Planet rolling step pulley of water tank wire-drawing machine

The technology of a water tank wire drawing machine and a planetary wheel is applied in the field of drawing tower wheels, which can solve the problems of damage to the lubricating layer of the wire, shorten the service life of the abrasive tool, increase the energy consumption of drawing, etc. The effect of pulling force and reducing frictional power consumption

Inactive Publication Date: 2010-01-27

严国语

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the problems of tower wheel wear, wire lubricating layer damage, shortening the service life of abrasive tools, and increasing drawing energy consumption have not been fundamentally improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

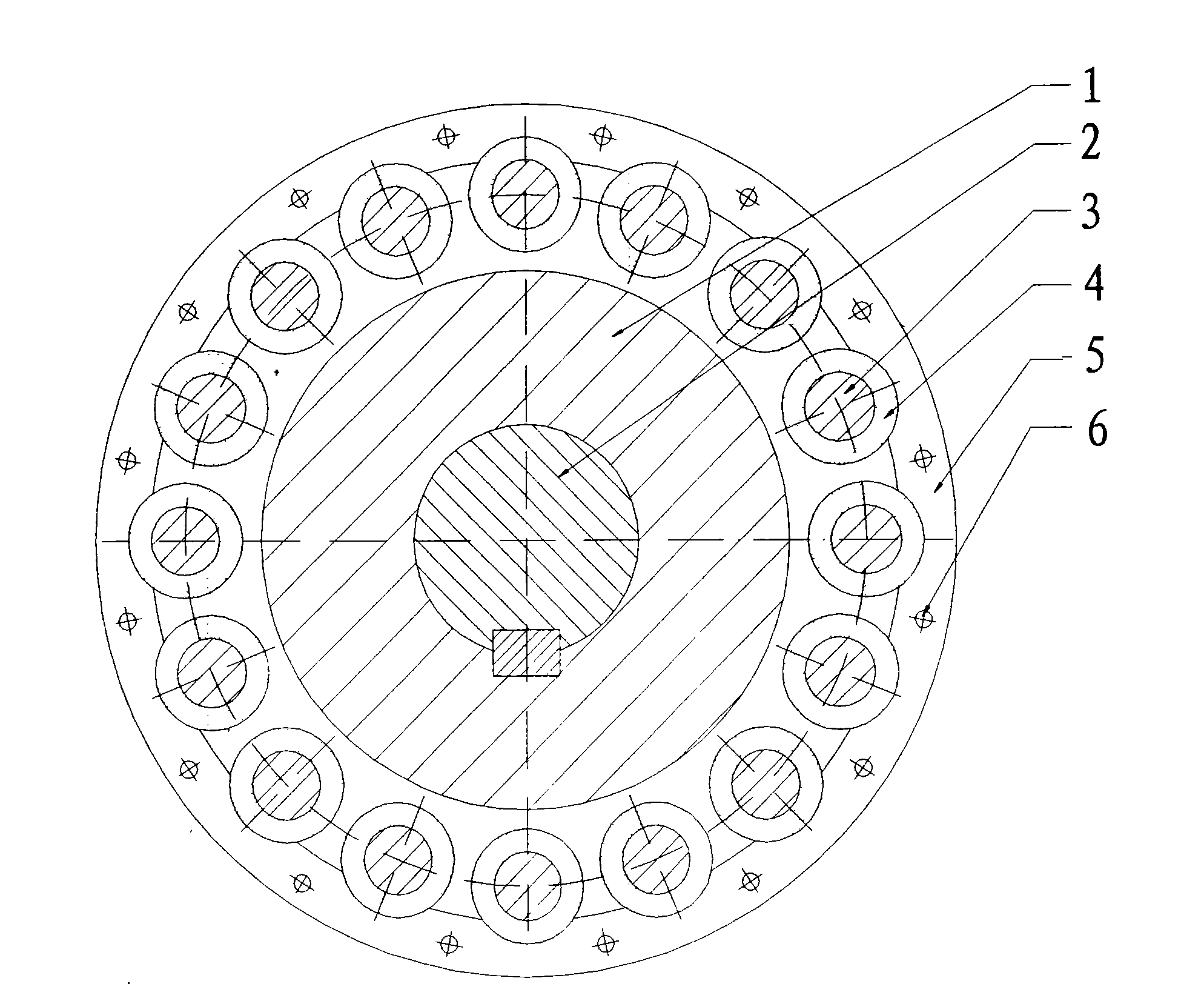

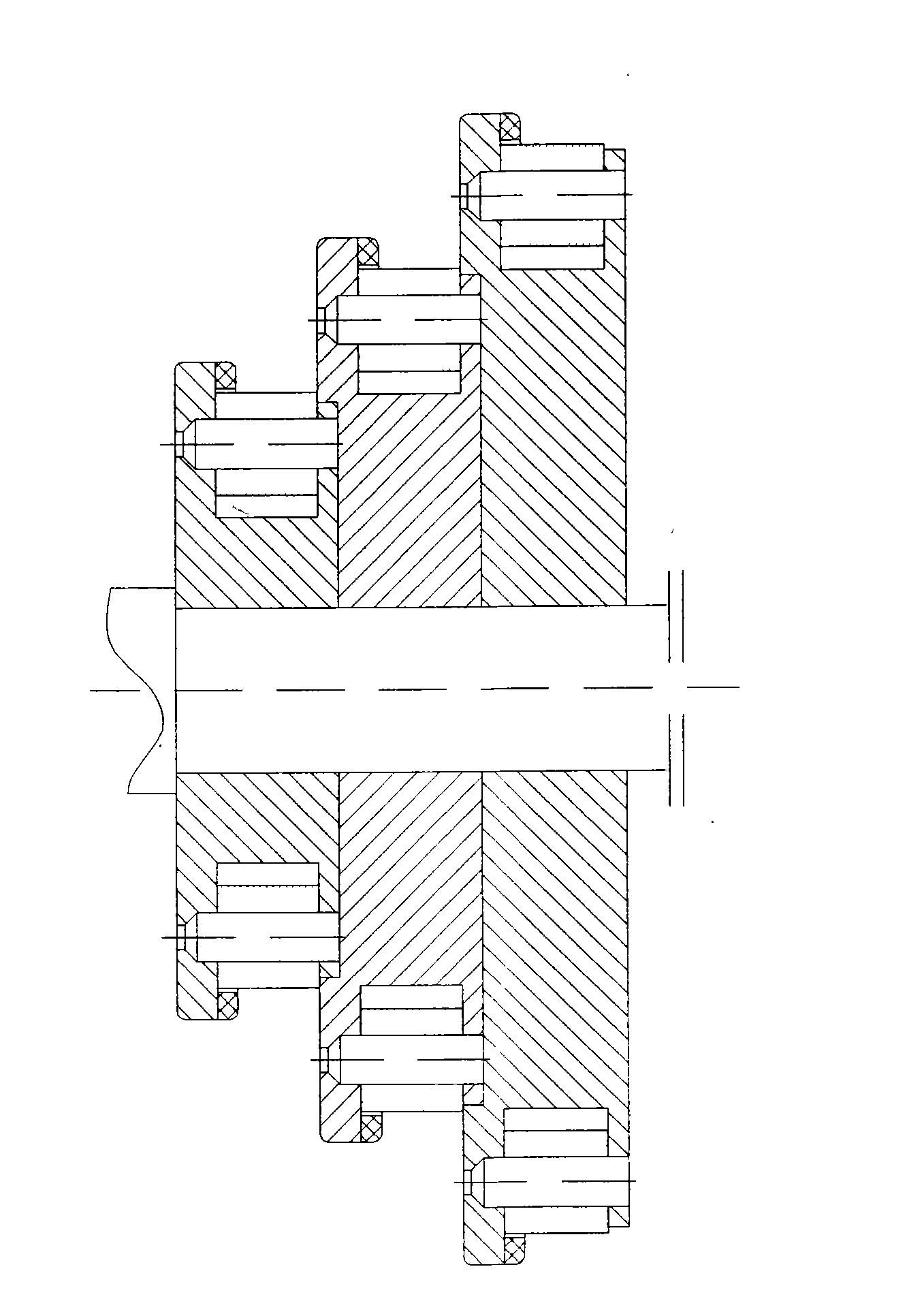

[0007] The present invention consists of a group of planetary gears (4) capable of rotating on the planetary gear shaft (3), the planetary gear shaft (3) is placed on the tower wheel (1), and the anti-scratch plate (5) is fixed by a rivet (6). On the tower pulley (1); N pieces of tower pulleys (1) are assembled on the transmission shaft (2) to form a water tank wire drawing machine planetary rolling tower.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to wire-drawing production equipment in wire product industry, in particular to a drawing step pulley of a water tank wire-drawing machine. The drawing step pulley comprises pulley plates, a planet wheel, a planet wheel shaft, a chafing plate and a planet rolling step pulley of water tank wire-drawing machine assembled by the plurality of pulley plates. The invention provides a planet rolling step pulley, which has a counter pull drawing effect and avoids a wire sliding on the planet rolling step pulley. Breaking a principle that the size of a drawing force used in wire drawing is determined by the size of a friction force between the wire and the step pulley, the planet rolling step pulley allows the size of the drawing force to be determined by the size of the friction torque of the planet wheel and the number of the planet wheel, and allows the planet wheel to rotate freely when the wire slide back on the planet rolling step pulley, thereby avoiding the sliding friction of the wire on the step pulley and converting the power consumption for sliding friction into rolling friction torque to do work. The planet rolling step pulley can obviously reduce energy consumption for drawing and effectively solve the problem of step pulley wear and wire chafing.

Description

Technical field: [0001] The invention relates to wire drawing production equipment in the wire product industry, in particular to a drawing cone of a water tank wire drawing machine. Background technique: [0002] At present, the drawing tower pulleys of water tank wire drawing machines in the wire product industry are generally cast steel (iron) wheel bodies. When drawing the wire, there is always relative sliding between the wire and the tower pulley, which leads to adhesive wear and abrasive wear, which leads to the wear and tear of the tower pulley (rework), increases the energy consumption of drawing, wears the surface of the wire rod, and damages the lubrication of the wire rod layer, reducing the service life of the abrasive tool, and in severe cases, the phenomenon of whitening and cracking will occur, making drawing impossible. [0003] In order to improve the sliding state between the wire and the cone wheel and prolong the service life of the cone wheel, chromium...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21C1/14

Inventor 严国语

Owner 严国语

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com