Patents

Literature

54results about How to "Reduce the number of assemblies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

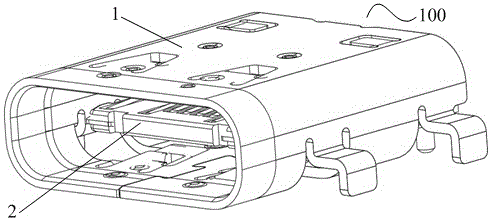

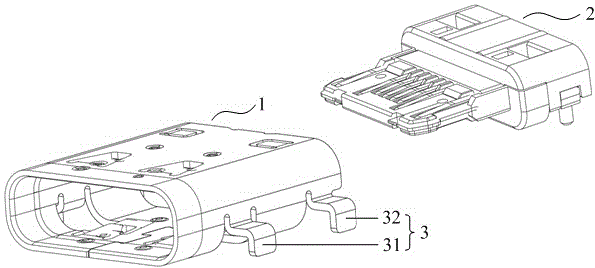

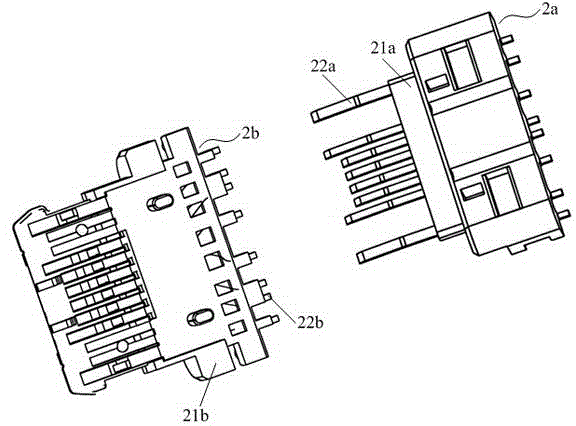

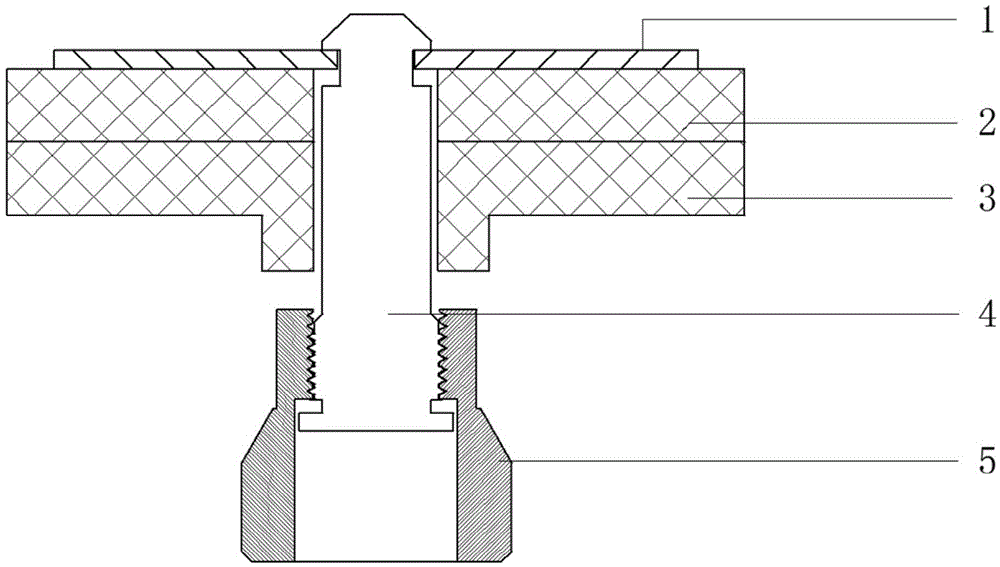

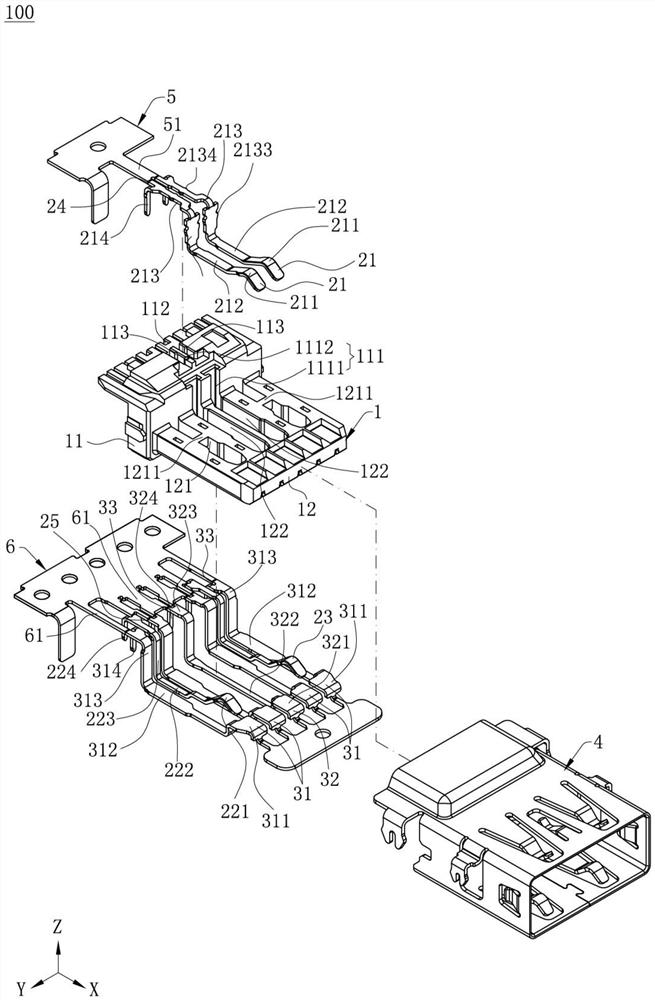

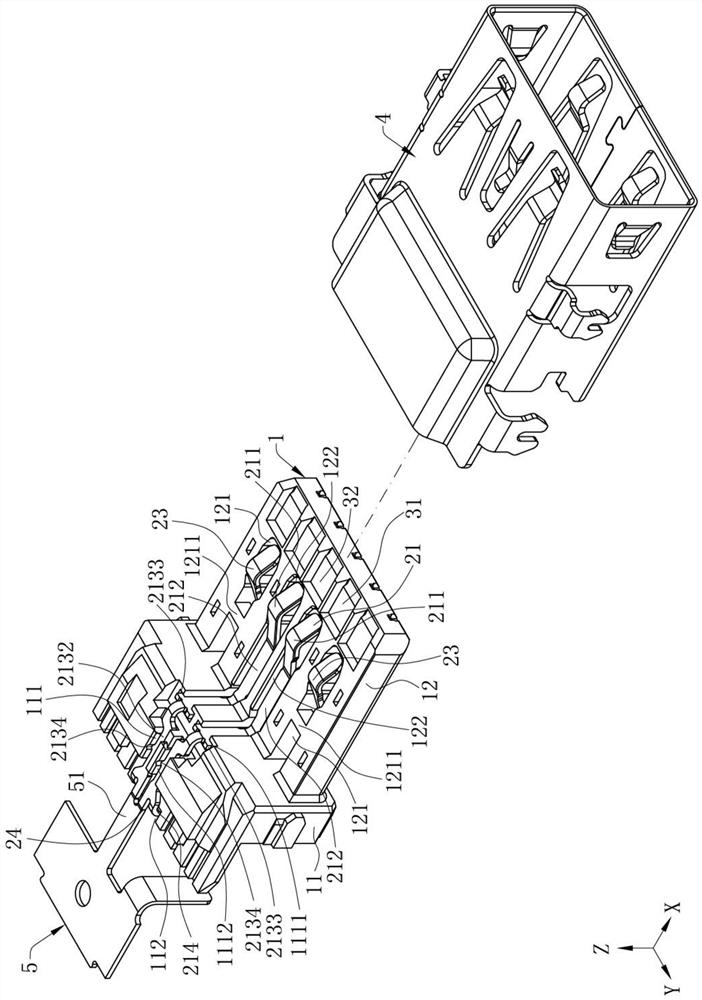

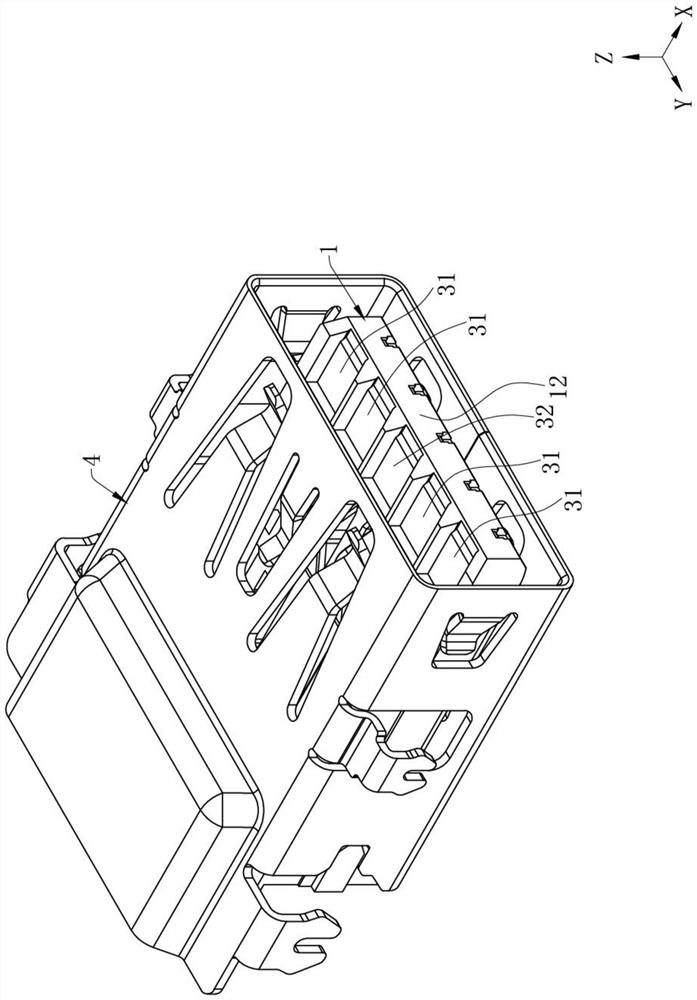

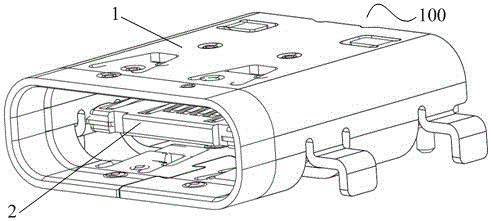

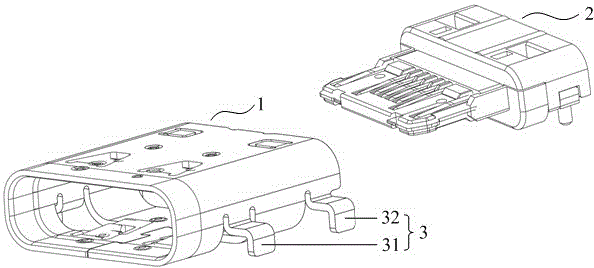

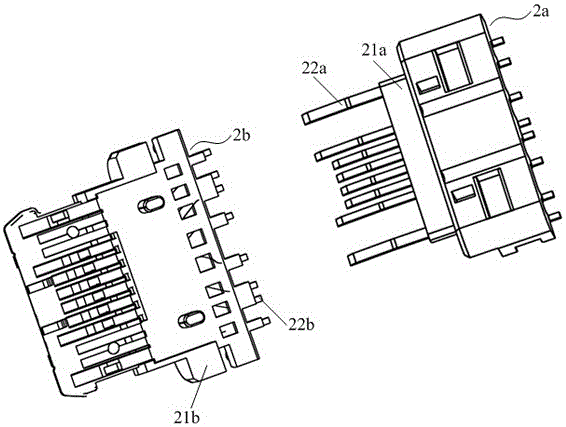

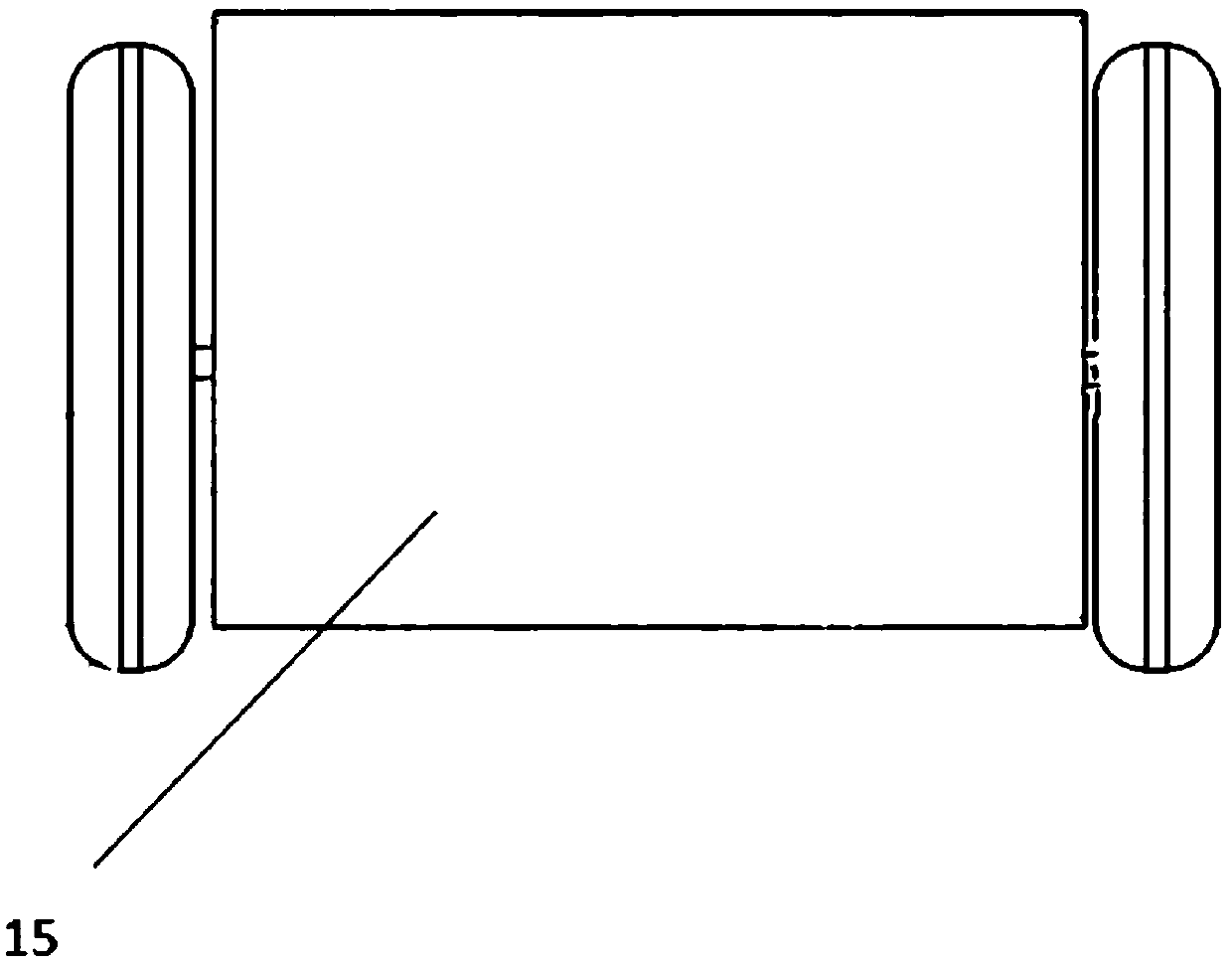

Type-C socket connector

ActiveCN104810657AReduce the number of assembliesReduce Tolerance RollupCoupling protective earth/shielding arrangementsEngineeringElectrical and Electronics engineering

The invention discloses a Type-C socket connector. The Type-C socket connector comprises a shell and an inserting component; the inserting component comprises an upper inserting component and a lower inserting component; the upper inserting component comprises an upper insulating body and an upper row of electric conductive terminals integrally formed with the upper insulating body; the lower inserting component comprises a lower insulating body, and a metallic shield sheet and a lower row of electric conductive terminals integrally formed with the lower insulating body; each insulating body is provided with twelve grooves respectively; each row of the electric conductive terminals is provided with eight terminals respectively; the metallic shield sheet is integrally formed with any two terminals in the lower row of the electric conductive terminals; the metallic shield sheet is downwards protruded to form a plate-shaped grounding part; the position of the terminals integrally formed with the metallic shield sheet corresponds to the position of the grounding part; and the grounding part and the metallic shield sheet are located in the different planes. The Type-C socket connector is used for reducing the assembly number of the parts, reducing the tolerance accumulation, satisfying the USB2.0 application, and greatly decreasing the number of the terminals, and is good for the stability of the product.

Owner:ALL BEST ELECTRONICS TECH CO LTD

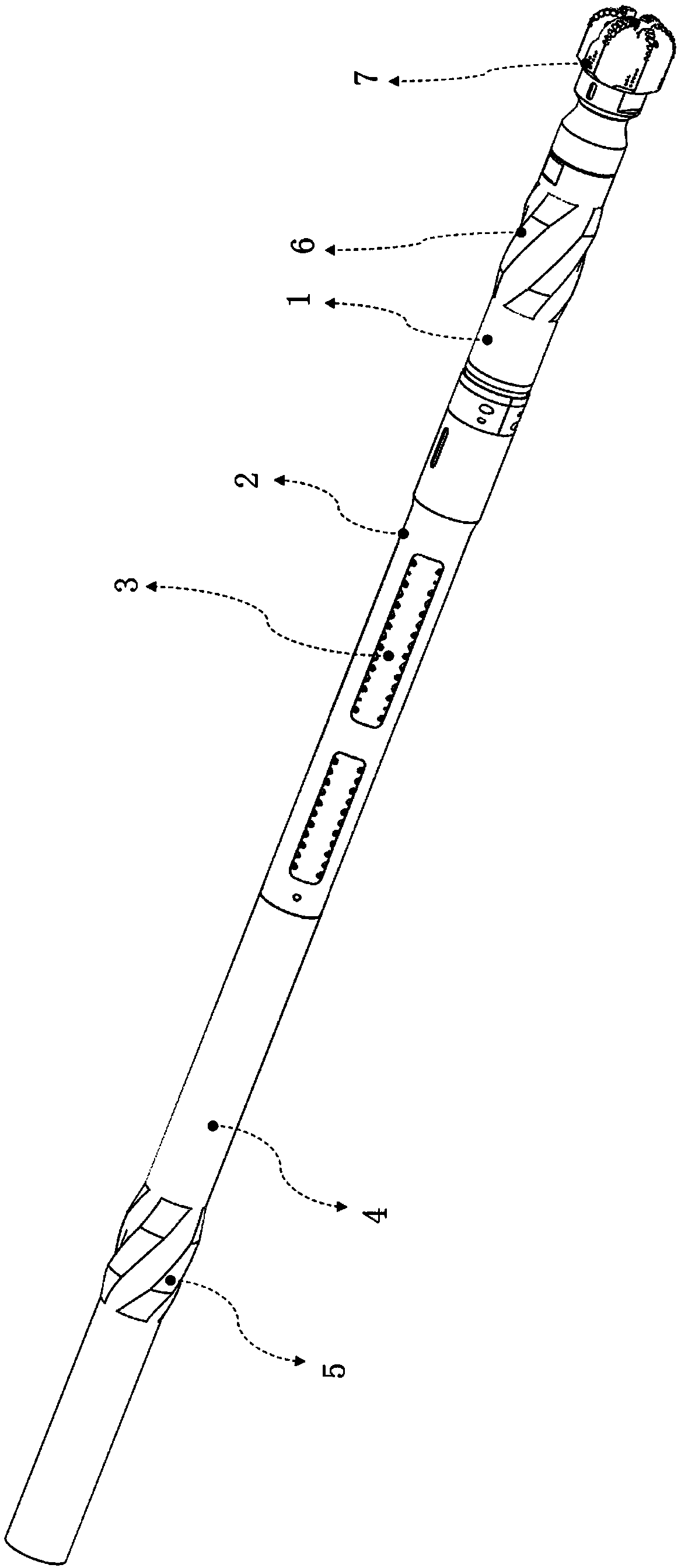

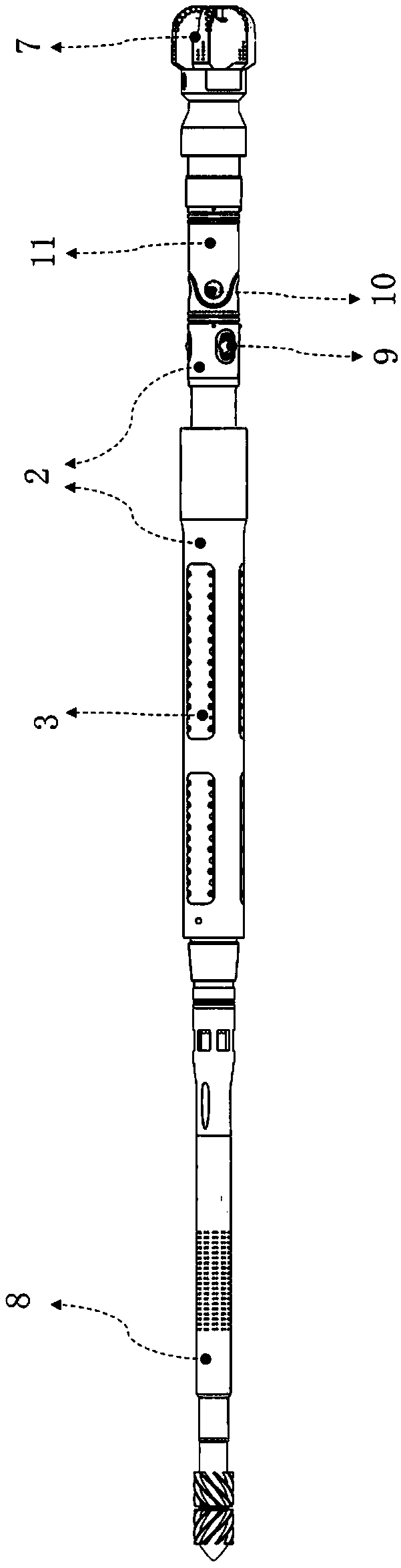

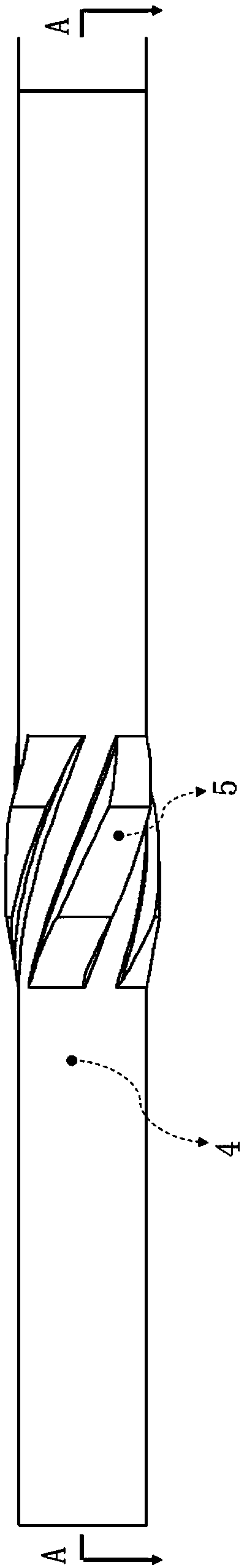

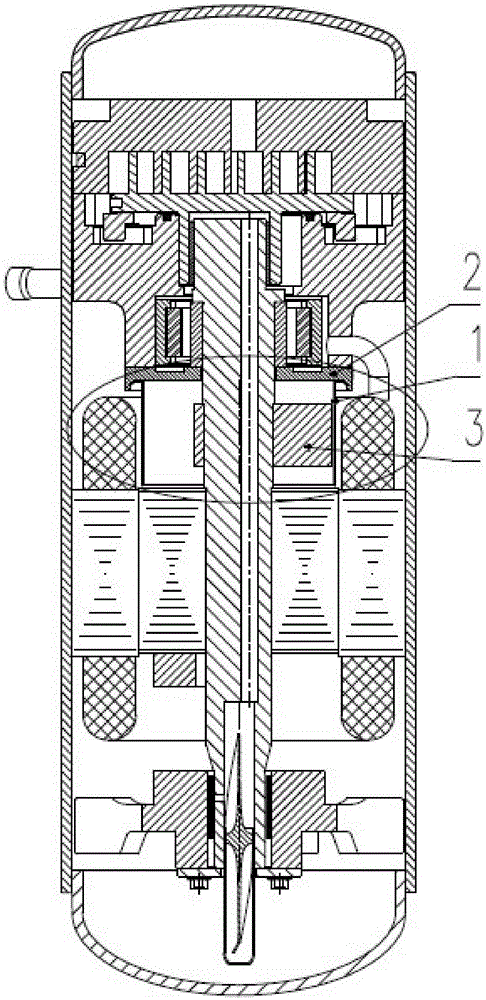

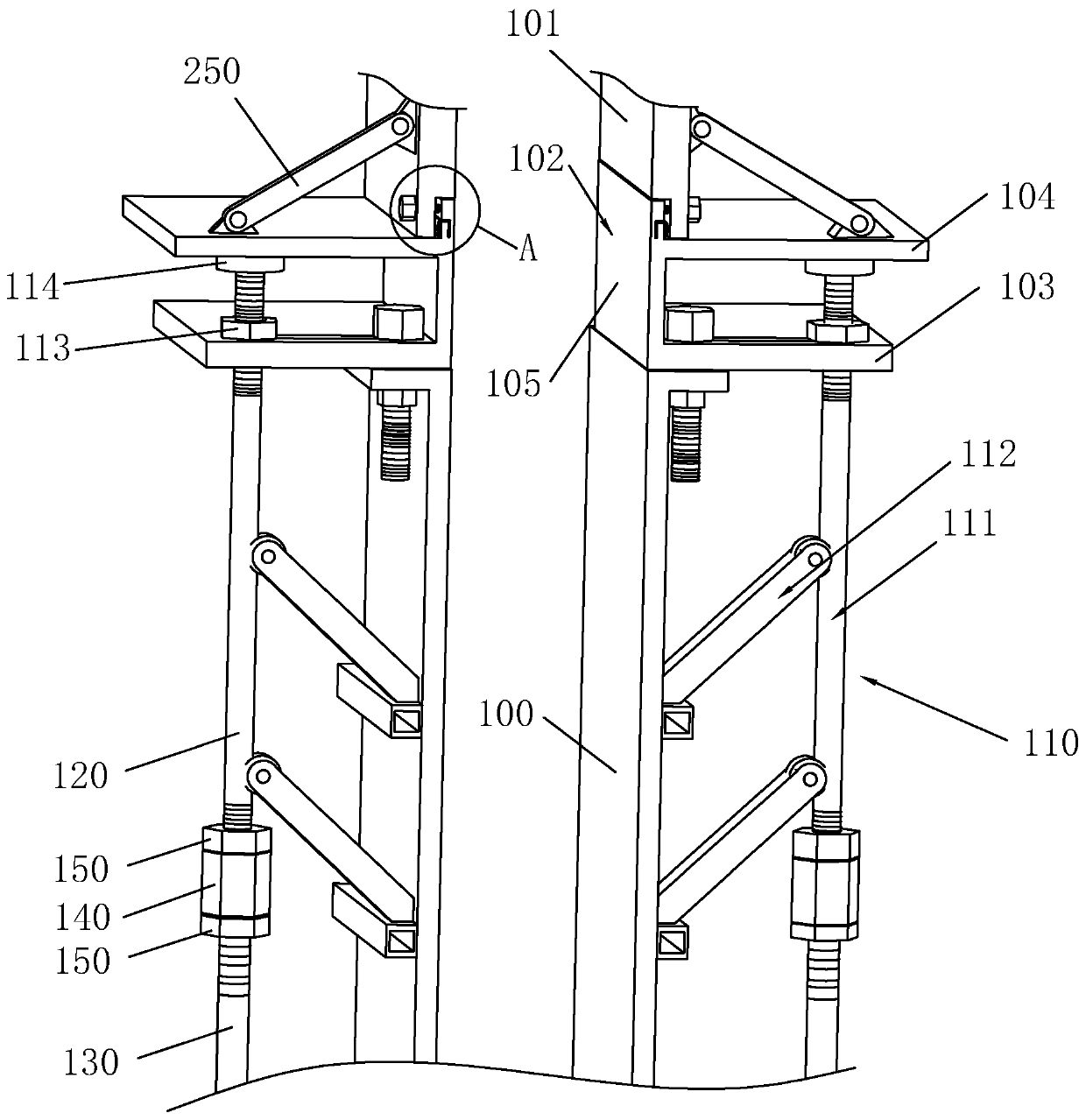

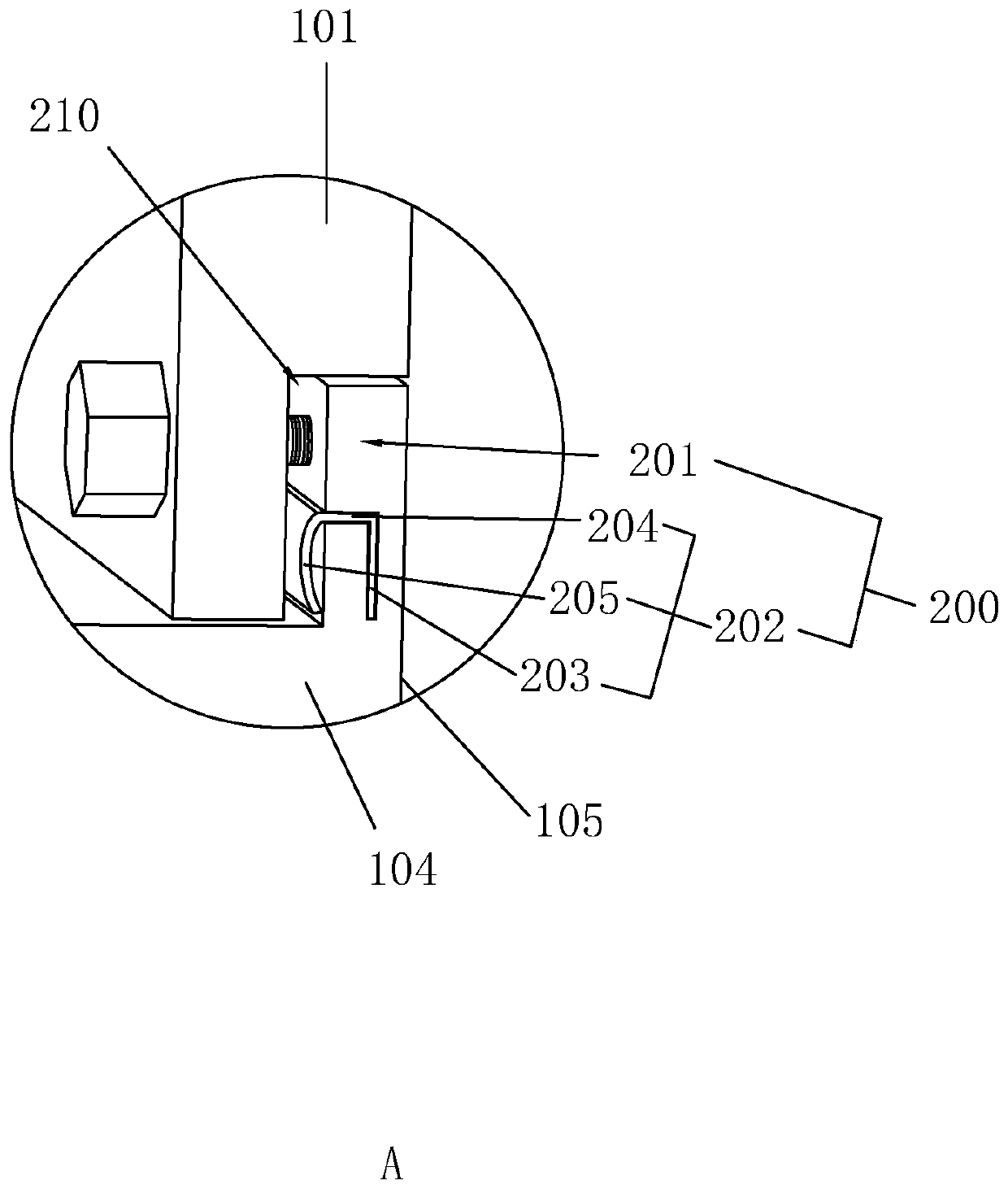

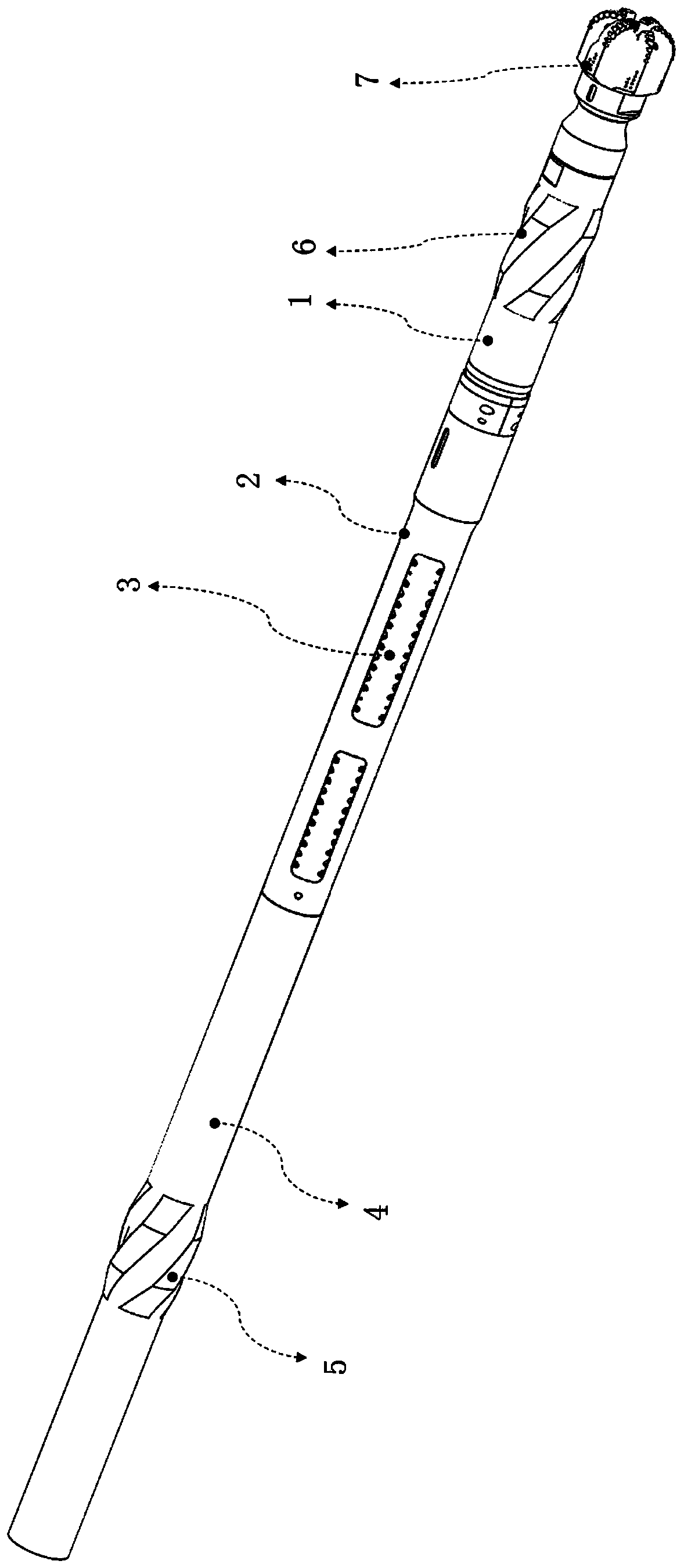

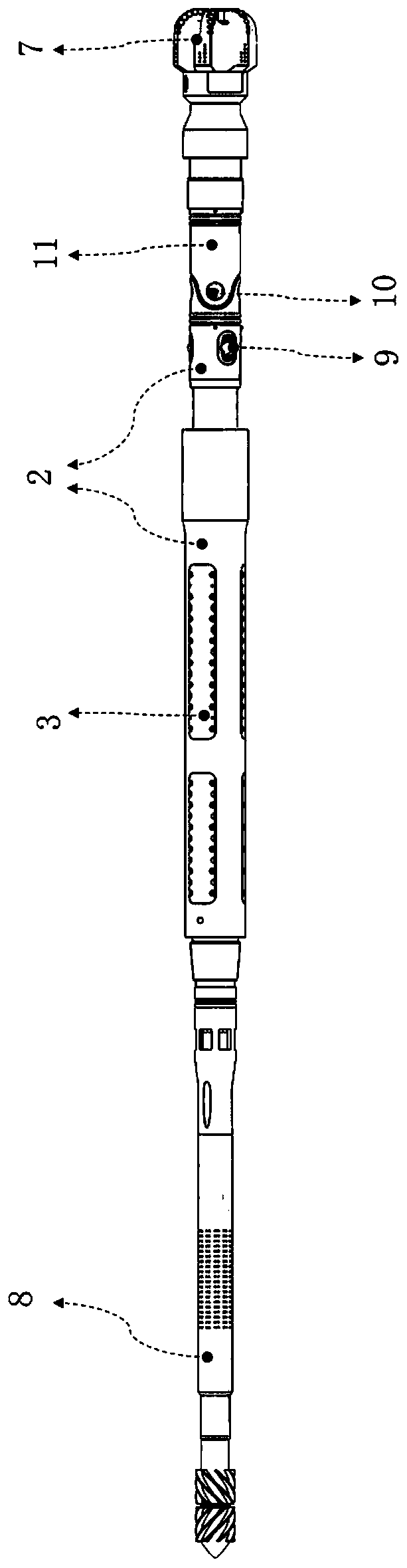

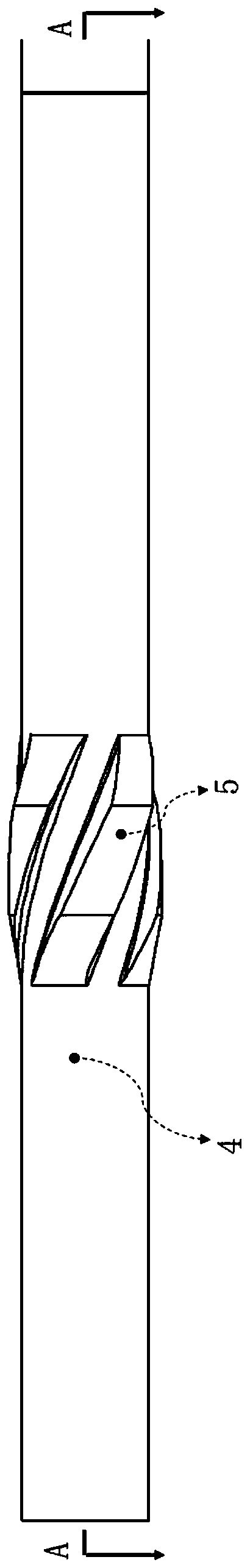

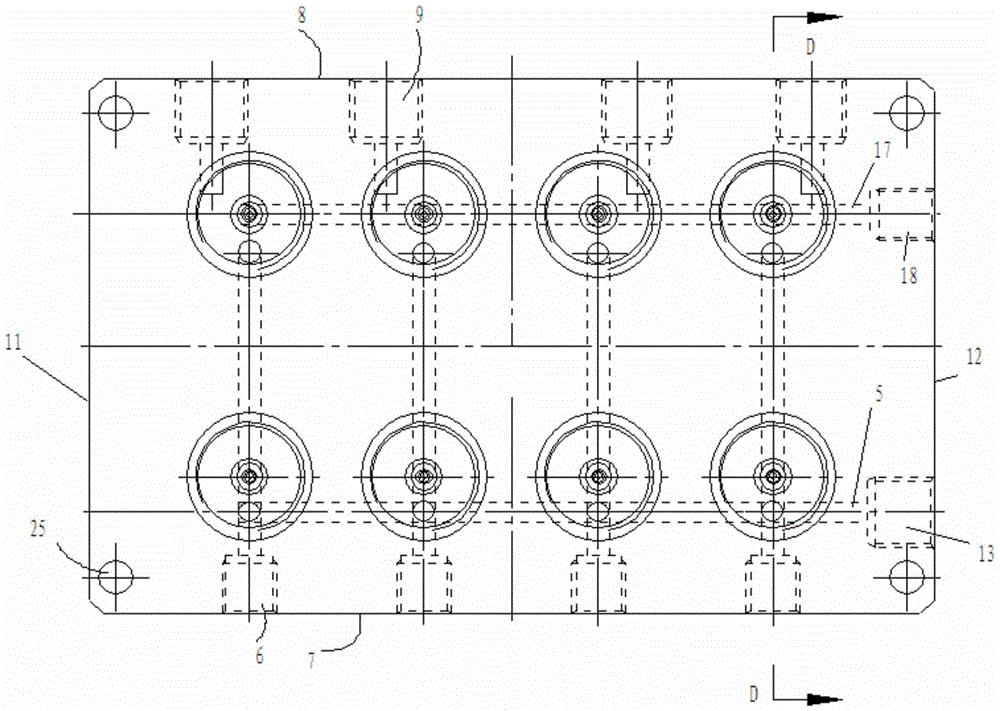

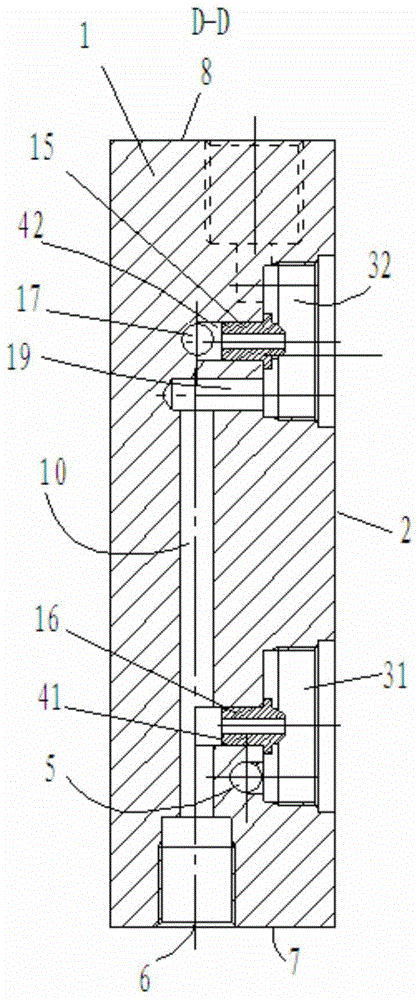

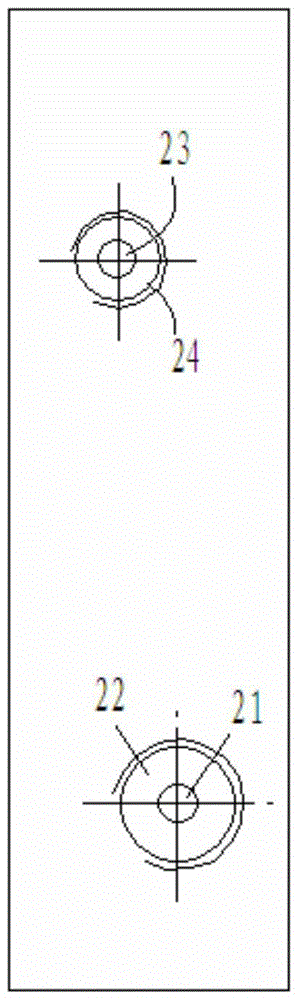

Full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool

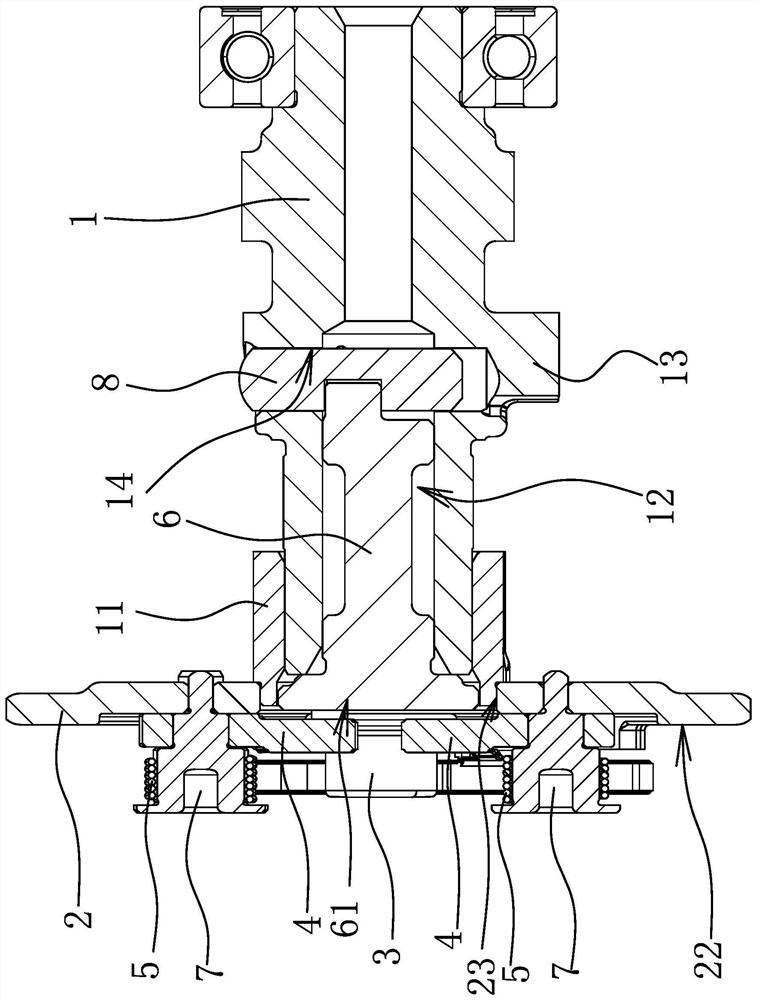

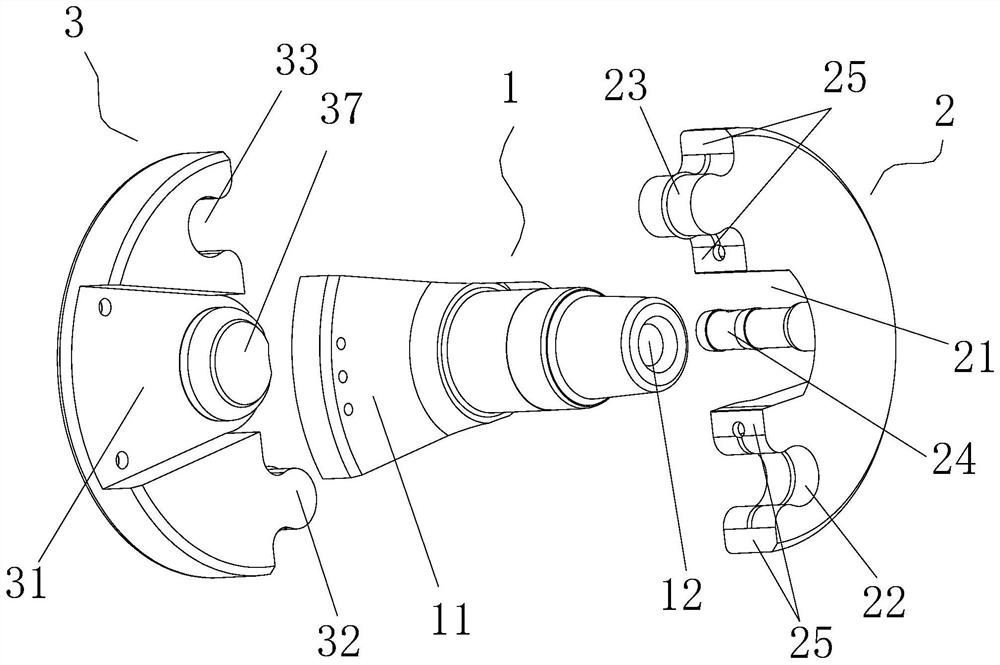

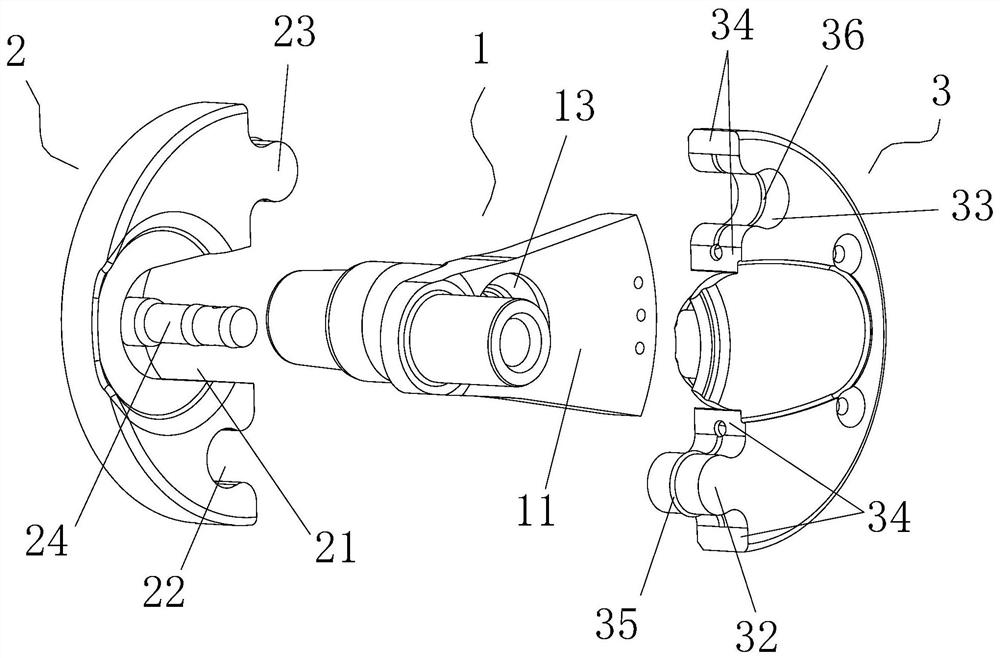

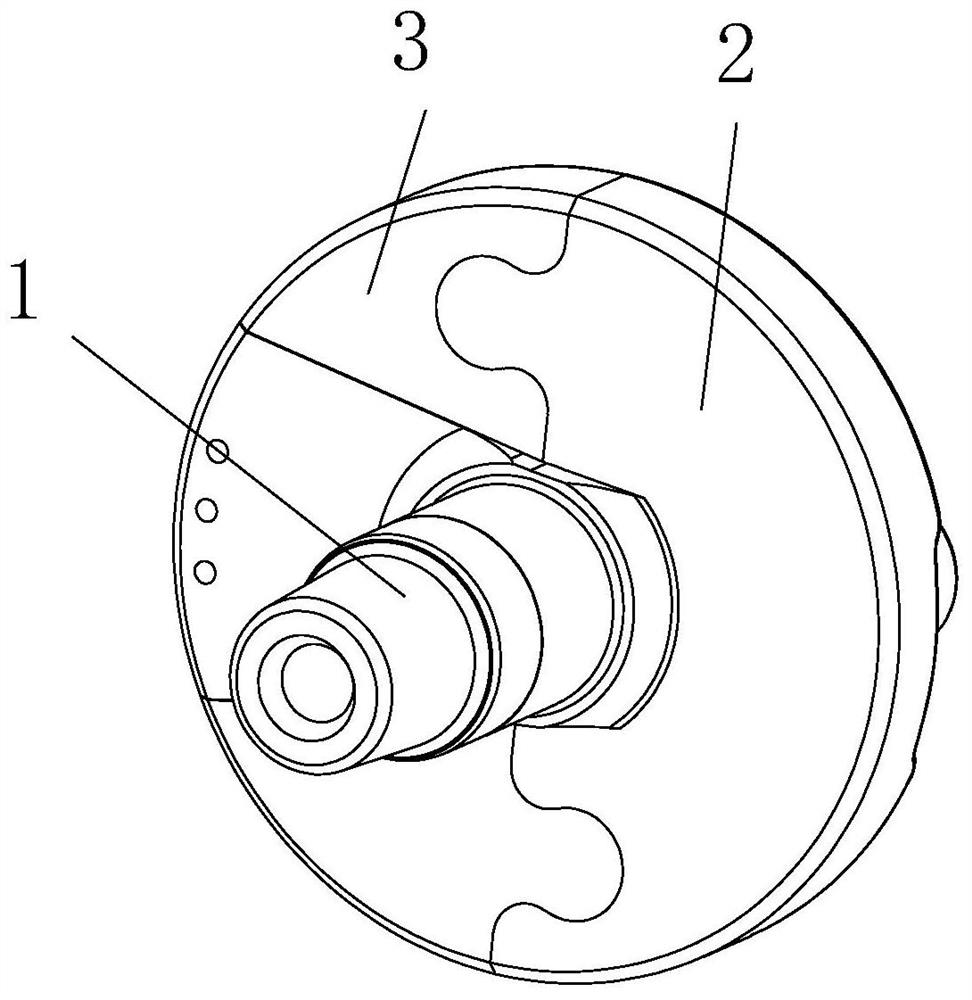

ActiveCN109025820AReduce in quantityReduce power supplyDirectional drillingMachines/enginesPush outPiston

The invention mainly belongs to the technical field of rotary guide systems, and particularly relates to a full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool. The full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool adopts a hydraulic system driven by a turbine and a generator set to convert the energy of the pressure mud into the hydraulic energy. By adopting the hydraulic system driven by the turbine and the generator set, the power is provided for a piston through the hydraulic mode, so that the lateral force obtained by a drillbit is larger. Meanwhile, the hinged mode is adopted, so that the optimal steering capability is achieved. As a result, the high build-up rate is easier to achieve. The hydraulic piston pushes againstthe inner wall of a lower rotating sleeve instead of the wall of a well, so that the abrasion can be reduced. At the same time, only one set of pushing piston assemblies is pushed out at the same moment, so that the unnecessary work is reduced. The service life of the piston is prolonged.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

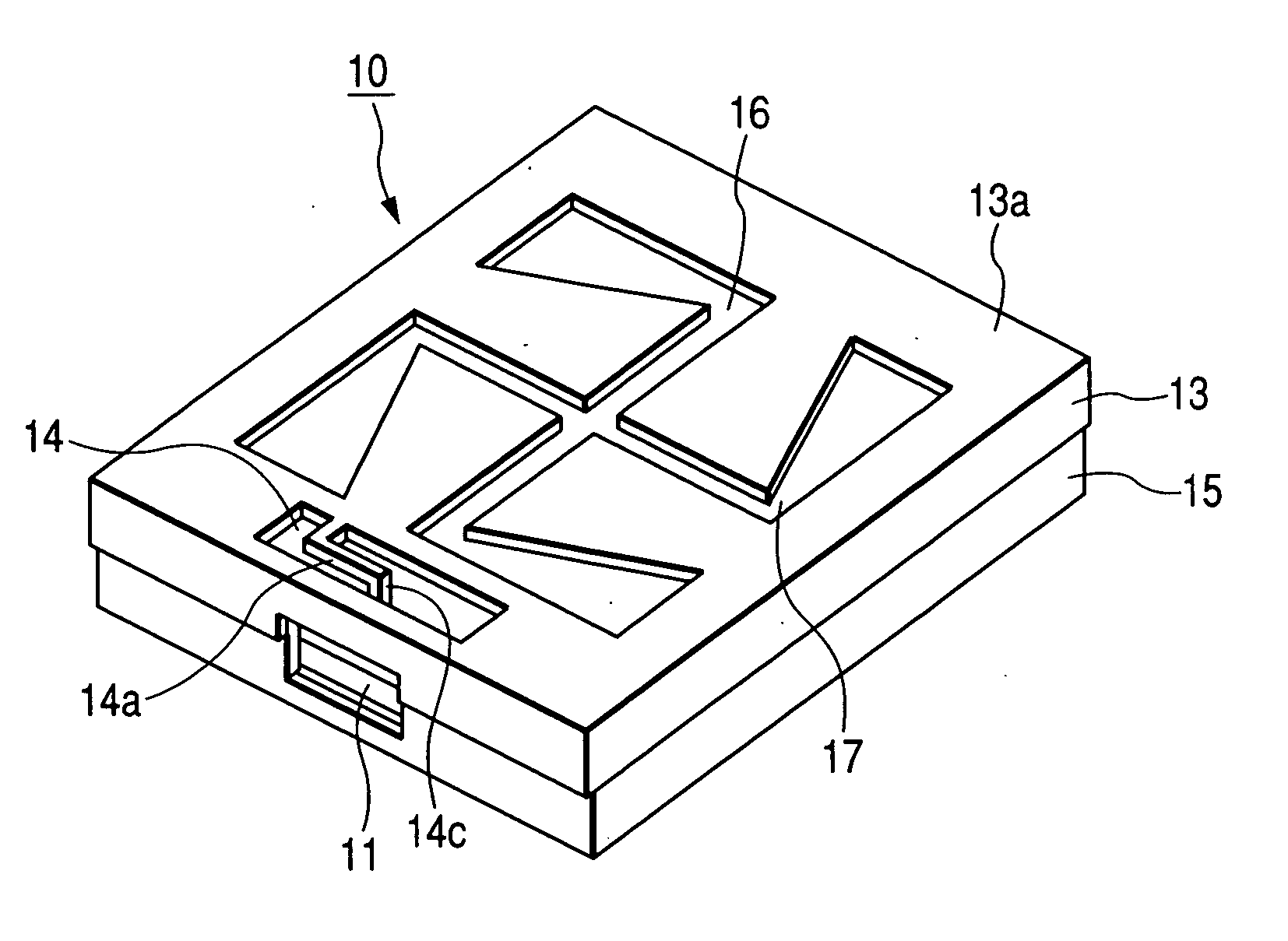

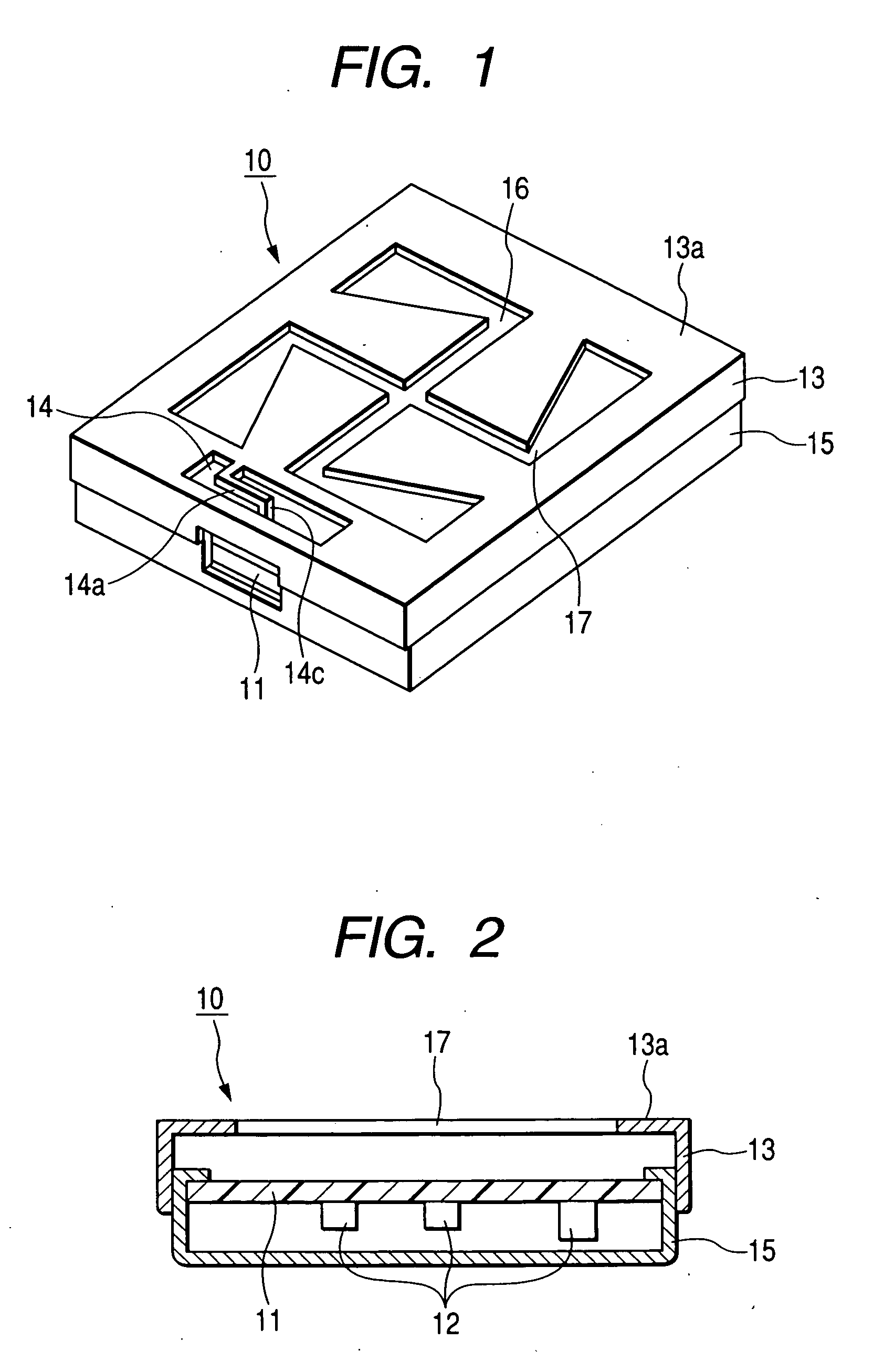

Antenna device for vehicle

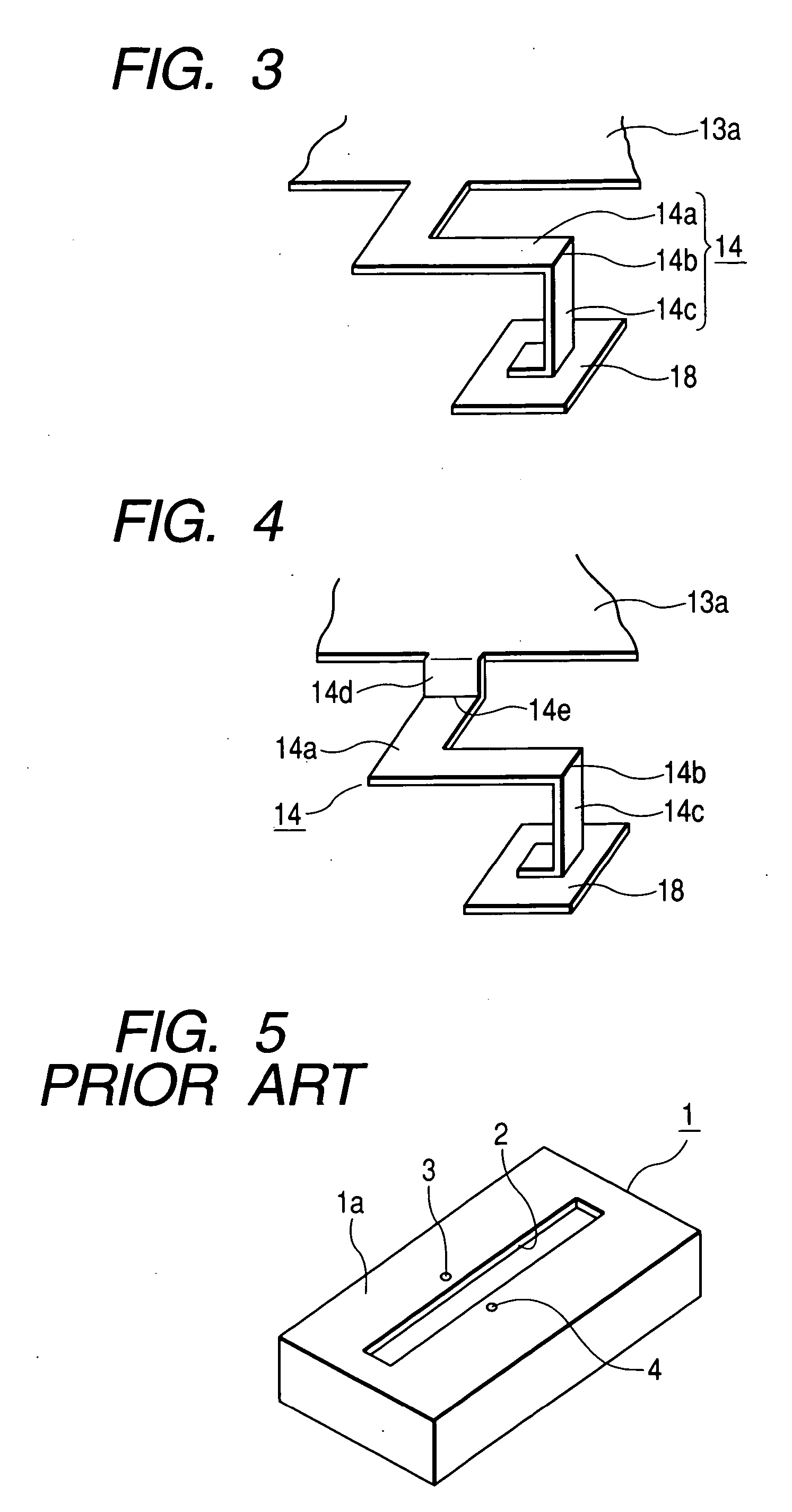

InactiveUS20060077113A1Prevent solder from crackingReducing stress appliedElectrically short antennasSlot antennasEngineeringElectrical and Electronics engineering

An antenna device includes a circuit board, an upper shield case, a lower shield case, and a power feeding member. The circuit board has high frequency circuits arranged thereon. The upper shield case and the lower shield case cover the circuit board. The power feeding member extends from an upper plate of the upper shield case. Radiation slots and are formed in the upper plate. The power feeding member includes a horizontal portion, a bent portion, and a drooping portion, and a front end of the drooping portion is mounted on a land of the circuit board and soldered thereto. The horizontal portion protrudes from a base end which is continuous to the upper plate in a horizontal direction. The bent portion is formed by bending a front end of the horizontal portion at a right angle. The drooping portion extends downward from the bent portion.

Owner:ALPS ALPINE CO LTD

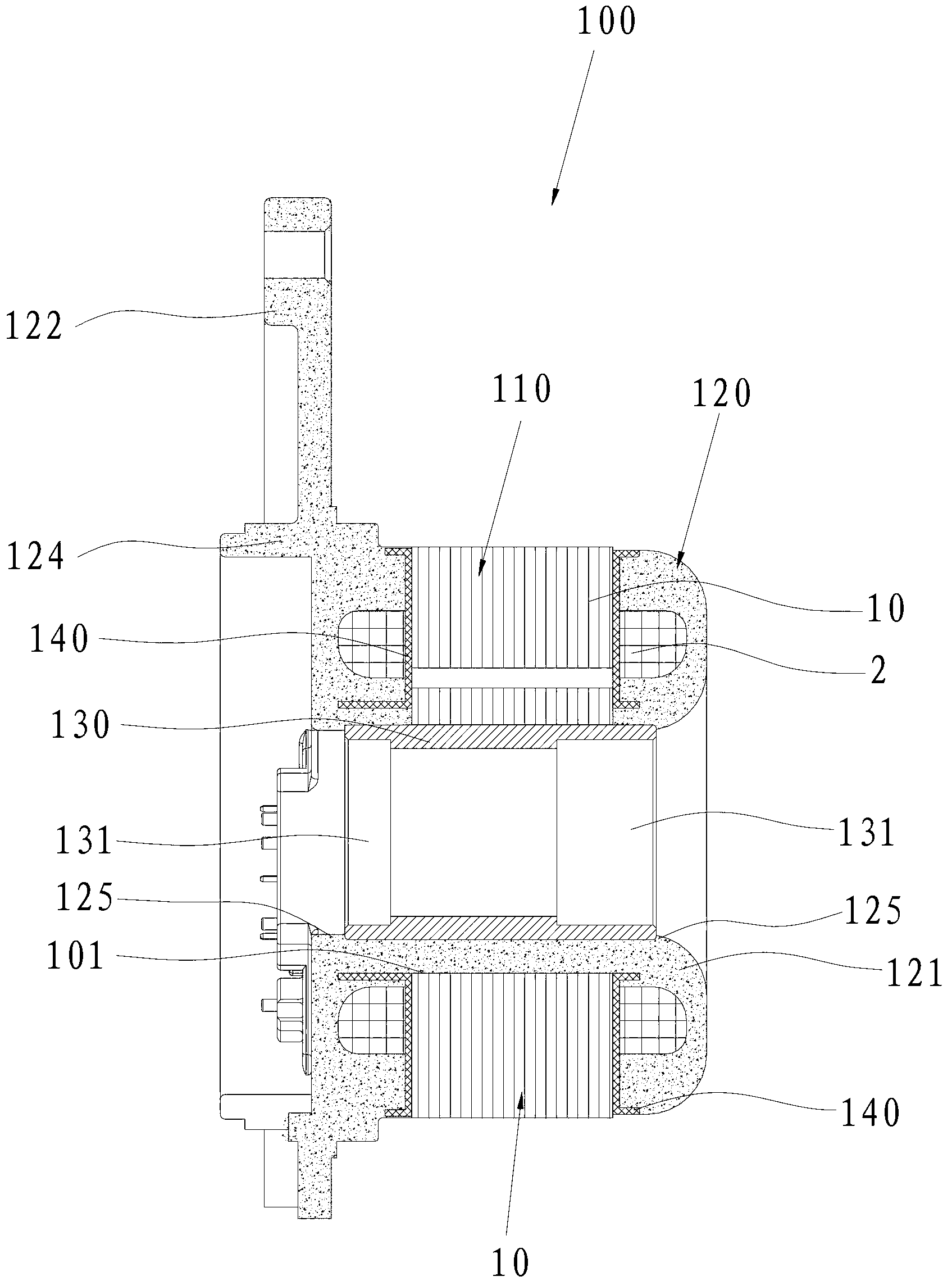

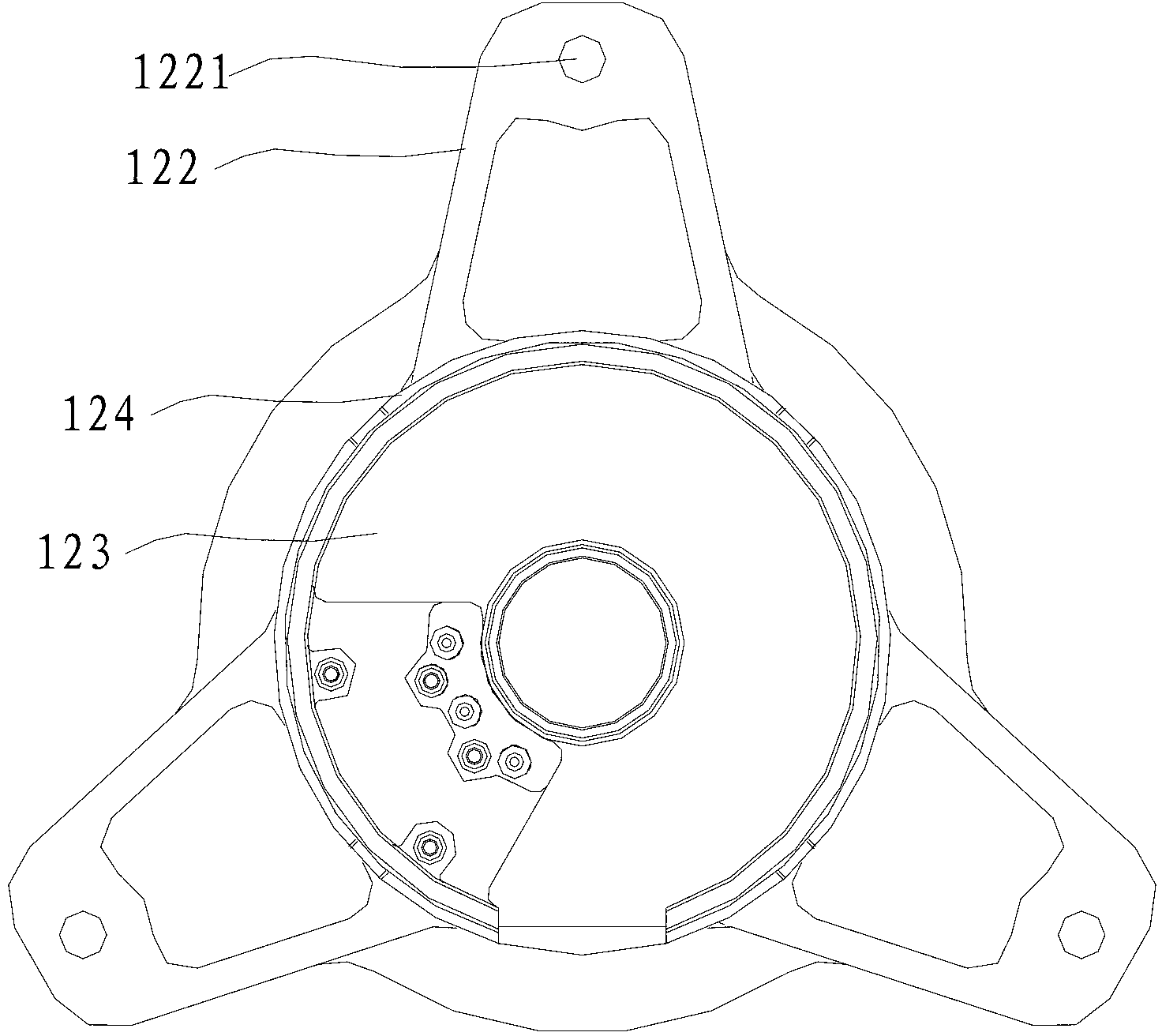

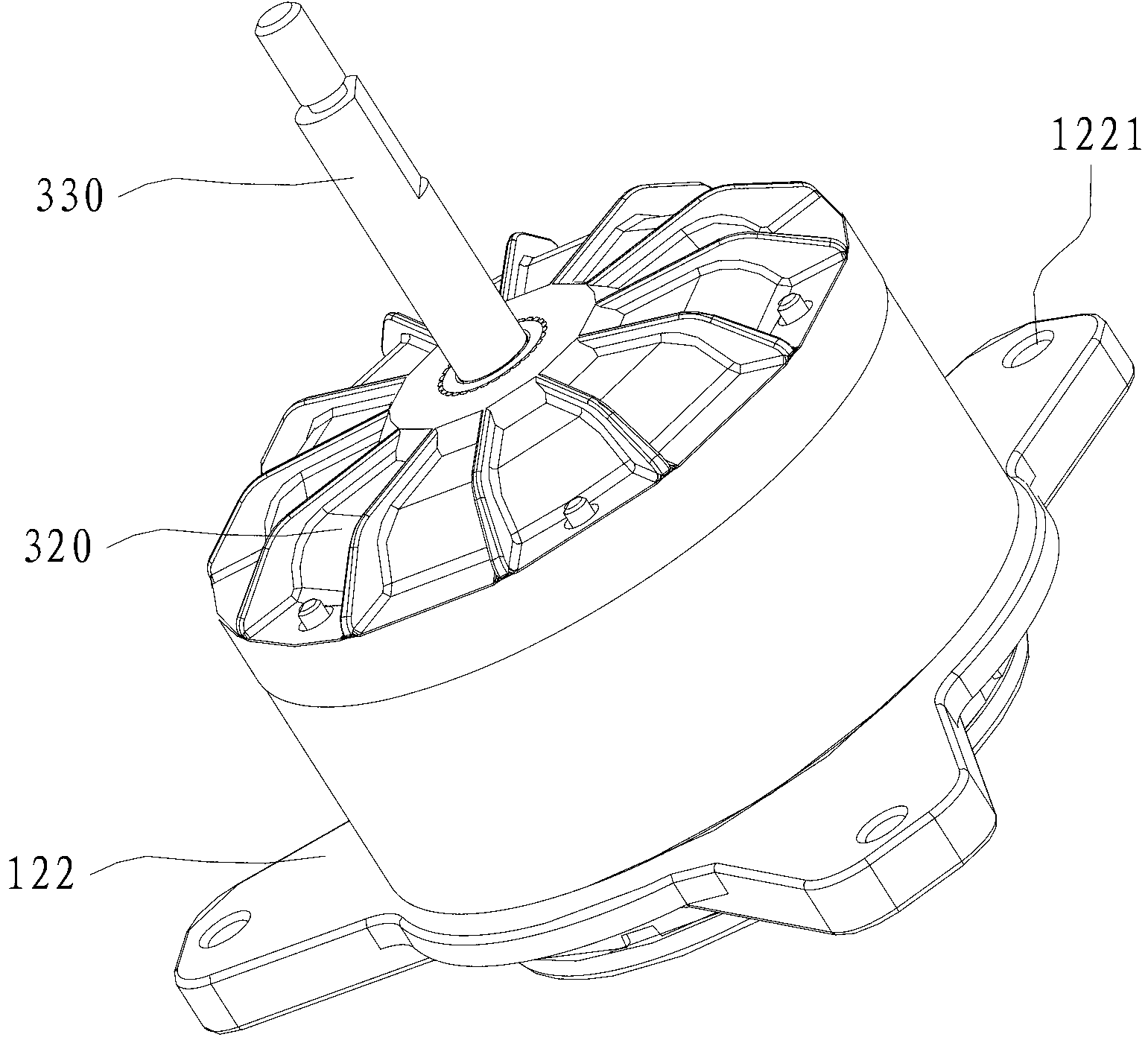

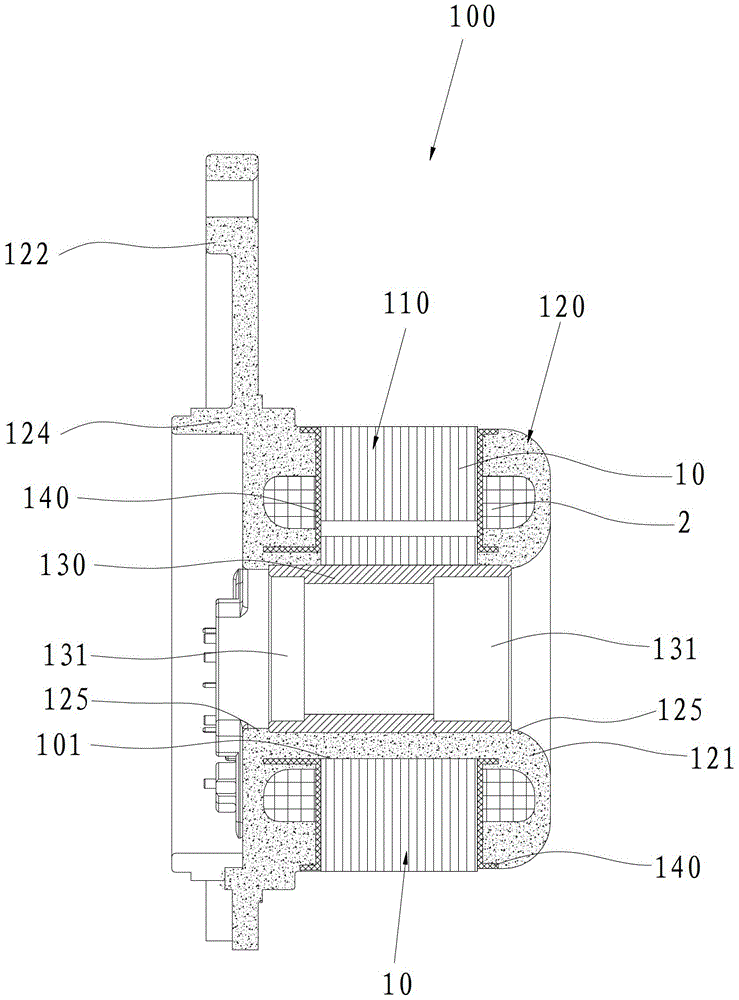

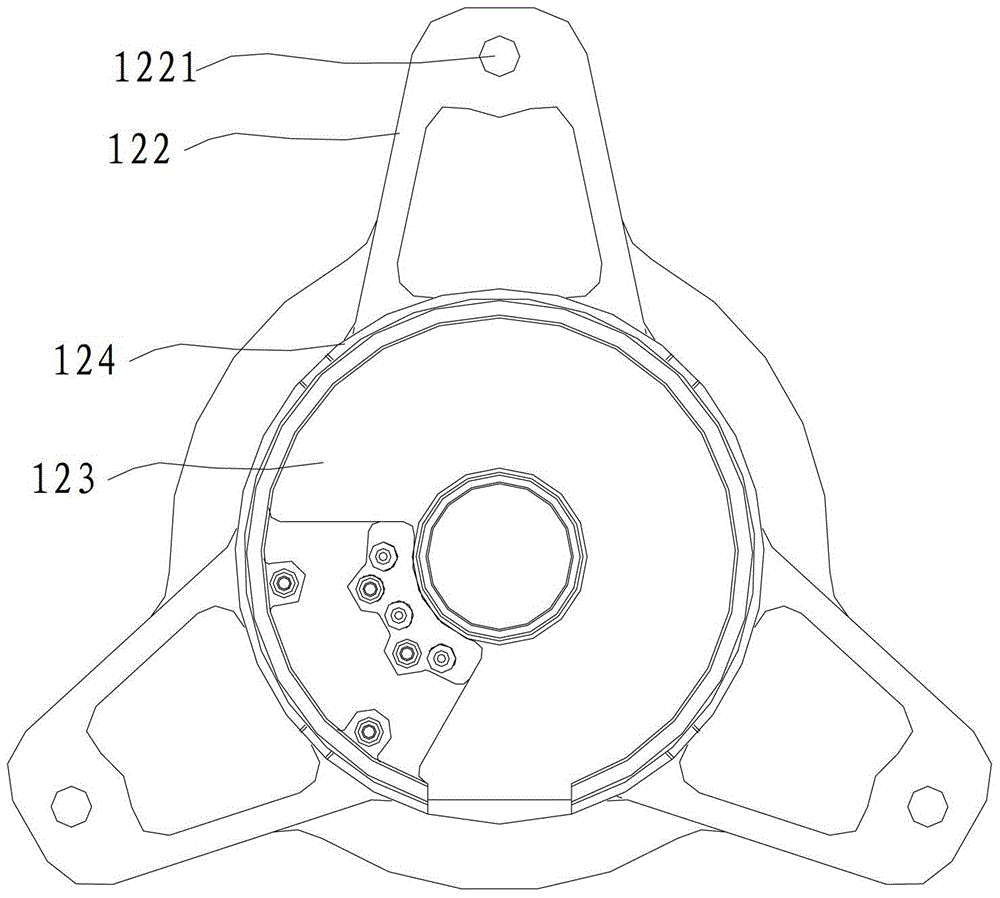

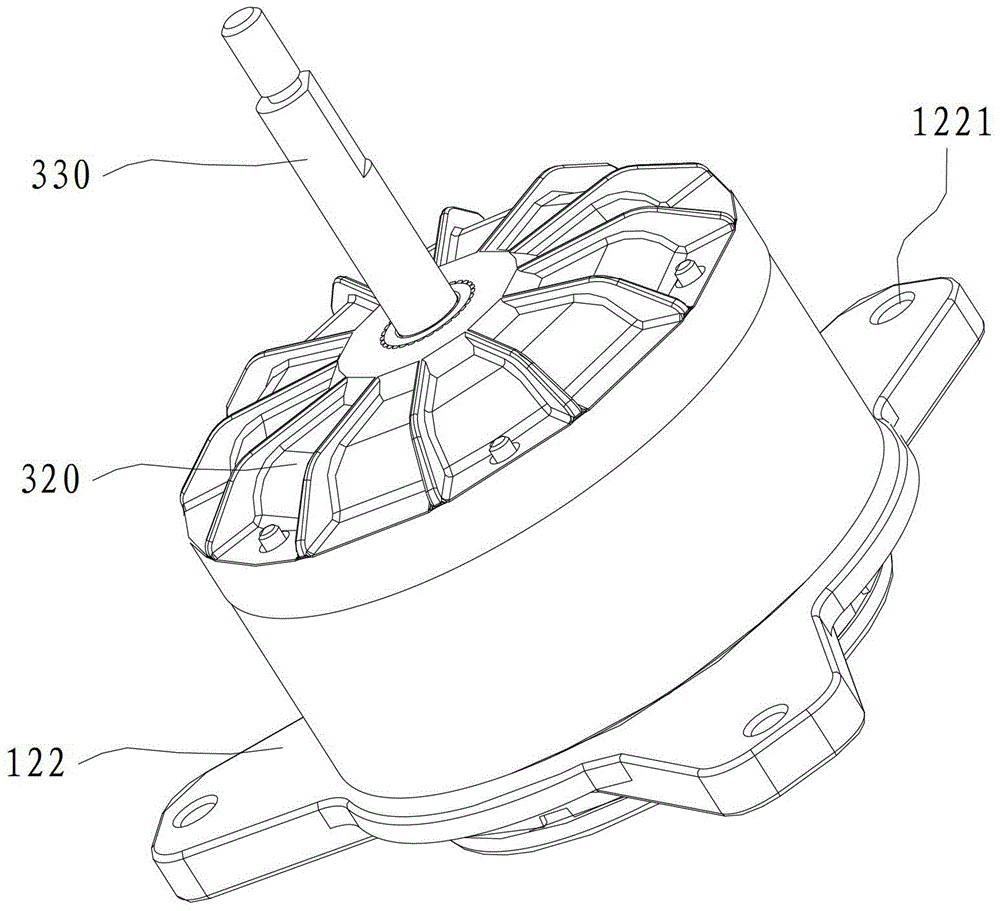

Motor stator and external rotor motor with motor stator

ActiveCN103227519AReduce vibrationReduce noiseMagnetic circuit stationary partsSupports/enclosures/casingsPhysicsStator

The invention is appropriate for the technical field of motors, and discloses a motor stator and an external rotor motor with the motor stator. The motor stator comprises a stator assembly which comprises a stator iron core with a through hole and a winding winded on the stator iron core. The motor stator further comprises a plastic package body wrapping the stator assembly and a bearing sleeve which is positioned in the through hole and used for mounting of a bearing. The plastic package body comprises a body plastic package part which covers the stator iron core and the winding. The plastic package body limits the bearing sleeve by means of arranging a limiting part integrated with the body plastic package part. The external rotor motor comprises the motor stator arranged in the rotor. The motor stator and the external rotor motor with the motor stator provided by the invention are convenient to assemble, less in production vibration and noise and high in reliability.

Owner:FOSHAN WEILING WASHER MOTOR MFG

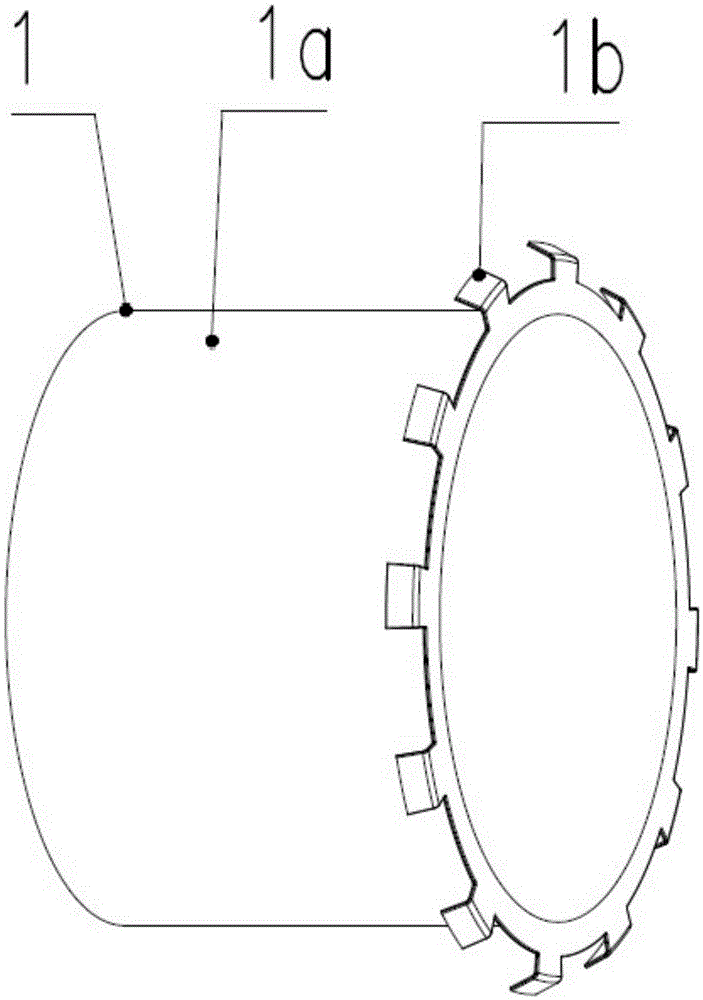

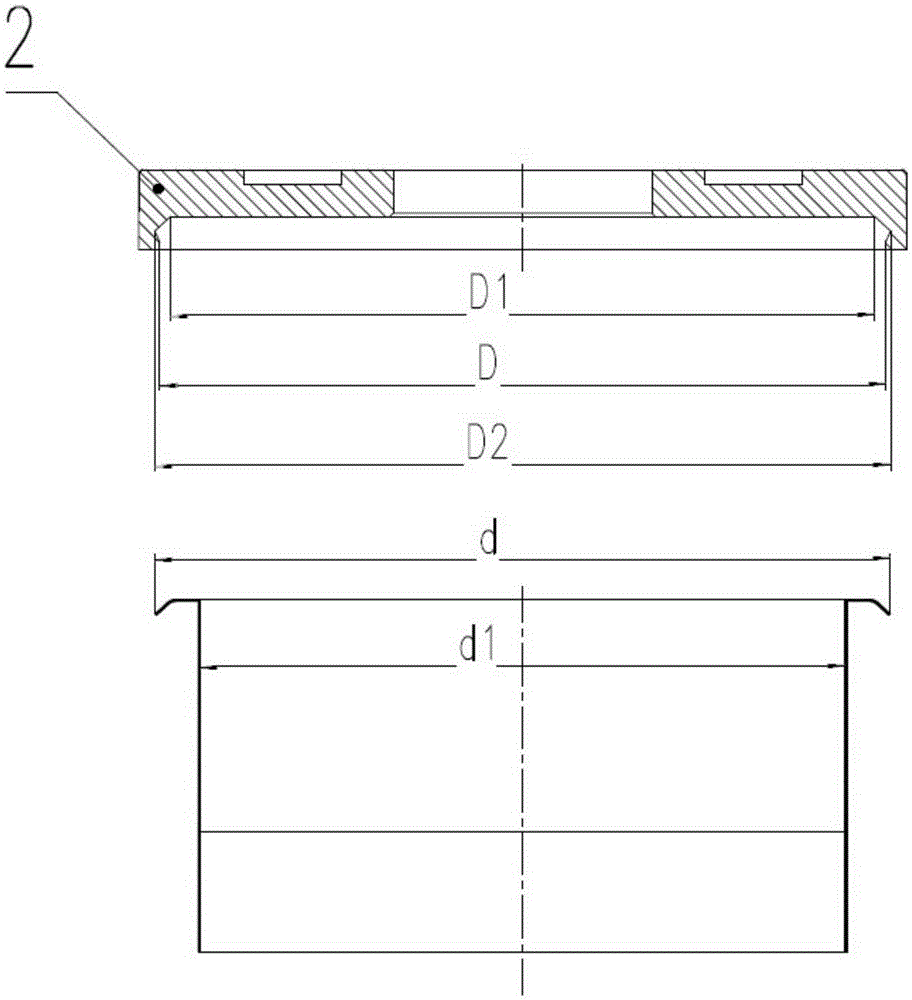

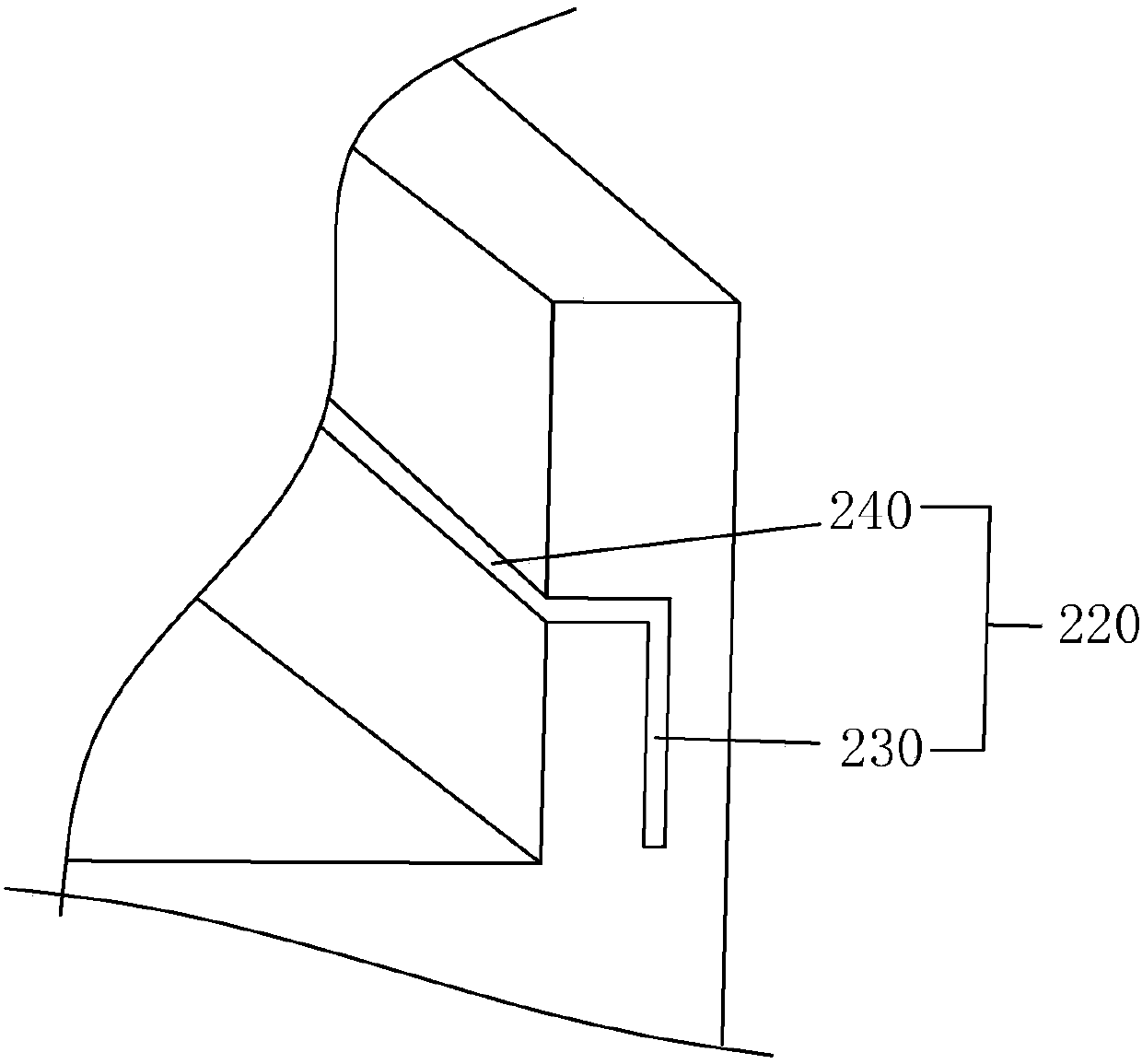

Oil-proofing cover and scroll compressor comprising same

ActiveCN105402134AImprove assembly efficiencyImprove reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsMechanical engineeringScroll compressor

Firstly, the invention provides an oil-proofing cover. The oil-proofing cover comprises a cylinder body part and a buckling part, wherein the buckling part is annularly arranged at one end of the cylinder body part and comprises a ring which extends outwards along one end of the cylinder body part, and tooth type claw structures which are uniformly arranged along the outer circumference of the ring and protrude outwards from the outer circumferential surface of the ring; each tooth type claw structure is of a flexible structure. Secondly, the invention provides a scroll compressor. The scroll compressor comprises an upper bracket bearing cover plate, a main balance weight and any oil-proofing cover mentioned above, wherein the main balance weight is accommodated inside the cylinder body part of the oil-proofing cover; the buckling part of the oil-proofing cover is buckled at the lower end of the upper bracket bearing cover plate. The oil-proof cover structure provided by the invention has the advantages of effectively improving the firmness of connection of the oil-proofing cover and a bracket or the bracket bearing cover plate, also improving the assembly efficiency of the oil-proofing cover and reducing the amount of assembled parts, so the production cost is partly lowered.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

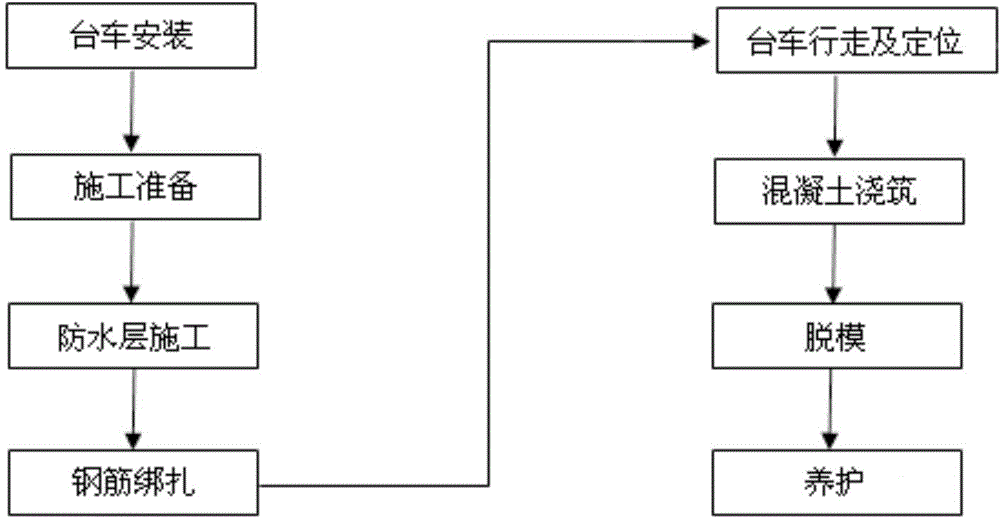

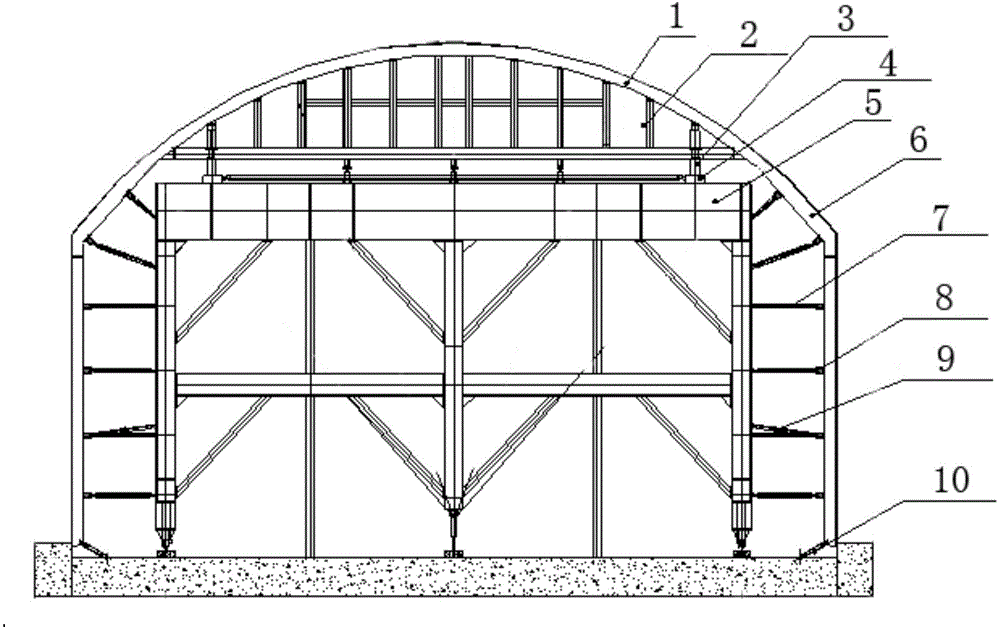

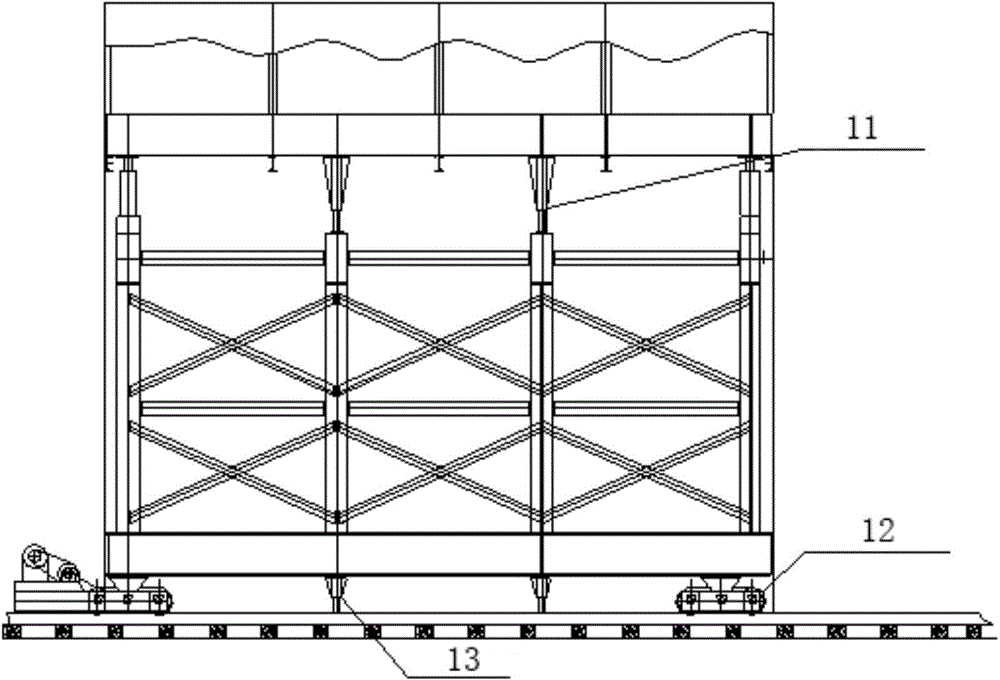

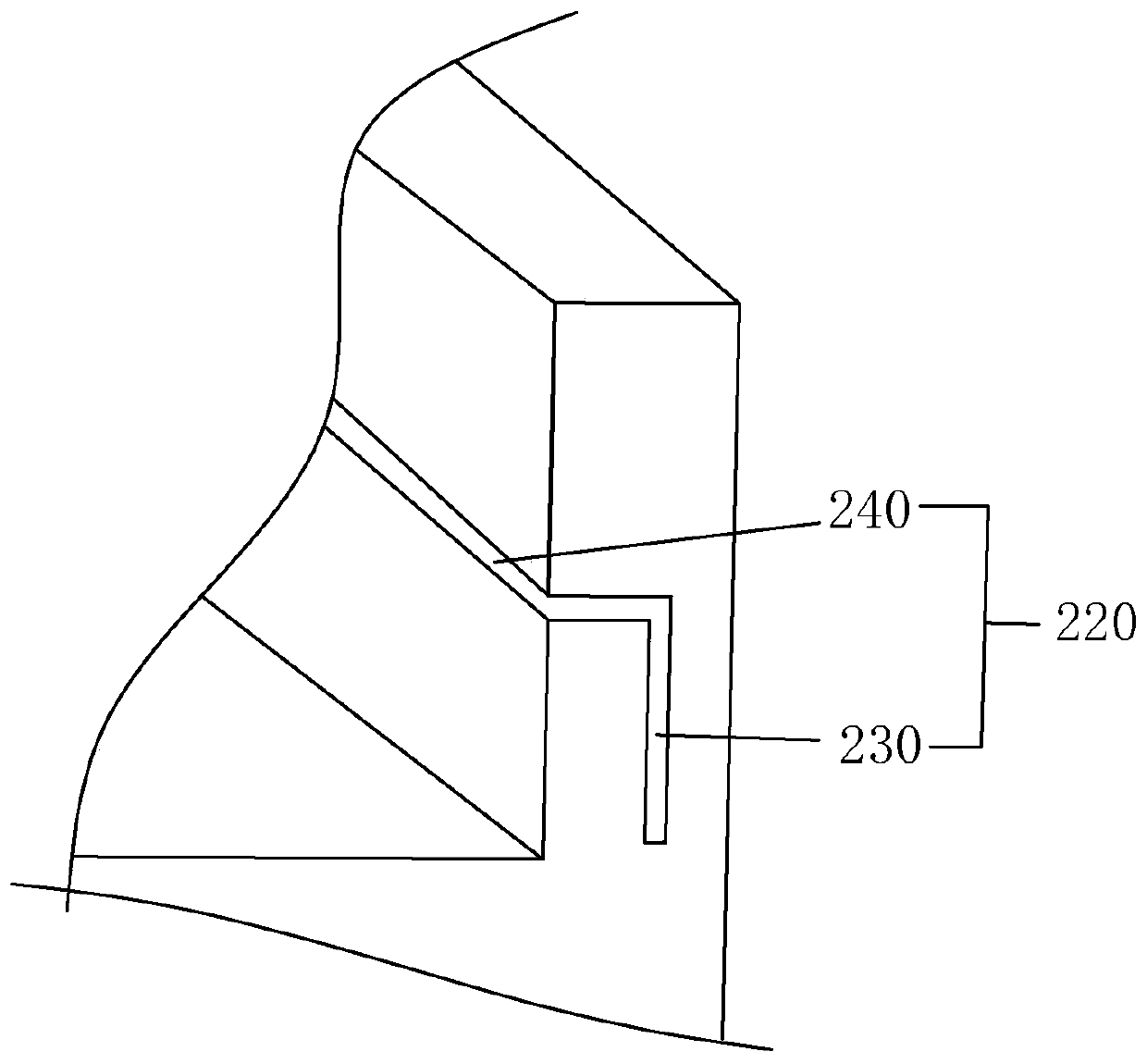

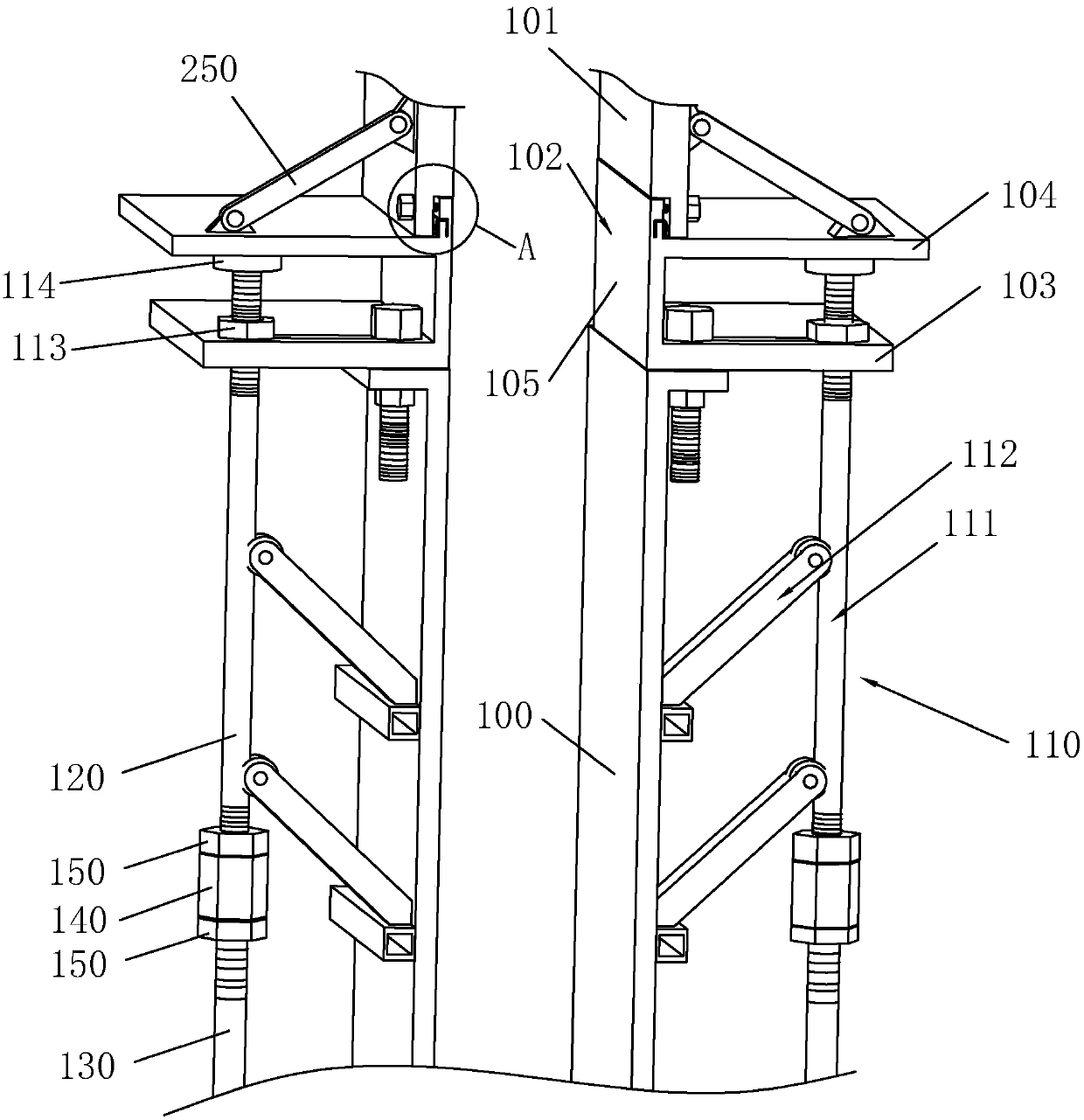

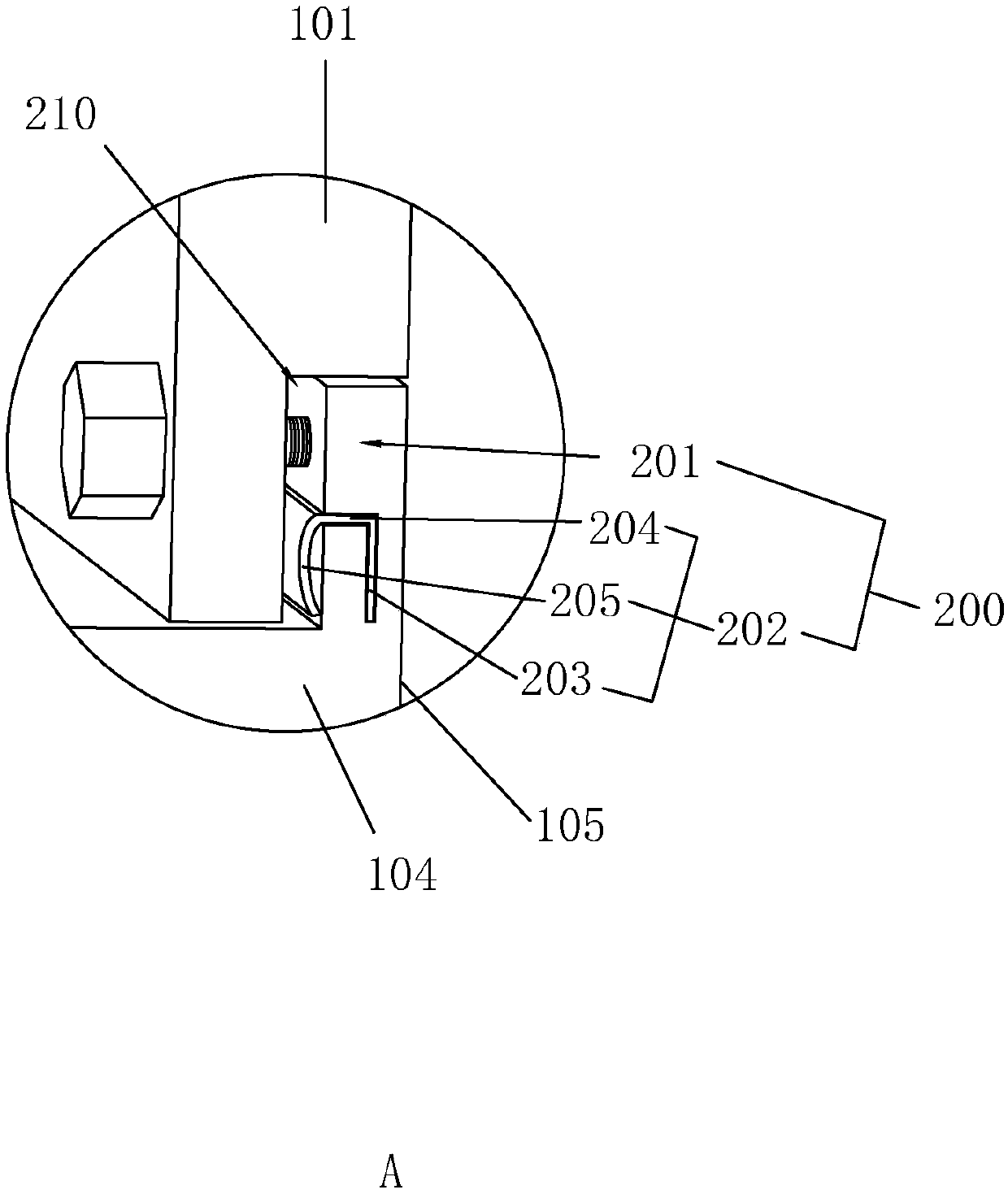

Super-large section chamber reinforced concrete modelling construction method

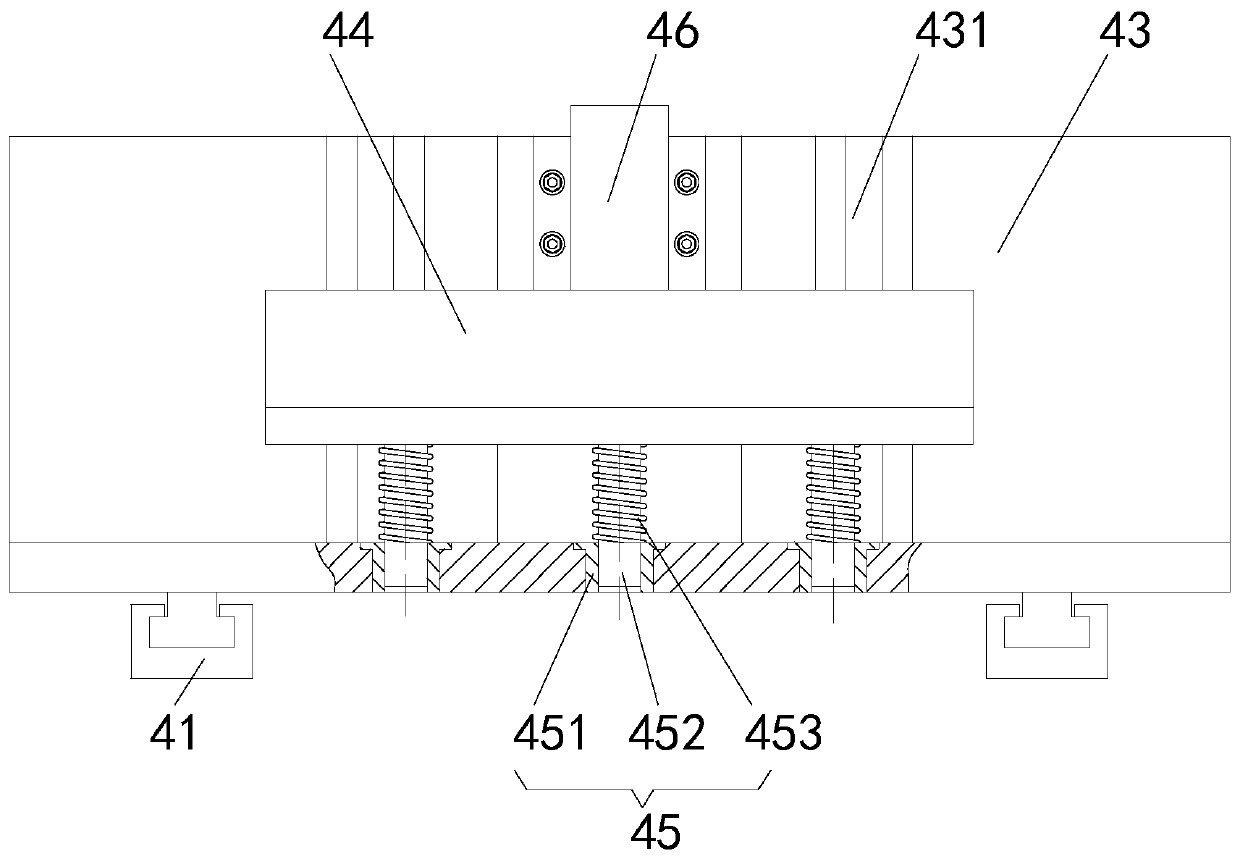

ActiveCN104533456AMove fastFast positioningUnderground chambersTunnel liningReinforced concreteMotor drive

The invention relates to the technical field of construction, in particular to a reinforced concrete modelling construction method which is applicable to a large section chamber. According to the super-large section chamber reinforced concrete modelling construction method, a multi-vertical-rod type lining trolley is adopted to control the integral rigidity of a rack, a motor drives a walking mechanism to drive the trolley to move, formwork in place and tunnel reinforced concrete forming of closing mold are adjusted through a hydraulic oil cylinder and a screw jack, the multi-rod type lining trolley adopts a method of pouring the side wall and the arc portion together or separately pouring the arc wall according to the size, the construction period and the concrete supply conditions of the tunnel section. According to the reinforced concrete modelling construction method, the multi-rod type lining trolley is adopted, the side wall and the arc portion can be poured separately and simultaneously, the construction period and costs are saved, the splicing time and material reshipment are reduced, the trolley movement and positioning speed is rapid, and personnel operation is facilitated; the multi-rod trolley adopts full-hydraulic vertical closing mold, the motor driving is matched with walking of the rail, accurate positioning is easy, braking is convenient, movement safety risks are small, and the structure is reasonable.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

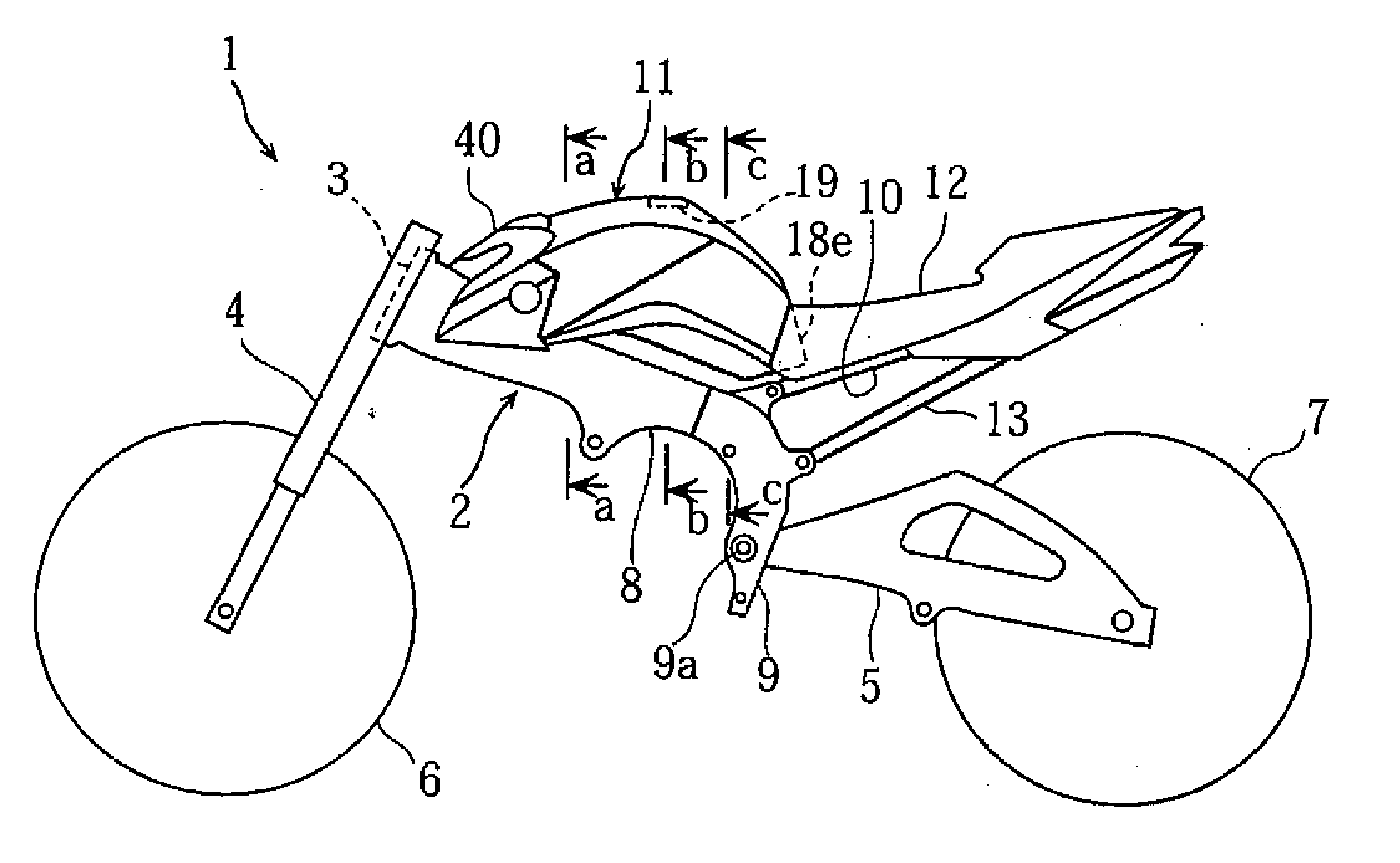

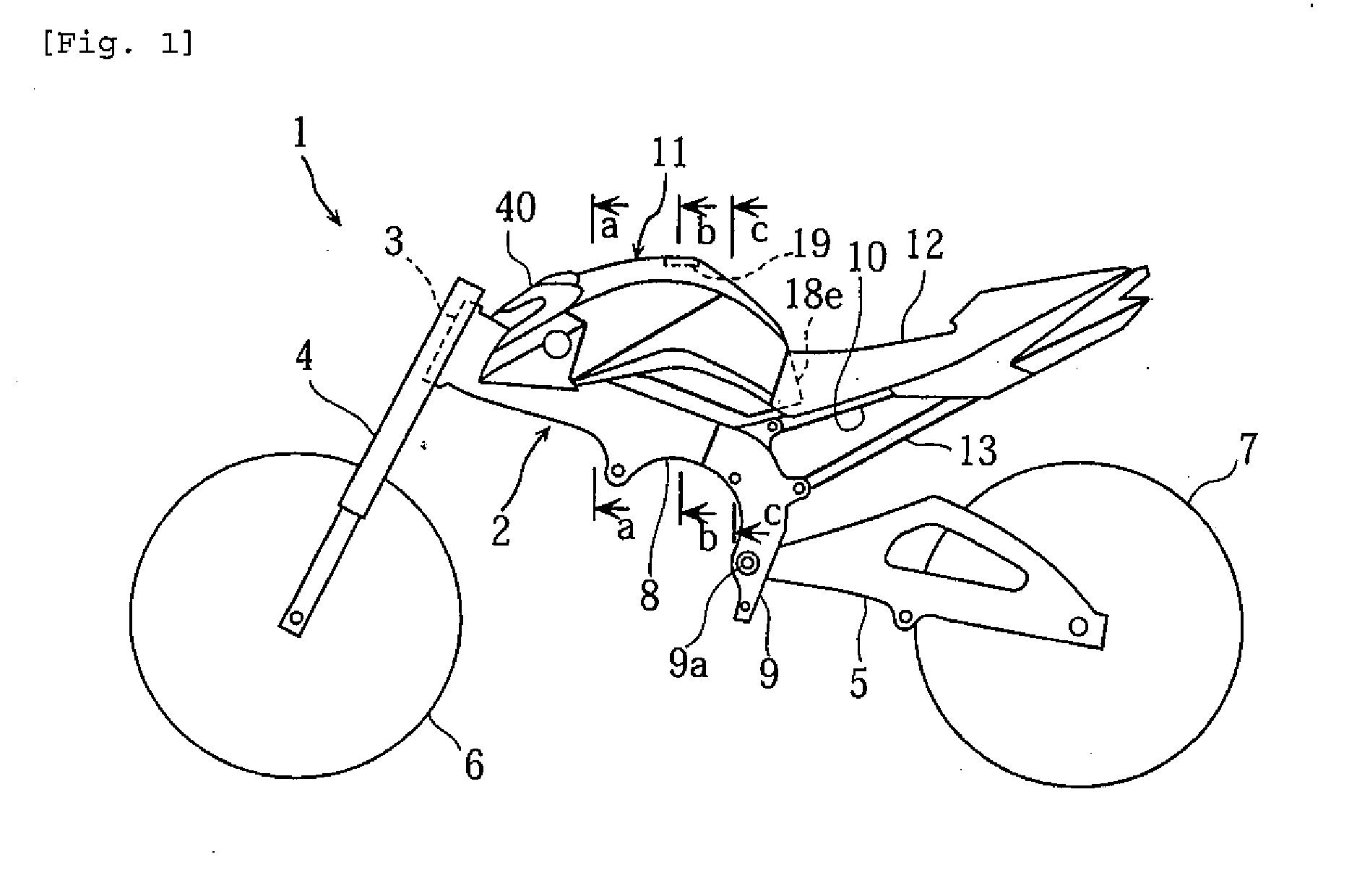

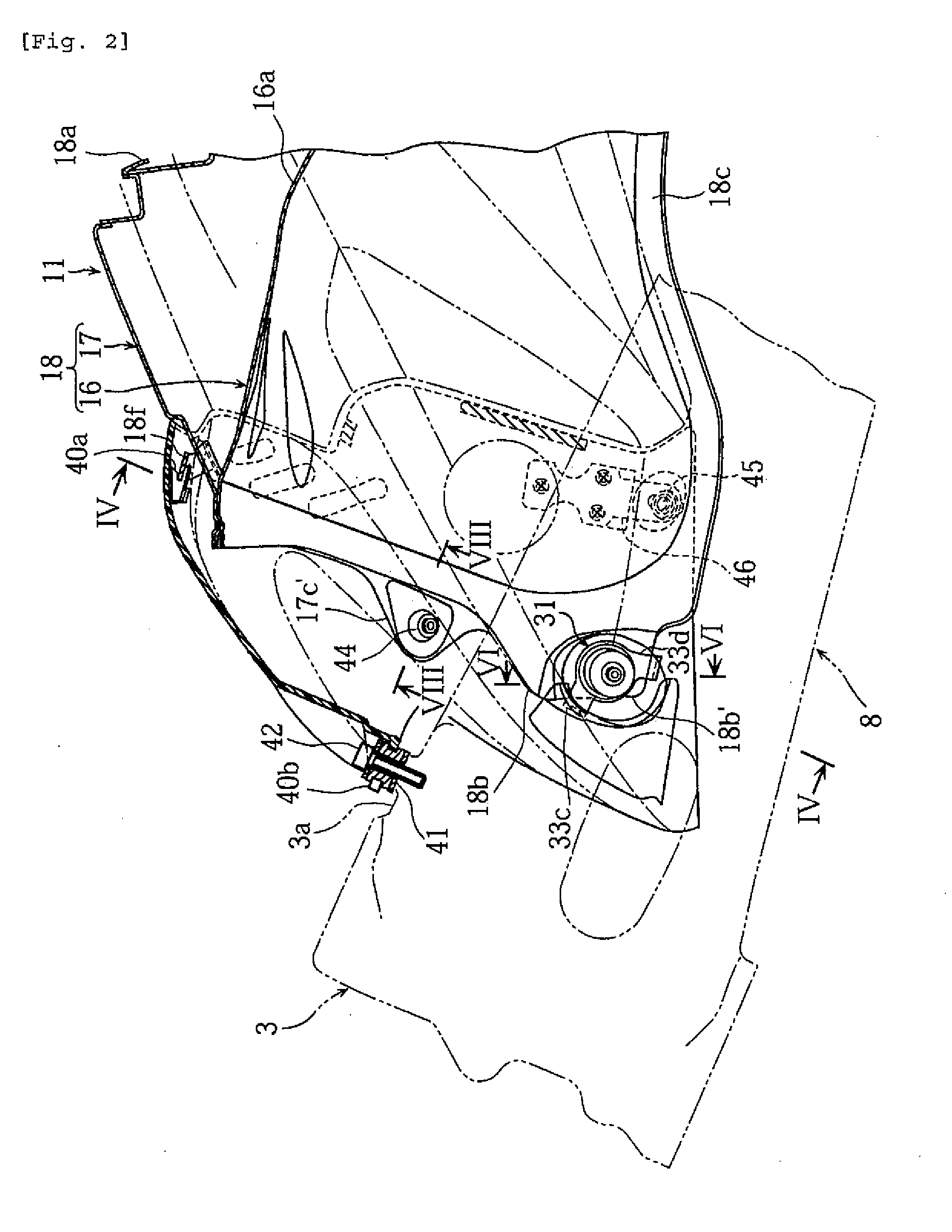

Saddle-Type Vehicle

InactiveUS20070200332A1Reduce load capacityAvoid deformationTank vehiclesFuel tanksFuel tankEngineering

A saddle-type vehicle that securely supports a fuel tank with sufficient strength when load in a vertical direction is applied. A pair of frame members extend in a front-and-rear direction of the vehicle and support a fuel tank. The fuel tank has a pair of flanges contacting the outer sides of the frame members. The flanges are attached to the frame members by attachment members inserted from outside in a vehicle width direction.

Owner:YAMAHA MOTOR CO LTD

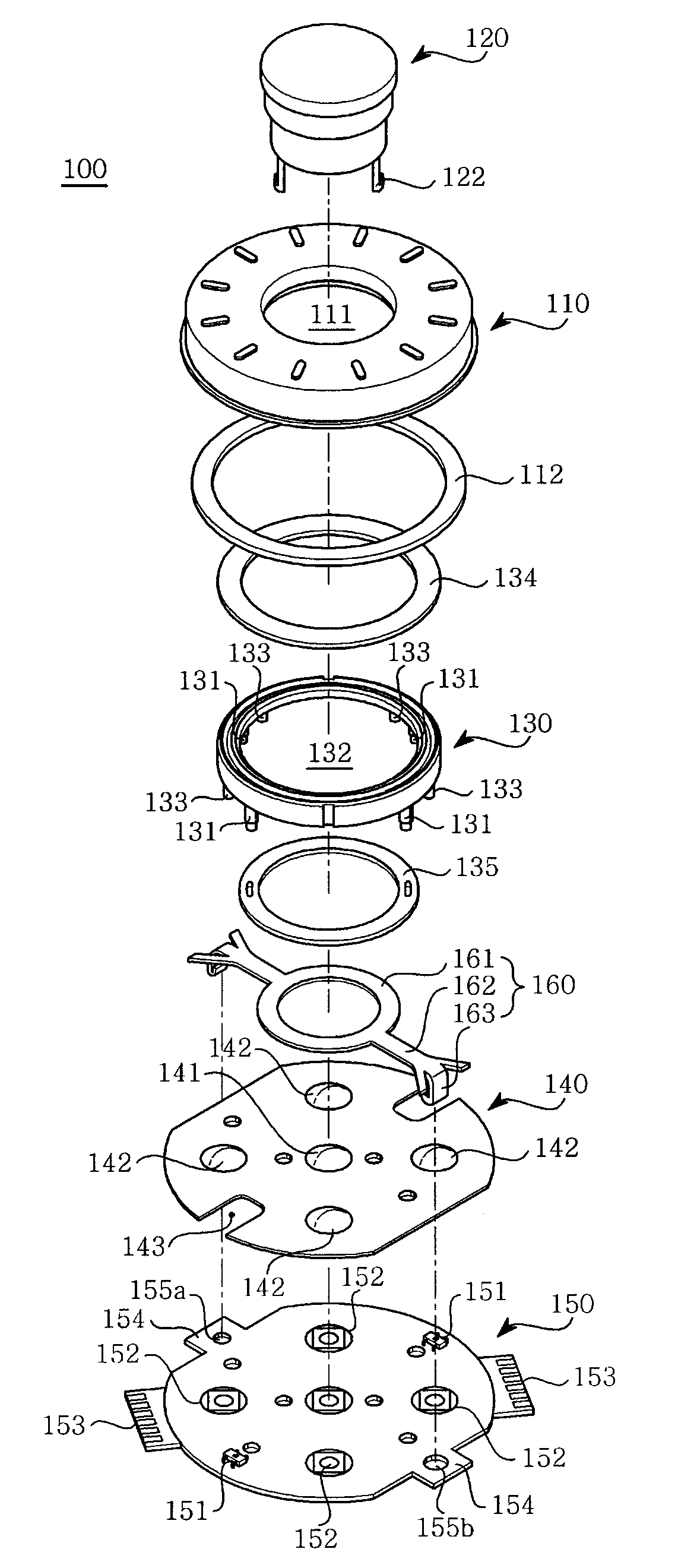

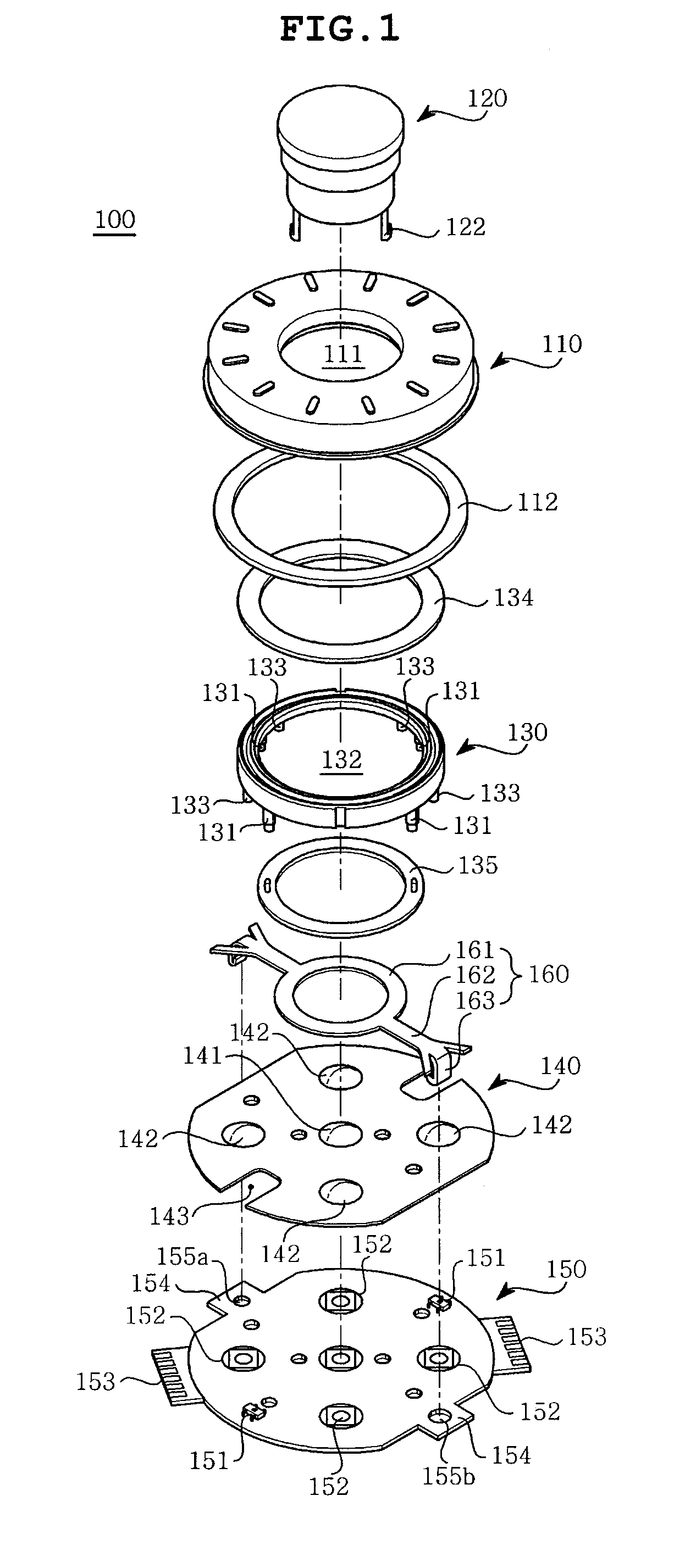

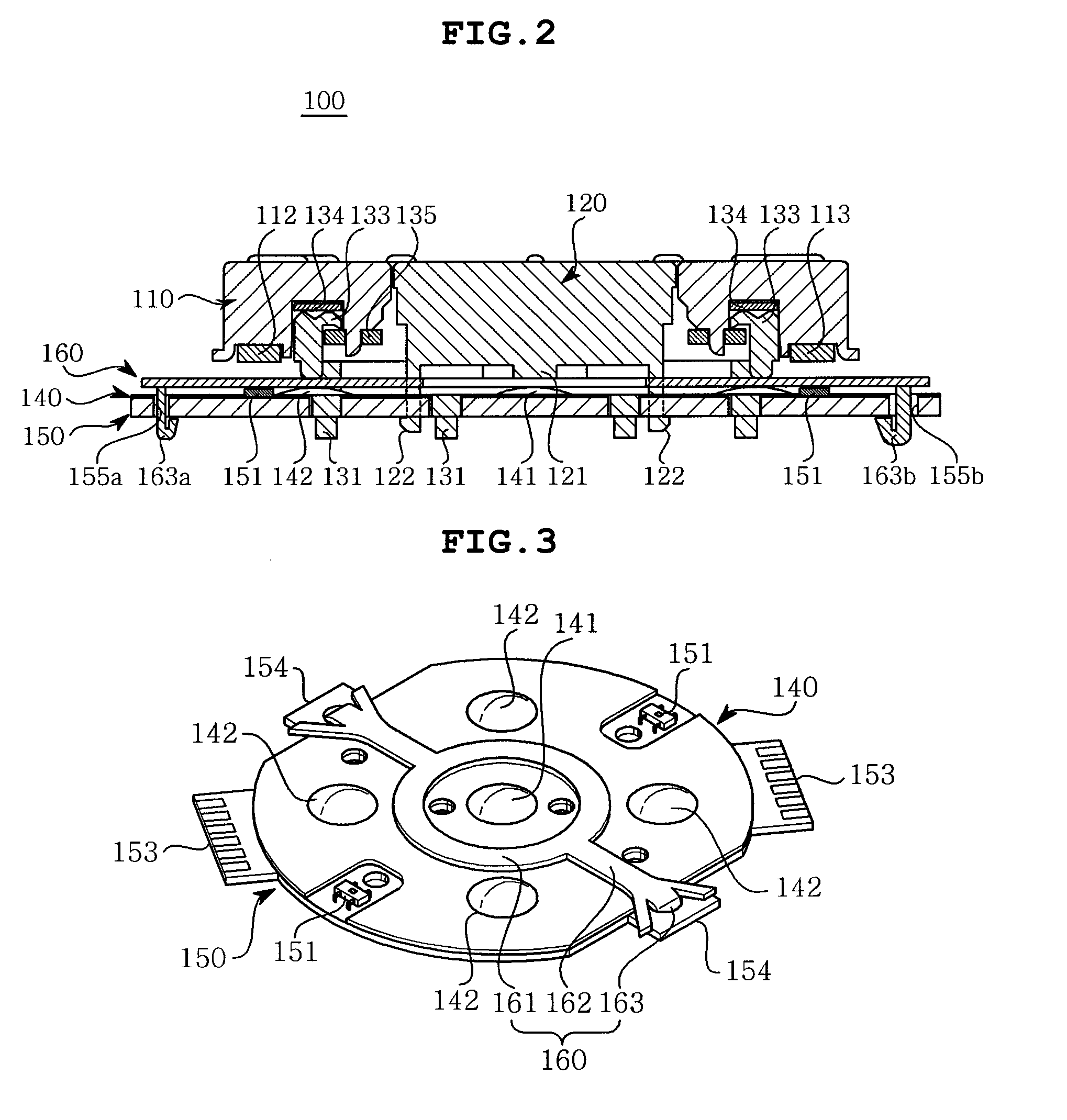

Rotatable inputting apparatus

InactiveUS20090301855A1Easy to set upReduce the number of assembliesContactsInput/output processes for data processingMagnetEngineering

Disclosed herein is a rotatable inputting apparatus. When a circuit board of the rotatable inputting apparatus is coupled to a main circuit board of a terminal or remote control, the rotatable inputting apparatus of the invention allows reference points of the boards to be instinctively recognized without the necessity of forming reference projections or using screws, thus enabling its easy assembly. The rotatable inputting apparatus includes a wheel having a ring magnet, a support having a pressure pin, a center key moving in a vertical direction, a dome seat including a central dome button and peripheral dome buttons, a circuit board to which the dome seat is attached, and a connecting guide which is secured to the circuit board and has a connecting part. The connecting part passes through the circuit board and is inserted into the main circuit board.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

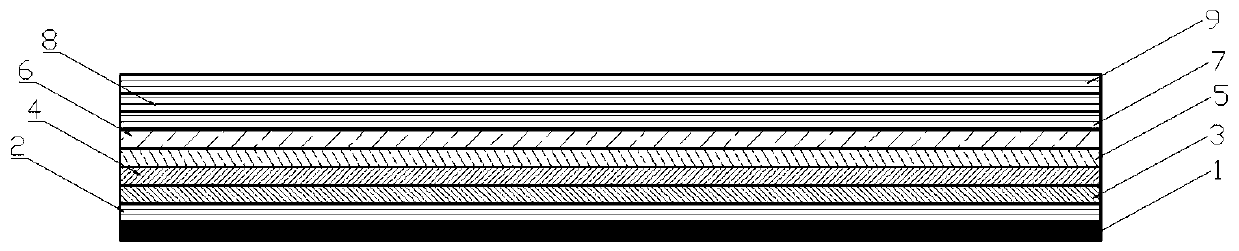

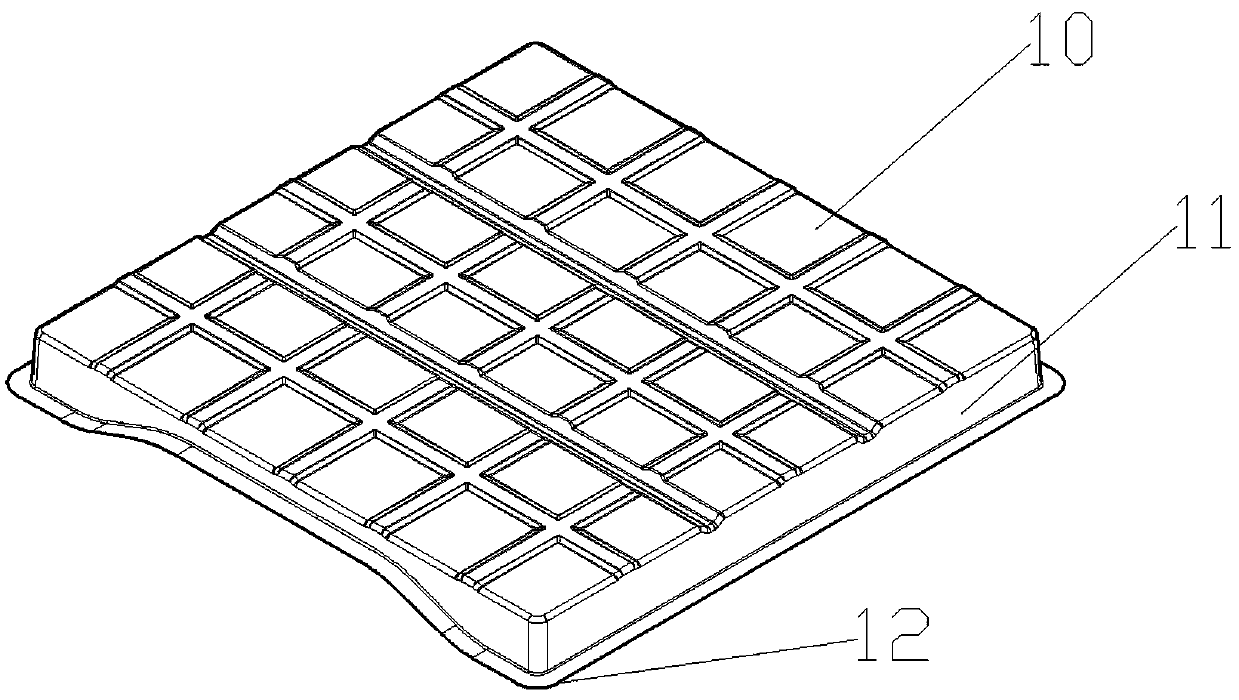

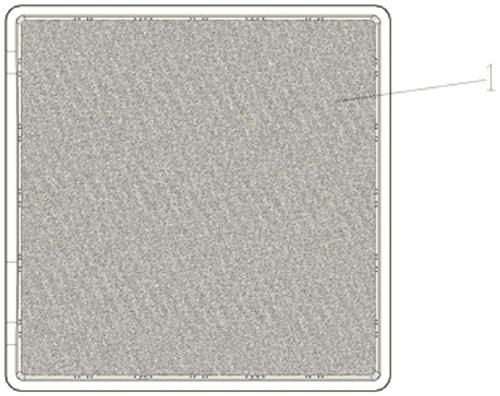

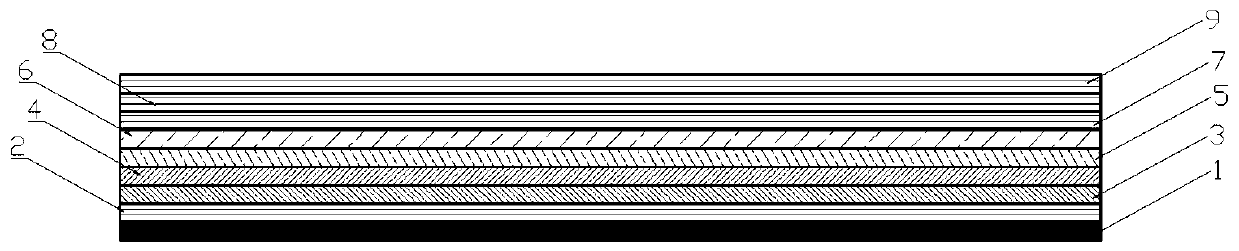

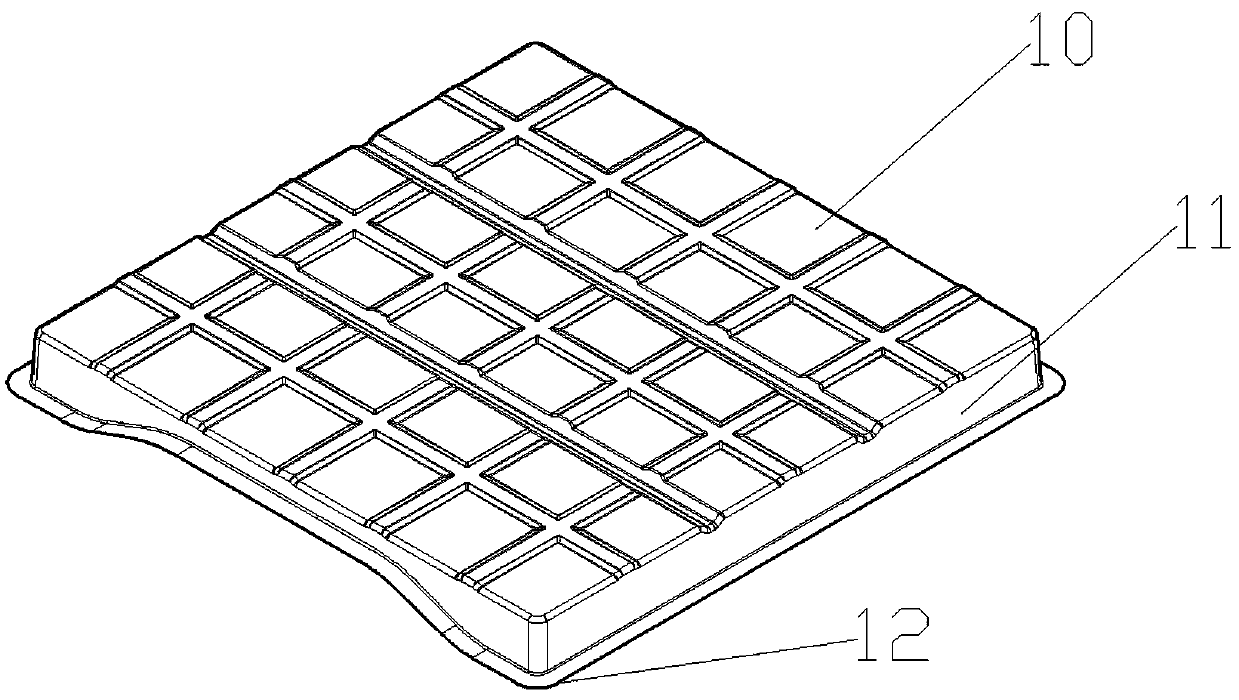

Forming process method of thermal runaway prevention composite material battery box upper cover and product

ActiveCN111284035AImprove the ability to prevent thermal runawayImprove space utilizationCell component detailsDomestic articlesFiberManufacturing cost reduction

The invention discloses a forming process method of a thermal runaway prevention composite material battery box upper cover and a product. The composite material comprises a mica paper layer, a firstcomposite material layer, a second composite material layer, a third composite material layer, a fourth composite material layer, a fifth composite material layer, a sixth composite material layer, aseventh composite material layer and an eighth composite material layer which are sequentially laid from bottom to top. According to the molding process method of the thermal runaway prevention composite material battery box upper cover and the product provided by the invention, different thermal runaway requirements can be met, flexible design, different thermal runaway temperatures, corresponding changes of the mica powder content and layer number of the layers and the layer sequence are realized, the preparation procedures of parts can be reduced, the assembly number of the parts is reduced, the production cost is reduced, by combining the high-strength advantage of the continuous fibers and the heat resistance of the mica material, the thermal runaway prevention capacity of the composite material battery box upper cover is improved, the manufacturing cost is reduced, the space of the battery pack is not occupied, open fire is prevented from overflowing, and the safety of the electric automobile is improved.

Owner:溧阳康本复合材料有限公司

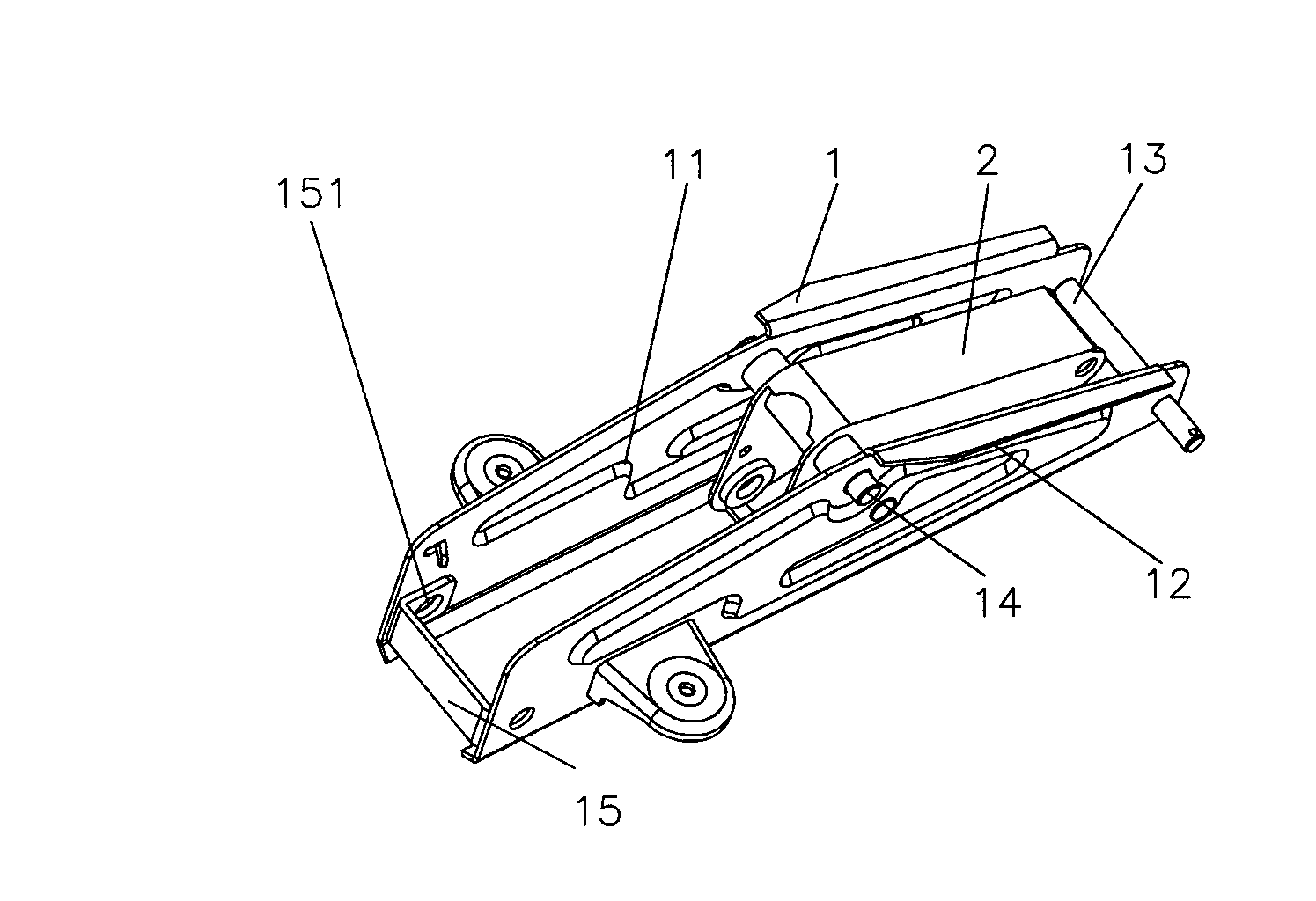

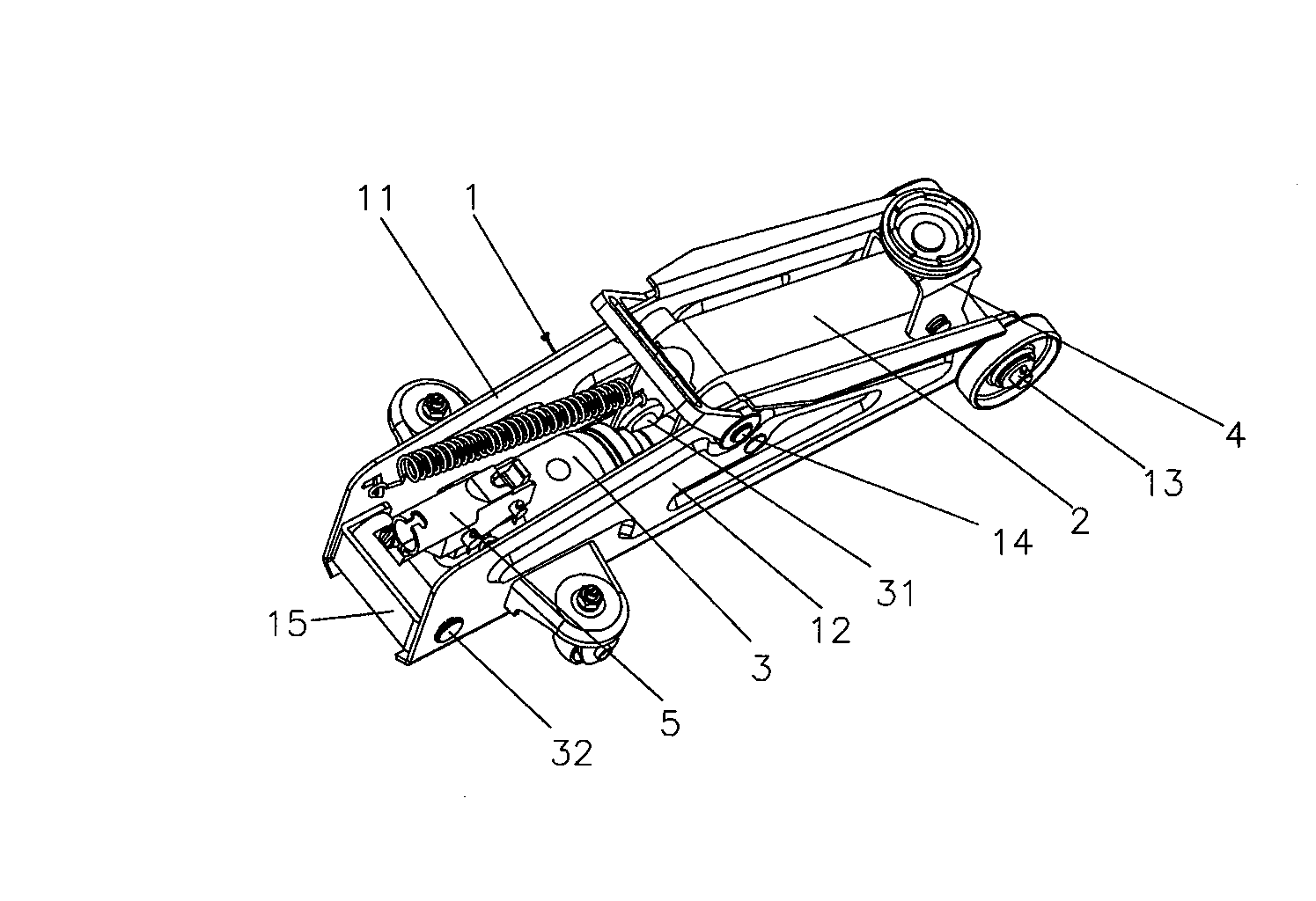

Integrated rack type hydraulic horizontal jack with improved structure

The invention discloses an integrated rack type hydraulic horizontal jack with an improved structure, and belongs to the technical field of lifting devices. The integrated rack type hydraulic horizontal jack with the improved structure comprises a rack component, a cargo boom component, a hydraulic component, a bracket component and a pressing handle, wherein the rack component comprises a left wall plate and a right wall plate, the left wall plate and the right wall plate are arranged in a mutually-parallel mode, the bracket component is installed at the front end in the length direction of the cargo boom component, and the pressing handle is installed on the hydraulic component. The integrated rack type hydraulic horizontal jack with the improved structure is characterized in that the front portion, the middle portion and the rear end portion of the left wall plate in the length direction and the front portion, the middle portion and the rear end portion of the right wall plate in the length direction are fixedly connected through a front wheel shaft, a supporting shaft and a rear fixing plate respectively, the cargo boom component is sleeved on the supporting shaft and can rotate around the supporting shaft, the front end of the hydraulic component is installed on the cargo boom component through a piston pin roll, and the rear end of the hydraulic component is installed on the rear end portion of the left wall plate and the rear end portion of the right wall plate in the length direction through a rear shaft, and is matched with the rear fixing plate. The integrated rack type hydraulic horizontal jack with the improved structure has the advantages of being reasonable in structure and reliable in movement, improves the integral strength, reduces the number of assembled parts, improves production efficiency and reduces production cost.

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

Electromagnetic control valve

InactiveCN104197078ASimple structureReduce the number of assembliesOperating means/releasing devices for valvesFiltration separationControl valvesWear resistance

The invention discloses an electromagnetic control valve. The electromagnet control valve comprises a valve body and an electromagnetic coil portion connected with the valve body. The electromagnetic coil portion comprises a plunger. The valve body is composed of a valve sleeve, a spring, a valve element and an ejector rod. An oil inlet is formed in the end of the valve sleeve, the spring, the valve element and the ejector rod are sequentially arranged in the valve sleeve through the oil inlet, the valve element and the ejector rod are integrally formed, an oil outlet and an oil return opening are formed in the lateral wall of the valve sleeve, and a protrusion which is matched with the oil outlet and extends outwards in the radial direction is arranged on the outer side of the valve element. The electromagnetic control valve is simple in structure; due to the fact that the valve element and the ejector rod are integrally formed, the element assembly number is reduced, the assembly technology is made to be simple and the assembly precision is improved; in addition, abrasive resistance of the electromagnetic control valve is good.

Owner:ANHUI HUANMING FINE CONTROL

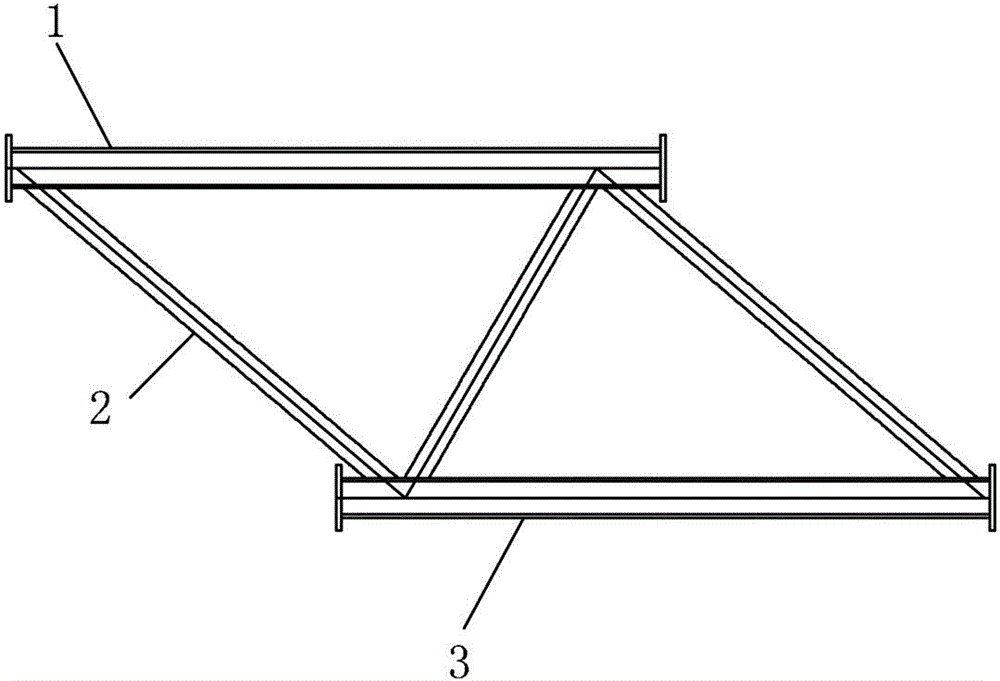

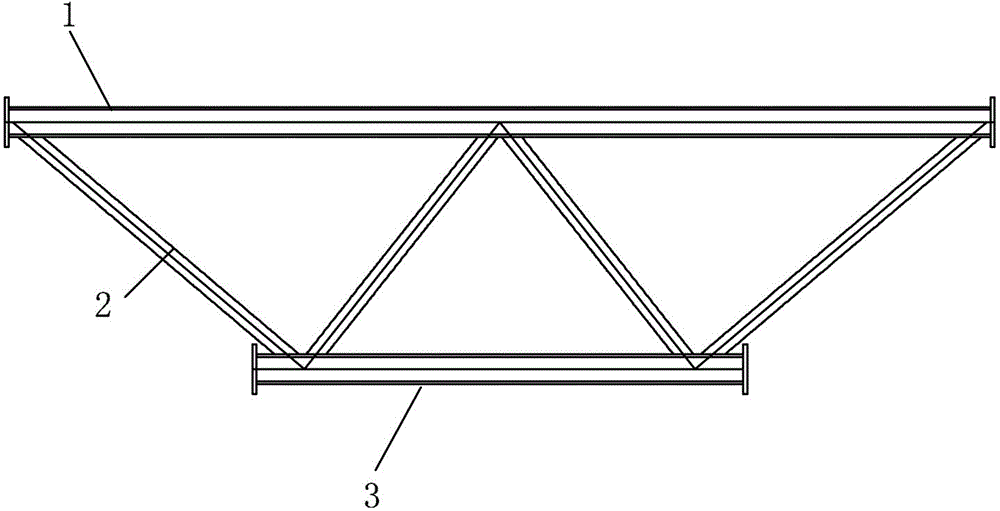

Assembly type truss formwork support

ActiveCN104453222AGuaranteed stiffnessReduce the effect of eccentricityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksVertical deflectionEngineering

The invention provides an assembly type truss formwork support, belongs to the technical field of construction, and particularly relates to a truss and a support which are used for construction. The truss is obtained by assembling one-meter single-rod units, I type truss units (one meter), II type truss units (two meters) and end rods through shaping truss units with end plates by means of bolt connection joints instead of assembling existing single rods. Upper chords, lower chords and inclined supports of all the truss units are connected through welding, the end plates with bolt holes are adopted for the ends of the truss units, the truss units are connected through bolts, different spans of trusses can be formed after assembly, the end rods are additionally arranged at the ends of the assembly truss, vertical supports are additionally arranged on the end rods, and the assembly type truss formwork support is formed. The assembly type truss formwork support is obtained by connecting and assembling the end plate shaping truss units with the bolt holes through the bolts, the number of splicing times is reduced, and therefore the rigidity of the trusses is ensured, web member eccentric influences and assembly gaps are reduced, the vertical deflection is reduced, and the bearing capacity is improved. All the truss units are assembled through the connection plate joints with the bolt holes, and different spans of trusses can be obtained after assembly.

Owner:山东高速德建集团有限公司

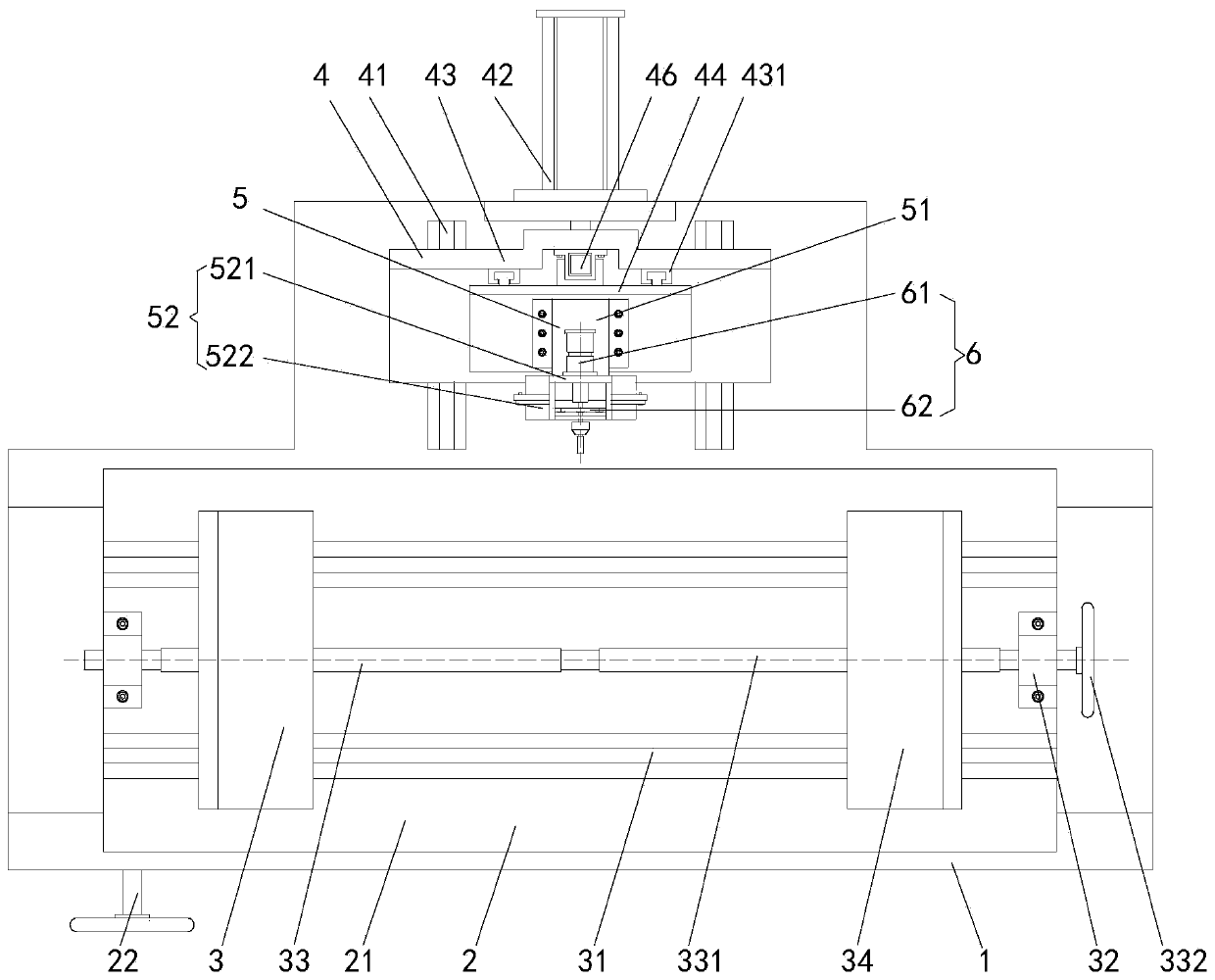

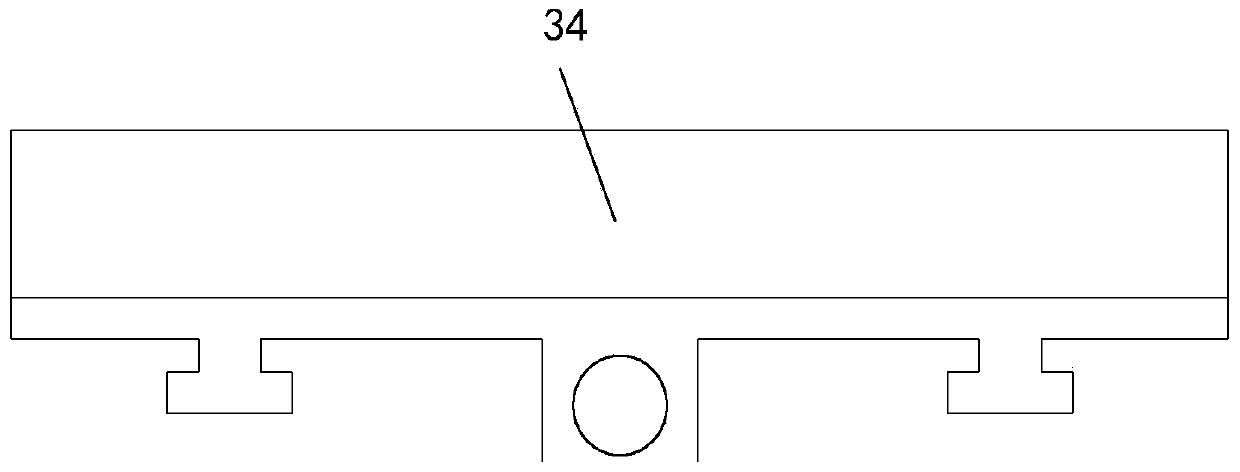

Multifunctional plate slotting machine for customized production of furniture

ActiveCN110466017AReduce the number of assembliesEasy to switchPolishing machinesGrinding drivesMechanical engineeringSlot machine

The invention relates to a multifunctional plate slotting machine for customized production of furniture. The multifunctional plate slotting machine comprises a working table, a horizontal moving platform arranged on the working table, a plate clamping mechanism arranged on the horizontal moving platform, a moving platform mechanism arranged on the top of the working table, a slotting mechanism installed on the horizontal moving platform, and a regulating mechanism installed on the slotting mechanism. According to the plate slotting machine provided by the invention, a plate is slotted under the condition that the plate is clamped effectively, and the slotting accuracy is high; not only can the slotting be finished, but also the surface of a formed slot can be further cleaned, simply polished and deburred; and the assembly quality of the customized furniture is ensured.

Owner:LAOMUJIANG WOOD IND XIANGCHENG DIST ZHANGZHOU CITY

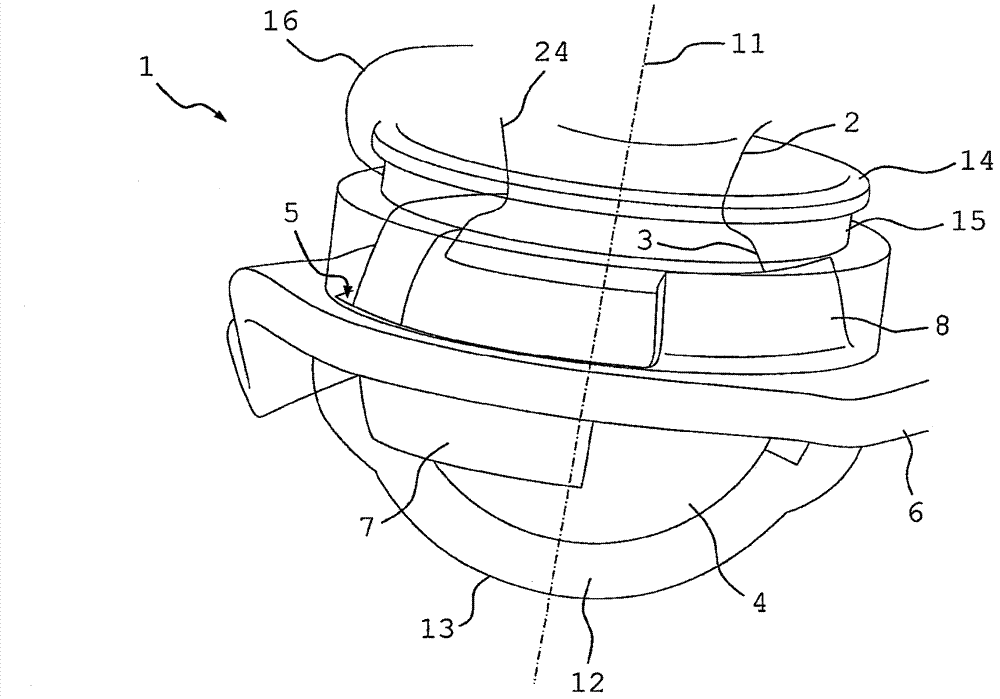

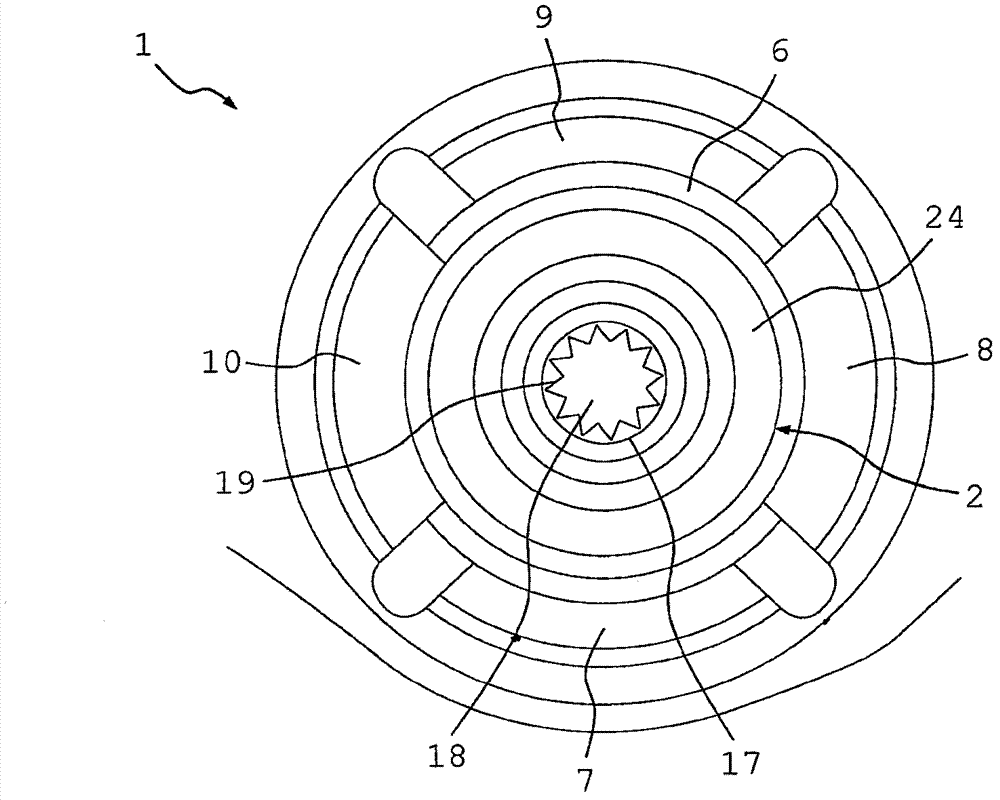

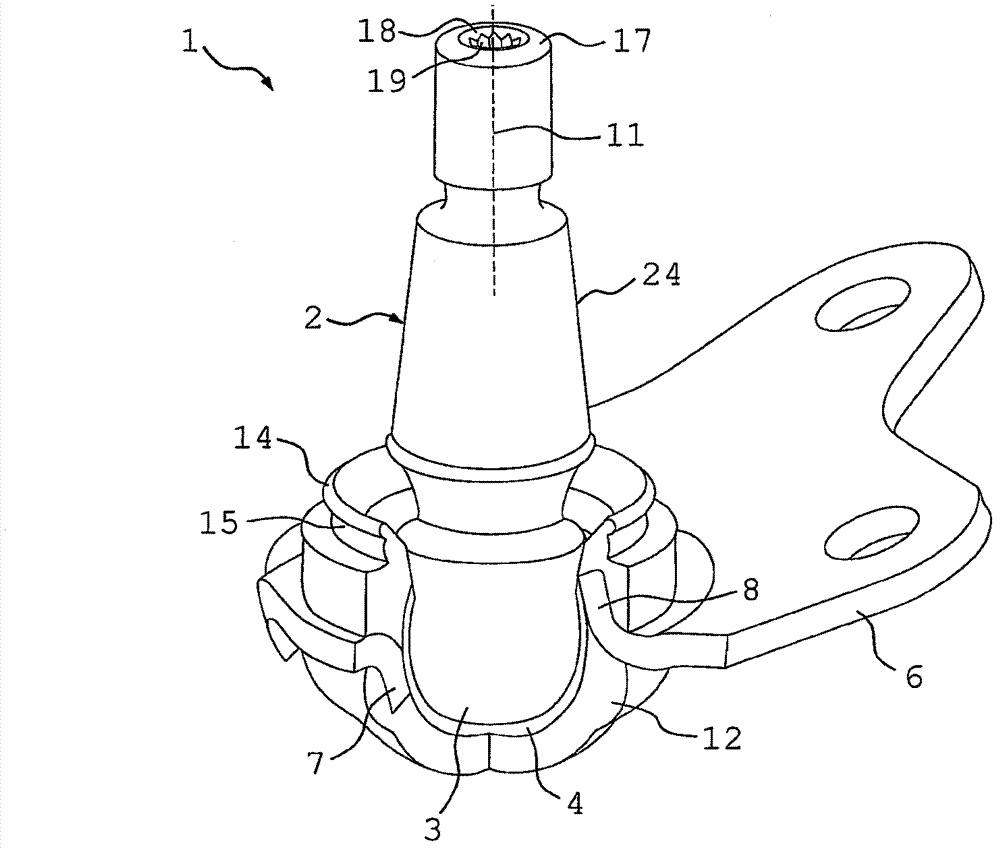

Ball joint

ActiveCN102959255AIncrease pulling forceImprove performanceSuspensionsPivotal connectionsSpherical bearingEngineering

Owner:ZF FRIEDRICHSHAFEN AG

An aluminum-wood mixed formwork used in building construction

ActiveCN107905521BIncrease flexibilityShorten the timeAuxillary members of forms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringMechanical engineering

The invention discloses aluminum-wood mixed formworks applied to building construction. The aluminum-wood mixed formworks solve the problem that in the prior art, accumulation deformation is large after assembling of multiple aluminum formworks is finished, and the wall deviation is large after construction. According to the key points of the technical scheme, the aluminum-wood mixed formworks comprise standard aluminum formworks, non-standard wood formworks and connecting assemblies; the connecting assemblies comprise lower connecting plates used for connecting the tops of the standard aluminum formworks, upper connecting plates used for connecting the bottoms of the non-standard wood formworks and side plates used for connecting the upper connecting plates and the lower connecting plates, and the upper connecting plates and the lower connecting plates are parallel to each other and are perpendicular to the side plates; the connecting assemblies further comprise supporting rods, the supporting rods comprise main rod bodies and auxiliary rod bodies hinged to the main rod bodies, the upper ends of the main rod bodies are supported on the upper connecting plates, the lower ends of the main rod bodies are supported on a bottom foundation, and the auxiliary rod bodies are obliquely supported on the side surfaces of the aluminum formworks; and the aluminum-wood mixed formworks applied to building construction has the advantages of reducing the accumulation deformation after assembling, reducing the large wall deviation after construction, and meeting the requirement of the walldeviation range.

Owner:SHENZHEN DONGSHEN ENG CO LTD

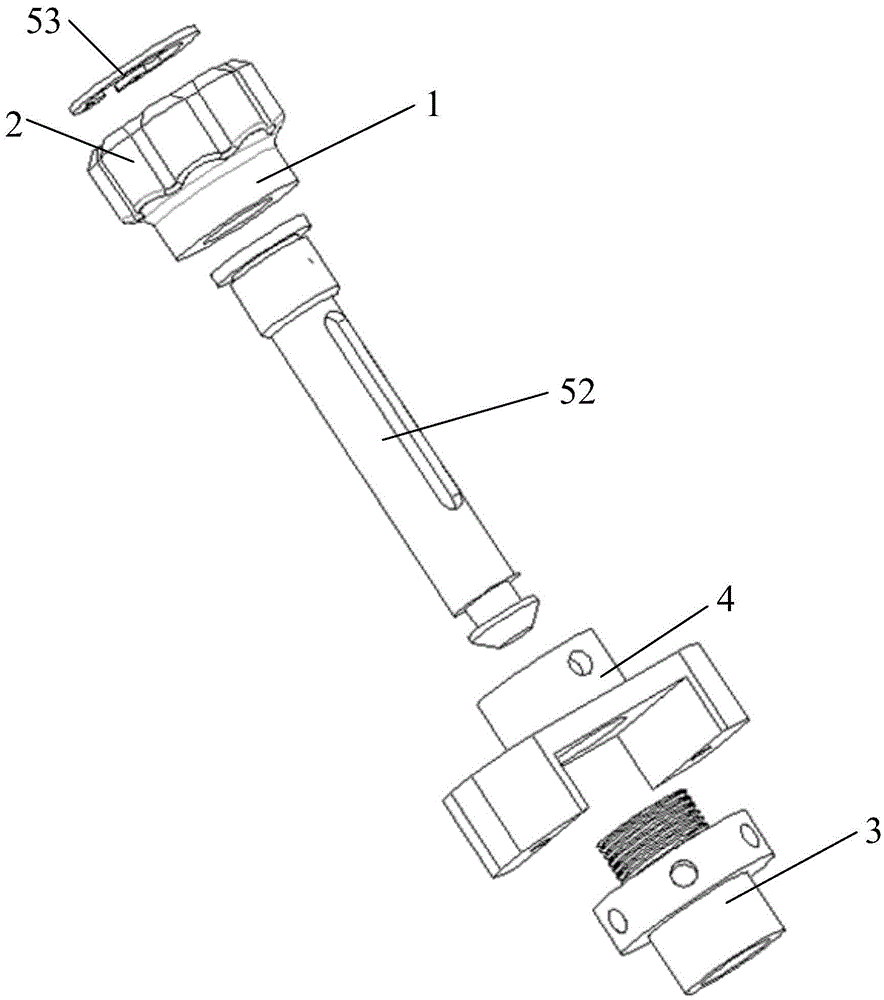

Spliced assembly and locking attaching module thereof

InactiveCN105605042AAdjust the locking gapReduce the accuracy requirements of external dimensionsFriction grip releasable fasteningsIdentification meansEngineeringDark line

The invention relates to the technical field of electronics, and discloses a locking attaching module and a spliced assembly with the same. The locking attaching module comprises a first to-be-locked piece with a first lock hole, a second to-be-locked piece, an adjustment rod, an adjustment base and a locking assembly. The adjustment base is arranged on the first to-be-locked piece, the adjustment rod is adjustably positioned to the adjustment base and penetrates through the first lock hole, and the locking assembly sequentially penetrates through the adjustment rod and the second to-be-locked piece so as to attach the second to-be-locked piece to the first to-be-locked piece in a locked mode. When moving in the direction of the second to-be-locked piece, the adjustment rod can extend out of the first lock hole and abut against the second to-be-locked piece so as to adjust a locking attaching gap between the first to-be-locked piece and the second to-be-locked piece. By means of the structure, the locking attaching gap can be subjected to fine adjustment, the requirement for the accuracy of the outline size of the to-be-connected pieces is reduced accordingly, and then the machining difficulty and the machining cost of the to-be-locked pieces are reduced; bright lines and dark lines caused by the error of the outline size of the to-be-locked pieces and generated after multiple to-be-locked pieces are combined are avoided.

Owner:DONGGUAN DONGSHAN PRECISION MFG CO LTD

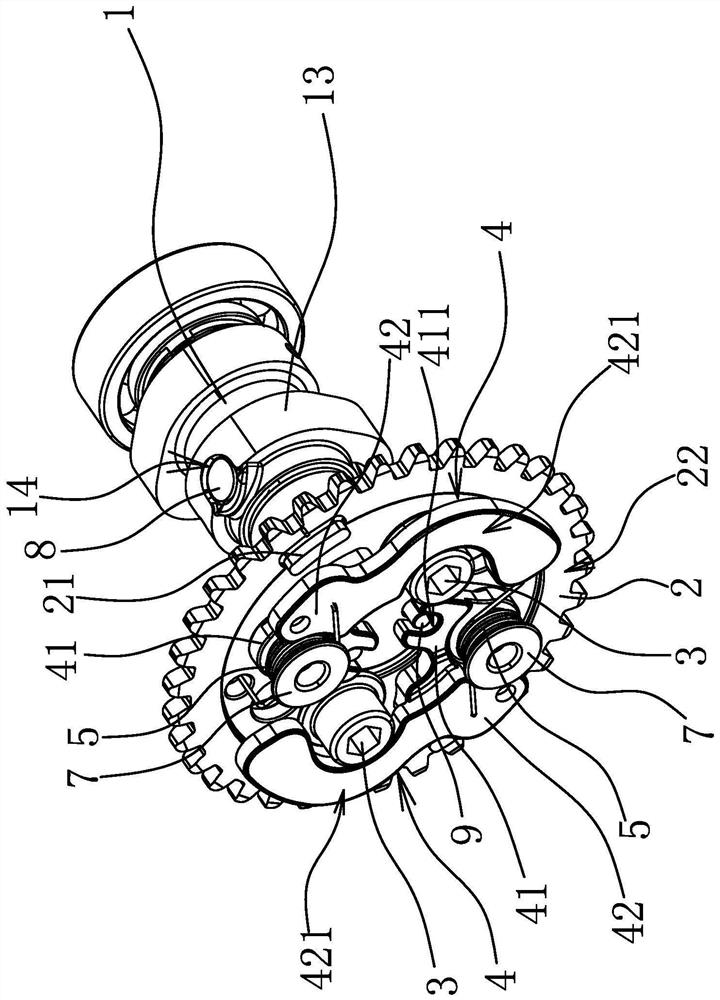

Motorcycle engine starting pressure reduction structure

The invention provides a motorcycle engine starting pressure reduction structure, and belongs to the technical field of motorcycles. The problem that an existing engine starting pressure reduction structure is insufficient in light weight is solved. The motorcycle engine starting pressure reduction structure comprises a cam shaft, a chain wheel and a pressure reduction valve assembly, wherein thechain wheel is provided with a fastener and fixedly connected to the cam shaft through the fastener; the pressure reduction valve assembly comprises a throwing block arranged on the side face of the chain wheel; one end of the throwing block is hinged to the chain wheel, and the throwing block can be thrown out in the radial direction of the chain wheel under the action of centrifugal force; the throwing block is connected with a reset elastic piece; the throwing block abuts against the fastener after being reset under the action of the reset elastic piece; a limiting protrusion is arranged onthe edge of the chain wheel; and after the throwing block is thrown out, the hinged end of the throwing block abuts against the limiting protrusion, and then the throwing stroke of the throwing blockis limited. According to the motorcycle engine starting pressure reduction structure, the light weight design of the chain wheel assembly is achieved, and meanwhile the beneficial effect of the compact structure is achieved.

Owner:ZHEJIANG QIANJIANG MOTORCYCLE

Crankshaft assembly and engine

ActiveCN112727905AReduce quality problemsImprove performanceCrankshaftsMachines/enginesWhole bodyCrankshaft

The invention discloses a crankshaft assembly. The crankshaft assembly comprises a crankshaft and a filler, wherein the filler is in interference connection with the crankshaft, so that the filler and the crankshaft are connected into a whole body. The filler is fixed to the crankshaft in an interference connection mode, so that the crankshaft assembly is simple and compact in structure, the number of assembled parts is reduced, the assembling efficiency is improved, the weight of the crankshaft assembly is reduced, the rotating inertia force of the crankshaft is reduced, and the production cost is saved; and the crankshaft assembly is installed on an engine, so that the overall mass of the engine is reduced, the lightweight design is realized, the scavenging efficiency of an engine cylinder body is improved, the performance of the engine is improved, the production cost is reduced, and the market competitiveness is improved.

Owner:CHONGQING IONCIN NAVIGATION ENGINE MFG C0 LTD

Motor stator and outer rotor motor having the same

ActiveCN103227519BReduce vibrationReduce noiseMagnetic circuit stationary partsSupports/enclosures/casingsEngineeringConductor Coil

The invention is appropriate for the technical field of motors, and discloses a motor stator and an external rotor motor with the motor stator. The motor stator comprises a stator assembly which comprises a stator iron core with a through hole and a winding winded on the stator iron core. The motor stator further comprises a plastic package body wrapping the stator assembly and a bearing sleeve which is positioned in the through hole and used for mounting of a bearing. The plastic package body comprises a body plastic package part which covers the stator iron core and the winding. The plastic package body limits the bearing sleeve by means of arranging a limiting part integrated with the body plastic package part. The external rotor motor comprises the motor stator arranged in the rotor. The motor stator and the external rotor motor with the motor stator provided by the invention are convenient to assemble, less in production vibration and noise and high in reliability.

Owner:FOSHAN WEILING WASHER MOTOR MFG

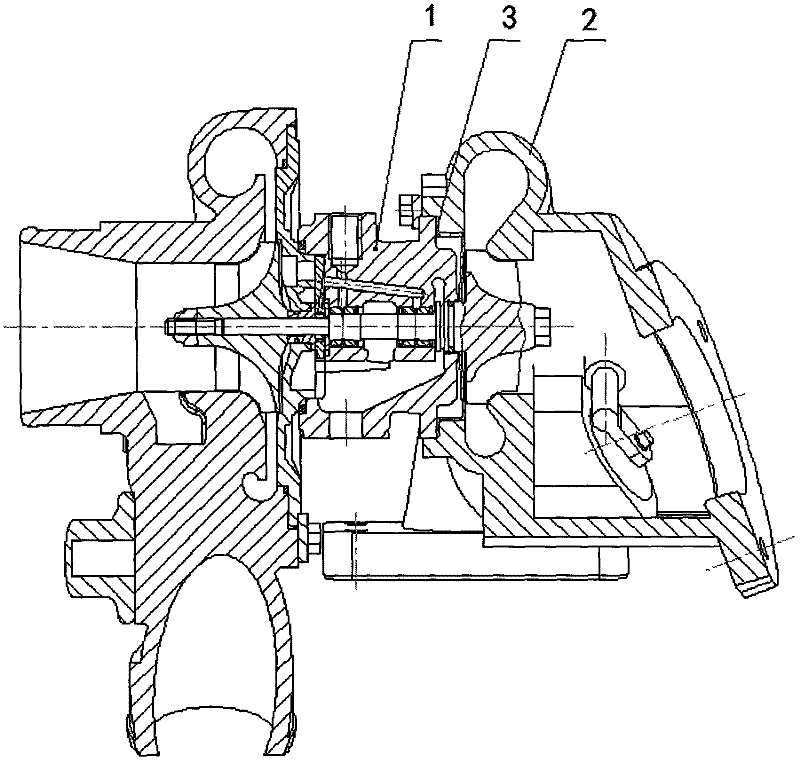

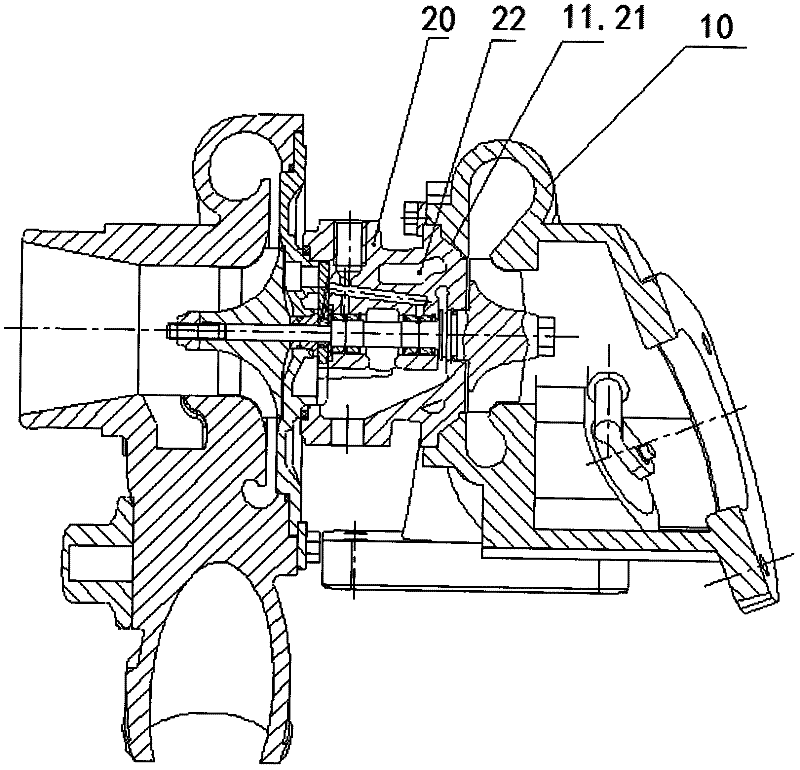

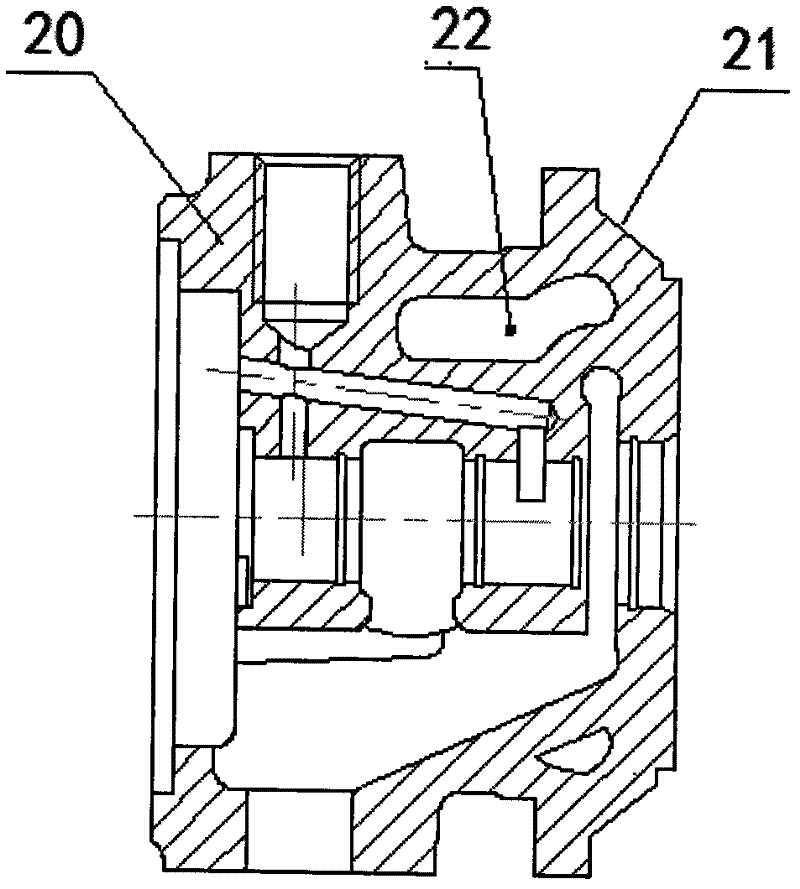

Turbocharger heat insulation structure

InactiveCN102392696AReduce management costsReduce the number of assembliesMachines/enginesEngine componentsState of artTurbocharger

The invention discloses a turbocharger heat insulation structure which comprises a turbine box and a bearing box, wherein the turbine end of the bearing body is jointly connected with the turbine box in a step-structure mode, a circulating cooling water cavity is arranged at the inner end side, close to the turbine, of the bearing body, a water inlet and a water outlet which penetrate through the circulating cooling water cavity are arranged on the bearing body, and the bearing body and the water cavity are cast and molded by using the same material. According to the invention, an insulation sleeve structure can be omitted, a joint type contact seal can be designed between the bearing body and the turbine box and the joint position can be designed with a step section so as to reach the sealing effect; the water cavity arranged at the inner end part, close to the turbine, of the bearing body can be used for achieving the heat insulation effect; and the bearing body and the water cavity are cast and molded by using the same material, so that the deformation difference between the bearing body and the water cavity can be lessened. Compared with the prior art, the turbocharger heat insulation structure provided by the invention has the advantages that the management cost of parts can be lowered because insulation sleeve parts and dies are not required; and meanwhile, the part assembly amount can be reduced and the transferred assembly efficiency can be improved, thus the turbocharger heat insulation structure is suitable for popularization.

Owner:HUNAN TYEN MACHINERY

Electric connector

ActiveCN112736529AReduce the number of assembliesImprove electrical performanceCoupling contact membersElectric vehicle charging technologyElectrical connectionElectrical performance

The invention discloses an electric connector which comprises a first terminal set, a second terminal set and an insulating body, wherein the first terminal set comprises a first grounding terminal and a signal terminal; the second terminal set comprises a second ground terminal and a differential terminal; and the first grounding terminal, the second grounding terminal and the differential terminal are embedded and molded into a whole with the insulating body, so that a first grounding embedding part of the first grounding terminal, a second grounding embedding part of the second grounding terminal and a differential embedding part of the differential terminal are embedded in the insulating body, and a signal inserting part of the signal terminal is correspondingly assembled in an assembling groove of the insulating body, so that the signal terminal and the differential terminal have large design adjusting spaces, and the structures and the assembling positions of the signal terminal and the differential terminal can be adjusted according to actual signal transmission requirements. Therefore, the position relation of the signal terminal and the differential terminal relative to other terminals is adjusted, impedance is flexibly adjusted, crosstalk is reduced, the electrical performance of the first terminal group and the second terminal group is improved, and installation is convenient at the same time.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

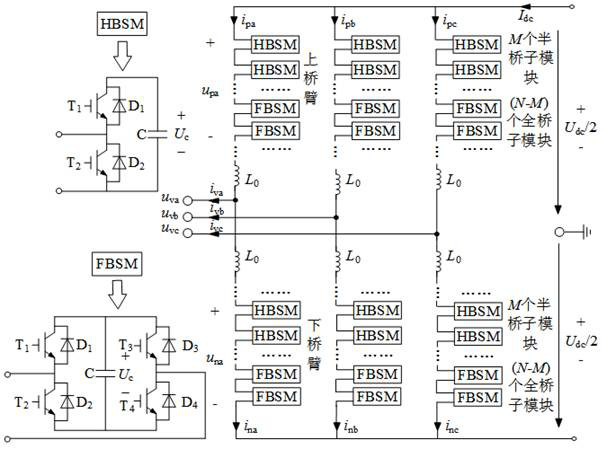

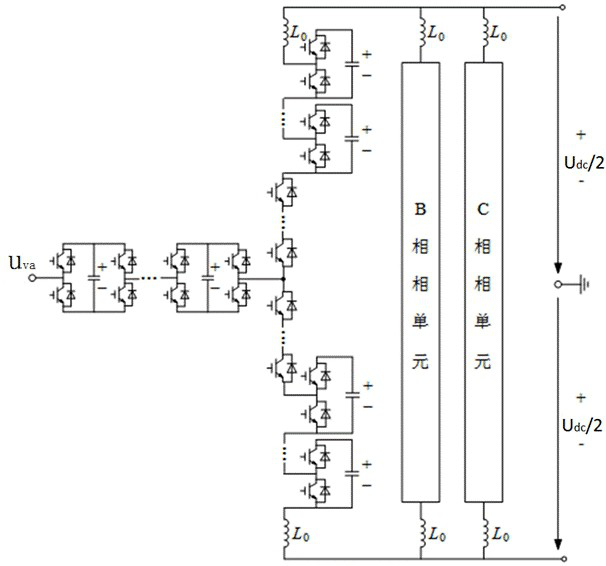

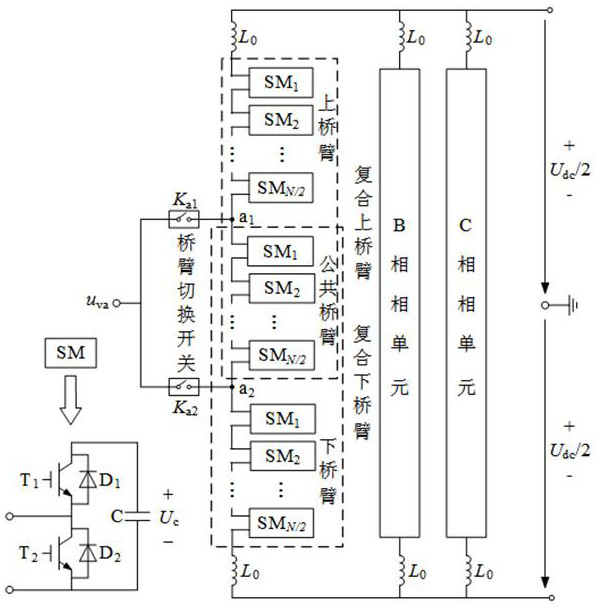

Capacitor multiplexing type modular multilevel converter and control method thereof

ActiveCN114553020AReduce the number of assembliesReduce volumeAc-dc conversionMultiplexingCapacitance

The invention discloses a capacitor multiplexing type modular multilevel converter and a control method thereof, and relates to the technical field of power supply power systems. The capacitor multiplexing type modular multilevel converter comprises an upper bridge arm, a lower bridge arm and a multiplexing capacitor; each of the upper bridge arm and the lower bridge arm comprises a plurality of cascaded sub-modules, a direct current side port of any sub-module of the upper bridge arm is connected in parallel with a direct current side port of the corresponding sub-module in the lower bridge arm, and the direct current side port of any sub-module of the upper bridge arm and the direct current side port of the corresponding sub-module in the lower bridge arm are connected in parallel with the same multiplexing capacitor; the working states of the two sub-modules sharing the multiplexing capacitor are opposite; one sub-module of each phase of upper bridge arm and one corresponding sub-module of each phase of lower bridge arm share the same capacitor, so that on the premise of ensuring high operation reliability and simple control strategy, the assembling number of the capacitors is reduced, and the weight, volume and occupied area of the converter station are reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

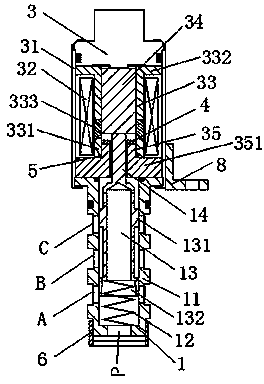

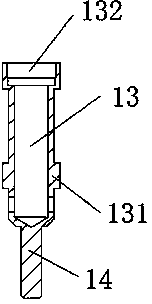

A type‑c socket connector

ActiveCN104810657BReduce the number of assembliesReduce Tolerance RollupCoupling protective earth/shielding arrangementsEngineeringElectrical and Electronics engineering

The invention discloses a Type-C socket connector. The Type-C socket connector comprises a shell and an inserting component; the inserting component comprises an upper inserting component and a lower inserting component; the upper inserting component comprises an upper insulating body and an upper row of electric conductive terminals integrally formed with the upper insulating body; the lower inserting component comprises a lower insulating body, and a metallic shield sheet and a lower row of electric conductive terminals integrally formed with the lower insulating body; each insulating body is provided with twelve grooves respectively; each row of the electric conductive terminals is provided with eight terminals respectively; the metallic shield sheet is integrally formed with any two terminals in the lower row of the electric conductive terminals; the metallic shield sheet is downwards protruded to form a plate-shaped grounding part; the position of the terminals integrally formed with the metallic shield sheet corresponds to the position of the grounding part; and the grounding part and the metallic shield sheet are located in the different planes. The Type-C socket connector is used for reducing the assembly number of the parts, reducing the tolerance accumulation, satisfying the USB2.0 application, and greatly decreasing the number of the terminals, and is good for the stability of the product.

Owner:ALL BEST ELECTRONICS TECH CO LTD

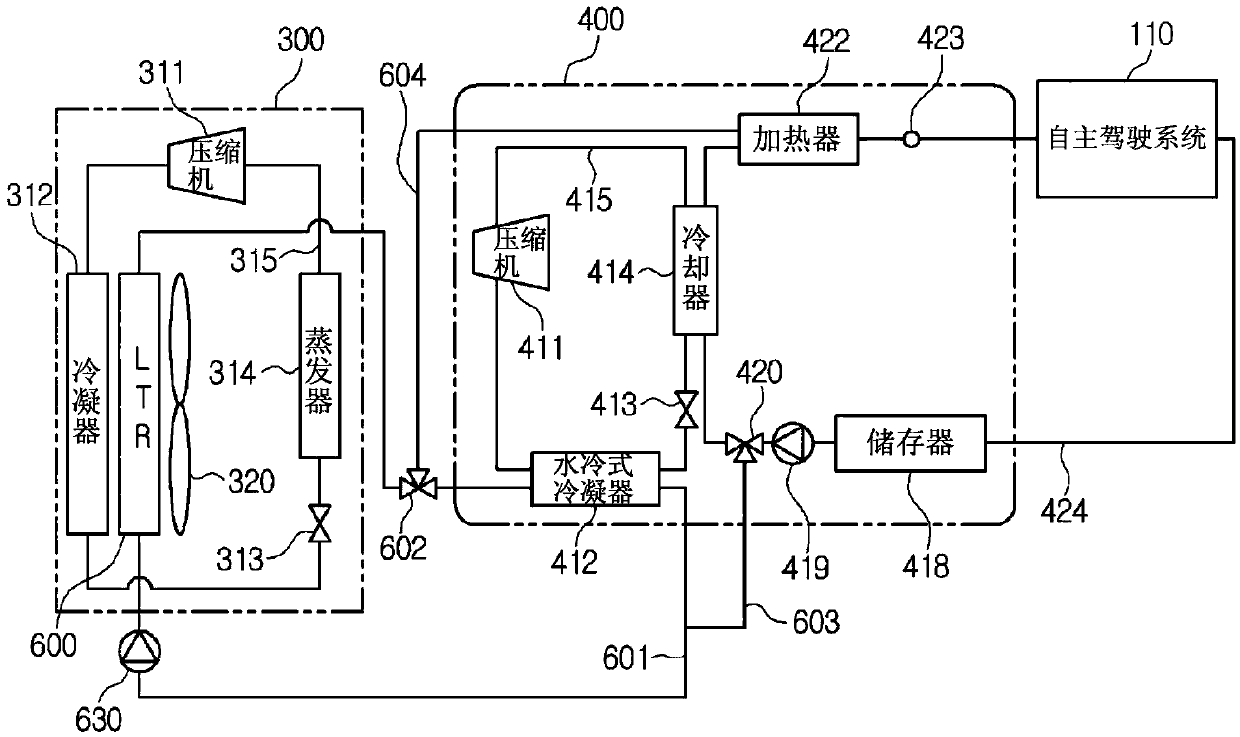

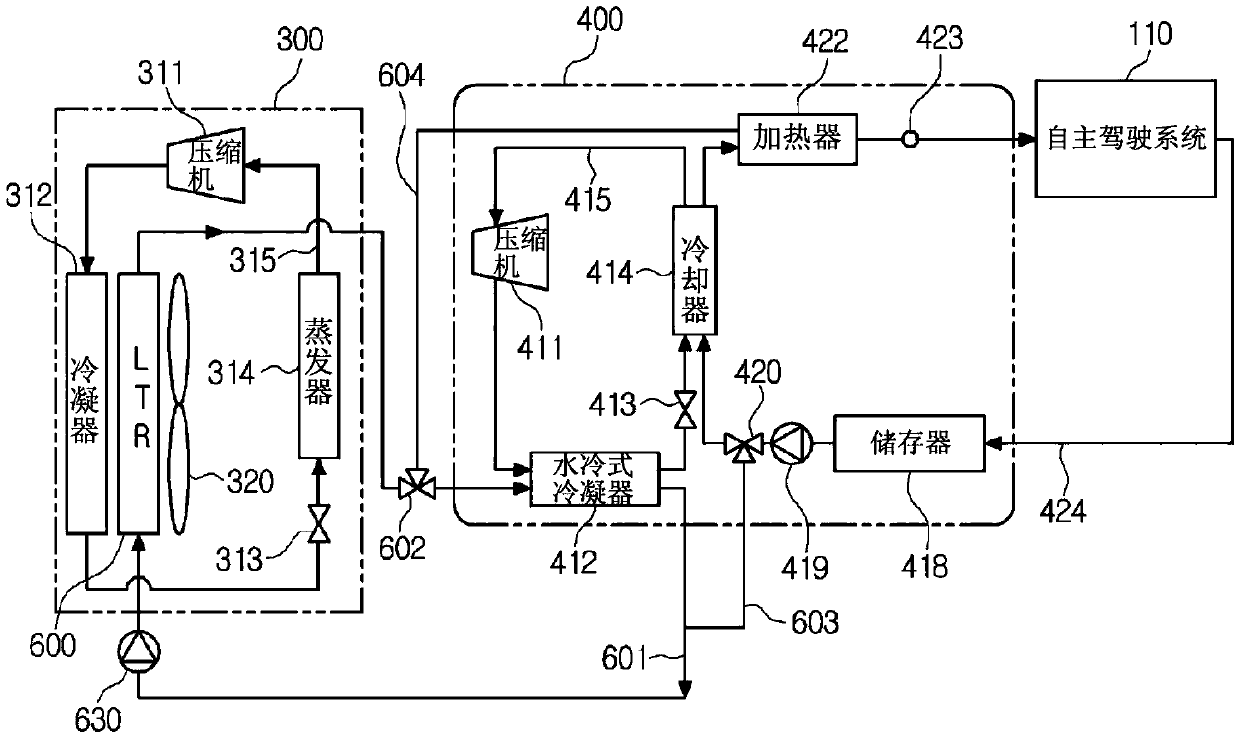

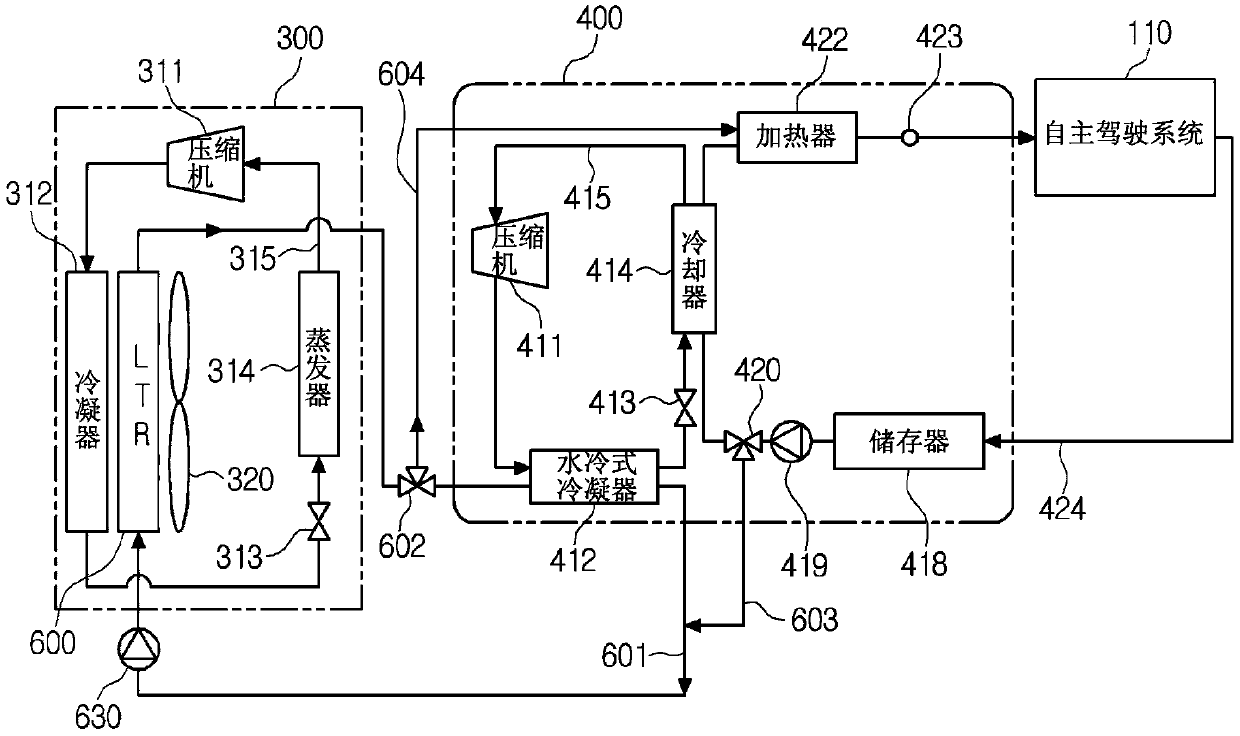

Vehicle thermal management system

ActiveCN109661316AReduce noiseImprove cooling effectAir-treating devicesVehicle sub-unit featuresThermal management systemProcess engineering

Owner:HANON SYST

Aluminum-wood mixed formworks applied to building construction

ActiveCN107905521AIncrease flexibilityShorten the timeAuxillary members of forms/shuttering/falseworksForming/stuttering elementsBuilding constructionAluminium

The invention discloses aluminum-wood mixed formworks applied to building construction. The aluminum-wood mixed formworks solve the problem that in the prior art, accumulation deformation is large after assembling of multiple aluminum formworks is finished, and the wall deviation is large after construction. According to the key points of the technical scheme, the aluminum-wood mixed formworks comprise standard aluminum formworks, non-standard wood formworks and connecting assemblies; the connecting assemblies comprise lower connecting plates used for connecting the tops of the standard aluminum formworks, upper connecting plates used for connecting the bottoms of the non-standard wood formworks and side plates used for connecting the upper connecting plates and the lower connecting plates, and the upper connecting plates and the lower connecting plates are parallel to each other and are perpendicular to the side plates; the connecting assemblies further comprise supporting rods, the supporting rods comprise main rod bodies and auxiliary rod bodies hinged to the main rod bodies, the upper ends of the main rod bodies are supported on the upper connecting plates, the lower ends of the main rod bodies are supported on a bottom foundation, and the auxiliary rod bodies are obliquely supported on the side surfaces of the aluminum formworks; and the aluminum-wood mixed formworks applied to building construction has the advantages of reducing the accumulation deformation after assembling, reducing the large wall deviation after construction, and meeting the requirement of the walldeviation range.

Owner:SHENZHEN DONGSHEN ENG CO LTD

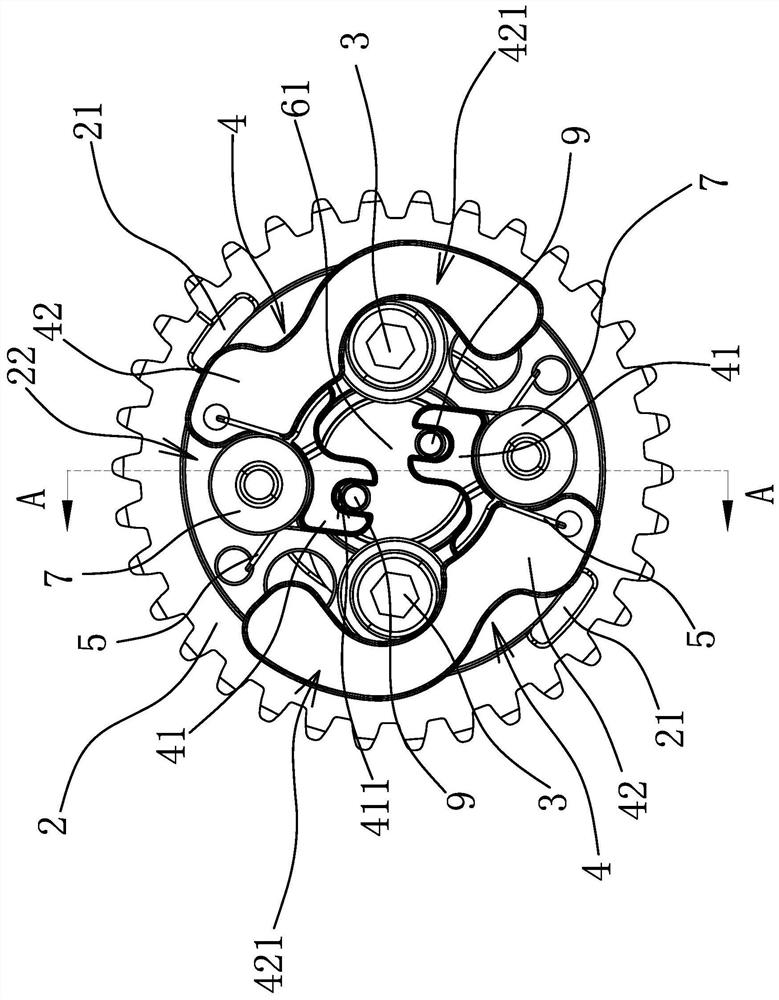

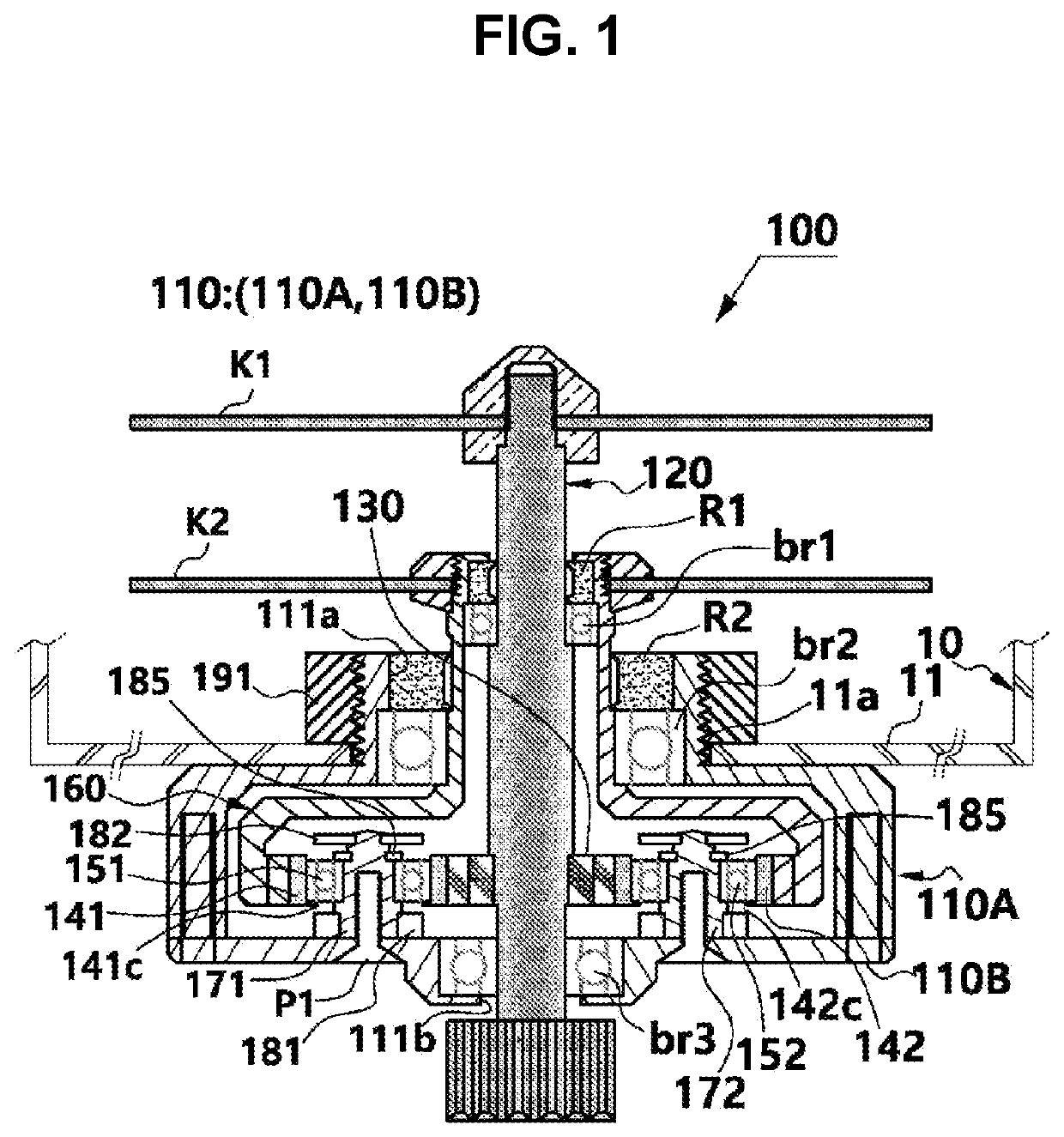

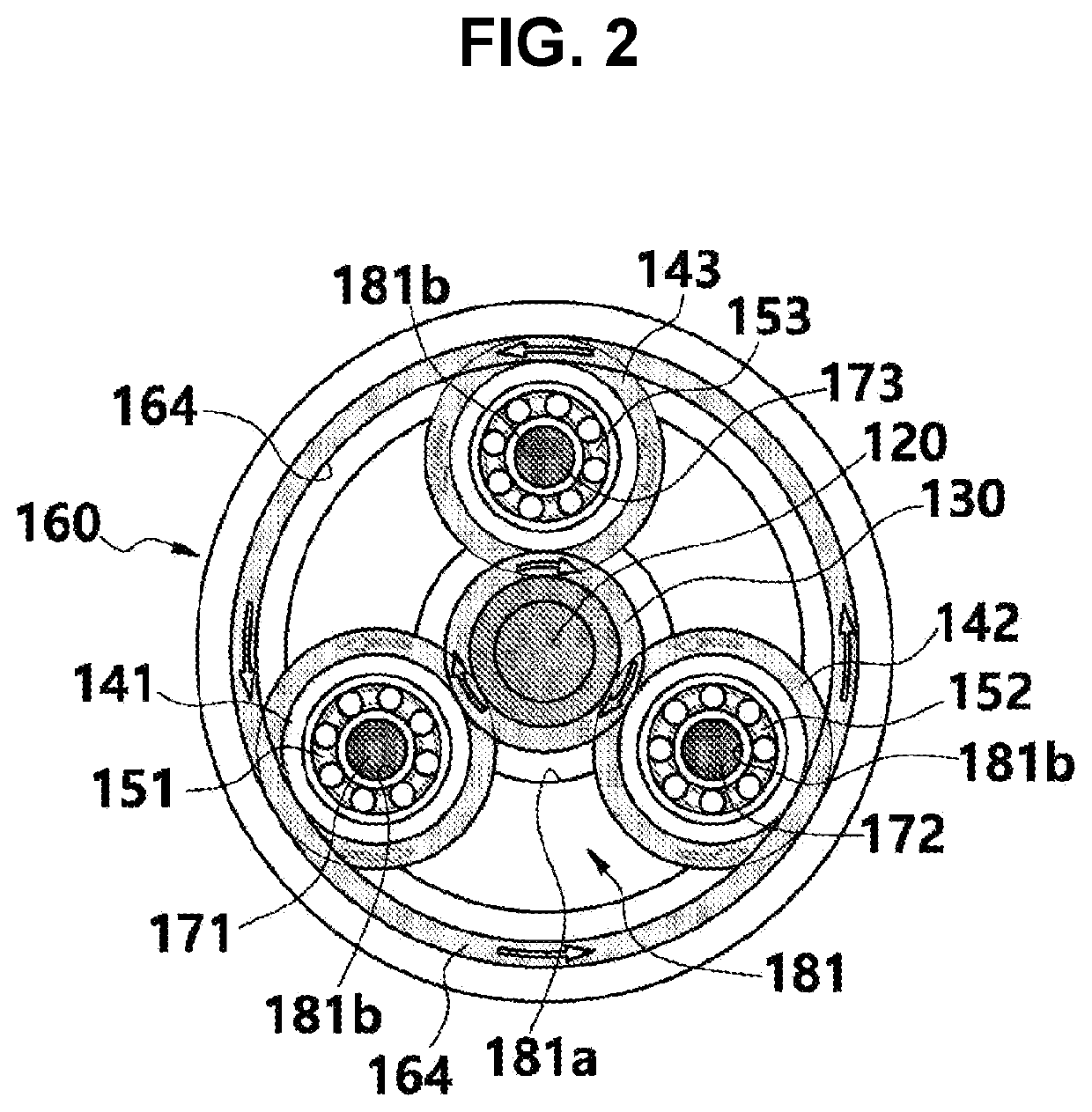

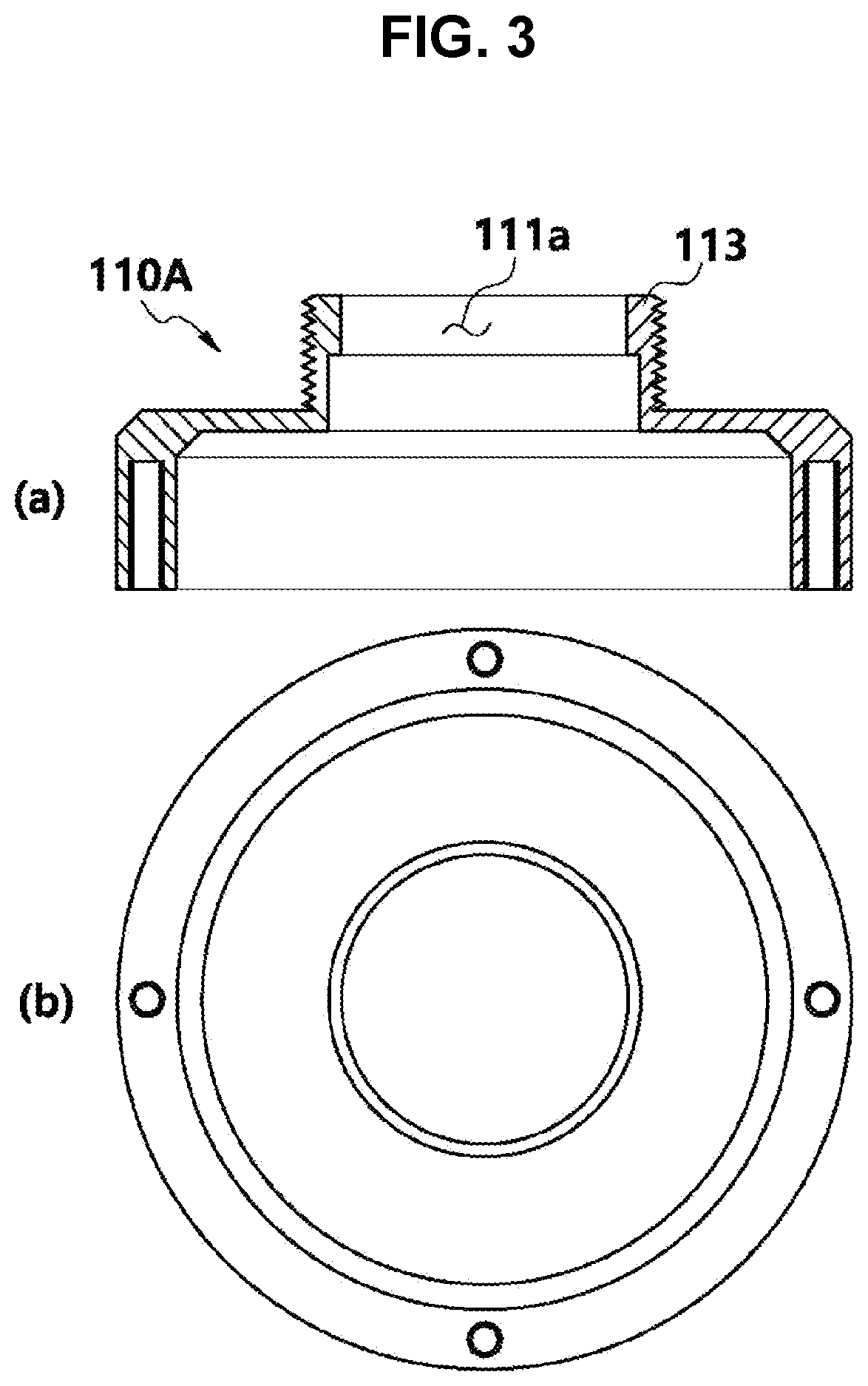

Bidirectional simultaneous rotary blade bundle for mixer

PendingUS20220039601A1Avoid it happening againStable and reliableRotary stirring mixersTransportation and packagingGear wheelEngineering

Provided is a bidirectional simultaneous rotary blade bundle for a mixer, the bidirectional simultaneous rotary blade bundle comprising: a housing (110); a forward rotary shaft (120) installed on the housing (110); a forward rotation blade (K1) provided on the forward rotary shaft (120); a central gear (130) axially installed on the forward rotary shaft (120); horizontal insertion gears (141,142, and 143) engaged with the central gear (130); a reverse rotor (160), of which inner gear teeth (164) are engaged with and rotate on the outside of the horizontal insertion gears (141, 142, and 143); and a reverse rotation blade (K2) installed on the reverse rotor (160), wherein the horizontal insertion gears (141, 142, and 143) are rotated in the reverse direction according to the forward rotation of the central gear (130) such that the inner gear teeth (164) are rotated in the reverse direction.

Owner:CUCKOO ELECTRONICS CO LTD

A full-rotation hydraulic internal push-type high-build slope rotary guide tool

ActiveCN109025820BReduce the number of assembliesReduce power supplyDirectional drillingMachines/enginesHydraulic ramEngineering

The invention mainly belongs to the technical field of rotary guide systems, and particularly relates to a full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool. The full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool adopts a hydraulic system driven by a turbine and a generator set to convert the energy of the pressure mud into the hydraulic energy. By adopting the hydraulic system driven by the turbine and the generator set, the power is provided for a piston through the hydraulic mode, so that the lateral force obtained by a drillbit is larger. Meanwhile, the hinged mode is adopted, so that the optimal steering capability is achieved. As a result, the high build-up rate is easier to achieve. The hydraulic piston pushes againstthe inner wall of a lower rotating sleeve instead of the wall of a well, so that the abrasion can be reduced. At the same time, only one set of pushing piston assemblies is pushed out at the same moment, so that the unnecessary work is reduced. The service life of the piston is prolonged.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

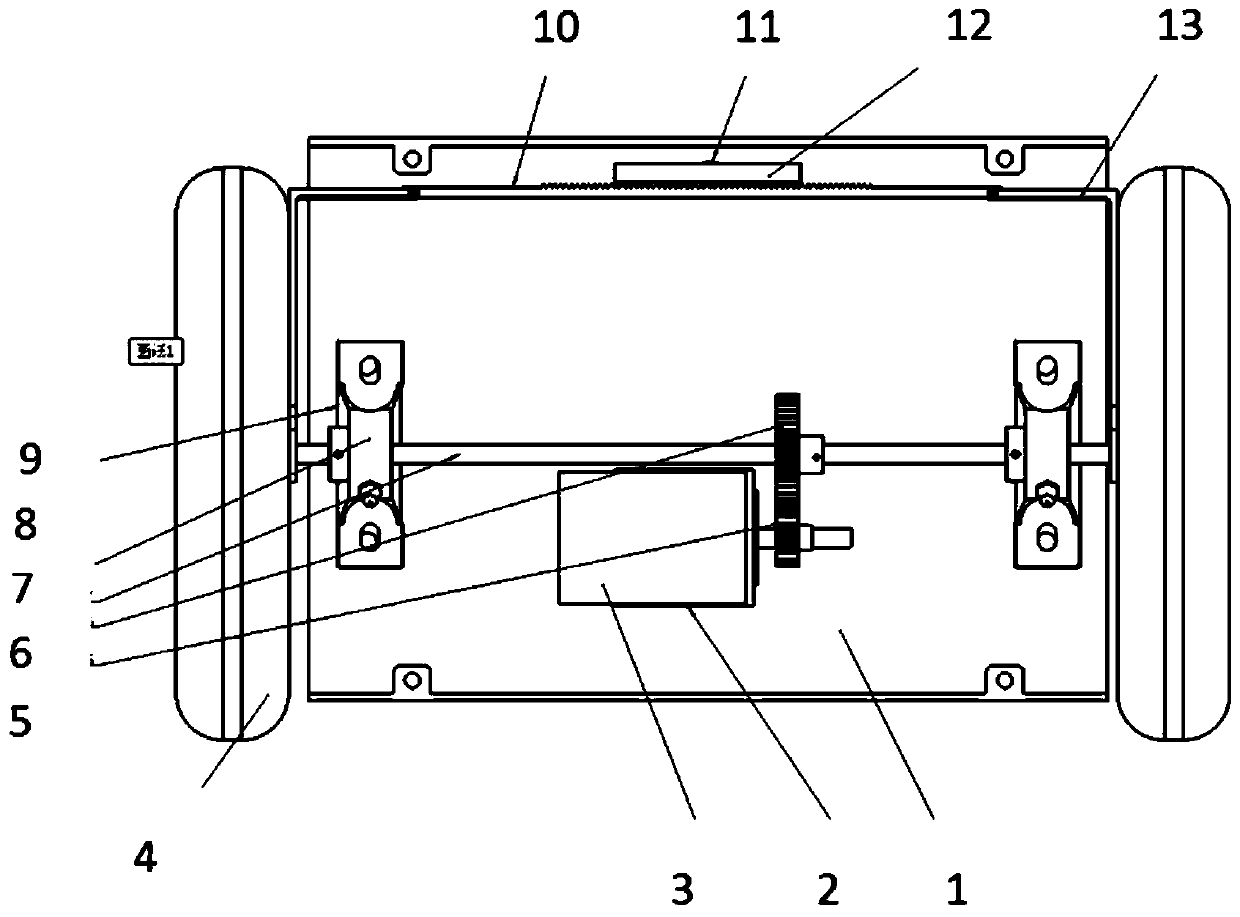

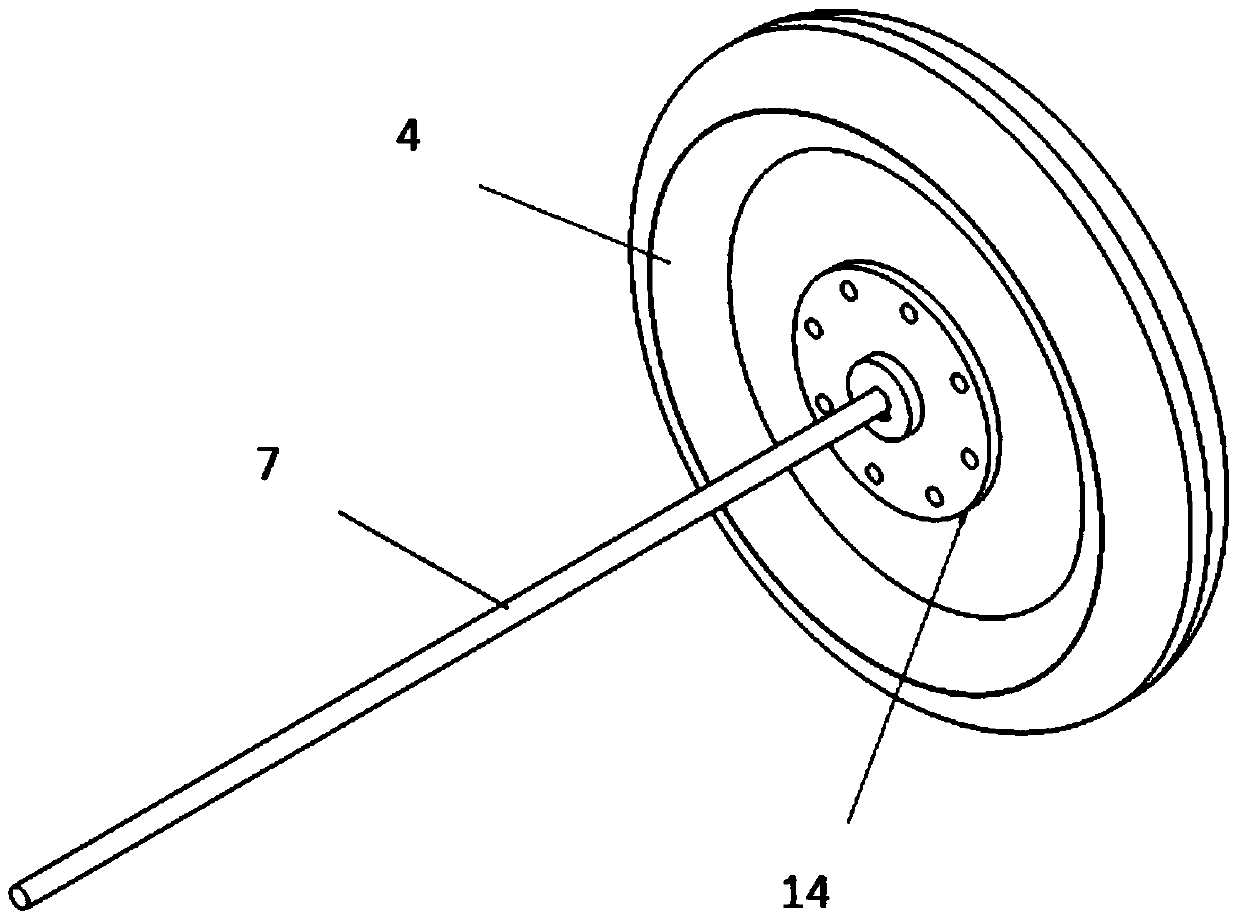

A two-wheel self-balancing vehicle driven by a single shaft

InactiveCN103600796BReduce usageReduce the number of assembliesMotorcyclesElectric machineEngineering

The invention discloses a two-wheel self-balancing vehicle driven by a single axis. The two-wheeled self-balancing vehicle includes: pedals for carrying the operator; body for loading the motor and control circuit; two wheels, the two wheels are coaxial, and a single drive motor is used for single-axis drive; steering The steering rod is used for parallel steering of the car body; the control circuit system uses the sensor to measure the inclination of the car body to control the operation of the car body. The vehicle has the characteristics of light weight and smooth driving.

Owner:SHANGHAI JIAO TONG UNIV

A molding process method and product for the upper cover of a composite material battery box for preventing thermal runaway

ActiveCN111284035BImprove the ability to prevent thermal runawayImprove space utilizationCell component detailsDomestic articlesFiberManufacturing cost reduction

The invention discloses a forming process method of a thermal runaway prevention composite material battery box upper cover and a product. The composite material comprises a mica paper layer, a firstcomposite material layer, a second composite material layer, a third composite material layer, a fourth composite material layer, a fifth composite material layer, a sixth composite material layer, aseventh composite material layer and an eighth composite material layer which are sequentially laid from bottom to top. According to the molding process method of the thermal runaway prevention composite material battery box upper cover and the product provided by the invention, different thermal runaway requirements can be met, flexible design, different thermal runaway temperatures, corresponding changes of the mica powder content and layer number of the layers and the layer sequence are realized, the preparation procedures of parts can be reduced, the assembly number of the parts is reduced, the production cost is reduced, by combining the high-strength advantage of the continuous fibers and the heat resistance of the mica material, the thermal runaway prevention capacity of the composite material battery box upper cover is improved, the manufacturing cost is reduced, the space of the battery pack is not occupied, open fire is prevented from overflowing, and the safety of the electric automobile is improved.

Owner:溧阳康本复合材料有限公司

Multi-manifold valve seat

ActiveCN104776079BReduce the number of assembliesReduced space required for installationServomotor componentsMultiple way valvesEngineeringPilot valve

The invention discloses a multi-connected integrated assembling valve seat. The multi-connected integrated assembling valve seat comprises a valve seat body, wherein multiple air grooves I, multiple air grooves II, multiple valve nozzle installation holes I and multiple valve nozzle installation holes II are formed in the valve seat body; valve nozzles I and valve nozzles II are arranged in the valve nozzle installation holes I and the valve nozzle installation holes II; one side of each valve nozzle installation hole I is provided with an air inlet passage I which is connected with the corresponding air groove I; the air inlet passages I are connected with input openings I; the valve seat body is provided with an air inlet passage II and an air inlet passage III; the air inlet passage II is connected with an air passage I; an air output opening I of the air passage I is formed in the front end surface of the valve seat body; an air output opening II is formed in the valve seat body; the valve nozzle installation holes I are connected with the air passage I; the air inlet passage III is connected with an input opening II; the air inlet passage III is connected with the air grooves II. According to the multi-connected integrated assembling valve seat disclosed by the invention, by changing a pilot valve seat which is in dispersed installation into an integrated installation structure, the assembling number and the installation space of parts are reduced, the difficulty of a machining technology is reduced, the problems of an existing pilot valve seat that the occupied space is large and the whole weight is heavy are solved, and the multi-connected integrated assembling valve seat is particularly suitable for scale production.

Owner:JINAN FUCHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com