Large-scale garbage dump slope shaping construction method

A construction method and technology for garbage dumps are applied in the field of slope shaping construction of large garbage dumps, which can solve the problems of slope slippage, difficulty in ensuring the stability of the slope, and increase the instability of the slope, so as to save construction land and improve the Effective storage capacity, the effect of relieving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

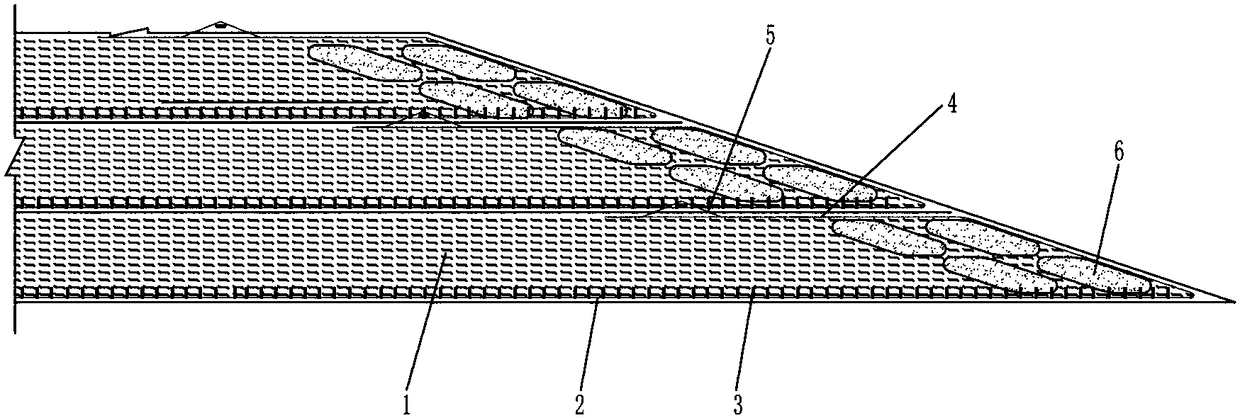

[0016] Such as figure 1 As shown, the schematic diagram of slope shaping of a large garbage dump is composed of compacted garbage 1, tiled geogrid 2, U-shaped rivets 3, folded geogrid 4, geotechnical connecting rod 5, and bagged gravel 6. The compacted garbage 1 is placed on the fully paved geogrid 2, and the compacted garbage pile must be rolled repeatedly to reduce the settlement of the garbage in the later stage. The tiled geogrid 1 is fixed with U-shaped rivets 3 to prevent the grid from shifting. When construction is compacting the rubbish heap 1, bagged crushed stones 6 at the edge of the pile are piled up simultaneously, and the particle diameter of the crushed stones is 5-16mm. The upper part of the compacted garbage 1 is folded back to a certain length to lay the geogrid 4 flatly, and the folded geogrid 4 is reserved for the bottom of the compacted garbage 1 to lay the geogrid flatly, and the bagged gravel 6 at the edge of the compacted garbage 1 is wrapped. The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com