Meat slice inclined cutting device

A technology of oblique cutting and sliced meat, which is applied in the direction of processed meat, meat processing equipment, slaughtering, etc., can solve the problems of poor stability and difficult maintenance, and achieve the effect of reducing maintenance requirements, reducing use, and simple and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

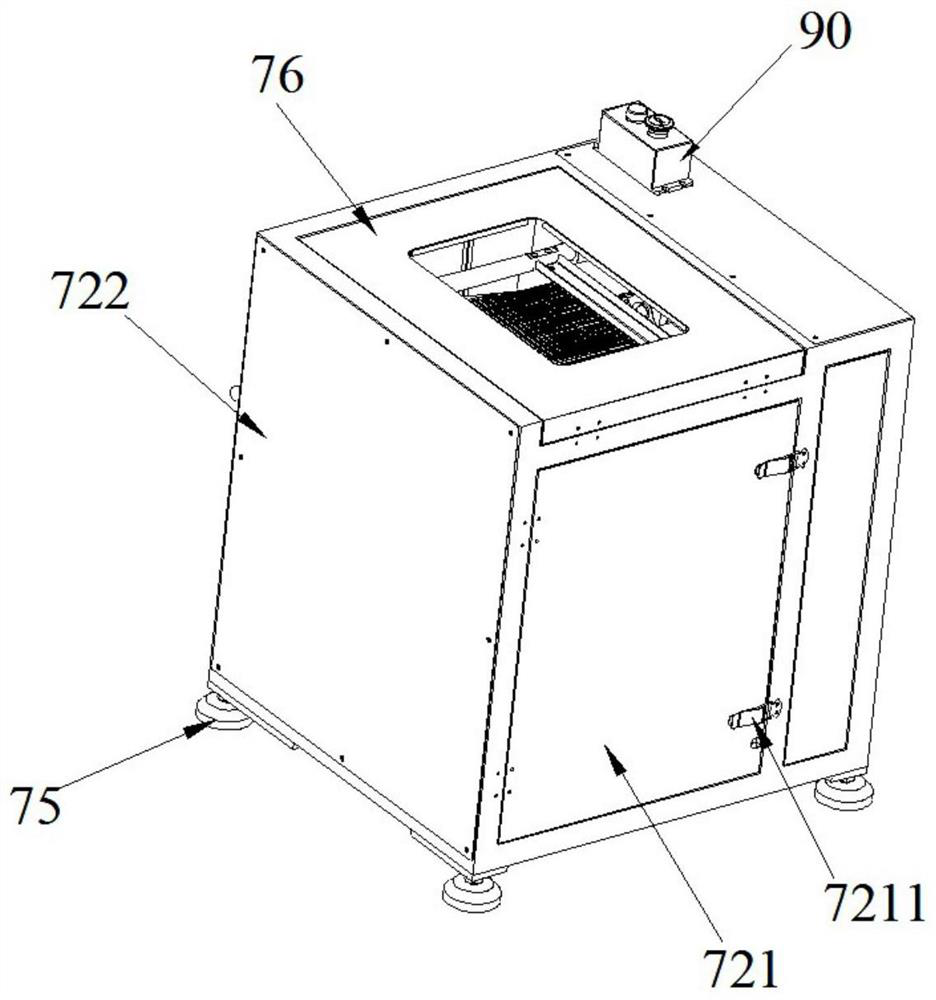

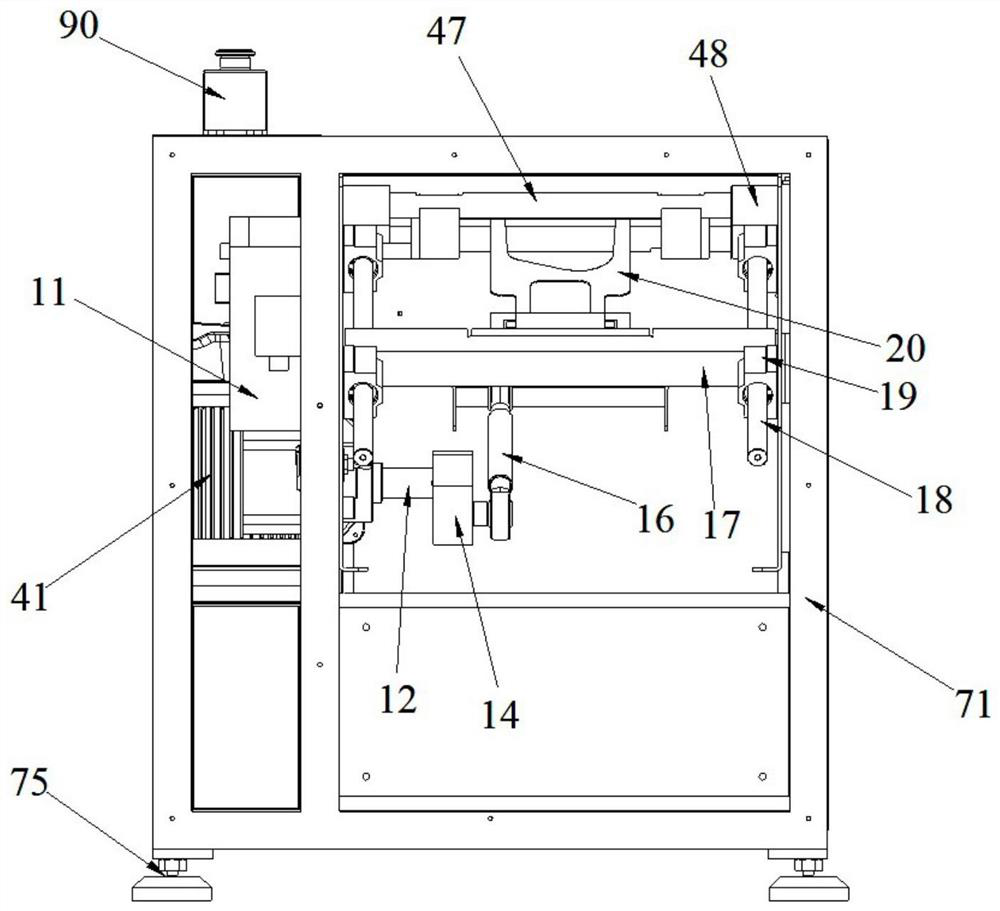

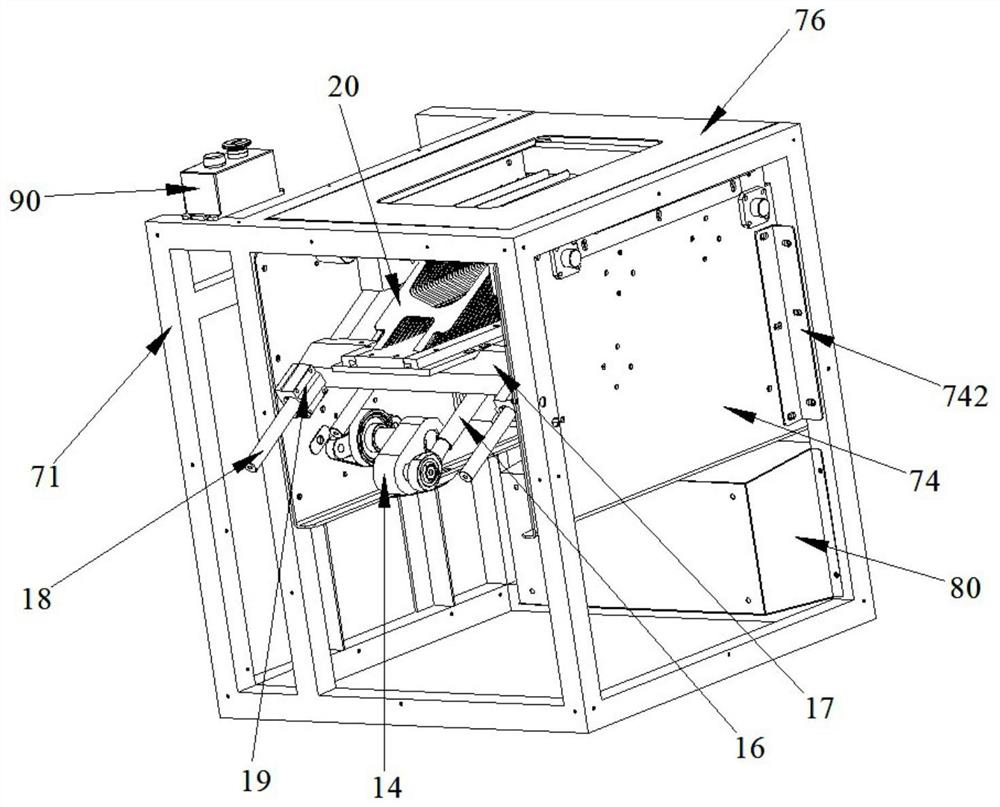

[0039] Please refer to Figure 1-12Shown, a kind of sliced meat oblique cutting device, it comprises frame 71, and is arranged on the knife rest and comb plate frame 30 on frame 71, knife frame is driven by knife frame power mechanism to do lateral movement, and comb plate frame 30 is driven by comb plate frame. Plate frame power mechanism 10 is driven to move up and down inclined; blade 50 and comb plate 20 which are installed on the knife rest and comb plate frame 30 are respectively installed with an inclination, and the inclination angles of blade 50 and comb plate 20 are the same and are distributed in a staggered manner.

[0040] When cutting obliquely, the material (i.e. meat material, including fish, beef and mutton, etc.) is placed on the comb plate 20, the comb plate 20 drives the material to move obliquely, and the comb plate 20 is distributed to the blade 50 alternately, and when the material reaches the blade 50 position, drive blade 50 lateral movement (horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com