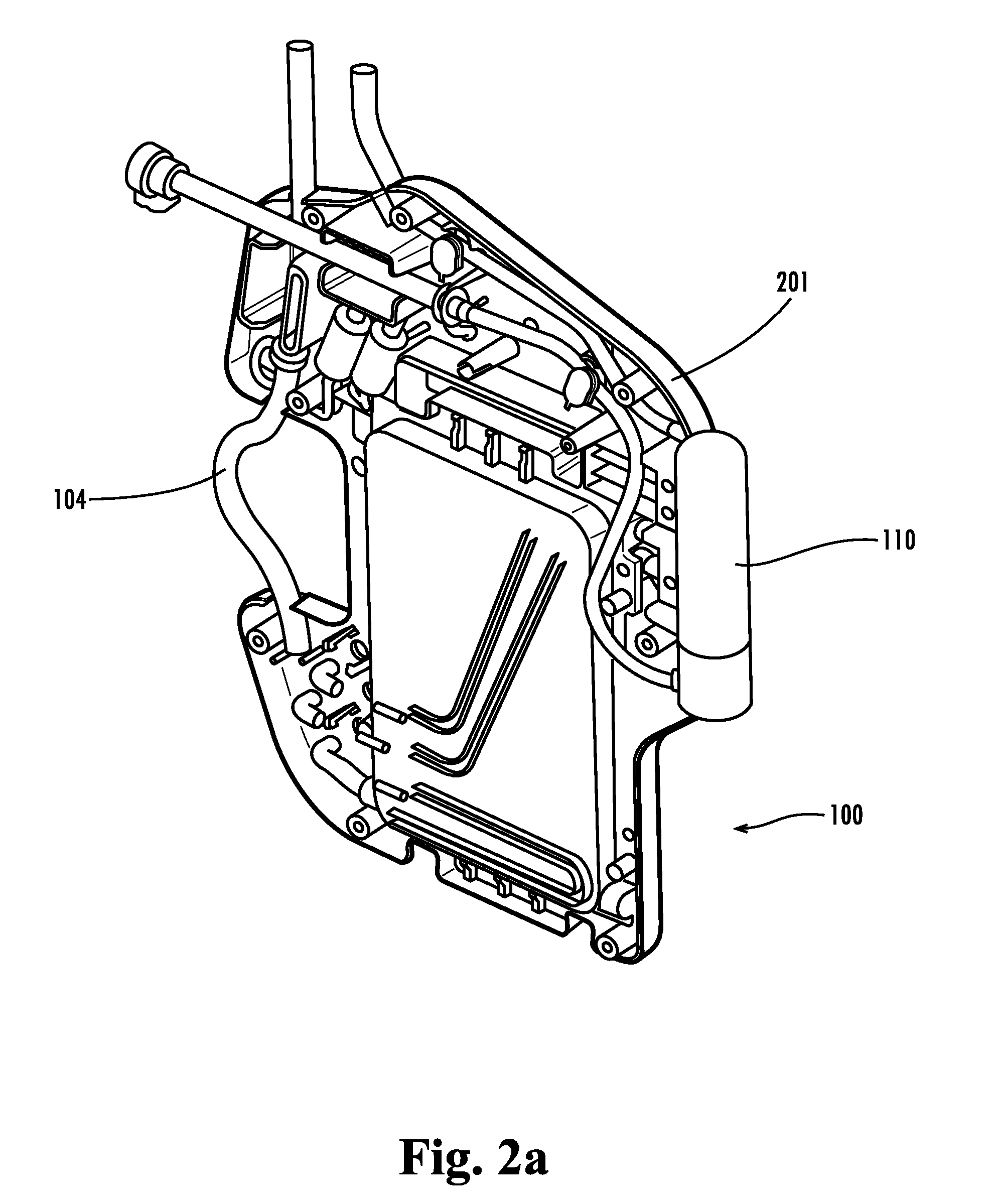

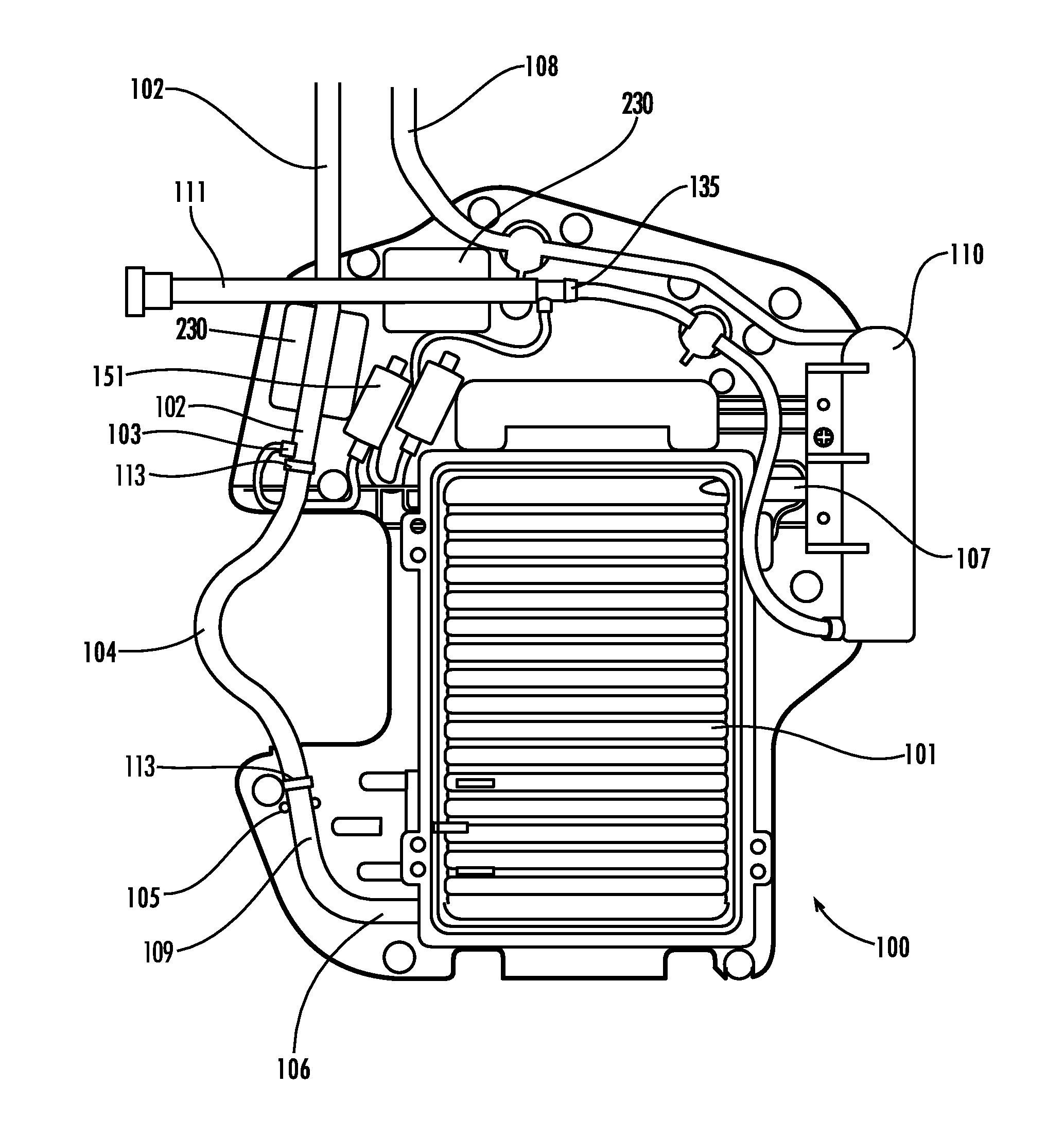

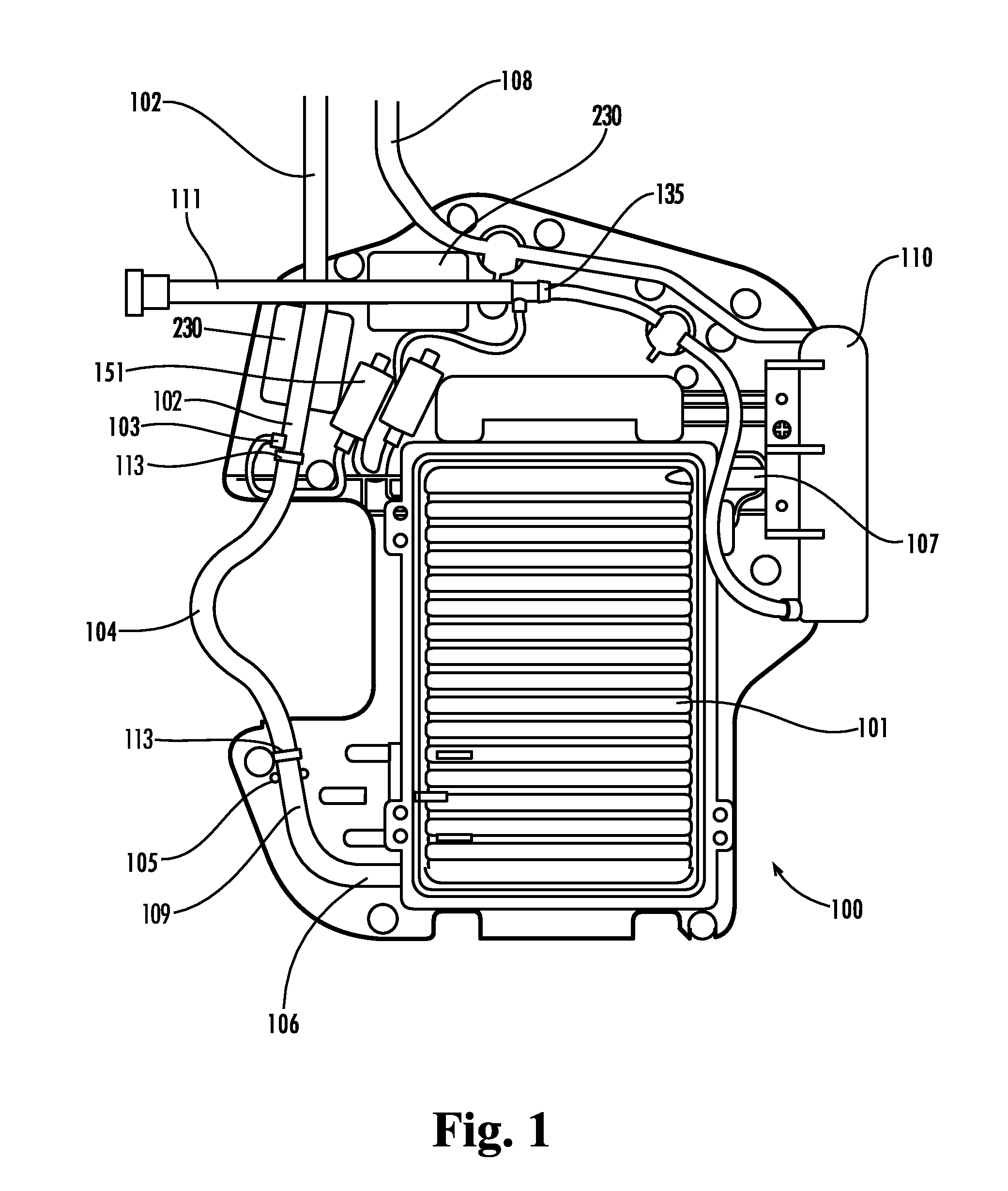

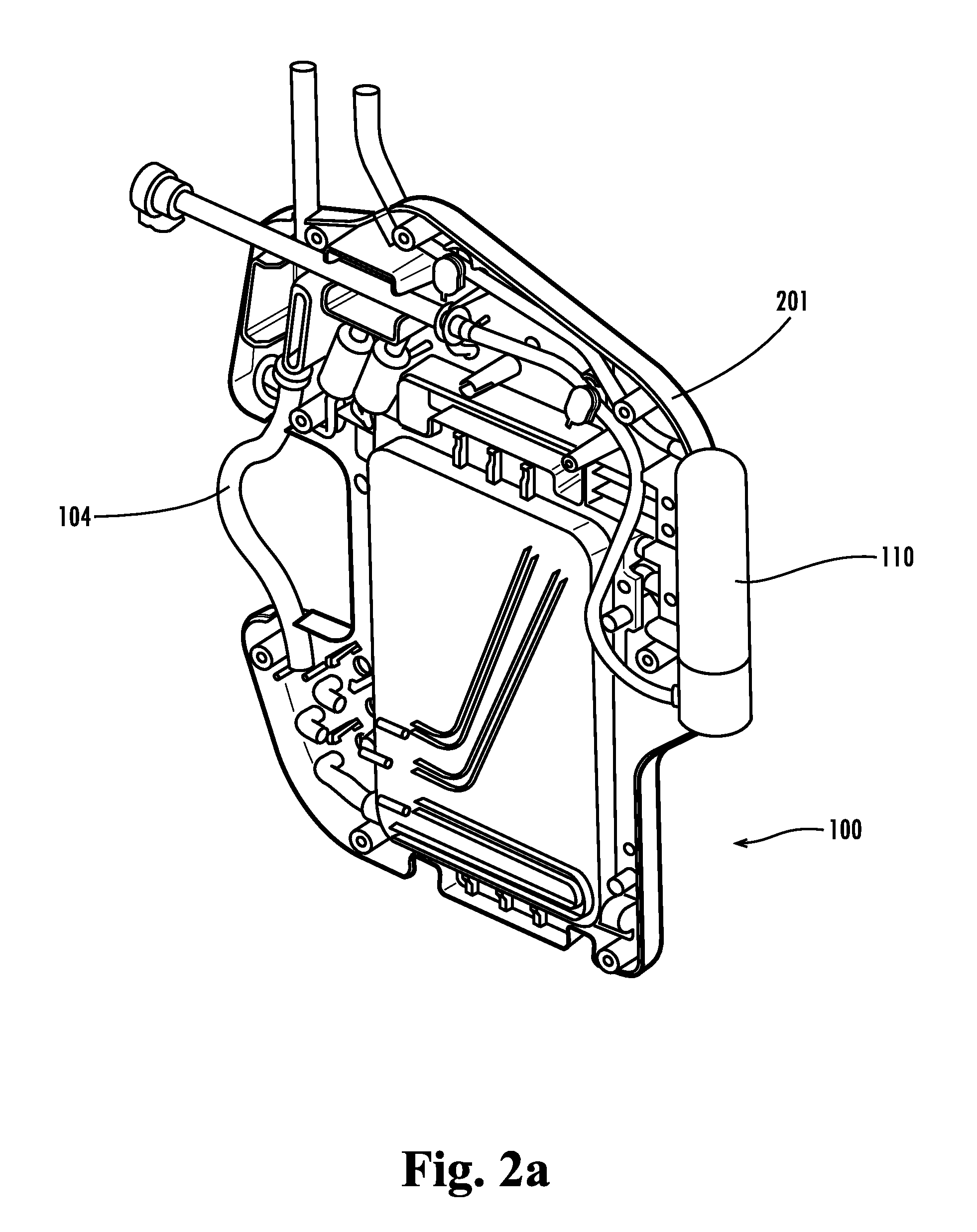

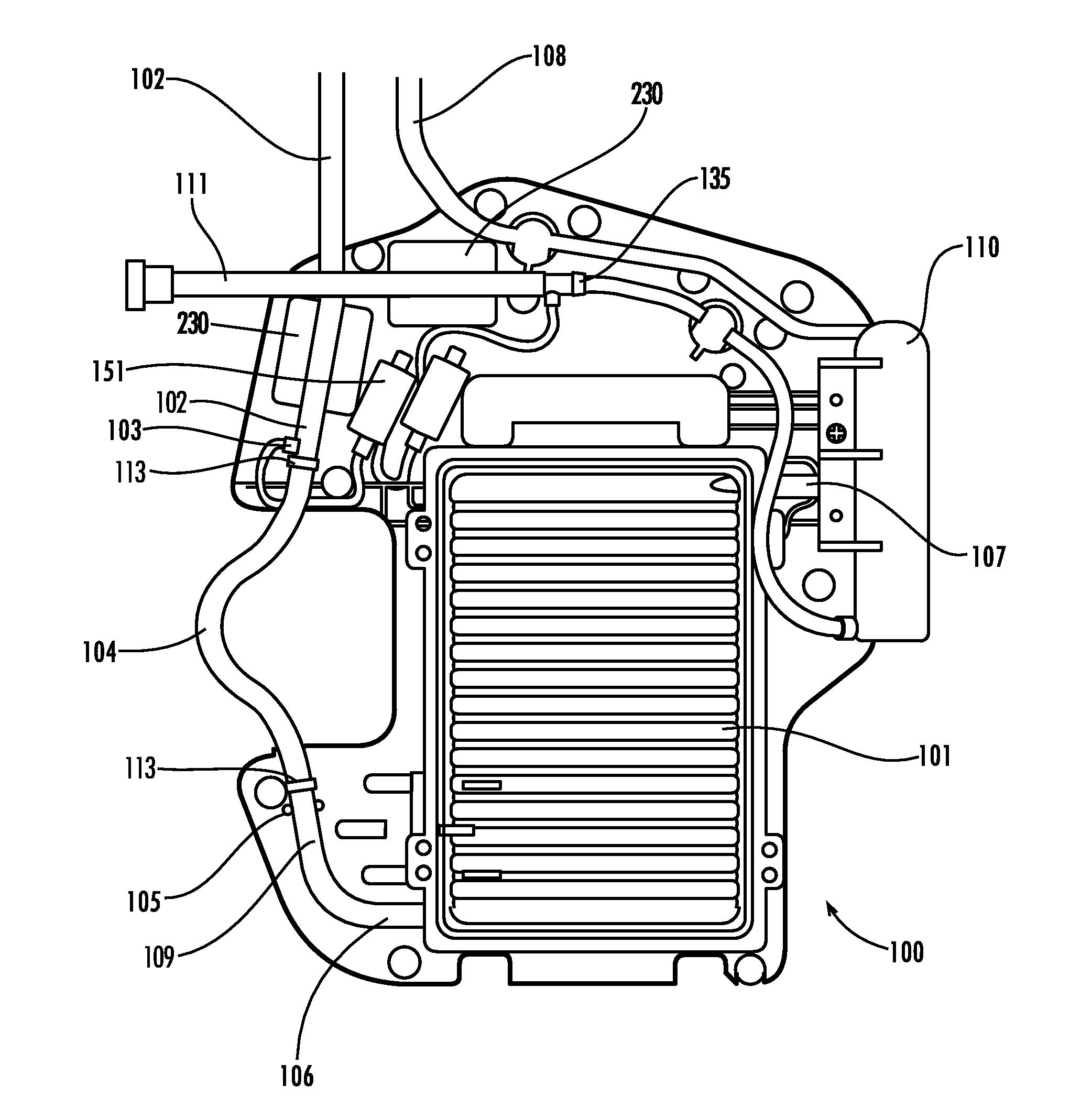

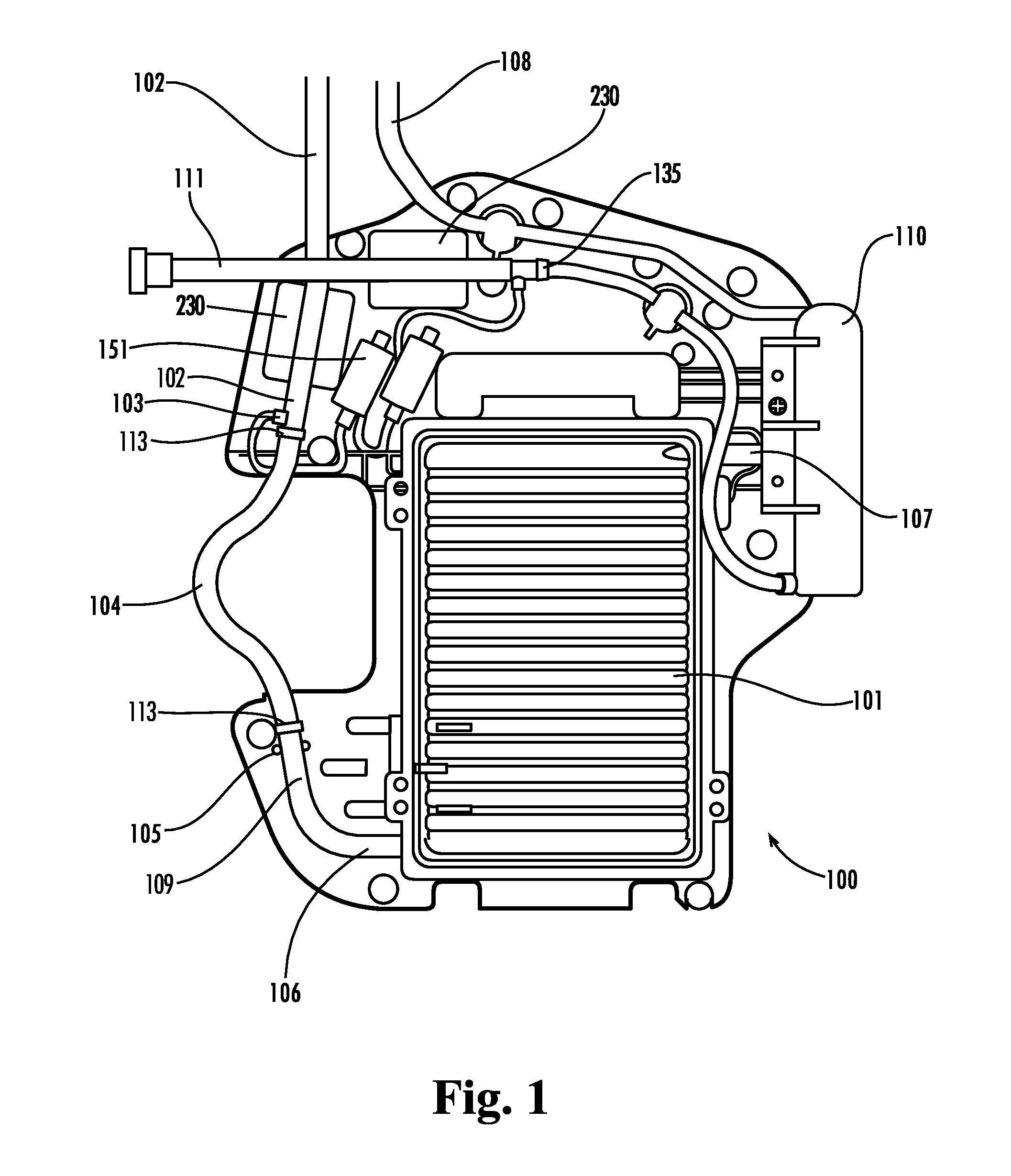

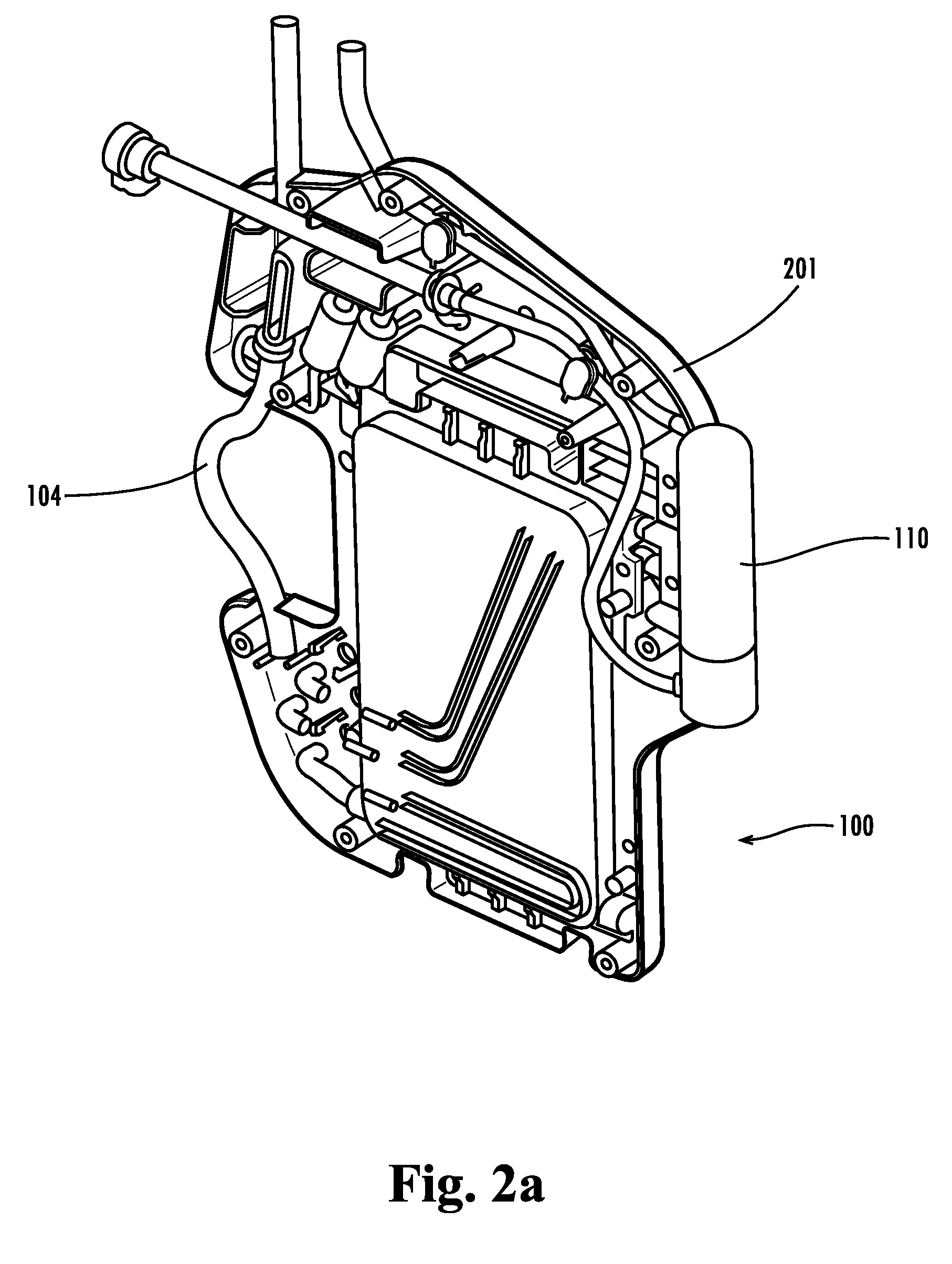

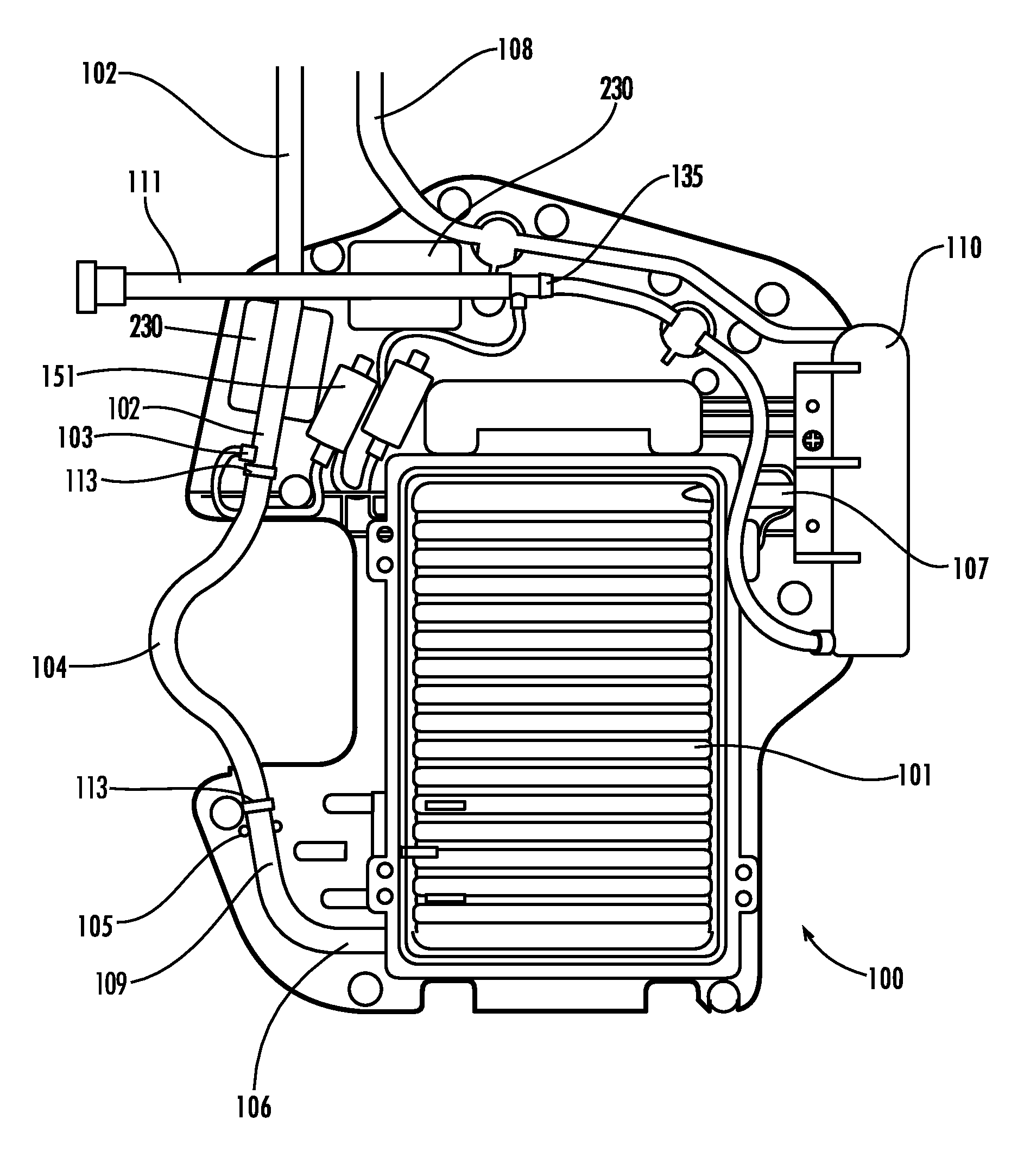

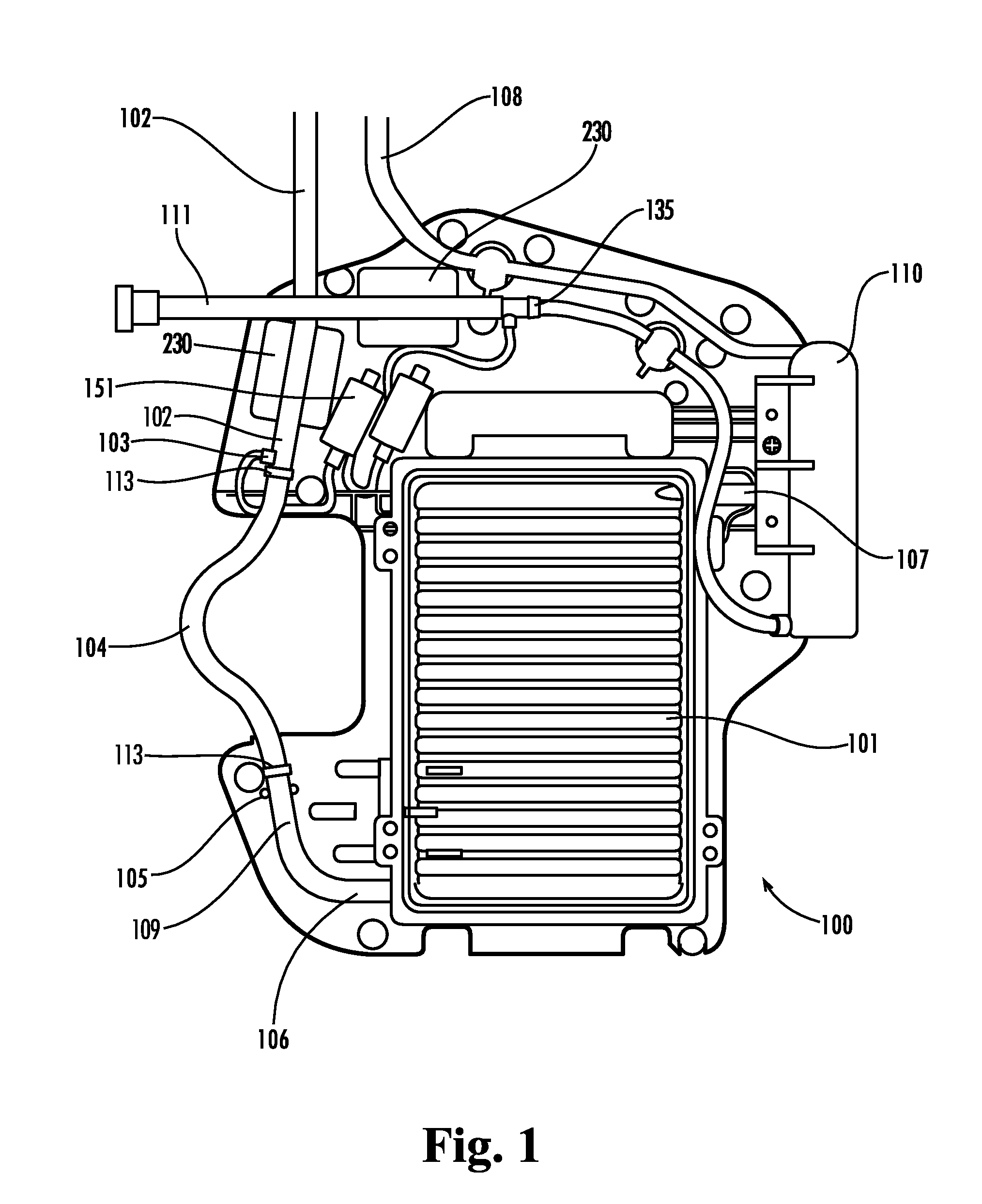

Heat Exchange System For A Pump Device

ActiveUS20080156476A1Easy to control accuratelyReduce riskHeater elementsIndirect heat exchangersEngineeringConductive materials

A heat exchange system selectably controls the temperature of a fluid being delivered to a patient's body by a pump device. The heat exchange system includes a thermal element and a heat exchanger that is removably coupled under pressure to the thermal element. The heat exchanger includes a first half made from thermally conductive material that correspondingly mates with the thermal element, a second half made from thermally conductive material opposite the first half, and an internal heat exchange zone existing between the first half and the second half, wherein fluid flows therethrough. The thermal element of the heat exchange system may controllably and safely warm and / or cool the fluid prior to delivery.

Owner:SMISSON CARTLEDGE BIOMEDICAL

Alignment and Attachment of a Heat Exchanger Cartridge to a Pump Device

ActiveUS20080146995A1Avoid crimpingAvoid obstructionMedical devicesFlow monitorsBubble DetectorEngineering

A pump system selectably controls the temperature, flow rate, flow volume, and flow pressure of a fluid being infused into a patient's body. The pump system includes a cartridge and components that removably connect with a pump housing and corresponding components, providing simple attachment of the cartridge to the pump housing. The pump housing includes a pressure sensor, a bubble detector, and a temperature sensor on a first side of the pump housing, and an engaging actuator and a central controller. The cartridge includes on a first side a heat exchanger, a pressure receptor correspondingly aligned with the pressure sensor, and a detector interface correspondingly aligned with the bubble detector and temperature sensor. Upon aligning the cartridge with the pump housing and actuating the engaging actuator, the pressure receptor communicates with the pressure sensor and the detector interface aligns with the bubble detector and temperature sensor.

Owner:SMISSON CARTLEDGE BIOMEDICAL

Control Of A Pump Device

ActiveUS20080146996A1Easy to control accuratelyReduce riskFlexible member pumpsMedical devicesTemperature controlUser input

A pump system simply and selectably controls the temperature, flow rate flow volume, and flow pressure of a fluid being infused into a patient's body. The pump system a includes a central controller and user inputs that allow for simple selection and efficient operation of the pump system, which includes manually or automatically priming the pump system to remove air, selectably controlling and rapidly adjusting the flow rate over a wide range, selectably and safely controlling the pump system temperature controls, and selectably controlling the flow pressure during delivery. The pump system includes a pump housing with a central controller and a cartridge with infusion tubing removably coupled to the pump housing.

Owner:SMISSON CARTLEDGE BIOMEDICAL

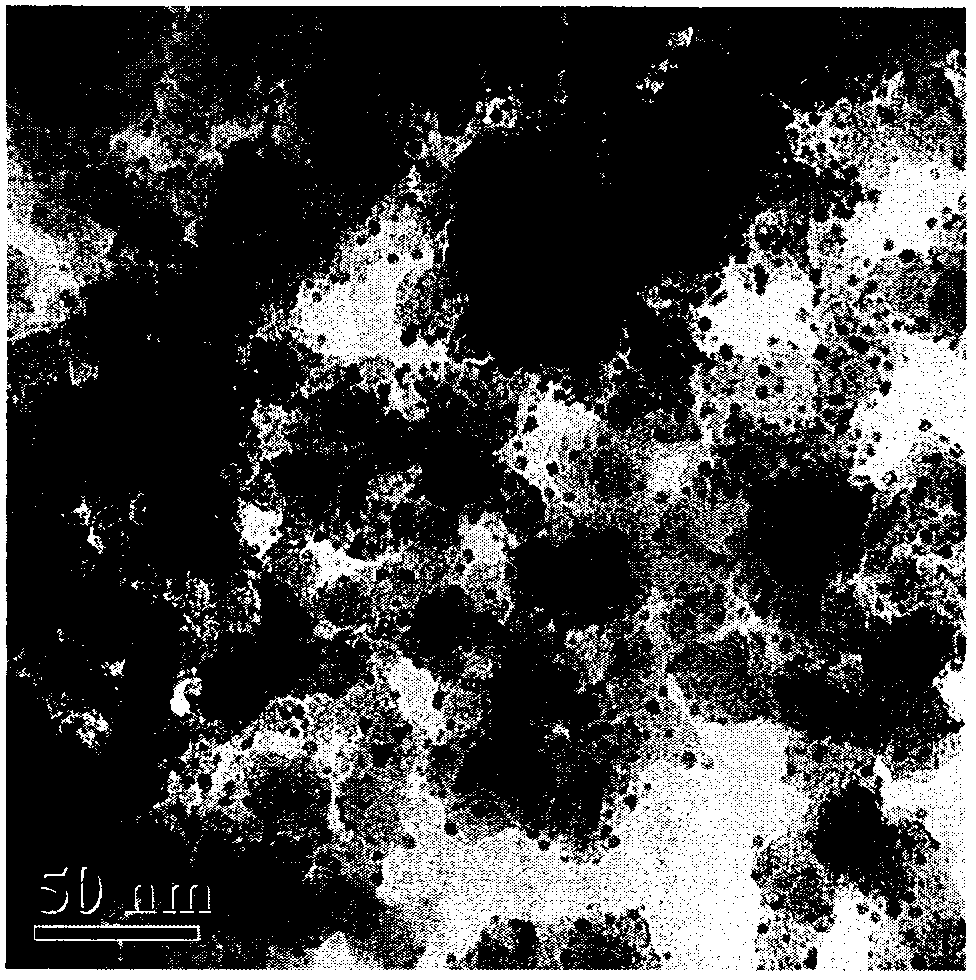

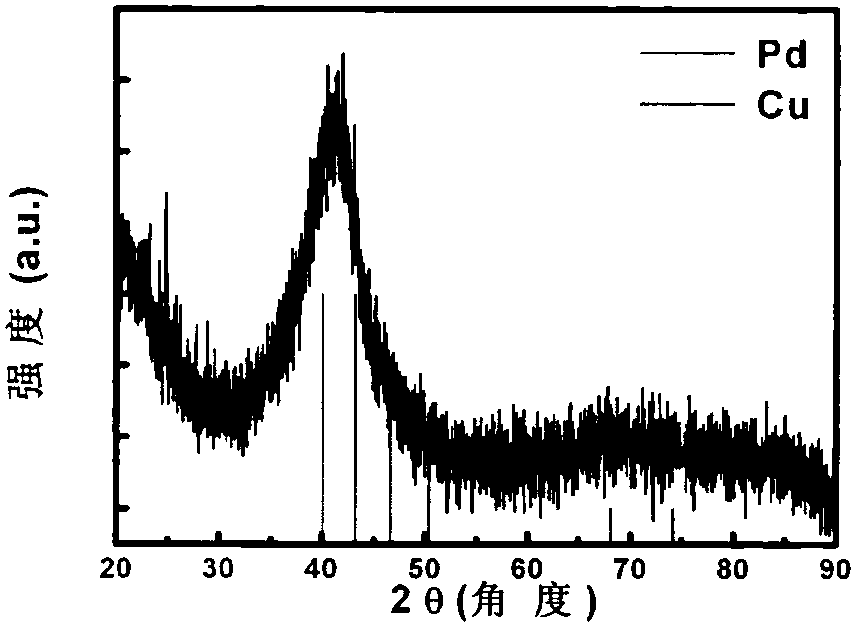

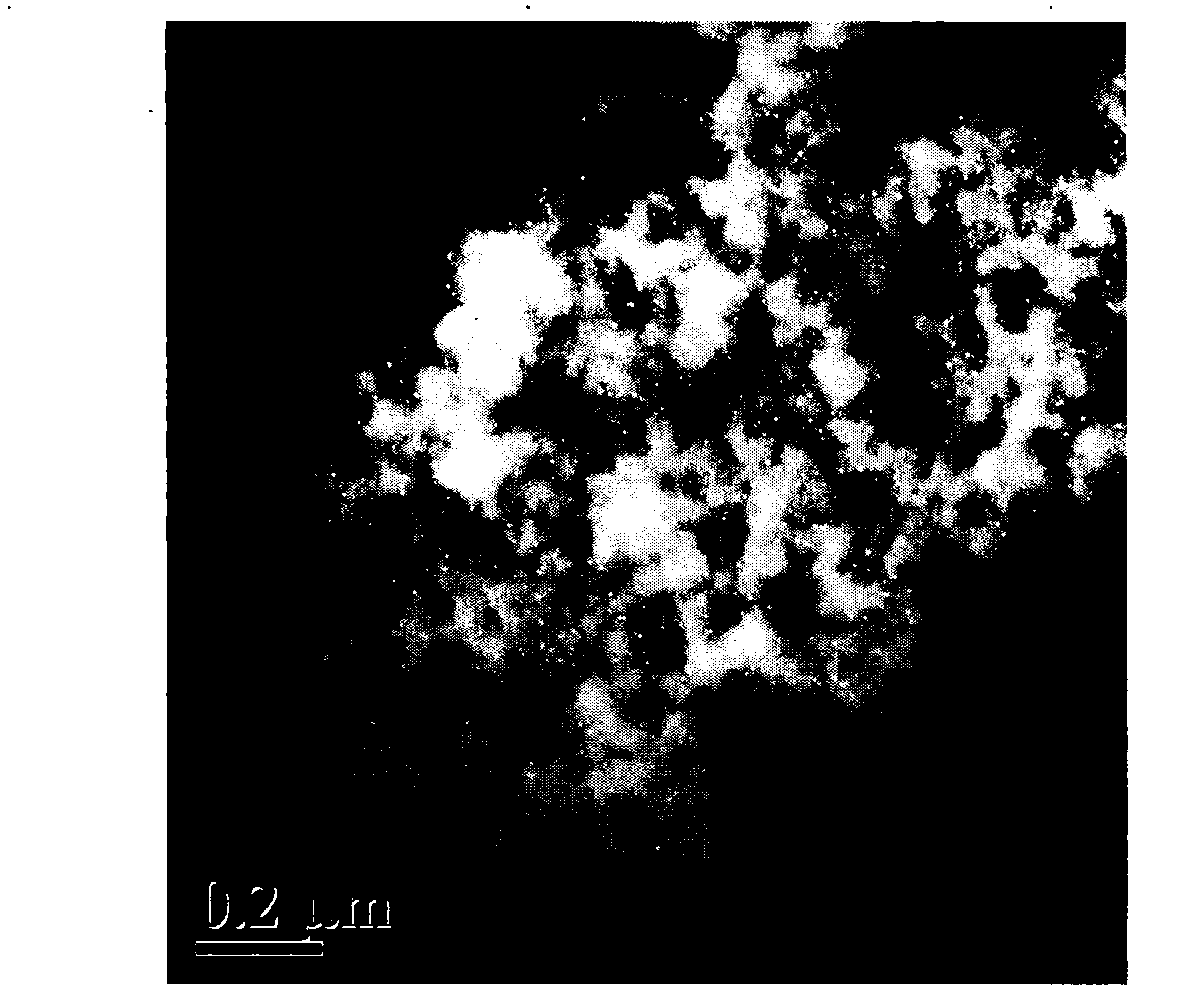

Method for preparing load type high-dispersion multi-component precious metal nanoparticle catalyst

InactiveCN102974365AGood dispersionUniform particle size distributionMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureSurface-active agents

The invention relates to a method for preparing a load type high-dispersion multi-component precious metal nanoparticle catalyst. The method comprises the steps of 1) under inert atmosphere, uniformly stirring a solvent and a surface active agent, then adding a precious metal precursor solution, rising the temperature, reacting for a certain period of time, cooling to the room temperature, adding normal hexane, and performing extraction layering; 2) uniformly mixing the obtained upper layer nanoparticle solution with a carrier, and stirring or performing ultrasonic treatment; and 3) centrifugating, washing and drying or baking the mixed solution to obtain the catalyst. For the precious metal catalyst, even under a relatively high carrying amount, relatively good precious metal nanoparticle dispersion degree can be still guaranteed; the particle sizes of the particles are uniformly distributed; the precious metal carrying amount is controlled easily and accurately; the particle sizes and the components of multi-component particles can be controlled; and the catalysis application range is wide. The process is simple; the preparation cost is low; the applicability is high; and load-type high-dispersion precious metal and the multi-component precious metal nanoparticle catalyst can be prepared in a large scale.

Owner:TIANJIN POLYTECHNIC UNIV

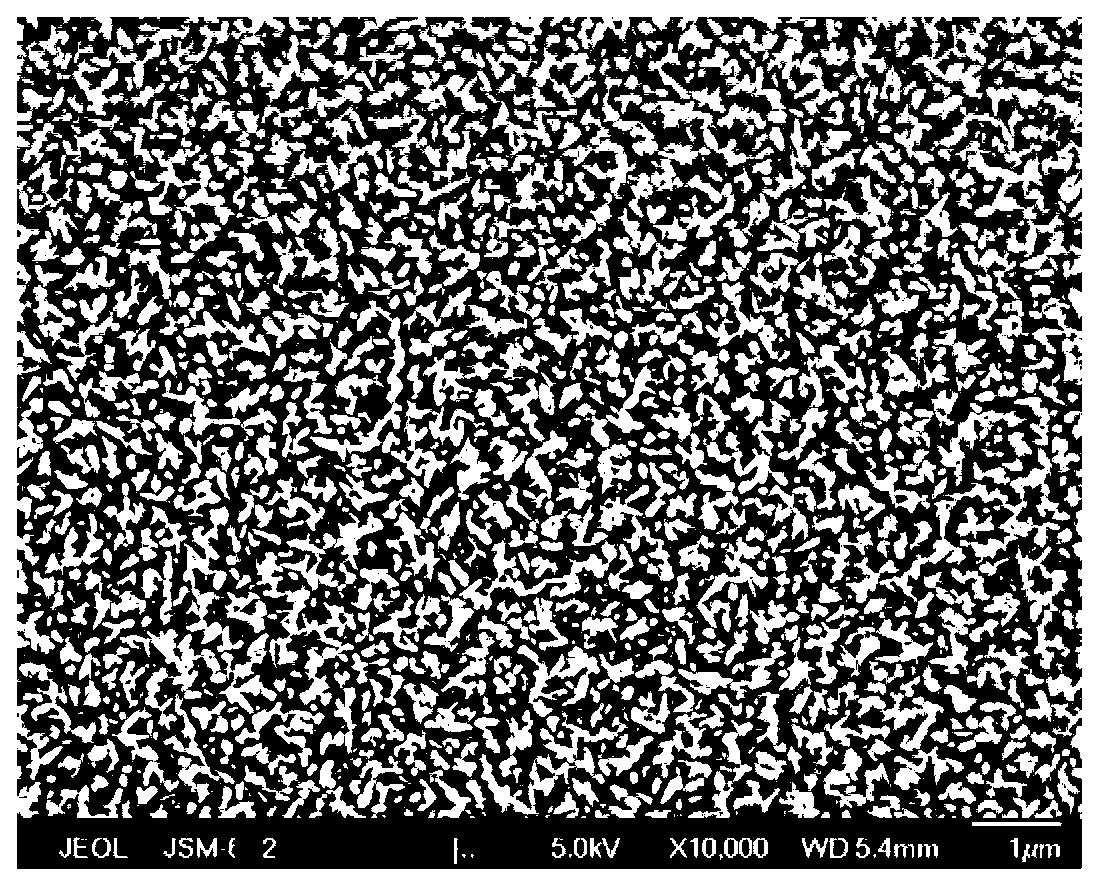

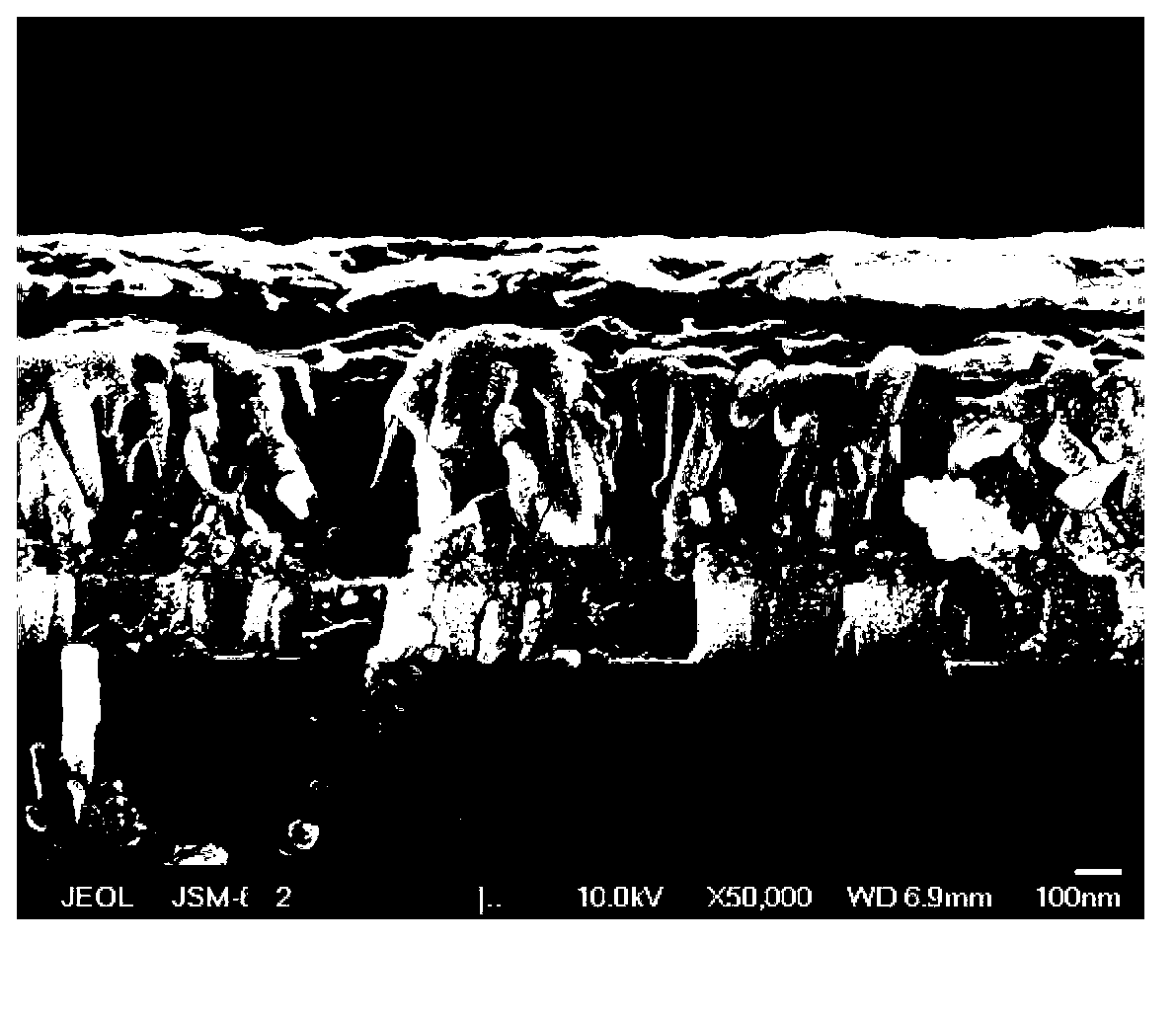

Atomic layer deposition processes

InactiveUS20100227476A1Easy to control accuratelyGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemisorptionThin membrane

This invention relates to method of forming a thin film on a substrate in a reaction chamber by an atomic layer deposition process comprising a plurality of individual cycles. The plurality of individual cycles comprise at least two groupings of individual cycles. The individual cycles comprise (i) introducing a gaseous metal containing precursor into the reaction chamber and exposing the substrate to the gaseous metal containing precursor, wherein at least a portion of the metal containing precursor is chemisorbed onto the surface of the substrate to form a monolayer thereon, (ii) stopping introduction of the metal containing precursor and purging the volume of the reaction chamber; (iii) introducing a gaseous oxygen source compound into the reaction chamber and exposing the monolayer to the gaseous oxygen source compound, wherein at least a portion of the oxygen source compound chemically reacts with the monolayer; and (iv) stopping introduction of the oxygen source compound and purging the volume of the reaction chamber. The method involves repeating the individual cycles until a thin film of desired thickness is obtained. The method also involves carrying out at least two groupings of individual cycles at different process conditions. The methods are useful for producing a thin film on a semiconductor substrate, particularly metal containing thin films for electrode applications in microelectronics.

Owner:PRAXAIR TECH INC

Heat exchange system for a pump device

ActiveUS7975491B2Easy to control accuratelyReduce riskIndirect heat exchangersMachines using electric/magnetic effectsEngineeringConductive materials

Owner:SMISSON CARTLEDGE BIOMEDICAL

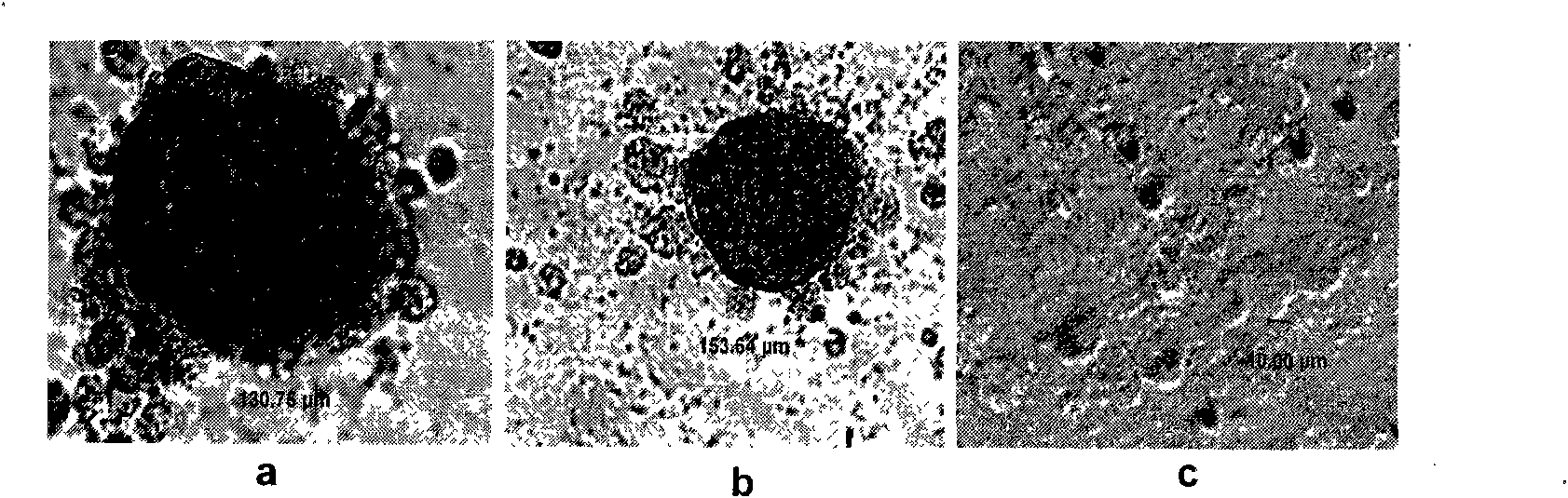

Method for inducing in vitro human medulla mesenchymal stem cells to be divided into islet-like cells

InactiveCN101603027AIslet-like cells are abundantExcellent effectTissue culturePancreatic structureMesenchymal stem cell differentiation

The invention relates to a method for inducing in vitro human medulla mesenchymal stem cells to be divided into islet-like cells, comprising four inducing methods for dividing the human medulla mesenchymal stem cells into islet-like cells, wherein the main inducing liquid firstly adopts porcine fetal pancreas extracting solution and the inducing ingredients of zinc acetate, and the secretory volume of insulin which is divided into the islet-like cells is remarkably improved. The islet-like cells obtained by the method are possible to break through the current technical problem of diabetes mellitus and are suitable for experimental research and future large-scale production.

Owner:NORTHWEST A & F UNIV

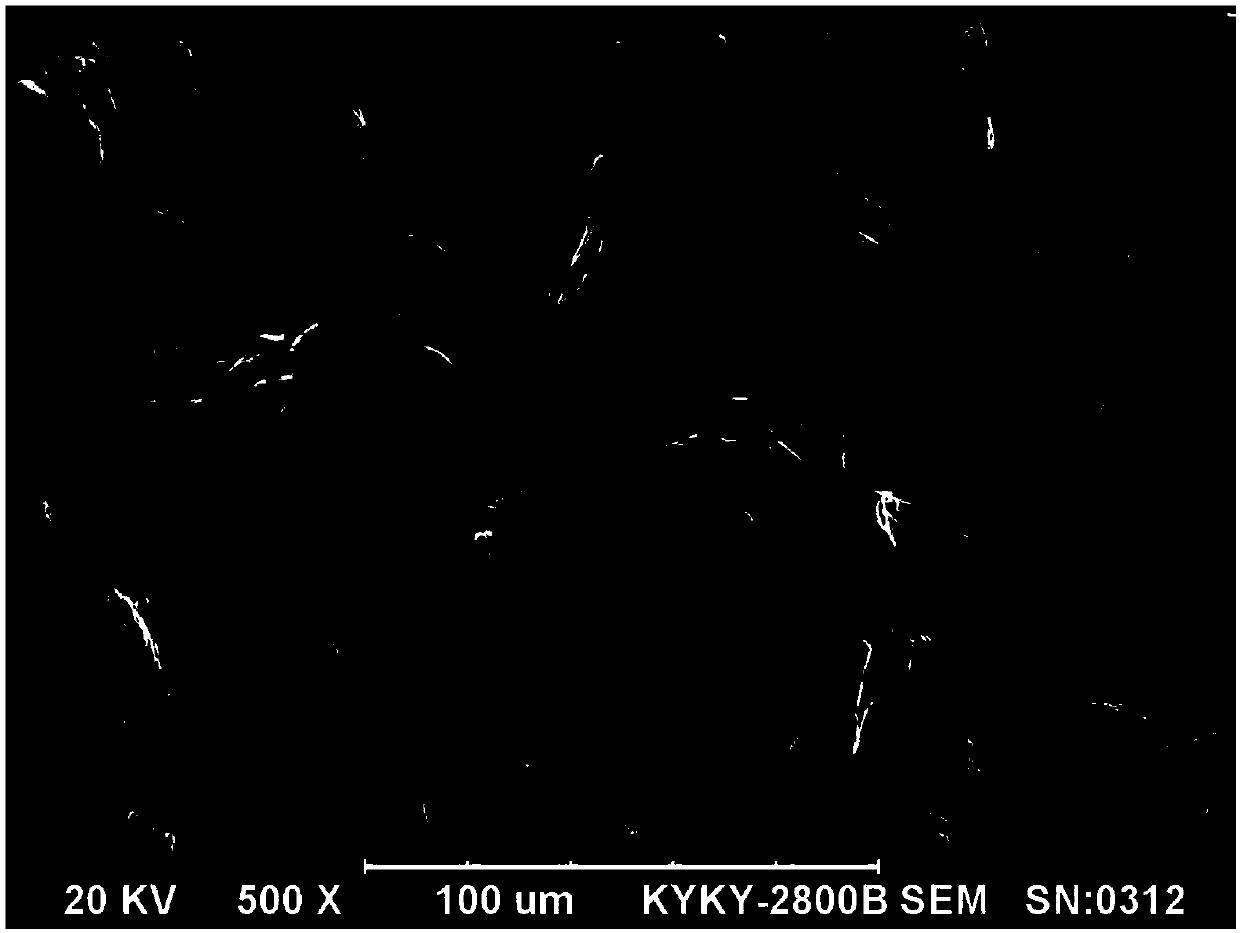

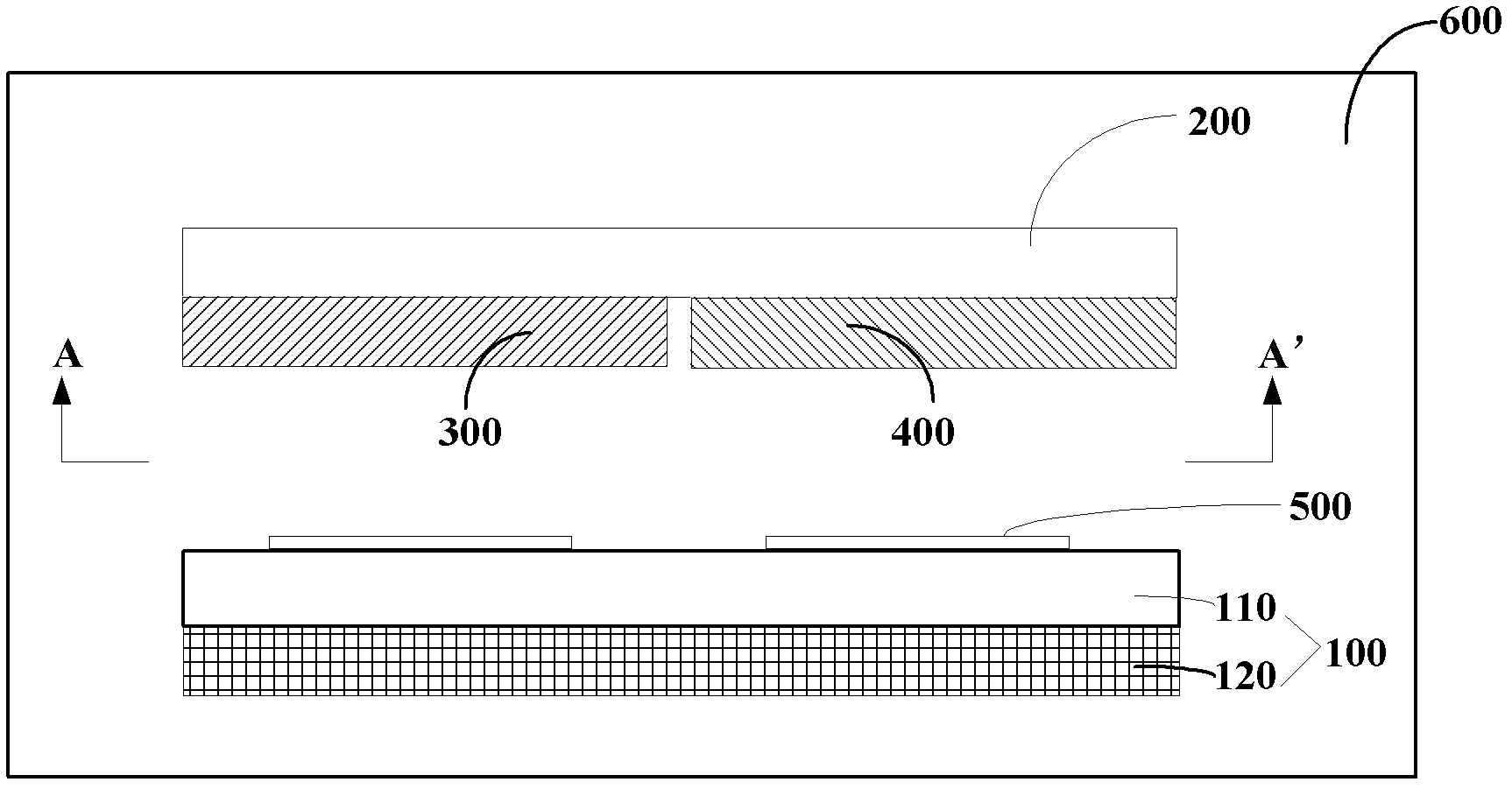

Organic/inorganic hybrid solar battery and preparation method thereof

ActiveCN103078058ASimple methodEasy to operateFinal product manufactureSolid-state devicesOrganic semiconductorEngineering

The invention provides an organic / inorganic hybrid solar battery and a preparation method thereof and belongs to the technical field of hybrid solar batteries. The overall structure layers of the organic / inorganic hybrid solar battery are sequentially as follows: a transparent conductive substrate, an zinc oxide crystal seed layer, a one-dimensional zinc oxide and organic semiconductor material mixed layer, an organic semiconductor layer and a metal film, According to the solar battery structure, the solar battery is prepared layer by layer; and during metal film preparation, a adhesive tape masking process is adopted; and the photoelectric conversion efficiency of the obtained solar battery is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

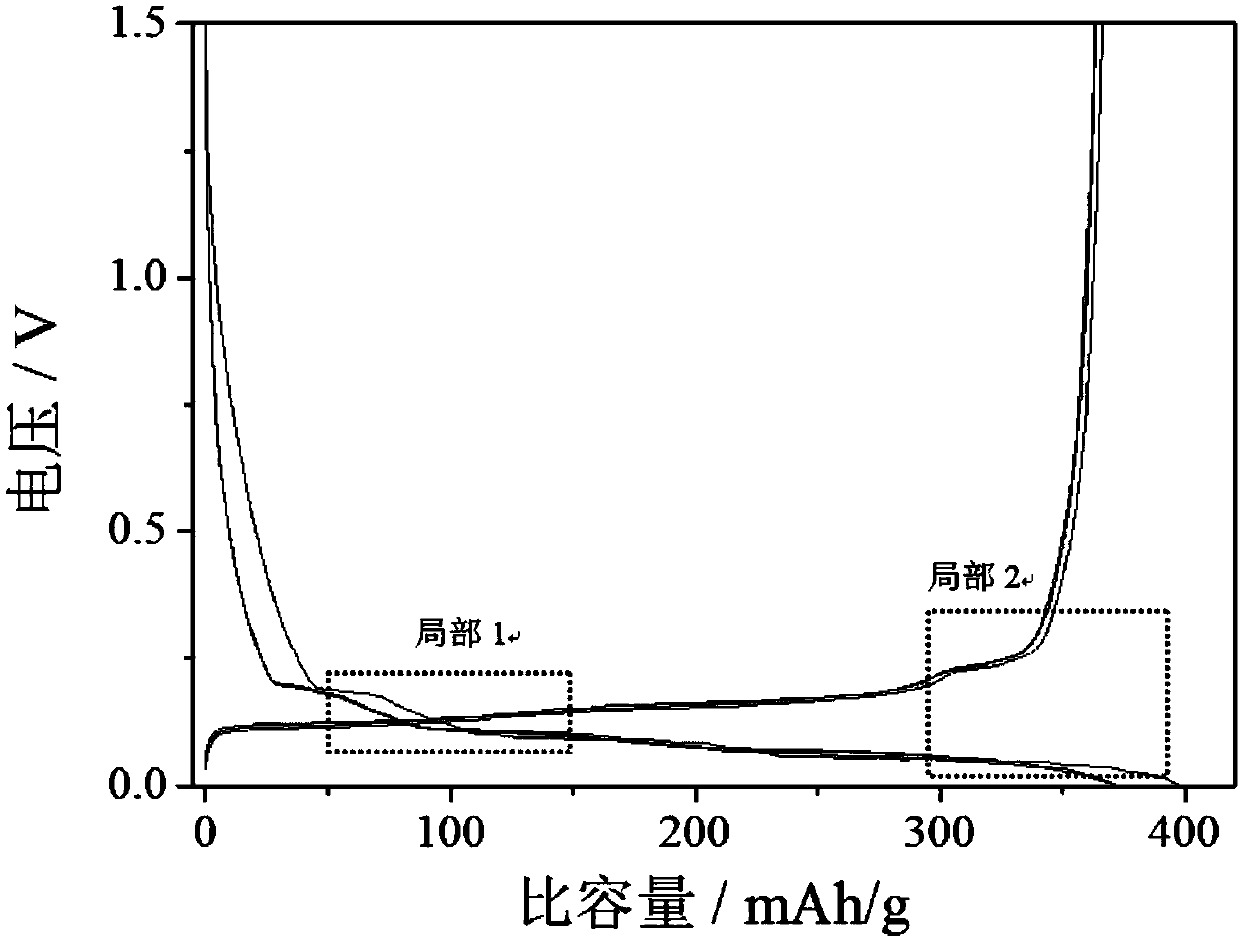

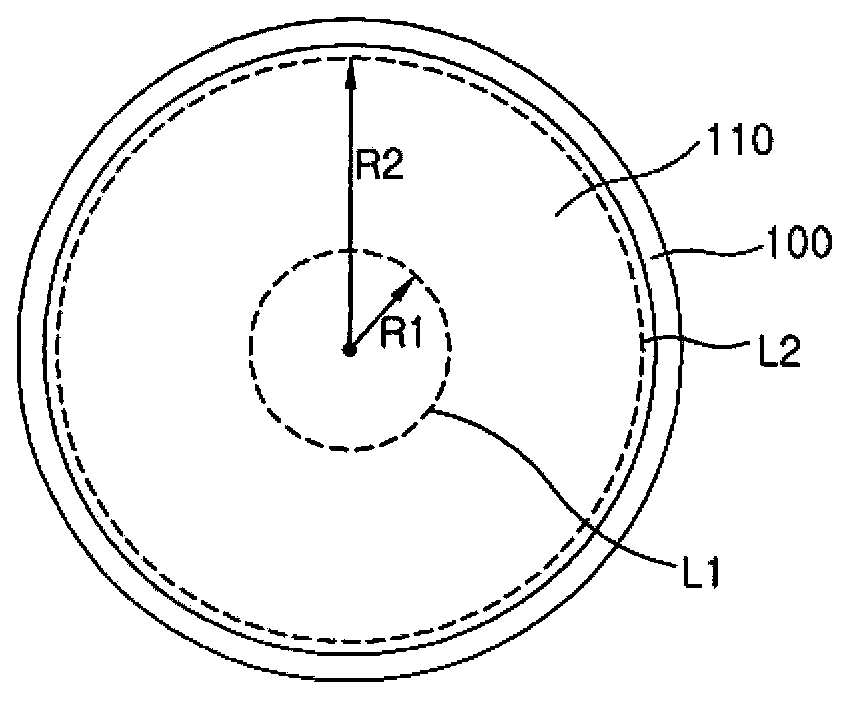

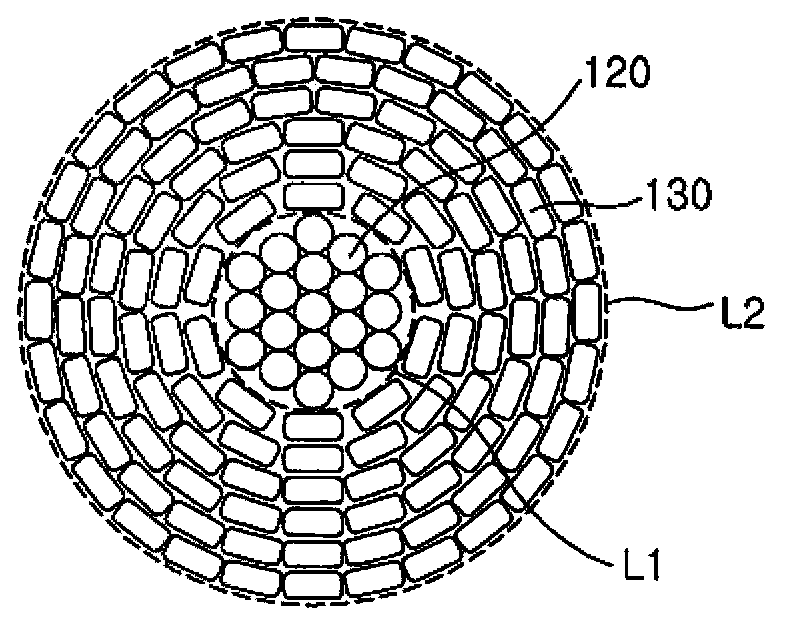

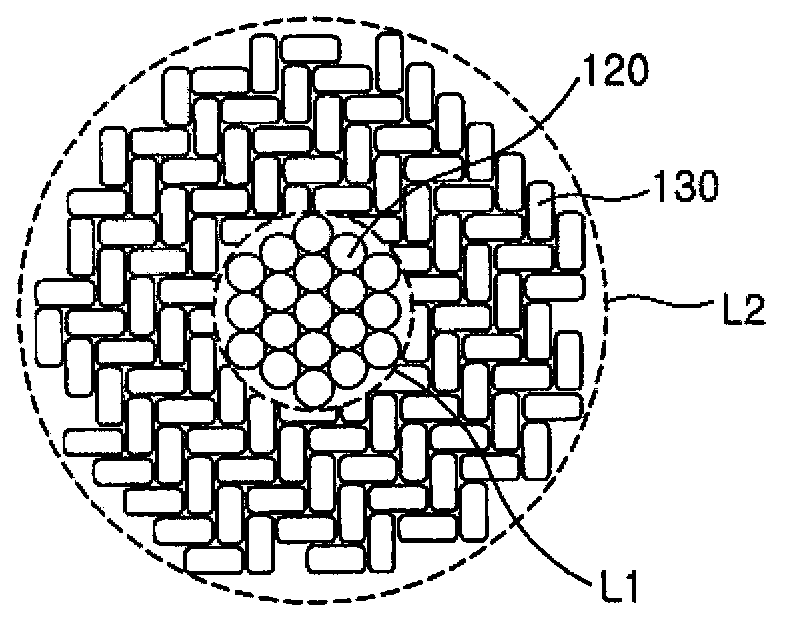

Composite negative electrode material and preparation method therefor and lithium ion battery

ActiveCN107706387AShorten the diffusion pathImprove electrochemical performanceCell electrodesSecondary cellsHigh rateLithium electrode

The invention relates to a composite negative electrode material and a preparation method therefor and a lithium ion battery. The composite negative electrode material comprises a carbonaceous material with an embedding structure and formed by embedding first carbon component small particles into a second carbon component framework carrier, wherein the first carbon component is converted by a small particle precursor (green coke and / or burning coke and / or carbon microspheres); and the second carbon component framework carrier is converted by a binder. The composite negative electrode materialdisclosed in the invention combines the "embedding type" structure and a "gradient type crystal form" structure; the small particles of different appearances are embedded in the relatively thick framework carrier to form a bigger particle; the small particles embedded in the interior adopt a graphite structure with the best crystal form; the framework carrier adopts a graphite structure with the ordinary crystal form; and the outermost layer also can be coated with an amorphous carbon structure with the worst crystal form. The composite negative electrode material provided by the invention hasstructural stability, high orientation, low expansion, high rate capability, excellent liquid absorption performance and cycle performance, and can satisfy various kinds of demands in the application.

Owner:贝特瑞(四川)新材料科技有限公司

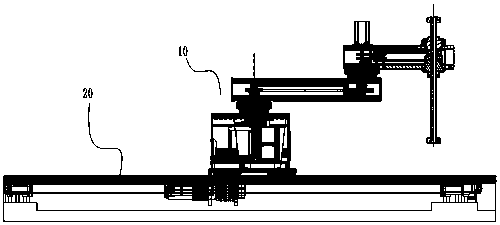

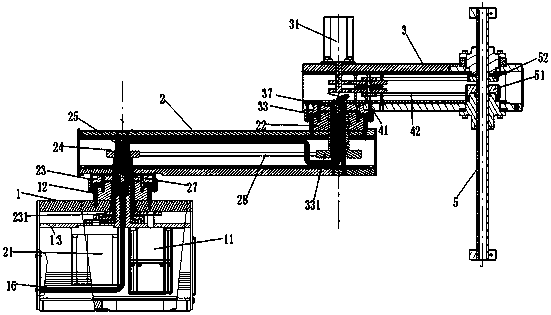

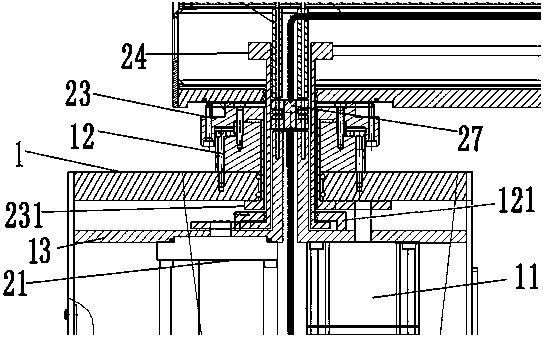

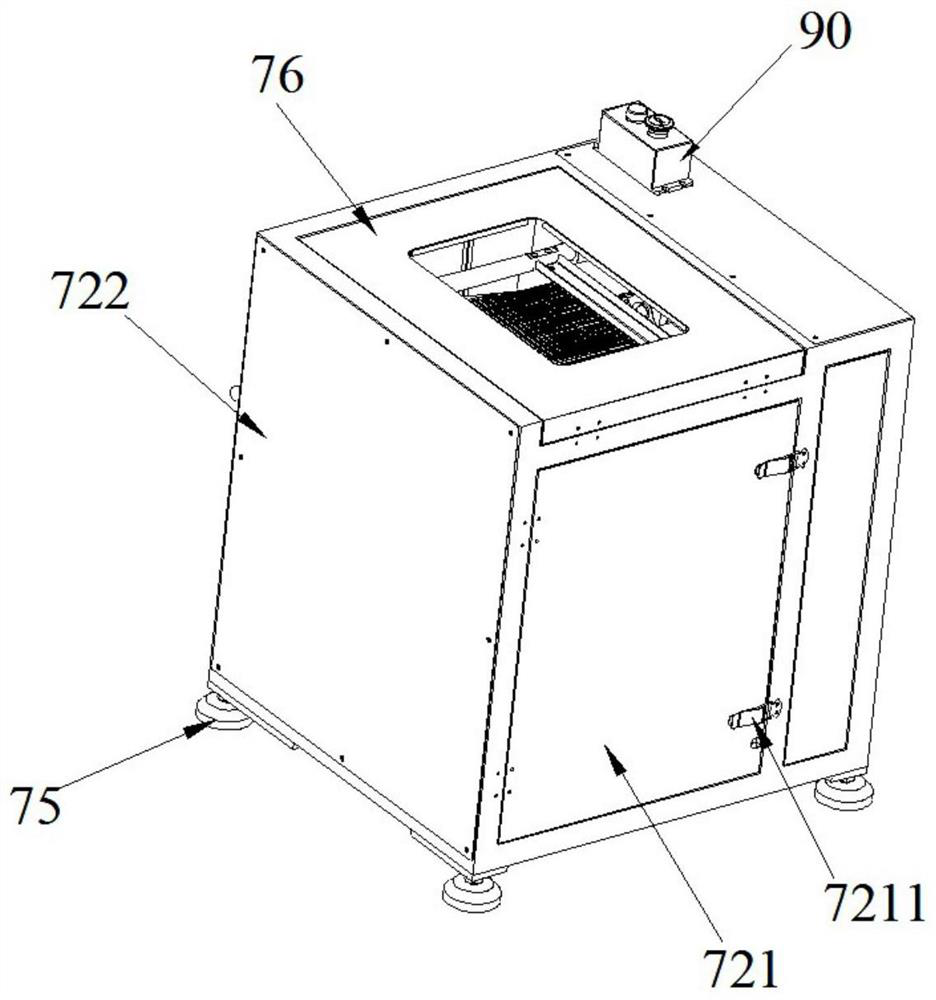

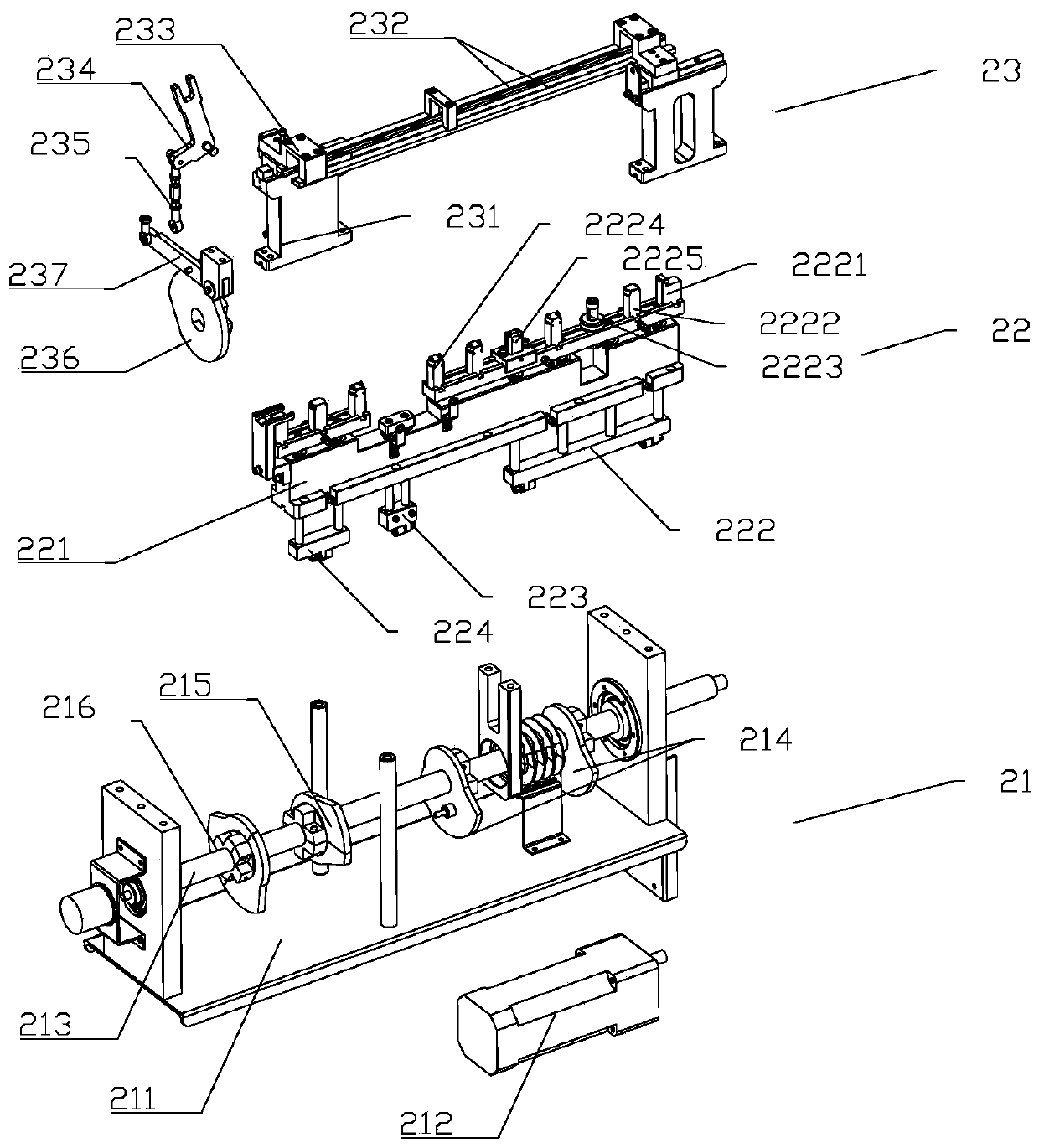

Multi-station SCARA industrial robot

PendingCN107639631ALower acquisition costsReduce weightProgramme-controlled manipulatorWire rodControl engineering

The invention discloses a multi-station SCARA industrial robot. The industrial robot includes a SCARA robot mechanism and a displacement drive mechanism, and the SCARA robot mechanism comprises a base, a first arm, a first arm drive device, a second arm, a second arm drive device, a ball spline wire rod and a power supply cable; a first motor and a second motor on the first and second arm drive devices are arranged inside the base, the rotation and lifting of the ball spline screw rod are driven by a third motor through a third drive component, and the SCARA robot mechanism can move under thedrive of the displacement drive mechanism. When the multi-station SCARA industrial robot is produced, multiple workstations require sharing only one SCARA robot mechanism, and thus the occupied spaceand the acquisition costs of equipment are reduced. Additionally, in the SCARA robot mechanism, the first and second motors are arranged inside the base, only the third motor is arranged on the secondarm, the weight of the load on the second arm can be reduced, the cost of spare parts is reduced, and the motion accuracy is improved.

Owner:GUANGDONG INST OF INTELLIGENT MFG

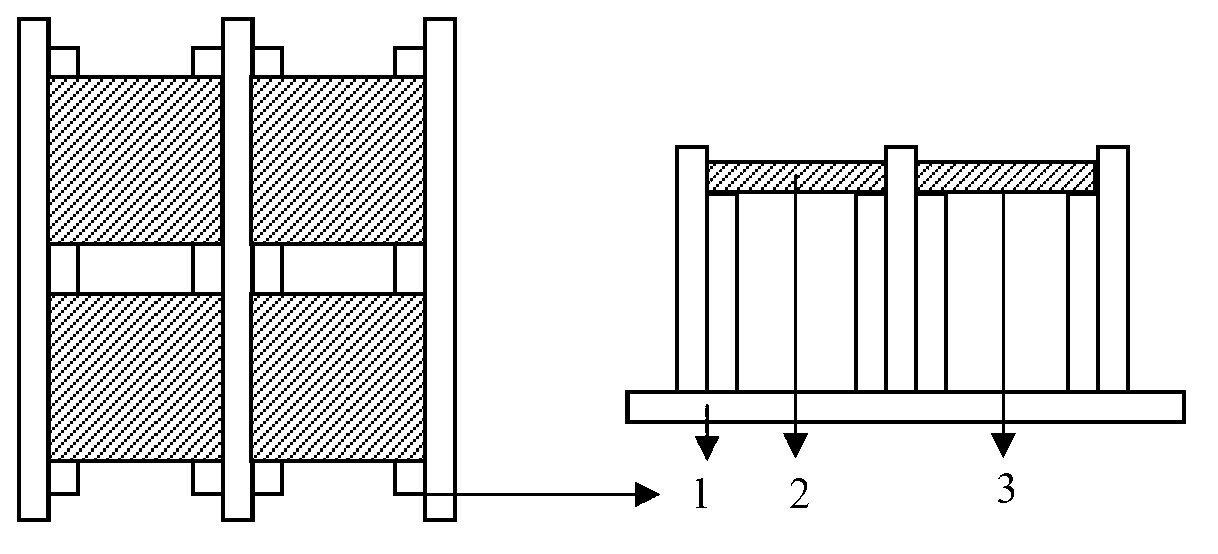

Chemical vapor deposition (CVD) device

ActiveCN103014667AAvoid it happening againReduces the possibility of detachment from the filmChemical vapor deposition coatingGas phaseProduct gas

The invention provides a chemical vapor deposition (CVD) device. The device comprises a reaction chamber, a cooling device, a spraying assembly arranged at the top of the reaction chamber and a base arranged opposite to the spraying assembly, wherein the base is provided with a heating unit; the spraying assembly comprises a first gas inlet device and a second gas inlet device which are respectively used for transmitting first gases and second gases to a reaction zone between the base and the spraying assembly; the cooling device and the first gas inlet device are stacked; the cooling device and the second gas inlet device are stacked; the first gas inlet device and the second gas inlet device are arranged side by side; the thermal conductivity of the first gas inlet device is greater than that of the second gas inlet device; and in the heating process of the heating unit, the first gas inlet device and the second gas inlet device have different temperatures. The device can provide different temperatures for gases in different gas inlet devices.

Owner:DEPOSITION EQUIP & APPL SHANGHAI LTD

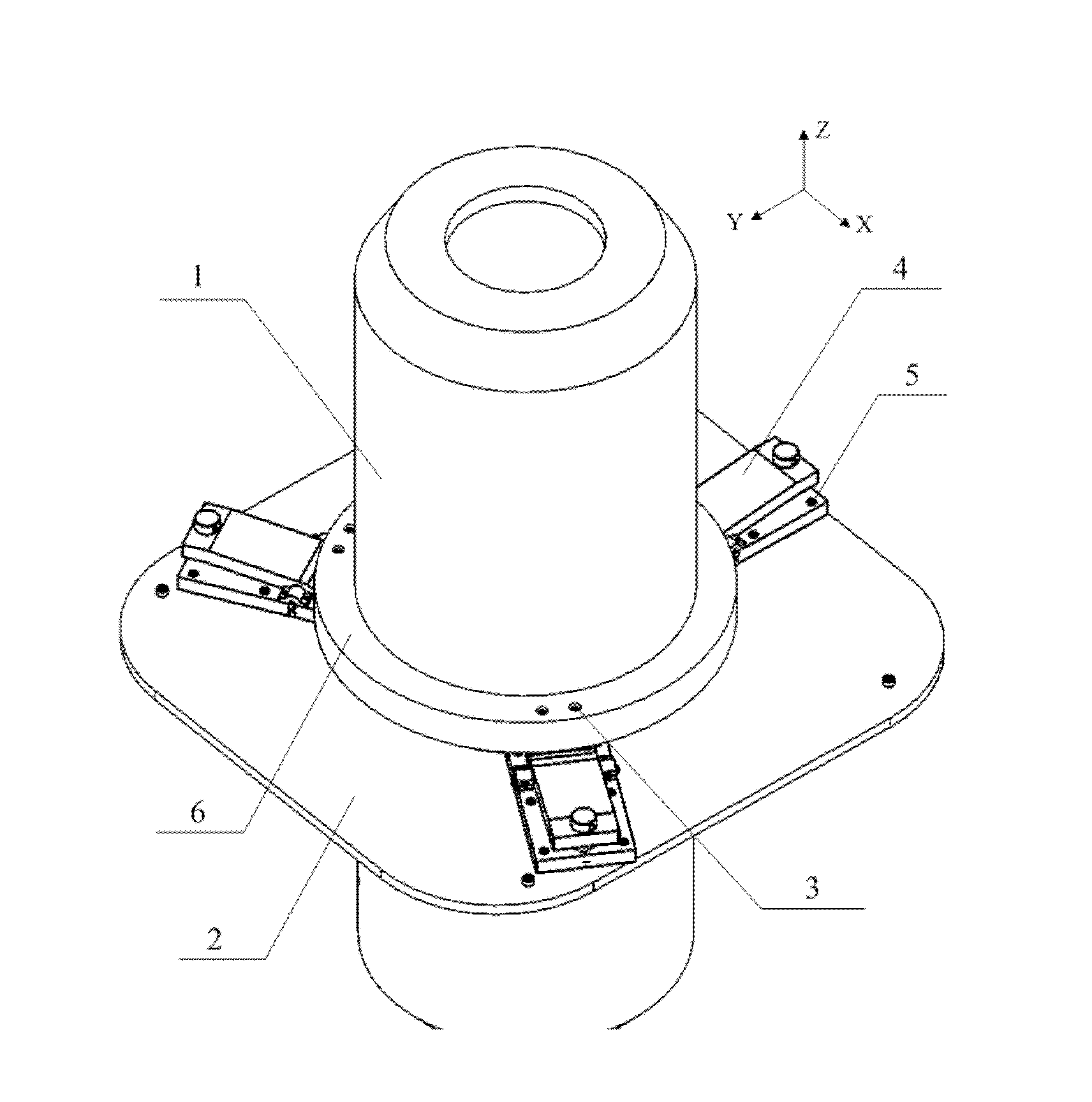

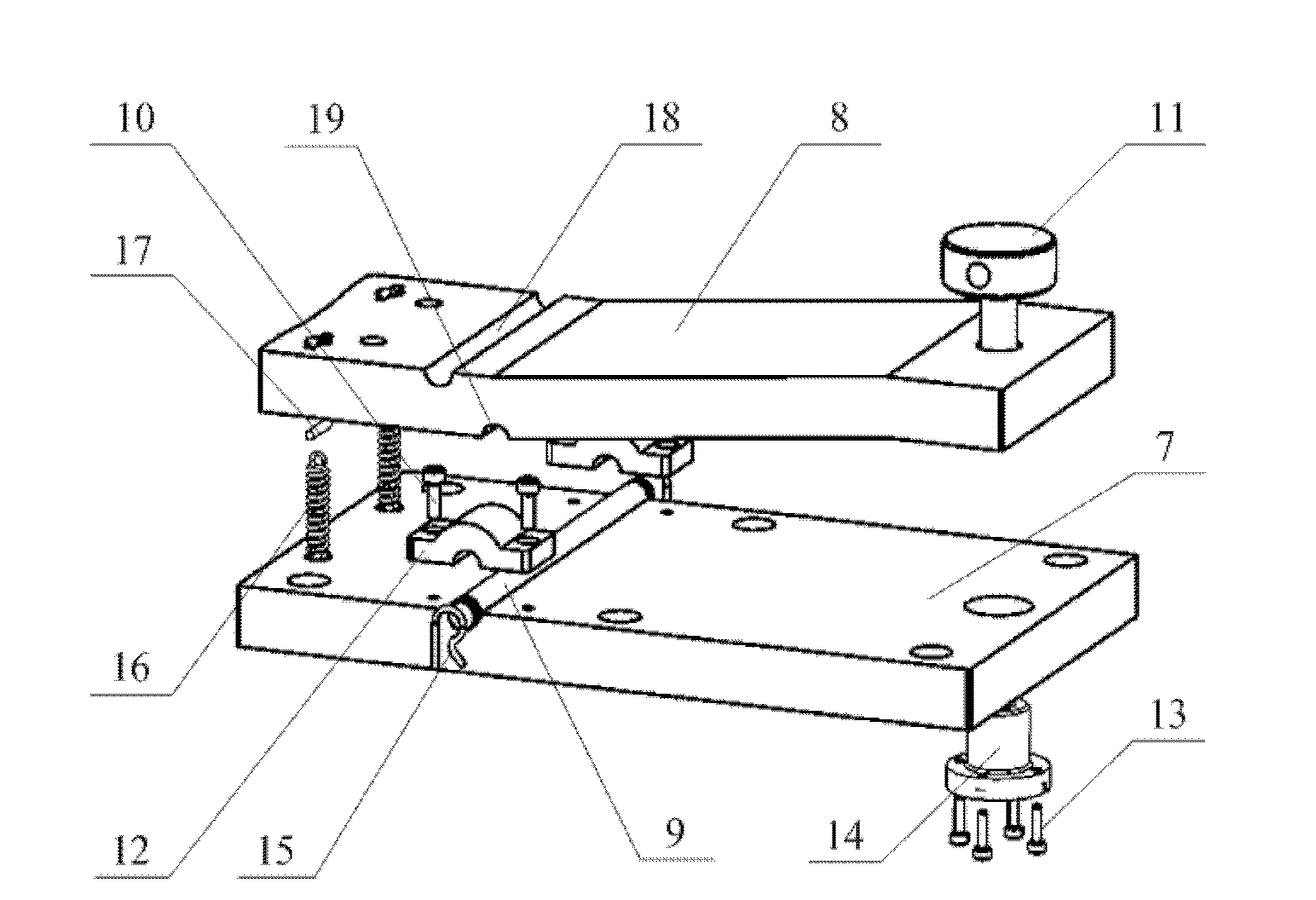

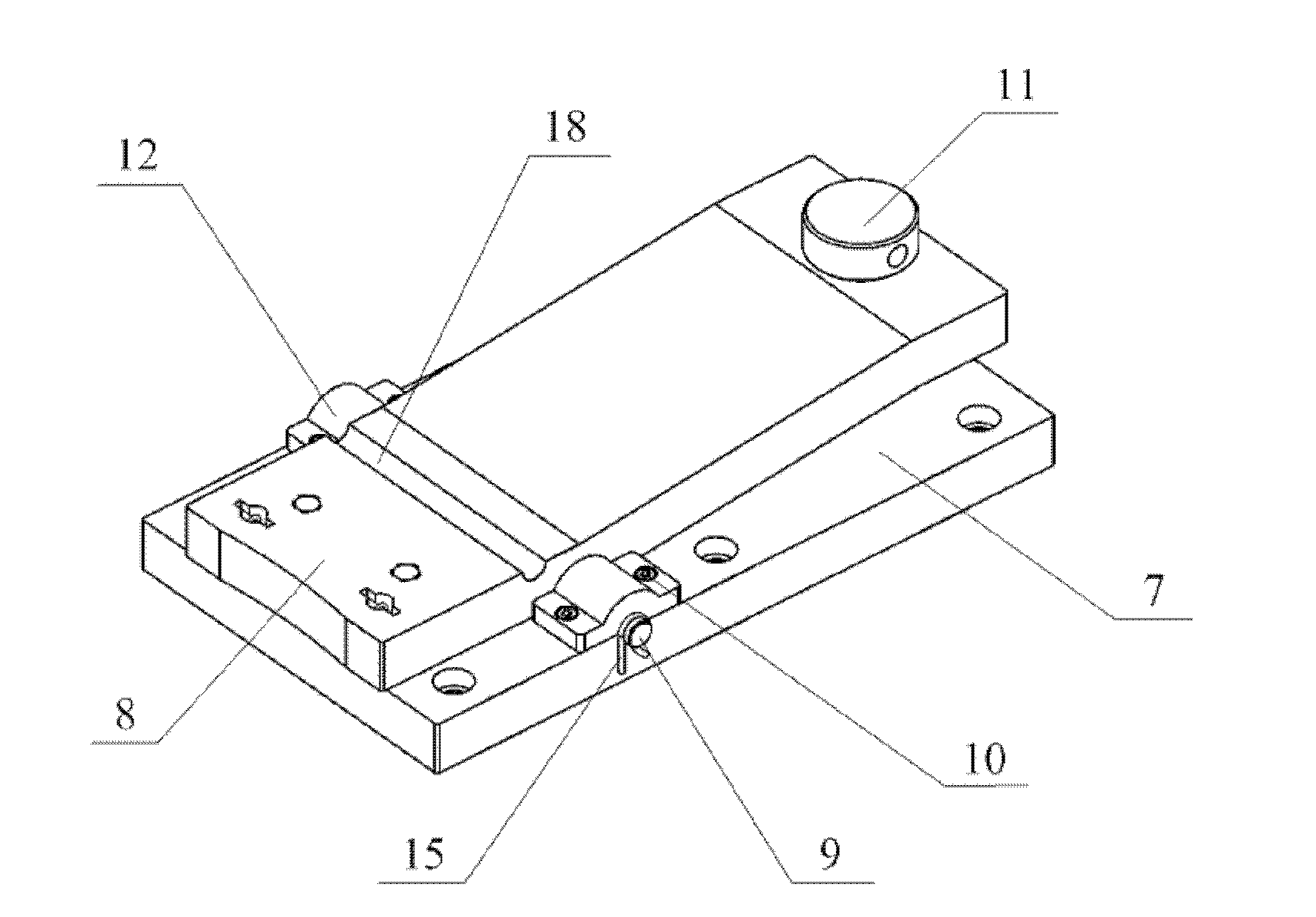

Micro leveling mechanism of projection objective of lithography machine

InactiveCN102141741ASimple structureEasy to control accuratelyPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistAmplification factor

The invention discloses a micro leveling mechanism of a projection objective of a lithography machine, and belongs to the technical field of projection lithography. The mechanism mainly consists of a mounting substrate, three support adjusting lever mechanisms, mounting pieces and fixing pieces, wherein each support adjusting lever mechanism consists of a lever mounting base, an adjusting lever, an adjusting screw, a shaft, a shaft end cover, a pre-tightening spring, an adjusting screw and the like; and the lever mounting bases of the support adjusting lever mechanisms are fixed with the mounting substrate through the fixing pieces, and objective flanges are connected with the front ends of the adjusting levers through the mounting pieces. The micro leveling mechanism is uniformly distributed on the edge of an objective in a three-point support mode; through the support adjusting lever mechanisms, not only the precision of thread adjustment can be improved, but also the load borne on threads can be reduced; and the amplification factors of the levers can be set according to different precision requirements.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Collecting device for stamped radiating fins

ActiveCN103552124AShorten the transportation distanceLabor savingGearingMetal working apparatusParking spaceEngineering

The invention relates to a collecting device for stamped radiating fins. The collecting device comprises a workbench and collecting trolleys, wherein the workbench comprises a base and a flat plate which is arranged on the base and can be used for allowing the collecting trolleys to be parked; the flat plate can be arranged on the base in a sliding way; the base is provided with a trolley switching mechanism for driving the flat plate to slide; at least two parking spaces are arranged on the flat plate at certain intervals along the sliding direction of the flat plate; each parking lot can be used for allowing one collecting trolley to be parked. According to the collecting device, after receiving pins of one collecting trolley are full of radiating fins, the flat plate slides to drive the no-load trolley on the other parking spaces to move below an adsorption device for receiving, the receiving trolley which is full of the radiating fins is driven away from the adsorption device, and workers pull the collecting trolley which is full of the radiating fins out of the flat plate to another machining place for unloading, so that the carrying distance of the workers can be reduced, and a large amount of labor force is saved; on the other hand, the trolley switching time is short, next collection can be performed without taking the radiating fins out, so that the collecting device has the advantages of high machining flexibility and high working efficiency.

Owner:OMS MASCH CO LTD

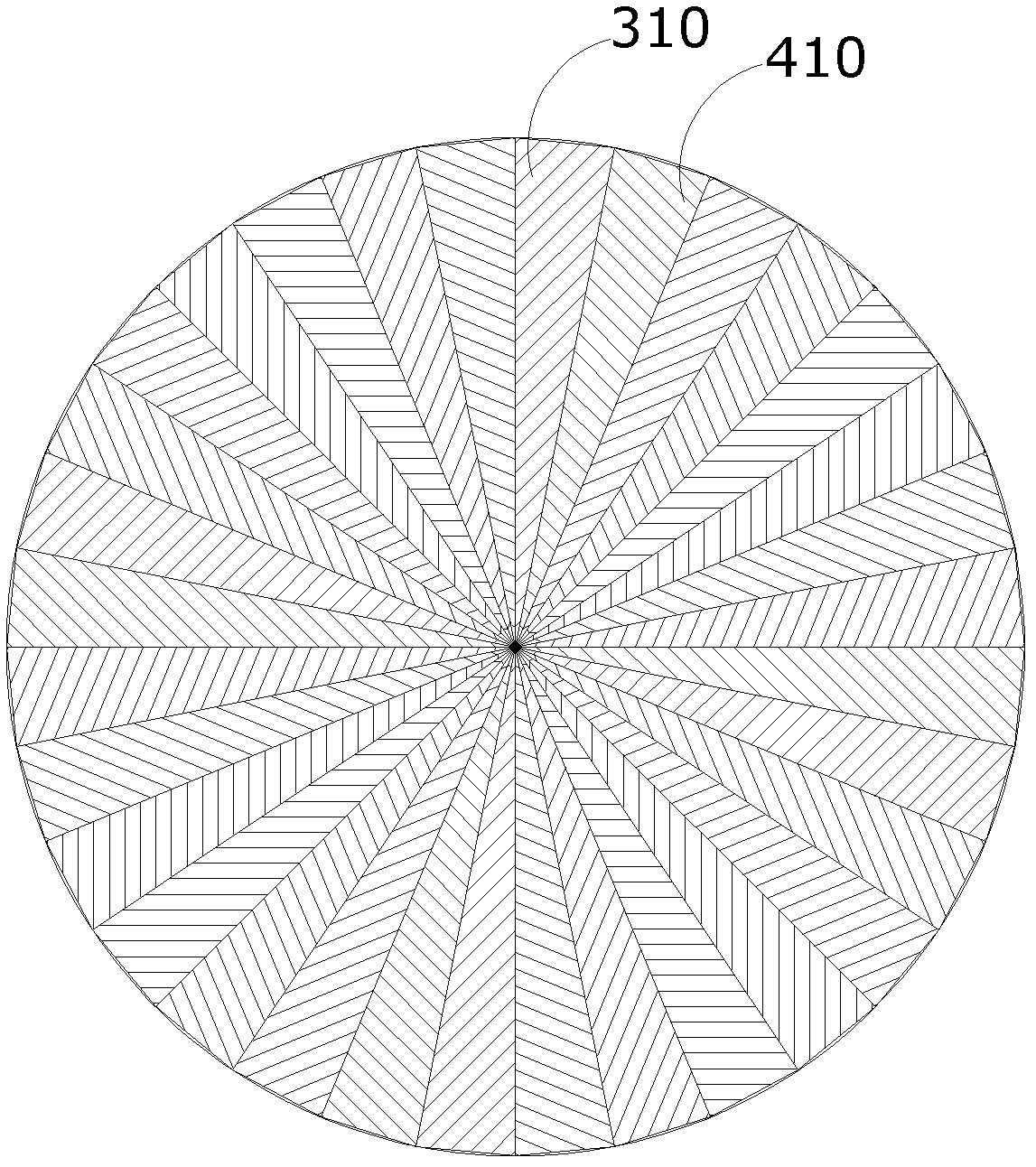

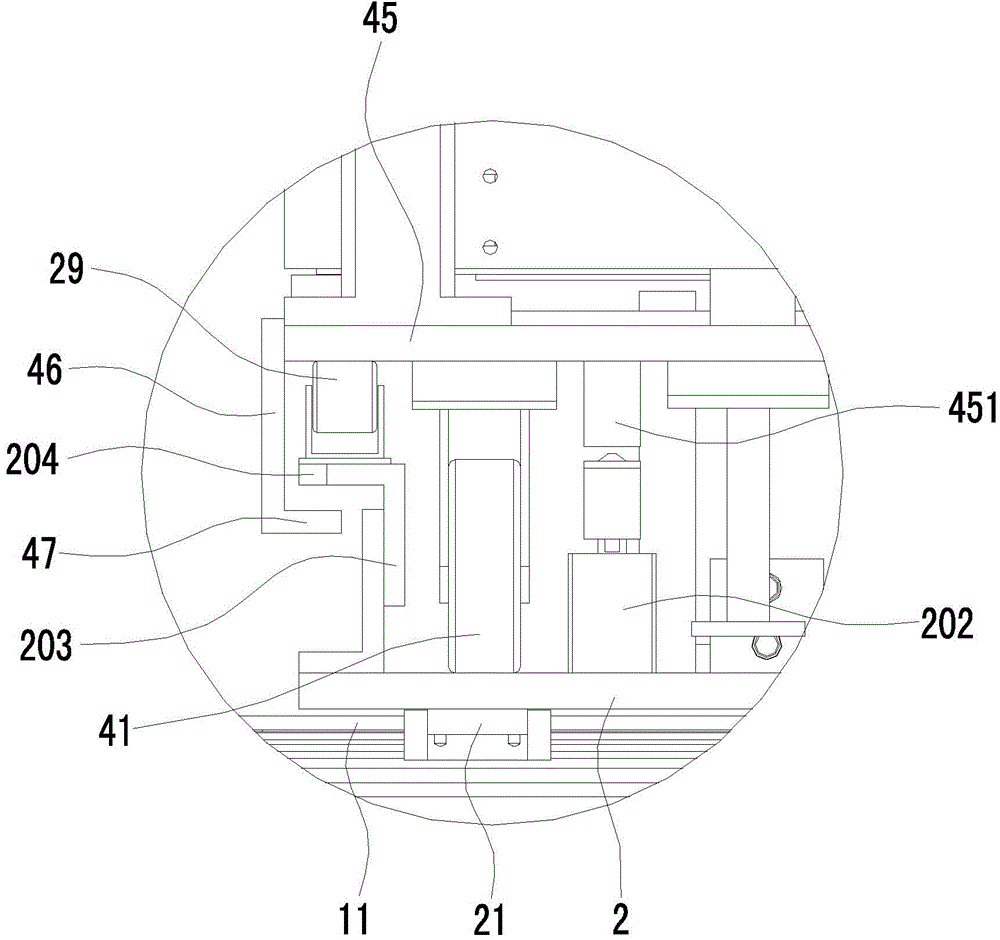

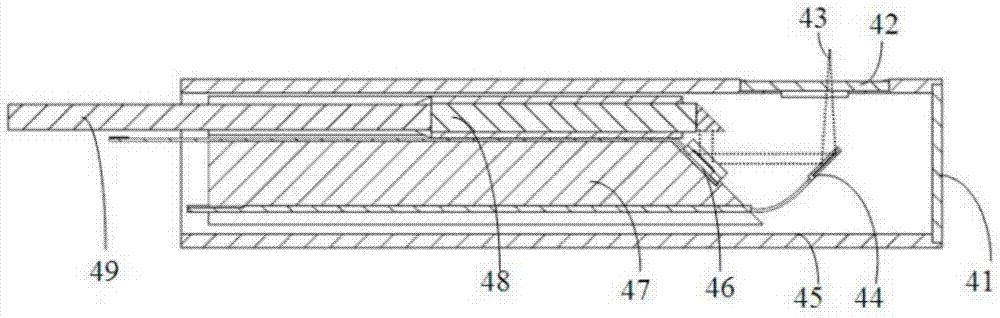

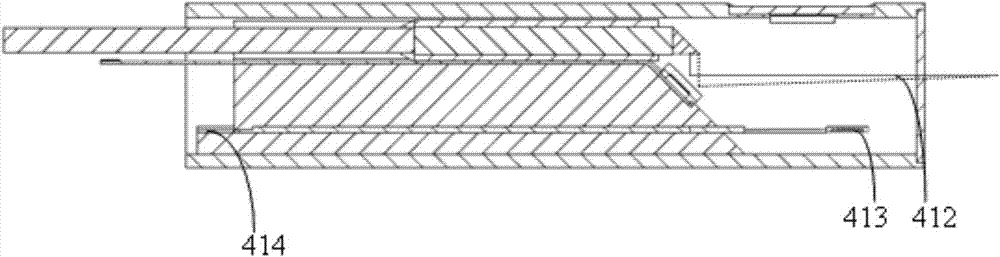

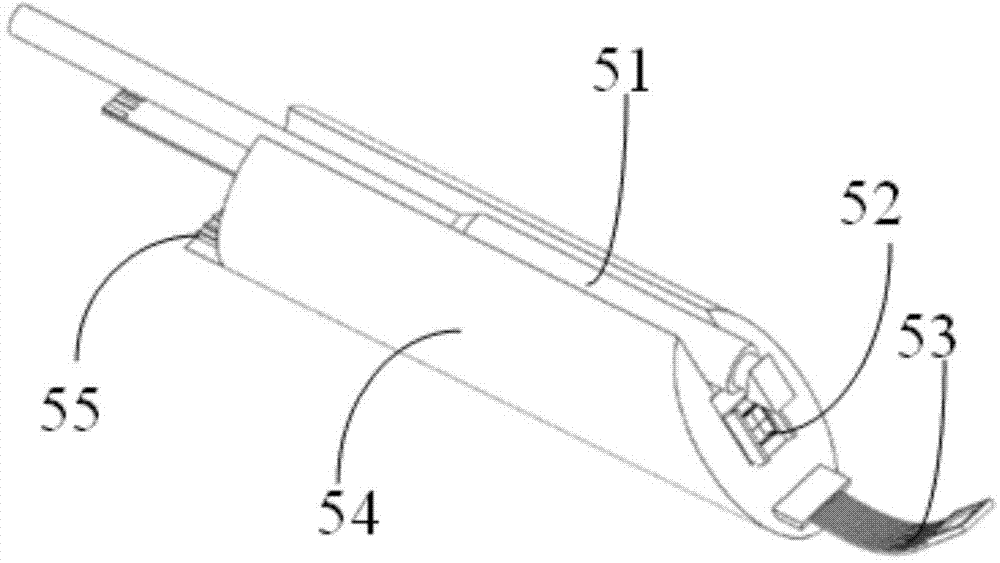

MEMS (micro electro mechanical system) optical scanning probe capable of switching work modes

ActiveCN103860143AEasy to control accuratelyFlexible useSurgeryOptically investigating flaws/contaminationLight beamEngineering

The invention discloses an MEMS (micro electro mechanical system) optical scanning probe capable of switching work modes. The MEMS optical scanning probe comprises a case and a main body base assembled in the case, wherein a lens assembly is arranged in a groove formed in the upper side of the main body base, a first MEMS micro lens is arranged in a groove of the slope surface of the main body base, a second MEMS micro lens is arranged in a groove formed in the lower side of the main body base, light beams are emitted onto the first MEMS micro lens through a lens assembly via optical fibers and are then reflected onto the second MEMS micro lens through the first MEMS micro lens, an external circuit controls the on-off state of the voltage on the second MEMS micro lens, further, the second MEMS micro lens is controlled to be in the in-space tilting or in-space flat expanding state for realizing the free switching among the forward scanning, the lateral scanning and the lateral forward scanning of the probe. The MEMS optical scanning probe has the advantages that the probe only adopts one lens assembly, so the double MEMS micro lenses can realize the switching of various work modes, and the use is more flexible.

Owner:无锡微文半导体科技有限公司

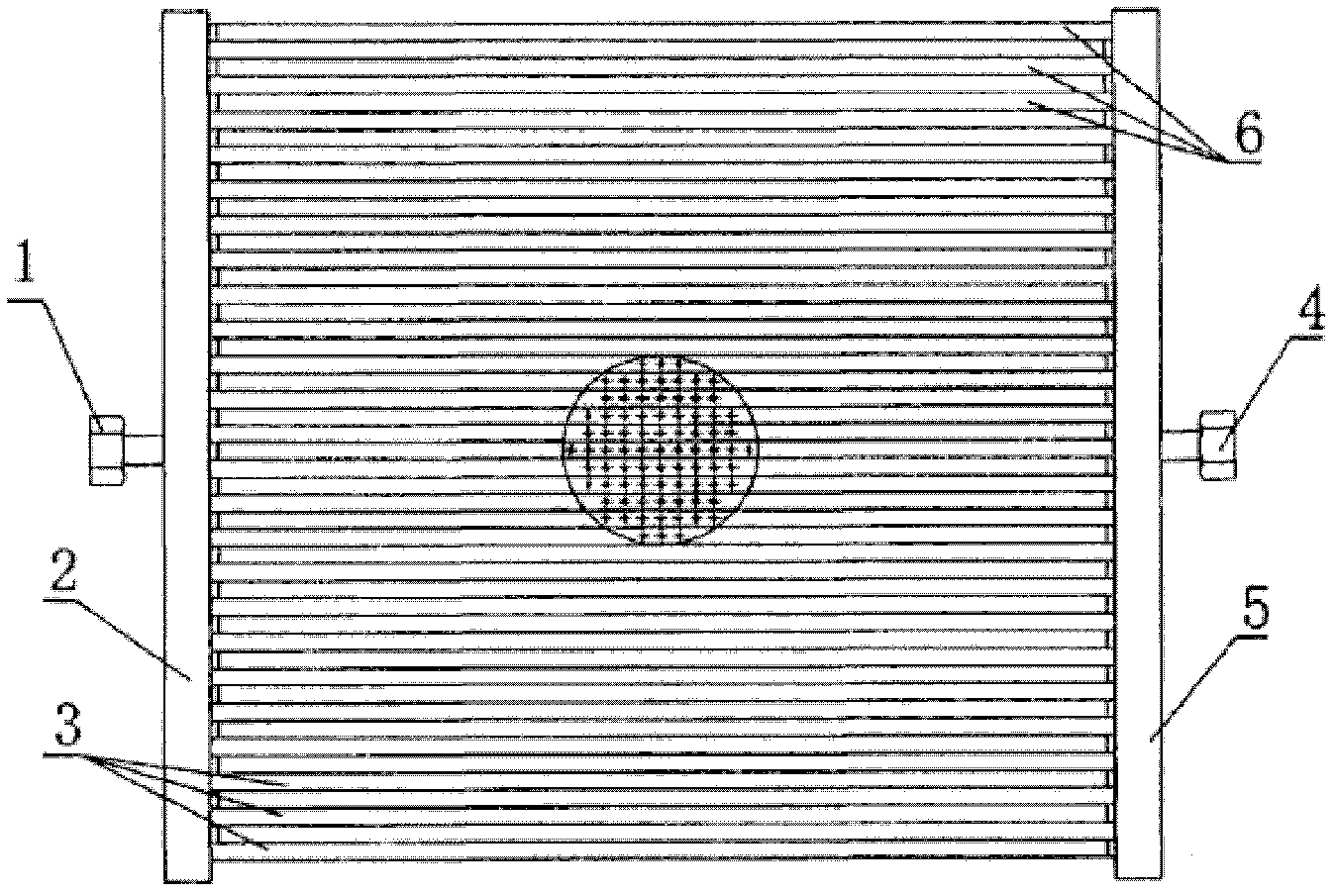

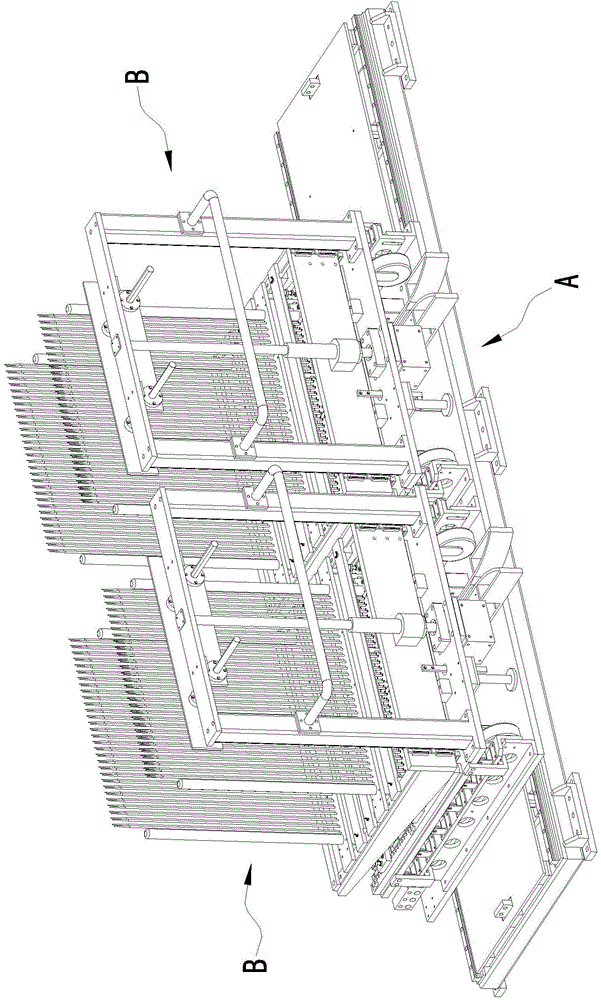

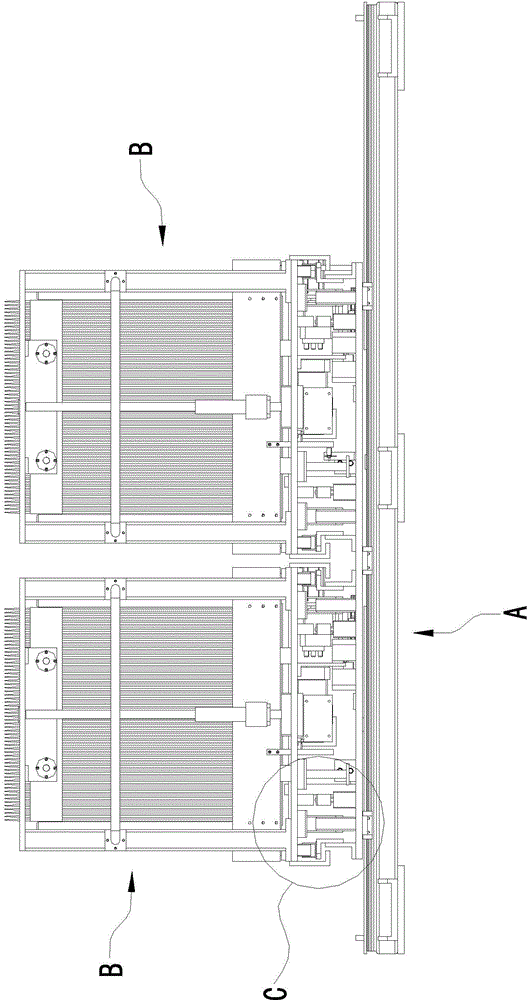

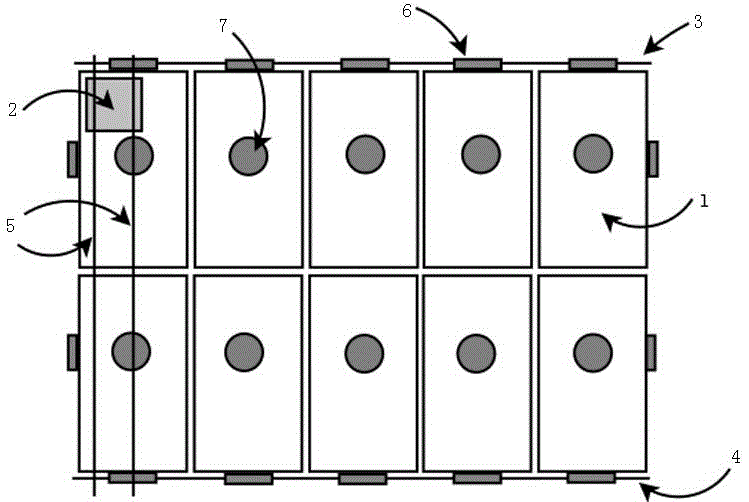

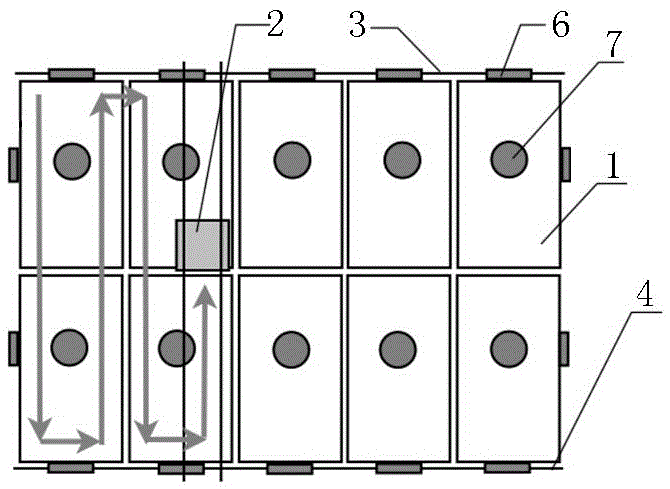

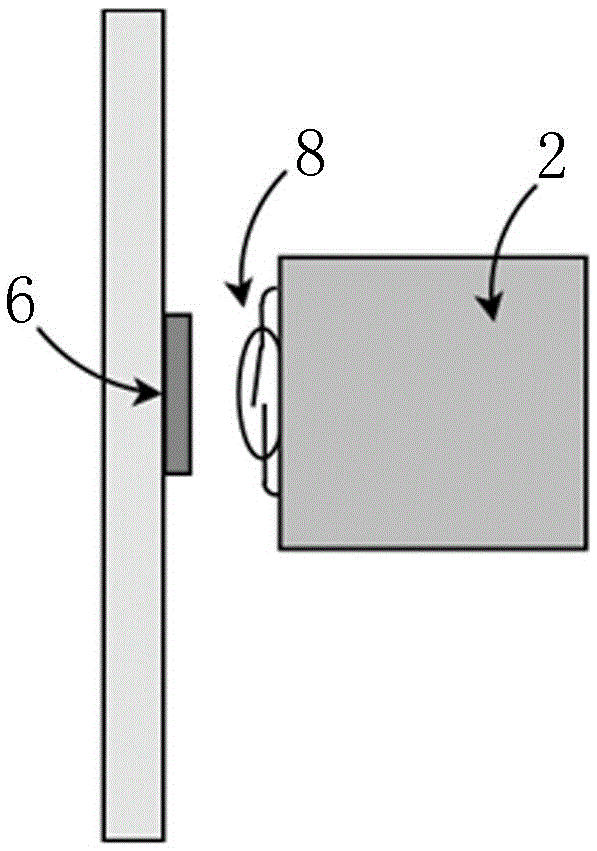

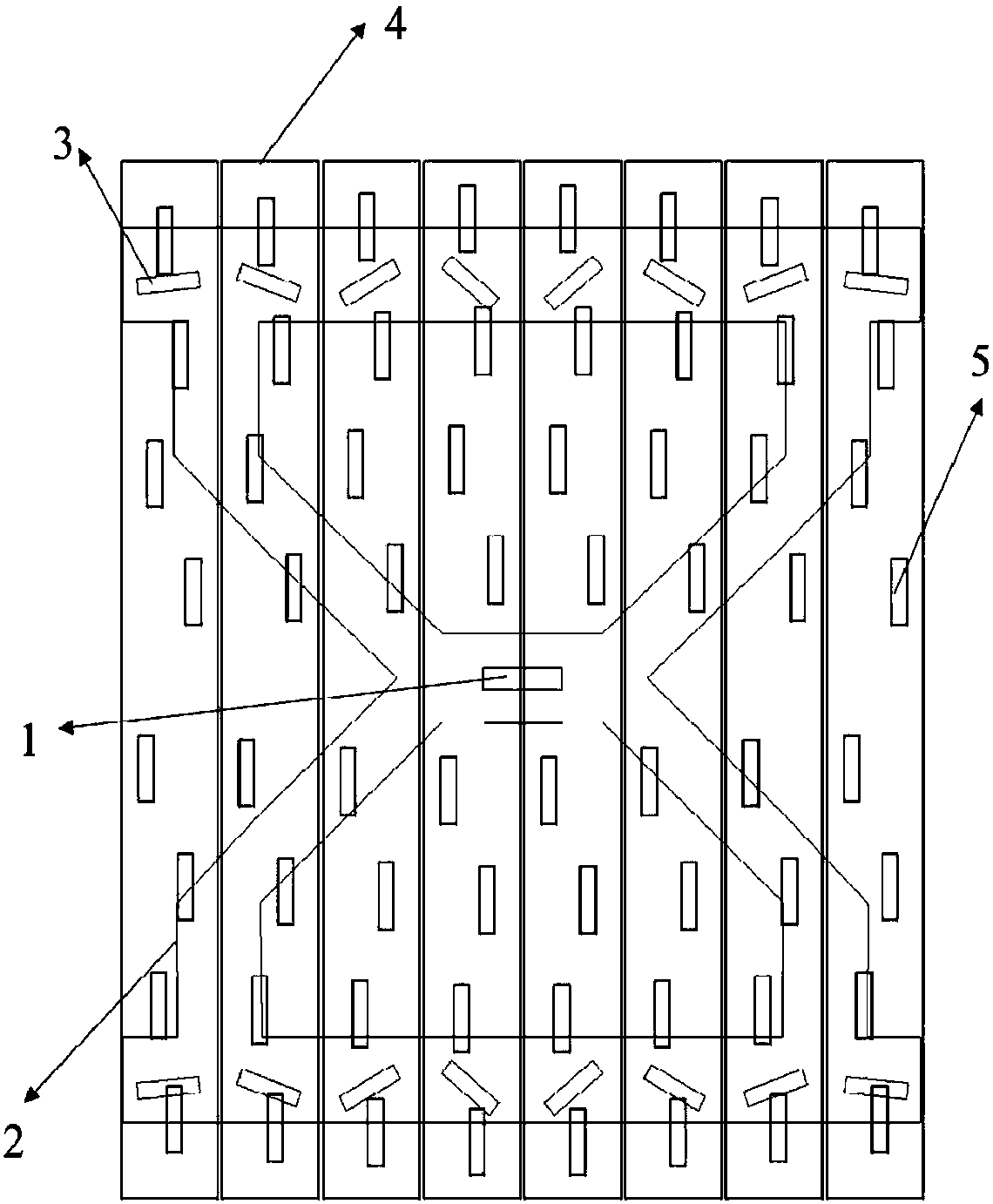

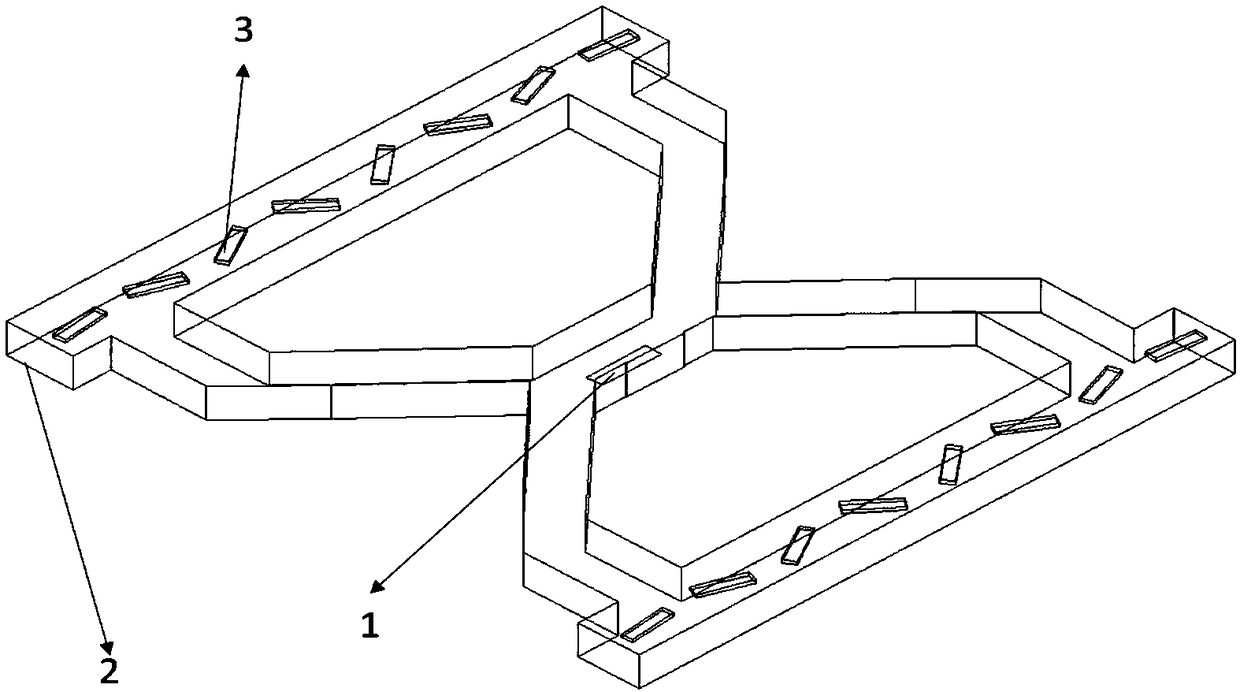

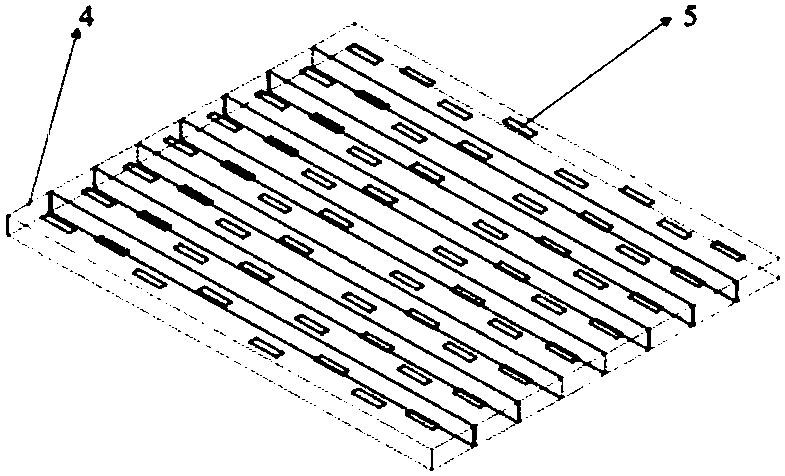

Intelligent cleaning robot device for photovoltaic cell panel set and positioning method of cleaning robot

InactiveCN106272336AAccurate calculationLow costProgramme-controlled manipulatorCells panelEngineering

The invention relates to an intelligent cleaning robot device for a photovoltaic cell panel set and a positioning method of a cleaning robot. The photovoltaic cell panel set comprises a photovoltaic cell panel array formed by a plurality of photovoltaic cell panels. An upper guide rail and a lower guide rail which are used for allowing the robot to move transversely are respectively mounted above and below the photovoltaic cell panel set. Longitudinal guide rails capable of controlling the robot to move left and right are arranged on the upper guide rail and the lower guide rail through roller racks. The robot can also move up and down along the longitudinal guide rails. Magnetic steel pieces are respectively mounted on the left and right sides of the upper guide rail, the lower guide rail and the photovoltaic cell panel set. A unique RFID label is adhered to each photovoltaic cell panel. The intelligent cleaning robot device for the photovoltaic cell panel set and the positioning method of the cleaning robot have the advantages that by the robot, the magnetic steel pieces and the RFID labels, the robot can be positioned accurately during the cleaning of the photovoltaic cell panels, commands can be remotely transmitted to the robot to allow the robot to accurately move to another position, the positions of the robot can be reliably monitored and controlled, and the moving trajectories of the robot can be precisely controlled and recorded.

Owner:浙江克里蒂弗机器人科技有限公司

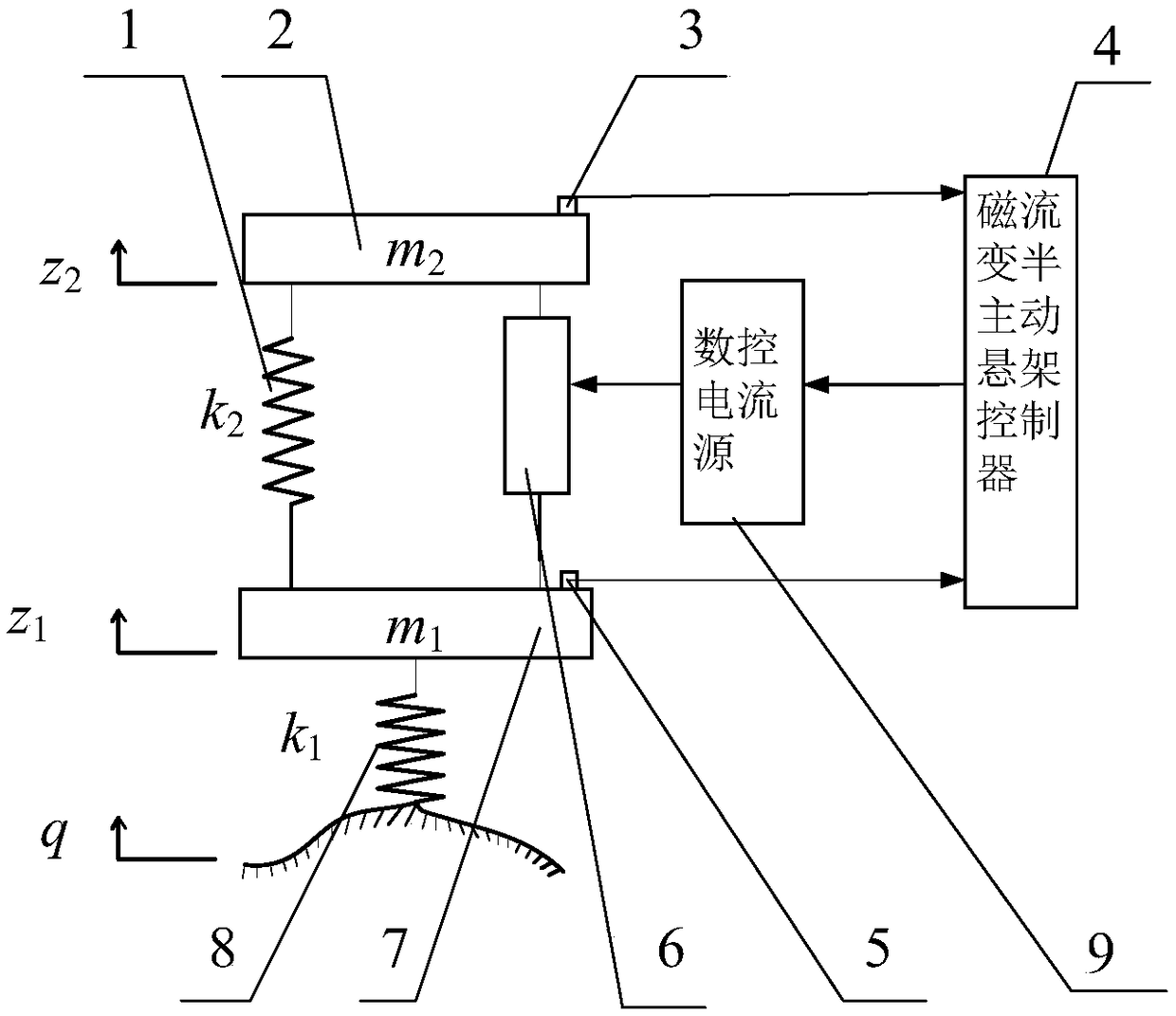

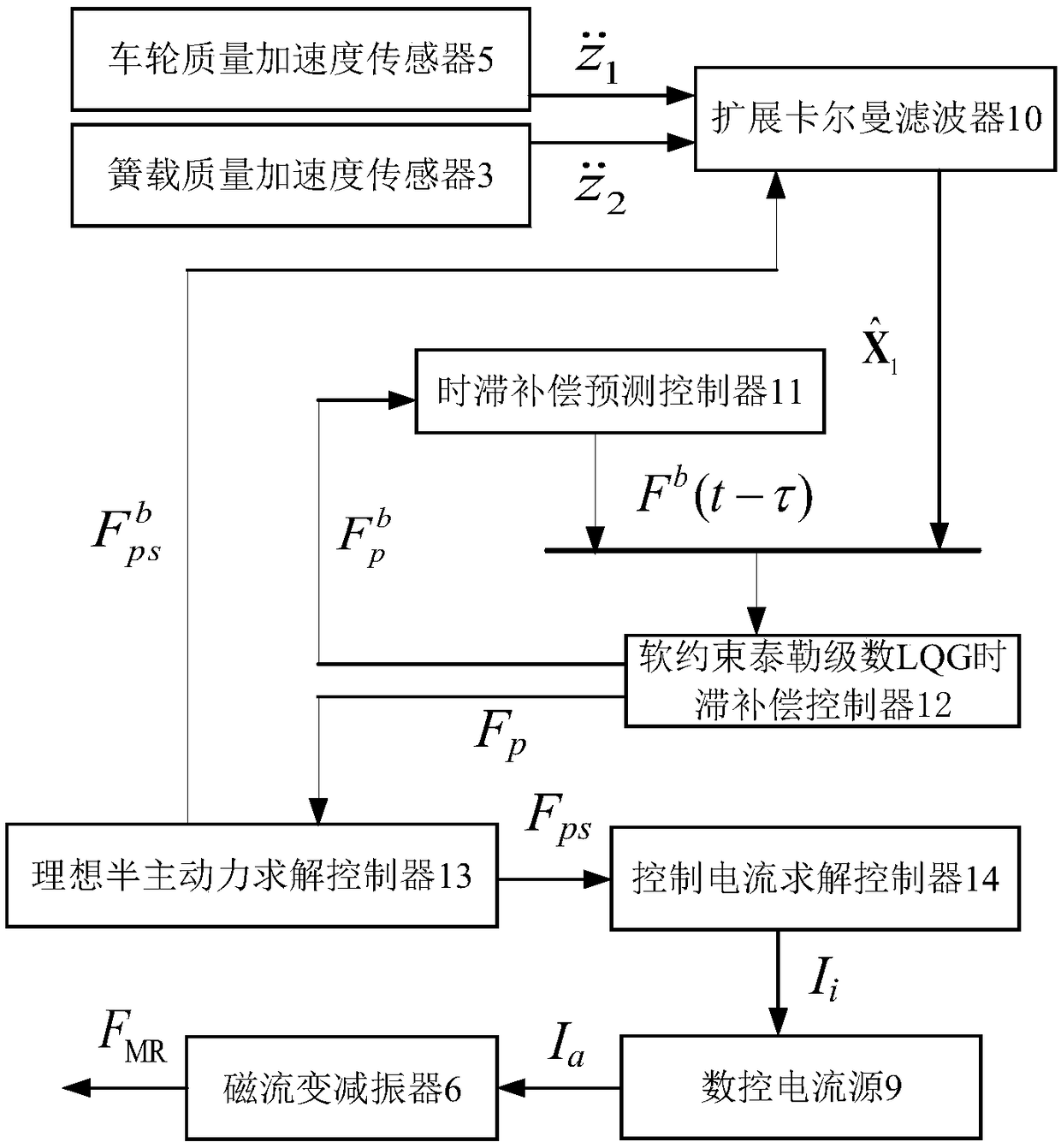

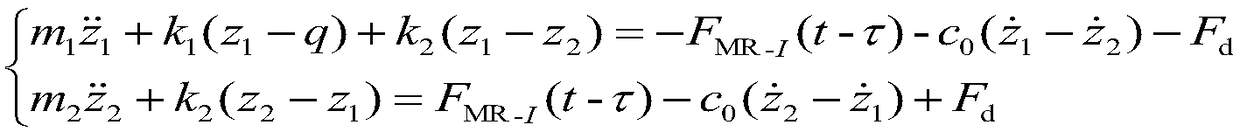

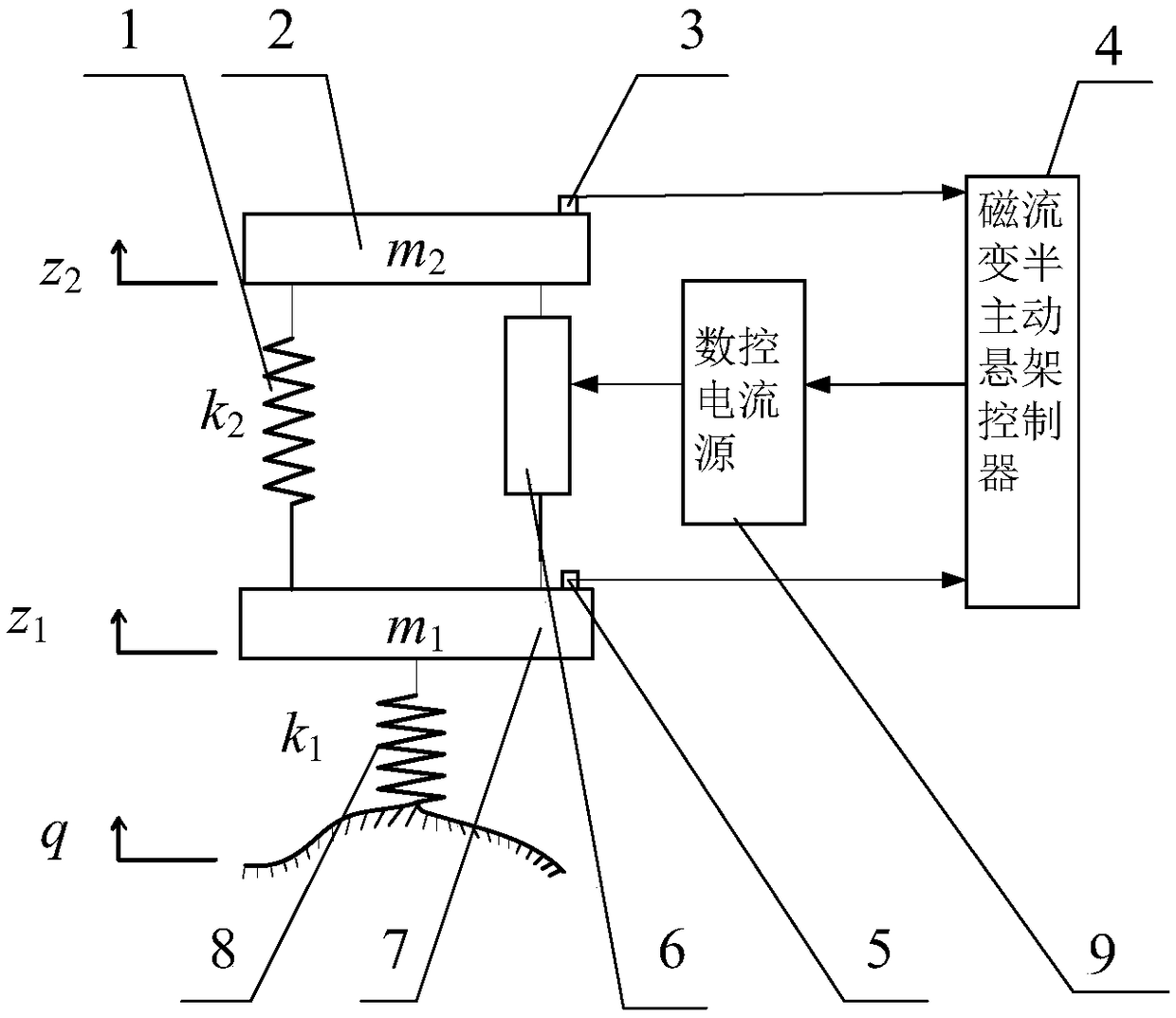

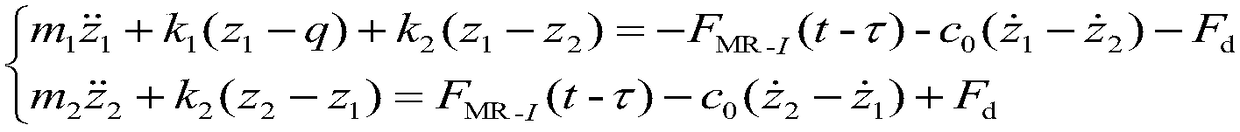

Time-varying compensation control system for damper mechanical characteristics of magnetorheological semi-active suspension and construction method of time-varying compensation control system

ActiveCN109334376AEasy to control accuratelyIdeal time-delay compensation control effectResilient suspensionsMagnetic currentNumerical control

The invention discloses a time-varying compensation control system for damper mechanical characteristics of a magnetorheological semi-active suspension and a construction method of the time-varying compensation control system. The output ends of a sprung mass acceleration sensor and a wheel mass acceleration sensor are connected to an extended Kalman filter, and the output end of the extended Kalman filter is connected to a soft-constraint Taylor series LQG time-delay compensation controller. The soft-constraint Taylor series LQG time-delay compensation controller is connected with a time-delay compensation prediction controller and a semi-active power acquisition controller separately, and the time-delay compensation prediction controller is connected to the input end of the soft-constraint Taylor series LQG time-delay compensation controller. The semi-active power acquisition controller is connected with the extended Kalman filter and a control current solution controller separately,the control current solution controller is connected to a numerical control current source to realize the compensation control over damper response time delay and mechanical characteristic time variation of the magnetorheological semi-active suspension, the situation that a hard-constraint Taylor series LQG time-delay compensation control method directly utilizes a saturation function to performhard constraint on the predictive control force can be avoided, and thus a more ideal time-delay compensation control effect can be achieved.

Owner:JIANGSU UNIV

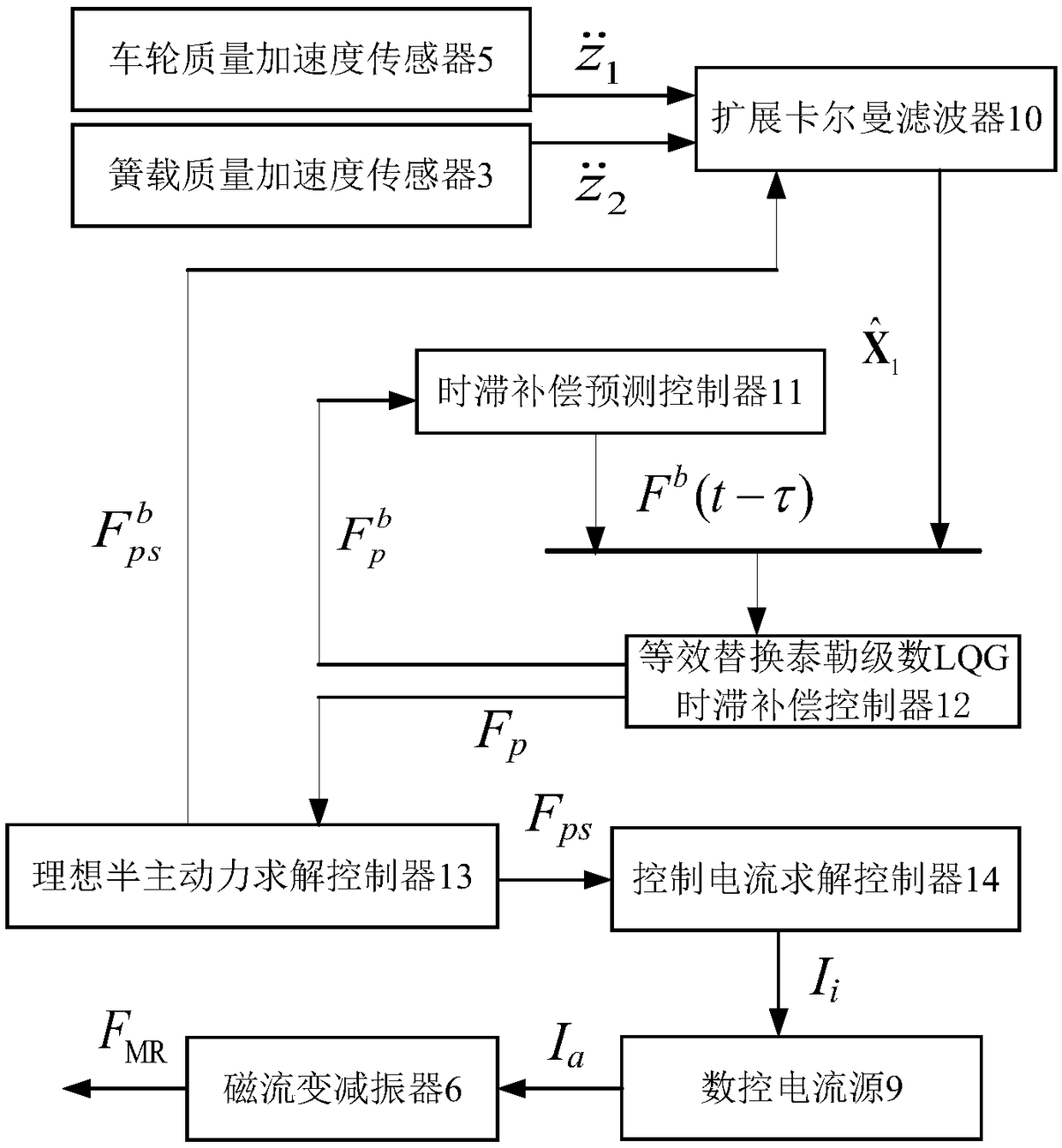

Equivalent replacement Taylor series LQG time-delay compensation control system of magnetorheological semi-active suspension and construction method of equivalent replacement Taylor series LQG time-delay compensation control system

ActiveCN109334377AEasy to control accuratelyAccurately track comprehensive performance metricsResilient suspensionsCurrent sourceSemi active

The invention discloses an equivalent replacement Taylor series LQG time-delay compensation control system of a magnetorheological semi-active suspension and a construction method of the equivalent replacement Taylor series LQG time-delay compensation control system. The output ends of a sprung mass acceleration sensor and a wheel mass acceleration sensor are connected to an extended Kalman filter, and the output end of the extended Kalman filter is connected to an equivalent replacement Taylor series LQG time-delay compensation controller. The equivalent replacement Taylor series LQG time-delay compensation controller is connected with a time-delay compensation prediction controller and a semi-active power acquisition controller separately, and the time-delay compensation prediction controller is connected to the input end of the equivalent replacement Taylor series LQG time-delay compensation controller. The semi-active power acquisition controller is connected with the extended Kalman filter and a control current solution controller separately, and the control current solution controller is connected to a numerical control current source to realize the compensation control overdamper response time delay and mechanical characteristic time variation of the magnetorheological semi-active suspension. Through the equivalent replacement Taylor series LQG time-delay compensation control, the comprehensive performance index of the suspension can be accurately tracked, and thus a more ideal time-delay compensation control effect can be obtained.

Owner:JIANGSU UNIV

Quadrangle feeding-based dual-layer waveguide gap near-field focusing array antenna

InactiveCN108173007AIncrease antenna bandwidthLower levelAntennas earthing switches associationLinear waveguide fed arraysIncident waveWaveguide

The invention relates to a quadrangle feeding-based dual-layer waveguide gap near-field focusing array antenna, and relates to a waveguide gap antenna. The quadrangle feeding-based dual-layer waveguide gap near-field focusing array antenna comprises a lower-layer feeding waveguide and an upper-layer radiation waveguide, an incident wave sequentially passes through the feeding waveguide, a couplinggap and the radiation waveguide from a feeding port and is finally radiated to an external space by a radiation gap, the feeding port and the feeding waveguide are fed through a central hole from a back surface by employing a standard feeding wave, quadrangle feeding is employed to substitute traditional central feeding, a signal is extended to four antenna angles from the center by the feeding waveguide with four arms, uniform-amplitude and same-direction feeding is performed from two ends to a middle part, a PMC boundary can be formed in the center of the feeding waveguide, thus, a metal boundary is substituted, the size is reduced, and the design cost is reduced. The length of the feeding waveguide is 44.8 millimeters, the width of the feeding waveguide is 5 millimeters, and the heightof the feeding waveguide is 2 millimeters.

Owner:XIAMEN UNIV

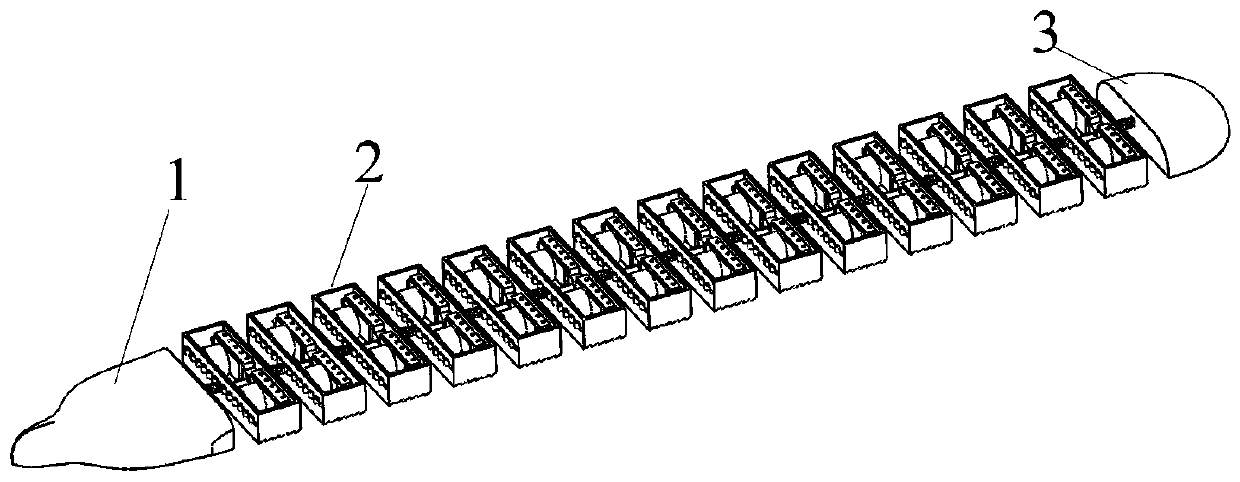

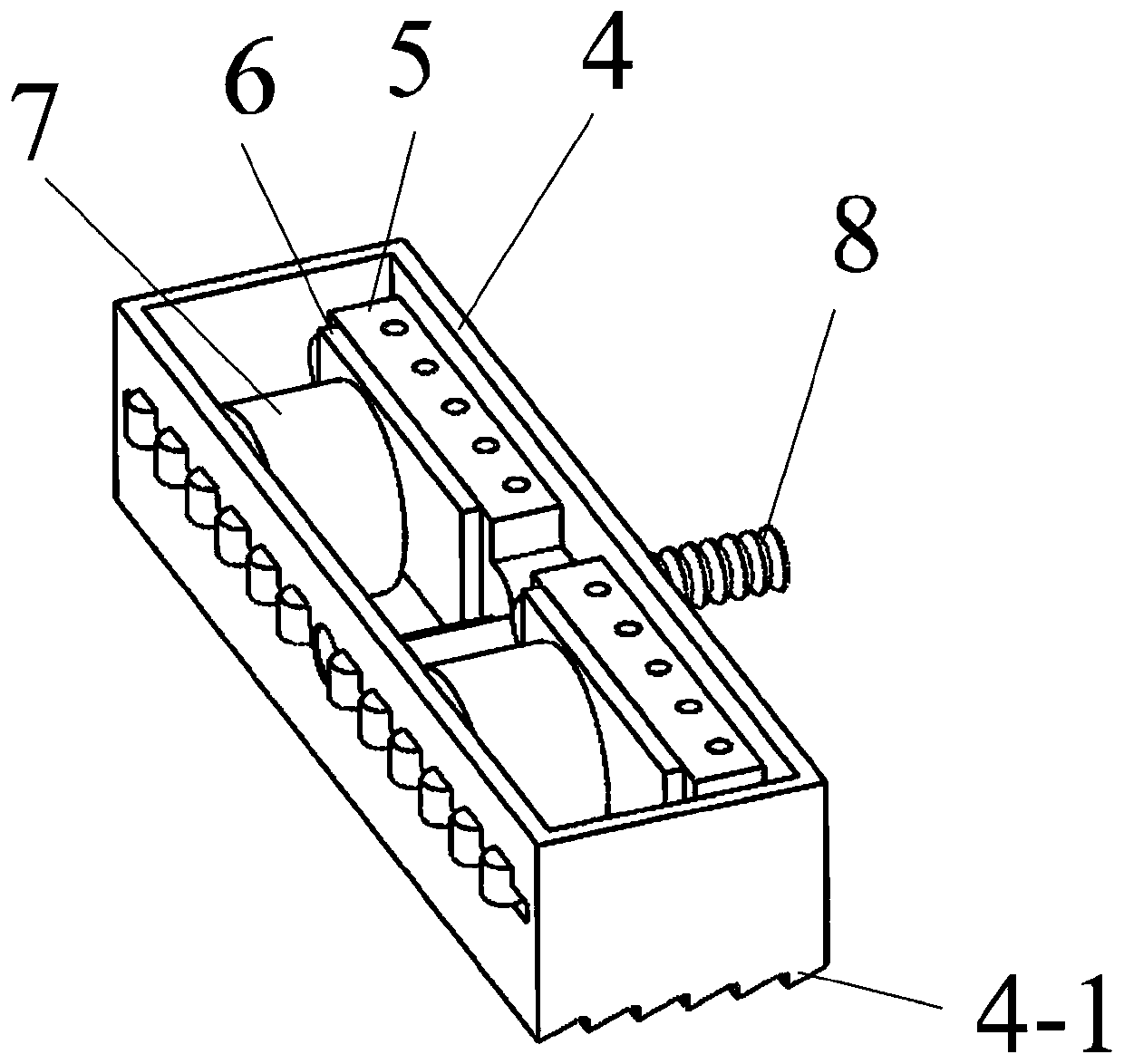

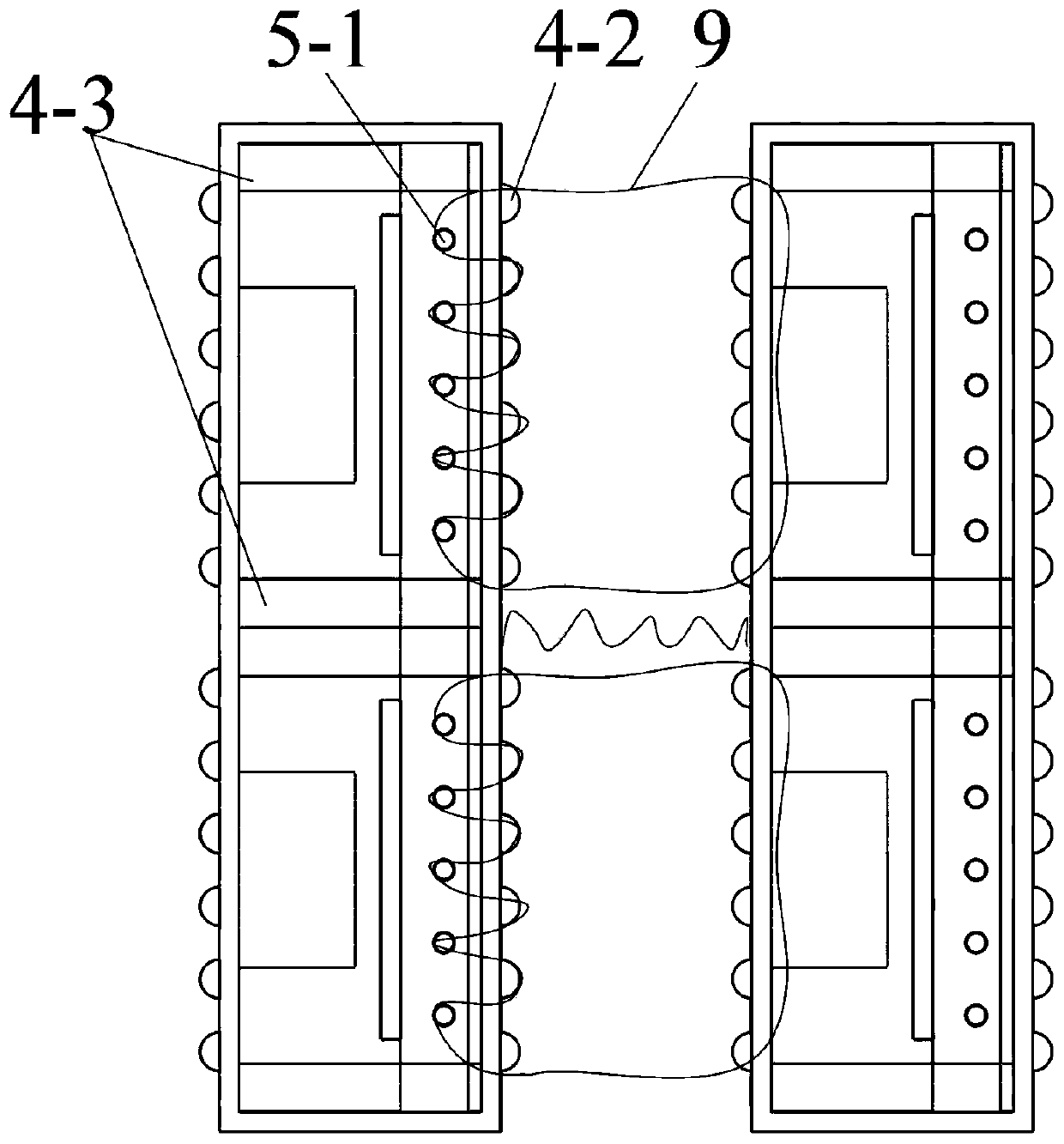

Bionic S-shaped moving robot

InactiveCN109877817AReduce volumeEasy to control accuratelyProgramme-controlled manipulatorClosed loopMiniaturization

The invention discloses a bionic S-shaped moving robot. The bionic S-shaped moving robot comprises a head, a tail and a plurality of unit modules connected between the head and the tail in series, theadjacent two unit modules are elastically connected, each unit module comprises a shell, a sliding block arranged in the shell in the form capable of reciprocating sliding, a electromagnet used for absorbing the sliding block to slide, and a winding amplification mechanism connected between the sliding block and the shells of the adjacent unit modules, and the winding amplification mechanism comprises a sliding block winding column fixed on the sliding block, a shell winding column fixed on the shell, and a line rope wound between the shell winding column and the sliding block winding columnand forming a closed loop by penetrating through the shells of the adjacent unit modules. The bionic S-shaped moving robot overcomes the shortcoming of small electromagnetic iron action distance through a rope amplification mechanism, and has the advantages that the control is simple, the miniaturization is achieved, and the pure electromagnetic drive is achieved.

Owner:CHONGQING UNIV

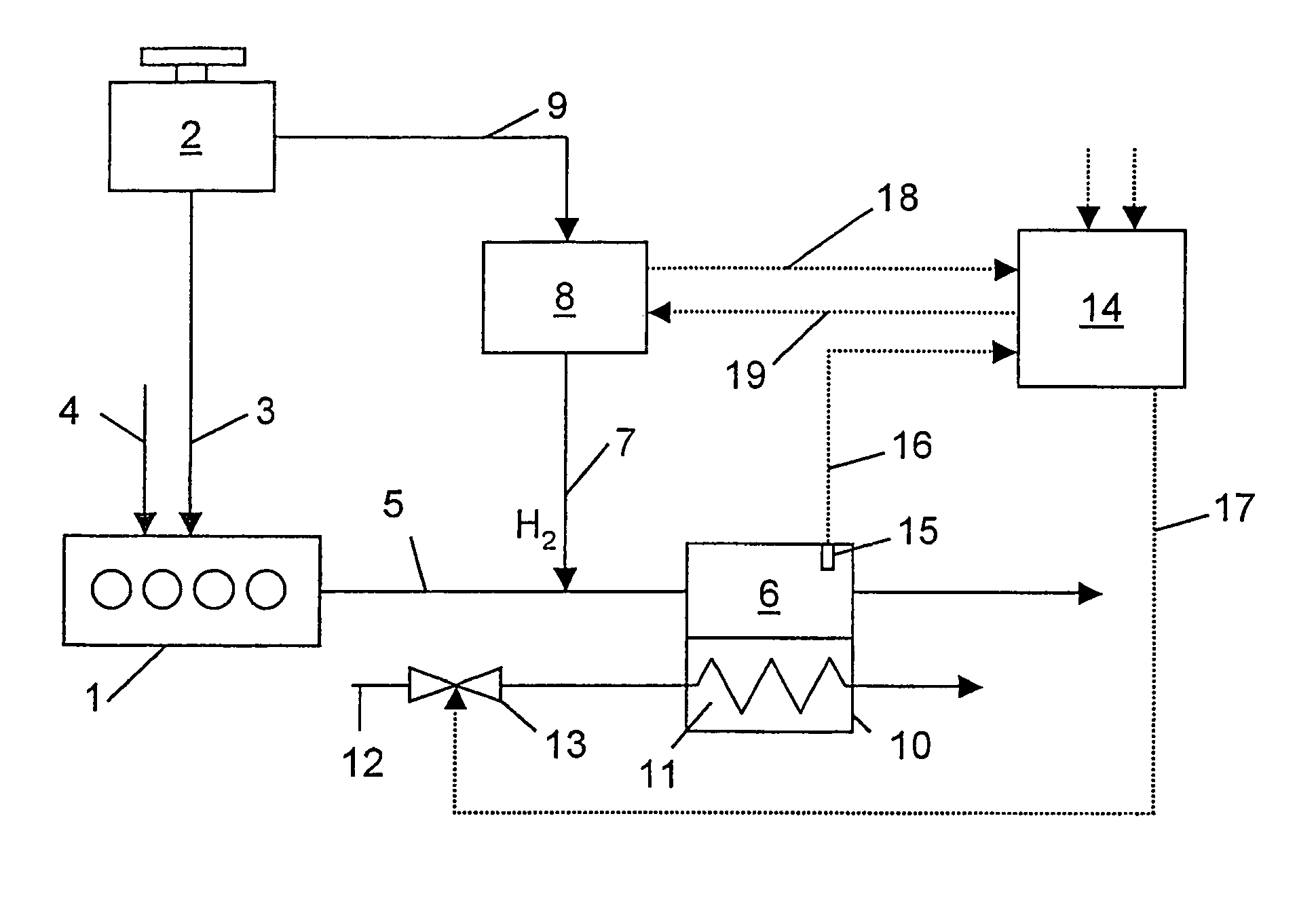

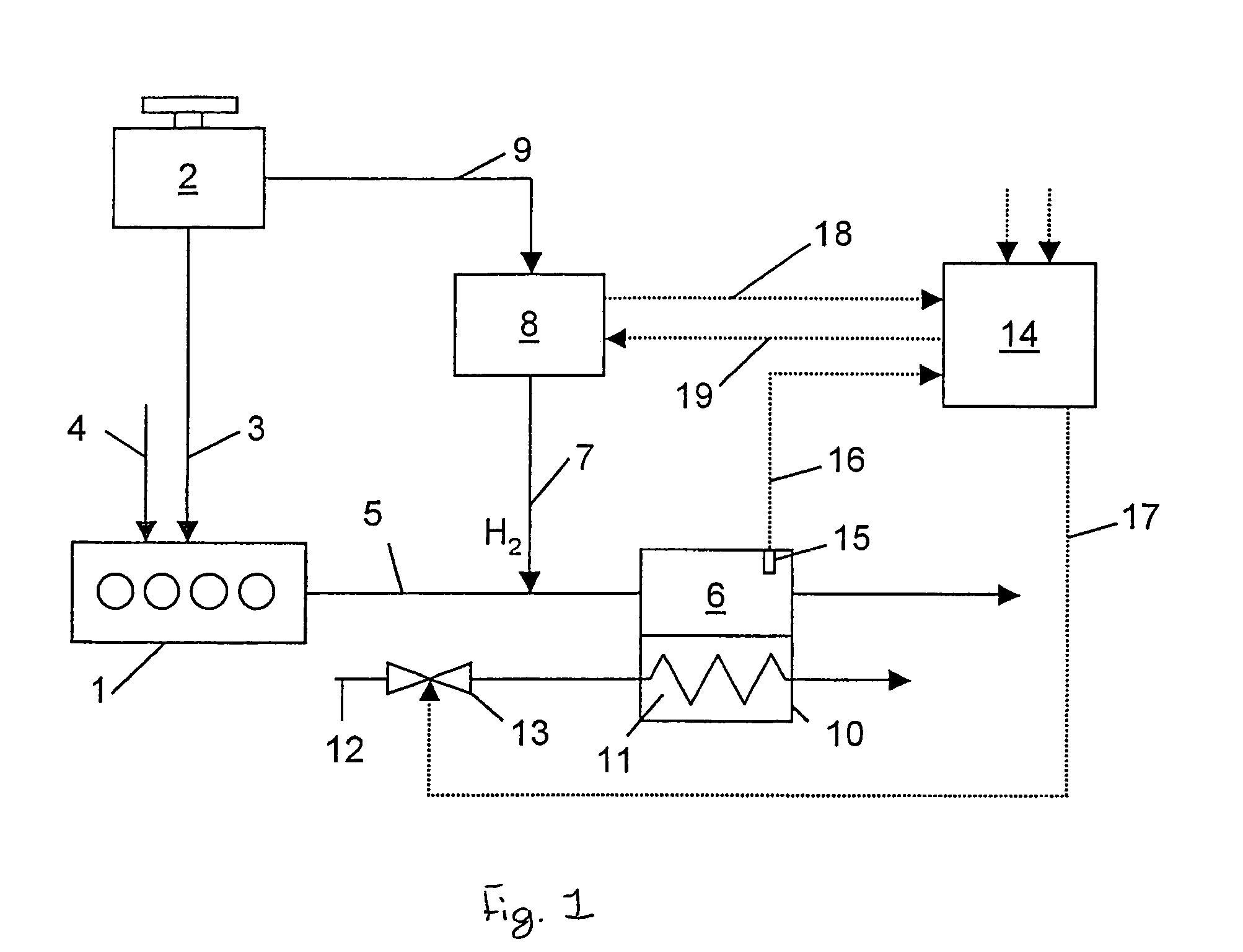

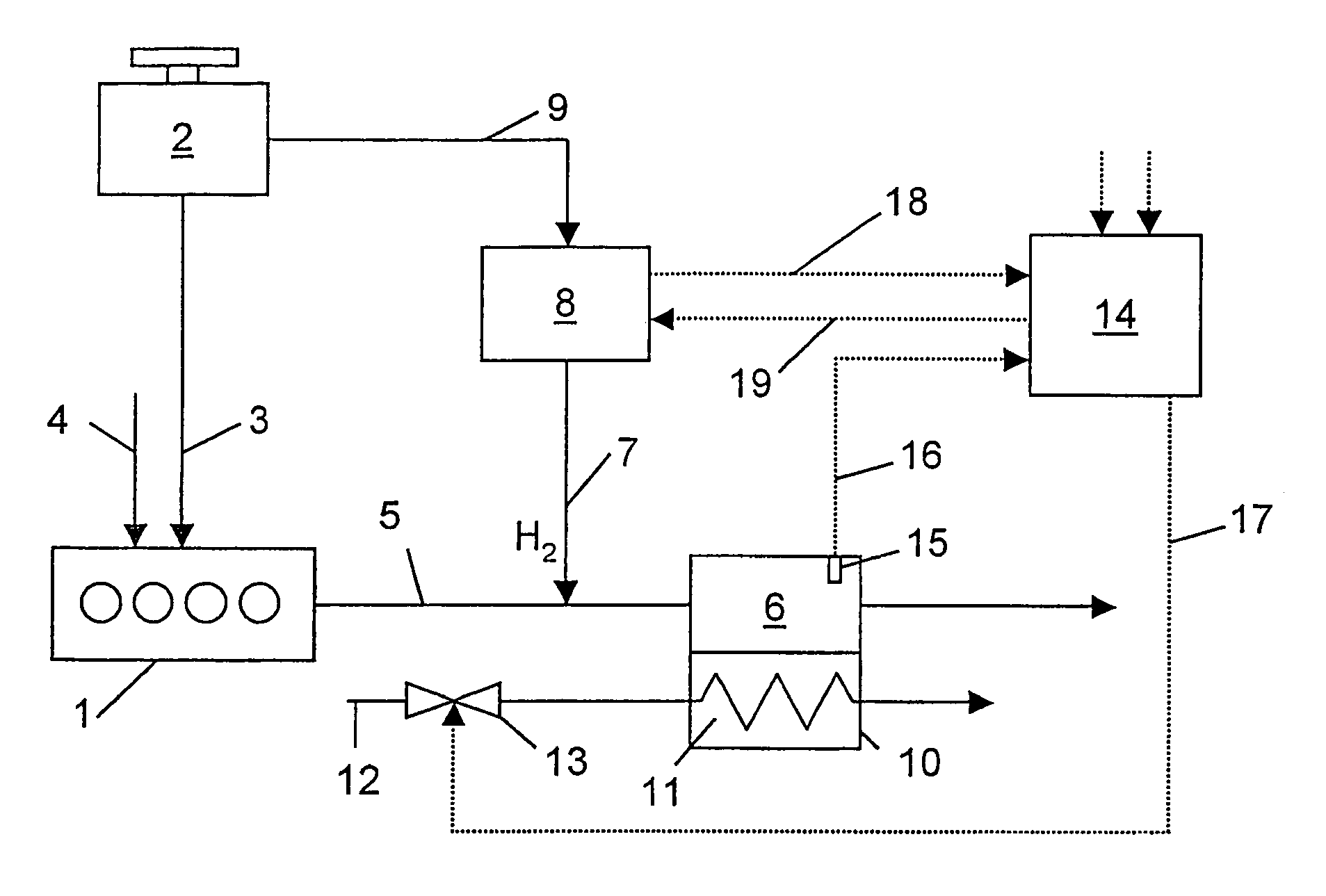

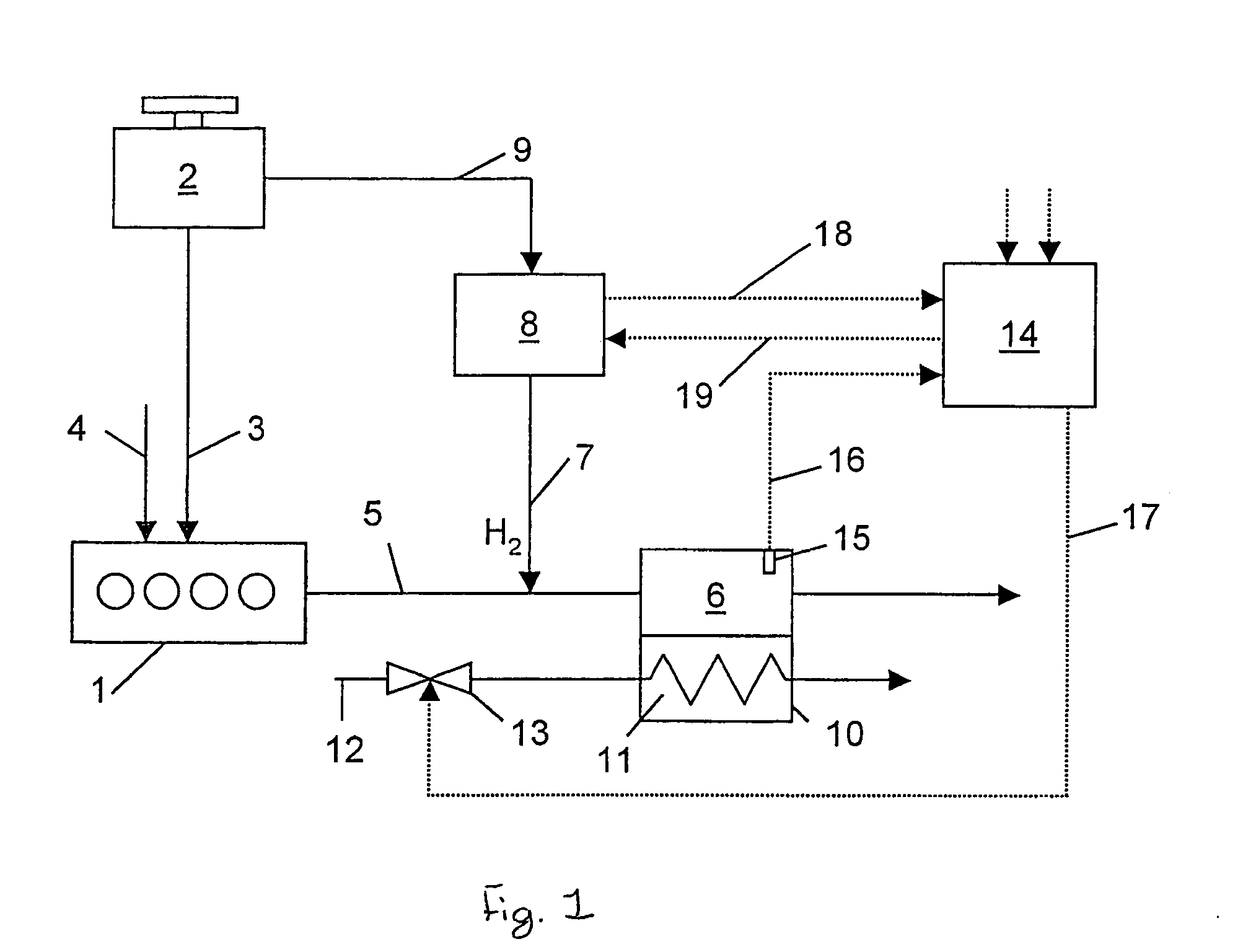

System and method for reducing nitrogen oxides in the exhaust of an internal combustion engine

InactiveUS7152394B2High selectivityHigh levelInternal combustion piston enginesExhaust apparatusTemperature controlNitrogen oxides

In a system and method for the reduction of nitrogen oxides in the exhaust of an internal combustion engine, the exhaust line of the internal combustion engine contains a DeNOx catalytic converter, in which the nitrogen oxides are reduced by means of hydrogen that is produced on-board the vehicle. The DeNOx catalytic converter is incorporated into a temperature-controlled heat exchanger, allowing the DeNOx catalytic converter to be operated within a desired temperature range, thereby improving the level of conversion.

Owner:NUCELLSYS GMBH

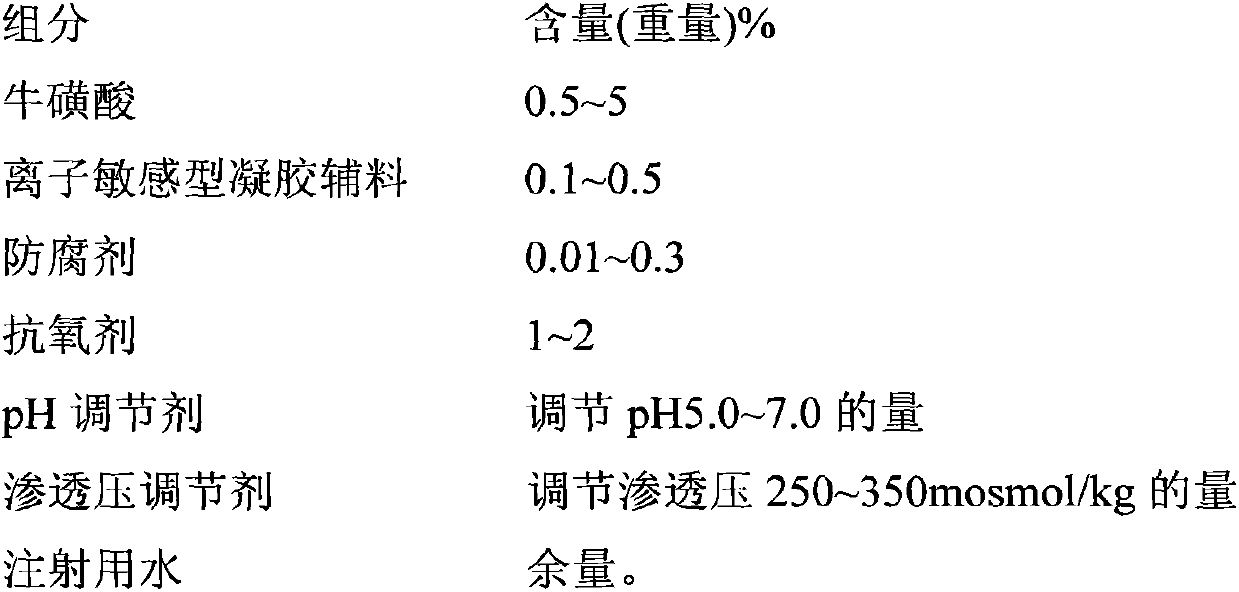

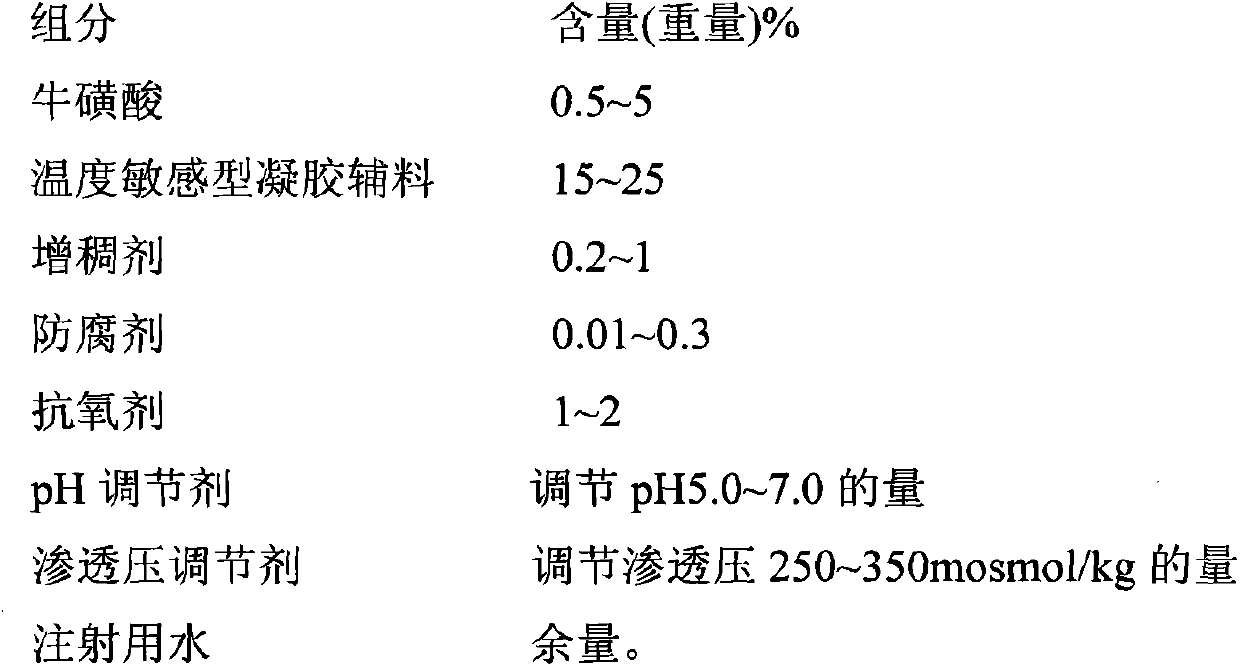

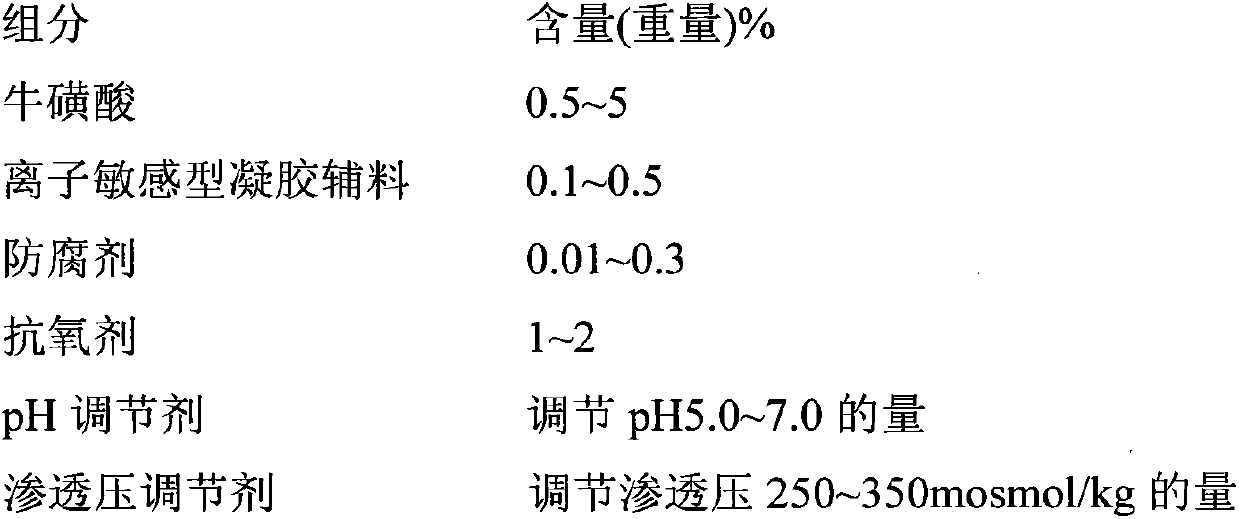

Taurine-containing ophthalmic in-vivo gel preparation and preparation method thereof

InactiveCN103720641AEffectively maintain effective concentrationLow toxicitySenses disorderAerosol deliveryDiseaseAdjuvant

The invention relates to a taurine-containing ophthalmic in-vivo gel preparation and a preparation method thereof. The taurine-containing ophthalmic gel is an ophthalmic preparation which is in a liquid state in vitro and forms a gel state after dropped into eyes. The taurine-containing ophthalmic gel is prepared by taking taurine as an active substance and supplementing a gel adjuvant, a thickening agent, a preservative, an osmotic-pressure conditioning agent, a pH conditioning agent and water for injection. The taurine-containing ophthalmic gel is suitable for treatment of diseases such as retinopathy and the like; and the ophthalmic gel is in the liquid state in vitro, a dosage is easy and accurate to control, the use is convenient, the ophthalmic gel can be uniformly spread after dropped into the eyes, gelates, is retained in the eyes for longer time and is not prone to loss, effective drug concentration can be effectively maintained, the treatment effect is enhanced, further, the toxicity is low, the irritation is small, the biocompatibility is good, and the taurine-containing ophthalmic gel is effective, facilitates clinical application, and has a wide development prospect.

Owner:INST OF CHINESE MATERIA MEDICA CHINA ACAD OF CHINESE MEDICAL SCI

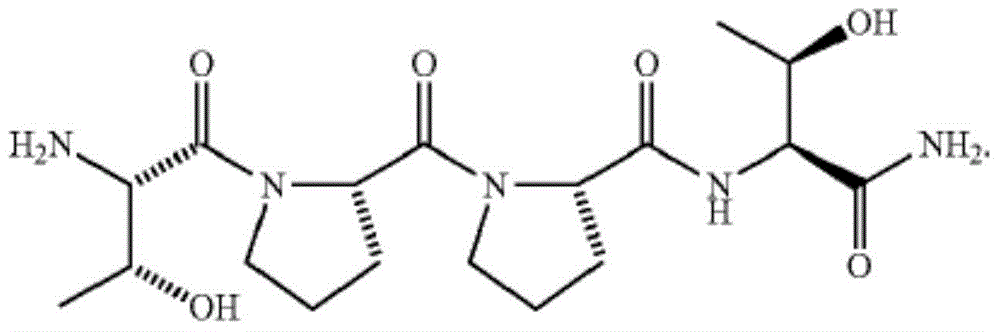

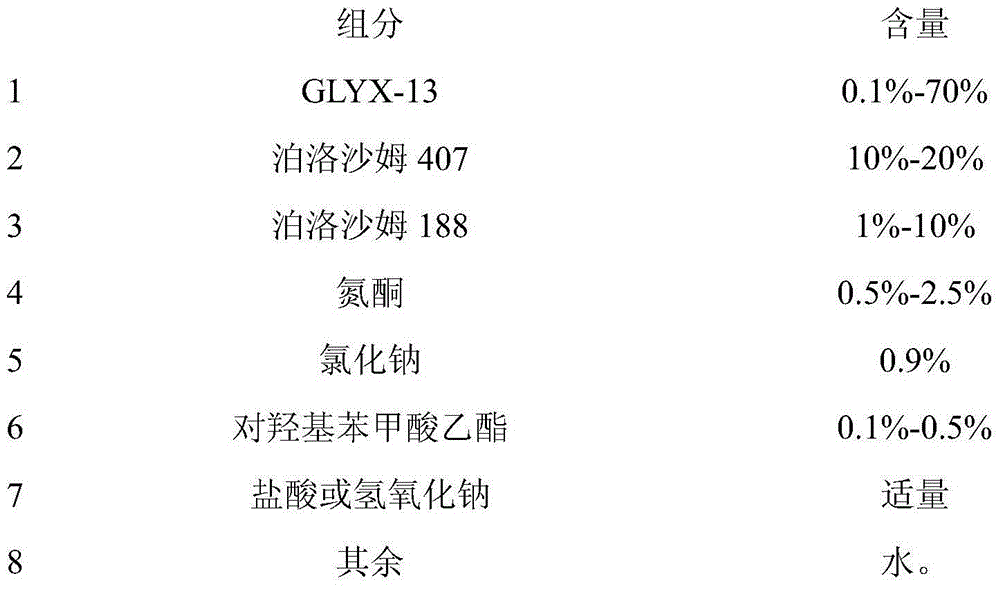

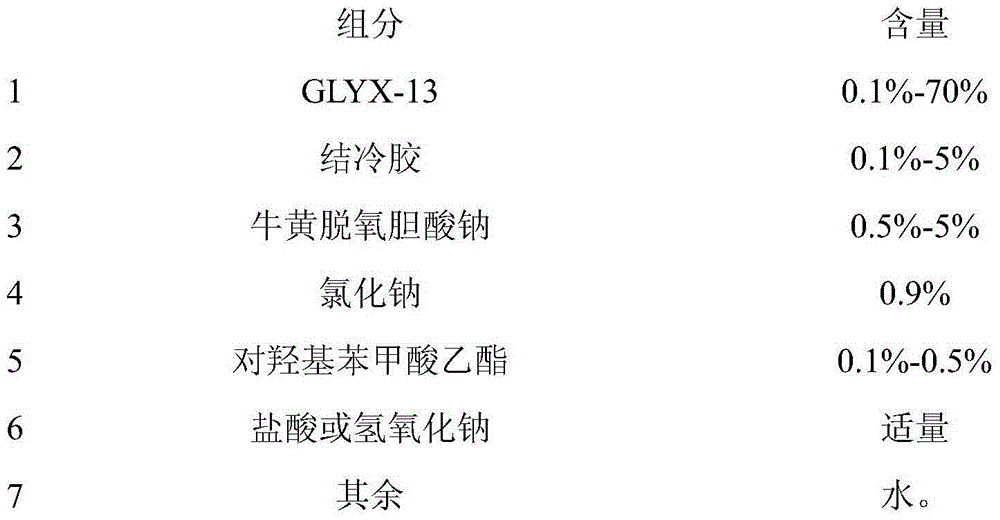

Medical purpose of NMDA acceptor antagonist and pharmaceutical composition thereof

InactiveCN105327349AEasy accessImprove bioavailabilityPowder deliveryOrganic active ingredientsNR1 NMDA receptorDisease

The invention discloses a medical purpose of an NMDA acceptor antagonist and a pharmaceutical composition thereof. The invention concretely discloses a medicine for using the NMDA acceptor antagonist, a pharmaceutically acceptable salt or a pharmaceutical composition thereof for treating or preventing central nervous system disease and / or mental diseases, and the NMDA acceptor antagonist is delivered to a human central nervous system through target administration. An application of the pharmaceutical composition can increase the concentration of the NMDA acceptor antagonist in brain tissue, medicine amount is greatly reduced, and systematic side effect is reduced; biology availability in the brain is high, autonomous drug administration can be carried out by patients, no pain is generated, usage is convenient, and thus the pharmaceutical composition has good patient compliance, and has wide clinical medical science application.

Owner:SHANGHAI HANSOH BIOMEDICAL

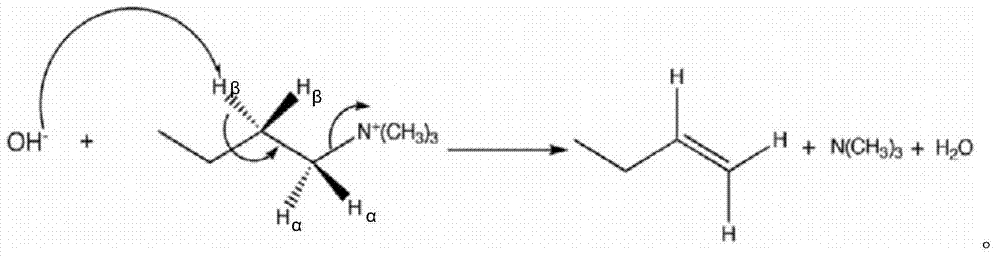

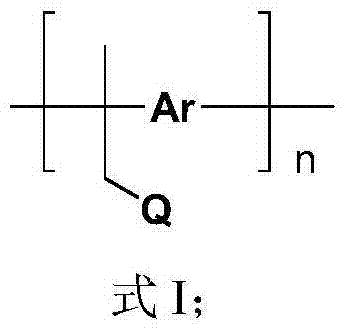

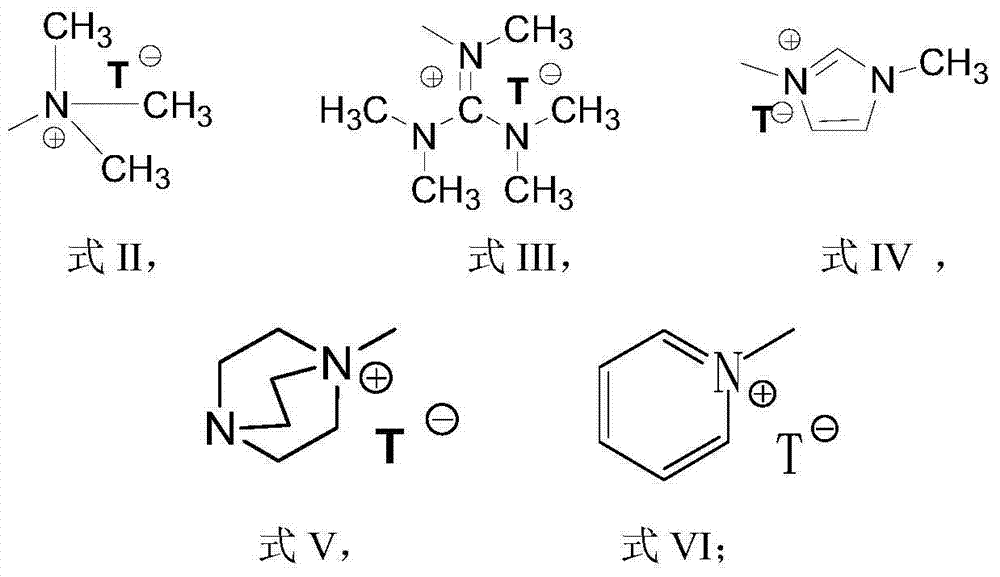

Cationic polymer and preparation method thereof, and anionic exchange membrane and preparation method thereof

InactiveCN104844785AImprove mechanical propertiesThe synthesis method is simplePolymer scienceIce water

The invention discloses a cationic polymer and a preparation method thereof, and an anionic exchange membrane and a preparation method thereof. The cationic polymer has a structural formula as shown in a formula I. In the formula I, Q is a quaternary ammonium group; Ar is a group with aromatic rings included in two ends of the main chain; and n is an integer in a range of 10 to 150. The preparation method for the cationic polymer comprises the following steps: under the protection of inert gas, mixing quaternary ammonium monomer, aryl monomer and trifluoromethanesulfonic acid, carrying out reaction at 0 to 60 DEG C for 1 to 24 hours, then adding the obtained reaction liquid into ice water, and collecting precipitate so as to obtain the cationic polymer. According to the invention, the main chain of the cationic polymer is mainly composed of benzene rings, which enables the prepared anionic exchange membrane to have good mechanical properties, and the side chain of the cationic polymer contains cationic groups (quaternary ammonium groups) which have high alkali resistance; meanwhile, the cationic polymer is simple to synthesize, has controllable ionic group content and can be applied to production of the anionic exchange membrane with good mechanical properties, high conductivity and strong alkali resistance.

Owner:NANYANG NORMAL UNIV

System and method for reducing nitrogen oxides in the exhaust of an internal combustion engine

InactiveUS20050126158A1Improve selectivityHigh conversion levelInternal combustion piston enginesExhaust apparatusProcess engineeringOxide

In a system and method for the reduction of nitrogen oxides in the exhaust of an internal combustion engine, the exhaust line of the internal combustion engine contains a DeNOx catalytic converter, in which the nitrogen oxides are reduced by means of hydrogen that is produced on-board the vehicle. The DeNOx catalytic converter is incorporated into a temperature-controlled heat exchanger, allowing the DeNOx catalytic converter to be operated within a desired temperature range, thereby improving the level of conversion.

Owner:NUCELLSYS

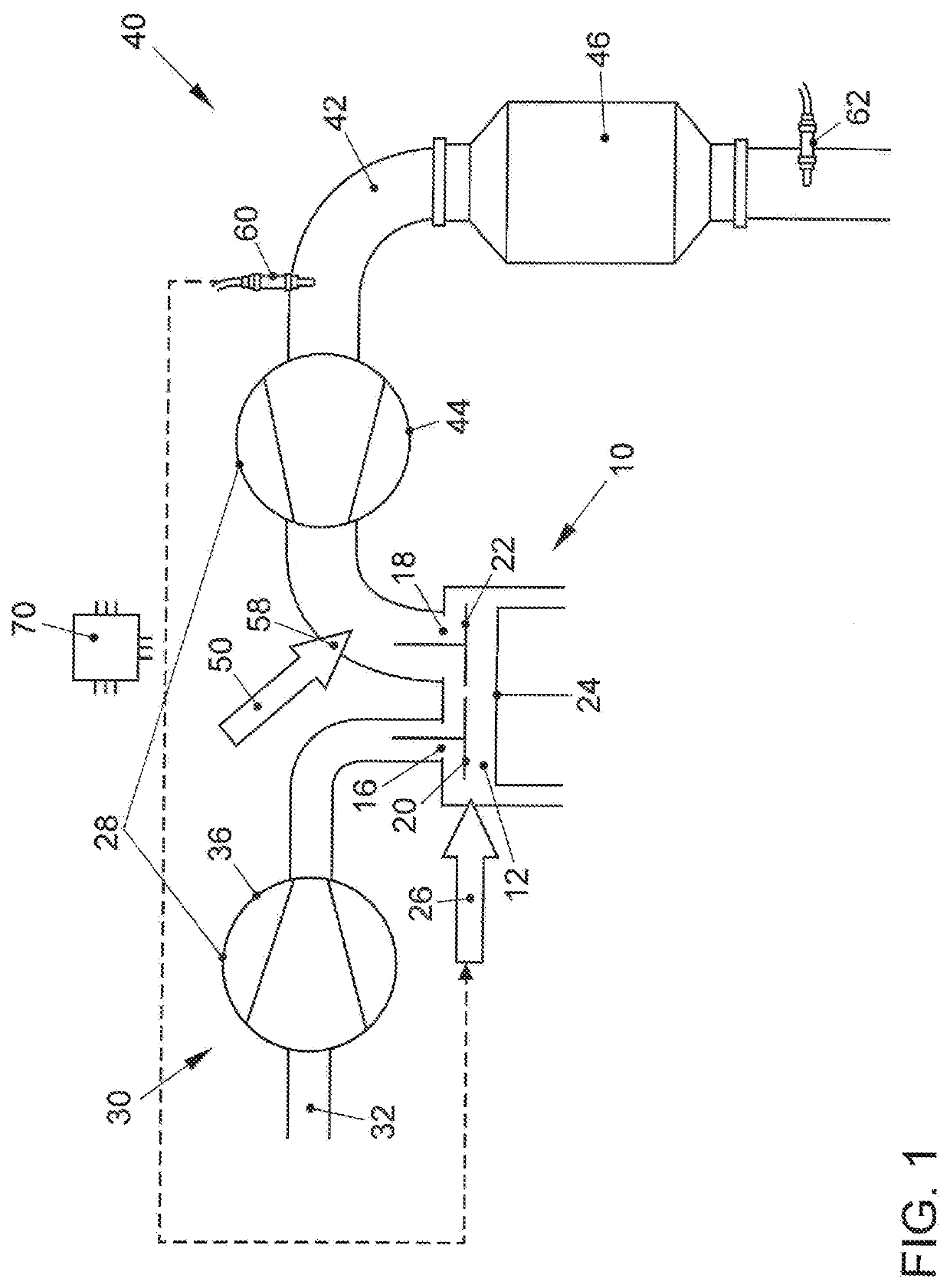

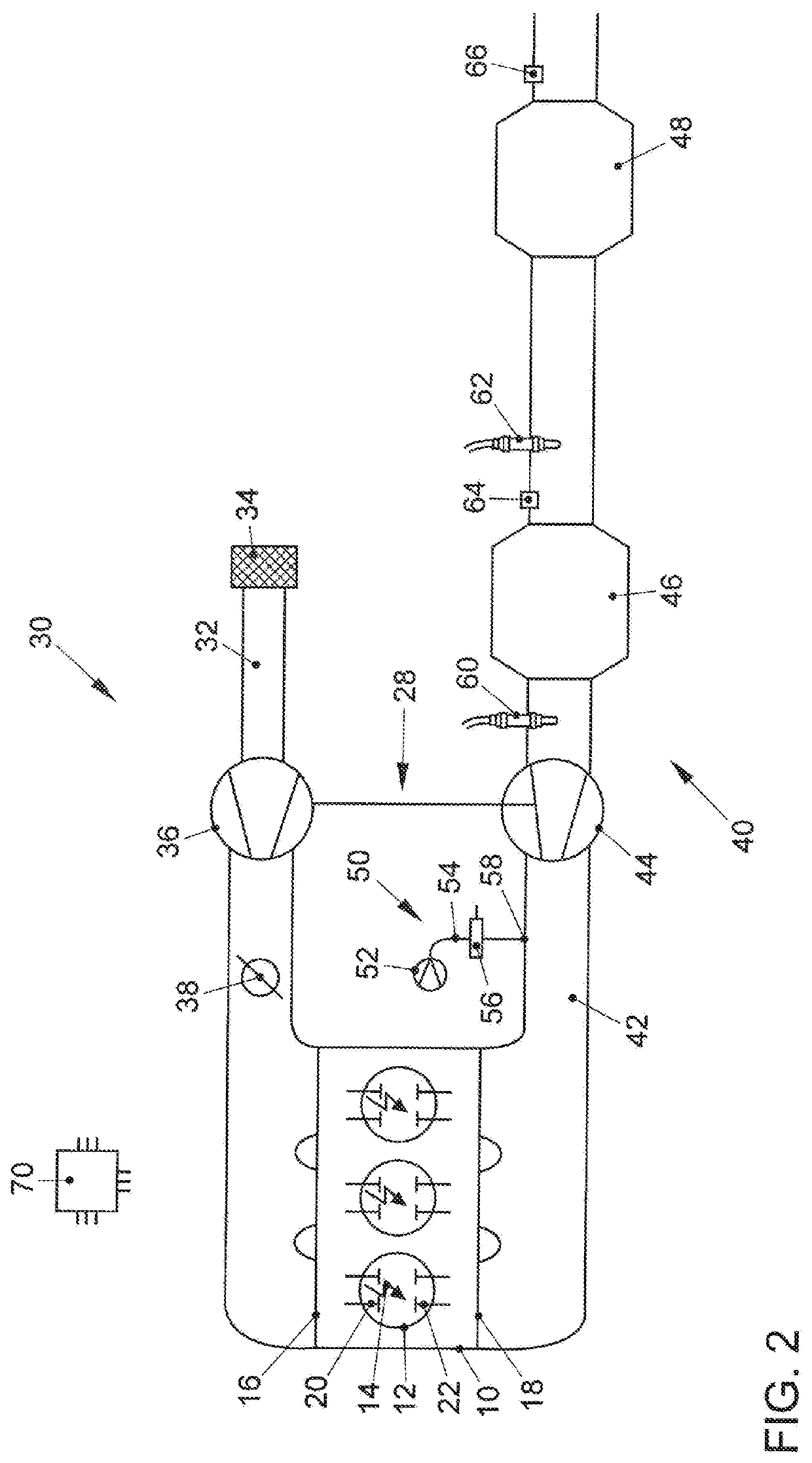

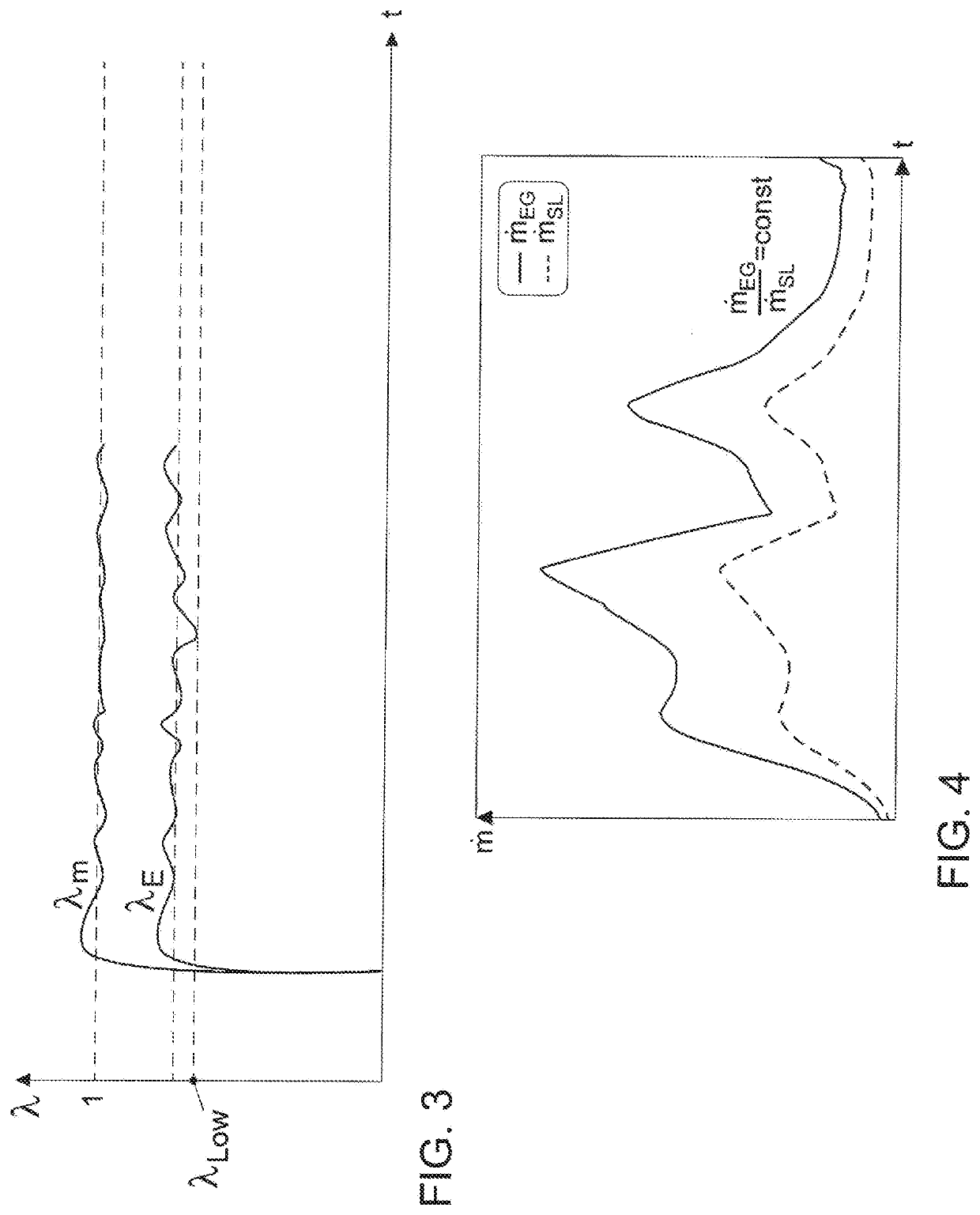

Method and device for the exhaust aftertreatment of an internal combustion engine

InactiveUS20200191084A1Easy to control accuratelyIncrease or decreaseElectrical controlInternal combustion piston enginesCatalytic transformationCombustion chamber

The invention relates to a method for exhaust aftertreatment of an internal combustion engine with at least one combustion chamber and an outlet that is connected to an exhaust system, wherein at least one catalytic converter is arranged in the exhaust system. Furthermore, a secondary-air system is provided with which secondary air can be introduced into an exhaust duct of the exhaust system at an intake point downstream from the outlet of the internal combustion engine and upstream from the catalytic converter, and a first lambda sensor is arranged in the exhaust duct downstream from the intake point and upstream from the catalytic converter. The internal combustion engine is operated immediately after start-up with a substoichiometric combustion air ratio (λ E<1), and secondary air is introduced into the exhaust duct of the exhaust system downstream from an outlet of the internal combustion engine and upstream from the first lambda sensor. An exhaust-gas lambda is determined by the first lambda sensor and a stoichiometric exhaust-gas lambda (λ m=1) set, with the quantity of secondary air being maintained constant and the quantity of fuel being adjusted such that the stoichiometric exhaust-gas lambda (λ m=1) is achieved.

Owner:VOLKSWAGEN AG

Meat slice inclined cutting device

PendingCN112088923ASmooth transmissionNo need for regular refueling maintenanceFish processingMeat processing devicesEngineeringStructural engineering

The present invention discloses a meat slice inclined cutting device and relates to the technical field of cutting. The meat slice inclined cutting device comprises a rack, a knife rest and a comb plate frame arranged on the rack, the knife rest is driven by a knife rest power mechanism to move transversely, the knife rest power mechanism comprises a knife rest power source and a cam transmissionassembly, and the knife rest power source drives the knife rest to move through the cam transmission assembly; the comb plate frame is driven by a comb plate frame power mechanism to obliquely move upand down; and blades and comb plates are obliquely arranged on the knife rest and the comb plate frame respectively, and the blades and the comb plates are identical in inclination angles and distributed in a staggered mode. By arranging the knife rest power mechanism of the cam transmission assembly, transmission is more stable and besides, regular oiling maintenance is not needed.

Owner:广东严工食品机械有限公司

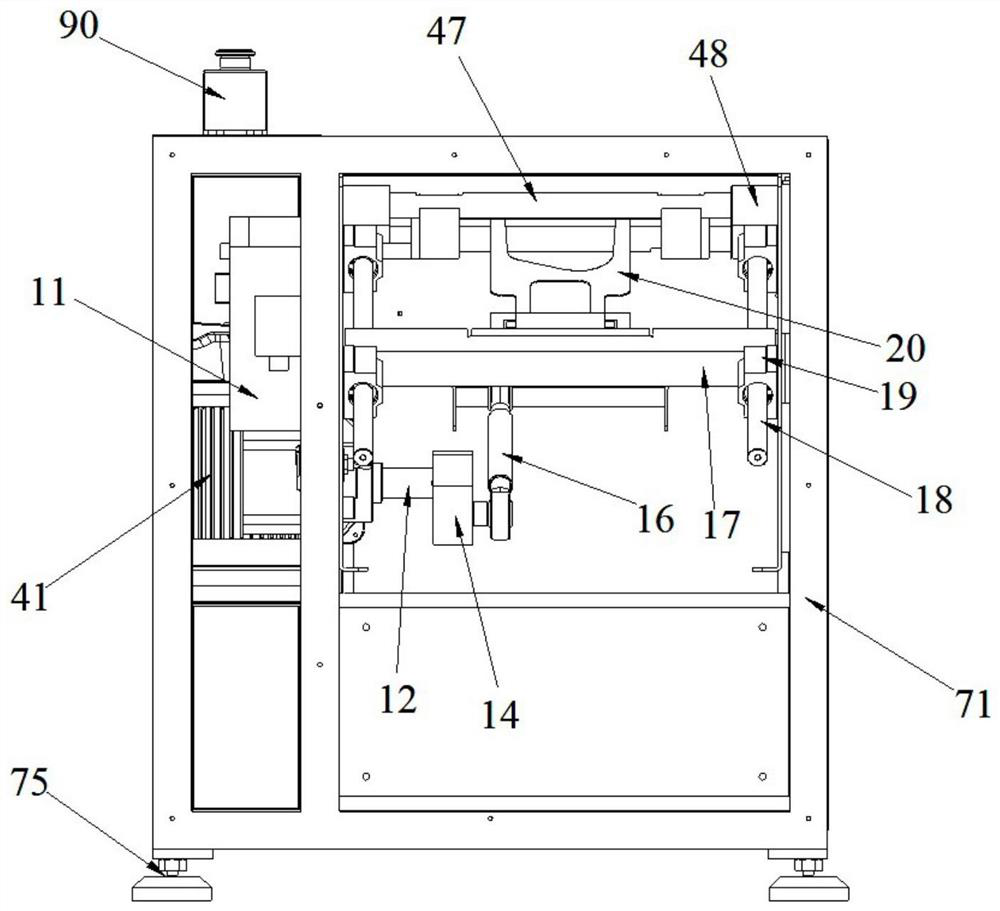

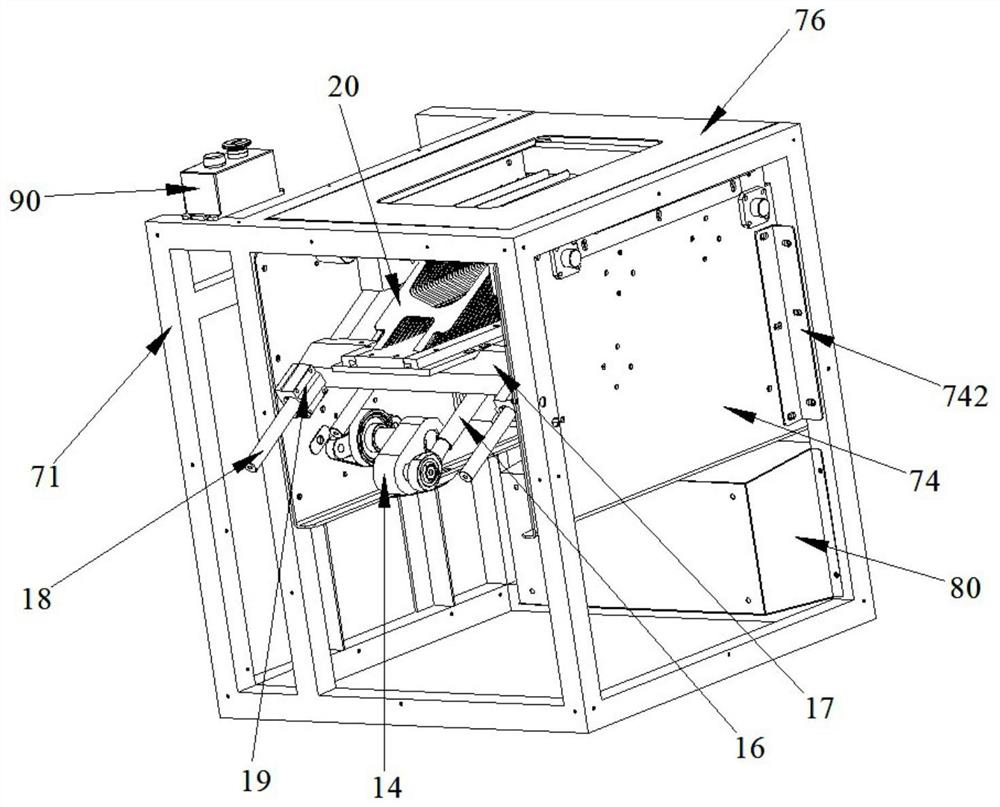

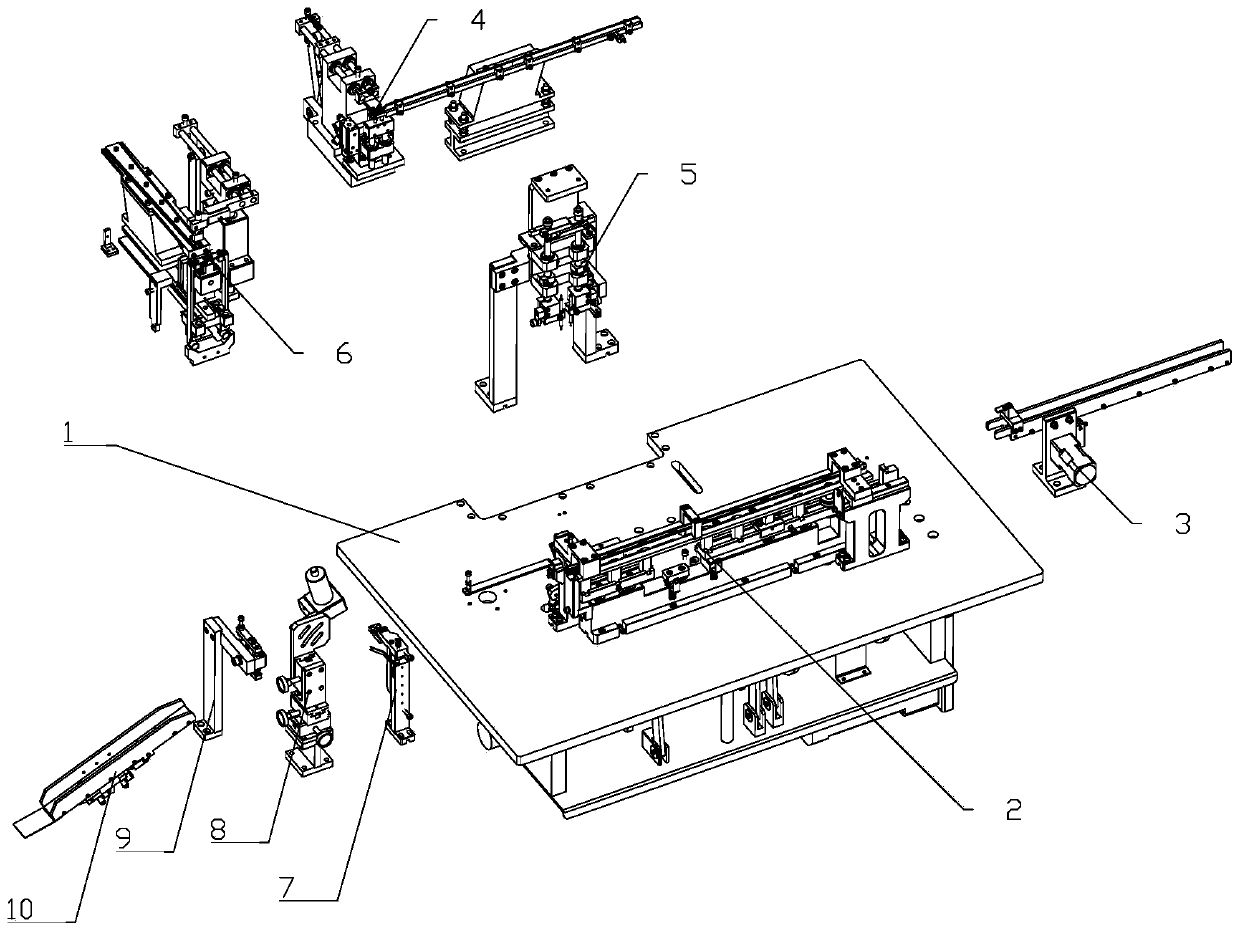

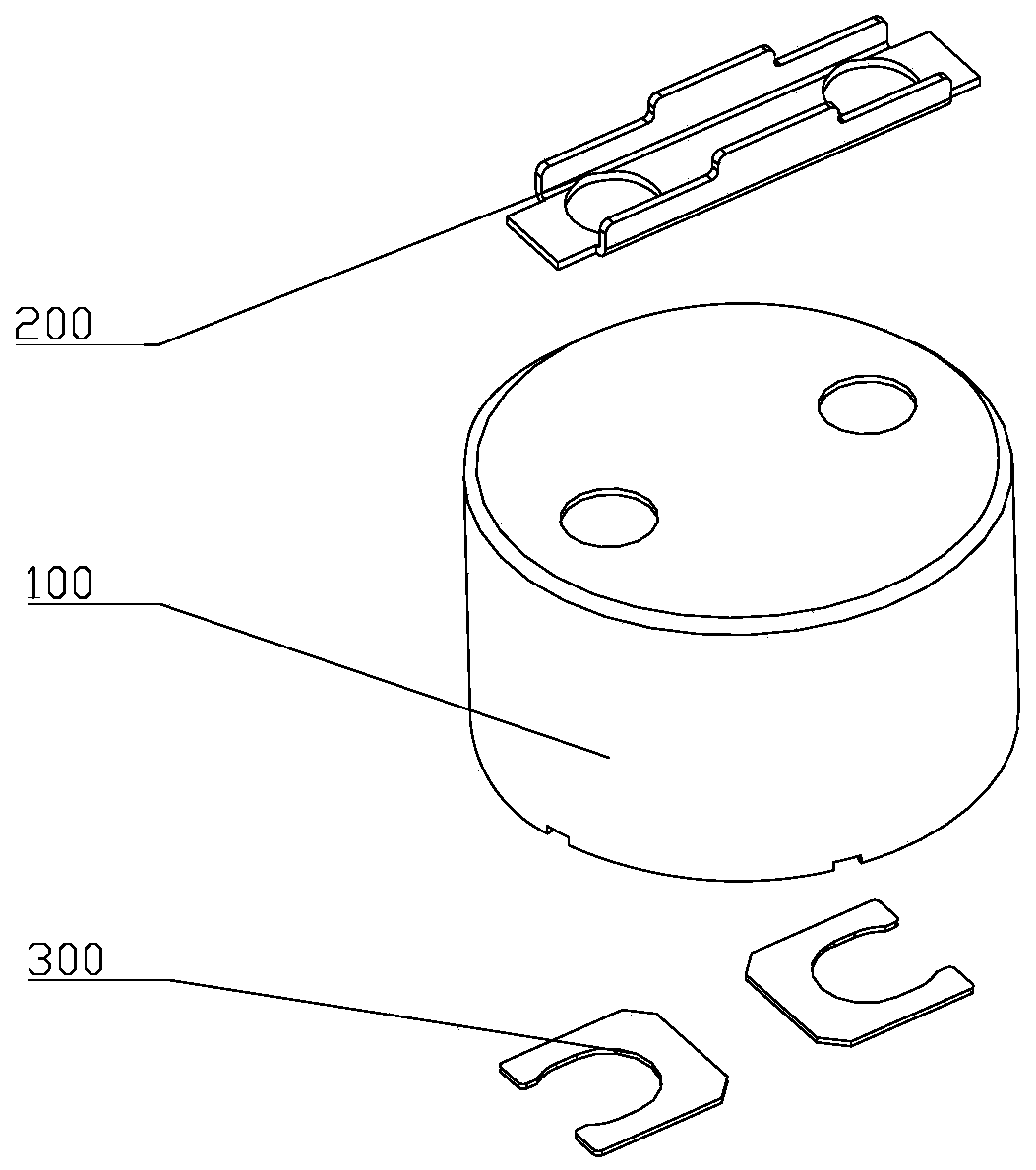

Electrode holder feeding device and method for cylinder capacitance electrode holder welding machine

InactiveCN111203637AReduce in quantityImprove transfer efficiencyConveyor partsLaser beam welding apparatusCapacitanceEngineering

The invention provides an electrode holder feeding device for a cylinder capacitance electrode holder welding machine. The device comprises a vibrating device, a base, a moving frame, a material receiving absorbing block, a material receiving base, a lifting assembly, a drive rod and a cam drive assembly. The base is arranged on the rack. A material receiving base is installed on the base. A material receiving groove is formed in the upper end of the material receiving base. The moving frame is movably fit on the base. The material receiving absorbing block is installed on the end portion of the moving frame. The moving frame is provided with a spring connected with the base. The middle portion of the drive rod is hinged to the base. A ball is arranged at the upper end of the drive rod. The upper end of the drive rod abuts against the end portion of the moving frame. The cam drive assembly is connected to a power part. The cam drive assembly drives the drive rod to move. The lifting assembly is installed on the base. The lifting assembly corresponds to the material receiving base and used for locating and separating an electrode base in the material receiving base. The electrode holder feeding device has the advantages that the electrode holder feeding success rate is high, and moving and taking of an electrode holder are reliable.

Owner:陆小波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com