Patents

Literature

106results about How to "Increase pulling force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

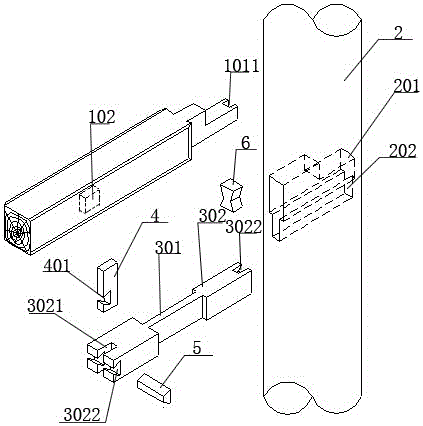

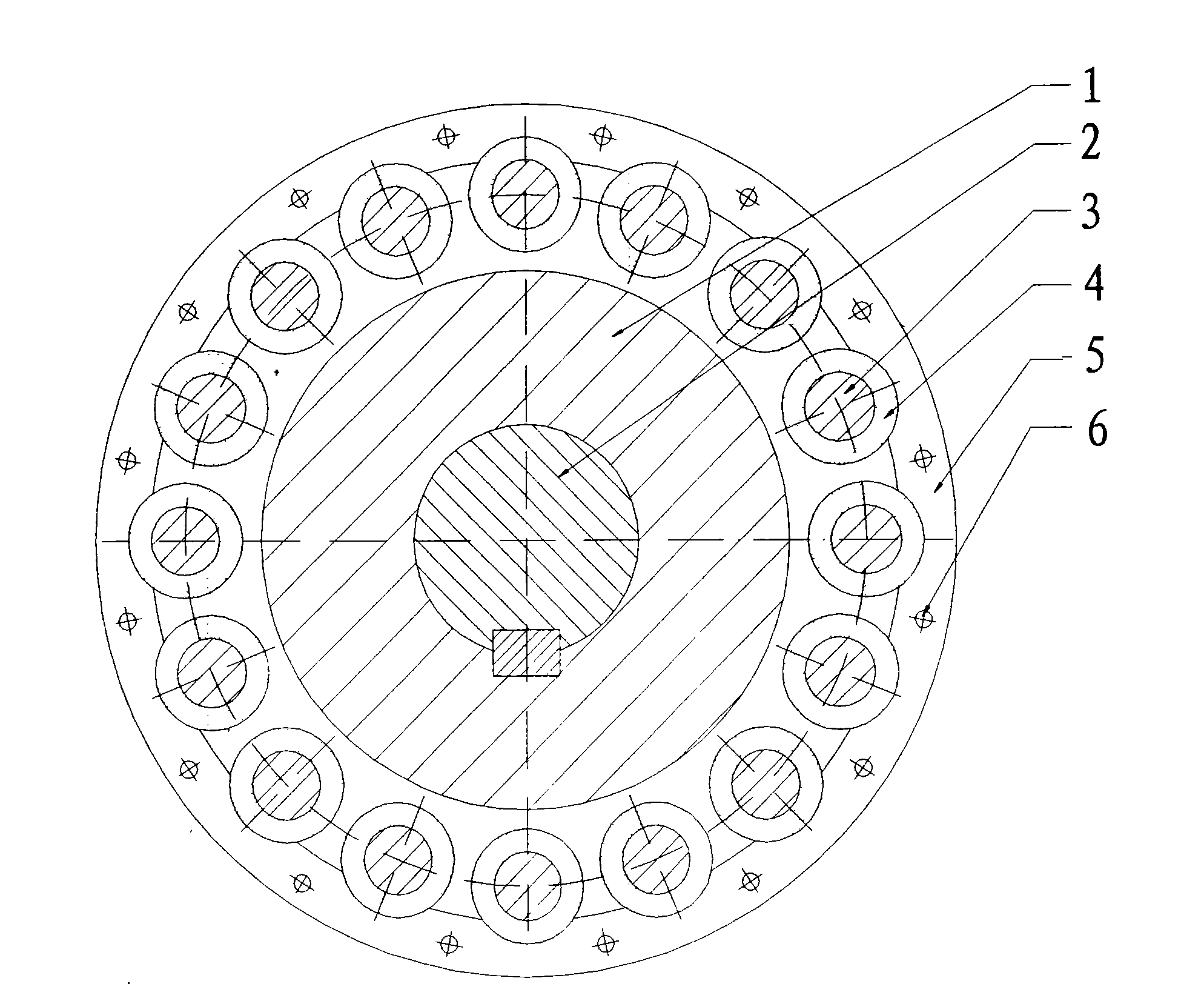

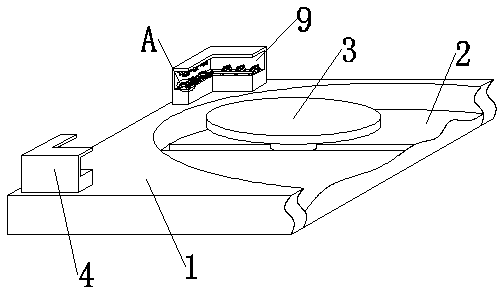

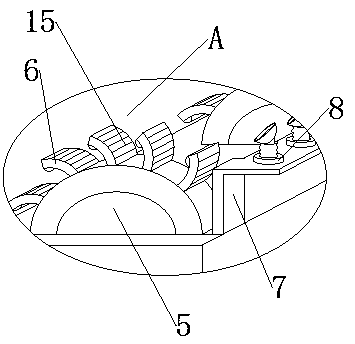

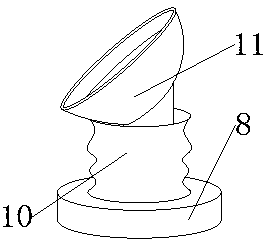

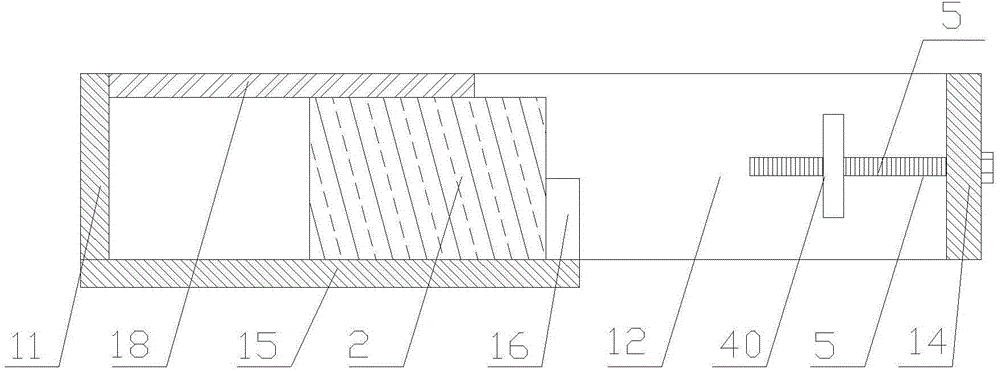

Flexible chip oriented multi-thimble peeling apparatus and peeling method

ActiveCN105140156ARealize switchingImprove adsorption capacitySemiconductor/solid-state device manufacturingEngineeringCam

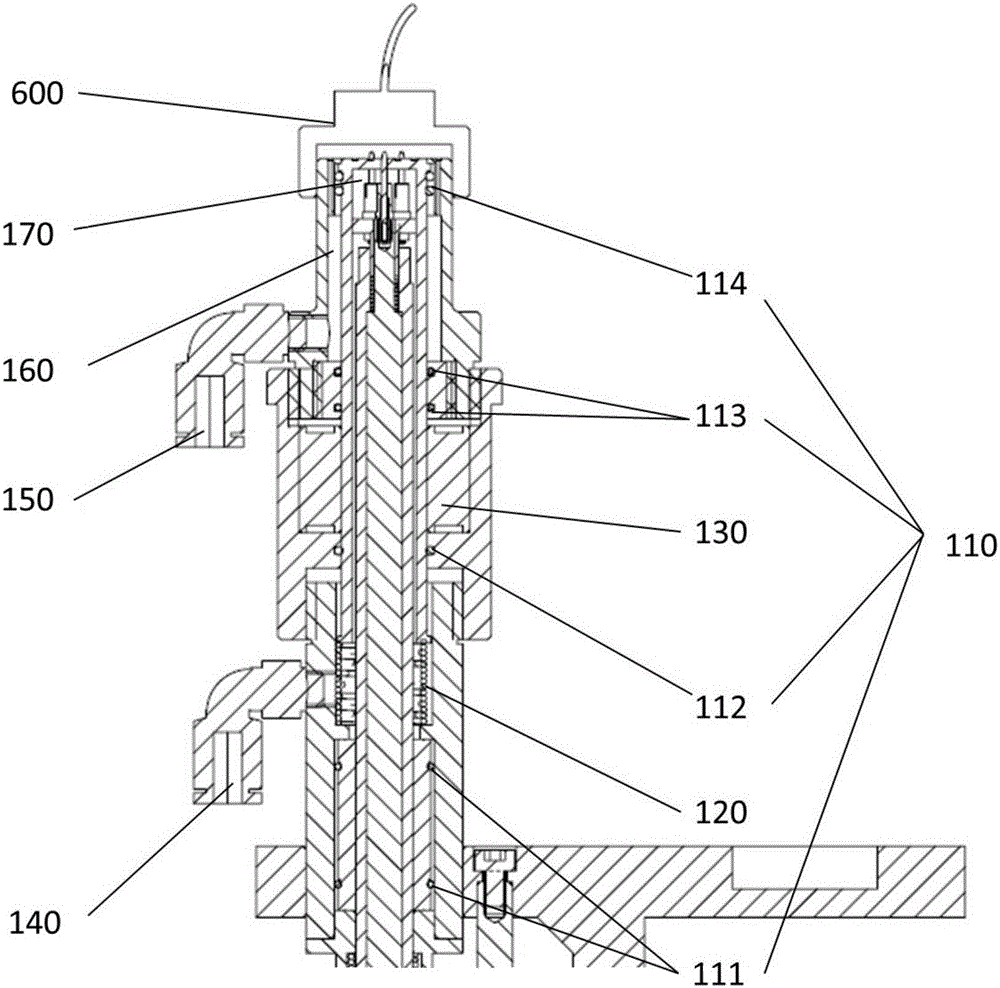

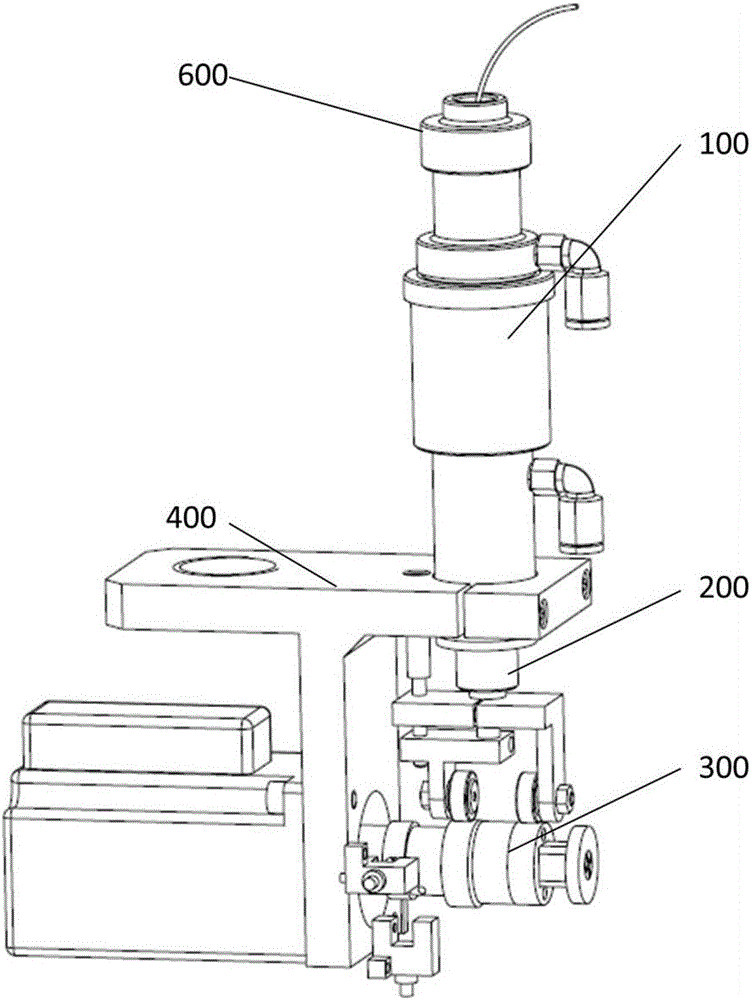

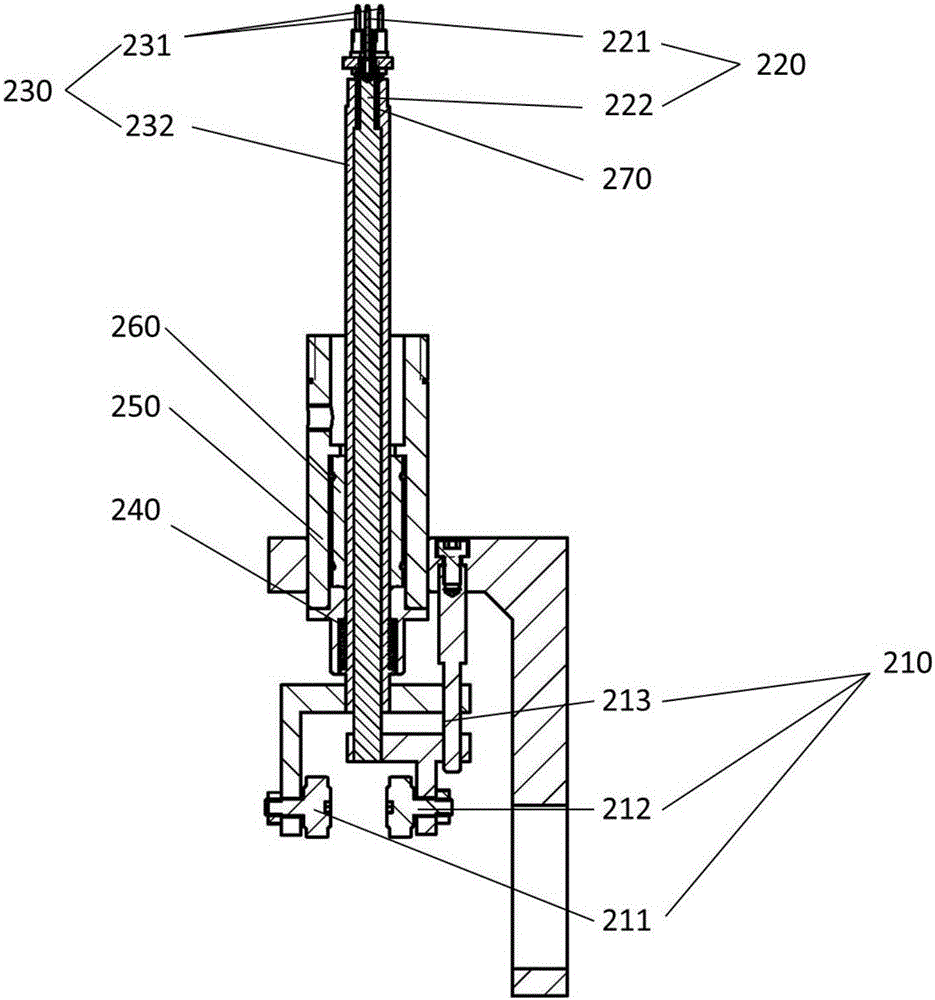

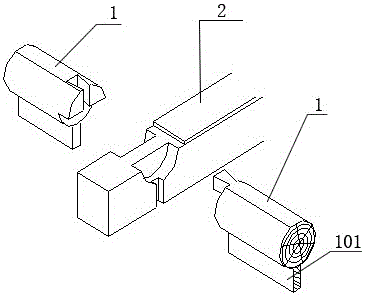

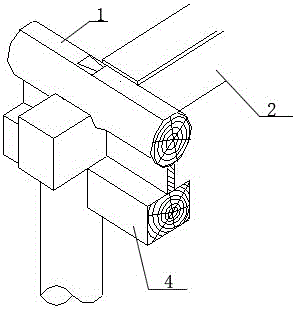

The invention discloses a flexible chip oriented multi-thimble peeling apparatus. The peeling apparatus comprises a fixed seat, a dual-vacuum cavity, a multi-thimble mechanism and a cam rotation driving mechanism, wherein the dual-vacuum cavity consists of an inner vacuum cavity and an outer vacuum cavity formed in the inner side and the outer side respectively; the inner vacuum cavity can slide up and down independently; the multi-thimble mechanism consists of an inner-ring thimble mechanism and an outer-ring thimble mechanism which are coaxially mounted and operated and controlled independently; the inner-ring thimble mechanism and the outer-ring thimble mechanism are integrally arranged at the lower part of the inner vacuum cavity in a vertical direction, and each of the inner-ring thimble mechanism and the outer-ring thimble mechanism comprises thimbles, a supporting frame and a follower; and the cam rotation driving mechanism is used for controlling time sequence of up and down actions of the inner-ring thimble mechanism and the outer-ring thimble mechanism as well as for realizing flexible switching between single-thimble and multi-thimble. The invention also discloses a corresponding peeling method. Through the peeling apparatus and the peeling method, the peeling precision and peeling efficiency can be dramatically improved, and damage on the flexible chip and a blue membrane in the peeling process can be effectively reduced; and meanwhile, the peeling apparatus has the characteristics of compact structure, convenience in operation, control and use, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

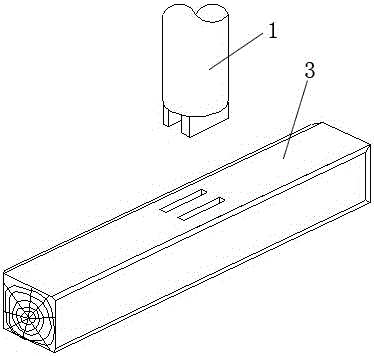

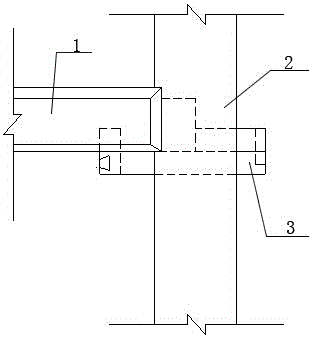

Reinforcing and repairing structure for purlin and beam node of historic building

InactiveCN105863295AIncrease the bearing areaImprove bending abilityBuilding repairsPurlinStructural engineering

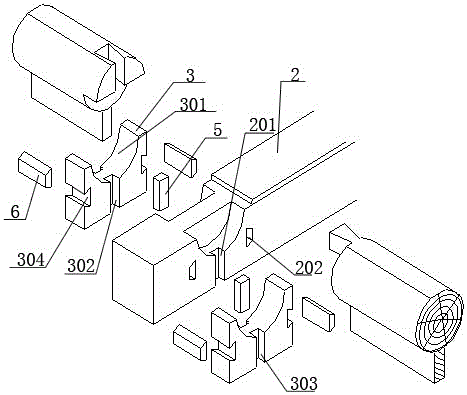

The invention provides a reinforcing and repairing structure for a purlin and a beam node of a historic building. The two ends of the purlin are erected above a beam head; pillow-shaped timbers are arranged on the left and right sides of the beam head; the pillow-shaped timbers are arranged between the purlin and a purlin frame; the bottom surfaces of the pillow-shaped timbers are ejected above the purlin frame; the heights of the pillow-shaped timbers are greater than the height of the beam head; the widths of the pillow-shaped timbers are greater than the diameter of the purlin; and on the basis of not changing raw materials and a construction process, the purlin and the beam node of the historic building are reinforced.

Owner:LUOYANG INST OF SCI & TECH

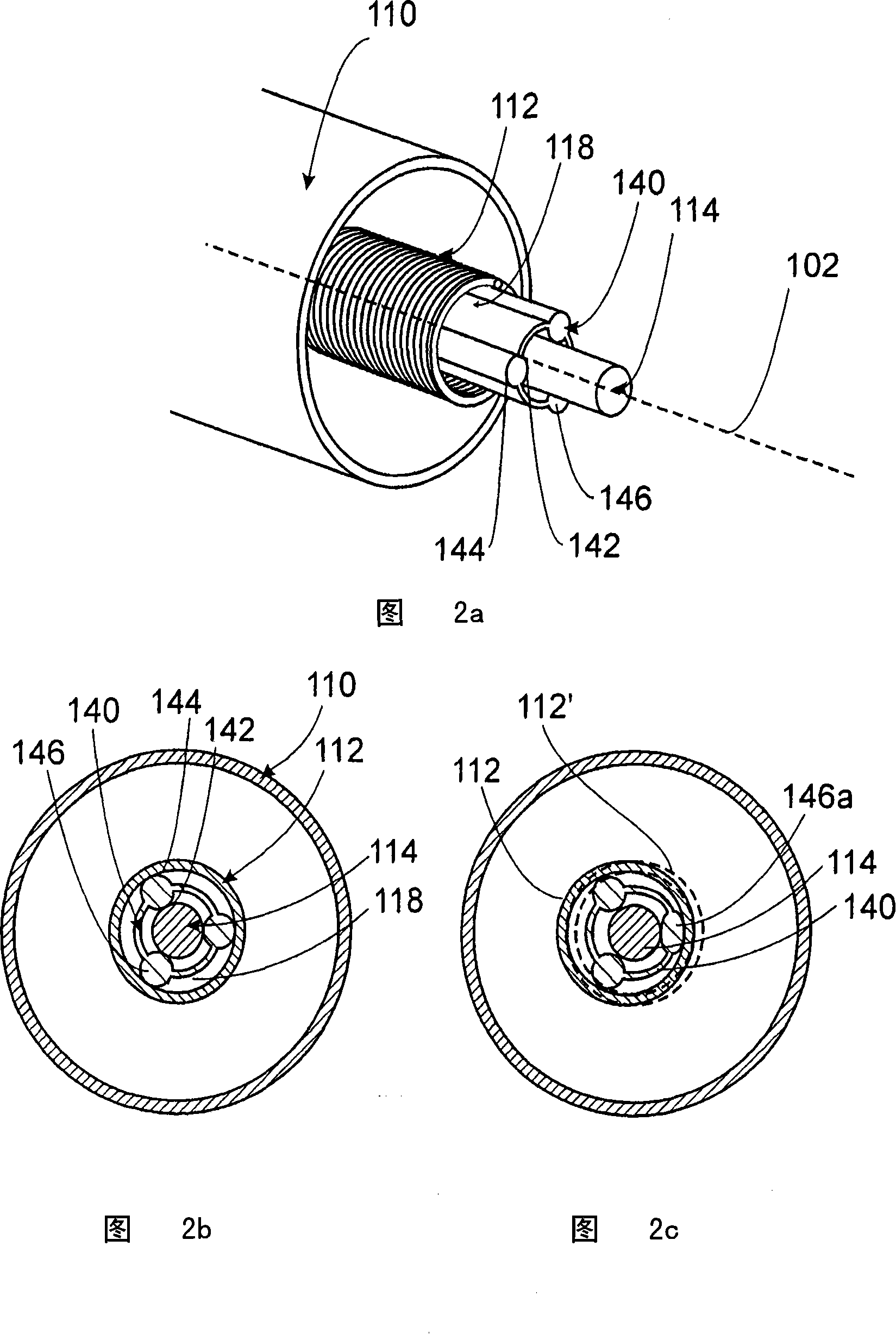

Apparatus and method for producing round brushes

The present invention relates to an apparatus and method for producing round brushes. The apparatus for producing round brushes, which have bristles twisted in between two portions of a folded wire. The apparatus has a bristle feeding device and a rotary gripper for twisting two portions of wire with bristles located therebetween, a deflecting device with two deflecting rollers spaced apart in the longitudinal direction of the wire. The rotary gripper is linearly displaceable transversely in relation to the longitudinal direction of the wire, for gripping the folded region of the wire that is formed by force being applied by an application element that is adjustable between the deflecting rollers transversely in relation to the longitudinal direction of the wire. A bristle feeding device, for feeding bristles to the bent-around portions of wire, is provided in the region of the deflecting rollers. In the region of the unfolded portions of wire there is provided a device for slowing the advancement of the wire.

Owner:ZAHORANSKY AG

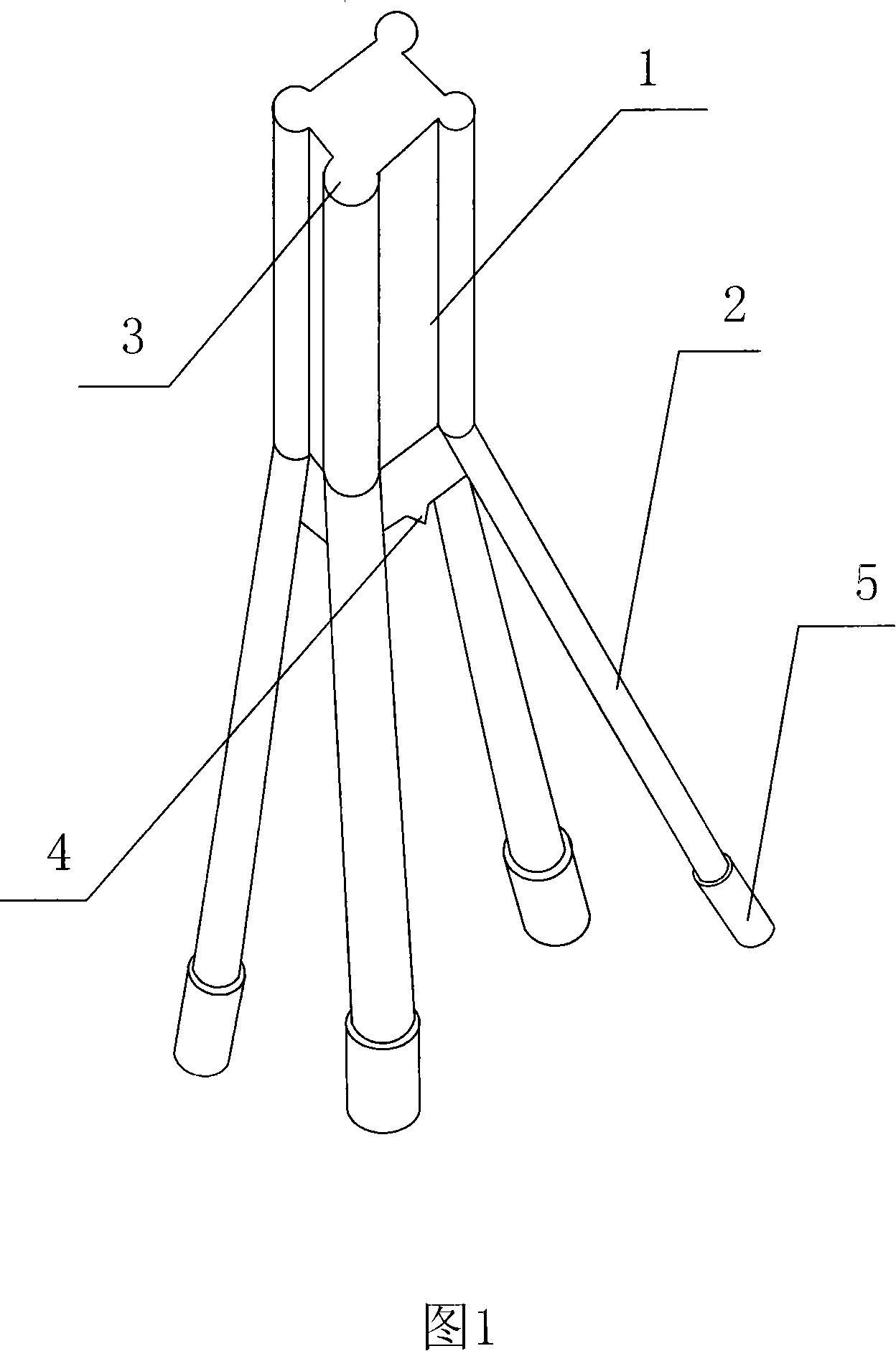

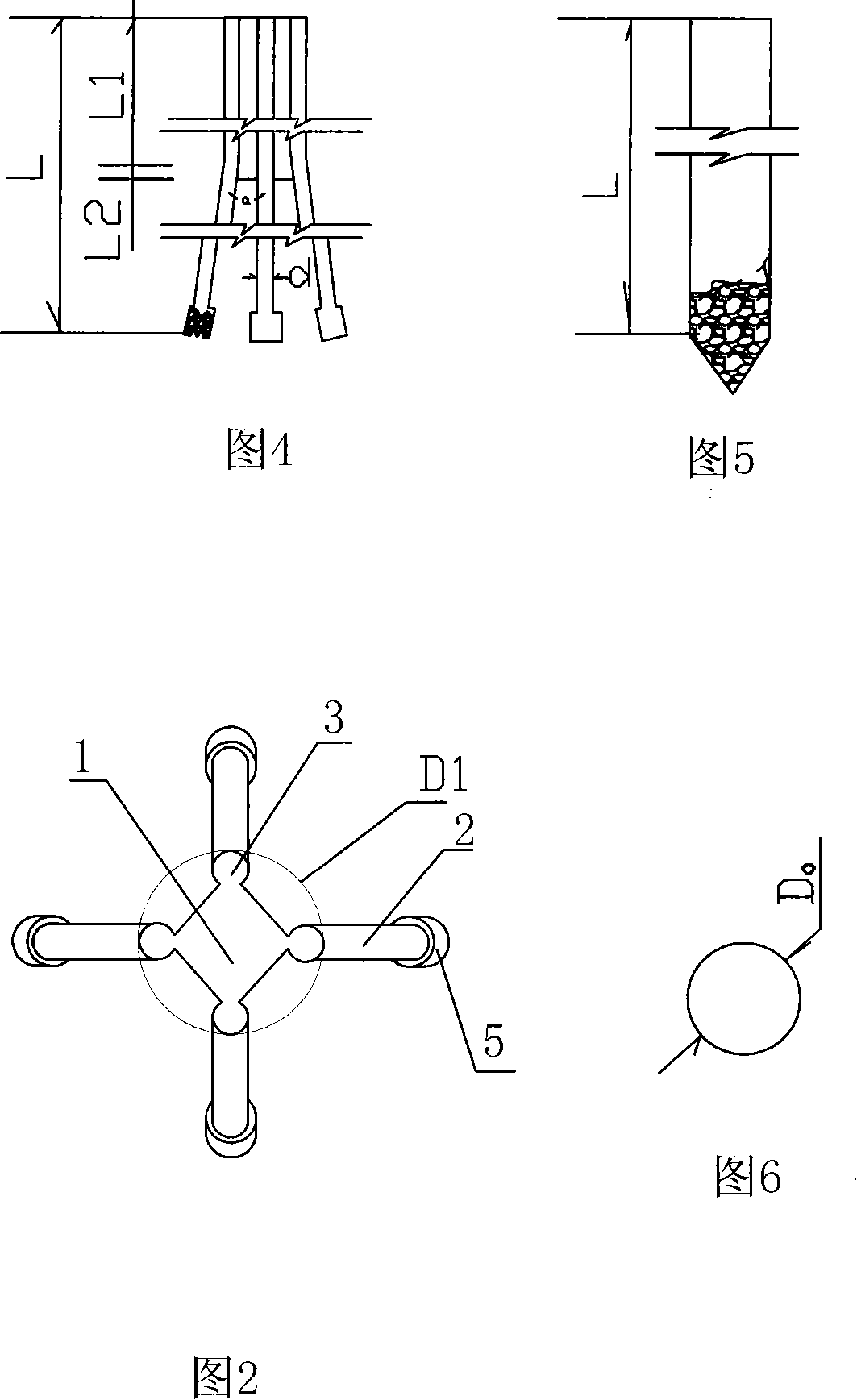

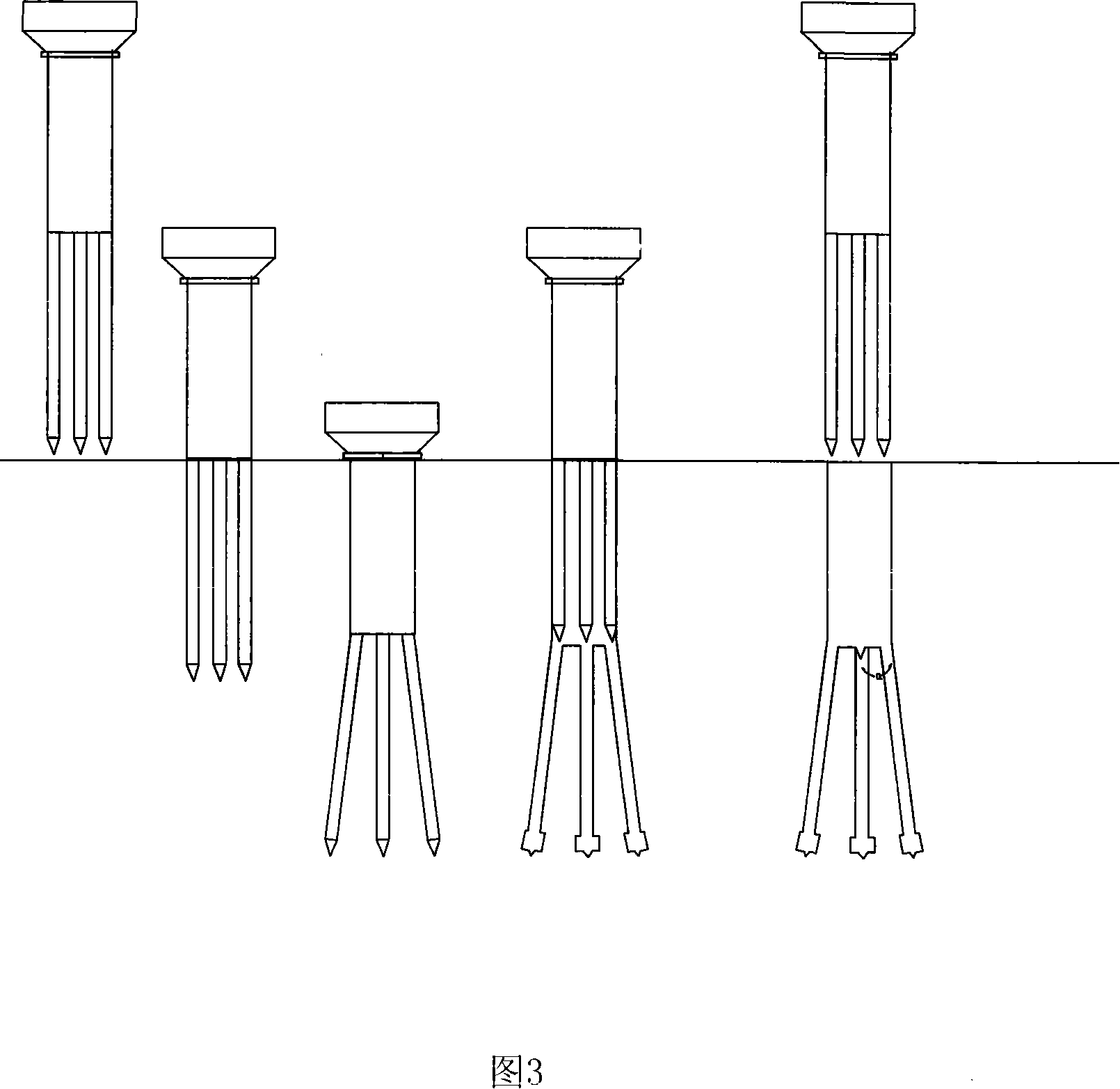

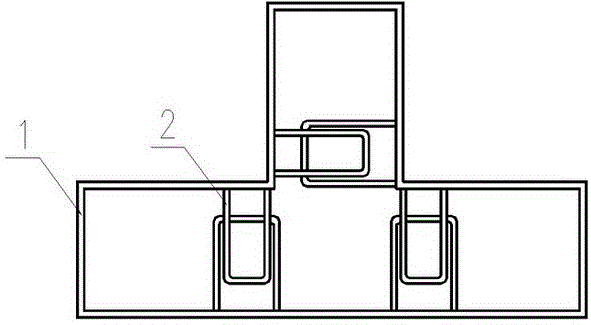

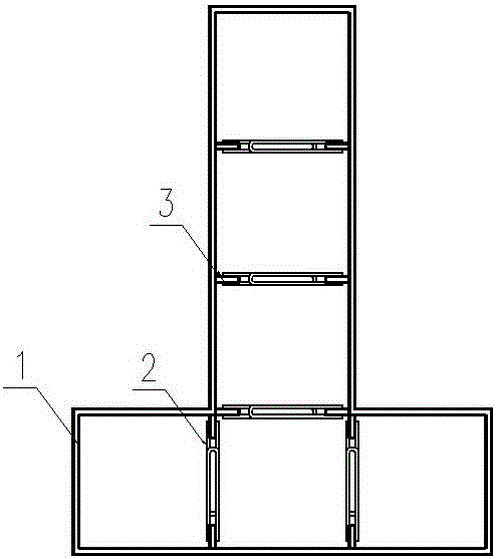

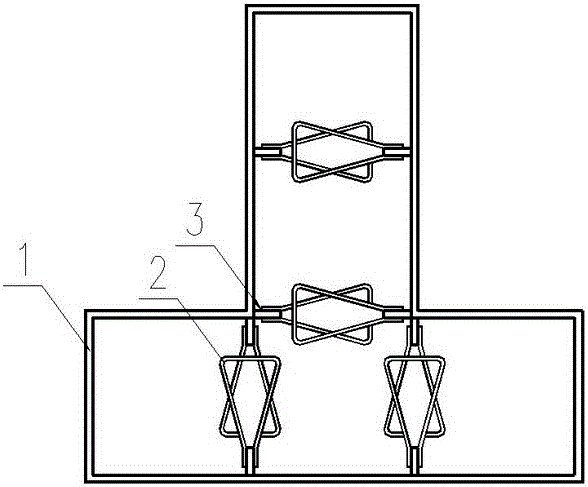

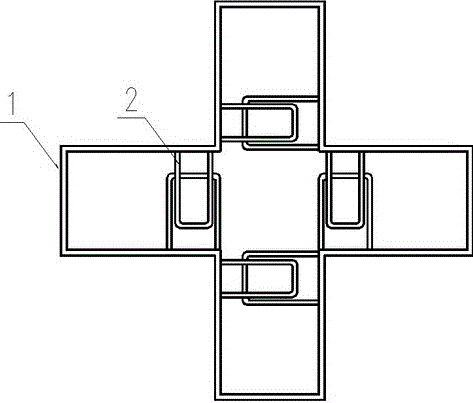

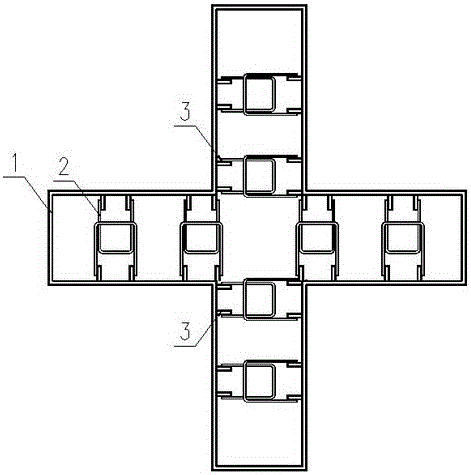

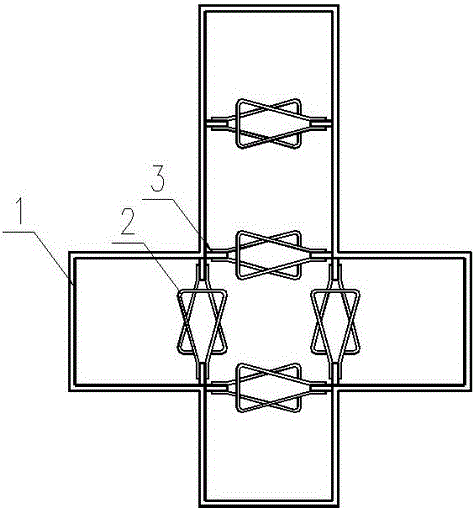

Concrete pile structure

InactiveCN101139834AImprove the bending stiffness EIIncrease pressureBulkheads/pilesStructural engineeringFriction force

The invention discloses an invented concrete pile structure appearing in a tree root shape. The structure is characterized in that the pile looks like a tree root; the trunk is a big pile body (1); the tree root is a small pile body (2); the corss section of the big pile body (1) is in a petal shape; the number of the small pile bodies (2) corresponds with that of the petal-shaped leaf structure (3); the central line of the small pile body (2) is formed into an included angle ''a'' against that of the big pile body (1). The invention is characterized by high friction force against foundation earth; if executed throughout the country, the consumption of cement, sand, macadam and steel can be considerably lowered, so that large quantity of resources can be saved. Therefore, it is hoped to result in a revolution in architectural engineering execution.

Owner:夏良站

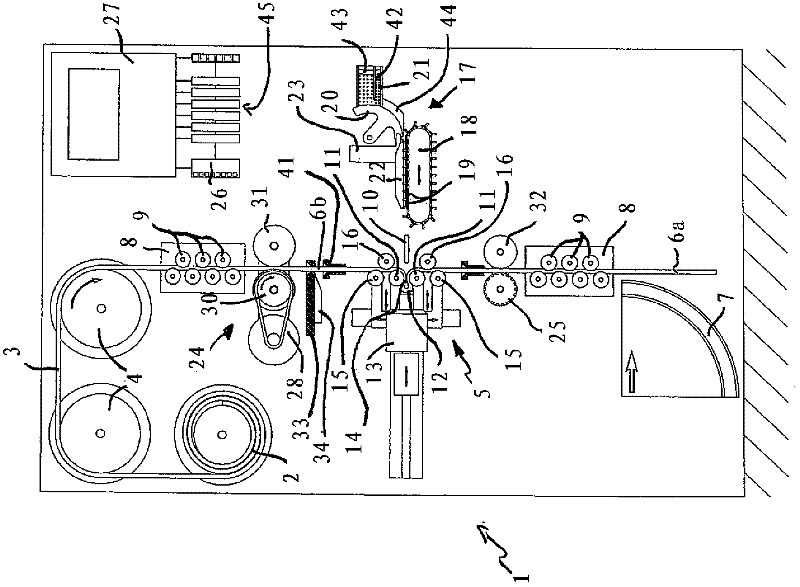

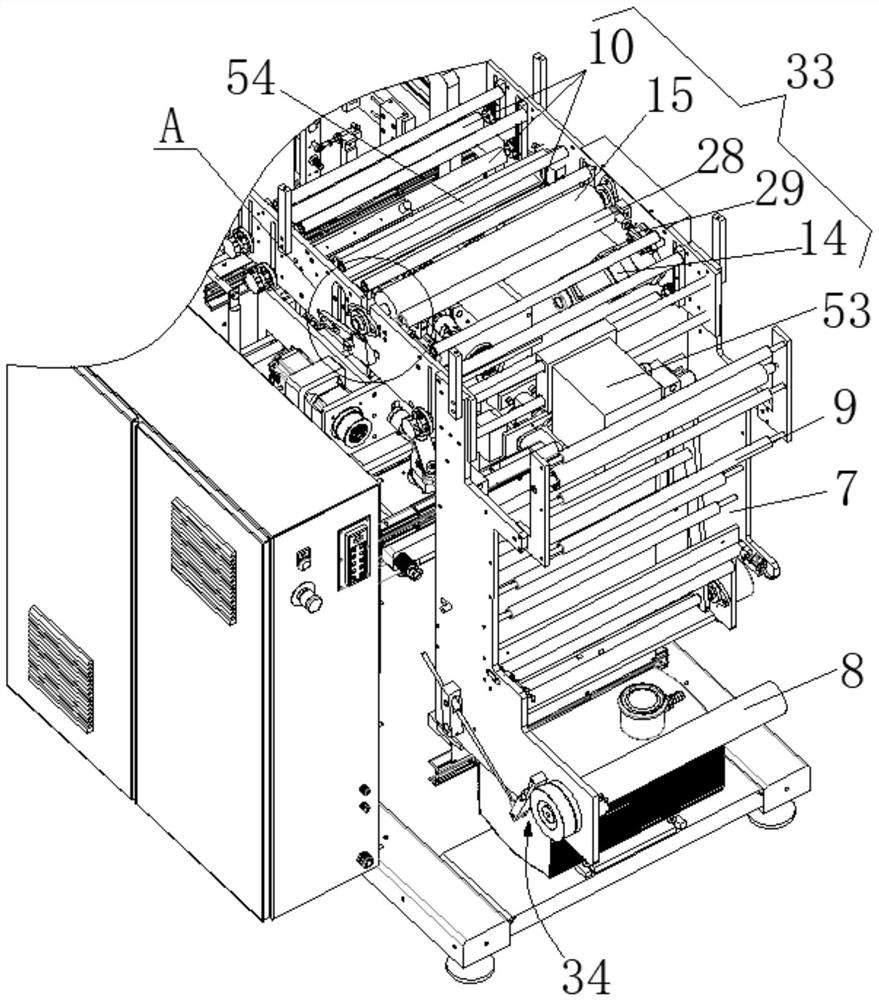

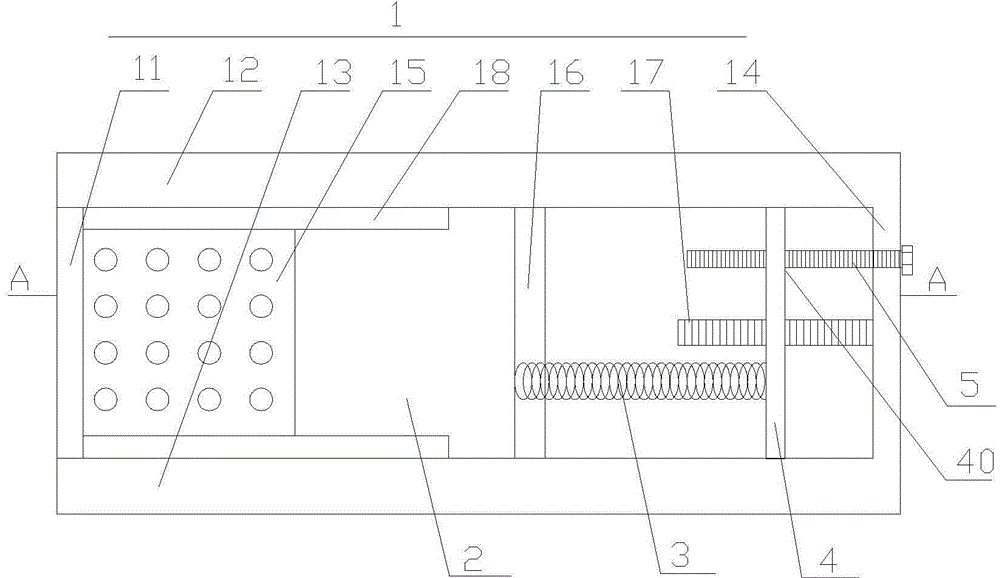

Continuous printing and dyeing ironing machine

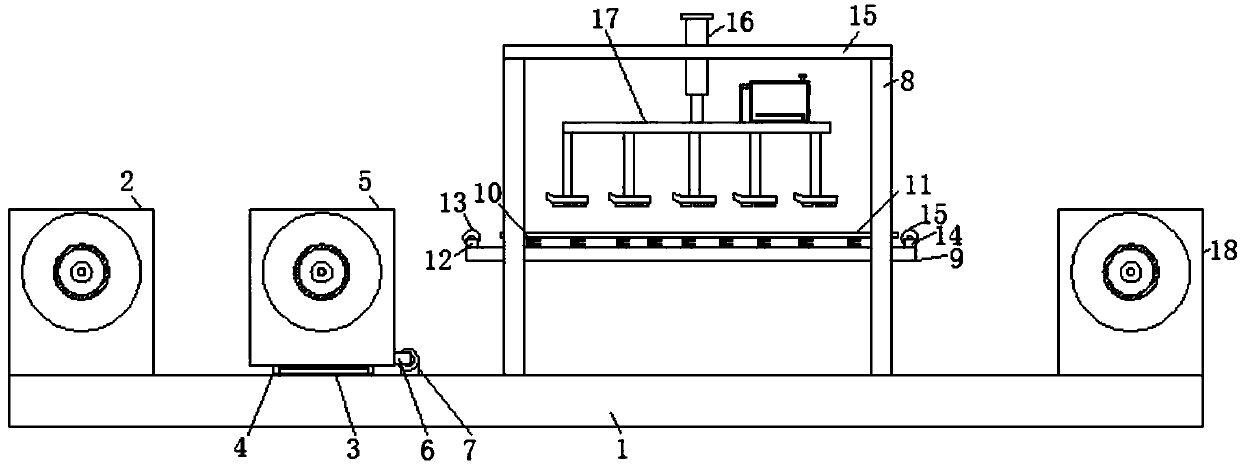

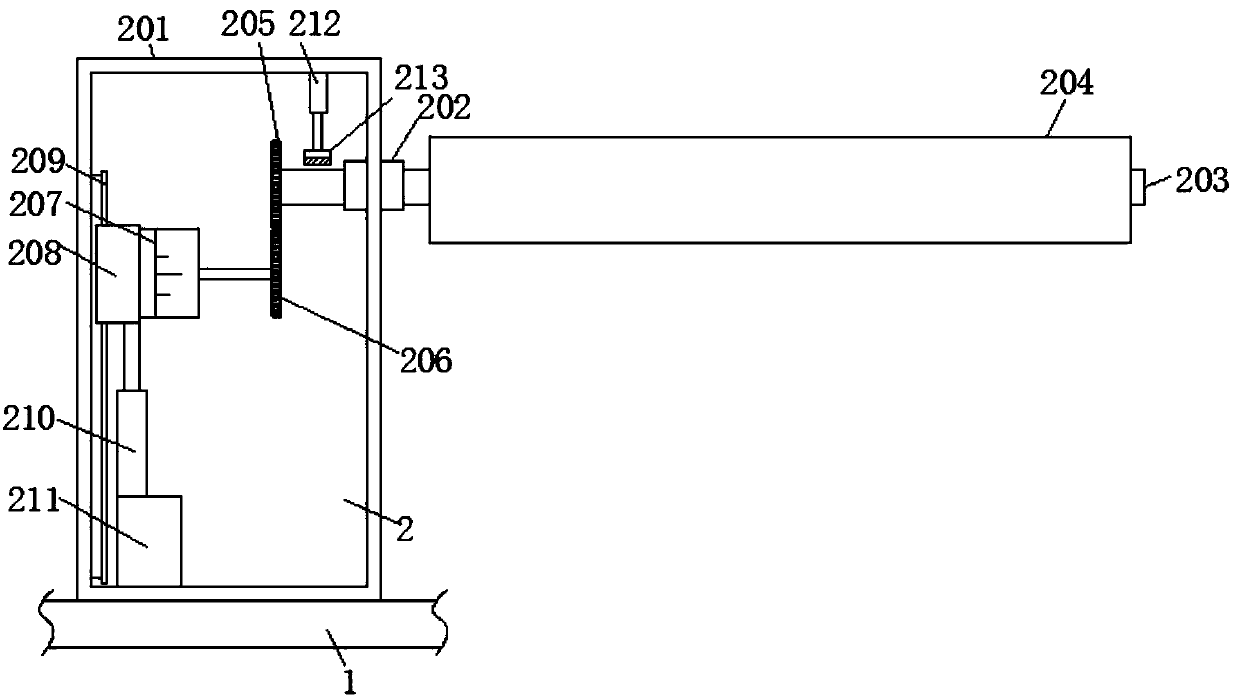

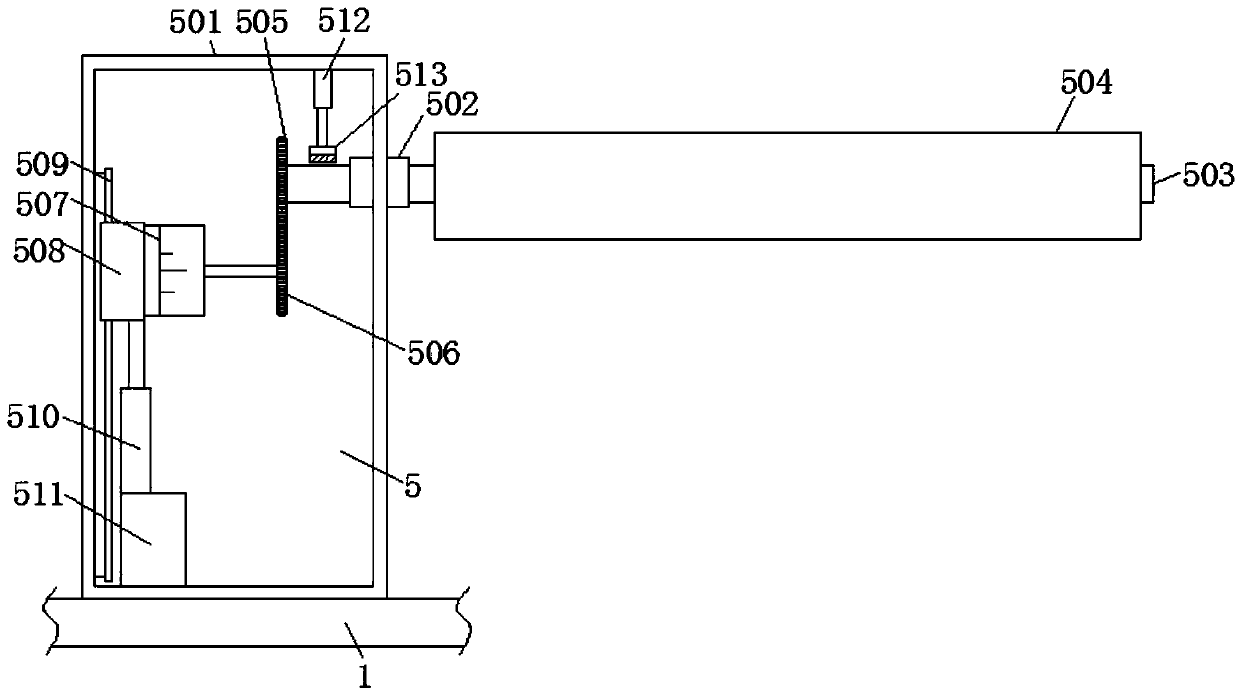

PendingCN107938240APlay the effect of ironing fabricIncrease pulling forceTextile shapingWebs handlingWinding machineElectric machine

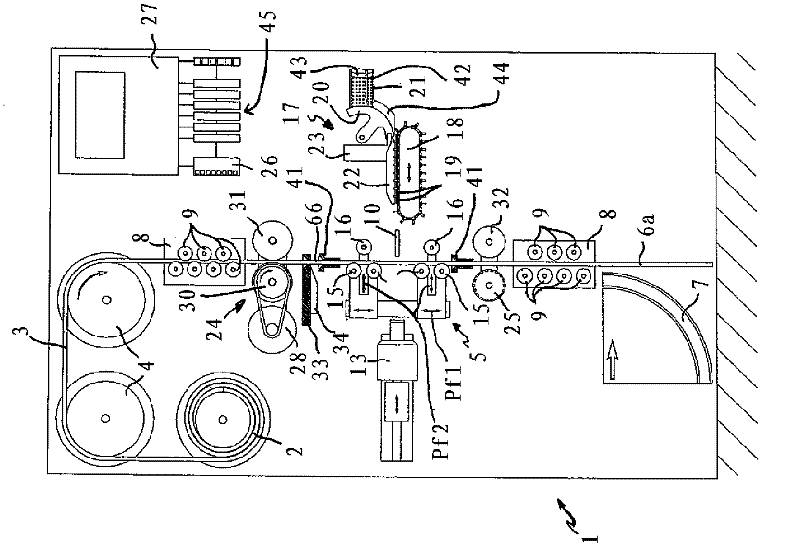

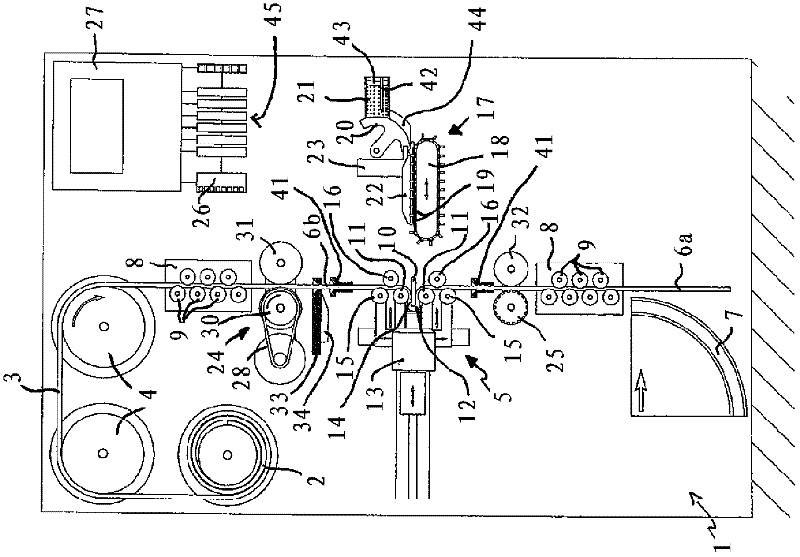

The invention relates to the technical field of printing and dyeing equipment and discloses a continuous printing and dyeing ironing machine. The continuous printing and dyeing ironing machine comprises a base plate, wherein the top of the base plate is fixedly connected with the bottom of a first unreeling machine and the bottoms of first sliding rails; in addition, the first sliding rails are positioned right above the first unreeling machine and are in sliding connection with a first sliding block; the tops of the first sliding rails are fixedly connected with the bottom of a second unreeling machine; one side, away from the first unreeling machine, of the second unreeling machine, is fixedly connected with one side of a baffle; the back side of the baffle is fixedly connected with thefront side of a first electric push rod. According to the continuous printing and dyeing ironing machine, the first unreeling machine which is fixedly connected with the top of the base plate and a reeling which is fixedly connected with the top of the base plate are matched with the first sliding rails, the first sliding block, the second unreeling machine and the first electric push rod; when cloth on the second unreeling machine is unreeled, cloth on the first unreeling machine is connected with the cloth on the second unreeling machine, so that an effect of continuously ironing the cloth is realized.

Owner:绍兴尹创机械科技有限公司

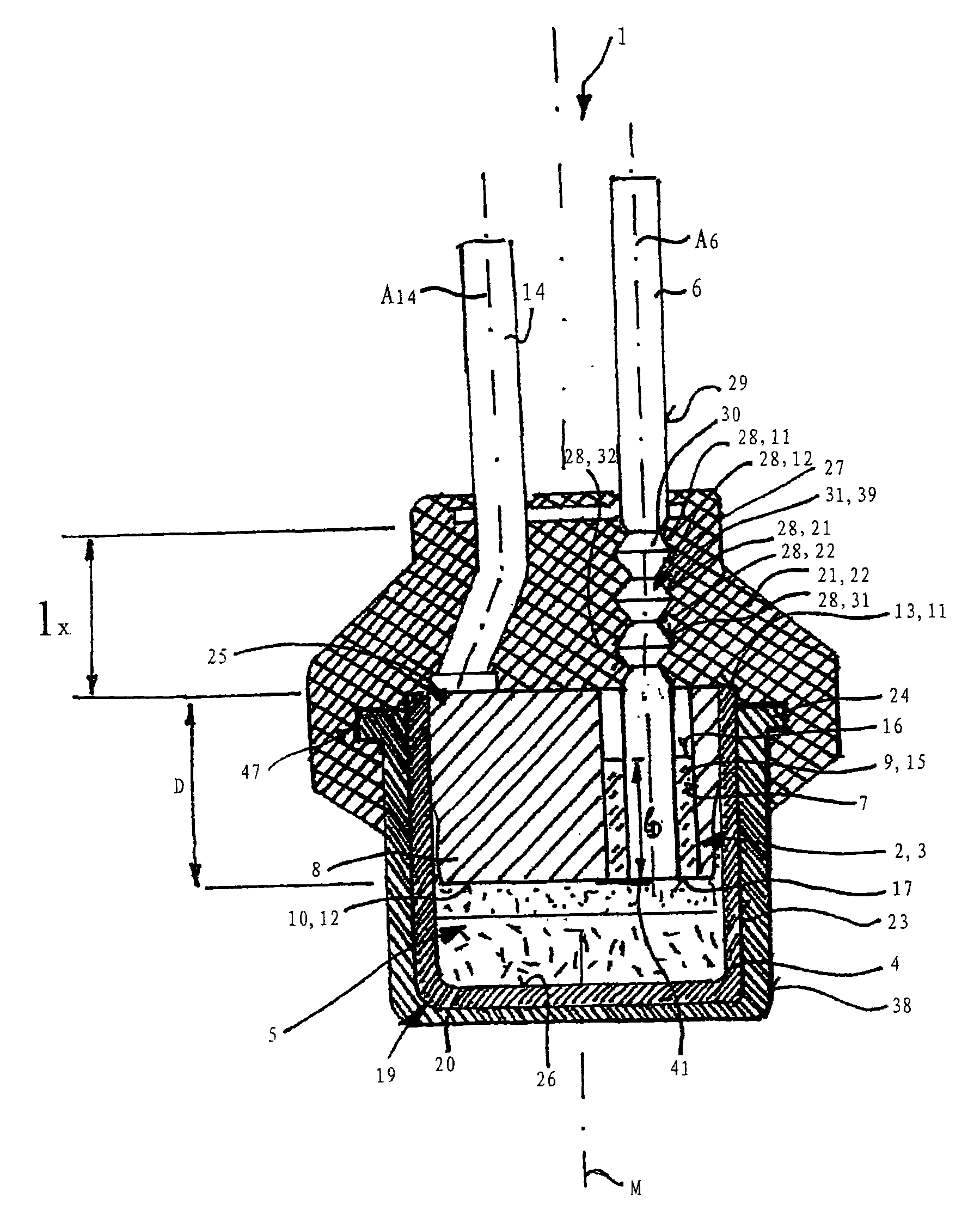

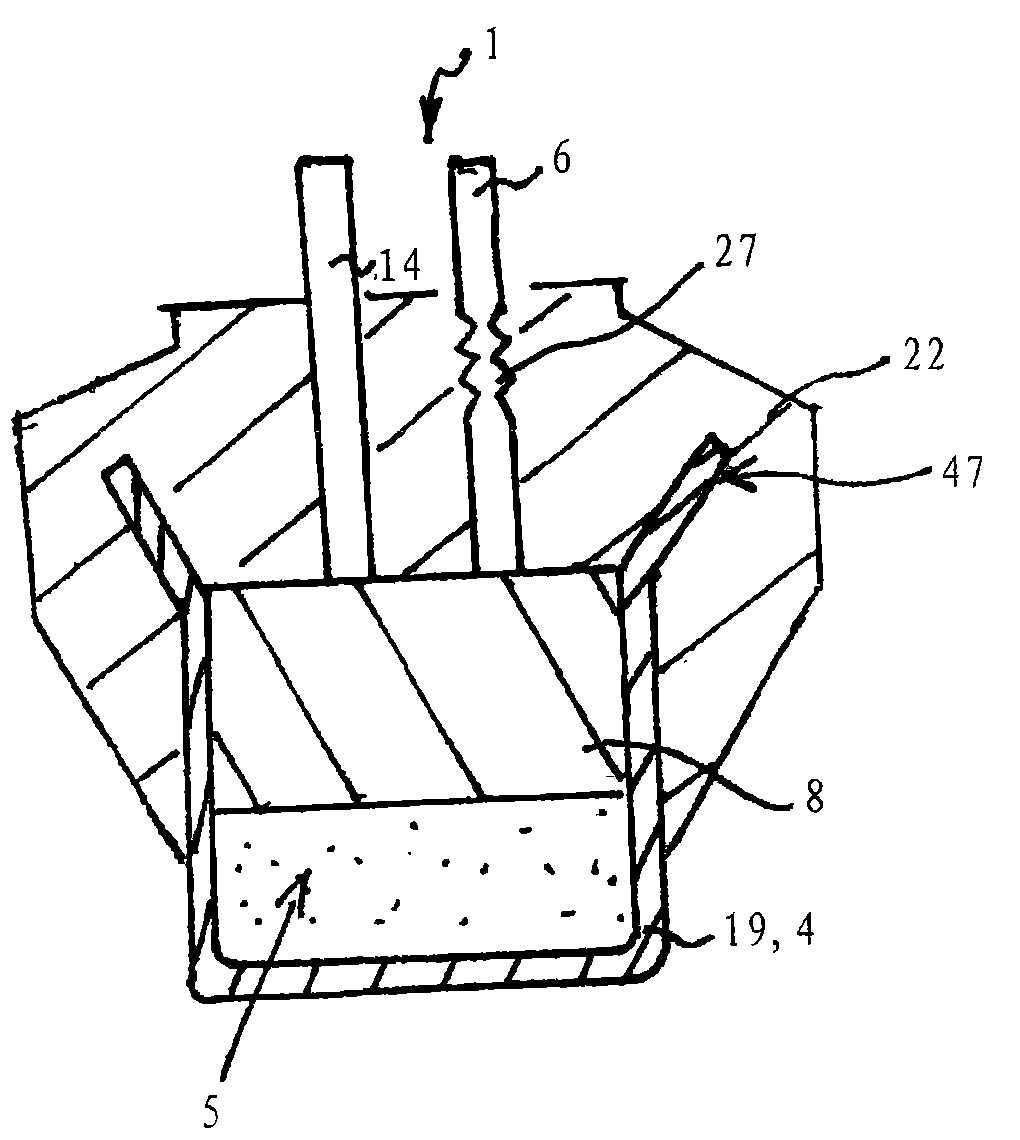

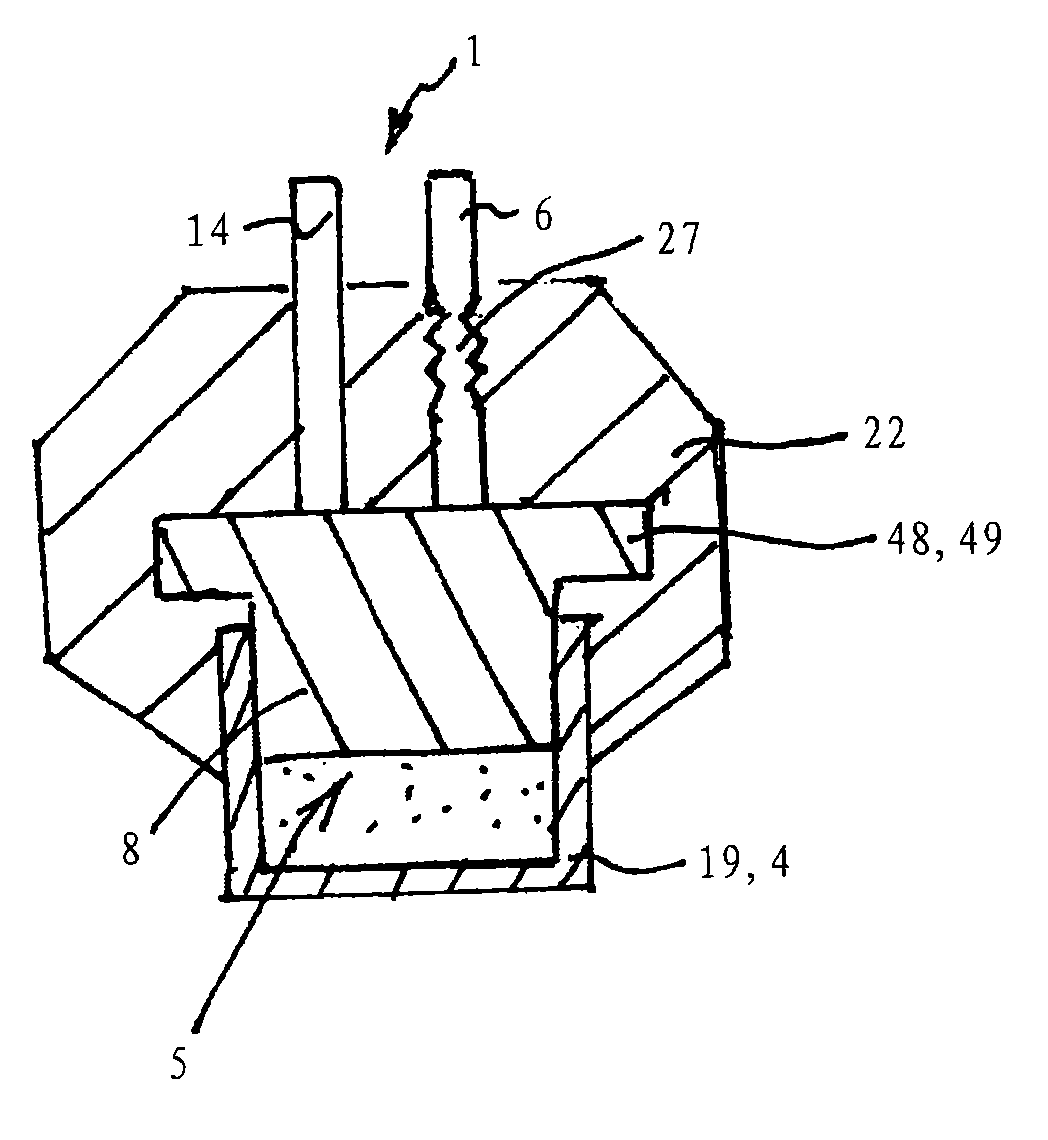

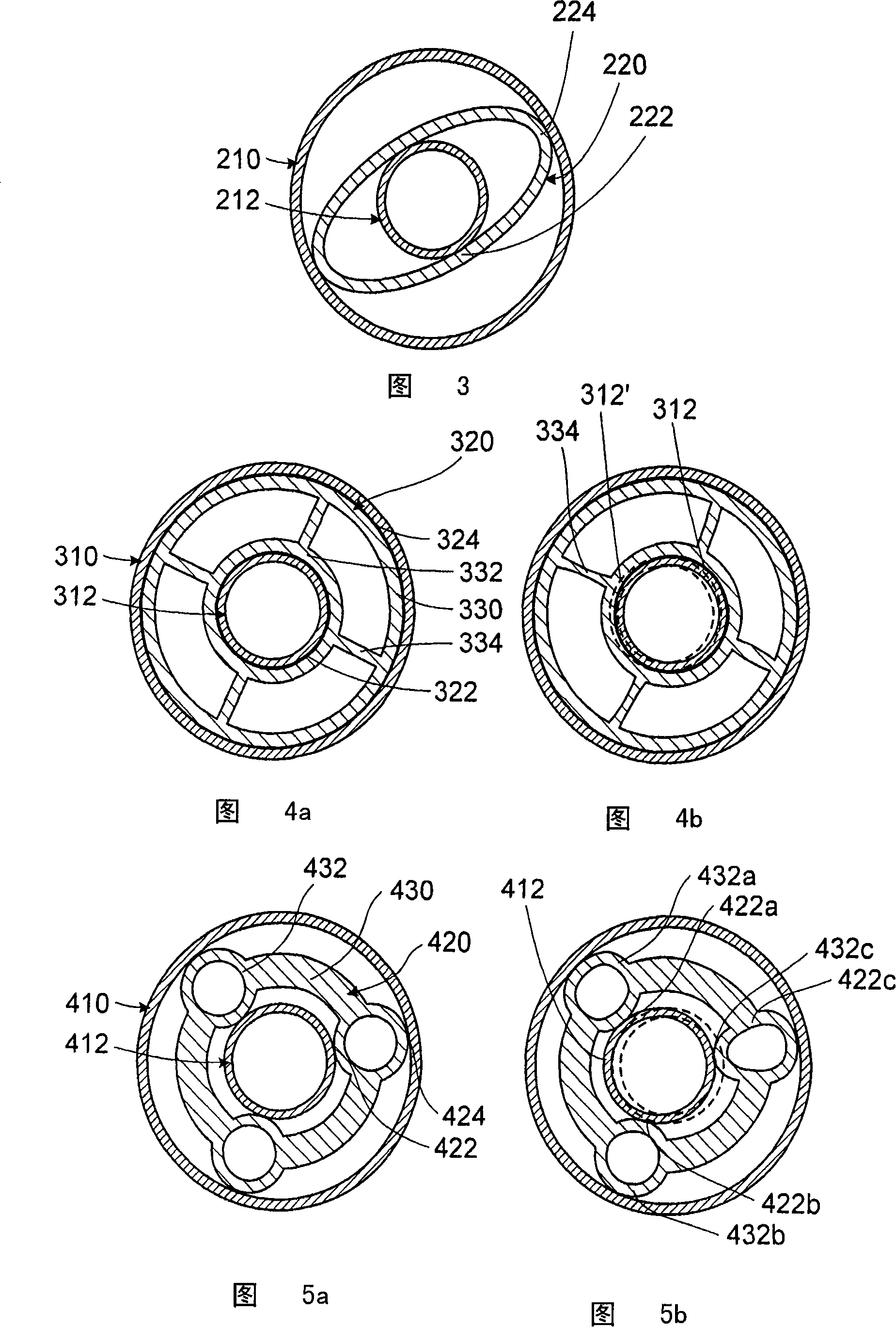

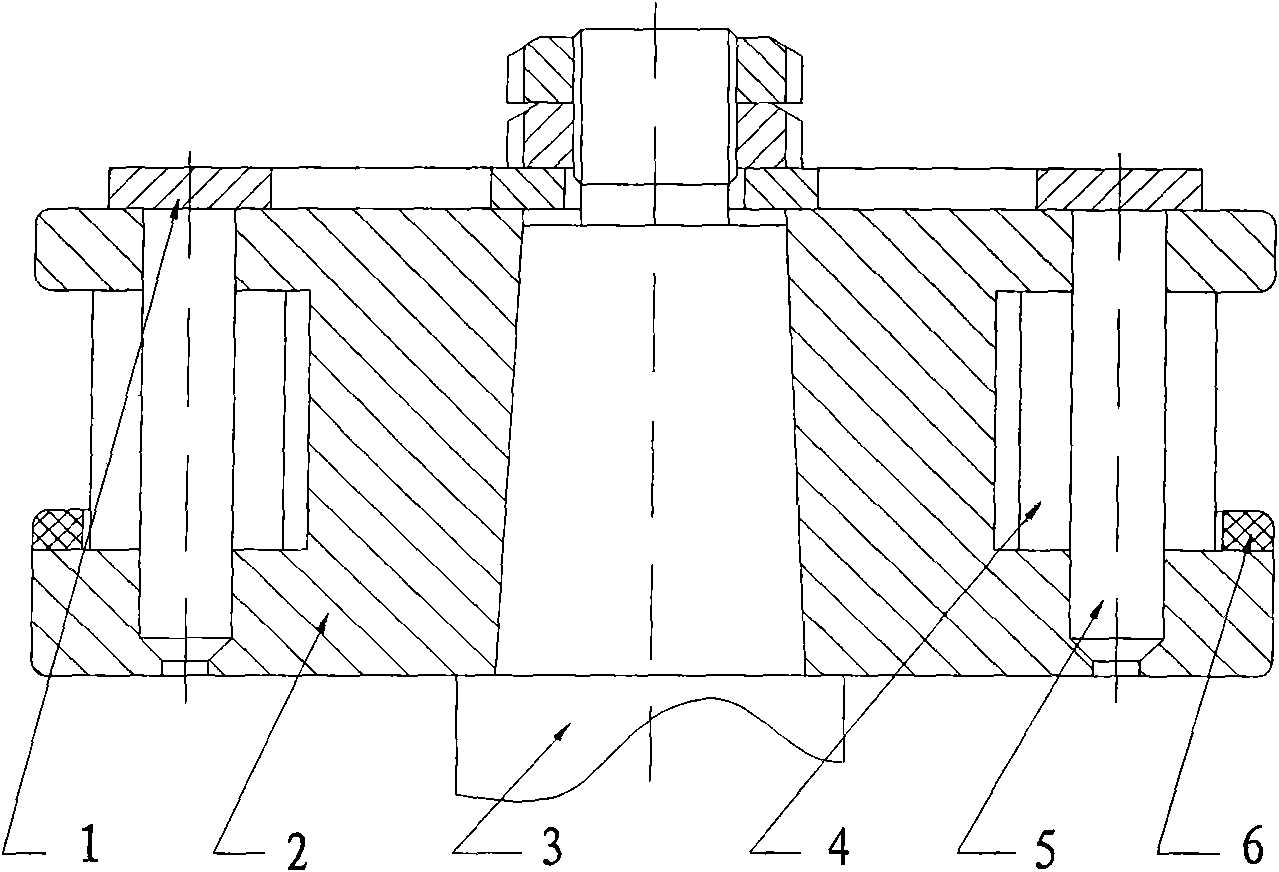

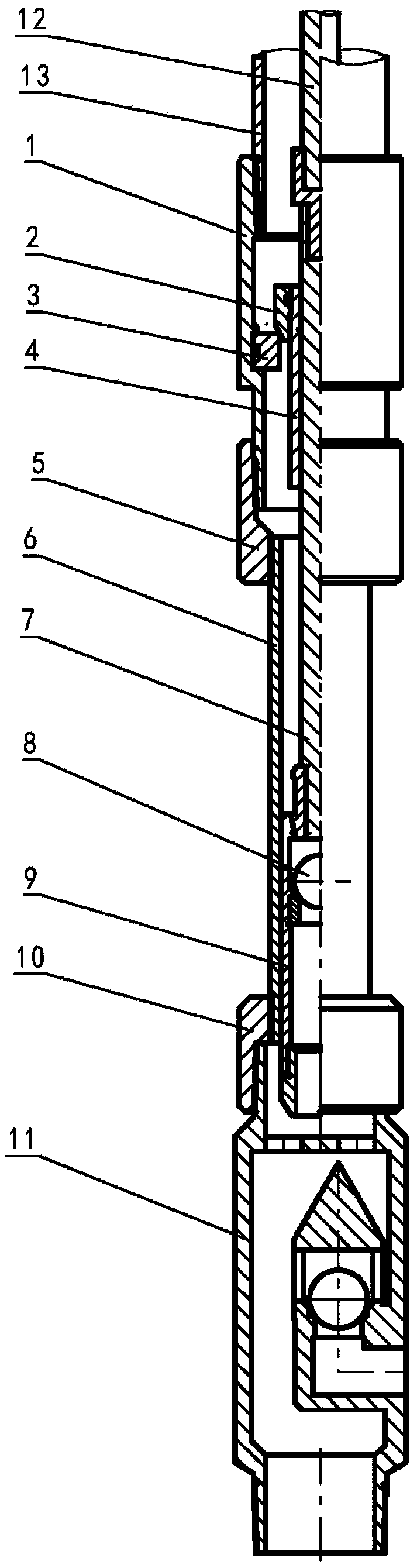

Firing apparatus for a pyrotechnic protection apparatus

ActiveCN101595363AIncrease pulling forceHigh strengthBlasting cartridgesAmmunition fuzesEngineeringAirbag

The invention relates to an apparatus, in particular a firing apparatus (1) for a pyrotechnic protection apparatus, in particular an airbag or belt pretensioner, comprising: a power leadthrough, in particular a metal fixing material leadthrough (2), comprising a base body (8) which is provided with a passage opening (7), and at least one metal pin (6) which is arranged in the passage opening (7) in the base body (8) in a fixing material (6); a housing part (19, 4) which at least partially accommodates the power leadthrough so as to form a space for accommodating a propellant charge (5); a casing (22) which at least partially surrounds the power leadthrough (2), the metal pin (6) and the housing part (19, 4); wherein the base body (8) has a thickness D in the range of from 2.0 mm to 0.1 mm, preferably in the range of from less than 1.0 mm to 0.1 mm, in particular less than 0.8 mm to 0.5 mm, and means (27) are provided on the metal pin (6) in such a way that the casing (22) engages with the metal pin, wherein the casing and the base body together absorb a pull-out force of the metal pin which is greater than 150 N, in particular greater than 165 N, preferably greater than 200 N, in particular greater than 250 N, in particular greater than 300 N.

Owner:SCHOTT AG

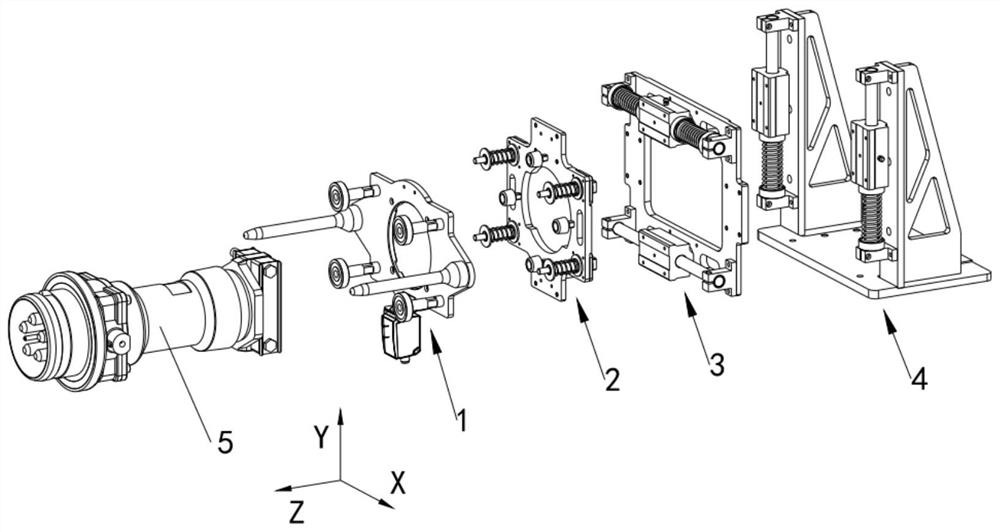

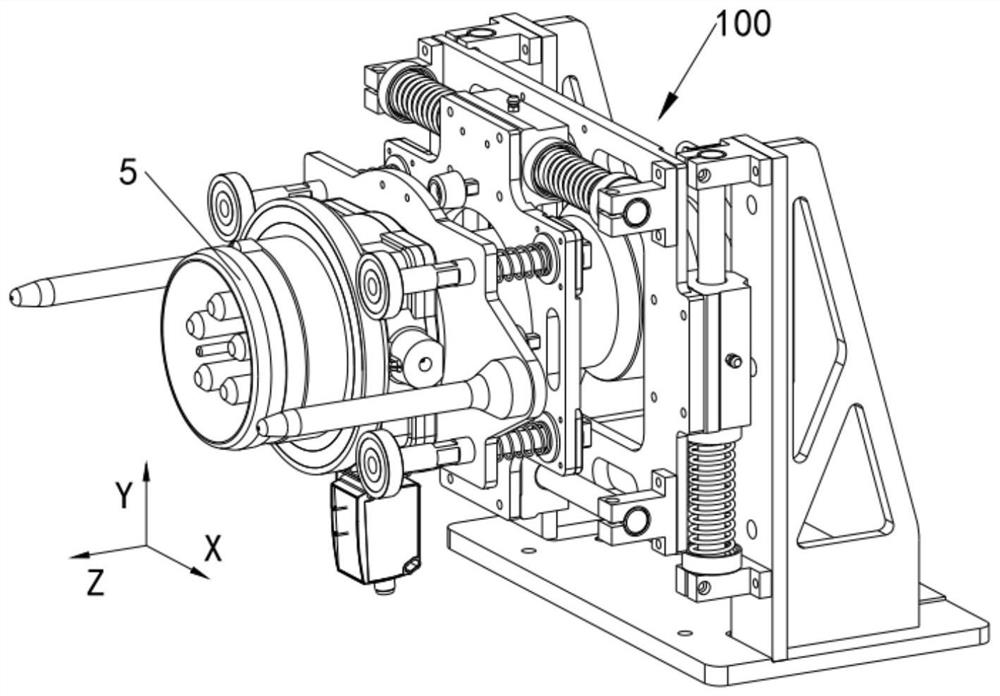

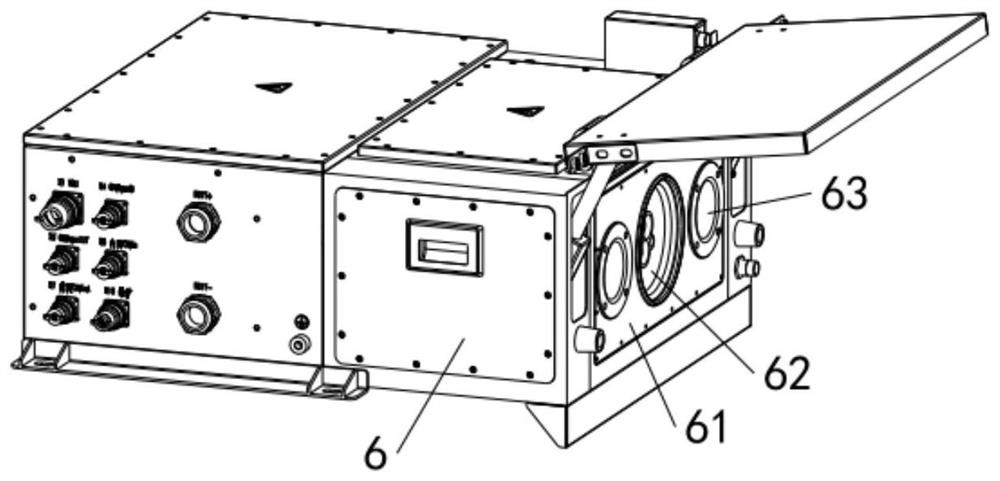

Pose compensation device for butting connector and connector assembly

PendingCN111740279ASimple structureRealize full compensationCharging stationsElectric vehicle charging technologyStructural engineeringMechanical engineering

The invention relates to the field of connectors, and discloses a pose compensation device for butting a connector and a connector assembly. The pose compensation device comprises a mounting assembly,a first panel assembly, a second panel assembly and a base assembly which are sequentially arranged in the Z direction. The pose compensation device provided by the invention is simple in structure;the connector can rotate in the X direction, the Y direction and the Z direction and reciprocate in the Z direction through the first panel assembly. The second panel assembly enables the connector tomove back and forth along the X direction. The connector can move back and forth in the Y direction through the base assembly, so that the connector is in floating connection with a structure in buttjoint with the connector, six-degree-of-freedom omnibearing compensation of the connector is achieved, the connector cannot bear large pulling force, and the connector and the structure in butt jointwith the connector are protected. The invention further provides the connector assembly which comprises the connector and the pose compensation device used for butting the connector, and the connector is connected to the installation assembly.

Owner:SHANGHAI AOWEI TECH DEV

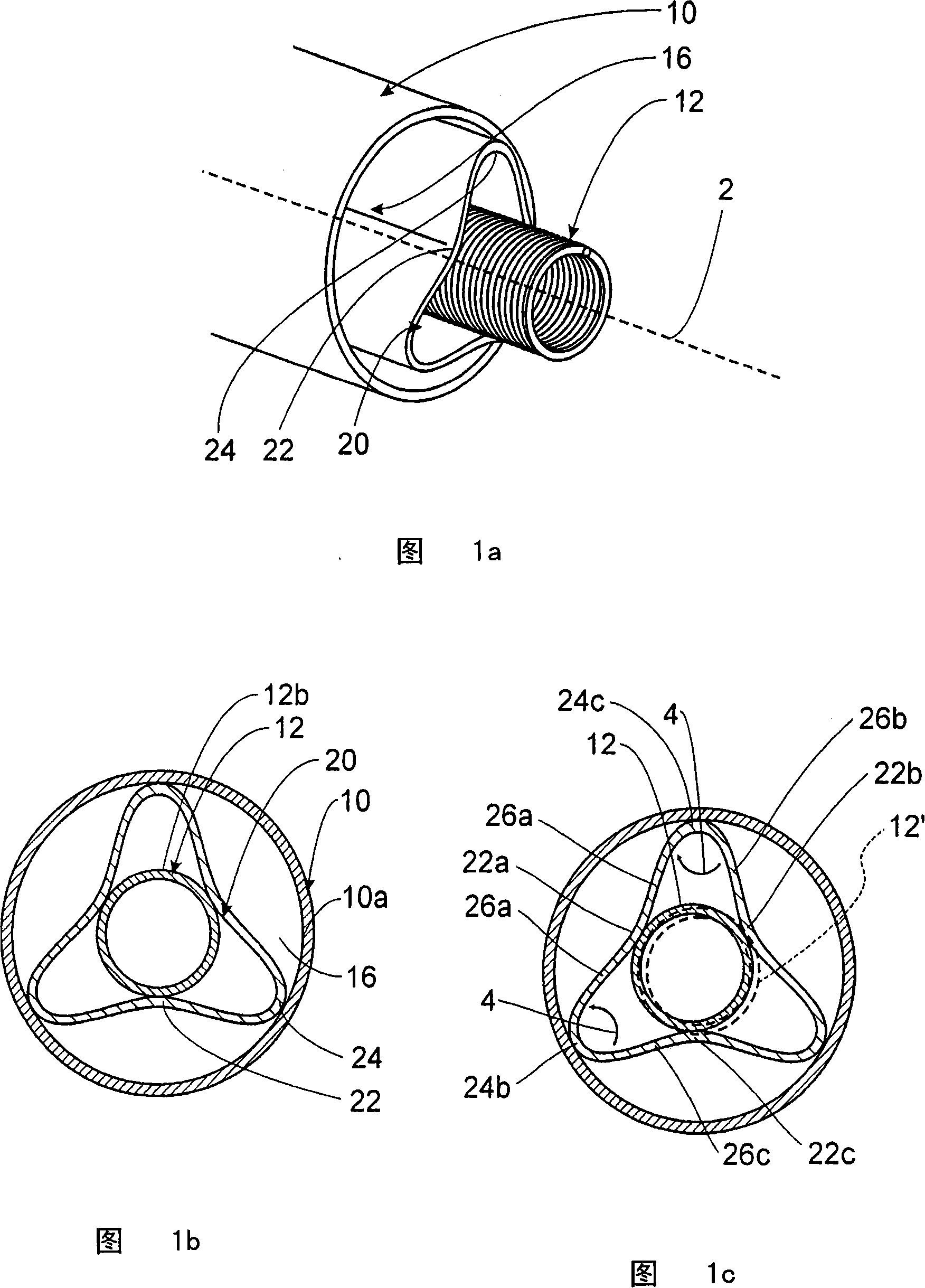

Roller blind assembly

InactiveCN101152933AEasy to fixIncrease pulling forceWindowsShutters/ movable grillesIn vehicleCoil spring

The invention relates to a roller blind arrangement, in particular for use in a vehicle, with a winding shaft ( 10 ) which extends in a main direction of extent ( 2 ), is in the form of a hollow tube and is intended for receiving an unwindable flexible sheetlike structure, a winding spring ( 12 ) which is inserted into the winding shaft ( 10 ), is designed as a helical spring and extends in the main direction of extent, and a damping profile ( 20 ) which extends in the main direction of extent ( 2 ) and is arranged in an annular space ( 16 ) between the winding shaft ( 10 ) and the winding spring ( 12 ). According to the invention, the damping profile ( 20 ) is designed in such a manner that it bears with outer contact sections ( 24 ) against an inner side of the winding shaft ( 10 ) and with inner contact sections ( 22 ) against an outer side of the winding spring ( 12 ). Use, in particular roller blind arrangements in vehicles, for example for coverings of the boot.

Owner:BOS

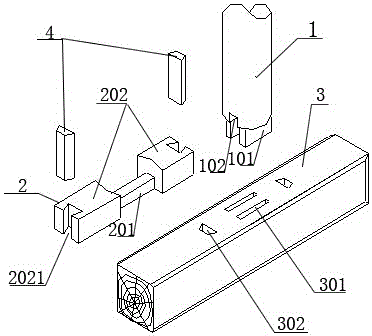

Reinforcement treatment structure for joint of squat queen post and beam of historic building

The invention relates to a reinforcement treatment structure for a joint of a squat queen post and a beam of a historic building. A base of the squat queen post is clamped on the beam by virtue of a wood component, a double tenon is arranged on the base of the squat queen post, a double tenon mortise matched with the double tenon is formed in the beam, and reinforcement is carried out without adopting an iron clasp nail, flat steel or angle steel on the basis that the original material and construction technology are not changed, and only a wood structure is adopted for carrying out reinforcement treatment on the joint of the squat queen post and the beam of the historic building.

Owner:河南梦森建筑工程服务有限公司

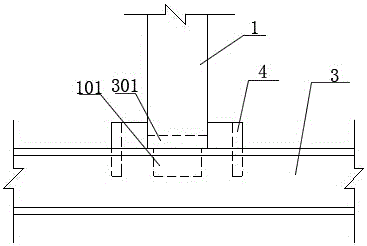

Reinforcement treatment structure for joint of baotou beam and hypostyle column of historic building

ActiveCN105888289AImproves integrity and shock resistanceReduce the chance of damageBuilding repairsThick sectionThin section

The invention discloses a reinforcement treatment structure for a joint of a baotou beam and a hypostyle column of a historic building. One end of the baotou beam is a through tenon. The hypostyle column is provided with a baotou beam mortise. The through tenon is inserted into the baotou beam mortise and passes through from the other side of the hypostyle column. A crosser is arranged below the baotou beam in parallel. The crosser is composed of a thin section in the middle and thick sections at the two ends of the thin section, wherein the thin section and the thick sections have the same height. A thin section mortise is formed below the baotou beam mortise. The thin section is clamped into the thin section mortise. The thick sections at the two ends are clamped to the two sides of the hypostyle column. On the basis of not changing raw materials and construction technology, the joint of the baotou beam and the hypostyle column of the historic building is reinforced.

Owner:江苏殷巧建设有限公司

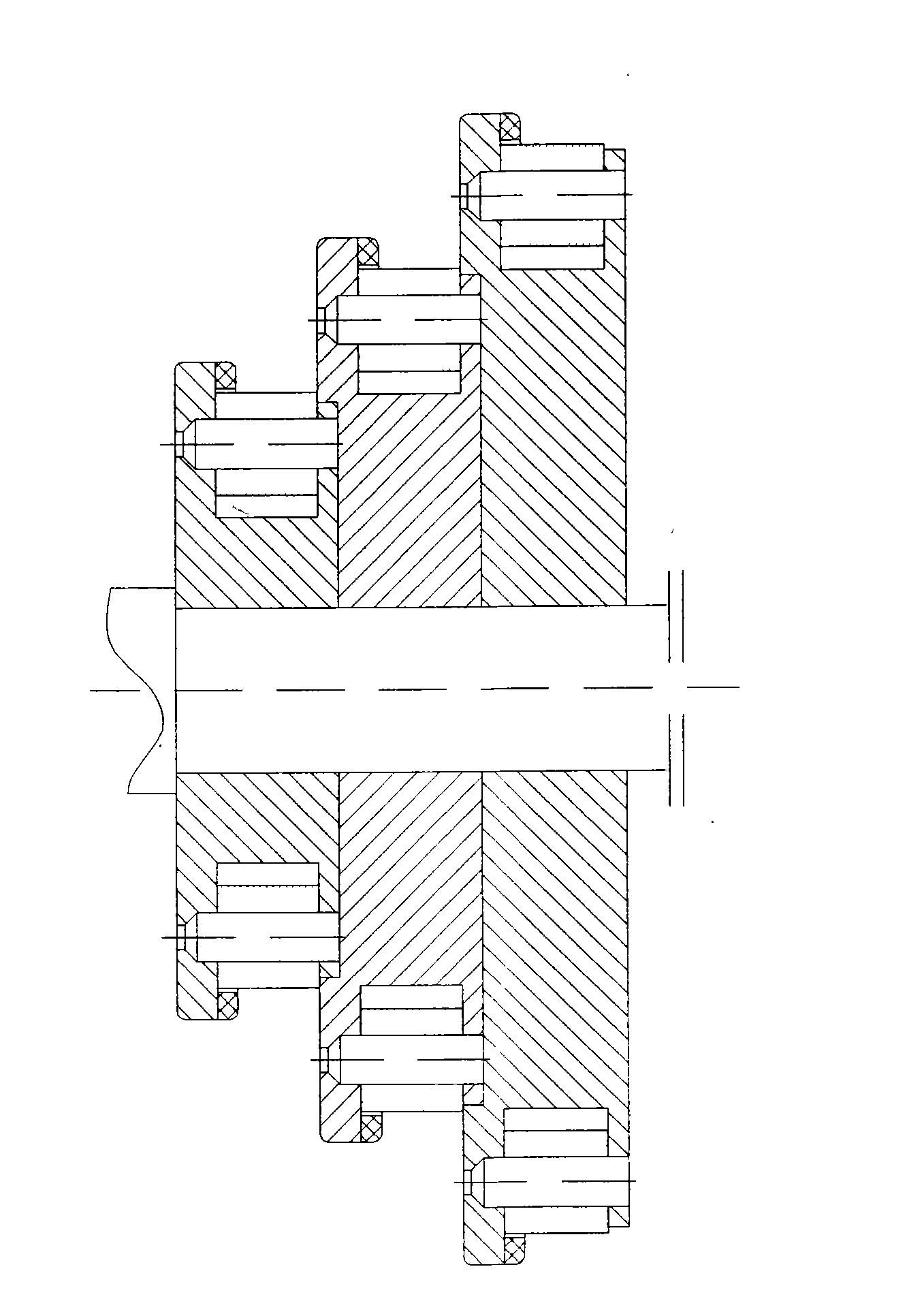

Planet rolling intermediate winding drum of wire drawing machine

The invention relates to wire drawing production equipment of the wire product industry, in particular to a straight line type wire drawing machine, a loop type wire drawing machine and a pulley typecontinuous wire drawing machine. The wire drawing production equipment comprises a planet rolling intermediate winding drum of the wire drawing machine, which is assembled by a drawing wheel, a planetary wheel, a planetary wheel shaft, a chafing slice and a compression ring. The invention provides the planet rolling intermediate winding drum of the wire drawing machine, which has the effect of back pull drawing. The planet rolling intermediate winding drum of the wire drawing machine can eliminate an automatic speed regulation system with the complicated and expensive intermediate winding drumand obviously reduce equipment cost when used in the straight line type wire drawing machine and the loop type wire drawing machine; and the planet intermediate winding drum can make the pulley typecontinuous wire drawing machine have the property characteristics of the straight line type wire drawing machine and has obvious effect of back pull drawing when used as the intermediate winding drumof the pulley type continuous wire drawing machine. The magnitude of a drawing force of the planet rolling intermediate winding drum is determined by friction moment and the quantity of the planetarywheel; and when the wire slides off on the planet rolling intermediate winding drum, the planetary wheel can freely rotate and apply work by using the rolling friction moment of the planetary wheel. The wire drawing production equipment can obviously reduce drawing energy consumption, prolong the service life of grinding tools, and effectively solve the problem of scratching wires.

Owner:严国语

Massive concrete pouring method

The invention discloses a massive concrete pouring method. The massive concrete pouring method comprises the steps of erecting of formworks, grout making, pouring, curing, secondary pouring and the like. The ratio of the length of cooling pipes to the size of a grouting body serves as a guidance parameter for distributing the cooling pipes, so that the difficulty of secondary grouting is lowered on the premise of ensuring the proper cooling capacity of the cooling pipes, and the usage quantity of the cooling pipes and the cost are reduced; galvanized corrugated pipes or finned galvanized steel pipes are used as the cooling pipes, the contact area between the cooling pipes and the pouring body is enlarged, the stress direction is changed, and complete planar stress is changed to arc stress along the surfaces of the corrugated pipes; part of ice blocks are used for replacing part of water to carry out mixed grout making, and ice particles absorb hydration heat and melt gradually; temperature is not increased while the melting ice particles absorb a large amount of hydration heat, evaporate, dissipate and melt into water, so that the temperature inside the pouring body is further decreased.

Owner:王丰利

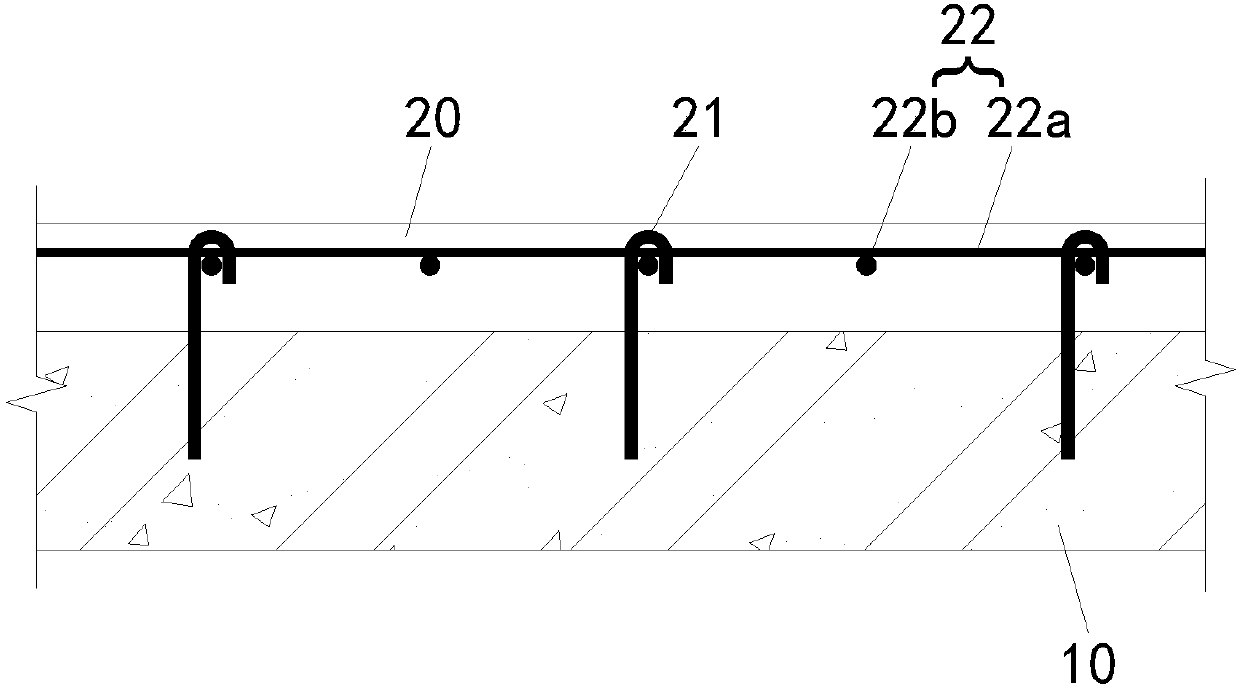

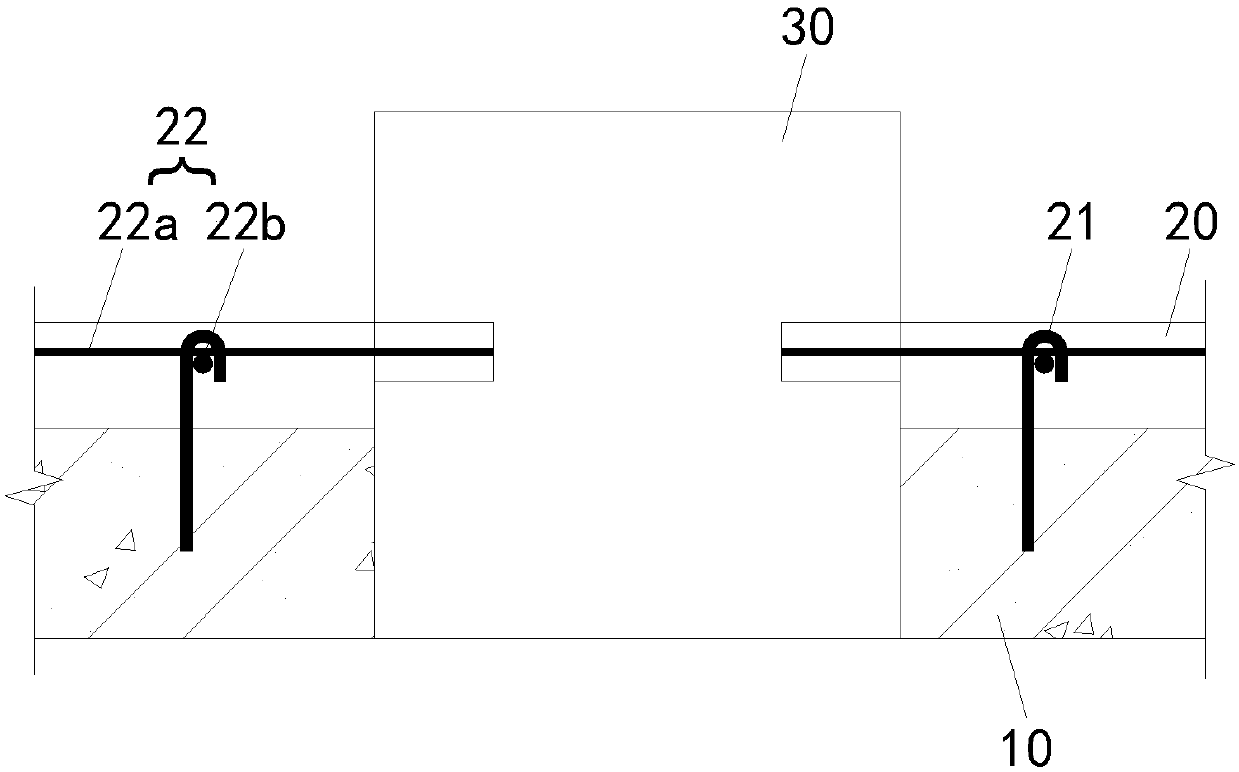

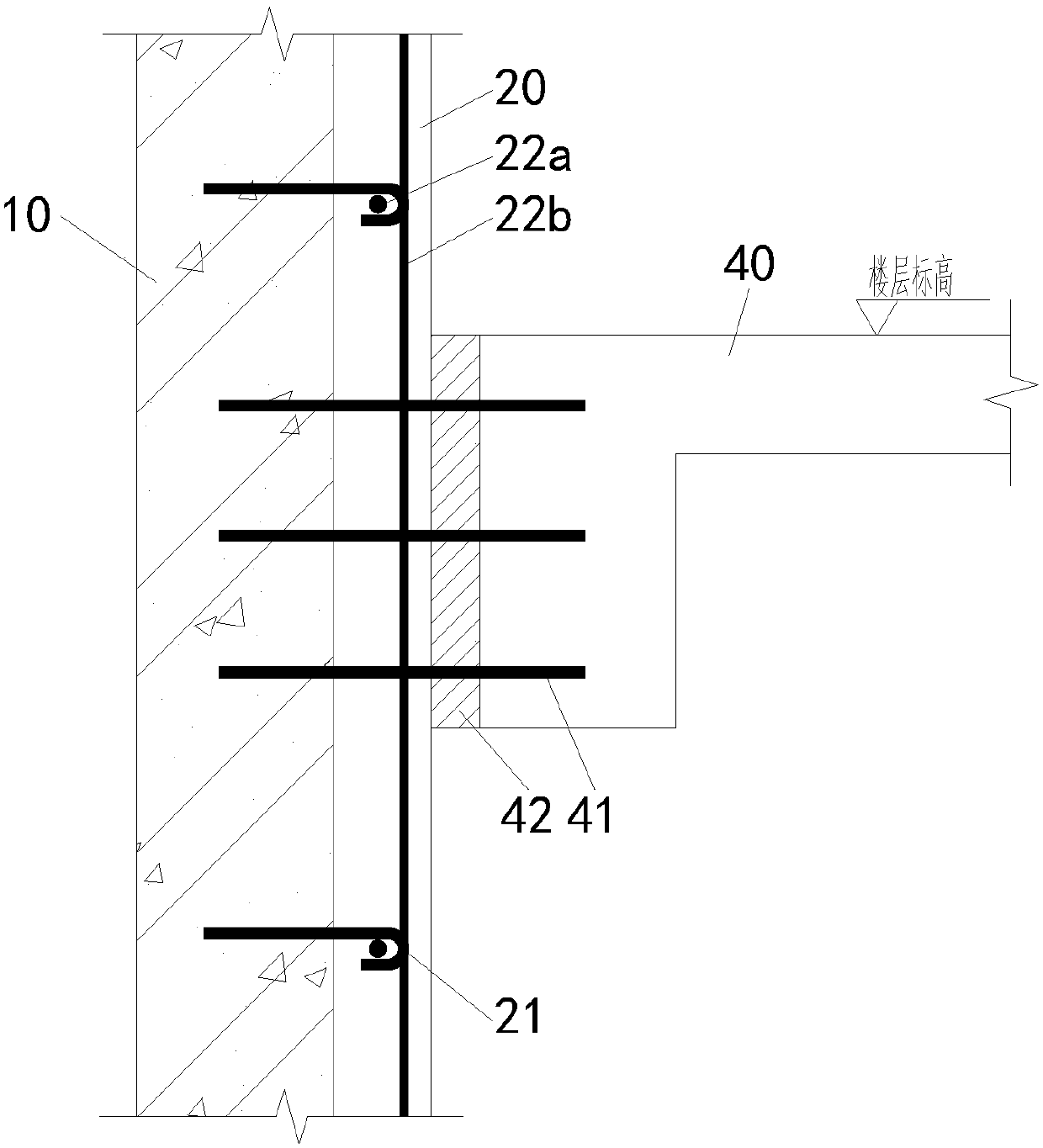

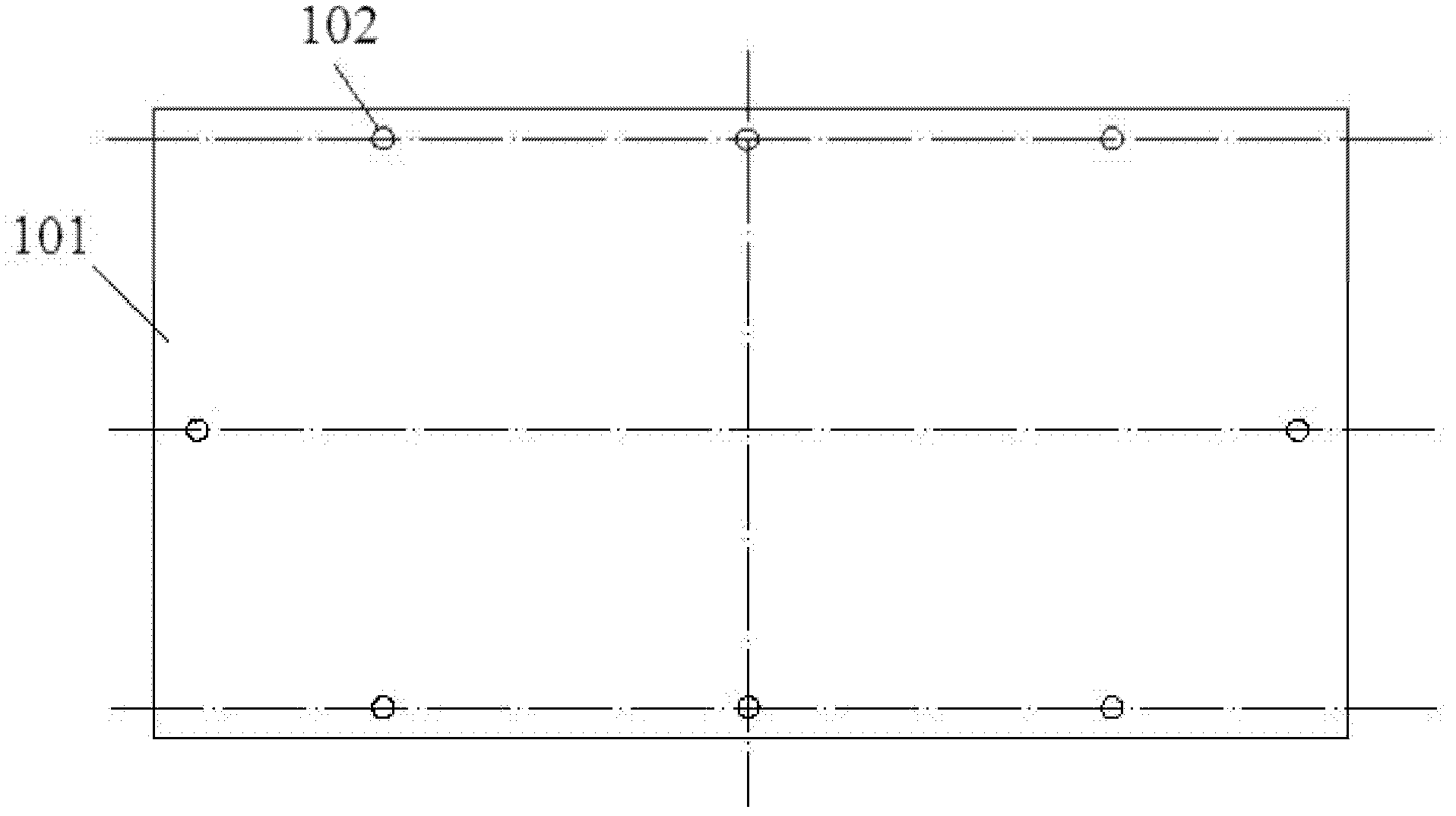

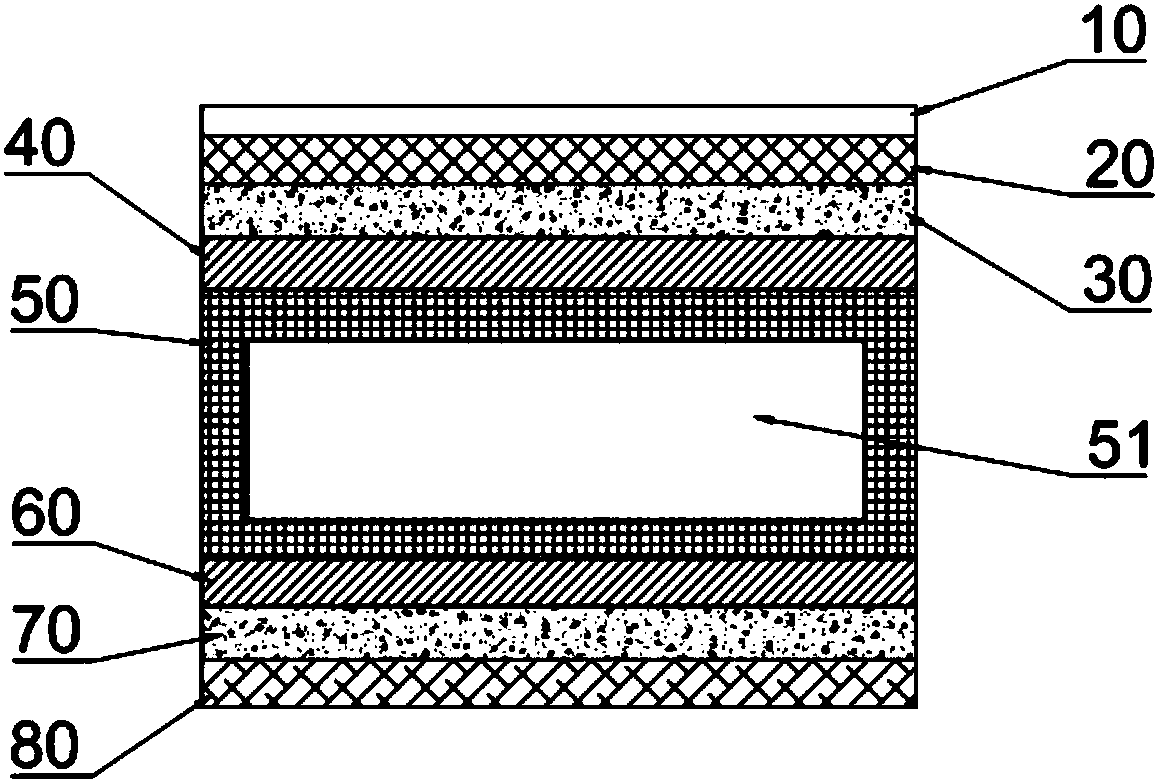

Connecting structure of reserved external wall and newly-constructed reinforced concrete horizontal component and construction method of connecting structure

InactiveCN107700668AImprove stabilityAvoid damageBuilding material handlingReinforced concreteSteel bar

The connection structure of the retained outer wall and the new steel-concrete horizontal component and the construction method thereof of the present invention relate to the technical field of building reconstruction engineering. Aiming at the problems of adding support or thickening the wall to reinforce and retain the outer wall, the internal space of the building is occupied, and the construction efficiency is low and the quality is poor. The inner lining wall is close to the inner side of the reserved outer wall, and a steel grid frame is embedded in the inner lining wall, and a number of tension bars are arranged between the reserved outer wall and the inner lining wall. It is connected with the longitudinal reinforcement of the steel grid frame, and the two ends of the horizontal shear reinforcement are implanted into the retained outer wall and the new steel-concrete horizontal member respectively. Construction method: connect one end of the tie bar with the reserved outer wall by planting bars, erect the steel grid frame of the inner wall, set the prefabricated elbow at the other end of the tie bar on the longitudinal bar of the steel grid frame, set up the formwork and pour the inner lining Wall; connect one end of several horizontal shear steel bars to the retained exterior wall by planting bars, and implant the other end into the newly-built steel-concrete horizontal member.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Asphalt mixture pavement

The invention discloses an asphalt mixture pavement. The asphalt mixture pavement is composed of an asphalt mixture and a reinforcing framework, wherein the reinforcing framework is a latticed framework, the asphalt mixture is prepared from, by weight, 15-22 parts of asphalt, 8-12 parts of gravel, 2-8 parts of waste tire particles, 22-38 parts of basalt fiber staples and 2-6 parts of mineral powder, the reinforcing framework is made from, by weight, 24-38 parts of continuous basalt fiber, 12-22 parts of glass fiber and 14-28 parts of carbon fiber. The basalt fiber staples are added in the asphalt mixture to improve the strength and high temperature and low temperature resisting performance of the asphalt mixture, the asphalt mixture pavement is not damaged both in icy and snowy weather in the north and sun exposure in the south and is good in road surface evenness, no track is also left, and the potential safety hazards brought by tracks are eliminated.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

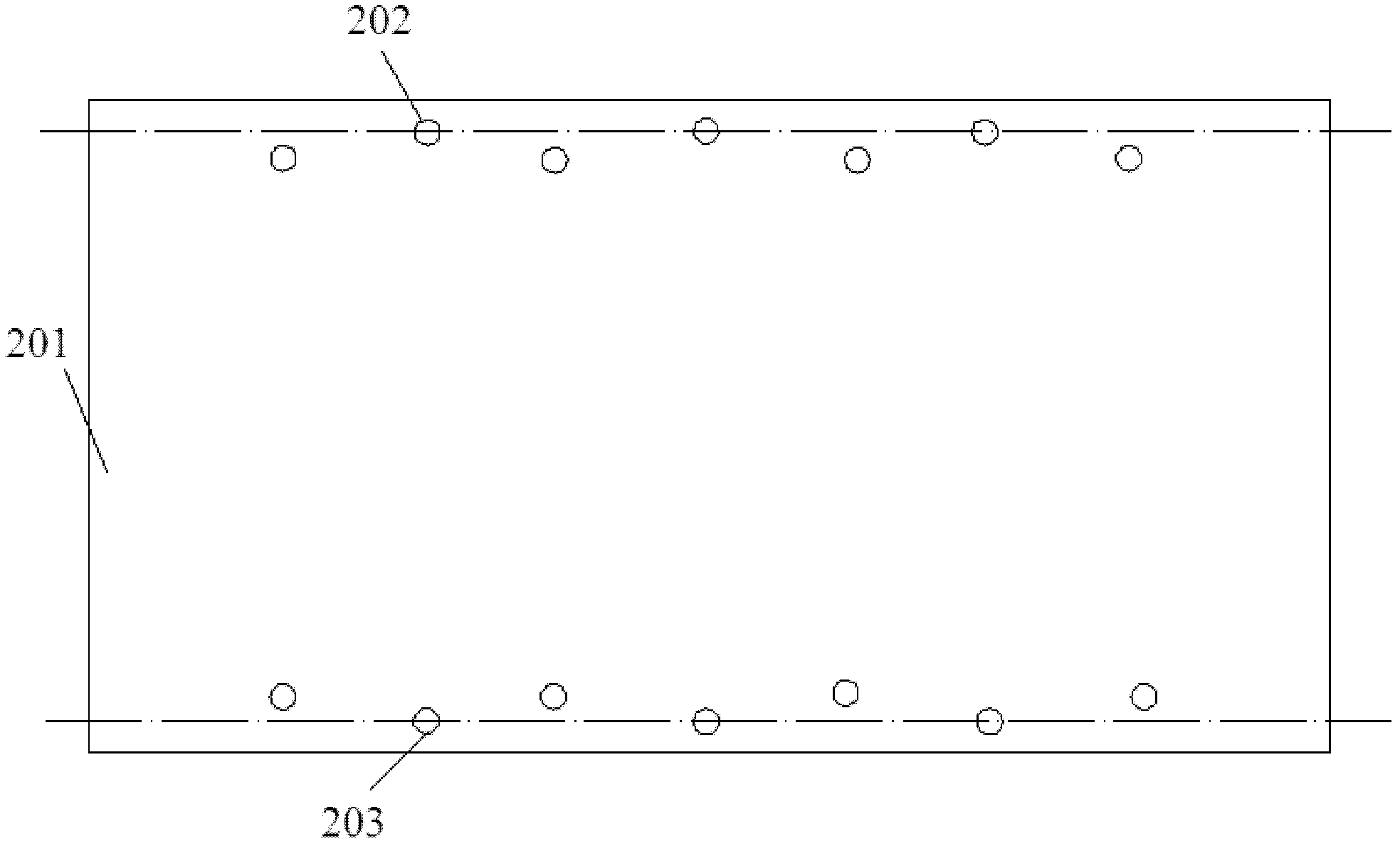

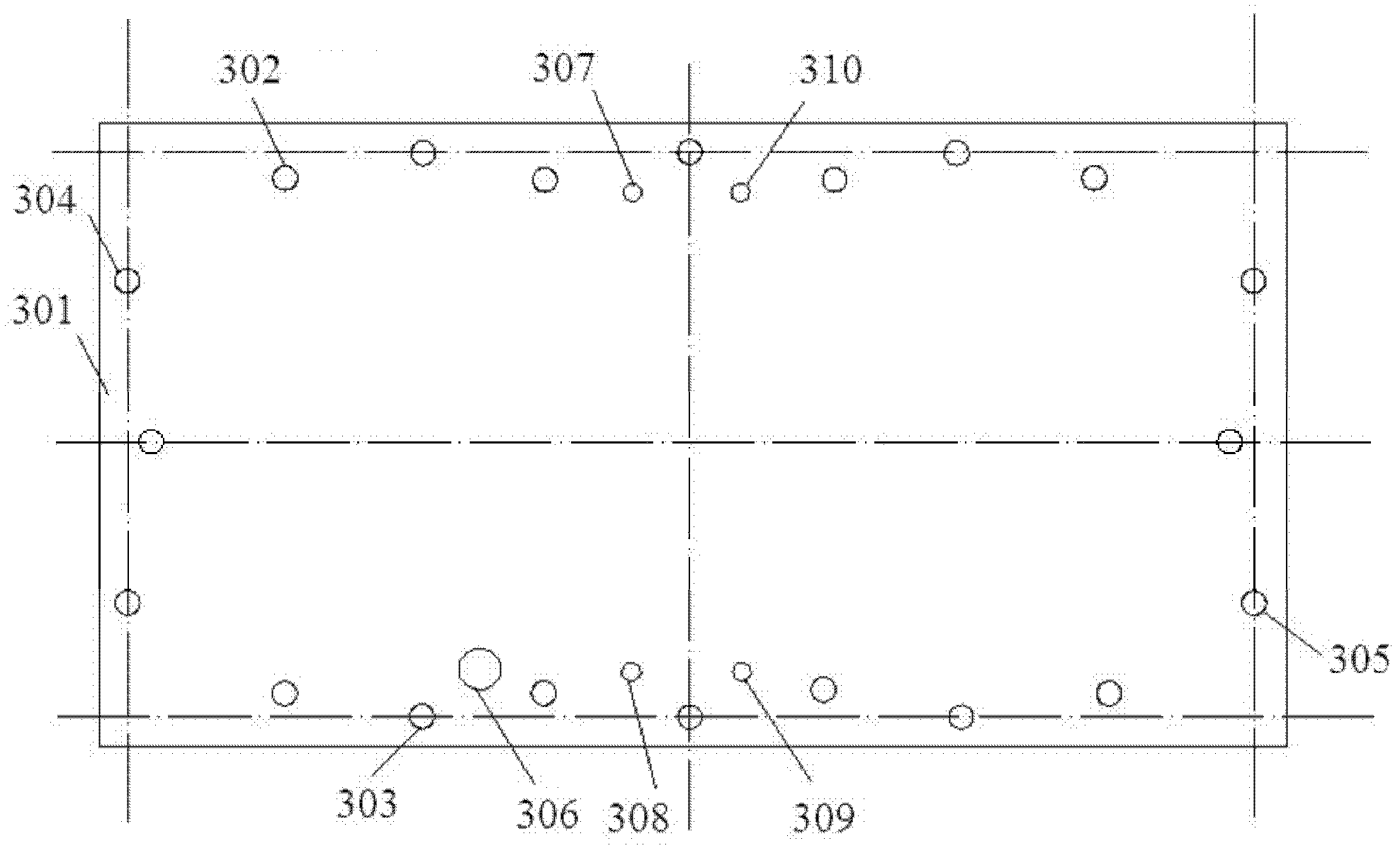

PCB (printed circuit board)

InactiveCN102638932AAvoid misalignmentIncrease pulling forcePrinted circuit detailsEngineeringSlide plate

The invention discloses a PCB (printed circuit board), wherein a first end of the PCB is provided with first press fit positioning holes; a second end of the PCB is provided with second press fit positioning holes; and the first press fit positioning holes on the PCB are arrayed in a wave type horizontally. The diagonal dragging force in the press fit positioning of the PCB is increased through the first press fit holes arrayed in the wave type, thereby being beneficial to the fixing of the PCB and a tool plate, avoiding the integral sliding plate malposition of the PCB and improving the positioning accuracy.

Owner:SHENNAN CIRCUITS

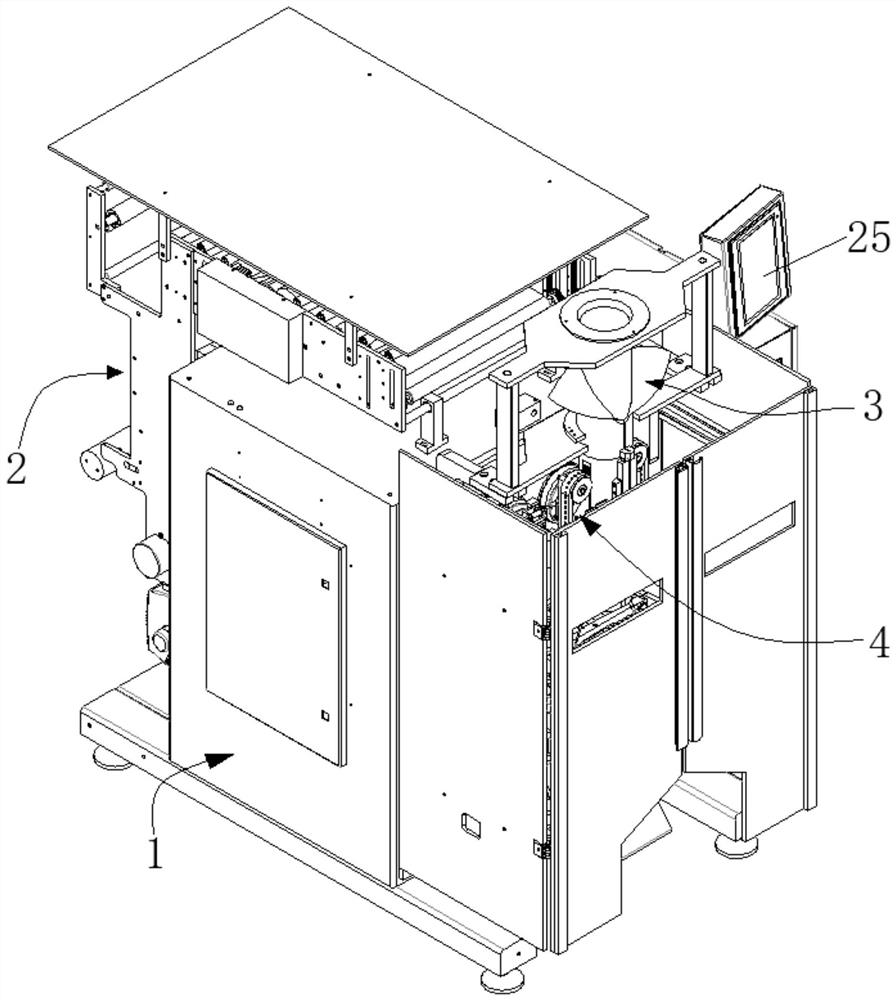

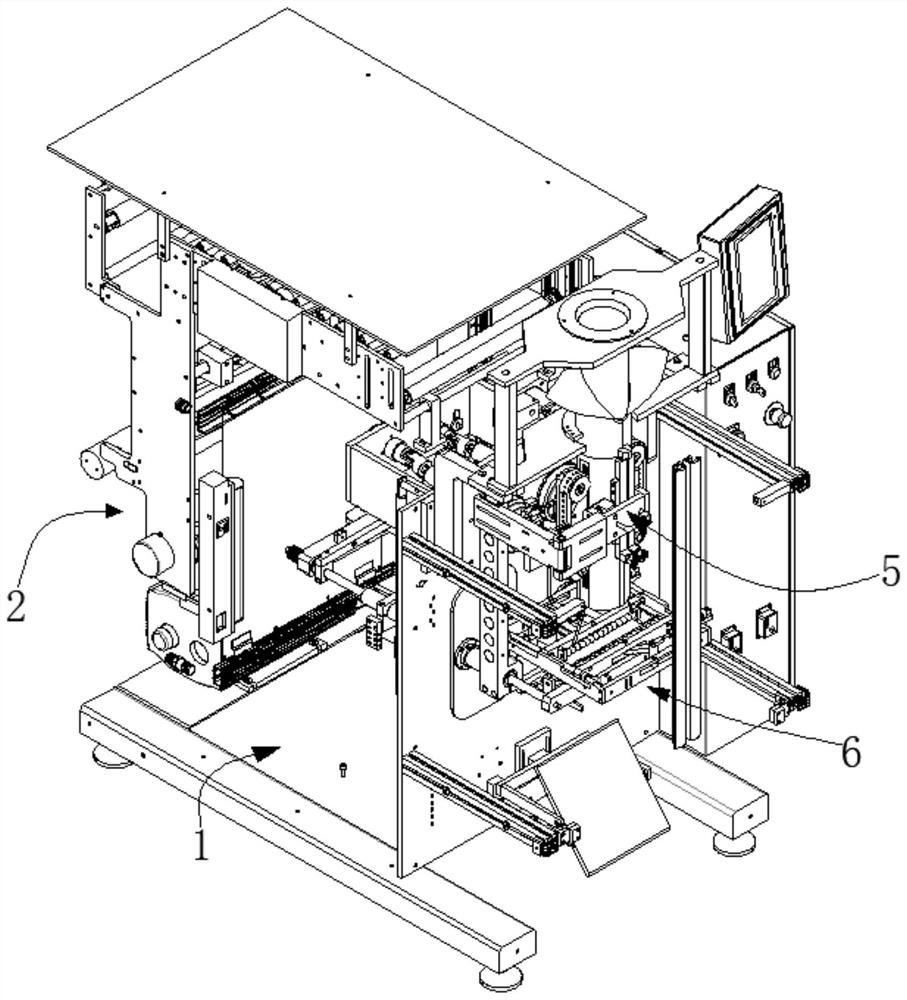

Vertical automatic bag making and packaging machine

ActiveCN113291515AEasy to controlEasy to operateWrapping material feeding apparatusWrapper twisting/gatheringEngineeringSmall footprint

The invention relates to the technical field of bag making and packaging equipment, and discloses a vertical automatic bag making and packaging machine. The vertical automatic bag making and packaging machine comprises a mounting main frame, and a film guiding mechanism, a forming mechanism, a film pulling mechanism, a vertical sealing mechanism and a transverse sealing mechanism which are sequentially mounted on the mounting main frame, wherein the forming mechanism is mainly used for turning and coiling a packaging film, the film pulling mechanism is mainly used for providing power to pull the packaging film to move, the vertical sealing mechanism is mainly used for sealing side seams of the packaging film formed by coiling, and the transverse sealing mechanism is mainly used for transversely sealing a packaging film coiling block vertically sealed by the vertical sealing mechanism at intervals to form a packaging bag. The vertical automatic bag making and packaging machine is high in integration degree and small in occupied area, it is no need to arranged two drives, the cost is saved, the forming time is saved, the production efficiency is greatly improved, the tightness degree of the packaging film is guaranteed, therefore, the quality of the packaging film during forming is improved, the situation that the packaging film is damaged is avoided, and the production quality is high.

Owner:杭州荣祥包装科技有限公司

Double-pumping-prevention oil pump

InactiveCN109253072AAvoid bendingAvoid partial wearPositive displacement pump componentsFlexible member pumpsPull forcePressure system

The invention discloses a double-pumping-prevention oil pump. The double-pumping-prevention oil pump comprises a pump barrel, wherein the pump barrel is connected with a working barrel through an upper joint; the pump barrel is connected with a bias fixed valve through a lower joint; a ring valve seat is fixed on the working barrel; a sliding sleeve sleeves the outside of a slipping rod; a ring-shaped valve plug is fixed at the upper end of the sliding sleeve; and the ring-shaped valve plug is matched with the ring valve seat. According to the double-pumping-prevention oil pump, because the ring-shaped valve plug is used in the pump, the ring-shaped valve plug is closed in a downward stroke, liquid column high pressure exists above the valve plug, the inside of a pump cavity has low pressure, a rod string is stretched by pressure difference, and the circumstance that eccentric wear of a rod tube is caused by bending of the rod string is avoided; and in down stroke, down pull force caused by difference of pressures of the upper end surface and the lower end surface of the slipping rod is increased, and thus, downward polished rod load is higher than downward polished rod load when aconventional pump is used. When in up stroke, due to opening of the ring-shaped valve plug, the same pressure system is arranged above a plunger, under the condition that the pump diameter is not changed, upward polished rod load is the same as that of the conventional pump, up load is not changed, down load is increased, action of a suspension point is relieved, and therefore, an energy-saving effect is achieved.

Owner:延安奇源石油工程技术服务有限公司

Planet rolling step pulley of water tank wire-drawing machine

InactiveCN101633007ASignificant anti-pull pulling effectRelieve pressureFriction torqueRolling resistance

The invention relates to wire-drawing production equipment in wire product industry, in particular to a drawing step pulley of a water tank wire-drawing machine. The drawing step pulley comprises pulley plates, a planet wheel, a planet wheel shaft, a chafing plate and a planet rolling step pulley of water tank wire-drawing machine assembled by the plurality of pulley plates. The invention provides a planet rolling step pulley, which has a counter pull drawing effect and avoids a wire sliding on the planet rolling step pulley. Breaking a principle that the size of a drawing force used in wire drawing is determined by the size of a friction force between the wire and the step pulley, the planet rolling step pulley allows the size of the drawing force to be determined by the size of the friction torque of the planet wheel and the number of the planet wheel, and allows the planet wheel to rotate freely when the wire slide back on the planet rolling step pulley, thereby avoiding the sliding friction of the wire on the step pulley and converting the power consumption for sliding friction into rolling friction torque to do work. The planet rolling step pulley can obviously reduce energy consumption for drawing and effectively solve the problem of step pulley wear and wire chafing.

Owner:严国语

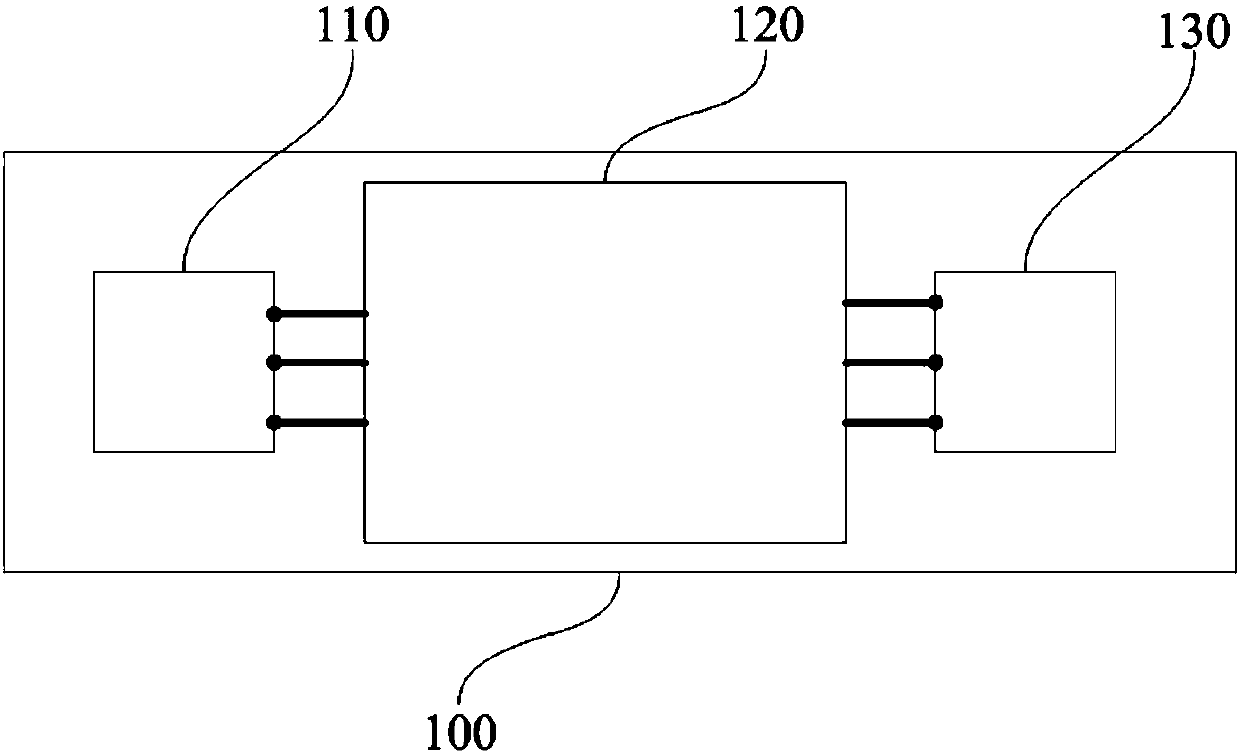

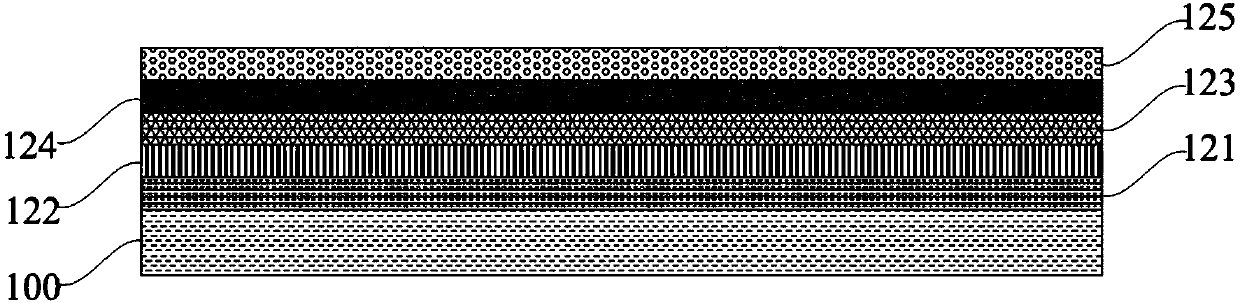

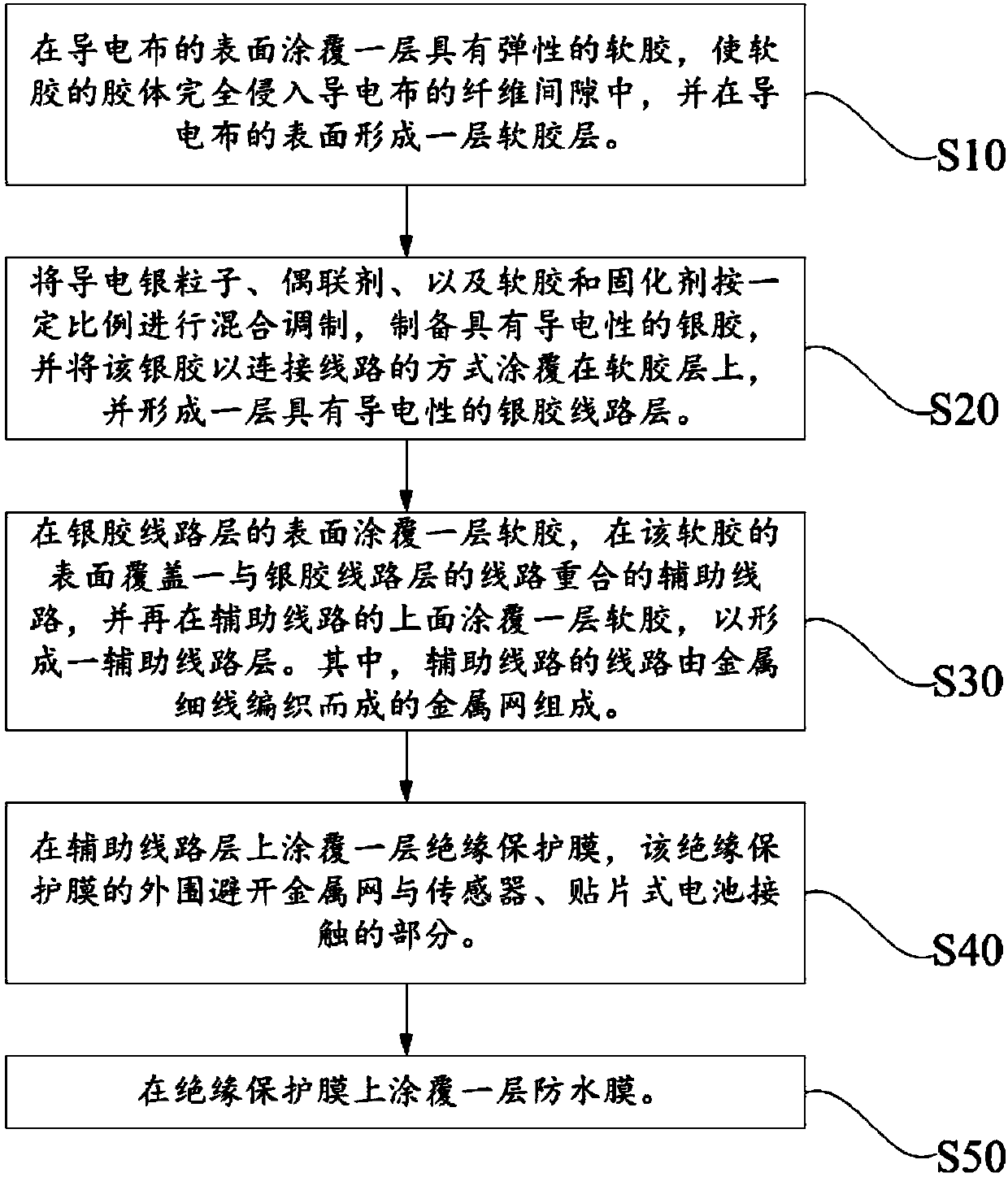

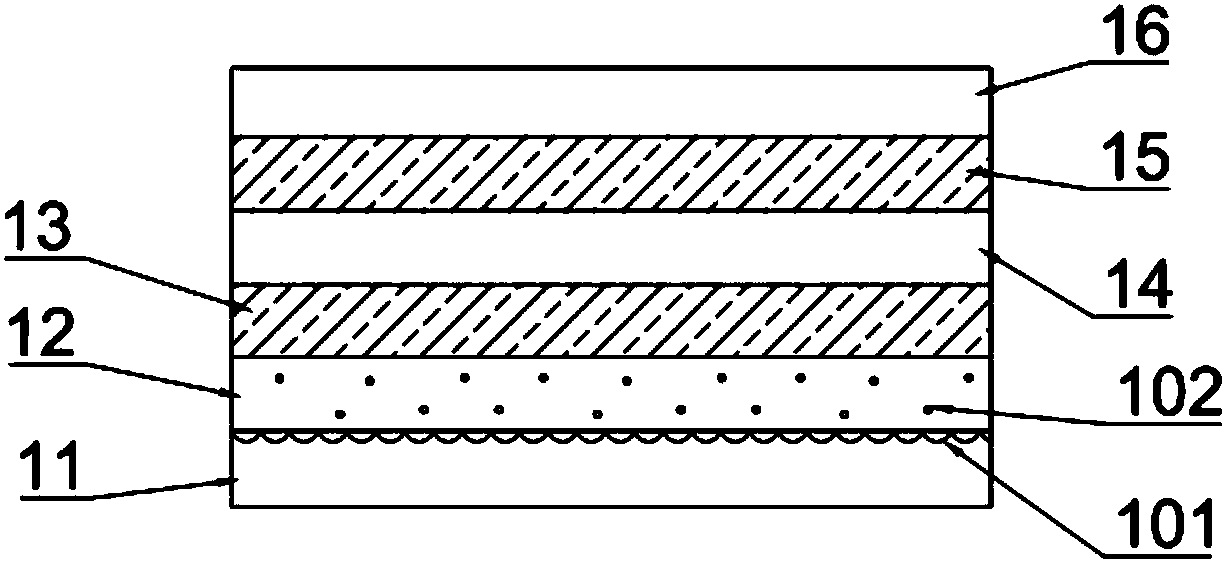

Wearable telescopic conductive cloth and manufacturing method thereof

ActiveCN107734831AAvoid breakingImprove toughnessCircuit bendability/stretchabilityElastomeric polymer dielectricsFiberElectrical connection

The present invention discloses a wearable telescopic conductive cloth. A conductive cloth body is elastic cloth and is used for making smart clothes. The surface of the conductive cloth body is provided with a first area for sticking a sensor, a second area for sticking a chip-type battery, and a third area for printing a connection circuit. A connection circuit at the surface of the third area comprises a soft rubber layer, a silver glue circuit layer, an auxiliary circuit layer, an insulation protection layer and a waterproof layer sequentially stacked on the surface of the conductive clothbody. The soft rubber layer is made of soft rubber with elasticity, and a rubber body on a first surface is in contact with the conductive cloth body and is immersed in a fiber gap of the conductivecloth body. A circuit of the silver glue circuit layer is drawn from silver glue and is arranged on a second surface of the soft rubber layer. The auxiliary circuit layer, the insulation protection layer and the waterproof layer sequentially cover the silver glue circuit layer. The conductive cloth provided by the invention is not easily broken when the conductive cloth is stretched, and the normal electrical connection between the sensors can be effectively ensured.

Owner:BAIQIANG ELECTRONICS SHENZHEN

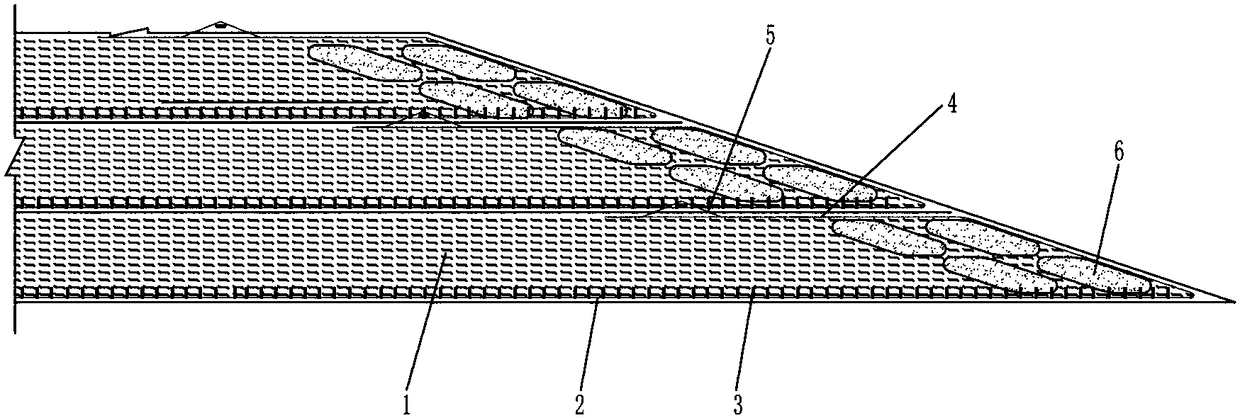

Large-scale garbage dump slope shaping construction method

ActiveCN108580503AQuality improvementImprove stabilitySolid waste disposalCrushed stoneArchitectural engineering

The invention discloses a large-scale garbage dump slope shaping construction method, which is characterized by comprising the following steps: step A, laterally opening a film in the upper part of agarbage dump to separate the construction section from the upper film, and then disassembling at two ends of a transverse slit, and separating the film and simultaneously packaging and binding the separated films and transporting the films out of the construction area; B. vertically excavating the garbage slope from the outside to the inside at the first construction section; C. laying tiled geogrids at the bottom of the dump pit and anchoring with U-shaped rivets; D. piling up bagged gravels in the marginal area of the garbage slope; and E, backfilling the garbage and wrapping the gravel jutebags with the folded geogrids at the edge of the garbage slope. The upper and lower layers of tiled geogrids are connected by connecting rods so as to form a high-quality and stable garbage slope toensure sustainable operation of the landfill. The construction process is simple.

Owner:GUANGZHOU FOURTH CONSTR

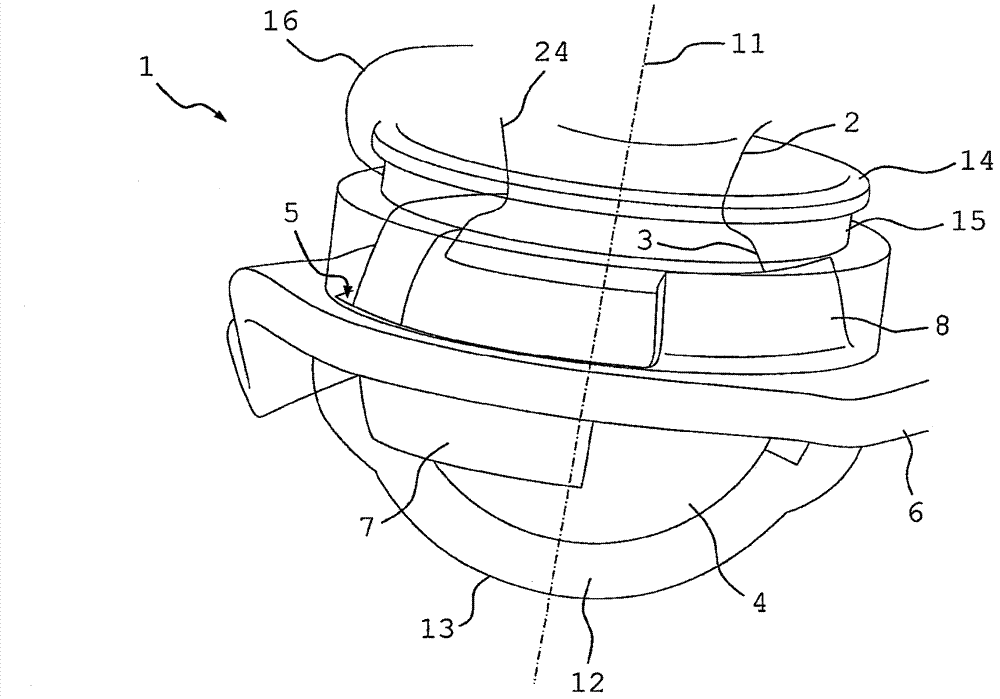

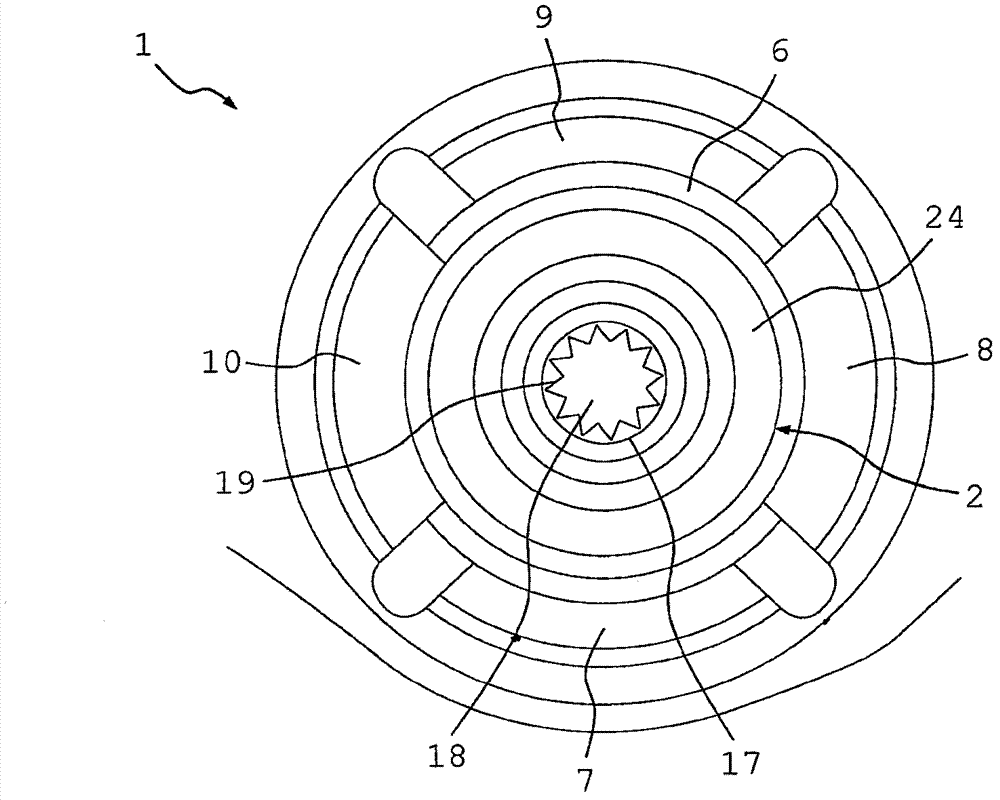

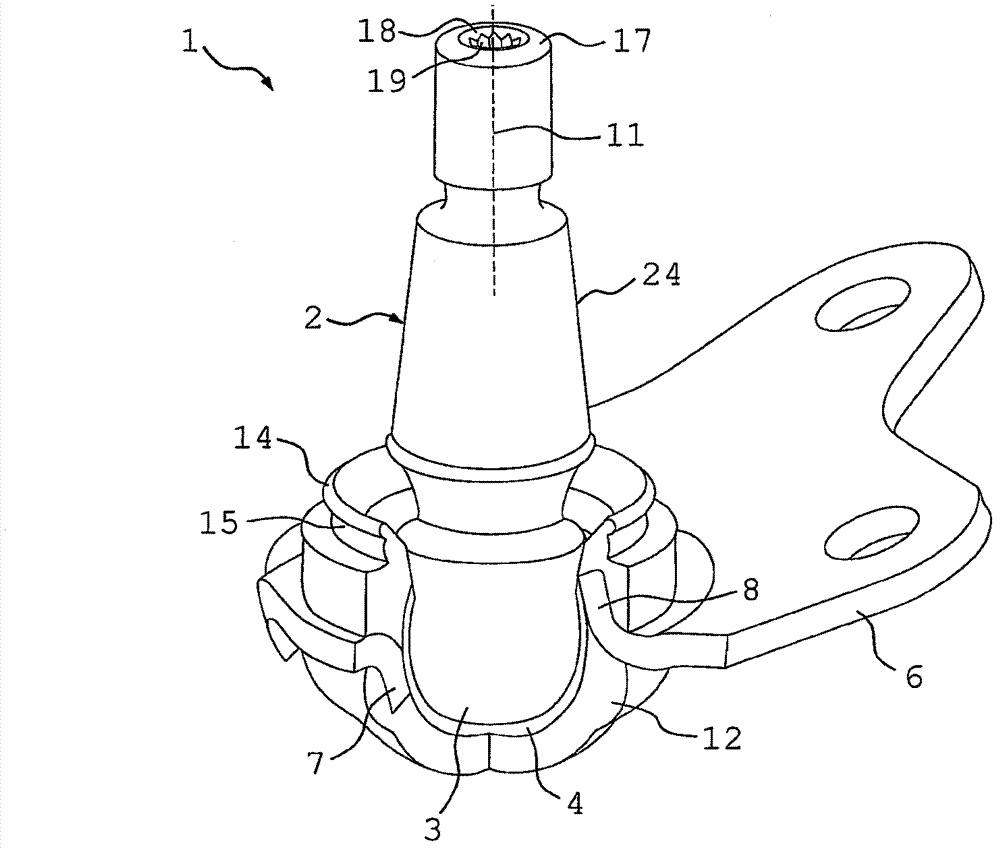

Ball joint

ActiveCN102959255AIncrease pulling forceImprove performanceSuspensionsPivotal connectionsSpherical bearingEngineering

Owner:ZF FRIEDRICHSHAFEN AG

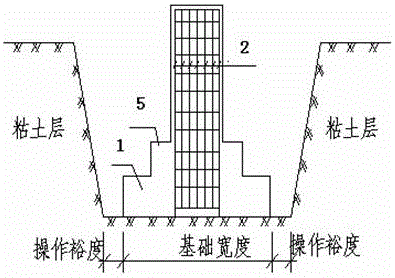

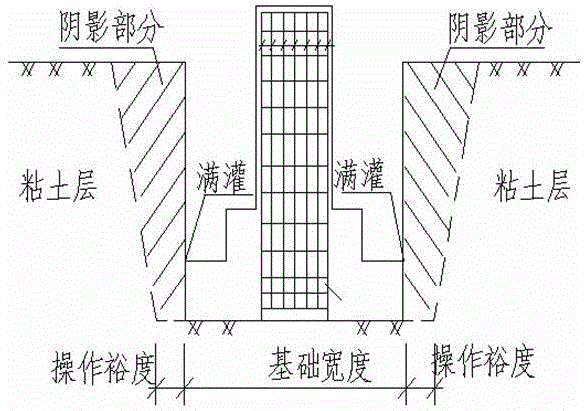

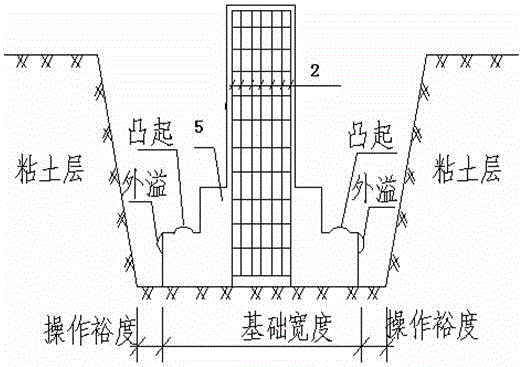

Pole and tower foundation construction method

The invention provides a pole and tower foundation construction method. The pole and tower foundation construction method comprises the following specific steps that 1, a foundation pit is excavated, specifically, the periphery of the foundation pit is not sloped, and an operation margin is not reserved; 2, formworks are supported, specifically, a natural pit wall is used as a foundation formwork, a cylinder formwork is supported, and a step formwork is supported when steps exist; 3, reinforcing steel bars are bound, specifically, cylinder reinforcing steel bars are mounted according to design requirements, and the reinforcing steel bars at the four corners of a cylinder are inserted into the position 8-20 cm deep in the ground; 4, steel meshes are bound, specifically, the steel meshes are arranged along the reinforcing steel bars on the periphery of the cylinder and cover the foundation portion in height, and the steel meshes are bound to the reinforcing steel bars; and 5, pouring is conducted, specifically, the foundation portion adopts a full irrigation mode, and the interior and exterior of the cylinder are poured in a balanced mode. The periphery of the foundation pit is not sloped, the operation margin is not reserved, the earthwork volume is reduced by 10% or above, and eight man-hours or above can be saved.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

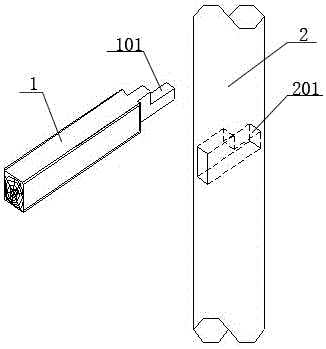

T-shaped steel member

InactiveCN105952056AReduce welding workloadReduce steel consumptionStrutsGirdersMaterials scienceSteel plates

The invention relates to a T-shaped steel member, and belongs to the technical field of steel structures. The steel member comprises a T-shaped steel part of which the outer contour is shaped like T and connectors, the connectors are connected to steel part long edge steel plates, and the connectors on the opposite sides are connected in a lapped mode. According to the T-shaped steel member, the stress performance of the structure and an industrialization level are improved.

Owner:初明进

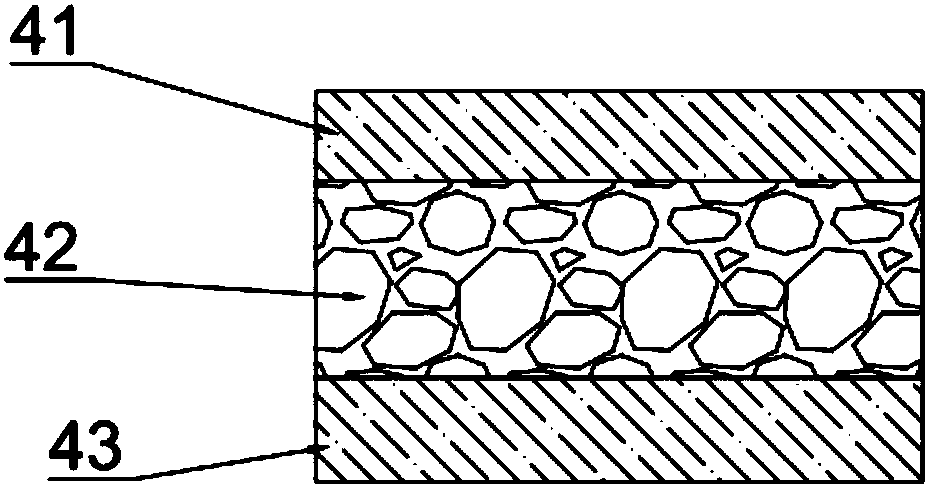

Method for preparing heat-insulating board for building wall

InactiveCN1323046CHigh strengthWith waterproof functionSolid waste managementCarboxymethyl celluloseWood fibre

The invention relates to a process for making heat-insulating board in architecture thermal insulation system, which comprises using vitrified pearl, light calcium carbonate, dispersable rubber powder, polypropylene fiber, wood fibre, sodium carboxymethyl cellulose and water as raw material through agitating homogeneously, charging water, spraying water and stirring, compacting and loading into molds, pressurizing demoulding and drying.

Owner:闻峰

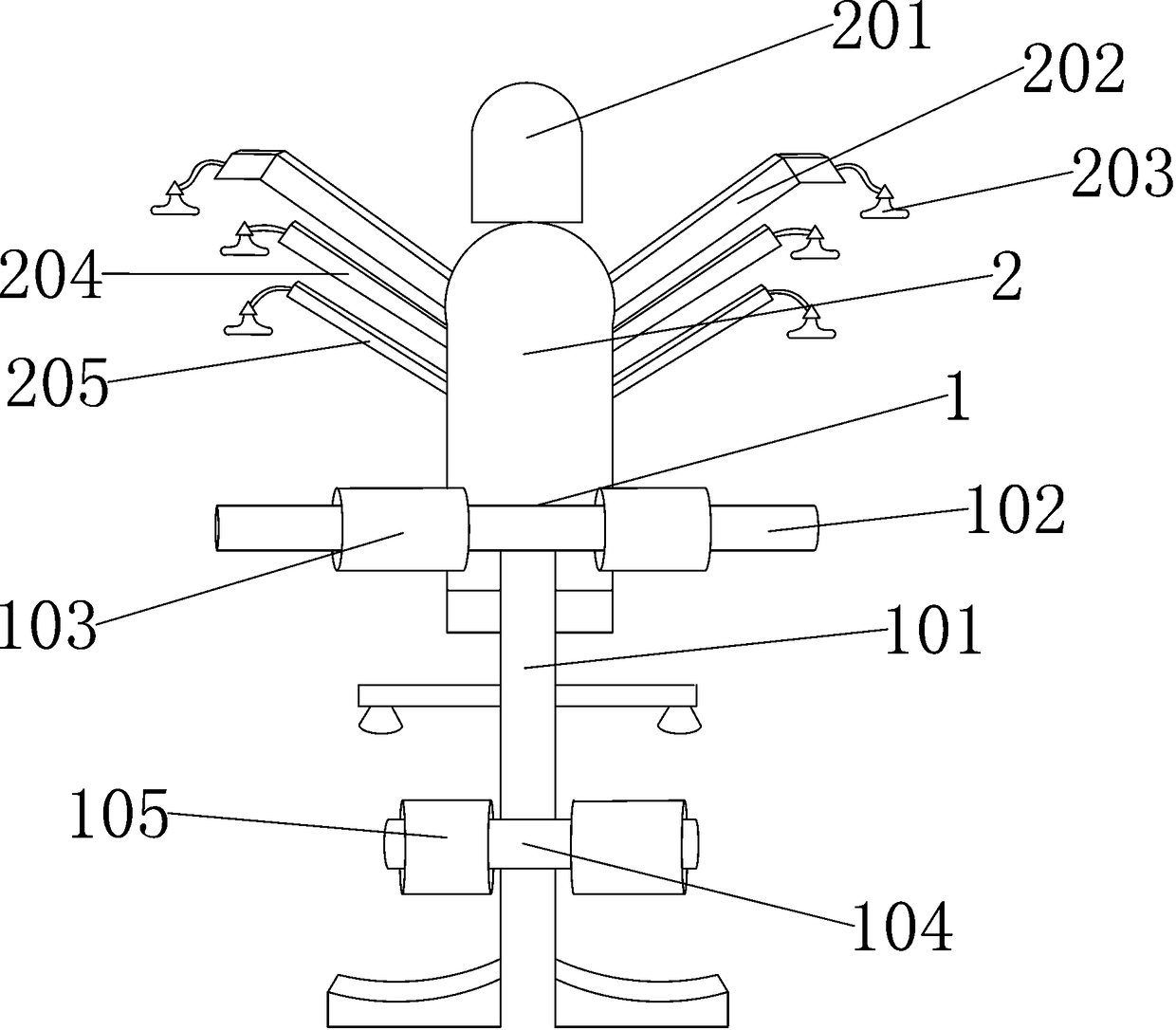

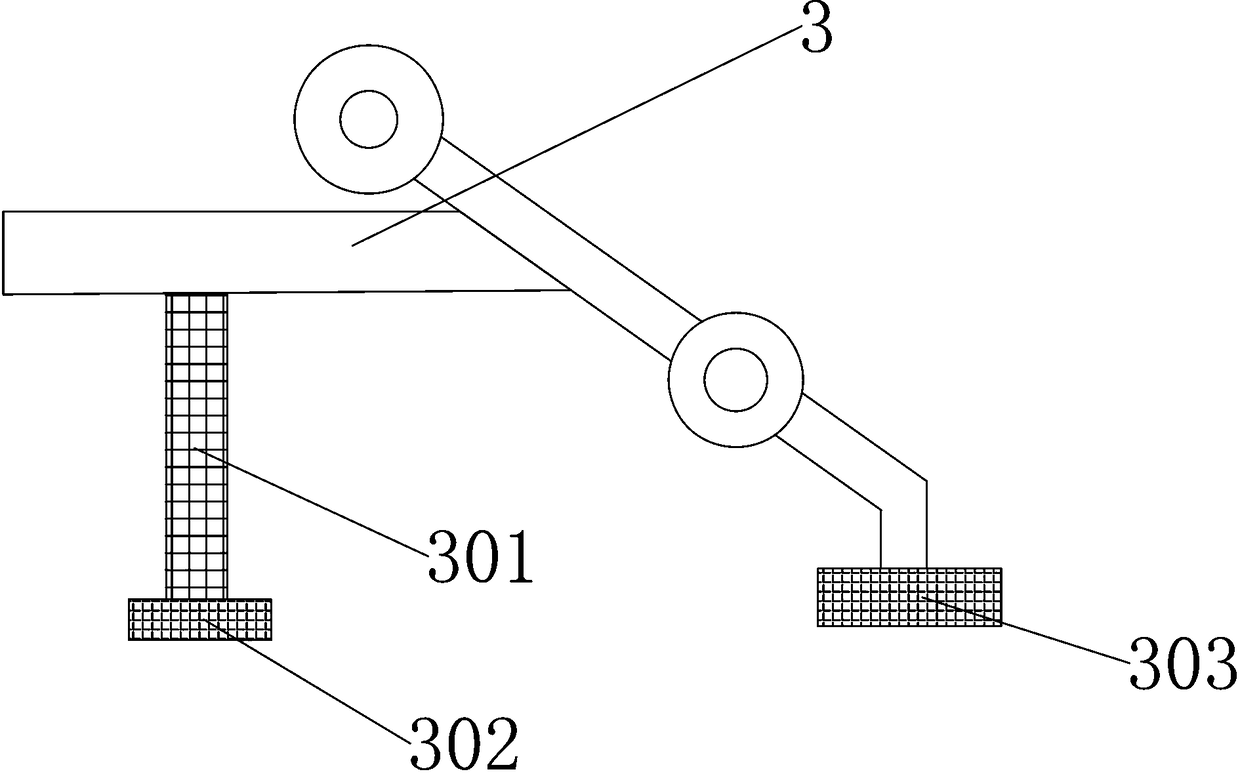

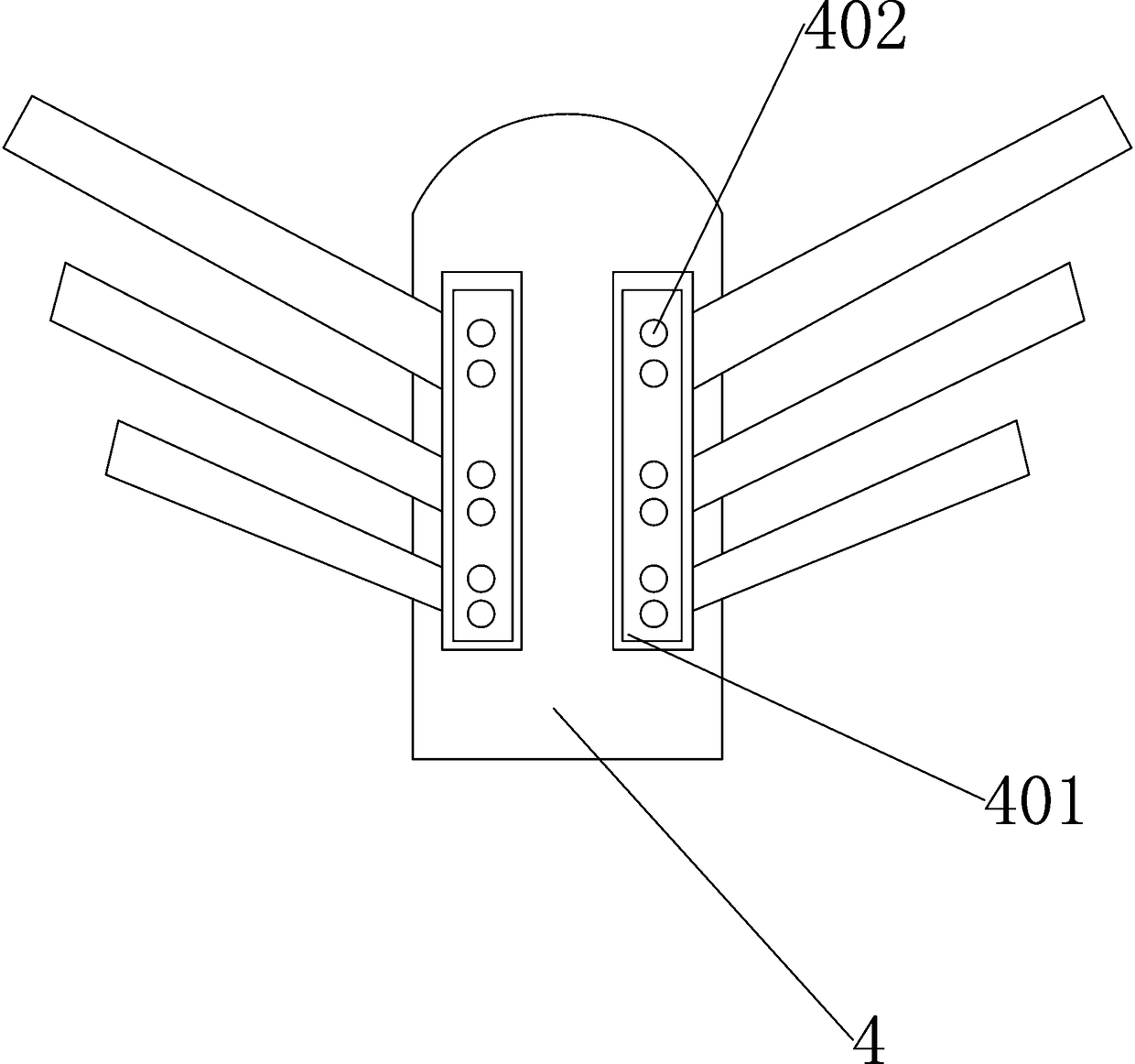

Adjustable tension pull rope for fitness arm strength exercise

PendingCN108939399AEasy to adapt to usage habitsImprove comfortMuscle exercising devicesThighPull force

The invention discloses an adjustable tension pull rope for fitness arm strength exercise, and belongs to the technical field of fitness equipment. The adjustable tension pull rope is characterized bycomprising a main device body, a pull rope assembly, a bottom seat cushion and a seat back and a cushion assembly; large pull rope bodies, middle pull rope bodies and small pull rope bodies are fixedly connected to the left and right sides of the pull rope assembly and symmetrically distributed, an inclined rope is welded to the front end of the main device body, a thigh pressing rod is welded tothe top of the inclined rod, and calf cushion layers are fixedly connected to the bottom of the inclined rod; the pull rope assembly is fixedly connected to the middle of the main device body, a headbacking cushion is fixedly connected to the rear end of the pull rope assembly, and the bottom seat cushion is welded to the bottom of the main device body. According to the adjustable tension pull rope, different tension strengths are set, the rear end of the seat back is provided with the large pull rope bodies, the middle pull rope bodies and the small pull rope bodies, and the tensions required by the three kinds of pull rope bodies are different.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

Wooden door processing and shaping device

ActiveCN109605531AAvoid easy displacement and falling offIncrease frictionWood working apparatusGrinding machinesEngineeringFriction force

The invention provides a wooden door processing and shaping device. The wooden door processing and shaping device comprises a fixed plate, wherein a limiting frame is arranged at the upper end of thefixed plate; one side of the limiting frame is embedded into a limiting groove; a fixed block is arranged in the limiting groove; movable rings are distributed on the outer side of the fixed block; acontact surface is arranged on one side of each movable ring; a contact block is arranged on the other side of each movable ring; a friction ring is arranged on one side of each contact block. According to the wooden door processing and shaping device, the movable rings are arranged, so that when a wooden door is embedded into the limiting groove, the friction force between the wooden door and thelimiting frame can be improved through the movable rings; when the wooden door is pulled, the movable rings rotate, so that the wooden door can be conveniently limited by the contact blocks; the situation that the wooden door easily moves and falls off when processing the wooden door after the existing shaping device limits the wooden door is avoided, so that the pulling force generated when processing the wooden door is used for further reinforcing the wooden door.

Owner:浙江美轩门业有限公司

Rotary adjustable brake horseshoe

The invention provides a rotary adjustable brake horseshoe. The rotary adjustable brake horseshoe comprises a body, a friction body, a reset telescopic piece, a rotating plate and a retainer; the body comprises a baffle, a first side plate, a second side plate, a front wall plate and a bottom plate; the baffle, the first side plate, the front wall plate and the second side plate are sequentially connected to form a rectangular frame; the length of the bottom plate is smaller than that of the rectangular frame; the bottom plate is horizontally arranged right below the rectangular frame body and is connected with the baffle; a limiting plate which is parallel and opposite to the baffle is arranged on one end, away from the baffle plate, of the bottom plate; the friction body is slidably arranged on the bottom plate and is positioned between the baffle and the limiting plate; a shaft body extending towards the baffle is horizontally arranged on the front wall plate; the rotating plate is rotatably arranged on the shaft body; the retainer is movably arranged on the front wall plate; the rotating plate is provided with at least one positioning hole. According to the rotary adjustable brake horseshoe disclosed by the invention, pulling force to the friction body when the reset telescopic piece performs deformation recovery can be improved by adjusting the position of the rotating plate, so as to ensure that the friction body can be reset smoothly.

Owner:ANHUI GUIDA AUTO PARTS

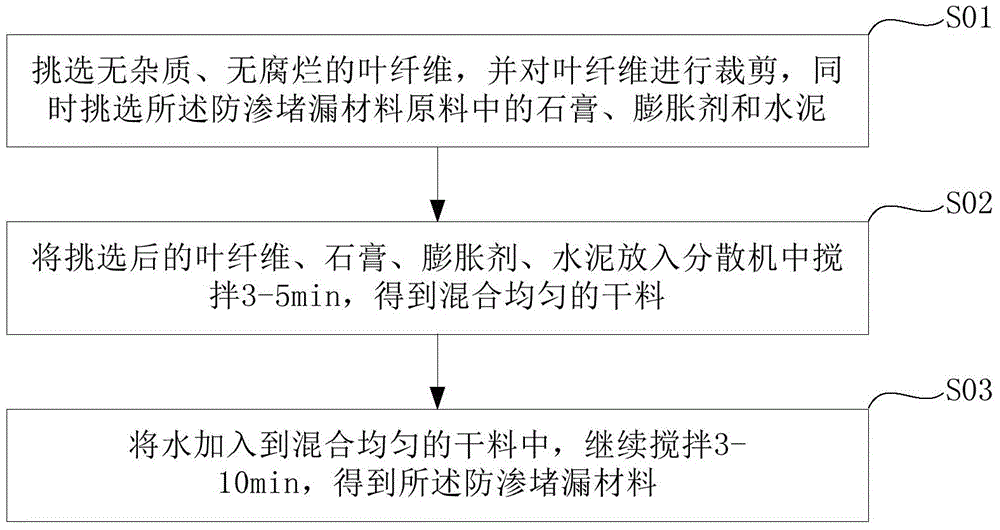

Seepage-proofing leaking-stopping material and preparation method thereof

The invention provides a seepage-proofing leaking-stopping material and a preparation method thereof. The seepage-proofing leaking-stopping material comprises leaf fibers, gypsum, an expanding agent, cement and water. The leaf fibers are added to the cement, so that the tensile strength of cement mortar is improved. Meanwhile, the cost of the seepage-proofing leaking-stopping material can be greatly reduced through the leaf fibers, and the seepage-proofing leaking-stopping material can be widely applied to the fields of tunnels and underground structures, mine excavation and water conservancy and hydropower foundation reinforcement projects and the like.

Owner:重庆市十八土鑫诚灌浆防水工程有限公司

Colorful gypsum decorative sheet and preparing method thereof

PendingCN107587680AImprove waterproof and moisture-proof performanceImprove sound insulationCovering/liningsPolyvinyl chlorideGypsum

The invention discloses a colorful gypsum decorative sheet and a preparing method thereof. The colorful gypsum decorative sheet comprises a gypsum plate, the two side faces of the gypsum plate are provided with a protective layer and a polyvinyl chloride film, and a bonding glue layer is arranged between the polyvinyl chloride film and the gypsum plate; and the protective layer is a paper protective layer, a plastic protective layer or a steel mesh. The polyvinyl chloride film is arranged, and therefore the waterproof and dampproof performance of the gypsum plate is improved. According to thecolorful gypsum decorative sheet prepared through the preparing method, the waterproof and dampproof effect is good, and the sound insulation performance is good.

Owner:张鑫

Cross steel member

InactiveCN106013604AReduce welding workloadReduce steel consumptionStrutsPillarsSheet steelLap joint

The invention relates to a cross-shaped steel component, which belongs to the technical field of steel structures; the steel component includes a cross-shaped steel piece and a connecting piece, the connecting piece is connected to the steel plate on the long side of the steel piece, and the opposite side connecting piece is overlapped Together. The invention will improve the mechanical performance and industrialization level of the structure.

Owner:初明进

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com