Patents

Literature

183results about How to "Reduce frictional power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

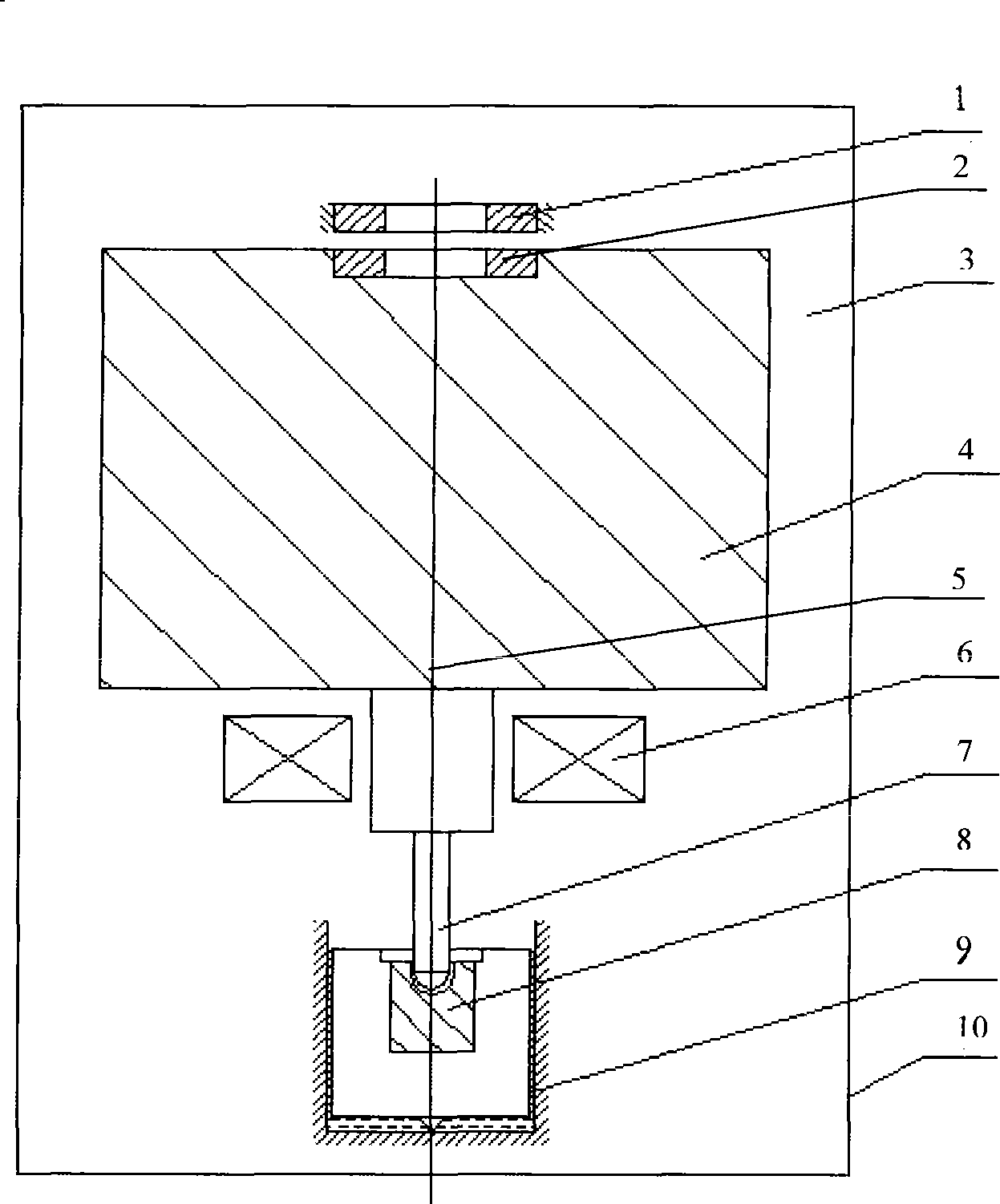

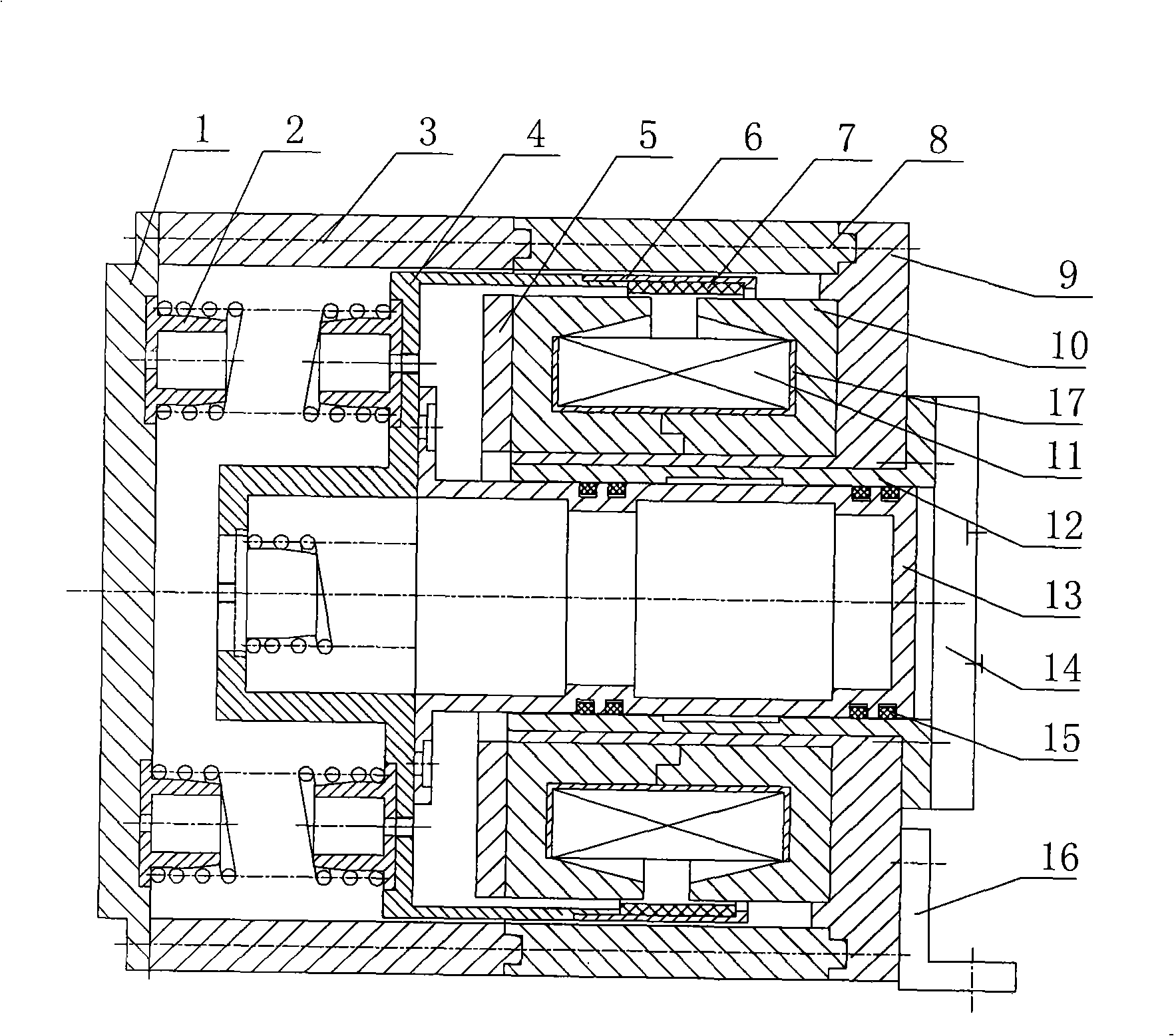

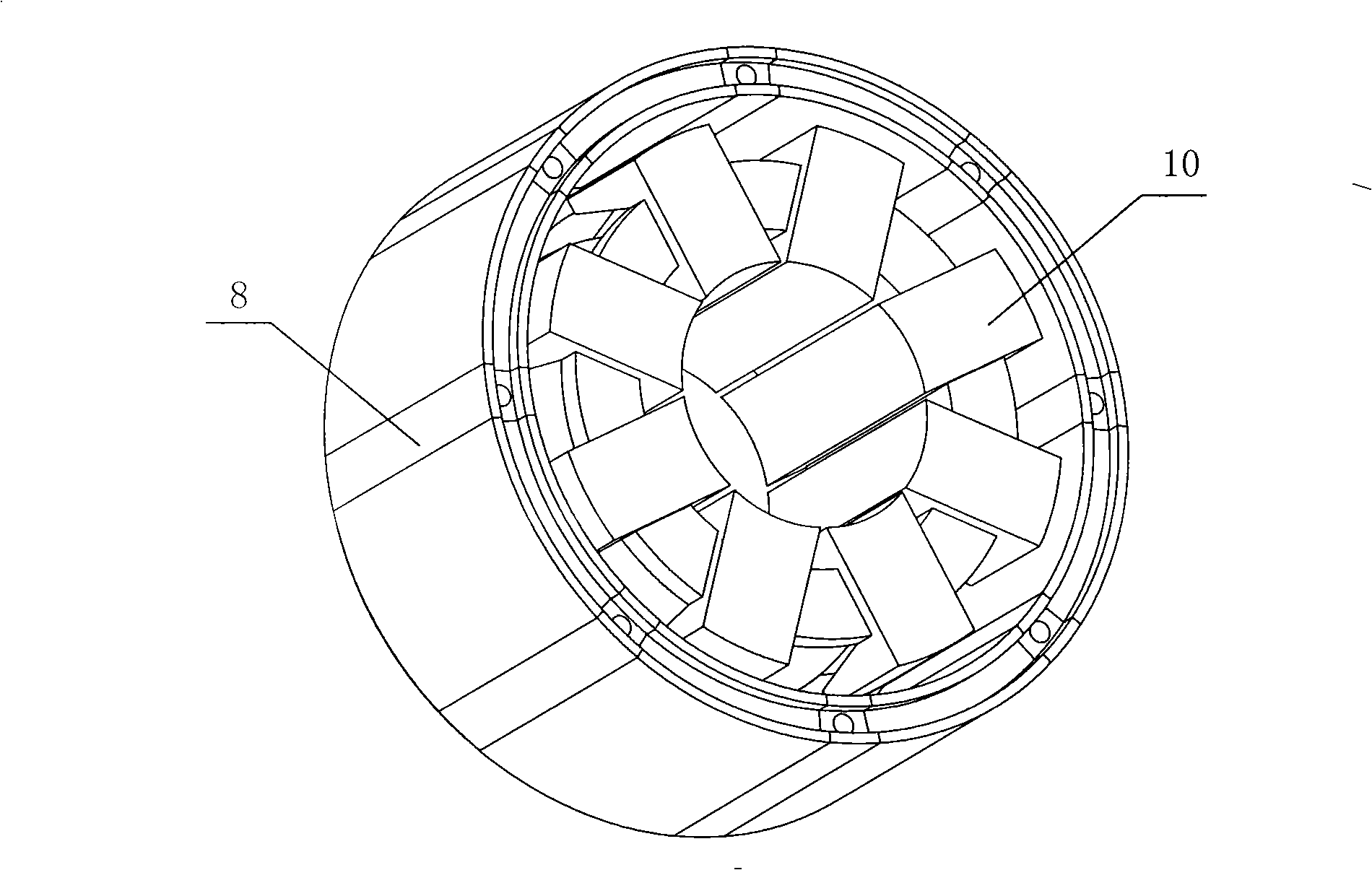

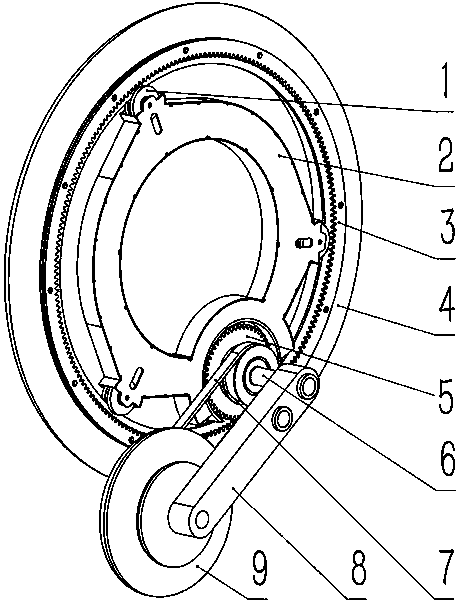

Energy accumulation device for fly wheel

InactiveCN101420150ASimple structureEasy maintenanceEngine componentsSliding contact bearingsMagnetic bearingHigh energy

The invention provides a high-efficient flywheel energy storage device, comprising a shell, a motor arranged in the cavity of the shell, a flywheel and a support structure, wherein, the cavity is vacuumized; the motor is arranged under the flywheel; a flywheel shaft of the flywheel and a rotor of the motor are integrated into a whole; the support structure is formed by mixing a pivot thrust bearing and a permanent magnetic bearing. The device of the invention has the advantages of simple structure, convenient maintenance, low cost, good stability, simultaneous and quick charging and discharging and high energy storage efficiency.

Owner:SOUTHEAST UNIV

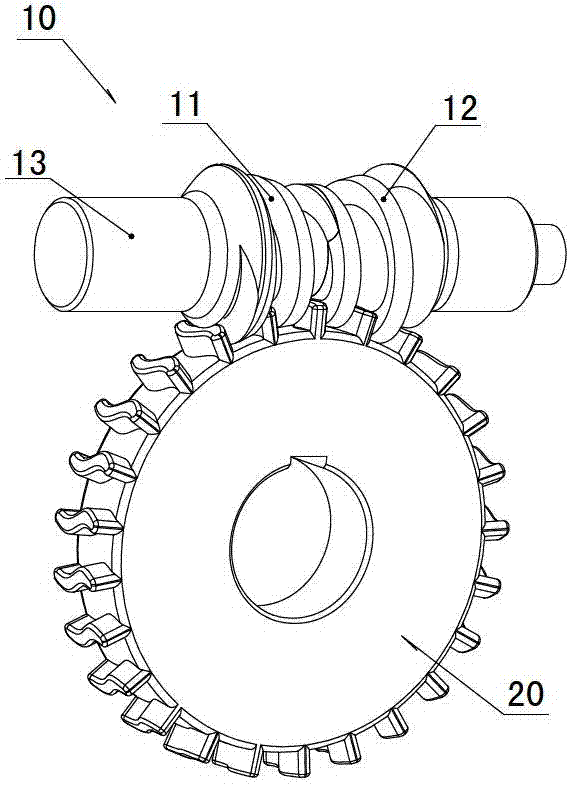

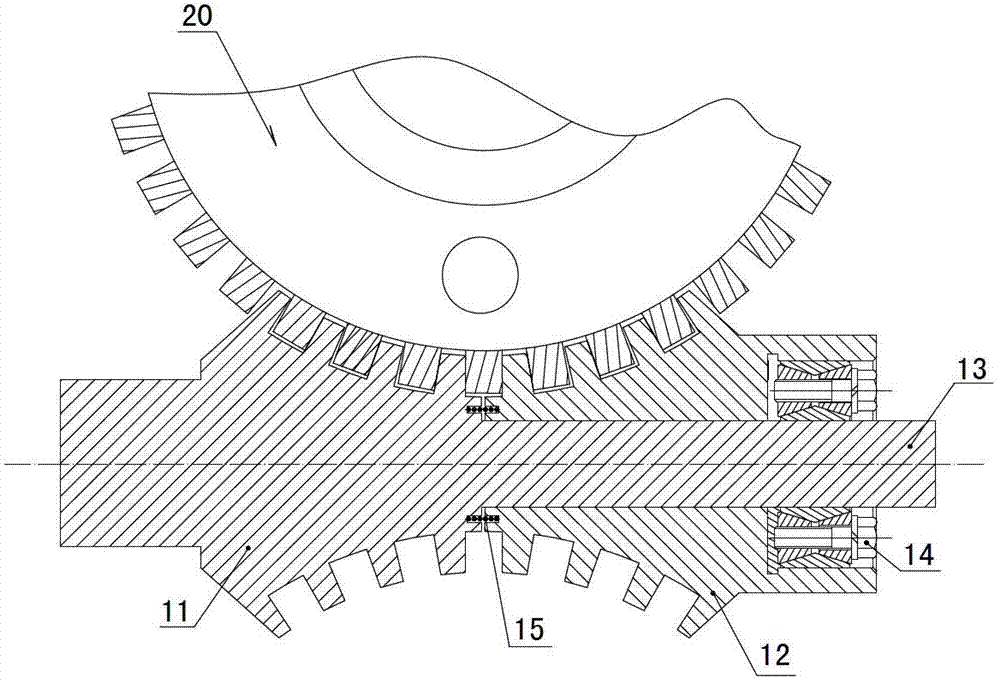

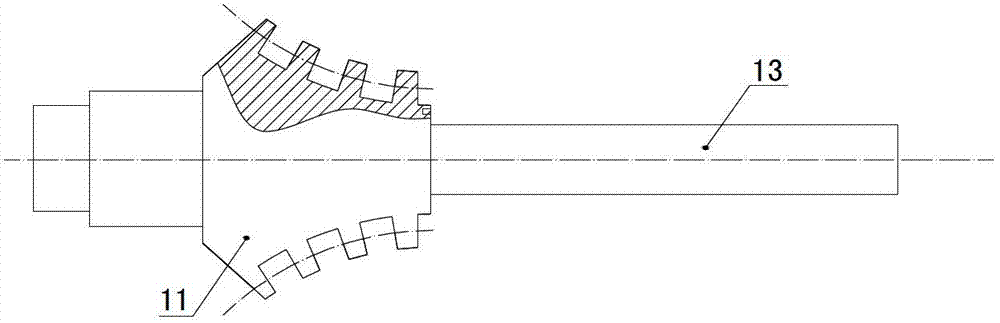

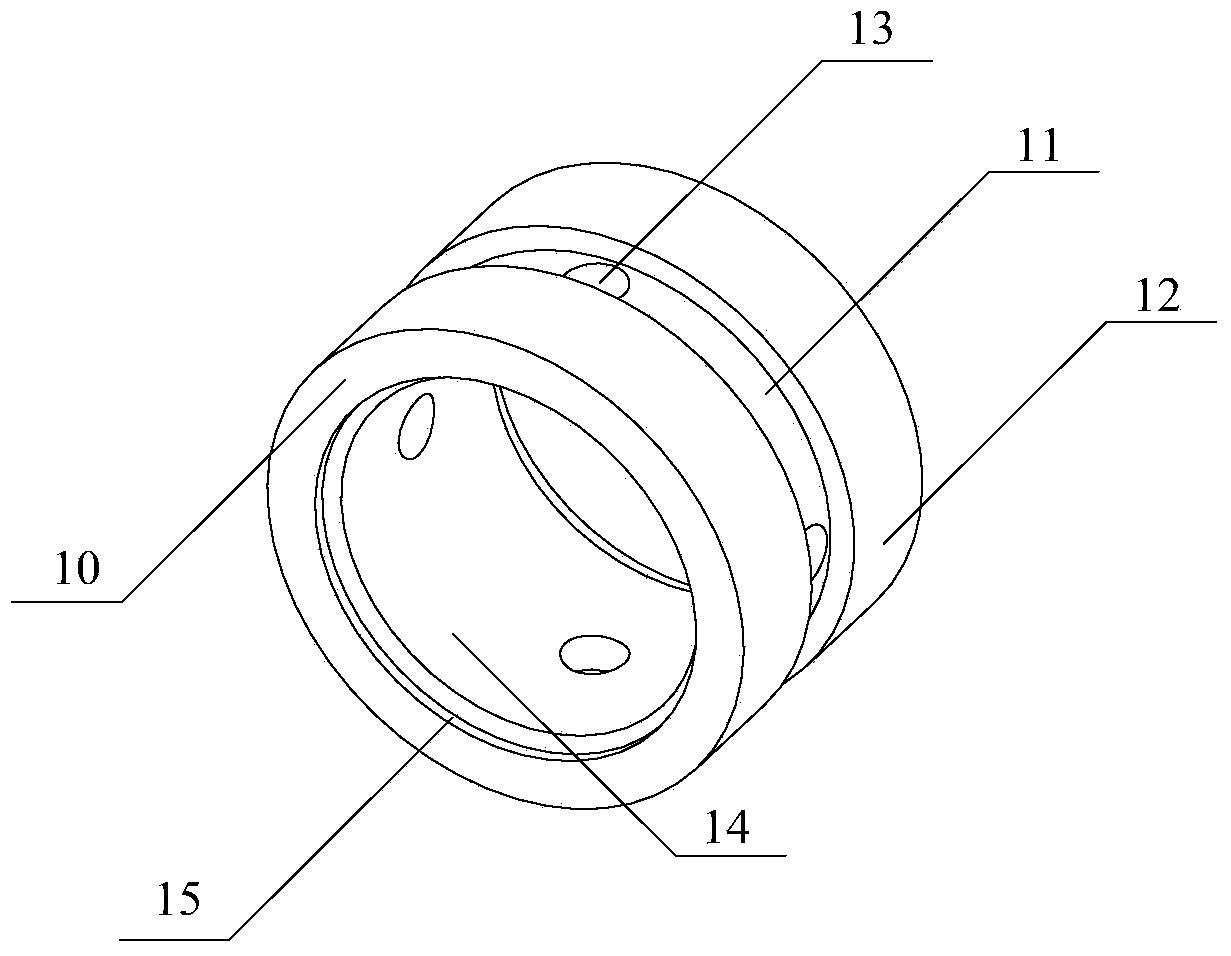

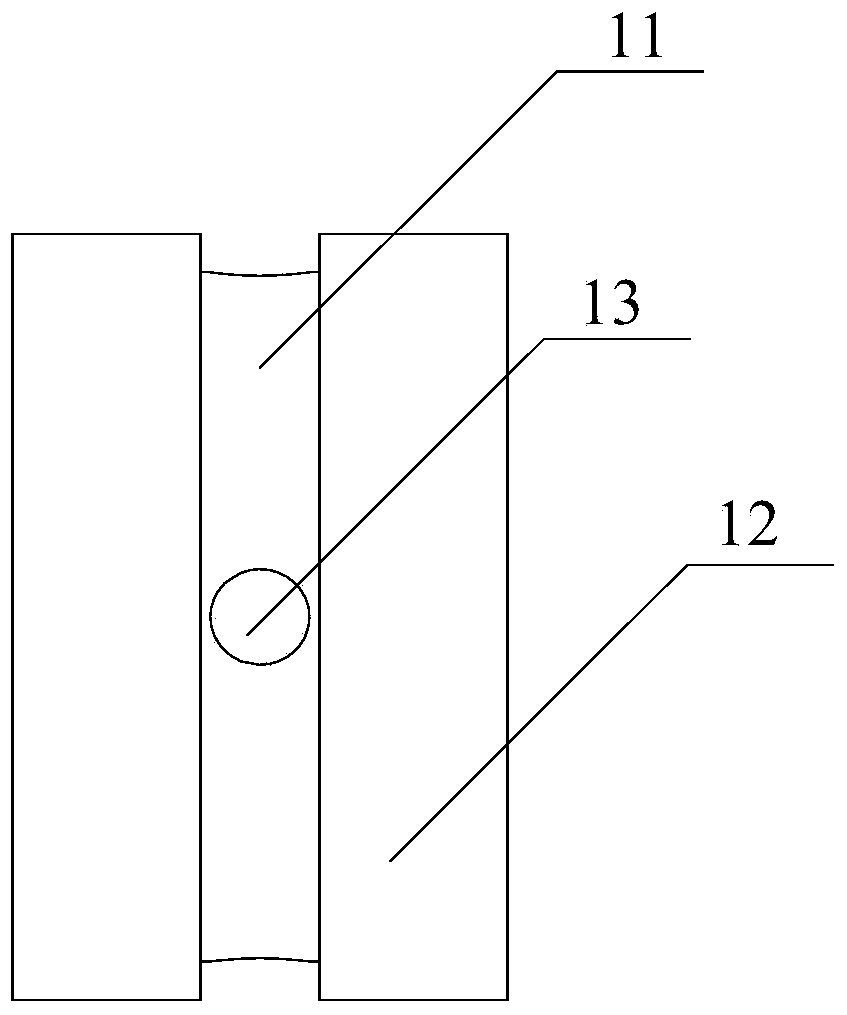

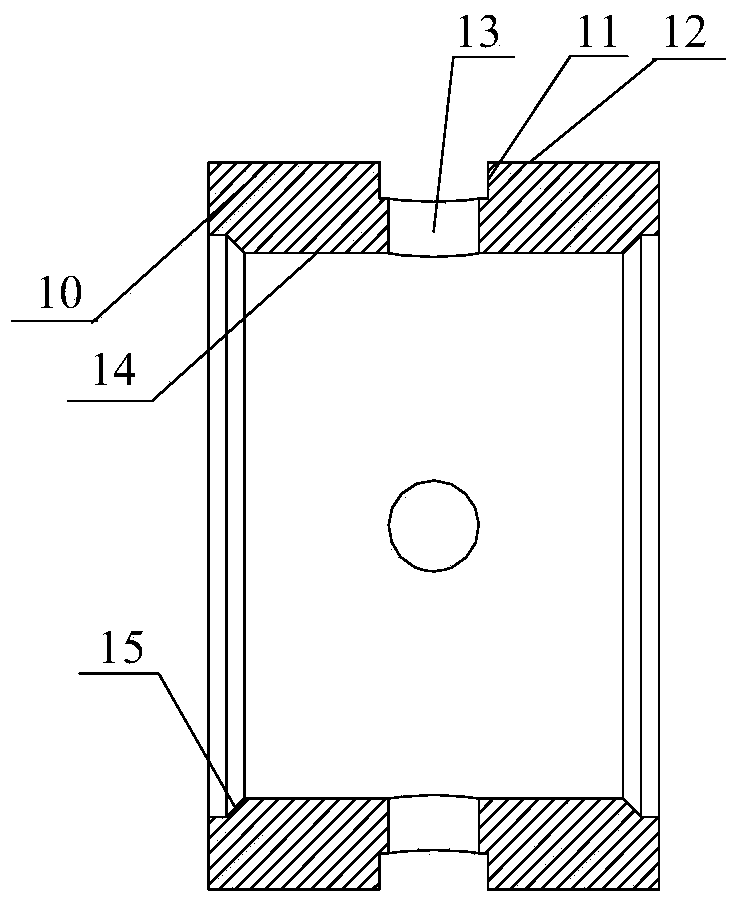

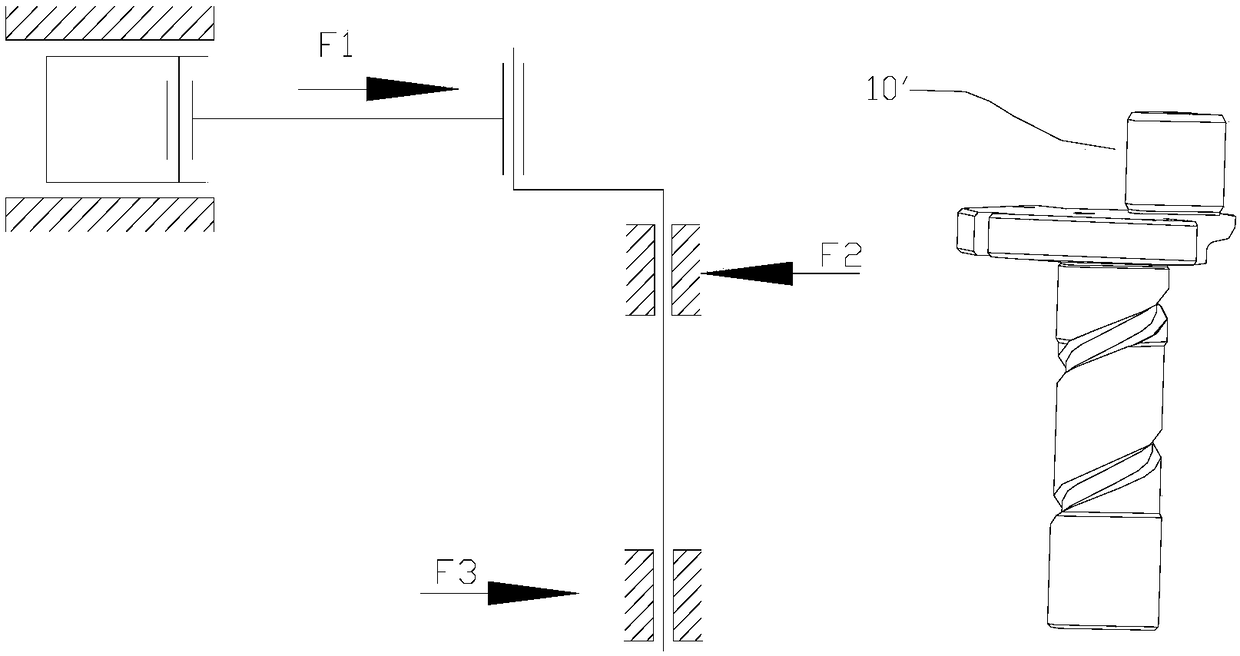

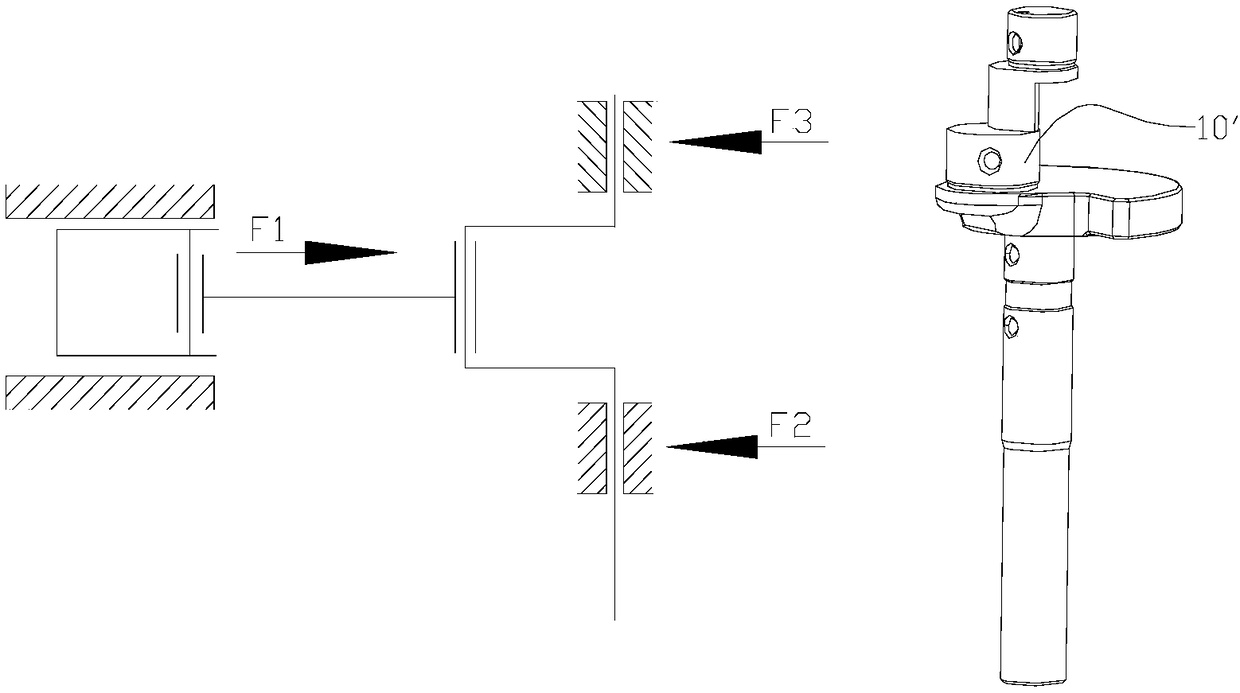

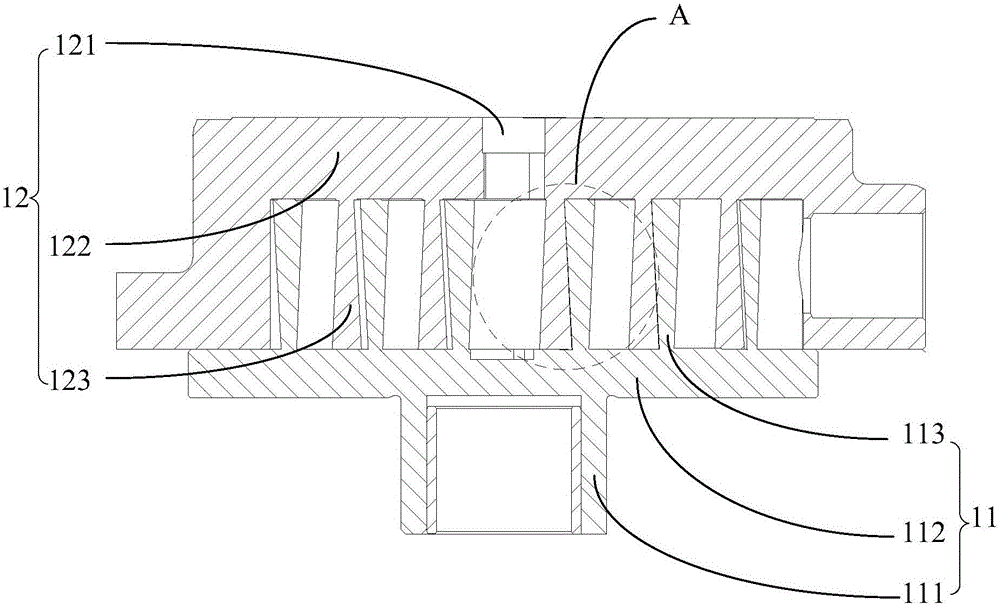

Worm transmission device capable of eliminating gear backlash

InactiveCN102734389AEase of precision manufacturingImprove carrying capacityPortable liftingToothed gearingsEngineeringGrinding wheel

The invention discloses a worm transmission device capable of eliminating a gear backlash and aims to achieve effects that the gear backlash is reduced or eliminated, precision transmission is realized, the bearing capacity is large, and the worm transmission device is convenient to machine and manufacture. The worm transmission device comprises a worm (10) and a worm gear (20), wherein the worm (10) consists of a left section of worm (11) and a right section of worm (12) which are coaxially arranged; left and right tooth surfaces are respectively formed by enveloping different surfaces of a sinusoidal line grinding wheel once; sinusoidal gear teeth are radially and uniformly distributed on the worm gear (20) and formed by enveloping a hob of which the shape is consistent with that of the worm twice; and an adjustment mechanism for adjusting the relative position and the relative rotation angle of the left section of worm (11) and the right section of worm (12) is arranged between the left section of worm (11) and the right section of worm (12).

Owner:XIHUA UNIV

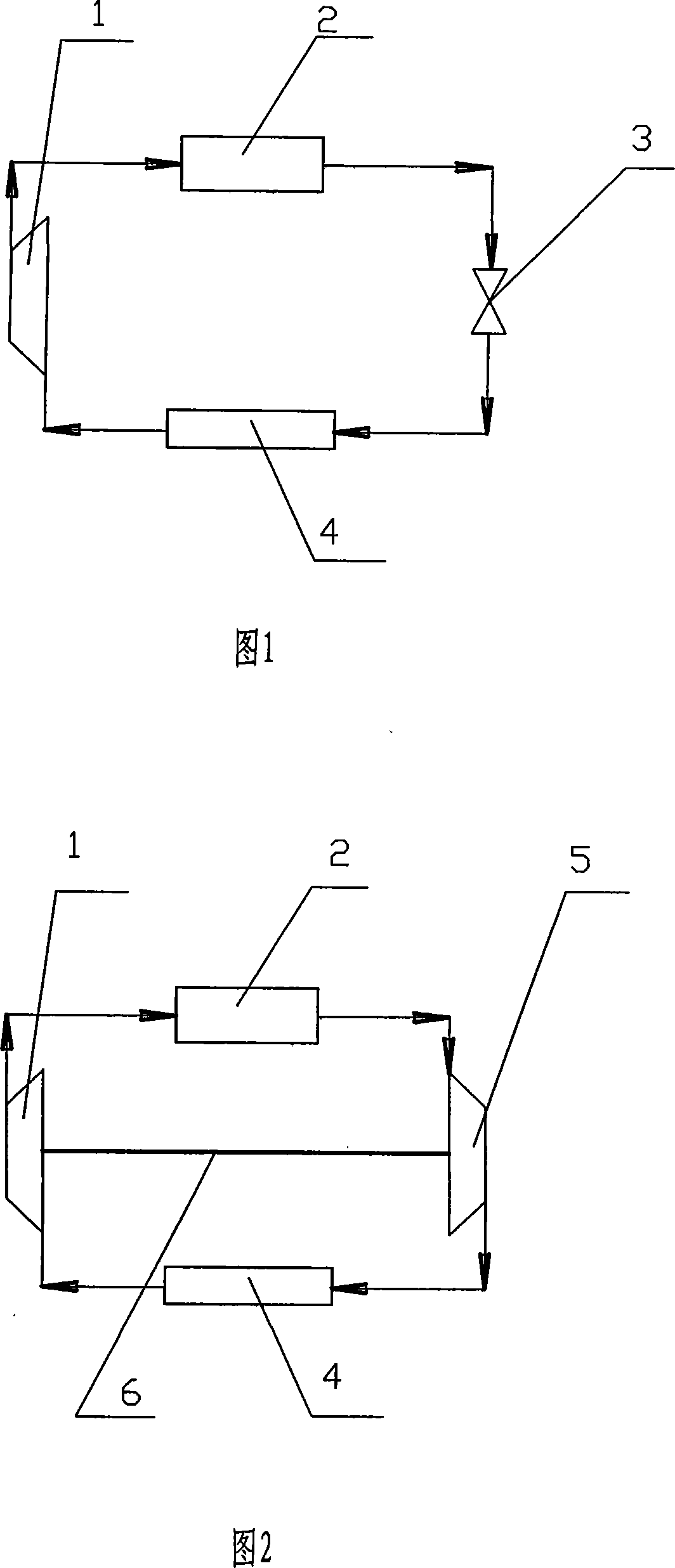

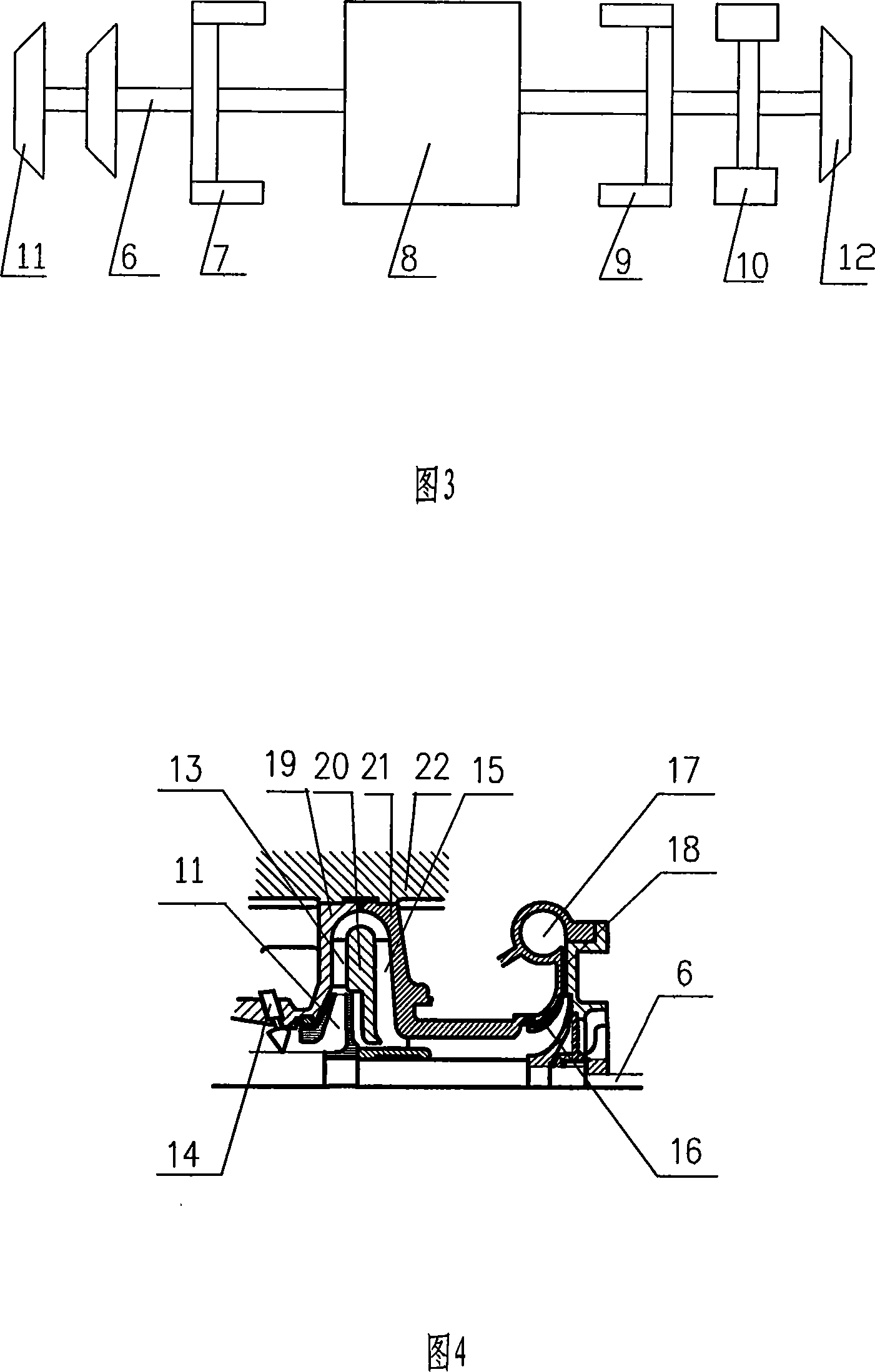

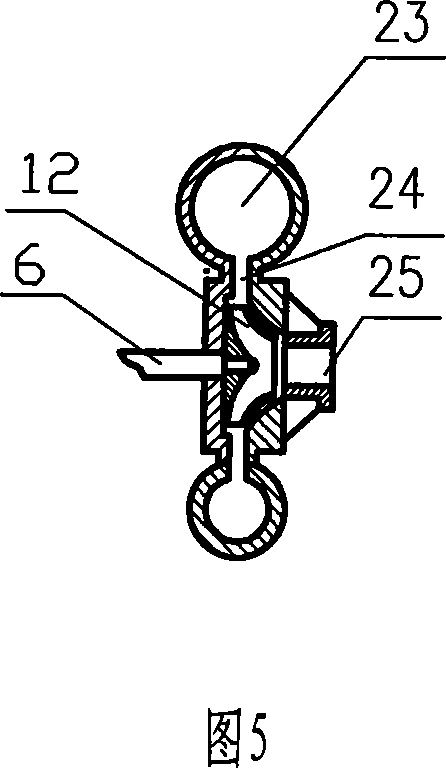

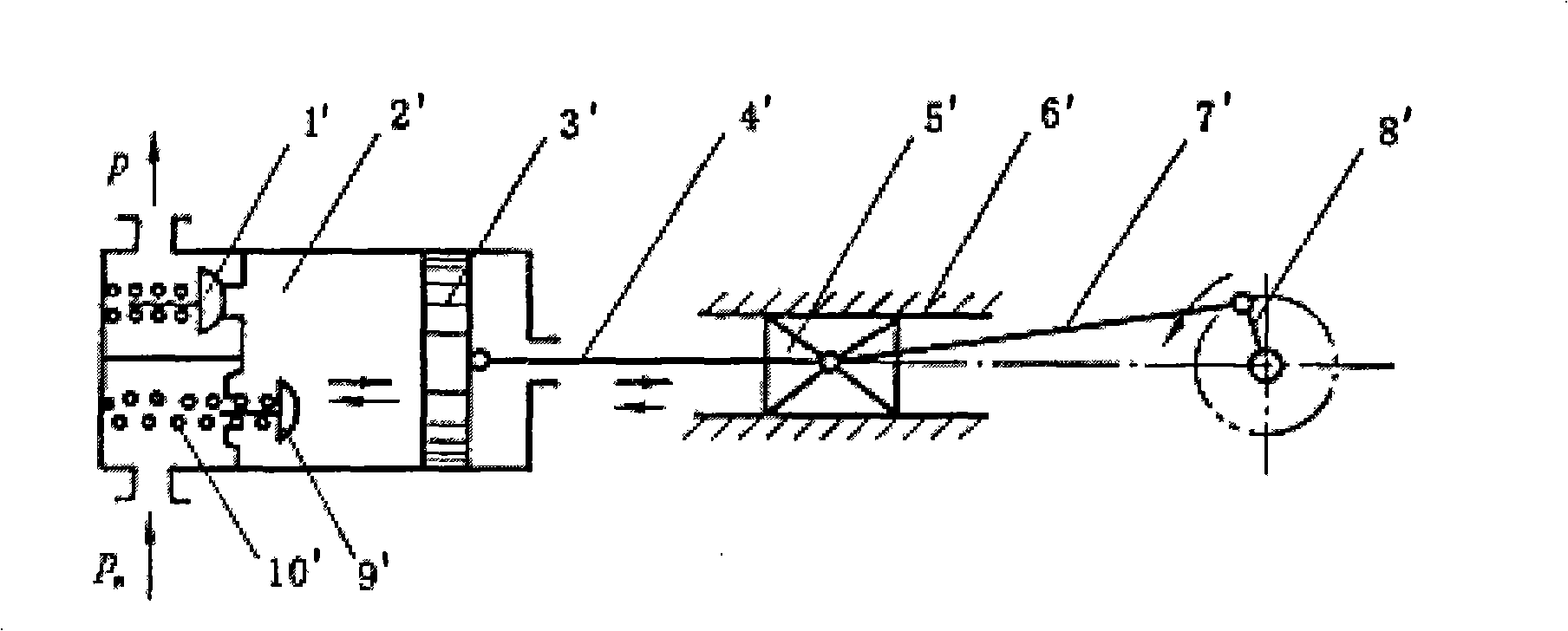

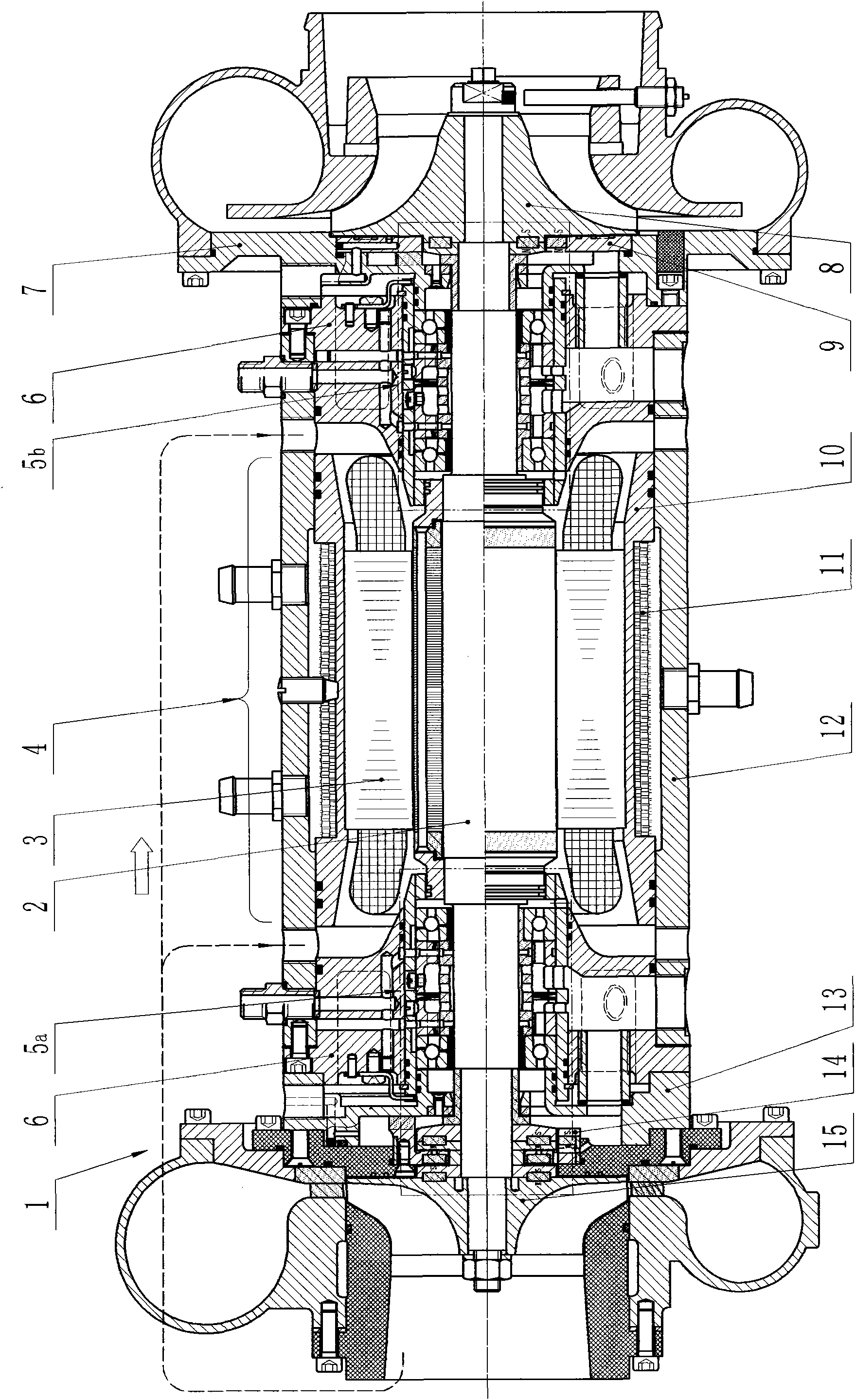

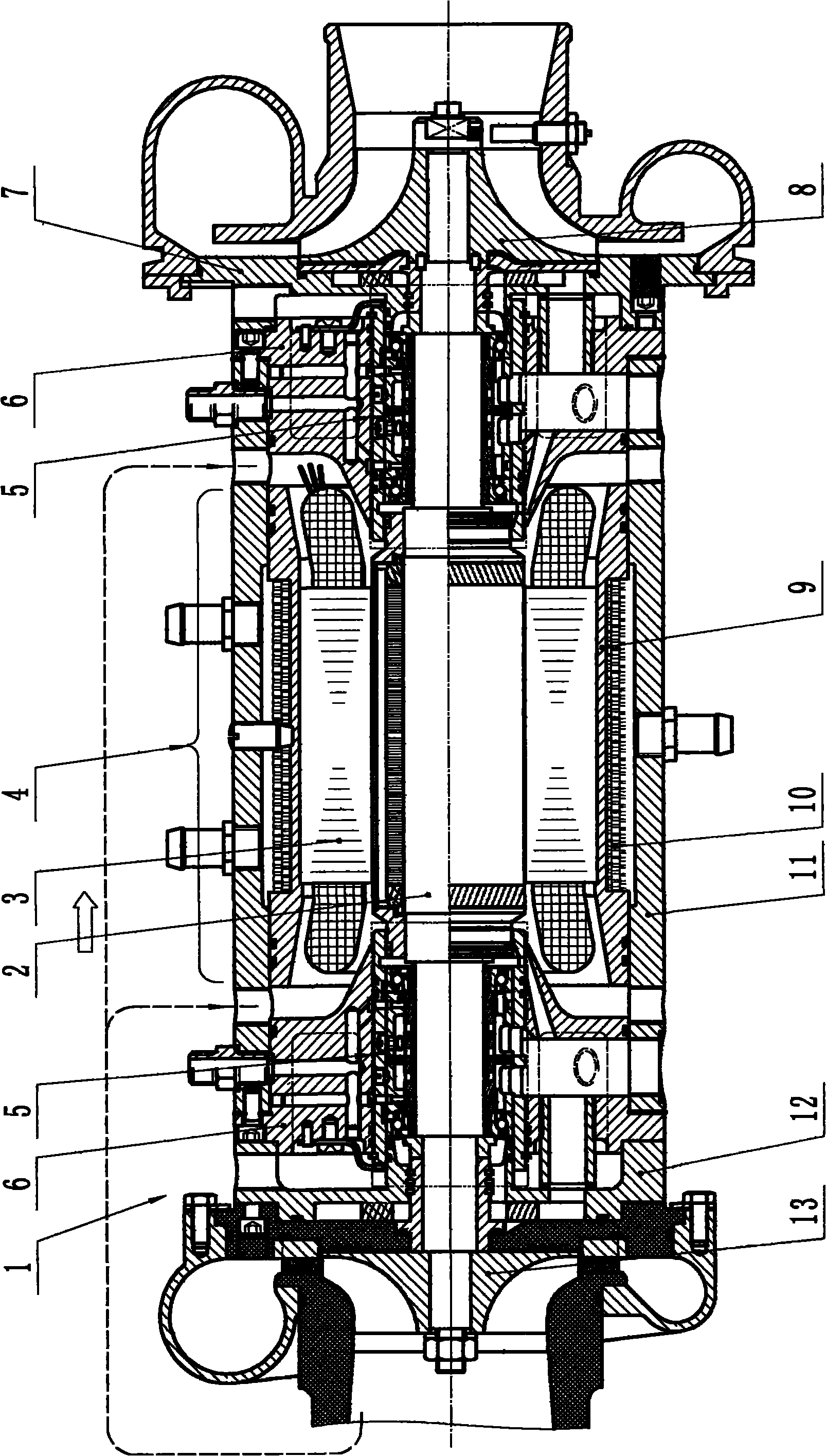

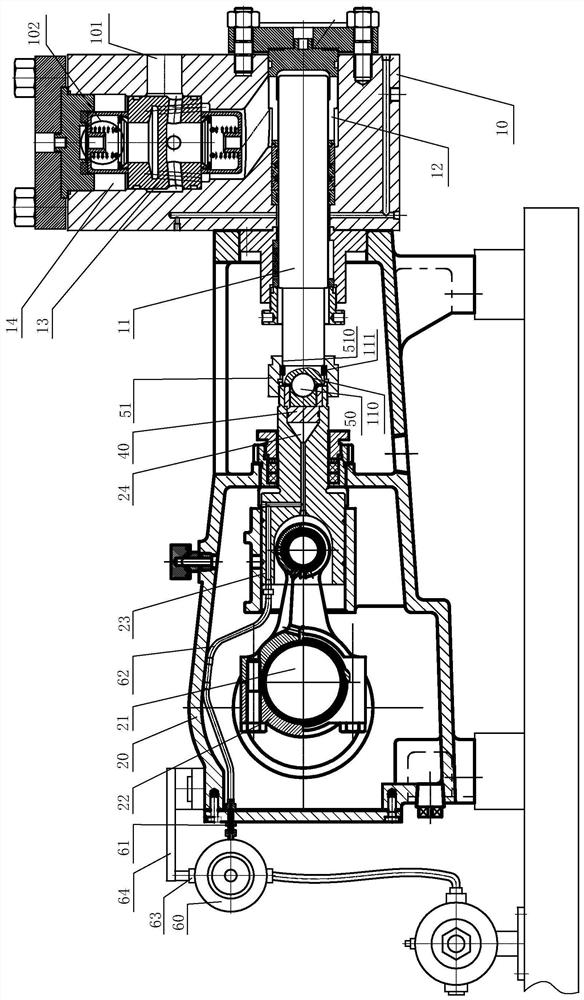

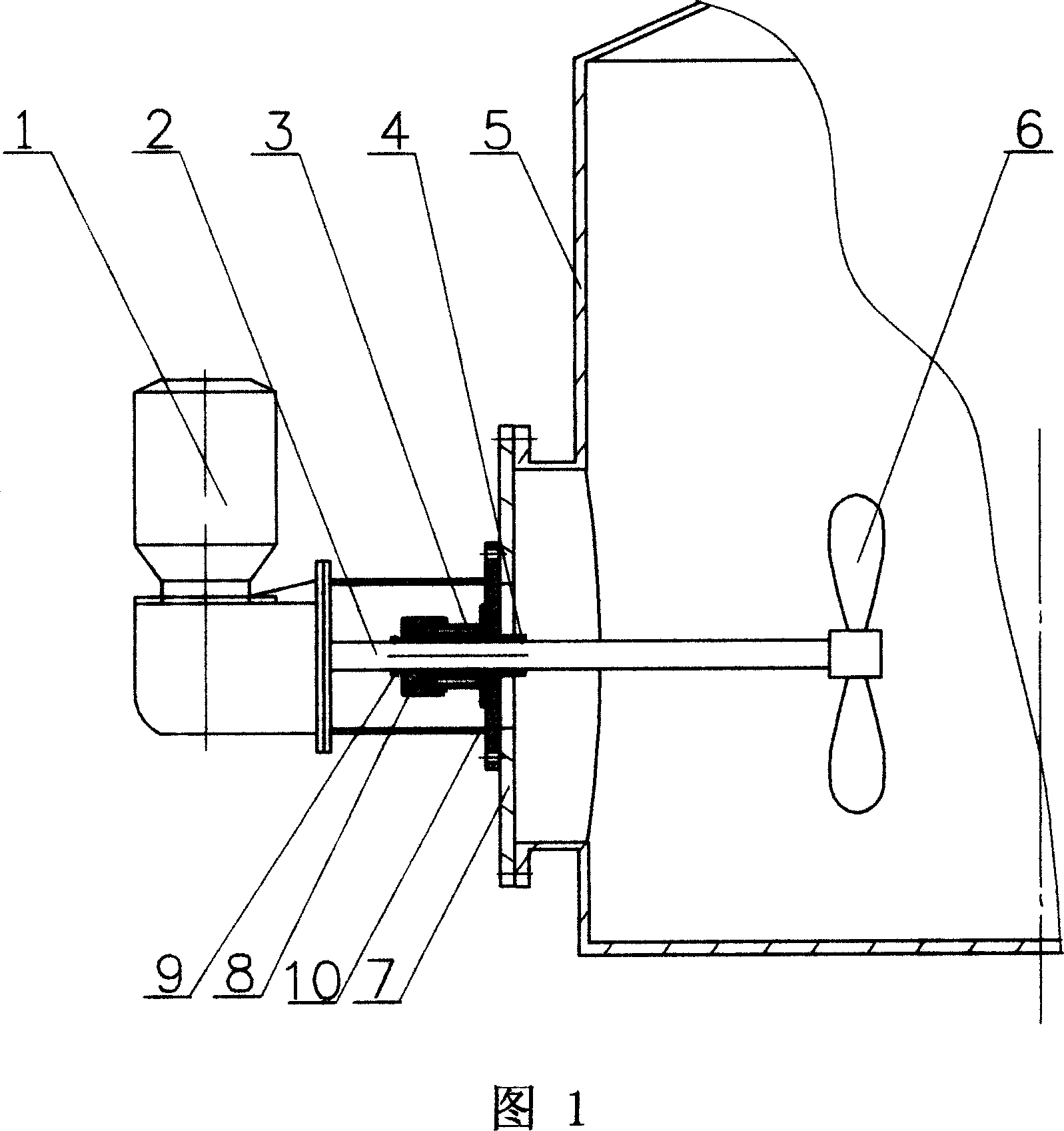

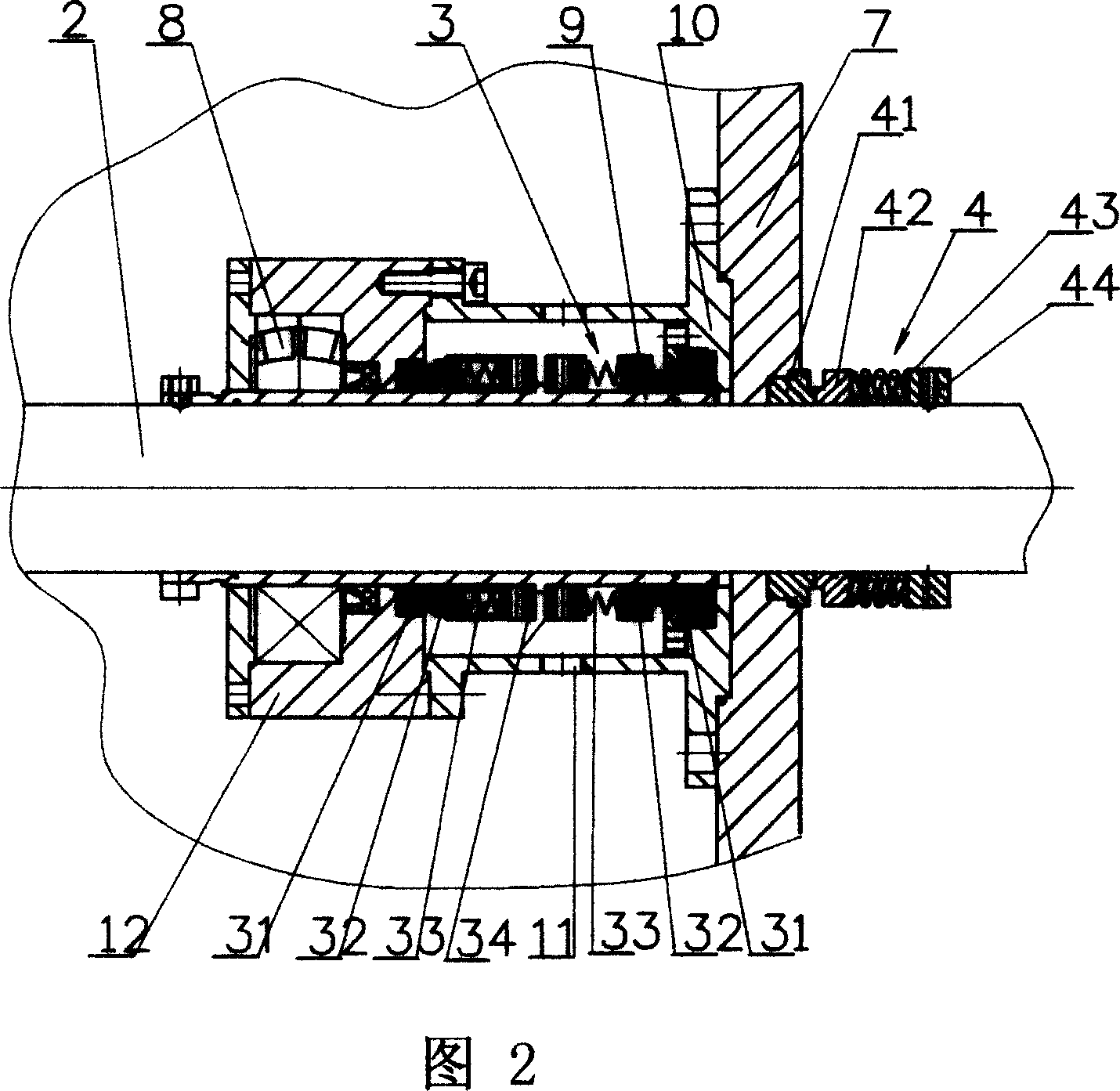

Frequency conversion magnetic levitation compression expansion engine set

ActiveCN101105346AReduce frictional power consumptionHigh heat transfer efficiencyPump componentsCompression machines using turbinesLubricationEvaporator

A variable frequency magnetic suspension compressional expansion assembly comprises a compressor, an evaporator and an expansion machine that are connected. A magnetic suspension bearing centrifugal compressor is directly connected with a radial flow type expansion machine via a shaft, the shaft is suspended on a left radial magnetic suspension bearing, a right radial magnetic suspension bearing and an axial magnetic suspension bearing, a variable frequency motor is provided between the left radial magnetic suspension bearing and the right radial magnetic suspension bearing and used for driving the centrifugal compressor; and the radial flow type expansion machine comprises an air inlet chamber and an air outlet pipe, nozzles and impellers are provided between the air inlet chamber and air outlet pipe and passed through the air inlet chamber and air outlet pipe, and the impellers are fixedly connected on the shaft. The power from expansion is transmitted to the compressor, and the refrigerant after expansion is entered into the evaporator to carry out evaporative cooling; after being evaporated in the evaporator, the refrigerant is sucked by the compressor to carry out circulatory flow; and the magnetic suspension bearings assure that the shaft does not contact with the bearings when the assembly operates, so that lubrication via lubricating oil is not needed.

Owner:广东西屋康达空调有限公司

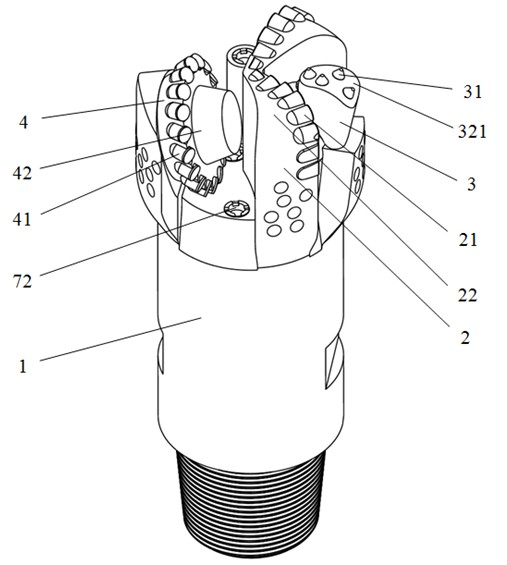

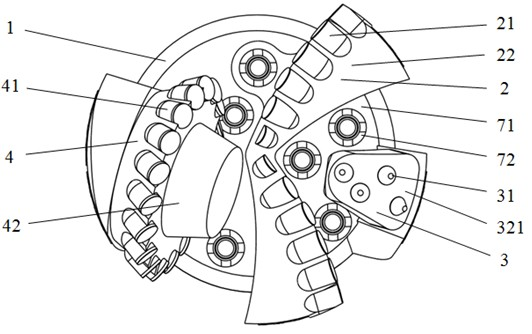

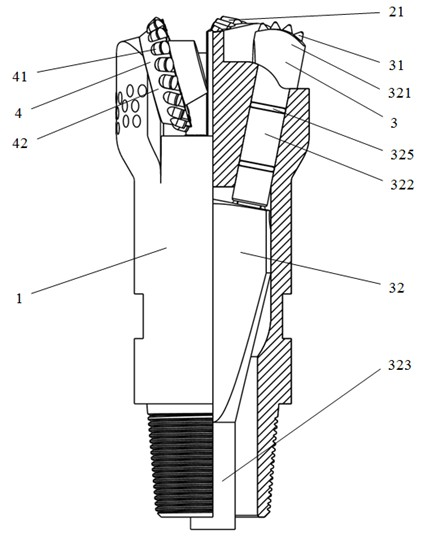

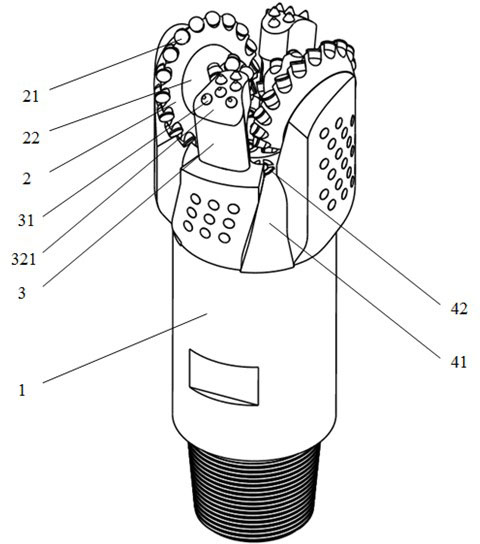

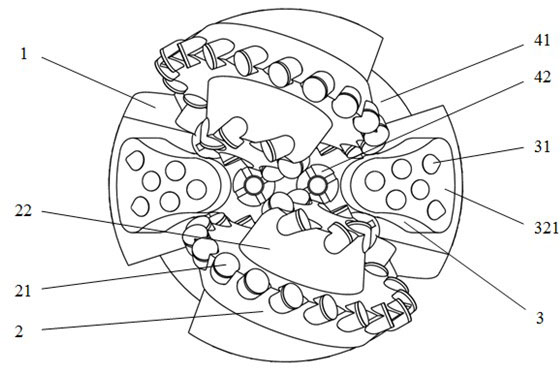

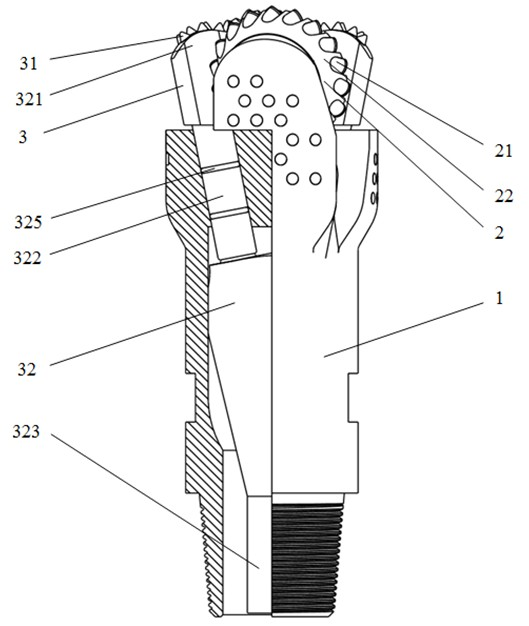

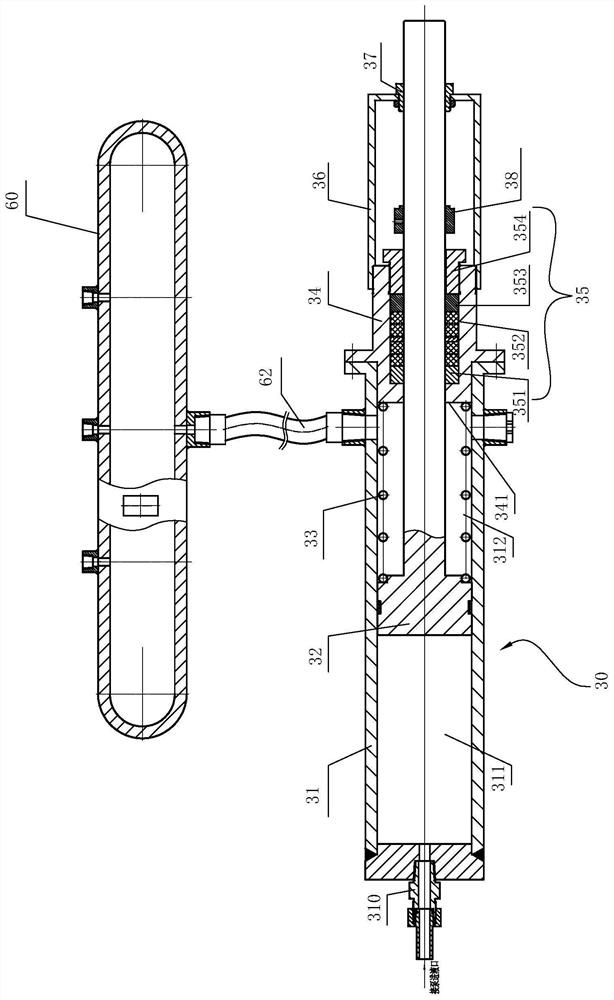

Crossed scraping-impacting composite drill bit

ActiveCN102678053AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringHydraulic structure

The invention discloses a crossed scraping-impacting composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The crossed scraping-impacting composite drill bit comprises a drill bit body, a fixed cutting structure, a disc cutter cutting structure and a hydraulic structure, wherein the fixed cutting structure, the disc cutter cutting structure and the hydraulic structure are arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact forces and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit for blasting a rock in a cutting way, the crossed scraping-impacting composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

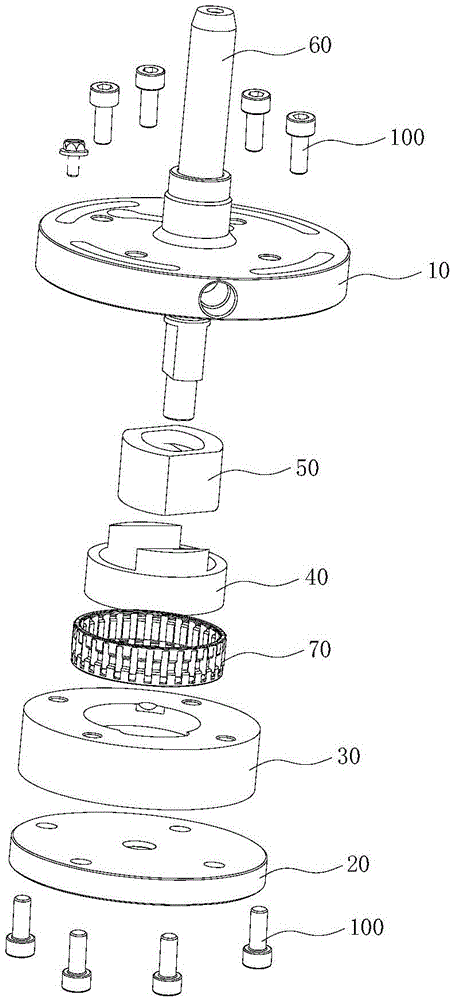

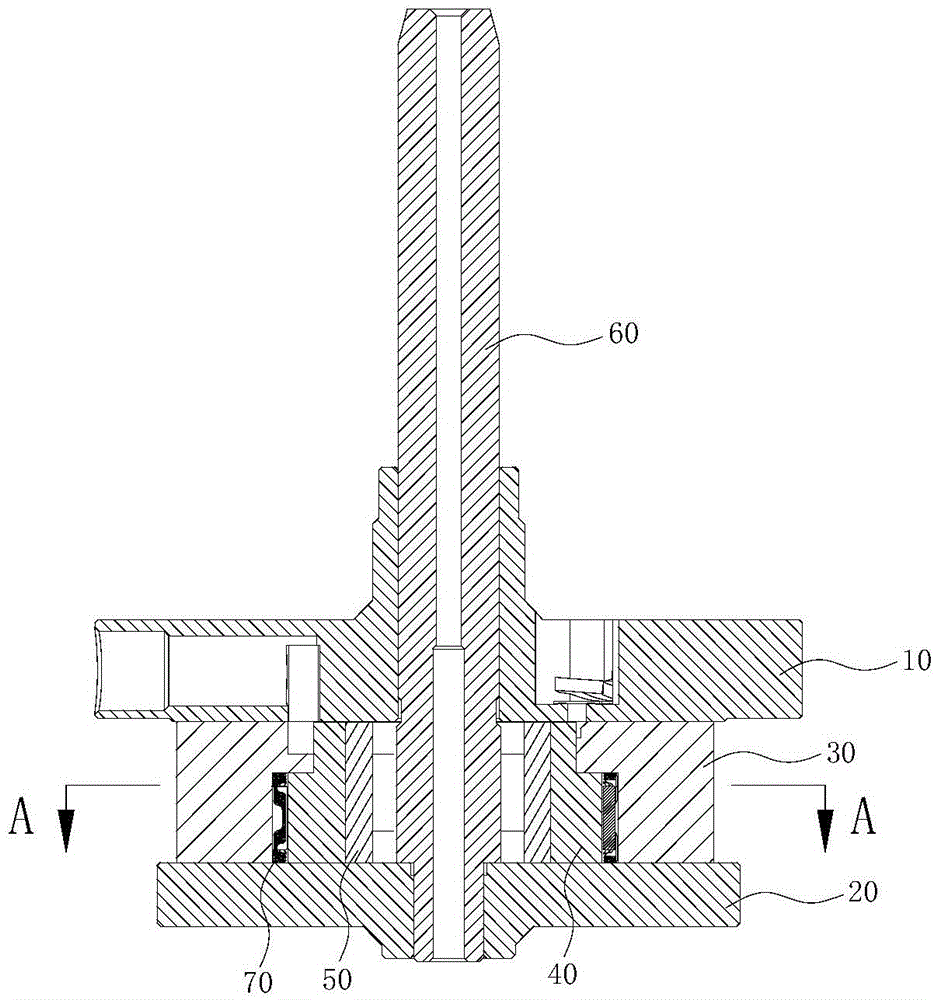

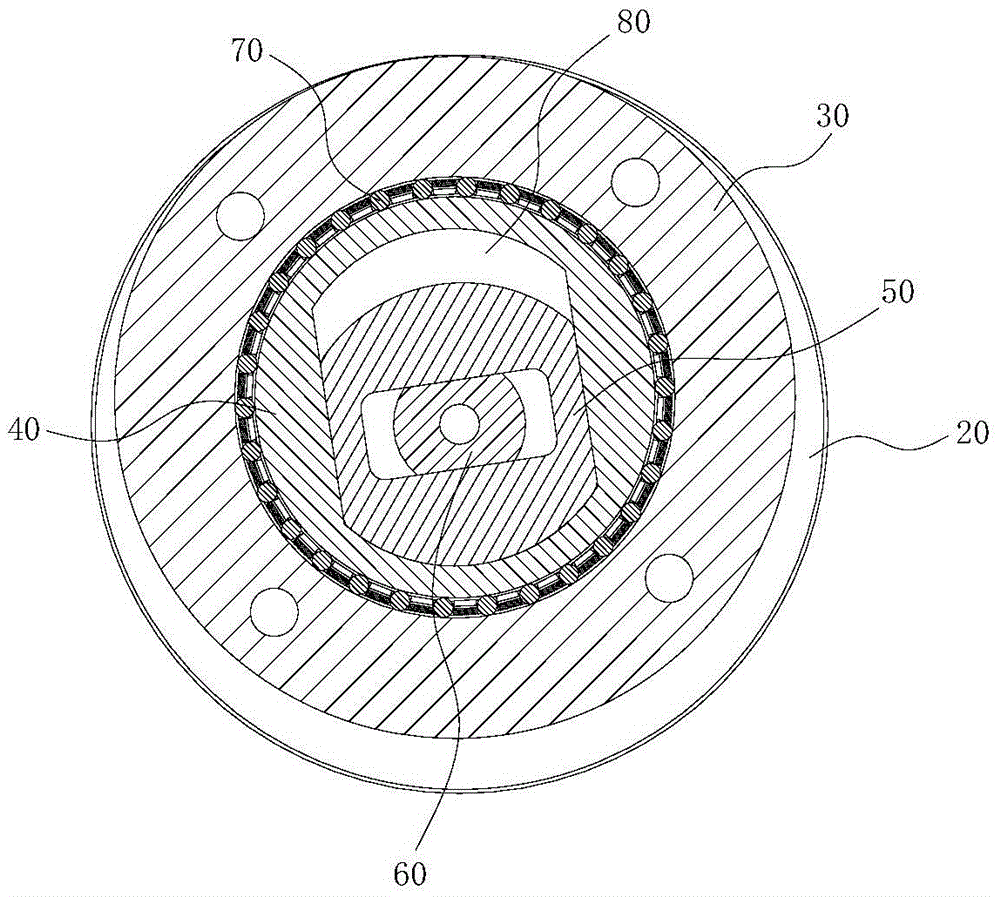

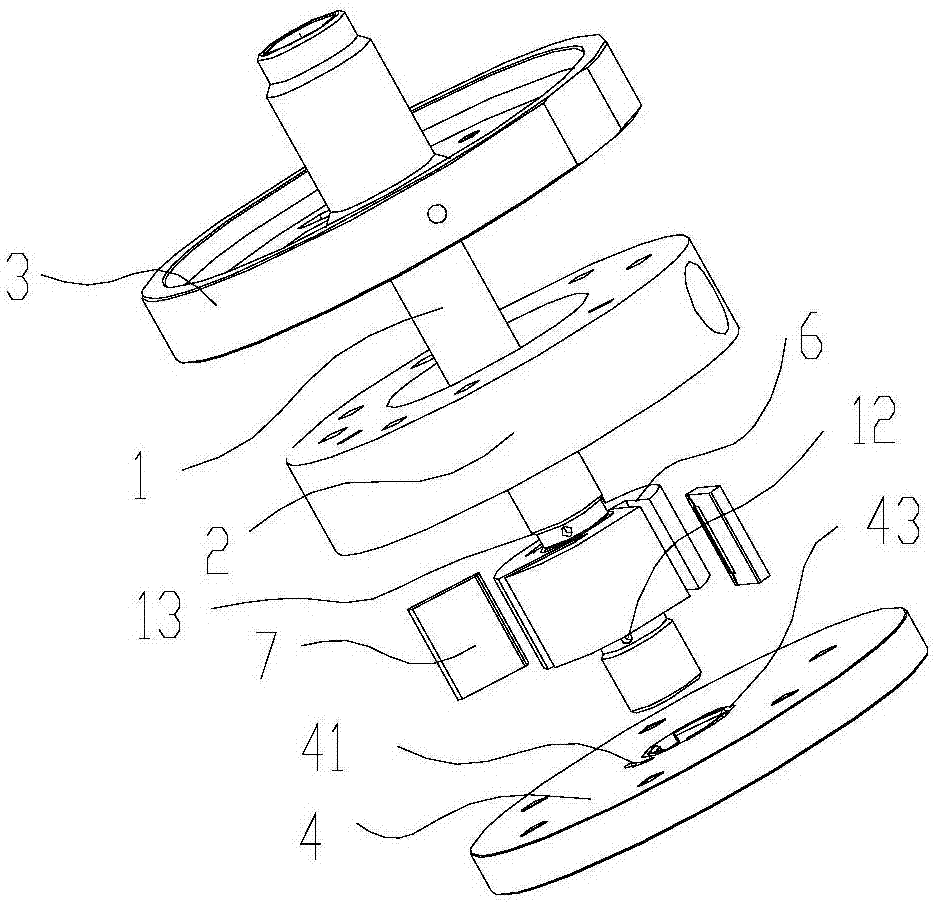

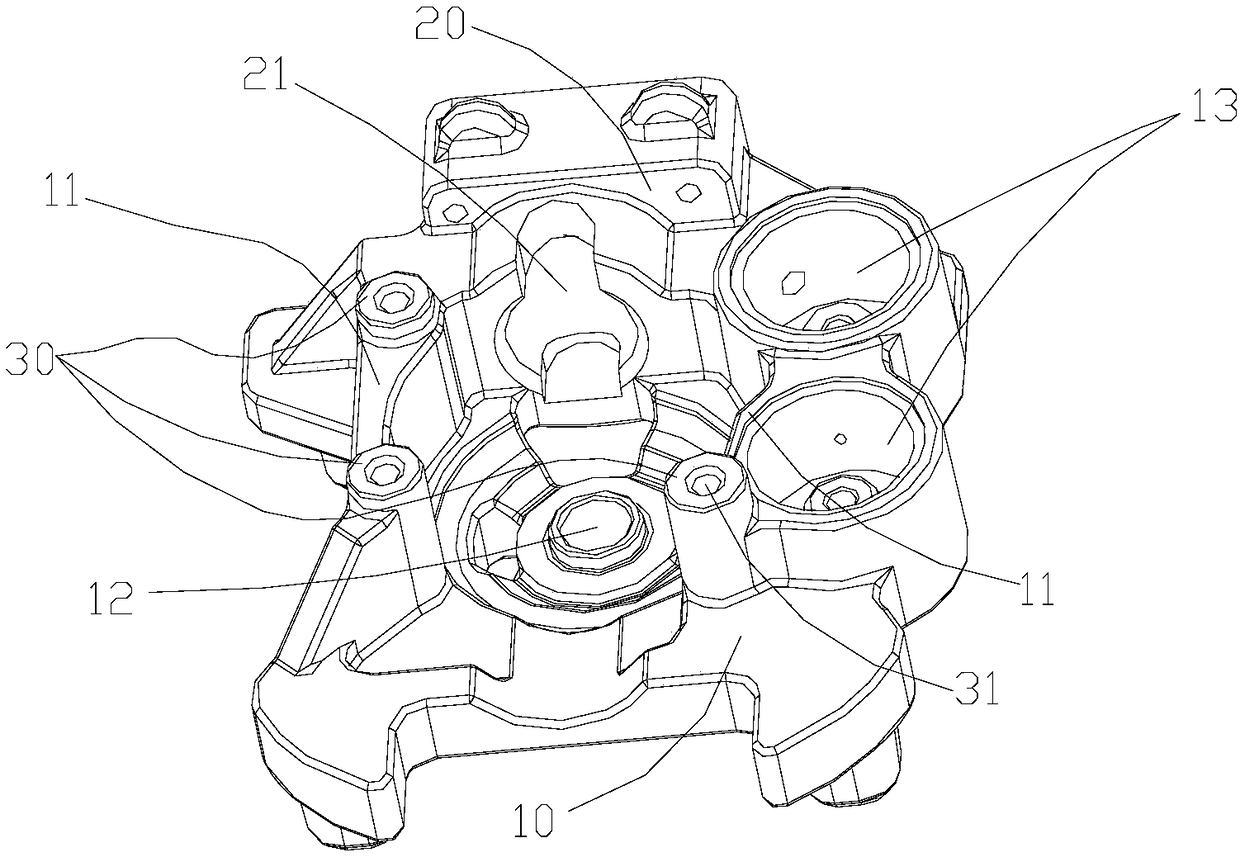

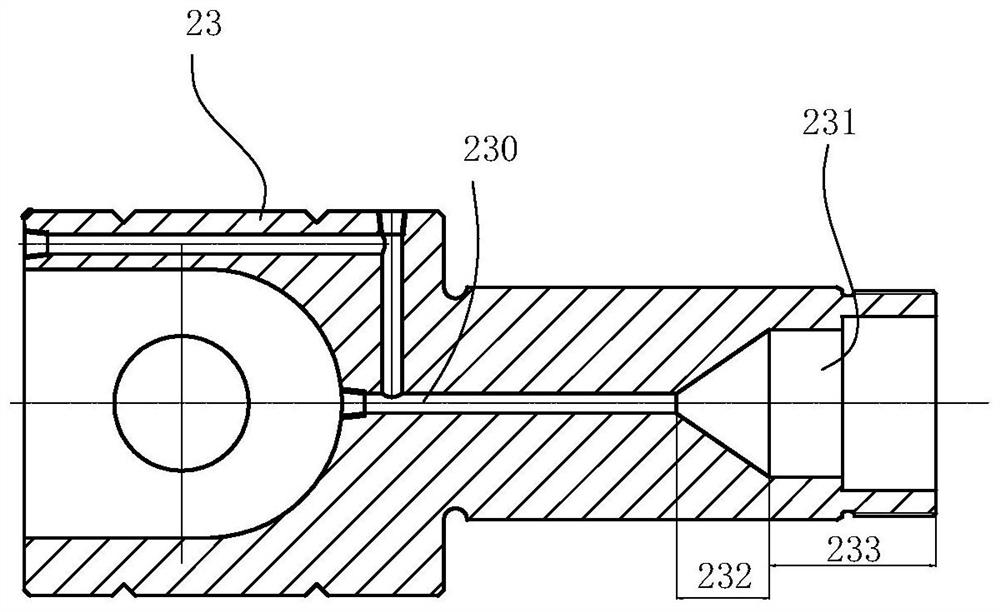

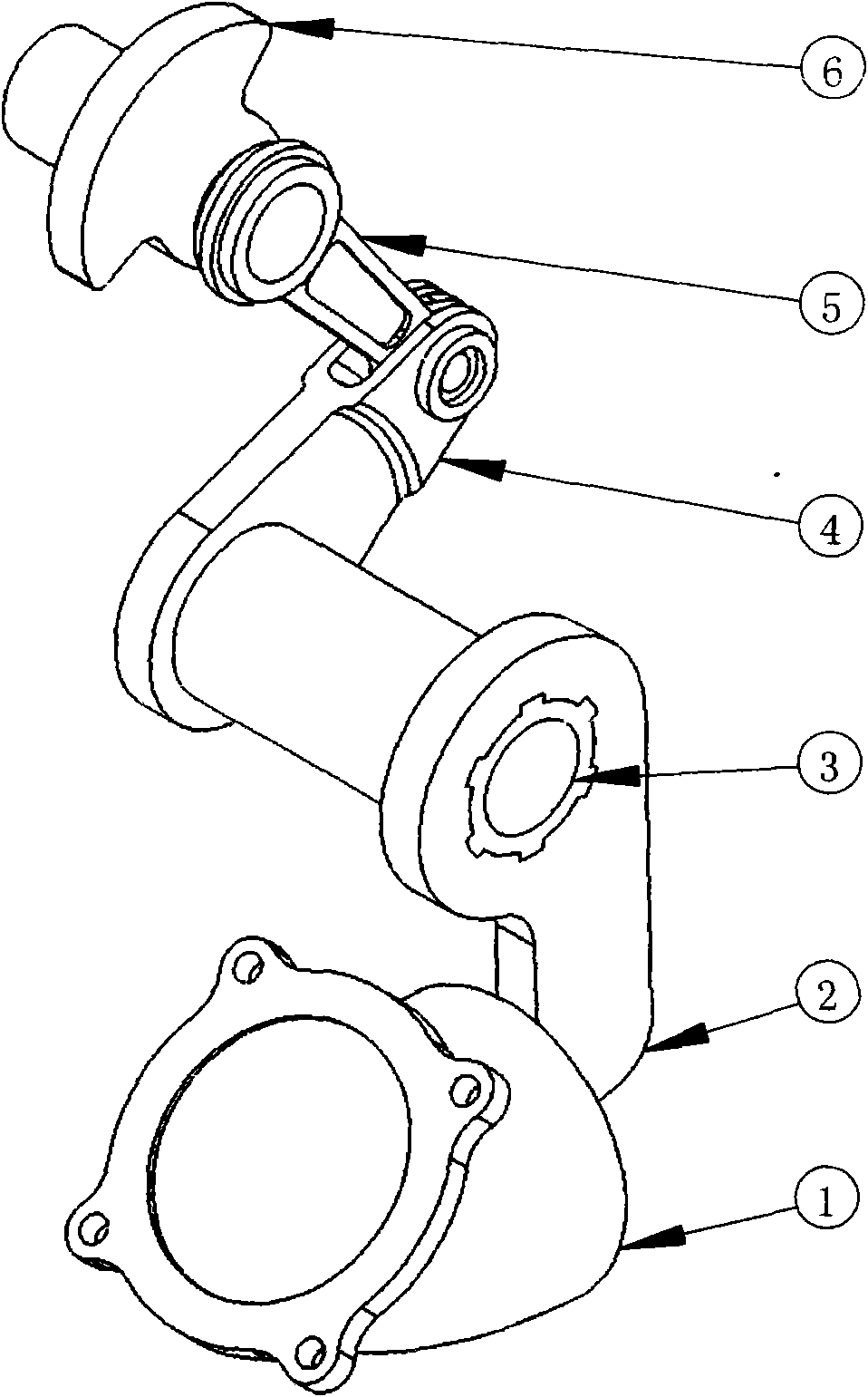

Compressor pump structure and compressor

ActiveCN105570128AImprove performanceSimplify processing difficultyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringMachining process

The invention discloses a compressor pump structure, and belongs to the field of compressors. A cylinder sleeve is arranged between an upper flange and a lower flange; a cylinder is arranged in the cylinder sleeve; a piston is slidingly arranged in the cylinder; a variable volume cavity is formed among the cylinder sleeve, the cylinder and the piston; a rotating shaft is inserted in the piston; the axis of the rotating shaft is eccentric from the axis of the cylinder, and the eccentric distance is fixed; the rotating shaft drives the piston and the cylinder to rotate; and the piston slides in the cylinder when rotating to change the volume of the variable volume cavity. The cylinder sleeve is arranged, the variable volume cavity is formed among the cylinder sleeve, the cylinder and the piston, and the structure of a piston sleeve is replaced, so that the problem of peripheral leakage channel is not generated anymore, the compressor leakage is radically reduced, and the compressor performance is improved; and the pump structure is simple in machining process and convenient for assembly.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Disc cutter composite drill bit

InactiveCN102678052AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringTransfer mechanism

The invention discloses a disc cutter composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The disc cutter composite drill bit comprises a drill bit body and a disc cutter cutting structure arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact force and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit (also named as wheel type drill bit) with the disc cutter cutting structure, the disc cutter composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

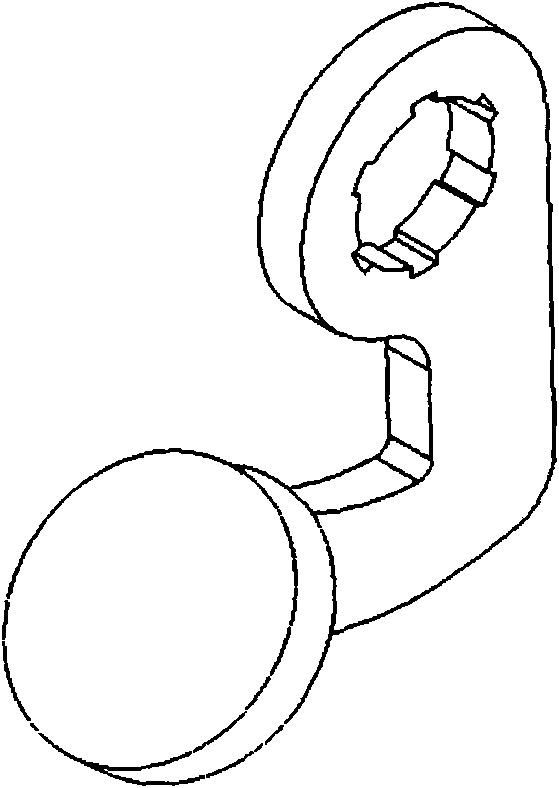

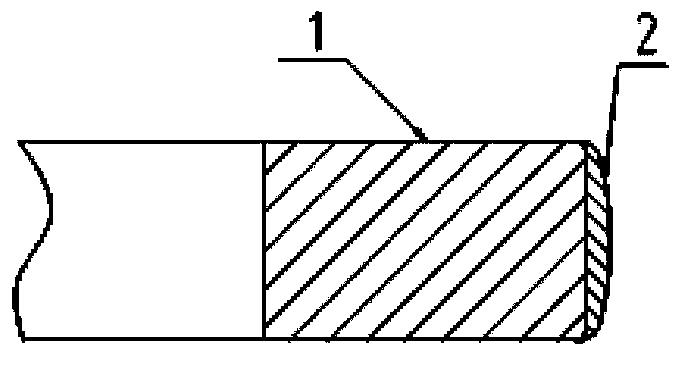

Laser micro-texturing method of piston ring

InactiveCN103894732ALow coefficient of kinetic frictionExtended service lifePistonsMetal working apparatusPiston ringEmission standard

The invention discloses a laser micro-texturing method of a piston ring meeting the national V emission standard. The method includes the following steps that the optimal friction pair contact surface parameter is selected, and a piston ring-cylinder sleeve friction pair surface fluid lubrication theoretical model is built; the optimal theoretical morphology of the friction surface of the piston ring is built, and the radius and the depth of a cavity in the outer-circle sealing surface of the piston ring, the area ratio of the cavity, the radius and the depth of cavities in the upper end face and the lower end face and the area ratio of the cavities are determined; the same-point single pulse interval multiple laser micro-machining process is used for performing laser micro-texturing machining on the working surface of the piston ring. According to the laser micro-texturing method of the piston ring, through the surface morphology of the laser micro-textured piston ring, the piston ring can be directly machined in the air environment, and no pollution is generated, and no noise is generated; the kinetic friction coefficient of the piston ring can be reduced in the use process of the piston ring, the friction power consumption is reduced, the service life of the piston ring is effectively prolonged, the fuel consumption rate and machine oil are reduced, and the PM2.5 value in tail gas is lowered.

Owner:NANJING FAYN PISTON RING

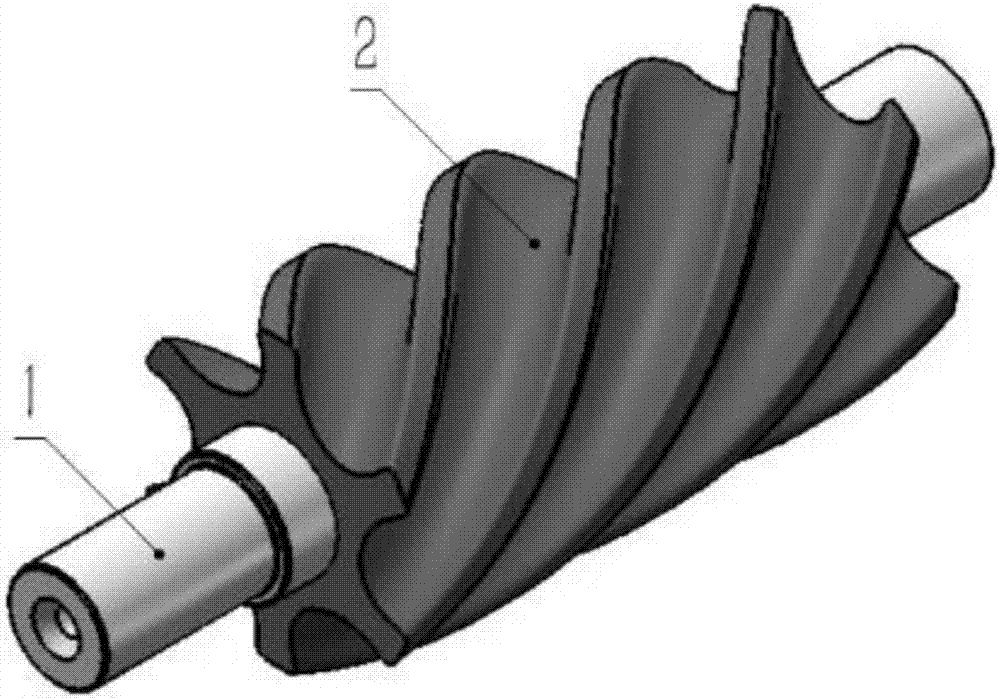

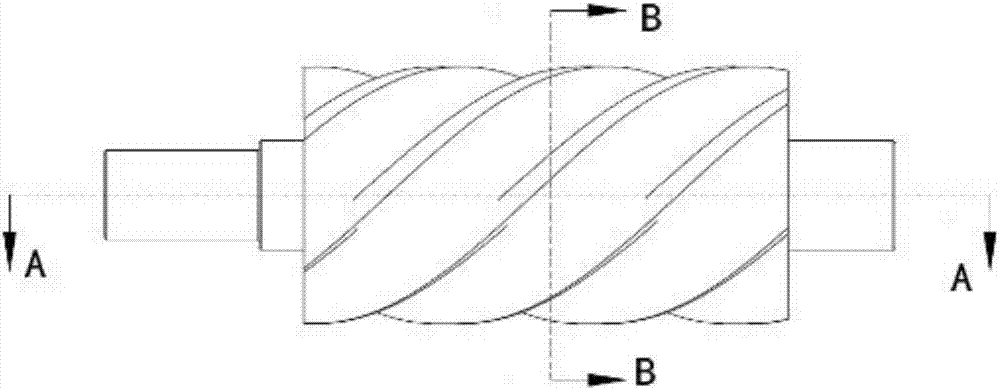

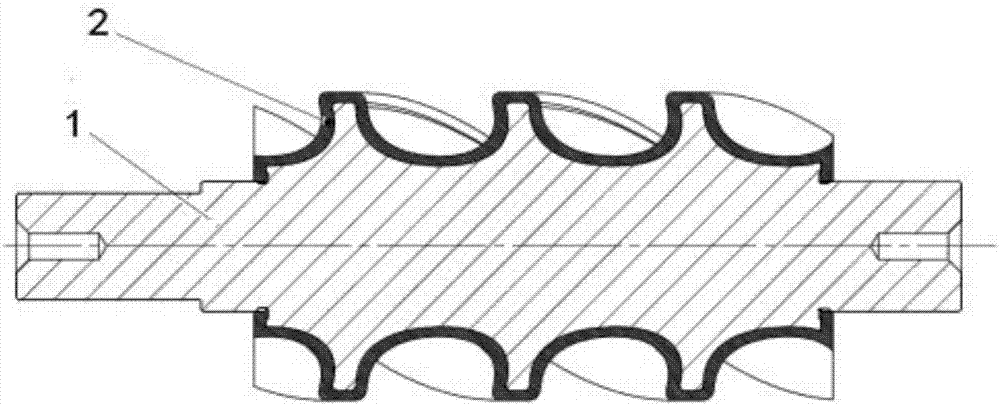

Manufacturing method for double-screw-rod compressor rotor

InactiveCN107448384AGood sealing conditionImprove lubrication conditionsRotary piston pumpsGear wheelsMilling cutterOil free

The invention discloses a manufacturing method for a double-screw-rod compressor rotor. A screw-rod compressor rotor is formed by a stainless steel rotor core and a PEEK engineering plastic tooth-shaped shell through high-temperature mold pressing. In order to make an oil-free screw rod compressor reach the higher exhaust pressure (the gage pressure of 1.3 MPa) and guarantee the long-time operating reliability of the rotor, a screw rod rotor structure is made of the stainless steel rotor core and a special modified PEEK material which is 1-5 mm thick and die-cast to the surface; finally, the die-cast PEEK surface is finished in place by a form milling cutter; and to increase the bonding degree of the PEEK engineering plastic and the stainless steel rotor core, some regular circular pits are machined in the two tooth-shaped end faces of the stainless steel rotor. By the adoption of the manufacturing method, the manufacturing difficulty of the oil-free screw rod compressor rotor can be lowered greatly, the structure manner of an oil-free air screw rod compressor, an oil-free process screw rod compressor and a refrigeration screw rod compressor can be simplified, and finally the service life of the screw rod compressors can be prolonged, and the maintenance cost is lowered.

Owner:SUZHOU ALRBETTER PRECISION MACHINERY

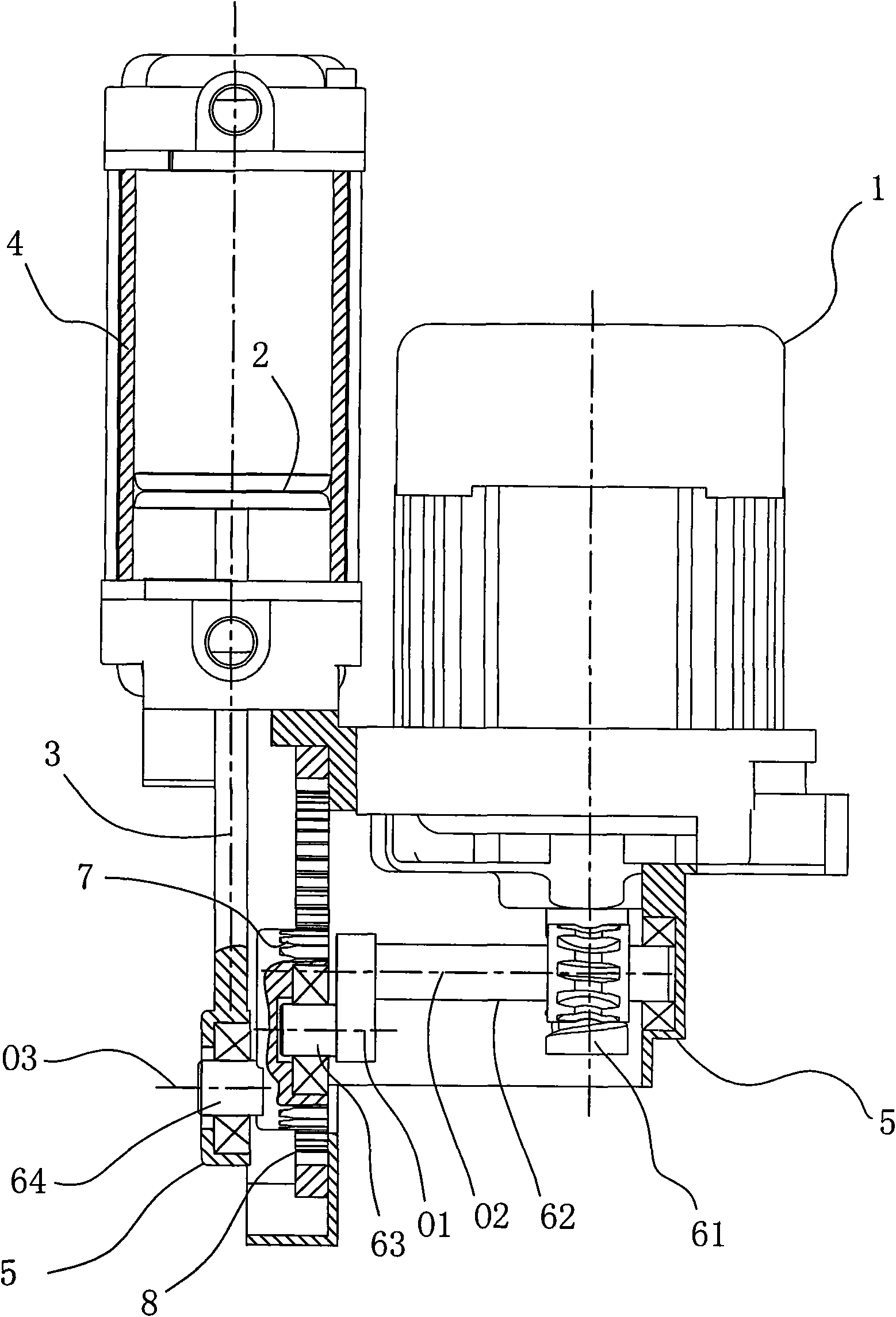

Low-noise reciprocating piston compressor

InactiveCN101634286AReduced reciprocating frequencyReduce noisePositive displacement pump componentsPositive-displacement liquid enginesLow noiseCold air

The invention belongs to the technical field of piston compressors and relates to a low-noise reciprocating piston compressor, comprising a motor, a piston body, a connecting rod, a cylinder and an air inlet and output device. The cylinder is connected on a transmission box body which is internally provided with a deceleration transmission gear; a spindle of the motor is connected to an input shaft of the deceleration transmission gear; an output shaft of the deceleration transmission mechanism is provided with a first eccentric shaft which is rotatably sleeved with a planetary gear; the transmission box is internally provided with a stationary gear; the planetary gear is engaged with the stationary gear; the planetary gear is provided with a second eccentric shaft; one end of the connecting rod is sleeved on the second eccentric shaft of the planetary gear; and the other end of the connecting rod is connected with the piston body. The invention has long piston stroke, little vibration, low noise, low exhaust temperature and long service life, and is suitable for producing pump bodies such as various types of reciprocating piston-type hydraulic pumps, vacuum pumps and cold air pumps or compressors.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

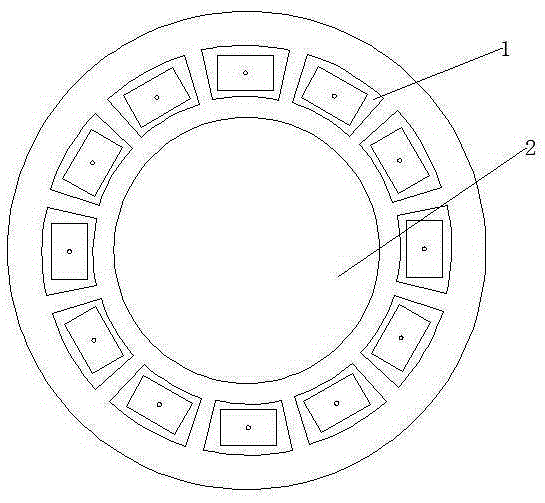

Straight line type air compressor

InactiveCN101294560AReduce radial forceReduce frictionPiston pumpsDynamo-electric machinesGas compressorLinear compressor

The invention discloses an air compressor, in particular to a linear air compressor without a crank and connecting rod structure. The air compressor comprises a motor mover and an air cylinder; wherein the motor mover capable of moving linearly is positioned in the air cylinder. The air compressor is structurally characterized in that an internal yoke component and an external yoke component are further included, wherein, the internal yoke component comprises a coil and a plurality of internal silicon steel sheets with internal hollow cavities, the internal silicon steel sheets are distributed and fixed on the external wall of the air cylinder, and the coil is positioned in the hollow cavities of the internal silicon steel sheets; the external yoke component comprises external silicon steel sheets, and clearance is formed between the external silicon steel sheets and the internal silicon steel sheets; a magnet part of the motor mover is positioned in the clearance. The linear air compressor with the motor mover directly connected with the piston and without the crank and the connecting rod structure has the advantages of small friction, high efficiency, low vibration and compact structure.

Owner:ZHEJIANG UNIV

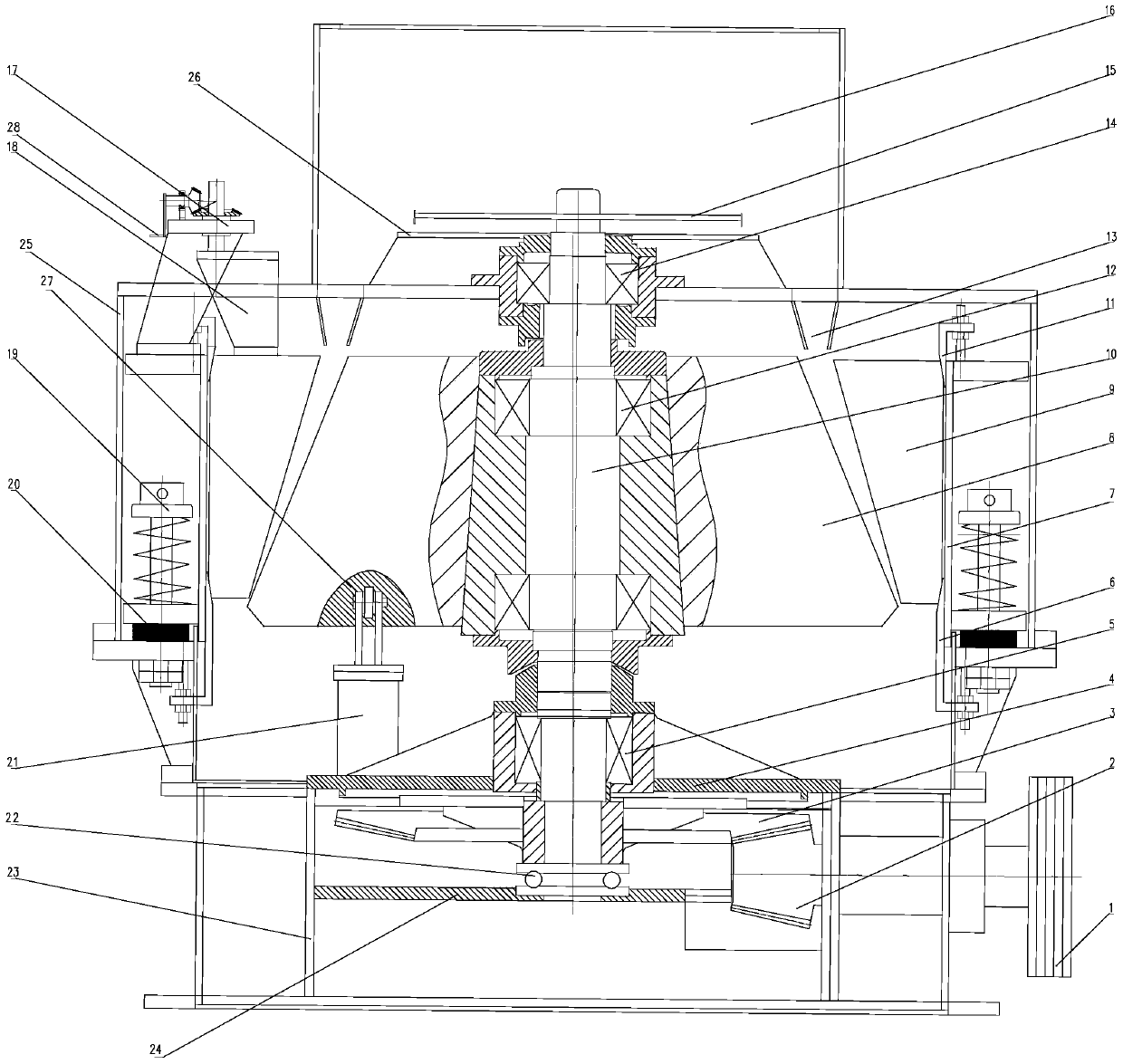

Cone rolling sand-making machine

InactiveCN105498895AImprove performanceImprove work performanceGrain treatmentsEffective powerAgricultural engineering

The invention discloses a cone rolling sand-making machine which comprises a machine base, an eccentric main shaft, an inner cone and an outer cone, wherein the eccentric main shaft is rotatably connected to the machine base; the inner cone is connected to the eccentric main shaft; the outer cone covers the inner cone; a gap is formed between the outer cone and the inner cone; the inner cone is rotatably connected to the eccentric main shaft; an inner cone non-rotation device is arranged on the machine base; and the inner cone non-rotation device is connected to the inner cone. According to the cone rolling sand-making machine disclosed by the invention, the continuous rotation of the eccentric main shaft is converted into continuous and all-around radial extrusion of the inner cone, so that the effective power is lasting, the working efficiency is good, the friction power consumption is less, working energy consumption can be reduced, abrasion of inner and outer cones can be greatly relieved, equipment is ensured to have a relatively long service life, and the gap between inner and outer cones is conveniently regulated.

Owner:杭州富阳新建机械有限公司

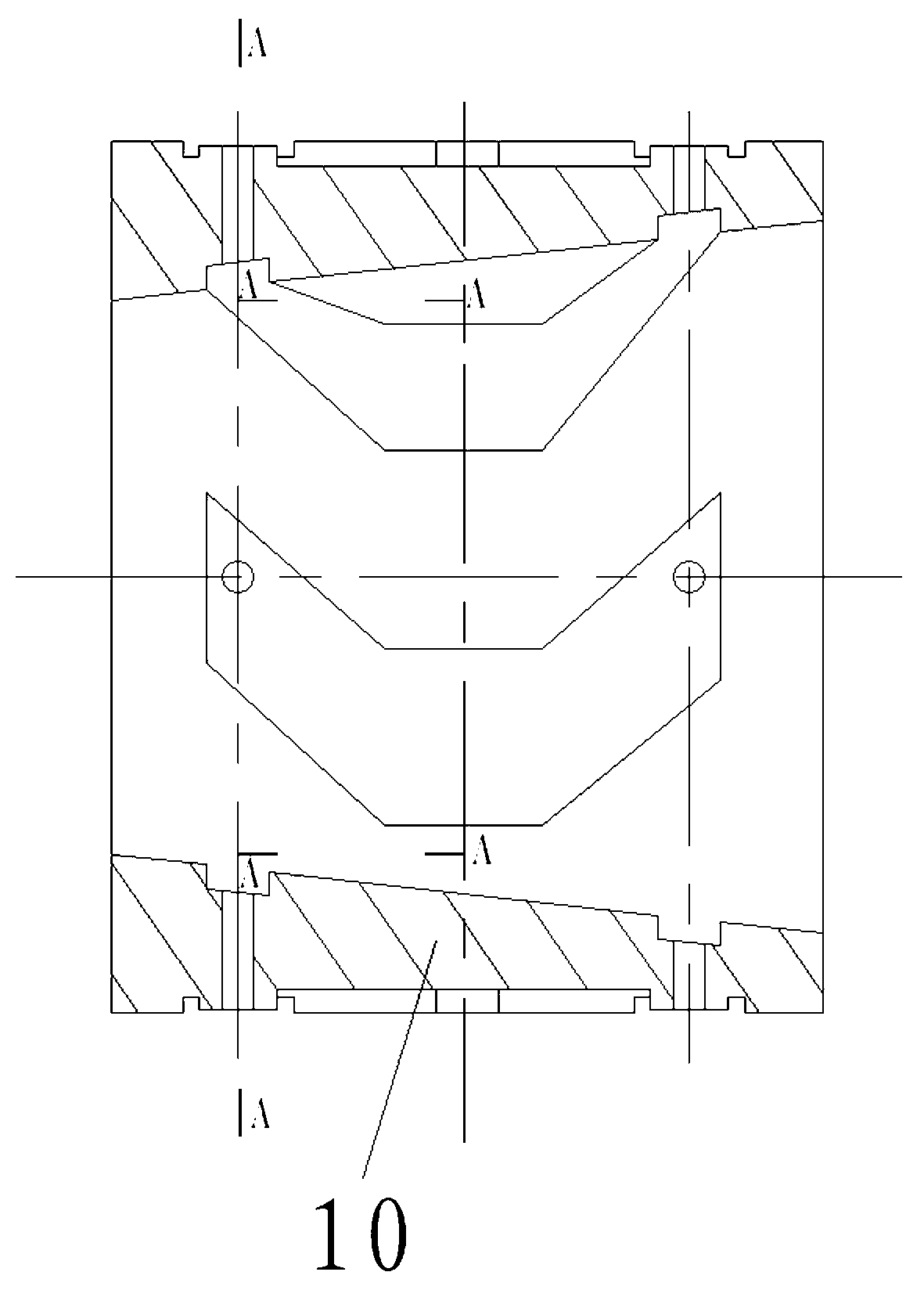

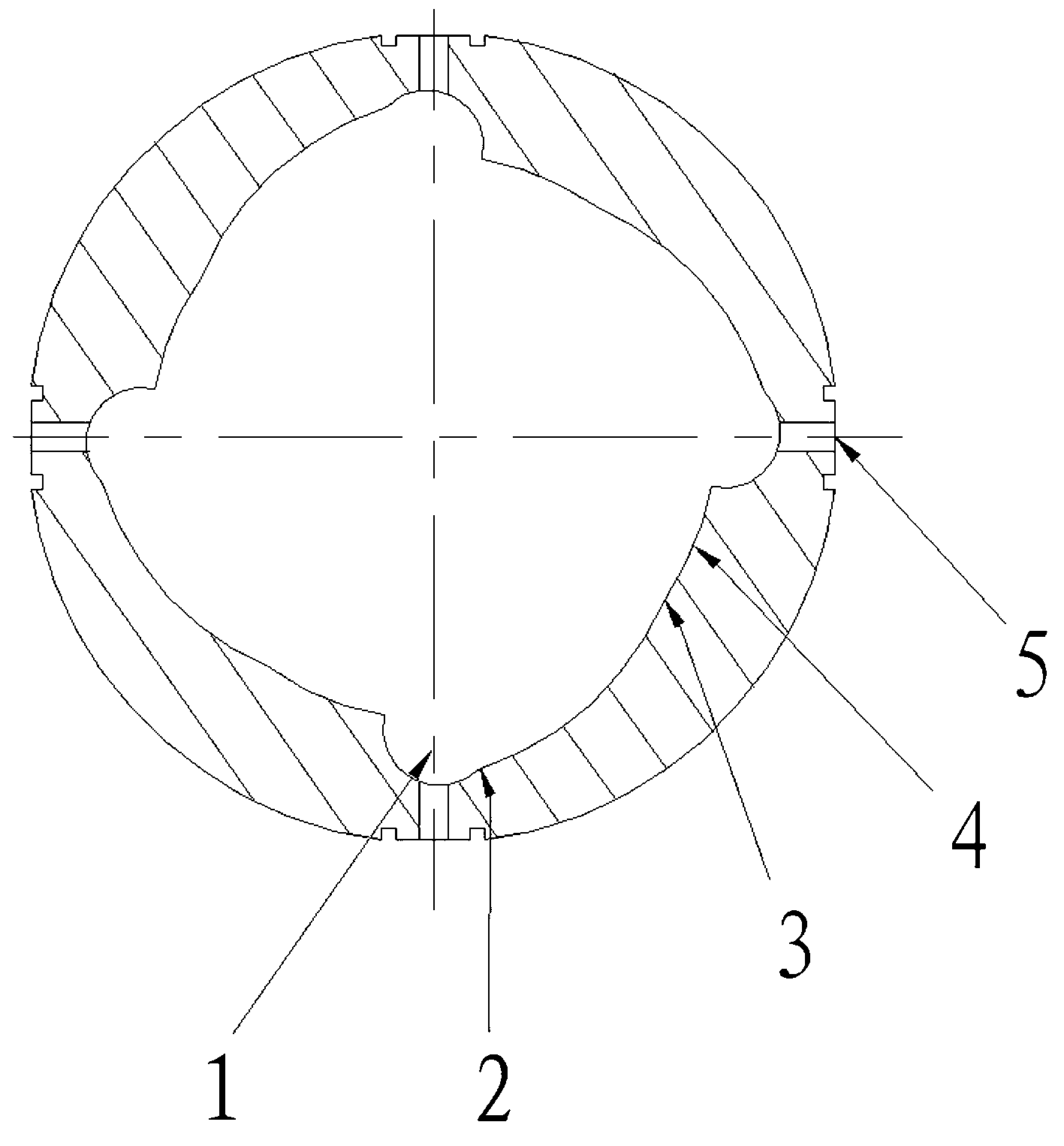

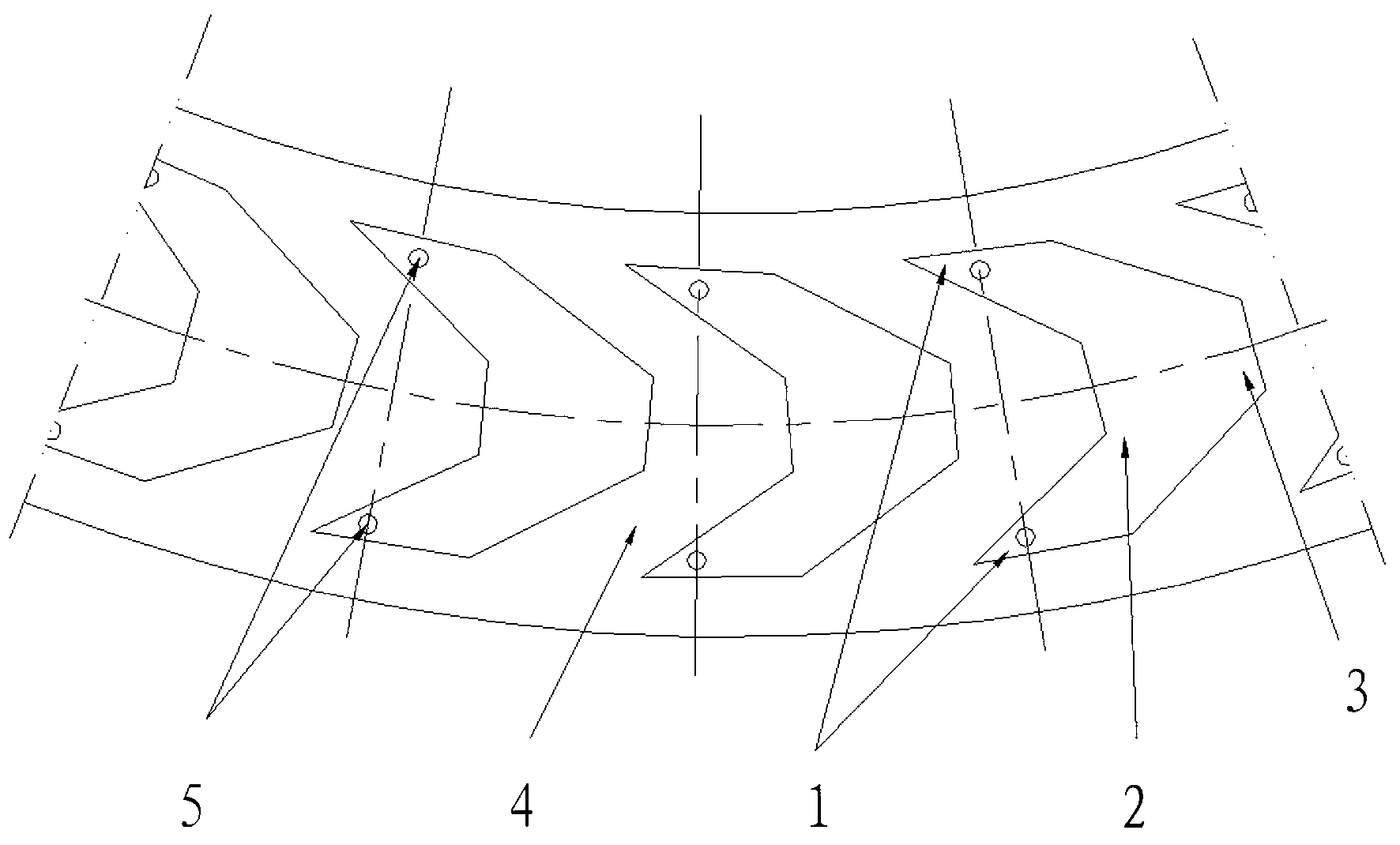

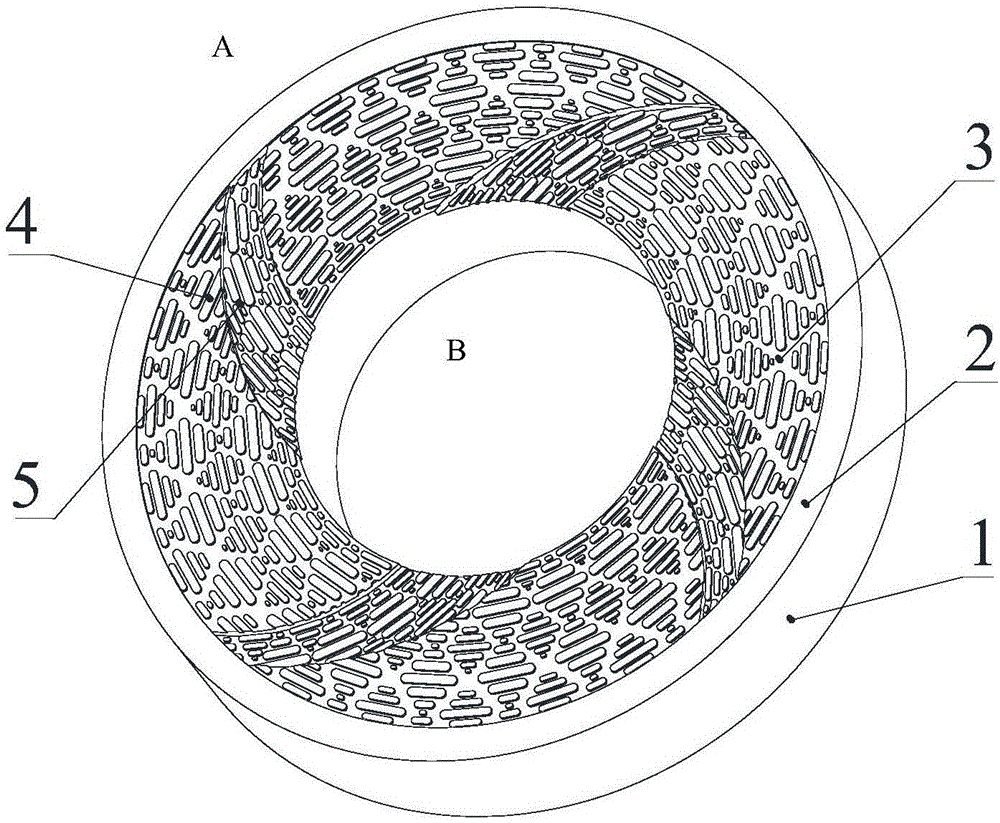

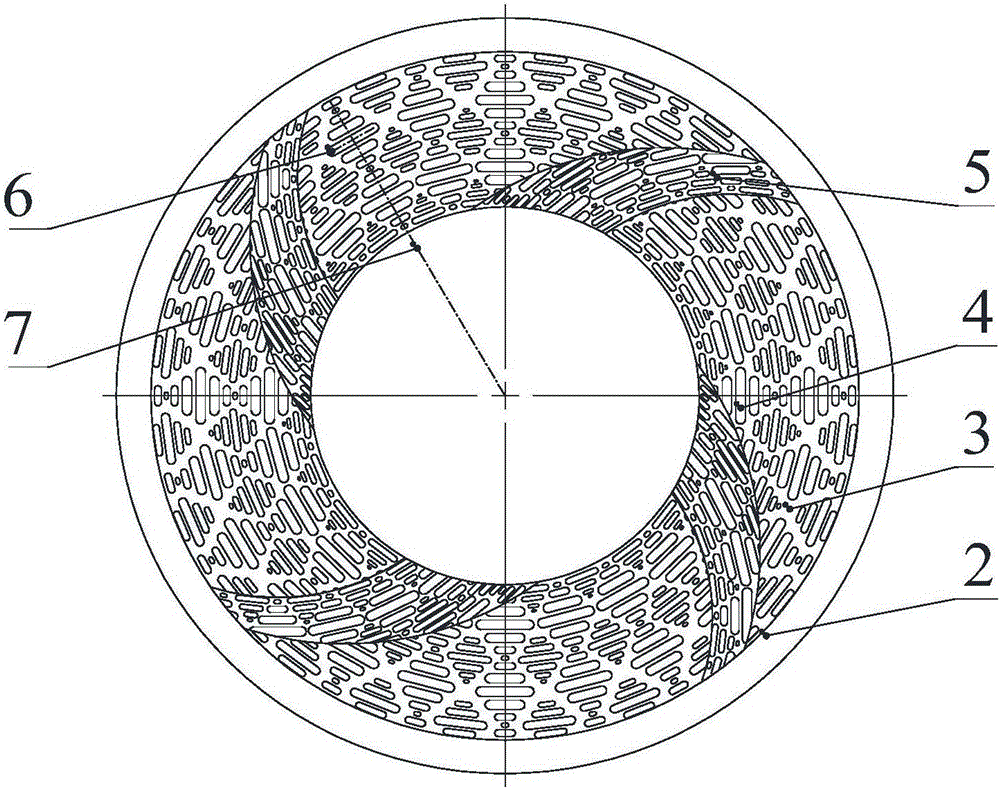

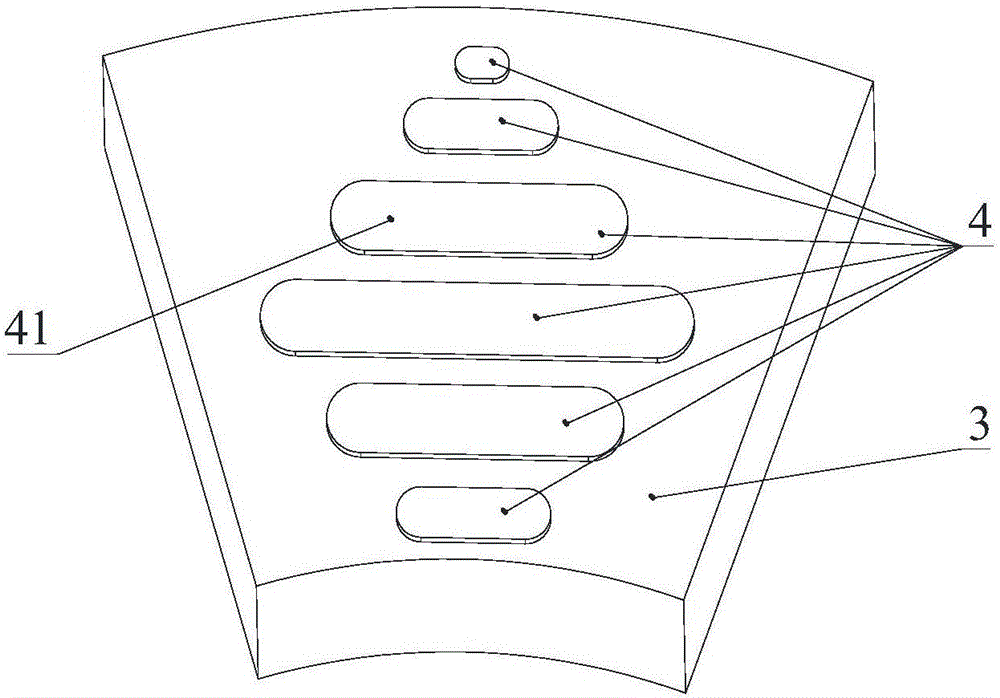

Dynamic and static pressure conical bearing with wedged dovetail cavities

InactiveCN103075416ASolve the situation of lack of oilIncrease profitBearing componentsSliding contact bearingsAxial loadMain bearing

The invention discloses a dynamic and static pressure conical bearing with wedged dovetail cavities. An oil film is formed between a main bearing and a bearing bush; the inner surface of the bearing bush is an inner conical surface; four oil cavities with wedged dovetail cavity structures are uniformly arranged on the inner conical surface along the circumferential direction; each wedged dovetail cavity comprises a deep cavity zone, a wedged cavity large-end zone and a wedged tip zone; the edge of each oil cavity is an oil sealing side; two oil inlet holes connected with an oil supply groove are formed in each deep cavity zone; the outer surface of the bearing bush is cylindrical; an annular small-end oil supply groove and an annular large-end oil supply groove are formed in the surface of the bearing bush, are throttled by ring clearances and are communicated with the oil inlet hole in the deep cavity zone; an annular main oil supply channel is formed in the middle of the outer surface of the bearing bush; and the main oil supply channel is communicated with the small-end oil supply groove and the large-end oil supply groove in the outer surface of the bearing bush through a branch oil supply channel. The dynamic and static pressure conical bearing disclosed by the invention can simultaneously bear radial and axial loads; meanwhile, self alignment can be realized by the oil cavities; and a high-efficient throttling mode and no blockage are realized. The dynamic and static pressure conical bearing has the characteristics of convenience in clearance adjustment of the oil film, low friction power consumption and compact structure.

Owner:ZHENGZHOU UNIV

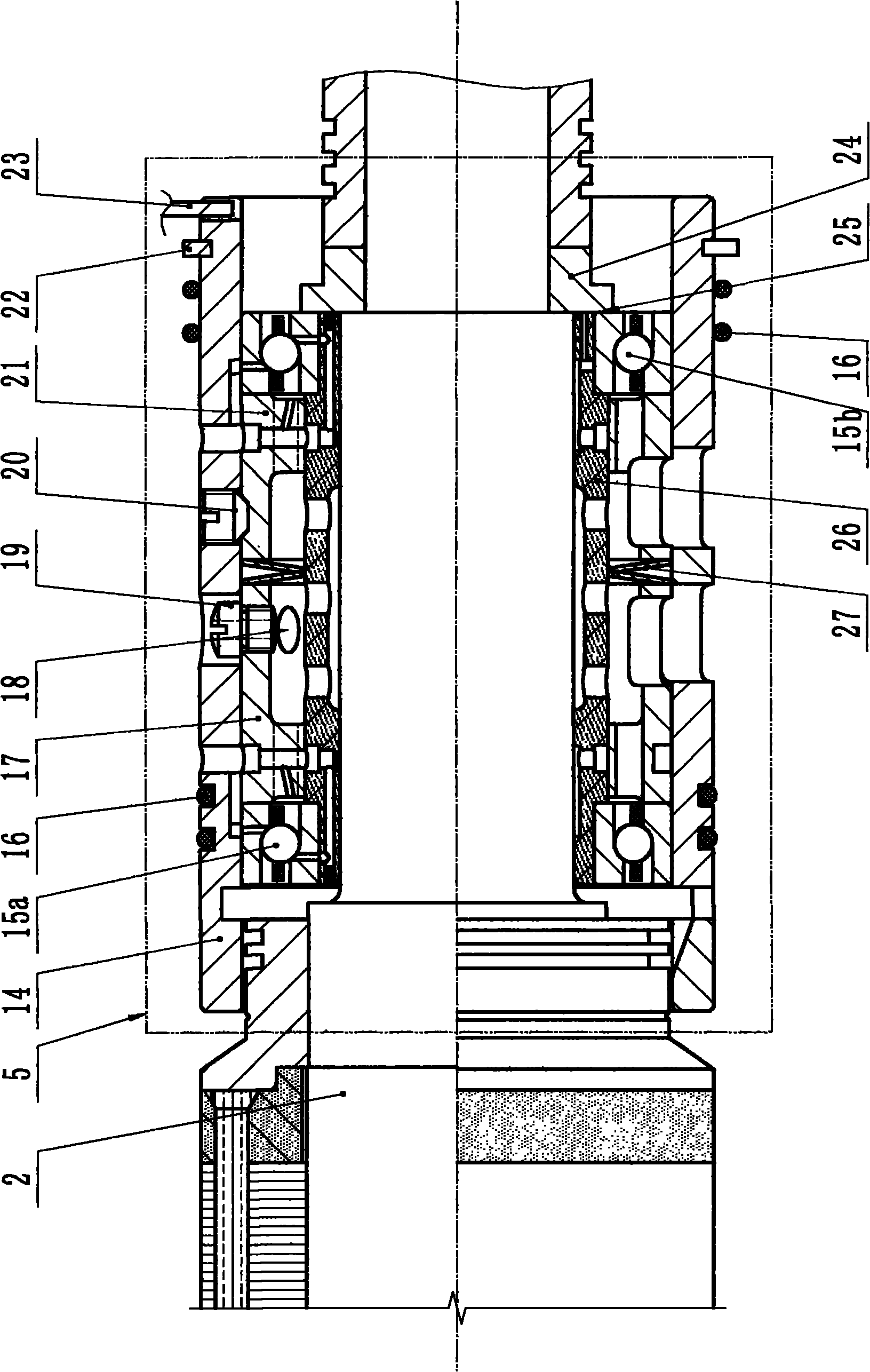

Sliding bearing and centrifugal pump

ActiveCN103953641AImprove mechanical efficiencyImprove reliabilityPump componentsShaftsNoise levelEngineering

The invention relates to a sliding bearing and a centrifugal pump. The sliding bearing comprises an oil groove, a bearing outer ring, an oil hole and a bearing inner ring, wherein the oil groove is annularly formed in the outer side of a bearing body; the bearing outer ring is in sliding fit with an outer bearing block; when the sliding bearing and the bearing block rotate relative to each other, an outer oil film is formed between the bearing outer ring and the bearing block through lubricating oil supplied to the oil groove; the oil hole is formed in the oil groove in a through mode; the bearing inner ring is positioned at the inner side of the bearing body; the bearing inner ring and an outer high-speed spindle are arranged in a sliding mode; when the high-speed spindle and the sliding bearing rotate relative to each other, an inner oil film is formed between the bearing inner ring and the high-speed spindle through the lubricating oil supplied to the oil groove via the oil hole. According to the sliding bearing and the centrifugal pump, because the frictional power consumption between the high-speed spindle and the sliding bearing is reduced, the mechanical efficiency of a high-speed centrifugal pump is improved; the temperature between the high-speed spindle and the sliding bearing is reduced, and the reliability of the high-speed centrifugal pump is improved; transmission of mechanical vibration is reduced due to two oil film dampers, and the vibration and noise level of the high-speed centrifugal pump are reduced.

Owner:WILO CHINA

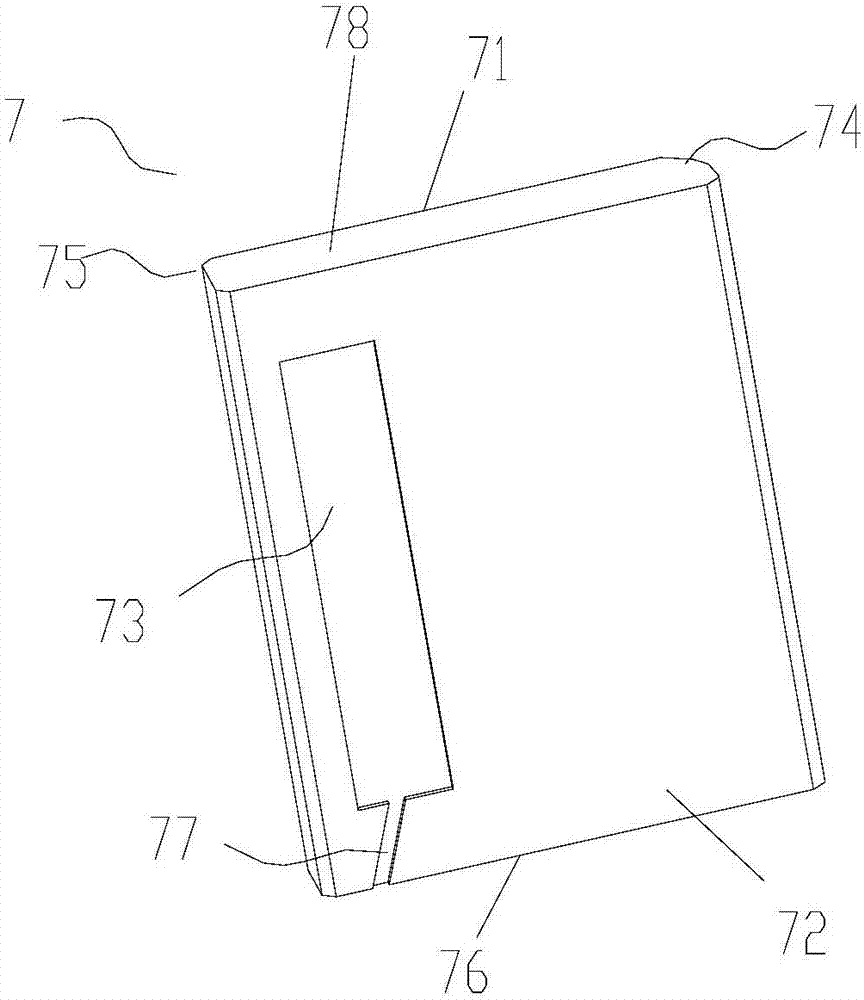

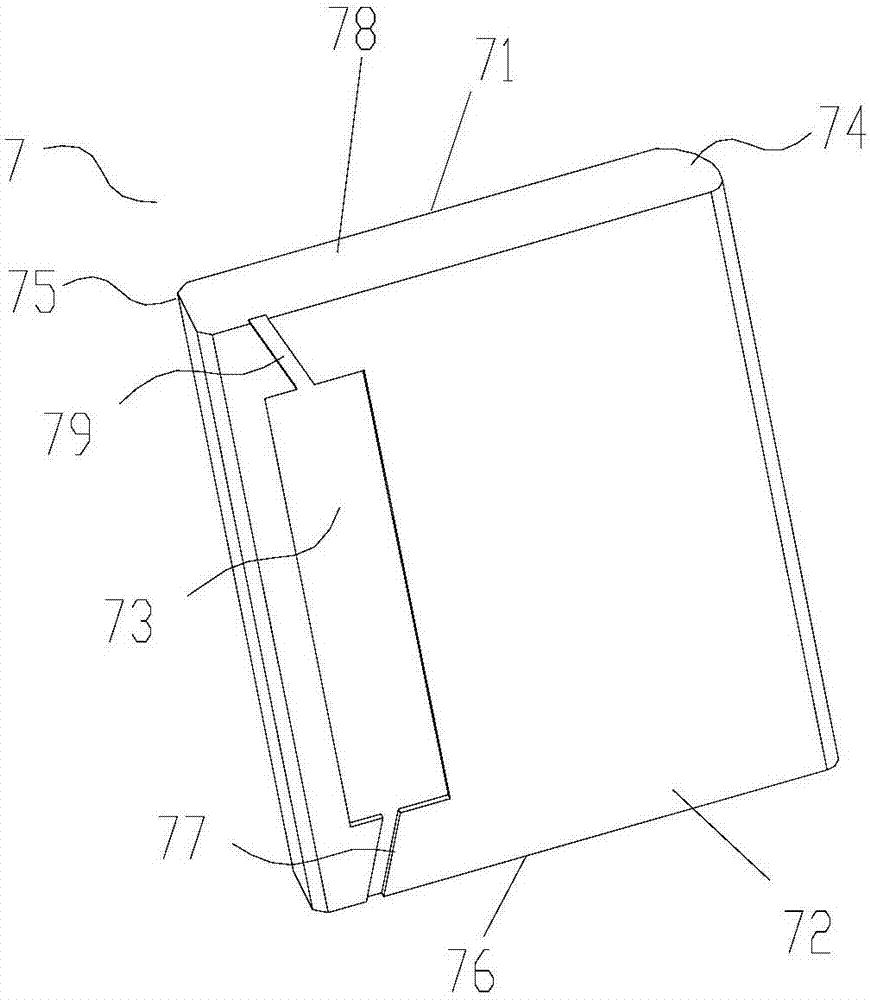

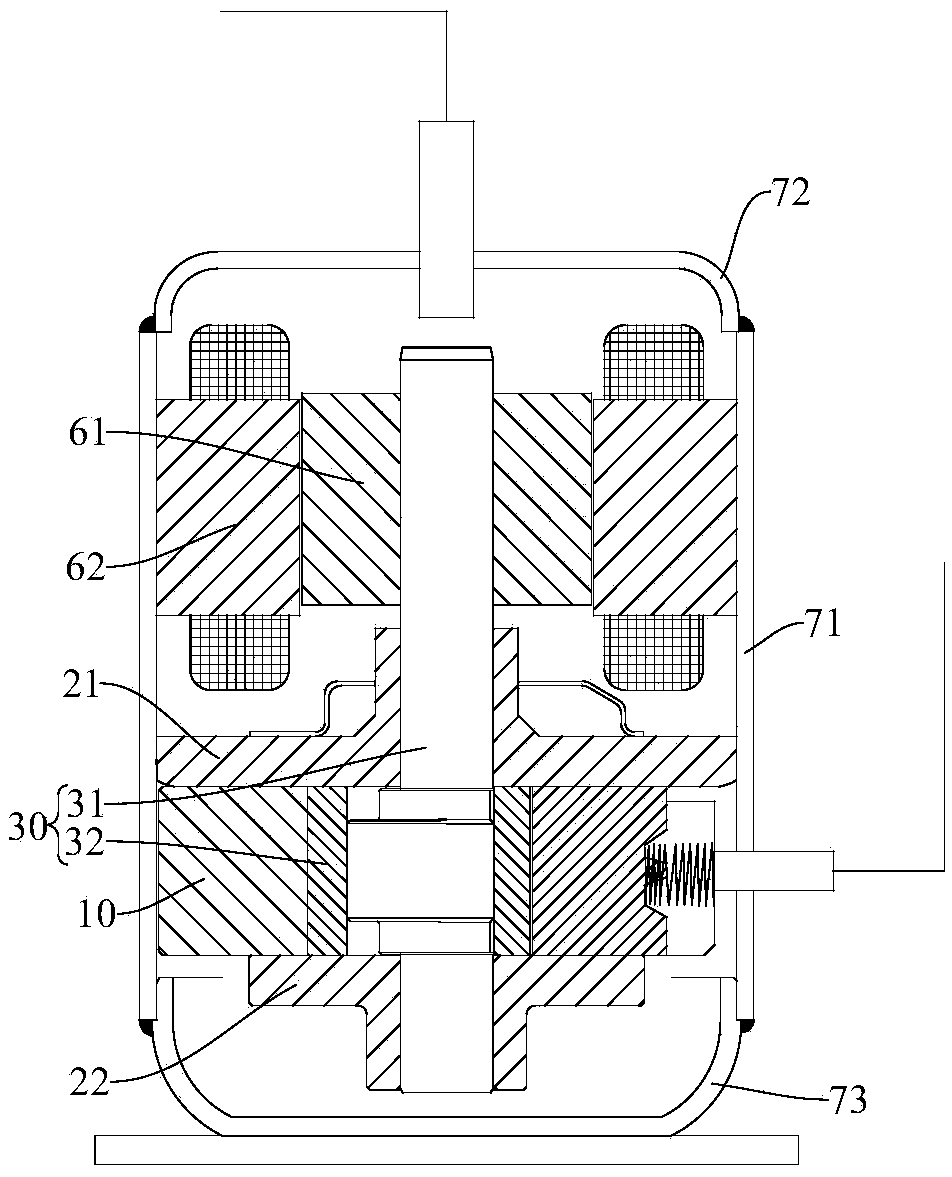

Slip sheet of vane type compressor and vane type compressor

ActiveCN107013456AReduce bias forceAvoid abnormal wearRotary piston pumpsRotary piston liquid enginesSlip sheetEngineering

The invention provides a slip sheet of a vane type compressor and the vane type compressor. The slip sheet comprises a first side face (71) and a second side face (72), wherein the first side face (71) and the second side face (72) are arranged back to back; a side face oil groove (73) for accommodating high pressure oil is formed in the second side face (72); and the side face oil groove (73) is formed in the direction towards the first side face (71) from the second side face (72) and does not penetrate through the first side face (71). According to the invention, high pressure oil can be fed in through the side face oil groove, so that pressure perpendicular to the slip sheet is formed on the second side face of the slip sheet to balance or reduce biasing force, moment of force is enabled to reach balance as much as possible, the slip sheet is prevented from abnormal abrasion generated by line contact formed between the slip sheet and a slip sheet notch due to the biasing force, surface contact is formed, the service life of the slip sheet is prolonged to certain degree, and the frictional power consumption at the part is reduced, wherein the biasing force is generated when the front end of the slip sheet is subjected to pressure of a high-pressure cavity and a lower-pressure cavity on two sides.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

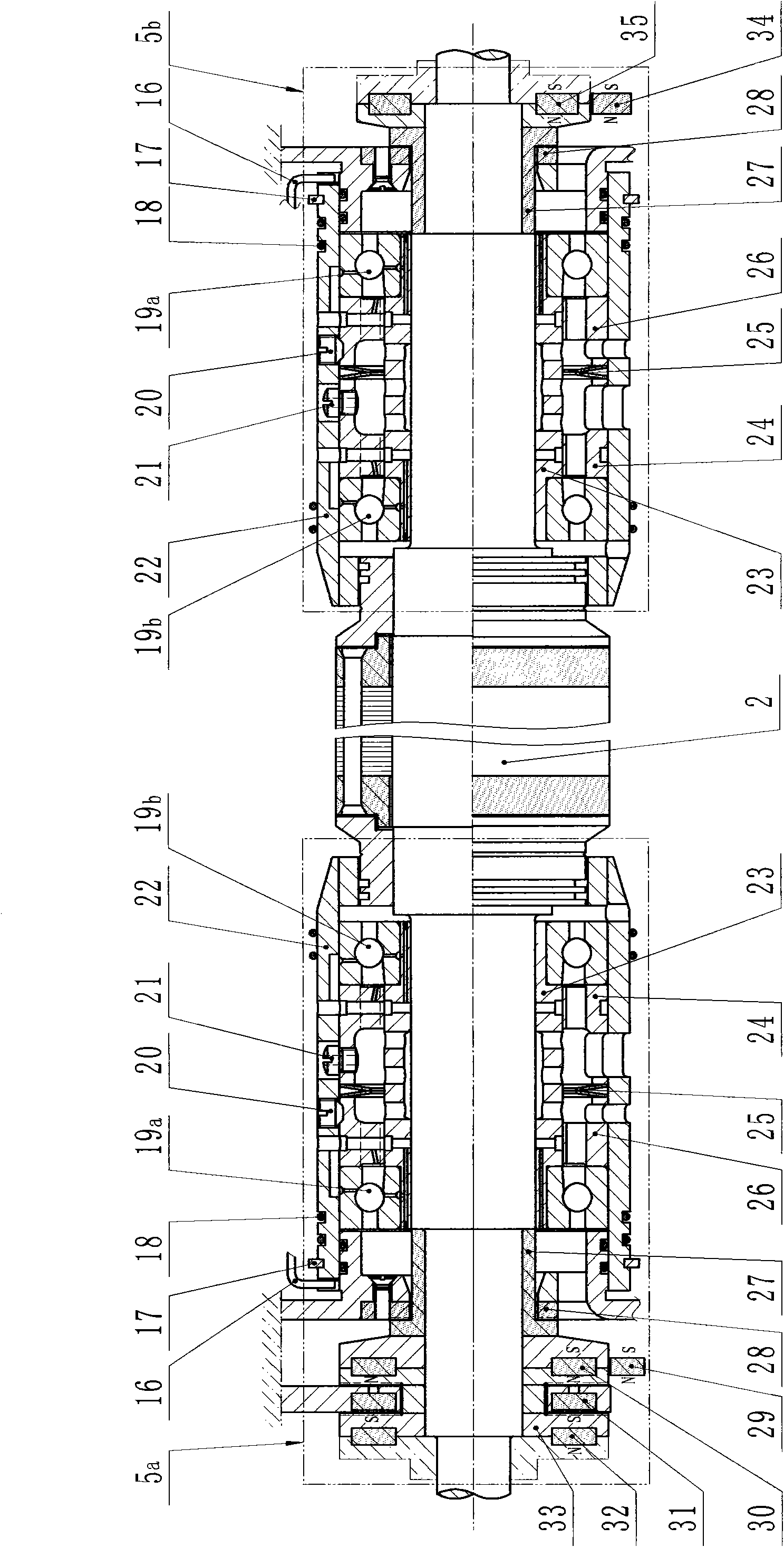

Permanent magnet and rolling-sliding bearing type motor rotor bearing and rotary machine with same

InactiveCN101924413AExtended service lifeReduce frictional power consumptionSupports/enclosures/casingsBall bearingPre compression

The invention relates to a rotor bearing used in a high-speed electric rotary machine. In the rotor bearing, a pair of angular contact ball bearings is nested at the two ends of a radial sliding bearing on the shaft neck of the two ends of a rotor, constant pressure pre-compression is adopted between the two ball bearings, the whole is embedded in a floating bushing; the outside end of the floating bushing is provided with a check ring and a check block for limiting the axial movement and rotation of the floating bushing, ensuring that the whole is in a semifloating state when installed in a bearing seat hole with a certain fit clearance and constructing a semifloating type rolling-sliding bearing. The two ends of the rotor are separately provided with a permanent magnet unloading bearing. When a high-power high-speed electric rotary machine using the rotor bearing of the invention is installed on a vehicle and operates in the rotate speed of more than 60000r / min, the operation of the system can be stable and reliable owning to the combined action of the semifloating rolling-sliding bearing and the permanent magnet unloading bearings.

Owner:何君 +2

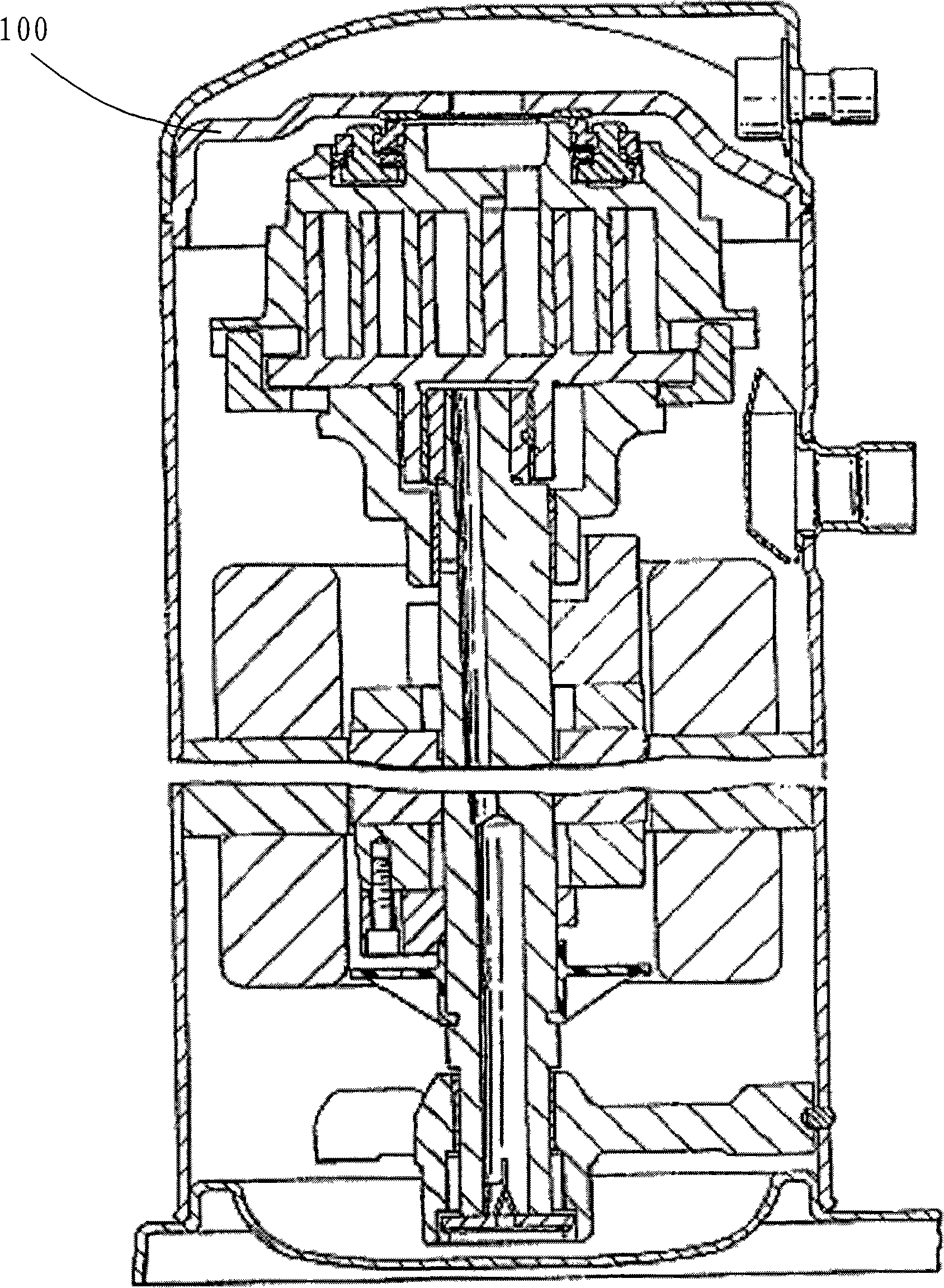

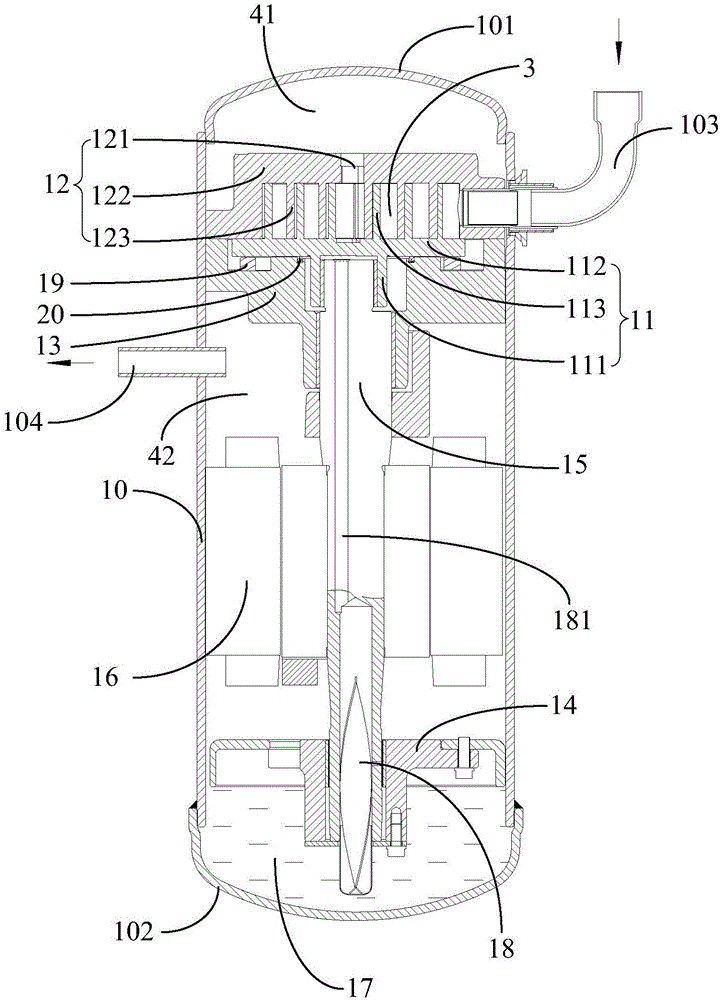

Scroll compressor

InactiveCN101270751AImprove reliabilityImprove performanceRotary piston pumpsRotary piston liquid enginesPressure functionDrive shaft

The invention relates to a scroll compressor which includes a non-revolution vortex part and a revolution vortex part. An elastic deadening cavity for discharging air consists of a driving shaft which is supported by the bearing of a frame, the back lateral of the non-revolution vortex part and an upper casing commonly. The back lateral of the non-revolution vortex part is pressed to be in contact with the inner wall of the deadening cavity through a sealing component in a way of sliding. The deadening cavity is communicated with an air discharging cavity which is arranged on a motor side on the lower part of the compressor and is formed by a frame, a main casing and a sealing part in a way of sealing. The design optimizes the contact force between the non-revolution vortex part and the revolution vortex part and between the revolution vortex part and the frame in the maximal degree. The non-revolution vortex part under the pressure function of high-pressure gas in the deadening cavity on the back lateral of the non-revolution vortex part and the revolution vortex part under the pressure function of high-pressure fluid on the back lateral of the revolution vortex part are in closely contact with each other and are sealed axially. The non-revolution vortex part is arranged on an installation mechanism in a way of sliding upwards and downwards and can move axially within a certain range.

Owner:MIDEA GRP CO LTD

Cylinder block and compressor

PendingCN108119340AEasy to get stuckReduce frictional power consumptionPositive displacement pump componentsPositive-displacement liquid enginesCylinder blockFastener

The invention provides a cylinder block and a compressor. The cylinder block comprises a flat plate seat, a lateral plate seat and support columns, wherein the flat plate seat is provided with a shafthole; the lateral plate seat is vertically arranged on the first side of the flat plate seat and provided with an air cylinder hole; the support columns are arranged on the flat plate seat, and a preset distance exists between each support column and the air cylinder hole. Due to the fact that the preset distance exists between each support column and the air cylinder hole, air cylinder hole deformation cannot occur easily during the screwing of fasteners for fixing a support plate when the support plate is mounted, the problem that a piston easily gets stuck in the air cylinder hole is solved, the friction power consumption of the compressor is lowered, and the mechanical efficiency of the compressor is increased.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

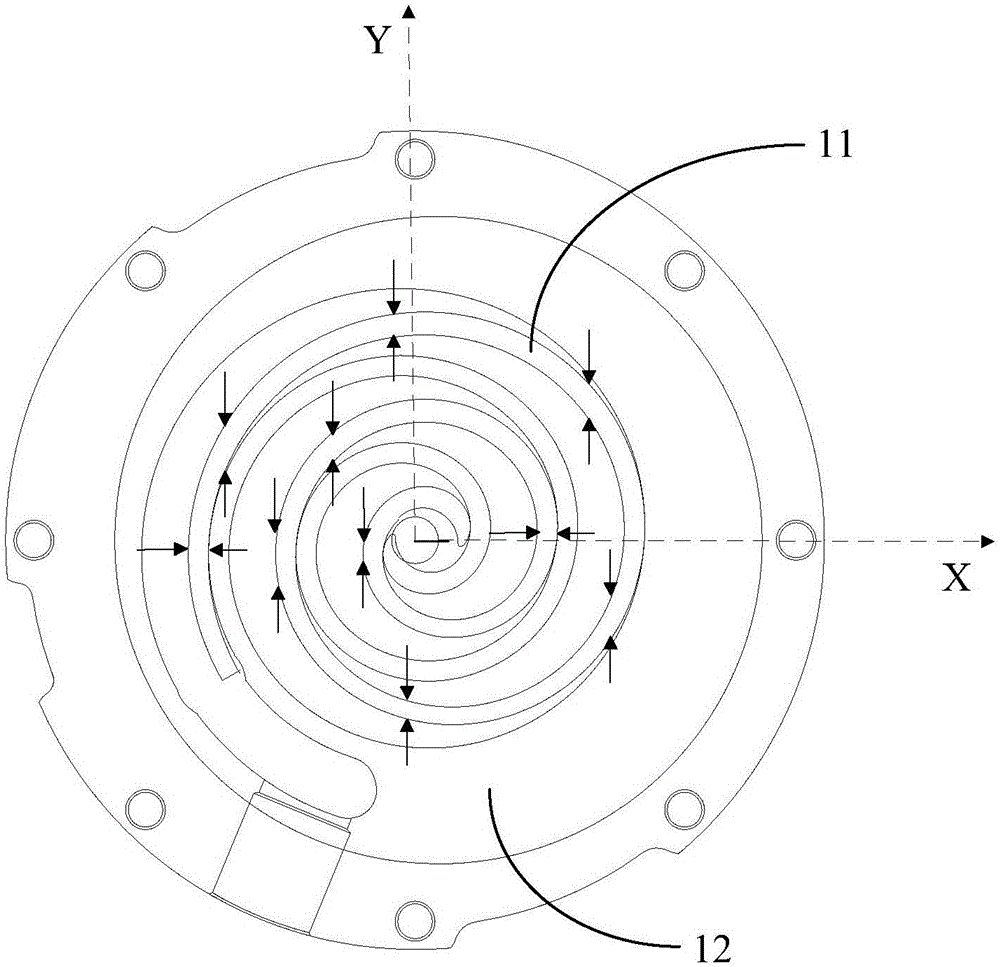

Scroll plate, scroll compressor and air conditioner

InactiveCN106438369AReduce frictional power consumptionImprove reliabilityRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention discloses a scroll plate of a scroll compressor. The scroll plate comprises a plate body, and a scroll tooth projected on the plate body, wherein the wall thickness of the scroll tooth is gradually changed in the projection direction of the scroll tooth. The invention further discloses a scroll compressor with the scroll plate, and an air conditioner provided with the scroll compressor. The scroll plate can reduce the force thereof in the radial direction and the axial direction, so that the friction power consumption of the scroll compressor is reduced, and the reliability of a crankshaft bearing is improved.

Owner:GUANGDONG MIDEA ENVIRONMENTAL TECH CO LTD

Rotor supporting structure of high speed electric rotary machine and rotary machine

InactiveCN101771307AAbsorb vibrational energyExtend your lifePump componentsPumpsBall bearingEngineering

The invention discloses a rotor supporting structure of a high speed electric rotary machine. Two end parts of radical sliding bearings at journals of two ends of a rotor are sheathed with a pair of angular contact ball bearings, constant-pressure prestressing is adopted between the two ball bearings, the two balling bearings are embedded in a floating bush, and the outer side end of the floating bush is provided with a check ring and a stop dog to limit the floating bush from moving and rotating along the axial direction and enable the floating bush to be loaded in a bearing seat hole with a certain fit clearance to be in a semi-floating state, thus forming a semi-floating rolling-sliding double bearing. When the high power high speed electric rotary machine adopting the rotor supporting structure of the invention is arranged in a vehicle which runs high speed of above 60000r / min, due to the action of the semi-floating rolling-sliding double bearing, the system can be stably and reliably operated.

Owner:何君 +2

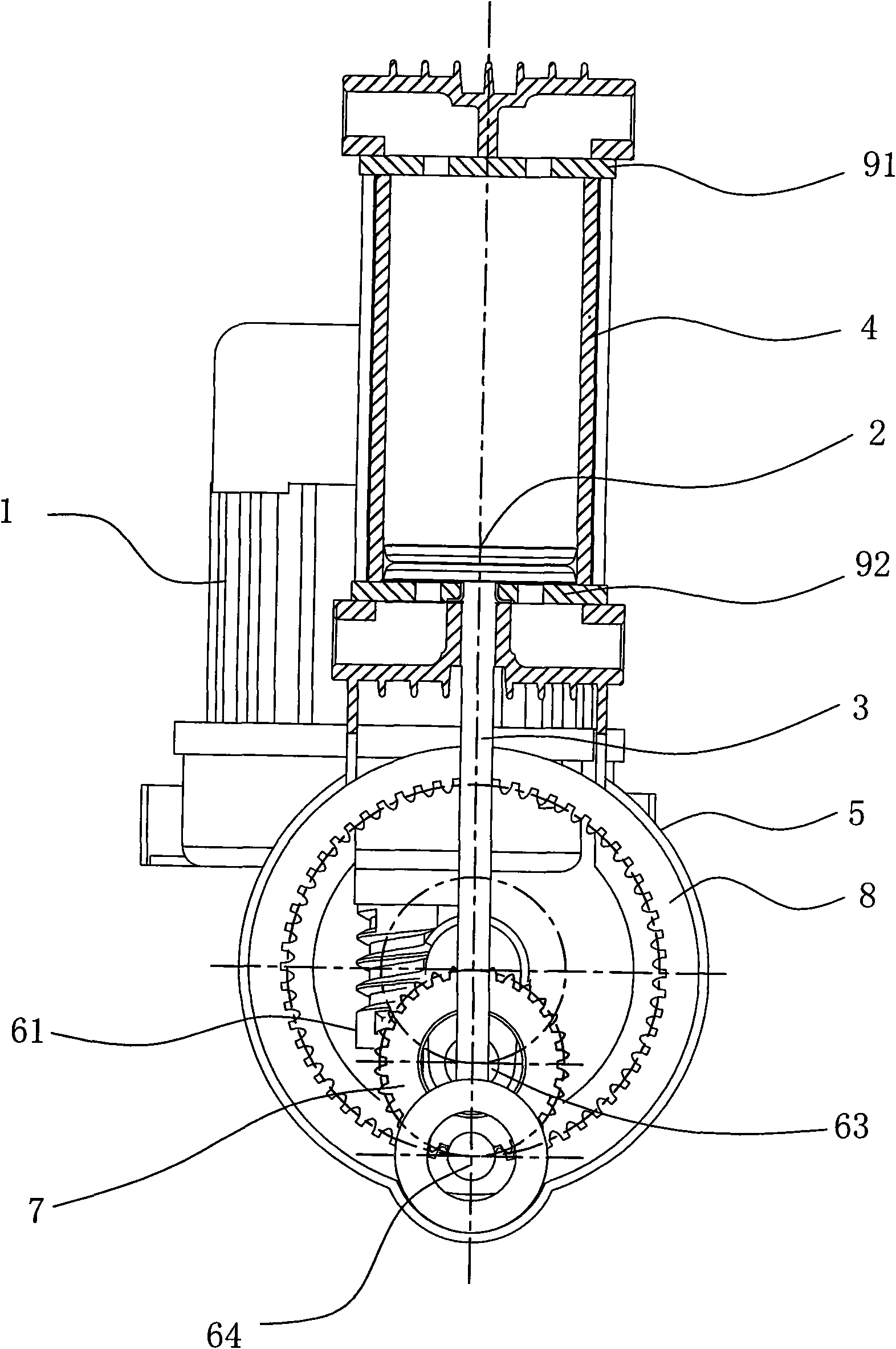

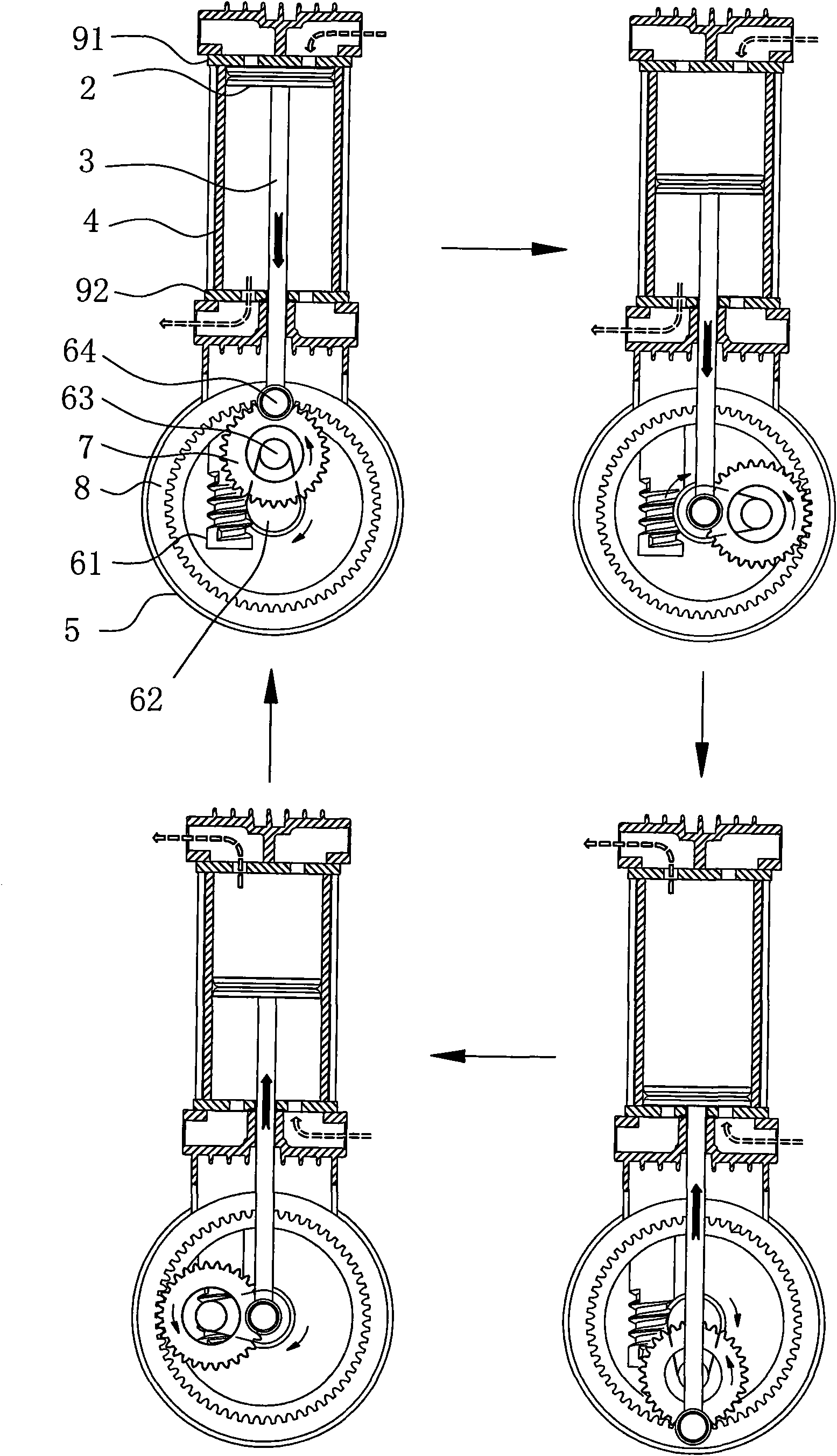

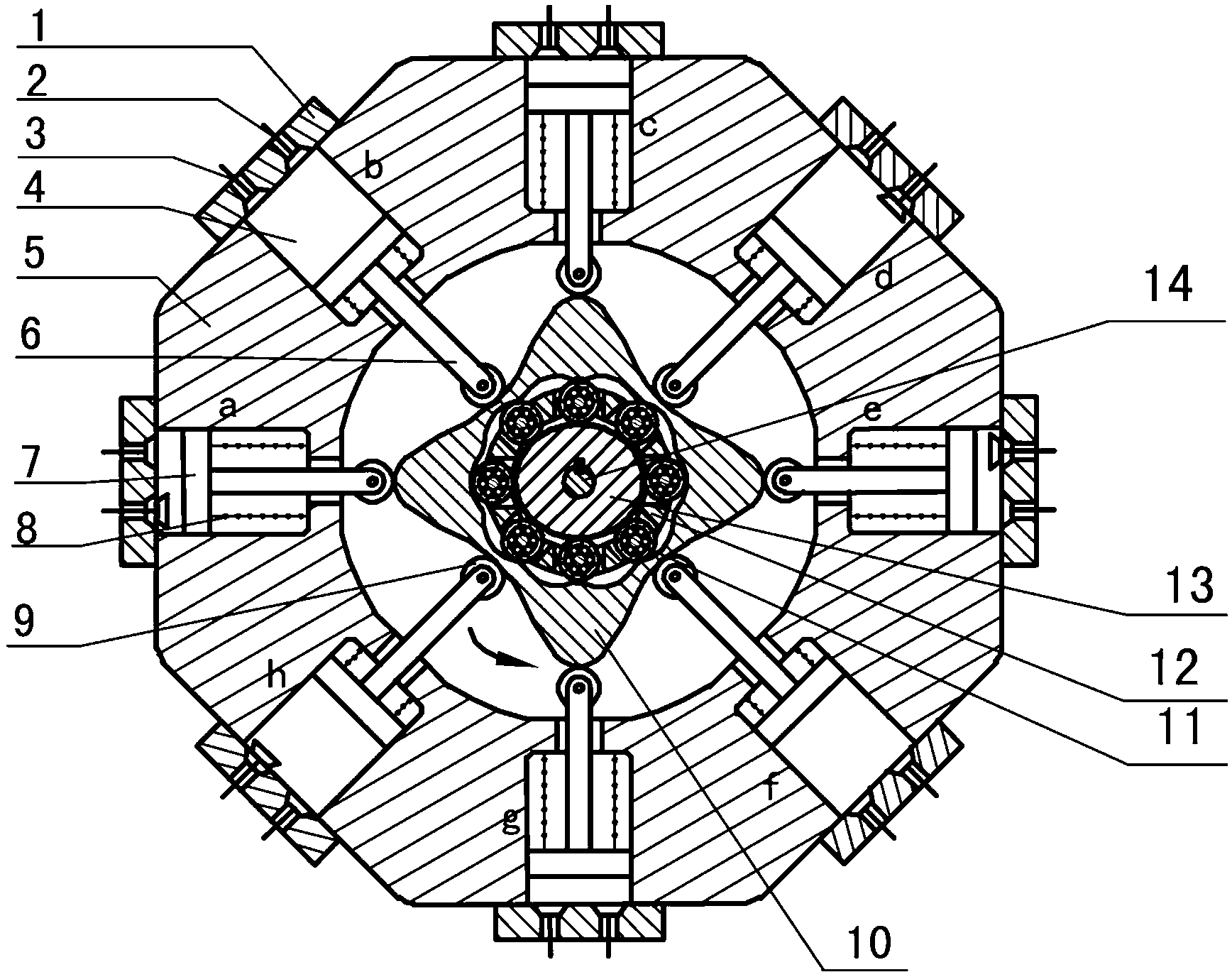

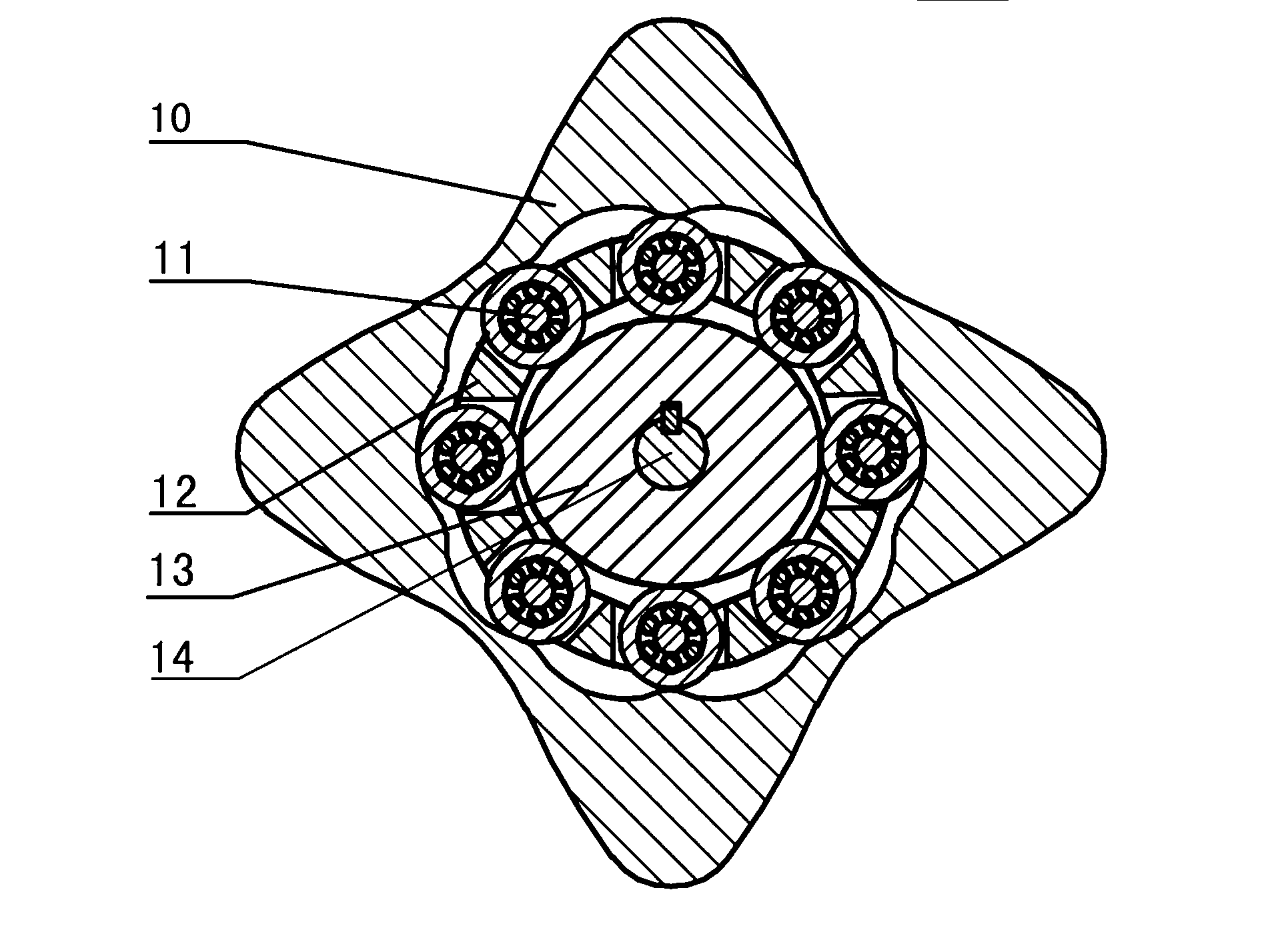

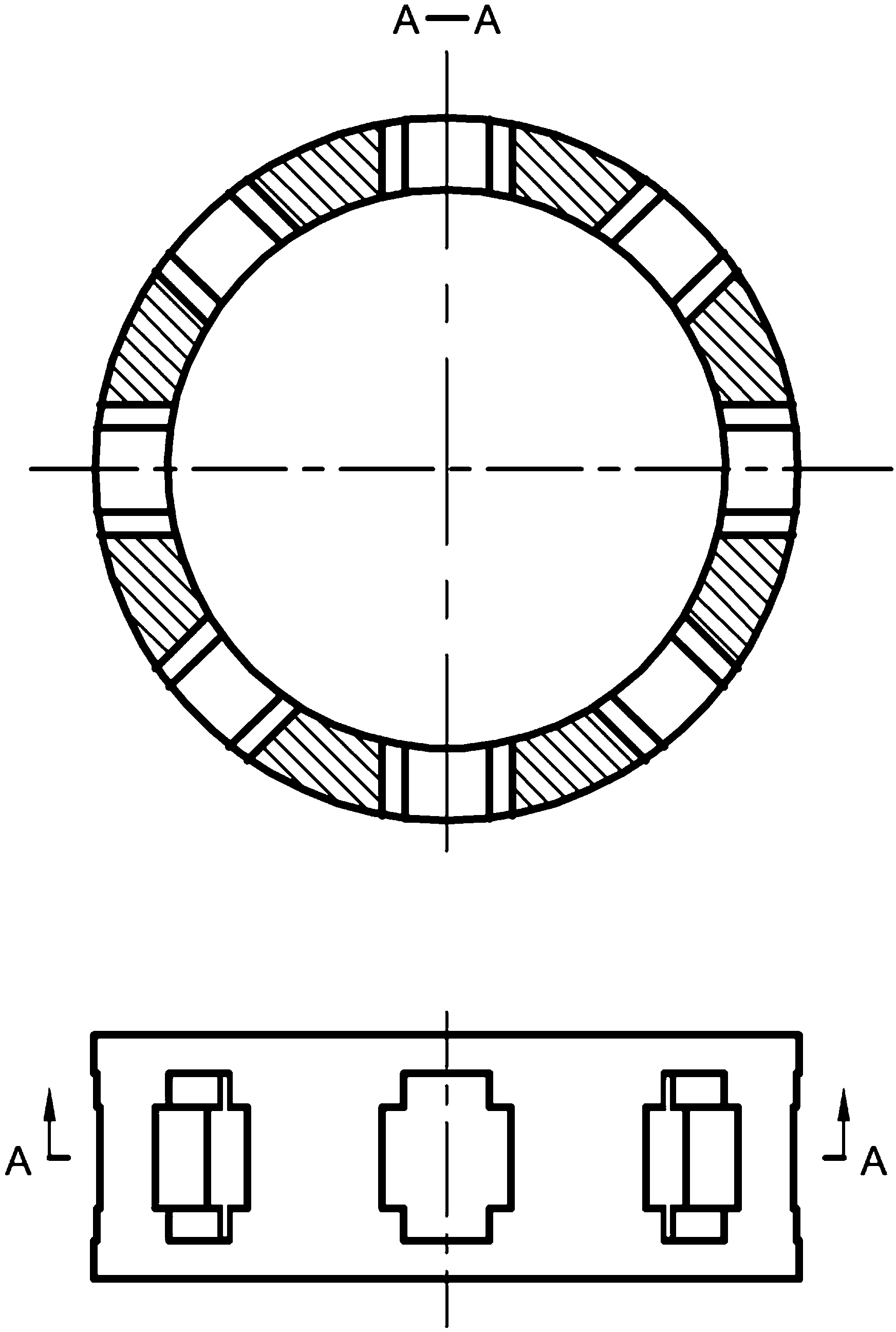

Two-phase outer cam shock wave rolling transmission internal combustion engine

InactiveCN102937048AReduce axial sizeCompact structureValve drivesMachines/enginesShock waveExternal combustion engine

The invention provides a two-phase outer cam shock wave rolling transmission internal combustion engine and relates to the field of gas power. According to the novel internal combustion engine, eight cylinders are annularly symmetrically evenly distributed around a convex inner tooth ring, the resultant force which the convex inner tooth ring is subjected to is zero, and a cylinder piston directly acts on the convex inner tooth ring through a push rod, power is transmitted to an output shaft connected with a two-phase outer cam key by two-phase outer cam shock wave rolling oscillating tooth transmission through the convex inner tooth ring. According to the internal combustion engine, a connecting rod and a crankshaft in a traditional internal combustion engine are not required, a convex inner two-phase shock wave rolling transmission mechanism does not have eccentric mass and has the advantages of self balancing of inertia force and working load, and the rotating speed of the output shaft depends on the transmission ratio of oscillating tooth transmission. If an oscillating tooth brace is fixed, a two-phase outer cam performs high-speed output and can be widely applied to the fields requiring for high rotating speeds, such as helicopter engines and small generators, and discharge of harmful gas can be reduced when the output rotating speed is fixed. The internal combustion engine is simple and compact in structure, small in axial dimensions self-balancing in stress and runs stably.

Owner:SICHUAN UNIV

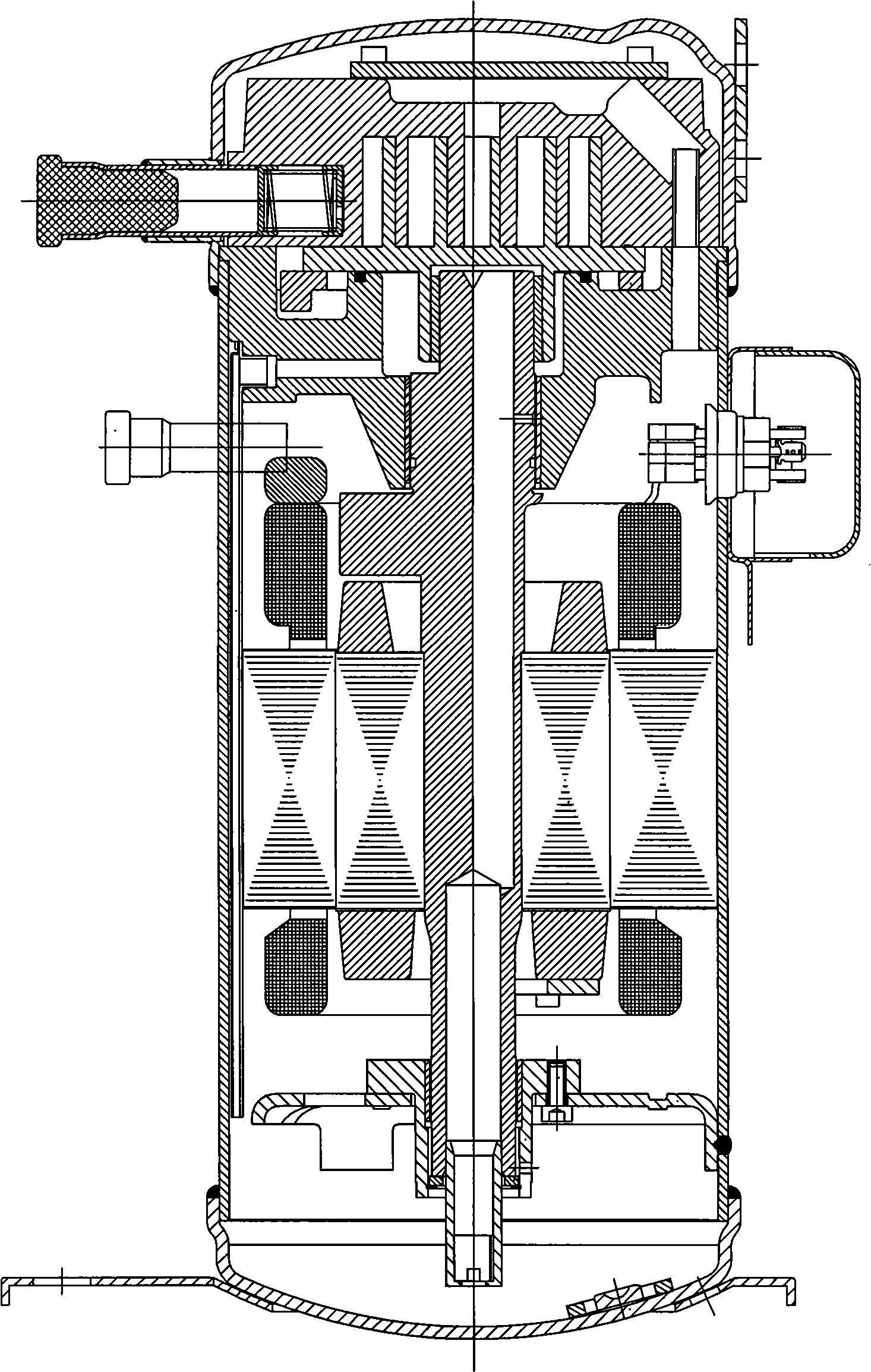

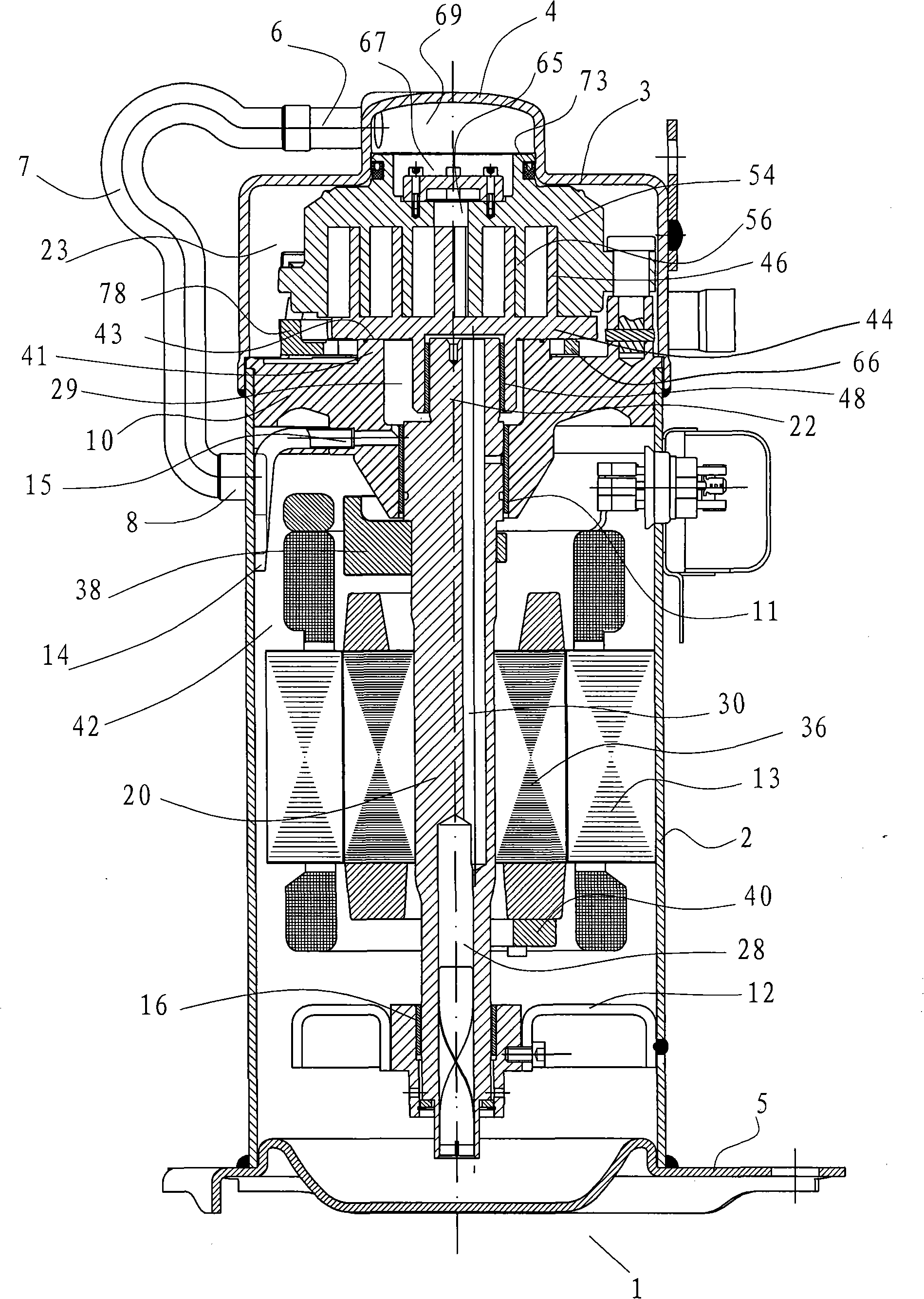

Rotary compressor, gas compression system, refrigeration system and heat pump system

ActiveCN108825497AIncrease stressImprove lubrication statusRotary piston pumpsRotary piston liquid enginesFriction lossEngineering

The invention discloses a rotary compressor, a gas compression system, a refrigeration system and a heat pump system. The rotary compressor comprises an air cylinder, a crankshaft, a piston, a main bearing, an auxiliary bearing, a sliding piece and a rocking block, wherein the piston sleeves the eccentric part of a crankshaft, and the piston is rotatably arranged in an air cylinder; a clamping structure which is used for limiting circumferential direction movement generated between the crankshaft and the piston is arranged between the eccentric part of the crankshaft and the piston, and a sliding piece groove is formed in the air cylinder, the sliding piece is installed in the sliding piece groove, the rocking block and the tip end of the sliding piece wind around a first axis in a hingedmode, the first axis is parallel to the axis of the air cylinder, and the rocking block is abutted against the outer circle face of the piston in a pressed mode. According to the rotary compressor, the lubricating state between the sliding piece and the friction pair of a cam part is improved, the friction power consumption between the friction pair of the cam part and the sliding piece is greatlyreduced, and friction loss between the eccentric part of the crankshaft and the piston can be effectively reduced.

Owner:GUANGDONG MEIZHI PRECISION MFG

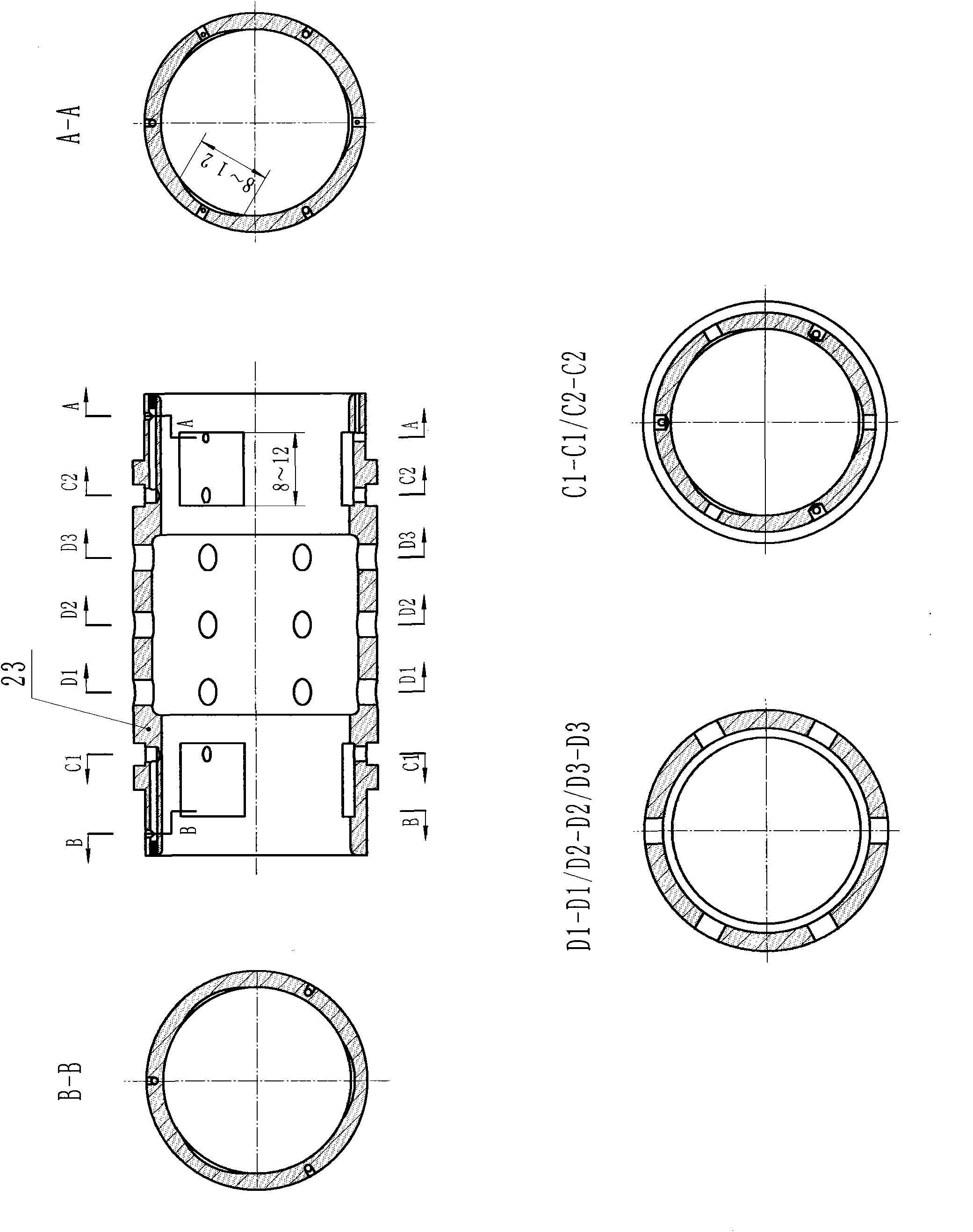

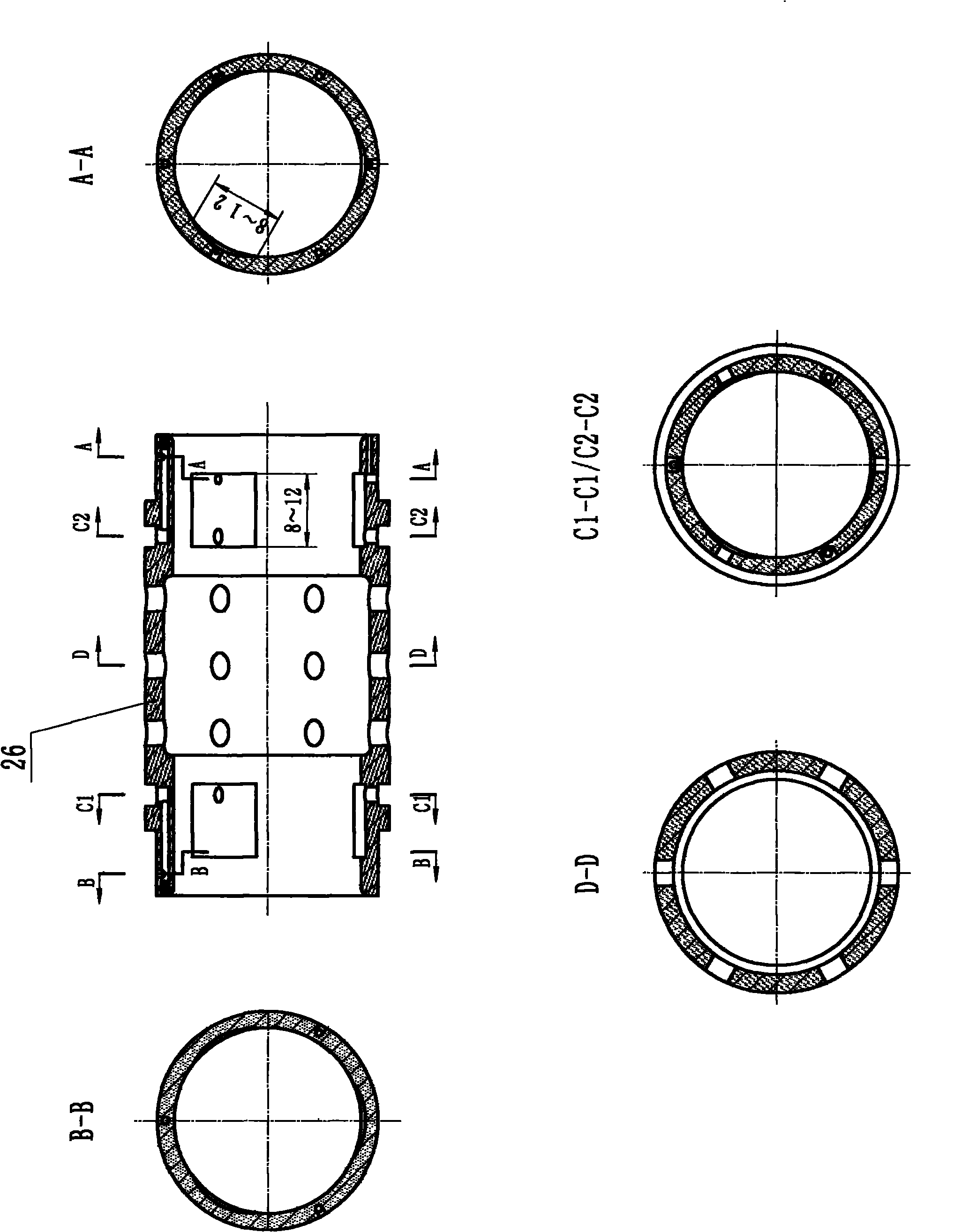

Hydrostatic pressure supporting device with rectangular cavity

InactiveCN105351362AImprove deformationReduce temperature riseLiquid cushion bearingsLarge fixed membersNumerical controlThrust bearing

The invention discloses a hydrostatic pressure supporting device with a rectangular cavity. When large vertical numerical-control machining equipment is under a high-speed, heavy-load and micro-gap extreme working condition, the shear force of an oil film is increased, the oil film deforms seriously, boundary lubrication or dry friction is formed locally, hydrostatic pressure losses are severe, and thus the situations that the supporting rigidity is reduced, the bearing capacity is insufficient, and the machining precision is low are caused. In order to solve the problems, a hydrostatic pressure supporting oil cavity is designed to be rectangular, the oil pressures of all portions of the bottom surface of the oil cavity are made equal by increasing the area of the oil cavity, so that the bearing capacity is improved, and accordingly deformation of the oil film in the operation process is effectively reduced, the supporting rigidity is improved, and a hydrostatic pressure thrust bearing can operate efficiently.

Owner:HARBIN UNIV OF SCI & TECH

Hydraulic balance reciprocating pump

PendingCN111794929AReduce the problem of dry grinding heating and burningReduce friction areaPositive displacement pump componentsPiston pumpsOil canEngineering

The invention relates to a hydraulic balance reciprocating pump. The hydraulic balance reciprocating pump comprises a synchronous isolation device, an isolation sleeve with an inner cavity and a piston movably arranged in the inner cavity of the isolation sleeve, wherein the periphery of the piston is in sealing fit with the inner wall of the isolation sleeve and divides the inner cavity of the isolation sleeve into a first cavity and a second cavity, the first cavity communicates with a liquid inlet of a pump body, the second cavity is filled with hydraulic oil, an overflowing runner is arranged in a crosshead, a balance cavity is formed in the position, connected with the rear end of s plunger, of the front end of the crosshead, and the overflowing runner communicates with the second cavity so that the hydraulic oil in the second cavity can enter the balance cavity and act on the rear end of the plunger in a hydraulic mode. According to the hydraulic balance reciprocating pump, a pressure source of the hydraulic end compresses hydraulic oil through a piston in the isolation sleeve to transmit pressure to an overflowing runner and a balance cavity of the crosshead, then hydraulicforce acts on the plunger, the purpose of balancing plunger force is achieved, the motion stress face of the power end is promoted to enter lubricating oil, and the problem that dry grinding, heatingand burning loss occur due to the fact that lubricating oil cannot be supplied in an unbalanced mode is solved.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

Ring cylinder engine

InactiveCN101963095AReduce frictional power consumptionImprove efficiencyInternal combustion piston enginesReciprocating engineCylinder block

The invention relates to a ring cylinder engine which can obviously reduce engine friction power consumption, reduce the restriction of piston inertial force and linear velocity to the engine, simplify the engine structure, reduce engine manufacturing and use cost and widen the application field of new heat engine materials. The engine comprises a new ring curved surface cylinder and a piston, the restriction mode of a revolute pair is used for substituting a movement pair between a cylinder and a piston of the traditional reciprocating piston engine, so that no direct contact exists between the engine cylinder and the piston, the movement pair is also not in direct contact with fuel gas, and thus, various defects caused by direct contact of the movement pair used by the traditional reciprocating engine cylinder and the piston with the fuel gas are avoided. The greatest friction power consumption source of the traditional reciprocating piston engine is eliminated, and the heat efficiency of the engine is improved. The invention eliminates an impact between the engine cylinder and the piston, provides a possibility to manufacture the engine cylinder and the piston by using high temperature structural ceramics and also provides a possibility for the engine cylinder and the piston to thoroughly get rid of the restriction of linear velocity.

Owner:蔡盛龙 +1

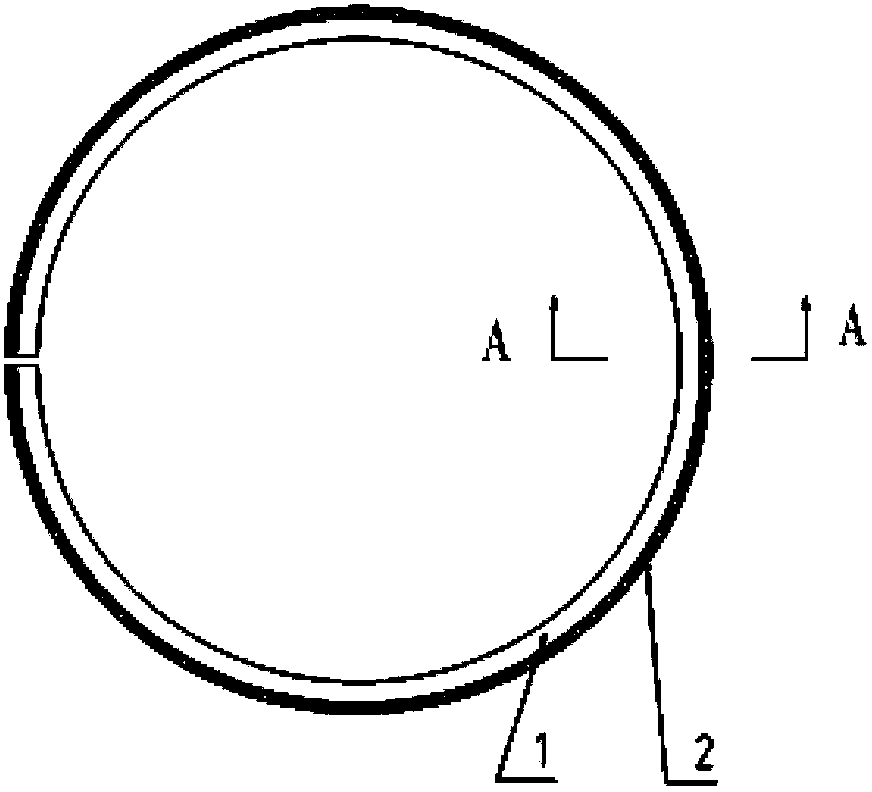

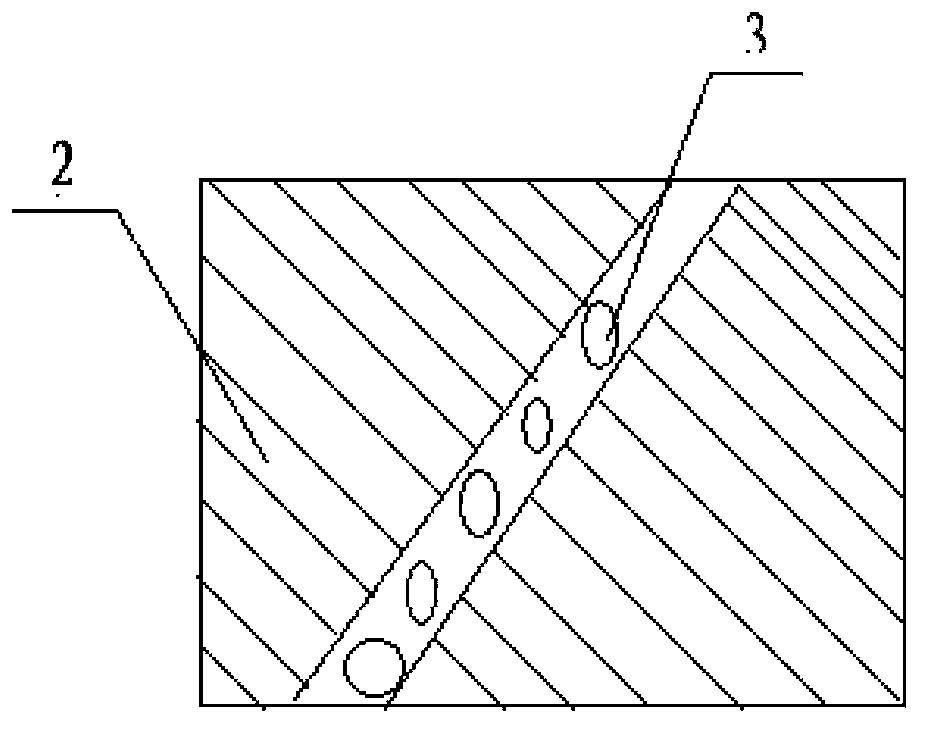

Composite coating piston ring inlaid with wear-resistant particles, and processing method thereof

InactiveCN103469283AImprove wear resistanceReduce coefficient of frictionPiston ringsElectrolytic coatingsBenzoic acidEtching

The invention discloses a composite coating piston ring inlaid with wear-resistant particles. The composite coating piston ring comprises a cast iron body and a composite coating layer plated on the outer circle of the main body, wherein the composite coating layer is a mesh-patterned electroplating coating inlaid with the wear-resistant particles; and the wear-resistant particles are one or more selected from silicon carbide, silicon dioxide, aluminium trioxide and diamond. A processing method of the composite coating piston ring inlaid with the wear-resistant particles comprises the steps of preparing a composite plating solution with a concentration of chromic anhydride being 200-400 g / L, a concentration of sulfuric acid being 2-6 g / L, a concentration of benzoic acid being 4-10 g / L and 100-130 g / L of the wear-resistant particles; forming a hard chrome layer on the surface of the piston main body by applying a forward current; carrying out reverse etching by applying a backward current, the wear-resistant particles being adsorbed to cracks during the reverse etching process; and repeating the reverse etching process, so that the wear-resistant particles are inlaid in the composite plating layer. The composite coating piston ring inlaid with the wear-resistant particles has good wear-resistant performance, high oil storage property and long service life. The production method provided by the invention is simple in operations and is stable.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

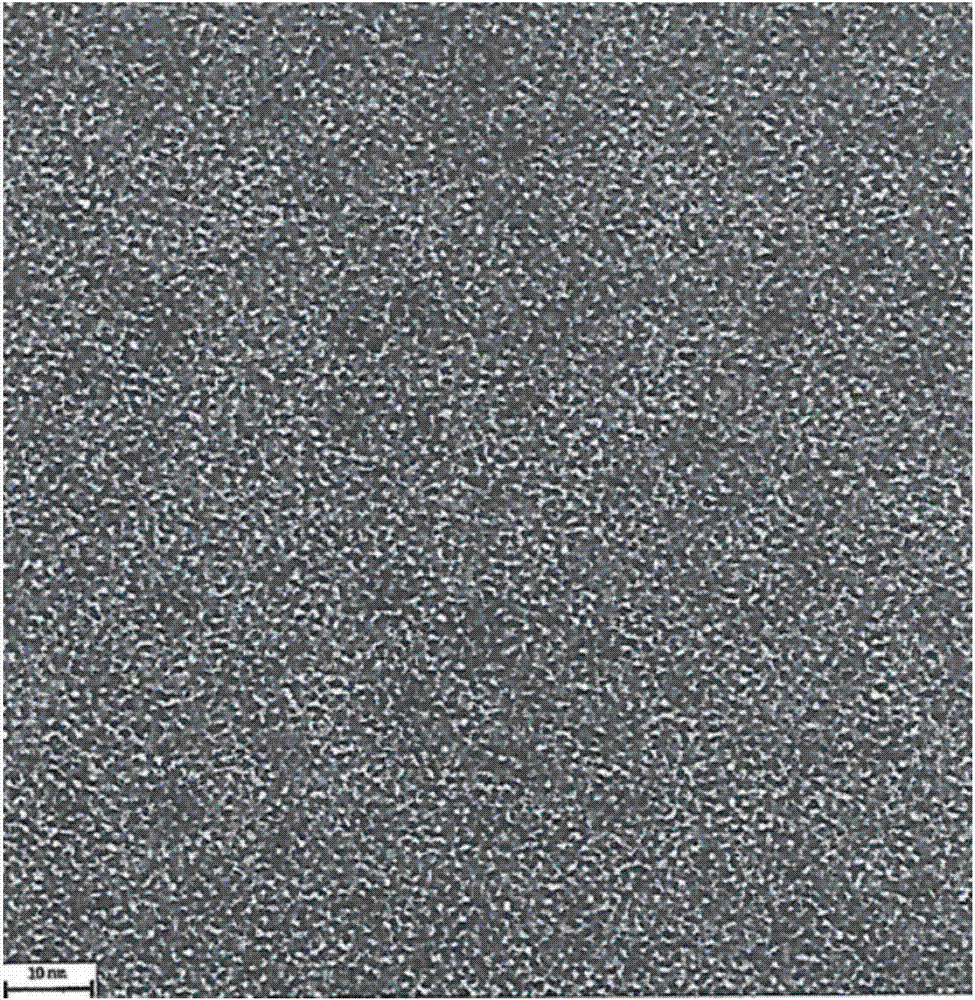

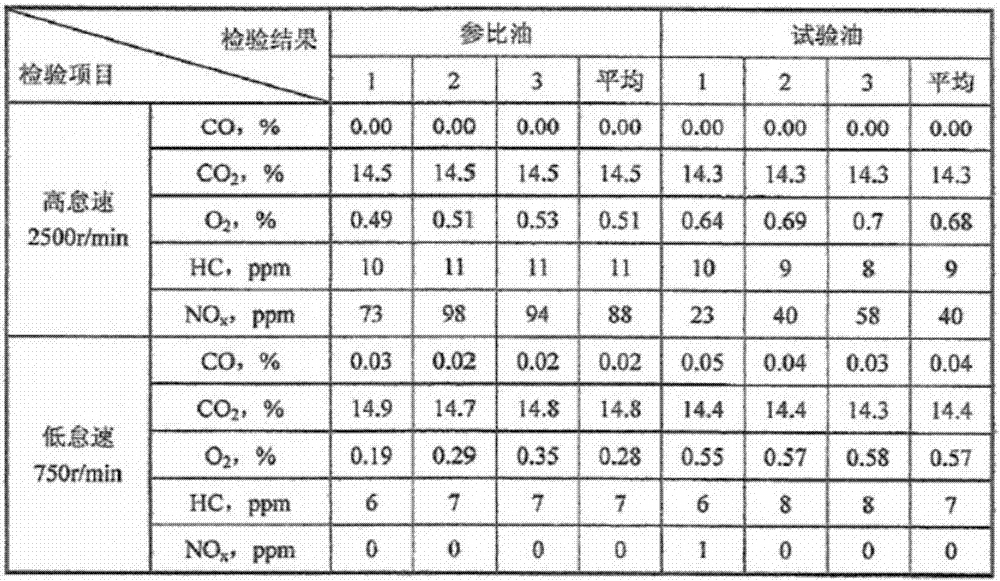

Energy-saving and environment-friendly lubricating oil capable of self-repairing wear for internal combustion engine and preparation method of energy-saving and environment-friendly lubricating oil

ActiveCN107488491AWon't fall offWork effectively for a long timeLubricant compositionExternal combustion engineAntioxidant

The invention discloses energy-saving and environment-friendly lubricating oil capable of self-repairing wear for an internal combustion engine and a preparation method of the energy-saving and environment-friendly lubricating oil, and belongs to the field of lubricating materials. The energy-saving and environment-friendly lubricating oil is prepared from the following components in percentage by weight: 87 to 90 percent of base oil and 10 to 13 percent of additive, wherein the additive is prepared from the following components in percentage by weight: 1.2 to 2.5 percent of a calcium-containing clearing agent, 1.3 to 2 percent of a dispersing agent, 0.5 to 1.4 percent of an anti-wear agent, 1.5 to 2.5 percent of an antioxidant, 0.5 to 0.8 percent of a corrosion inhibitor, 1.5 to 2 percent of a viscosity index improver and 1.1 to 3.5 percent of a friction improver; the friction improver is polytetrafluoroethylen high-molecular compound ultramicro nano-powder and the particle size of the powder is 2 to 12 nm. According to the energy-saving and environment-friendly lubricating oil disclosed by the invention, the problem that existing lubricating oil for the internal combustion engine cannot repair friction and wear of internal parts in the engine is solved; in addition, the design tolerance gap can be automatically compensated and non-disassembly in-situ repair can be carried out, thereby improving the sealing property of a cylinder, a piston and other parts; in addition, a compression ratio and an air-fuel ratio of the engine are improved, fuel oil is combusted more sufficiently, the discharge of exhaust pollutants is reduced and the frictional resistance is reduced.

Owner:安徽游能润滑新技术有限公司

Sided-intake sealer of agitator

InactiveCN101073755AGuaranteed vacuumSlightly wornEngine sealsRotary stirring mixersEnd face mechanical seal

The invention is concerned with the sealing equipment for the side moving beater, it is: fixes inside end surface machine seal that crosses the inside wall of the container, fixes outside end surface machine seal between the beating axis and the outside wall of the container. The outside end surface machine seal is double end surface machine seal that fixes on the beating axis by the sealing fixing bushing. The invention is small fraying consumption, better sealing efficiency.

Owner:华宝付

Method for realizing stair climbing of robot

InactiveCN111409727AReduce frictional power consumptionFlexible turning in placeVehiclesGear wheelControl theory

The invention discloses a method for realizing stair climbing of a robot. The robot takes a wheel set as a walking structure, planetary gears in the wheel set drives front wheels to change obstacle torque, stair climbing is achieved through cooperation with the boosting effect of synchronous power rear wheels, the wheel sets are installed on the robot or an electric wheelchair in a bilateral symmetry structure, and during turning, flexible in-situ turning can be achieved only by controlling the power wheel on one side to rotate forwards and controlling the power wheel on the other side to rotate reversely. The method is advantaged in that the robot or the electric wheelchair can stably climb stairs or cross obstacles with small torque, in-situ turning is flexible, and ground friction powerconsumption is low.

Owner:SUZHOU ANHUI SAIERWODE INTERNET OF THINGS TECH CO LTD

End-surface mechanical seal structure with sharkskin-imitated surface three-dimensional shape

ActiveCN106838323APrevent adhesionTo achieve the effect of enhanced heat dissipationEngine sealsThree dimensional shapeEngineering

The invention discloses an end-surface mechanical seal structure with a sharkskin-imitated surface three-dimensional shape. The end-surface mechanical seal structure comprises a moving ring or a fixed ring as mechanical seal, wherein the outer ends of the seal end surfaces of the moving ring and the fixed ring are taken as high-pressure sides, namely upstream parts, and the inner ends of the seal end surfaces are taken as low-pressure sides, namely downstream parts; a circle of closed seal dam is arranged at the upstream high-pressure side of at least one seal end surface in the moving ring or the fixed ring, a plurality of upstream pump grooves are uniformly arranged on the circumference of the surface of the seal end surface, a first end of each upstream pump groove extends to the high-pressure side of the seal end surface, and a second end extends to the low-pressure side of the seal end surface; an area between two adjacent upstream pump grooves is a seal weir; micro convex body clusters with the sharkskin-imitated surface shape are processed on the bottoms of the grooves and the surfaces of the seal weirs; the micro convex body clusters are arranged in a staggered manner until the micro convex body clusters uniformly bestrew the whole seal weirs and the bottoms of the upstream pump grooves; and the micro convex body clusters are formed by a plurality of parallel micro convex body units. The end-surface mechanical seal structure has the beneficial effects that attachment, drag reduction, wear resistance and enhanced heat dissipation of marine fouling organisms are prevented through the sharkskin-imitated surface three-dimensional shape.

Owner:ZHEJIANG UNIV OF TECH

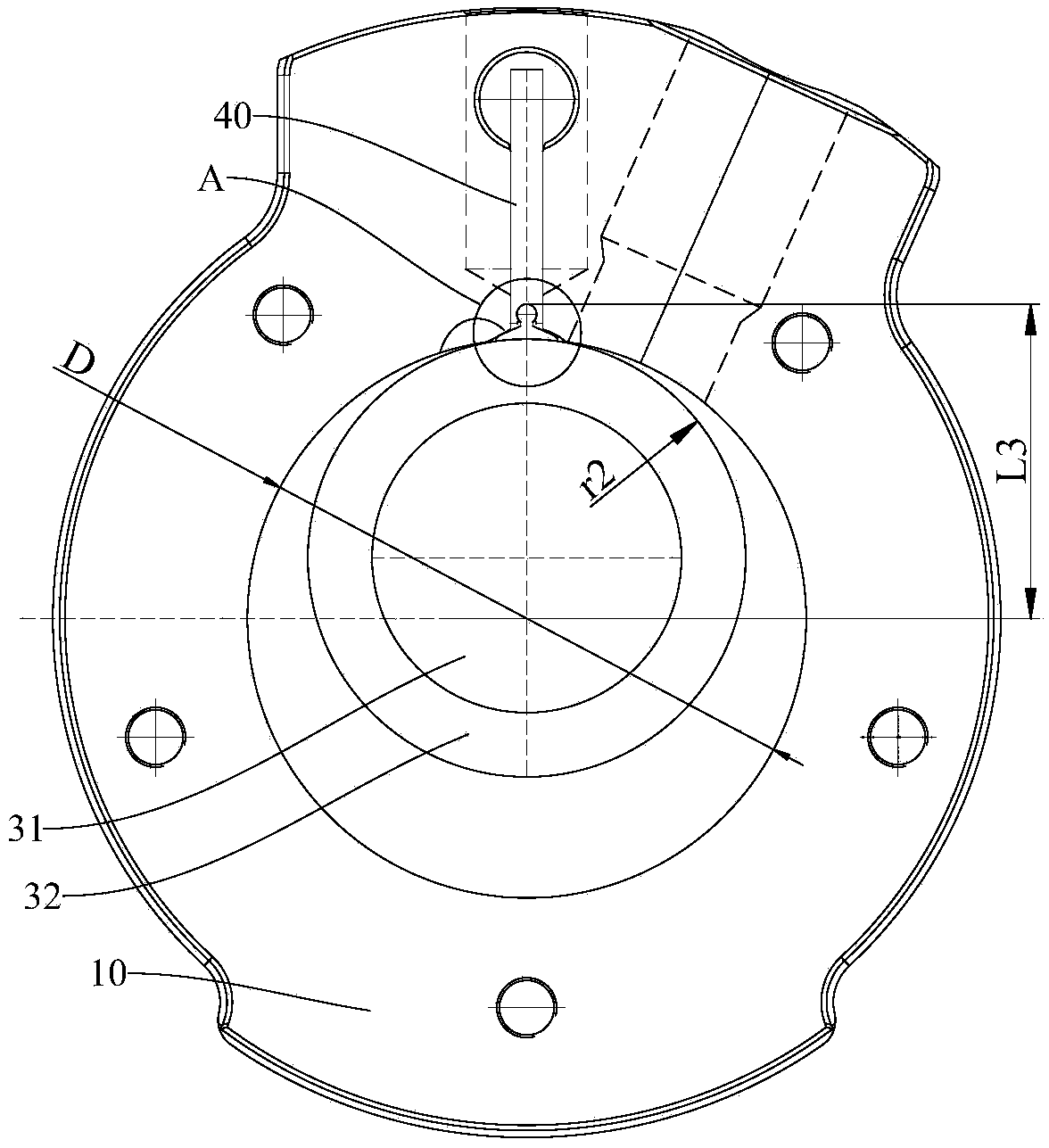

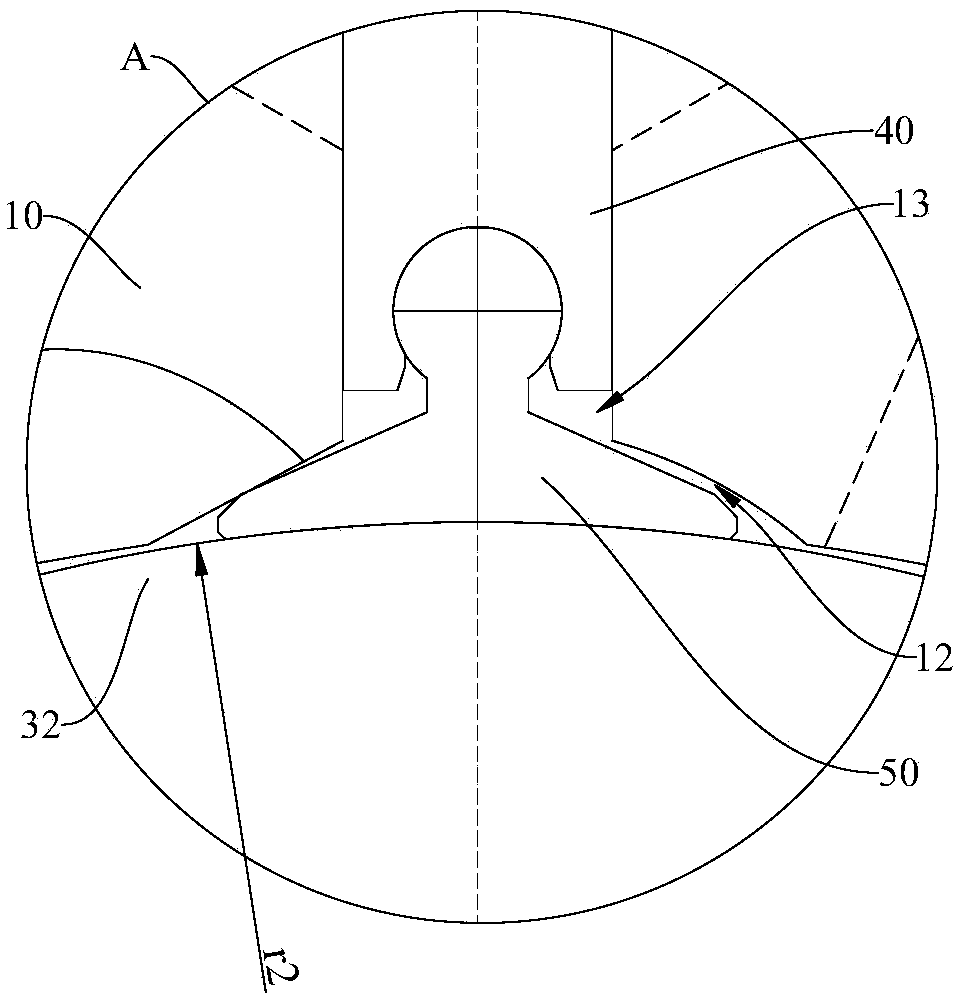

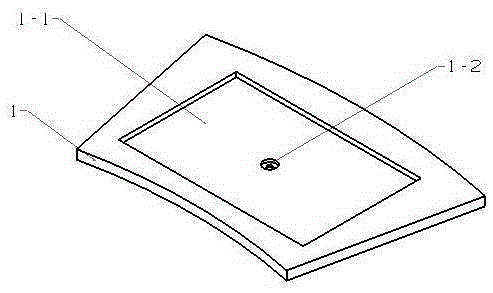

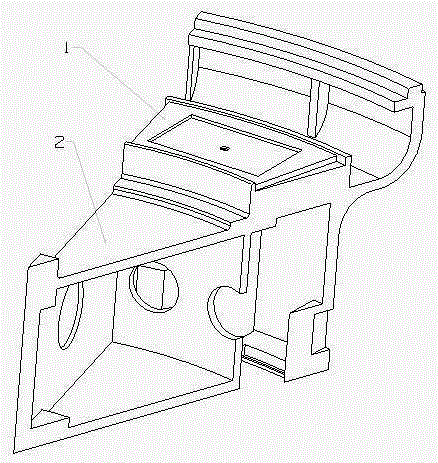

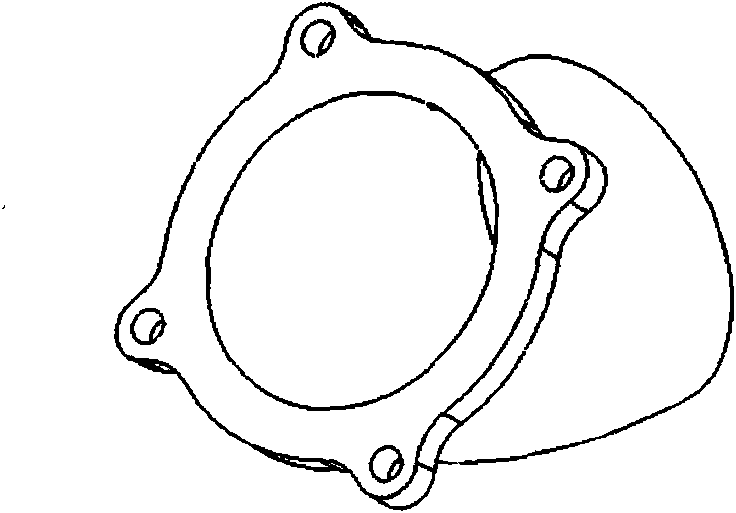

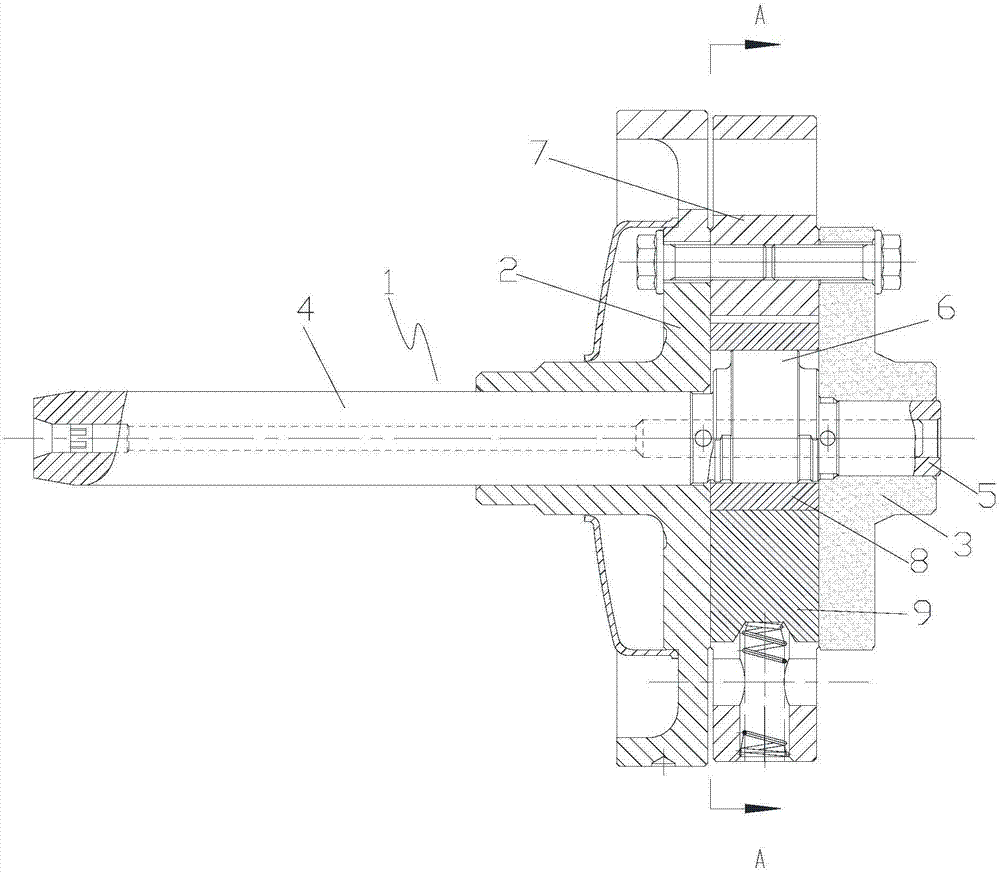

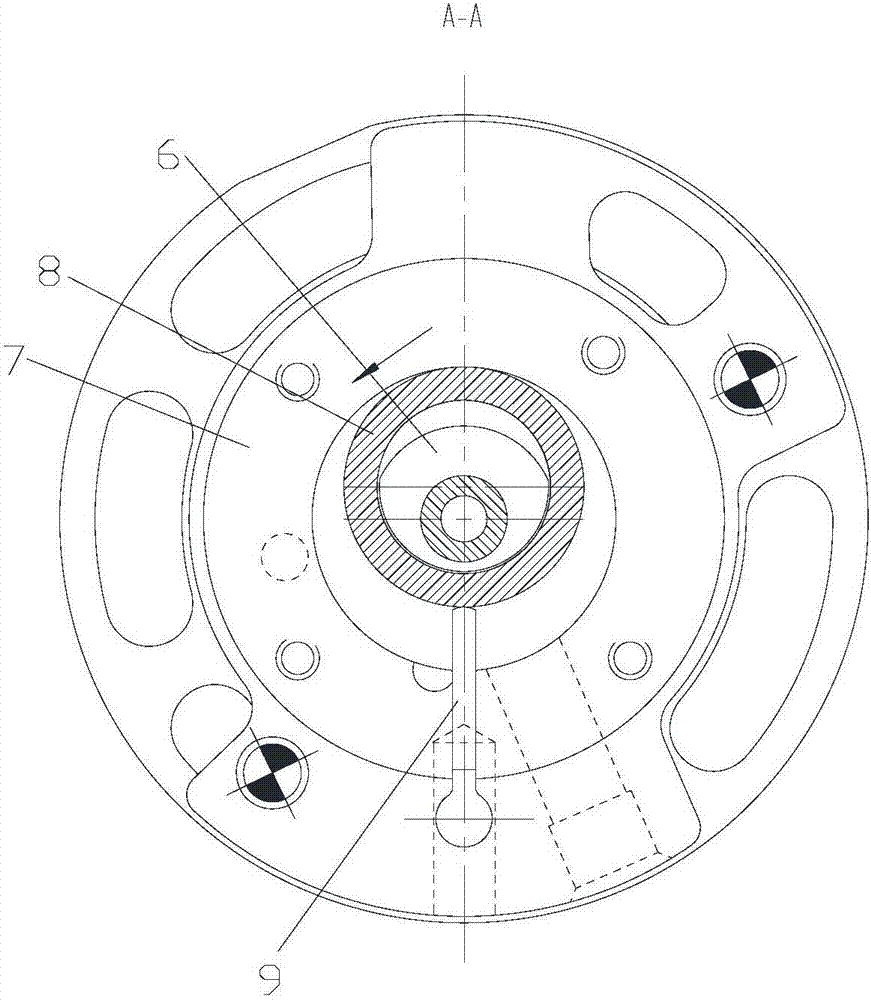

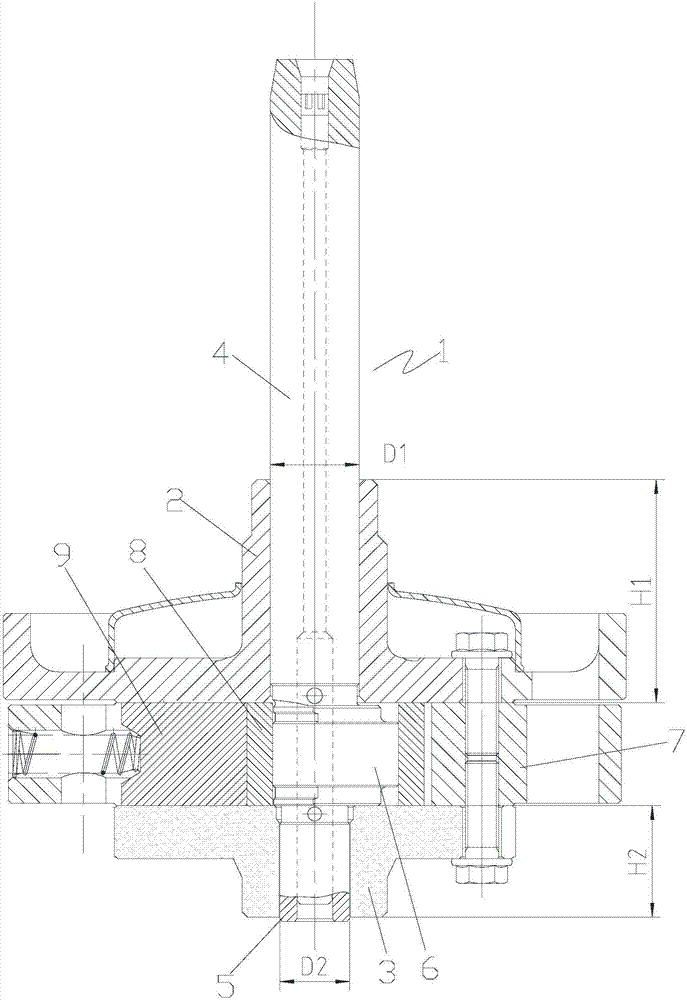

Pump body assembly and compressor

PendingCN107882727AGuaranteed Bearer RequirementsReduce friction areaRotary piston pumpsRotary piston liquid enginesWork performanceEngineering

The invention provides a pump body assembly and a compressor. The pump body assembly comprises a crankshaft (1), an upper flange (2) and a lower flange (3); the crankshaft (1) comprises a long shaft (4) which is matched with the upper flange (2) and a short shaft (5) which is matched with the lower flange (3); the range of the ratio of the shaft diameter of the long shaft (4) to the axial height of the upper flange (2) is 0.25 to 0.45; and / or the range of the ratio of the shaft diameter of the short shaft (5) to the axial height of the lower flange (3) is 0.55 to 0.75. According to the pump body assembly provided by the invention, the friction power consumption of the compressor in a working process can be reduced, and the work performance of the compressor can be improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com