Pipe static mixing component and pipe static mixer containing pipe static mixing component

A technology of static mixing elements and static mixers, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of large fluid resistance, complex fluid channels, and easy fouling, and achieve small pressure loss, Versatile, radially mixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

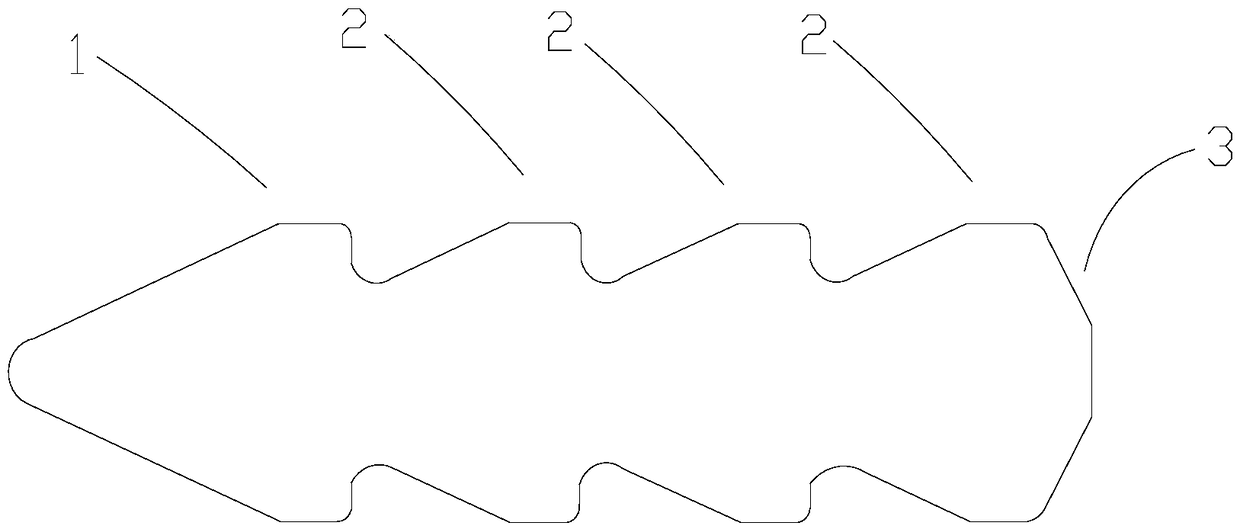

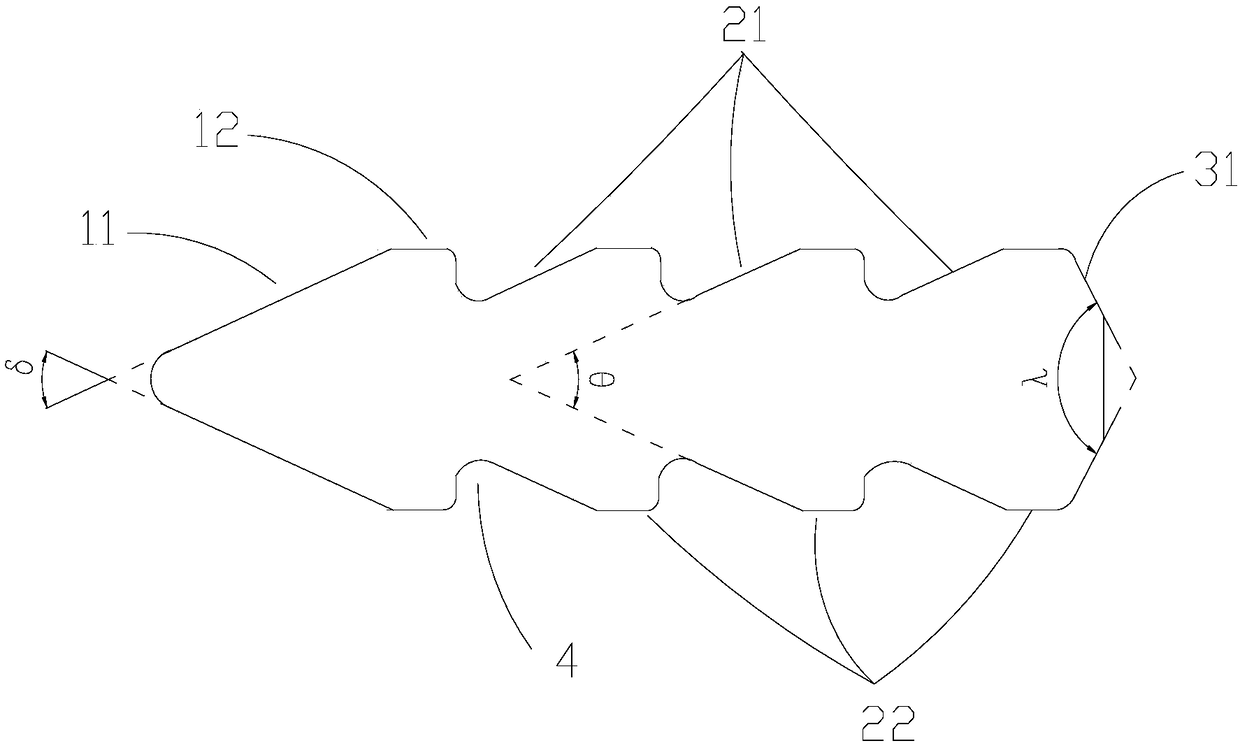

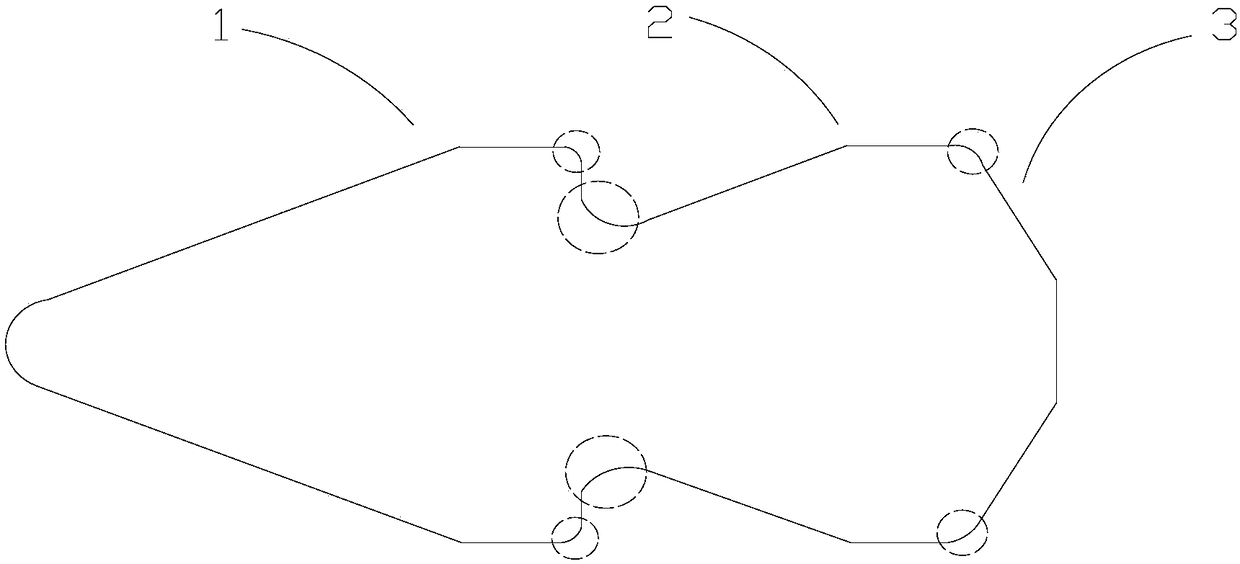

[0055] Figure 1~2 Schematically shows a ducted static mixing element according to one embodiment of the invention. As shown in the figure, the device is integrally formed as an integral structure without moving parts, which includes: a set of first elements 1, three sets of second elements 2 and a set of third elements 3, the first elements 1, The second element 2 and the third element 3 are connected sequentially and the axes of the three are coincident.

[0056] The first element 1 comprises a conical surface 11, and a first cylindrical surface 12 located at the maximum diameter of the conical surface 11, wherein the cone angle δ of the conical surface 11 is 45°, and the diameter d of the first cylindrical surface 1 Determined according to the equivalent diameter ratio β = 0.55, that is, d 1 = 0.84D.

[0057] The second element 2 includes a first circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com