Worm transmission device capable of eliminating gear backlash

A technology of worm drive and tooth backlash, which is applied in the direction of gear transmission, transmission, hoisting device, etc., can solve the problems of difficult transmission accuracy, many transmission components, complex structure, etc., and achieve high transmission efficiency and low friction power consumption. Small, low calorie effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

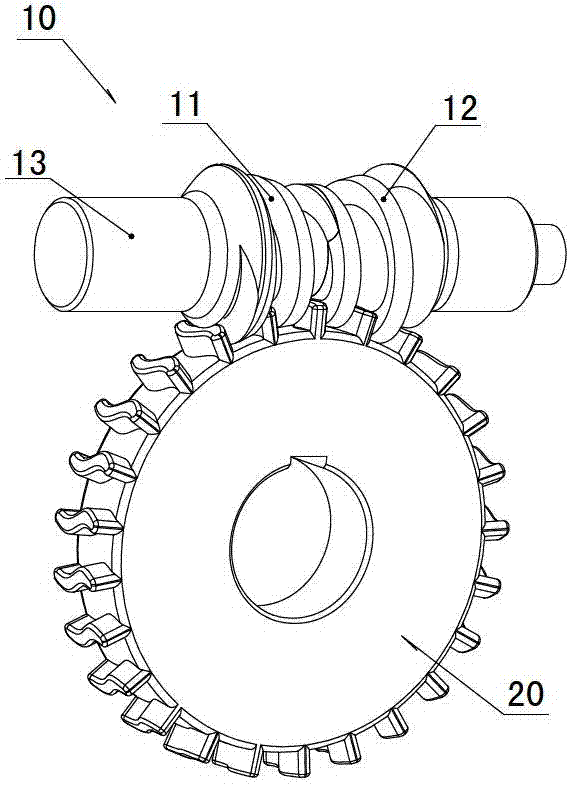

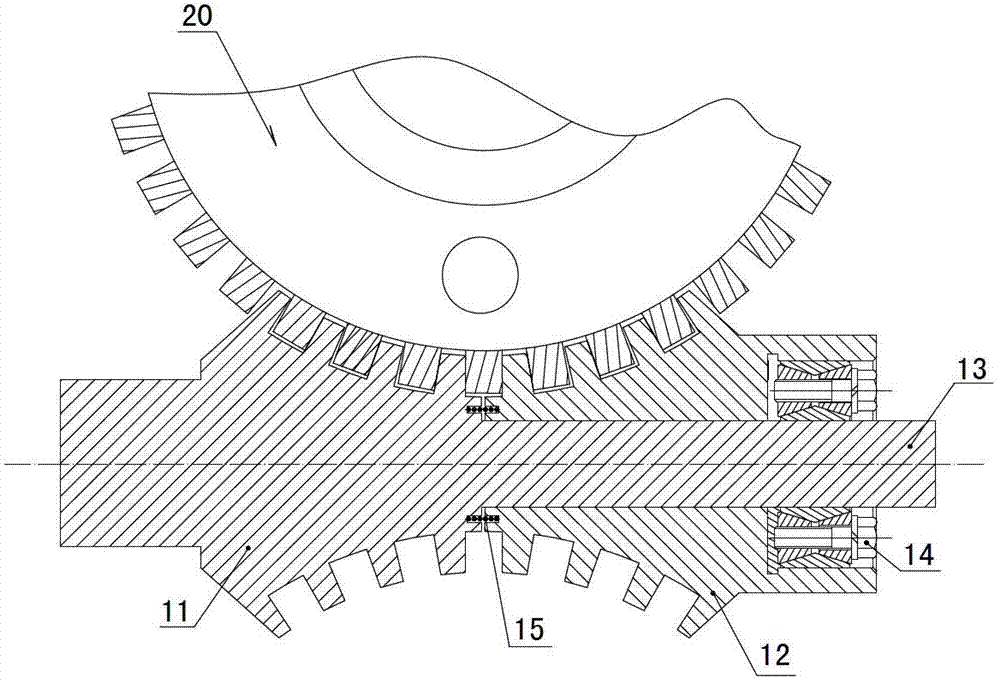

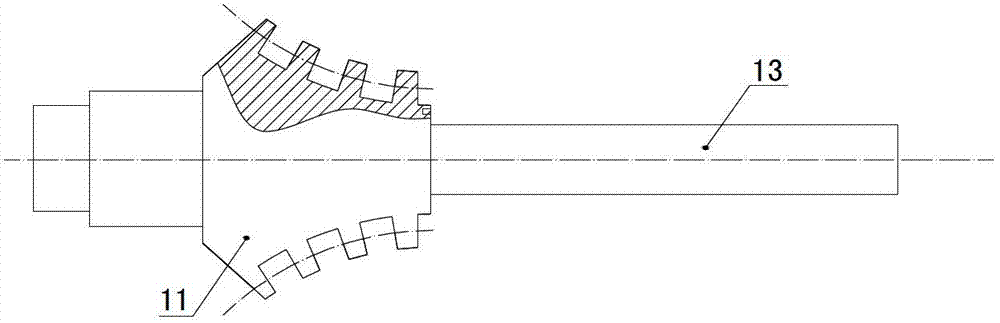

[0023] refer to figure 1 with figure 2 , the present invention is a worm gear that can eliminate backlash, including a worm 10 and a worm wheel 20, characterized in that: the worm 10 is composed of a left section worm 11 and a right section worm 12 installed coaxially, and the left and right tooth surfaces The worm wheel 20 is formed by enveloping the different surfaces of the sinusoidal linear grinding wheel once; the worm wheel 20 has sinusoidal teeth evenly distributed in the radial direction, and the teeth are formed by enveloping the hob in the same shape as the worm twice; the left worm 11. An adjustment mechanism for adjusting its relative position and relative rotation angle is arranged between the right section worm 12 . The worm 10 is arranged by adjusting the rotation angle of the left section worm 11 and the right section worm 12. The lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com