90-degree rectification rectangular bent pipe

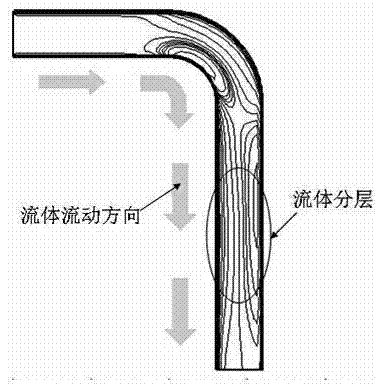

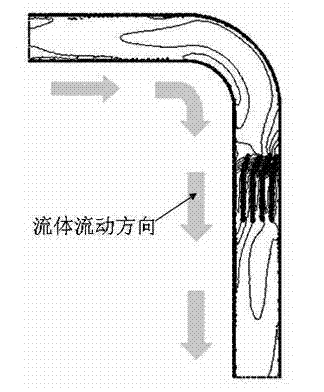

A curved pipe and rectangular technology, applied in the field of local components, can solve the problems that the actual indoor comfort cannot meet the design requirements, the fluid flow rate is uneven, and the indoor air distribution is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

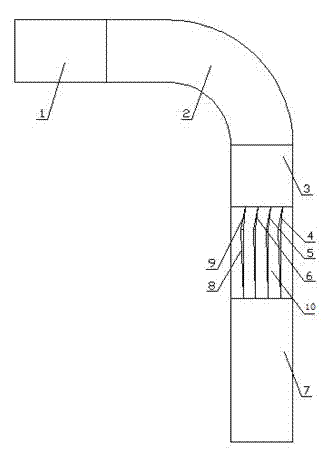

[0039] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

[0040] Following the above technical scheme, taking the optimization process of the central air-conditioning duct connecting the 90° rectangular elbow as an example, first determine the dimensions of each part of the 90° rectangular elbow pipe, where the size of the inlet section 1 is 300mm×300mm, and the size of the outlet section 7 is 300mm ×300mm, the camber is 1.5, the length of the rectification section 10 is 300mm, the length of the rectification vane in the rectification section is 100mm, and the length of the guide vane is 300mm, then list the discrete format of the momentum equation and the continuity equation, and use the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com