Pole and tower foundation construction method

A construction method and tower foundation technology, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems such as the influence of formwork removal, high fluidity, and the inability to remove turnover materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

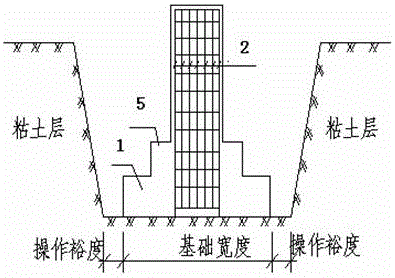

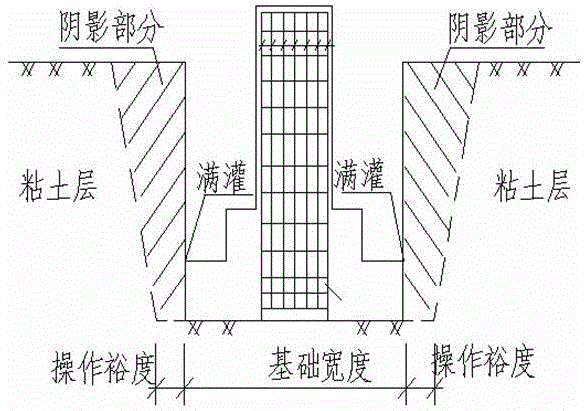

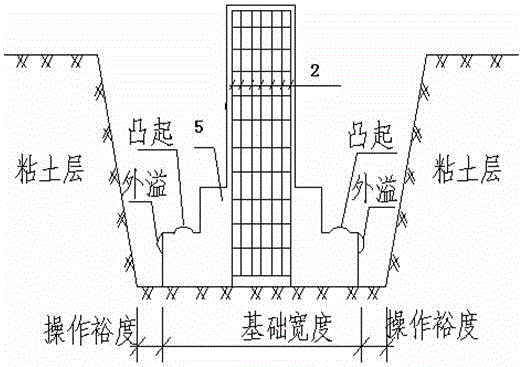

[0045] Refer below figure 2 and Figure 4 , introducing a tower foundation construction method, including the following steps:

[0046] 1) Foundation pit excavation: foundation pit excavation uses a combination of machinery and manpower. When the mechanical excavation foundation pit is close to the edge, the side wall of the foundation pit is manually cleaned; there is no slope around the foundation pit, and no operating margin is left; advantages: reduce earthwork The quantity is more than 10%, saving more than 8 working hours; figure 2 The middle shaded part is the soil and rocks that are excavated without grading.

[0047] 2) Formwork support: the formwork is divided into base formwork, column formwork and step formwork according to the position; the present invention uses the natural pit wall as the base formwork; the step formwork and the upper part of the column formwork can be vertically and horizontally erected steel pipes on the floor first, and then supported Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com