Patents

Literature

131results about How to "Same width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

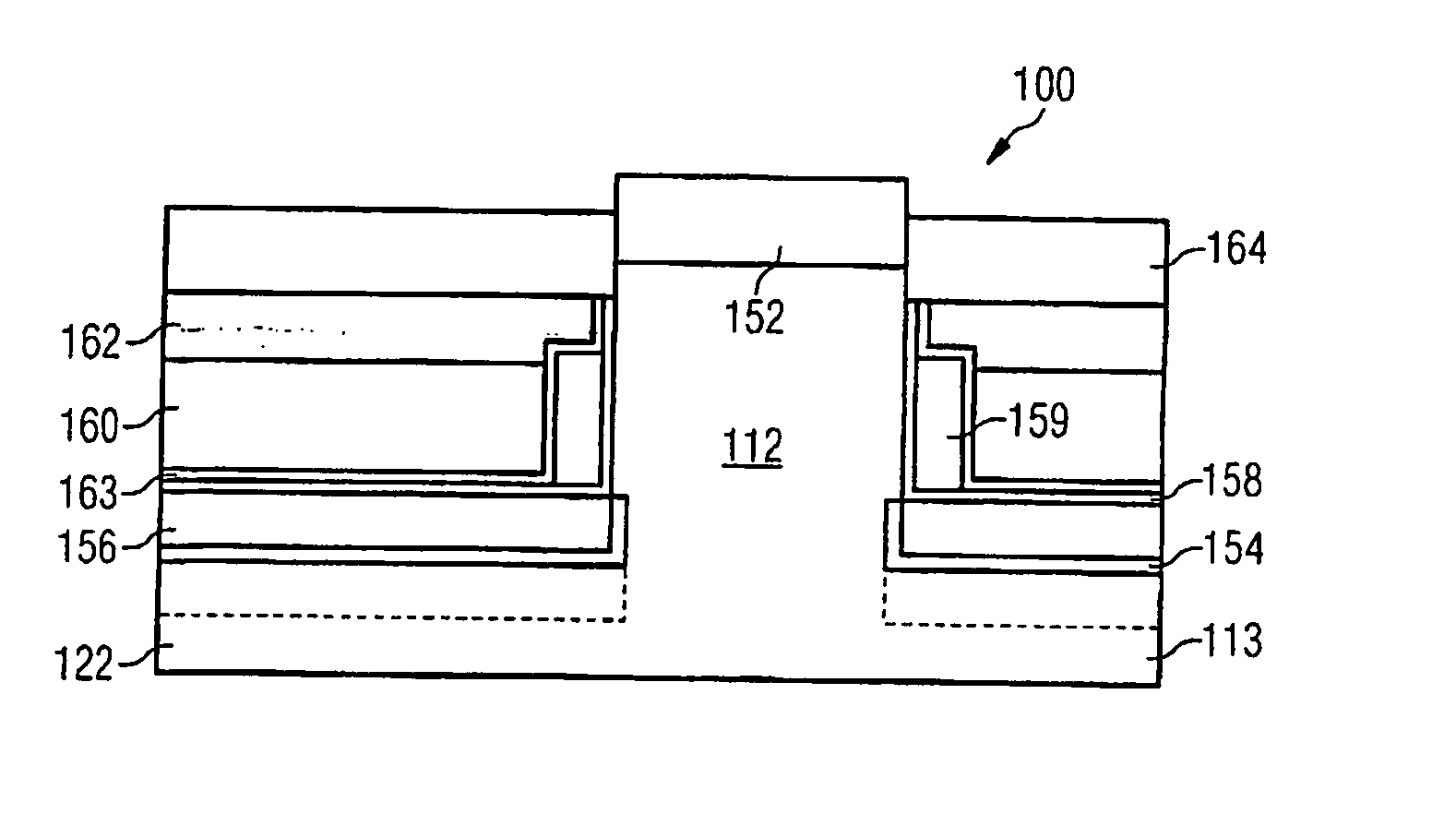

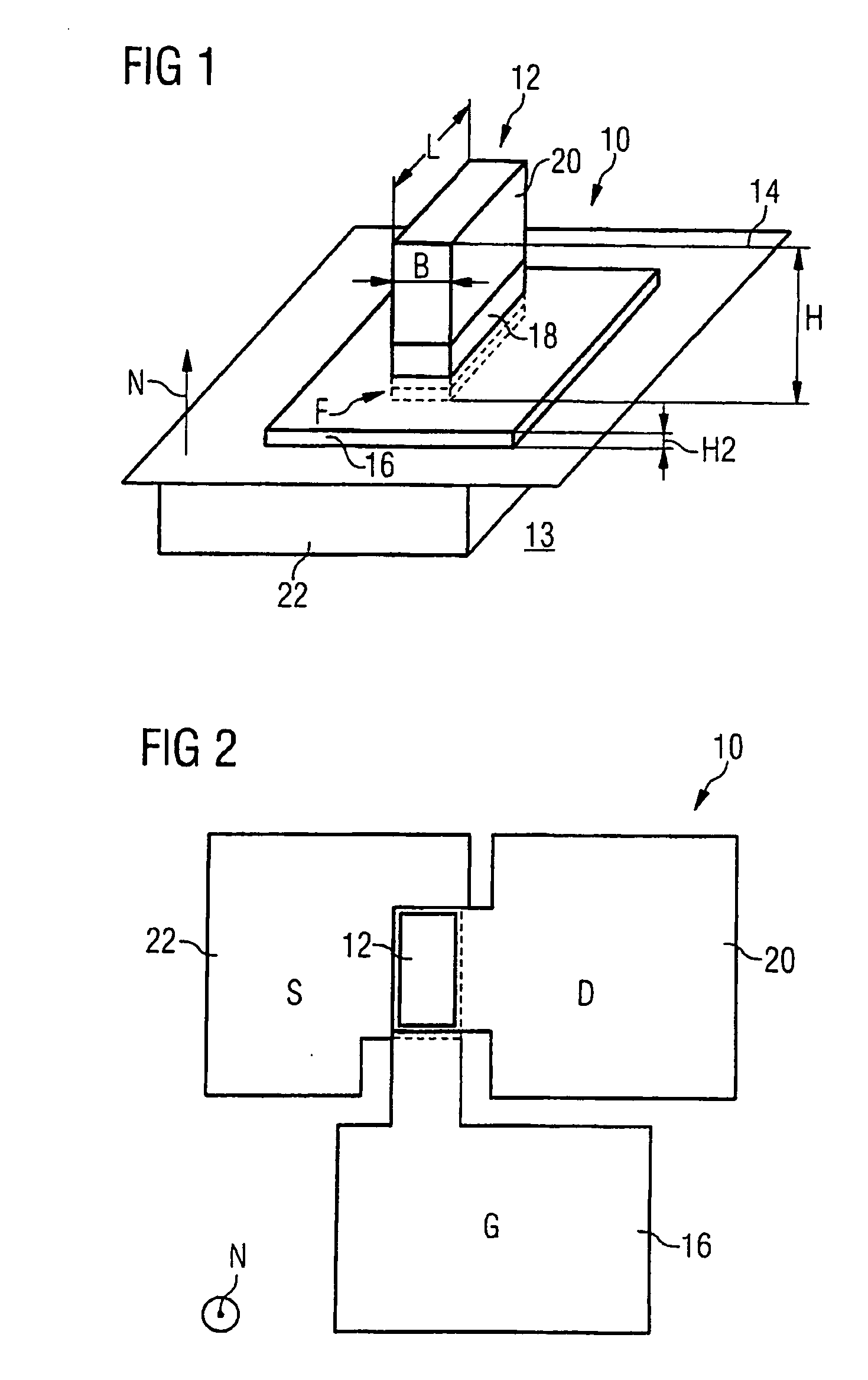

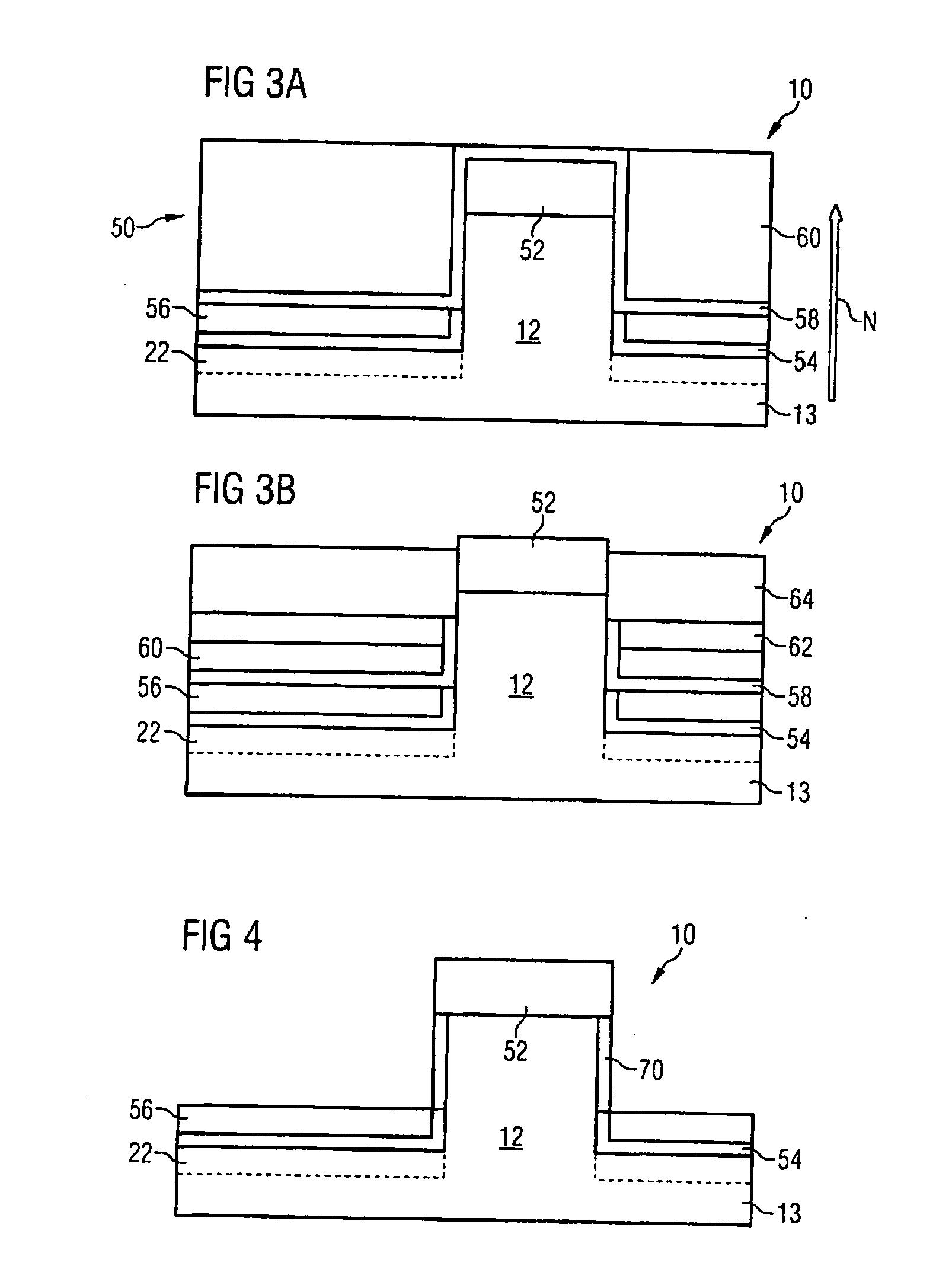

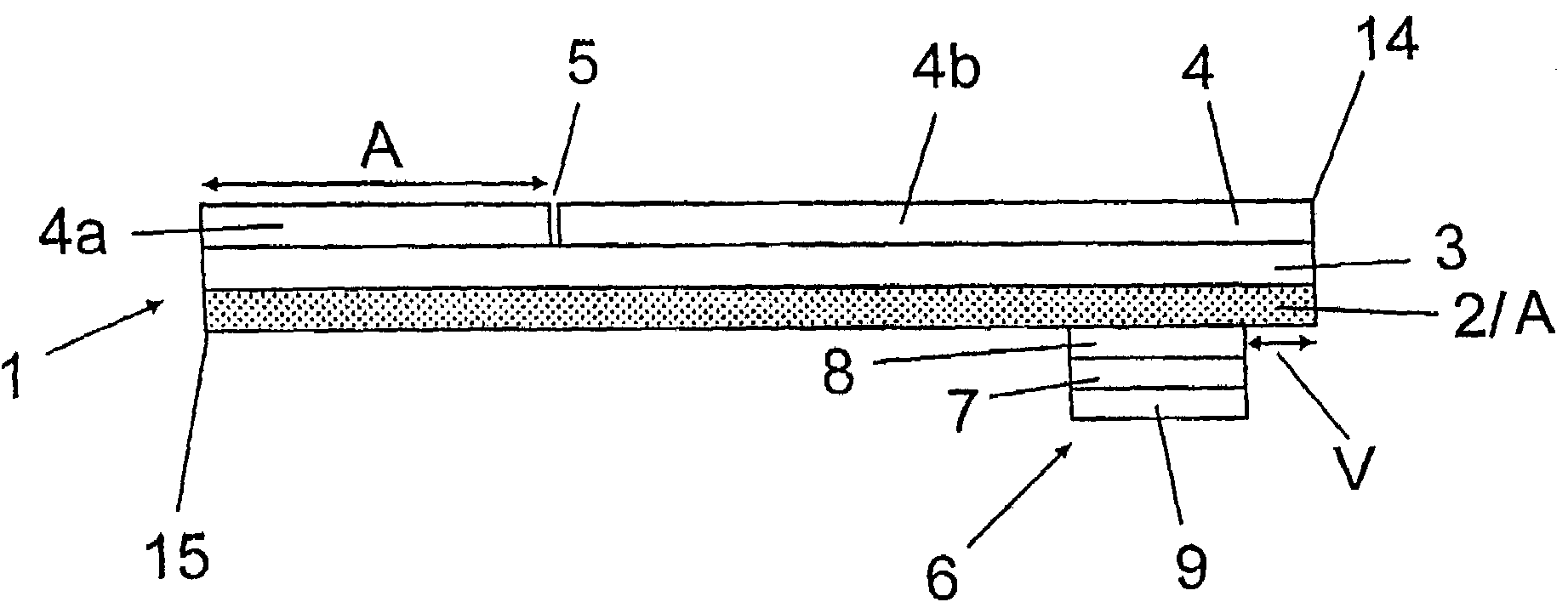

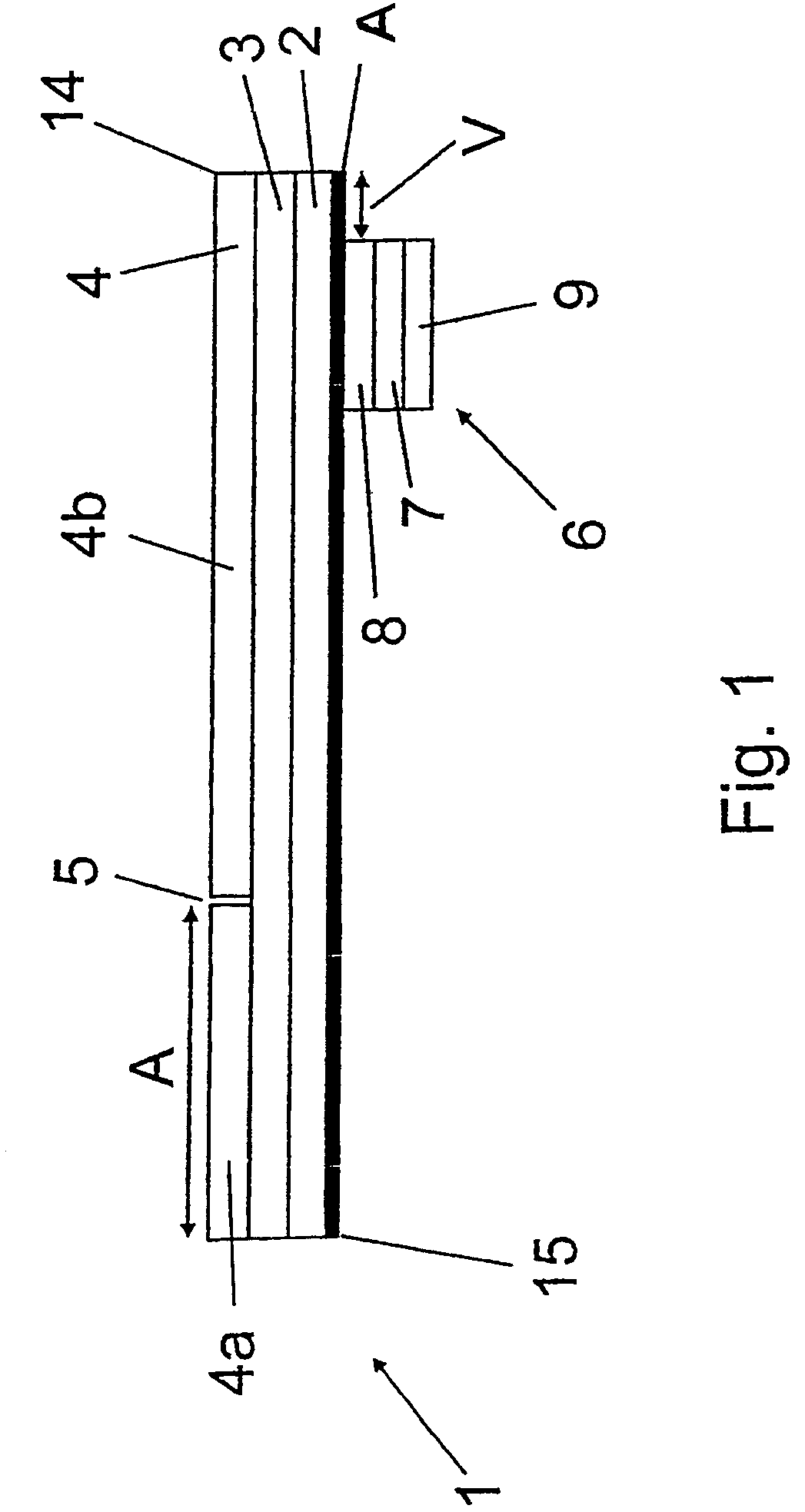

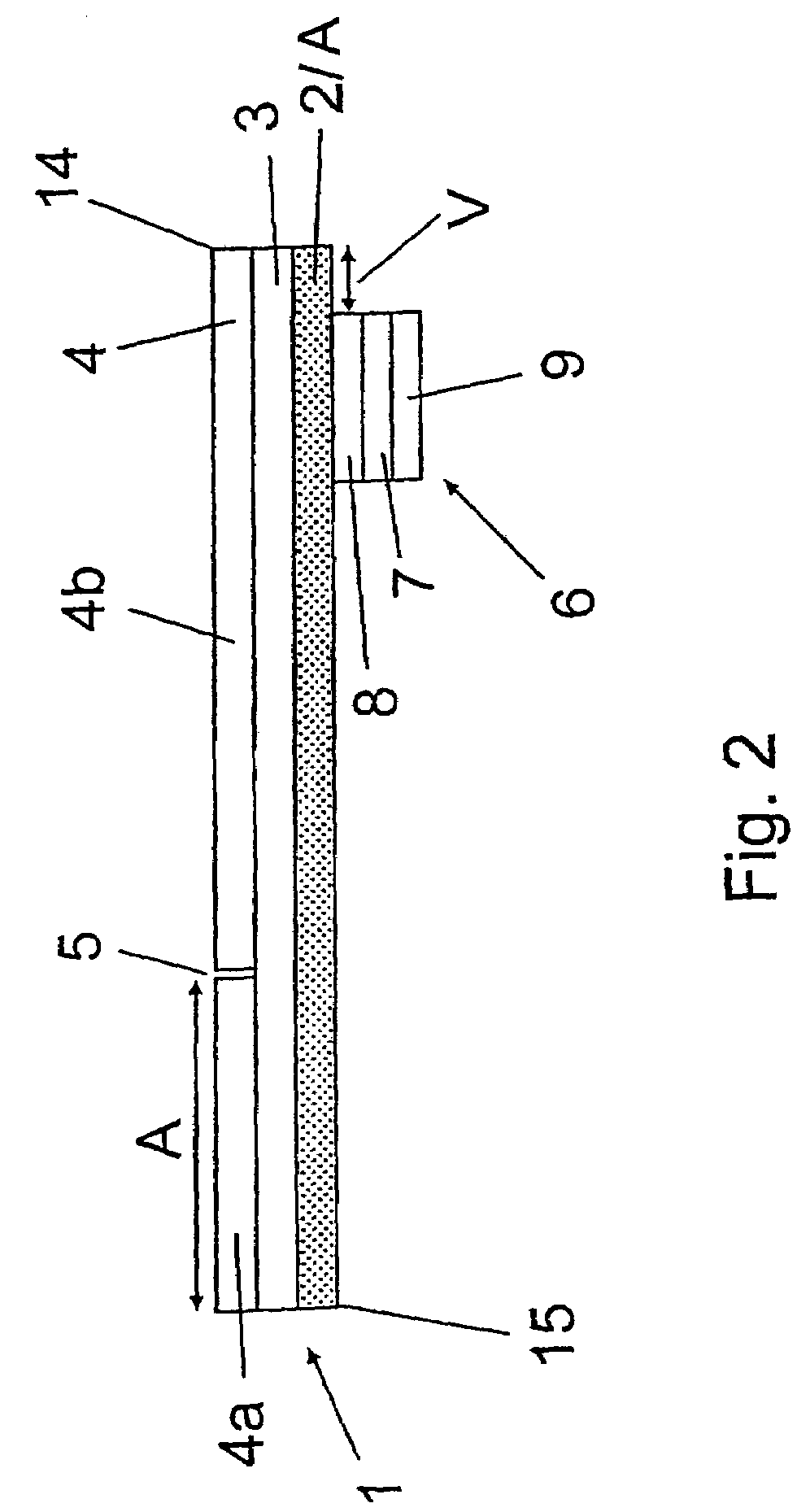

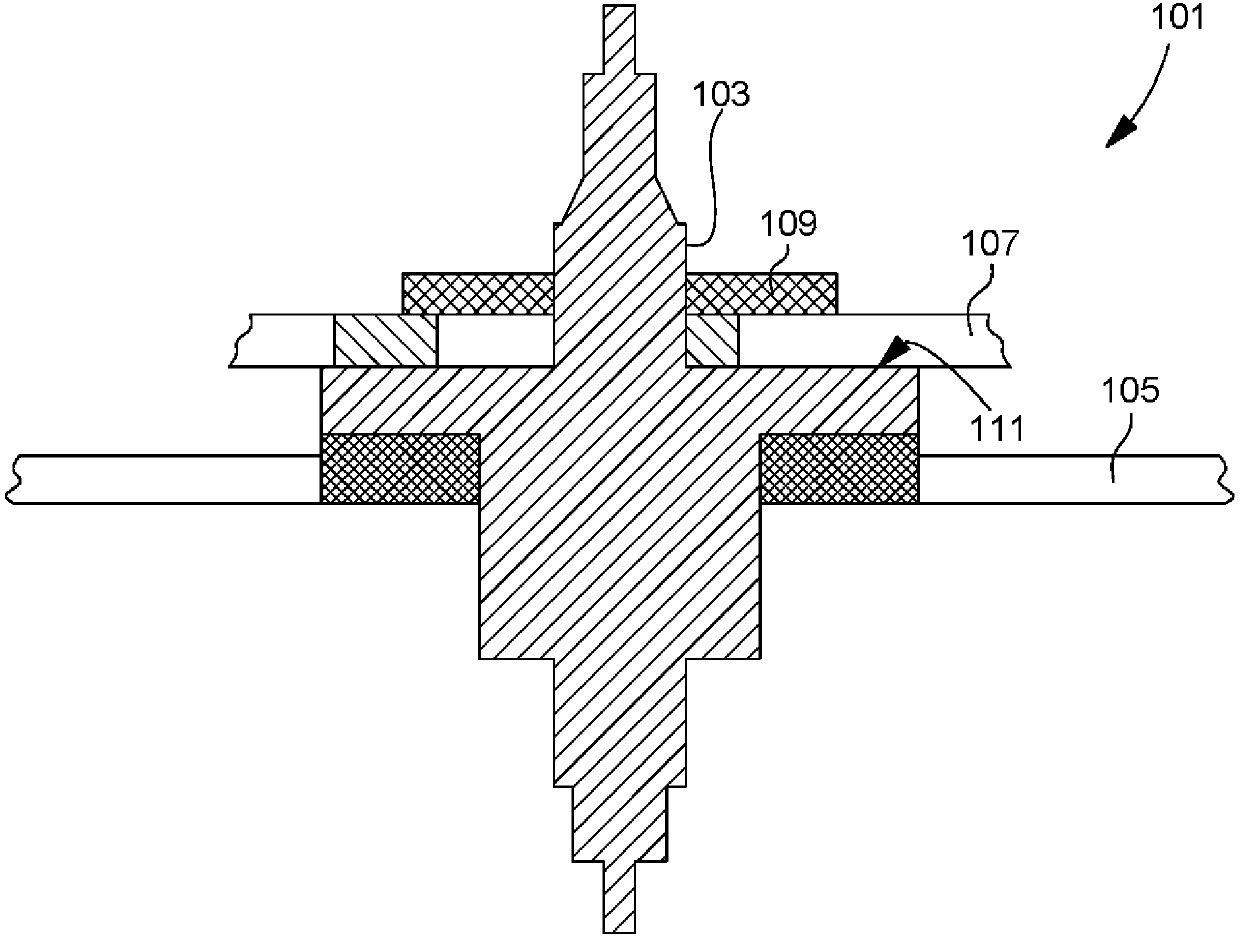

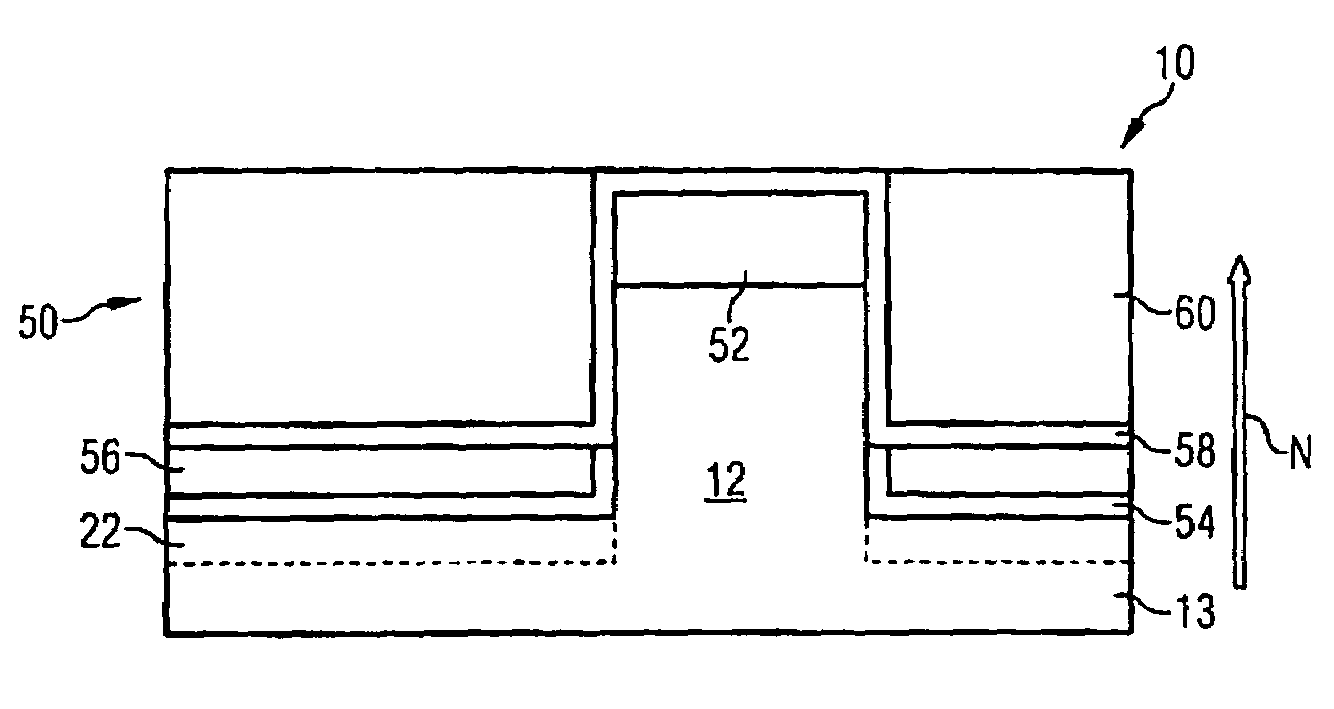

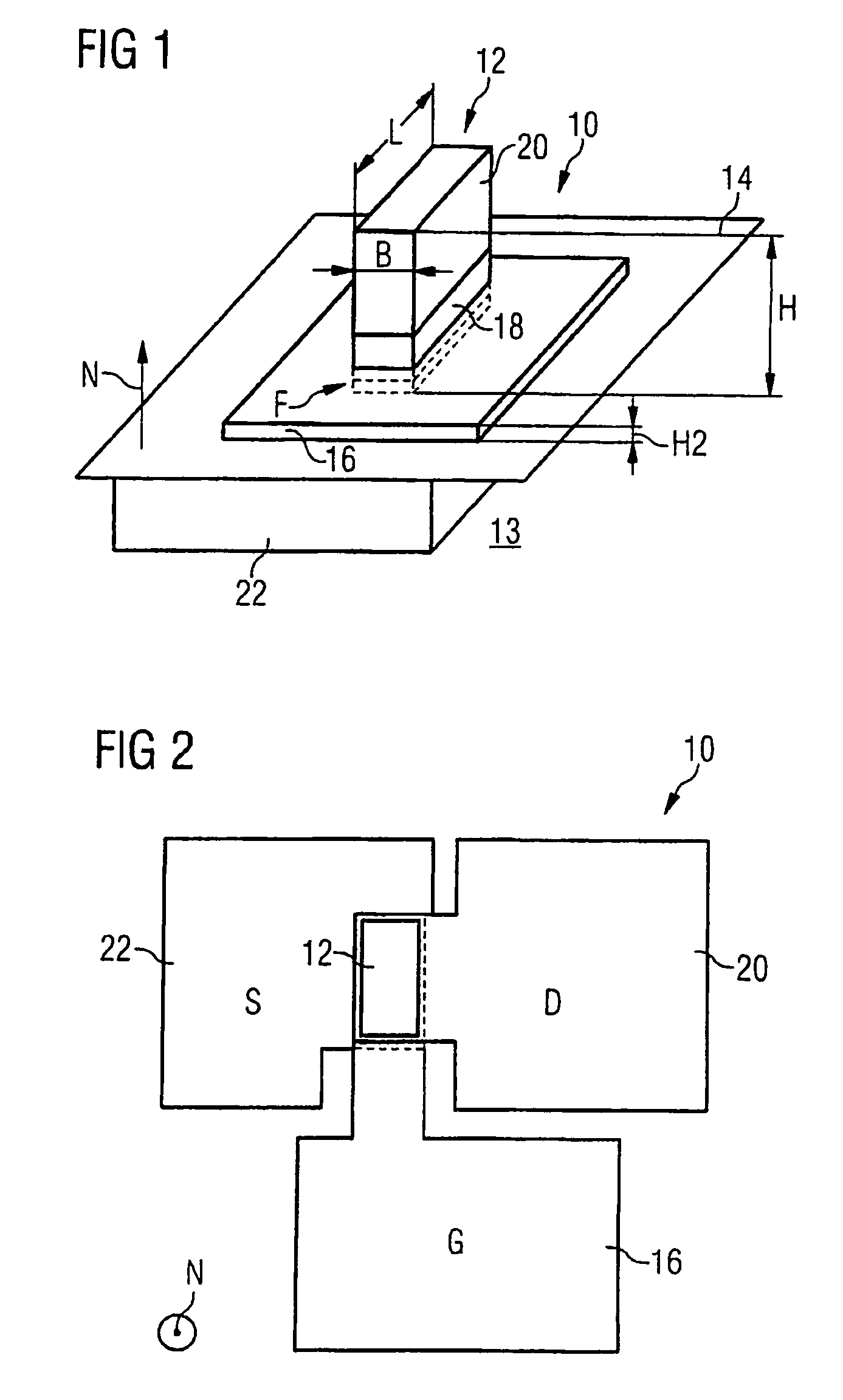

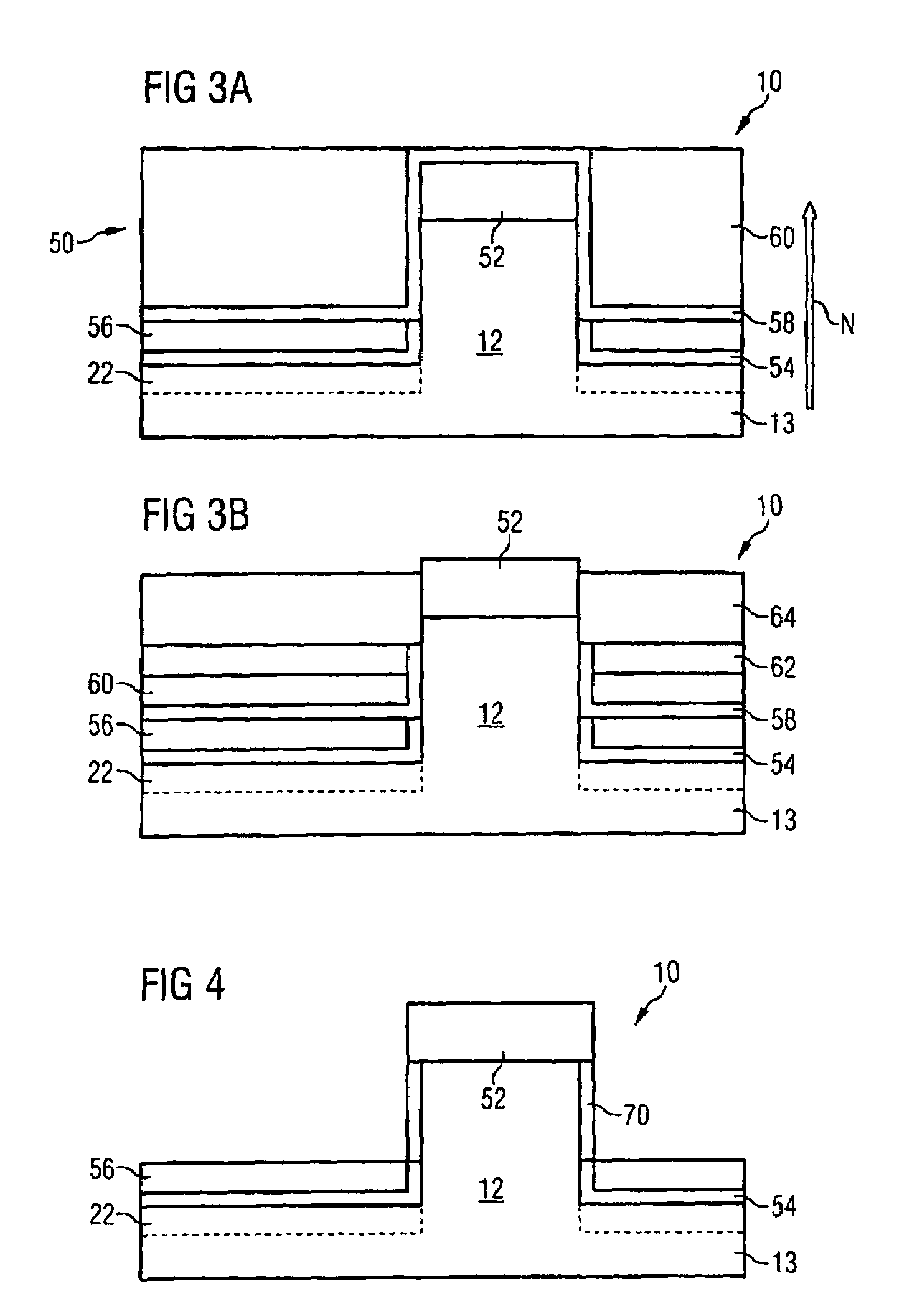

Method for producing a vertical field effect transistor

InactiveUS20070004149A1Improve electrical performanceEasy to produceTransistorSemiconductor/solid-state device manufacturingEngineeringField-effect transistor

A method for producing a field effect transistor, in which a plurality of layers are in each case deposited, planarized and etched back, in particular a gate electrode layer, is disclosed. This method allows the manufacturing of transistors having outstanding electrical properties and having outstanding reproducibility.

Owner:INFINEON TECH AG

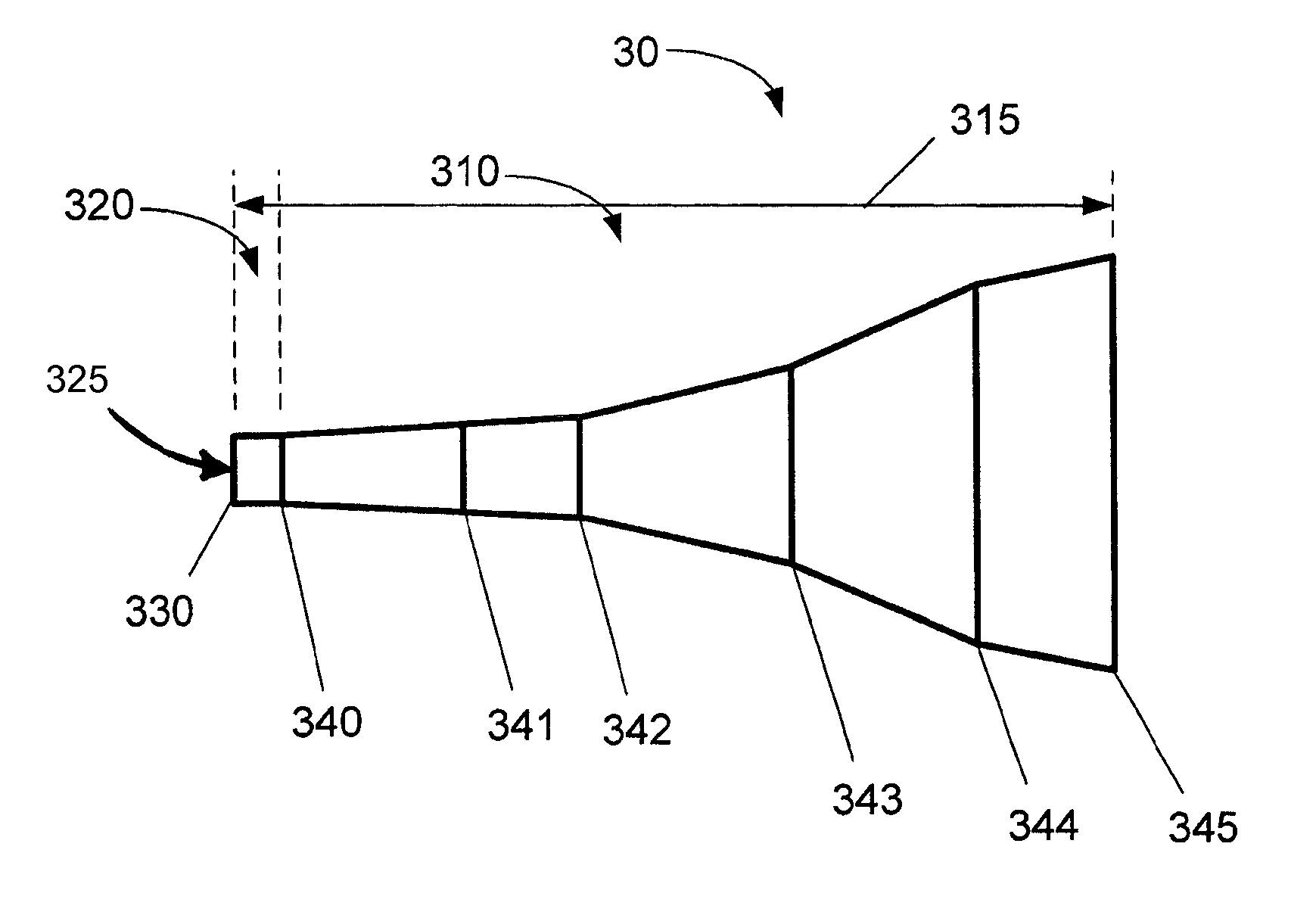

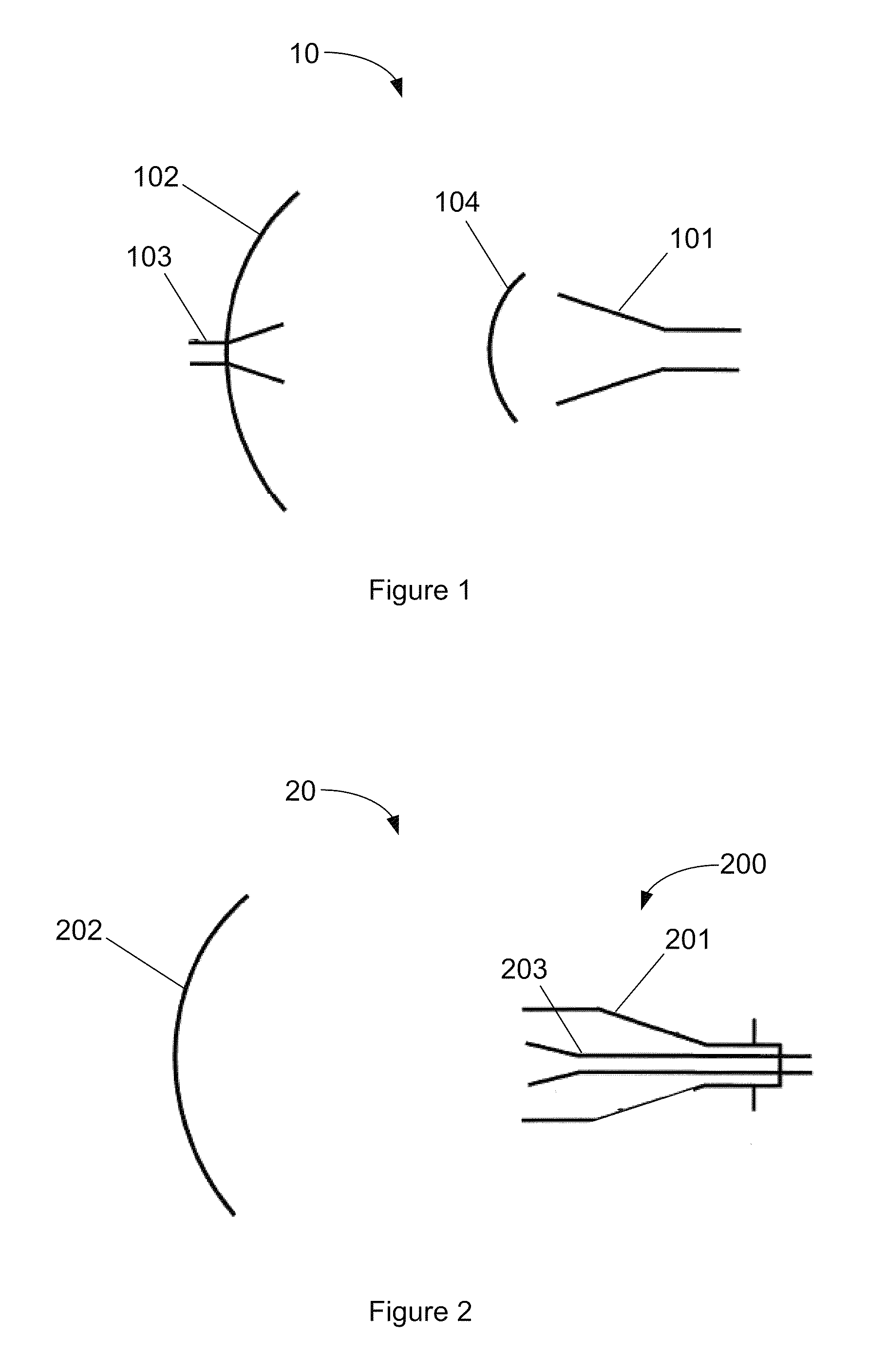

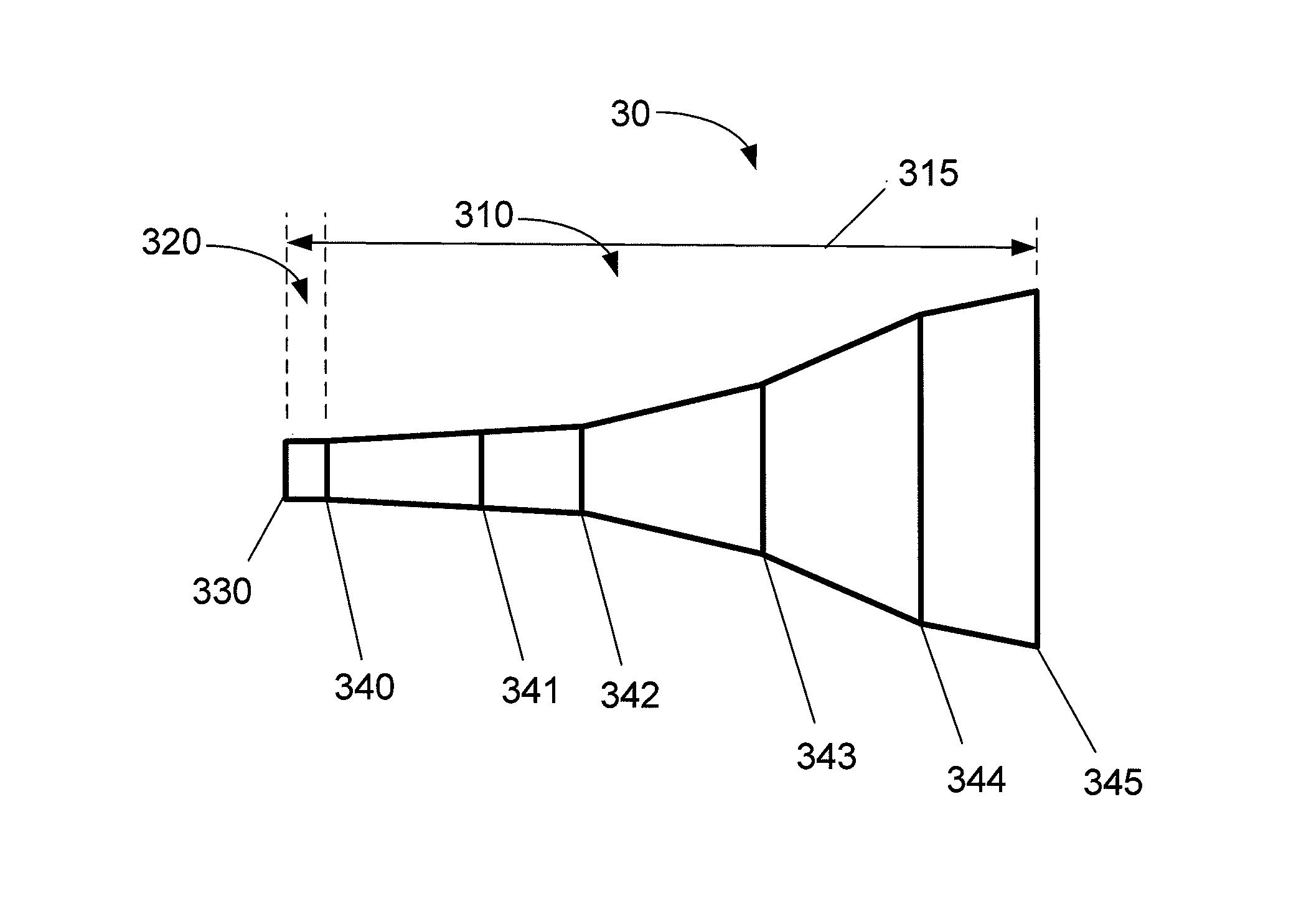

Dual-band feed horn with common beam widths

ActiveUS8957821B1Reduces pointing requirementLow efficiencySimultaneous aerial operationsDual frequencyLow frequency band

Owner:LOCKHEED MARTIN CORP

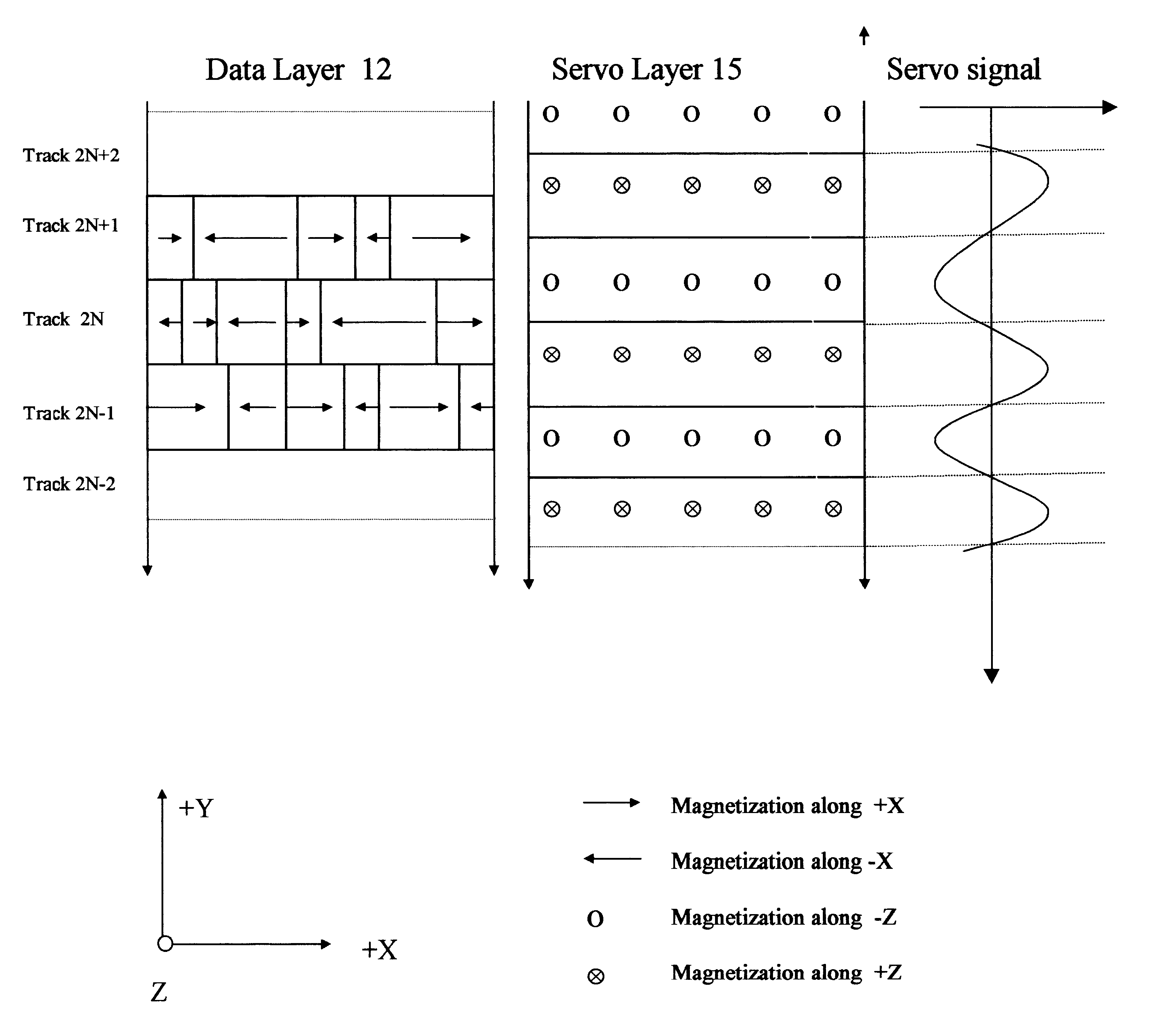

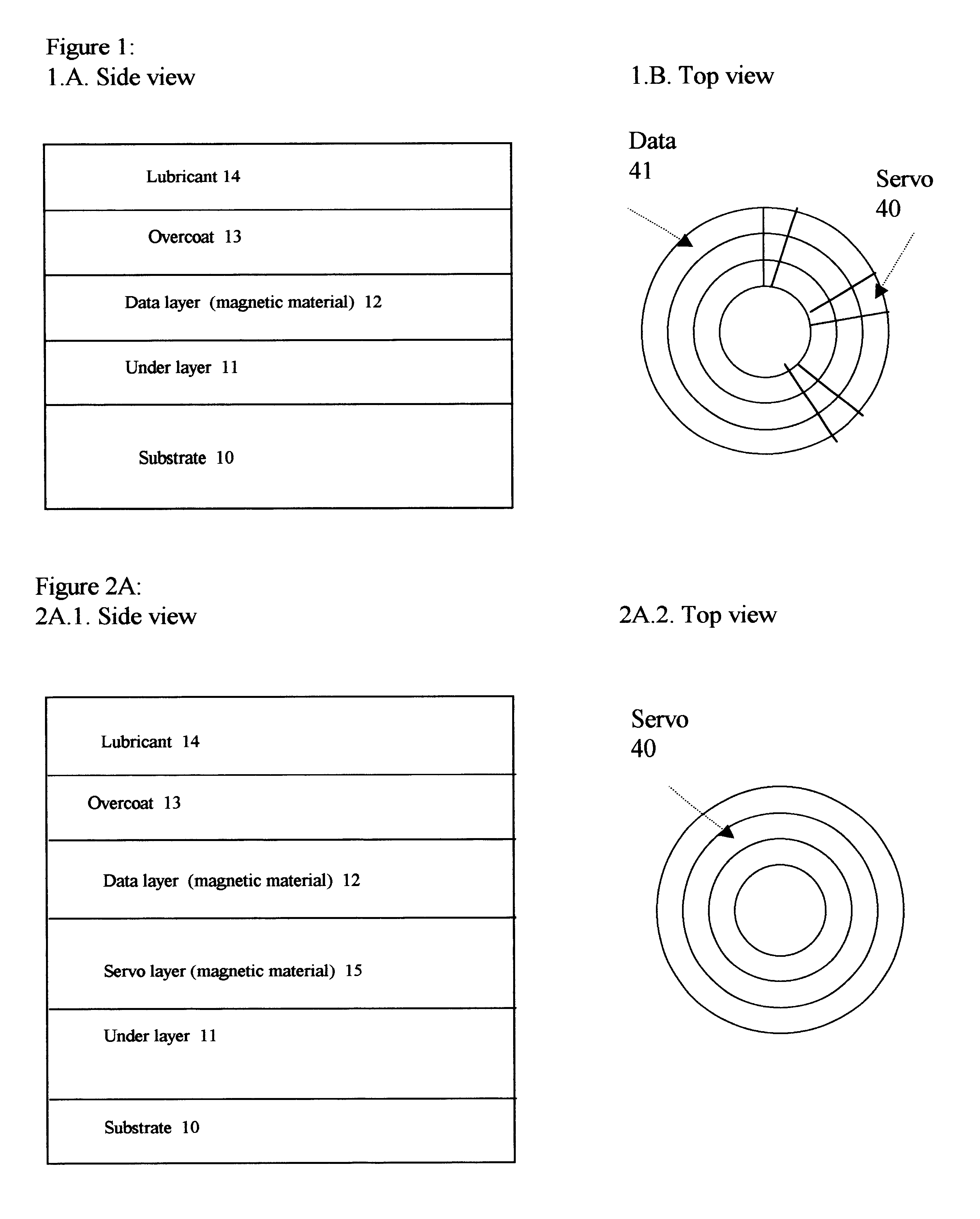

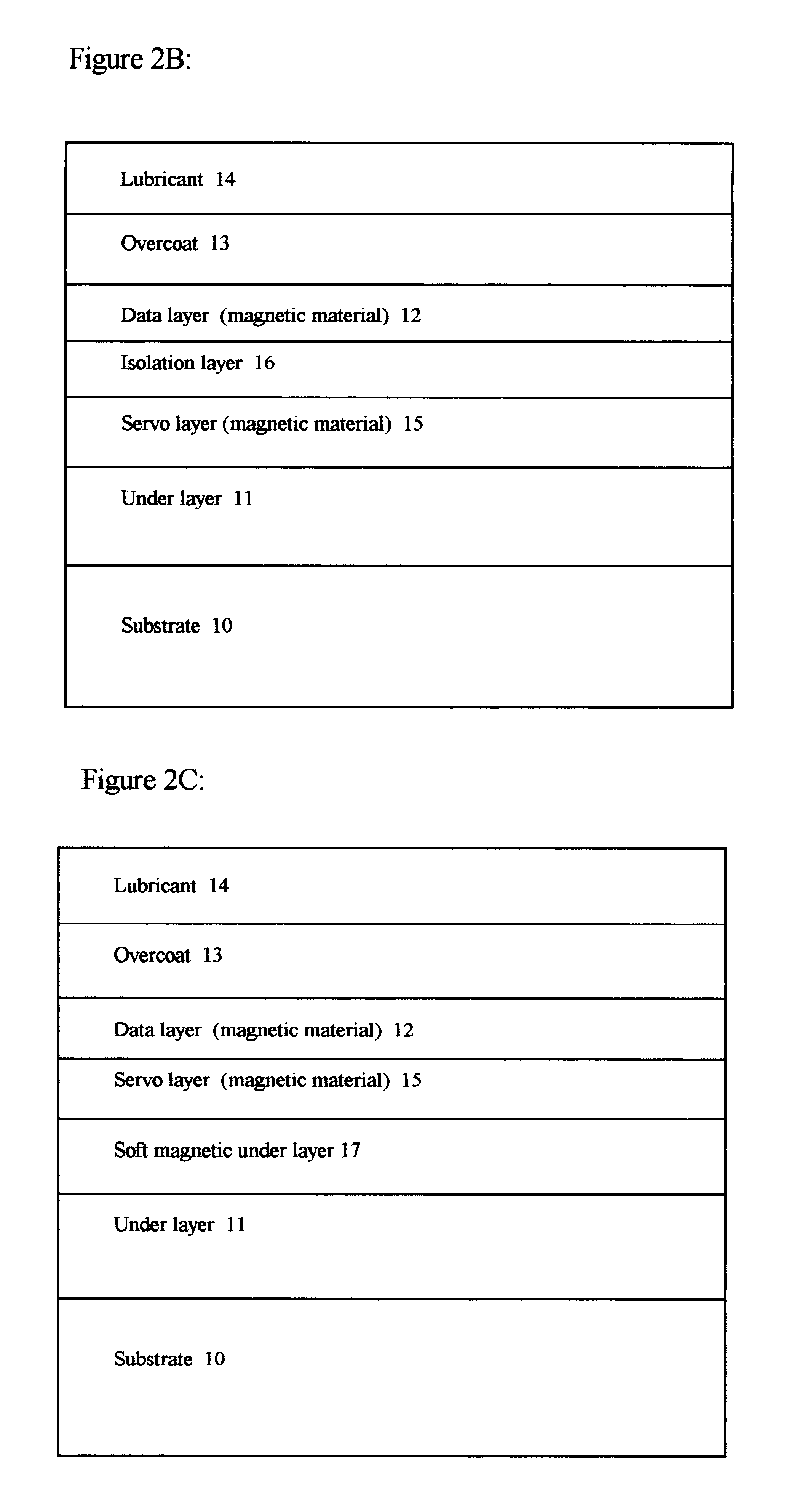

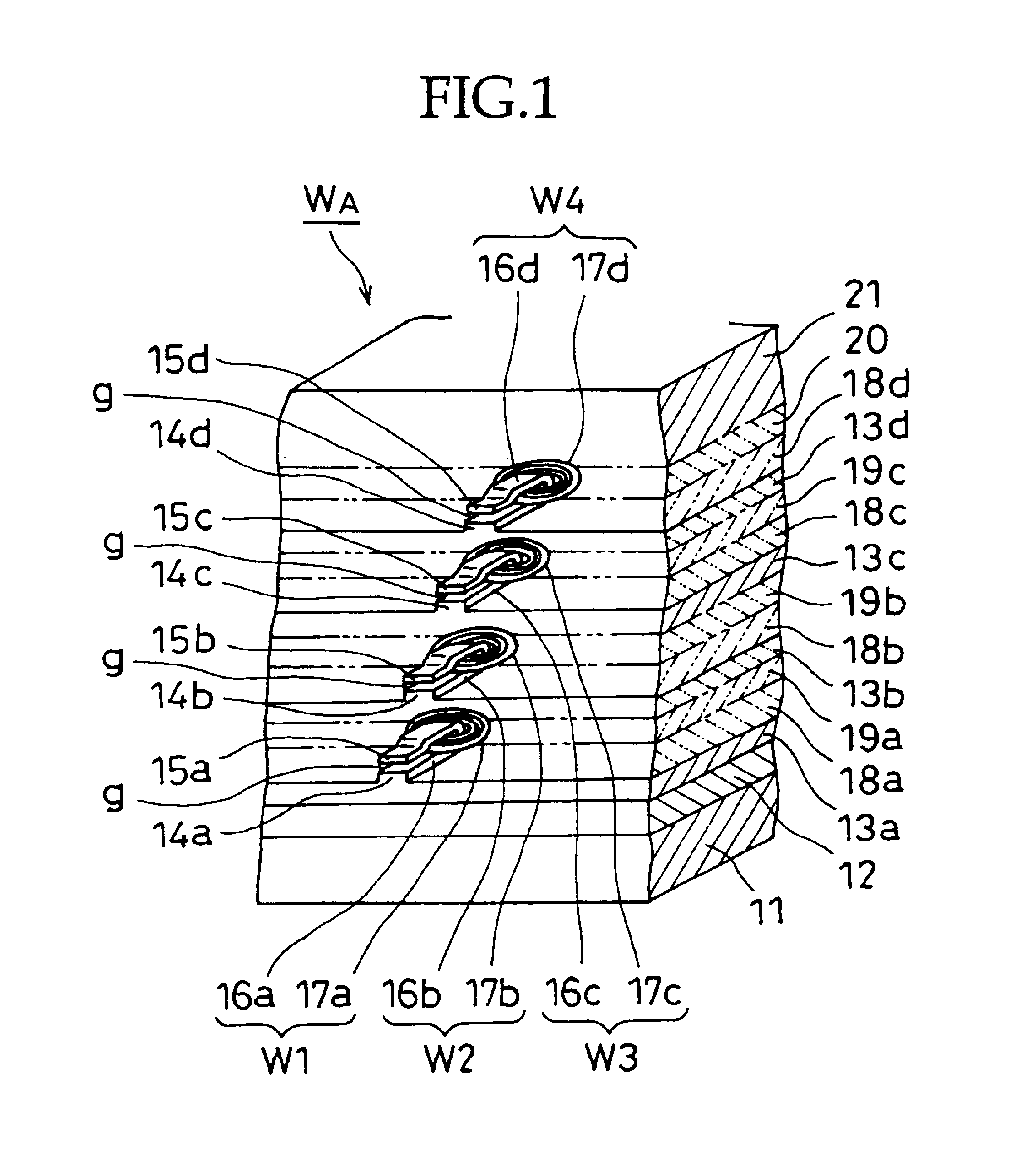

Magnetic recording drive with continuous magnetic servo system

InactiveUS6873482B1High track densityInterferenceRecord information storageAlignment for track following on disksTrack densityEngineering

A magnetic recording system containing magnetic recording media with separate data and servo magnetic layers is disclosed. A servo magnetic layer resides usually below the data layer and has higher coercivity than that of the data layer. Interference between the data and servo signals is minimized by recording the servo patterns perpendicular or transverse direction with respect to the orientation of data bits. In addition, servo patterns are selected so that no interference with the data is generated by the servo pattern when the reader is in the middle of data tracks. Tracking error signals are approximately linear with track misregistration around the middle of data tracks. Finally, interference between the data and servo signals is further reduced by electronic processing. Continuous servo signals permit increased track densities with a single actuator and very high track densities with dual microactuator-actuator system.

Owner:HSIEH YUNG CHIEH +1

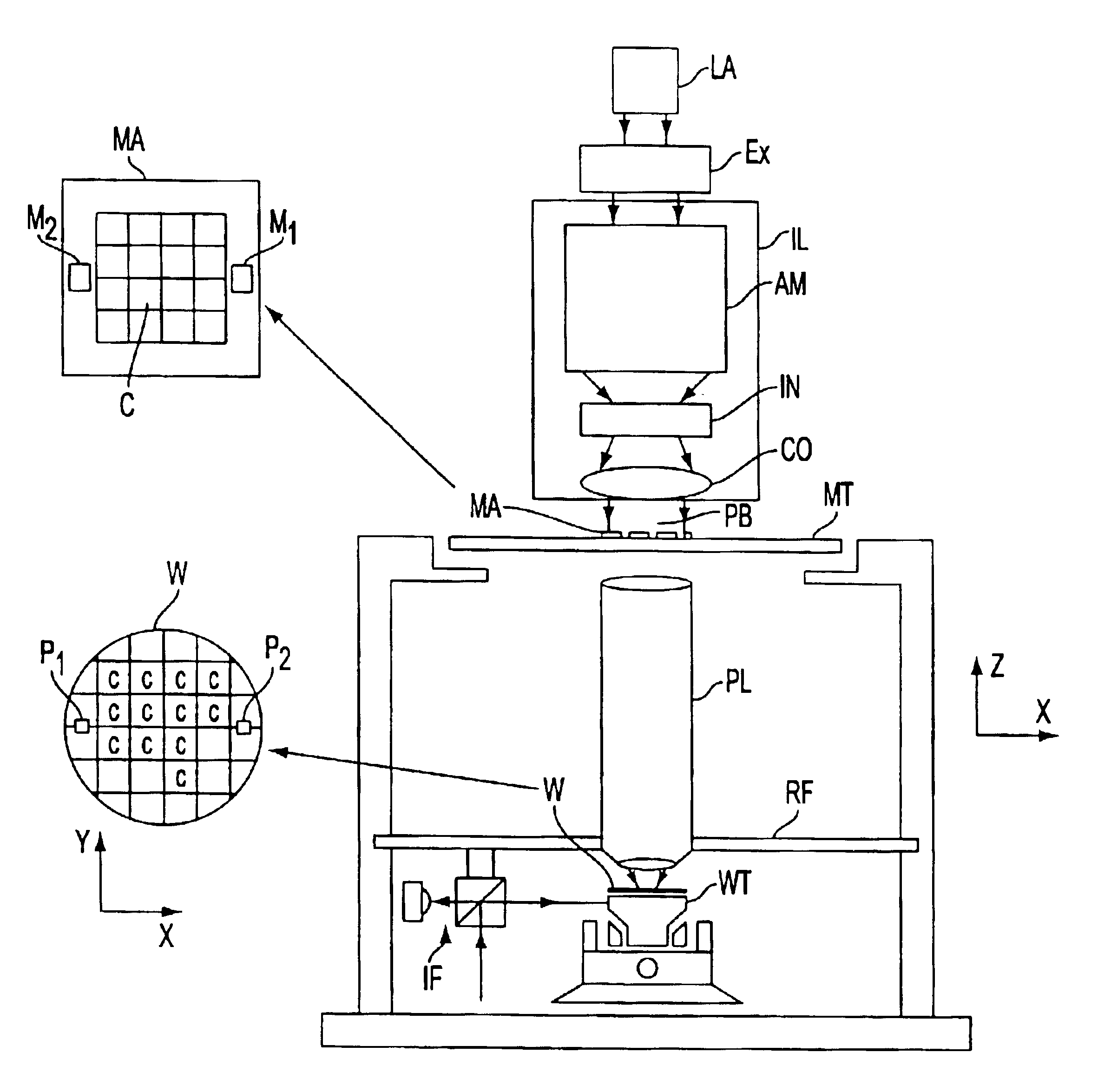

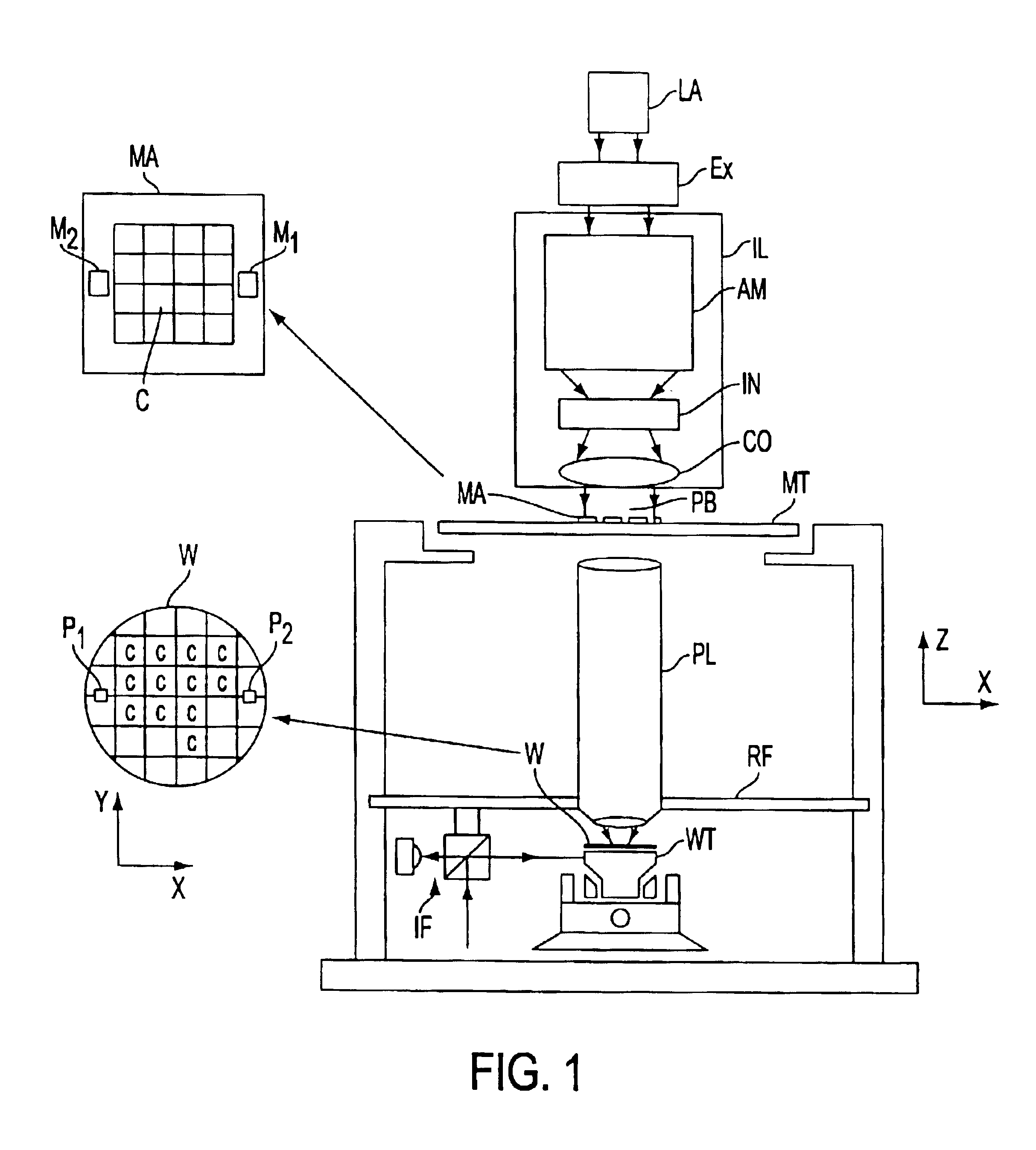

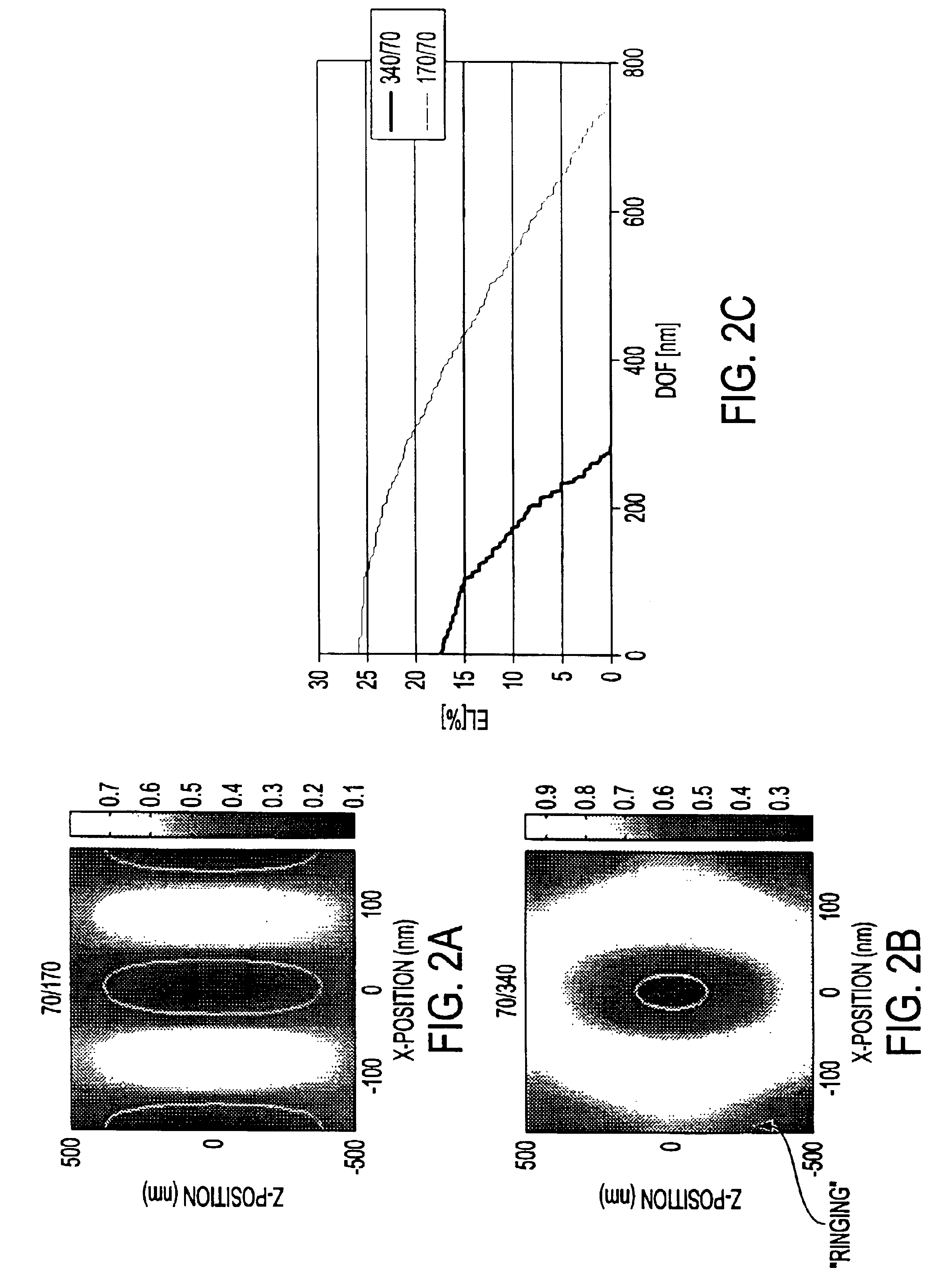

Method of removing assist features utilized to improve process latitude

InactiveUS6875545B2Without degrade overall latitudeIncrease depth of focusSemiconductor/solid-state device manufacturingRecord information storageImage resolutionEngineering

Owner:ASML NETHERLANDS BV

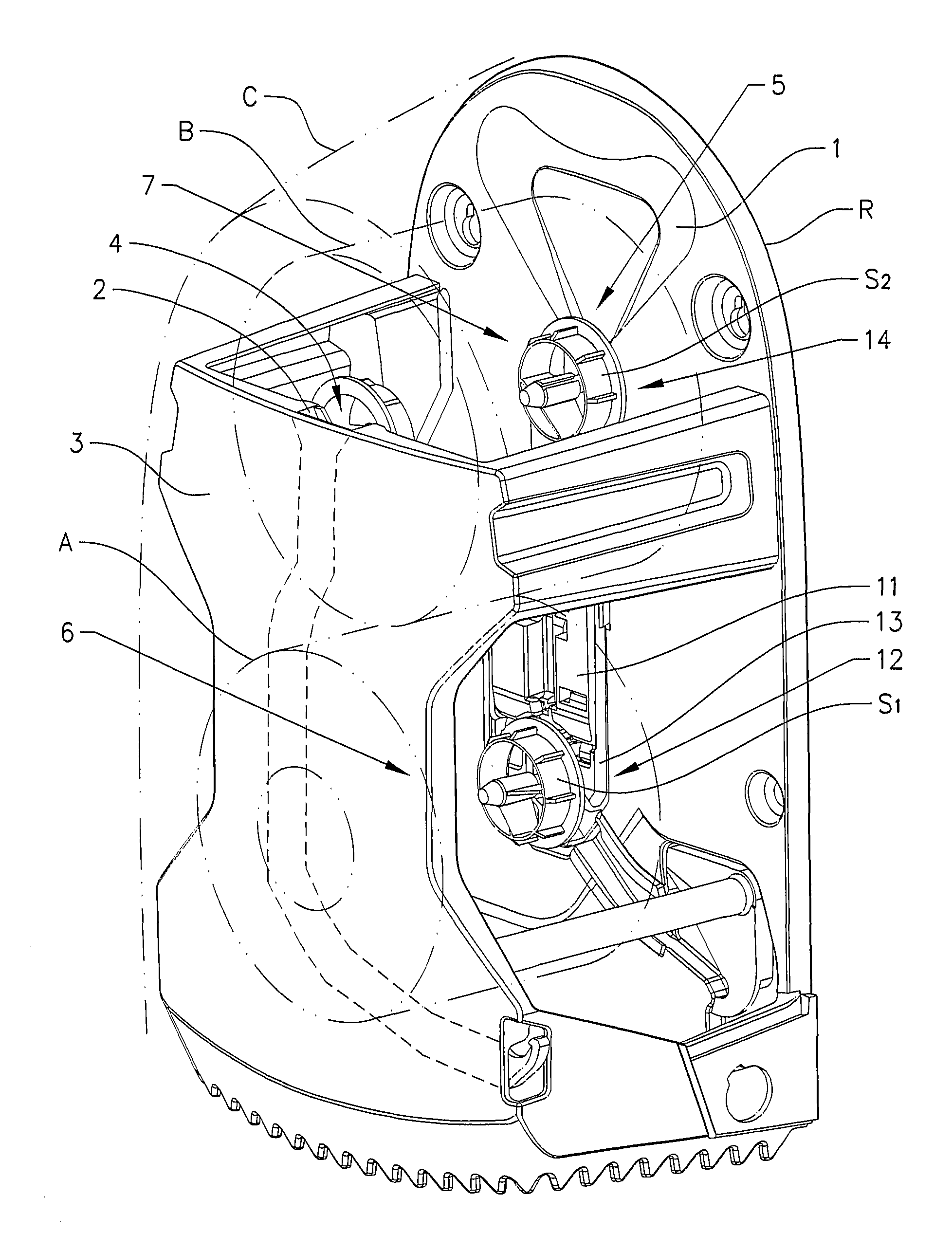

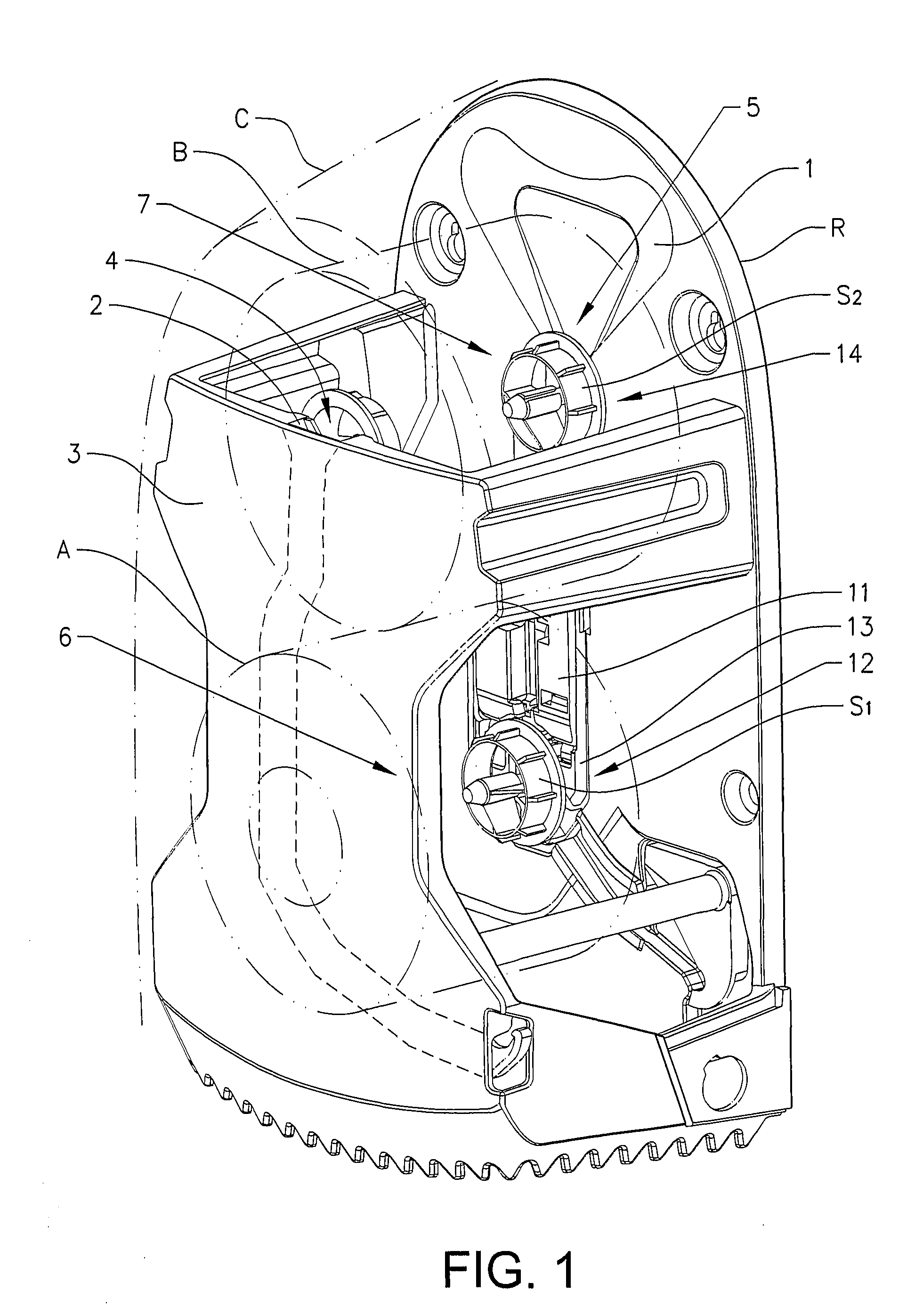

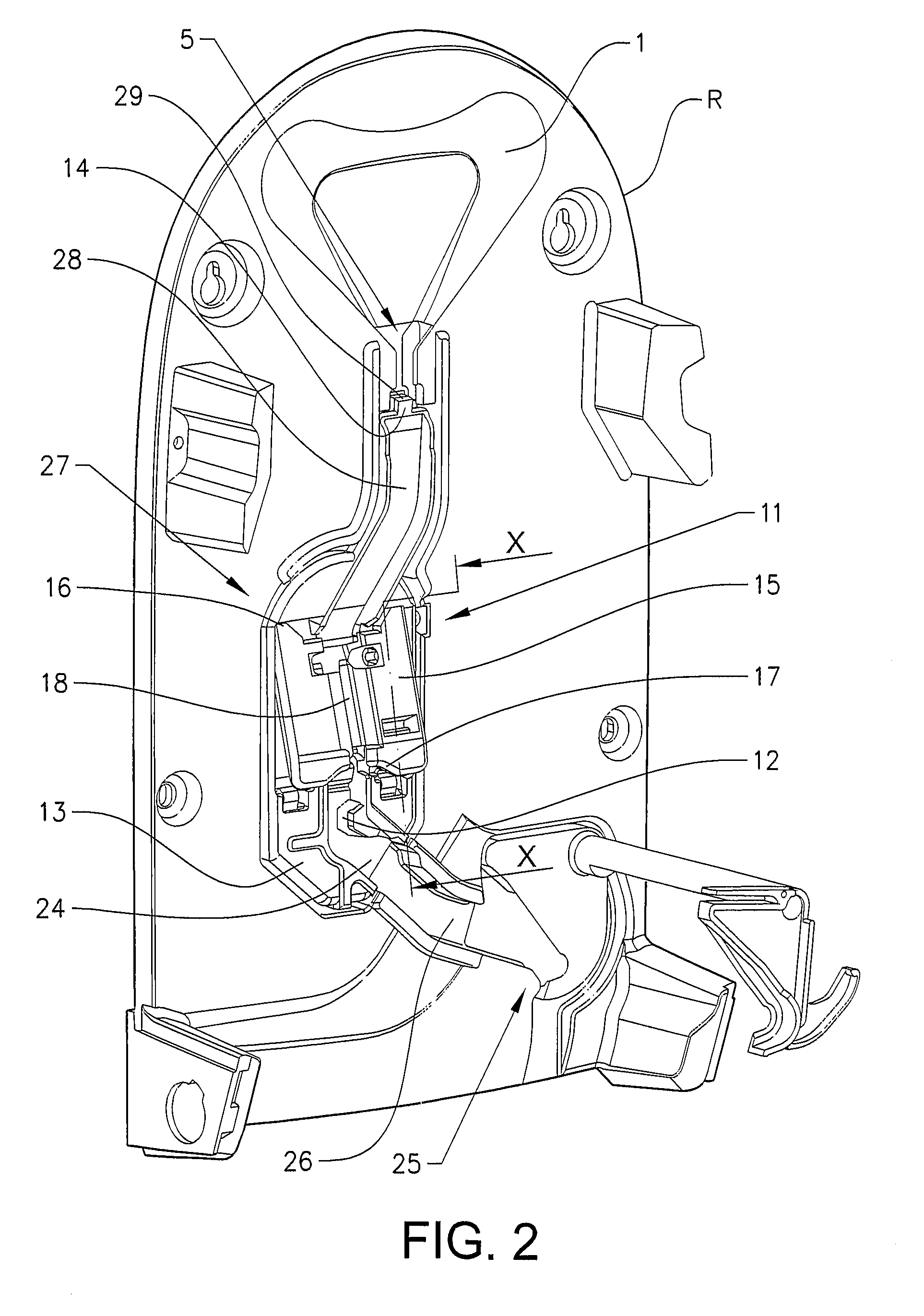

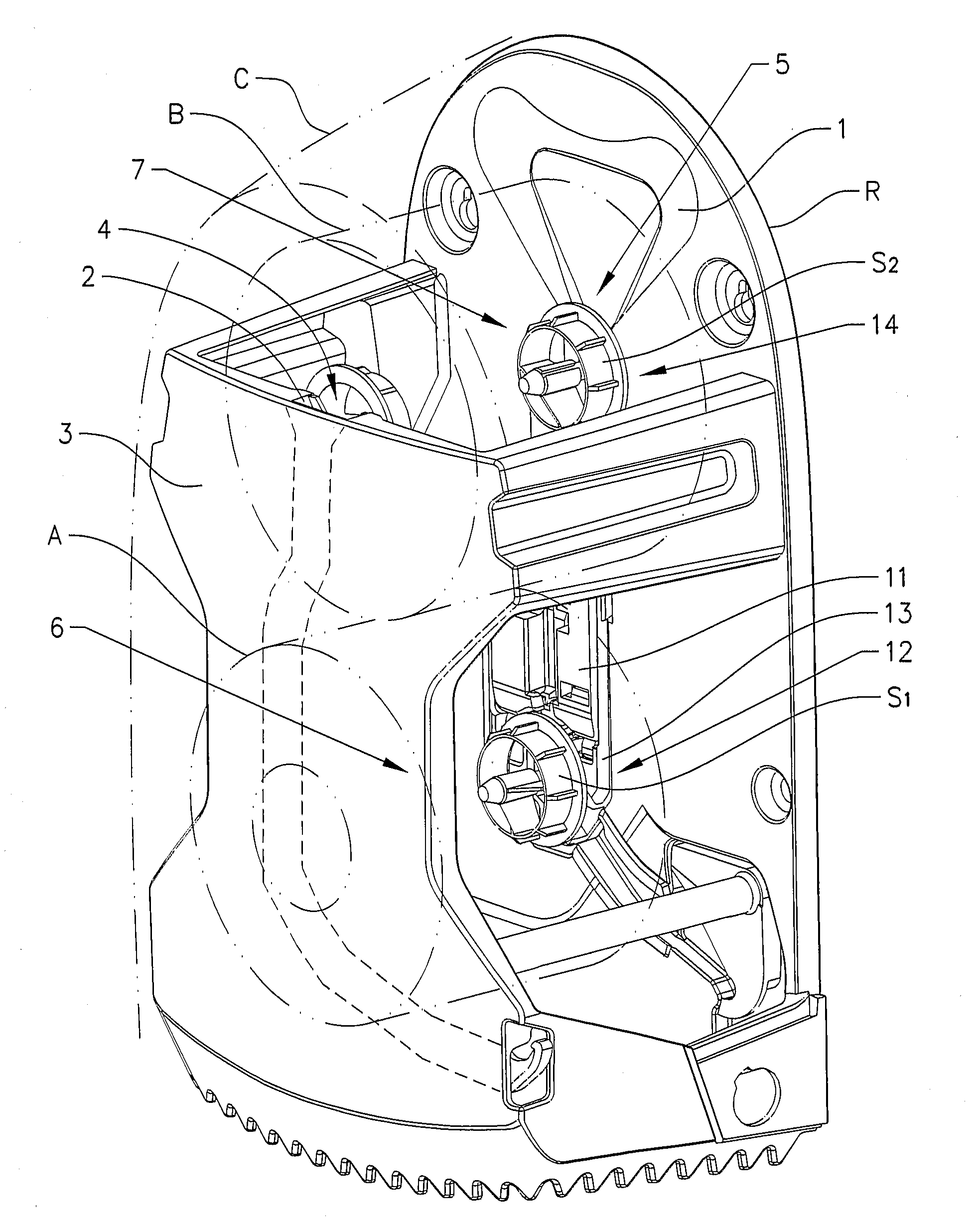

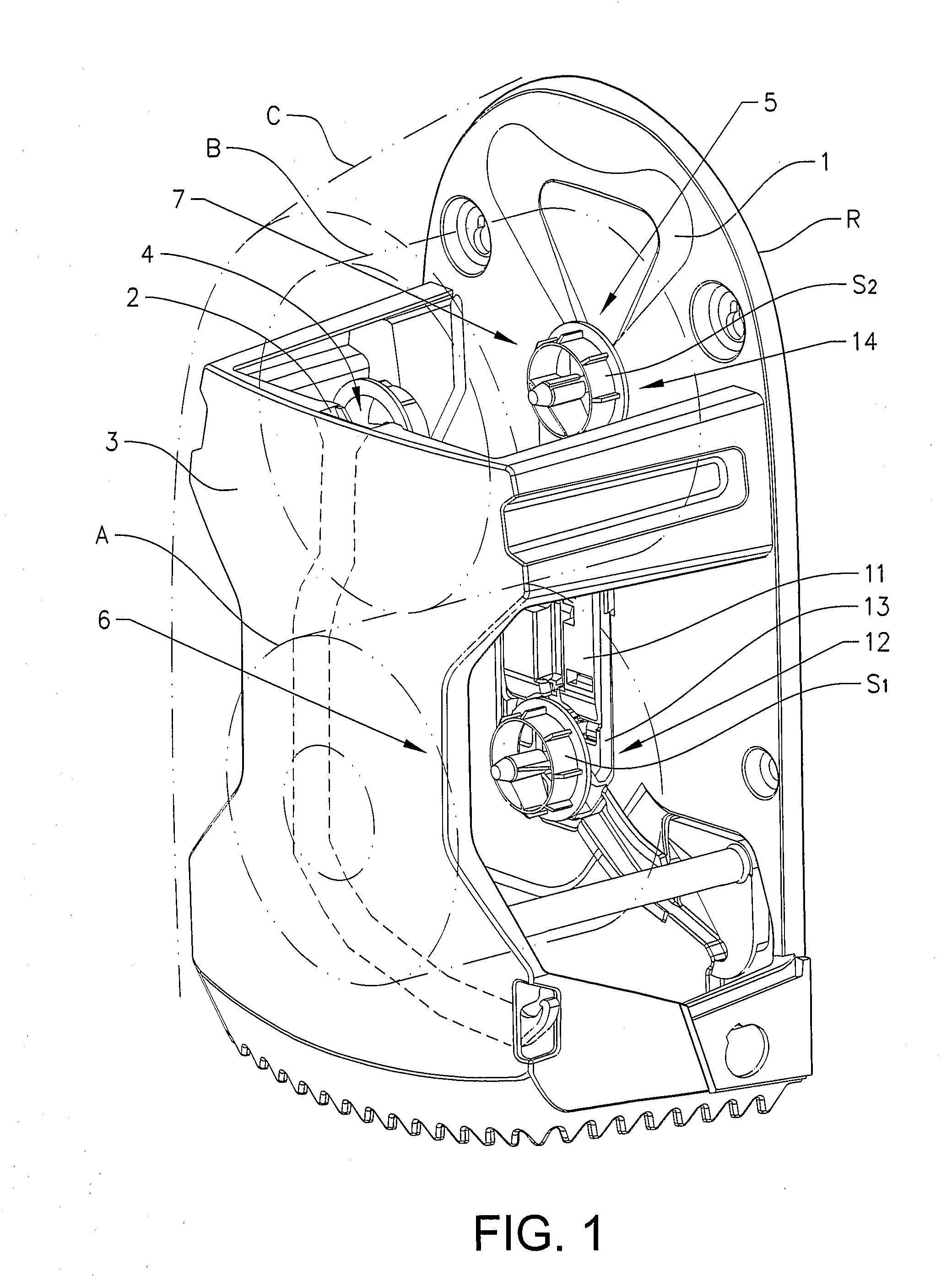

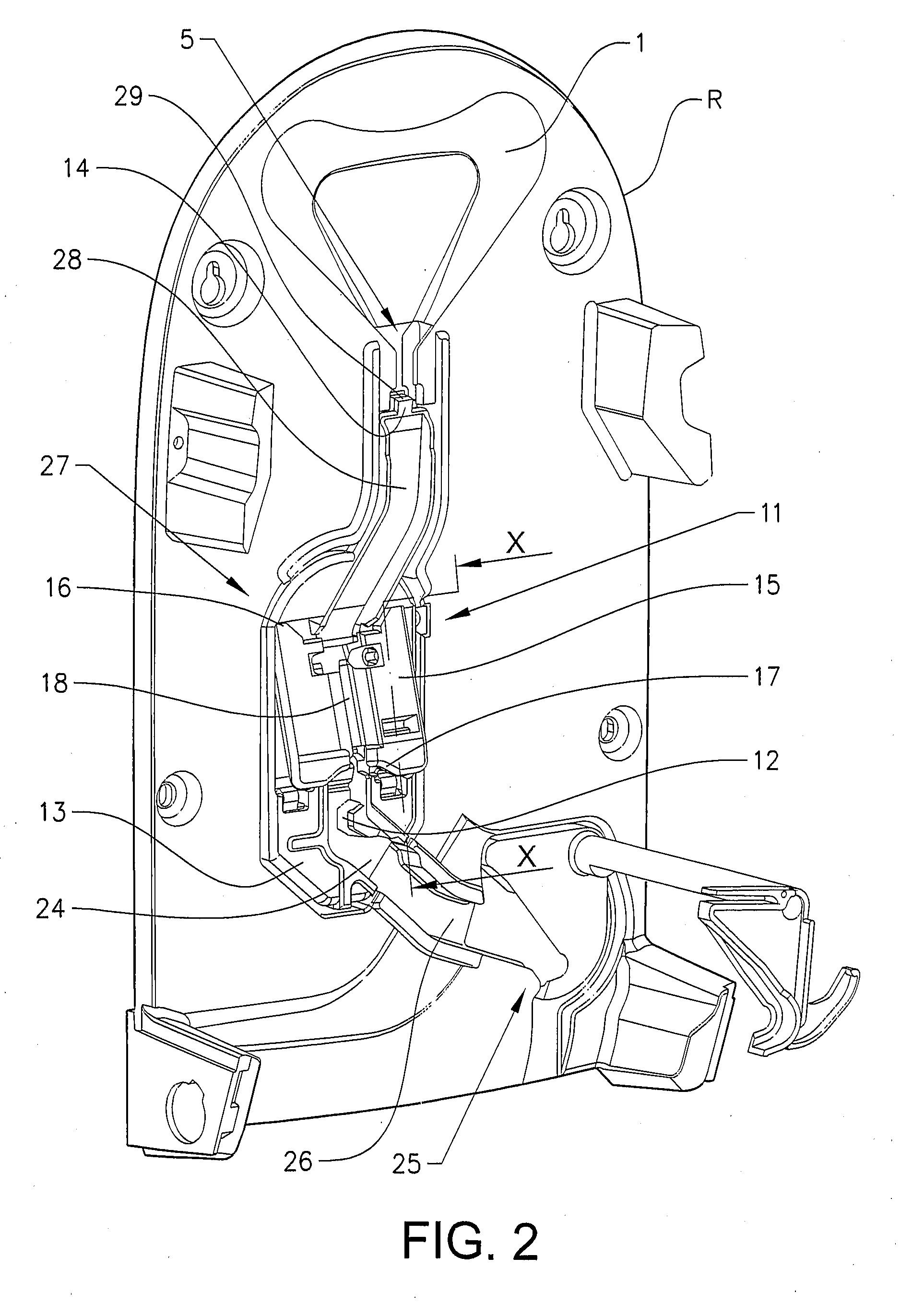

Dispenser for rolls

InactiveUS7832678B2Large caliberSame widthFilament handlingDomestic applicationsEngineeringMechanical engineering

Owner:ESSITY HYGIENE & HEALTH AB

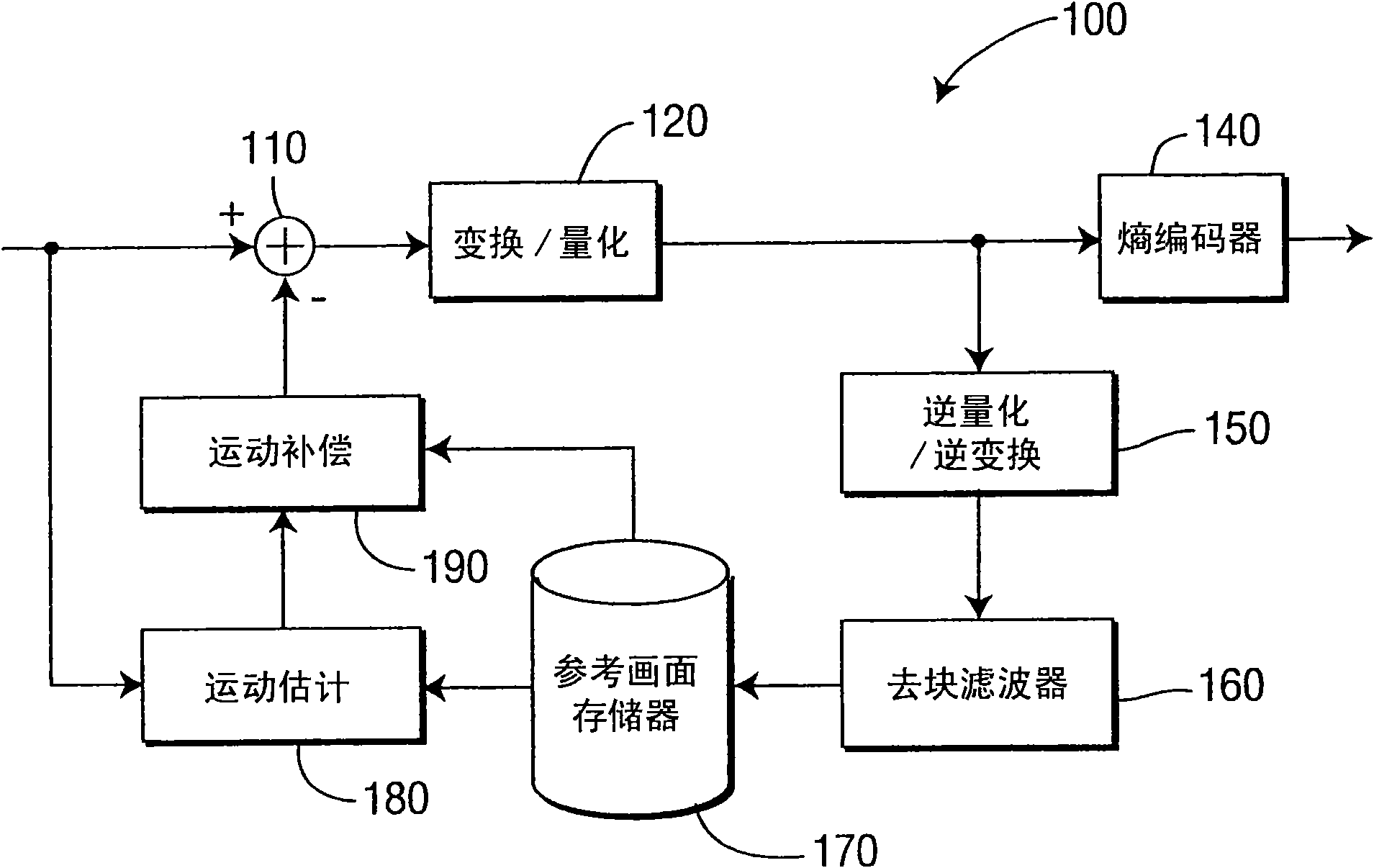

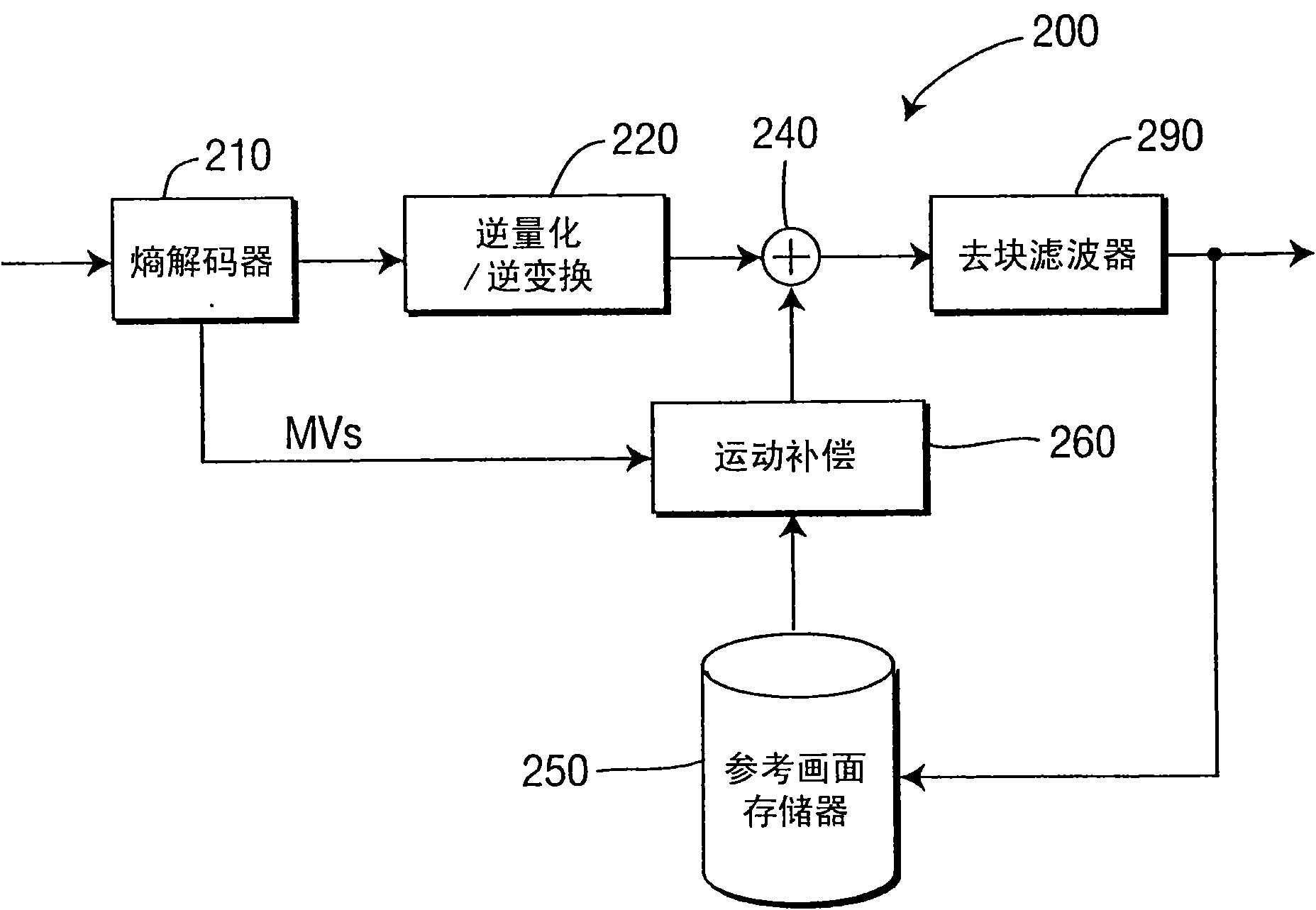

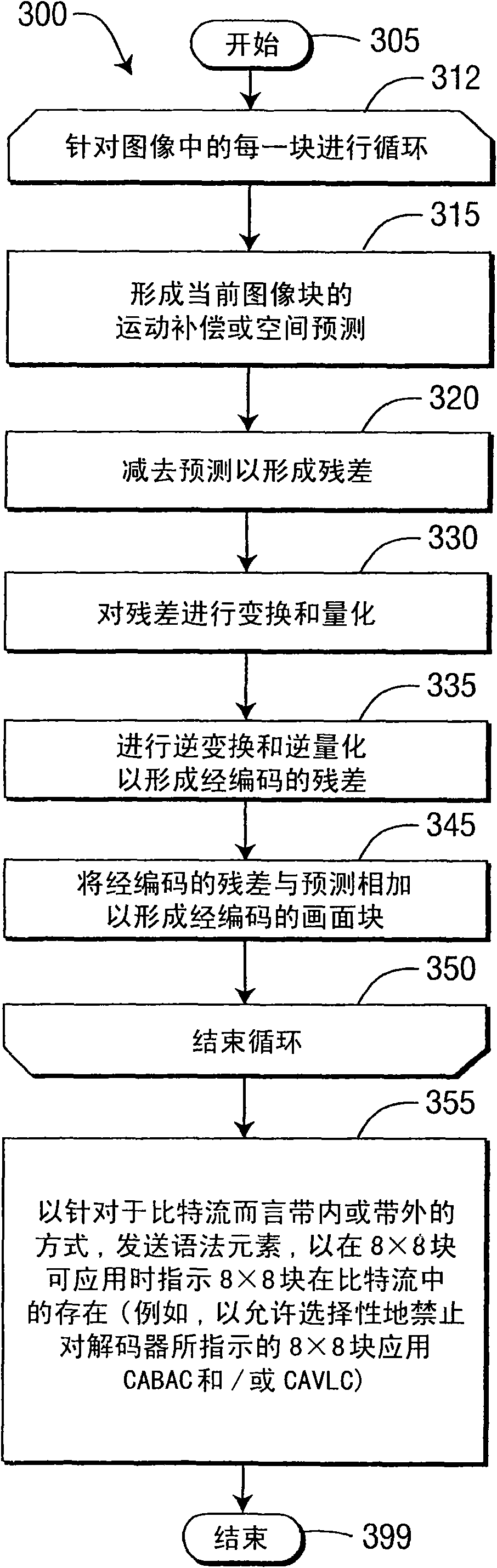

Methods and apparatus for using syntax for the coded_block_flag syntax element and the coded_block_pattern syntax element for the cavlc 4:4:4 intra, high 4:4:4 intra, and high 4:4:4 predictive profile

ActiveCN101578877AThe same heightSame widthPulse modulation television signal transmissionDigital video signal modificationData encodingSyntax

There are provided methods and apparatus for using syntax for the coded_block_flag syntax element for the CAVLC 4:4:4 Intra, High 4:4:4 Intra, and High 4:4:4 Predictive profiles in MPEG-4 AVC high level coding. An apparatus includes an encoder (100) for encoding image data into a resultant bitstream in accordance with an encoding profile that encodes a sample of the image data such that the sample includes two chrominance arrays and a luminance array. Each of the two chrominance arrays has a same height and a same width as the luminance array. The encoder (100) indicates a presence of at least one 8x8 block in the resultant bitstream using a syntax element.

Owner:INTERDIGITAL VC HLDG INC

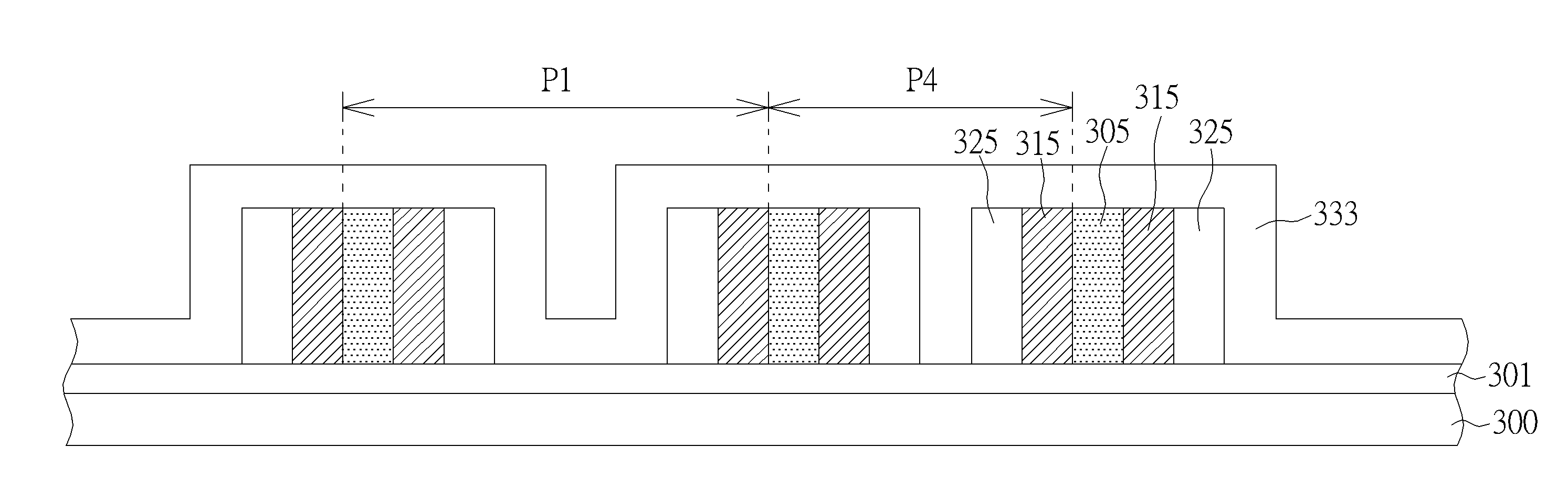

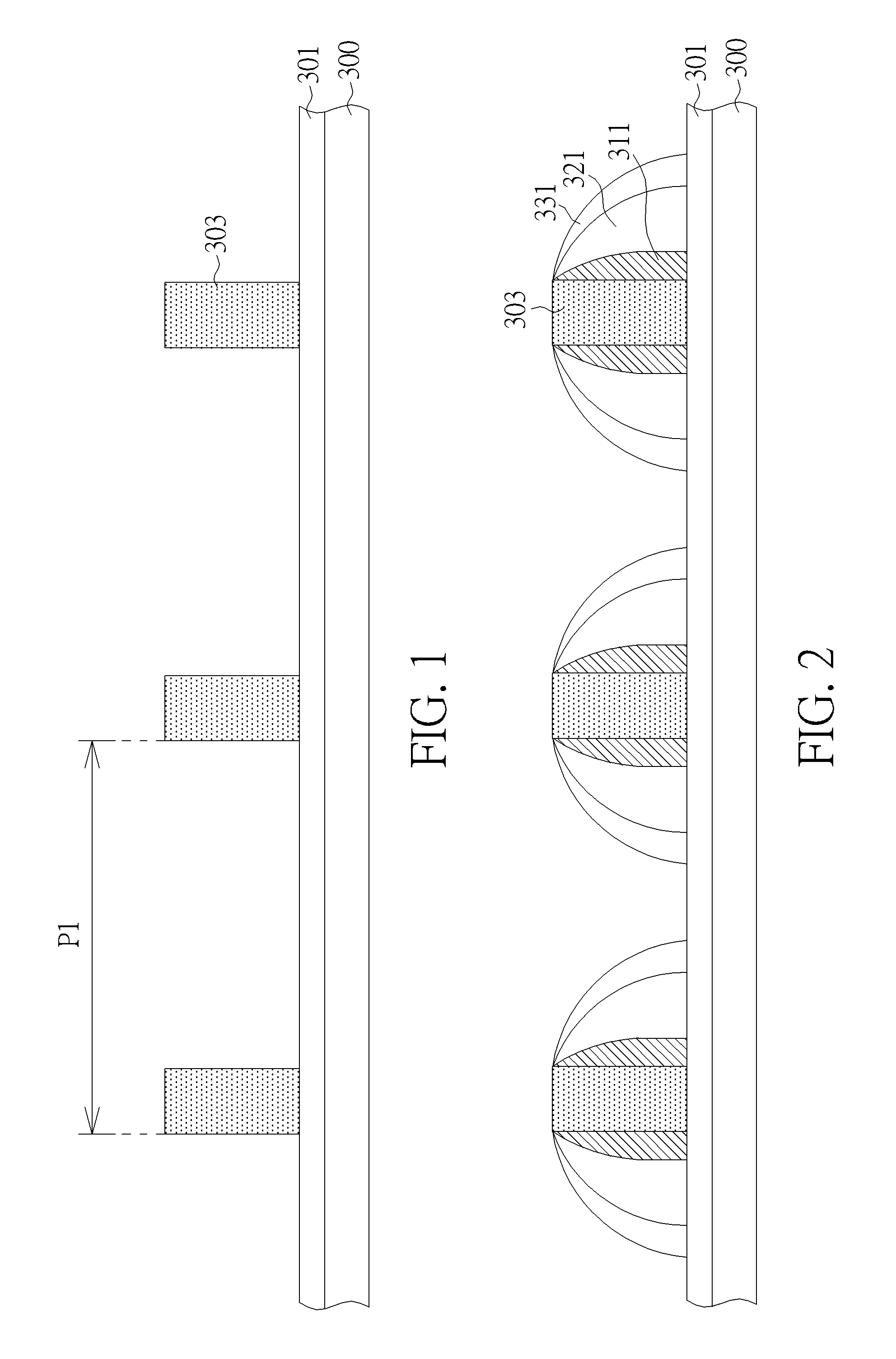

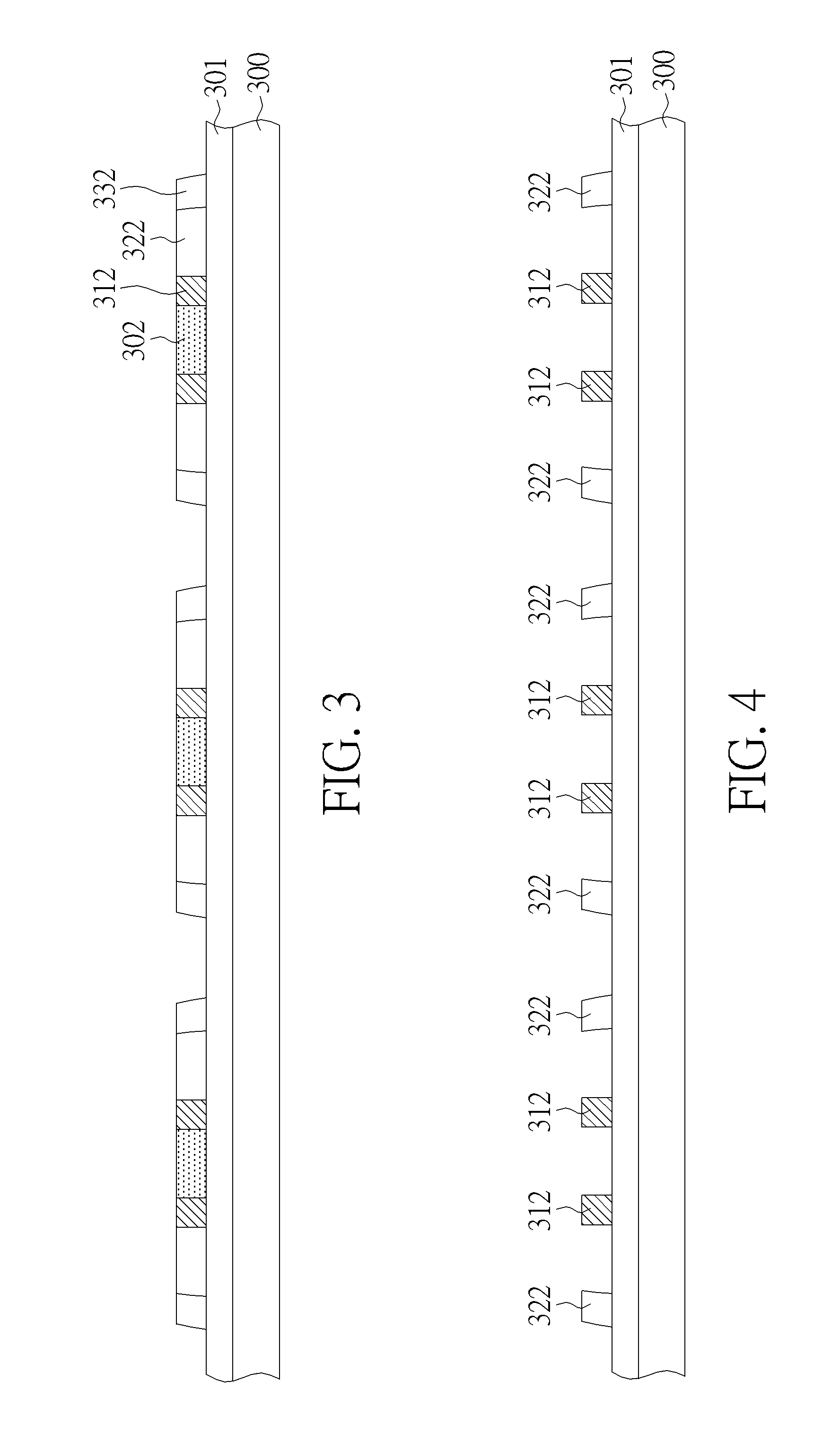

Method of forming semiconductor structure

InactiveUS20160336187A1Accurate shapePrecise layoutSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

A method of forming a semiconductor structure includes following steps. First of all, a plurality of mandrels is formed on a target layer. Next, a plurality of first liner is formed adjacent to two sides of the mandrels. Then, a plurality of second liners is formed adjacent to two sides of the first liners. After these, a plurality of third liners is formed adjacent to two sides of the second liners. Finally, the mandrels and the second liners are simultaneously removed.

Owner:UNITED MICROELECTRONICS CORP

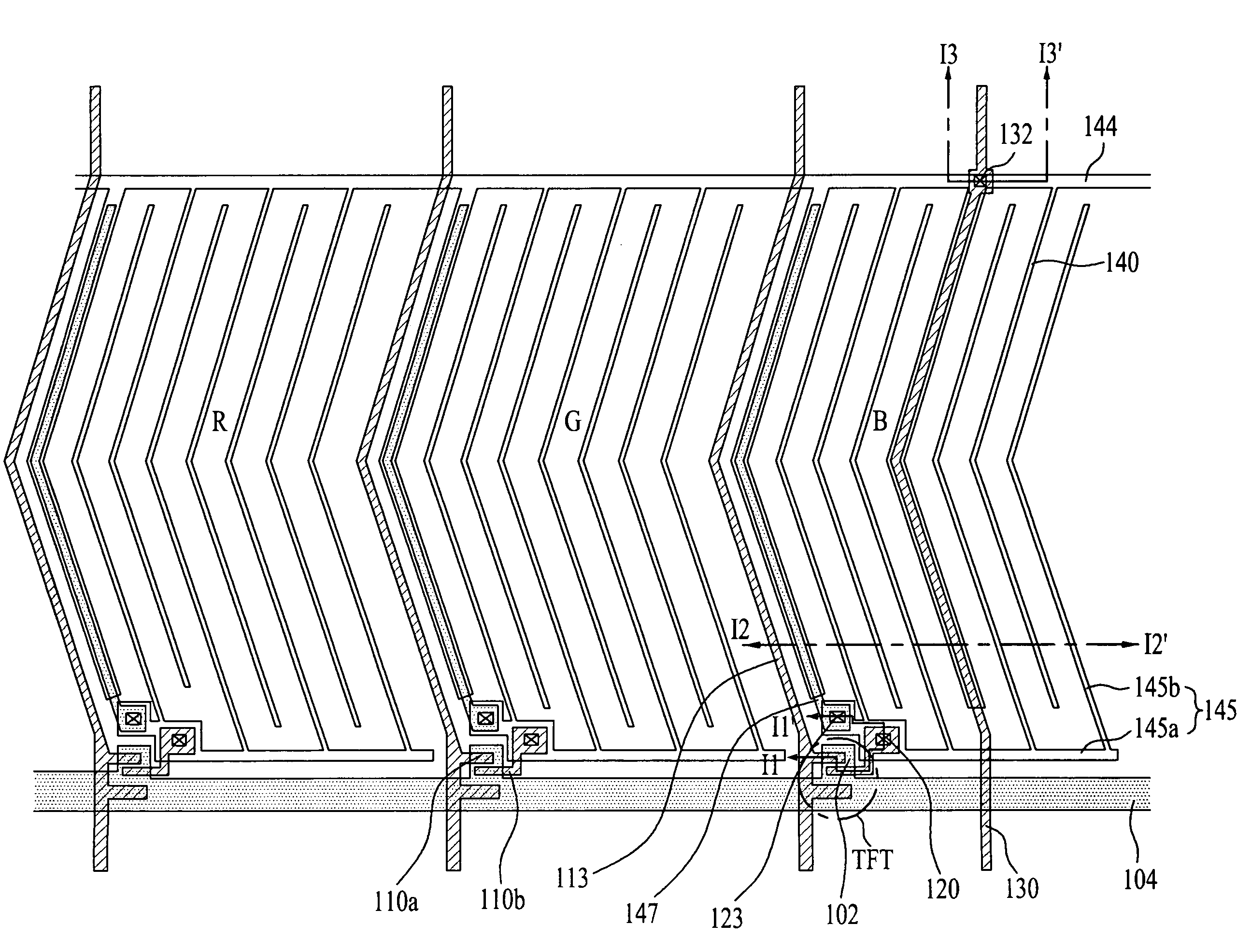

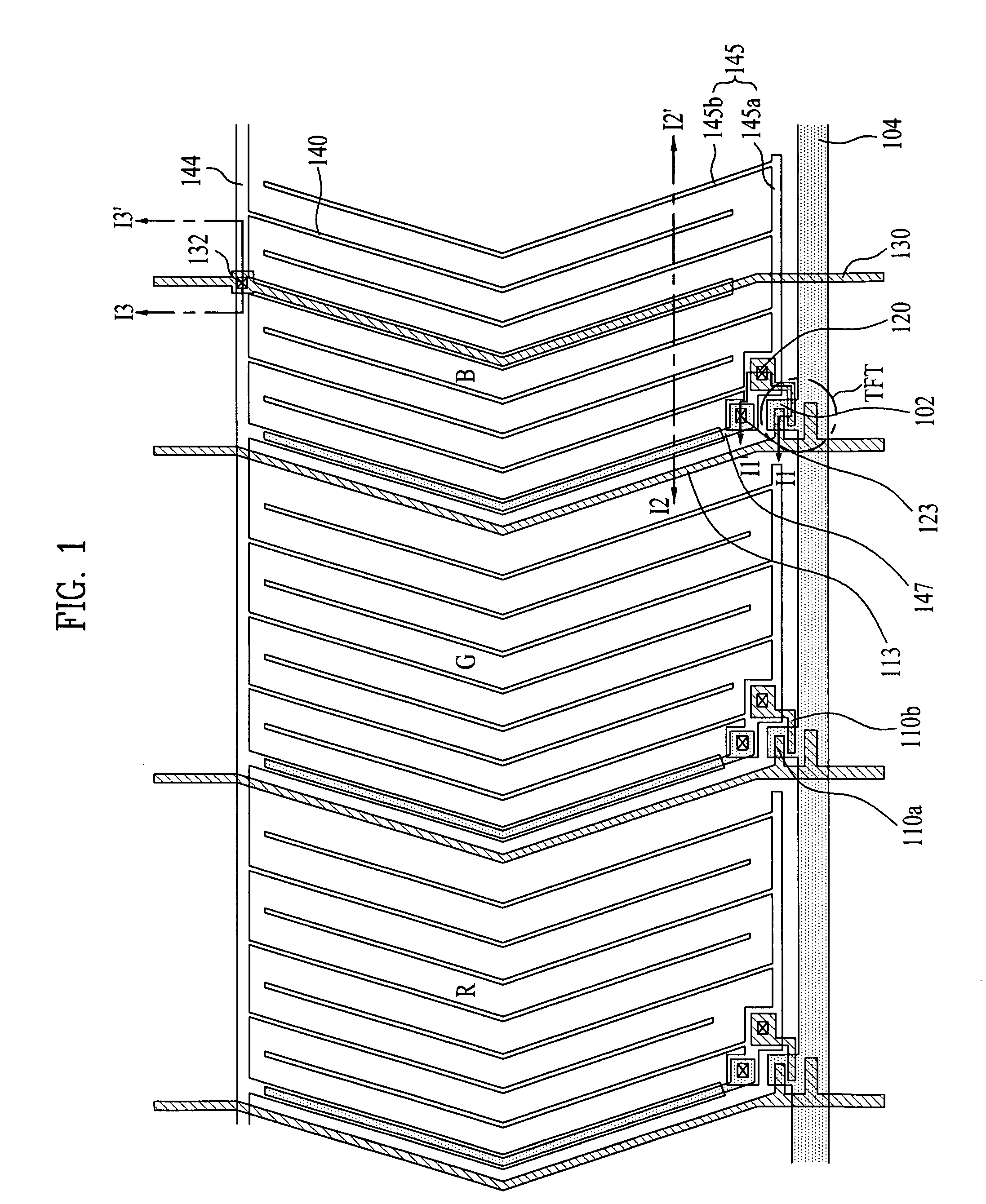

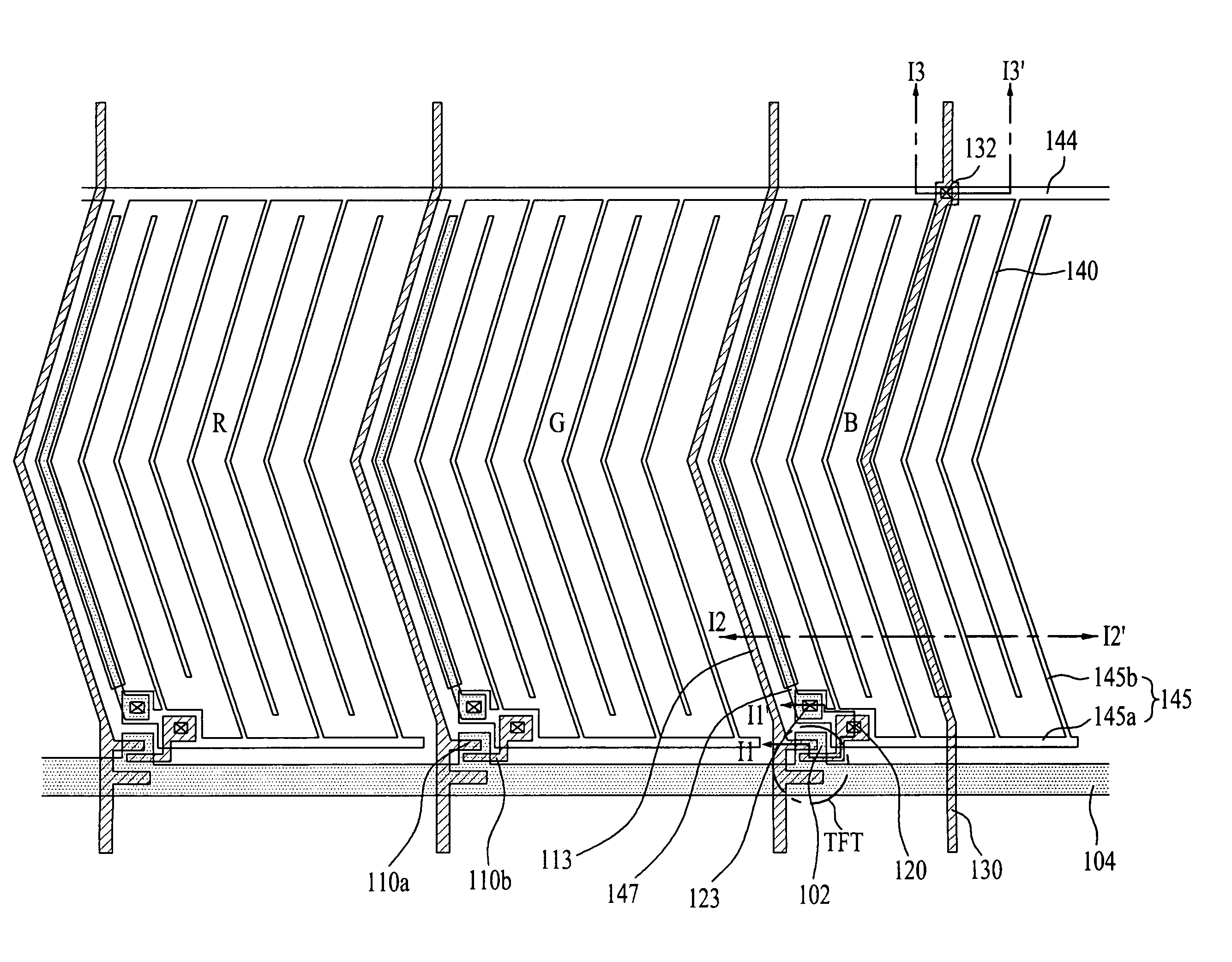

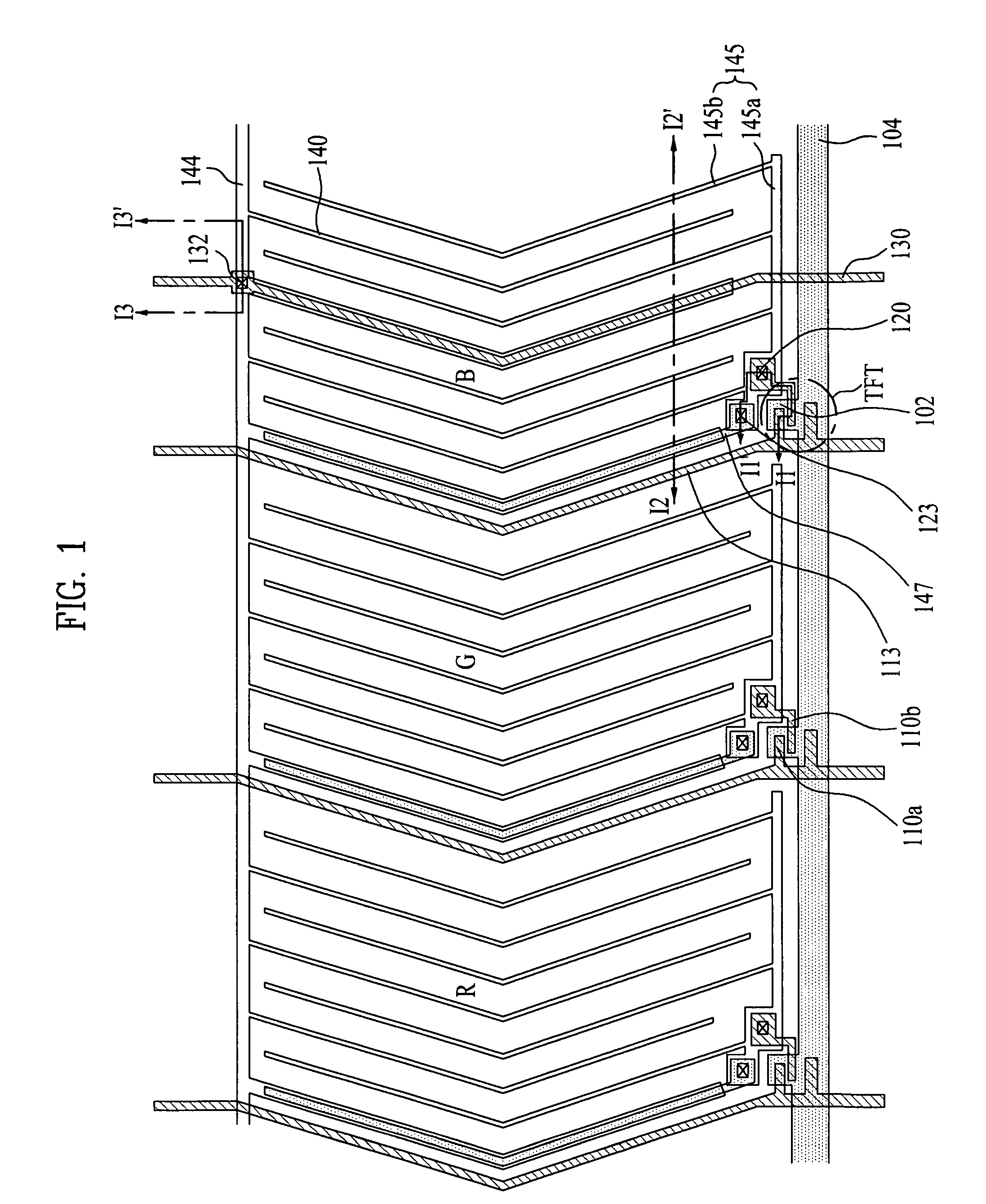

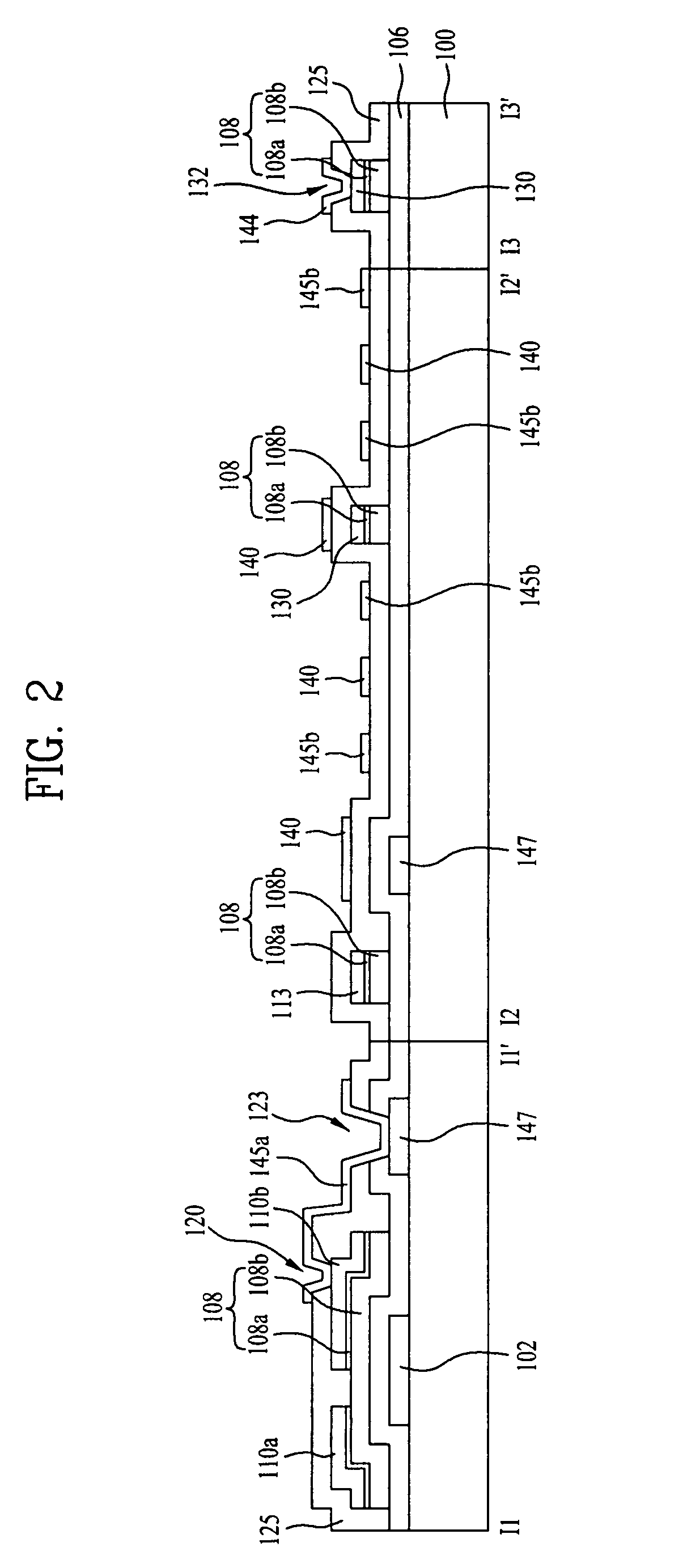

Liquid crystal display device

ActiveUS20090207365A1Increase the aperture ratioImprove picture qualityNon-linear opticsSemiconductor devicesLiquid-crystal displayEngineering

A liquid crystal display device is disclosed. The disclosed liquid crystal display device includes gate lines, data lines formed to intersect with the gate lines, thereby defining sub-pixel regions, vertical common lines formed in parallel to the data lines such that at least one vertical common line is arranged for one pixel region, which is constituted by at least three sub-pixel regions, thin film transistors each connected to a corresponding one of the gate lines and a corresponding one of the data lines, pixel electrodes each connected to a corresponding one of the thin film transistors, and common electrodes each connected to a corresponding one of the vertical common lines.

Owner:LG DISPLAY CO LTD

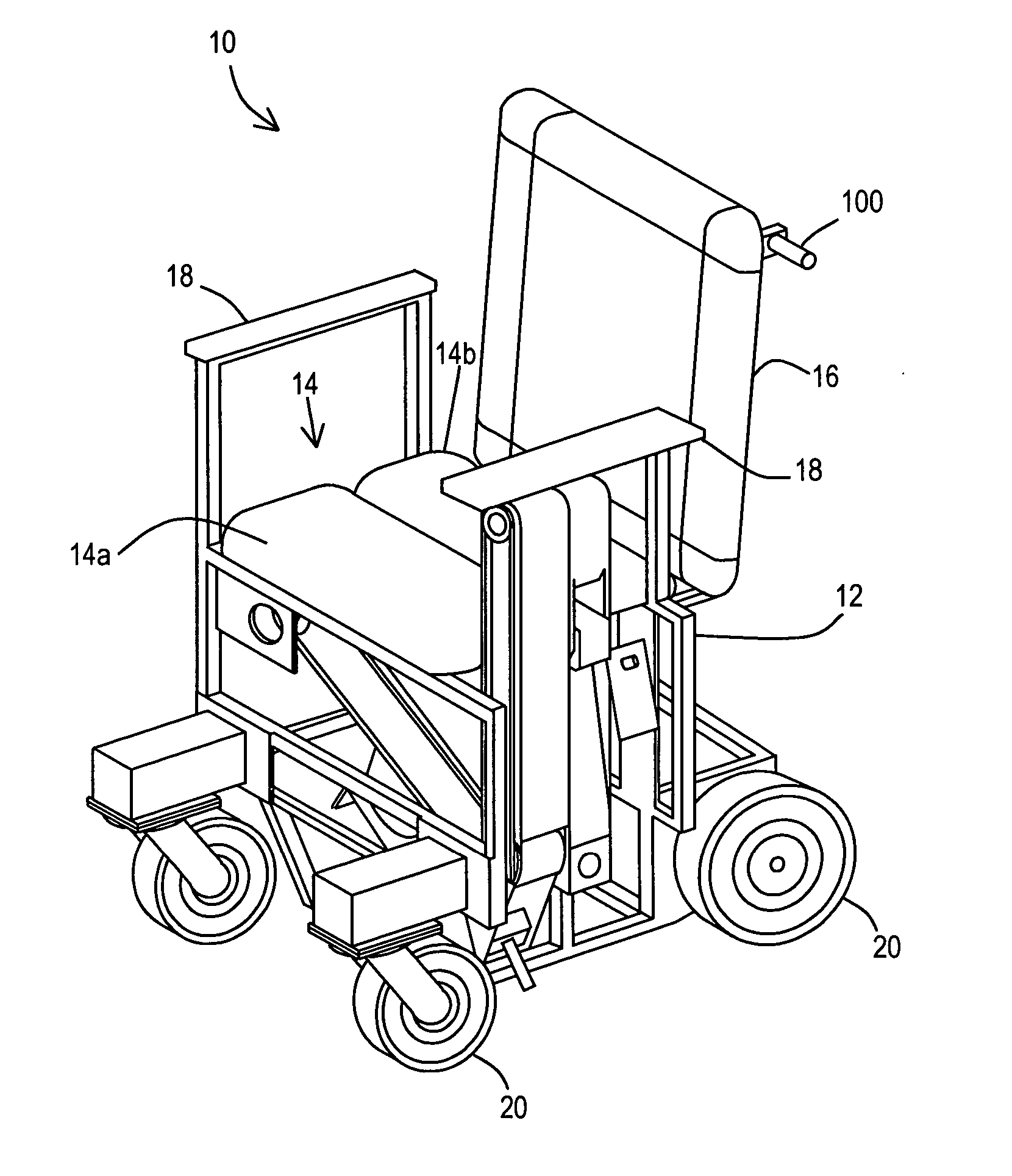

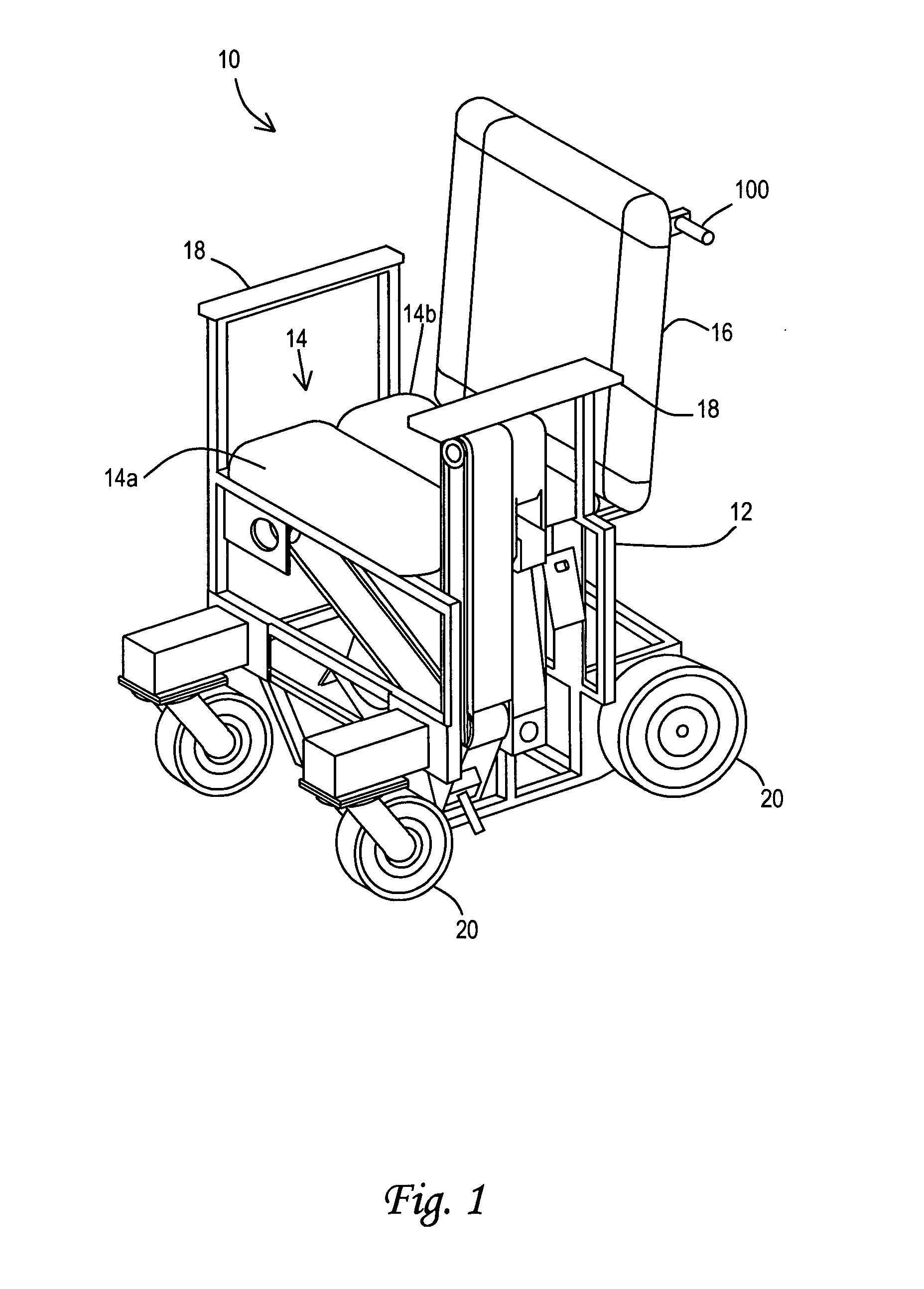

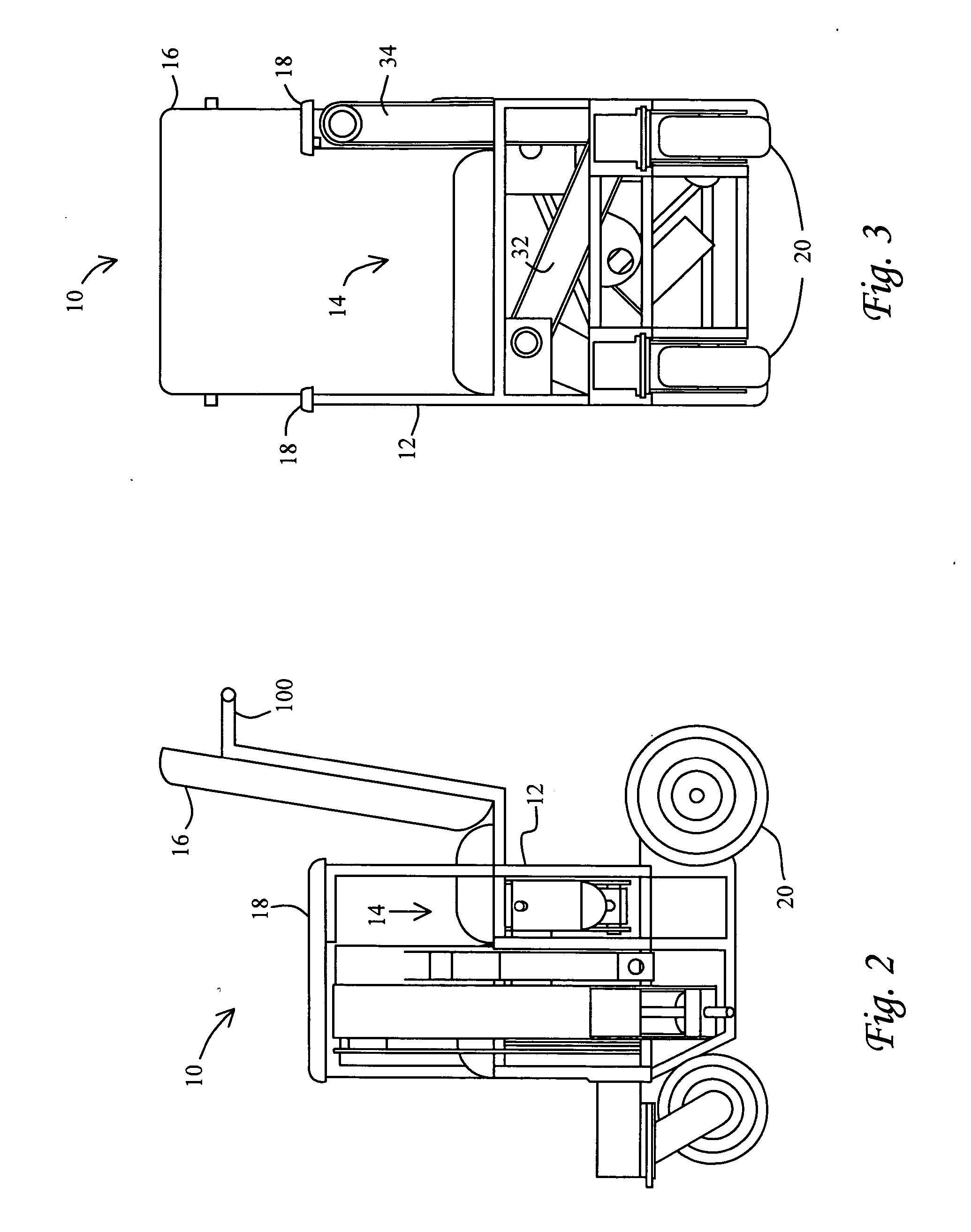

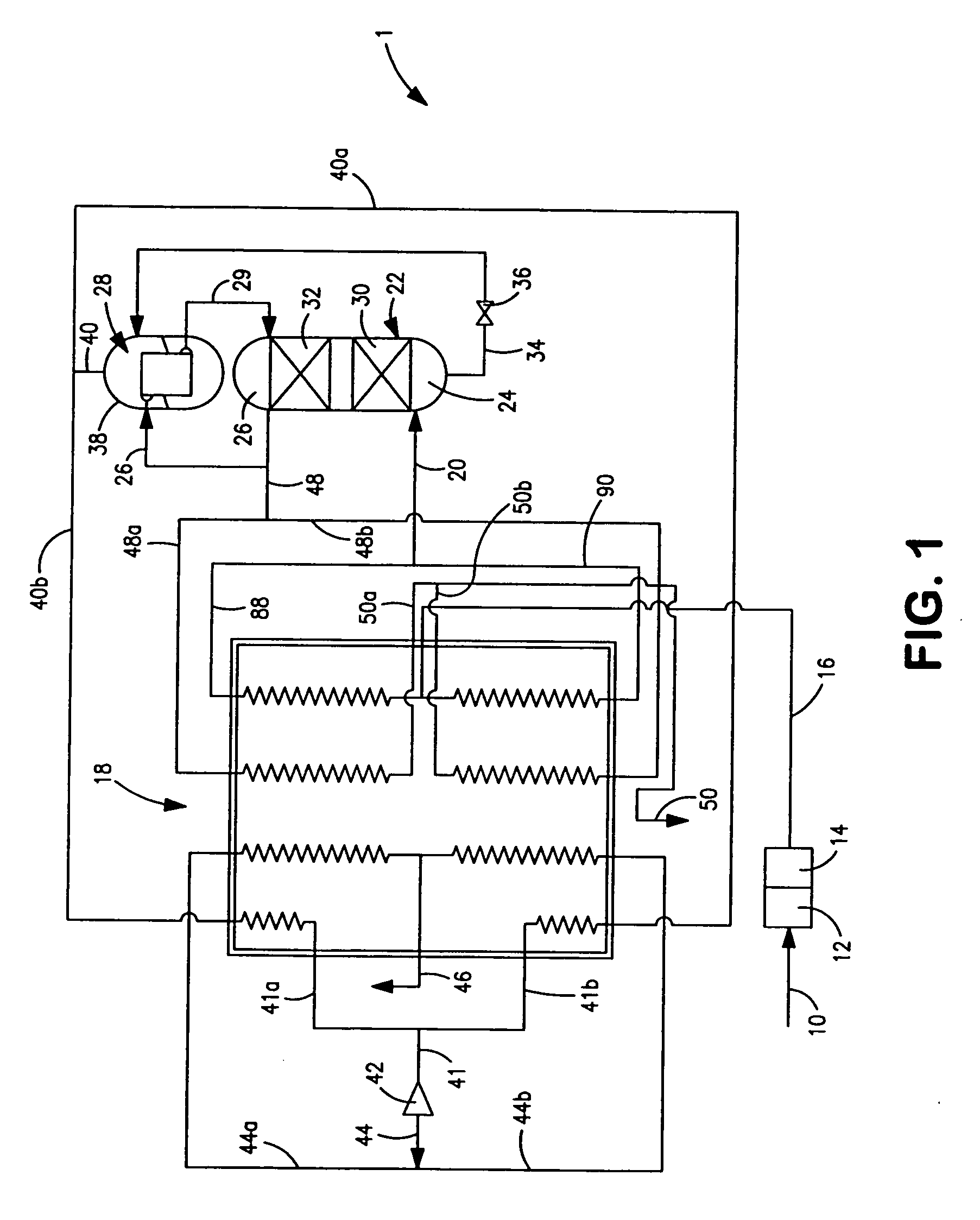

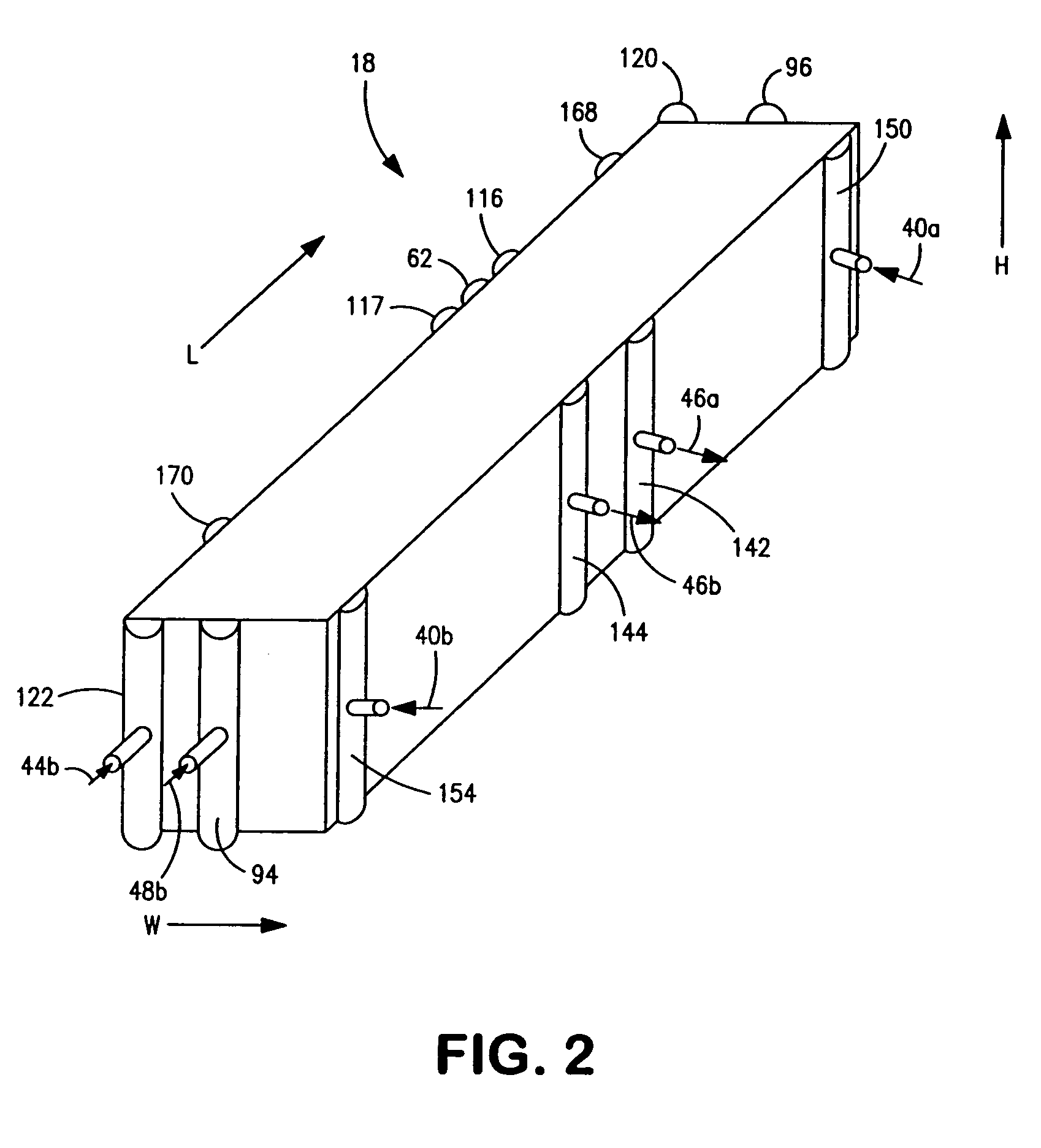

Lift and transfer chair

InactiveUS20040251656A1Same lengthSame widthWheelchairs/patient conveyanceNursing bedsDocking stationElectronic controller

A transfer chair has a chair frame, a seat, wheels, and a lift arm which has an articulated path between home and target positions. The articulated path may define a limited clearance height to allow use with, e.g., cars having a small door opening. In one embodiment the seat is split and moves to allow passage of the lift arm as it travels along the articulated path. The lift arm is articulated such that a lifting bridle attached to a distal end of the lift arm is maintained in a constant angular orientation with respect to the chair frame during movement. The lift arm further has multiple deployment paths for target positions with different heights and distances. A transfer seat for the lift arm includes two flexible webs removably attached to the lifting bridle. The lift arm is constructed using four links which are pivotally connected end-to-end. The links can be folded to a stowed position within the chair frame. An actuation mechanism uses a lead-screw actuator coupled to one of the links which lifts the remaining links by rotation about its pivotal attachment to the chair frame, and similarly uses another lead-screw actuator coupled to the next link. The actuation mechanism can be operated by an on-board motion control computer for controlling the trajectory and velocity of the arm. Sensors provide trajectory information to the on-board computer, and a docking switch can select one of a plurality of target trajectories for deploying the lift arm. A docking station integrated with the frame mates with a docking feature on the target object and stabilizes the chair while transferring the user. The docking station may include a receptacle for electrical connection to a power supply. A more comprehensive transfer system is provided using a path sensor which tracks a sensible path proximate the target object, and an electronic controller responsive to the path sensor which operates the drive wheels to follow the sensible path to a stowage location. The transfer chair drive wheels may be caregiver-operated using throttle handlebars.

Owner:PATTERSON RICHARD A

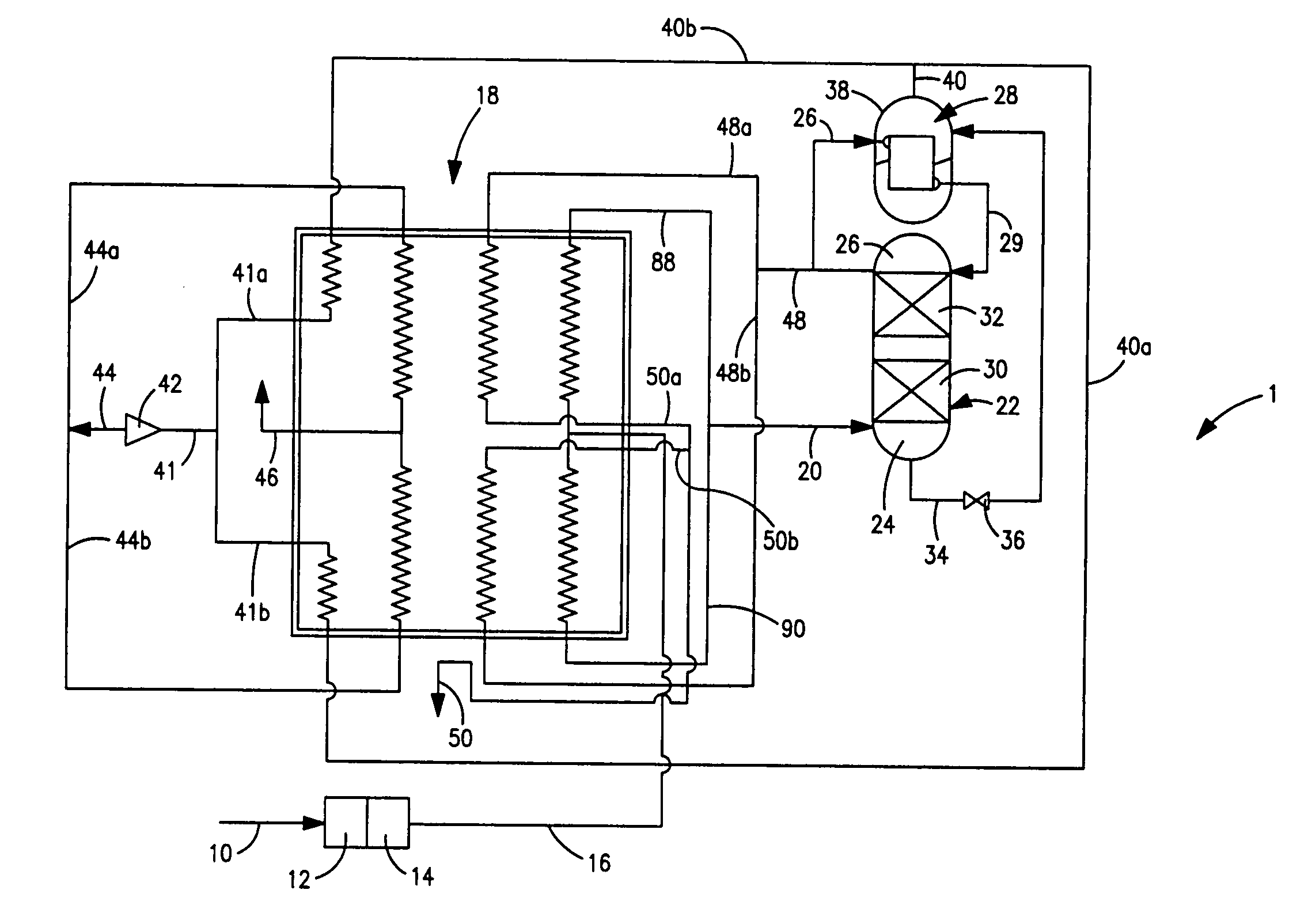

Plate-fin heat exchanger

InactiveUS20070295027A1Great fin densityLower overall pressure dropSolidificationLiquefactionEngineeringHeat exchanger

A plate-fin heat exchanger having a plurality of layers for indirectly exchanging heat between two or more fluids. The heat exchanger is provided with two sections and inlets and outlets to the sections to cause streams of the fluids to flow within the two sections parallel to the length of the heat exchanger between central locations and the ends of the heat exchanger. In such manner, the cross-sectional flow area of such a heat exchanger is greater than the heat exchanger in which the flow is from one end to the other end of the heat exchanger. This increase in cross-sectional flow area reduces the pressure drop within the heat exchanger.

Owner:PRAXAIR TECH INC

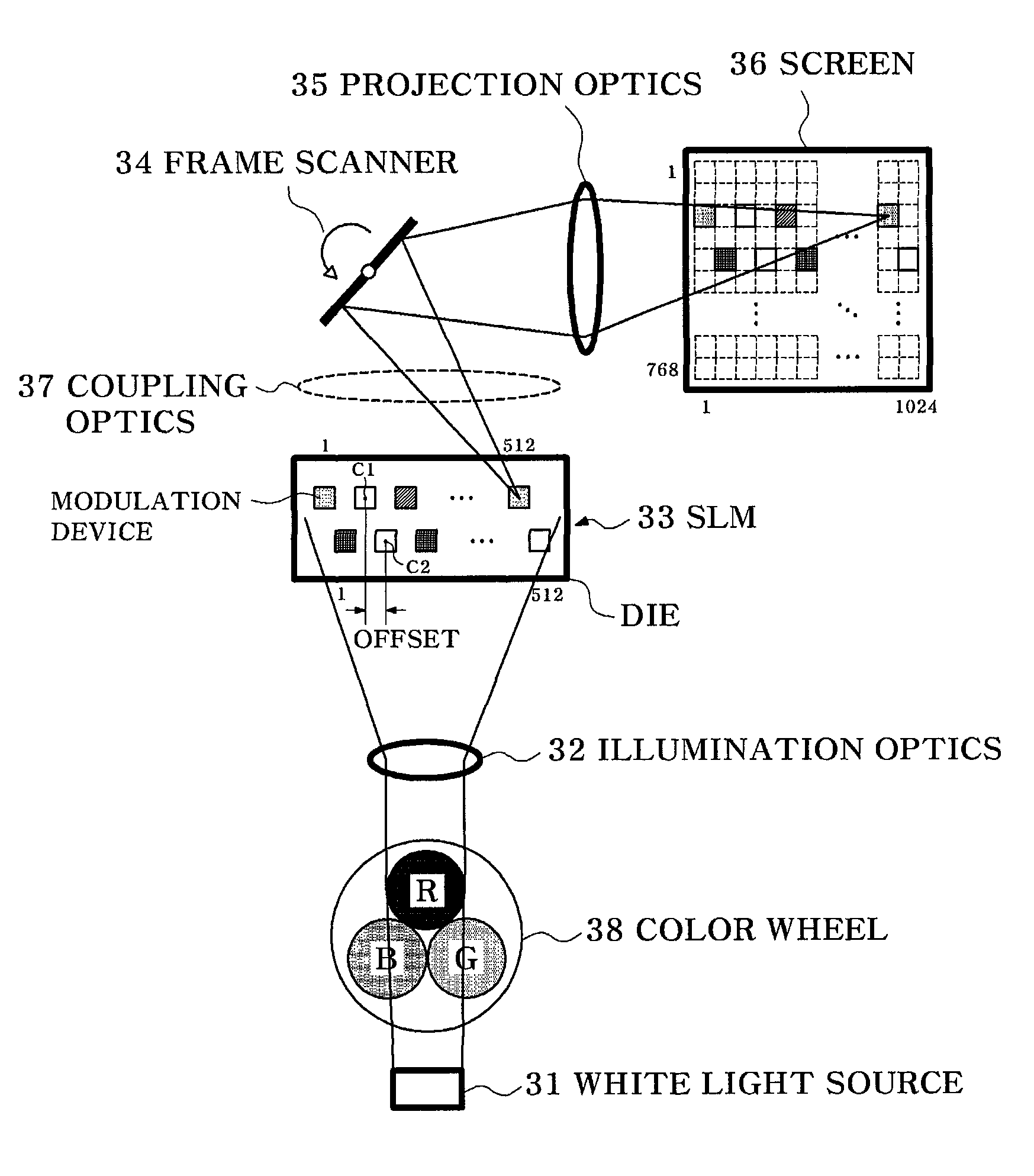

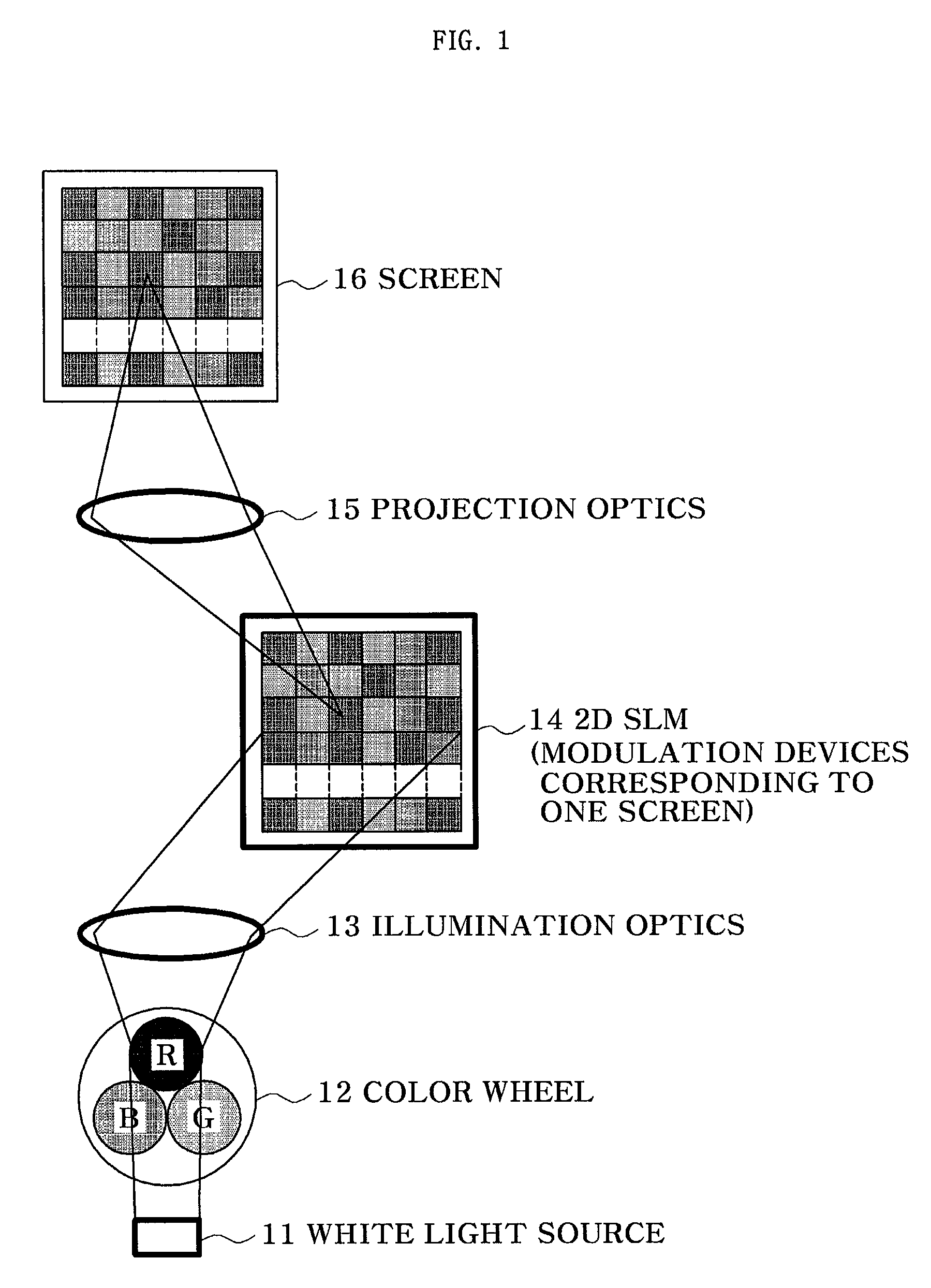

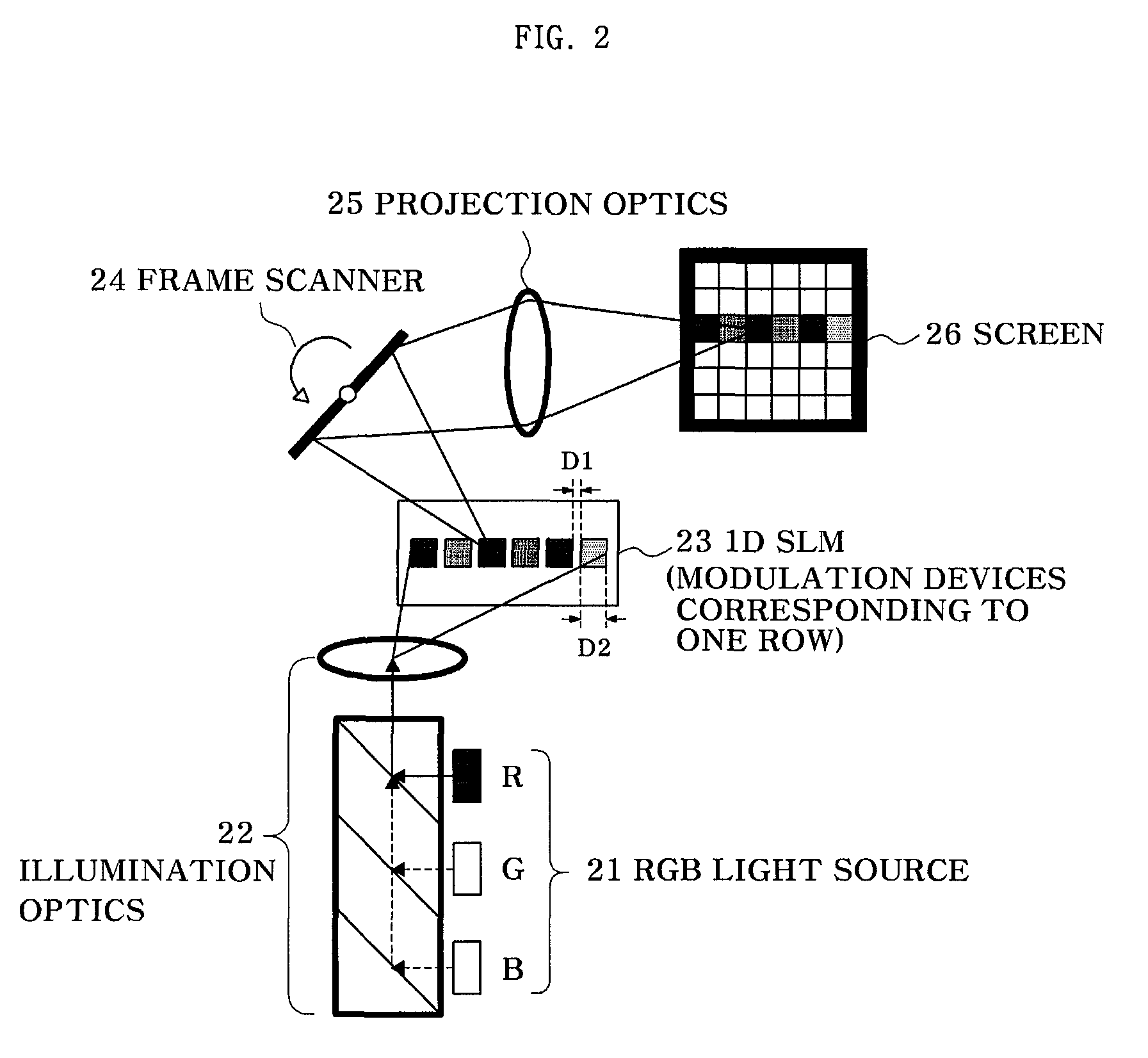

Image projection system and method

ActiveUS8104901B2Easy to useReduce widthTelevision system detailsProjectorsProjection opticsSpatial light modulator

Provided are an image projection system and method, the image projection system including: a light source for providing illumination light; an illumination optics for receiving and illuminating the illumination light; a Spatial Light Modulator (SLM) having 2 rows of modulation devices formed to be offset from each other, each of the modulation devices modulating the light illuminated from the illumination optics; a frame scanner for scanning the modulated light from the SLM onto a screen to thereby generate a two-dimensional (2D) image corresponding to one frame on the screen; and a projection optics for projecting and focusing the modulated light transmitted from the frame scanner onto the screen.

Owner:KWON SUNG HOON

Machine-detectable adhesive tape

InactiveUS7264194B2Correction errorSame widthNatural rubber adhesivesFilm/foil adhesivesEngineeringOptical detector

The invention relates to an adhesive tape for a flying reel change of a flat material wound up over a reel, provided with a main support, a self-adhesive composition on the face side and at least, on the back side, one strip of a double-sided adhesive tape which has a detachable support provided on its two sides with a self-adhesive composition. The invention is characterized in that the adhesive tape is provided with at least one device which can be detected by an optical detector.

Owner:TESA SE

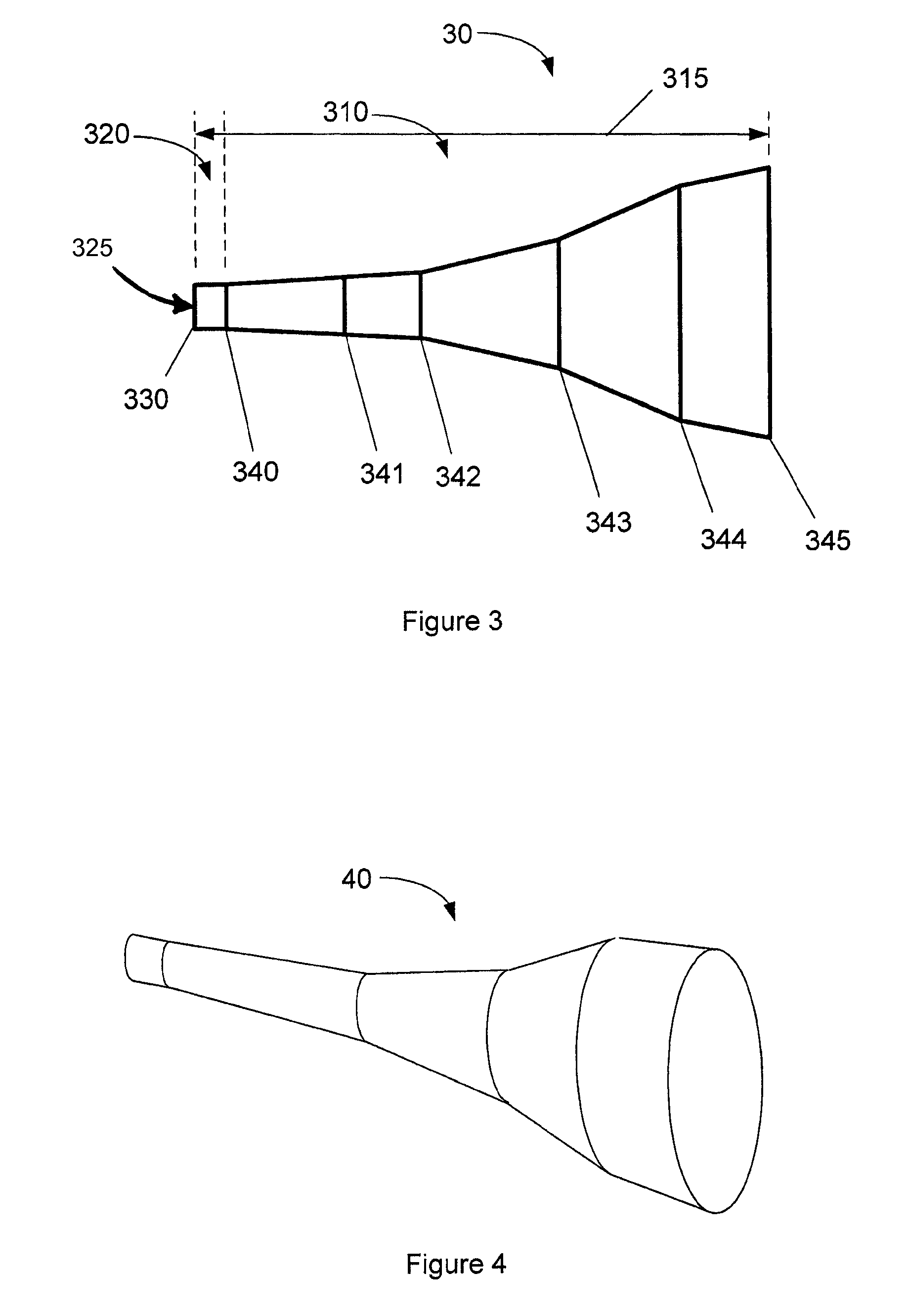

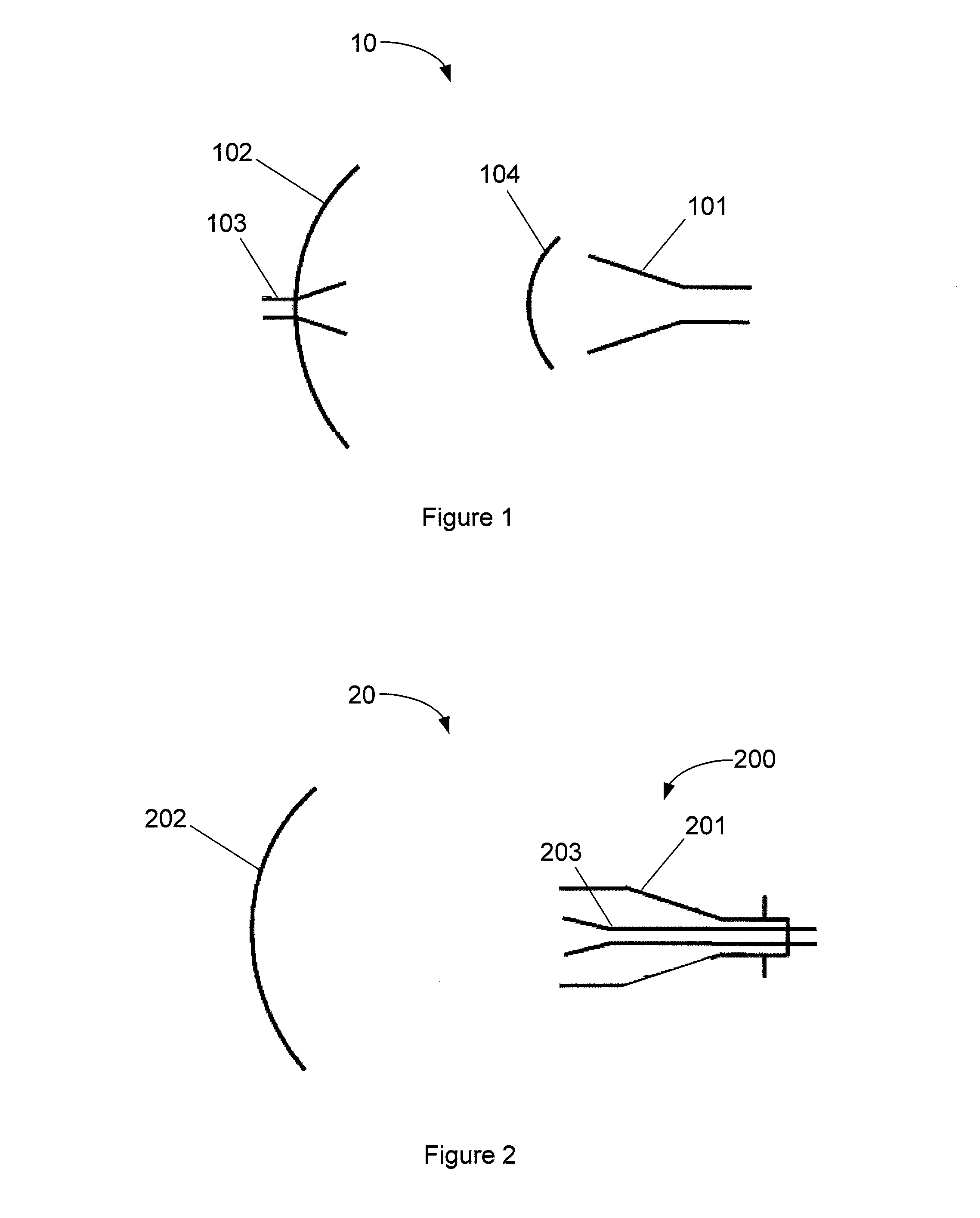

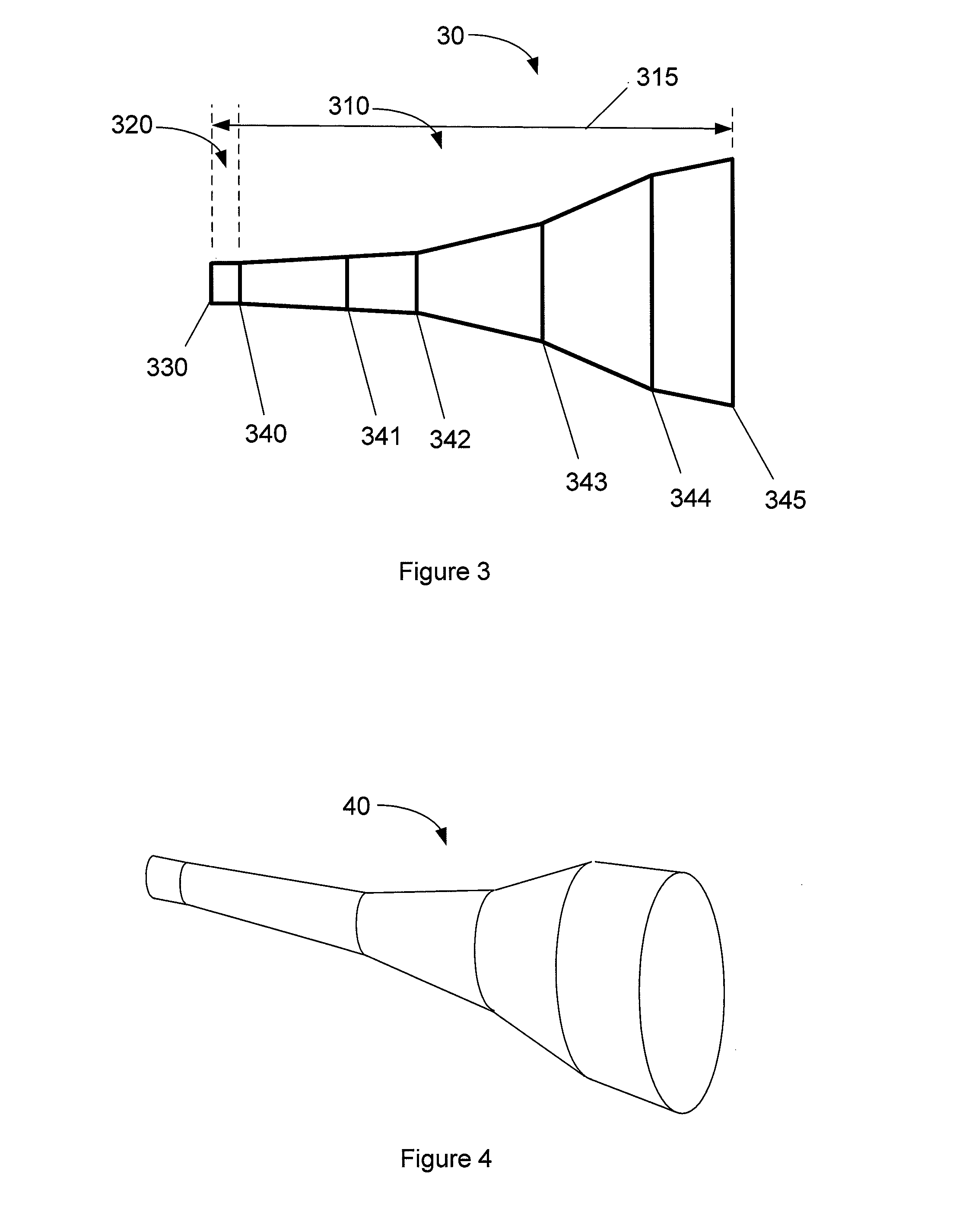

Dual-band antenna using high/low efficiency feed horn for optimal radiation patterns

ActiveUS8514140B1Reduces pointing requirementLow efficiencySimultaneous aerial operationsDual frequencyRadiation mode

A dual-band antenna system configured to transmit and / or receive microwave beams over two or more frequency bands with substantially similar beam widths and substantially similar sidelobe levels is disclosed. The antenna system includes at least one reflector and at least one feed horn, the horn configured to provide a first efficiency over a first frequency band and lower efficiencies over one or more second frequency bands. The horn includes a substantially conical wall having an internal surface with a variable slope. The internal surface includes one or more slope discontinuities, wherein the slope discontinuities are configured to generate primarily TE1,m modes within the first frequency band and within the second frequency bands and generate TM1,n modes substantially only within the second frequency bands.

Owner:LOCKHEED MARTIN CORP

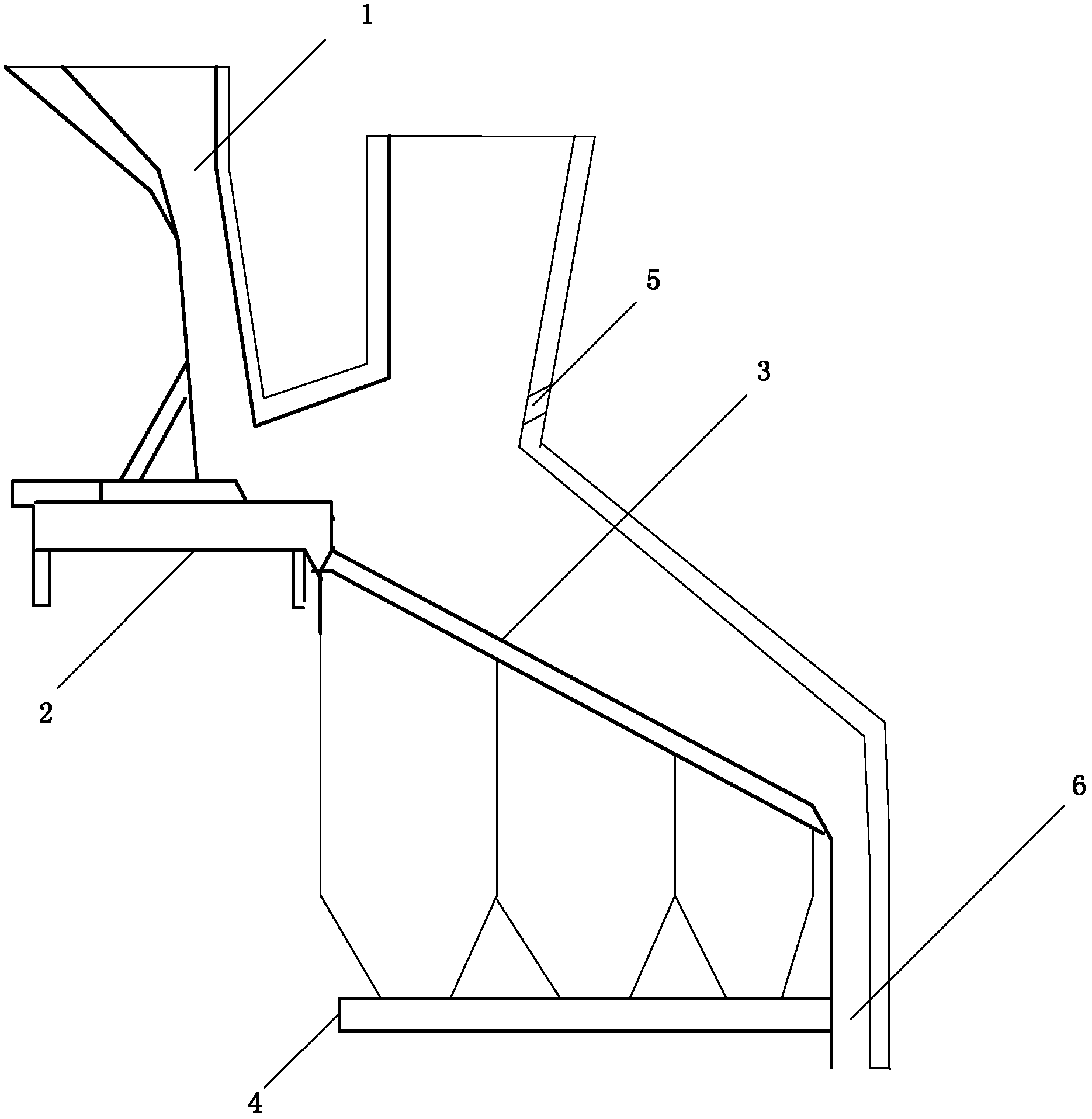

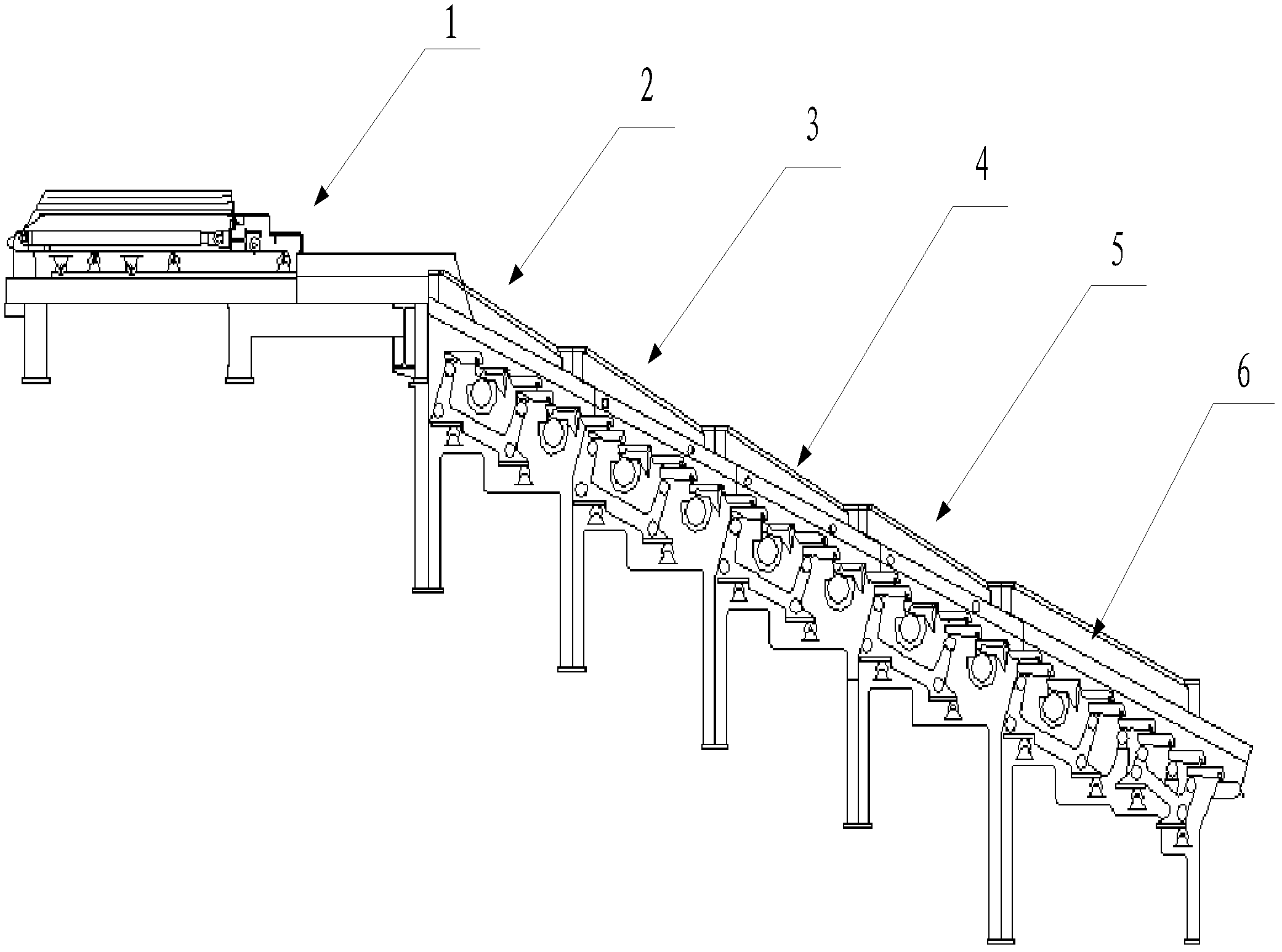

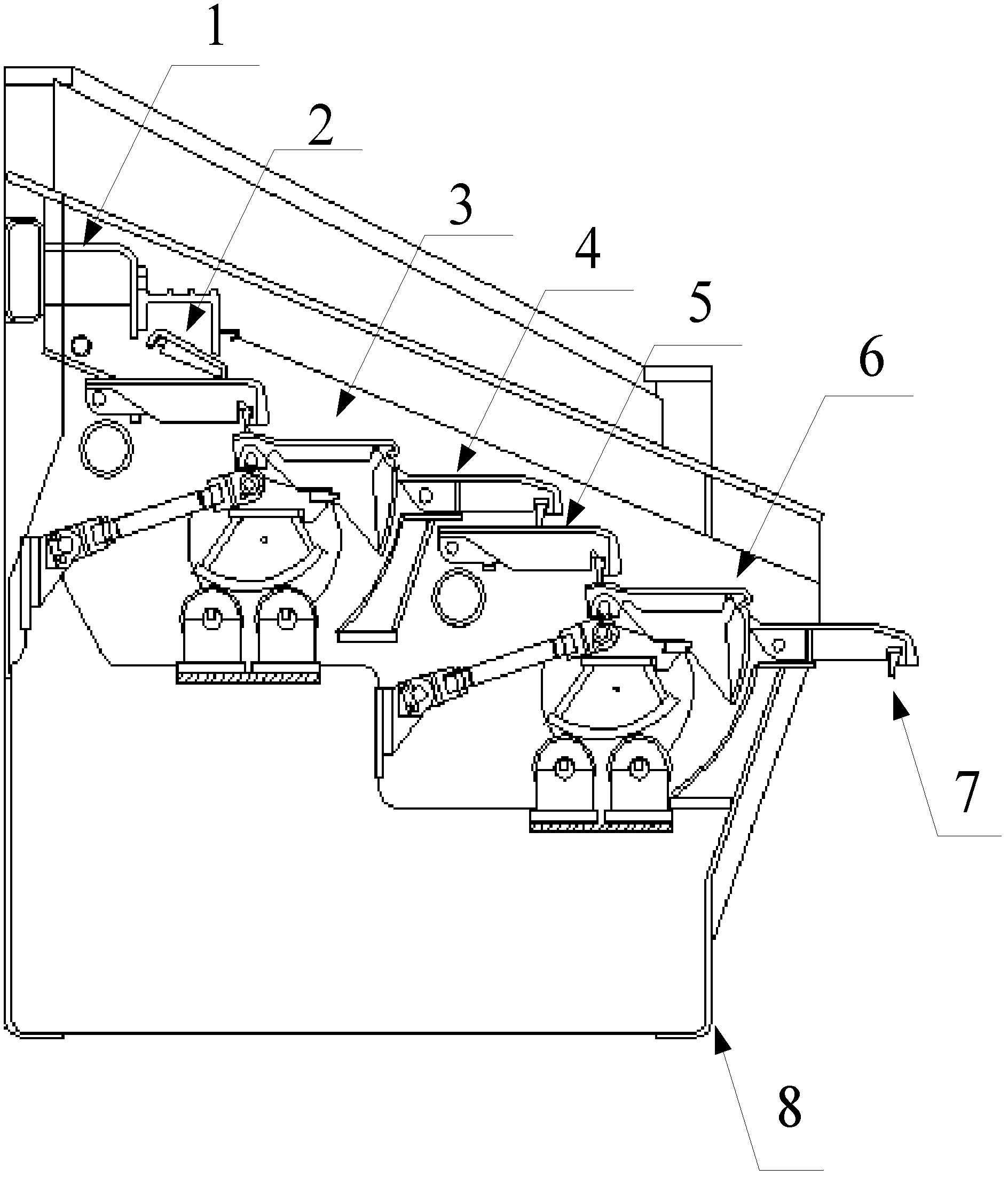

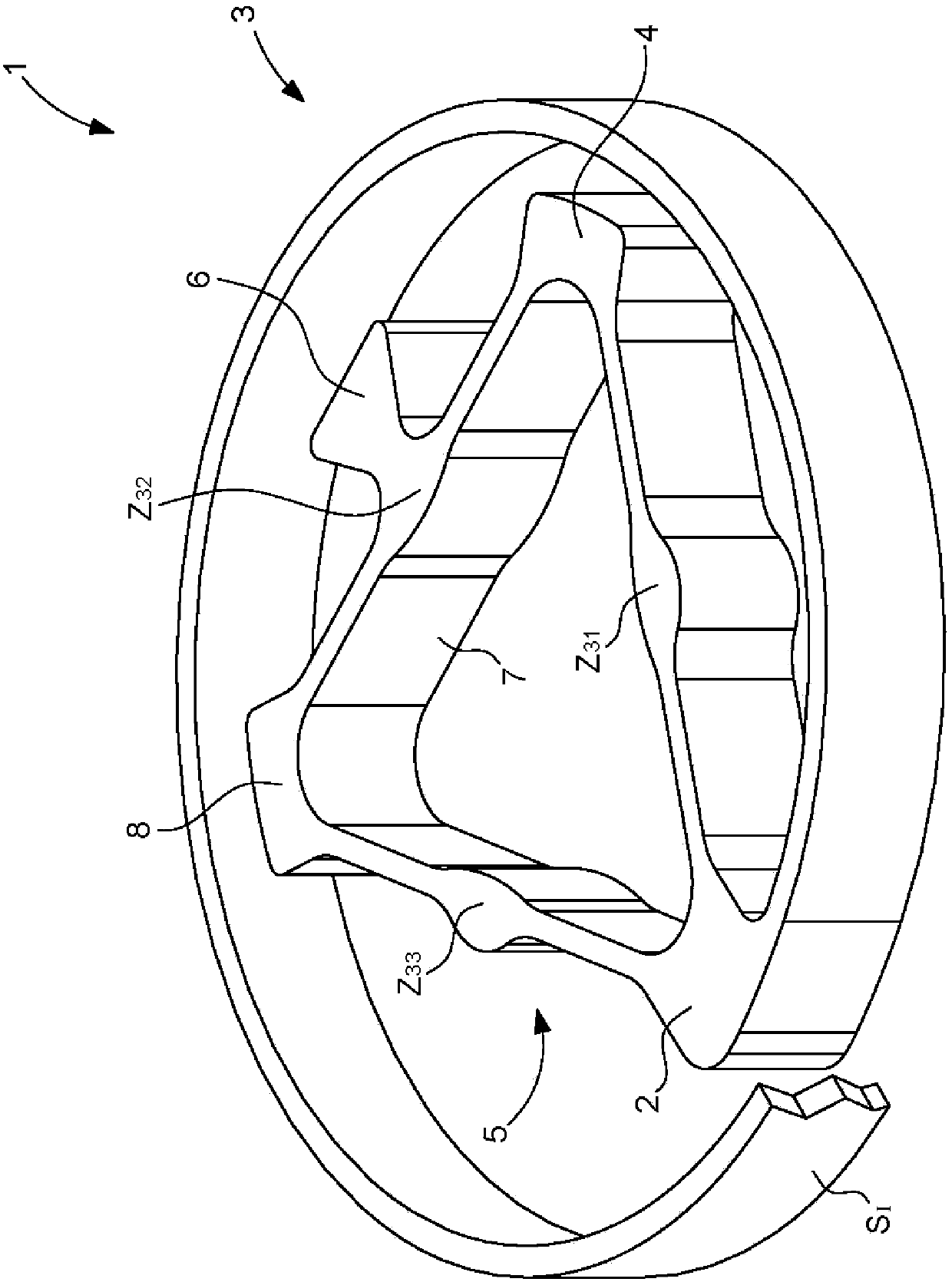

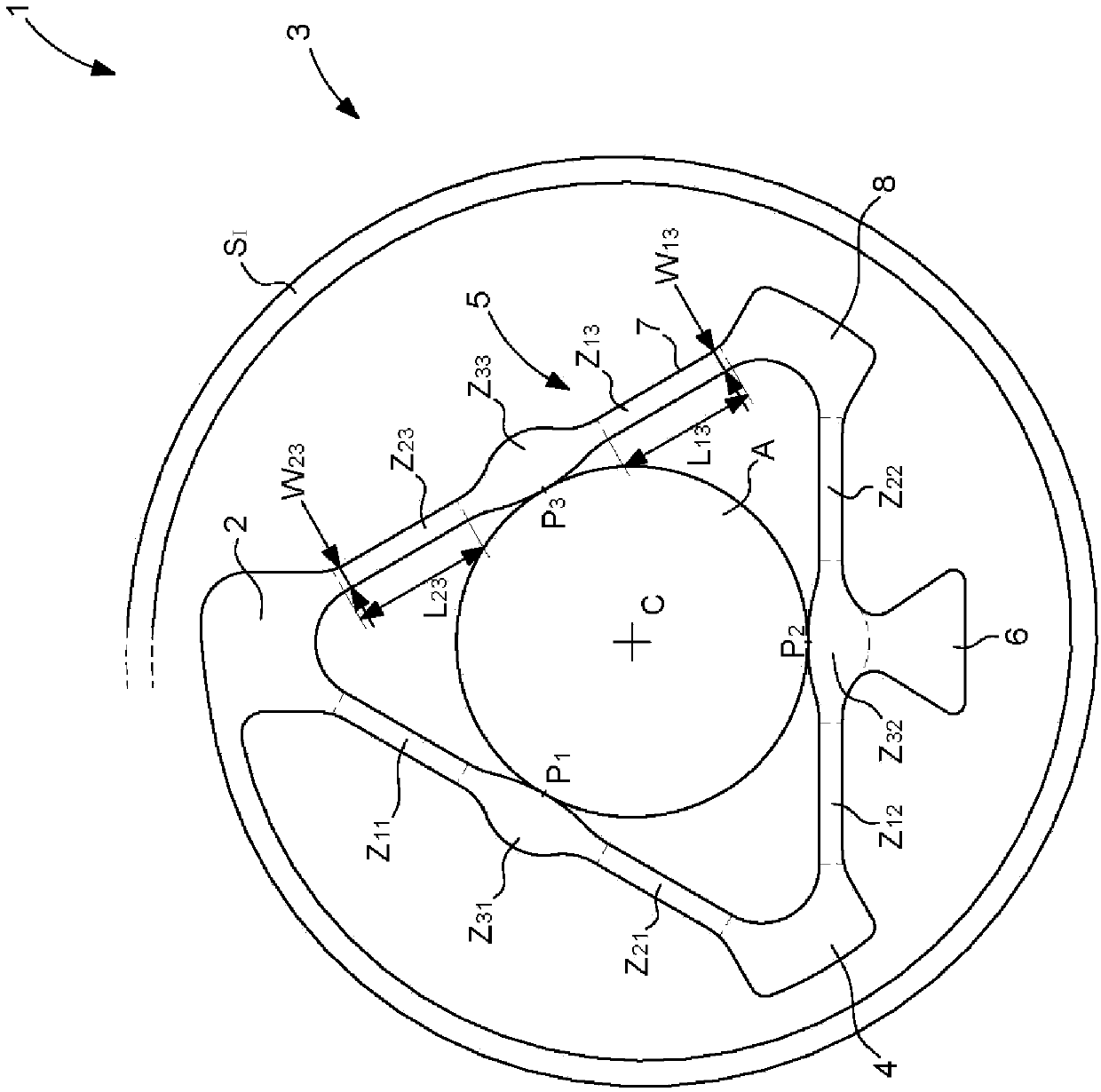

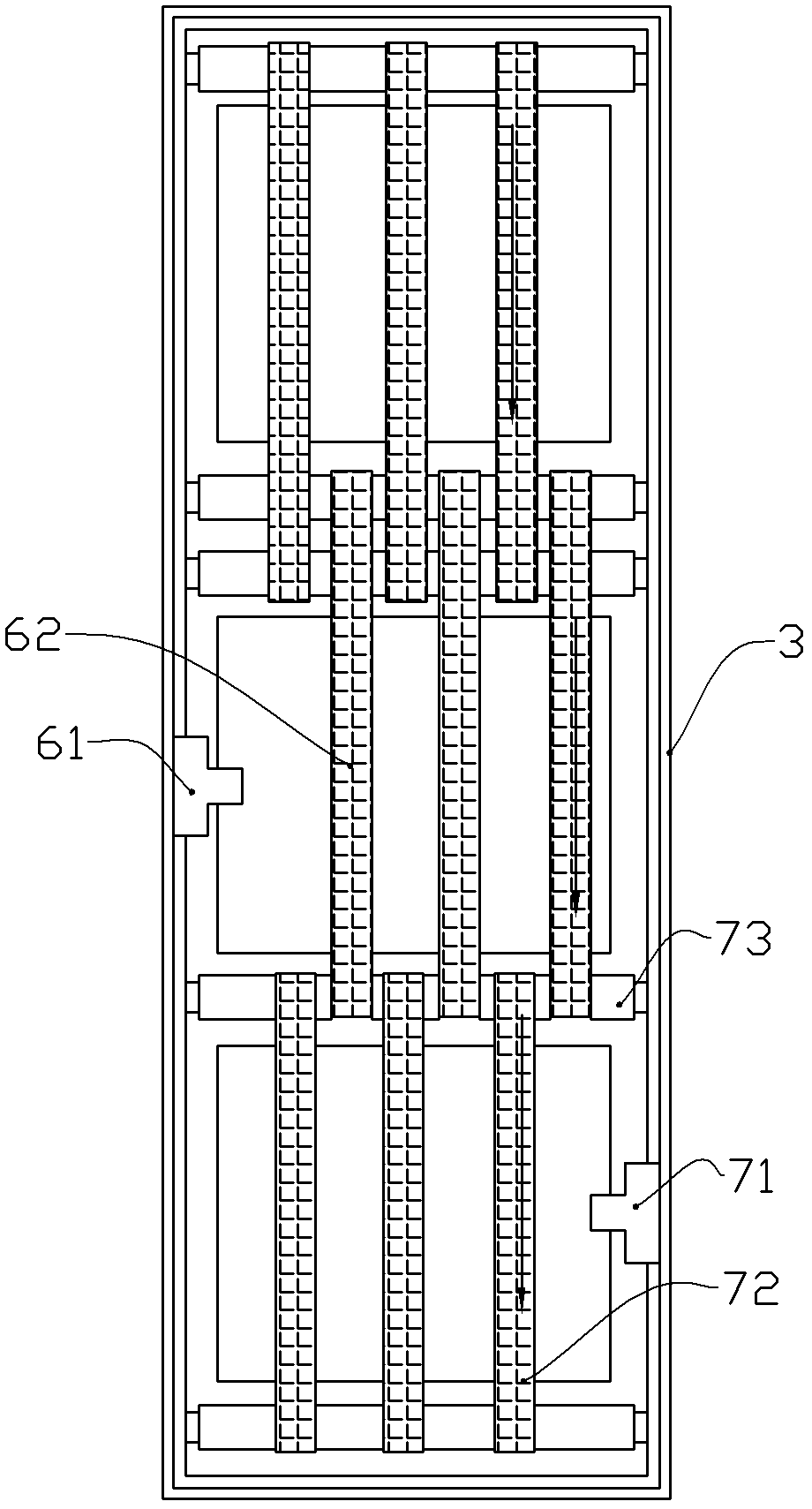

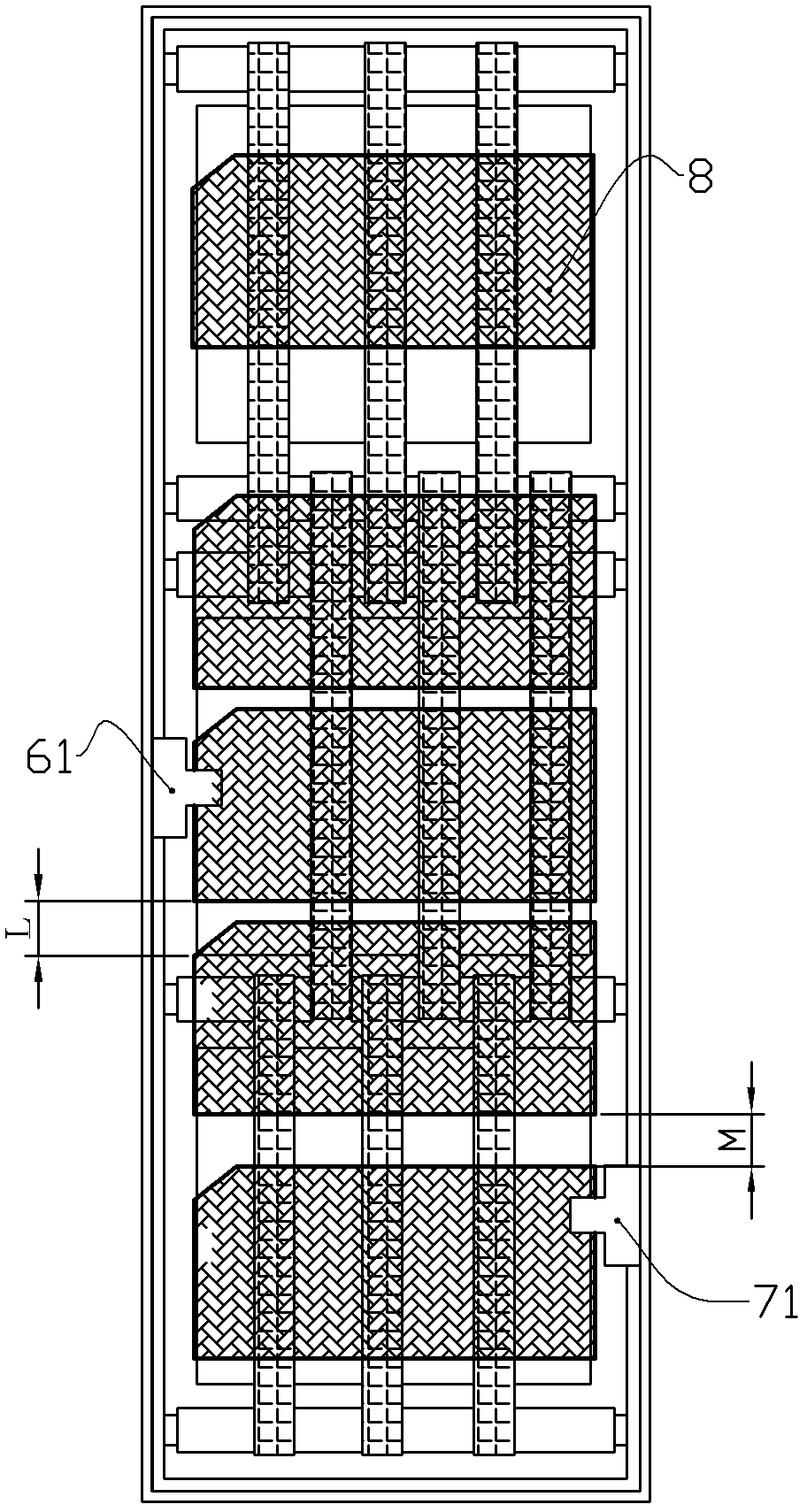

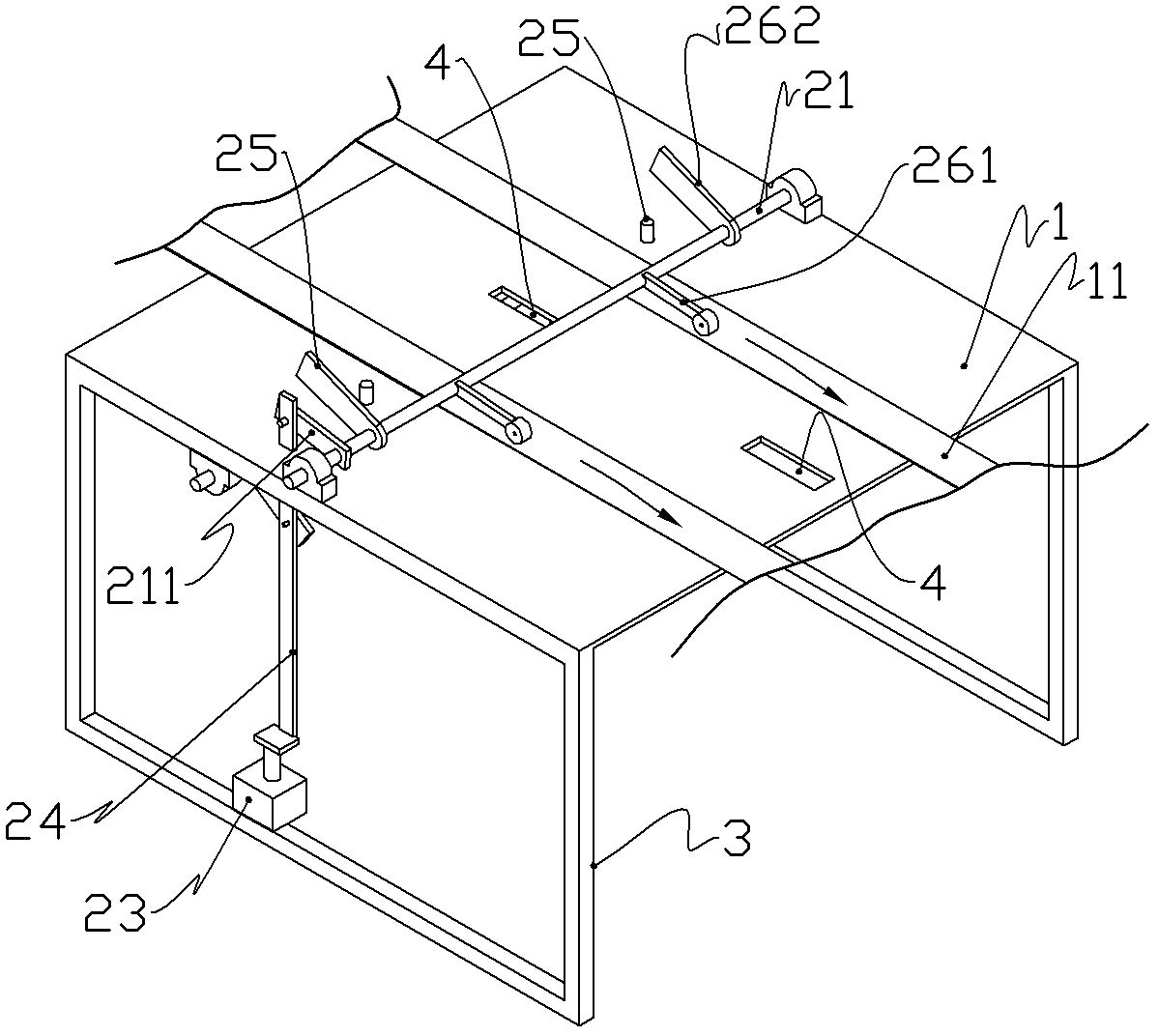

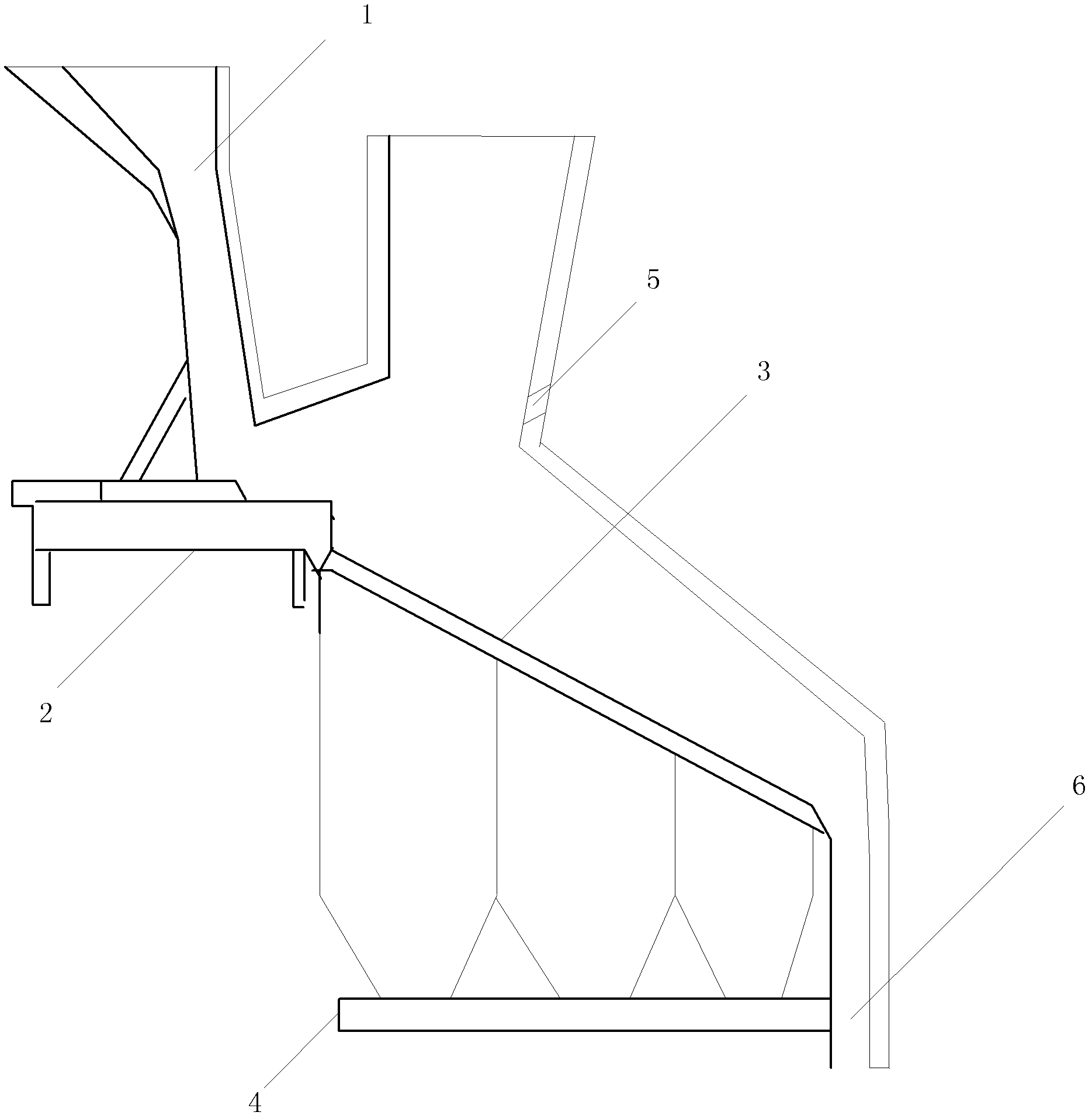

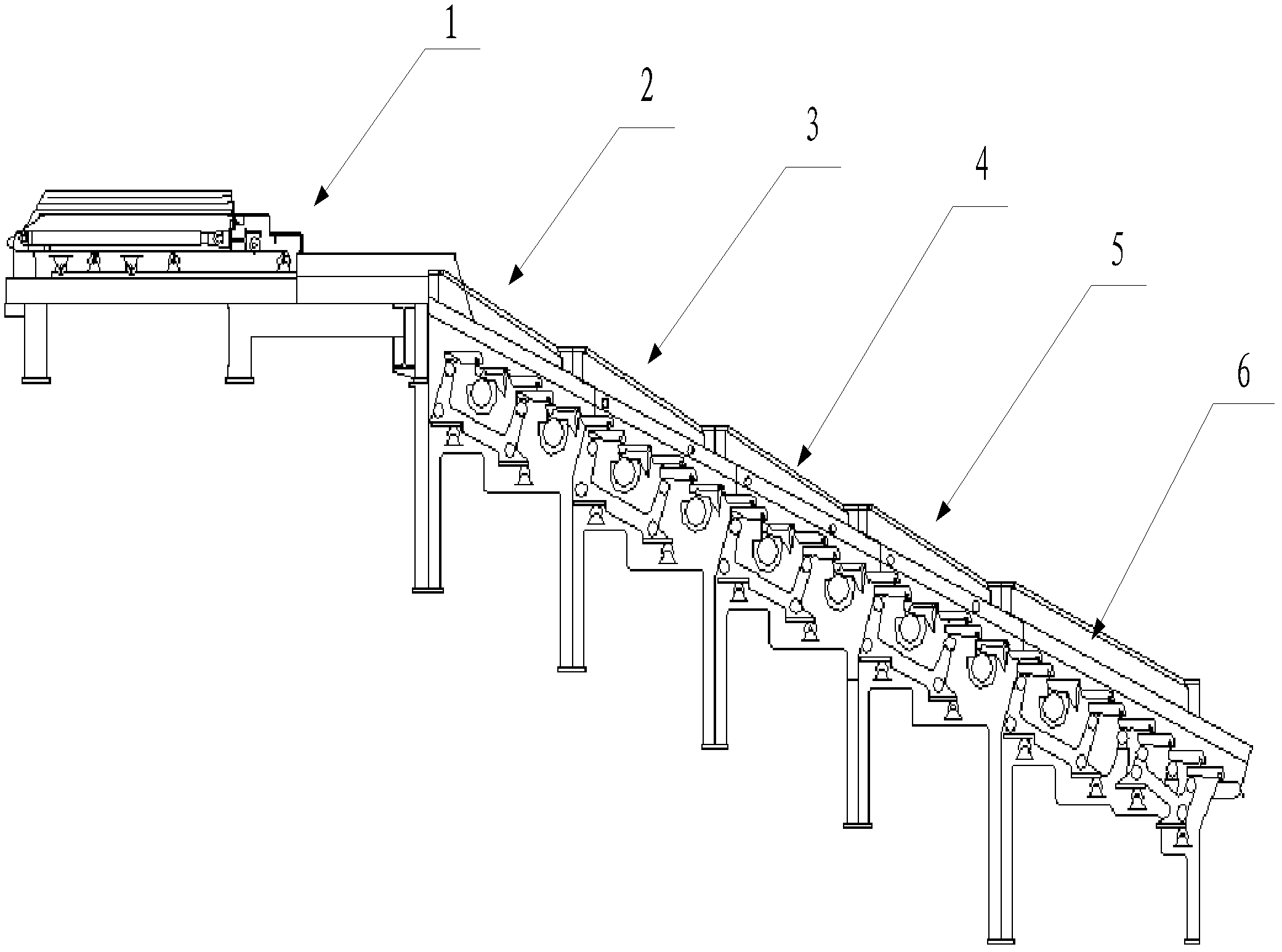

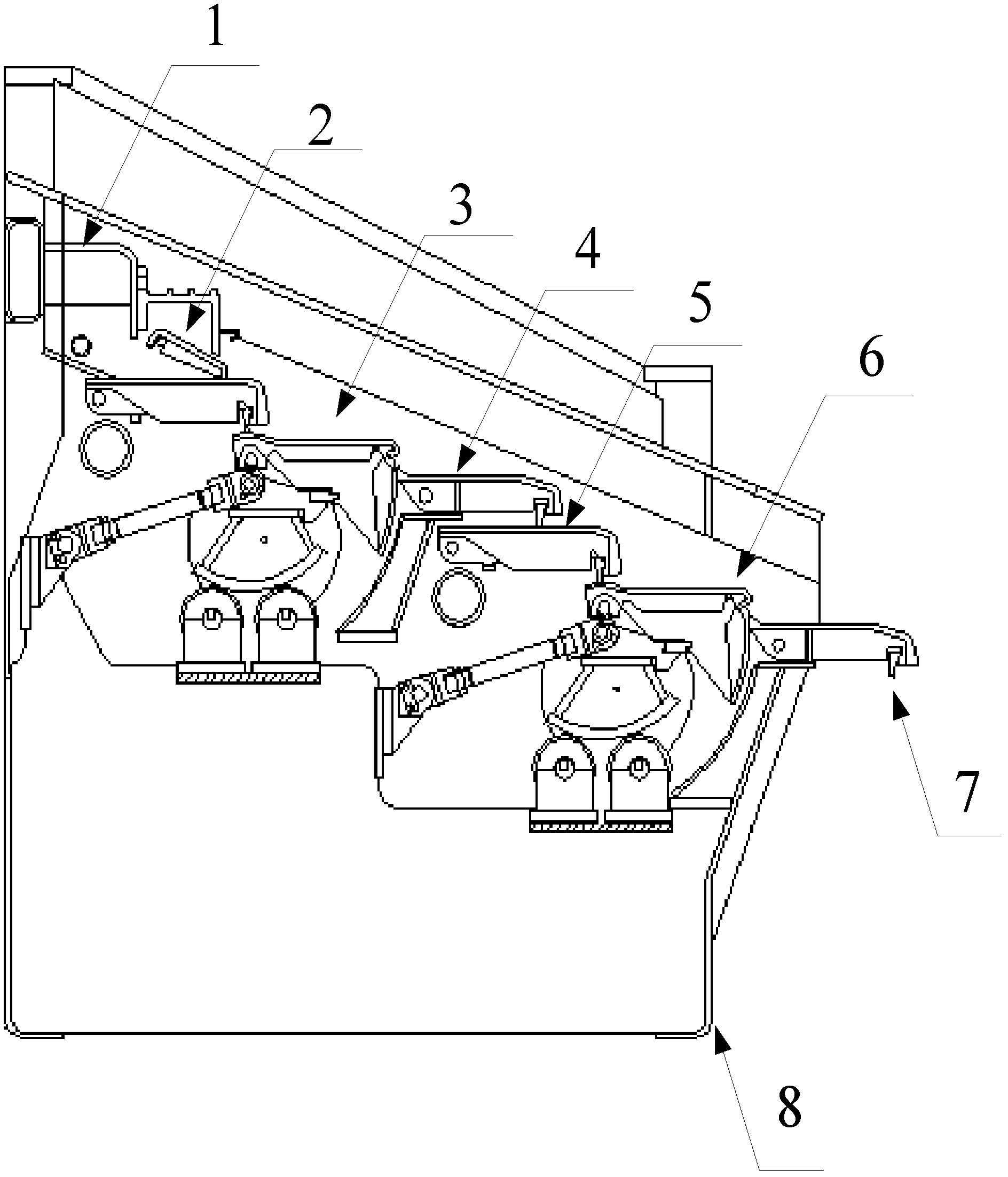

Multistage hydraulic mechanical garbage incinerator and control method for same

ActiveCN102607037AImprove combustionImprove burnout rateHollow bar grateInclined grateHydraulic machinerySteel frame

The invention provides a multistage hydraulic mechanical garbage incinerator and a control method for the same. The multistage hydraulic mechanical garbage incinerator comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally and longitudinally divided into a drying section, a burning section and a burnout section by the five units. The multistage hydraulic mechanical garbage incinerator is characterized in that the fire grate segments in each row of the incinerating fire grate are transversely driven by a shaft and transversely supported by a steel frame at three positions at the least. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +1

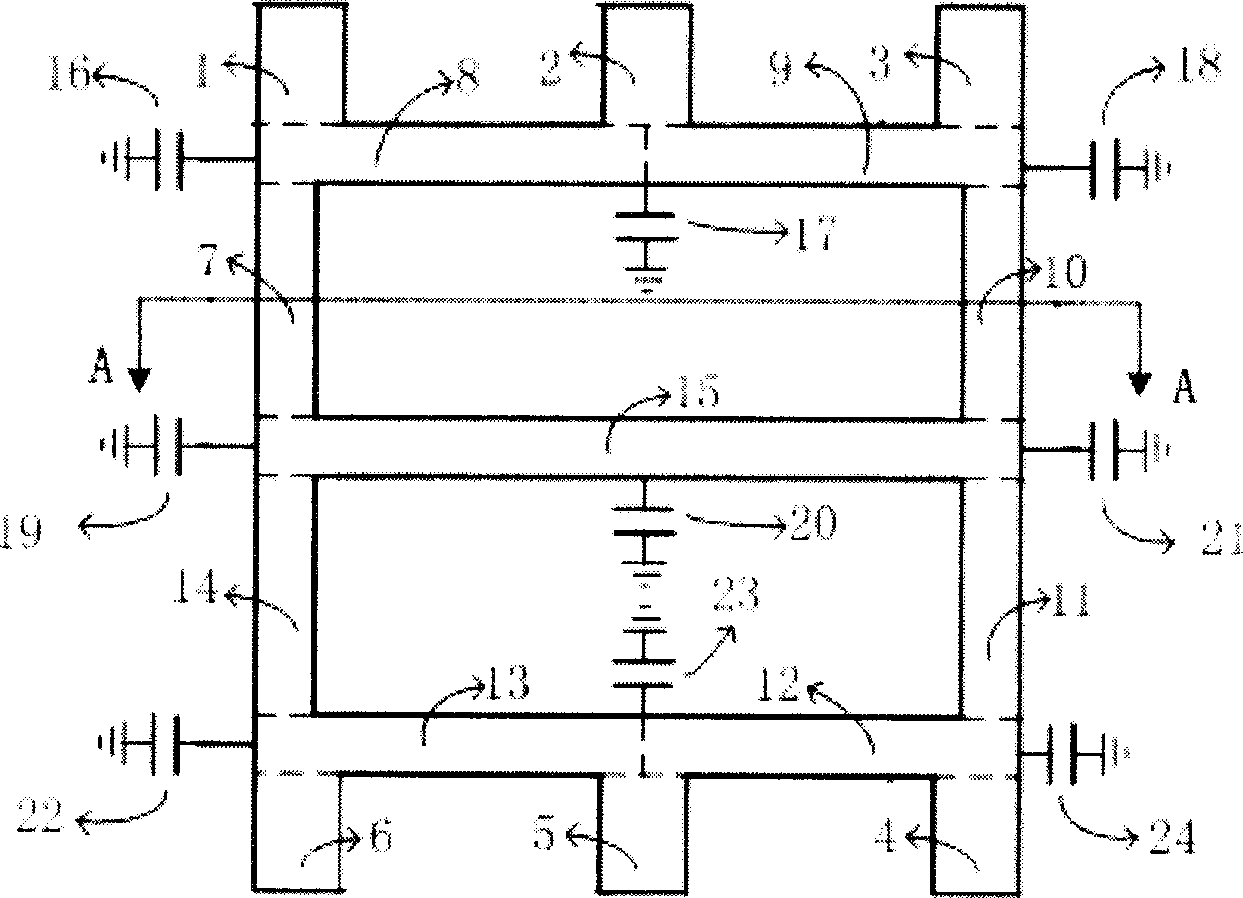

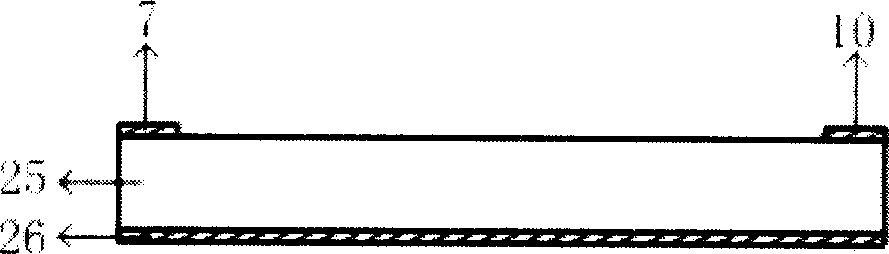

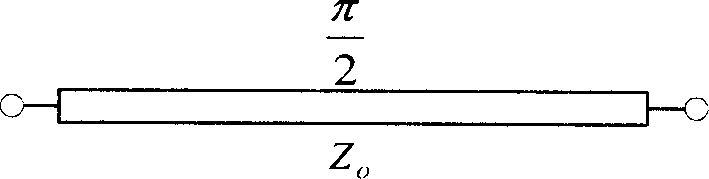

Microwave power distributor with multiple power distributing ratios

InactiveCN1825688AImprove VSWRImprove isolationWaveguidesCapacitanceElectrical resistance and conductance

This invention relates to a microwave power splitter having multiple kinds of power splitting ratios, in which, the microstrip lines of said power splitter form a square, every edge of which is connected by two equivalent 1 / 4 wavelength lines, the cross points of two equivalent 1 / 4 wavelength lines at the right and left of the square are connected by an equivalent 1 / 2 line and the property impedance, the electric length and loaded capacitance value are determined by the output power distribution ratio of the power splitter, which gets high isolation without using any isolation resistors and the stationary ratio is good.

Owner:SOUTH CHINA UNIV OF TECH

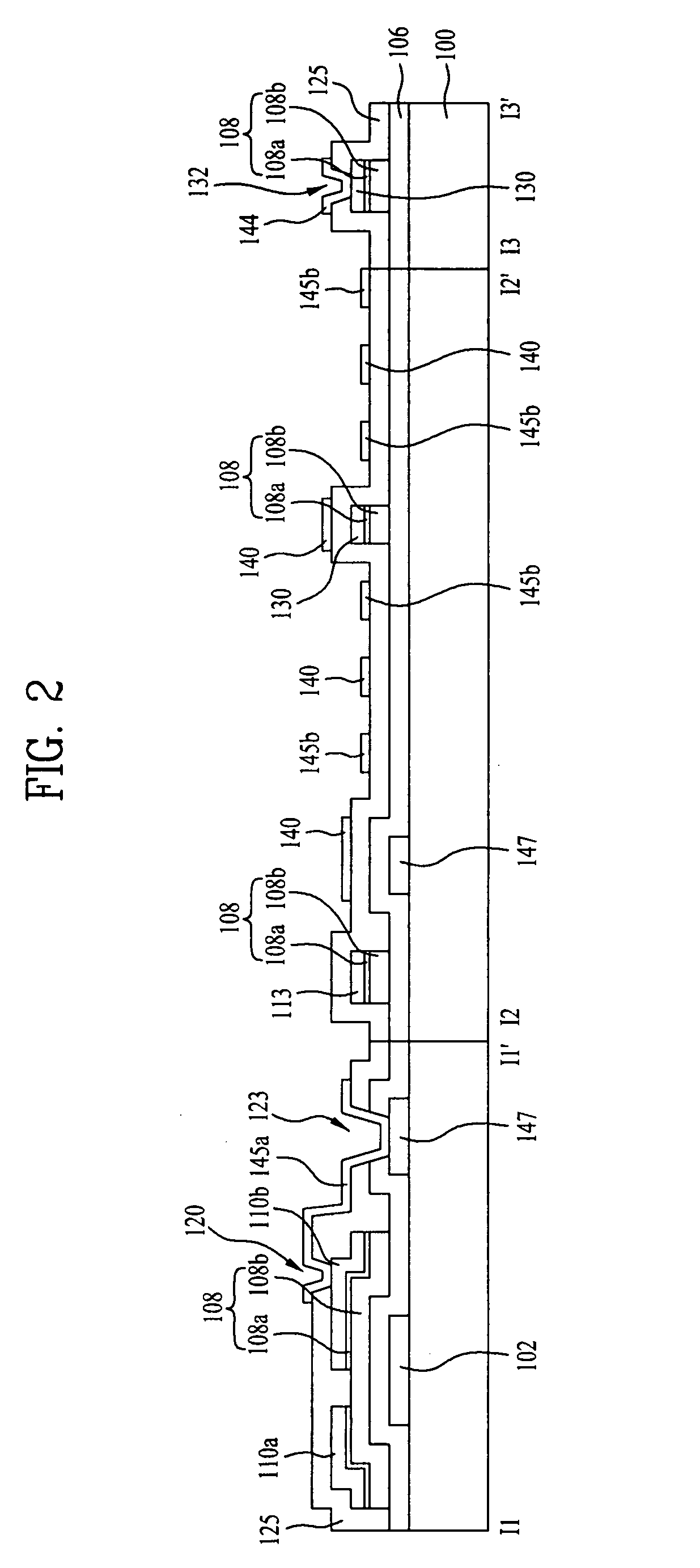

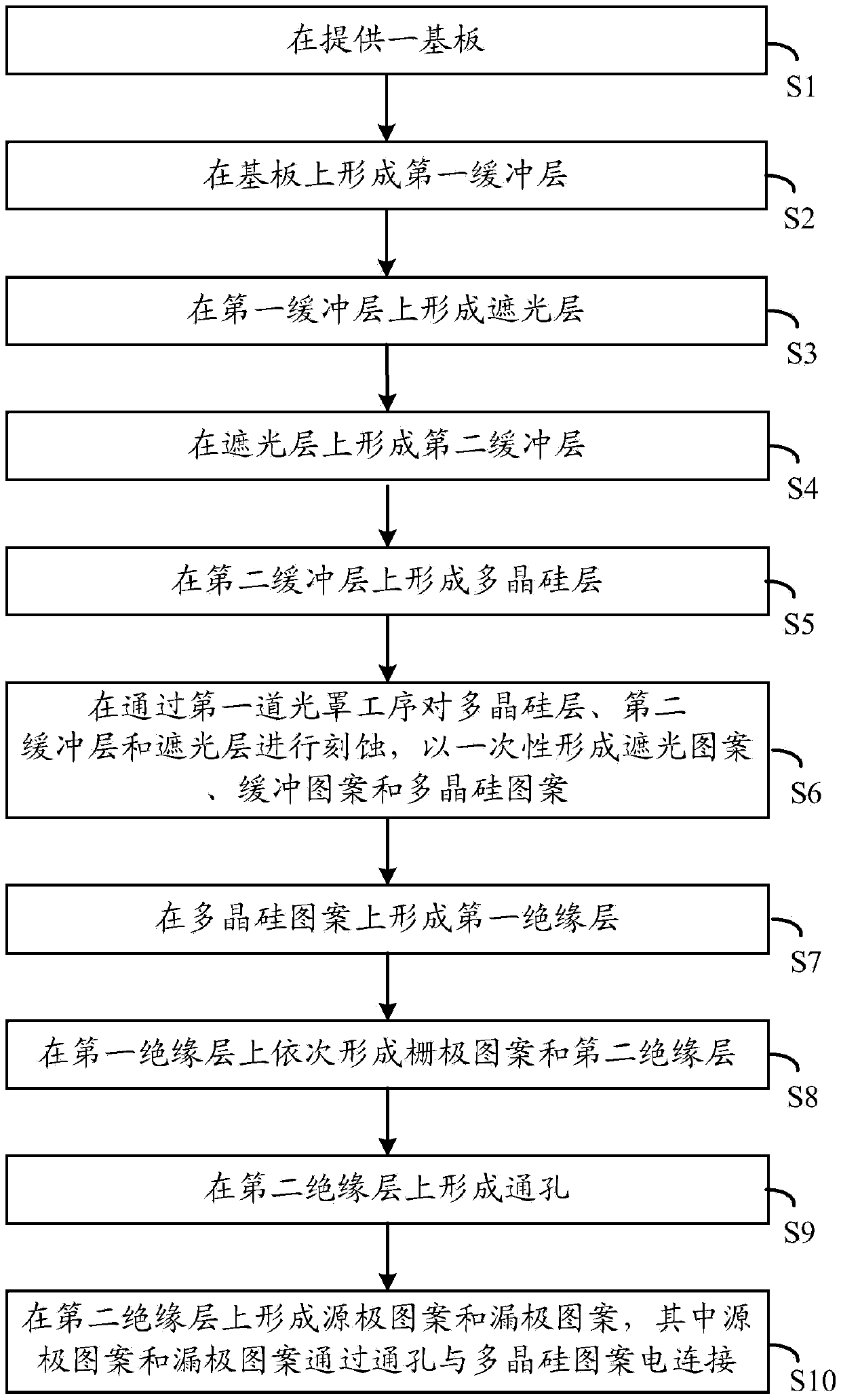

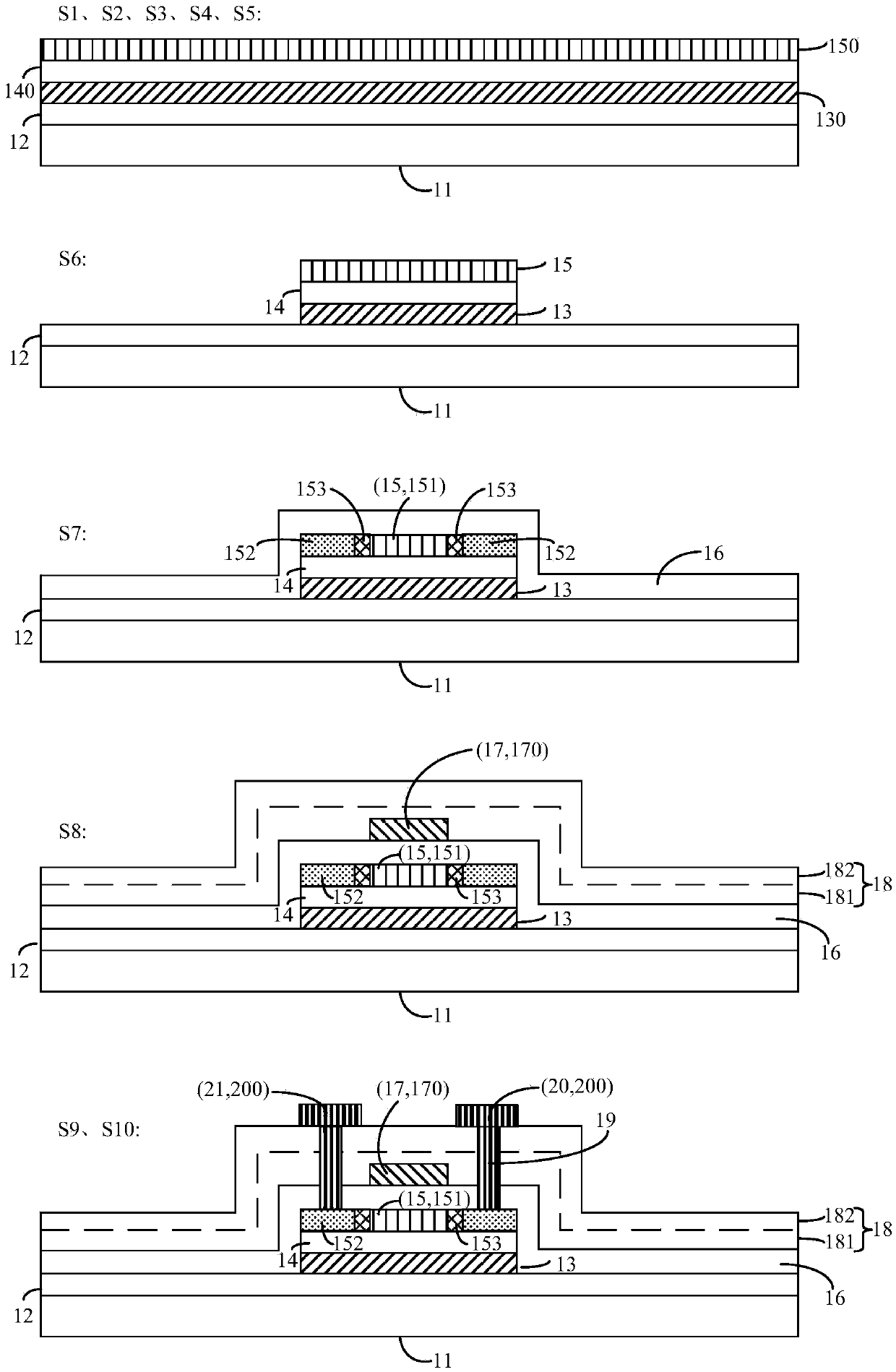

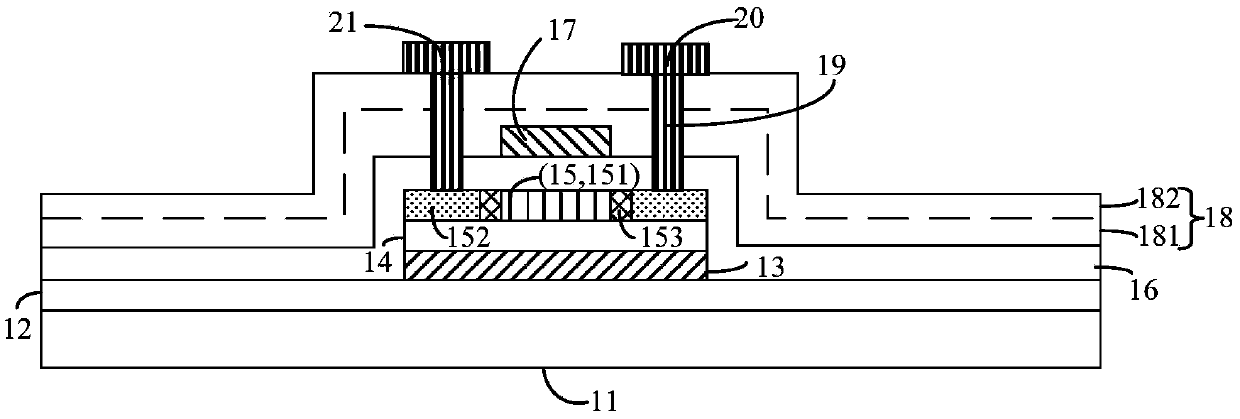

TFT and manufacturing method thereof

ActiveCN105374749AReduce processLow costSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsPolycrystalline silicon

The invention discloses a TFT and a manufacturing method thereof. The method comprises the steps of: providing a substrate; forming a first buffer layer on the substrate, and forming a light shield layer on the first buffer layer; forming a second buffer layer on the light shield layer; forming a poly silicon layer on the second buffer layer; and etching the poly silicon layer, the second buffer layer and the light shield layer through a first photomask process to from a light shield pattern, a buffer pattern and a poly silicon pattern once. Compared with the prior art, the method can reduce manufacturing processes so as to reduce costs, furthermore make the width of the light shield pattern same with the width of the poly silicon pattern, and improve display effects.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

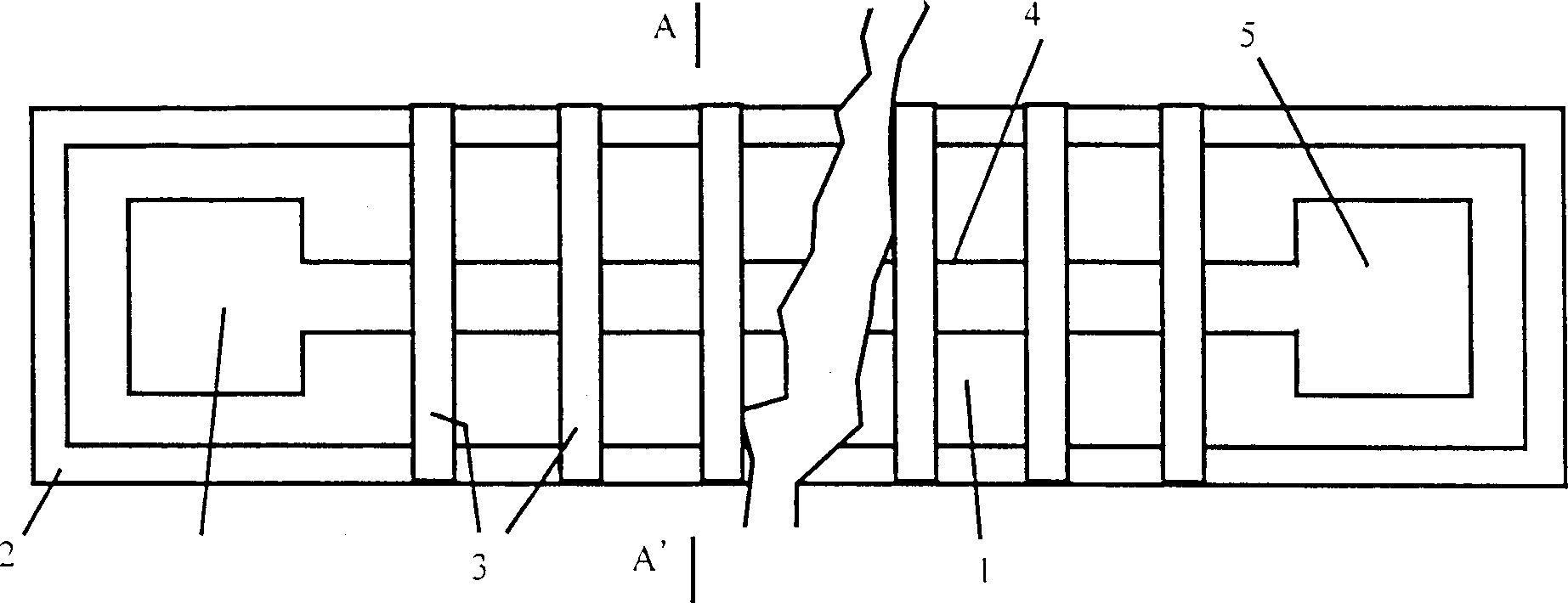

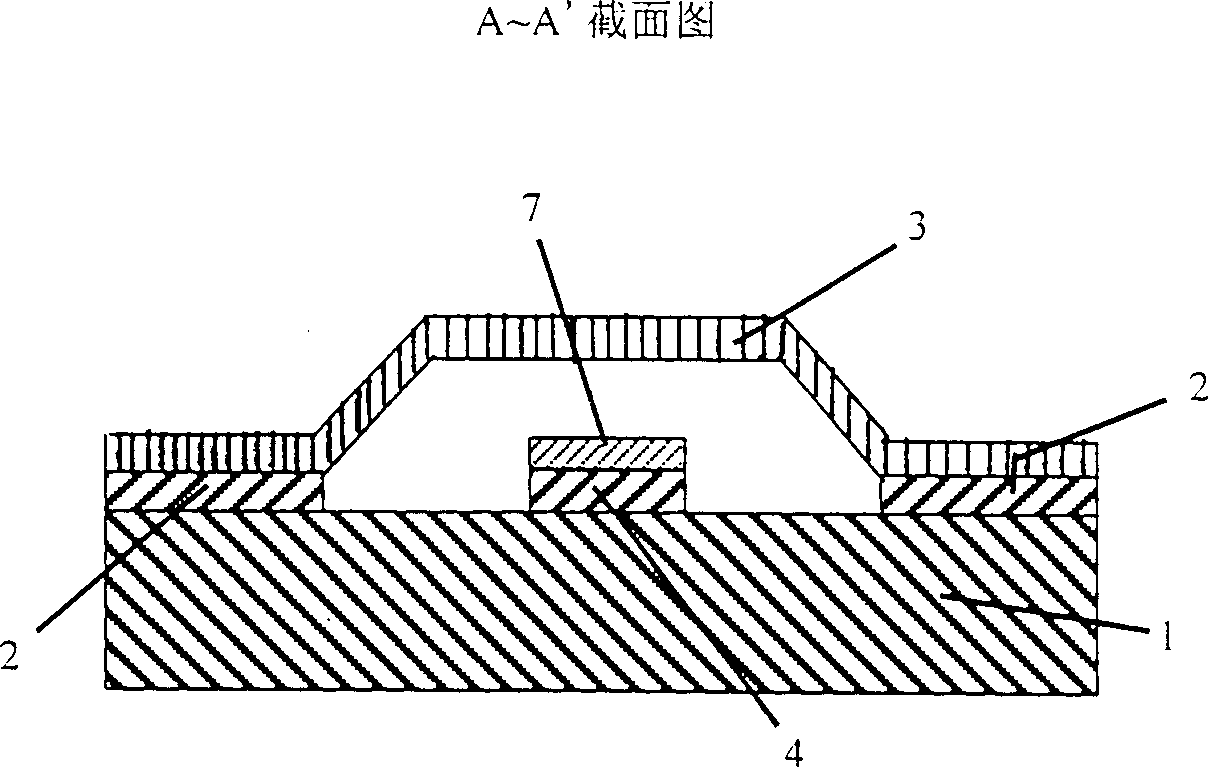

Production method of millimetric wave voltage-controlled phase shifter for microelectronic machine

InactiveCN1380245AHighly consistentSame widthDecorative surface effectsPhotomechanical apparatusPhotoresistWork in process

The production method of millimetric wave voltage-controlled phase shifter belongs to the field of microelectronic solid device production technology, and is characterized by that it uses the semifinished product of said invented product, i.e. processed substrate whose surface has etched strip pattern containing grounding conductor strip, signal wire and connecting terminal and on the signal wirethe silicon nitride layer is grown as raw material, adopts prepared thermoprene negative photoresist as sacrificial layer and photoresist coating technology to make 20-30-odd metal microbridges whichare arranged regularly and whose height is uniform and width is identical on the semi-finished product. It possesses excellent electric performance, can be used as millimetric wave voltage-controlledphase shifter.

Owner:EAST CHINA NORMAL UNIVERSITY

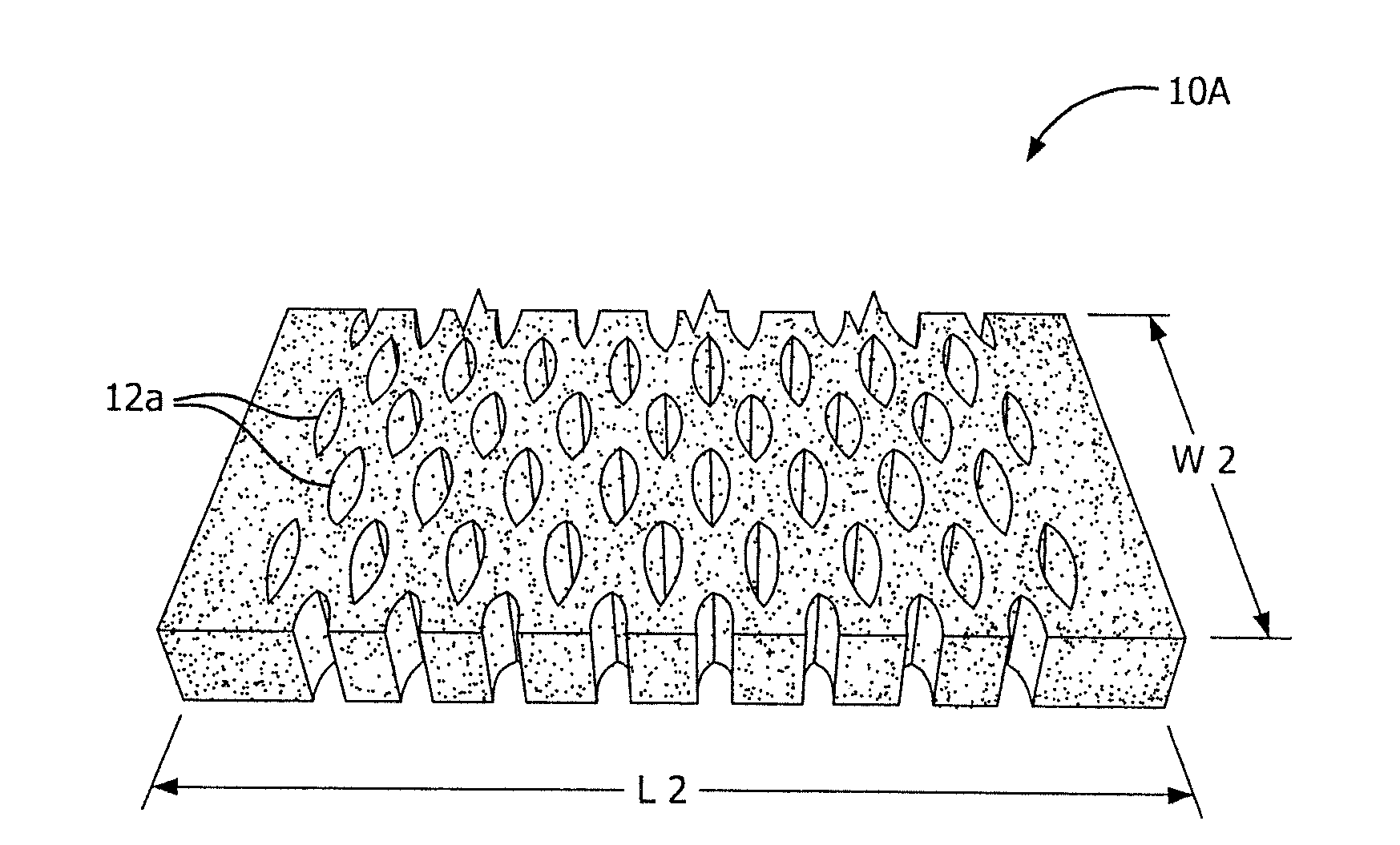

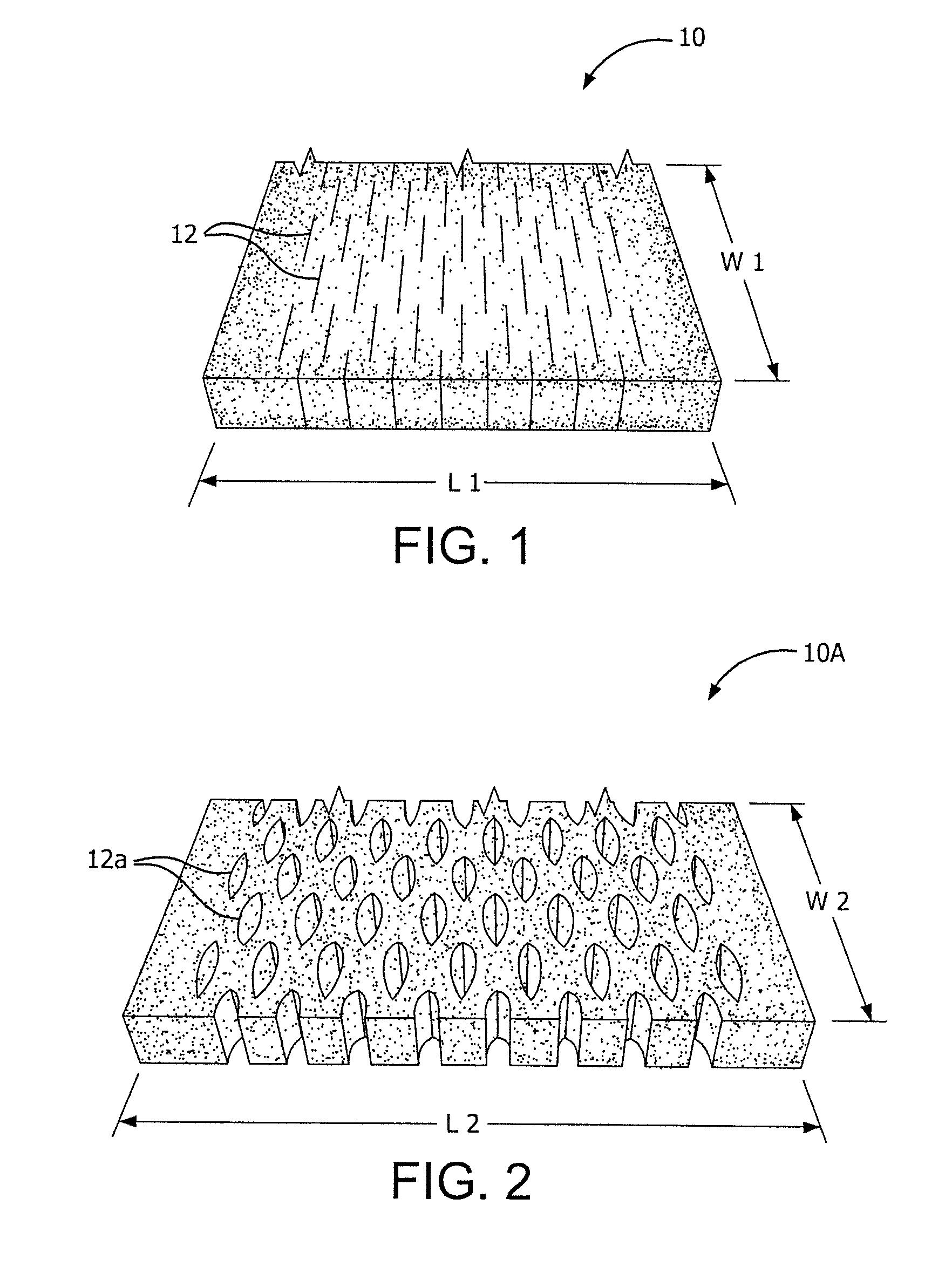

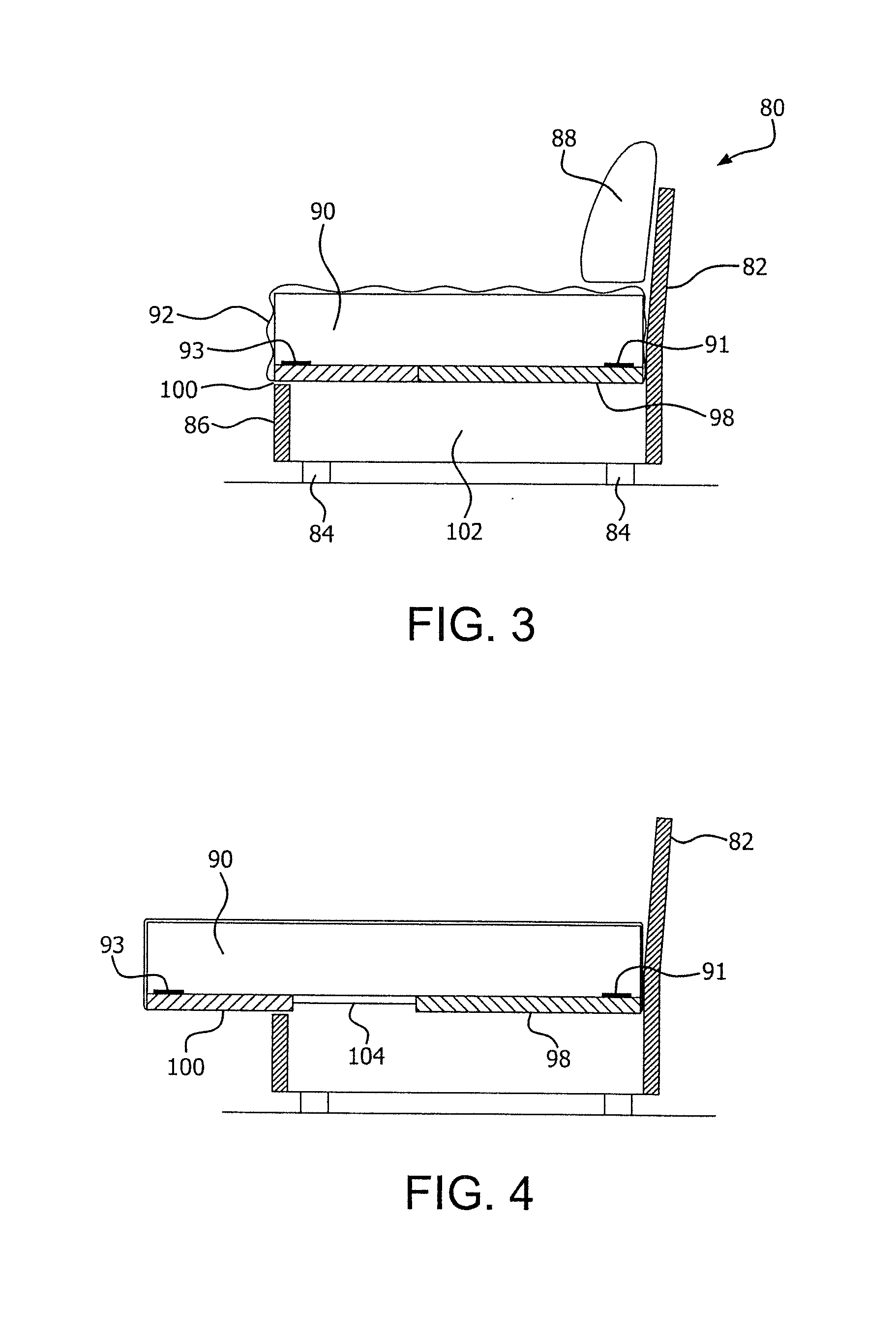

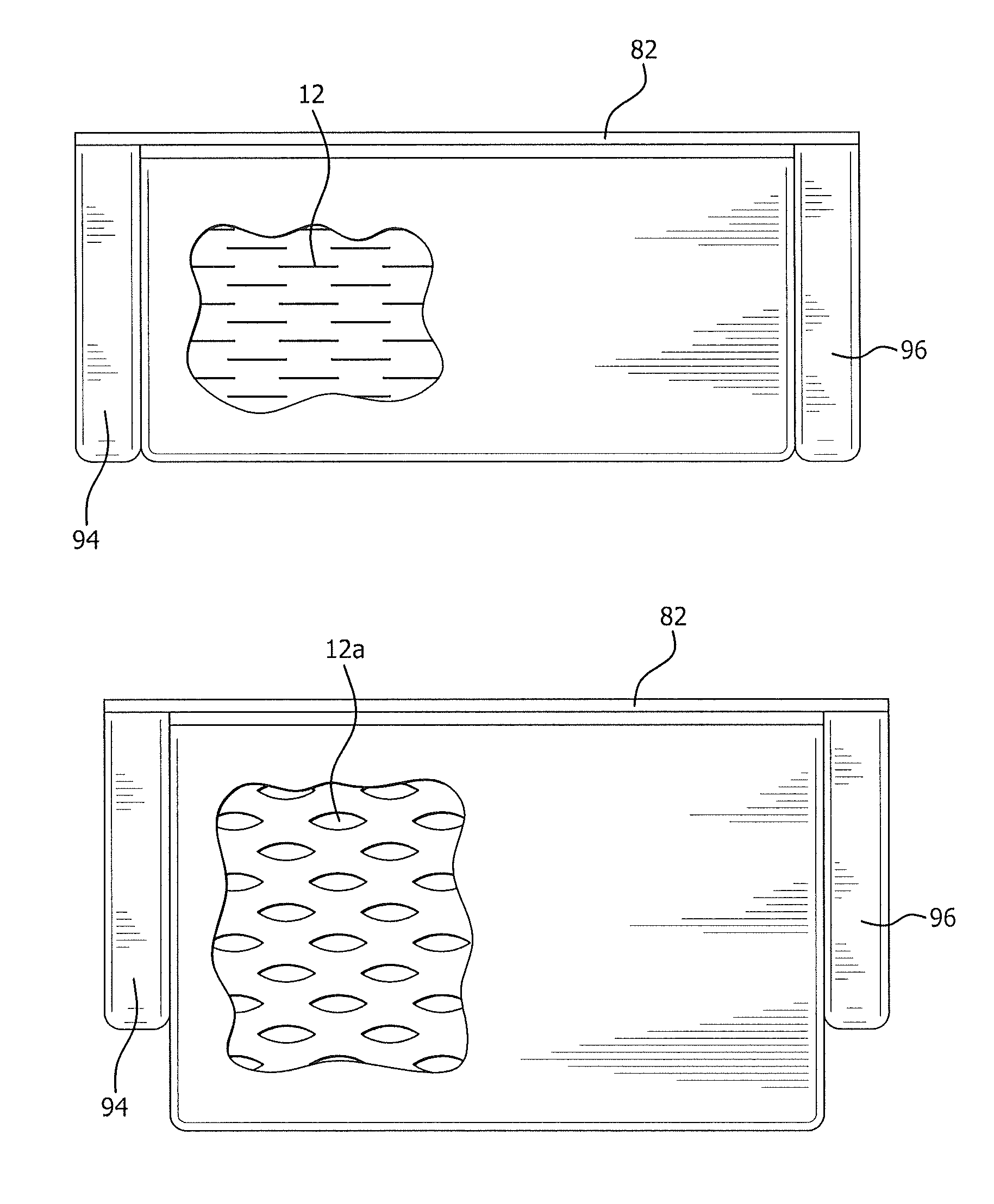

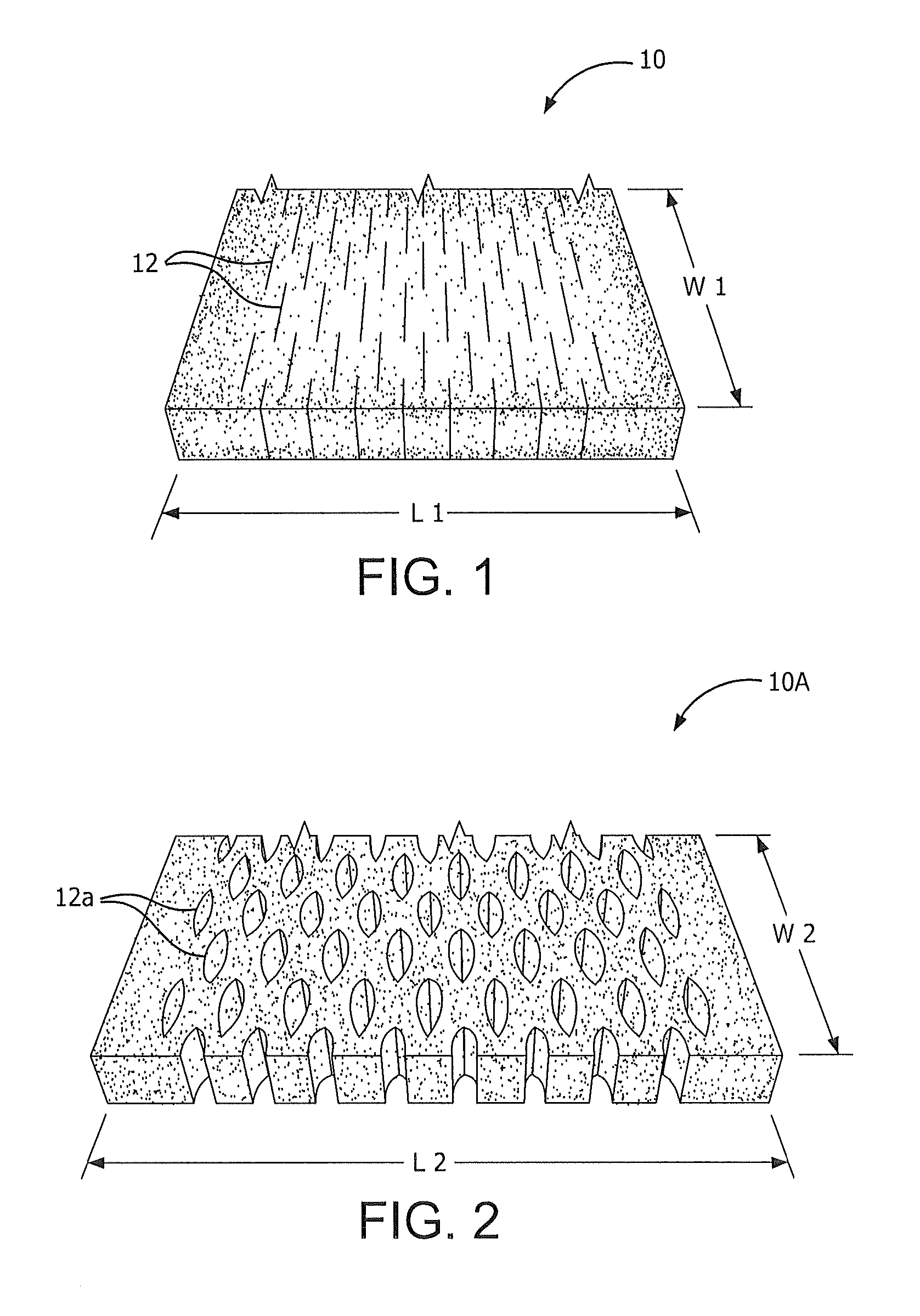

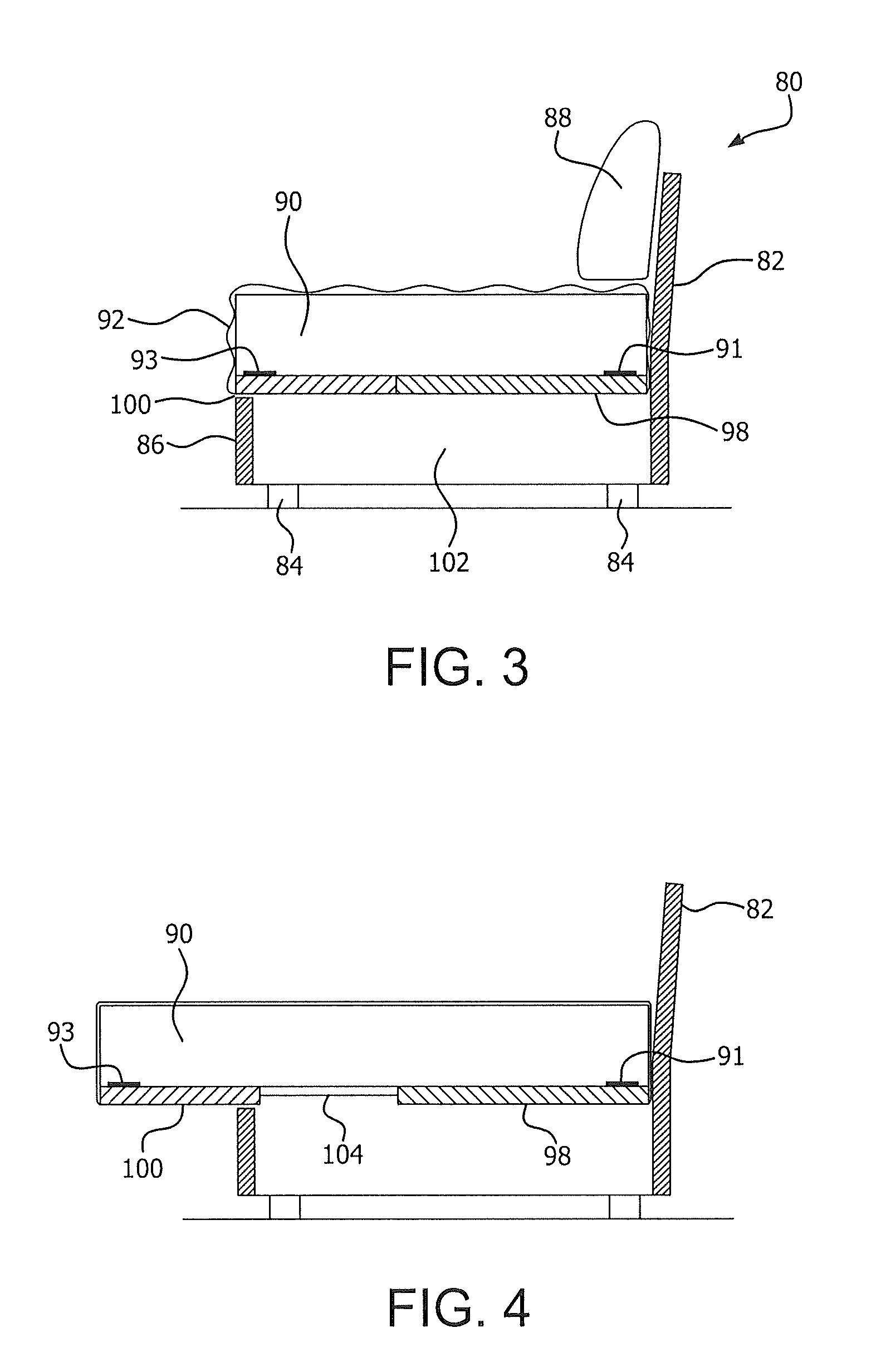

Convertible furniture with selectively expandable mattress cushion section(s)

InactiveUS20150305513A1Quantity minimizationSame depthStuffed mattressesSpring mattressesEngineeringCushion

A cushion, mattress or mattress section for a convertible furniture article defines a plurality of apertures, such as slits or slots or recesses, extending into or through the cushion or mattress section that are cut in a direction at an angle to the first length of the mattress section. The cushion or mattress section expands from its first length to a second length that is longer than the first length upon applying a stretching force to the cushion or mattress section and thereby positioning the mattress section into the open or sleeping configuration. Expansion is due to resilience of the material forming the mattress or mattress section in combination with opening of the apertures. The sleeping surface of the mattress or mattress section may remain substantially planar in both the open (sleeping) position and closed (seating) position.

Owner:TIFFANY & TIFFANY DESIGNERS

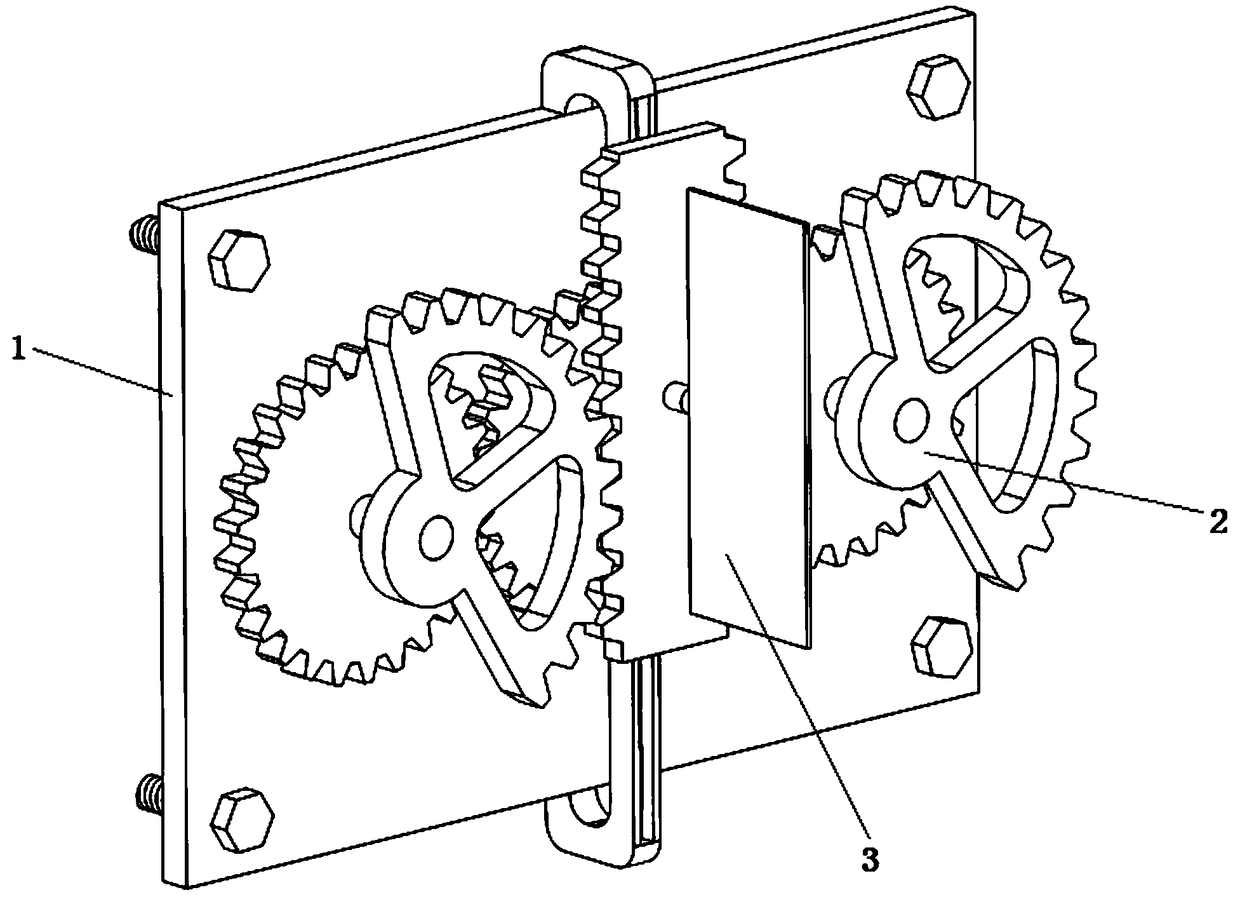

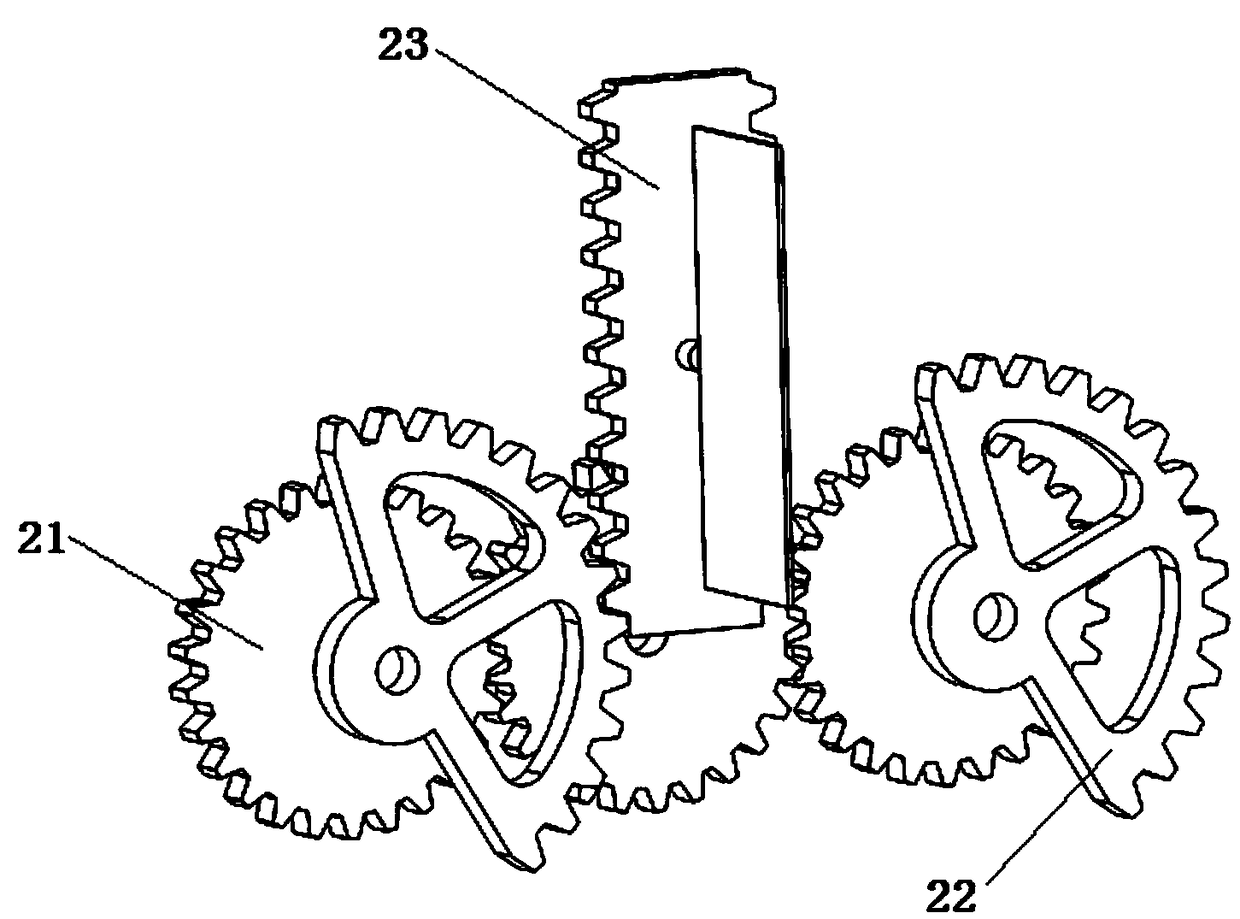

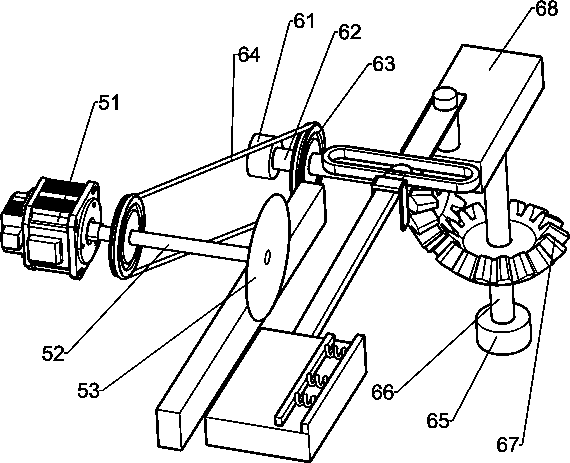

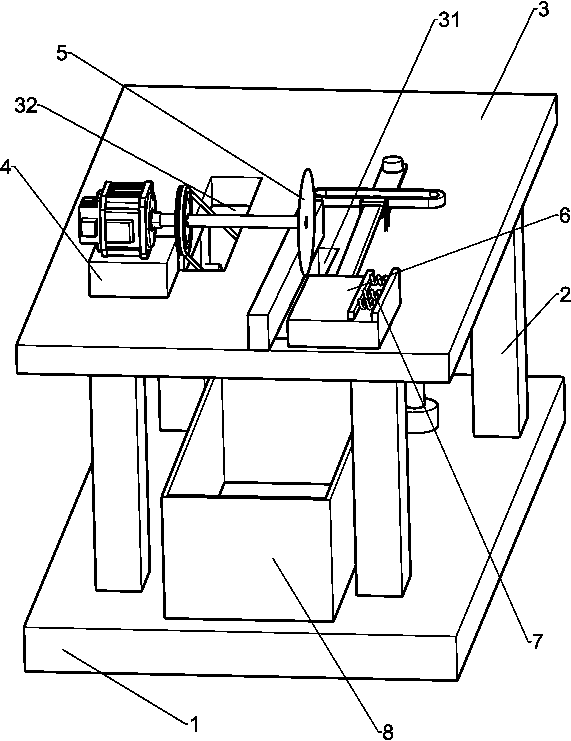

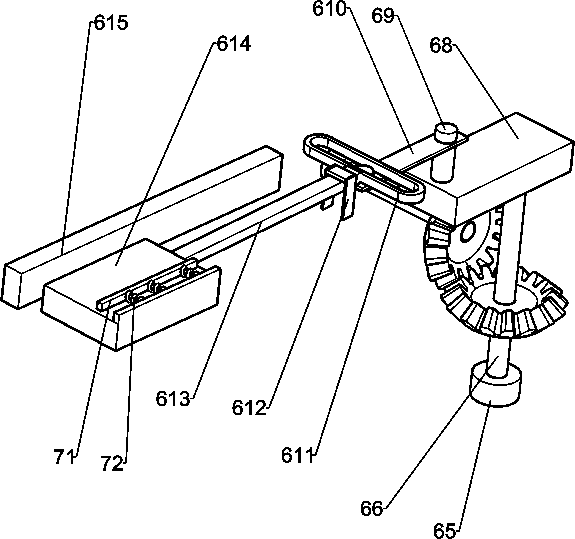

Cigarette packaging paper slitting device

The invention discloses a cigarette packaging paper slitting device comprising a fixed bearing device and a cutting device mounted on the fixed bearing device. The fixed bearing device comprises a mounting plate, a driving shaft rod is fixed to the center of the surface of the mounting plate in a penetrating mode, and a first driven shaft rod and a second driven shaft rod are fixed to the surfaceof the mounting plate; the cutting device comprises a gear set, a section gear set and a cutting structure; the gear set comprises a driving gear, a first driven gear and a second driven gear, and thedriving gear is fixed to the driving shaft rod; and the sector gear set comprises a first sector gear and a second sector gear, the first sector gear is fixed to the first driven shaft rod, and the second sector gear is fixed to the second driven shaft rod. The cigarette packaging paper slitting device is simple is structure, easy to operate and automatic in operation, the production efficiency can be effectively improved, and meanwhile, it can be ensured that the widths of slit cigarette packaging paper are the same.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Convertible furniture with selectively expandable mattress cushion section(s)

InactiveUS9095221B1Quantity minimizationSame depthStuffed mattressesSpring mattressesEngineeringCushion

A cushion, mattress or mattress section for a convertible furniture article defines a plurality of apertures, such as slits or slots or recesses, extending into or through the cushion or mattress section that are cut in a direction at an angle to the first length of the mattress section. The cushion or mattress section expands from its first length to a second length that is longer than the first length upon applying a stretching force to the cushion or mattress section and thereby positioning the mattress section into the open or sleeping configuration. Expansion is due to resilience of the material forming the mattress or mattress section in combination with opening of the apertures. The sleeping surface of the mattress or mattress section may remain substantially planar in both the open (sleeping) position and closed (seating) position.

Owner:TIFFANY & TIFFANY DESIGNERS

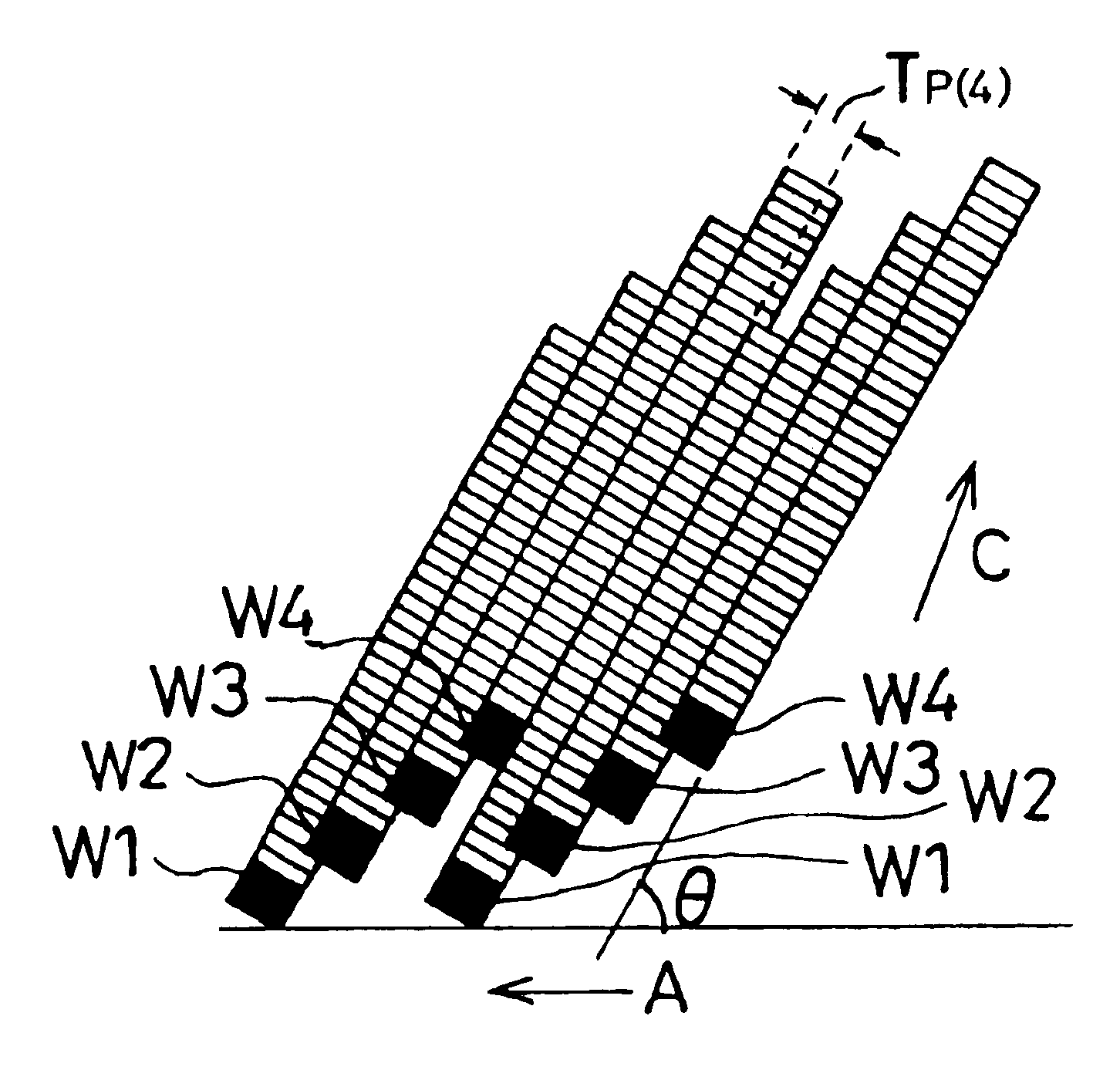

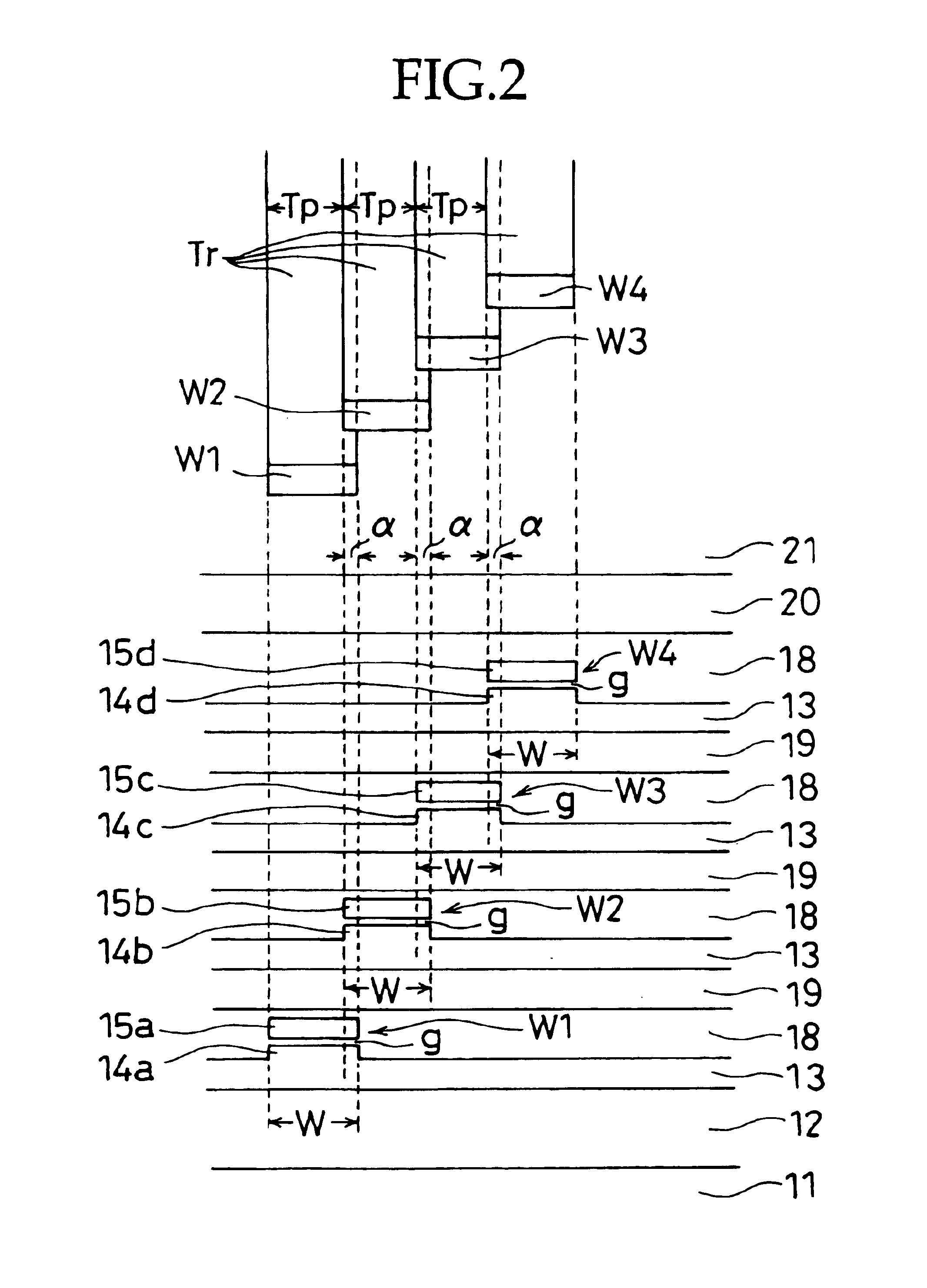

Magnetic tape recording apparatus for recording tracks having same track pitch

InactiveUS6922298B2Eliminating and reducing causeEliminate or reduce the cause of deterioration in accuracy of recording track widthFilamentary/web carriers operation controlDriving/moving recording headsHelical scanTape speed

In a helical scan type magnetic tape recording apparatus, one thin film multi-recording head is mounted on a rotary drum, wherein the multi-recording head includes N recording heads for recording N recording tracks at a predetermined track angle on a magnetic tape by one rotation of the rotary drum to perform recording for forming continuous recording tracks having the same track pitches, by determining rotary drum rotation and a tape speed in accordance with equation V1=Tp·N·(RPS) / sin θ, such that (N−1) recording tracks having the same track pitches narrower than the head width and one recording track having a wider track width than that are formed by a first rotation of the drum, then by a second rotation, a preceding recording head overwrites the recording track having the wider track width to form a recording track having a track width equal to the track width of the recording track.

Owner:SONY CORP

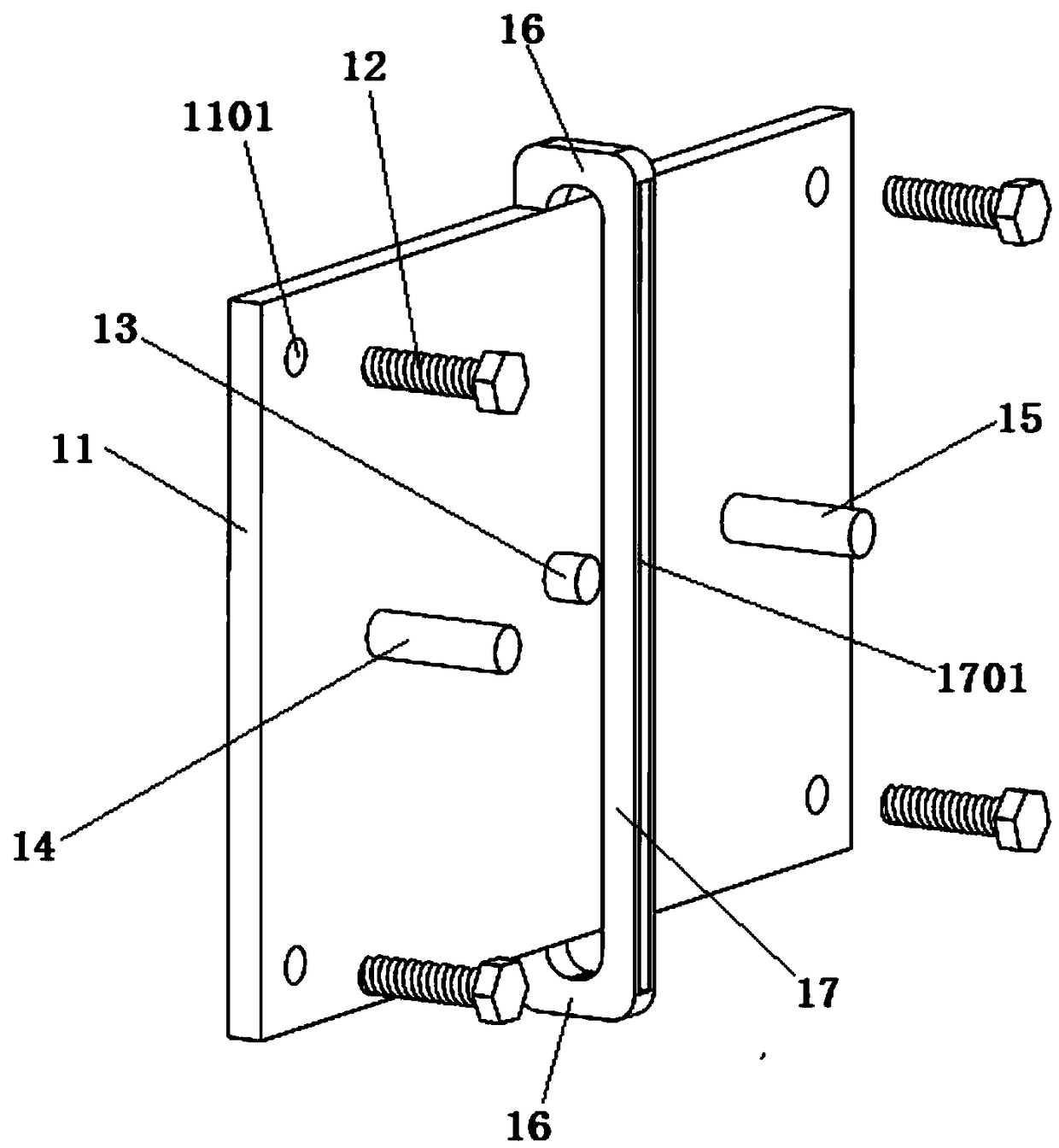

New type wood board strip cutting machine

InactiveCN111590695ACutting autonomySlow back and forth movementProfiling/shaping machinesWood working safety devicesKnife bladesWood plank

The invention relates to a strip cutting machine, in particular to a new type wood board strip cutting machine. The new type wood board strip cutting machine aims to achieve the technical aims that the use is safe, wooden strips with equal widths can be cut out and the integrity of the wooden strips can be ensured. The new type wood board strip cutting machine comprises a base, a bracket, a tabletop, a support base, a cutting mechanism, a movement mechanism, a fixing mechanism and the like; the base is provided with the bracket, the top end of the bracket is provided with the table top, a first groove is opened in the front part of the right side of the table top, a second groove is opened in the middle of the left side of the table top, the support seat is arranged on the front part of of the left side the table top, the cutting mechanism is arranged on the support seat, the movement mechanism is arranged between the bracket and on the table top, the movement mechanism is connected with the cutting mechanism, and the movement mechanism is provided with the fixing mechanism. According to the machine, a cutting blade is driven to move through a servo motor, and at the same time, combined action of a push plate and a spring enables the whole mechanism to independently cut wooden strips.

Owner:邹锦明

Method for producing a vertical field effect transistor

InactiveUS7405127B2Improve electrical performanceEasy to produceTransistorSemiconductor/solid-state device manufacturingField-effect transistorVertical field

Owner:INFINEON TECH AG

Valve bag sealing machine

InactiveCN102602564ASame widthSame effectWrapper twisting/gatheringMechanical engineeringEngineering

A valve bag sealing machine is capable of automatically adjusting the distance between two valve bags in conveying, and sealing a top opening and a bottom opening according to the belt speed difference between a second belt conveying device and a third belt conveying device under equal sewing width and sewing effect. A feeding mechanism is reasonable in design, all actions can be controlled through one air cylinder, a pressure rod and an ejector match with each other to feed one single valve bag during feeding, and the feeding is even and stable.

Owner:JINAN LIYU MACHINERY TECH

Production process of highly wear-resistant polyester-viscose fabrics

InactiveCN102517755AFlat surfaceSame widthHeating/cooling textile fabricsWoven fabricsSmooth surfacePolyester

The invention discloses a production process of highly wear-resistant polyester-viscose fabrics, which includes steps: firstly, subjecting two types of raw yarns including 20S / 1 polyester-viscose yarns and 14S / 1 polyester-viscose yarns to high-temperature yarn steaming for shaping; secondly, placing for more than 30 days for balance damping; thirdly, spooling; fourthly, wrapping the 14S / 1 polyester-viscose yarns with 40D spandex; fifthly, double twisting for preparing 20S / 1 polyester-viscose hard-twisted yarns, 14S / 1 polyester-viscose hard-twisted yarns and 14S / 1 polyester-viscose+40D spandex hard-twisted yarns; sixthly, shaping the three types of hard-twisted yarns at high temperature; seventhly, using the 20S / 1 polyester-viscose hard-twisted yarns as warps, beaming and starching; eighthly, drafting and denting, namely using the 14S / 1 polyester-viscose hard-twisted yarns as first wefts and the 14S / 1 polyester-viscose+40D spandex hard-twisted yarns as second wefts; ninthly, weaving, wherein the weft insertion proportion of the first wefts to the second wefts is 1:1; and tenthly, dyeing and finishing, wherein at least three-time preshrinking shaping and twice high-temperature shaping are performed for dyeing and finishing. Finished products produced by the production process are thick in texture, high in wear resistance, stiff and elastic, high in breathability and uniform in width and have smooth surfaces.

Owner:HANGZHOU FUEN TEXTILE

Multistage hydraulic mechanical garbage incinerator

ActiveCN102607036ASolve technical problemsGuaranteed uptimeHollow bar grateInclined grateHydraulic machineryIncineration

The invention provides a multistage hydraulic mechanical garbage incinerator, which comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally divided into a drying section, a burning section and a burnout section by the five units along the garbage moving direction. The multistage hydraulic mechanical garbage incinerator is characterized in that a limiting support device for limiting a feeding trolley to move upward is arranged on the upper surface of a tail of the feeding trolley of the feeding fire grate. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

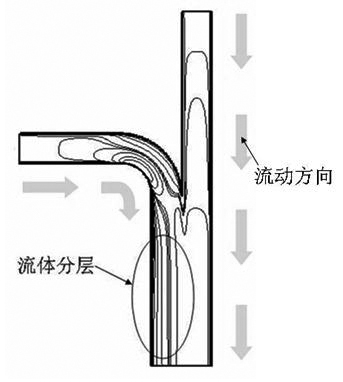

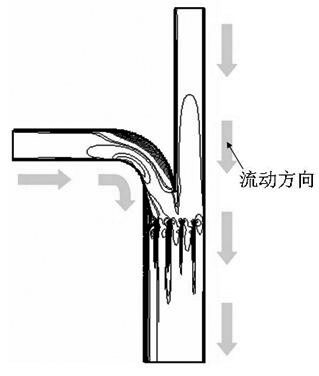

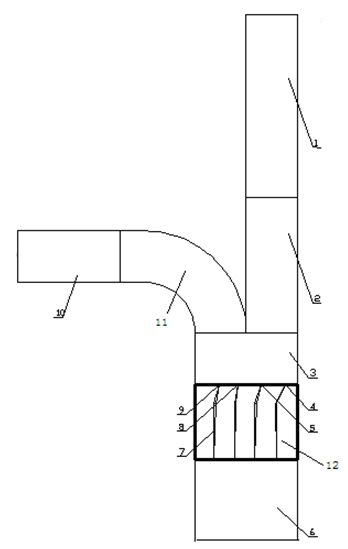

Rectangular wind-pipe separate converging-rectifying three-way pipe

InactiveCN101975321ASame widthEntrance size meetsDucting arrangementsFluid dynamicsEqual sizeEngineering

The invention discloses a rectangular wind-pipe separate converging-rectifying three-way pipe which comprises a first inlet segment, a second inlet segment and an outlet segment, wherein the extension lines of the first inlet segment and the second inlet segment form an included angle of 90 degrees, the lower end of the first inlet segment is connected with a linear converging segment, one side of the second inlet segment is connected with a flexural converging segment, the linear converging segment and the flexural converging segment are both connected with a buffer segment, and a rectifying segment connected with the outlet segment is arranged below the buffer segment; and rectifying vanes are arranged at the upper end in the rectifying segment, and each rectifying vane is provided with a guide vane to divide the rectifying segment into five fluid passages with equal size. The unique design of the invention eliminates the speed layering formed after a fluid passes through the rectangular wind-pipe separate converging three-way pipe to finally achieve the purpose of rectifying the fluid after passing through the rectangular wind-pipe separate converging three-way pipe.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Liquid crystal display device

ActiveUS7978294B2Increase the aperture ratioImprove picture qualityNon-linear opticsSemiconductor devicesLiquid-crystal displayEngineering

A liquid crystal display device is disclosed. The disclosed liquid crystal display device includes gate lines, data lines formed to intersect with the gate lines, thereby defining sub-pixel regions, vertical common lines formed in parallel to the data lines such that at least one vertical common line is arranged for one pixel region, which is constituted by at least three sub-pixel regions, thin film transistors each connected to a corresponding one of the gate lines and a corresponding one of the data lines, pixel electrodes each connected to a corresponding one of the thin film transistors, and common electrodes each connected to a corresponding one of the vertical common lines.

Owner:LG DISPLAY CO LTD

Dispenser for rolls

InactiveUS20090308966A1Large caliberSame widthFilament handlingDomestic applicationsEngineeringMechanical engineering

Owner:ESSITY HYGIENE & HEALTH AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com