Ball joint

A ball joint and spherical shell technology, applied in the field of ball joints, can solve problems such as insufficient fracture resistance of ball joints, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

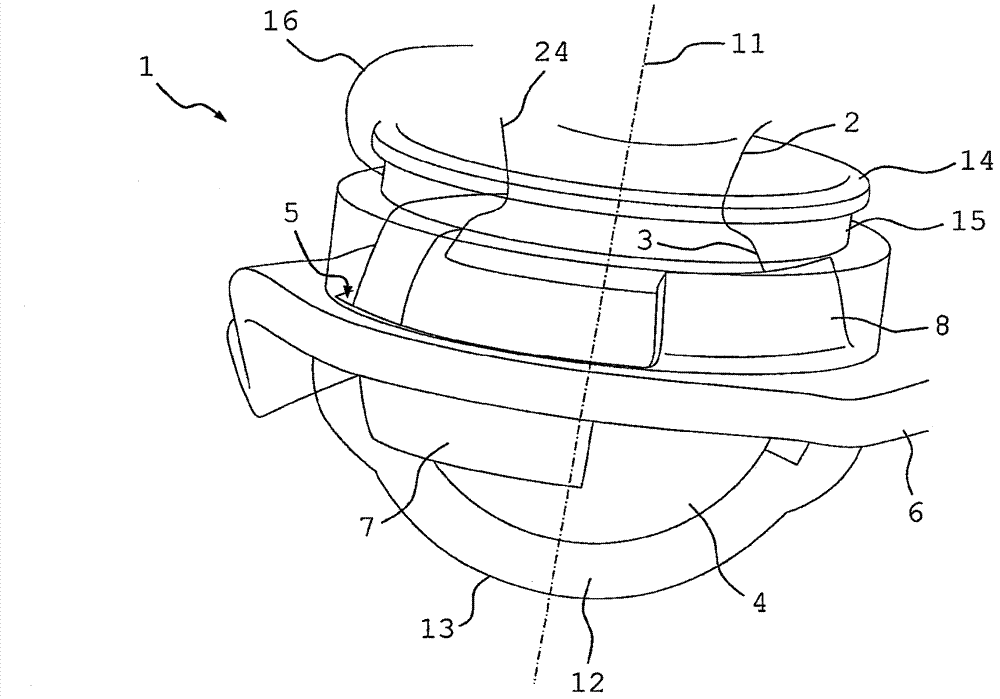

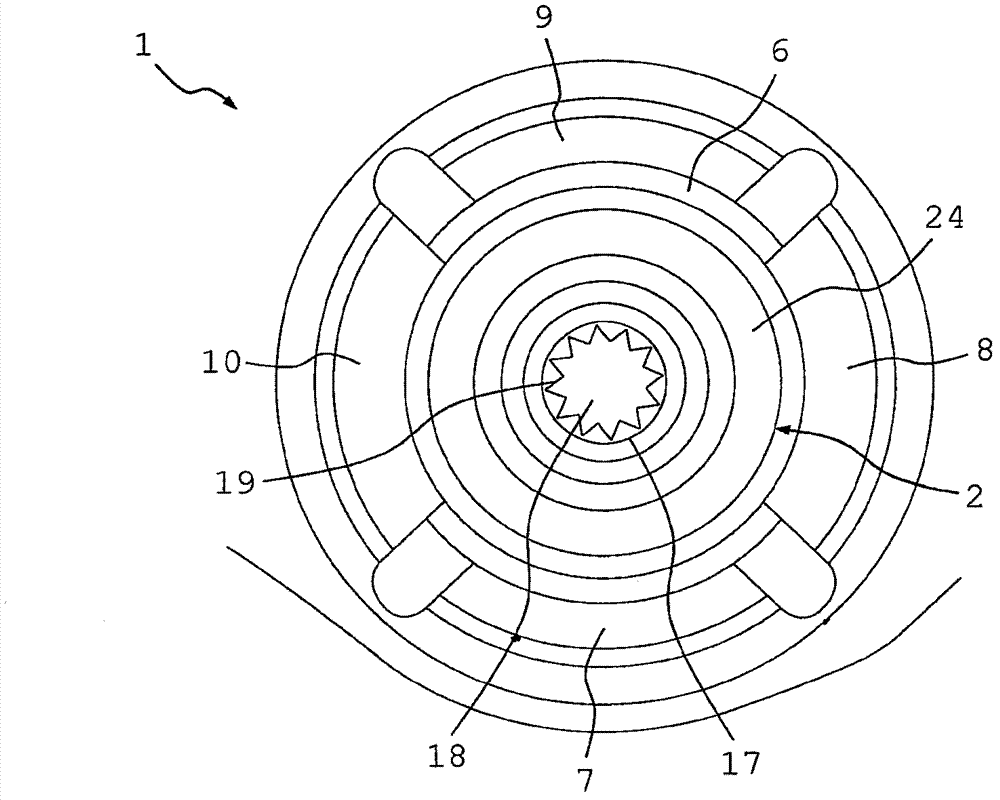

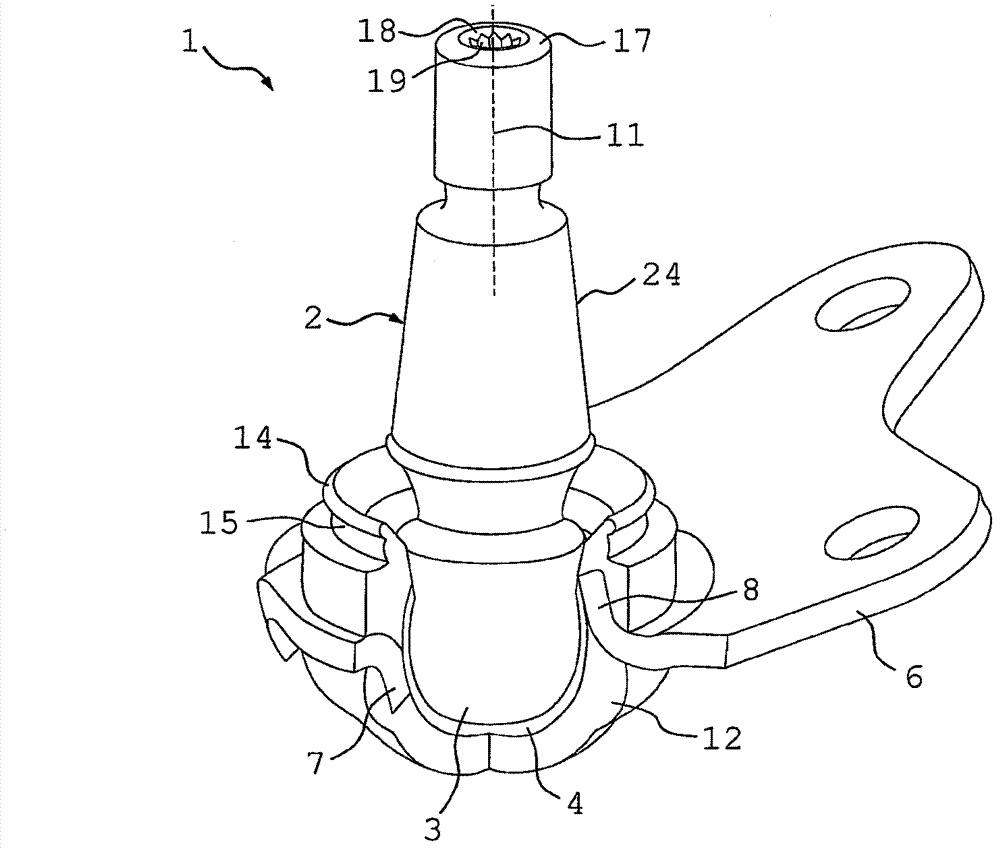

[0029] from Figures 1 to 3 A different view of a ball joint 1 according to a first embodiment of the invention can be seen in FIG. It is slidably mounted in the ball housing 4 . The ball pin 2 is rotatably and pivotally engaged in a ball housing 4 which is arranged in a through-bore 5 of the carrier 6 . The bracket 6 surrounds the undeflected ball pin 2 at the level of the equator of the joint ball 3 , so that the bracket 6 can absorb radial forces introduced on the ball pin 2 . Edge sections 7 , 8 , 9 and 10 are bent out of the carrier 6 , which extend obliquely with respect to the axial direction 11 and cover the ball housing axially with their free ends. 4. In this case, the edge sections are bent alternately in opposite directions, wherein, according to the illustration, edge sections 8 and 10 extend upward and edge sections 7 and 9 extend downward. Before the part formed by the spherical shell 4 and the ball pin 2 is inserted into the hole 5 , the edge section or at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com