PCB (printed circuit board)

A PCB board, positioning hole technology, applied in the direction of printed circuit components, etc., can solve the problems of easy sliding and inaccurate positioning, and achieve the effect of increasing the pulling force, accurate positioning, and avoiding the dislocation of the overall skateboard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

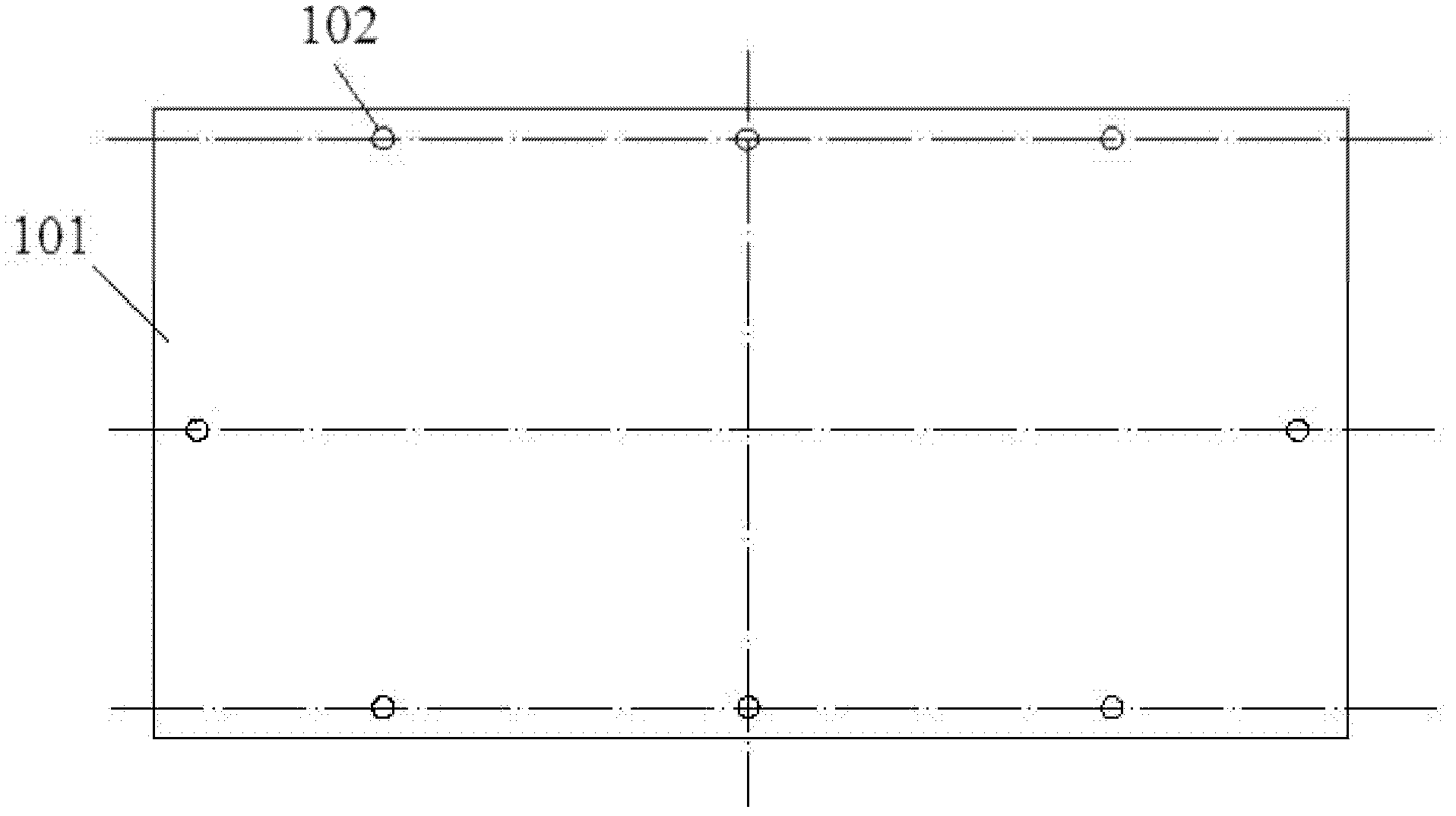

Embodiment 1

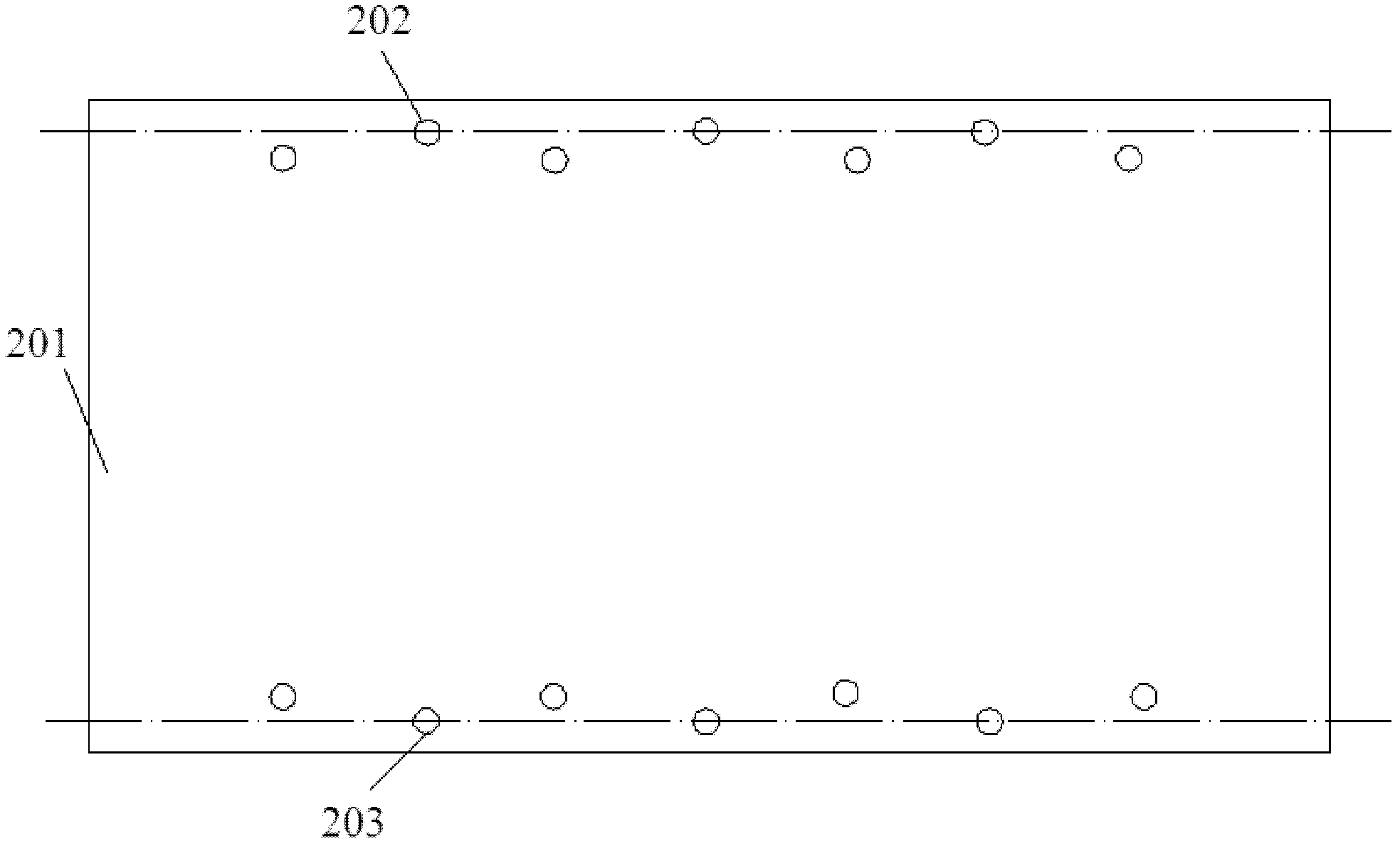

[0021] like figure 2 As shown, a PCB board 201 includes: the first end of the PCB board 201 is provided with a first press-fit positioning hole 202, and the second end of the PCB board is provided with a second press-fit positioning hole 203. The first press-fit positioning holes 202 are arranged in waves in the transverse direction, and the first end is opposite to the second end. The first press-fit positioning holes 202 arranged in a wavy pattern enable the PCB board to be pulled obliquely when it is press-fitted and positioned, and will not cause the overall slide of the PCB to be dislocated.

Embodiment 2

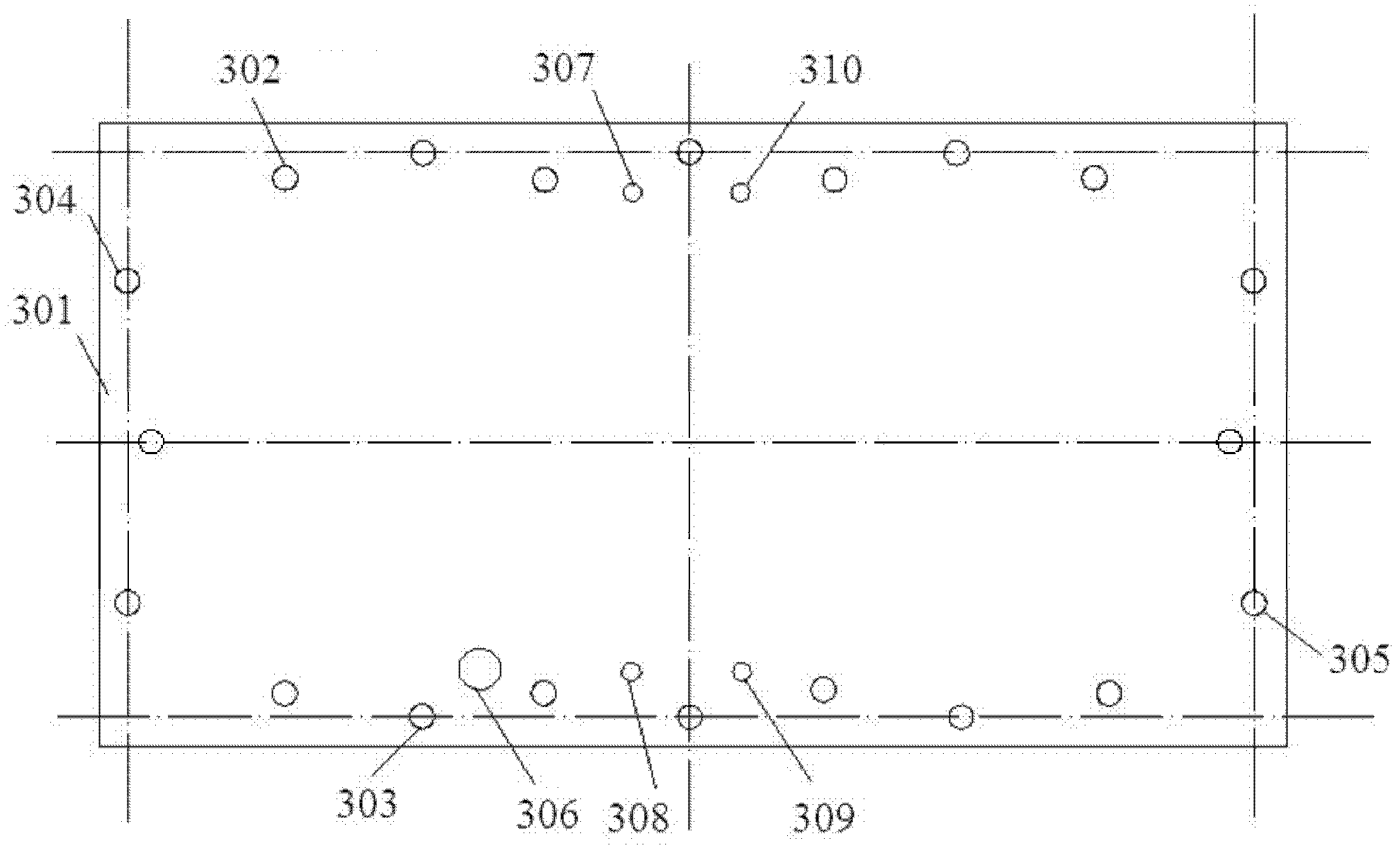

[0023] like image 3 As shown, a PCB board 301, the first end of the PCB board 301 is provided with a first pressing positioning hole 302, the second end of the PCB board is provided with a second pressing positioning hole 303, the first The press-fit positioning holes 302 are arranged in waves in the transverse direction, the second press-fit positioning holes 303 are arranged in waves in the transverse direction, and the first end is opposite to the second end. The press-fit positioning holes at the second end of the PCB board are arranged in waves, so that when the PCB board is press-fit and positioned, the oblique pulling force is greater, and the overall slide plate misalignment of the CB board is better avoided.

[0024] like image 3 As shown, the first end and the second end of the PCB board are respectively located on both sides of the transverse centerline of the PCB board. Preferably, the first press-fit positioning holes 302 and the second press-fit positioning h...

Embodiment 3

[0037] The present invention also provides a tool board corresponding to the above-mentioned embodiment, and the tool board is provided with positioning holes for fixed connection corresponding to the press-fit positioning holes on the PCB described in Embodiment 1 or 2. hole. The tool board is matched with the PCB board in Embodiment 1 or 2, and fixedly connected by pins, so that the positioning accuracy of the PCB is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com