New type wood board strip cutting machine

A technology of slitting machine and wood board, applied in the direction of woodworking safety device, forming/shaping machine, wood processing equipment, etc., can solve the problems of easily damaged raw materials, danger, low efficiency, etc., and achieve the effect of convenient cutting and blade protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

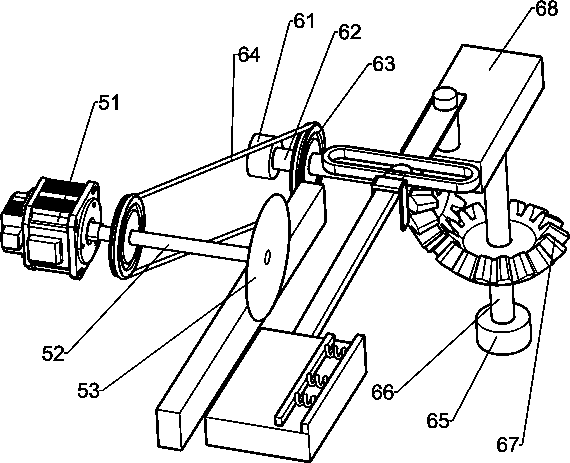

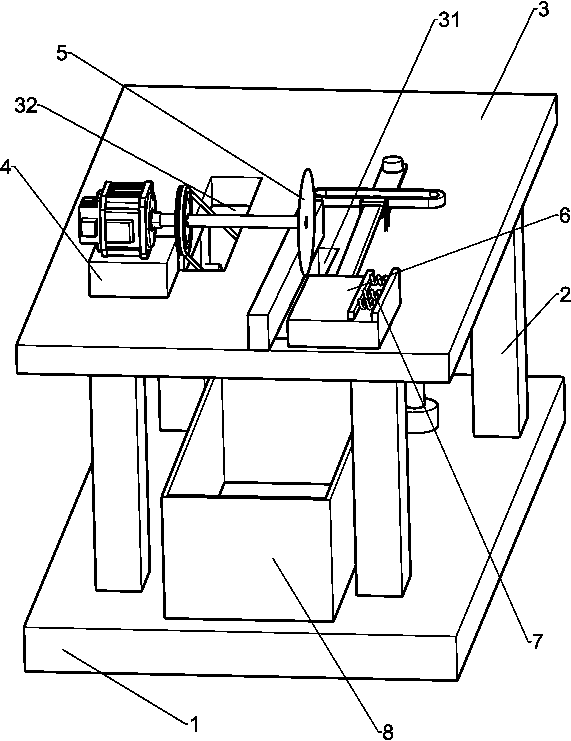

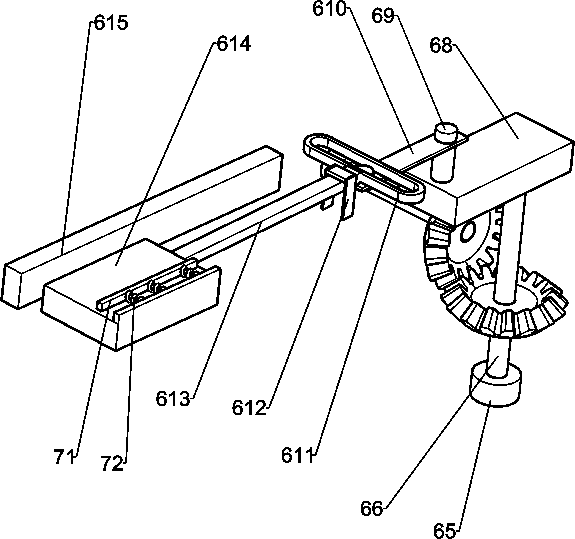

[0021] A new type of wood cutting machine, such as Figure 1-3 As shown, it includes a base 1, a bracket 2, a desktop 3, a support seat 4, a cutting mechanism 5, a moving mechanism 6 and a fixing mechanism 7, the base 1 is provided with a bracket 2, the top of the bracket 2 is provided with a desktop 3, and the right side of the desktop 3 The front part is provided with a first groove 31, and the middle part of the left side of the table top 3 is provided with a second groove 32. And desktop 3 is provided with kinematic mechanism 6, and kinematic mechanism 6 is connected with cutting mechanism 5, and kinematic mechanism 6 is provided with fixing mechanism 7.

[0022] When people need to cut a plank, they first place the plank on the fixing mechanism 7, fix the plank through the fixing mechanism 7, and then start the cutting mechanism 5. The movement of the cutting mechanism 5 will drive the movement mechanism 6 to move back and forth, and the movement mechanism 6 will drive th...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 As shown, a collection box 8 is also included, and the collection box 8 is placed on the front side of the upper middle part of the base 1 .

[0031] After the wooden strips are cut, they will pass through the first groove 31 and enter into the collection box 8 to facilitate the collection of the wooden strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com